Stator winding configuration of three-phase electric motor

A stator winding and three-phase motor technology, applied in the direction of winding conductive materials, winding conductor shape/style/structure, etc., can solve the problems of motor winding burnout, aluminum wire is easy to heat, aluminum wire temperature rise, etc., to reduce weight , easy heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

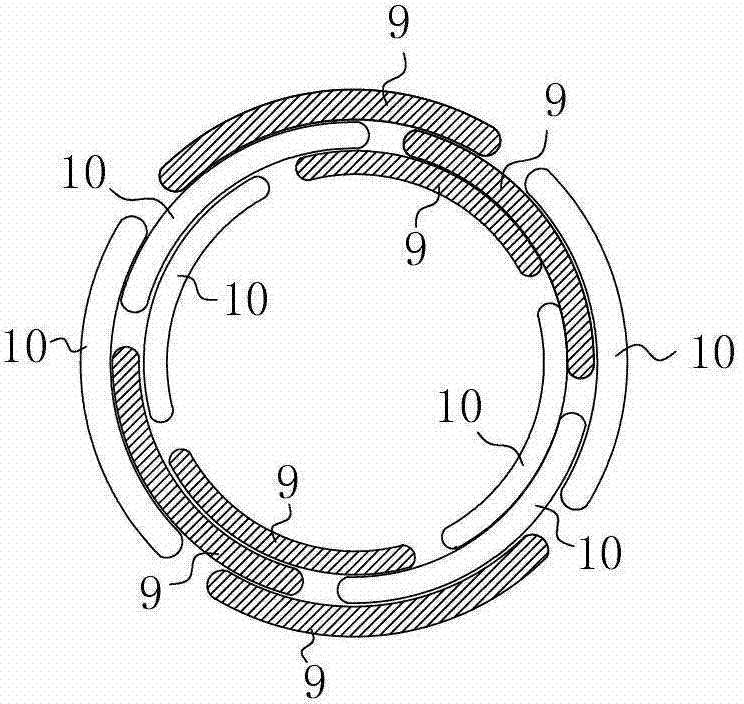

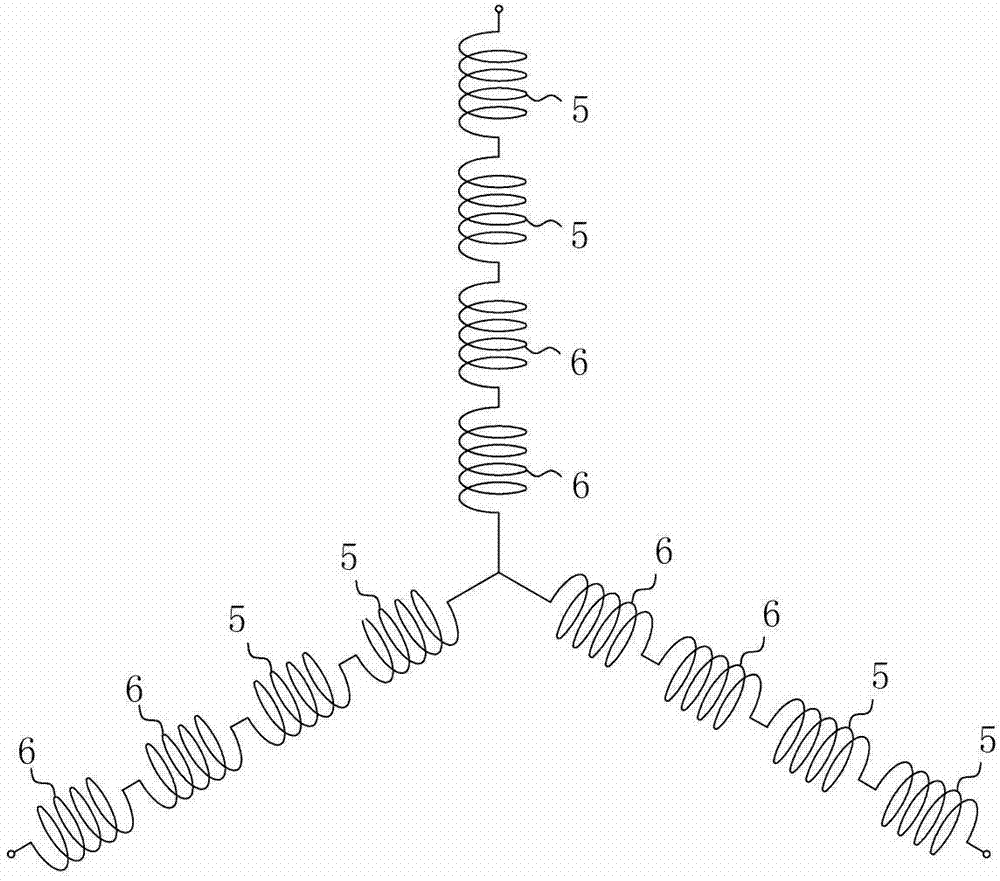

[0031] like Figure 5 to Figure 8 As shown, n is 2, then there are two units of copper wire 5 and aluminum wire 6 in the coil slot 4 in each phase coil, two aluminum wire units 8 in the first phase coil 1, and two aluminum wire units 8 in the second phase coil 1 The two aluminum wire units 8 in the coil 2 and the two aluminum wire units 8 in the third phase coil 3 are one-to-one corresponding and overlapped respectively. The two aluminum wire units 8 in the first phase coil and the two aluminum wire units 8 in the third phase coil The wire units 8 are respectively located at both ends of the two aluminum wire units 8 in the second phase coil. In this embodiment, the two aluminum wire units 8 in the first phase coil 1, the two aluminum wire units 8 in the second phase coil 2, and the two aluminum wire units 8 in the third phase coil 3 are sequentially clockwise. Overlapping, the overlapping lengths of the two aluminum wire units 8 in the first phase coil 1 and the two aluminum...

Embodiment 2

[0033] like Figure 9 , Figure 10 As shown, the difference from the first embodiment is that there are two aluminum wire units 8 in the first phase coil 1, two aluminum wire units 8 in the second phase coil 2, and two aluminum wire units 8 in the third phase coil 3 respectively overlap in a counterclockwise direction.

Embodiment 3

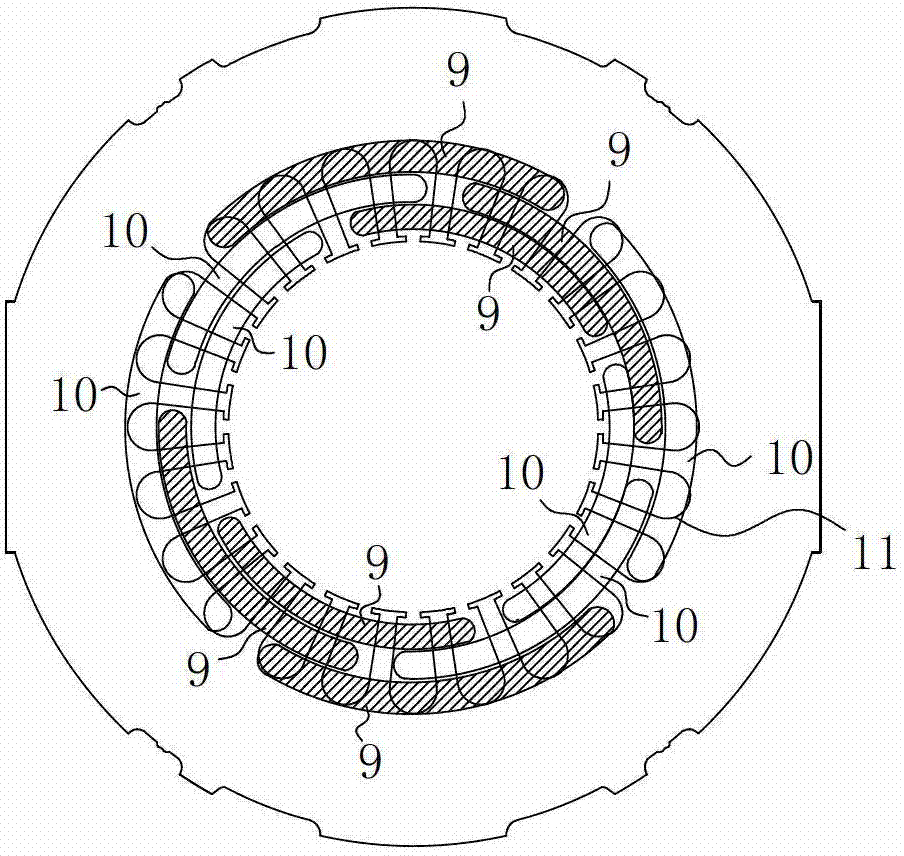

[0035] like Figure 11 , Figure 12 As shown, the difference from Embodiment 1 is that n is 3, and there are three units of copper wire 5 and aluminum wire 6 in the coil slot 4 in each phase coil, and three aluminum wires in the first phase coil 1 The unit 8, the three aluminum wire units 8 in the second phase coil 2, and the three aluminum wire units 8 in the third phase coil 3 correspond one-to-one and overlap in sequence respectively. The three aluminum wire units 8 in the first phase coil 1, the three aluminum wire units 8 in the third phase coil 3, The three aluminum wire units 8 in the three-phase coil 3 are respectively located at the two ends of the three aluminum wire units 8 in the second phase coil 2, and the three aluminum wire units 8 in the first phase coil 1 are connected to the two ends of the three aluminum wire units 8 in the second phase coil 2. The overlapping lengths of the three aluminum wire units 8 are less than 1 / 2 of the lengths of the three aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com