Golf club head with elastic weight members

a golf club head and weight technology, applied in the field of golf club heads, can solve the problems of golf club head cracking, weight member, etc., and achieve the effect of improving the vibration-absorbing effect of the golf club head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

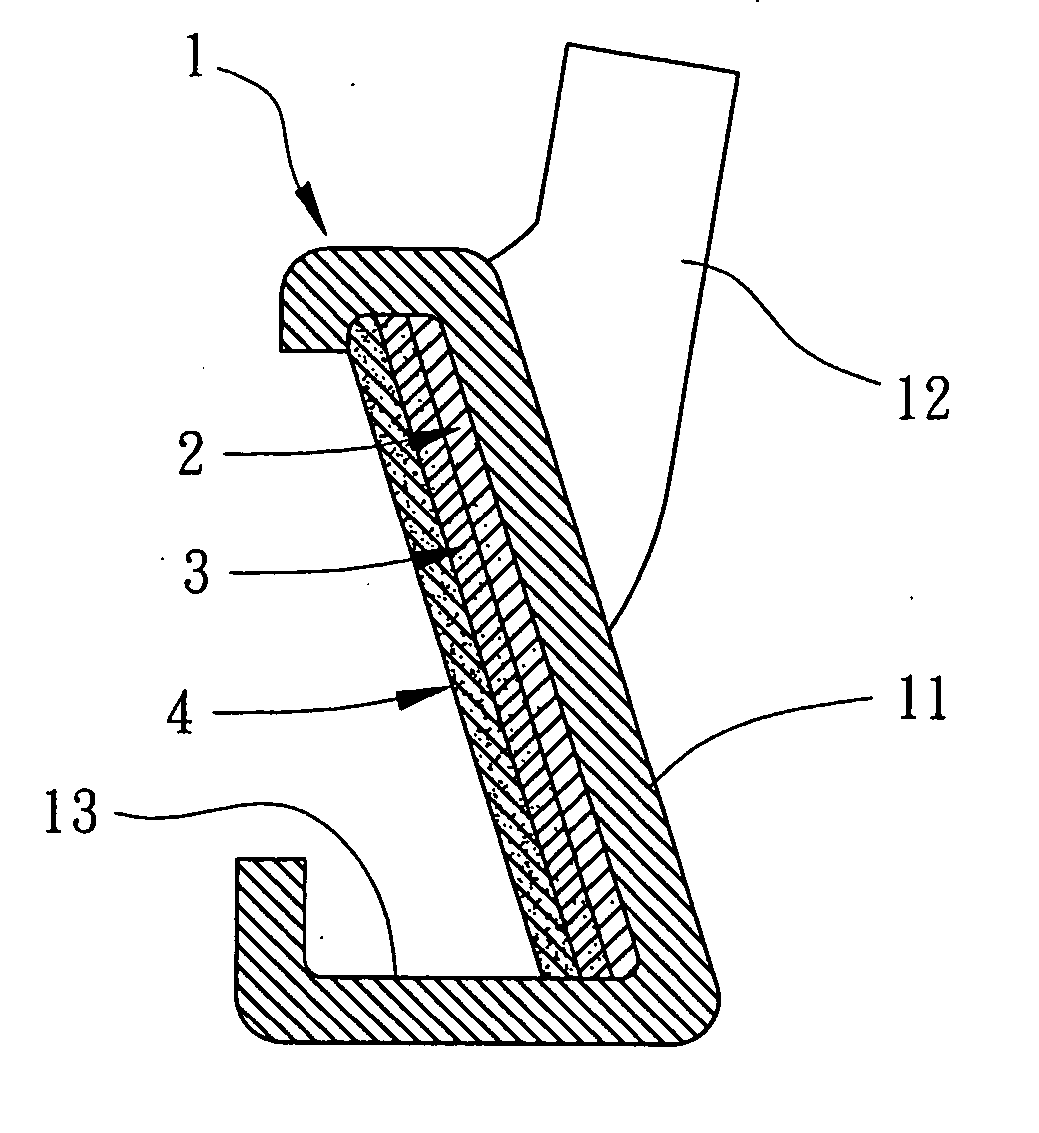

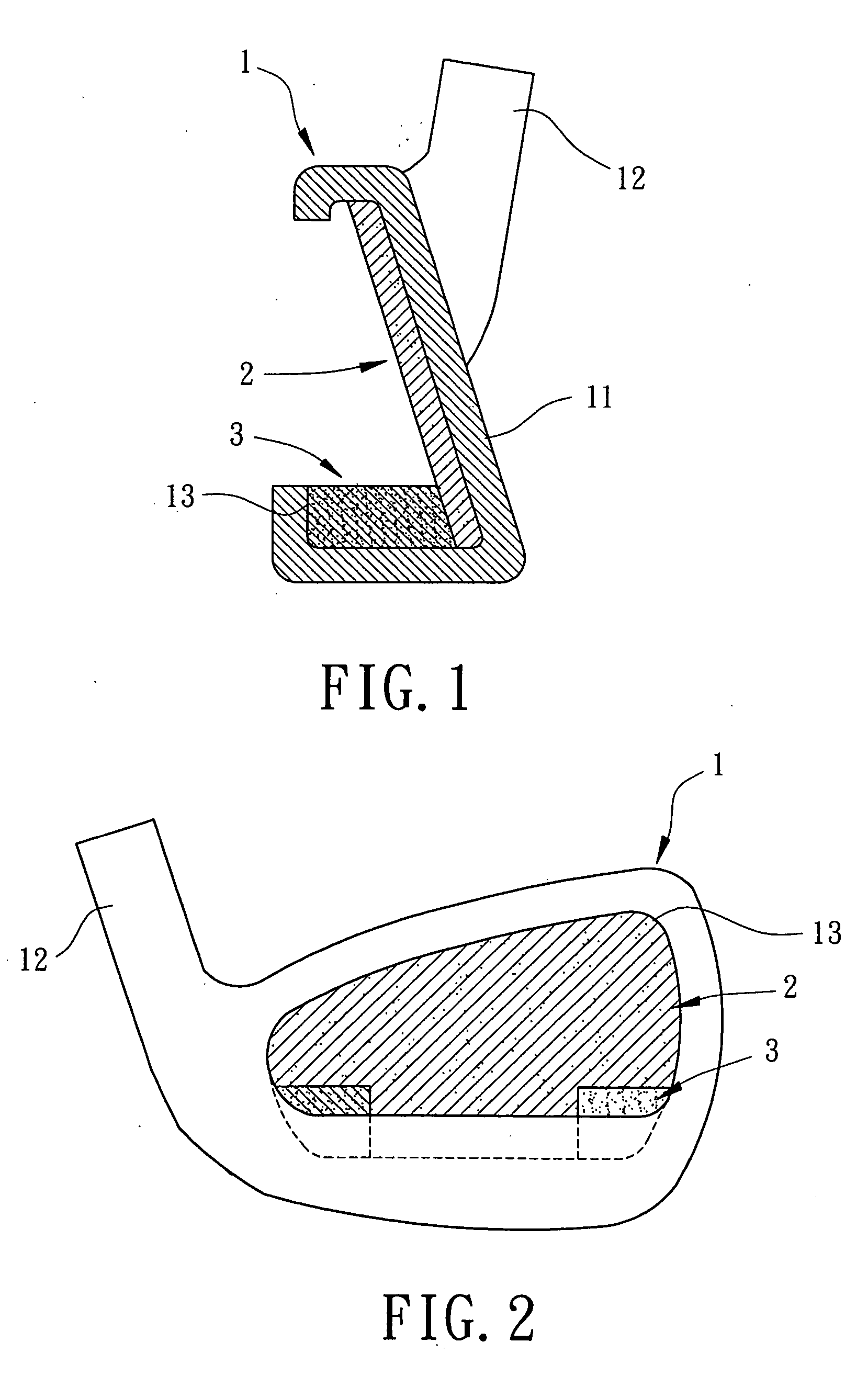

[0042] Referring to FIGS. 1 and 2, a golf club head in accordance with the present invention comprises a body 1, a first elastic weight member 2, and a second elastic weight member 3. The body 1 may be a body for an iron club head, a wood club head, or a putter. The first and second elastic weight members 2 and 3 are used to adjust the center of gravity of the golf club head while providing a vibration-absorbing effect for the golf club head.

[0043] In the illustrated embodiment, the body 1 is for an iron club head. The body 1 is made of metal, alloy, or non-metal material. The body 1 includes a striking plate 11, a hosel 12, and a cavity. 13. The striking plate 11 and the hosel 12 may be of a conventional design and can be mounted to the body 1 by welding, brazing, insertion, screwing, or bonding. The striking plate 11 has a front side for striking golf balls. Alternatively, the body 1, the hosel 12, and the striking plate 11 can be integrally formed, with the striking plate 11 prov...

second embodiment

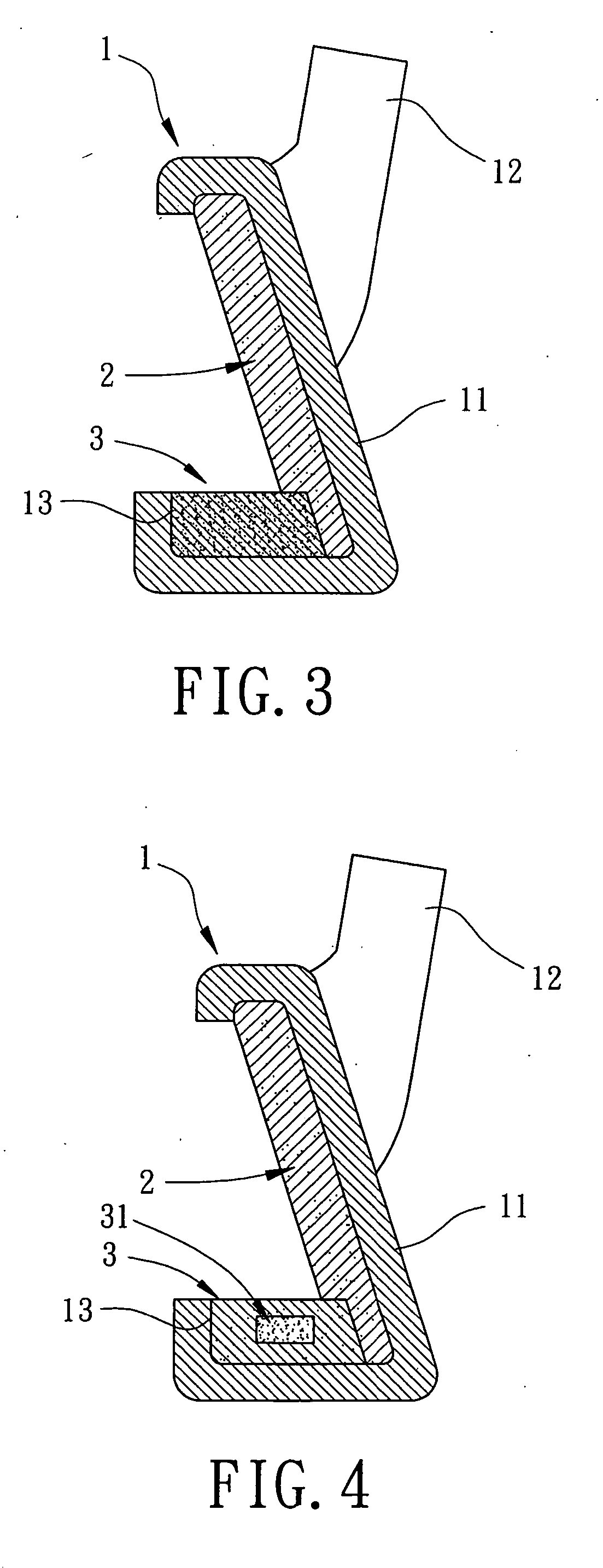

[0051]FIG. 3 illustrates the invention, wherein the first elastic weight member 2 and the second elastic weight member 3 are assembled in a different manner. In this embodiment, the second elastic weight member 3 is pre-manufactured and then fixed to a bottom wall delimiting the cavity 13 of the body 1 by bonding or insertion. Next, a mixture of the elastic matrix and the metal powder are injected into the cavity 13 to form the first elastic weight member 2 (injection molding). Thus, the second elastic weight member 3 is partially embedded in the first elastic weight member 2. This arrangement improves the assembling reliability of the first elastic weight member 2 and the second elastic weight member 3 while allowing absorption of the vibration and the adjustment of the center of gravity of the golf club head.

[0052]FIG. 4 illustrates a third embodiment of the invention modified from the second embodiment. In this embodiment, a metal weight member 31 is embedded in the second elasti...

fifth embodiment

[0054]FIG. 6 illustrates the invention. In this embodiment, the body 1 is for a wood club head. The body 1 comprises a striking plate 11, a hosel 12, and an inner space 10 that provides an assembling portion for mounting at least two elastic weight members. The first and second elastic weight members 2 and 3 may be mounted in an appropriate location of the inner space 10 of the body 1. At least one of the first and second elastic weight members 2 and 3 (e.g., the first elastic weight member 2) is in contact with the rear side of the striking plate 11 to provide a vibration-absorbing function and to increase the coefficient of restitution of the striking plate 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com