Compound processing method of boron-containing high-speed steel roller material

A composite treatment, high-speed steel technology, applied in the field of wear-resistant materials, can solve the problems of insignificant changes in the form and distribution of carbon and boron compounds, reduce the strength and toughness of the rolls, and affect the normal operation of equipment, and improve the form and distribution of carbon and boron compounds. , Improve the strength and toughness, the effect of small solidification structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

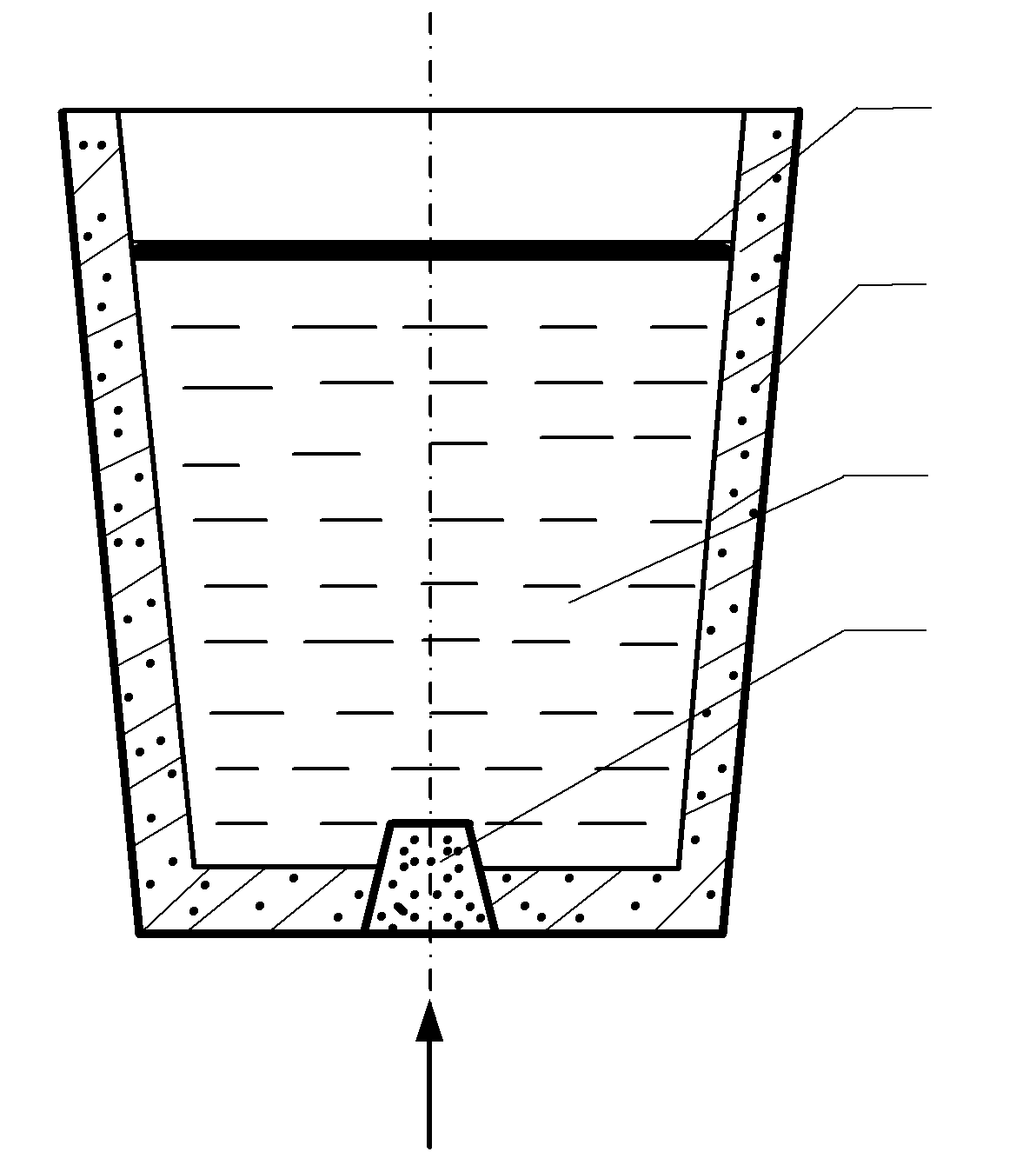

Image

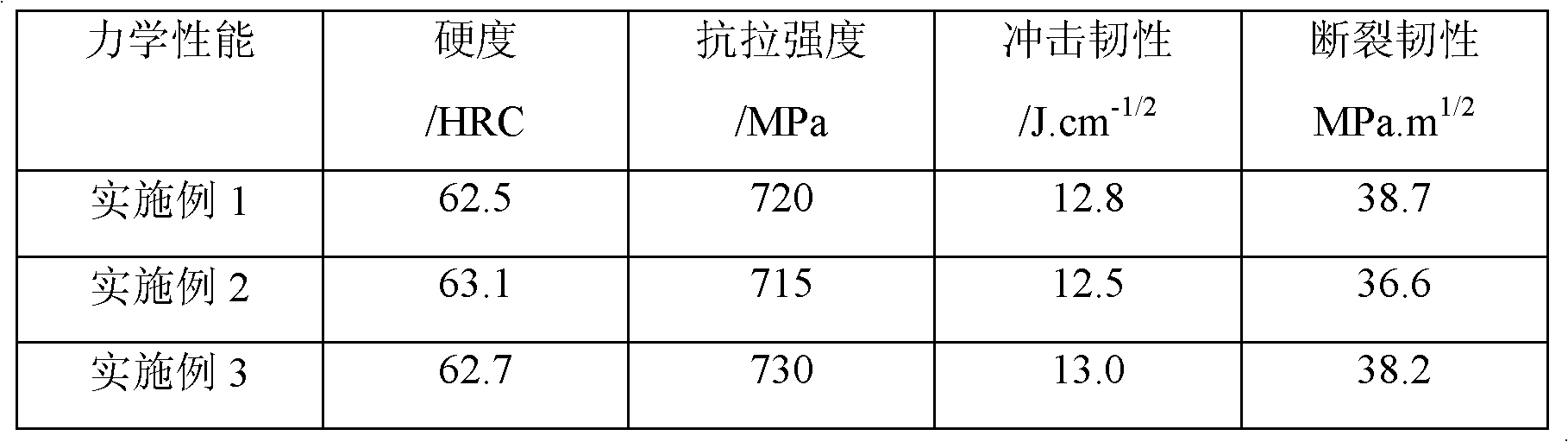

Examples

Embodiment 1

[0026] The material of the present invention adopts 1000 kilograms of medium-frequency induction furnace melting, and concrete composite treatment steps are as follows:

[0027]1) Melt the high-speed steel roll material in the electric furnace first. When the composition of molten steel is adjusted to pass, add silicon-calcium alloy accounting for 0.15% of the total mass of molten steel for pre-deoxidation and desulfurization. The mass fraction (%) of silicon-calcium alloy is: 55-65Si , Ca>31, Al<2.4, C<0.8, P≤0.04, S≤0.06, and the balance is Fe. Then add 0.15% aluminum for final deoxidation, and finally raise the temperature of molten steel to 1630°C and then release it from the furnace.

[0028] 2) During the process of molten steel coming out of the furnace, the ferroboron particles are washed into the ladle with the flow. The amount of ferroboron particles flushed into the ladle accounts for 3.0% of the total mass of molten steel. The size of ferroboron particles is 2-6m...

Embodiment 2

[0032] The material of the present invention adopts 500 kilograms of medium-frequency induction furnace melting, and concrete composite treatment steps are as follows:

[0033] 1) Melt the high-speed steel roll material in the electric furnace first. When the composition of molten steel is adjusted to pass, add silicon-calcium alloy accounting for 0.25% of the total mass of molten steel for pre-deoxidation and desulfurization. The mass fraction (%) of silicon-calcium alloy is: 55-65Si , Ca≥31, Al≤2.4, C≤0.8, P≤0.04, S≤0.06, the balance Fe. Then add 0.08% aluminum for final deoxidation, and finally raise the temperature of molten steel to 1648°C and then release it from the furnace.

[0034] 2) During the process of molten steel coming out of the furnace, the ferroboron particles are washed into the ladle with the flow. The amount of ferroboron particles flushed into the ladle accounts for 3.5% of the total mass of molten steel. The size of ferroboron particles is 2-6mm. Befo...

Embodiment 3

[0038] The material of the present invention adopts 1000 kilograms of medium-frequency induction furnace melting, and concrete composite treatment steps are as follows:

[0039] 1) Melt the high-speed steel roll material in the electric furnace first. When the composition of molten steel is adjusted to pass, add silicon-calcium alloy accounting for 0.18% of the total mass of molten steel for pre-deoxidation and desulfurization. The mass fraction (%) of silicon-calcium alloy is: 55-65Si , Ca≥31, Al≤2.4, C≤0.8, P≤0.04, S≤0.06, the balance Fe. Then add 0.12% aluminum for final deoxidation, and finally raise the temperature of the molten steel to 1630-1650°C before it is released from the furnace.

[0040] 2) During the process of molten steel coming out of the furnace, the ferroboron particles are washed into the ladle with the flow. The amount of ferroboron particles flushed into the ladle accounts for 3.2% of the total mass of molten steel. The size of ferroboron particles is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com