Gas generant and manufacturing method thereof

a technology of gas generant and manufacturing method, which is applied in the direction of pressure gas generation, explosives, weapons, etc., can solve the problems of unacceptably high toxic gas levels, poor thermal stability of nonazide gas generant compositions, and inability to manufacture, etc., to facilitate the curing or polymerization of mixtures, facilitate melt processing, and facilitate the solubility of other gas generant constituents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

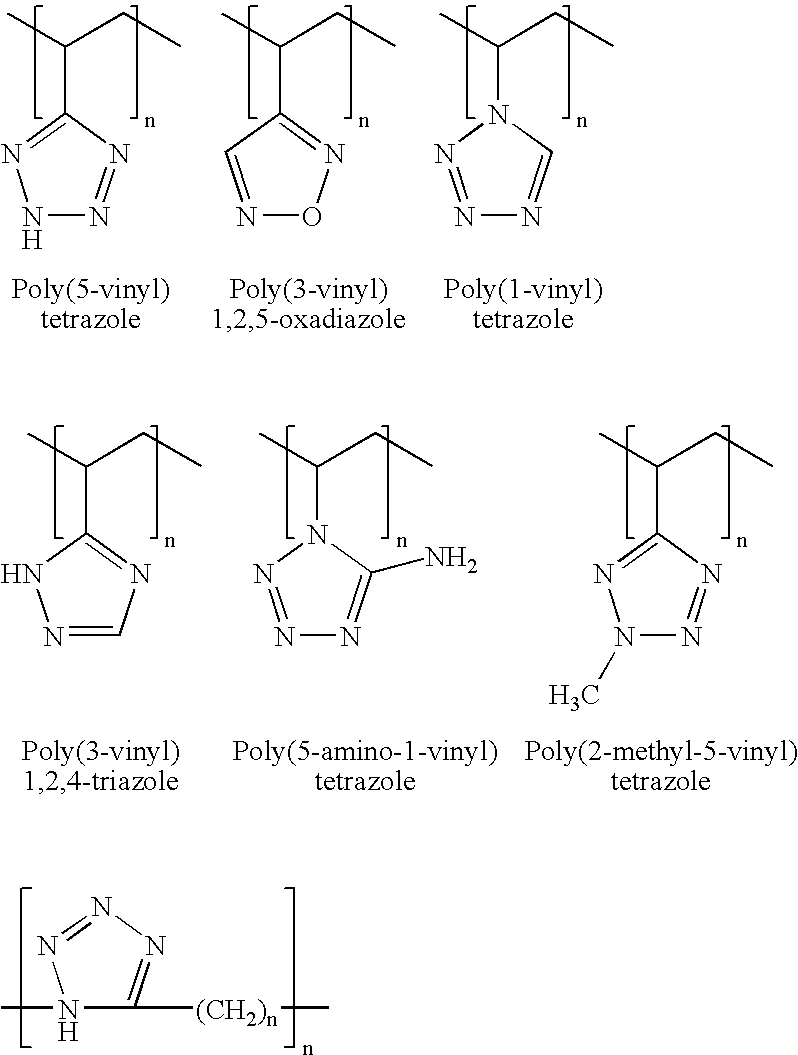

example 1

[0033] A gas generant composition of the present invention is formed by first synthesizing a polyvinyltetrazole. A generic substituted tetrazole and vinyl acetate are combined to vinylate the tetrazole. The vinylated tetrazole is added to a molar equivalent of mercury acetate and boron trifluoride-etherate for polymerization thereof. The resulting products may then be separated by oil distillation for example. The polyvinyltetrazoles illustrated in the drawings may be formed in the same way. Reaction 3 exemplifies the process described above.

example 2

[0034] A gas generant composition of the present invention is formed by first synthesizing a polyvinyltriazole. A generic substituted triazole metal or nonmetal salt is added to a molar equivalent amount of a free radical brominating reagent such as n-bromo-succinamide and to a benzoyl-peroxide free radical initiator to form a brominated triazole. The brominated triazole is then added to triphenyl phosphine to form a Wittig salt group on the substituted triazole salt. The triazole salt is then added to a metal or nonmetal organic or inorganic base, and also to formaldehyde to form a vinylated triazole salt. The vinylated triazole salt is next added to a free radical polymerization reagent such as azoisobutyronitrile and a catalytic amount of a cationic polmerizer or Ziegler-Natta catalyst such as a metal or titanium complex. Reaction 2 exemplifies the process described above wherein the synthesis of poly(vinyl-1,2,4-triazole) is described.

example 3

[0035] A gas generant composition of the present invention is formed by first synthesizing a polyvinyldiazole. An alkenol containing two —OH groups is added to acetic anhydride to form a substituted diazole. The substituted diazole is then added to a molar equivalent amount of a free radical brominating reagent such as n-bromo-succinamide and to a free radical initiator such as benzoyl-peroxide to form a brominated diazole. The substituted diazole is then added to triphenyl phosphine to form a Wittig salt group on the substituted diazole salt. The diazole salt is then added to a metal or nonmetal organic or inorganic base, and also to formaldehyde to form a vinylated diazole salt. The vinylated diazole salt is next added to a free radical polymerization reagent such as azoisobutyronitrile and a catalytic amount of a cationic polymerizer or Ziegler-Natta reagent such as a metal complex. Reaction 1 exemplifies the process described above wherein the synthesis of poly(vinyl-1,2,5-oxadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com