Patents

Literature

208 results about "Burn rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Burn rate is the rate at which a company is losing money. It is typically expressed in monthly terms. E.g., "the company's burn rate is currently $65,000 per month." In this sense, the word "burn" is a synonymous term for negative cash flow. It is also measure for how fast a company will use up its shareholder capital. If the shareholder capital is exhausted, the company will either have to start making a profit, find additional funding, or close down.

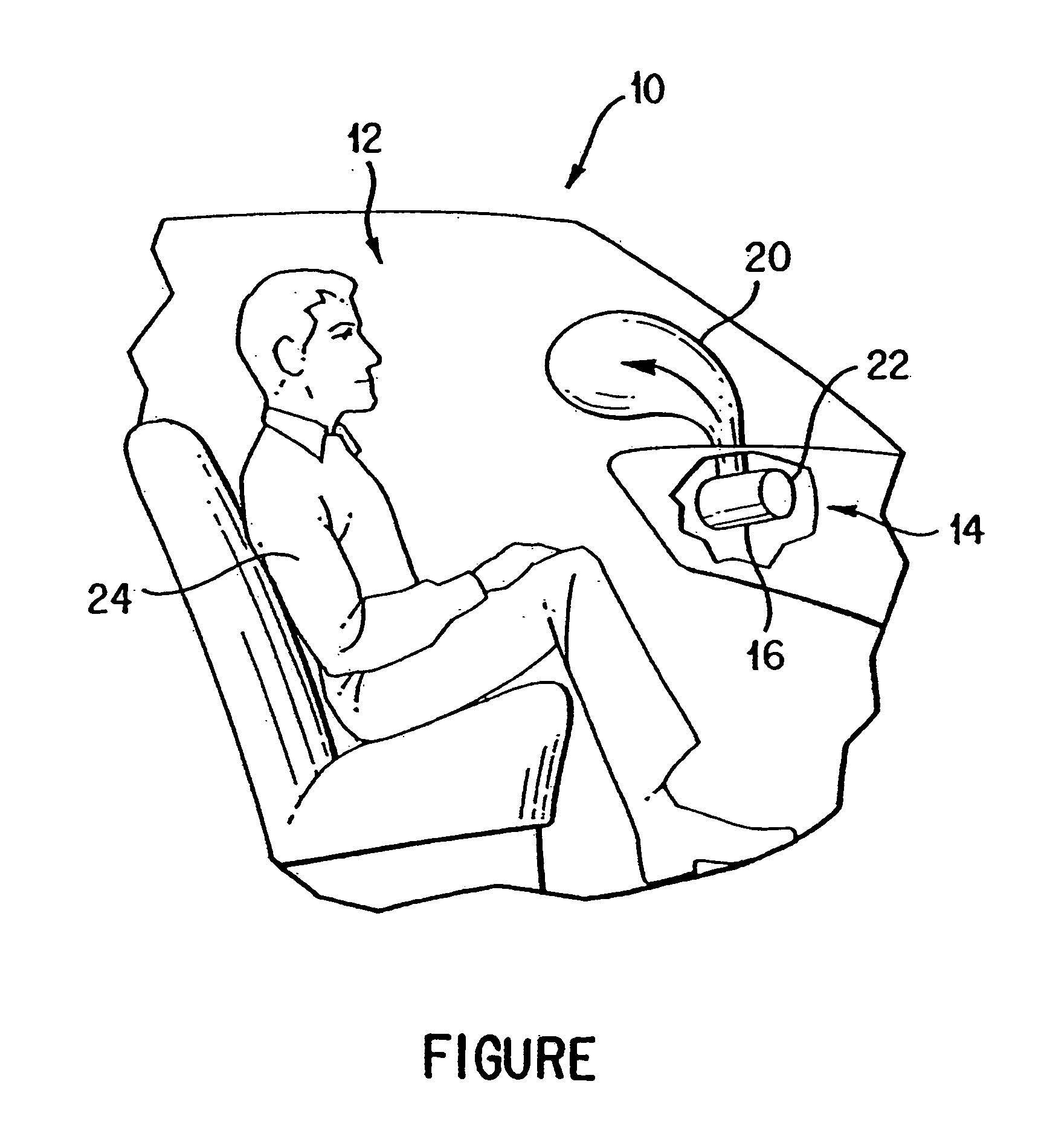

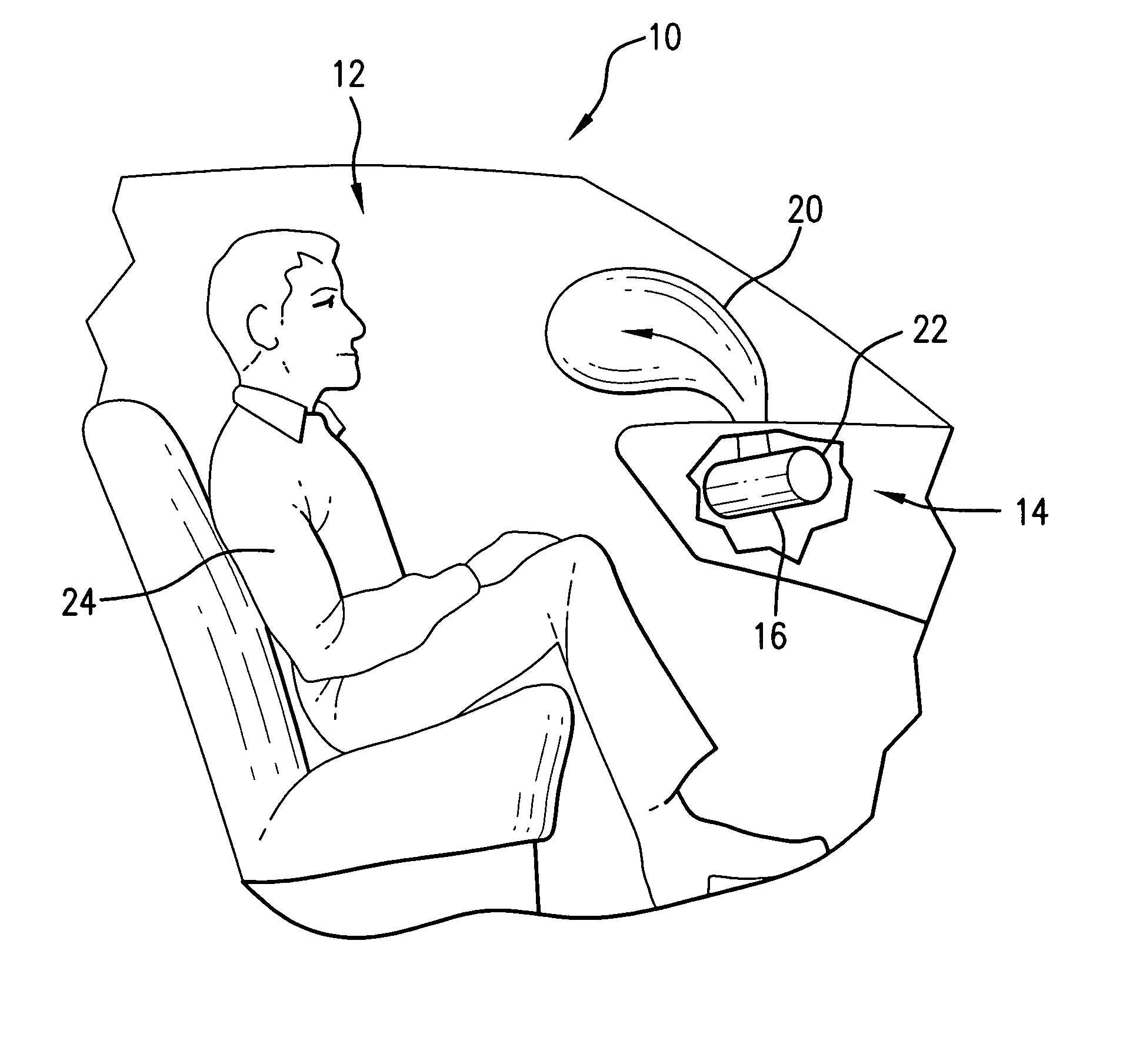

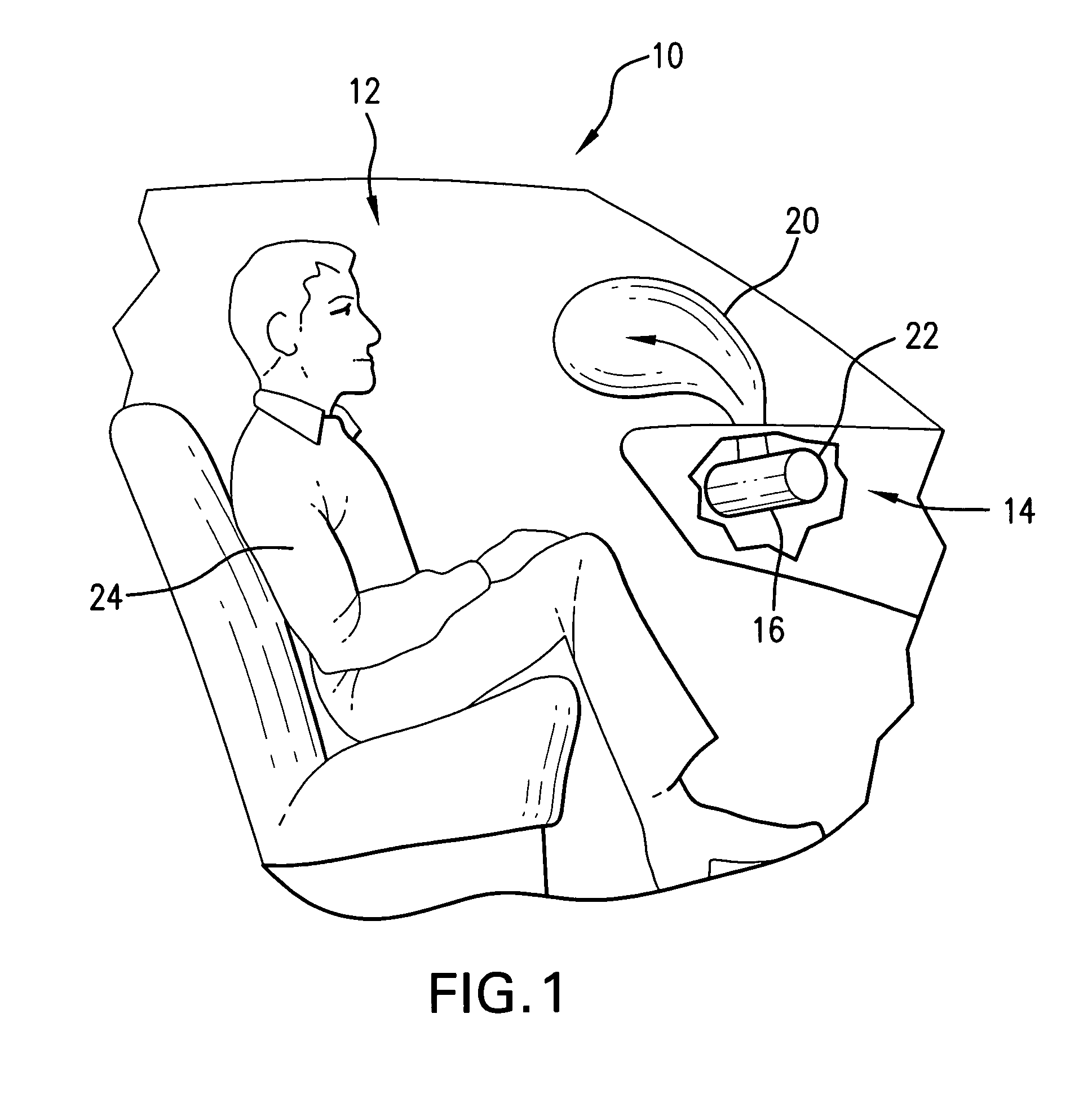

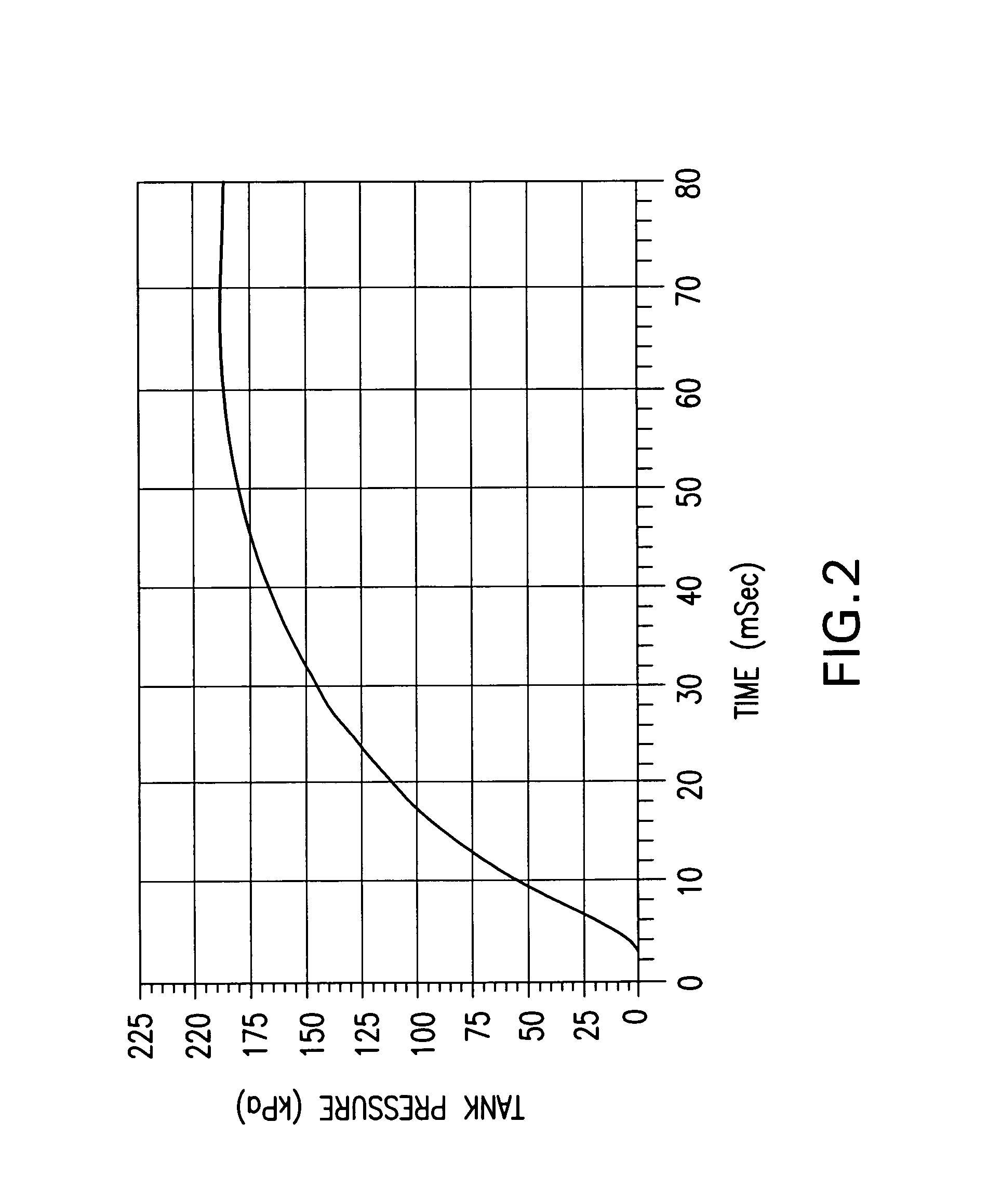

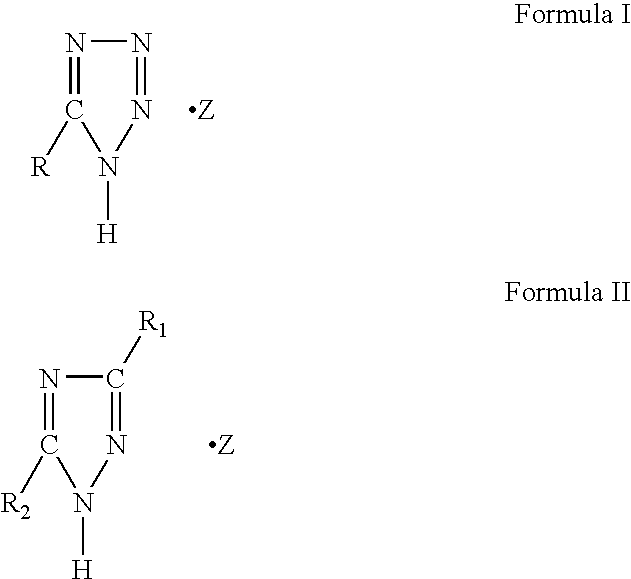

Smokeless gas generant compositions

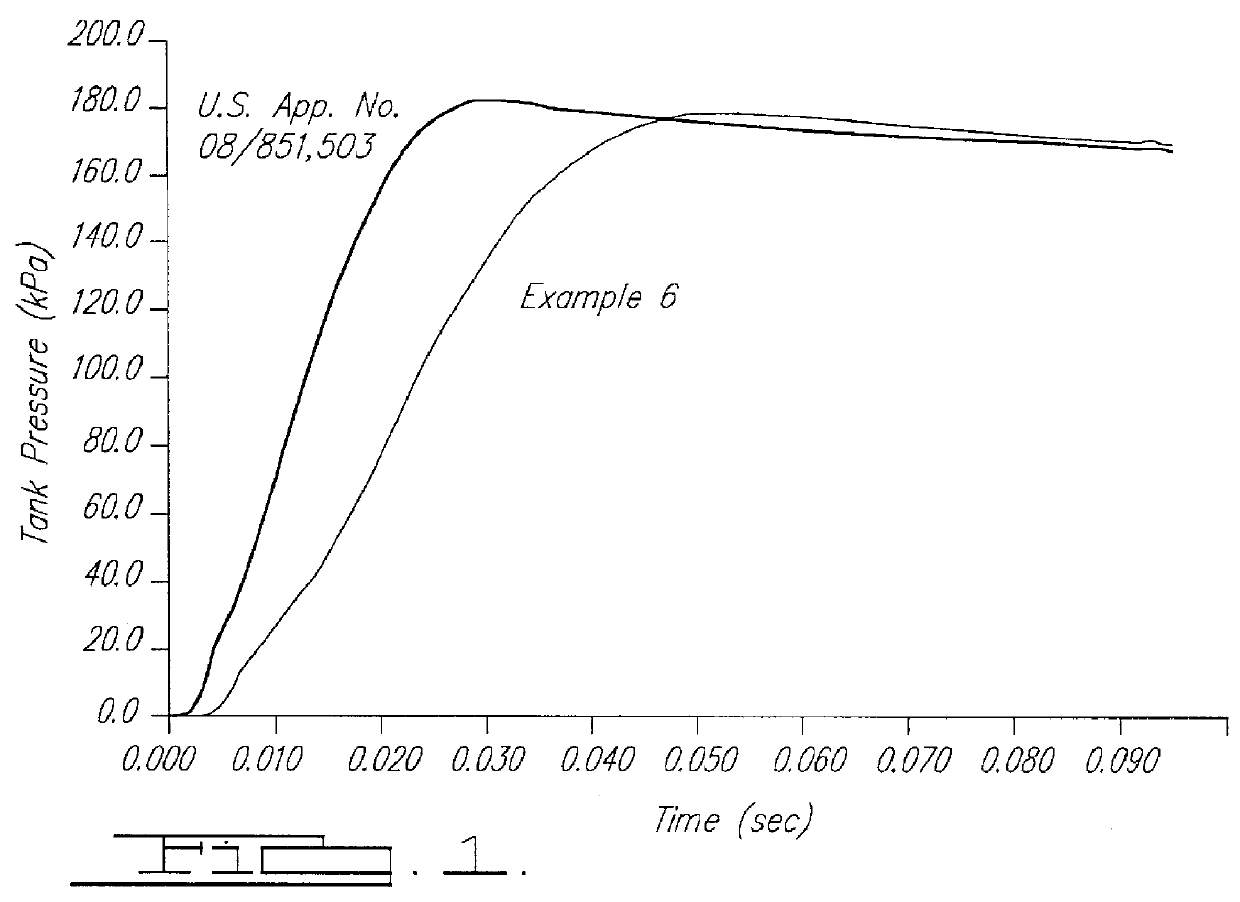

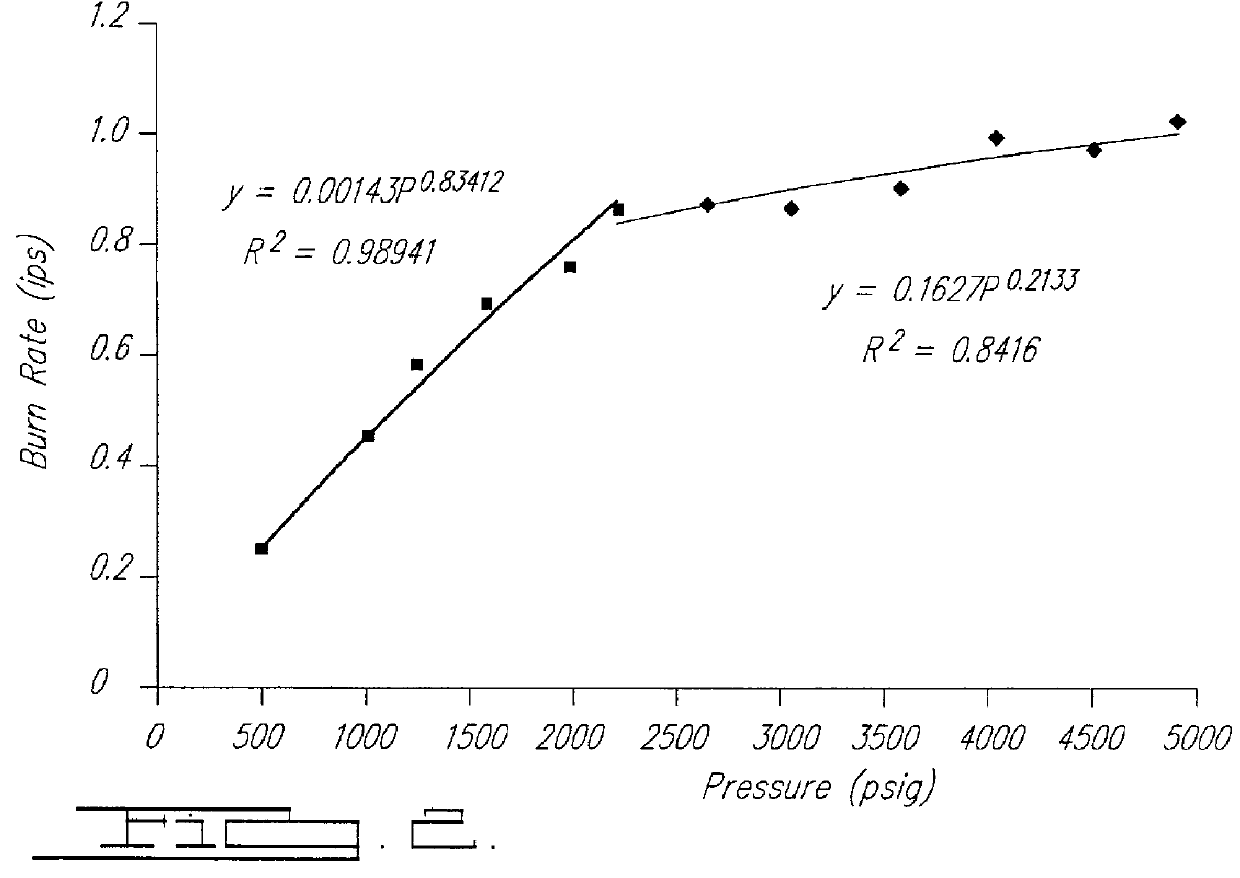

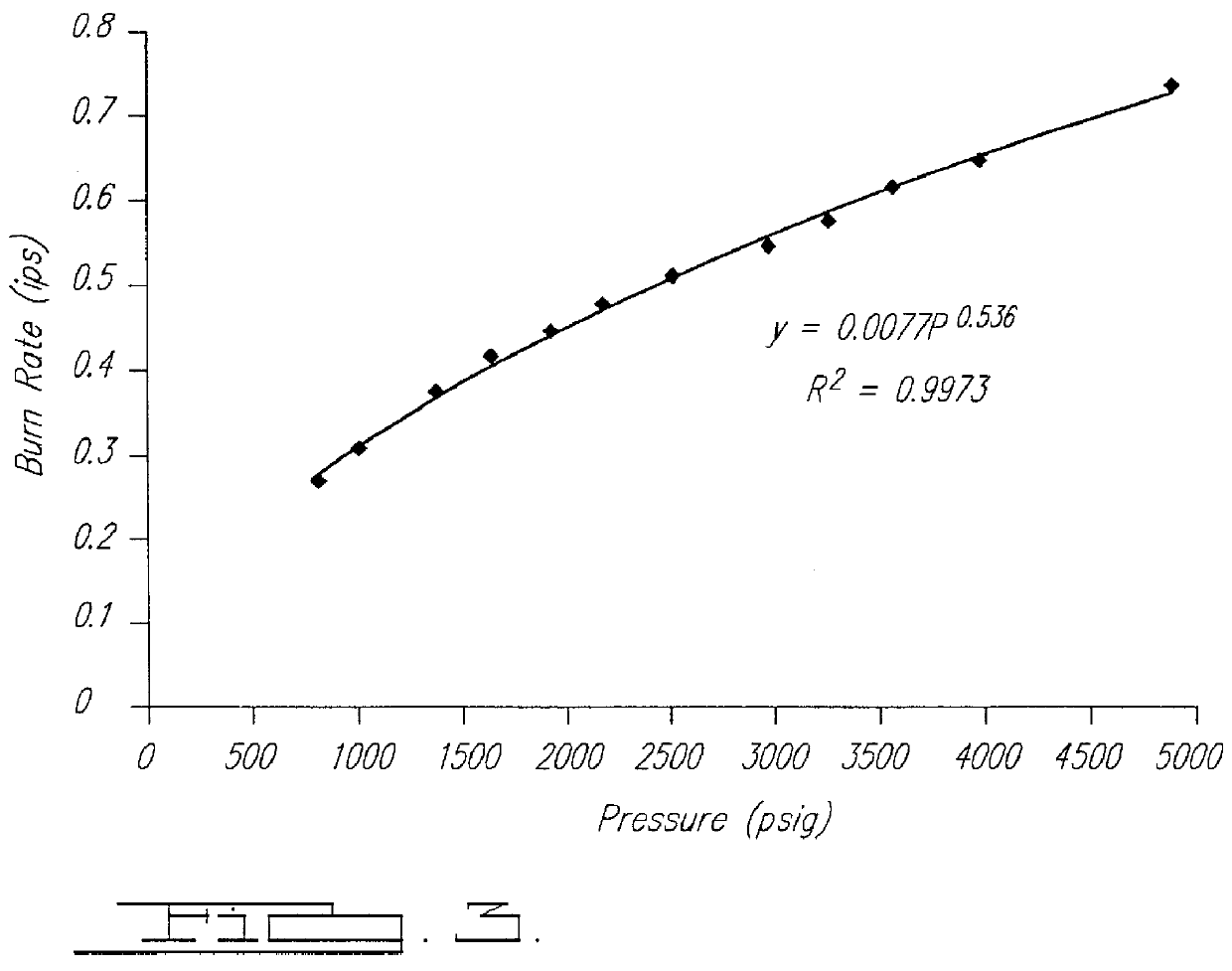

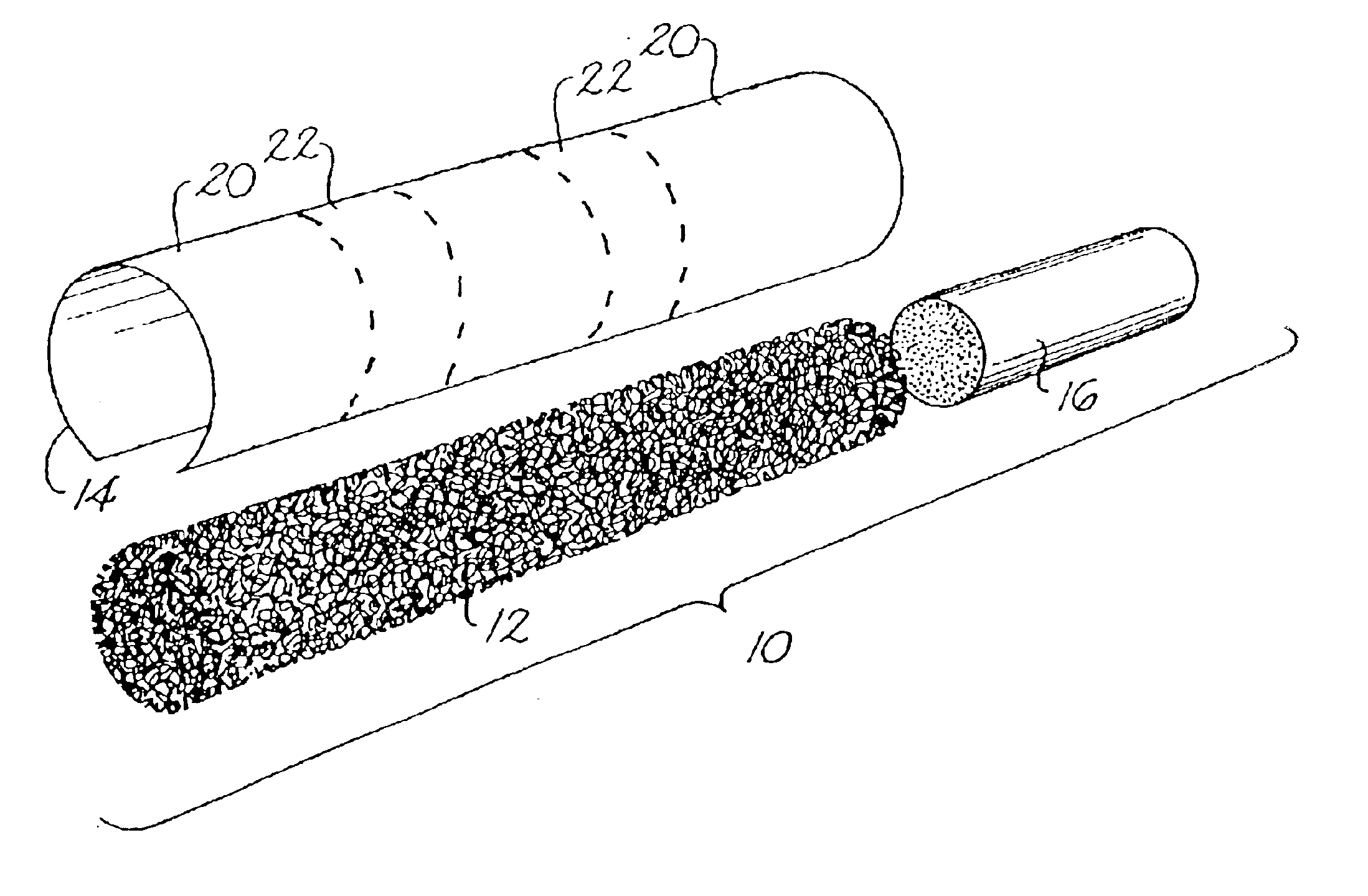

Thermally stable gas generant compositions incorporate a combination of one or more primary nonazide high-nitrogen fuels selected from a group including tetrazoles, bitetrazoles, and triazoles, and salts thereof; and one or more secondary nonazide high nitrogen fuels selected from azodicarbonamide and hydrazodicarbonamide. The primary and secondary fuels are combined with phase-stabilized ammonium nitrate that when combusted, results in a greater yield of gaseous products per mass unit of gas generant, a reduced yield of solid combustion products, lower combustion temperatures, and acceptable burn rates, thermal stability, and ballistic properties. These compositions are especially suitable for inflating air bags in passenger-restraint devices.

Owner:AUTOMOTIVE SYST LAB

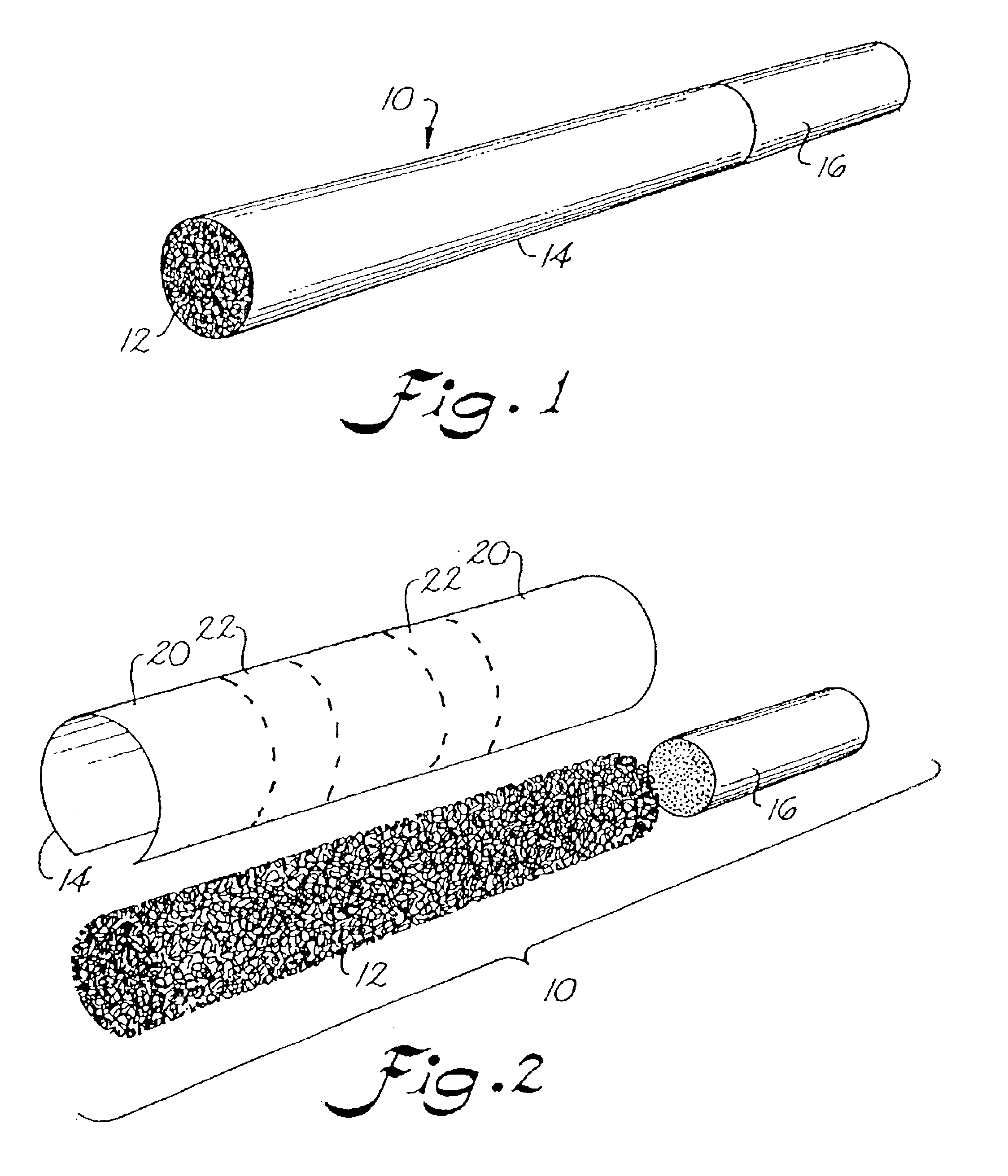

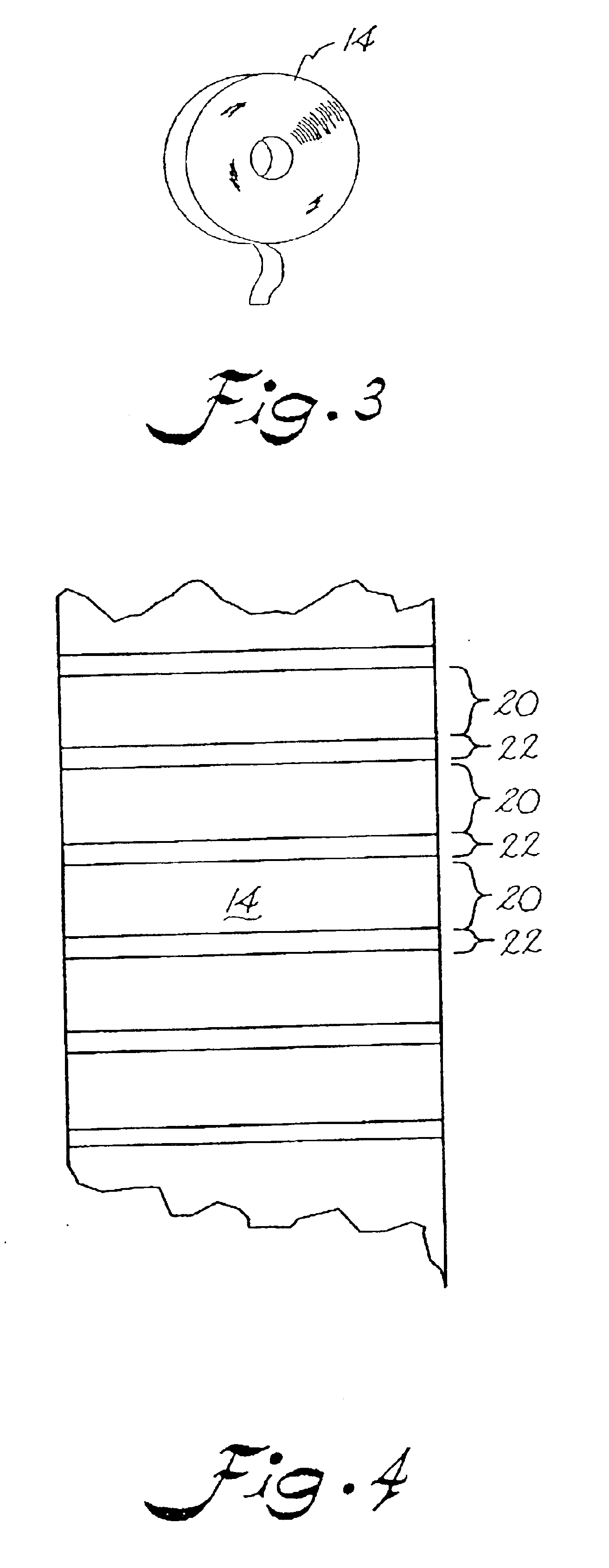

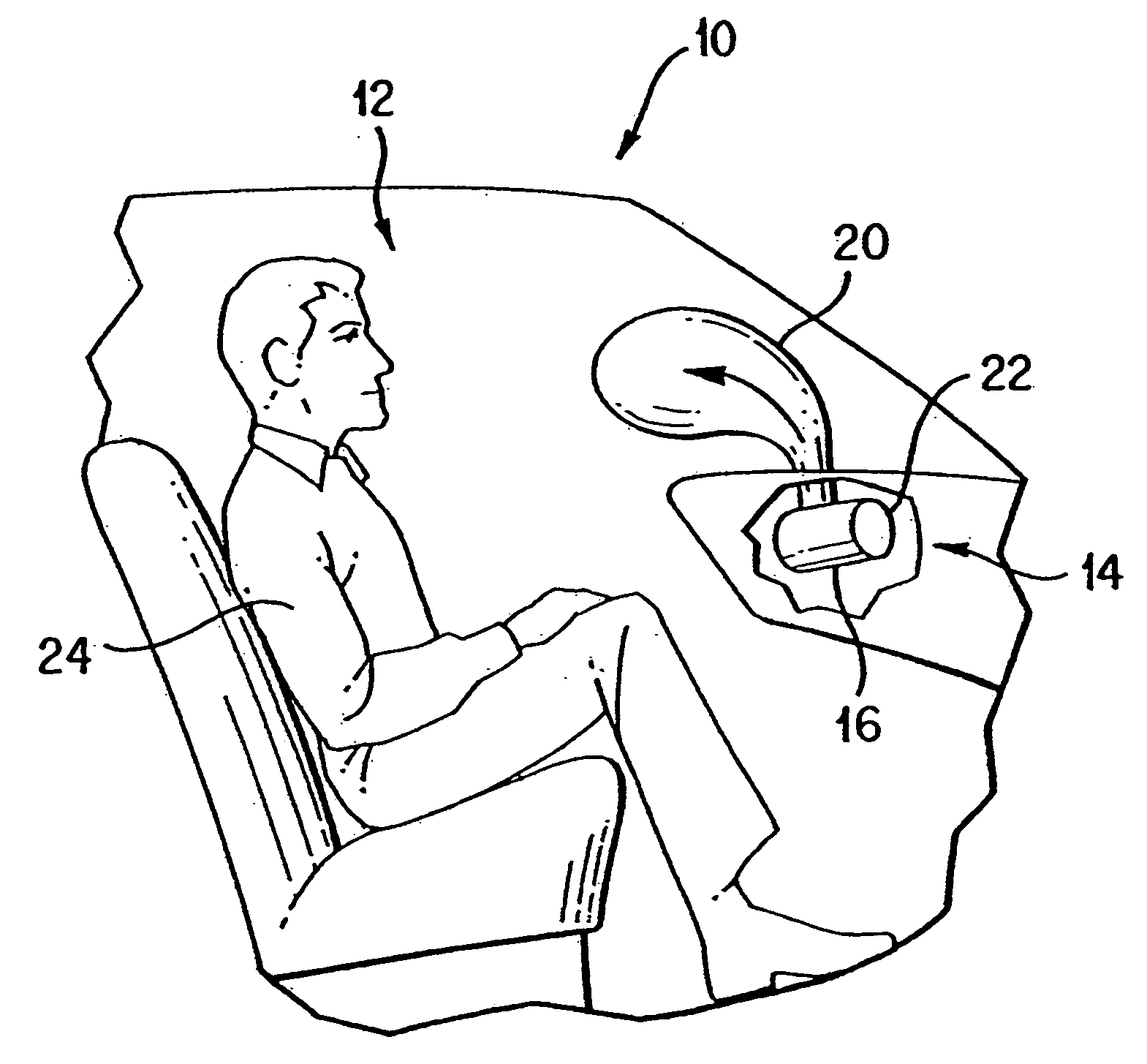

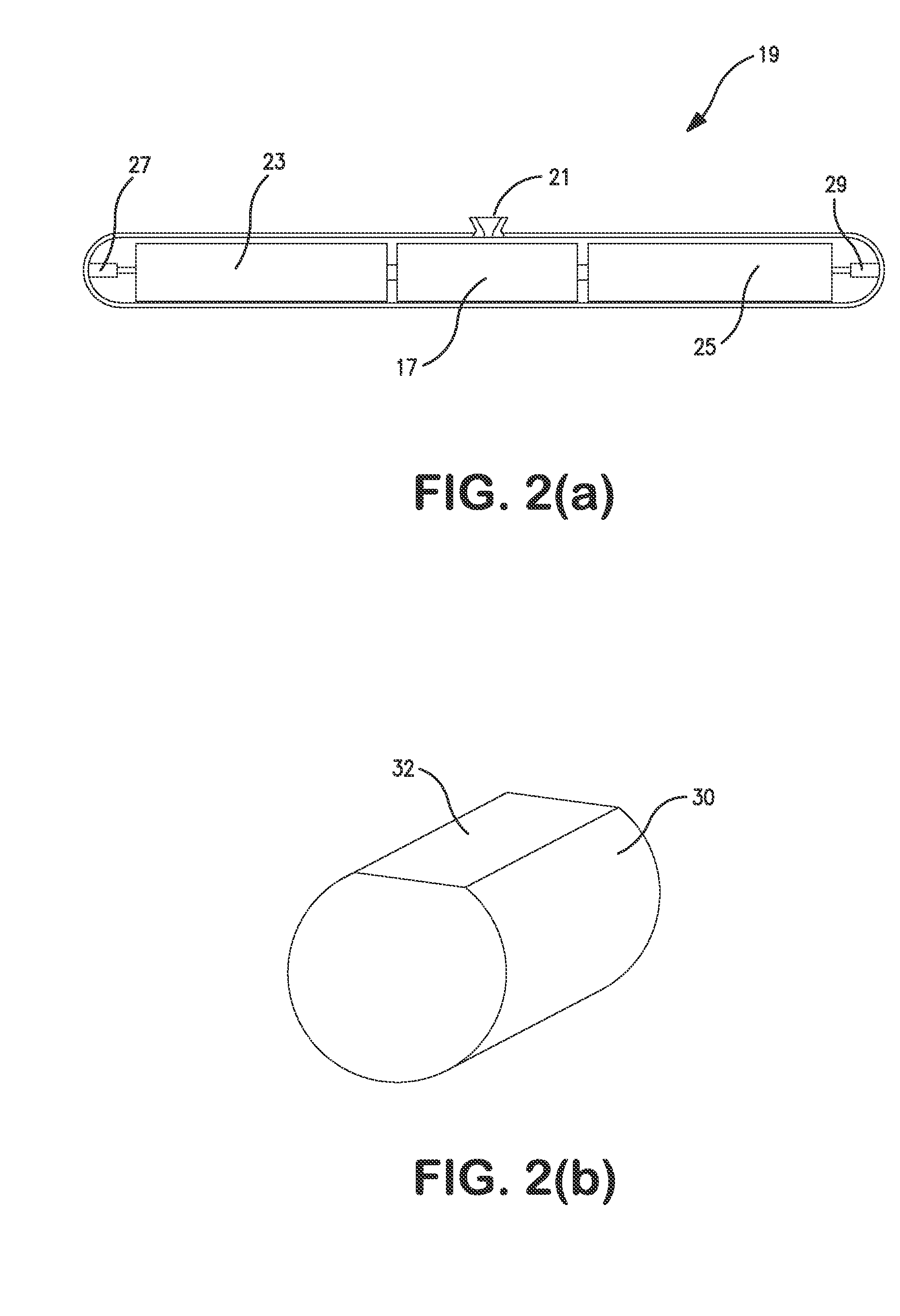

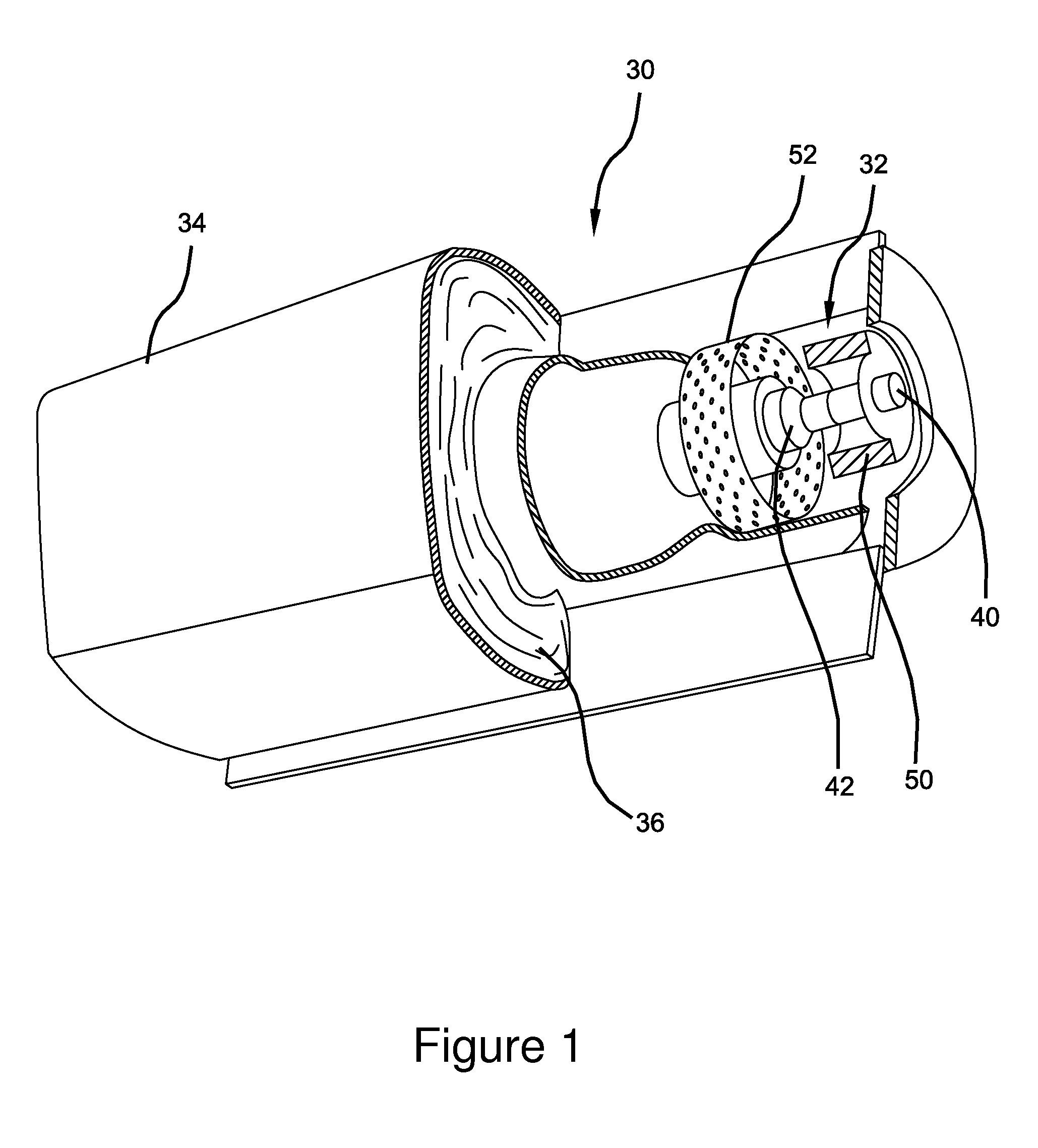

Reduced ignition propensity smoking article

InactiveUS6837248B2Reduced IPReduce penetrationNon-fibrous pulp additionNatural cellulose pulp/paperBurn rateEngineering

A smoking article having reduced ignition propensity is disclosed. The smoking article includes a tobacco column, a wrapper surrounding the tobacco column and a filter element. The wrapper has a base permeability, an untreated area and a least one discrete area treated with a composition to reducing the base permeability. The discretely treated area interacts with a coal of a burning tobacco firecone as it advances to self-extinguish the smoking article. The composition of the treated area includes a permeability reducing substance, a burn rate retarding substance and a burn rate accelerating substance. Either the burn rate retarding substance or the burn rate accelerating substance acts as an organoleptic enhancing substance. In this way a smoker's experience when smoking either the at least one treated area or the untreated area is substantially the same.

Owner:LORILLARD LICENSING

Gas generating composition for inflator containing melamine cyanurate

InactiveUS20050263224A1Low toxicitySafe handlingExplosivesPressure gas generationSimple Organic CompoundsBurn rate

To provide a gas generating composition for air bag which is low in toxicity, large in burning rate, and low in combustion temperature. Gas generating compositions comprising (a) melamine cyanurate or a mixture of melamine cyanurate and nitrogen-containing organic compound and (b) oxygen-containing oxidant, and gas generating compositions comprising (c) binder and (d) additive are provided.

Owner:DAICEL CHEM IND LTD

Substituted basic metal nitrates in gas generation

A material for a pyrotechnic composition and related pyrotechnic compositions are provided in which the material includes a substituted basic metal nitrate including a reaction product of an acidic organic compound and a basic metal nitrate. A method for enhancing a burn rate of a gas generant composition and a burn rate enhanced gas generant composition including a reaction product of basic metal nitrate and tetrazoles, tetrazole derivatives, and combinations thereof, and a nitrogen-containing co-fuel such as guanidine nitrate are also disclosed. The burn rate enhance gas generant composition may optionally include an additional oxidizer such as basic copper nitrate.

Owner:AUTOLIV ASP INC

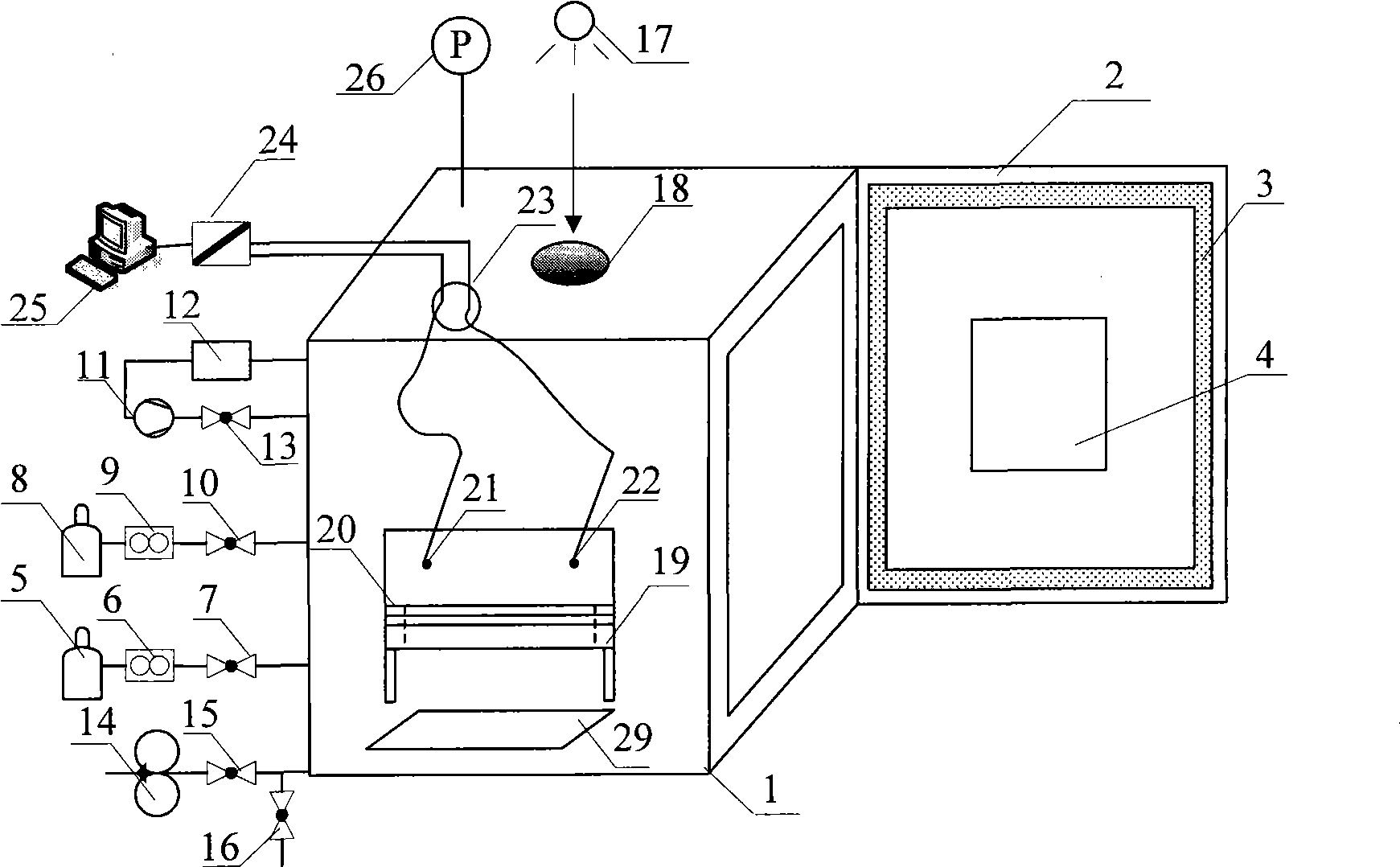

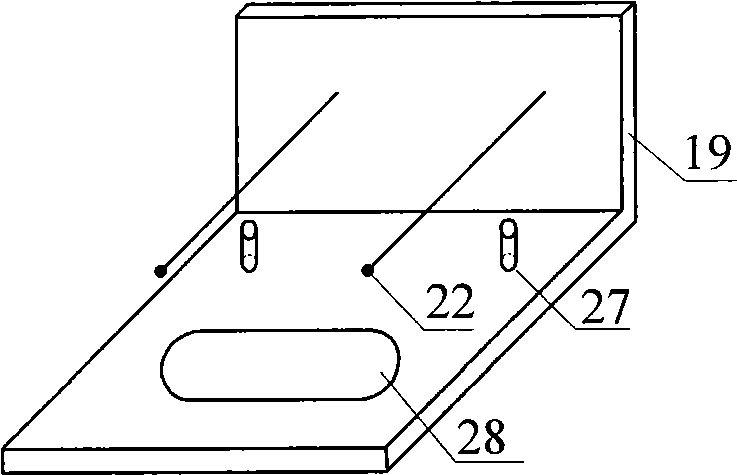

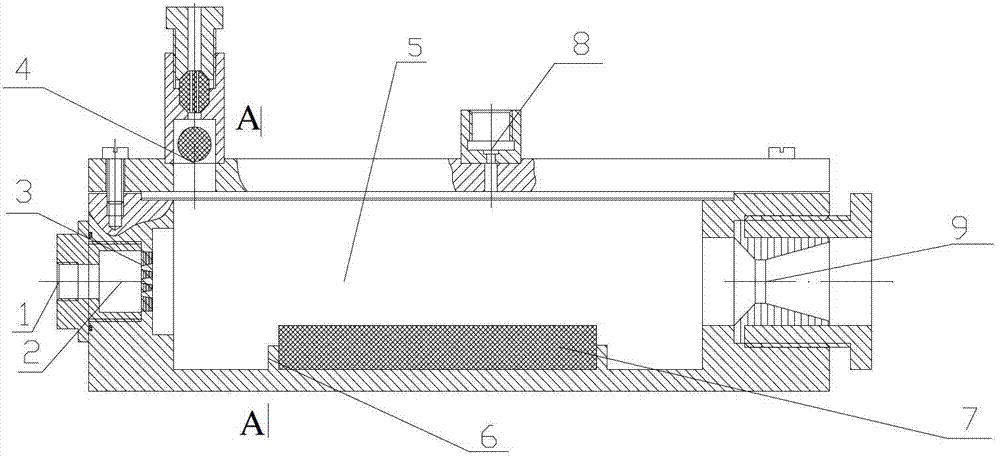

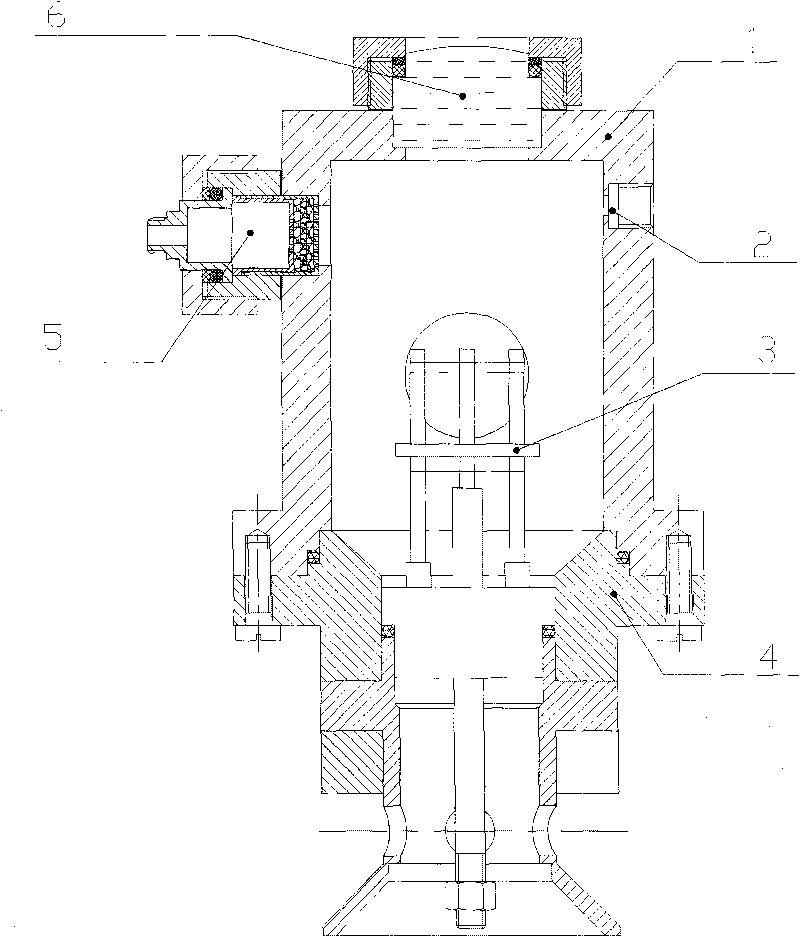

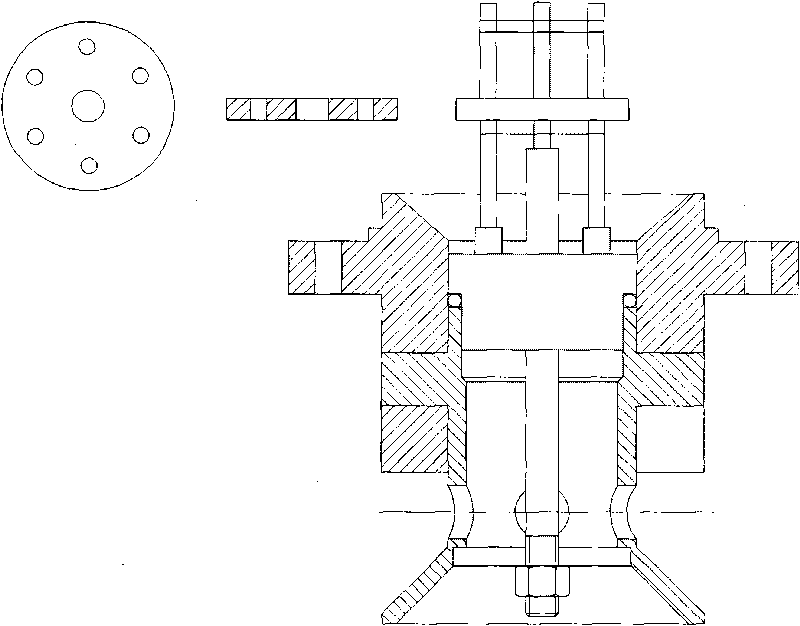

Combustible burning rate test device in plateau artificial oxygen-enriched environment

InactiveCN101509908AStable and reliable test performanceChemical analysis using combustionMaterial heat developmentCombustion chamberGas composition

The invention provides a testing device for the combustion rate of combustibles in a plateau artificial oxygen-enriched environment, belonging to a field of fire safety. The testing device consists of the following seven parts: a combustion chamber, a positioning mechanism, an air distribution system, an airflow-circulation and concentration-monitoring system, a vacuum-pumping system, an ignition system and a data acquisition system. A sample is arranged on a sample support by a sample clamper, and then vacuum-pumping is carried out to a sealed chamber by the vacuum-pumping system; each single high-purity gases are mixed in the sealed chamber after passing through a mass flowmeter and a flow regulating valve; the total pressure of the gases is displayed by a high-precision vacuum manometer; when the requirements of the total pressure of the gases and gas compositions are met, a micro-air pump is started to mix the airflow in the sealed chamber; a laser light source is started to ignite the sample after the concentration of the gas compositions is steady; the sample combustion flame passes through two thermocouples sequentially; temperature change curves of the thermocouples are obtained by A / D conversion and the data acquisition system; and the time between two maximum temperature points of the curves corresponding to the two thermocouples is taken as the combustion time of the sample between the thermocouples with fixed distance, thus obtaining the combustion rate of the sample under the total pressure of the gases and the concentration of the gas compositions. The testing device has stable and reliable testing performance, and is simple and convenient.

Owner:UNIV OF SCI & TECH BEIJING

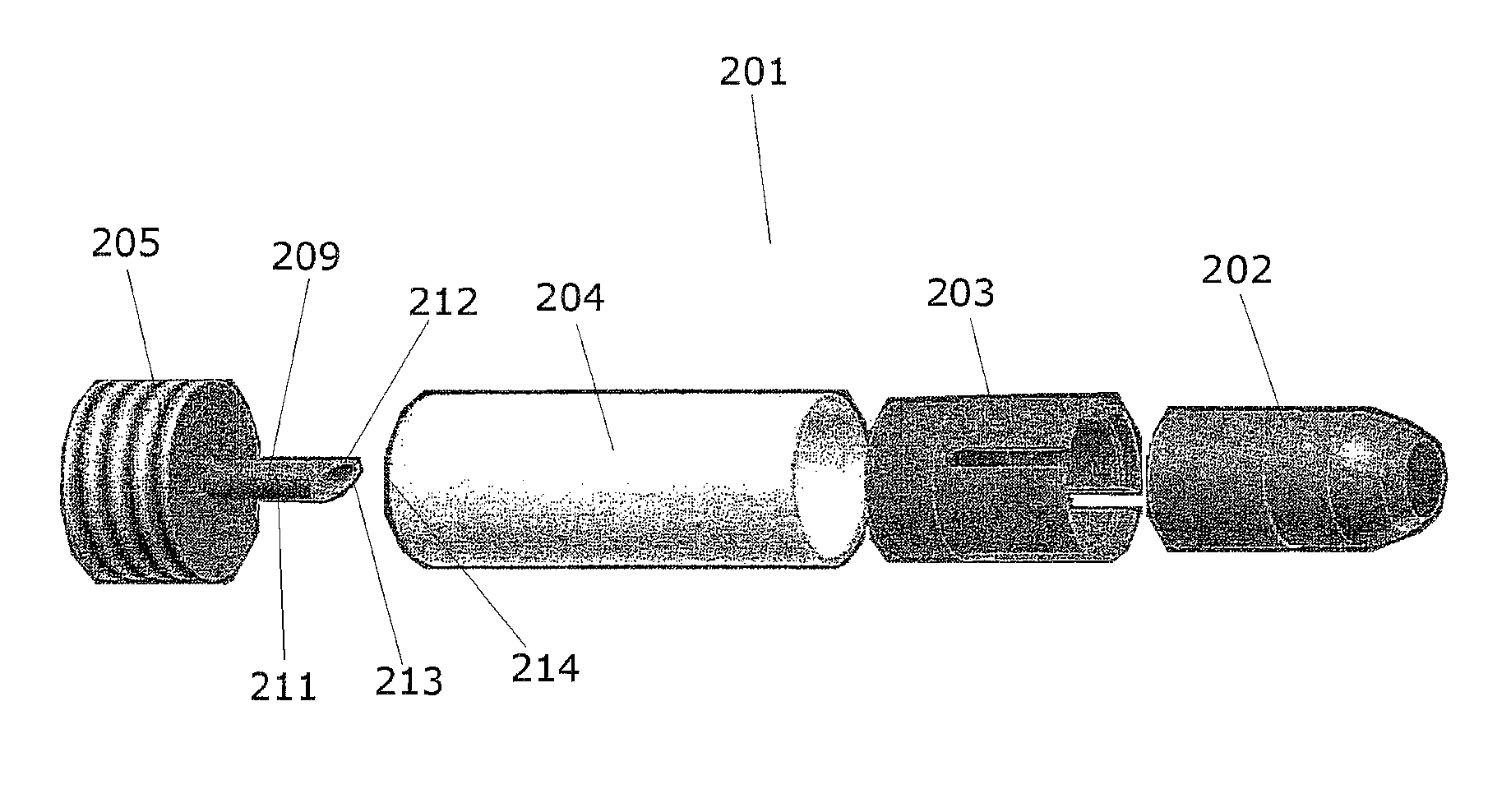

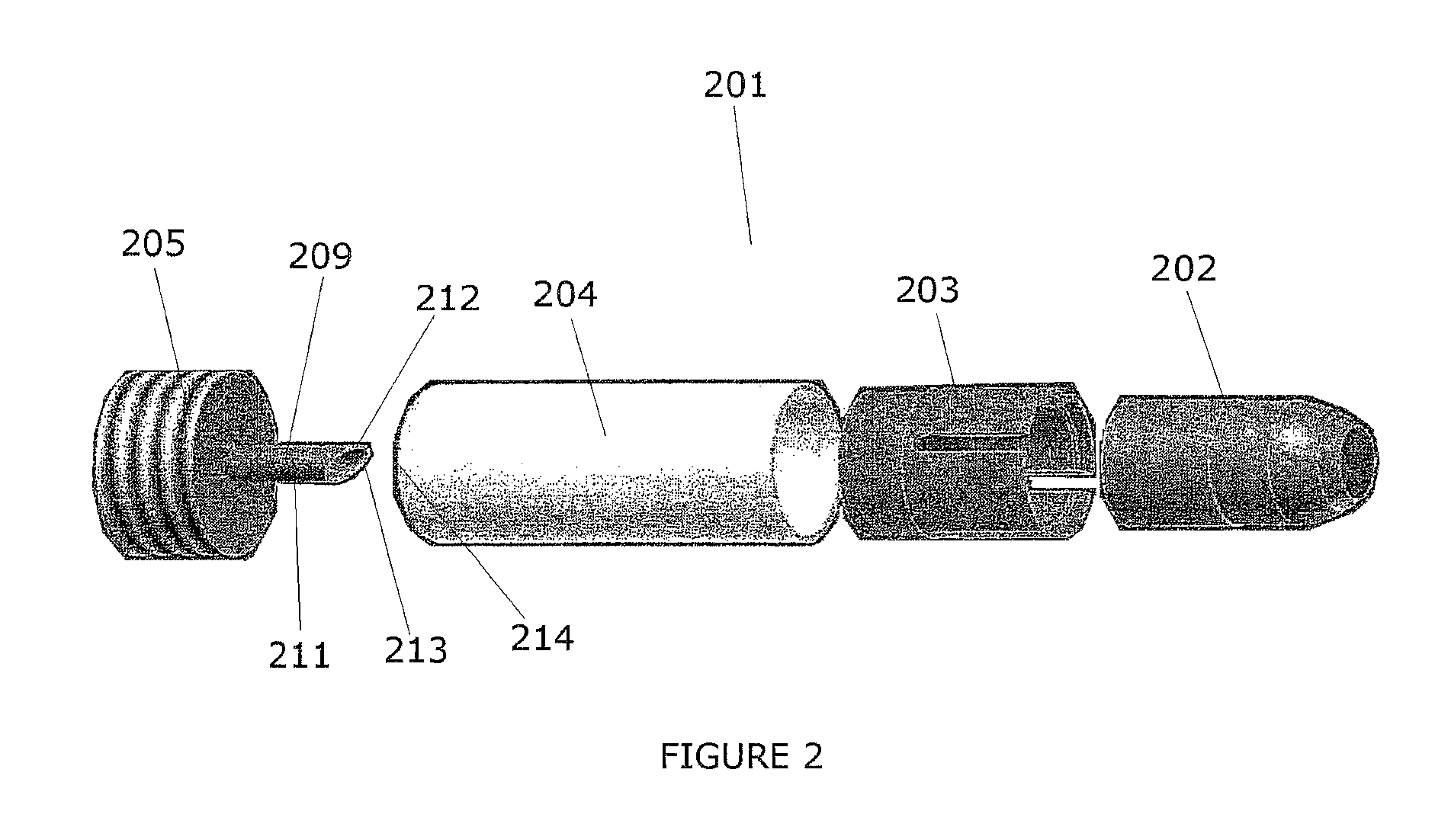

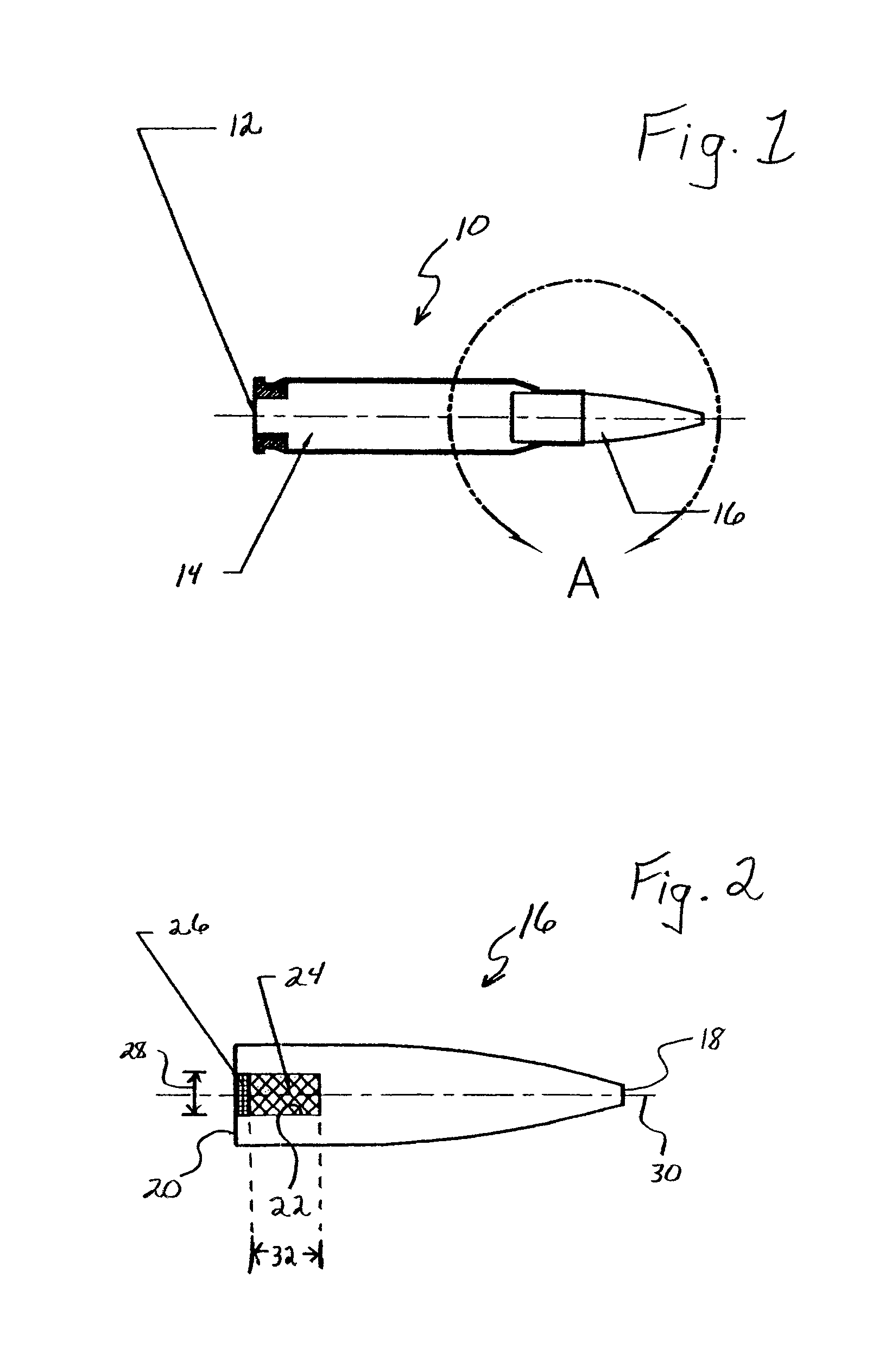

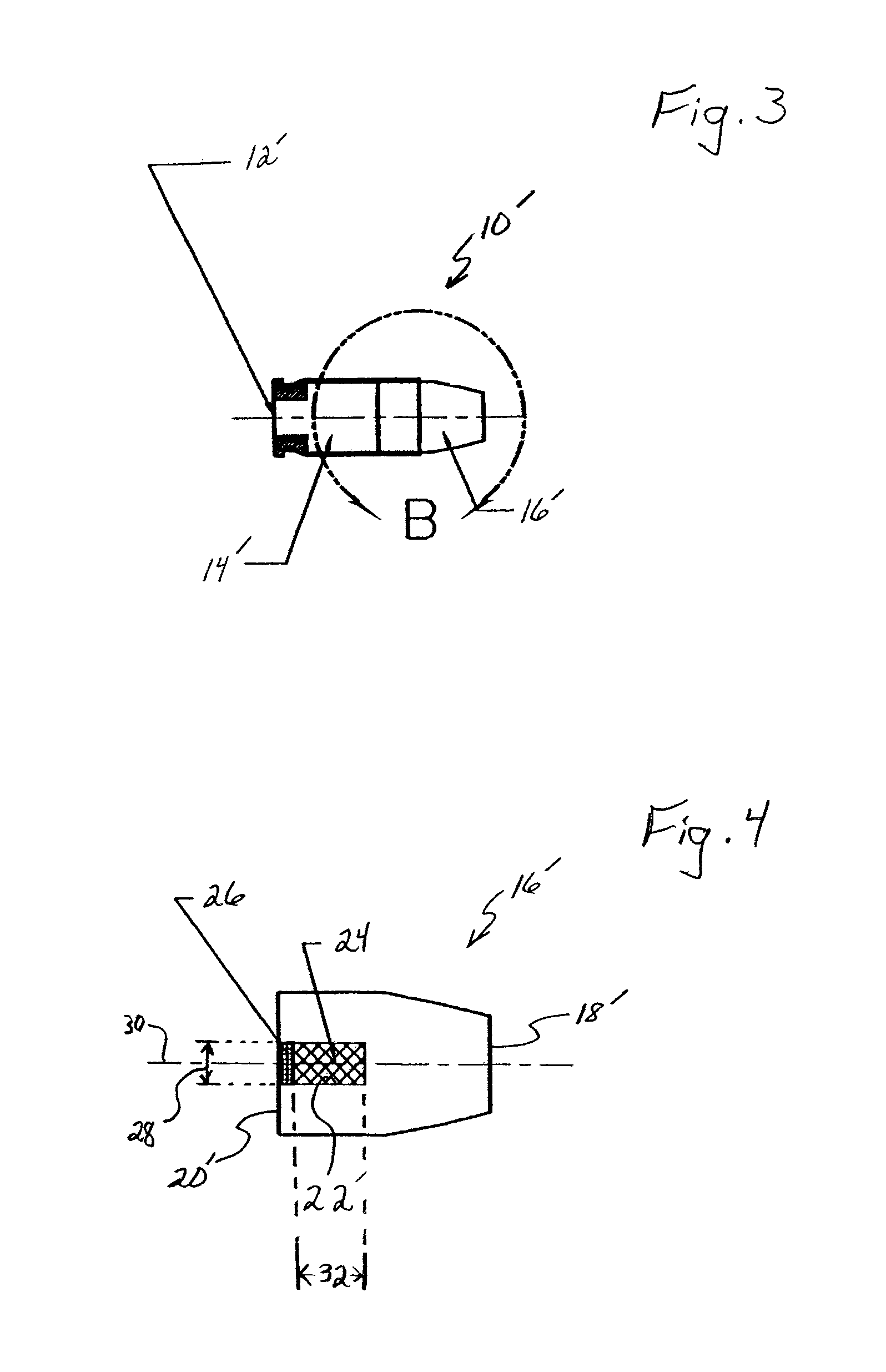

Muzzleloader ammunition

ActiveUS7726245B2Accurate CalibrationAmmunition projectilesFiring/trigger mechanismsBurn rateEnergetic material

A fixed round of ammunition for a muzzle loader firearm. The round has a bullet within a sabot that is engaged to a consumable cartridge case. The case is filled with propellant that is precisely calibrated to provide optimal ballistic properties with the particular bullet it is engaged to. The consumable cartridge case can be more tailored to respectively increase or decrease the burn rate of the consumable cartridge case. The consumable cartridge case can be constructed out of nitrocellulose or other energetic materials. A wide range of propellant formulas can be used that are safe because the burn rate is precisely calibrated for the bullet used. The propellant can contain pyrotechnic material and / or other ingredients to reduce the burn rate of a smokeless propellant and can contain a stabilizer to increase the shelf life of the ammunition round.

Owner:FEDERAL CARTRIDGE

Reduced ignition propensity smoking article

A smoking article having reduced ignition propensity is disclosed. The smoking article includes a tobacco column, a wrapper surrounding the tobacco column and a filter element. The wrapper has a base permeability, an untreated area and a least one discrete area treated with a composition to reducing the base permeability. The discretely treated area interacts with a coal of a burning tobacco firecone as it advances to self-extinguish the smoking article. The composition of the treated area includes a permeability reducing substance, a burn rate retarding substance and a burn rate accelerating substance. Either the burn rate retarding substance or the burn rate accelerating substance acts as an organoleptic enhancing substance. In this way a smoker's experience when smoking either the at least one treated area or the untreated area is substantially the same.

Owner:LORILLARD LICENSING

Gas generant materials

InactiveUS20060054257A1Simple compositionReduce sensitivityNon-explosive/non-thermic compositionsPressure gas generationAzideBurn rate

A gas generant composition includes a non-azide, organic, nitrogen-containing fuel; a substituted basic metal nitrate and at least one transition metal complex of diammonium bitetrazole. The substituted basic metal nitrate can be a reaction product of an acidic organic compound and a basic metal nitrate. The transition metal complex of diammonium bitetrazole is effective to enhance the burn rate presure sensitivity of the gas generant composition as compared to the same gas generant composition without inclusion of the at least one transition metal complex of diammonium bitetrazole.

Owner:AUTOLIV ASP INC

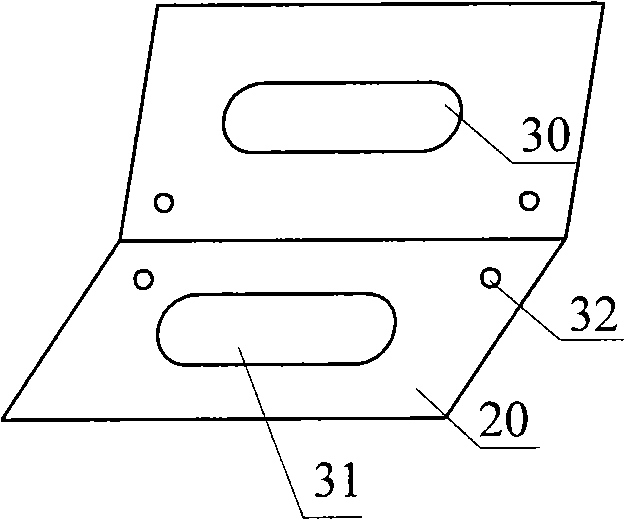

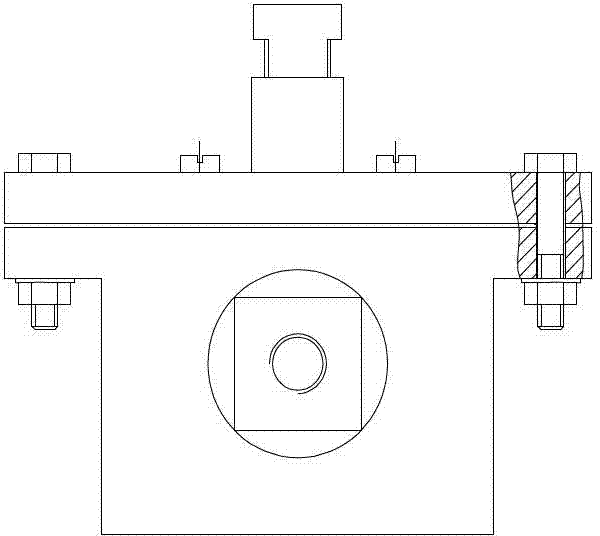

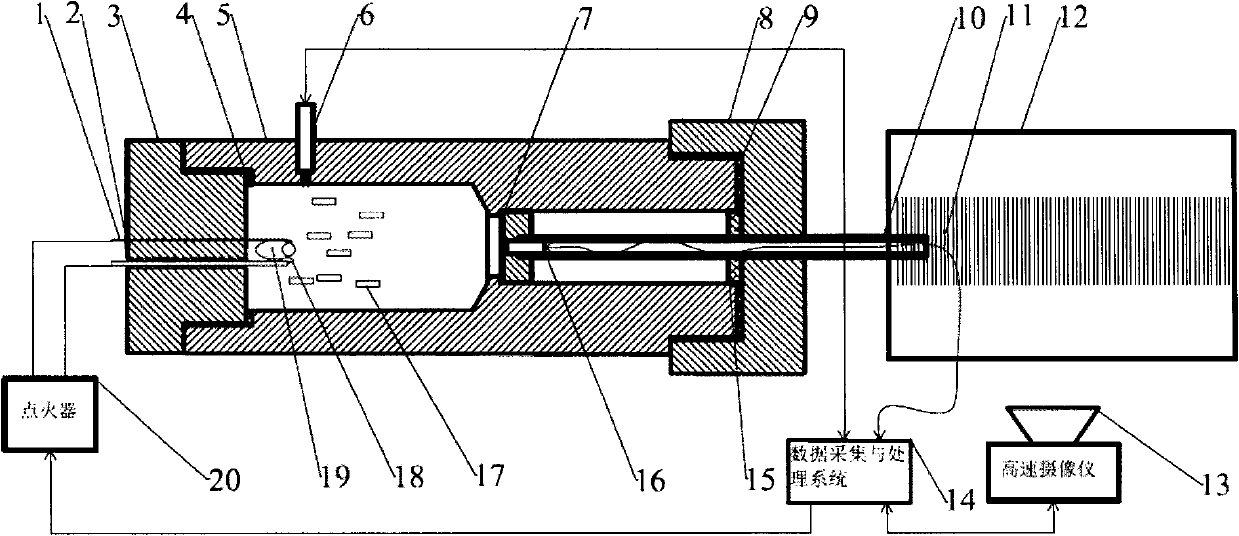

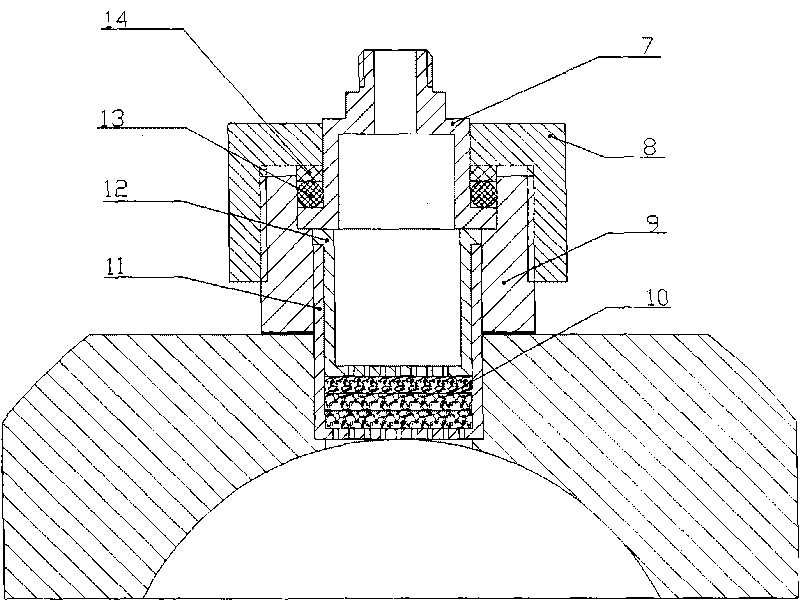

Solid fuel regression rate test device

InactiveCN102854284AReduce complexityLow costChemical analysis using combustionCombustion chamberSprayer

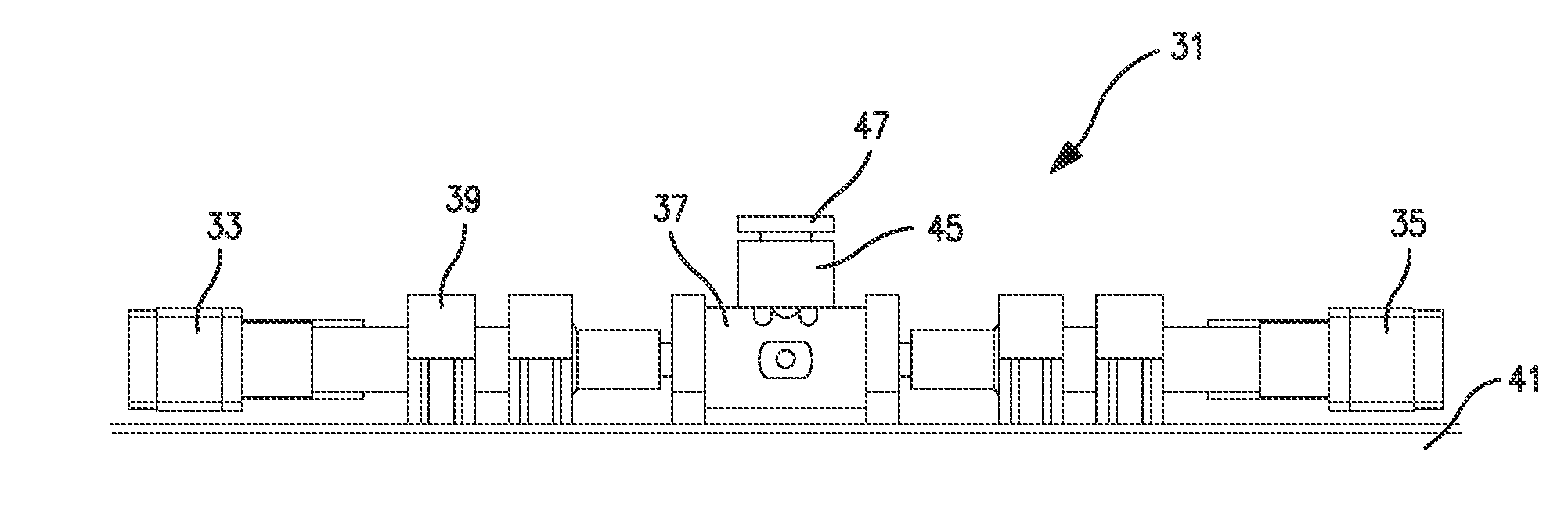

The invention discloses a solid fuel regression rate test device. According to the invention, a combustion chamber with a rectangular recess structure is adopted. An igniter is arranged on the front of an upper cap, and communicates with the combustion chamber. A pressure measurement port is fixed on the middle of the upper cap, and communicates with the combustion chamber. An air inlet pipe is connected to a balancing chamber. An air inlet plate is positioned between the balancing chamber and the combustion chamber. A Laval sprayer nozzle is fixed on the back part of the combustion chamber. A fixing slot is positioned at a central part on the bottom in the combustion chamber. An agent column is placed in the fixing slot, and testing can be carried out. During the operation of the test device, combustion chamber pressure intensity and oxidant flow are both adjustable. Through the changes on the pressure intensity and the flow, a functional relationship between a burning rate and the pressure intensity and the oxidant flow can be obtained, such that test complexity can be effectively reduced. The test device provided by the invention has the advantages of simple structure, low cost, easy processing, and safe and reliable operation. With the test device, the solid fuel regression rate of a hybrid rocket motor can be tested. The test device has low requirements on various propellants. Once a propellant is prepared into a rectangular body, testing can be carried out by using the test device provided by the invention.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

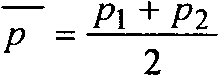

Propellant powder variable capacity burning rate testing device

InactiveCN101907426AResearch Influencing FactorsSolve the technical problem that the bomb bottom pressure cannot be directly measuredAmmunition testingCombustion chamberPressure curve

The invention discloses a propellant powder variable capacity burning rate testing device, belonging to the explosive property test field. The technical characteristics include that a pressure sensor is respectively arranged on the wall of a combustion chamber and a piston, the piston and a piston cavity are in slide fit, a piston rod fixedly connected with the piston is used for leading the connecting wire of the sensor in the piston to the outside of the piston cavity, and ignition cartridge bag and propellant powder to be tested are placed in the combustion chamber; when in test, the propellant powder to be tested is burned in the combustion chamber and the piston is pushed to move, the two pressure sensors respectively record pressure curves of combustion chamber fixed position and piston bottom, namely curve p1-t and curve p2-t, and a high speed camera record piston rod moving stroke-time curve, namely L-t curve; and computing and processing are carried out by virtue of a data acquisition and processing system, thus finally obtaining the burning rate pressure coefficient and burning rate pressure index of propellant powder to be tested. The invention not only solves the problem of measuring propellant powder variable capacity burning rate but also solves the technical problem that cartridge bottom pressure measurement is simulated.

Owner:XIAN MODERN CHEM RES INST

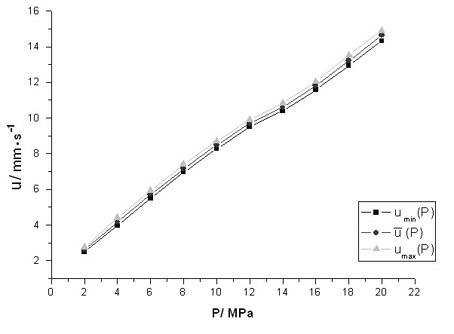

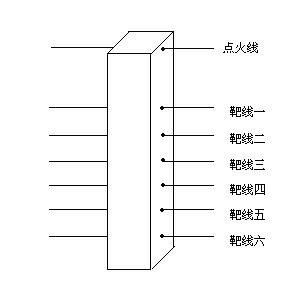

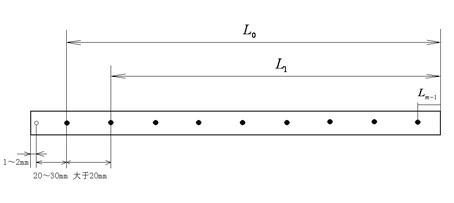

Method for testing multi-target line quasi dynamic combustion performance of solid propellant

InactiveCN102175830AShorten the development and production cycleEasy detectionFuel testingCombustion chamberBurn rate

The invention discloses a method for testing the multi-target line quasi dynamic combustion performance of a solid propellant, comprising the following steps: (1) testing static burning rates of a solid propellant to be tested under various pressures from low pressure to high pressure, so as to obtain the relation curve of the average combustion rate and pressure, the relation curve of the maximum effective combustion rate and the test pressure, and the relation curve of the minimum effective combustion rate and the test pressure; (2) performing a combustion pressurization test for a solid propeller sample under a close state, so that the pressure reaches the pressure range to be tested; (3) drilling 6-10 target holes on the covered solid propeller sample, and enabling the target lines and an ignition wire to pass through the target holes; (4) predetermining an initial pressure and an initial temperature, igniting the solid propeller sample in a close combustion chamber, and recording the fusing time of each target line during the combustion procedure of the solid propeller sample; and (5) obtaining the dynamic relation of the combustion length, pressure, temperature and time during the combustion procedure of the solid propeller via analysis, and calculating the combustion rate, combustion rate pressure index and combustion rate temperature sensitive coefficient of the solid propeller sample in a certain pressure range. The method disclosed by the invention is suitable for fast detecting performance, controlling quality and the like for each batch of products during the production procedure of the solid propeller, and can shorten the research and production period of the solid propeller and reduce the cost.

Owner:XIAN MODERN CHEM RES INST +1

Diesel particulate filter

InactiveUS20060245985A1Increasing particulate burning rateEasy to oxidizeCombination devicesLoose filtering material filtersRare-earth elementMixed oxide

The present invention is intended to configure a diesel particulate filter to allow the burning rate of particulates to increase even with a small amount of catalytic metal or even without using any catalytic metal. In the diesel particulate filter, walls forming exhaust gas channels in a filter body on which the particulates are trapped are coated with a catalyst layer for promoting the burning of the trapped particulates. The catalyst layer contains a mixed oxide in which Ce, Zr and a rare earth element R other than Ce are contained in a Ce / (Ce+Zr) mole ratio between 10% and 90% both inclusive or between 20% exclusive and 80% inclusive.

Owner:MAZDA MOTOR CORP

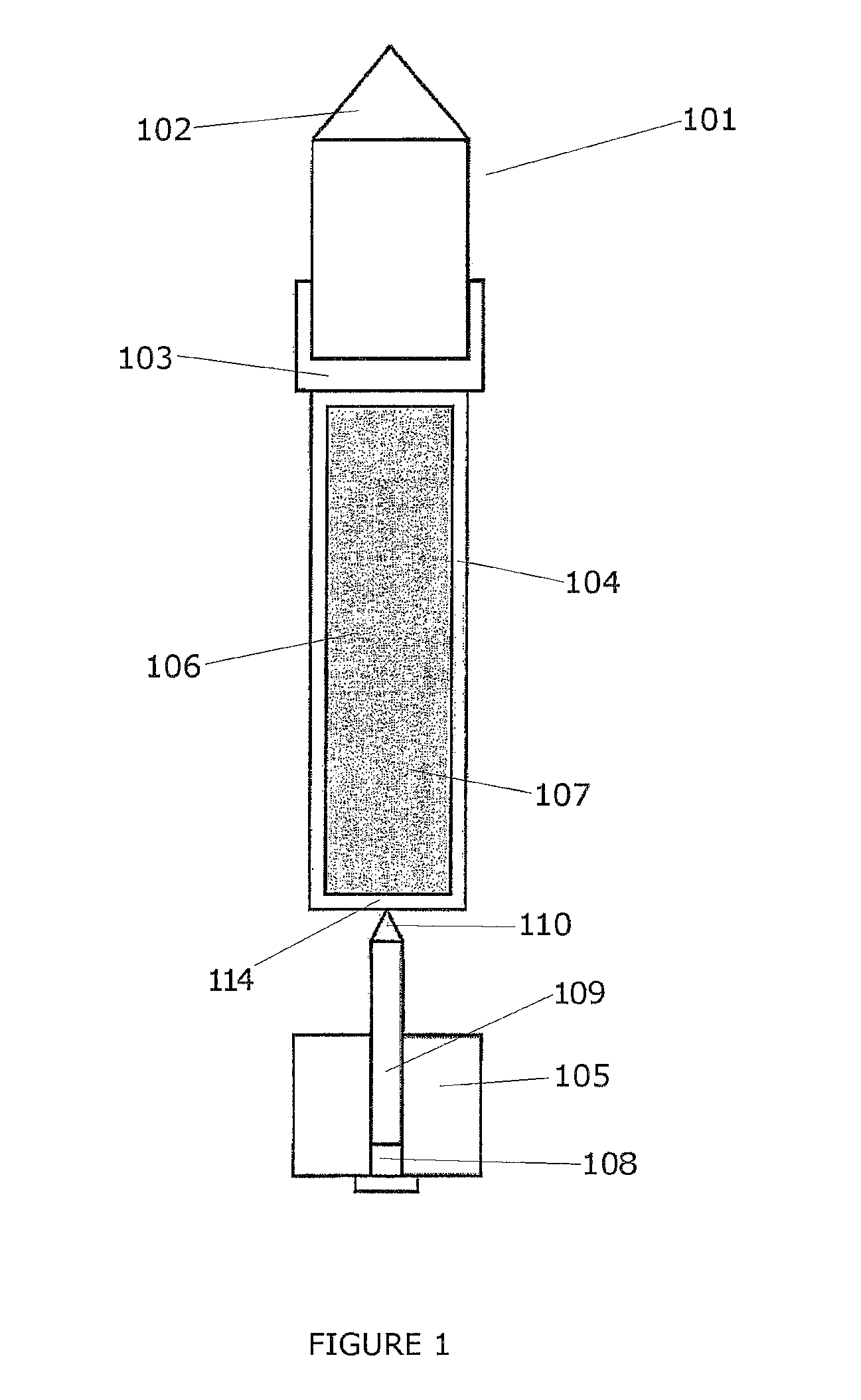

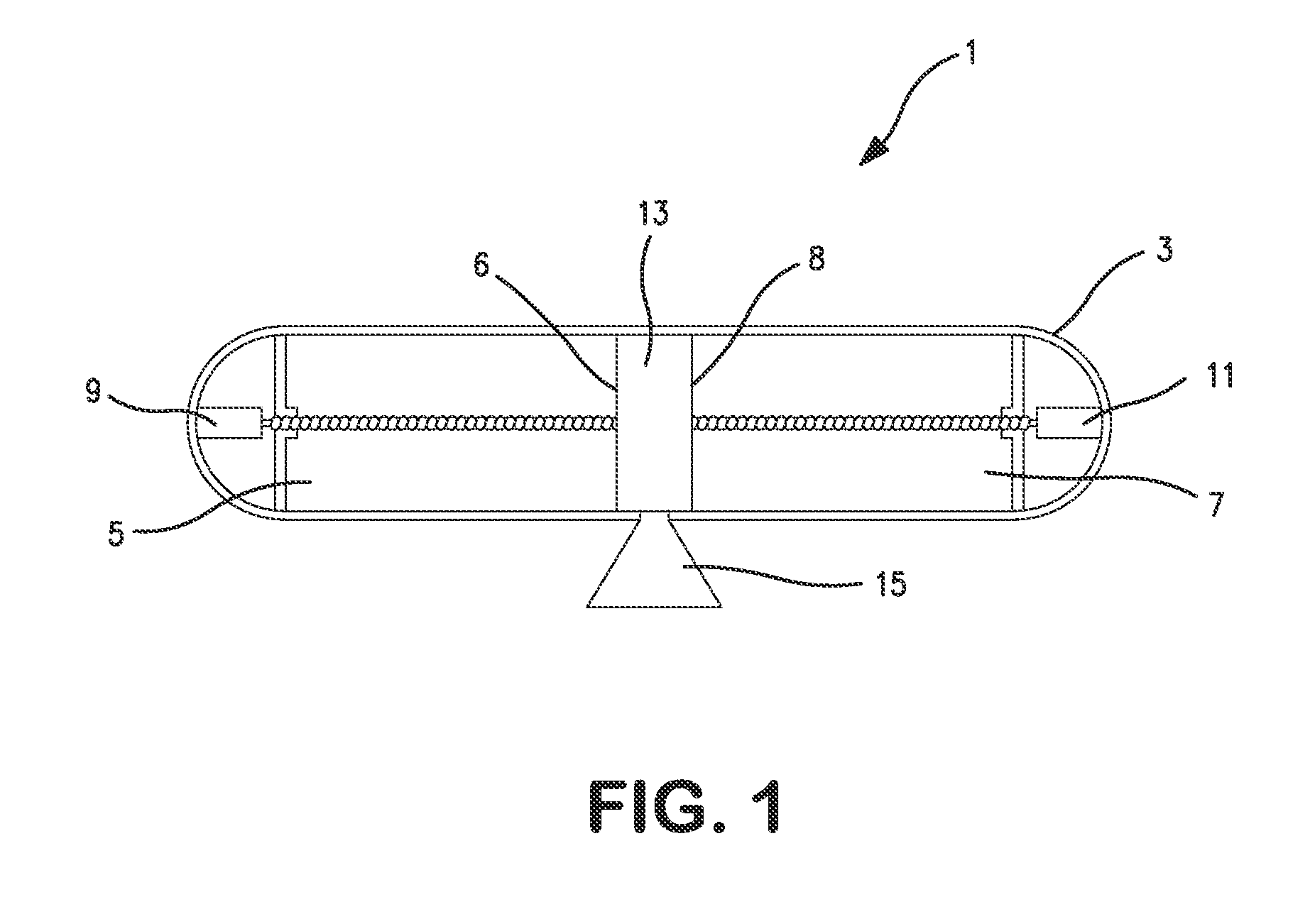

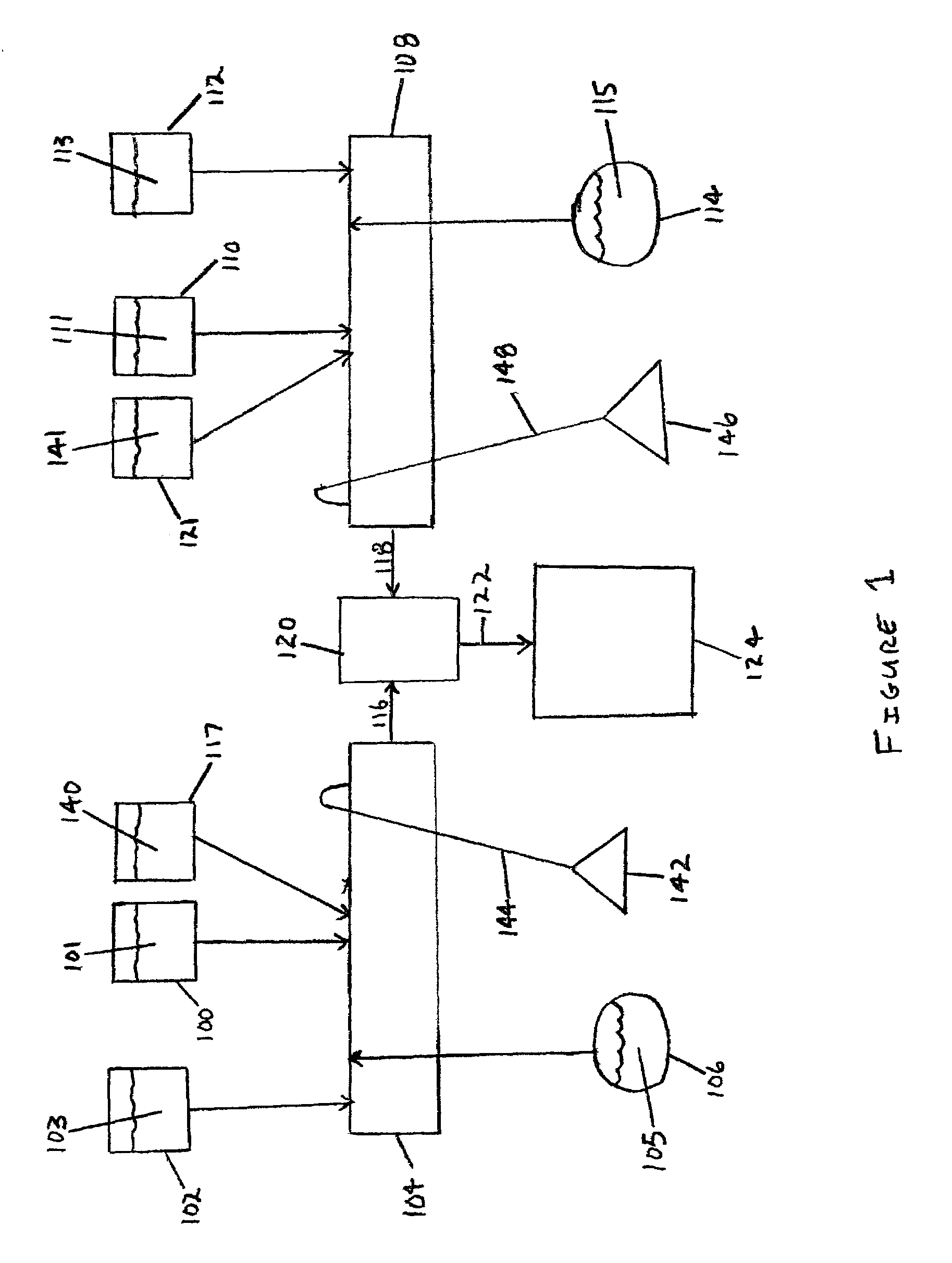

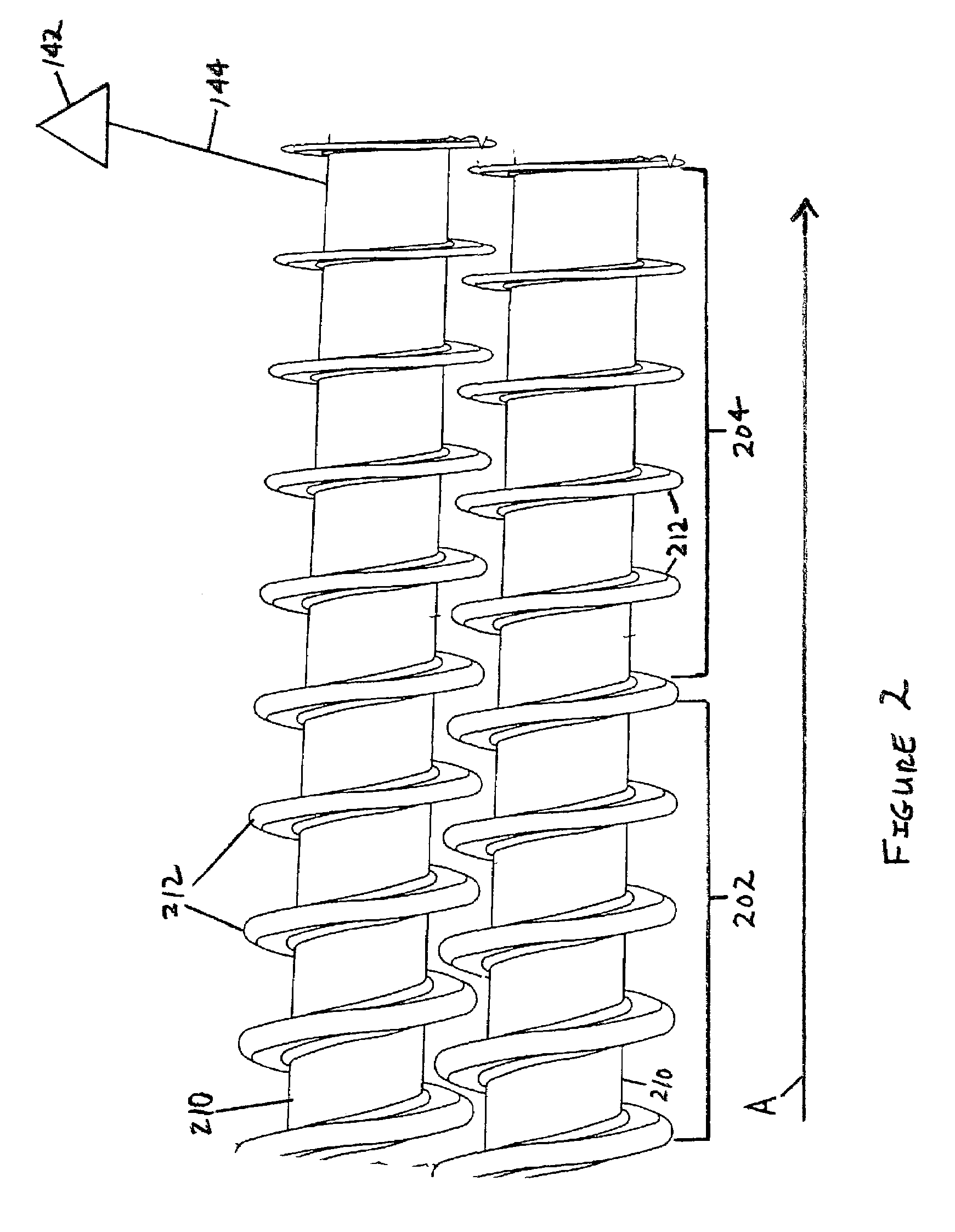

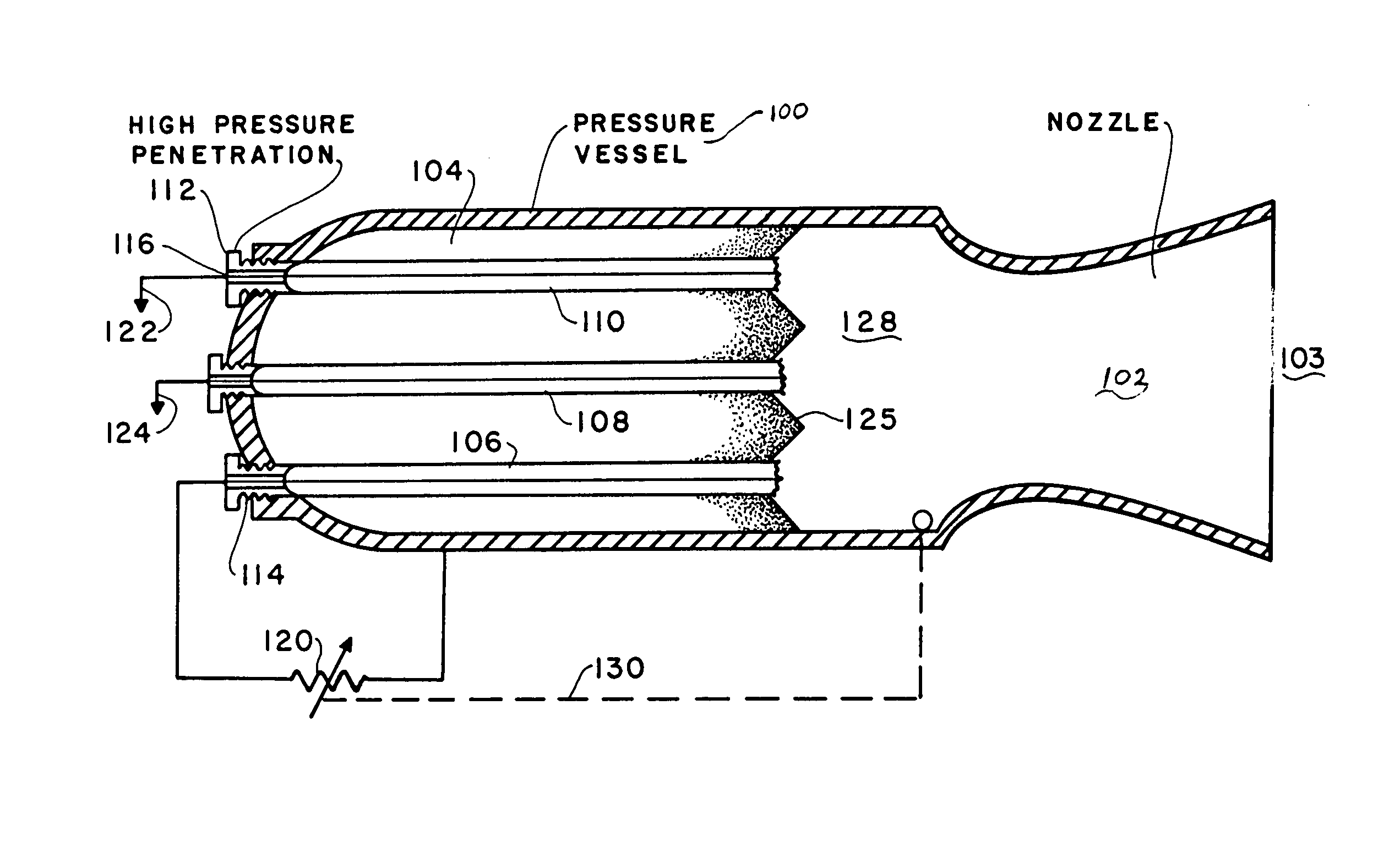

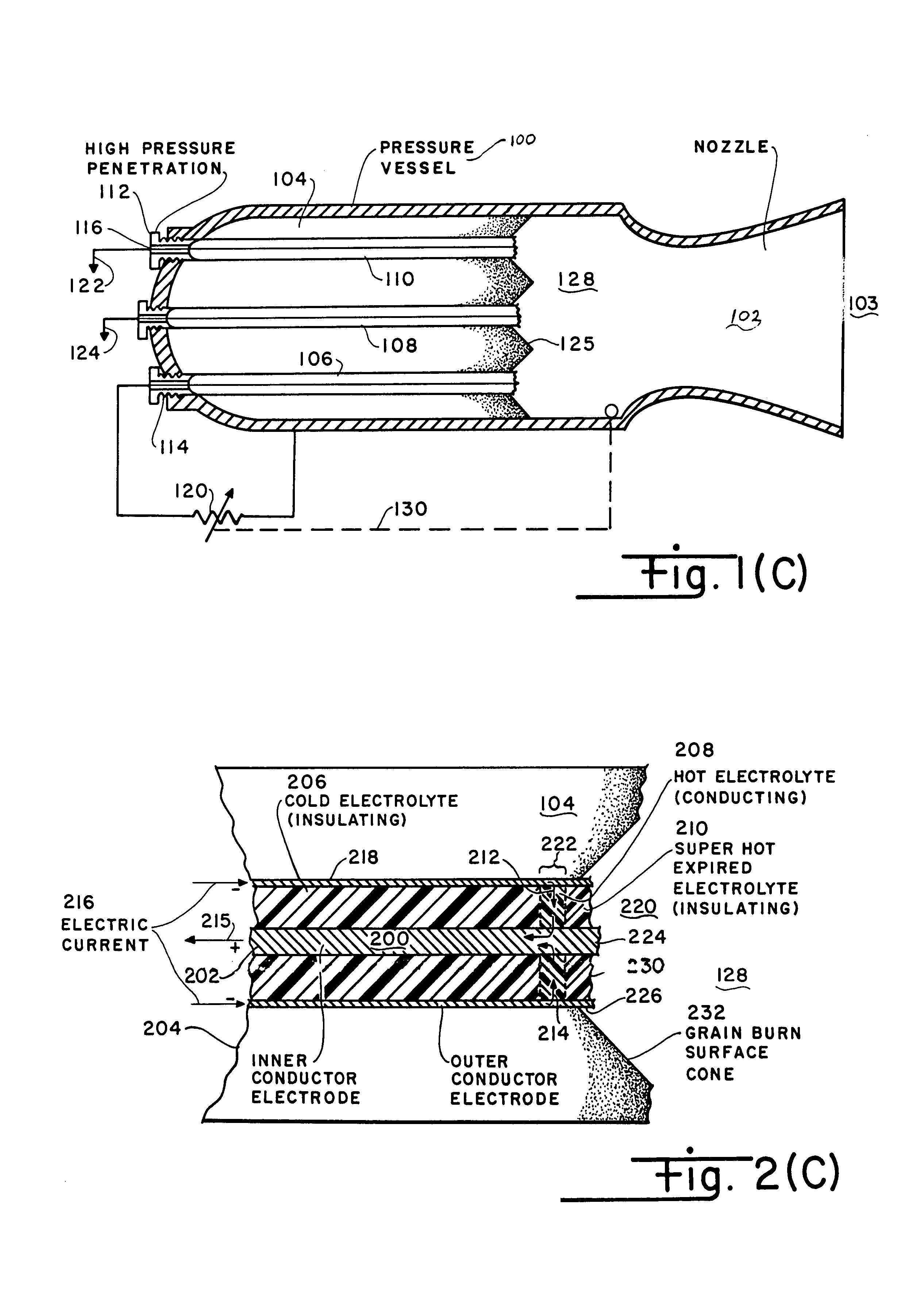

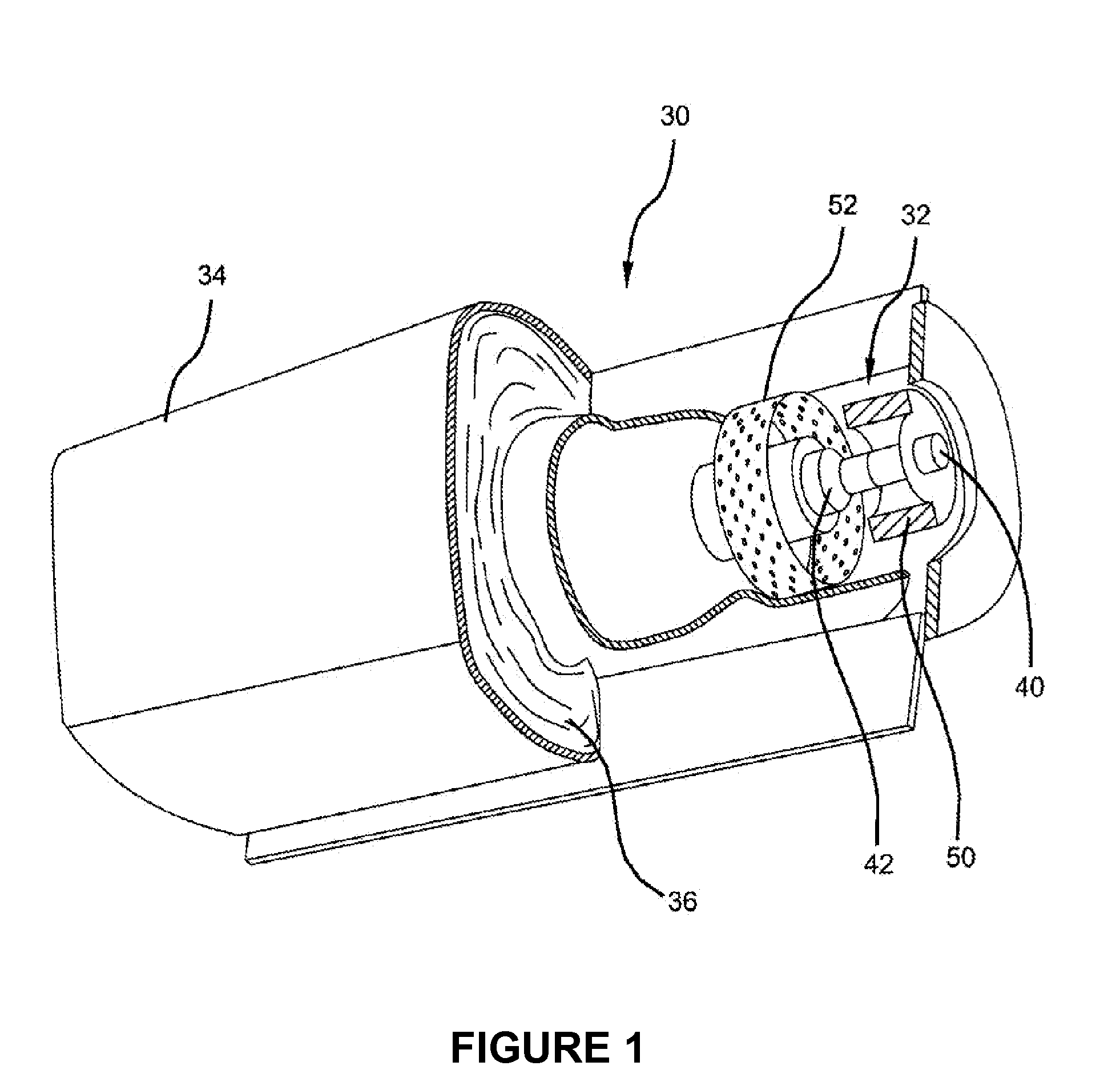

Propulsion system, opposing grains rocket engine, and method for controlling the burn rate of solid propellant grains

InactiveUS20090320443A1Heat flux of also increaseIncrease combustion pressureExplosivesRocket engine plantsControl systemBurn rate

A solid propellant thrust control system, method, and apparatus for controlling combustion of solid propellants in an opposing grains solid propellant rocket engine (OGRE) is provided. In particular, an opposing grains rocket engine and propulsion system is provided, in which actuator means connected are connected to solid propellant grains disposed in the pressure vessel of the engine. The actuator means are operable to selectively move the solid propellant grains together or apart relative to one another, such that the burning ends of the solid propellant grains decrease or increase relative to one another. This action controls the rate of combustion of the solid propellant grains by varying spacing distance between the burning ends of the solid propellant grains, and enables extinguishment and reignition of the OGRE. Further, a method is providing for controlling the burn rate of solid propellant grains undergoing combustion in an opposing grains rocket engine.

Owner:EXQUADRUM

Device for testing transfiguration burning rate of gun propellant

InactiveCN101907427AResearch Influencing FactorsAmmunition testingChemical analysis using combustionPressure curveCombustion chamber

The invention discloses a device for testing the transfiguration burning rate of gun propellant, belonging to the field of performance test of gun propellant. The device comprises a body assembly having a body and a piston, an ignition assembly, two pressure sensors and a data collecting and processing system. The body is provided with a combustion chamber and a piston working cavity to form a closed space through a corresponding end cap; the piston is glidingly matched with the piston working cavity; an igniting powder package in the ignition assembly is located in the combustion chamber and is connected with an igniter outside the body through an electrode and a lead. During a test, the tested gun propellant combusts in the combustion chamber and pushes the piston to move; the two pressure sensors respectively record the pressure curves p1-t and p2-t of the combustion chamber and the piston working cavity in the test process; after combustion of the tested gun propellant, the data collecting and processing system collects the curve p1-t and the curve p2-t and performs a series of calculating and processing to finally obtain the burning rate pressure coefficient and burning rate pressure index of the tested gun propellant. The invention solves the problem for testing the transfiguration burning rate of gun propellant.

Owner:XIAN MODERN CHEM RES INST

Castable double base solid rocket propellant containing ballistic modifier pasted in an inert polymer

InactiveUS6024810AHigh sensitivityLow smokeCosmonautic propulsion system apparatusNitrocellulose explosive compositionsDetonationBurn rate

Castable propellant formulations are provided including reduced toxicity ballistic modifiers that do not adversely increase the sensitivity of the propellant to shock detonation. Failure to adequately control the propellant burn rate often results in unacceptable performance of the propellant. Carbon can act as an effective ballistic, but not to the extent of metal compounds. It has been found that pasting a ballistic modifier, including ballistic modifiers containing lead, in an inert polymer modifies the burn rate of propellants while allowing the use of a reduced amount of modifier to achieve the same desired burn rate modification as the prior art, and therefore creating reduced shortcomings associated with the ballistic modifiers. Accordingly, the use of from about 1% to about 6% burn rate modifier wherein the burn rate modifier includes a ballistic modifier pasted in an inert polymer is taught as an effective burn rate modifier in a propellant, in order to provide reduced toxicity means for modifying the propellant burn rate without increasing the sensitivity of the propellant to shock detonation.

Owner:AEROJET ROCKETDYNE INC

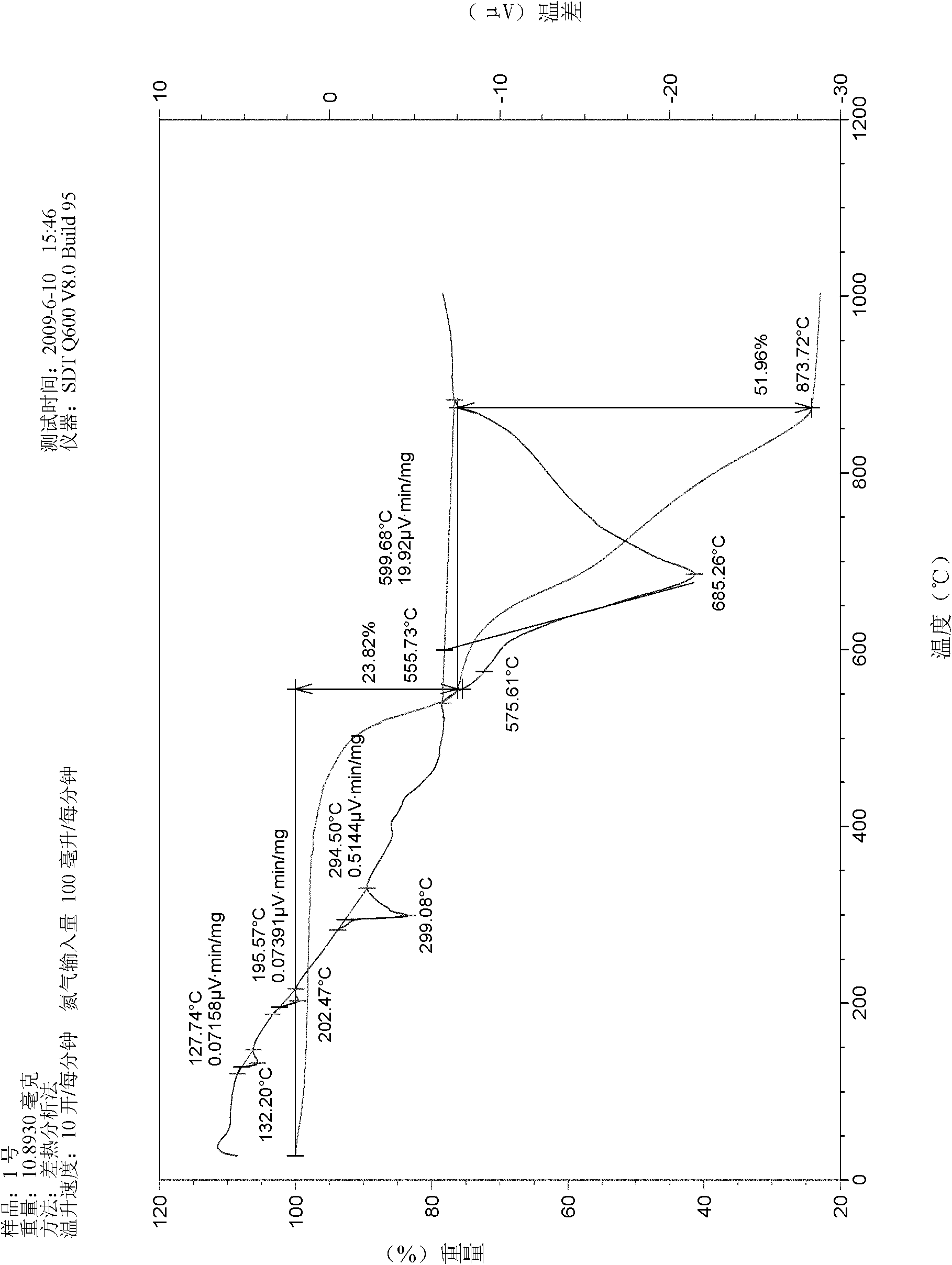

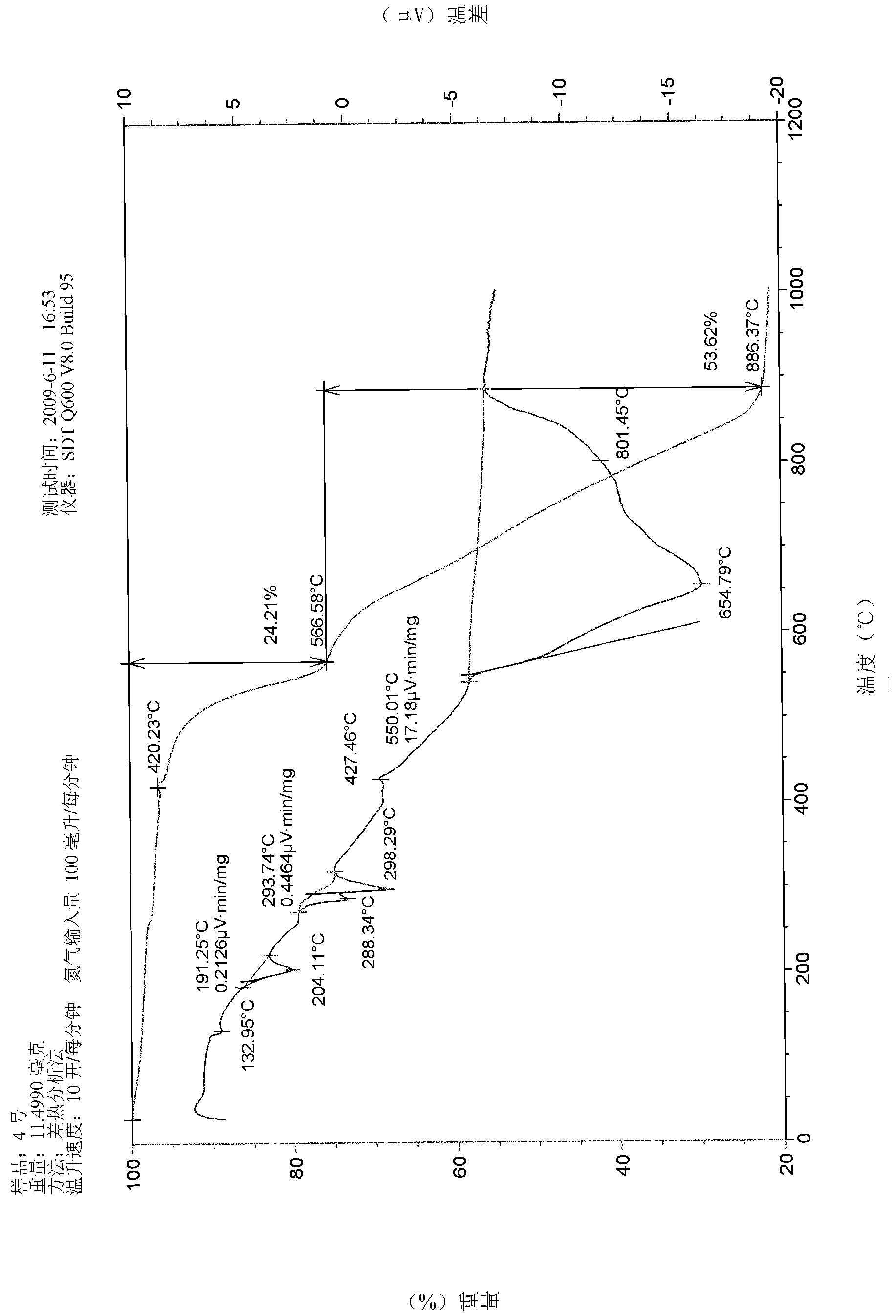

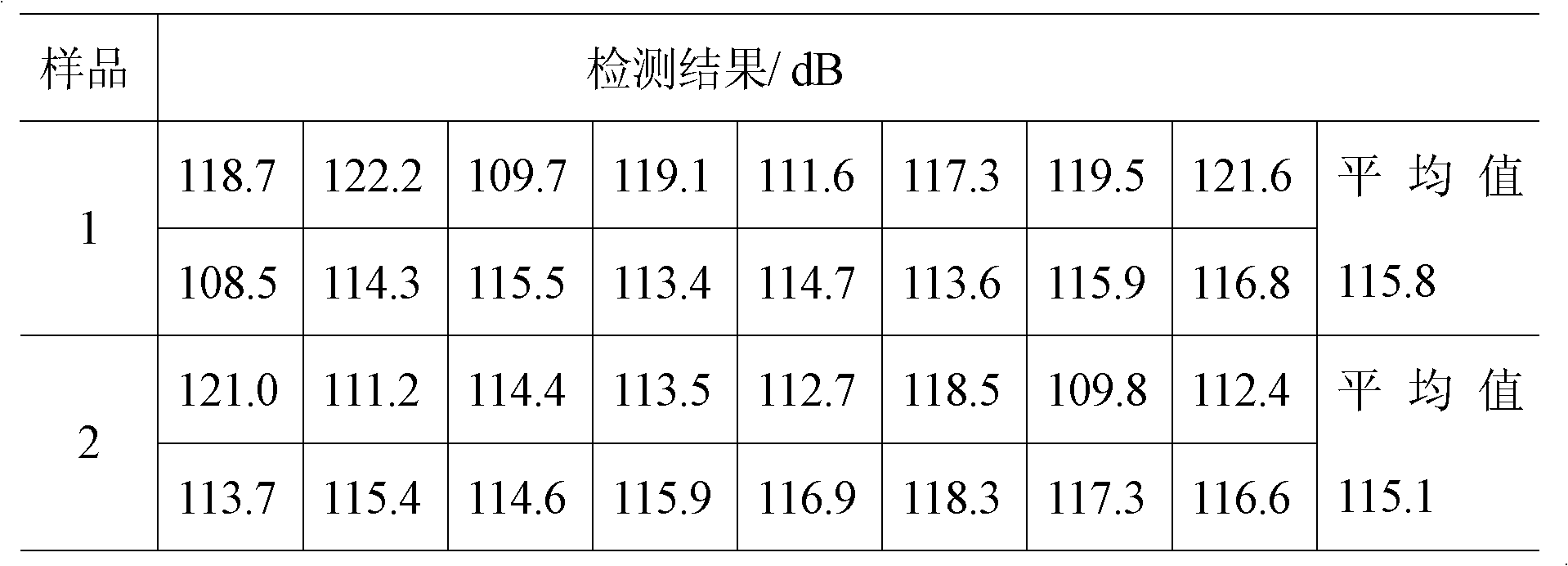

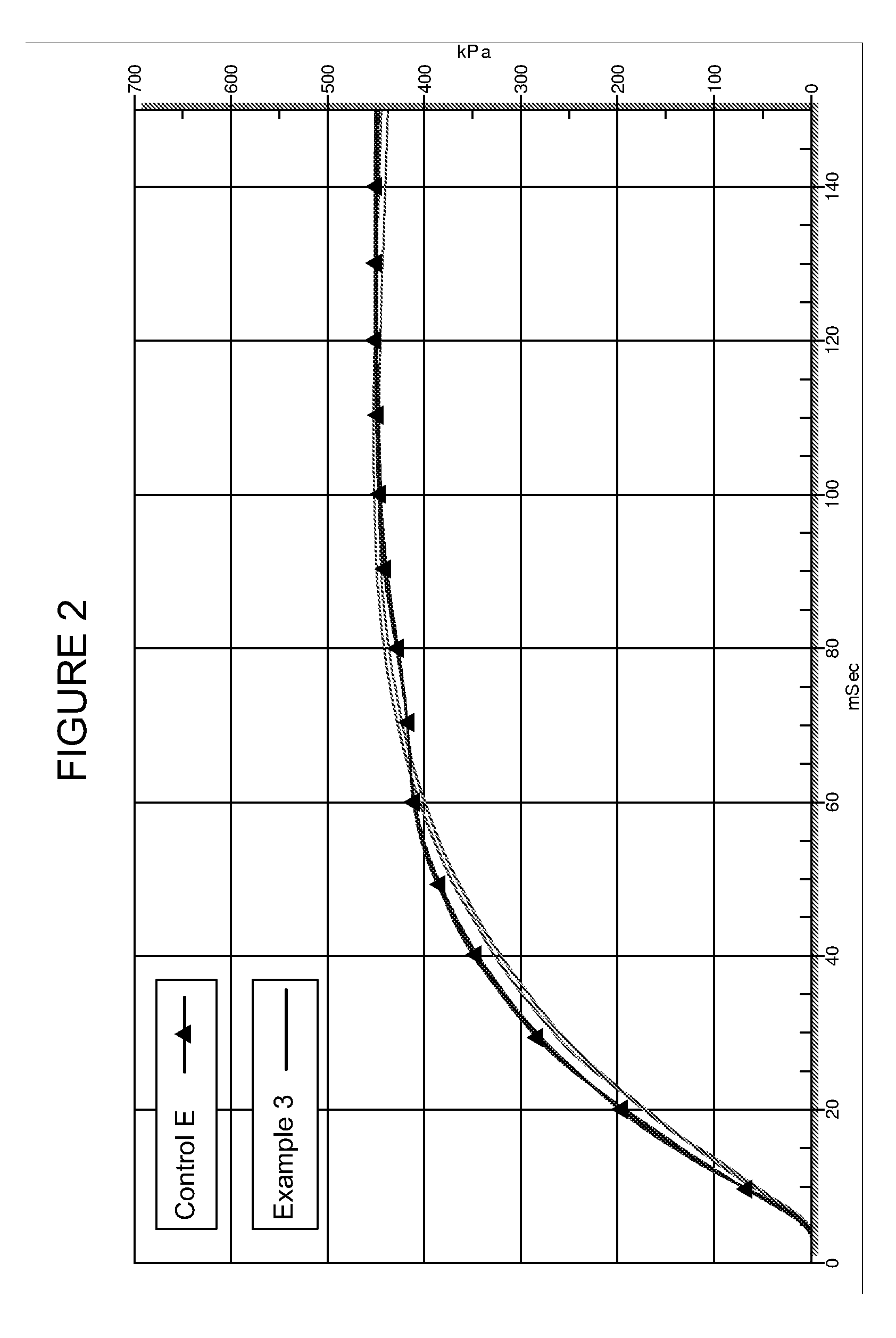

Sulfur-free and pearlite-free firecracker reagent and preparation method thereof

The invention discloses a sulfur-free and pearlite-free firecracker reagent and a preparation method thereof. The reagent comprises the following mass components: 35-65 percent of A component and 35-65 percent of B component, wherein the A component comprises the mass compositions: a mixture formed by 20-50 percent of potassium perchlorate, 0-30 percent of potassium nitrate and 30-50 percent of barium nitrate and a complexing agent occupying 1-5 percent of the mixture, and the B component comprises the mass compositions: 50-80 percent of aluminum powder, 10-25 percent of charcoal powder and 10-25 percent of organic foaming powder. The burning rate of a firecracker prepared from the reagent is more than 98 percent, the sound level value is no less than 100dB and is no more than 140dB, the time the gas product pressure rises from 0.69MPa to 2.07MPa is 1.74ms, a pH value of the pyrotechnic composition is 5-9, the moisture is no more than 1.5 percent, the hygroscopicity is no more than 2.0 percent, the thermal stability is 75 DEG C plus / minus 2 DEG C, the firecracker has no decomposition phenomenon under the condition of 48h, the friction sensitivity is no more than 40 percent, and the impact sensitivity of the pyrotechnic composition is no more than 0 percent. The key is that the reagent reduces the environmental pollution without harm to human bodies and has great application prospect.

Owner:HUNAN VOCATIONAL INST OF SAFETY TECH +1

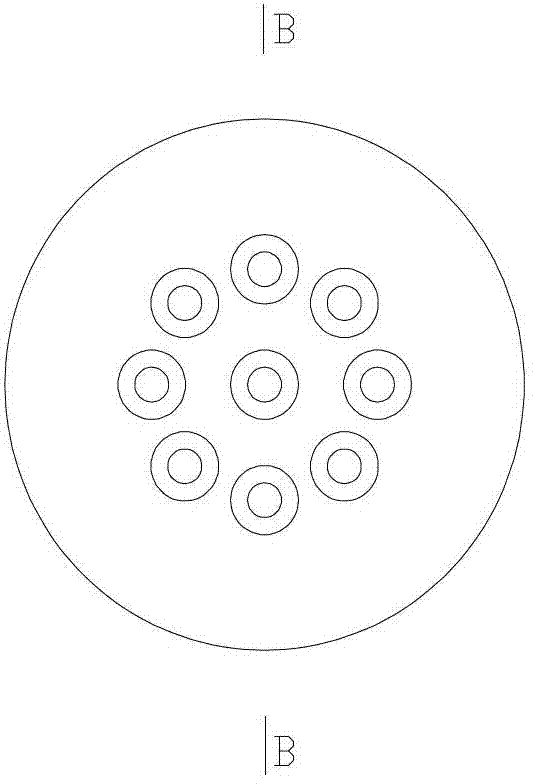

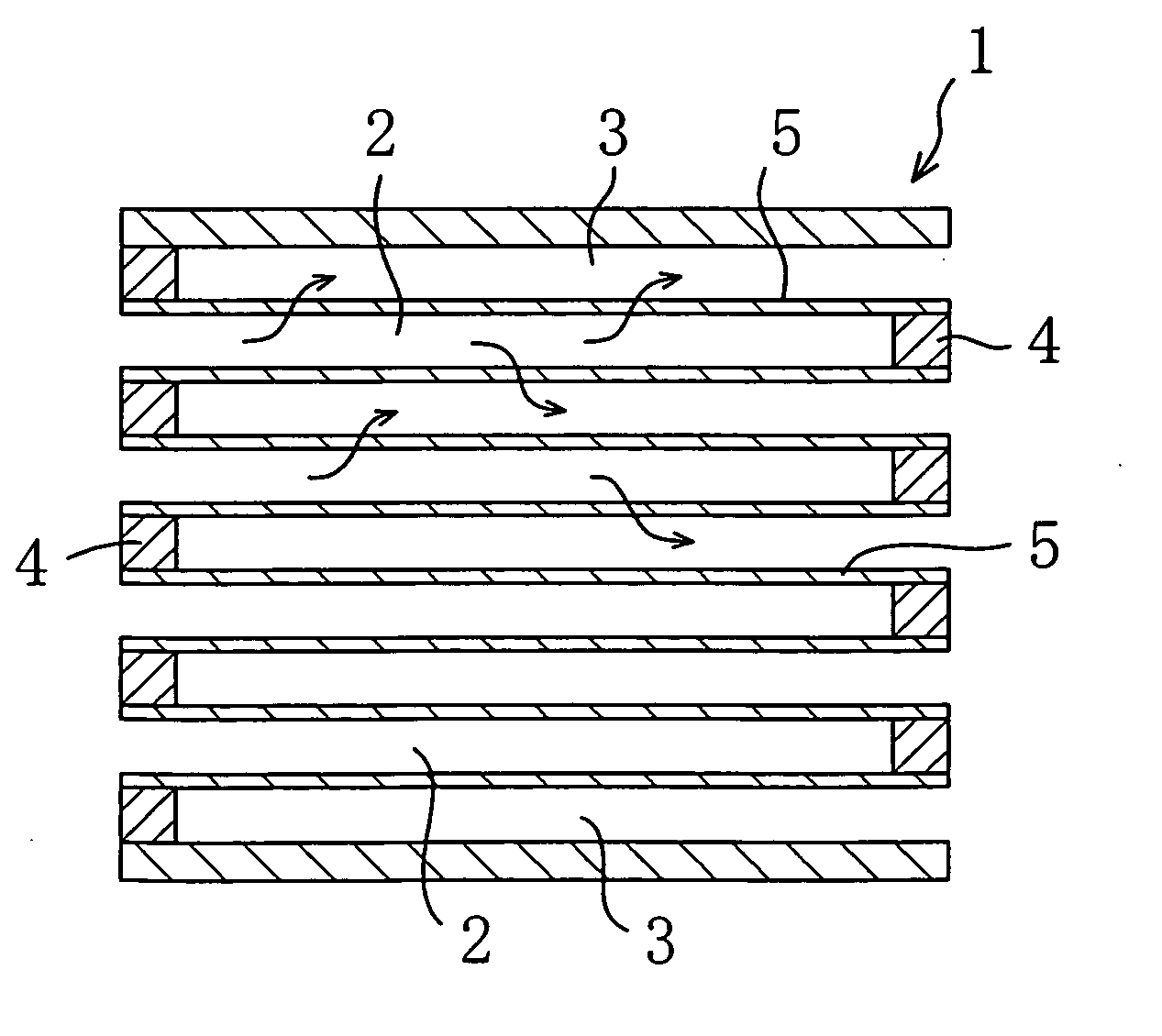

Device for testing burning rate of multi-residue solid propellant

InactiveCN101738450AEasy to makeSimple structureChemical analysis using combustionFuel testingCombustion chamberBurn rate

The invention discloses a device for testing burning rate of multi-residue solid propellant, a combustion chamber and a filter collector of which are connected into a whole. The combustion chamber is internally provided with a burn-out proof round bakelite sheet which is made of insulating wood material, arranged between two target lines and penetrates through 6 tapered binding posts arranged on a foundation with the view to avoiding undesirable disruption in the testing as hot combustion products come off, which affects normal operation. The top of the combustion chamber is provided with a transparent observation window, the middle part of the shell of the combustion chamber is provided with two transparent observation windows which are arranged in a 180-degree staggering manner along the circumferential direction, thus facilitating experimental observation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

High energy thermoplastic elastomer propellant

InactiveUS6997996B1Eliminate needHigh energyLoomsExplosive working-up apparatusHigh energyPlasticizer

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

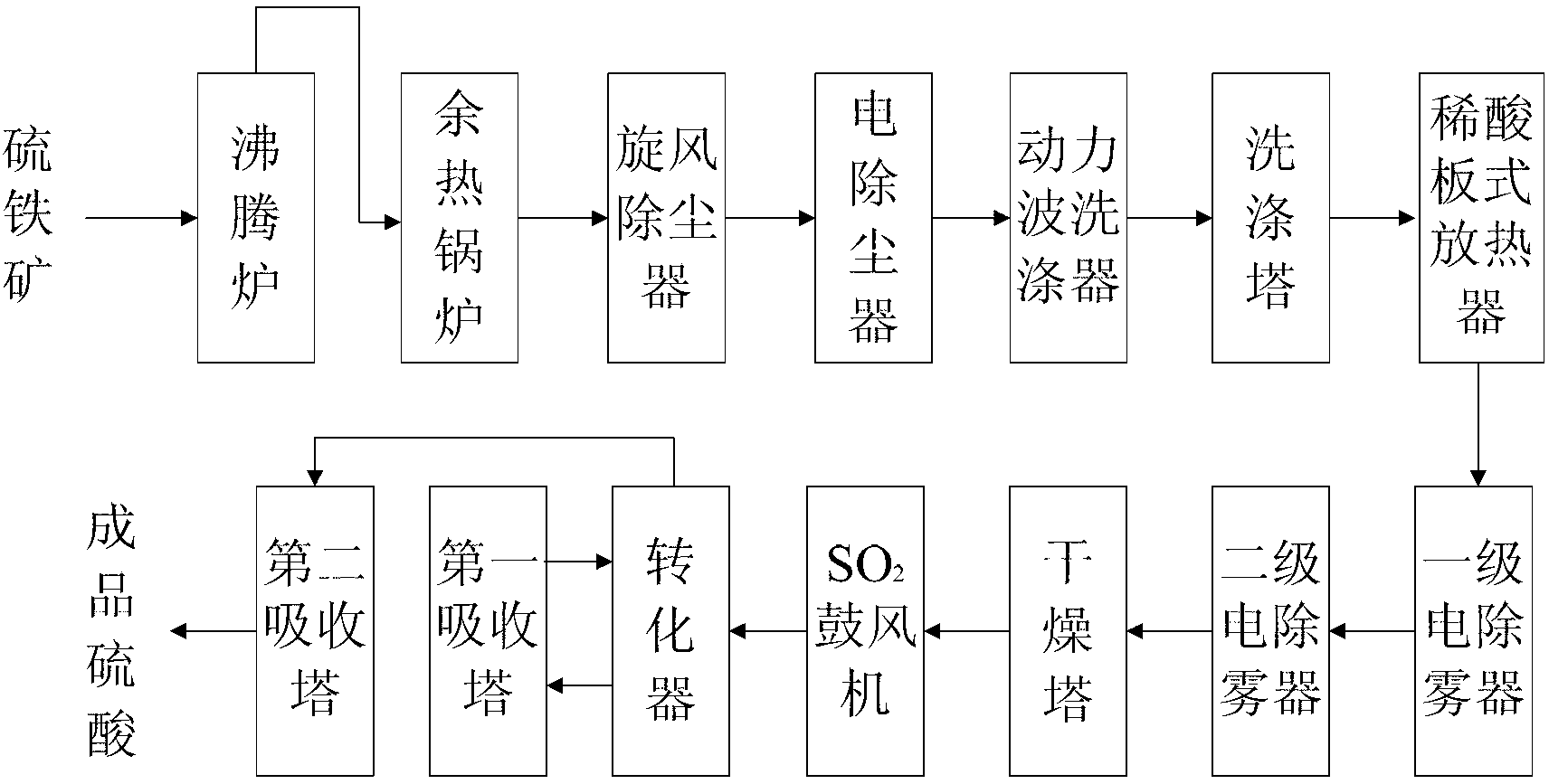

Method for preparing sulfuric acid by iron pyrite

The invention relates to a method for preparing sulfuric acid by iron pyrite. The method comprises the steps of oxidizing roasting, flue gas cleaning, drying and conversion absorption steps, wherein the flue gas cleaning step comprises primary cooling, dedusting, pickling, secondary cooling and demisting treatment, and the conversion absorption step adopts 'three plus two' twice conversion and twice absorption. Compared with the prior art, the method has the following advantages that the burning rate of sulfur can be improved; the production of diluted acid can be reduced; while the production cost is lowered, the total conversion rate of SO2 is ensured to be greater than 99.7%, and Sox in the tail gas can be ensured to be emitted by standard; the formation of sulfuric acid mist grains can be effectively inhibited, the grain size of the mist grains can be increased so as to demist; the working efficiency and product quality can be improved; and the formation of the acid mist can be effectively controlled, the product quality can be improved, and the emission of the tail gas pollutant can be reduced.

Owner:FUJIAN YONGJING TECH CO LTD

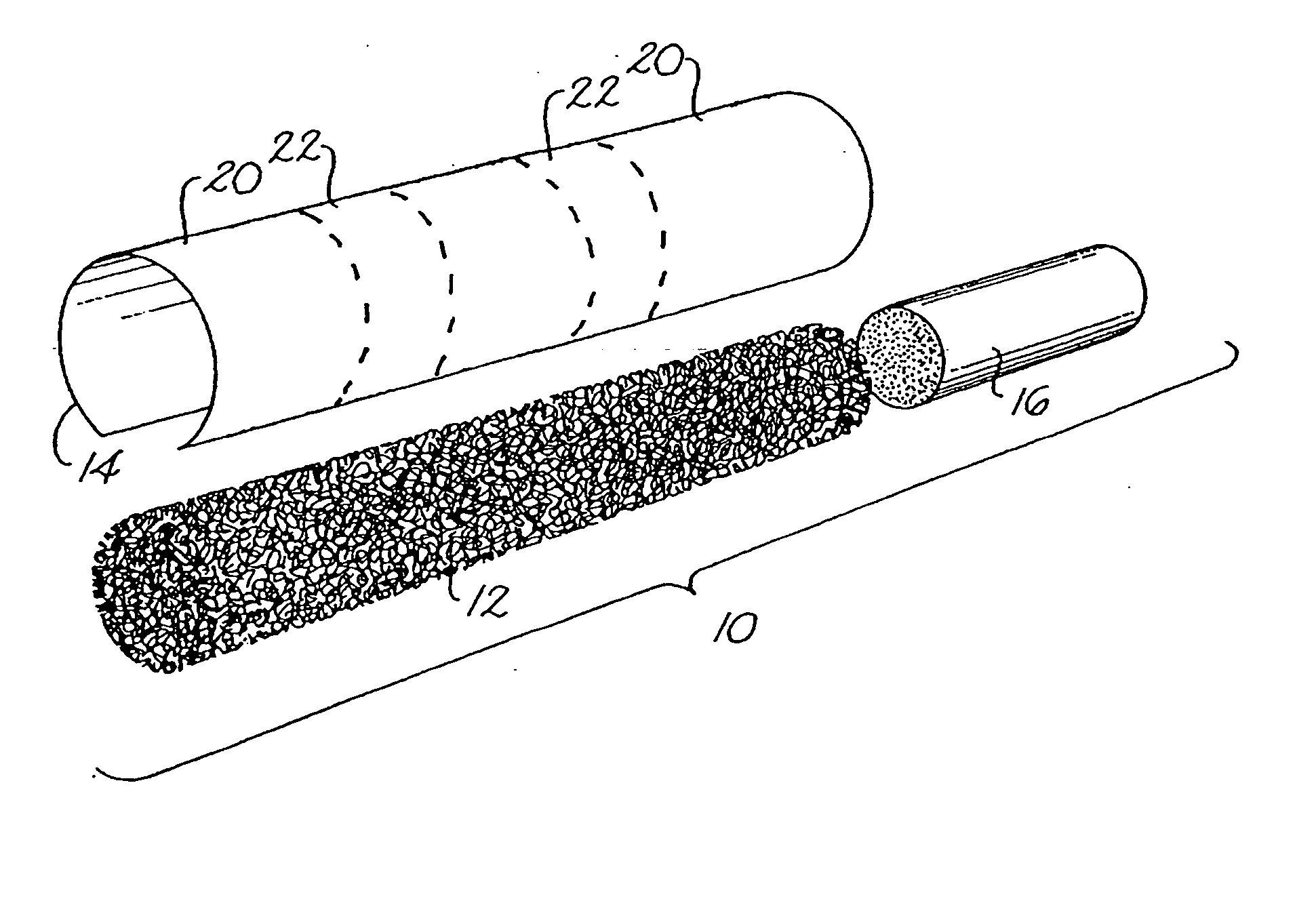

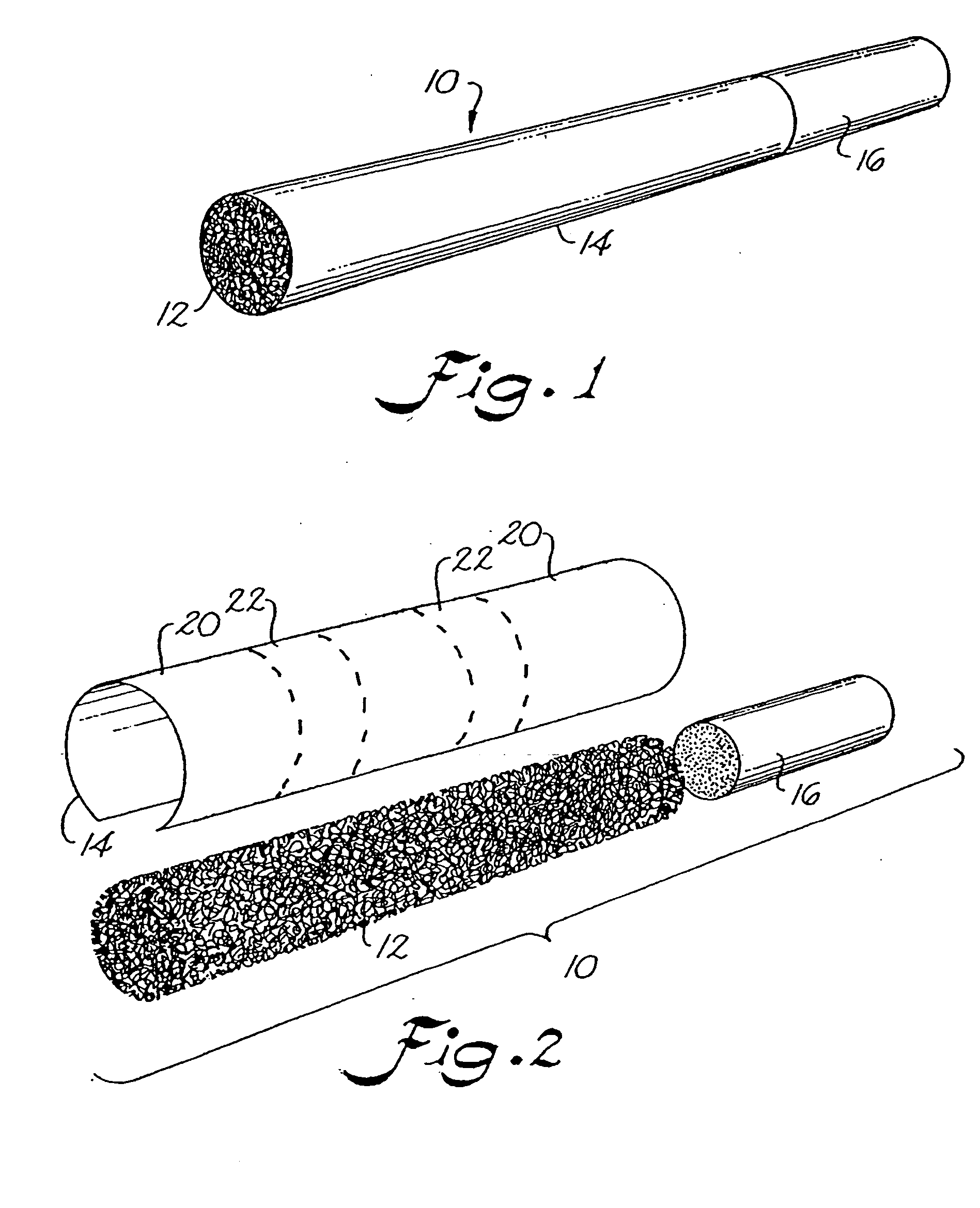

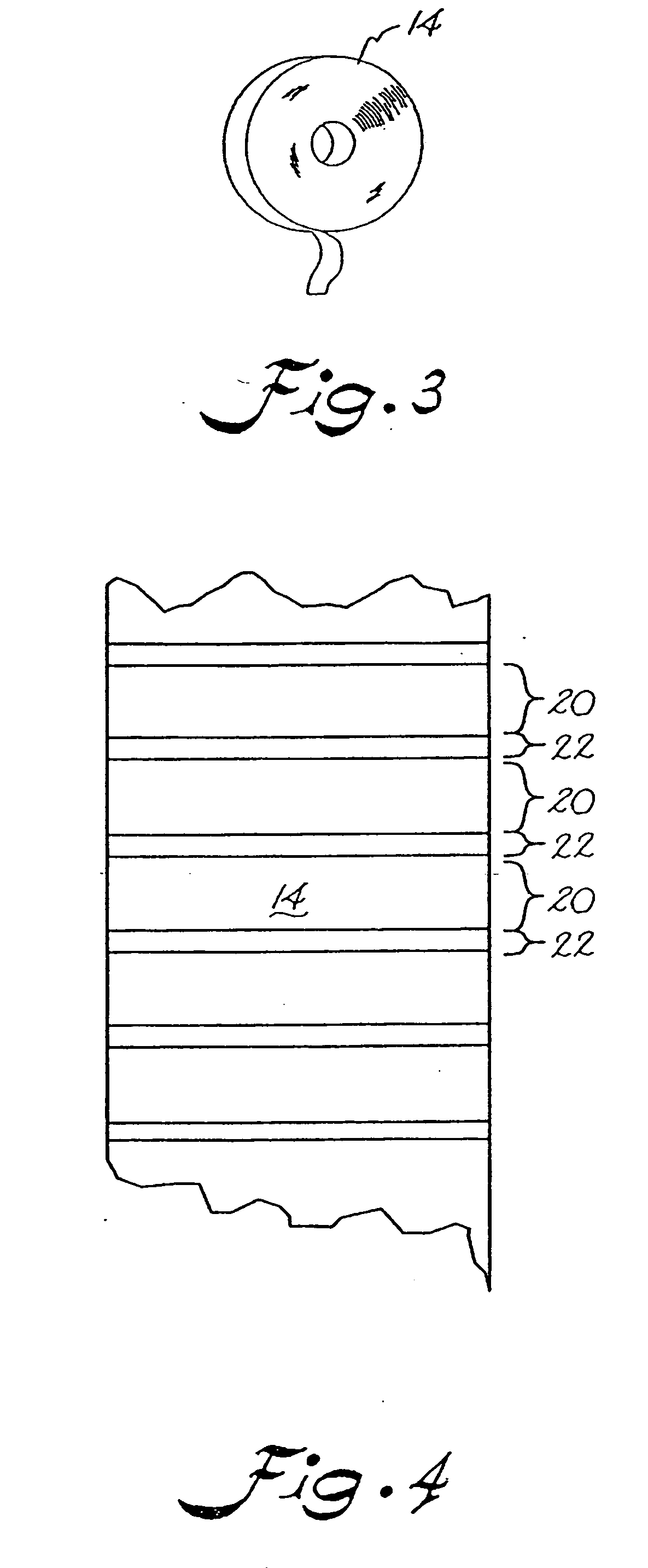

Co-extrusion of energetic materials using multiple twin screw extruders

InactiveUS7063810B1Improve securityReduce wasteChemical industryExplosive working-up apparatusBurn rateEngineering

The invention comprises a continuous, integrated process to produce a multiple layered energetic material where the layers comprise energetic materials having, at least, two different burning rates. The process uses at least two twin-screw extruders to process at least two different energetic materials. These energetic materials are extruded into a co-extrusion die that, first, thins each energetic material flow into layers, and, then, combines the layers into a multiple layered energetic material. One embodiment of the invention also includes a remote take away system that completes processing the multiple layered energetic material after it leaves the co-extrusion die. The outer edges of the multiple layered material are first trim cut, then rolled into wrapped spools. Finally, the wrapped spools are cut into specified lengths for final use. These cutting, trimming and rolling steps are all done automatically, with no personnel handling required.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Solid fuel rocket thrust control

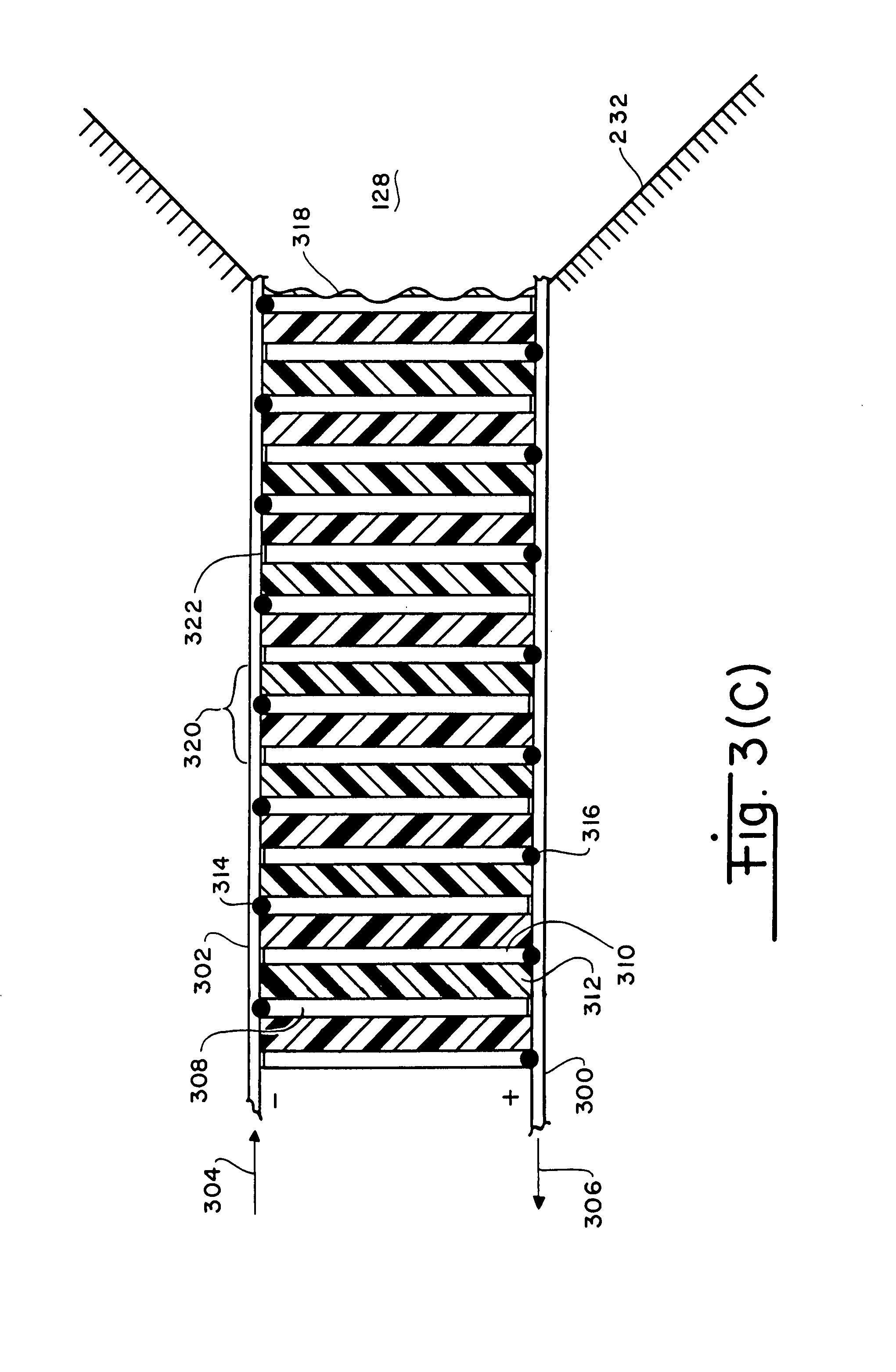

InactiveUS8015920B1Increase burn ratePromotes burn surface area increase and actionDirection controllersExplosivesElectrical batteryBurn rate

A solid fuel rocket burn rate control employing electrical energy preheating of the fuel grain at a plurality of locations dispersed over the grain burn face cross-section as a thrust control arrangement. The electrical energy of the preheating is generated by electrical battery cells which are dispersed across the grain cross-section and are triggered from an inert state into energy generation by burn face heat. The preheating situs moves continually in response to movement of the grain burn face; this is achieved through the use of high temperature electrical battery cell materials responding to the approach of the grain burn face by increased chemical activity and decreased electrical resistance. Preferably, the preheating is directly accomplished by the heat from electrical and other losses in the battery cells.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Gas generation with copper complexed imidazole and derivatives

InactiveUS20070240797A1Improve combustion effectImprove flammabilityNon-explosive/non-thermic compositionsPressure gas generationNitrogenBurn rate

A compound including at least one copper II complex of a material selected from the group of imidazole and imidazole derivatives is provided for use in a gas generant composition. An associated burn rate enhanced gas generant composition, in addition to such copper complex-containing compound, also includes a nitrogen-containing non-azide fuel. Additionally provided are methods for improving the combustion performance of a non-azide gas generant composition in at least one aspect selected from the group consisting of ignitability, burn rate and burn rate pressure sensitivity, through the addition of such copper complex-containing compound to the non-azide gas generant composition.

Owner:AUTOLIV ASP INC

Gas generating composition

InactiveUS20120055593A1LoomsPedestrian/occupant safety arrangementBASIC CUPRIC CARBONATEBasic copper carbonate

The present invention is a gas generating composition including fuel and an oxidizing agent, which can be used for an inflator of a vehicle airbag apparatus, wherein the oxidizing agent includes basic copper carbonate, the gas generating composition having the content of the basic copper carbonate of more than 40% by mass and 60% by mass or lower, and satisfying the following requirements (a) to (c):(a) the burning rate is 7.0 mm / sec or above;(b) the gas output is 2.30 mol / 100 g or above; and(c) the calorific value per mol of generated gas is 100 kJ / mol or lower.

Owner:DAICEL CHEM IND LTD

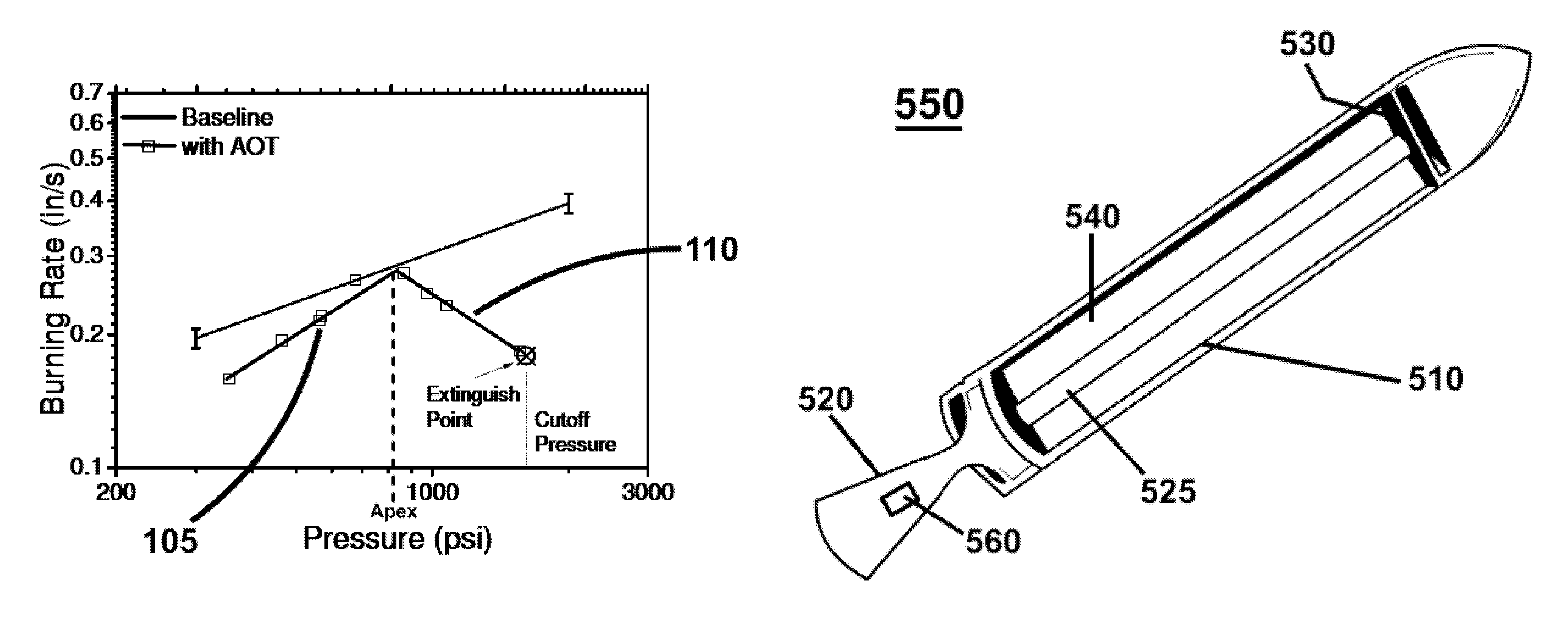

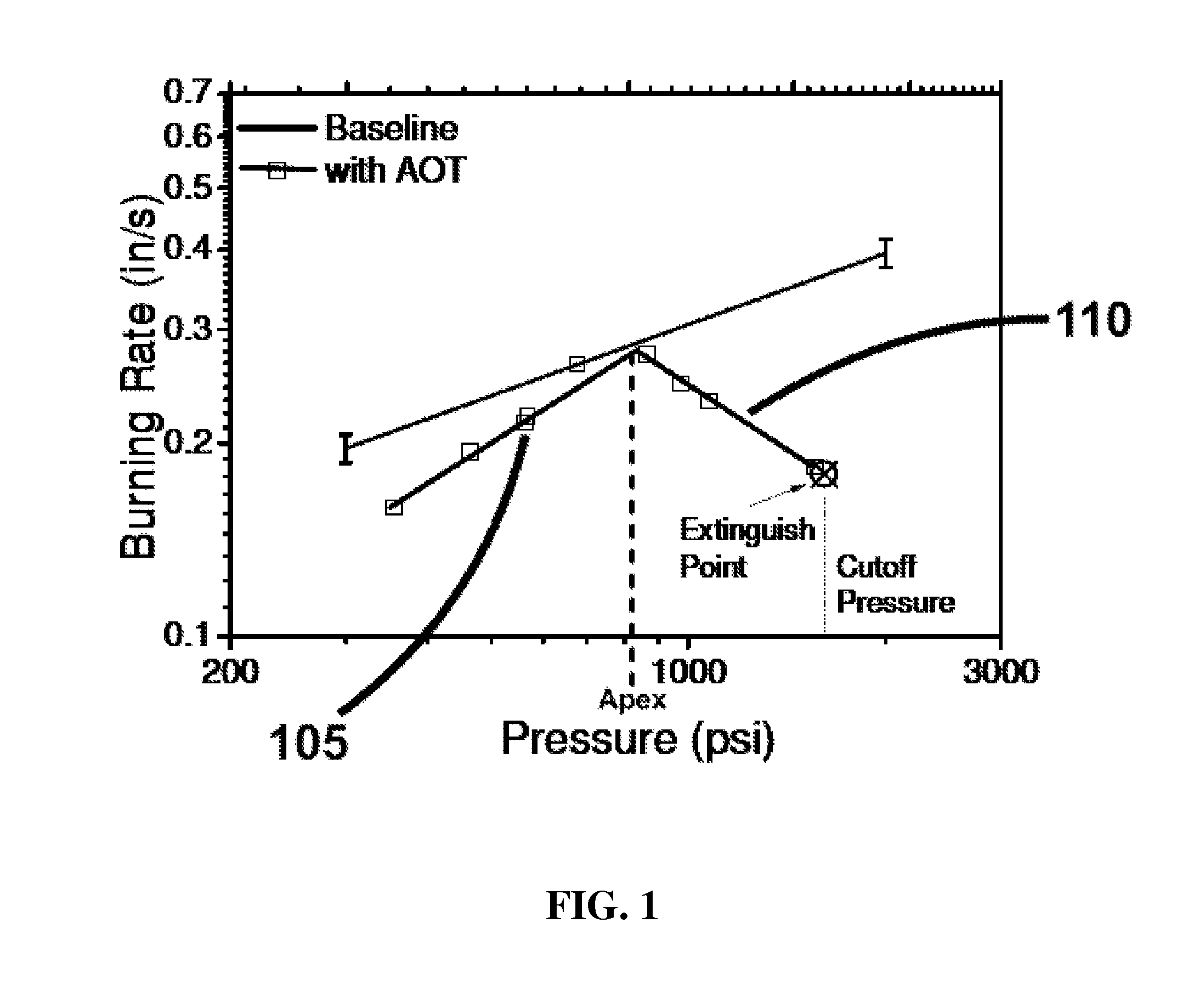

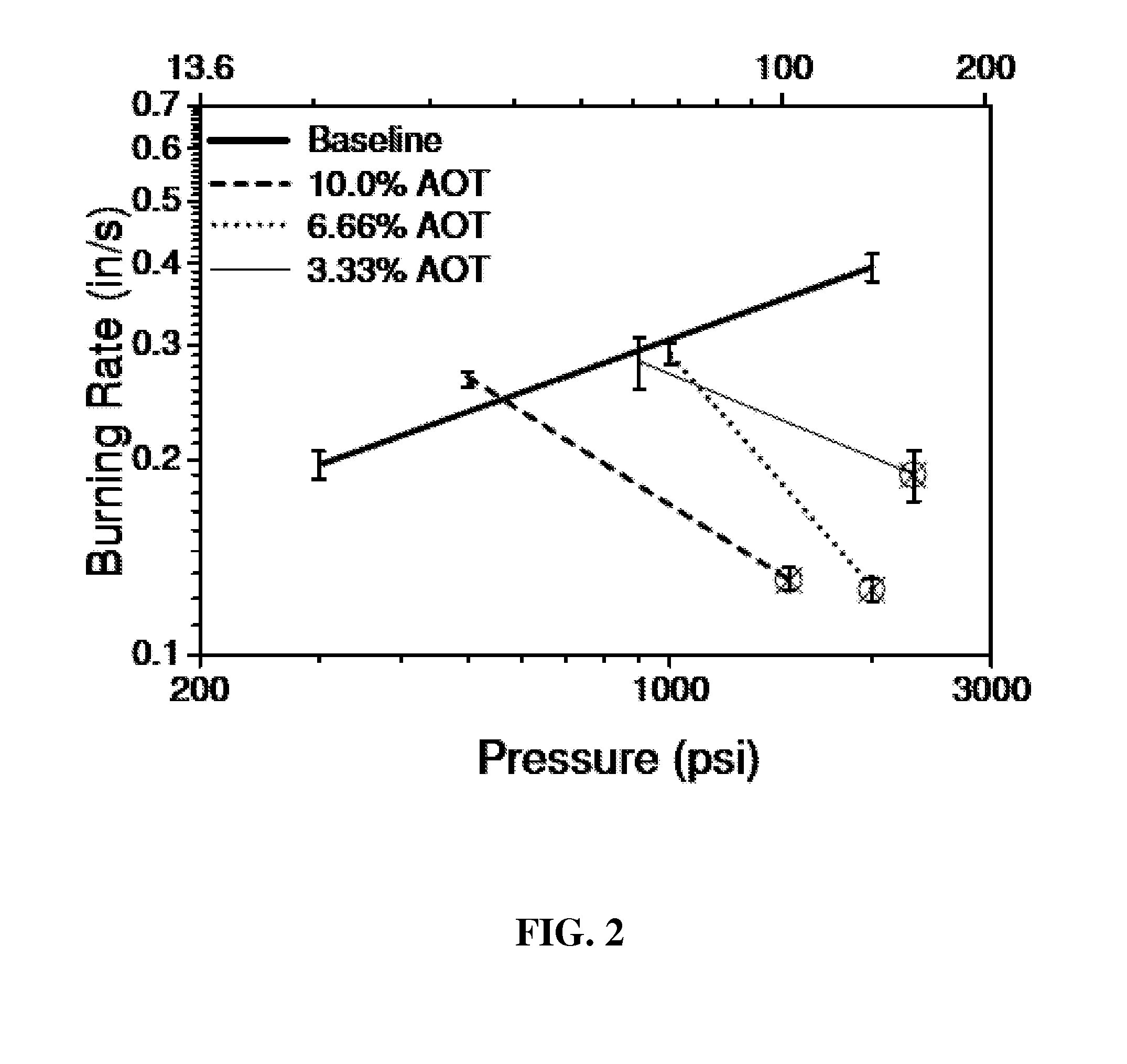

Solid propellant rocket motor having self-extinguishing propellant grain and systems therefrom

ActiveUS8336287B1Rocket engine plantsNon-explosive/non-thermic compositionsCombustion chamberPressure dependence

A solid rocket motor includes a combustion chamber bounded by an outer casing, a propellant grain within the combustion chamber, and an igniter within the outer casing for igniting the propellant grain. A nozzle is coupled to the combustion chamber for releasing hot gasses evolved from burning the propellant grain to provide thrust for propelling the solid rocket motor. The propellant grain is a self-extinguishing propellant grain that includes at least one fuel, at least one oxidizing agent, at least one binder, and at least one surfactant that imparts the self-extinguishing property. The propellant grain provides a burning rate as a function of pressure that includes a negative pressure dependence portion, wherein the burning rate in the negative pressure dependence portion decreases with increasing pressure until a cutoff pressure is reached which results in extinguishment of the propellant grain.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

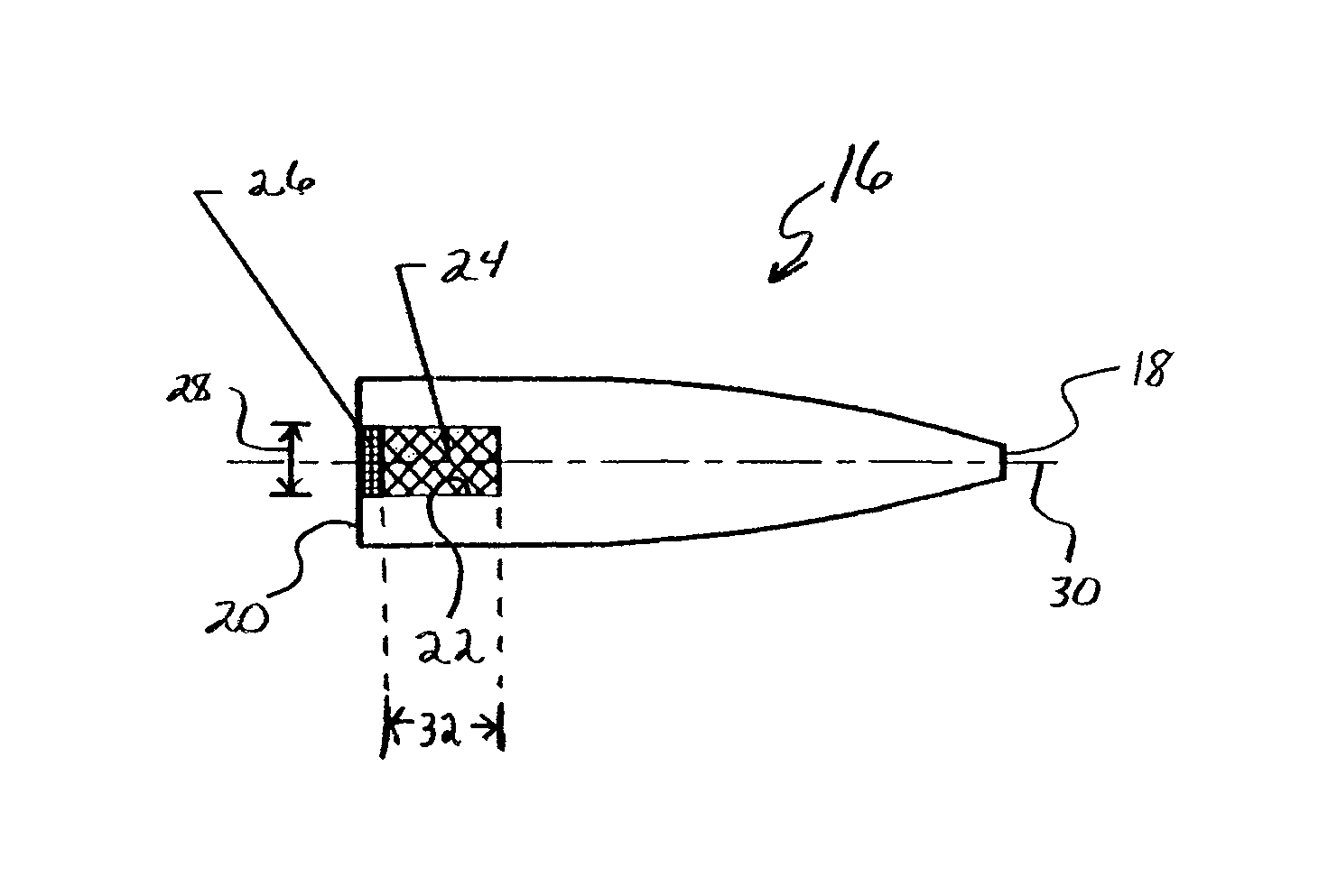

Infrared tracer composition and tracer projectile

The present invention is directed to a tracer composition for tracer bullets and other projectiles. One preferred formula of the tracer composition generally includes about 58 parts by weight of magnesium, about 38 parts by weight of polytetraflouroethylene, about 4 parts by weight of acrylic rubber, and a burn rate stabilizer such as about 1.5 parts by weight of carbon black or graphite. Tracer bullets including the tracer composition of the invention tend to exhibit a projectile path that is almost unnoticeable to the naked eye but quite visible through the use of equipment detecting energy in the near infrared range.

Owner:KILGORE FLARES

Micro-smoke colorful bright bead for firework

The invention discloses a colorful trace fume star used in fireworks. The star consists of an effect agent core, an intermediate agent isolation layer and an ignition agent layer. A layer of intermediate agent is stuck on the effect agent core granules as the intermediate agent isolation layer; and a layer of black powder is stuck on the intermediate agent isolation layer as the ignition agent layer. The effect agent core comprises the following ingredients by weight: 15-30 parts of ammonium perchlorate, 5-15 parts of a colorant, 50-75 parts of single-base and double-base agent and 0-5 parts of magnalium. The intermediate agent comprises the following ingredients by weight: 20-35 parts of potassium perchlorate, 5-15 parts of the colorant, 50-75 parts of the single-base and double-base agent and 0-5 parts of the magnalium. The colorful trace fume star used in fireworks generates fume which is less than 30% of that of the existing agent after burning, and has good moisture resistant performance and long shelf life; and visual observation at the burning field proves that burning rate, lightness and color saturation of the star achieve or exceed the effects of the existing products.

Owner:浏阳市达浒花炮艺术焰火燃放集团有限公司

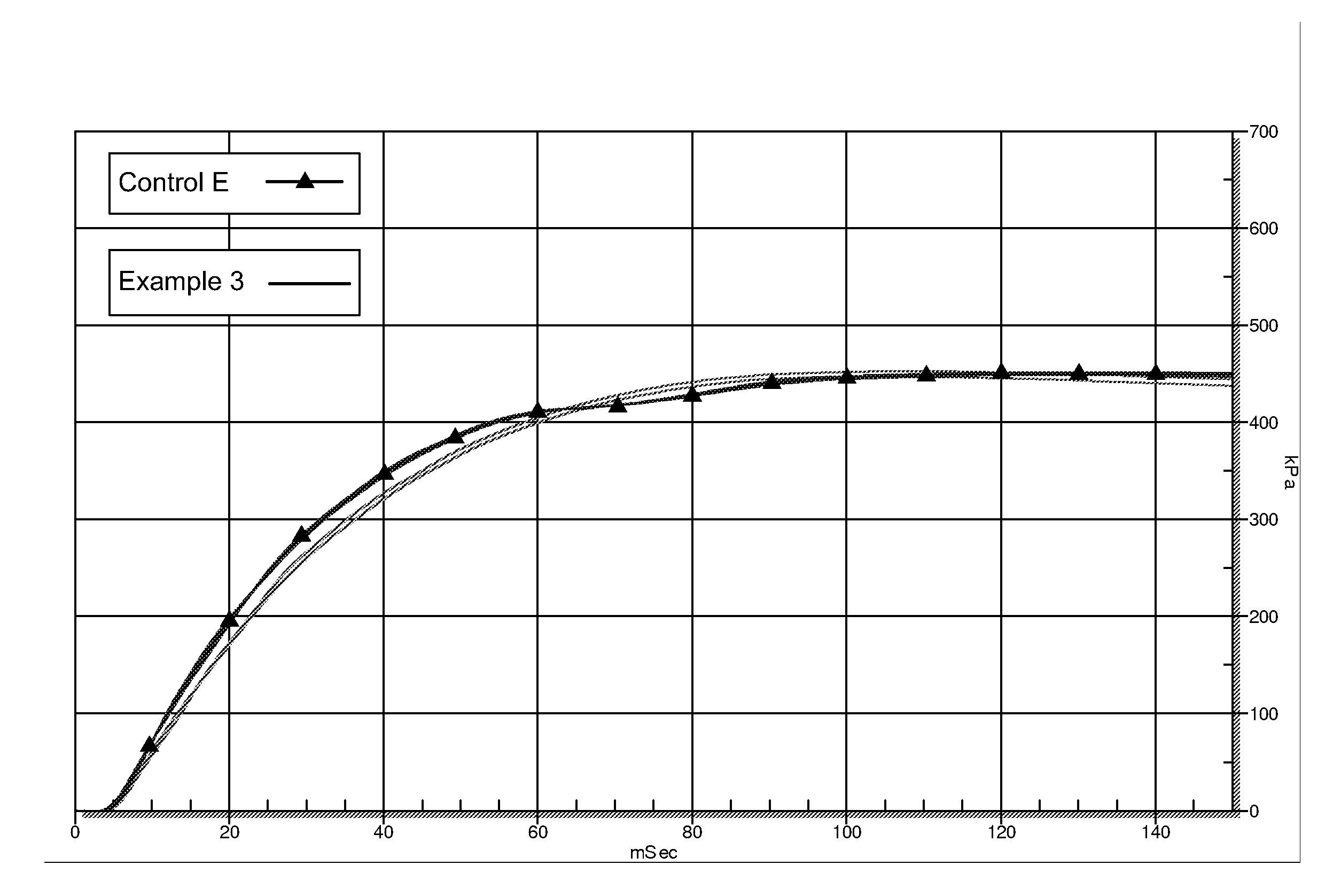

High peformance gas generating compositions

ActiveUS20090255611A1Easily pressed into complex grainFew chip and voidCeramic shaping apparatusExplosive working-up apparatusBurn rateCopper nitrate

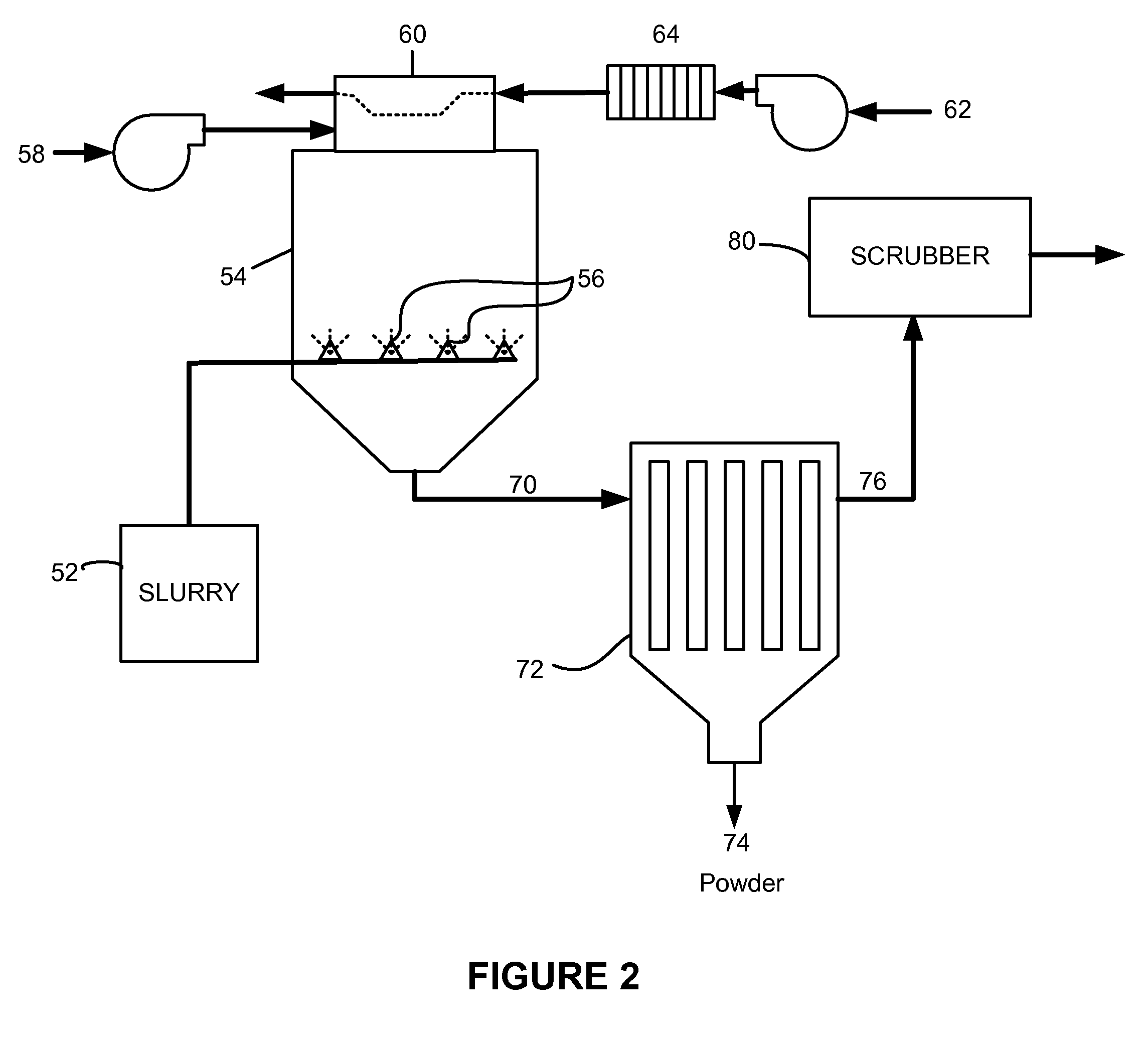

Compositions and methods relating to gas generants used in inflatable restraint systems. The gas generant grains formed via spray drying techniques of the present disclosure provide superior performance, including high burn rates and high gas yields. Further, processing of the gas generant grain products can be streamlined. Such gas generants include by way of non-limiting example, guanidine nitrate, basic copper nitrate, and a secondary oxidizer, such as potassium perchlorate.

Owner:AUTOLIV ASP INC

Nonazide gas generant compositions

Owner:AUTOMOTIVE SYST LAB

Gas generating compositions having glass fibers

ActiveUS20100116384A1Reduce sensitivity to pressureLessening burn rate pressure sensitivityNon-explosive fillers/gelling/thickening agentsExplosive working-up apparatusGlass fiberBurn rate

Compositions and methods relate to gas generants used in inflatable restraint systems. The gas generant grains include a fuel mixture having at least one fuel and at least one oxidizer, which have a burn rate that is susceptible to pressure sensitivity during combustion. The gas generant composition further includes a plurality of pressure sensitivity modifying glass fiber particles distributed therein to lessen the pressure sensitivity and / or to increase combustion stability of the gas generant. Such gas generants can be formed via spray drying techniques.

Owner:AUTOLIV ASP INC

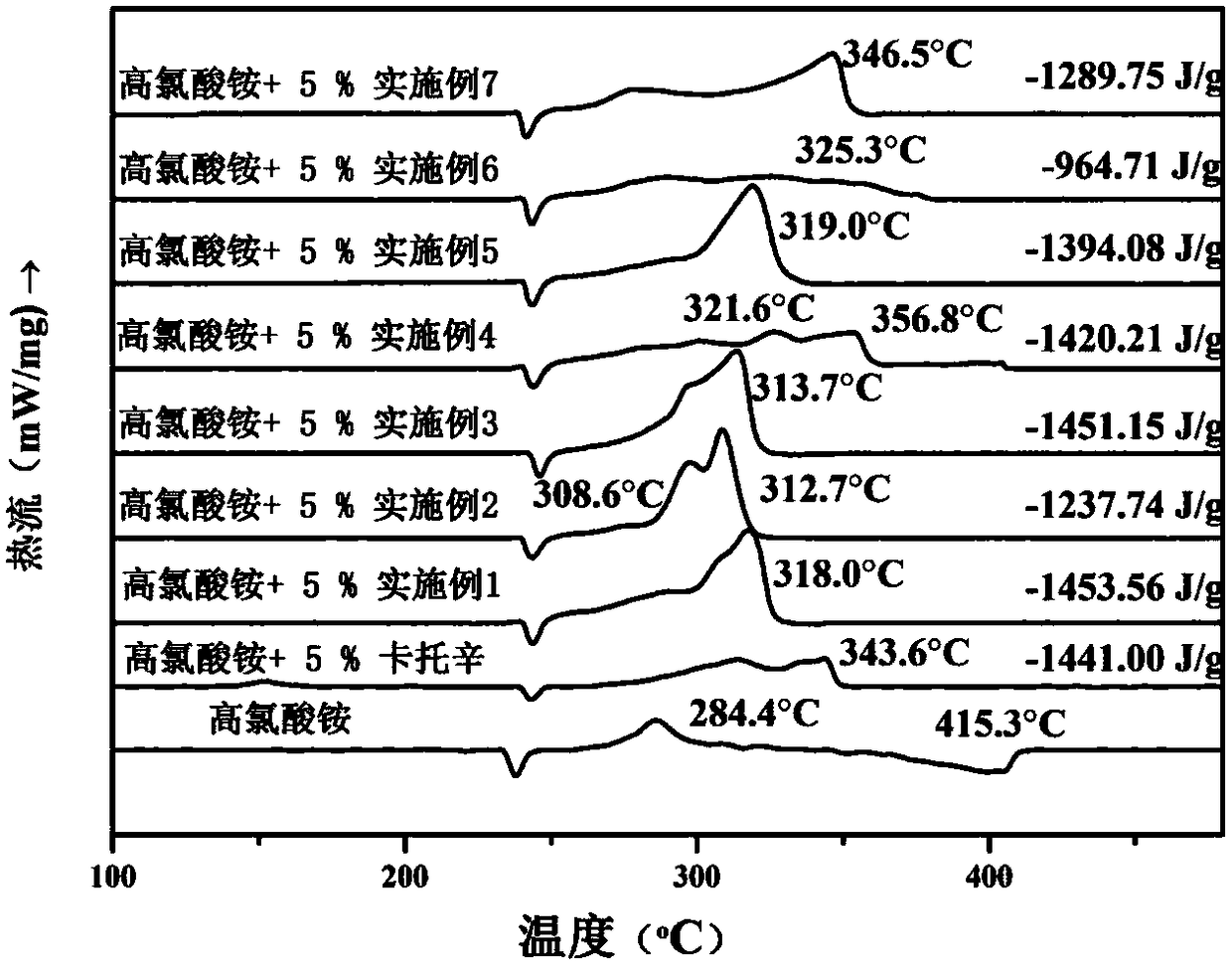

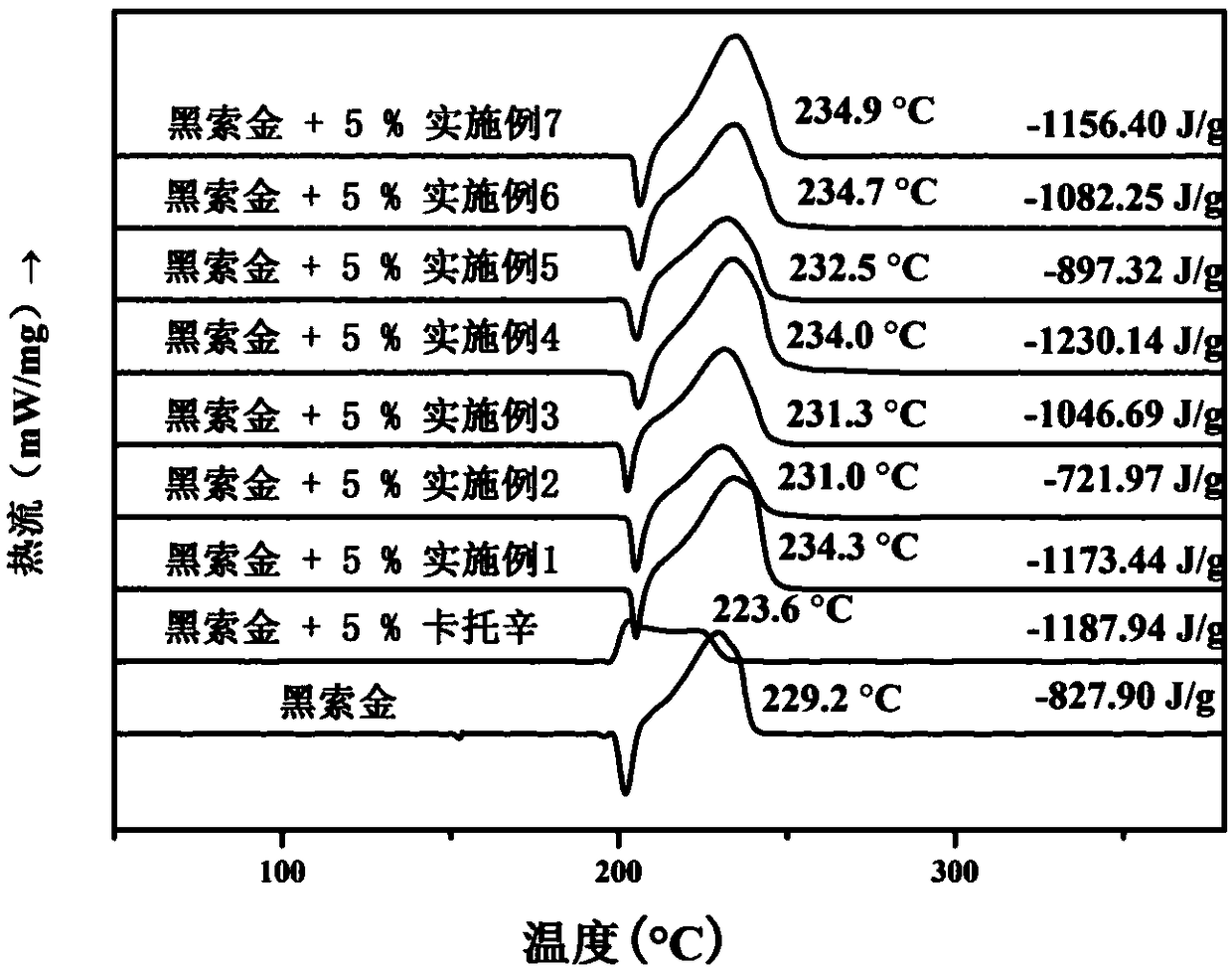

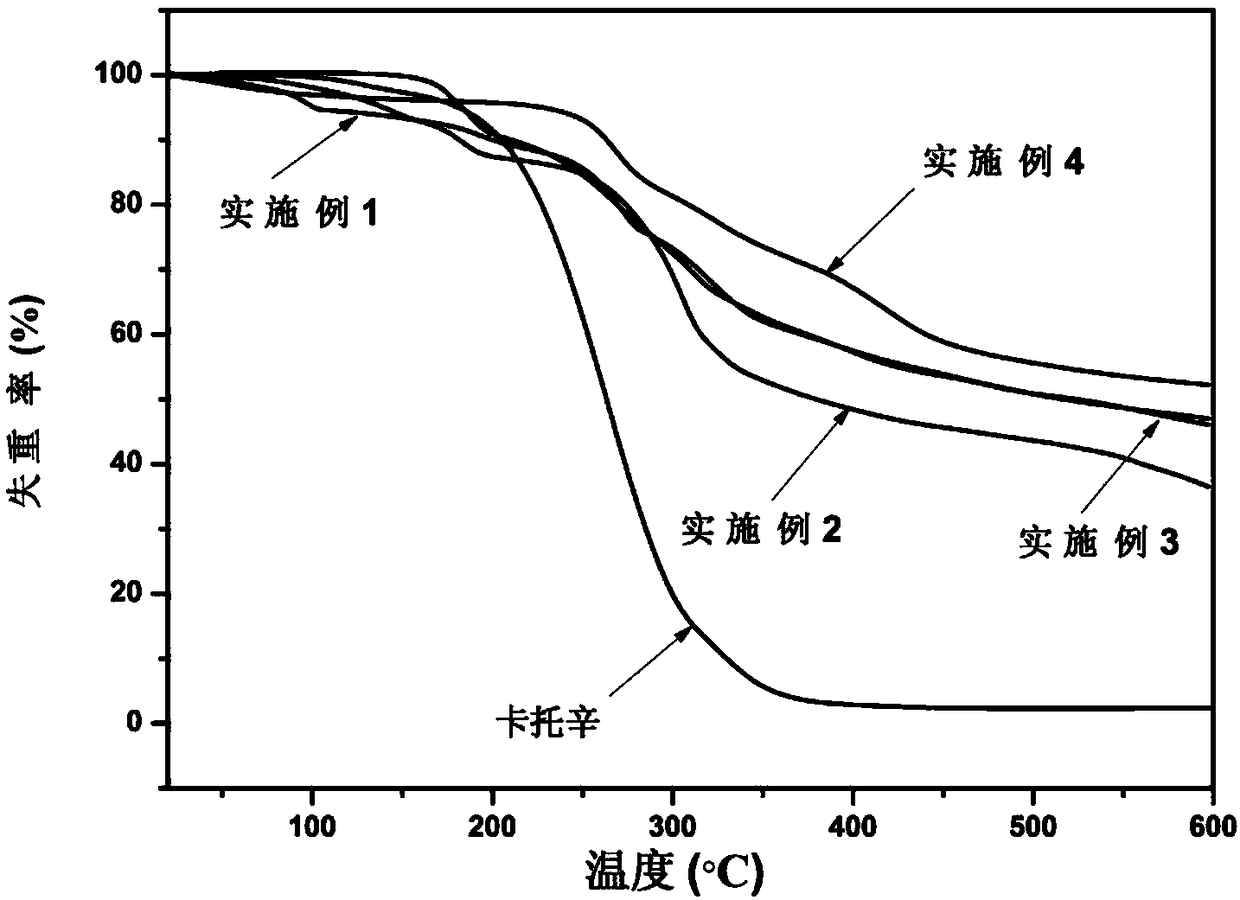

N-ferrocenylmethyl-3-amino-1,2,4-triazole energy-containing transition metal complex and preparation method thereof

ActiveCN108558957AEasy to migrateSolve volatileMagnesium fertilisersMetallocenesBurn rateNitrogen gas

The invention discloses an N-ferrocenylmethyl-3-amino-1,2,4-triazole energy-containing transition metal complex and a preparation method thereof. The structural formula of the complex is as shown in the description, wherein M represents Cu, Zn, Mn, Ni, Co, Cd or Fe, L is 1H, 1'H-(5,5'-bistetrazole)-1,1'-diol dianion, and x is an integer from 0 to 3. The complex disclosed by the invention is simplein preparation method, low in cost and high in yield and has better burning catalysis effect on main components (ammonium perchlorate and hexogen) of a composite solid propellant; the N-ferrocenylmethyl-3-amino-1,2,4-triazole ligand in the complex has high nitrogen content, has higher positive enthalpy of formation and has synergistic catalysis effect with transition metal ions; and by addition of energy-containing compound 1,1'-dihydroxy-5,5'-bistetrazole disodium salt tetrahydrate, the sensitivity of a burning rate catalyst can be reduced, the energy can be supplied for the solid propellant, and the decomposed and released nitrogen gas is friendly to the environment.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com