Solid fuel regression rate test device

A technology of retreat rate and testing device, which is applied in chemical analysis by means of combustion, etc., can solve problems such as difficulty in measuring rocket engine fuel retreat rate, reduce test complexity, etc., achieve good retreat rate, low cost, and safe operation reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

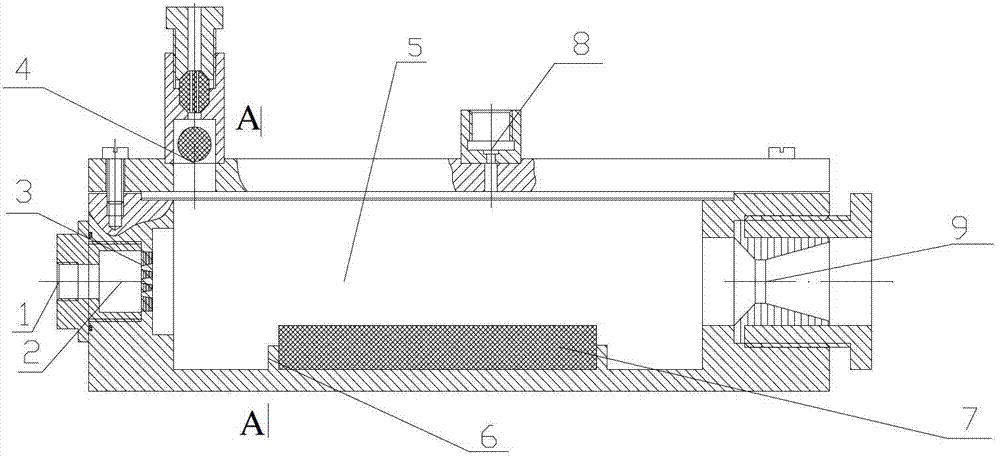

[0025] This embodiment is a solid fuel retreat rate testing device. The combustion chamber with a rectangular groove structure is used, and the propellant is made into a rectangular parallelepiped for testing to test the solid-liquid rocket engine solid fuel retreat rate.

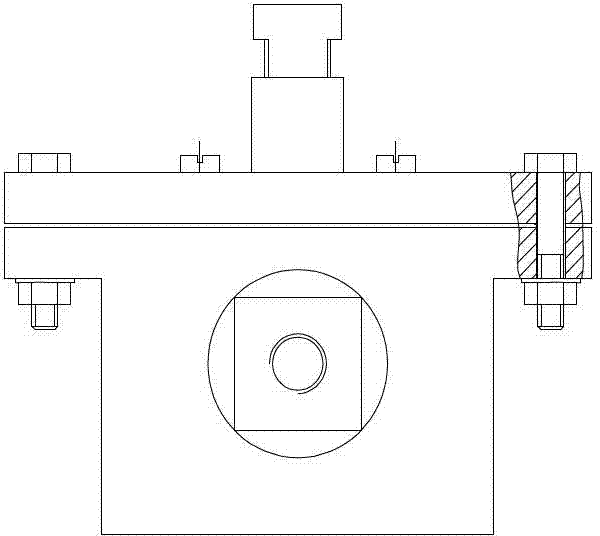

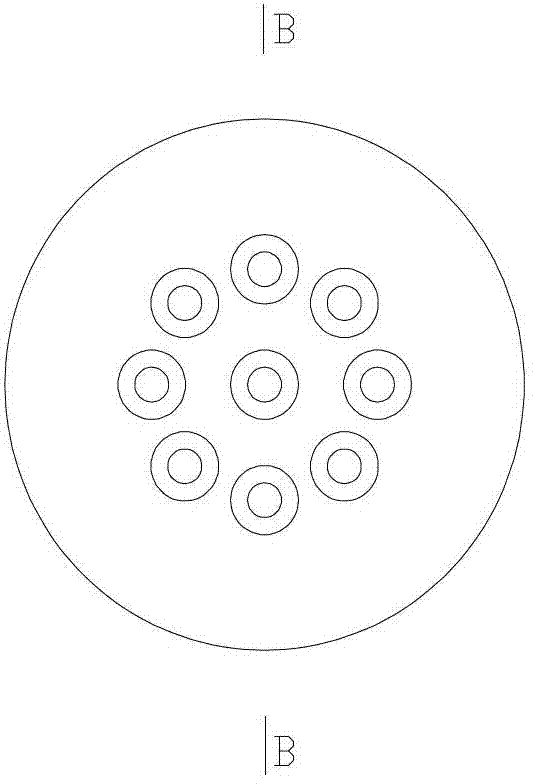

[0026] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the solid fuel retreat rate testing device of the present invention comprises an intake pipe 1, a balance chamber 2, an intake plate 3, an igniter 4, a combustion chamber 5, a card slot 6, a charge column 7, a pressure measuring nozzle 8, and a Laval nozzle 9. The combustion chamber 5 has a rectangular groove structure, and the upper part has a rectangular upper cover. There are screw holes at the front and rear ends of the upper cover, which are fastened to the combustion chamber 5 by screws, and the inner wall of the combustion chamber 5 is covered with a heat insulation layer. The integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com