Device for testing burning rate of multi-residue solid propellant

A solid propellant and testing device technology, which is applied in fuel oil testing, chemical analysis by combustion, material inspection products, etc., and can solve problems such as abnormal interruption and breaking of the target line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

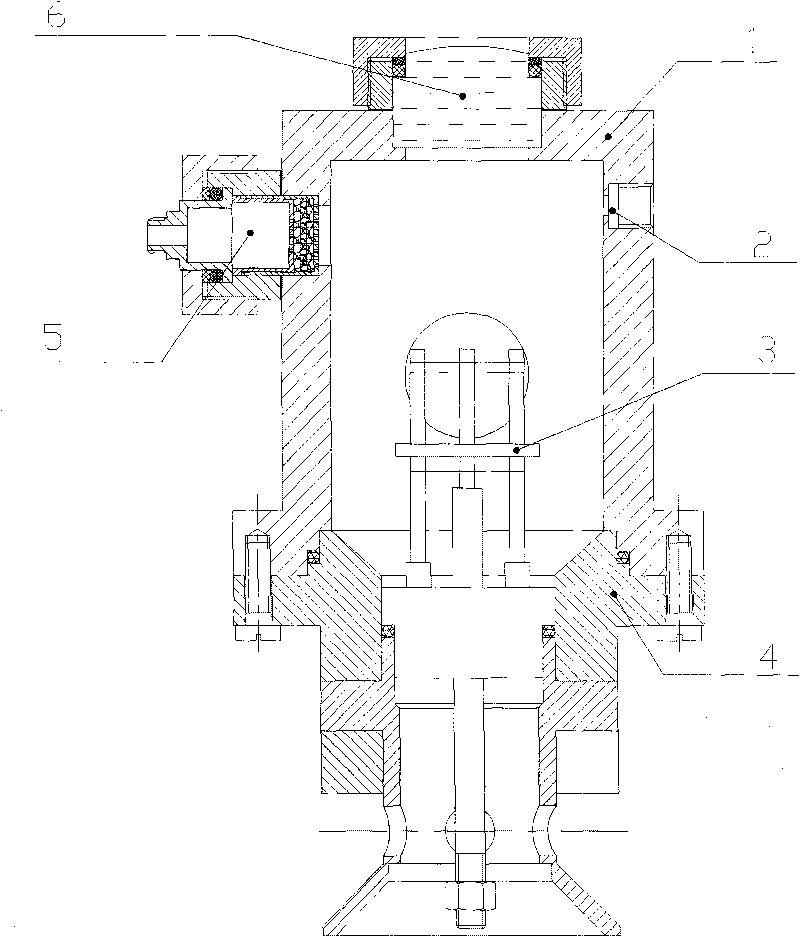

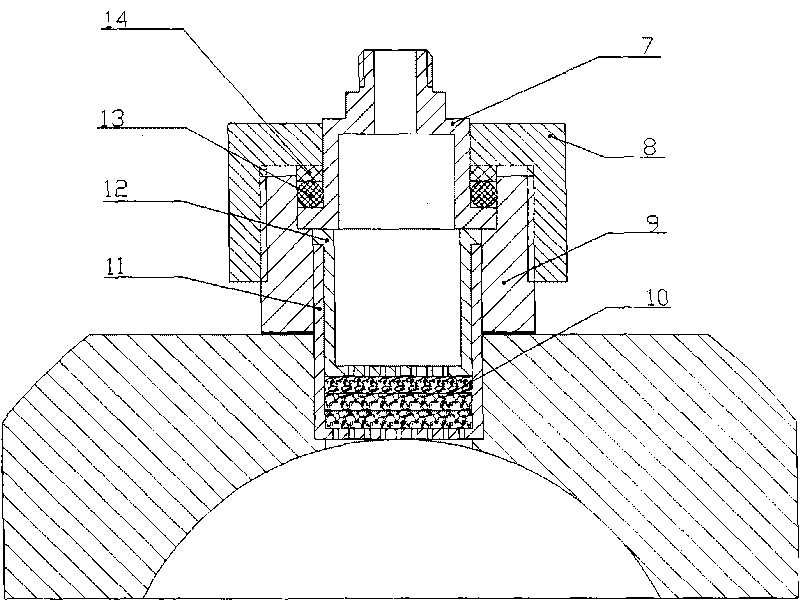

[0017] figure 1 It shows the part of the combustion chamber in a sectional view. When installing three transparent observation windows 6, install them in the step-shaped round holes on the combustion chamber respectively. After the sealing ring 13 and the metal ring 14 are installed on the observation window steps, , Tighten the end cap 8 to ensure its airtightness. When testing the burning rate, first install mesh screen and pickling asbestos in the filter cartridge designed and made by the present invention according to the experimental needs, and install them in the circular boss 9 welded on the combustion chamber after the inspection is completed, and then install Core 7. After the sealing ring 13 and the metal ring 14 are installed, tighten the end cap 8, then connect the pipeline connecting the buffer bottle and the exhaust pipe with the core body 7, and install the propellant cartridge and the combustion chamber base 4 . The present invention changes the way in which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com