Patents

Literature

2737results about "Fuel testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

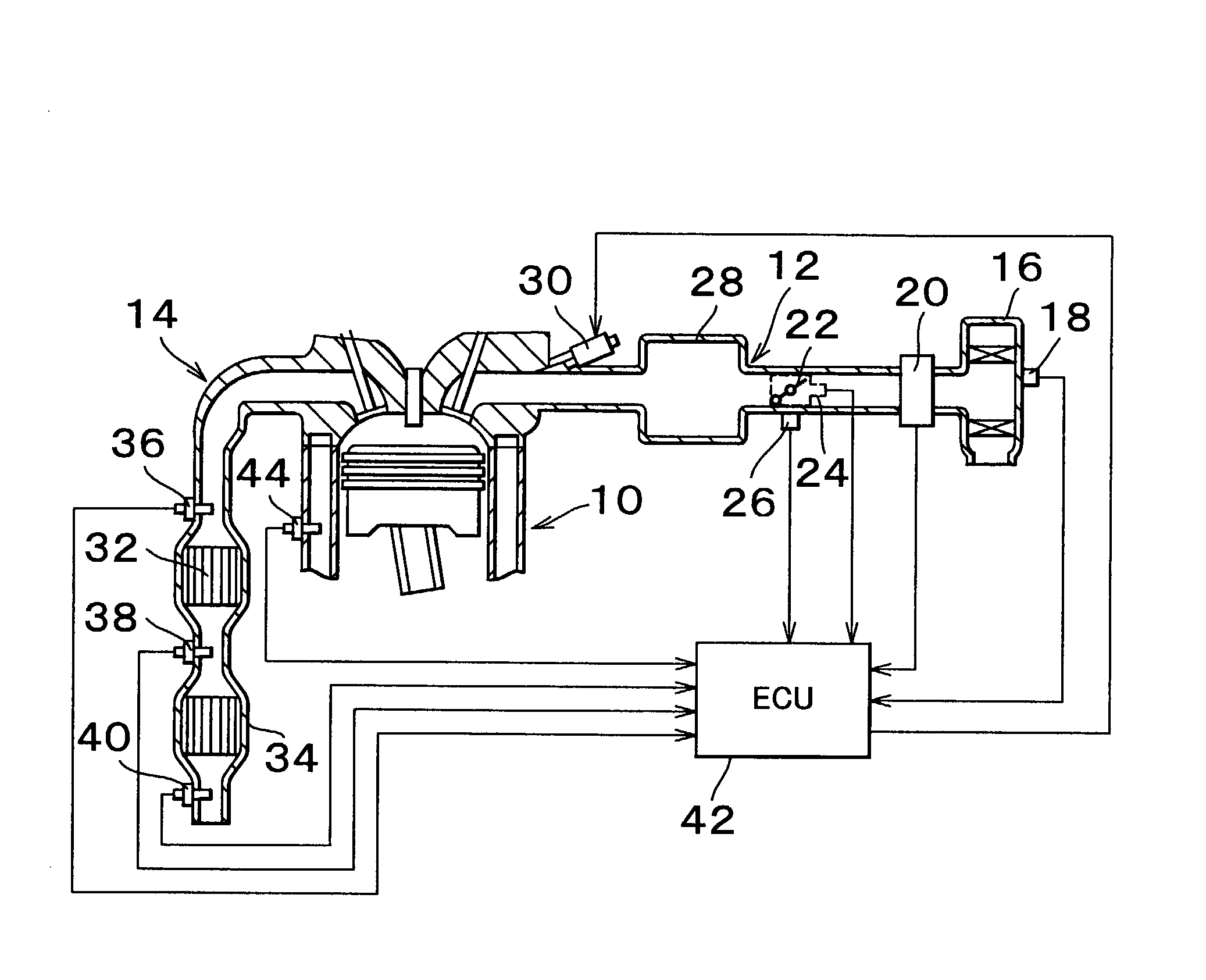

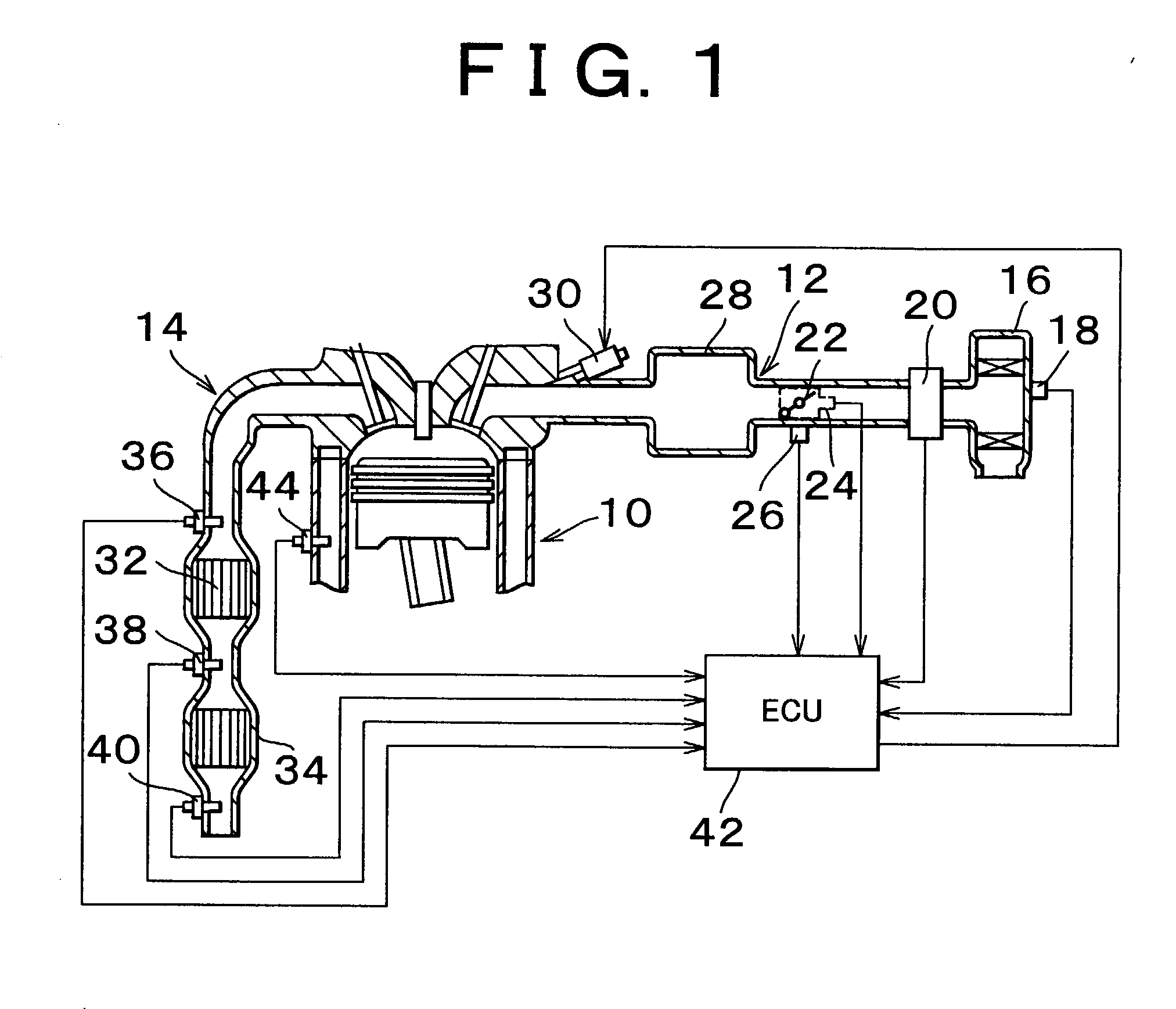

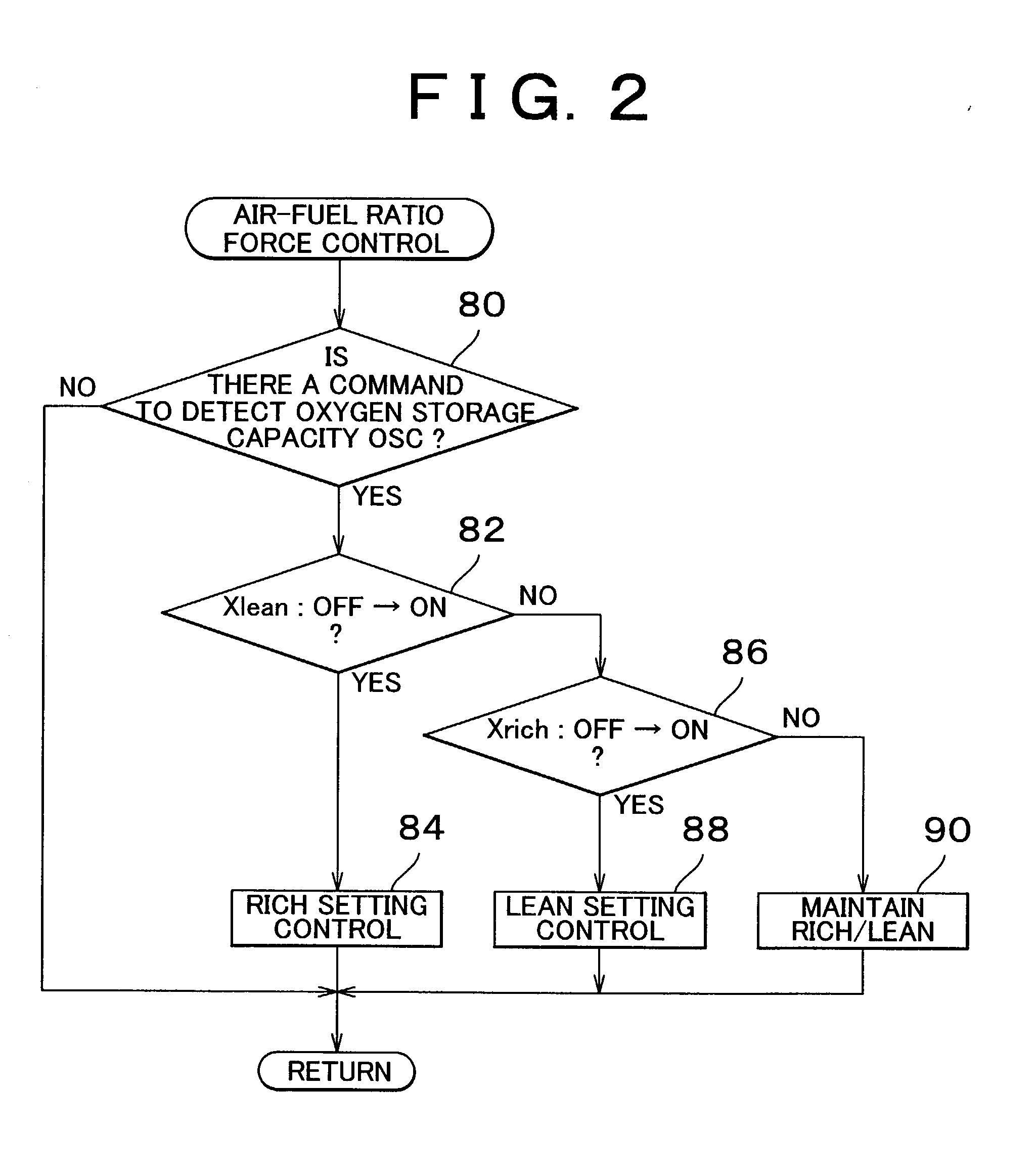

Catalyst deterioration detecting apparatus and method

InactiveUS20030017603A1Electrical controlInternal combustion piston enginesOxygen sensorEnvironmental engineering

An upstream side catalyst and a downstream side catalyst are disposed in an exhaust passage. A first oxygen sensor is disposed between these two catalysts and a second oxygen sensor is disposed downstream of the downstream side catalyst. The air-fuel ratio is forcibly oscillated and the oxygen storage capacity of the upstream side catalyst is detected. Deterioration of the upstream side catalyst is then detected based on whether this oxygen storage capacity is larger than a predetermined value. The forced oscillation of the air-fuel ratio is performed only when the oxygen storage state of the downstream side catalyst is appropriate.

Owner:TOYOTA JIDOSHA KK

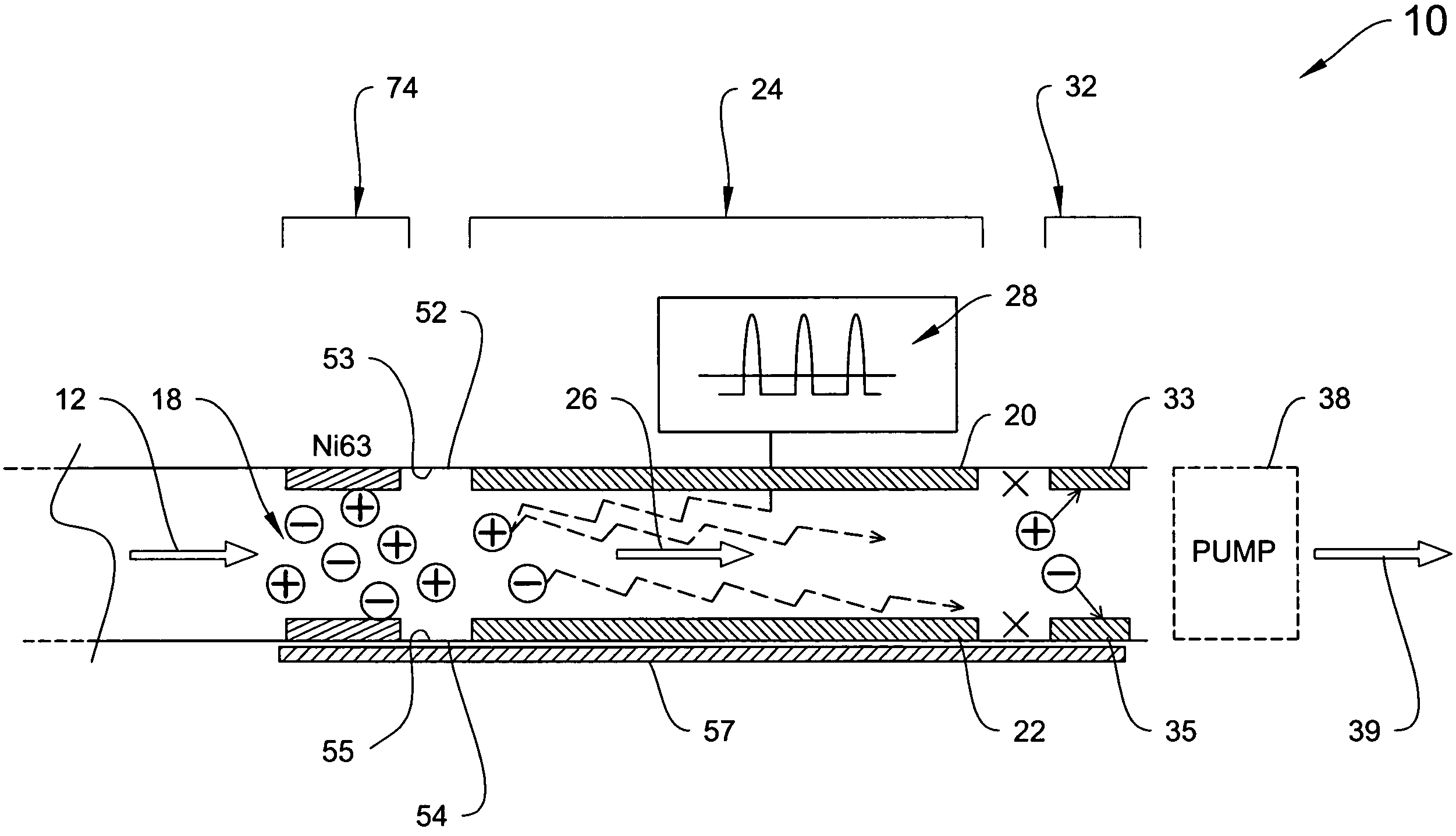

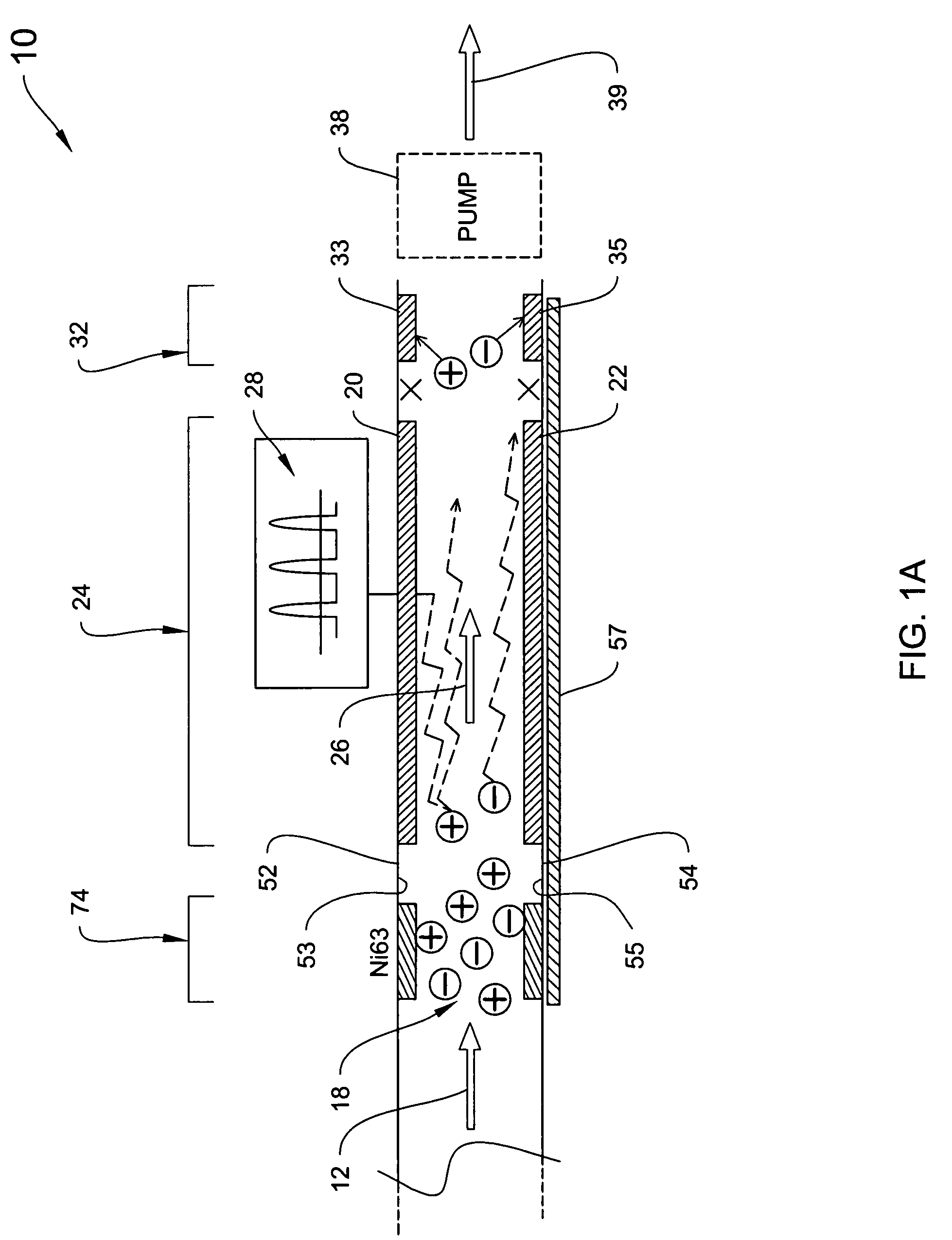

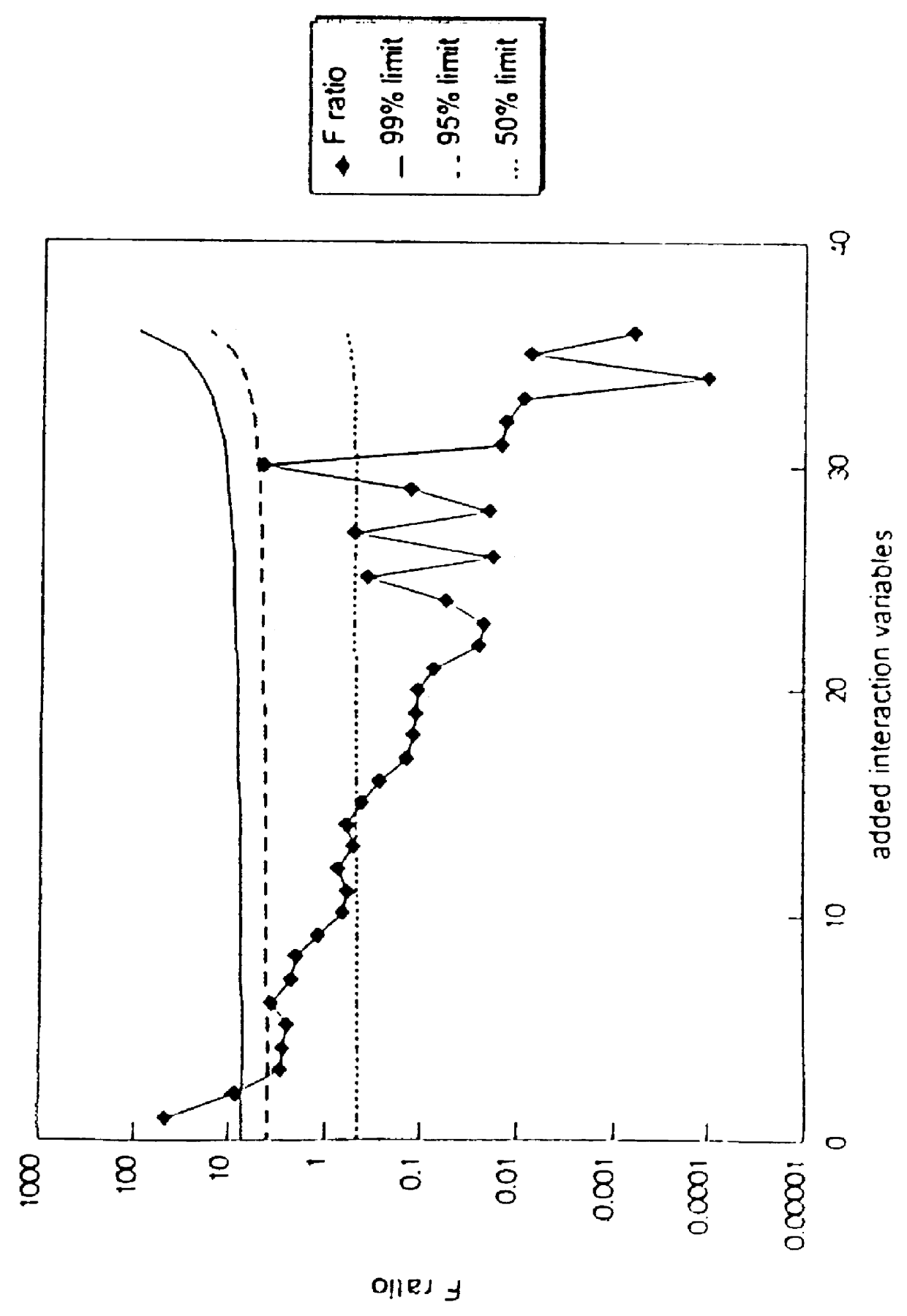

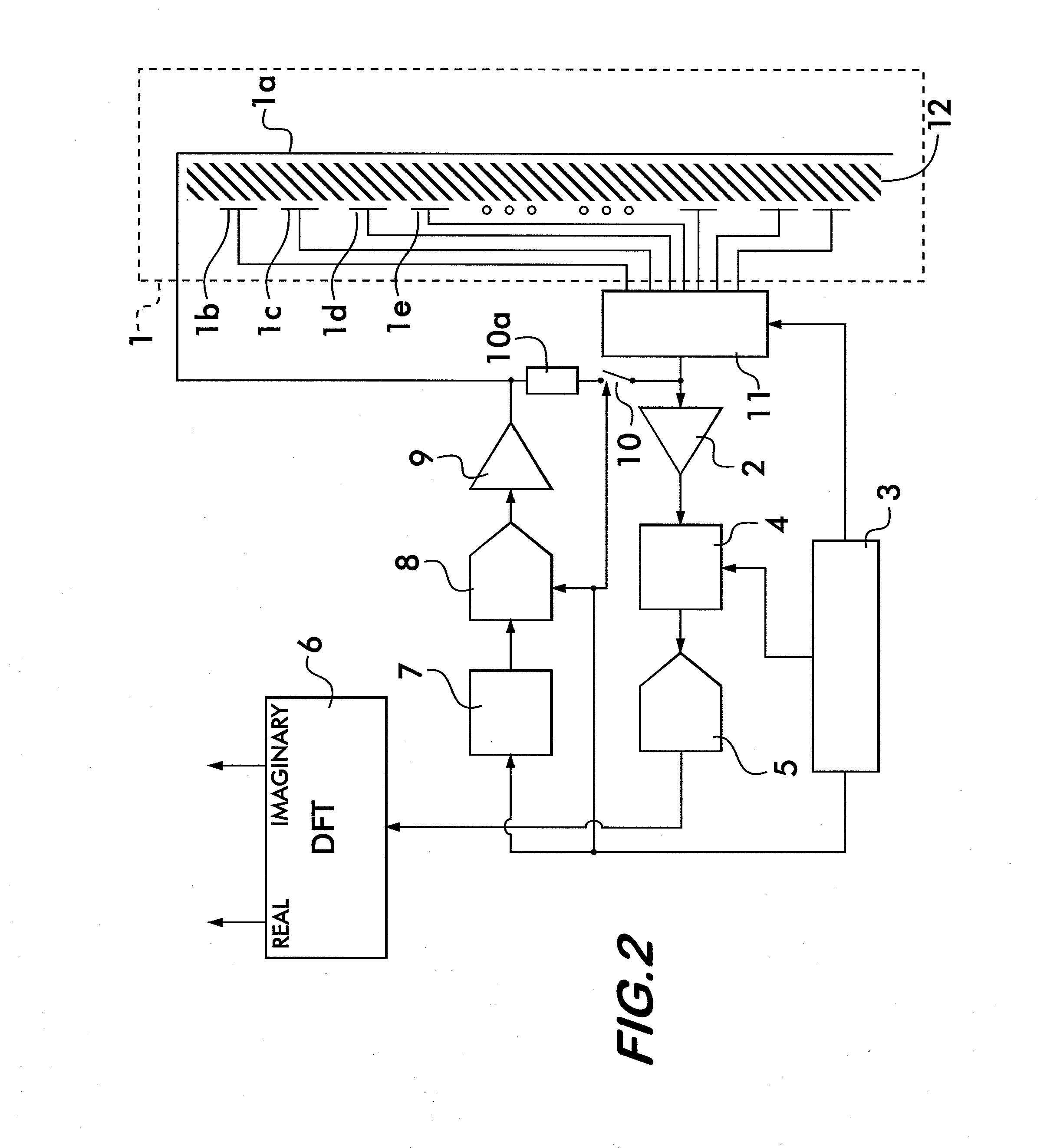

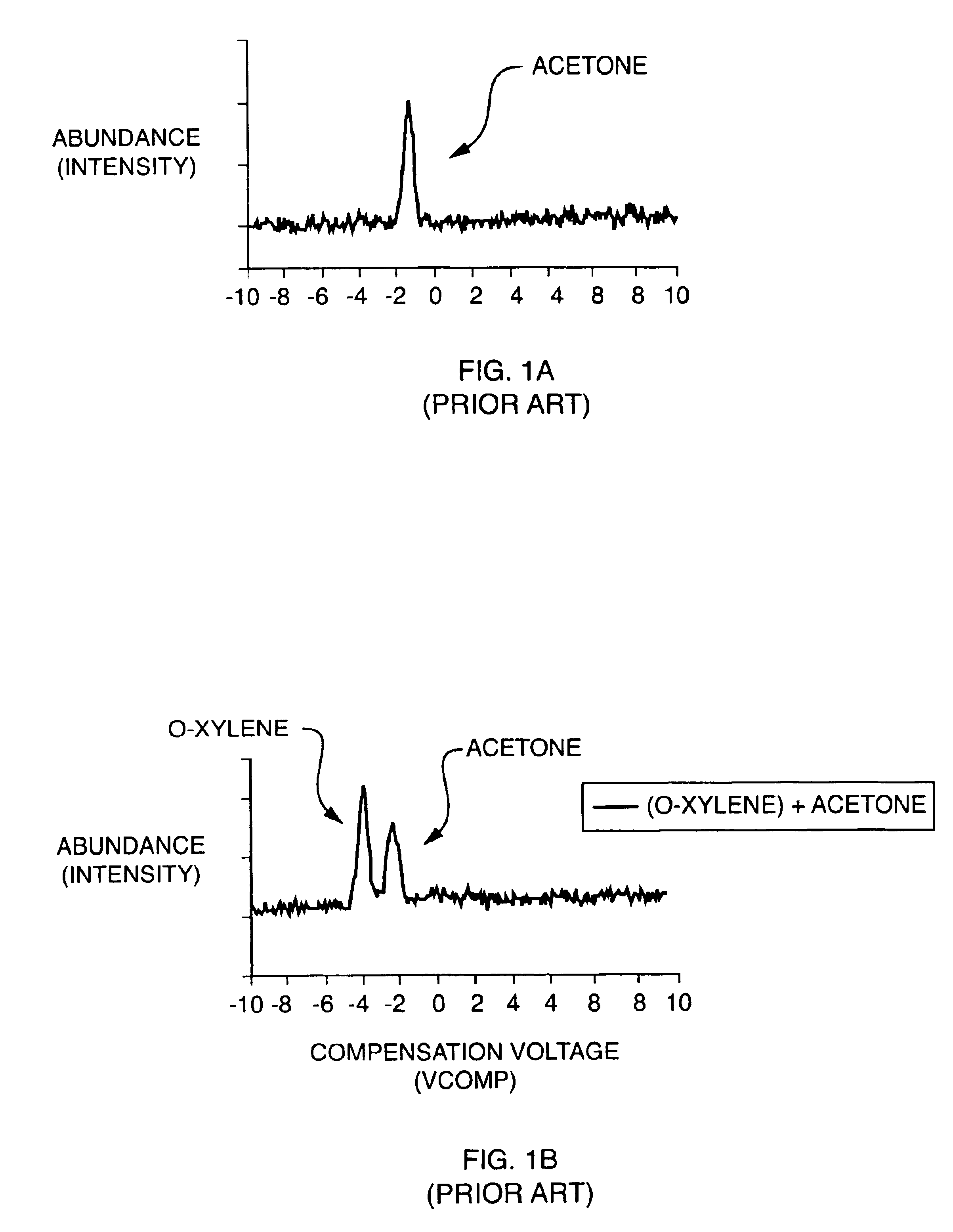

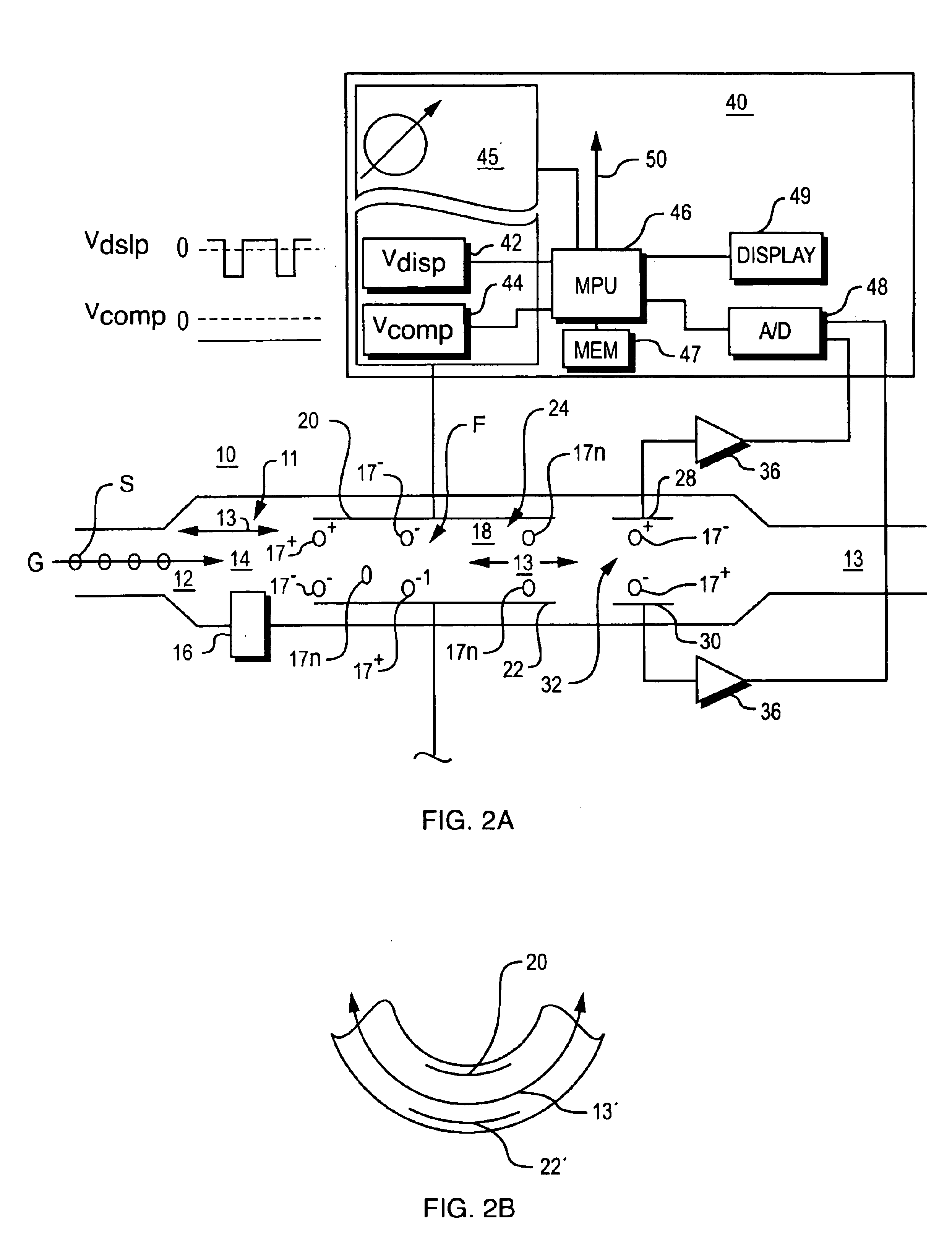

Explosives detection using differential ion mobility spectrometry

InactiveUS20050133716A1Easy to separateHigh resolutionTime-of-flight spectrometersFuel testingOptical spectrometerPhysical chemistry

System for control of ion species behavior in a time-varying filter field of an ion mobility-based spectrometer to improve species identification for explosives detection.

Owner:DH TECH DEVMENT PTE

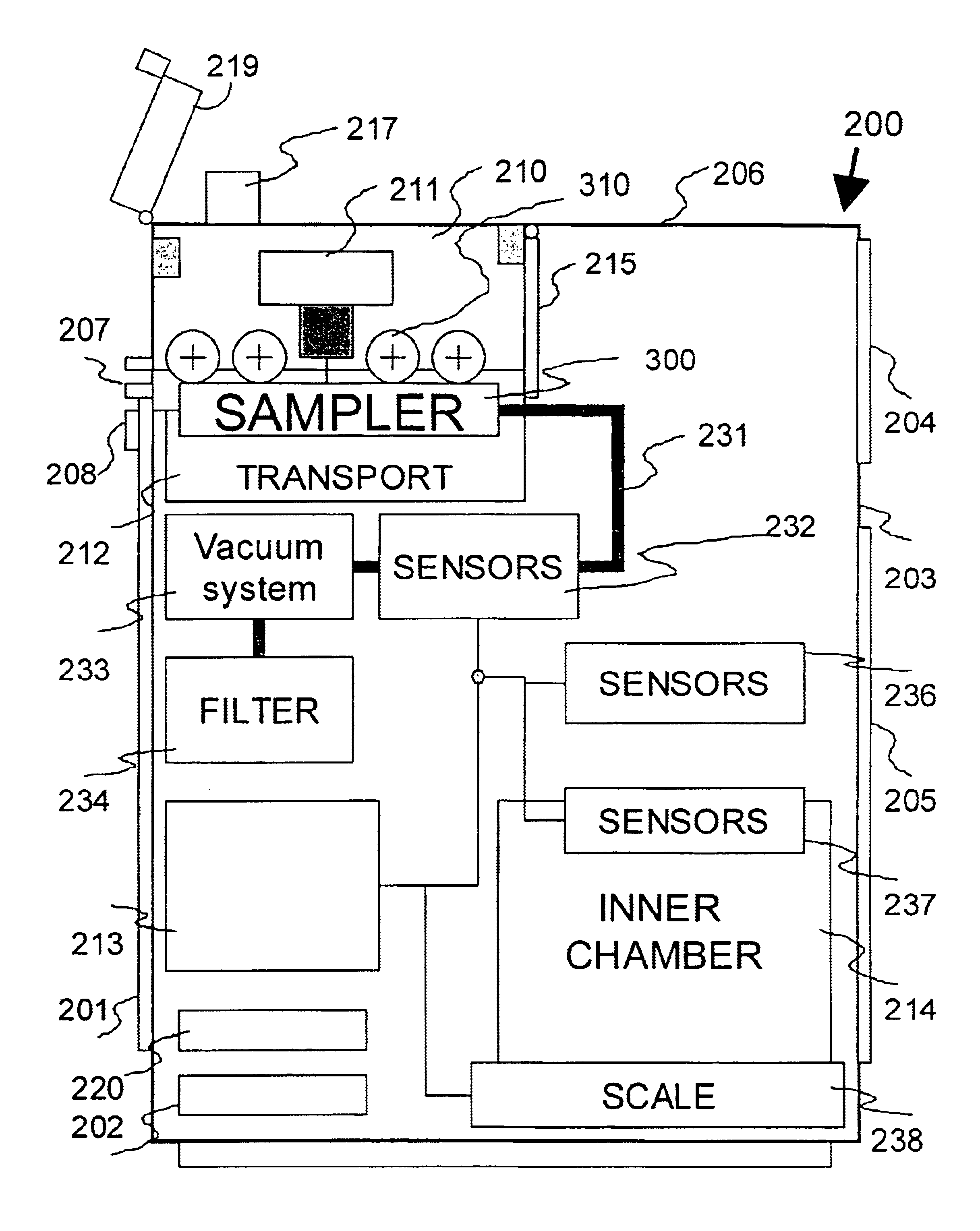

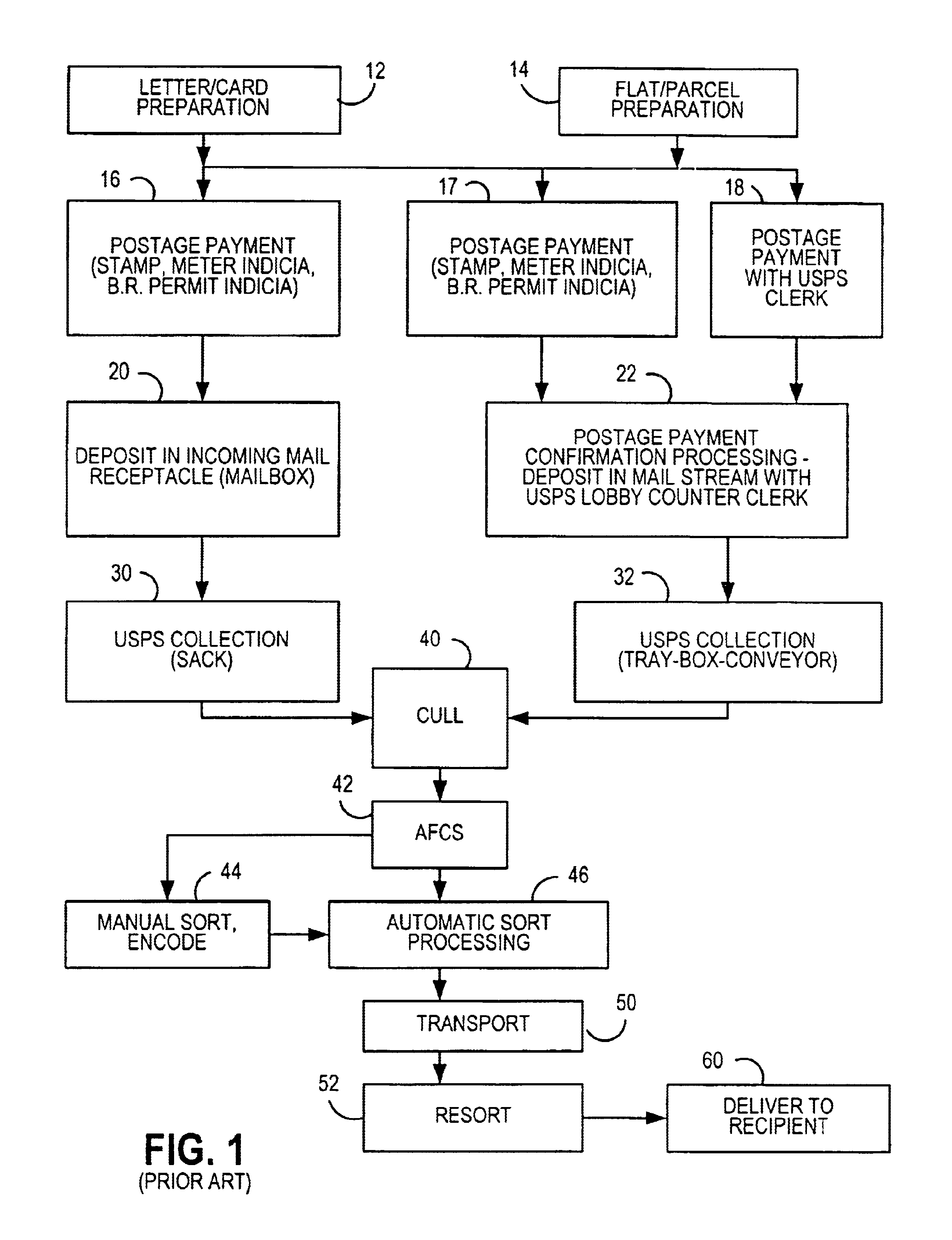

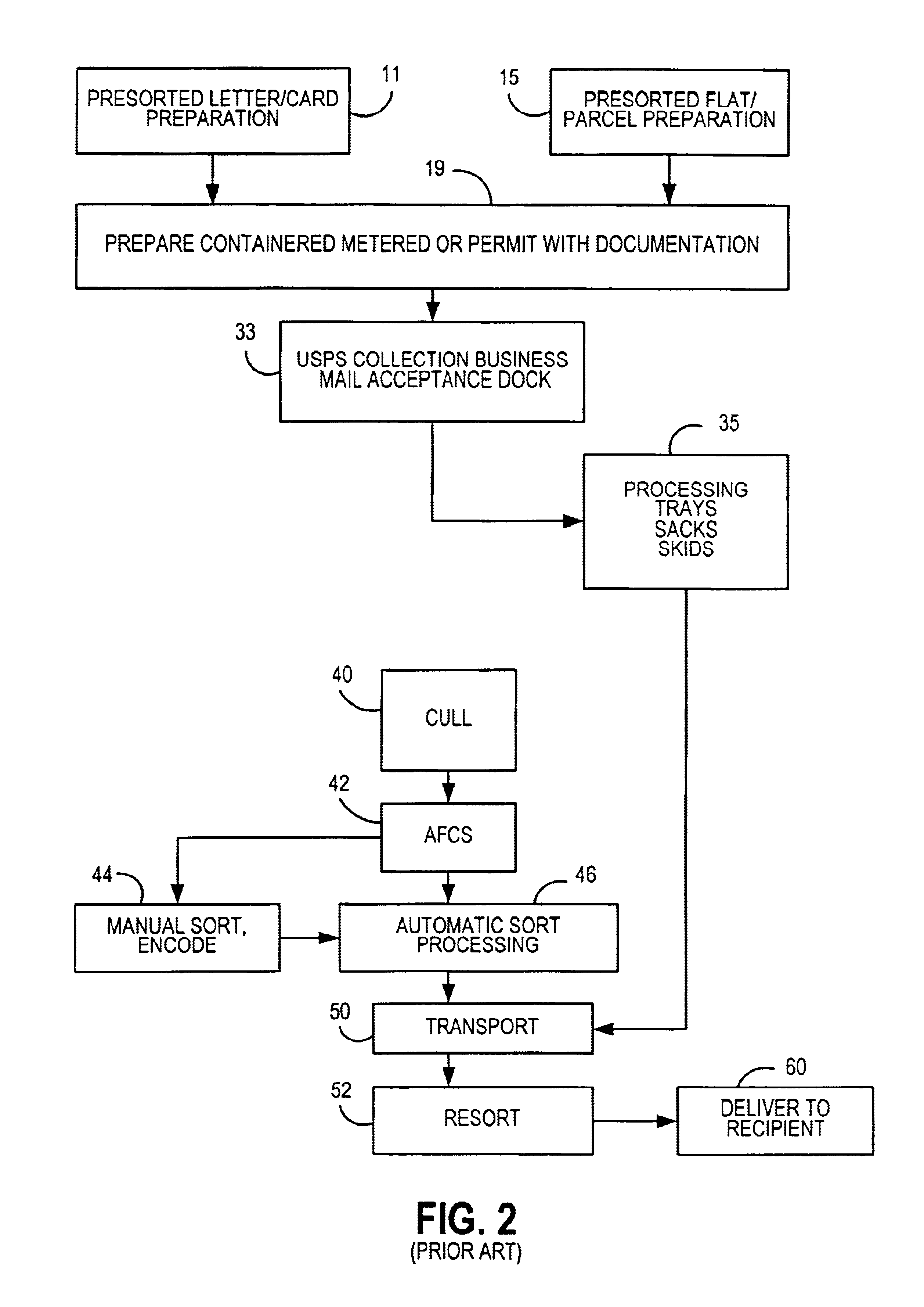

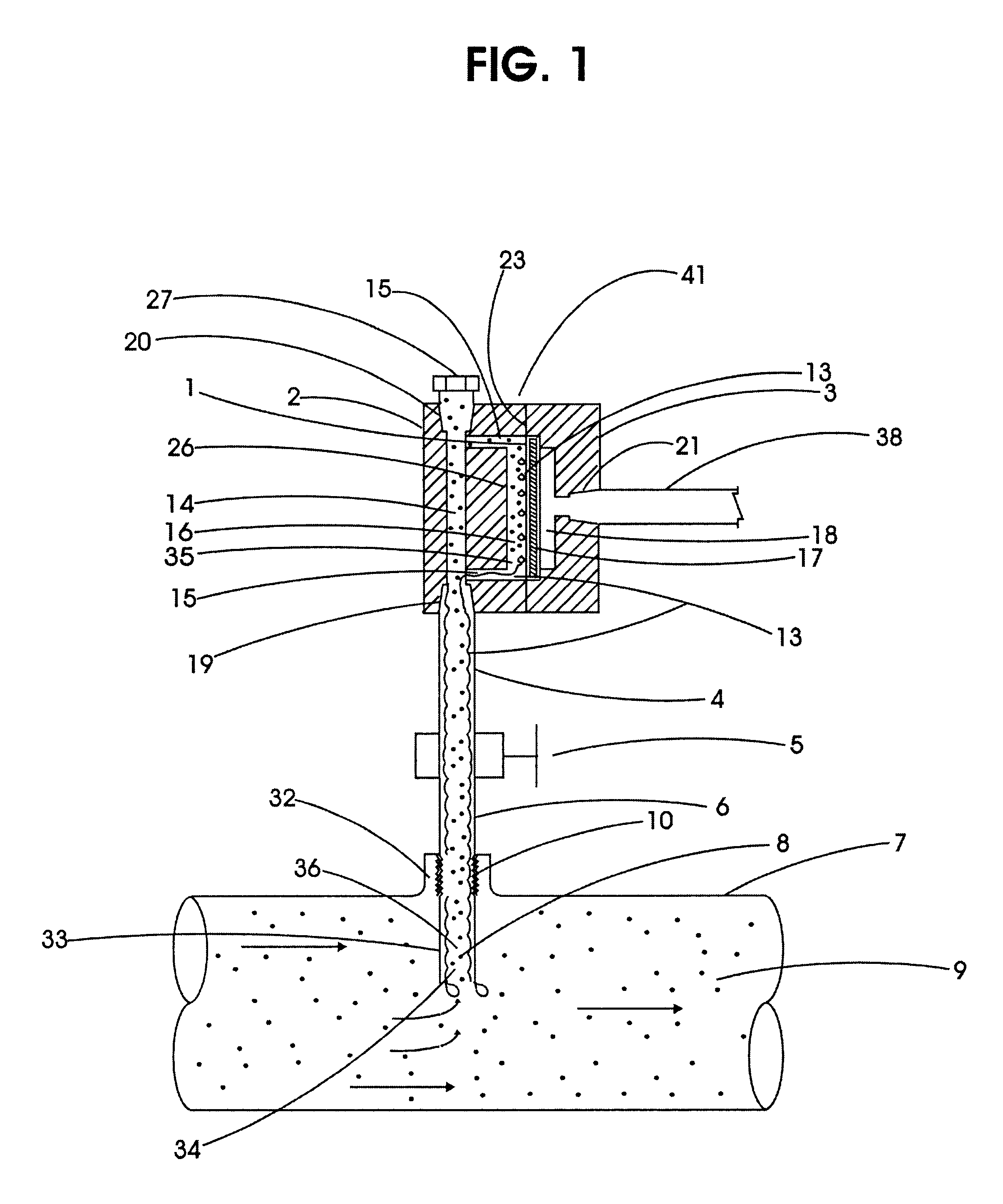

Method and system for detecting biological and chemical hazards in networked incoming mailboxes

InactiveUS6867044B2Material analysis by electric/magnetic meansMaterial analysis by optical meansBiological hazardComputer science

A method and system for detecting chemical or biological hazards in items is provided. A plurality of incoming mail mailboxes each include a sampler to sample air from a letter that is tested using a first sensor. Source information corresponding to hazard flagged mail pieces is utilized to block mail from that source at other mailboxes.

Owner:PITNEY BOWES INC

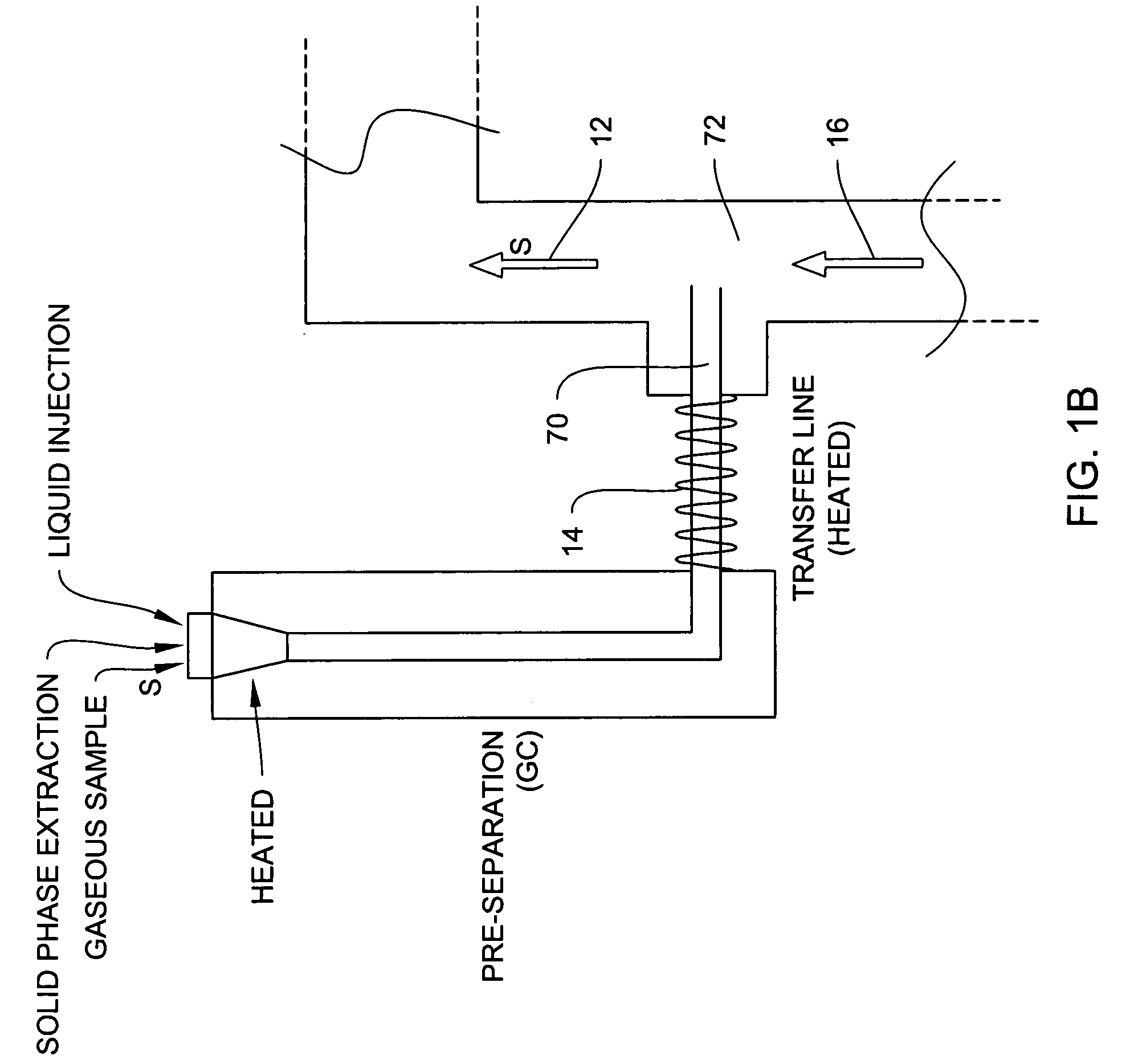

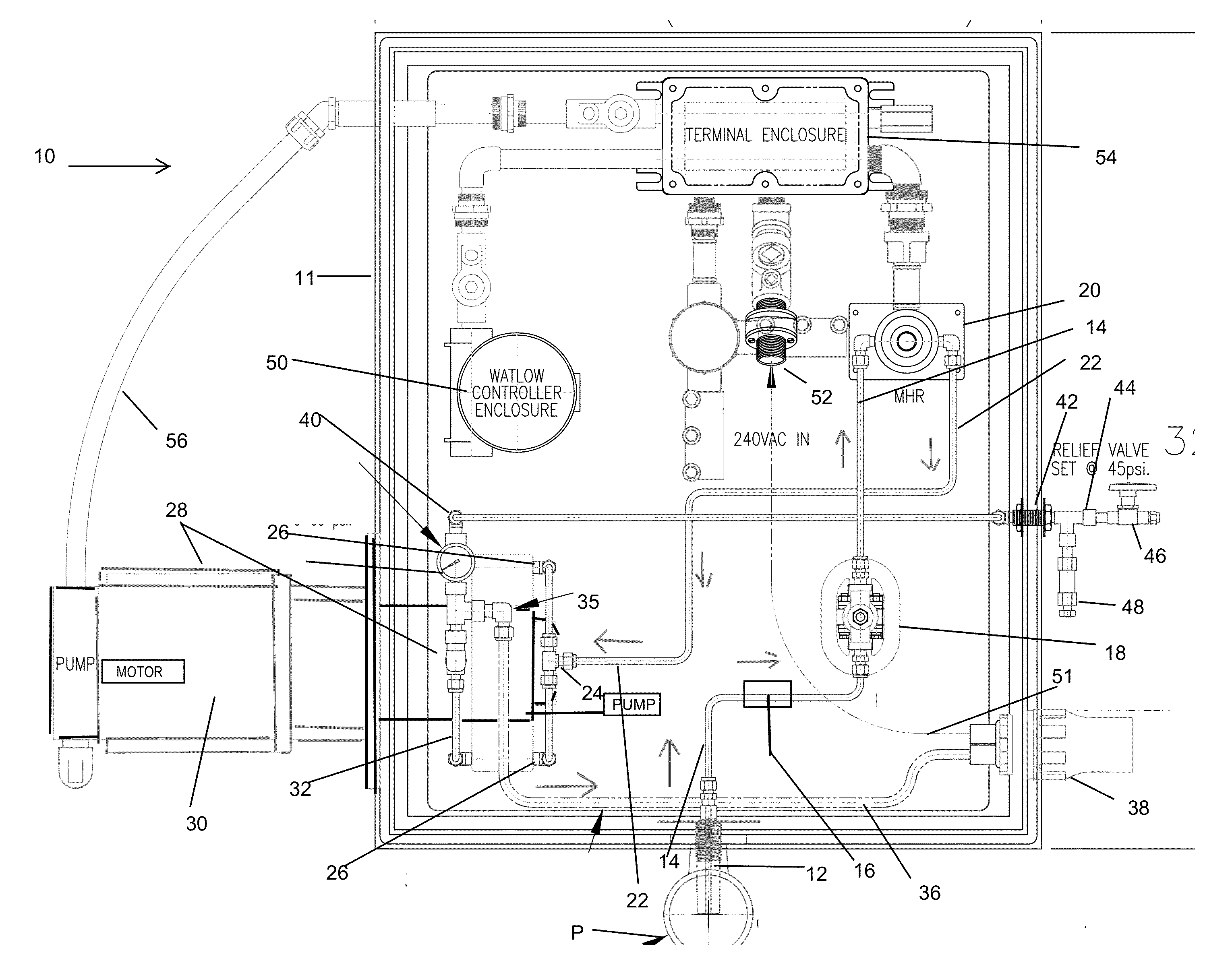

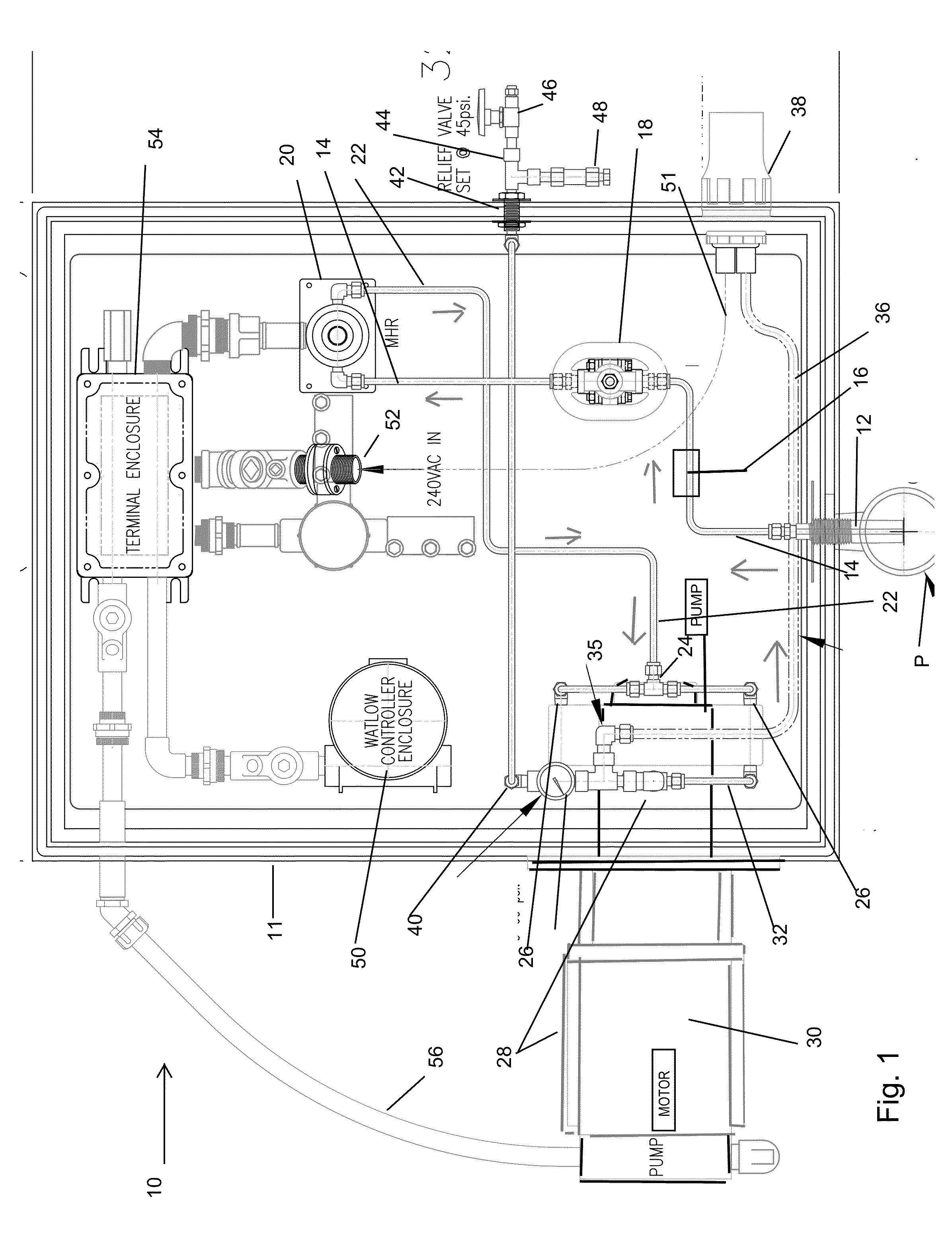

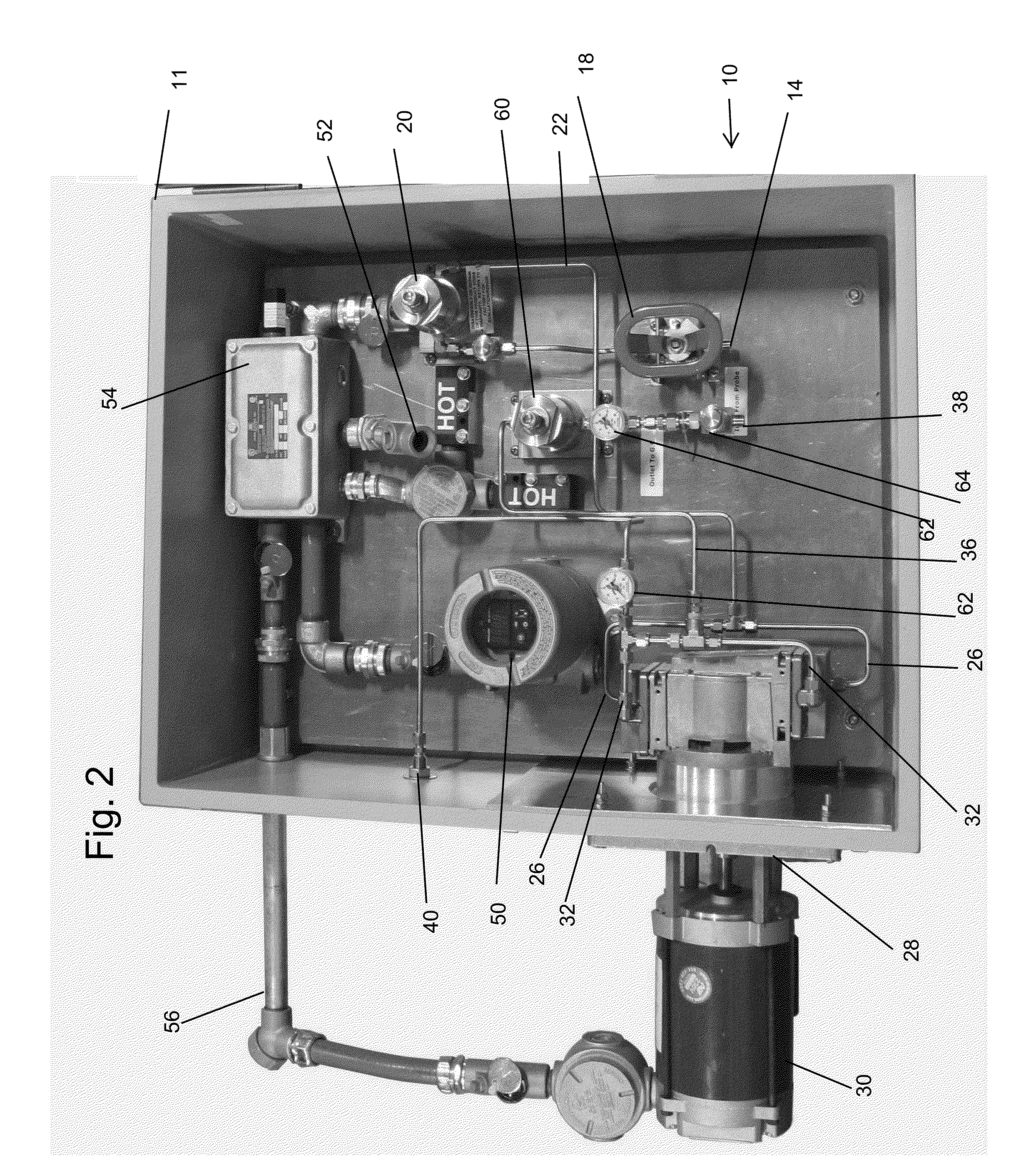

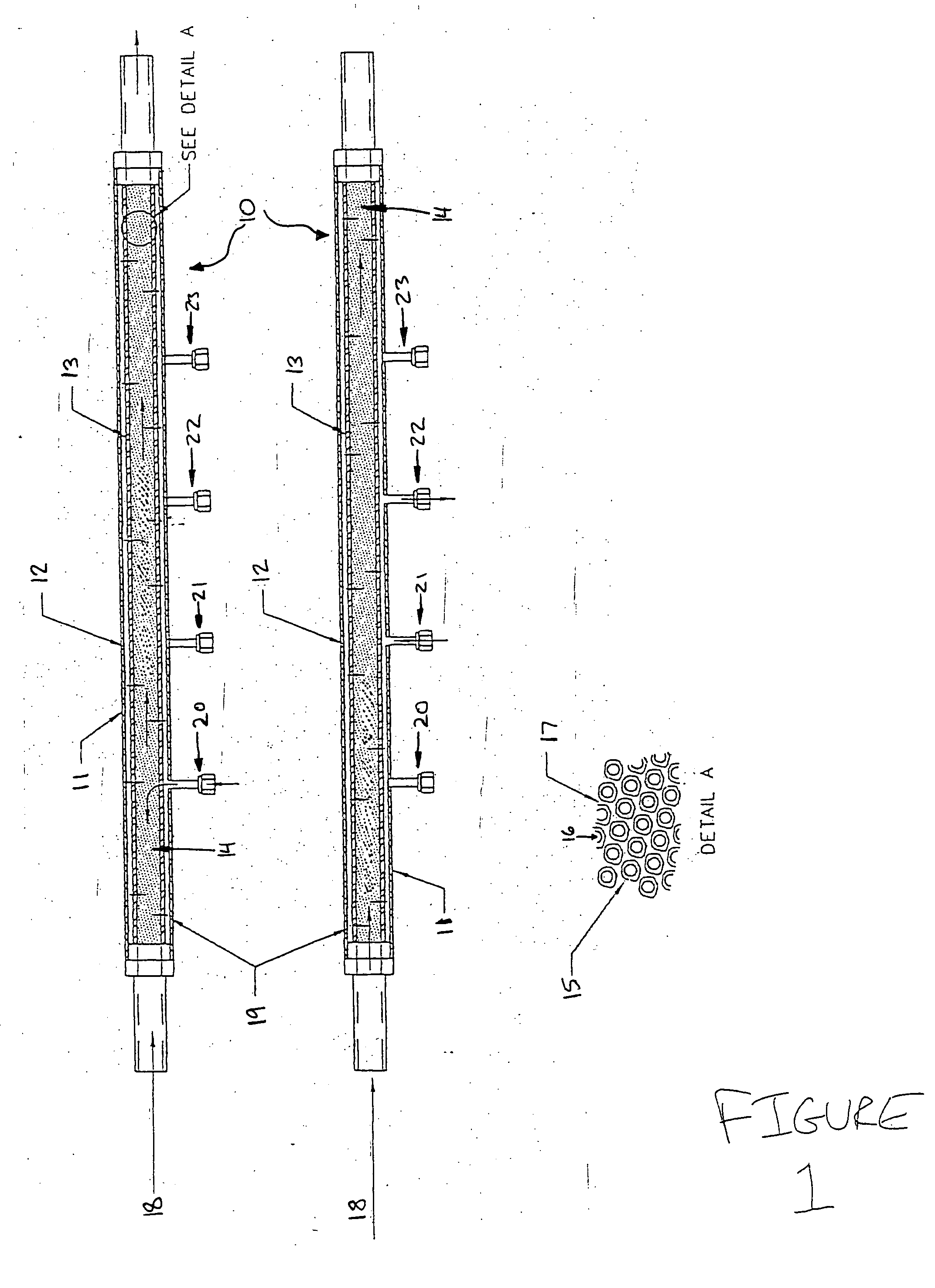

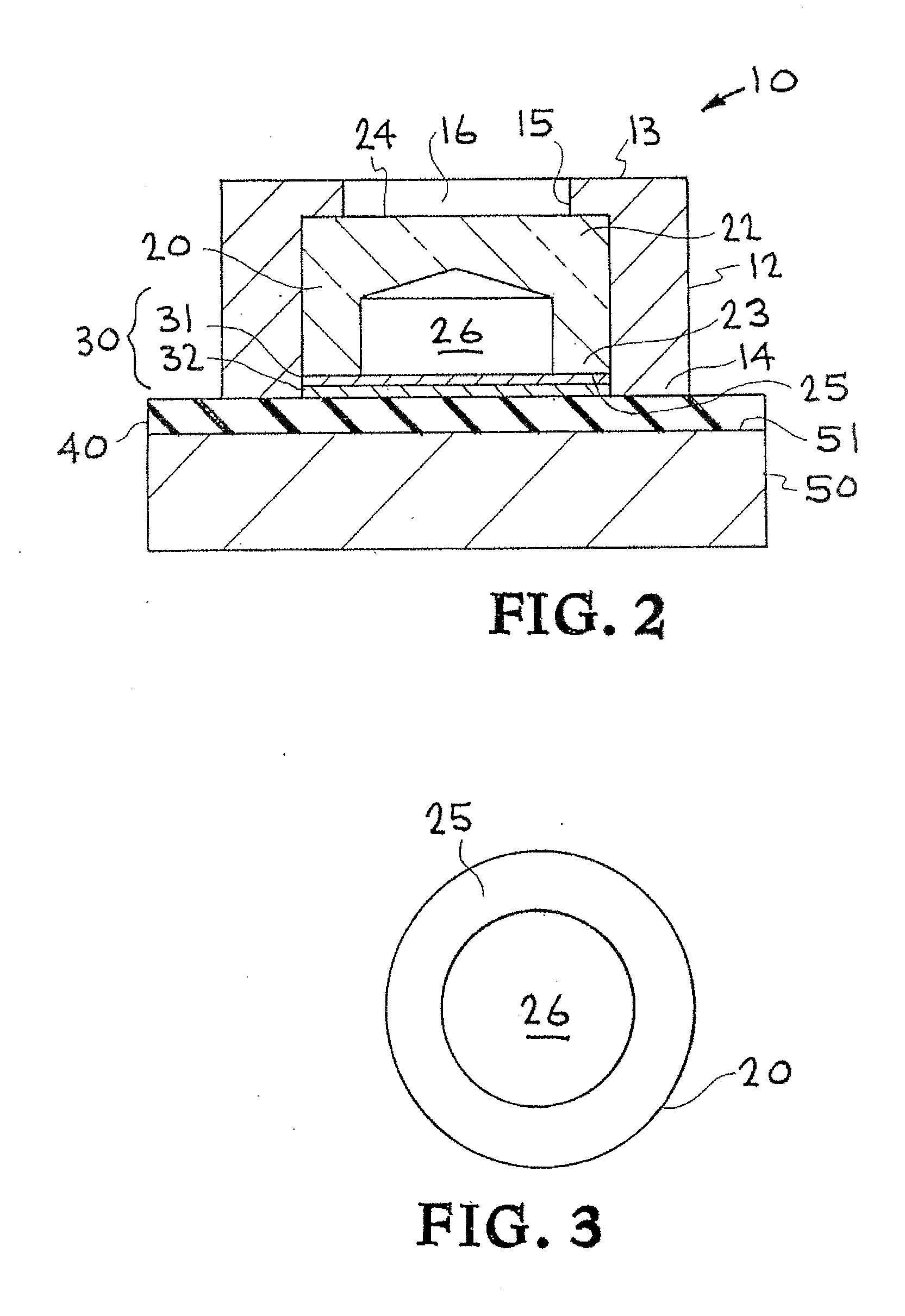

Sample Conditioning System for Low Pressure Gas

InactiveUS20150000426A1MaintenanceFacilitate pressureComponent separationWithdrawing sample devicesProduct gasEngineering

A system and method for conditioning of very low pressure gas samples extracted from a source, heating the samples, boosting the pressure to a level appropriate for analysis, regulating the gas sample temperature and pressure to prevent dew-point dropout from Joules Thompson condensation, and passing the gas sample to an a remotely located analyzer or analyzer array where the electrical power for the pressurizing pump and heated regulator is provided by heat tracing.

Owner:MUSTANG SAMPLING

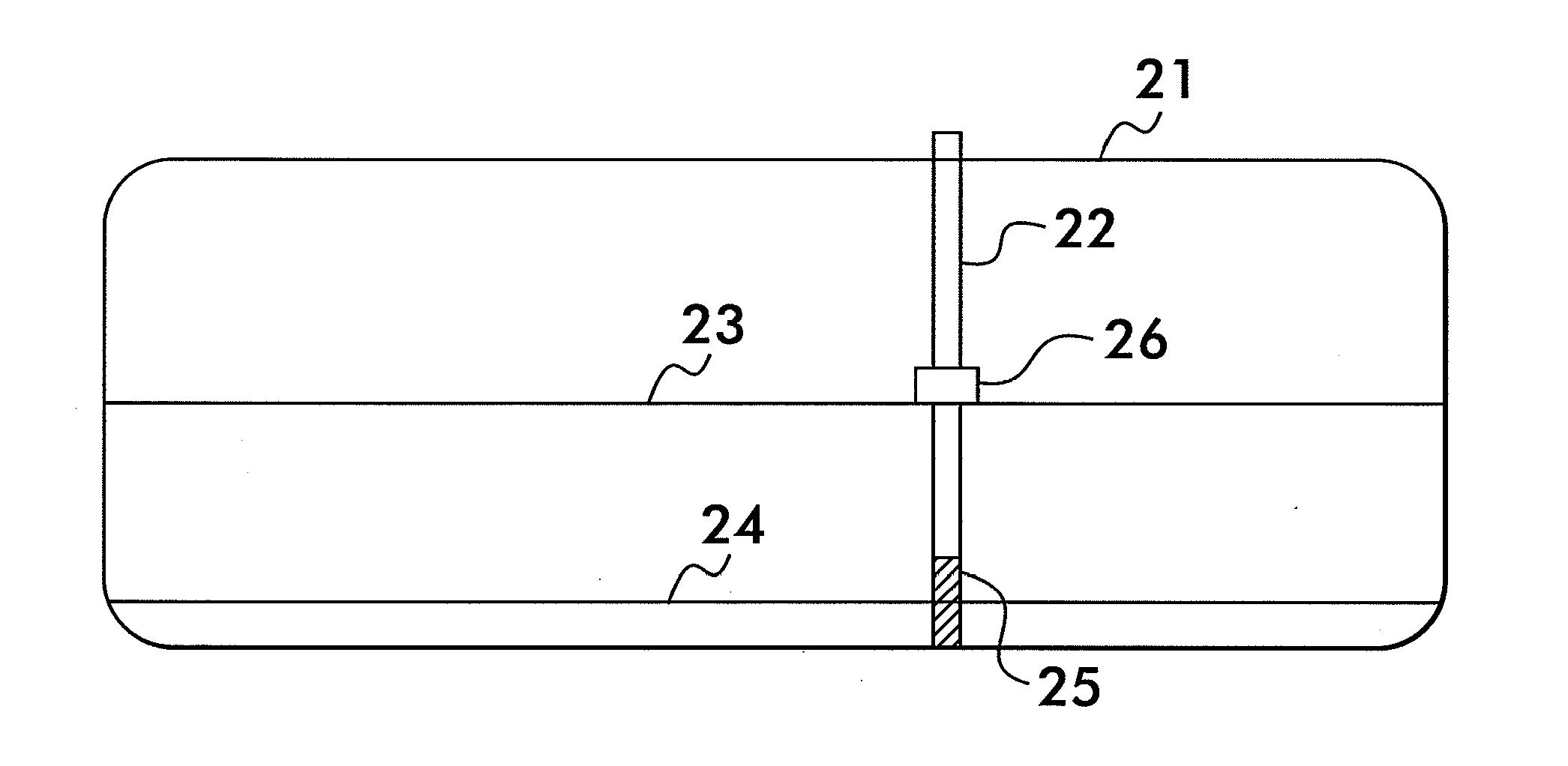

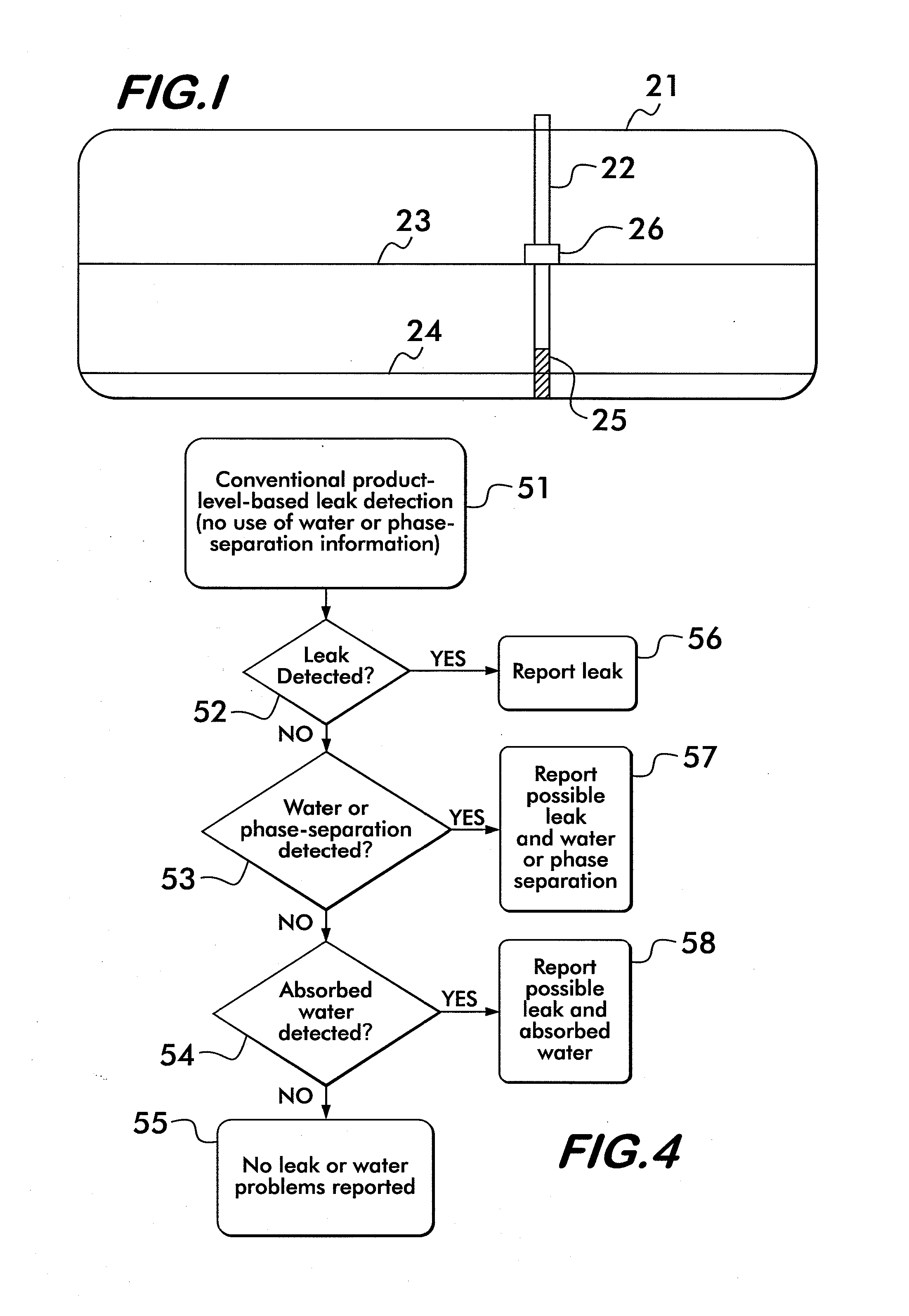

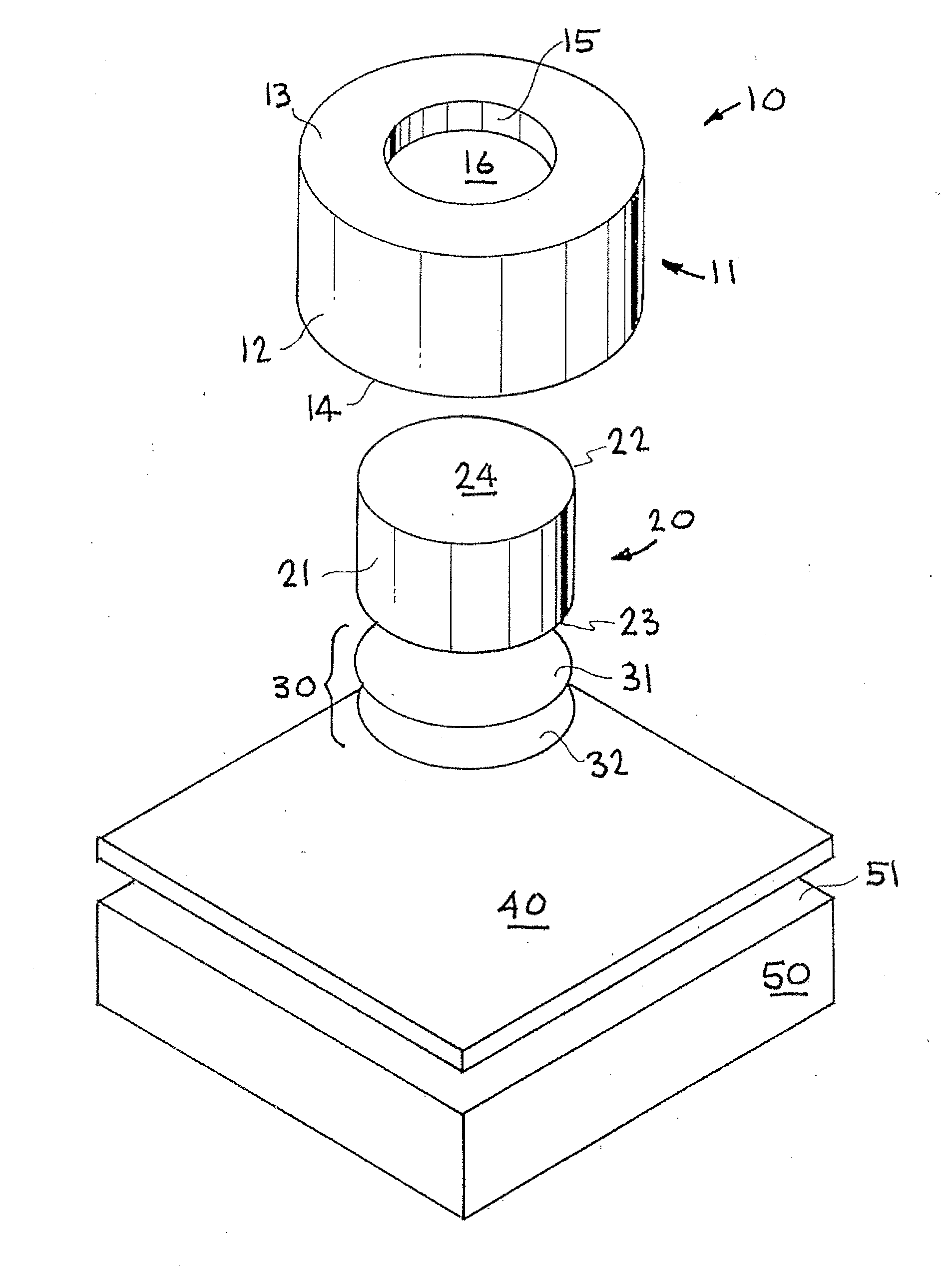

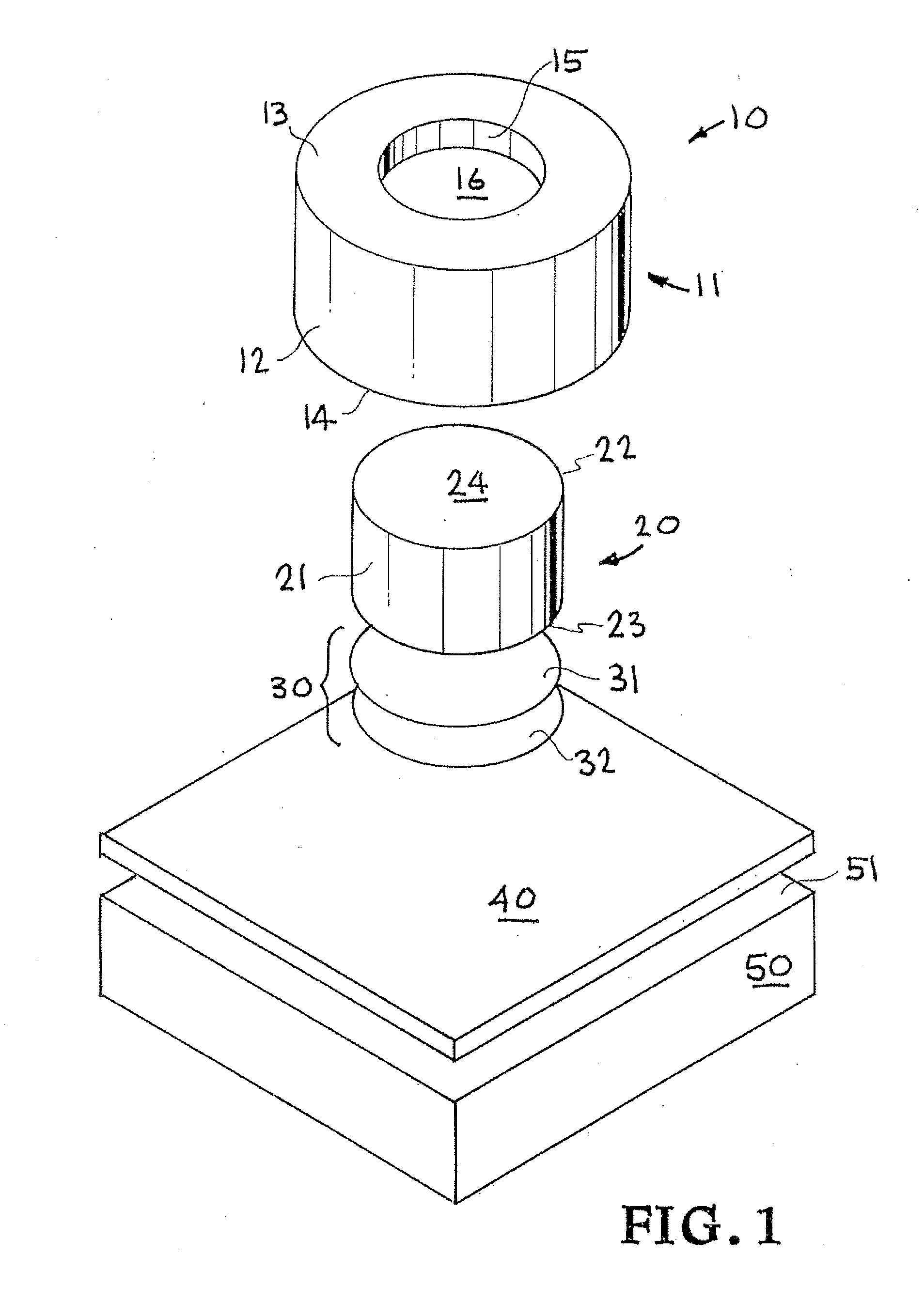

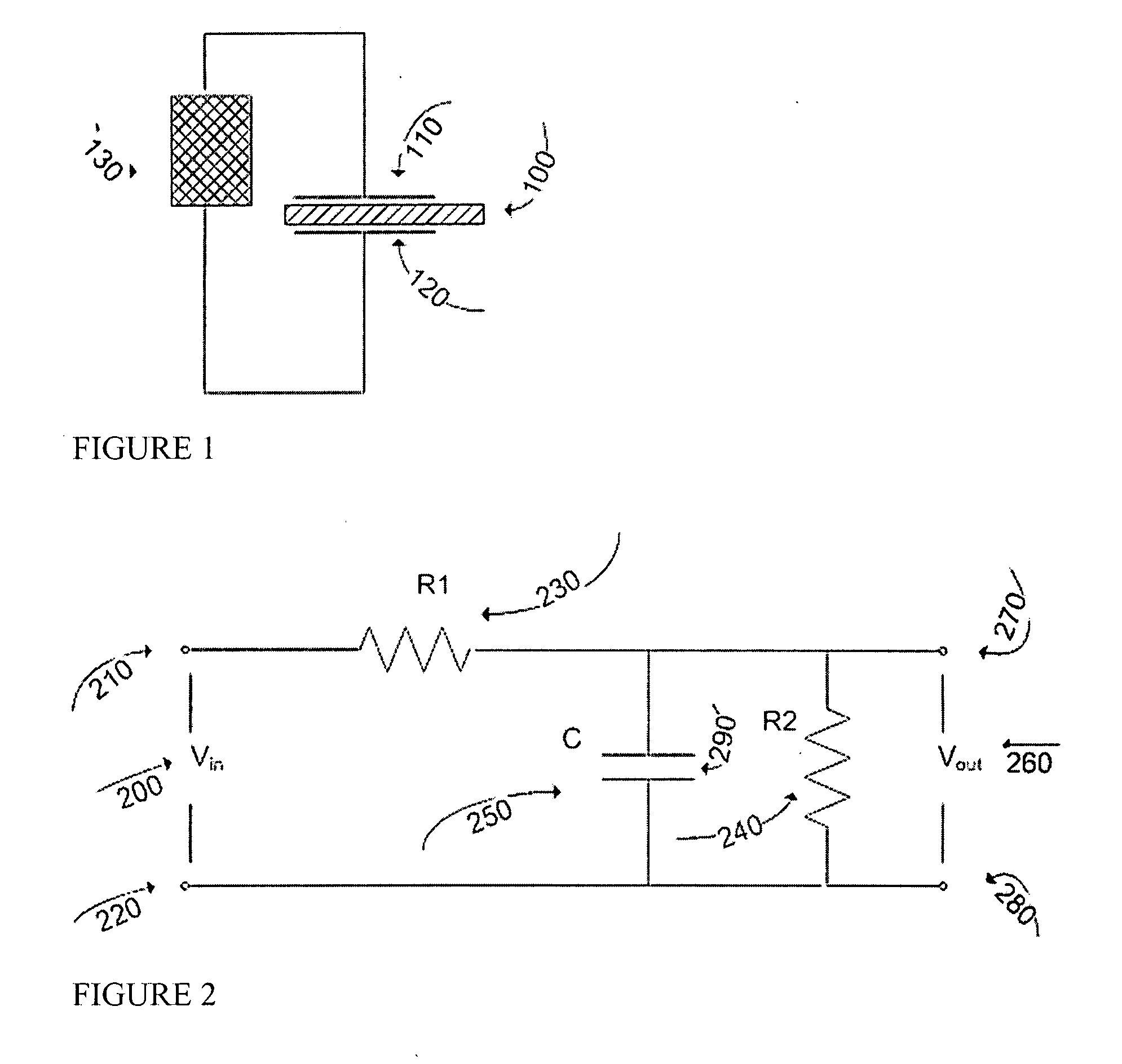

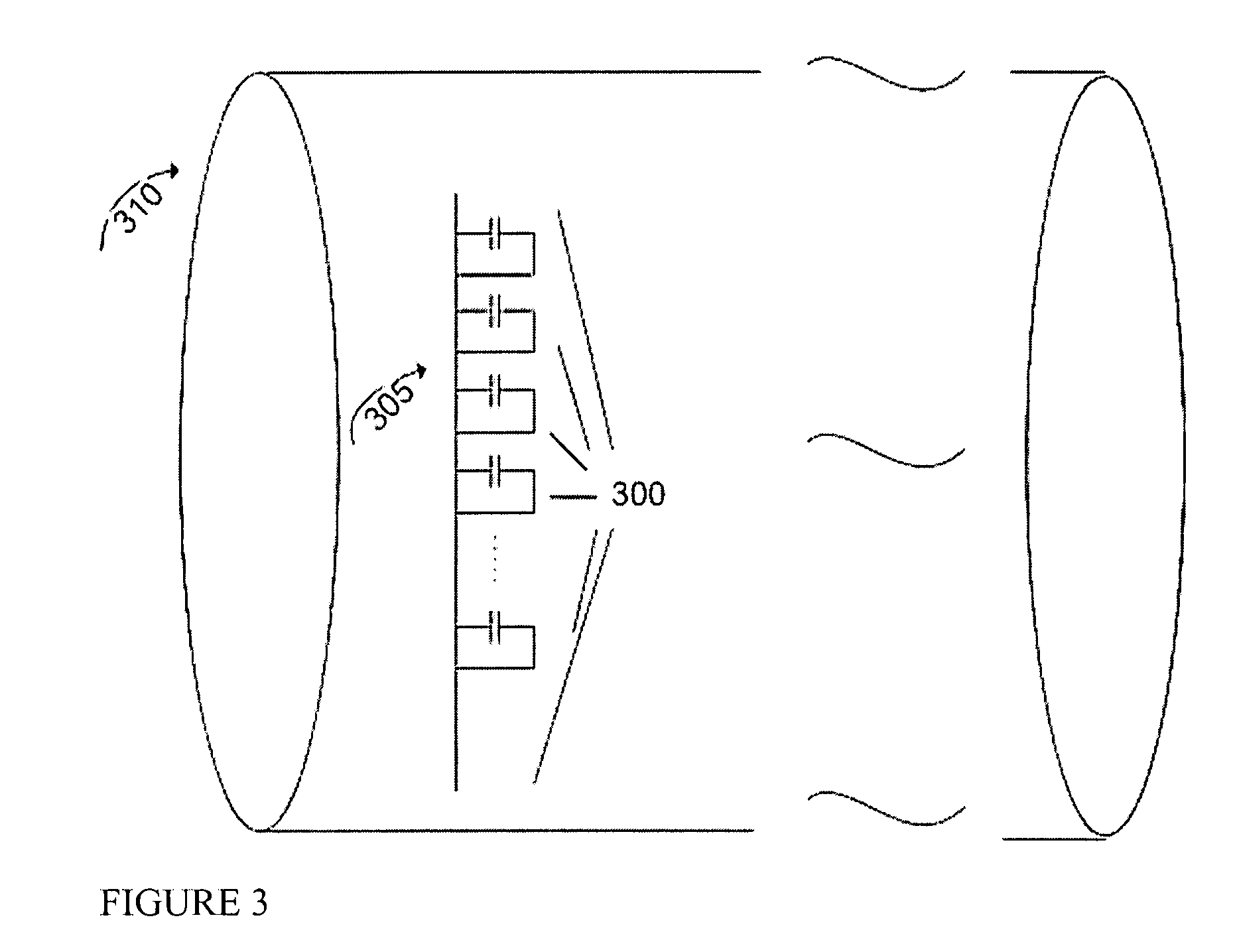

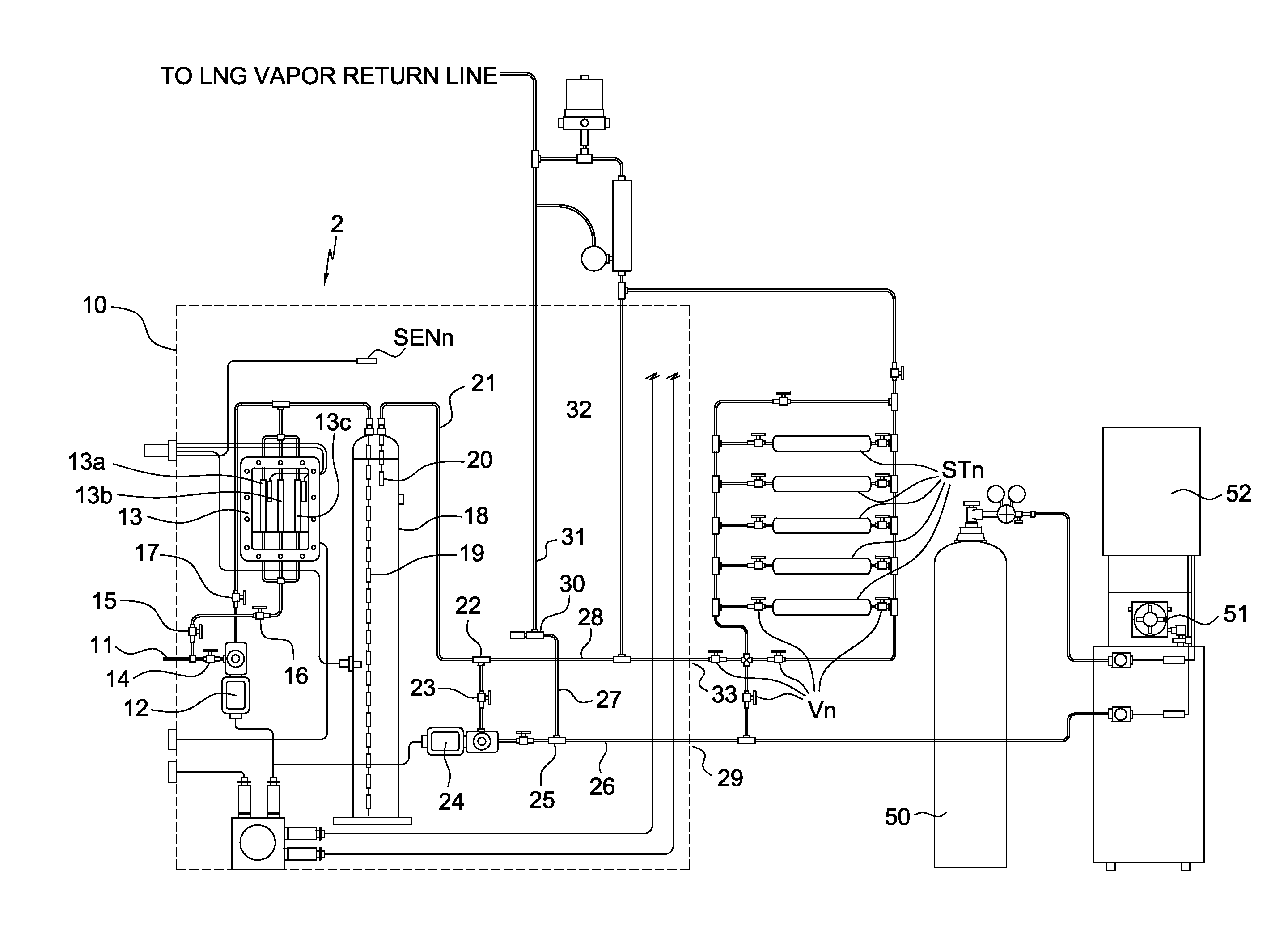

Automated phase separation and fuel quality sensor

InactiveUS20100295565A1Not easy to make mistakesMinimize attractionVolume measurement apparatus/methodsResistance/reactance/impedenceFuel qualityEngineering

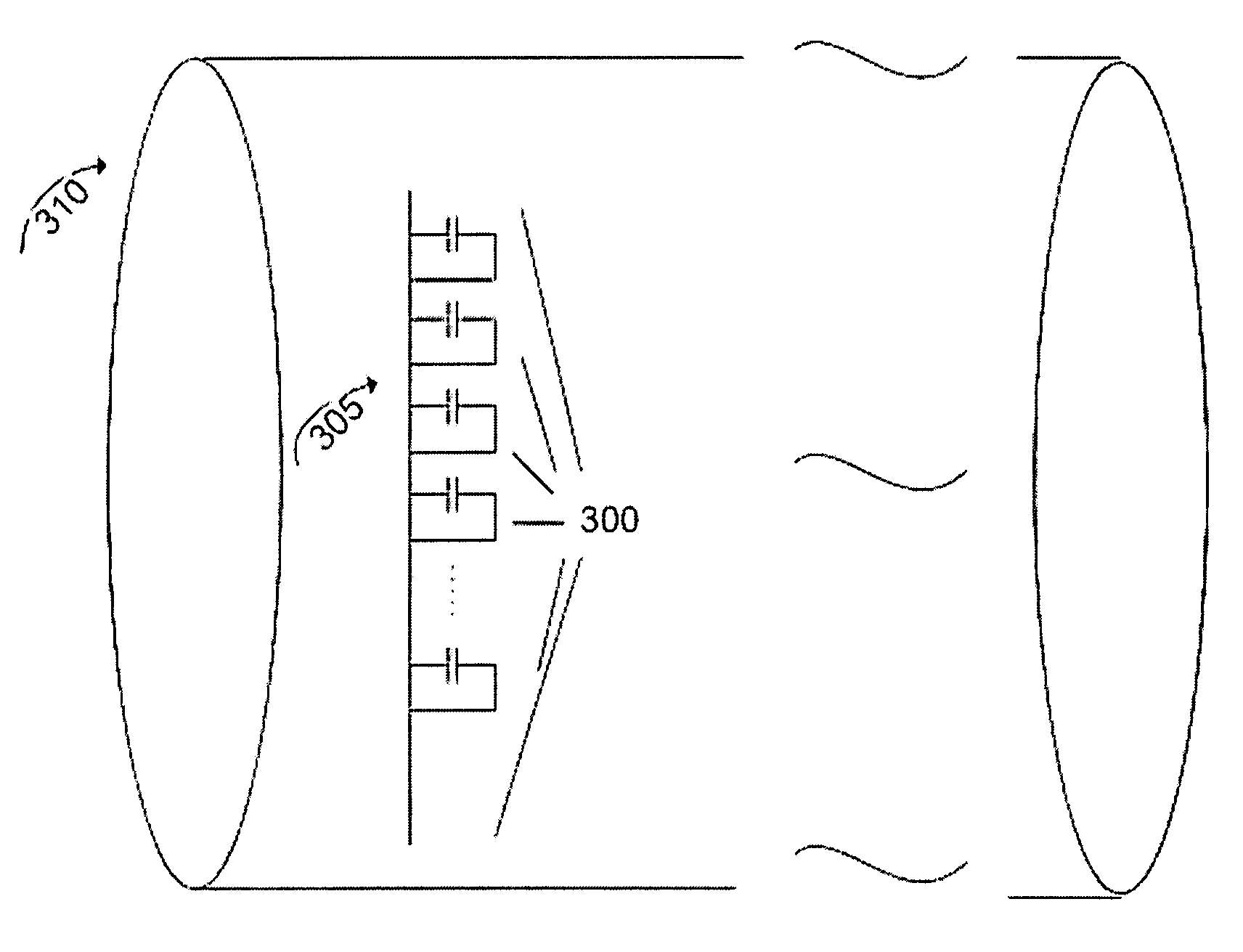

A fluid characterization sensor comprising a plurality of sensor segments is disclosed. Each segment comprises two electrodes, spaced apart so the fluid in the corresponding interval of depth for that segment is positioned between them. Complex current or impedance is measured by exciting one electrode with an AC signal, and measuring the amplitude and phase of the current in the other electrode. After automatically measuring and accounting for pre-determined gain, offset, temperature, and other parasitic influences on the raw sensor signal, the complex electrical impedance of the fluid between the electrodes is calculated from the measured phase / amplitude and / or real / imaginary components of the received electrical current signal and / or the variation of the measured response with variation in excitation frequency. Comparison of measured results with results taken using known fluids identifies fluid properties. Alternatively, measured results are compared to predicted results using forward models describing expected results for different fluids or contaminants.

Owner:DIRACTION

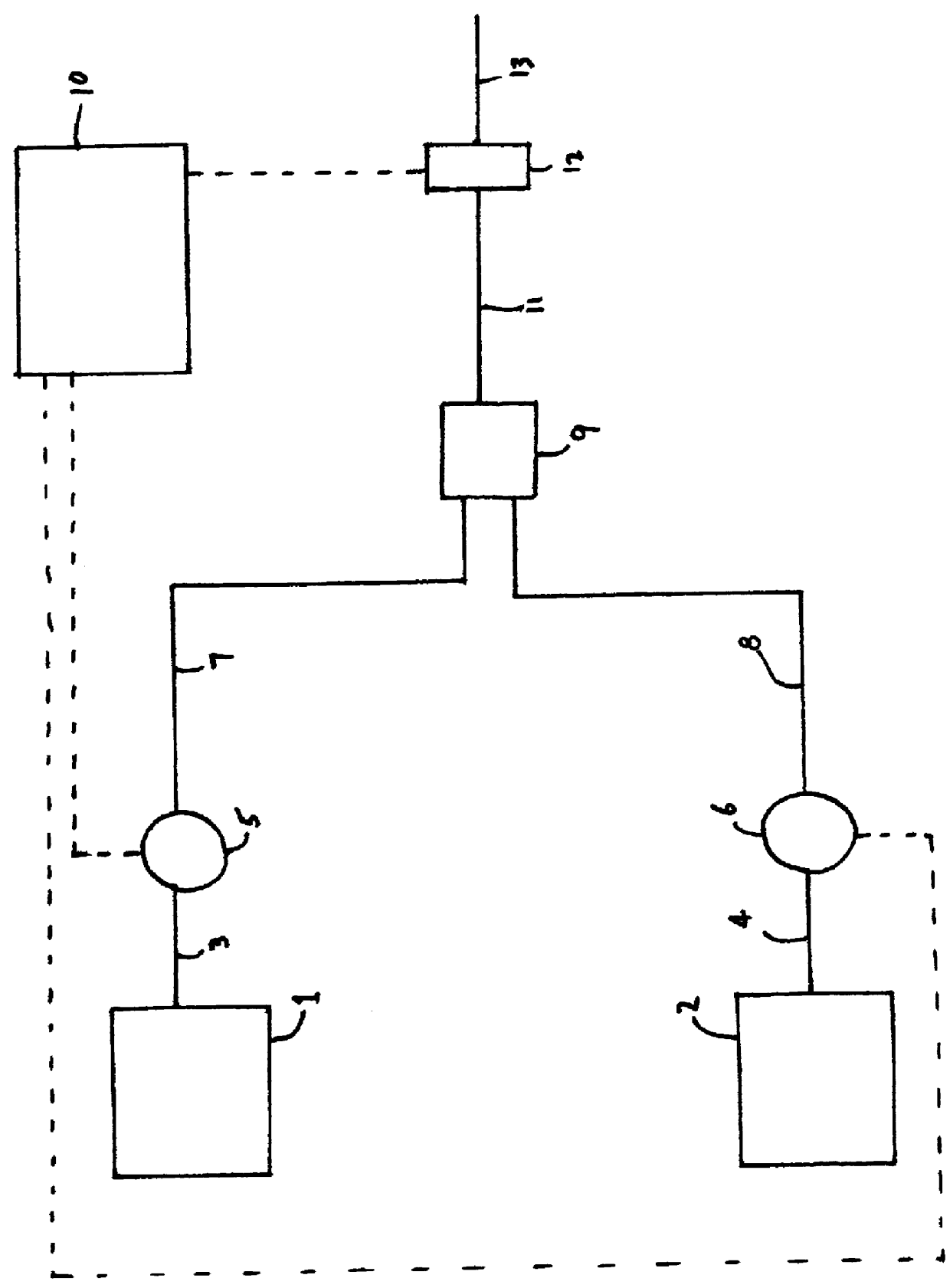

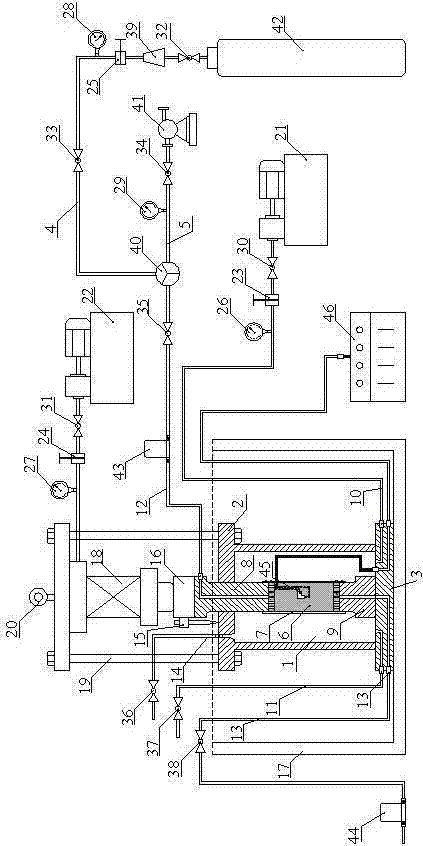

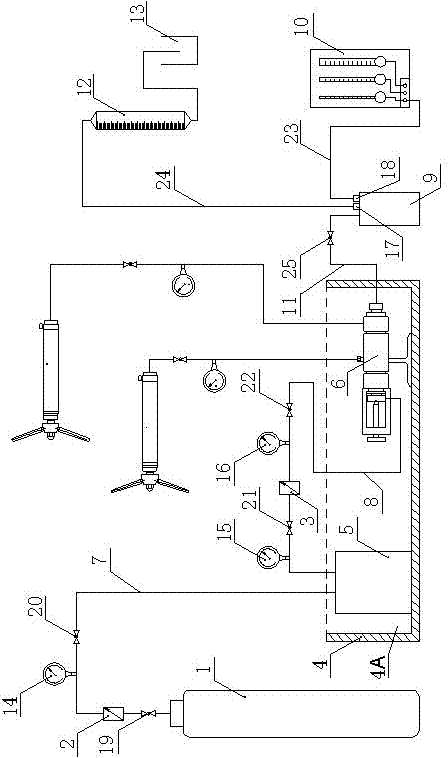

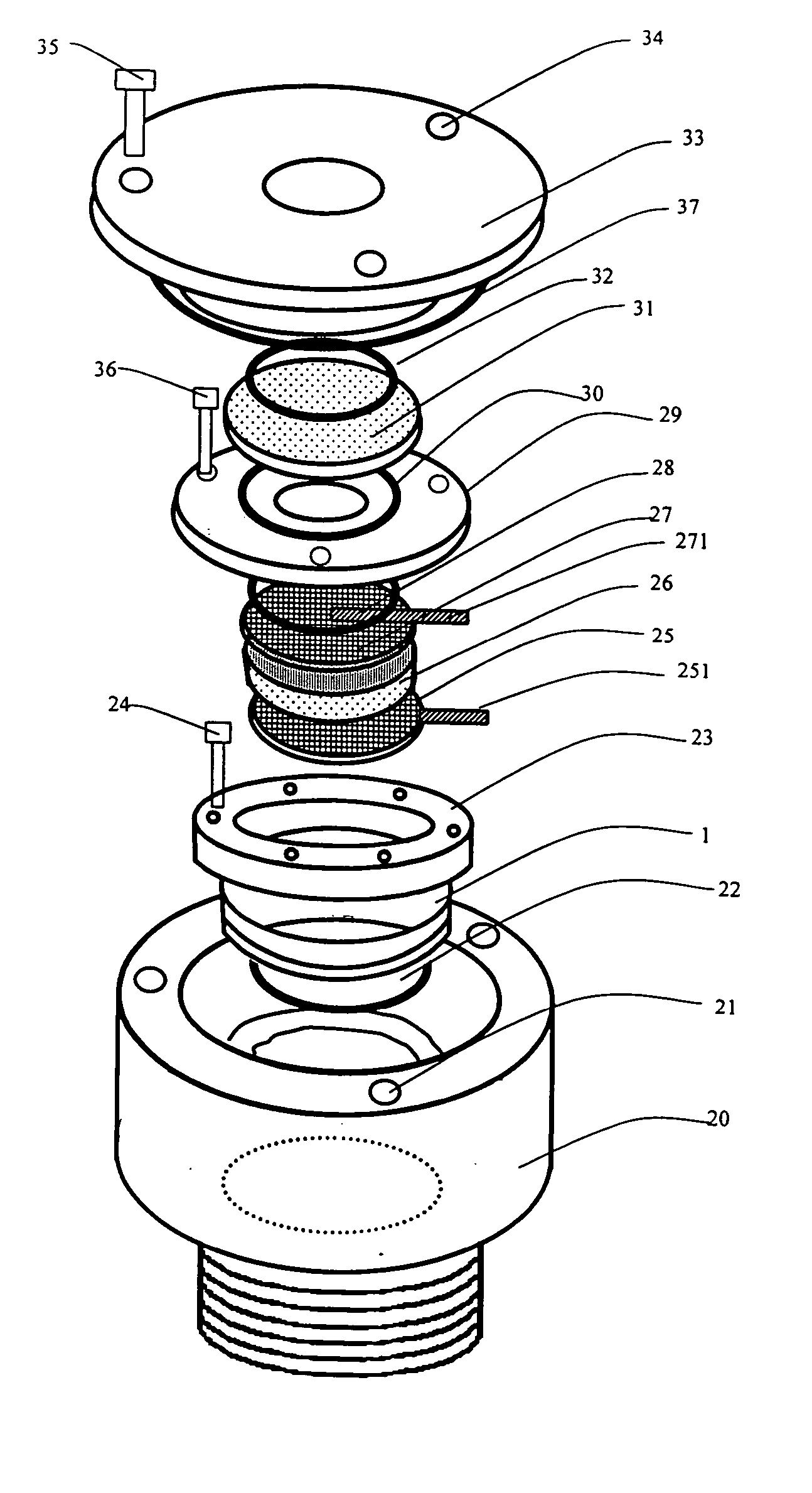

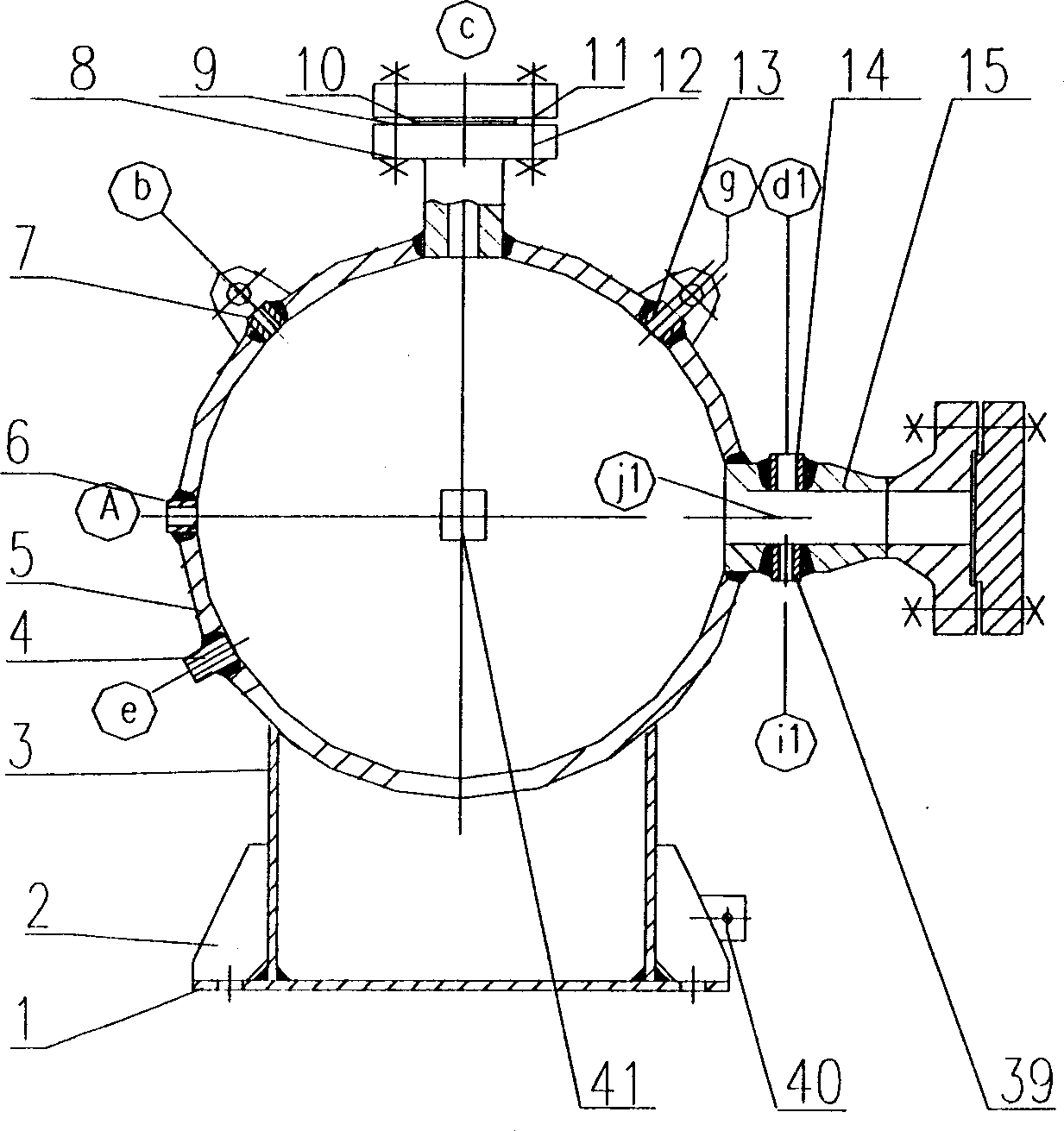

Adsorption-desorption-seepage experiment system for loaded coal containing gas under condition of varying temperatures

The invention discloses an adsorption-desorption-seepage experiment system for loaded coal containing gas under the condition of varying temperatures. The experiment system comprises a tank body used for holding constant-temperature water bath. A triaxial pressure chamber is arranged in the tank body; a coal chamber is arranged in the triaxial pressure chamber; a coal sample is installed in the coal chamber; a foil gauge is adhered onto the coal sample and is connected with a dynamic strain meter; one end of the coal chamber is provided with an opening, and a pressure head is mounted in the opening and connected with a pressure unit; the coal chamber is communicated with a vacuum pipeline and a high pressure gas-transmission pipeline; and a confining pressure pipeline used for conveying hydraulic oil is communicated with a cavity between the coal chamber and the triaxial pressure chamber. The adsorption-desorption-seepage experiment system for loaded coal containing gas under the condition of varying temperatures in the invention has the advantages of a simple structure, convenient operation, reasonable design, high experiment precision and a low price.

Owner:HENAN POLYTECHNIC UNIV

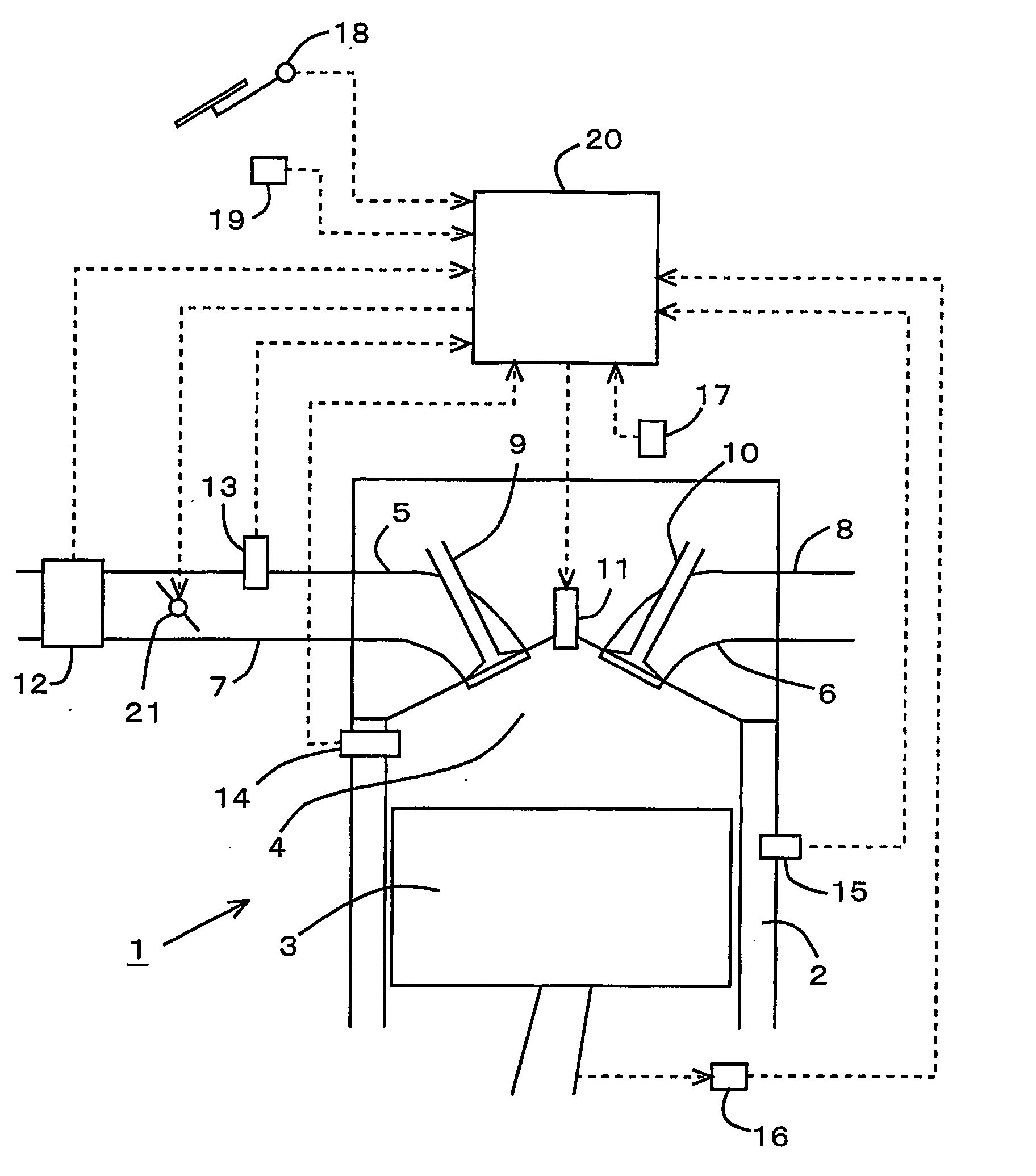

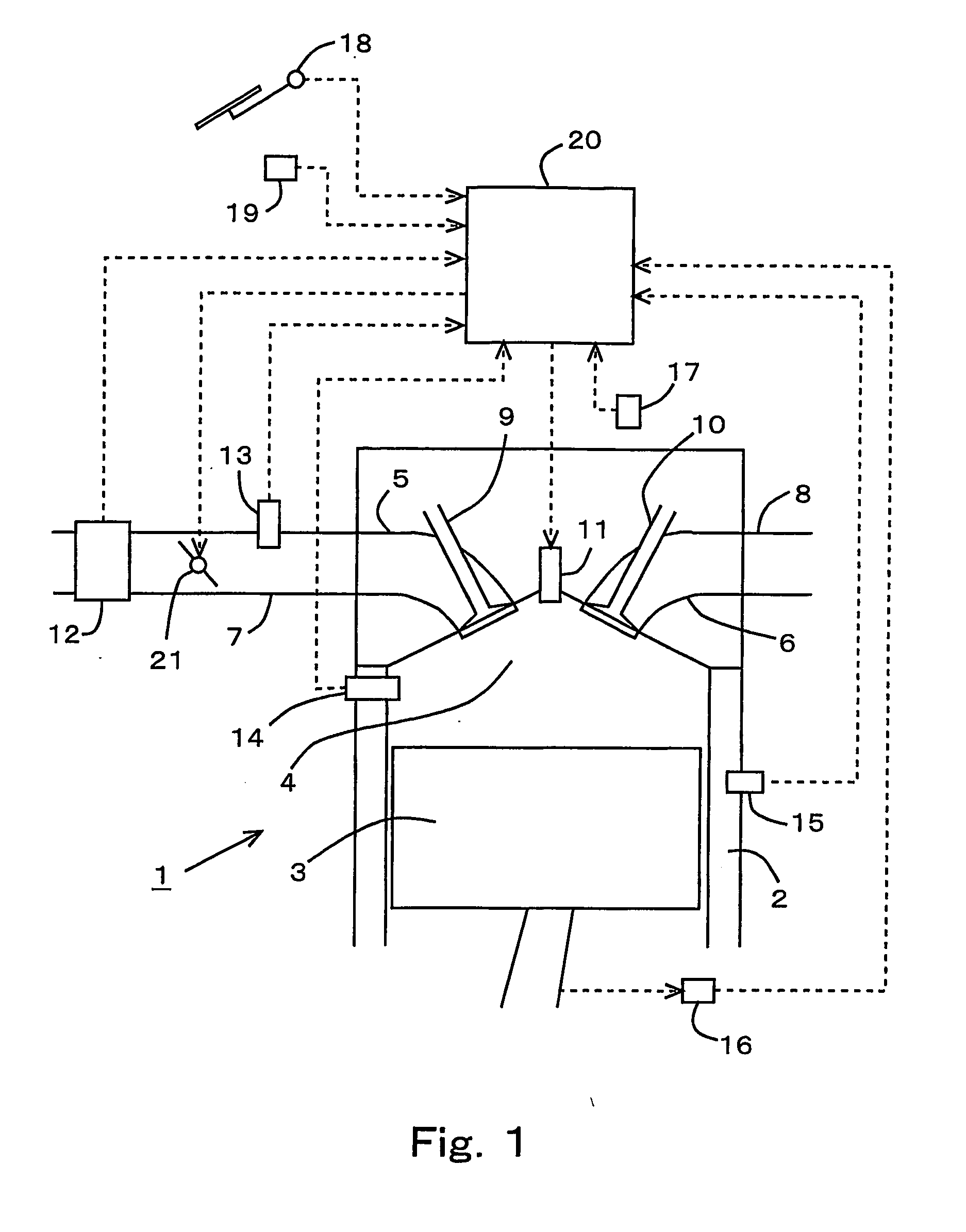

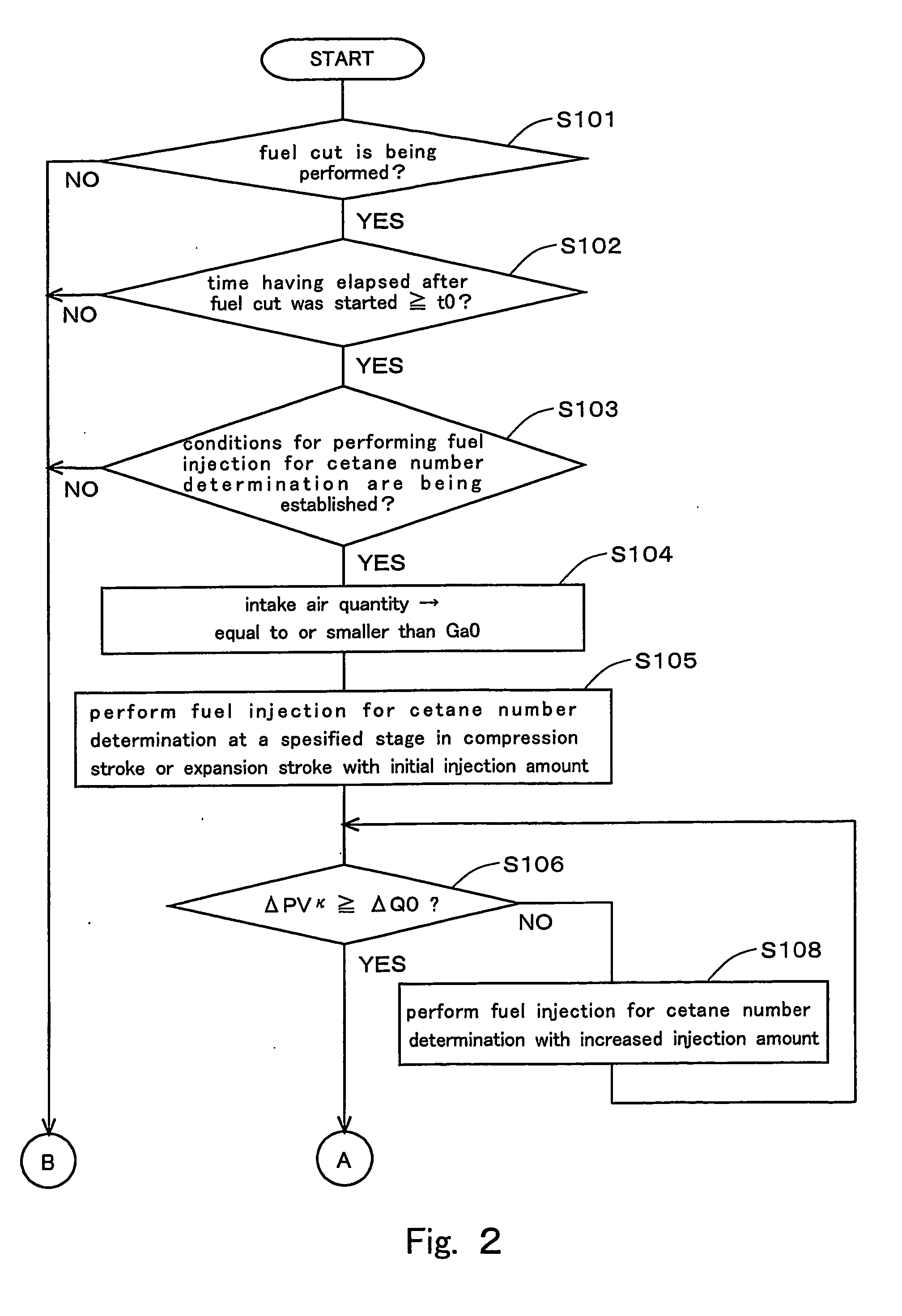

Method of determining cetane number of fuel in internal combustion engine

InactiveUS20070079647A1Easy to igniteShorter ignition delay timeElectrical controlInternal combustion piston enginesCombustion chamberEngineering

An object of the present invention is to provide a technology that enables to determine the cetane number of fuel in a state in which it is actually used for running an internal combustion engine with an improved degree of accuracy. A fuel injection for cetane number determination in which a specified quantity of fuel is injected into a combustion chamber during a compression stroke or expansion stroke, is performed while the internal combustion engine is in a fuel cut state. The cetane number of the fuel is determined based on the time period from a specified time to a time of ignition at which the fuel injected by the fuel injection for cetane number determination is ignited.

Owner:TOYOTA JIDOSHA KK

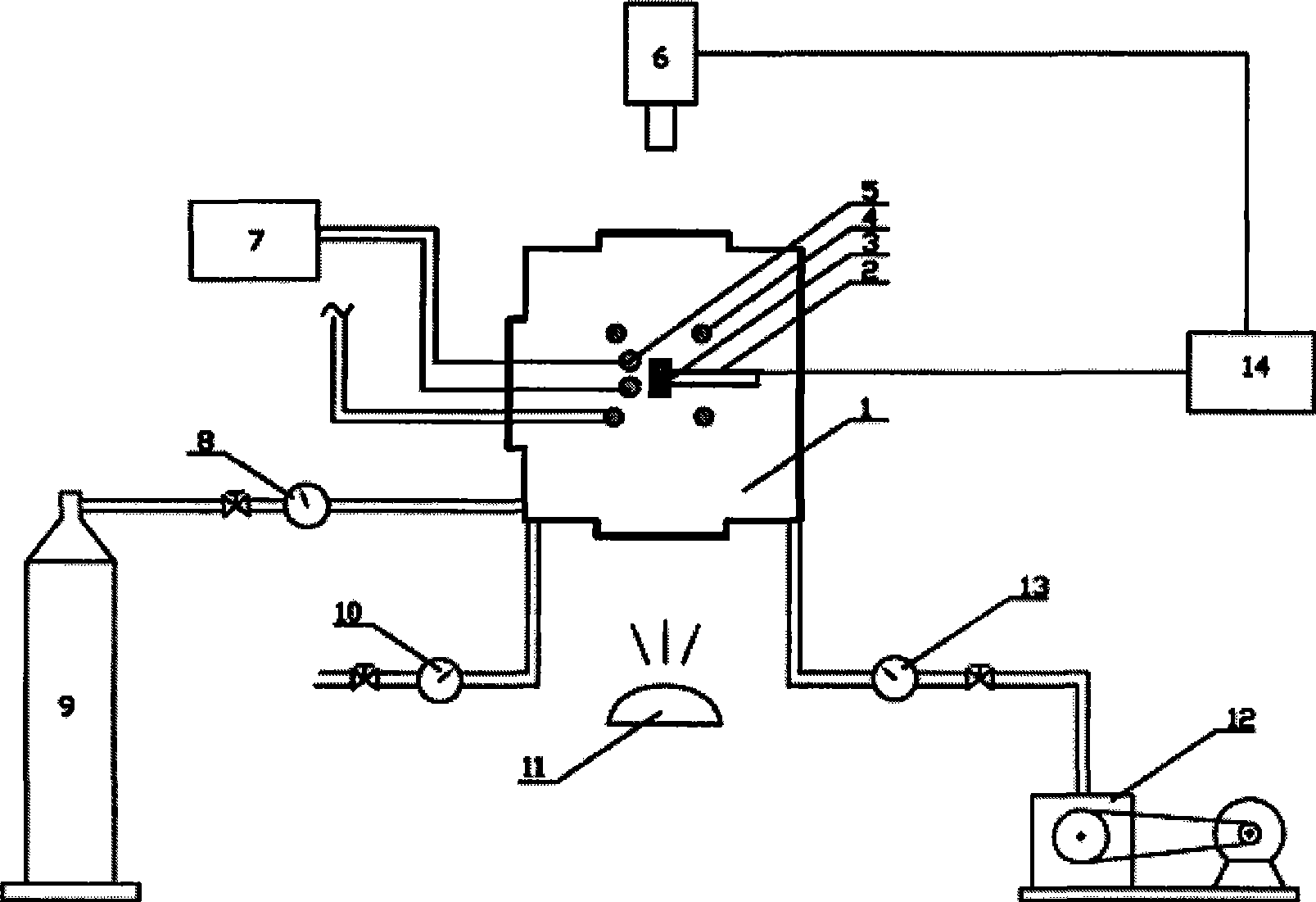

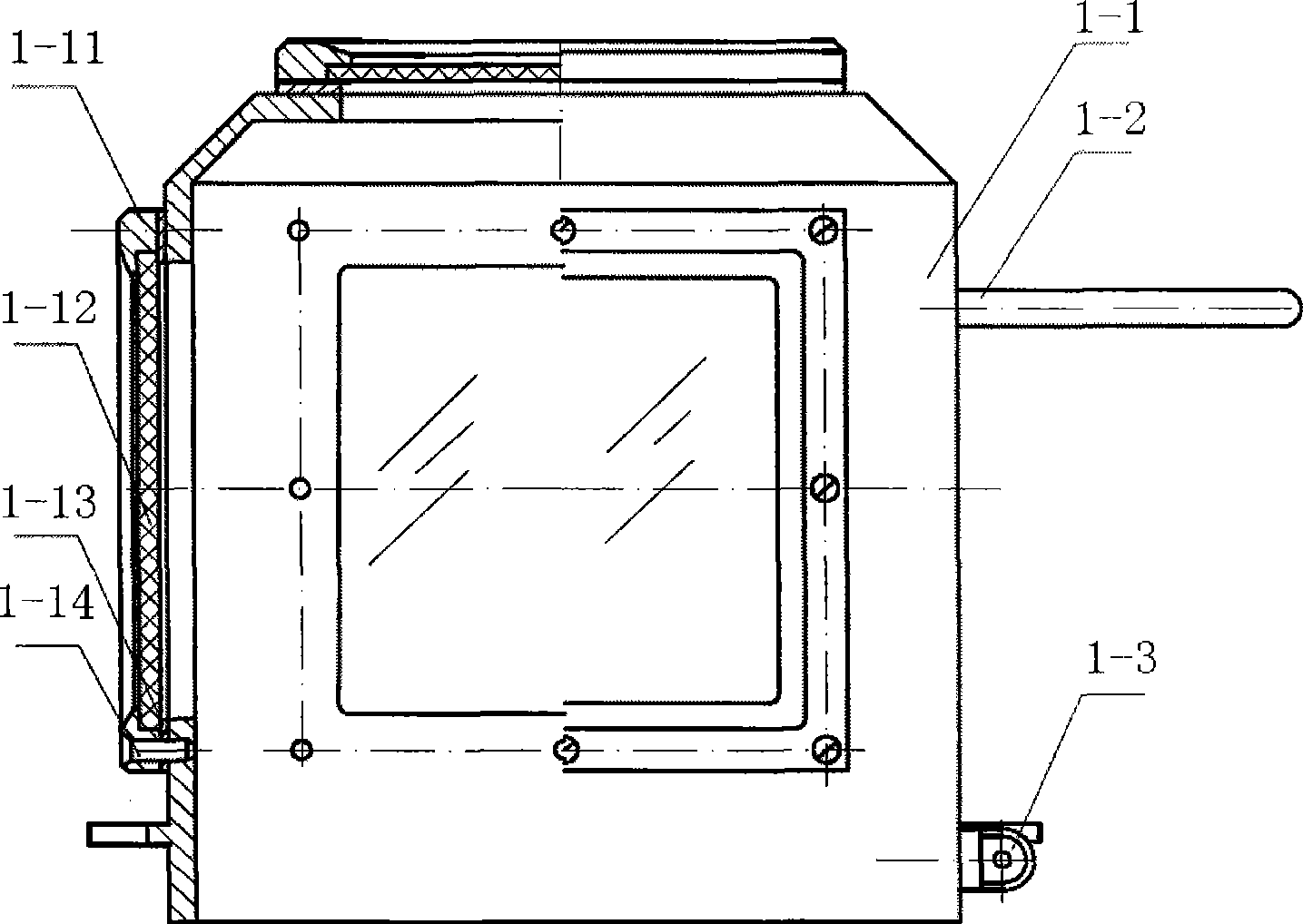

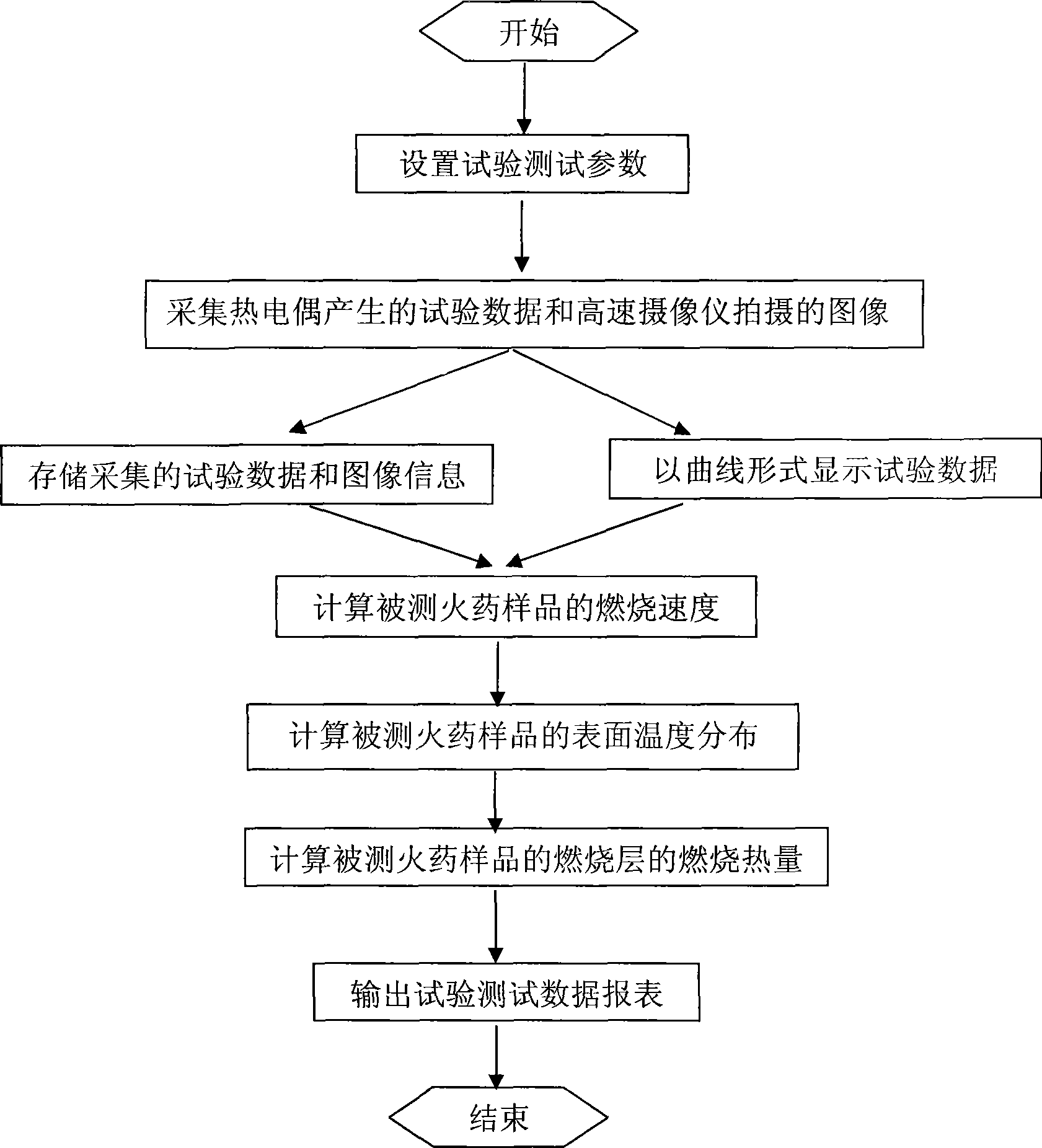

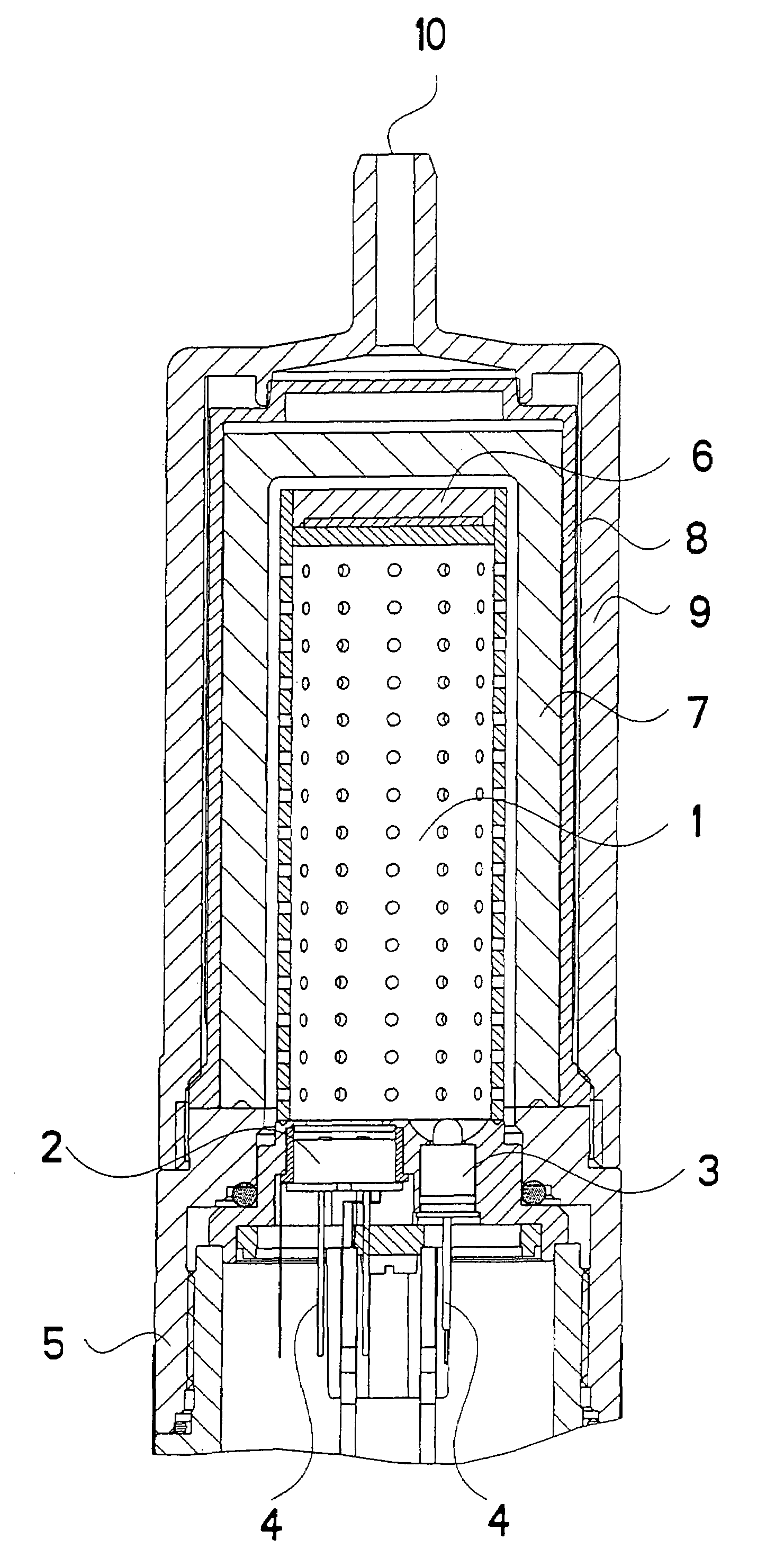

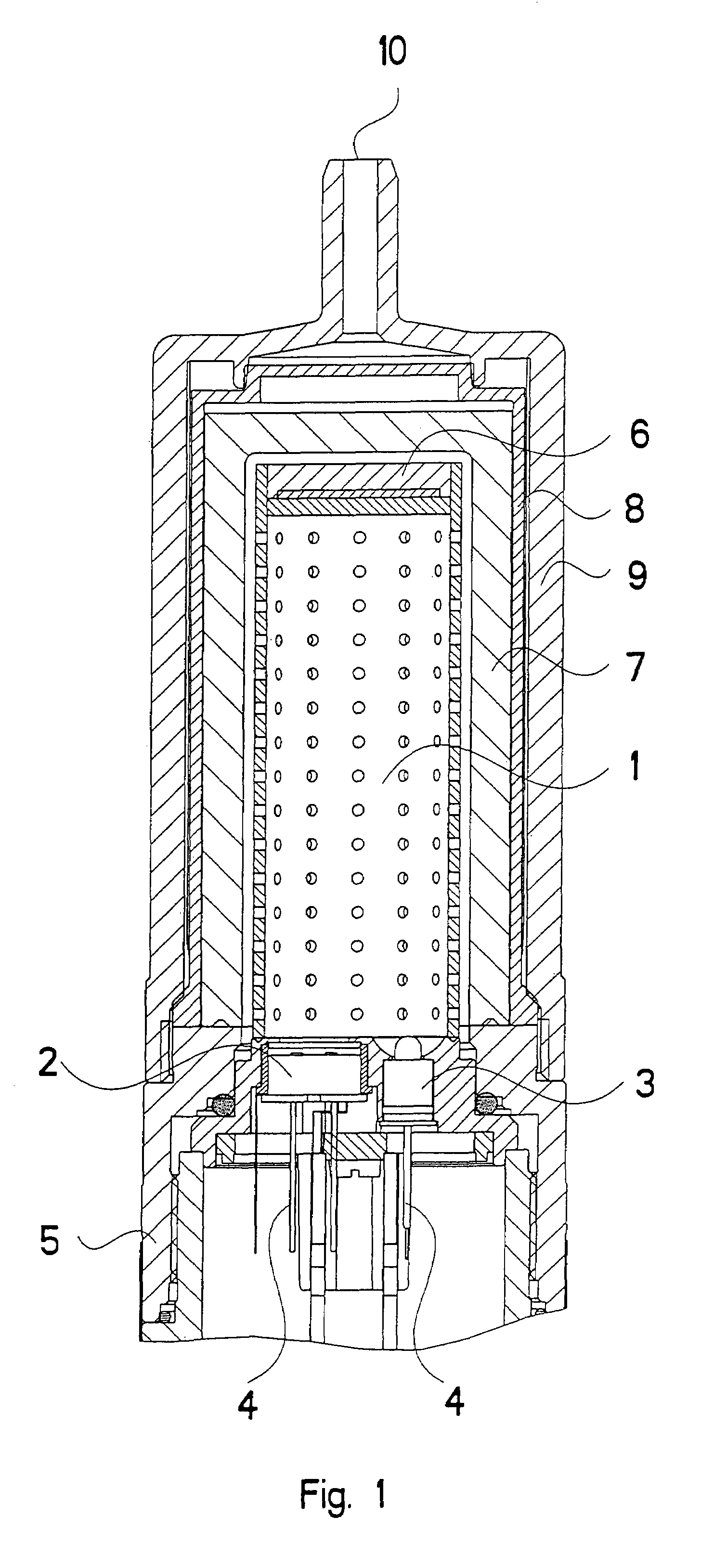

Device for testing powder combustion characteristics in vacuum condition

InactiveCN101382533ARealize measurementEfficient use ofChemical analysis using combustionFuel testingCombustion chamberHeating time

The invention discloses a testing device of gunpowder combustion characteristics in vacuum, which mainly comprises a combustion chamber, a vacuum pump, an electric heater, a thermoelectric couple, a high speed camera and a data acquisition and processing system; wherein, the vacuum pump provides vacuum environment for the combustion chamber; by controlling the heating current and the heating time of the electric heater, different ignition isoperibols can be provided for tested gunpowder samples in the combustion chamber; and the data acquisition and processing system collects the test data generated by the thermoelectric couple and the gunpowder combustion images shot by the high speed camera when the tested gunpowder samples combust, and finally obtains the combustion characteristics of the tested gunpowder samples through corresponding processing and calculation. The invention not only can be used for testing the parameters such as combustion speed, combustion surface temperature and combustion heat and the like of the gunpowder in vacuum, but also can be used for the generation and collection of the combustion products of the gunpowder under different vacuum conditions. The invention has the overriding advantages of high integration level, obtaining various parameters by one testing and low testing expenses.

Owner:XIAN MODERN CHEM RES INST

Filter for determination of mercury in exhaust gases

InactiveUS20050084976A1Improve accuracyPreventing catalyzed oxidationComponent separationWithdrawing sample devicesFlue gasExhaust fumes

An apparatus, process, coating, and filter for the accurate measurement of total mercury concentration in flue gas. In a preferred aspect, the concentrations of both elemental and oxidized mercury are preserved by the apparatus for analysis. Accordingly, embodiments of the present apparatus and process can be used to determine regulatory compliance or for process control measurement.

Owner:PERMA PURE LLC

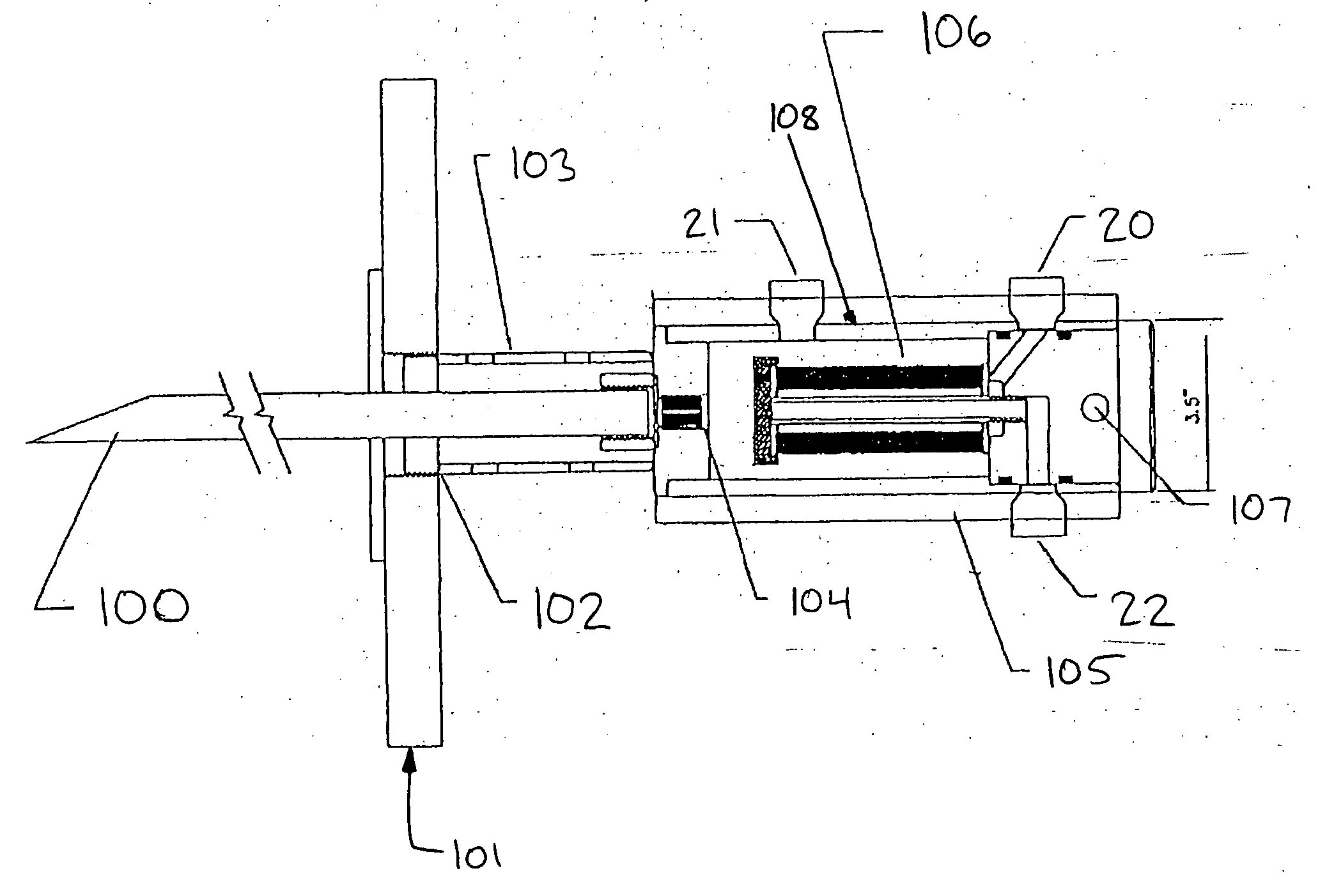

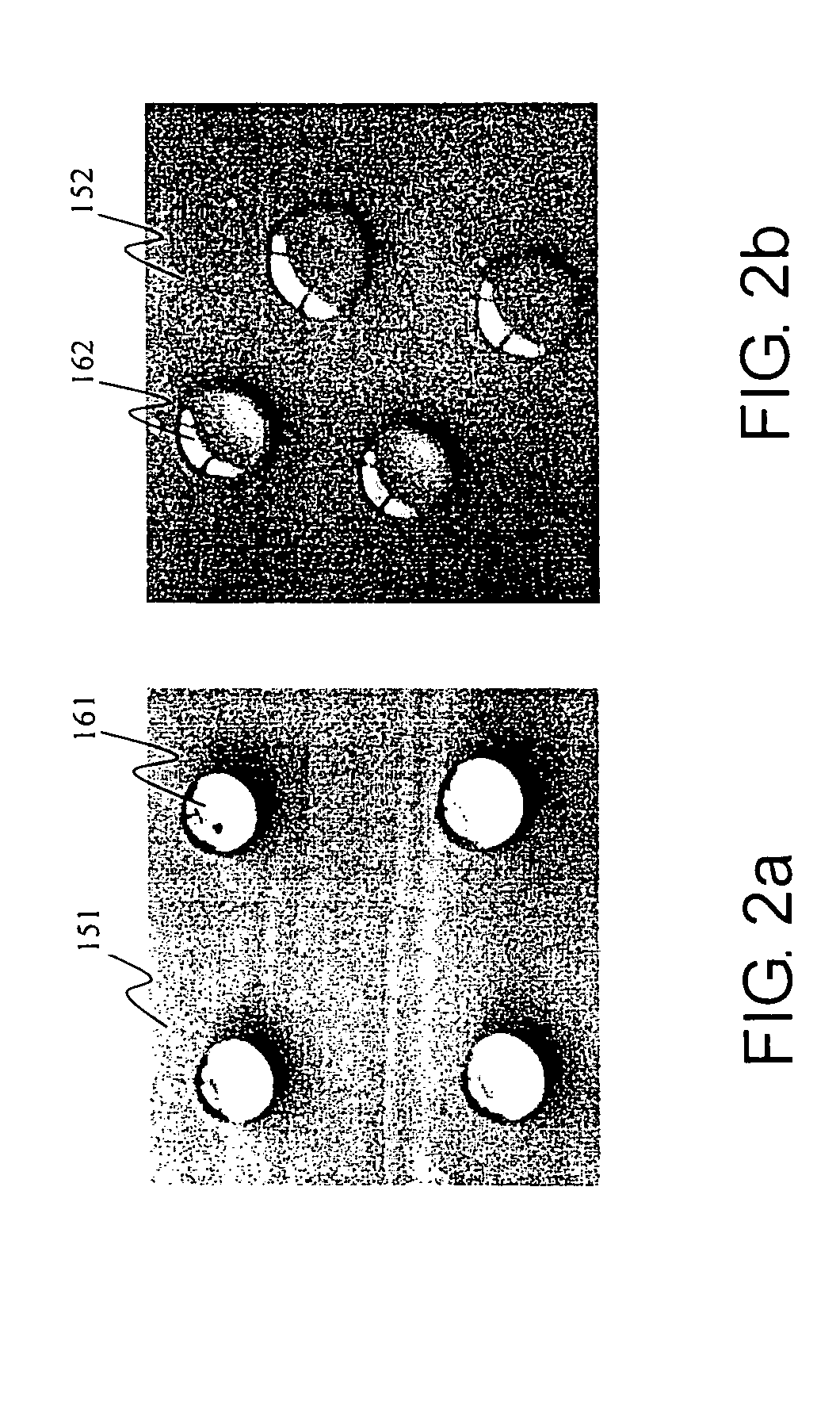

Passive blast pressure sensor

ActiveUS20100275676A1Easy and quick to readChange colorFuel testingAcceleration measurementChange colorEngineering

A passive blast pressure sensor for detecting blast overpressures of at least a predetermined minimum threshold pressure. The blast pressure sensor includes a piston-cylinder arrangement with one end of the piston having a detection surface exposed to a blast event monitored medium through one end of the cylinder and the other end of the piston having a striker surface positioned to impact a contact stress sensitive film that is positioned against a strike surface of a rigid body, such as a backing plate. The contact stress sensitive film is of a type which changes color in response to at least a predetermined minimum contact stress which is defined as a product of the predetermined minimum threshold pressure and an amplification factor of the piston. In this manner, a color change in the film arising from impact of the piston accelerated by a blast event provides visual indication that a blast overpressure encountered from the blast event was not less than the predetermined minimum threshold pressure.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Water-gas two-phase adsorption-desorption-seepage experimental system and method for loaded coal containing methane

ActiveCN102901803AAccurate detectionAccurate measurementFuel testingPermeability/surface area analysisWater bathsHigh pressure

The invention discloses a water-gas two-phase adsorption-desorption-seepage experimental system and method for loaded coal containing methane. The water-gas two-phase adsorption-desorption-seepage experimental system for loaded coal containing methane comprises a pressure loading part, wherein the pressure loading part comprises a tank body for containing a constant-temperature water bath, a reference pot and a coal sample holder are arranged in the tank body, the gas inlet of the reference pot is connected with a high-pressure methane delivery pipeline, the gas outlet of the reference pot is connected with the gas inlet of the coal sample holder through a connecting pipeline, and the gas outlet of the coal sample holder is connected with a water-gas separation device. The water-gas two-phase seepage experimental method for loaded coal containing methane is carried out on the basis of the experimental system. By changing different loading conditions, loading paths and experimental temperatures, adsorption-desorption experiments and methane seepage experiments for the loaded coal containing methane under the conditions of different solid-gas thermal coupling can be realized, and water-gas two-phase seepage experiments and methane adsorption-desorption experiments under the condition of different moisture contents also can be realized.

Owner:HENAN POLYTECHNIC UNIV

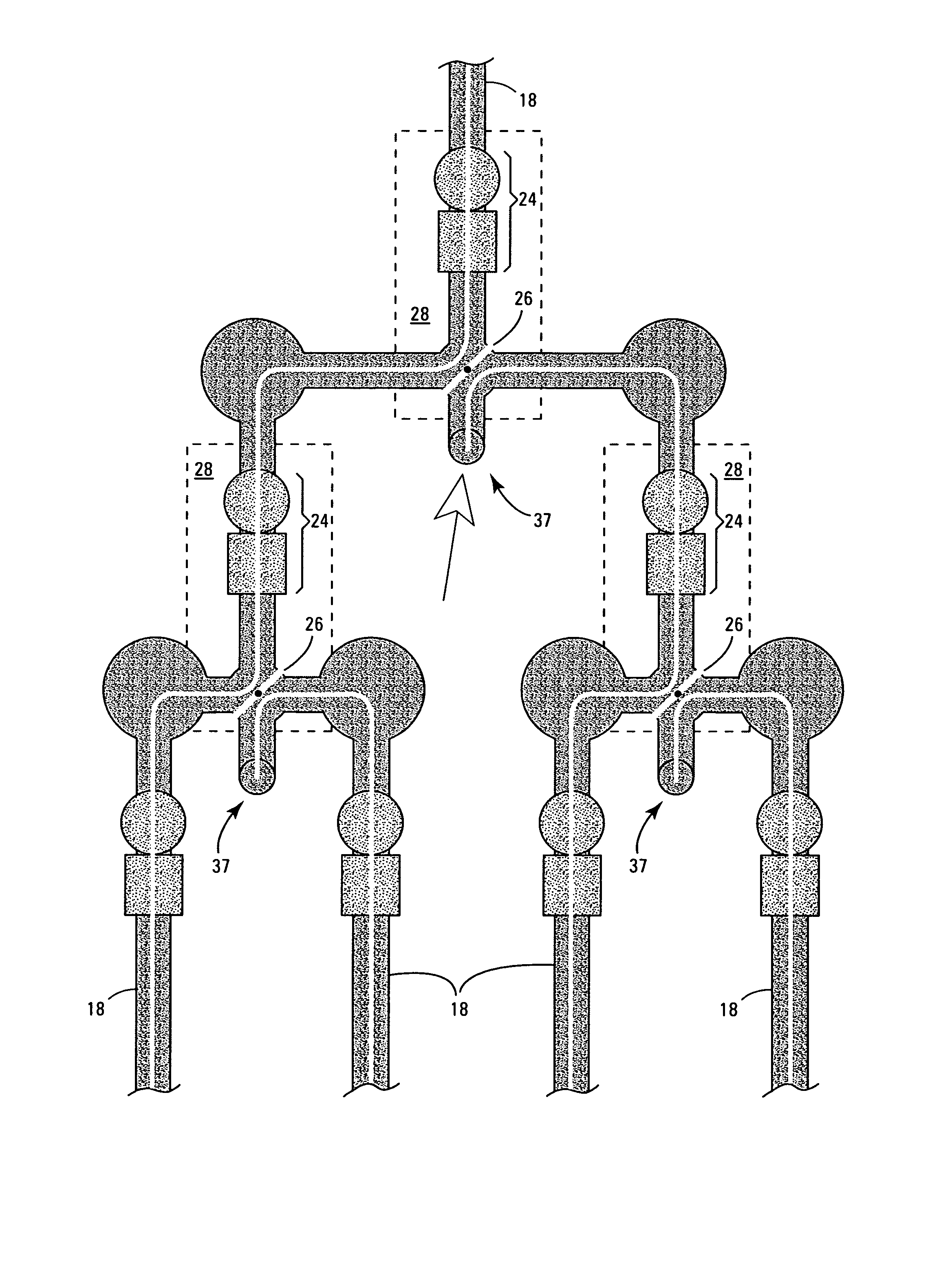

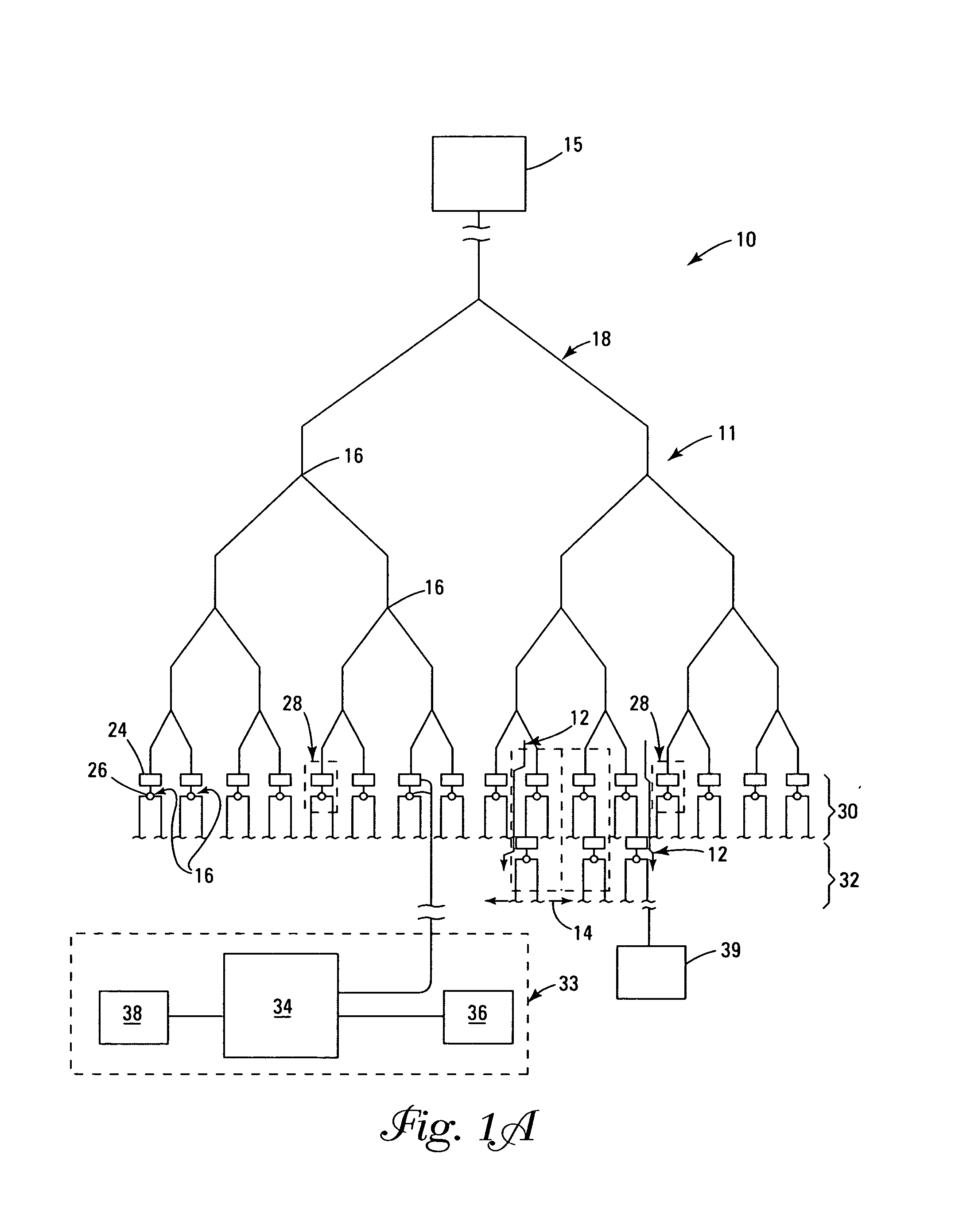

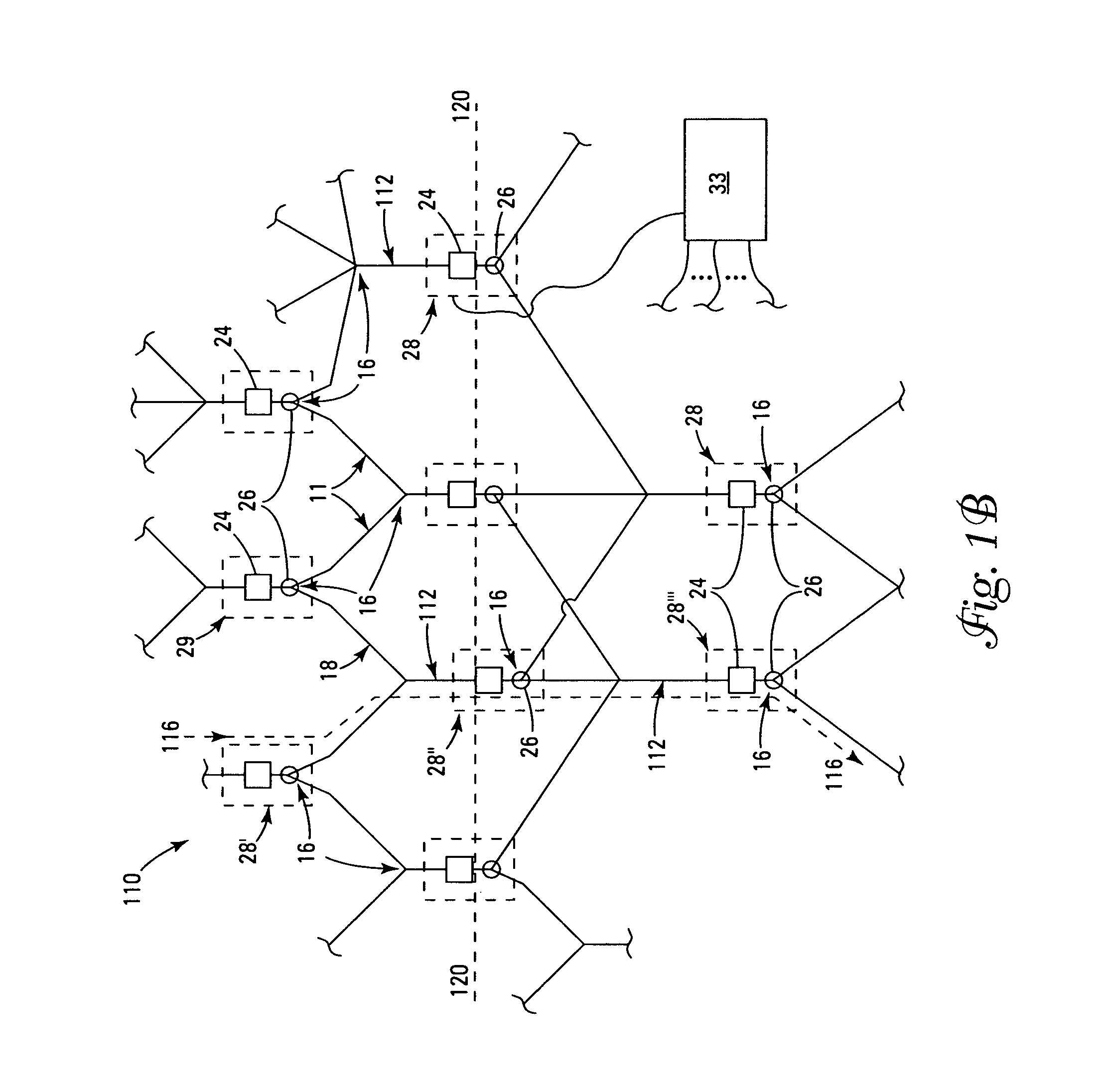

Flow sorting system and methods regarding same

InactiveUS7452725B2Increase speedBioreactor/fermenter combinationsBiological substance pretreatmentsObject basedPath network

A system and method for sorting of objects that includes a pathway network that has a plurality of pathways and one or more branch points. A fluid composition including one or more objects can be transported through the pathway network, where one or more of the objects are analyzed and sorted at one or more branch points based on the analysis of the objects.

Owner:NEUROBIOTEX +1

Method and apparatus for control of mobility-based ion species identification

InactiveUS7005632B2Improve system performanceGuaranteed accuracyTime-of-flight spectrometersFuel testingBiologySpectrometer

Owner:DH TECH DEVMENT PTE

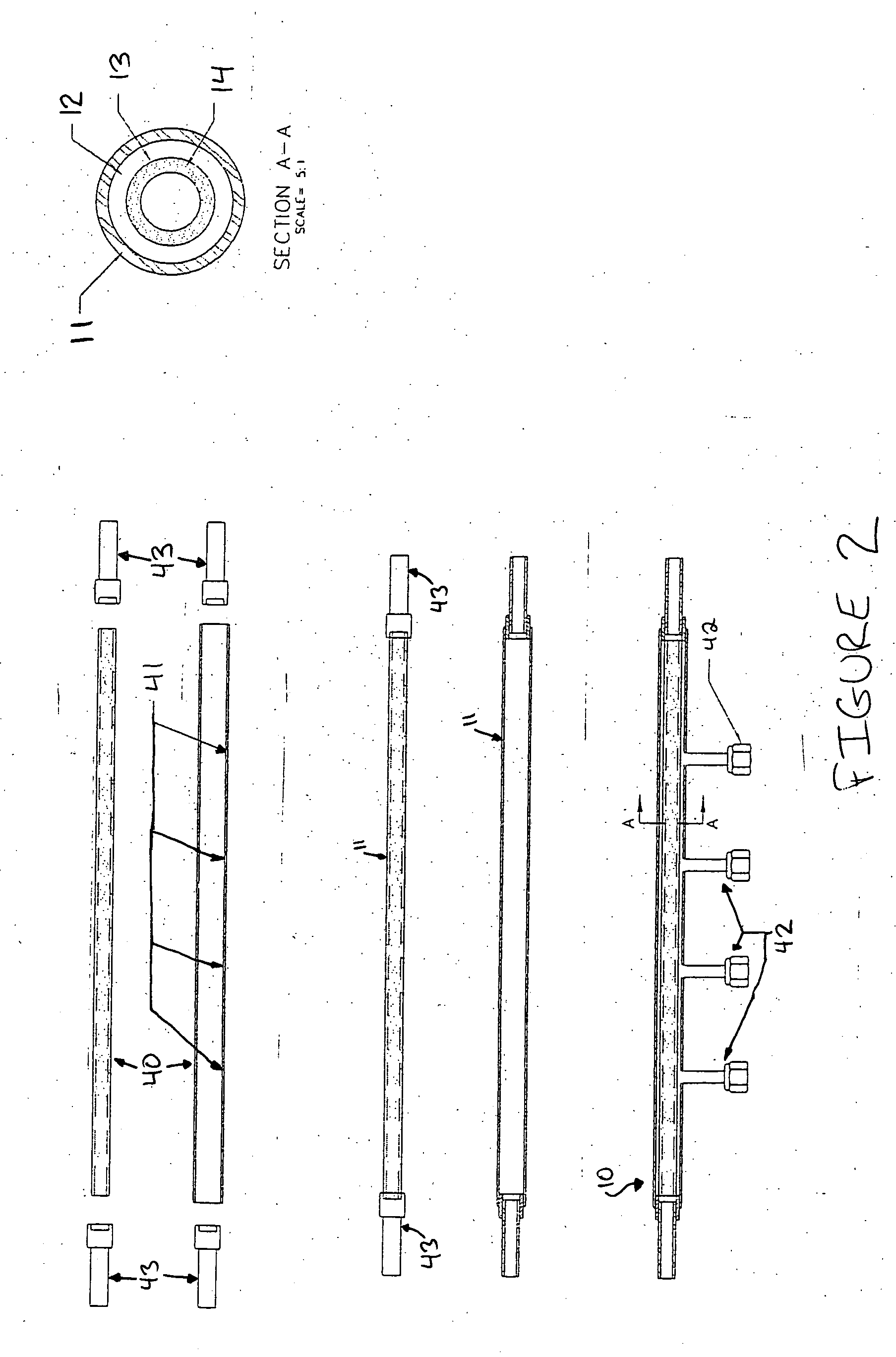

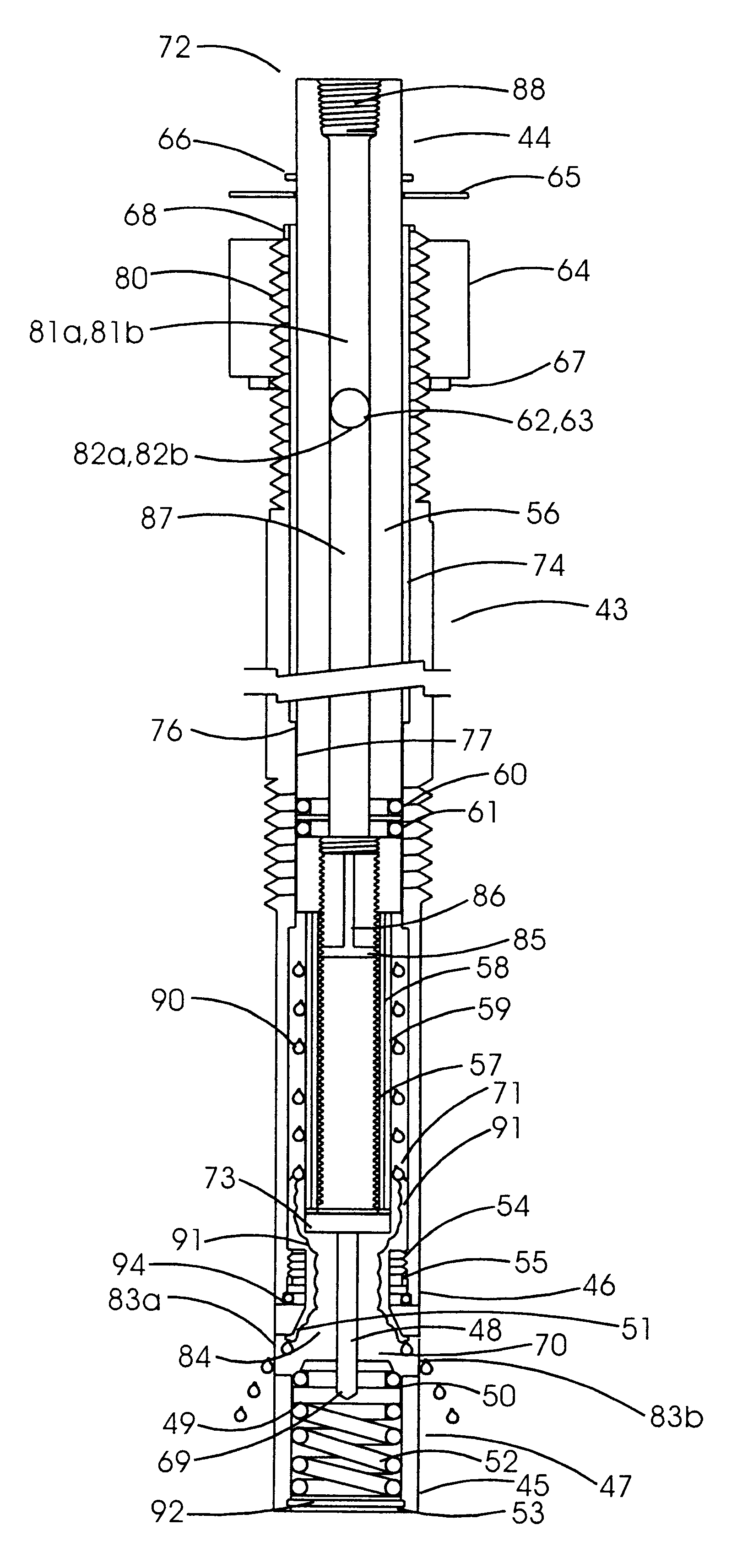

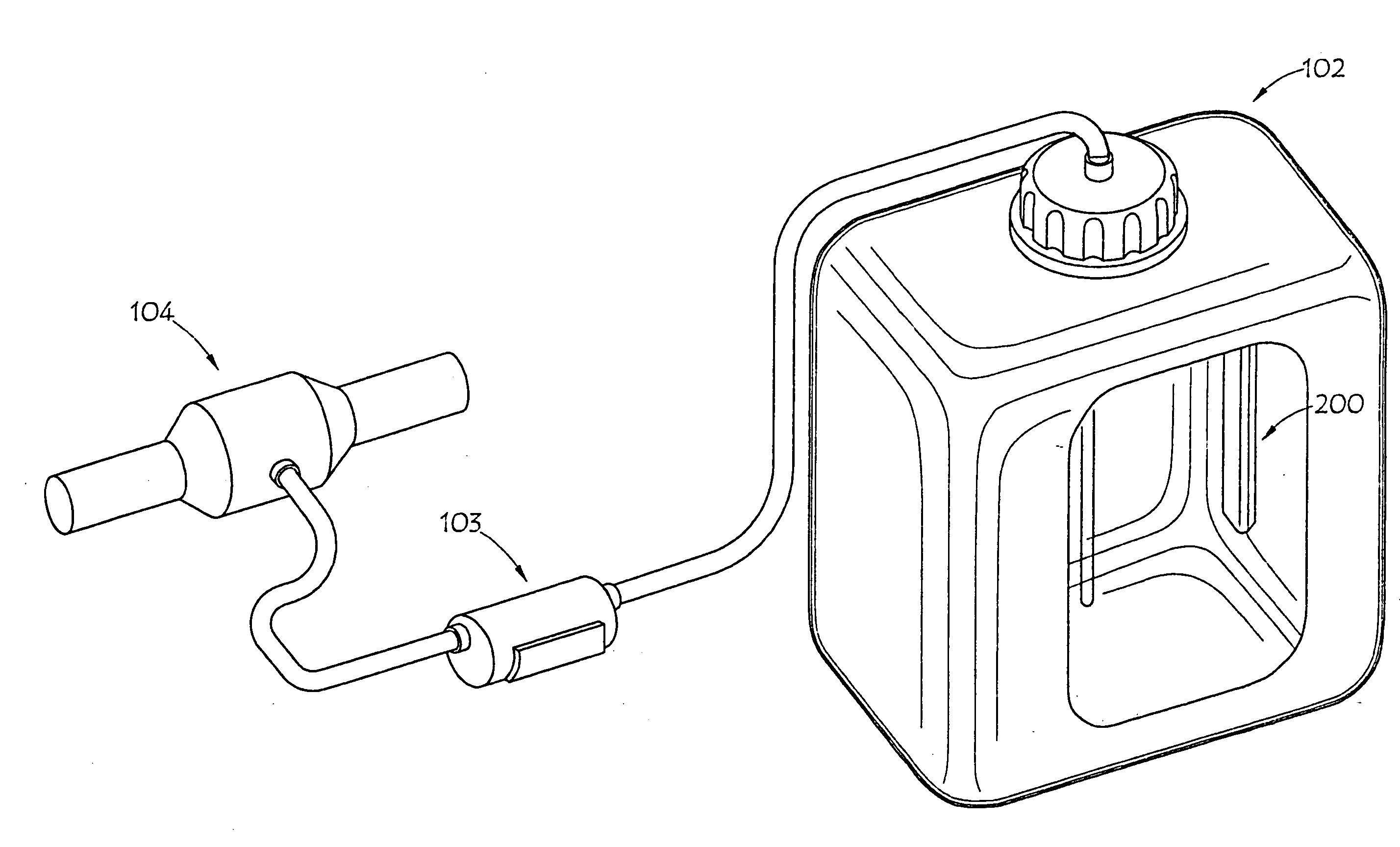

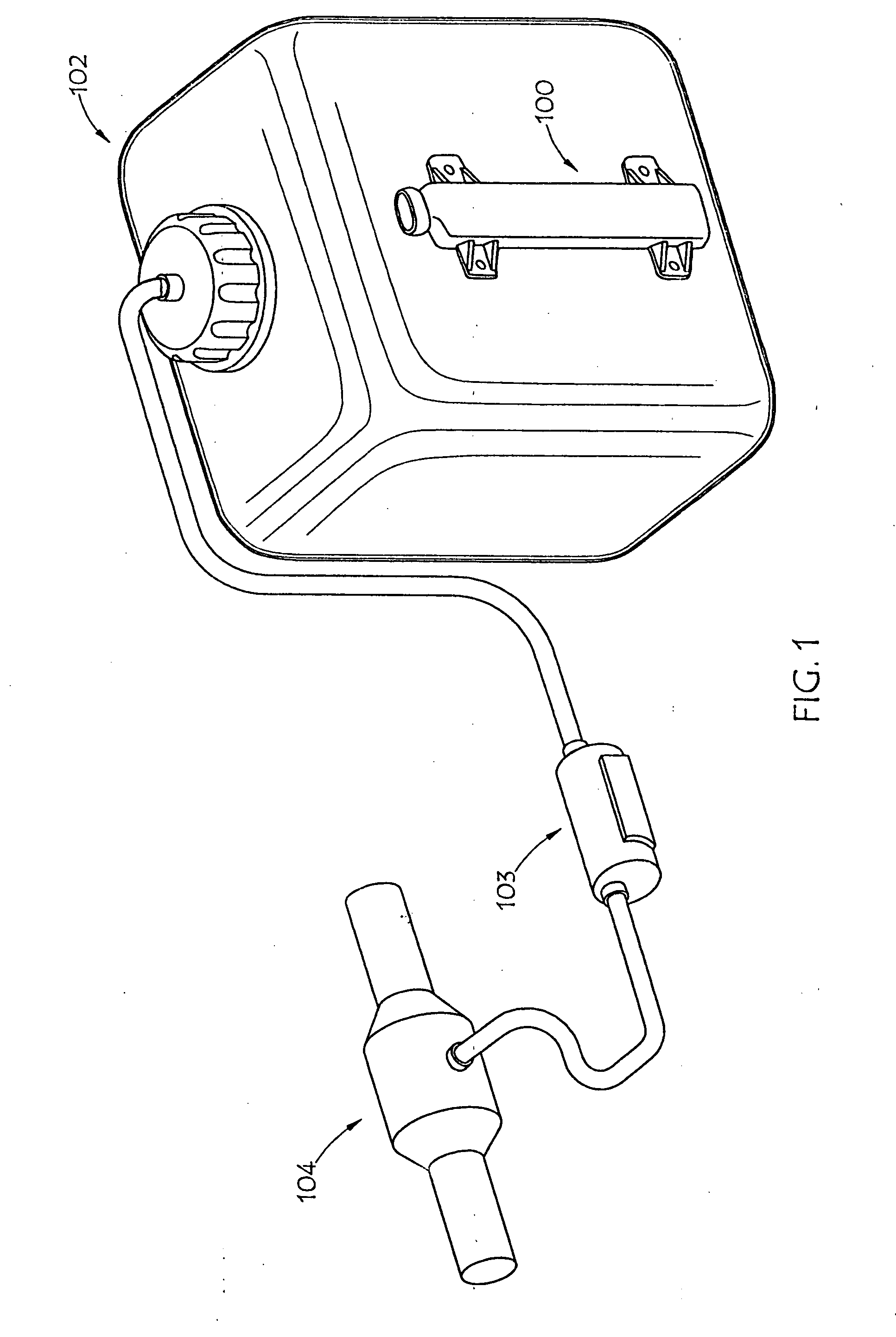

System for retrieving a gas phase sample from a gas stream containing entrained liquid, and sample conditioner assembly therefore

InactiveUS6357304B1Preventing gas phase composition changeOvercome problemsWithdrawing sample devicesFuel testingGas phaseProcess engineering

A system for the retrieval and initial conditioning of sample gas for "on line" analyzers or filling of gas sample cylinders. The preferred embodiment of the present invention contemplates a system configured to obtain a representative gas phase sample from a process gas containing entrained liquid, or a process gas which generally is highly susceptible to partial condensation of some gas phase components. The preferred embodiment of the present invention teaches an assembly including a phase separation membrane and housing configured to facilitate the removal of entrained liquid from a sample gas stream. Accuracy of the sample is enhanced, and compositional changes are avoided by first extracting a sample from the process gas followed by removal of entrained liquid it may contain, with the entrained liquid removal being conducted at the prevailing process gas pressure and temperature. Thereafter the liquid free sample may be desaturated by lowering its pressure to reduce its susceptibility to condensation.

Owner:MAYEAUX HLDG

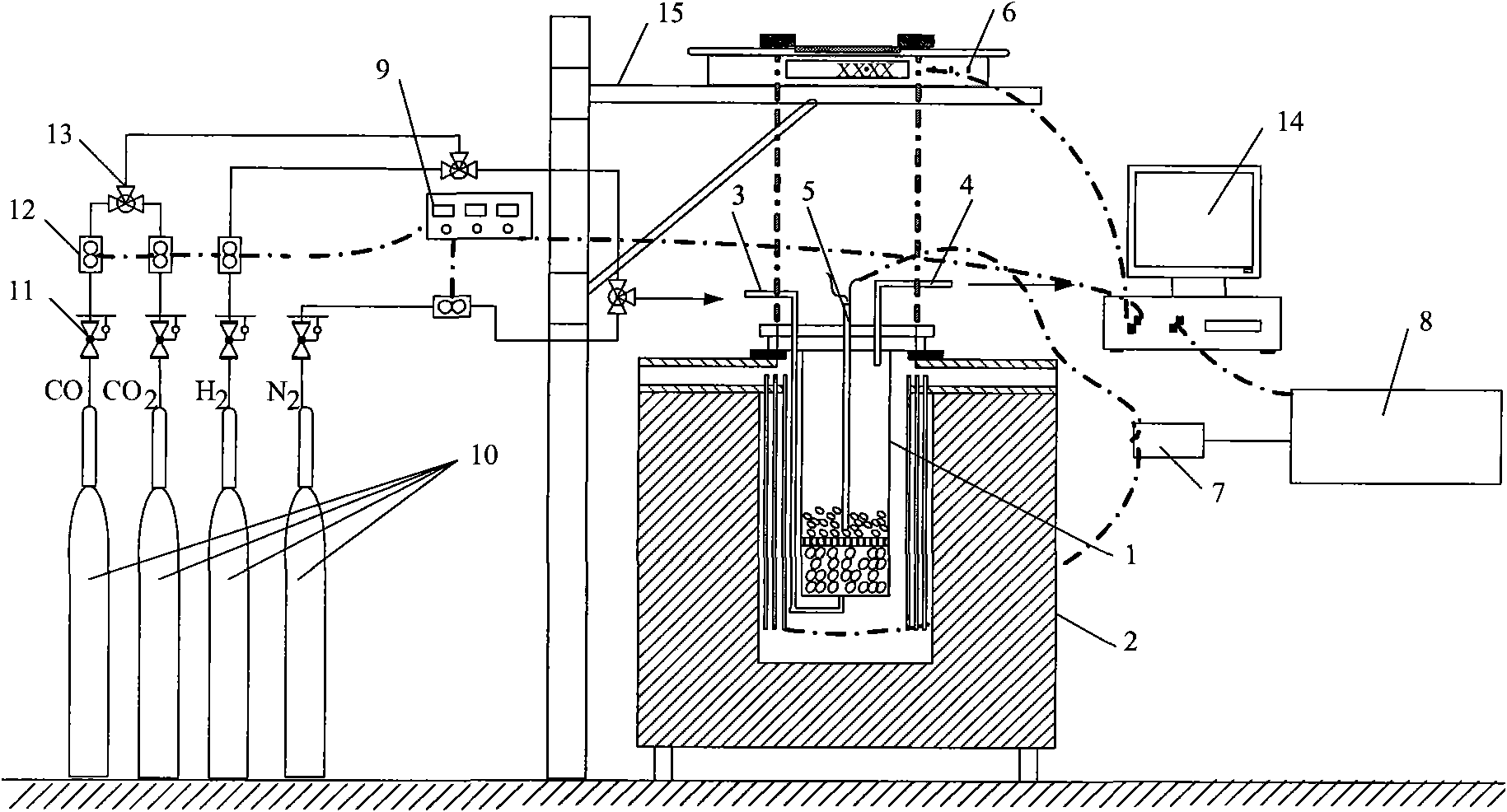

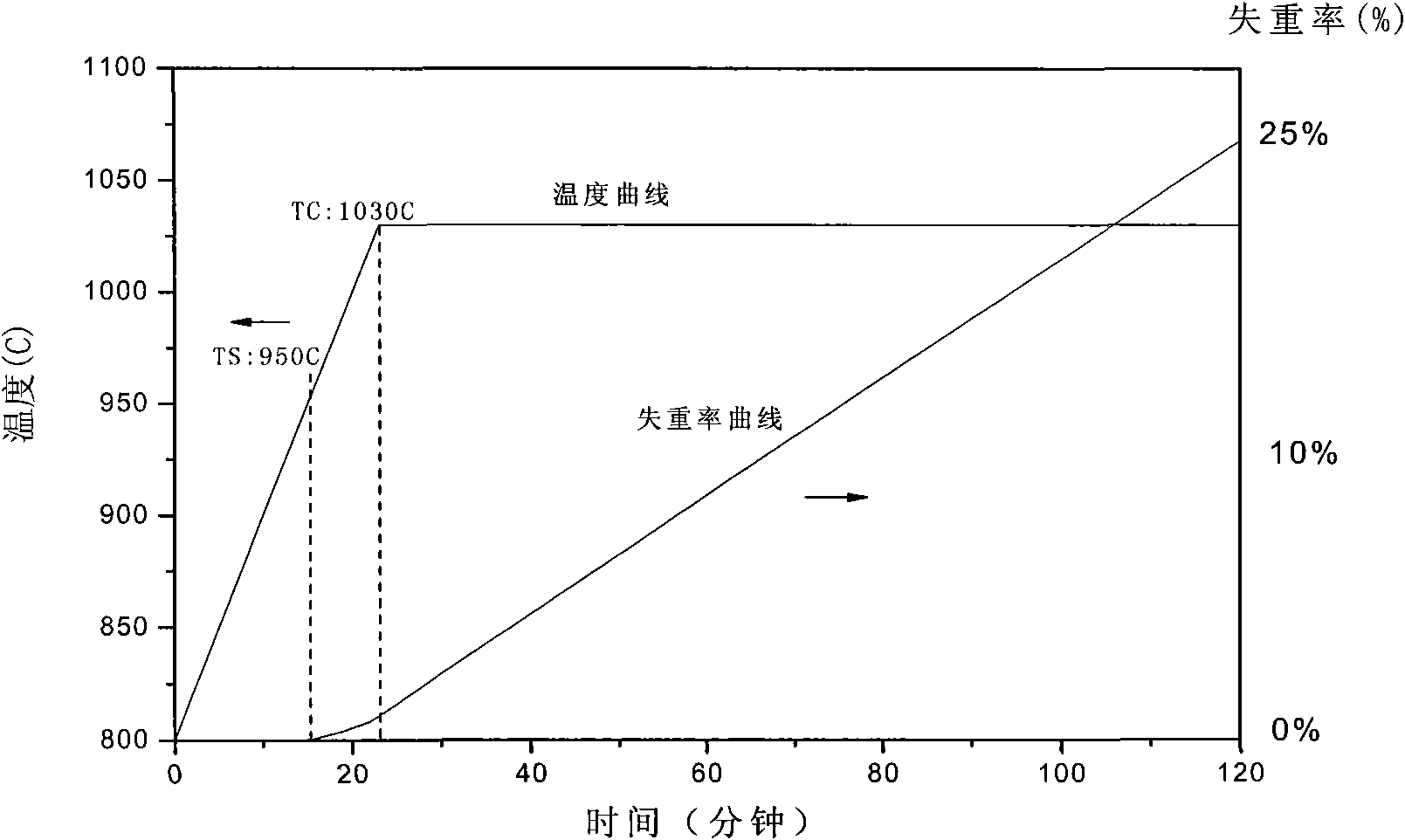

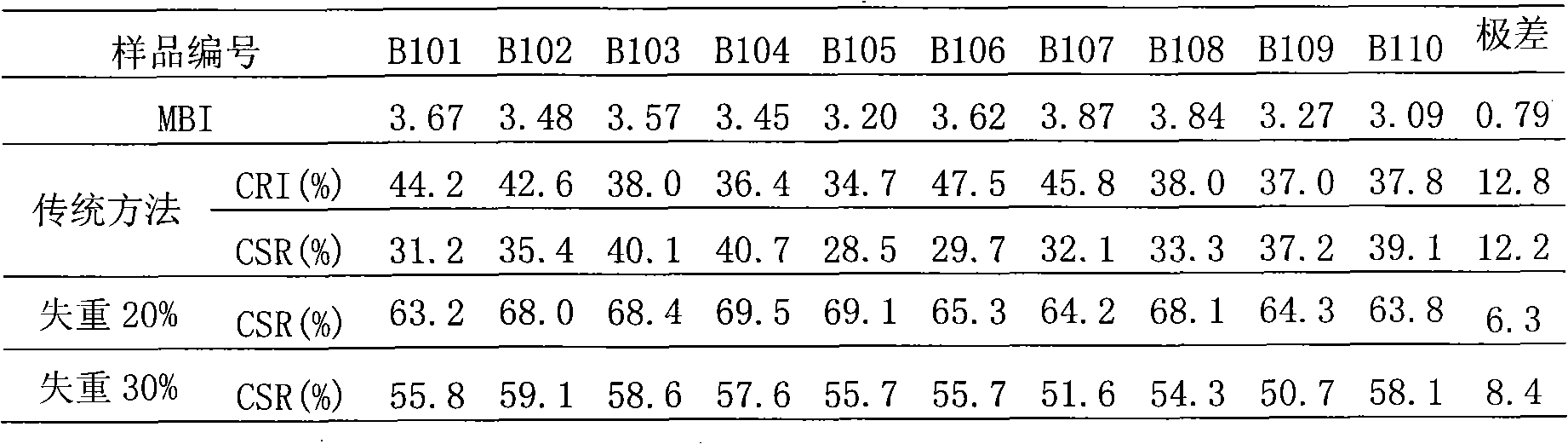

Strength determination method and device for reacted blast furnace coke

ActiveCN101936979ASolving thermal property evaluationSolve the situationFuel testingChemical methods analysisNitrogen gasInsertion reaction

The invention discloses a strength determination method for reacted blast furnace coke, which comprises the following steps of: (1) placing a coke sample in a reactor; (2) putting the reactor in an electric heating furnace; (3) inserting a temperature thermocouple into the coke in the reactor;(4) putting an electronic balance on a lifting table and connecting the electronic balance and the reactor through a chain; (5) regulating the electric furnace to heat through a temperature controller and introducing nitrogen when the temperature in the center of a material layer reaches 400 DEG C; (6) introducing carbon dioxide gas when the temperature in the center of the material layer reaches 780 DEG C; (7) cutting the nitrogen and introducing prepared mixed gas when the temperature in the centerof the material layer reaches a certain value, maintaining the temperature of the heating furnace, and when the loss ratio of the coke samples reaches the required value continuously introducing the carbon dioxide gas or the mixed gas, introducing the nitrogen and cooling after the carbon dioxide gas or the mixed gas reaches the specified dissolve loss quantity; and (8) stopping introducing the nitrogen and cooling naturally when below 100 DEG C. The invention more truly reflects the actual conditions of the coke in a blast furnace, and the prediction of the thermal properties of the coke is more accurate.

Owner:BAOSHAN IRON & STEEL CO LTD

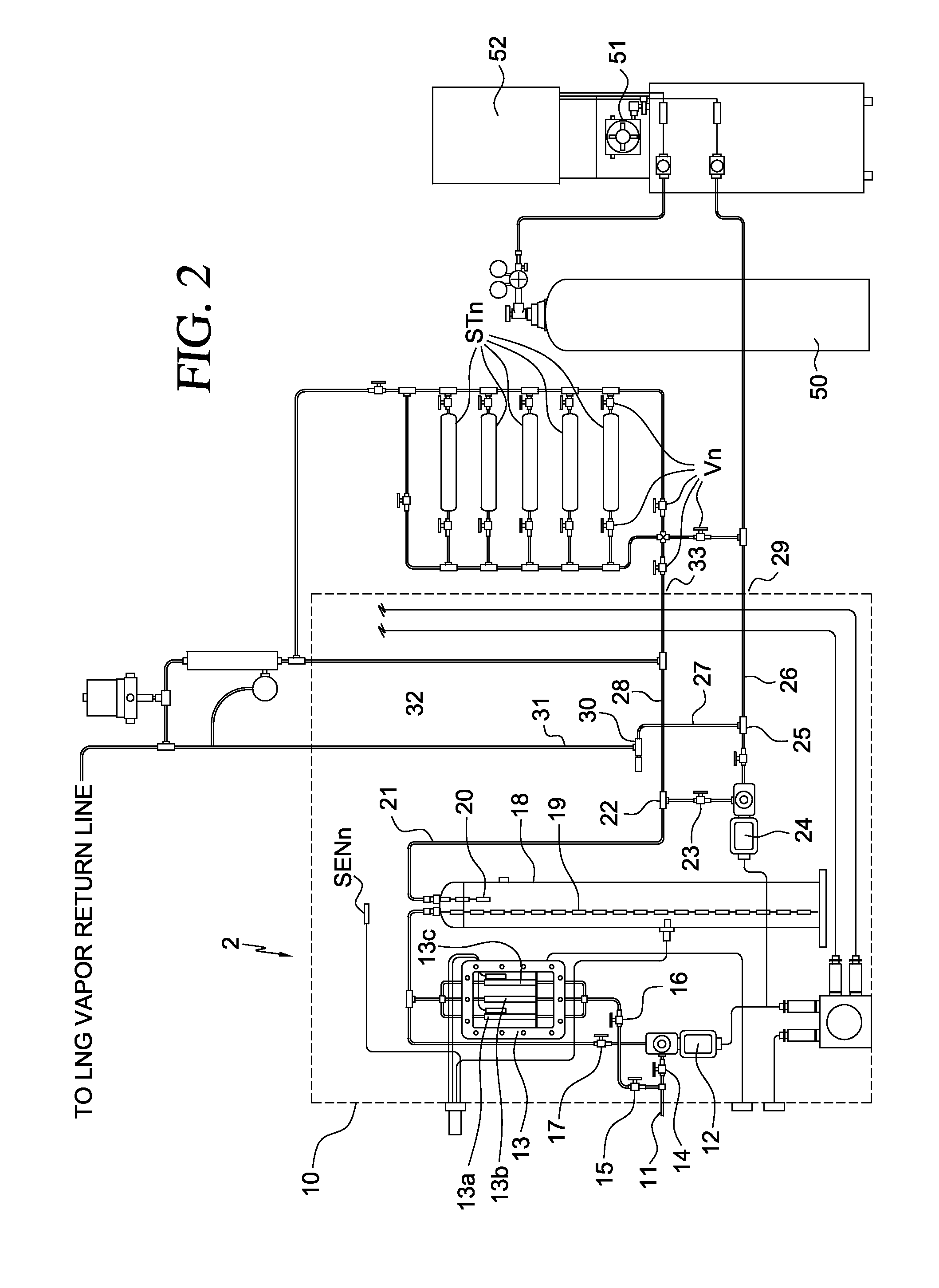

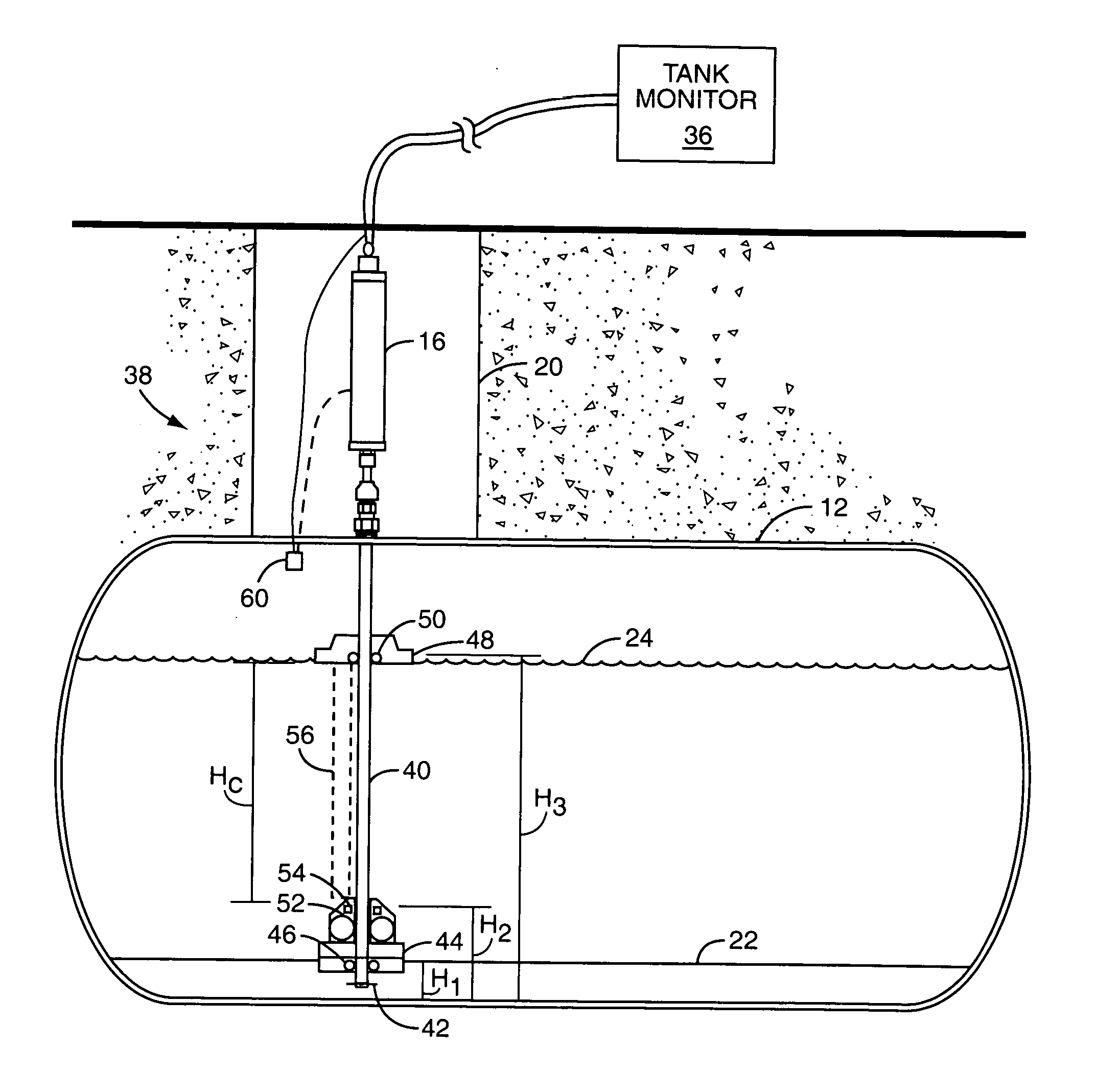

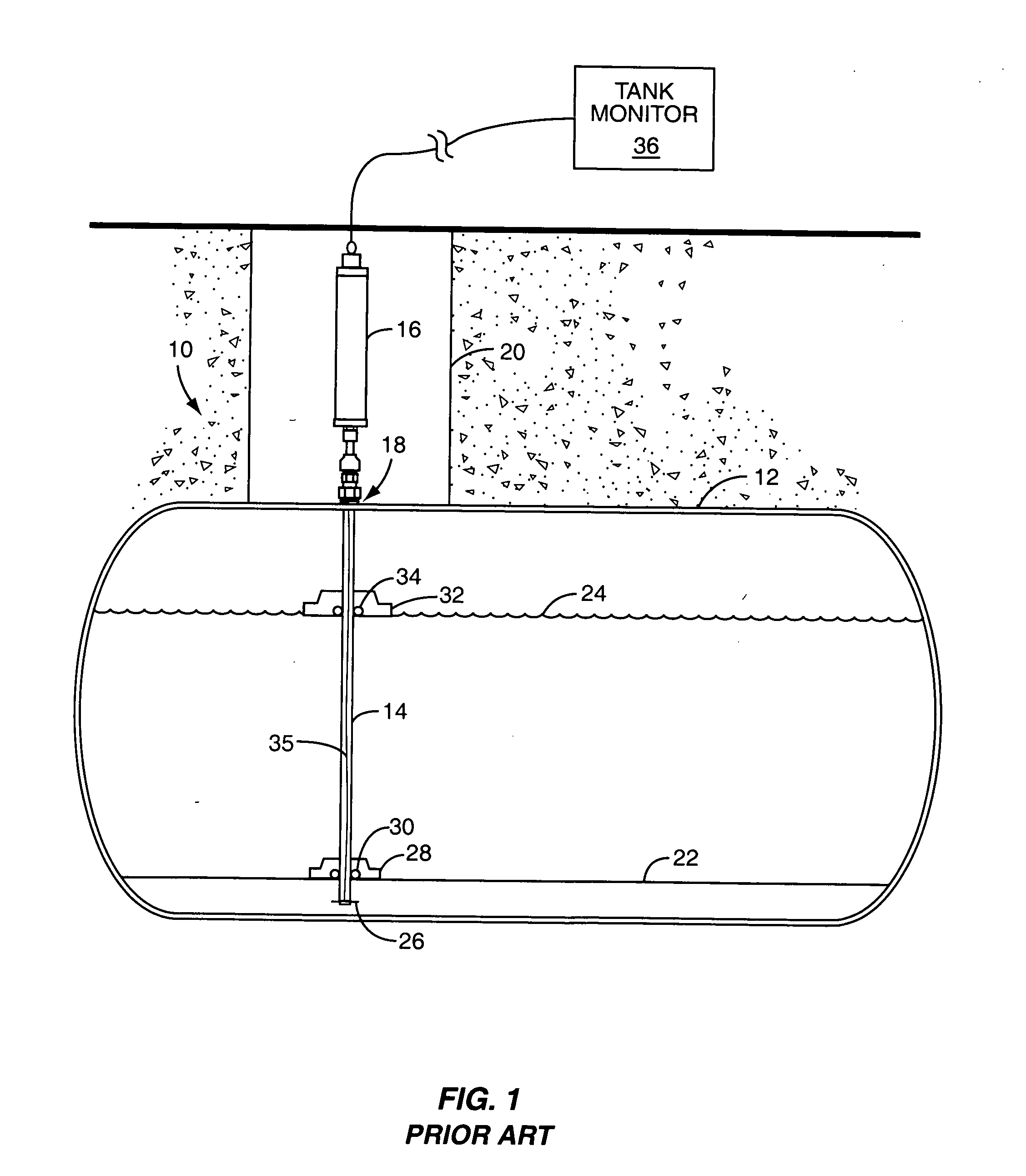

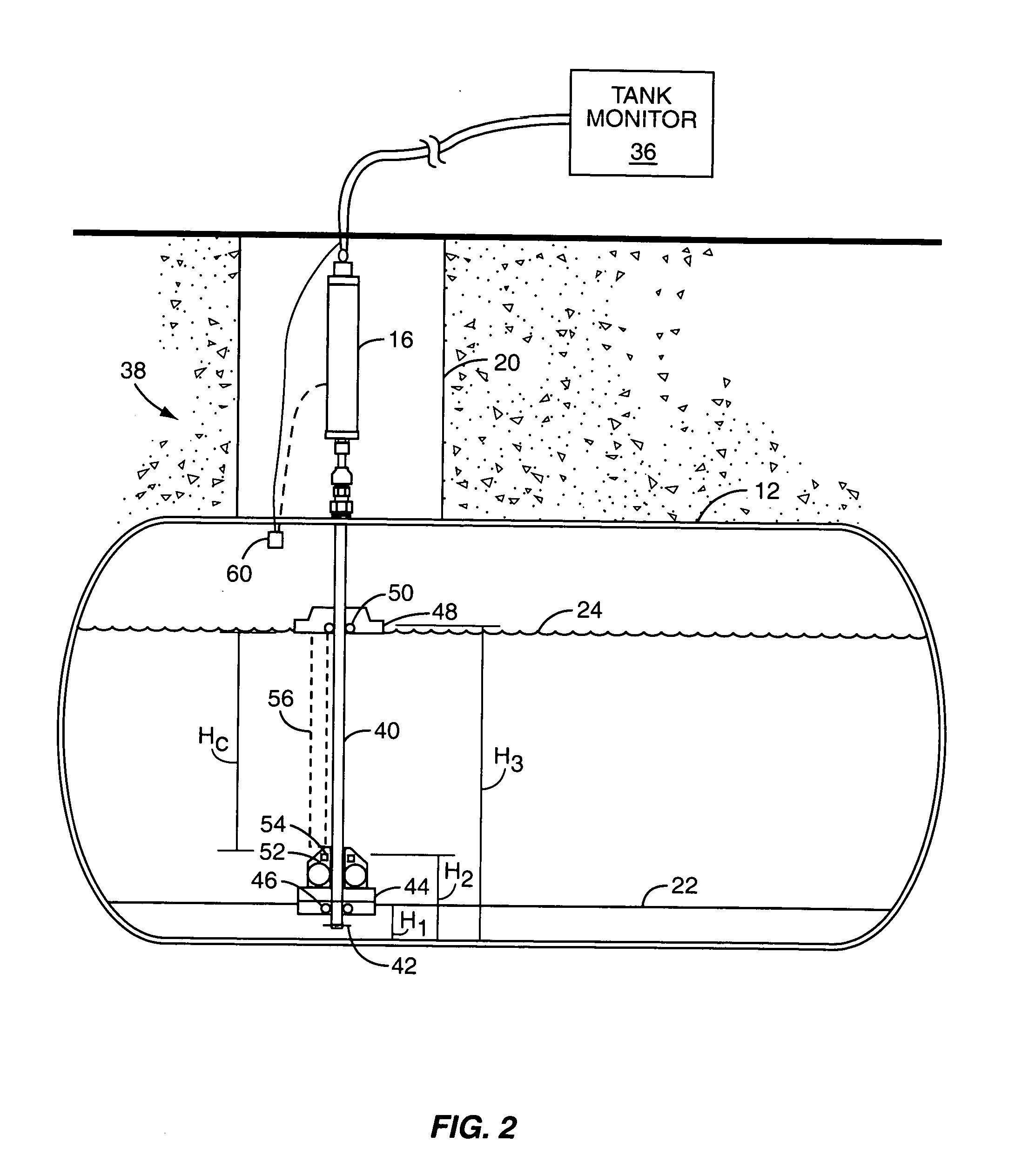

Devices, methods and systems for fuel monitoring

InactiveUS20080053202A1Level of precisionRadiation pyrometrySpectrum investigationElectrical resistance and conductanceGasoline

Disclosed are devices, methods and systems for the measurement of fuel composition and the detection and measurement of phase separation in fuel storage tanks. An embodiment measures optical and / or electrical impedance spectral features of the fuel by a series of sensors placed at a series of heights within a fuel storage tank. Embodiments are disclosed to measure aspects of the water, ethanol and gasoline content as well as other constituents of a fuel mixture, as well as the onset of the two phase event and the completed extent of the water intrusion into the system in concert with the level at which the layers exist in a fuel container.

Owner:PLAIN SIGHT SYST

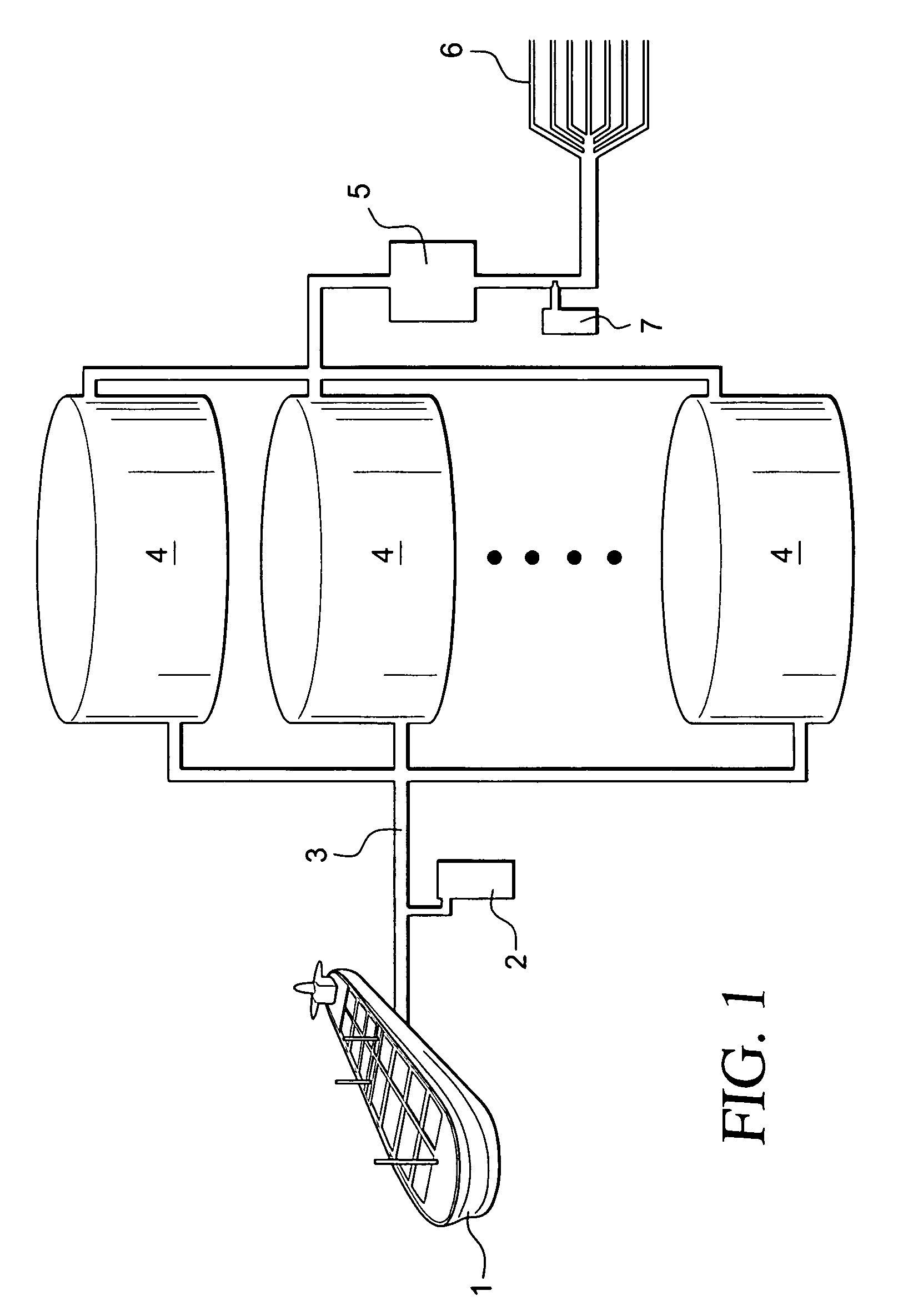

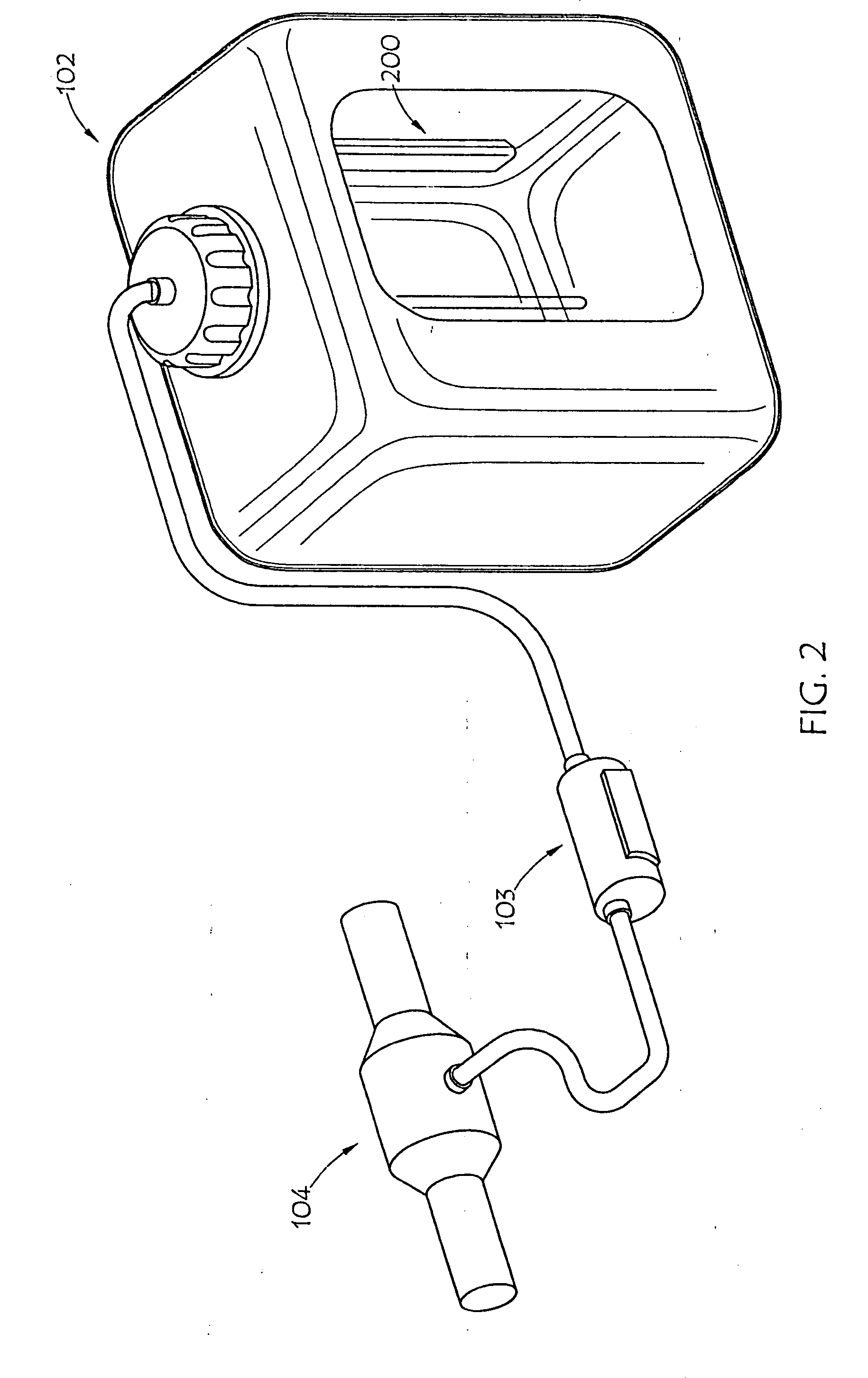

Liquid gas vaporization and measurement system and method

ActiveUS7484404B2Efficiently and accurately sampling and measuringEfficiently flash vaporizeComponent separationGas handling applicationsMass storageMeasuring instrument

A liquid gas vaporization and measurement system, and associated method, for efficiently vaporizing a continuous sample of liquid gas, such as liquid natural gas (LNG), and accurately determining the constituent components of the gas. A constant flow of liquid gas sampled from a mass storage device is maintained in a vaporizing device. Within the vaporizing device the liquid gas is flash vaporized within heated narrow tubing. The liquid gas is converted to vapor very quickly as it enters one or more independently operating vaporizer stages within the vaporizing device. The vapor gas is provided to a measuring instrument such as a chromatograph and the individual constituent components and the BTU value of the gas are determined to an accuracy of within + / −0.5 mole percent and 1 BTU, respectively.

Owner:MUSTANG SAMPLING

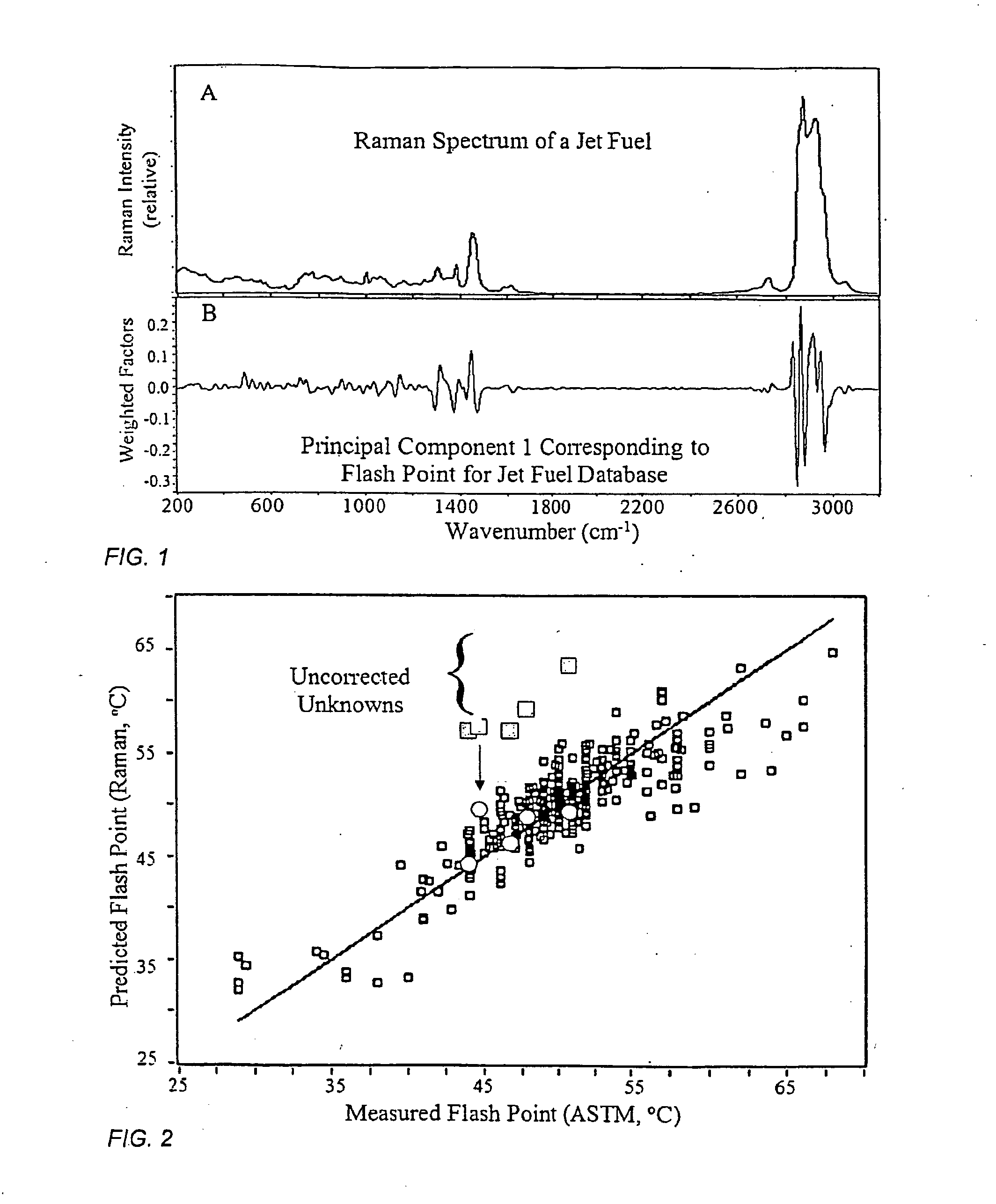

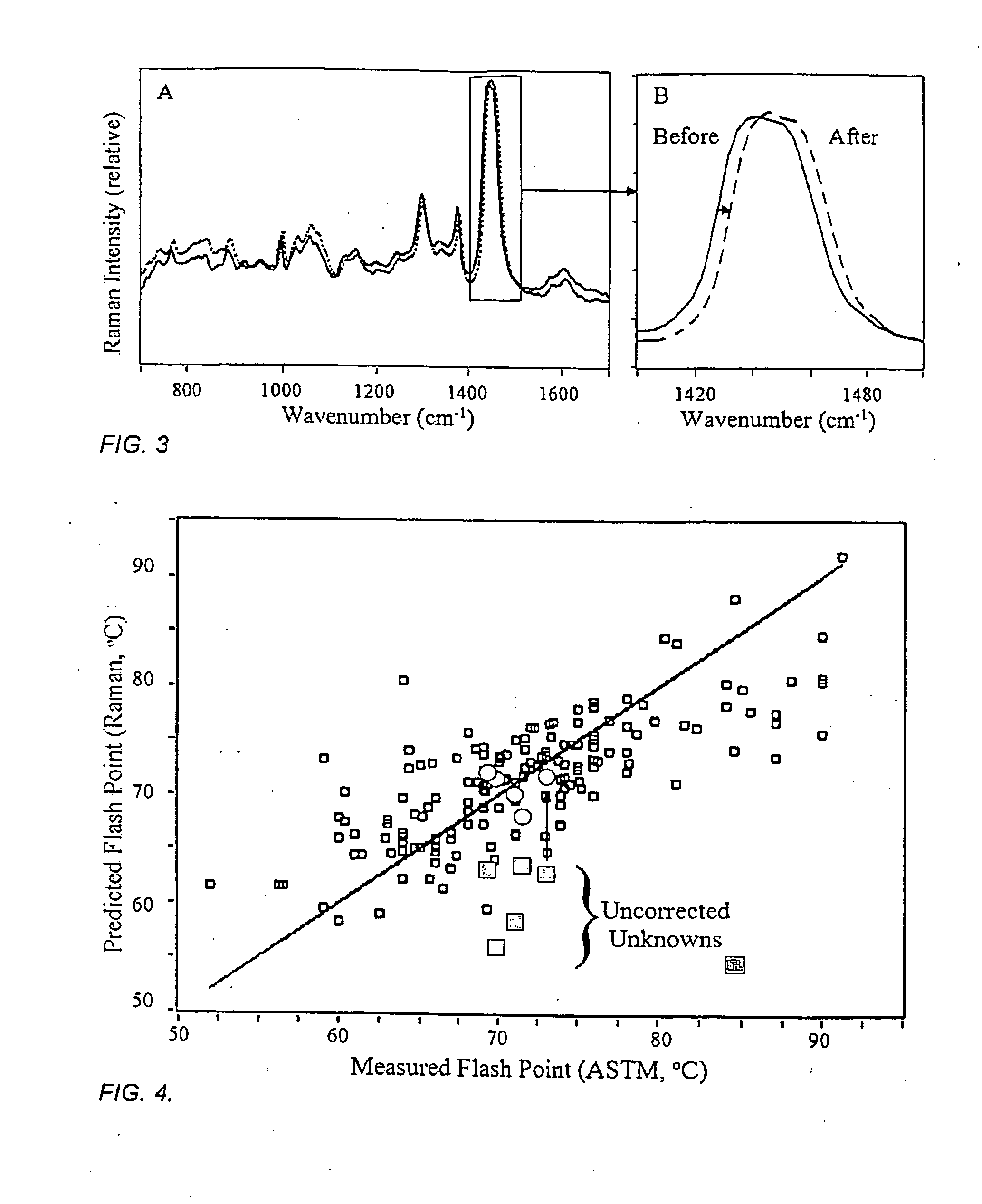

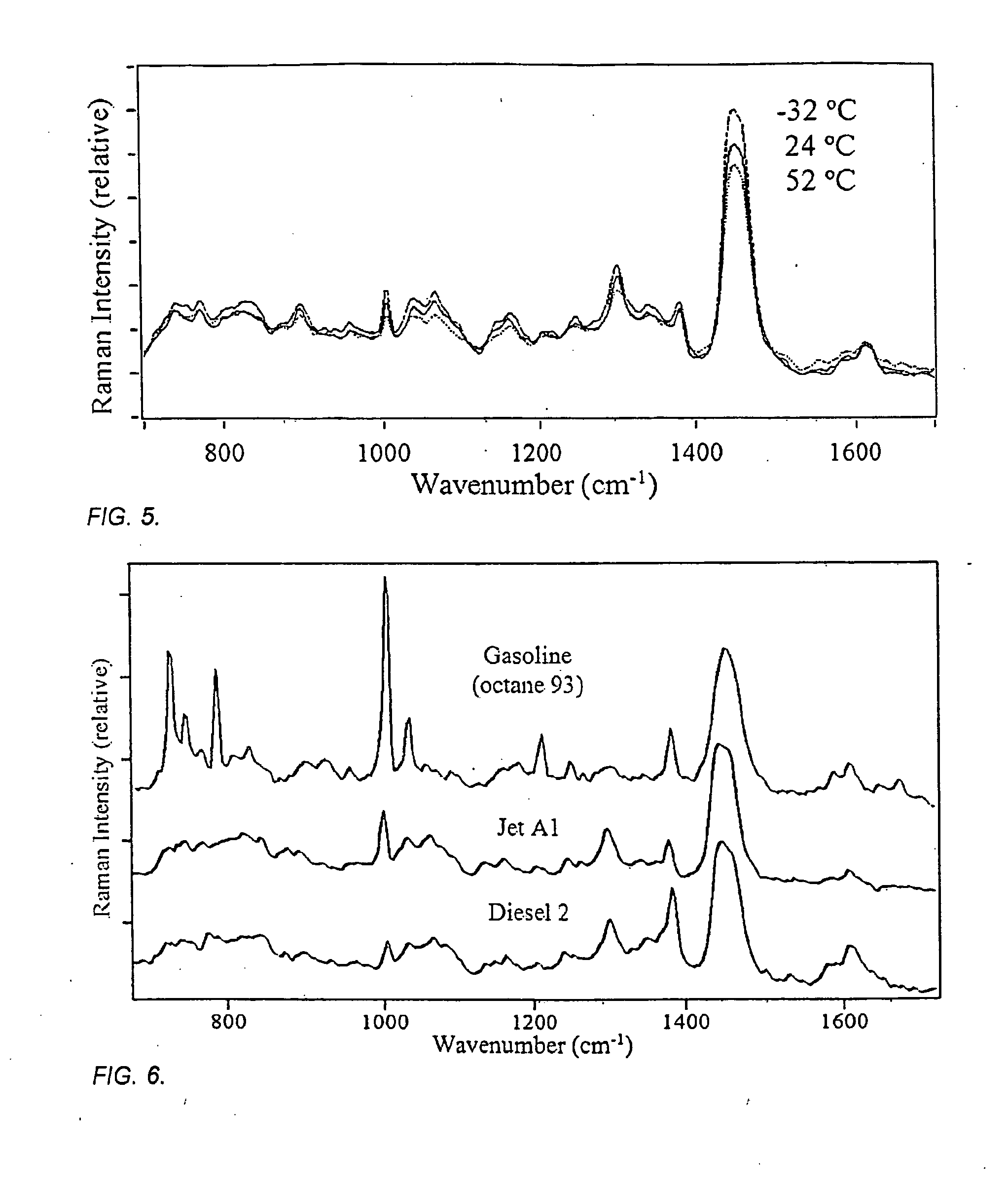

Method of monitoring and controlling activity involving a fuel composition

InactiveUS20140229010A1Easy to operateSampled-variable control systemsFuel testingPresent methodDistillation

The method and apparatus are used to determine class, grade and properties of fuel samples, regardless of ambient, instrument, or sample temperature, using mathematical correlations between fuel class, grade and properties and their spectra developed from a database of samples with measured properties and spectra. The ability to measure a fuel sample using the present method and apparatus is useful in identifying unknown fuel samples, determining suitability in equipment, and monitoring and controlling fuel processes, such as blending operations, distillation, and synthesis.

Owner:REAL TIME ANALYZERS

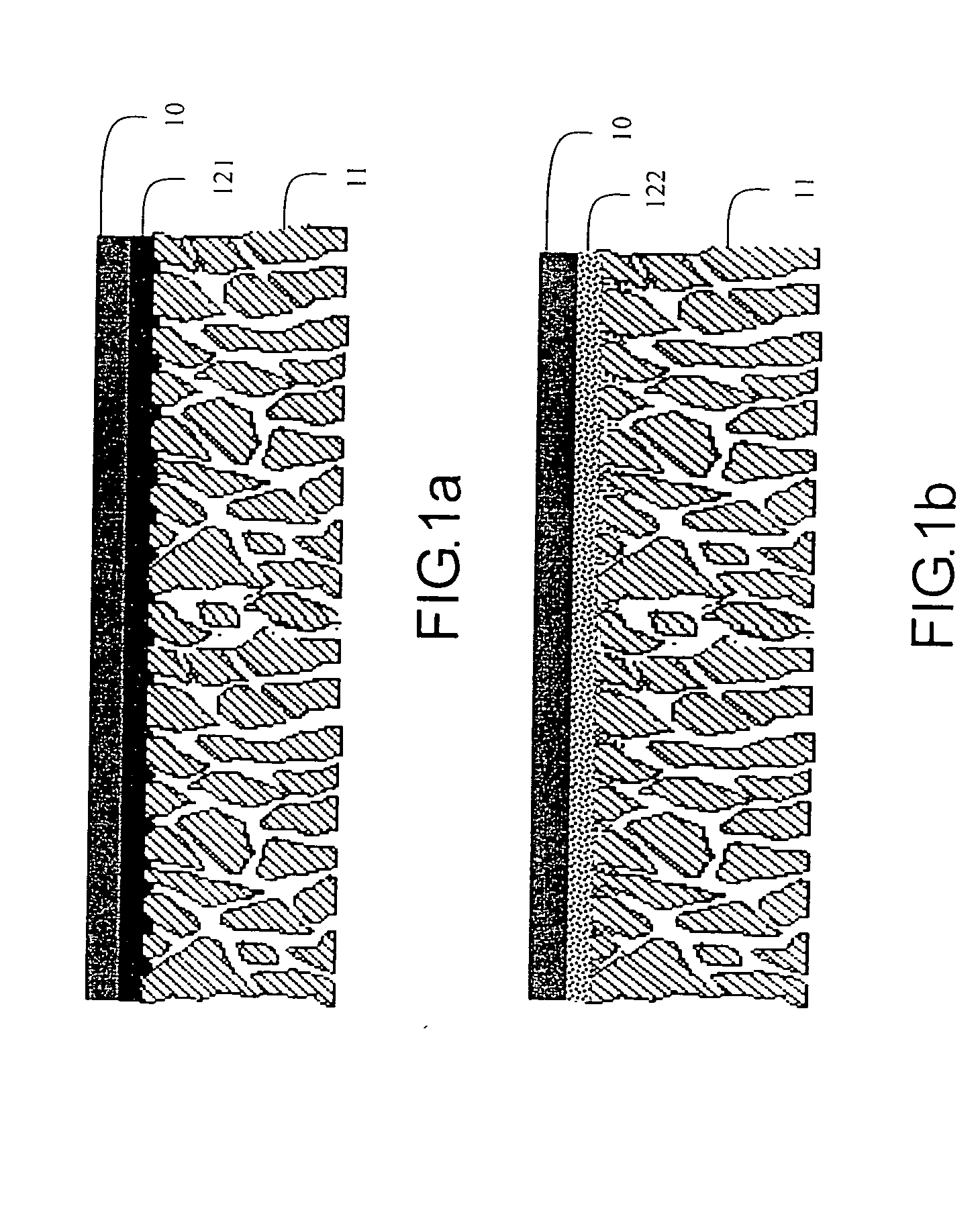

Oil/gas separation membrane, its use in gas sensor and process for producing the same

InactiveUS20050086998A1Losing mechanical propertyLosing permeation efficiencyPreparing sample for investigationFuel testingAdhesiveHexafluoropropylene

An oil gas separation membrane combines a gas permeable yet oil and temperature resistant bulk polymer membrane such as poly(tetrafluoroethylene) and poly(tetrafluoroethylene-co-hexafluoropropylene); a porous metal support such as sintered metal frit disk made with stainless steel, bronze or nickel; and an highly gas permeable adhesive that bonds firmly the bulk polymer membrane and the metal frit surface together. The adhesive is either a homogenous polymer that has desirable gas permeability, or a coalescent porous polymer particulates network. A gas sensor employing the oil gas separation membrane for detecting and monitoring fault gases of oil filled electrical equipment requires no mechanical wearing or moving part such as pump and valve and the gas sensor is operated normally under various temperature and pressure conditions.

Owner:ASENSOR TECH

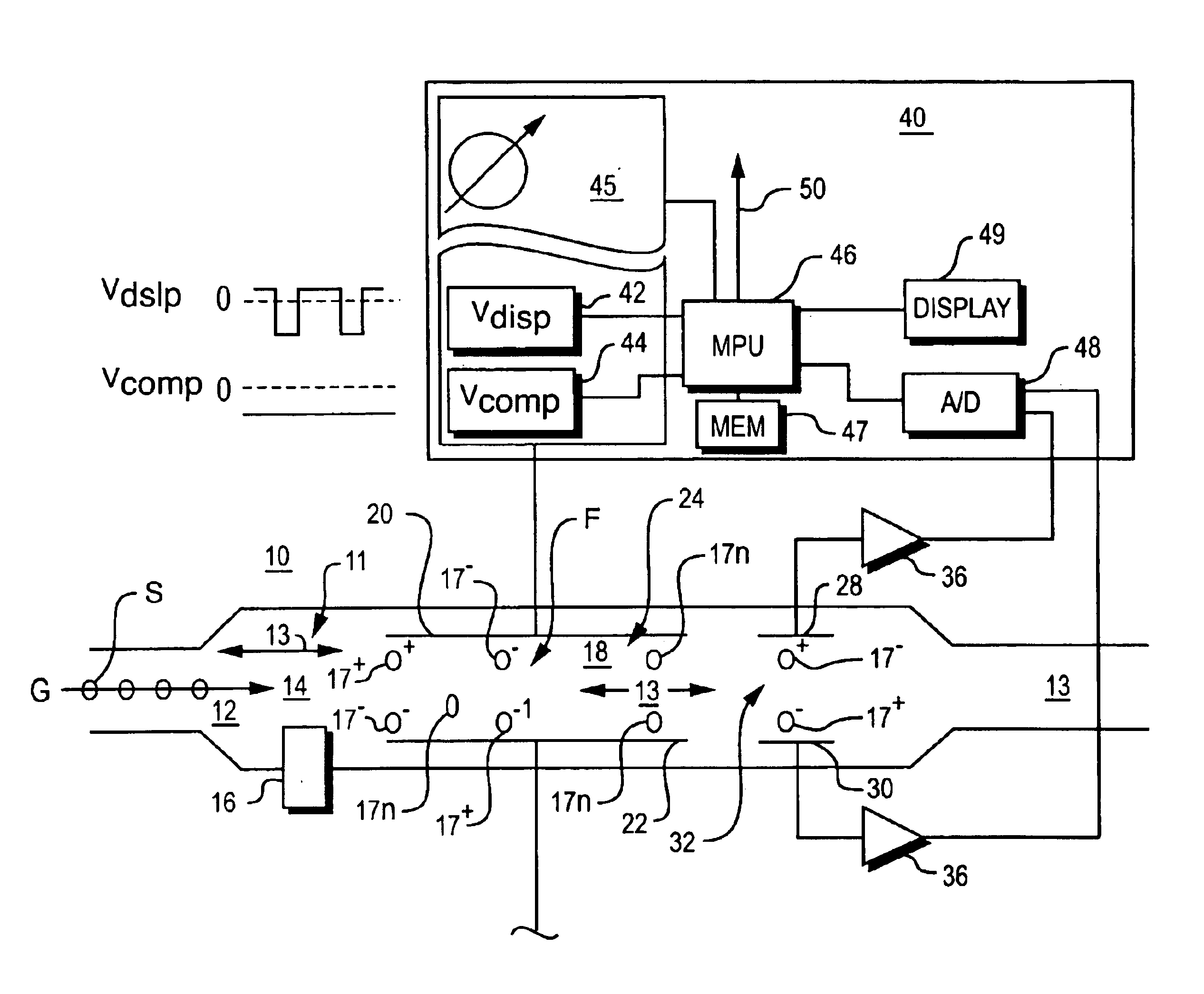

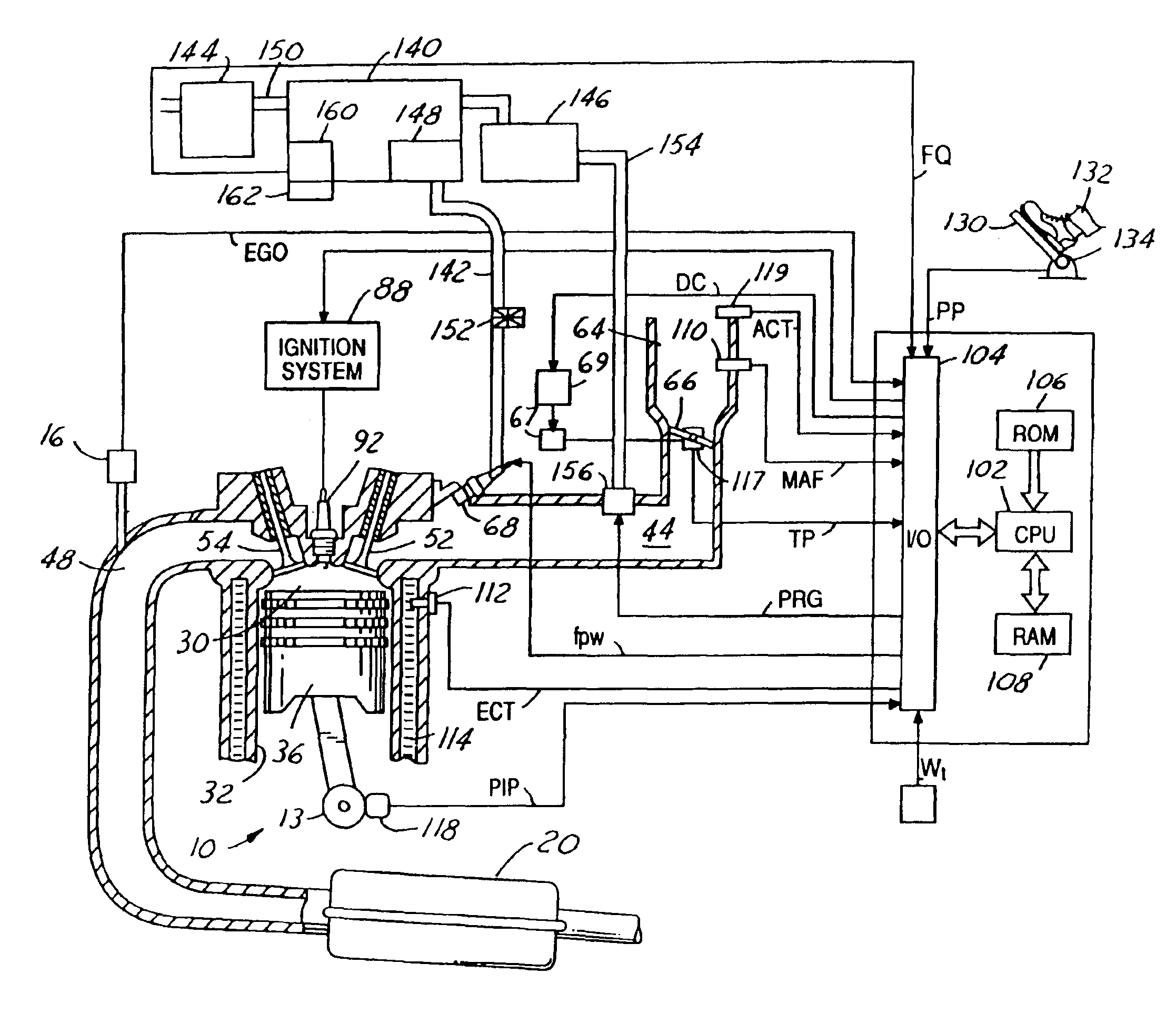

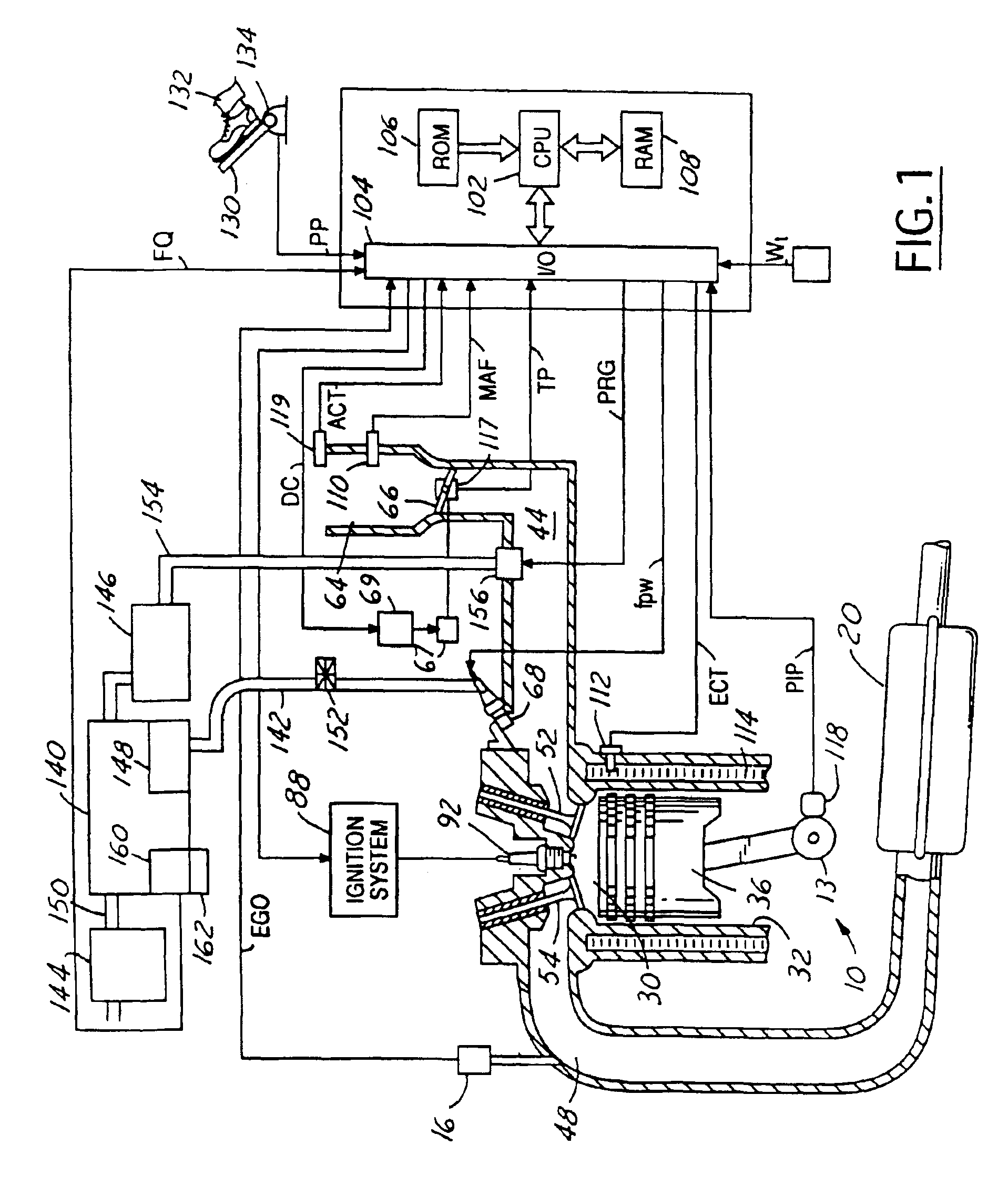

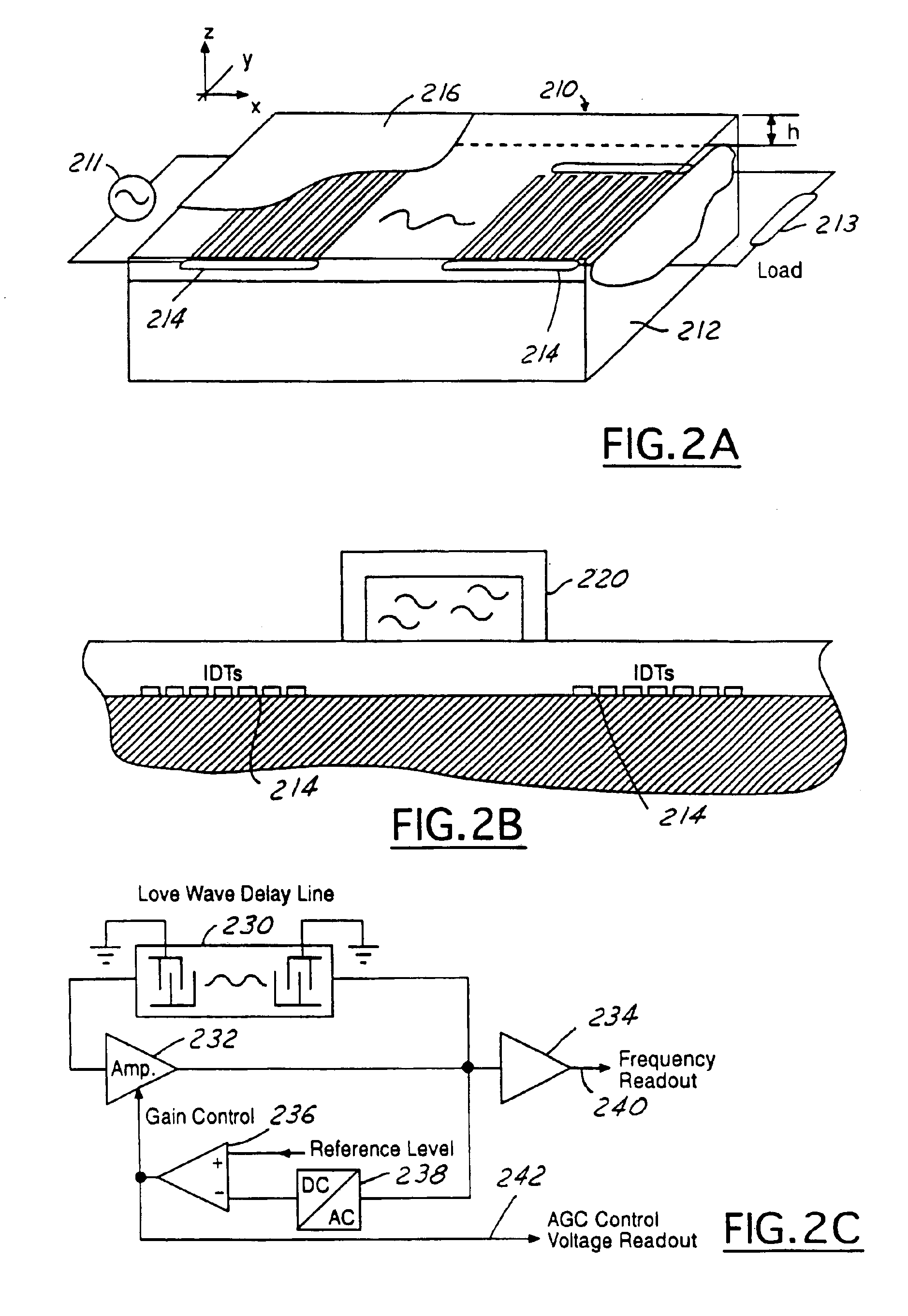

Engine control with fuel quality sensor

InactiveUS6935311B2Improved cold-start emissionImprove driveabilityElectrical controlInternal combustion piston enginesGasoline fuelFuel quality

A system is described using a fuel quality sensor for controlling various aspects of engine operation. In particular, an acoustic wave sensor is utilized to measure viscosity and density of gasoline fuels. This measurement is utilized to predict engine combustion quality during an engine start. Based on the prediction, the method adjusts engine operating parameters (such as fuel injection amount and ignition timing) to achieve improved vehicle driveability and engine combustion.

Owner:FORD GLOBAL TECH LLC

Liquid level and quality sensing apparatus, systems and methods using EMF wave propagation

InactiveUS20100327884A1Reduce and negate dependenceReduce and eliminate effectInternal combustion piston enginesResistance/reactance/impedenceResonanceRefractive index

A liquid level, composition and contamination sensor generates an RF signal across a resonant circuit that includes a variable inductor and capacitor. The resulting electromagnetic radiation is propagated into the liquid and changes in impedance and resonance of the resonant circuit that result from changes in the conductivity and dielectric properties of the liquid, which are proportional to liquid content and volume, are detected. The conductivity and dielectric properties of the liquid are measured, based on the changed impedance and resonance of the resonant circuit, and are compared to determine aging and contamination of the urea solution by other liquids. Also, an optical sensor may be submerged in the liquid to determine the refractive index of the liquid. The refractive index of the liquid may be used to determine: if the liquid is water or a urea solution; the concentration of a urea solution.

Owner:SCHRADER ELECTRONICS LTD

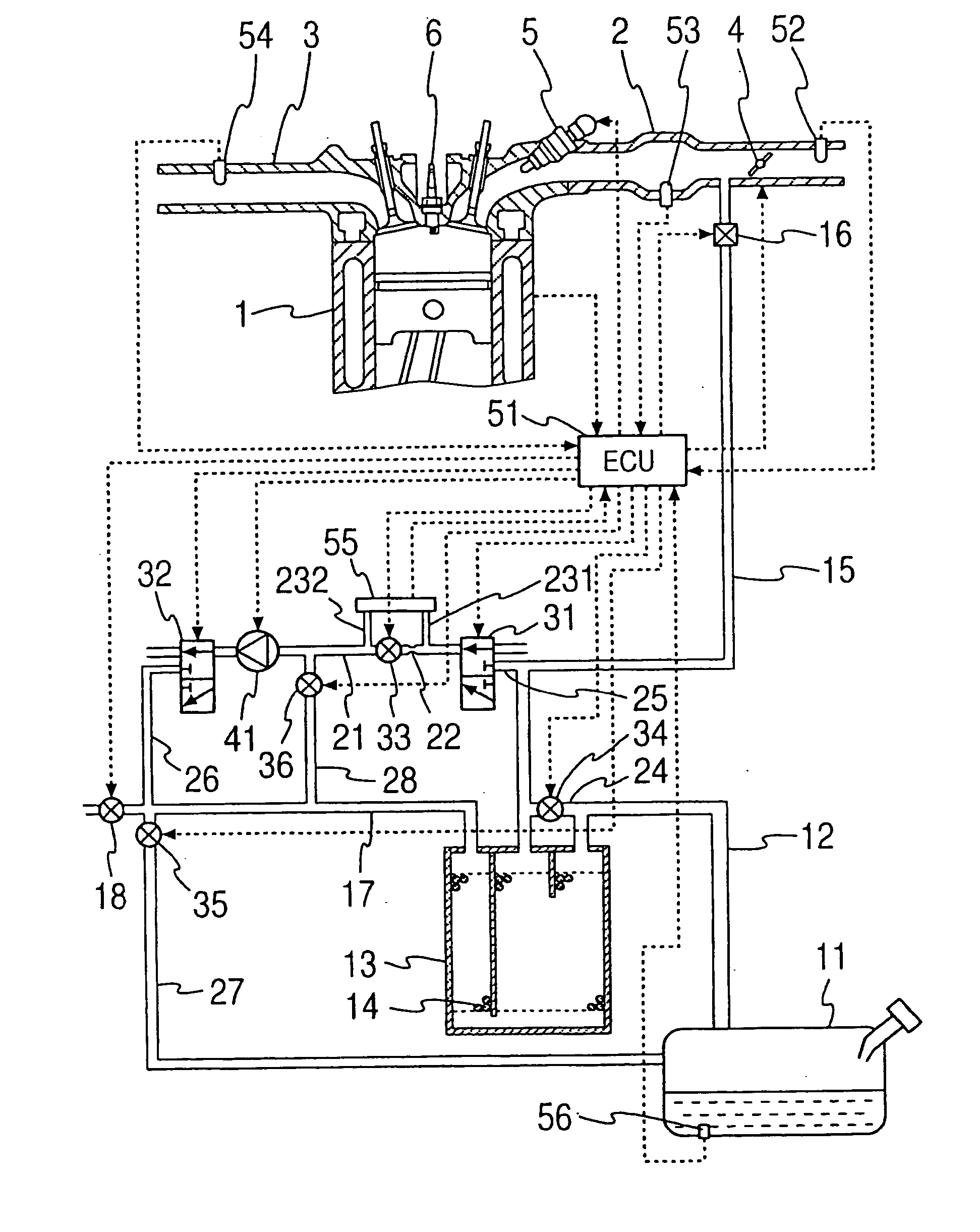

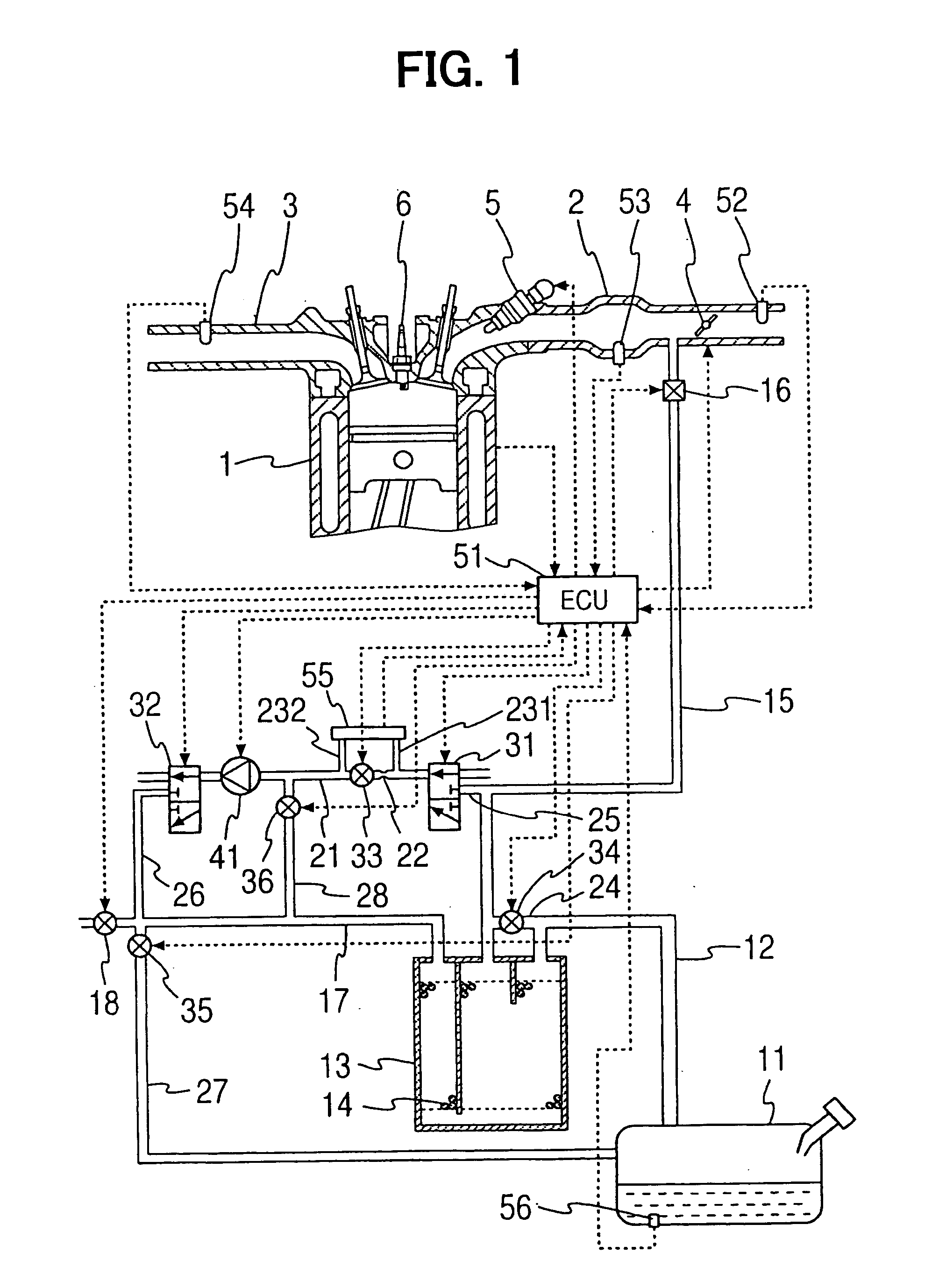

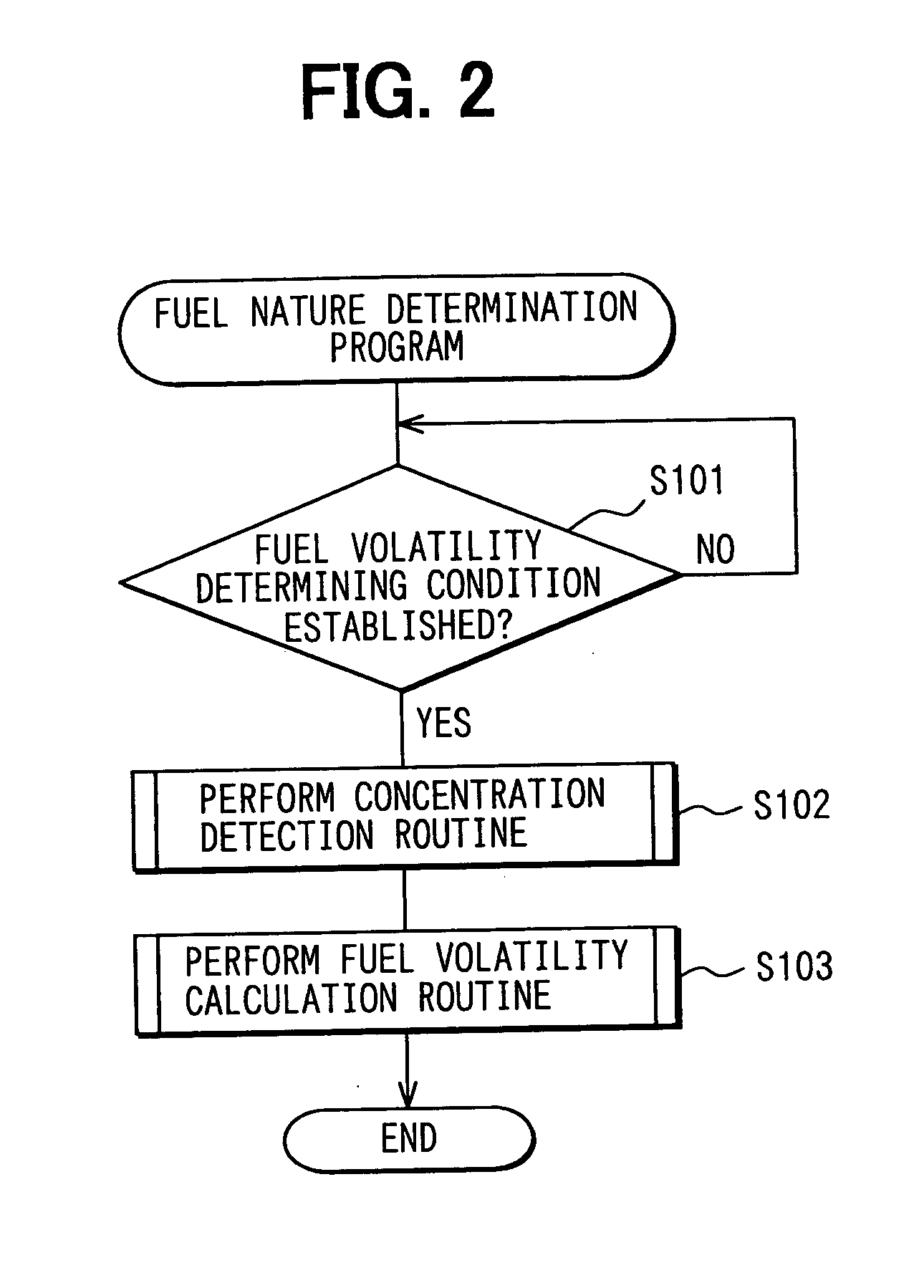

Fuel nature measuring device of internal combustion engine and internal combustion engine having the same

ActiveUS20060031000A1Reduce the amount of fuelReduce exhaust emissionsAnalogue computers for vehiclesElectrical controlDifferential pressureFuel tank

A fuel nature measuring device for measuring the nature of fuel stored in a fuel tank includes a measurement passage, a gas flow generator, a pressure detector, an concentration operator, a temperature detector, and a volatility calculator. The measurement passage has an orifice. The gas flow generator generates gas flow in the measurement passage. The pressure detector detects a differential pressure between opposite ends of the orifice. The concentration operator determines a concentration of evaporated fuel in the fuel tank based on the differential pressure detected when the opposite ends of the measurement passage communicate with the fuel tank and the fuel flows in the measurement passage. The temperature detector determines a temperature of the fuel in the fuel tank. The volatility calculator calculates a volatility of the fuel in the fuel tank based on the concentration of the evaporated fuel and the temperature of the fuel in the tank.

Owner:NIPPON SOKEN +1

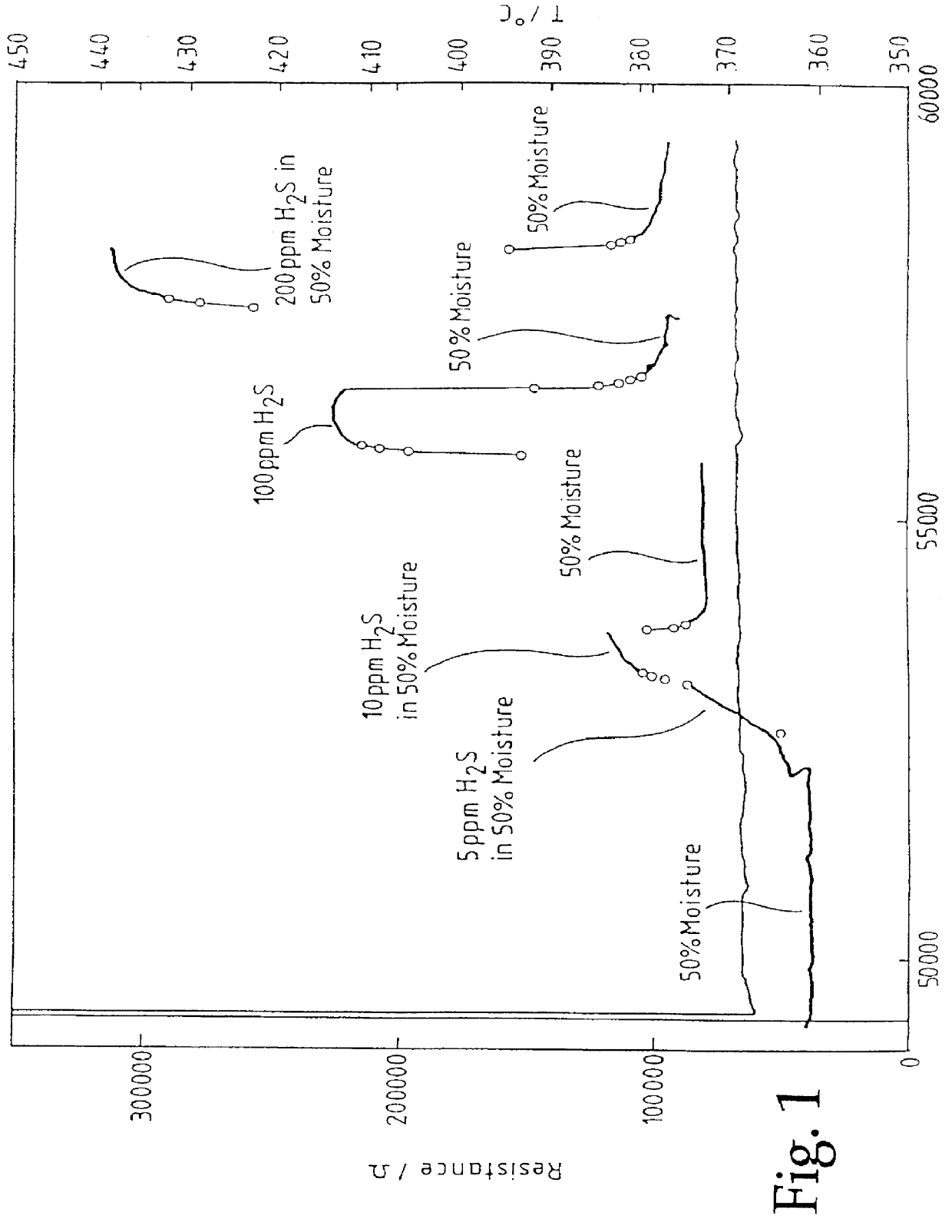

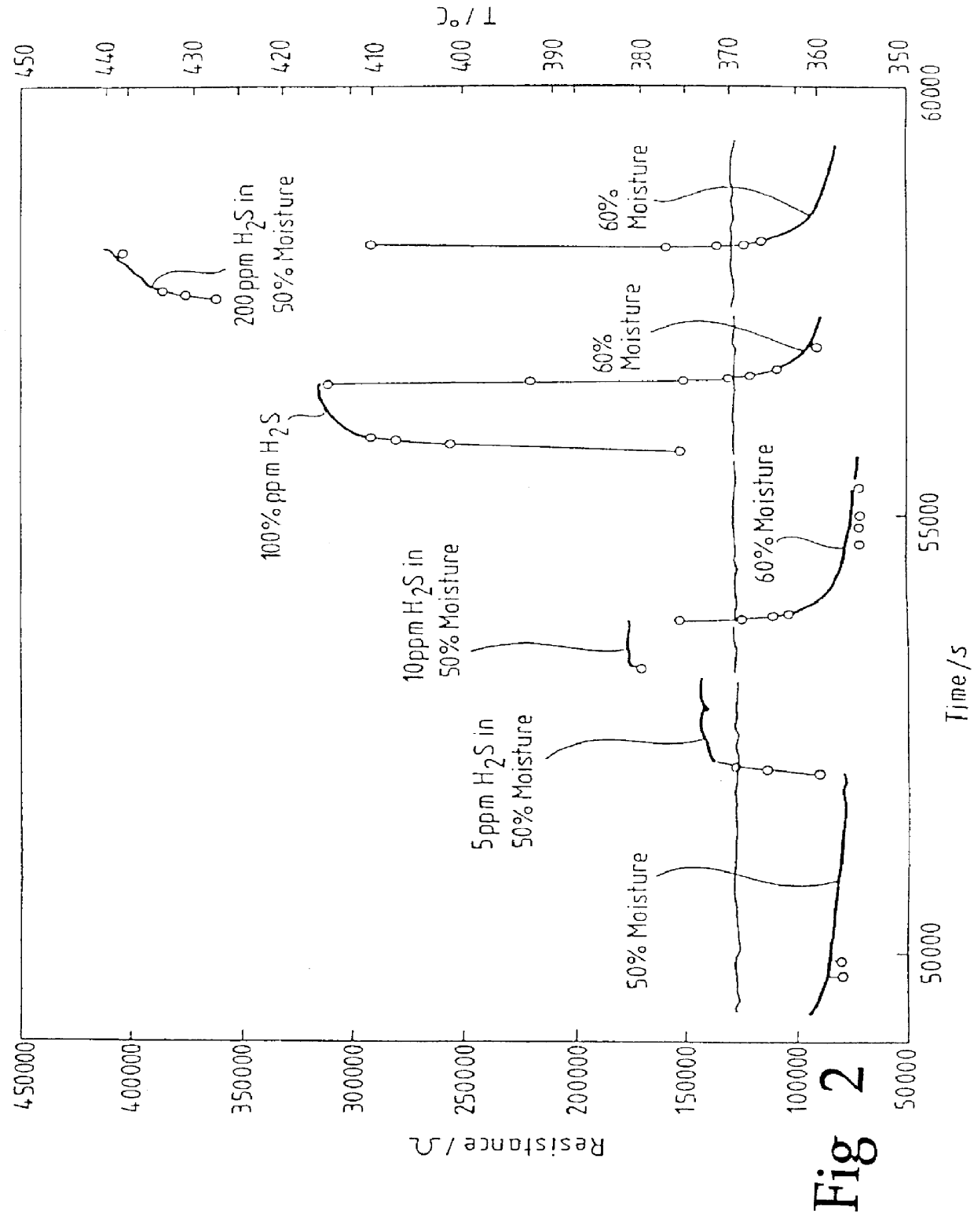

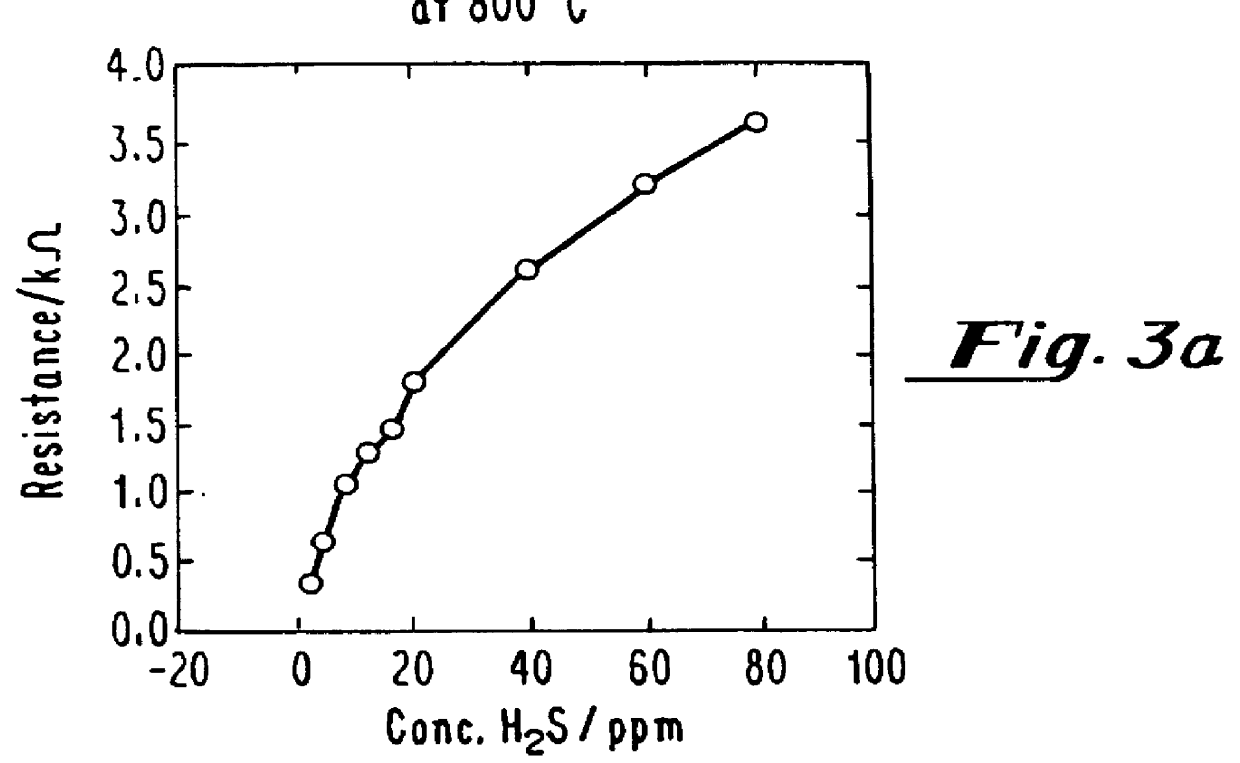

Semiconducting oxide gas sensors

InactiveUS6046054AShort stabilization timeGreatly reduced baseline driftFuel testingBiological testingAmmoniaPartial pressure

The selectivity of response of resistive gas sensors to specific gases or vapors is improved by the selection of specified gas-sensitive materials which are not previously known for the applications described, which include detection of hydrocarbons in the presence of CO, H2S, SO2, chlorine, NO2, CO2 (especially in low concentrations), CFC's, ammonia, free oxygen by determination of partial pressures, and numerous organic gases and vapors.

Owner:CAPTEUR SENSORS & ANALYZERS +1

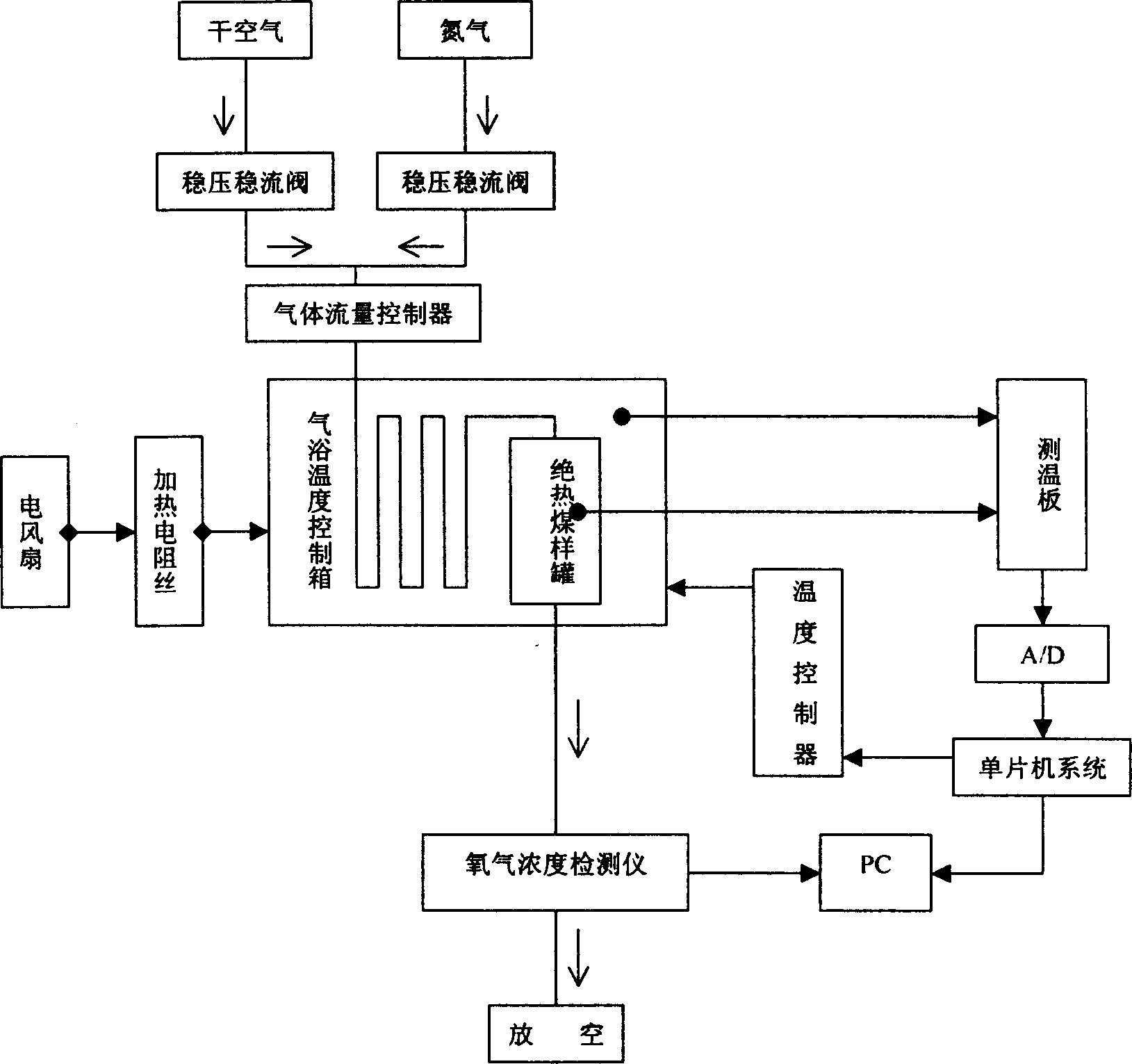

Thermal insulation testing process and apparatus for simulating coal spontaneous combustion procedure

InactiveCN1595129ASmall test coal sample volumeReduce volumeChemical analysis using combustionMaterial heat developmentTemperature controlCoal spontaneous combustion

It is an adiabatic test method and its apparatus for stimulating the coal autoignition process, which is to locate an adiabatic coal sample jar served as coal low temperature oxidation reaction and to let the gas in the jar firstly go through the copper gas guide pipe in the gas bath temperature control box for preheating and the environment temperature in the box of the reaction always traces the temperature changes in the coal sample jar. It adopts preheat gas path apparatus, gas bath temperature control box, adiabatic coal jar in the temperature control box, temperature control system, which makes the heat generated during the reaction remain in the coal sample to stimulate the coal autoignition process.

Owner:CHINA UNIV OF MINING & TECH

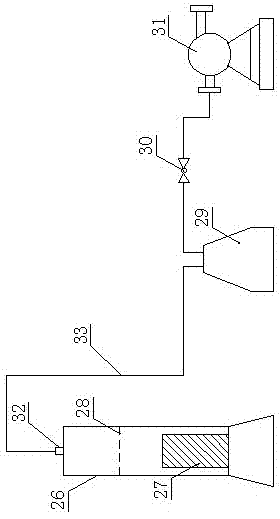

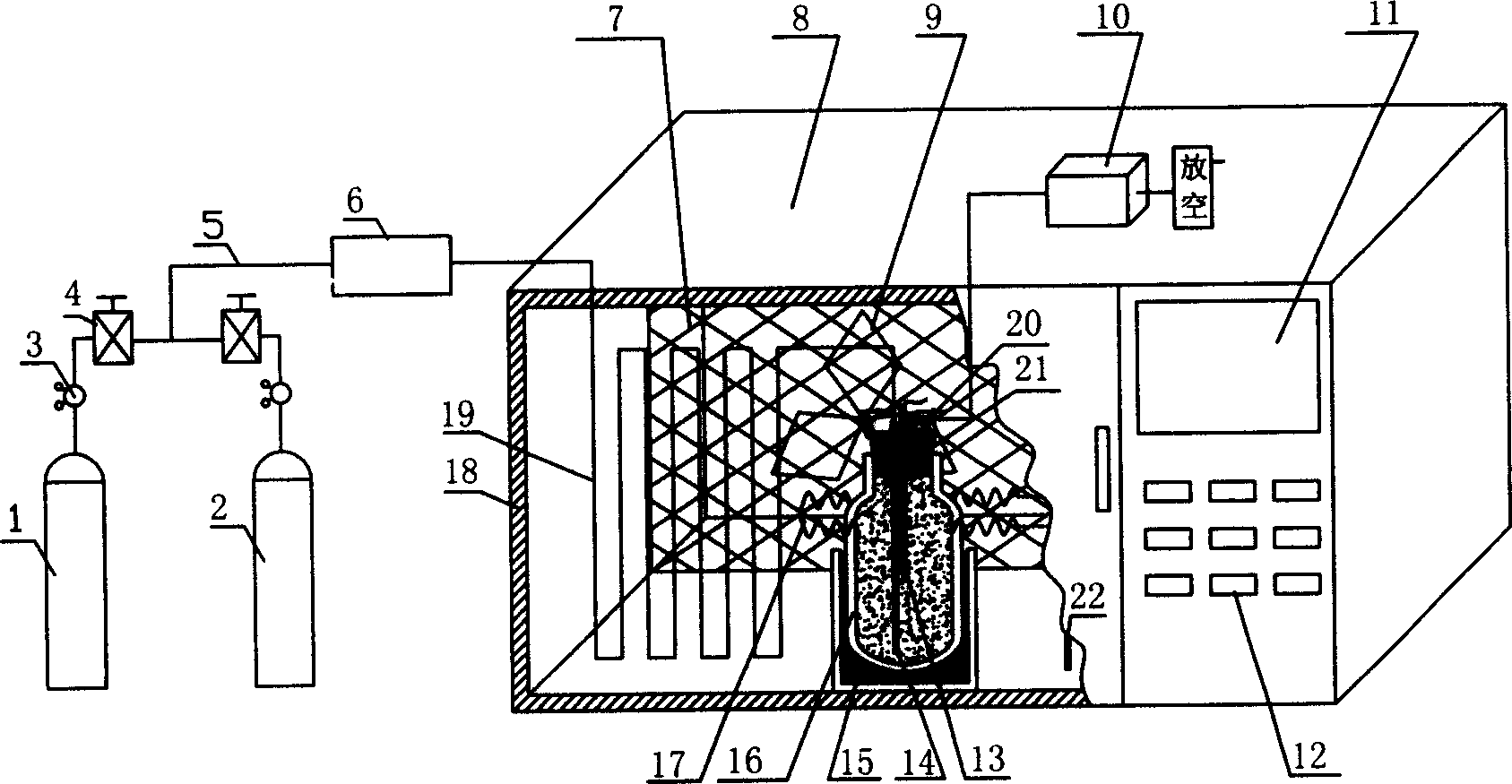

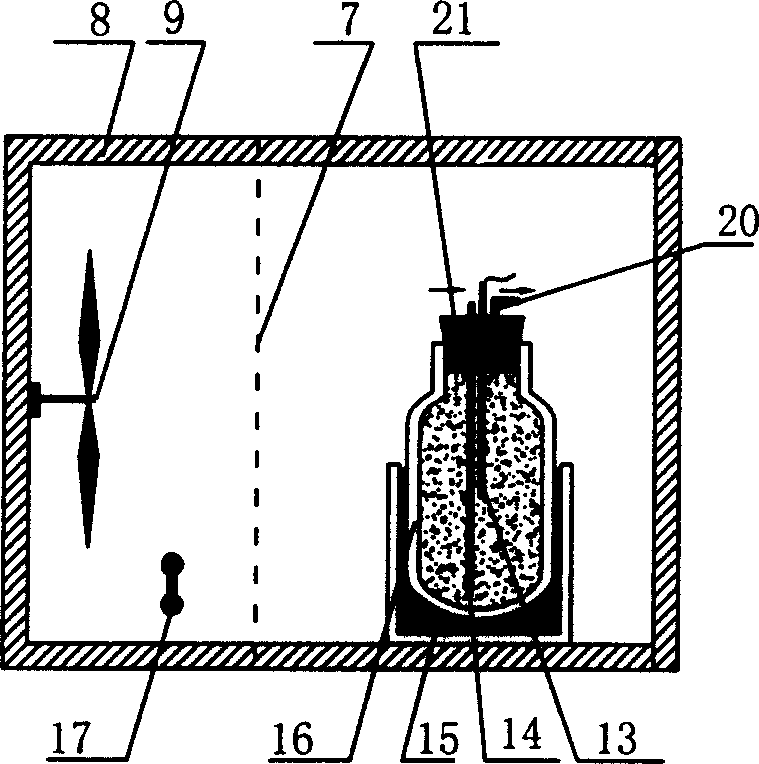

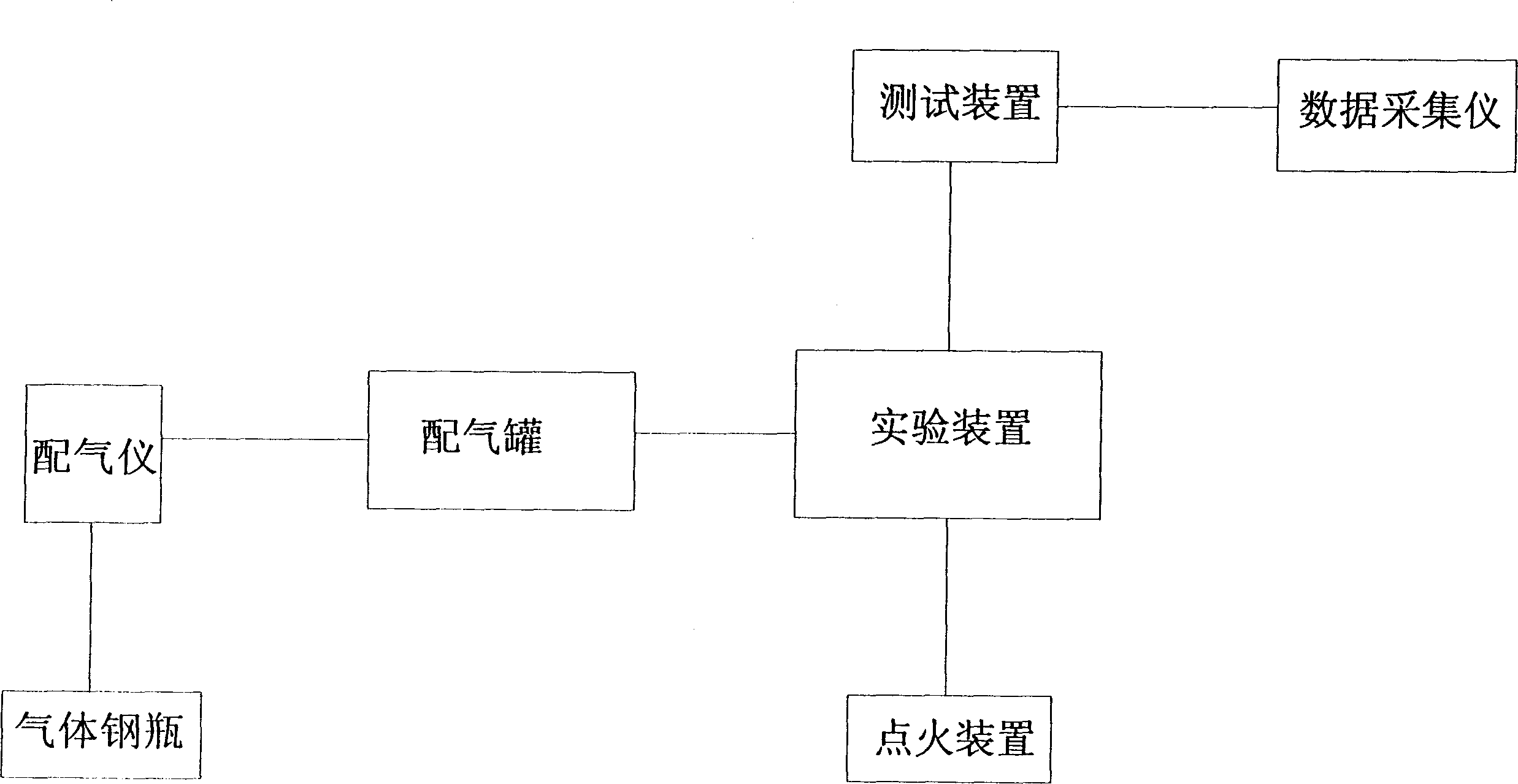

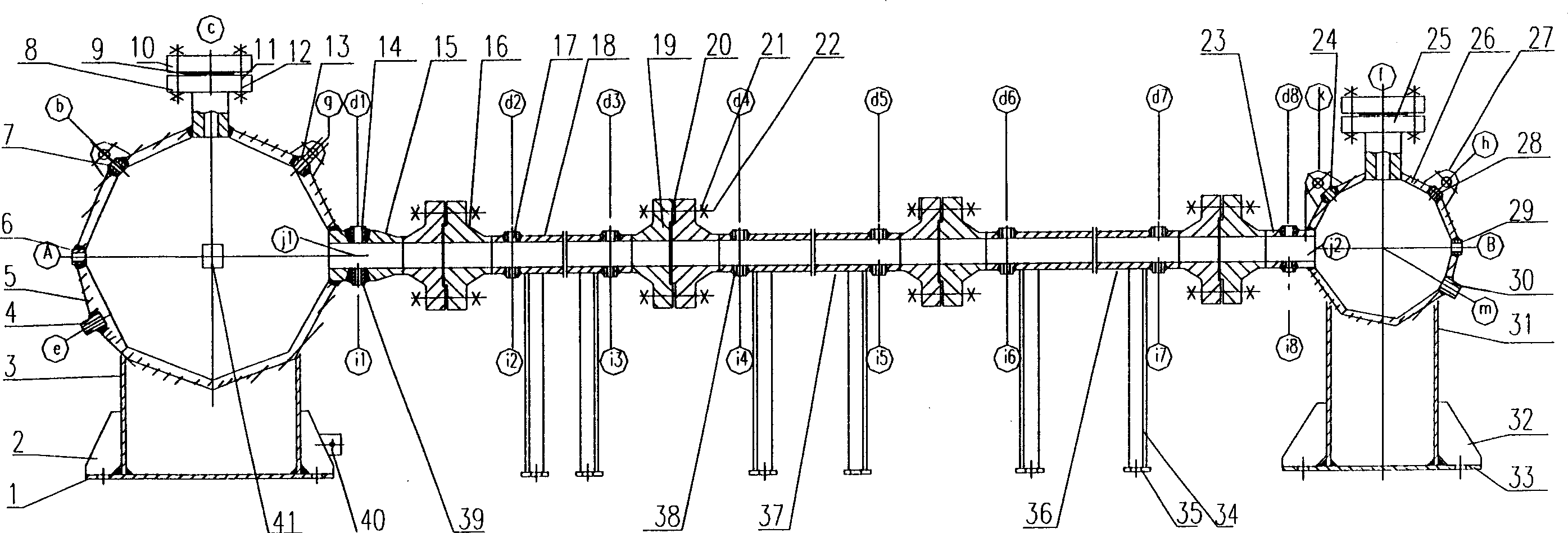

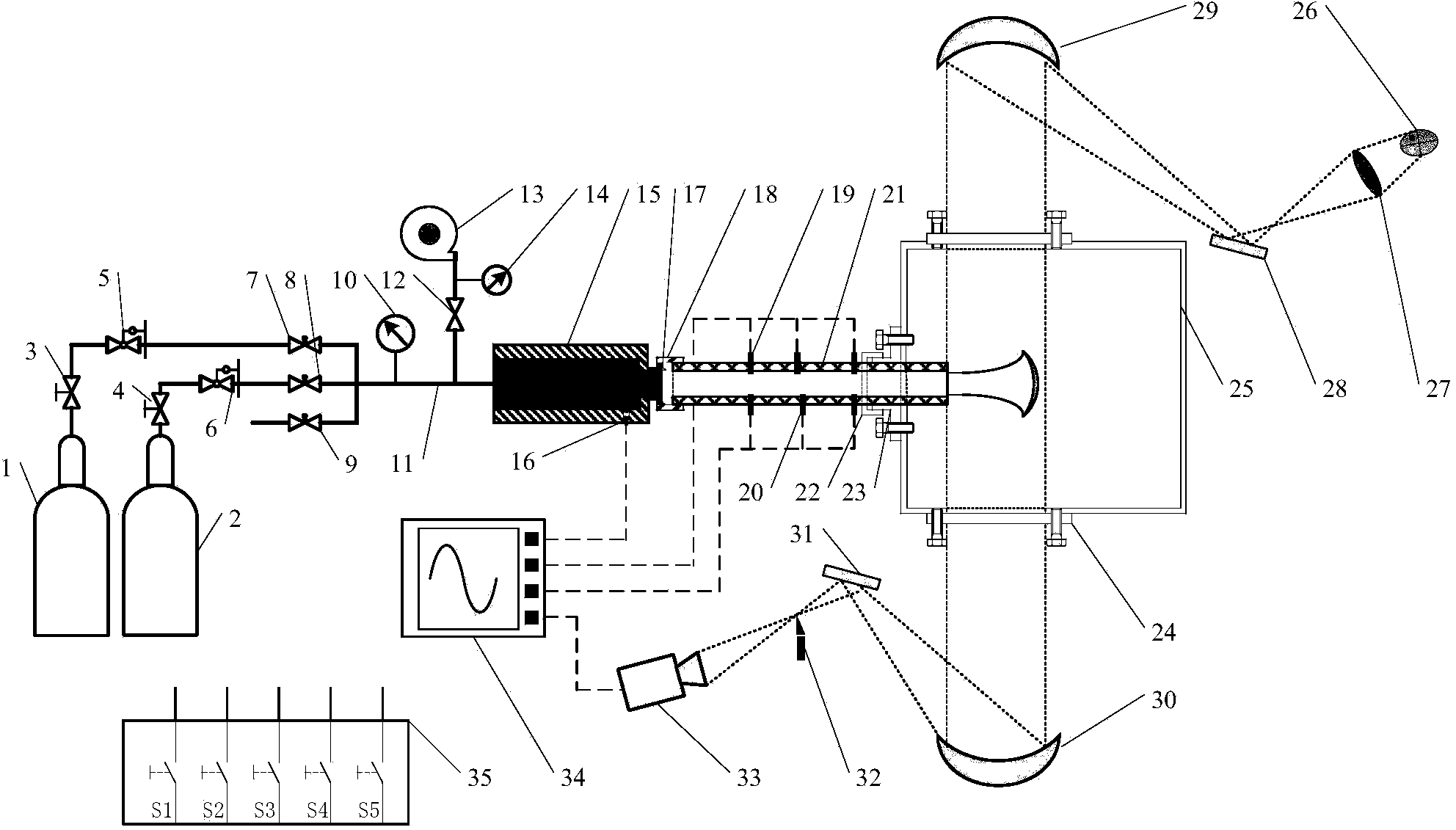

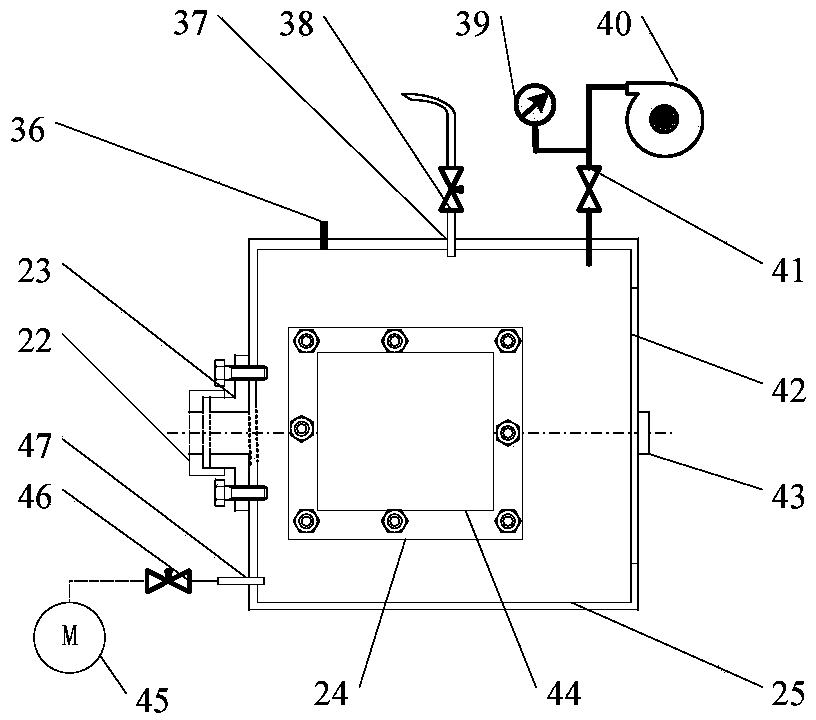

Multifunctional gas explosion experiment system

The related multifunction container-pipe gas blast experiment system comprises: an experiment device with two ball containers and pipe all arranged with sensor hole, gas in-out hole, vacuum-pressure gauge interface, discharging blast hole and an ignition hole; a gas distributing device with a steel bottle, a distribution meter, a tank and delivery pipe,; an ignition device with an electric spark generator, a spark plug and wire; a test device with a vacuum-pressure gauge, a pressure transmitter, a flame sensor and sensor wire; and a data acquisition and process part with multichannel data collector and software.

Owner:NANJING UNIV OF TECH

Fuel density measurement device, system, and method

InactiveUS20060169039A1Simple calculationEffective movementFuel testingMachines/enginesShape changeMeasurement device

A fuel tank probe includes a water level float and a fuel level float. A fuel weight sensor is incorporated into the fuel tank probe to report the density of the fuel within the tank. The fuel weight sensor includes a compressible bladder whose shape changes as a function of the density of the fuel. A magnet on the compressible bladder moves in conjunction with the changing shape of the compressible bladder, and allows a fuel column height to be measured. The density of the fuel can be determined from the measured fuel column height.

Owner:VEEDER ROOT

Test device for high-pressure combustible gas leakage spontaneous combustion and shock wave induction ignition

InactiveCN103454396APerfect spontaneous ignition mechanismEnable Visualization ResearchFuel testingSpontaneous combustionShock wave

The invention discloses a test device for high-pressure combustible gas leakage spontaneous combustion and shock wave induction ignition. The whole test device comprises a test gas bottle, a nitrogen gas bottle, a high-pressure ventilating pipeline, a pressure stabilization valve, an electromagnetic valve, a pressure gauge, a vacuum pump, a high-pressure storage tank, a pressure transducer, an ICP (inductively coupled plasma) pressure sensor, a photoelectric diode, a rupture disk clamp (in which a rupture disk is arranged), downstream pipelines, a schlieren, a high-speed camera, a protection box, an air compressor and the like. The device can be used for (1) researching the influence of factors, such as different leakage pressures, shapes, lengths and diameters of different downstream pipelines, the gas initial temperature, a breakage shape of the rupture disk and obstacles outside an orifice, on the spontaneous combustion ignition, and further completing a spontaneous combustion ignition mechanism; (2) researching a shock wave induction ignition process and disclosing a shock wave induction ignition mechanism and influence factors thereof; (3) realizing the visible research on spontaneous combustion ignition and shock wave induction processes.

Owner:UNIV OF SCI & TECH OF CHINA

Gas sensor

ActiveUS7406854B2Reduce effortCalibration reducedFuel testingTransmissivity measurementsSpecial designEnvironmental engineering

Owner:DRAGER SAFETY

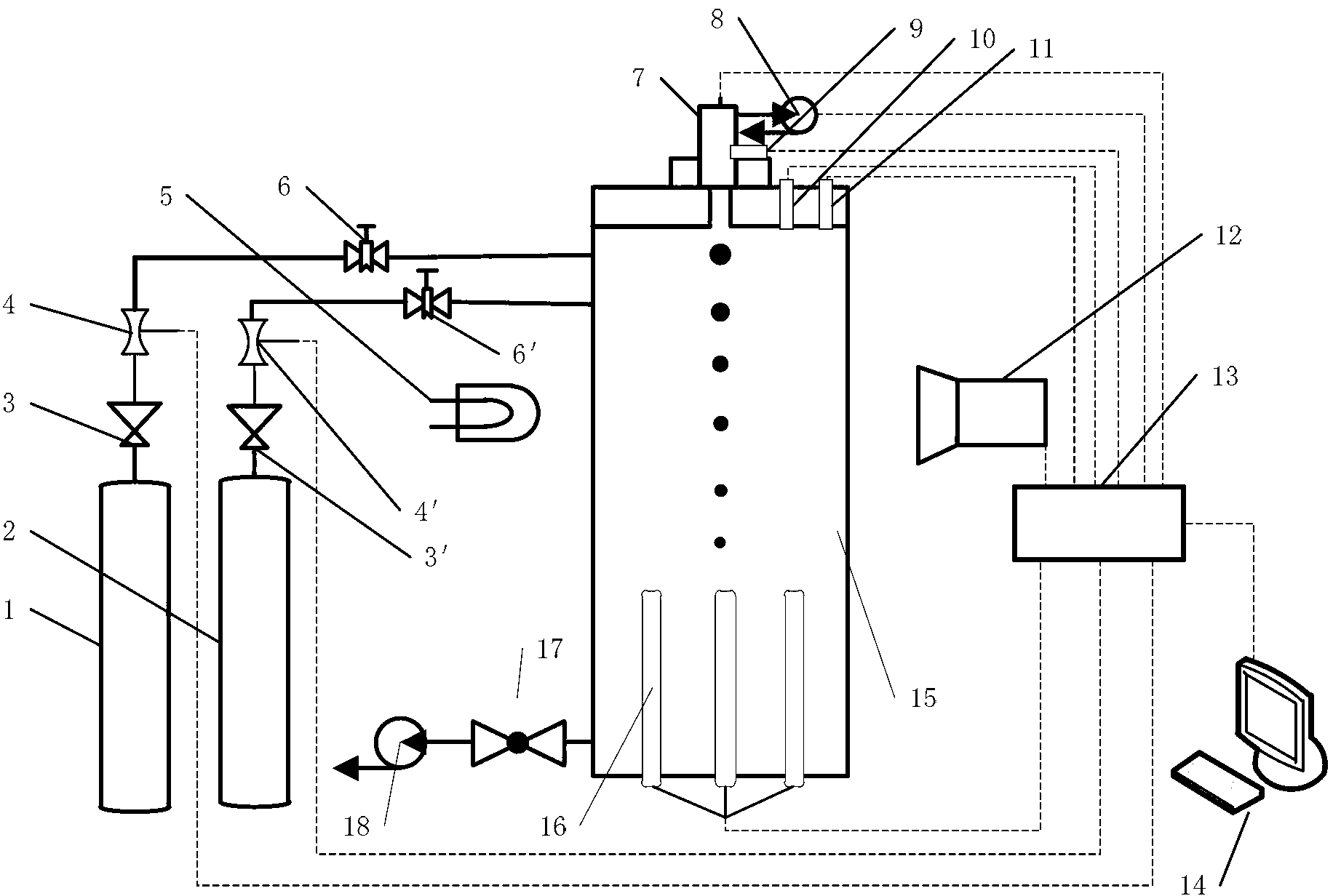

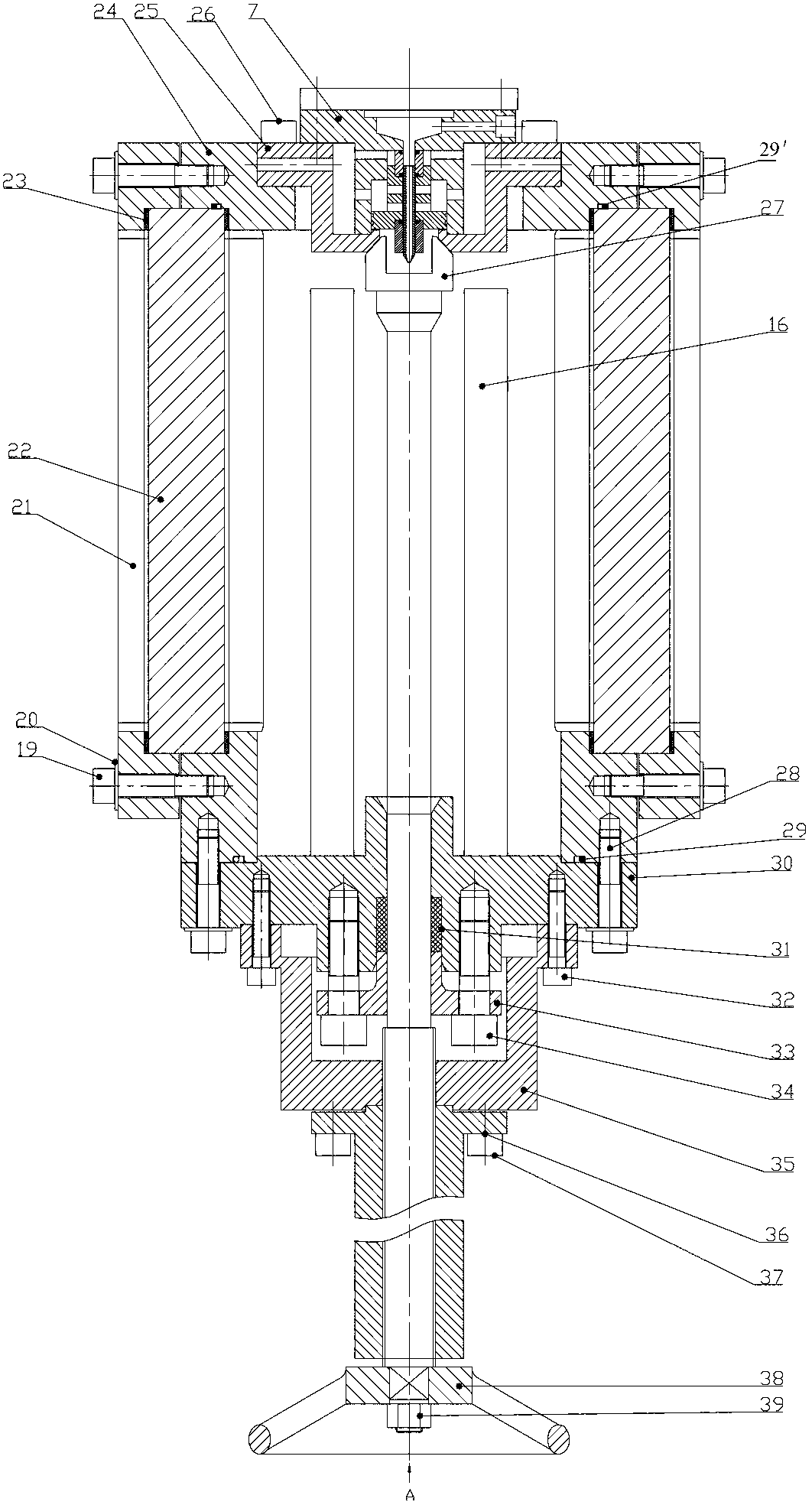

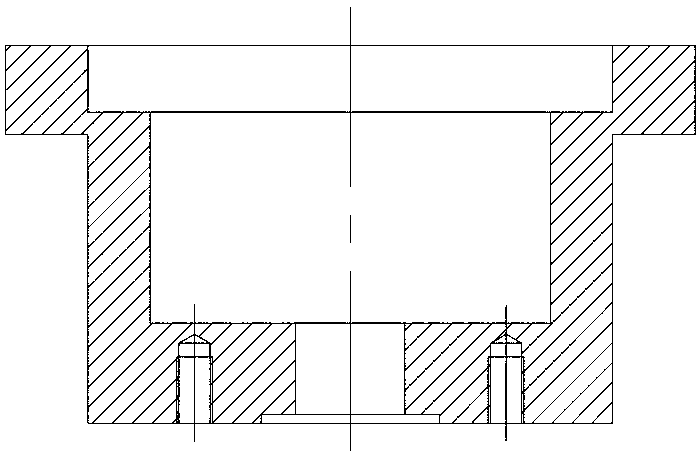

High-temperature and high-pressure single-drop evaporating and burning device

InactiveCN103308662AGuaranteed initial temperatureSolving the Difficulty of Changing Fuel FluidsFuel testingEngineeringThermocouple Wire

The invention provides a high-temperature and high-pressure single-drop evaporating and burning device. The high-temperature and high-pressure single-drop evaporating and burning device comprises a gas supplying device, a burning and evaporating projectile body (15), a single-drop generator (7), a single-drop generator cooling device and a control unit (13), wherein the burning and evaporating projectile body (15) is connected with the gas supplying device; the single-drop generator (7) and the single-drop generator cooling device are positioned at the upper part of the burning and evaporating projectile body (15); the control unit (13) is connected with the burning and evaporating projectile body (15) by a wire; the single-drop generator (7) comprises a piezoelectric piece type sprayer inside; the single-drop generator cooling device comprises a water pump (8) connected with the single-drop generator (7) and a thermocouple wire temperature sensor (9) positioned in the single-drop generator (7). The high-temperature and high-pressure single-drop evaporating and burning device provided by the invention has the advantage that the research for micro-drop evaporating and burning characteristics can be realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com