Strength determination method and device for reacted blast furnace coke

A technology of post-reaction strength and measurement method, applied in measurement devices, chemical method analysis, fuel oil testing, etc., can solve the problems of strength enhancement, excessive weight loss in high-reactivity coke reaction, and different reaction temperatures, so as to solve the problem of overreaction , the effect of resolving incomplete responses and resolving contradictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

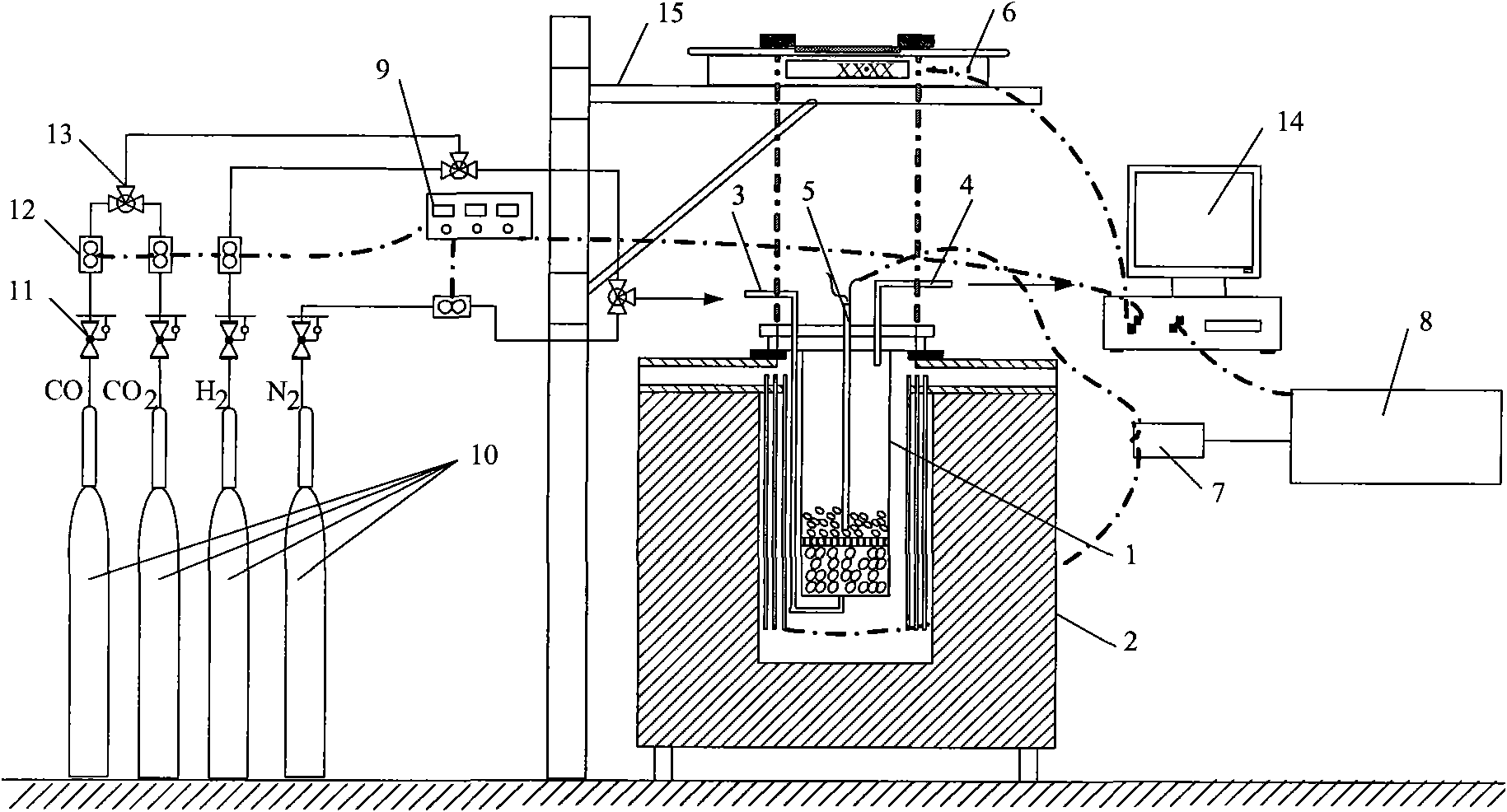

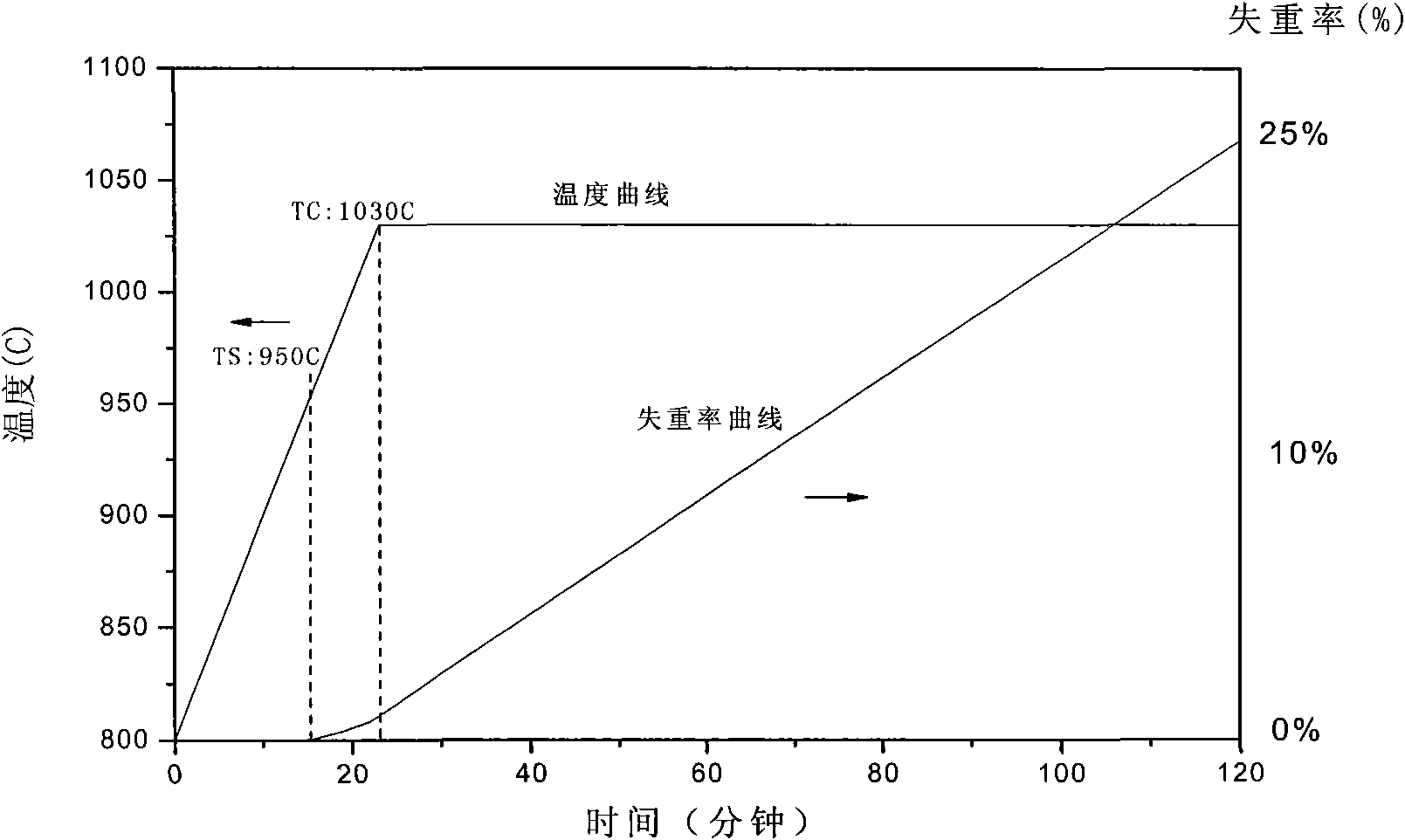

Method used

Image

Examples

Embodiment 1

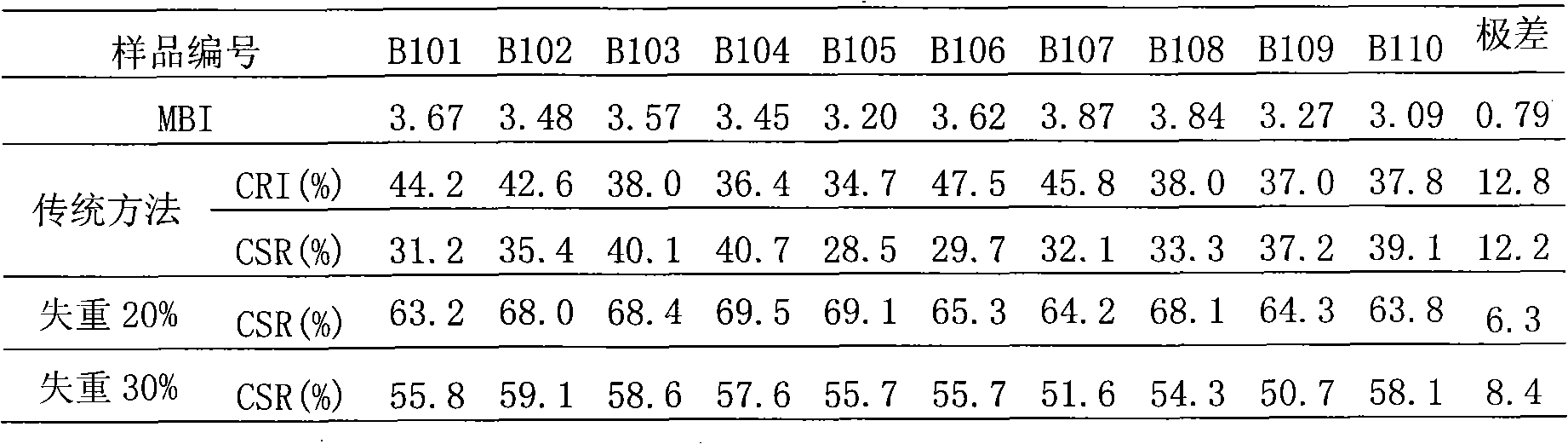

[0054] The present invention has chosen the coke of A enterprise and B enterprise to carry out the contrast of new and old thermal performance evaluation method, and experimental result is as shown in table 1:

[0055] Table 1 Test results of coke constant reaction weight loss and traditional method in enterprises A and B

[0056] Sample serial number

[0057] No matter whether the coke used in the production of A company uses the traditional method or the method of the present invention, its thermal strength has reached the production standard; the raw coke coal used in the production of B company is Aiweiergou coal, and the special catalytic index of its ash component is particularly high. Intensity is only 23 as unqualified coke according to the traditional requirements, and the thermal intensity evaluated by the method of the present invention is 65, which is very different from the thermal intensity 23 of the traditional method. 20% The difference is small. Fac...

Embodiment 2

[0059] Then select 10 kinds of cokes for small blast furnaces, and carry out three tests of traditional method, 20% constant weight loss and 30% constant weight loss of the present invention respectively. Table 2 shows the results of the three tests. The MBI of the selected 10 cokes is very high and differs greatly from each other, and the traditional thermal properties are extremely poor and differ greatly from each other. The post-reaction strength of constant weight loss is all improved than the post-reaction strength of traditional method, and the post-reaction strength of 20% constant weight loss is all greater than 63%, and the post-reaction strength of 30% constant weight loss is also all greater than 51%, and the mutual difference narrows, and 10 The strength difference law of different cokes after reaction is not consistent with the traditional method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com