Patents

Literature

126results about How to "Feeding safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microbial fermented feed and production process thereof

InactiveCN103156057APromote digestion and absorptionImprove digestion and absorption rateAnimal feeding stuffBiotechnologyMicroorganism

The invention relates to the technical field of feed processing and specifically provides a microbial fermented feed and a production process thereof. The microbial fermented feed is composed of 60% by mass of waste stevia rebaudiana residue, 15% by mass of corn flour, 15% by mass of soybean meal and 10% by mass of liquid strains, wherein the liquid strains comprise lactobacillus fermenti, saccharomyces cerevisiae, bacillus subtilis and clostridium butyricum. According to the invention, a plurality of microbes are utilized and scientifically collocated for fermentation of processing waste of stevia rebaudiana, and the microbial fermented feed with the advantages of low cost, a high nutritional value, fragrant flavor and agreeable taste is produced.

Owner:邝素明

Special straw granule feed for growing and fattening of non-grain type beef cattle

The present invention relates to a special straw granule feed for growing and fattening of non-grain type beef cattle and belongs to the technical field of feed recipes. The feed consists of the following raw material sin ratios: 30-65% of straw powder, 10-40% of distiller's grains, 10-40% of bagasse, 30-65% of potato residues, 5-30% of leeria soyanuka powder, 10-30% of molasses, 2-4% of stone powder, 0.35-0.5% of salt, 0.5-1% of baking soda and 0.5-1% of urea. The special straw granule feed solves the problems that the conventional feed is made from grains as a raw material, uses various additives, is long in fermentation time and high in raw material cost, etc., and is environment-friendly and eco-environmental protective feed which is rich in various natural nutrient contents, free of antibiotics and hormones, and low in price. The feed can also improve body resistance and immunity resistance to diseases of the beef cattle, and is high in digestibility, fast in growth of the beef cattle, high in feed rewards, and suitable for selection and feeding in beef cattle culture farms of different sizes.

Owner:吴聚定

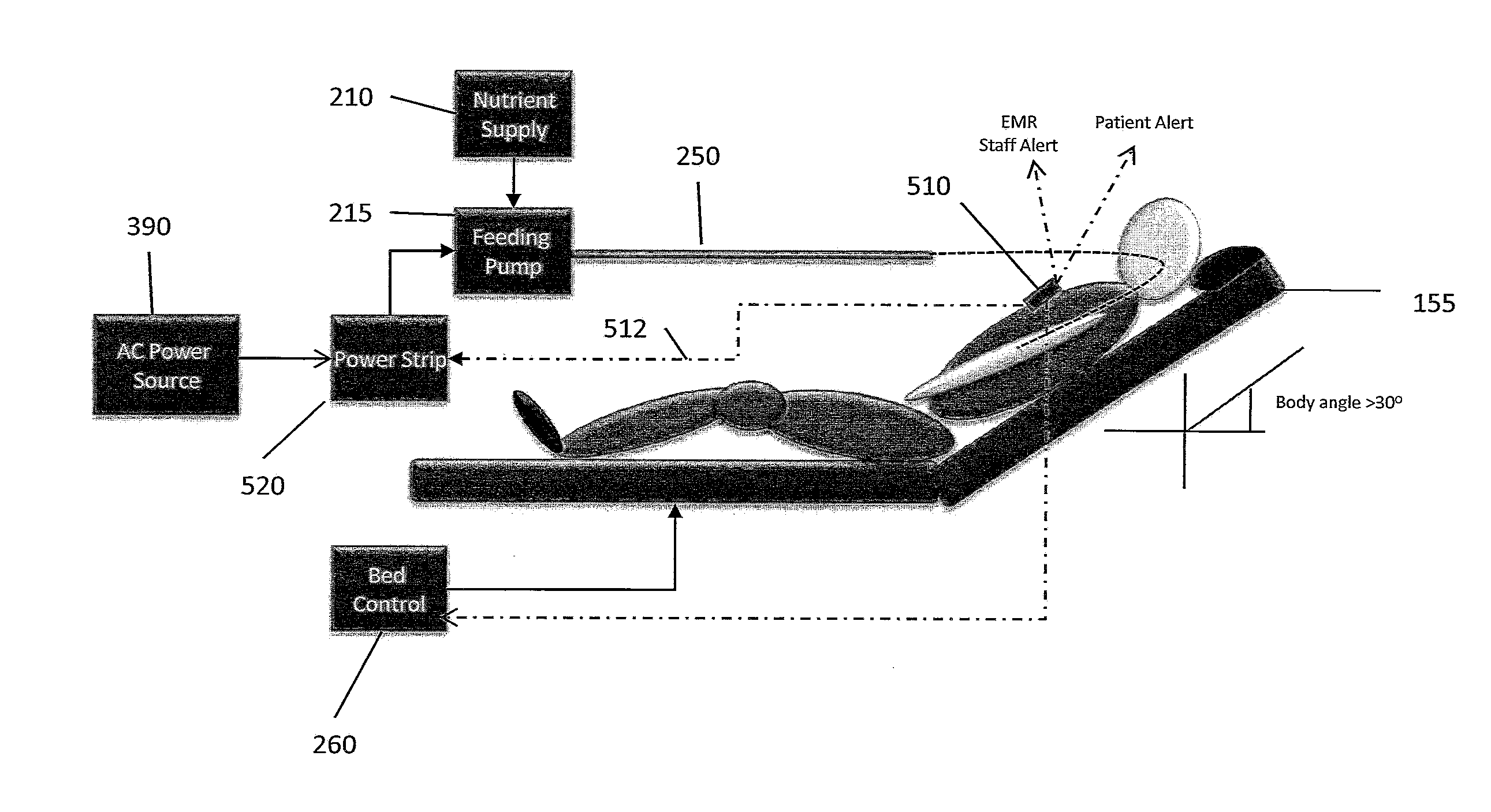

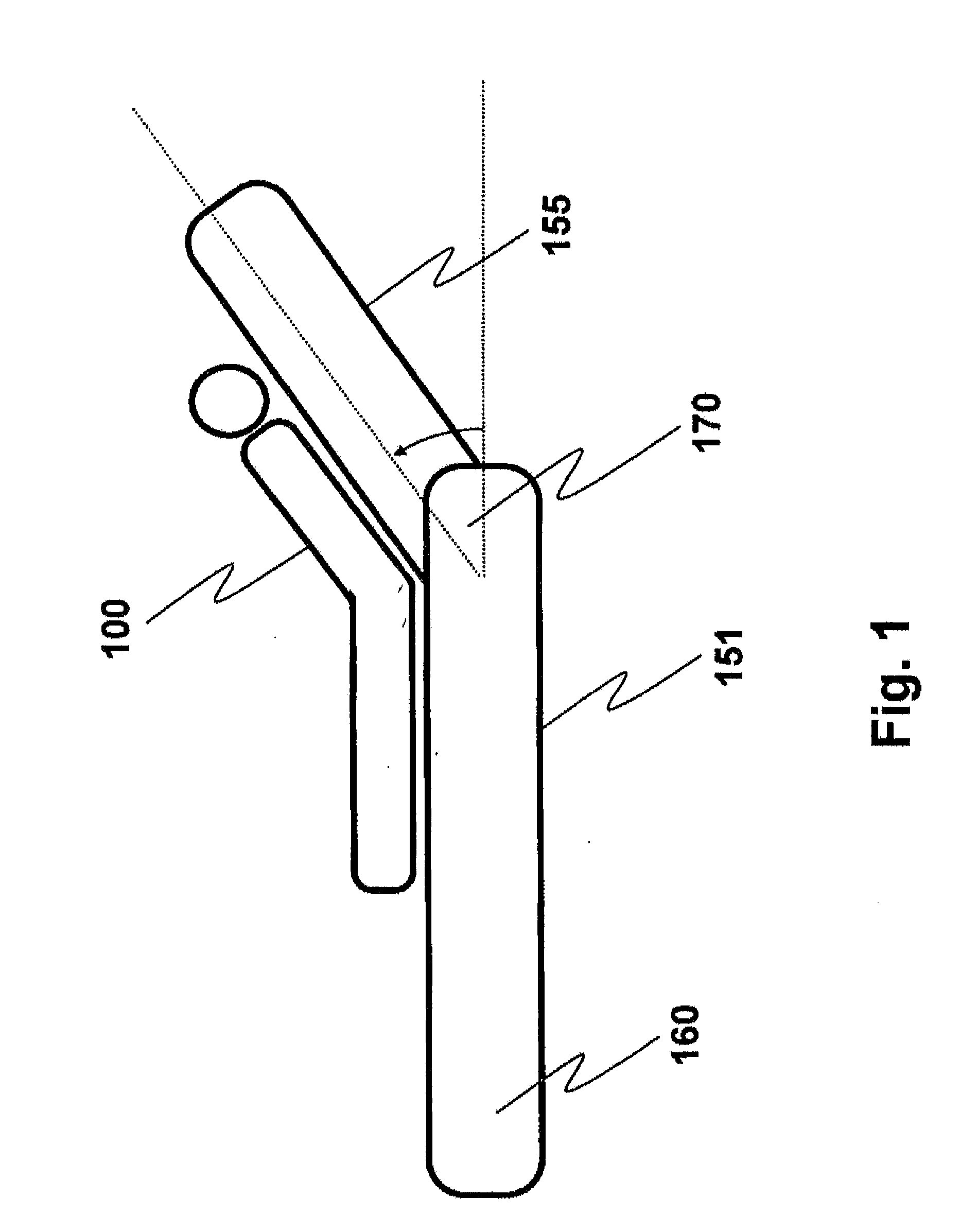

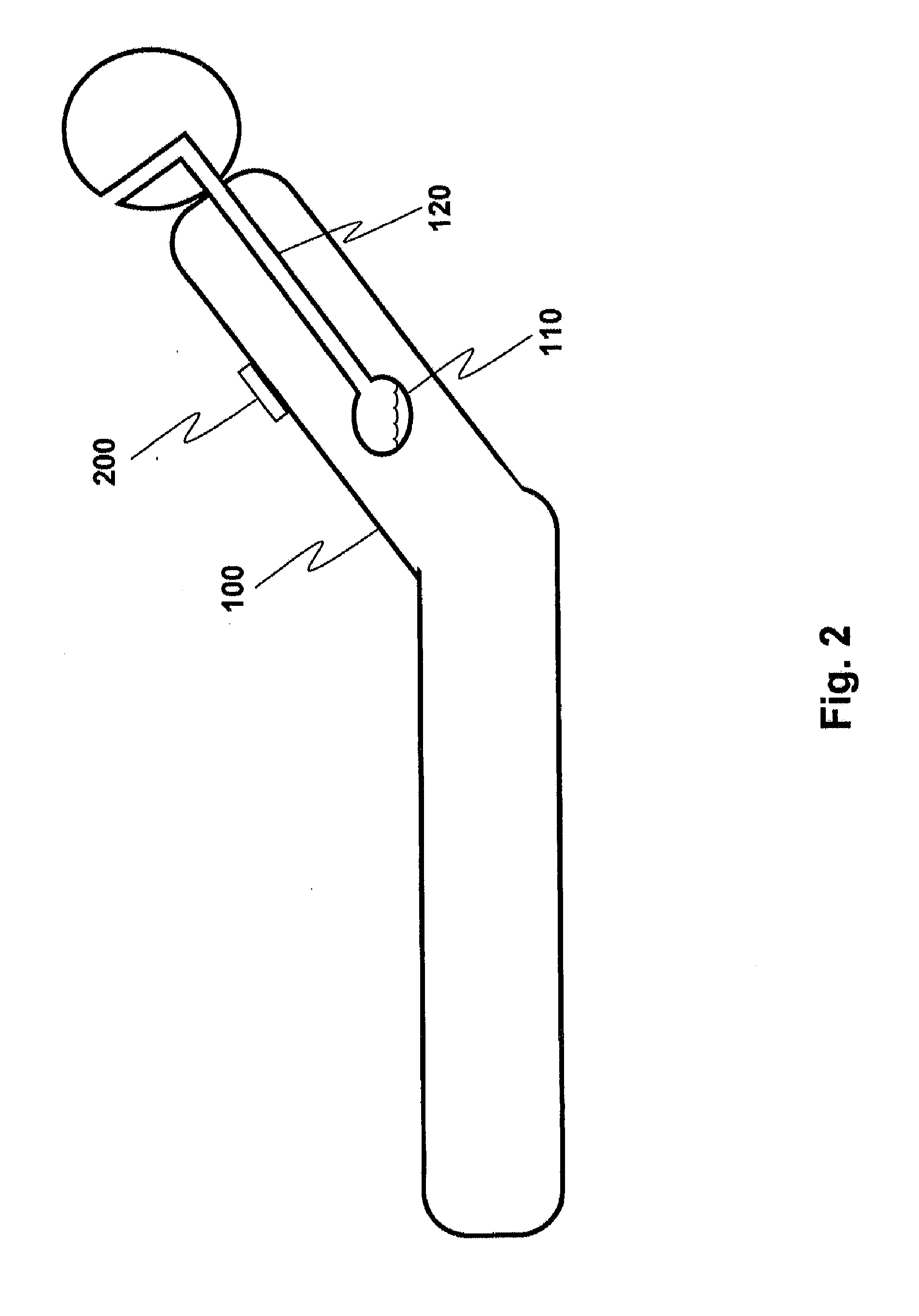

Retrofittable aspiration prevention mechanism for patients

InactiveUS20120191038A1Reduce and eliminate problem of aspirationReduce eliminateInertial sensorsMedical devicesControl powerFeeding tube

A device is employed that can be retrofit onto existing feed pumps to remediate the problem of fluid aspiration in patients being fed through a feeding tube from the pump. In one embodiment the feeding pump is plugged into the device which is plugged into a power outlet. A patient angle sensor triggers power cutoff to the pump and stoppage of fluid flow. The angle sensor and operating program may be part of a smart phone. Power to the pump may be shut off due to a Bluetooth signal from the smart phone to a Bluetooth controlled power strip into which the pump is plugged to receive power.

Owner:GERBER ALLEN

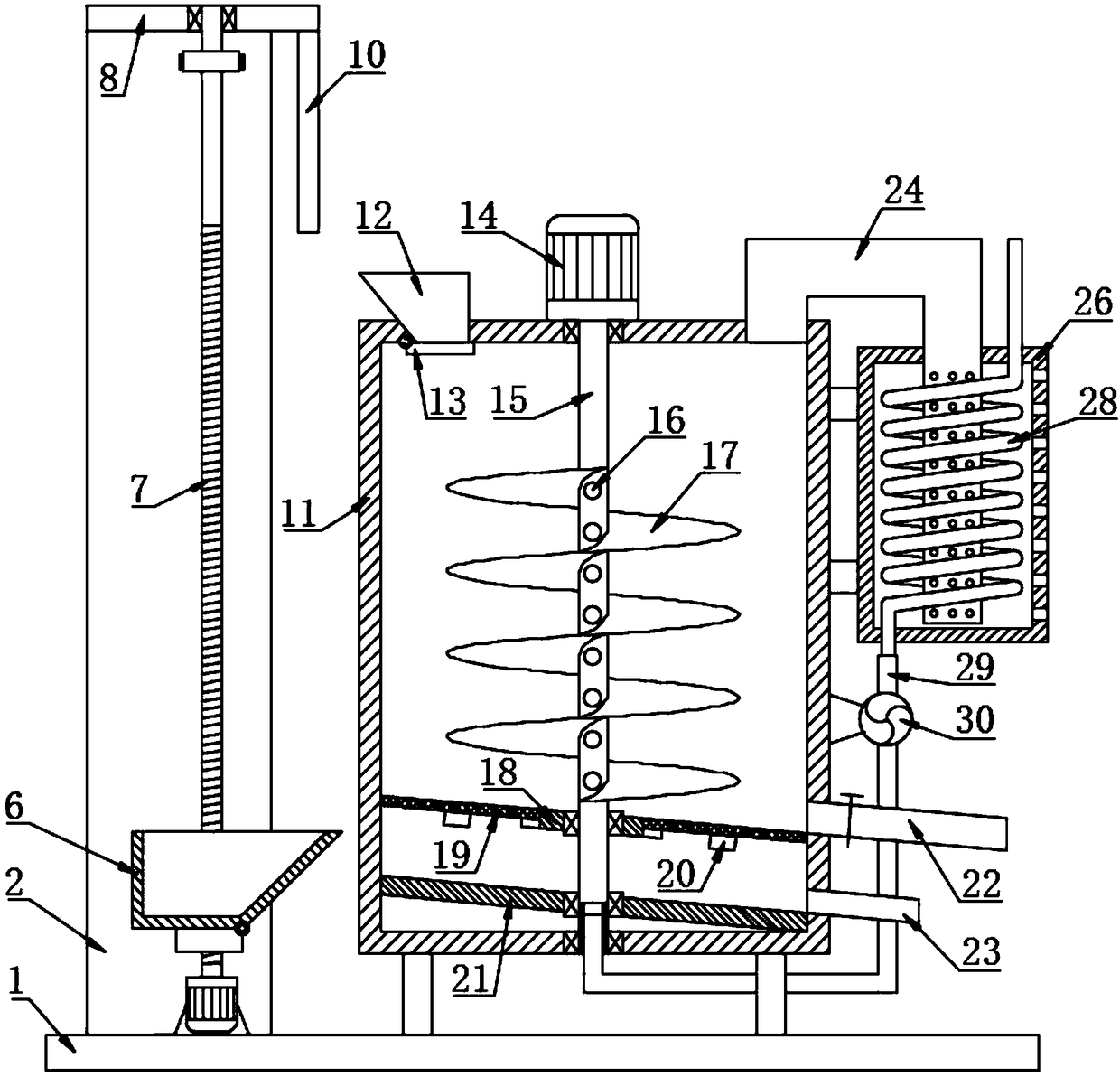

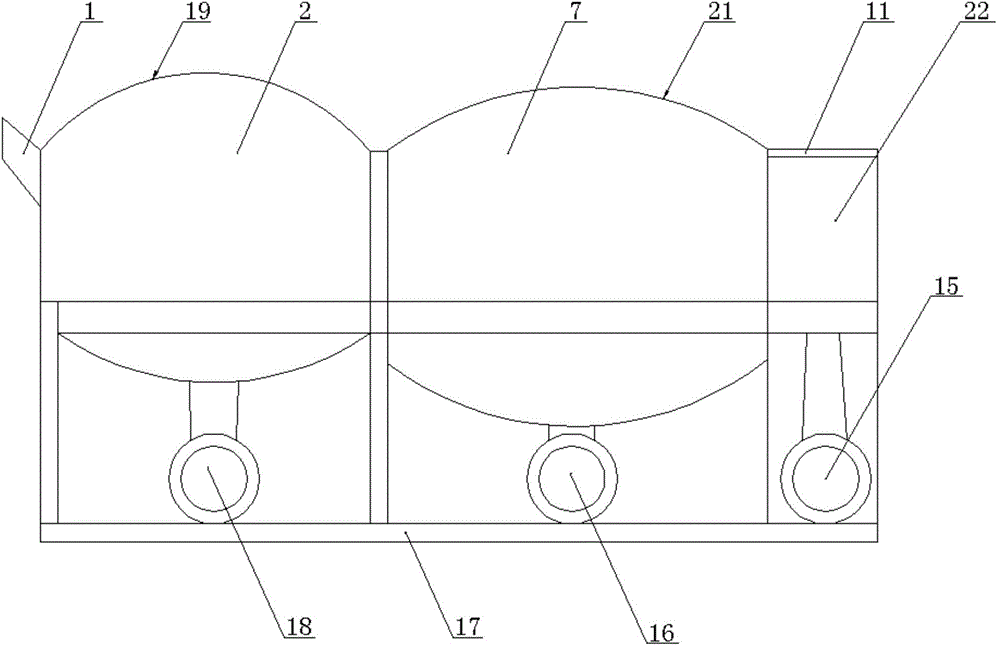

Self-feeding type energy-saving grain drying device

InactiveCN108800832AEvenly heatedImprove drying effectFood processingDrying gas arrangementsSpiral bladePulp and paper industry

The invention discloses a self-feeding type energy-saving grain drying device comprising a base. A drying barrel is fixed to the top of the base through a support, a rotating tube is arranged in the center in the drying barrel, and the upper end and the lower end of the rotating tube are rotationally connected with the top wall and the bottom wall of the drying barrel correspondingly. A second speed reducing motor is fixedly arranged at the center of the top of the drying barrel, a motor shaft at the bottom end of the second speed reducing motor is fixedly connected with the top end of the rotating tube, and spiral blades are fixedly mounted at the tube section, located above a screen plate, of the rotating tube. A plurality of one-way air outlet holes are uniformly formed in the tube section, between the spiral blades, of the rotating tube. A hot air blower is fixedly arranged at the right part of the side wall of the drying barrel, the air inlet end and the air outlet end of the hotair blower are connected with hot air tubes correspondingly, and the air outlet end of each hot air tube is connected into the rotating tube. The hot air blower is used for introducing hot air into the rotating tube, the hot air is discharged from the one-way air outlet holes to dry grains, and the heat is uniformly distributed; and the spiral blades are driven by the rotating tube to rotate to drive the grains to roll, so that the grains are heated more uniformly when dried, and the drying effect is good.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

Woody feed fermenting and enzymolyzing prepn process

InactiveCN1739373AImprove absorption rateGood flexibilityFood processingAnimal feeding stuffDigestionEnzyme

The present invention relates to feed preparing technology, and is especially woody feed fermenting and enzymolyzing preparation process. The present invention features that intermediate peashrub is crushed and mixed with concentrated material in 20-25 wt% of intermediate peashrub, activated compound enzyme in 3-4 wt% and Shengtaibao or EM bacterial preparation in 0.1-0.2 wt%, and the mixture is sealed and fermented to reach pH 4.0-5.0 to obtain the woody feed. The woody feed has the advantages of rich nutrients, easy digestion, feeding safety, low cost, etc.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

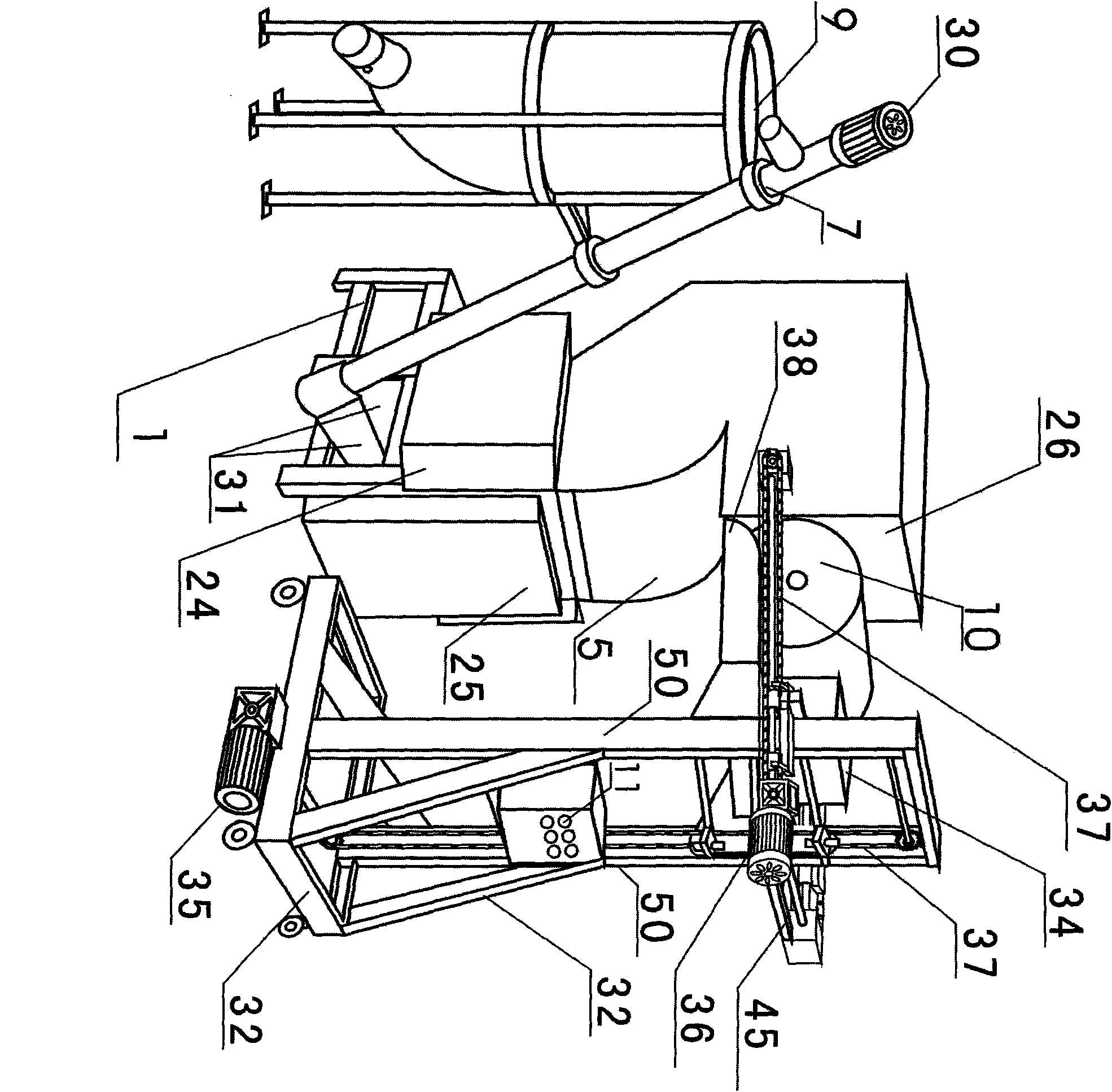

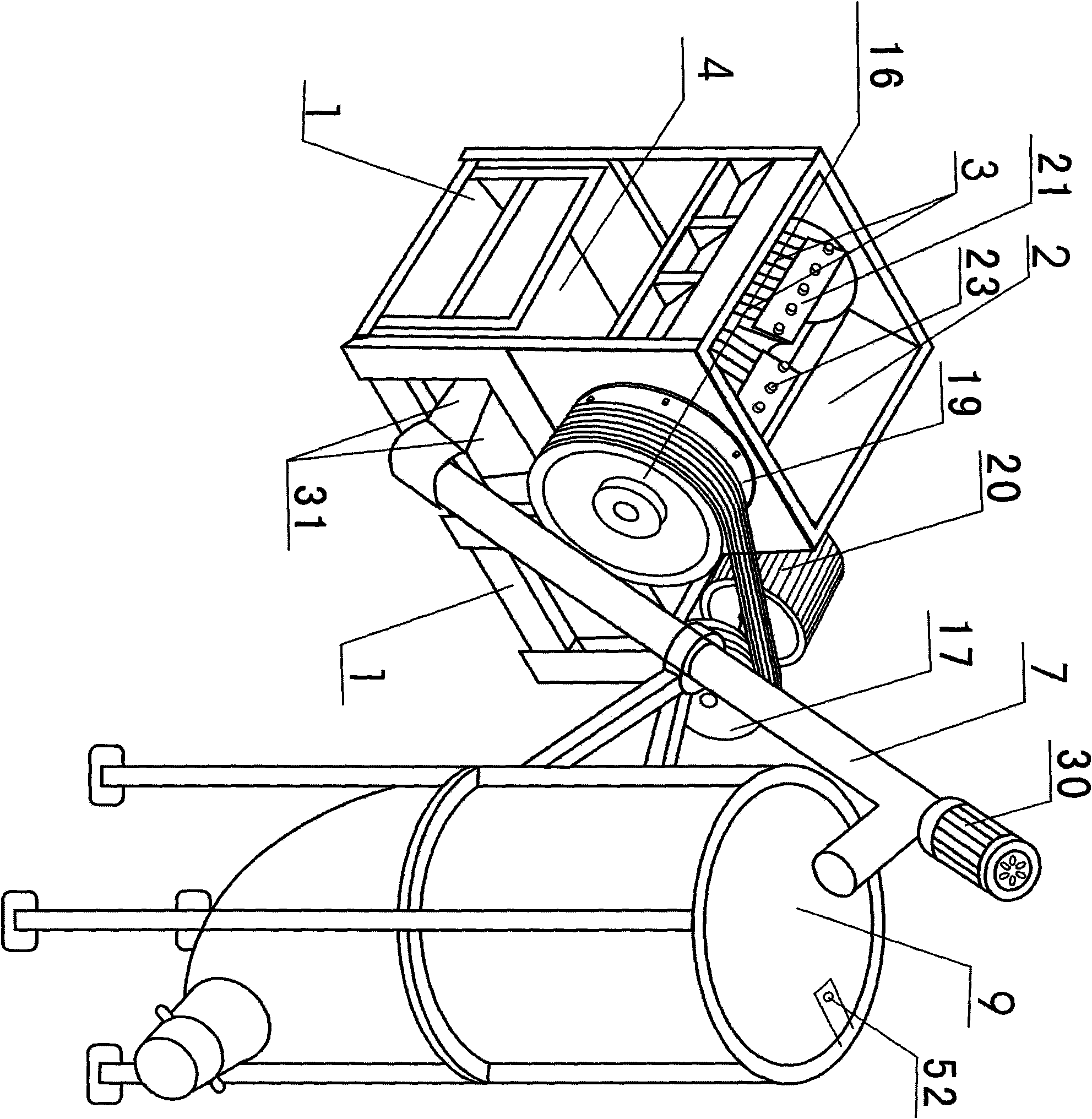

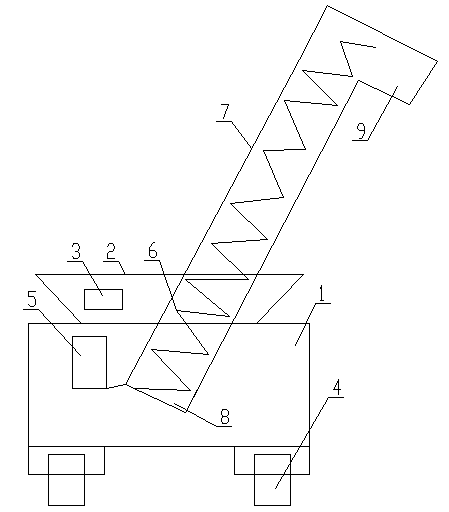

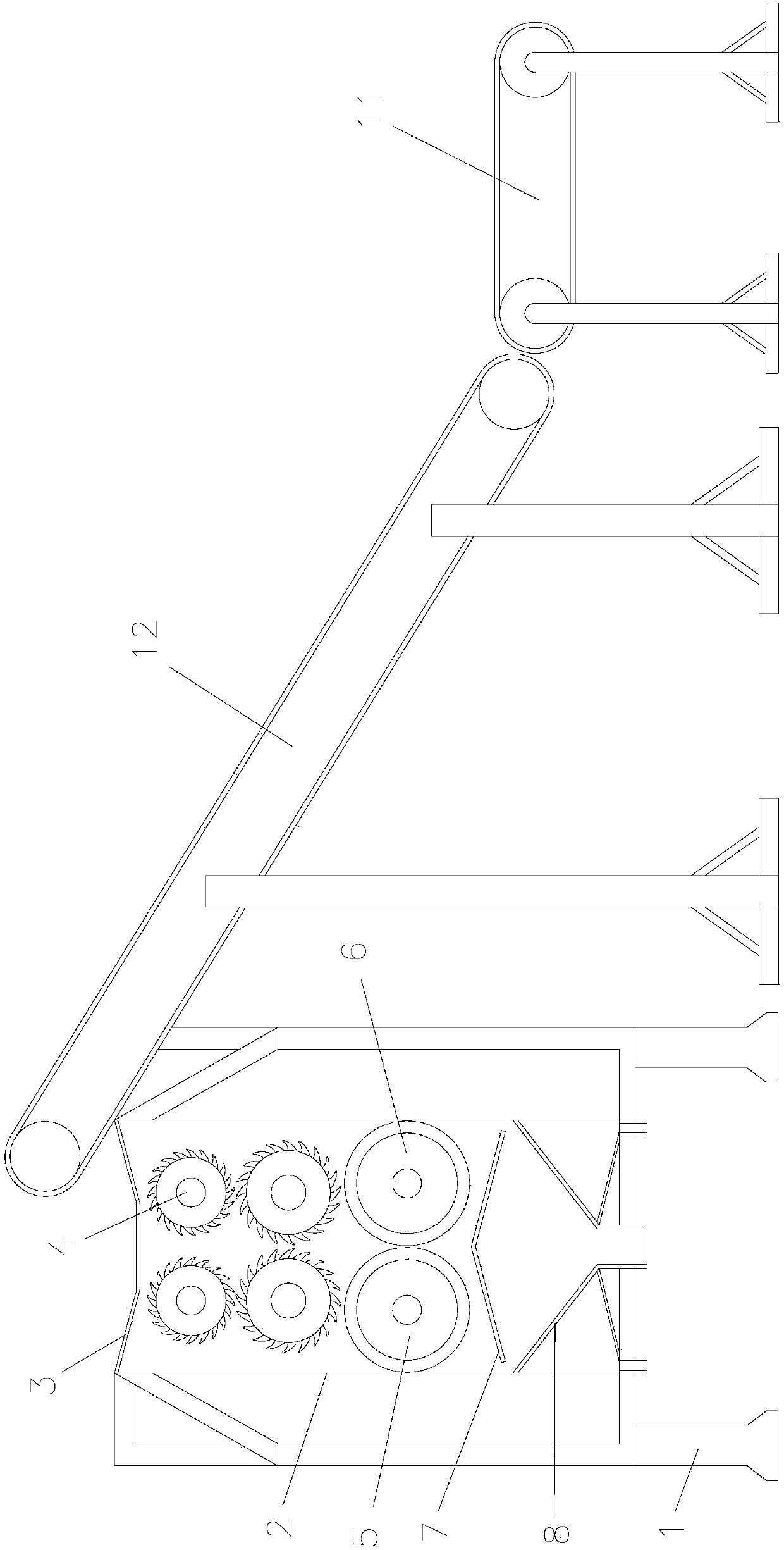

Automatic high-efficiency plastic crusher

ActiveCN101987485AFeeding safetyReduce deliveryPlastic recyclingGrain treatmentsResource savingEngineering

The invention relates to a plastic processing device, in particular to an automatic high-efficiency plastic crusher of coiled corners remained after a container is produced through thermal formation. The automatic high-efficiency plastic crusher is characterized by comprising a crusher main body base frame, a crusher crushing chamber, a crusher cover, a crusher main body transmission device, a blanking hopper, a screen device, a feeding helical rod, a feeding lifting device, a storage barrel and a distribution box, wherein the crusher crushing chamber is arranged above the front of the crusher main body base frame, the crusher cover is arranged above the crushing chamber, a feeding hole is arranged above the cover, the screen device is arranged below a crushing tool apron in the crusher crushing chamber, and the blanking hopper is arranged in the base, i.e. below the screen device. A fastening main transmission motor is arranged above the rear of the crusher main body base frame. The invention has the advantages of high efficiency, automation, environment protection, sanitation, safety and reliability, convenience and rapidness, time and labor saving, resource saving, attractive appearance and durability.

Owner:广东祺兴包装实业有限公司

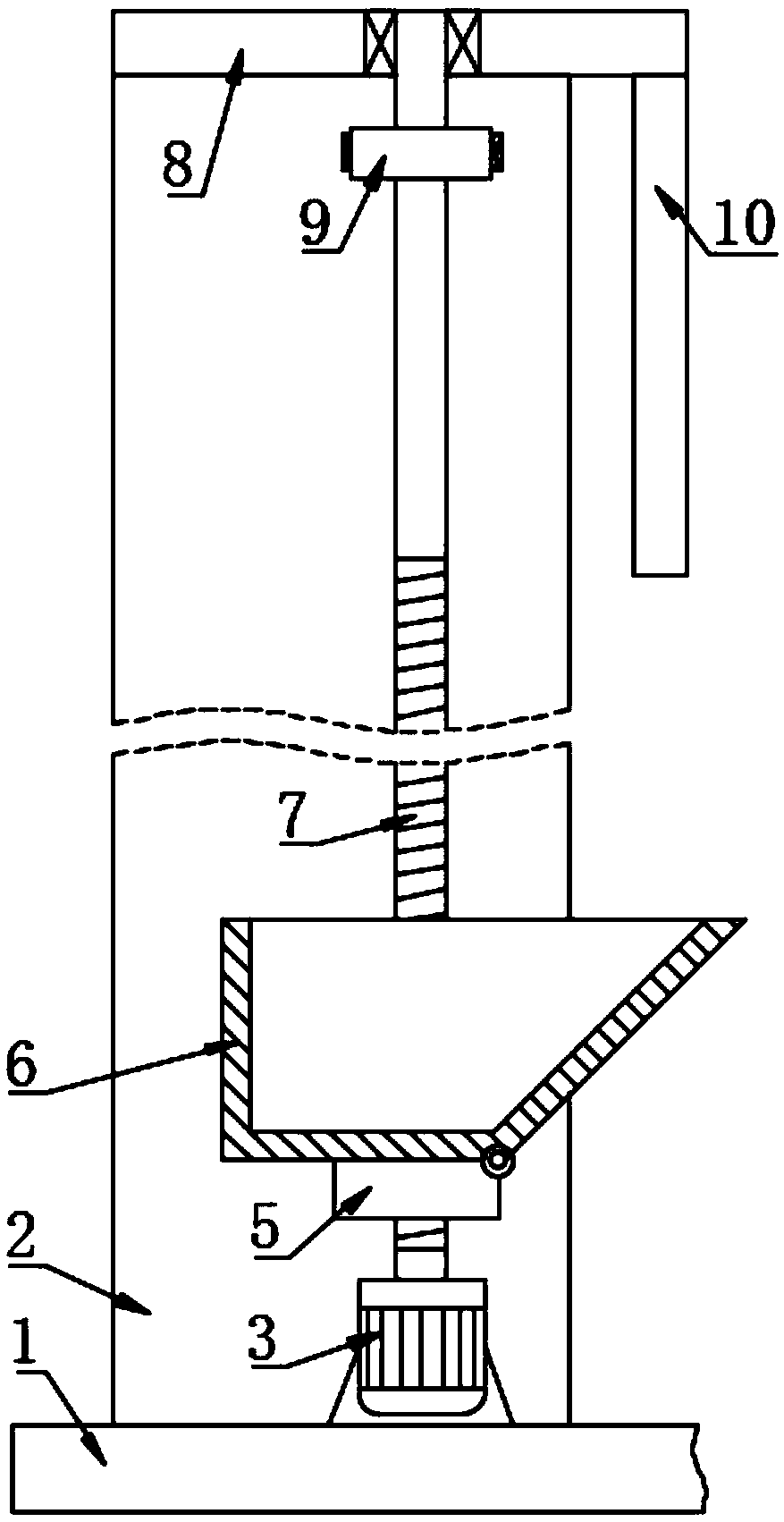

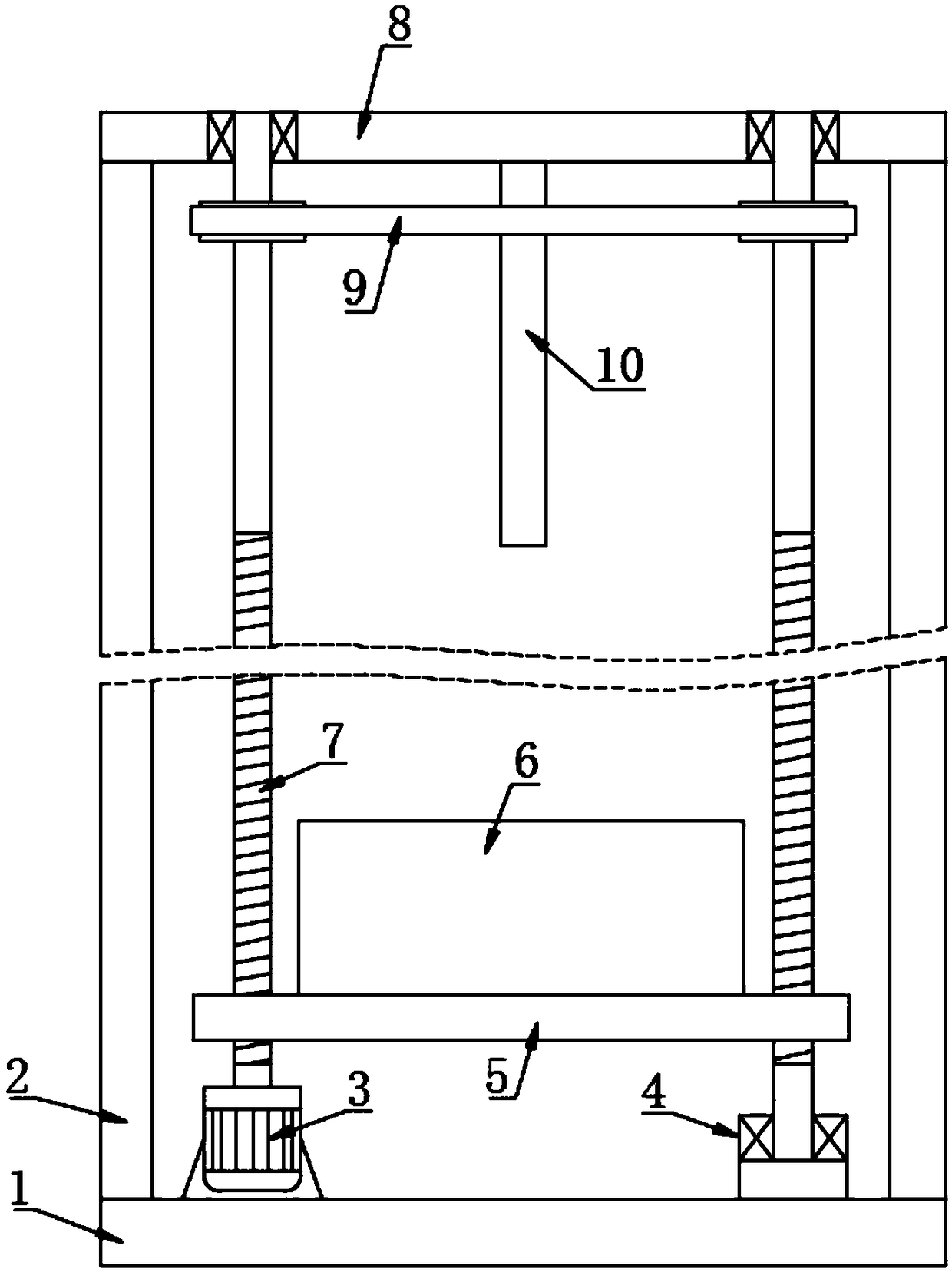

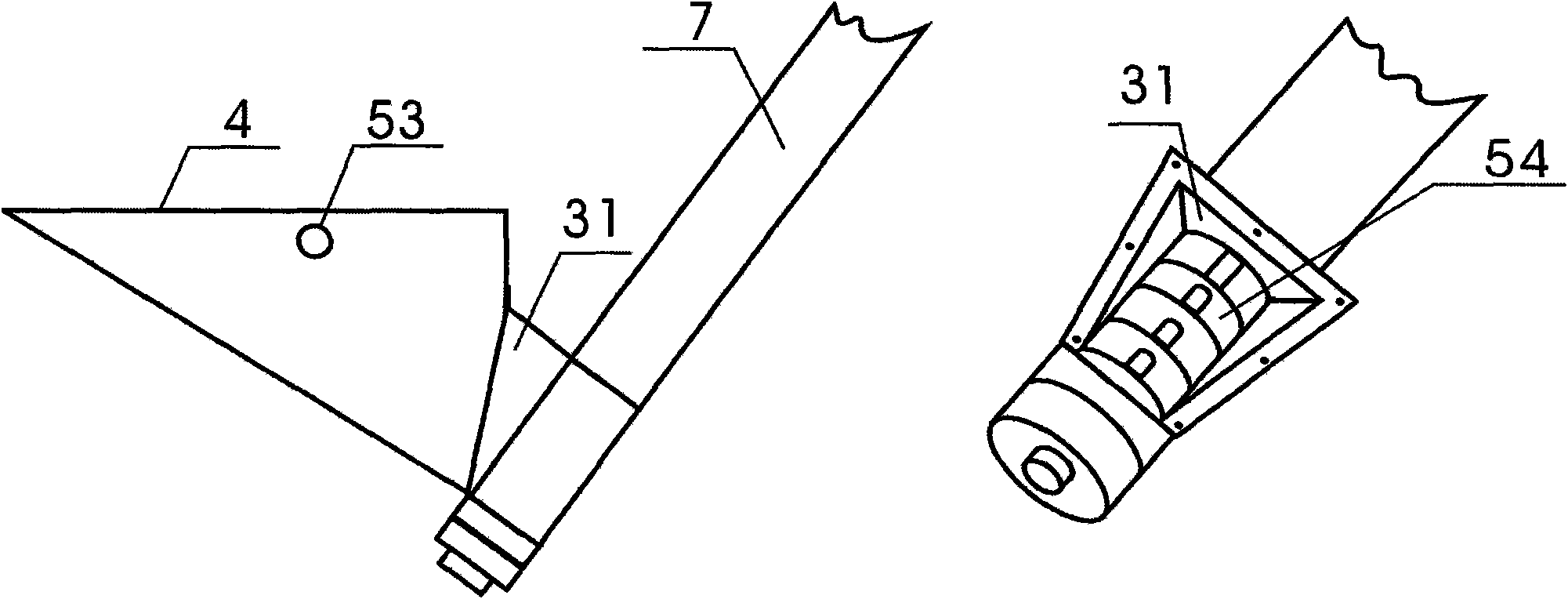

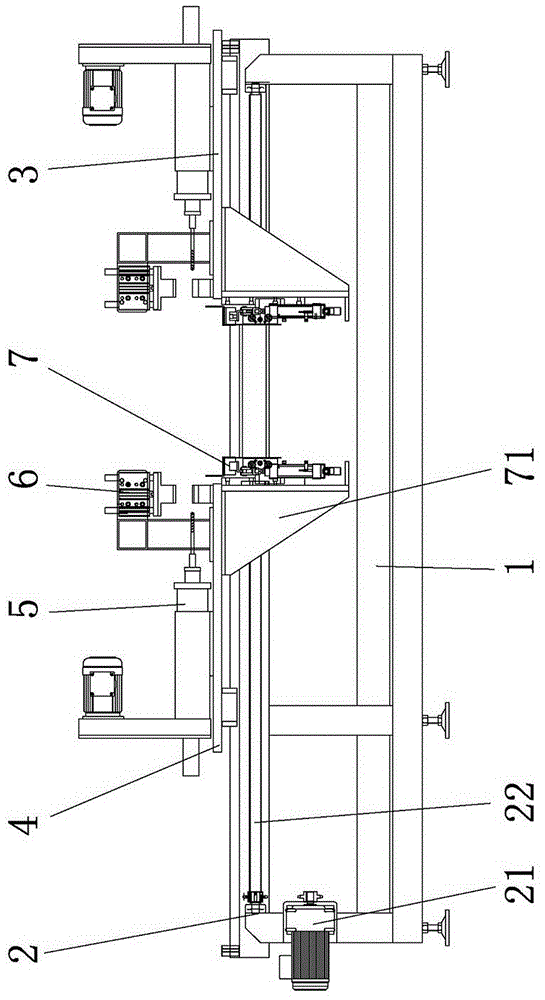

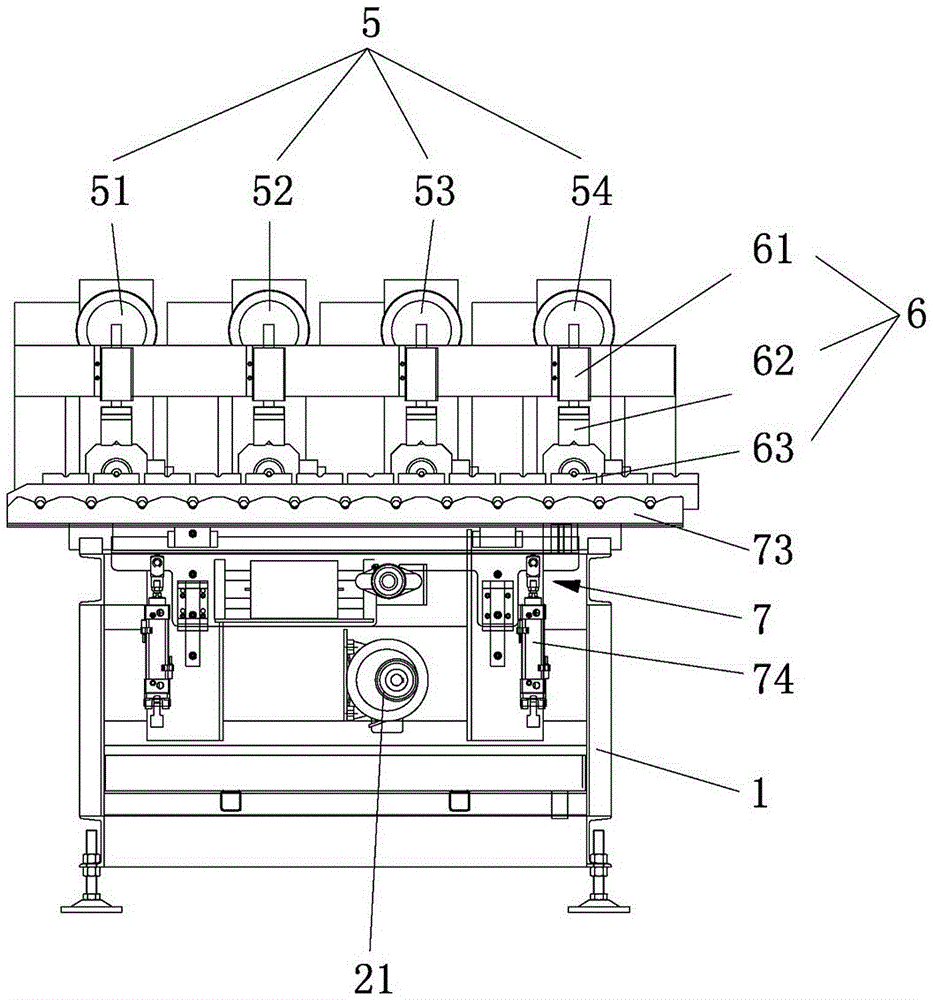

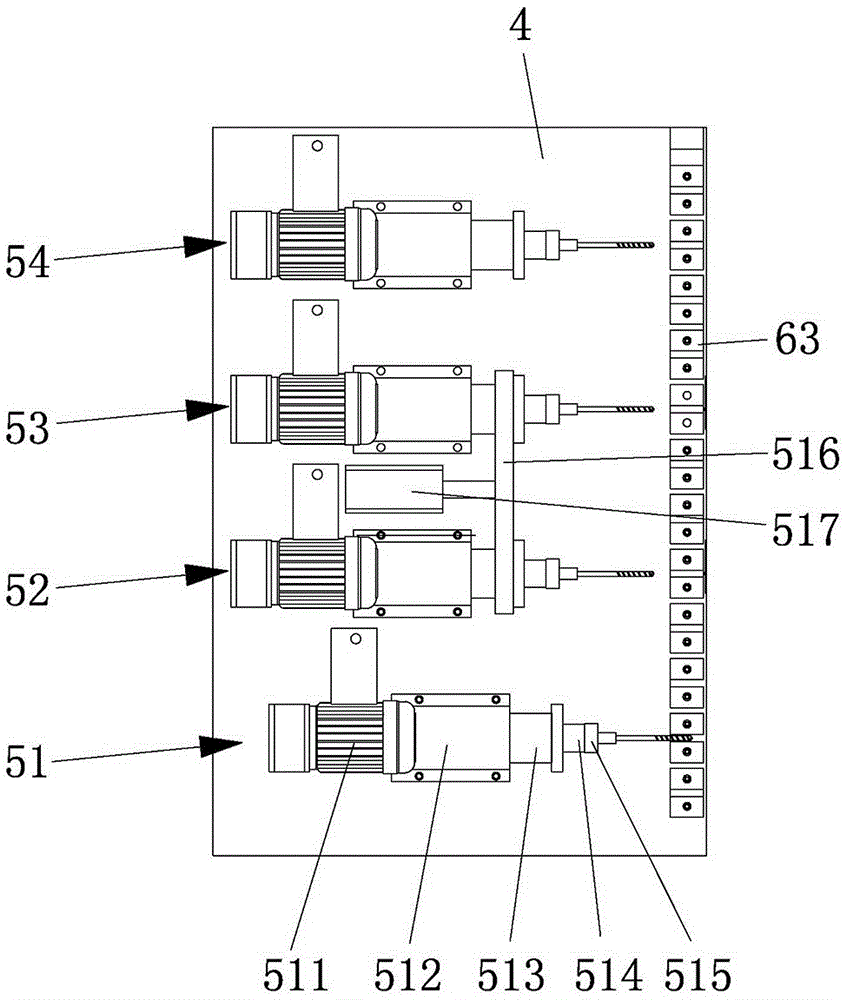

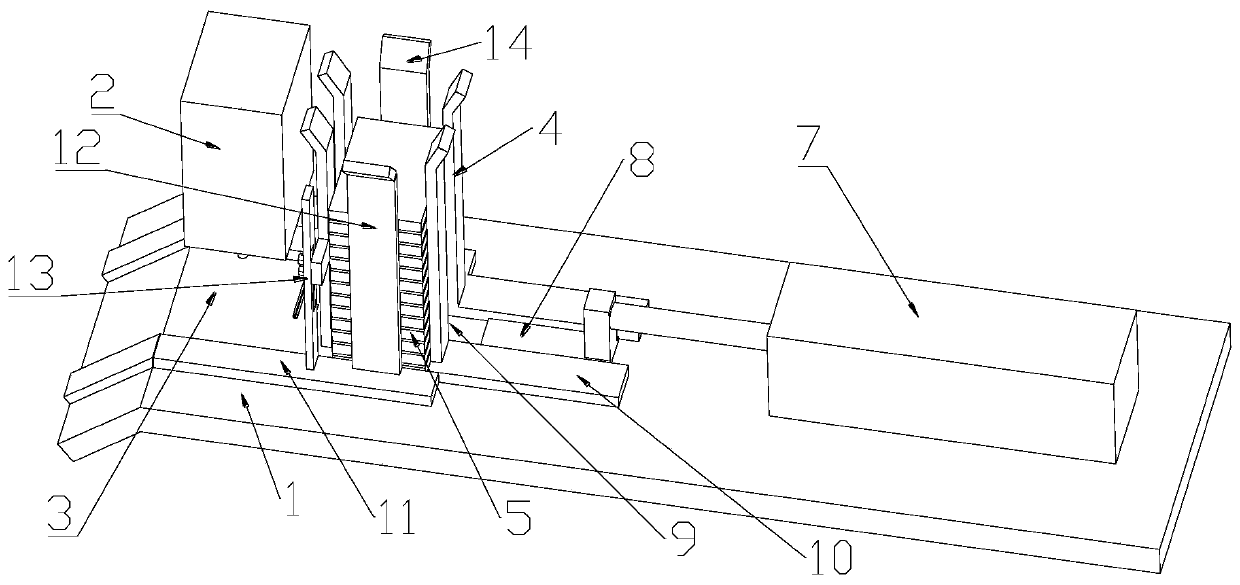

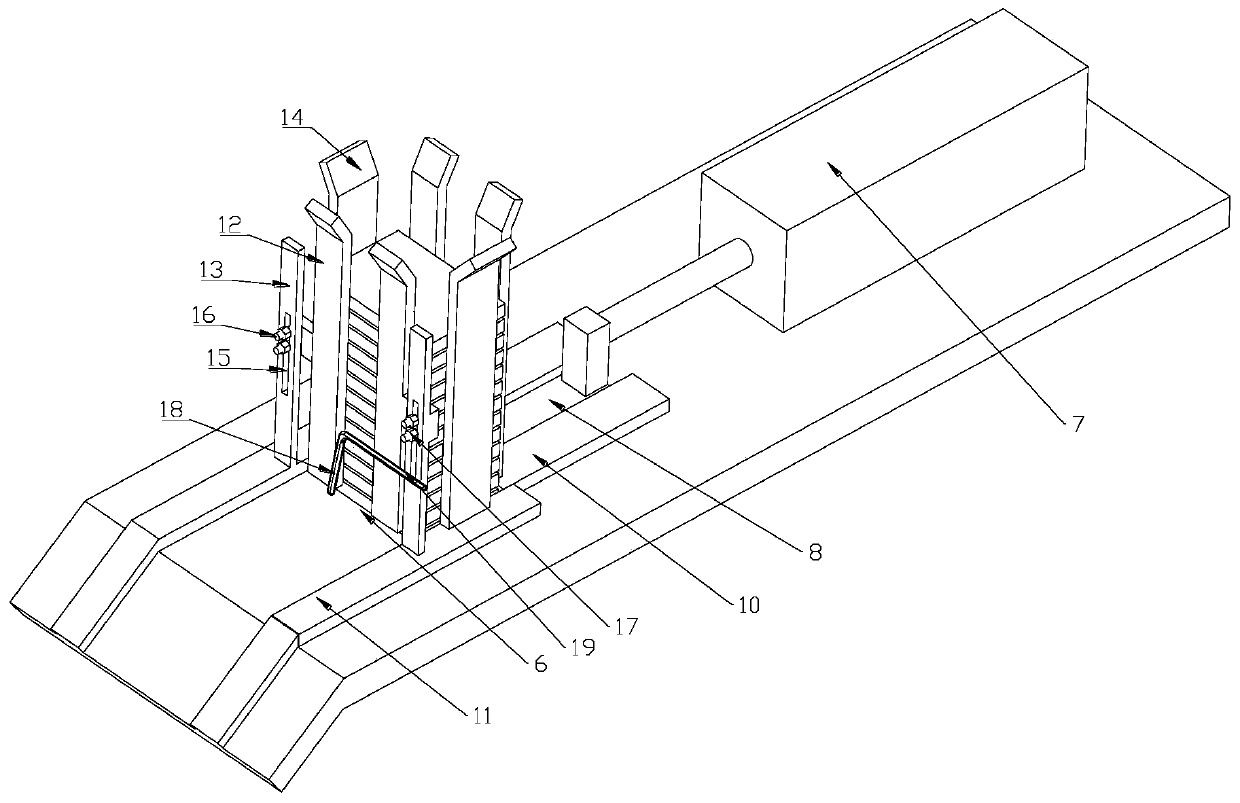

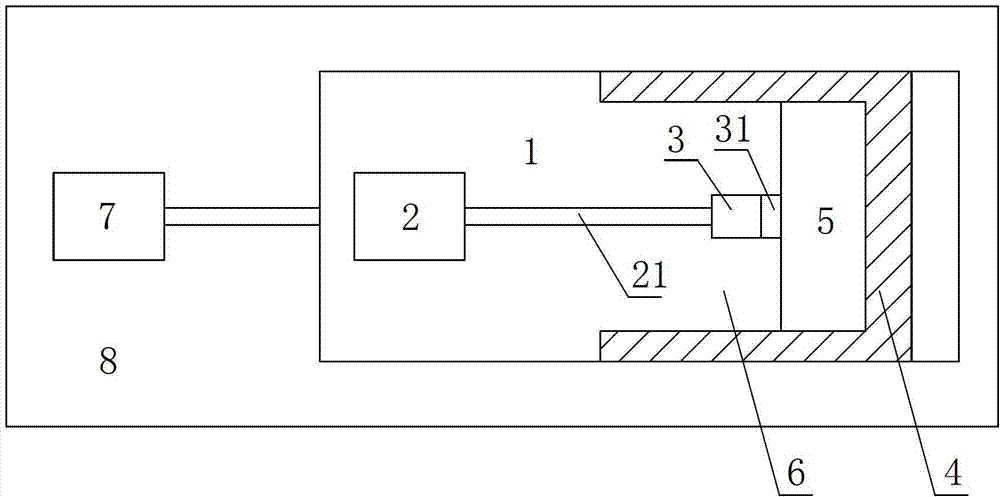

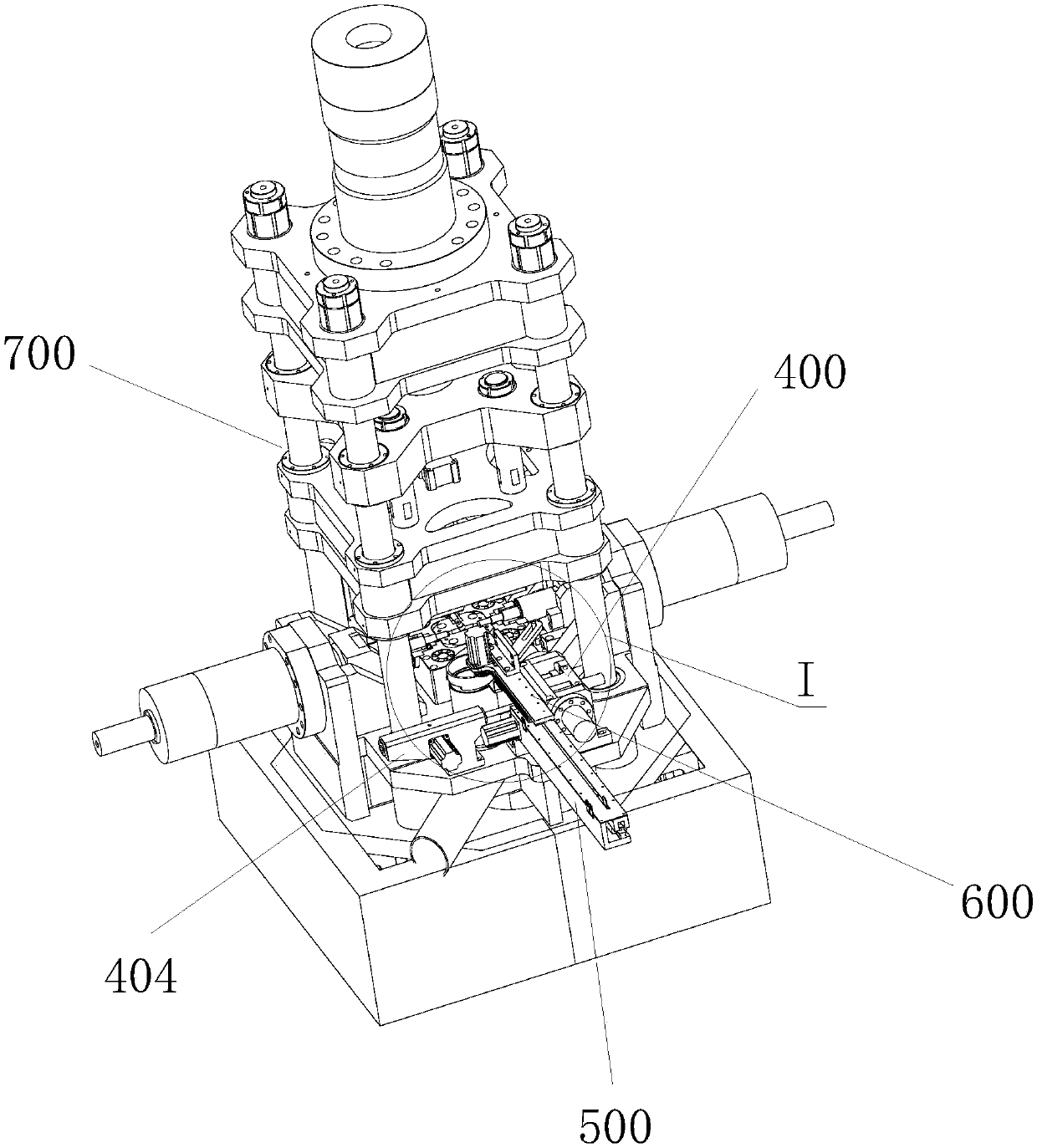

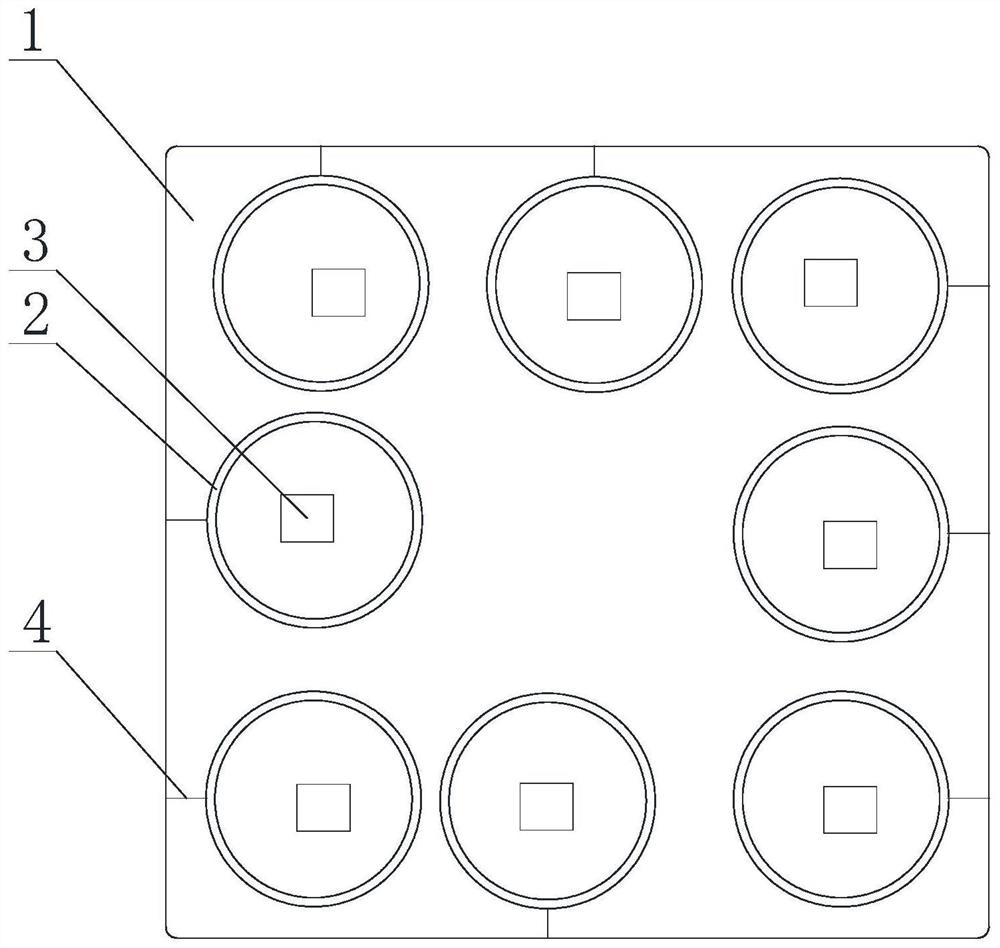

Automatic boring tapping all-in-one machine

ActiveCN106736560APrecise positioningHigh degree of automationOther manufacturing equipments/toolsEngineeringMachining

The invention relates to the technical field of automatic machining equipment, in particular to an automatic boring tapping all-in-one machine. The automatic boring tapping all-in-one machine includes a rack, a fixed workbench, a movable workbench, a driving device, and two boring tapping device; one boring tapping device is arranged on the fixe workbench, and the other boring tapping device is arranged on the movable workbench and can move with the movable workbench; fixing devices and circulating feeding devices are arranged between the two boring tapping devices, the circulating feeding devices can transfer a work piece to a boring working station, and can transfer the bored work piece to a tapping working station from the boring working station. The automatic boring tapping all-in-one machine can achieve central hole drilling, boring, tapping and chamfering at the same time, can achieve synchronous machining at two ends, is high in automation level, is simple to operate, can greatly save human resources, can greatly improve the production efficiency, is safe and reliable in feeding, is accurate in work piece positioning, and can avoid inaccurate work piece positioning due to accumulated errors of stepping feeding.

Owner:HUZHOU JIUTONG LOGISTIC MACHINERY

Sheet iron feeding device of punch

PendingCN110899471AFeeding safetyPrecise feedingMetal-working feeding devicesCleaning using gasesStructural engineeringPunching

The invention discloses a sheet iron feeding device of a punch. The punch comprises a machine table and a punch head arranged at the upper portion of the machine table, and a pressing station is arranged below the punch head; the feeding device comprises a material groove formed vertically, sheet iron is stacked from the bottom to the top in the material groove in sequence, the size of the sheet iron is matched the size of the cross section of the material groove, a sheet iron outlet is formed in the side, close to the punching station, of the bottom of the material groove, and the height of the sheet iron outlet is matched with the thickness of single sheet iron; and a cylinder is mounted on the machine table, a push plate is fixed on the telescopic rod of the cylinder, an opening is formed in the side, opposite to the sheet iron outlet, of the bottom of the material groove, the push plate is capable of being inserted into the material groove from the opening and opposite to the lowest piece of the sheet iron in the material groove, and the thickness of the push plate is no greater than that of the sheet iron. According to the sheet iron feeding device of the punch, sequence feeding of the sheet iron is achieved, a worker does not need to extend the hands under the punch, sheet iron feeding is safe, accurate and fast, and the efficiency of the sheet iron punching processing isimproved.

Owner:平湖市喜峰达金属制品有限公司

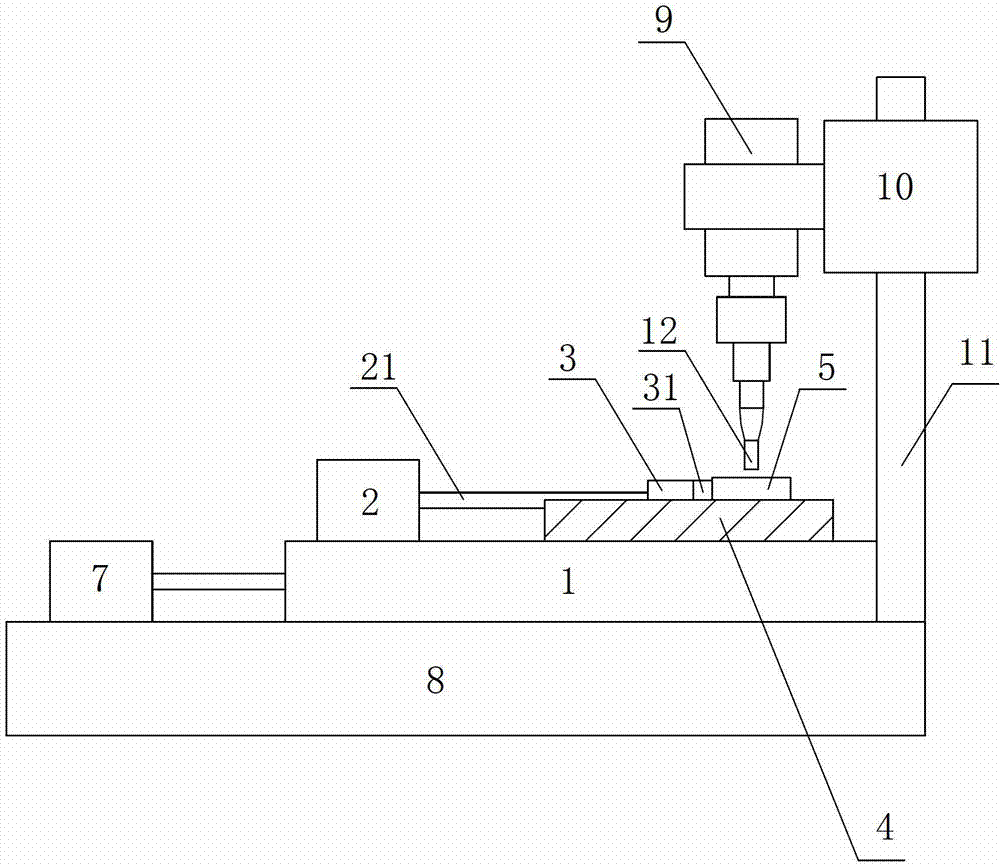

Drilling device

InactiveCN102773511AImprove processing efficiencySafe loading and unloading processPositioning apparatusMetal-working holdersDrill holeDrill bit

The invention discloses a drilling device which comprises a base, wherein a guide column and a first power device are fixed on the base, the guide column is flexibly connected with a first motor, and the first motor moves upwards / downwards along the guide column. The first motor is fixedly connected with a second motor, the second motor is connected with a drill bit in rotating mode, the first power device is flexibly connected with a sliding block, and a second power device and a limit block are fixed on the sliding block. A containing space for placing parts is arranged in the limit block, and the second power device drives a jacking head to enter the containing space and fix parts in the containing space. The drilling device can improve part processing efficiency and simultaneously improves safety performance in processing.

Owner:ANHUI QIFENG MACHINERY & EQUIP

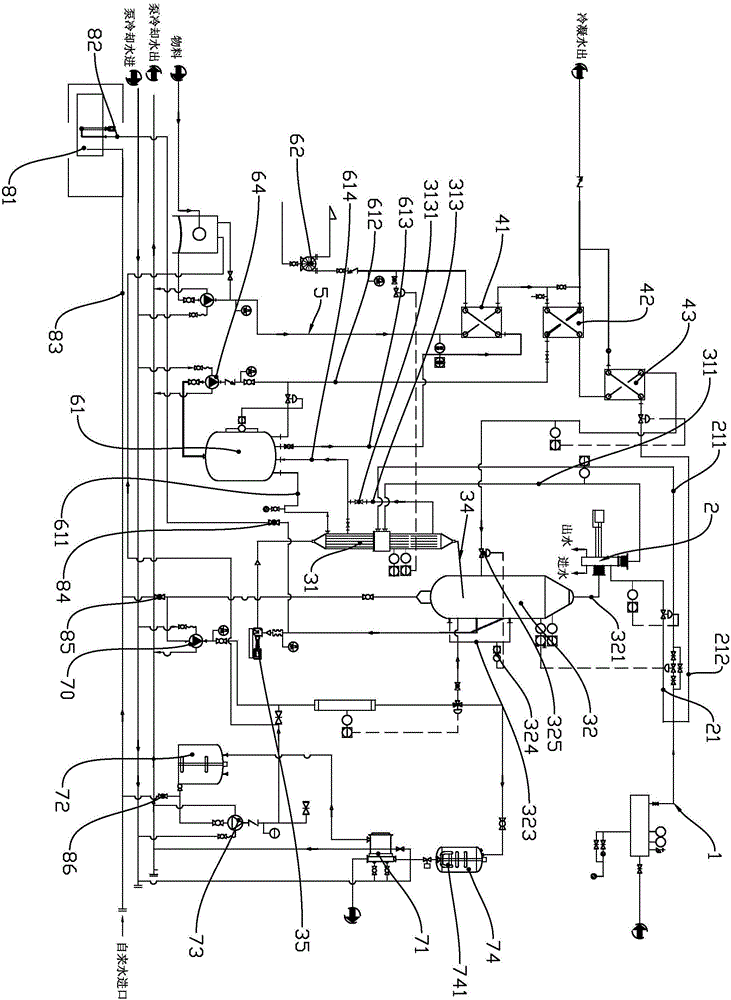

MVR continuous evaporative crystallization system

InactiveCN105879426AIncrease profitImprove energy savingEvaporator accessoriesSolution crystallizationEngineeringVacuum pump

The invention relates to a MVR continuous evaporative crystallization system which comprises a heating system, an evaporative crystallization system, a crystallization separation system and a condensation system. The heating system comprises a live steam compensation pipeline, a steam compressor and a material preheating device. The evaporative crystallization system comprises a circulation evaporator and a crystallizer. The crystallization separation system comprises a centrifugal machine. The condensation system comprises a condensate collection tank. The circulation evaporator comprises is connected with the condensate collection tank through a condensate water inlet pipe. The material preheating device comprises a primary preheater, a secondary preheater and a tertiary preheater. A second branch pipe, used for conveying live steam, connected to the steam compressor is connected into the tertiary preheater. The condensate collection tank is connected with the secondary preheater through a condensate water outlet pipe. The condensate collection tank is connected with the primary preheater through a non-condensation gas pipe. A non-condensation gas outlet of the primary preheater is connected with a vacuum pump. The MVR continuous evaporative crystallization system has the advantages of being high in heat utilization rate, good in energy-saving performance, low in pollution, high in efficiency and stable in work.

Owner:WENZHOU TAIKANG EVAPORATOR

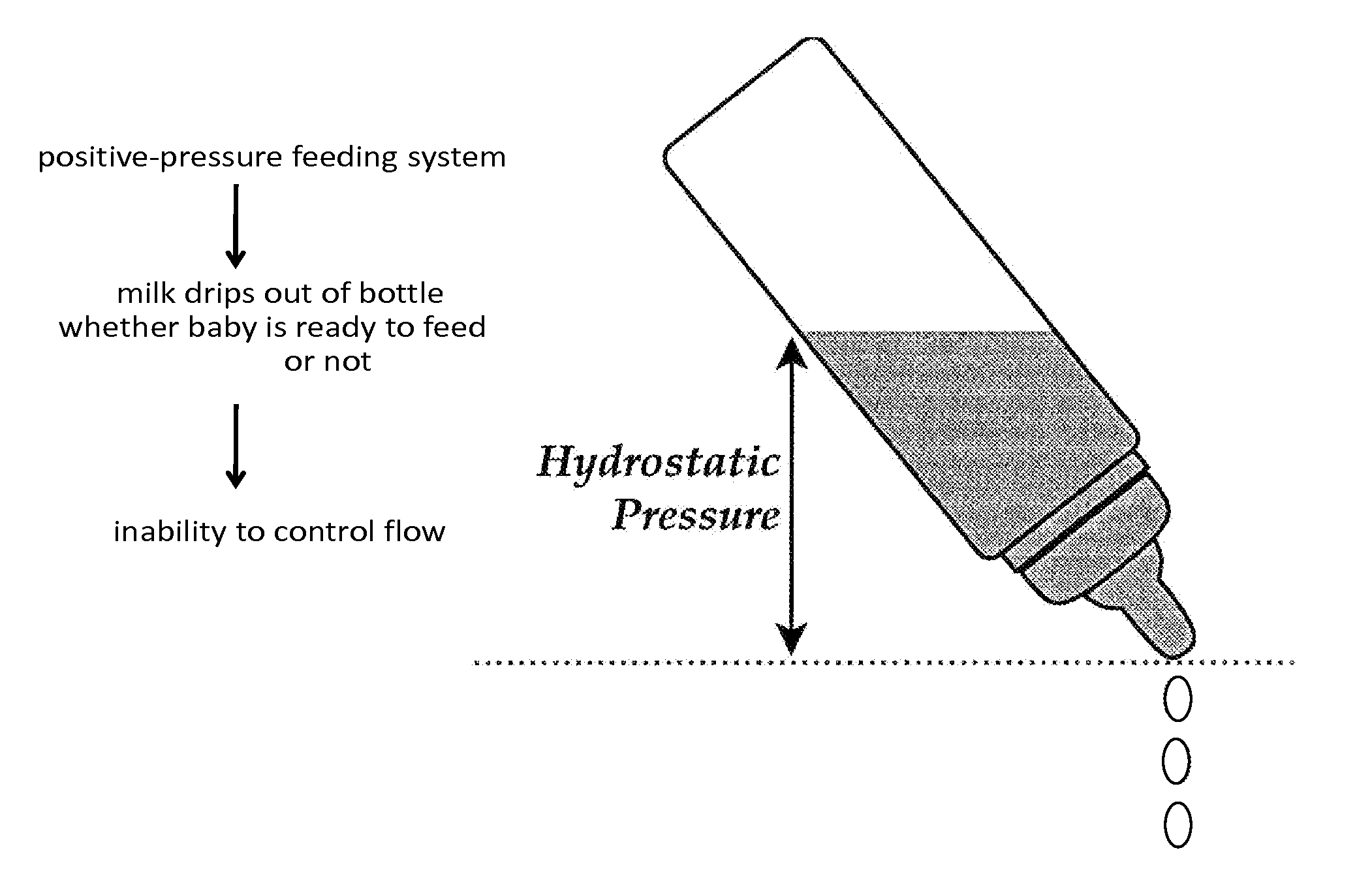

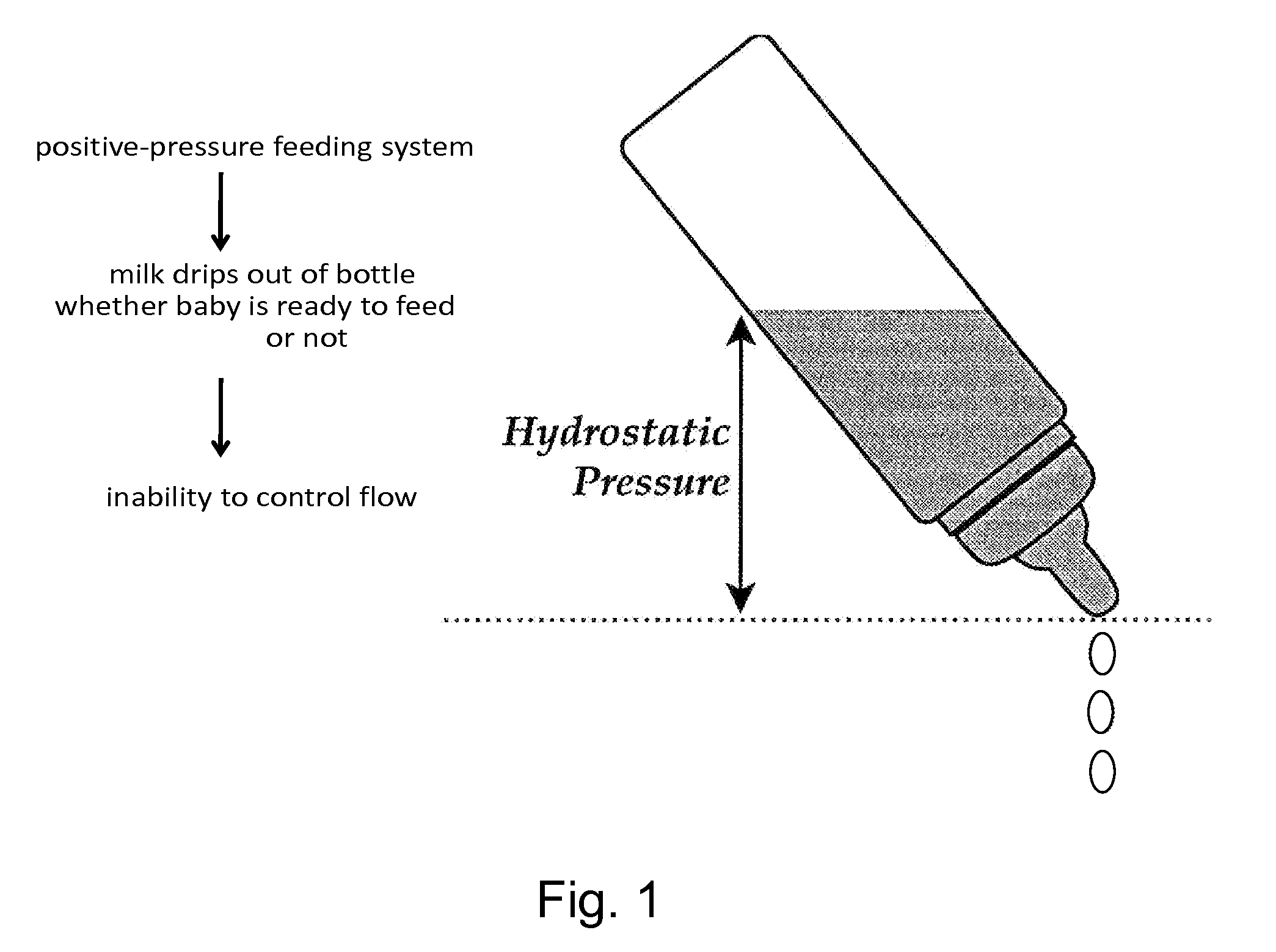

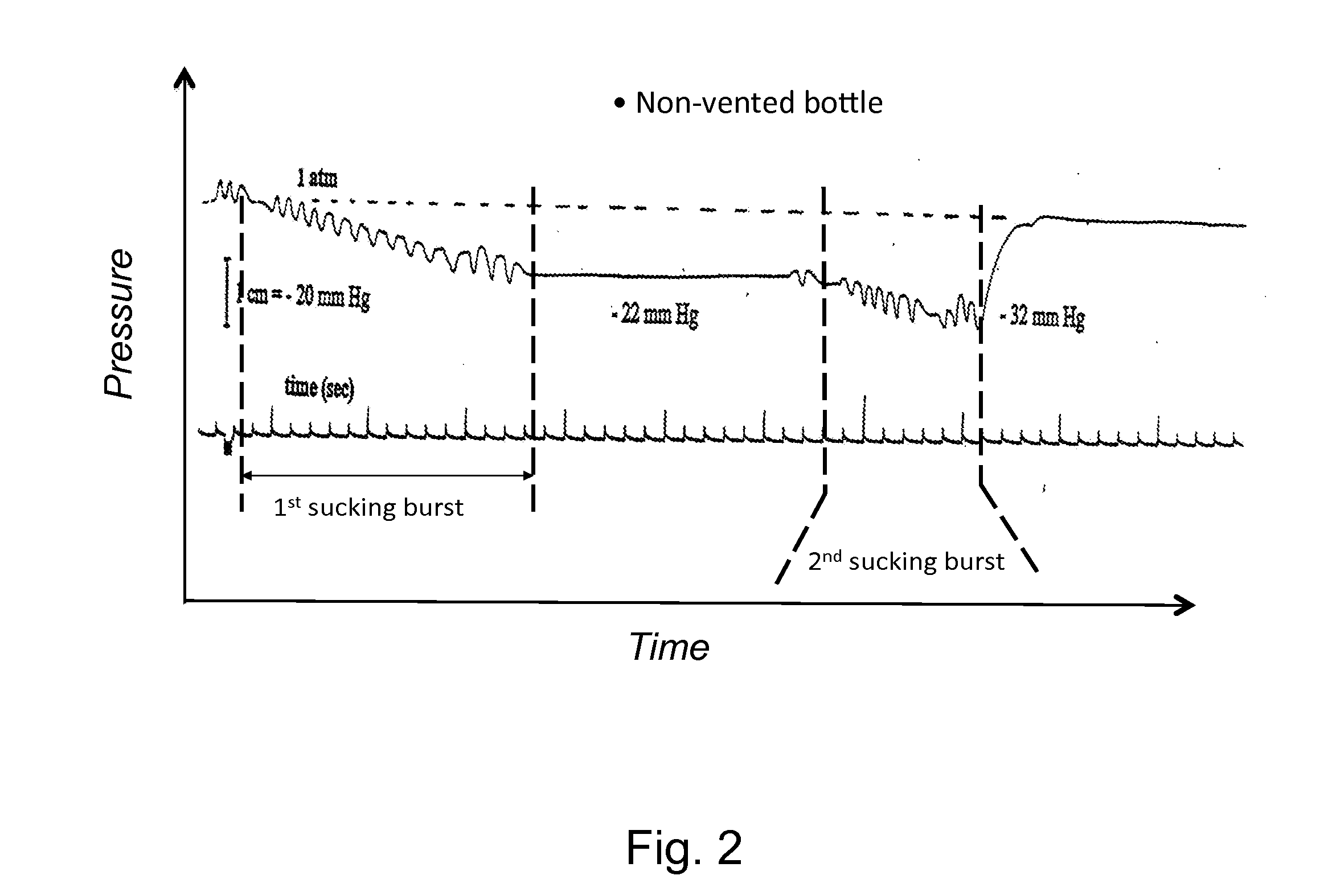

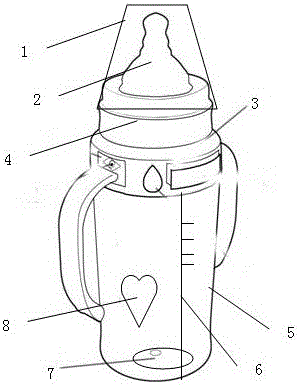

Infant Oral Feeding System

InactiveUS20110266245A1Eliminate resistanceEliminate hydrostatic pressureDomestic plumbingFeeding-bottlesHydrostatic pressureWrist injury

An oral feeding system using anti-drip visual positioning markers and a unidirectional, anti-vacuum valve to simultaneously and rapidly eliminate the hydrostatic pressure and vacuum build-up, respectively, normally occurring in conventional feeding bottles. In one version, the anti-drip visual positioning markers and valve are part of the same bottle (standard or ergonomically-shaped). In another version, a nipple is held by a nipple crown that screws onto an adaptor with anti-drip visual positioning markers and a hole into which the anti-vacuum valve is inserted. The adaptor screws onto a standard or ergonomically designed feeding bottle. The anti-vacuum valve can have one or more extended tabs that make it easier to grip when removing the valve. The use of an ergonomically shaped, hard-wall bottle optimizes caregivers' comfort and minimize potential hand and / or wrist injury. Transparent materials can be used for the components of the system.

Owner:LAU CHANTAL

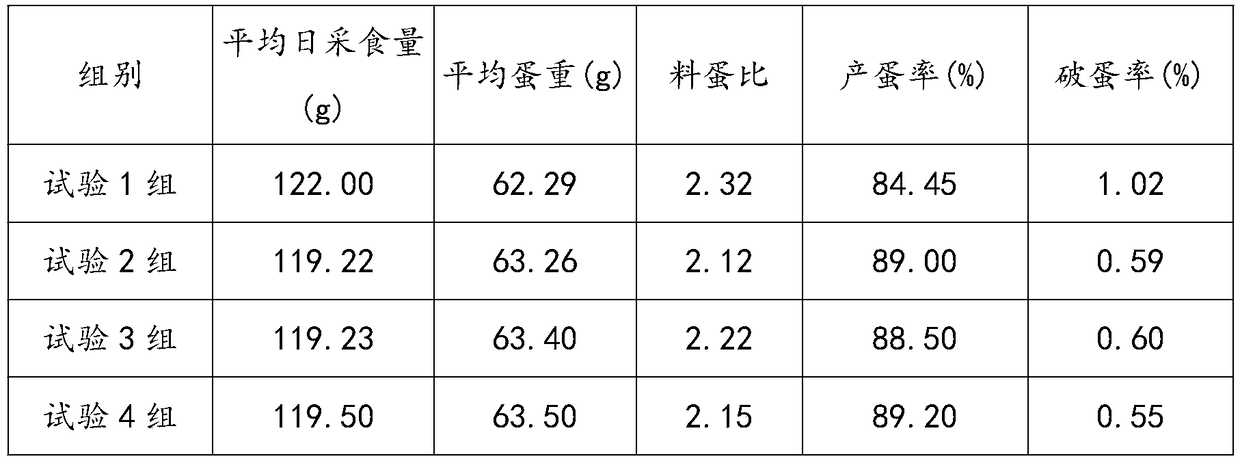

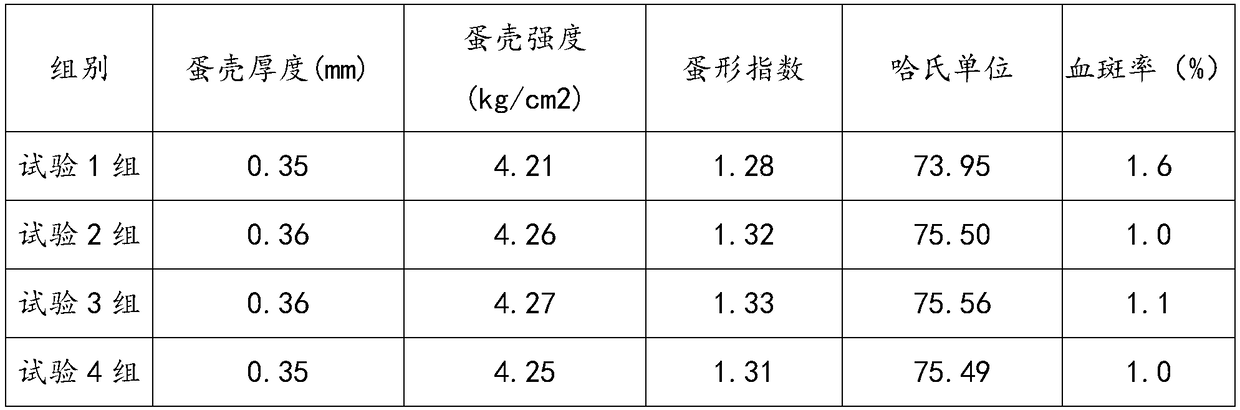

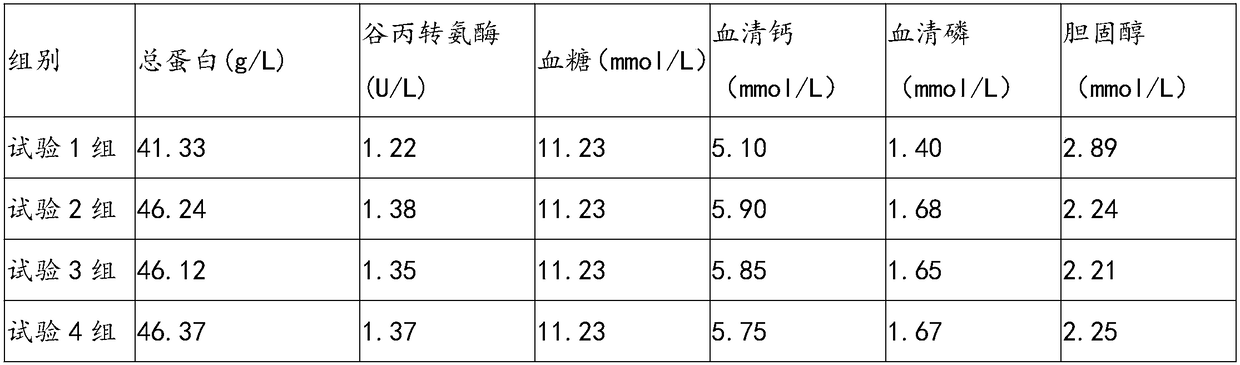

Feed for egg-laying breeding hens and processing method thereof

InactiveCN108902533ARegulates digestionSimple structureFood processingAnimal feeding stuffAnimal scienceStone particle

The invention discloses feed for egg-laying breeding hens and a processing method thereof, and relates to the field of feed. The provided feed for egg-laying breeding hens is balanced in nutrients andfree of antibiotic additives. The feed for egg-laying breeding hens includes the following raw materials in parts by weight: 40-65 parts of corn, 18-28 parts of expanded soybean meal, 2-6 parts of corn germ cakes, 1-5 parts of corn germ meal, 0.2-0.5 part of xylo-oligosaccharide, 1-4 parts of organic calcium, 4-8 parts of stone particles, 0.8-2.0 parts of calcium hydrogen phosphate, 0.5-2.0 partsof soybean oil, 0.3-1.0 part of compound Chinese herbal medicine preparation, 0.5-2.5 parts of compound probiotic fermented feed, 0.01-0.03 part of fluazifop and 1 part of premix for egg-laying hens.The preparation method is simple and easy to operate, and the prepared feed for egg-laying breeding hens is not only rich in nutrient components, but also free of any antibiotics and green and environmentally friendly in additives.

Owner:HENAN MUHE GROUP FEED

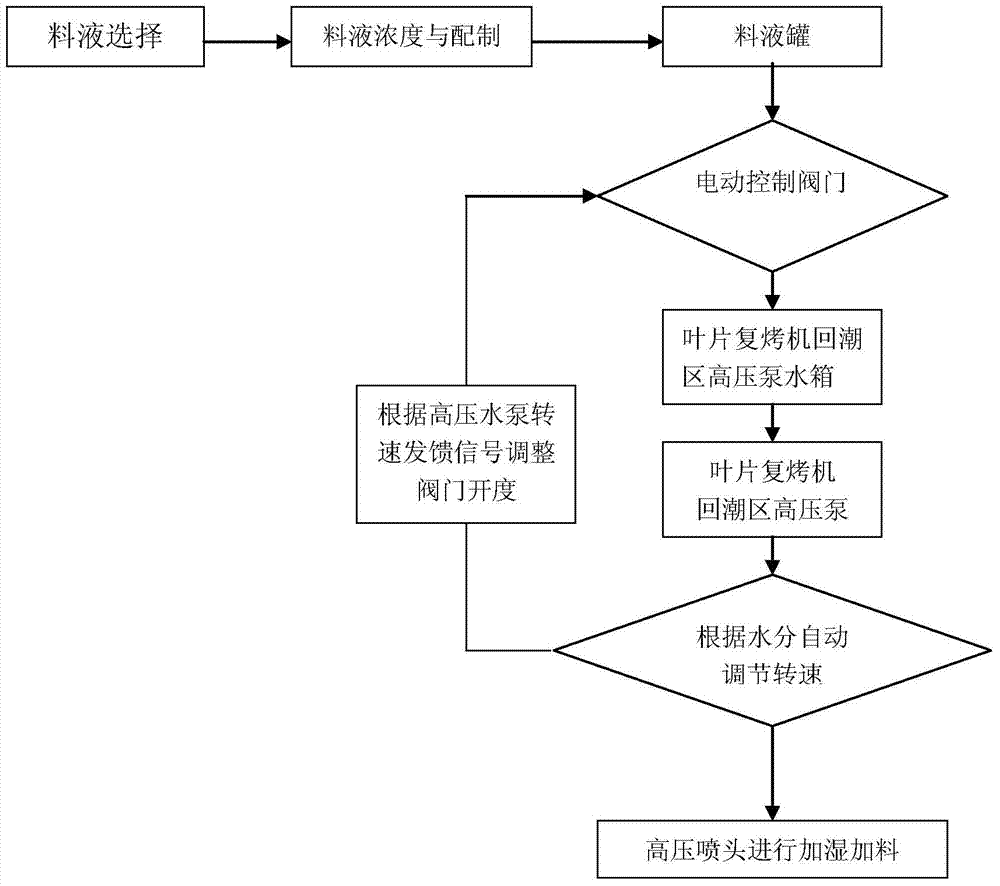

Feeding method in processes of tobacco leaf threshing and re-drying

ActiveCN103610225AIncrease profitImprove atomization effectTobacco preparationEngineeringHigh pressure water

The invention relates to a feeding method in processes of tobacco leaf threshing and re-drying. Feed liquid is selected according to quality characteristics of tobacco leaves and added into a moisture regain section of a re-drying machine according to the 0.4% proportion of tobacco leaf weight, high-pressure water is used for carrying the feed liquid to be sprayed on the tobacco leaves of the moisture regain section after sprayer nozzle atomizing, and the temperature at the moisture regain section is controlled to be 55-65 DEG C. The feeding method is even in feeding, high in feed liquid utilization rate and good in feeding effect and keeps a biological agent active, and therefore the purposes that tobacco leaves are safely stored, the quality of the tobacco leaves is improved, and use value of the tobacco leaves is improved are achieved. The feeding is performed on the moisture regain section of the re-drying machine, so that feeding evenness and tobacco lamina safety are guaranteed.

Owner:CHINA TOBACCO SHANDONG IND

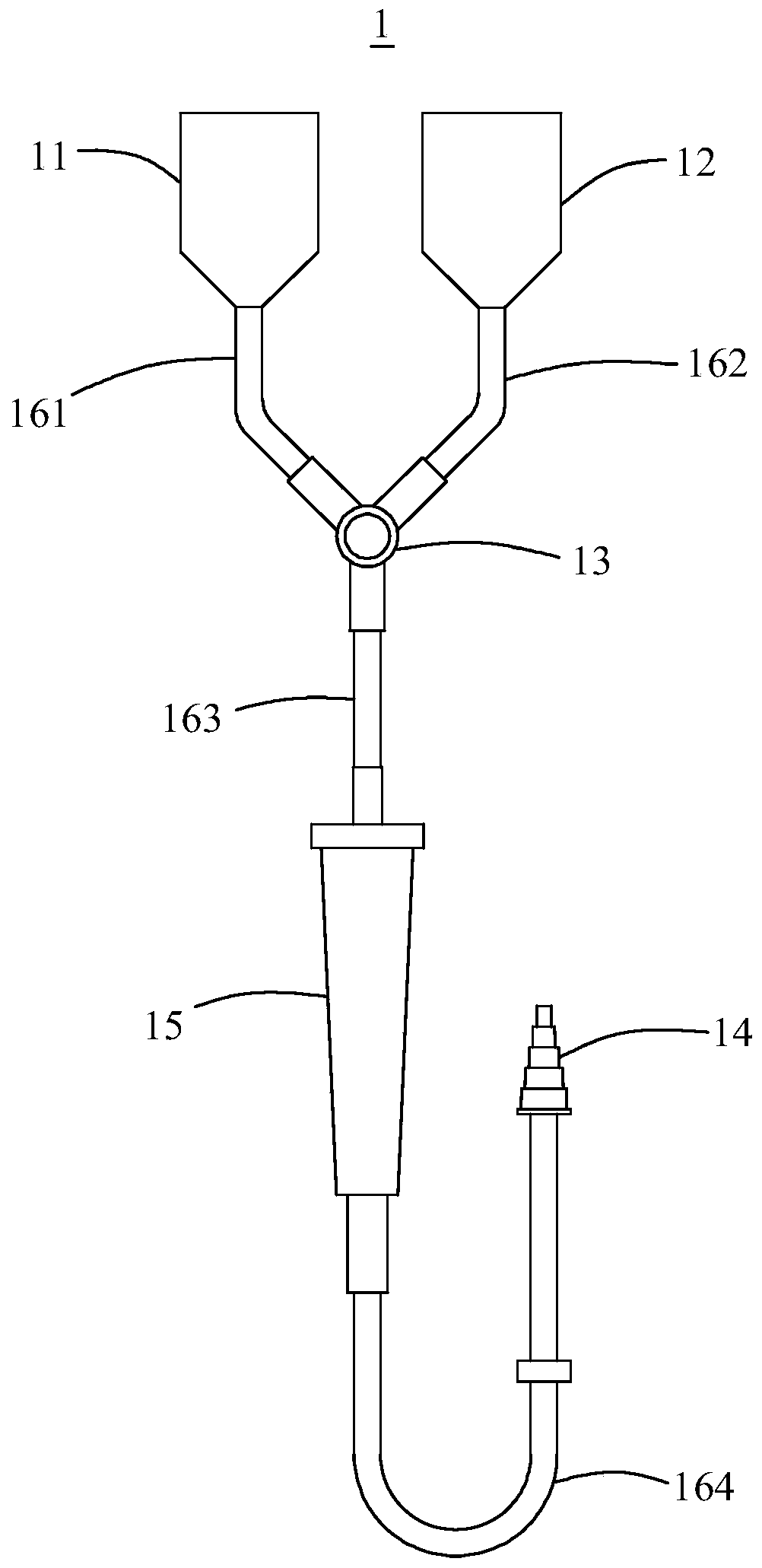

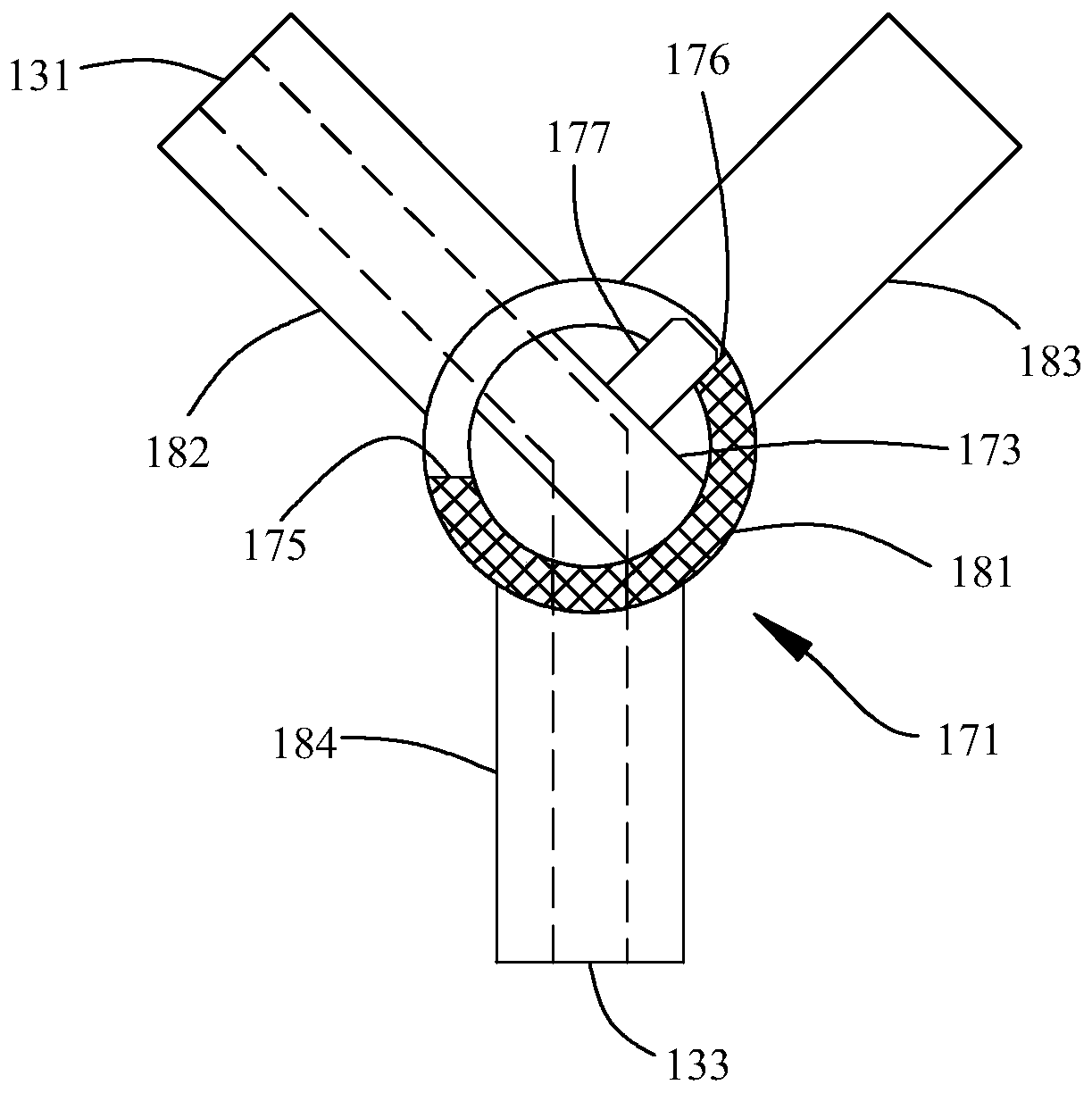

Nutrition device, nutrition pump and enteral feeding system

PendingCN110327218ARealize automatic switchingSimple structureFeeding-tubesEnteral feedingsNutrition

The application relates to a nutrition device, a nutrition pump and an enteral feeding system, and belongs to the technical field of enteral feeding systems. The nutrition device comprises a first pipeline, a second pipeline, a three-way valve and an output joint, one end of the first pipeline is connected with a first liquid storage container, the other end of the first pipeline communicates witha first inlet of the three-way valve, one end of the second pipeline is connected with a second liquid storage container, the other end of the second pipeline communicates with a second inlet of thethree-way valve, an outlet of the three-way valve is in communication with the output joint, the three-way valve is selectively in a first working position or a second working position, in the first working position, the first inlet of the three-way valve communicates with the outlet of the three-way valve, and in the second working position, the second inlet of the three-way valve communicates with the outlet of the three-way valve. The nutrition device, the nutrition pump and the enteral feeding system are simple in structure, low in cost, convenient in operation, and high in reliability andsafety, and meet needs of nutrient feeding and cleaning.

Owner:北京新科华大医疗技术有限公司

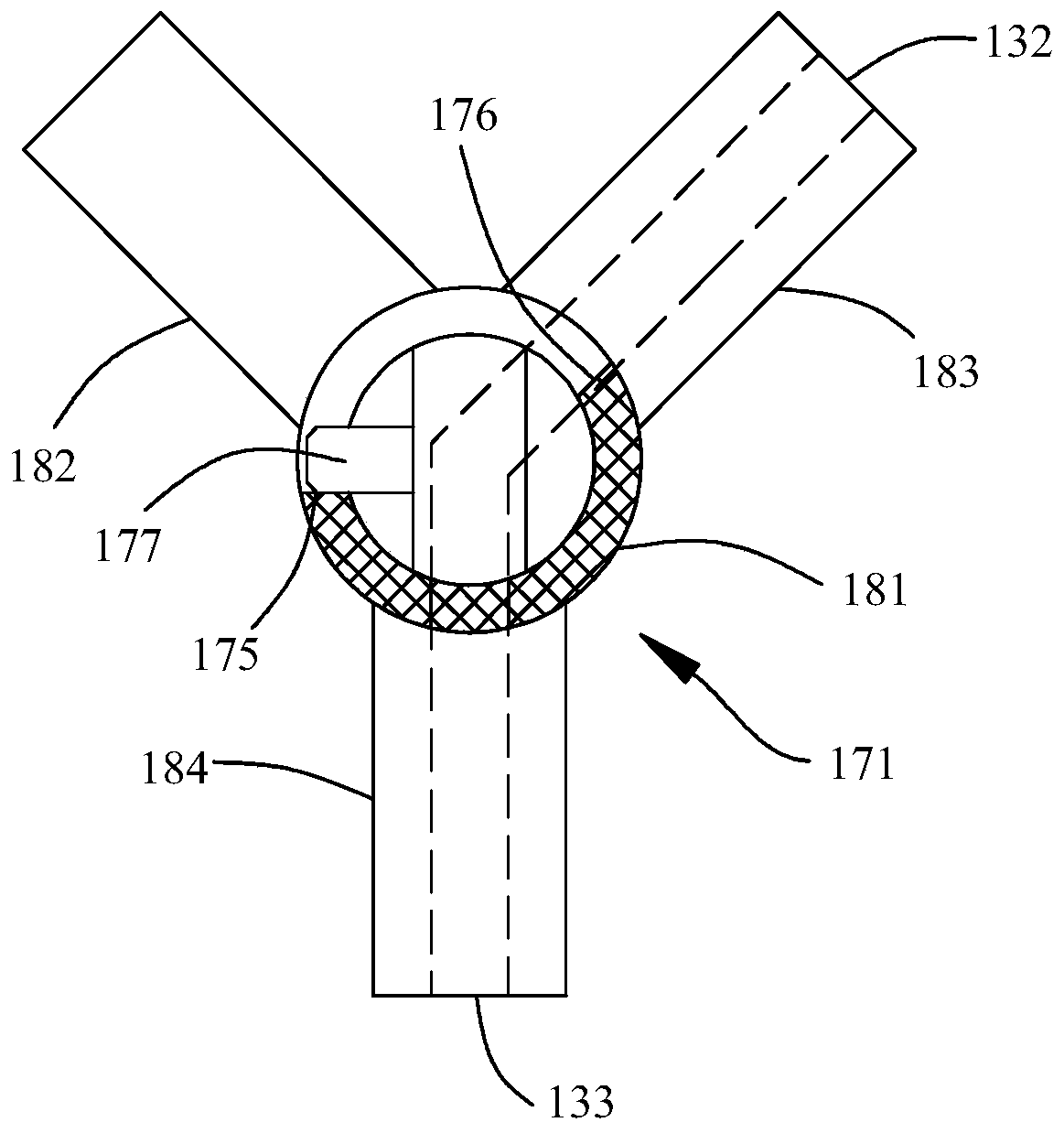

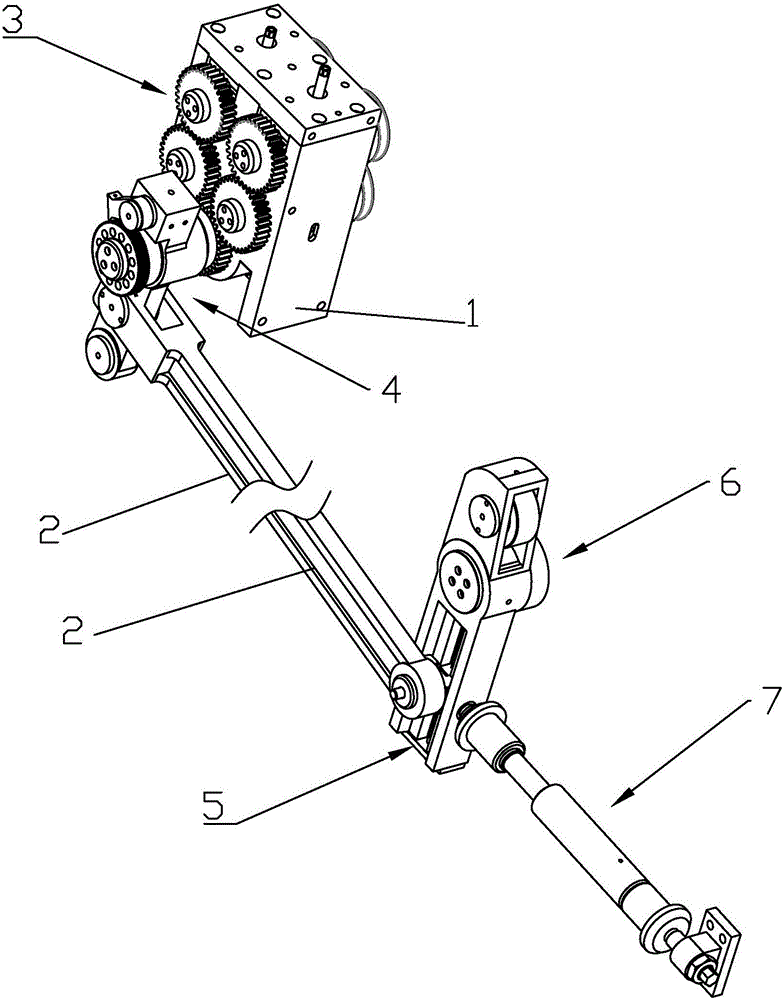

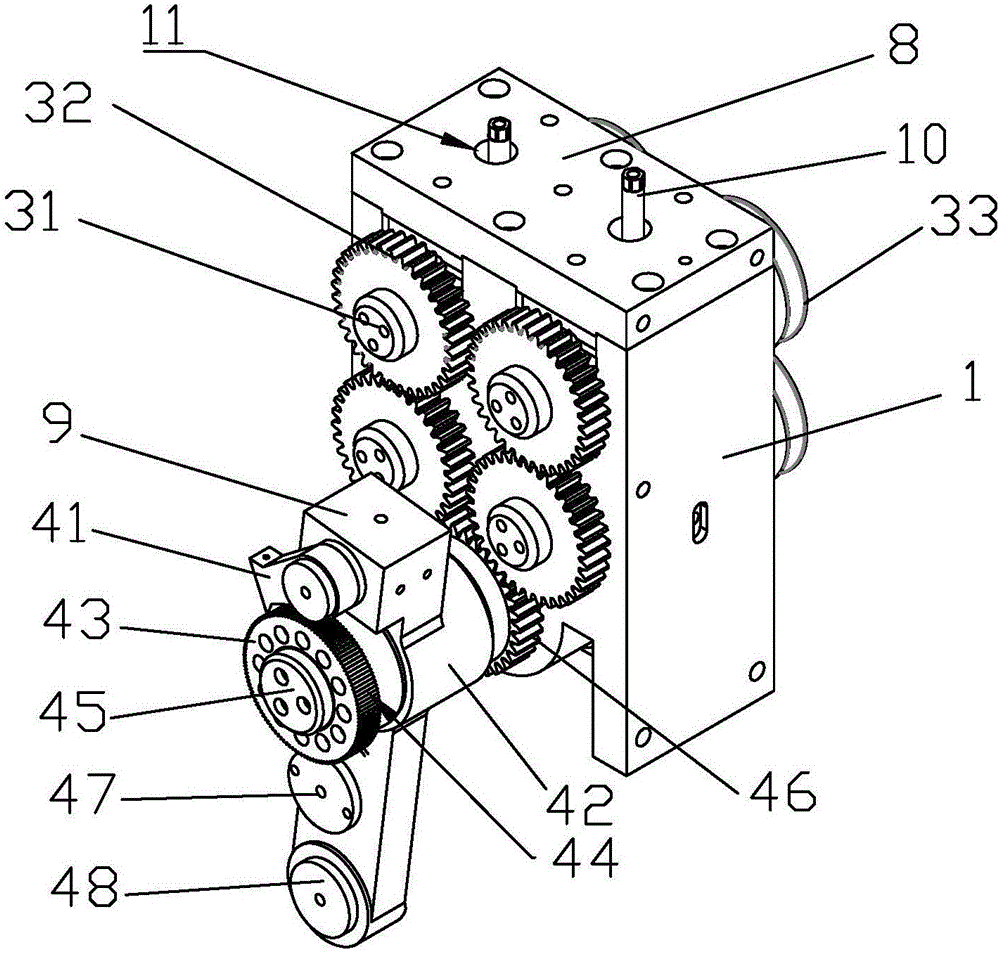

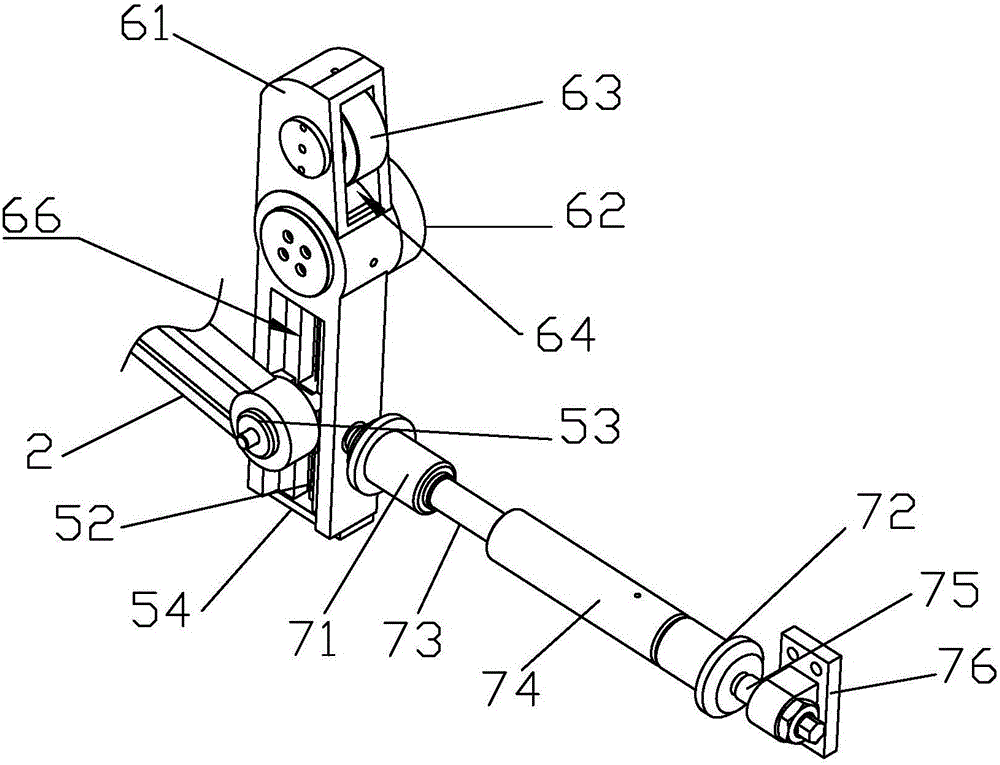

Feeding device of eight-station cold header

The invention discloses a feeding device of an eight-station cold header. The feeding device comprises a feeding box and a feeding connection rod. A feeding transmission mechanism is disposed in the feeding box, one end of the feeding connection rod is connected with a ratchet wheel rocker mechanism, the ratchet wheel rocker mechanism is connected with the feeding transmission mechanism, a height adjusting mechanism is connected with the other end of the feeding connection rod and connected with a feeding rocker arm mechanism, and the feeding rocker arm mechanism is connected to a spring return mechanism. The feeding length is adjusted by adjusting the height adjusting mechanism on a feeding rocker arm and adjusting the positions of the feeding connection rod and a ratchet wheel rocker so that whole feeding work can be quickly, accurately, stably and orderly conducted. The feeding device is simple in structure, scientific and convenient to use, high in automation degree, safe and reliable in feeding, good in equipment reliability and long in service life, and well solves the feeding problem of the cold header.

Owner:浙江东雄机床有限公司

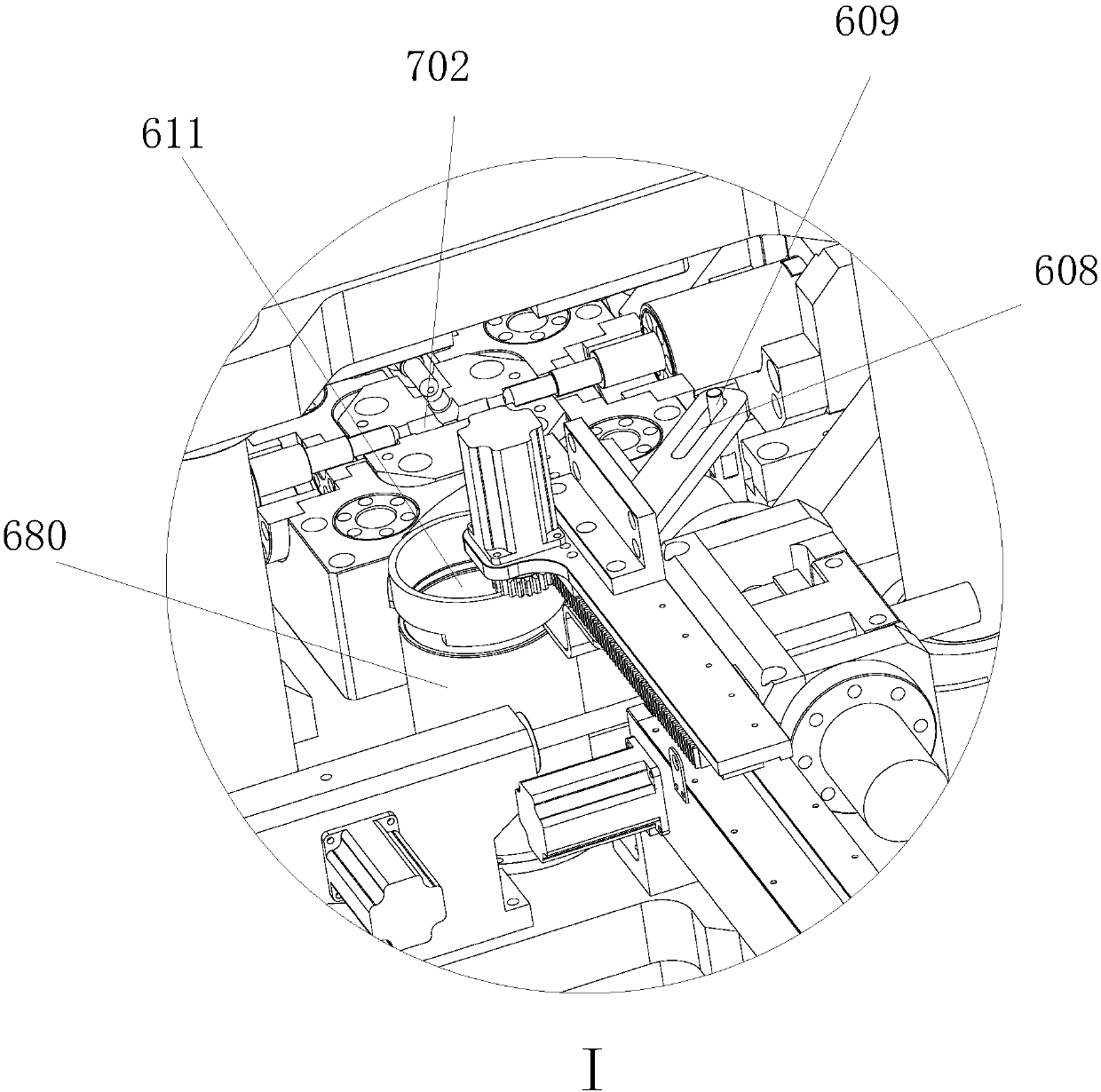

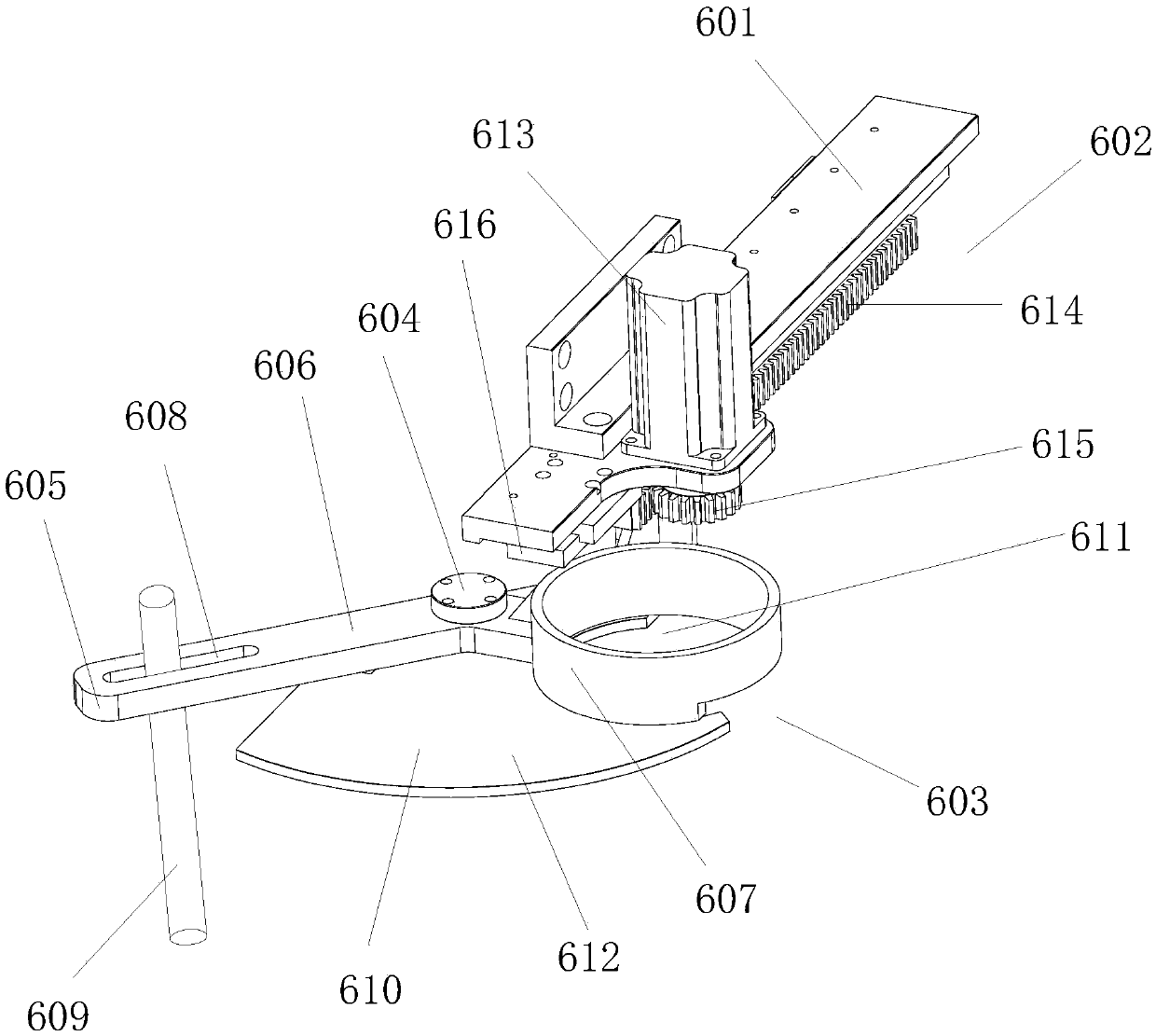

Workpiece machining device

ActiveCN107891117AHigh degree of automationReasonable structureForging/hammering/pressing machinesHandling devicesLinear motionManipulator

The invention relates to the field of molds and discloses a workpiece machining device. According to the workpiece machining device, a material taking manipulator (600) comprises a mounting frame (601); a moving assembly (602) which moves along the mounting frame (601) is arranged on the mounting frame (601); a material taking assembly (603) is arranged on the moving assembly (602); the material taking assembly (603) comprises a rotating shaft (604) and a rotating rod (605); the rotating rod (605) rotates around the rotating shaft (604); the rotating rod (605) comprises a driving rod (606) positioned on one side of the rotating shaft (604) and a material receiving disc (607) positioned on the other side of the rotating shaft; a sliding groove (608) is formed in the rotating rod (605); a stop rod (609) inserted into the sliding groove (608) is arranged on a workbench (725); and during the linear motion, the rotating rod (605) rotates around the rotating shaft (604) in such a manner thatthe stop rod (609) is pushed by the sliding groove (608) to slide. The workpiece machining device has the advantages that the automatic material loading operation, the automatic material taking operation and the automatic machining operation can be achieved. Furthermore, both the material loading operation and the material taking operation are accurate.

Owner:叶腾斌

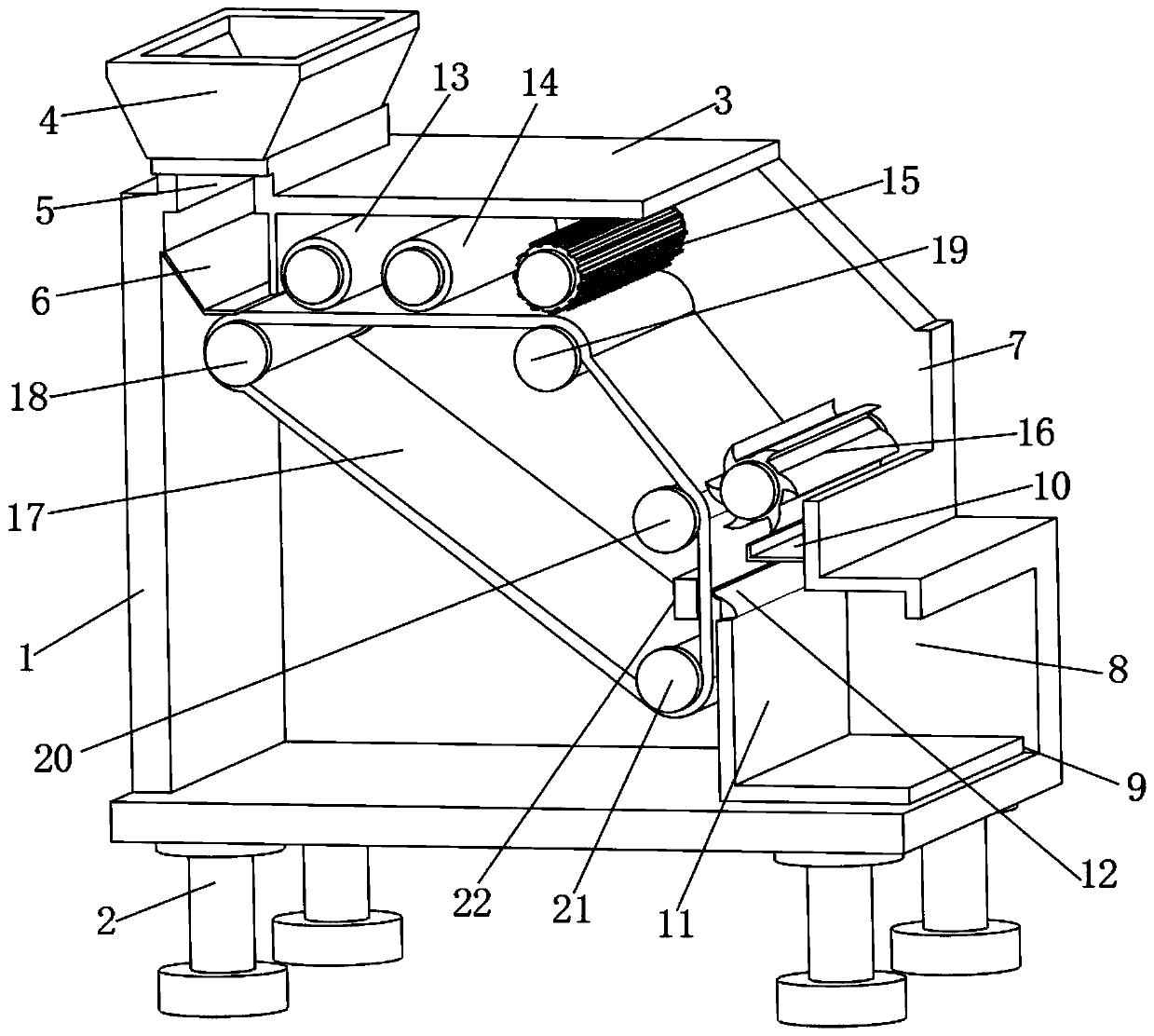

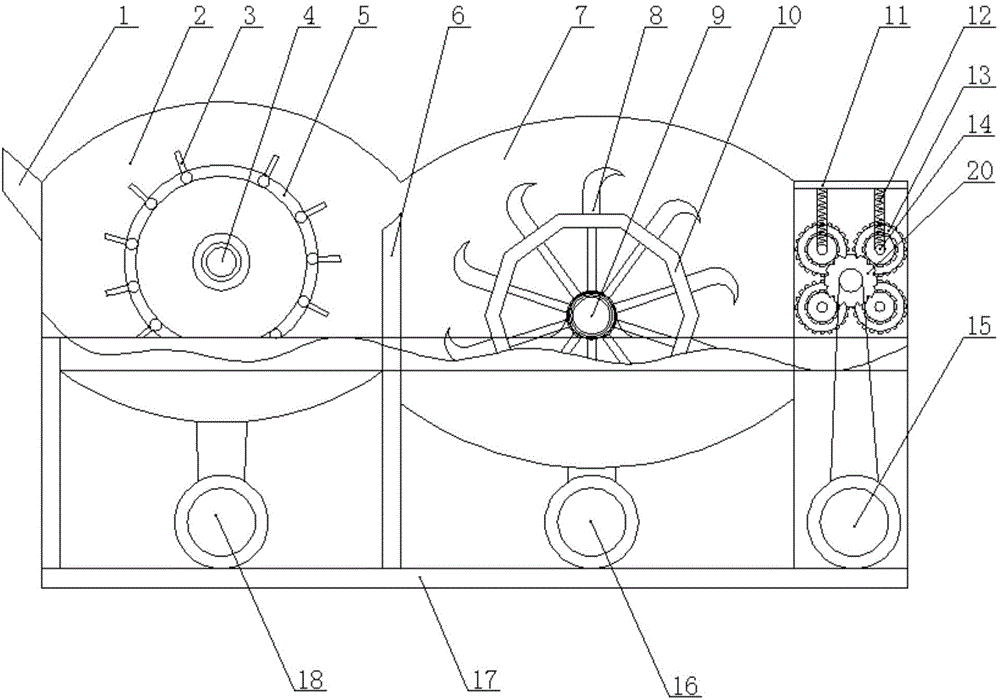

Carding machine for effectively cleaning cotton ball of cotton raw materials

InactiveCN109811430AFeeding safetyQuality improvementCarding machinesAgricultural engineeringCotton balls

The invention discloses a carding machine for effectively cleaning cotton ball of cotton raw materials. The carding machine comprises a carding machine shell, wherein the lower end surface of the carding machine shell is fixedly supported by supporting columns arranged at four corner positions, and a top plate is connected to the upper end surface of the carding machine shell through bolts; and afeed port is formed in the left end of the upper end surface of the top plate, and a visual window is connected to the right end of the top plate; and a first rotating shaft, a second rotating shaft and a third rotating shaft are arranged at the lower end of the top plate, and a feed funnel is fixedly welded to the upper end of the feed port. The carding machine peels off the cotton ball on the carded cotton raw materials, the quality of carded products is improved, meanwhile, a belt is used for forming a loop, the purpose of uninterrupted work is achieved, and the carding efficiency is improved.

Owner:南昌汇达知识产权有限公司

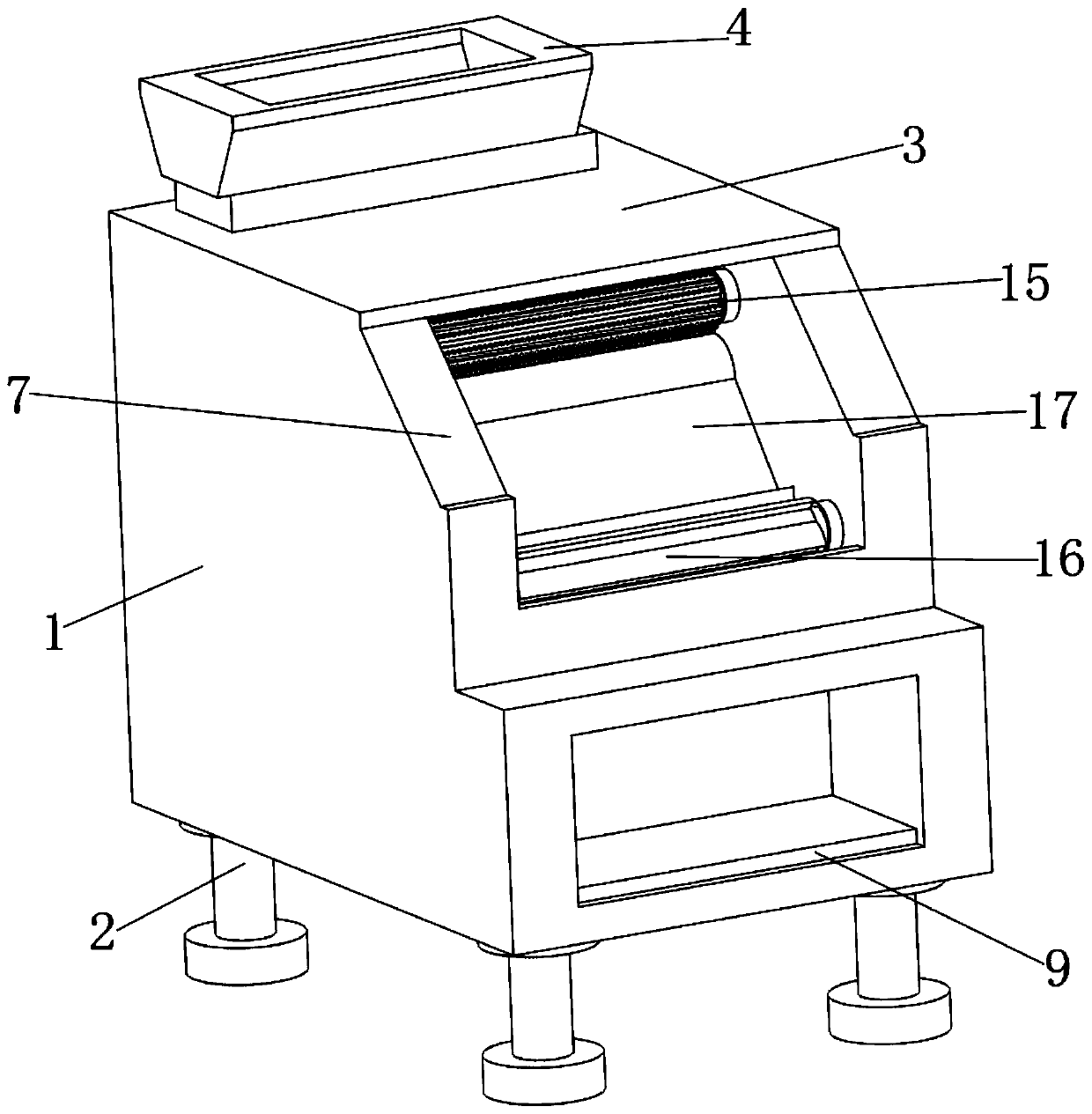

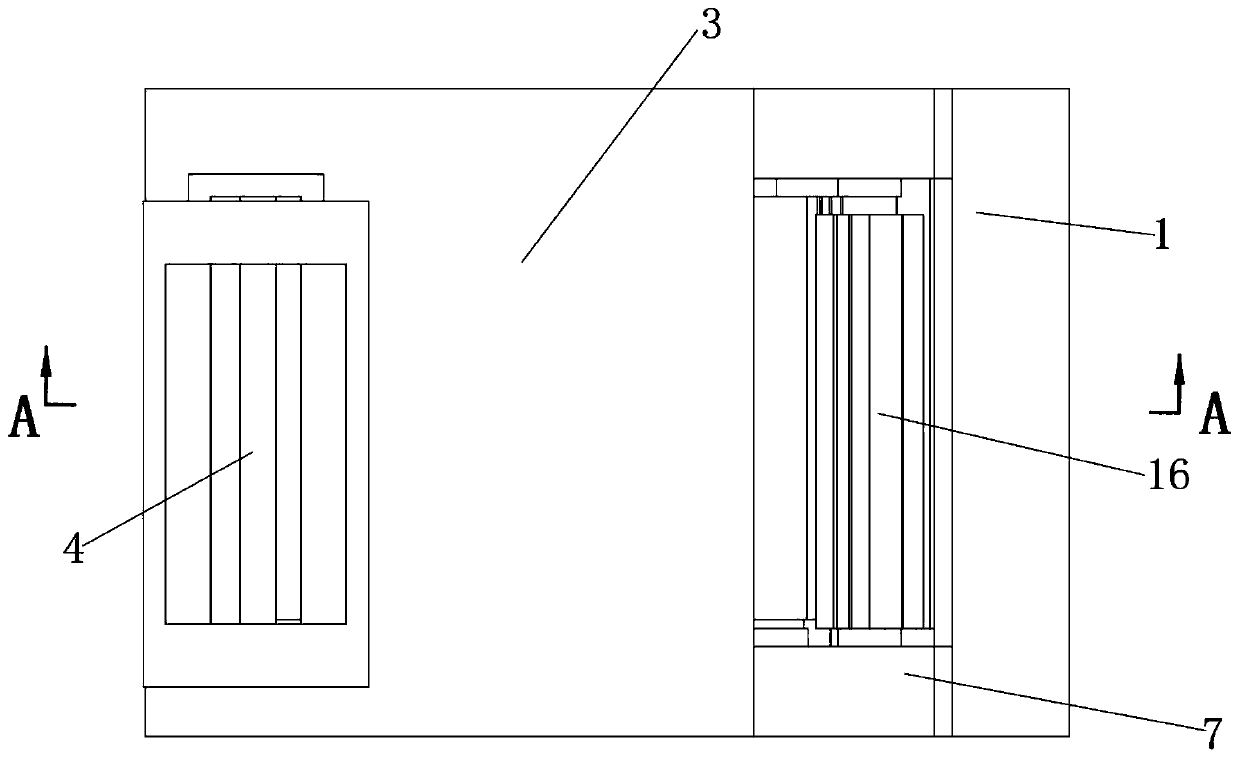

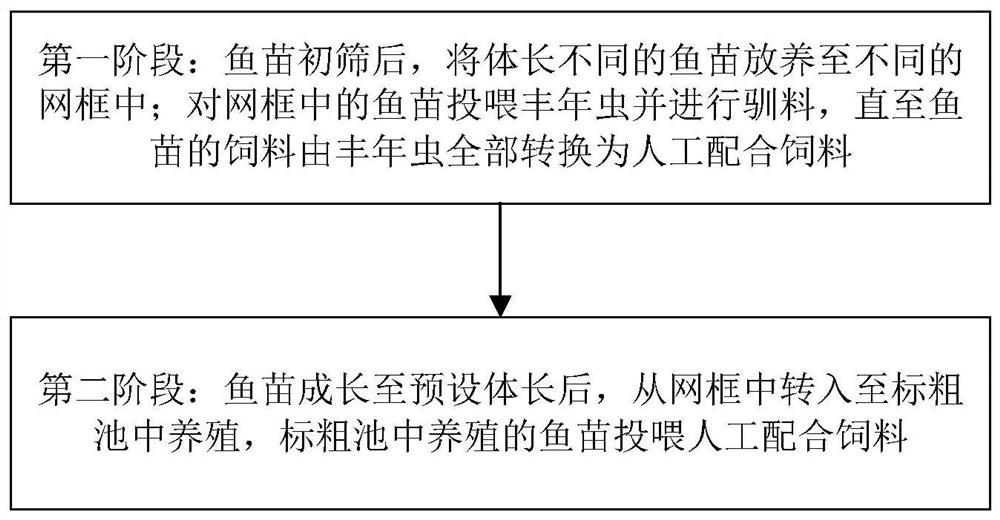

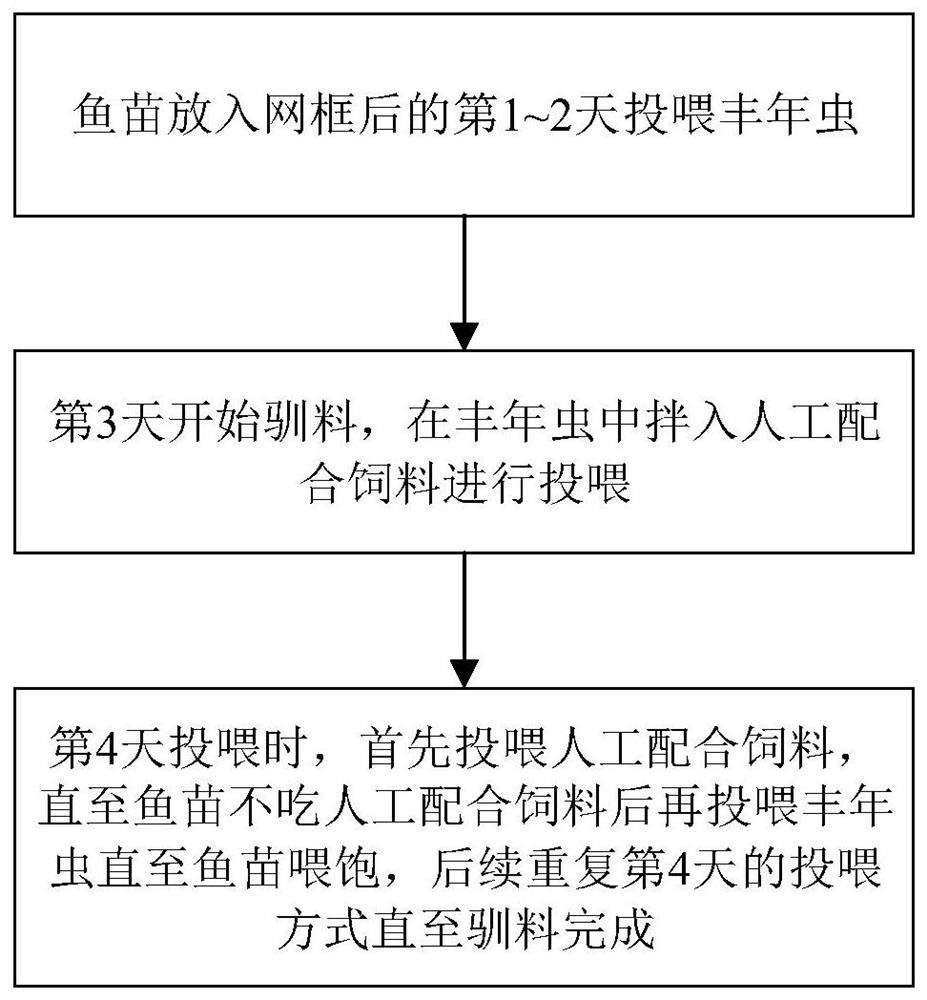

Sectional type rapid temporary culture method for grouper fries

ActiveCN113133424AReduce incubation timeShort incubation timeClimate change adaptationPisciculture and aquariaAnimal scienceFishery

The invention discloses a sectional type rapid temporary culture method for grouper fries, which comprises the following steps: after primary screening of fries at the first stage, stocking the fries with different body lengths into different net frames; feeding fairy shrimps to the fries in the net frames and domesticating the fries until the feed of the fries is completely converted into artificial compound feed from fairy shrimps; and at the second stage, after the fry grow to the preset body length, transferring the fries from the net frames into a temporary culture pond to be cultured, and feeding the fries cultured in the temporary culture pond with artificial compound feed. According to the method, a sectional type temporary culture method is adopted, fry centralized domestication is completed in all the net frames at the first stage, the domestication time of artificial compound feed is greatly shortened, then fries with the body length reaching the preset body length are fed in the temporary culture pond at the second stage, the culture space is increased, rapid growth of grouper fries is facilitated, the fry culture time is further shortened, the whole fry culture time is shorter, and the yield per unit water body and the survival rate of the fries are higher.

Owner:广东海元农业科技有限公司 +1

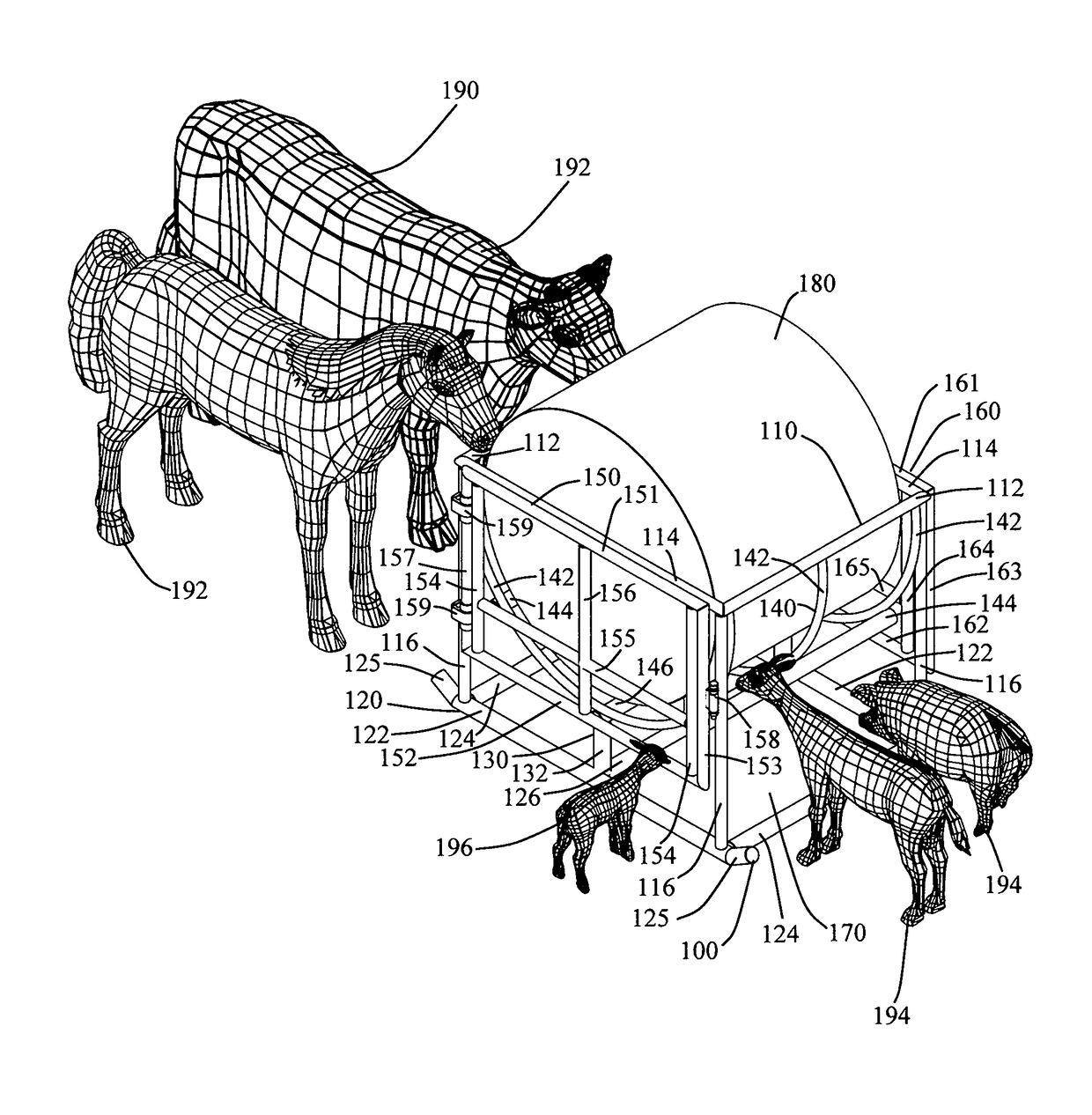

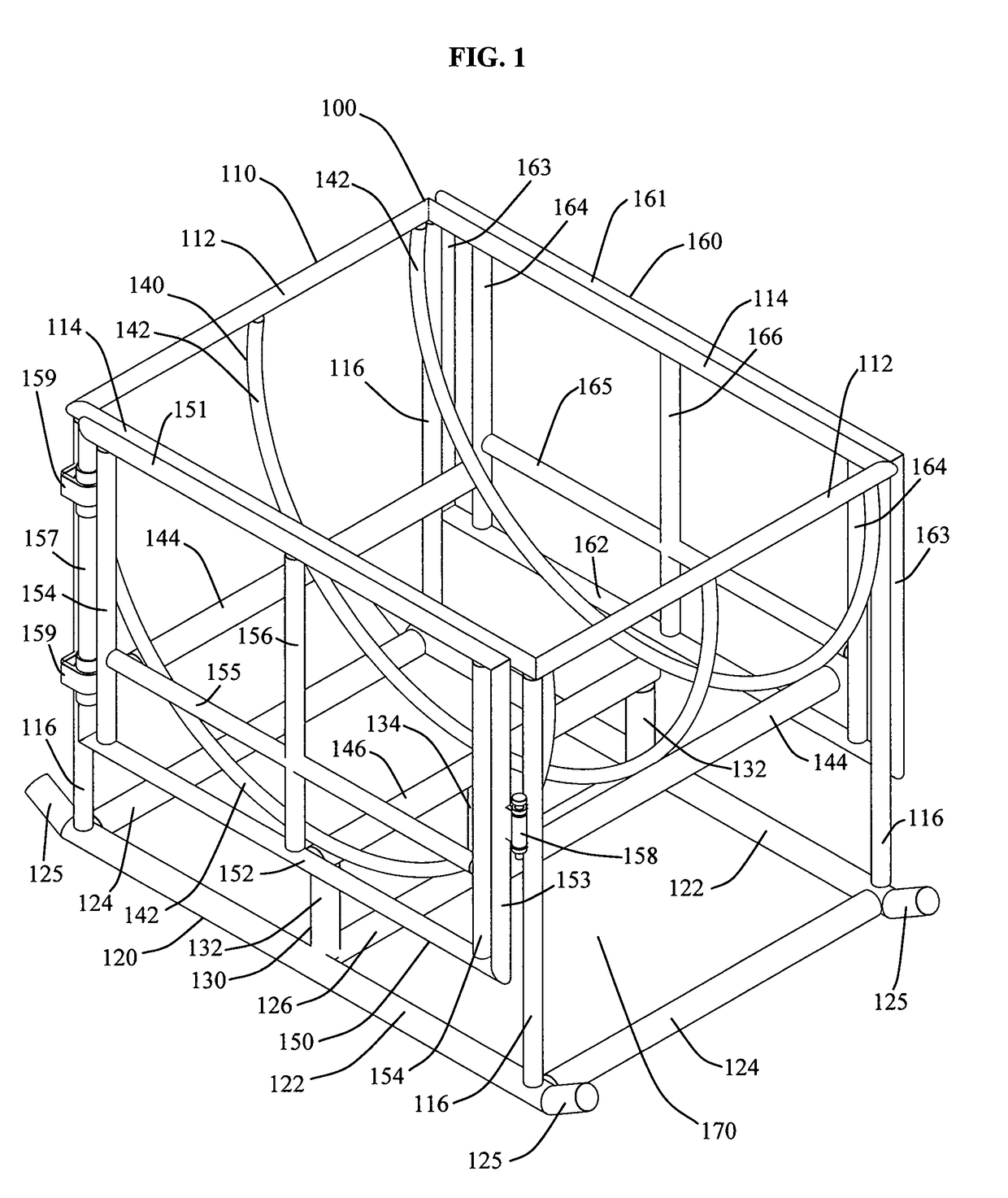

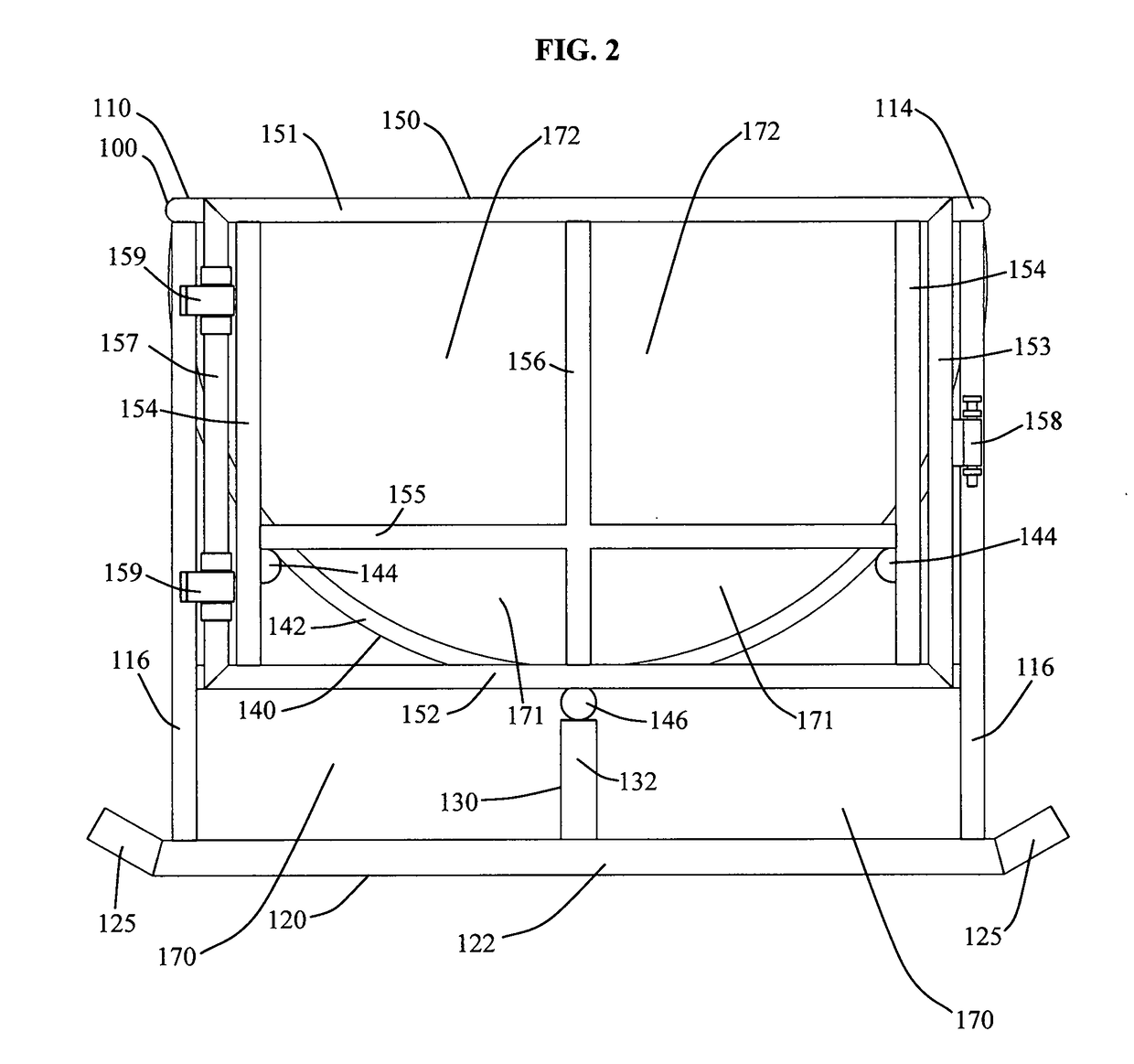

Round Bale Saddle Feeder

Disclosed herein is an apparatus for feeding livestock, which suspends one or more round hay bales above the ground, preventing hay rot, at a height that enables large livestock to feed on the round hay bales while small or young livestock feed from the underside of the bale where they are better protected from the larger animals. The round hay bale feeder comprises a box frame; one or more baskets for supporting a round hay bale disposed within the box frame; a base comprising pipe skids, and a plurality of vertical supports that support the basket or baskets, which allow enough space for small or young animals to feed underneath the feeder; and one or more hinged and latched gates for accessing the feeder.

Owner:ROBISON DENNIS

Feeding bottle with thermochromic lamp

InactiveCN105816332AFeeding safetyHappy to drink milkLighting applicationsElectric circuit arrangementsBiochemical engineeringColor changes

The invention discloses a feeding bottle with a temperature-sensitive color-changing lamp, which mainly includes (1) a dustproof cover, (2) a nipple, (3) a screw cap, (4) a leak-proof gasket, (5) a bottle body, (6) Capacity scale, (7) battery slot, (8) color-changing LED lights. It solves the problem that parents do not know the actual temperature of the milk powder and easily scalds the baby. The clear and clear color change can easily let the parents know the approximate temperature in the bottle and feed the baby more safely; at the same time, the changing LED light makes the bottle more comfortable. For fun and cute, make baby more happy to drink milk.

Owner:王立云

Loading device of mixing machine

The invention discloses a loading device of a mixing machine. The loading device of the mixing machine is high in working efficiency and comprises a feed box and a feed opening formed in the upper end of the feed box, wherein a vibrating motor is arranged on the outer side of the feed opening; rollers are arranged at the lower end of the feed box; a driving motor and a convey screw rod connected with the driving motor are arranged in the feed box; the convey screw rod is arranged in a conveying pipe; a feed inlet is formed in the lower end of the conveying pipe and in the feed box; and a discharge opening is formed in the upper end of the conveying pipe. The loading device of the mixing machine has the advantages of mechanically automatic loading, high working efficiency, convenience in operation and loading safety.

Owner:中科鑫洋(江苏)生物技术有限公司

Granulated feed capable of improving quality of carcasses of beeves

InactiveCN102178098AIncrease calcium levelsLower cholesterol levelsFood processingAnimal feeding stuffAdditive ingredientCholesterol

The invention discloses granulated feed capable of improving quality of carcasses of beeves and relates to beef feed. The invention aims to solve the problems of low quality of current carcasses of beeves and resource waste and environment pollution due to the landfill treatment of fresh citrus residue. The granulated feed consists of a main ingredient and an auxiliary ingredient, wherein the main ingredient is citrus residue; and the auxiliary ingredient consists of urea, corn flour, molasses, sodium sulfate, zeolite, sodium dihydrogen phosphate and table salt. The granulated feed of the invention can obviously improve the meat weight and meat rate of the carcasses of beeves, lower the shearing force of muscle, improve meat color grade, obviously lowers cholesterol content in beef, obviously improve calcium content and obviously improve the quality of the carcasses of beeves. Meanwhile, the granulated feed disclosed by the invention is low in cost and has high palatability, high protein content, a balance nitrogen to sulfur ratio and a balance calcium to phosphorus ratio, and has a great significance for improving the economic benefit of beef breeding and realizing circular and high-efficiency utilization of resources. The granulated feed has a bright application prospect in beef feed field.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

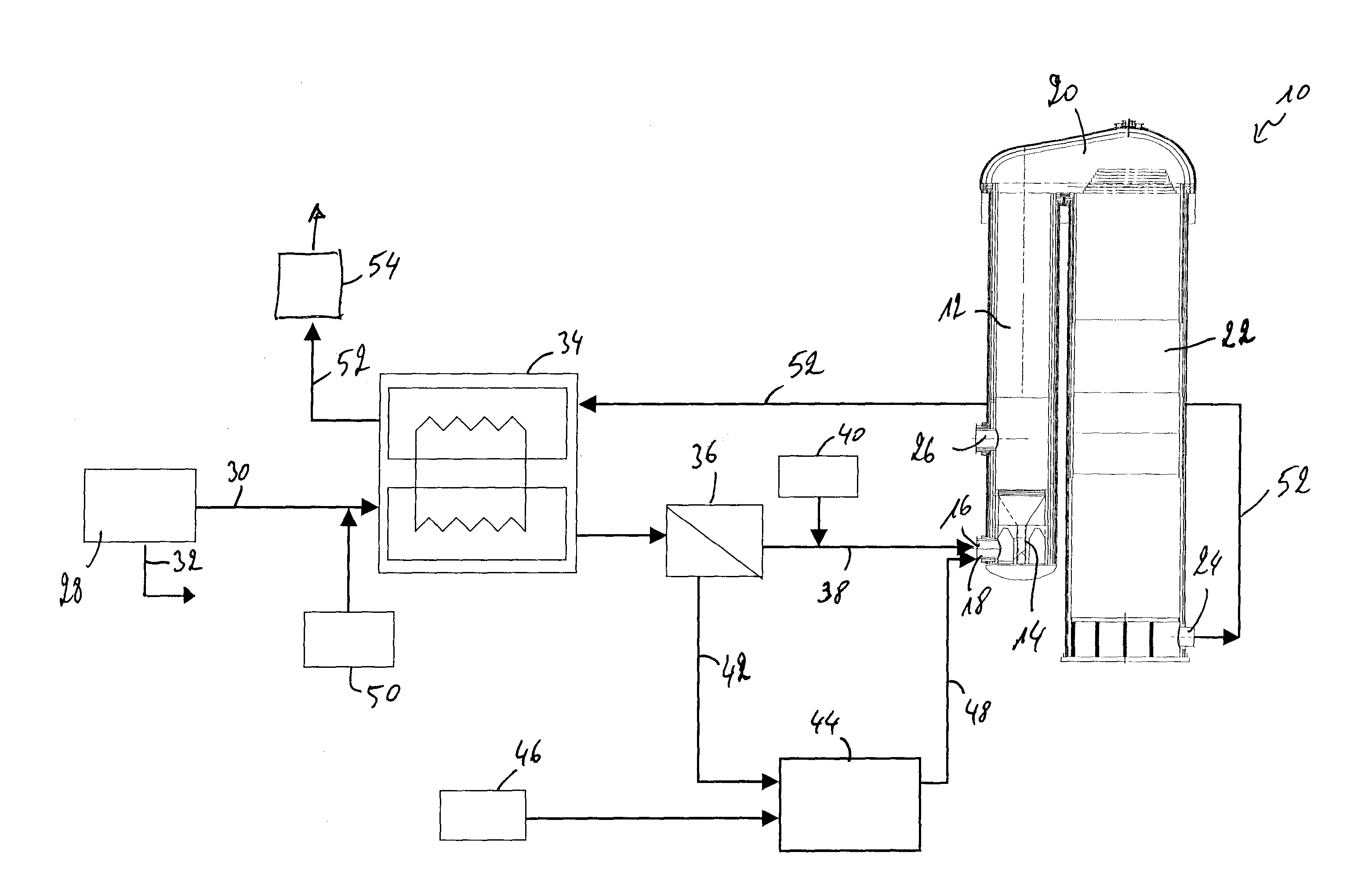

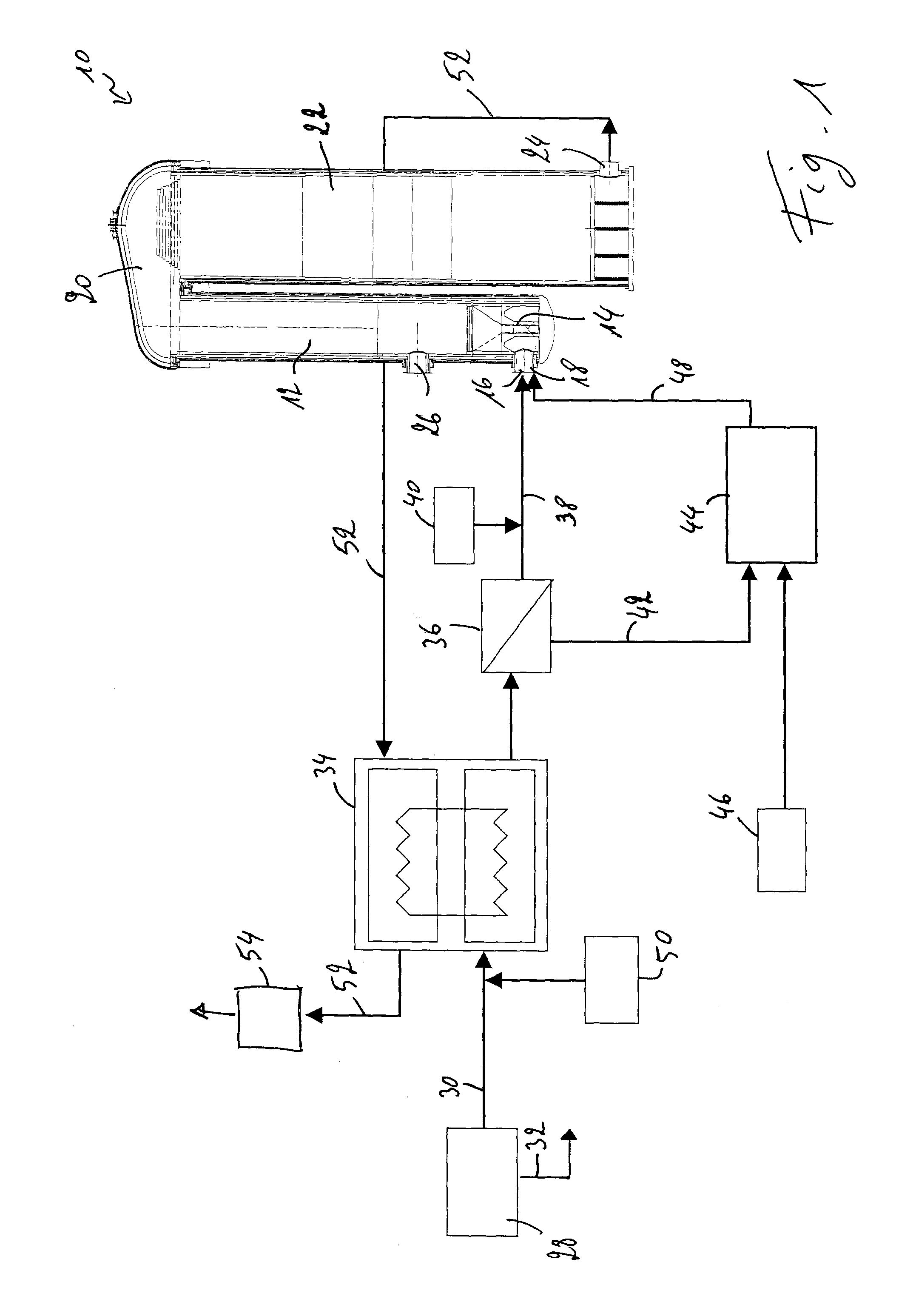

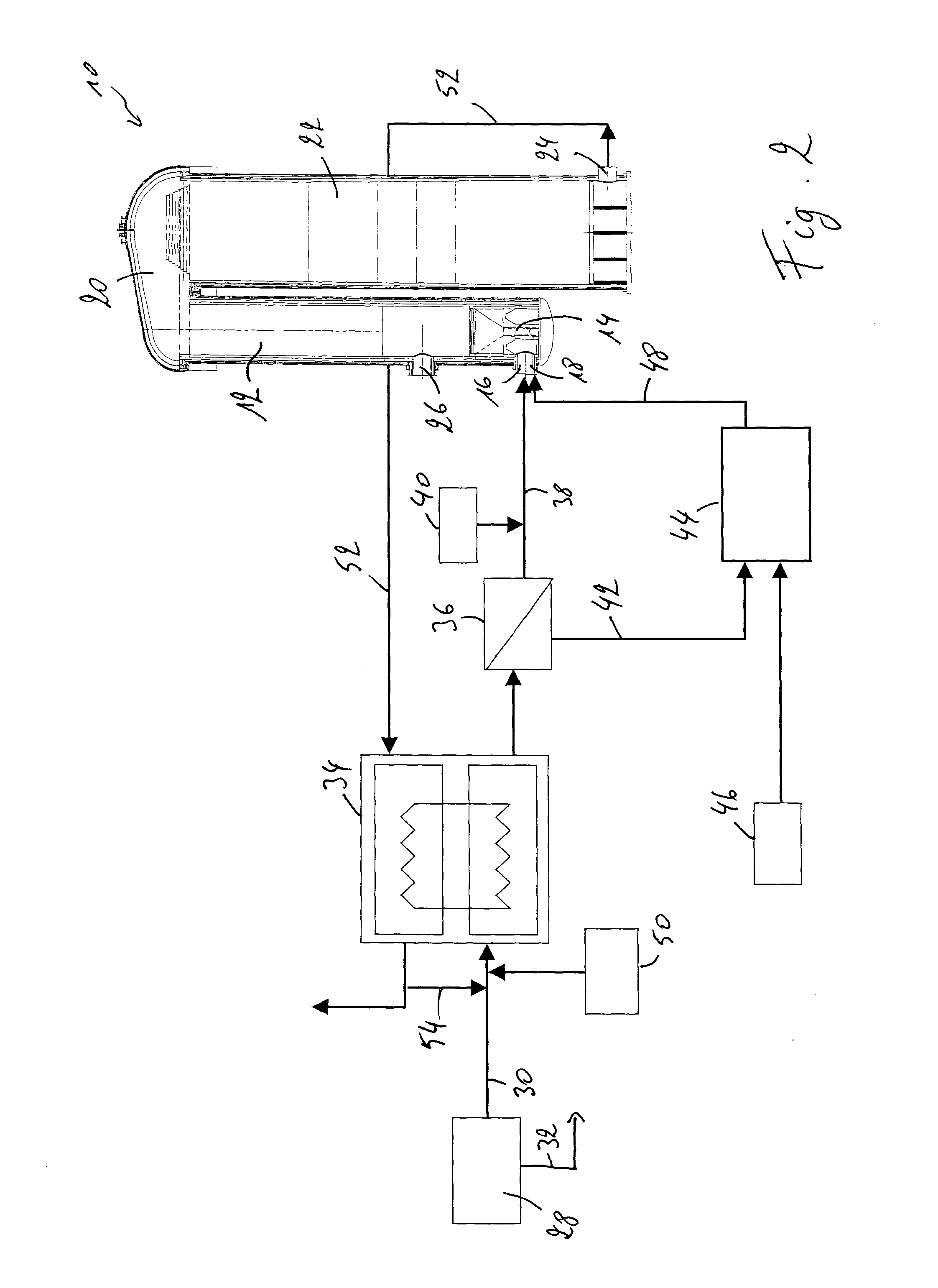

Method for operating a regenerative heater

ActiveUS20120064471A1Improve burnsEasy to igniteBrick-hot blast stovesStorage heatersCombustorNuclear engineering

The present invention proposes a method for operating a regenerative heater (10), in particular a hot blast stove of a blast furnace, the regenerative heater (10) comprising a first chamber (12) and a second chamber (22), the first chamber (12) having a burner (14) arranged therein, the second chamber (22) comprising heat storage means. Such a method comprises a heating cycle wherein fuel and oxidizing gas are fed to the burner (14) of the first chamber (12) and allowed to burn and wherein hot flue gasses are led through the second chamber (22) to heat the heat storage means; and a blowing cycle wherein a process gas is fed through the second chamber (22) to pick up heat from the heat storage means. According to an important aspect of the present invention, the heating cycle comprises the steps of feeding a first stream (38) of fuel to the burner (14) of the regenerative heater (10); feeding a second stream (42) of fuel to a pre-combustion chamber (44); feeding oxygen (46) to the pre-combustion chamber (44); allowing the second stream (42) of fuel and the oxygen (46) to interact so as to form oxidizing gas (48); and feeding the oxidizing gas (48) to the burner (14) of the regenerative heater (10). At the end of the heating cycle, the supply of oxygen (46) to the pre-combustion chamber (44) is discontinued, while further feeding the second stream (42) of fuel to the pre-combustion chamber (44) and further feeding the first stream (38) of fuel to the burner (14).

Owner:PAUL WURTH SA

Grain pulp for improving quality of sheep meat

InactiveCN102178097AReduce usageEasy to useFood processingAnimal feeding stuffAnimal scienceAdditive ingredient

The invention provides grain pulp for improving the quality of sheep meat, relates to a sheep feed, and aims to solve the problems that the current sheep meat has poor quality, and landfill treatment of fresh citrus pulp causes resource waste and environmental pollution. The grain pulp consists of a main component and an auxiliary component, wherein the main component is citrus pulp; and the auxiliary component consists of urea, corn flour, molasses, sodium sulfate, zeolite, sodium dihydrogen phosphate and edible salt. By the grain pulp, the carcass net meat weight and pure meat percentage ofthe sheep can be remarkably improved, the muscle shearing force is reduced, the level of meat color is improved, the content of cholesterol in the sheep meat can be remarkably reduced, and the level of calcium is remarkably improved, so that the quality of sheep meat is remarkably improved; and the grain pulp has low cost, good palatability, high content of protein and balanced nitrogen-sulfur proportion and calcium-sulfur proportion, and has important significance for improving the economical benefit of sheep breeding and realizing sustainable circulation and efficient utilization of resources. The grain pulp has a wide prospect in the field of sheep feeds.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

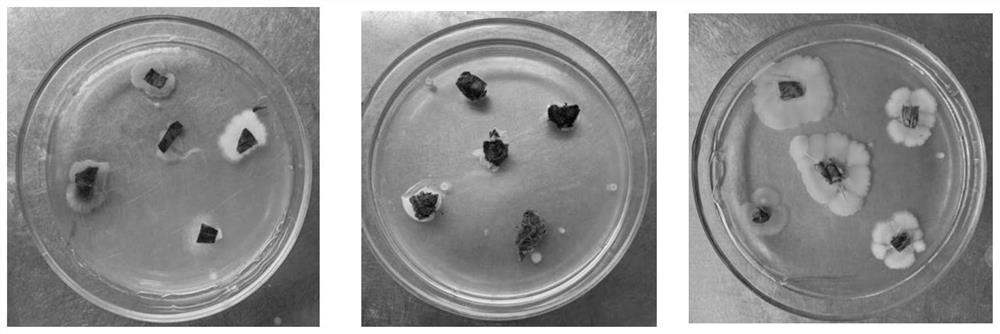

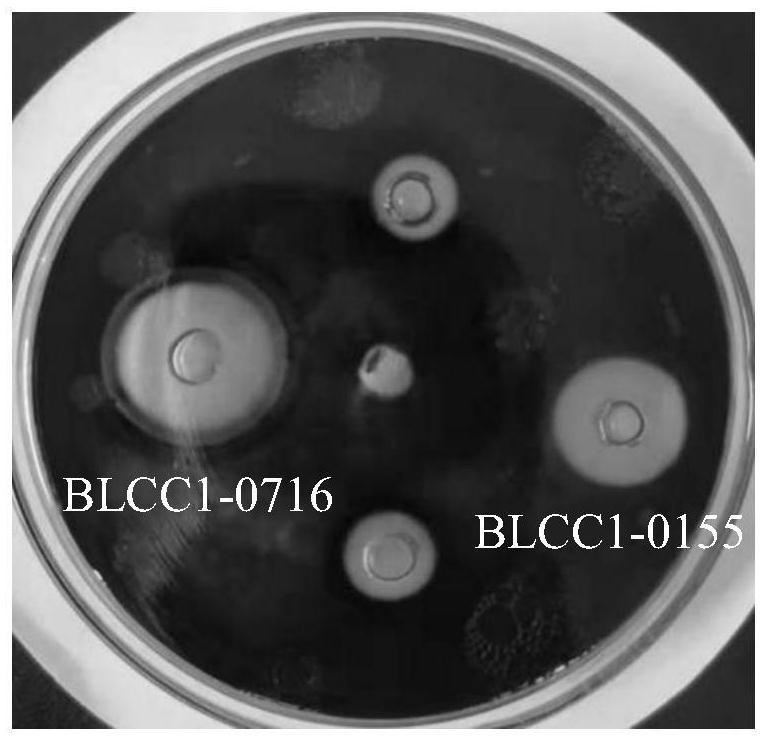

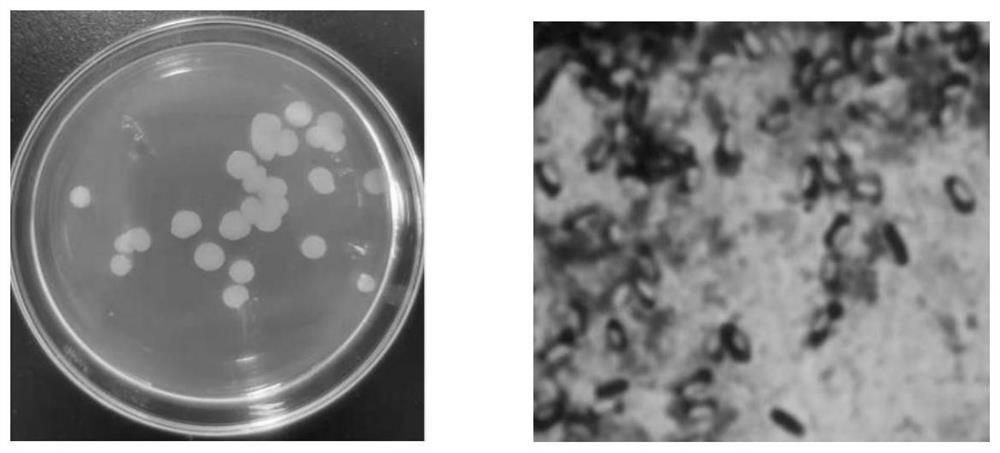

Brevibacillus laterosporus and application thereof

ActiveCN114107134AEase intestinal inflammationImprove disease resistanceBacteriaDigestive systemBiotechnologyBacterial strain

The invention provides brevibacillus laterosporus, which is named as brevibacillus laterosporus BLCC1-0716, the brevibacillus laterosporus BLCC1-0716 is preserved in the China Center for Type Culture Collection on November 11, 2021, and the preservation number of the brevibacillus laterosporus BLCC1-0716 is CCTCC (China Center for Type Culture Collection) NO: M 20211397. The bacterial strain is obtained by screening and separating from the tissue of a drug source plant honeysuckle flower, is wide in antibacterial spectrum, good in antibacterial performance, good in tolerance and good in safety, and has good functions of resisting inflammation, protecting intestinal tracts and preventing and treating enteritis.

Owner:山东宝来利来生物工程股份有限公司

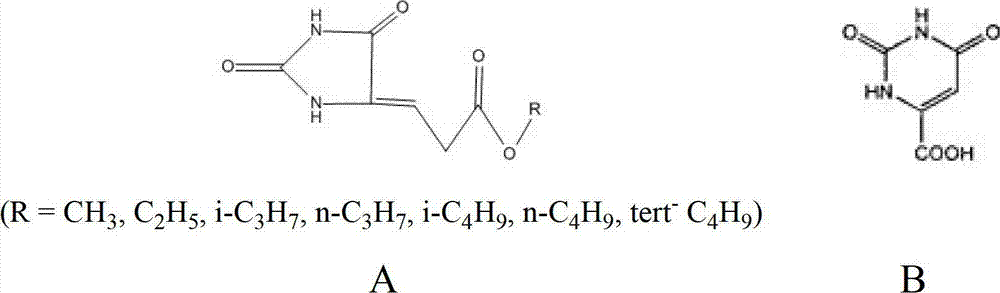

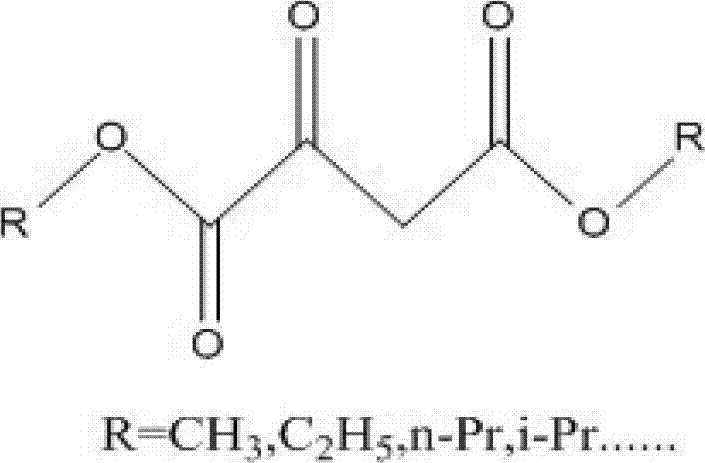

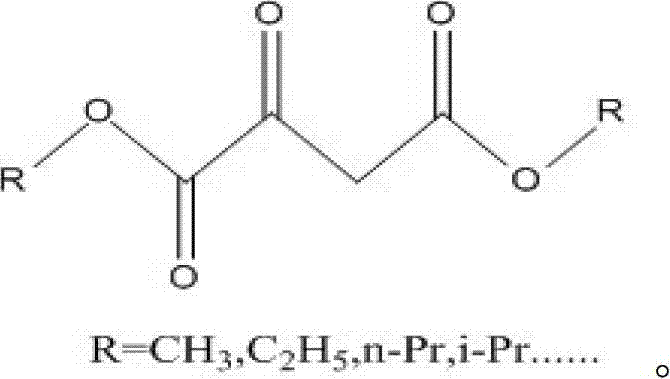

Synthetic method for orotic acid intermediate 5-alkoxy methylene hydantoin

InactiveCN102786478AReduce usageImprove the operating environmentOrganic chemistryChemical recyclingIncreased orotic acidKetone

The invention discloses a synthetic method for orotic acid intermediate 5-alkoxy methylene hydantoin. The method comprises the steps of using solid super acid as a catalyst; adding the solid super acid and urea to a benzene solvent; heating; dropping 2-keto-succinate to reaction liquid; agitating to react; and then filtering the solid super acid catalyst to be recycled after the reaction; distilling mother liquor to recover solvent which can be recycled, so as to obtain a raw product; and washing the crude product to obtain a target product. Compared with the prior art, the synthetic method disclosed by the invention has the advantages of simple and economical post-processing technology, less three wastes, and high yield, and is a novel method for synthesizing the 5-alkoxy methylene hydantoin.

Owner:SHANGHAI HUAYI GRP CO

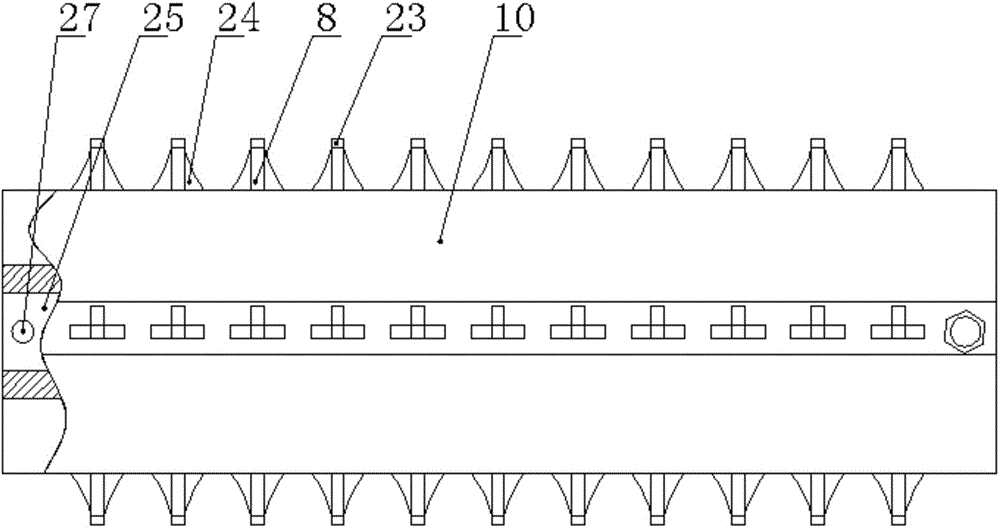

Palm sheet cutting and crushing device

InactiveCN104624318AOvercome technical difficulties of incomplete decompositionMeet production needsGrain treatmentsDecompositionPalm fiber

The invention relates to a palm sheet cutting and crushing device, which comprises a rack, a feeding mechanism, a decomposition mechanism and a discharge opening, wherein the feeding mechanism and the discharge opening are respectively arranged on an formed in the front part and the rear part of the rack; the decomposition mechanism is arranged in the middle of the rack; the feeding mechanism is composed of at least four feeding roll shafts, feeding rolls, gears, bearings, and a transmission mechanism; the feeding rolls sleeve the feeding roll shafts; the gears are arranged at two ends of each feeding roll shaft; the bearings are arranged on the outer sides of the gears; the transmission mechanism is connected with the feeding roll shafts; the decomposition mechanism is composed of a cutting mechanism and a crushing mechanism; and the cutting mechanism is communicated with the crushing mechanism. According to the palm sheet cutting and crushing device, the technical problems that a palm sheet fiber is relatively tightly entwisted, and is incompletely decomposed to cause incomplete decomposition are overcome; by virtue of coordination of the cutting mechanism and the crushing mechanism, the palm sheet fiber which relatively tightly entwisted can be easily cut into small palm fiber sections through the cutting mechanism; the palm fiber is completely decomposed through the crushing mechanism; and the palm sheet cutting and crushing device conforms to the production requirements.

Owner:TIANJIN CITY SHANGDE WIRE MACHINERY

Method of producing bio-fermentation feedstuff by using the waste stalk dregs generated in the preparation course of ethanol by sorgo stalk

InactiveCN101138388AHigh nutritional valueImprove product qualityFood processingAnimal feeding stuffCelsius DegreeSweet sorghum

The present invention relates to a method for producing biologically fermented feed with the waste stalk dregs left after the sweet sorghum stalk is used for preparing ethanol as the raw material; the method belongs to the technical field of feed processing. The waste stalk dregs after the sweet sorghum stalk is used for preparing ethanol are matched with oilseed residue and cottonseed residue to be the backing material. The cultured bacteria are inoculated on the smashed raw material and mixed evenly with the backing material; and then the mixture is packed in a plastic bag for solid fermentation; the raw materials in the plastic bag are compressed tightly and compacted; the bag is sealed to form an anaerobic environment for controlling the growing of bacteria and fermenting for 15 to 20 days within the temperature range of 20 to 38 Celsius degrees. The present invention produces full-price feed which is rich in nutrition and at the same time the present invention can solve the problem of environmental pollution caused by ethanol industry. Nutrition is richer after the waste stalk dregs of sweet sorghum is mixed for use with a plurality of other raw materials such as oilseed residue and cottonseed residue and the crude protein content is obviously increased. As for feeding, the fermented feed can replace 20 percent of the basal ration; the rate of gain and slaughter rate are obviously increased and the feed cost can be saved by about 10 percent.

Owner:王孟杰

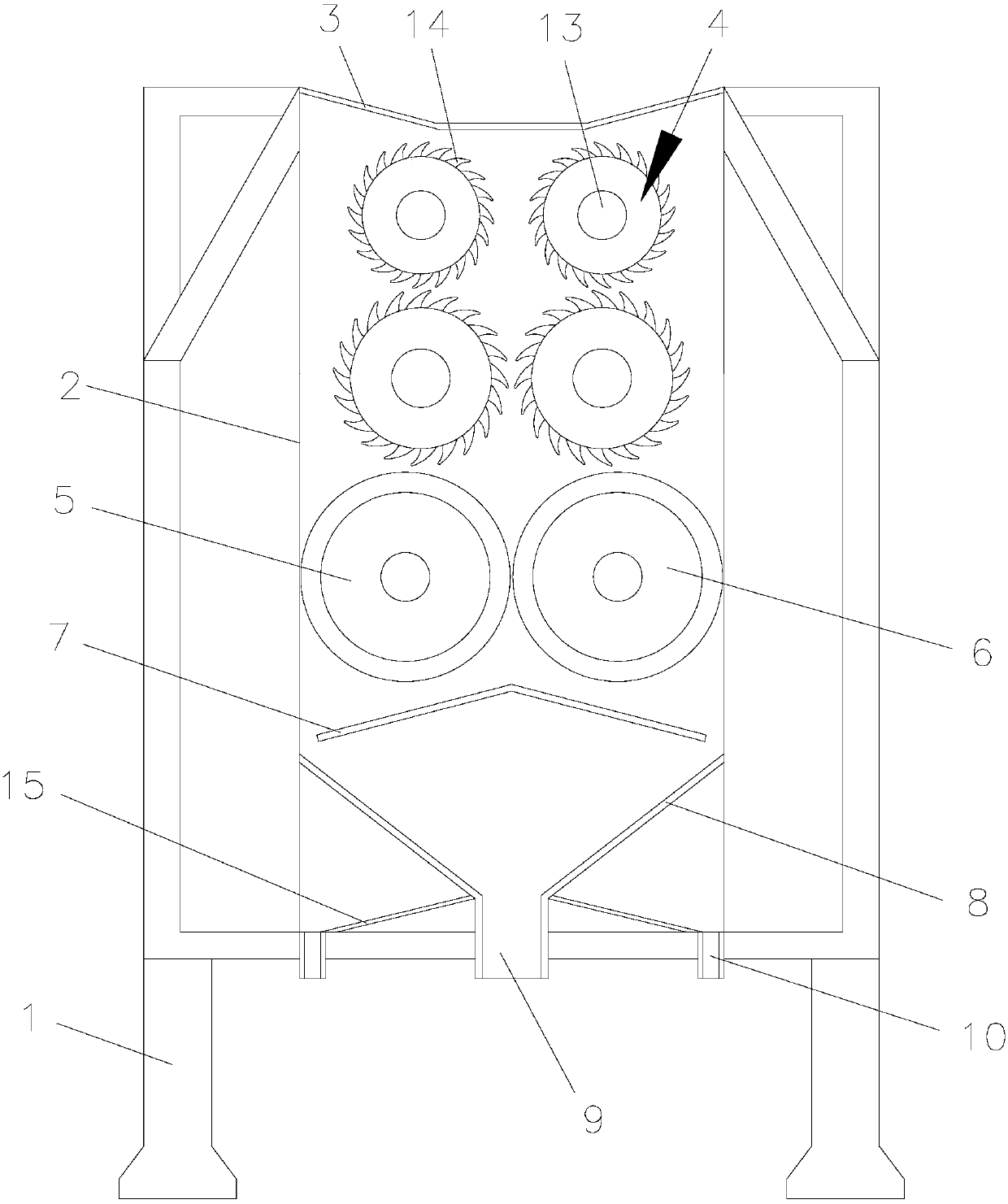

Fully automatic sand box crusher

The invention relates to a full-automatic sand box crushing machine.The full-automatic sand box crushing machine comprises a support and a crushing box.The crushing box is fixedly installed on the support.A feeding funnel is connected to the top end of the crushing box.A plurality of rows of smashing rollers are rotationally installed on the upper side in the crushing box.The rollers in each row are sequentially arranged from top to bottom.The distance between every two smashing rollers in each row sequentially reduces from top to bottom.Every two smashing rollers in each row rotate oppositely.A first crushing roller and a second crushing roller are arranged in the middle in the crushing box side by side, and the distance between the first crushing roller and the second crushing roller is adjustable.A material distributing board is fixedly installed on the lower side in the crushing box.Two oblique screening nets are fixedly installed below the two sides of the material distributing board in the crushing box and are arranged in a V shape.A first discharge port is formed in the bottom of the crushing box and located between the two screening nets.Second discharging ports are formed below the two screening nets.A sand box conveying mechanism is connected with the feeding funnel.By means of the full-automatic sand box crushing machine, crushing is uniform, and the crushing efficiency and quality are high.

Owner:CHANGZHOU XIANGDE MACHINERY MFG

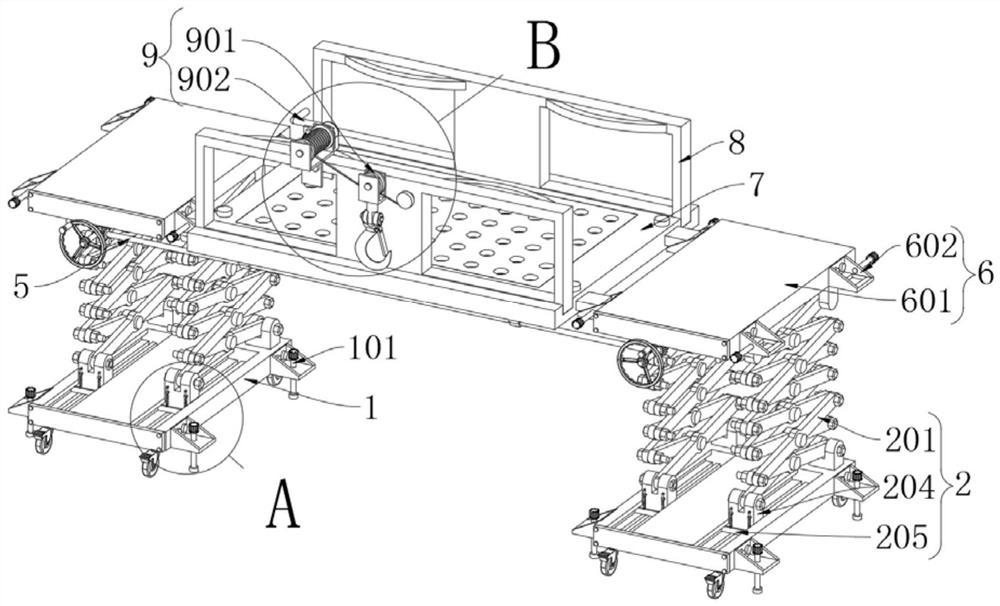

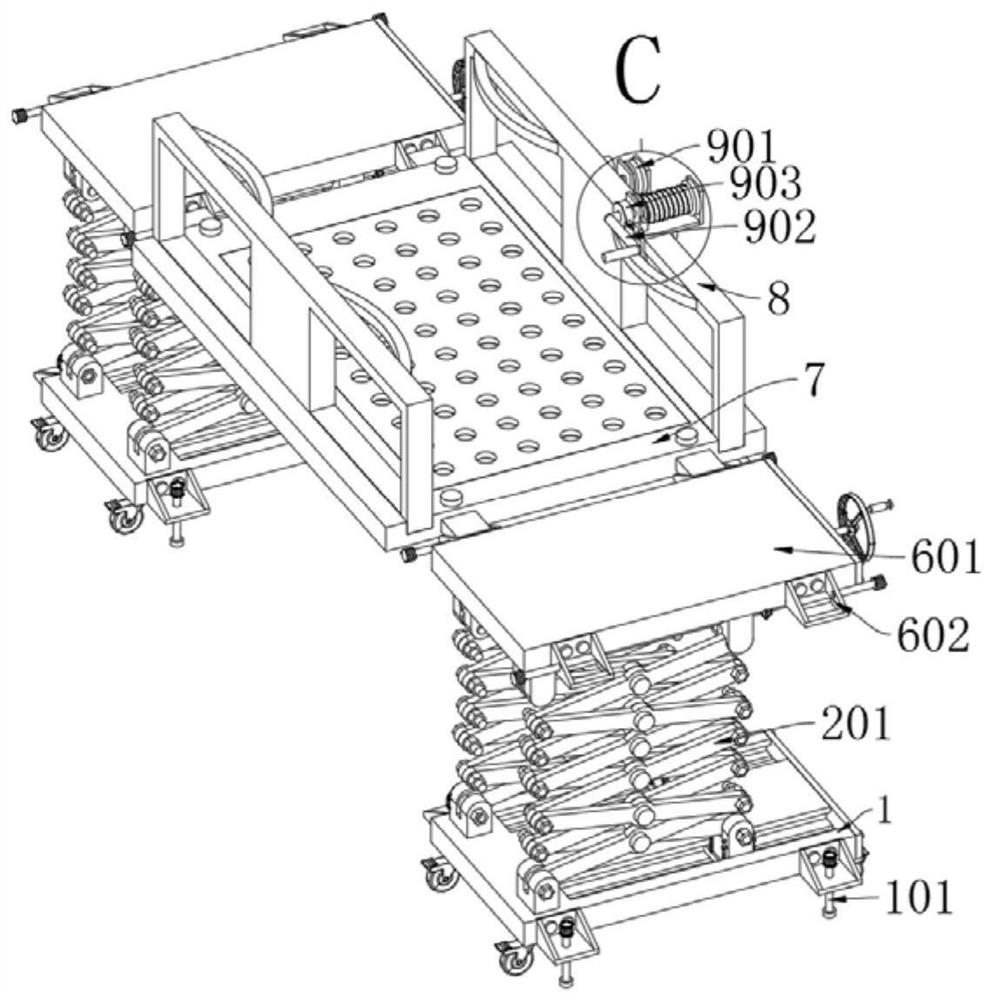

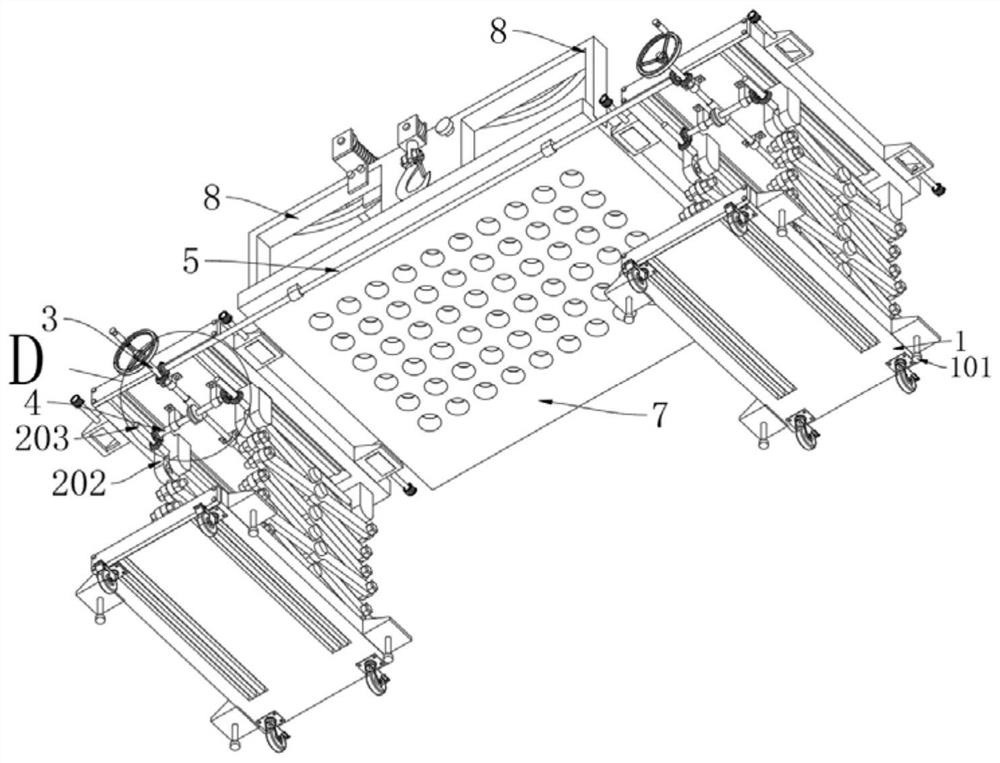

Synchronous lifting structure for building machinery and building construction

InactiveCN111977532AEasy to operate aloneEasy to load by yourselfSafety devices for lifting equipmentsWinding mechanismsRatchetDrive shaft

The invention provides a synchronous lifting structure for building machinery and building construction. The structure comprises a base, wherein four universal wheels are installed at the bottom of the base, and a rectangular baffle is fixed on the base by bolts; a lifting mechanism is installed on the base, and the other end of the lifting mechanism is connected to a connecting mechanism; the bottom of the connecting mechanism is equipped with a driving shaft and a transmission shaft A, a labor-saving worm is installed on the driving shaft, and a turbine is installed in the middle of the transmission shaft A. A feeding structure is improved, a rocker is provided on a guardrail, the rocker and a movable pulley are connected by a wire rope, the other end of the wire rope is fixed on the guardrail, and a labor-saving arm is formed between the movable pulley and the rocker. When the wire rope is wound by rotating the rocker, the movable pulley will rise, which is convenient for the construction personnel on a support plate B to load the material alone. A ratchet is provided at one end of the handle, and the setting of the ratchet makes the feeding safer.

Owner:牛林会

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com