Workpiece machining device

A processing device and workpiece technology, applied in the field of workpiece processing and transportation, can solve the problems of non-replacement of molds, inconvenient removal of workpieces, unstable mold clamping process, etc., and achieve the effects of compact structure, wide processing range and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

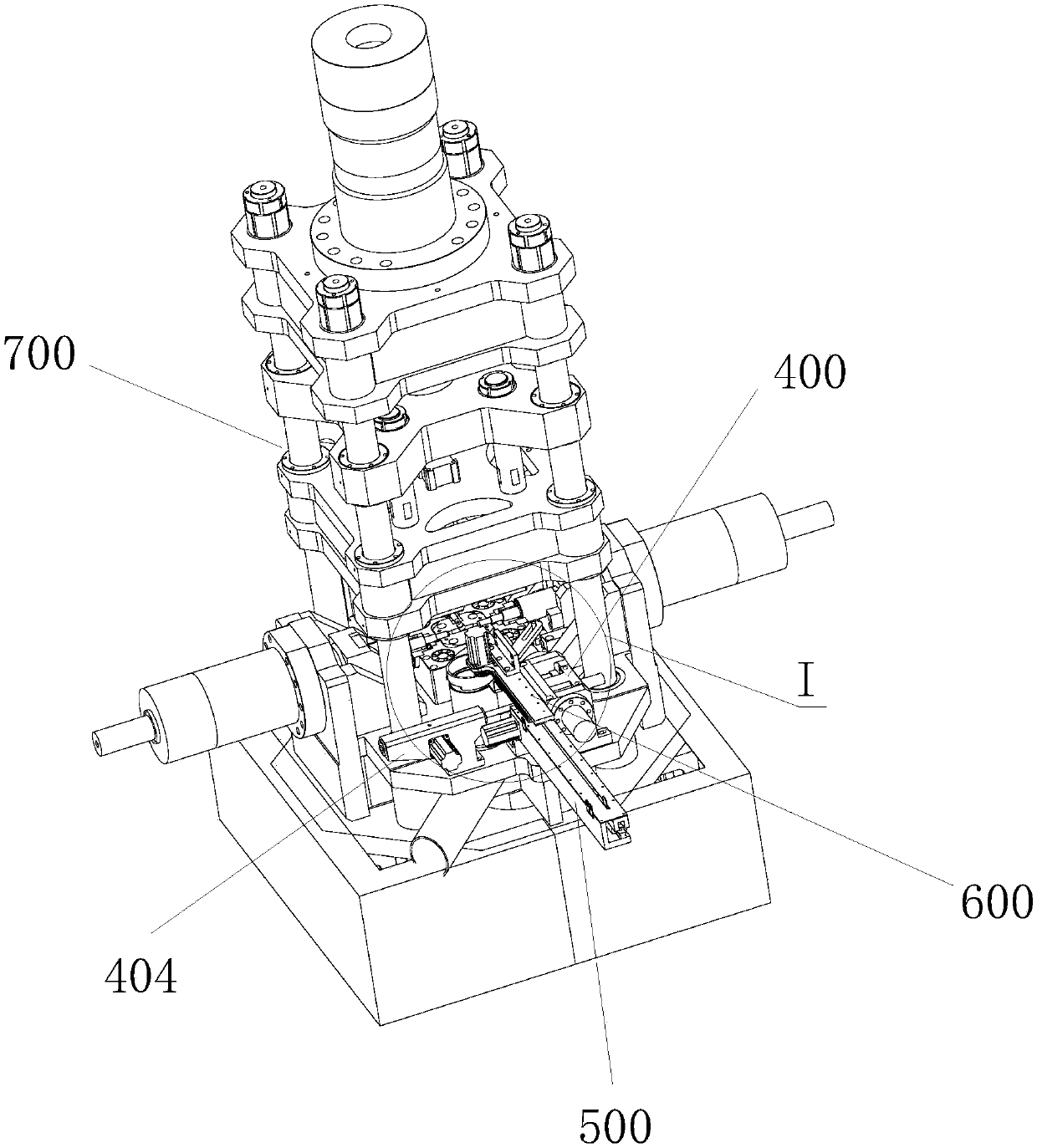

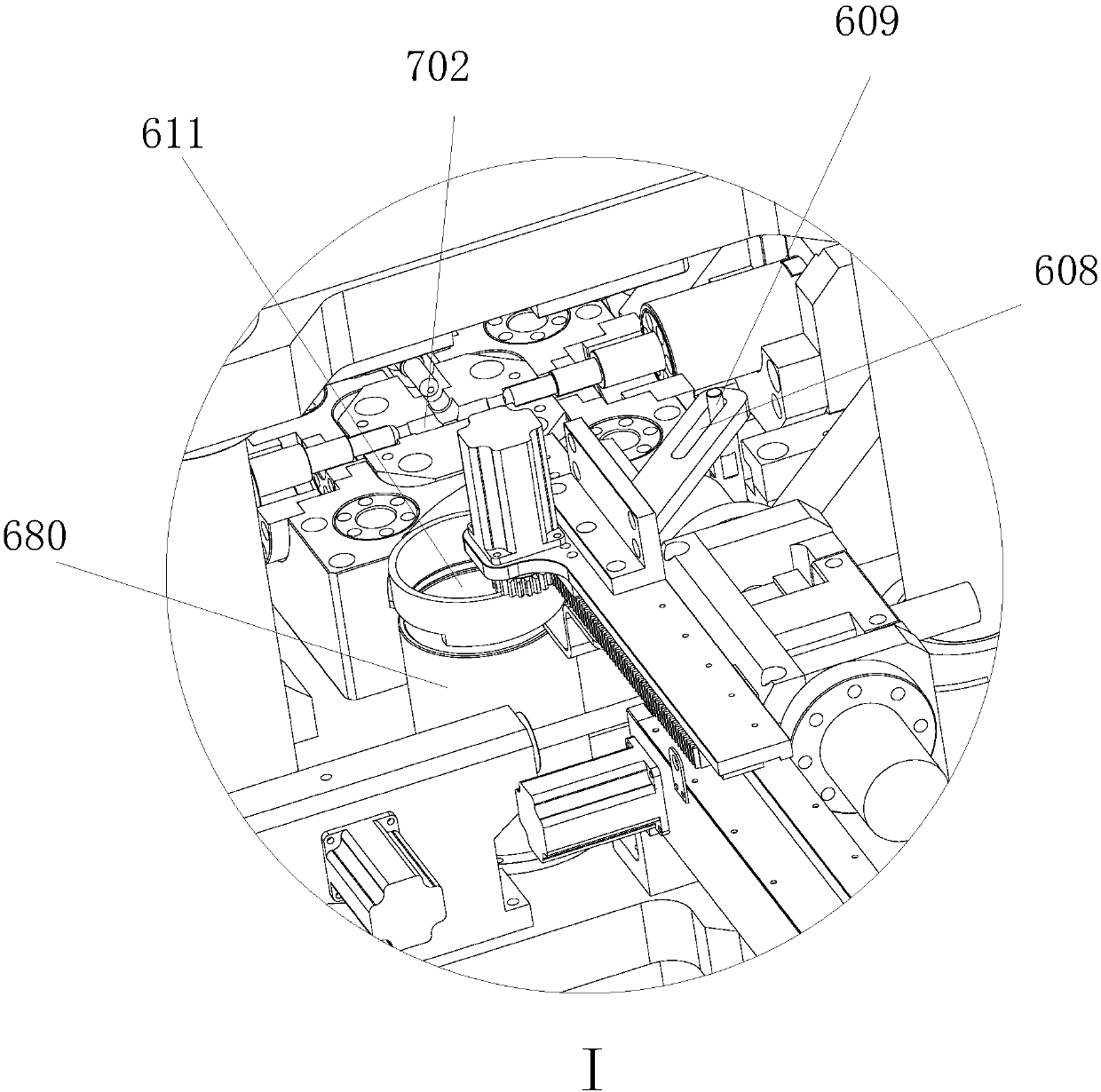

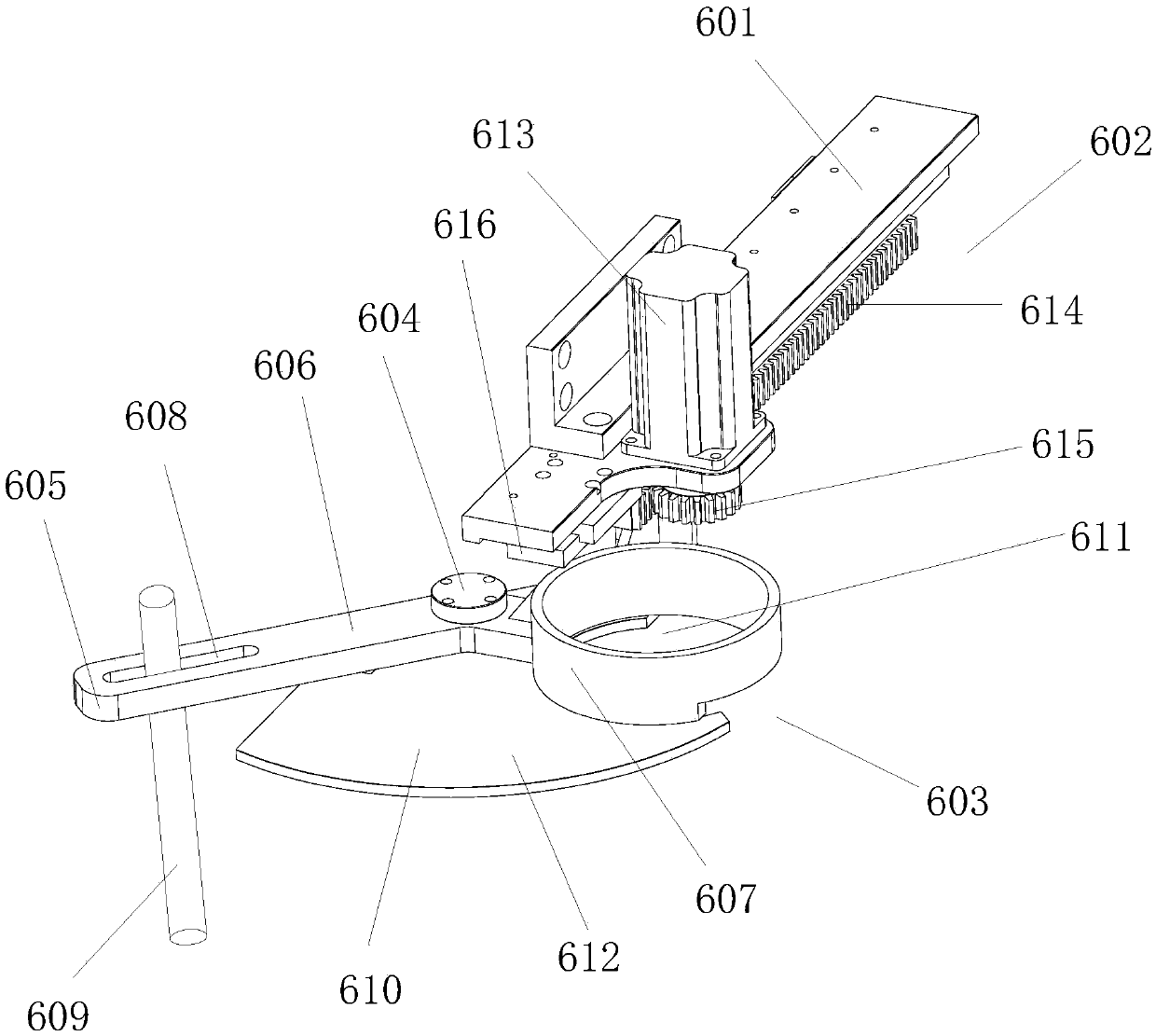

[0039] Such as Figure 1 to Figure 16As shown, a workpiece processing device includes a feeding manipulator 500 for sending a workpiece to be processed, a retrieving manipulator 600 for taking out a completed workpiece, and a workbench 725. The feeding manipulator 500 and the reclaiming manipulator 600 are arranged on the workbench 725; The material manipulator 600 includes a mounting frame 601, the mounting frame 601 is provided with a mobile assembly 602 that moves along the mounting frame 601, and the mobile assembly 602 is provided with a material receiving assembly 603; the material receiving assembly 603 includes a rotating shaft 604 and a rotating rod 605, and the rotating rod 605 Rotate around the rotating shaft 604; the rotating rod 605 includes a drive rod 606 on one side of the rotating shaft 604 and a material receiving tray 607 on the other side, the rotating rod 605 is provided with a chute 608, and the workbench 725 is provided with a The blocking rod 609 ; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com