Feeding method in processes of tobacco leaf threshing and re-drying

A technology of threshing and redrying and feeding method, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of uneven feeding, inability to fully maintain the activity of biological agents, and low utilization rate of feed liquid, so as to improve the feeding effect and improve Tobacco leaf use value and high utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

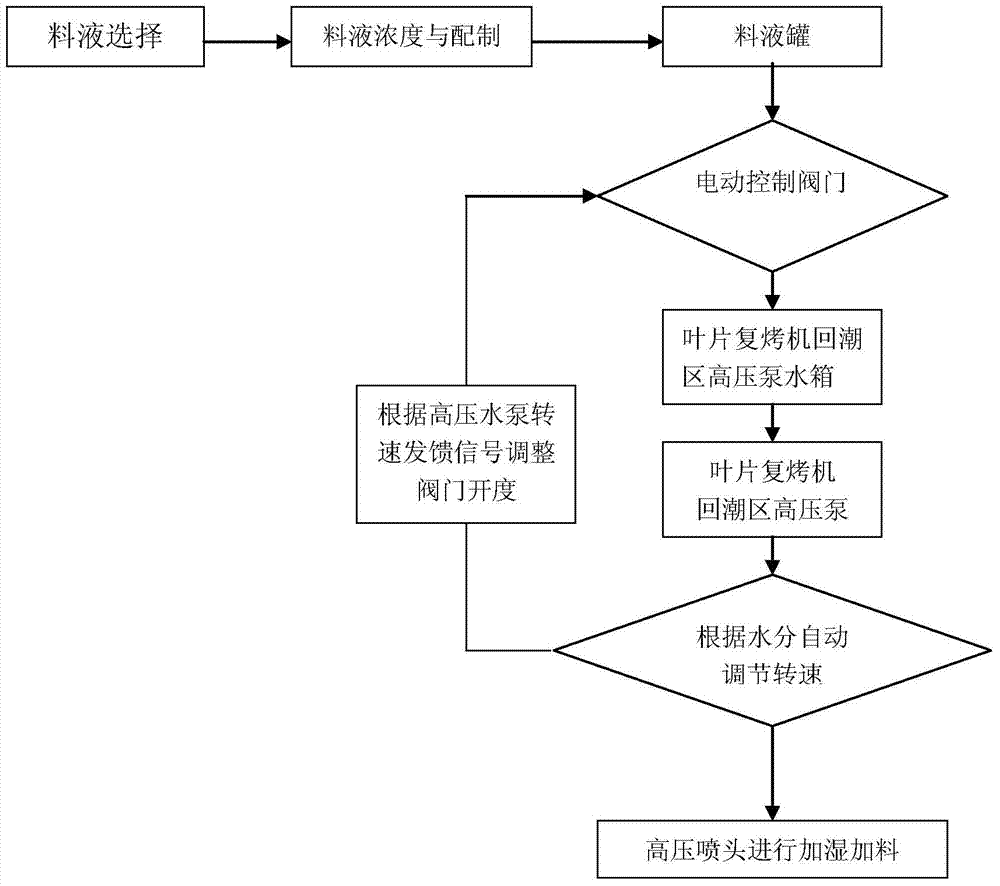

Method used

Image

Examples

Embodiment 1

[0021] 1. Select the feed liquid according to the quality characteristics of the original tobacco and the formula requirements, and select the suitable feed liquid (such as biological preparations, the specific composition is: neutral protease 2wt‰; cellulase 5wt‰; glucoamylase 4wt‰; melanoid 8.9 wt%; tobacco leaf pre-fermentation extract 20wt%; purified water 70wt%), determine the application ratio: feed liquid: tobacco leaves = 40kg: 10000kg.

[0022] 2. According to the concentration of the feed liquid and the volume of the high-pressure water tank, the concentration of the feed liquid added to the tobacco leaves is calculated as 0.4%, and the feed liquid in the liquid storage tank is prepared according to the concentration.

[0023] 3. Use the existing plunger high-pressure pump and high-pressure nozzle system of the re-roasting machine for feeding, and feed in the re-moisture section of the re-roasting machine. Use 4MPa high-pressure water to carry the material liquid thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com