Patents

Literature

649results about How to "Add evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

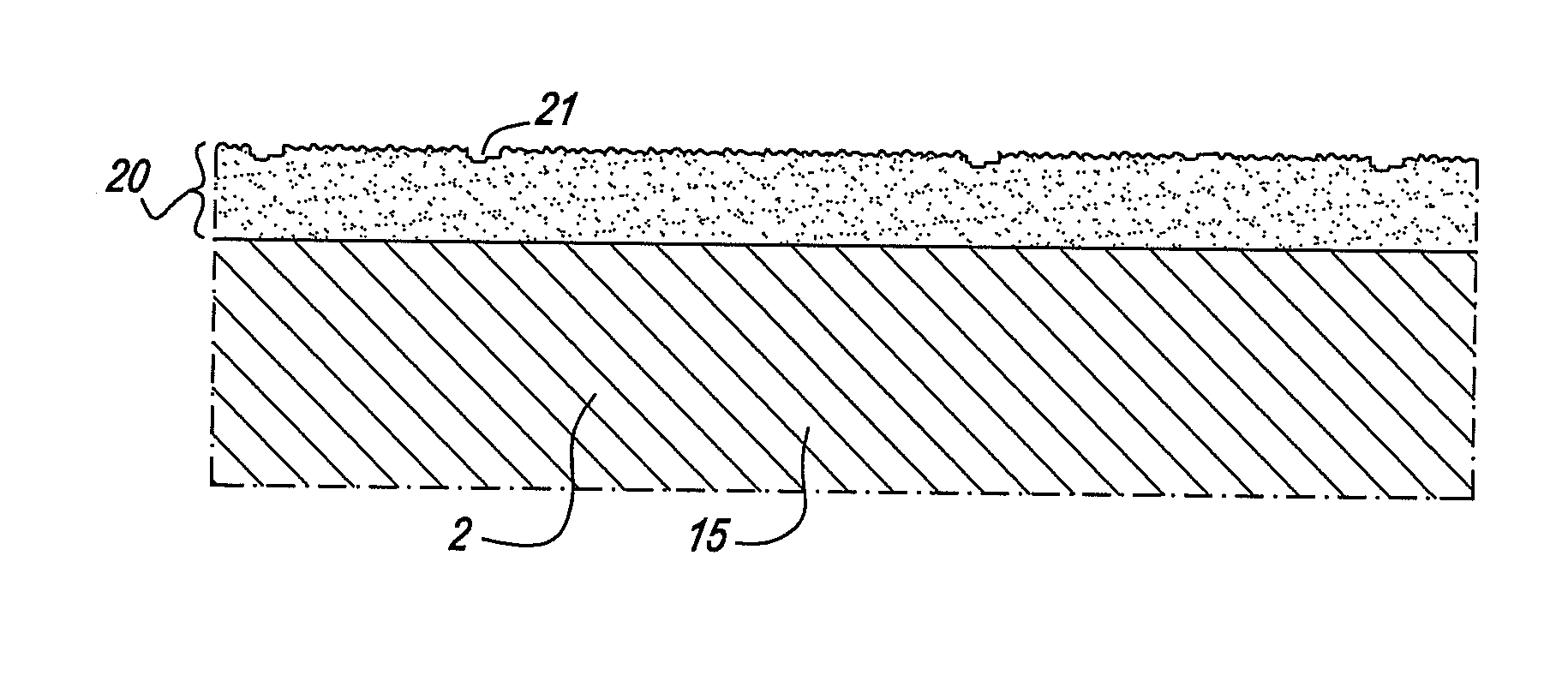

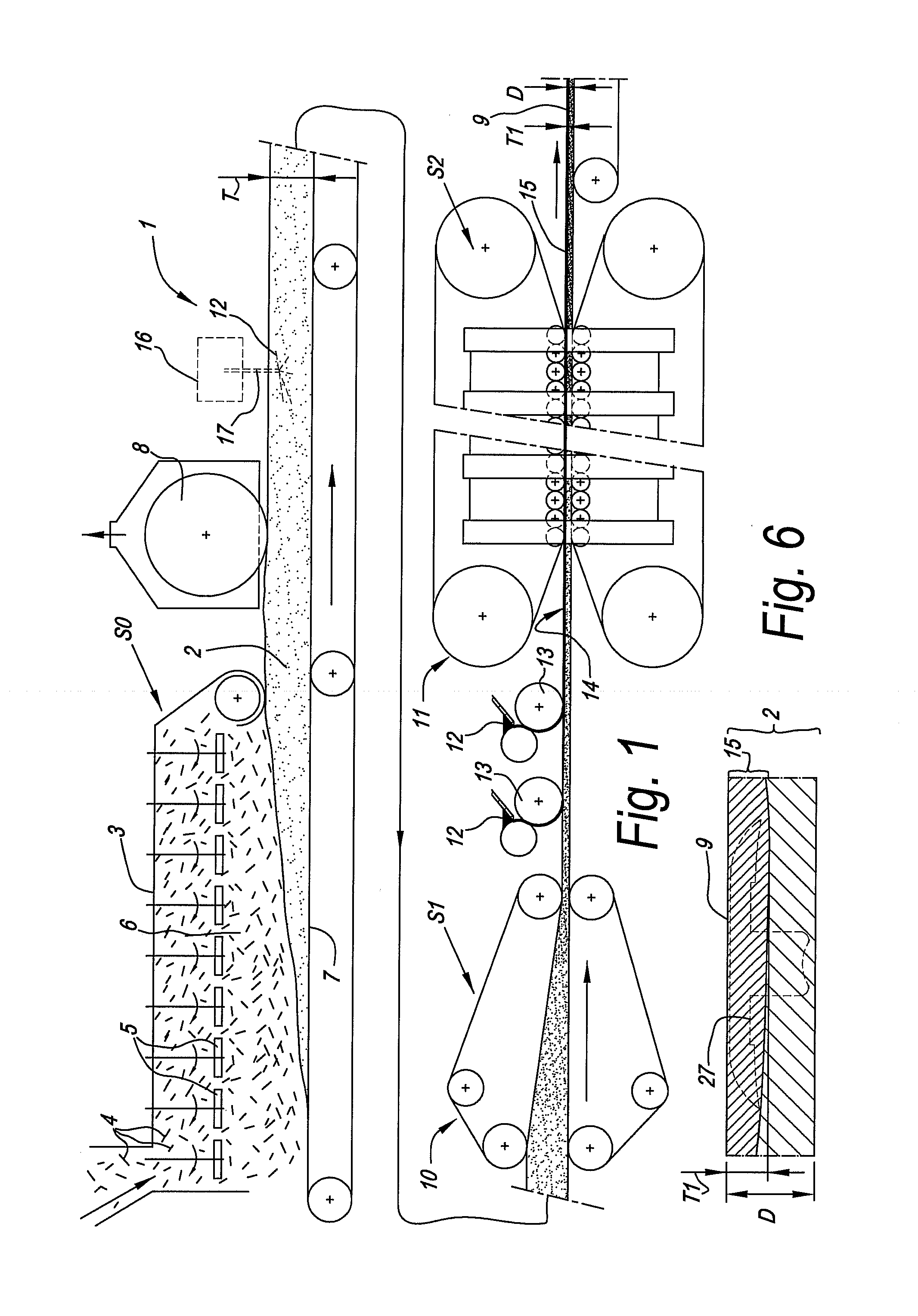

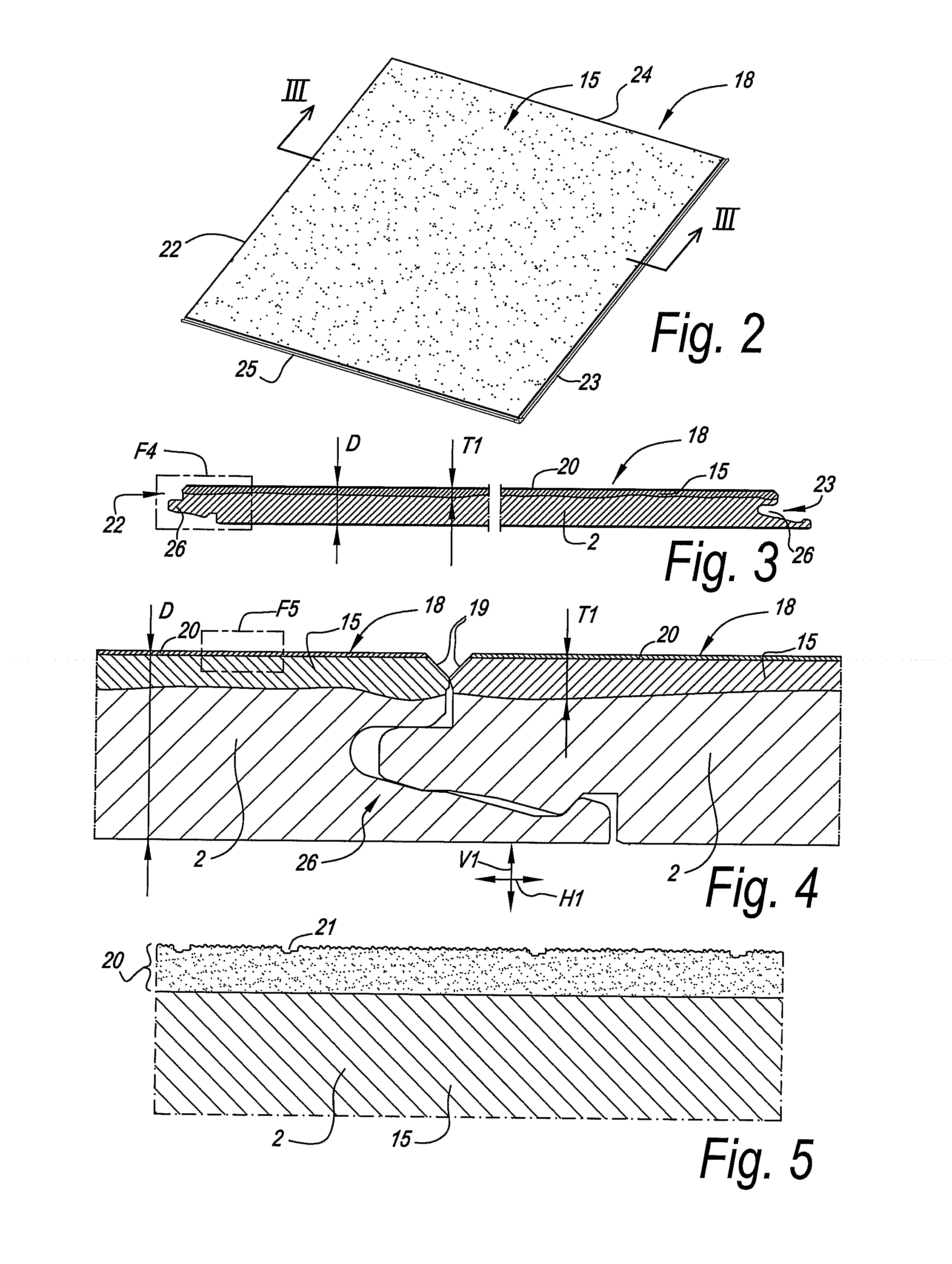

Method for manufacturing panels and panels obtained hereby

InactiveUS20110311806A1Simply formedFine surfaceLayered productsMonocomponent cellulose artificial filamentVolumetric Mass DensityEngineering

A method for manufacturing panels including a substrate on the basis of a pressed material mass, whereby it is started from a material mass to be densified, wherein the density of this material mass, in one or more densifying steps, is at least doubled. Prior to one or more of these densifying steps, a colorant is added to the material mass.

Owner:FLOORING IND LTD

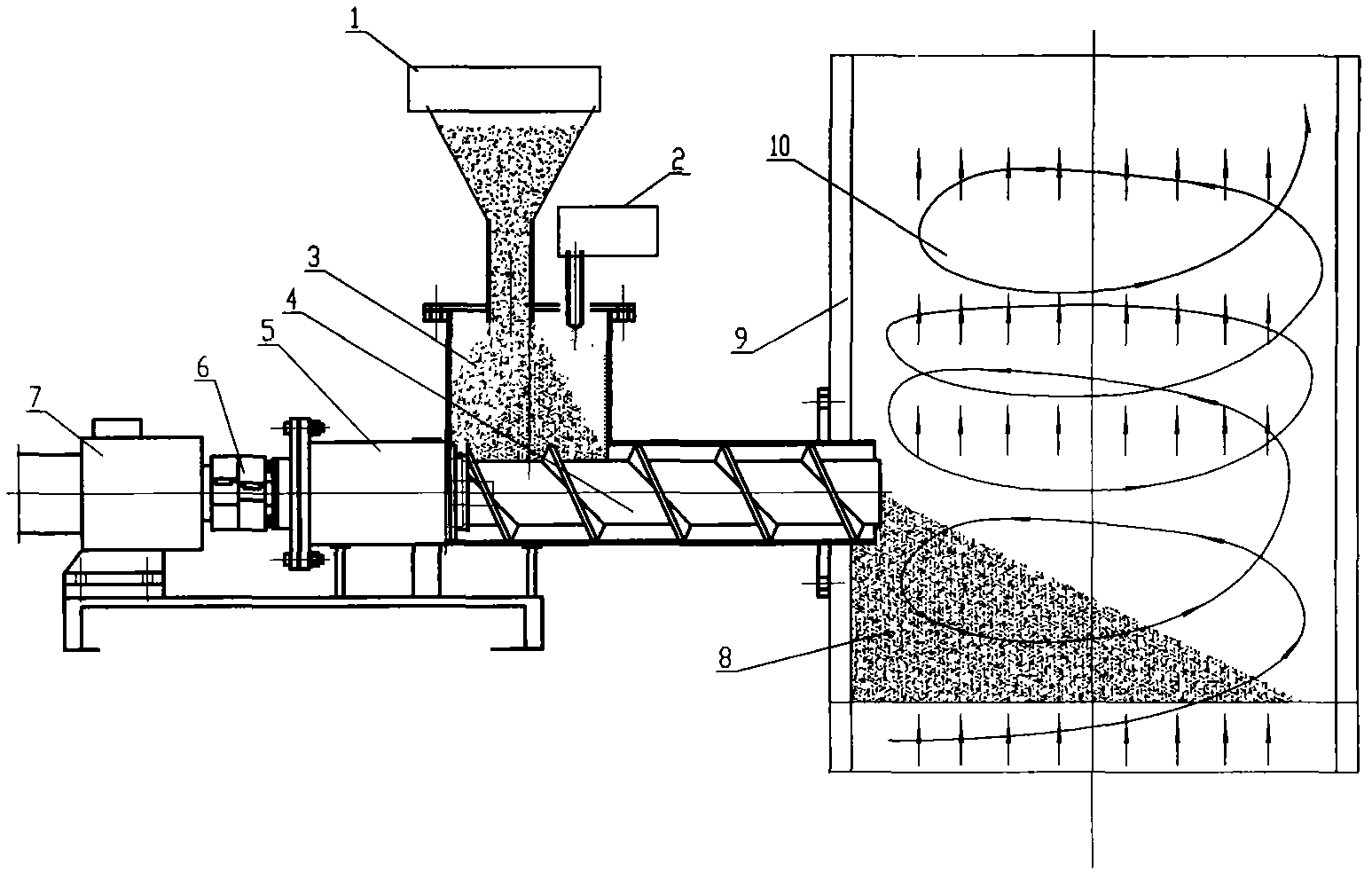

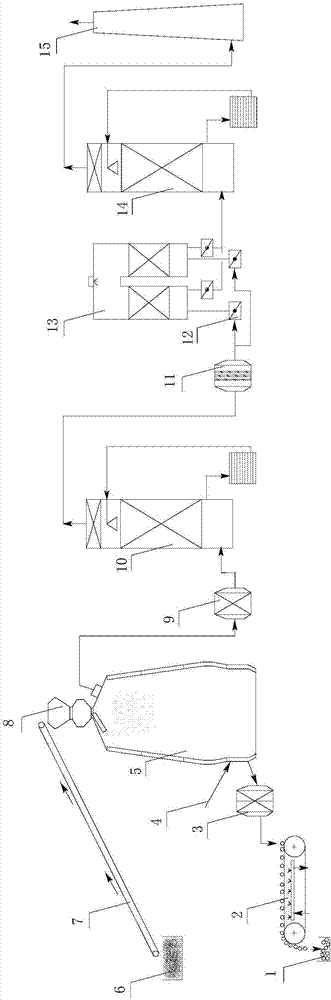

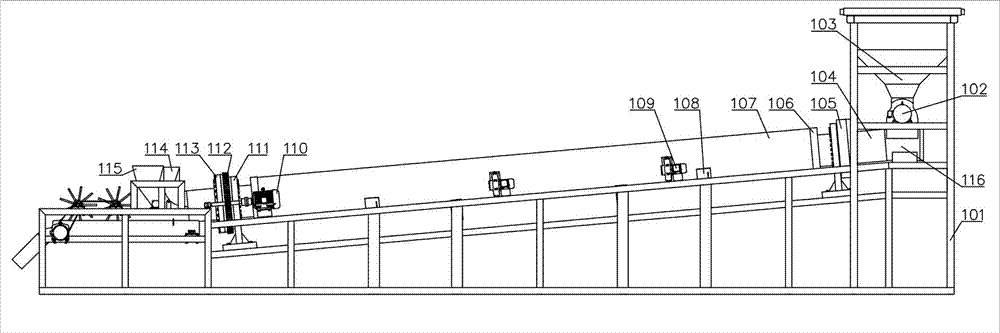

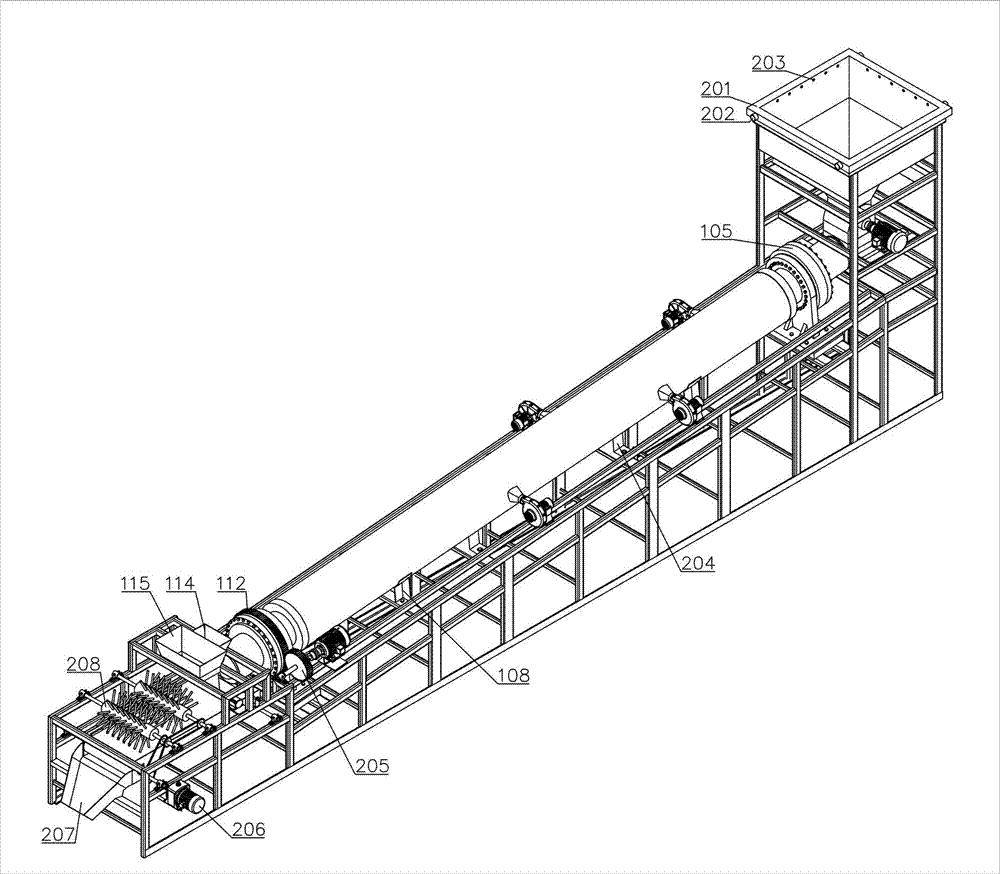

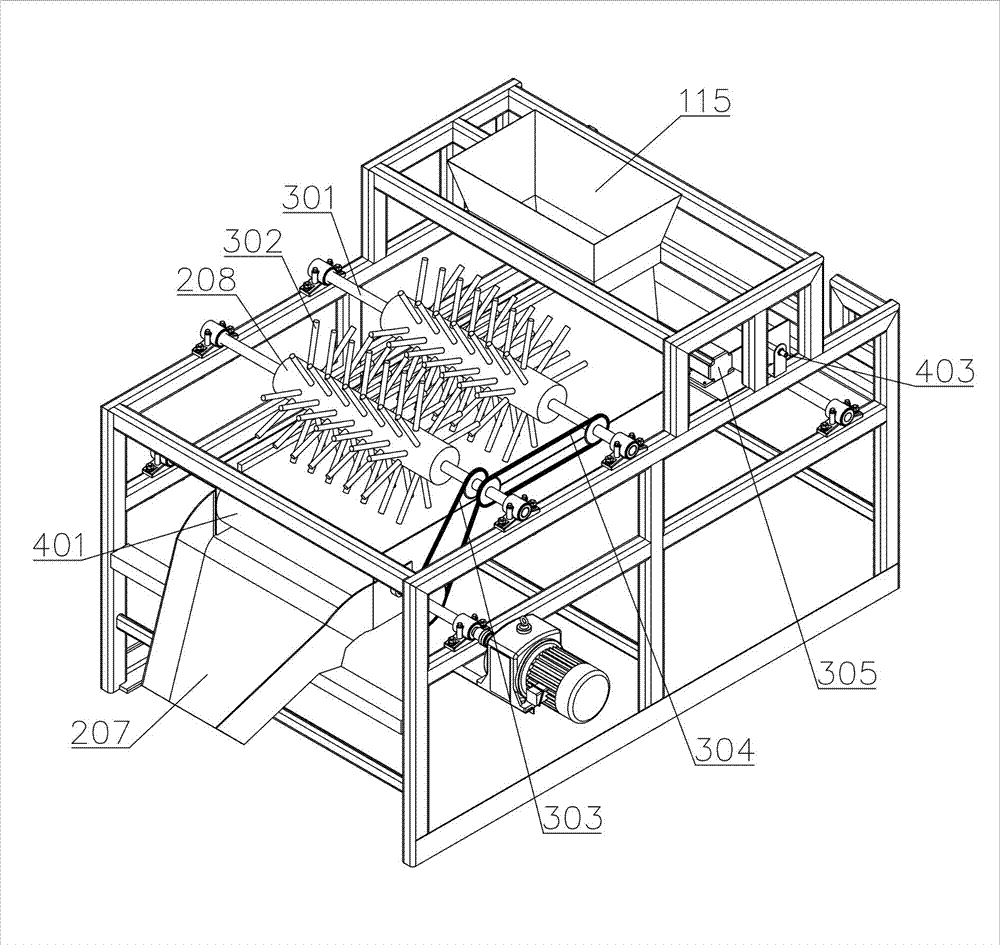

Catalyst successive impregnation equipment and method

ActiveCN102806109AImprove impregnation efficiencyImprove impregnation uniformityCatalyst activation/preparationEngineeringCatalyst support

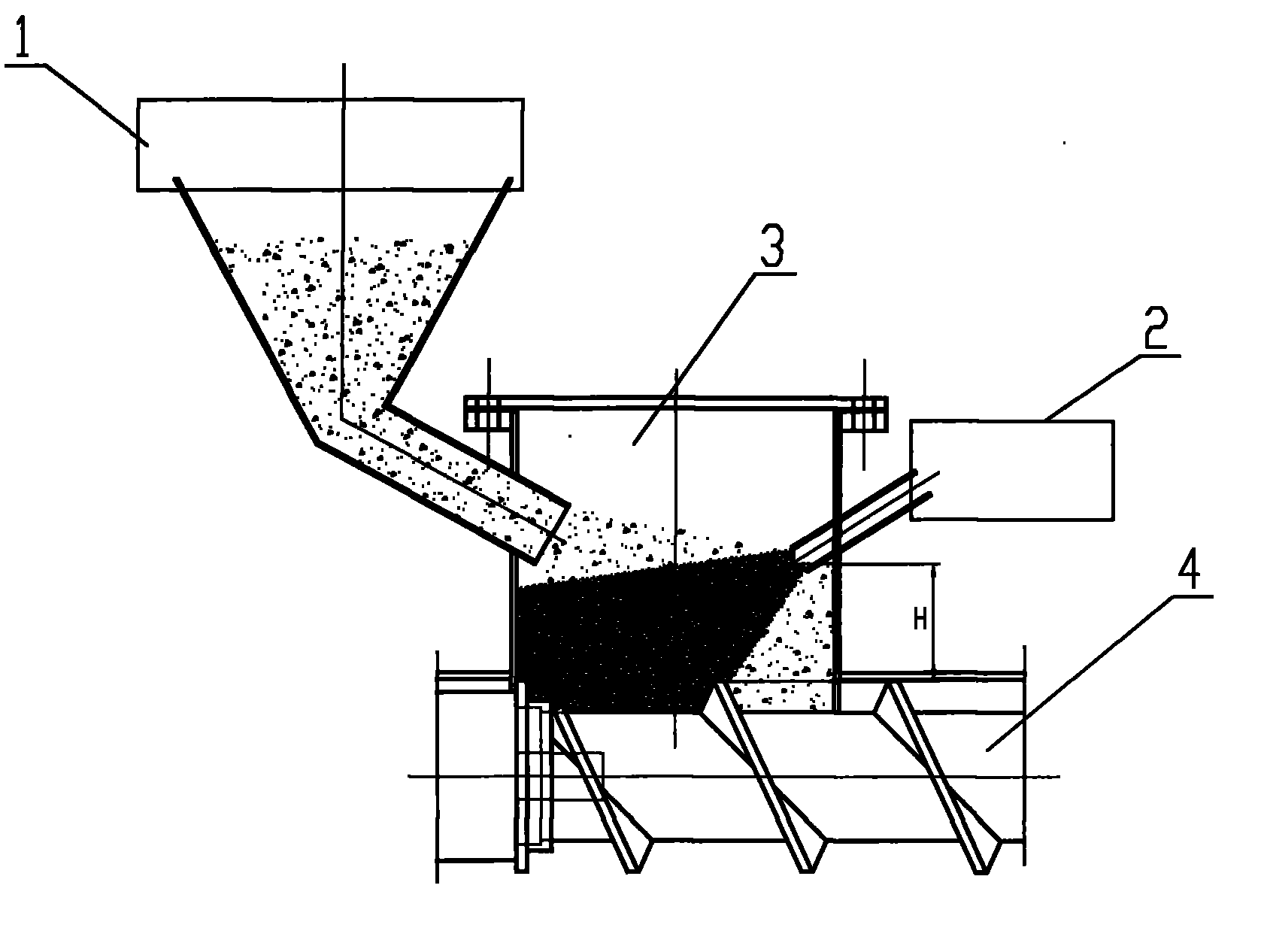

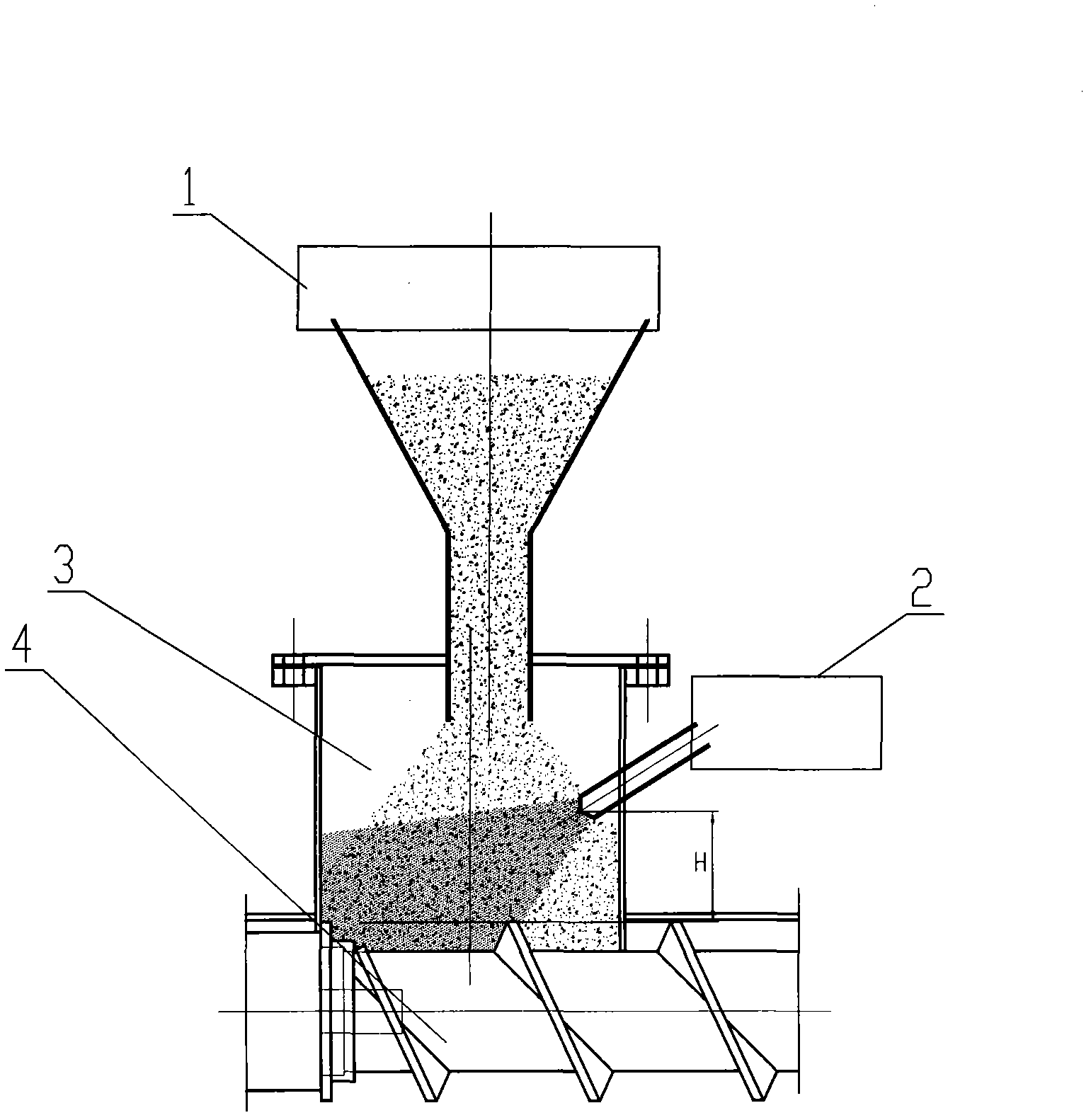

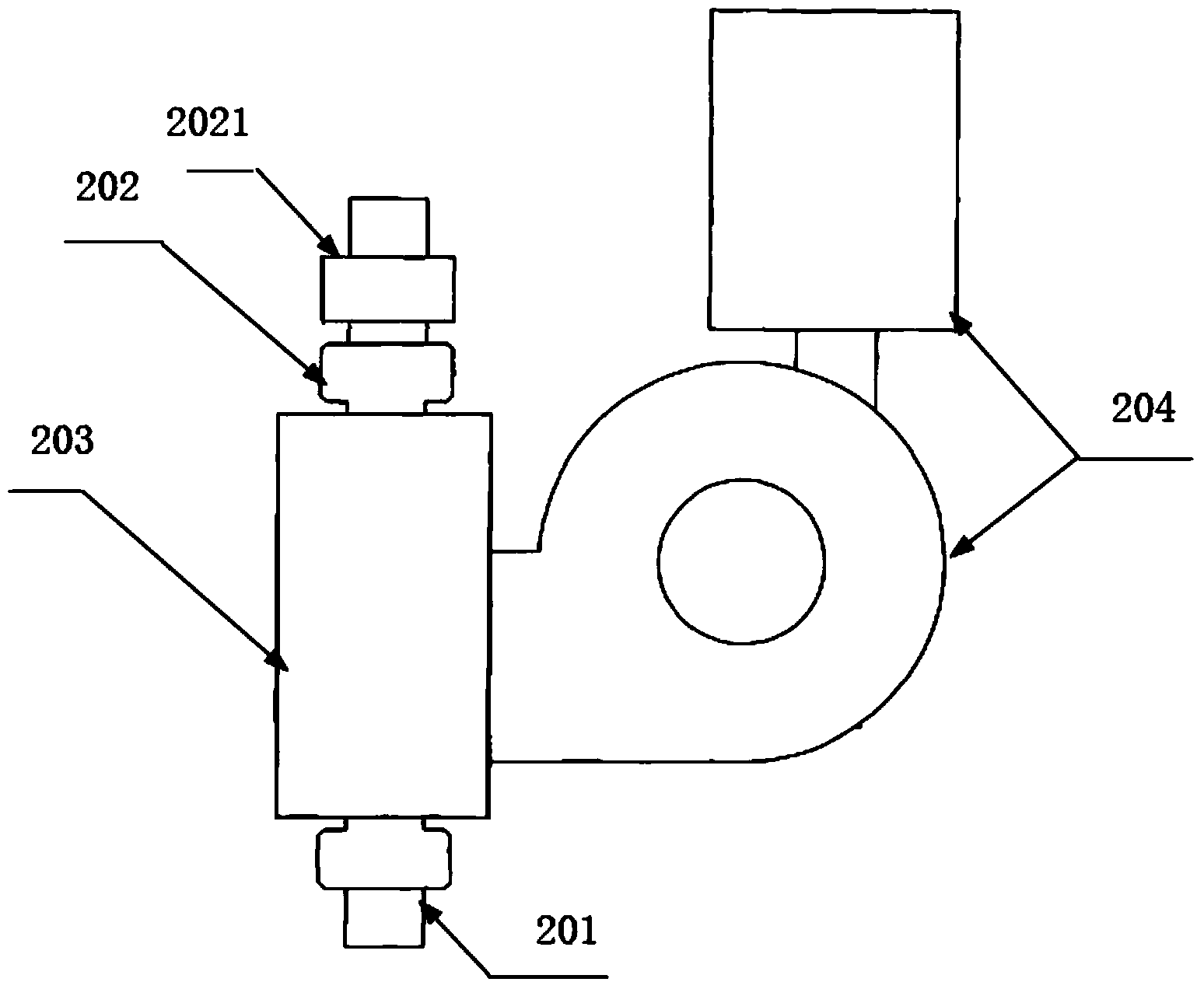

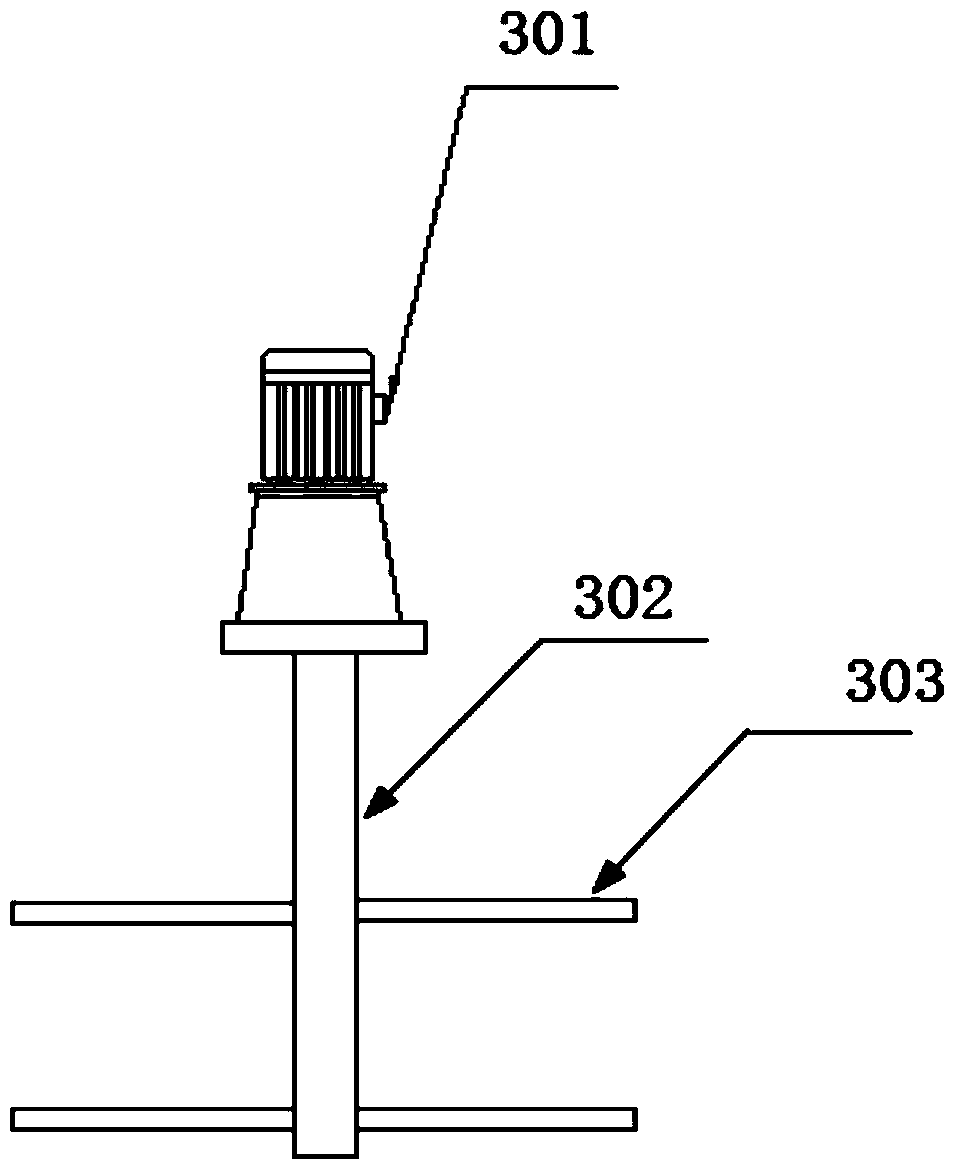

The invention relates to catalyst successive impregnation equipment and a method. The catalyst successive impregnation equipment comprises a carrier continuous feeding system (1), an impregnation liquid conveying system (2), an impregnation chamber (3), a conveying part (4), a dryer (9) and a power system; the carrier continuous feeding system (1) and the impregnation liquid conveying system (2) are open in the impregnation chamber (3); the bottom of the impregnation chamber (3) is open at the initial end of the conveying part (4); the conveying part (4) is positioned between the impregnation chamber (3) and the dryer (9); an outlet at the tail end of the conveying part (4) is communicated with the dryer (9); and power is provided for the operation of the conveying part (4) by the power system. The invention also discloses the method applying the equipment. The catalyst successive impregnation equipment and the method which are provided by the invention can be used for carrying out catalyst carrier impregnation to prepare a catalyst; a catalyst carrier is continuously impregnated; the impregnation efficiency is high; the impregnation uniformity is good; and the catalyst carrier is crushed a little.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paper cigarette filter rod filter media and processing method thereof

ActiveCN102747647AImprove sensory qualityEvenly distributedTobacco smoke filtersTextiles and paperFiberFilter media

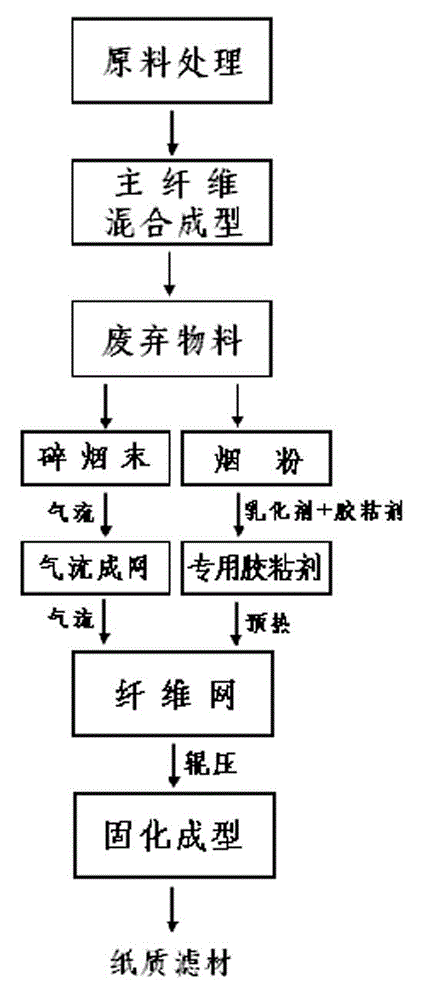

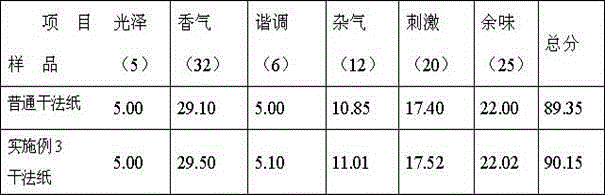

The present invention discloses a paper cigarette filter rod filter media and a processing method thereof, wherein the paper filter media is obtained through performing a dry process on the following components: 40-74% of natural cigarette fiber, 4-40% of bast fiber, 1-12% of natural tobacco waste raw material, and 4-20% of adhesive. The method comprises the following steps: raw material processing, main fiber mixing shaping, waste material adding and prepared paper shaping process. After the natural tobacco fiber is mixed with the bast fiber, discongestion is performed. After sufficient dispersion, the mixed material is conveyed to a shaping section through a blower for being laid on a net and shaped. A fluffy and uniform fiber net is formed on a shaping net belt. The cigarette filter media paper is obtained through adhesive applying, preheating, roller pressing, solidifying and shaping. As the cigarette fiber is used as the main fiber raw material, the paper cigarette filter rod filter media according to the invention has reduced foreign gas of wood and settles a problem that the fragrance quality is reduced by the foreign gas of wood in the prior-art paper filter rod. The natural tobacco waste raw material is added in the paper shaping process. Not only is whole aesthetic quality of the cigarette improved, but also the tobacco raw material is uniformly distributed in the dry process paper and does not easily drop off. The quality of the filter rod is more stable.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

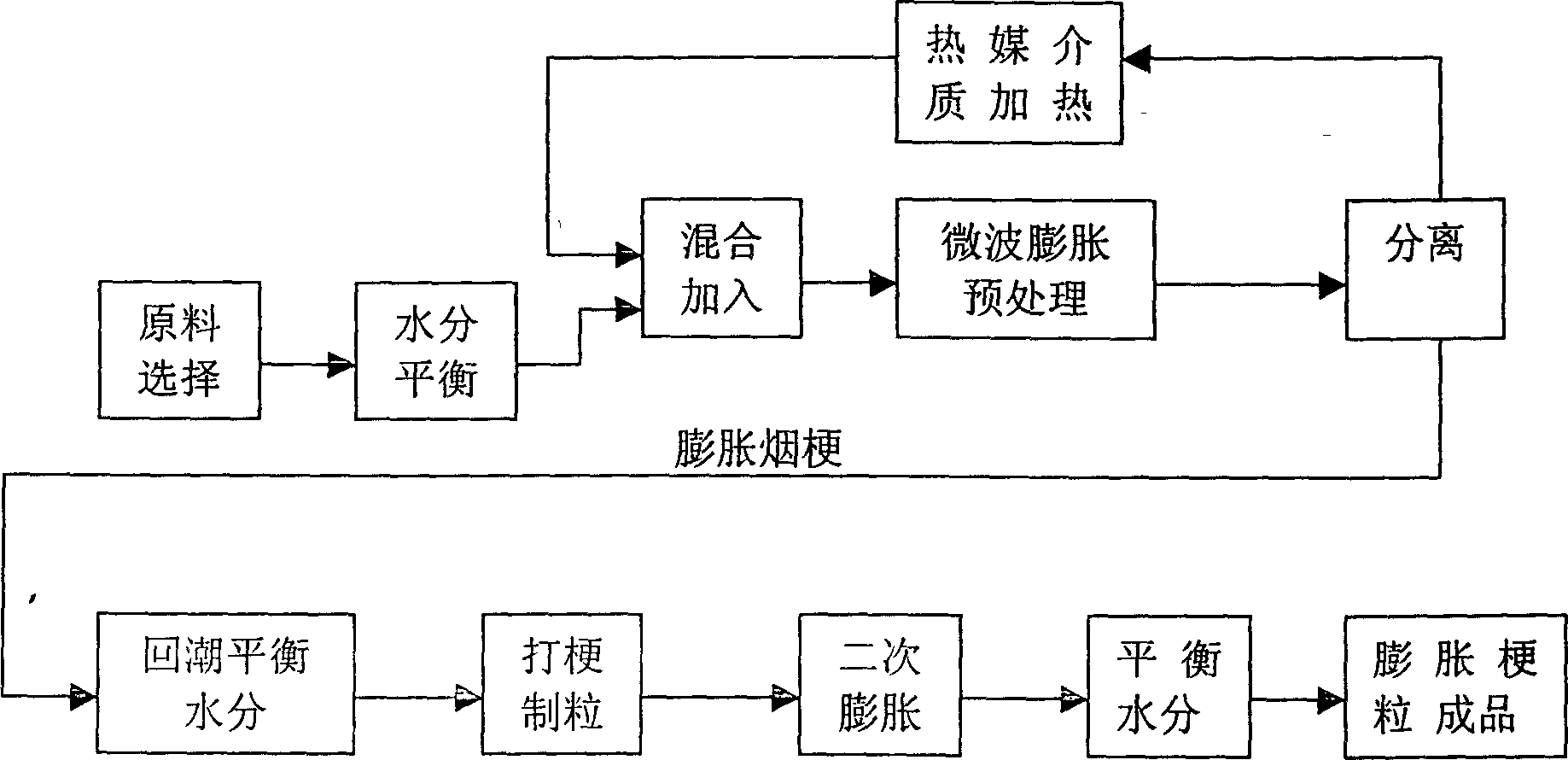

Preparation method of cigarette expansion cabo granule filling material

The invention discloses a preparation method of cigarette expansion cabo granule filling material, which comprises subjecting expanded cabo containing 5-9% of water to moisture regaining and balanced water treatment, loading into wind separation cabo beating machine, conveying bulked cabo particles into drying equipment for quick-speed drying till the moisture content is 7-14%, resulting cabo particles reexpansion, finally balancing water content of the cabo particles to 13+-0.5%.

Owner:SHENZHEN HONGXIANG YISHENG TECH CO LTD

Feed raw material rich in energy and protein of omega-3 fatty acid and preparation method thereof

InactiveCN101473889AChange ingredientsChange natureAnimal feeding stuffAdditive ingredientAnti nutritional

The invention discloses a prescription for preparing an energy and protein feeding stuff raw material full of omega-3 fatty acid by using rubber seeds and a method thereof. The weight percentages of the omega-3 energy and protein feeding stuff raw materials are as follows: rubber seeds 20-80%, bean pulp, corn, rapeseed cake (pulp), cottonseed cake (pulp), rice bran and wheat bran or any combination thereof 20-80%. The preparation method is as follows: the exuviated and dried rubber seeds are mixed with various ingredients evenly and puffed, and then finished product is gained. By the invention, the nutrient components such as omega-3 fatty acid, energy and protein and the like contained in the rubber seeds can be used fully, meanwhile, anti-nutritional components such as hydrocyanic acid and the like contained in the rubber seeds are removed, the energy and protein raw materials full of omega-3 fatty acid widely accepted by the feeding stuff industry and applicable to various birds, livestock and fish feeding stuff are processed. The price of the energy and protein raw material is low.

Owner:云南三环生物技术有限公司

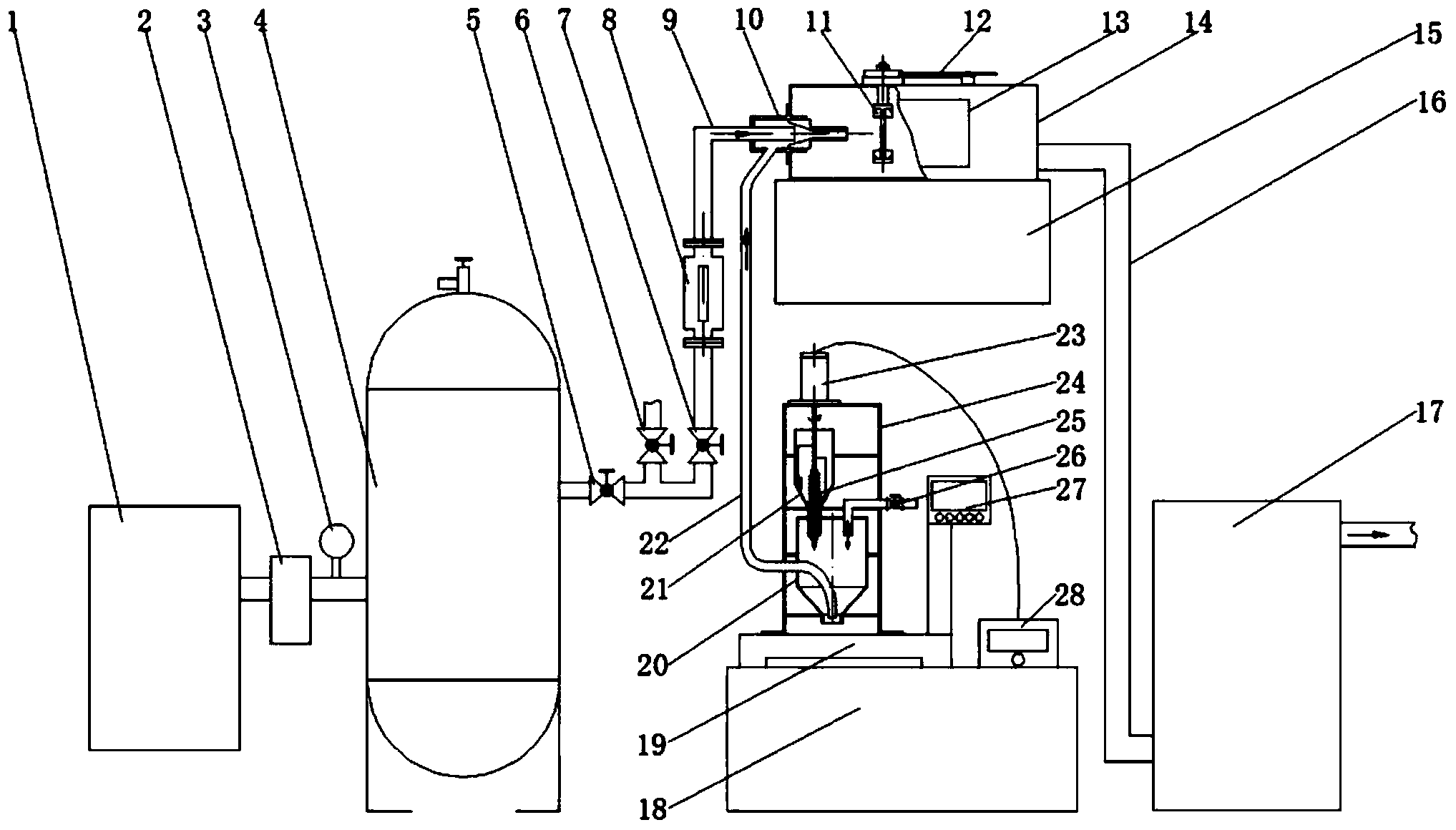

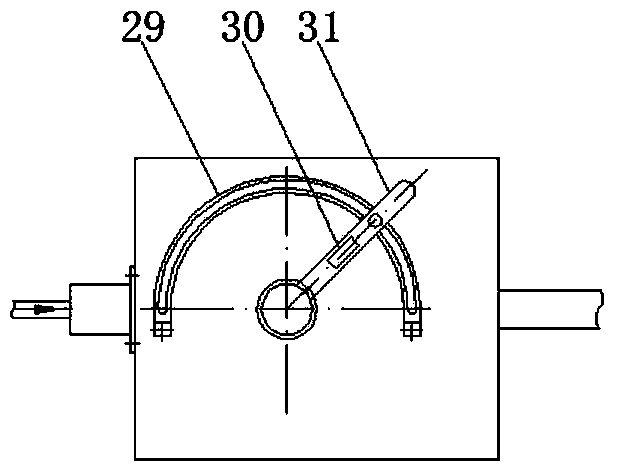

Air flow sand-blasting-type erosive wear testing machine

InactiveCN103760048AEasy to adjustSmooth feedingInvestigating abrasion/wear resistanceWear testingExhaust valve

The invention discloses an air flow sand-blasting-type erosive wear testing machine. The air flow sand-blasting-type erosive wear testing machine comprises a high-speed air flow unit, a screw rod charging unit, an erosive testing unit and a purifying and dedusting unit, wherein the high-speed air flow unit and the screw rod charging unit are both communicated with an inlet of the erosive testing unit; the dedusting unit is communicated with an outlet of the erosive testing unit; the screw rod charging unit comprises an electronic scale, a material storage chamber, a charging funnel, a charging screw rod and a screw rod electromotor, wherein the electronic scale is provided with the material storage chamber; the material storage chamber is provided with the charging funnel communicated with the material storage chamber; the charging funnel is provided with the charging screw rod driven by the screw rod electromotor, and the material storage chamber is communicated with a suction spray gun by a charging pipeline; the screw rod electromotor is controlled by a controller. According to the erosive wear testing machine, the air flow impact speed can be up to 0m / s-200m / s by regulating an air exhaust valve and a flow meter. The erosive angle is changed between 0 degree and 90 degrees by a specimen rotary table. The uniform charging can be ensured by means of a screw rod charger.

Owner:SHANDONG UNIV

Waste salt recycling process and special device thereof

InactiveCN107321755AFully mineralizedHigh net salt puritySolid waste disposalTransportation and packagingFlame arresterPollutant emissions

The invention discloses a waste salt recycling process and a special device thereof. According to the process, a waste salt supply system, a waste salt melting system, a tail gas treatment system and a molten salt cooling and pelleting system are included. The special device comprises a waste salt feeder, a waste salt distributor, a drying, preheating and melting integrated salt-melting furnace, a belt cooling and pelleting machine, an RTO furnace, a filter, a fire arrester, an alkaline washing tower and the like. By means of the waste salt recycling process and the special device thereof, organic matter in waste salt is completely burnt out, the recycling standard is met, organic matter generated in the purifying process of waste salt is further treated in a thermal destruction mode, and emission of secondary pollutants like waste water and waste gas in the utilization process of the waste salt is avoided. Meanwhile, the vertical salt-melting furnace is adopted, the waste salt drying, preheating and melting processes are achieved in the furnace, high investment and waste gas pollution caused by equipment units for drying, grinding and the like are reduced, and the problem that it is difficult for the device to operate continuously and stably due to salt adhesion is solved.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

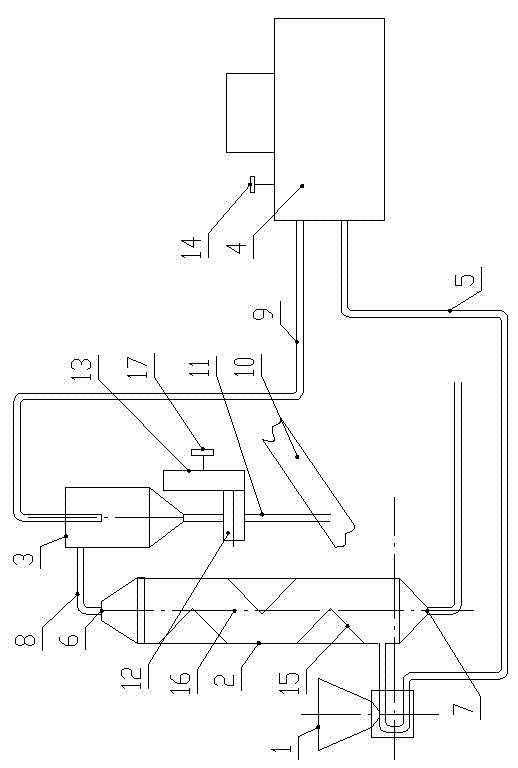

RH injection refining device and application thereof

The invention provides an RH injection refining device and application thereof. The device comprises an RH ascending pipe and an RH descending pipe; pipe walls of the RH ascending pipe and the RH descending pipe are provided with through holes which are connected with an external air supply or a feeding device by spraying pipes. A method of removing small inclusions by using the device comprises:after deoxidation alloying, blowing inert gas into the descending pipe by using the spraying pipes, wherein the gas flow is 10-500L / min and air pressure is 1.0-15atm; or blowing carbonate power into steel liquid, wherein the particle size of the powder is less than 3mm, the feeding rate is 1-100kg / ton steel, the carrier is Ar, N2 or CO2 inert gas, the gas flow is 10-800L / min, and air pressure is 1.0-20atm. The invention has the characteristics of simple equipment, convenient operation, reasonable process, low cost, and good effect. The invention has the advantages of effectively removing small inclusions from steel, regulating alloying elements, manufacturing dispersion steel of small oxide, and achieving the aims of decarburization, desulfurization, dephosphorization, steel slag modification and the like.

Owner:ANGANG STEEL CO LTD

Method for preparing plastic biologic packing material of even adulterated powder

InactiveCN101092486AIncreased maximum amount addedImprove the effect of addingSustainable biological treatmentBiological water/sewage treatmentAdhesiveInjection moulding

This invention discloses a method for preparing uniformly powder-doped plastic biofiller. The method comprises: placing plastic granular matrix in a stirring kettle, heating or spraying liquid adhesive so that the surface of plastic granular matrix has viscosity, adding powder, stirring, adhering powder to the surface of plastic granular matrix, adding coupling agent and wetting agent, placing in an injection molding machine, and injection-molding to obtain uniformly powder-doped plastic biofiller. The obtained uniformly powder-doped plastic biofiller has such advantages as high uniformity, good appearance, and high powder doping amount, high processability, no dust, no environmental pollution and no harm to operator's health.

Owner:SOUTH CHINA UNIV OF TECH

Light scattering polycarbonate composite and light scattering materials (such as films, sheets, plates) prepared from light scattering polycarbonate composite

InactiveCN102702713AAdd evenlyParticle size can be adjustedDiffusing elementsLiquid-crystal displayLight guide

The invention provides a light scattering polycarbonate composite and light scattering materials (such as films, sheets, plates) prepared from the composite. The composite comprises (A) a base material, namely a polycarbonate resin and (B) a scatterer material which can be molten and deformed into polymer in the forming process of polycarbonate, such as acrylonitrile copolymer. The light scattering materials (such as films, sheets, plates) with isotropic scatterning performance or anisotropic (such as linear )scattering performance can be prepared from the composite material, and the requirements of high light transmittance and high haze can be met; and the light scattering materials are suitable for light scattering films, sheets, plates and the like in the field of liquid crystal displays, and the illumination materials of light guide plates, lampshades or advertising light boxes, show windows and the like.

Owner:SICHUAN UNIV

Single type tobacco stem and shred online separating and recovering system of cigarette making machine

ActiveCN102894476ALight weightDoes not affect the way of workGas current separationCigarette manufactureEconomic benefitsEngineering

The invention discloses a single type tobacco stem and shred online separating and recovering system of a cigarette making machine. The system comprises a receiving hopper, a tower-type separator, a cyclone separator and an electric blower, wherein a blowing port of the electric blower is connected with the lower side of the tower-type separator through a blowing pipe, a discharge port of the receiving hopper is formed in the blowing pipe, a tobacco shred discharge port is connected with a feed port of the cyclone separator through a section of pipeline, and a sucking port of the electric blower is connected with an air suction port of the cyclone separator through a sucking pipe. According to different weights of tobacco shreds and tobacco stems at the rated humidity, the light qualified tobacco shreds and the heavy tobacco stems are separated from each other through utilizing airflow, the recovered tobacco shreds are continuously fed to a tobacco shred vibration tank of a cigarette making machine body to be directly recovered and utilized, and the water and aroma losses of the separated tobacco shreds are less, the separated tobacco shreds can be directly recovered and utilized, the tobacco shred consumption of the cigarette making machine is reduced, the environment is protected, and the economic benefits of enterprises are improved.

Owner:郑州格兰高环境工程有限公司

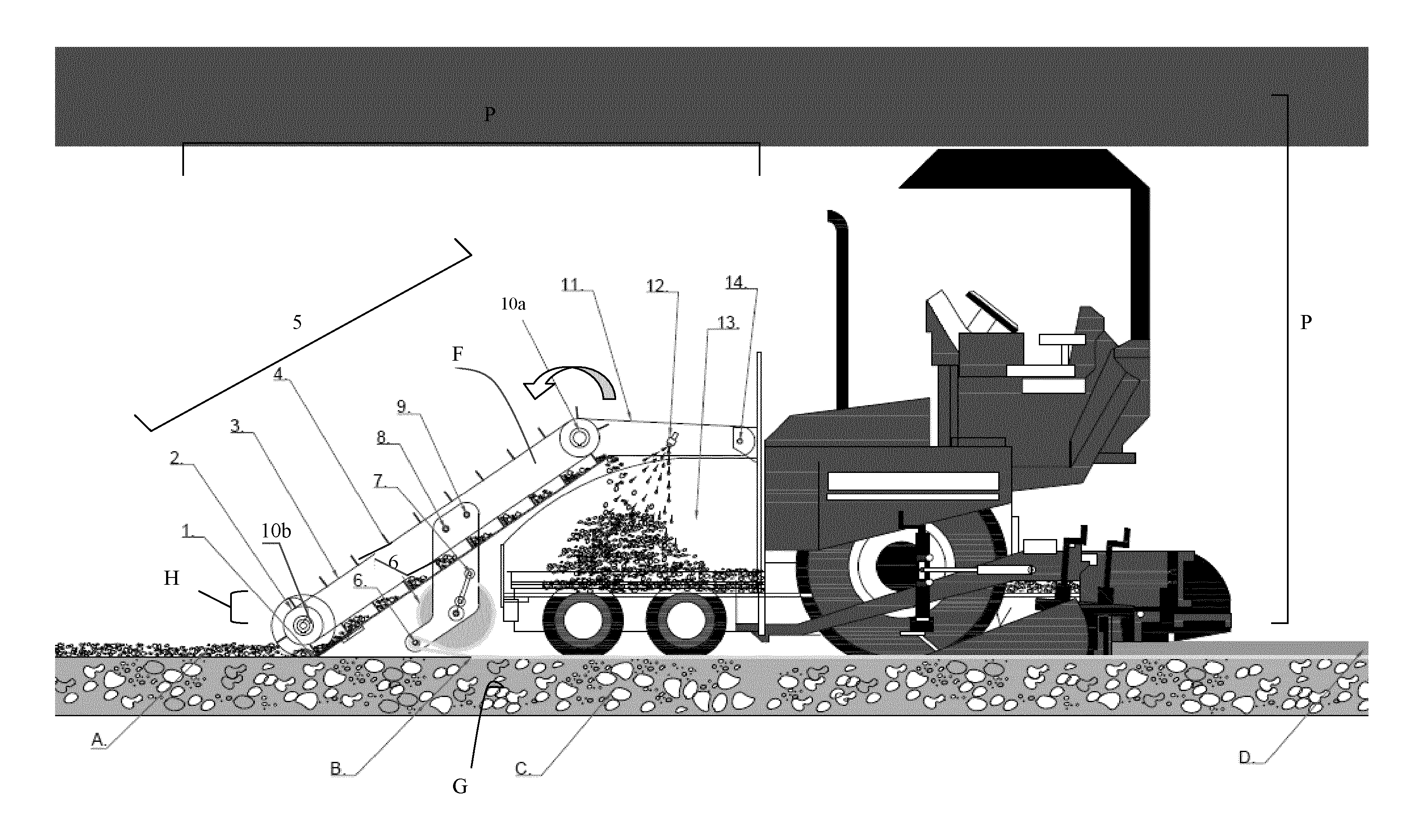

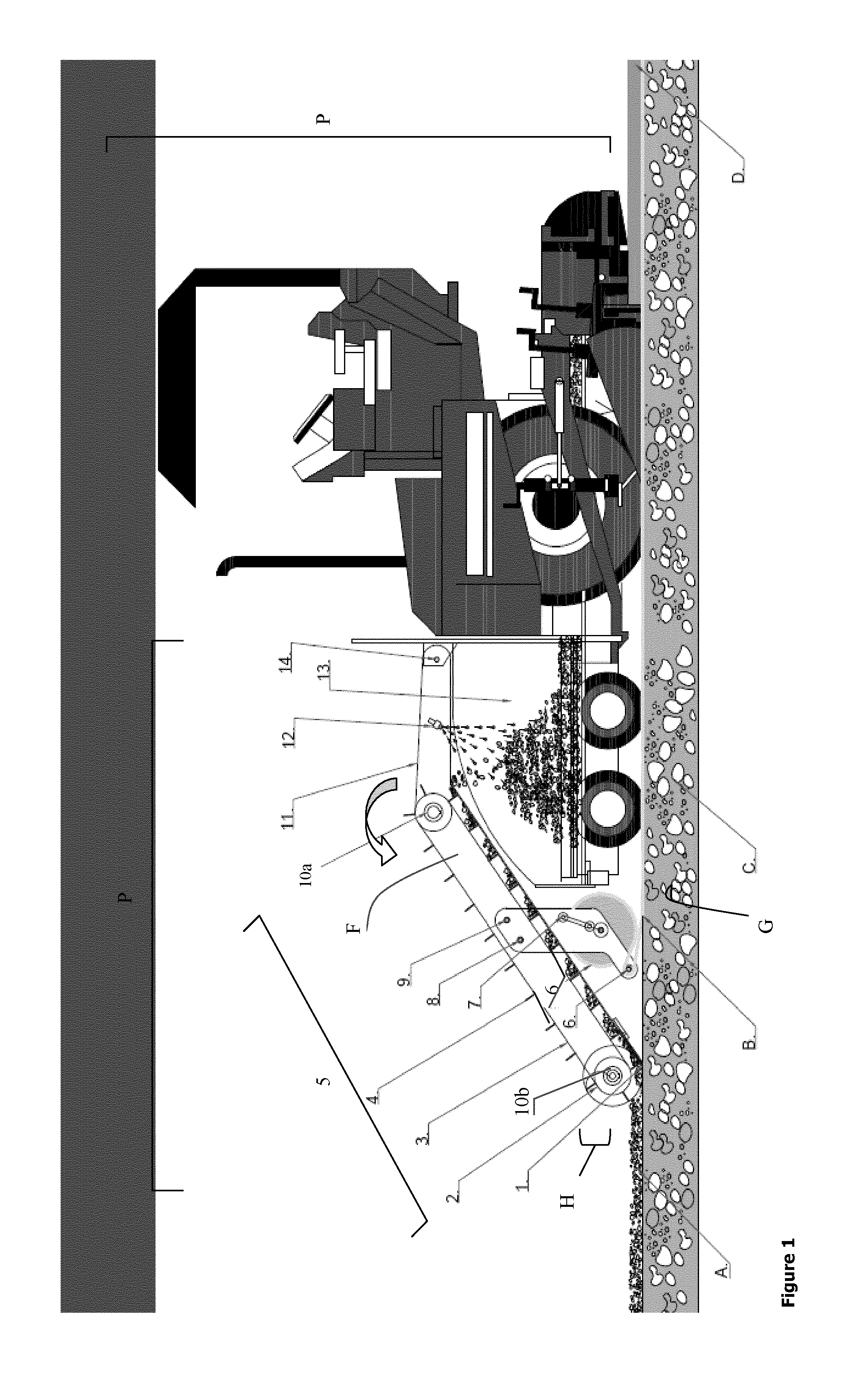

Road strengthening and reinforcement during a recycling process

InactiveUS20140270953A1Prevent kinkingAvoid creasesIn situ pavingsOther manufacturing equipments/toolsCyclic processRoad surface

The invention relates to an optional additional process during routine rehabilitation or recycling of road surfaces. More particularly, the invention relates to a process whereby a geomaterial, whether mesh, membrane, textile, grid or fabric membrane is placed underneath in-situ road surface material, which has been loosened as part of a regenerative or recycling process, as an added structural benefit to the rehabilitated road structure.

Owner:TONY DUFFY ENG

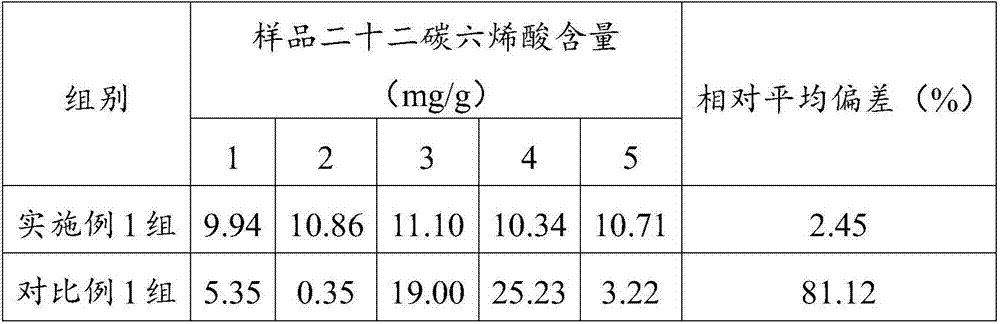

Beef pickling method

The invention discloses a beef pickling method. The method mainly comprises the following steps: beef soaking and ultrasonic pickling. Fresh beef is pickled through combining soaking, ultrasonic treatment and pickling and adopting a special trace element adding technology to finally realize the reasonable supplementation of zinc and docosahexaenoic acid and meet people's requirements of the taste, the appearance, the flavor, the nutrient components and the shelf life of beef, and the pickled beef can be further processed to obtain various beef products, such as beef granules, beef sauce, beef balls, beef seasonings and so on.

Owner:山东如康清真食品有限公司

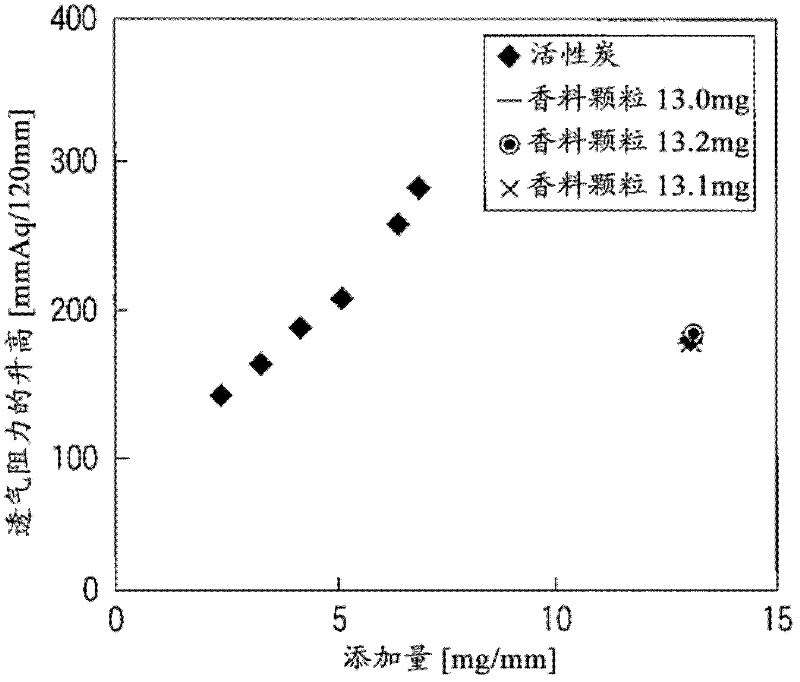

cigarette filter

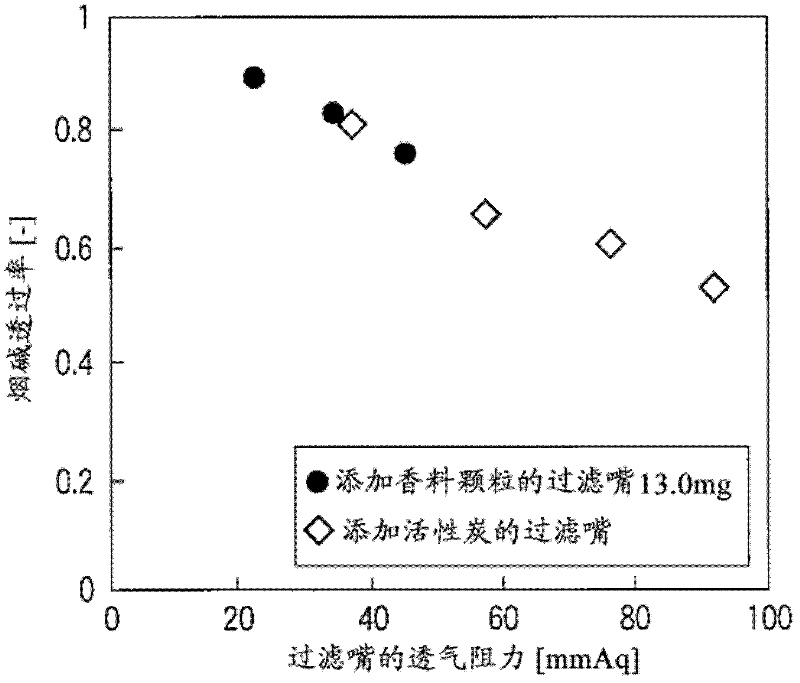

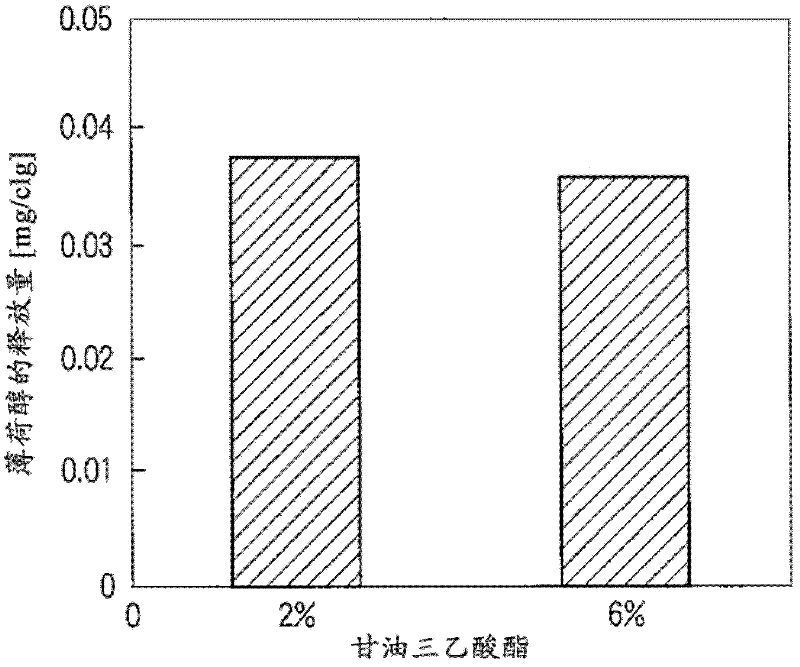

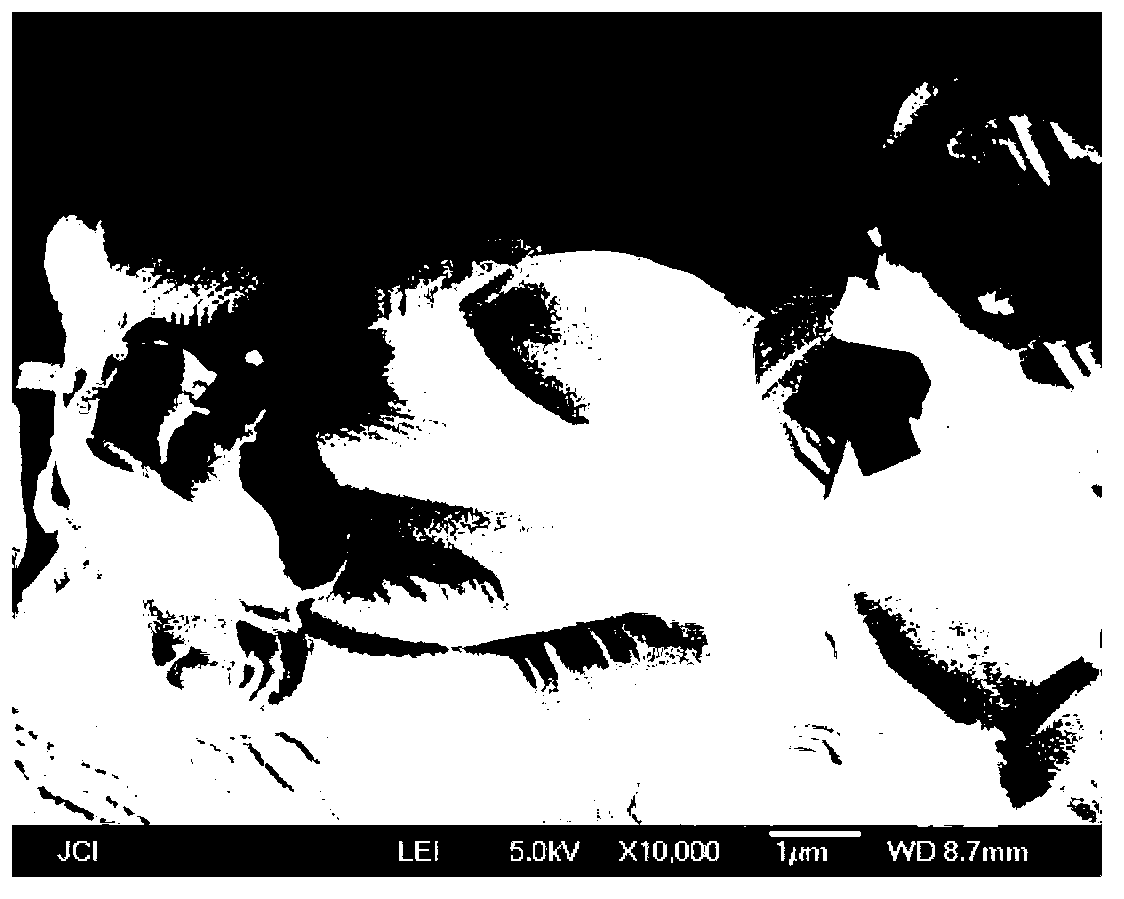

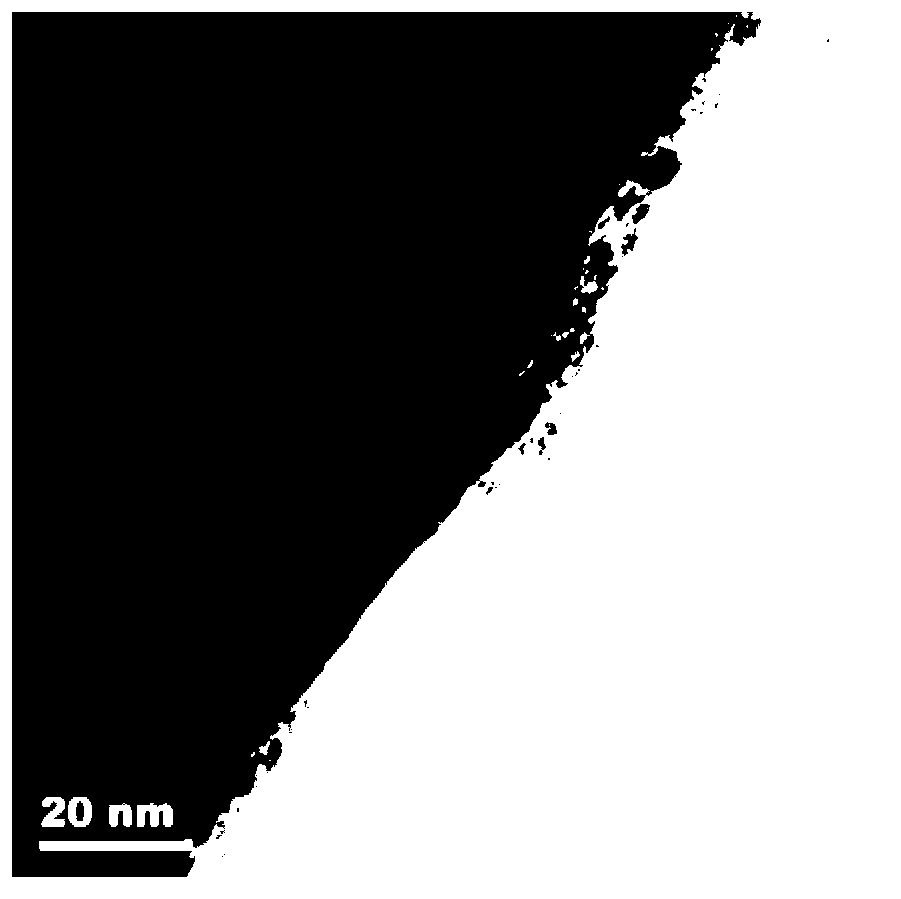

InactiveCN102271542APrevent volatilizationSuppression of adsorption to activated carbonTobacco smoke filtersFlavorCigarette filter

The present invention relates to a filter tip for cigarettes, comprising a filter tip body and flavor particles added to the filter tip body, the flavor particles comprising a core material and a flavor-loaded carrier attached to the surface of the core material, the flavor particles A particle size distribution is shown in which particles with a particle diameter of 100 μm or more account for 99% by mass or more, and particles with a particle diameter of 200 μm or more account for 70% by mass or more.

Owner:JAPAN TOBACCO INC

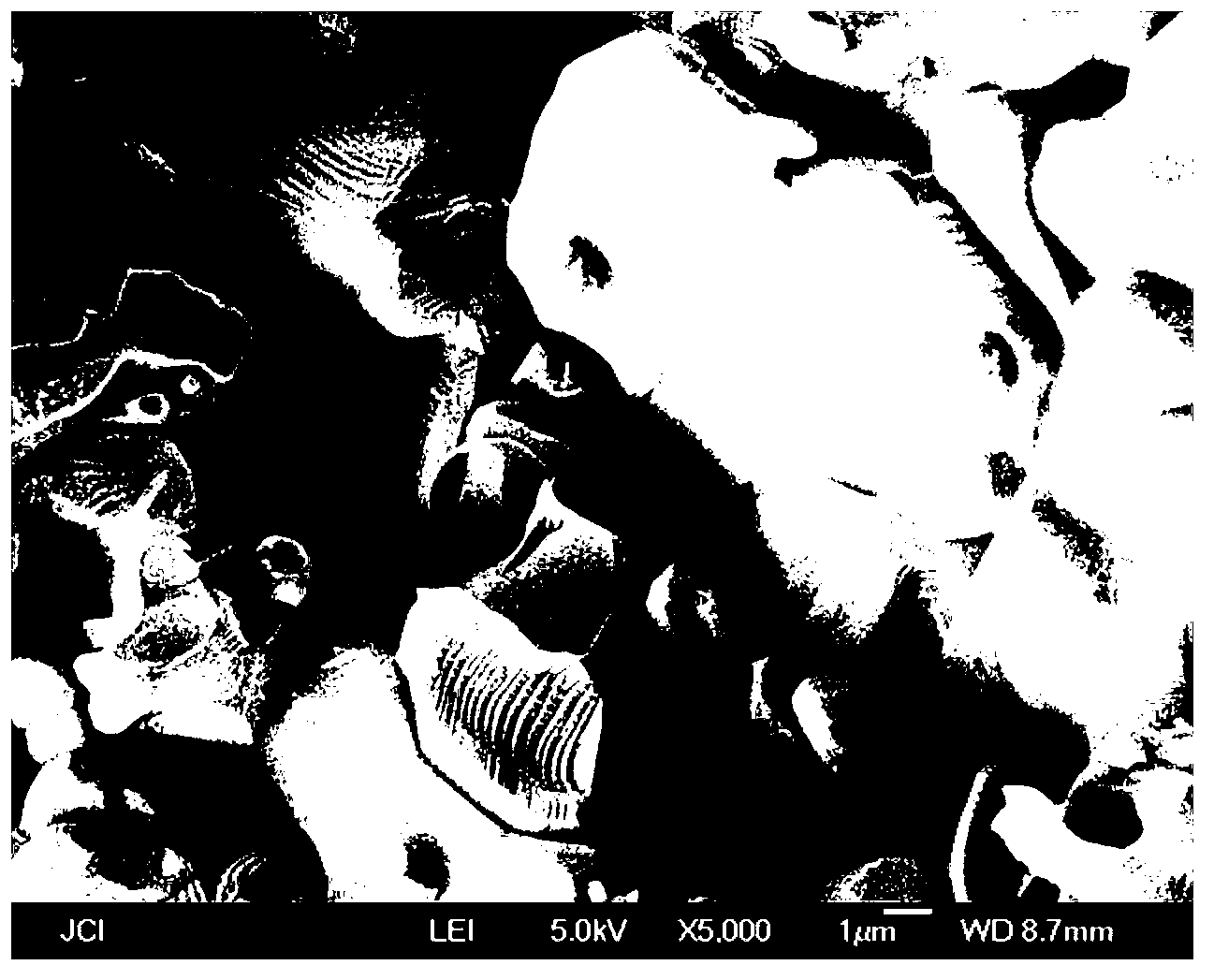

Preparation method of high-purity aluminum oxide ceramic

The invention discloses a preparation method of a high-purity aluminum oxide ceramic. According to the preparation method, a nano Al2O3 coating formed on the surfaces of aluminum oxide particles is used as a sintering aid to ensure that a small amount of the sintering aid can be uniformly dispersed in a main phase, so that uniform adding of a small dose of the sintering aid is realized. The preparation method not only ensures the purity and performance of the high-purity aluminum oxide ceramic and meets process requirements for preparation of the aluminum oxide ceramic, but also effectively solves the problem that when the particle size difference of main phase powder and the sintering aid is large, particles of a nano auxiliary agent are gathered in a main phase powder particle gap; and moreover, partial over-firing is avoided, so that the uniformity of sintering of the main phase powder particles and the sintering assisting effect of the sintering aid are effectively improved.

Owner:重庆兀盾纳米科技有限公司

Centrifugal ceramic composite vertical mill roller sleeve and manufacturing method thereof

The invention discloses a centrifugal ceramic composite vertical mill roller sleeve and a manufacturing method thereof. The centrifugal ceramic composite vertical mill roller sleeve comprises an inner layer and an outer layer. The outer layer is high-chromium cast iron, and ceramic particles are embedded in the outer layer. The high-chromium cast iron is prepared from, by weight, 2.3-3.3% of C, 0.3-1.0% of Si, 0.6-1.2% of Mn, 18-22% of Cr, 0.7-1.7% of Ni, 1.5-3.0% of Mo, 0-0.03% of P, 0-0.03% of S and the balance Fe and inevitable impurities. According to the vertical mill roller sleeve, the material proportion of the inner layer and the outer layer is optimized; high-alloy elements are adopted by the outer layer, the matrix can be effectively reinforced by increasing the content of alloy such as C, Cr, Mo and V, the total amount of carbide is increased, and therefore the smoothness of a friction surface can be effectively improved; the outer layer of the roller sleeve is made to be high in abrasion resistance, high in strength and enough in toughness, and the service life of the roller sleeve is effectively prolonged. According to the manufacturing method, a heat treatment technique of annealing, quenching and tempering is adopted, the purposes of improving the carbide form, promoting structural transformation and refining structures are achieved, so that the abrasion resistance and fracture toughness of the roller sleeve are improved.

Owner:河北津西钢铁集团重工科技有限公司

Cigarette paper and preparation method thereof

InactiveCN1793500AImprove aftertasteIncrease the sense of thicknessVegetable material additionPulp material addition processesHerbSmoke paper

The invention discloses cigarette paper and its manufacturing method. The cigarette paper is used working of paper as carrier, plant alcohol extract cream body with 1.2000+ / -0.0050 relative density as additive. The quality of the working of paper is used as criterion. Thus the mass percent of the additive is 0.01%-0.05%. the relative density of additive cream body is 1.2000+ / -0.0050. The plant is one of aromatic tobacco, burley tobacco, Maryland, drying tobacco, Pu'er tea, golden buckwheat rhizome, pseudo-ginseng, or Broadleaf Herb leaf, or their mixture. The invention can obviously improve cigarette sucking aftertaste, reduce sting, and coordinate cigarette smoke.

Owner:YUNNAN RES INST OF TOBACCO SCI

Environment-friendly flocculation type sewage treatment device capable of quantitatively feeding chemicals

ActiveCN112010464AIncrease flow rateImprove practicalityTransportation and packagingRotary stirring mixersWater wheelSewage

The invention discloses an environment-friendly flocculation type sewage treatment device capable of quantitatively feeding chemicals. The device comprises a body, a driving rod, a water wheel and a collecting bin, and a medicament bin is mounted in the middle of the upper end of the machine body; a first movable plate is connected to the inner side of a discharging opening through a bearing; thelower end of a linkage block is connected with a connecting rod, a reset spring is connected between an extrusion plate and a push plate, a cleaning brush is fixed to the upper end of the rotating shaft through a bolt, a blow-down valve is installed on the side wall of the lower end of the body, a sealing plate is hinged to the outer side of a water collecting opening, and the collecting bin is arranged on the outer side of the body. According to the environment-friendly flocculation type sewage treatment device capable of quantitatively feeding chemicals, the device can be driven by utilizingthe potential energy of sewage to automatically and quantitatively feed a flocculant according to the treatment capacity of the sewage, the use convenience and the environmental friendliness of the device are improved; and the interior of the device can be automatically cleaned through the buoyancy effect of sewage, so the workload of workers is reduced.

Owner:SICHUAN JINMEI ENVIRONMENTAL PROTECTION TECH

Cathode material of seawater battery, preparation method thereof, and seawater battery

ActiveCN108232194AWorking Voltage MitigationLow working voltagePositive electrodesImmersion cellsBiological activationPolyaniline

The invention discloses a cathode material of a seawater battery, a preparation method thereof, and a seawater battery. The cathode material is composed of conductive polyaniline, a stabilizer, a conductive agent, and a binder. The seawater battery comprises an anode, a cathode, and seawater electrolyte. The anode is composed of the cathode material and a current collector. The cathode is made ofa magnesium alloy. The seawater battery has characteristics of lightness, cheap price, good stability, and environmental friendliness and electrochemical advantages of short activation time, high discharge voltage, large capacity, and great specific energy.

Owner:CENT SOUTH UNIV +1

Technology for preparing black Fu brick tea by utilizing summer-autumn tea leaves

InactiveCN105053277AIncrease aromaMaintain nutrition and health functionPre-extraction tea treatmentBrickBlack tea

The invention relates to a technology for preparing a black Fu brick tea by utilizing summer-autumn tea leaves. The black Fu brick tea is prepared through the following steps: using summer / autumn fresh tea leaves as raw materials, merging the technology for forming the fragrance of orchids, and performing a series of operations of withering the summer / autumn fresh tea leaves, rocking the withered summer / autumn fresh tea leaves, rolling the rocked summer / autumn fresh tea leaves, fermenting the rolled summer / autumn fresh tea leaves, drying the fermented summer / autumn fresh tea leaves, and performing pile fermentation on the dried summer / autumn fresh tea leaves; and adding eurotium cristatum, enabling the eurotium cristatum to grow and breed to generate golden cleistothecia so as to obtain a finished tea, drying and forming the finished tea, and the like. The working procedure of rocking the withered summer / autumn fresh tea leaves is added in the making technology of the black tea, so that the fragrance of the orchids in the black Fu brick tea is generated, and the making technologies of the black tea and the Fu brick tea are combined for relevant optimization, the technology of rocking oolong and the technology of adding mycetes for generating the golden cleistothecia are merged, so that the promotion and the stabilization of the quality of products are realized, the fragrance of the black tea can be improved, and the nutrient health-care functions of the Fu brick tea can also be maintained; besides, the appearance feel of the finished products of the black Fu brick tea can also be effectively improved.

Owner:HUNAN LONGPING TEA HIGH TECH CO LTD +1

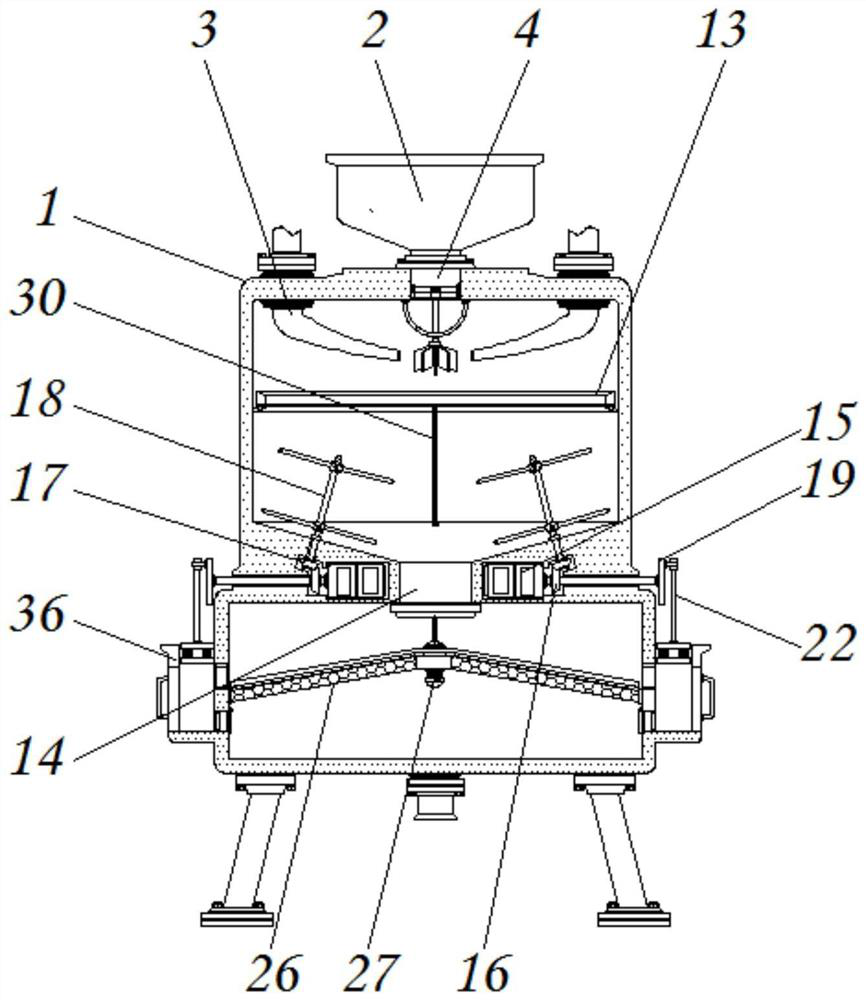

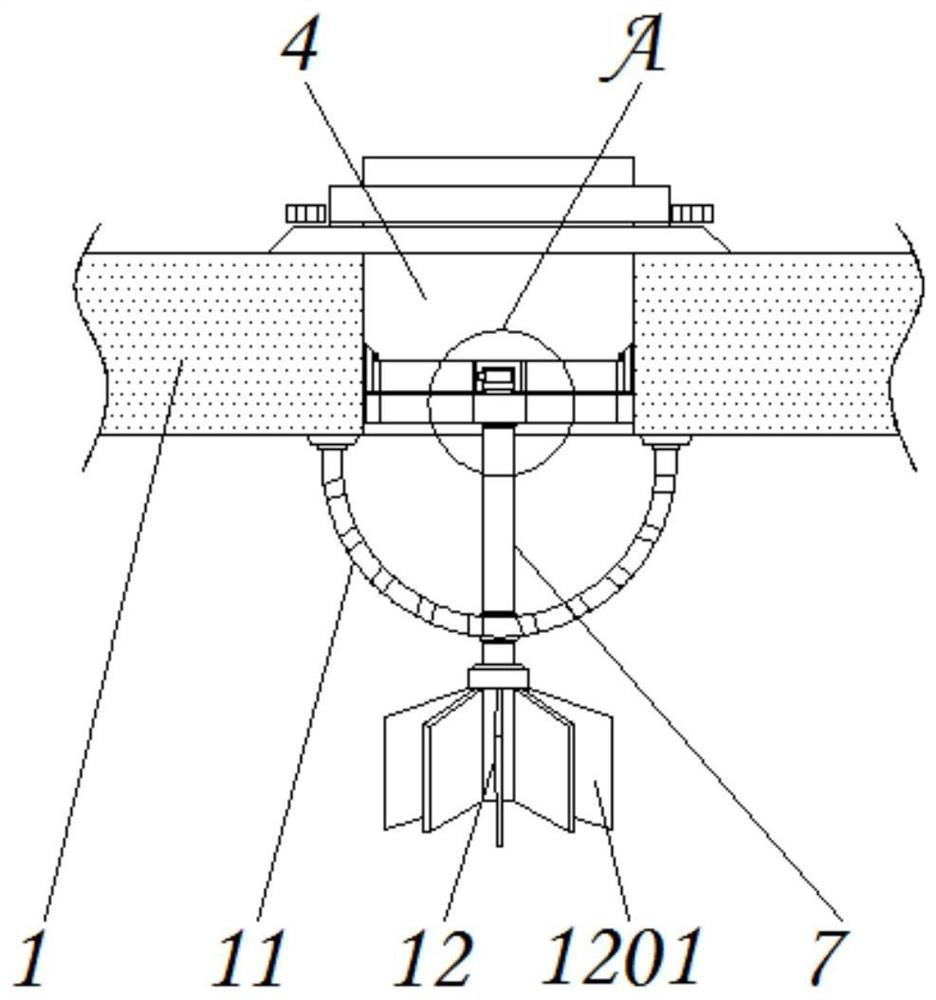

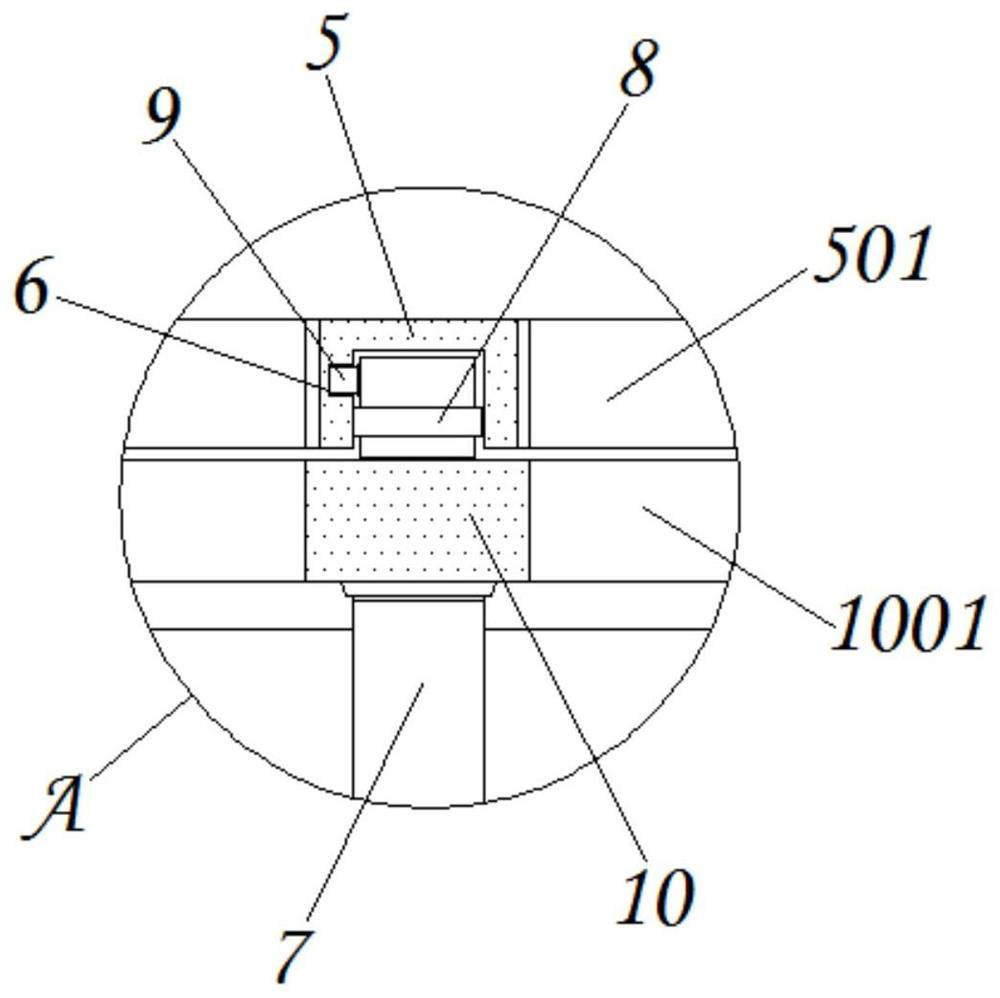

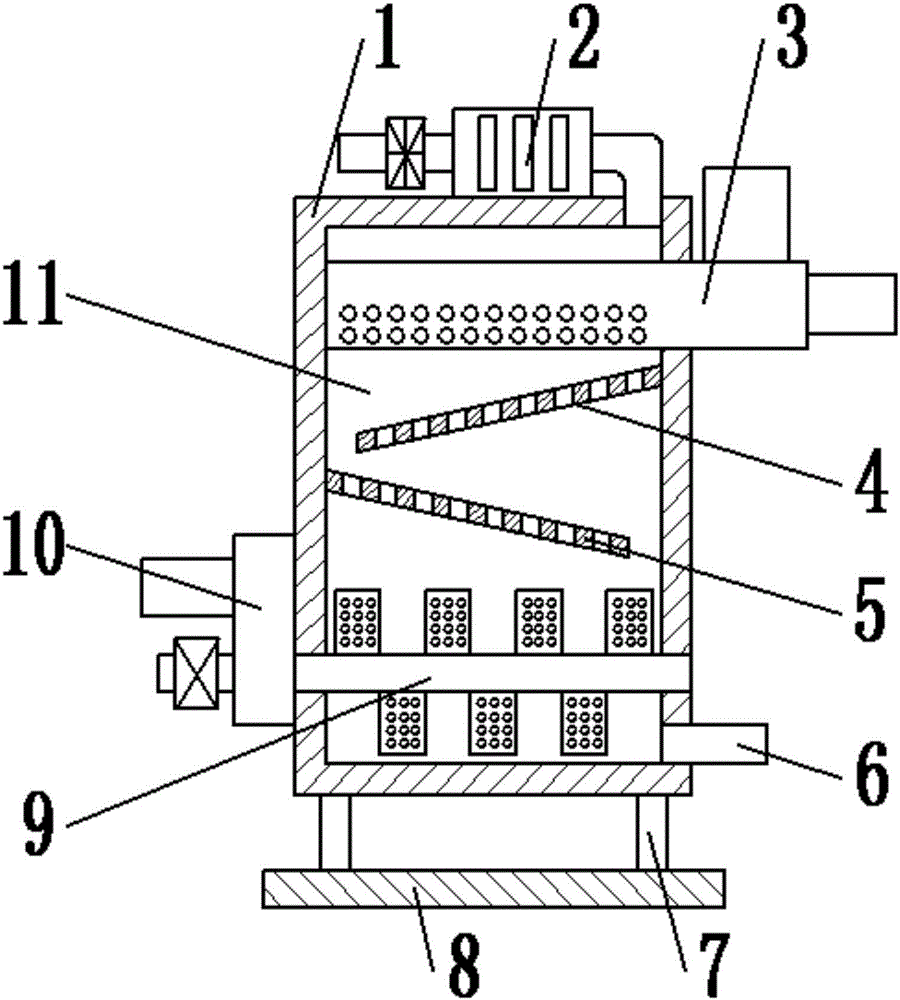

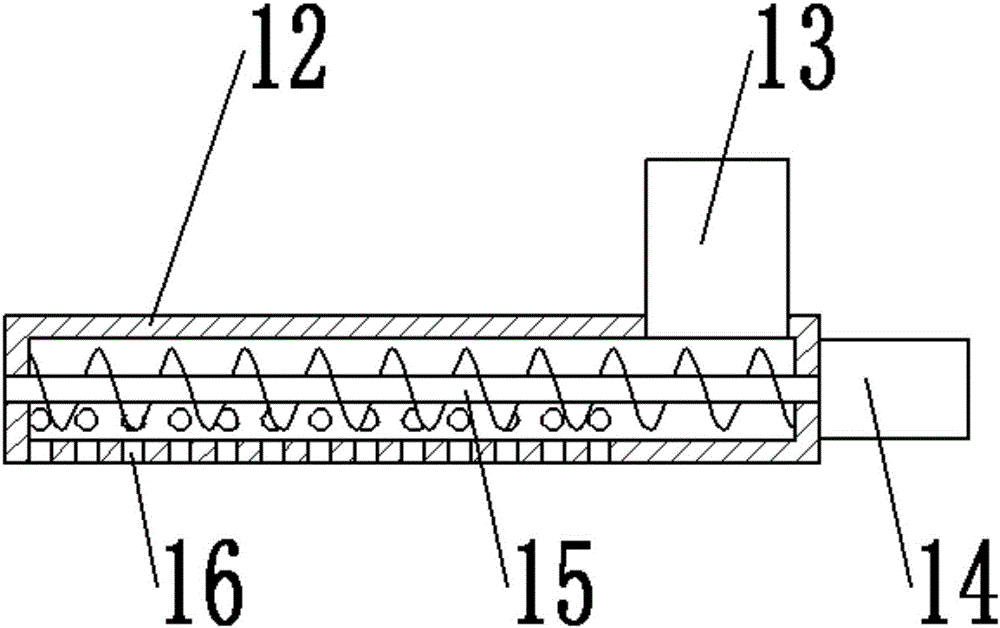

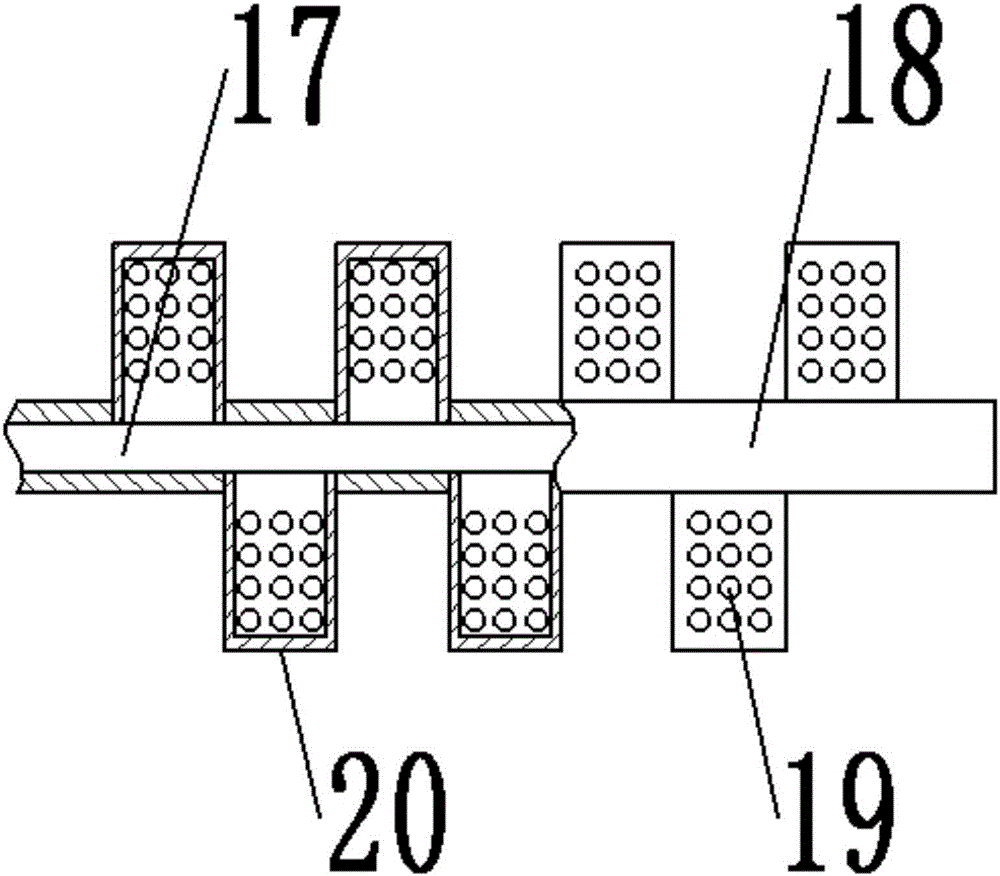

Pueraria powder hot air drying equipment with dehumidifying device

InactiveCN106440740APrevent drying efficiency from decreasingIncrease drying speedGranular material dryingDrying gas arrangementsEngineeringAir drying

The invention provides pueraria powder hot air drying equipment with a dehumidifying device. The pueraria powder hot air drying equipment comprises a tank body. A drying cavity is formed in the tank body. A feeding device is arranged on the top of the drying cavity. An upper material guide plate and a lower material guide plate are arranged in the middle of the drying cavity. A stirring device is arranged at the bottom of the drying cavity. The feeding device is composed of a conveying pipe and a feeding pipe. The upper material guide plate and the lower material guide plate are obliquely arranged. Multiple through holes are evenly formed in the surface of the upper material guide plate and the surface of the lower material guide plate. The stirring device is composed of a stirring shaft and stirring pieces. One end of the stirring shaft is connected with a drying and driving device. The drying and driving device is composed of a transmission box, a rotary motor and an air inlet pipe. The dehumidifying device is arranged on the top face of the tank body and is composed of a dehumidifying pipe, a filtering tank and a dehumidifier. According to the pueraria powder hot air drying equipment, the situation that too much pueraria powder is added once and consequently the drying efficiency is lowered is prevented through the feeding device; the falling distance of pueraria powder is increased through the upper material guide plate and the lower material guide plate; and the pueraria powder is dried efficiently through the drying and driving device.

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

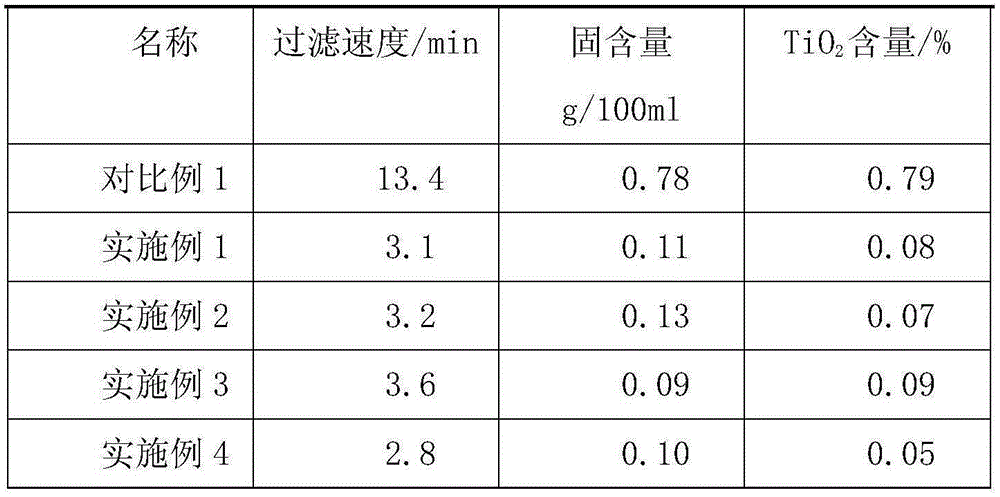

Method for acidolysis and reduction of ferric iron by titanium dioxide to improve quality of titaniferous solution through sulfuric acid method

The invention relates to a method for acidolysis and reduction of ferric iron by titanium dioxide to improve quality of a titaniferous solution through a sulfuric acid method. The method comprises the following steps: adding titania waste acid of which the mass fraction of sulfuric acid is 19%-25% and water to a solid-phase material which is formed by reaction of ilmenite and concentrated sulfuric acid to obtain the titaniferous solution; and adding iron powder to the reacted titaniferous solution, and reducing the ferric iron in the titaniferous solution into ferrous iron. According to the method, use of sulfuric acid is reduced; resource consumption is reduced; the leached titaniferous solution is pumped into a coiled pipe with cooling water, so that the temperature of the titaniferous solution is reduced; and reducing iron powder can be evenly and slowly added to the titaniferous solution to reduce the ferric iron; and the problem that of early hydrolysis of the titaniferous solution caused by a sharp increase of the reaction temperature and the problems that the quality of the titaniferous solution is reduced by colloid of generating metatitanic acid and the filtering speed of the procedure and the quality of the final titanium dioxide are affected are solved.

Owner:SHANDONG DONGJIA GRP CO LTD

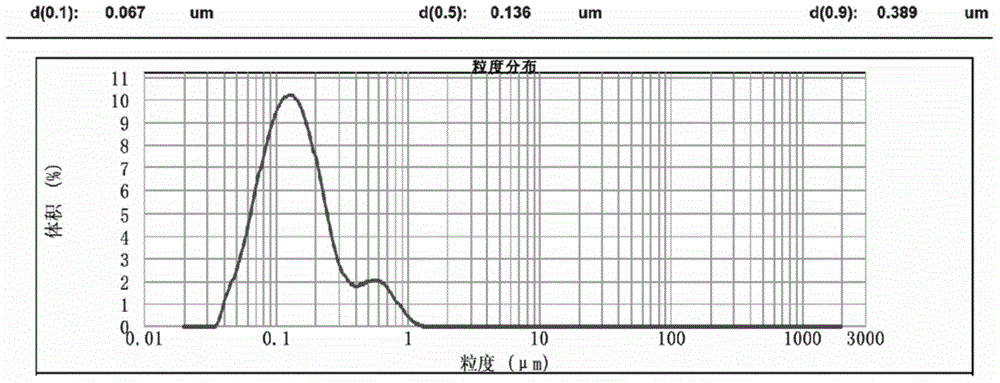

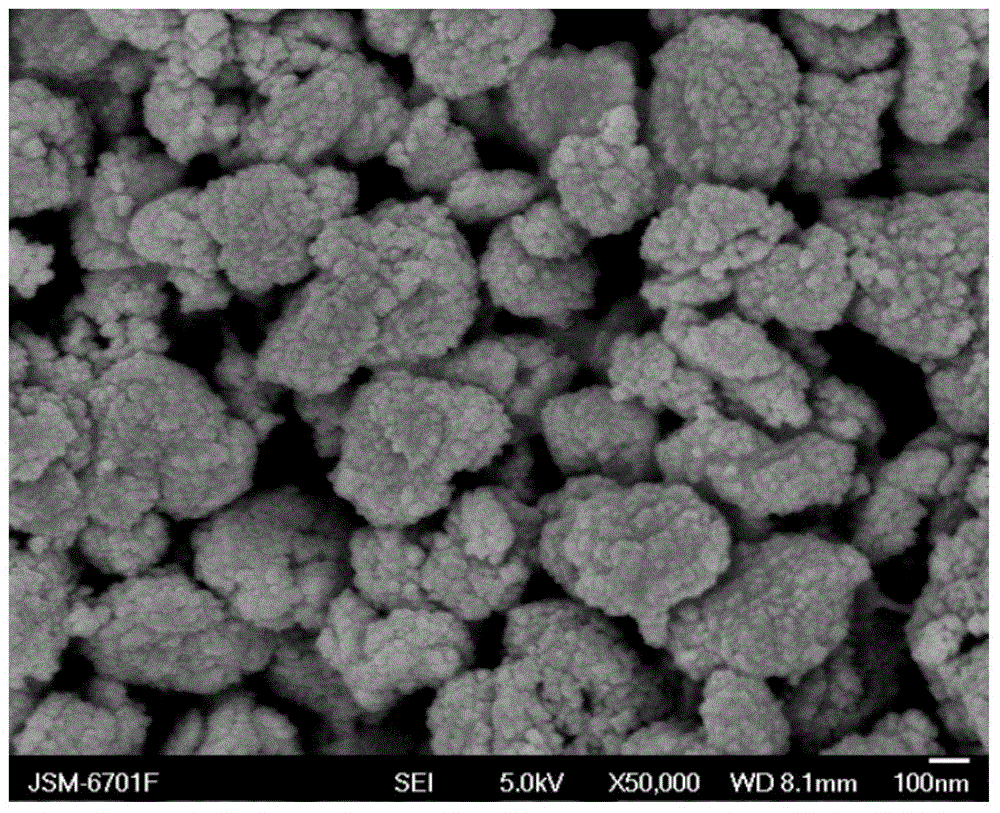

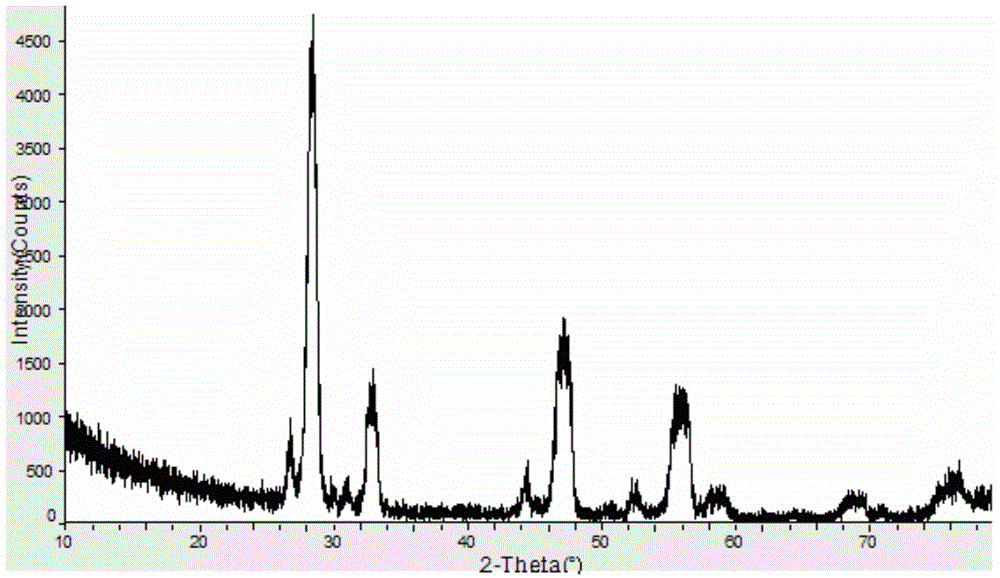

Fluorine doping method of cerium-based rare earth polishing powder

InactiveCN104419378AAdd evenlyEasy to control particle sizeOther chemical processesPolishing compositions with abrasivesFiltrationCerium

The invention discloses a fluorine doping method of cerium-based rare earth polishing powder. The fluorine doping method comprises the following steps: (1) respectively preparing a cerium-based rare earth salt solution, a precipitator and a fluorinating agent; (2) adding the rare earth salt solution, the precipitator and the fluorinating agent into a reaction kettle through parallel flow at a certain flow velocity, controlling the pH of the reaction system through controlling the flow velocity of the precipitator, controlling the fluorine doping proportion through controlling the flow velocity of the fluorinating agent, keeping a certain temperature in the reaction process, stirring violently, carrying out ageing after the reaction, and carrying out filtration, cleaning and drying on the sizing agent to obtain a cerium-based rare earth polishing powder precursor; and (3) calcining the prepared cerium-based rare earth polishing powder precursor, and carrying out natural cooling in the furnace to obtain the cerium-based rare earth polishing powder material. The fluorine doping method is simple in process, convenient to operate and suitable for industrial production. The cerium-based rare earth polishing powder prepared through the method is spherical in particle shape and controllable in particle size of product; and products with different particle sizes and different particle size distributions can be prepared according to the requirements of rare earth polishing powder with different applications.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

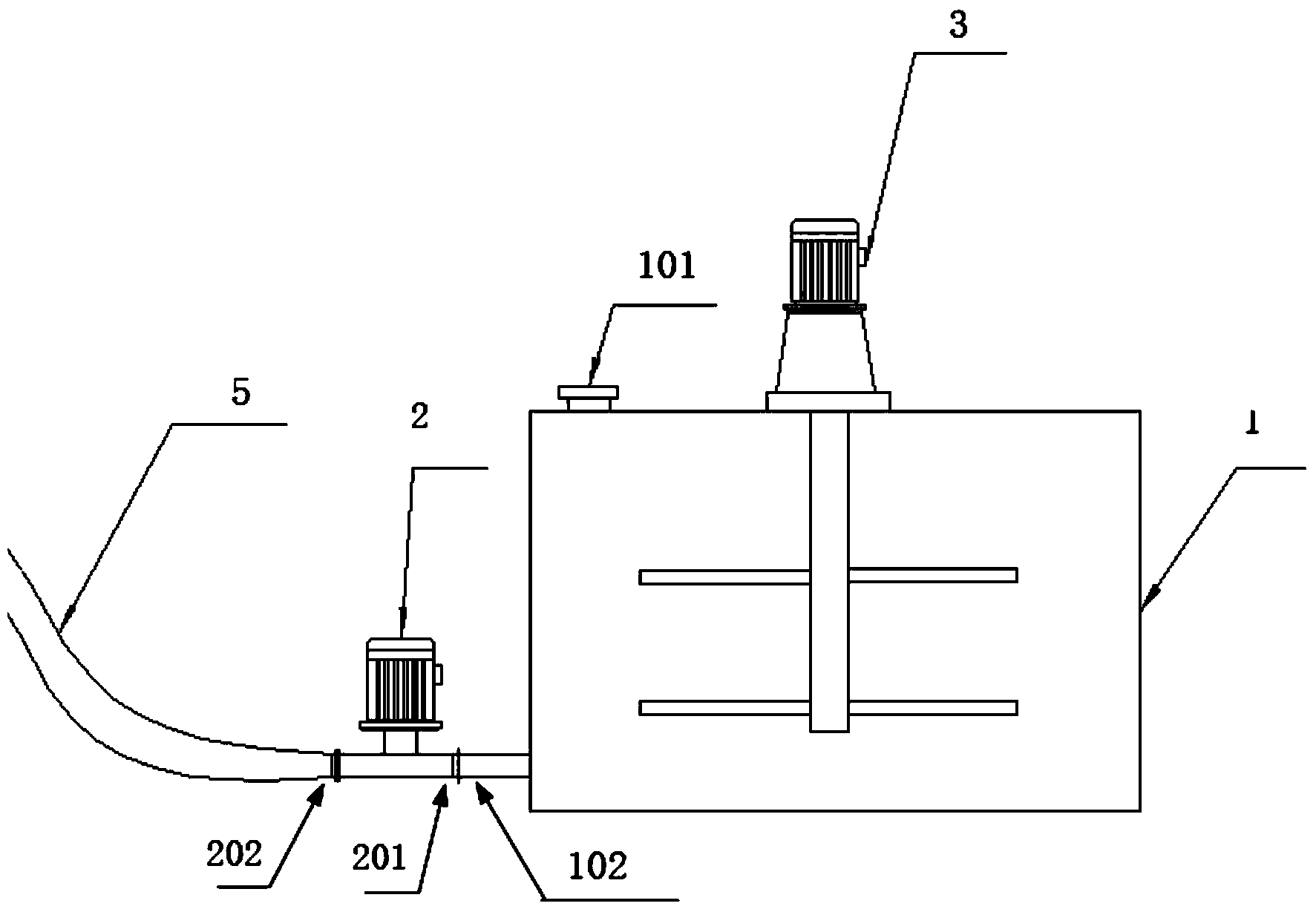

Device for adding fuel additives to steam-injection boiler and adding method

ActiveCN103611451ALow viscosityImprove combustion efficiencyLiquid fuel feeder/distributionRotary stirring mixersEngineeringWorkload

The invention provides a device for adding fuel additives to a steam-injection boiler and an adding method. The adding device comprises an additive box, a proportioning pump, a stirrer and a connecting pipeline, wherein the additive box is of a box body structure and comprises an additive adding port and an additive discharging port; the stirrer passes through an opening formed in the top part of the additive box; a control part of the stirrer is positioned outside the additive box and is fixedly connected with the additive box at the opening in the top part of the additive box; blades and a connecting shaft of the stirrer are positioned on the inner side of the additive box; the proportioning pump comprises an input port and an output port; the input port of the proportioning pump is connected with the additive discharging port of the additive box; the output port of the proportioning pump is connected with one end of the connecting pipeline; the other end of the connecting pipe is connected with the steam-injection boiler. The adding device and the adding method provided by the invention have the advantages that a manual adding mode is replaced, so that the technical problem that non-uniform mixing of fuel and the fuel additives is easily caused due to the manual adding mode is solved, the workload of operators is also reduced and the use efficiency of the fuel additives is improved.

Owner:PETROCHINA CO LTD

Acid tar processing method

The invention relates to a method of processing acid tar, concretely is a method of processing acid tar by coal blending coking, which mainly solves technical problems of environment pollution made by the acid tar. Technical project for solving the problems includes steps: a) adding alkaline solution into the acid tar to adjusting pH value of 6-8 at 80-100 DEG C; b) putting mixed liquid of the acid tar and the alkaline solution in waste acid groove beside coal blending belt of coal blending workshop, wherein the waste acid groove must be heated to 50-80 DEG C to prevent the mixed liquid from delaminating and depositing; c) adding the mixed solution befittingly into coal blending by pipe and spraying device. Adding mode of the mixed solution is continuously adding at upper of the coal blending belt when the belt is carrying coal, and stopping when the belt stops. The invention is mainly used for post-treatment of acid tar generated from coking plant.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Agricultural fig screening device

InactiveCN108212738AImprove screening effectAdd evenlySievingScreeningAgricultural engineeringReducer

The invention discloses an agricultural fig screening device. The agricultural fig screening device comprises a base. A first support plate is arranged at the right upper end of the base. A speed reducer is arranged at the right upper end of the first support plate. The input end of the speed reducer is connected with the output end of a driving motor. A rotating shaft is arranged at the output end of the speed reducer. A rotating sleeve sleeves the rotating shaft slidably. A limiting groove is formed in the inner wall of the rotating shelve. A limiting protrusion matched with the limiting groove is arranged on the outer side of the rotating shaft. Through interaction between the limiting groove and the limiting protrusion, relative rotation between the rotating shaft and the rotating sleeve is avoided. The agricultural fig screening device has the advantages that the agricultural fig screening device is convenient to carry and has high vibration resistance, a screening cylinder is driven to vibrate leftwards and rightwards, and accordingly, material screening efficiency is improved; during rotation of a second screening cylinder, a first polarization protrusion applies intermittent acting force to a stressed block, and a feed hopper vibrates up and down to feed materials evenly, so that later-period screening is benefited, and practicability is high.

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

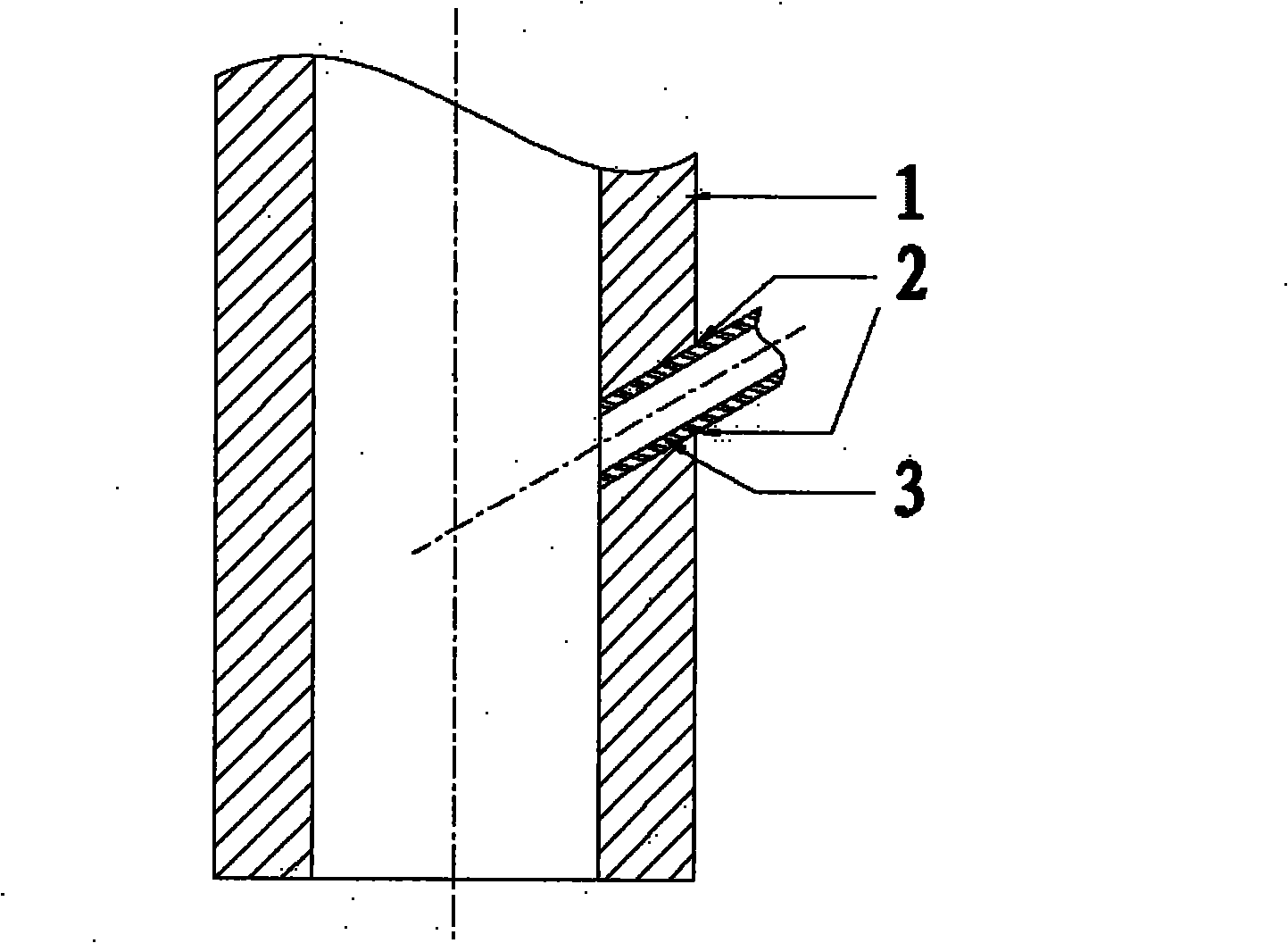

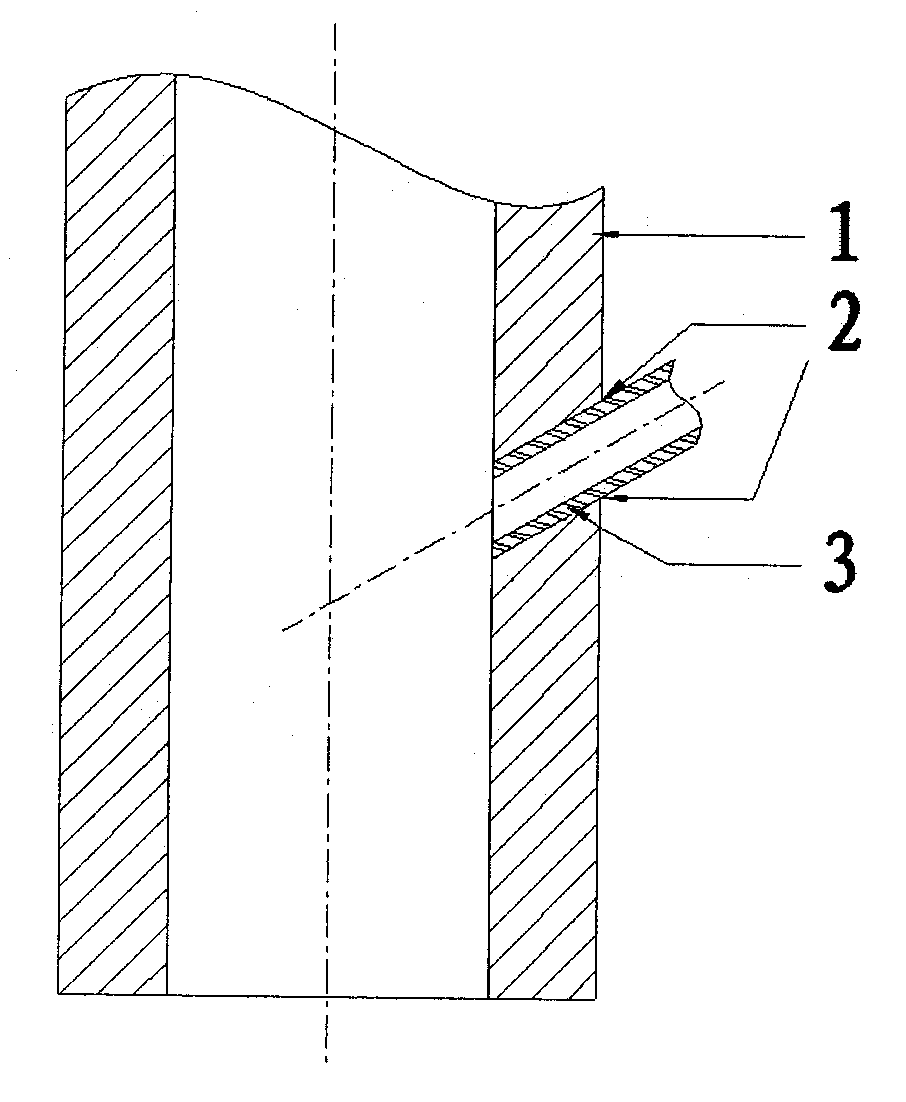

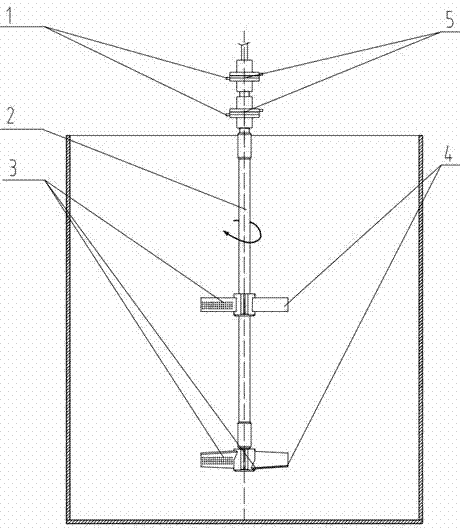

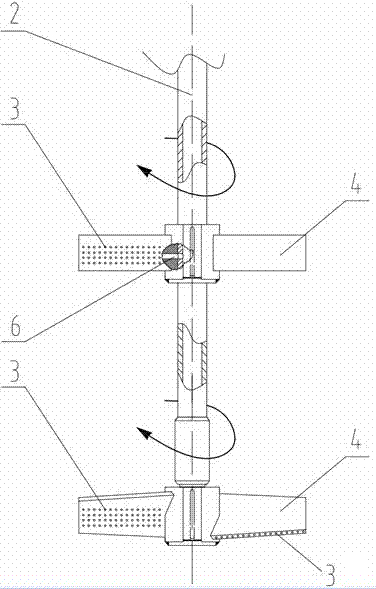

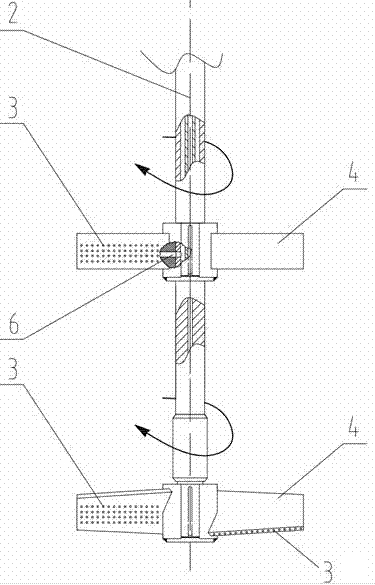

Feeding stirring device of wet metallurgy reactor

InactiveCN102965497AAdd evenlyAdd, and then add evenly through multiple sets of feeding holes on the stirring paddleRotary stirring mixersProcess efficiency improvementEngineeringReaction system

The invention discloses a feeding stirring device of a wet metallurgy reactor, relates to an improved feeding stirring device of a reactor for wet-process smelting and especially leaching, neutralizing, settling and crystallizing in wet metallurgy. The feeding stirring device structurally comprises a stirring shaft and stirring paddles arranged on the stirring shaft. The feeding stirring device is characterized in that the stirring shaft is a hollow rotating shaft, the upper end of the rotating shaft is provided with a feeding hole, positions, which are provided with the stirring paddles, on the stirring shaft are provided with discharging holes, the stirring paddles are provided with feeding through holes communicated with the discharging holes of the stirring shaft, and the blades of the stirring paddles are provided with discharging holes. According to the feeding stirring device disclosed by the invention, gas and / liquid is uniformly added in a reaction system effectively, so that the utilization rate is increased, the adding quantity is conveniently controlled, and the loss is reduced.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

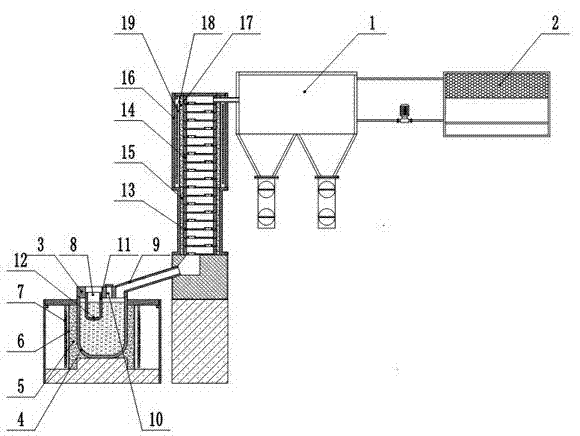

Device for automatically adding brewing water to distiller's grains and carrying out rotary cooling, distiller's yeast conveying and stirring device

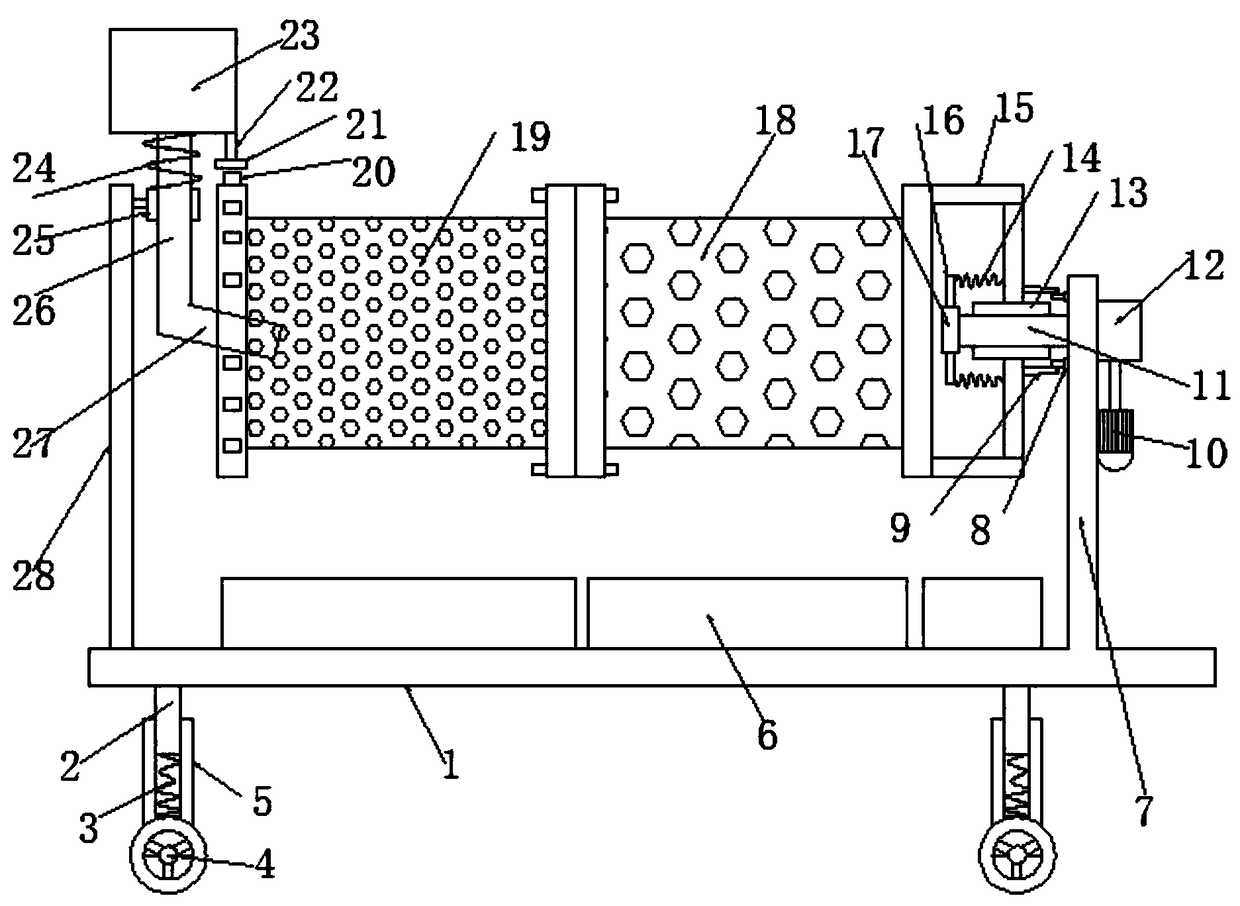

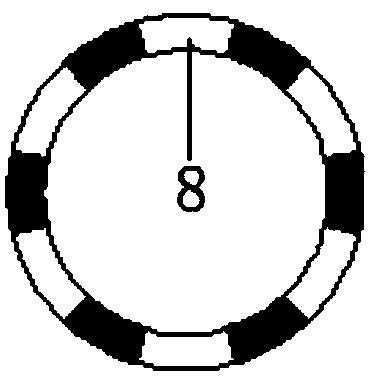

InactiveCN103789143AGuaranteed uniformity and accuracyGuaranteed even coolingAlcoholic beverage preparationElectric machineryEngineering

The invention discloses a device for automatically adding brewing water to distiller's grains and carrying out rotary cooling, distiller's yeast conveying and stirring device which comprises a frame, a brewing water adding conveying device, a rotary cooling device, a distiller's yeast discharging device, a distiller's yeast conveying stirring device and a device discharging hole, wherein four fans are arranged on the frame at two sides of the rotary cooling device; the rotary cooling device, the distiller's yeast discharging device and the distiller's yeast conveying stirring device are driven by a motor respectively. According to the device, a conventional manual brewing water adding process is changed to a process for adding brewing water by a fixed water pipe, so that the brewing water adding accuracy and uniformity are ensured; a manual stirring and fan air blast cooling process is changed to a mechanical drum stirring and fan ventilation forced cooling process; a temperature sensor is used to accurately measure the temperature of distiller's grains, so that full uniform cooling of the distiller's grains and the uniformity of cooling temperature are ensured; a manual distiller's yeast adding and stirring process is changed to a mechanical distiller's yeast adding and stirring process, so that uniform addition of distiller's yeasts and uniform mixing of the distiller's yeasts and the distiller's grains are ensured; in addition, the manpower can be effectively saved.

Owner:SICHUAN UNIV

Chocolate-added lactating sow compound feed and preparation method thereof

InactiveCN105053591AHigh nutrient concentrationImprove palatabilityAnimal feeding stuffAnimal sciencePeanut meal

The present invention relates to a chocolate adding lactating sow compound feed and a preparation method thereof, belonging to the technical field of culturing feed. The technical problem to be solved is to provide a lactating sow compound feed which is high in nutrient concentrations, enables the sow at a lactating period to have high lactating ability and more milk, and the weaning piglet to have heavy weight and litter weight, and provide a preparation method thereof. The technical solutions are as follows: the chocolate-added lactating sow compound feed includes the following raw materials in parts by weight, 400-500 parts of corn, 100-130 parts of soybean meal, 30-60 parts of peanut meal, 200-220 parts of wheat middling, 30-70 parts of extruded soybeans, 5-15 parts of fish meal, 5-15 parts of soybean oil, 5-15 parts of calcium hydrogen phosphate, 10-20 parts of mountain flour, 20-35 parts of white sugar, 20-30 parts of glucose, 15-25 parts of feed yeast, 30-50 parts of chocolate powder, and 10-30 parts of premix.

Owner:SHANXI B Y T FEED CO LTD

Device for producing nano-scale high-purity zinc powder by distillation method

The invention relates to a device for producing nano-scale high-purity zinc powder by a distillation method. The device is characterized by consisting of a continuously-fed inductive electric heating crucible distillation furnace, a reflux plate, a high-temperature overheat plate, a zinc powder condenser and a closed water cooling tower. A metal zinc ingot is smelted by a smelting crucible to form smelted metal zinc which absorb energy in a distillation crucible for vaporization and distillation, the zinc steam enters the reflux plate so as to remove high-boiling-point purities, the pure zinc steam enters the overheat plate to carry out secondary concurrent heating, overheat zinc steam of which the boiling point higher than that of zinc directly enters the zinc powder condenser to carry out quenching to produce zinc powder which contains little micron-scale high-purity zinc powder and vast majority of nano-scale high-purity zinc powder, wherein the granularity of the produced zinc powder can be controlled within 50nm-100nm, and the purity of the produced zinc powder is up to over 99.999 percent; the zinc powder can be continuously produced by uniform feeding without pollution, the energy consumption is low and the automation degree is high.

Owner:长沙科力威蒸馏技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com