Device for automatically adding brewing water to distiller's grains and carrying out rotary cooling, distiller's yeast conveying and stirring device

An automatic technology of distiller's grains, applied in the preparation of alcoholic beverages, etc., can solve the problems of a large amount of labor and the inability to ensure the uniform mixing of distiller's grains and distiller's yeast, and achieve the effects of saving labor, ensuring accuracy and uniformity, and ensuring uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

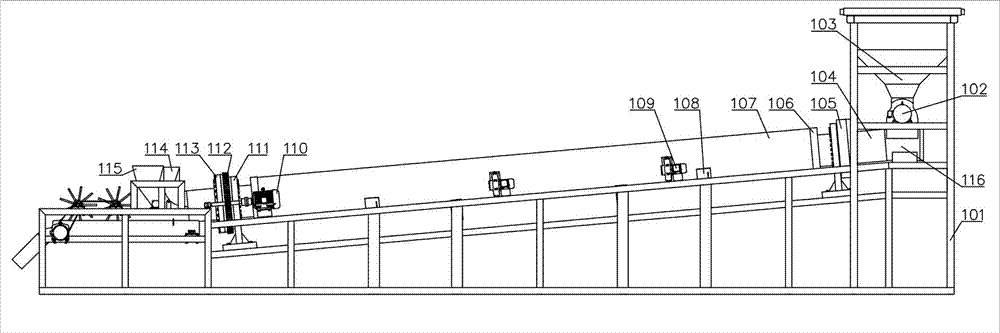

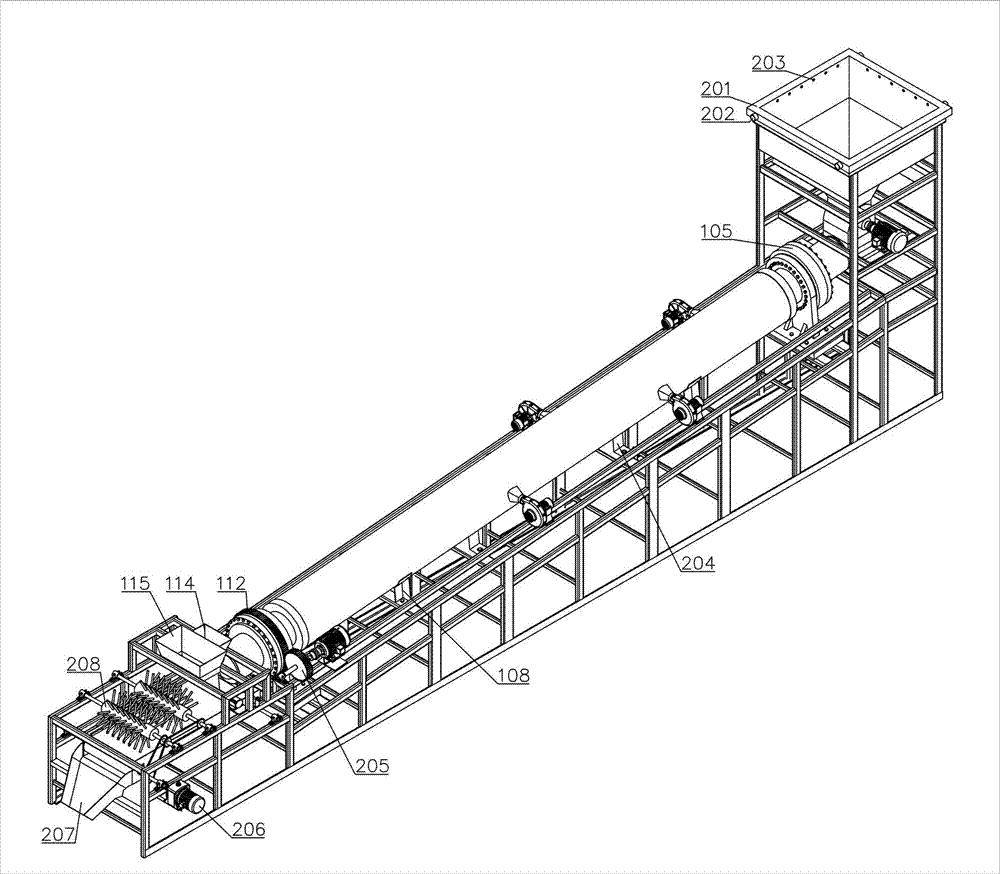

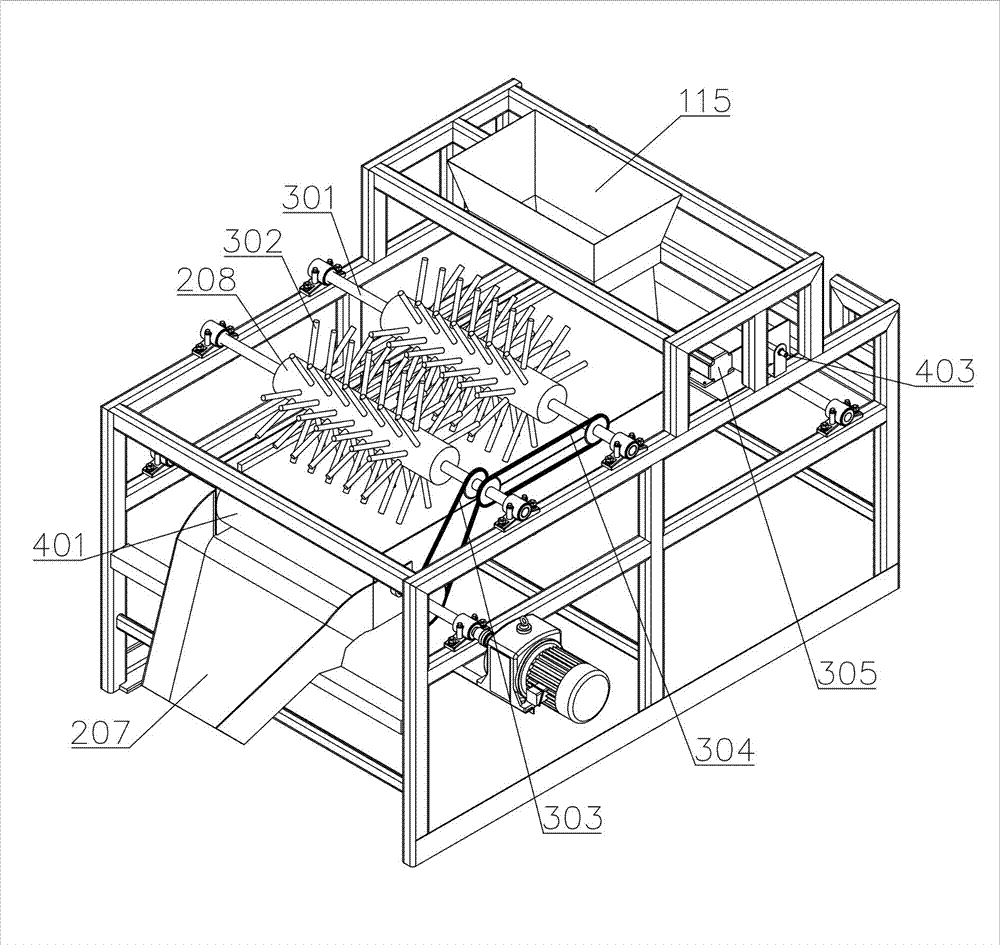

[0021] combine Figure 1~Figure 6, the embodiment is: the frame 101 is a frame structure welded with section steel, and other components of the device are installed on the frame 101 . A hopper 103 is arranged at the highest position of the frame, and the hopper 103 is fixedly installed on the frame by welding. A water tank 201 is arranged around the outer side of the top port of the hopper; A circular water outlet 203 is provided. A screw feeding mechanism 116 is arranged at the outlet of the bottom of the hopper 103 . The screw feeding mechanism 116 is driven by the screw feeding motor 102 . Both ends of the slewing inner cylinder 104 are respectively connected to the rotating outer rings of the toothless slewing bearing 105 and the outer gear slewing bearing 112 through the movable flange 113, and then the fixed inner rings of the two slewing bearings pass through the fixed flange 111 respectively. Installed on the inclined frame 101. Among them, the gearless slewing bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com