Electric rice cooker based on minimum cooking amount and heating control method thereof

An electric rice cooker, the smallest technology, applied in timing control of ignition mechanism, heating device, kitchen utensils, etc., can solve problems such as insufficient cooking time, raw rice, inconsistent rice temperature, etc., to overcome inaccurate temperature measurement and improve taste , Guarantee the effect of uniformity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with several embodiments.

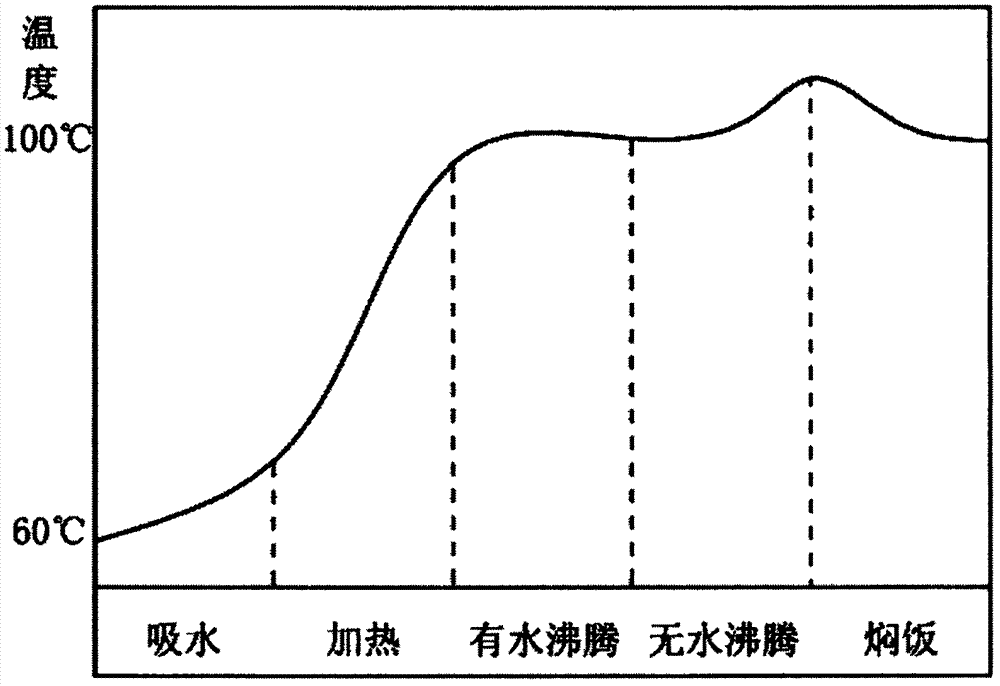

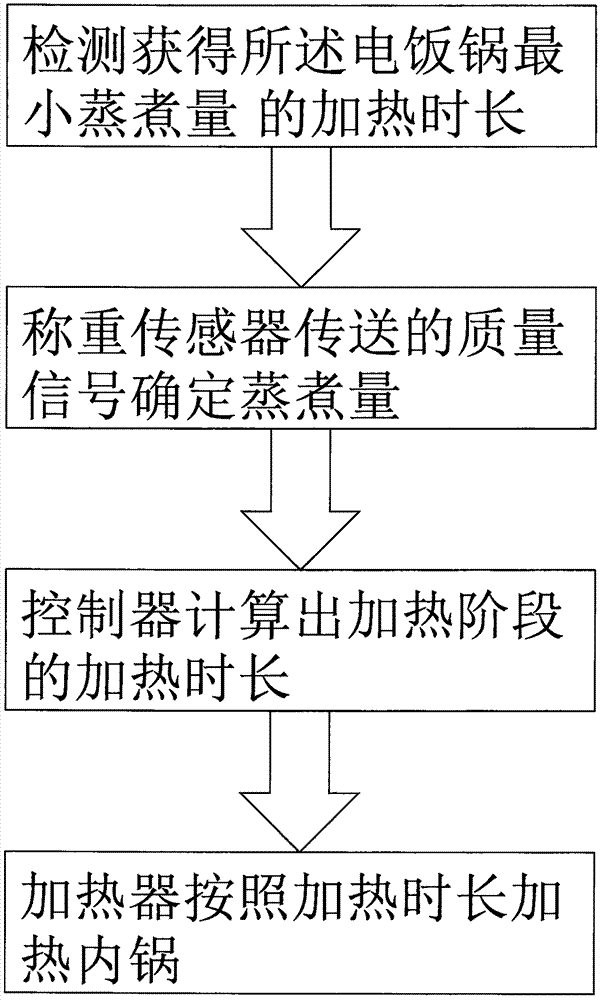

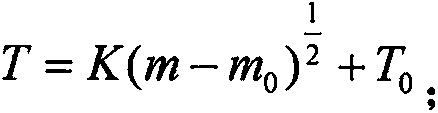

[0018] In one embodiment, the electric rice cooker of the present invention includes a pot body, an inner pot disposed in the pot body, and a pot cover for covering the inner pot, and a weighing sensor is arranged at the lower part of the inner pot, The weighing sensor is used to detect the quality of rice and water in the inner pot, and transmits the quality signal to the controller. The heater heats the inner pot; the controller receives the quality signal sent by the quality sensor, and outputs a control signal to control the power and heating time of the heater. Wherein, the process of cooking rice in the electric rice cooker is divided into a water absorption stage, a heating stage, a water boiling stage, an anhydrous boiling stage and a stewing rice stage. 0 and the basic heating time T 0 Calculate the heating time T of the heating phase.

[0019] In a preferred emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com