Patents

Literature

86results about How to "Particle size can be adjusted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

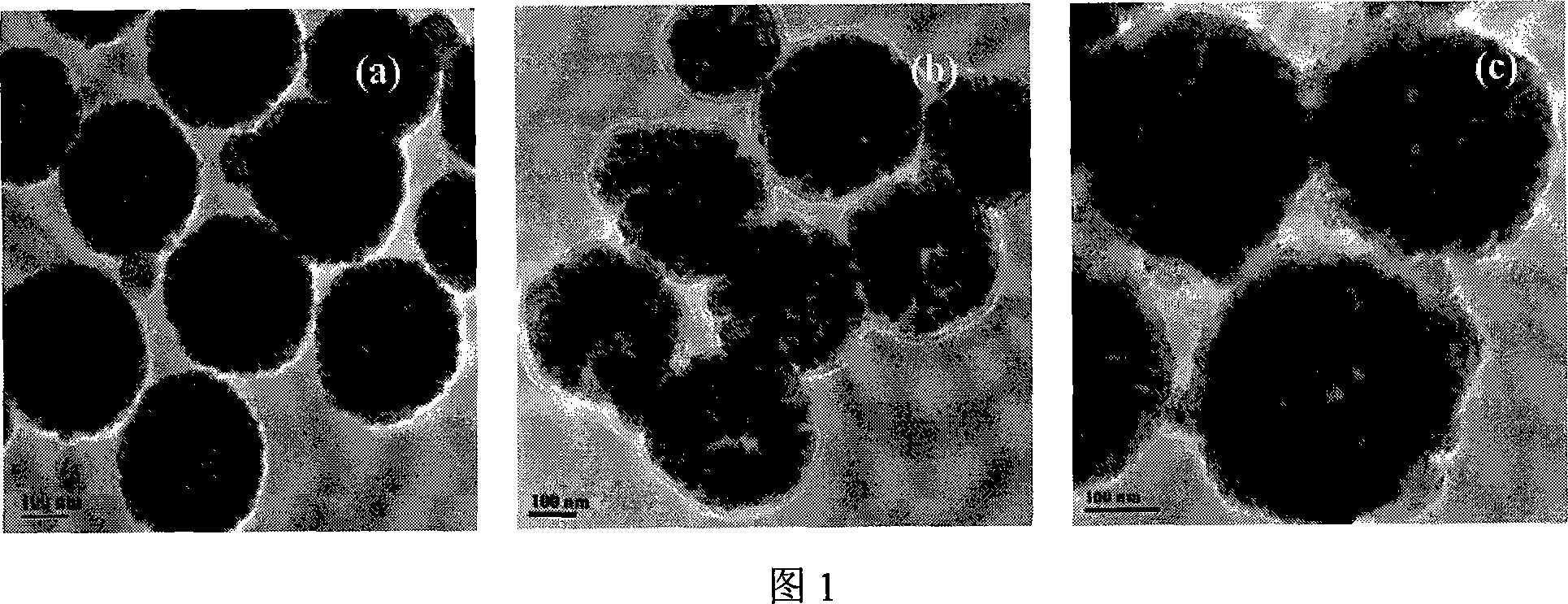

Magnetic fluorescent double functional microballoon with core-shell structure and preparation method thereof

InactiveCN1523076ASimple methodRaw materials are easy to getMicroballoon preparationLuminescent compositionsCitrate sodiumChemistry

The present invention relates to a magnetic fluorescent double-functional microsphere with core-shell structure and its preparation method. Firstly, said invention uses strong acid and sodium citrate to modify surface of inorganic magnetic nano granules, then uses alkyl orthosilicate as precursor body, and adopts gel-sol process to prepare silicon dioxide magnetic microsphere with core-shell structure, finally utilizes the copolycondensation method of alkyl orthosilicate and silane coupling agent of bonded fluorescein to prepare silicon dixide fluorescent microsphere with magnetism. Said microsphere has magnetic response characteristic, and can send out fluorescence under the excitation of UV-light and visible light.

Owner:FUDAN UNIV

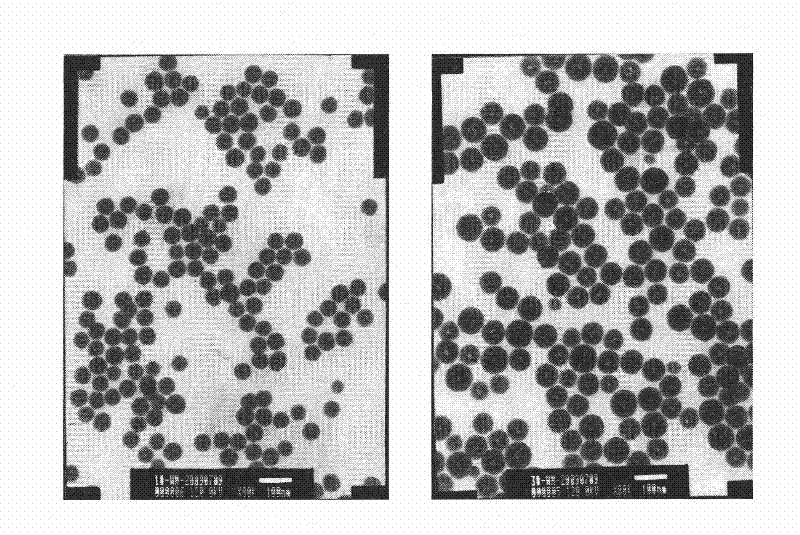

Magnetic silicon dioxide microspheres with nuclear shell and surface anisotropic double functional groups and preparation method thereof

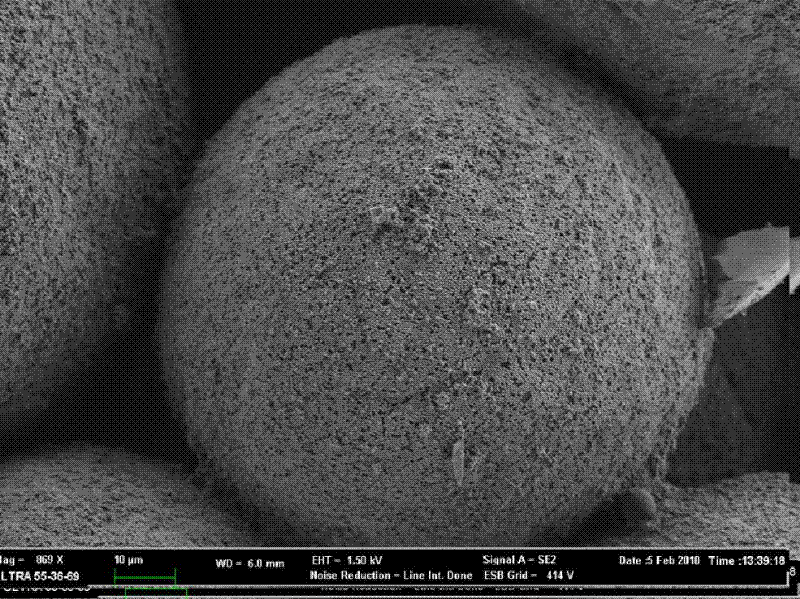

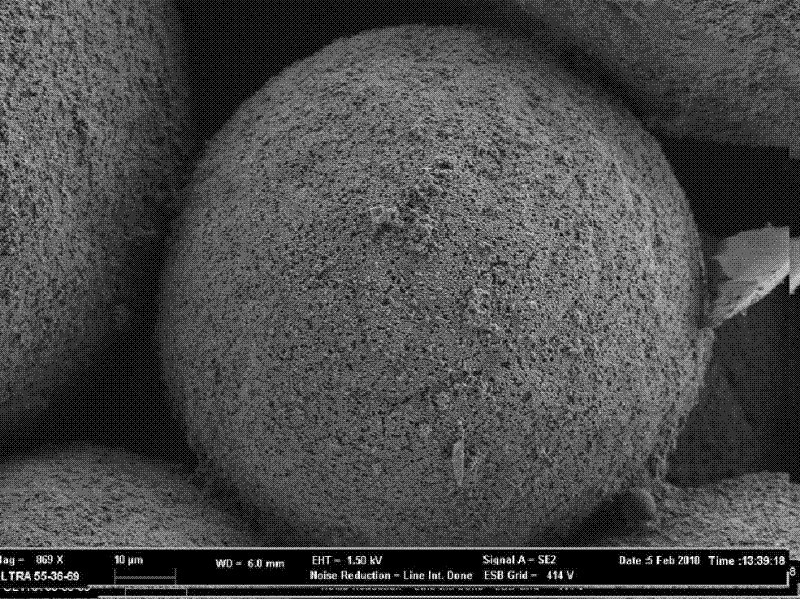

ActiveCN102160985ARegular shapeQuantity is easy to controlInorganic material magnetismMicroballoon preparationCarboxyl radicalButanedioic acid

The invention relates to magnetic silicon dioxide microspheres with a nuclear shell and surface anisotropic double functional groups and a preparation method thereof. The preparation method comprises the following steps of: preparing superparamagetic microspheres by a solvothermal process; preparing magnetic microspheres which are coated by silicon dioxide by a sol-gel process; preparing the magnetic silicon dioxide microspheres of which the surface has amino group by taking the magnetic silicon dioxide microspheres as seeds and by the copolycondensation of alkyl ester orthosilicate and a silane coupling agent, and drying the magnetic silicon dioxide microspheres to obtain samples; and by a PICKERING emulsion technology, stabilizing a paraffin / aqueous emulsion system with a micrometer scale by using the aminated magnetic microspheres to form single-layer close packing of the magnetic microspheres on the surface of paraffin spheres, then reacting the amino group on the surface of the magnetic microspheres which is exposed in a liquid phase with succinic anhydride to introduce carboxyl into the partial surface of the microspheres, so that the surfaces of the magnetic microspheres have the anisotropic double functional groups. The obtained magnetic microspheres with the double functional groups have the advantages that: magnetic responsiveness is high; grain size can be controlled between 200 and 800 namometers; and the density of the surface functional groups can be adjusted.

Owner:SUZHOU WIN BIO TECH CO LTD

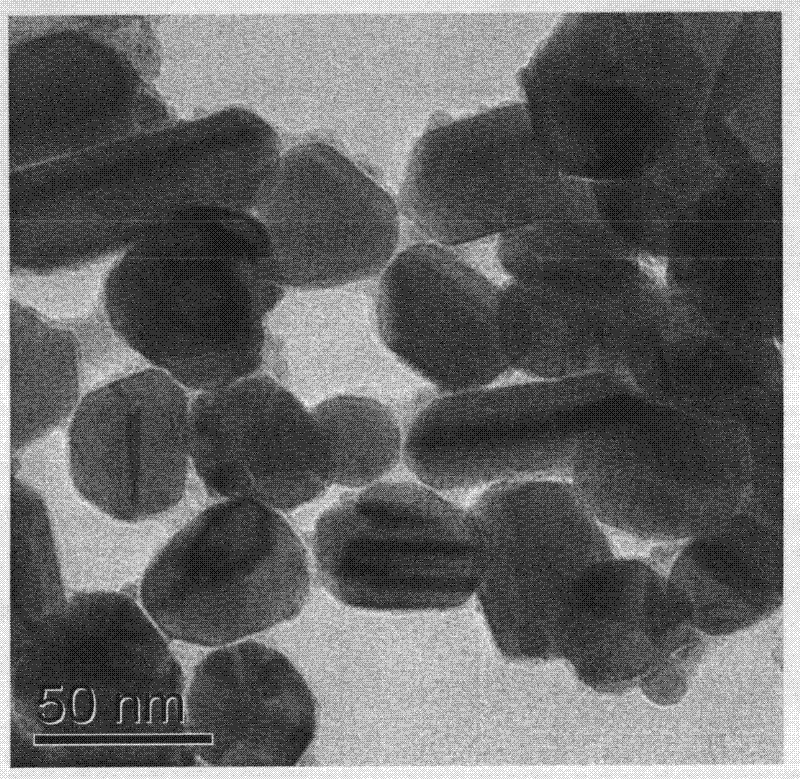

Magnetic metal oxide microsphere in core-shell structure and its prepn process

InactiveCN101066988AMagnetically responsiveNarrow particle size distributionFerroso-ferric oxidesPeptide preparation methodsMicrosphereNitrogen gas

The present invention belongs to the field of inorganic material technology, and is especially one kind of magnetic metal oxide microsphere in core-shell structure and its preparation process. The microsphere has ferroferric oxide microsphere as the core and metal oxide as the shell. It is prepared through the first hydrothermal process to cover one layer of amorphous carbon onto ferroferric oxide microsphere to form magnetic carbon microsphere Fe3O4@C, the subsequent dispersing microsphere Fe3O4@C in alcohol water solution of pre-hydrolyzed metal alkoxide for adsorbing inorganic oligomer to the surface of the microsphere, and the final calcining in nitrogen atmosphere to obtain the magnetic metal oxide microsphere in core-shell structure. The process is simple and practical, and has adjustable size of the microsphere. The magnetic metal oxide microsphere has important application in separating protein, separating polypeptide and other fields.

Owner:FUDAN UNIV

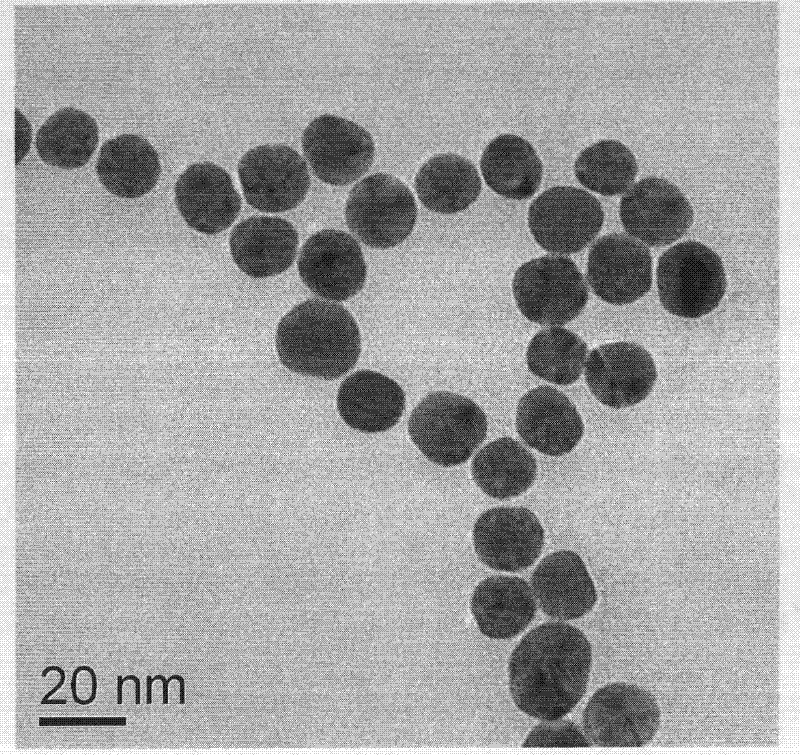

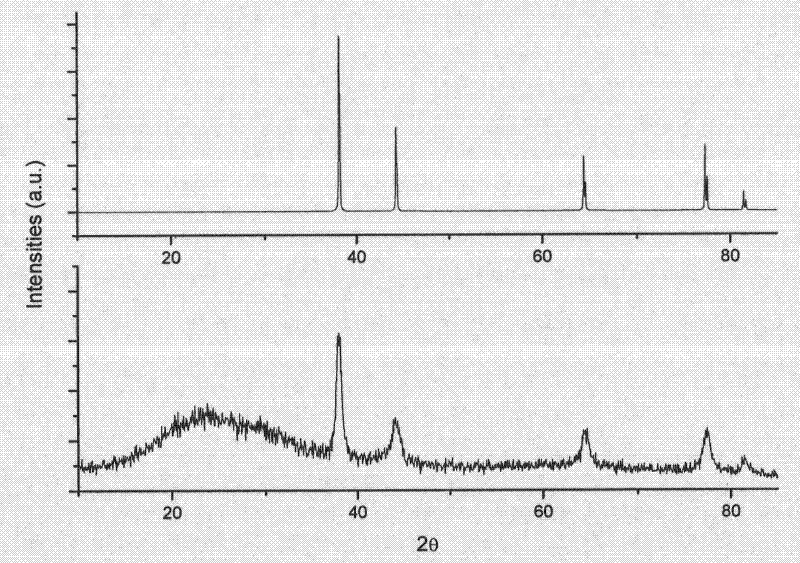

Method for preparing gold and silver nanoparticles with hydro-thermal method

The invention provides a method for preparing gold and silver nanoparticles with a hydro-thermal method. The method comprises the following step of: reducing metal ions into corresponding metal nanoparticles by taking citric acid as a reducing agent under a hydro-thermal condition. The method has a simple process and low cost; and the prepared gold and silver nanoparticles are crystalline and have high purities and controllable particle diameters. The method can be applied to the fields such as chemical catalysis, cosmetics and biology and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

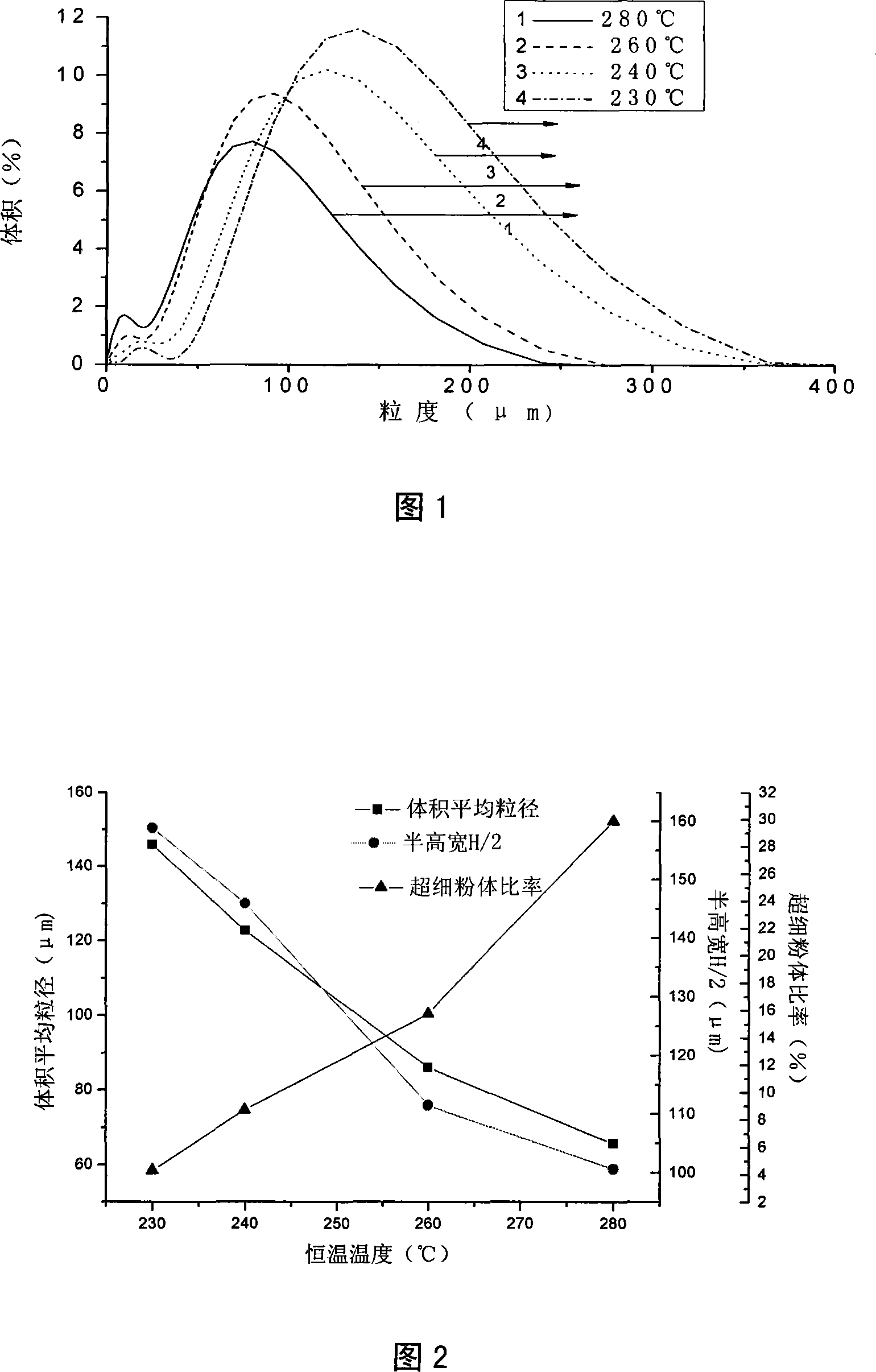

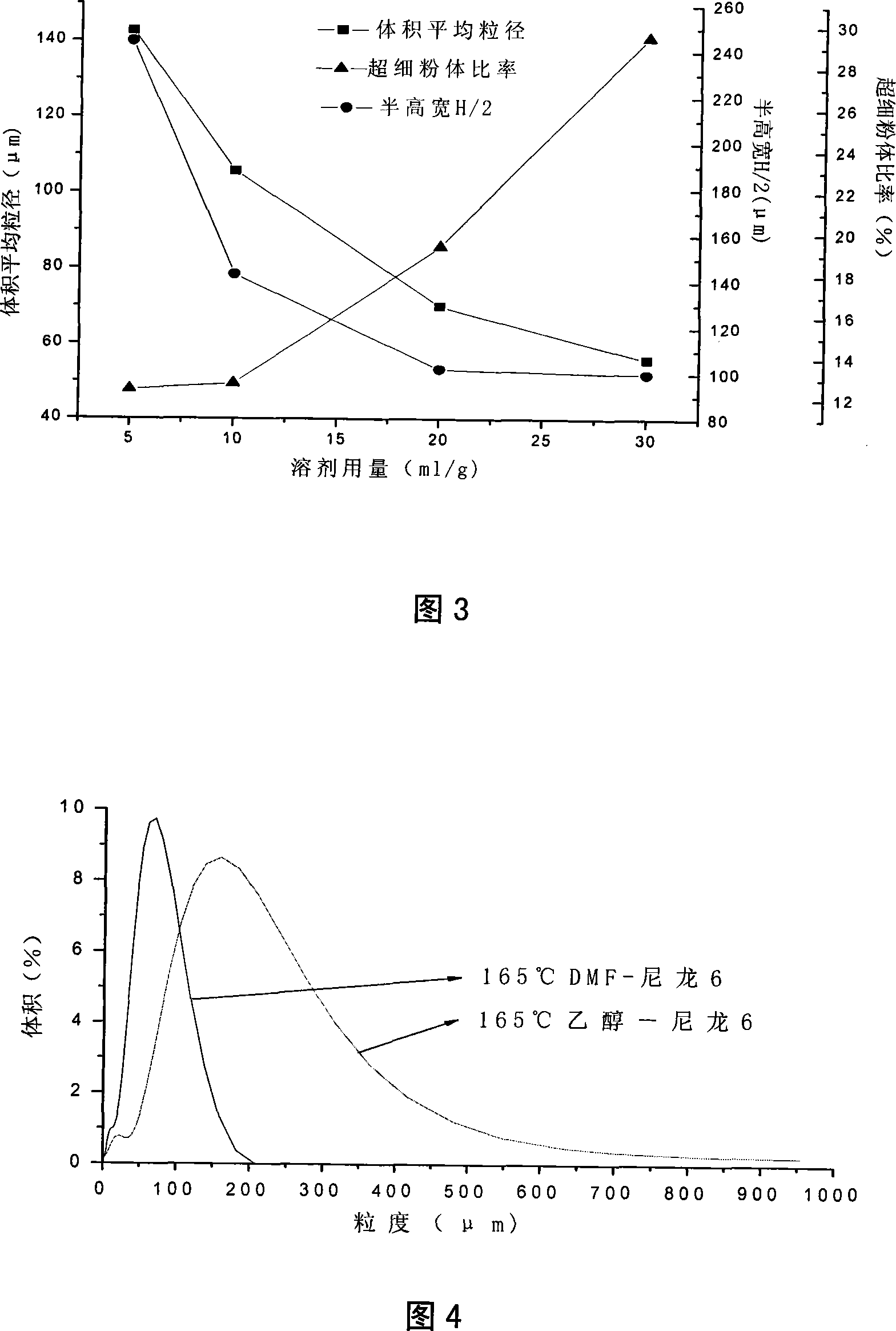

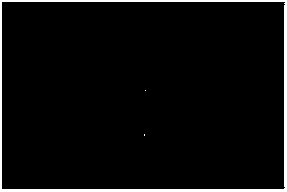

Method for preparing nylon powder by employing DMF

The present invention discloses a preparation method of nylon powder by making use of DMF. The method is that nylon resin is dissolved in the N-dimethylformamide (DMF) solvent, so as to prepare the nylon powder by high temperature, pressure keeping, cooling and drying, the high temperature is controlled at 145DEG C to 290DEG C, the pressure is 0.7 to 1.5MPa; the preparation method of the nylon powder which is provided by the present invention has simple equipment, the preparation process is easy to be operated, the purchase of the solvent is convenient, and the solvent can be recovered and utilized, the particle size of the obtained nylon powder product can be modulated, the granule is spherical approximately, the powder liquidity is good, and the specific surface area is large. The obtained various nylon powders according to the present invention can be used as the nucleating agents of polymer, coating powder of electrostatic spraying technology, powder for magnetic materials and so on.

Owner:ZHENGZHOU UNIV

Light scattering polycarbonate composite and light scattering materials (such as films, sheets, plates) prepared from light scattering polycarbonate composite

InactiveCN102702713AAdd evenlyParticle size can be adjustedDiffusing elementsLiquid-crystal displayLight guide

The invention provides a light scattering polycarbonate composite and light scattering materials (such as films, sheets, plates) prepared from the composite. The composite comprises (A) a base material, namely a polycarbonate resin and (B) a scatterer material which can be molten and deformed into polymer in the forming process of polycarbonate, such as acrylonitrile copolymer. The light scattering materials (such as films, sheets, plates) with isotropic scatterning performance or anisotropic (such as linear )scattering performance can be prepared from the composite material, and the requirements of high light transmittance and high haze can be met; and the light scattering materials are suitable for light scattering films, sheets, plates and the like in the field of liquid crystal displays, and the illumination materials of light guide plates, lampshades or advertising light boxes, show windows and the like.

Owner:SICHUAN UNIV

Emulsion stabilizer for food and preparation method thereof

The invention relates to a food emulsion stabilizer formed by compounding ultra-fine microcrystalline cellulose of less than 10 Mum and food gum, wherein the weight of the food gum is 50-150% of the weight of the ultra-fine microcrystalline cellulose, preferably 10-40%. When the consumption of the food emulsion stabilizer is lower, very good emulsification stabilization is brought to the beverage or food with higher content of insoluble matters and fat constituents and the slide and full feel is given to the food. The food emulsion stabilizer can not be replaced on many occasions.

Owner:PEKING UNIV +2

Process for preparing high hydroscopicity resin from polyacrylonitrile powder

A process for producing high water absorption resin using polyacrylonitrile powder is provided. In the process, polyacrylonitrile powder, water, alcohols compound and hydrolytic reagent are heated up to a temperature under stirring action and dispersive hydrolytic reaction is carried out. After the hydrolytic reaction, the resin product is filtered out and dried, and the powdered or granular product is obtained. The water absorbing multiple and salt tolerance of the product can be improved greatly.

Owner:SINOPEC QILU CO

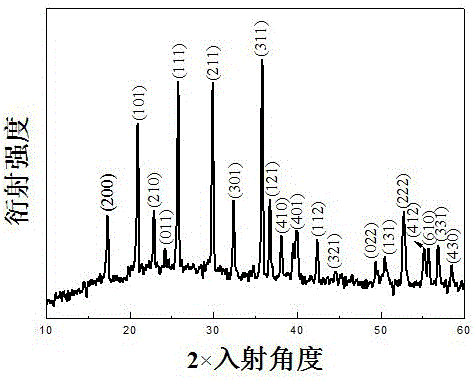

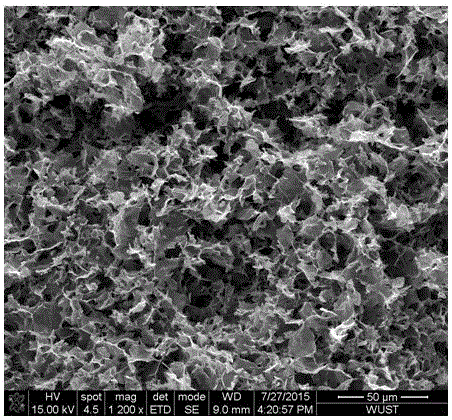

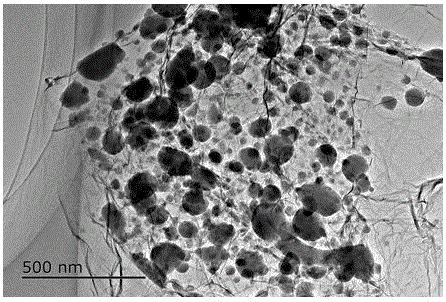

Graphene aerogel loaded lithium iron phosphate porous composite material and preparation method thereof

ActiveCN106025241AImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsHigh ratePhosphate

The invention relates to a graphene aerogel loaded lithium iron phosphate porous composite material and a preparation method thereof. The technical scheme of the invention is as follows: the preparation method comprises the steps: adding a graphene oxide into deionized water, and carrying out stirring so as to obtain a solution I with the concentration of 2kg / m<3> to 5kg / m<3>; adding a ferric salt into the solution I in accordance with that the mass ratio of the ferric salt to the graphene oxide is 1: (0.03 to 0.3), and carrying out stirring so as to obtain a solution II; adding phosphate and a lithium salt into the solution II in accordance with that the mass ratio of the ferric salt to the phosphate to the lithium salt is 1: 1: 2, carrying out stirring, carrying out a hydrothermal reaction in a reactor, carrying out washing, carrying out freezing, and carrying out drying in a vacuum freeze drier; carrying out heat preservation for 4 to 10 hours in a tube type furnace in a protective atmosphere at the temperature of 550 DEG C to 850 DEG C, and carrying out furnace cooling, thereby preparing the graphene aerogel loaded lithium iron phosphate porous composite material. According to the graphene aerogel loaded lithium iron phosphate porous composite material and the preparation method thereof, the operation is convenient, industrial production is facilitated, the prepared product is adjustable in pore structure and particle size of lithium iron phosphate loaded on the surface of graphene, and the structural stability, cycle performance and high rate capability are excellent.

Owner:WUHAN UNIV OF SCI & TECH

Method for identifying varieties of residual silk of antique silk fabric based on immune trace method

ActiveCN107462728ATake advantage ofGood fluorescence stabilityBiological testingEnvironmental resistanceFluorescence

The invention relates to the field of detection of cultural relics and discloses a method for identifying the varieties of residual silk of antique silk fabric based on an immune trace method. The method comprises the following steps: preparing a fluorescent carbon point by taking a sweet potato as a carbon source, marking secondary antibodies of mulberry silk and tussah silk by using the fluorescent carbon point, hydrolyzing promiscuous antique silk fabric cultural relic samples by using ionic liquid and PM13-alkaline protease step by step, performing dialysis and purification after protein extracting liquid is obtained, performing SDS-PAGE gel electrophoresis, transferring the obtained protein band to a PVDF membrane, incubating silk primary antibodies and the secondary antibodies marked by the fluorescent carbon point, observing the immunofluorescence band in a gel imaging system, and identifying the varieties of the antique silk fabric. According to the method, the use amount of a chemical reagent is small, and the reaction is mild, environment-friendly and harmless; and when the antique silk fabric is detected, the method has the characteristics of small use amount of samples, intuitive performance, rapidness and high sensitivity.

Owner:ZHEJIANG SCI-TECH UNIV

Modified starch nano composite solid gum stock and preparation method thereof

InactiveCN101787649AParticle size can be adjustedImprove stabilityFibre treatmentPolyvinyl alcoholSlurry

The invention relates to a modified starch nano composite solid gum stock and a preparation method thereof, belonging to the technical field of fine chemical engineering. The modified starch nano composite solid gum stock is made from nano particles, the gum stock is in the shape of solid power and features good stability in the process of storage and usage and non-agglomeration of the nano particles. The preparation method comprises the following steps: adding soluble starch as polymeric dispersant when collosol reaction happens inorganic salt and acid or alkaline; then adding modified starch and carrying out ageing reaction with the nano particles before carrying out centrifugal separation; finally drying. As the gum stock is in the shape of solid powder, so that period of validity is lengthened, packaging, storage and transportation are facilitated, maintenance and transportation fees are reduced. With sizing agent prepared from the solid gum stock applied to warp sizing, the anchoring strength of the sizing agent is good, warp sizing filoplume is appressed, abrasive resistance is improved by 15-20%; in particular, the nano particles in the sizing agent features stability and non-agglomeration and retrogradation, improves weaving efficiency, can completely replace polyving alcohol and belongs to warp sizing assisting agent for ecological fabrics.

Owner:石绍华

Preparation method of high-precision aluminum oxide polishing powder

ActiveCN104403575AAccelerateUniform particle sizePolishing compositions with abrasivesCerium oxideTitanium oxide

The invention discloses a preparation method of high-precision aluminum oxide polishing powder. The polishing powder is used as an abrasive material, and mainly contains aluminum oxide, silicon oxide, cerium oxide and titanium oxide. The Al2O3:SiO2 ratio is 12:1-8:3, and the CeO2:TiO2 ratio is 1:1-3:1. In order to enhance the polishing effect, the dispersing agent is added in the synthesis and preparation process, so that the prepared aluminum oxide polishing powder can be utilized to obtain a favorable polished and ground surface. The preparation method comprises the following steps: thoroughly mixing aluminum nitrate, silica sol, cerium nitrate, titanium oxide powder and a dispersing agent, carrying out spray drying, and roasting to obtain the aluminum oxide polishing powder. The aluminum oxide polishing powder has the advantages of favorable suspensibility, favorable dispersity, narrow particle size distribution, high smoothness of the polished and ground surface, high polishing capacity and long service life.

Owner:包头市华辰稀土材料有限公司

Glycyrrhizin triple composition nano micro particle and its preparing method

InactiveCN1586487ASimple methodEasy to makeOrganic active ingredientsPowder deliveryCarboxymethyl celluloseBioavailability

The nano ternary composite glycyrrhizin particle of the present invention results in raised orally taken absorption rate and bioavailability of glycyrrhizin. The present invention prepares nano ternary composite glycyrrhizin particle through ion gelifying process of sodium tripolyphosphate, sodium carboxymethyl cellulose as anion polymer and chitosan or quaternized N-(2-hydroxy) propyl-3-trimethyl ammonium chloride, and the mutual action between glycyrrhizin and chitosan. Nano particles of different sizes may be obtained via controlling the molecular weight of chitosan and the concentration and ratio of the components. The nano particle is positively charged and thus favorable to surface modification. The method of the present invention is simple, feasible, repeatable and practical.

Owner:FUDAN UNIV

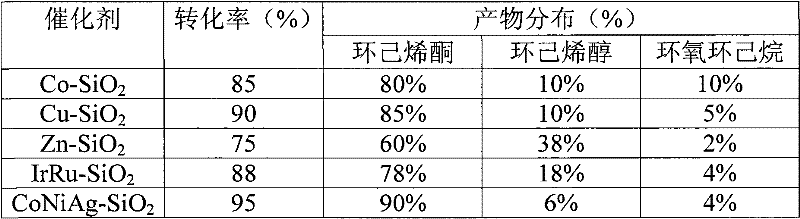

Hollow nanocomposite oxide material and preparation thereof

InactiveCN102451688AParticle size can be adjustedUniform particle sizeMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideMaterials science

The invention relates to a hollow nanocomposite oxide material. The material is prepared by embedding inorganic metal oxide into a hollow silicon oxide substrate, wherein the inorganic metal oxide is highly dispersed into the silicon oxide substrate; and inorganic metal is one or more of Co, Cu, Ni, Zn, Ag, Au, Ir, Rh, Pt, Pd and Ru. The hollow nanocomposite oxide material synthesized by the method has the particle size of 20 to 500nm and the hollow size of 5 to 20nm, has the characteristics of controllable and uniform particle size, high dispersibility and the like, and is easy to operate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

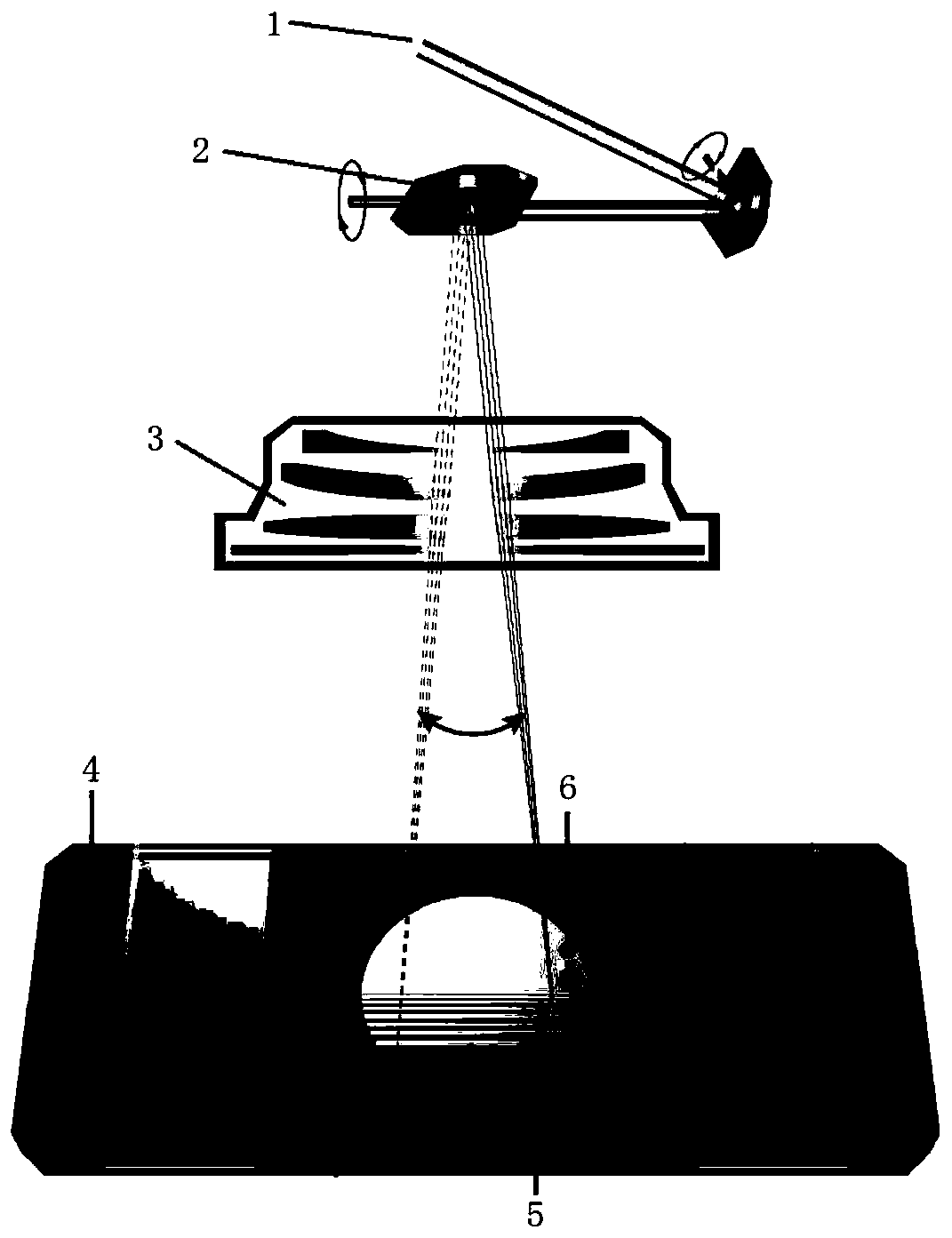

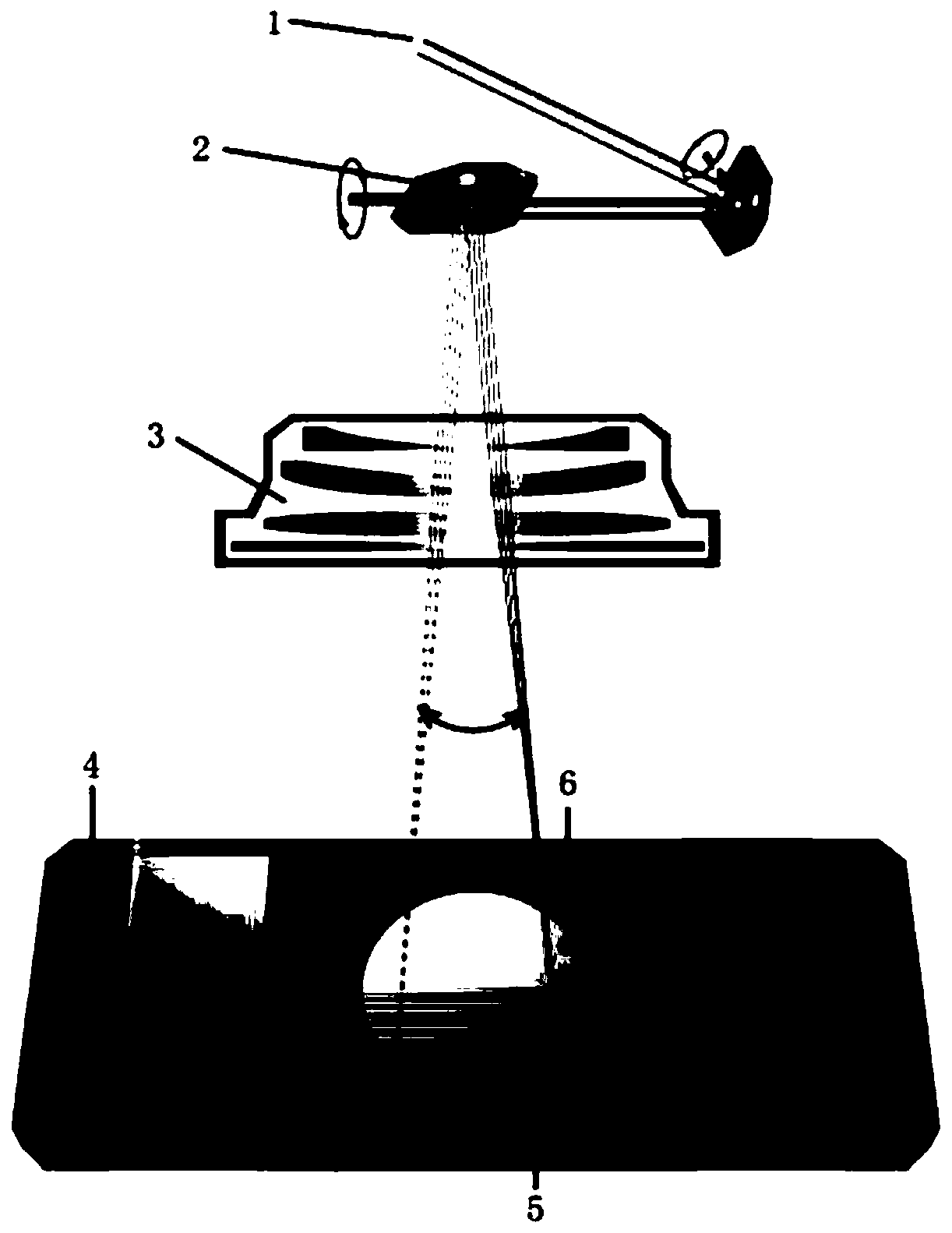

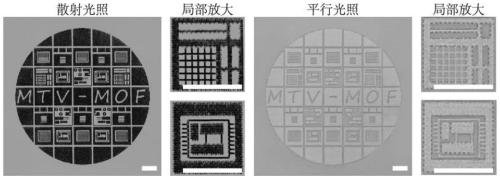

Smelting method and patterning method of nano metal particles

ActiveCN109877341AImprove efficiencyLow costMaterial nanotechnologyChemical vapor deposition coatingNanometreLight source

The invention belongs to the field of nano metal particles materials and devices thereof, particularly relates to a smelting method and a patterning method of nano metal particles. The smelting methodof the nano metal particles include the following steps that (A1) metal organic compounds uniformly cover the surface of a substrate to form a metal organic compound layer; and (A2) the metal organiccompound layer is irradiated by light sources, and the nano metal particles deposited on the substrate are prepared. The smelting method of the nano metal particles has the advantages of being low incost and high in producing efficiency; the nano metal particles produced by the smelting method is adjustable in particle size and particle space and good in chemical stability in air; and the patterning method of the nano metal particles has the advantages that the producing cost is low, the producing efficiency is high, the produced nano metal particles are good in stability, patterns can be customized randomly and the like, and the patterning method of the nano metal particles is more suitable for the next generation of large-scale producing of micro-electronic devices, sensors, optoelectronic devices and the like based on the nano metal particles.

Owner:WUHAN UNIV

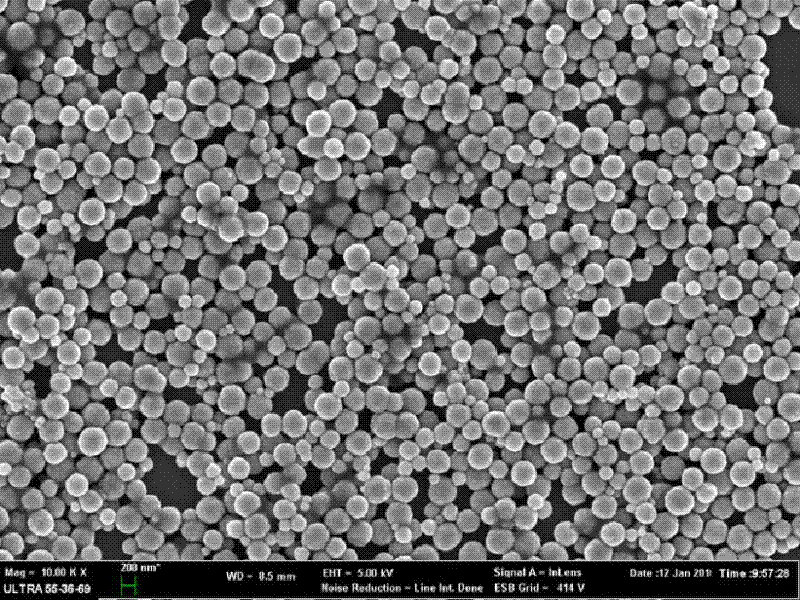

Preparation method of silicon dioxide material with hierarchical pore structure

ActiveCN110759348AParticle size can be adjustedAvoid pollutionMaterial nanotechnologySilicaPtru catalystSilicic acid

The invention belongs to the field of nanometer materials, and relates to a preparation method of a silicon dioxide material with a hierarchical pore structure. Tetraethyl orthosilicate is adopted asa silicon source, triethanolamine is adopted as a basic catalyst, sodium salicylate and hexadecyl trimethyl ammonium bromide are adopted as a structure-directing agent and a template, and the silicondioxide material with the hierarchical pore structure is prepared in a water solution. The silicon dioxide material prepared through the method is uniform in particle size and larger in pore volume, and not only has a dendritic large pore path structure radially from inside to outside but also has a small-size mesoporous structure. The method provided by the invention is simple to prepare, low incost, good in repeatability and friendly to the environment, the particle size is adjustable in the range from 50 to 500nm, and large-scale preparation can be realized. The silicon dioxide material with the hierarchical pore structure prepared by the invention can be applied to a drug delivery carrier, and particularly has a remarkable advantage on a common load of small molecule drugs and high molecular weight protein.

Owner:LANZHOU INST OF VETERINARY SCI CHINESE ACAD OF AGRI SCI

Mono-component polymeric nanocomposite superhydrophobic coating material and preparation method therefor

ActiveCN110144158APossesses superhydrophobic propertiesImprove adhesionCoatingsN dimethylformamideSilanes

The invention discloses a mono-component polymeric nanocomposite superhydrophobic coating material and a preparation method therefor. The method mainly comprises the following steps: uniformly mixingspherical silicon dioxide sol with gamma-aminopropyl triethoxysilane and octadecyl methoxy silane, and then, carrying out purifying and drying, so as to obtain hydrophobic spherical silicon dioxide; then, adding and dissolving the hydrophobic spherical silicon dioxide in N-N dimethylformamide, then, sequentially adding triethylamine and a halogenation reagent, and carrying out uniform mixing, so as to prepare hydrophobic spherical silicon dioxide, of which the surface contains halogen groups; and then, preparing a hydrophobic-modified spherical silicon dioxide particle brush from the hydrophobic spherical silicon dioxide, of which the surface contains the halogen groups, by an atom transfer free-radical polymerization method, thereby preparing the mono-component polymeric nanocomposite superhydrophobic coating material. The superhydrophobic coating material prepared by the method not only has superhydrophobic and self-film-forming properties, but also is high in substrate bonding power, good in durability and long in service life.

Owner:ANHUI UNIVERSITY

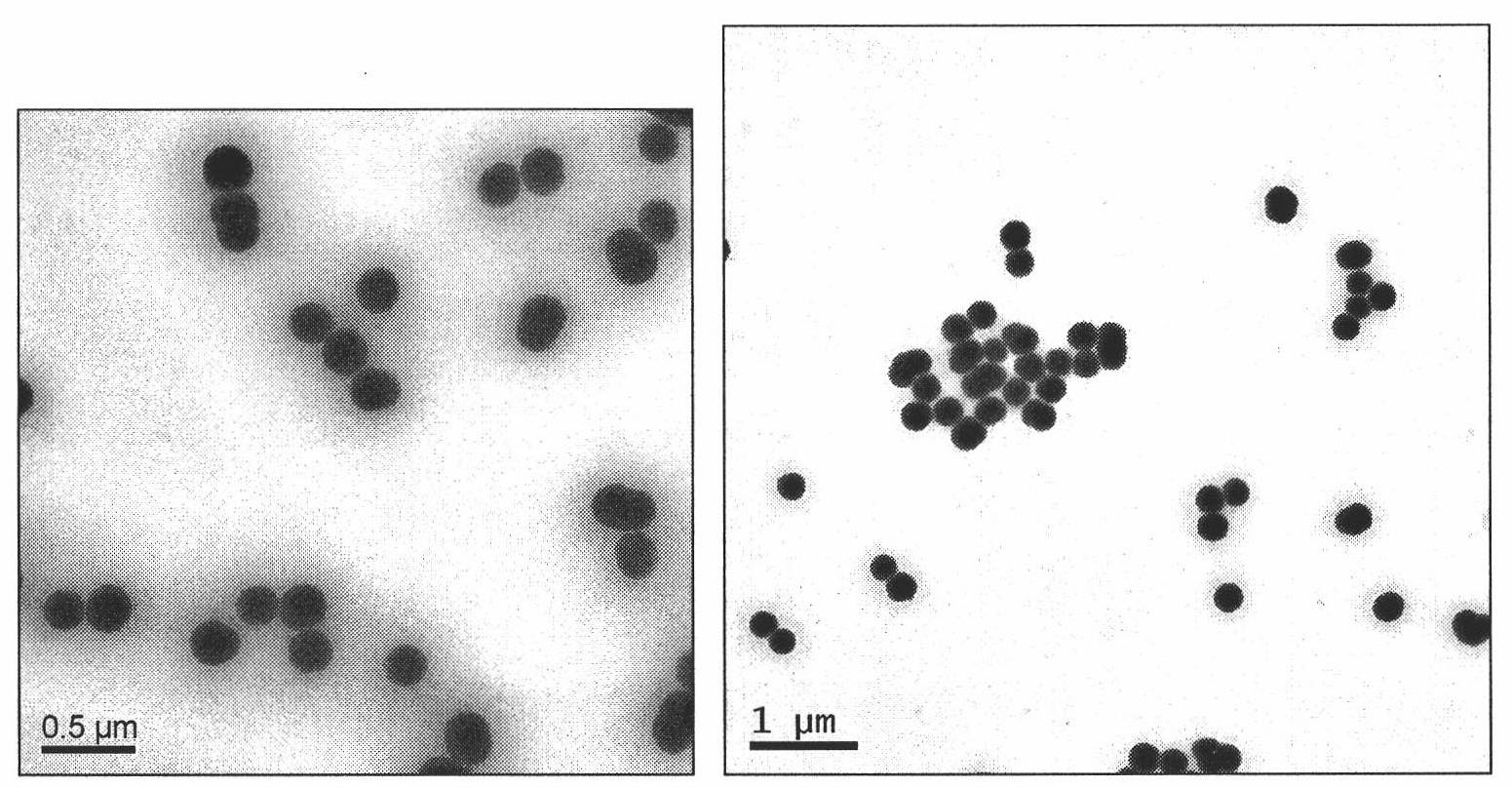

Water soluble microsphere preparation method and application thereof

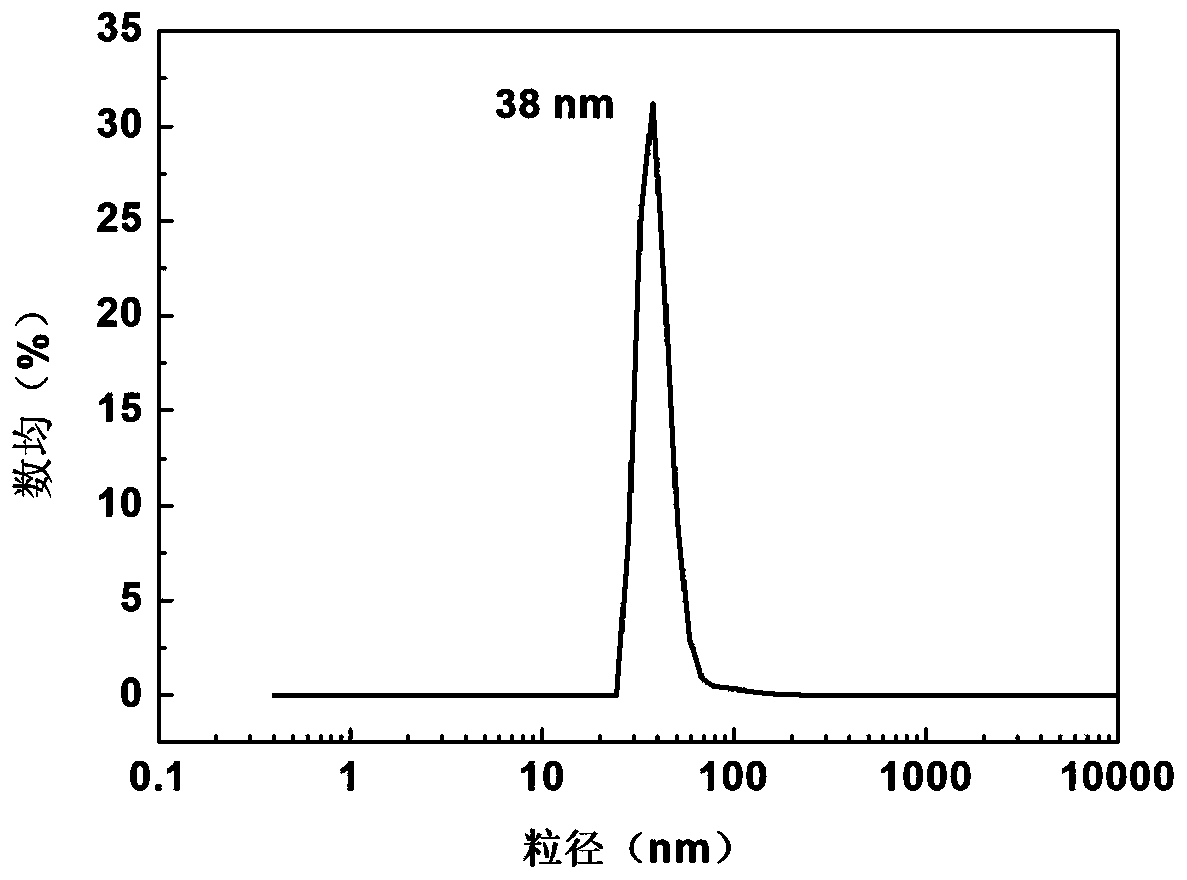

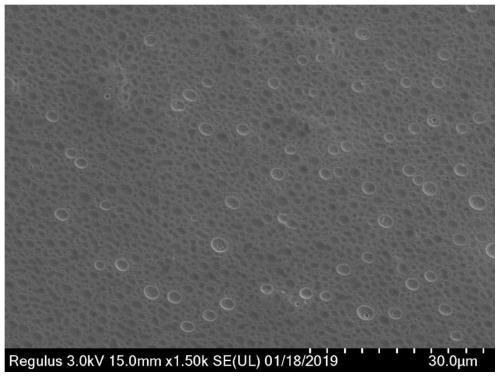

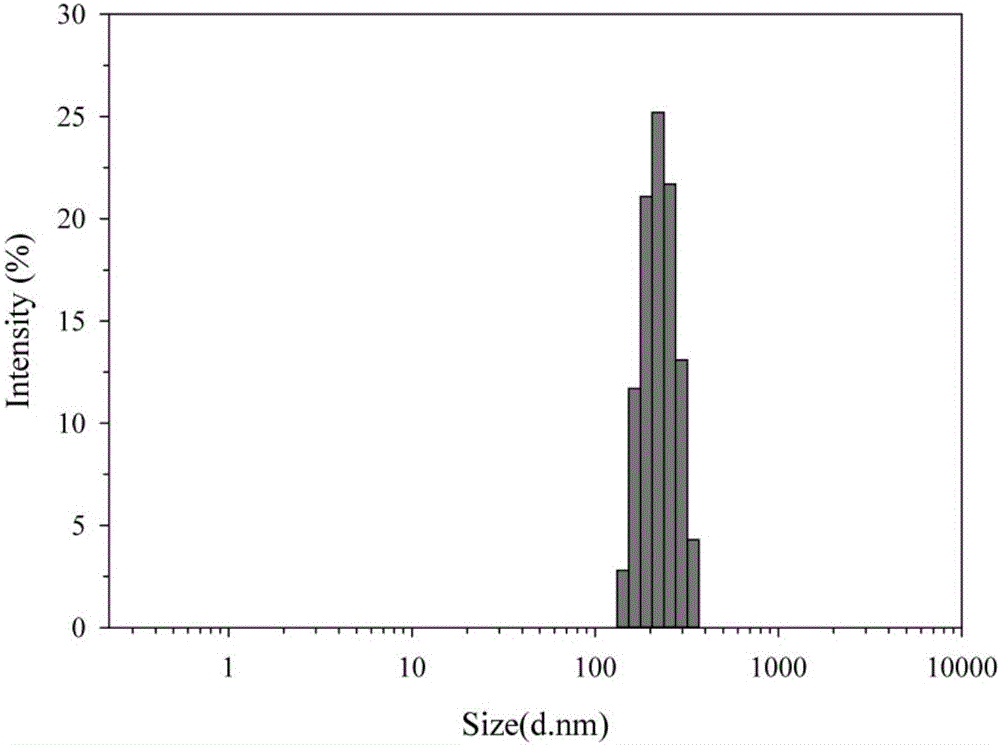

ActiveCN106124758AImprove stabilitySolve the problem of water-soluble modificationMaterial analysisSolubilityPrill

The invention discloses a preparation method of water soluble microspheres. Oil solubility nano-particles are dissolved into an organic solvent to obtain an oil phase, water-soluble hydrosulphonyl containing or disulfide bond biomacromolecules are dissolved into water to obtain a water phase; the oil phase and the water phase are premixed, and a crude emulsion is obtained; the crude emulsion is subjected to the cavatition through the physical stimulation means, biomacromolecule is subjected to a crosslinking reaction, and the biological macromolecule shells wrap the surfaces of the nano-particles. The preparation method is simple and mild in reaction conditions, the obtained microspheres have the good water solubility, the grain size is controllable, the grain size is uniform, the stability is good, the non-specific adsorption is low, the biological compatibility is good, the coupling marking is easy, and the method can be widely used for the fields of bioanalysis, environment analysis, food safety testing, sample separation and purification, medical examination, imaging, biological medicine research and the like.

Owner:武汉纳达康生物科技有限公司

Preparation and application of composite TiO*copolymer microspheres

InactiveCN101531734AEasy to operateAppropriate densityOrganic chemistryOther chemical processesBenzoyl peroxideMicrosphere

The invention relates to a method for preparing composite TiO2 copolymer microspheres and application of the composite TiO2 copolymer microspheres in natural product separation and purification. According to the method, an oil phase containing surface-modified TiO2, benzoyl peroxide serving as an initiator, GMA serving as a monomer, DVB serving as a crosslinking agent and the oil phase of a pore forming agent is added into a composite aqueous phase containing gelatin and sodium chloride, and the mixture is heated to cure to form microspheres; and beta-CD is directly immobilized on the microspheres serving as a immobilization matrix in the presence of sodium hydride to form the composite TiO2 copolymer microspheres. The copolymer microspheres can be used as an expanded bed adsorption medium to separate isoflavones from soybean waste molasses and purify the isoflavones. The method has the advantages of simple preparation process and easy control and amplification. The prepared TiO2 copolymer microspheres have the advantages of good medium sphericity, mild elution conditions, high biocompatibility, excellent hydrophilicity and wide application prospect in the natural product separation and purification.

Owner:BEIJING UNIV OF CHEM TECH

Insecticide pirimiphos-methyl microcapsule suspension and preparation method

InactiveCN102657160ANo side effectsParticle size can be adjustedBiocideAnimal repellantsChitosan derivativeChemistry

The invention discloses an insecticide pirimiphos-methyl microcapsule suspension and a preparation method. The insecticide pirimiphos-methyl microcapsule suspension comprises the following components in percentage by weight: 0.1-70 percent of pirimiphos-methyl, 1-10 percent of chitosan-aliphatic polyester grafted copolymer, 2-5 percent of organic solvent, 1-10 percent of emulsifier, 1-5 percent of dispersant, 2-10 percent of thickening agent, 1-5 percent of anti-freezing agent and the balance of water. The particle diameter of the microcapsules is 0.1-100 mum, and the particles are regular spheres. A chitosan derivative is used as a capsule material; and the insecticide pirimiphos-methyl microcapsule suspension has the advantages of biodegradability, bioavailability, biological adhesion, permeation promotion effect, no toxic or side effect and the like. The insecticide pirimiphos-methyl microcapsule suspension is mainly used for pest prevention and control of warehousing, homes, public sanitation and economic crops such as flowers and fruits.

Owner:HUNAN CHEM RES INST

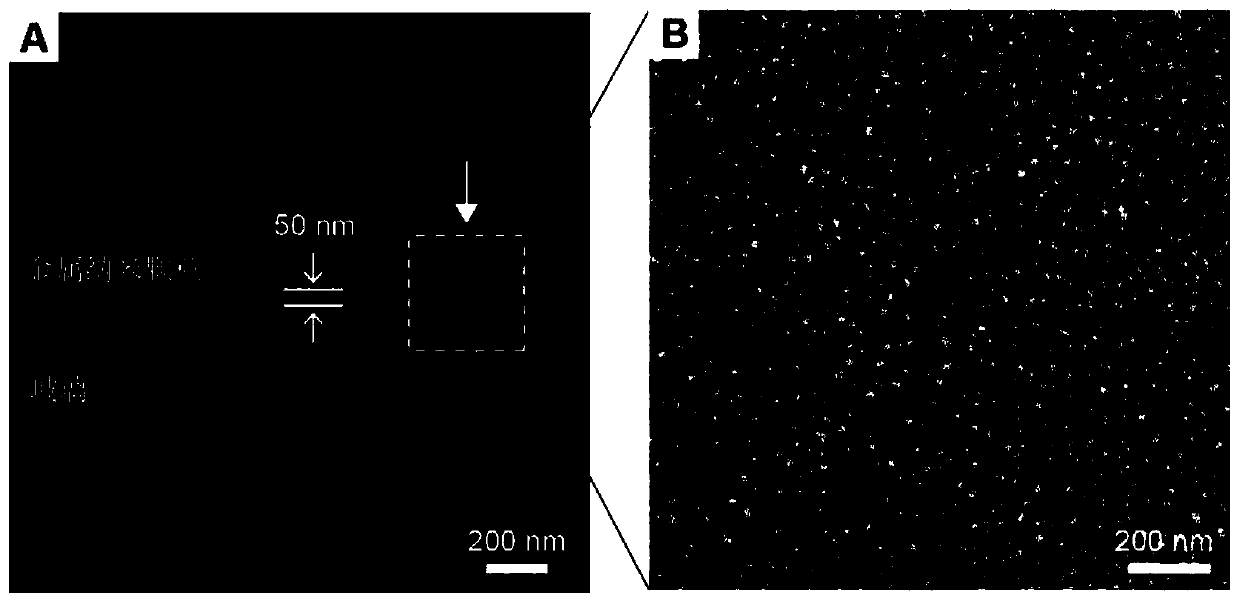

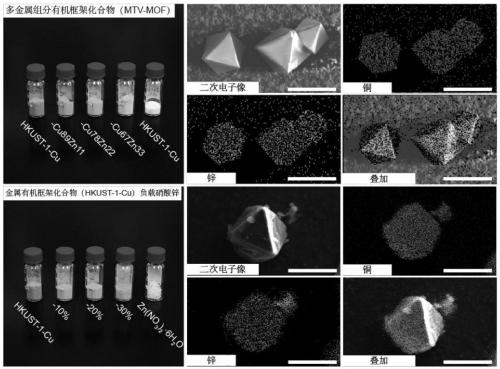

Nano-alloy particles and patterning method thereof

InactiveCN111235545AWill not oxidizeRealize photothermal reduction reactionMaterial nanotechnologyChemical vapor deposition coatingAlloyChemical stability

The invention discloses nano-alloy particles and a patterning method thereof. A smelting method of the nano-alloy particles comprises the following steps that (1.1) the surface of a substrate is evenly covered with multi-metal-component organic framework compounds to form a multi-metal-component organic framework compound layer; and (1.2) a light source is used for irradiating the multi-metal-component organic framework compound layer to prepare the nano-alloy particles deposited on the substrate. The smelting method has the advantages of low cost and high production efficiency. The nano-alloyparticles produced by the smelting method have the advantages of uniform mixing of metal elements, adjustable alloy ratio, good chemical stability in the air and the like. The patterning method has the advantages that the production cost is low, the production efficiency is high, stability of the generated nano-alloy particles is good and a pattern can be customized at will and is more suitable large-scale production for the next generation of microelectronic devices, sensors, and optoelectronic devices based on the nano-alloy particles.

Owner:WUHAN UNIV

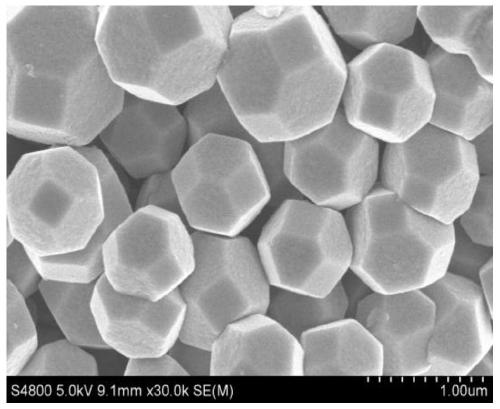

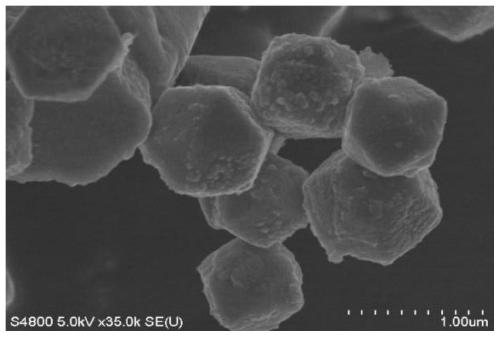

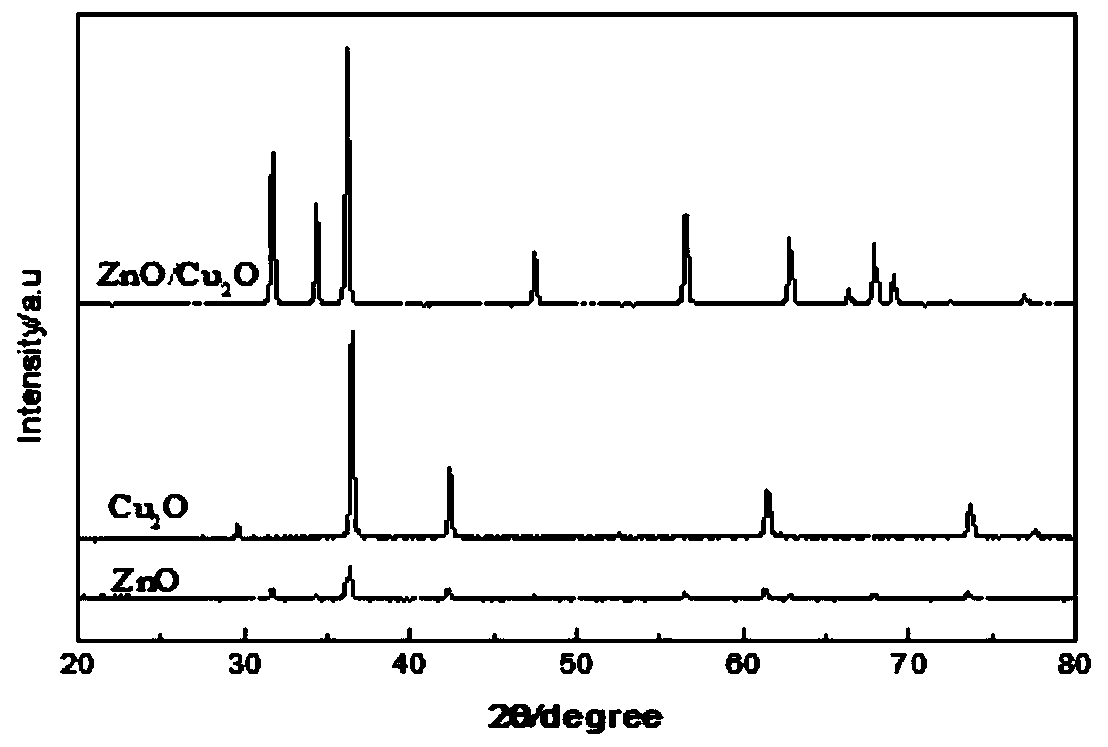

Composite nano cuprous oxide/zinc oxide material with photocatalytic performance as well as preparation method and application thereof

ActiveCN110479289AFast shippingEasy to separateMaterial nanotechnologyWater/sewage treatment by irradiationMaterials preparationZinc

The invention discloses a composite nano Cu2O / zinc oxide (ZnO) material with photocatalytic performance as well as a preparation method and application thereof, and belongs to the technical field of material preparation. A novel visible light catalyst is obtained. Nanometer zinc oxide particles are loaded on the surfaces of tetradecahedron cuprous oxide to form a heterostructure, rapid transportation and separation of photo-induced electrons and holes are effectively promoted, and the problems that a single cuprous oxide photocatalyst is high in cost, serious in photo-corrosion phenomenon, poor in stability and the like are solved. The preparation method of the composite material is simple, convenient to operate and beneficial to large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

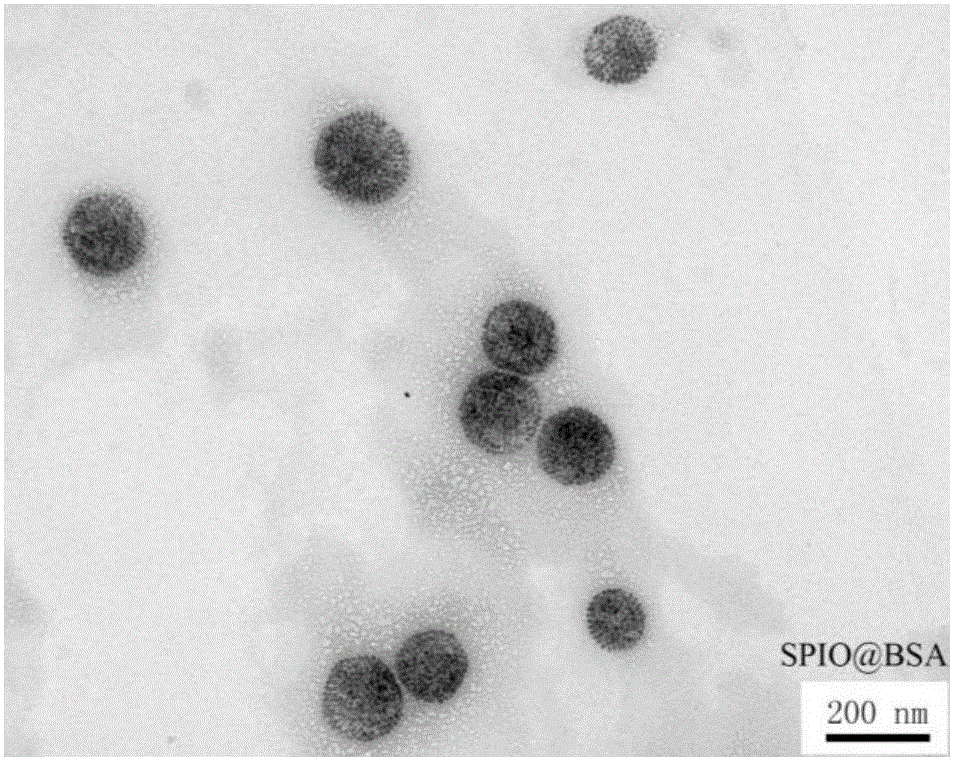

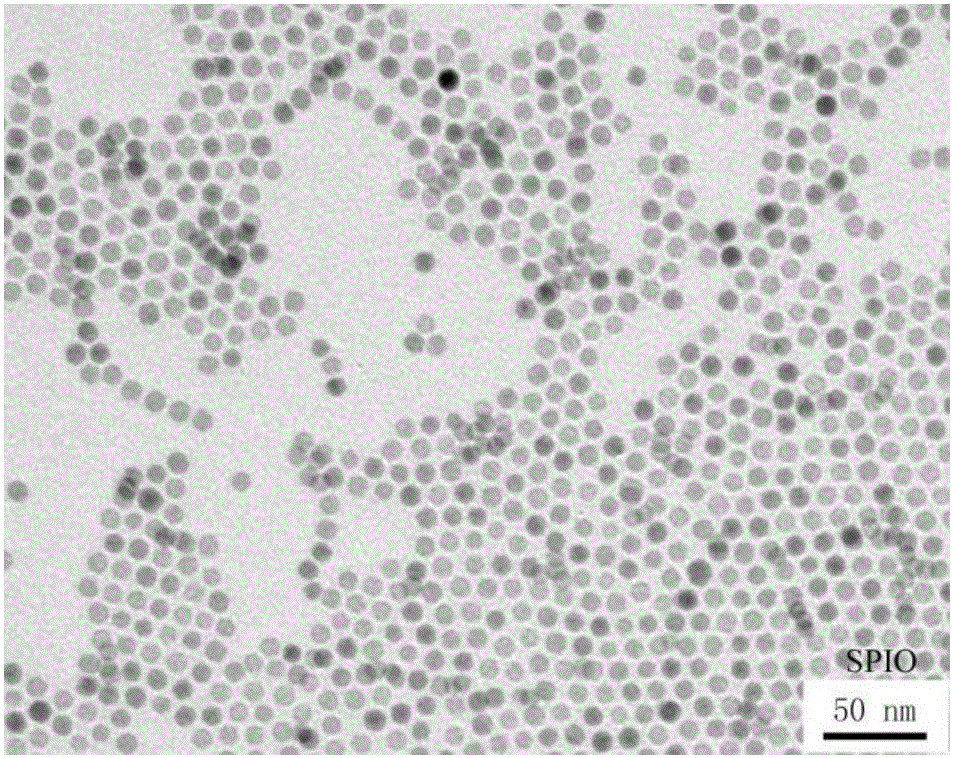

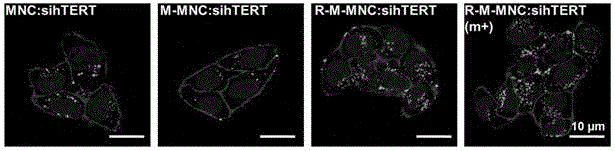

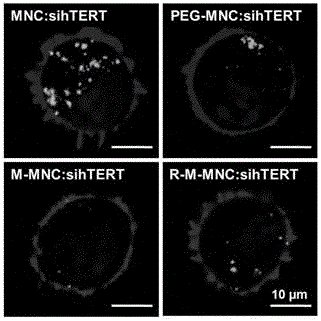

Bionic magnetosome loaded with siRNA and preparation method of magnetosome

ActiveCN106039324AEfficient aggregationFast gatheringOrganic active ingredientsEnergy modified materialsPeptideMagnetosome

The invention relates to a bionic magnetosome loaded with siRNA and a preparation method of the magnetosome, and belongs to the field of chemistry and biomedicine. According to the bionic magnetosome, water-soluble MNC serves as the kernel and is wrapped by a white cell membrane, and siRNA is loaded between the MNC and the white cell membrane; antibodies or peptides with modifying groups can be coupled outside the white cell membrane of the bionic magnetosome in a covalence mode. By preparing MNC, M and MNC:siRNA and mixing an MNC:siRNA solution, an M solution and a buffer solution, the bionic magnetosome is obtained; the white cell membrane of the bionic magnetosome is modified by the peptides or antibodies through the modifying groups, and the bionic magnetosome coupled with the antibodies or peptides is obtained. The MNC in the bionic magnetosome has positive charges, can adsorb siRNA and is wrapped by M for bionics, a focus is reached efficiently and rapidly, and meanwhile immune elimination of organisms is avoided.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

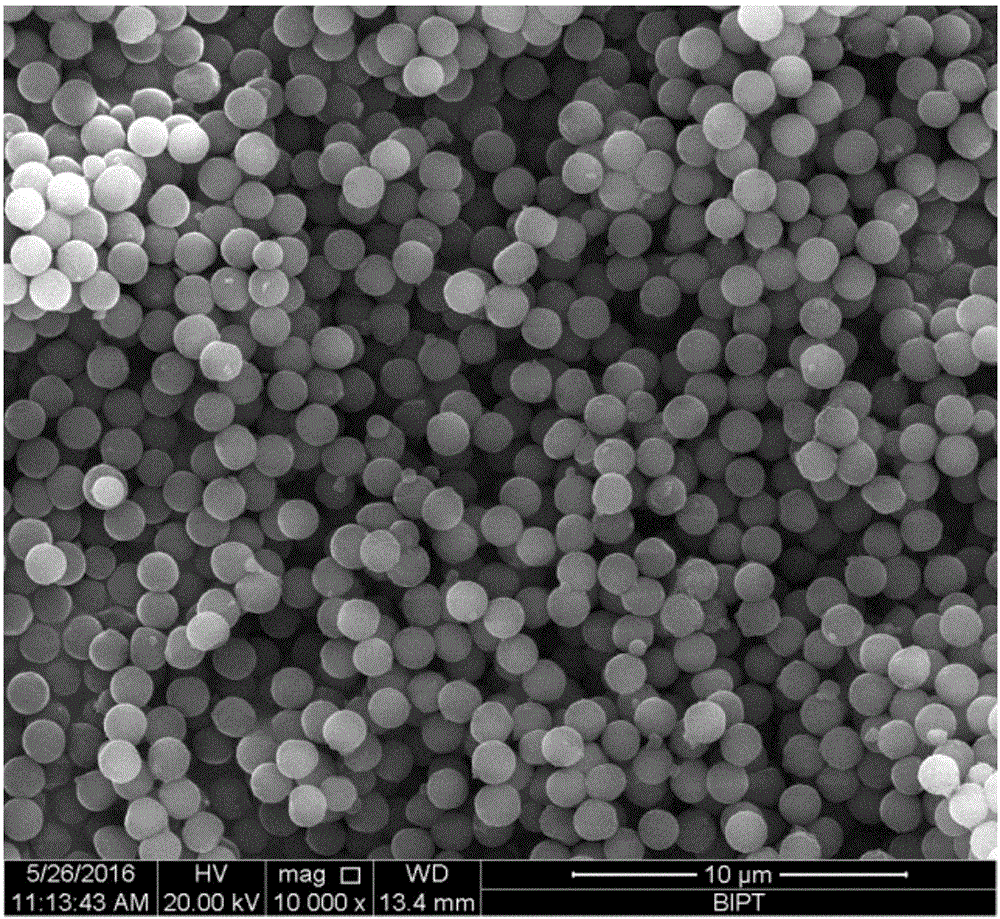

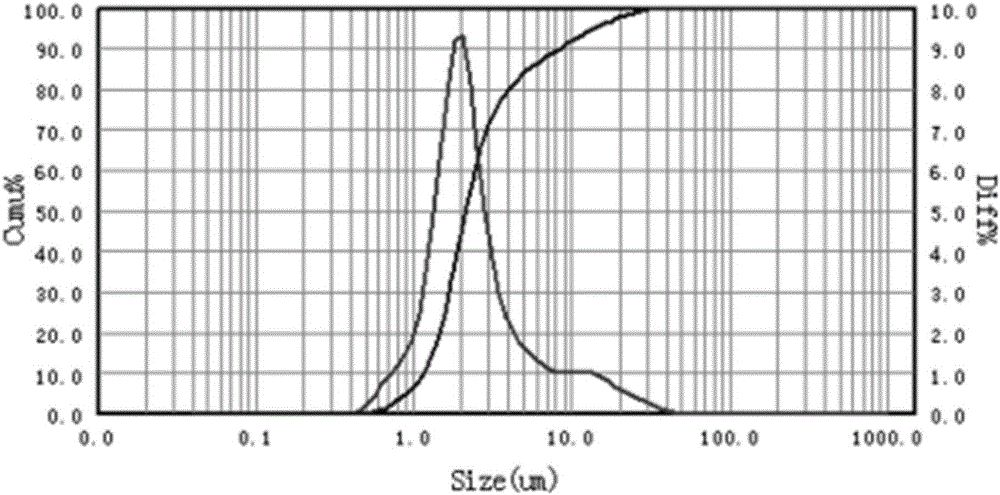

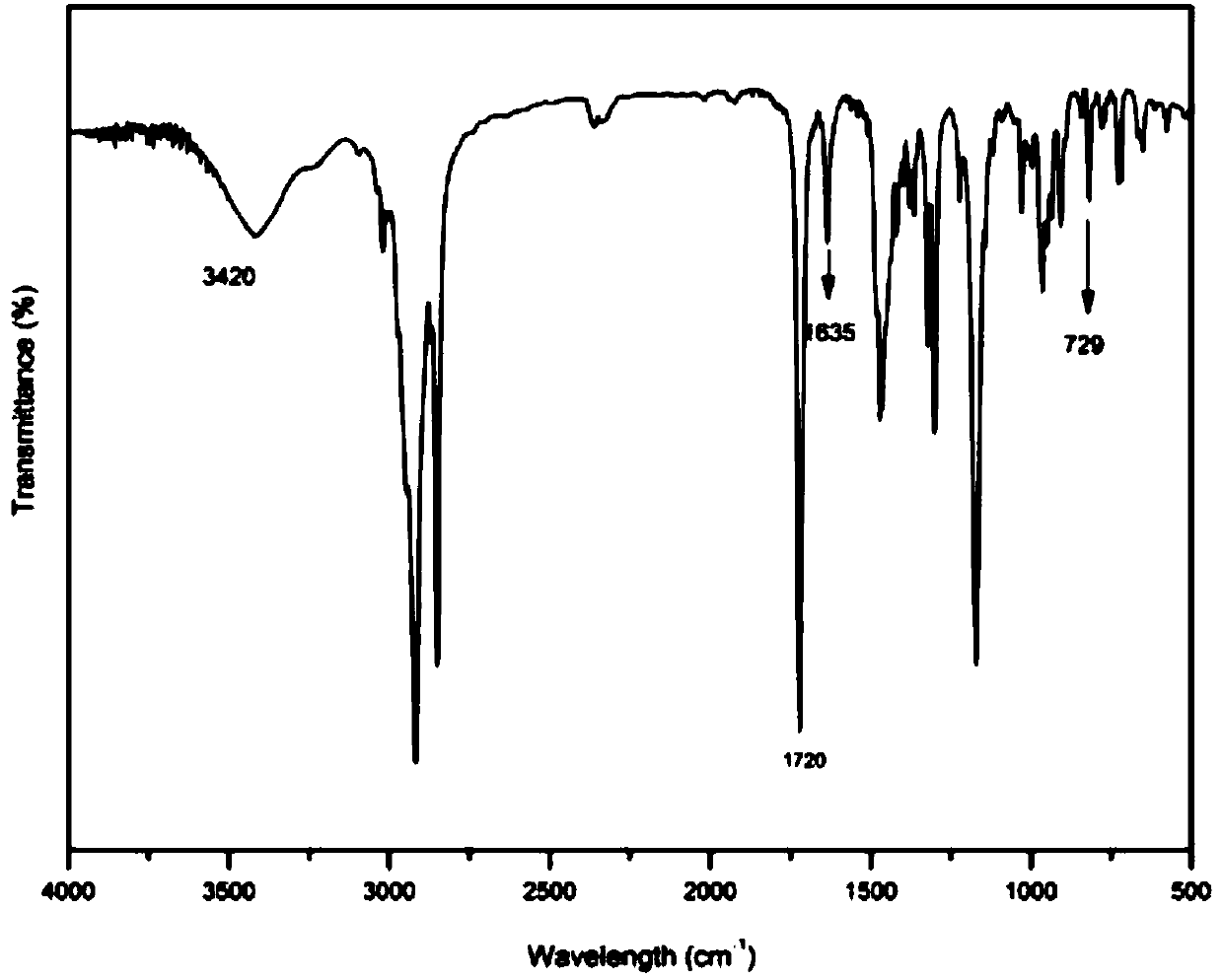

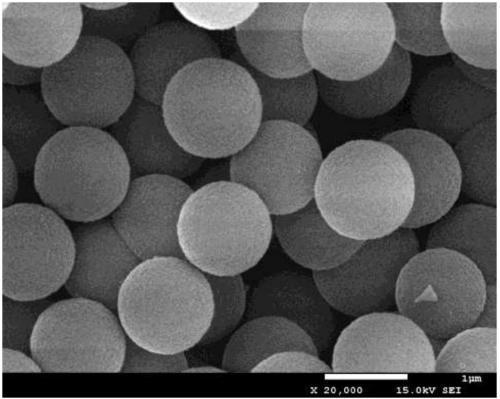

Method for preparing ultrafine cross-linked PMMA (polymethyl methacrylate) microspheres narrow in particle size dispersion

The invention discloses a method for preparing ultrafine cross-linked PMMA (polymethyl methacrylate) microspheres narrow in particle size dispersion. The method includes steps: adding a stabilizing agent, methyl methacrylate and an initiator into a dispersion medium of absolute ethyl alcohol and water, stirring to dissolve completely, and heating to 70 DEG C; after reaction for a period of time under the action of ultrasonic waves, adding a cross-linking agent for dispersion polymerization reaction; filtering, washing and drying to obtain monodisperse micron cross-linked PMMA microspheres, namely the ultrafine cross-linked PMMA microspheres narrow in particle size dispersion, wherein the microsphere particle size D50 is 2-4micron. The method is simple in reaction process, free of environment pollution organic solvents, few in types of raw materials, simple in postprocessing and low in preparation cost, the microsphere particle size is adjustable, and the obtained monodisperse micron cross-linked PMMA microspheres great in sphericity degree can be applied to LED (light emitting diode) lampshades to achieve light diffusion effects.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Water dispersion capsorubin mcrocapsule and its preparing method

InactiveCN100355837CSimple preparation processReduce manufacturing costNatural dyesMicroballoon preparationWater dispersibleMolecular materials

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI

Embedding and sintering method for production of ceramsite from raw materials of red mud and tile waste

InactiveCN104891959AHigh content of shavingsIncrease contentCeramic materials productionClaywaresRed mudGranularity

An embedding and sintering method for production of ceramsite from raw materials of red mud and tile waste belongs the technical field of ceramsite. The method is characterized by comprising the steps of: preparing raw materials containing 5-25% of red mud, 13% of tile green compact waste, 10-20% of polished tile waste, 25% of tile edging material, 10% of kaolin and 17-37% of quartz; milling for 2 h, drying the slurry, and producing the obtained powder through a pelletizer or manual way into raw ceramsite; mixing the raw ceramsite with an embedding filler in the mass ratio of 0: 1 to 0.4: 1, wherein the embedding filler is a mixed pellet containing quartz and magnesium oxide in the mass ratio of 1:0-5:1; sintering at 1170 DEG C for 15 minutes; cooling in the by furnace; and screening the embedding filler to obtain ceramsite using raw materials of red mud and tile waste. The method uses a large amount of red mud and tile waste material; the embedding filler after sintering and screening is reusable; and the obtained ceramsite using raw materials of red mud and tile waste has uniform granularity, high intensity and adjustable density.

Owner:SHANDONG UNIV OF TECH

Preparation method of surface cationic polystyrene microsphere

ActiveCN109679012AThe method is simple and controllablePlay a space stabilizing roleBiocideOrganic compound preparationZeta potentialFunctional monomer

The invention discloses a preparation method of a surface cationic polystyrene microsphere and belongs to the technical field of materials. The method comprises the steps as follows: styrene is used as an initial monomer, ethyl alcohol / water is used as a mixed dispersion medium, an initiator and a dispersant are added, a reaction is conducted in a nitrogen atmosphere, then, a cationic functional monomer and an ethyl alcohol / water medium mixture are added, the reaction is conducted continuously, washing and drying are performed after the reaction, and the surface cationic polystyrene microsphere is obtained. The system has better stability and Zeta potential values are all +25 mV or above; the preparation process is simple, the prepared functional polystyrene microsphere has good monodispersity, the particle size of the microsphere is controllable, efficient enrichment of surface functional groups of the microsphere can be realized, and the prepared microsphere has narrow particle sizedistribution and has variation coefficient of 0.6% or below.

Owner:SICHUAN UNIV

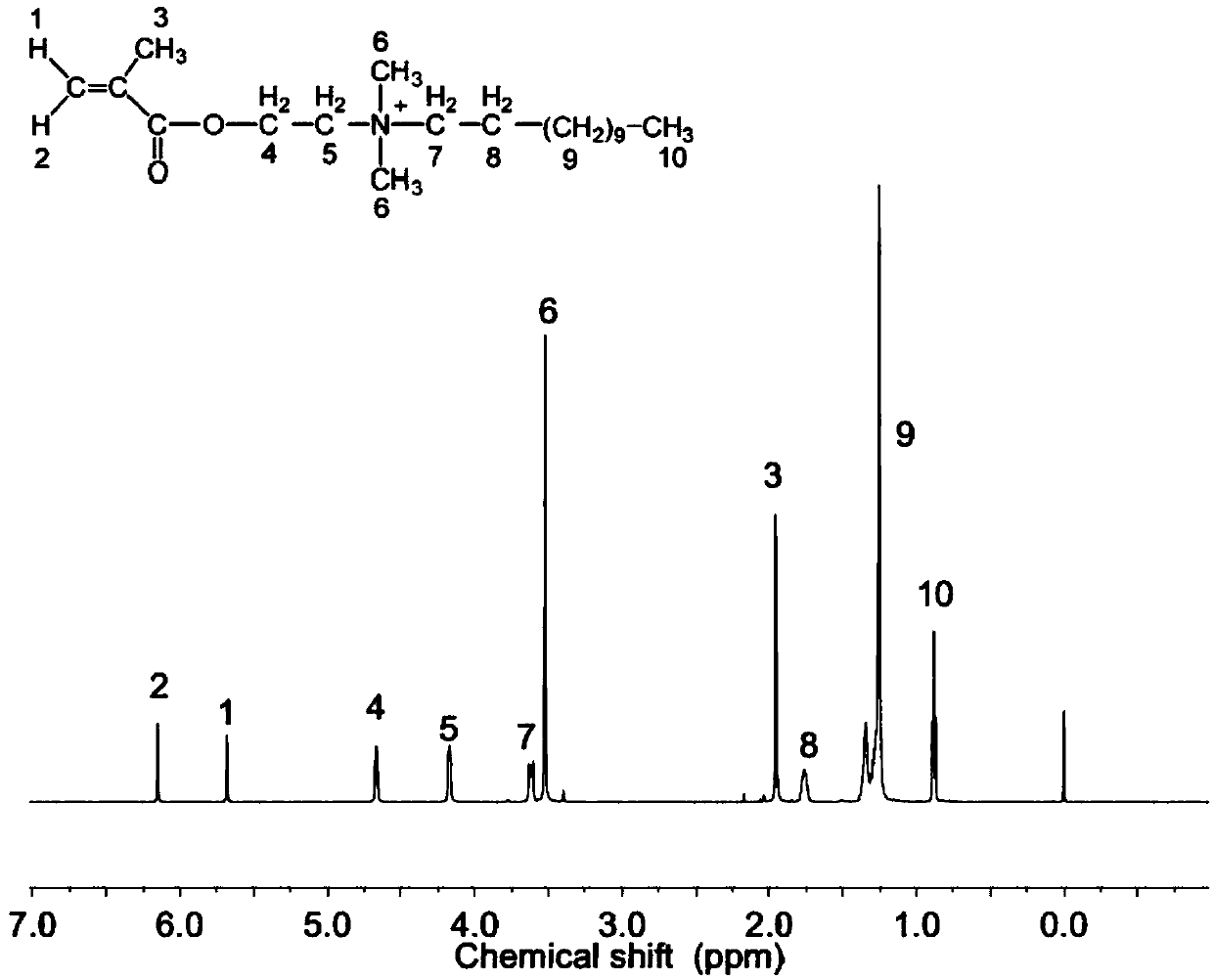

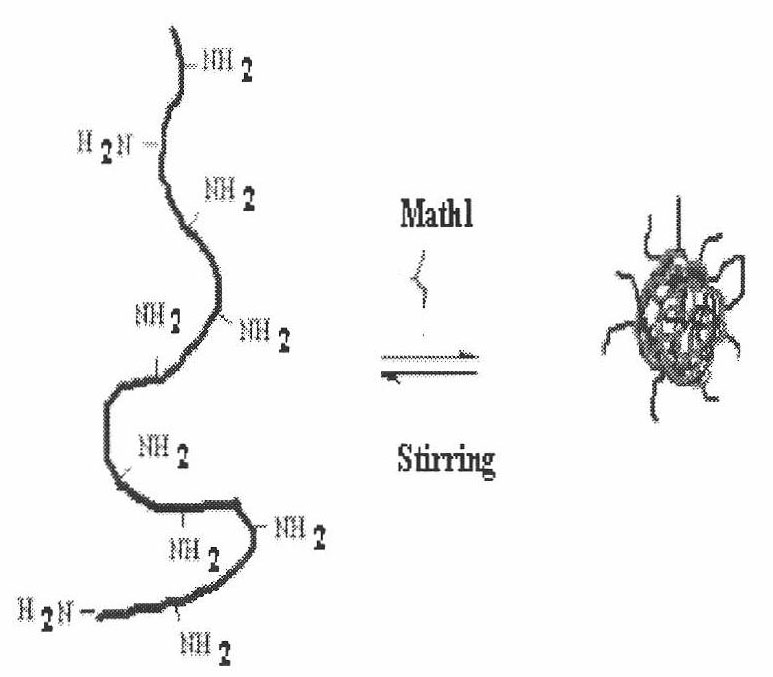

Chitosan-Math1 gene nanoparticle and application thereof in treatment of deafness

InactiveCN101897975AGood biocompatibilityNo side effectsSenses disorderPharmaceutical non-active ingredientsMedicinal poisoningNanoparticle

The invention discloses a chitosan and / or chitosan derivative-Math1 gene nanoparticle as well as a preparation method and application thereof. The gene nanoparticle is prepared by carrying out complex coacervation on chitosan and plasmid containing Math1 gene. The gene nanoparticle has controllable particle diameter and uniform size, is beneficial to surface modification, capable of improving theexpression and delivery capacities of the Math1 gene and being used for treating sensorineural deafness resulted from hair cell loss caused by noise, medicine poisoning, and the like.

Owner:GENERAL HOSPITAL OF PLA +1

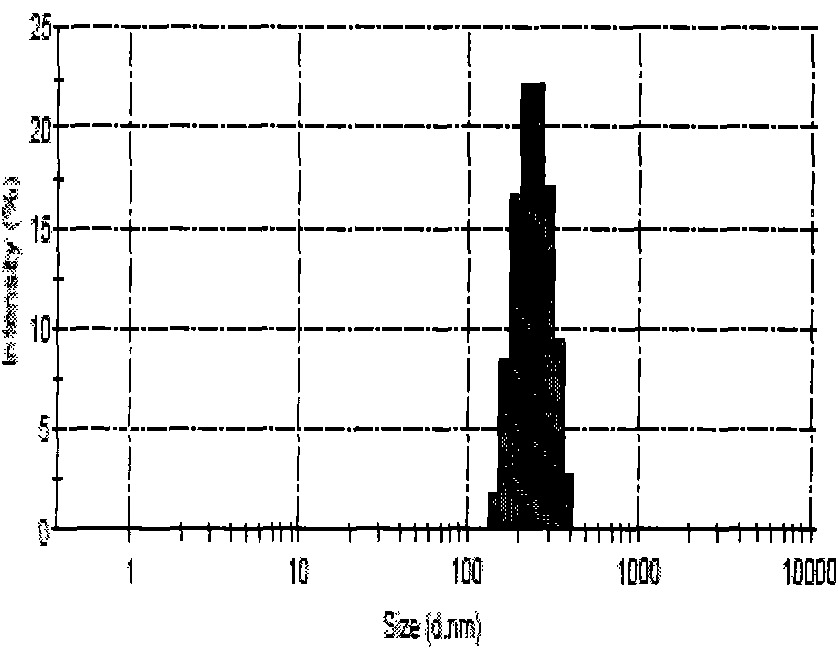

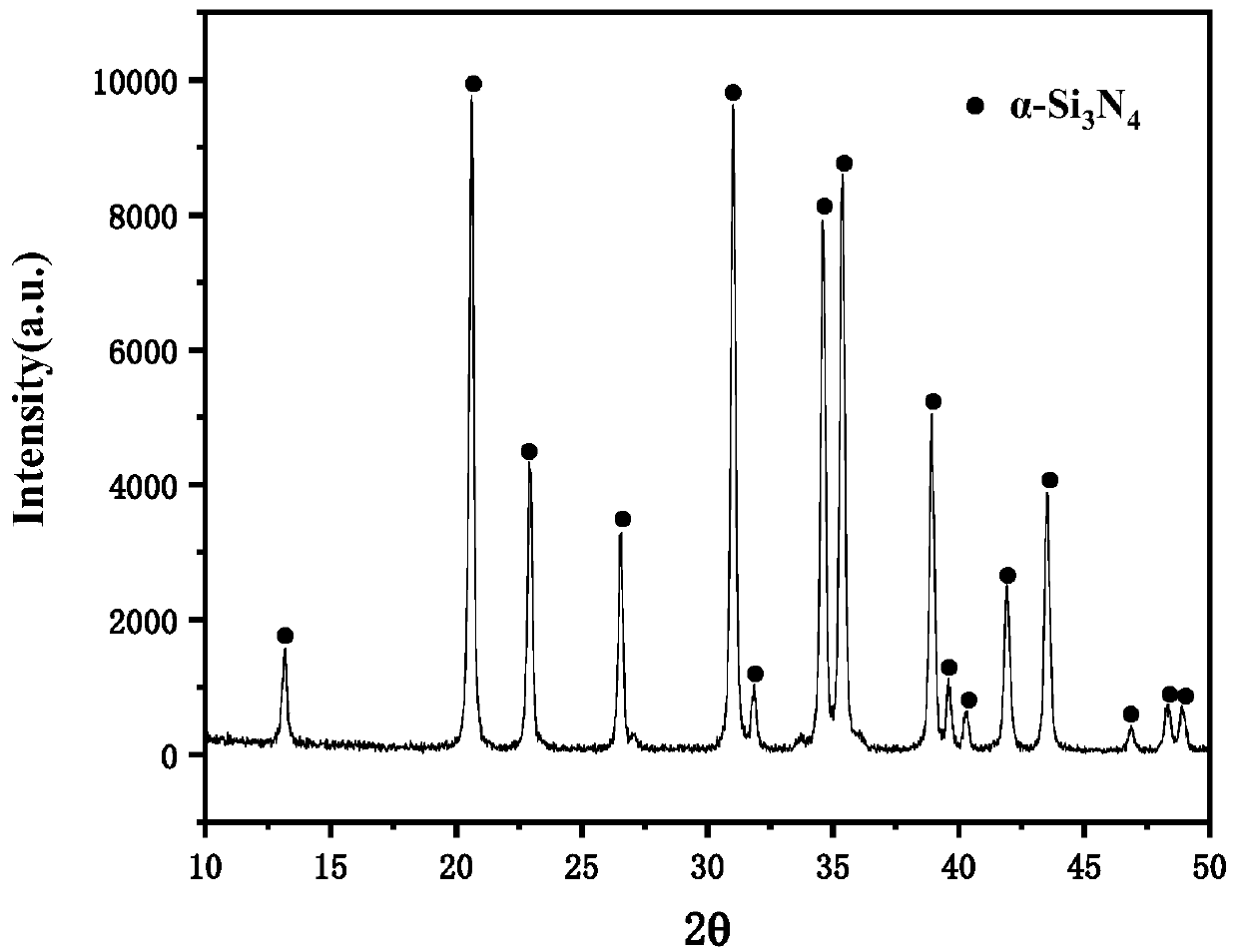

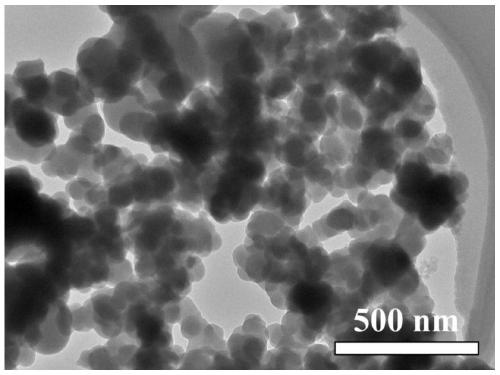

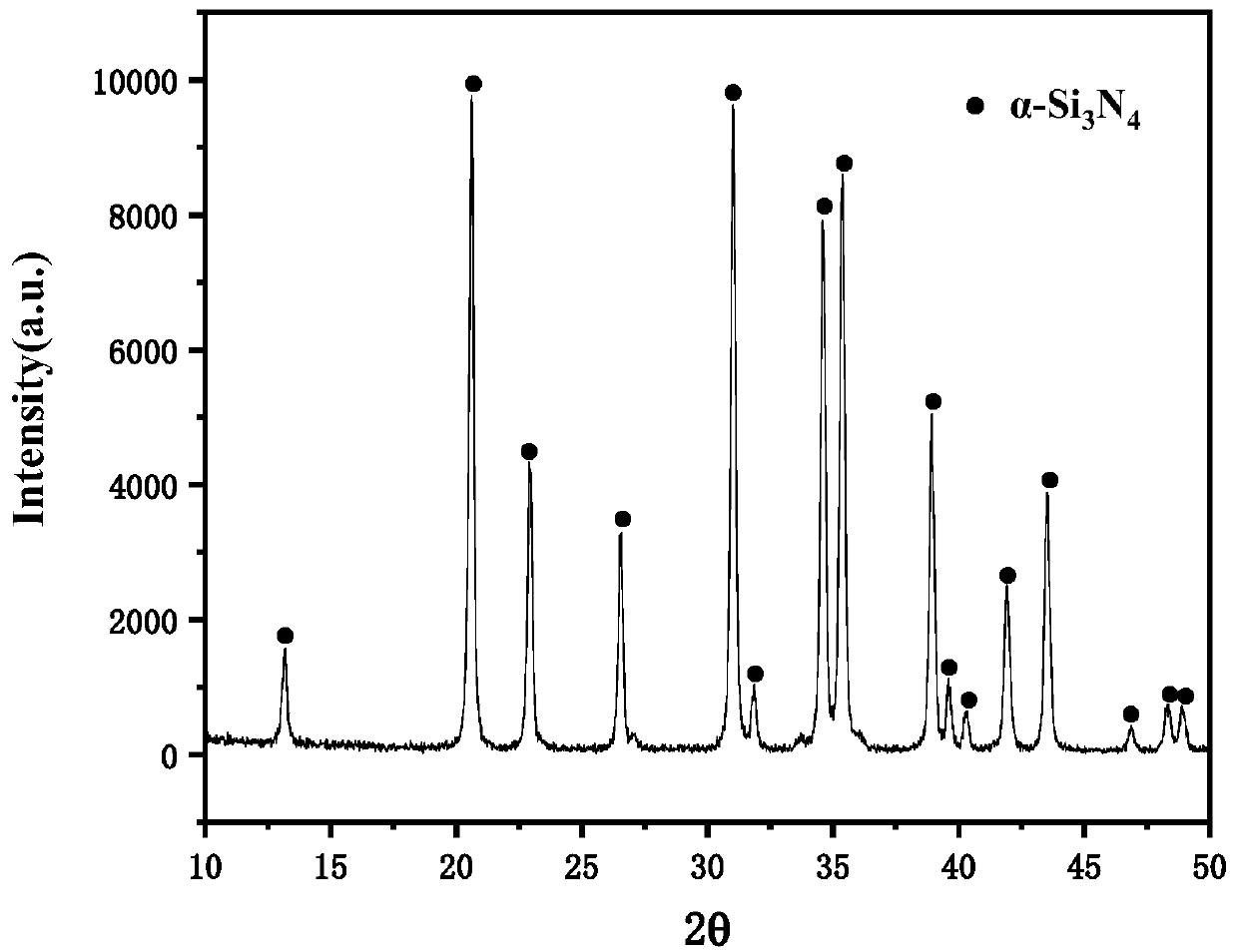

Preparation method of nanometer silicon nitride powder

ActiveCN111115592APrecise control ratioWell mixedMaterial nanotechnologyNitrogen compoundsSilicic acidNitrogen atmosphere

The invention discloses a preparation method of nanometer silicon nitride powder, and belongs to the technical field of ceramic powder preparation. The preparation method comprises the following steps: (1) preparing a mixed solution from tetraethyl orthosilicate, ammonium nitrate and a water-soluble organic matter according to a certain ratio; (2) heating and stirring the mixed solution at a temperature not higher than 100 DEG C to obtain a viscous slurry; (3) reacting the slurry in a non-oxygen environment of 100-400 DEG C to obtain a precursor; (4) carrying out a reaction on the precursor ina nitrogen atmosphere at 1300-1500 DEG C for 1-10 h to obtain silicon nitride powder; and (5) then removing excess carbon in the air. The method is simple in process, high in efficiency and low in cost, obtained silicon nitride powder particles are good in sphericity degree, and the particle size is smaller than 100 nm.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing nano silicon powder for lithium ion battery cathode material in one step

InactiveCN109046618AEasy to operateReduce manufacturing costGrain treatmentsSilica fumeLithium electrode

The invention relates to a method for preparing nano silicon powder for a lithium ion battery cathode material in one step, and belongs to the technical field of nano material and powder preparation.A dry method replaces a traditional wet method; a horizontal high-energy stirring ball mill replaces a roller ball mill and a vertical agitating ball mill, and a blade size and a gap between a bin wall and a blade tip are in certain ranges; at a certain temperature, micron silicon powder and an industrial auxiliary agent are added into a bin body; then a grinding medium is added in; vacuuming is performed, or inert gas is introduced in; grinding time, collision speed of the grinding medium, temperature of the bin body, pressure and the like are set; and thus the nano silicon powder with the average particle size of 50-200 nanometers, the tapping density of 1.2 to 1.5 g / cm<3>, the oxygen content of less than 0.05%, and the impurity content of less than 50 to 200 PPM is obtained and is usedas the cathode material for lithium ion batteries. The whole production process is performed in a closed system; no three wastes are discharged; the technique is simple, low in cost and high in efficiency; and large-scale industrial production is easy to realize.

Owner:昆明海创兴科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com