Method for preparing gold and silver nanoparticles with hydro-thermal method

A silver nanoparticle and hydrothermal technology, applied in the preparation of silver nanoparticles and gold fields, can solve the problems of complex preparation process, many steps and high cost, and achieve the effects of simple process, low cost and adjustable particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

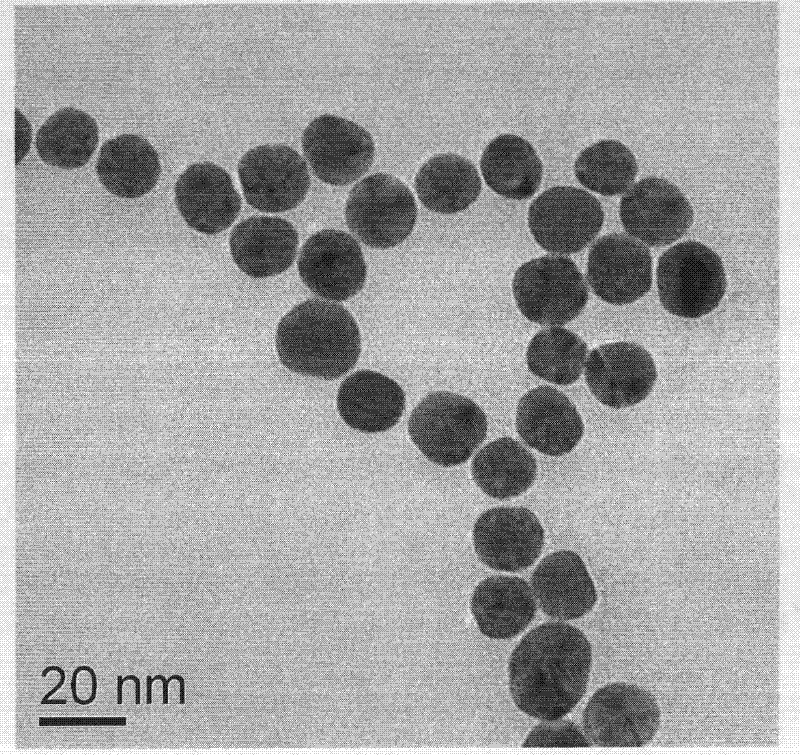

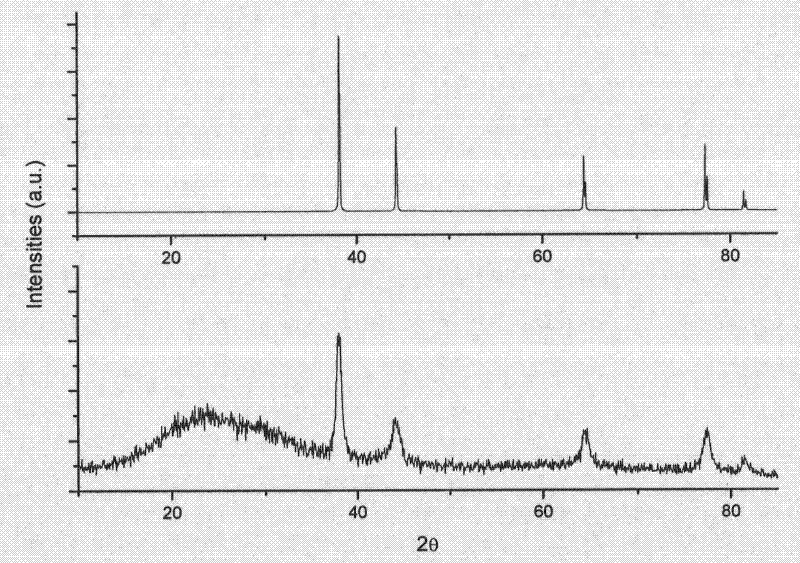

[0015] Example 1: Add 20 μl of 0.1M sodium citrate aqueous solution and 20 μl of 0.025M chloroauric acid aqueous solution to 15.0ml of deionized water, place them in a 40ml stainless steel pressure-resistant reaction kettle, and react at 120°C for 20 minutes, the resulting precipitate It was separated by high-speed centrifugation, washed with deionized water and absolute ethanol, evaporated and dried to obtain a black-red powder. figure 1 It can be seen that its morphology is nanoparticles with a narrow particle size distribution, and the average particle size is 15 nm. The diffraction peak of its powder X-ray diffraction pattern is consistent with the diffraction peak of gold standard pattern, shows that this product does not have other impurity ( figure 2 ).

example 2

[0016] Example 2: Add 200 μl of 0.1M sodium citrate aqueous solution and 200 μl of 0.025M chloroauric acid aqueous solution to 15.0ml of deionized water, place them in a 40ml stainless steel pressure-resistant reaction kettle, and react at 120°C for 10 hours to obtain a precipitate It was separated by high-speed centrifugation, washed with deionized water and absolute ethanol, evaporated and dried to obtain a black-red powder. The TEM electron microscope image shows that its morphology is nanoparticles with narrow particle size distribution, and the average particle size is 20nm.

example 3

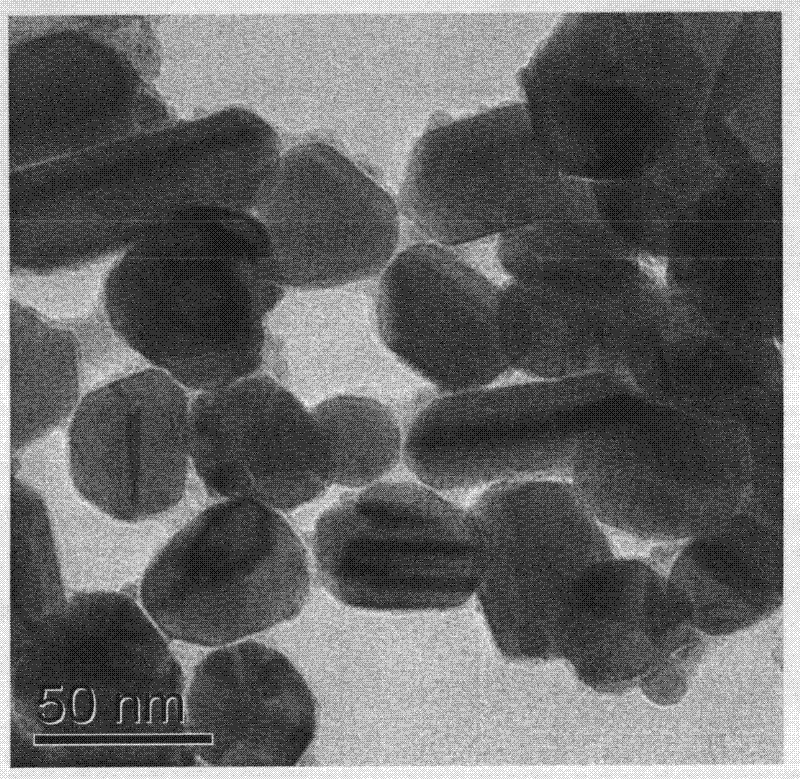

[0017] Example 3: Add 100 μl of 0.1M sodium citrate aqueous solution and 100 μl of 0.05M silver nitrate aqueous solution to 15.0ml deionized water, place them in a 40ml stainless steel pressure-resistant reactor, and react at 180°C for 10 hours. Centrifuge at high speed, wash with deionized water and absolute ethanol, evaporate and dry to obtain a yellow powder. image 3 It can be seen that they are nanoparticles with different shapes, and the average particle diameter is 43nm. The diffraction peak of its powder X-ray diffraction figure is consistent with the diffraction peak of silver standard figure, shows that this product does not have other impurity ( Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com