Mono-component polymeric nanocomposite superhydrophobic coating material and preparation method therefor

A super-hydrophobic coating and nano-composite technology, applied in the direction of coating, etc., can solve the problems of poor durability, weak effect, decreased hydrophobic performance of materials, etc., and achieve the effect of increasing the application range and good adhesion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

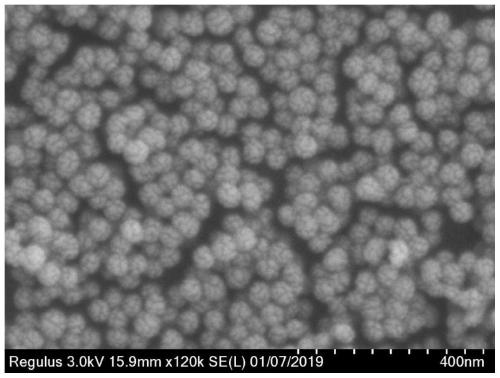

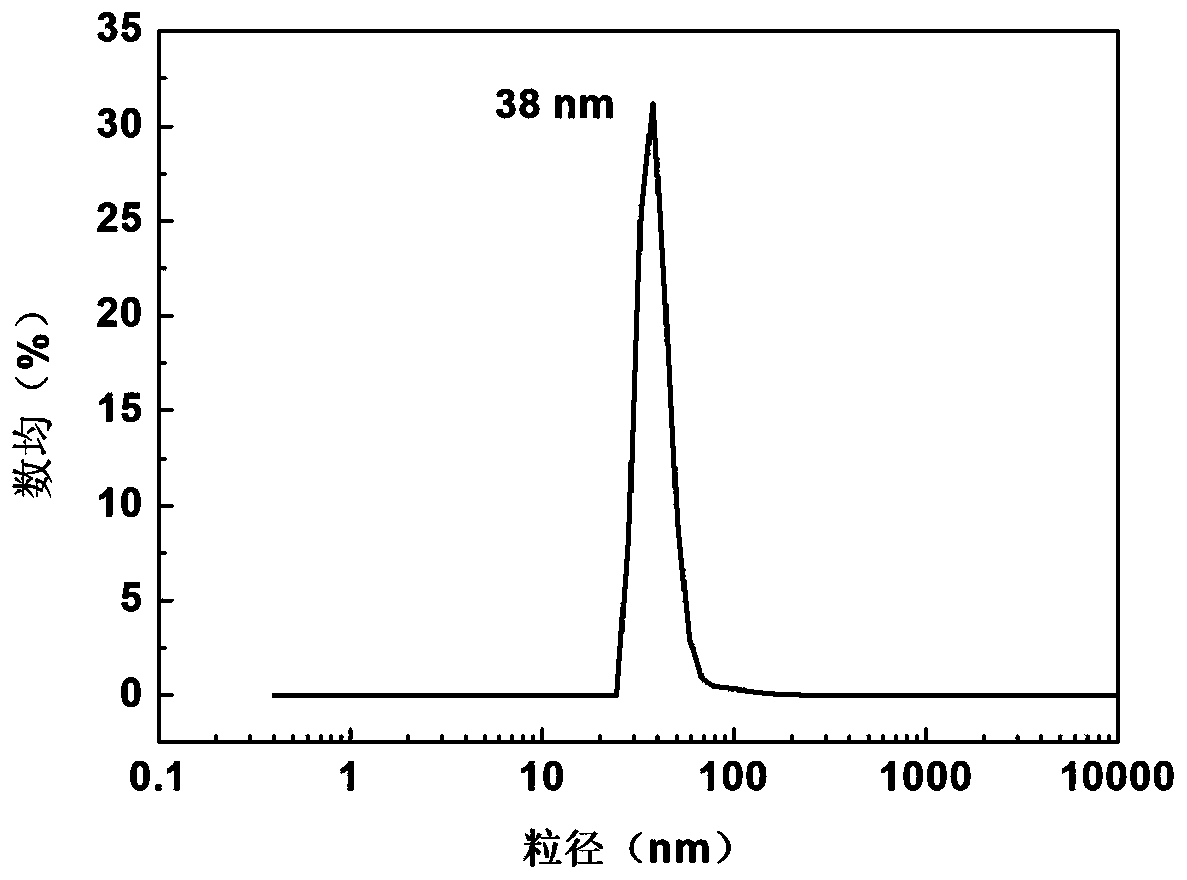

[0079] Mix 400mL of absolute ethanol and 80mL of ammonium hydroxide into a 1L round-bottomed flask, stir mechanically for 1h, add 2mL of ethyl orthosilicate under the condition of heating in a water bath at 30°C, stir for 24h, and then add 4mL of ethyl orthosilicate Add the ester dropwise to the flask, and stir at 30°C for 24 hours to obtain a spherical nano-silica sol; transfer 100 mL of the spherical nano-silica sol to a 250 mL round-bottomed flask, and add 70 μL of octadecyltrimethoxy After stirring the mixture of base silane and 10 μL of γ-aminopropyltriethoxysilane under the condition of heating in a water bath at 40°C for 24 hours, it was purified by centrifugation and dried to obtain powdery hydrophobic spherical silica.

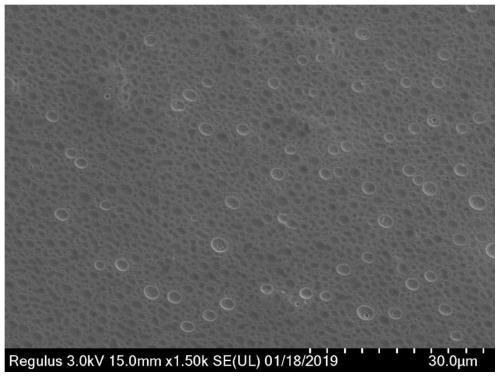

[0080] Dissolve the dried powdered hydrophobic spherical silica in 20mL N-N dimethylformamide, sonicate for 12h, add 1.5mL triethylamine and 1mL 2-bromoisobutyryl bromide dropwise, and mechanically stir in an ice-water bath After 48 hours, it was cent...

Embodiment 2

[0094] Mix 500mL of absolute ethanol and 100mL of ammonium hydroxide into a 1L round-bottomed flask, stir mechanically for 1h, add 2mL of ethyl orthosilicate under the condition of heating in a water bath at 30°C, stir for 24h, and then add 8mL of ethyl orthosilicate The ester was added dropwise to the flask, and after stirring for 24 hours, a spherical nano-silica sol was formed; 100 mL of the spherical nano-silica sol was transferred to a 250 mL round-bottomed flask, and 105 μL of octadecyltrimethoxysilane and 15 μL of the mixed product of γ-aminopropyltriethoxysilane was stirred for 24 hours under the condition of heating in a water bath at 40° C., purified by centrifugation and dried to obtain powdery hydrophobic spherical silica.

[0095] Dissolve the dried powdered hydrophobic spherical silica in 20mL N-N dimethylformamide, sonicate for 12h, add 1.5mL triethylamine and 1mL 2-bromoisobutyryl bromide dropwise, and stir in an ice-water bath for 48h After centrifugal purific...

Embodiment 3

[0099] Mix 600mL of absolute ethanol and 120mL of ammonium hydroxide into a 1L round bottom flask, stir mechanically for 1h, add 2mL of ethyl orthosilicate under the condition of heating in a water bath at 30°C, stir for 24h, and then add 18mL of ethyl orthosilicate Add the ester dropwise to the flask, and form a nano-silica sol after mechanical stirring for 24 hours; transfer 100 mL of the nano-silica sol to a 250 mL round-bottomed flask, and add 140 μL octadecyltrimethoxysilane dropwise to it After mixing with 20 μL of γ-aminopropyltriethoxysilane, mechanically stirring for 24 hours under the condition of heating in a water bath at 40° C., centrifugally purifying and drying to obtain powdery hydrophobic spherical silica.

[0100] Dissolve the dried powdered hydrophobic spherical silica in 20mL N-N dimethylformamide, sonicate for 12h, add 1.5mL triethylamine and 1mL 2-bromoisobutyryl bromide dropwise, and mechanically stir in an ice-water bath After 48 hours, it was purified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com