A superhydrophobic modification method for greenhouse films

A super-hydrophobic modification and greenhouse film technology, applied in the field of super-hydrophobic modification of greenhouse films, can solve problems such as damage, unfavorable plant growth, and poor film hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

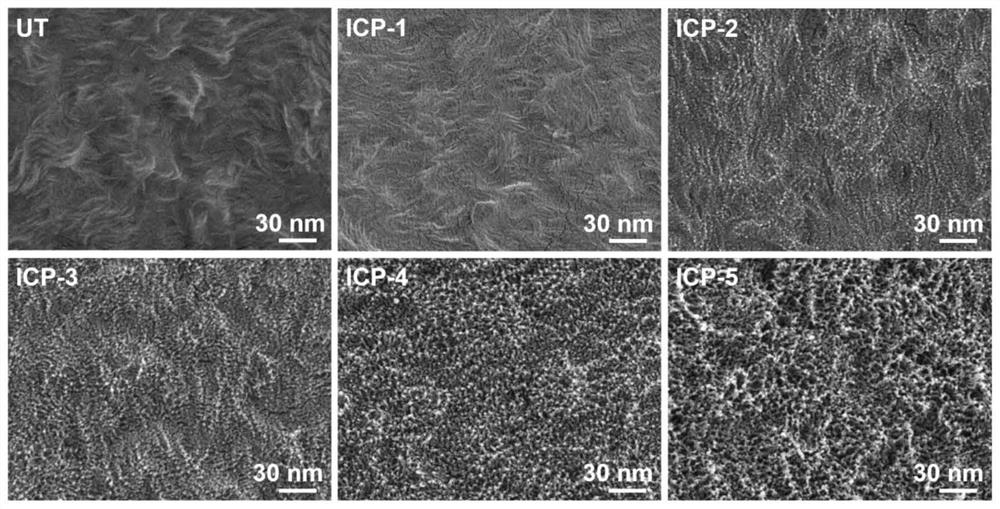

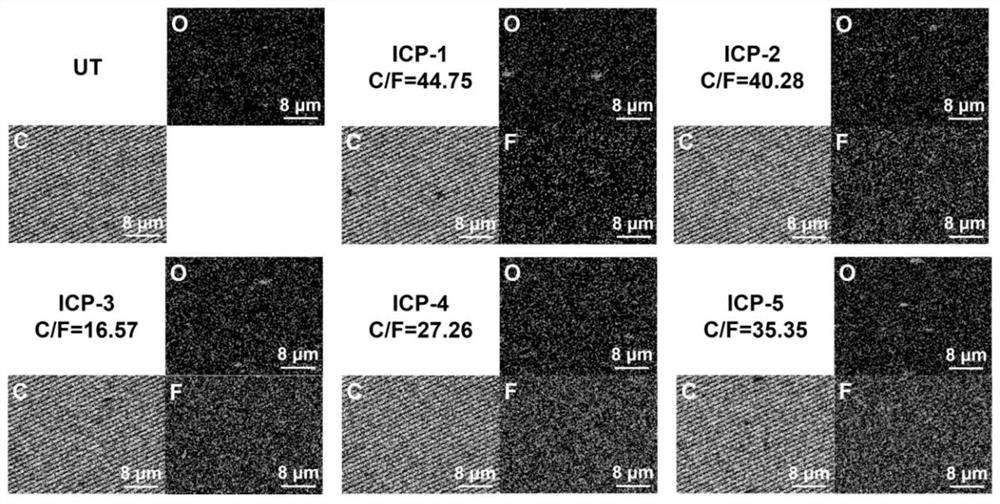

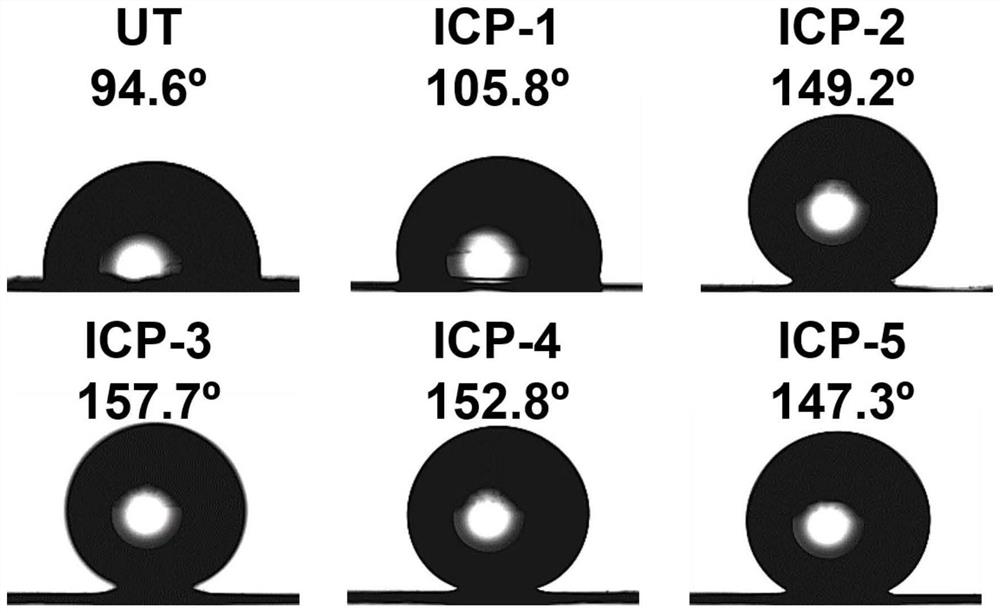

[0036] 1) placing the PE film in an inductively coupled plasma etcher;

[0037] 2) The set ICP power is 100W, the RF power is 50W; the gas selection is O 2 and CHF 3 , O 2 and CHF 3 The flow rate is set to 15:45sccm, and the air pressure is 30 millitorr; the upper surface of the PE film is etched for 10 minutes by an inductively coupled plasma etcher, so that a nano-textured structure is formed on the upper surface of the PE film, and the nanometer textured structure is obtained. Structured PE film;

[0038] 3) The ICP power is set to 100W, the RF power is 50W, and the gas is only carbon tetrafluoride C 4 f 8 , C 4 f 8 The flow rate is set to 50sccm; the air pressure is 30mTorr; the upper surface of the PE film is deposited by an inductively coupled plasma etching instrument for 30s, so that a layer of fluorocarbon layer is deposited on the upper surface of the nano-textured structure on the PE film, and the improvement is completed. Sex and take out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com