Patents

Literature

212results about How to "Stain resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

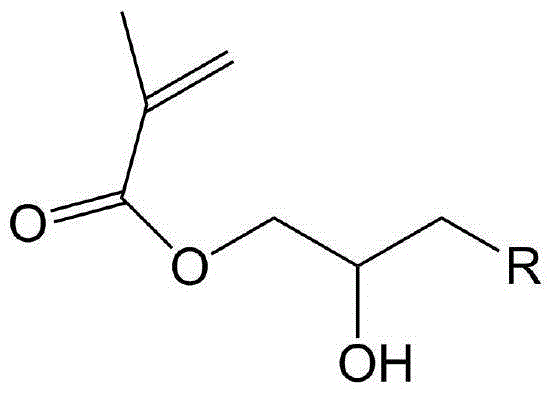

Self-layering organic-inorganic nano composite emulsion and method for preparing same

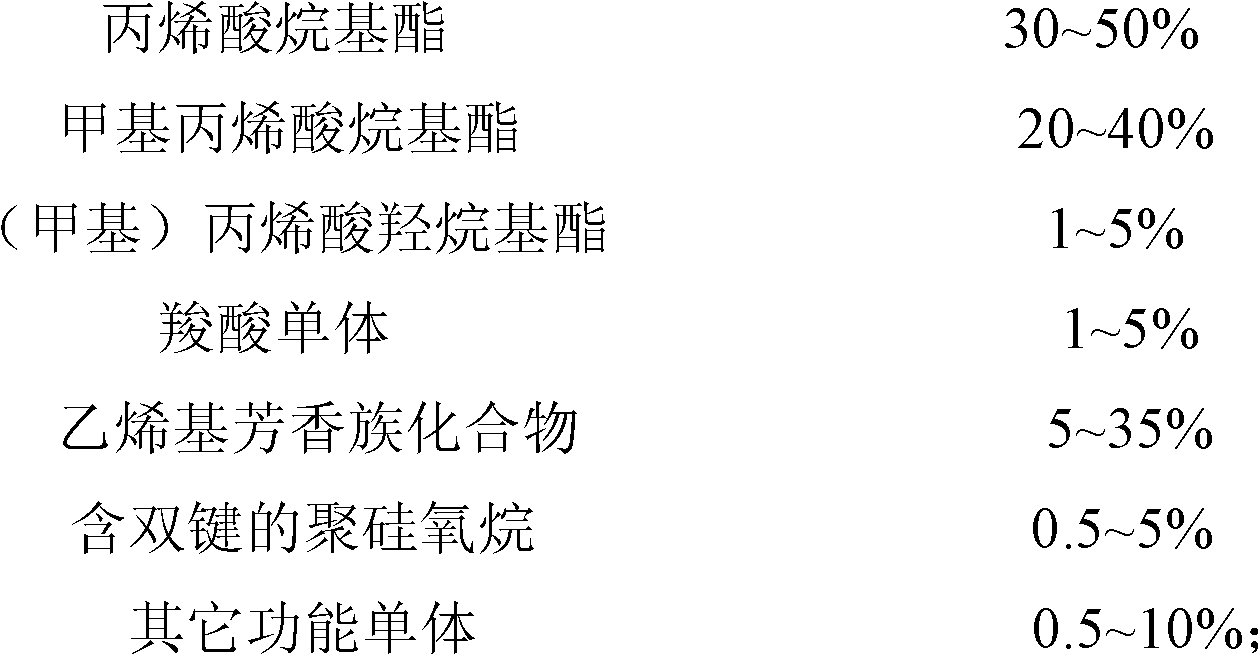

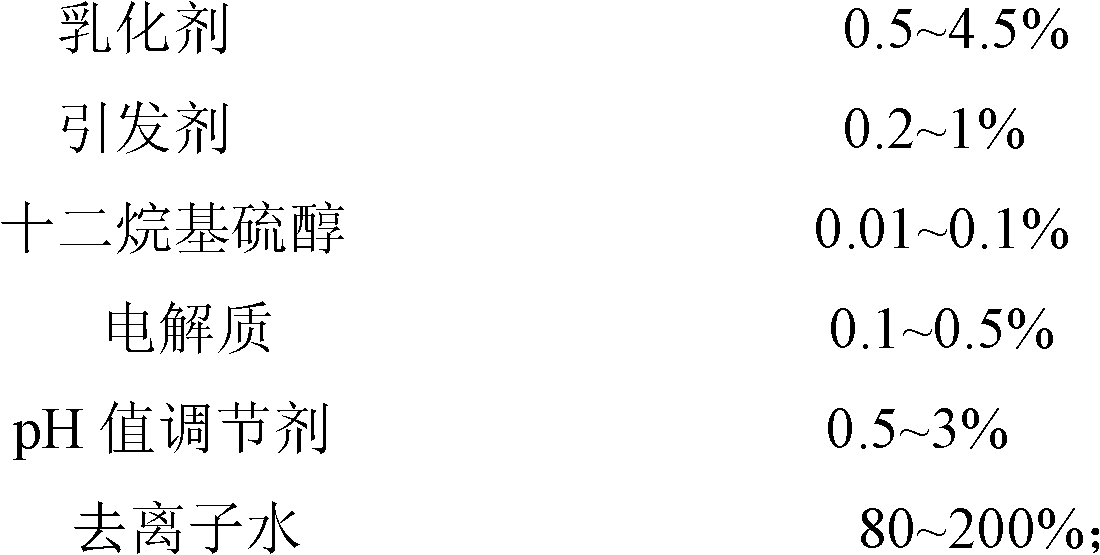

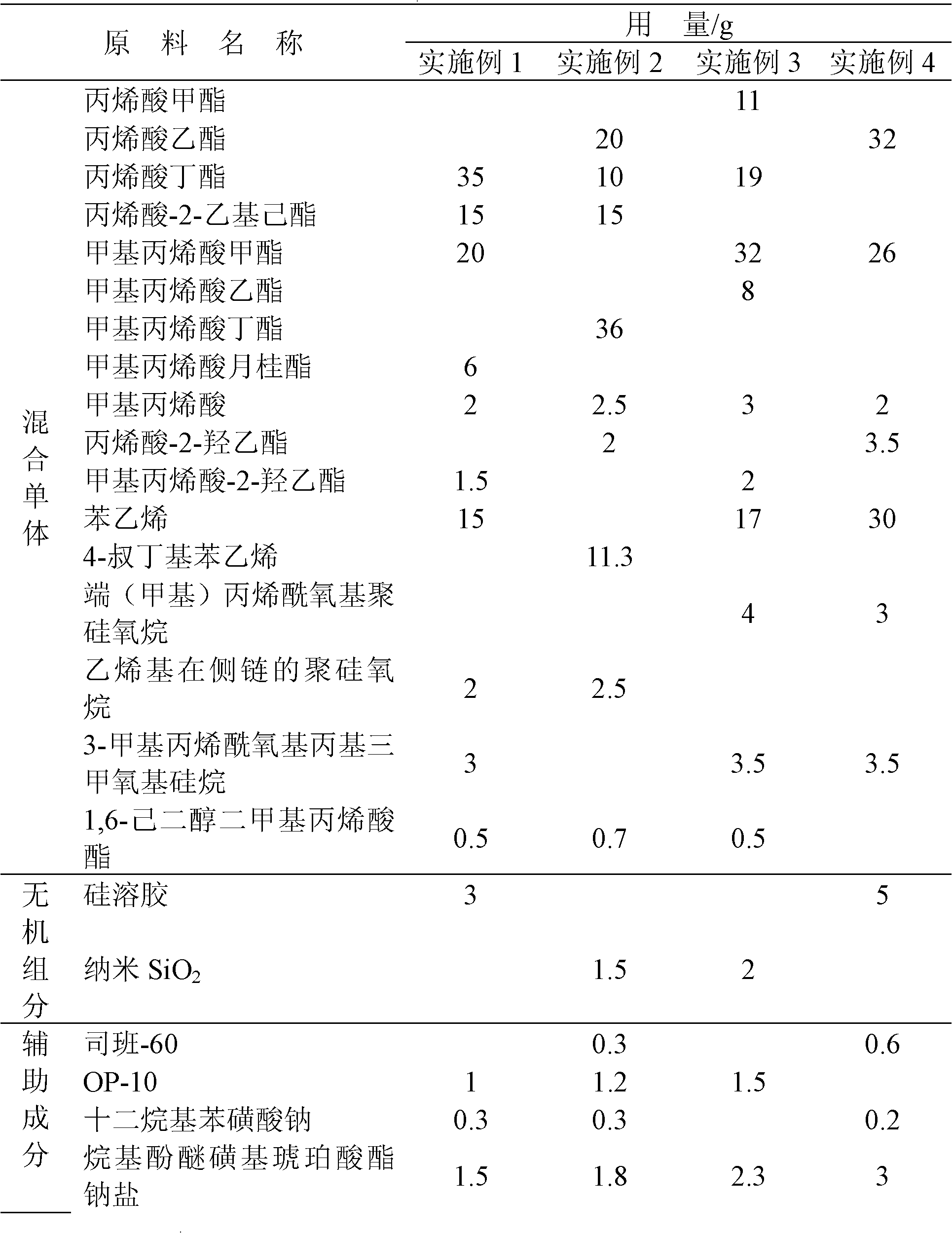

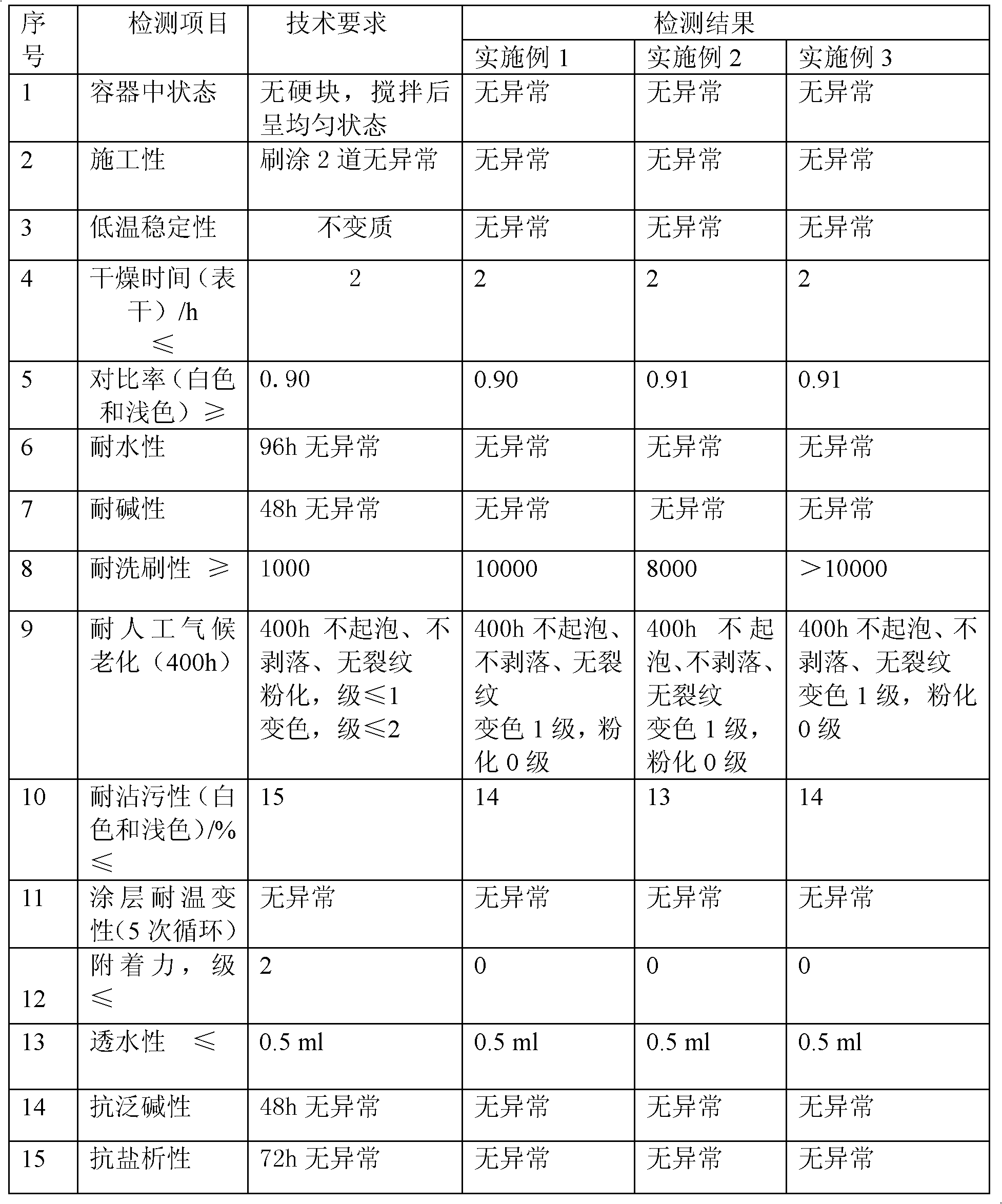

The invention relates to self-layering organic-inorganic nano composite emulsion and a method for preparing the same. The emulsion is made of mixed monomers, inorganic components and auxiliary components. The self-layering organic-inorganic nano composite emulsion is obtained by generating (or precipitating) organic nano particles inside (or on the surface) of latex particles in situ while introducing double-bond polysiloxane, and the emulsion is high in solid content, low in viscosity and high in storage stability. Due to differences of surface energy and compatibility (solubility parameters) between polysiloxane and other components in filming of emulsion, the polysiloxane molecules migrate to be enriched to a coating surface to form a self-layering structure.

Owner:DALIAN POLYTECHNIC UNIVERSITY

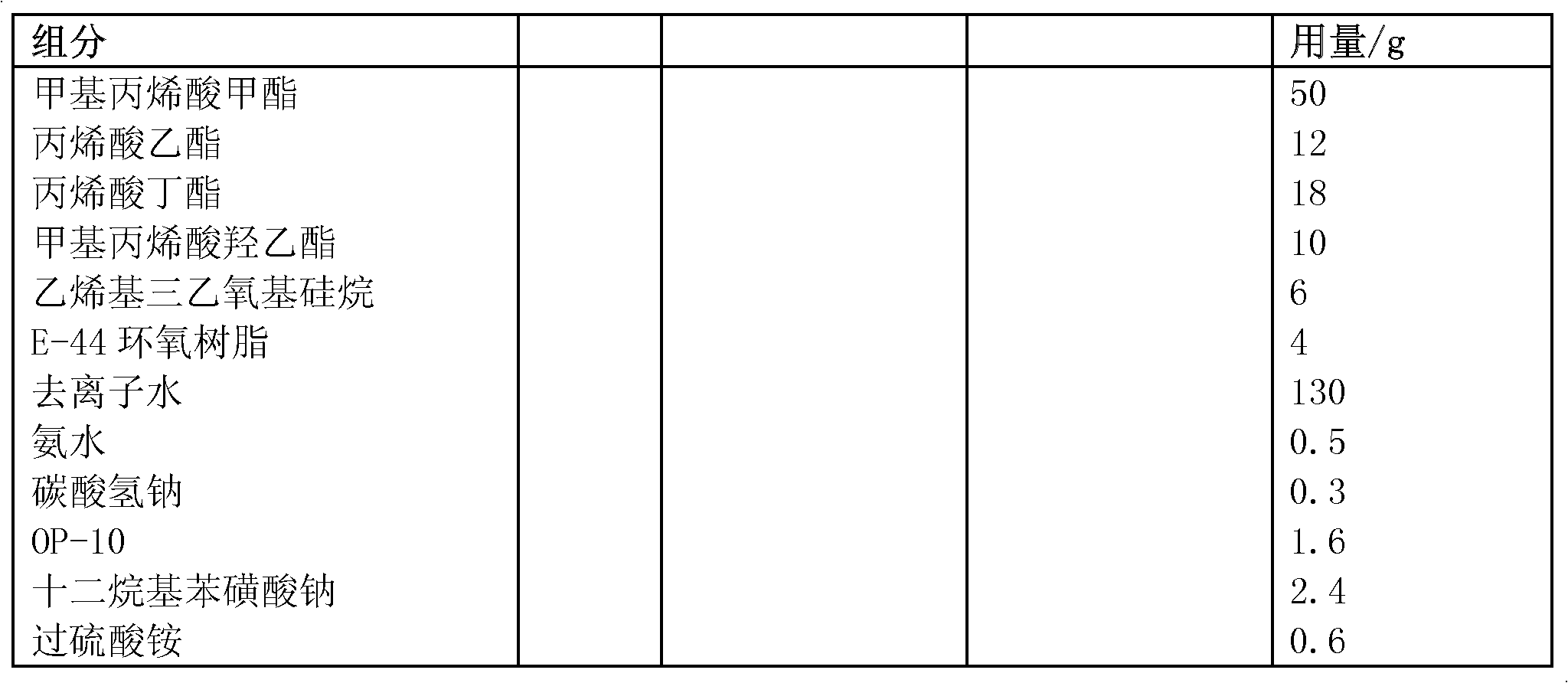

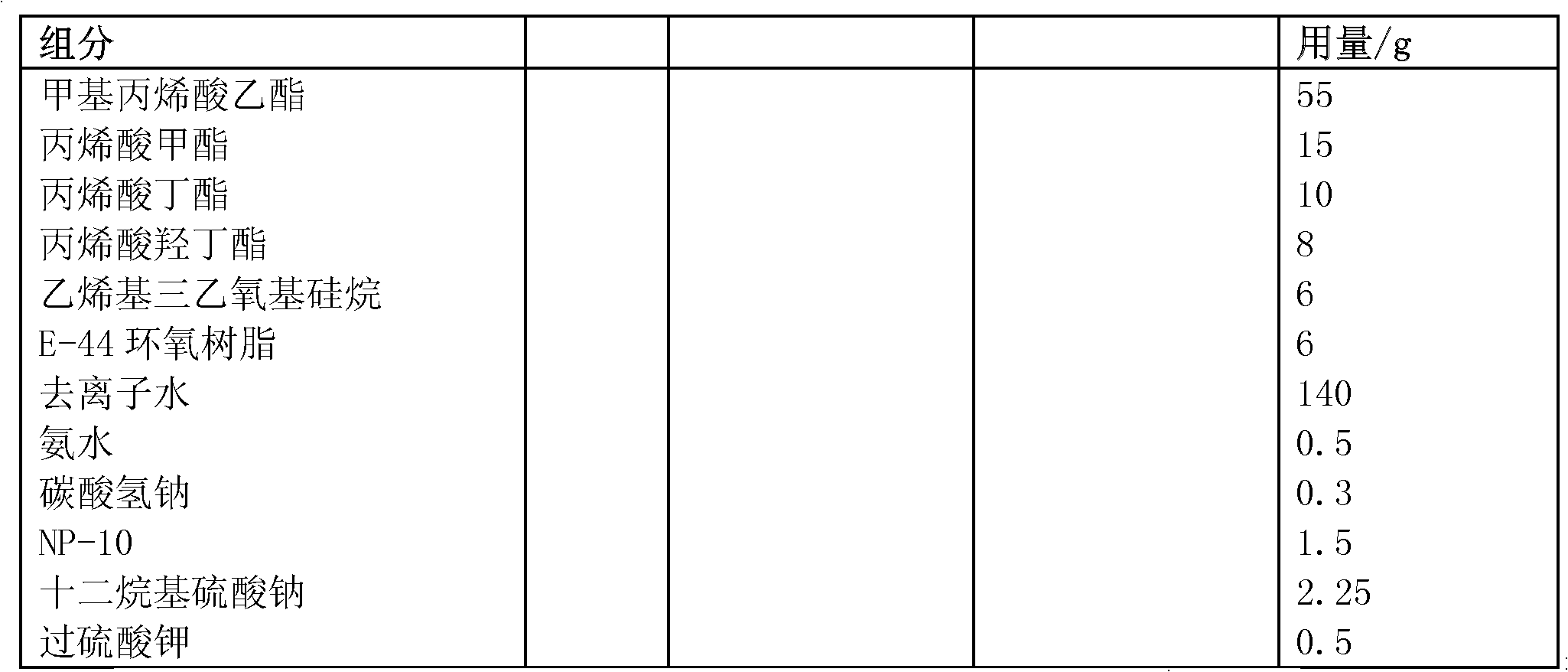

Water-based primer-topcoat in one type paint

The invention relates to water-based primer-topcoat in one type paint for an exterior wall of a building. Current latex paint for the exterior wall has the problems of poor weather resistance, poor stain resistance, poor color retention, greater labor intensity of workers and high labor cost, as well as the phenomena that a coating film is easy to bulge for forming bubbles or crust to form a skin due to the poor matching property between a primer and a topcoat and the color fading can emerge within a shorter period of time, and needs to be reworked after just a few of years. The invention provides the water-based primer-topcoat in one type paint which comprises epoxy-modified silicone acrylic emulsion and a plurality of auxiliaries, wherein the epoxy-modified silicone acrylic emulsion comprises emulsion total monomers, epoxy resin and auxiliary components, the emulsion total monomers comprise methacrylate type monomers, acrylate type monomer, hydroxyl monomers containing double bonds and organic silicon monomers, the formula of the latex paint is simultaneously optimized, the obtained water-based primer-topcoat in one type paint only needs to perform forming twice during the surface contraction of a base layer of the exterior wall, after a coating is formed, the performances of the primer and the topcoat are simultaneously integrated.

Owner:ZHEJIANG TRANSFER PAINT CO LTD

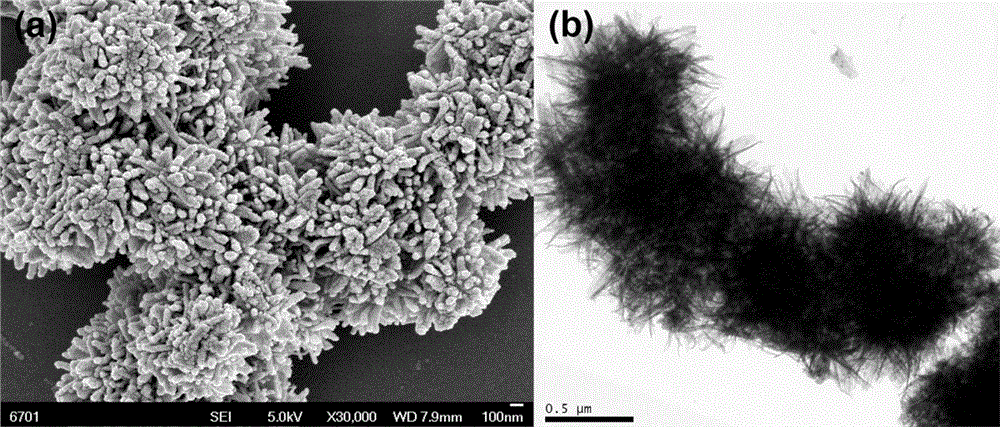

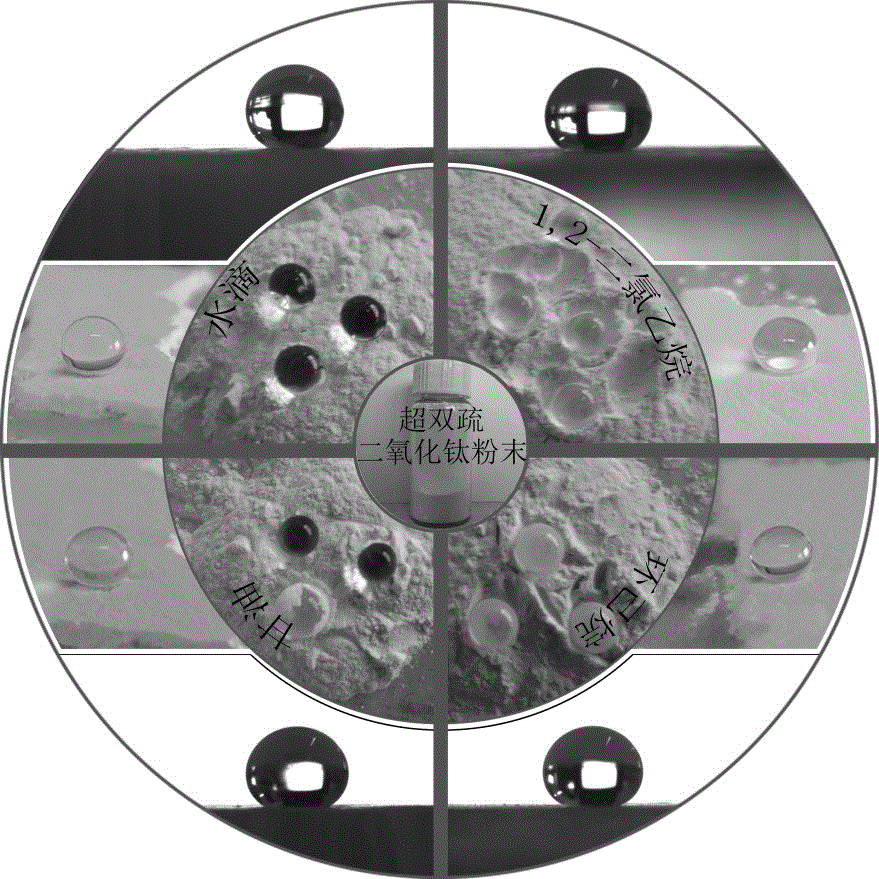

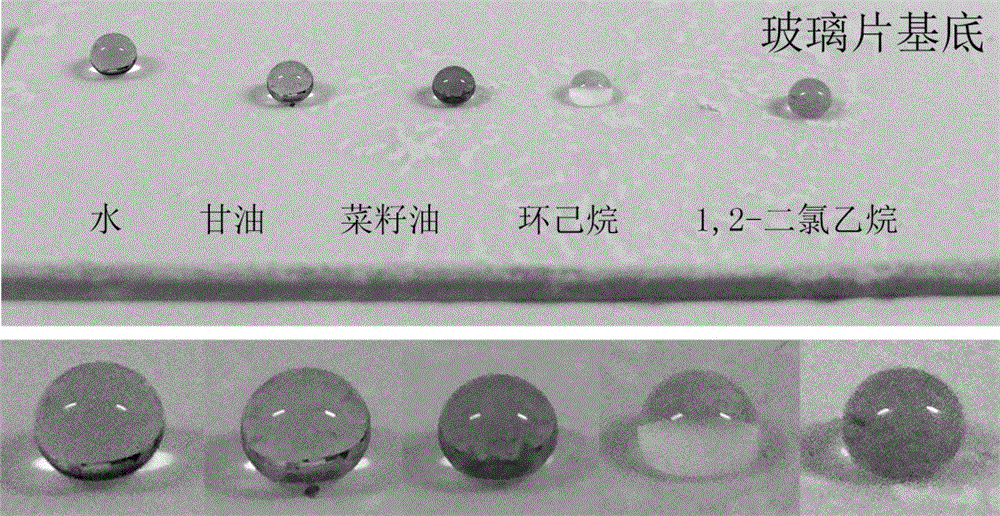

Preparation method of universal super-amphiphobic nano coating based on flower shape titanium dioxide nano particles

ActiveCN105820605AStabilized superamphiphobiaUniversalMaterial nanotechnologyAntifouling/underwater paintsOil waterChemical stability

The invention belongs to the technical field of super-amphiphobic nano coating preparation, and especially relates to a preparation method of a universal super-amphiphobic nano coating based on flower shape titanium dioxide nano particles. The preparation method comprises steps of flower shape titanium dioxide nano particle preparation, low surface energy modification, and combination between super-amphiphobic powder and a substrate. The contact angles between various substrates coated by super-amphiphobic powder and water / oil are all larger than 150 degrees and the roll angles are all smaller than 10 degrees. Moreover, after combination, the super-amphiphobic substrate has a strong performance on resisting wear, extrusion, and stretching and high chemical stability. The preparation technology is simple, the raw materials are easily available, not toxic, and environment-friendly; the cost is low, the stability is high, and the preparation method is suitable for large scale preparation and application. The coating is suitable for being used in an extreme work environment, can be applied to oil stain resistant equipment or waterproof equipment, and at the same time, can also be used in the fields such as industrial pipeline transportation, oil-water separation metal network, and the like.

Owner:HUBEI UNIV

Stain-resisting ultraviolet curing painting

InactiveCN102070984ASolve wear resistanceSmall particle sizeAntifouling/underwater paintsPaints with biocidesPolymer sciencePhotoinitiator

The invention discloses a stain-resisting ultraviolet curing painting, which comprises the following components in percentage by mass: 35 to 55 percent of photosensitive resin, 20 to 40 percent of crosslinking diluent, 2 to 12 percent of photoinitiator, and 10 to 25 percent of fluorine modified resin. By adding the fluorine modified resin into the formula, the stain-resisting ultraviolet curing painting is hydrophobic and oleophobic under the action of fluorine with lower surface tension, so the stain-resisting ultraviolet curing painting has the characteristic of stain resistance.

Owner:上海硕律管理咨询有限公司

Thermal insulating coating integrated composite plate and preparation method thereof

ActiveCN106930492AImprove thermal insulation performanceLow thermal conductivityFireproof paintsCovering/liningsThermal insulationThermal printing

The invention belongs to the technical field of building thermal insulating and energy saving decoration integration materials. A thermal insulating coating integrated composite plate is characterized in that an acrylic emulsion, a silicone acrylic emulsion, silicon dioxide gel, aerogel, hollow glass microspheres, polypropylene fibers and hydroxyethyl cellulose (HEC) are adopted for preparing mucilage, the mucilage is smeared onto an alkali-resisting glass fiber net, and a thermal insulating coating layer is prepared; and a thermal insulating coating material prepared from an acrylic emulsion, a silicone acrylic emulsion, thermal insulation pigments, protection glue, aerogel, hollow glass microspheres and a multifunctional additive is sprayed to the thermal insulating coating layer, a thermal insulating coating material layer is prepared, and the thermal insulating coating integrated composite plate is obtained. The thermal insulating coating integrated composite plate has the effects of ultra low heat conduction coefficient, good thermal insulating performance, good flexibility, good decoration effect, durability, contamination resistance, high combustion level, high tensile strength, and safe, convenient and fast construction.

Owner:湖北邱氏节能建材高新技术股份有限公司

Raw material prescription of the heat preserving waterproof paint and method of preparing the same

InactiveCN101585987AHigh solar reflectanceIncrease elasticityReflecting/signal paintsEmulsionSun protection

The invention belongs to a heat preserving waterproof paint for structures such as exterior wall of building, thin roofing, and metal tank housing and so on and fabricating method thereof. Raw material prescription of the heat preserving waterproof paint of the invention based on weight is: 10 parts to 90 parts of water, 10 parts to 90 parts of elastic polyacrylic emulsion, 10 parts to 50 parts of filler, 1 part to 10 parts of propylene glycol, 1 part to 10 parts of thickener, 1 part to 10 parts of rutile type titanium dioxide, 1 part to 3 parts of water- and stain-proofing agent of exterior wall. The paint of the invention is great in heat preservation, waterproofing property, self-cleaning property, filling property, radioresistance and sun protection and has long service life.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

Inflaming-retarding flexible heat preservation facing material in building and preparing method thereof

The invention discloses an inflaming-retarding flexible heat preservation facing material in building and a preparing method thereof, which is prepared from the following components in part by weight: 1-50 parts of soil particles, 1-50 parts of hollow filler, 1-10 parts of reinforced fibers, 10-50 parts of flexible emulsion, 0-1 part of pigment, 1-10 parts of accessory ingredient and 10-40 parts of water, that are mixed to form slurry with appropriate viscosity, are formed in a template with decorative patterns, so as to prepare a composite material with functions of inflaming retarding, heat preservation and decoration after gradient temperature control, drying and demoulding. According to the invention, the production process is environmental-friendly, the construction process is simple, convenient and feasible, and the inflaming-retarding flexible heat preservation facing material in building is particularly suitable for external facing of high-rise buildings and old town transformation.

Owner:南通南京大学材料工程技术研究院

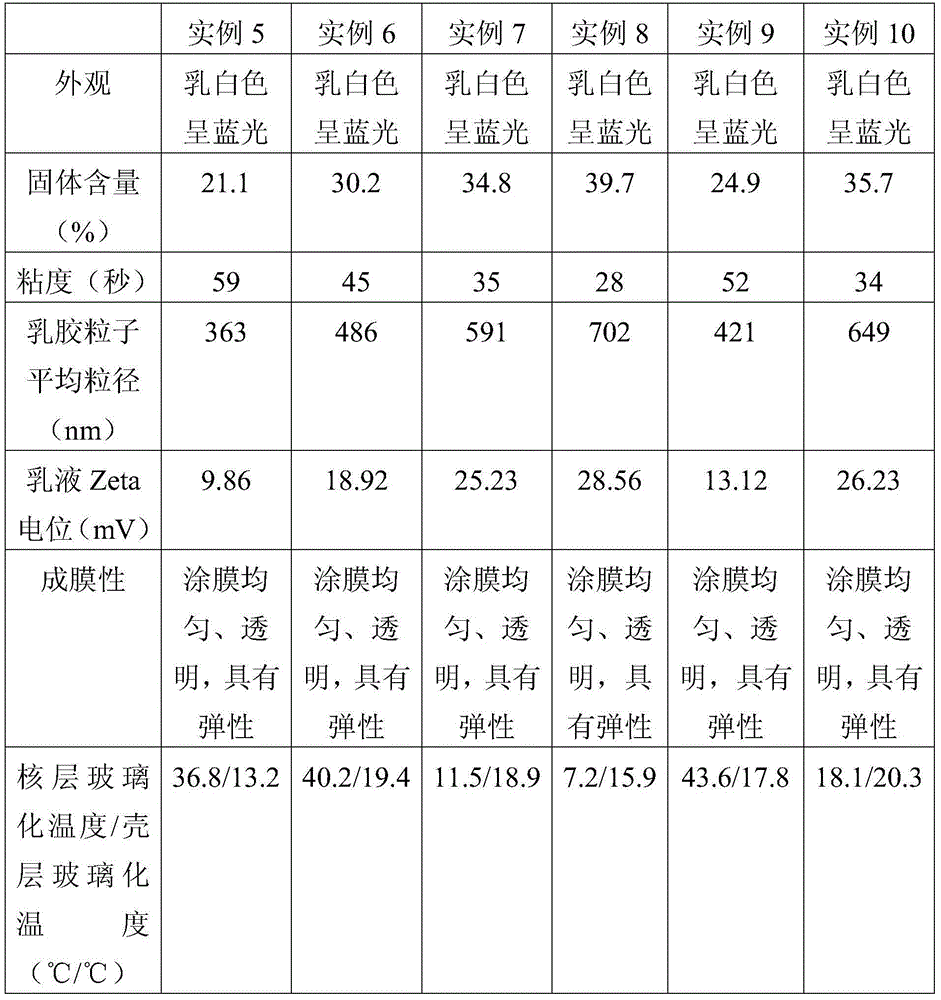

Nuclear shell type long-acting antibacterial emulsion and preparation method thereof

ActiveCN104592459ANot easy to scrub and dissolveLow film forming temperatureAntifouling/underwater paintsPaints with biocidesEmulsionChemistry

The invention relates to a nuclear shell type long-acting antibacterial emulsion. The nuclear shell type long-acting antibacterial emulsion comprises the following raw material components: water, n-butyl acrylate, isobutyl acrylate, isooctyl acrylate, styrene, methyl methacrylate, vinyl acetate, guanidinium oligomer macromonomers, an emulsifying agent, an initiating agent, a cross-linking agent and sodium bicarbonate. The preparation method comprises the following steps: preparing each raw material component; adding water, the emulsifying agent and isooctyl acrylate into a reactor, stirring, heating to 60-70 DEG C, adding the initiating agent to initiate reaction, and after the emulsion becomes blue, maintaining for 60-120 minutes, so as to obtain a nuclear layer emulsion; maintaining the temperature at 70-80 DEG C, adding n-butyl acrylate, heating to 81-85 DEG C, maintaining the temperature, cooling, and discharging, so as to obtain the nuclear shell type long-acting antibacterial emulsion. According to the preparation method, guanidinium and guazatine oligomers are taken as antibacterial functional groups, and guanidyl serves as a main antimicrobial group, has an obvious antibacterial effect and is very safe to human bodies. The preparation method for the nuclear shell type long-acting antibacterial emulsion is simple, rapid, environmentally friendly and suitable for industrial production, and the operation is easy.

Owner:GUANGXI UNIV

Heat reflection-obstruction composite energy-saving coating material and preparation method thereof

ActiveCN102911579AWith heat insulation functionStain resistantReflecting/signal paintsWeather resistanceThermal insulation

The invention provides a composite energy-saving coating material, which is made of multiple microporous silicate mineral raw materials after surface hydrophobic treatment and reflective fillers. The composite energy-saving coating material enhances the weather resistance and water resistance of a coating, avoids the excessive change of a coefficient of heat conductivity, combines two favorable performances of reflection and heat insulation, integrates two roles of the reflection and obstruction at a suit, has high sunlight reflectivity and good heat insulating effect, avoids repeated multilayer painting operation of an insulation surface and the like, can be formed at a time through painting, and has the advantages of stable performance, uniform coating, low cost, environmental-friendliness and the like. A preparation method is simple in technology and low in cost, saves energy and facilitates industrial popularization and application.

Owner:HEBEI UNIV OF TECH

Energy-saving type transparent coating with functions of heat reflection and heat insulation

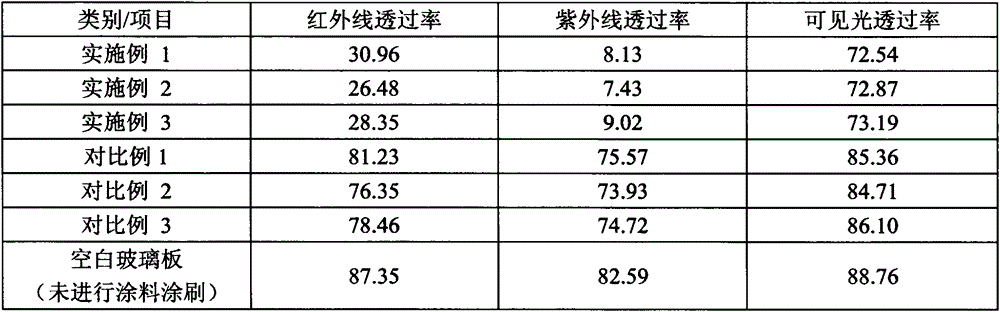

InactiveCN104789101AGood insulation performanceGood stain resistanceAntifouling/underwater paintsPaints with biocidesSolventTransmittance

The invention discloses an energy-saving type transparent coating with functions of heat reflection and heat insulation. The coating comprises components in parts by weight as follows: 10-30 parts of inorganic pigment, 0.5-25 parts of a solvent and 45-89.5 parts of resin, wherein the inorganic pigment comprises tin antimony oxide with the particle size of 10-80 nm, tin indium oxide and lanthanum hexaboride; the solvent is selected from one or more of alcohol, aliphatic hydrocarbon, aromatic hydrocarbon, ketone and ester solvents; the resin is selected from one or more of acrylate-based resin, polyurethane resin, inorganic silicon based resin, silica sol based resin and organic and inorganic mixed resin. The energy-saving type transparent coating with the functions of heat reflection and heat insulation can be applied on transparent glass directly exposed to the sun, thereby forming a coating film with the functions of heat reflection, heat insulation and energy saving, guaranteeing the transparency of the glass and having the continuous heat insulation effect, good visible light transmittance and certain stain resistance.

Owner:苏州绿科环保新材料有限公司

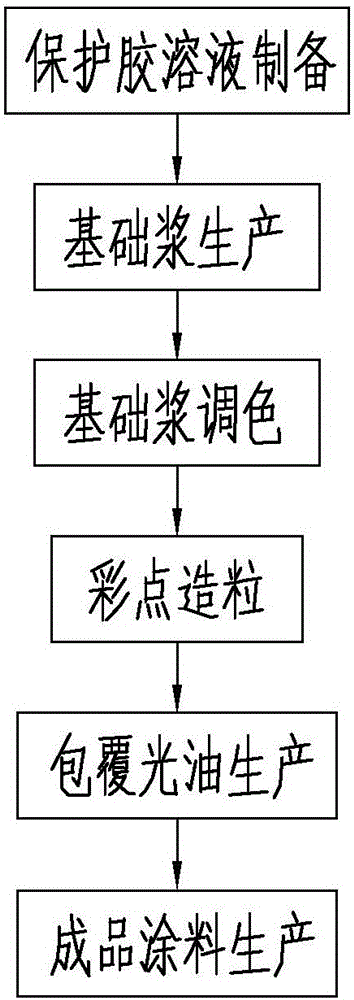

Production method of water-in-water colorful paint containing color sand

ActiveCN105925096ACost-effectiveFast manufacturingAntifouling/underwater paintsPaints with biocidesWeather resistanceSlurry

The invention discloses a production method of water-in-water colorful paint containing color sand. The production method comprises the following steps: (a), preparing a protection glue solution; (b), producing basic slurry; (c), matching the color of the basic slurry; (d), performing color point granulation; (e), producing coating gloss oil; (f), producing finished paint. Granite-shaped particle containing particles are formed on the surface of the paint produced by the method, imitated-marble granite paint can be prepared from the paint, formed patterns are simple, artistic and elegant, and the paint prepared by the method is level in surface and not easy to form ash deposition, can keep the overall appearance longer, and has stain resistance; the special coating gloss oil can keep the color on the surface of the paint to be permanent and fresh, and has weather resistance; the paint is high in water resistance and rot resistance, is neither absorbed by a wall surface nor damaged in rainy days, and can protect the overall shapes of buildings.

Owner:ZHEJIANG KEDA NEW BUILDING MATERIALS

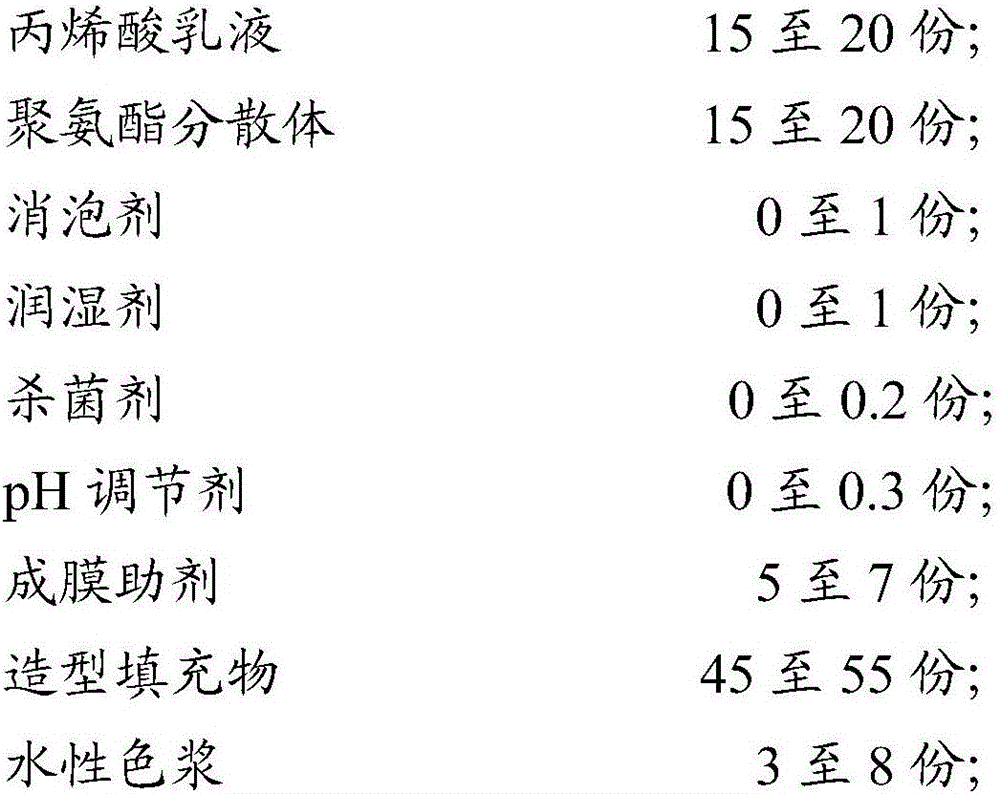

Water-borne wood coating

InactiveCN106634293AGood surface textureStain resistantAntifouling/underwater paintsPaints with biocidesFungicidePolyurethane dispersion

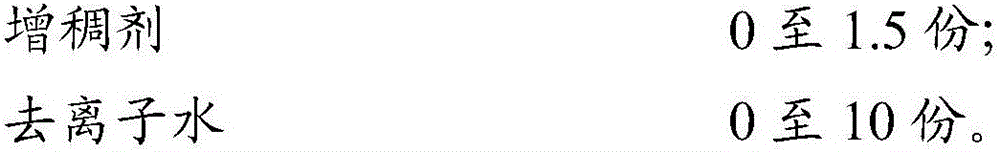

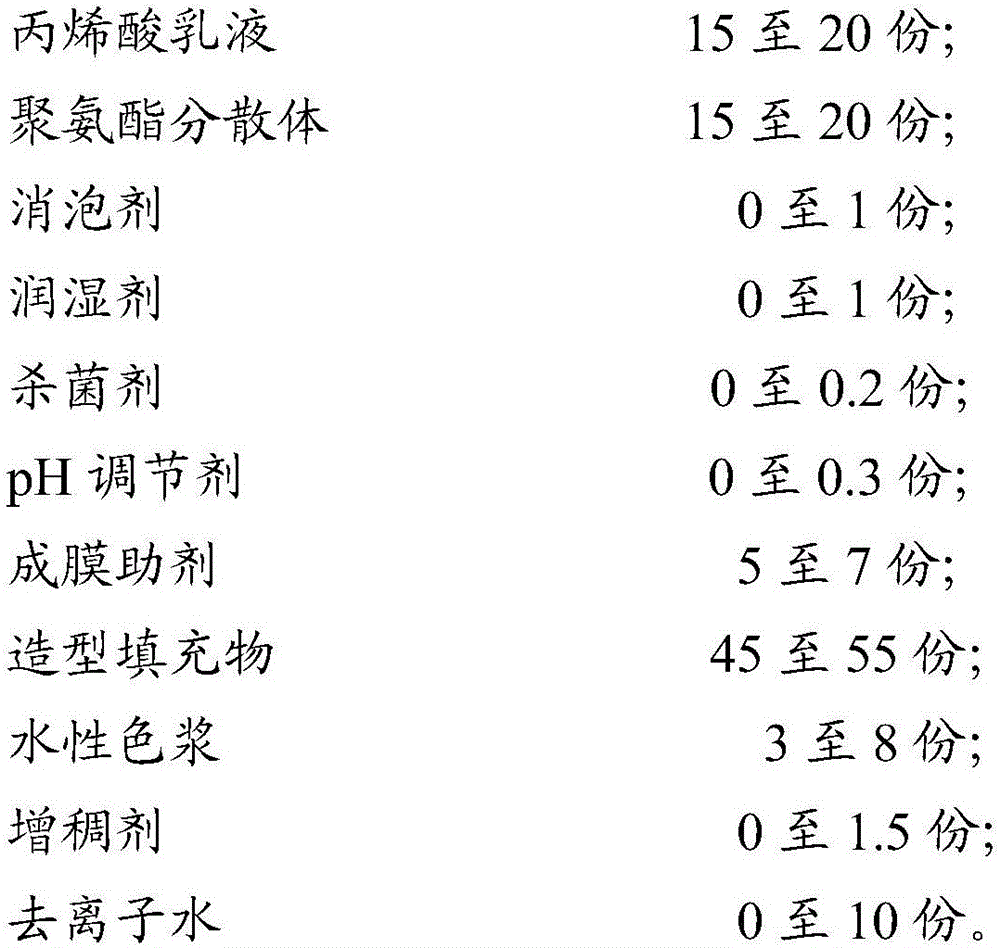

The embodiment of the invention discloses a water-borne wood coating which comprises, by weight parts, 15-20 parts of acrylic emulsion, 15-20 parts of polyurethane dispersion, 0-1 part of defoamer, 0-1 part of wetting agent, 0-0.2 part of fungicide, 0-0.3 part of pH modifier, 5-7 parts of coalescing agent, 45-55 parts of modelling filler, 3-8 parts of water-borne color paste, 0-1.5 parts of thickener and 0-10 parts of deionized water. The water-borne wood coating can be applied to woodwork furniture to achieve a coating effect of preparing the sand face, and the coating has the advantages of being high in three-dimensional effect and strength, excellent in adhesive force, good in water resistance and high in pollution resistance and art texture.

Owner:展辰新材料集团股份有限公司 +6

Fluorocarbon matte finishing paint curable at normal temperature and preparation method thereof

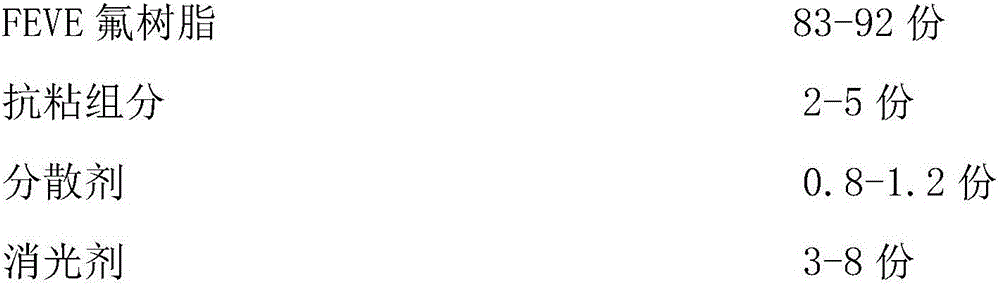

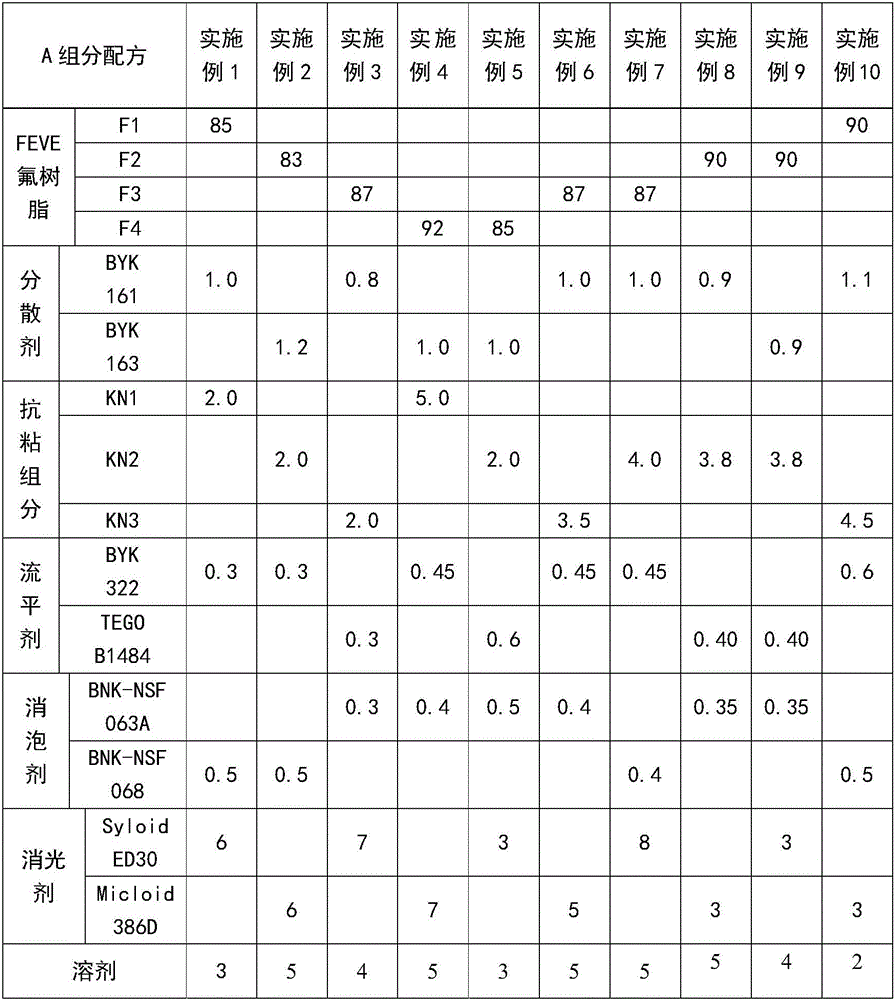

ActiveCN106243856AImprove liquidityImprove performance persistenceAnti-corrosive paintsSolventFluorocarbon

The invention discloses a fluorocarbon matte finishing paint curable at normal temperature. The fluorocarbon matte finishing paint comprises, by weight, a component A and a component B, wherein the component A comprises FEVE fluororesin, an anti-adhering agent, a dispersing agent, a delustering agent, a leveling agent, an antifoaming agent and a solvent, the component B comprises a curing agent, a drier and a solvent, wherein detailed proportions of the components and a preparation method for the paint are described in the specification. The fluorocarbon matte finishing paint has the advantages that 1, the paint has ultra-strong long-lasting corrosion resistance and aging resistance; 2, a film formed by the pain is compact, has good adhesion and allows water and steam to pass through in a long period of time; 3, the paint has the characteristics of long-term fingerprint resistance and contamination resistance; and 4, a protection construction method for metal-decorated buildings is simple, and the paint allows a coated part to be beautiful and presents stereoscopic sensation and decorous impression.

Owner:科创(衢州)化工技术开发有限公司

Preparing method for carving simulating UV scratch resisting wood grain decoration film

InactiveCN107877892ANot easily stainedImprove scratch resistanceFlat articlesWood splinterEngineering

The invention relates to a preparing method for a carving simulating UV scratch resisting wood grain decoration film. The preparing method comprises the technology steps that a PVC face film is prepared; a PVC base material is prepared; two to six polychrome printing is conducted on the surface of the PVC face film according to pattern requirements; color pulp of one color in each set is adopted,a colorful PVC face film is prepared, and finally the printed colorful PVC face film is rolled into a big roll; the printed colorful PVC face film and the PVC base material are heated, pressurized andattached on a double-roller attaching embossing machine, press rollers pressing and attaching the face of the PVC face film are wood splinter embossing rubber rollers, and the temperature of the tworollers can be adjusted to range from 100 DEG C to 200 DEG C; and the attached and embossed PVC decoration film is fed to a printing machine and coated with UV to be conveyed into an oven, secondary temperature increasing is conducted to range from 200 DEG C to 220 DEG C, and PVC face film foaming and cooling are conducted. The carving simulating UV scratch resisting wood grain decoration film prepared through the method has the functions of being capable of achieving the three-dimensional hand feeling, scratch resistance, inflaming retarding, rich colors, carving hollow-out three-dimension and flickering color changing.

Owner:JIANGYIN HUADONG DECORATIVE MATERIAL

Solar heat-absorbing paint

InactiveCN106010241AImprove stabilityGood weather resistanceFireproof paintsAntifouling/underwater paintsPolyethylene glycolSolvent

The invention discloses solar heat-absorbing paint which is prepared from the following components in parts by weight: 25-35 parts of an acrylate-modified composite emulsion, 2-6 parts of a fluorocarbon surfactant, 35-55 parts of a nano carbon powder and manganese dioxide mixture, 7-12 parts of a curing agent, 50-35 parts of a film forming agent, 1-3 parts of an absorption enhancer, 10-20 parts of a solvent, 5-10 parts of dispersants, and 0.5 to 0.7 part of a thickening agent, wherein the dispersants are sodium dodecyl sulfate and polyethylene glycol / polyvinyl pyrrolidone; the film forming agent is modified fibroin-gelatin; nano carbon powder is 10-20 nm in particle size, 150-180 m<2> / g in specific surface area and 90-95% in carbon content. The prepared solar heat-absorbing paint has excellent weather resistance and water resistance under the outdoor condition, the preparation process is simple and easy to understand, and the heat absorption efficiency of the heat-absorbing paint is further ensured.

Owner:NANNING KEYU ENERGY TECH CO LTD

Environment-friendly latex paint and preparation method thereof

InactiveCN108329765AStrong adhesionLight smellAntifouling/underwater paintsPaints with biocidesFiberWeather resistance

The invention discloses an environment-friendly latex paint and a preparation method thereof, and relates to the technical field of latex paint. The latex paint is prepared from the following raw materials in parts by weight: 85-105 parts of styrene-acrylic emulsion, 35-45 parts of nano-silica sol, 20-25 parts of diatom ooze, 10-15 parts of nano-TiO2, 10-15 parts of tourmaline anion powder, 10-15parts of glutinous rice glue, 7-8 parts of plant dehydrated filaments, 7-8 parts of antibacterial powder, 4-6 parts of active powder, 4-6 parts of essential oil components, 20-22 parts of an aid and 70-75 parts of deionized water. The latex paint has relatively powerful adhesive force, a paint film has light smell, low VOC and high adhesive force and is combined with the wall stably, peeling and bursting of the paint surface are not easily produced, and weather resistance of the latex paint is greatly improved.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Paint

InactiveCN104944836AStrong adhesion and toughnessImproves scratch and abrasion resistanceQuartzWater repellent

The invention discloses a paint which comprises rubber powder, starch, a water repellent, cellulose, wood fibers, tartaric acid, a water reducing agent, a thixotropic agent, titanium white, diatomite, a defoaming agent, heavy calcium carbonate powder, aggregate and quartz sand. The paint has characteristics of high safety, fire resistance, fouling resistance and the like of diatom ooze; and by combining the added amorphous silicon dioxide (quartz sand) and the added natural mineral materials (such as wood fibers, cellulose, titanium white, diatomite and the like), the paint can keep stable state for a long time, has the advantages of excellent adhesive force, excellent toughness, higher scratch resistance and higher wear resistance, and can be used for internal wall decoration and external wall decoration. By adopting common materials, the paint is lower in cost.

Owner:JILIN LYUSENLIN ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

Multifunctional composite coating of oil gas storage tank and preparation method thereof

InactiveCN101474907AImprove the protective effectStain resistantLiquid surface applicatorsLayered productsSolventFluorocarbon

The invention discloses a multifunctional composite coating for an oil-gas storage tank and a preparation method thereof, and solves the technical problems to achieve the aims of prolonging the service life of a coating material, saving energy and reducing discharge. The composite coating is compounded by a bottom layer and a surface layer; and the preparation method comprises: manufacturing finished products of the bottom layer and the surface layer, diluting the finished product of the bottom layer by an X501 solvent, spraying the diluted finished product of the bottom layer on an anti-corrosion coating of the oil-gas storage tank, drying the anti-corrosion coating, diluting diisocyanate curing agent HDI dimmer or trimer by an X502 solvent, mixing the diluted HDI curing agent with the finished product of the bottom layer, and spraying the mixture onto a dry film of the bottom layer to prepare the composite coating consisting of the bottom layer and the surface layer. Compared with the prior art, the composite coating adopted cannot be heated by sunning, so the composite coating saves power consuming and water spraying equipment and water spraying and temperature reducing control processes, avoids waste of water and electric resources, and has guarantee functions of static conduction, fire resistance and safety; and by means of the fluorocarbon surface layer, the composite coating has strong protection, stain resistance and service life of more than ten years.

Owner:SHENZHEN SAILING ENERGY SAVING NEW MATERIAL TECH

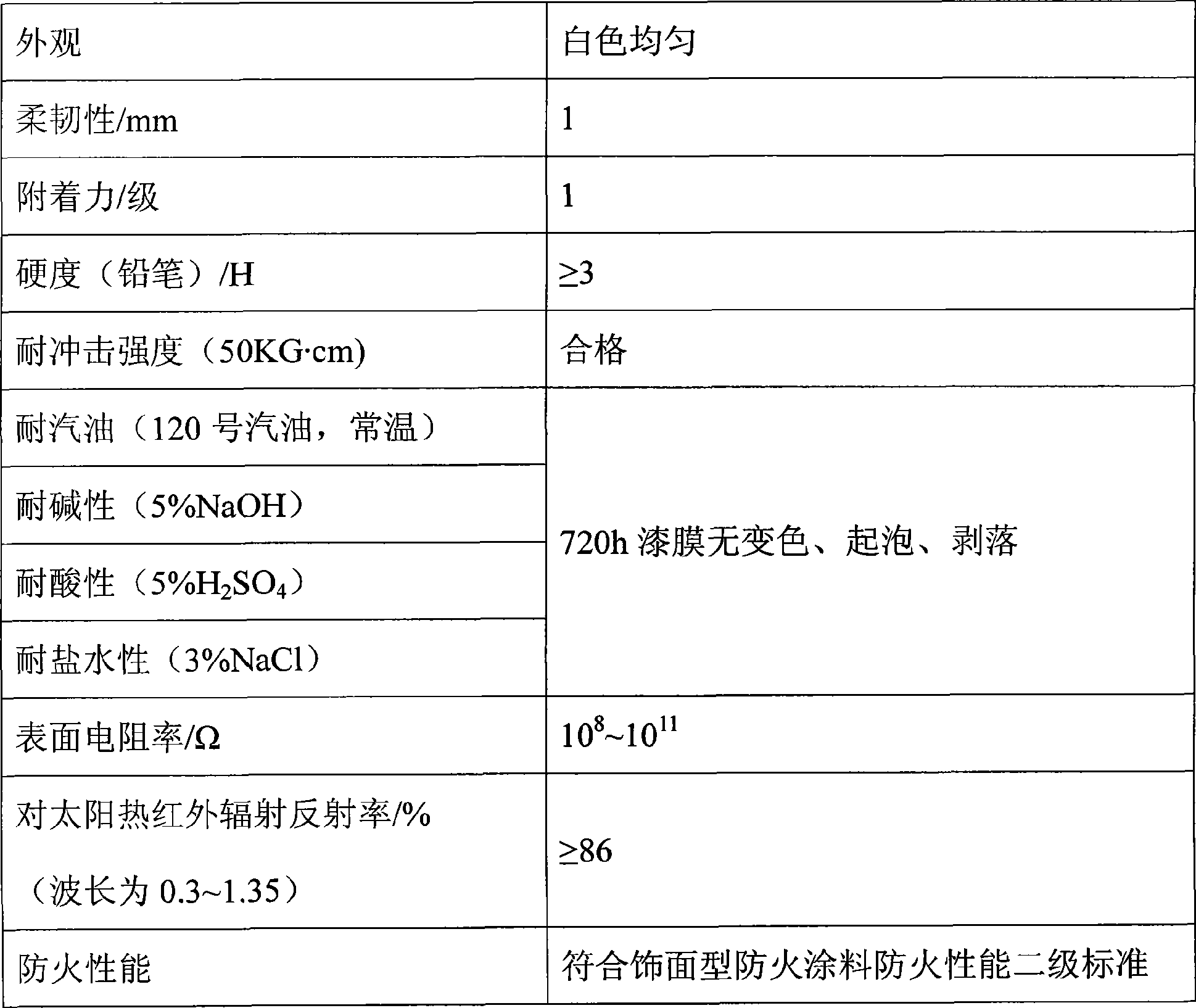

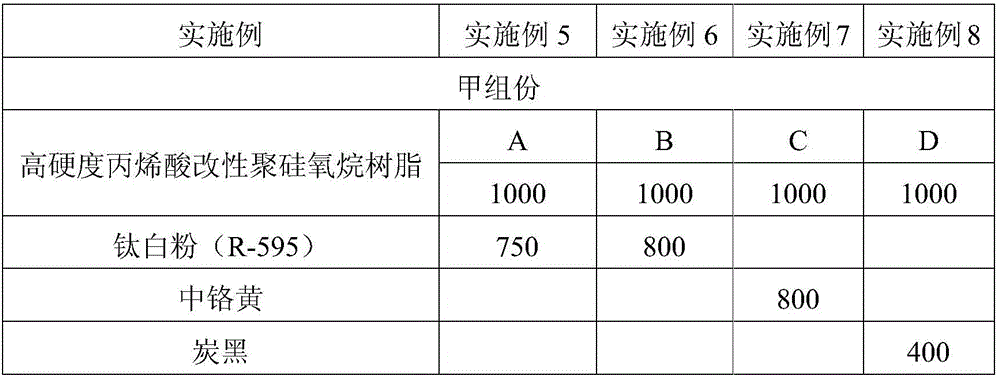

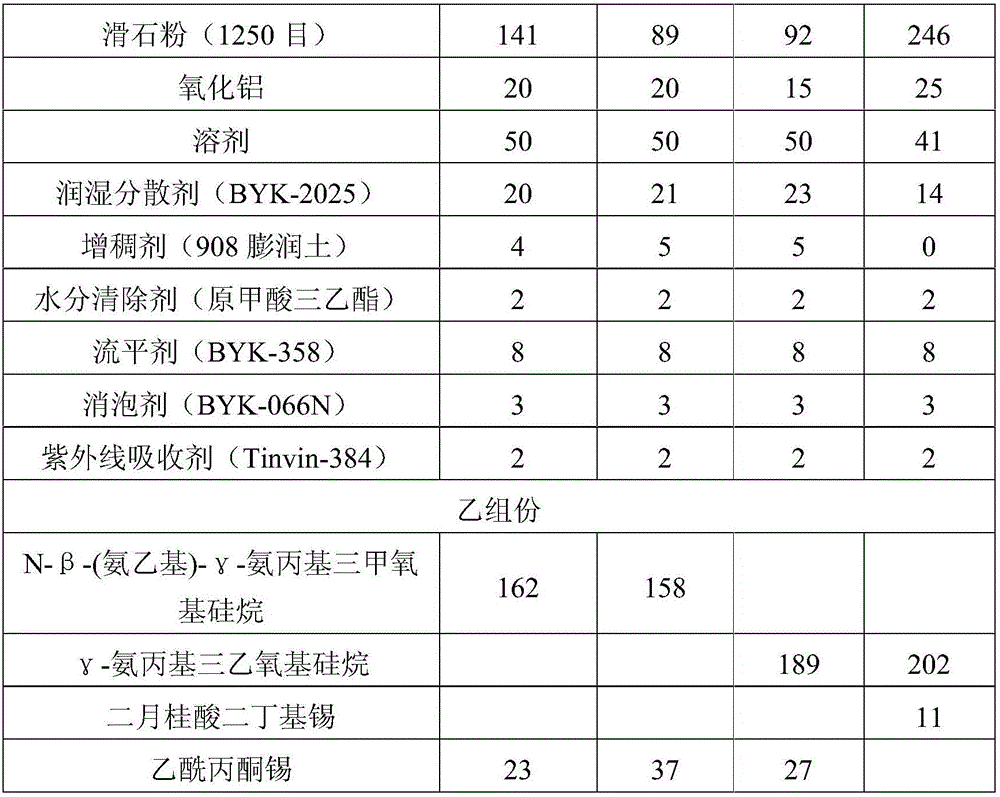

High-hardness acrylate-modified polysiloxane resin and coating employing high-hardness acrylate-modified polysiloxane resin as base material

ActiveCN106675133ALow viscosityLow VOCAntifouling/underwater paintsPaints with biocidesWeather resistanceRoom temperature

The invention discloses high-hardness acrylate-modified polysiloxane resin and a coating employing the high-hardness acrylate-modified polysiloxane resin as a base material. The resin is mainly prepared by compounding 41-65wt% of active polysiloxane intermediate, 15-36wt% of cyclohexyl-containing acrylic ester, 5-15wt% of polyfunctional acrylate monomer and 10-20wt% of amino-hydrocarbon alkoxy silane. The harness of a pencil solidified by a two-component coating prepared from the acrylate-modified polysiloxane resin as the base material is greater than or equal to 5H, and meanwhile, the acrylate-modified polysiloxane resin can meet high solid content, low viscosity, room-temperature fast curing performance, overlong weather resistance and anticorrosion performance, and can be widely applied to surface coating of rail vehicles of subways and high-speed rails.

Owner:中昊北方涂料工业研究设计院有限公司

Stone imitation paint and production method

InactiveCN107699123AHighlight substantive featuresSignificant progressAntifouling/underwater paintsPaints with biocidesGlass fiberWeather resistance

The invention discloses stone imitation paint and a production method. The stone imitation paint comprises raw materials, namely polyurethane, a glass fiber, an acrylic resin liquid, an elastic resinliquid, white quartz sand, natural colorful sand, water, a composite coupling agent, a leveling agent, a defoaming agent and an anti-settling agent. The stone imitation paint disclosed by the invention is diverse in color, sufficient in attractiveness and good in imitation property, and a constructed surface has the third-dimensional property and the multi-color decoration attractiveness, and haswaterproof anti-cracking properties, water and alkali resistance, weather resistance, water scrubbing resistance, anti-fouling properties, alga resistance and chemical resistance. In addition, the stone imitation paint is good in stone texture, good in waterproof and cracking resistance, relatively long in weather-resistant service life, vivid in color, relatively good in anti-fouling property, relatively simple and convenient to construct, relatively applicable to heat-preservation base materials, low in manufacturing cost, rich in color and specification, simple and easy to construct and excellent in anti-cracking waterproof property.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

Nanometer mesoporous titanium dioxide/nanometer silica sol coating and preparation method thereof

ActiveCN102585623ASolve technical problems that are easy to reuniteGood weather resistanceEmulsion paintsNano siliconWeather resistance

The invention relates to the field of building materials, in particular to a nanometer mesoporous titanium dioxide / nanometer silica sol coating and a preparation method thereof. The coating is characterized in that nanometer mesoporous titanium dioxide particles and nanometer silica sol particles are used. The preparation method comprises the following steps of: dispersing, and grinding; putting water, powder and an aid into a dispersion machine, grinding, and filtering to obtain slurry; and performing paint mixing, namely putting emulsion, nanometer mesoporous titanium dioxide, nanometer silica sol, water and an aid into the dispersed slurry, regulating the pH value and viscosity, and thus obtaining the coating. The coating is prepared by simple processes of dispersing, sanding, filtering and the like, the defects that the conventional coating has low stain resistance and weather resistance, is not environment-friendly and the like are overcome, and the coating is endowed with good new functions such as a self-cleaning function, an antibacterial function and the like, has high storage stability, scour resistance, stain resistance and weather resistance, and is suitable for an exterior wall coating.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

Production technology of waterborne polyurethane leather for automobile seat

The invention discloses a production technology of waterborne polyurethane leather for an automobile seat. The production technology comprises steps as follows: (1), release paper is coated with a waterborne composite sizing agent bottom layer and sent to a medium-wave infrared heating dryer to be dried; (2), the waterborne composite sizing agent bottom layer is coated with a waterborne composite sizing agent surface layer, sent to the medium-wave infrared heating dryer to be dried, then attached with a waterborne polyurethane superfine fiber synthetic leather base and dried, and a semi-finished product of the waterborne polyurethane leather for the automobile seat is obtained; (3), a spray agent is sprayed to the waterborne composite sizing agent surface layer in the semi-finished product of the waterborne polyurethane leather for the automobile seat, the semi-finished product is sent to the medium-wave infrared heating dryer to be dried, and the waterborne polyurethane leather for the automobile seat is obtained. The synthetic leather for the automobile seat is produced in combination of a synthetic leather dry-method film transfer technology and a spraying process, the technological steps are simple, environment-friendly and safe, the operability is high, and the obtained leather for the automobile seat has the characteristics of wear resistance, pollution resistance, ultraviolet ray resistance and the like, feels more fine, touches better and is like natural leather.

Owner:ZHEJIANG FANSHENG MICROFIBER PROD

Four sides elasticity chamois flannel

InactiveCN101191273AEasy to stretchEasy to replyMonocomponent polyurethanes artificial filamentWoven fabricsFiberExtensibility

The invention relates to a neoprene suede nap and belongs to the textile fabric technical field. The invention is mainly characterized in that: warp threads are wrapped yarns taking sea-island filament as urethane elastic fiber core yarns, and the sea-island filament is made to become elastic sea-island filament; weft yarns are wrapped yarns taking PTT polyester as urethane elastic fiber core yarns, thereby the PTT is made to have good tension and restoring force and advanced performances like softness, fluffiness, easy dyeing, easy washing and so on are fully displayed; because a little urethane elastic fiber is arranged inside the PTT, resilience of the PTT is strengthened. The invention utilizes stain resistance better than chinlon fiber, antistatic property better than nylon, fluffiness, resilience, chromaticity, good stain removal and antifouling properties, easy dyeing, soft hand feeling, abundance in elasticity, and extensibility same as urethane elastic fiber of the PTT fiber to prepare the suede nap through coating according to mixture ratio; advantages of the two fibers are given full play; due to addition of the PTT fiber, the cost of raw materials and processing costs like energy consumption and so on can be reduced; due to addition of the urethane elastic fiber, the resilience can be guaranteed; by weaving of the suede nap, disadvantages of thin fabrics are avoided.

Owner:YANGZHOU JIYUAN TEXTILE

Preparation method of intelligent oil-water separation membrane with stain-resistant performance

InactiveCN108744598AImprove adhesionImprove mechanical durabilitySemi-permeable membranesMembranesMetal fiberMicro nano

The invention discloses a preparation method of intelligent oil-water separation membrane with stain-resistant performance. Through etching and chemical deposition, a micro-nano layered structure is constructed on the surface of a stainless steel fiber mat with a 3D-net porous structure, the prepared stainless steel fiber mat is prone to be wet by water and oil, and after water is used for pre-wetting, the metal fiber mat shows the performance of super-hydrophilicity and super-lipophobicity in an oil-water mixture; while after oil is used for pre-wetting, the metal fiber mat shows the performance of super-lipophilicity and super-hydrophobicity in the oil-water mixture, and the prepared stainless steel fiber mat oil-water separation membrane can be used for separating oil-water mixtures ofmany types. The preparation method of the intelligent membrane which has the advantages of good durable performance and mechanical performance, high flux, high separation efficiency, stain resistant,low cost, easiness of industrialize and capability of continuous oil-water mixture separation is provided.

Owner:洛阳纳诺环保科技有限公司

Anticorrosive and environmentally-friendly water-based coating and preparation method thereof

InactiveCN109021788AAvoid pollutionAvoid wastingFireproof paintsAntifouling/underwater paintsWater basedEpoxy

The invention discloses an anticorrosive and environmentally-friendly water-based coating. The coating is mainly prepared from, by weight, 40-50 parts of waterborne epoxy resin, 30-50 parts of a basematerial, 5-10 parts of a filler, 4-6 parts of modified graphene oxide, 1-2 parts of a photocatalyst, 1-3 parts of an emulsifier, 2-3 parts of a silicone acrylate leveling agent, 3-5 parts of sodium diisooctyl sulfosuccinate, 2-5 parts of an NXZ defoamer, 2-3 parts of hydroxyethyl cellulose, 20-30 parts of deionized water and 0.5-1 part of 2-amino-2-methyl-1-propanol. The invention also disclosesa preparation method of the coating. The preparation method comprises the following steps: emulsification of the waterborne epoxy resin, preparation of a filler mixture, preparation of a base materialmixture, and uniform grinding and stirring. Potassium silicate, sodium silicate and silica sol are compounded as a base material, the waterborne epoxy resin is used as an emulsion, and water as a dispersion medium, so environmental pollution and resource waste caused by using of an organic solvent are avoided, and the coating has no pollution in the production or use process, and has excellent environmental protection performance and mechanical performances.

Owner:SHENZHEN NANSHUO MINGTAI TECH CO LTD

Waterborne thin-coating diatom mud

InactiveCN105838121AReduce humidityConvenient lifeAntifouling/underwater paintsPaints with biocidesEmulsionPreservative

The invention relates to a water-based thin coating type diatom mud, including deionized water, cellulose, antifreeze agent, defoamer, wetting agent, multifunctional auxiliary agent, dispersant, negative ion slurry, titanium dioxide, kaolin 4000 mesh , Talc powder 1250 mesh, heavy calcium 1250 mesh, multifunctional polymer powder, diatomite 800 mesh, sepiolite, inorganic composite gel, emulsion f208, film-forming aid, defoamer, preservative, antifungal agent, Thickener ase‑60 and thickener 180. The invention is a wall material integrating environmental protection and functionality. It has the functions of heat preservation and heat insulation, and can save electricity and heating costs for houses decorated with it. The energy saving standard reaches more than 80%. The coating surface not only No blistering, shedding, obvious discoloration, etc. It also has the advantages of tensile resistance, fracture resistance, noise resistance, acid and alkali resistance, water resistance, aging resistance, chalking resistance, discoloration resistance and formaldehyde purification.

Owner:赵广全

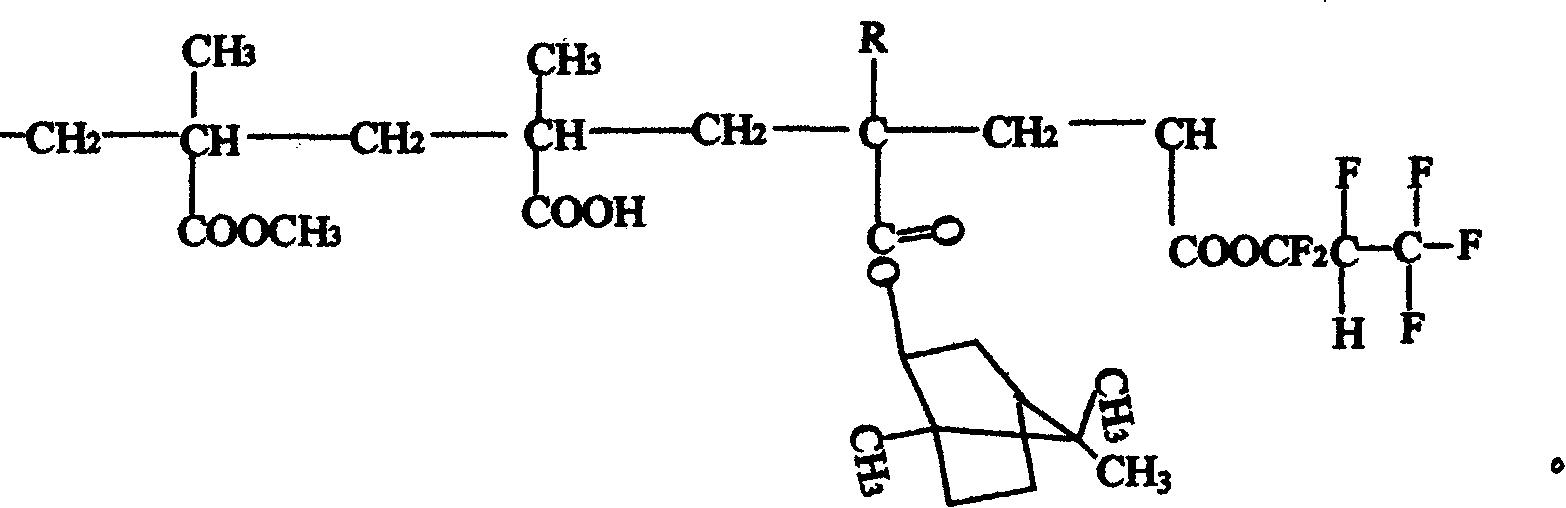

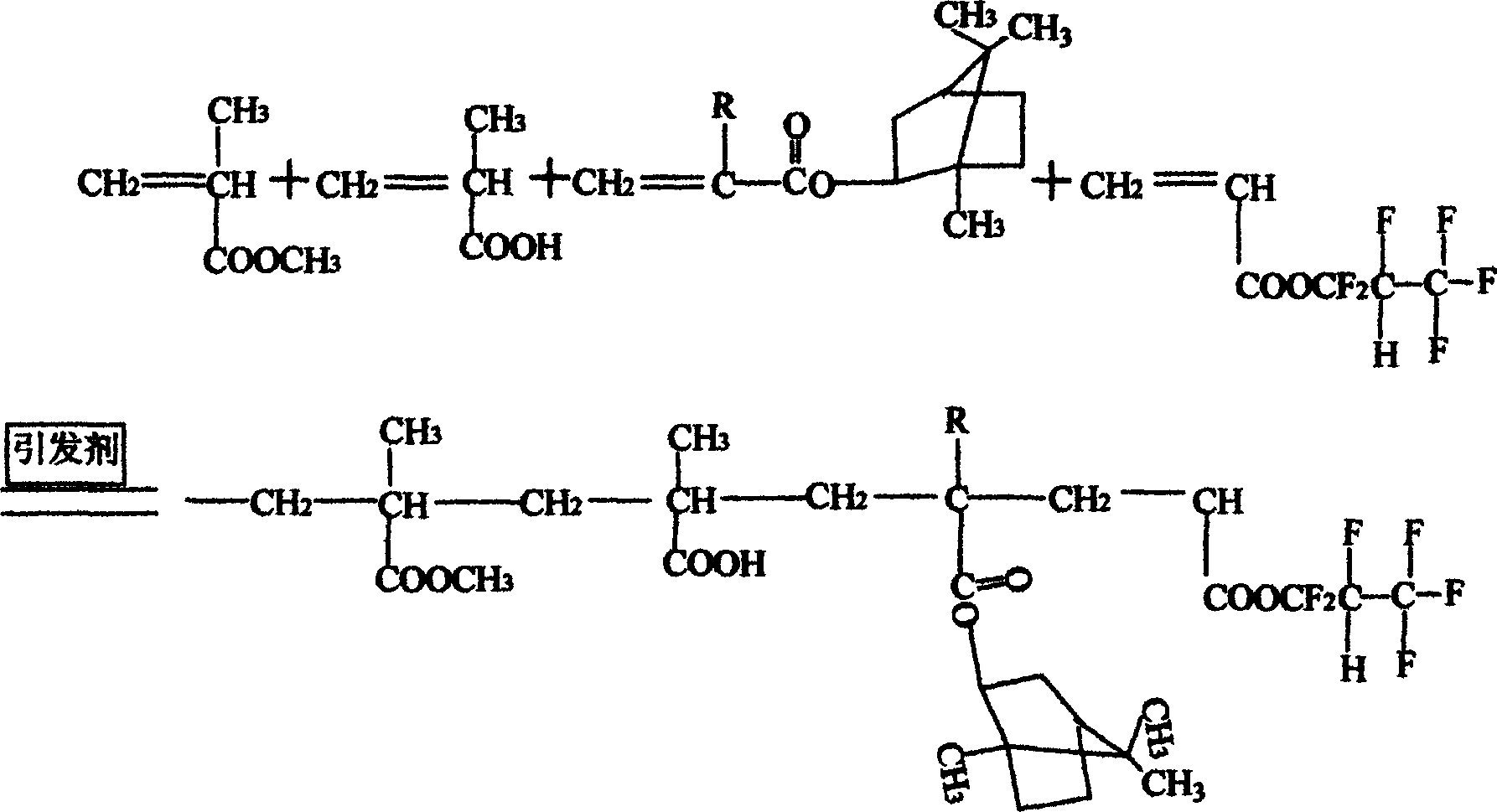

Fluorocarbon elastomer latex and its preparation method

The invention relates to a fluorocarbon elastic solid emulsion and it's preparing method. The method uses fluorocarbon base to quench the acrylate macromole. The formation of the emulsion used base is that the organic fluorine base with the base total amount 10-30%, the olefin unsaturated acid ester base with the base total amount 5-15% and the olefin acrylate base with the base total amount 55-85%.

Owner:高明

Surface bright anodic oxidation coloring method for titanium and titanium alloy

ActiveCN105316744ANo variegationNo anti-fingerprintSurface reaction electrolytic coatingMegasonic cleaningTitanium

Owner:TRAUSON CHINA MEDICAL INSTR COMPANY

Quick-drying friction-resisting high-temperature-resistant primer and preparation method thereof

ActiveCN104212313AStir wellImprove friction resistanceEpoxy resin coatingsAcrylic resinPolyethylene glycol

The invention discloses a quick-drying friction-resisting high-temperature-resistant primer. The primer consists of bisphenol F type liquid epoxy resin, iron oxide red powder, titanium dioxide, silicon micro-powder, a multifunctional auxiliary agent AMP-95, graphite powder, polyethylene glycol and organic fluorine modified acrylic resin; the primer comprises the following components in percentage by weight: 23-25% of bisphenol F type liquid epoxy resin, 5-8% of iron oxide red powder, 12-15% of titanium dioxide, 10-12% of silicon micro-powder, 15-18% of multifunctional auxiliary agent AMP-95, 12-15% of graphite powder, 3-8% of polyethylene glycol and the balance of organic fluorine modified acrylic resin. The invention also provides a preparation method of the quick-drying friction-resisting high-temperature-resistant primer. The primer disclosed by the invention is quick to dry, is odor-free, has stability in alkali and most of solvents, has good anti-corrosion, gas-blocking and water-stopping properties and the like, has good friction resistance and high temperature resistance, and is long in service life.

Owner:JIANGSU MARINE VICTORY COATING

High-flame-retardant sofa leather production method

The invention discloses a high-flame-retardant sofa leather production method, which comprises the following steps of: wet-process mixing for proportioning: evenly agitating dimethylformamide and color paste and filtering the mixture slurry for future use; evenly agitating dimethylformamide, wood powder and flame retardant, standing the mixture for 20-45 minutes, and evenly mixing and agitating the mixture with the mixed slurry; adding polyurethane wet-process resin, evenly agitating the mixture and removing foam; coating the slurry on fabric fibers and immersing the fabric fibers in dimethylformamide water solution to obtain a wet-process bass through solidification, multi-pass water squeezing, water washing and drying; evenly agitating polyurethane dry-process resin, dimethylformamide, butanone, flame retardant, assistants and toner to obtain dry-process slurry; coating the dry-process slurry on patterned release paper, bonding the wet-process bass through bonding agent, separating the release paper after drying, finally and fully immersing the obtained product in flame-retardant water solution, squeezing the product, and wrinkling the product to obtain high-flame-retardant sofa leather. The high-flame-retardant sofa leather production method has the advantages that the process is simple and the production operation is facilitated; and the synthetic leather produced by adopting the production method provided by the invention has the advantages of fire prevention, high safety, attractive appearance, staining resistance and the like.

Owner:昆山协兴合成革有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com