Patents

Literature

108results about How to "With heat insulation function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

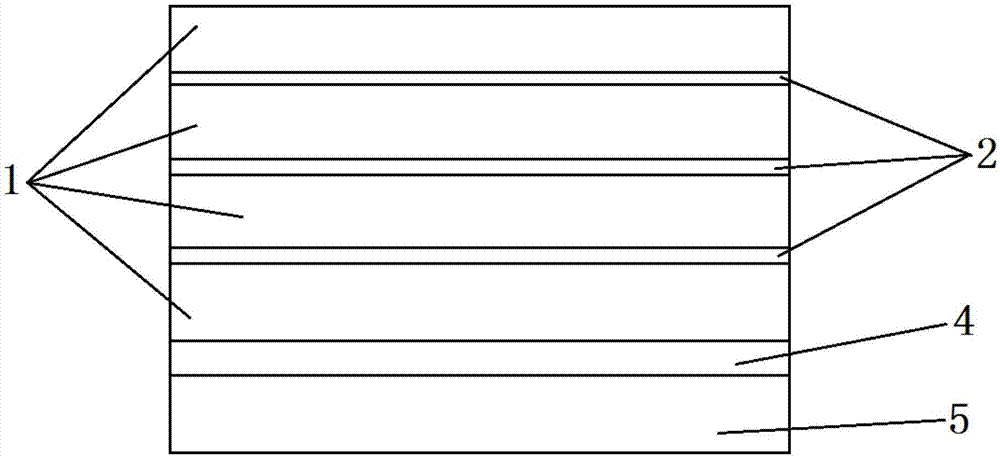

Heat isolating composite film and its prepn and use

InactiveCN1672921ASimple compositionReasonable functionSynthetic resin layered productsComposite filmHeat conducting

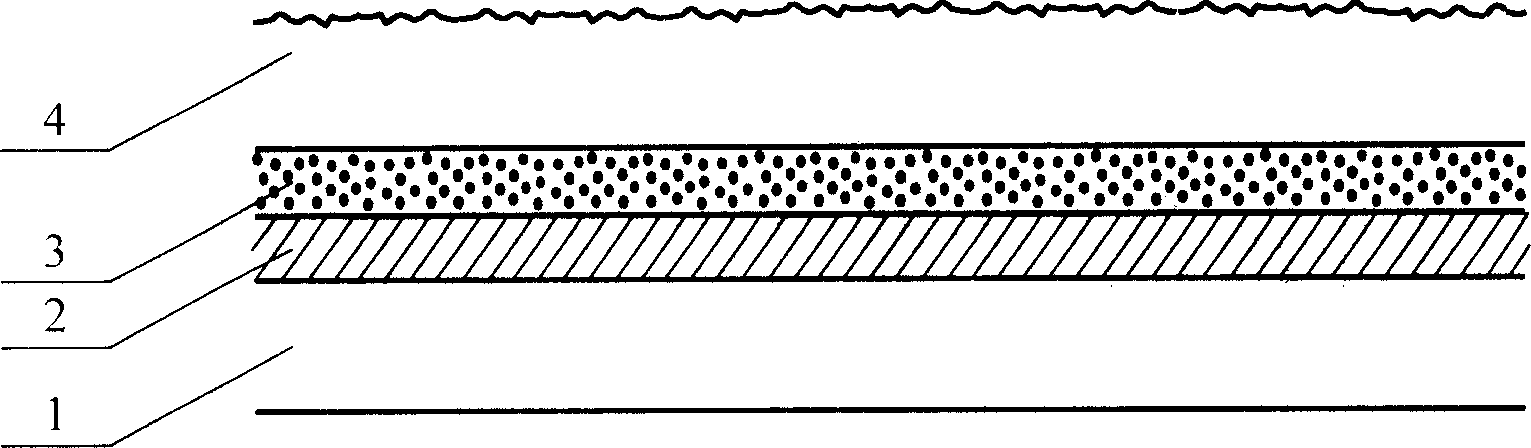

The present invention relates to one kind of heat isolating composite film and its preparation process and use. Structurally, the heat isolating composite film consists of compounded base polymer film of high strength and low heat conducting coefficient, metal layer with high reflecting performance, metal oxide layer with high heat isolating performance and outer polymer film with low heat conducting coefficient and high hot adhering strength. The composite film may have thickness of 12-1000 micron. The heat isolating composite film is prepared through evaporation plating one very thin compact metal layer and one very thin loose metal layer successively onto rolled polymer film and then oxidizing, or evaporation plating metal oxide layer directly; and final rolling or curtain coating one other polymer film layer. The heat isolating composite film has excellent heat insulating performance, is light, thin and soft, and may be used in various flexible heat insulating material.

Owner:DONGHUA UNIV

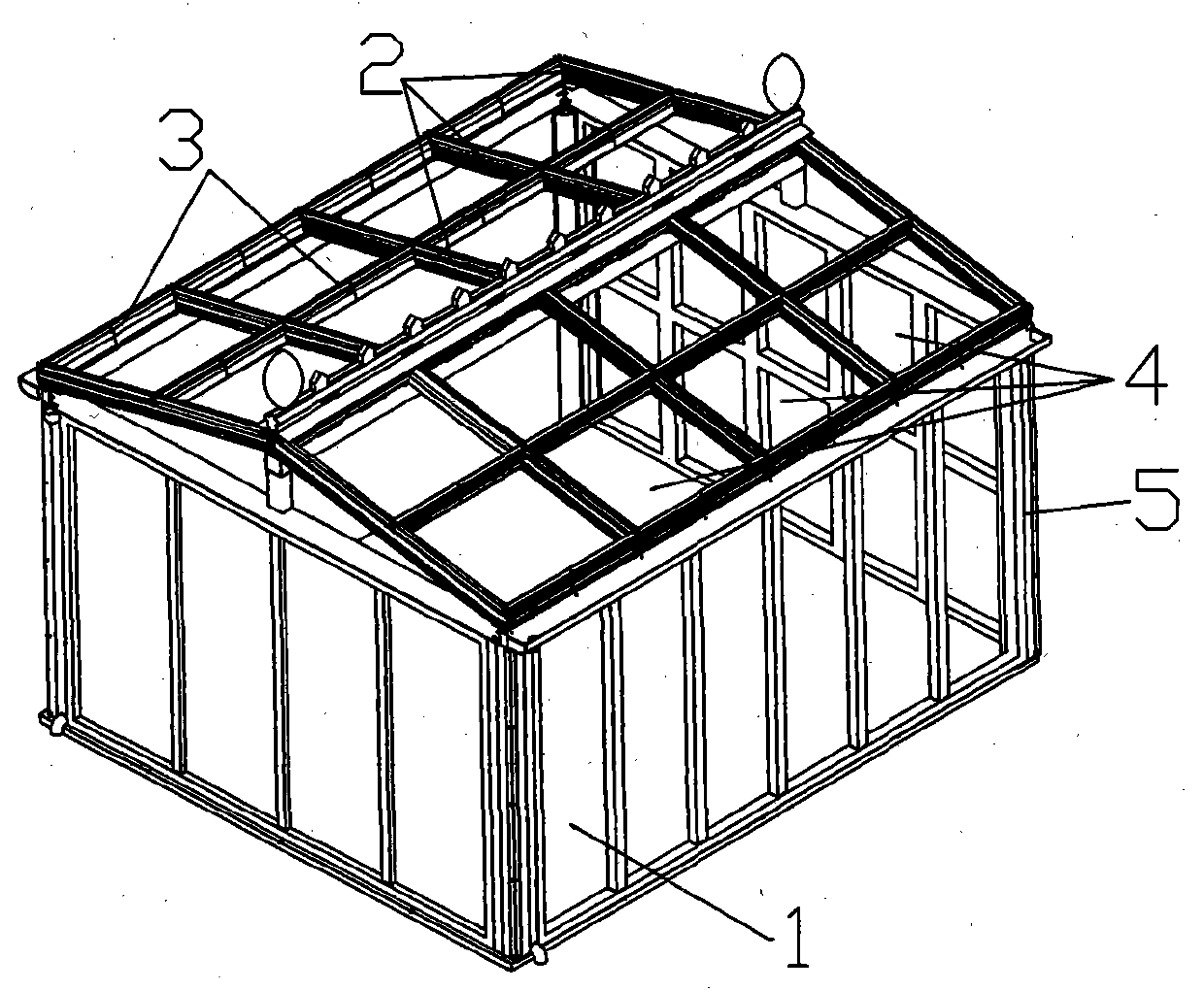

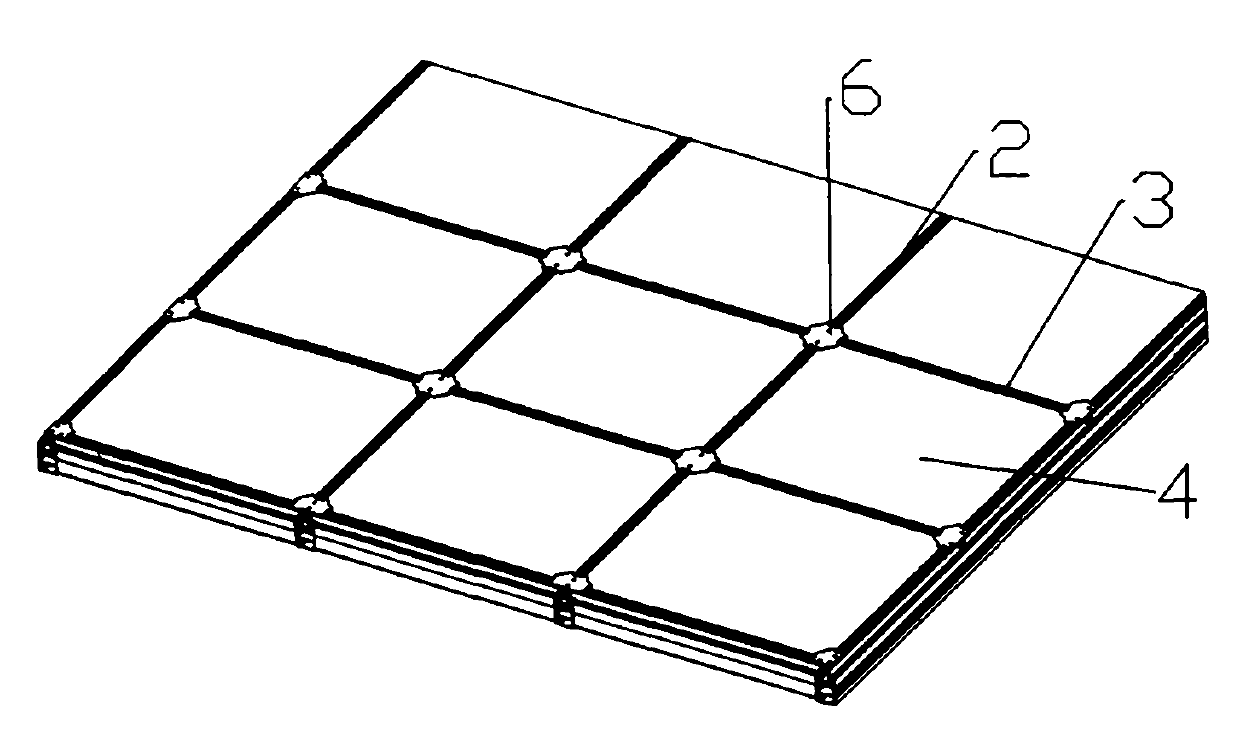

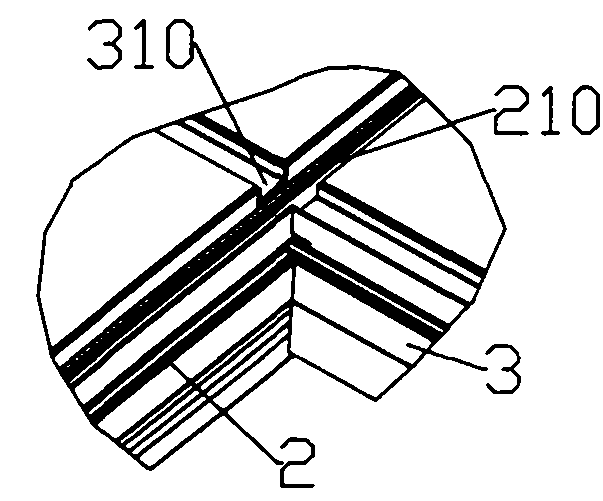

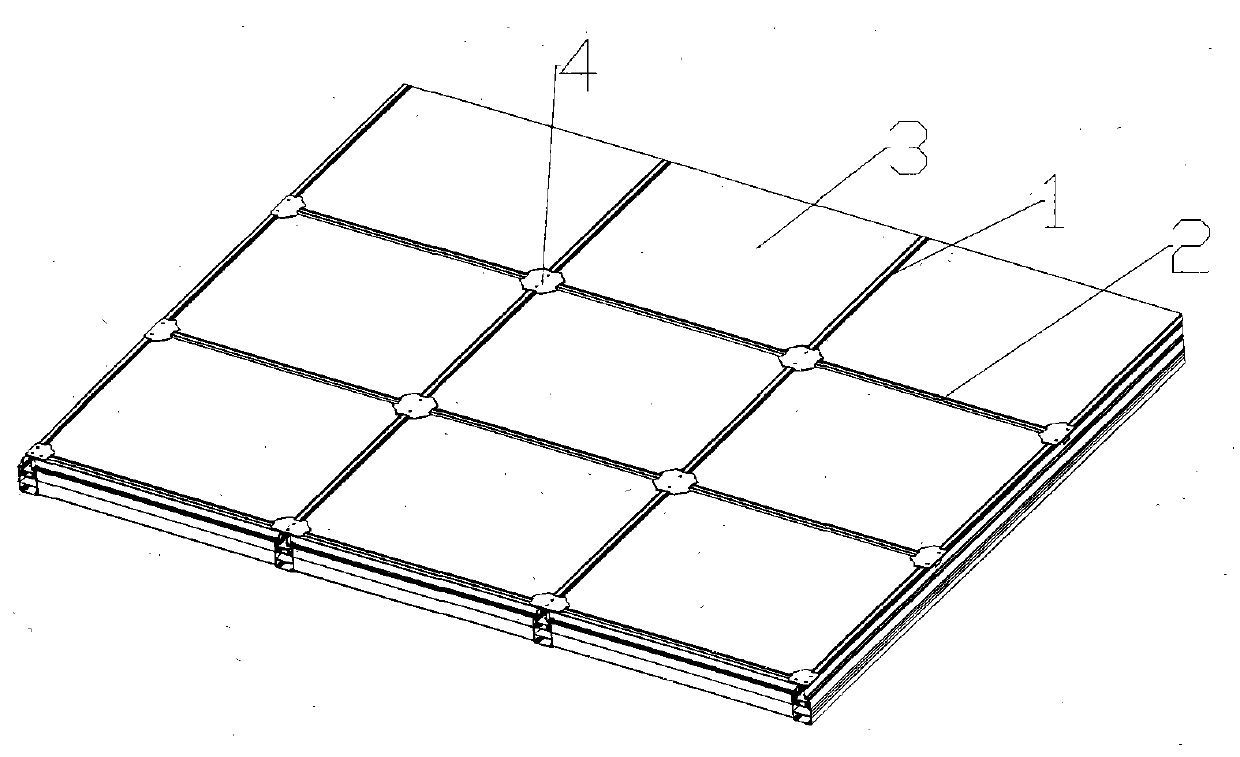

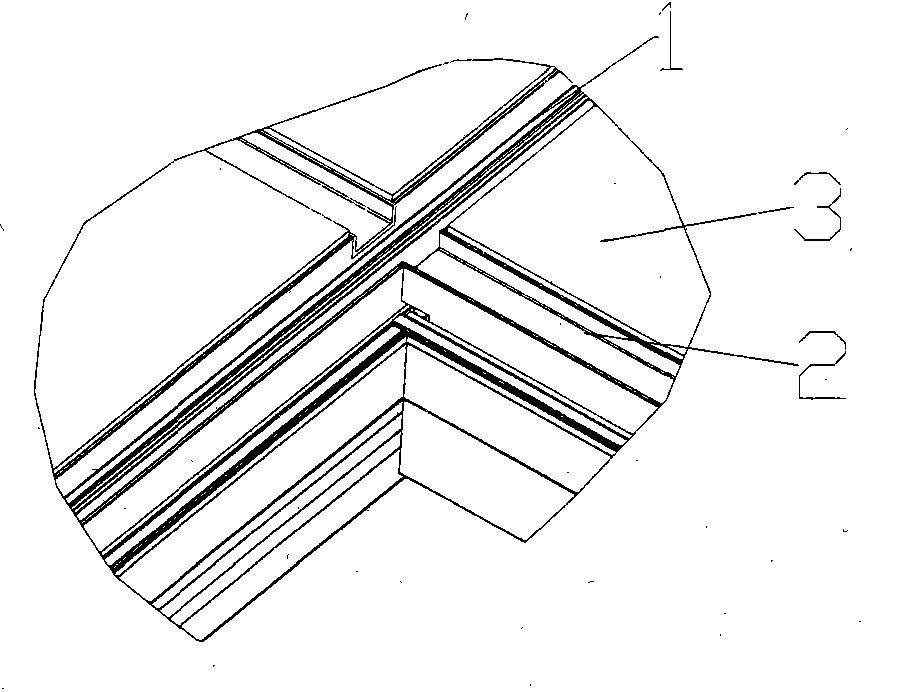

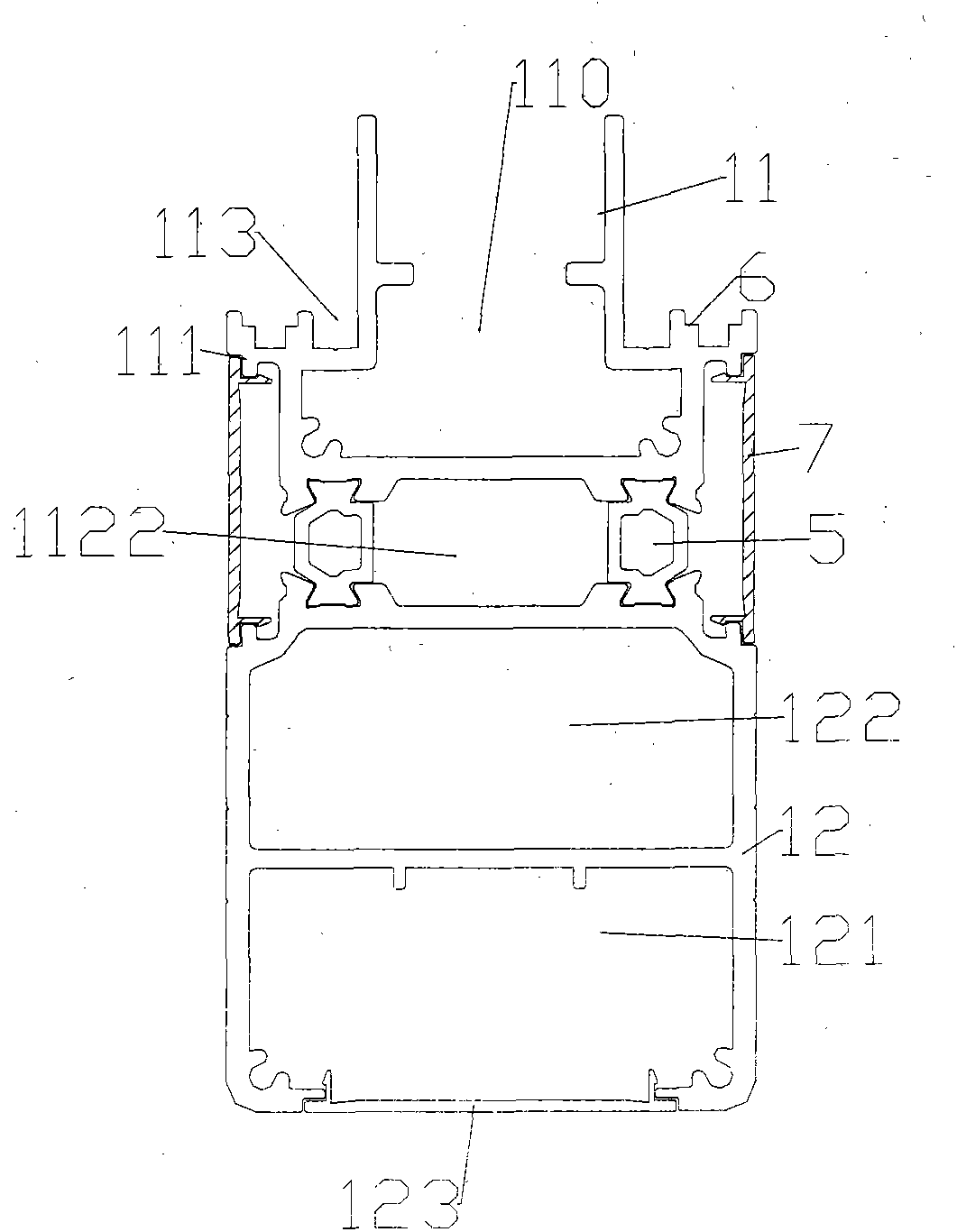

Sunshine room

ActiveCN103741891ASolve the leakReduce viscosityRoof covering using slabs/sheetsStructural engineeringEngineering

Owner:佛山市淇特科技有限公司

Low-carbon humidity controlling functional coating

The invention relates to a low-carbon humidity controlling functional coating which comprises component A, component B and component C in parts by weight, wherein the component A comprises a thickening agent, a dispersing agent, a defoaming agent, a solvent, a bactericide, a wetting agent and water; the component B comprises powder, titanium white, kaolin and heavy calcium carbonate powder; and the component C comprises an emulsion, a defoaming agent and a film forming agent. Compared with the traditional inside wall emulsion coatings, the coating has the advantages that hydrophilic porous inorganic minerals are added to ensure that a coating film has excellent pollution resistance; after an ordinary coating film absorbs 40g of water in per square meter, the coating film reaches a saturation state, and most part on the surface of the coating film has a dew formation phenomenon, however, after one square meter of the humidity controlling coating film absorbs 60g of water, the surface of the film has no dew formation phenomenon; when the indoor humidity is too high, the porous structure of the film can automatically absorb water in the air and stores the water, and when the room is dry, the water in the film can be released so as to automatically regulate the indoor humidity; and due to the porous structure, the film also has the functions of absorbing sound, insulating heat and deodorizing.

Owner:贺佑康

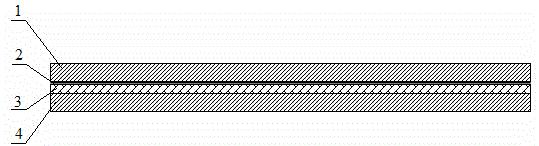

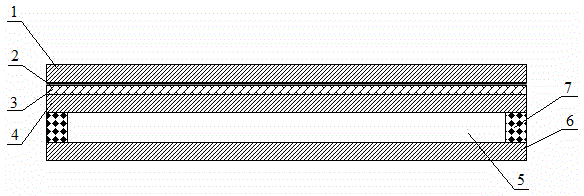

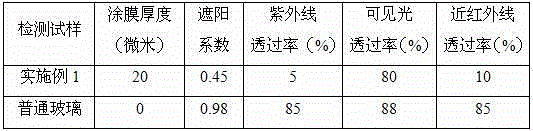

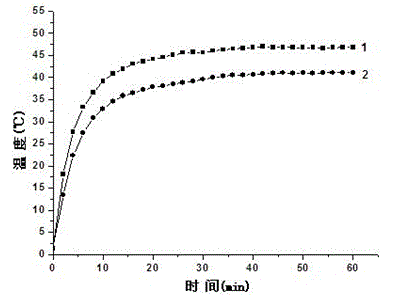

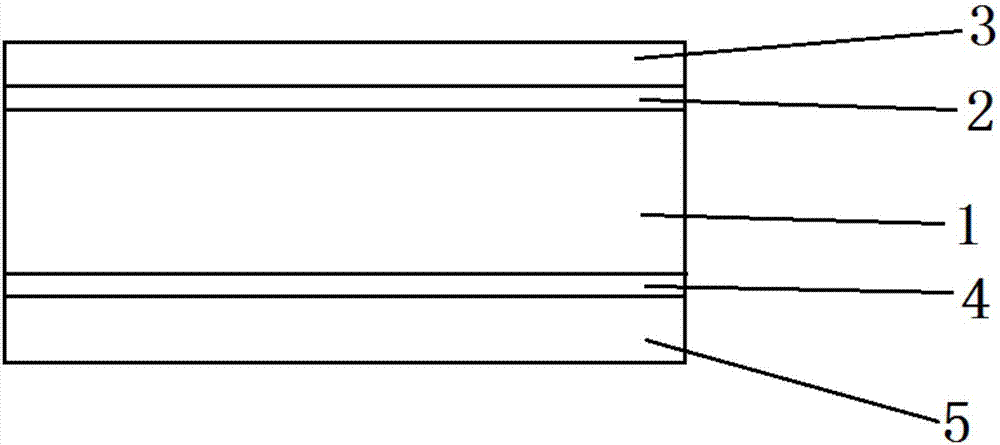

Thermal-insulating heat-preserving laminated safety glass and manufacturing method thereof

ActiveCN104960277ALow costReduce transmittanceLaminationLamination apparatusPolymer adhesiveThermal insulation

The invention provides a thermal-insulating heat-preserving laminated safety glass and a manufacturing method thereof. The structure of the thermal-insulating heat-preserving laminated safety glass comprises, from top to bottom, a first glass layer, a transparent thermal-insulating coating the inner surface of the first glass layer, a polymer film and a second glass layer; or the thermal-insulating heat-preserving laminated safety glass is further provided with a gas spacing layer and a third glass layer. The manufacturing method comprises the following steps: (1) preparing the transparent thermal-insulating coating; and (2) preparing the thermal-insulating heat-preserving laminated safety glass; or preparing a thermal-insulating heat-preserving laminated safe hollow glass from the thermal-insulating heat-preserving laminated safety glass. The thermal-insulating heat-preserving laminated safety glass or thermal-insulating heat-preserving laminated safe hollow glass has good impact resistance, low shading coefficient, low thermal coefficient, low ultraviolet transmittance, high visible transmittance and low near-infrared transmittance and is capable of preventing radiant heat of the sun entering a room in summer so as to realize thermal insulation and capable of reducing indoor heat loss in winter so as to realize heat preservation.

Owner:湖南省华京粉体材料有限公司

Heat reflection-obstruction composite energy-saving coating material and preparation method thereof

ActiveCN102911579AWith heat insulation functionStain resistantReflecting/signal paintsWeather resistanceThermal insulation

The invention provides a composite energy-saving coating material, which is made of multiple microporous silicate mineral raw materials after surface hydrophobic treatment and reflective fillers. The composite energy-saving coating material enhances the weather resistance and water resistance of a coating, avoids the excessive change of a coefficient of heat conductivity, combines two favorable performances of reflection and heat insulation, integrates two roles of the reflection and obstruction at a suit, has high sunlight reflectivity and good heat insulating effect, avoids repeated multilayer painting operation of an insulation surface and the like, can be formed at a time through painting, and has the advantages of stable performance, uniform coating, low cost, environmental-friendliness and the like. A preparation method is simple in technology and low in cost, saves energy and facilitates industrial popularization and application.

Owner:HEBEI UNIV OF TECH

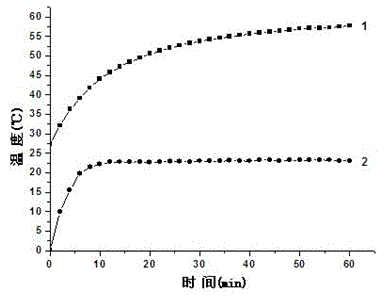

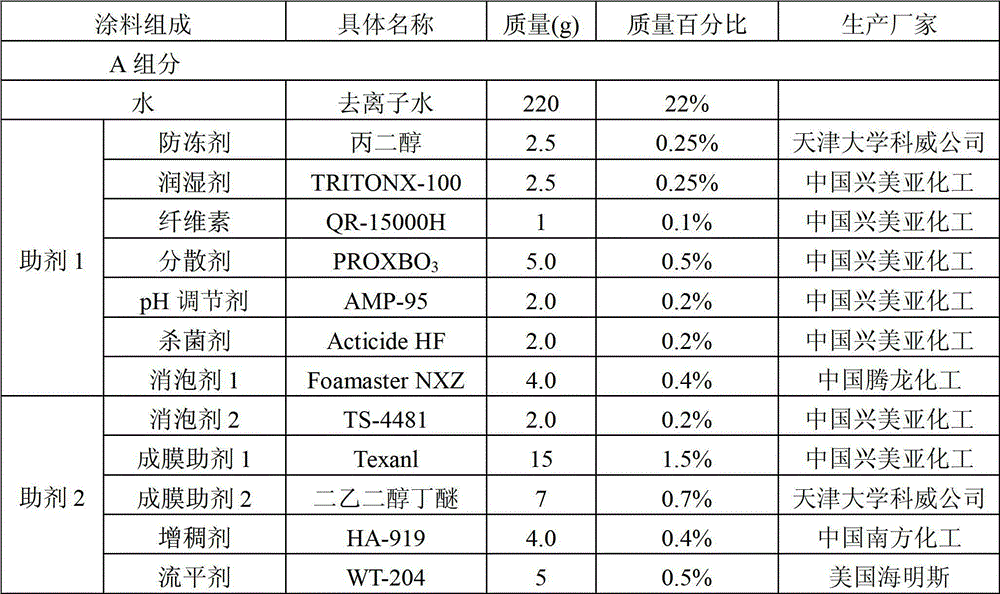

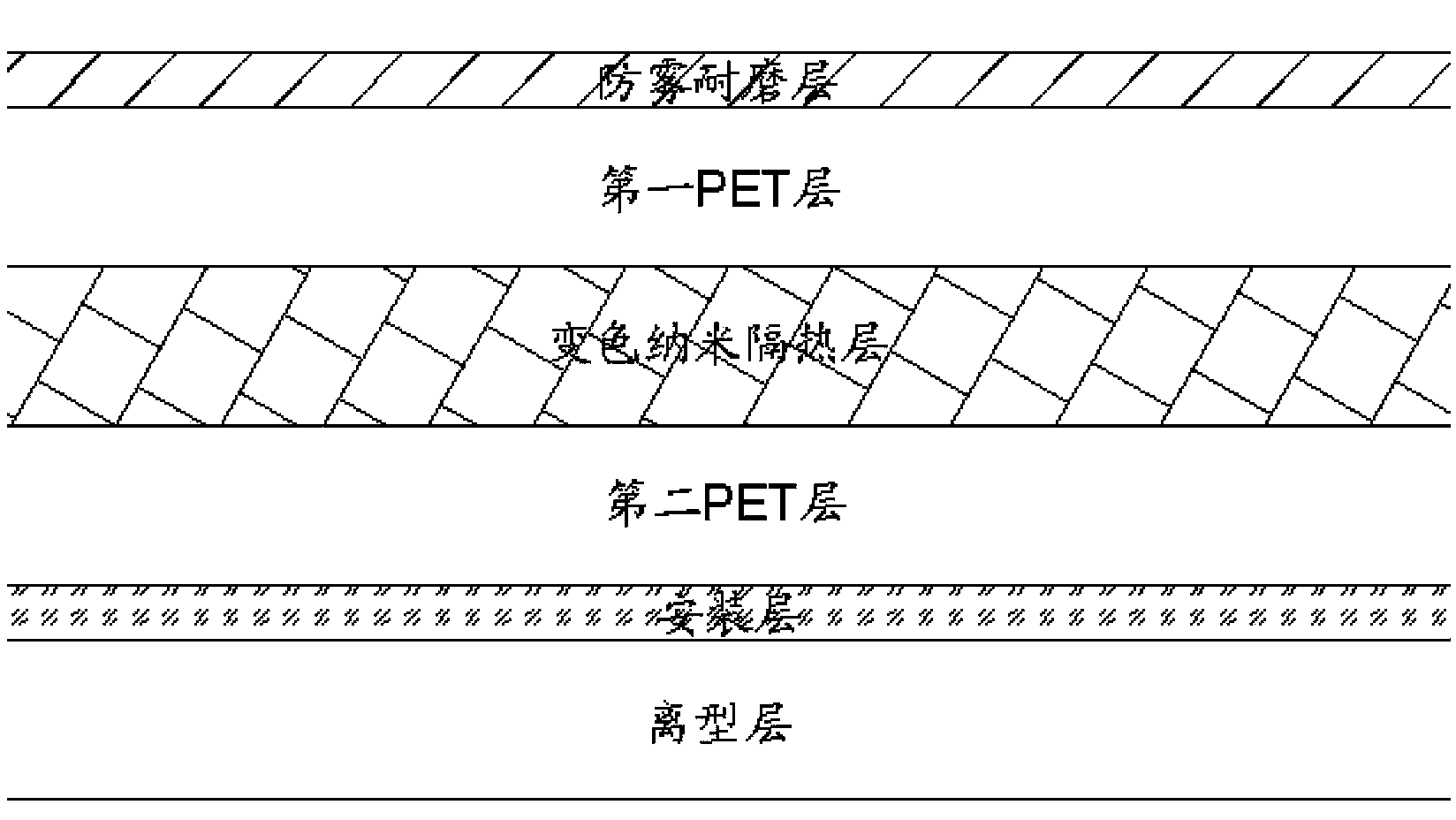

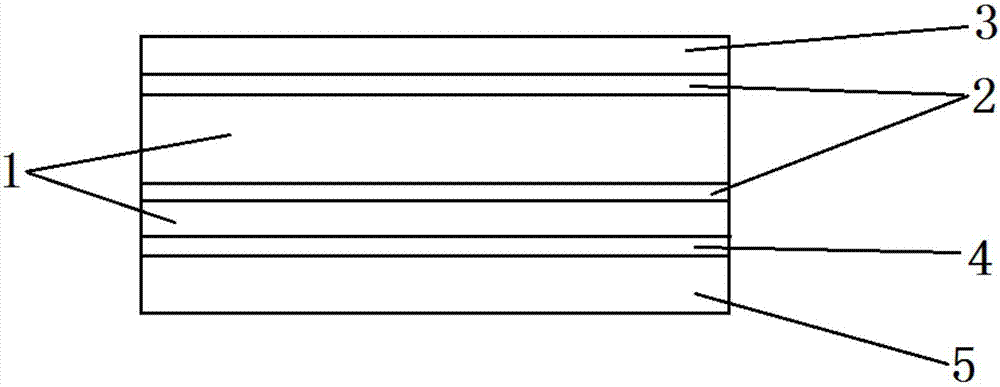

Multifunctional nanometer composite heat insulation film and making method thereof

ActiveCN104277727AImprove mechanical propertiesIncrease surface areaNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterInsulation layer

The invention discloses a multifunctional nanometer composite heat insulation film. The multifunctional nanometer composite heat insulation film is formed by sequentially arranging a fog and wear resistant layer, a first PET layer, a discoloration nanometer heat insulation layer, a second PET layer, an installation layer and a release layer, and the fog and wear resistant layer is formed through coating an ultraviolet-curable fog resistant coating and carrying out light curing; the first PET layer is coated with a discoloration nanometer heat insulation adhesive, the obtained layer is heated and dried, and the heated and dried layer is compounded with the second PET layer; the discoloration nanometer heat insulation layer is formed by the discoloration nanometer heat insulation adhesive; the installation layer is formed by an installation adhesive; and the release layer is a polyester film with the surface subject to a low energy process. The composite heat insulation film has fog resistance, heat insulation, discoloration and ultraviolet resistance functions, can automatically change its color with the external temperature change or light irradiation, has good optical performances, high visible light transparency, high ultraviolet and infrared blocking rate and good mechanical performances, is sturdy and wearable, can resist high and low temperature, and has good adhesion on glass substrates. The invention also discloses a making method of the multifunctional nanometer composite heat insulation film.

Owner:上海沪正新材料有限公司

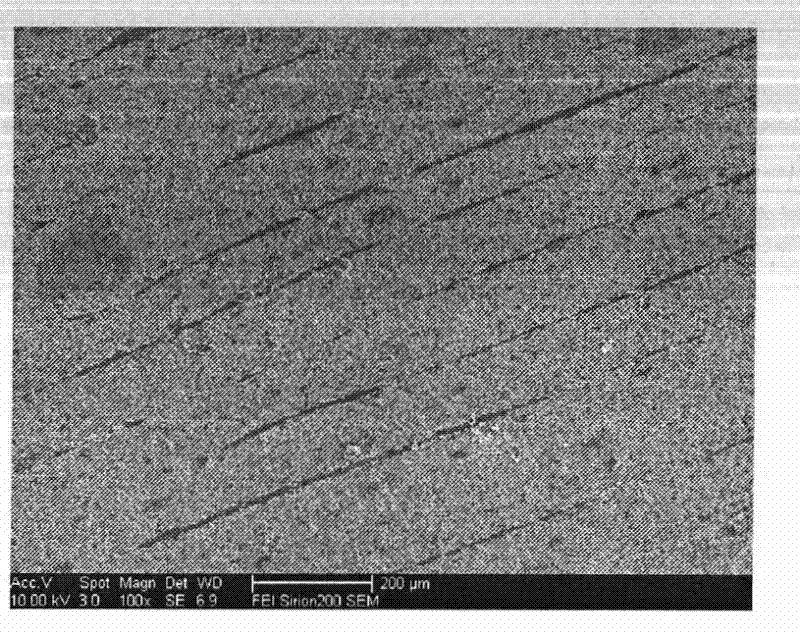

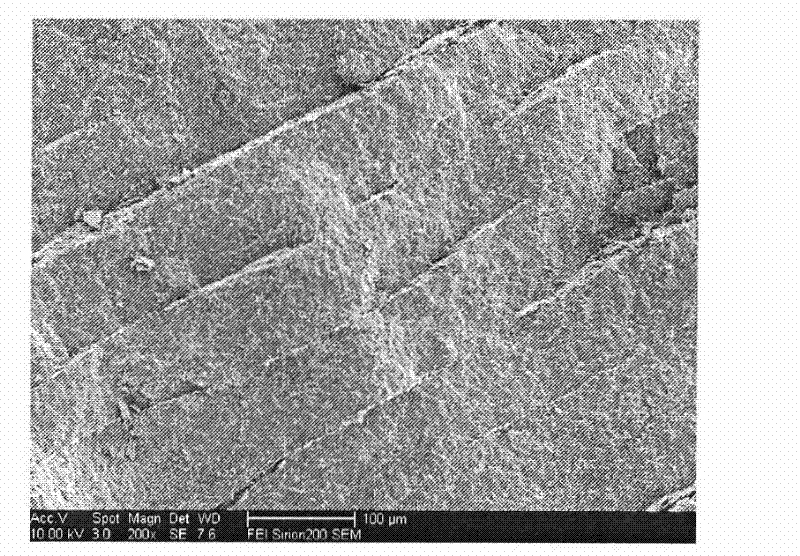

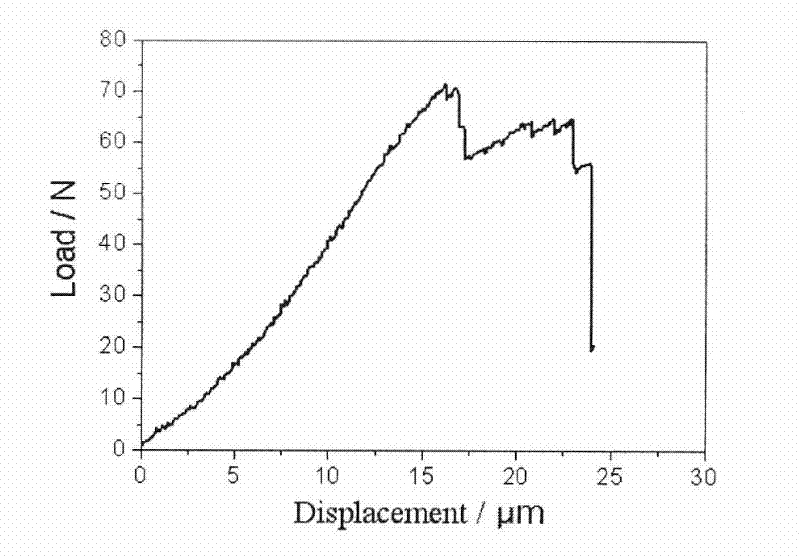

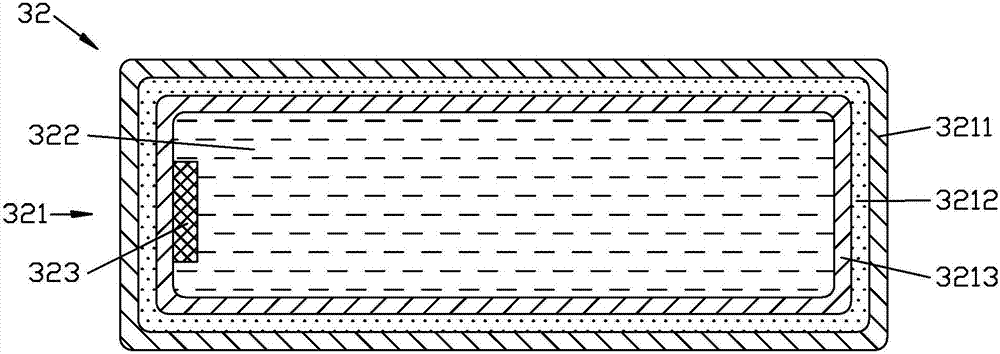

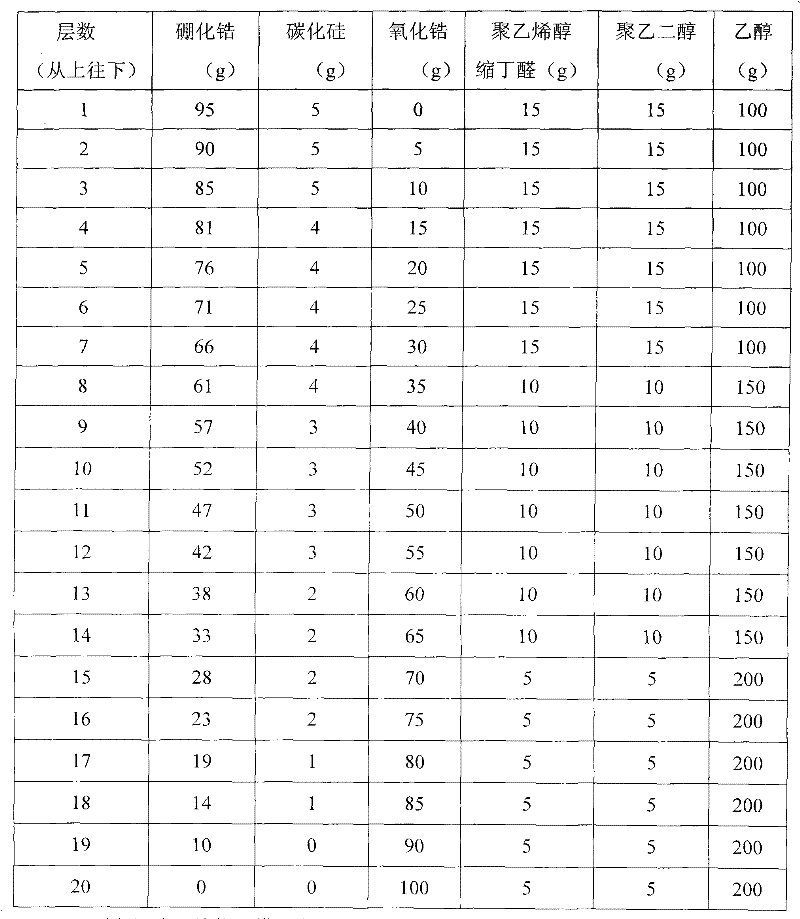

Preparation method of layered zirconium boride superhigh temperature ceramic with heat insulation function

The invention provides a preparation method of layered zirconium boride superhigh temperature ceramic with a heat insulation function. The preparation method is characterized by comprising the following steps: 1) preparing a casting sheet, namely, evenly mixing a binder, a plasticizer and a solvent, adding zirconium boride ceramic powder material to form a casting material, then carrying out casting forming, and drying at room temperature and demoulding to obtain a casting sheet with the thickness of 200-1000 mu m; 2) coating zirconium oxide slurry on the surface of the casting sheet by usinga coating method, and controlling the thickness of the coating through coating times; 3) slicing the casting sheet according to the size of a mould; 4) putting the sliced casting sheets in the mould in an overlapping way for vacuum derosination; and 5) carrying out hot pressed sintering in an argon atmosphere so as to obtain the layered zirconium boride superhigh temperature ceramic with heat insulation function, wherein the fracture toughness of the ceramic is up to 9.1MPa.m<1 / 2>, and the heat conduction of the ceramic vertical to a layer direction is 8w / m.k at room temperature. The fracturemode of the layered zirconium boride ceramic is non-brittle fracture which refers to a gradual fracture having a certain tolerance capability to flaw damage. The layered zirconium boride superhigh temperature ceramic has the advantages of heat insulation function and excellent property.

Owner:SHANDONG UNIV OF TECH

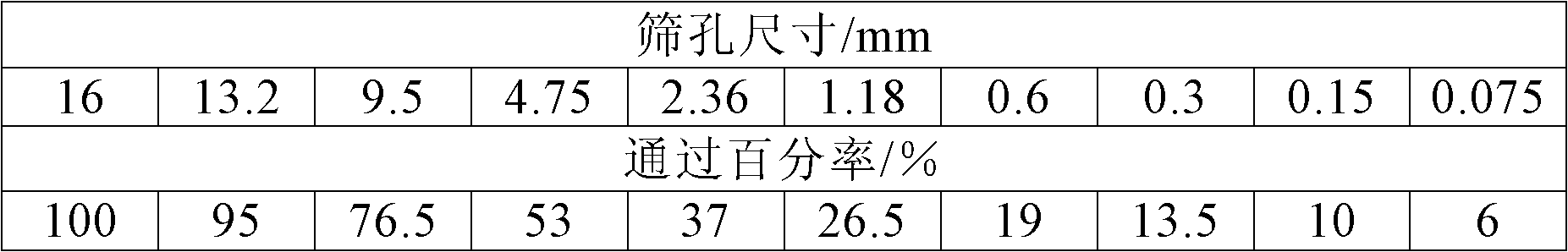

Heat-insulating bituminous mixture for roads and production method thereof

The invention discloses a heat-insulating bituminous mixture for roads, which comprises the following materials in percentage by volume: 26 and 49 percent of limestone aggregate, 31 to 37 percent of porous basalt aggregate, 11 to 23 percent of coal ash floating bead, 1 to 4 percent of limestone mineral powder and 8 to 10 percent of SBS modified oil asphalt. The production method comprises the steps of: drying the limestone aggregate, the porous basalt aggregate, the coal ash floating bead with 0.15 and 0.075 millimeter, the limestone mineral powder, and the coal ash floating bead of less than 0.075 millimeter at 185 DEG C for 24 hours; mixing the limestone mineral powder and the coal ash floating bead of less than 0.075 millimeter in a proportion, and mixing the mixture and the SBS modified oil asphalt at 170 DEG C for uniform stirring; and adding the limestone aggregate, the porous basalt aggregate and the coal ash floating bead with 0.15 and 0.075 millimeter into the mixture for uniform stirring. The heat-insulating bituminous mixture has the heat-insulating function, and can prevent heat from transferring in structures of bituminous pavements and improve the service life of the pavements.

Owner:CHANGAN UNIV

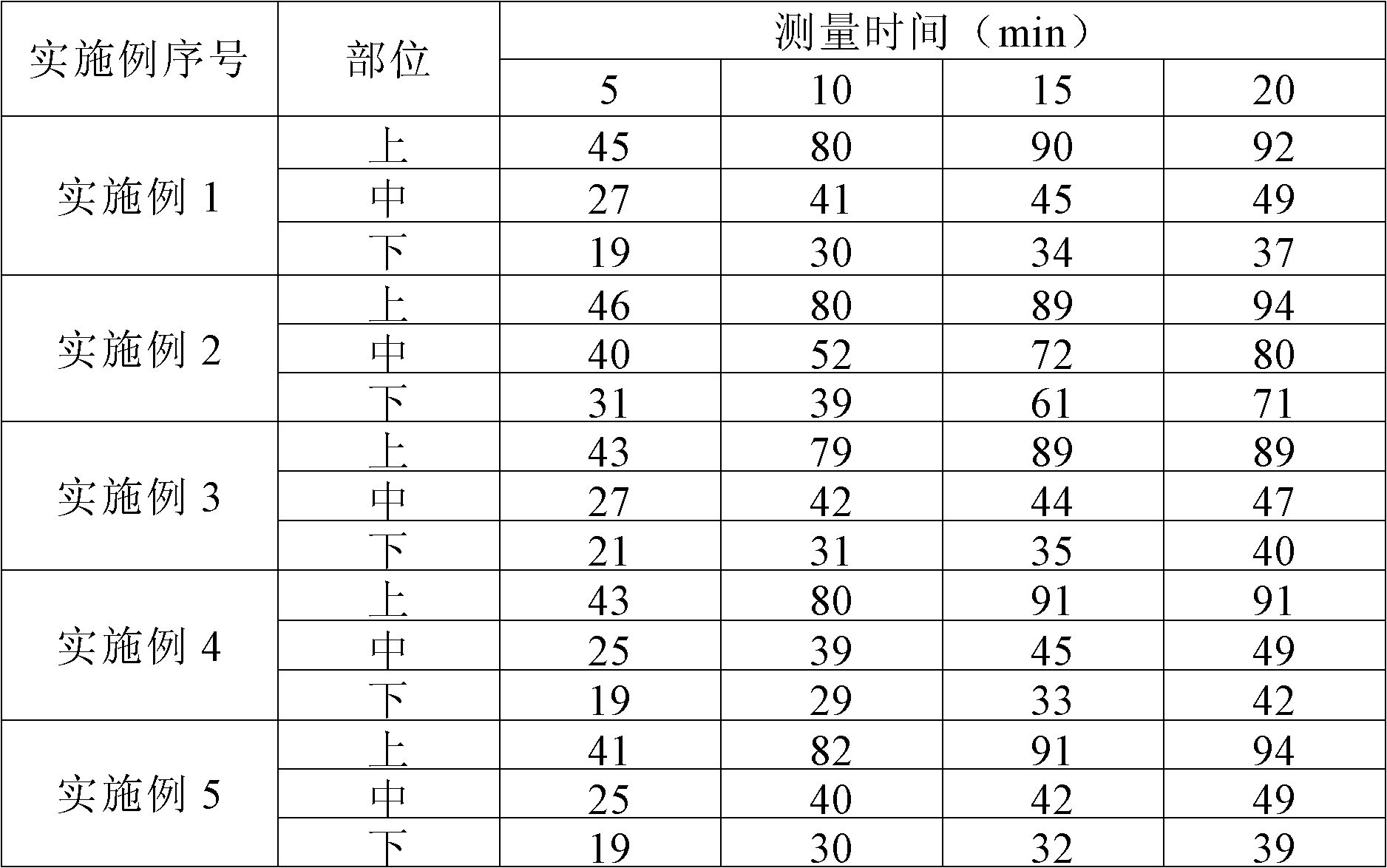

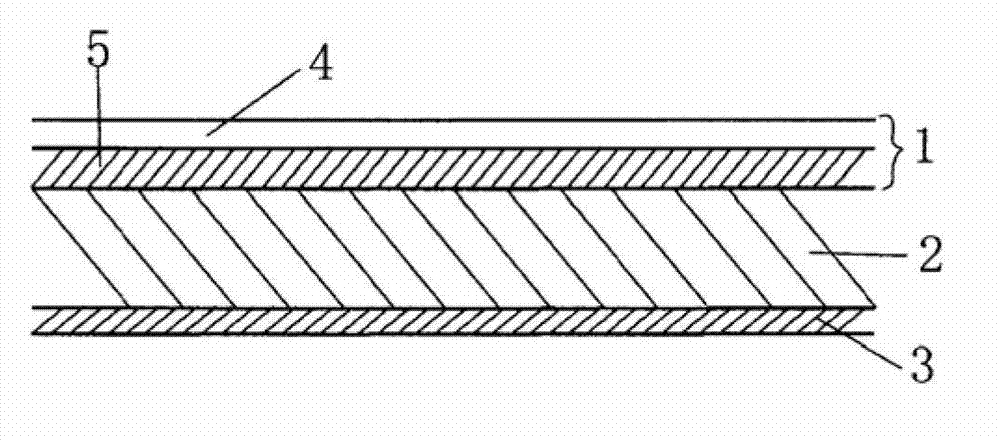

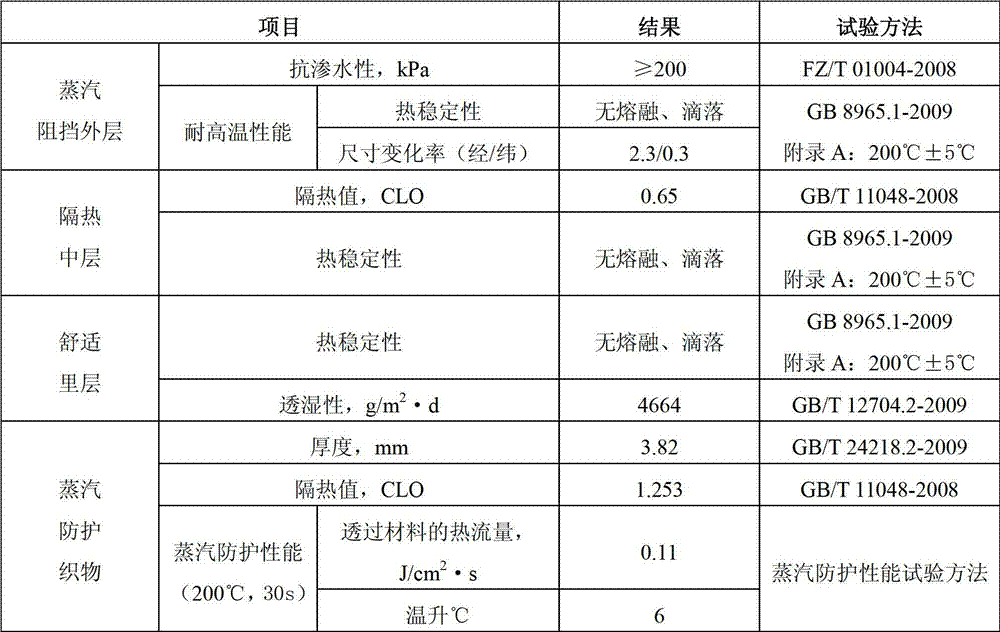

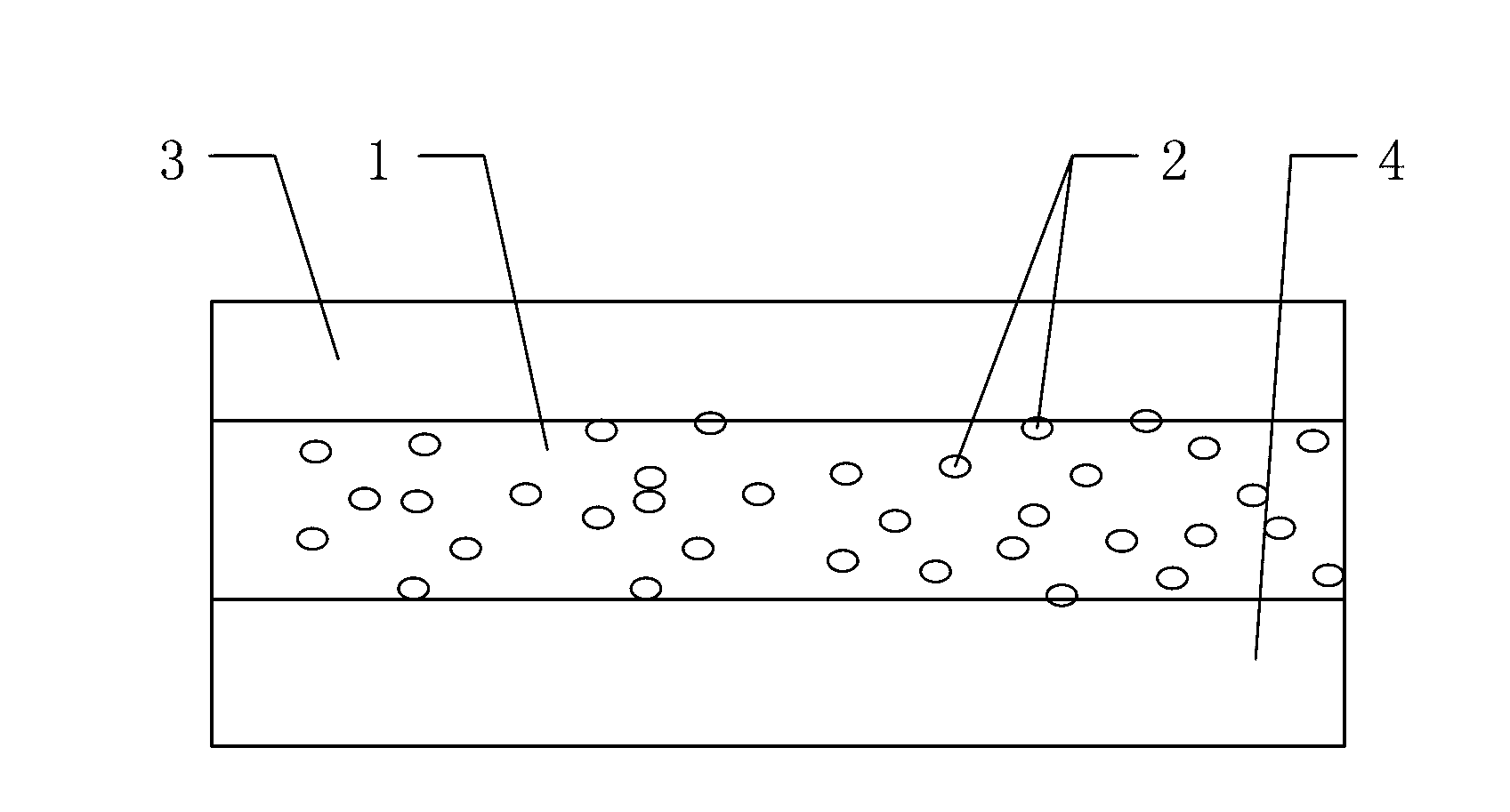

Steam protective fabric and application thereof

The invention relates to the field of protective fabrics, in particular to a steam protective fabric and an application thereof. The steam protective fabric comprises a steam blocking outer layer, a heat insulation middle layer and a comfortable inner layer, wherein the steam blocking outer layer comprises a high temperature resistant fiber fabric layer and a high temperature resistant waterproof film layer, the high temperature resistant fiber fabric layer is positioned between the high temperature resistant waterproof film layer and the heat insulation middle layer, the high temperature resistant fiber fabric layer is a high temperature resistant fiber pure yarn fabric or a high temperature resistant fiber blending fabric, the heat insulation middle layer is a needle-punched non-woven fabric made of high temperature resistant fiber, and the comfortable inner layer is a high temperature resistant fiber and flame-retardant viscose fiber blending fabric. The steam protective fabric provided by the invention has the advantages that the number of fabric layers is little, the weight is light, the processing is simple, the functions of steam penetration prevention, high temperature resistance and heat insulation are realized, and the wearing comfort is also realized.

Owner:NAVY MEDICINE RES INST OF PLA

Flame-retardant heat preservation type shading curtain fabric

InactiveCN103317797AInsulation hasWith flame retardant functionSynthetic resin layered productsCurtainsEngineeringWeft yarn

The invention provides a flame-retardant heat preservation type shading curtain fabric. The fabric comprises a fabric body, wherein the fabric body is prepared from outer warps, inner warps and weft yarns according to a double-tissue structure; the outer warps, the inner warps and the weft yarns are flame-retardant polyester filament yarns; and a heat-storage heat-preservation microcapsule is arranged on the fabric body. The flame-retardant heat preservation type shading curtain fabric has functions of flame retardance, heat preservation, heat storage and heat insulation.

Owner:ZHEJIANG XINTAO TEXTILE TECH

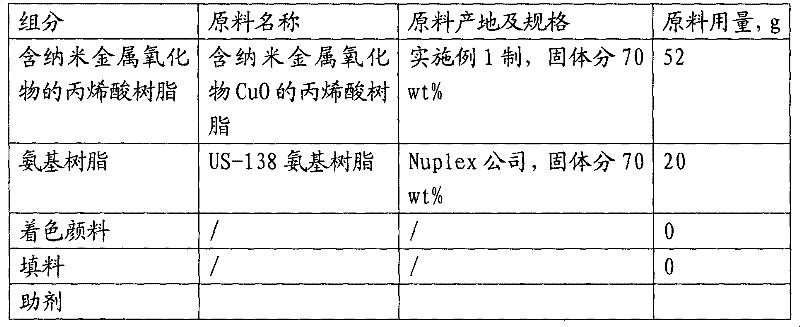

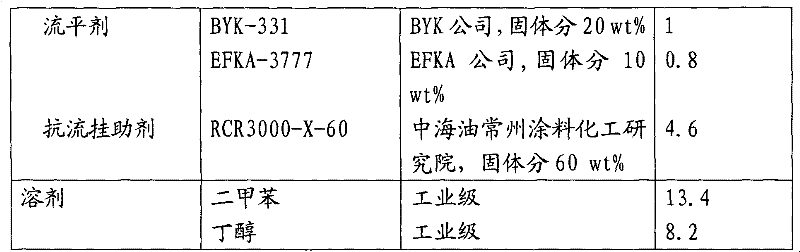

Nano metal oxide-containing solvent-based vehicle thermal insulation coating

ActiveCN102504664AOvercome the shortcoming of easy aggregationMeet performance requirementsAnti-corrosive paintsThermal insulationAcrylic resin

The invention relates to a nano metal oxide-containing solvent-based vehicle thermal insulation coating, which consists of the following components based on solids in percentage by weight: 17 to 48 percent of nano metal oxide-containing acrylic resin, 7 to 21 percent of amino resin, 0 to 20 percent of coloring pigment, 0 to 4 percent of filler, 1 to 6 percent of aid and the balance of solvent, wherein the nano metal oxide-containing acrylic resin is prepared by dripping a mixed liquor containing vinyl monomers and an initiator into a nano metal oxide sol prepared from nano metal oxide, a silane coupling agent and a solvent for radical polymerization. The nano metal oxide-containing solvent-based vehicle thermal insulation coating has a good thermal insulation effect, the mechanical properties and various medium resistance of a film formed by the coating still can reach the levels of common acrylic resin vehicle coatings, and the aims of thermal insulation, decoration and corrosion resistance are fulfilled.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

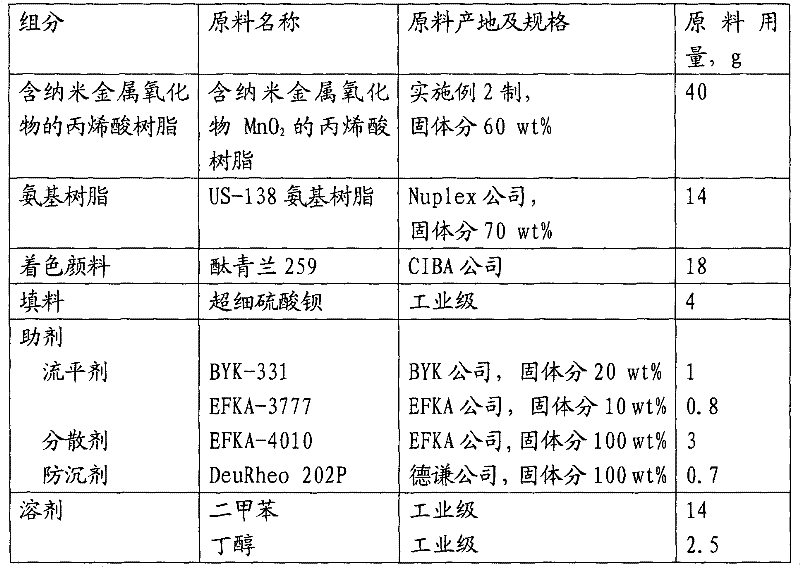

Heat-proof silica gel material containing inorganic ceramic hollow particle sphere

The invention discloses a heatproof silica gel material with inorganic hollow microparticle, which is characterized by the following: adopting inorganic hollow microparticle at 80-100um as raw material; adding nanometer ceramic powder to form heatproof silica gel material to 450 deg.c; transmitting heat into energy with frequency wavelength about 2-80um.

Owner:黄福得 +1

Sunshine room roof leakage-proof method and sunshine room roof structure

ActiveCN103741890ASolve the leakOvercome the defect of water leakageRoof covering using slabs/sheetsEngineeringTextile

Owner:佛山市淇特科技有限公司

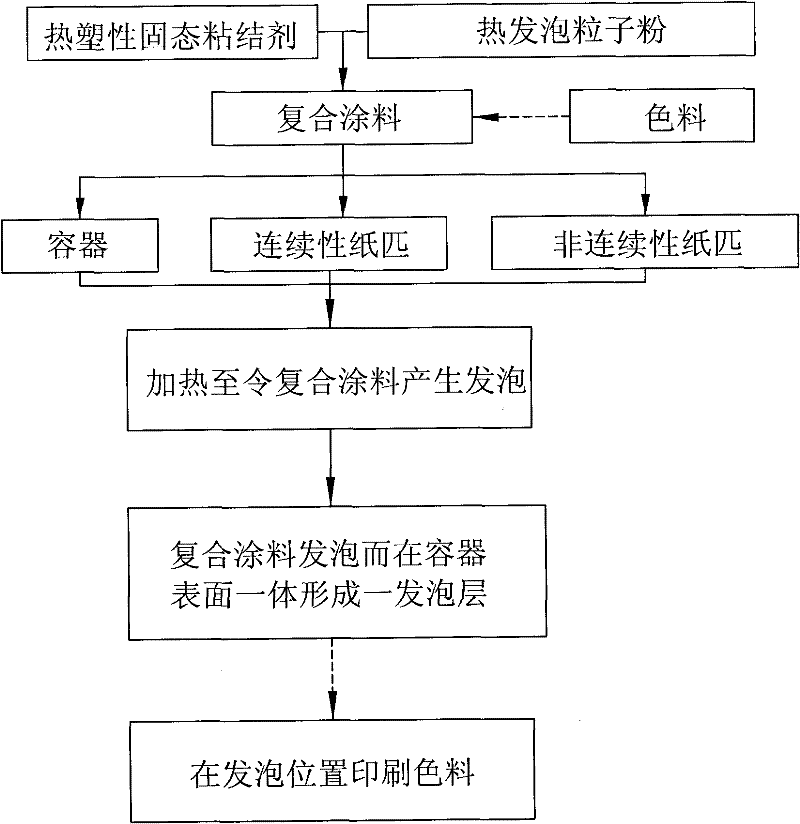

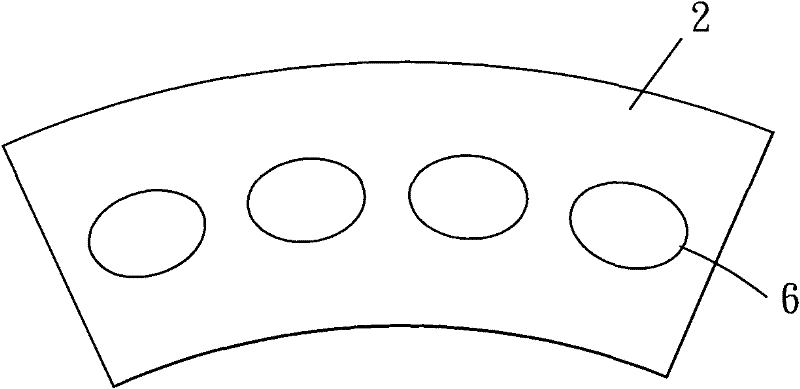

Method for forming foaming layer on surface of container or container semi-finished product

InactiveCN102218793AWith heat insulation functionWith waterproof functionHollow articlesBoiling pointWork in process

The invention relates to a method for forming a foaming layer on the surface of a container or container semi-finished product. The method comprises the following steps of: heating and stirring or kneading a thermoplastic solid binder and a plurality of solid foaming particles until the thermoplastic solid binder becomes gelatinous, and uniformly dispersing the solid foaming particles into the gelatinous binder to form a composite coating, wherein each foaming particle is formed by coating a low boiling point solvent in a thermoplastic polymer, and the heating temperature is lower than the boiling point of the low boiling point solvent; coating the composite coating on at least one part of the surface of the container by using coating equipment; and heating the container coated with the composite coating to ensure that the low boiling point solvent coated in the thermoplastic polymer is vaporized to prop up the thermoplastic polymer, so that a forming effect is generated on the surface of the container, and the foaming layer is formed and is integrated with the surface of the container.

Owner:RICH CUP BIO CHEM TECH

Interior wall reflection and heat insulation coating and preparation method thereof

InactiveCN105062344AImprove thermal insulationAddresses poor stability issuesPolyurea/polyurethane coatingsReflecting/signal paintsEmulsionDefoaming Agents

The invention discloses an interior wall reflection and heat insulation coating and a preparation method thereof. The coating comprises, by weight, 20-35 parts of a modified polyurethane emulsion, 0.1-0.2 part of a PH adjusting agent, 0.4-0.8 part of a dispersing agent, 0.3-0.6 part of a defoaming agent, 0.1-0.3 part of a wetting agent, 1-2 parts of an antifreezing agent, 1-3 parts of a coalescing agent, 0.5-2 parts of a thickening agent, 0.05-0.15 part of a corrosion remover, 5-20 parts of titanium dioxide, 5-25 parts of coarse whiting and 5-15 parts of water. The interior wall reflection and heat insulation coating can be cooperated with an exterior wall reflection and heat insulation coating and an exterior wall heat insulation and preservation board, a building is helped to have the better heat insulation and insulation effect, and the building saves more energy and is more environmentally friendly. Meanwhile, the problem that the stability is poor due to the fact that hollow heat insulation materials are added in other reflection and heat insulation coatings is well solved.

Owner:LANZHOU KETIAN ENVIRONMENTAL PROTECTION ENERGY SAVING TECH CO LTD

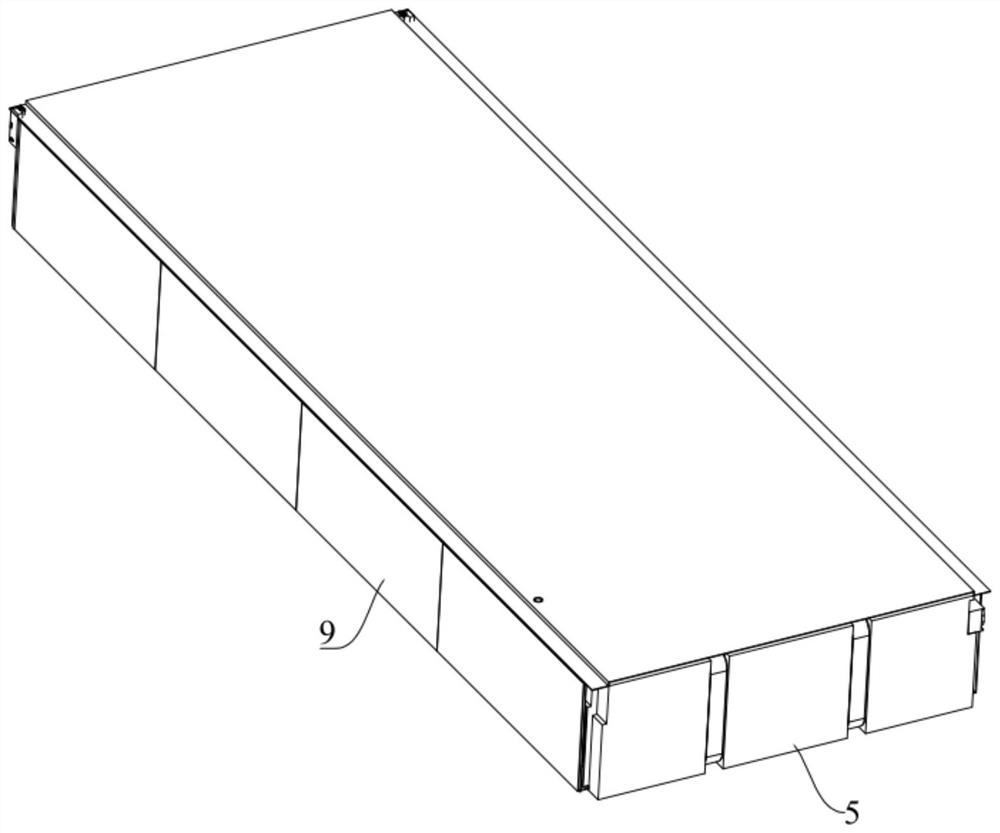

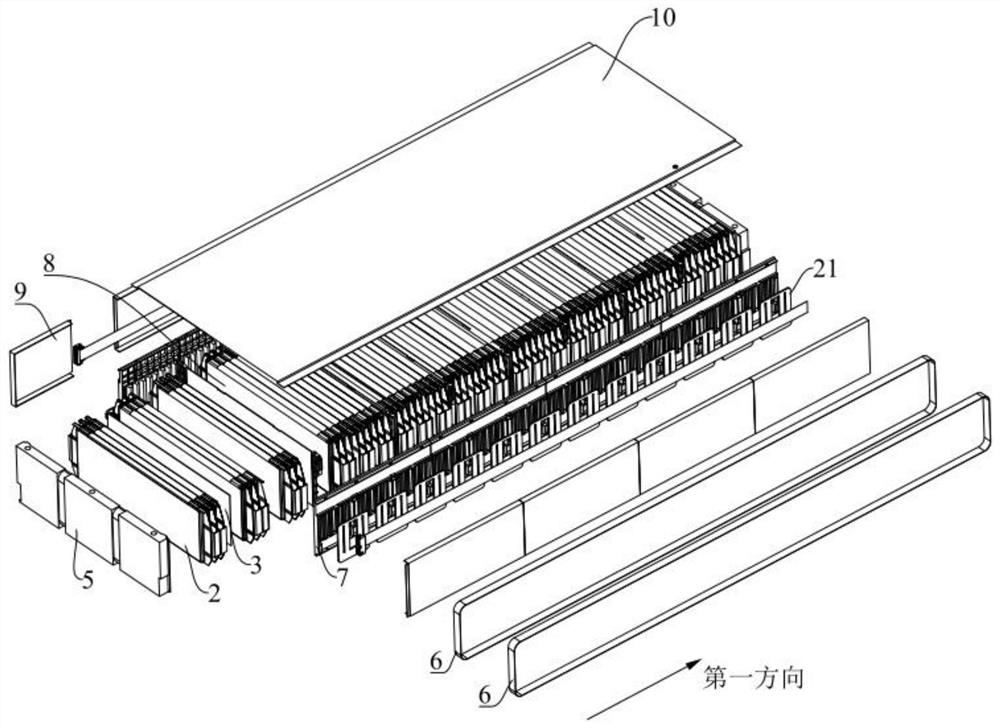

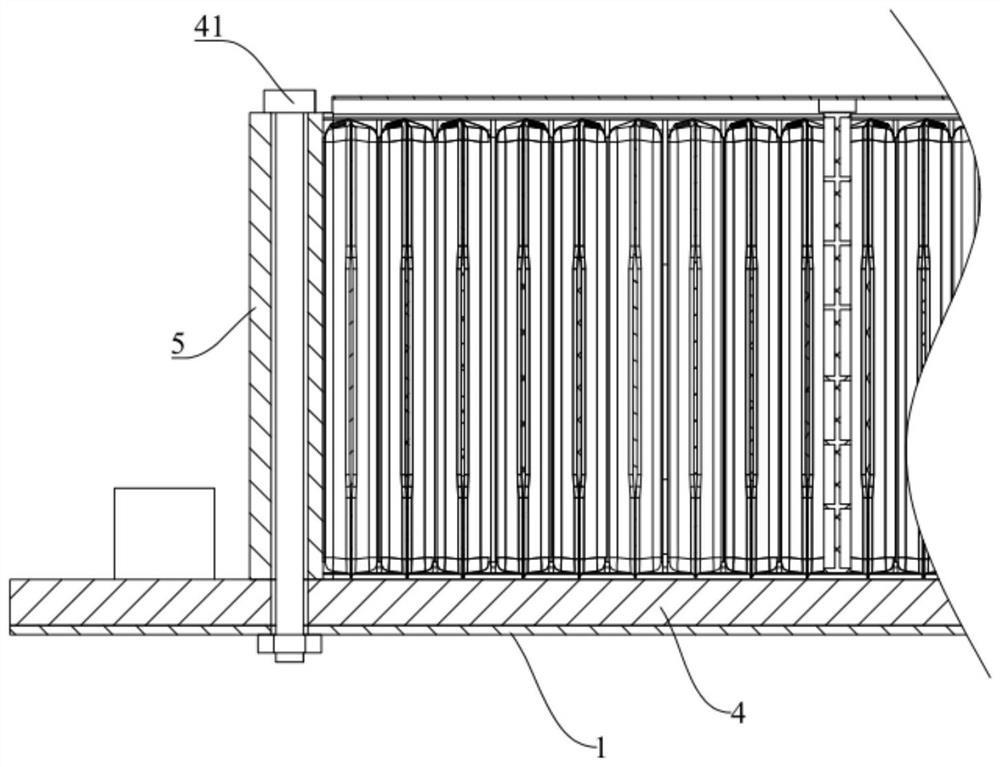

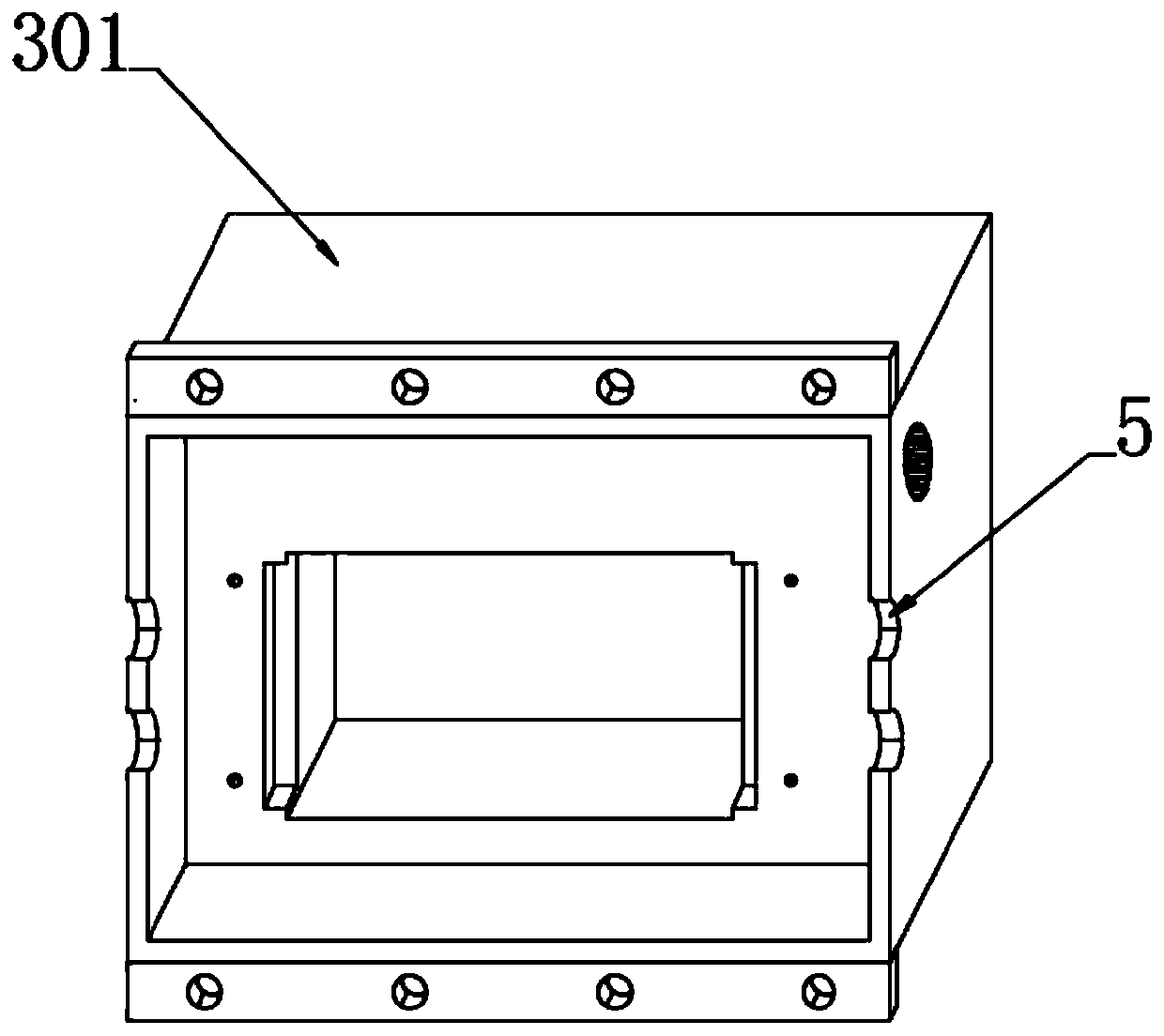

Solid-state battery module, battery pack and design method of battery pack

InactiveCN113113708AFew partsLow costSecondary cellsCell component detailsEngineeringMechanical engineering

The invention discloses a solid-state battery module, a battery pack and a design method of the battery pack, and belongs to the technical field of batteries. The solid-state battery module comprises a plurality of battery cells, wherein the plurality of battery cells are sequentially arranged along a first direction to form a battery cell row, an elastic medium is arranged between every two adjacent battery cells, and the two opposite side surfaces of the elastic medium are respectively bonded with the adjacent battery cells; a liquid cooling plate to which the bottoms of the plurality of battery cells are adhered; end plates, wherein the two opposite ends of the battery cell row are respectively provided with the end plates; and a strapping tape which is wound on the peripheries of the battery cell row and the end plates along the first direction, wherein a connecting piece can sequentially penetrate through the end plates and the liquid cooling plate and is fixed on a lower box body of the battery pack. According to the present invention, the parts of the solid-state battery module are reduced, the cost is reduced, and the mounting steps are simple.

Owner:CHINA FIRST AUTOMOBILE

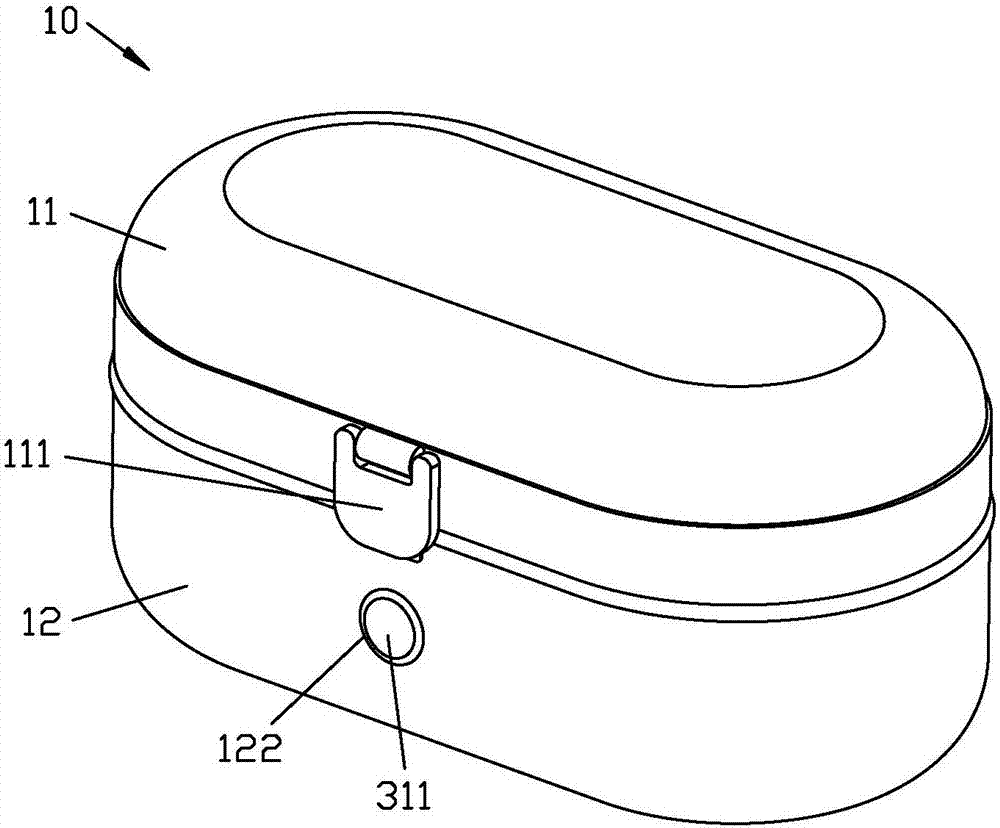

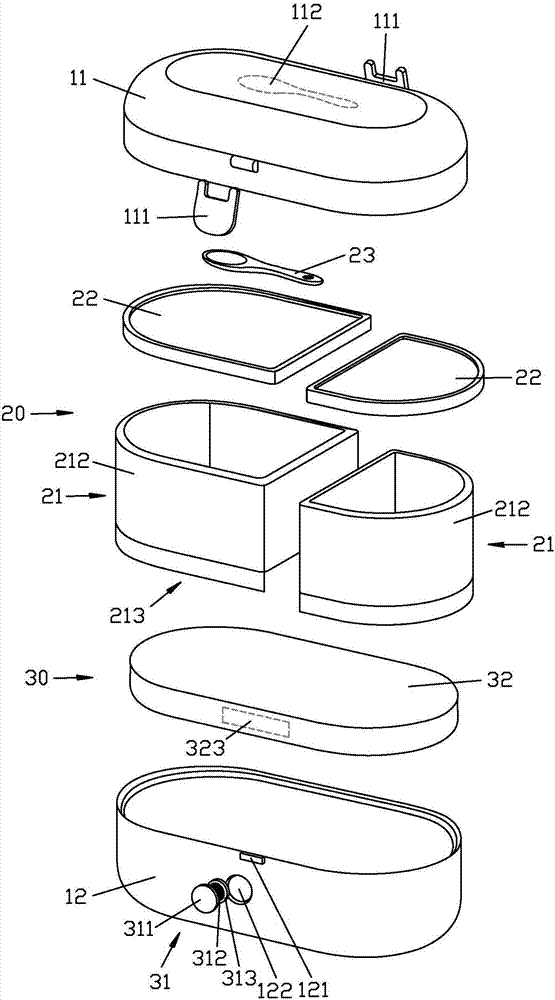

Power-supply-free re-heatable lunch box

ActiveCN107048655AReduce cooling rateThere will be no difficult heat penetrationOther accessoriesWarming devicesPolyesterSodium acetate

The invention discloses a power-supply-free re-heatable lunch box, comprising a shell, a lunch box component and a heating component; the lunch box comprises a box body and a box cover; the bottom of the box body is of single-layer aluminum structure, the sidewall of the box body is of double-layer aluminum hollow structure, the sidewall is at least partially extended down out of the bottom wall to form extension portions which cooperate to form a circular raised edge; the heating component comprises a startup module and a heating module; the heating module is mounted within the circular raised edge and is in contact with the bottom wall of the box body; the heating module comprises a sealed bag that is formed by combining a polyester film layer, an aluminum foil layer and a tinfoil layer, and oversaturated sodium acetate solution and a memory alloy sheet are arranged in the sealed bag; by extruding the memory alloy sheet through the startup module and deforming the memory alloy sheet, the oversaturated sodium acetate solution in the sealed bag is caused to release heat through phase change, and a meal in the box body is heated. The power-supply-free re-heatable lunch box has the advantages of good portability, high heating efficiency and reusability.

Owner:林昌坤

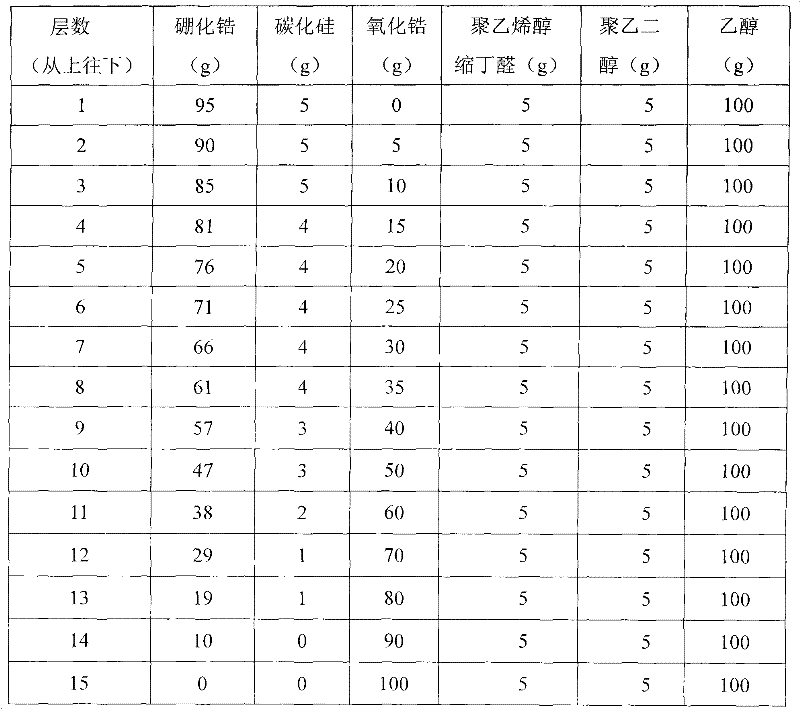

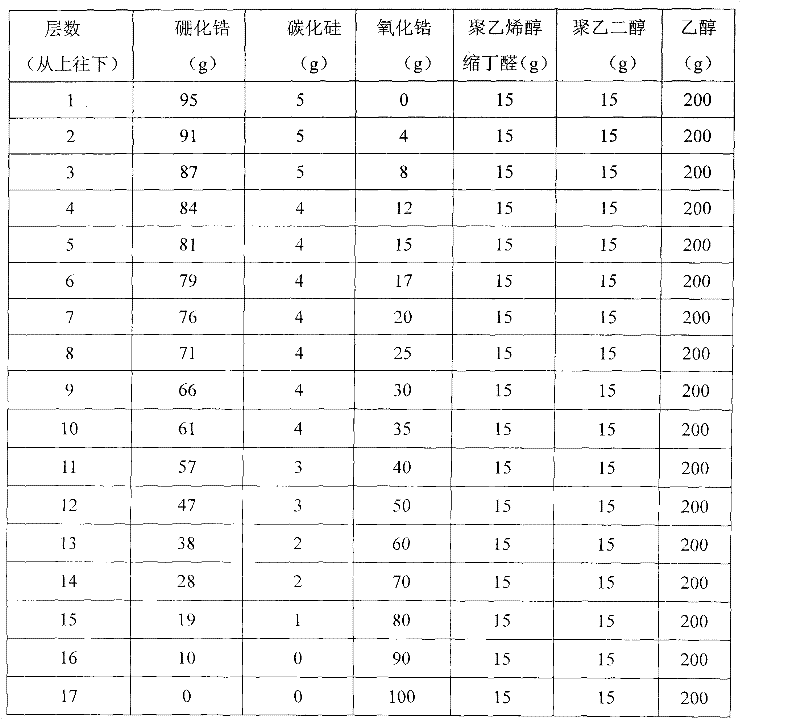

Preparation method of gradient zirconium boride ultrahigh-temperature ceramic

InactiveCN102173809ALittle change in compositionSmall residual thermal stressZirconium hydrideBoride

The invention provides a preparation method of gradient zirconium boride ultrahigh-temperature ceramic. The preparation method is characterized by comprising the following steps of: 1) preparing casting sheets with different components respectively by a casting method, namely adding a binder and a plasticizer into a solvent to stir uniformly, adding zirconium boride ceramic powder respectively tostir uniformly to form casting materials, and performing casting forming; 2) slicing; 3) overlapping the slices sequentially according to the component size of the zirconium boride, placing the slices into a graphite grinding apparatus, and then performing vacuum degreasing, wherein the layer number is more than 15; the mass percentage of the zirconium boride in the zirconium boride ceramic powder of each layer of casting slice is reduced sequentially; the mass percentage of silicon carbide is not changed or is reduced; the mass percentage of zirconium oxide is increased sequentially; and themass percentage sum of three components in the zirconium boride ceramic powder of each casting slice is 100 percent; and 4) performing hot pressed sintering to prepare the gradient zirconium boride ultrahigh-temperature ceramic with a heat insulation function. The preparation process is simple and the cost is low. By the preparation method, an ultrathin ceramic part can be prepared and has fracture toughness of up to 8 MPa.m1 / 2.

Owner:SHANDONG UNIV OF TECH

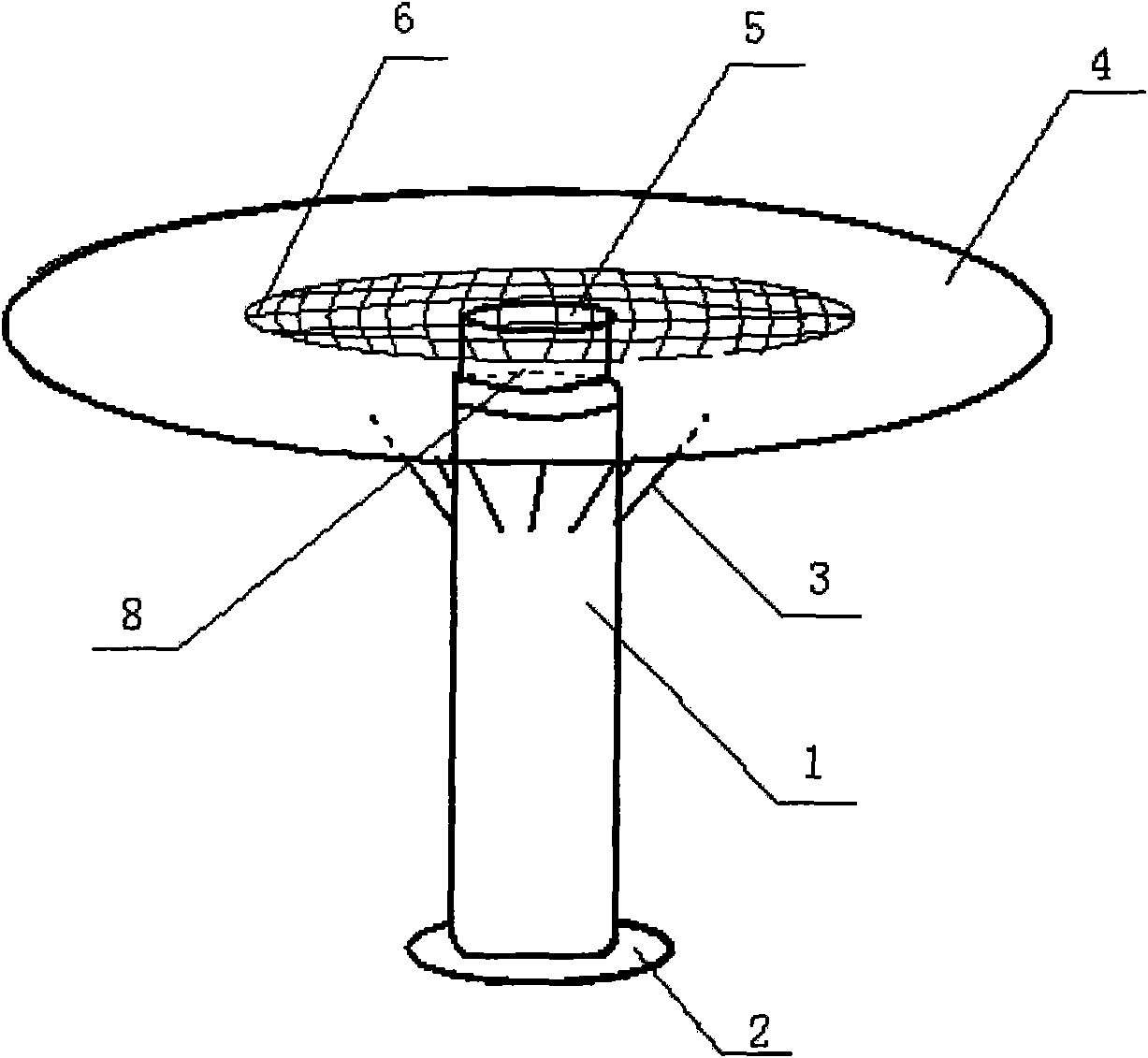

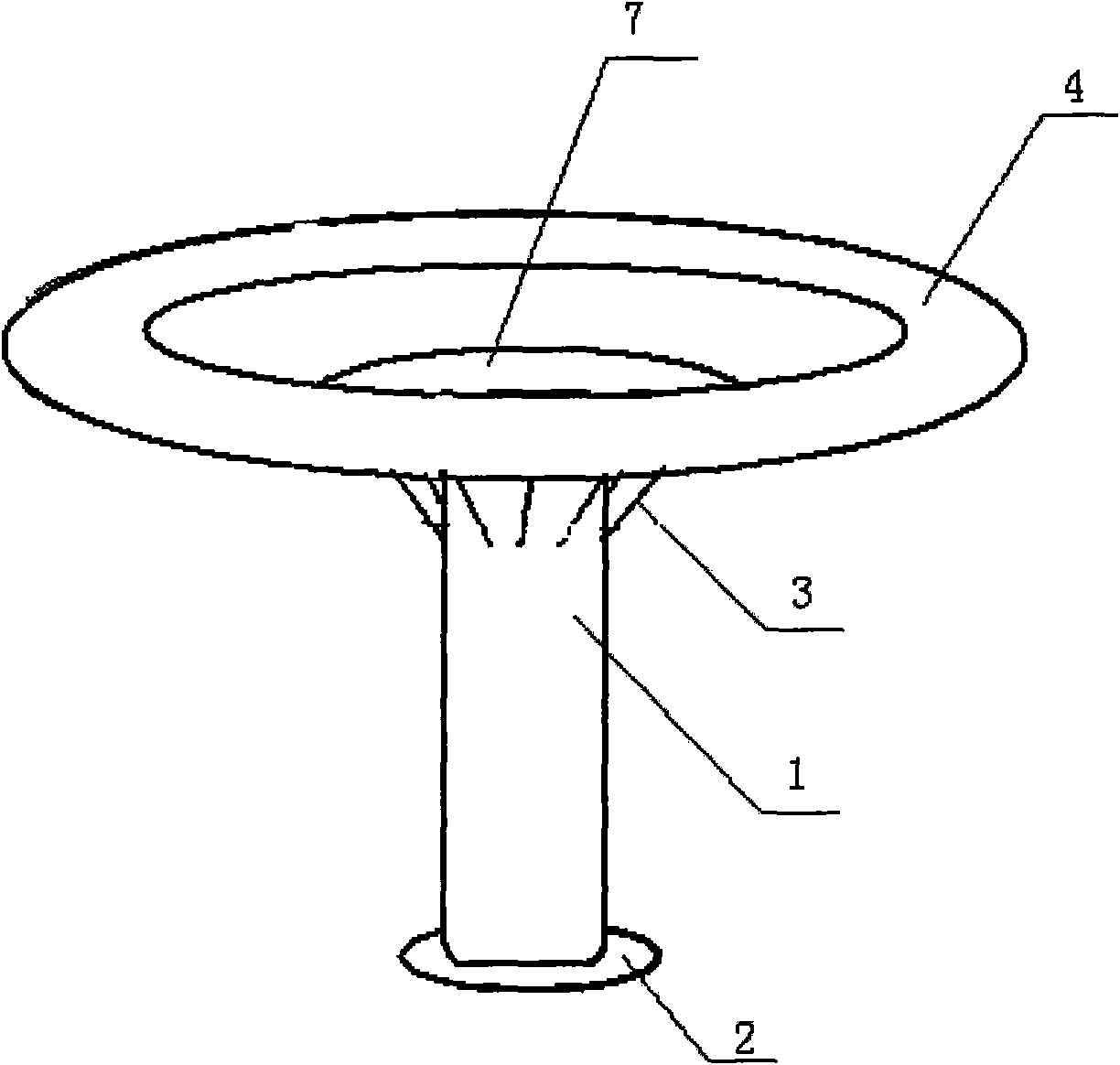

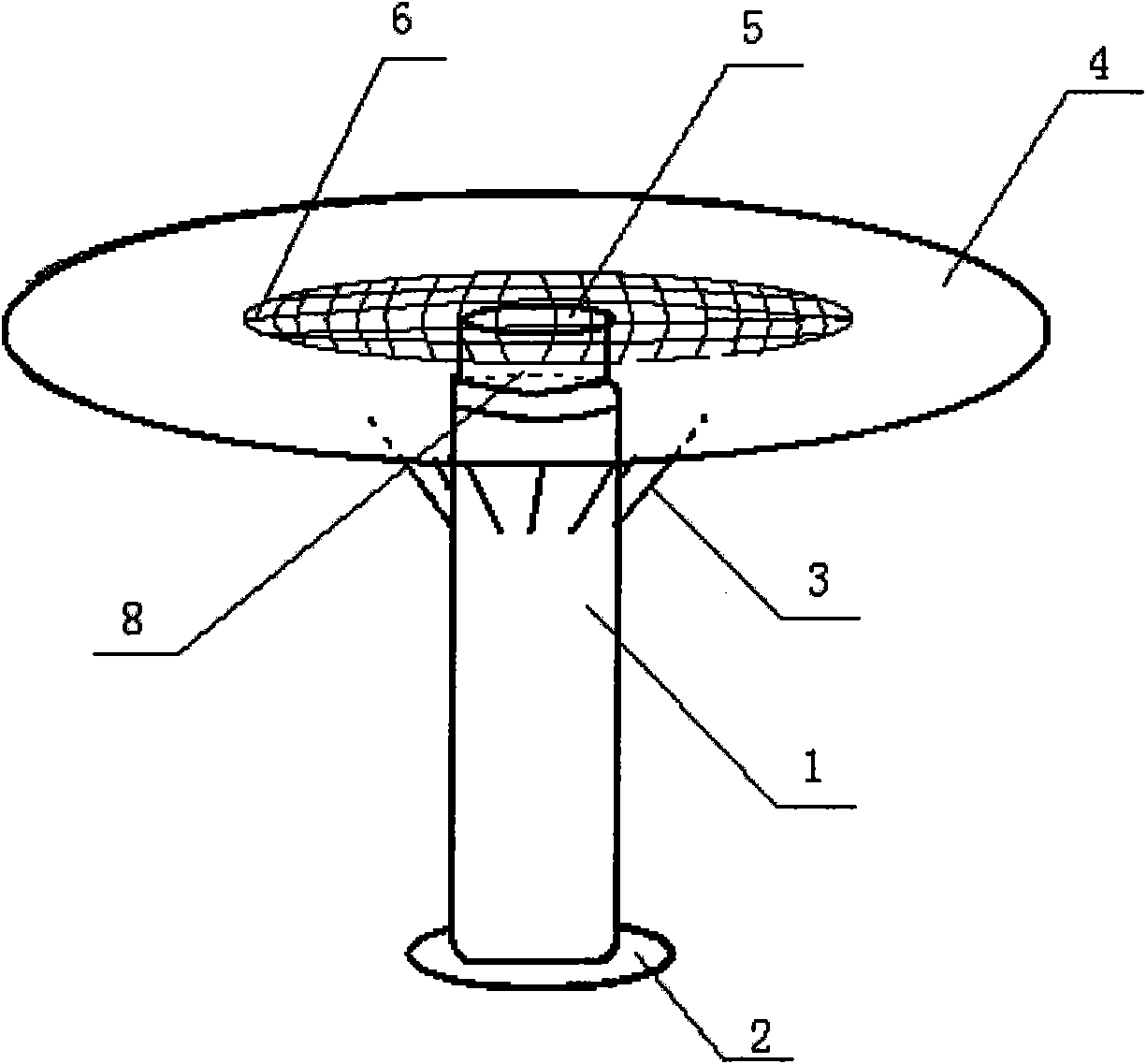

Telescopic rotary dining table

InactiveCN102462155AExtended service lifeSave materialVariable height tablesRevolvable tablesInsulation layerGeneral family

The invention discloses a telescopic rotary dining table, and belongs to the field of daily necessities. The dining table comprises a hollow circular table top, a circular rotary table top, a rotating disk, a telescopic rod, a table leg, a circular bottom board, a heat insulation layer and supporting rods; one end of each supporting rod is arranged on the hollow circular table top, and the other end of the each supporting rod is arranged on the lateral surface of the table leg; the heat insulation layer is arranged on the circular rotary table top; the circular rotary table top is arranged on the rotating disk; the rotating disk is arranged on the telescopic rod; the telescopic rod is embedded into the table leg; and the table leg is embedded into the circular bottom board. The dining table is material-saving, convenient, clean, attractive, simple in structure and reasonable in price, and has heat insulation function; the service life of the dining table is prolonged; and the dining table is suitable for common families and dining halls.

Owner:夏新珍

Diatomite plate and processing method thereof

The invention discloses a processing method for a diatomite plate. The processing method is characterized by including the steps of preparing materials, wherein natural diatomite, cement, kaolin, attapulgite, sepiolite mine powder, bentonite, expanded perlite powder, natural linen fibers, hydroxypropyl methylcellulose powder, emulsified silicone oil and water are stirred according to the amount, and evenly-mixed material slurry is prepared; forming, wherein the prepared material slurry is subjected to water filtering and dewatered in a fourdrinier-wire salvaging machine, and a blank is prepared; cutting and drying, wherein the blank is cut into a plate with the size of 1,200 mm*600 mm to be dried, cooling is carried out at the room temperature, and the diatomite base plate is prepared. The method is scientific and reasonable, the weight of the made diatomite plate is light, cutting is easy to achieve, indoor decoration and indoor construction are convenient, and indoor environmental protection can be achieved.

Owner:NORTHEAST DIANLI UNIVERSITY

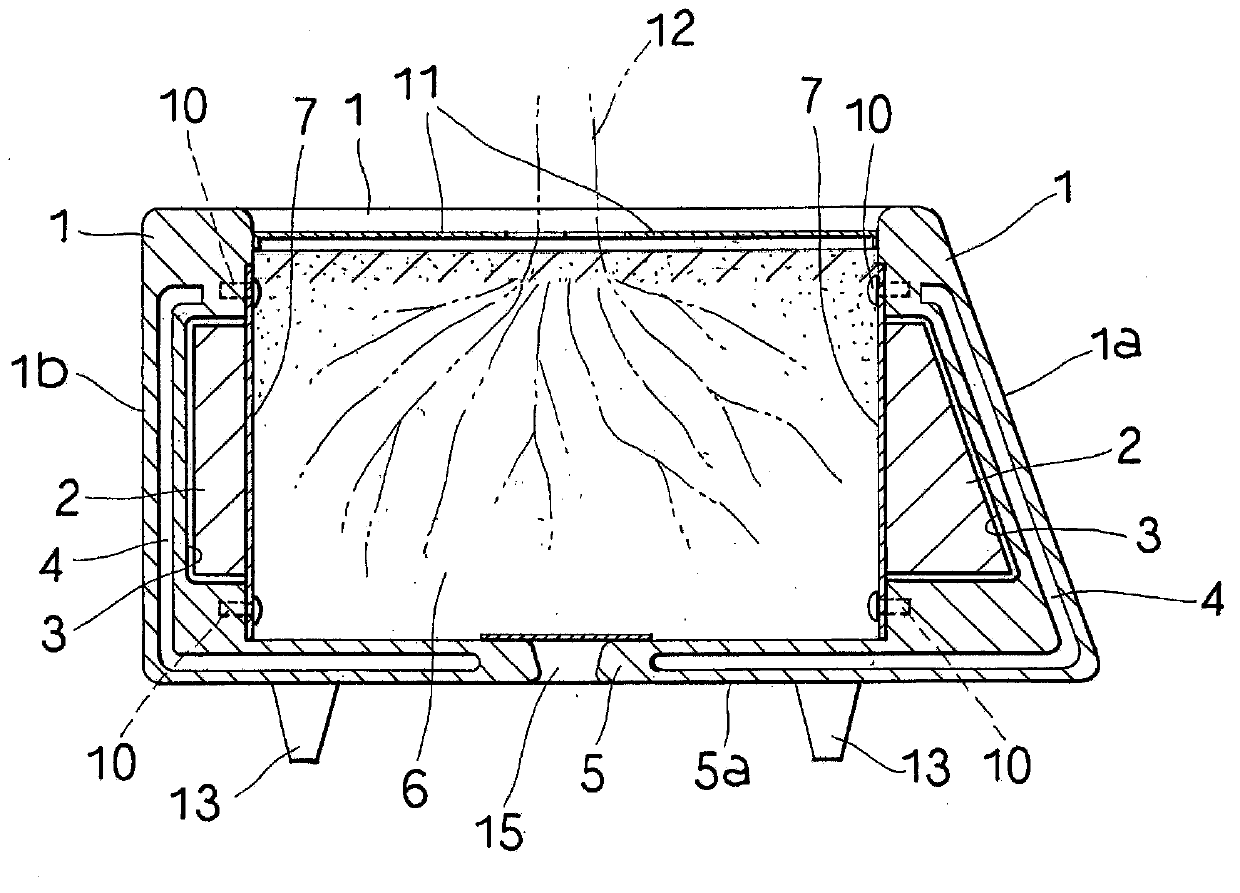

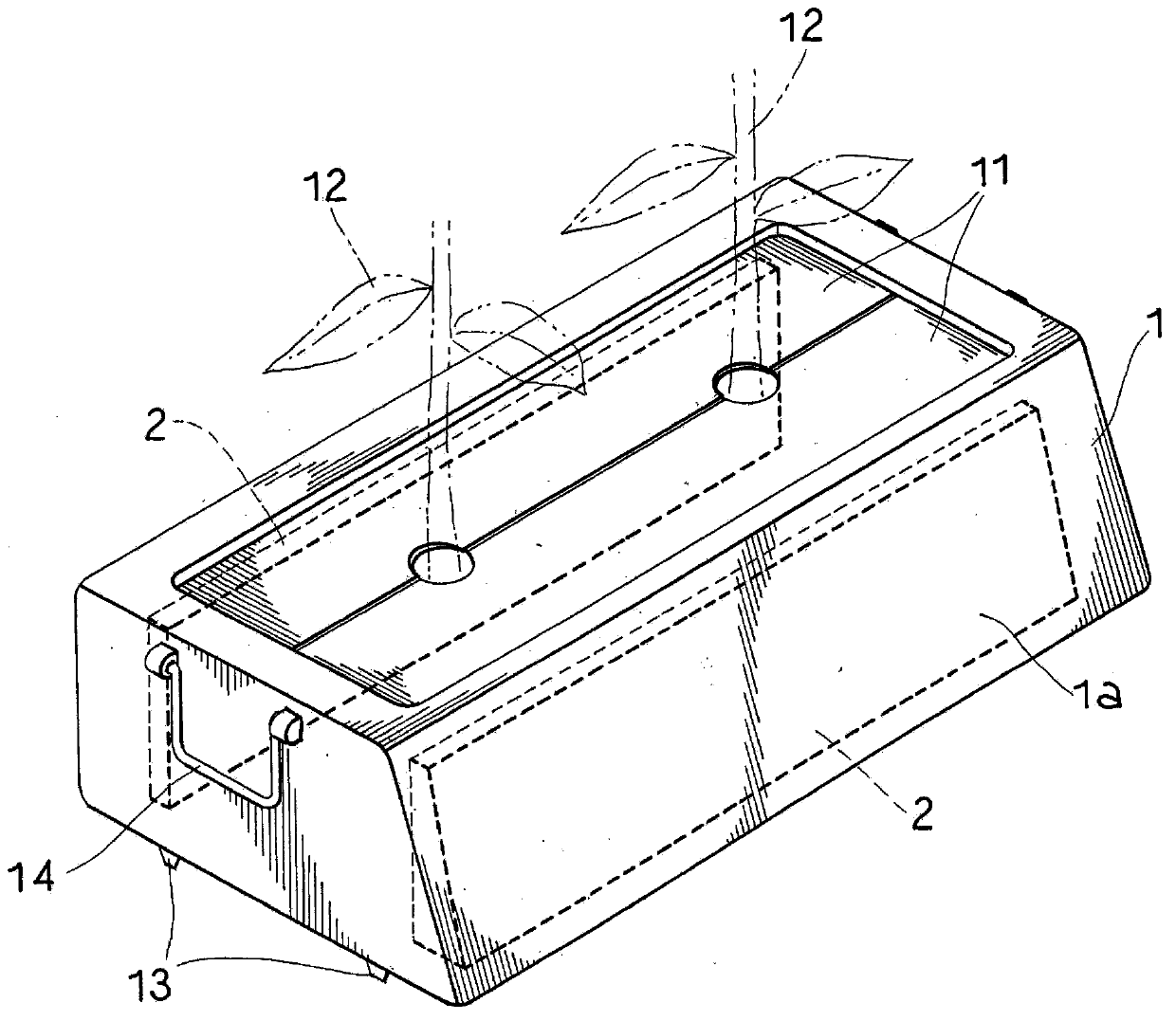

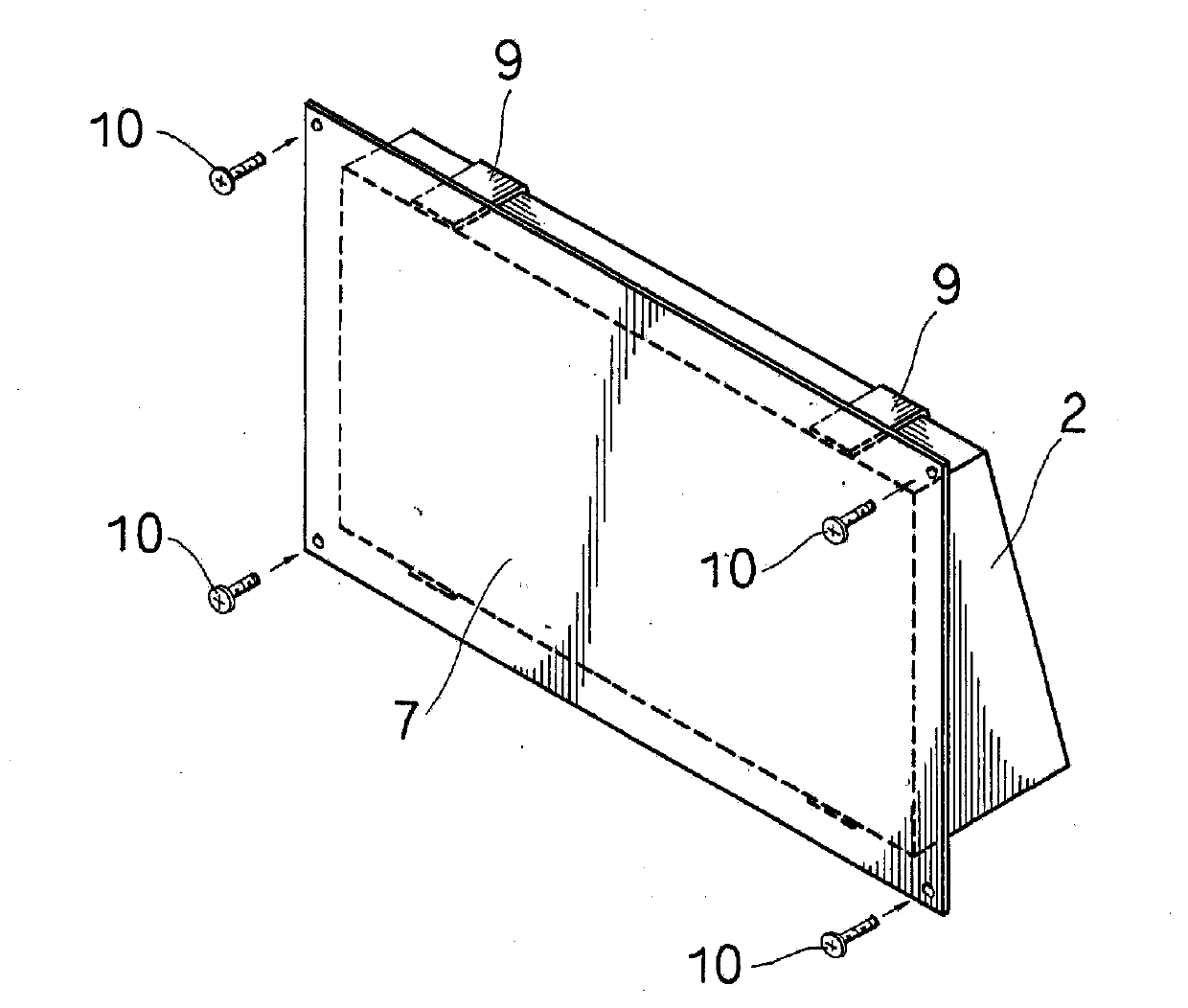

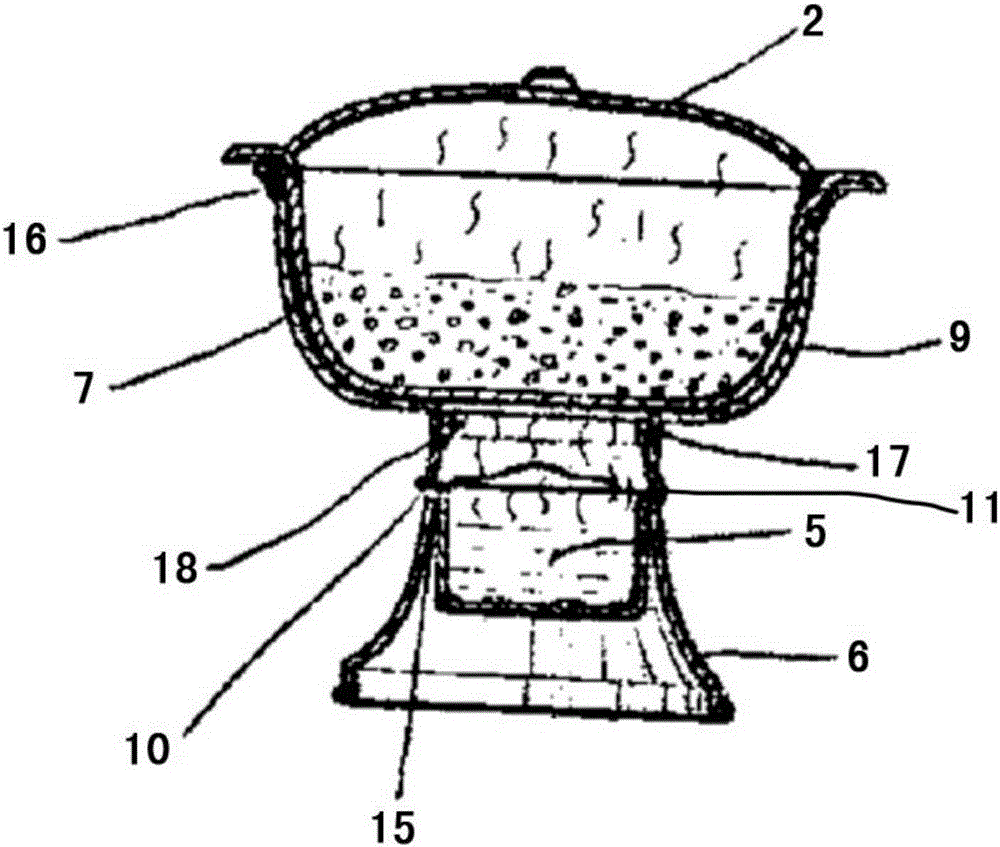

Solar heat utilizing planter

InactiveCN103371070APrevent ground temperature from droppingPrevent rising temperaturesReceptacle cultivationGround temperatureThermal insulation

The invention provides a solar heat utilizing planter which enables the good heat conduction of the soil in the planter and heat accumulation materials, and can prevent the extreme reduction of the ground temperature in winter and can suppress the raising of the ground temperature in autumn, as well as has the functions of heat insulation, external temperature isolation, and capability of receiving sunlight and directly storing the solar heat with the heat accumulation materials. The heat accumulation materials (2) are accumulated in the side wall (1). A heat conduction surface (7) for exchanging heat between the heat accumulation materials (2) and the soil (6) in the planter is arranged on the inner surface of the side wall (1). The heat accumulation materials (2) are formed in a free replacing manner. Furthermore, the composite resin materials having the properties of low heat conduction rate and light transmission form the side wall (1), and the composite resin materials have an air layer (4) for the thermal insulation of the accommodating part (3) of the heat accumulation materials (2).

Owner:HINOX SHOJI

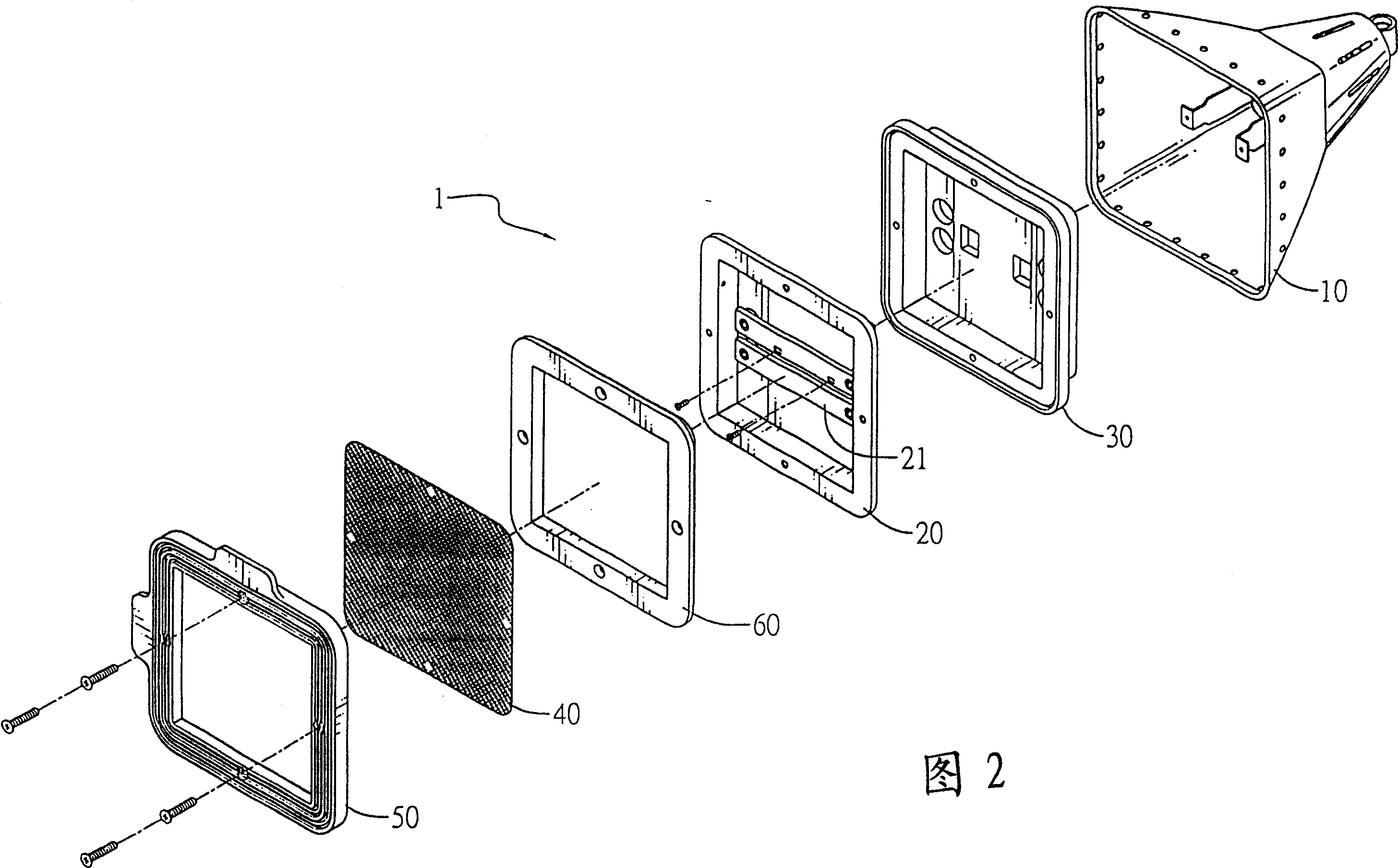

Construction method for machine-made glass magnesium composite plate air pipes

ActiveCN108591634AWith sound insulationWith heat insulation functionPipe laying and repairRigid pipesArchitectural engineeringSmall footprint

The invention discloses a construction method for machine-made glass magnesium composite plate air pipes. The construction method comprises the following steps that (1) plates of the air pipes are cut; (2) the air pipes are spliced; (3) the air pipes are hoisted and connected; and (4) parts of the air pipes are mounted. Compared with a tradition construction method for a galvanized steel plate airpipe, the construction method for the machine-made glass magnesium composite plate air pipes has the characteristics of less construction machines, simple construction procedures, less auxiliary material using amount, small floor space, short construction period and the like. Due to the fact that the air pipes are connected without flanges, a large amount of engineering materials such as angle steel, gaskets, bolts, welding rods, rivets, oxygen and acetylene can be saved; and the average construction efficiency of the galvanized air pipe is 3 m<2> / d per person, the average construction efficiency of the machine-made glass magnesium composite plate air pipes can reach to 12.1 m<2> / d per person, and as for manufacturing and mounting of the air pipes with the same area, the construction period can be shortened obviously for the machine-made glass magnesium composite plate air pipes.

Owner:QINGDAO XINHUAYOU CONSTR GROUP

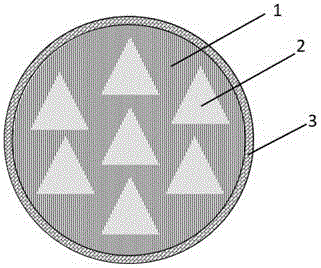

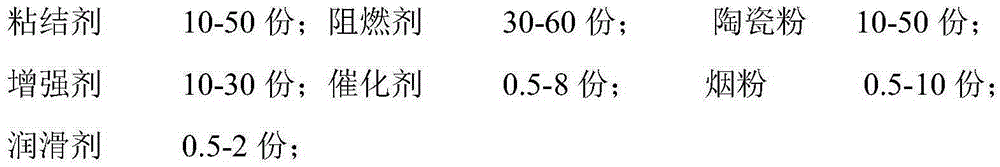

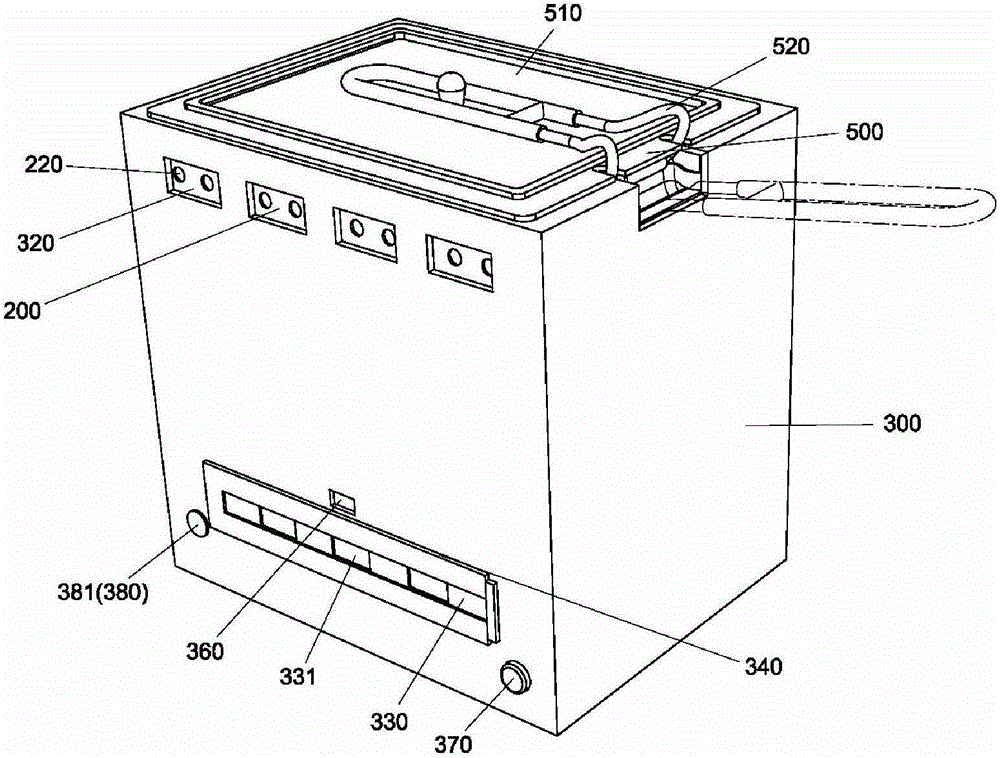

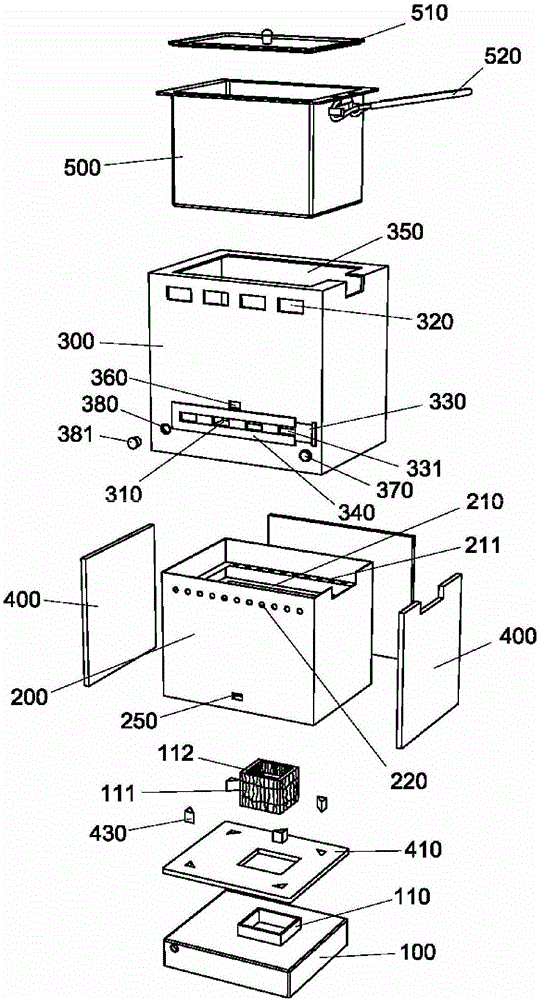

Carbonaceous heat source covered by flame-retardant material

ActiveCN105411001APrevent the problem of easy sheddingWith heat insulation functionTobacco devicesGlass fiberSource material

The invention discloses a carbonaceous heat source covered by a flame-retardant material. The carbonaceous heat source is composed of a carbonaceous heat source material which includes a plurality of triangular longitudinal runners therein and the flame-retardant material covering the periphery of the carbonaceous heat source material. By virtue of the flame-retardant covering layer, the problem that the carbonaceous heat source, when burnt, is easy to become fallen off is effectively avoided; and meanwhile, heat loss can be reduced to the greatest extent, and harm to human bodies in the case of the invasion of glass fibers when glass fibers and like heat-insulating materials are adopted to cover is avoided.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Protable Burner

InactiveCN105180228AReduce volumeEasy to keepDomestic stoves or rangesLiquid heating fuelHeat resistanceFuel tank

Owner:INDONG

Preparing method and application of heat-insulation vibration-restraining material

InactiveCN107351465AReduce processing requirementsWith heat insulation functionSynthetic resin layered productsRubber layered productsOrganic solventEngineering

The invention provides a preparing method and application of a heat-insulation vibration-restraining material. The heat-insulation vibration-restraining material is of a specific block-up vibration reduction structure, one or more foam block-up layers are combined in use, and the heat-insulation vibration-restraining material has the multiple functions of heat insulation, vibration reduction and noise reduction; the added mass is small, the vibration reduction performance is excellent, the vibration reduction temperature range is wide, the vibration reduction and noise reduction effects are remarkable, and the heat-insulation vibration-restraining material can be used for heat insulation, vibration reduction and noise reduction of devices in the ship field, the rail traffic field, the aerospace field and the like; in addition, the heat-insulation vibration-restraining material is nontoxic and tasteless, the bottom-material processing requirement is low, and the universality is high. According to the heat-insulation vibration-restraining material, the technology of the preparing method is simple, preparing time is short, the construction speed is high, the hardness, the thickness and the modulus are adjustable by the adoption of different raw materials and thicknesses, an organic solvent is not adopted, the heat-insulation vibration-restraining material is nontoxic, and the flammable and explosive problem is solved.

Owner:BEIJING HAIYUEXING SCI & TECH CO LTD

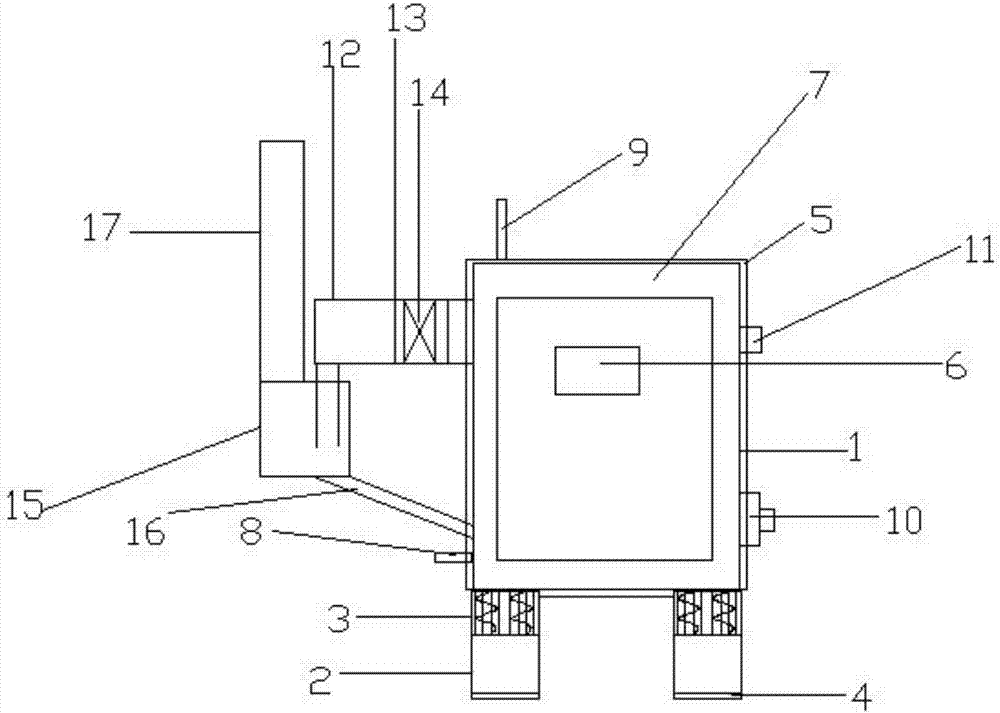

Energy-saving environmentally-friendly heating stove

InactiveCN107166440AAchieving shock absorbing capacityAvoid damageLighting and heating apparatusStove/ranges for heating waterFiltrationEngineering

The invention discloses an energy-saving and environment-friendly heating furnace, which comprises a furnace body, the bottom of the furnace body is provided with support legs, the top of the support legs is provided with a buffer mechanism, the bottom of the support legs is provided with an anti-skid mat, and The outside of the shell of the furnace body is provided with a heat insulation layer, and the surface of the shell of the furnace body is provided with an observation window. The furnace body is a double-layer furnace jacket, and a water storage interlayer is arranged inside the double-layer furnace jacket. The bottom of the water storage interlayer is provided with a water inlet, the top of the water storage interlayer is provided with a water outlet, the top of the other side of the furnace body is provided with a flue, the flue is provided with a chute, and the chute There is a filtering mechanism inside, one end of the flue is connected to the furnace body, the other end of the flue is provided with a water tank, the bottom of the water tank is provided with a support frame, and the support frame is connected to the furnace body Fixedly connected, the top of the water tank is provided with a chimney. The energy-saving and environment-friendly heating furnace has the advantages of simple structure, convenient operation, shockproof and heat insulation functions, and the ability to purify waste gas.

Owner:合肥速锐知识产权代理有限公司

Environment-friendly aluminum veneer manufacturing method

InactiveCN109403478AWith heat insulation functionClimate change adaptationInsulation improvementVarnishMetal

The invention discloses an environment-friendly aluminum veneer manufacturing method. The environment-friendly aluminum veneer manufacturing method comprises the steps of metal plate preparation, primer layer treatment, finishing coat layer treatment and varnish layer treatment, and the finishing coat uses a nano-ATO modified photocurable coating. The aluminum veneer manufacturing method skillfully utilizes nano materials in the coating to achieve the environment-friendly coating concept, and imparts the heat insulation effect on the aluminum veneer at the same time.

Owner:嘉兴吉祥才蛮幕墙材料科技股份有限公司

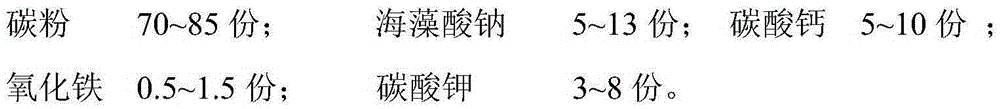

Sandy utensil with heat insulation function, and making method thereof

InactiveCN106518017AImprove breathabilityImprove thermal stabilityCeramic materials productionClaywaresSodium BentoniteThermal stability

The invention concretely relates to a sandy utensil with heat insulation function, and a making method thereof. Floating beads, green gangue, bentonite and Datong sands are adopted as raw materials, natural green gangue which is 30 meters below the local coal seam and is moistened in the crustal bathyderm for billions of years is adopted as a main raw material, other auxiliary materials are added, the matching ratio of all the raw materials is determined, the sintering schedule is made, the yield is guaranteed, a sandy heater with good air permeability, good thermal stability and heat insulation function is produced through burdening, mud production, blank production, blank repairing, decoration, drying and sintering, and the method is characterized by burdening, blank production and sintering. The sandy utensil used as a breathable sandy heater has the advantages of good heat insulation effect, long life and high safety.

Owner:平定县冠窑砂器陶艺有限公司

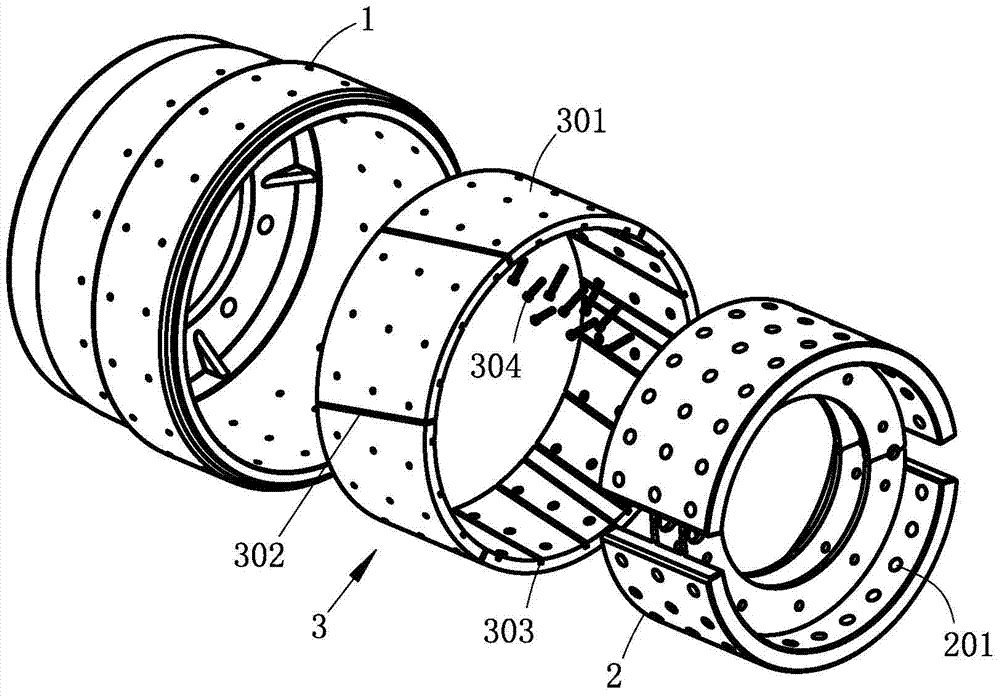

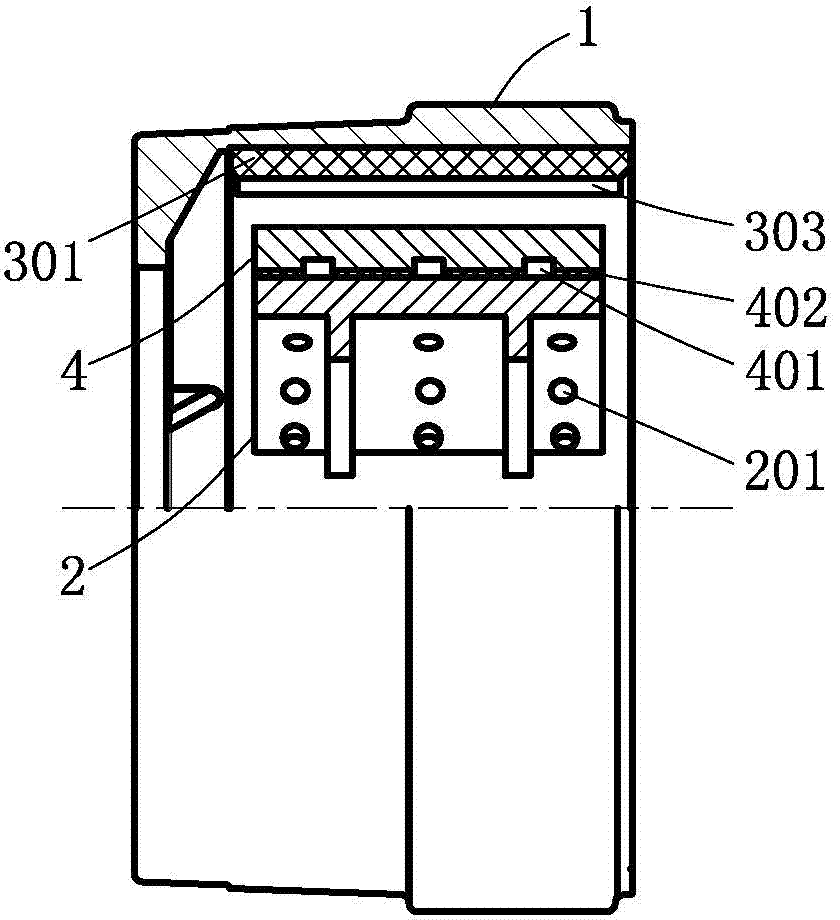

Drum brake

InactiveCN104728316ANo thermal deformationWith heat insulation functionBraking membersEngineeringDrum brake

The invention discloses a drum brake and belongs to the technical field of brakes. The drum brake comprises a brake drum, a friction plate and a brake shoe, wherein the friction plate is fixedly installed on the inner side of the brake drum, and a friction face is formed on the inner surface of the friction plate. The heat deformation of the brake drum is avoided, the service life of the friction plate and the maintenance period of the brake drum are prolonged, the using performance of the drum brake is improved, and the drum brake is widely produced and used.

Owner:李瑾瞳

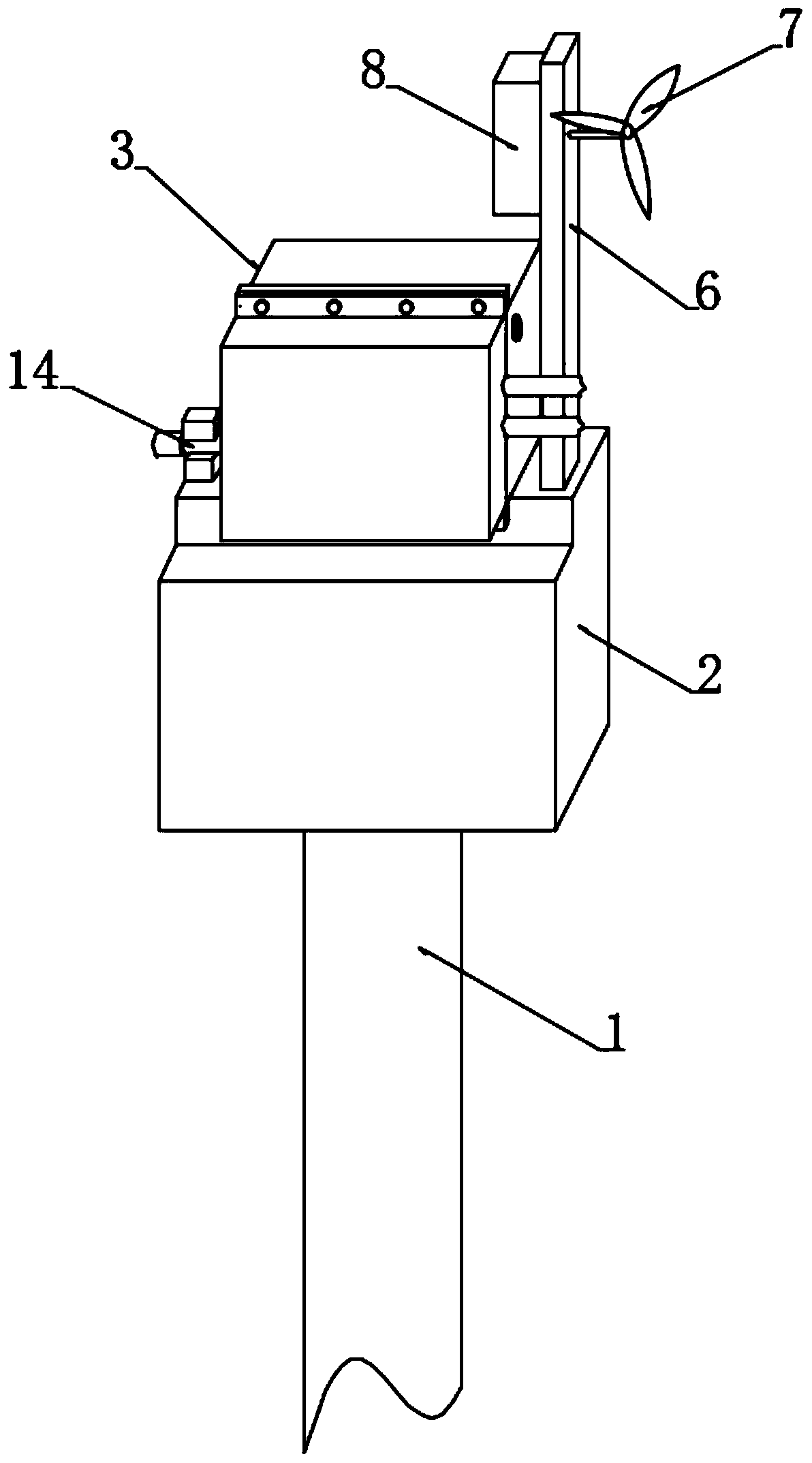

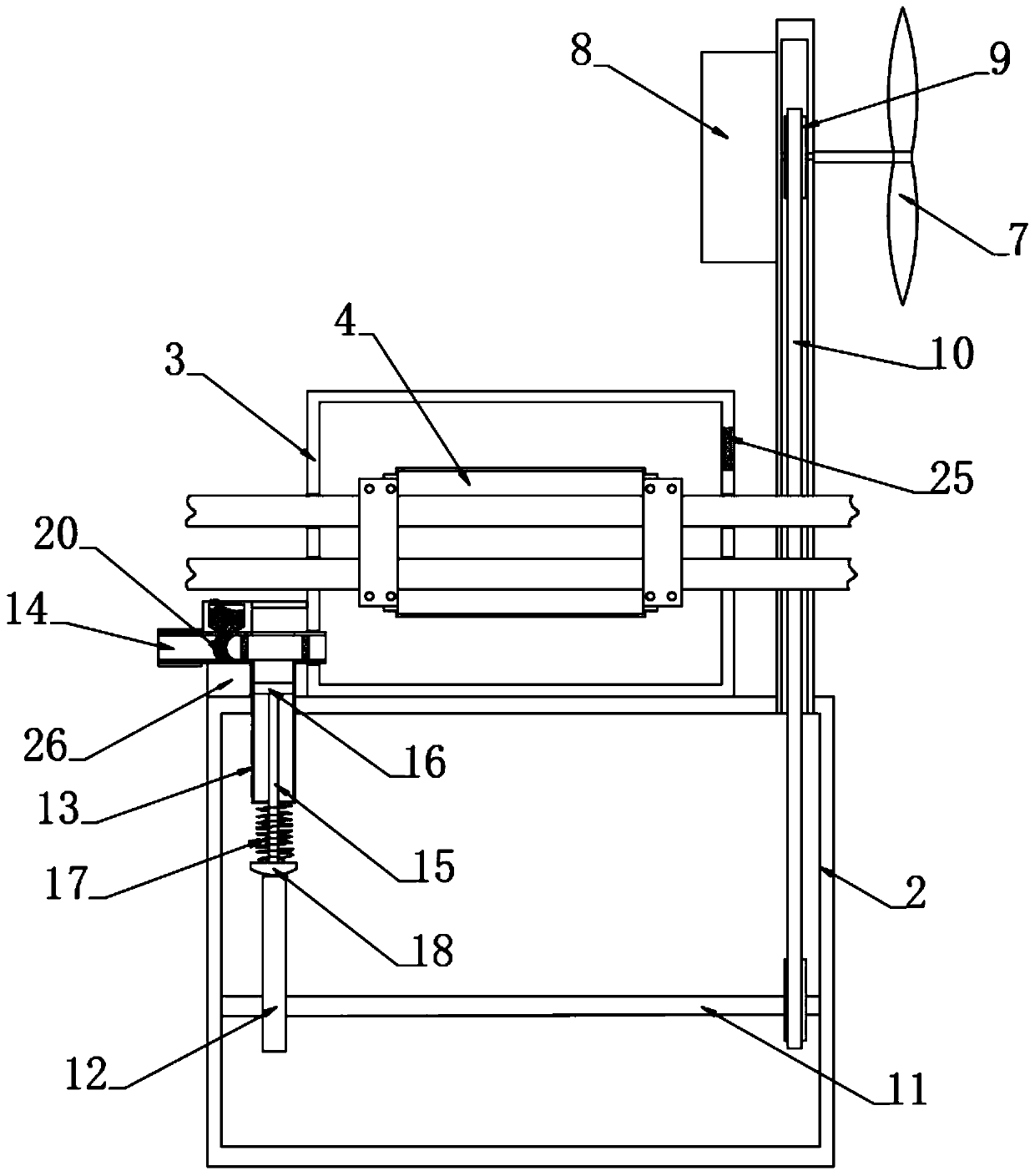

Power monitoring containing pile and application method thereof

ActiveCN111441908ASpeed up circulationReduce outputGas treatmentThermal insulationControl powerProcess engineering

The invention discloses a power monitoring containing pile and an application method thereof, and belongs to the technical field of power monitoring equipment. According to the power monitoring containing pile and the application method thereof, through cooperation of a windmill, a linkage mechanism and an air storage mechanism, outside air is continuously guided into a monitoring control shell through an air inlet pipe, ventilation is enhanced, and the heat radiation effect is improved; meanwhile, wind energy is converted into electric energy, natural wind is effectively utilized for controlling power of monitoring equipment or other controllers of the equipment, and energy output is saved; in addition, an outer port of the air inlet pipe is filled with a water absorption ball, moisture adsorption and removal are carried out on guided-in air, it is effectively guaranteed that circulating air is dry air, and the situation that equipment elements are influenced by moisture is avoided toa certain degree; and the left side and the right side of the water absorption ball are coated with high-porosity cooling layers, when the temperature of outside air is too high, hot steam is precooled, liquefied and cooled, and some water drops formed by liquidation can fully adsorb and dry the water absorption ball.

Owner:海南电网有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com