Preparation method of layered zirconium boride superhigh temperature ceramic with heat insulation function

A technology of ultra-high-temperature ceramics and zirconium boride, which is applied in the field of preparation of ultra-high-temperature ceramics, can solve the problems of poor toughness and heat insulation performance of zirconium boride ultra-high-temperature ceramics, and achieve the goal of improving ceramic toughness, increasing expansion paths, and reducing heat conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

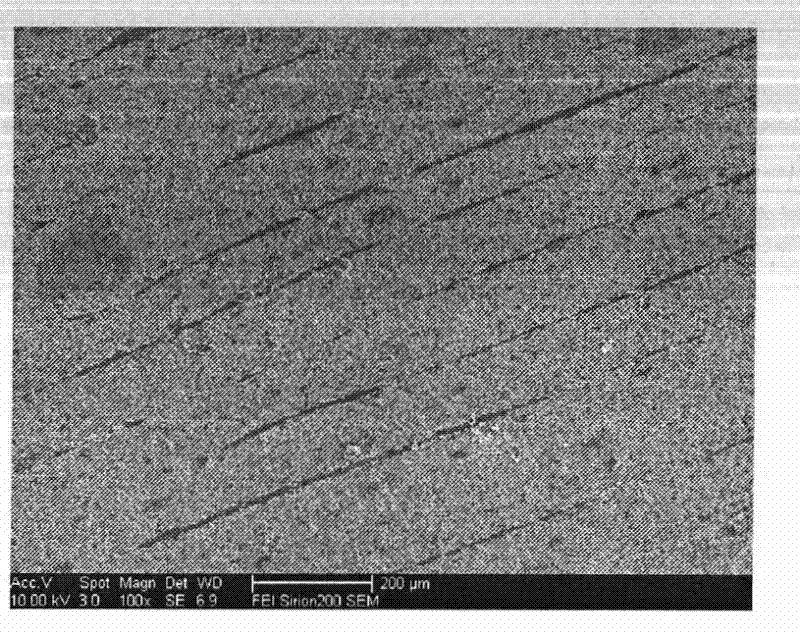

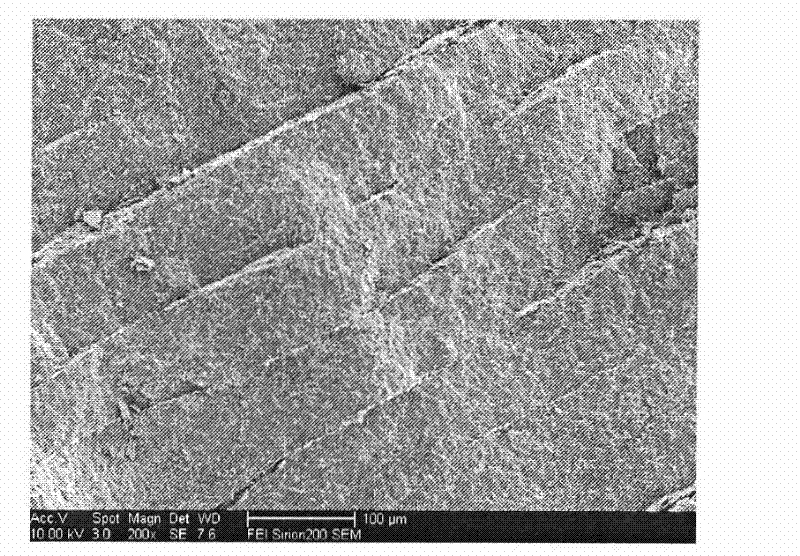

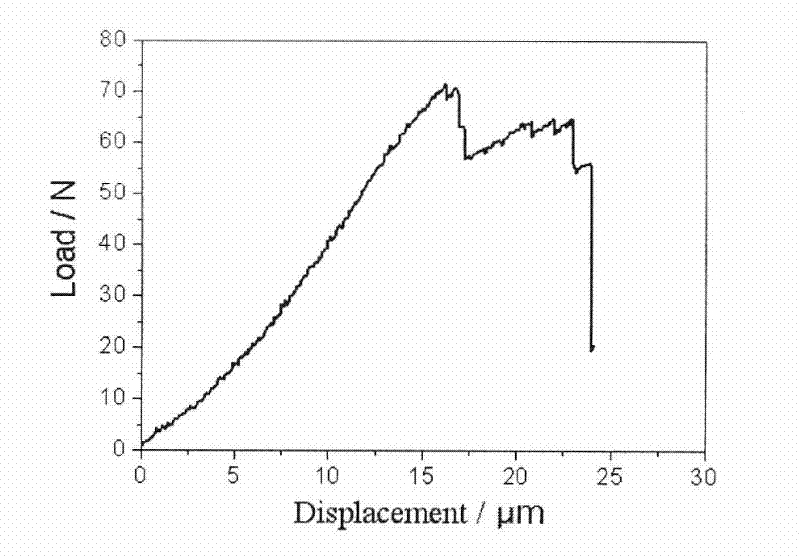

Image

Examples

Embodiment 1

[0024] 1. Preparation of zirconium boride casting sheet: first weigh 2.61 grams of polyvinyl butyral, 2.61 grams of polyethylene glycol, and 52.23 grams of ethanol, stir to mix evenly, then add 42.63 grams of 1 μm zirconium boride powder, 9.60 grams of 0.5 μm silicon carbide powder are stirred evenly to form a cast material, cast, dried at room temperature and demoulded to obtain a 1000 μm thick cast sheet, wherein the zirconium boride powder and silicon carbide powder are according to the volume percentage of 70%: 30% Weigh;

[0025] 2. Coating: First weigh 2 grams of polyethylene glycol and add 100 grams of deionized water to stir evenly, then add 10 grams of zirconia to form a slurry; then use the coating method to coat the zirconia slurry on the casting sheet Surface, coated once;

[0026] 3. Slice the cast film according to the size of the mold;

[0027] 4. Put the sliced casting sheets into the mold, and vacuum degrease. When degreasing, the heating rate is 2°C / min, ...

Embodiment 2

[0030] 1. Preparation of zirconium boride casting sheet: first weigh 5.51 grams of polyvinyl butyral, 5.51 grams of polyethylene glycol, and 82.68 grams of ethanol, stir to mix evenly, then add 48.72 grams of 2 μm zirconium boride powder, 6.40 grams of 1 μm silicon carbide powder are stirred evenly to form a casting material, cast, and after room temperature drying and demoulding, a 700 μm thick casting sheet is obtained, wherein the zirconium boride powder and the silicon carbide powder are weighed according to the volume percentage of 80%: 20%. Pick;

[0031] 2. Coating: First weigh 3 grams of polyvinyl alcohol and add 150 grams of deionized water to stir evenly, then add 10 grams of zirconia to form a slurry; then use the coating method to coat the zirconia slurry on the upper surface of the casting sheet , coated 2 times;

[0032] 3. Slice the cast film according to the size of the mold;

[0033] 4. Put the sliced casting sheets into the mold, and vacuum degrease. When...

Embodiment 3

[0036] 1. Preparation of zirconium boride casting sheet: first weigh 4.06 grams of polyvinyl butyral, 4.06 grams of polyvinyl alcohol, and 116.02 grams of ethanol, and mix them evenly by stirring, then add 54.81 grams of 5 μm zirconium boride powder, 3.20 Gram of 2 μm silicon carbide powder, stirred evenly to form a cast material, cast, dried at room temperature and demoulded to obtain a 200 μm thick cast sheet, wherein the zirconium boride powder and silicon carbide powder were weighed according to the volume percentage of 90%: 10% ;

[0037] 2. Coating: First weigh 2.5 grams of polyvinyl alcohol and add 200 grams of deionized water to stir evenly, then add 10 grams of zirconia to form a slurry; then use the coating method to coat the zirconia slurry on the upper surface of the casting sheet , coated 3 times;

[0038] 3. Slice the cast film according to the size of the mold;

[0039] 4. Put the sliced casting sheets into the mold, and vacuum degrease. When degreasing, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com