Patents

Literature

45results about How to "Add extension path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

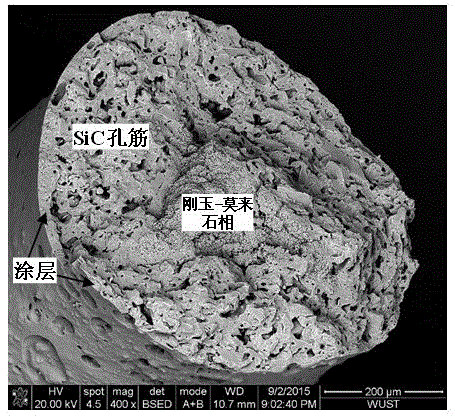

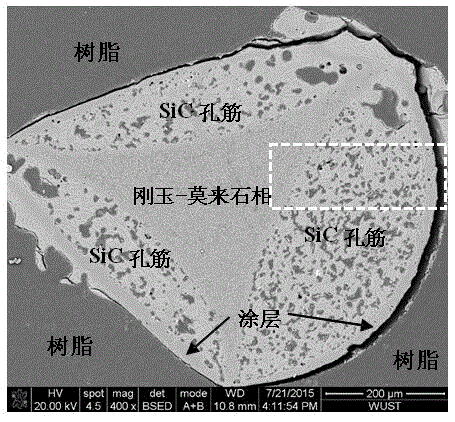

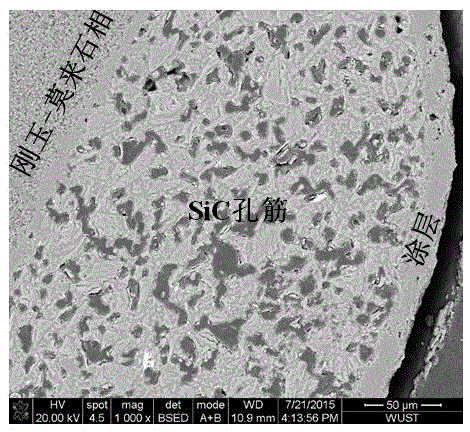

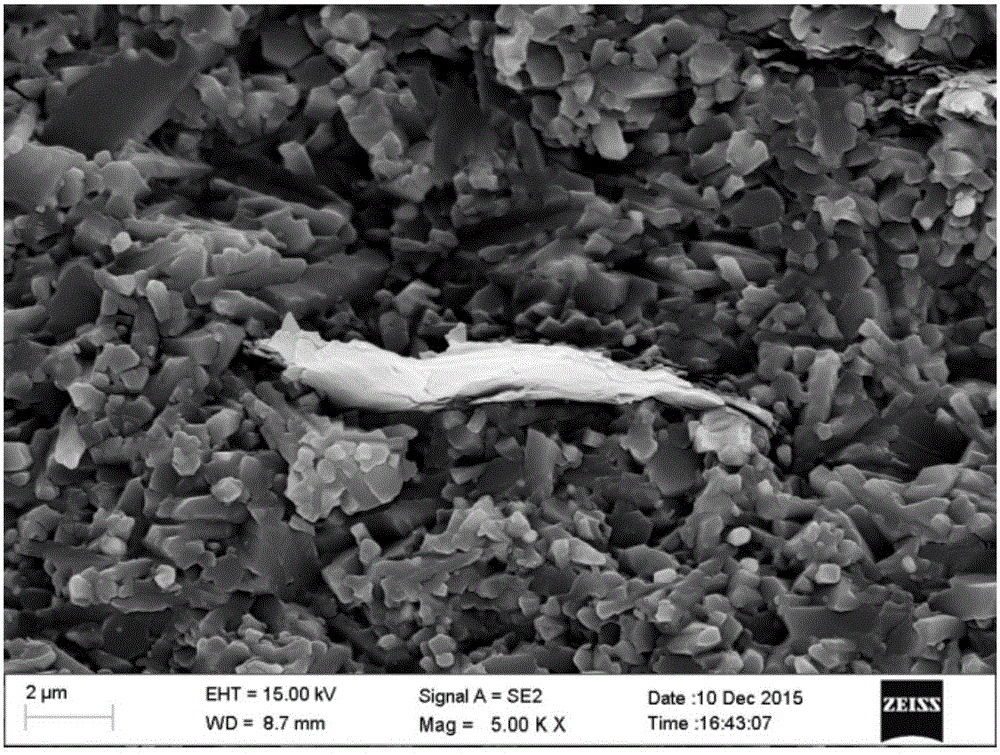

Silicon carbide-based composite foamed ceramic of multilayer hole rib structure and preparation method thereof

The invention discloses a silicon carbide-based composite foamed ceramic of a multilayer hole rib structure and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing silicon carbide, micro alumina powder, silicon powder, ammonium lignosulfonate, polycarboxylate and water so as to prepare slurry I; uniformly mixing micro alumina powder, a silicon source polycarboxylate and water so as to prepare slurry II; then dipping polyurethane sponge in the slurry I, and successively carrying out extruding or slurry centrifugation, drying and heat preservation at 600 to 850 DEG C for 0.5 to 3 h so as to obtain a presintered body of silicon carbide foamed ceramic; subjecting the presintered body of silicon carbide foamed ceramic to vacuum dipping in the slurry II and successively carrying out slurry centrifugation and drying so as to obtain a green body of silicon carbide-based composite foamed ceramic; and carrying out heat preservation at 1300 to 1500 DEG C in an air atmosphere for 2 to 4 h so as to prepare the silicon carbide-based composite foamed ceramic of the multilayer hole rib structure. The preparation method has the characteristics of simple process and low cost; and the prepared silicon carbide-based composite foamed ceramic of the multilayer hole rib structure has high mechanical strength, good thermal shock resistance and excellent high-temperature anti-oxidation performance.

Owner:WUHAN UNIV OF SCI & TECH

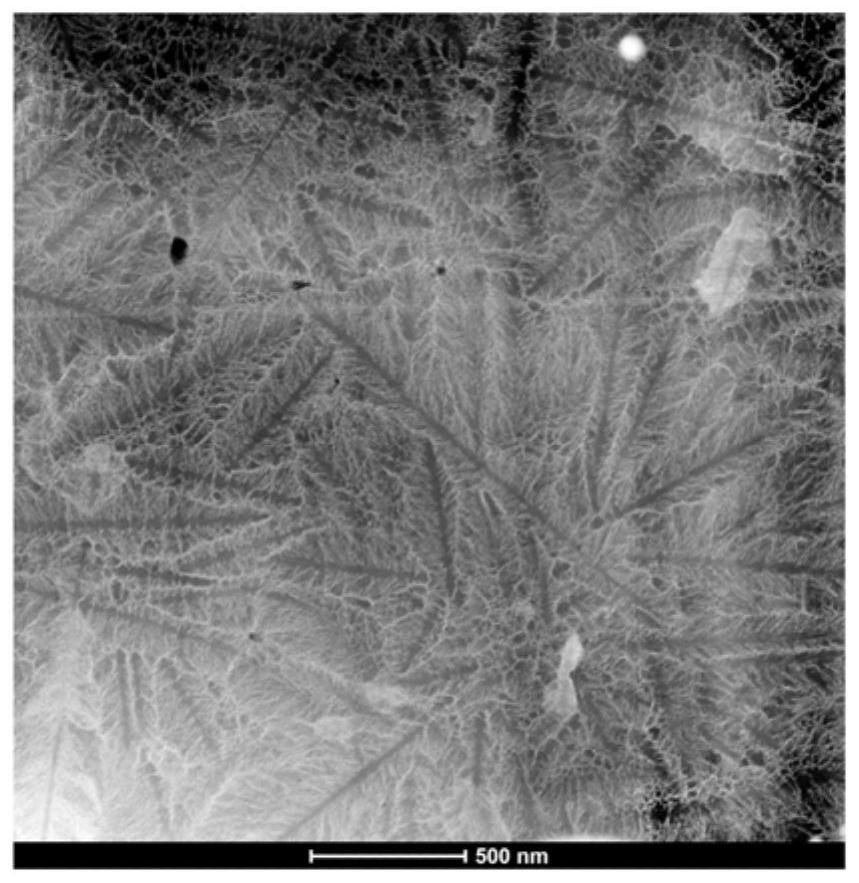

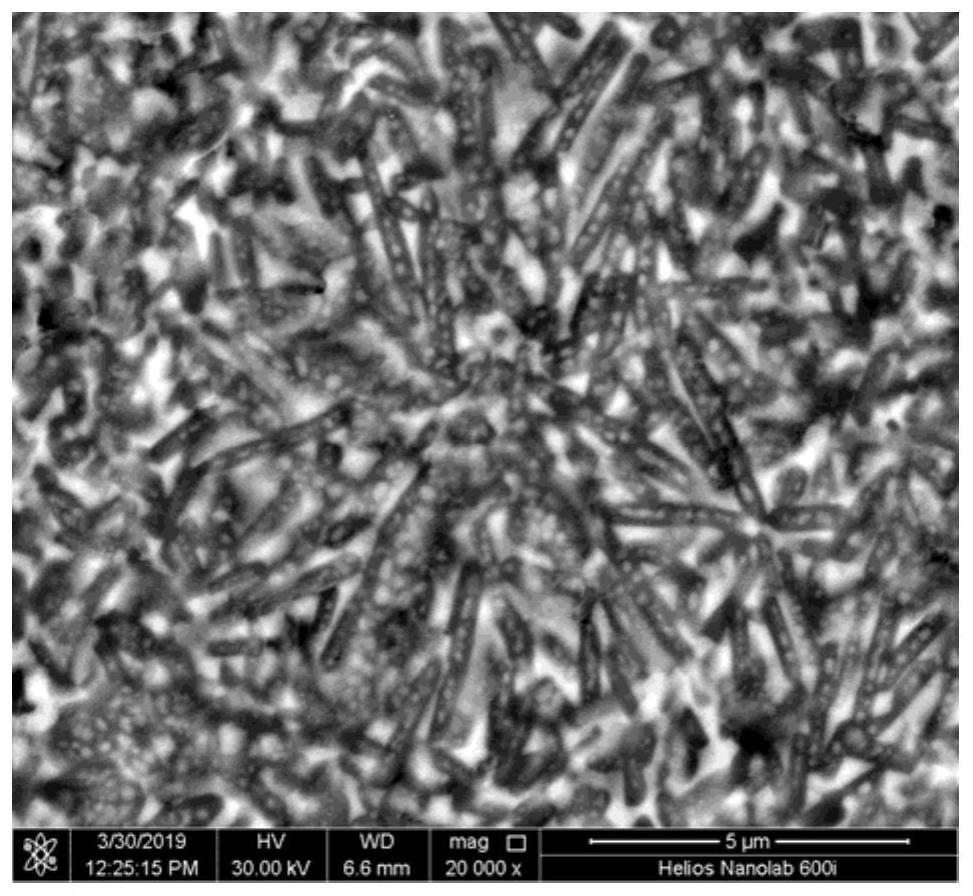

Si3N4-based ceramic cutter material with added graphene and preparation method of material

The invention relates to a Si3N4-based ceramic cutter material with added graphene and a preparation method of the material. According to the ceramic cutter material, silicon nitride serves as a matrix, graphene serves as a reinforced phase, and MgO, Al2O3 and Y2O3 serve as composite sintering auxiliaries. The ceramic cutter material is prepared through the processes of independent dispersion of raw materials, compound dispersion, ball milling, drying and screening, cold pressing and hot pressed sintering. In the Si3N4 / graphene composite ceramic cutter material, mechanical properties of the silicon nitride ceramic cutter material are remarkably influenced by graphene, the coefficient friction of the material is reduced by adding graphene, and self-lubricating performance of the material is improved.

Owner:QILU UNIV OF TECH

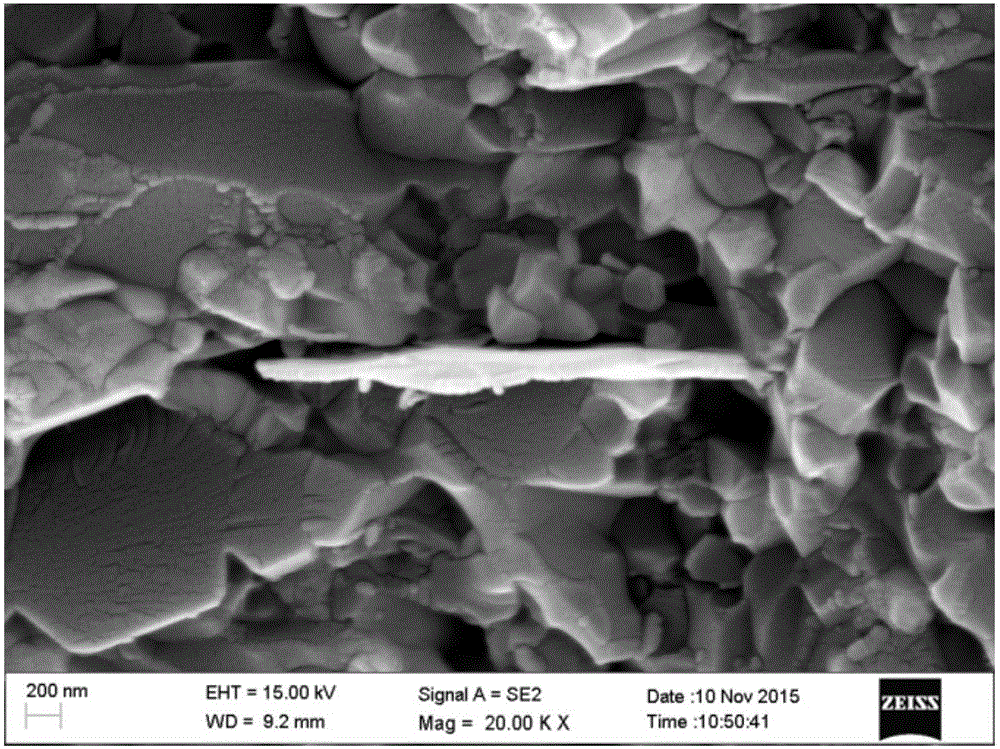

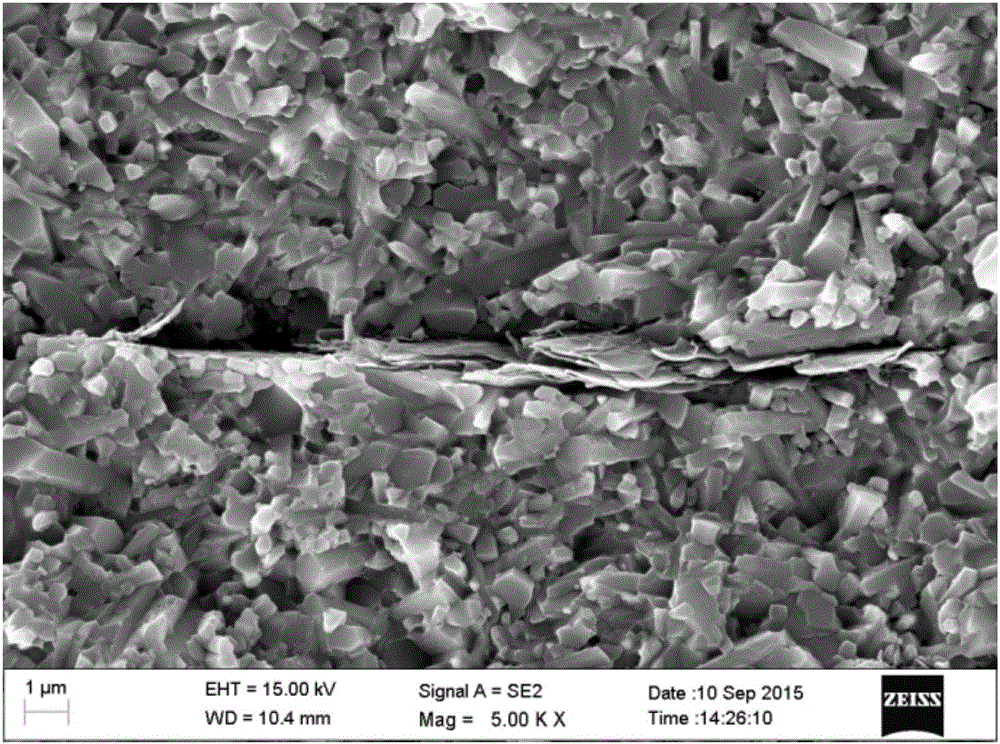

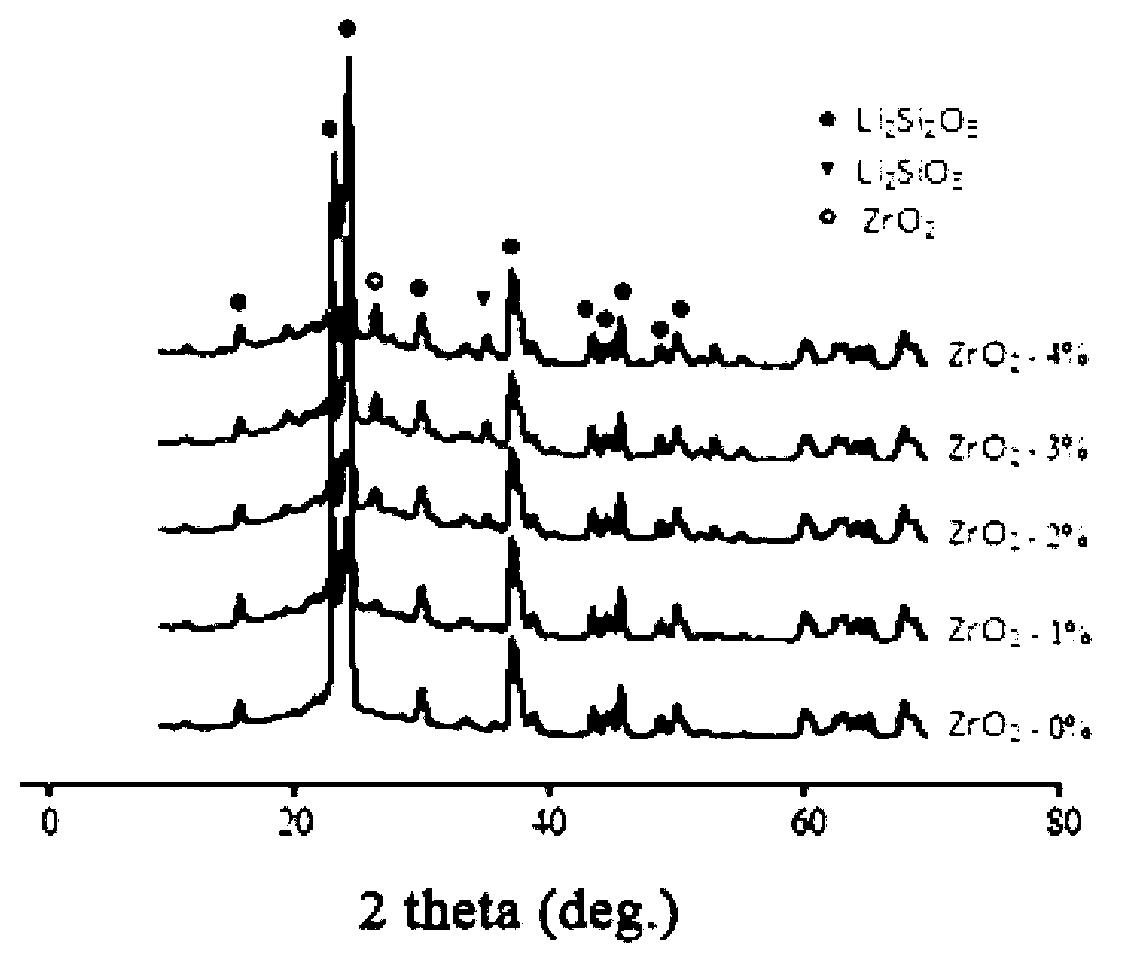

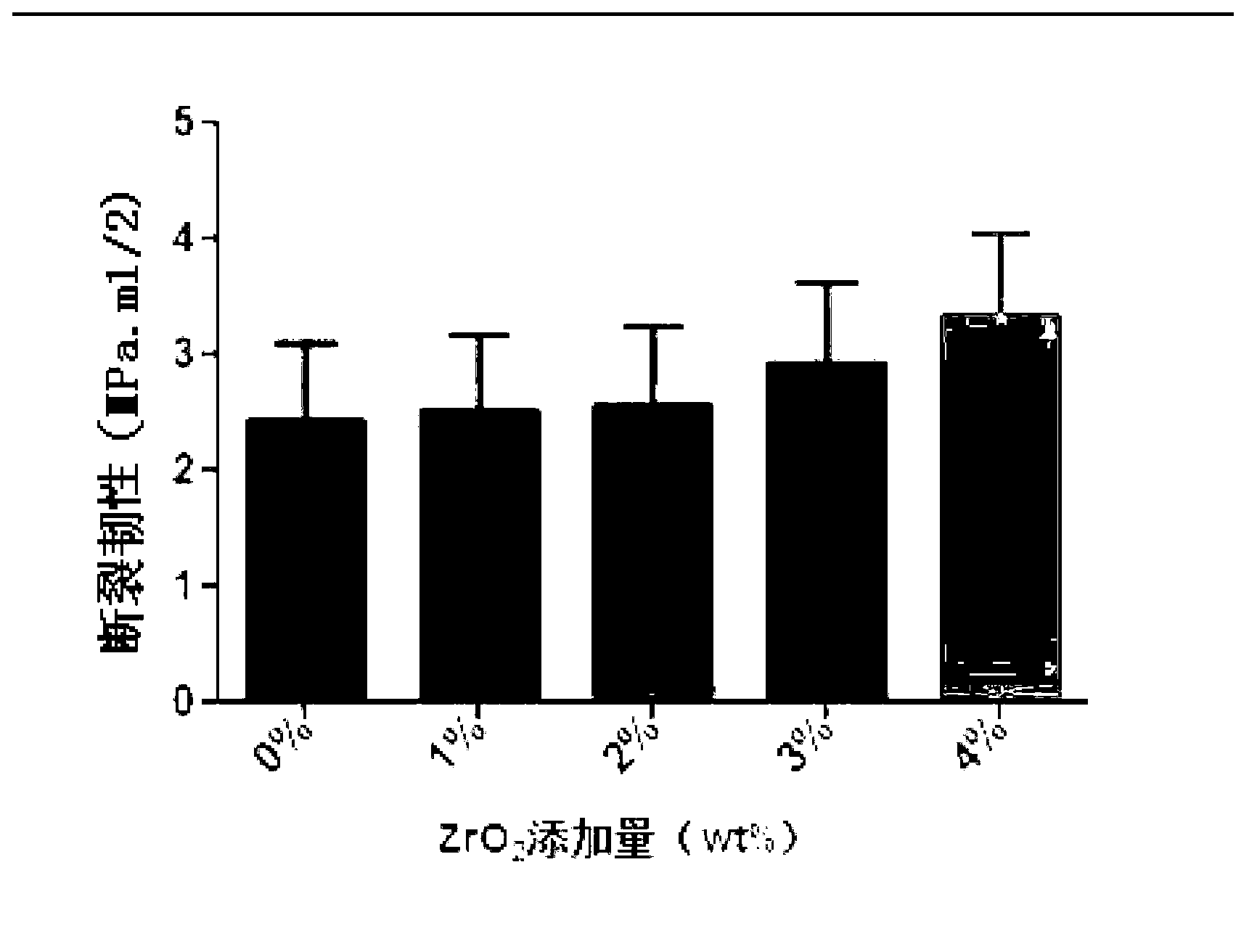

Strengthening-toughening glass ceramic and preparation method thereof

The invention belongs to the field of all-ceramics materials for the dentistry, and discloses a strengthening-toughening glass ceramic and a preparation method thereof. The strengthening-toughening glass ceramic comprises the following components in percentage by mass: 96 to 99% of basic component, and 1.0 to 4.0% of toughening component, wherein the basic component comprises the following components in percentage by mass: 58 to 62% of SiO2, 28 to 30% of Li2CO3, 3.5 to 4.0% of K2CO3, 2.5 to 3.0% of Al2O3, 11.4 to 1.6% of CeO2, and 2.6 to 3.0% of P2O5, and the toughening component is ZrO2.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

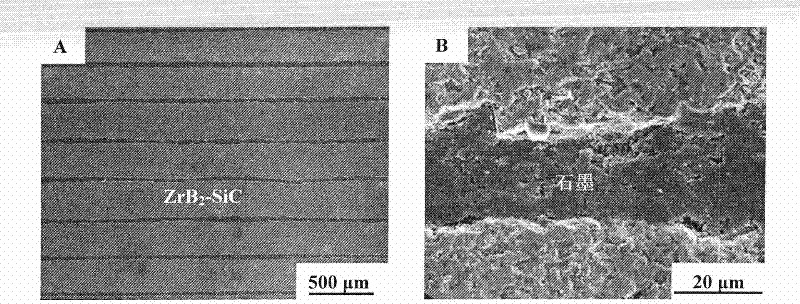

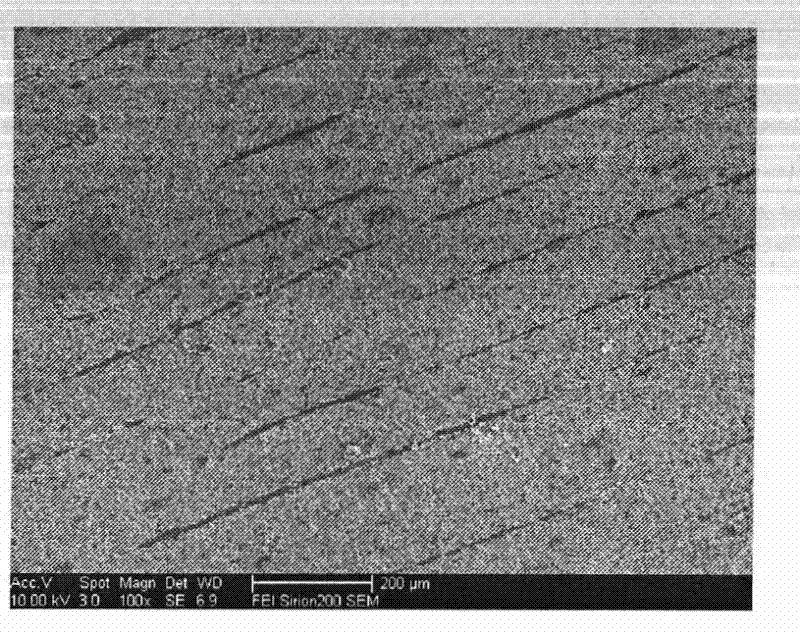

Preparation method of zirconium boride-silicon carbide/graphite layered superhigh temperature ceramic

InactiveCN102173829AAdd extension pathImprove fracture toughnessCeramic layered productsSolventPlasticizer

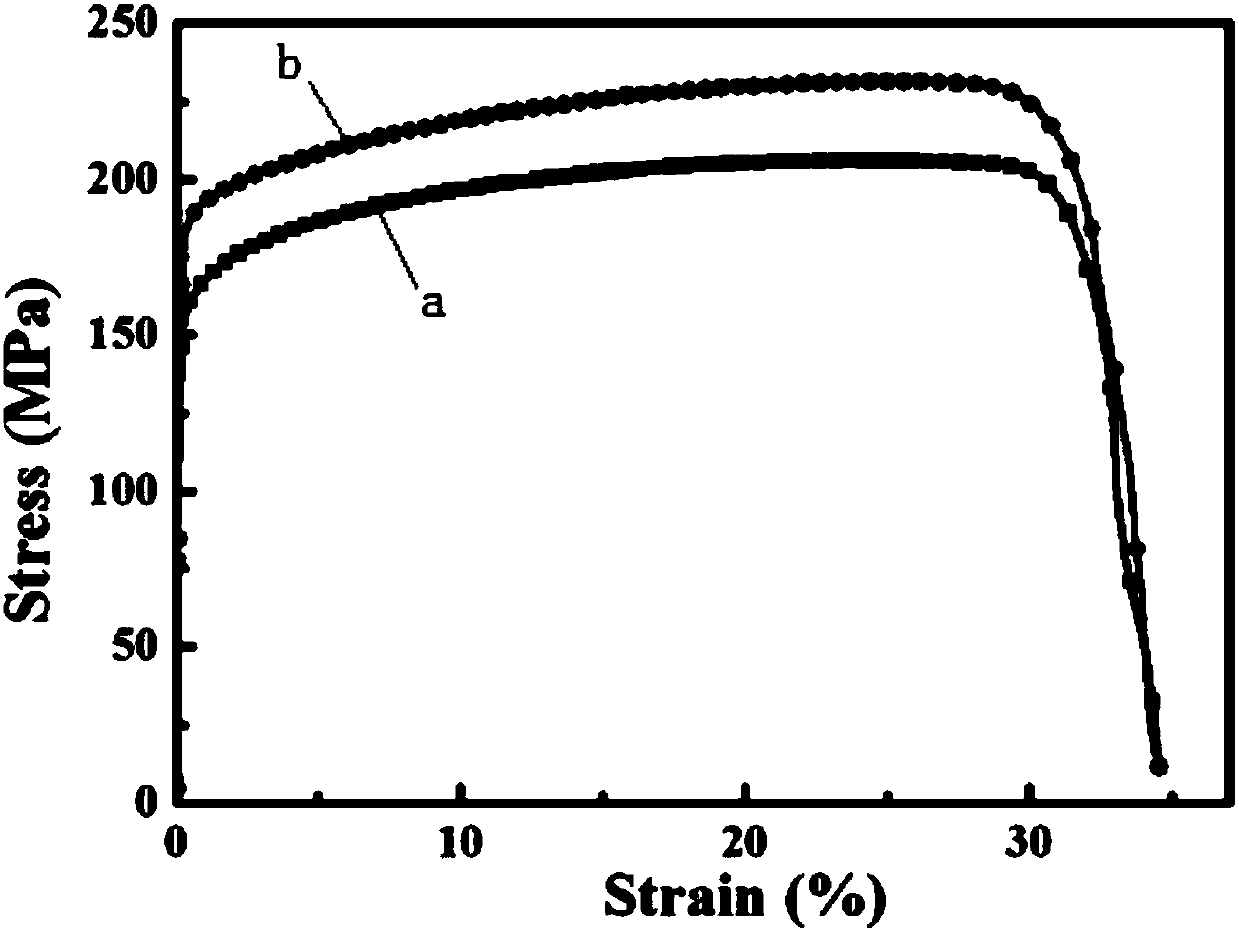

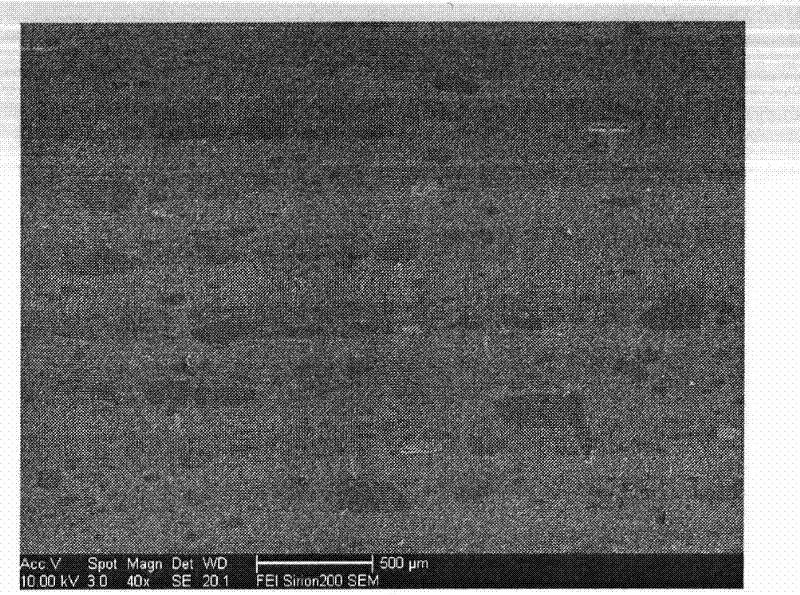

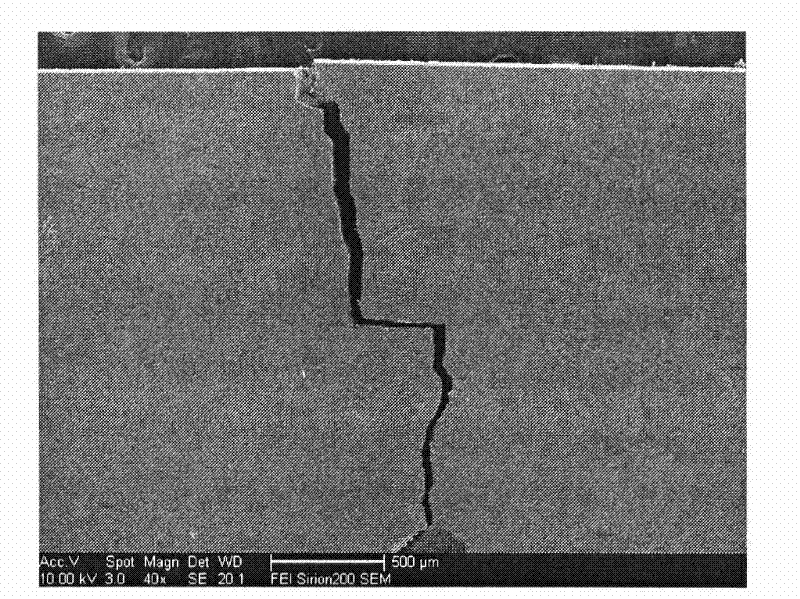

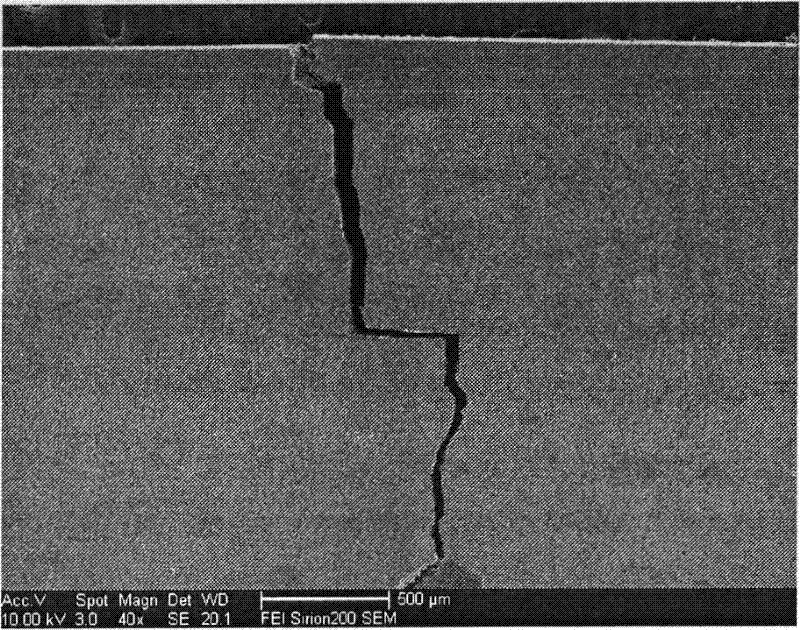

The invention provides a preparation method of zirconium boride-silicon carbide / graphite layered superhigh temperature ceramic. The preparation method is characterized by comprising the following steps: 1) separately preparing a zirconium boride casting sheet and a zirconium oxide casting sheet by using a casting method, namely, adding a binder and a plasticizer in a solvent and evenly mixing, separately adding a zirconium boride ceramic powder material and a graphite ceramic powder material, and evenly mixing to form a casting material, then carrying out casting forming, and drying at room temperature and demoulding to respectively obtain the zirconium boride casting sheet with the thickness of 200-1000 mu m and the graphite casting sheet with the thickness of 20-100 mu m; 2) respectively slicing the zirconium boride casting sheet and the graphite casting sheet according to the size of a mould; 3) putting the zirconium boride sheet and the graphite sheet in a graphite mould in an alternatively overlapping way for vacuum derosination; and 4) hot pressed sintering in an argon atmosphere to prepare the layered superhigh temperature ceramic. According to the invention, preparation process is simple, cost is low, the machinability of the material is strong, compositions are controllable, and the toughness of the material is up to 11.3MPa.m<1 / 2>.

Owner:SHANDONG UNIV OF TECH

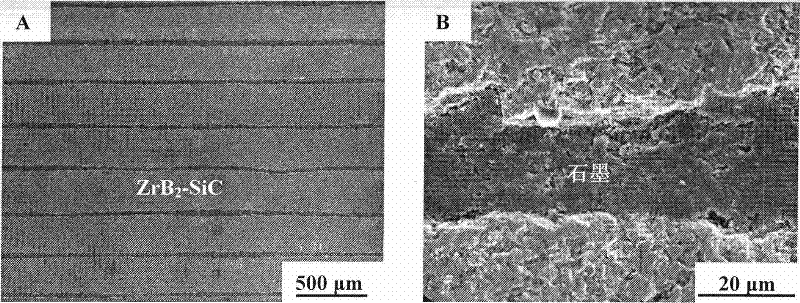

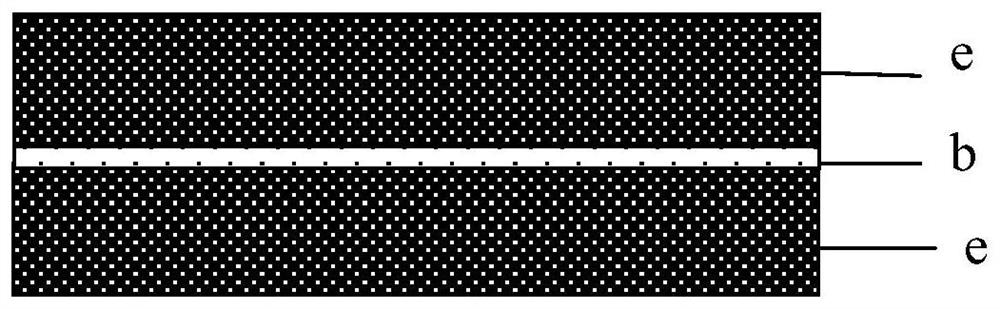

Preparation method of layered zirconium boride superhigh temperature ceramic with heat insulation function

The invention provides a preparation method of layered zirconium boride superhigh temperature ceramic with a heat insulation function. The preparation method is characterized by comprising the following steps: 1) preparing a casting sheet, namely, evenly mixing a binder, a plasticizer and a solvent, adding zirconium boride ceramic powder material to form a casting material, then carrying out casting forming, and drying at room temperature and demoulding to obtain a casting sheet with the thickness of 200-1000 mu m; 2) coating zirconium oxide slurry on the surface of the casting sheet by usinga coating method, and controlling the thickness of the coating through coating times; 3) slicing the casting sheet according to the size of a mould; 4) putting the sliced casting sheets in the mould in an overlapping way for vacuum derosination; and 5) carrying out hot pressed sintering in an argon atmosphere so as to obtain the layered zirconium boride superhigh temperature ceramic with heat insulation function, wherein the fracture toughness of the ceramic is up to 9.1MPa.m<1 / 2>, and the heat conduction of the ceramic vertical to a layer direction is 8w / m.k at room temperature. The fracturemode of the layered zirconium boride ceramic is non-brittle fracture which refers to a gradual fracture having a certain tolerance capability to flaw damage. The layered zirconium boride superhigh temperature ceramic has the advantages of heat insulation function and excellent property.

Owner:SHANDONG UNIV OF TECH

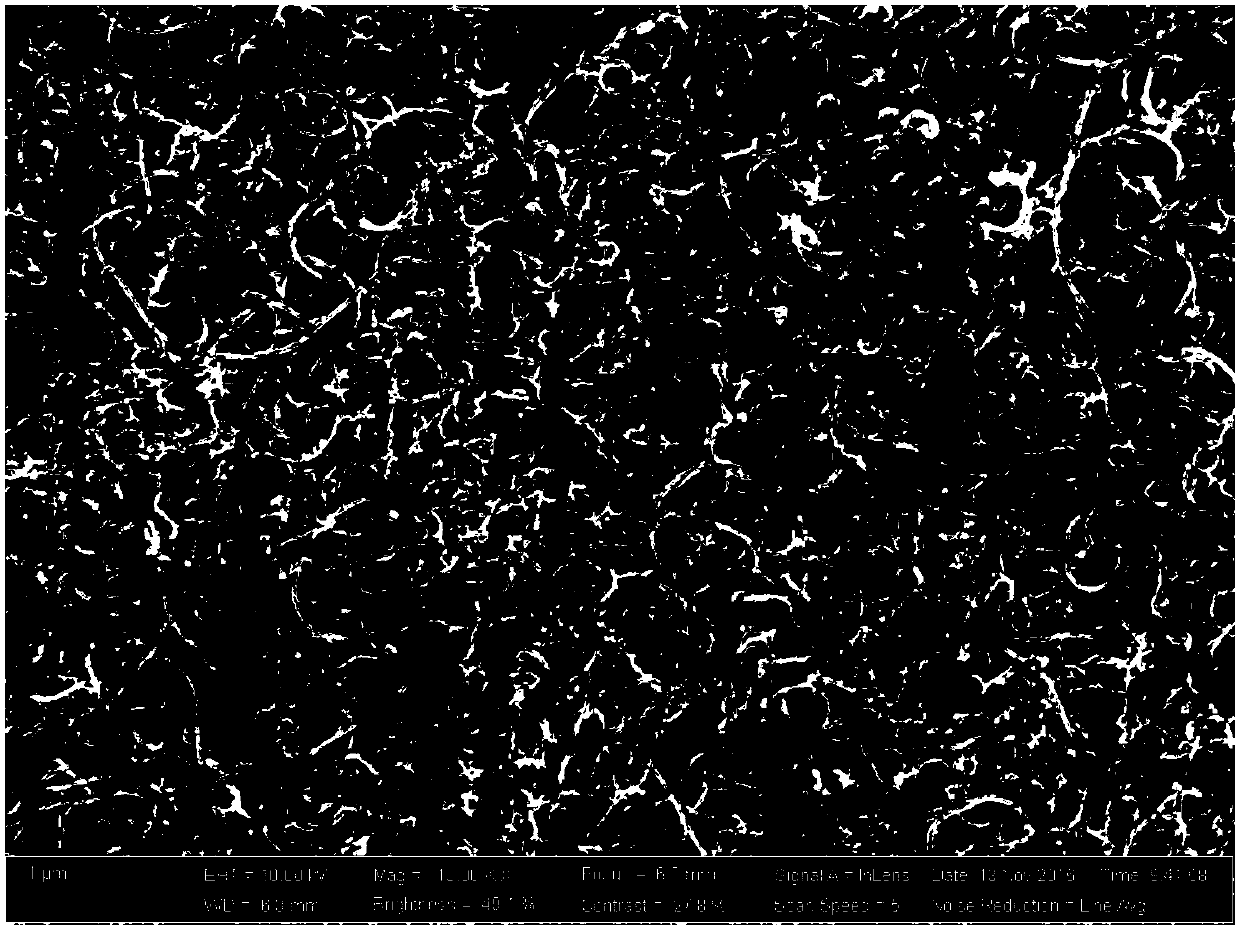

Method for preparing carbon nanotube copper-based laminated composite material

The invention discloses a method for preparing a carbon nanotube copper-based laminated composite material, relates to a method for preparing a carbon nanotube copper-based composite material and aimsto solve the problem that a carbon nanotube copper-based composite material prepared by using a conventional method is unmatched in toughness. The method comprises the following steps: I, performingacidizing treatment on carbon nanotubes, and cleaning copper sheets; II, preparing composite sheets; III, preparing a composite material. By adopting the method, carbon nanotubes are dispersed by using an electrophoretic deposition method, the carbon nanotubes are directly uniformly dispersed on the surface of a metal plate, the dispersion degree of the carbon nanotubes is increased, and a composite material laminated structure can be constructed by using methods of hot-pressing sintering and later rolling. By adopting the composite material laminated structure, breakage of the material is changed, energy consumption in the breakage process is increased, the strength of the composite material can be remarkably improved when being compared with that of a substrate, and meanwhile the toughness is correspondingly improved. The method is adopted to prepare the carbon nanotube copper-based composite material.

Owner:HARBIN INST OF TECH

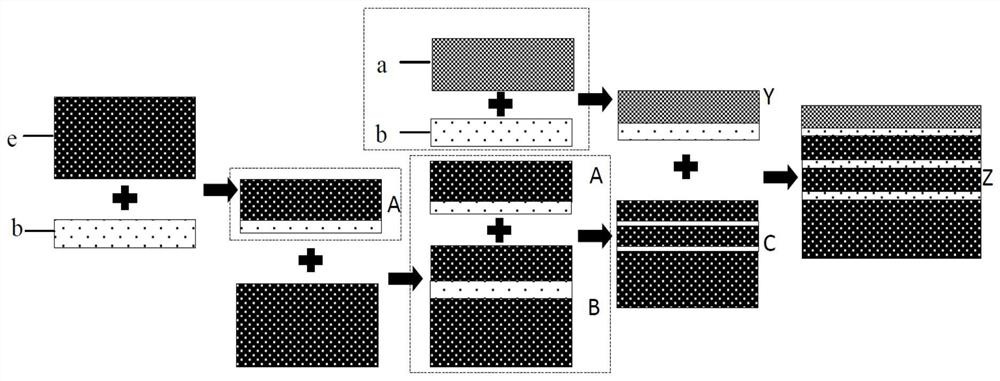

Method for preparing lamellar zirconium boride ultrahigh-temperature ceramic through casting method

InactiveCN102173831AAdd extension pathImprove fracture toughnessCeramic layered productsBorideArgon atmosphere

The invention provides a method for preparing lamellar zirconium boride ultrahigh-temperature ceramic through a casting method. The method is characterized by comprising the following steps of: (1) respectively preparing two zirconium boride casting sheets with different components and thicknesses by adopting the casting method: firstly adding a binder and a plasticizer to a solvent, uniformly stirring, then respectively adding zirconium boride ceramic powder, uniformly stirring to form two casting materials with different components, then carrying out casting forming, and drying and demoulding at room temperature to respectively obtain a zirconium boride casting sheet A with the thickness of 300-1000 micrometers and a zirconium boride casting sheet with the thickness of 20-100 micrometers; (2) respectively slicing the zirconium boride casting sheet A and the zirconium boride casting sheet B according to the size of a mould; (3) alternately overlapping the sliced zirconium boride casting sheet A and the sliced zirconium boride casting sheet B, placing into a graphite grinding tool, and degreasing in vacuum; and (4) carrying out hot pressed sintering in an argon atmosphere at the sintering temperature of 1900-2000 DEG C under the pressure of 20-40 MPa so as to obtain the lamellar zirconium boride ultrahigh-temperature ceramic. A casting forming technology is adopted in the invention and the method has simple process; and in addition, an obtained material reaches high toughness value at 9.3 MPa.m<1 / 2>.

Owner:SHANDONG UNIV OF TECH

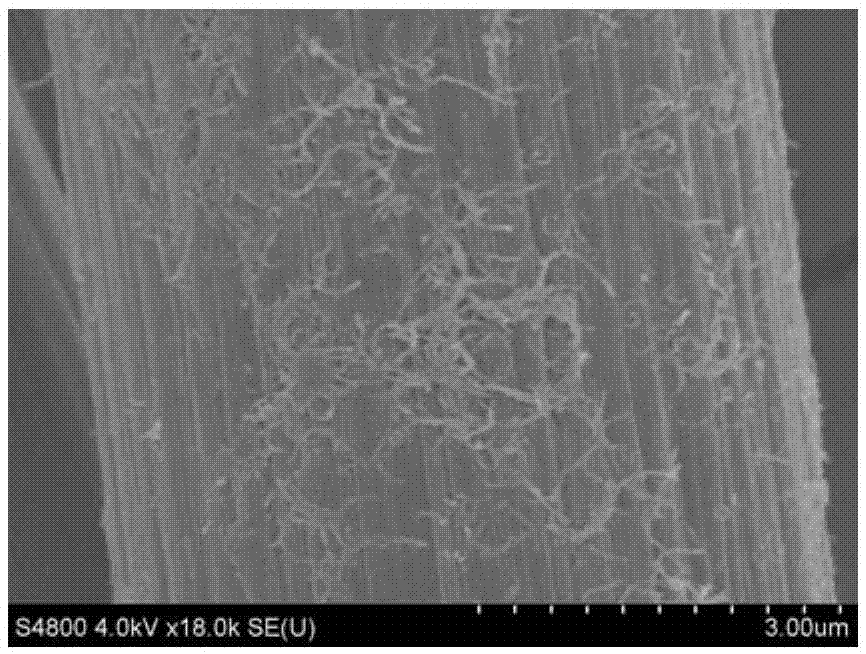

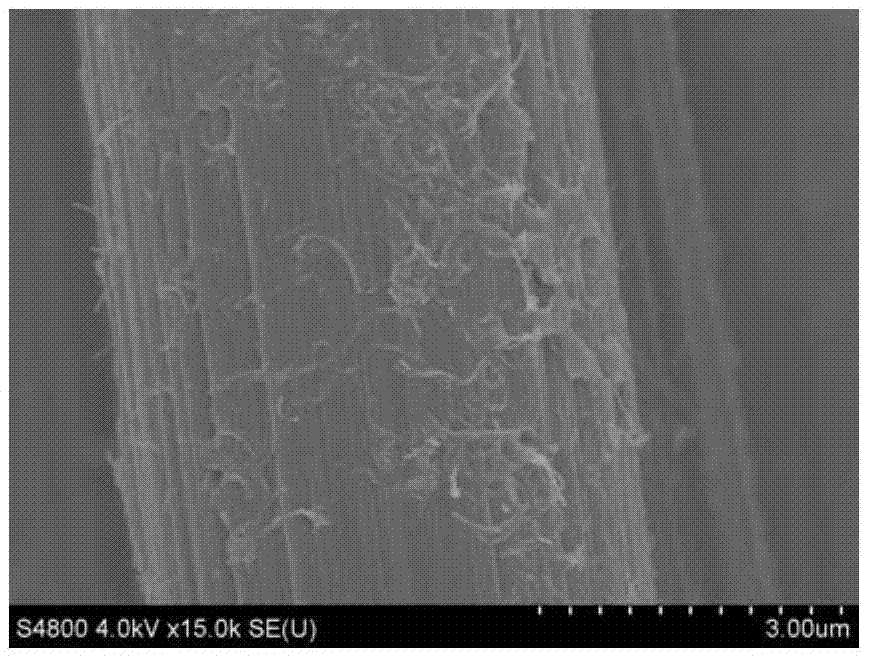

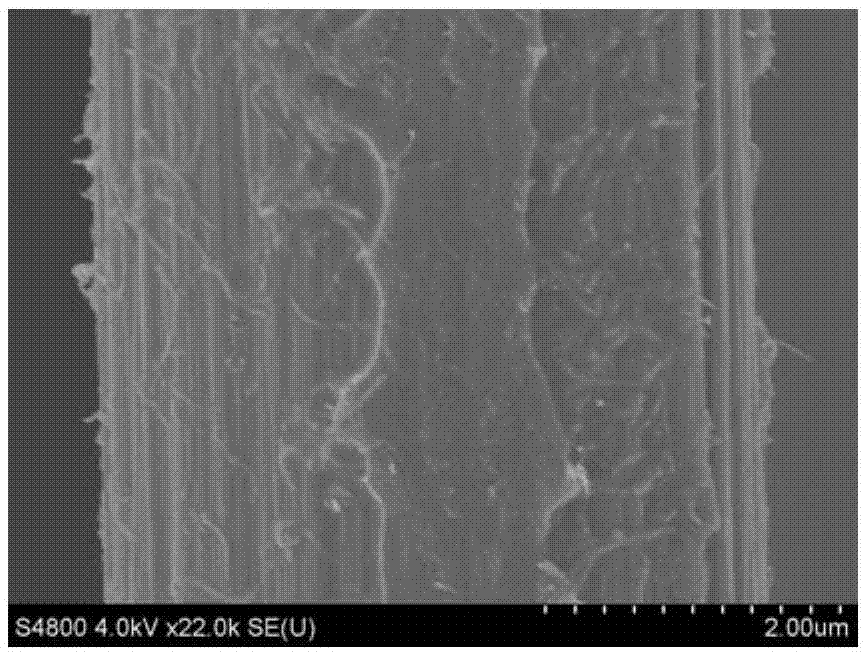

Method for preparing carbon fiber composite material interface layer

The invention provides a method for preparing a carbon fiber composite material interface layer. The method comprises the following steps: coating the surface of a carbon fiber by using a sizing agent with carbon nanotubes, phenolic resin, a curing agent and a solvent, curing, and performing high temperature thermal treatment, thereby obtaining a pyrolytic carbon coated layer with the carbon nanotubes. Effects of strengthening and toughening can be achieved in a composite material with the carbon fiber as a reinforcing part. The method is simple and feasible and low in cost, the process complexity of the method is greatly reduced as compared with those of conventional CVD and EPD, in addition, process conditions are easy to control, the carbon fiber self is not damaged in the preparation process, and the influence upon the performance of the carbon fiber self is reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Wrought superalloy production process

The invention discloses a wrought superalloy production process. The process comprises the following steps: S1, pretreatment of alloy raw materials; S2: melting in a vacuum induction furnace; S3: electroslag remelting; S4: vacuum self-consumption remelting; S5: high temperature diffusion homogenization annealing; S6: extruding of a desired bar on an extruder; S7: sample cutting by wire cutting, and heat treating of the sample; and S8: oxidation treatment. The rought superalloy production process ensures good comprehensive performance of the alloy through the specific reasonable ratio of each alloying element. Compared with existing alloy, the processed wrought superalloy has the advantages of excellent workability, high high-temperature mechanical properties and tissue stability, and excellent oxidation resistance. The process has low total production cost, can meet the low-cost manufacturing requirements of aero-engine turbine disks, has good economic and social benefits, and is suitable for use and popularization.

Owner:宁国市华成金研科技有限公司

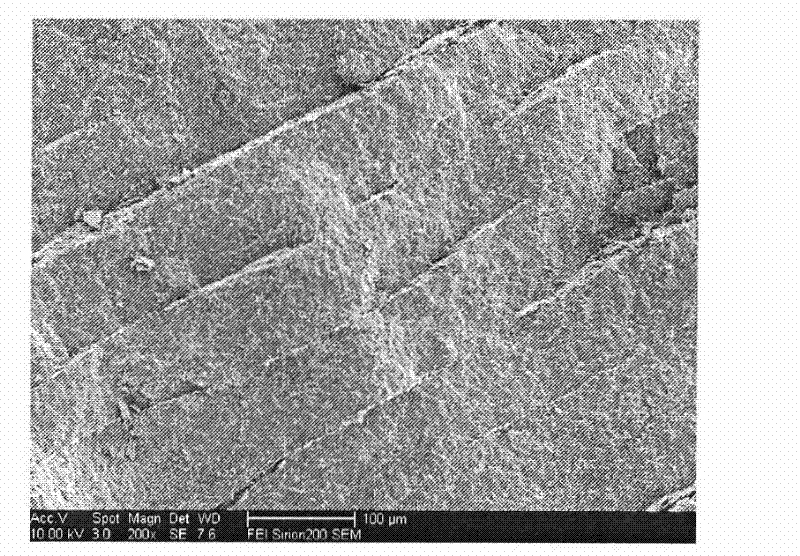

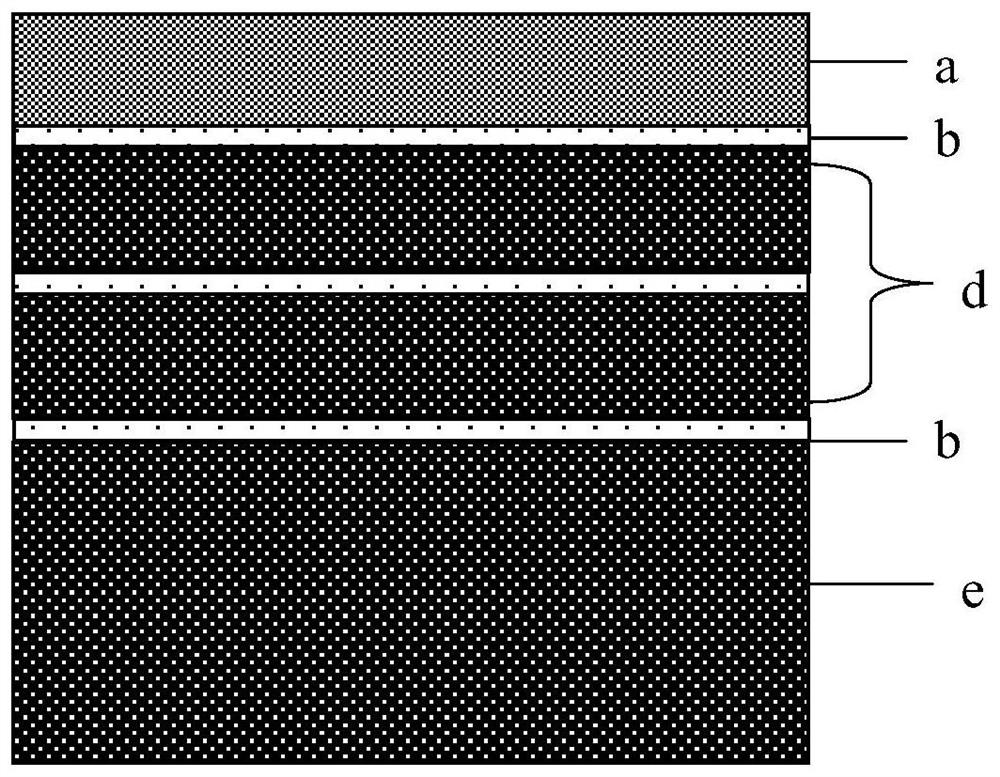

Preparation method of zirconium boride-silicon carbide/boron nitride lamellar ultrahigh-temperature ceramic

InactiveCN102173827AImprove fracture toughnessAdd extension pathCeramic layered productsBorideHigh fracture

The invention provides a preparation method of zirconium boride-silicon carbide / boron nitride lamellar ultrahigh-temperature ceramic. The preparation method of the zirconium boride-silicon carbide / boron nitride lamellar ultrahigh-temperature ceramic is characterized by comprising the following steps of: (1) respectively preparing a zirconium boride casting sheet and a boron nitride casting sheet by adopting a casting method: firstly adding a binder and a plasticizer to a solvent, uniformly stirring, then respectively adding zirconium boride ceramic powder and boron nitride boride ceramic powder, uniformly stirring to form casting materials, then carrying out casting forming, and drying and demoulding at room temperature to respectively obtain the zirconium boride casting sheet with the thickness of 200-1000 micrometers and the boron nitride casting sheet with the thickness of 20-100 micrometers; (2) respectively slicing the zirconium boride casting sheet and the boron nitride casting sheet according to the size of a mould; (3) alternately overlapping the zirconium boride slices and the boron nitride slices, placing into a graphite grinding tool, and degreasing in vacuum; and (4) carrying out hot pressed sintering in an argon atmosphere to prepare the lamellar ultrahigh-temperature ceramic. The invention has simple preparation process, low cost and controllable component; and in addition, an obtained material has higher high-temperature oxidation resistance and reaches high fracture toughness at 18.1 MPa.m<1 / 2>.

Owner:SHANDONG UNIV OF TECH

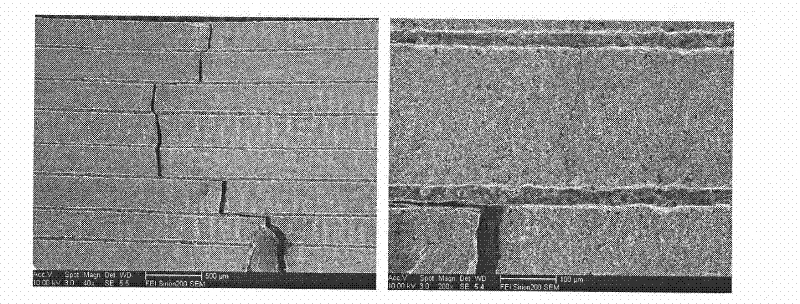

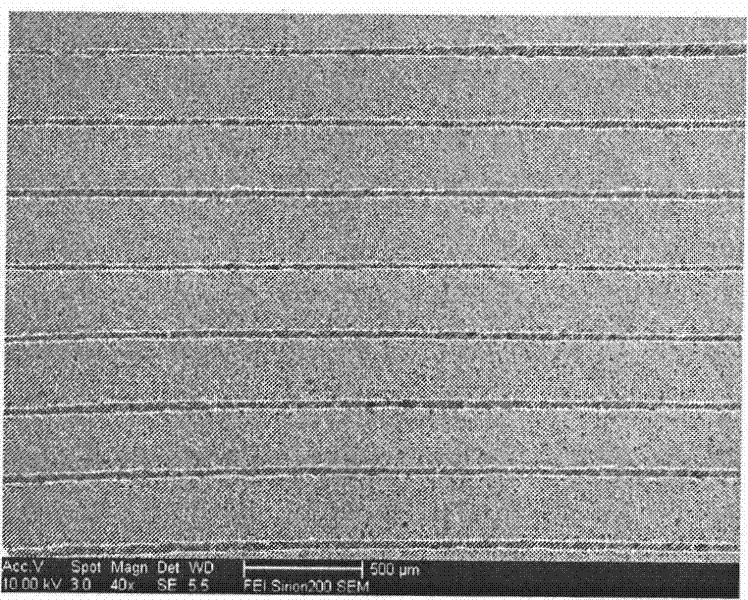

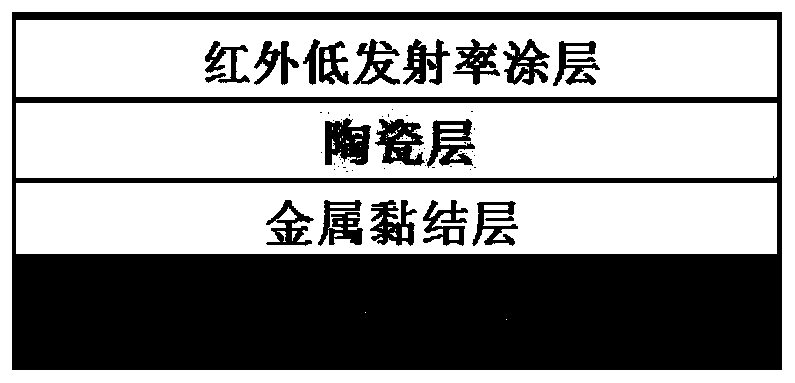

Thickness-adjustable heat insulation/infrared stealth composite coating, titanium alloy material with surface coated with coating and preparation method of titanium alloy material

ActiveCN111118439AWith thermal insulationWith high temperature infrared stealth performanceMolten spray coatingAluminateCeramic coating

The invention relates to the field of high-temperature functional ceramic coating materials, and particularly discloses a thickness-adjustable thermal insulation / infrared stealth composite coating. The composite coating is of a multi-layer stacked structure and sequentially comprises a metal bonding layer, a ceramic layer and an infrared low-emissivity layer from inside to outside, the ceramic layer is a lanthanum phosphate-hexaaluminate composite ceramic layer, and the infrared low-emissivity layer is a low-emissivity coating which is formed by taking Bi2O3-Al2O3-TiO2-Li2O-SiO2 series low-melting-point glass as a binding phase and taking silver as a conductive phase. A titanium alloy material with the surface coated with the coating and a preparation method of the titanium alloy materialare further provided. The heat insulation / infrared stealth composite coating has the characteristics of excellent thermal shock resistance and high-temperature infrared low emissivity; and the thickness of the coating can be regulated and controlled according to different actual application requirements, and the density and the heat insulation performance of the coating surface can be regulated.

Owner:NAT UNIV OF DEFENSE TECH

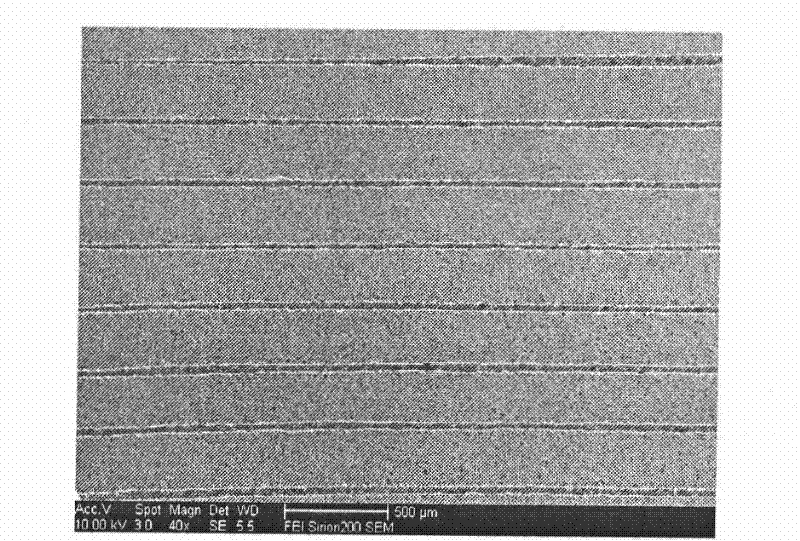

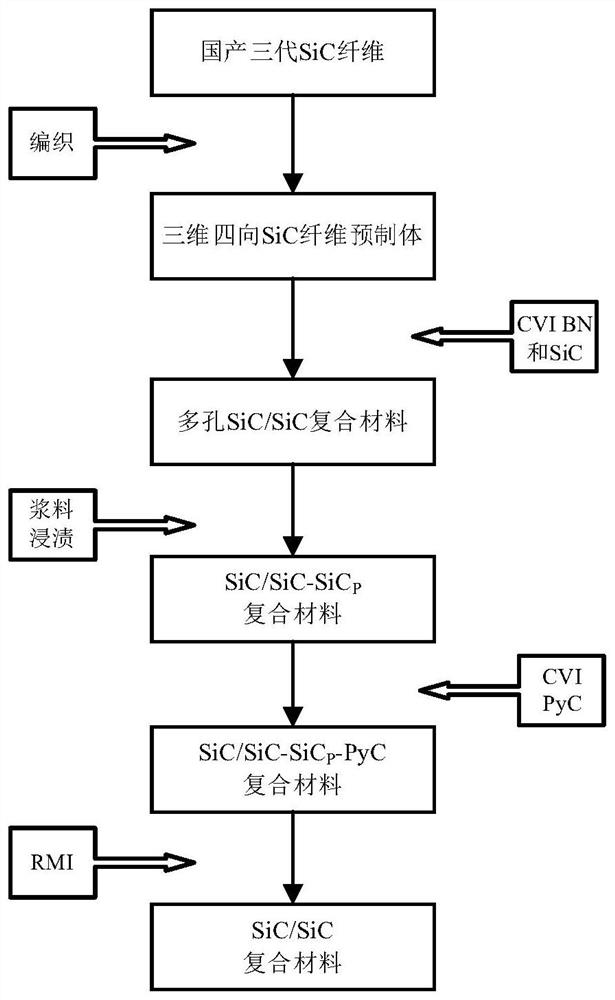

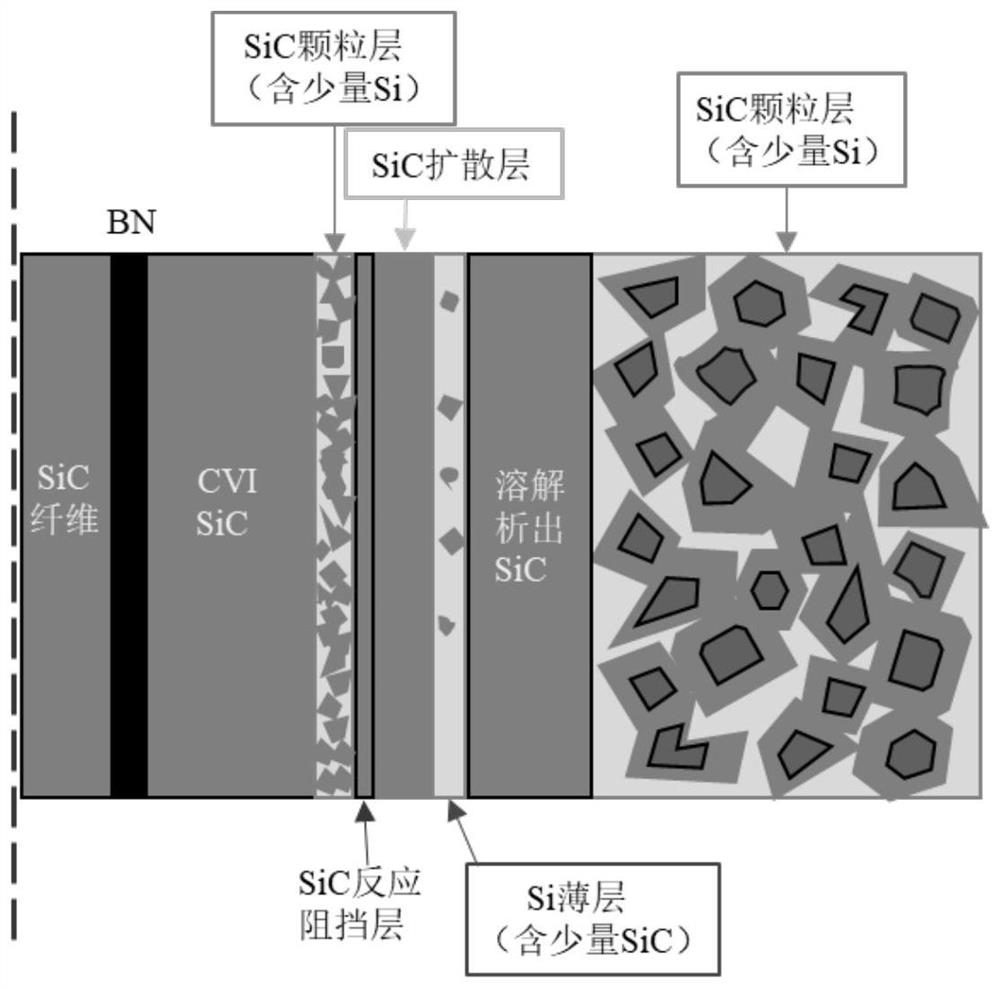

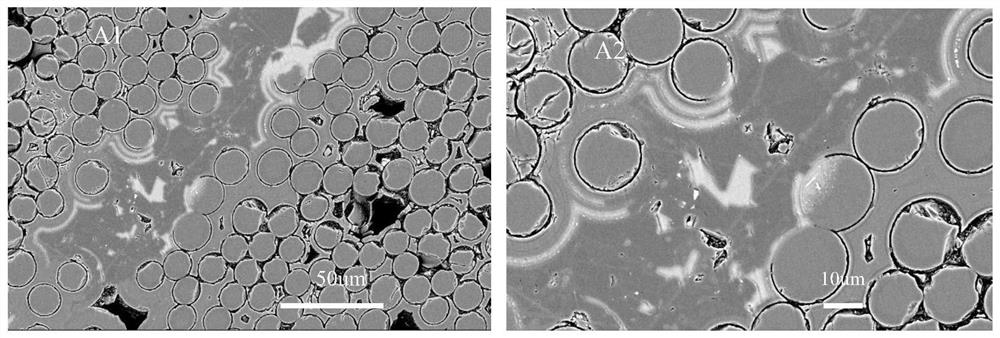

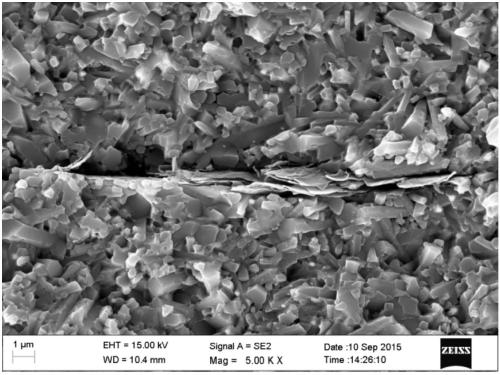

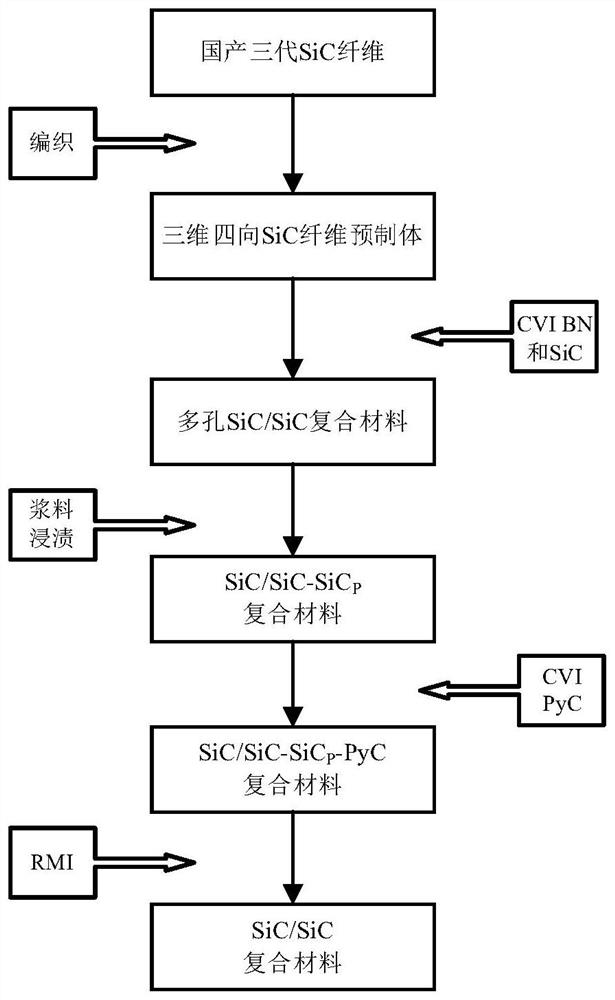

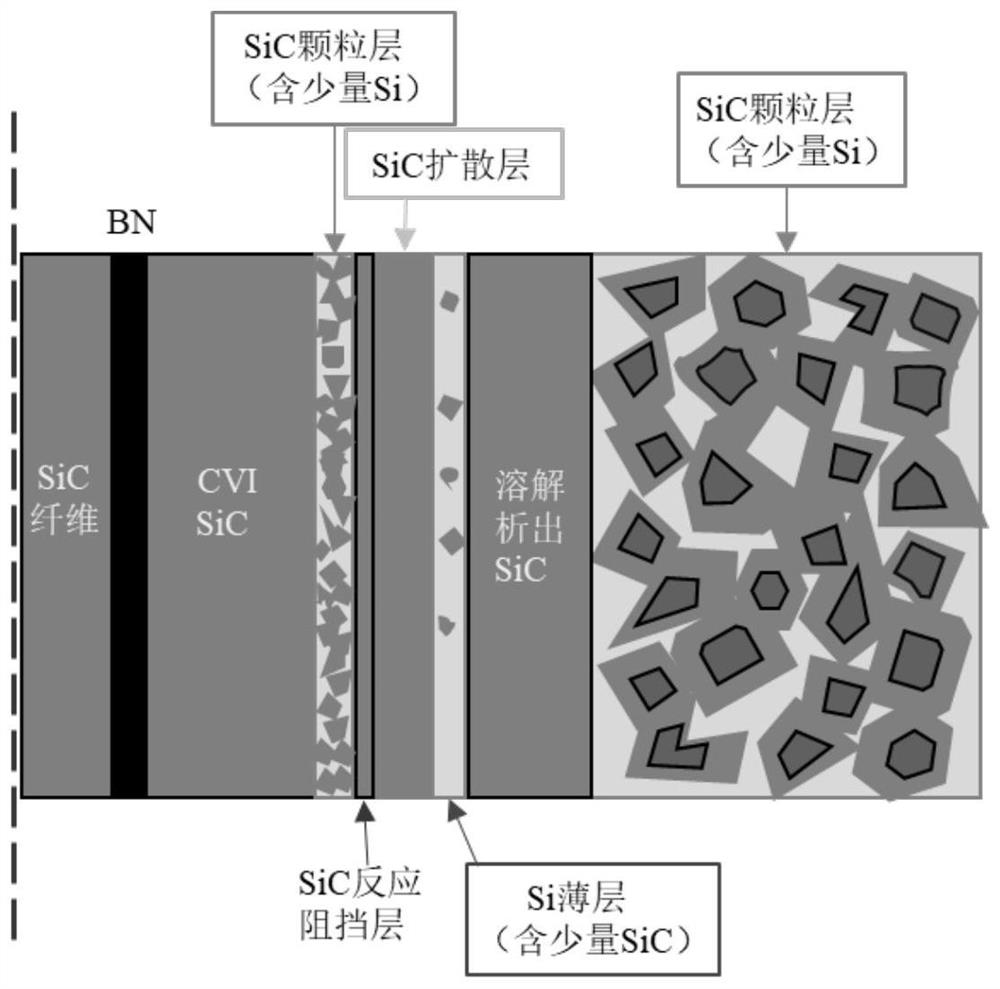

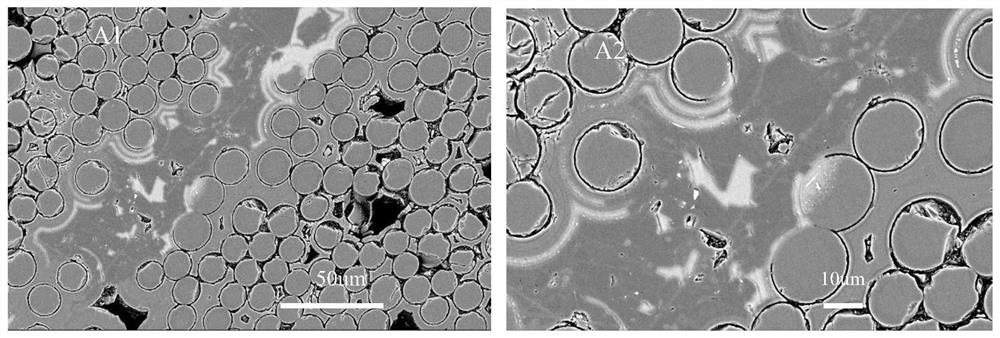

SiC/SiC composite material high-density multilayer matrix and preparation method thereof

The invention relates to a SiC / SiC composite material high-density multilayer matrix and a preparation method thereof. Prepared SiC particle (SiCp) slurry is introduced into a porous SiC / SiC composite material through vacuum impregnation and pressure impregnation methods, then a certain content of pyrolytic carbon is prepared in the porous SiC / SiC composite material by adopting a CVI method, the SiC particles are uniformly wrapped by the pyrolytic carbon, and finally, densification of the SiC / SiC composite material is completed through reaction of pyrolytic carbon and molten silicon by adopting an RMI method. SiC particles with different particle sizes are sequentially introduced to form a layered structure, so that a genetic effect is generated on subsequently prepared PyC and SiC matrixes, a uniform SiC matrix phase with a high volume fraction is obtained, the density of the composite material is increased, the energy of crack propagation is increased, and the mechanical property of the composite material is effectively improved. The composite material prepared by the method has a SiC matrix phase with high volume fraction and uniform distribution, high mechanical property and low open porosity, and solves the problems of low SiC phase content, non-uniform distribution and insufficient toughness in the SiC / SiC matrix prepared by the existing RMI process method.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

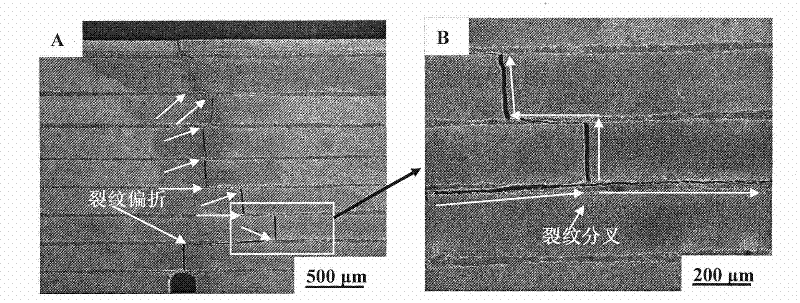

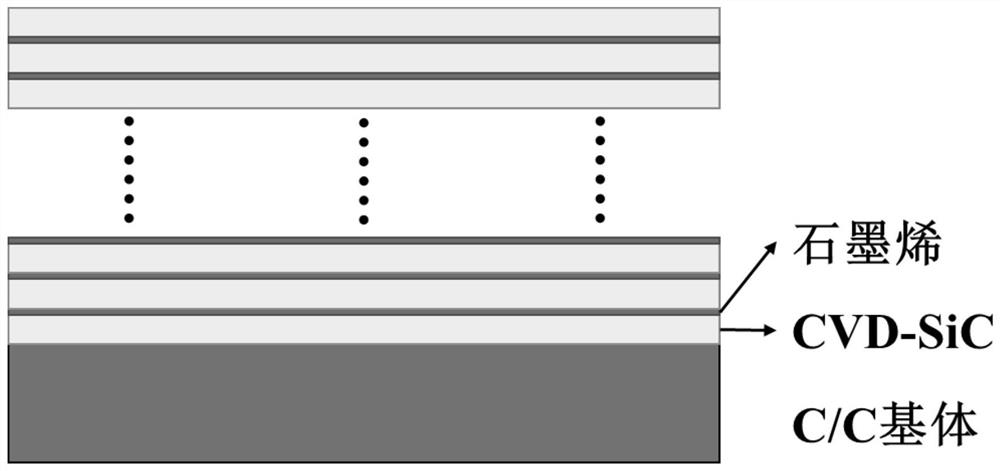

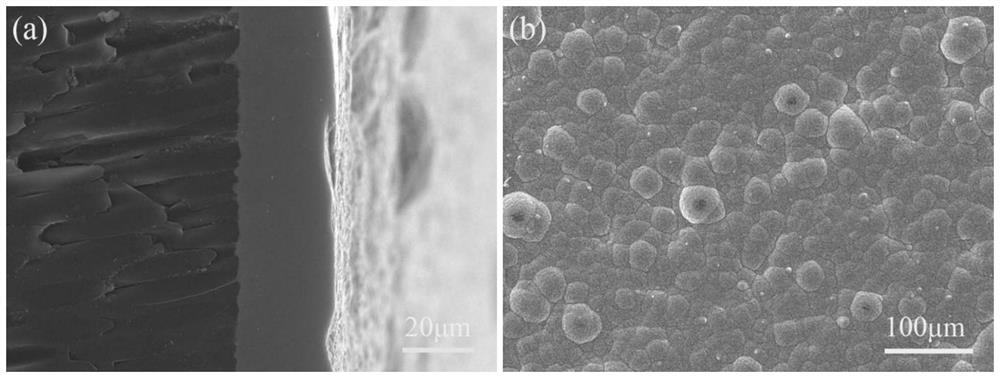

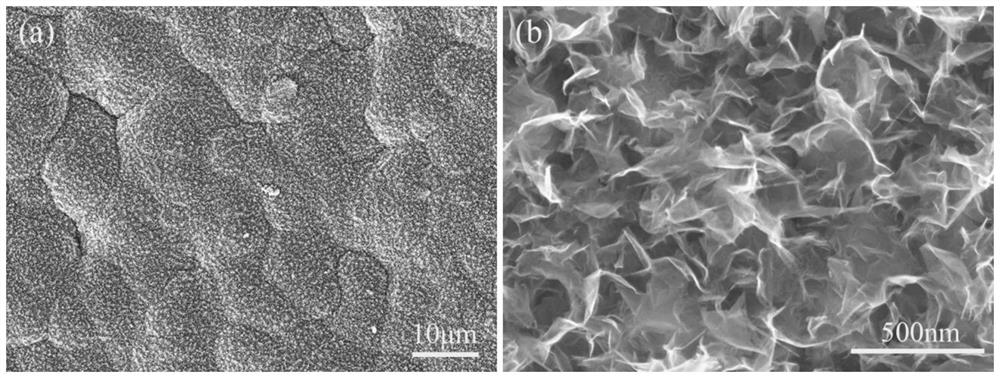

Silicon carbide/graphene bionic laminated coating and preparation method thereof

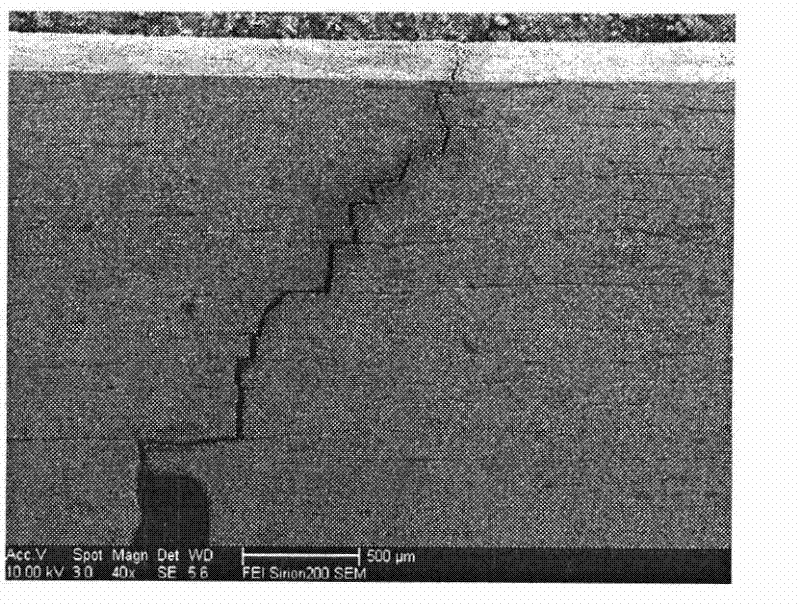

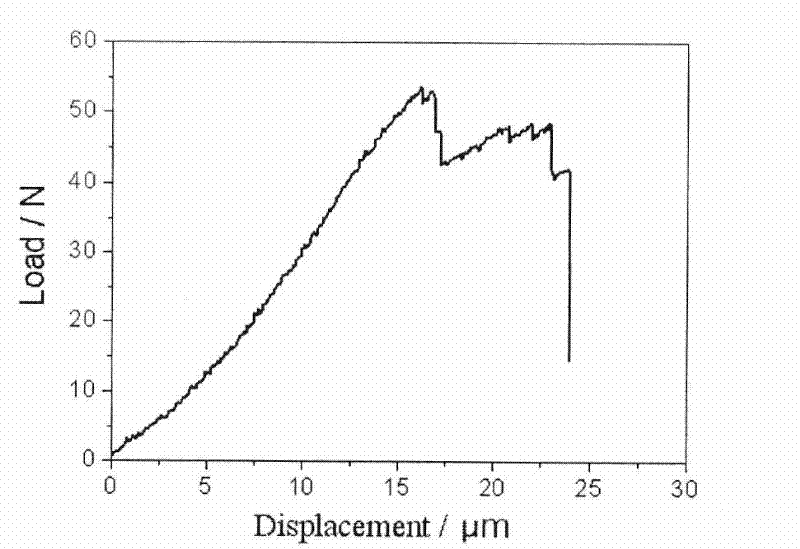

The invention relates to a silicon carbide / graphene bionic laminated coating and a preparation method thereof. SiC and graphene are alternately deposited through a chemical vapor deposition method to obtain a novel ceramic coating with a bionic multi-layer structure, and the structural effect of the novel ceramic coating is utilized to realize toughening of the ceramic coating. The introduced graphene plays a role as a weak interface, when the crack expands to the weak interface, the crack deflects, and after the crack expands for a certain distance along the weak interface, the crack continues to expand towards a next SiC layer and deflects again when reaching the weak interface. The crack propagation path is greatly increased and more energy can be absorbed due to repeated deflection of the crack on the weak interface, so that the fracture work is greatly increased and the fracture toughness is improved. Through the designed laminated coating, the sensitivity to cracks can be reduced, the cracks are expanded in a stepped manner, and the generation of penetrating cracks is avoided, so that the oxidation resistance of the coating is improved, and a C / C substrate can be more effectively protected.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

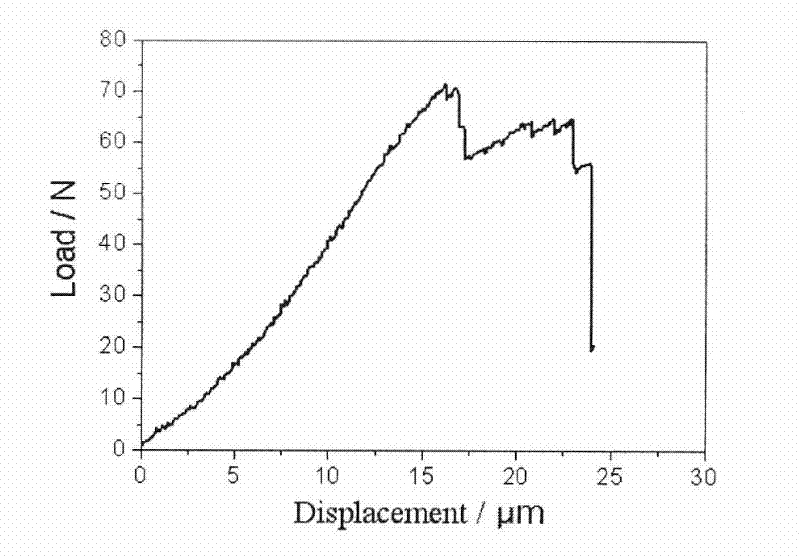

Process for preparing laminar zirconium boride superhigh-temperature ceramic by casting-impregnation method

InactiveCN102173830AAdd extension pathImprove fracture toughnessCeramic layered productsBorideArgon atmosphere

The invention provides a process for preparing laminar zirconium boride superhigh-temperature ceramic by a casting-impregnation method, which is characterized by comprising the following steps: (1) preparing a zirconium boride casting sheet by a casting method: evenly stirring adhesive, plasticizer and solvent, adding zirconium boride ceramic powder to form a casting material, carrying out casting molding, drying at room temperature, and demolding to obtain the casting sheet which is 200-1000 mu m thick; (2) impregnating the casting sheet in graphite or boron nitride slurry by an impregnationmethod so as to impregnate the casting sheet; (3) slicing the casting sheet according to the size of a mold; (4) superposing the sliced casting sheets into the mold, and degreasing in vacuum; and (5)carrying out hot pressed sintering in an argon atmosphere to obtain the laminar zirconium boride superhigh-temperature ceramic of which the fracture toughness is up to 8.3 MPa.m<1 / 2>. The fracture mode of the laminar zirconium boride ceramic is non-brittle fracture, i.e. the laminar zirconium boride ceramic gradually fractures while having certain tolerance to cracking damage, and has favorable performance.

Owner:SHANDONG UNIV OF TECH

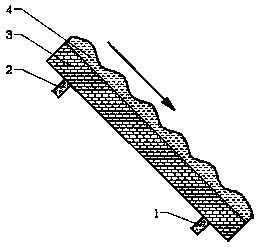

Preparation method for layered multiphase ceramic

The invention discloses a preparation method for a layered multiphase ceramic. The method includes the following preparation steps: firstly preparing an interfacial layer casting sheet and ceramic granulation powder, flatly spreading a layer of the ceramic granulation powder on the top surface of a pressure head of a mold, spreading a layer of the interfacial layer casting sheet on the basis, sequentially repeating the operation of reducing the height of the pressure head of the mold, flatly spreading a layer of the ceramic granulation powder and spreading a layer of the interfacial layer casting sheet on the ceramic granulation powder, reducing the height of the pressure head of the mold for the last time, flatly spreading the ceramic granulation powder, performing one-time pressure forming to obtain a layered multi-phase ceramic green body, finally performing degreasing, and performing sintering to obtain the required layered multi-phase ceramic product. The method provided by the invention uses a combination of the casting technology and the dry pressure forming technology, uses the casting technology to form the interface sheet to make the thickness of an interface layer accurate and controllable, and adopts the one-time pressure forming method to prepare the layered multi-phase ceramic, and the wavy structure of the interface layer makes a crack propagation path increased,and further improves the fracture toughness of the ceramic.

Owner:NINGBO VULCAN TECH CO LTD

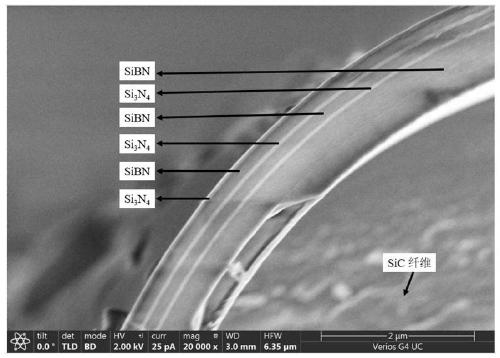

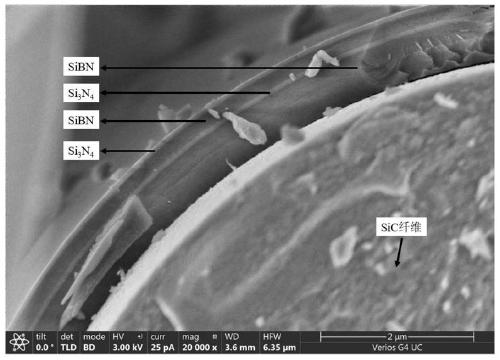

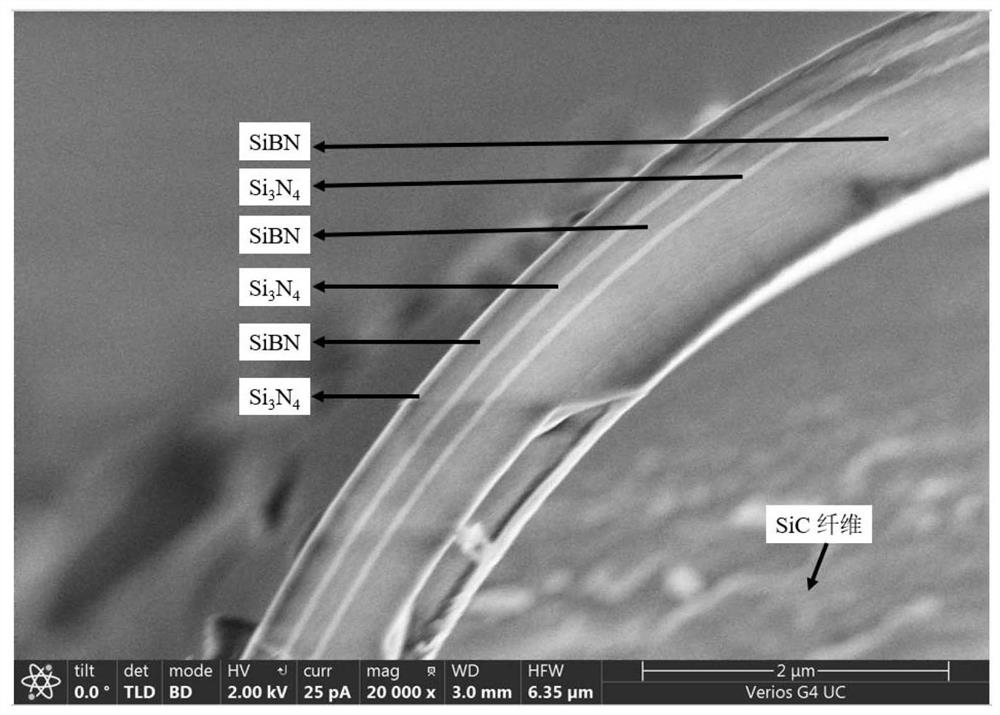

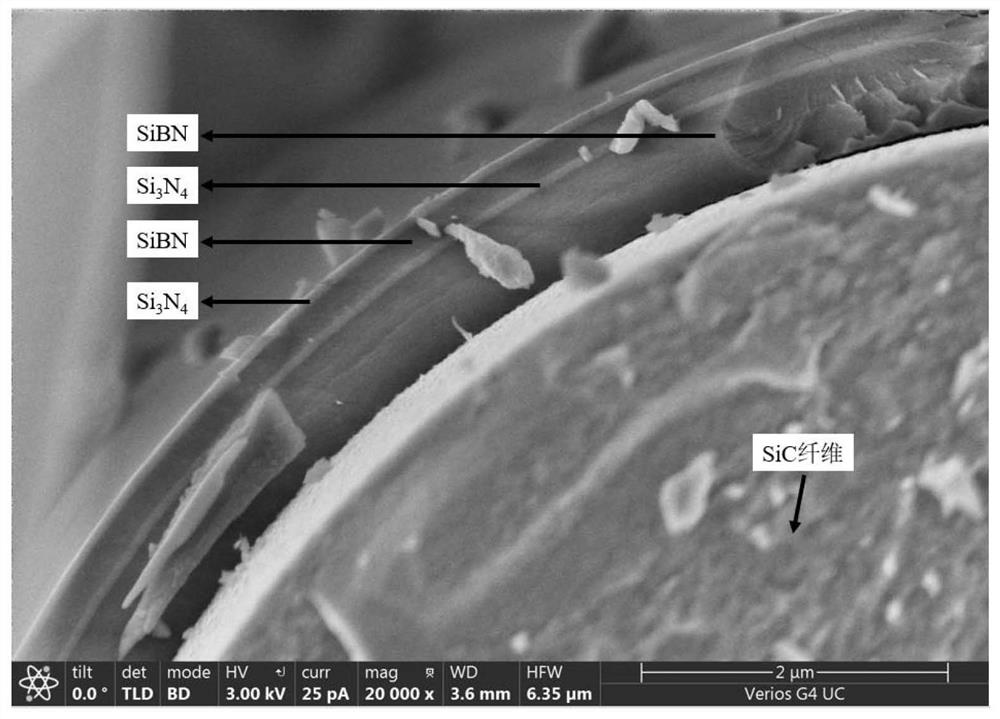

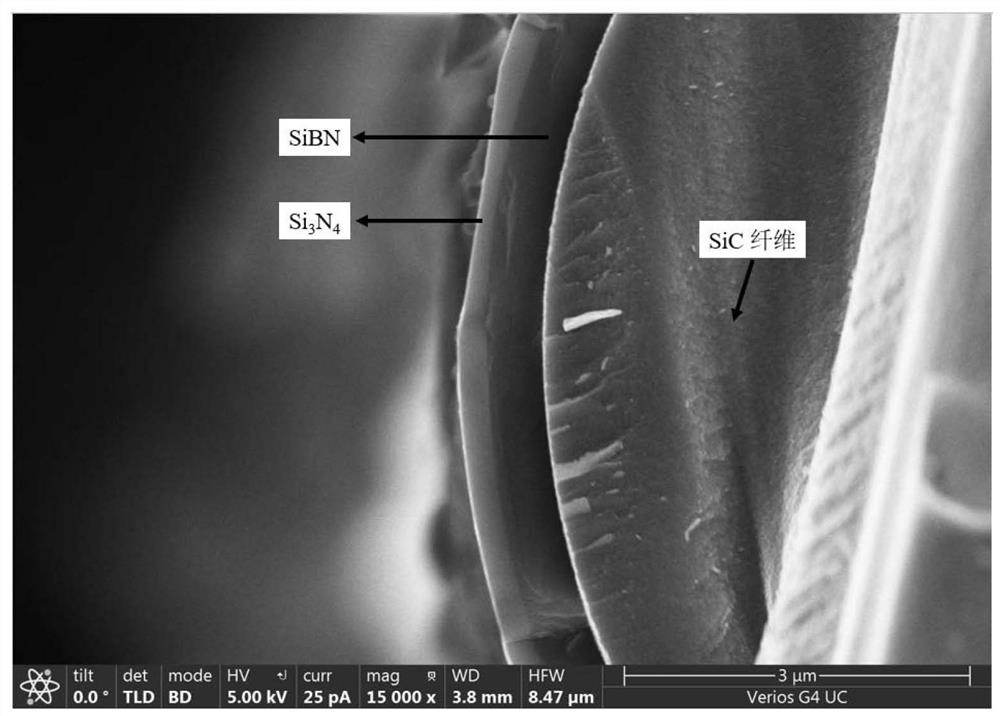

Multi-layer interface coating, and preparation method and application thereof

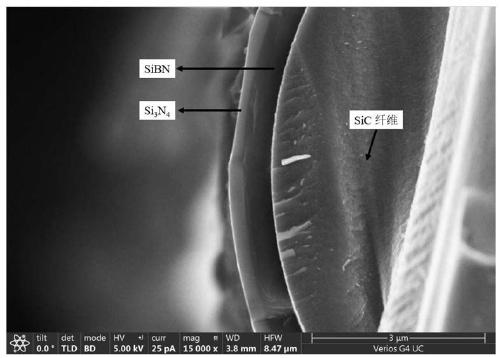

The invention relates to a multi-layer interface coating, and a preparation method and application thereof. The multi-layer interface coating comprises SiBN coating layers and Si3N4 coating layers which are alternately formed on the surface of a substrate in sequence, wherein the number of layers of the SiBN coating layers is larger than or equal to 1, and is preferably in a range of 2-5.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

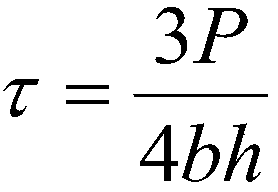

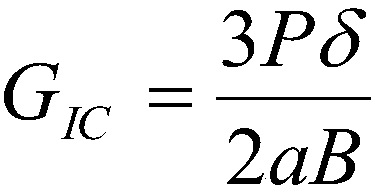

Method for improving interlayer mechanical property of two-dimensional fiber cloth reinforced ceramic-based composite material

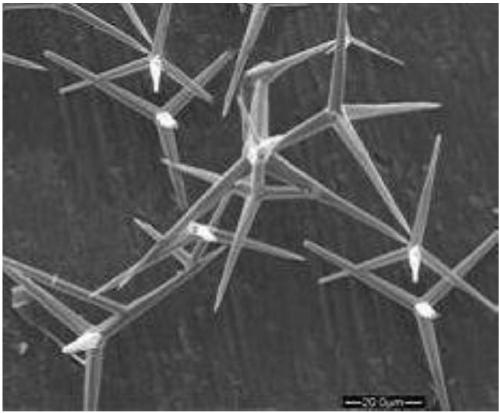

ActiveCN109228604AImproved shear strength and toughnessSimple methodLamination ancillary operationsLaminationOxideZinc

The invention provides a method for improving interlayer mechanical property of a two-dimensional fiber cloth reinforced ceramic-based composite material. The method solves the problem that interlayersubstrate slurry and sol are not uniformly microcosmically distributed in the prior art, thus the interlayer shearing intensity is excessively low, or the interlayer shearing intensity greatly increases, and as a result, the damage tolerance limit of a material decreases. The method comprises the steps of coating slurry or sol in which tetrapod-like zinc oxide whiskers are uniformly mixed or themixture of the slurry and the sol on two-dimensional fabric clothes; overlapping; thermally pressing; permeating; drying; removing ester; sintering, wherein the tetrapod-like zinc oxide whiskers can form a network; each tetrapod-like zinc oxide whisker can coat the slurry or the soil in order to be uniformly distributed among the two-dimensional fabric clothes; a tetrapod-like bodies can penetratethe two-dimensional fabric cloth and perform bridging reinforcing effect among the two-dimensional fabric clothes; in addition, the expansion route of cracks in a substrate can be greatly increased;the quantity of added tetrapod-like zinc oxide whiskers can be adjusted to improve the interlayer shearing intensity and toughness of the two-dimensional fiber cloth reinforced ceramic-based compositematerial.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

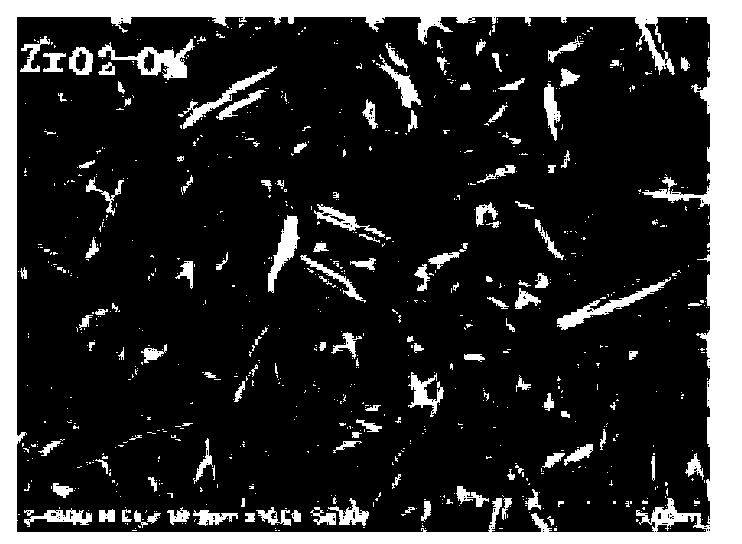

Preparation method of microcrystalline zirconium nano ceramic material

The invention relates to a preparation method of a microcrystalline zirconium nano-ceramic material, which belongs to the field of ceramic preparation. This method uses zirconium oxychloride as raw material to prepare nano-zirconia, and then through gel titration, magnesium oxide is used as crystal nucleating agent to obtain microcrystalline zirconia, supplemented with silicon dioxide, etc., and finally microcrystalline is obtained by plasma sintering. Zirconium nano ceramic material. The microcrystalline zirconium nano ceramic material prepared by the present invention also has high thermal conductivity and extremely low coefficient of thermal expansion, no water absorption, good insulation performance, compact and uniform structure, excellent properties such as impact resistance, wear resistance and corrosion resistance, and has wide applications. prospect.

Owner:张静

A kind of multi-layer interface coating and its preparation method and application

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing TiB2 and CuO codoped 3Y-TZP nano composite ceramics by microwave sintering at low temperature

The invention relates to a method for preparing TiB2 and CuO codoped 3Y-TZP nano composite ceramics by microwave sintering at a low temperature, which comprises the following steps: carrying out liquid phase dispersion and ultrasonic dispersion on TiB2, CuO and 3Y-TZP nano powder in a certain proportion for 40 min; then, pouring uniformly mixed suspension into a ball-milling jar, and carrying out continuous mechanical ball milling on the suspension for 50 h by using a cemented carbide ball; rapidly pouring the ball-milled and mixed slurry into a stainless steel powder plate; putting the obtained product into an electrothermal vacuum drying oven to carry out continuous drying; passing the dried composite powder through a 100-mesh steel sieve so as to obtain TiB2 and CuO codoped3Y-TZP nano composite powder; carrying out dry pressing on the nano composite powder; carrying out isostatic pressing on the nano composite powder; and sintering the obtained product by using a MW-L0316V microwave high-temperature sintering furnace so as to obtain a 3Y-TZP nano composite ceramic. The method disclosed by the invention has the advantages that the preparation method is simple, low in energy consumption and high in strength and fracture toughness of products; obtained nano composite ceramics are suitable for industrialized production, more and more taken seriously in the industries of electronics, machinery, petroleum, chemical engineering and the like, and have a broad application prospect.

Owner:NANCHANG HANGKONG UNIVERSITY

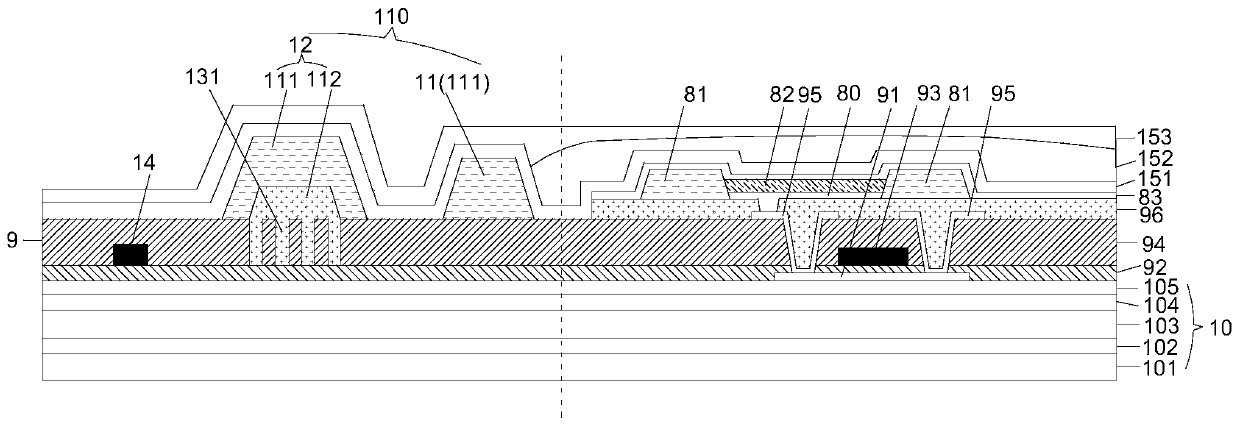

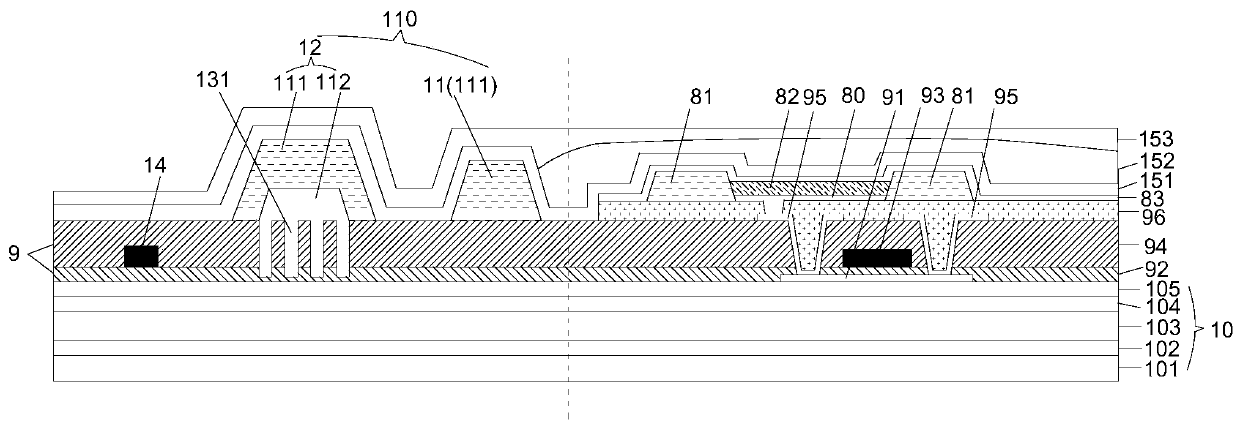

Display panel, preparation method thereof and display device

PendingCN111490181AAvoid damageImprove packaging effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringDisplay device

The invention provides a display panel, a preparation method thereof and a display device. The display panel comprises a substrate, an insulating layer is arranged in the peripheral area of the substrate, at least one packaging dam is arranged on the side, away from the substrate, of the insulating layer, the packaging dam is located in the peripheral area of the substrate and surrounds a displayarea, and at least one groove is formed in the insulating layer and surrounds the display area, wherein the projection of the at least one groove on the substrate is located in the projection of the packaging dam on the substrate. The groove can slow down or prevent a crack from extending towards the display area, and the packaging effect is improved. Meanwhile, because the groove is arranged below the packaging dam, the width of the peripheral area can be reduced, and the screen-to-body ratio is improved.

Owner:BOE TECH GRP CO LTD +1

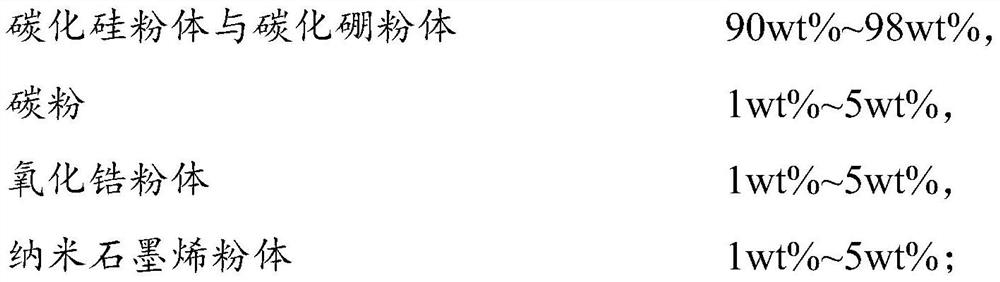

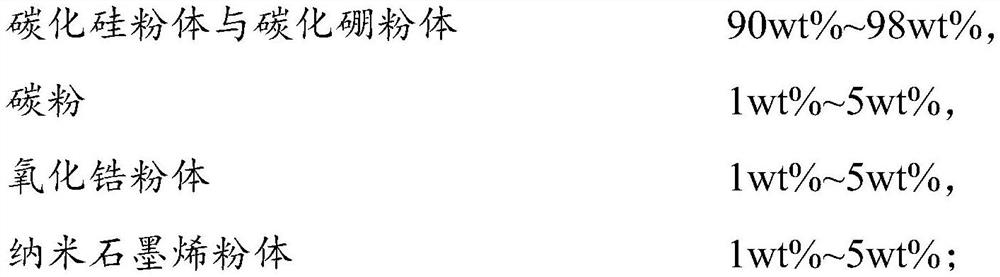

Nano-powder modified silicon carbide-boron carbide composite ceramic and preparation method thereof

ActiveCN114591086AAdd extension pathAbsorb moreNuclear energy generationCarbide siliconComposite ceramic

The invention discloses a nano-powder modified silicon carbide-boron carbide composite ceramic, which is prepared from the following components in percentage by mass: 90 to 98 weight percent of silicon carbide powder and boron carbide powder, 1 to 5 weight percent of carbon powder, 1 to 5 weight percent of zirconium oxide powder and 1 to 5 weight percent of nano graphene powder, wherein the mass ratio of the silicon carbide powder to the boron carbide powder is (1: 4)-(4: 1); the silicon carbide powder comprises nano silicon carbide powder and micron silicon carbide powder, the mass of the nano silicon carbide powder is 5wt%-20wt%, the boron carbide powder comprises nano boron carbide powder and micron boron carbide powder, and the mass of the nano boron carbide powder is 5wt%-20wt%. The invention also provides a preparation method of the composite ceramic. The preparation method comprises the following steps: (1) primary nano-powder mixing; (2) secondary powder mixing; (3) spray granulation; (4) pressure forming; (5) presintering; and (6) final sintering. According to the preparation method, the SiC-B4C composite ceramic with improved hardness and strength can be prepared, the uniformity of the performance of the composite ceramic is improved, the sintering temperature is low, and the preparation efficiency is improved.

Owner:YANTAI BRANCH NO 52 INST OF CHINA NORTH IND GRP

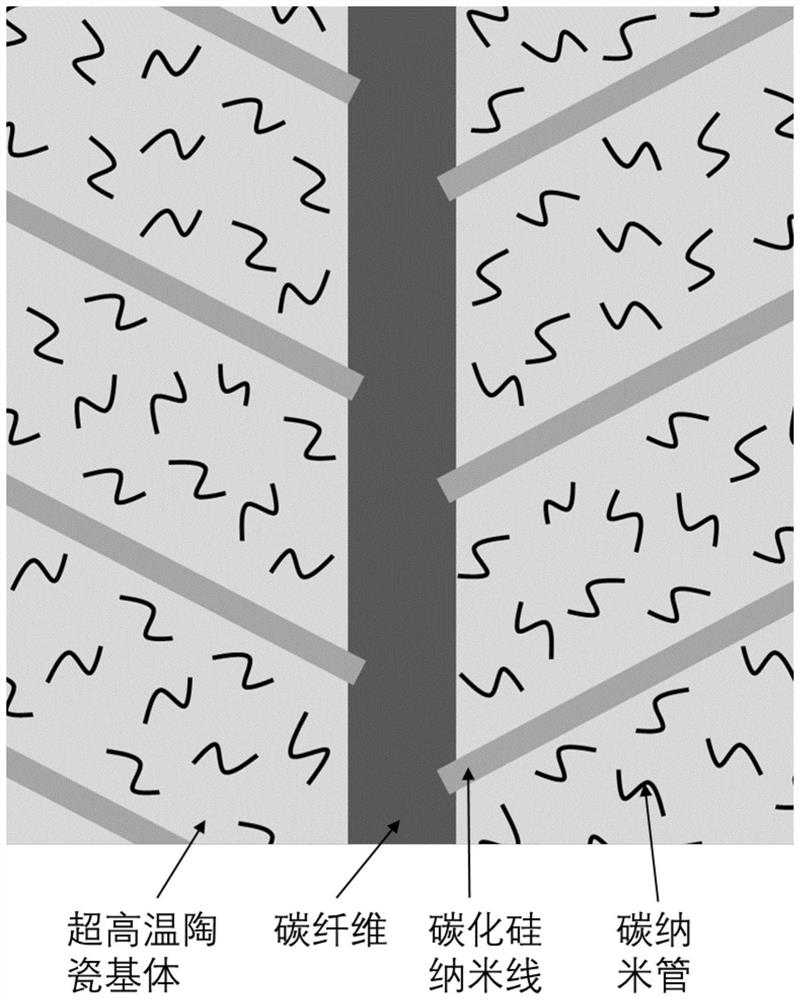

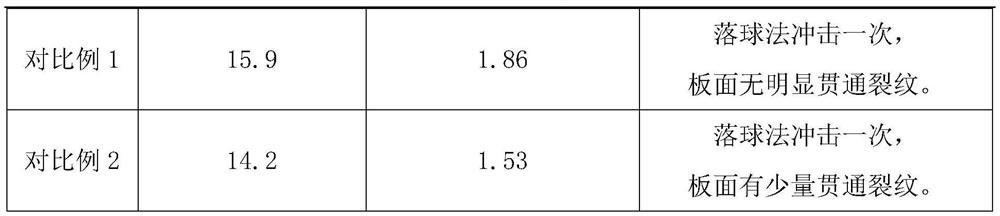

Graded toughened ultrahigh-temperature ceramic-based composite material inspired by leaves and preparation method thereof

The invention belongs to the field of ultrahigh-temperature ceramic-based composite materials, and particularly relates to a graded toughened ultrahigh-temperature ceramic-based composite material inspired by leaves and a preparation method thereof. The preparation method includes the steps that firstly, carbon fibers are coated with a polyethersulfone coating, then silicon carbide nanowires growon the carbon fibers with polyethersulfone as a carbon source, and first-level veins and second-level veins are constructed; secondly, impregnating the carbon fiber on which the silicon carbide nanowires grow into the ultrahigh-temperature ceramic slurry containing the carbon nanotubes, constructing third-stage veins, and drying to obtain a pre-sintered blank; and finally, preparing the graded toughened ultrahigh-temperature ceramic-based composite material inspired by the leaves through hot-pressing sintering. According to the special hierarchical structure, the expansion direction of crackscan be changed through mechanisms such as pulling out, debonding and bridging of the first-stage vein, the second-stage vein and the third-stage vein, the expansion path of the cracks is increased, more breaking energy is absorbed, and the prepared composite material has excellent thermal shock resistance and breaking resistance.

Owner:DALIAN UNIV OF TECH

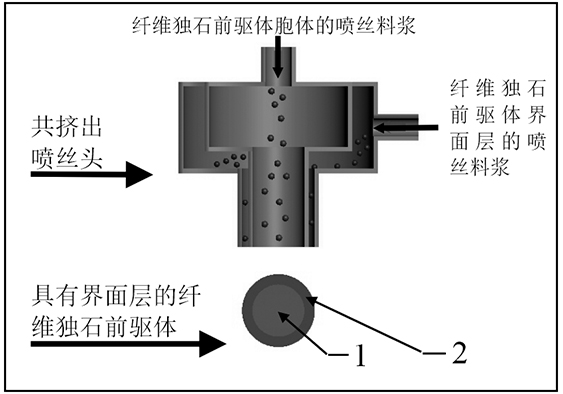

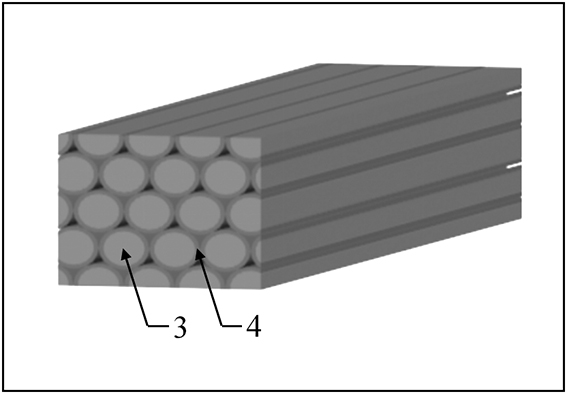

Process for preparing weak interface fiber monolith hafnium boride ceramic by wet spinning and co-extrusion method

InactiveCN111848175AThin diameterImprove plasticityInorganic material artificial filamentsWet spinning methodsFiberBoride

The invention provides a process for preparing weak interface fiber monolith hafnium boride ceramic by a wet spinning and co-extrusion method. The method is characterized by comprising the following steps of: (1) adding a curing agent and a plasticizer into an organic solvent, stirring for dissolving the curing agent and the plasticizer, respectively adding ceramic powder of a fibrous monolith precursor cell and ceramic powder of a fibrous monolith precursor interfacial layer, uniformly stirring to form two spinneret slurries with different components, spraying the spinneret slurries into a gel tank filled with water through a co-extrusion spinneret under mechanical pressure, and carrying out solidification molding to obtain a fibrous monolith precursor with an interfacial layer; (2) carrying out warm-pressing molding; (3) carrying out vacuum degreasing; and (4) carrying out hot-pressing sintering to obtain the weak interface fiber monolith hafnium boride ceramic, the fracture toughness of which can reach 9 MPa.m<1 / 2> or above. The process for forming the fibrous monolith precursor through the wet spinning co-extrusion method is simplified, mechanical arrangement is facilitated, the microstructure of the obtained fibrous monolith hafnium boride super-high-temperature ceramic is accurately controlled, the fracture mode is non-brittle fracture, and the performance is excellent.

Owner:SHANDONG UNIV OF TECH

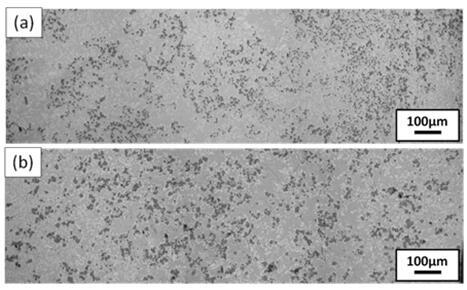

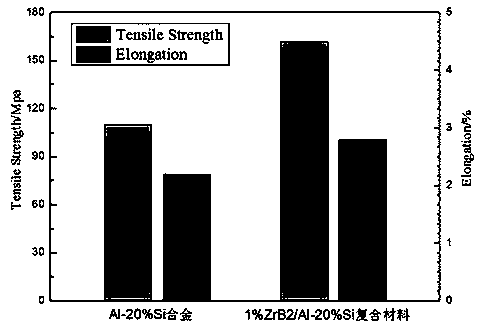

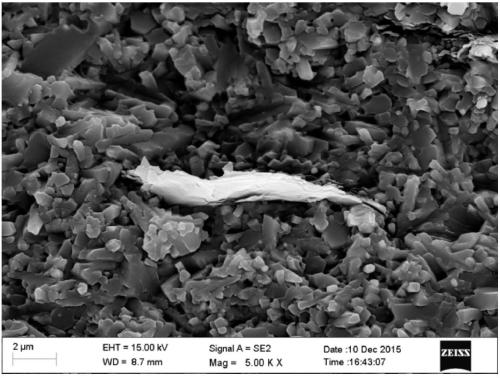

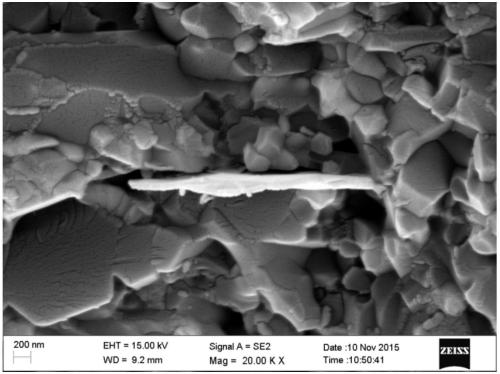

Method for regulating and controlling overall performance of hypereutectic aluminum-silicon alloy casting

The invention discloses a method for regulating and controlling the overall performance of a hypereutectic aluminum-silicon alloy casting. According to the method, in the preparation process of an eutectic aluminum-silicon alloy casting, submicron second-phase particles are introduced into a melt to prepare a particle-reinforced hypereutectic aluminum-silicon alloy composite material, when the temperature of the particle-reinforced hypereutectic aluminum-silicon alloy composite material subjected to slag removal and degassing is cooled to 20-30 DEG C above the liquidus temperature, the melt is subjected to over-flow cooling treatment, and the casting with uniform and strengthened micro structures is obtained through semi-solid forming. According to the method, the second-phase reinforcement and the over-flow cooling treatment are combined together, so that the synergistic optimization of the uniformity of the overall performance and the strength and toughness of the particle-reinforced hypereutectic aluminum-silicon alloy composite material casting is realized; and the method is convenient to operate, low in cost, and has high engineering application value.

Owner:KUNMING UNIV OF SCI & TECH

A Si3N4-based ceramic tool material with graphene added and its preparation method

ActiveCN106145957BImprove the lubrication effectToughen and reinforceComposite ceramicFrictional coefficient

Owner:QILU UNIV OF TECH

A kind of sic/sic composite material high density multilayer matrix and preparation method

ActiveCN113754442BHigh densityImprove mechanical propertiesNuclear energy generationCrazingHigh density

The invention relates to a high-density multi-layer matrix of SiC / SiC composite material and a preparation method. p ) The slurry was introduced into the porous SiC / SiC composite material by vacuum impregnation and pressure impregnation, and then a certain content of pyrolytic carbon was prepared in the porous SiC / SiC composite material by the CVI method to make it evenly wrap the SiC particles. The densification of SiC / SiC composites was accomplished by the reaction of pyrolytic carbon and molten silicon by RMI method. The sequential introduction of SiC particles with different particle sizes forms a layered structure, which has a genetic effect on the subsequent preparation of PyC and SiC matrix, and obtains a uniform and high volume fraction of SiC matrix phase, which increases the density of the composite material and increases the energy of crack propagation. Effectively improve the mechanical properties of composite materials. The composite material prepared by this method has a SiC matrix phase with high volume fraction and uniform distribution, high mechanical properties and low open porosity, which solves the problem of low SiC phase content and uneven distribution and strong toughness in the SiC / SiC matrix prepared by the current RMI process. insufficient problem.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

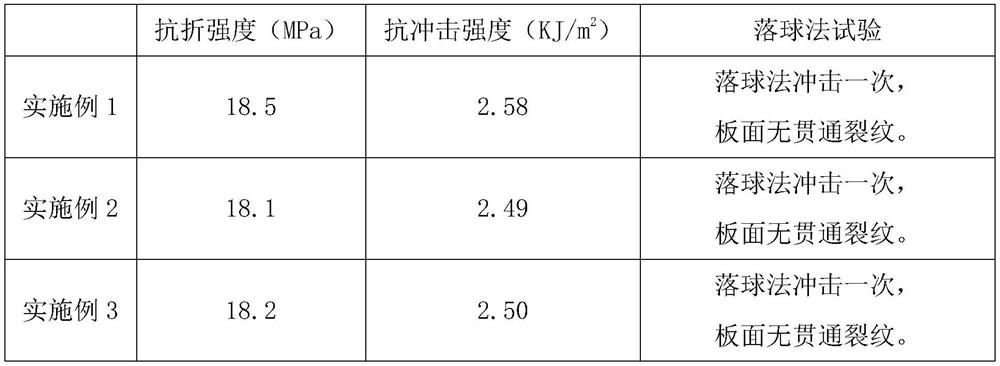

A kind of anti-cracking calcium silicate board and its preparation process

ActiveCN112661473BNo toxicityPlay the role of toughening and strengtheningSolid waste managementCalcium silicateGlass fiber

Owner:广东雄塑环保板业有限公司

Preparation method of columnar crystal alumina/zirconia composite ceramic powder

The invention discloses a preparation method of columnar crystal aluminum oxide / zirconium oxide composite ceramic powder, relates to the field of aluminum oxide / zirconium oxide composite ceramics, and aims to solve the problems that columnar crystals induced by columnar crystal ceramics prepared by a conventional method are low in content, non-uniform in distribution and large in grain size, so that the strength and toughness of the ceramics are insufficient. The method comprises the steps: 1, drying aluminum powder and a diluent; 2, mixing the aluminum powder and the diluent, and carrying out ball milling and sieving to obtain a mixed material; and 3, filling the mixed material into a high-pressure reactor, filling O2 or O2 mixed gas, arranging a nozzle at the lower end, igniting the mixed material, carrying out high-temperature combustion synthesis reaction, forming a high-temperature melt after the reaction is finished, keeping the temperature, opening the nozzle, spraying out the melt, and carrying out liquid-phase cooling to obtain the columnar crystal aluminum oxide / zirconium oxide composite ceramic powder. The prepared ceramic powder has the nano columnar crystal seed, the content of the columnar crystal seed is high, and the ceramic powder has high strength and toughness after being sintered. The method is applied to the field of columnar crystal ceramics.

Owner:HARBIN INST OF TECH

A kind of impact-resistant aluminum alloy composite plate and its preparation method

ActiveCN109263179BAdd extension pathChange direction of expansionMetal layered productsMetallurgyAlloy composite

The invention relates to an impact-resistant aluminum alloy composite plate and a preparation method thereof. The impact-resistant aluminum alloy composite plate includes a first aluminum alloy layer, an aluminum alloy connecting layer, a second aluminum alloy unit, an aluminum alloy connecting layer, and a second aluminum alloy layer connected in sequence, and the second aluminum alloy unit includes One or more second aluminum alloy layers connected by the connection layer; the thicknesses of the first aluminum alloy layer, the second aluminum alloy layer and the aluminum alloy connection layer are respectively 8-15%, 85-92%, and 1-5%. The preparation method provided by the invention can prepare an aluminum alloy composite plate with a component layer ratio of 20% to 40%, and the aluminum alloy composite plate has high strength and excellent impact resistance.

Owner:YINBANG CLAD MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com