Nano-powder modified silicon carbide-boron carbide composite ceramic and preparation method thereof

A technology of nano-boron carbide and nano-silicon carbide, which is applied in the field of bullet-resistant ceramic materials, can solve the problems of no significant improvement in performance, low reliability of bullet-resistant ability, and high sintering temperature, so as to increase the crack propagation path, Lightweight bulletproof performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

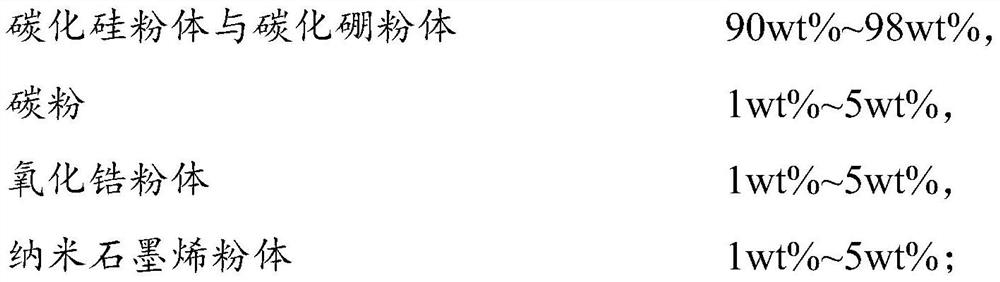

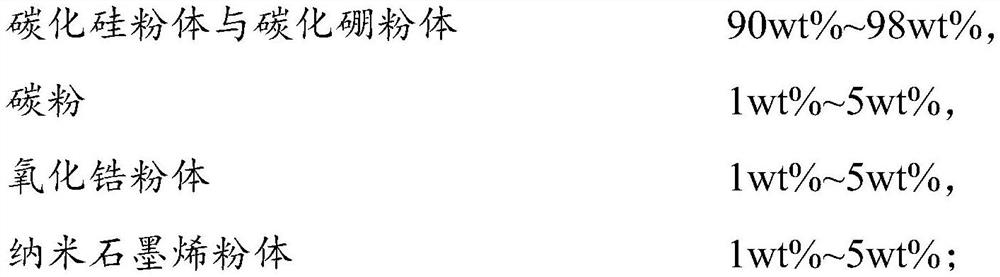

[0038] A nano-modified SiC-B 4 C multiphase ceramics, the composition of the raw materials and the mass fraction of each component are calculated according to the mass percentage: the mass ratio of silicon carbide powder to boron carbide powder is 4:1, and the two powders account for 98wt% of the total mass, The mass of carbon powder with a particle size of 20nm is 1wt%, and the mass of zirconia powder is 1wt%. Among them, the particle size of nano-SiC is 50nm, accounting for 20wt% of the SiC powder, the particle size of micro-SiC is 0.58μm, and the particle size of micron B is 50nm. 4 C particle size is 0.58μm;

[0039] The preparation method is:

[0040] The first step, nano-powder mixing ball milling: put nano-SiC and nano-carbon powder into the ball mill tank, add deionized water and dispersant for ball milling for 6 hours, and the ball milling speed is 400r / min, in which the ratio of ball to material is 3:1, and the ratio of liquid to material is 3:1. is 1:1; wherein, the...

Embodiment 2

[0048] A nano-modified SiC-B 4 C multiphase ceramics, the composition of the raw materials and the mass fraction of each component are calculated according to the mass percentage: the mass ratio of silicon carbide powder and boron carbide powder is 1:1, the two powders account for 96wt% of the total mass, and the particle size The mass of 50nm carbon powder is 2wt%, and the mass of zirconia is 2wt%. Among them, nano B 4 The particle size of C is 50nm, accounting for B 4 20wt% of C powder, micron B 4 The particle size of C is 0.8 μm, and the particle size of micron SiC is 0.8 μm;

[0049] The preparation method is:

[0050] The first step, nano-powder mixing ball milling: the nano-B 4 C, the nano carbon powder is loaded into the ball mill tank, deionized water and dispersant are added for ball milling for 8h, and the ball milling speed is 450r / min, wherein the ratio of ball to material is 3.5:1, and the ratio of liquid to material is 2:1; wherein, the dispersant is polyacry...

Embodiment 3

[0058] A nano-modified SiC-B 4 C multiphase ceramics, the composition of the raw materials and the mass fraction of each component are calculated according to the mass percentage: the mass ratio of silicon carbide powder and boron carbide powder is 1:4, the two powders account for 93wt% of the total mass, and the particle size The mass of carbon powder with a thickness of 50nm is 2wt%, the mass of zirconia is 2wt%, and the content of graphene with a thickness of 50nm is 3wt%; among them, the nano-B 4 The particle size of C is 70nm, accounting for B 4 20wt% of C powder; particle size of nano-SiC is 70nm, accounting for 10wt% of SiC powder; Micron B 4 The particle size of C is 1.0 μm, and the particle size of micron SiC is 1.0 μm;

[0059] The preparation method is:

[0060] The first step, nano-powder mixing ball milling: the nano-B 4 C. Nano carbon powder, nano SiC and nano graphene powder are loaded into the ball mill tank, deionized water and dispersant are added for bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com