Preparation method of columnar crystal alumina/zirconia composite ceramic powder

A technology of crystalline alumina and composite ceramics, which is applied in the field of preparation of columnar crystalline alumina/zirconia composite ceramic powder, which can solve the problems of insufficient ceramic strength and toughness, less columnar crystal content, uneven distribution, etc., and increase crack propagation path, uniform distribution, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

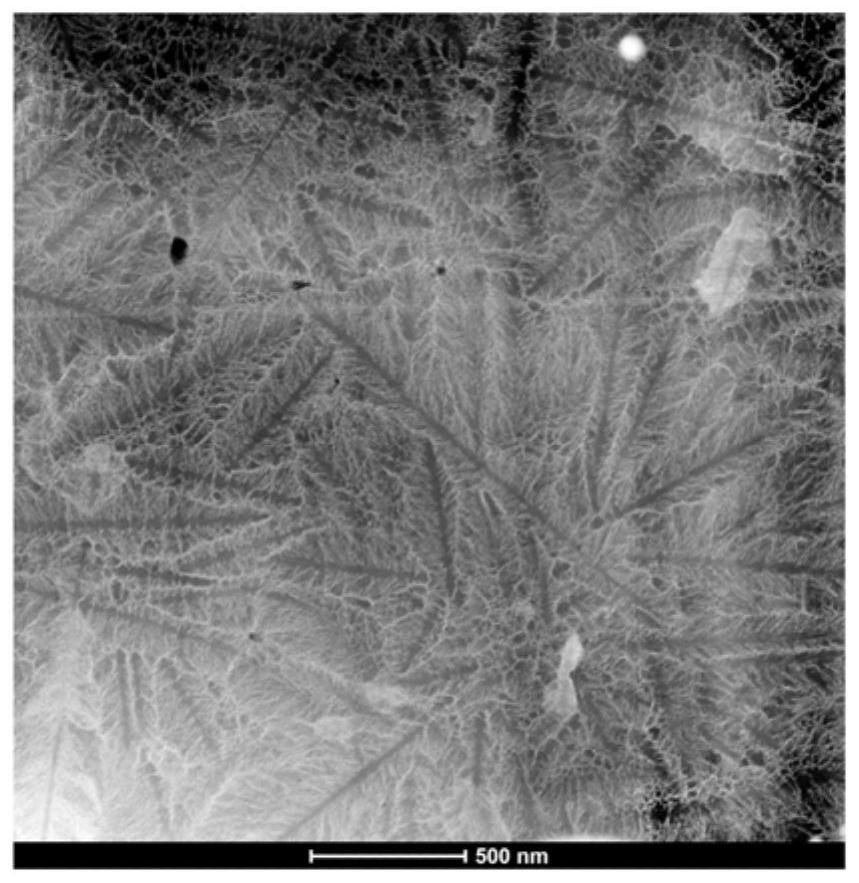

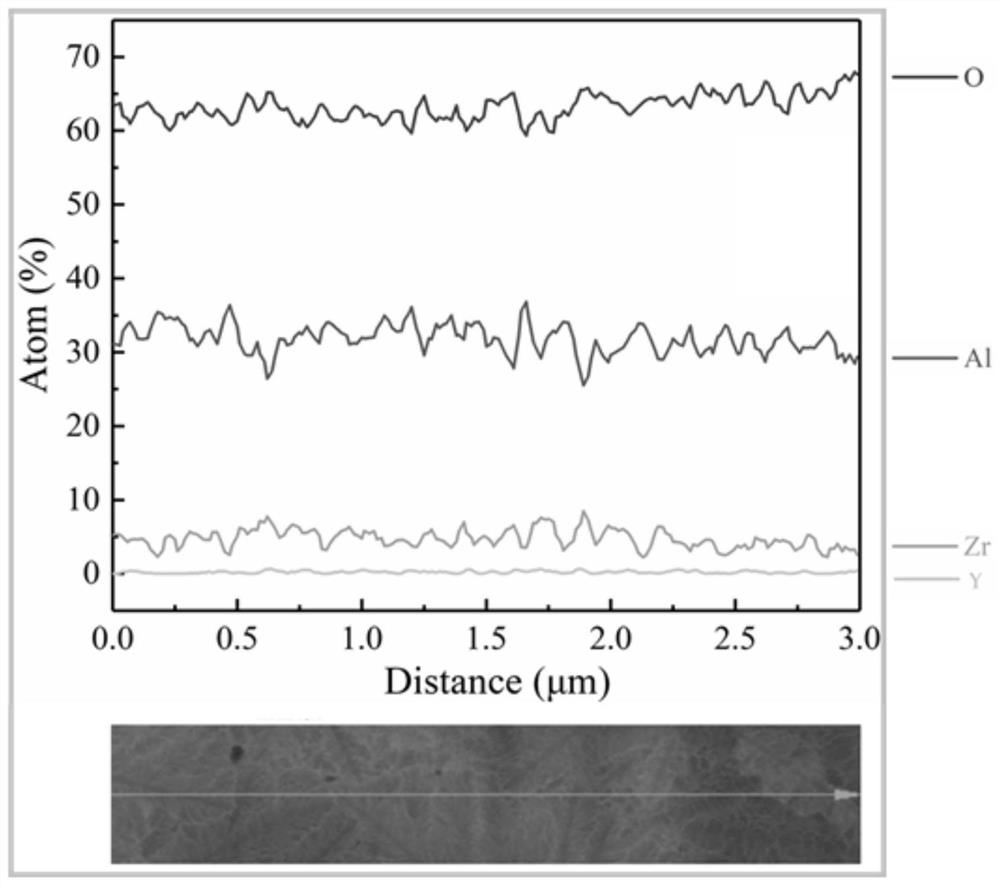

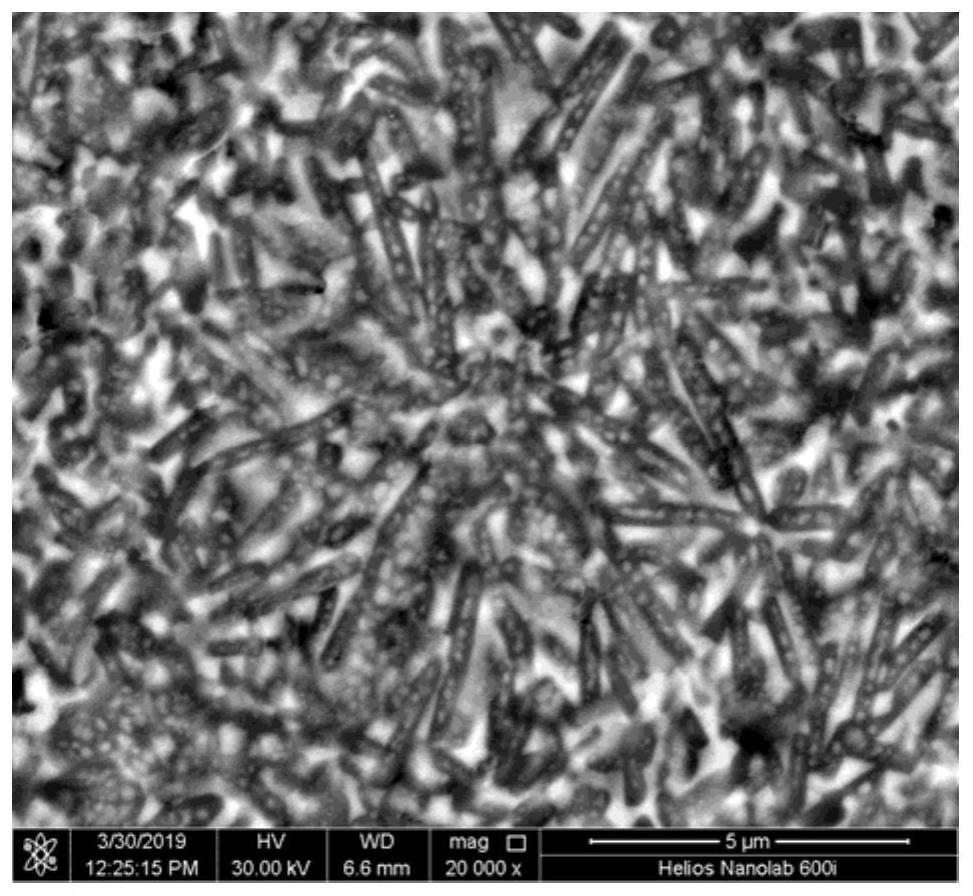

[0027] Specific implementation mode 1: The preparation method of columnar crystal alumina / zirconia composite ceramics in this implementation mode specifically includes the following steps:

[0028] Step 1: drying the aluminum powder and diluent; the diluent is a mixture of zirconia and alumina, wherein alumina accounts for 0-93% of the total mass of the diluent;

[0029] Step 2: Mix the dried aluminum powder and diluent, ball mill, and sieve after ball milling to obtain a mixed material; wherein the mass fraction of the aluminum powder in the mixed material is 12%-40%, and the mass fraction of the diluent is 60%- 88%;

[0030] Step 3: Put the mixed material into the high-pressure reactor, and fill the high-pressure reactor with O 2 or O 2 Mixed gas, the lower end of the high-pressure reactor is equipped with a nozzle, the diameter of the nozzle is 1-6mm, the mixed material is ignited, and the high-temperature combustion synthesis reaction is carried out. The reaction tempera...

specific Embodiment approach 2

[0032] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 2, a dry inducer is also added for ball milling to obtain a mixed material composed of aluminum powder, diluent and inducer; wherein the amount of inducer added is The proportion in the mixed material is less than 6wt%. Others are the same as in the first embodiment.

[0033] In addition to inducing nano columnar crystal seeds (supersaturated solid solution) in the process of rapid cooling and solidification of the alumina / zirconia composite melt, the present invention can also induce columnar crystal seeds by adding an inducer, so that rapid cooling can be achieved. The "double induction" of inducing columnar crystal seeds and additives inducing columnar crystal seeds can greatly reduce the amount of inducing agent added. This is completely different from the existing process methods.

[0034] Excessive triggering agent content will deteriorate some properties of c...

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the inducer is MgO, TiO 2 , SiO 2 、Cr 2 o 3 , Y 2 o 3 , CoO, La 2 o 3 , CeO 2 、Nd 2 o 3 、Sm 2 o 3 、Eu 2 o 3 、Gd 2 o 3 , Tb 2 o 3 、Dy 2 o 3 、Ho 2 o 3 、Er 2 o 3 , Yb 2 o 3 、Lu 2 o 3 , SrO, NiO or a mixture of several components. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com