Patents

Literature

72 results about "Oxide ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc oxide ceramics and a manufacturing method for the same, a sputtering target

InactiveUS20090197757A1Improve featuresDensified zinc oxide ceramicsCellsVacuum evaporation coatingOxide ceramicsZinc

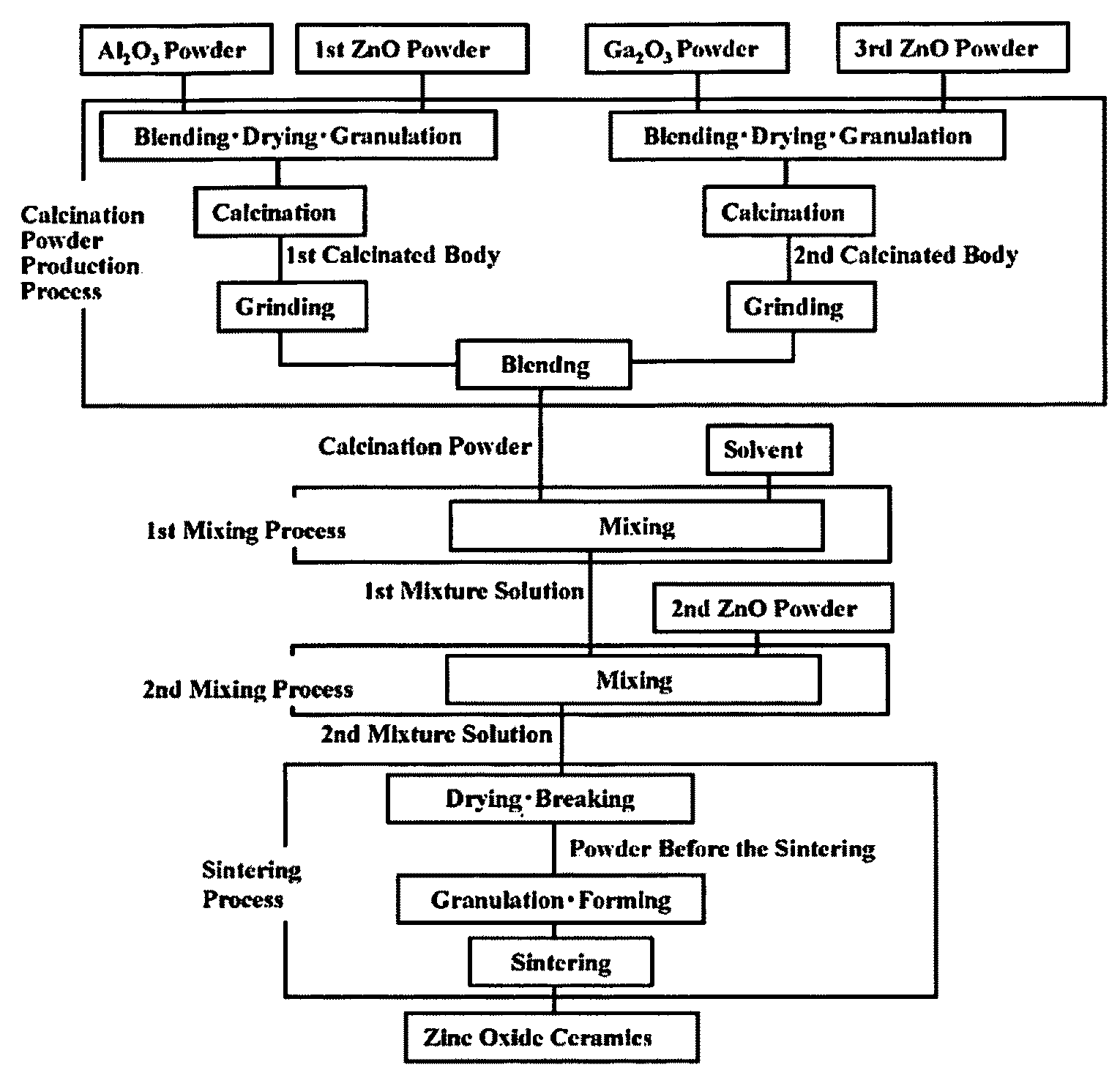

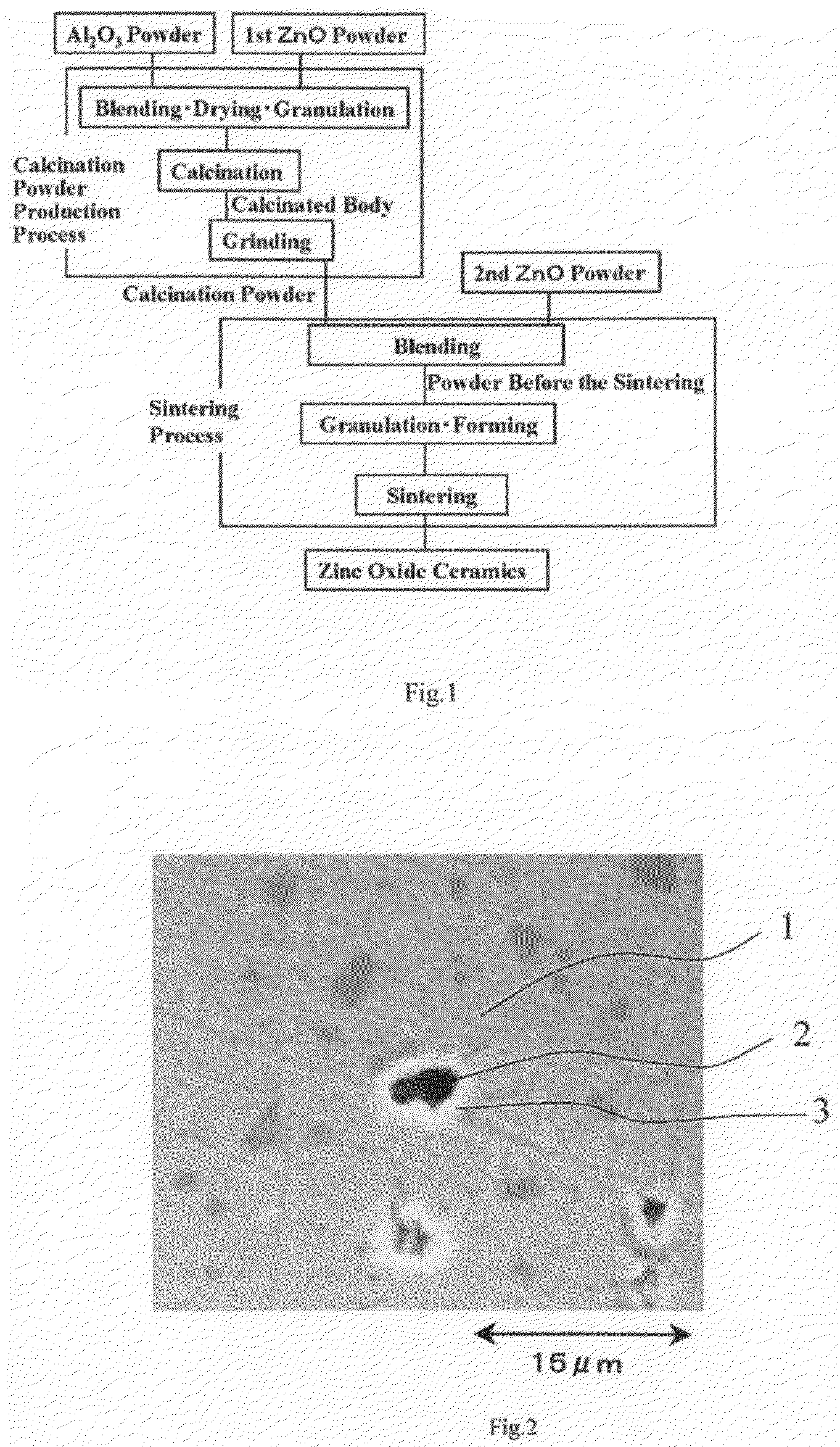

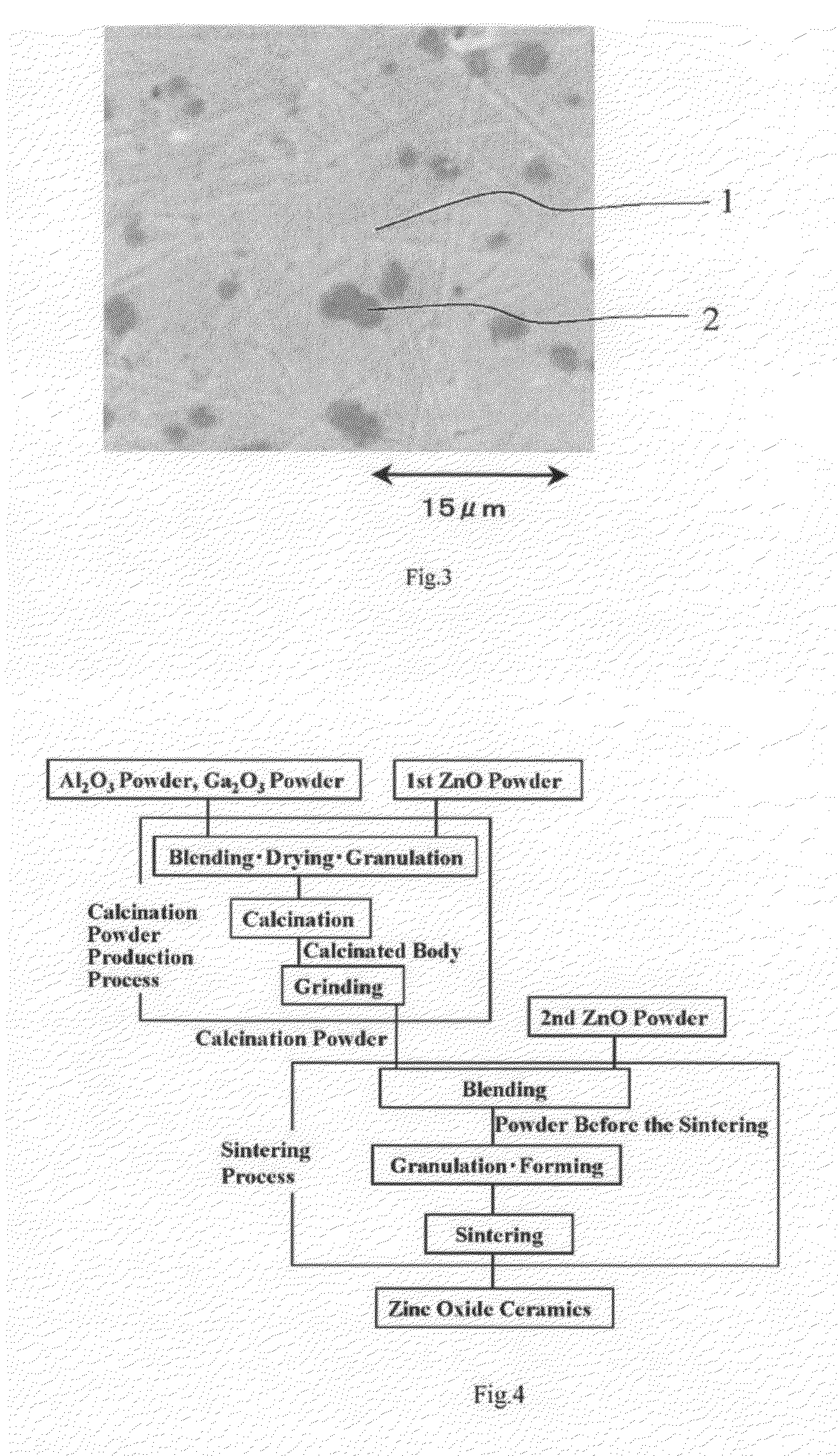

Densified zinc oxide ceramics can be obtained so that transparent electrodes with good characteristics can be obtained using the ceramics as a sputtering target. This manufacturing method is used to manufacture the zinc oxide ceramics doped with Al in ZnO. This method comprises, calcination powder production process by which calcination powder is produced after blending Al2O3 powder and a 1st ZnO powder and by calcinating them, and sintering process by which said zinc oxide ceramics are manufactured after sintering formed body composed of powder before the sintering which is made by blending said calcination powder and a 2nd ZnO powder. Here, the ceramics are manufactured not by sintering a formed body composed of Al2O3 powder and ZnO powder, but by sintering the formed body composed of the calcination powder containing ZnAl2O4 phase and ZnO powder.

Owner:HITACHI METALS LTD

Ceramic base/NAO composite friction material and preparation method thereof

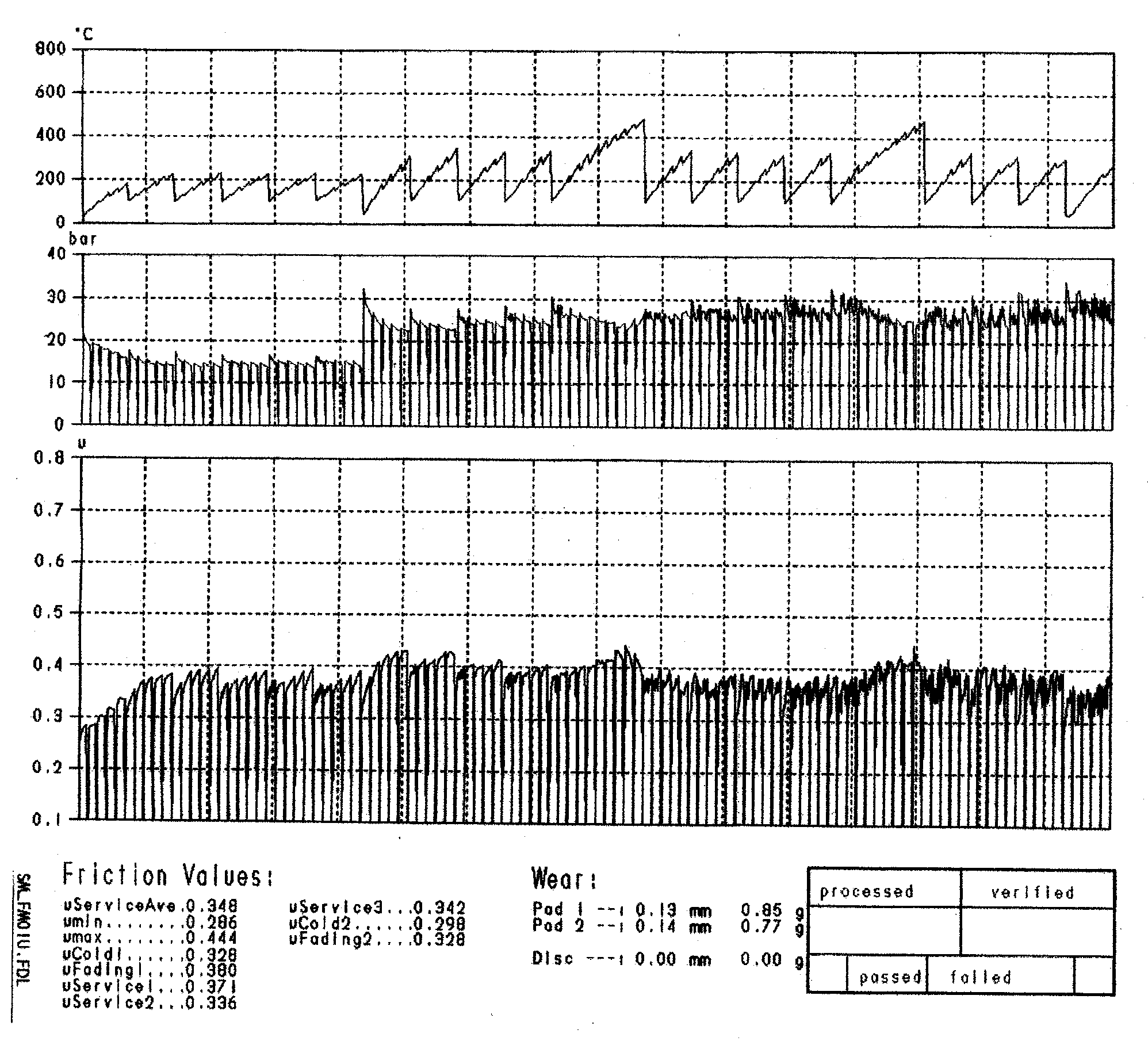

The invention relates to an oxide ceramic base / NAO composite friction material used in a brake of a medium or high-grade car and a preparation method thereof. In the composite friction material, mixed fibers comprise aramid fibers, potassium titanate fibers and silicon, magnesium and calcium oxide ceramic fibers; aedelforsite or mineral fibers and copper fibers are used as the enhancement and conduction fibers; phenolic resin is used as the organic bonding agent; pure oxide ceramics, such as Al2O3, ZrO2, MgO, CaO and the like, are used as the abrasives; solid lubricant, sulfide, graphite coke and the like are used as the abrasion resistant lubricants; and sodium bicarbonate is used as the blowing agent and pairing antioxidant, and barium sulfate inorganic filler is used as the function and toughening filler. The ceramic base / NAO organic friction material mainly maintains the unique performance of the asbestos friction material, remakably lowers the noise, reduces the abrasion possibility, and is beneficial to prolonging the service life of a brake disc, there by being a novel green (less-dust) low-noise environmentally-friendly friction material.

Owner:HUBEI CHIBI SALFER FRICTION MATERIAL

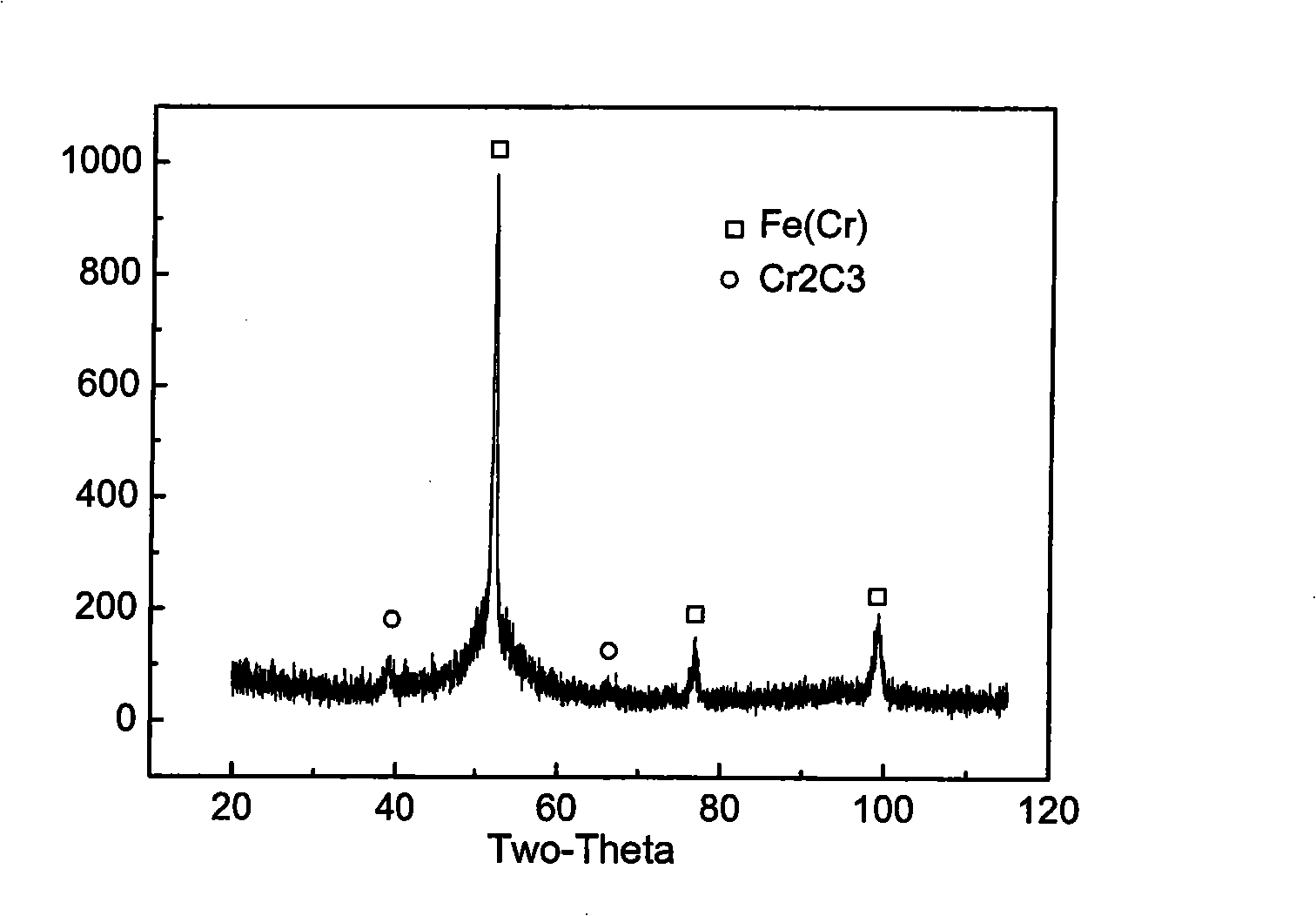

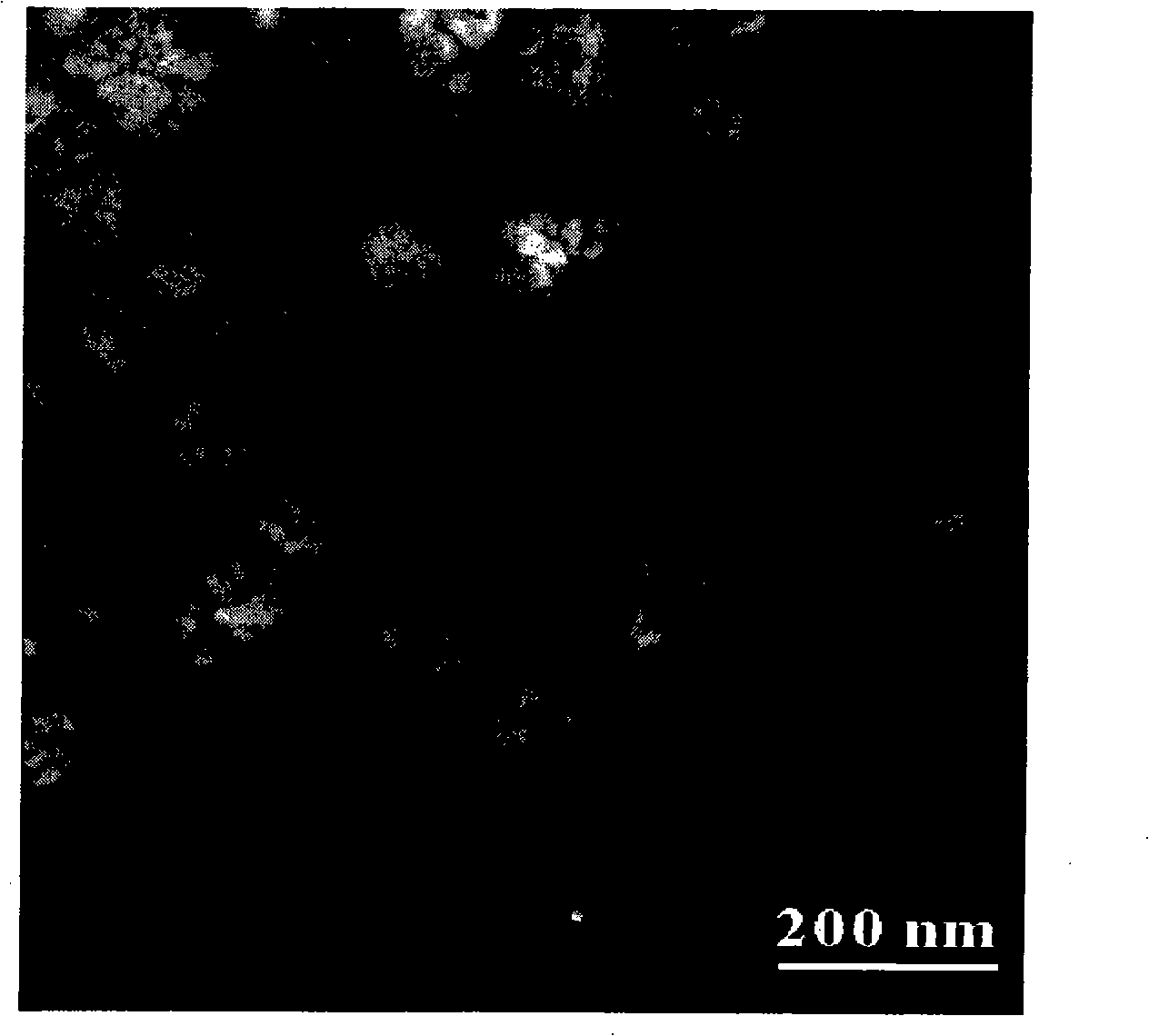

Ceramic-phase-containing iron-based amorphous nanocrystalline composite coating and preparation thereof

ActiveCN101298654AEasy to useExtended service lifeMolten spray coatingOxide ceramicsThermal spraying

The invention belongs to the field of thermal spraying and particularly relates to a composite amorphous and nano-crystalline coating layer with ceramic phase and ferrum base and a preparation method thereof. Carbide or oxide ceramics of Co or Ni ladles are firstly added into a flux core, a flux-cored wire is prepared together with the flux core and a ferrum-base alloy with amorphous ingredients and used as a spraying material, and the electric arc spraying method is adopted for leading the flux-cored wire to be melted, atomized into fused drops and finally deposited on a substrate, thus preparing the composite amorphous and nano-crystalline coating layer with ceramic-phase structure and ferrum base, which has the performance of high bond strength, good wear resistance, corrosion resistance and oxidation resistance as well as remarkably prolonged service life of the substrate, and the composite amorphous and nano-crystalline coating layer with ceramic phase and ferrum base can be widely applied to the restoration and the protection of device parts in the fields of metallurgy, electric power and petroleum, etc.

Owner:CENT IRON & STEEL RES INST

Mesostructured oxide ceramics and their synthesis method

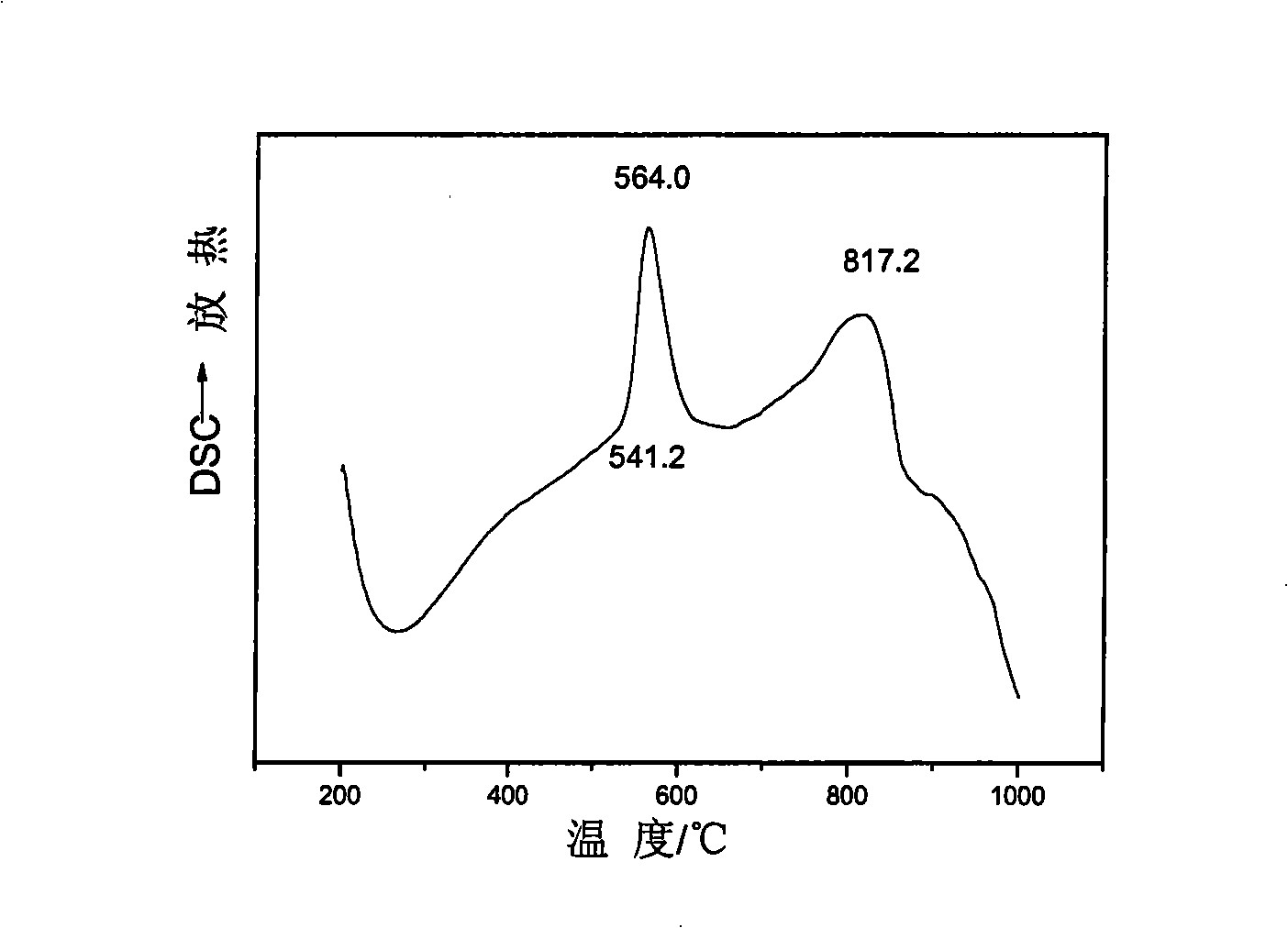

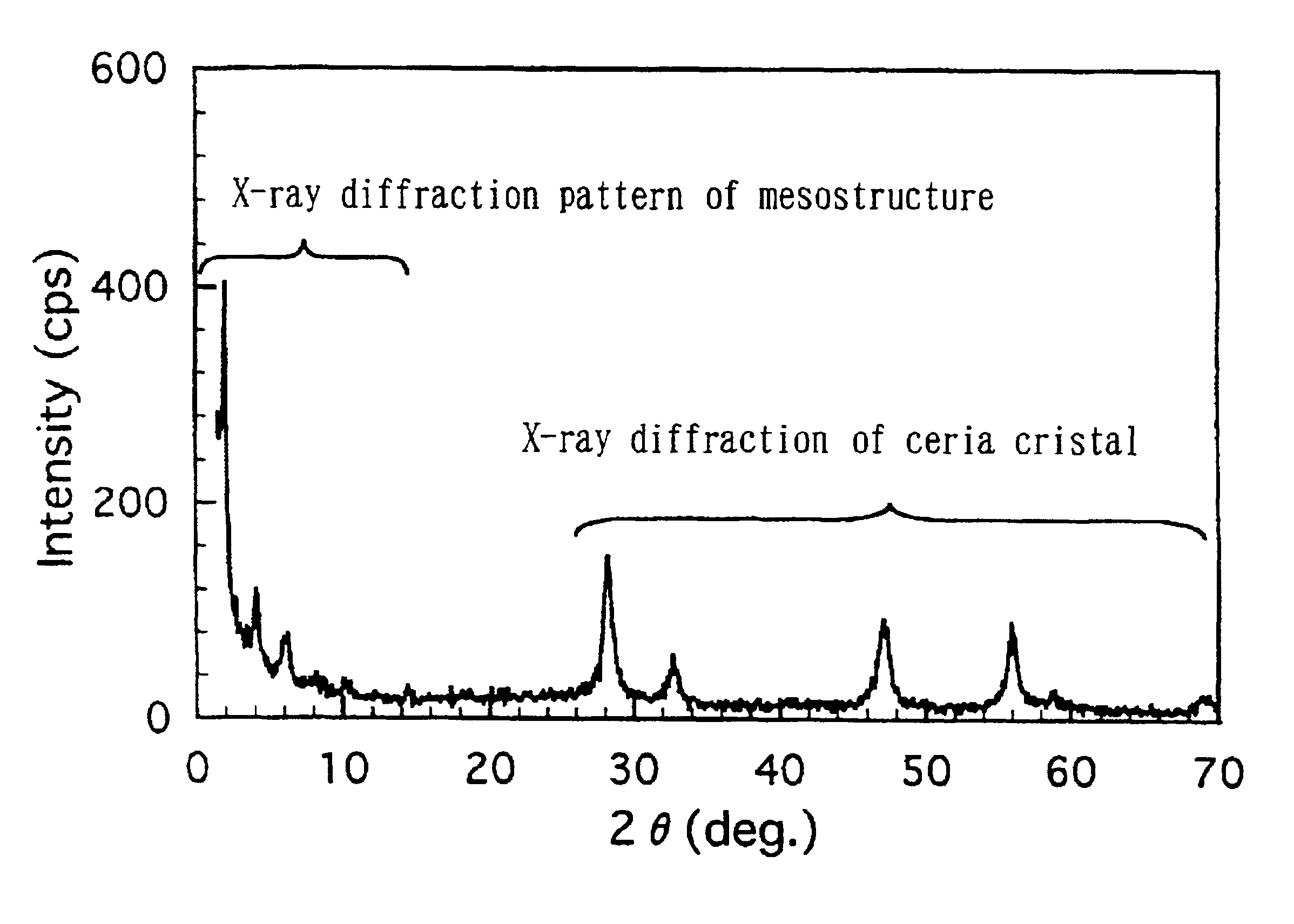

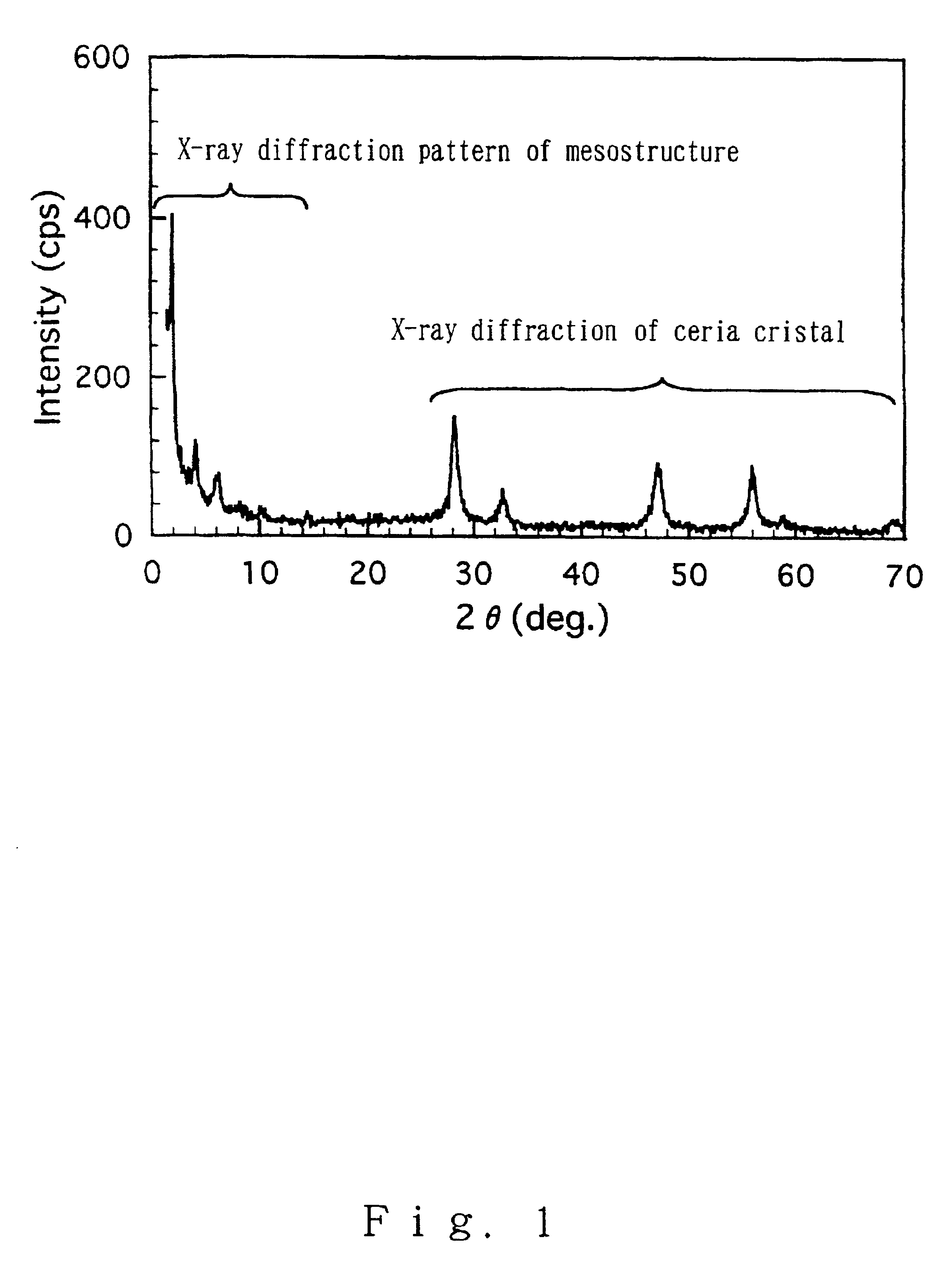

This invention provides mesostructured oxide ceramics and a synthesizing method thereof, the synthesizing method employs a water-based solvent containing a metallic salt or metal complex as the ceramics precursor, template formed from an organic compound or the association thereof, and a precipitant, wherein mesostructured oxide ceramics are obtained from self-assembled oxide ceramics and organic substance by directly extracting oxide ceramics at a low temperature of 200° C. or less by utilizing a homogenous precipitation reaction from said ceramics precursor under the coexistence of a nanometer-sized template in the solvent, and separating and collecting the obtained precipitation, and mesostructured oxide ceramics is prepared by employing the synthesizing method described above.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Process for preparing neodymium-iron-boron permanent magnetic material surface gradient function coating layer

InactiveCN1900361ARealize the purpose of industrial applicationPretreated surfacesLiquid/solution decomposition chemical coatingOxide ceramicsSurface gradient

A neodymium-iron-boron permanent magnetic materials surface gradient function coating preparation method overcomes current slug type neodymium iron boron surface processing method existent problem. Said method adopts new surface modification process means combined with tradition electroplating ( or chemical plating ) advantages and sol-gel technologic property, thereby avoiding single cladding material poor cladding material adhesion, less compactness, easy resulting slough, having pore and too thin single sol coating shortages. Said method forms tight sol coating on neodymium iron boron base material surface, to obtain oxide ceramics coating after sintering treatment, then cladding material on gel coating to form function gradient coating to take complete corrosion protection.

Owner:SOUTHWEST UNIVERSITY

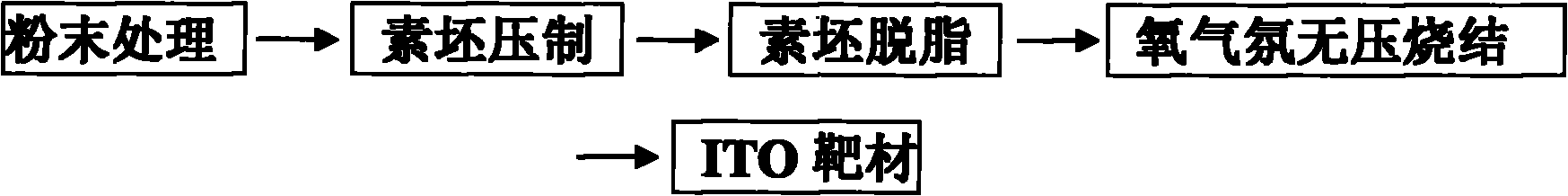

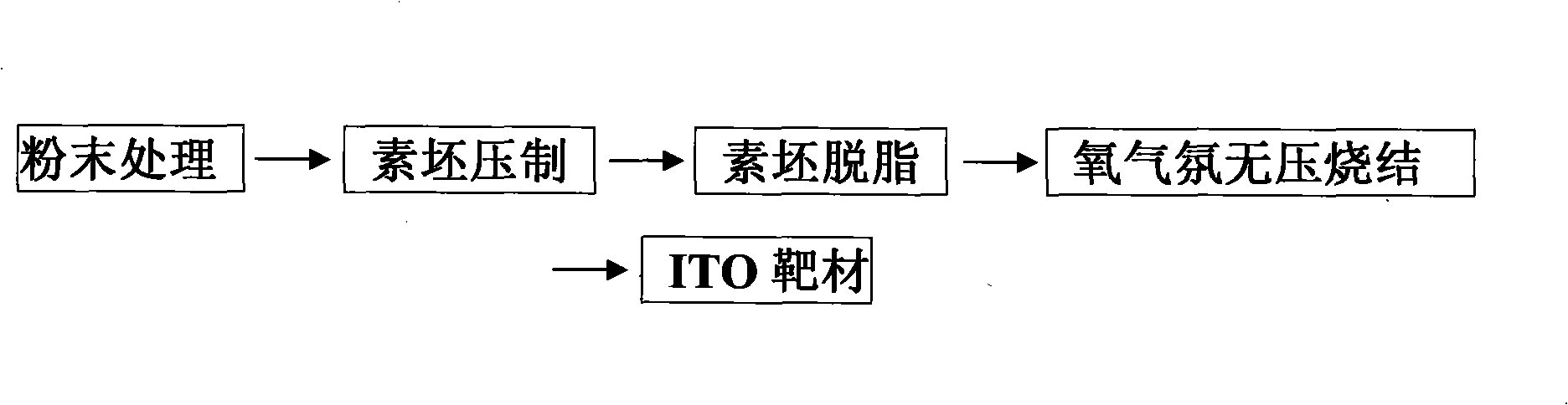

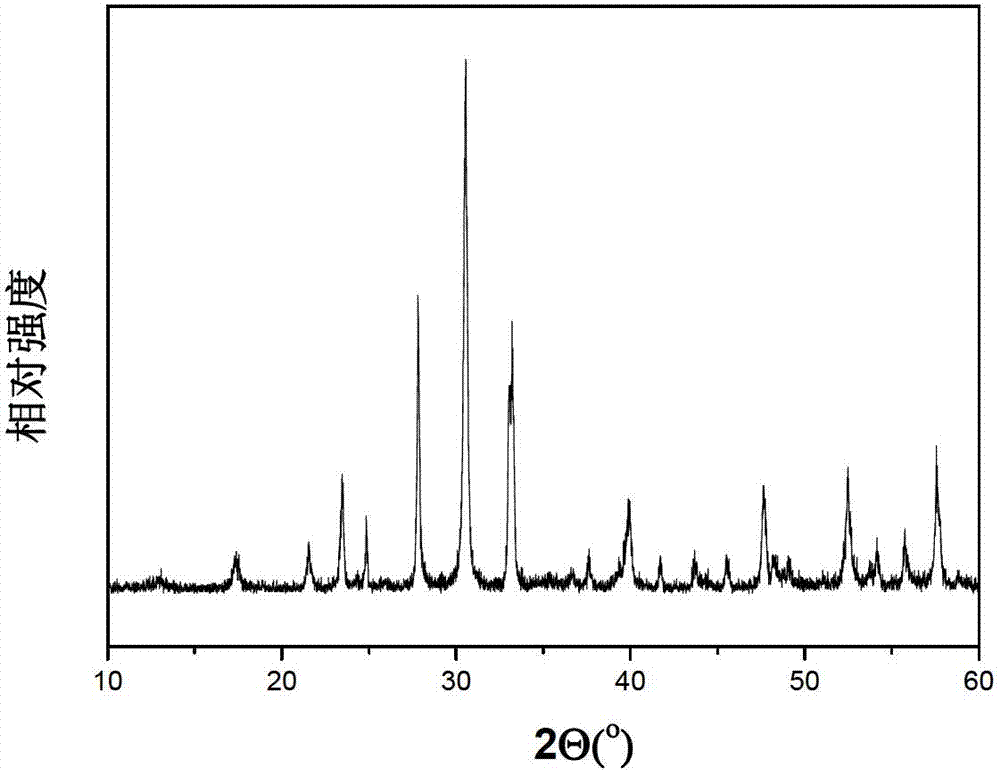

Method of preparing ITO target material by oxygen atmosphere pressureless sintering process

The invention discloses an innovative method of sintering ITO target material, and aims to realize pressureless oxygen atmosphere sintering by optimizing sintering process, and finally to obtain target material having high density and high performance. With sintering method as the basis and according to sintering characteristics of the ITO target material, the method adopts segmented sintering process, and controls oxygen partial pressure of the sintering atmosphere by controlling oxygen flow entering into a hearth to inhibit decomposition of the target material, and to finally obtain the high conductive performance target material, the density of which is more than 99.3%. The oxygen atmosphere pressureless sintering method is a novel ceramic sintering method, and is mainly applied to thesintering of oxide ceramics easy to decompose. Equipment for the method is simple, and products to be sintered are not restricted by size, so large-size ceramics can be produced. It is the first timeto produce the ITO target material by the method, and the ITO target material produced by the method is better than that produced by the commonly used sintering process with hot pressing, sintering process with hot isostatic pressing or common normal pressure sintering process.

Owner:KUNMING UNIV OF SCI & TECH

Heat-resistant coated member

InactiveUS7157148B2Highly non-reactiveIncrease resistanceMolten spray coatingCharge supportsOxide ceramicsRare earth

A heat-resistant coated member comprises a substrate composed of a material selected from among molybdenum, tantalum, tungsten, zirconium, aluminum, titanium, carbon, and alloys, oxide ceramics, non-oxide ceramics and carbide materials thereof, which is covered with a layer composed primarily of a rare earth-containing oxide. In addition to heat resistance, the coated member has good corrosion resistance and non-reactivity, making it highly suitable as a part for sintering or heat-treating metals and ceramics in a vacuum, an inert atmosphere or a reducing atmosphere.

Owner:SHIN ETSU CHEM IND CO LTD

Member having composite coating and process for producing the same

InactiveUS6129994AImprove adhesionAdequate unevennessMolten spray coatingLaminationOxide ceramicsNon oxide ceramics

PCT No. PCT / JP96 / 00546 Sec. 371 Date Sep. 3, 1997 Sec. 102(e) Date Sep. 3, 1997 PCT Filed Mar. 6, 1996 PCT Pub. No. WO96 / 27694 PCT Pub. Date Sep. 12, 1996A composite steel sheet including a steel base member; an undercoat having opposed surfaces and a thickness of 10-750 mu m obtained by spraying one or more spraying materials selected from metals, non-oxide ceramics, oxide ceramics and cermets onto the steel base member. The undercoat has an oxide layer of not less then 0.5 mu m in thickness on one of the opposed surfaces positioned away from said steel base member. A fired topcoat is formed on the oxide layer of the undercoat from a vitreous coating having a linear expansion coefficient of 4-11x10-6 / DEG C.

Owner:TOCALO CO LTD

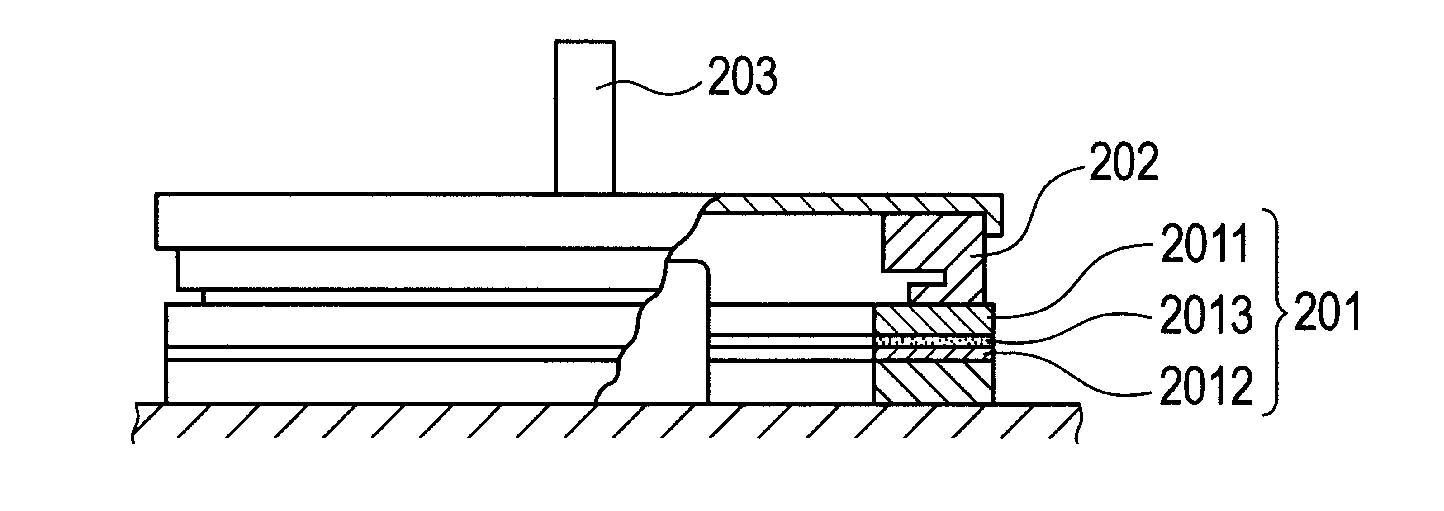

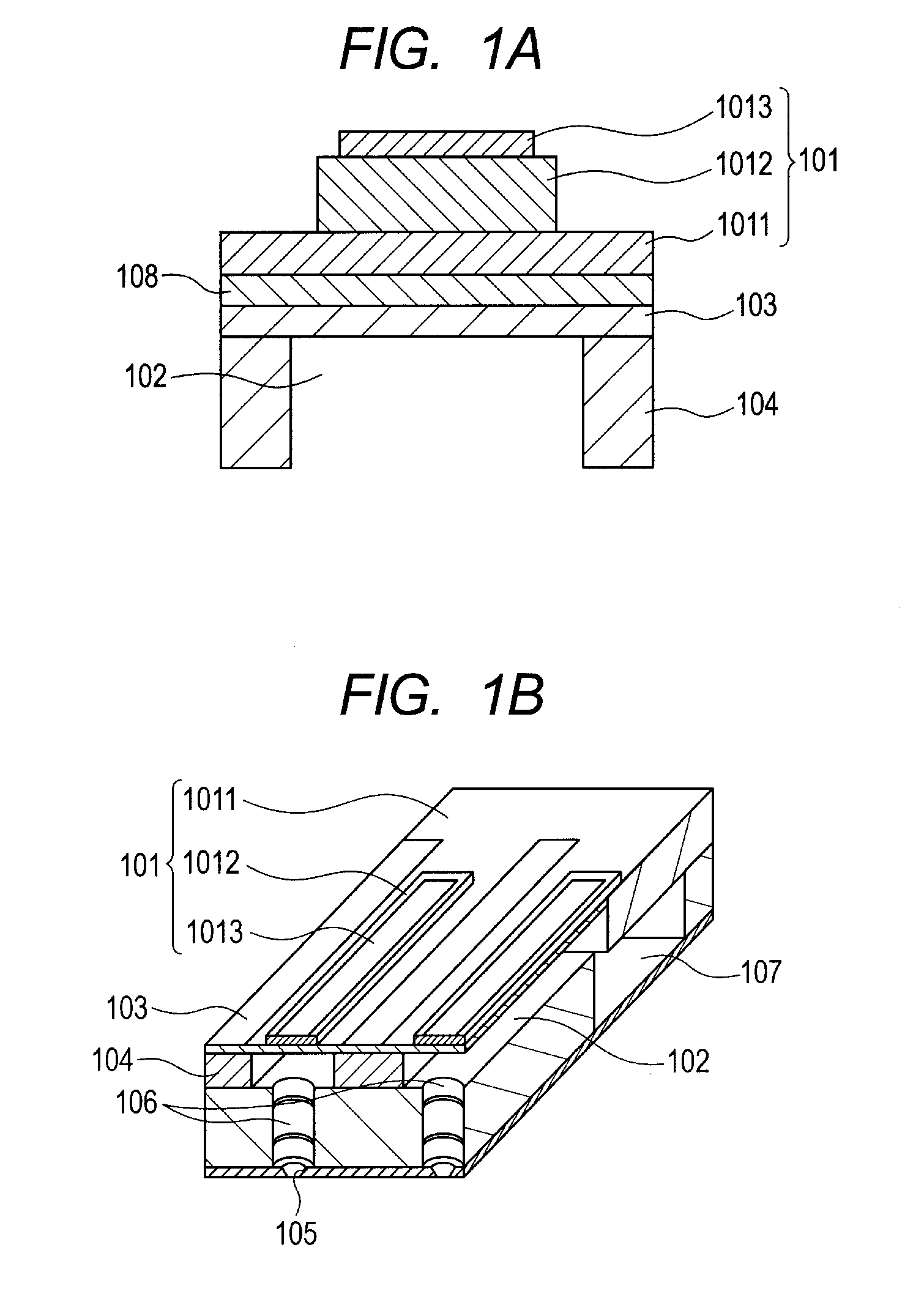

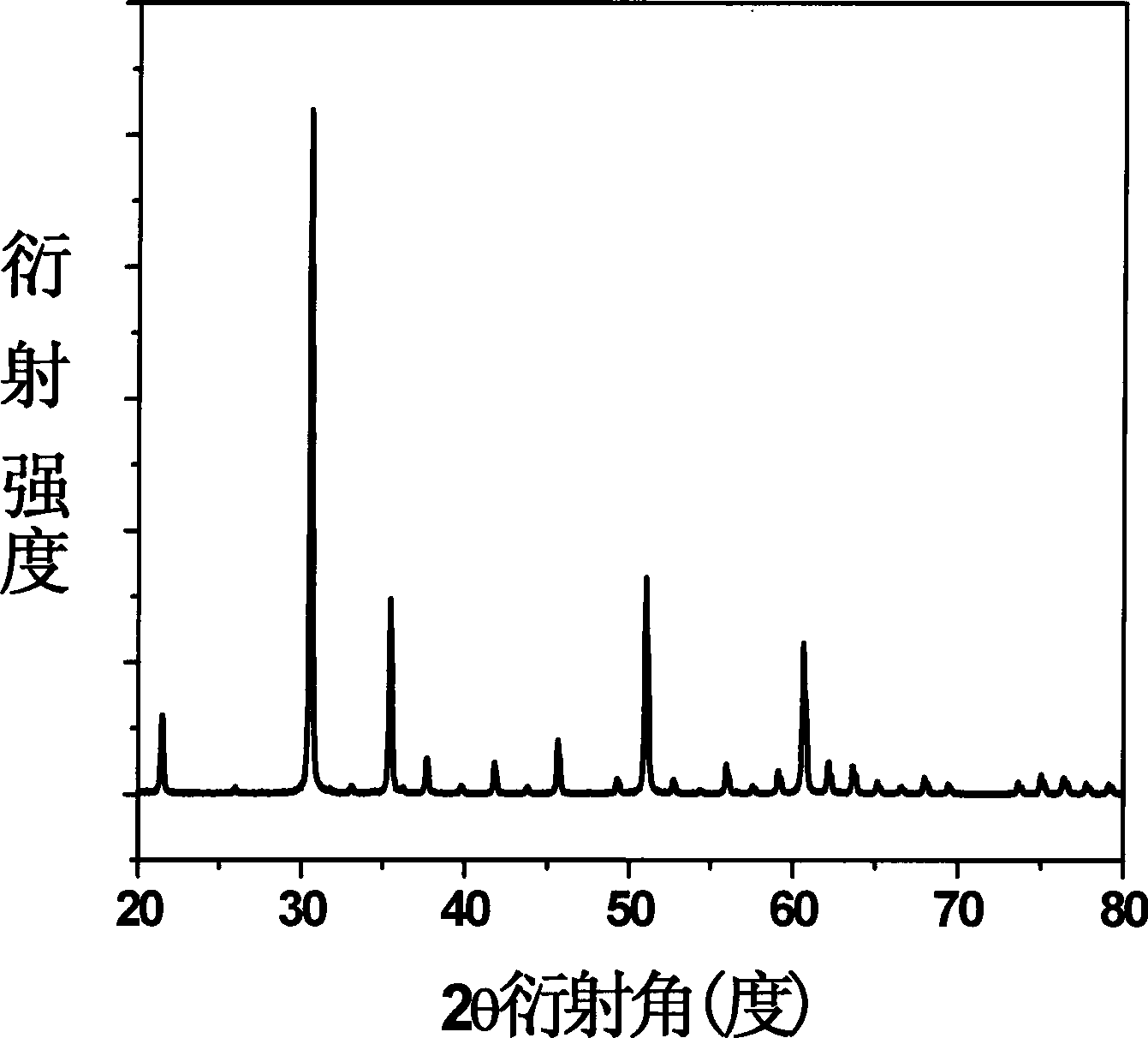

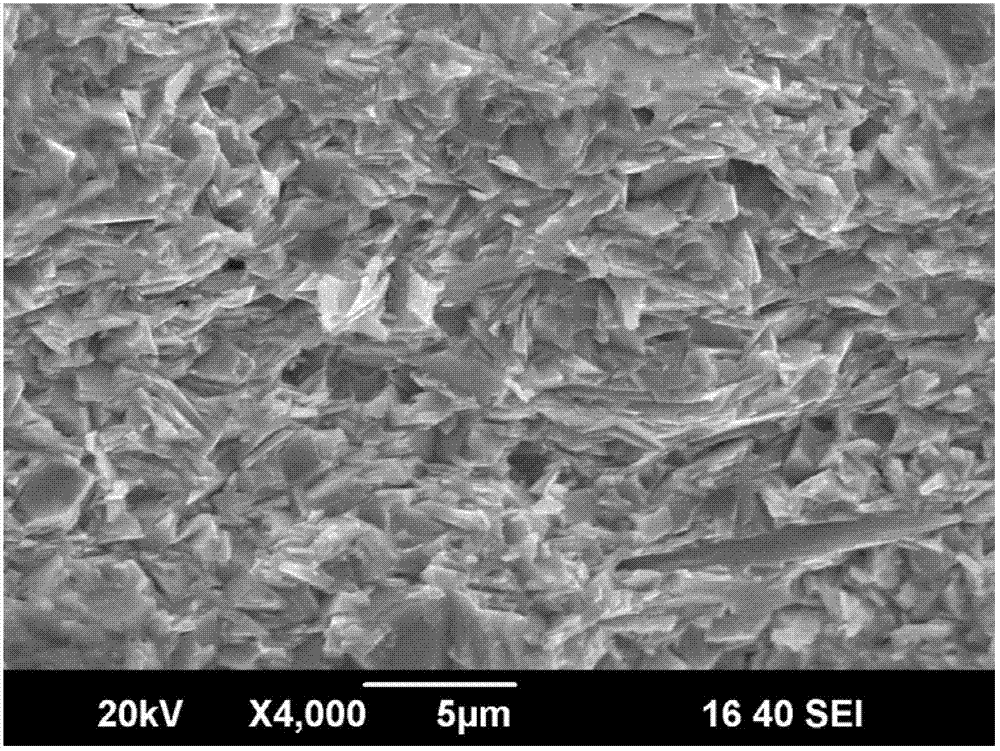

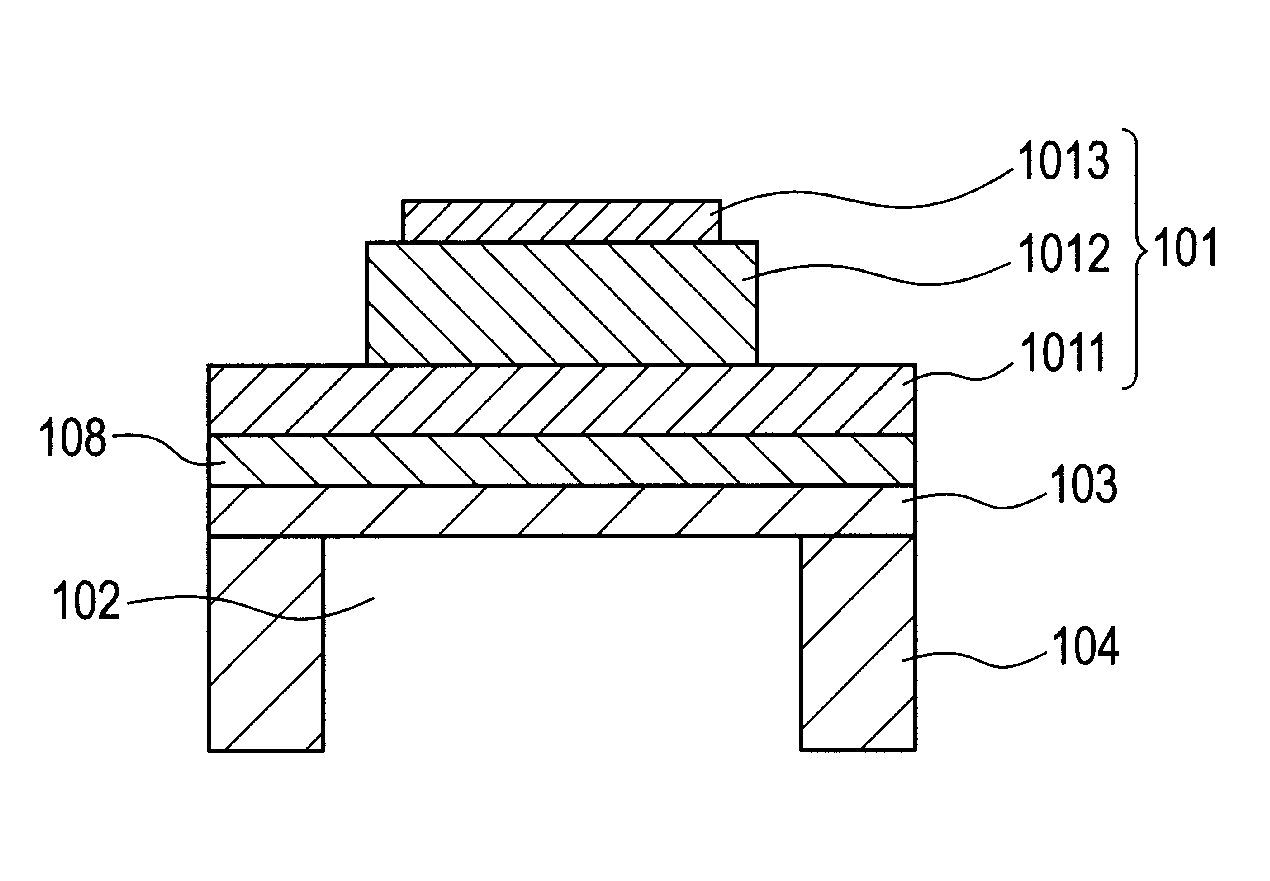

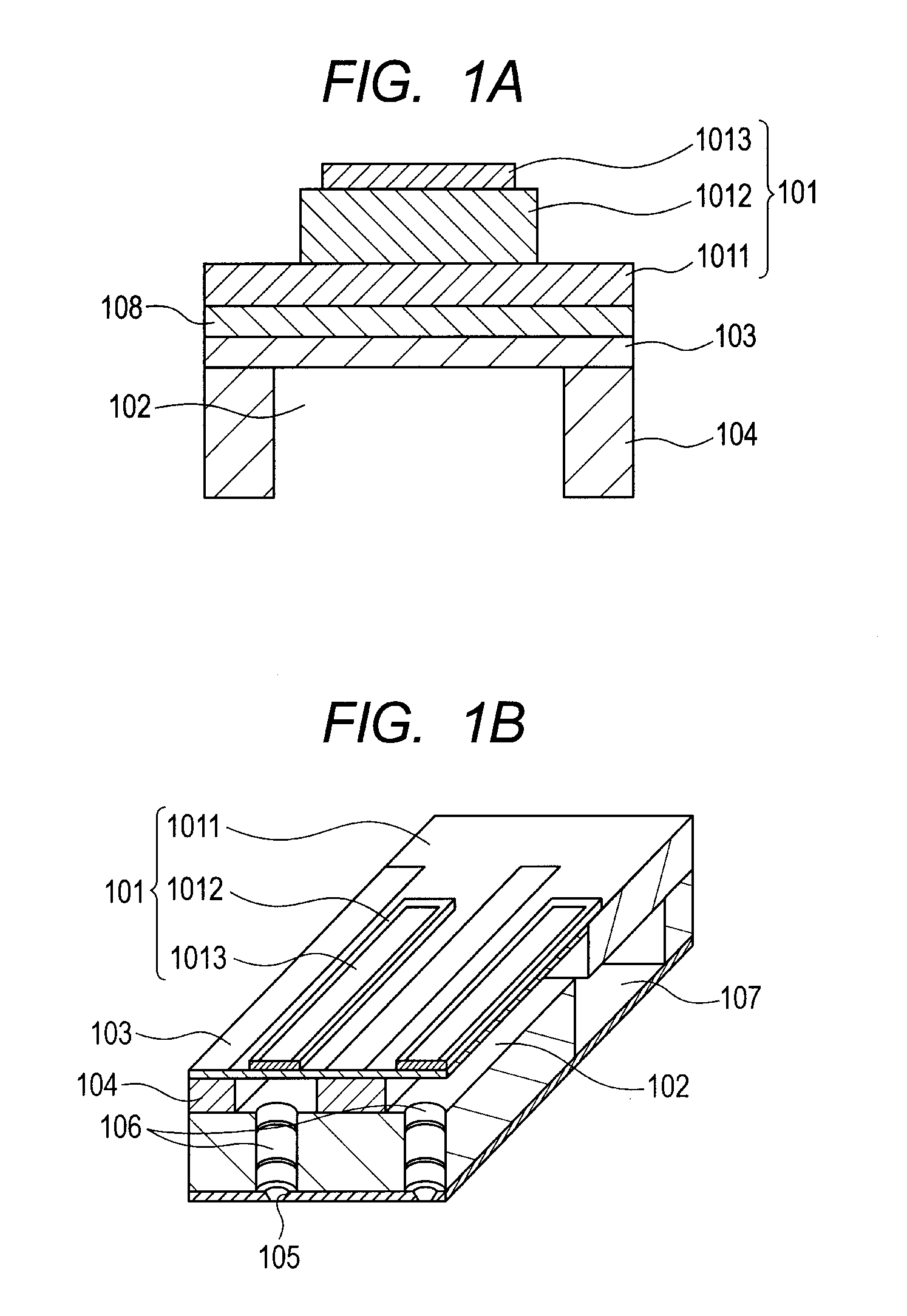

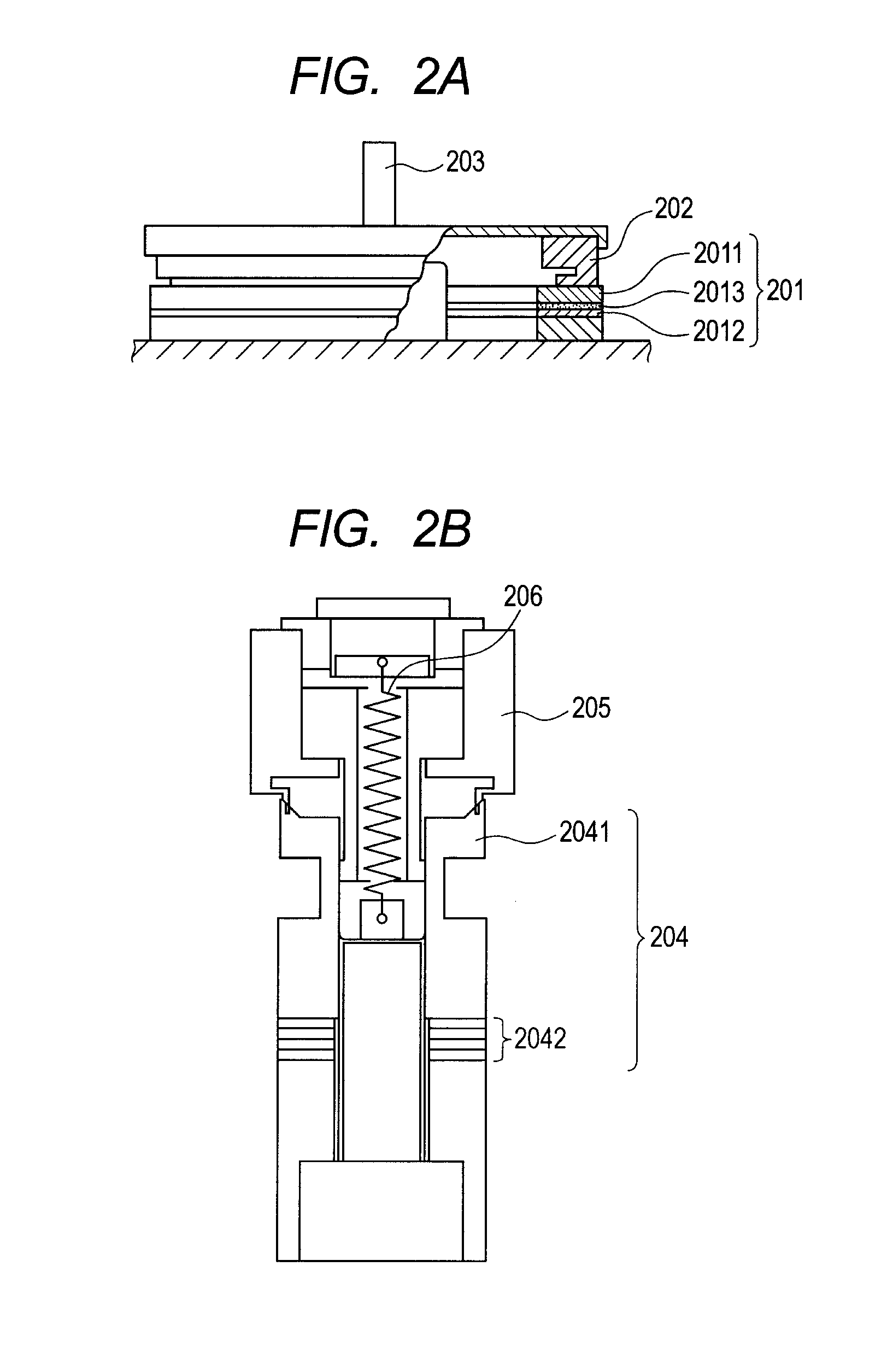

Manufacturing method for preferentially-oriented oxide ceramics, preferentially-oriented oxide ceramics, piezoelectric element, liquid discharge head, ultrasonic motor, and dust removing device

ActiveUS20110193451A1High degree of crystal orientationMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyOxide ceramicsCrystal system

Provided is a manufacturing method for preferentially-oriented oxide ceramics having a high degree of crystal orientation. The manufacturing method includes: obtaining slurry containing an oxide crystal B having magnetic anisotropy; applying a magnetic field to the oxide crystal B, and obtaining a compact of the oxide crystal B; and subjecting the compact to oxidation treatment to obtain preferentially-oriented oxide ceramics including a compact of an oxide crystal C having a crystal system that is different from a crystal system of one of a part and a whole of the oxide crystal B. By (1) reacting raw materials, (2) reducing the oxide crystal A, or (3) keeping the oxide crystal A at high temperature and quenching the oxide crystal A, the oxide crystal B is obtained to be used in the slurry.

Owner:CANON KK +1

Method for preparing high-temperature resisting organic adhesive by utilizing liquid silicon carbide precursor

InactiveCN102504258AImprove high temperature resistanceImprove responseAdhesivesCross-linkOxide ceramics

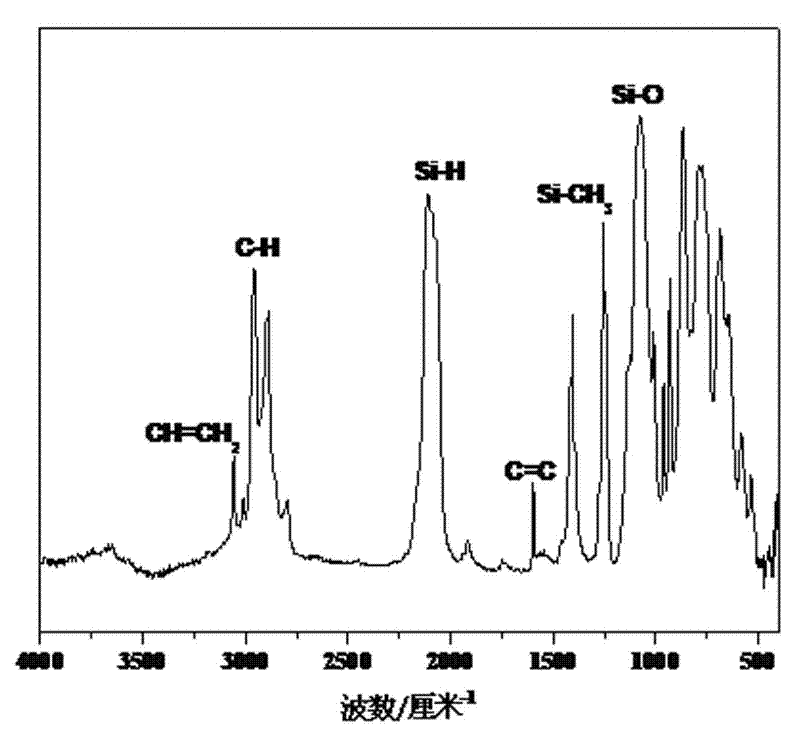

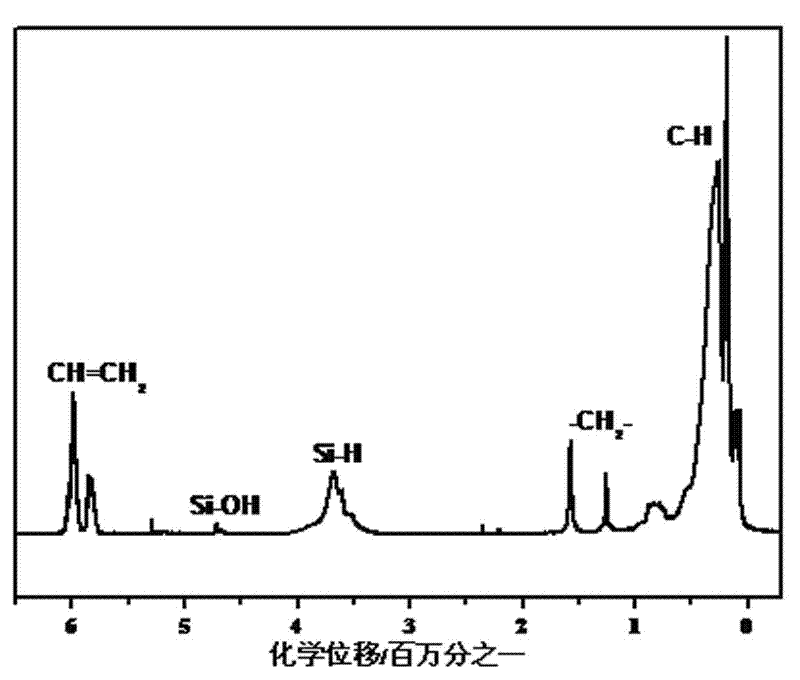

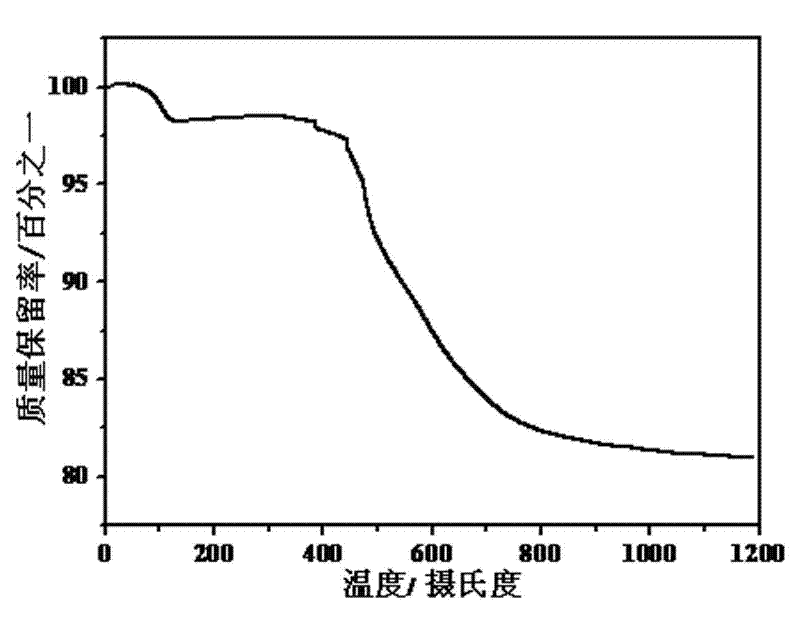

The invention relates to a method for preparing a high-temperature resisting organic adhesive by utilizing a liquid silicon carbide precursor. The method comprises the following steps: taking the liquid silicon carbide precursor (liquid polysilane, polymethylsilane and liquid polycarbosilane) and low-molecule siloxane containing an ethylene group as original raw materials, taking methylbenzene or tetrahydrofuran as a solvent and taking chloroplatinic acid as a catalyst; after mixing at a certain ratio, increasing the temperature to 20-300 DEG C; keeping the temperature for a period of time; cooling the temperature to a certain temperature and then performing pressure-reducing distillation; and cooling to the room temperature, thereby obtaining the high-temperature resisting organic adhesive, namely, the poly-carbon siloxane. The raw materials are simply and easily obtained; the resource is reliable; the reaction process is simple; the obtained products have excellent high-temperature resistance; the adhesive contains a plenty of active Si-H, Si-OH, Si-Si and CH-CH2 groups, so that the adhesive can be easily cross-linked and cured; the surface energy is lower; the adhesive can be easily paved and wetted on the surface of objects, such as ceramics, metal, and the like; the adhering property is better; and the adhesive has wide application prospect in adhering SiC ceramic materials, oxide ceramics, carbon materials and titanium alloy materials.

Owner:NAT UNIV OF DEFENSE TECH

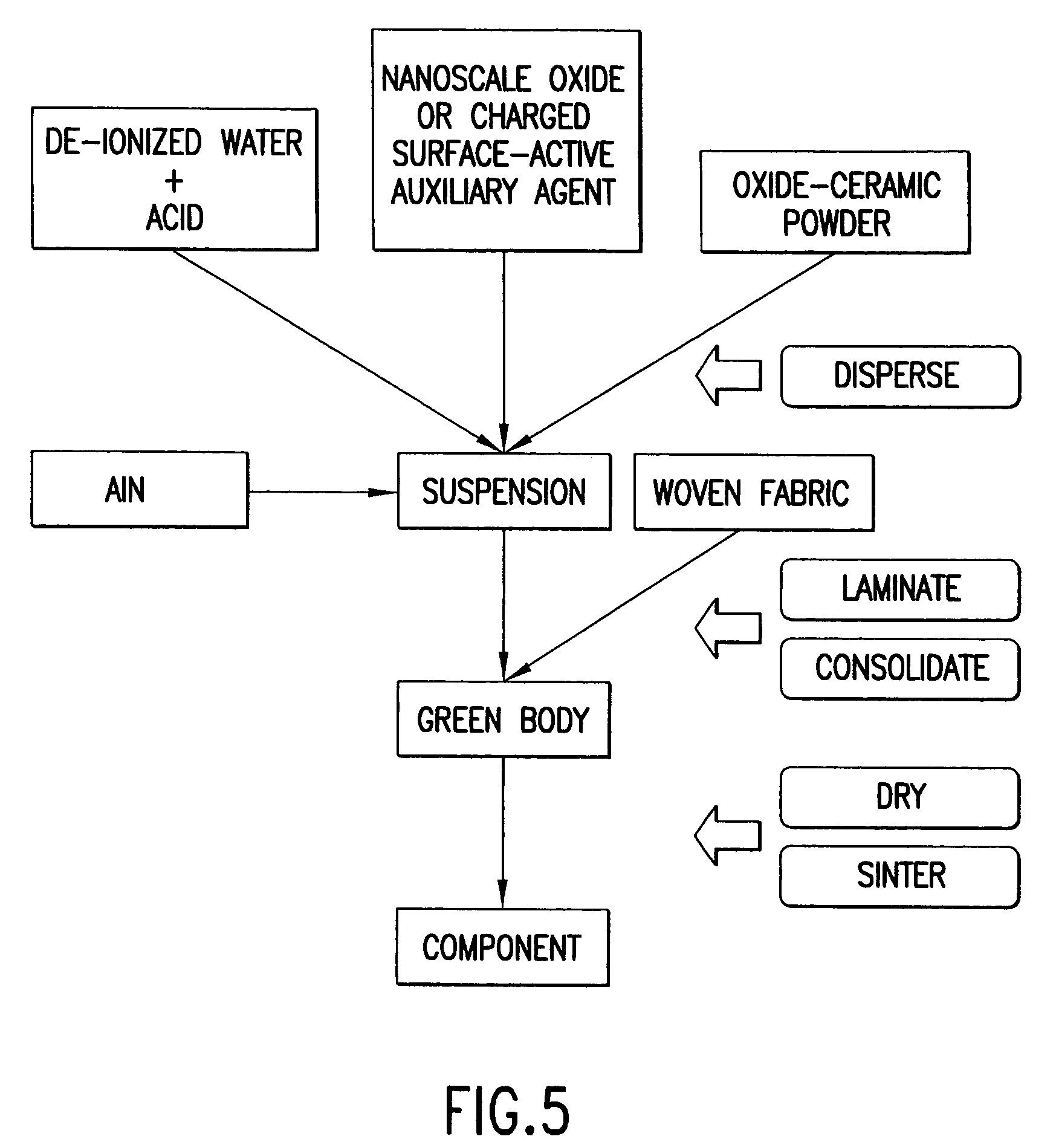

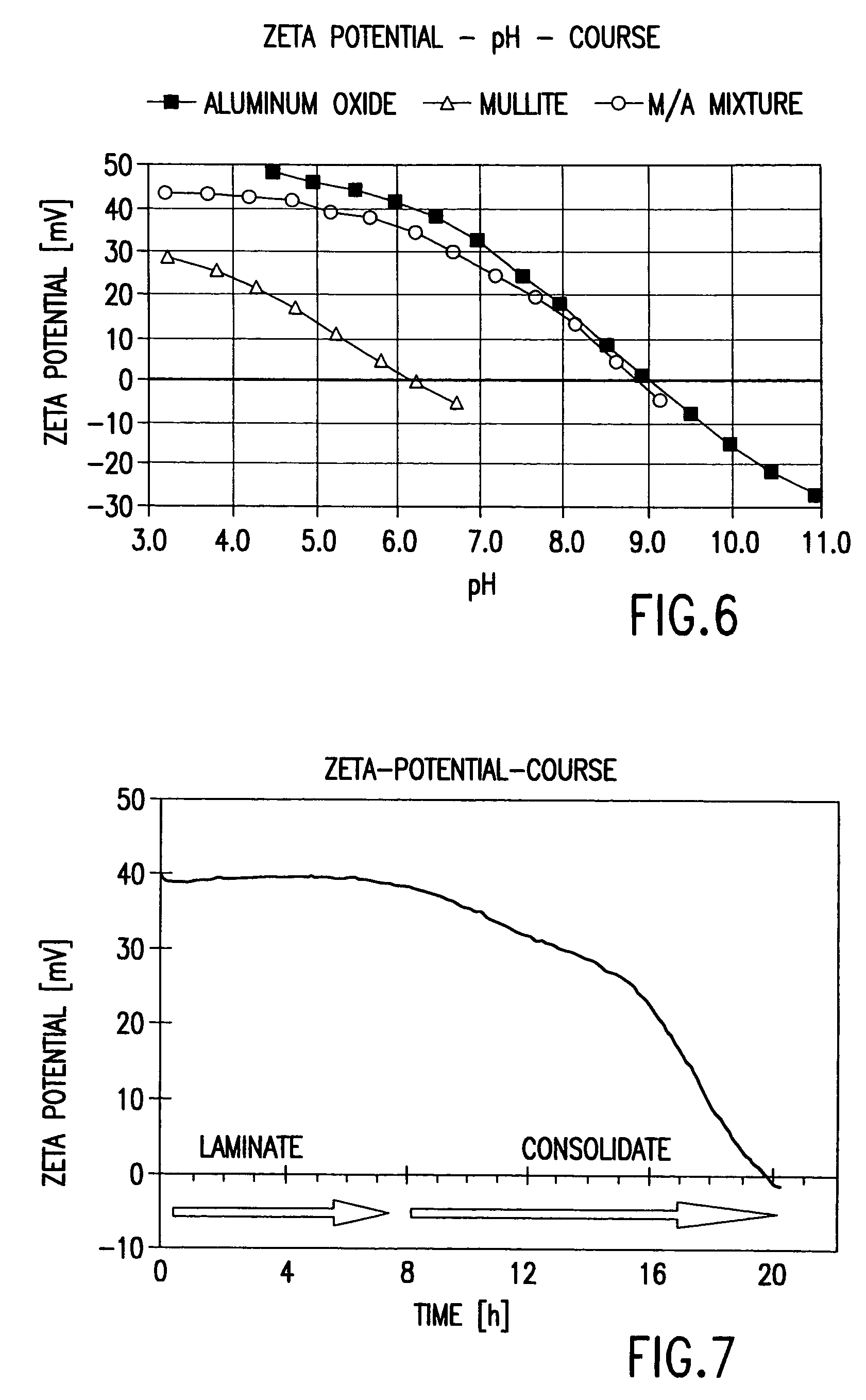

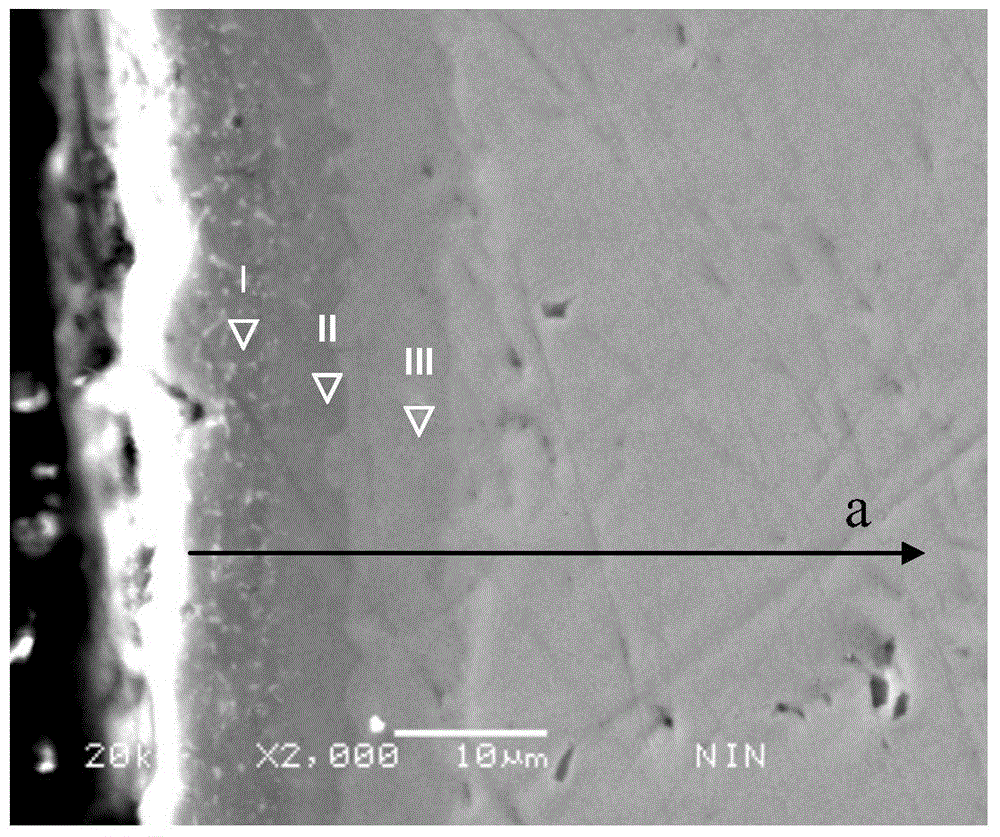

Multi-layer ceramic composite material with a thermal-protective effect

InactiveUS7118802B2Increasing the thicknessSufficient effectCombination devicesCosmonautic thermal protectionOxide ceramicsCeramic composite

A two-layer ceramic composite material, wherein the first predominantly load-bearing layer is an oxidic, carbon-free fiber-reinforced ceramic layer which is made by a colloidal process. The second predominantly thermally insulating layer is an oxide-ceramic foam. The colloidal process produces carbon-free oxide ceramics which, because of their high purity, have low dielectric losses in the entire usage temperature range. In addition, the colloidal process provides a simple and cost-effective production method.

Owner:LFK LENKLUGKOERPERSYST

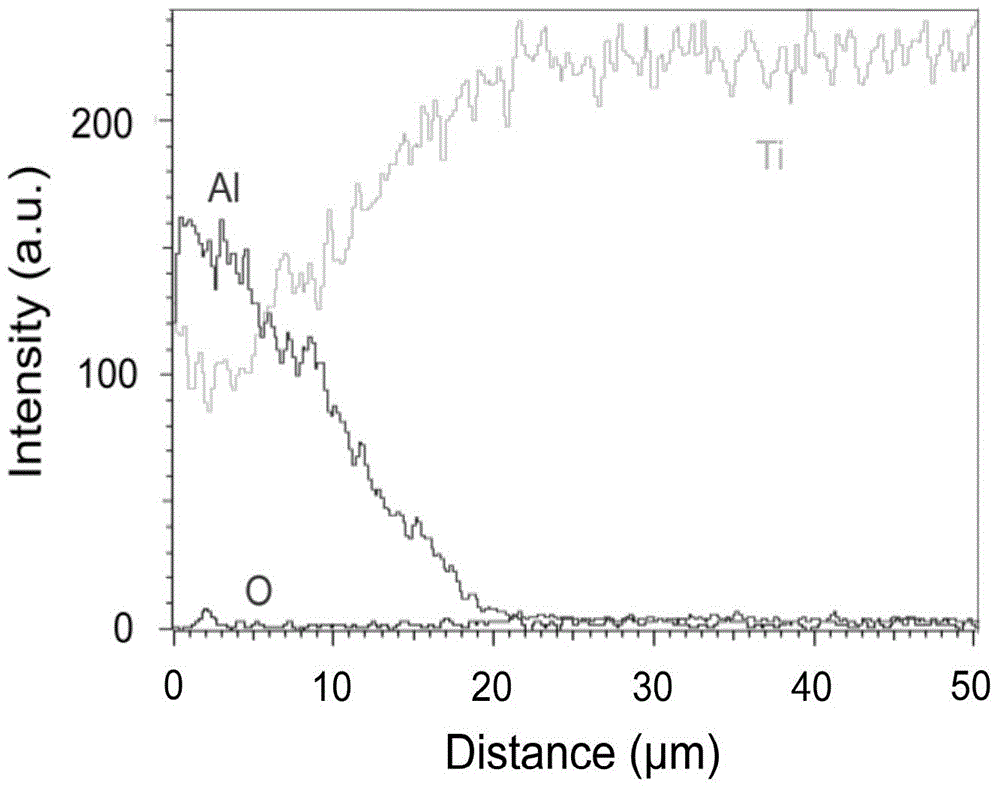

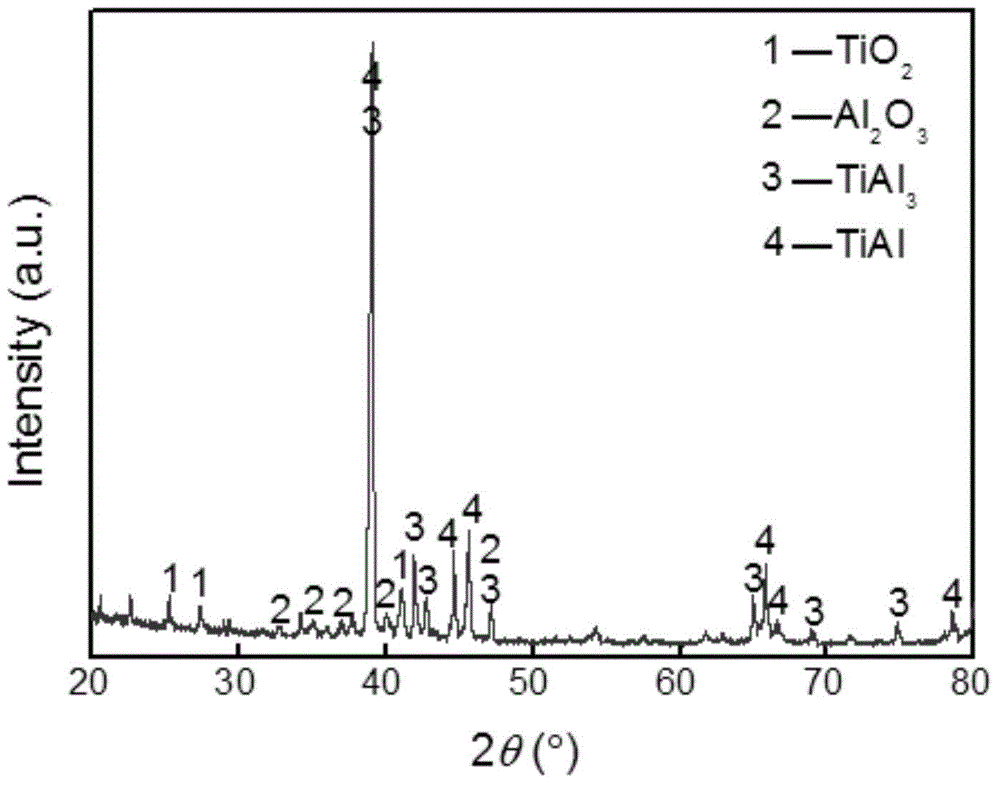

Preparation method of titanium substrate surface high-temperature antioxidant composite coating

ActiveCN104674218AImprove high temperature oxidation resistanceContinuous and dense structureVacuum evaporation coatingSurface reaction electrolytic coatingOxide ceramicsOxidation resistant

The invention discloses a preparation method of a titanium substrate surface high-temperature antioxidant composite coating. The preparation method comprises the following steps: I, carrying out the surface polishing treatment for a titanium substrate, oxidizing the titanium substrate subjected to the surface polishing treatment to obtain a titanium substrate with a titanium dioxide ceramic layer on the surface, and depositing metal aluminum on the titanium dioxide ceramic layer to obtain the titanium substrate with a titanium dioxide ceramic layer and an aluminum coating on the surface; and II, carrying out the vacuum heat treatment for the titanium substrate with the titanium dioxide ceramic layer and the aluminum coating on the surface, and obtaining a high-temperature antioxidant composite coating on the surface of the titanium substrate. The high-temperature antioxidant composite coating consisting of Ti and Al intermetallic compounds and oxide ceramics can be prepared on the surface of the titanium substrate, and the high-temperature antioxidant composite coating structure is continuous and compact and has no hole defect; moreover, the surface of the high temperature antioxidant composite coating is provided with an Al2O3 membrane, the Al2O3 membrane can prevent an oxygen element from diffusing into the titanium substrate, and the high temperature antioxidant capability of the titanium substrate can be improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

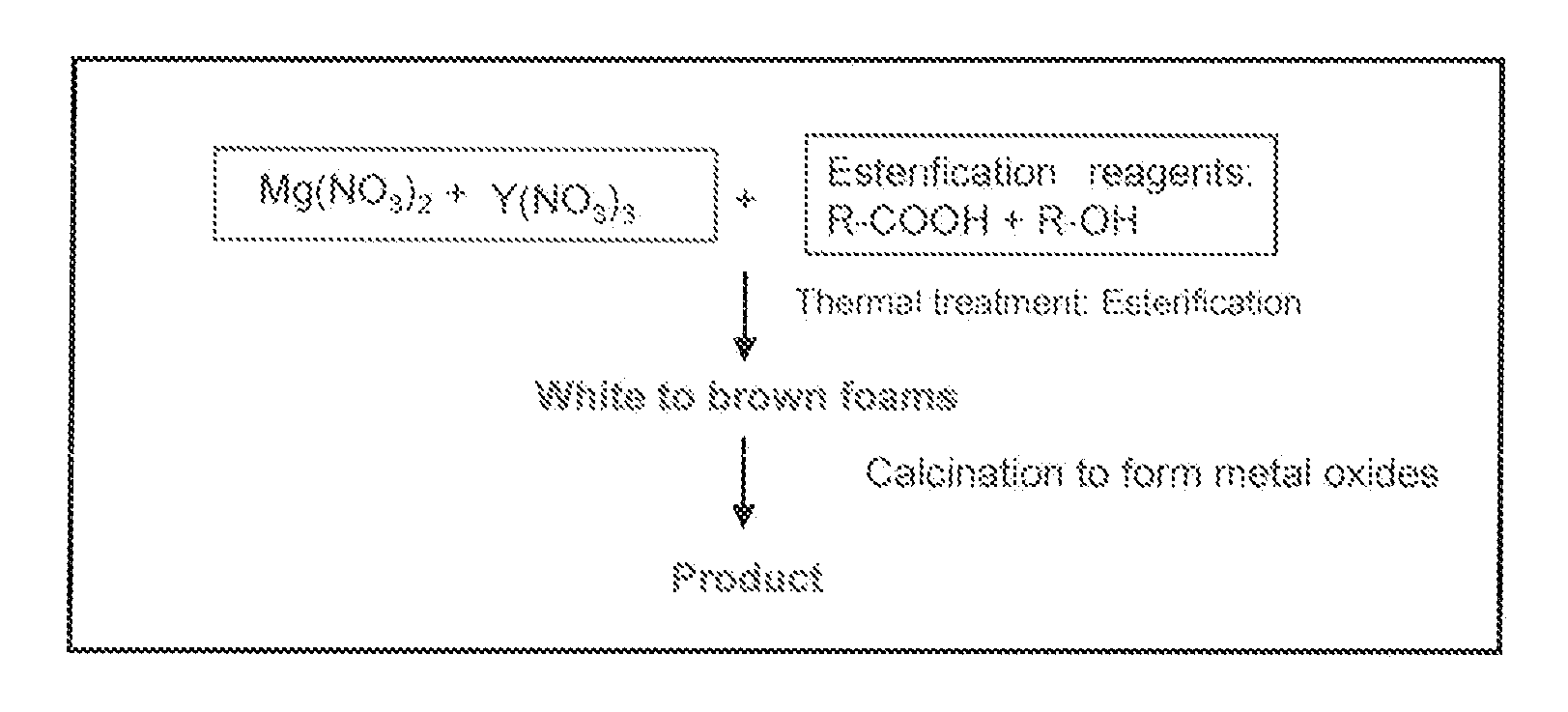

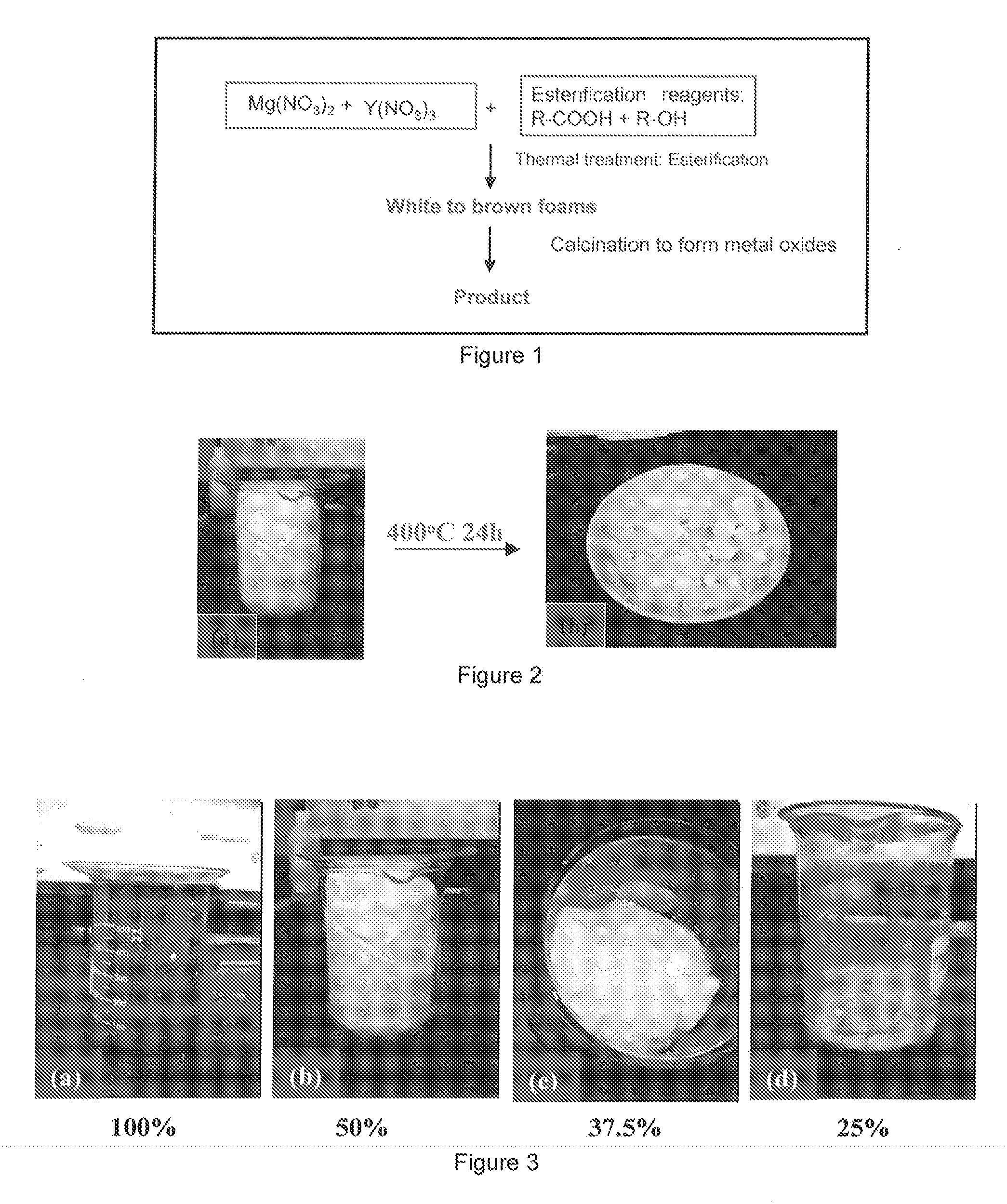

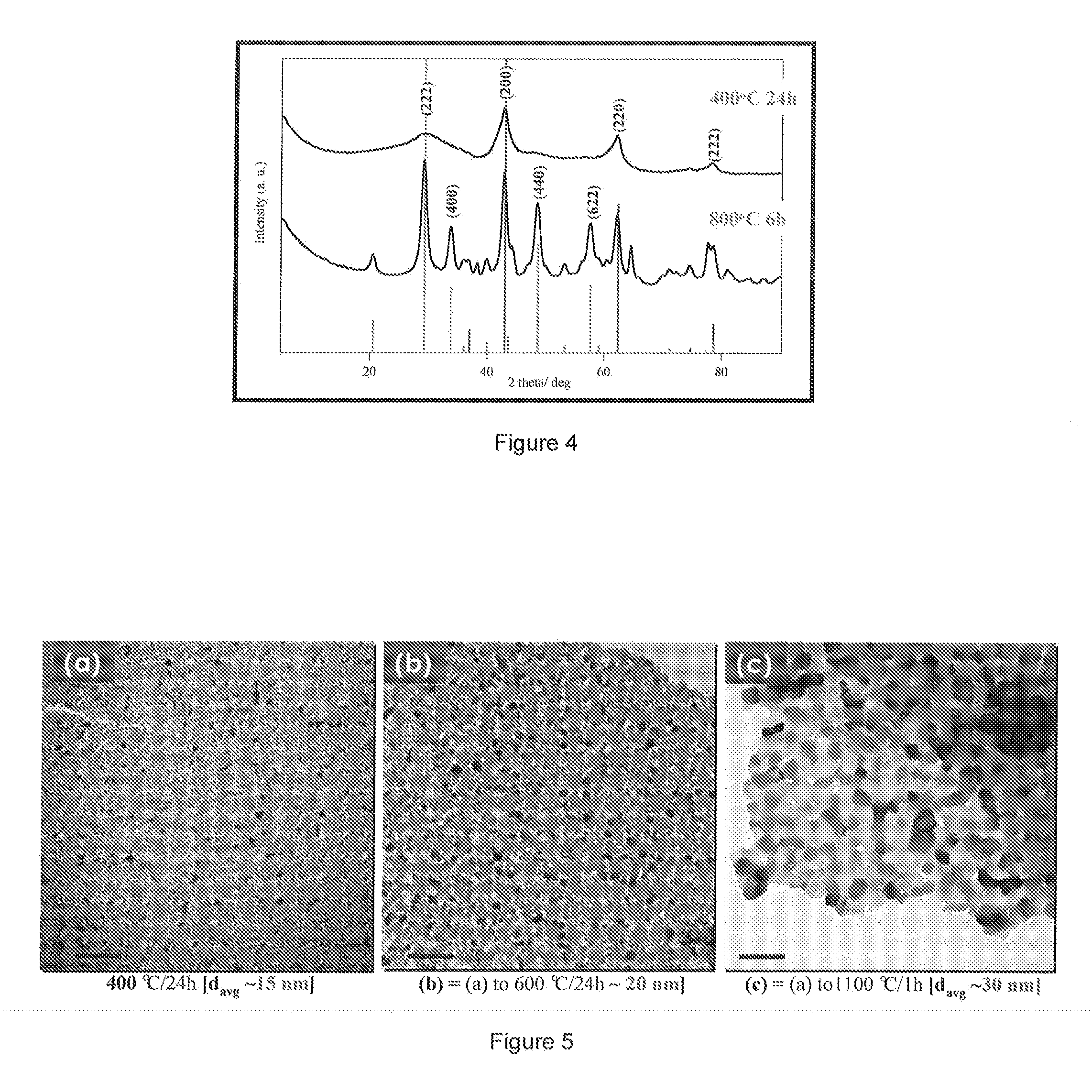

Method of synthesizing multi-iphase oxide ceramics with small phase domain sizes

InactiveUS20120322645A1Inhibit aggregationPrevent precipitationMaterial nanotechnologyOxide/hydroxide preparationOxide ceramicsMicroscopic scale

Nanocomposites of multi-phase metal oxide ceramics have been produced from water soluble salts of the resulting metal oxides by a foaming esterification sol-gel method. The evolution of volatile gases at elevated temperature during the esterification reaction causes the formation of a foam product. Nanocomposites of multi-phase metal oxide ceramics have also been produced by a cation polymer precursor method. In this second method, the metal cations are chelated by the polymer and the resulting product is gelled and foamed. Calcination of the resulting foams gives nanocomposite powders with extremely fine, uniform grains and phase domains. These microstructures are remarkably stable both under post-calcination heat treatment and during consolidation by hot-pressing.

Owner:UNIV OF CONNECTICUT CENT FOR SCI & TECH COMMLIZATION

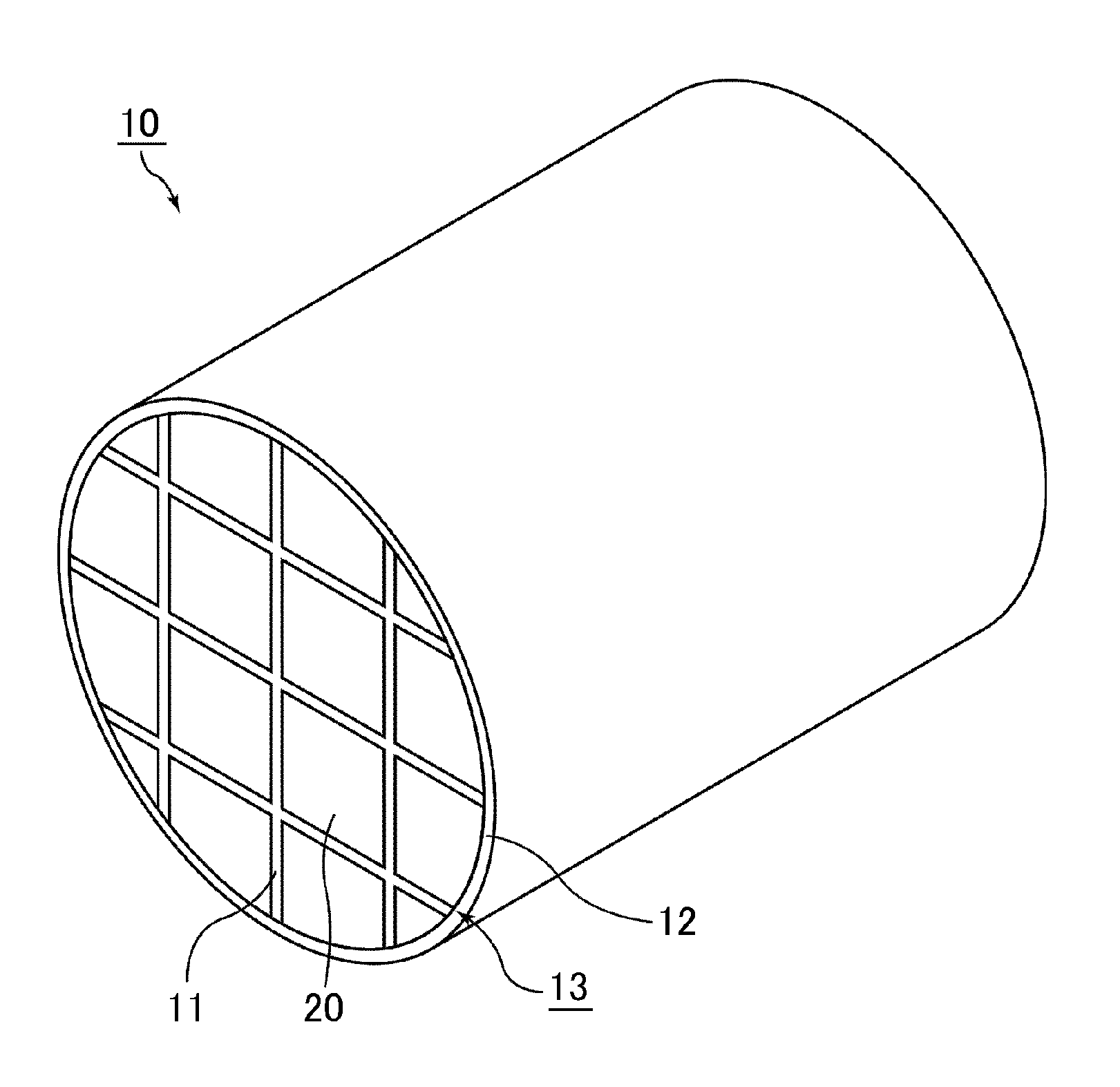

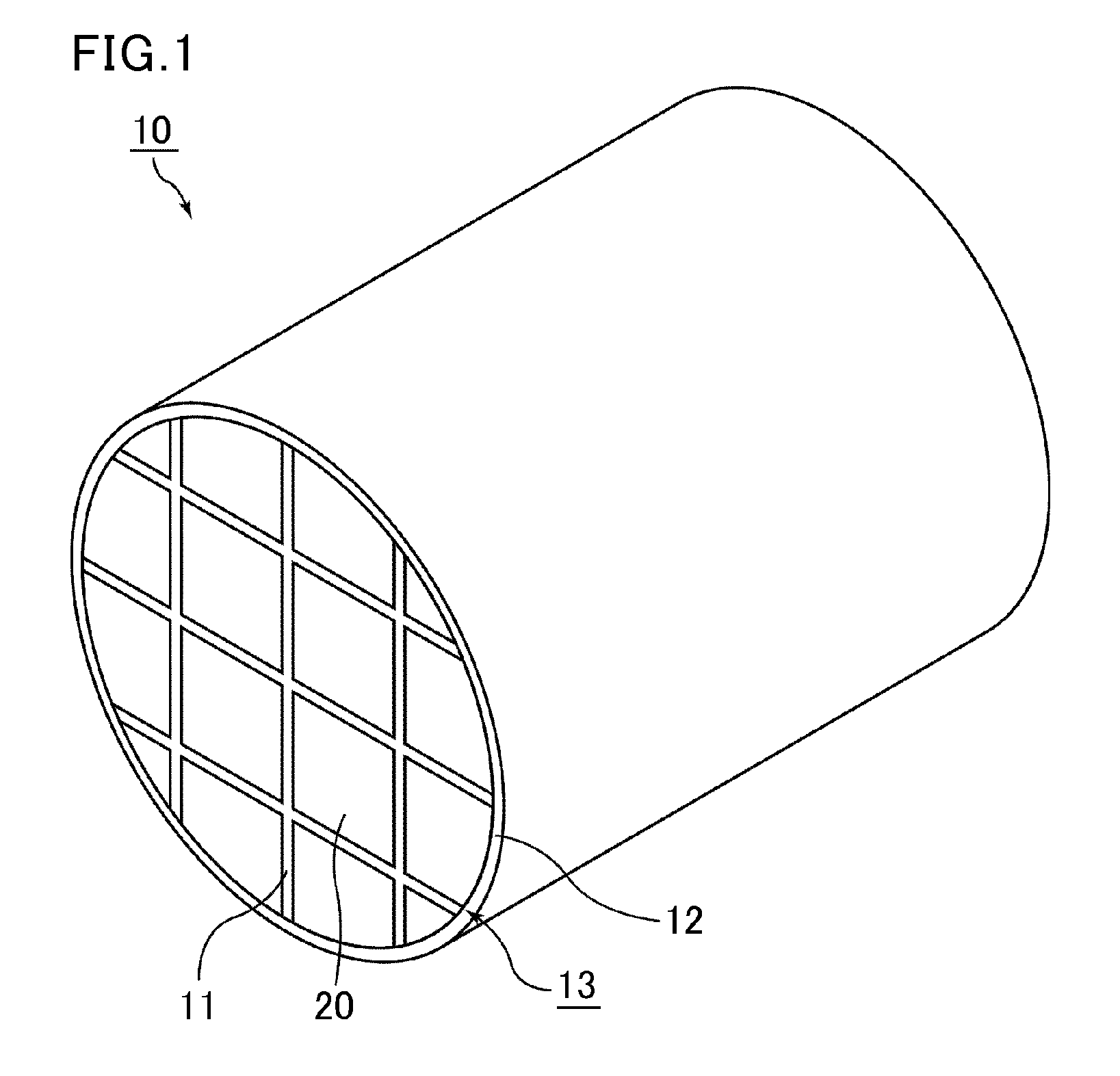

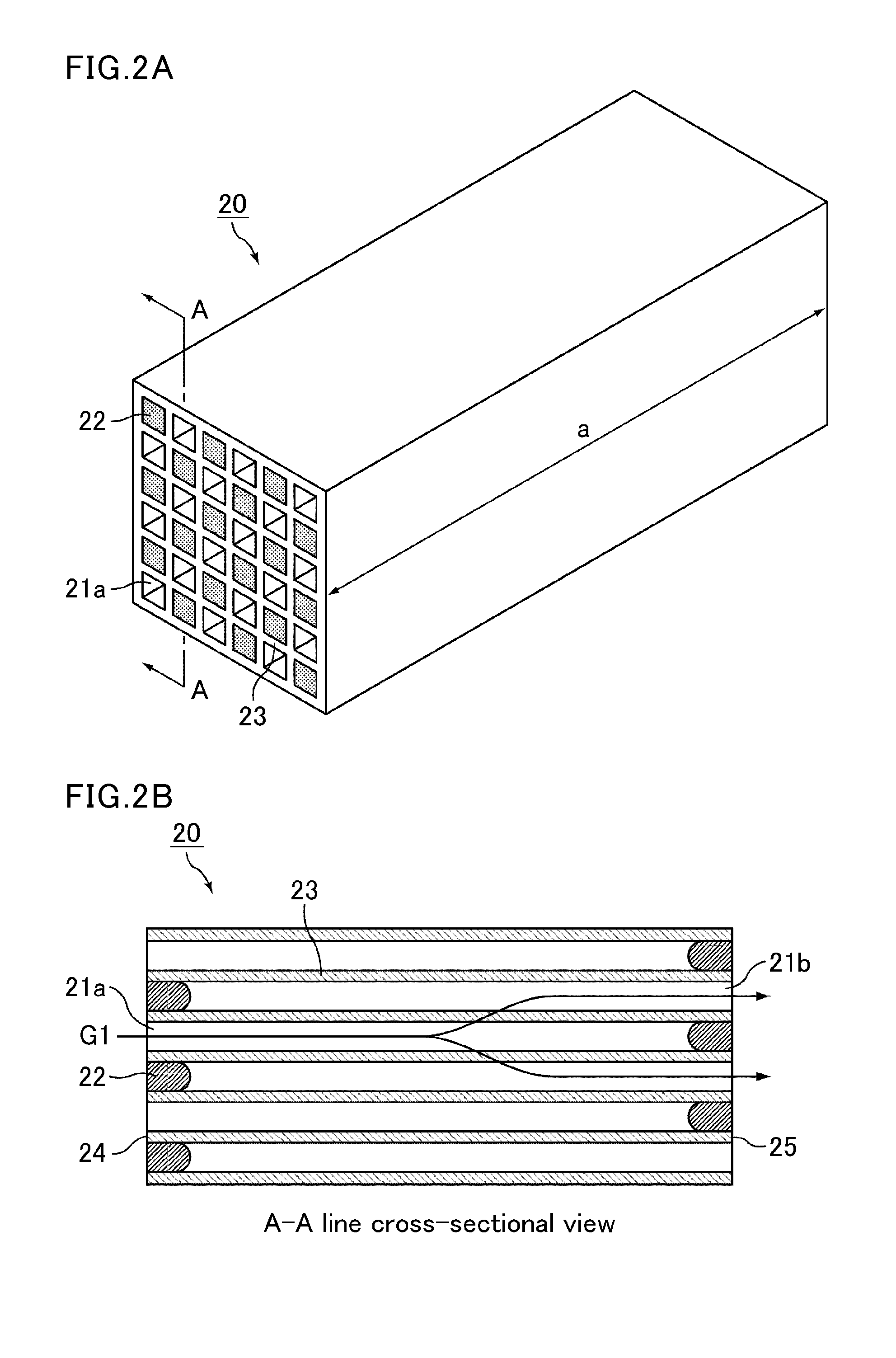

Honeycomb catalyst body and method for manufacturing honeycomb catalyst body

A honeycomb catalyst body includes a honeycomb structure and a catalyst. The honeycomb structure includes a porous honeycomb fired body having at least one cell wall defining a plurality of cells extending along a longitudinal direction of the porous honeycomb fired body. The plurality of cells is provided in parallel with one another. The honeycomb fired body contains silicon carbide particles and a silica layer formed on a surface of each of the silicon carbide particles. The silica layer has a thickness of from about 5 nm to about 100 nm measured by X-ray photoelectron spectroscopy. The catalyst contains at least one of oxide ceramics and zeolite. The catalyst is provided on a surface of the silica layer. An amount of at least one of the oxide ceramics and the zeolite is about 50 g / L or more.

Owner:IBIDEN CO LTD

Process for producing codoped In2O3 based pyroelectric material

InactiveCN101508560AImprove performanceShort reaction timeThermoelectric device manufacture/treatmentThermoelectric device junction materialsOxide ceramicsThermoelectric materials

A method for preparing double-doped In2O3 based thermoelectric materials relates to oxide ceramics and the preparation thereof. The method comprises the following steps: powders of ZnO, GeO2 and In2O3 are weighed and taken according to the stoichiometric ratio of In(2-2x)ZnxGexO3 (x is more than 0 but less than or equal to 0.20), and then the powders are mixed and calcined at the temperature of 250-700 DEG C, the phase-forming stage is completed; the calcined powder is put into a graphite mould and compacted, and then is sintered into a bulk material by the discharge plasma at the temperature of 850-1000 DEG C, thus obtaining the double-doped In2O3 oxide thermoelectric materials of Zn and Ge. Compared with the common solid phase sintering, the invention has short reaction time and low sintering temperature and can effectively overcome the disadvantages that the reaction temperature in the prior art is high, the reaction time is long, the energy consumption is high and the compound deviates from the stoichiometric ratio, etc. Besides, the property of the sintered samples is greatly enhanced and the ZT value thereof can achieve 0.6 at the temperature of 700 DEG C.

Owner:TSINGHUA UNIV

Oxide ceramics multiple phase refractory material

InactiveCN1919796AIncrease temperatureHigh compressive and flexural strengthOxide ceramicsClay minerals

The invention discloses an oxide ceramic composite phased fireproof material based on clay as raw material, which is characterized by the following: adopting clay minerals, industrial carbon powder and nitrogen as main raw material to form beta-sialon connecting phase; adding reacting accelerant, alumina or mullite particle to blend evenly; moulding; drying; aerating nitrogen in the high-temperature kiln to proceed carbon heat reducing-nitrogenizing reaction to sinter into combined beta-sialon alumina or mullite fireproof ceramic product with 10-30% beta-sialon continuous base phase and 70-90% alumina or mullite particle dispersing phase.

Owner:QINGDAO UNIV

Electrical-melting yttrium oxide ceramic crucible for titanium alloy melting casting and preparation method of ceramic crucible

The invention relates to the field of application of oxide ceramics, in particular to an electrical-melting yttrium oxide ceramic crucible for titanium alloy melting casting and a preparation method of the ceramic crucible. The ceramic crucible is prepared from, by oxide weight, 70%-99.5% of Y2O, 30%-0.5% of ZrO2 and not more than 0.5% of other trace impurities, wherein the trace impurities are oxides. The preparation method comprises the steps of conducting magnetic stirring melting on an yttrium oxide melting body through a high-frequency heating melting method for preparing a high-purity crystal material, crushing the yttrium oxide crystal for meeting the granularity and conducting shaping, sintering the yttrium oxide ceramic crucible and the like. The yttrium oxide ceramic crucible has the advantages of being free of adhesion and infiltration, good in thermal shock resistance, ultralong in service life and the like, the safe using temperature is below 2,300 DEG C, and the problems that due to the fact that the activity of a titanium alloy metal solution is high under high temperature, a chemical reaction is caused, the service life of the crucible is short, and the purity of titanium alloy is reduced due to disengagement after the reaction are solved.

Owner:ZHENGZHOU FANGMING HIGH TEMPERATURE CERAMIC NEW MATERIAL CO LTD

Inert anode and preparation method thereof

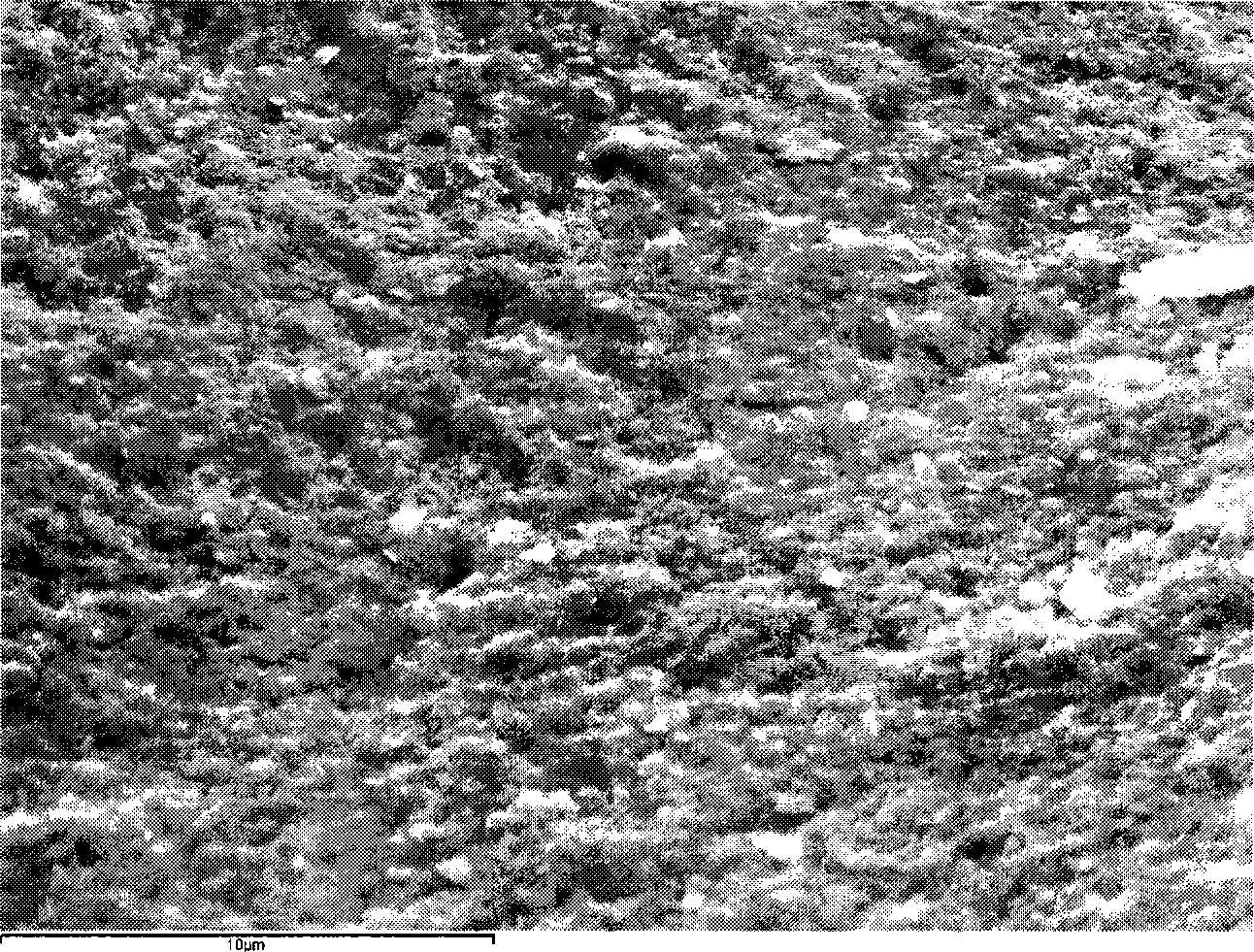

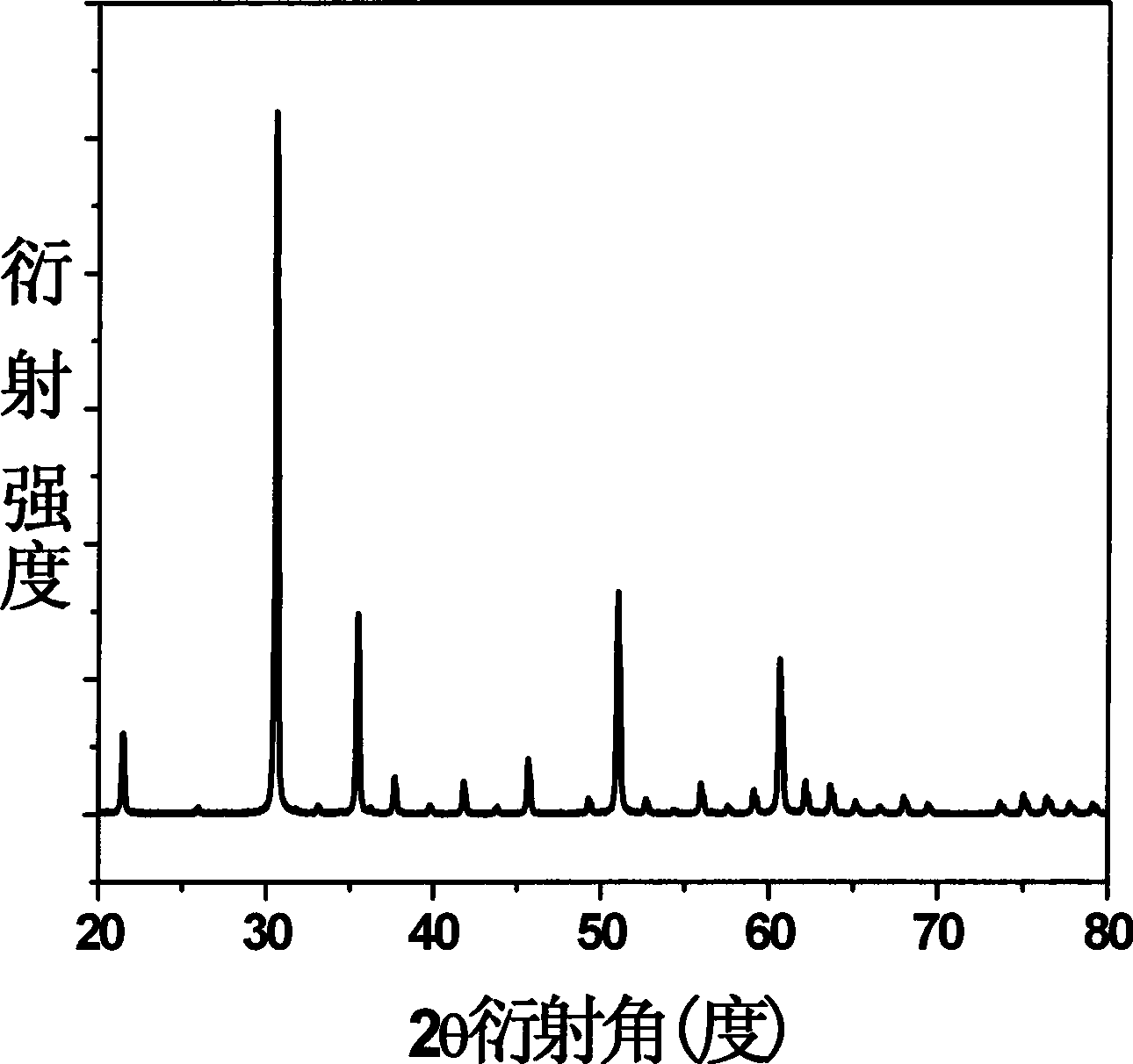

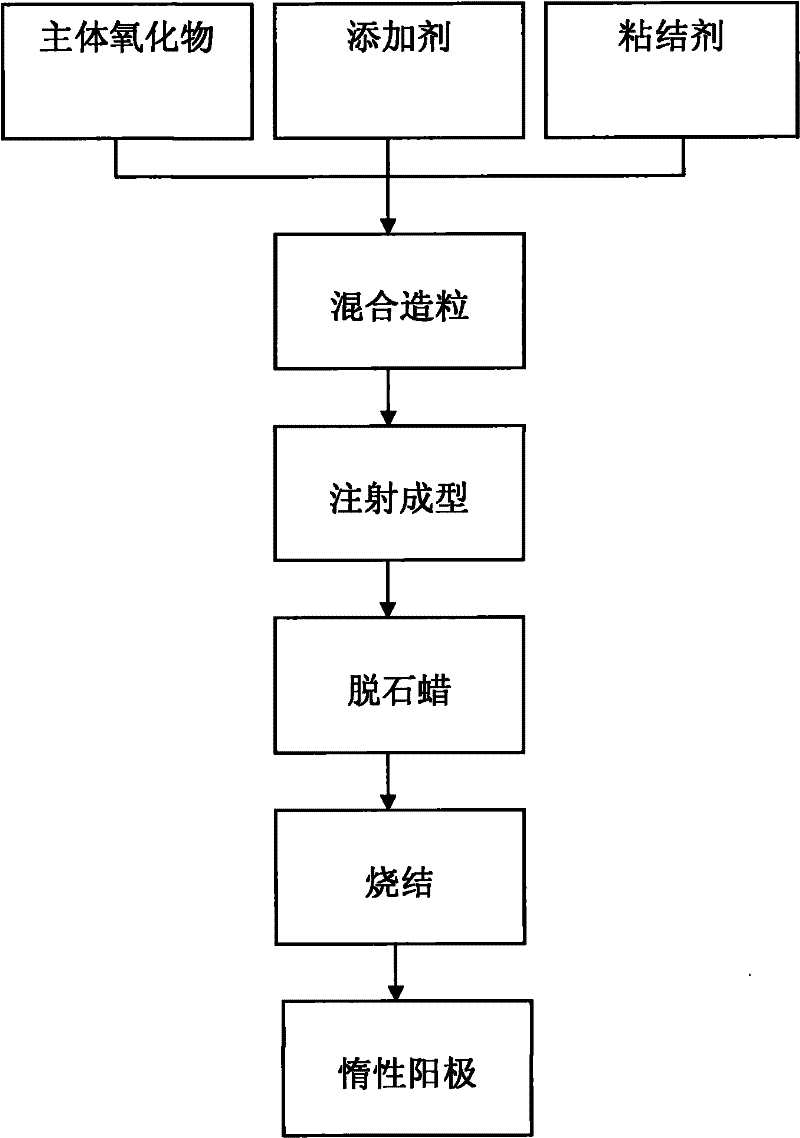

InactiveCN102206837ASolve the technical problem of low conductivityConductivity average increaseElectrodesOxide ceramicsElectrolysis

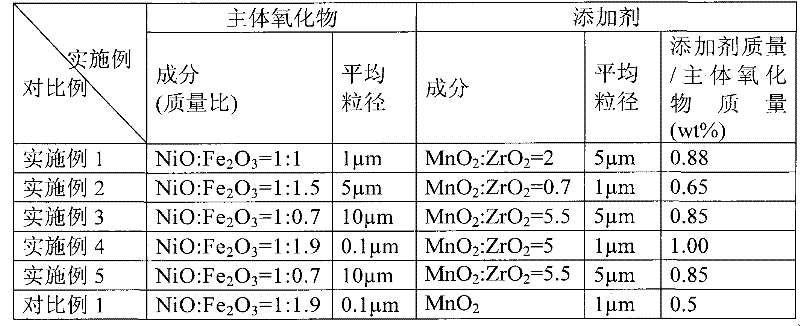

The invention belongs to the technical field of electrolysis, in particular to the technical field of metal oxide ceramic inert anodes. The invention provides an inert anode, which comprises main oxides and additives, wherein the main oxides comprise nickel oxide and ferric oxide; and the additives are at least two of magnesium oxide, titanium oxide, tin oxide, zinc oxide, zirconium oxide and alumina, and are 0.1 to 1 percent of the weight of the main oxides. The inert anode solves the technical problem of low electric conductivity when the conventional metal oxide ceramics serve as inert anodes, and the electric conductivity is averagely improved by about 8.4S / cm. In addition, the corrosion resistance of the inert anode is also improved. Correspondingly, the invention also provides an inert anode production method.

Owner:BYD CO LTD

Method of starch in situ coagulation colloidal shaping oxide ceramic

A process for shaping the raw oxide ceramics by in-situ solidification of starch includes dispersing the powder of oxide ceramics (Al2O3 ceramics, ZrO2 ceramics, Al2O3 -base ceramics, etc) in the water containing disperser, ball grinding, adding starch or modified starch, stirring, removing foams, pouring it in mould, keeping the temp for a certain time, and demoulding.

Owner:SOUTH CHINA UNIV OF TECH

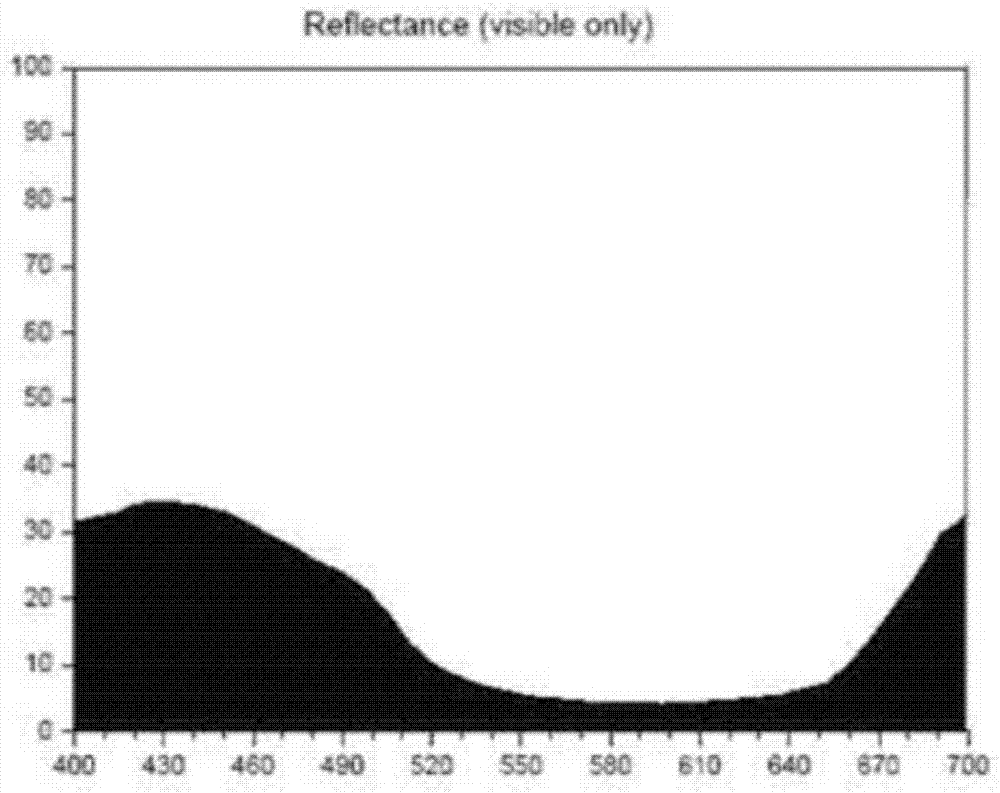

Method for preparing dark blue zirconia ceramic

The invention belongs to the technical field of oxide ceramics and in particular relates to a method for preparing a dark blue zirconia ceramic. The method comprises the following steps: by taking zirconium n-butoxide as a base material, yttrium acetate as a stabilizer, polyvinylpyrrolidone as a dispersing agent and an adhesive coating material, and absolute ethyl alcohol as a solvent, performing an ultrasonic reaction so as to obtain a sol solution wrapped by polyvinylpyrrolidone; by taking stearic acid as a dispersing agent and a medium, aluminum monoacetate and cobaltous acetate as raw materials, and ammonium hydroxide as a reaction agent and a pH adjusting agent, and an ethanol solution as a solvent, performing a sealing reaction so as to obtain clear pink sol; mixing the clear pink sol with a penetrant, putting into the sol solution wrapped by polyvinylpyrrolidone, and performing a sealed constant-pressure distillation reaction and a vacuum distillation reaction so as to obtain ceramic powder; and finally performing constant-temperature pressurizing sintering and gradient high-temperature sintering on the ceramic powder, thereby obtaining the dark blue zirconia ceramic. The method provided by the invention is simple and easy to operate, the obtained zirconia ceramic structure is dense and stable and uniform in coloring, and meanwhile has the mechanical properties of zirconium oxide.

Owner:无锡特科精细陶瓷有限公司

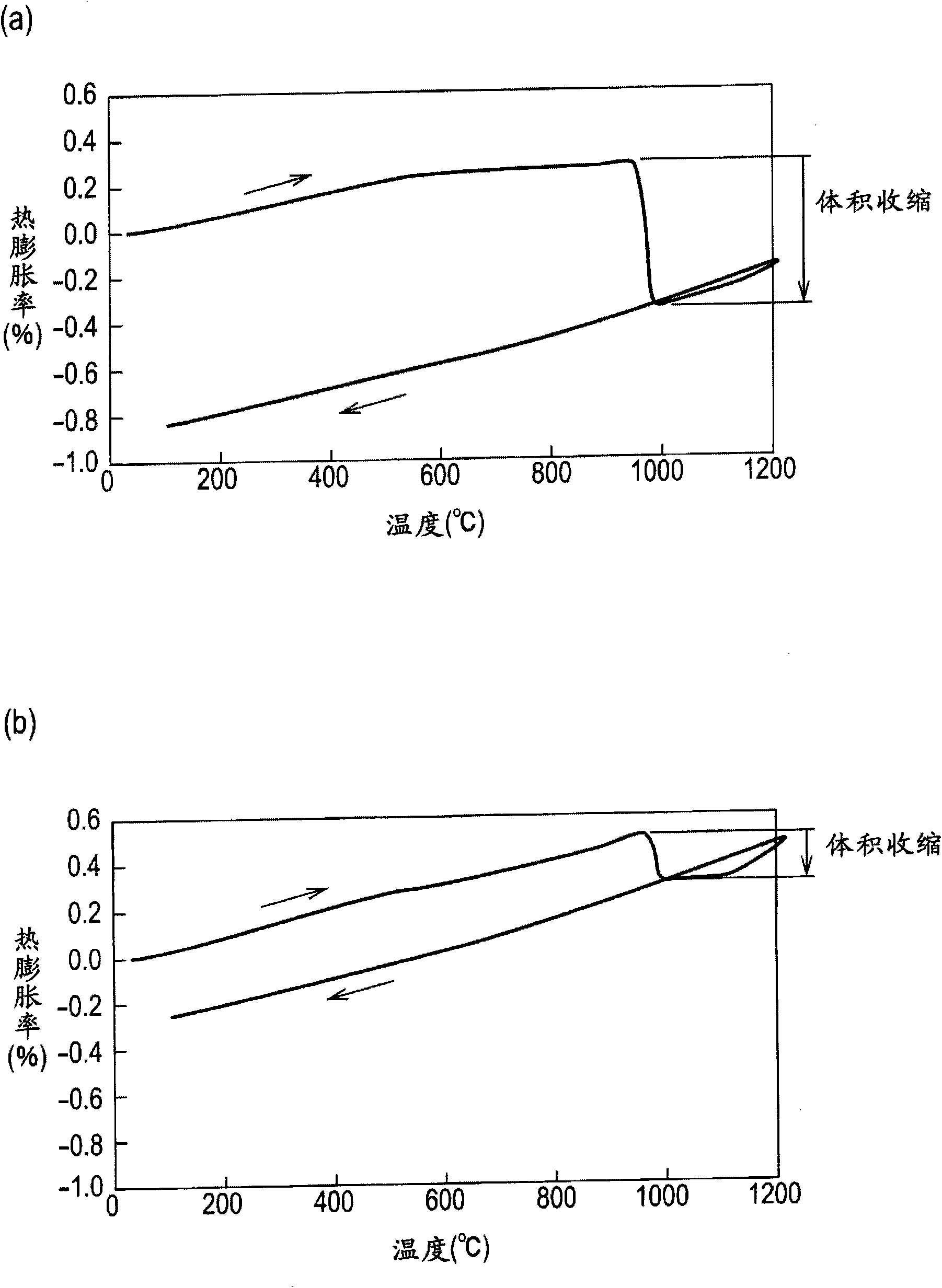

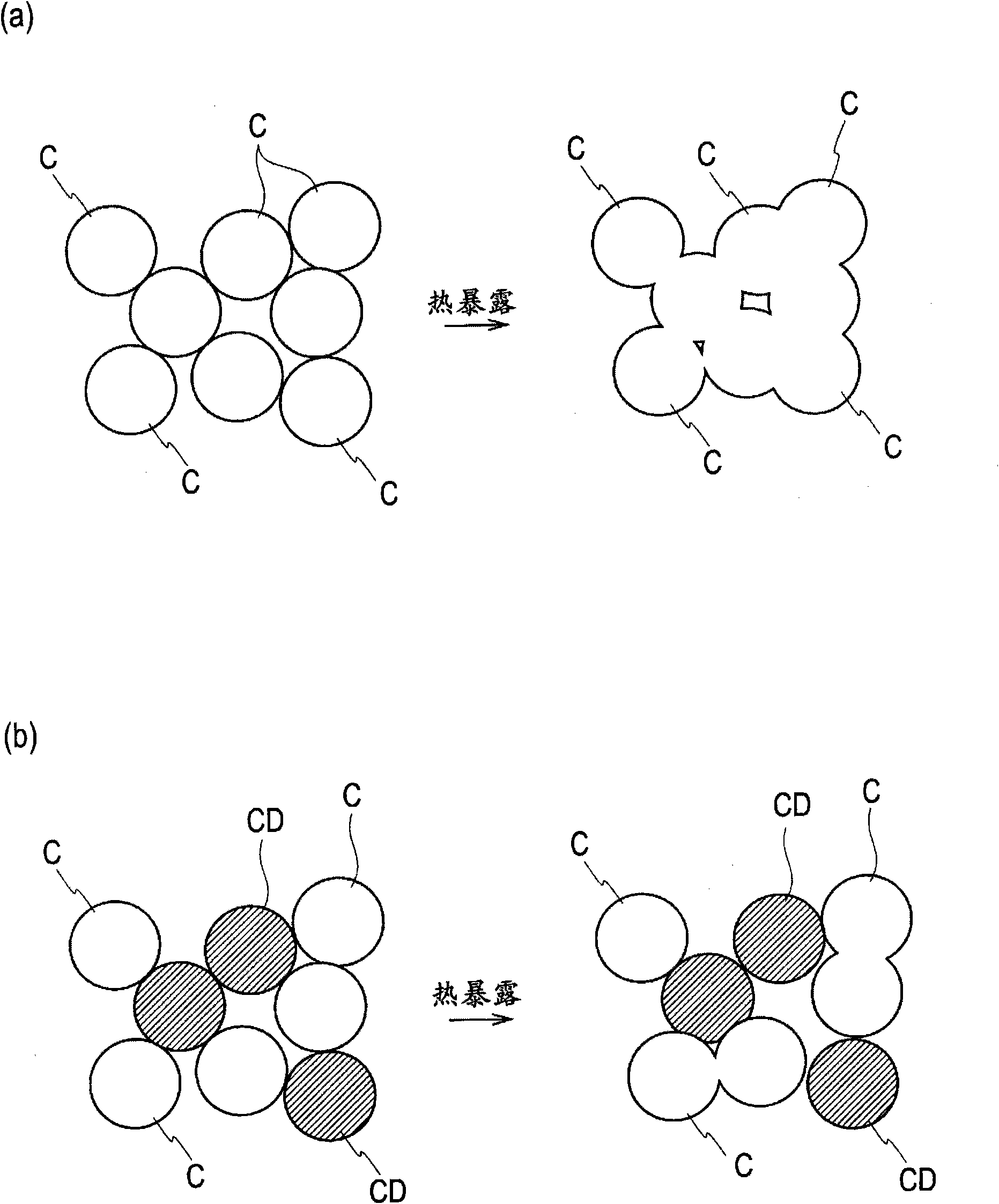

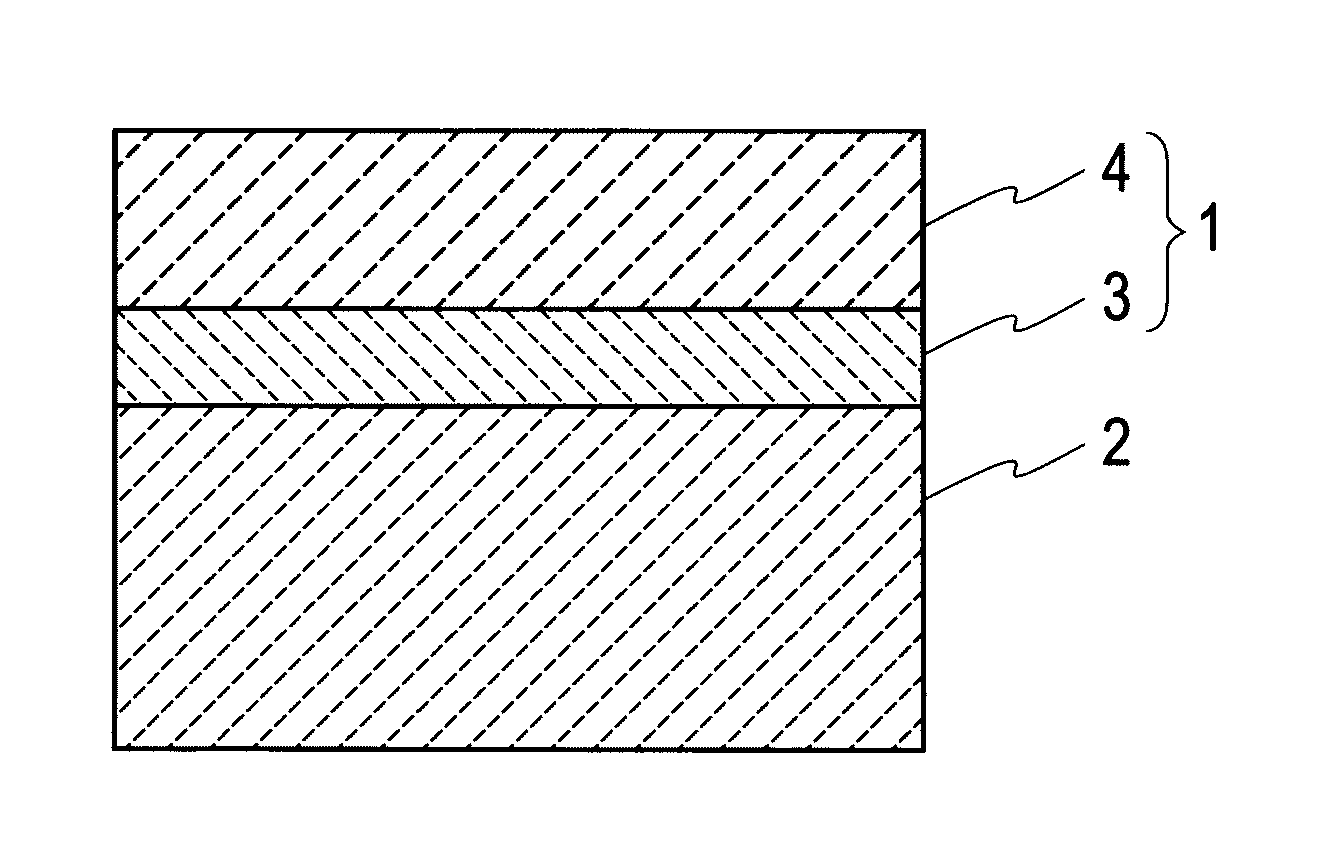

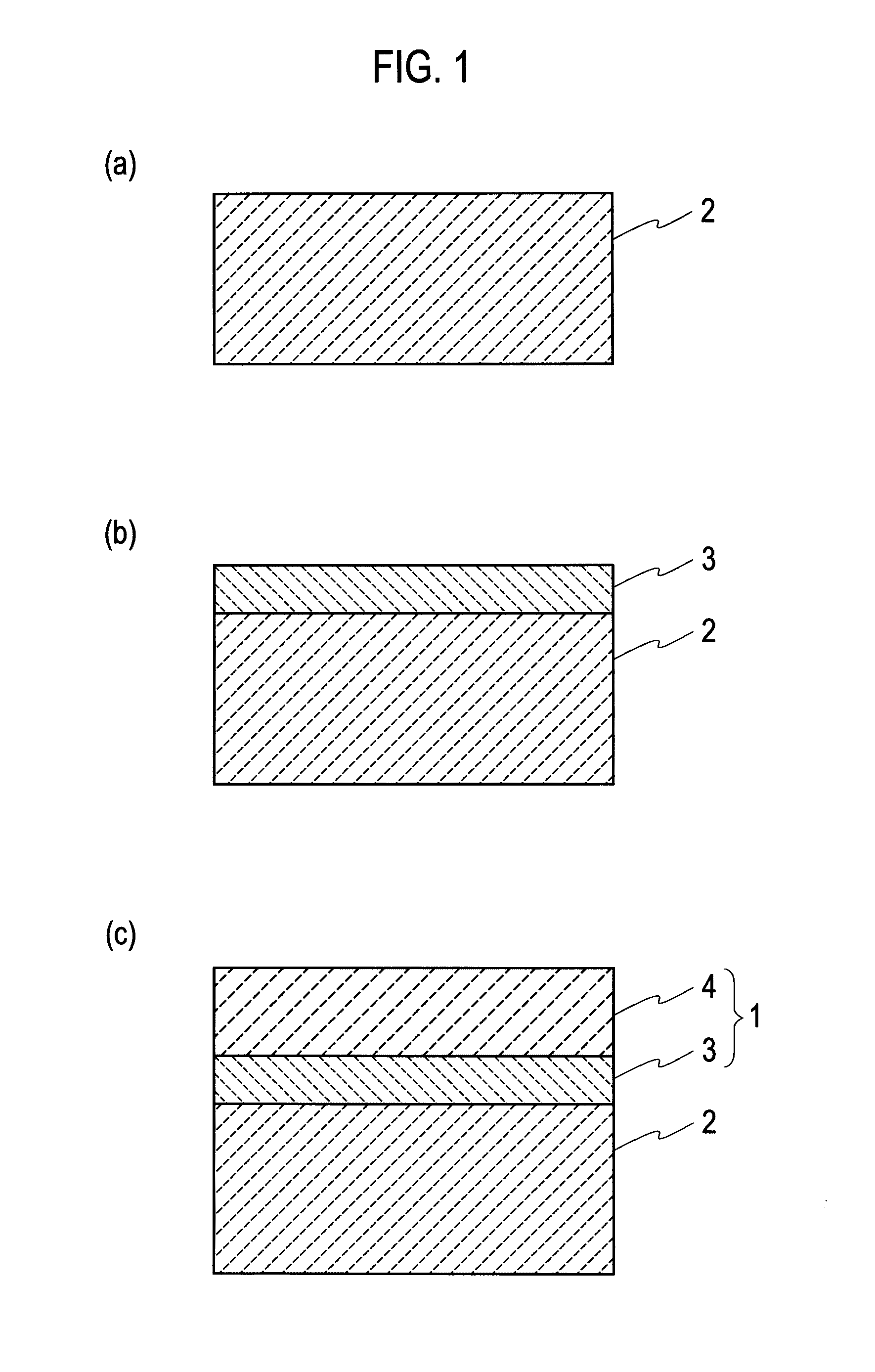

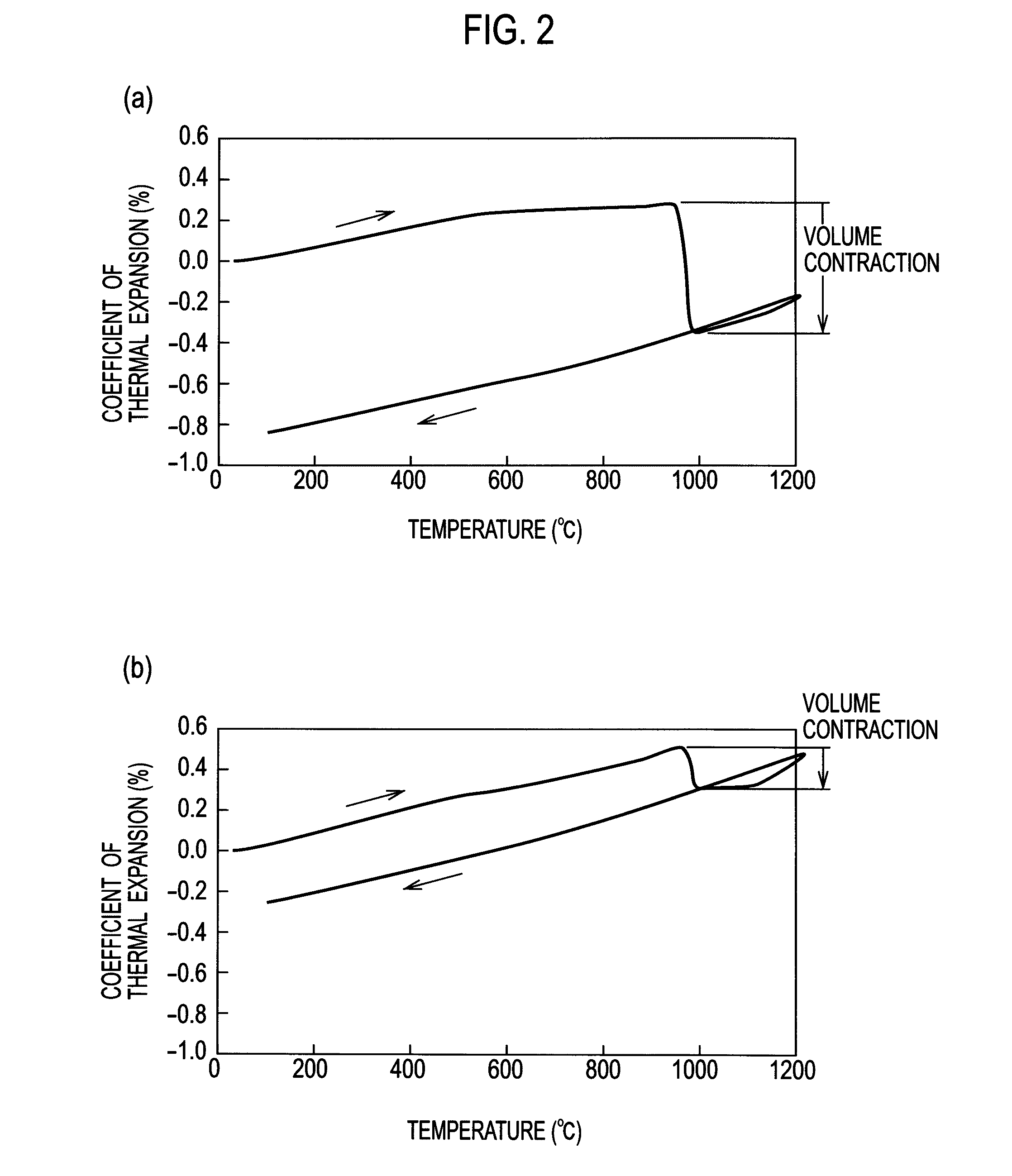

Coating structure and surface treating method

Disclosed are a coating structure and a surface treating method. The coating structure comprises a high-temperature component (2). An intermediate layer (3) formed of a glass-containing oxide ceramic is provided by thermal spraying on the surface of a part of the high-temperature component (2). An environmentally resistant film (4) formed of a coating material, which has heat resistance and resistance to a thickness reduction upon exposure to steam, is provided on the surface of the intermediate layer (3). The oxide ceramic comprises a plurality of oxide ceramics that do not undergo a change in crystal phase in a temperature range of a room temperature to 1400 DEG C or can maintain an identical volume even if the crystal phase changes. The coefficient of thermal expansion of the plurality of oxide ceramics is intermediate between the coefficient of thermal expansion of an SiC ceramic-based composite material constituting the high-temperature component (2) and the coefficient of thermal expansion of the coating material constituting the environmentally resistant film (4).

Owner:IHI CORP

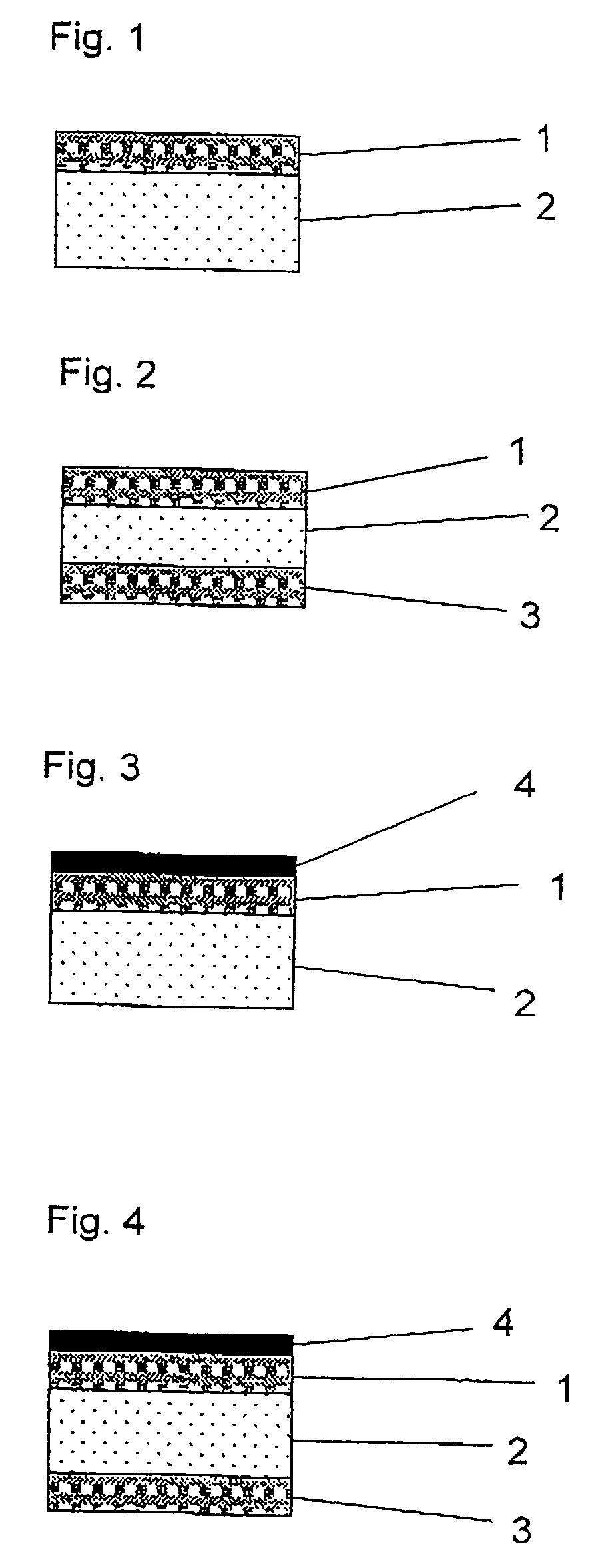

Preparation method of ceramic sealing coating with high thermal shock resistance

ActiveCN104451675AImprove bonded stateImprove thermal shock resistanceMolten spray coatingVacuum evaporation coatingOxide ceramicsSurface layer

The invention discloses a preparation method of a ceramic sealing coating with high thermal shock resistance. According to the preparation method, the structure of a conventional ceramic sealing coating is improved, a layer of compact continuous ceramic thin film is prepared between a ceramic surface layer and an MCrAlY bonding bottom layer to ensure that the ceramic thin film is in defect-free combination with the MCrAlY bonding bottom layer, and a good base surface is provided for deposition of the ceramic surface layer, so that an interface bonding state of a ceramic layer and a metal layer can be improved, and the thermal shock resistance of the coating can be improved. A preparation process of the ceramic thin film can be selected from compact thin film preparation technologies such as a super-low-pressure plasma-thin film (LPPS-TF) technology or CVD, the thickness of the thin film is 10 nanometers to 200 microns, components of the thin film can be various oxide ceramics, or can be the same as or similar to the components of the surface layer, and tissue structures of the thin film can be uniform or gradient.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Coating structure and surface processing method

A high temperature component (2) has an intermediate layer (3) formed by a spraying on a surface in part thereof and comprised of an oxide ceramics set containing a glass, and an environment resistant coat (4) formed on a surface of the intermediate layer (3) and comprised of a coating material having a heat resistance and a water vapor wall-thinning resistance. The oxide ceramics set is a set of kinds of oxide ceramics adapted to be unchanged in crystalline phase, or isometric in cubic volume even when phase-changed, within a temperature range from a room temperature to 1,400 degrees C., the set of kinds of oxide ceramics having a coefficient of thermal expansion between a coefficient of thermal expansion of an SiC series ceramics matrix composite constituting the high temperature component (2) and a coefficient of thermal expansion of the coating material constituting the environment resistant coat (4).

Owner:IHI CORP

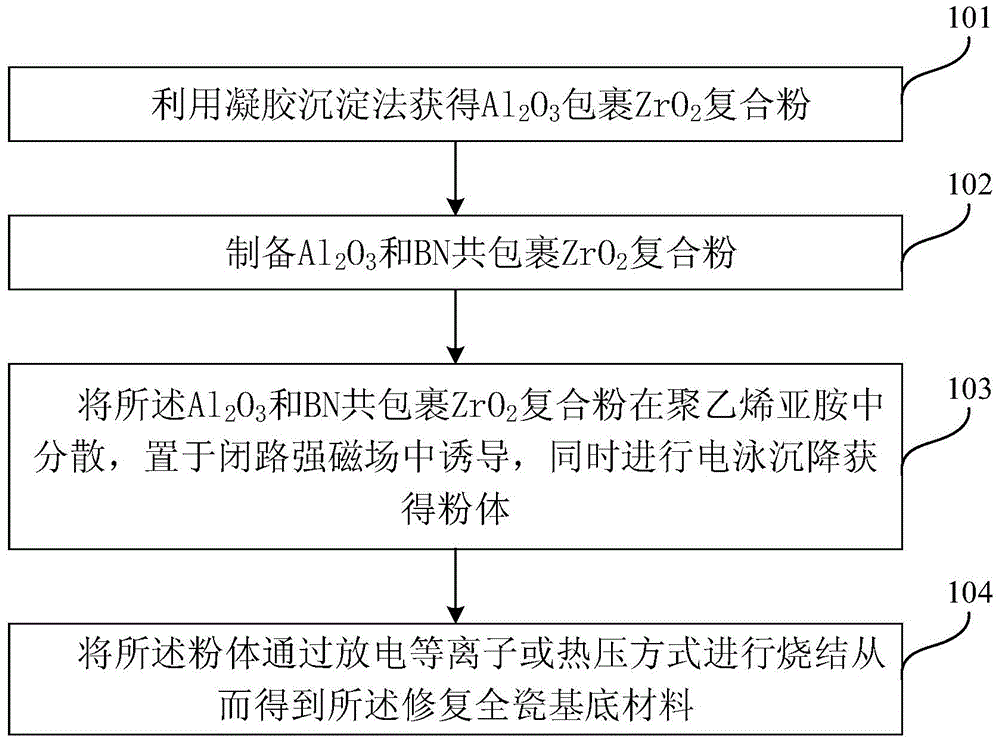

Processing method for restoring all-ceramic substrate material

The invention relates to a processing method for restoring an all-ceramic substrate material. The method comprises the following steps: acquiring Al2O3-coated ZrO2 composite powder by utilizing a gel precipitation method; preparing Al2O3 / BN co-coated ZrO2 composite powder; dispersing the Al2O3 and BN co-coated ZrO2 composite powder in polyethyleneimine, inducing in a closed circuit high-intensity magnetic field, and meanwhile carrying out electrophoretic sedimentation so as to obtain powder body; sintering the powder body in a spark plasma or hot pressing mode so as to obtain the restored all-ceramic substrate material. According to the invention, free energy is generated by an echelon standard so as to solve the problems of deoxidation and discoloration during hot pressing and sintering of oxide ceramics. Components and the chemical states of a crystal boundary are controlled, so that a sintered body of the material has the processability; the deformation problem of an incomplete sintered block body of a commercial substrate ceramic after densifying at present is overcome; chemical bonding with a conventional veneering ceramic is achieved; the problem of poor bonding force of a zirconia all-ceramic substrate and the veneering ceramic is solved.

Owner:GENERAL HOSPITAL OF PLA

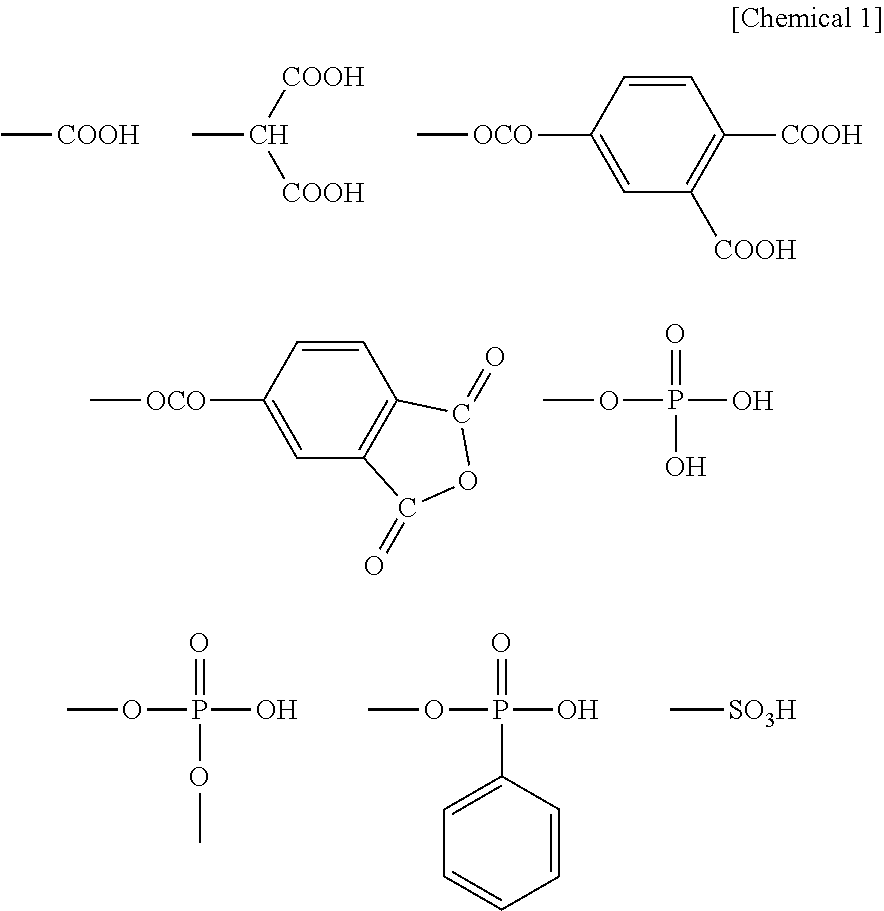

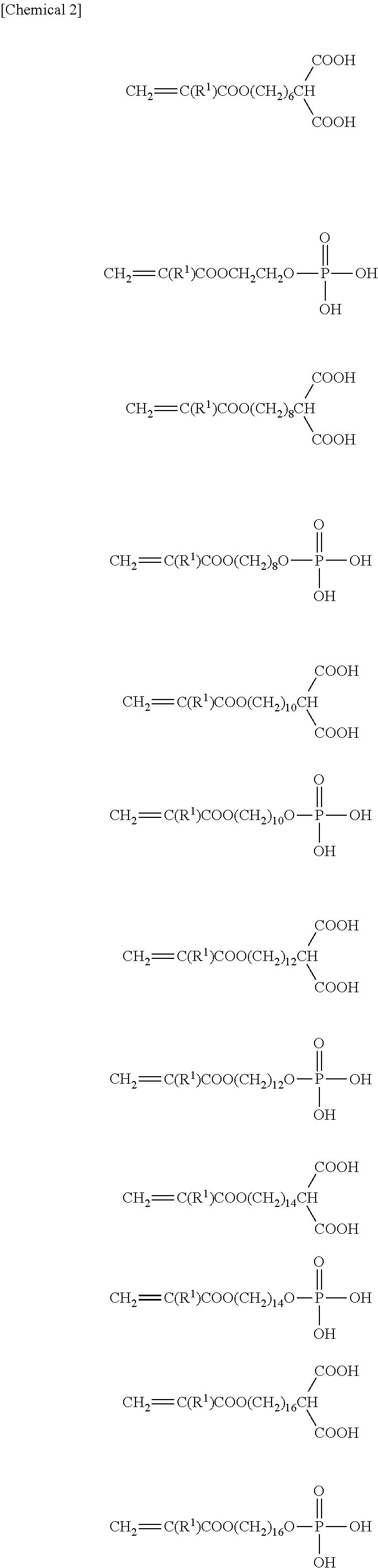

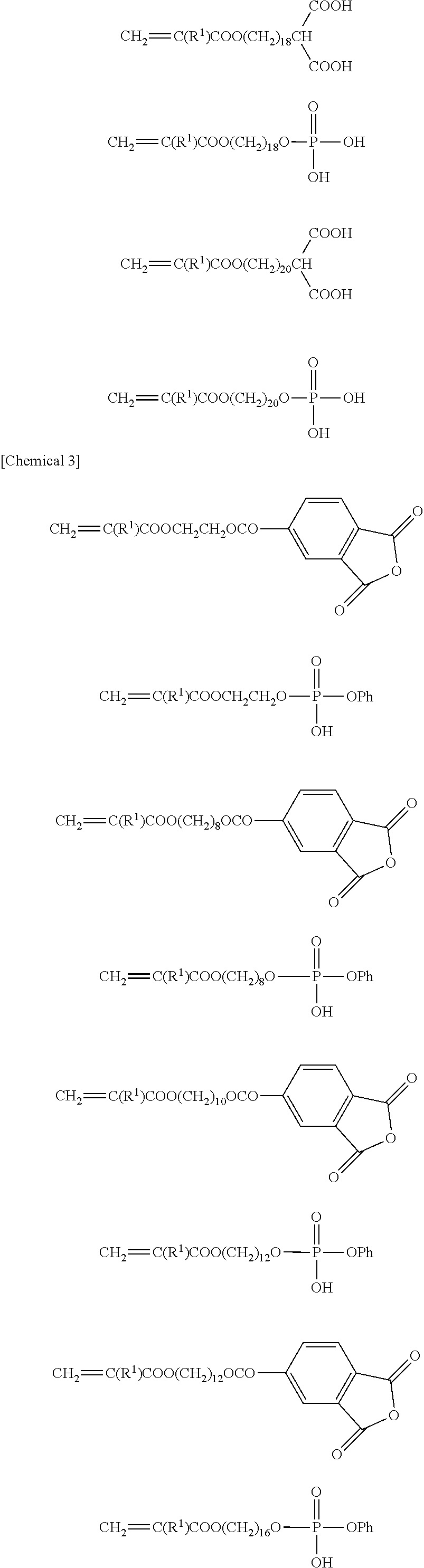

Primer composition for metal oxide ceramics

ActiveUS20110143015A1Excellent adhesion durabilityHigh strengthImpression capsPretreated surfacesOxide ceramicsTriethyleneglycol dimethacrylate

[Problems] A primer used for pre-treating the surfaces of a prosthetic, which exhibits a large adhering force at the time of adhering a prosthetic of metal oxide ceramics to an object to be joined by using an adhesive such as a dental cement, the large adhering force being maintained for extended periods of time even in a severe environment such as in an oral cavity.[Means for Solution] A primer composition for metal oxide ceramics, comprising (A) a polymerizable monomer component containing 5% by mass or more, preferably, 5% by mass to 80% by mass of an acidic group-containing polymerizable monomer as represented by a 11-methacryloyloxy-1,1-undecanedicarboxylic acid and a rest of a polymerizable monomer without acidic group, such as triethylene glycol dimethacrylate; (B) polyvalent metal ions resulting from a titanium tetrabutoxide or the like; and (C) an organic solvent such as acetone or ethyl alcohol, wherein water is not substantially contained.

Owner:TOKUYAMA DENTAL CORP

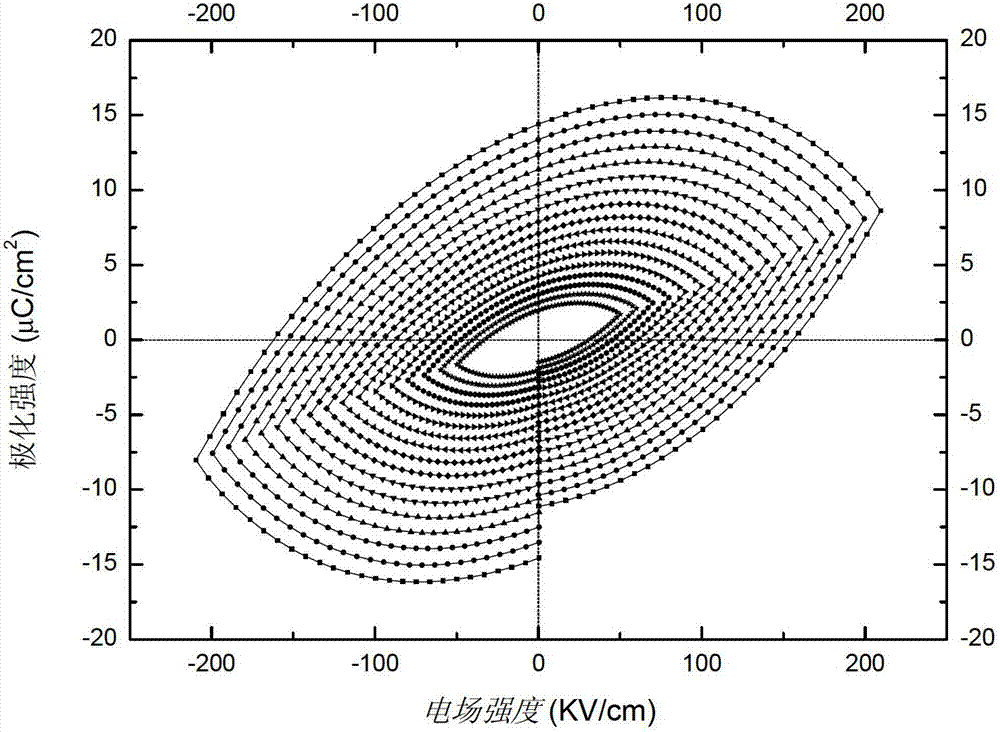

Titanium-iron-gadolinium cobaltate-bismuth ceramic material in layer structure and preparation method of titanium-iron-gadolinium cobaltate-bismuth ceramic material

InactiveCN102863211AImprove ferroelectric propertiesImprove ferromagnetic propertiesOxide ceramicsOctahedron

The invention provides a titanium-iron-gadolinium cobaltate-bismuth ceramic material in a layer structure. Gadolinium ions substitute for part of bismuth ions, and cobalt ions substitute for part of iron ions so that Bi7-xGdxFe1.5Co1.5Ti3O21 layered Aurivillius type multiferroic oxide ceramics are obtained. The titanium-iron-gadolinium cobaltate-bismuth ceramic material has the advantages that on one hand, an iron atomic structure and a cobalt atomic structure are approximate, and after part of the cobalt ions substitutes for part of iron ions in position, Fe-O octahedrons and Co-O octahedrons are arrayed in order, and Fe-O-Co coupling can be generated partially, so that ferroelectricity and ferromagnetism of the ceramic material can be improved; and on the other hand, since the gadolinium ions partially having magnetism substitute for part of bismuth ions, leakage current is effectively reduced while ferroelectricity of the ceramic material is enhanced, and partially existing coupling of Gd-O-Co / Fe enables the ferromagnetism of the ceramic material to be improved.

Owner:UNIV OF SCI & TECH OF CHINA

Fused diyttrium trioxide ceramic crucible for melting casting of titanium alloy and preparation method thereof

The invention relates to the field of application of oxide ceramics, in particular to an electrical-melting yttrium oxide ceramic crucible for titanium alloy melting casting and a preparation method of the ceramic crucible. The ceramic crucible is prepared from, by oxide weight, 70%-99.5% of Y2O, 30%-0.5% of ZrO2 and not more than 0.5% of other trace impurities, wherein the trace impurities are oxides. The preparation method comprises the steps of conducting magnetic stirring melting on an yttrium oxide melting body through a high-frequency heating melting method for preparing a high-purity crystal material, crushing the yttrium oxide crystal for meeting the granularity and conducting shaping, sintering the yttrium oxide ceramic crucible and the like. The yttrium oxide ceramic crucible has the advantages of being free of adhesion and infiltration, good in thermal shock resistance, ultralong in service life and the like, the safe using temperature is below 2,300 DEG C, and the problems that due to the fact that the activity of a titanium alloy metal solution is high under high temperature, a chemical reaction is caused, the service life of the crucible is short, and the purity of titanium alloy is reduced due to disengagement after the reaction are solved.

Owner:ZHENGZHOU FANGMING HIGH TEMPERATURE CERAMIC NEW MATERIAL CO LTD

Preferentially-oriented oxide ceramics, piezoelectric element, liquid discharge head, ultrasonic motor, and dust removing device

ActiveUS20130200750A1High degree of crystal orientationMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyCrystal systemOxide ceramics

Provided is a manufacturing method for preferentially-oriented oxide ceramics having a high degree of crystal orientation. The manufacturing method includes: obtaining slurry containing an oxide crystal B having magnetic anisotropy; applying a magnetic field to the oxide crystal B, and obtaining a compact of the oxide crystal B; and subjecting the compact to oxidation treatment to obtain preferentially-oriented oxide ceramics including a compact of an oxide crystal C having a crystal system that is different from a crystal system of one of a part and a whole of the oxide crystal B. By (1) reacting raw materials, (2) reducing the oxide crystal A, or (3) keeping the oxide crystal A at high temperature and quenching the oxide crystal A, the oxide crystal B is obtained to be used in the slurry.

Owner:CANON KK +1

Dry-pressing preparation method of magnesium oxide ceramics

The invention belongs to the technical field of metallurgy, and particularly relates to a dry-pressing preparation method of magnesium oxide ceramics. In view of problems of tedious operations and high production costs of an existing preparation method of magnesium oxide ceramics, the invention provides the dry-pressing preparation method of magnesium oxide ceramics, wherein the dry-pressing preparation method comprises the following steps: a, magnetically separating magnesium oxide powder by an electromagnetic separator, ball-milling into a certain degree of fineness after magnetic separation; b, using an airflow granulation method for granulating the magnesium oxide powder; c, pressing the magnesium oxide particles after granulation by a powder pressing machine to form a semi-finished product; and d, placing the semi-finished product obtained in the step c into a sintering furnace for sintering, and obtaining the magnesium oxide ceramics after finishing sintering. The dry-pressing preparation method provided by the invention obtains the semi-finished product with relatively high density by controlling pressing conditions, prepares the magnesium oxide ceramics with high density and hardness and good compactness by controlling sintering conditions, has few production steps and low production costs, and is a simple method for preparing magnesium oxide ceramics.

Owner:盐城市华康电热绝缘材料厂

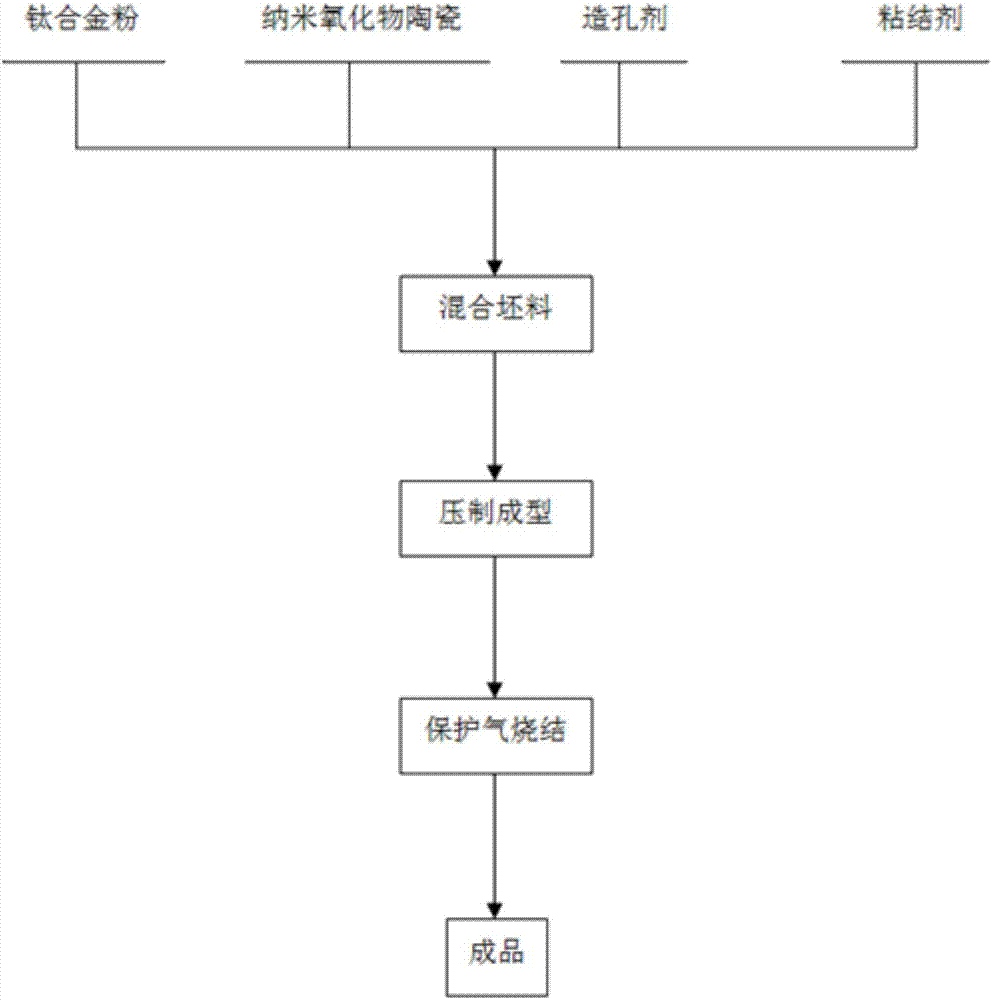

Preparation method for porous titanium-ceramic composite biological material

The invention discloses a preparation method for a porous titanium-ceramic composite biological material, and relates to the field of porous composite materials and medical metal materials. The preparation method specifically comprises the technical steps of firstly, mixing an titanium alloy and nano-oxide ceramics according to a preset ratio, carrying out ball milling and then adding a pore forming agent and a binding agent for pressing; and then, sintering a sample in a high-temperature furnace according to a preset sintering parameter and carrying out furnace cooling so as to obtain a final product. The method has the advantages that the defects of poor mechanical property, low biocompatibility, no biological activity and the like of a traditional medical titanium alloy can be overcome, the process is simple, the consumption is low, the environment can be protected, the cost is low, the economical efficiency can be achieved, and industrial production can be realized easily.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com