Method for preparing dark blue zirconia ceramic

A zirconia ceramic and dark blue technology, which is applied in the field of preparation of dark blue zirconia ceramics, can solve the problems of easy agglomeration of nano-scale zirconia, poor stability of colorants, and reduced product quality, etc., and achieves a simple and easy-to-operate preparation method and a structure. Dense and stable, the effect of solving poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

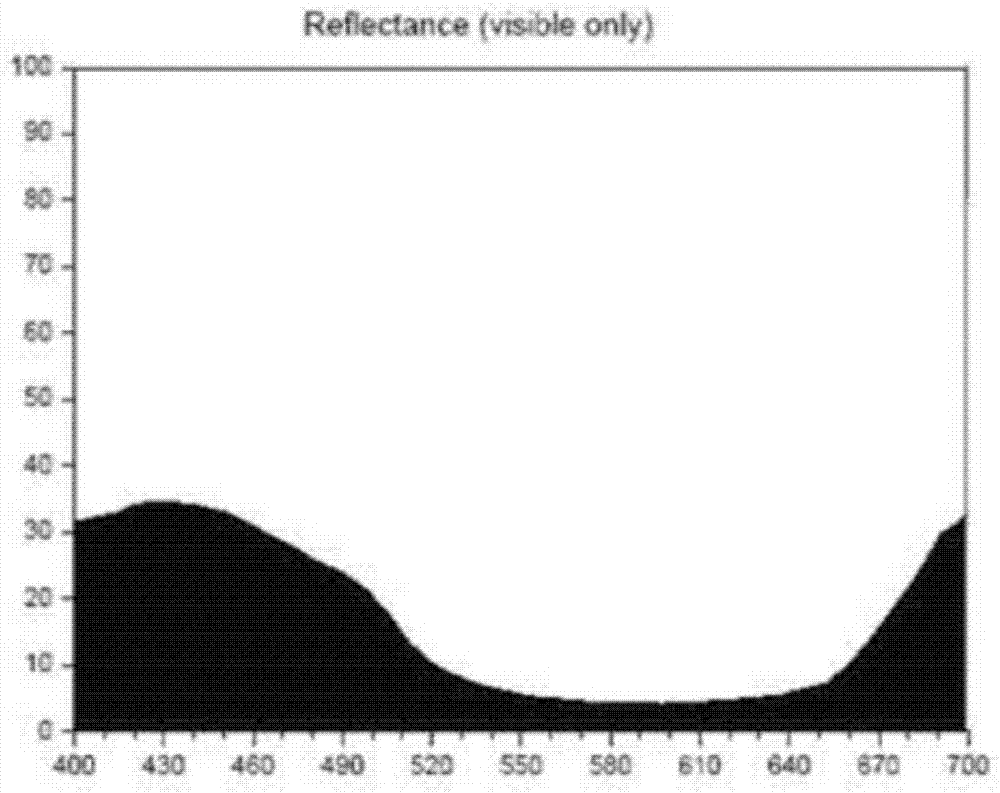

Image

Examples

Embodiment 1

[0035] A preparation method of dark blue zirconia ceramics, the formula quality ratio is as follows:

[0036] 10 parts of polyvinylpyrrolidone, 20 parts of absolute ethanol, 10 parts of tetrabutyl zirconate, 1 part of yttrium acetate, 0.5 part of stearic acid, 5 parts of ethanol aqueous solution, 2 parts of aluminum monoacetate, 1 part of cobalt acetate, 2 parts of ammonia 0.1 part of penetrant; the ethanol concentration in the ethanol aqueous solution is 50%, the ammonia concentration is 8%, and the penetrant uses nonylphenol polyoxyethylene ether.

[0037] The preparation steps are as follows:

[0038] Step 1. Add polyvinylpyrrolidone to absolute ethanol, mechanically stir until it is completely dissolved to obtain a low-viscosity alcohol solution, and the mechanical stirring speed is 1000r / min;

[0039] Polyvinylpyrrolidone is abbreviated as PVP. It is a non-ionic polymer compound with colloidal protection, film-forming properties, adhesion, moisture absorption, solubilization and ...

Embodiment 2

[0055] A preparation method of dark blue zirconia ceramics, the formula quality ratio is as follows:

[0056] 15 parts of polyvinylpyrrolidone, 40 parts of absolute ethanol, 12 parts of tetrabutyl zirconate, 2 parts of yttrium acetate, 1.3 parts of stearic acid, 10 parts of ethanol aqueous solution, 2.5 parts of aluminum monoacetate, 1.2 parts of cobalt acetate, 4 parts of ammonia 0.3 parts of penetrant; the ethanol concentration in the ethanol aqueous solution is 80%, the ammonia concentration is 15%, and the penetrant uses octylphenol polyoxyethylene ether.

[0057] The preparation steps are as follows:

[0058] Step 1. Add polyvinylpyrrolidone to absolute ethanol, mechanically stir until it is completely dissolved to obtain a low-viscosity alcohol liquid, and the mechanical stirring speed is 1500r / min;

[0059] Step 2: Add tetrabutyl zirconate and yttrium acetate slowly to the low-viscosity alcohol solution, and mechanically stir until completely dissolved; then ultrasonically reac...

Embodiment 3

[0069] A preparation method of dark blue zirconia ceramics, the formula quality ratio is as follows:

[0070] 12 parts of polyvinylpyrrolidone, 30 parts of absolute ethanol, 11 parts of tetrabutyl zirconate, 1 part of yttrium acetate, 0.9 part of stearic acid, 8 parts of ethanol aqueous solution, 2.2 parts of aluminum monoacetate, 1.1 parts of cobalt acetate, 3 parts of ammonia , 0.2 parts of penetrant; the ethanol concentration in the ethanol aqueous solution is 60%, the concentration of the ammonia water is 12%, and the penetrant uses lauryl polyoxyethylene ether.

[0071] The preparation steps are as follows:

[0072] Step 1. Add polyvinylpyrrolidone to absolute ethanol, mechanically stir until it is completely dissolved to obtain a low-viscosity alcohol liquid, and the mechanical stirring speed is 1300r / min;

[0073] Step 2: Add tetrabutyl zirconate and yttrium acetate slowly to the low-viscosity alcohol solution, and mechanically stir until completely dissolved; then ultrasonic r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com