Sodium alginate and chitosan skin tissue engineering scaffold material and preparation method thereof

A technology of skin tissue engineering and sodium alginate, which is applied in the field of sodium alginate-chitosan skin tissue engineering scaffold material and its preparation, which can solve the problems of unfavorable cell adhesion, lack of cell recognition signal and poor mechanical properties of synthetic scaffold materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A. Prepare a scaffold matrix with a total solid content of 4 wt%. The mass ratio of sodium alginate powder to chitosan powder is 5:3, and the pH value of the system is adjusted to 4-5 with dilute acetic acid (pH=1-2).

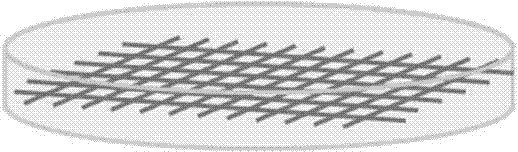

[0022] B. Preparation of interlayer by RP technology: 2 wt% sodium alginate solution was used to obtain a dense mesh interlayer with a mesh size of 1 × 1 mm and a thickness of about 0.5 mm. In 4% CaCl 2 The solution was cross-linked for 30 min to obtain alginic acid mesh interlayer.

[0023] C. Pour the above-prepared scaffold matrix solution into the petri dish with the interlayer so that it covers the interlayer of the grid. Let stand at -7°C for 12 hours, then transfer to 2°C for 4 hours. Finally, the stents were moved to a -7°C environment and left to freeze for 12 hours.

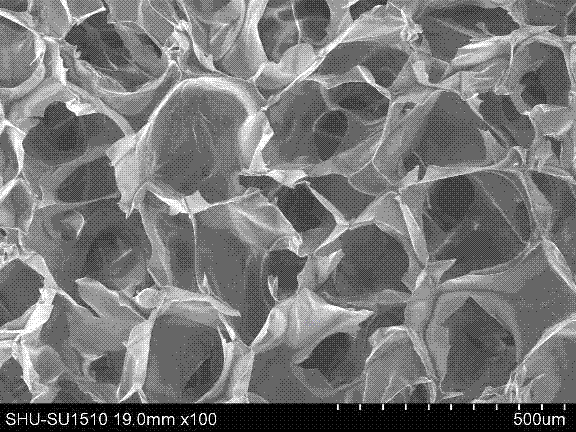

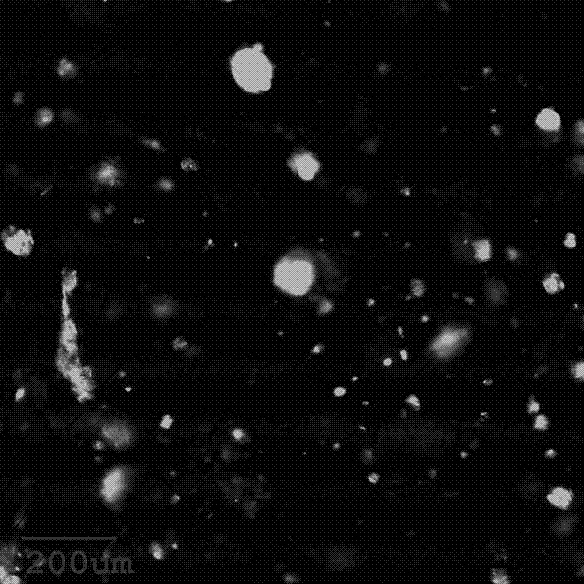

[0024] D. Put it into a freeze dryer to freeze dry, take it out and soak it in ethanol, and vacuum dry the ethanol. with 4% CaCl 2 The solution was cross-linked for 40 min, an...

Embodiment 2

[0026] A. Prepare a scaffold matrix with a total solid content of 4 wt%. The mass ratio of sodium alginate powder to chitosan powder is 5:3, and the pH value of the system is adjusted to 4-5 with dilute acetic acid (pH=1-2).

[0027] B. Preparation of interlayer by RP technology: 4 wt% sodium alginate solution was used to obtain a dense mesh interlayer with a mesh size of 1 × 1 mm and a thickness of about 0.5 mm. In 4% CaCl 2 The solution was cross-linked for 30 min to obtain alginic acid mesh interlayer.

[0028] C. Pour the above-prepared scaffold matrix solution into the petri dish with the interlayer so that it covers the interlayer of the grid. Let stand at -7°C for 12 hours, then transfer to 2°C for 4 hours. Finally, the stents were moved to a -7°C environment and left to freeze for 12 hours.

[0029] D. Put it into a freeze dryer to freeze dry, take it out and soak it in ethanol, and vacuum dry the ethanol. with 4% CaCl 2 The solution was cross-linked for 40 min, an...

Embodiment 3

[0031] A. Prepare a scaffold matrix with a total solid content of 4 wt%. The mass ratio of sodium alginate powder to chitosan powder is 5:3, and the pH value of the system is adjusted to 4-5 with dilute acetic acid (pH=1-2).

[0032] B. Preparation of interlayer by RP technology: 4 wt% sodium alginate solution was used to obtain a dense mesh interlayer with a mesh size of 2 × 2 mm and a thickness of about 0.5 mm. In 4% CaCl 2 The solution was cross-linked for 30 min to obtain alginic acid mesh interlayer.

[0033] C. Pour the above-prepared scaffold matrix solution into the petri dish with the interlayer so that it covers the interlayer of the grid. Let stand at -7°C for 12 hours, then transfer to 2°C for 4 hours. Finally, the stents were moved to a -7°C environment and left to freeze for 12 hours.

[0034] D. Put it into a freeze dryer to freeze dry, take it out and soak it in ethanol, and vacuum dry the ethanol. with 4% CaCl 2 The solution was cross-linked for 40 min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com