Novel calcium titanate slag system flux-cored wire and preparation method thereof

A technology of flux-cored welding wire and calcium titanate, which is applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as poor operability, low low-temperature impact toughness, and instability, and achieve reduced content, excellent crack resistance, The effect of improving the comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

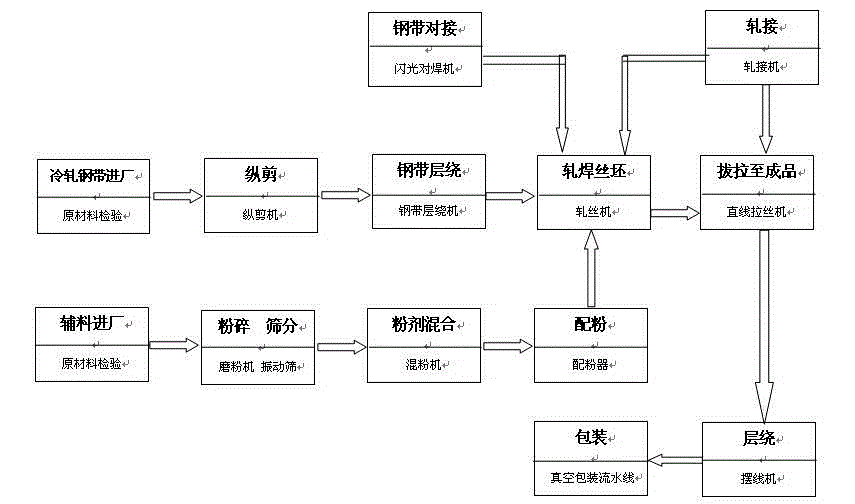

Image

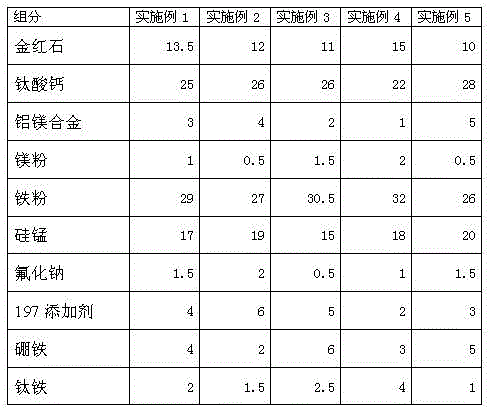

Examples

Embodiment Construction

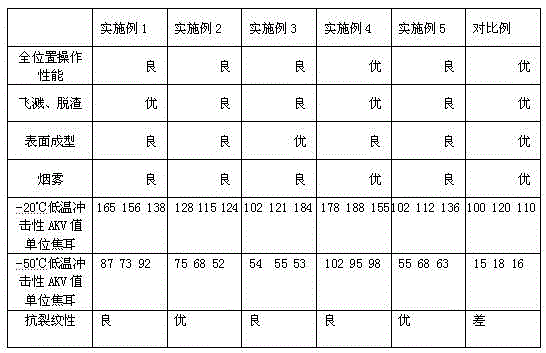

[0039] The novel calcium titanate slag-based flux-cored welding wire of Examples 1-5 of the present invention, the flux of the flux core is prepared according to the ratio listed in Table 1, and the unit is g

[0040] Table 1:

[0041]

[0042] Among them, the proportioning ratio of each component of the 197 additives by mass is shown in Table 2.

[0043] Table 2:

[0044] components Example 1 Example 2 Example 3 Example 4 Example 5 Bauxite 1 1 quartz 1 Potassium feldspar 1.5 Albite 1 Alkali metal oxide 1 2 1.5 1.5 Cerium fluoride 1 0.5 Yttrium oxide 2 2 Teflon powder 1 cryolite 1 1

[0045] Table 3 shows the mass ratios of the components in calcium titanate corresponding to the above-mentioned examples.

[0046] table 3

[0047] components Example 1 Example 2 Example 3 Example 4 Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com