White ink with high reflectivity as well as preparation method and application thereof

A white ink, high reflectivity technology, used in applications, inks, household appliances, etc., can solve the problems of poor high temperature yellowing resistance, uneven printing thickness, and poor flexibility of white ink cover films, saving labor hours , Improve the effect of good and good mechanical properties of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

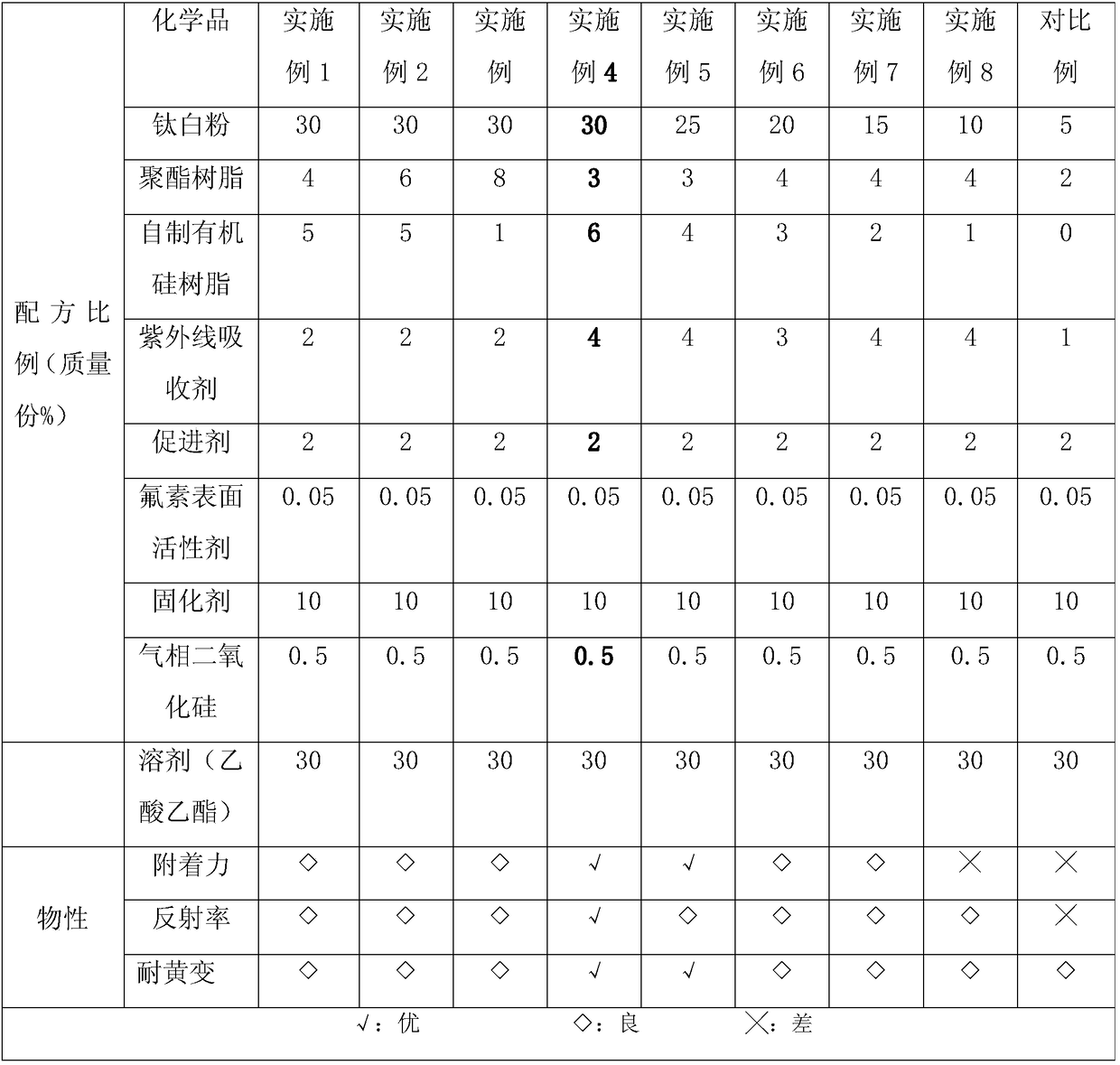

Embodiment 1

[0053] Prepare the following mass ratio raw materials:

[0054] 30 parts of titanium dioxide, 4 parts of polyester resin, 5 parts of silicone resin, 10 parts of curing agent, 2 parts of ultraviolet absorber, 2 parts of accelerator, 0.05 part of fluorosurfactant, 0.5 part of fumed silica, solvent ( ethyl acetate) 30 parts.

[0055] Adhesive preparation: add silicone resin (self-made, improve weather resistance), 1200 polyester resin (increase cross-linking density), H18 fumed silica (reduce expansion and contraction coefficient), 2310 titanium dioxide (whitening agent) in sequence according to the formula ), ultraviolet absorber UV-531, antioxidant EVERNOX-10, trimer curing agent N3390, accelerator U-CAT 3513, ethyl acetate solvent, etc., after stirring for 5 h, a white ink with a solid content of 70% was prepared Adhesive solution.

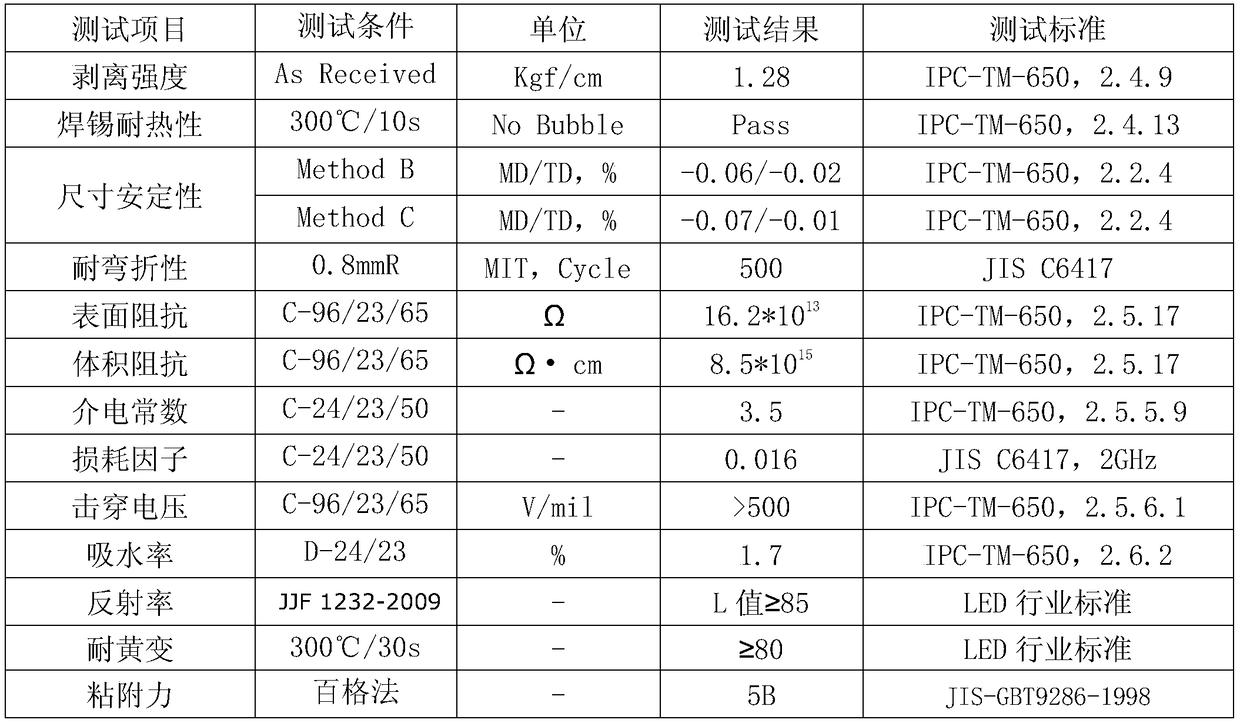

[0056] Preparation of white LED single-sided substrate: the white ink adhesive solution prepared above is coated on the polyimide (PI) of FCCL ...

Embodiment 2

[0058] 30 parts of titanium dioxide, 6 parts of polyester resin, 5 parts of silicone resin, 10 parts of curing agent, 2 parts of ultraviolet absorber, 2 parts of accelerator, 0.05 part of fluorosurfactant, 0.5 part of fumed silica, solvent ( ethyl acetate) 30 parts.

[0059] The preparation method of the adhesive is the same as the preparation method of the white LED single-sided substrate as in Example 1.

Embodiment 3

[0061] 30 parts of titanium dioxide, 8 parts of polyester resin, 1 part of silicone resin, 10 parts of curing agent, 2 parts of ultraviolet absorber, 2 parts of accelerator, 0.05 part of fluorosurfactant, 0.5 part of fumed silica, solvent ( ethyl acetate) 30 parts.

[0062] The preparation method of the adhesive is the same as the preparation method of the white LED single-sided substrate as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com