Locking and lifting mechanism for reactor fuel assembly and locking and lifting method

A fuel assembly and reactor technology, applied in the direction of reactor fuel elements, reactors, greenhouse gas reduction, etc., can solve the problem that it is difficult to withstand the high temperature of liquid lead-bismuth coolant, high corrosion and high radiation environment, and the comprehensive effect of seismic load, etc., to achieve complex structure The effect of reduced sex, good operability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Exemplary embodiments of the present invention are described in detail below with reference to the accompanying drawings.

[0031] 【The overall structure】

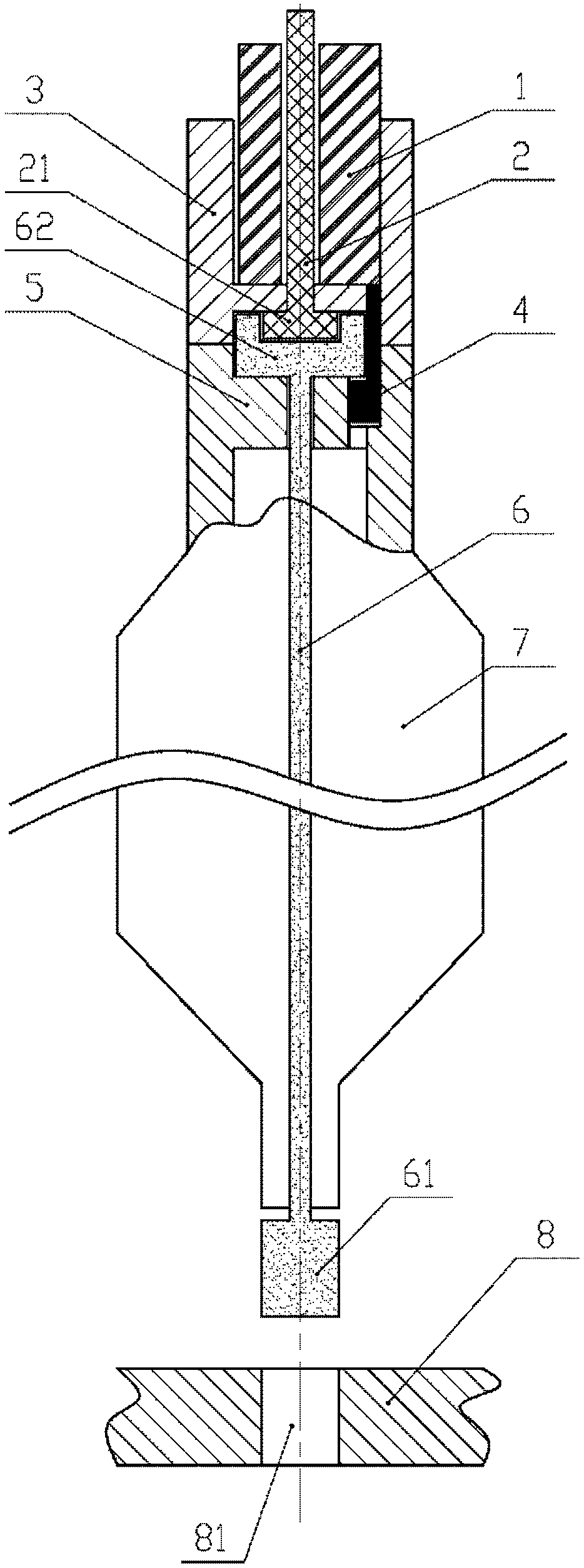

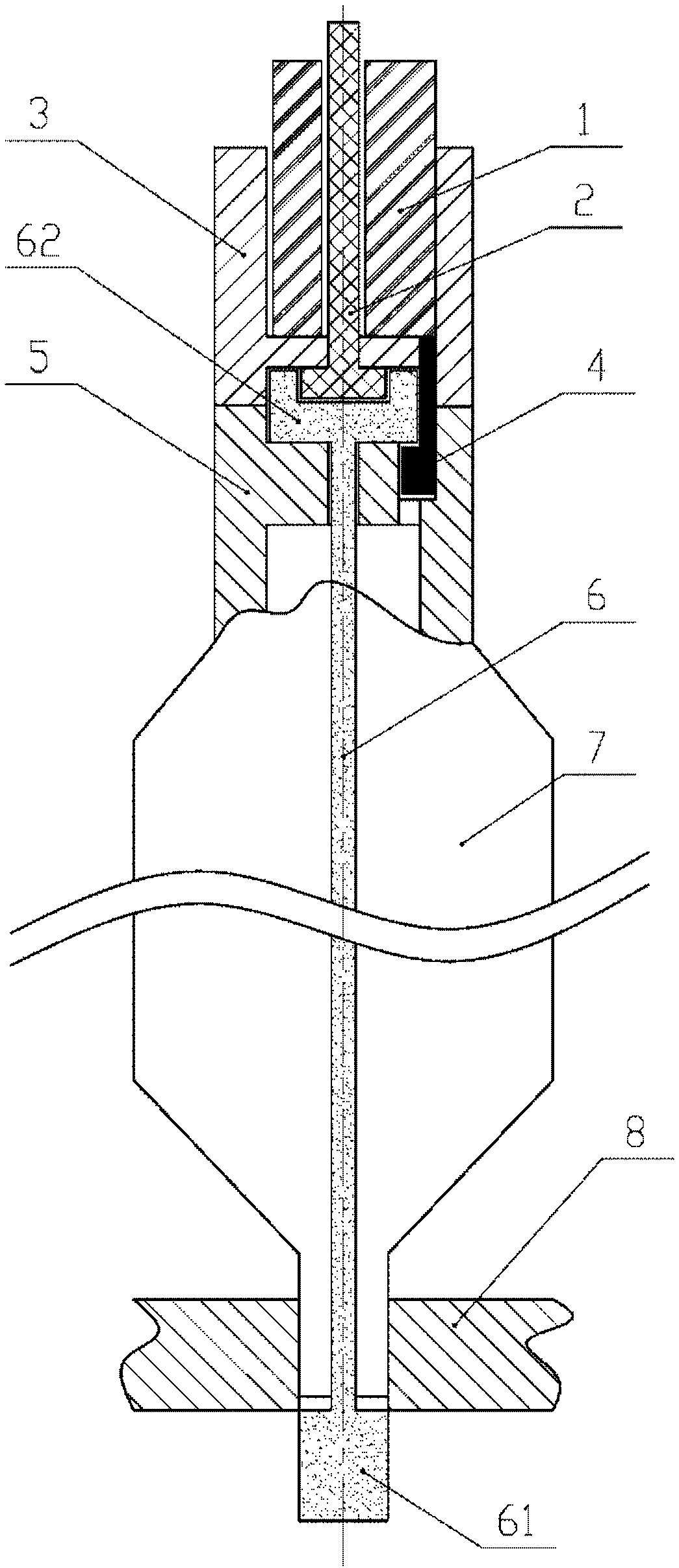

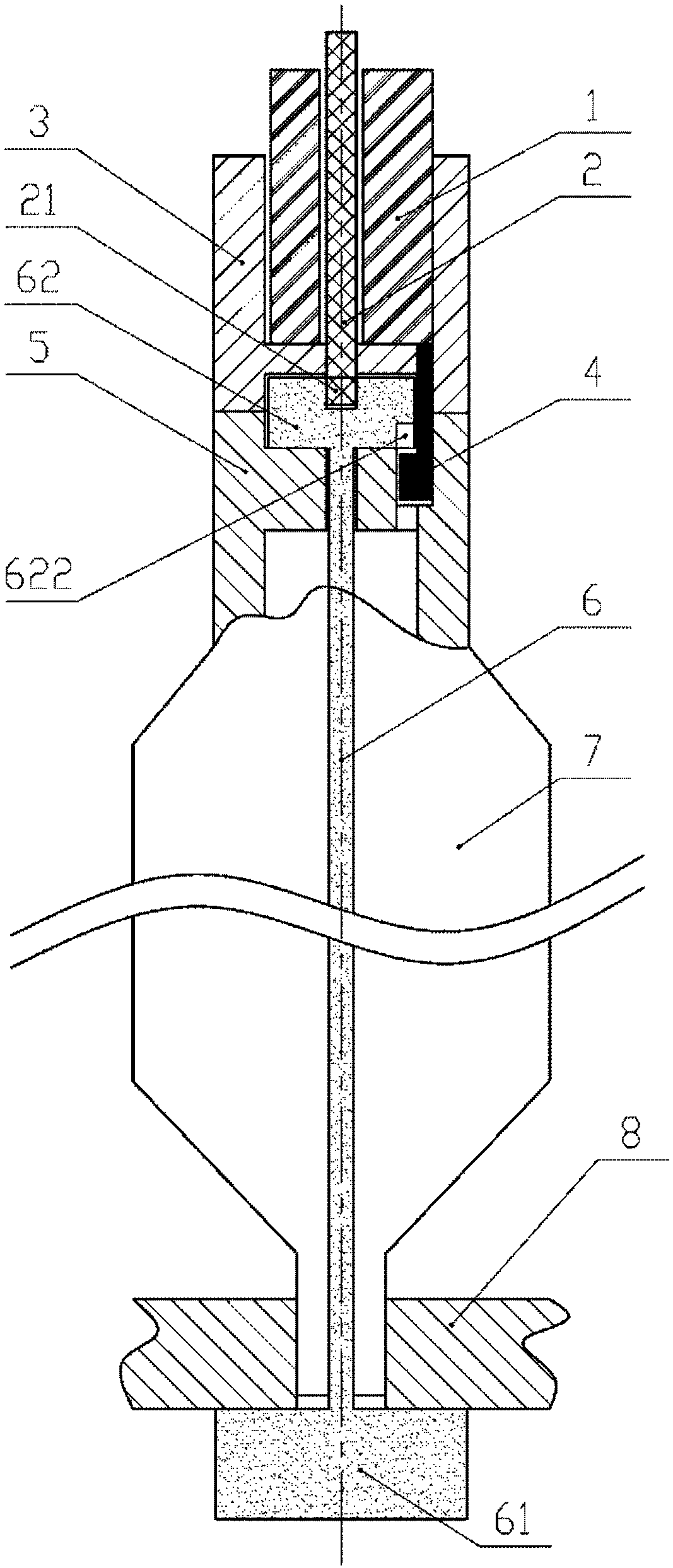

[0032] refer to figure 1 , image 3 , Figure 4 and Figure 5 , an exemplary locking and lifting mechanism according to an embodiment of the present invention includes a guide shaft 1 , a rotary claw 2 , an operating head 3 , a buoyancy pin 4 , a positioning sleeve 5 , a locking rod 6 and a lower grid plate 8 .

[0033] Specifically, the guide shaft 1 can move up and down in the vertical direction. The rotary claw 2 runs through the guide shaft 1 in the vertical direction, can move up and down together with the guide shaft 1, and can rotate around its own vertical axis. The operating head 3 has a cavity for accommodating the guide shaft 1 and the claw 2 . The bottom of the operating head 3 is provided with a through hole 31 . The through hole 31 has a shape matched with the shape of the lower end lock head 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com