Patents

Literature

121 results about "Tetragonal zirconia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

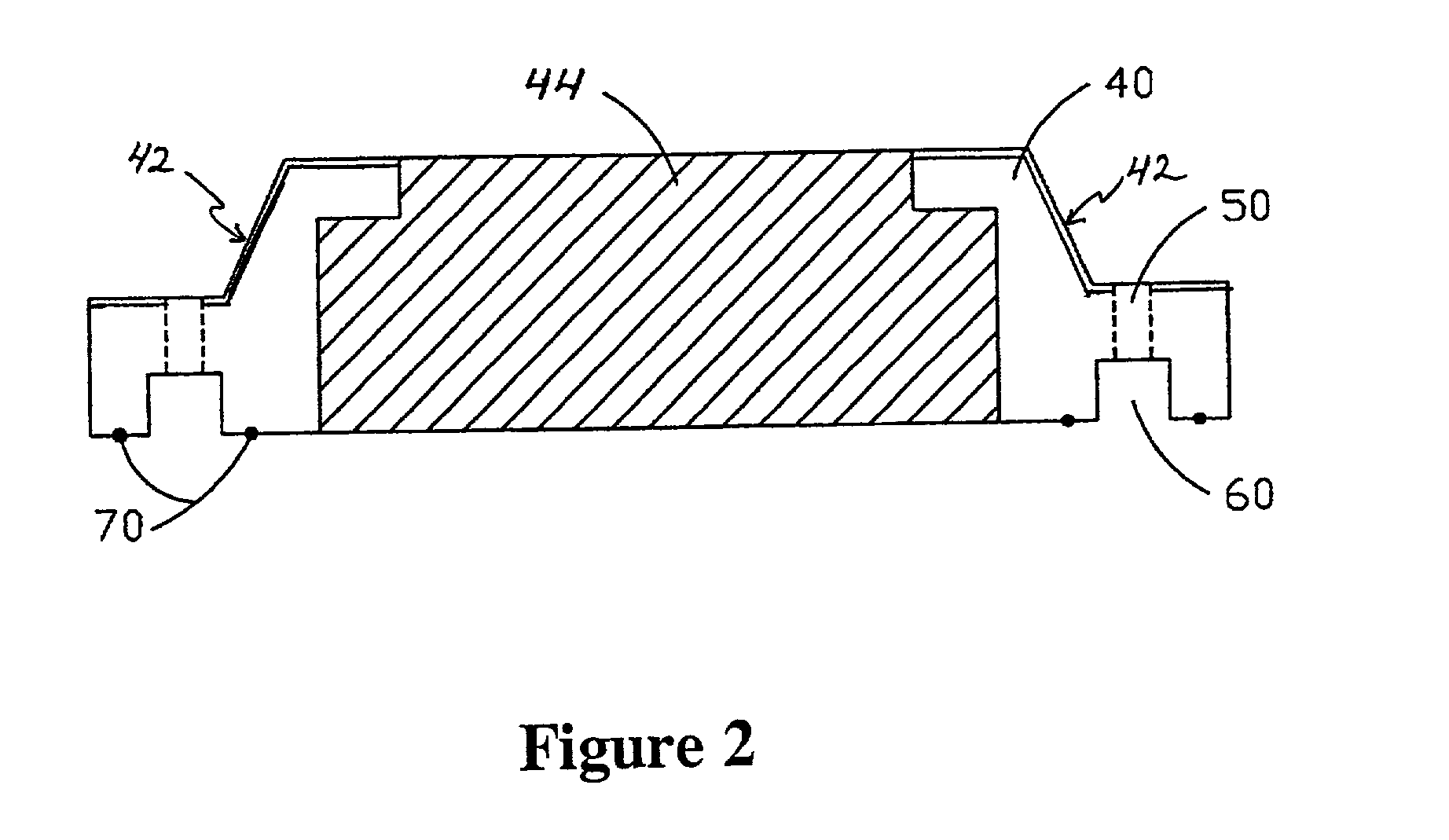

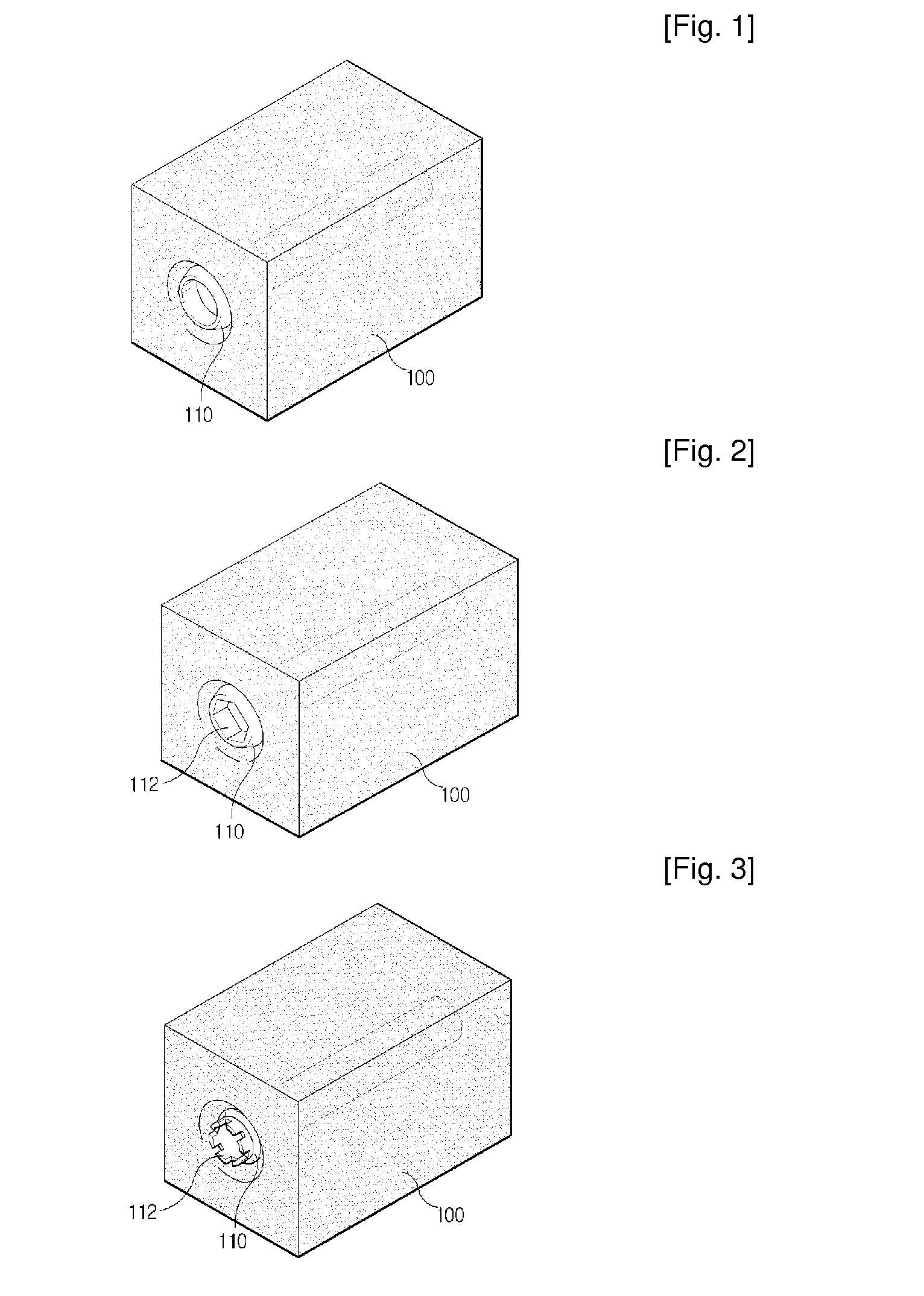

Zirconia toughened ceramic components and coatings in semiconductor processing equipment and method of manufacture thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises zirconia toughened ceramic material as an outermost surface of the component. The component can be made entirely of the ceramic material or the ceramic material can be provided as a coating on a substrate such as aluminum or aluminum alloy, stainless steel, or refractory metal. The zirconia toughened ceramic can be tetragonal zirconia polycrystalline (TZP) material, partially-stabilized zirconia (PSZ), or a zirconia dispersion toughened ceramic (ZTC) such as zirconia-toughened alumina (tetragonal zirconia particles dispersed in Al2O3). In the case of a ceramic zirconia toughened coating, one or more intermediate layers may be provided between the component and the ceramic coating. To promote adhesion of the ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

Zirconia toughened ceramic components and coatings in semiconductor processing equipment and method of manufacture thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises zirconia toughened ceramic material as an outermost surface of the component. The component can be made entirely of the ceramic material or the ceramic material can be provided as a coating on a substrate such as aluminum or aluminum alloy, stainless steel, or refractory metal. The zirconia toughened ceramic can be tetragonal zirconia polycrystalline (TZP) material, partially-stabilized zirconia (PSZ), or a zirconia dispersion toughened ceramic (ZTC) such as zirconia-toughened alumina (tetragonal zirconia particles dispersed in Al2O3). In the case of a ceramic zirconia toughened coating, one or more intermediate layers may be provided between the component and the ceramic coating. To promote adhesion of the ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

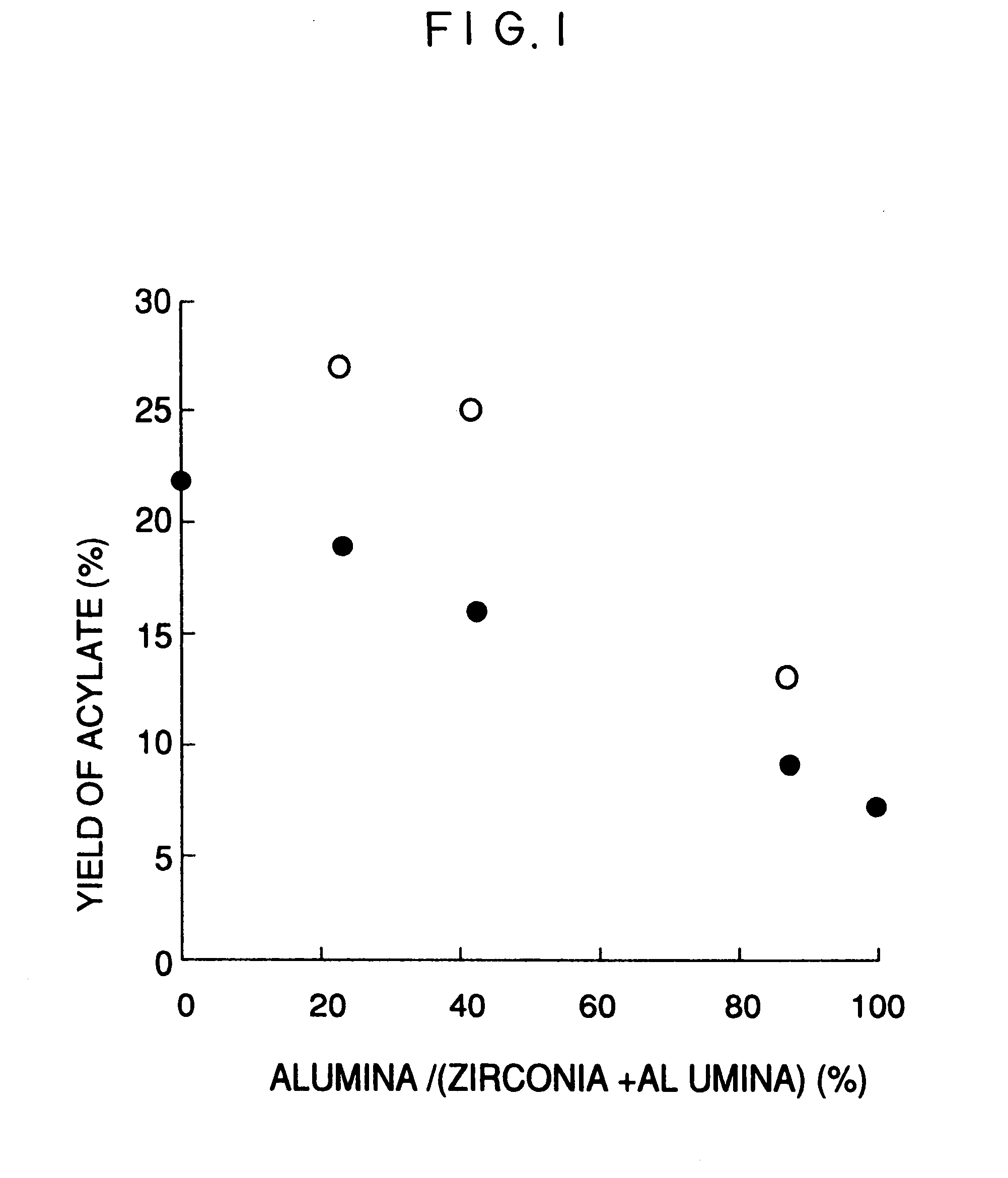

Solid acid catalyst and process for preparing the same

InactiveUS6326328B1High catalytic activityHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsIsomerizationPartial oxidation

The present invention relates to a shaped solid acid catalyst for the isomerization of hydrocarbons and so on, which has a high activity and is excellent in strength and easily handleable, and processes for the preparation thereof. This catalyst comprises a support comprising portions of zirconia having a tetragonal form and portions of alumina, and a sulfureous component and, if necessary, a Group 8, 9 or 10 metal component both being supported on the support, and has a specific surface area of 150 m2 / g or above. The catalyst can be prepared by kneading aluminum hydroxide, zirconium hydroxide and a sulfureous compound, shaping the kneaded mixture, calcining the shaped material at such a temperature as to form tetragonal zirconia and, if necessary, supporting a Group 8, 9 or 10 metal component on the calcined material and calcining the resulting molding at 300 to 700° C.

Owner:JAPAN ENERGY CORP

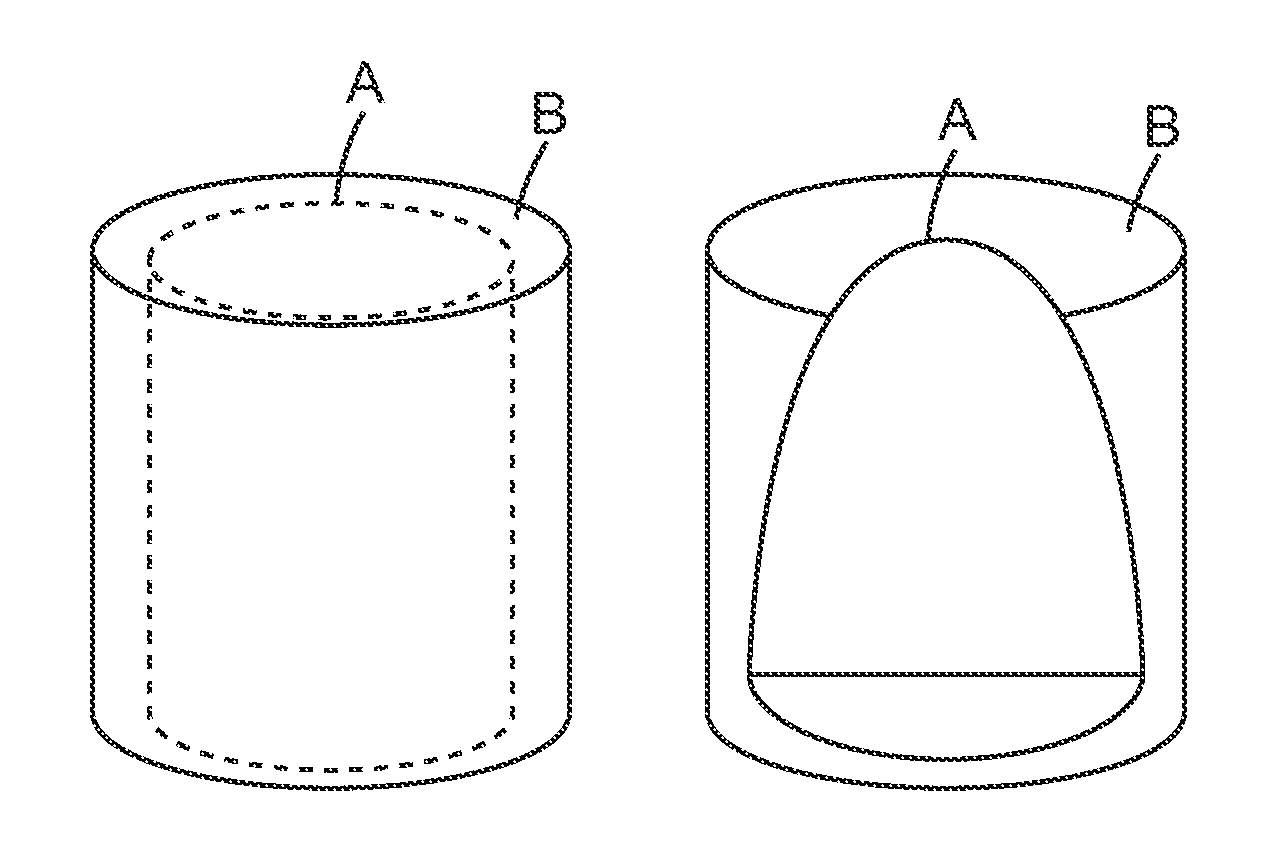

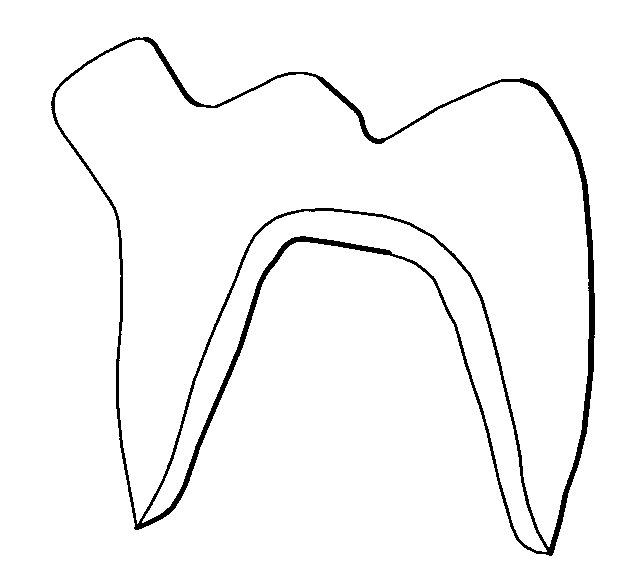

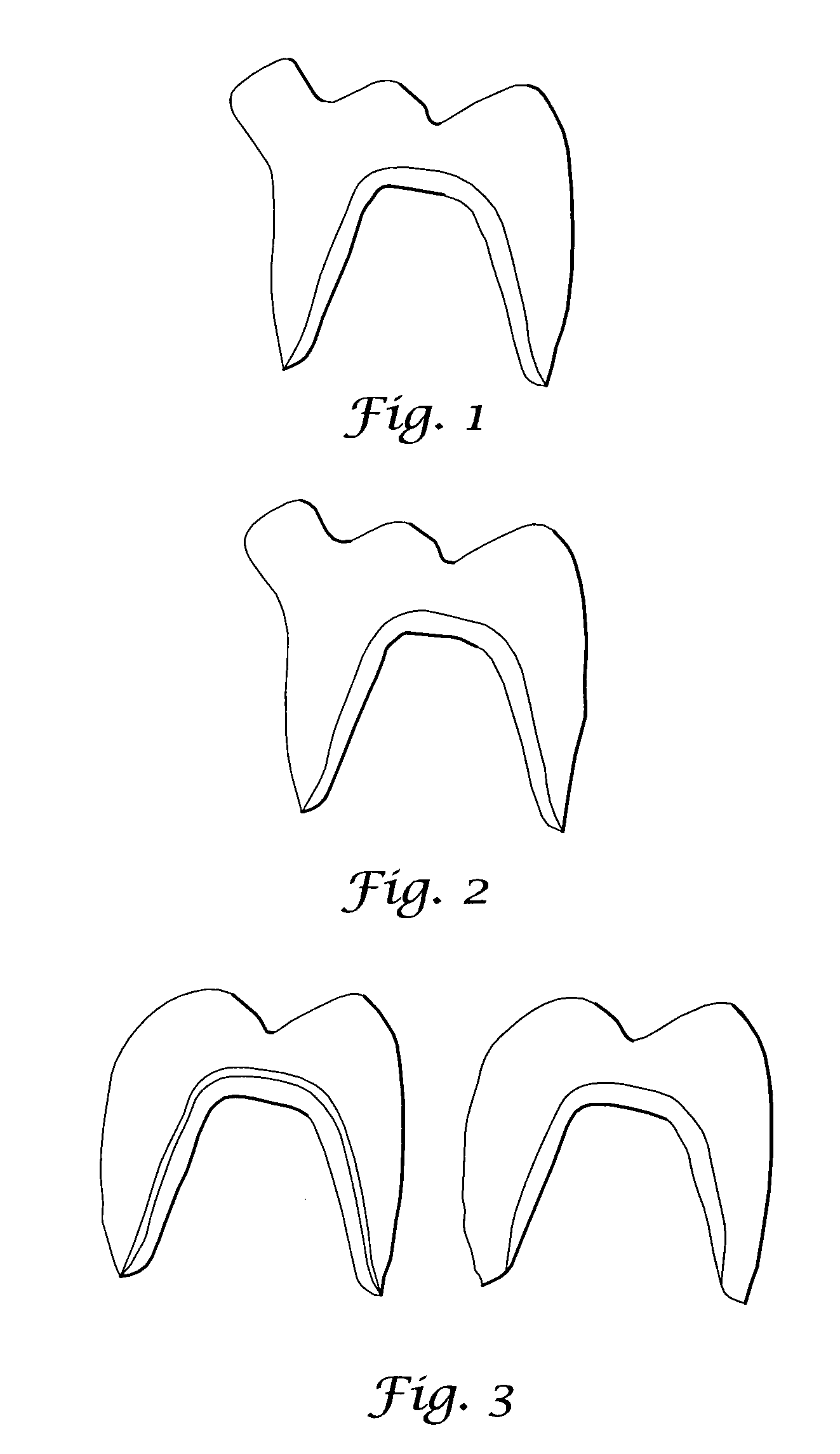

Multi sectional dental zirconia milling block, process of production and use thereof

ActiveUS20150282905A1Easy to produceMaterial nanotechnologyArtificial teethMethods of productionTetragonal zirconia

The invention relates to a porous dental milling block comprising at least two geometrically defined Material Sections A and B, Material Section A comprising a tetragonal zirconia crystal phase in an amount A-T in % and a cubic zirconia crystal phase in an amount A-C in %, Material Section B comprising cubic zirconia crystal phase in an amount B-T in % and cubic zirconia crystal phase in an amount B-C in %, wherein (amount of tetragonal phase A-T in %) / (amount of cubic phase content A-C in %)>1 and (amount of tetragonal phase content B-T in %) / (amount of cubic phase content B-C in %)<1. The invention also relates to a process of production of the porous dental milling block and its use for producing a dental article.

Owner:3M INNOVATIVE PROPERTIES CO

Novel dental zirconium oxide prosthesis and its preparing process

InactiveCN1943538AColoring natureFix color problemsImpression capsDentistry preparationsColor transparencyProsthesis

The invention relates to a dental prosthesis of zirconia material with tetragonal nanometer-sized ZrO2-CaO powder and much added amount of alumina. Said invention also relates to tooth body and false tooth prepared by said above tetragonal nanometer-sized ZrO2-CaO powder and zirconia material for prosthesis, so that making color transparency L*=64-81,colority a*=-1.04- 5.63 and b*=6.95-21.88,thus natural color.

Owner:温宁

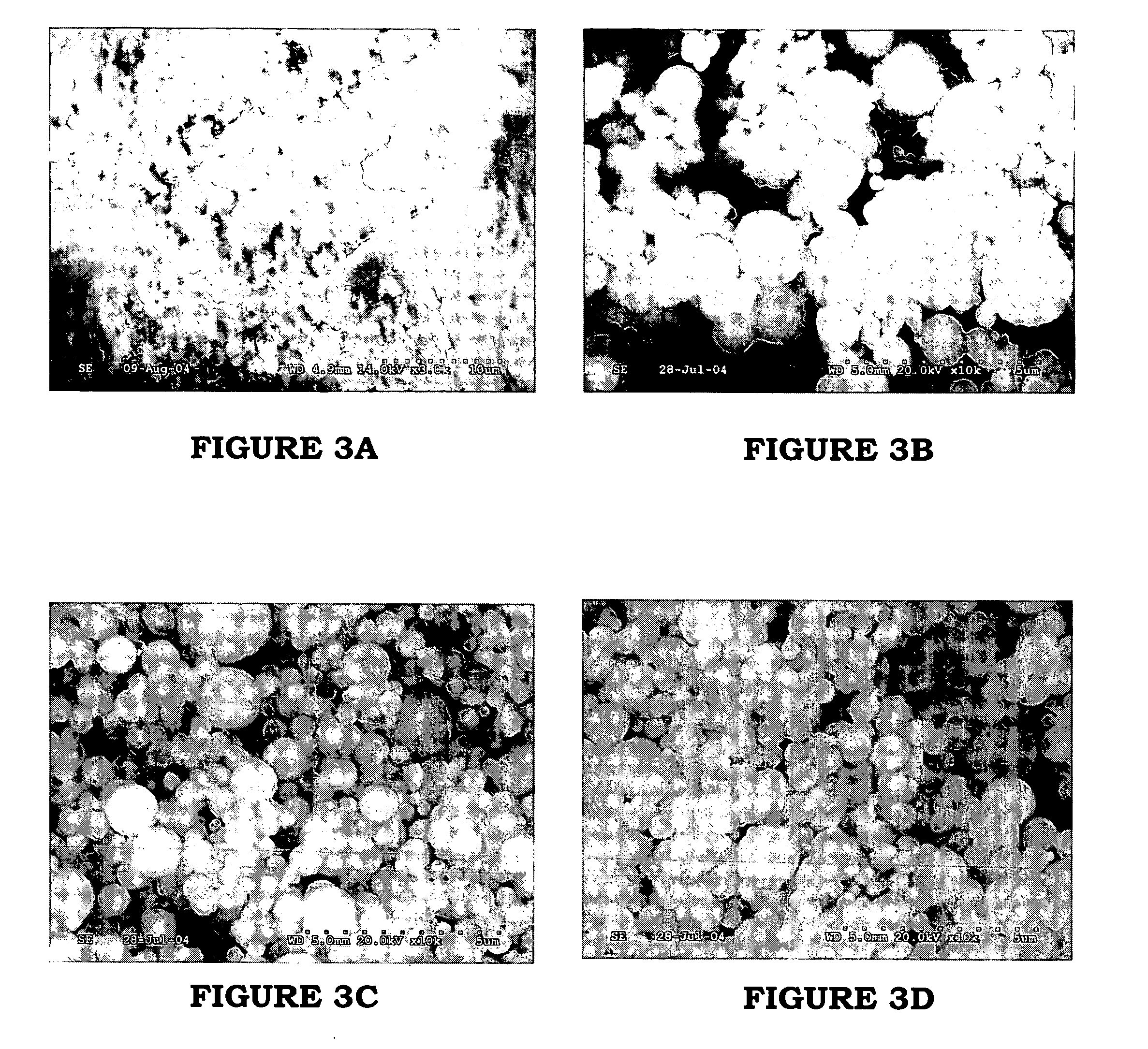

High surface area tetragonal zirconia and processes for synthesizing same

A zirconia-containing composition and processes for synthesizing same. The composition comprises least about 99.9 percent tetragonal phase zirconia, based on the total crystalline zirconia in the zirconia-containing composition as determined by x-ray diffraction (XRD). The composition also has a substantially spherical morphology and comprises less than 100 wppm chlorine, based on the total weight of the zirconia-containing composition. The zirconia-containing composition has an average surface area of at least 80 m2 / g and an average particle size of less than about 10 microns.

Owner:CABOT CORP

Colored zirconia ceramic

ActiveCN107244914ADoes not affect the phase change toughening effectReduce dosageRare-earth elementSolid solution

The invention discloses a colored zirconia ceramic, which is composed of tetragonal phase zirconia serving as the main crystalline phase and cubic phase zirconia serving as a minor crystalline phase, or is composed of tetragonal phase zirconia serving as the main crystalline phase, cubic phase zirconia serving as a minor crystalline phase, and a transition metal oxide. The colored zirconia ceramic realizes coloring through a rare earth metal that is in a solid solution state in cubic phase zirconia crystal grains, or achieves coloring through a rare earth metal that is in a solid solution state in cubic phase zirconia crystal grains, and is assisted by the transition metal oxide provided transition metal for toning. According to the invention, coloring rare earth metal ions are in a solid solution state in cubic zirconia lattices, and have no influence to the stability of tetragonal zirconia; solid solution rare earth metal ions in cubic zirconia are mainly adopted for coloring, then the consumption of other transition metal oxide coloring materials can be reduced or even the coloring materials can be not used, thus reducing the influence of transition metal oxide coloring materials concentrated at crystal boundaries to sintering densification, and avoiding the adverse effect on material strength.

Owner:HANGZHOU ERRAN TECH

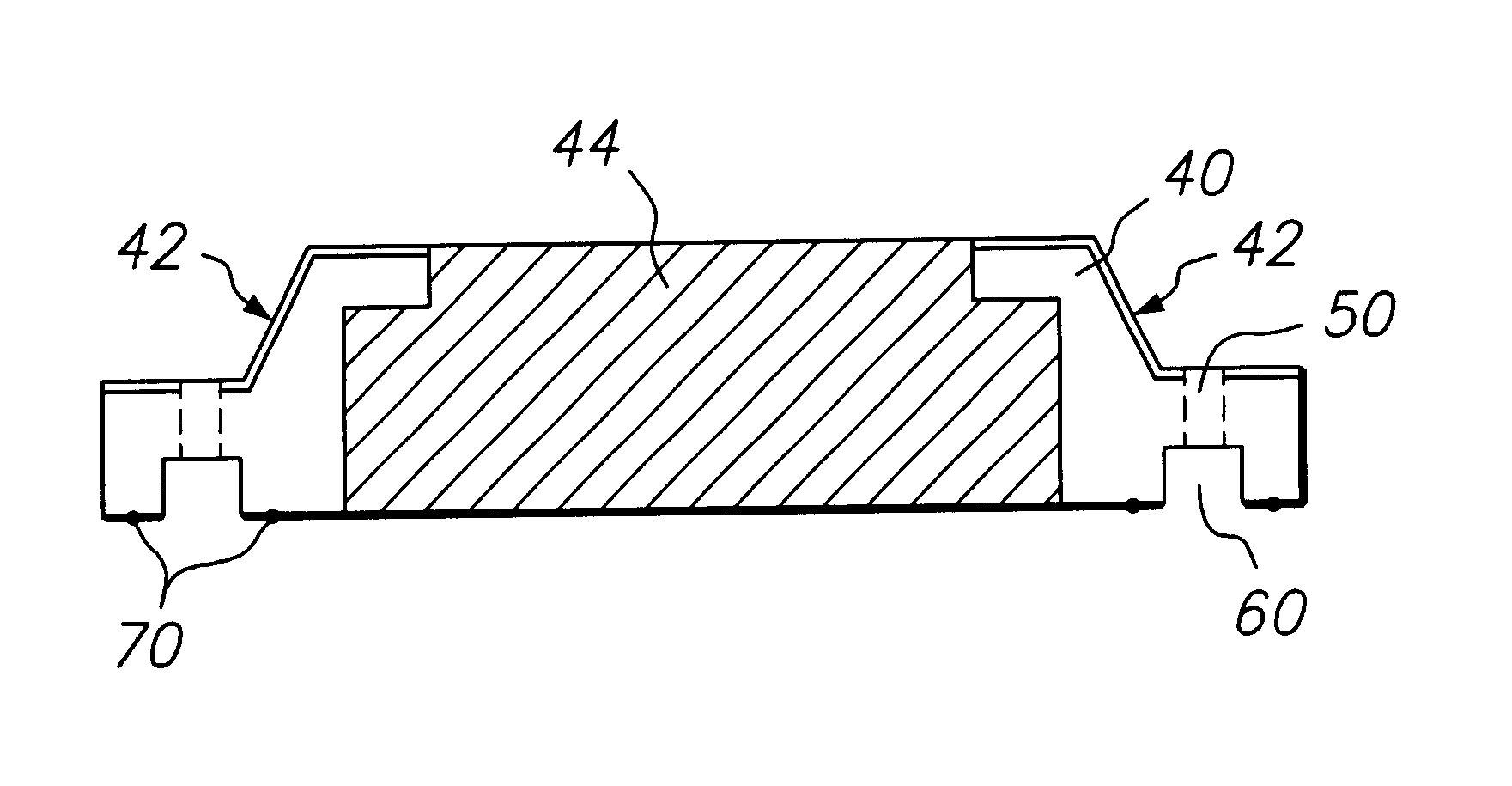

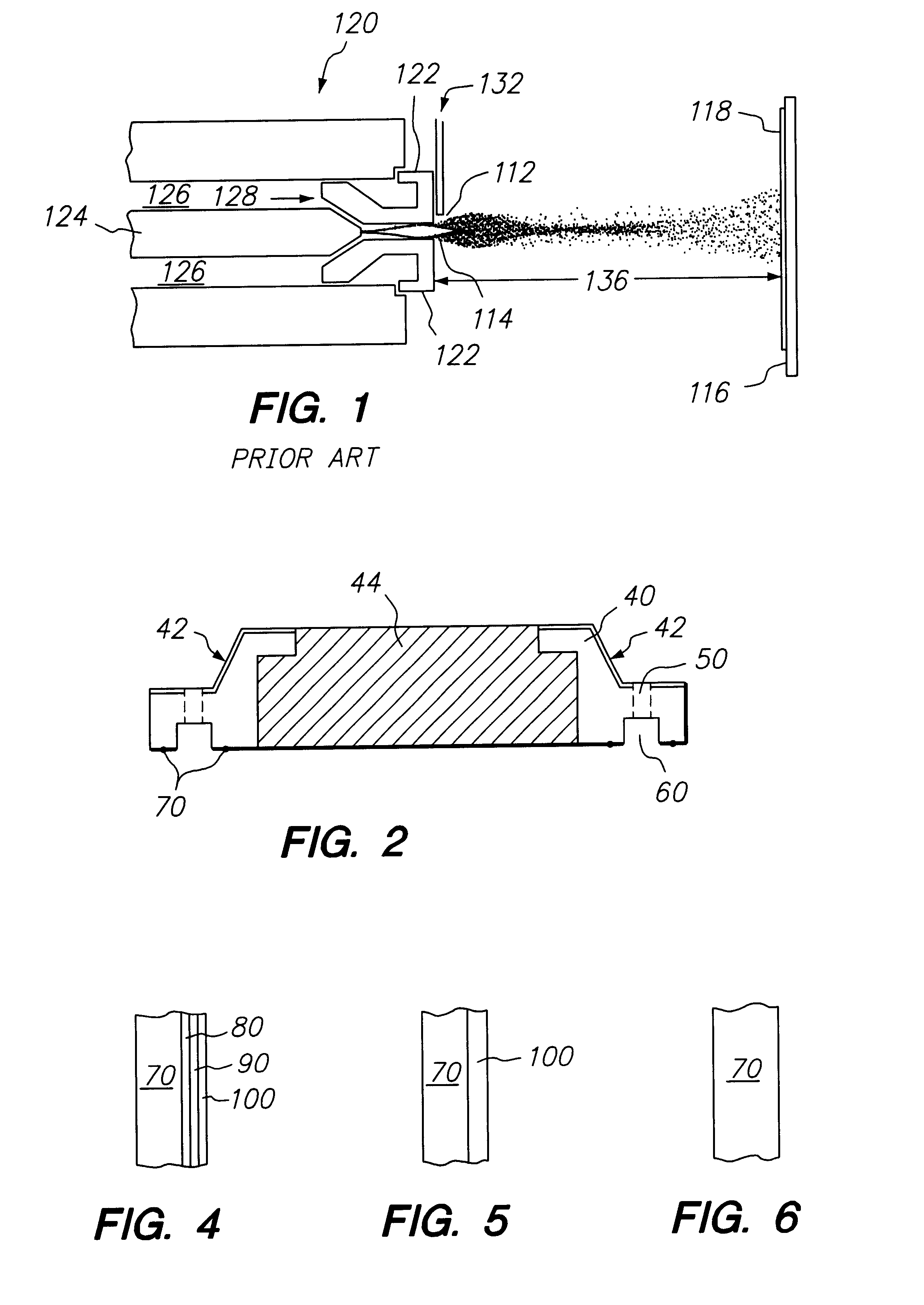

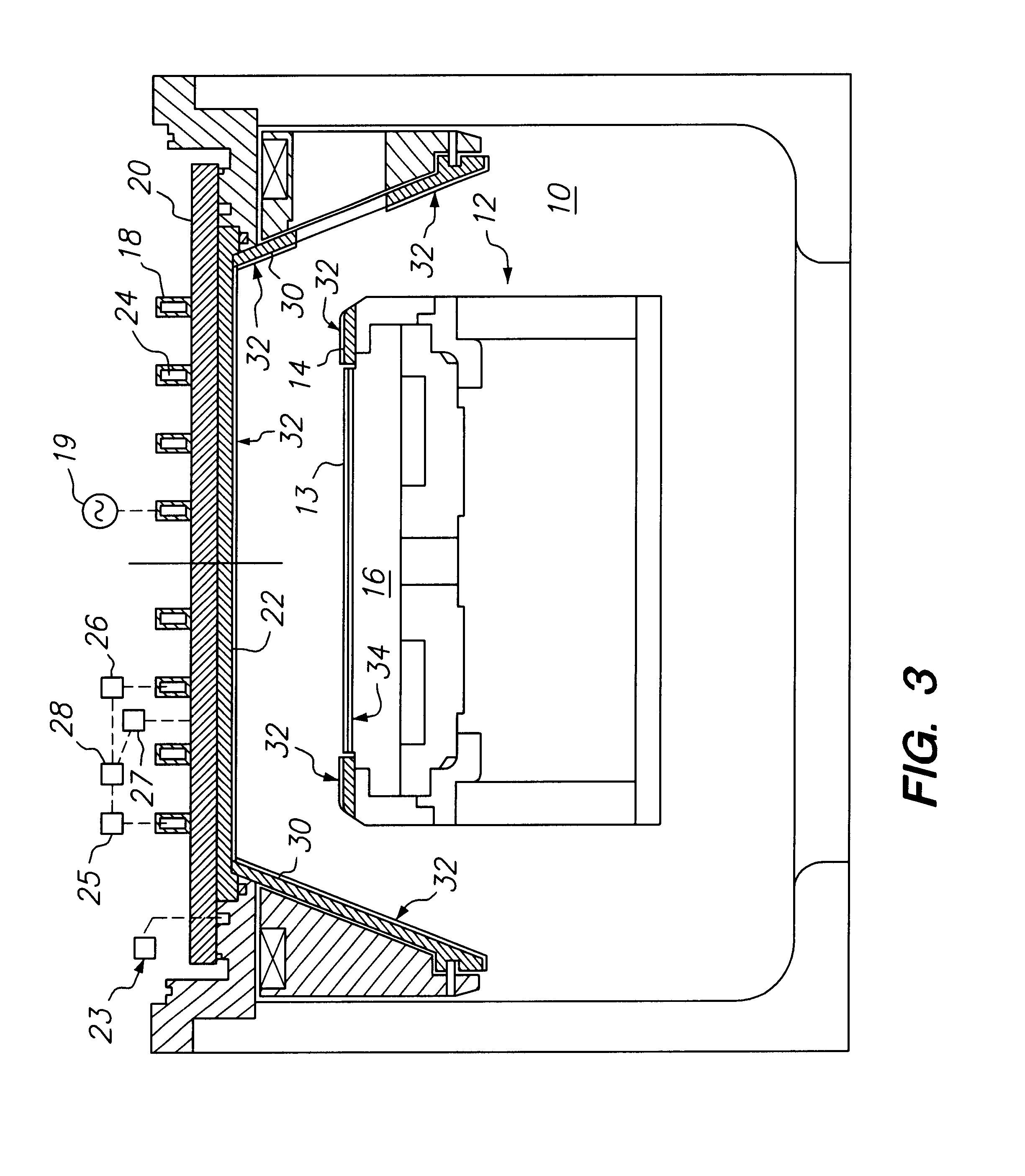

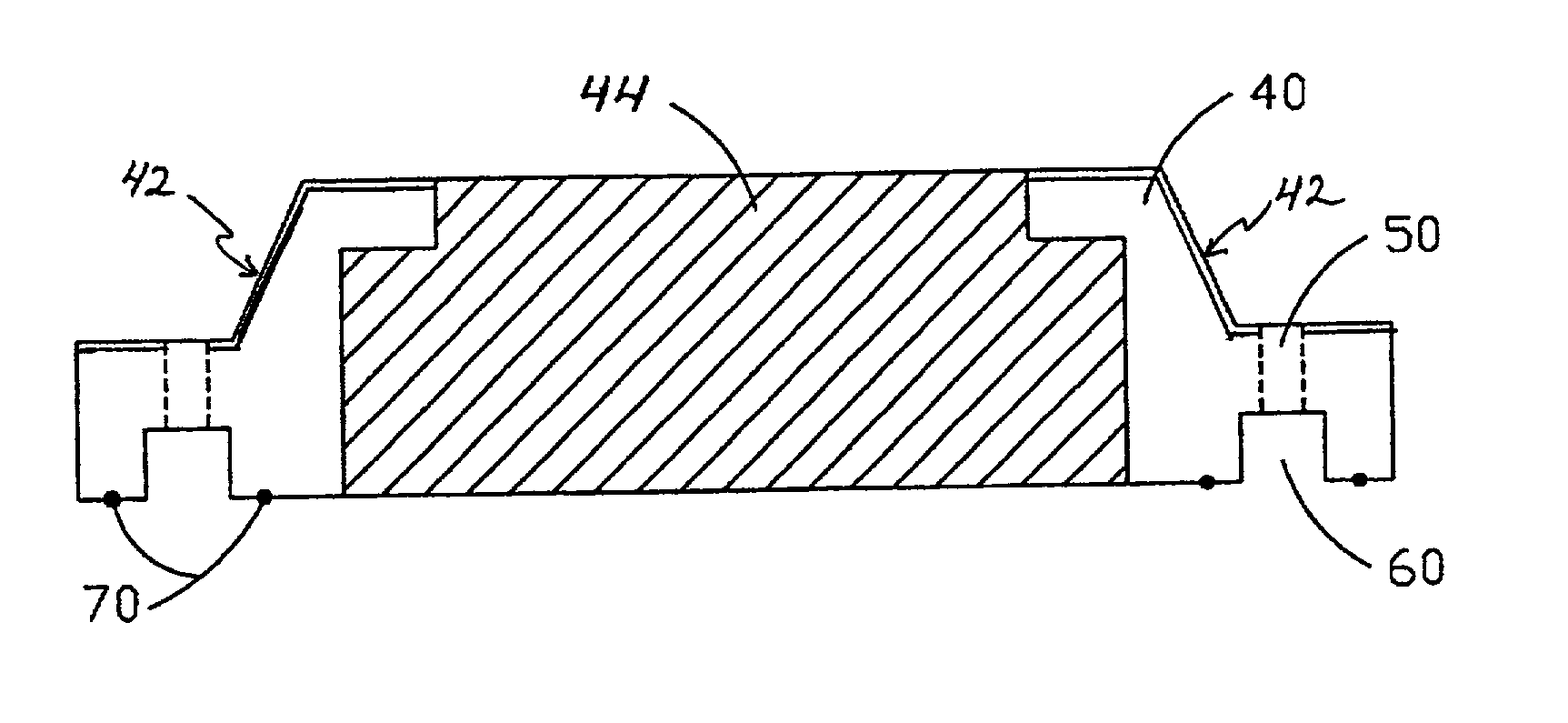

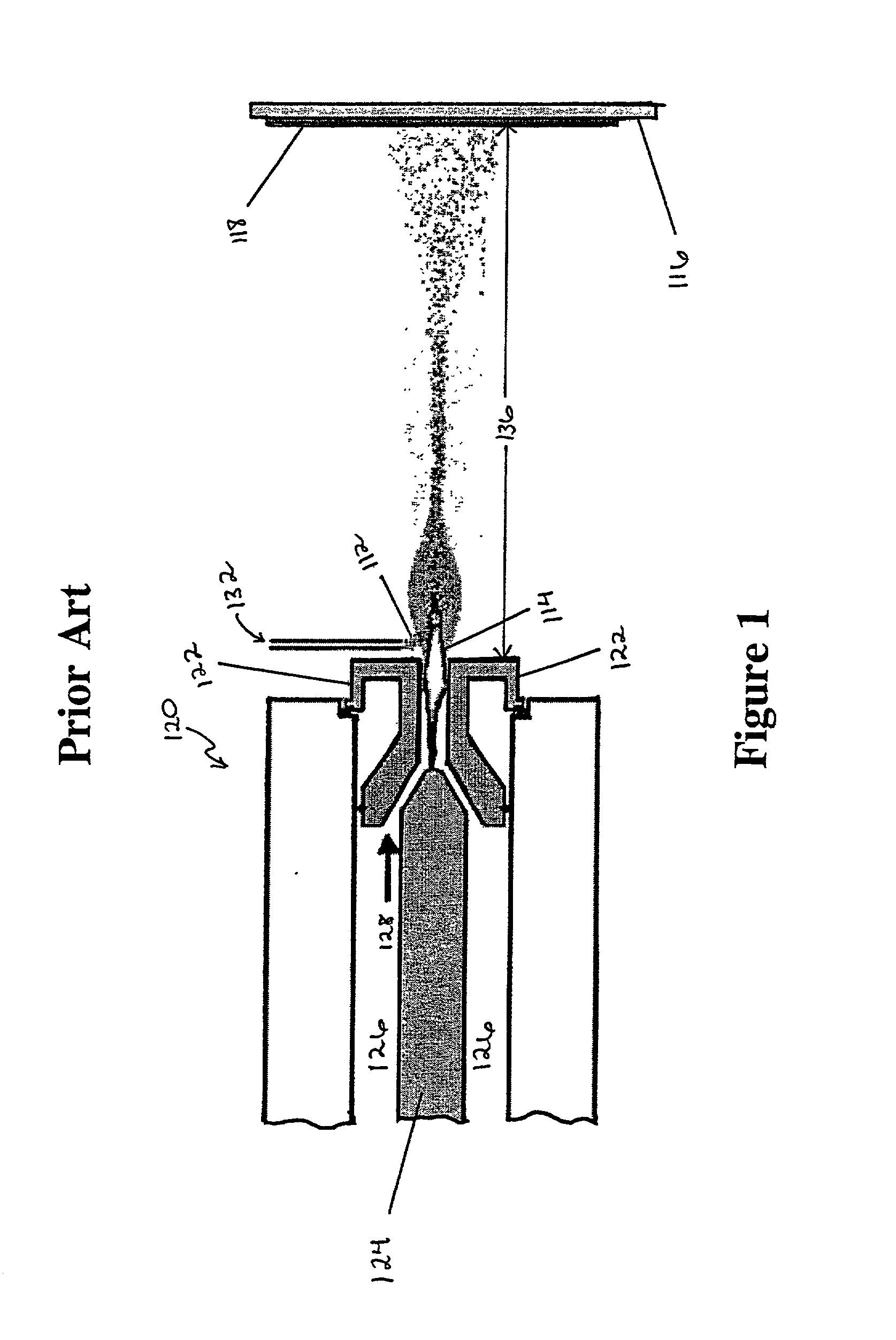

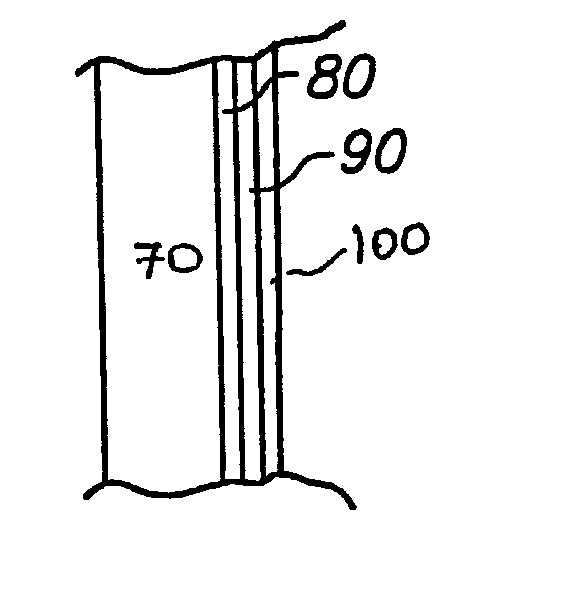

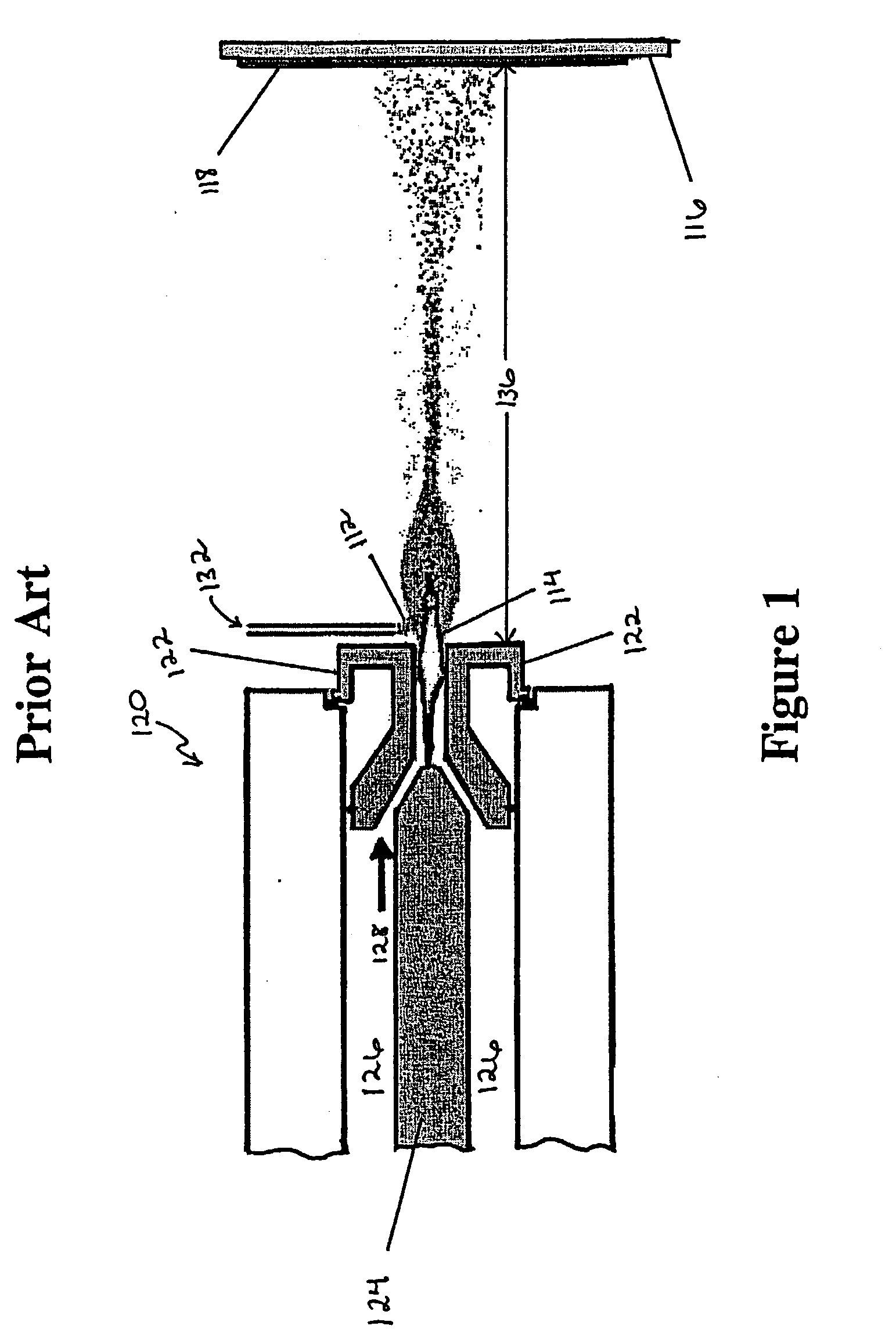

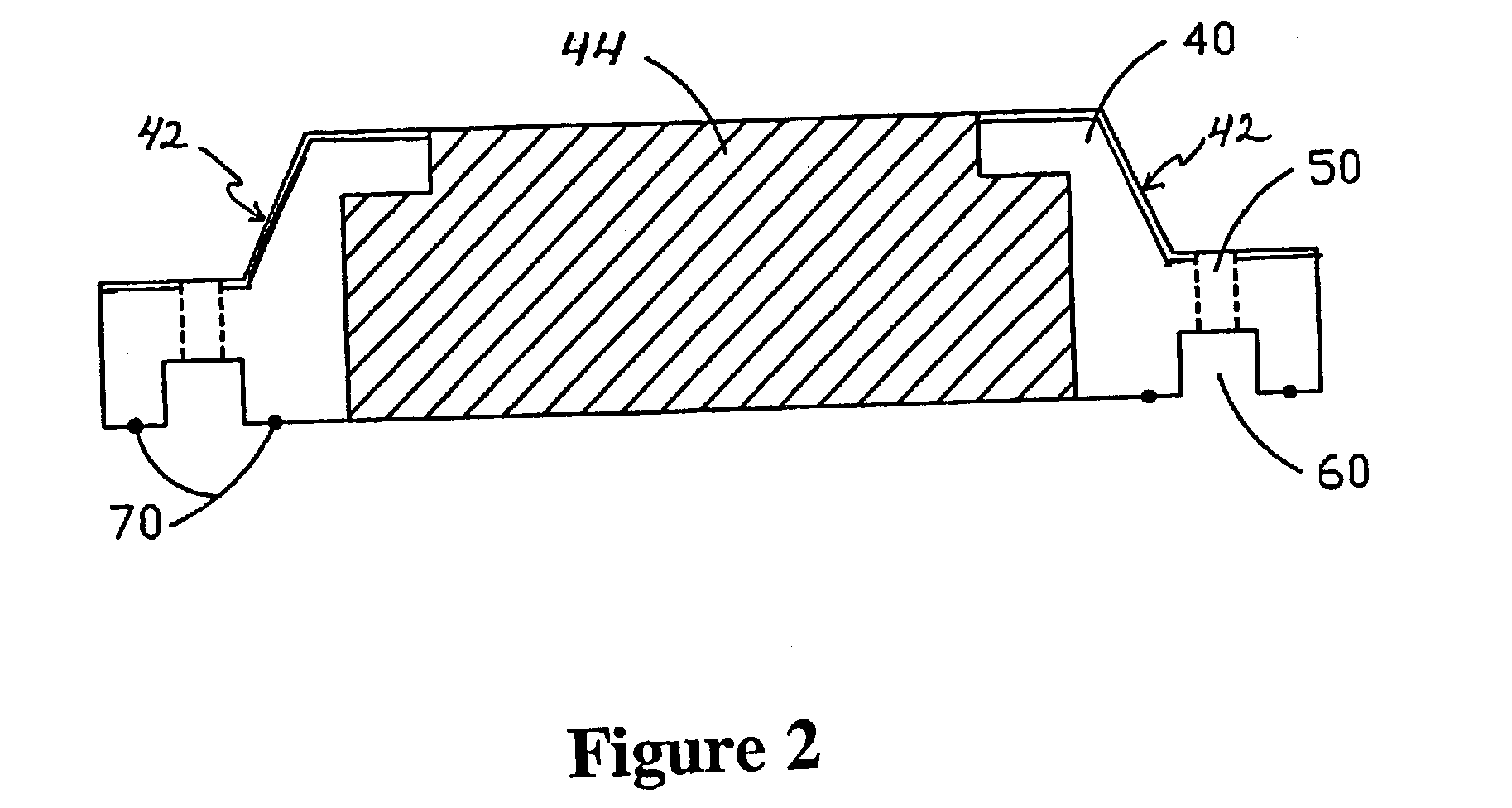

Zirconia toughened ceramic components and coatings in semiconductor processing equipment and method of manufacture thereof

InactiveUS20040023047A1Electric discharge tubesVacuum evaporation coatingCeramic coatingPlasma chamber

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises zirconia toughened ceramic material as an outermost surface of the component. The component can be made entirely of the ceramic material or the ceramic material can be provided as a coating on a substrate such as aluminum or aluminum alloy, stainless steel, or refractory metal. The zirconia toughened ceramic can be tetragonal zirconia polycrystalline (TZP) material, partially-stabilized zirconia (PSZ), or a zirconia dispersion toughened ceramic (ZTC) such as zirconia-toughened alumina (tetragonal zirconia particles dispersed in Al2O3). In the case of a ceramic zirconia toughened coating, one or more intermediate layers may be provided between the component and the ceramic coating. To promote adhesion of the ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

Anti-electrostatic ceramic material, preparation method thereof and firecrackers lead knitting needle made of material

ActiveCN101786878ALow resistivityImprove flexural strengthCeramic shaping apparatusFuse manufactureFirecrackerMass ratio

The invention discloses an anti-electrostatic ceramic material which comprises the following components in percentage by weight: 68-80 percent of yttria stabilized zirconia, 1-3 percent of silicon dioxide, 10-14 percent of tin oxide, 7-11 percent of zinc oxide, 1-2.5 percent of silicon 1-2.5 percent of silicon carbide. The preparation method of the ceramic material comprises the following steps of: firstly, mixing various raw materials in ultrathin powder state by a ball mill; then drying; melting and blending the dried mixed raw materials with an organic binder according to a mass ratio of (4-9):1; injecting and forming particles obtained by melting and blending to obtain a ceramic blank; and degreasing and sintering to obtain an anti-electrostatic ceramic material. In the method, the firecrackers lead knitting needle is injected and formed by a die. The anti-electrostatic ceramic material and the firecrackers lead knitting needle thereof have the advantages of electrostatic resistance, abrasion resistance, good anti-bending performance, simple preparation process, lower cost, and accurate size of a prepared ceramic product without post-processing.

Owner:JIANGSU JINSHENG CERAMIC TECH

Method for preparing ceramic coat with biphase gradients of zirconia and alumina on surface of zirconium base

InactiveCN101092732AHigh hardnessHigh bonding strengthSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

This invention discloses a process for preparing zirconium oxide-aluminum oxide biphase gradient ceramic coating on the surface of zirconium-based material. The process comprises: preparing an electrolyte, supplying zirconium or zirconium alloy as the anode and metal stainless steel as the cathode (spacing = 8-12 cm), and performing micro-arc oxidation treatment on zirconium or zirconium alloy at an electrolyte temperature of 15-40 deg.C, a constant voltage (supplied from an impulse power supply) of 300-650 V, an initial current density of 6-20 A / mm2, a frequency of 50-1000 Hz, and a duty ratio of 5-40% for 25-90 min to obtain the product. The zirconium oxide-aluminum oxide biphase gradient ceramic coating is composed of t-ZrO2 and alpha-Al2O3 biphase, and the content of alpha-Al2O3 biphase is decreased from the surface to the matrix. The zirconium oxide-aluminum oxide biphase gradient ceramic coating has a nanoporous structure and no interface with the matrix, and thus has high combination strength and high hardness (above 1200 Hv).

Owner:XI AN JIAOTONG UNIV

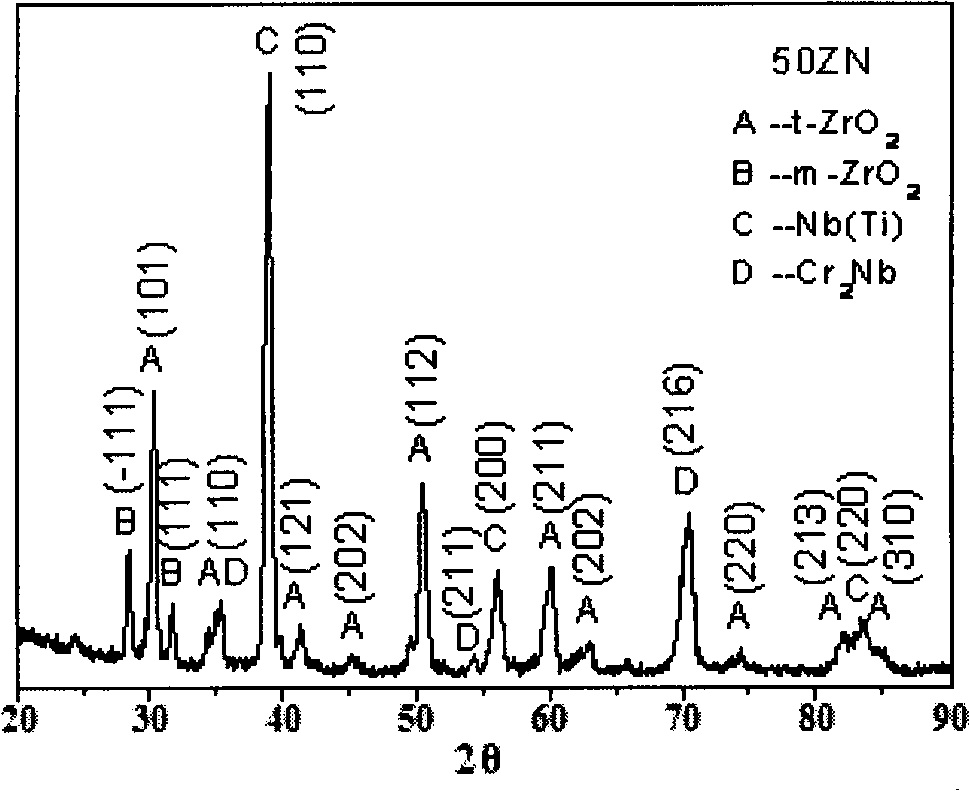

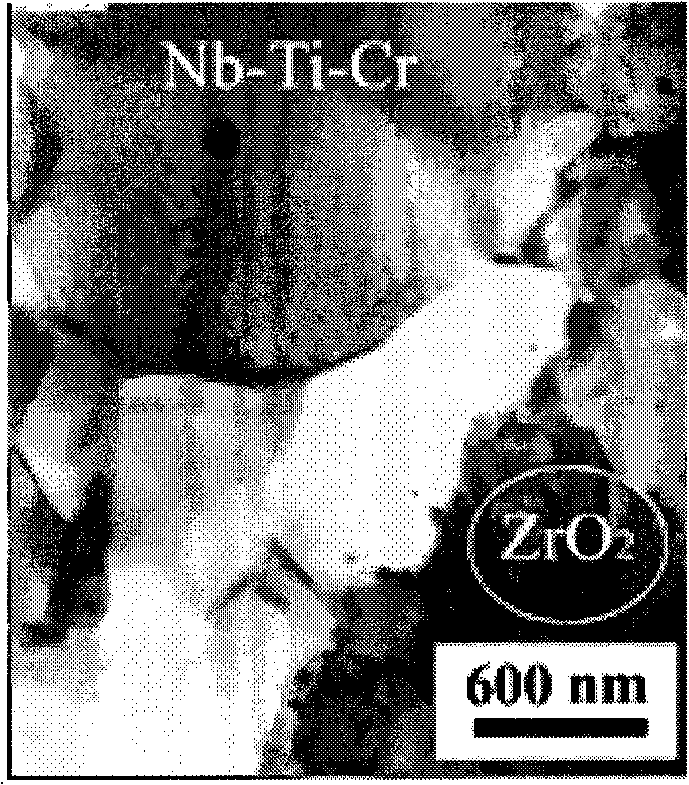

Zirconia ceramic matrix composite and preparation method thereof

InactiveCN101565306AExcellent high temperature mechanicsImprove antioxidant capacityOxidation resistantWhiskers

The invention relates to a zirconia ceramic matrix composite and a preparation method thereof. In the composite, tetragonal zirconia is used as a substrate, and a Nb-Ti-Cr phase is used as a toughening phase, wherein the substrate and the toughening phase account for 20 and 80 volume percent of the total volume of the composite respectively and a sum of the volume percentages of the substrate and the toughening phase is 100 percent. Nb powder, Ti powder and Cr powder are mixed according to the mass ratio of Nb atoms to Ti atoms to Cr atoms of 50:37:23. The preparation method of the zirconia ceramic matrix composite comprises the following steps: ball milling the substrate and the toughening phase and mixing the mixture obtained after ball milling; and preparing the zirconia ceramic matrix composite by hot pressed sintering the mixture under vacuum. The composite of the invention has excellent high-temperature mechanical property and antioxygenic property as well as low cost; and compared with fiber and whisker toughened ceramic, the zirconia ceramic matrix composite has a similar toughening effect, but has simple preparation process, low cost and far more excellent conductivity.

Owner:UNIV OF JINAN

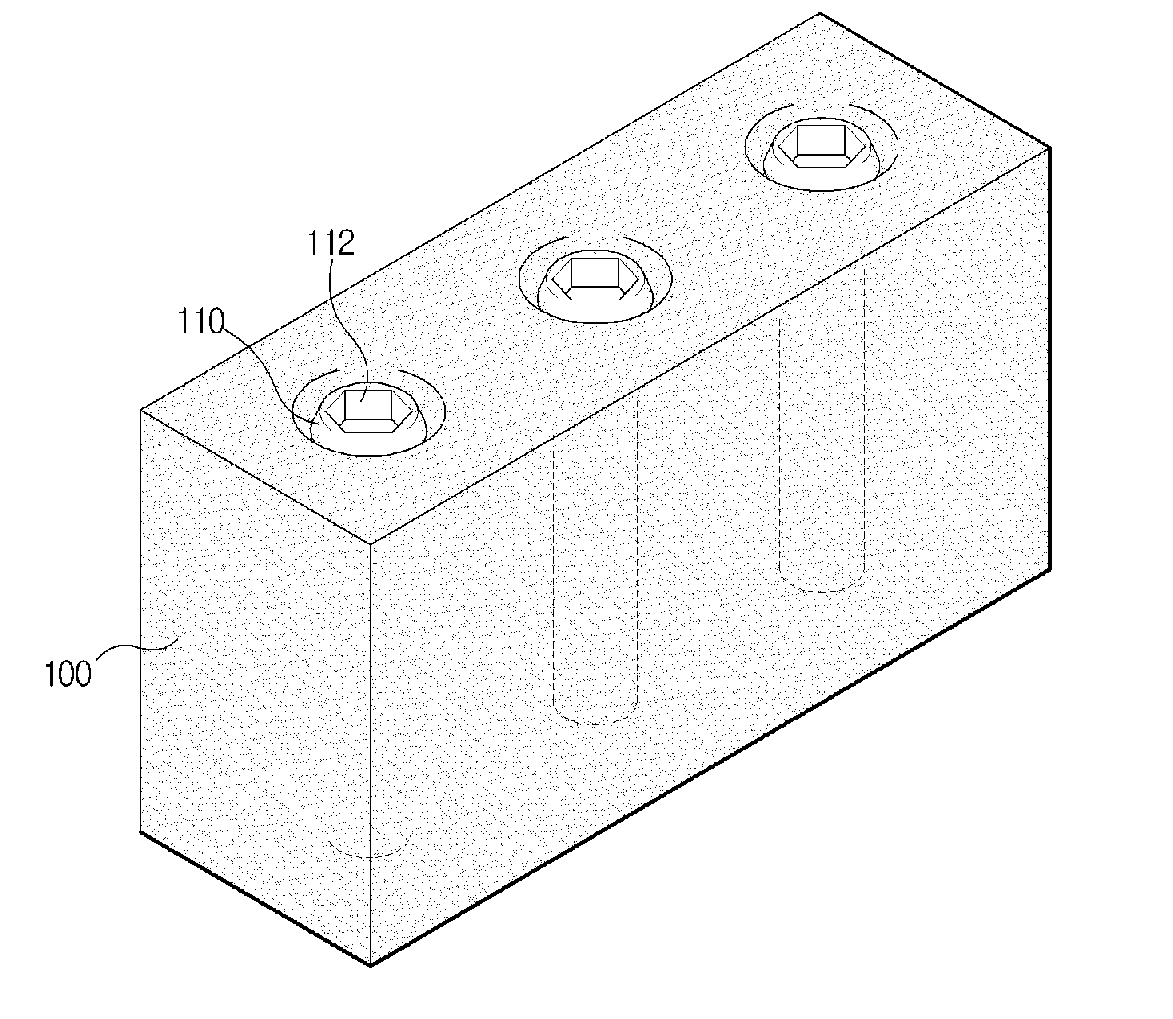

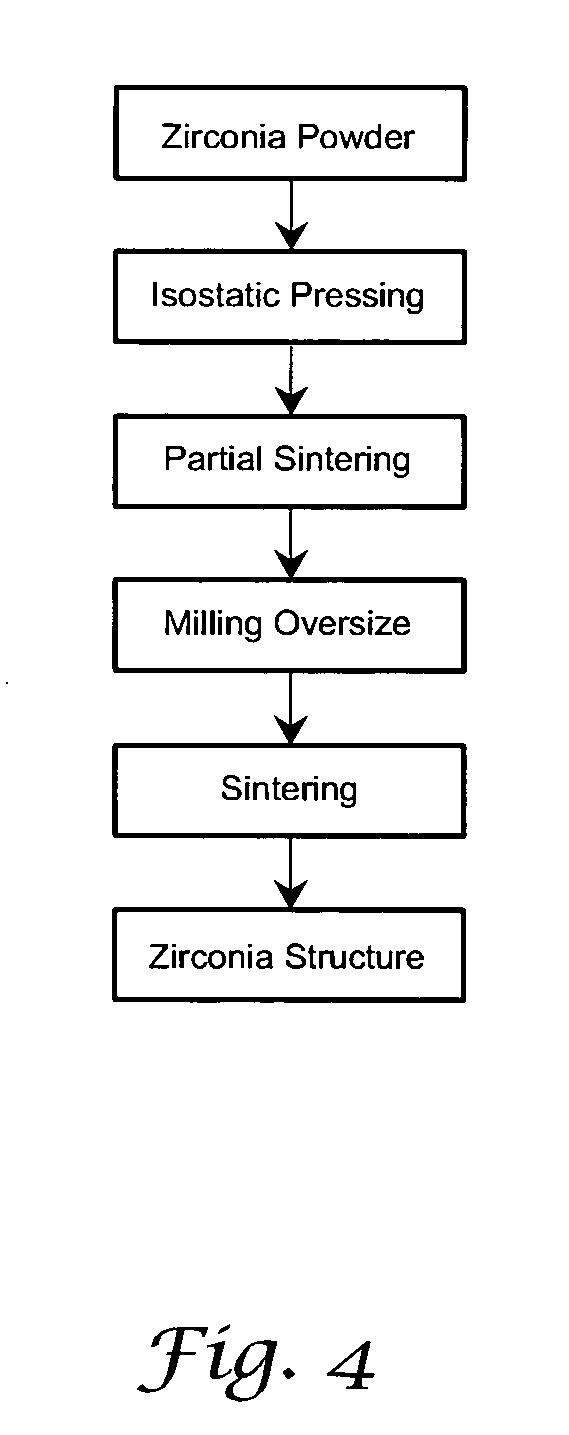

Blocking Having Joining Structure of Dental Implant Abutment and Upper Structure and Manufacturing Method of the Same

Disclosed are a block having a structure for joining an abutment and a superstructure for a dental implant and a method for manufacturing the same. An abutment and a superstructure are not shaped in advance, and instead, a block, in which a structure for joining a fixture and other connection parts of a dental prosthesis are formed, is manufactured such that the block can be machined through CAD / CAM, or, after a wax mock-up or a resin mock-up is scanned and drawn on a paper, the block can be machined through CAM to form an abutment or the crown of a superstructure. In order to provide high strength and high toughness, the block is made of a stabilized tetragonal zirconia polycrystalline (TZP)-based material or a composite of zirconia and oxide. The method comprises the steps of pressing a starting material for a block, machining a resultant formation, and sintering the machined formation.

Owner:KIM EE

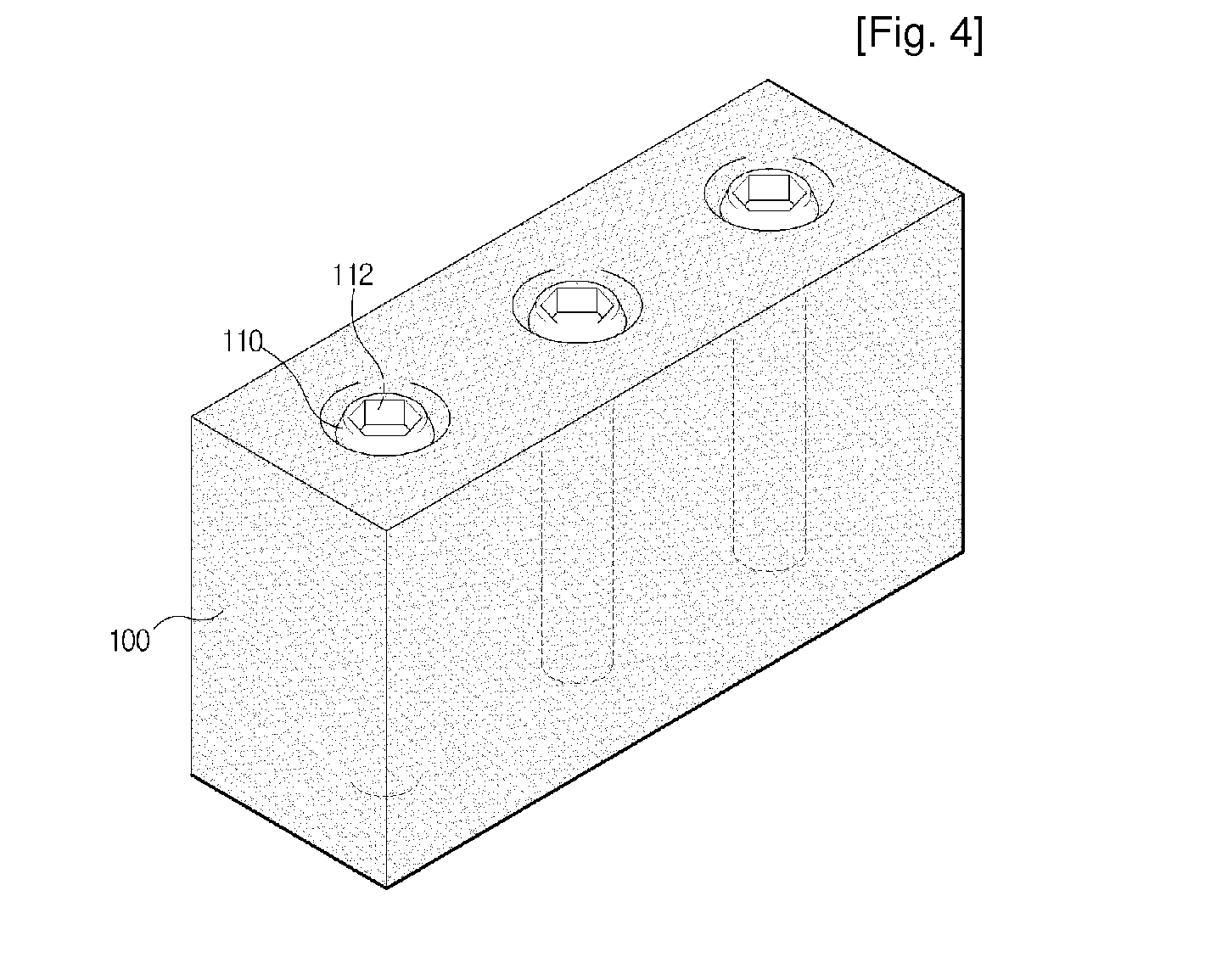

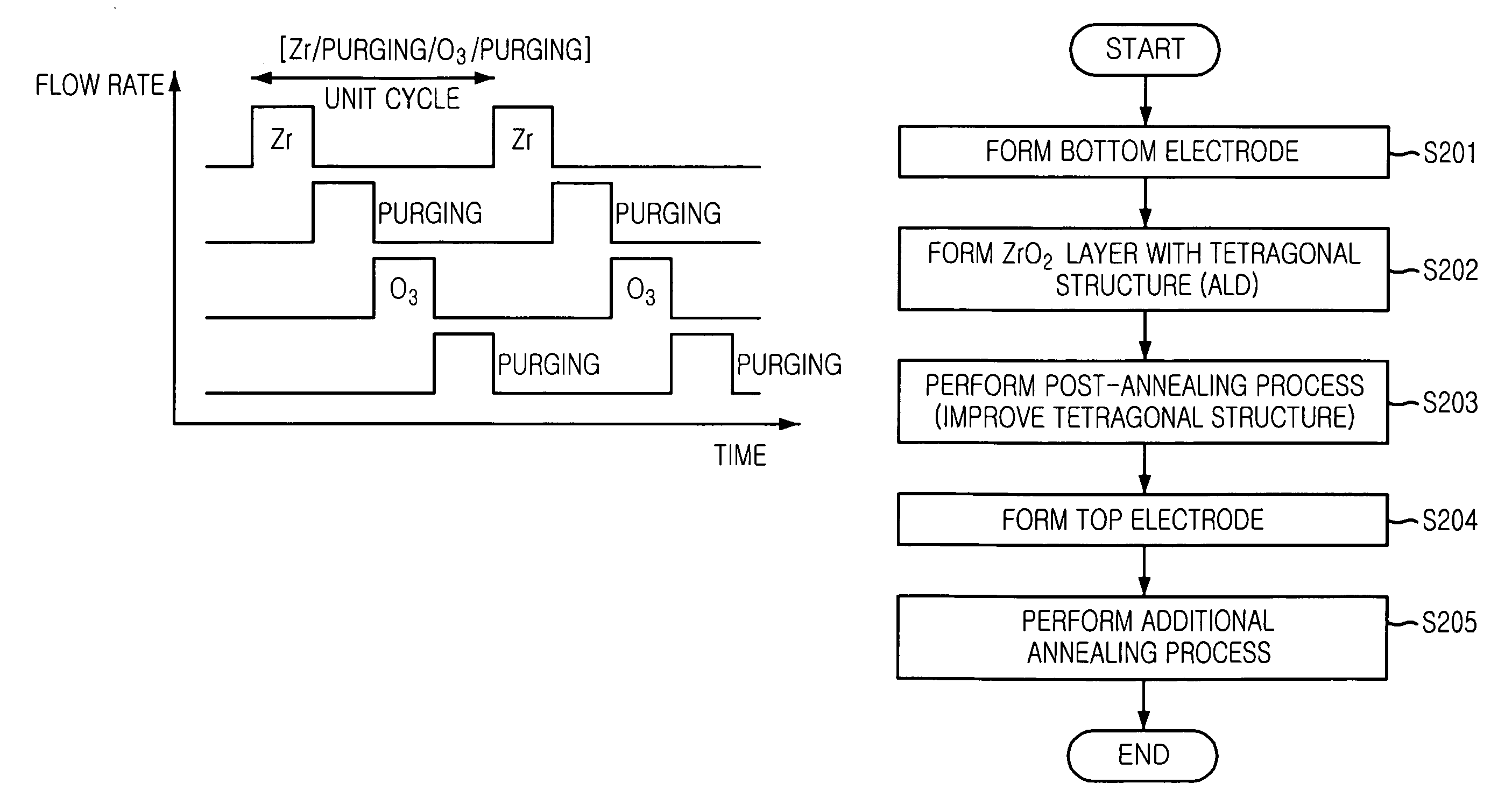

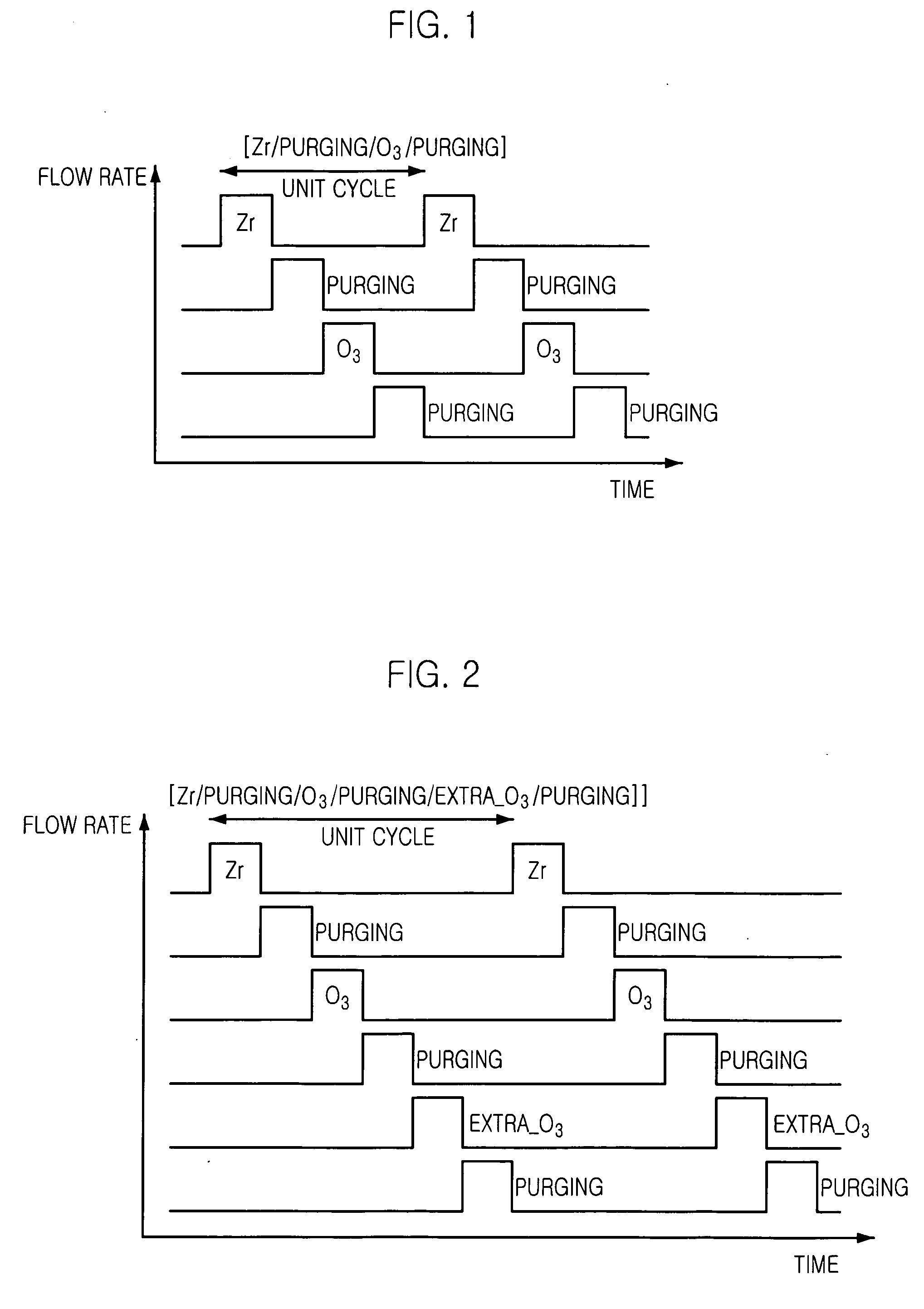

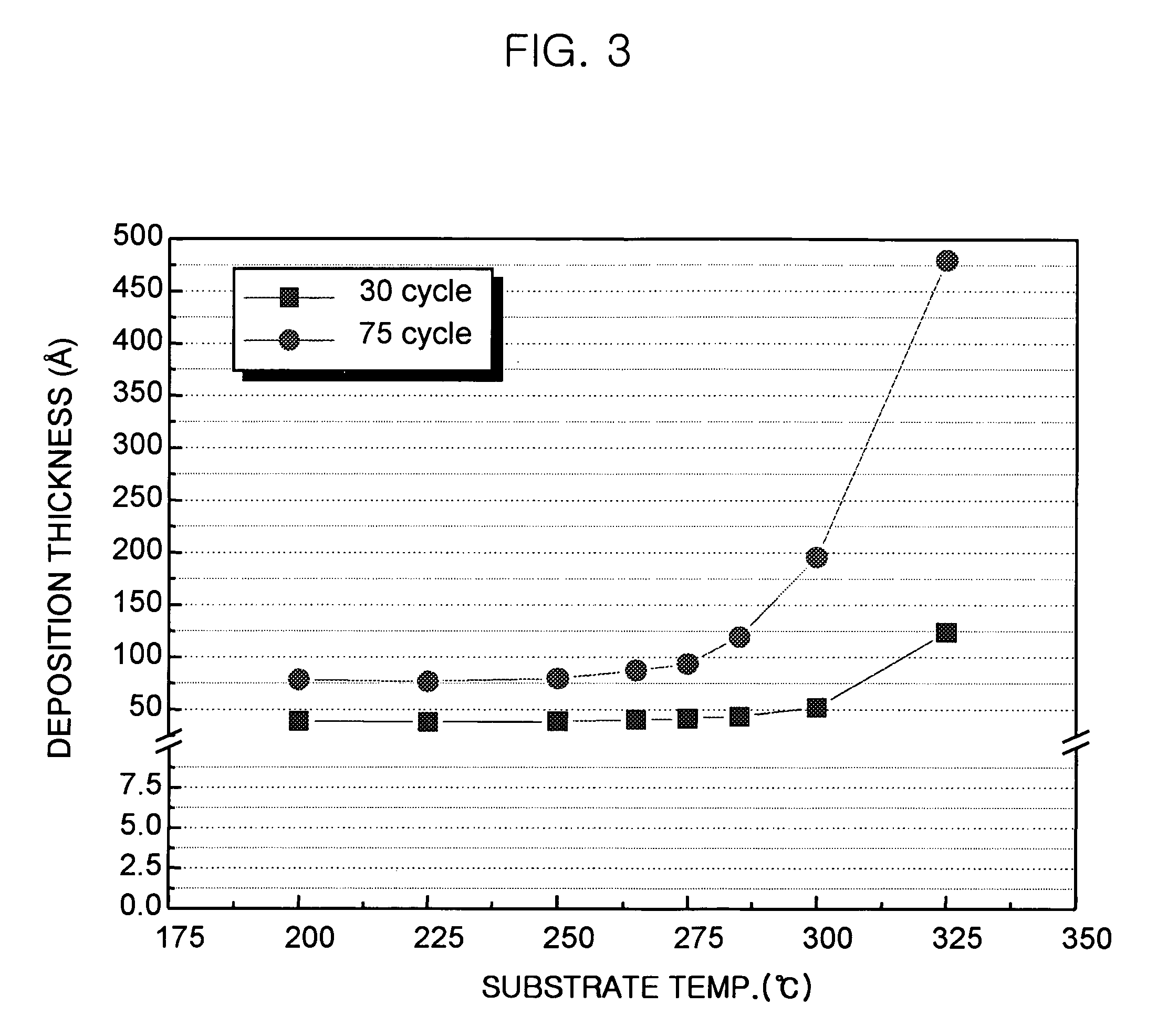

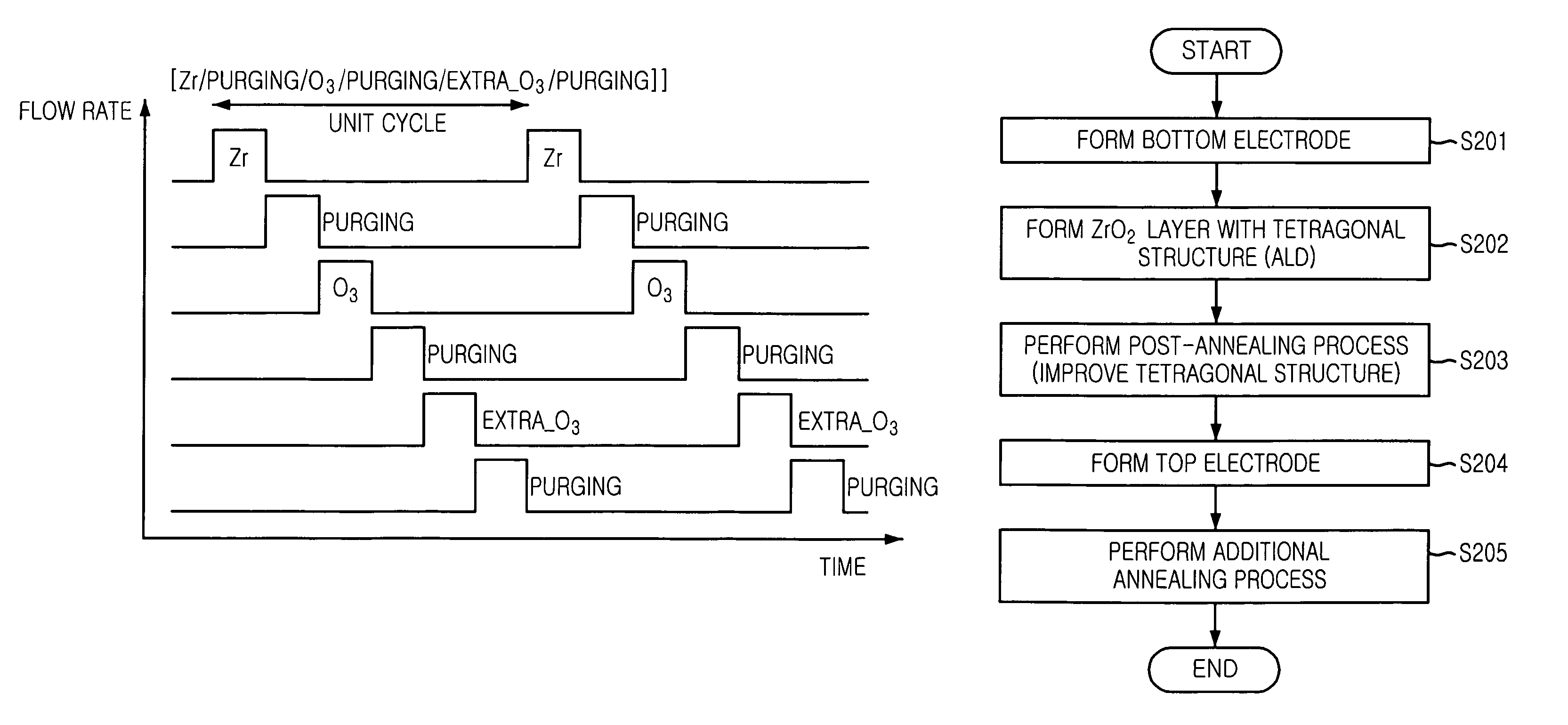

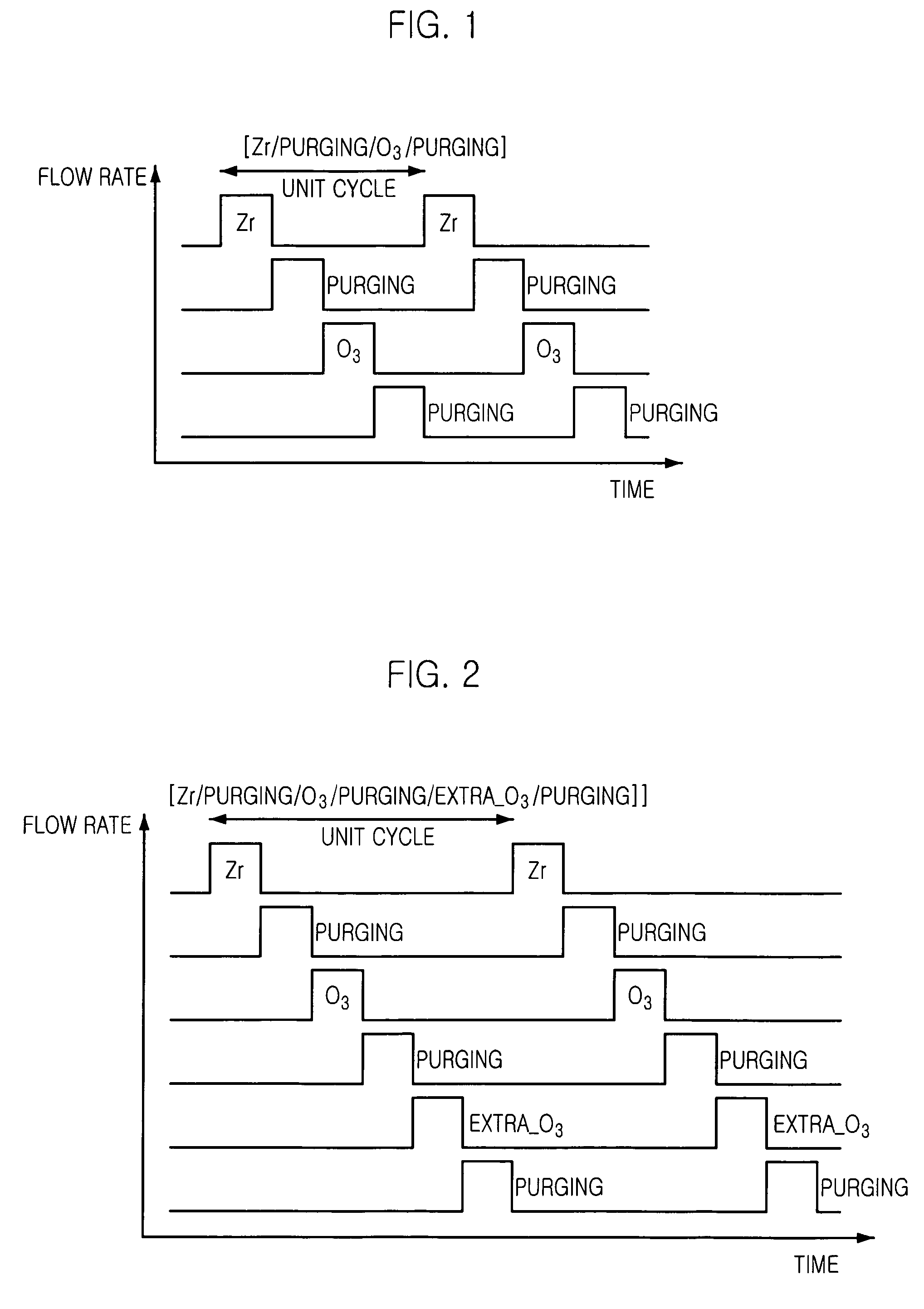

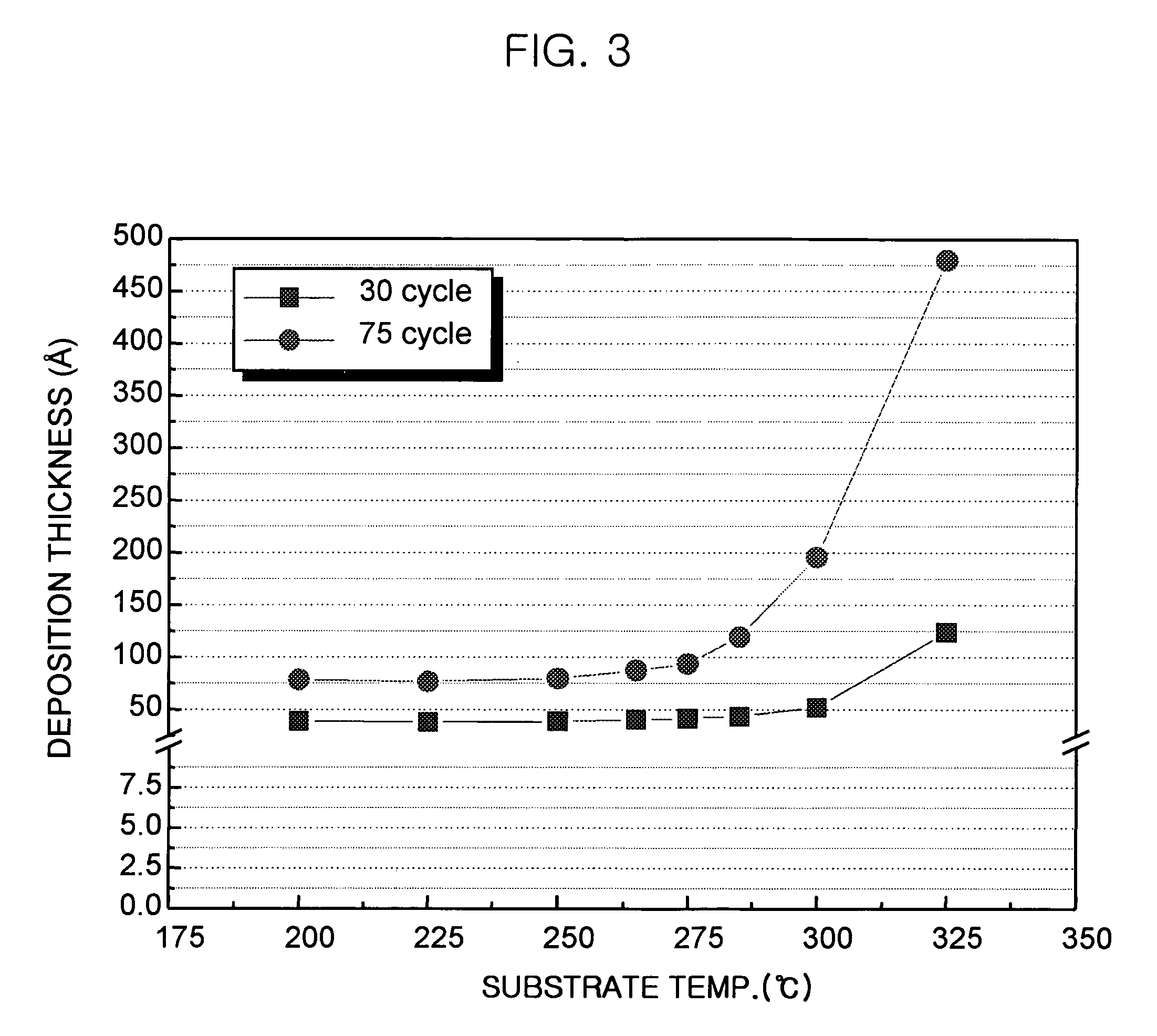

Method for forming tetragonal zirconium oxide layer and method for fabricating capacitor having the same

InactiveUS20070232081A1Improve tetragonalityExcellent dielectric propertiesSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringAtomic layer deposition

A method for forming a zirconium oxide (ZrO2) layer on a substrate in a chamber includes controlling a temperature of the substrate; and repeating a unit cycle of an atomic layer deposition (ALD) method. The unit cycle includes supplying a zirconium (Zr) source into a chamber, parts of the Zr source being adsorbed into a surface of the substrate; purging non-adsorbed parts of the Zr source remaining inside the chamber; supplying a reaction gas for reacting with the adsorbed parts of the Zr source; and purging non-reacted parts of the reaction gas remaining inside the chamber and reaction byproducts, wherein the temperature of the substrate and a concentration of the reaction gas are controlled such that the ZrO2 layer is formed with a tetragonal structure.

Owner:SK HYNIX INC

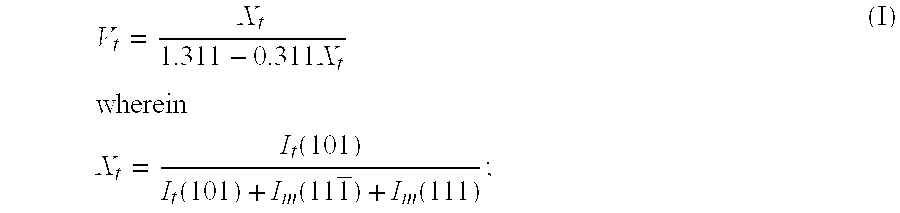

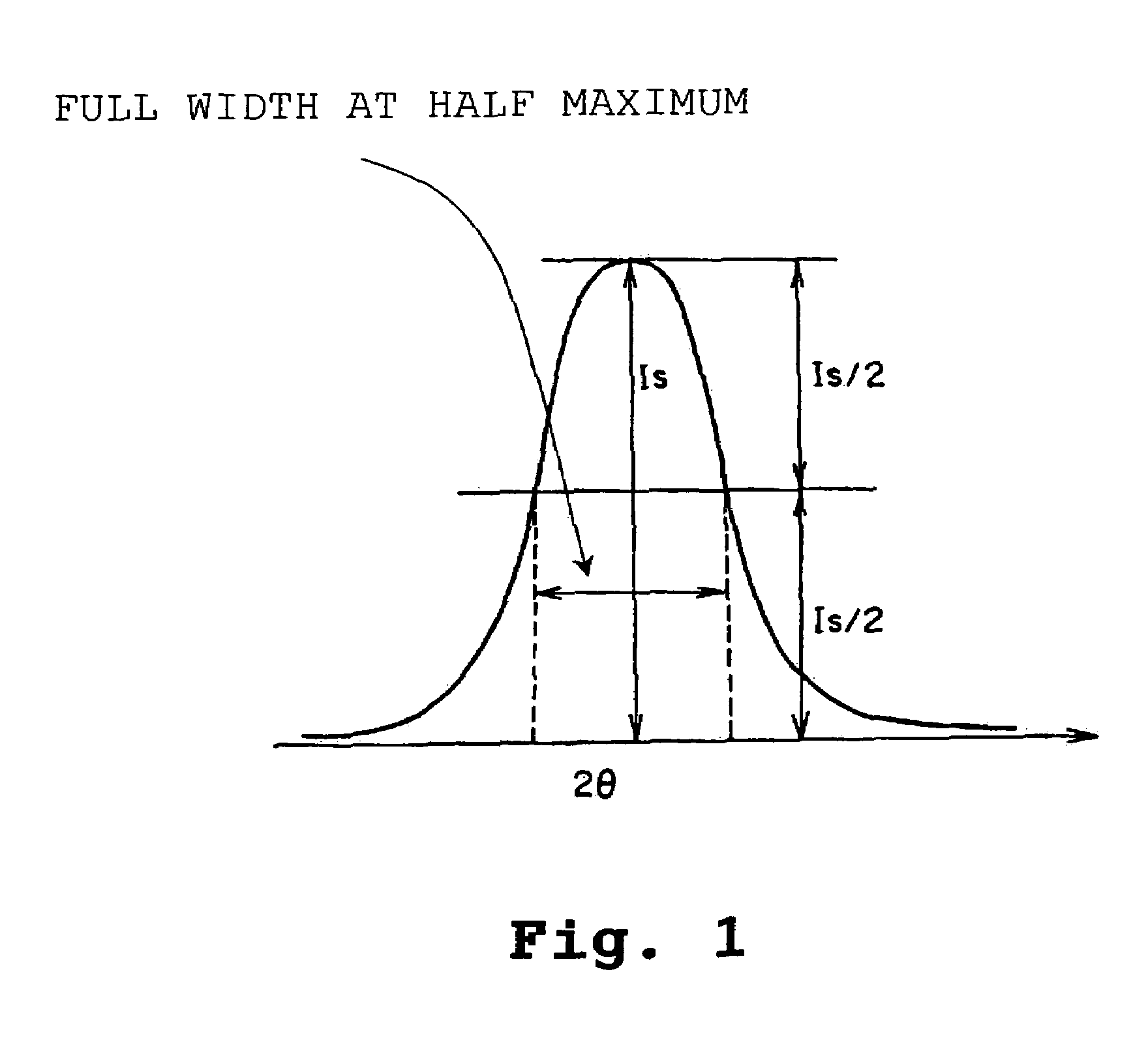

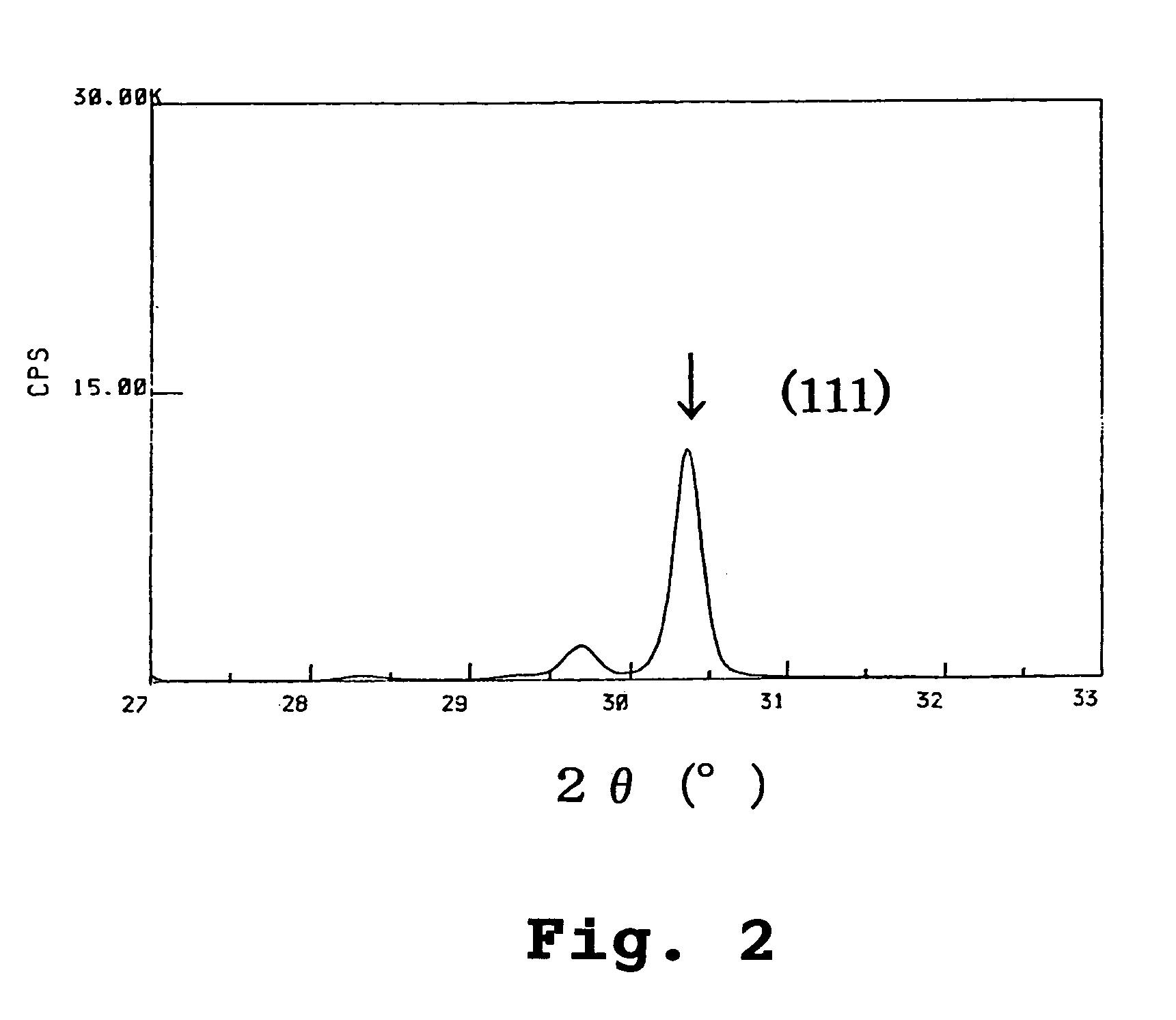

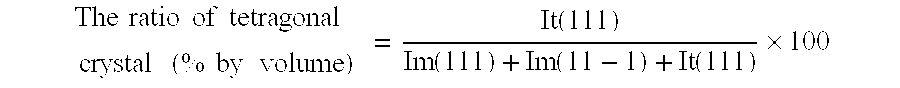

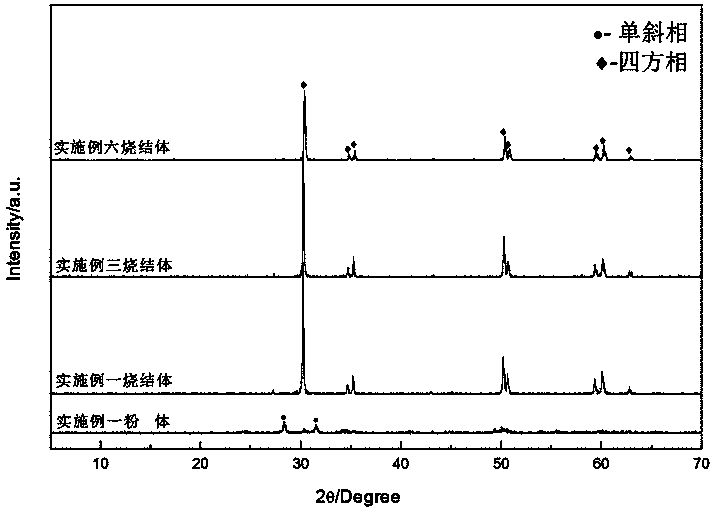

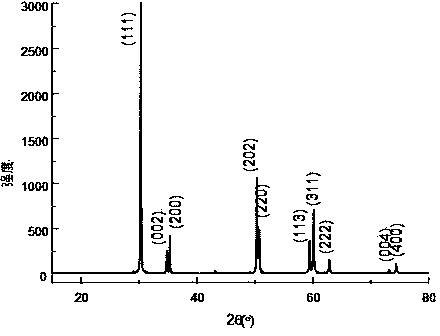

Zirconia sintered body and a method for producing the same

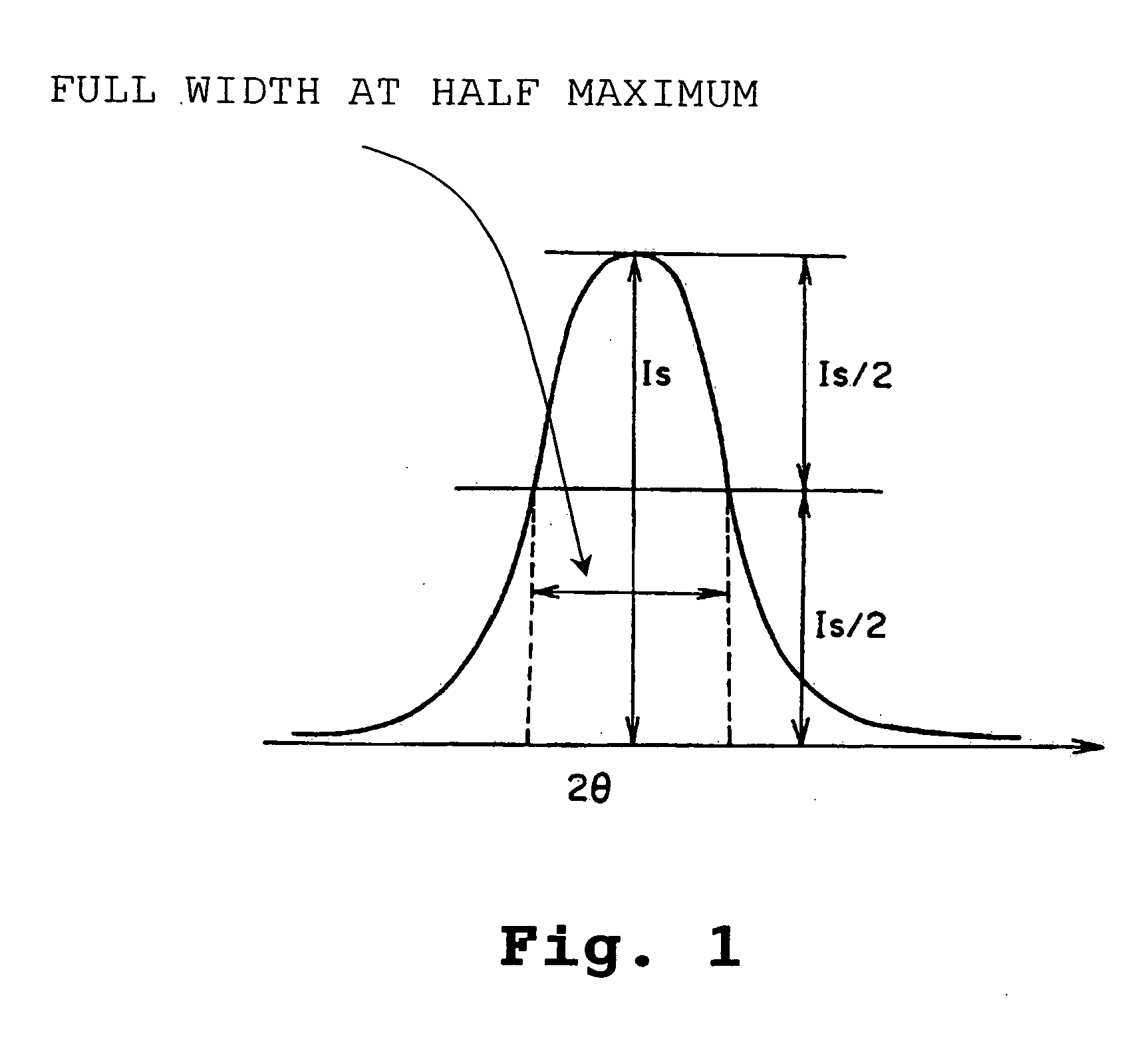

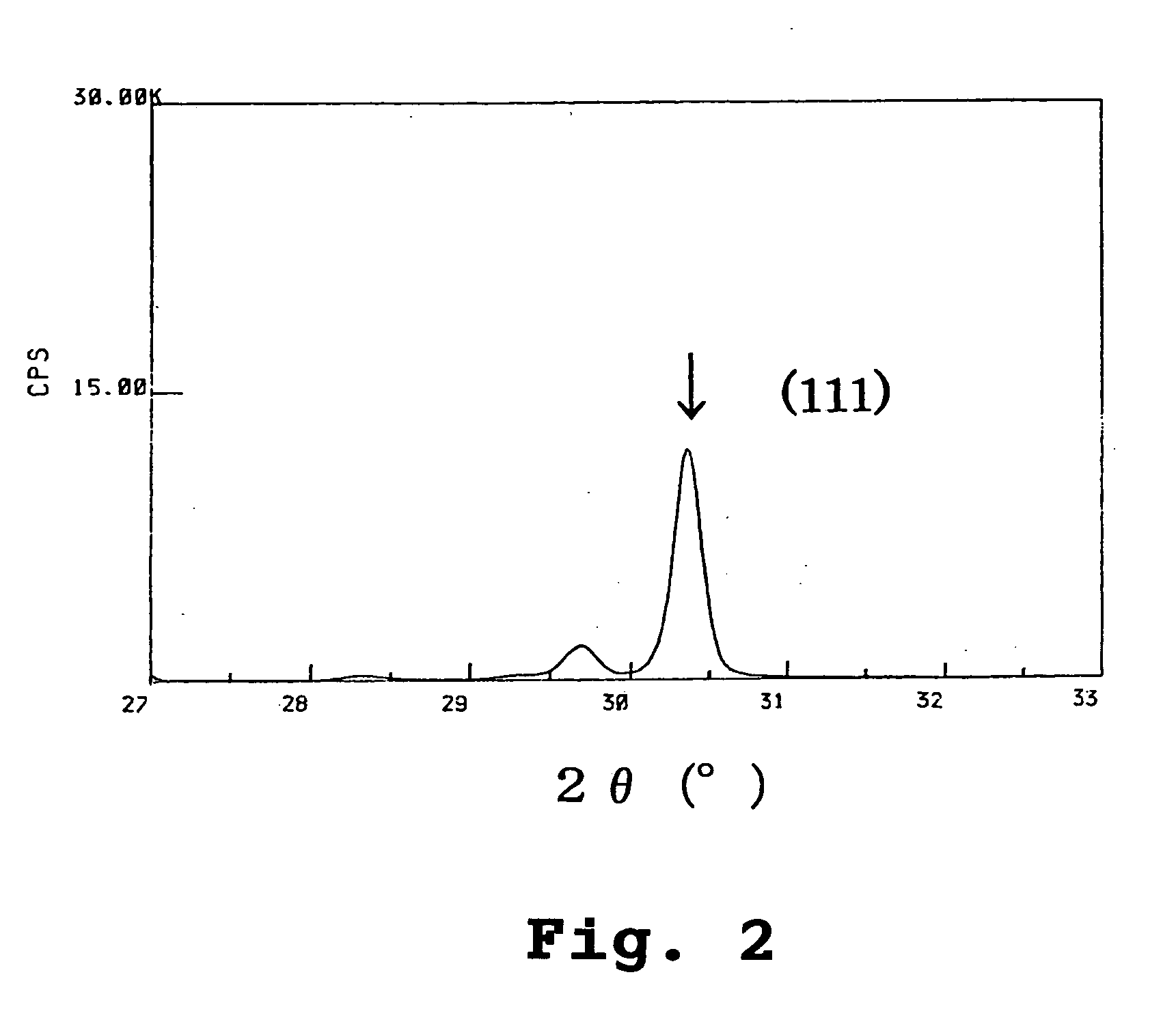

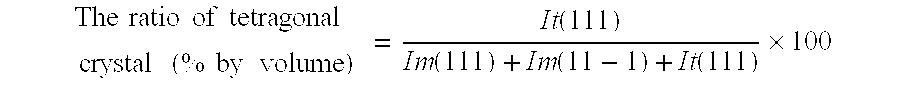

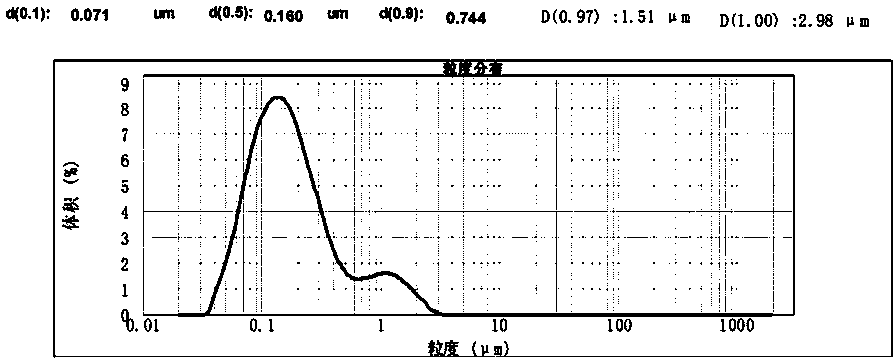

InactiveUS7291574B2High strengthImprove bending strengthLighting and heating apparatusCentral heating componentsX-rayFull width at half maximum

A zirconia sintered body having high strength and high toughness is provided, and a method for producing the same is also provided. The zirconia sintered body comprising tetragonal zirconia, wherein a full width at half maximum at (111) plane of the tetragonal zirconia obtained by X-ray diffraction pattern is from 0.38 to 4 degree. A method for producing the zirconia sintered body, wherein the method comprises steps of; molding zirconia powder having an average particle diameter of from 0.1 to 0.6 μm, a maximum particle diameter of 5 μm or less and a substantially polyhedral shape, and then sintering the molded green body under the temperature of from 1200 to 1400° C.

Owner:SUMITOMO CHEM CO LTD

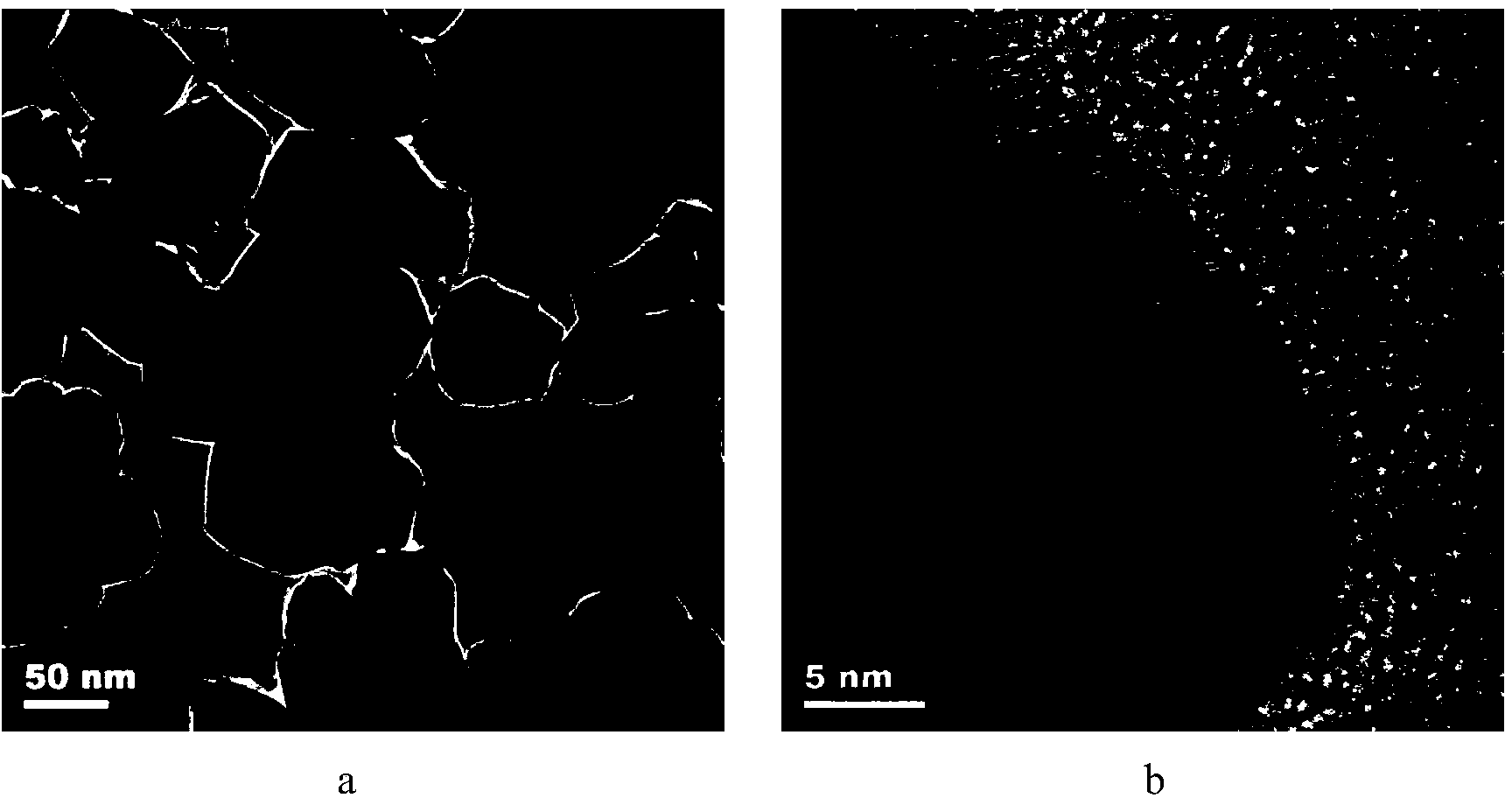

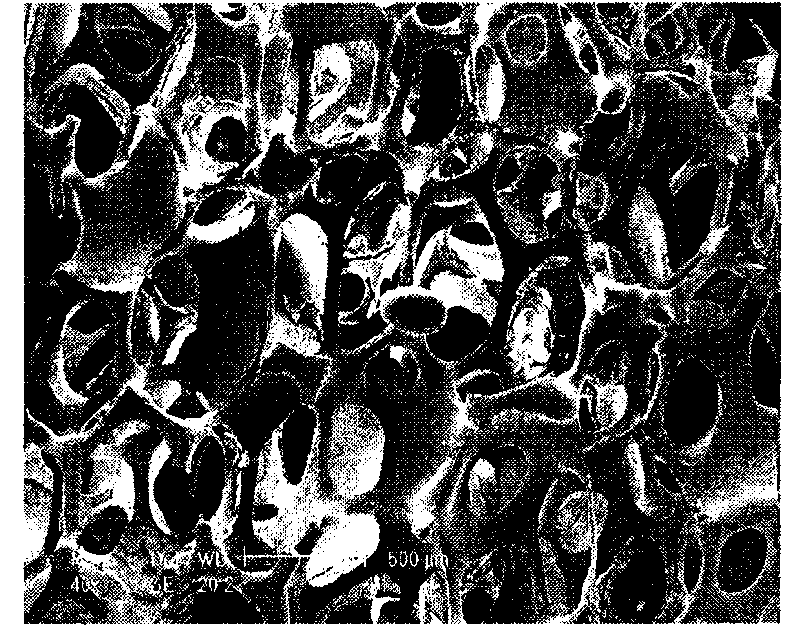

Preparation technique of zirconium radical surface porous nano zirconium oxide biologically active coating

InactiveCN101037784AImprove biological activityHigh bonding strengthSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a process for preparing zirconium surface porous nanometer zirconia biological activity coat. The porous nanometer zirconia biological activity coat is directly produced by micro-arc oxidation treating zirconium and zirconium alloy under high pressure using impulsing power source, with water solution containing calcium and phosphorous as electrolytic solution. The produced nanometer zirconia biological activity coat comprises tetragonal zirconia with the thickness of more than 40 mum and porous nanometer crystal structure, without interface between based bodys, accordingly it has high bonding strength, good tenacity and elastic modulus adjacent to sclerotin, bone apatite formed by inducing in similar body fluid has good biological activity usable as biological activity surface layer of zirconium medical implant.

Owner:XI AN JIAOTONG UNIV

Zirconia sintered body and a method for producing the same

InactiveUS20040192535A1Lighting and heating apparatusCentral heating componentsFull width at half maximumX-ray

A zirconia sintered body having high strength and high toughness is provided, and a method for producing the same is also provided. The zirconia sintered body comprising tetragonal zirconia, wherein a full width at half maximum at (111) plane of the tetragonal zirconia obtained by X-ray diffraction pattern is from 0.38 to 4 degree. A method for producing the zirconia sintered body, wherein the method comprises steps of; molding zirconia powder having an average particle diameter of from 0.1 to 0.6 mum, a maximum particle diameter of 5 mum or less and a substantially polyhedral shape, and then sintering the molded green body under the temperature of from 1200 to 1400° C.

Owner:SUMITOMO CHEM CO LTD

Powder material for preparing high-strength high-toughness yttrium stabilized tetragonal polycrystal zirconia ceramics and preparation method of powder material

The invention discloses a powder material for preparing high-strength high-toughness yttrium stabilized tetragonal polycrystal zirconia ceramics. The powder material is prepared from zirconia and yttrium oxide, wherein the content of the yttrium oxide is 1.4-2.6mol% of the total amount of Zr<4+>; and the average grain size of raw crystal of the powder material is 50-110nm. Moreover, the invention further discloses a preparation method of the powder material. According to the zirconia powder material, the doping amount of yttrium is reduced, the tetragonal polycrystal ceramics prepared by using the powder are capable of realizing full tetragonal phase stable existence of zirconia at room temperature to guarantee the characteristic of high strength, activating the tetragonal phase in TZP (tetragonal zirconia polycrystalline), improving the transformation toughening performance and further optimizing the fracture toughness of TZP ceramics. The preparation method is safe and reliable, has the advantages of wide raw material source, low energy consumption and remarkable effect on energy conservation and emission reduction, is convenient for popularization and application, is suitable for industrial large-scale production, and can be used for effectively promoting application and development of zirconia materials.

Owner:江西赛瓷材料有限公司 +1

Ceramic material powder used for denture preparation and preparation method of ceramic material powder

The invention relates to a material used for a denture, and in particular relates to a ceramic material powder used for denture preparation. The ceramic material powder comprises 90%-95% of stable tetragonal zirconia, and 2.5-3.49% of yttrium oxide used as a stabilizer, wherein a precursor is obtained by coprecipitation reaction of the ceramic material powder; the precursor is sequentially subjected to hydrothermal reaction and spray drying to obtain powder with bending strength greater than 600MPa. A method for preparing the powder comprises the following steps: a, forming 90%-95% of tetragonal zirconia, and 2.5-3.49% of yttrium oxide used as the stabilizer; b, carrying out hydrothermal reaction on the precursor produced in the step a, wherein the reaction temperature is 120-250 DEG C and the reaction time in a high-pressure reactor is 24-48 hours; c, adding a 2-5% polyvinyl alcohol solution into a product obtained in b as adhesive; d, carrying out centrifugal spray granulation on a product obtained in c at hot air temperature of 200-350 DEG C. Through the steps, high-quality ceramic powder with high bending strength greater than 600MPa, high fracture toughness, good chemical stability and good biocompatibility can be obtained.

Owner:厦门北大泰普医疗器械有限公司

Outer pipe shell material containing tetragonal zirconia and preparation method thereof

InactiveCN101800140ANo crackingAchieve mass production capacityFuse device manufactureYttriumMaterials science

The invention relates to an outer pipe shell material containing tetragonal zirconia and a preparation method thereof. The material comprises the components: aluminium oxide, superfine nano-zirconia and additive, wherein the aluminium oxide has the purity of 90-99.9% and the parts by weight of 70-95; the superfine nano-zirconia has the purity of 99-99.9% and the parts by weight of 5-30; the additive is one, two or more in four additives comprising yttrium oxide, magnesium oxide, calcium oxide or cerium oxide; and the four additives have the purity of 95-99.9% and the total parts by weight of 1-3. The invention adopts a thermal fluid injection molding technique to form a round or square thin wall tubular structure green body which is sintered at 1560-1580 DEG C for 20-24h. The sintered ceramic material microcosmic crystal phase contains 70-95wt% of aluminium oxide and 5-30wt% of zirconia, wherein the zirconia with the tetragonal stable phase has the weight percent of 5-70%. The invention better solves the technical problems of a thin wall mini-fuse outer pipe shell.

Owner:咸阳澳华瓷业有限公司

Method for forming tetragonal zirconium oxide layer and method for fabricating capacitor having the same

InactiveUS7772132B2Improve tetragonalityExcellent dielectric propertiesSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringAtomic layer deposition

A method for forming a zirconium oxide (ZrO2) layer on a substrate in a chamber includes controlling a temperature of the substrate; and repeating a unit cycle of an atomic layer deposition (ALD) method. The unit cycle includes supplying a zirconium (Zr) source into a chamber, parts of the Zr source being adsorbed into a surface of the substrate; purging non-adsorbed parts of the Zr source remaining inside the chamber; supplying a reaction gas for reacting with the adsorbed parts of the Zr source; and purging non-reacted parts of the reaction gas remaining inside the chamber and reaction byproducts, wherein the temperature of the substrate and a concentration of the reaction gas are controlled such that the ZrO2 layer is formed with a tetragonal structure.

Owner:SK HYNIX INC

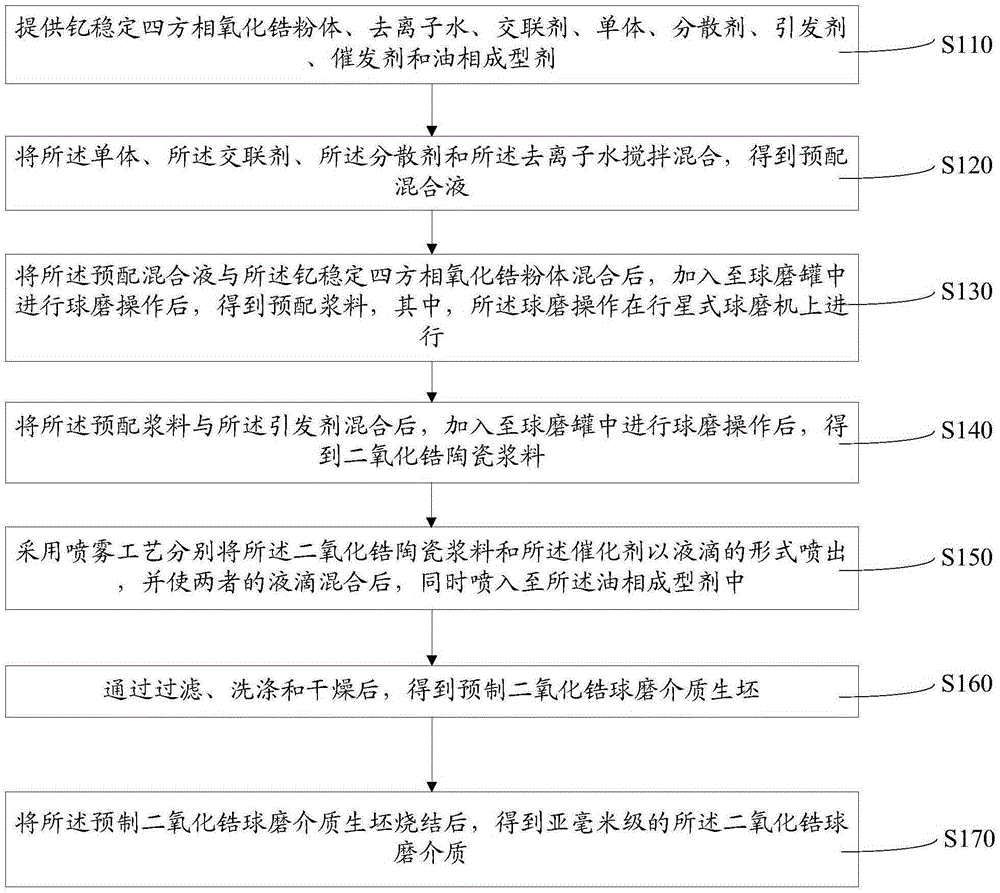

Preparation method for zirconium dioxide ball-milling medium

A preparation method for a zirconium dioxide ball-milling medium comprises the following steps: providing yttrium-stabilized tetragonal zirconia powder, deionized water, a crosslinking agent, a monomer, a dispersing agent, an initiator, a catalyst and an oil phase forming agent; stirring and mixing the monomer, the crosslinking agent, the dispersing agent and the deionized water so as to obtain a pre-preparation mixed solution; carrying out ball milling on the pre-preparation mixed solution and the yttrium-stabilized tetragonal zirconia powder on a planetary ball mill, so as to obtain pre-preparation slurry; carrying out ball milling on the pre-preparation slurry and the initiator so as to obtain zirconium dioxide ceramic slurry; spraying out the zirconium dioxide ceramic slurry and the catalyst in a liquid drop manner by using a spraying process, and after the liquid drops of the zirconium dioxide ceramic slurry and the catalyst are mixed, spraying the mixed liquid drops into the oil phase forming agent; filtering, washing and drying so as to obtain a prefabricated zirconium dioxide ball-milling medium blank; sintering the prefabricated zirconium dioxide ball-milling medium blank so as to obtain the submillimeter-level zirconium dioxide ball-milling medium. The preparation method has the advantages of relatively simple preparation process and relatively low cost.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

Strengthened ceramic restoration

InactiveUS20090004630A1Easy to spreadInhibit and reduce LTDTooth crownsArtificial teethTooth colourThermal compression

The present invention relates to a process for the preparation of a full-ceramic dental restoration, comprising heat pressing of a tooth coloured pressing glass on a fully or partially supporting structure of yttria doped tetragonal zirconia (YTZP), comprised of yttria doped tetragonal zirconia ceramic having a grain size, as measured by the linear intercept method, of less than 0.6 μm, wherein the pressing glass has a thermal expansion coefficient (TEC) of between 9.0 and 11.0 μm / m.K (measured in the range of from 25 to 500° C.) and wherein the pressing glass has a pressing temperature of between 750 and 1200° C. In a further aspect, the invention relates to a full-ceramic dental restoration, comprising a fully or partially supporting structure of yttria doped tetragonal zirconia (YTZP) and a heat pressed tooth coloured pressing glass, which restoration is modeled to be in occlusal contact with opposing teeth and in mesio-distal contact with neighbouring teeth.

Owner:VAN DER ZEL JOSEPH MARIA +5

High-intensity porous bone repair material and method for preparing same

The invention discloses a high-intensity porous bone repair material and a method for preparing the same. The method comprises the following: (1) a step of preparing a porous body, which is to use beta-tricalcium phosphate, bio-glass and a stable tetragonal zirconia power as a solid phase, add deionized water into the solid phase, add ammonium polyacrylate serving a dispersant, process the mixture by ball milling to prepare pulp, soak polyurethane foam completely into the pulp, take out the soaked foam, extrude excessive pulp out of the product so as to evenly coat the pulp on the pore walls of the porous body, dry the obtained product, place the dried product in a program control furnace or an electric resistance furnace, film the obtained product at a rising temperature and sinter the filmed product to form the porous body; (2) a step of soaking the obtained porous body in a water solution of NaOH, washing the product with deionized water in the atmosphere of ultra waves and drying the resulting product to obtain the high-intensity porous bone repair material. The high-intensity porous bone repair material of the invention has a high intensity and a high compressive strength, can be widely applied to repair skulls, frontal bones and the like and can also be used to reconstruct scaffolds of cell carriers in tissue engineering and repairing organs.

Owner:HEBEI UNIV OF TECH

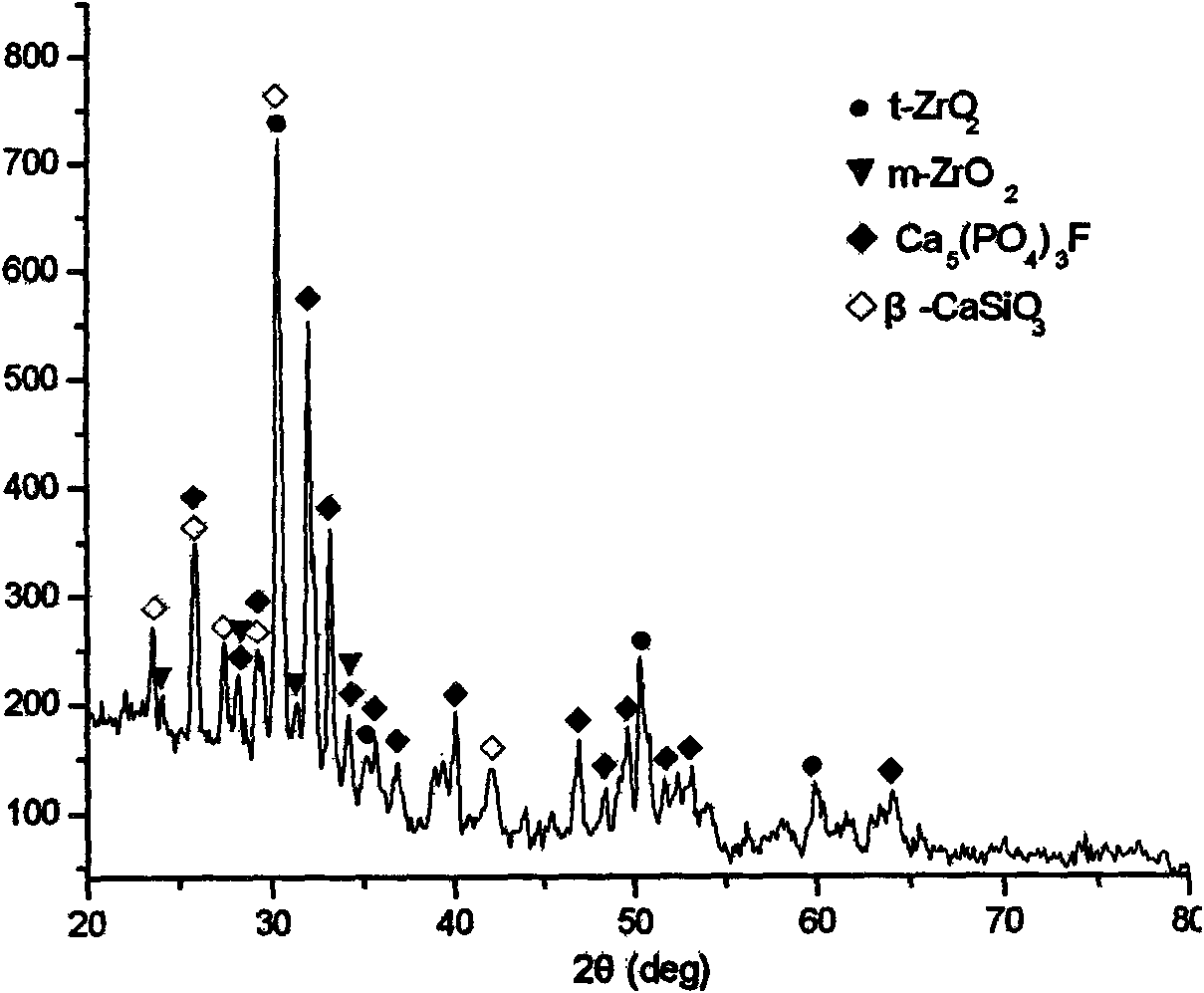

ZrO2 toughened bioactive glass-ceramics of MgO-CaO-SiO2-P2O5-CaF2 system and preparation method thereof

InactiveCN101559237AImprove bending strengthLower precipitation temperatureCoatingsProsthesisFlexural strengthArtificial bone

The invention discloses a ZrO2 toughened bioactive glass-ceramics of MgO-CaO-SiO2-P2O5-CaF2 system. The glass comprises the components with mass fractions as follows: 25.7-34.1% of SiO2, 3.4-4.6% of MgO, 33.7-44.8% of CaO, 12.2-16.3% of P2O5, 0.1-5% of CaF2 and 0.1-20% of ZrO2; wherein, the ZrO2 is tetragonal zirconia. The prepared ZrO2 toughened bioactive glass-ceramics of MgO-CaO-SiO2-P2O5-CaF2 system witnesses obviously improved bending strength and fracture toughness; the elastic module index of the bioactive glass-ceramics can serve as materials for restoring or replacing artificial bones and the linear expansibility index thereof meets the requirement of similarity to the linear expansibility of titanium and titanium alloy coating materials. The bioactive glass-ceramics show good bioactivity in the immersion test in the simulated body fluid.

Owner:SHANDONG UNIV

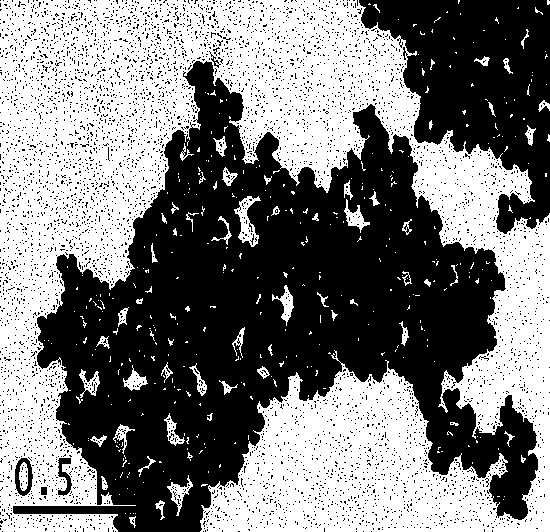

Stable tetragonal zirconia ceramics material of manganese oxide and method of preparing the same

The invention provides a tetragonal zirconia ceramic material with stable manganese oxide and a preparation method thereof. The ceramic material takes the zirconium oxide as a substrate and takes the transition metal oxide manganese oxide as a stabilizing agent. The preparation method comprises the steps as follows: the weighed mixed powder of the zirconium oxide and manganese oxide is poured into a mortar and fully ground and mixed; the powder is pressed into ceramic sheets with certain shapes by adopting a unidirectional dry press method under the pressure of 8 to 10MPa; the ceramic sheets are put into a high temperature pipe furnace to be sintered, wherein, a heat treatment regime is that the heating rate is less than 300 DEG C per hour, heat preservation is carried out for 12 to 24 hours in the argon atmosphere at 1,300 to 1,400 DEG C and the cooling is carried out on the ceramic sheets along with the furnace. The method is simple in process and low in cost. The tetragonal zirconia ceramic is prepared by a solid sintering process; the material obtained has good stability, is an excellent structural ceramic material and a solid electrolyte material and is beneficial to the application and popularization of the novel zirconia ceramic material.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Rare-earth oxide and manganese oxide co-stable zirconia ceramics and preparation thereof

The invention discloses a zirconia ceramic stabilized by rare earth oxide and manganese oxide and a method for preparing the same. The zirconia ceramic consists of a certain mol percent of zirconia, the rare earth oxide and the manganese oxide, wherein the zirconia is a matrix, and the rare earth oxide and transition metal oxide of manganese oxide serve as a stabilizing agent together. The preparation process comprises the following steps: pouring the weighed and mixed powder of the zirconia, the manganese oxide and the rare earth oxide into a mortar; after fully mixing and grinding the mixed powder, pressing the mixed powder into blank tablets at a pressure of between 8 and 10 MPa; sintering the blank tablets in a high-temperature tubular furnace; and then cooling the blank tablets with the furnace. The invention adopts the transition metal oxide and the rare earth oxide as a stabilizing agent together to prepare the stabilized zirconia, has the characteristics of simple operation method, accuracy, high efficiency, easy control of reaction conditions, full reaction and the like, and the prepared square zirconia ceramic material stabilized by the manganese oxide has good stability and conductivity.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Dentistry zirconia and leucite compound porcelain powder and preparing method thereof

InactiveCN101229100AReduce synthesis process proceduresUniform crystal phase distributionImpression capsDentistry preparationsHigh fractureLeucite

The invention relates to a tooth zirconia / leucite composite porcelain powder and a preparation method thereof. The material includes the following components: 50 to 60 percent of Sio2, 10 to 20 percent of Al2O3, 16 to 30 percent of K2O, 2 to 5 percent of Na2O and 2 to 15 percent of ZrO2. The preparation method of the material relates to: selecting a mineral potassium feldspar powder of the first grade, adding a certain amount of potash, nanometer tetragonal zirconia powder body and ethanol to uniformly mix in a globe mill and acquiring a raw material powder after drying; placing the raw material powder into a corundum crucible to calcine under a temperature of 1000 to 3000 DEG C for 30 to 90 minutes, cooling naturally and acquiring the zirconia / leucite composite porcelain powder with a grain diameter of 10 to 30Mum after crushing the raw material through ball milling. The crystalling phases of the zirconia and the leucite in the porcelain powder are distributed uniformly. The heat expansion coefficient of the powder is (12 to 16) multiplied by 10<-6>K and the anti-bending intensity of the powder is 90 to 130MPa. The invention is also characterized by good color masking property and high fracture toughness property, etc., and lays a foundation for the clinic application of mouth porcelain repairing.

Owner:SICHUAN UNIV

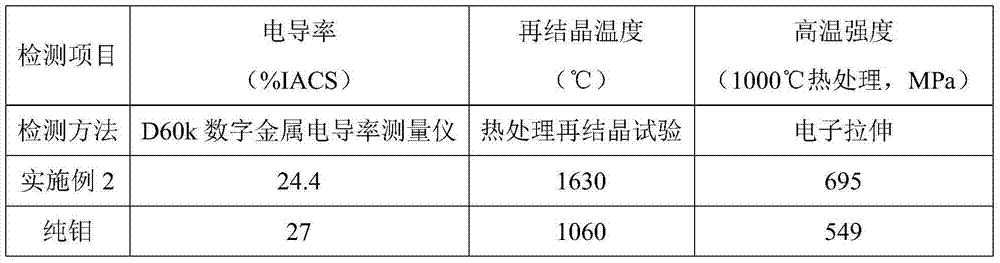

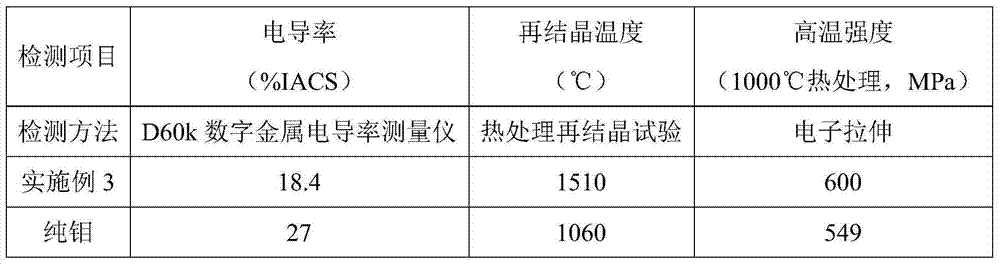

ZrO2 doped molybdenum electrode and preparation method thereof

The invention discloses ZrO2 doped molybdenum electrode and a preparation method thereof. The ZrO2 doped molybdenum electrode is mainly prepared from the following raw materials by weight: 40 parts of ammonium tetramolybdate, 8-10 parts of dilute nitric acid, 1-12 parts of zirconium nitrate, 0.4-4.5 parts of urea and 0.05-0.7 part of yttrium nitrate. According to the ZrO2 doped molybdenum electrode provided by the invention, tetragonal zirconia with stable crystal form is obtained by using ammonium tetramolybdate, dilute nitric acid, zirconium nitrate and urea as raw materials and adding yttrium oxide as a stabilizer; the problem of changes of zirconia with temperature is overcome; the service life of a molybdenum electrode is prolonged; the obtained ZrO2 doped molybdenum electrode keeps relatively high conductivity, has good recrystallization temperature and high temperature strength, has good corrosion resistance, and is suitable for popularization and application.

Owner:HENAN UNIV OF SCI & TECH

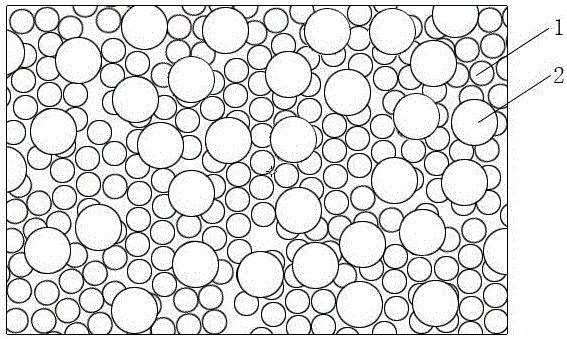

Tetragonal zirconia based composite ceramic ultrathin cover plate and preparation process thereof

The invention relates to a tetragonal zirconia based composite ceramic ultrathin cover plate and a preparation process thereof, and belongs to the field of preparation of fine ceramics. Ceramic powder of the composite ceramic ultrathin cover plate is a trans-scale mixture formed by nanometer zirconia powder and micrometer powder, wherein the nanometer zirconia powder accounts for 40-70% of the ceramic powder in volume. The preparation process comprises the following steps: adding appropriate dispersing agent, adhesive, plasticizer and defoamer into raw materials to prepare ceramic slurry; preparing an ultrathin ceramic green tape of which the solid content is above 63% through a tape casting process; then cutting and shaping; and preparing the ultrathin composite ceramic cover plate with high flatness and controllable shrinkage ratio for a fingerprint identification function through a special sintering pot. Compared with the existing fingerprint cover plate, the composite ceramic ultrathin cover plate prepared by the invention has low sintering temperature and favorable electrical and mechanical properties, satisfies the performance requirements of fingerprint identification for high sensitivity, drop resistance, wear resistance and ultrathinness, is low in cost, and has an important practical meaning.

Owner:SHANTOU UNIV

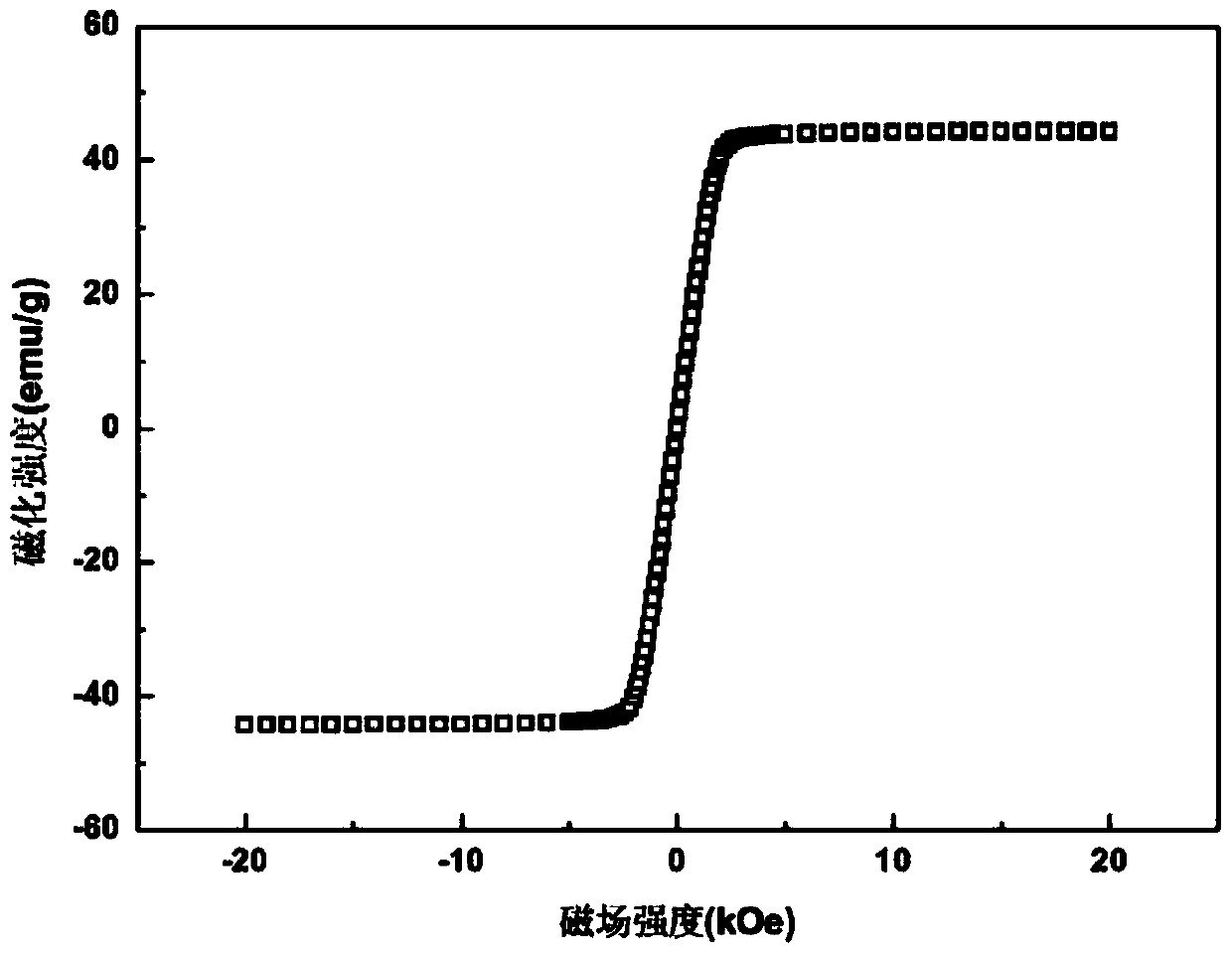

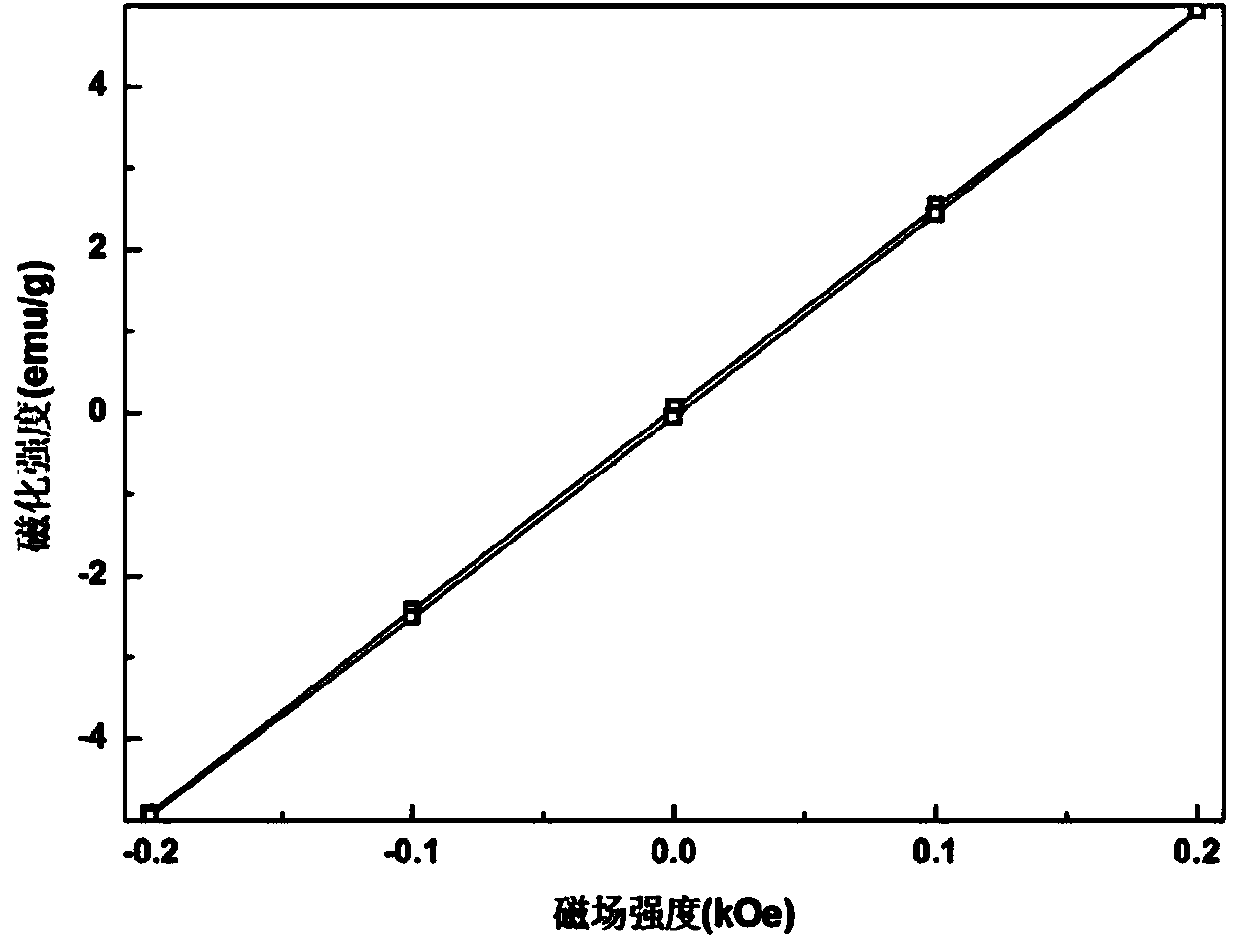

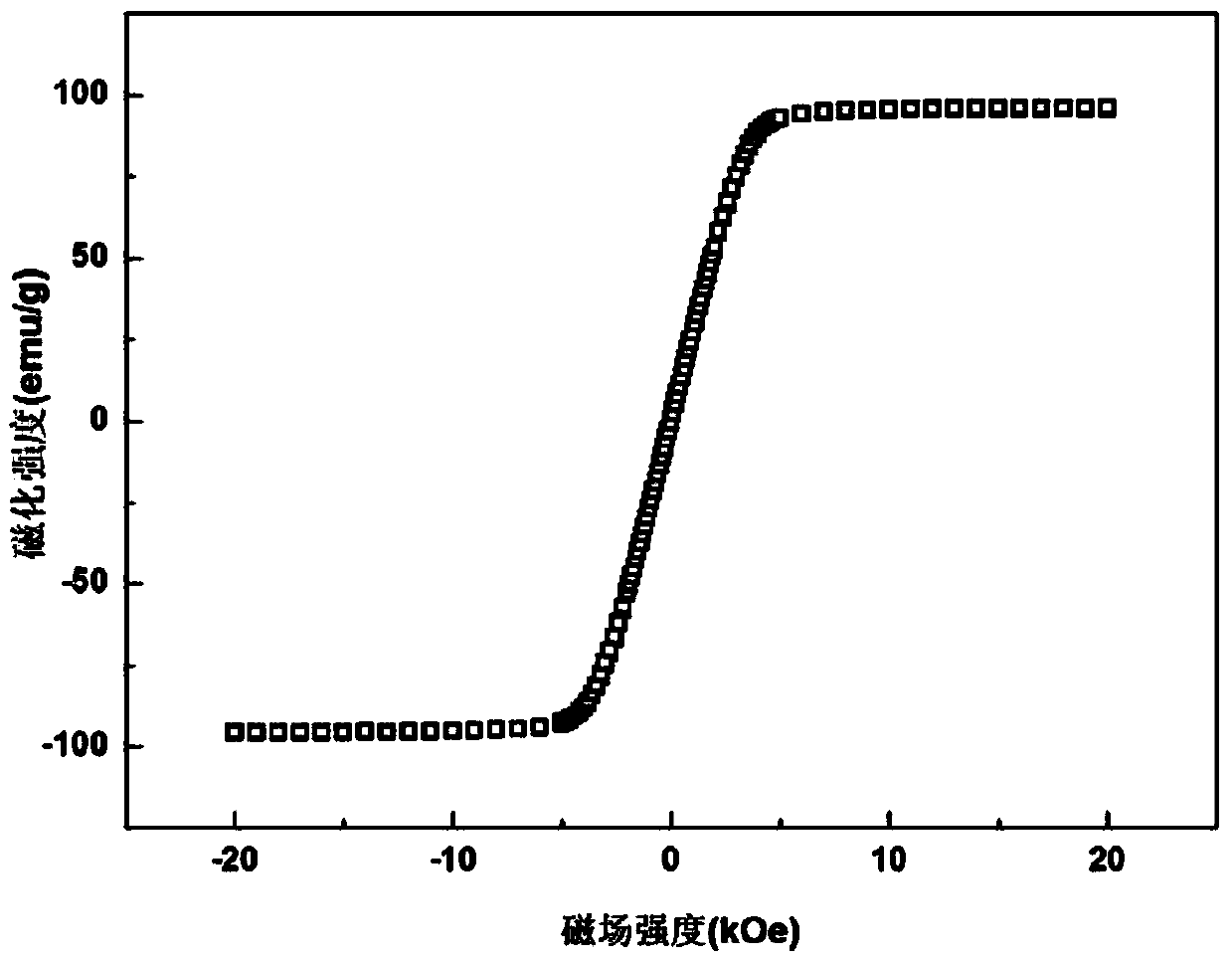

Nickel-cobalt alloy/tetragonal zirconia polycrystalline composite ceramic material and preparation method thereof

InactiveCN104178652AHarmonized Magnetic PropertiesLower sintering temperatureMagnetic phaseComposite ceramic

The invention relates to a nickel-cobalt alloy / tetragonal zirconia polycrystalline composite ceramic material and a preparation method thereof. Tetragonal zirconia polycrystalline with 3% by mole of stable Y2O3, namely 3Y-TZP is taken as a base body, nickel-cobalt alloy Ni[1-x]Cox (x is 0.25-0.75) is taken as a second magnetic phase, and the mass percent of raw materials of the alloy is 1%-40%. The composite ceramic with excellent mechanical and magnetic properties is obtained by taking the tetragonal zirconia polycrystalline with stable Y as the base body, adding the magnetic phase of the nickel-cobalt alloy, and performing the two-step method of milling in a reducing atmosphere and sintering in an insert atmosphere. The magnetic property of the alloy is improved by adjusting the content of cobalt in the alloy, meanwhile, the mechanical property of the material is improved by adjusting the additive amount of the alloy in the zirconia base body, and finally the composite material with excellent mechanical and magnetic properties is obtained.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com