ZrO2 doped molybdenum electrode and preparation method thereof

A technology of molybdenum electrode and ammonium tetramolybdate, which is applied in the preparation of ZrO2-doped molybdenum electrode and in the field of ZrO2-doped molybdenum electrode, can solve the problems of molybdenum electrode corrosion resistance and high-temperature strength difference, and achieve good corrosion resistance and improved Effect of lifetime, good recrystallization temperature and high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

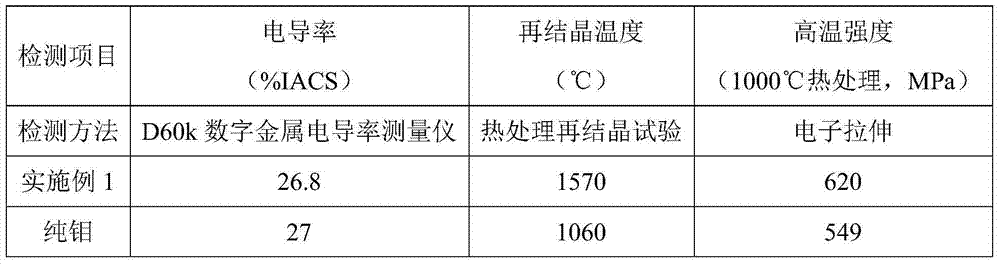

Embodiment 1

[0025] The ZrO of this embodiment 2 The doped molybdenum electrode is mainly made of the following raw materials: 40g of ammonium tetramolybdate, 8g of dilute nitric acid, 1.22g of zirconium nitrate, 0.46g of urea, and 0.06g of yttrium nitrate.

[0026] The ZrO of this embodiment 2 The preparation method of doped molybdenum electrode comprises the following steps:

[0027] 1) Take 40g of ammonium tetramolybdate in the autoclave, add 8g of dilute nitric acid with a pH value of 1, so that the filling degree of the autoclave is 80%, tighten the autoclave and place it in a vacuum drying oven Hydrothermal reaction, the temperature is 160°C, the time is 24h, after the reaction, cool down, discard the supernatant, and obtain the precipitate A;

[0028] 2) Take 1.22g of zirconium nitrate, 0.46g of urea and 0.06g of yttrium nitrate in the autoclave, add distilled water to make the filling degree of the autoclave 80%, tighten the autoclave and place it in a vacuum drying oven Carry o...

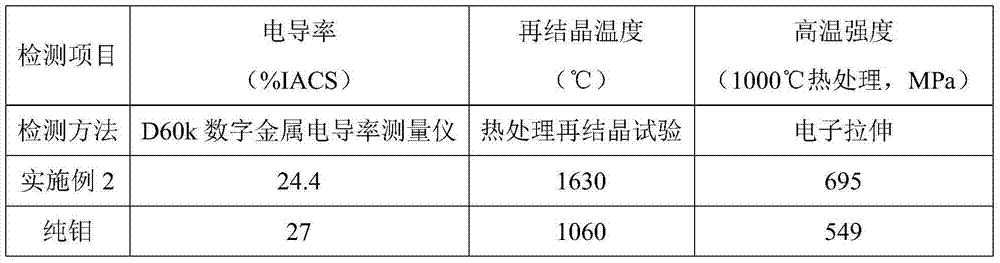

Embodiment 2

[0037] The ZrO of this embodiment 2 Molybdenum-doped electrodes are mainly made of the following raw materials by weight: 40g of ammonium tetramolybdate, 9g of dilute nitric acid, 6.37g of zirconium nitrate, 2.38g of urea, and 0.35g of yttrium nitrate.

[0038] The ZrO of this embodiment 2 The preparation method of doped molybdenum electrode comprises the following steps:

[0039] 1) Take 40g of ammonium tetramolybdate in the autoclave, add 9g of dilute nitric acid with a pH value of 1, so that the filling degree of the autoclave is 85%, tighten the autoclave and place it in a vacuum drying oven Hydrothermal reaction, the temperature is 180°C, the time is 20h, after the reaction is cooled, the supernatant is discarded, and the precipitate A is obtained;

[0040] 2) Take 6.37g of zirconium nitrate, 2.38g of urea and 0.35g of yttrium nitrate in the autoclave, add distilled water to make the filling degree of the autoclave 80%, tighten the autoclave and place it in a vacuum dry...

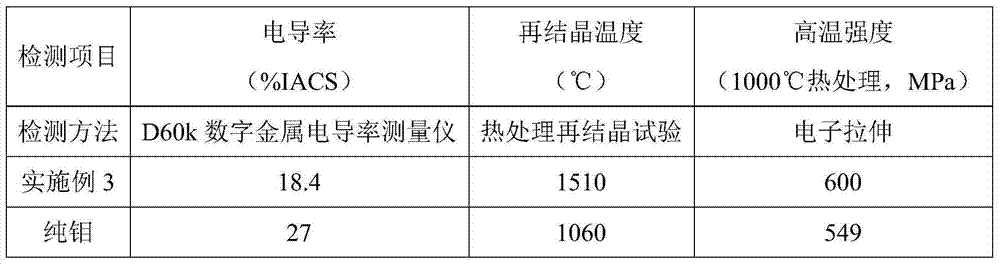

Embodiment 3

[0049] The ZrO of this embodiment 2 Molybdenum-doped electrodes are mainly made of the following raw materials: 40g of ammonium tetramolybdate, 10g of dilute nitric acid, 10.95g of zirconium nitrate, 4.08g of urea, and 0.61g of yttrium nitrate.

[0050] The ZrO of this embodiment2 The preparation method of doped molybdenum electrode comprises the following steps:

[0051] 1) Take 40g of ammonium tetramolybdate and put it in the autoclave, add dilute nitric acid with a pH value of 1 to make the filling degree of the autoclave 90%, tighten the autoclave and place it in a vacuum drying oven for water Heat reaction, the temperature is 170°C, the time is 22h, after the reaction is cooled, the supernatant is discarded, and the precipitate A is obtained;

[0052] 2) Take 10.95g of zirconium nitrate, 4.08g of urea and 0.61g of yttrium nitrate in the autoclave, add distilled water to make the filling degree of the autoclave 90%, tighten the autoclave and place it in a vacuum drying ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com