ZrO2 toughened bioactive glass-ceramics of MgO-CaO-SiO2-P2O5-CaF2 system and preparation method thereof

A glass-ceramic and biologically active technology, applied in medical science, prostheses, coatings, etc., can solve problems such as poor mechanical properties, low content of alkali metal oxides, material strength, and unsatisfactory mechanical processing performance of biological activity , to achieve the effect of improved bending strength and good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

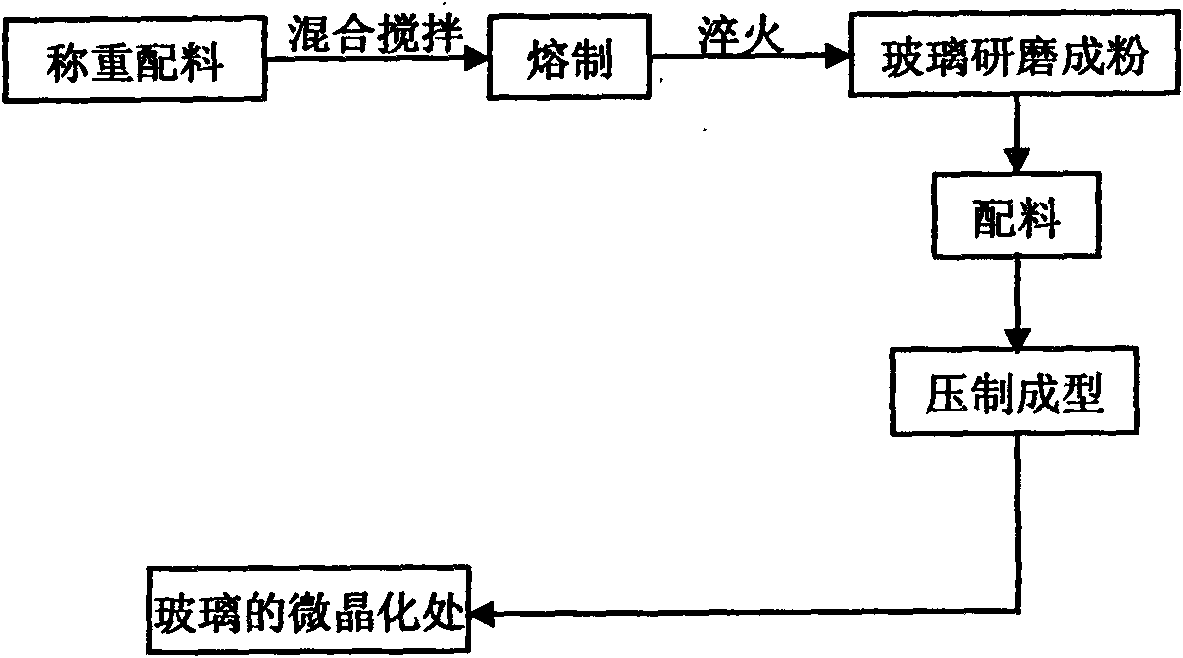

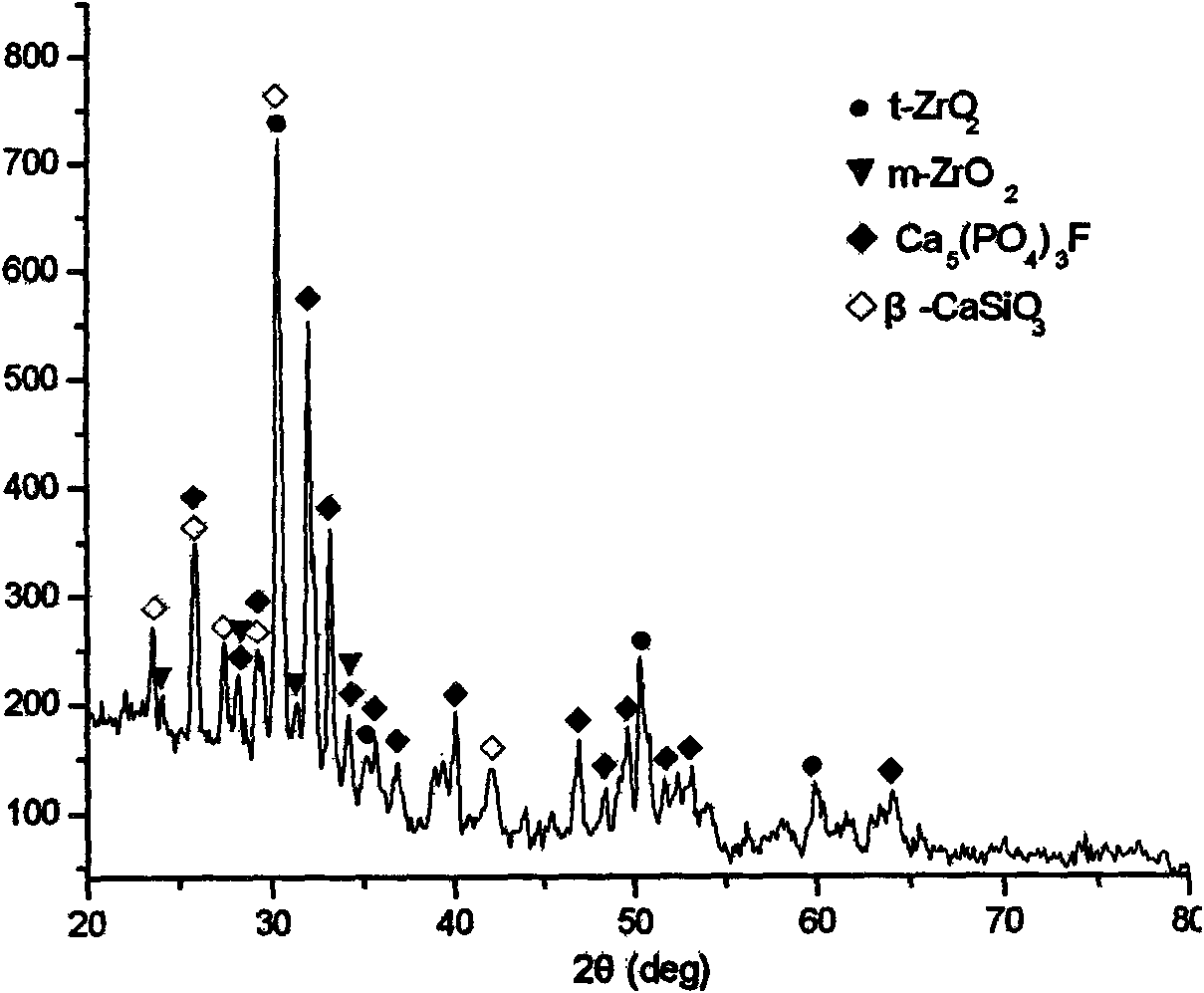

[0040] ZrO 2 Toughened MgO-CaO-SiO 2 -P 2 o 5 -CaF 2 Preparation of bioactive glass-ceramics (5GC2444):

[0041] The mass fraction of each component of the glass is: SiO 2 30.8%, MgO 4.1%, CaO 40.4%, P 2 o 5 14.7%, CaF 2 5%, ZrO 2 5%.

[0042] 1) will contain SiO 2 , MgO, CaO, P 2 o 5 , CaF 2 The pure raw materials for chemical analysis were mixed and put into an alumina ball mill tank, and alumina balls were added, and dry-mixed on a star ball mill at a speed of 250r / min for 5h.

[0043] 2) Put the dry-blended powder obtained in step 1) into a high-purity alumina crucible, and melt it in a high-temperature heating furnace. The raw material is heated up with the furnace at a heating rate of 5°C / min, and then kept at 1450°C 2h to form a uniform glass melt, quickly pour the high temperature glass melt into cold water for quenching treatment;

[0044] 3) Dry the quenched glass and add 1:1 mass of absolute ethanol, then put it into an alumina ball mill jar, add ...

Embodiment 2

[0048] ZrO 2 Toughened MgO-CaO-SiO 2 -P 2 o 5 -CaF 2 Preparation of bioactive glass-ceramics (8GC2442):

[0049] The mass fraction of each component of the glass is: SiO 2 29.8%, MgO 4%, CaO 39%, P 2 o 5 14.2%, CaF 2 5%, ZrO 2 8%.

[0050] 1) will contain SiO 2 , MgO, CaO, P 2 o 5 , CaF 2 Mix the pure raw materials for chemical analysis, put them into an alumina ball mill tank, add alumina balls, and dry mix them on a star ball mill at a speed of 250r / min for 5 hours.

[0051] 2) Put the dry-blended powder obtained in step 1) into a high-purity alumina crucible, and melt it in a high-temperature heating furnace. The raw material is heated up with the furnace at a heating rate of 5°C / min, and then kept at 1450°C 2h to form a uniform glass melt, quickly pour the high temperature glass melt into cold water for quenching treatment;

[0052] 3) Dry the quenched glass and add 1:1 mass of absolute ethanol, then put it into an alumina ball mill jar, add alumina ball...

Embodiment 3

[0056] MgO-CaO-SiO 2 -P 2 o 5 -CaF 2 Preparation of bioactive glass-ceramics (0GC2444):

[0057] The mass fraction of each component of the glass is: SiO 2 32.5%, MgO 4.4%, CaO 42.6%, P 2 o 5 15.5%, CaF 2 5%.

[0058] 1) will contain SiO 2 , MgO, CaO, P 2 o 5 , CaF 2 Mix the pure raw materials for chemical analysis, put them into an alumina ball mill tank, add alumina balls, and dry mix them on a star ball mill at a speed of 250r / min for 5 hours.

[0059] 2) Put the dry-blended powder obtained in step 1) into a high-purity alumina crucible, and melt it in a high-temperature heating furnace. The raw material is heated up with the furnace at a heating rate of 5°C / min, and then kept at 1450°C 2h to form a uniform glass melt, quickly pour the high temperature glass melt into cold water for quenching treatment;

[0060] 3) Dry the quenched glass and add 1:1 mass of absolute ethanol, then put it into an alumina ball mill jar, add alumina balls, and wet mix it on a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com