Patents

Literature

1081results about How to "Improve recording density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic signal reproduction system and magnetic signal reproduction method

InactiveUS20090027812A1Stable reproduction propertyDeterioration of reproduction propertyManufacture unitary devices of plural headsRecord information storageIridiumAlloy

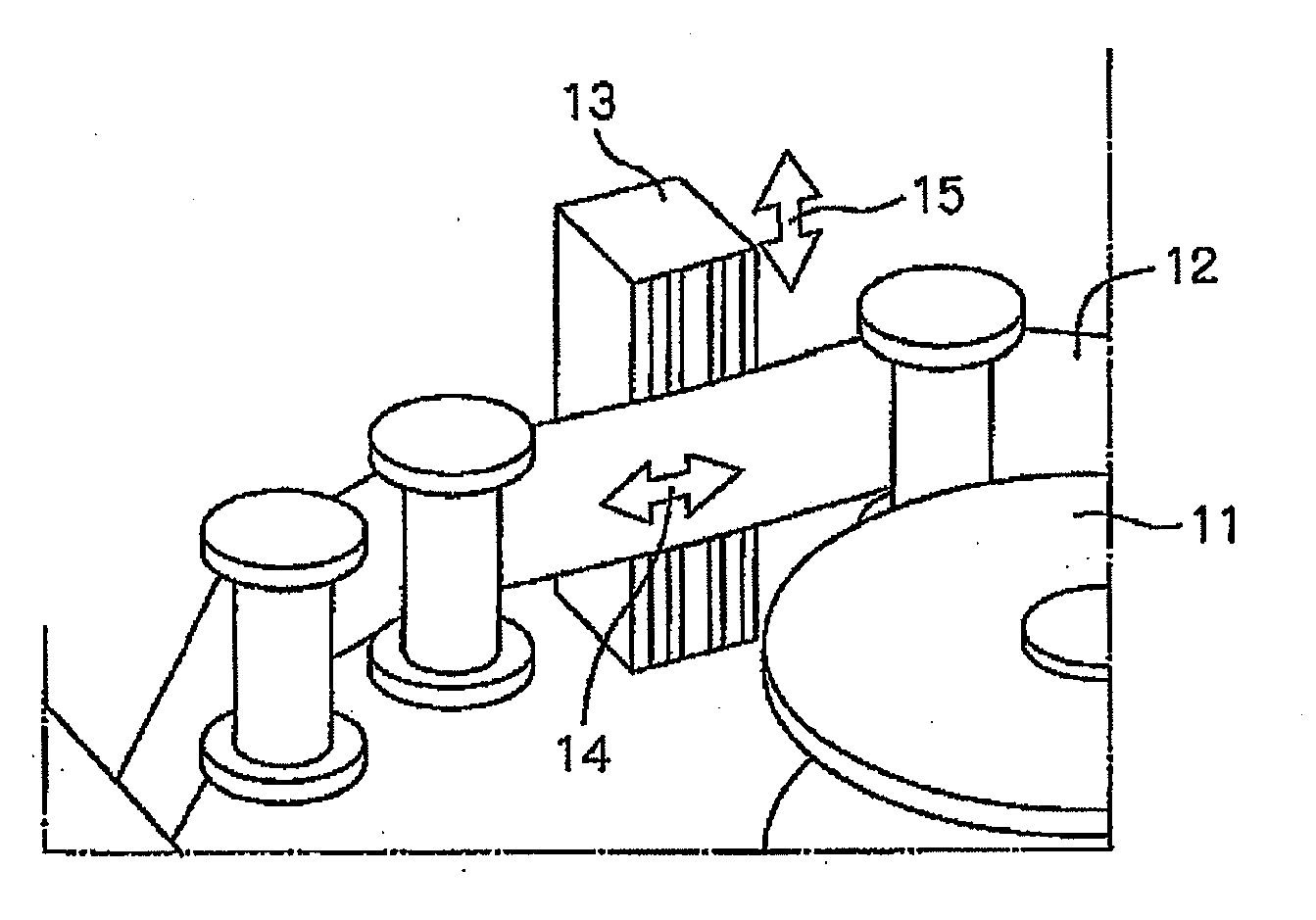

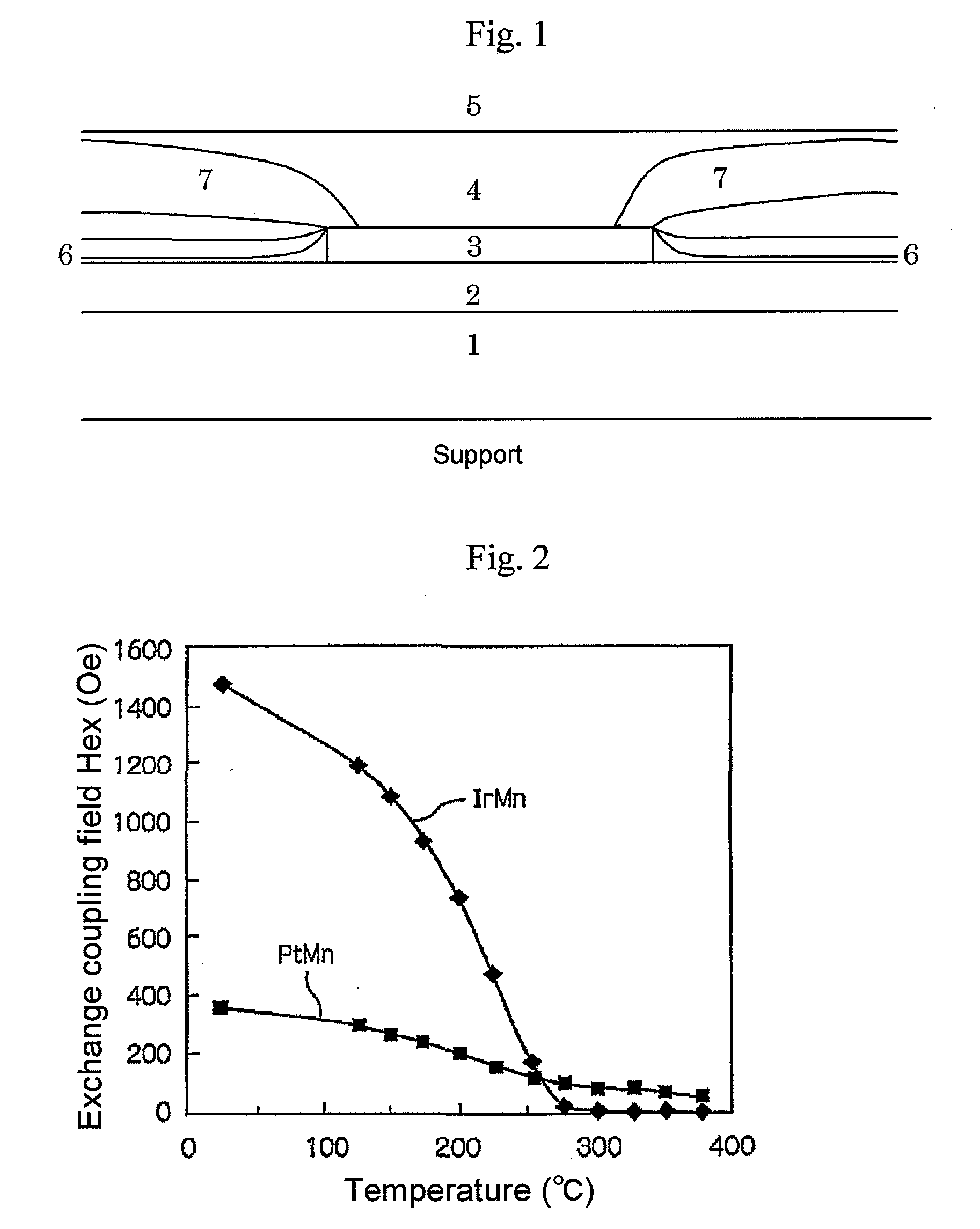

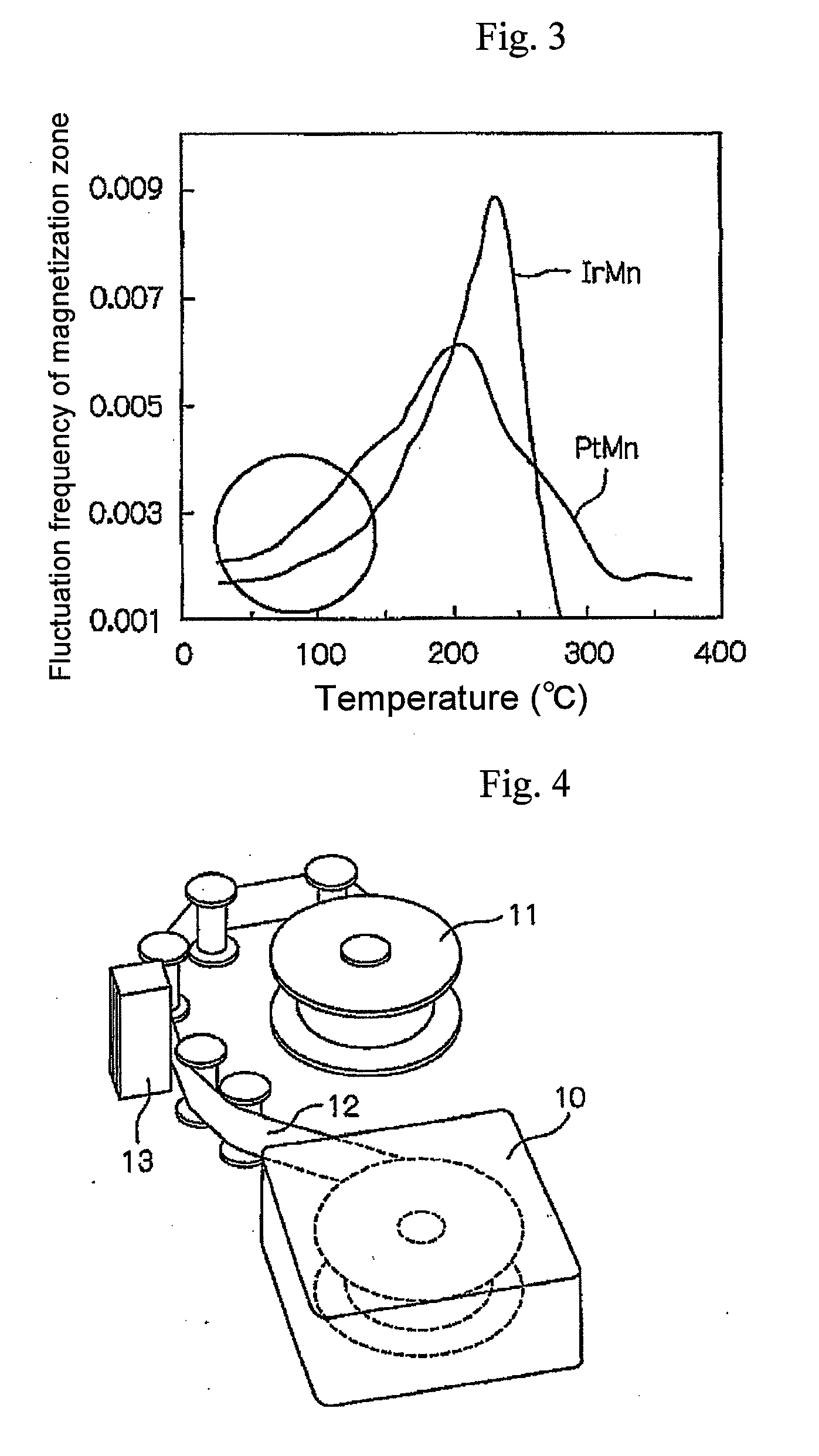

The magnetic signal reproduction system comprises a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support and a reproduction head, wherein a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 2500 / 10,000 μm2, a quantity of lubricant on the magnetic layer surface, denoted as a surface lubricant index, ranges from 0.5 to 5.0, a surface abrasive occupancy of the magnetic layer ranges from 2 to 20 percent, the reproduction head is a magnetoresistive magnetic head comprising a spin-valve layer, the spin-valve layer comprises a magnetization free layer, a magnetization pinned layer and an antiferromagnetic layer, and the antiferromagnetic layer is comprised of alloy comprising iridium and manganese, and the reproduction head comes in sliding contact with the magnetic recording medium during signal reproduction.

Owner:FUJIFILM CORP +1

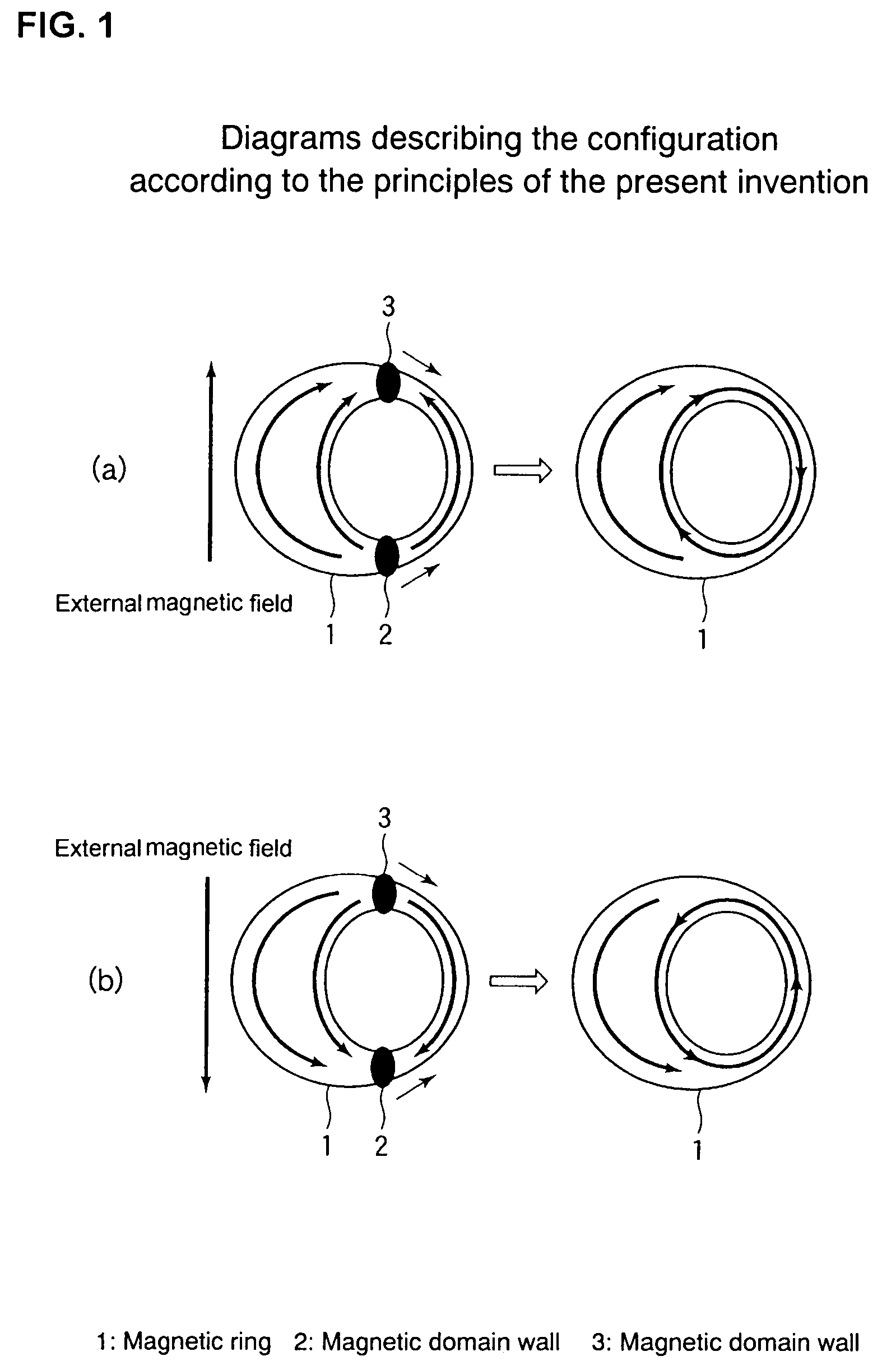

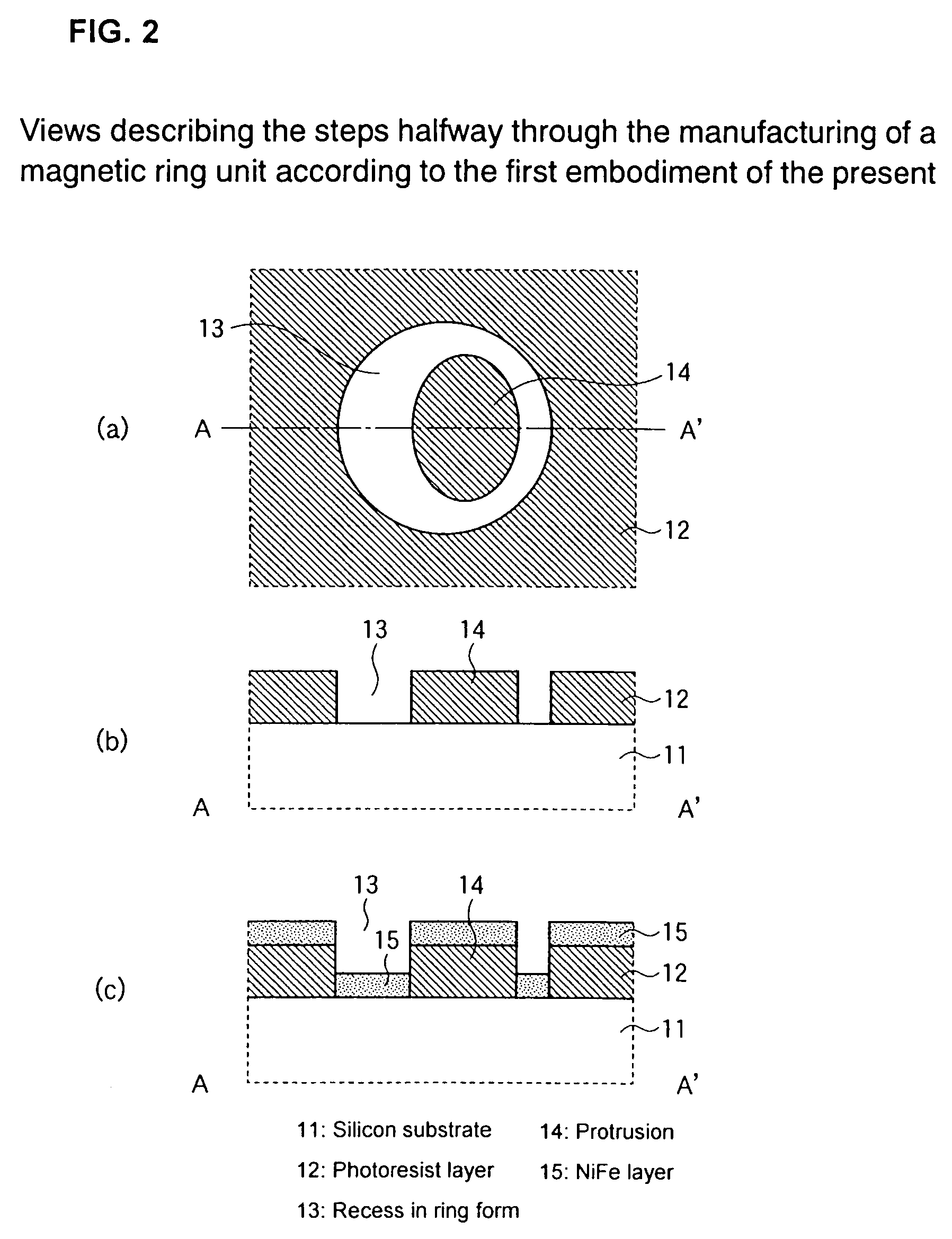

Magnetic ring unit and magnetic memory device

InactiveUS7002839B2Improve recording densityImprove reliabilityMagnetic-field-controlled resistorsSolid-state devicesMagnetic memoryMagnetic flux

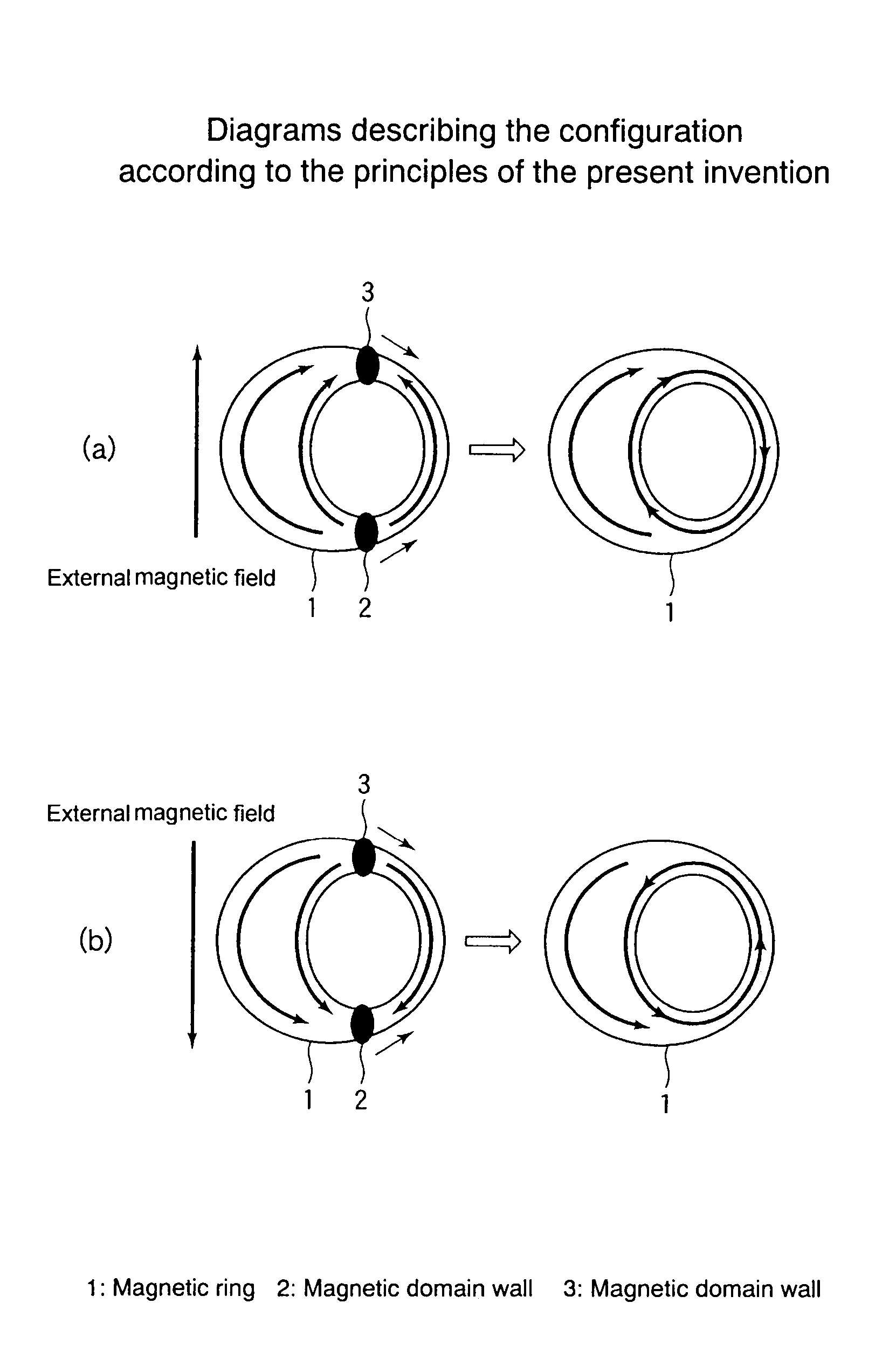

The present invention relates to a magnetic ring unit and a magnetic memory device; an object of the invention is to control the direction of rotation of the magnetic flux freely and with high reproducibility in a simple structure without using a thermal process such as pinning; and a magnetic ring unit is formed of a magnetic ring in eccentric ring form where the center of the inner diameter is located at a decentered position relative to the center of the outer diameter.

Owner:TOHOKU UNIV

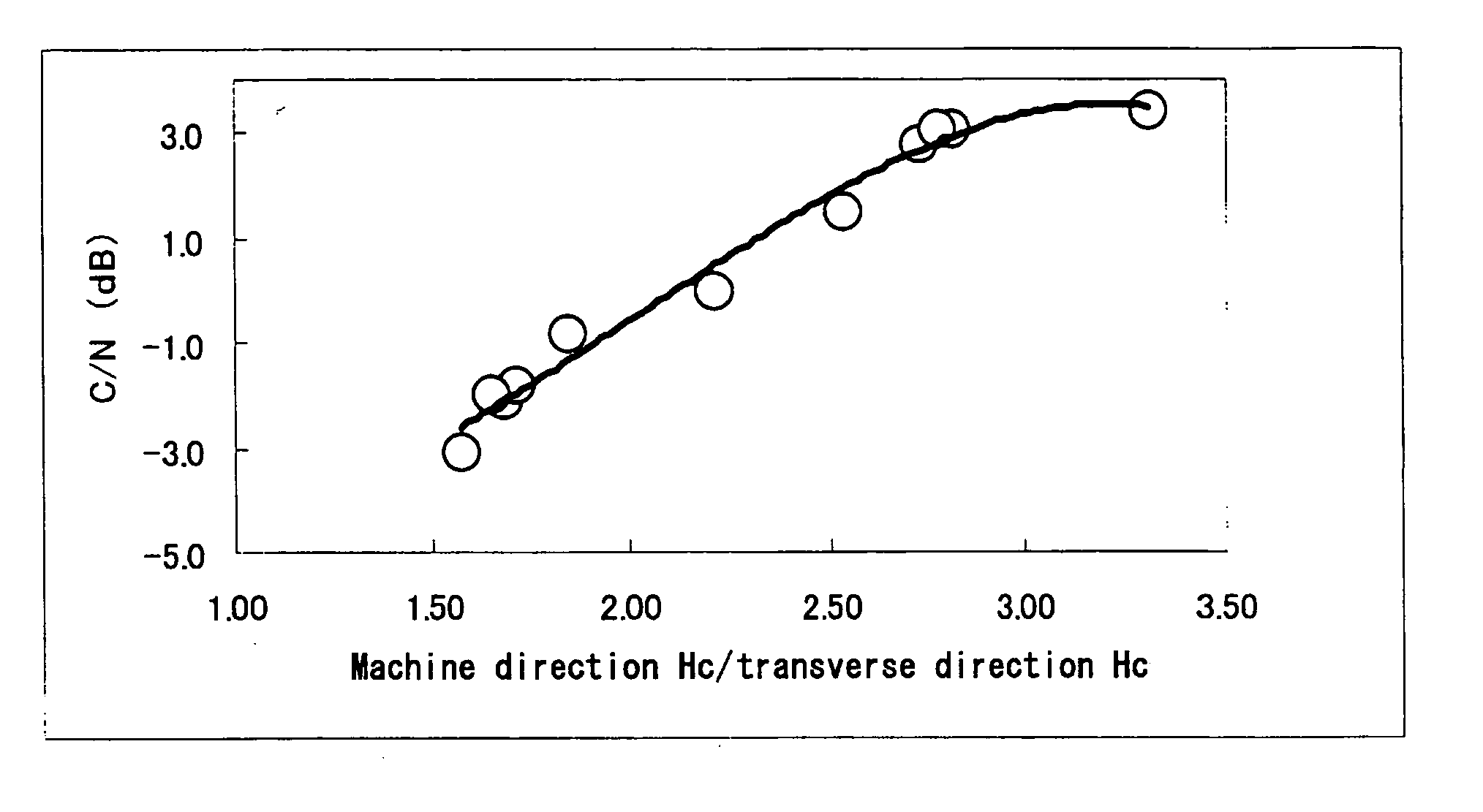

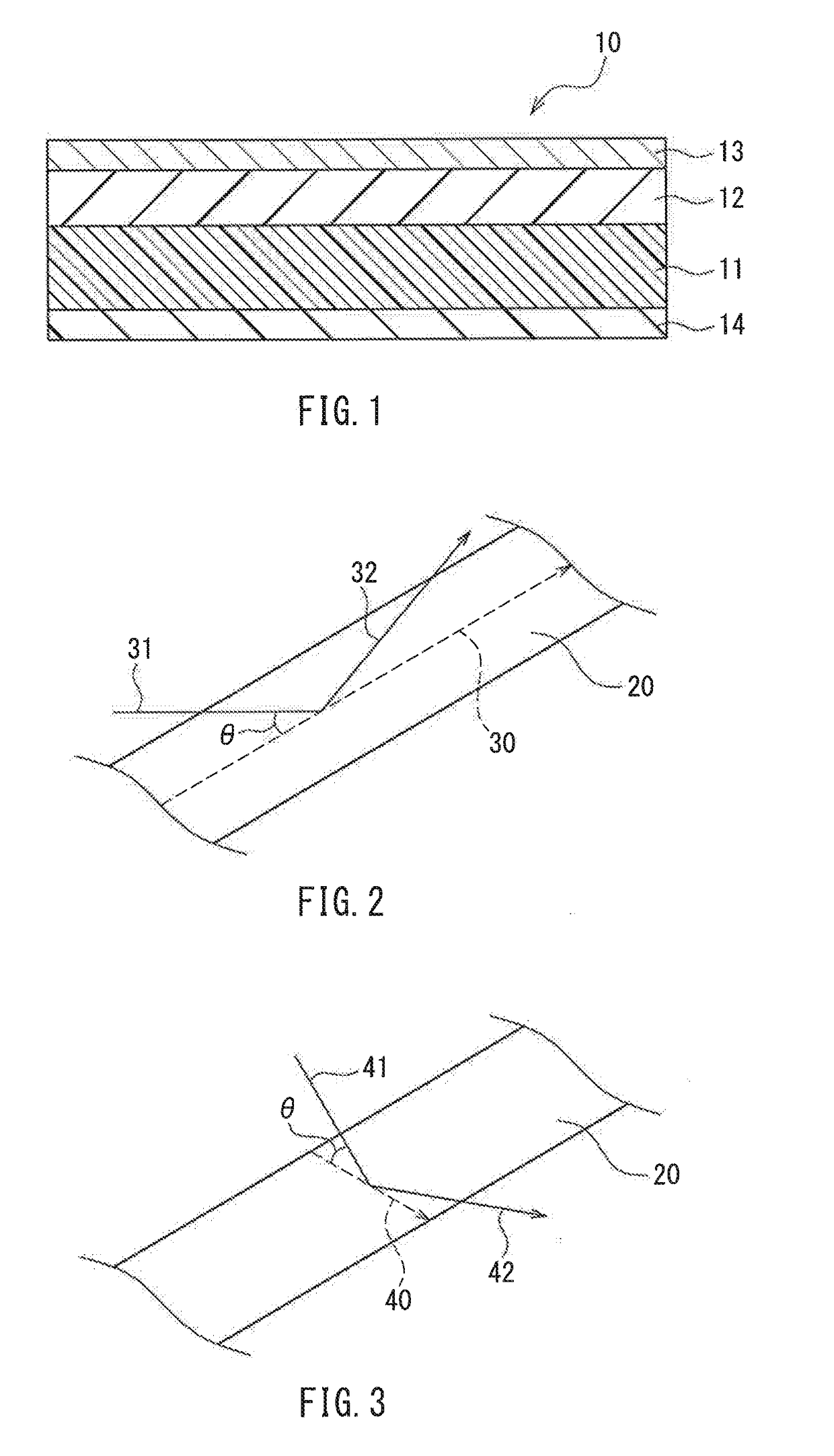

Magnetic tape

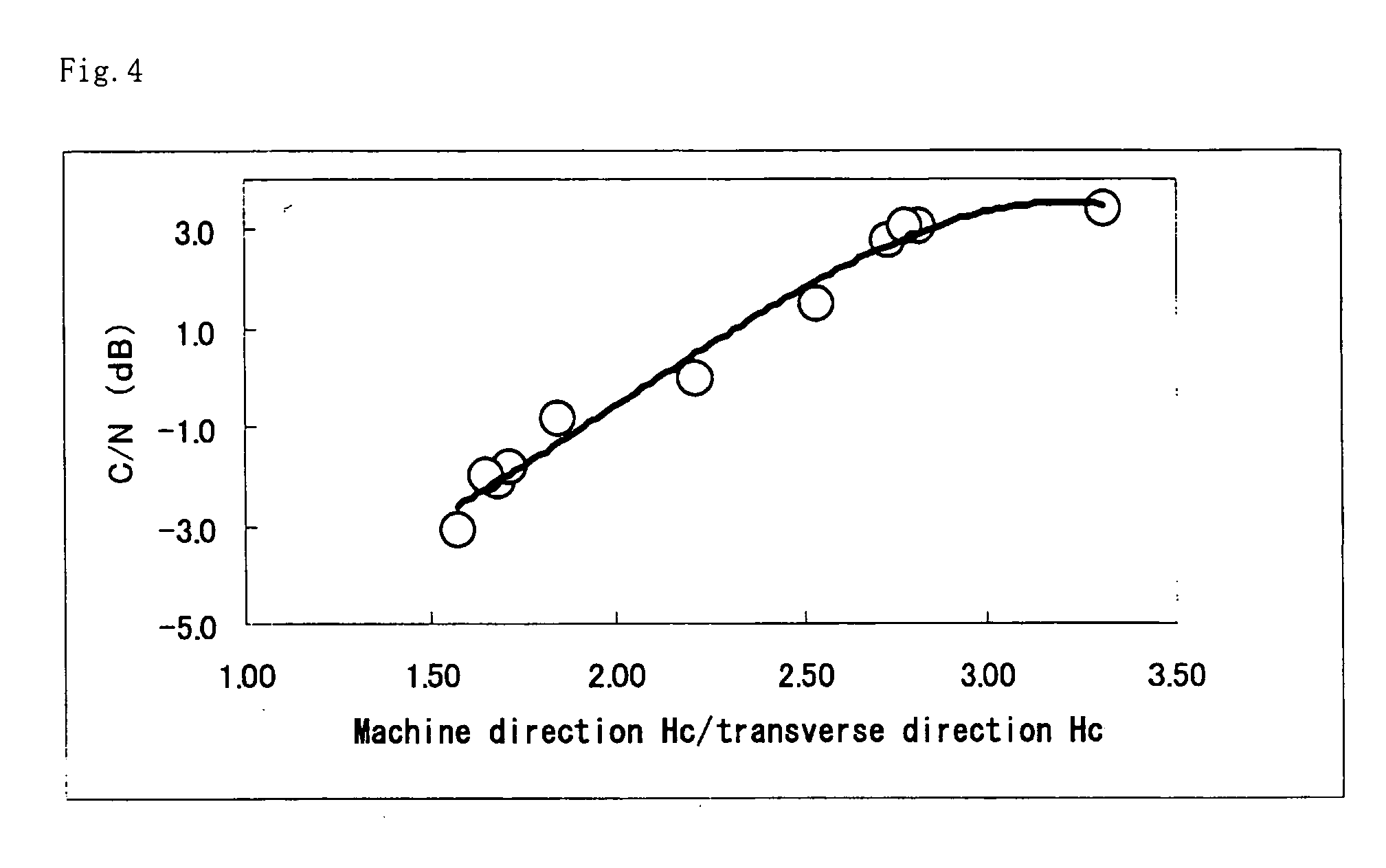

InactiveUS20060068232A1Ratio of C/N is moreRaise the ratioRecord information storageMaterials with non-metallic substancesMass storageHigh density

A magnetic tape comprising a non-magnetic substrate and at least one magnetic layer formed on one surface of the non-magnetic substrate, characterized in that magnetic particles contained in an uppermost magnetic layer of the magnetic layer are substantially granular particles with a particle size of 30 nm or less, and that the ratio of a coercive force HcM in the machine direction to a coercive force HcT in the transverse direction, i.e., [HcM / HcT], is at least 2.2. This magnetic tape has a capacity capable of corresponding to mass storage of 1 TB or more, and achieves a high ratio of reproducing output to noises (C / N), particularly for signals within a short wavelength range, thus showing excellent high-density recording performance.

Owner:HITACHT MAXELL LTD

Magnetic tape and magnetic tape device

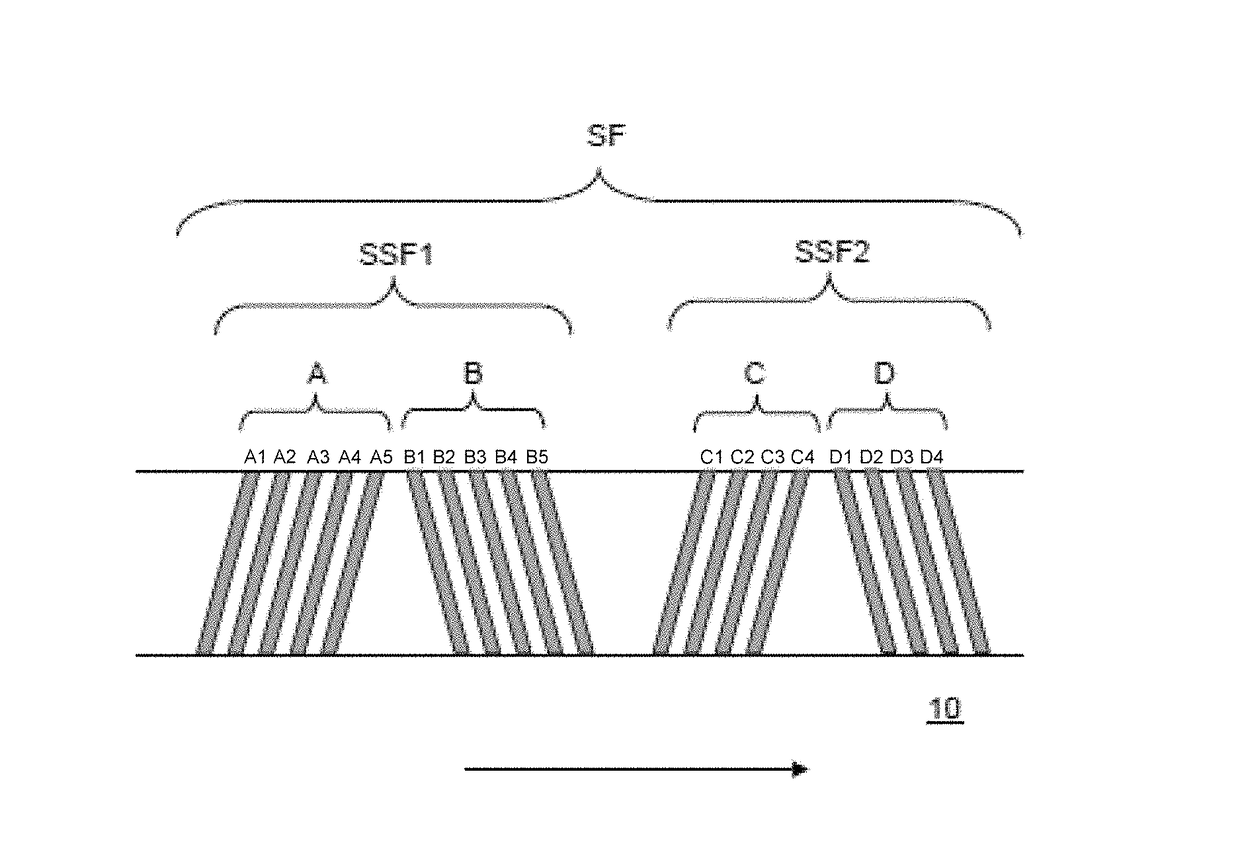

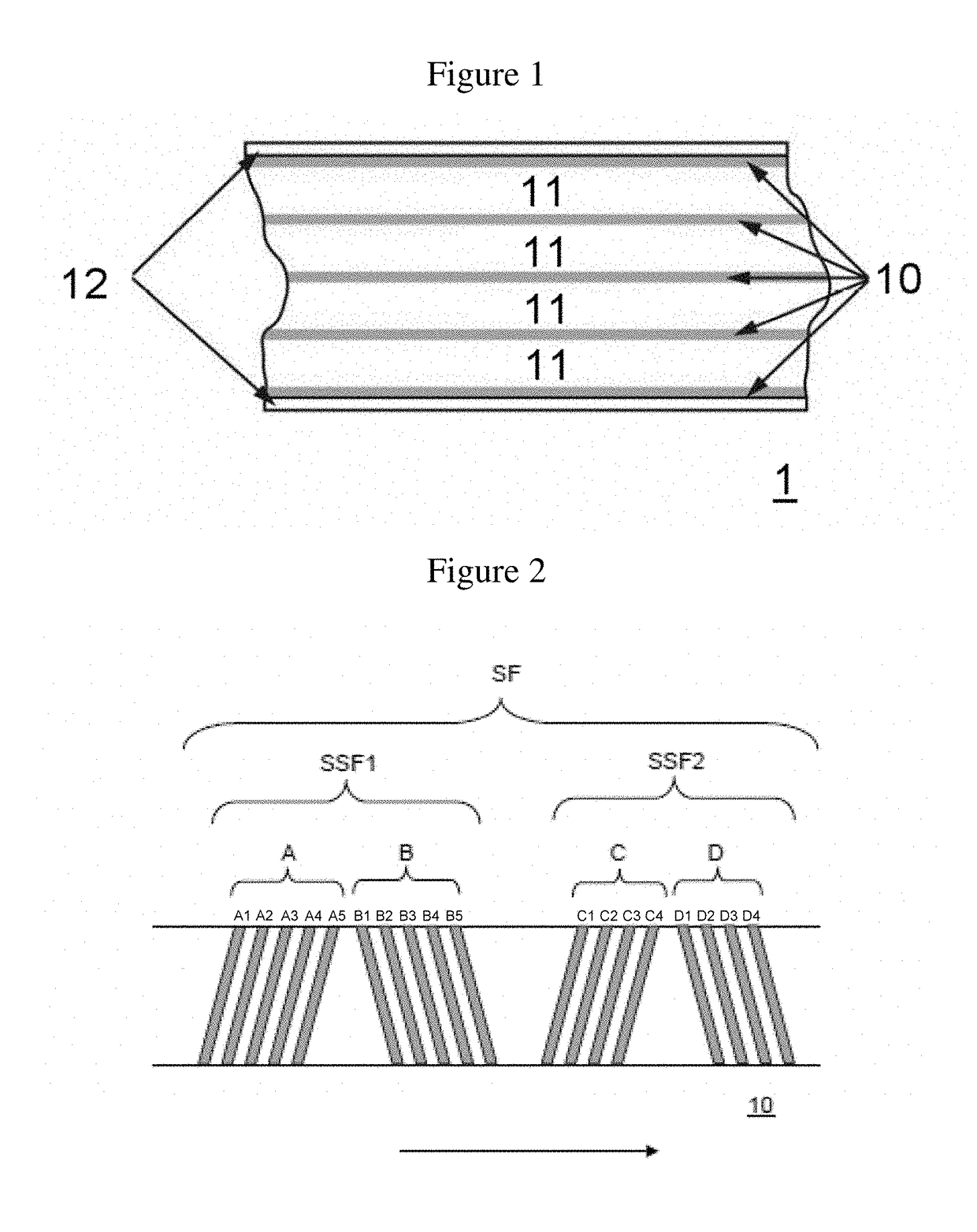

ActiveUS9837116B2Increase the number ofIncrease recording capacityAlignment for track following on tapesRecord information storageMagnetic tapeSurface roughness

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180286449A1Improve signal-to-noise ratioIncrease recording capacityRecord information storageManufacture of flux-sensitive headsMagnetic tapeX-ray

The magnetic tape device includes a magnetic tape and a TMR head, in which the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, an intensity ratio of a peak intensity Int(110) of a diffraction peak of a (110) plane with respect to a peak intensity Int(114) of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, and a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00.

Owner:FUJIFILM CORP

High recording density magnetic recording medium and recording/reproduction mechanism for the same

ActiveUS20180350398A1Improve recording densityMaintain good propertiesRecord information storageManufacture of flux-sensitive headsUltrasound attenuationRefractive index

A refractive index nL and an attenuation rate kL of a magnetic layer are obtained by irradiating linearly polarized light at an irradiation angle of 70° from a lengthwise direction of the magnetic layer to the surface of the magnetic layer, and a vertical reflectance RL during vertical incidence of the linearly polarized light in the lengthwise direction is obtained based on nL and kL. A refractive index nT and an attenuation rate kT of the magnetic layer are obtained by irradiating linearly polarized light at an irradiation angle of 70° from a width direction of the magnetic layer to the surface of the magnetic layer, and a vertical reflectance RT during vertical incidence of the linearly polarized light in the width direction is obtained from nT and kT. If a variation rate A (%) of RL and RT is A=|RL / RT−1|×100, the relationship A≤10% is established.

Owner:MAXELL HLDG LTD

Magnetic device, magnetic recording head, and magnetic recording apparatus

ActiveUS20080268291A1Improve recording densityIncrease recording capacityRecord information storageManufacture of flux-sensitive headsMagnetizationNon magnetic

A magnetic device includes a first magnetic layer having at least one magnetic material layer, a second magnetic layer having at least one magnetic material layer, a first nonmagnetic layer provided between the first magnetic layer and the second magnetic layer, a third magnetic layer including a ferromagnetic material with a fixed magnetization direction, and a pair of electrodes. The pair of electrodes are operable to pass a current through a laminated body including the first and second magnetic layers, the nonmagnetic layer, and the third magnetic layer.

Owner:KK TOSHIBA

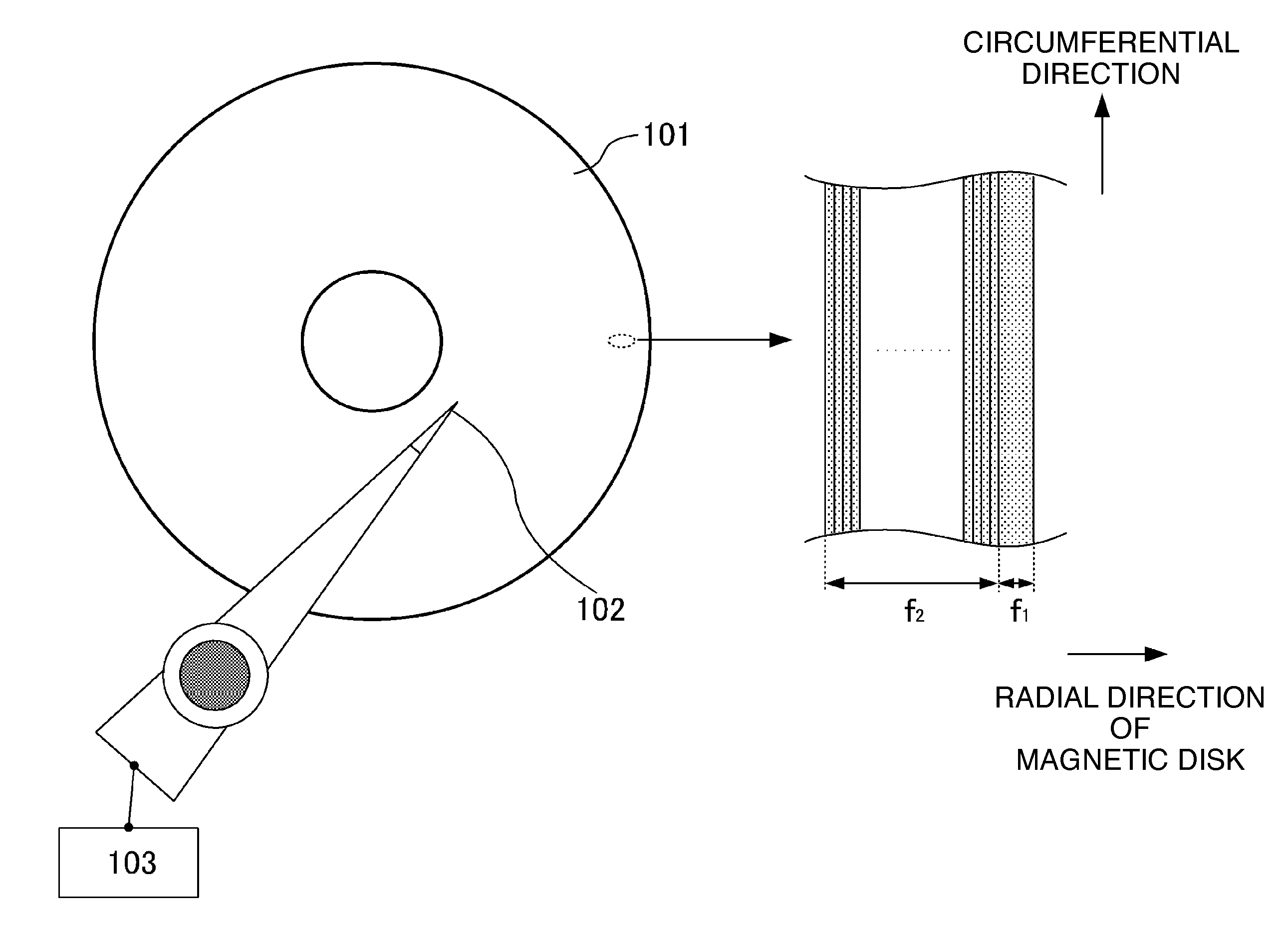

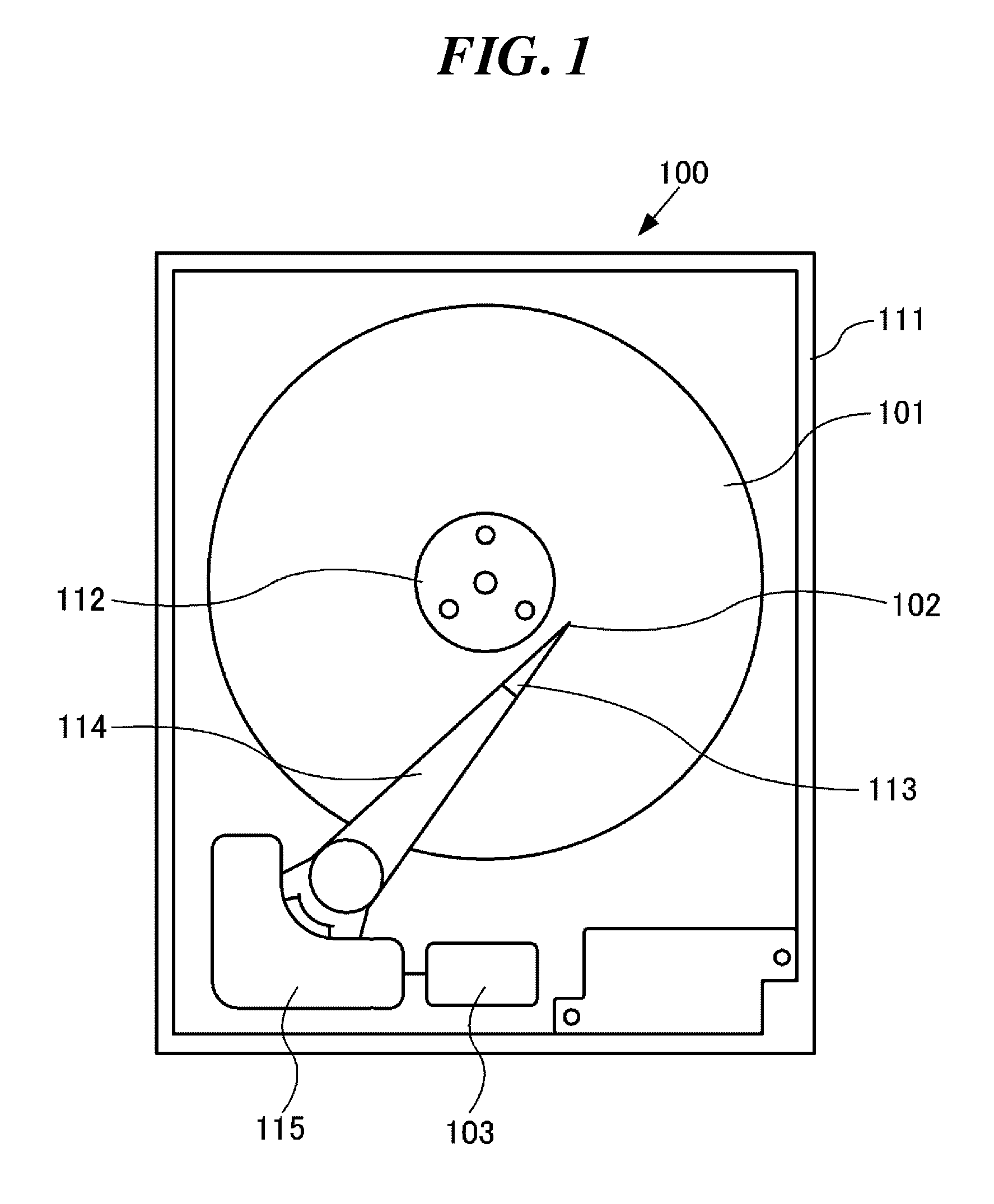

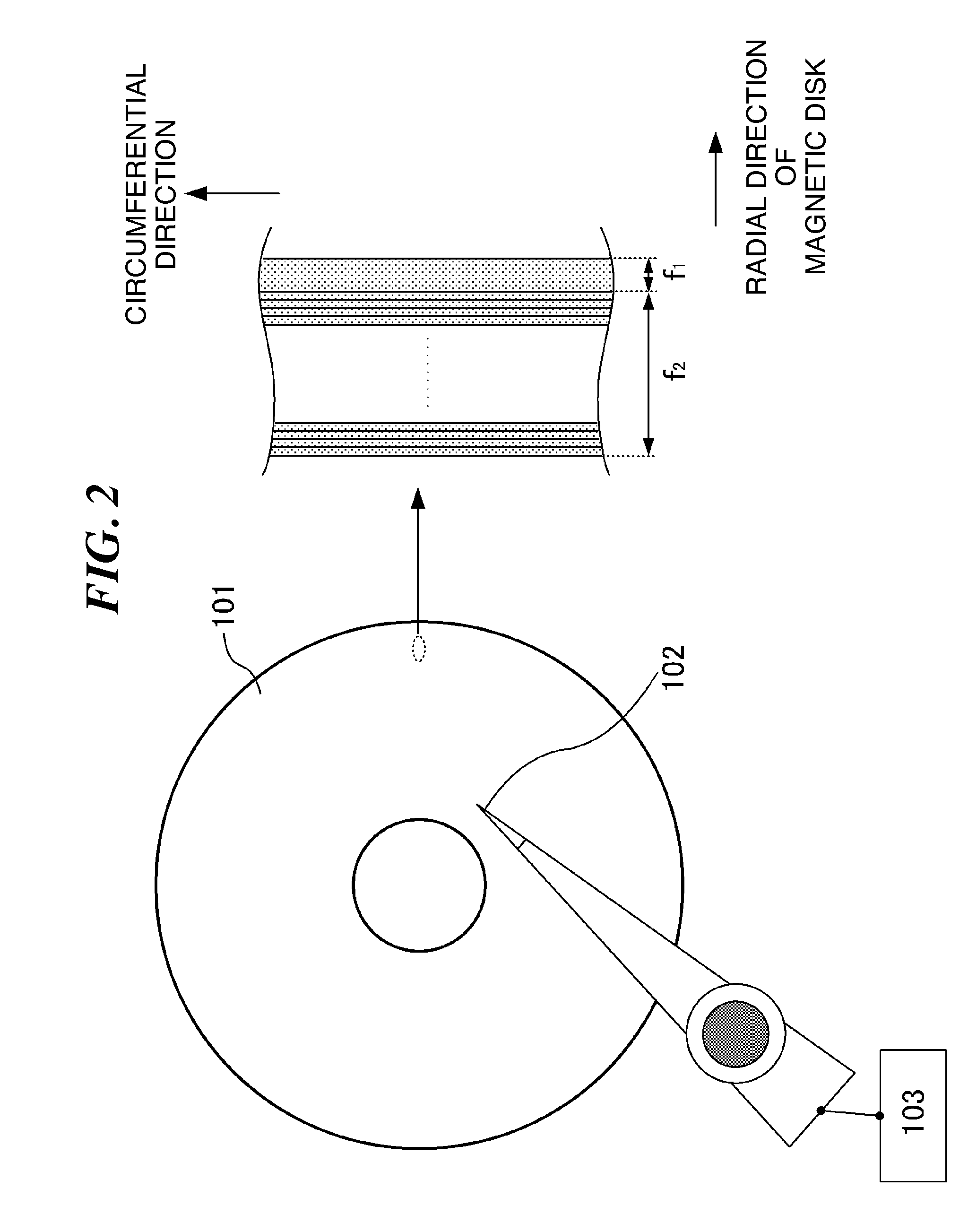

Apparatus of magnetic disc

ActiveUS20120069466A1Enhance BPIImprove recording densityRecord information storageAlignment for track following on disksMagnetic disksRecording head

Owner:WESTERN DIGITAL TECH INC

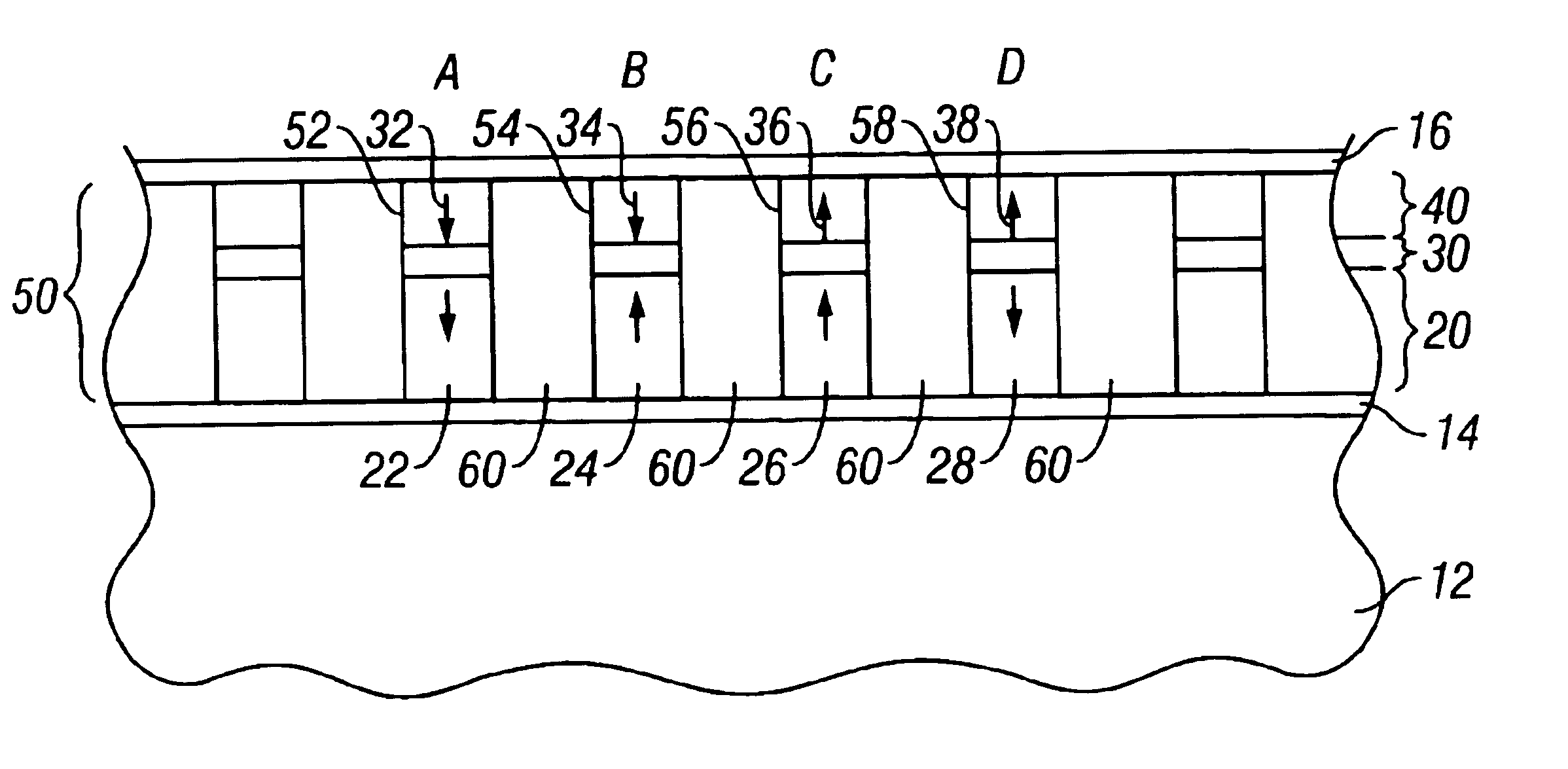

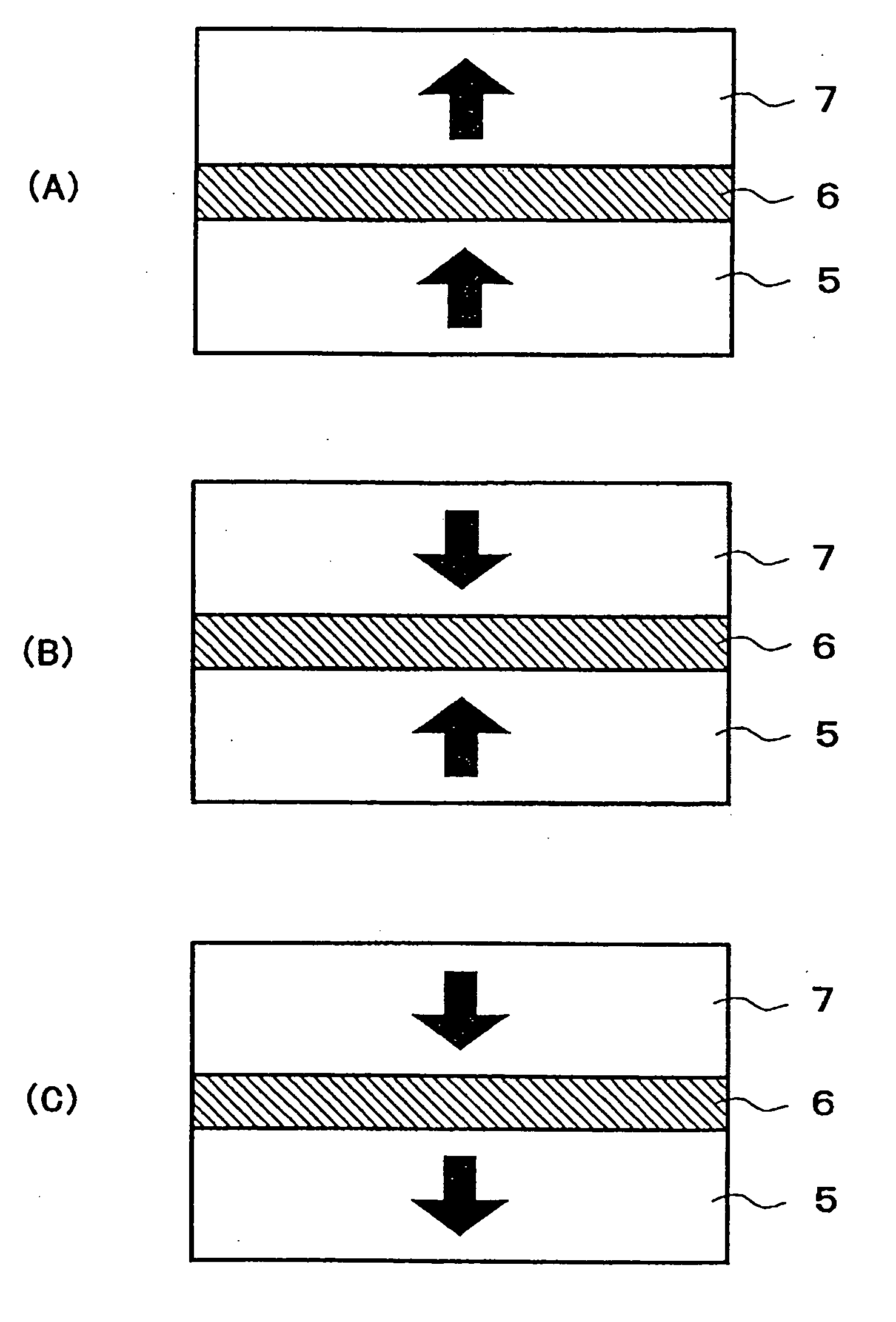

Patterned multilevel perpendicular magnetic recording media

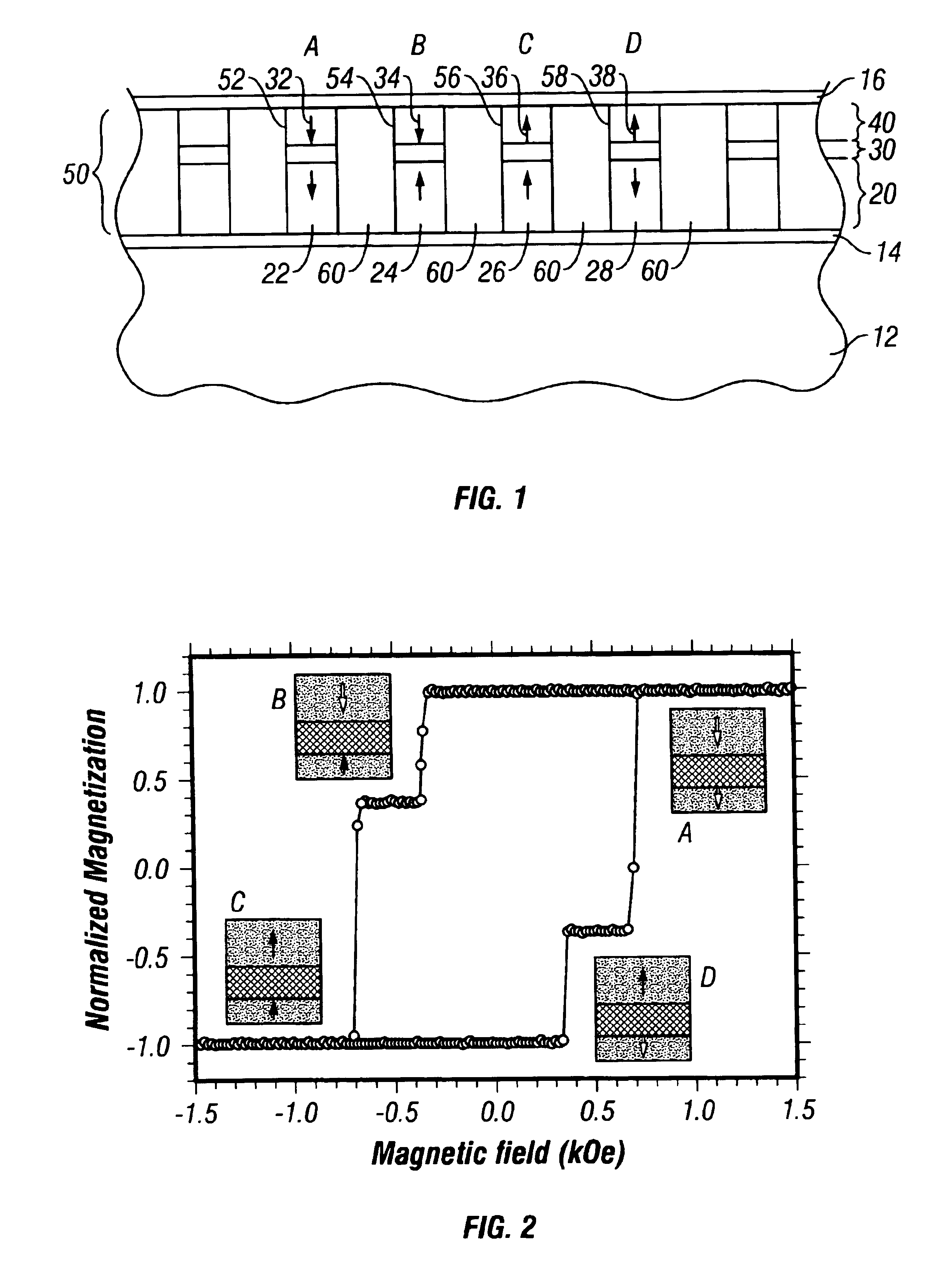

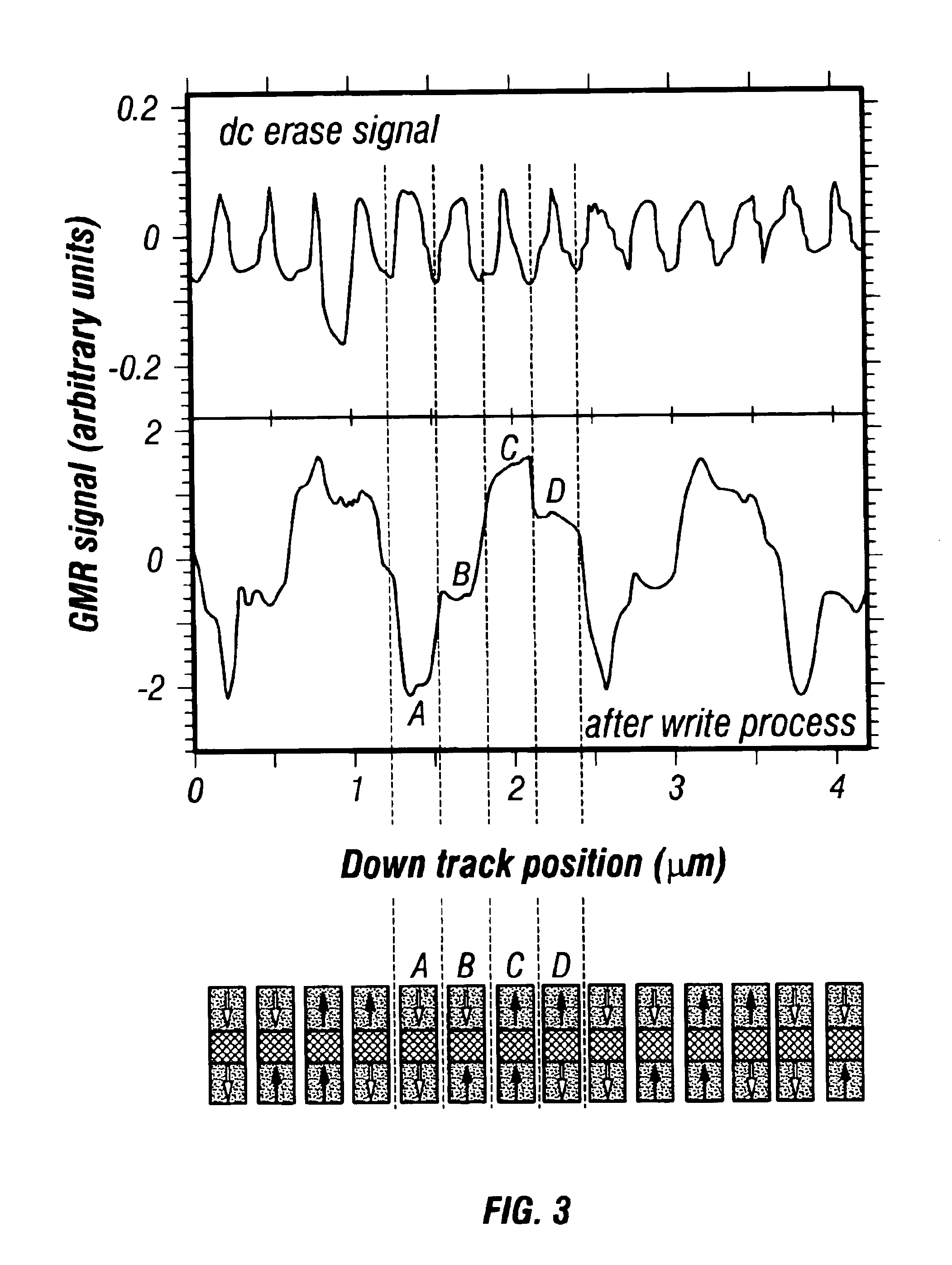

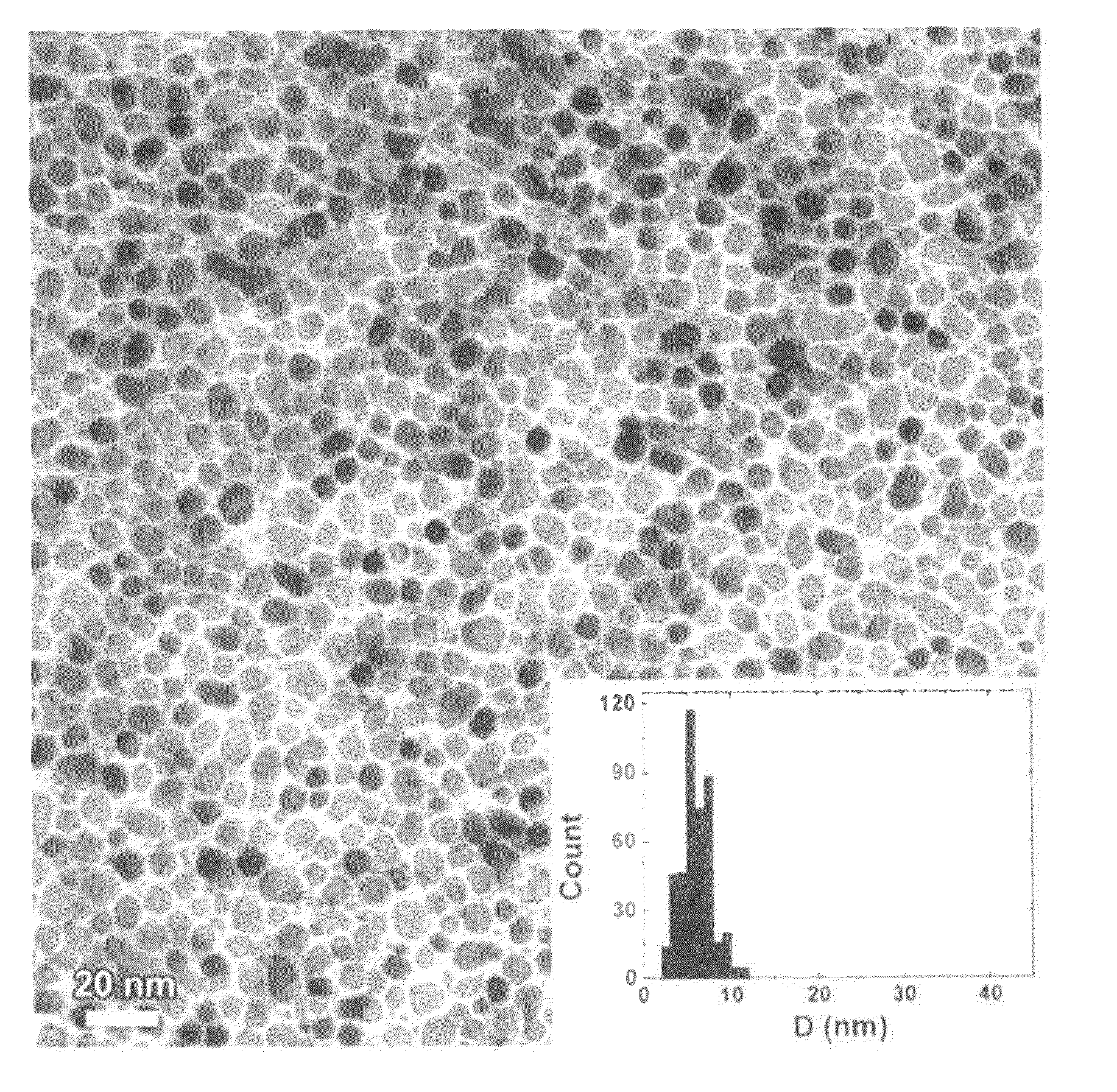

InactiveUS6947235B2Improve noiseImprove recording densityBase layers for recording layersPatterned record carriersMaterials scienceMagnetic moment

A patterned perpendicular magnetic recording medium has magnetic islands that contain stacks of individual magnetic cells to provide multilevel recording. Each cell in an island is formed of a material or set of materials to provide the cell with perpendicular magnetic anisotropy and is a single magnetic domain. Each cell is magnetically decoupled from the other cells in its island by nonmagnetic spacer layers. Thus each cell can have a magnetization (magnetic moment) in one of two directions (into or out of the plane of the layer making up the cell), and this magnetization is independent of the magnetization of the other cells in its island. This permits multiple magnetic levels or states to be recorded in each magnetic island.

Owner:WESTERN DIGITAL TECH INC

Perpendicular magnetic recording medium and its manufacturing method

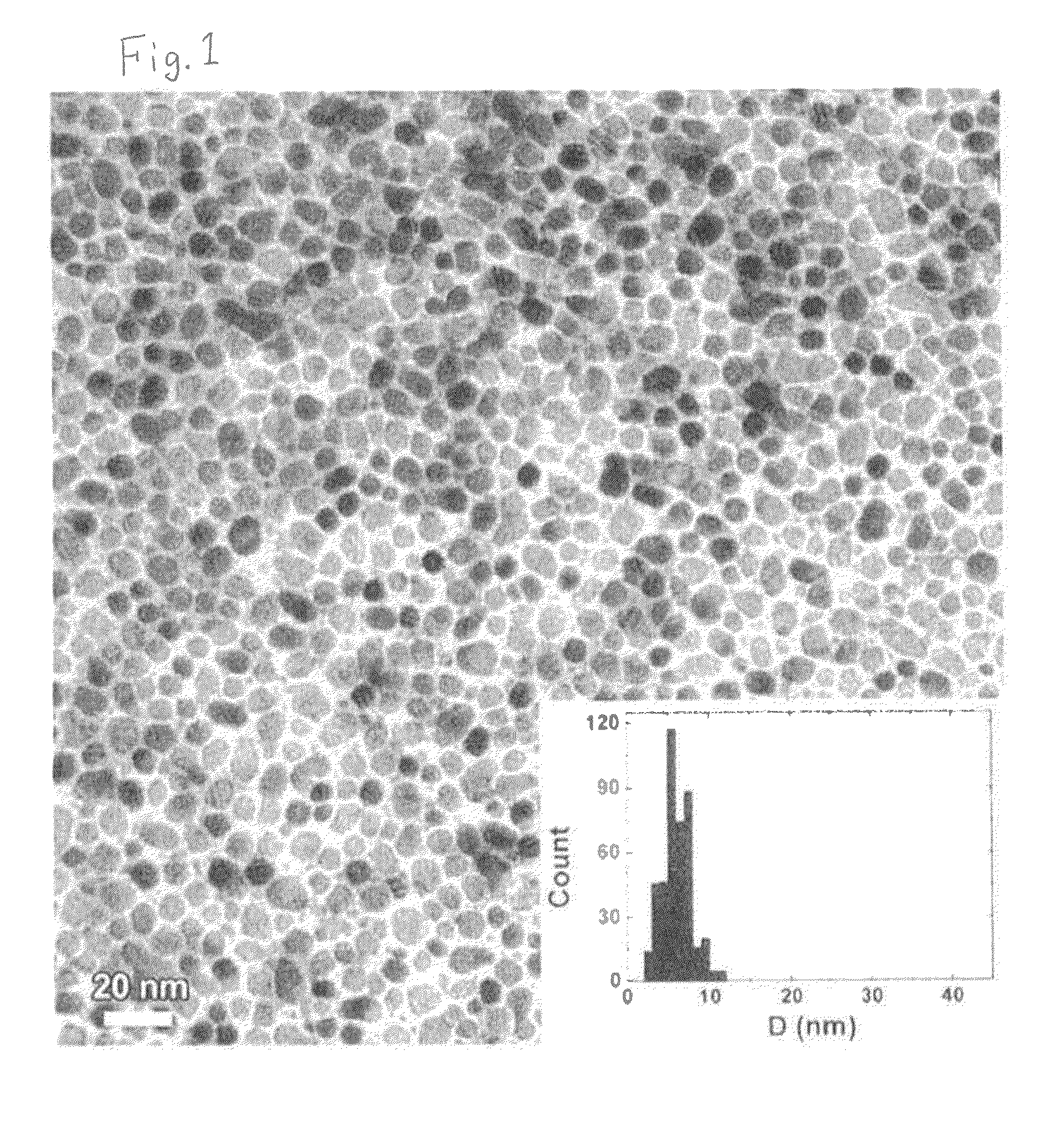

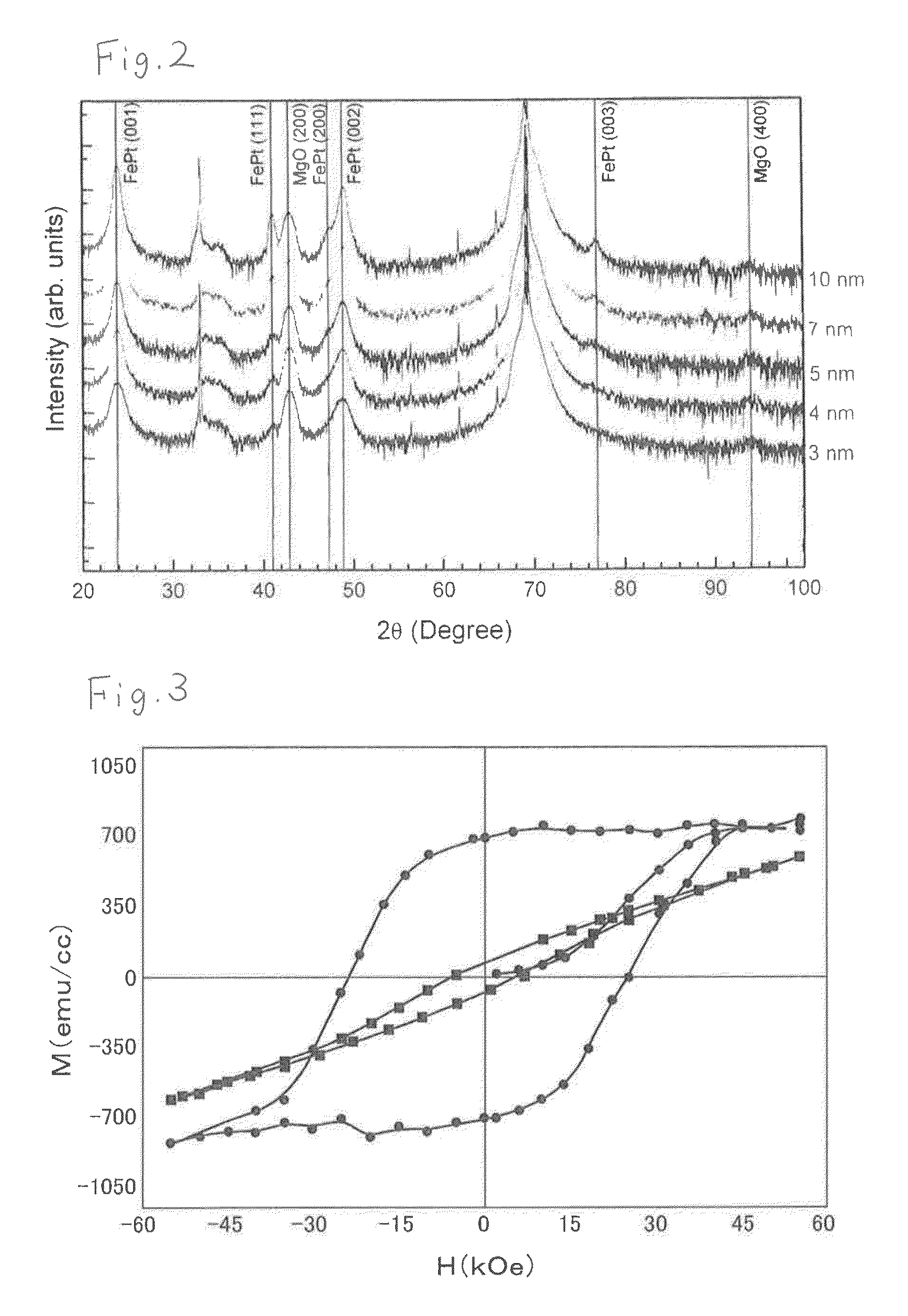

InactiveUS20130040167A1Suppress interferenceIncrease in ultra-high recording densityRecord information storageCoating by sputteringSputteringAlloy

It is aimed to provide a perpendicular magnetic recording medium capable of dealing with an ultra-higher recording density than before and its manufacturing method.The present invention concerns a perpendicular magnetic recording medium including at least a seed layer made of noncrystalline ceramic, a crystalline orientation control layer and a magnetic layer made of a material mainly containing a FePt alloy in this order on a substrate. This perpendicular magnetic recording medium is suitably manufactured by forming at least the seed layer, the orientation control layer and the magnetic layer made of the material mainly containing the FePt alloy in this order on the substrate by sputtering, wherein the magnetic layer is formed at a predetermined temperature of 500° C. or less.

Owner:WD MEDIA SINGAPORE PTE +1

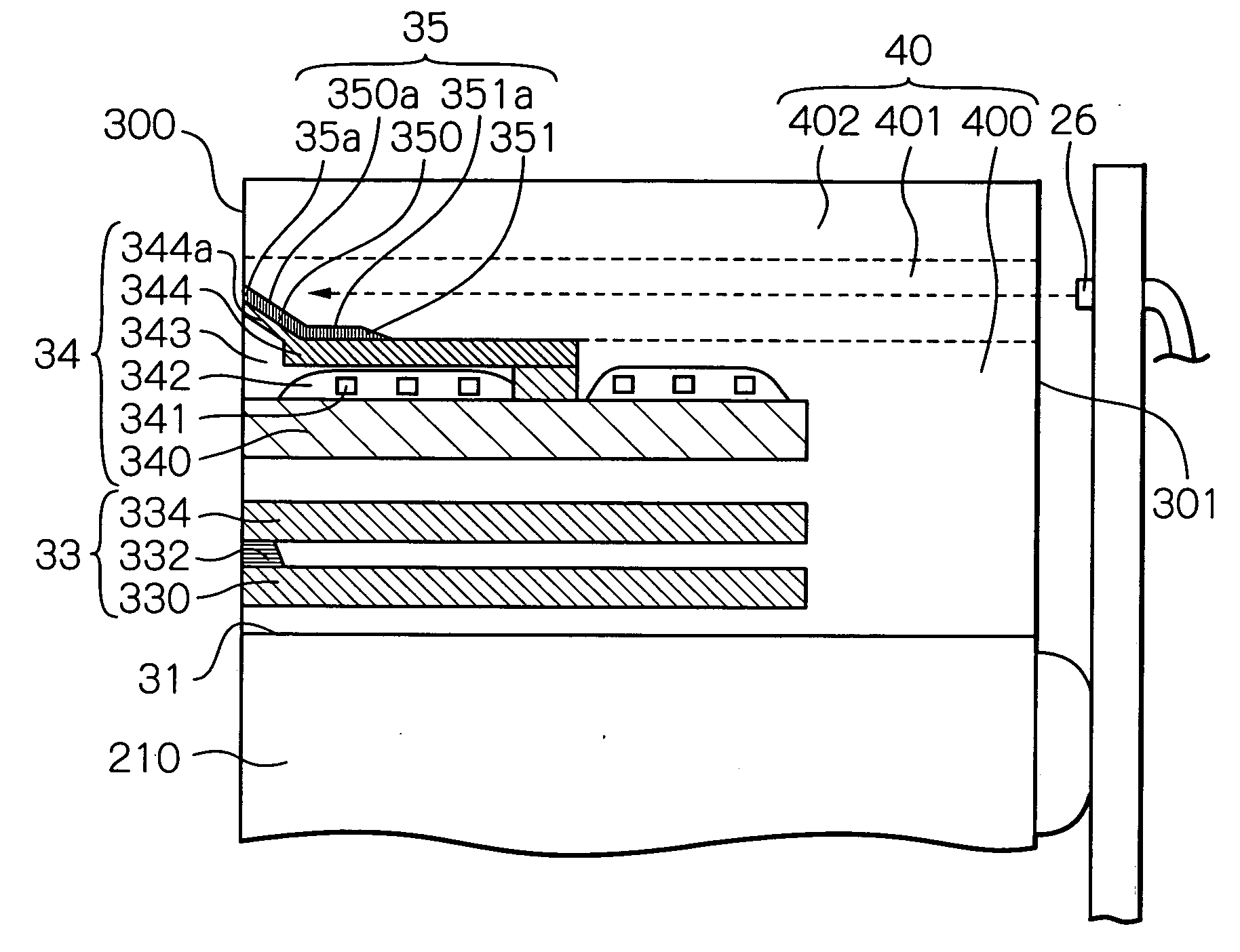

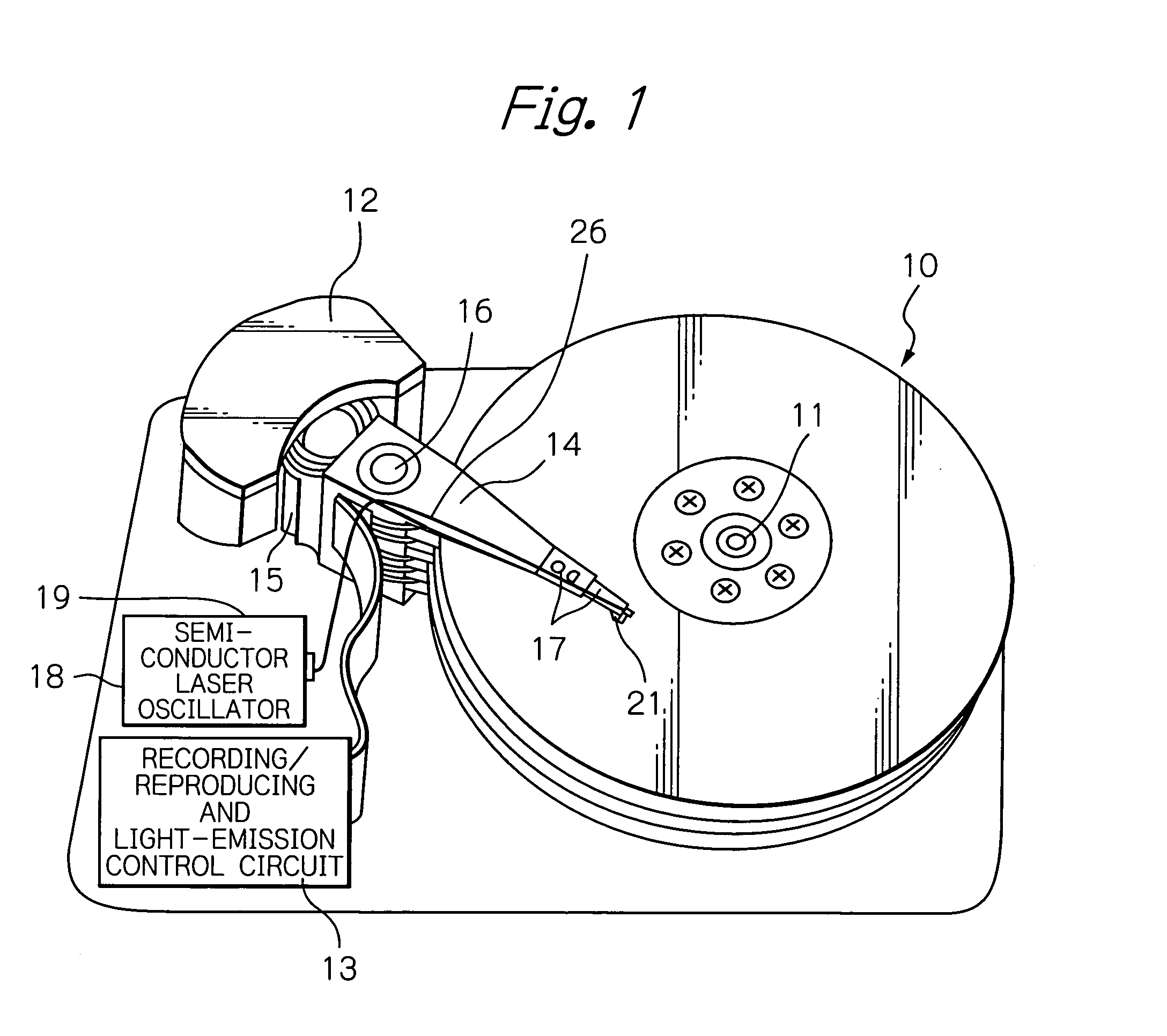

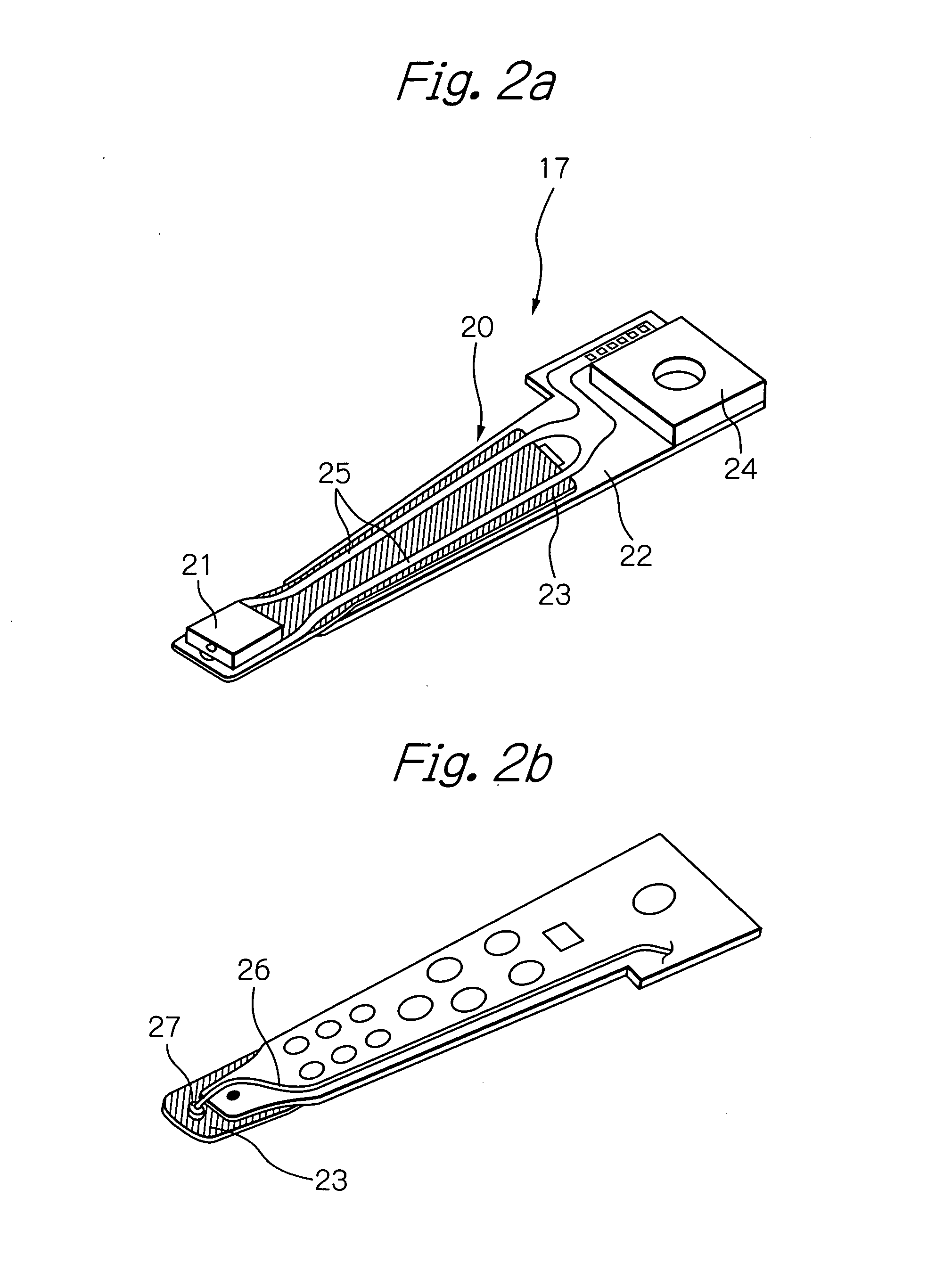

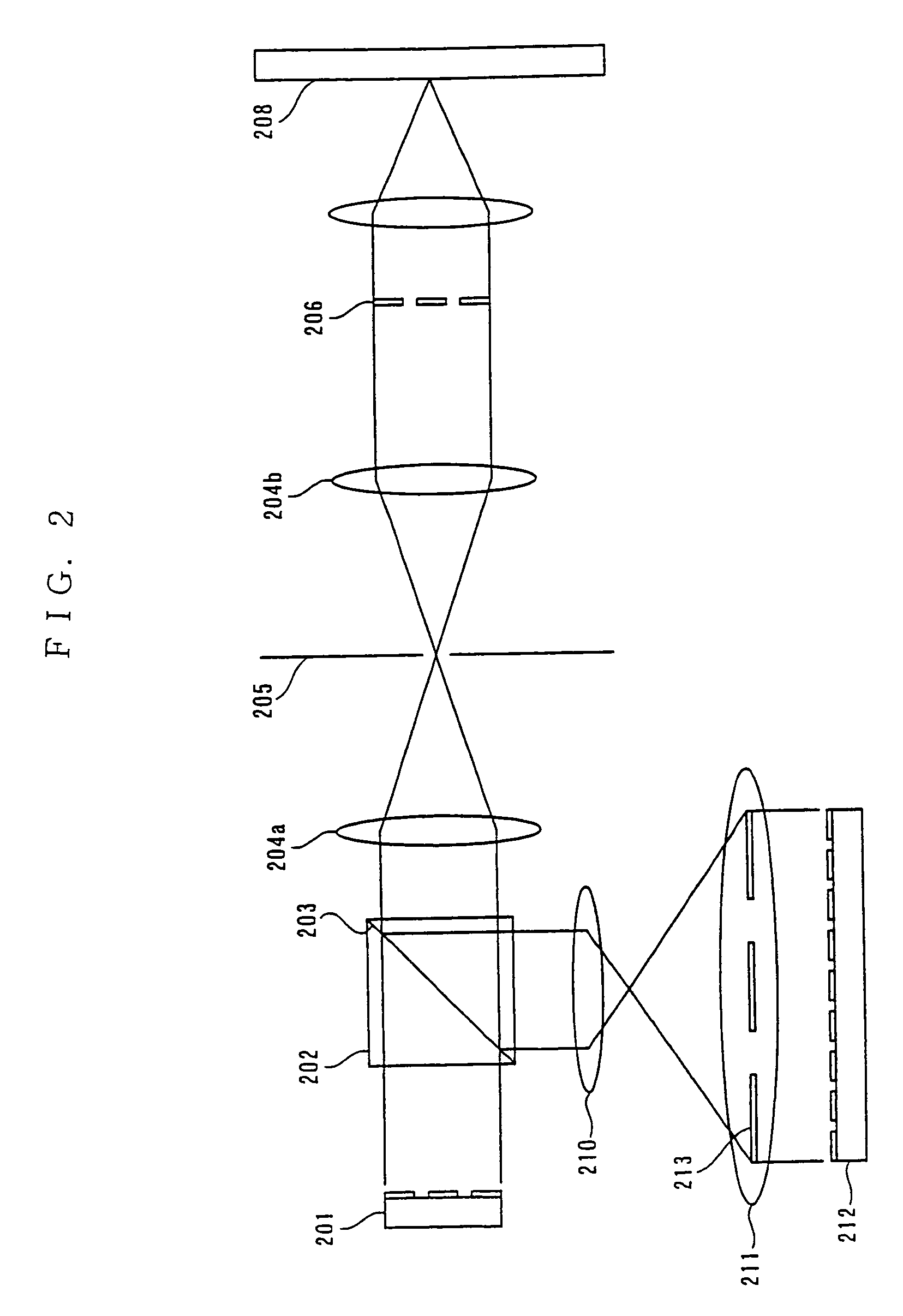

Thin-film magnetic head with near-field-light-generating layer

ActiveUS20070139818A1Improve reliabilityLow coercivityCombination recordingArm with optical waveguideMagnetic mediaBiomedical engineering

A thin-film magnetic head that has a configuration in which the element-formed surface and the opposed-to-medium surface are perpendicular to each other, and a light source is sufficiently distanced from the medium surface is provided. The head comprises at least one near-field-light-generating layer for heating a part of a magnetic medium during write operation by generating a near-field light, having a shape tapered toward a head end surface on the opposed-to-medium surface side, and comprising a near-field-light-generating portion having a light-received surface and a tip reaching the head end surface on the opposed-to-medium surface side, and the light-received surface being sloped in respect to the element-formed surface and being provided in a position where an incident light propagating from a head end surface opposite to the opposed-to-medium surface can reach at least a part of the light-received surface.

Owner:TDK CORPARATION

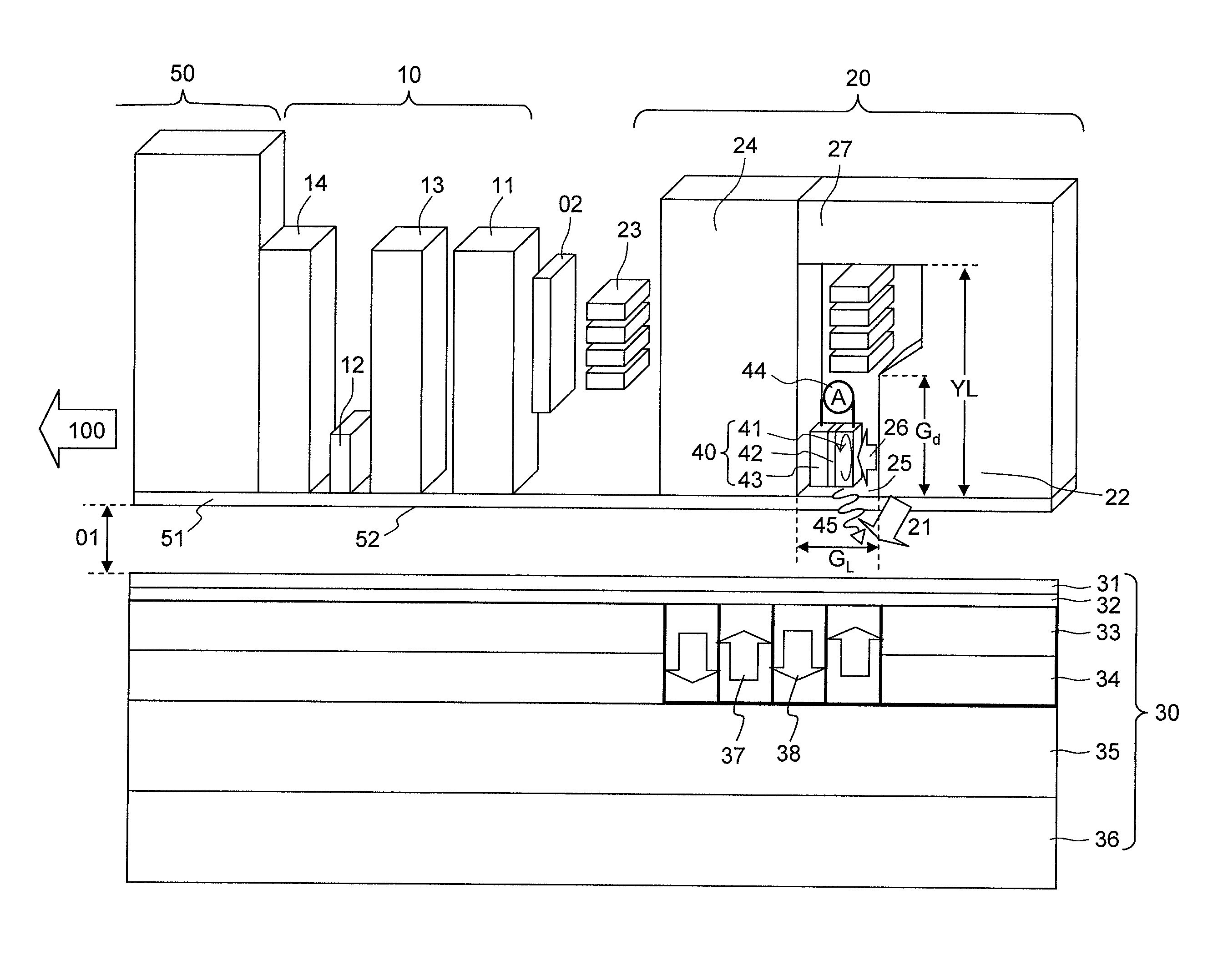

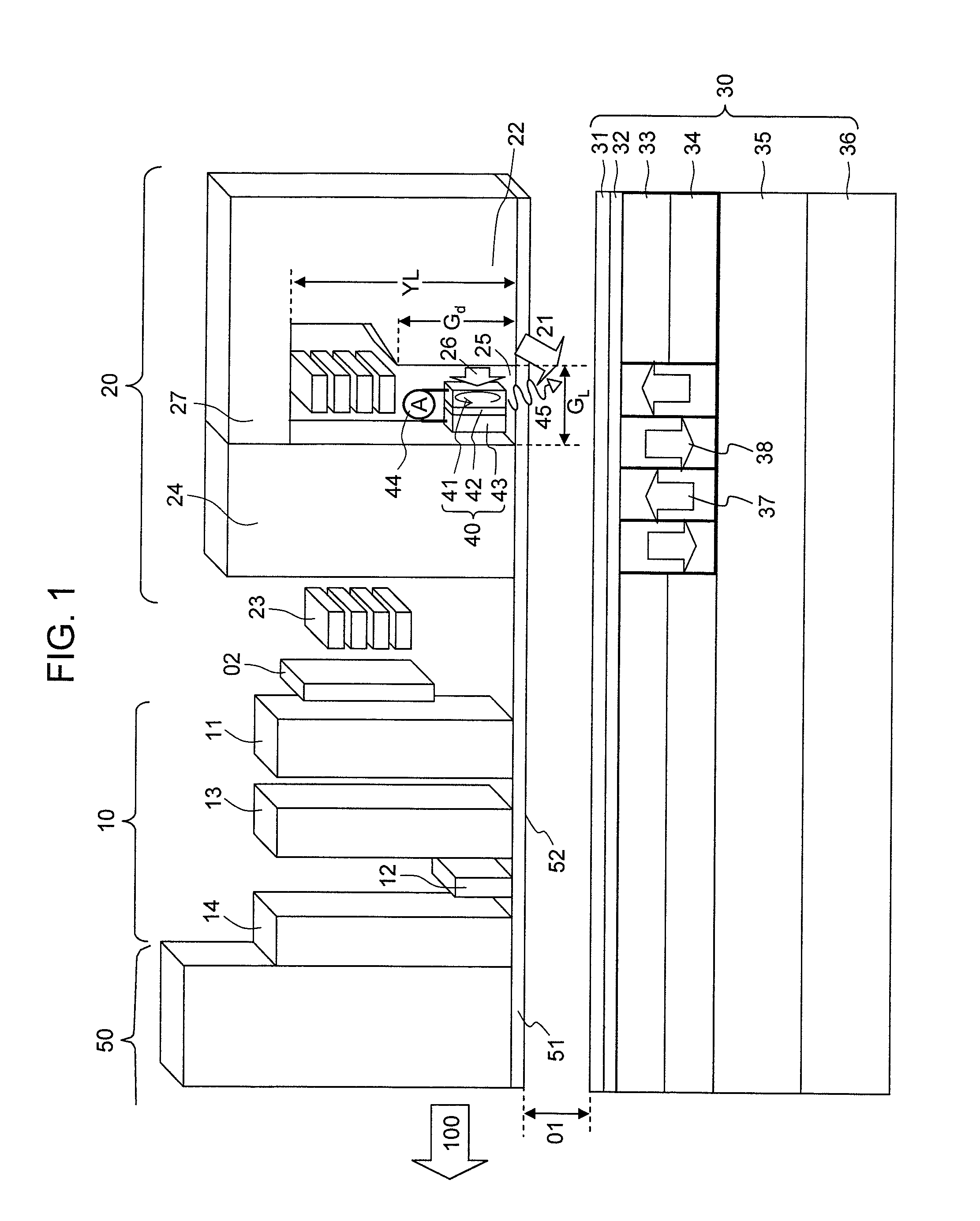

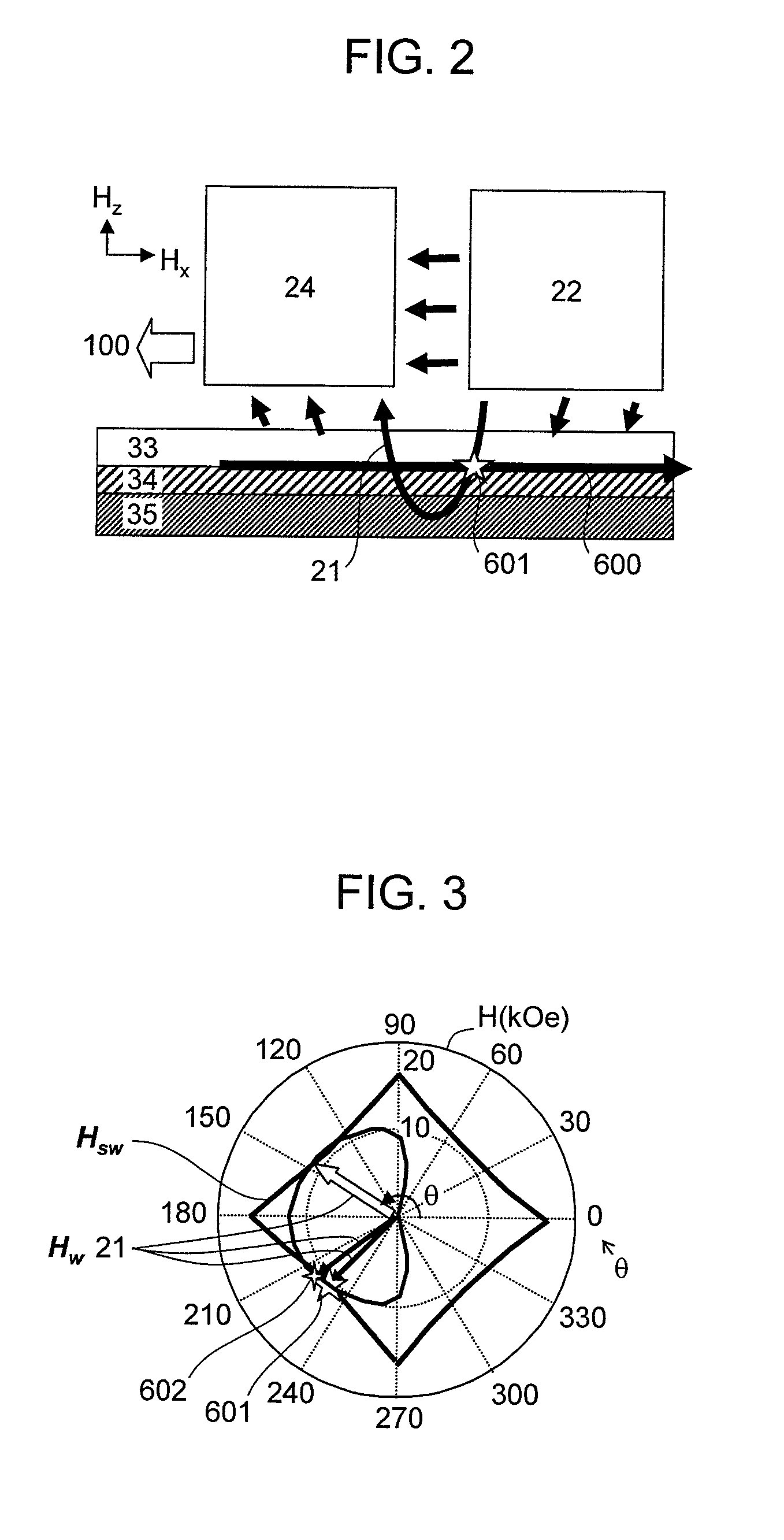

Magnetic head, magnetic recording method and apparatus for controlling magnetic head with spin torque oscillator in a disk drive

ActiveUS9275672B2Improve recording densityHigh densityManufacture head surfaceDriving/moving recording headsSpin torque oscillatorsMagnetic poles

A microwave assisted magnetic recording head includes a recording magnetic pole unit that produces a recording field for writing to a perpendicular magnetic recording medium, and a high-frequency magnetic field oscillator that produces a high-frequency magnetic field. The recording magnetic pole unit includes a magnetic core with a write gap portion at which a main recording field component is concentrated, and the high-frequency magnetic field oscillator is disposed in the write gap.

Owner:HITACHI LTD

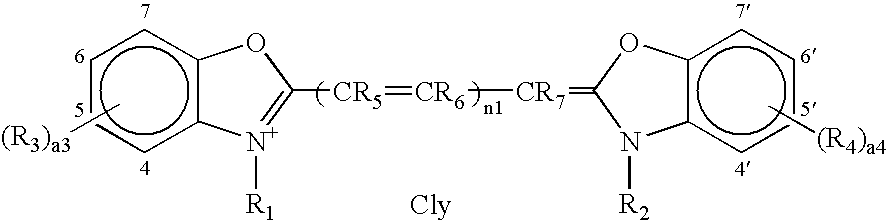

Hologram recording material, hologram recording method and optical recording medium

InactiveUS7572555B2Low shrinkageImprove recording densityPhotomechanical apparatusPhotosensitive material auxillary/base layersEnergy transferExcited state

Owner:FUJIFILM CORP +1

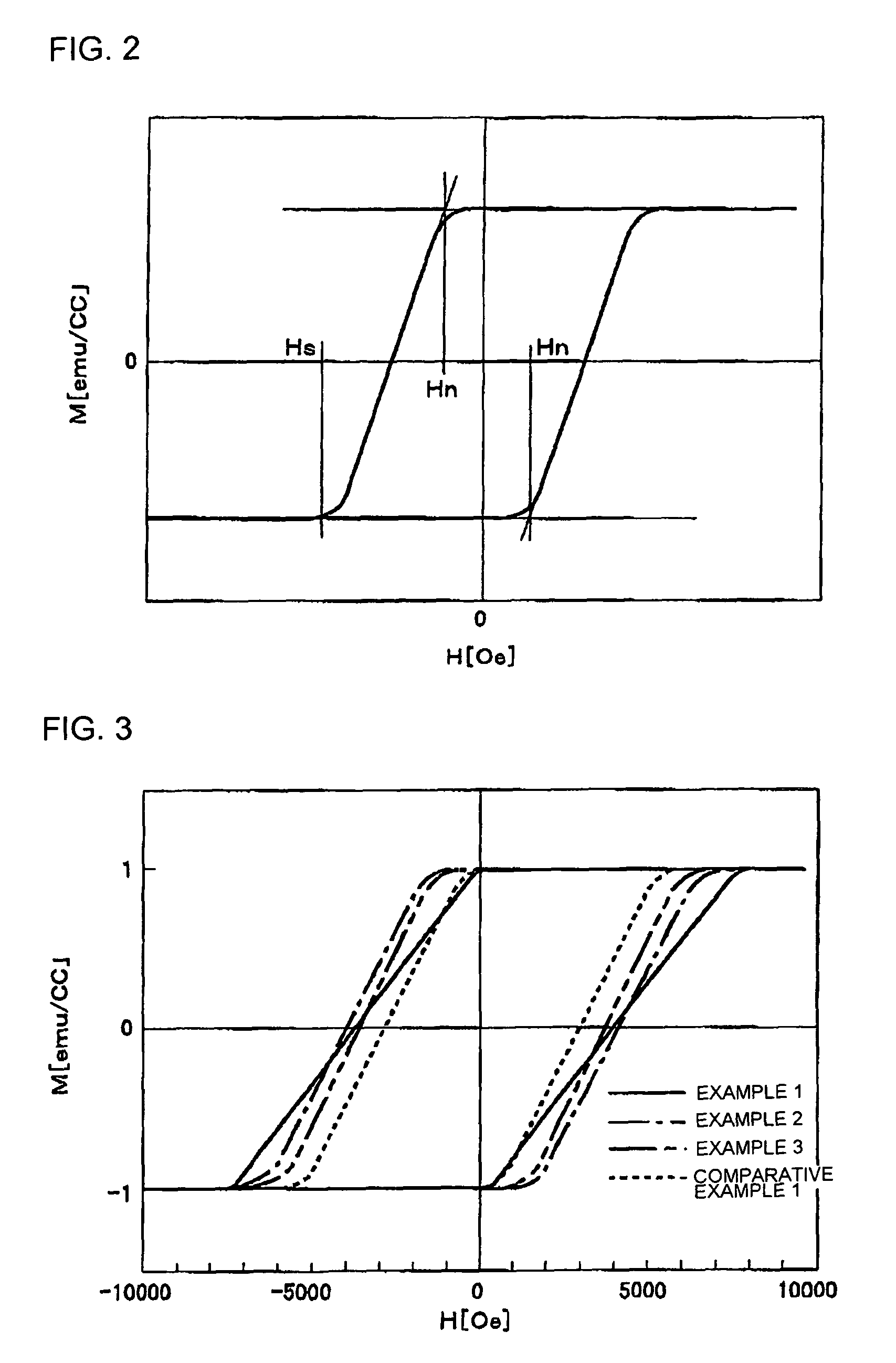

Perpendicular magnetic recording medium

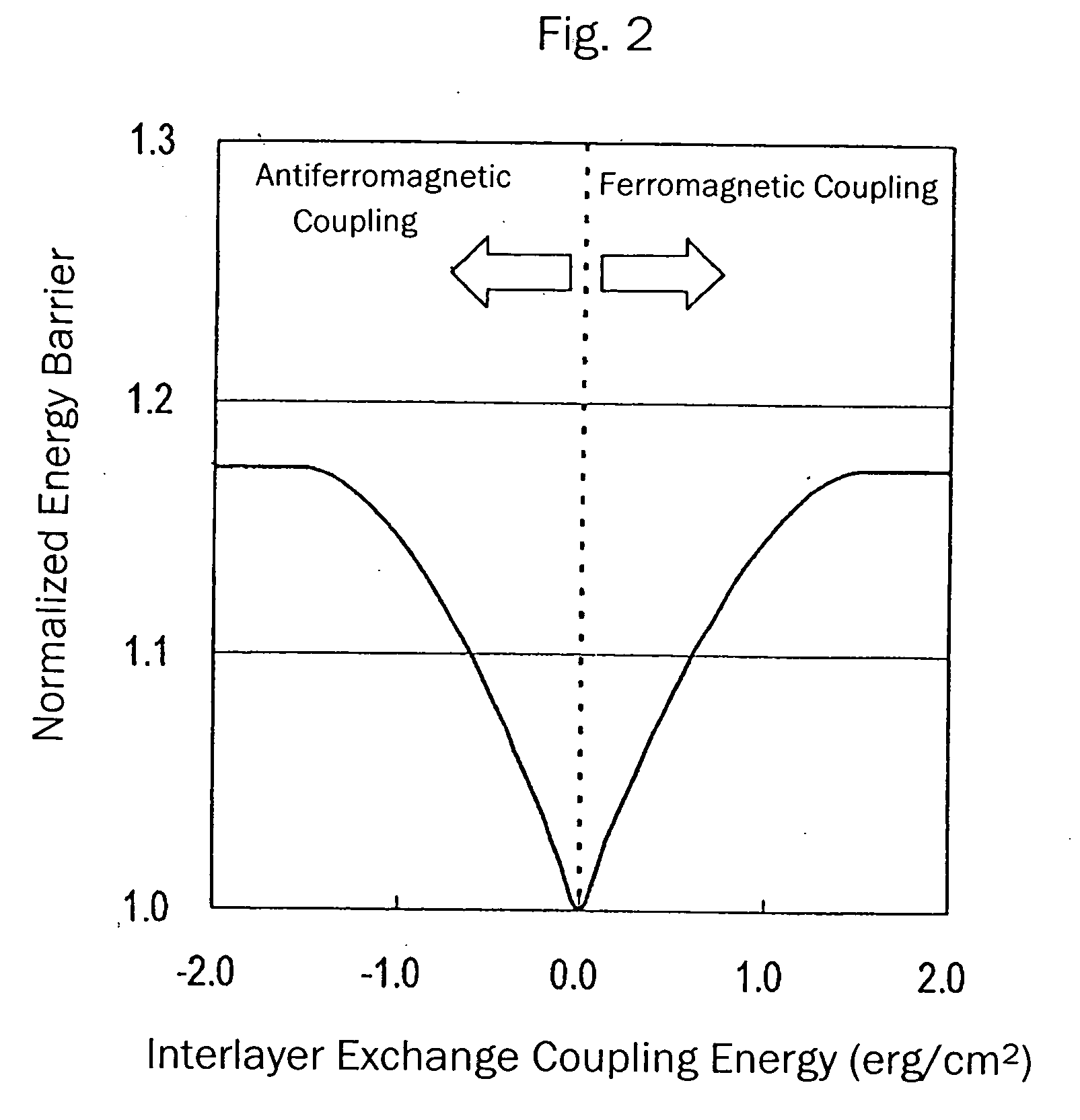

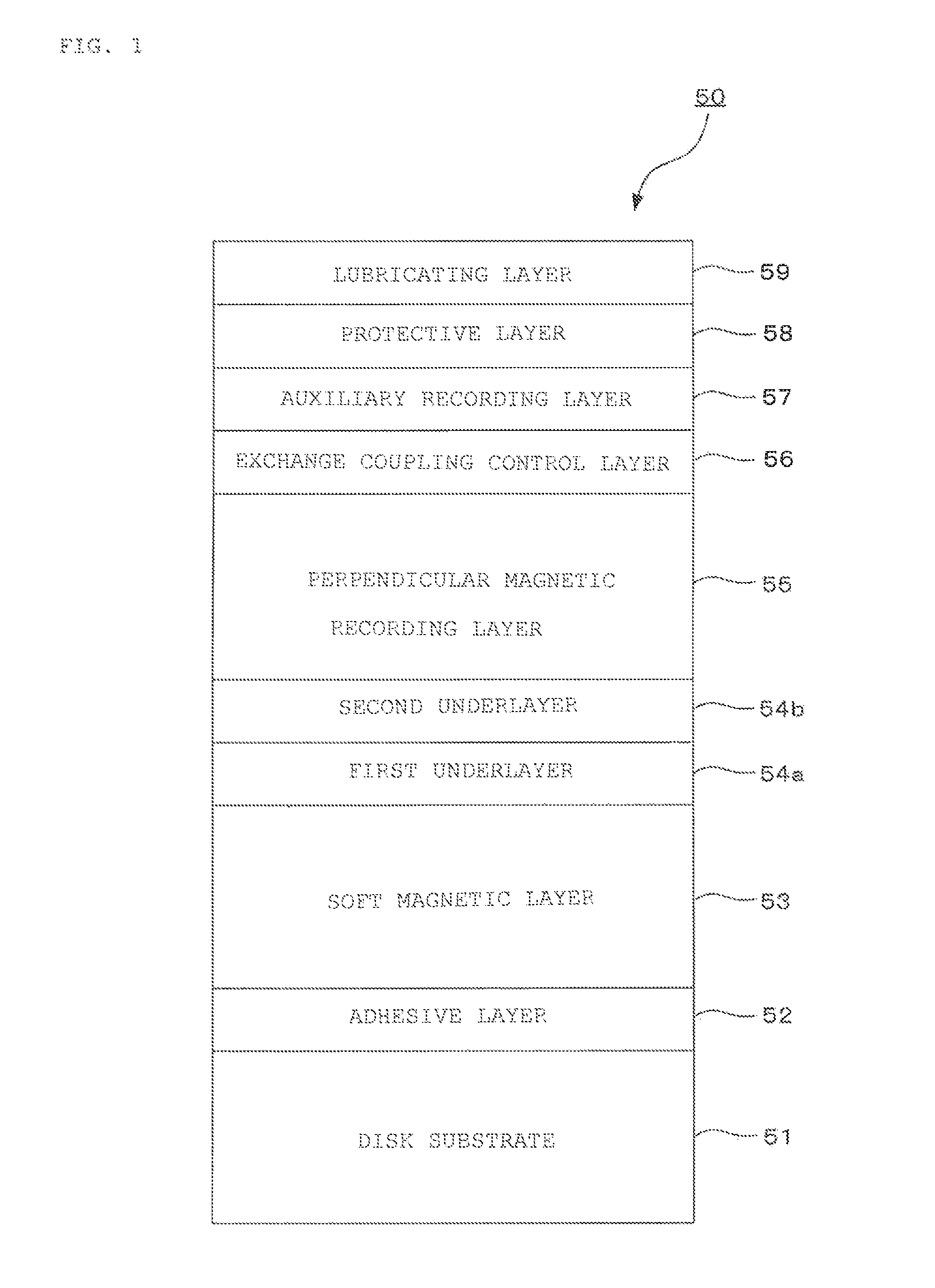

ActiveUS20060177703A1Improvement in recordability of recordingHigh densityRecord information storageMagnetic recordingCouplingThermal stability

A perpendicular magnetic recording medium is disclosed that achieves improved recordability without deteriorating thermal stability by reducing the switching field. A perpendicular magnetic recording medium of the invention has a first magnetic recording layer and a second magnetic recording layer between with is interposed a coupling layer that ferromagnetically couples the two layers. The first and second magnetic recording layers satisfy an inequality Ku1T1>Ku2T2 in the case where Hk1 >Hk2 and an inequality Ku1T1<Ku2T2 in the case where Hk1<Hk2, where Hk1 and Hk2 are anisotropy magnetic fields, Ku1 and Ku2 are uniaxial anisotropy constants, and T1 and T2 are thicknesses of the first magnetic recording layer and the second recording layer, respectively. An exchange coupling energy between the magnetic recording layers is preferably at least 5×10−3 erg / cm2. Advantageously, the coupling layer is mainly composed of a material selected from V, Cr, Fe, Co, Ni, Cu, Nb, Mo, Ru, Rh, Ta, W, Re, and Ir, and has a thickness of at most 2 nm. At least one of the magnetic recording layers preferably has a granular structure.

Owner:FUJI ELECTRIC CO LTD

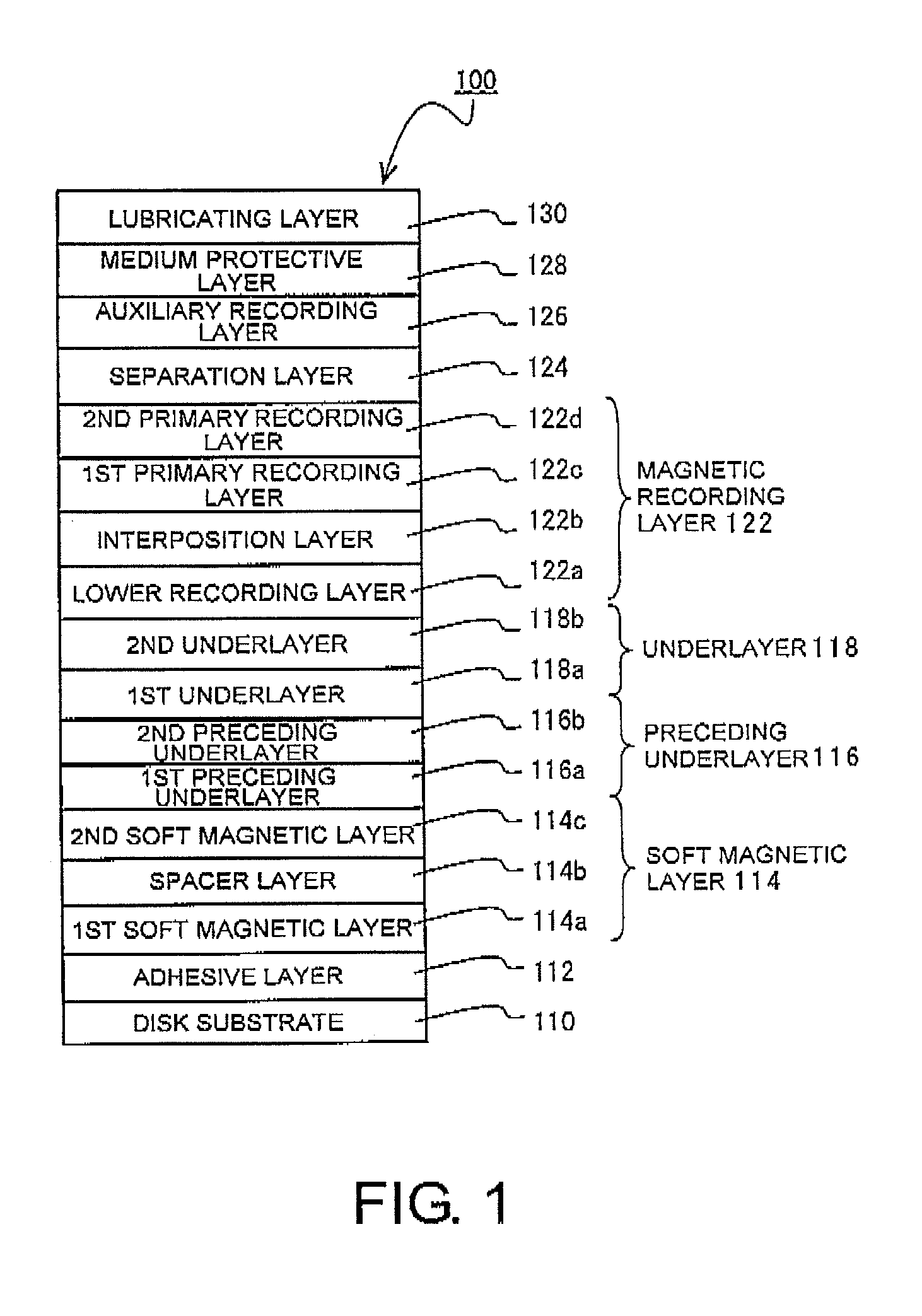

Perpendicular magnetic recording medium and method of manufacturing the same

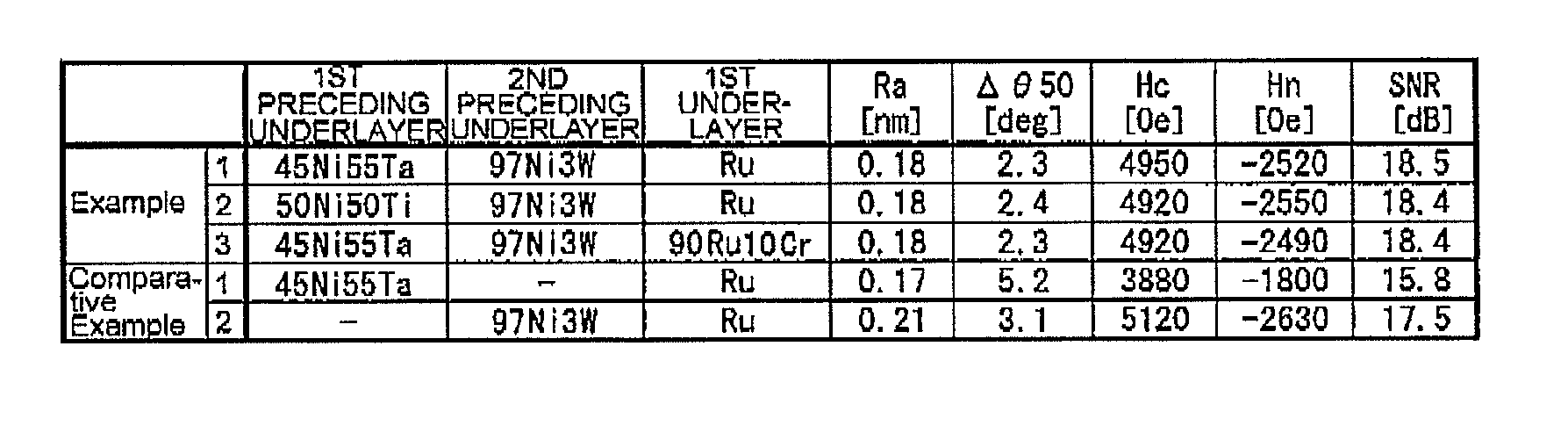

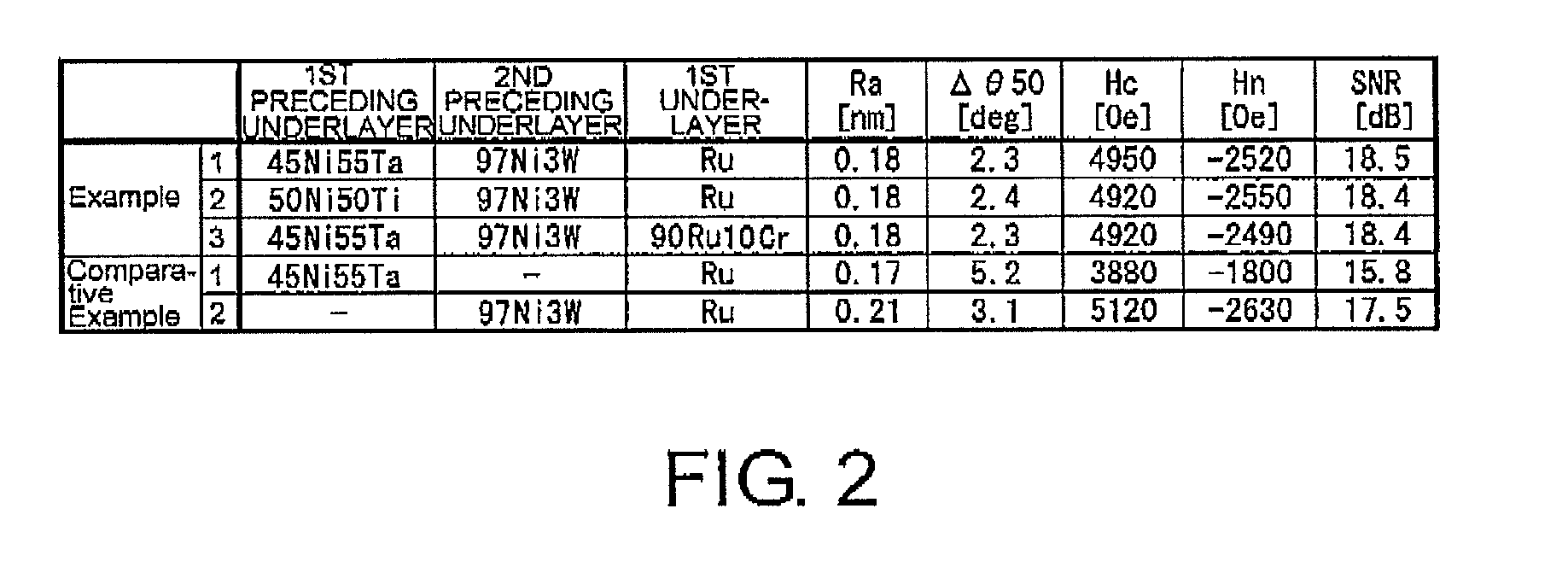

ActiveUS20100279151A1Improve recording densityImprove coercive forceRecord information storageCoatingsOptoelectronicsRecording layer

A perpendicular magnetic recording medium includes a substrate, a soft magnetic layer, a pre-underlayer, an underlayer, and a main recording layer serving as a magnetic recording layer. The pre-underlayer contains seed crystal grains that serve as a base for crystal grains of the underlayer, and an addition substance that is added between the seed crystal grains and composed of an element having an atomic radius smaller than that of an element forming the seed crystal grains.

Owner:WESTERN DIGITAL TECH INC

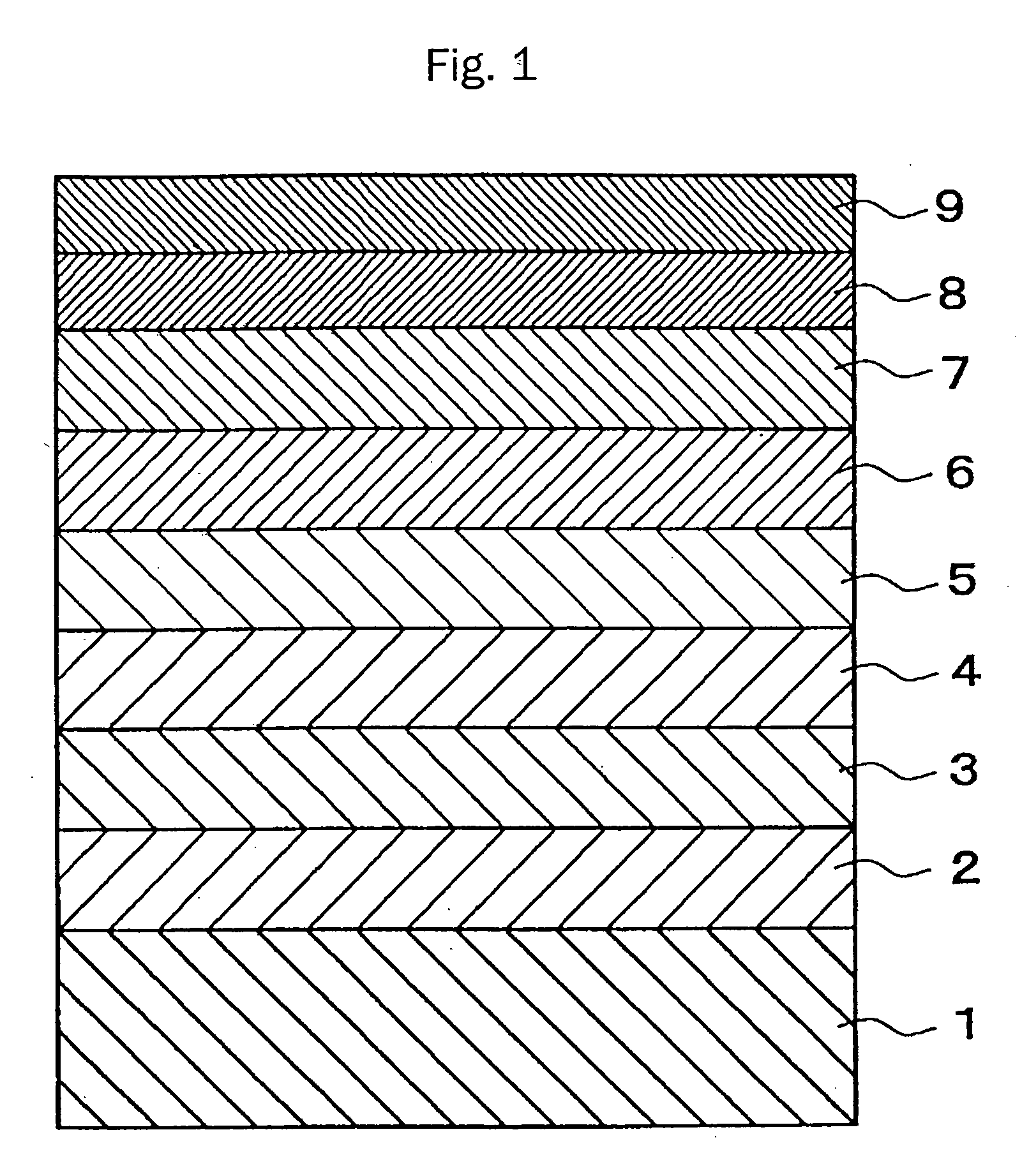

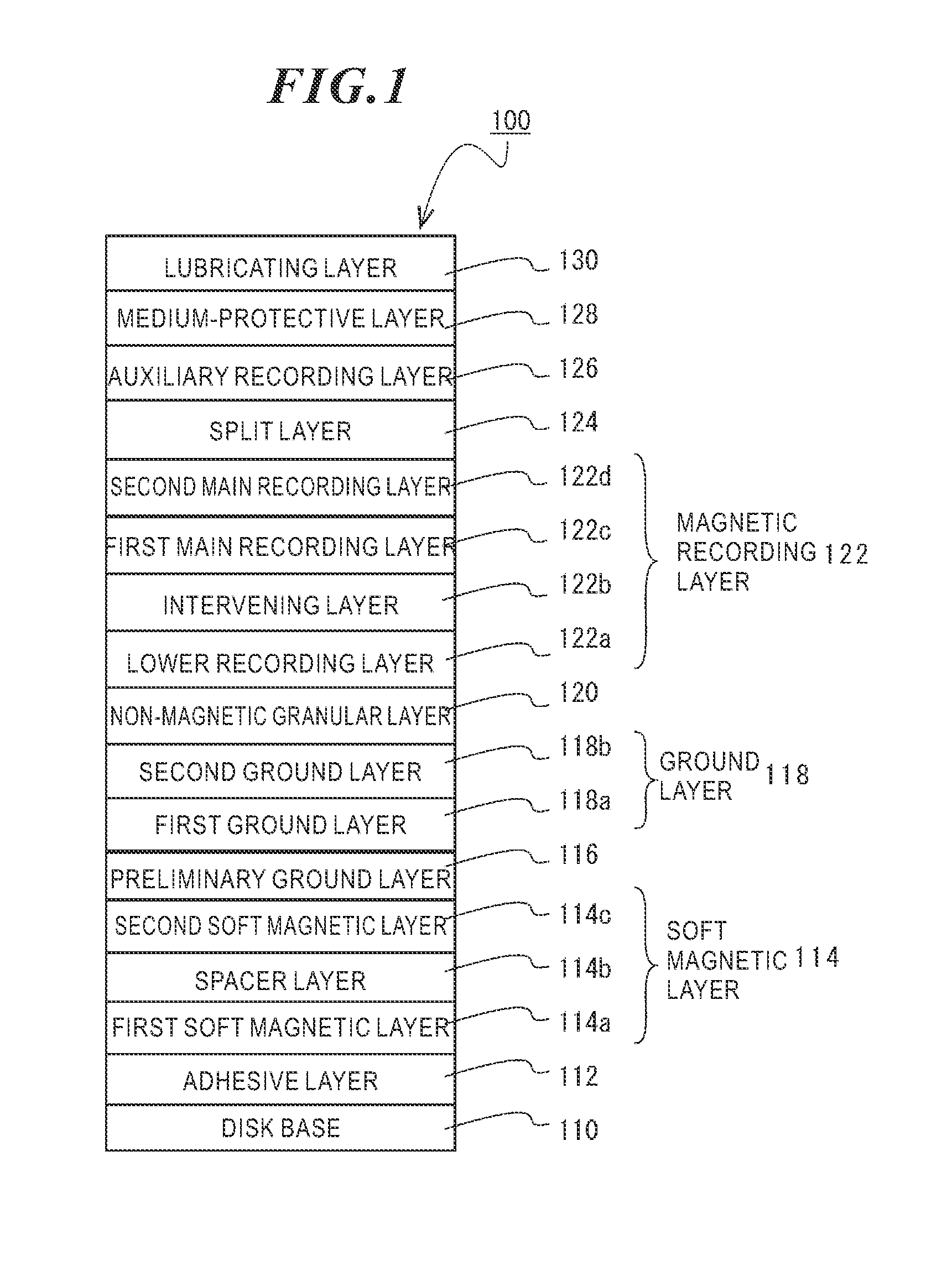

Perpendicular magnetic recording medium and method of manufacturing the same

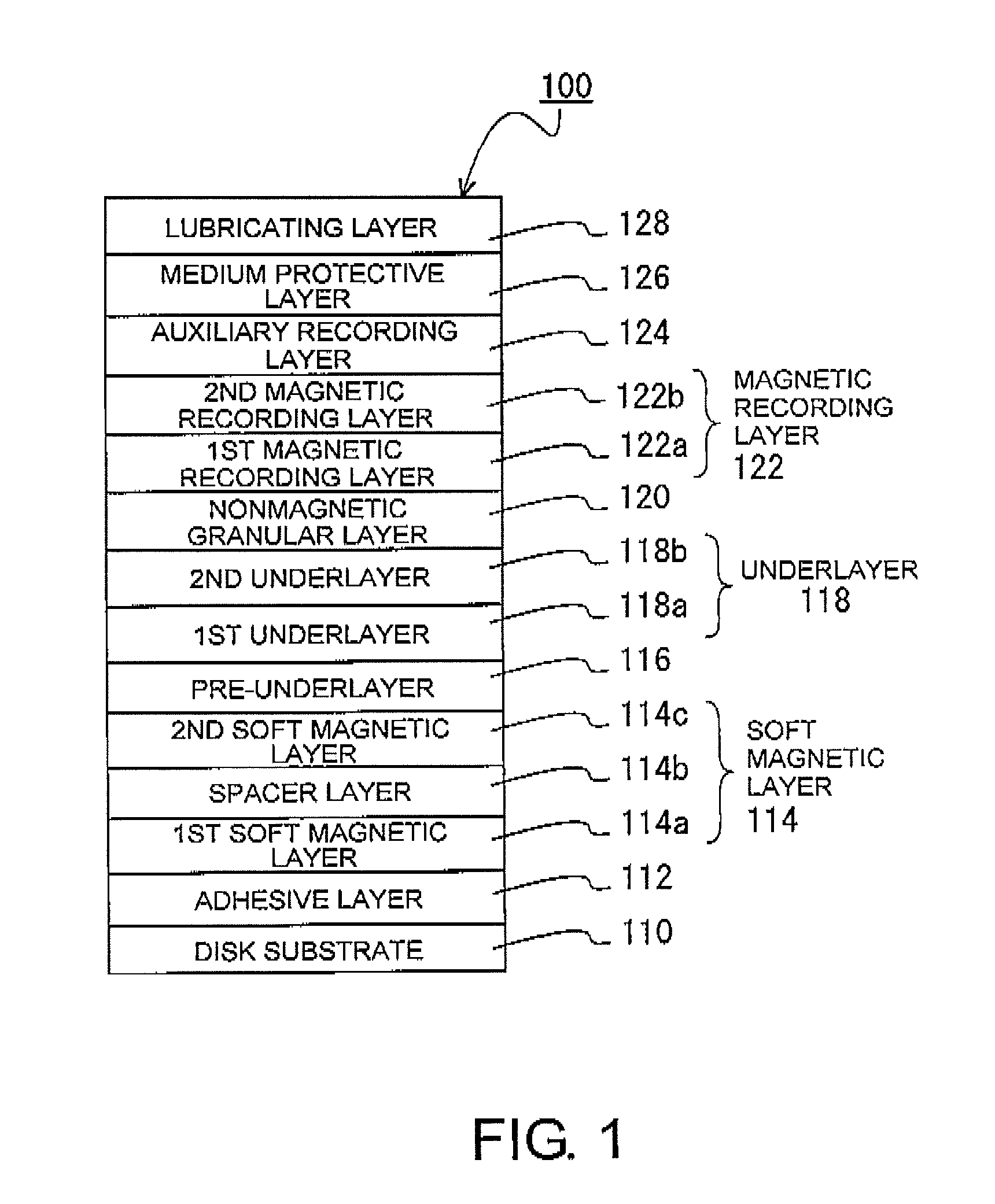

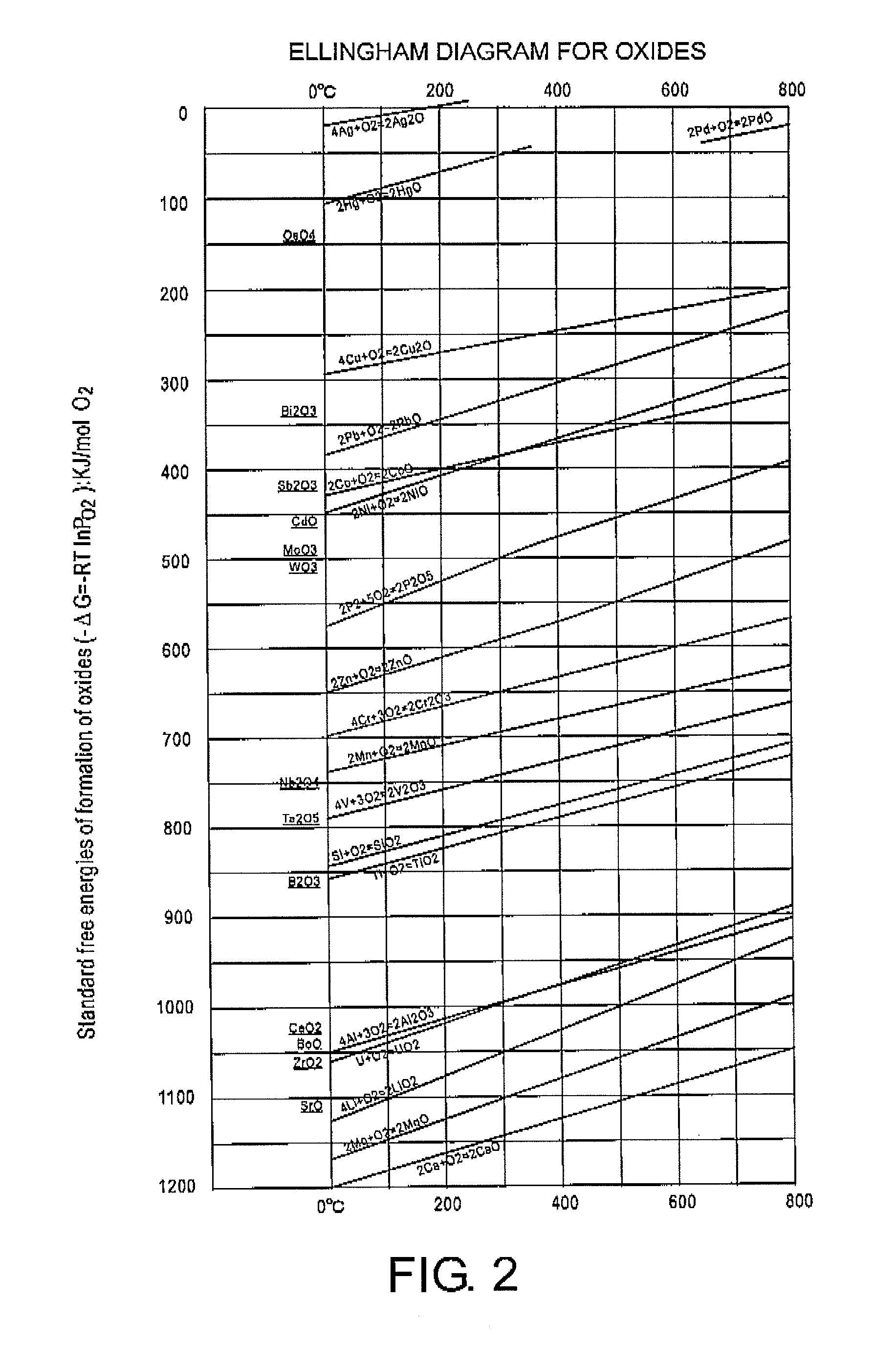

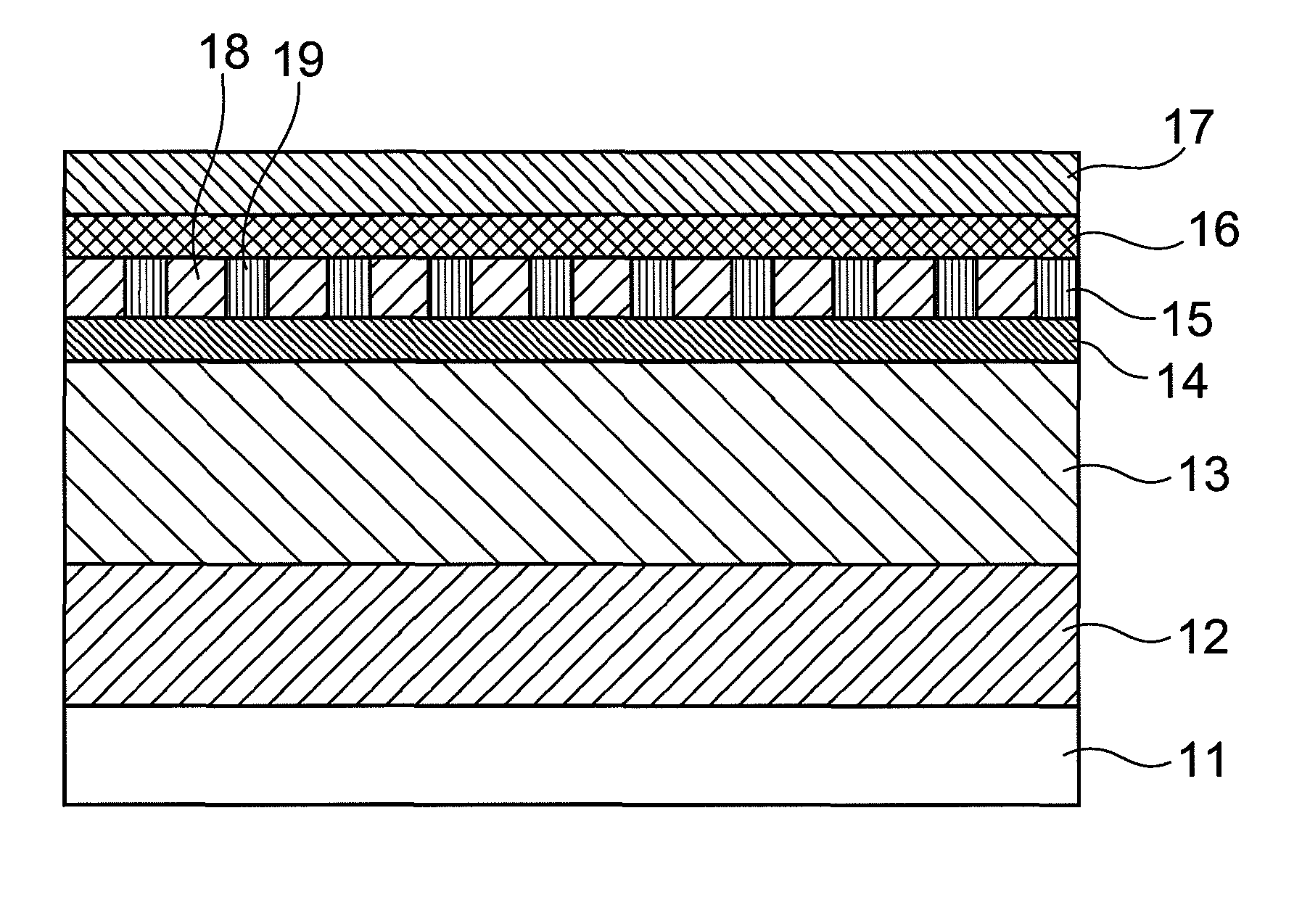

InactiveUS8404370B2Improve signal-to-noise ratioImprove recording densityCellsVacuum evaporation coatingGibbs free energyFree energies

A perpendicular magnetic recording medium 100 has, over a substrate, at least a magnetic recording layer 122 with a granular structure in which nonmagnetic grain boundaries are formed between magnetic grains continuously grown into a columnar shape. The magnetic grains of the magnetic recording layer 122 contain Co, Cr, and Pt. The magnetic recording layer 122 contains at least one oxide selected from a group A including SiO2, TiO2, and Cr2O3, at least one oxide selected from a group B consisting of oxides each having a larger Gibbs free energy ΔG than the group A, and a reducing agent adapted to reduce the oxides of the group B.

Owner:WD MEDIA SINGAPORE PTE

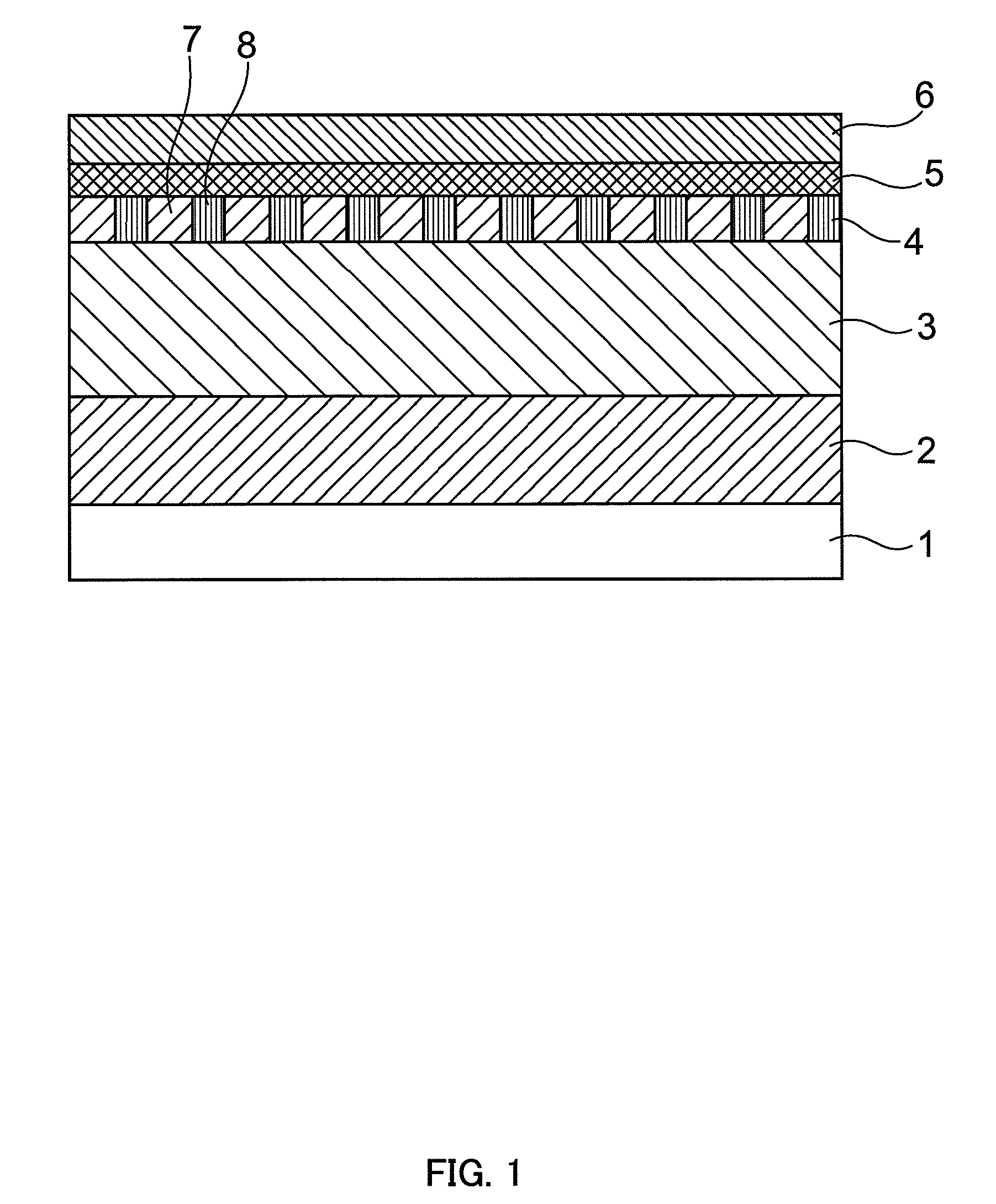

Magnetic recording medium with guard layer between auxiliary and magnetic recording layers and manufacturing method of the magnetic recording medium

ActiveUS8605388B2Improve recording densityThin thicknessRecord information storageDisk carriersMagnetizationNon magnetic

It is an object to manufacture magnetic recording media with the high recording density. Since nonmagnetic portions (8) with a predetermined pattern are formed in a recording auxiliary layer (4) formed on a magnetic recording layer (3), it is possible to actualize a magnetic recording medium where magnetic portions (7) and the magnetic recording layer (3) immediately below the portions (7) are recording units. The nonmagnetic portions (8) are formed by non-magnetization using ion implantation, and it is thereby possible to manufacture magnetic recording media with the high recording density.

Owner:WESTERN DIGITAL TECH INC +1

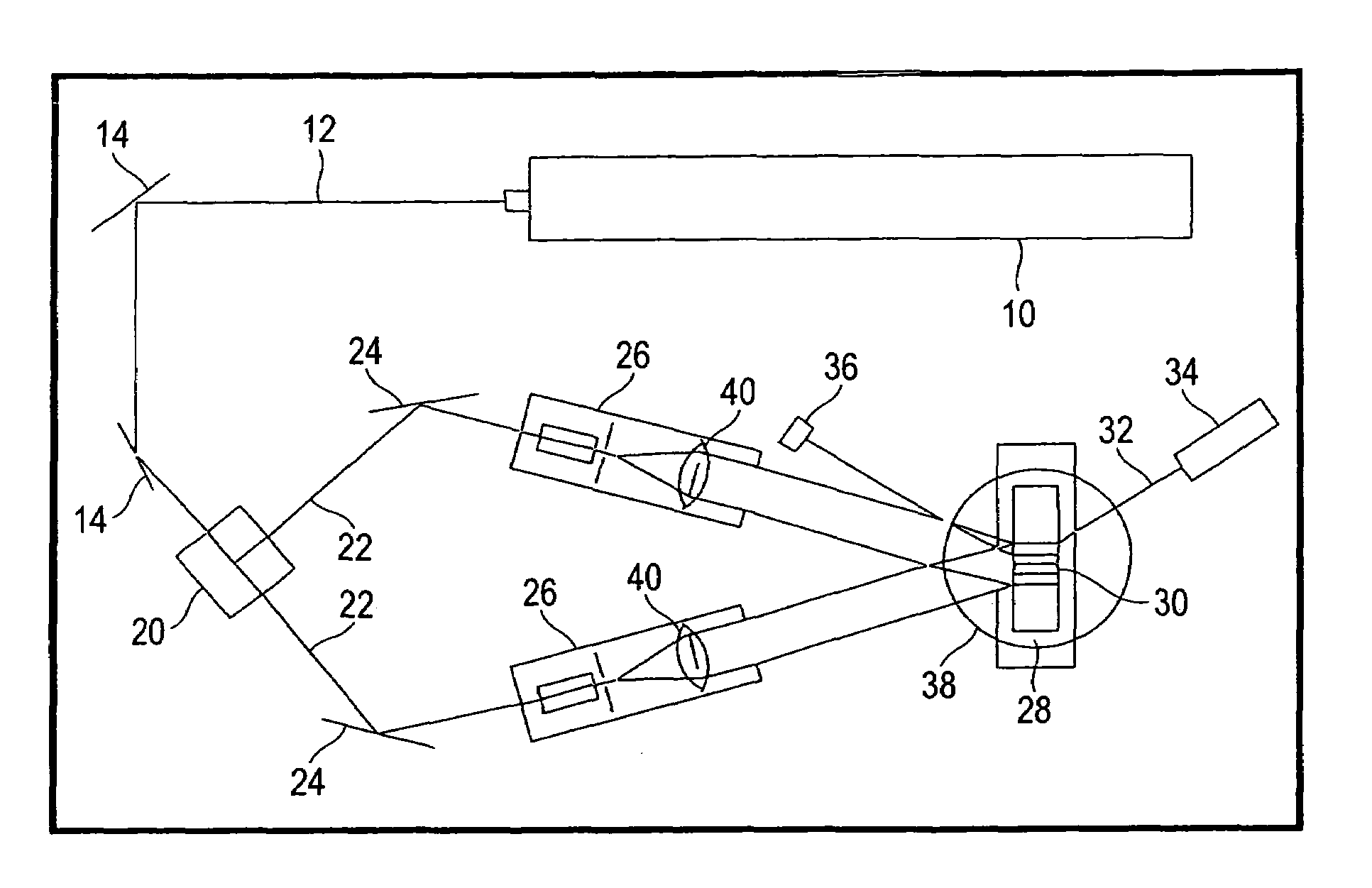

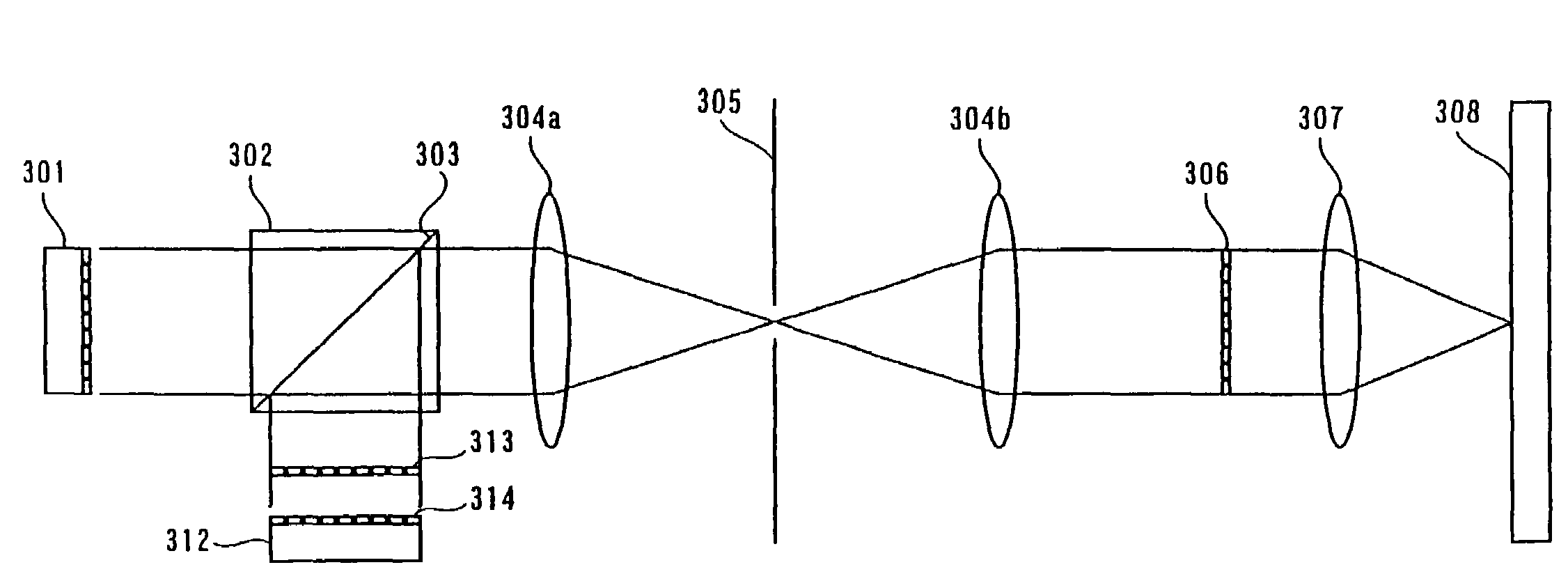

Information recording method, reproducing method, and recording/reproducing method utilizing holography

InactiveUS7321541B2Improve recording densityIncrease recording capacityRecord information storageDigital storageSpatial light modulatorRecording density

A method for recording information on a recording medium utilizing an interference pattern by interference between an information light modulated spatially with digital pattern information displayed on a spatial light modulator having multiple pixels and a reference light for recording. In order to provide a novel recording method capable of enhancing the recording density and the transfer rate furthermore, digital information to be recorded is represented by match / mismatch of the attributes of adjacent pixels in the spatial light modulator to produce digital pattern information.

Owner:OPTWARE

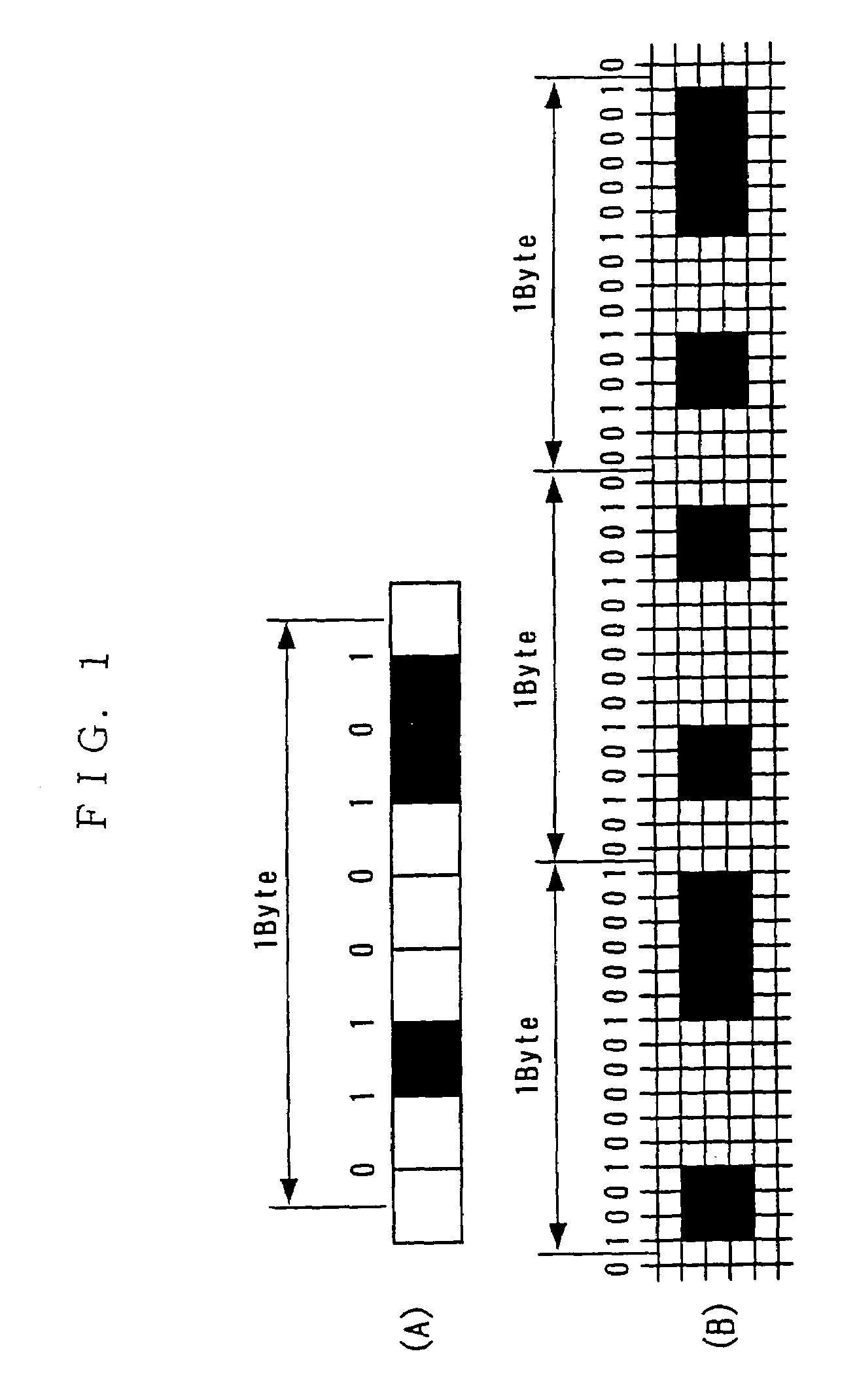

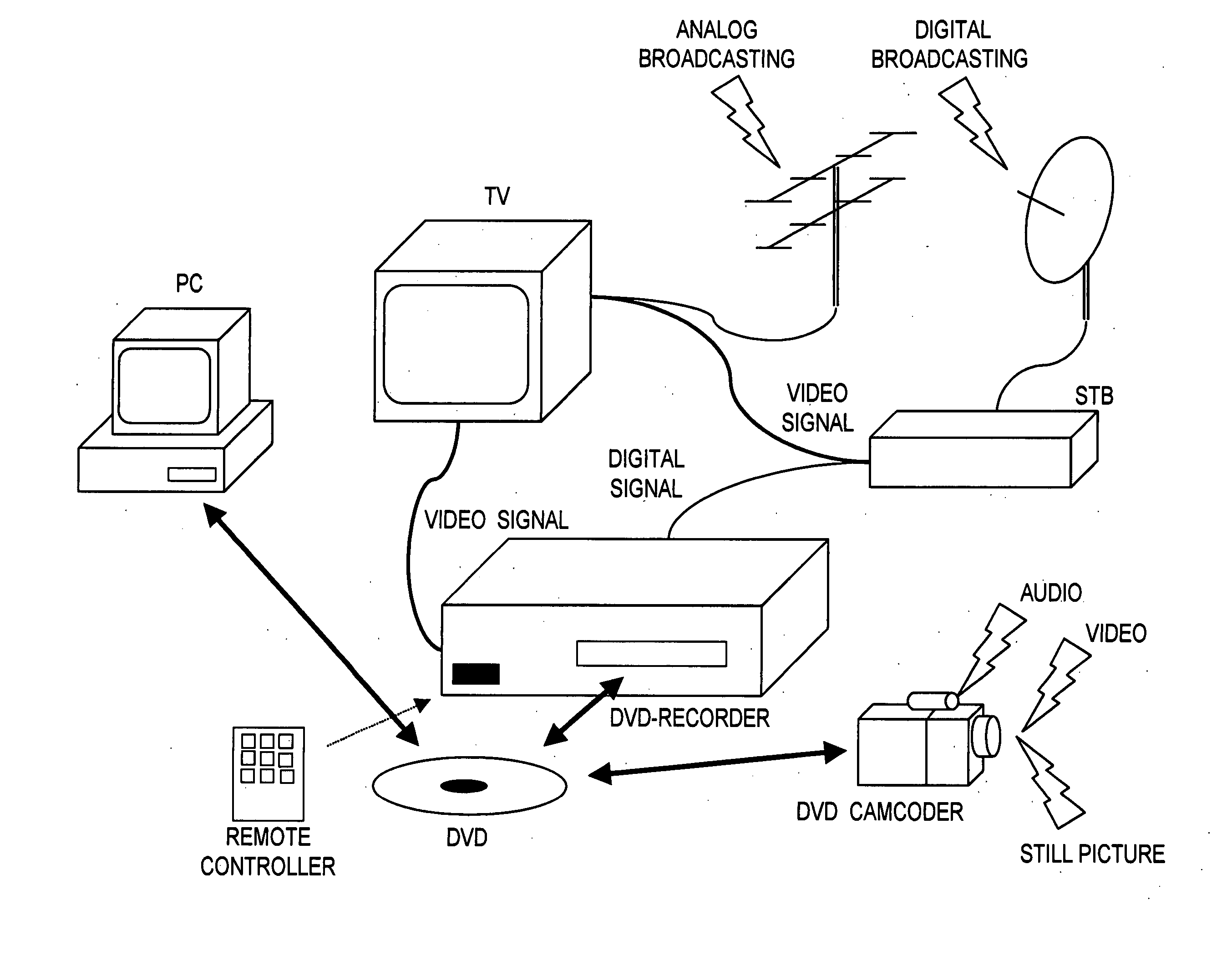

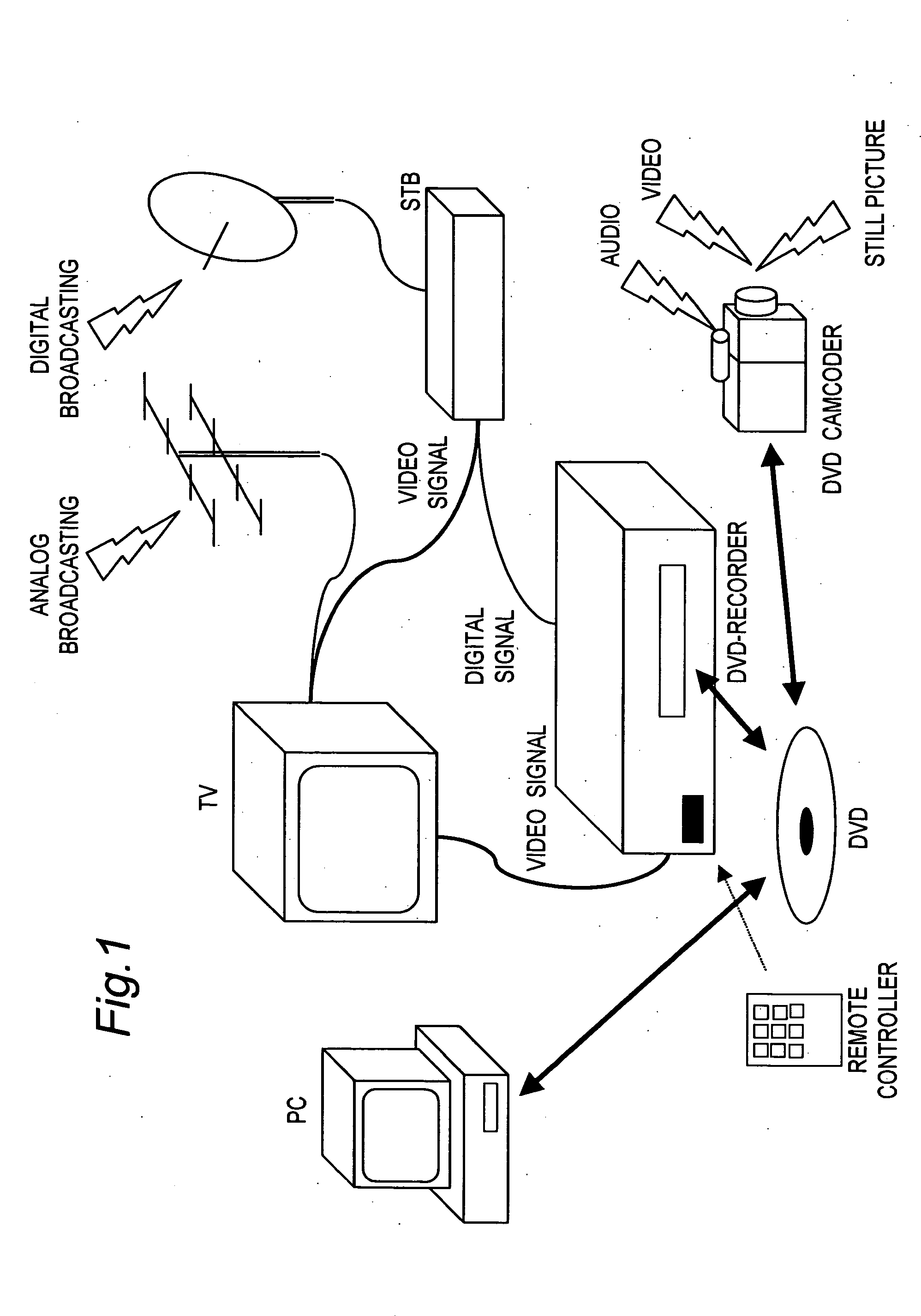

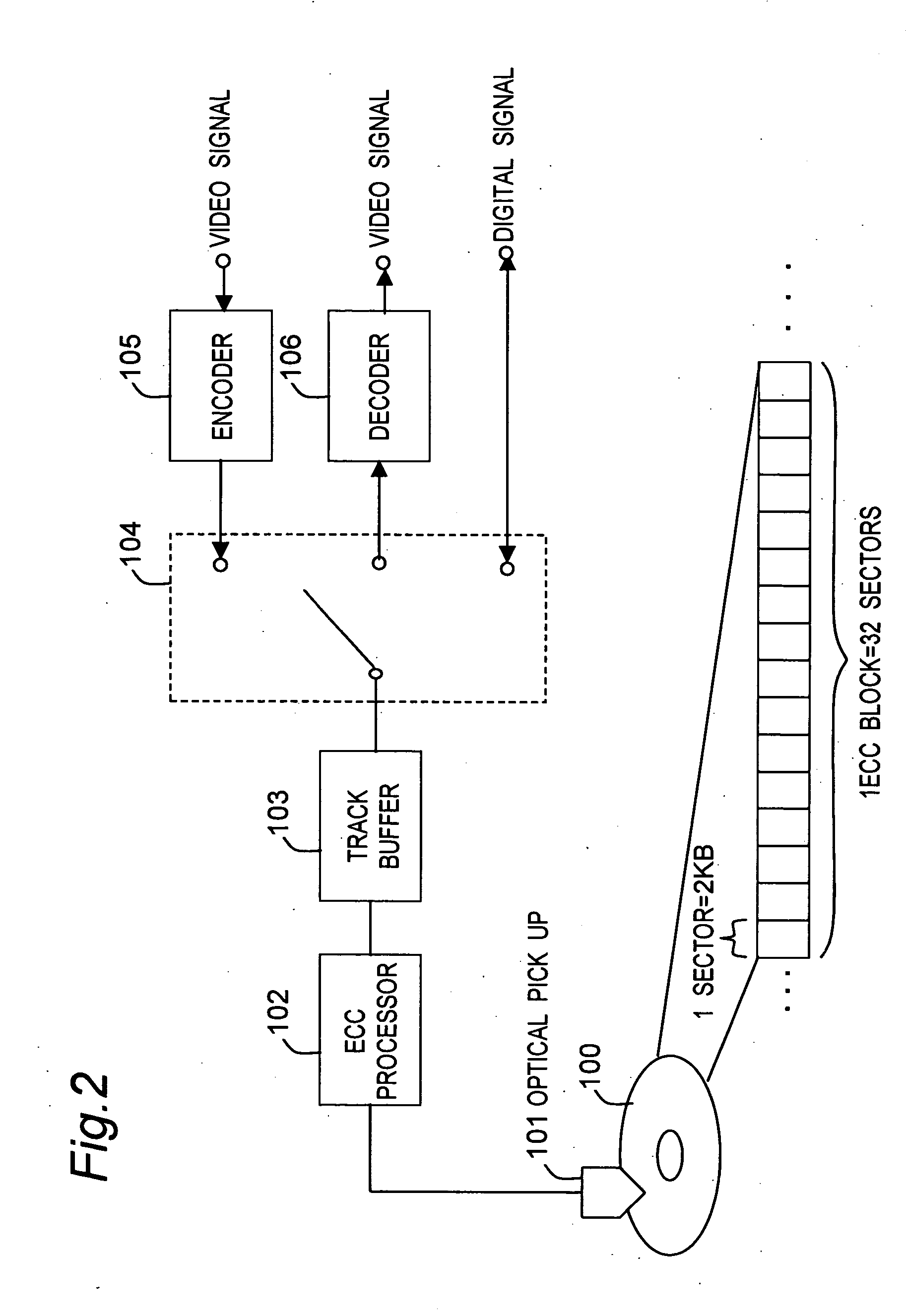

Information recording medium, and apparatus and method for recording information on information recording medium

ActiveUS20040240856A1Easy and fast conversionPromote conversionTelevision system detailsPulse modulation television signal transmissionData recordingMPEG program stream

A data recording medium by which, when encoding a externally input AV signal to an MPEG transport stream, the MPEG_TS can be quickly and efficiently converted to an MPEG program stream conforming to a DVD standard, is provided. An apparatus and method for recording to the data recording medium are also provided. A flag indicating that a first stream (such as an MPEG transport stream) is recorded in a constraint format enabling efficient conversion to a second stream (such as an MPEG program stream) is written to the management information (VOBI). By referencing this flag the recorder can easily determine if the recorded data was recorded in the specified constraint format without analyzing the data recorded to the data recording medium.

Owner:PANASONIC CORP

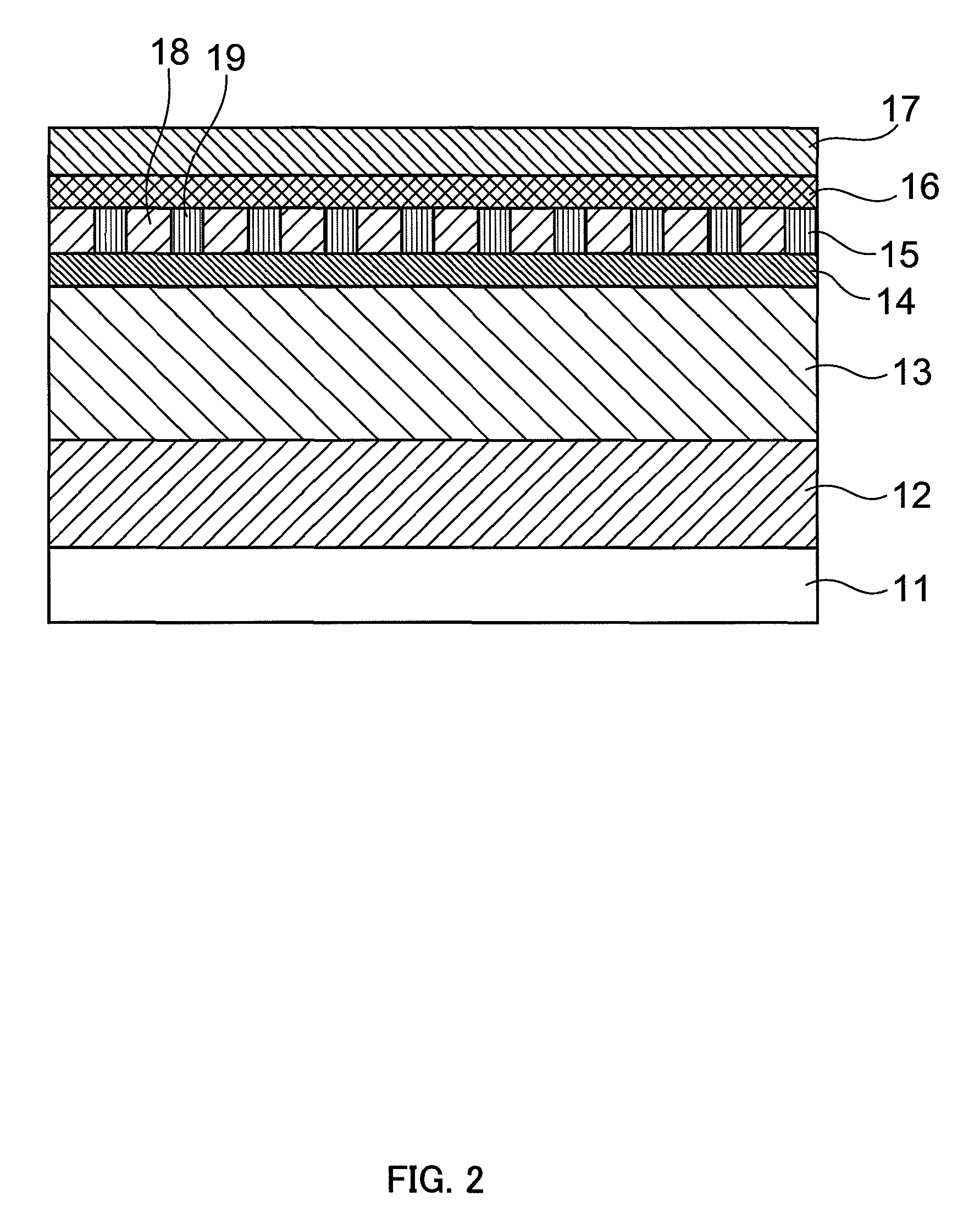

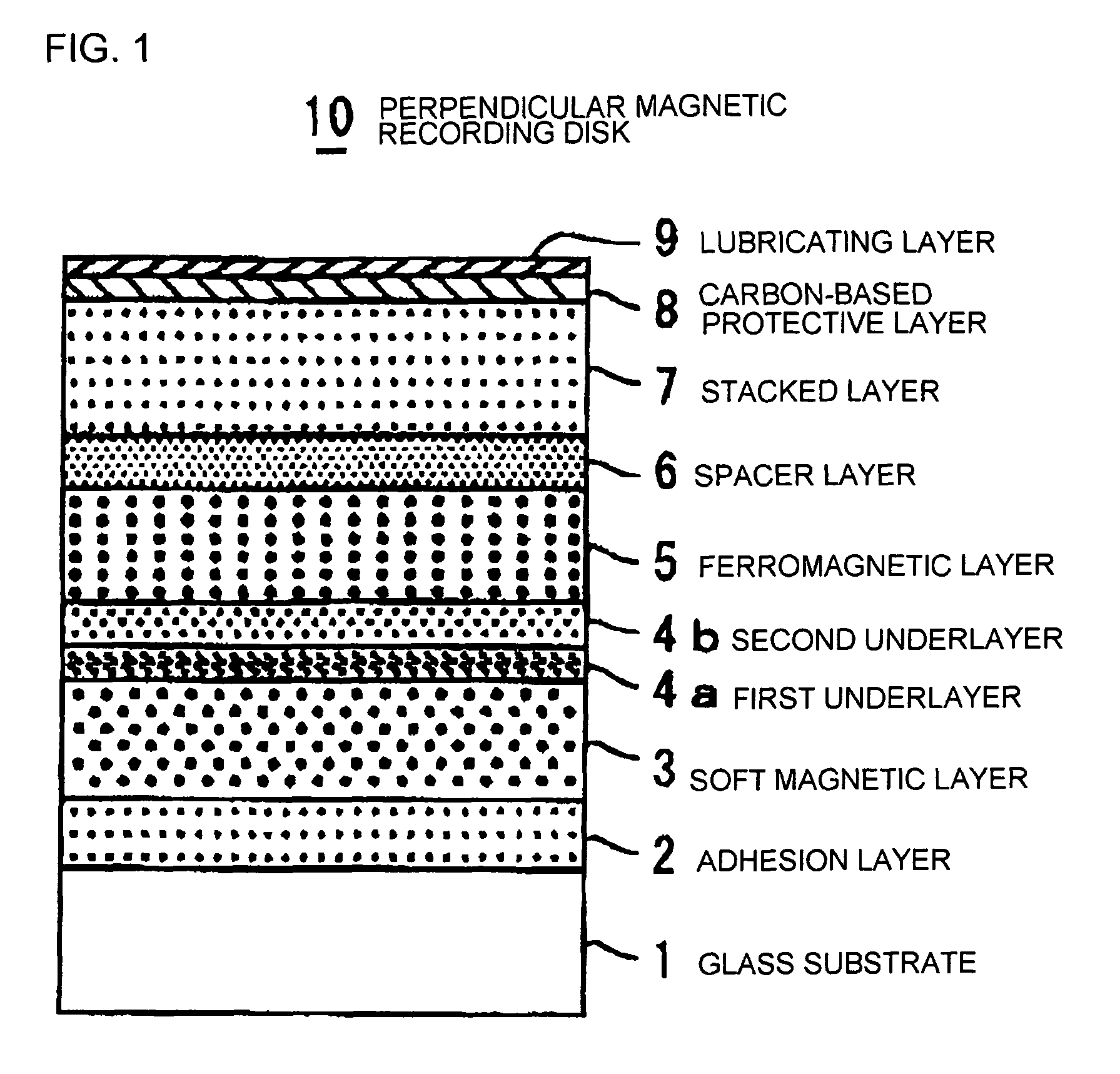

Perpendicular magnetic recording medium and method of manufacturing the same

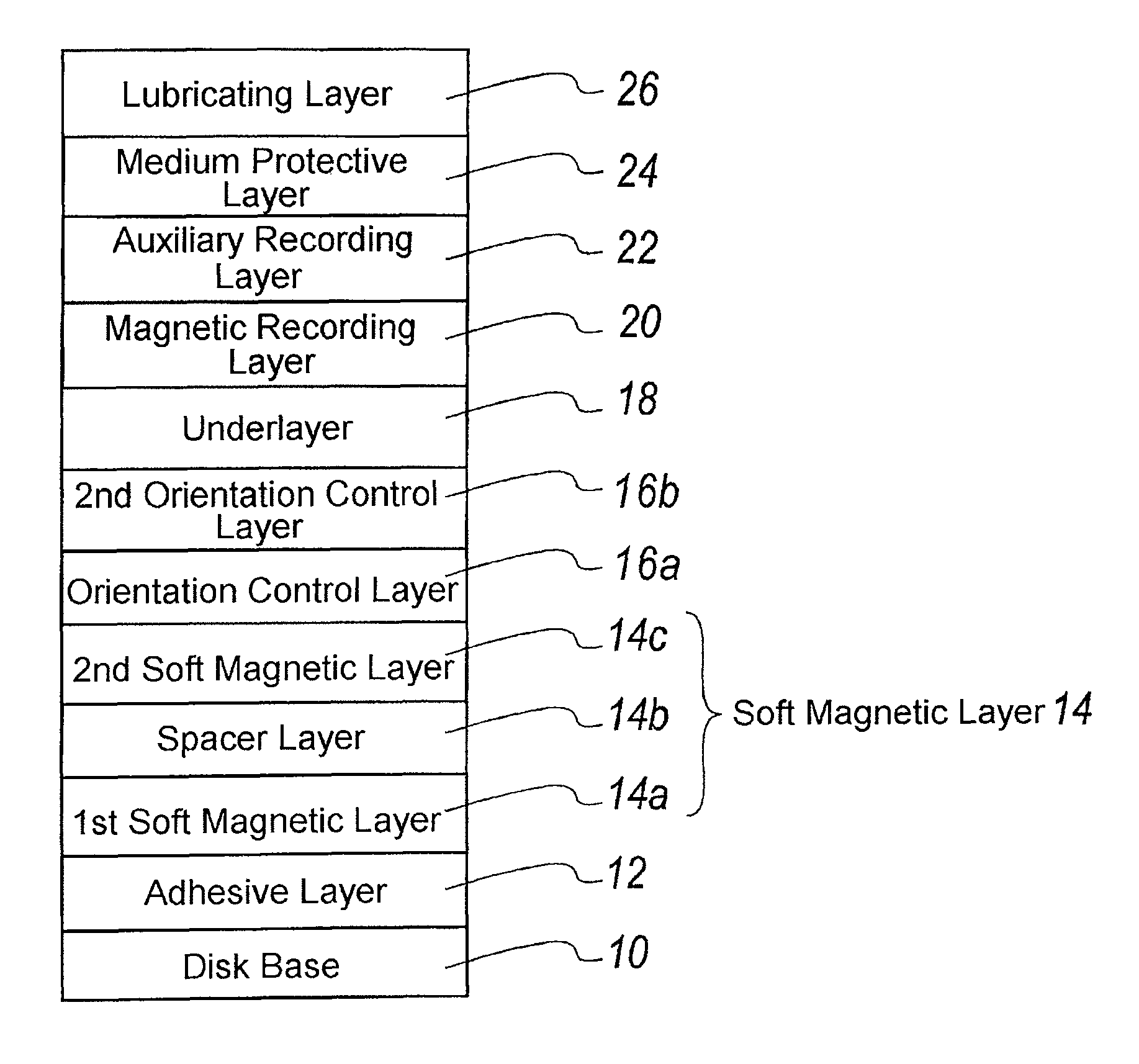

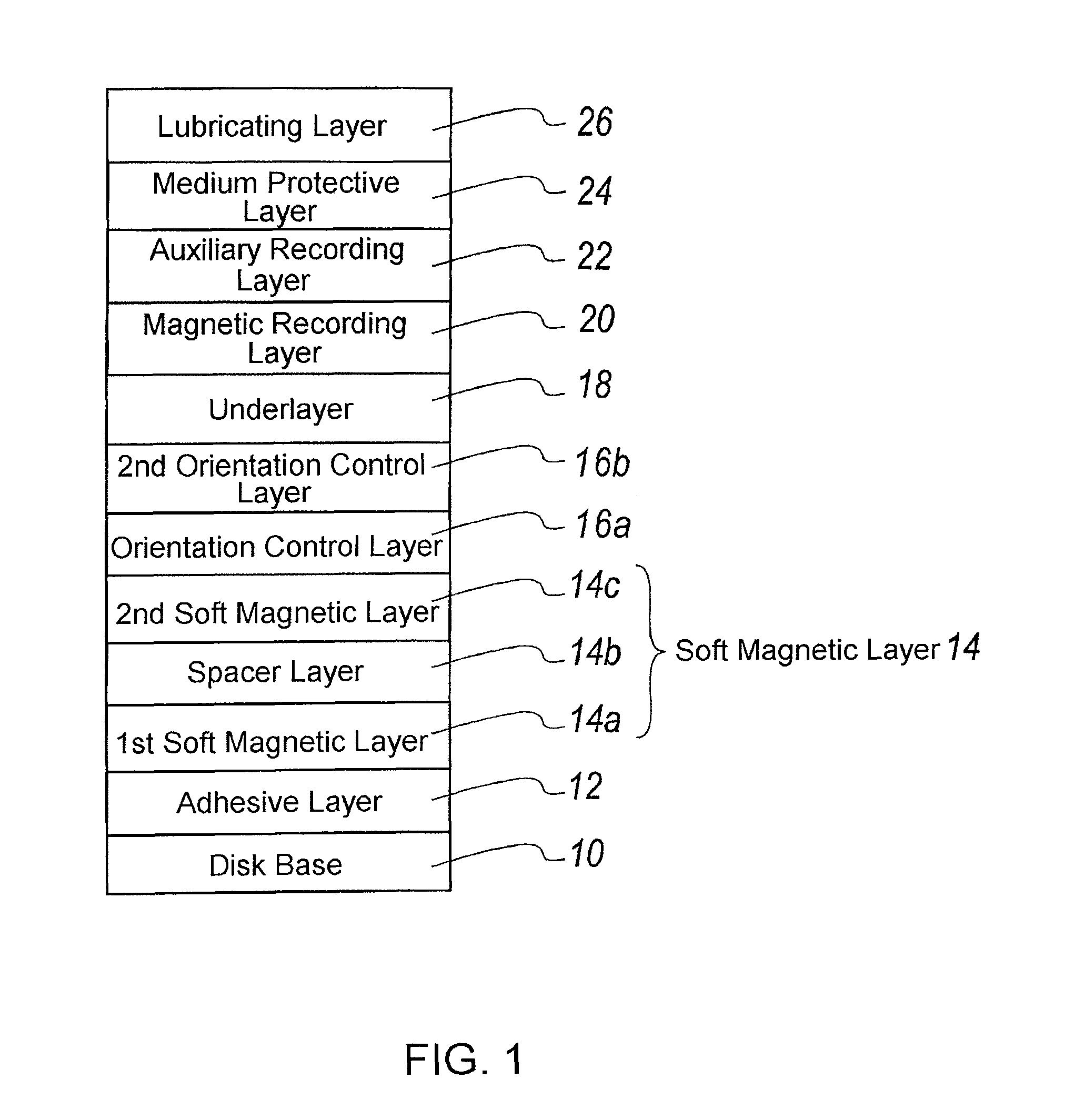

ActiveUS8431258B2Reduce roughnessCrystallinity is disorderedRecord information storageDisk carriersCrystal orientationOptoelectronics

A perpendicular magnetic recording medium comprises a magnetic recording layer that records a signal, an underlayer formed of Ru or Ru compound below the magnetic recording layer, a non-magnetic layer formed of a non-magnetic material below the underlayer to control crystal orientation of the underlayer, a soft magnetic layer provided below the non-magnetic layer, and a substrate on which the magnetic recording layer, the underlayer, the non-magnetic layer, and the soft magnetic layer are formed. The non-magnetic layer comprises a first non-magnetic layer formed above the soft magnetic layer and a second non-magnetic layer formed above the first non-magnetic layer. The first non-magnetic layer is formed of amorphous Ni compound while the second non-magnetic layer is formed of crystalline Ni or crystalline Ni compound.

Owner:WESTERN DIGITAL TECH INC

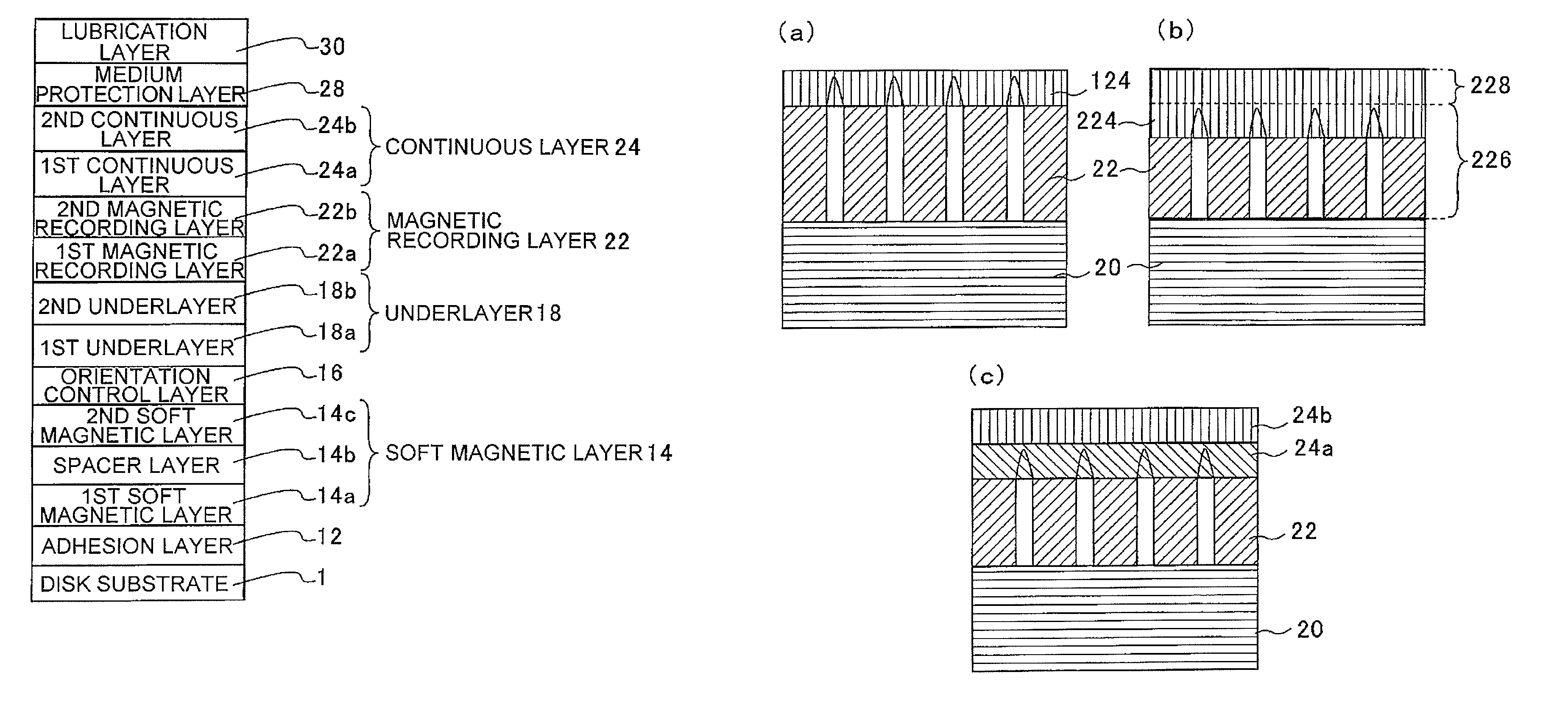

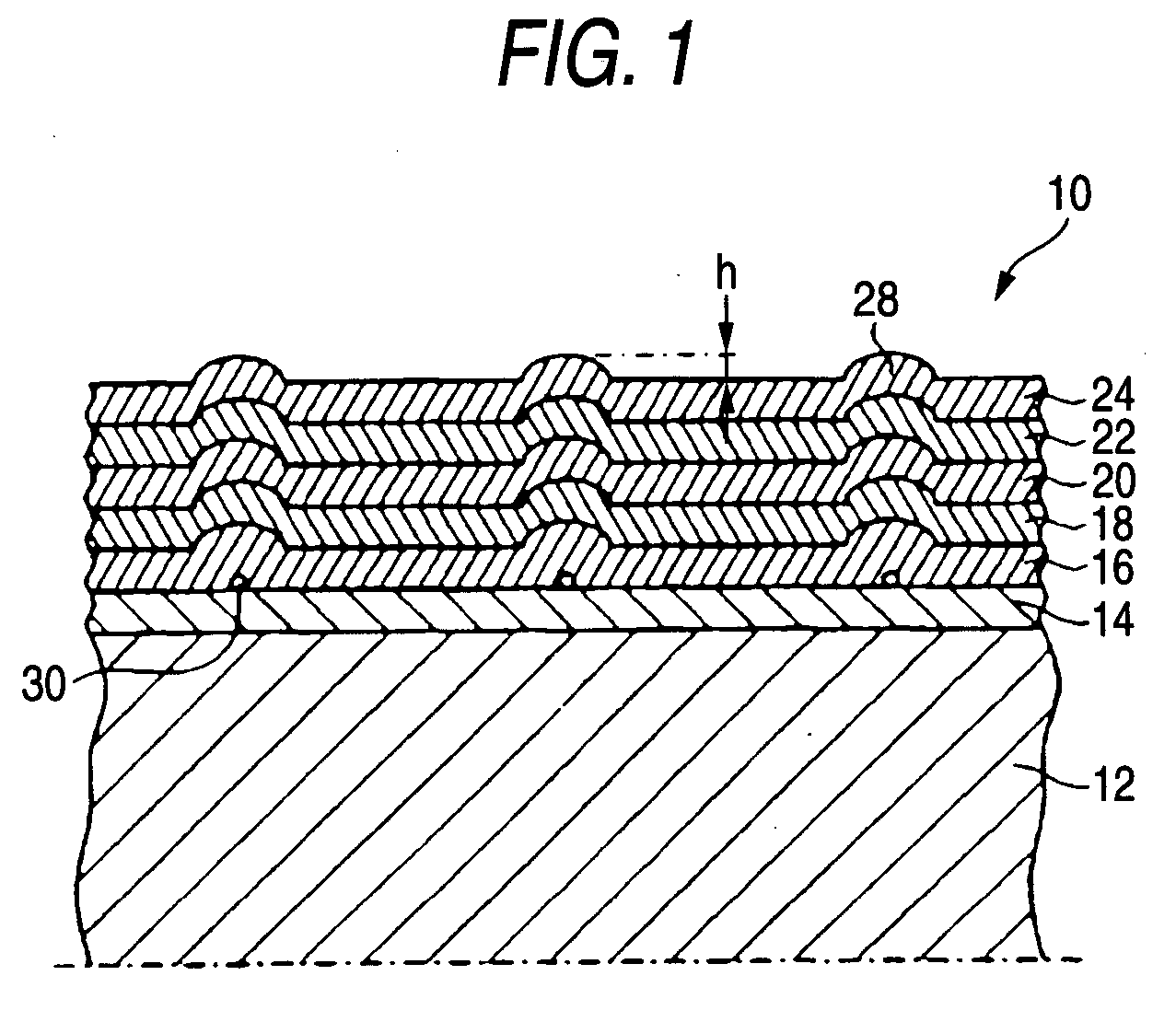

Perpendicular magnetic recording medium

ActiveUS8603649B2Improve recording densitySimple compositionRecord information storageMagnetic recordingPlatinumRecording layer

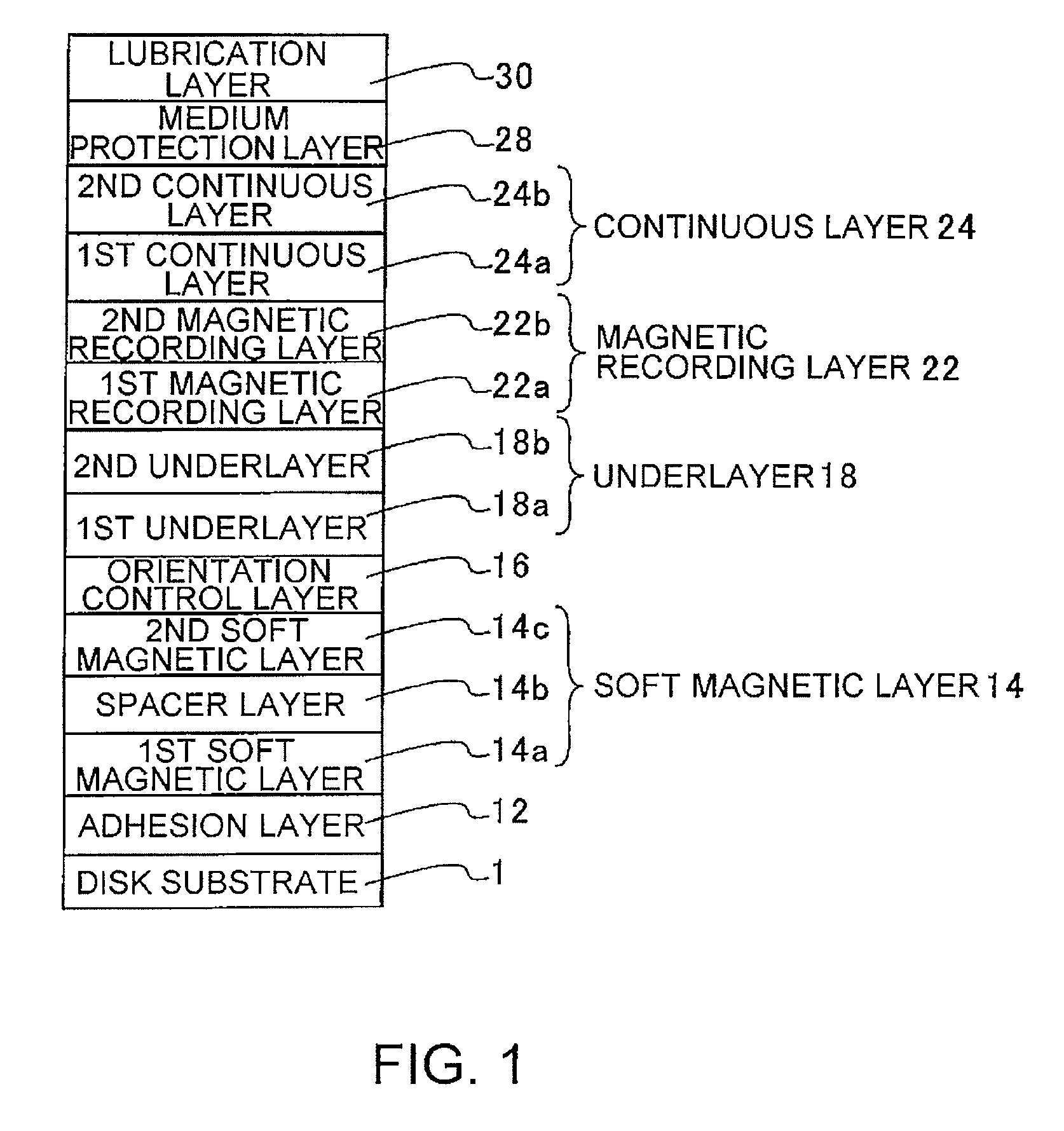

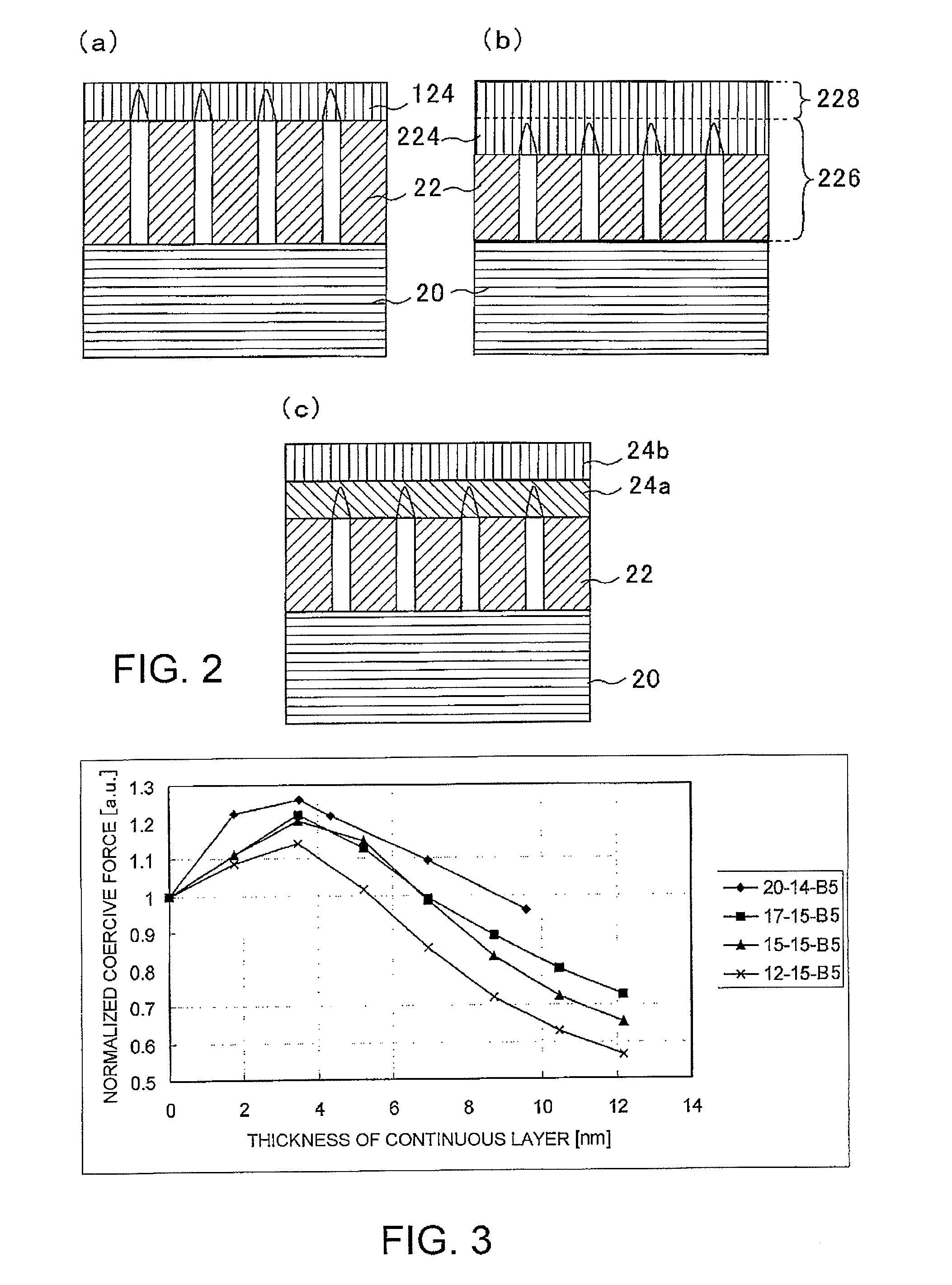

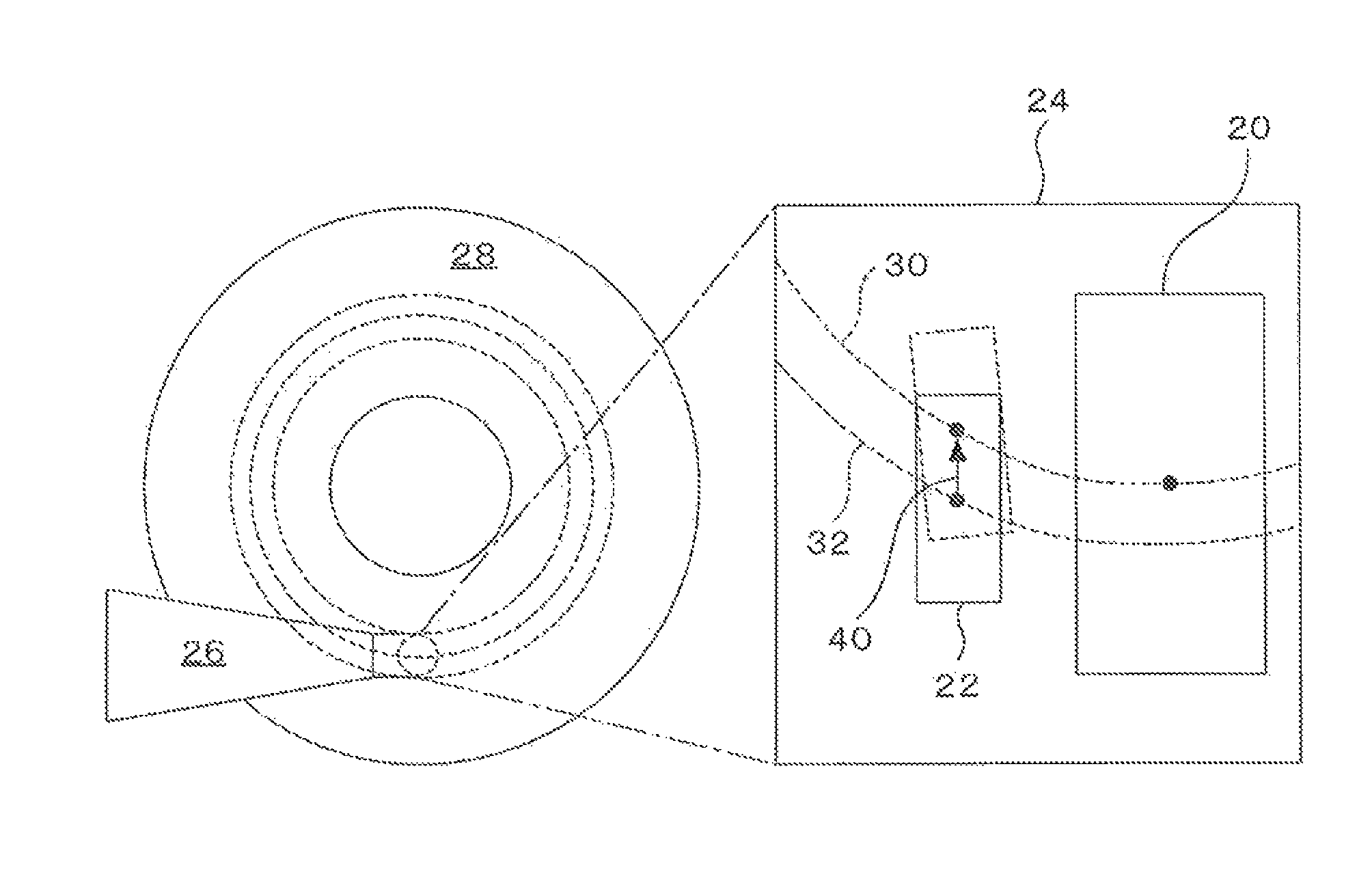

A perpendicular magnetic recording medium includes a magnetic recording layer 22 having a granular structure composed of crystal grains containing cobalt (Co) and grown in a columnar shape and a grain boundary portion comprising a nonmagnetic substance and formed between the crystal grains, and a continuous layer 24 of a thin film magnetically continuous in a film plane direction. The continuous layer 24 includes a plurality of layers 24a and 24b containing cobalt, chromium (Cr), and platinum (Pt). Among the layers, the layer 24a nearer to the magnetic recording layer has a greater chromium content.

Owner:WESTERN DIGITAL TECH INC

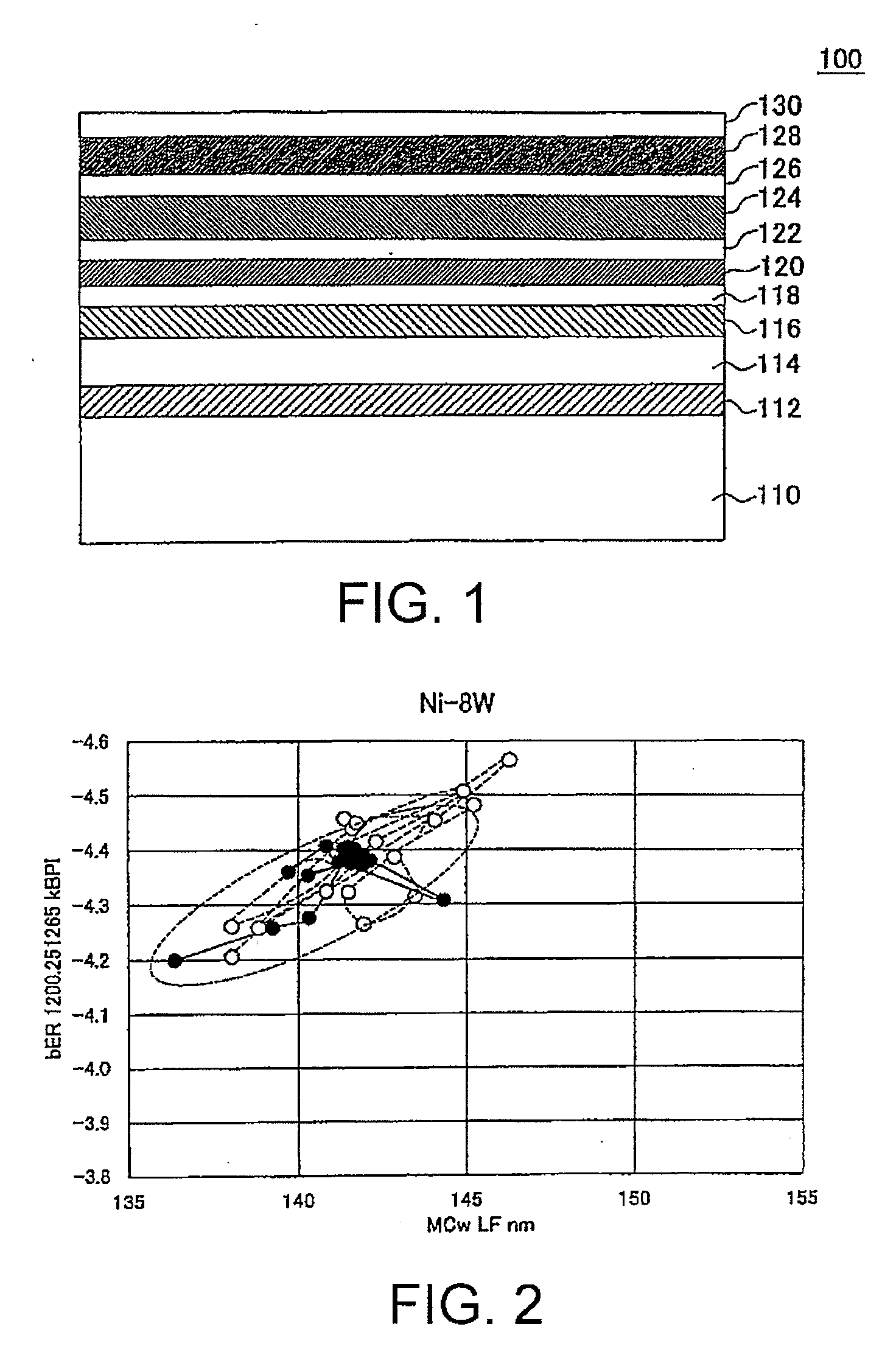

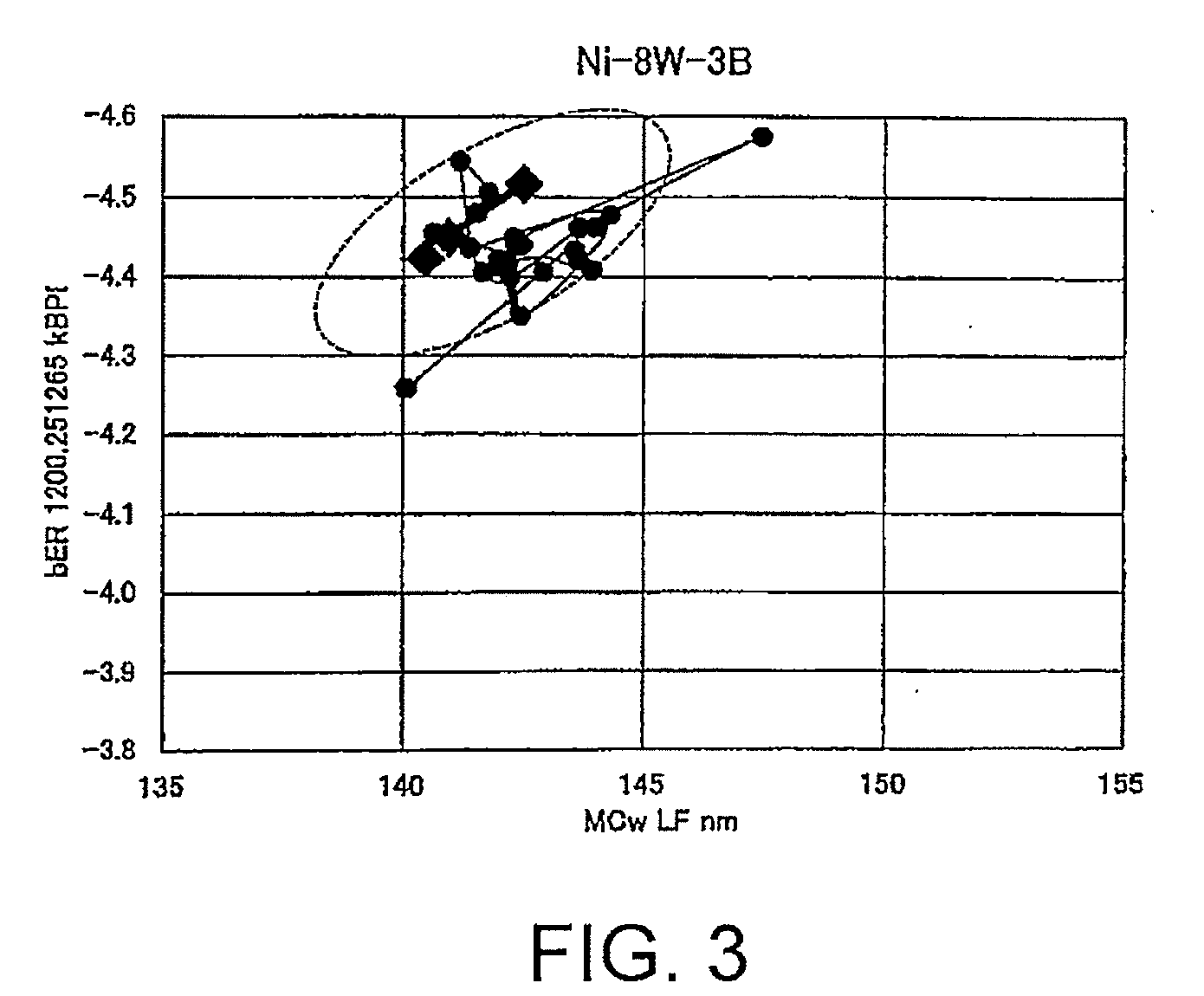

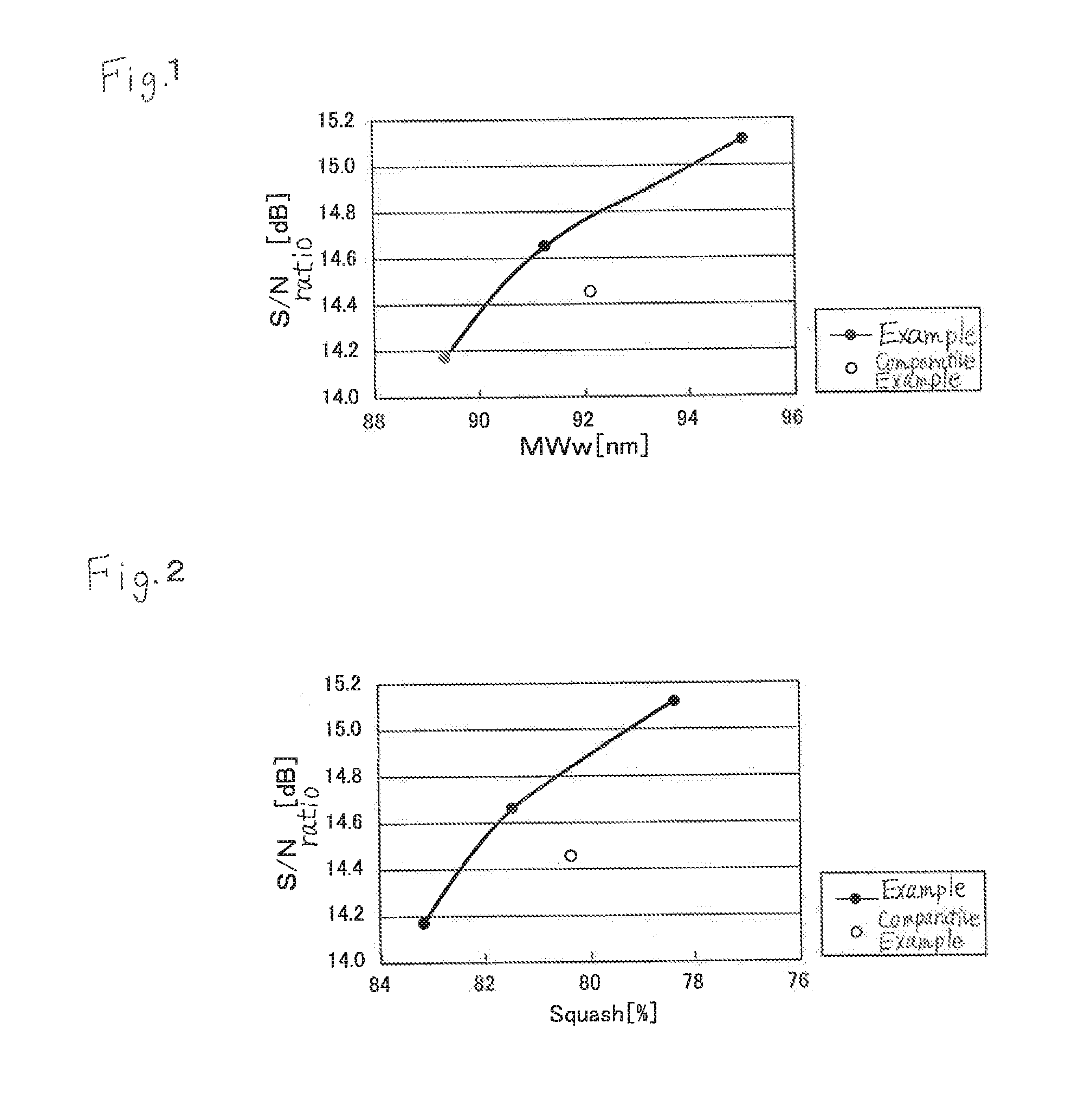

Evaluation method of perpendicular magnetic recording medium and manufacturing method of perpendicular magnetic recording medium

InactiveUS8665541B2Improve recording densityImprove productivityRecord information storageCarrier monitoringSignal-to-noise ratio (imaging)Engineering

A characteristic evaluation method of a perpendicular magnetic recording medium suitable for obtaining a perpendicular magnetic recording medium which can respond to much higher recording density is provided.This is an evaluation method of a perpendicular magnetic recording medium, including a process of recording a first signal of a specific frequency at an arbitrary first position in the perpendicular magnetic recording medium; a process of measuring a reproduction output of the first signal and of measuring a signal / noise ratio (initial value) of the first signal at a peak position where the reproduction output becomes the maximum; a process of recording a signal of a specific frequency at a second position away from the first position by a predetermined distance in the radial direction of the perpendicular magnetic recording medium; a process of measuring the signal / noise ratio of the first signal at the peak position again; a process of repeating the process of recording the signal of the specific frequency at a position brought close to the first position from the second position by a predetermined distance and of measuring the signal / noise ratio of the first signal at the peak position again while sequentially getting closer to the first position from the second position; and a process of determining whether the value of the signal / noise ratio has lowered from the initial value by a predetermined range or more.

Owner:WD MEDIA SINGAPORE PTE

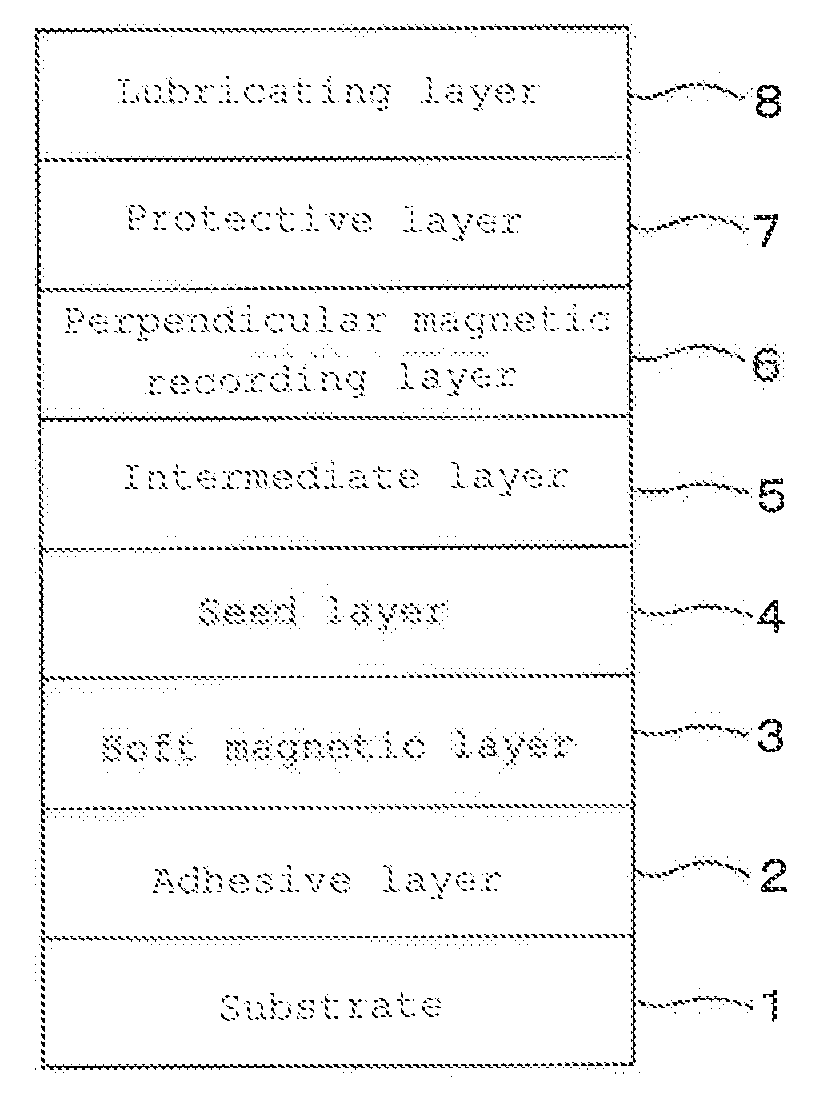

Method for producing a perpendicular magnetic recording medium

ActiveUS20120171369A1Improved separation propertiesImproved characteristicRecord information storageBase layer manufacturePhysicsRecording density

To provide a method for manufacturing a perpendicular magnetic recording medium, which is capable of coping with the much higher recording density.Disclosed is a method for manufacturing a perpendicular magnetic recording medium to be used for recording information by a perpendicular magnetic recording system, including at least a soft magnetic layer, an intermediate layer, and a magnetic recording layer on a substrate, characterized in that the method includes the step of:composing the intermediate layer of consecutive N layers (provided that N is an integer of at least 3 or more), depositing a first layer containing ruthenium (Ru) as a main component, first; setting a gas pressure during the deposition to the pressure which is higher than or the same as that in the first layer; depositing a second layer containing ruthenium (Ru), or ruthenium (Ru) containing oxygen or an oxide as a main component; and adjusting so that the oxygen content remains constant, or increases toward the uppermost layer in the second layer and succeeding layers.

Owner:WESTERN DIGITAL TECH INC

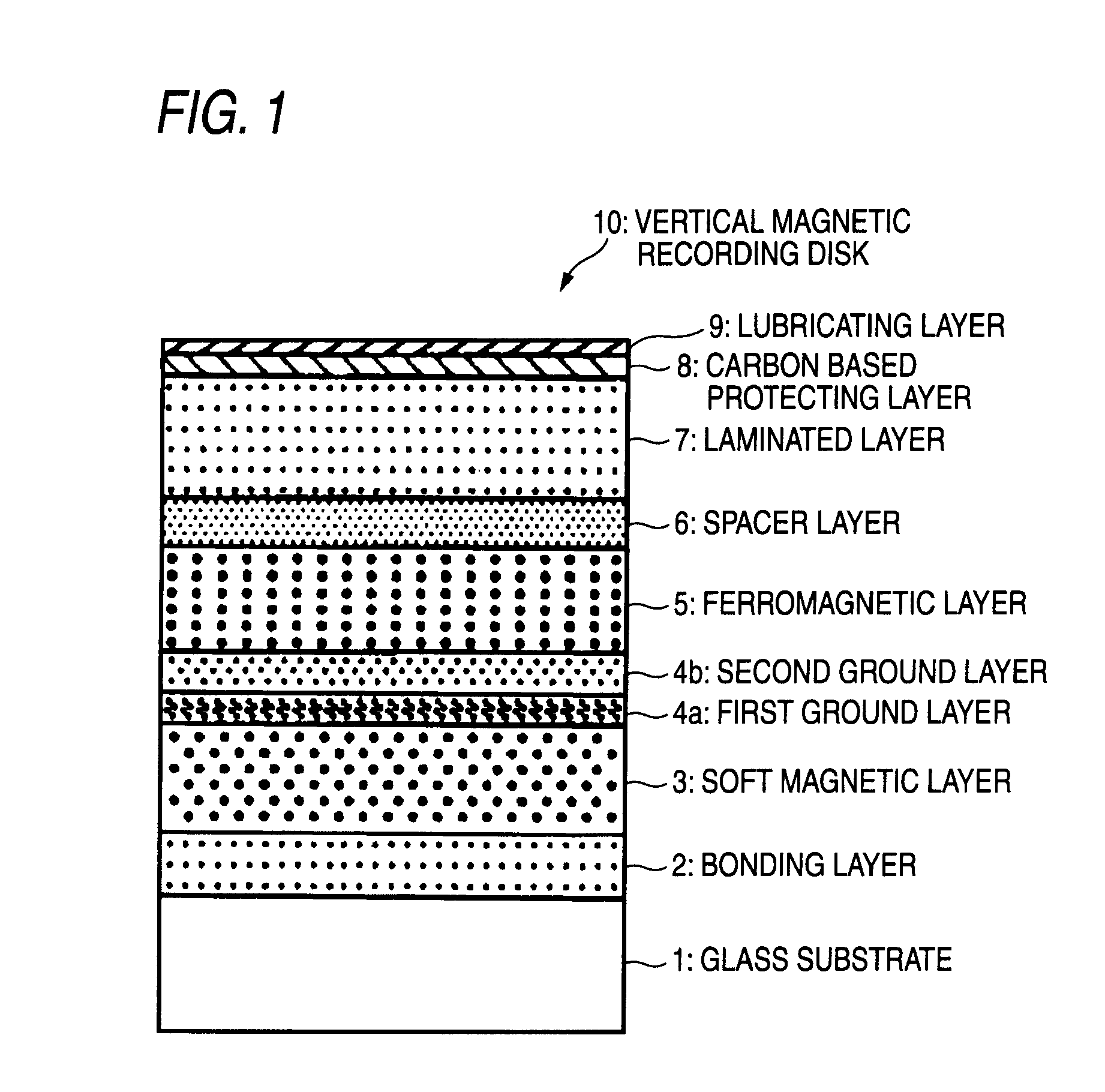

Vertical magnetic recording disk manufacturing method and vertical magnetic recording disk

ActiveUS20090202866A1Improve magnetic propertiesImprove recording densityVacuum evaporation coatingSputtering coatingKryptonSputtering

In a method of manufacturing a magnetic disk including at least a magnetic recording layer on a substrate 1 and used for vertical magnetic recording, in a step of forming, on the substrate 1, the magnetic recording layer composed of a ferromagnetic layer 5 having a granular structure and an exchange energy control layer 7 constituted by a laminated layer formed on the ferromagnetic layer 5, at least the exchange energy control layer 7 is formed through sputtering in an atmosphere of a rare gas having a greater mass than an argon gas. The rare gas having a greater mass than the argon gas is a krypton (Kr) gas, for example. The exchange energy control layer 7 is a laminated layer composed of a first layer containing Co or a Co-alloy and a second layer containing palladium (Pd) or platinum (Pt), for example.

Owner:WESTERN DIGITAL TECH INC

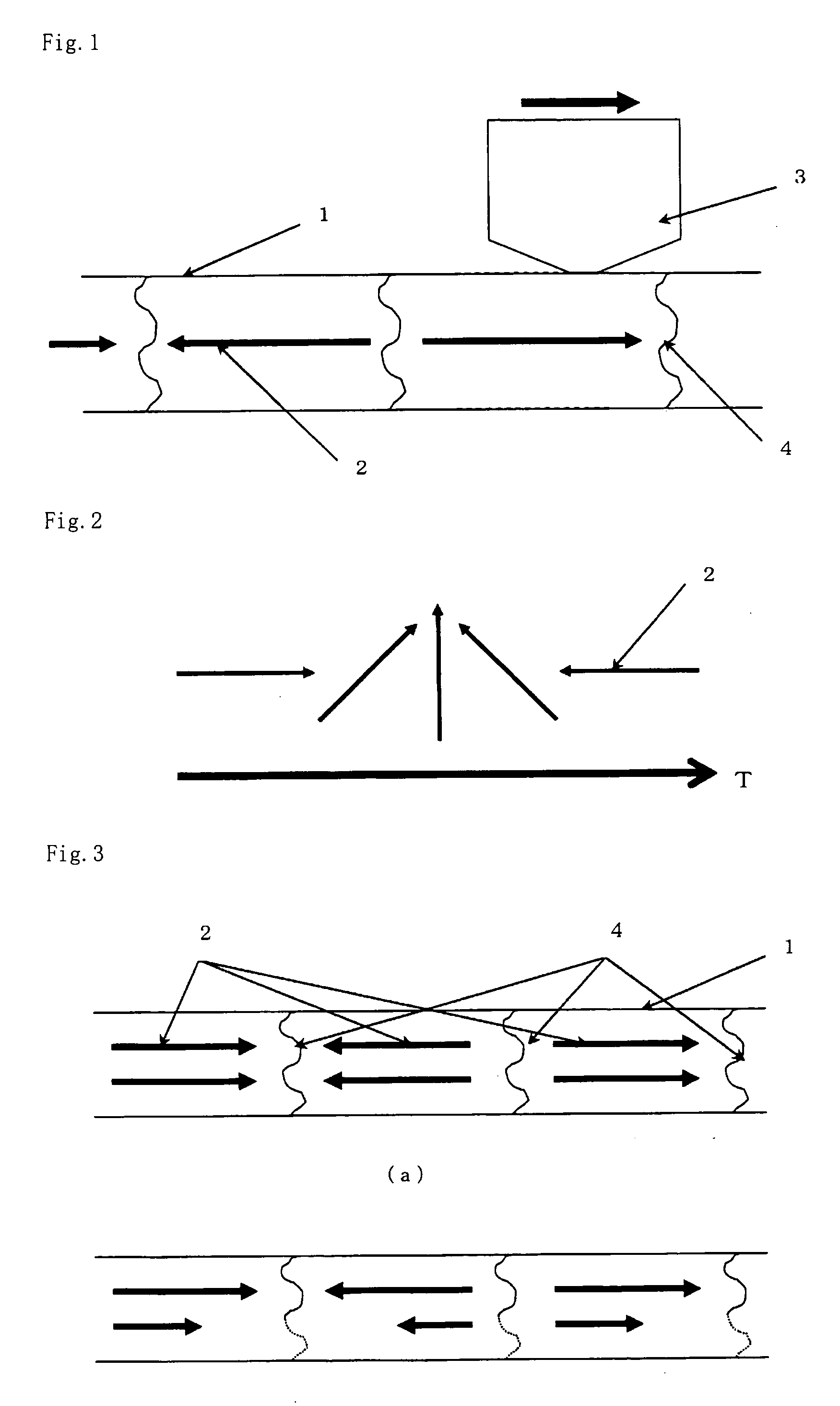

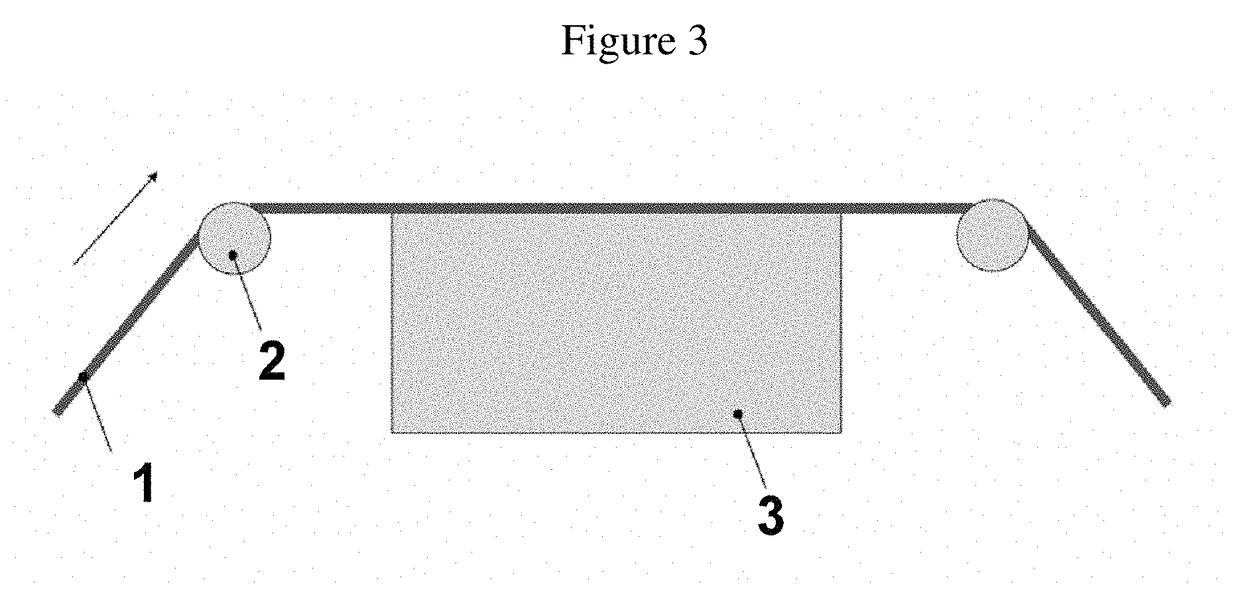

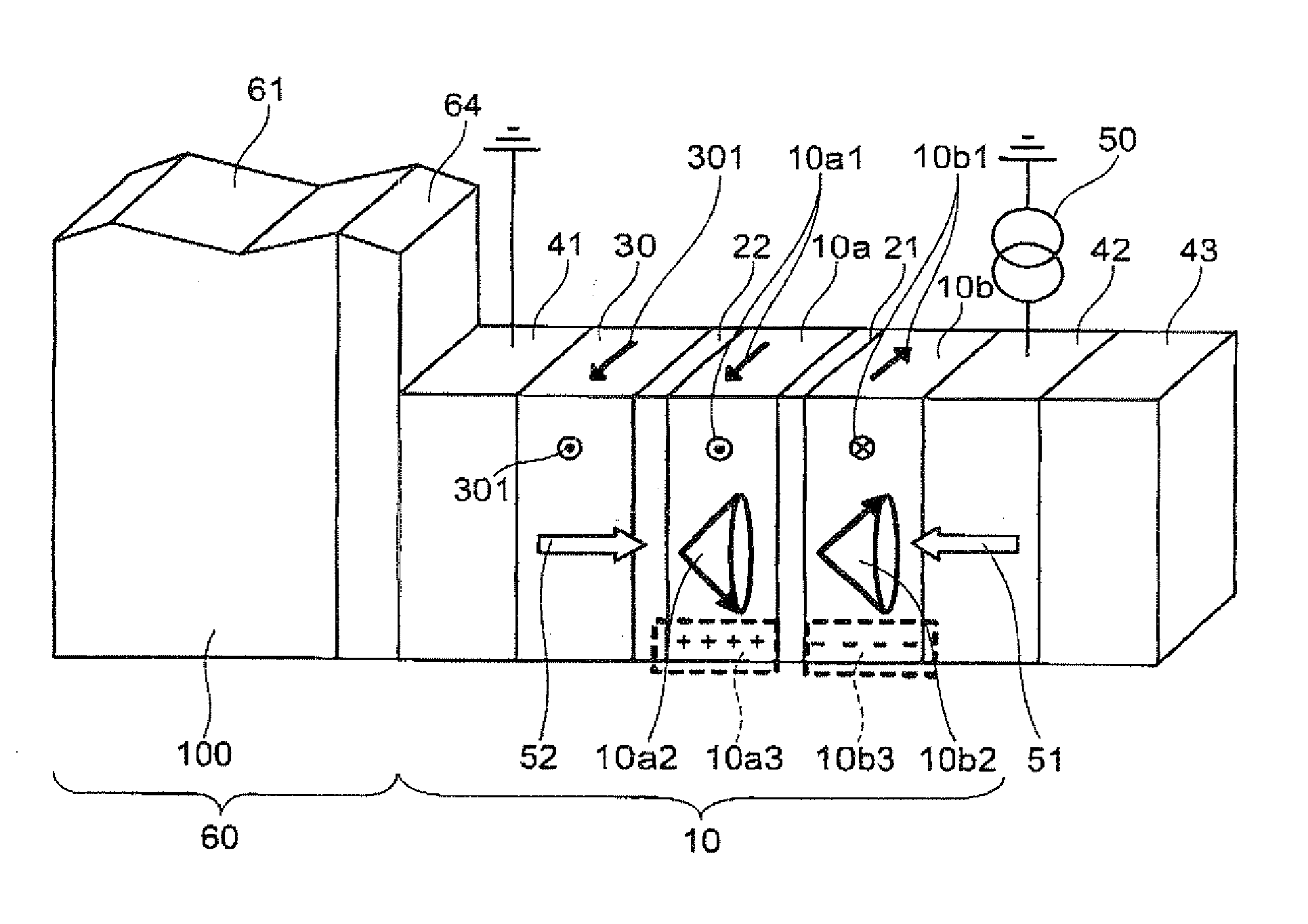

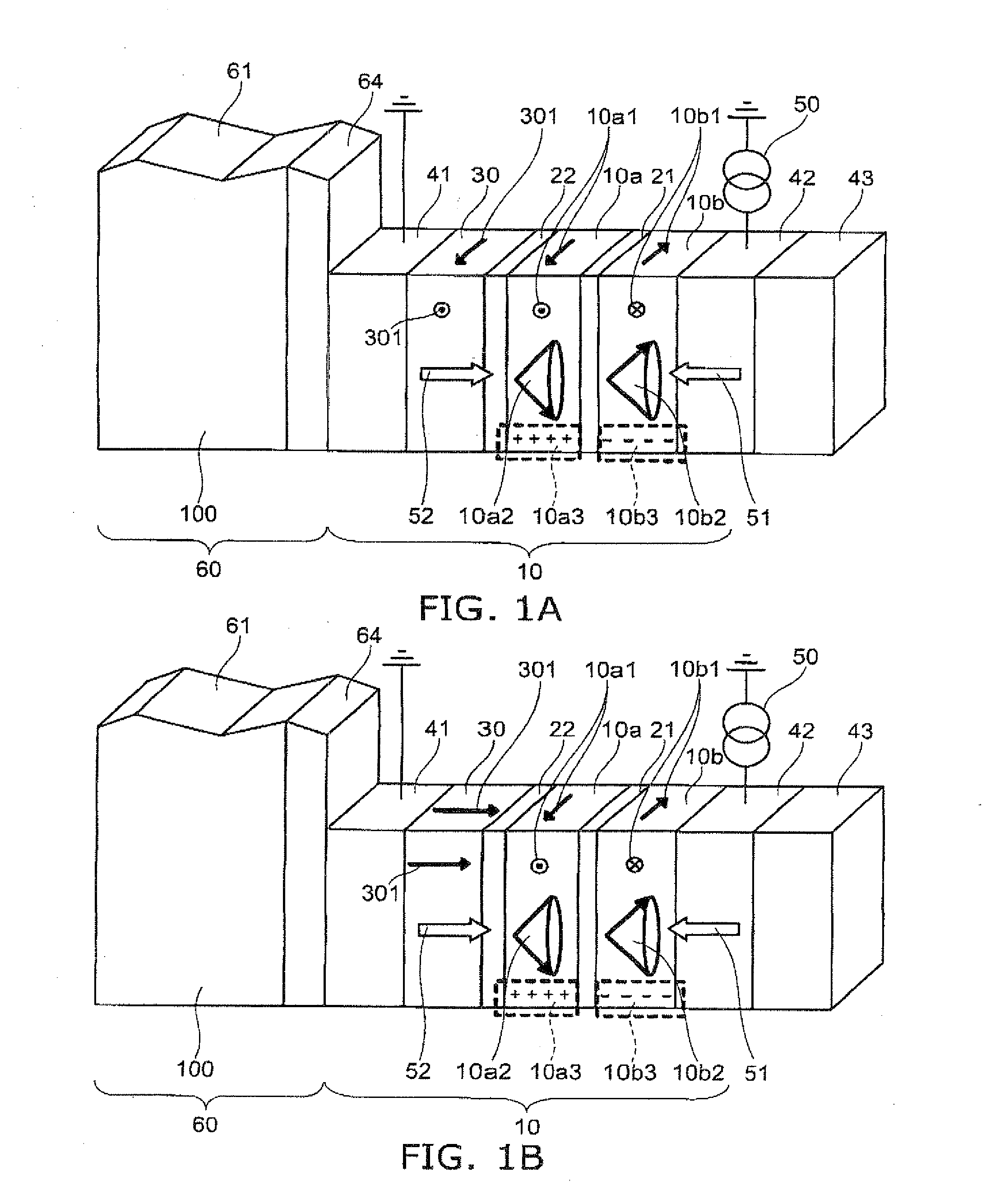

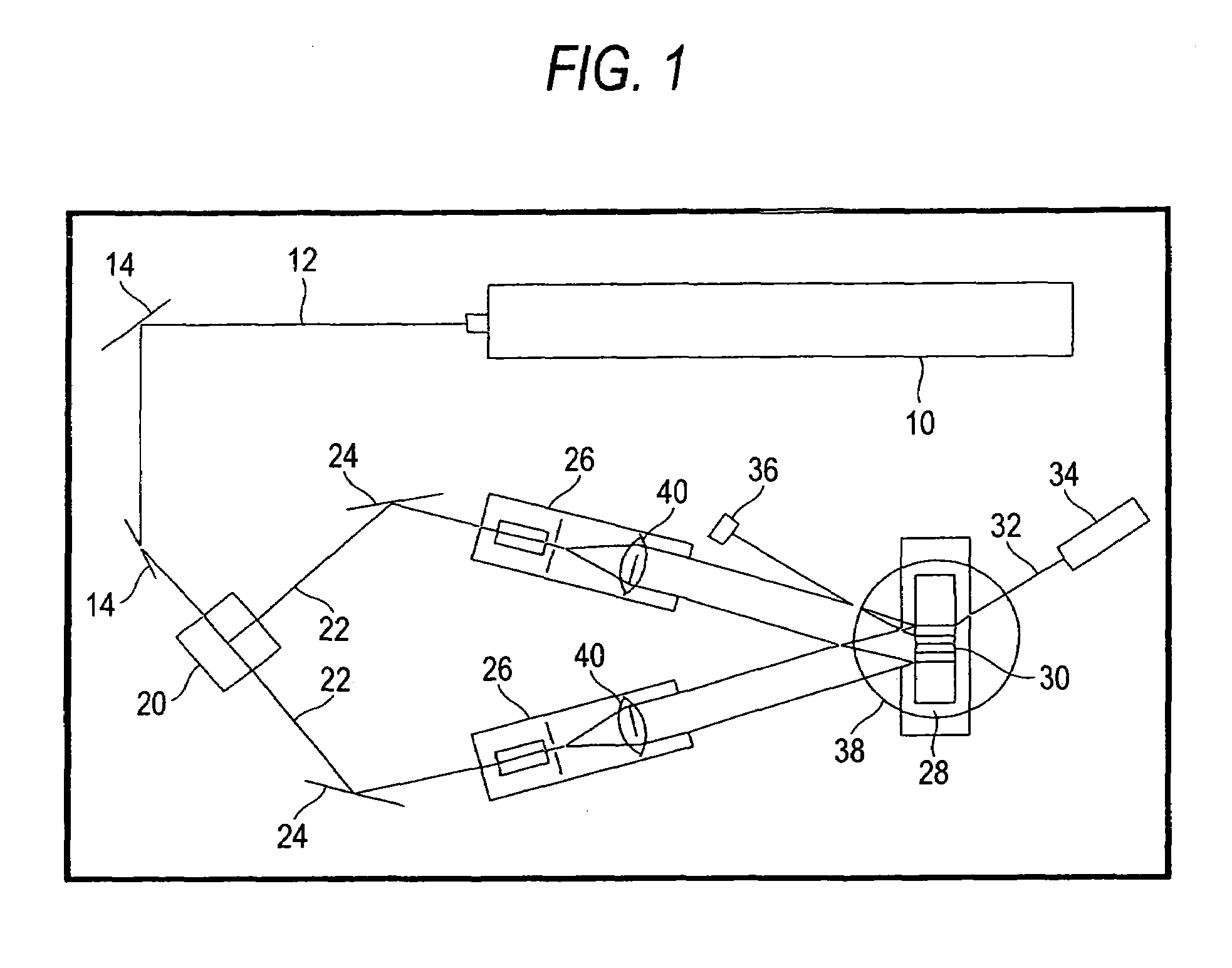

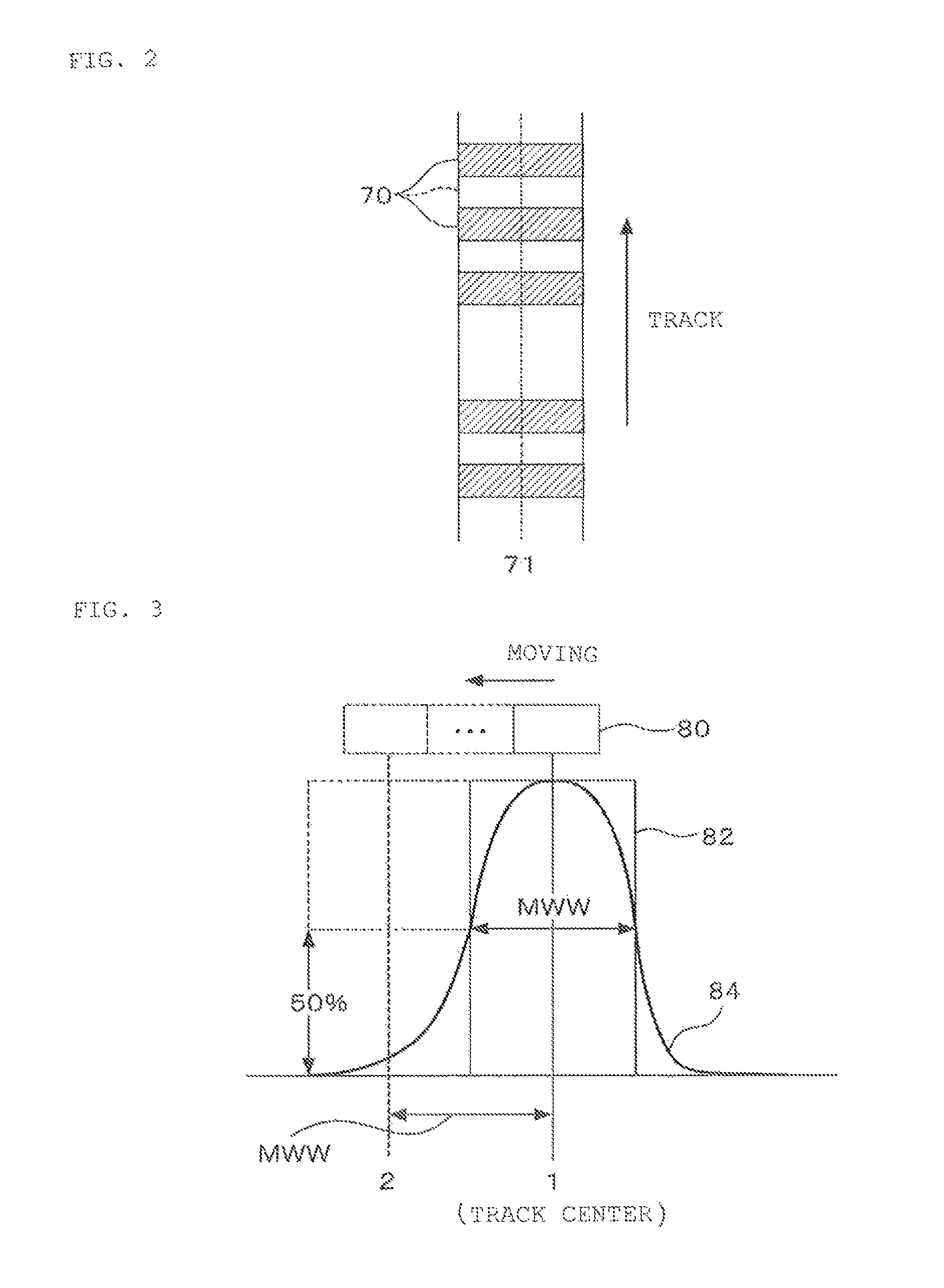

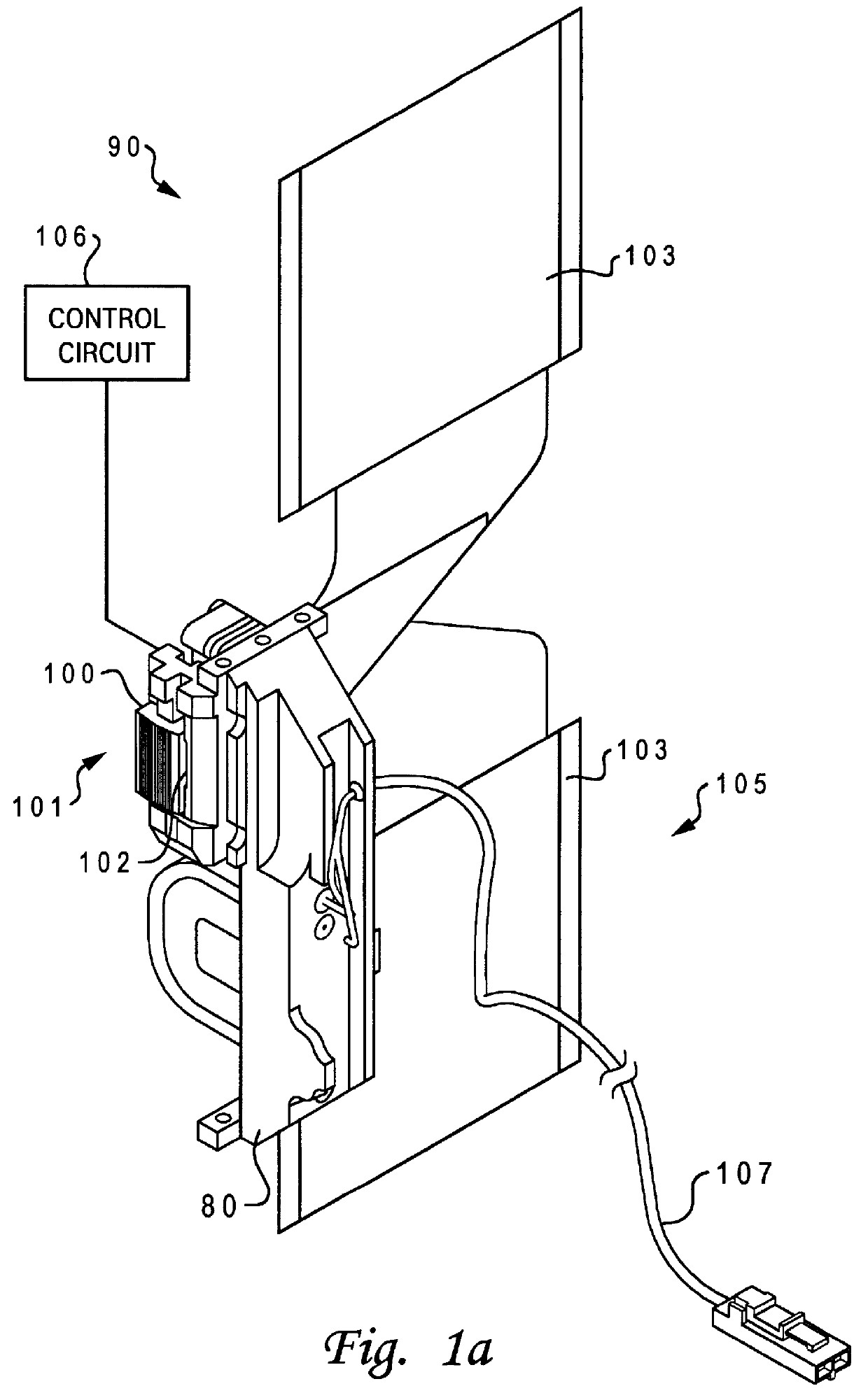

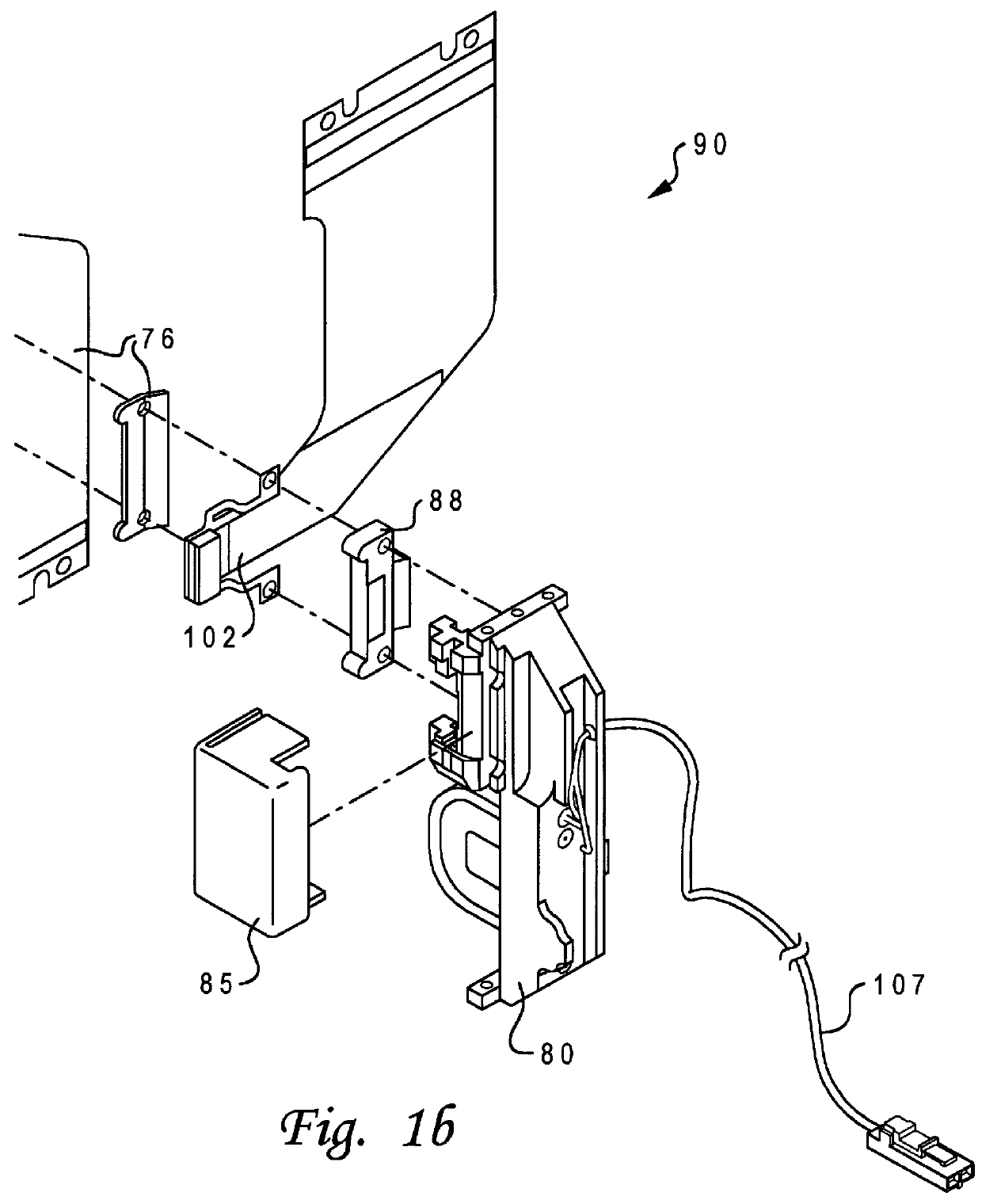

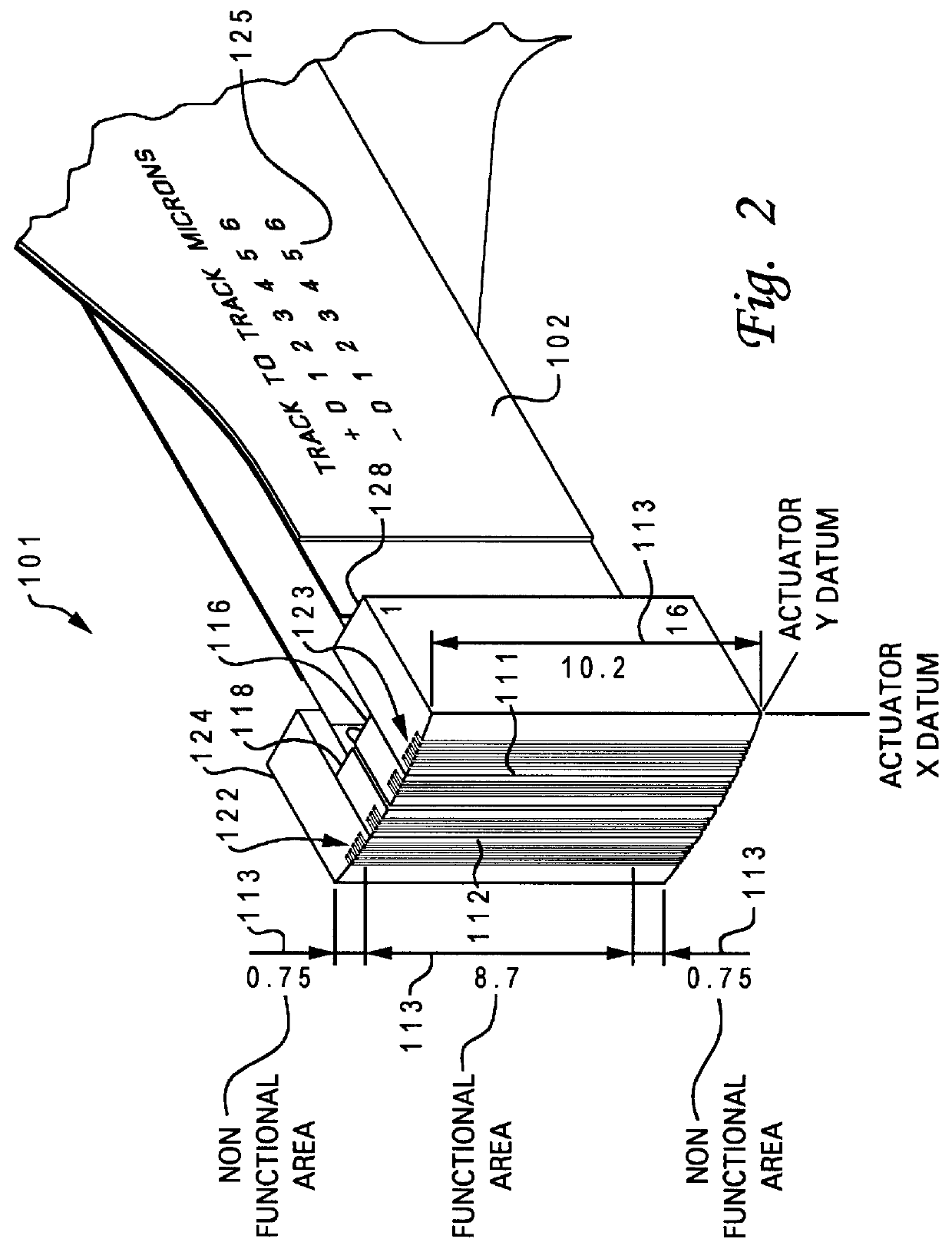

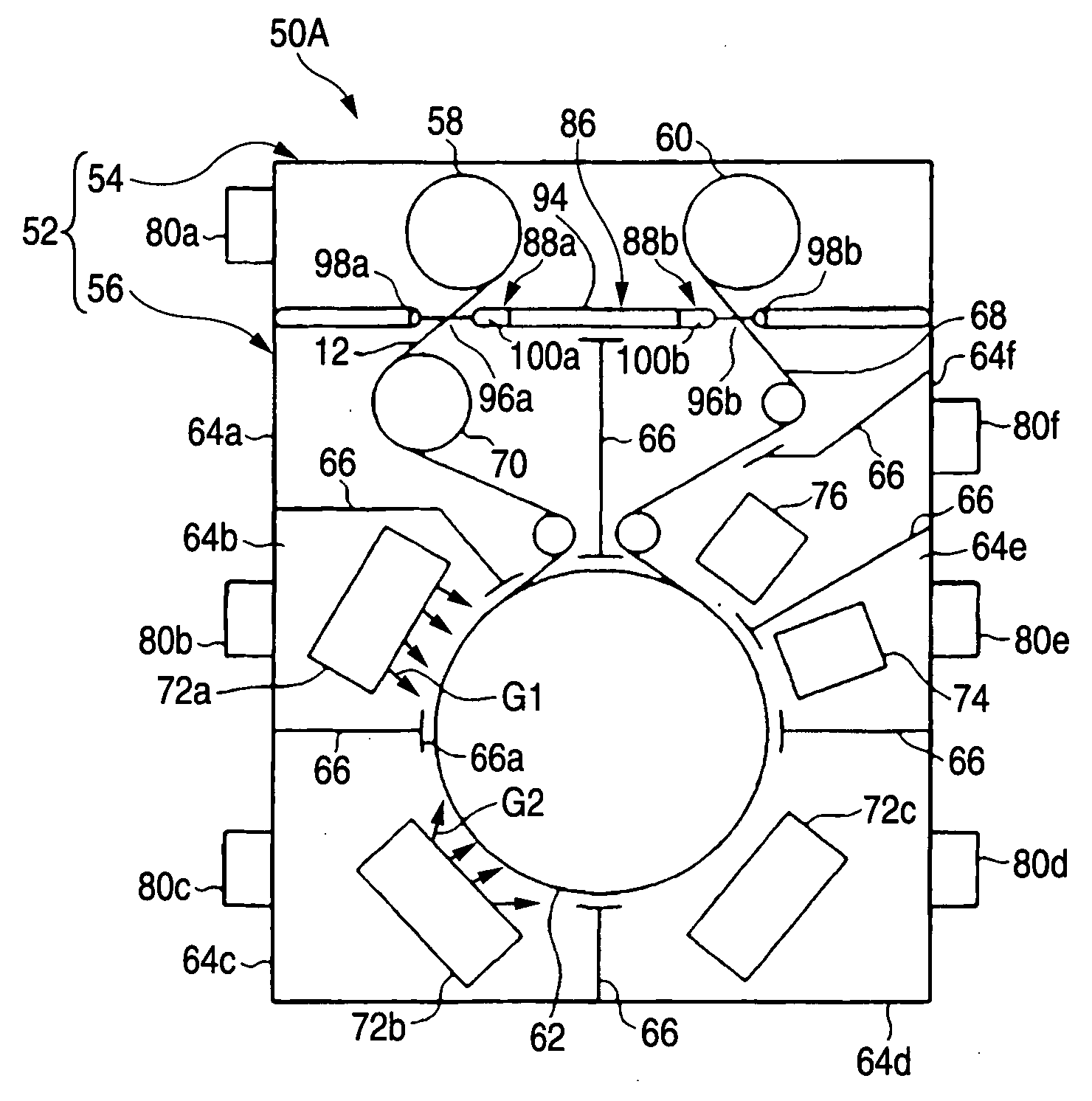

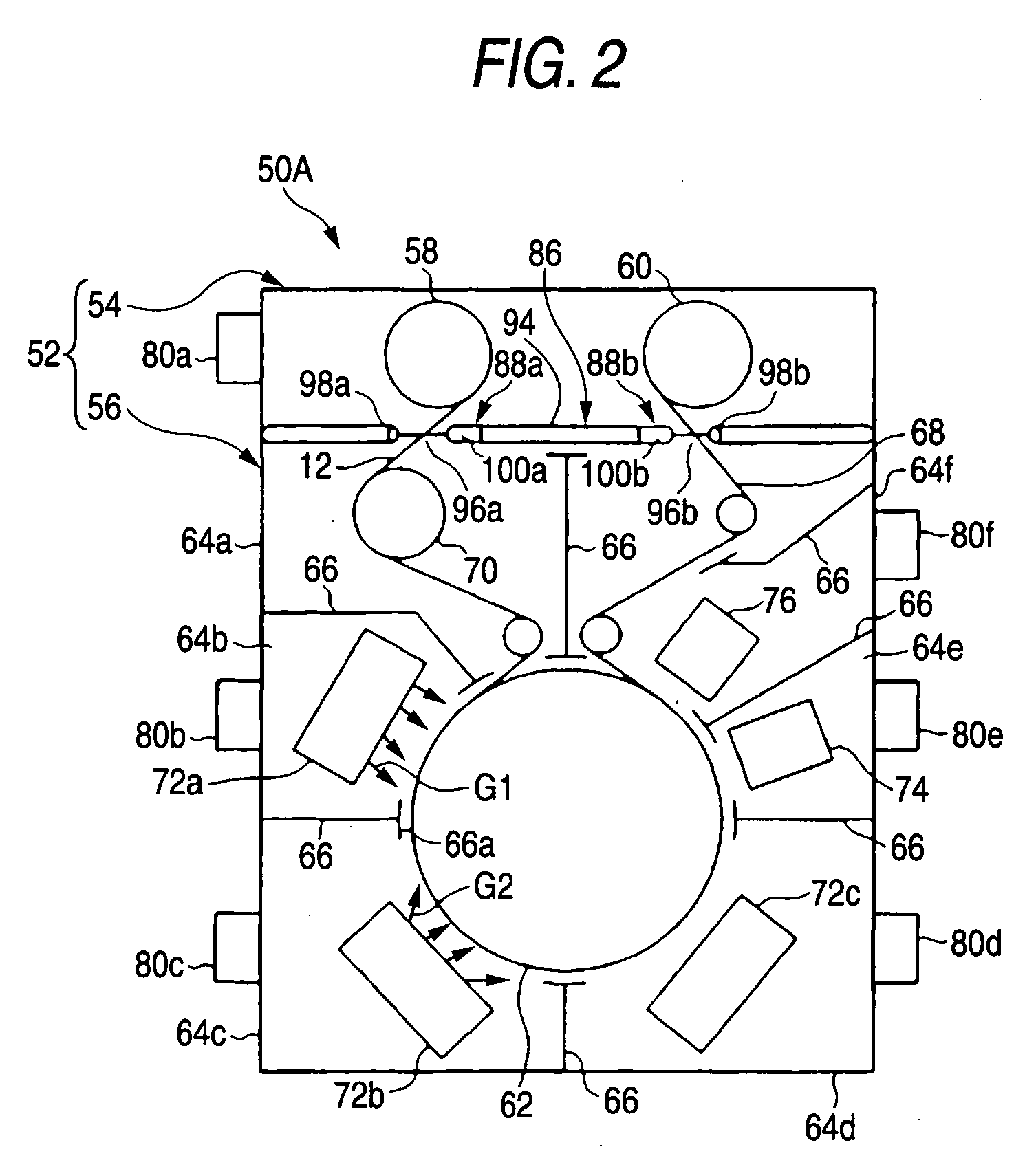

Apparatus and method for the control and positioning of magnetic recording heads in an azimuth recording system

InactiveUS6088184AImprove recording densityImproved azimuthal recordingDriving/moving recording headsFilamentary/web record carriersMagnetic tapeRecording density

A magnetic recording apparatus and method for the azimuthal recording of data to and from data storage tracks contained on digital linear tape. The magnetic recording apparatus includes a magnetic data recording head assembly. A magnetic recording head is centrally located within the magnetic data recording head assembly. The magnetic data recording head assembly includes a control device coupled to a left servo sensor, wherein the left sensor is located to the left of and external to the magnetic recording head. The magnetic recording apparatus additionally includes a control device coupled to a right servo sensor, wherein the right servo sensor is located to the right of and external to the magnetic recording head. The left and right servo sensors assist the magnetic recording head to tilt and rotate at a predetermined angle with respect to a particular data storage track contained on a digital linear tape, during a recording operation, thereby increasing recording density and providing improved azimuthal recording.

Owner:IBM CORP

Method of manufacturing a perpendicular magnetic recording medium

ActiveUS8298689B2Improve coercive forceImprove recording densityRecord information storageCoating by sputteringForming gasRecording layer

Owner:WESTERN DIGITAL TECH INC

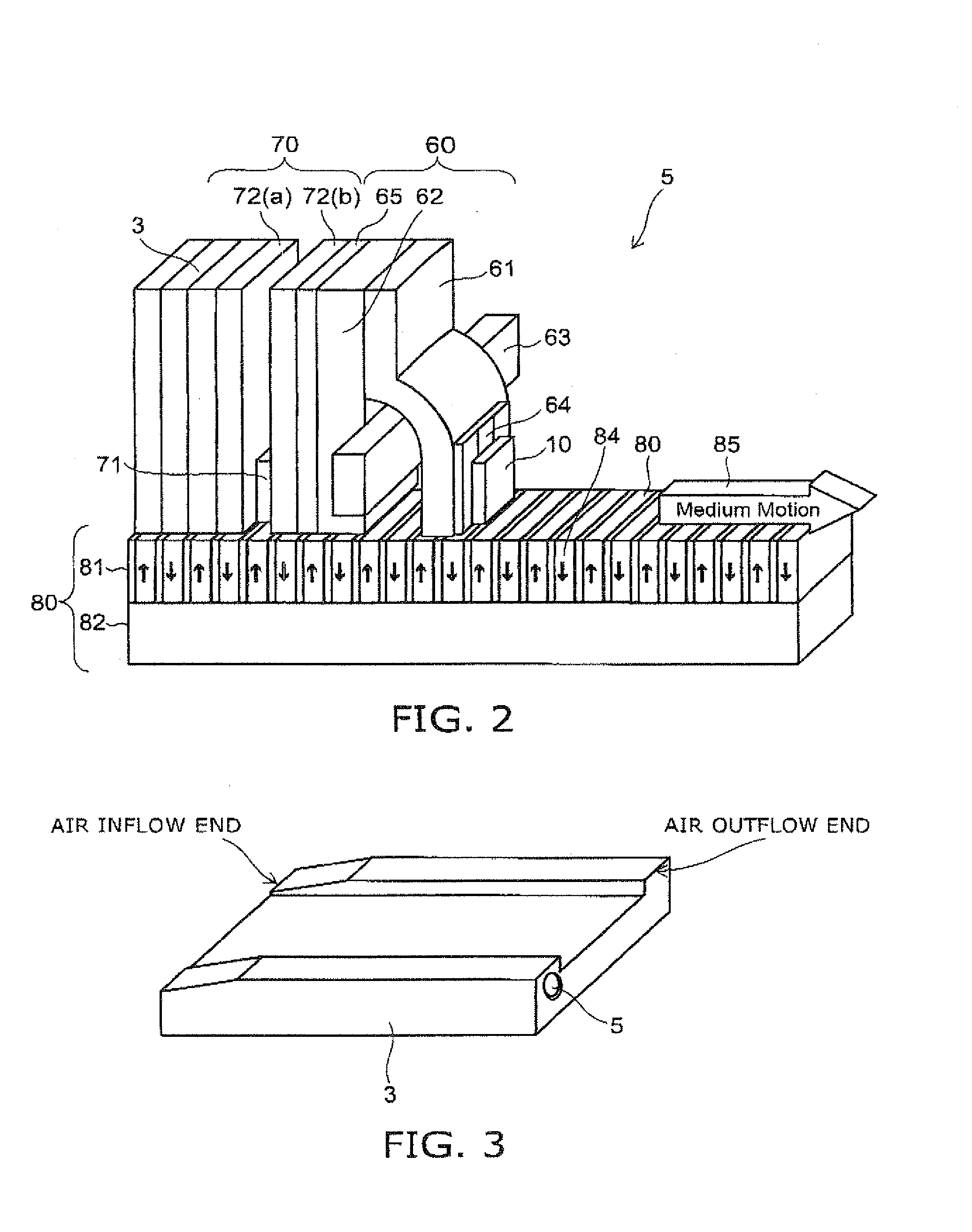

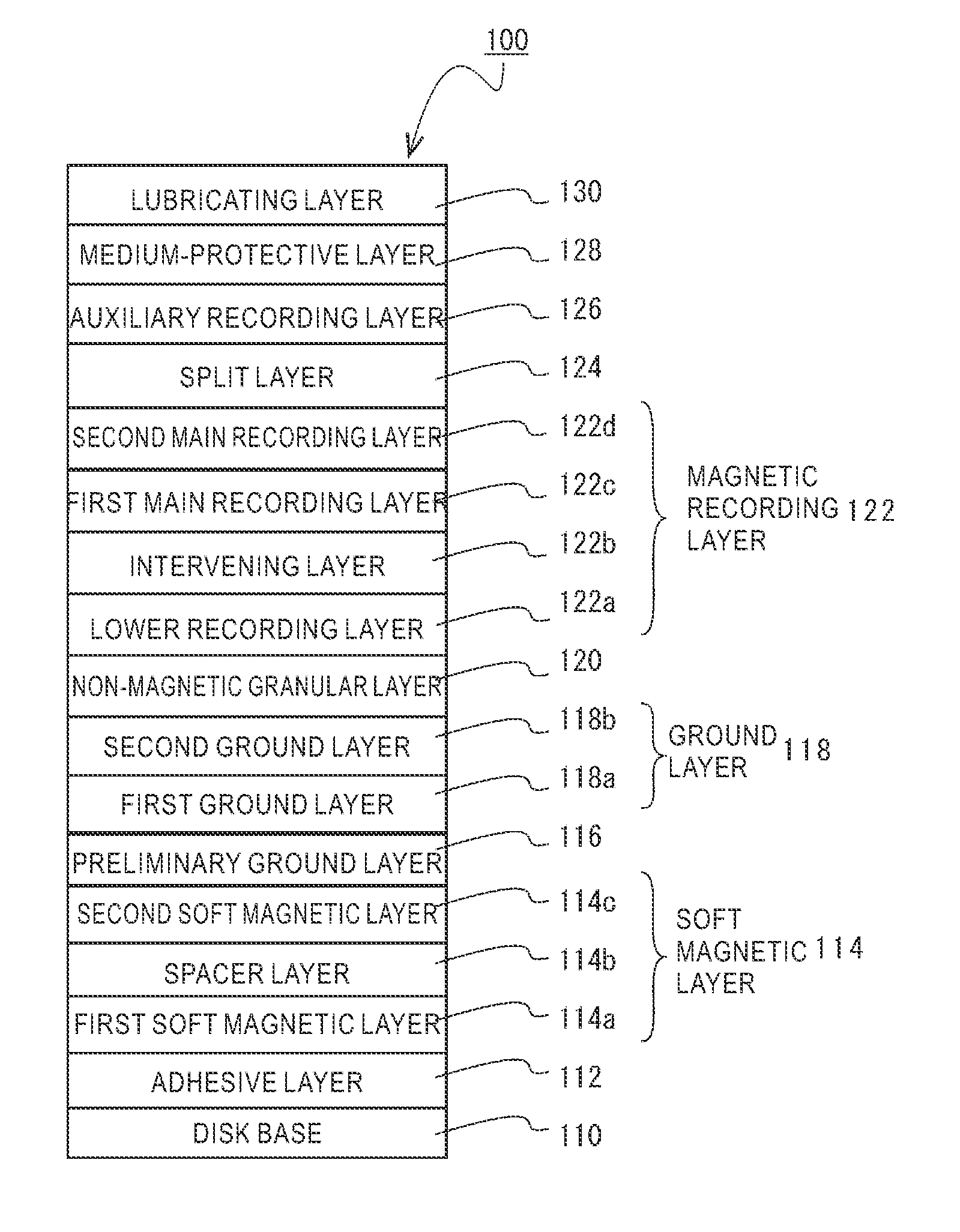

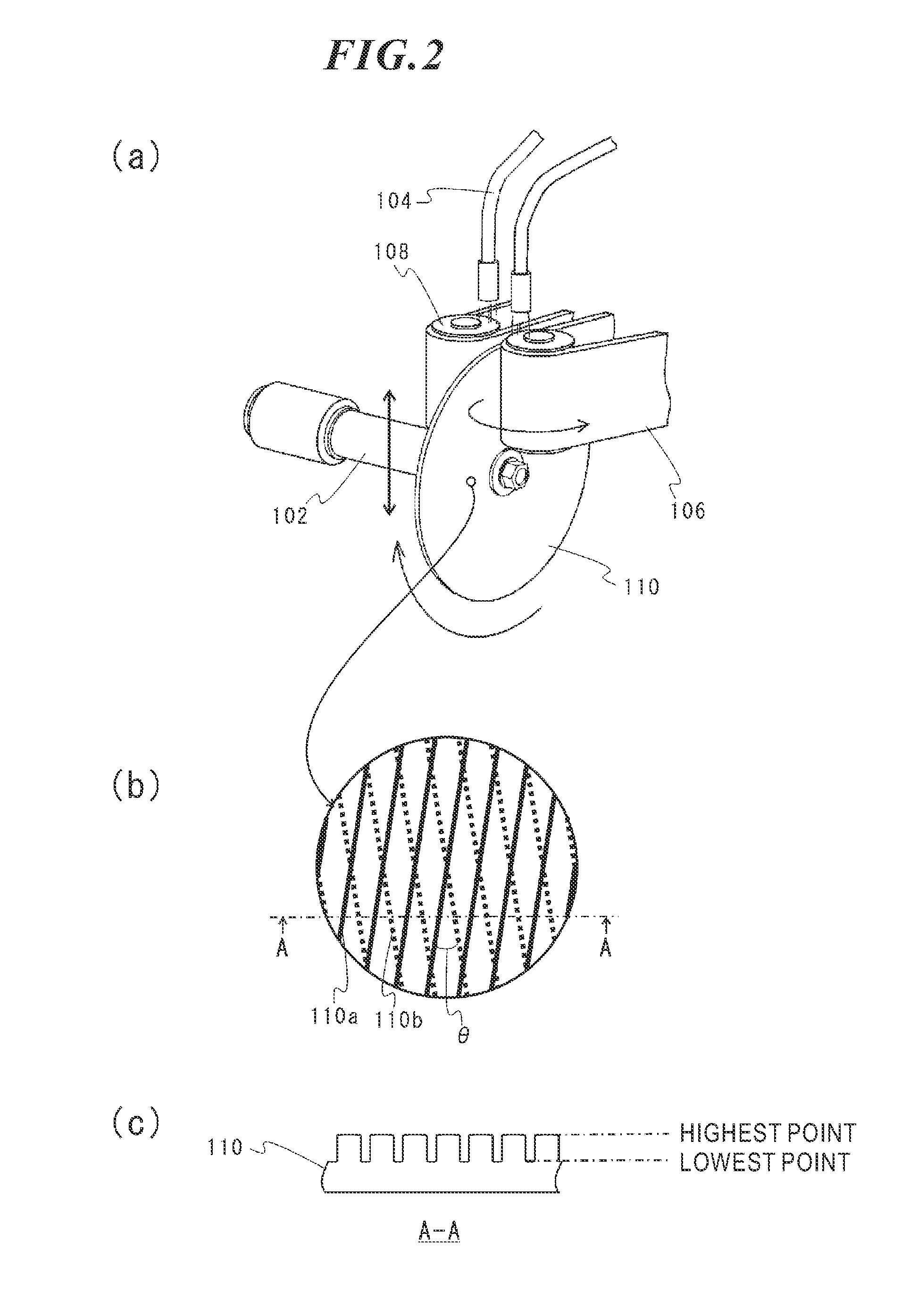

Perpendicular Magnetic Recording Media

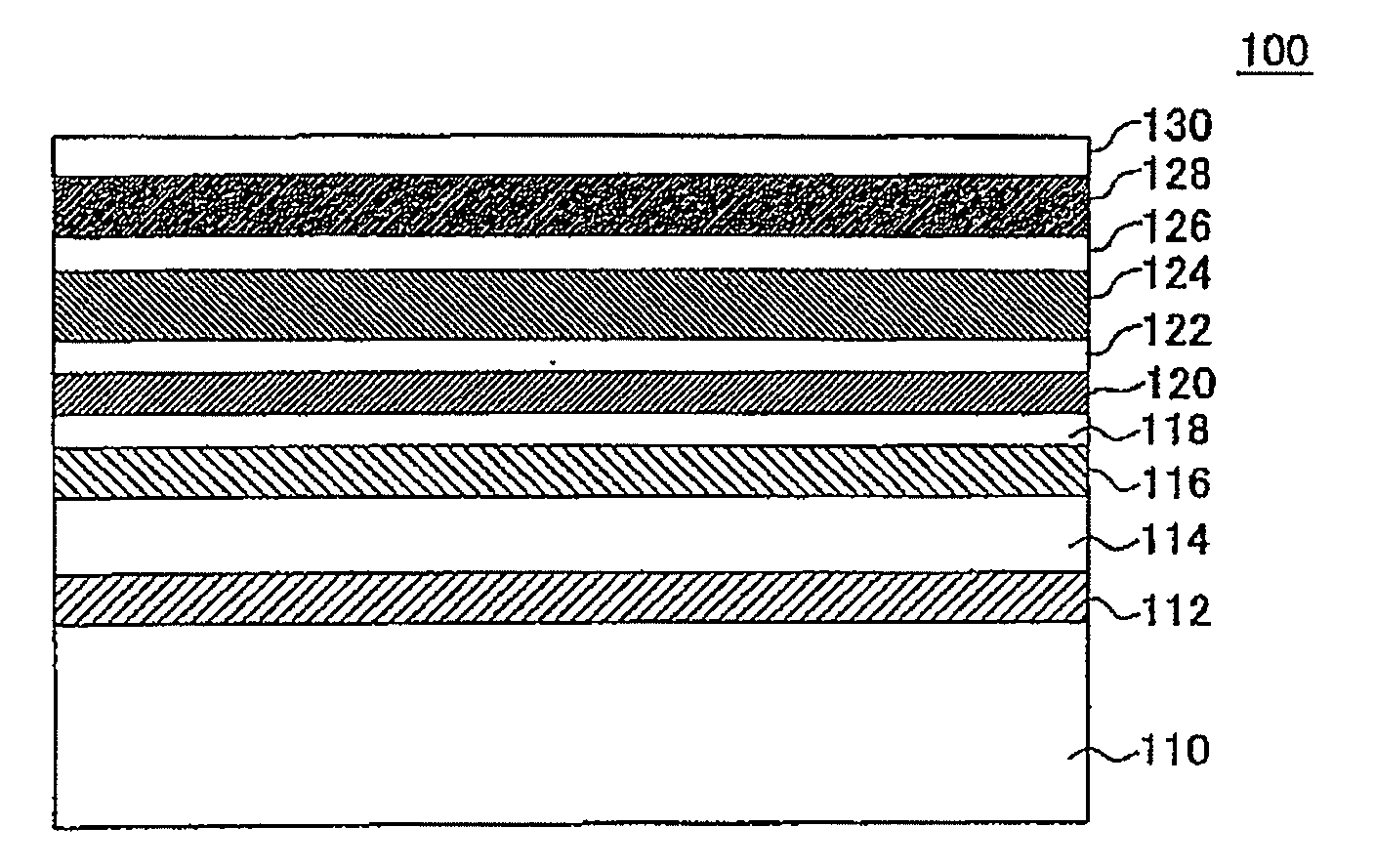

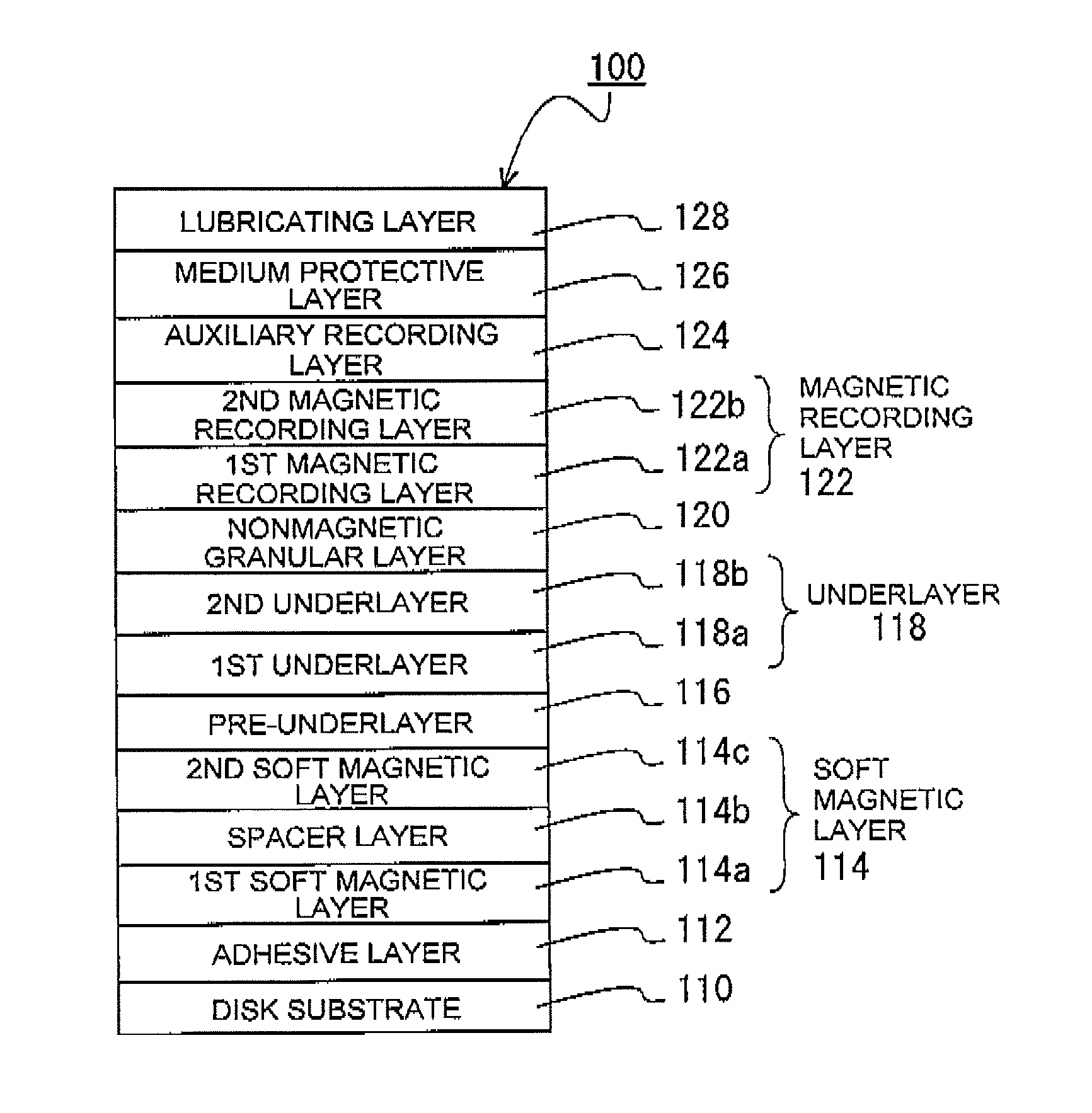

ActiveUS20120140359A1Improve recording densityNarrow widthRecord information storageDisk carriersRecording layerRecording density

[Summary][Problem] An object is to provide a perpendicular magnetic recording medium in which a narrower track width is achieved by enhancing an exchange coupling magnetic field Hex of a soft magnetic layer so that a higher recording density can be achieved.[Solution] A perpendicular magnetic recording medium according to the present invention is configured to include a magnetic recording layer 122 that records a signal, and a soft magnetic layer 114 provided below the magnetic recording layer, on a base 110 on a main surface of which textures are formed, wherein the textures includes first textures 110a that is linear rails in a certain direction, and second textures 110b that are trails intersecting at a predetermined angle with the first textures; and the angle of intersection between the first textures and the second textures is 10° or less.

Owner:WESTERN DIGITAL TECH INC

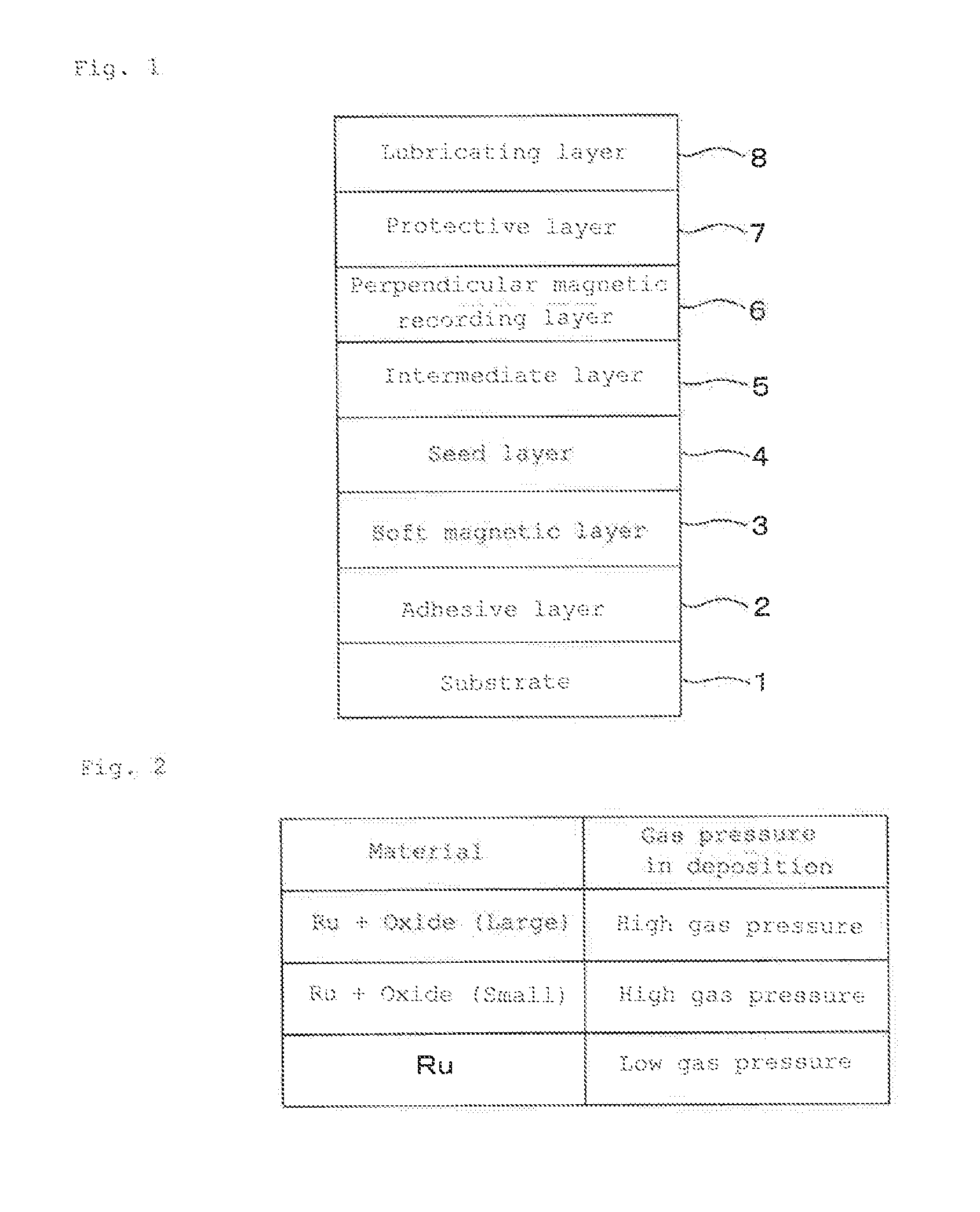

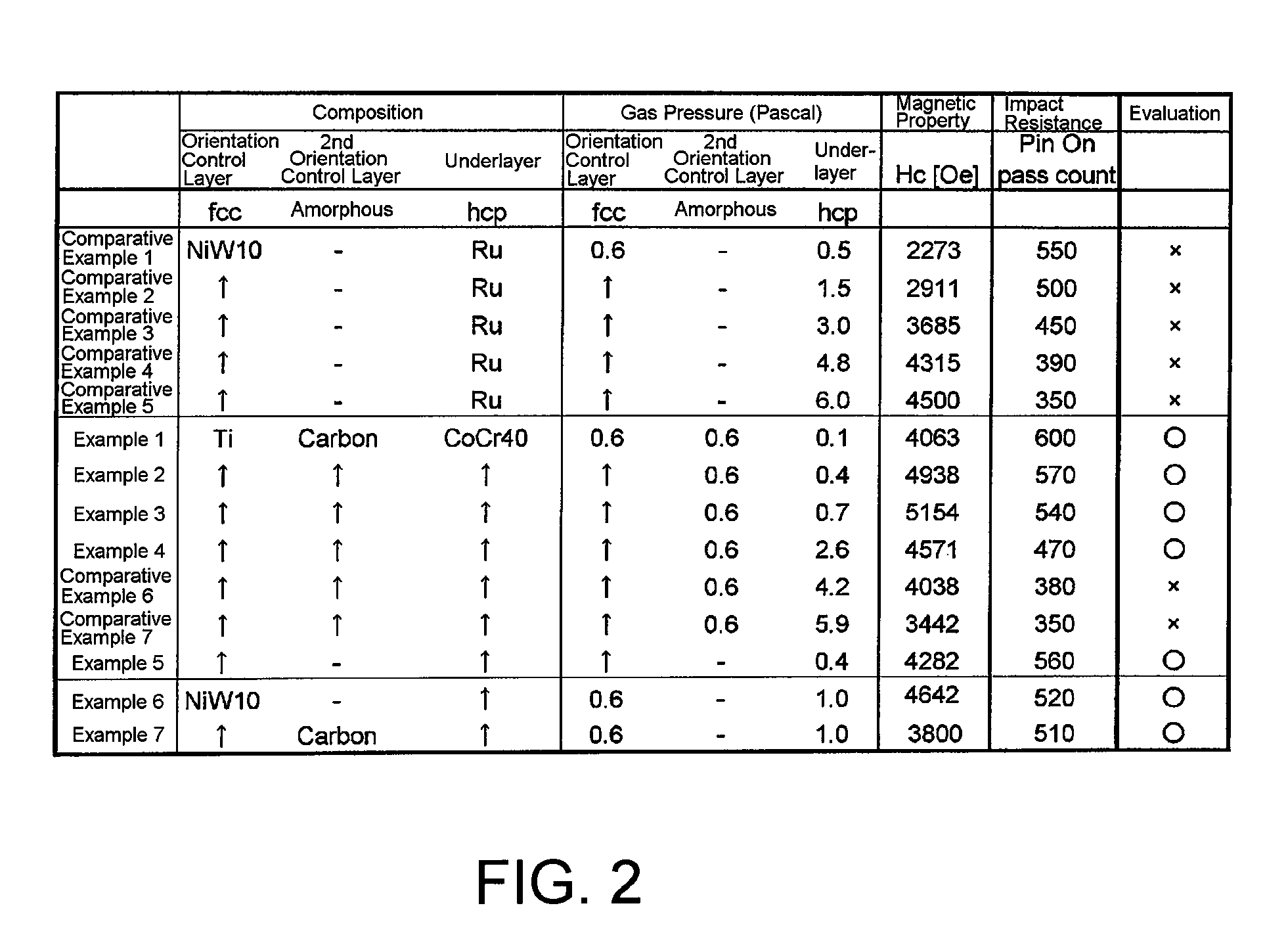

Method of producing a perpendicular magnetic recording medium

InactiveUS20120175243A1Improved propertyHigh recording densityVacuum evaporation coatingSputtering coatingRecording densitySputter deposition

To provide a method for manufacturing a perpendicular magnetic recording medium which has improved electromagnetic conversion characteristics, and thus making it possible to achieve the much higher recording density.Disclosed is a method for manufacturing a perpendicular magnetic recording medium to be used for recording information by a perpendicular magnetic recording system, the perpendicular magnetic recording medium including at least a soft magnetic layer, an underlayer, and a magnetic recording layer on a substrate. In the method, the underlayer is formed by sputtering deposition, including a low-gas-pressure deposited layer deposited at a low gas pressure during the deposition, and a high-gas-pressure deposited layer deposited at a high gas pressure during the deposition. The high-gas-pressure deposited layer is formed of a multilayer deposited by decreasing a deposition rate in a stepwise manner.

Owner:WD MEDIA SINGAPORE PTE

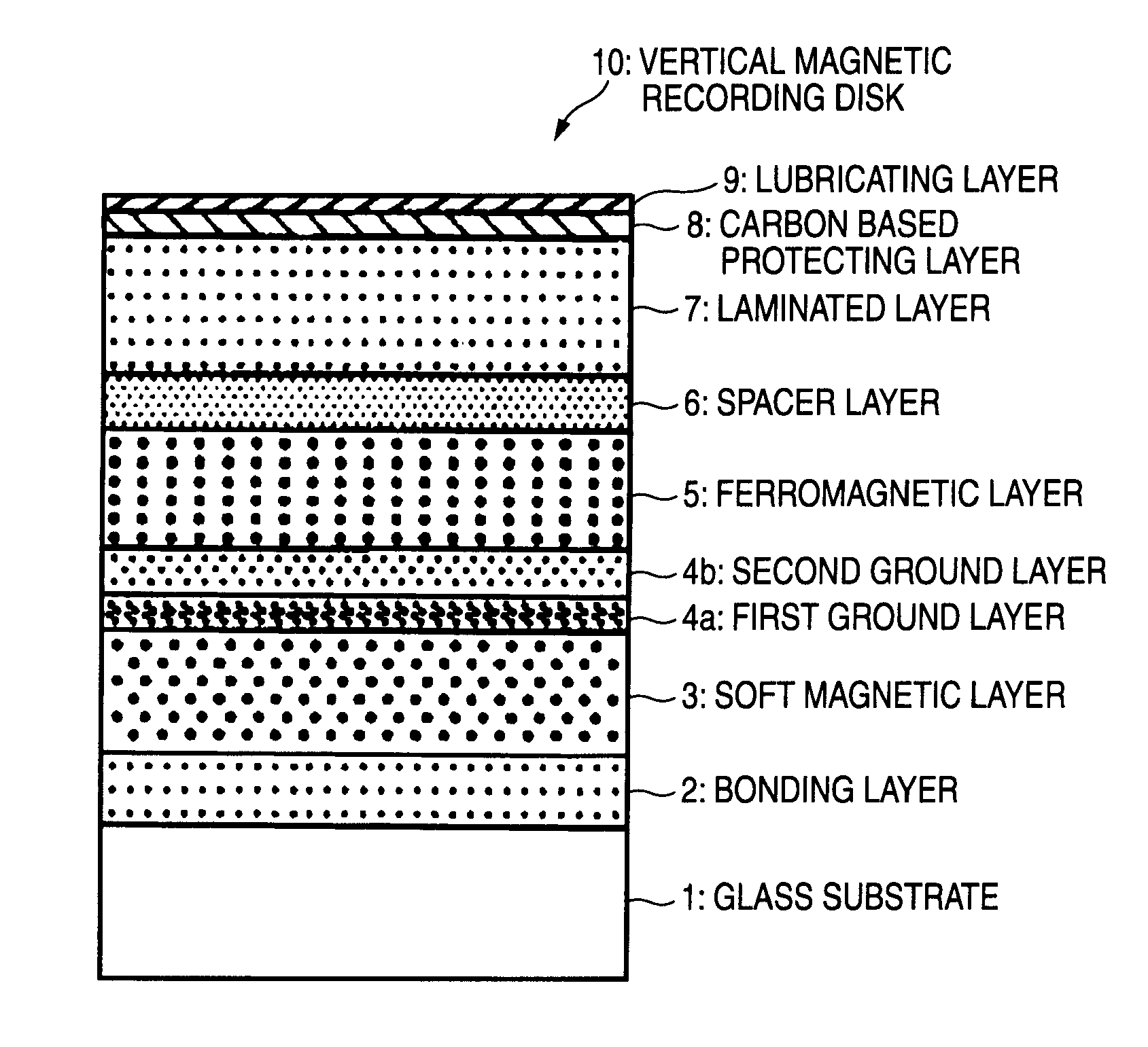

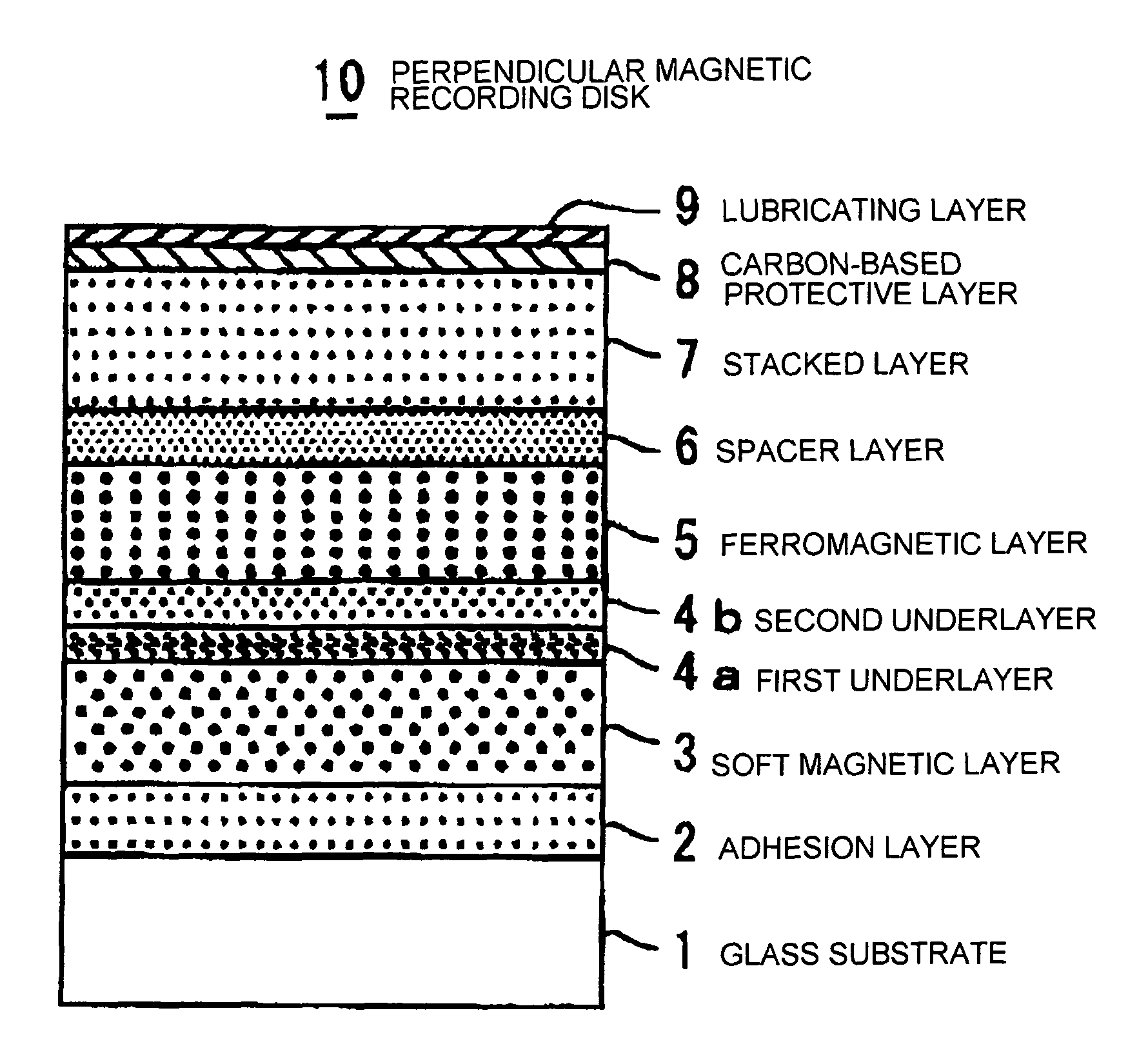

Perpendicular magnetic recording disk and manufacturing method thereof

ActiveUS8603650B2Improve noiseImprove recording densityNanomagnetismVacuum evaporation coatingAlloyRecording layer

A magnetic disk 10 for use in perpendicular magnetic recording has at least a magnetic recording layer on a substrate 1. The magnetic recording layer is composed of a ferromagnetic layer 5 of a granular structure containing silicon (Si) or an oxide of silicon (Si) between crystal grains containing cobalt (Co), a stacked layer 7 having a first layer containing cobalt (Co) or a Co alloy and a second layer containing palladium (Pd) or platinum (Pt), and a spacer layer 6 interposed between the ferromagnetic layer 5 and the stacked layer 7. After forming the ferromagnetic layer 5 on the substrate 1 by sputtering in an argon gas atmosphere, the stacked layer 7 is formed by sputtering in the argon gas atmosphere at a gas pressure lower than that used when forming the ferromagnetic layer 5.

Owner:WESTERN DIGITAL TECH INC

Process and apparatus for producing magnetic recording medium

InactiveUS20060159844A1Reduce defectsImprove applicabilityVacuum evaporation coatingSputtering coatingPolymer substrateEngineering

A process for producing a magnetic recording medium comprising: unrolling a flexible polymer substrate from a feed roll; forming a magnetic layer on at least one side of the flexible polymer substrate by a vacuum film forming method in a film forming chamber; and taking up the flexible polymer substrate on a take-up roll, wherein at least one of the feed roll and the take-up roll is replaced while maintaining a vacuum state for forming the magnetic layer in the film forming chamber.

Owner:FUJIFILM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com