Patents

Literature

65results about "Materials with non-metallic substances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic recording medium

ActiveUS20120045664A1Superior recording/reproducing characteristicSuperior characteristic transportMaterials with ironRecord information storageNon magneticHexane

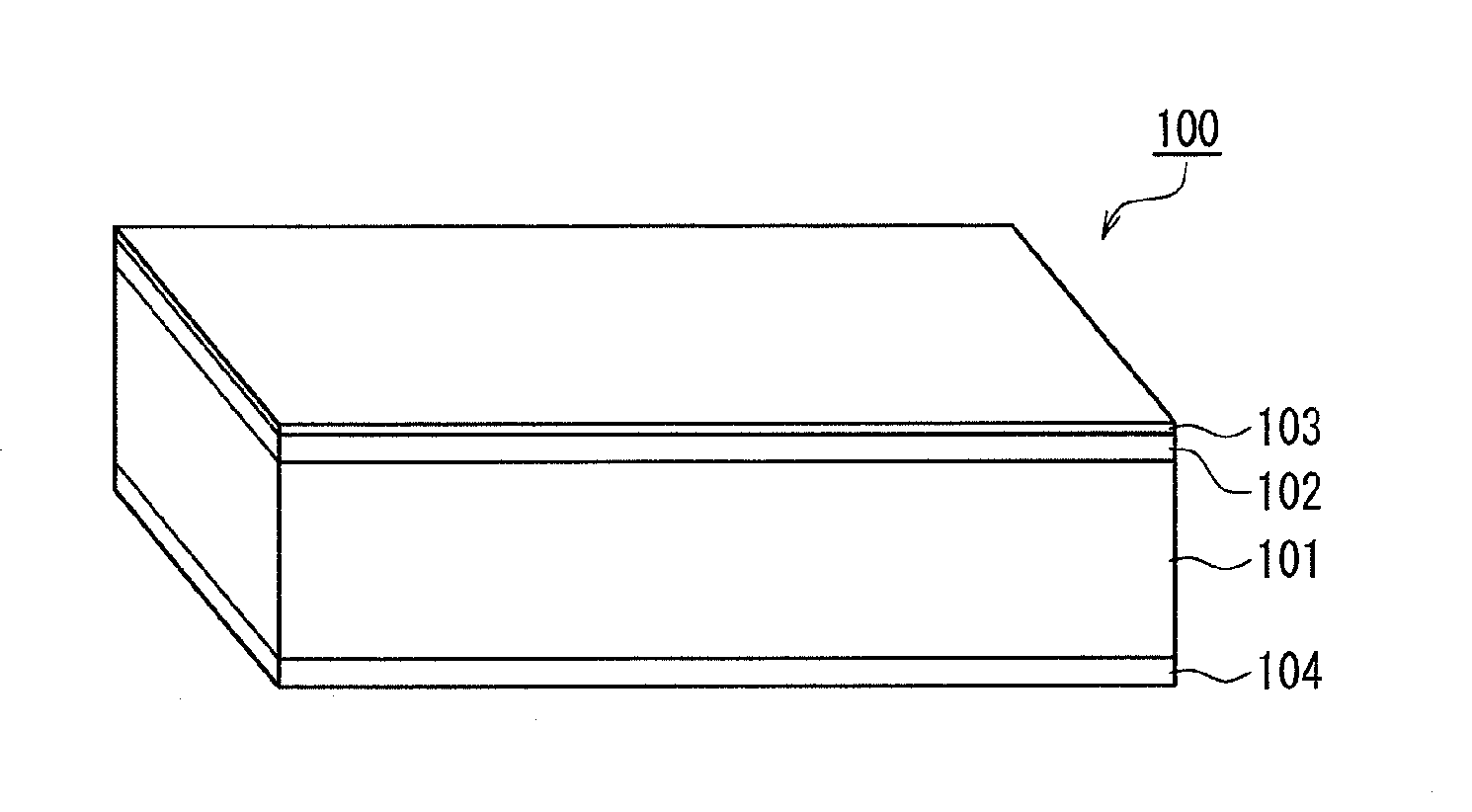

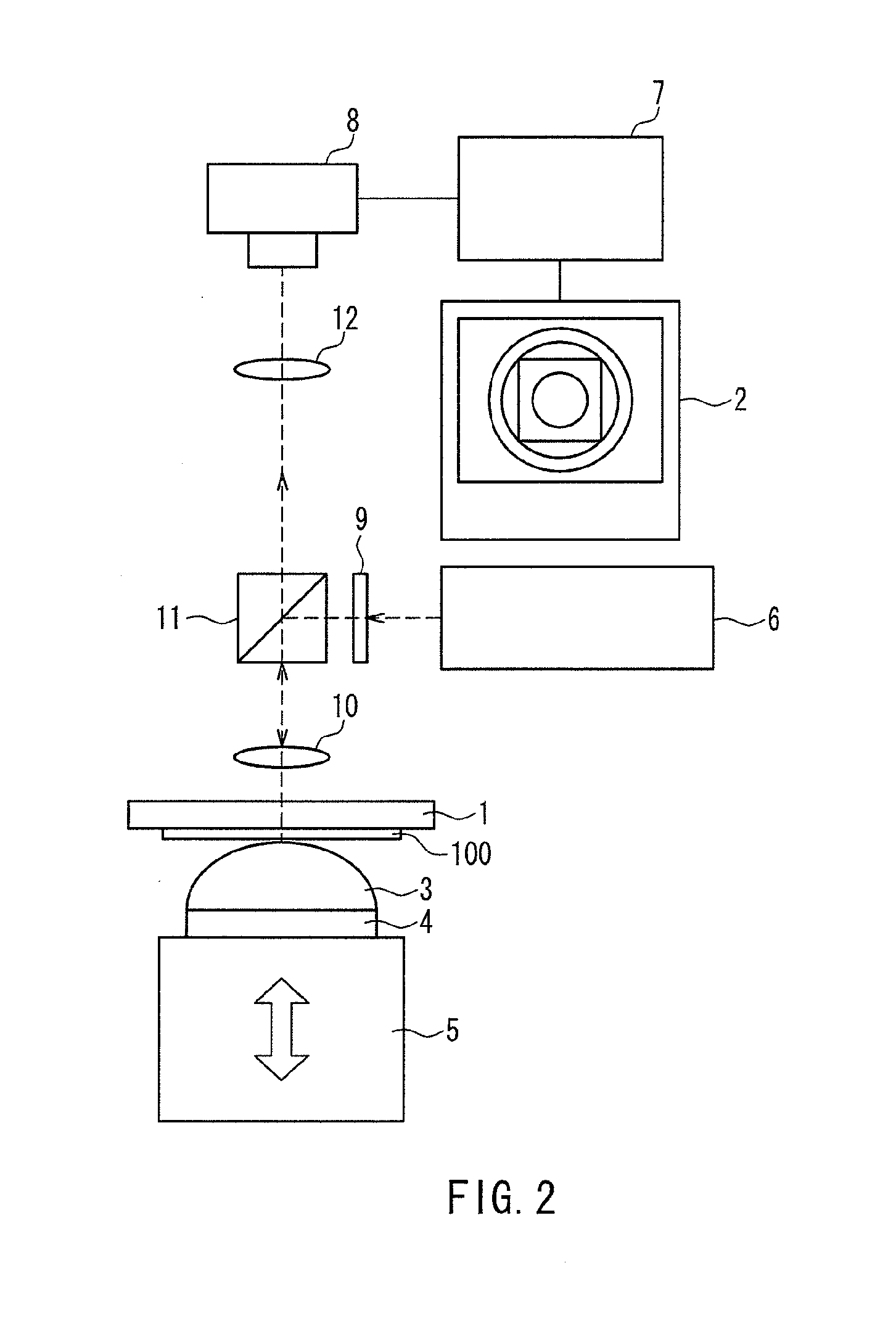

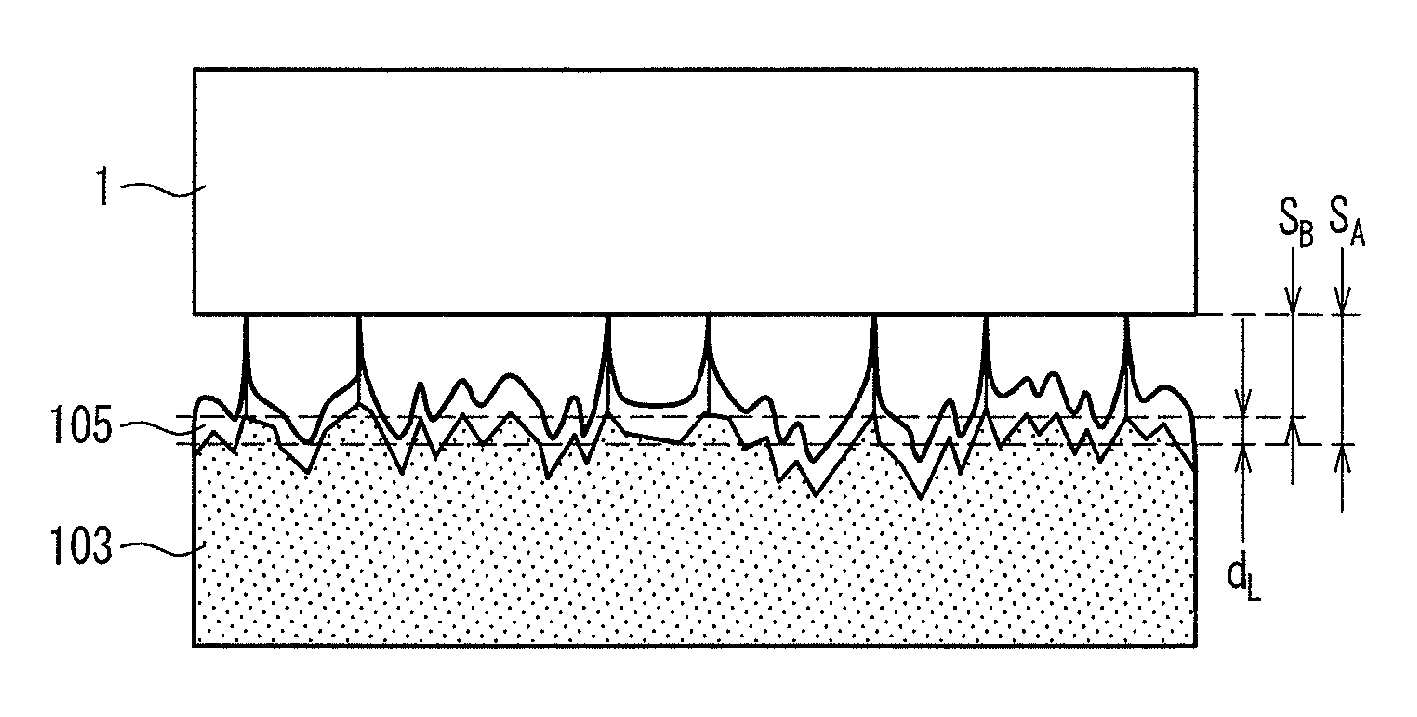

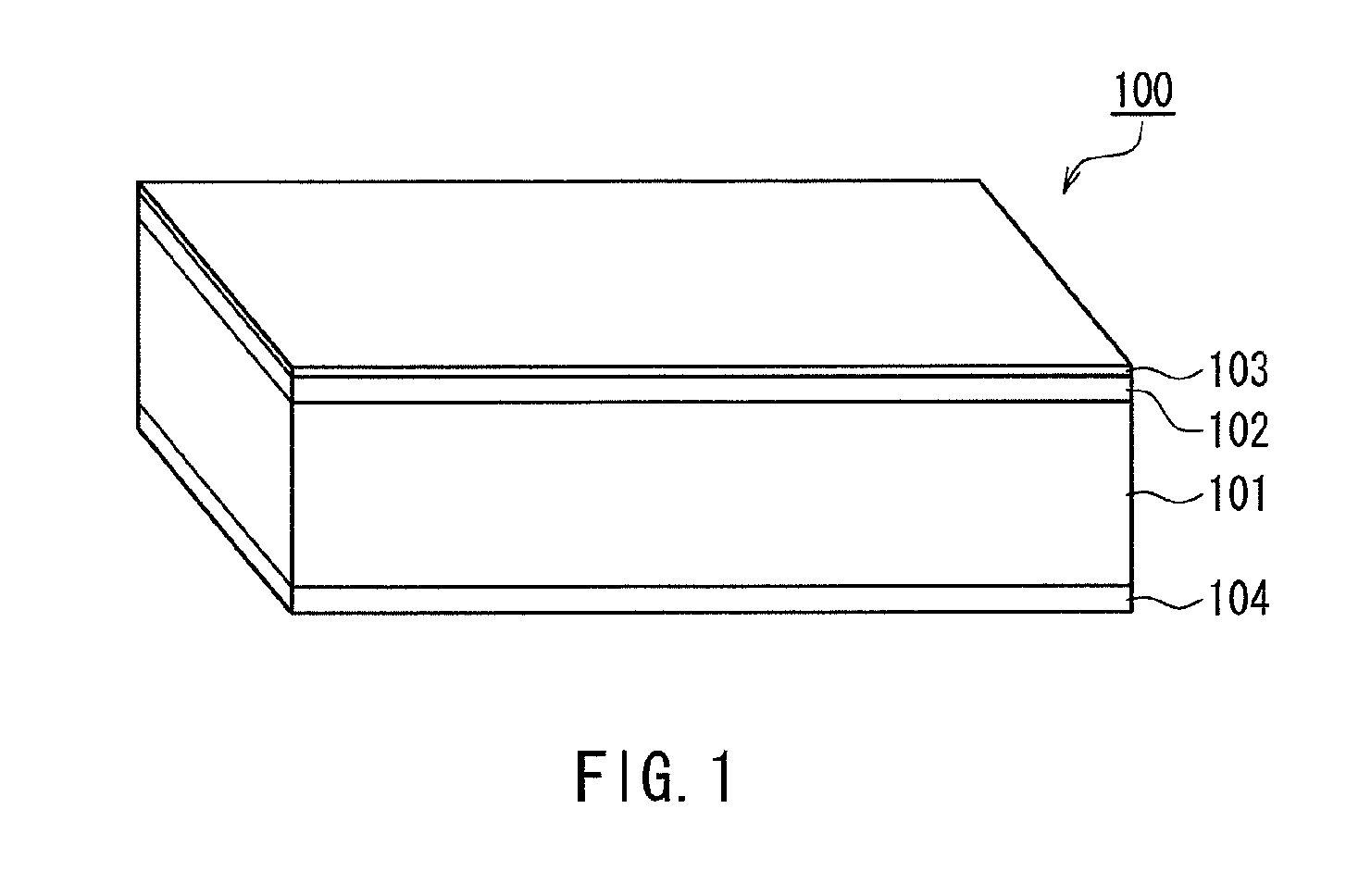

A magnetic recording medium of the present invention is a magnetic recording medium including a non-magnetic substrate; a non-magnetic layer that is formed on one of principal surfaces of the non-magnetic substrate and contains a non-magnetic powder, a binder, and a lubricant; and a magnetic layer that is formed on a principal surface of the non-magnetic layer opposite to the non-magnetic substrate and contains a magnetic powder and a binder. The magnetic powder has an average particle size between 10 inn and 35 nm inclusive. The lubricant is migratable to the magnetic layer and forms a lubricant layer on a surface of the magnetic layer when a pressure is applied to the magnetic layer. When spacing of the surface of the magnetic layer before and after washing the lubricant with n-hexane is measured with a TSA (Tape Spacing Analyzer), the value of the spacing after washing is 3 to 10 nm, and the value of the spacing before washing is 1 to 5 nm smaller than the value of the spacing after washing.

Owner:FUJIFILM CORP

Iron nitride magnetic powder and magnetic recording medium comprising the same

InactiveUS20100035086A1Magnetic interactionIncreasing magnetic interactionRecord information storageInorganic material magnetismIron nitrideYttrium

A spherical or ellipsoidal iron nitride magnetic powder having a core comprising iron nitride including a Fe16N2 phase as a primary phase and an outer layer containing yttrium (Y) and aluminum (Al), in which an average particle size r of the iron nitride magnetic powder is 20 nm or less, an average diameter d of the core is 4 to 10 nm, and a ratio of r to d (r / d) is 2 to 3, and average content of yttrium and aluminum in the outer layer are from 0.9 to 5 atomic % and from 30 to 50 atomic %, respectively, each based on the total number of iron atoms in the iron nitride magnetic powder, and standard deviations of the contents of yttrium and aluminum are 0.6 atomic % or less and 17 atomic % or less, respectively.

Owner:HITACHT MAXELL LTD

Magnetic recording medium

ActiveUS20140272474A1Increased durabilityReduce runningRecord information storageMaterials with non-metallic substancesScanning electron microscopeElectron microscope

An aspect of the present invention relates to a magnetic recording medium, which comprises a magnetic layer comprising ferromagnetic powder and binder on a nonmagnetic support, wherein the ferromagnetic powder is ferromagnetic hexagonal ferrite powder comprising 3 to 12 weight percent of Al, based on Al2O3 conversion, relative to 100 weight percent of a total weight of the powder, the magnetic layer further comprises abrasive, and a maximum plan view surface area of the abrasive as determined for a 4.3 μm×6.3 μm rectangular region of the magnetic layer by a scanning electron microscope is less than 0.06 percent relative to 100 percent of a total surface area of the region.

Owner:FUJIFILM CORP

Magnetic tape

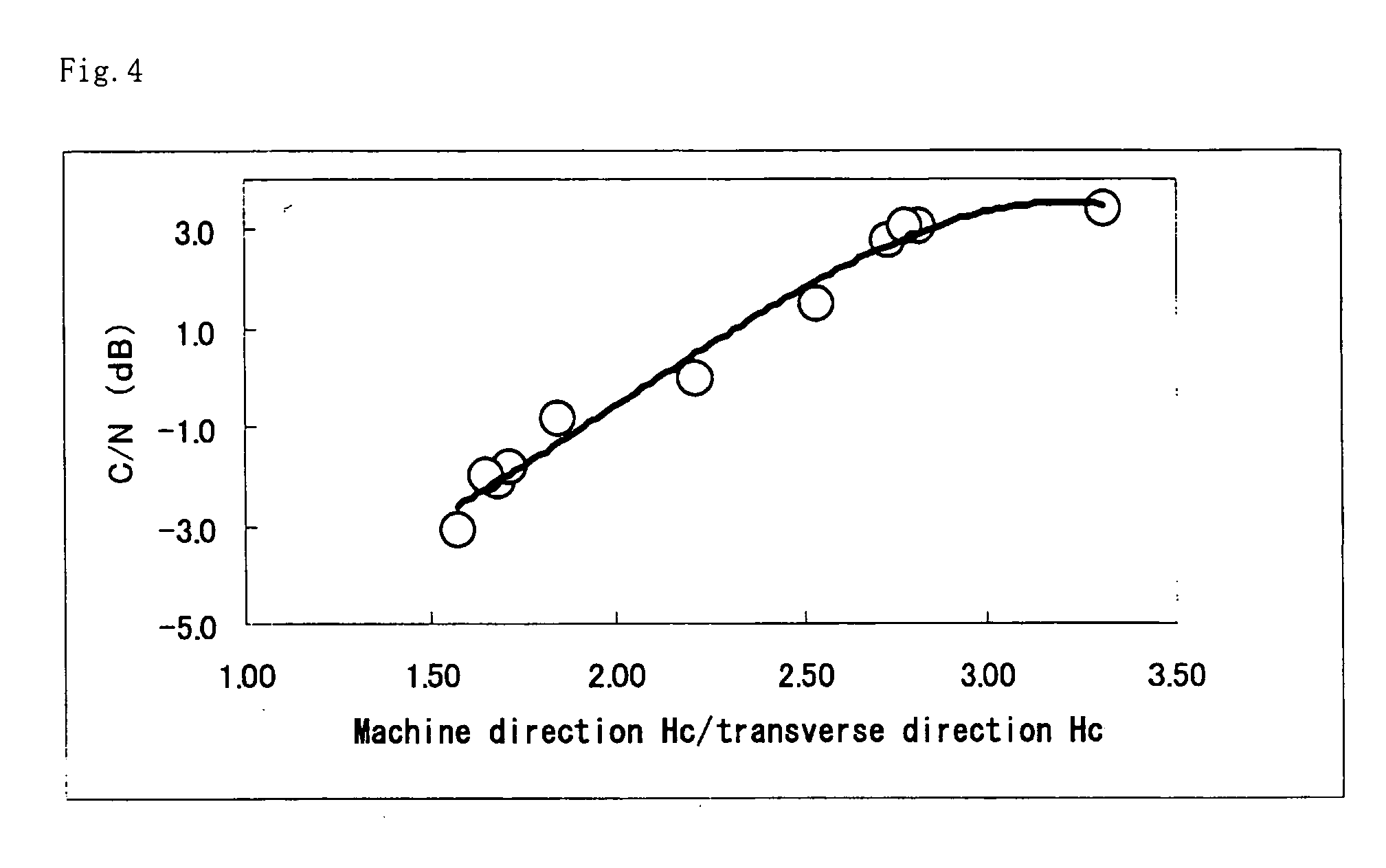

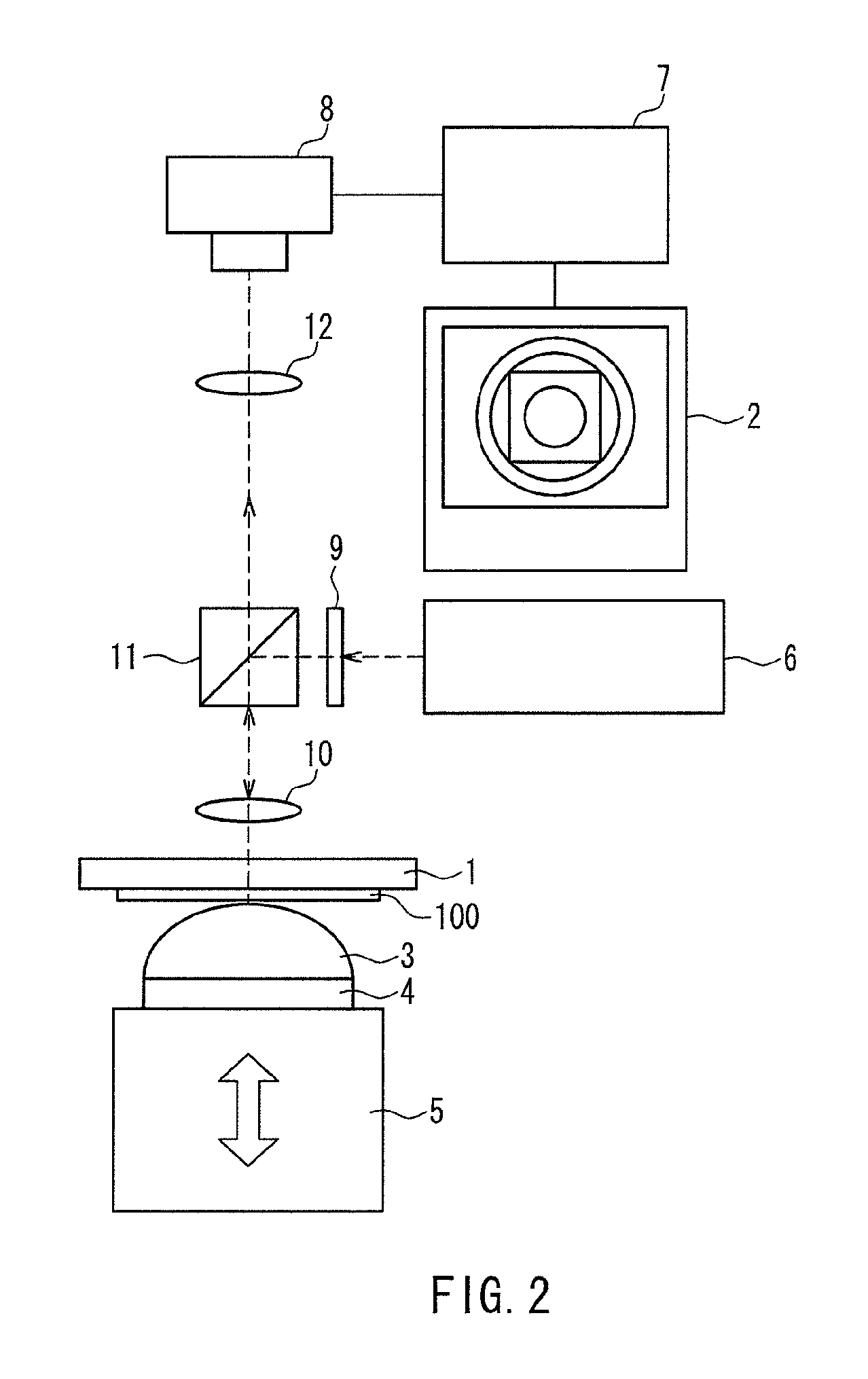

InactiveUS20060068232A1Ratio of C/N is moreRaise the ratioRecord information storageMaterials with non-metallic substancesMass storageHigh density

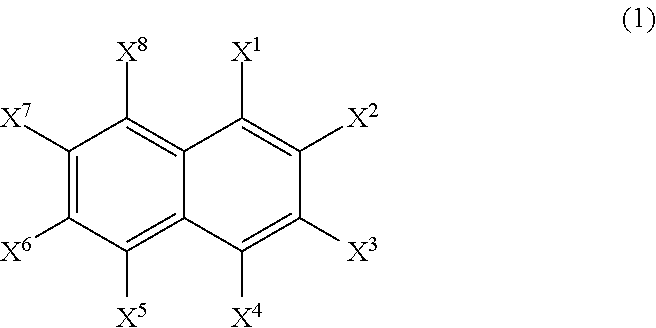

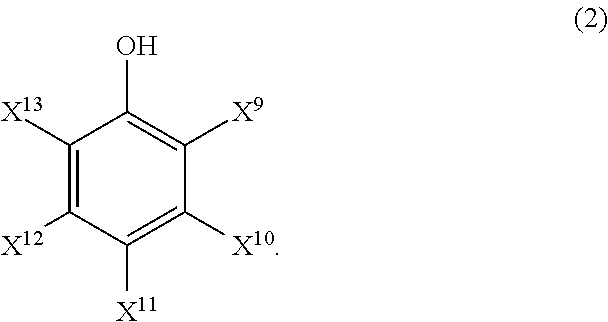

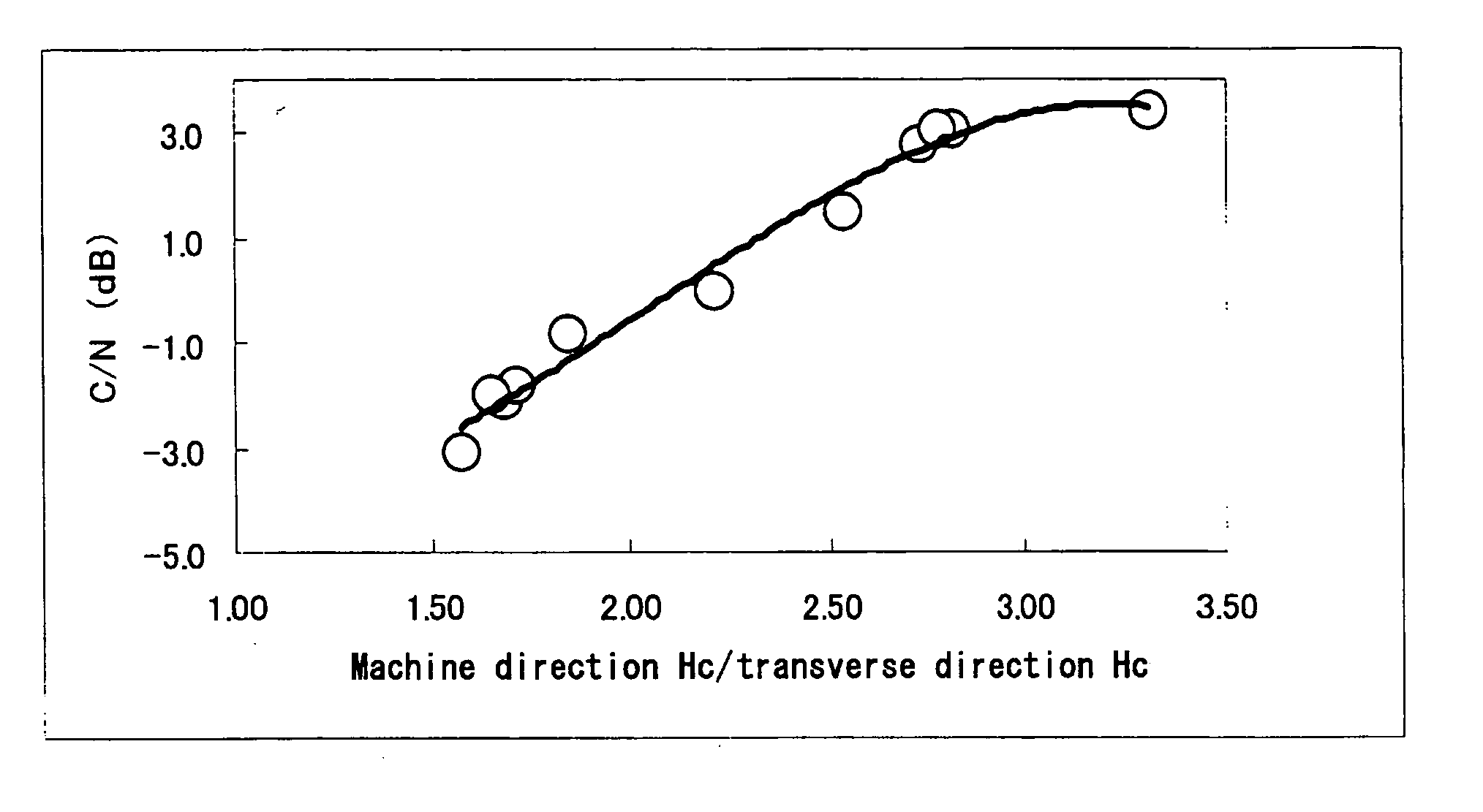

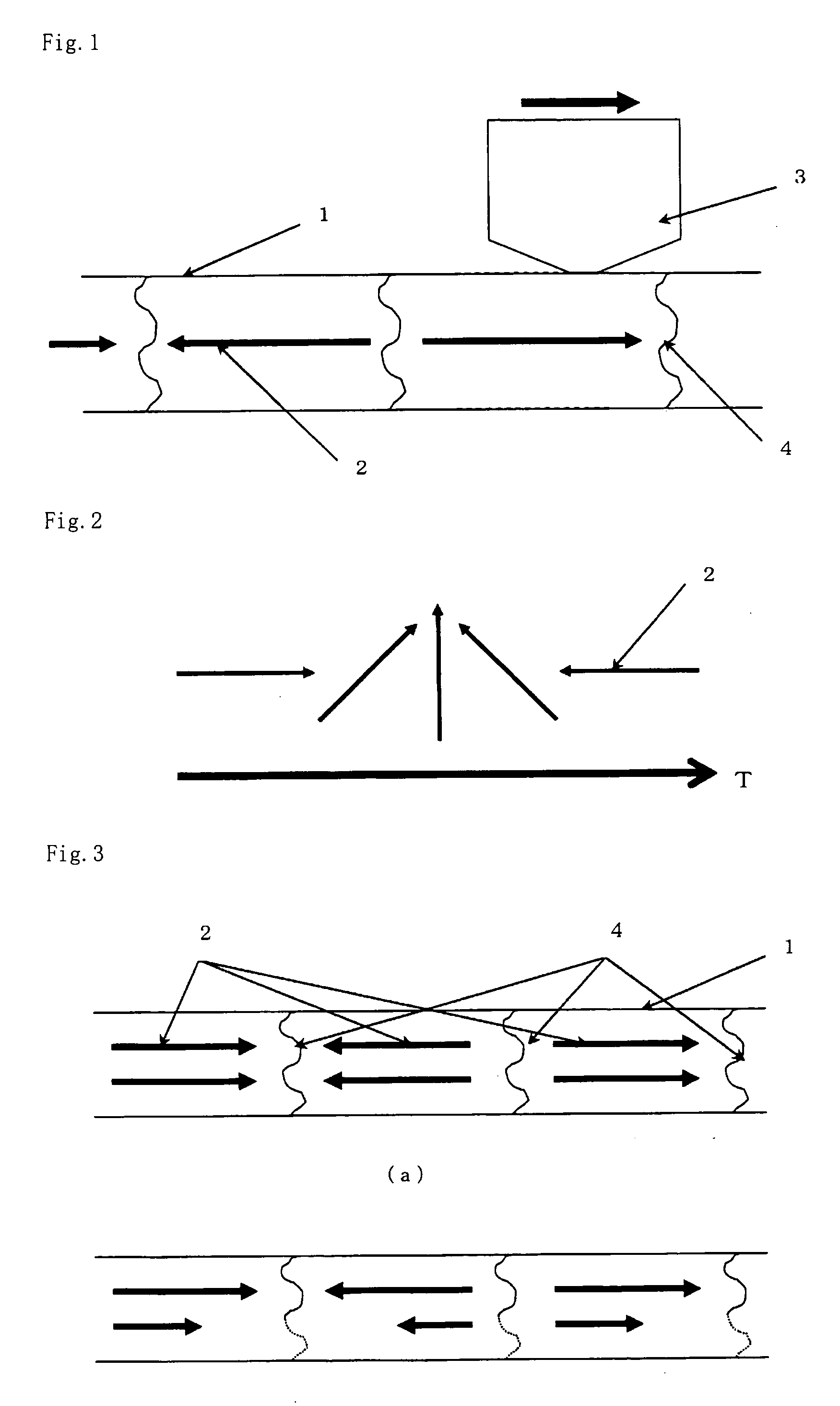

A magnetic tape comprising a non-magnetic substrate and at least one magnetic layer formed on one surface of the non-magnetic substrate, characterized in that magnetic particles contained in an uppermost magnetic layer of the magnetic layer are substantially granular particles with a particle size of 30 nm or less, and that the ratio of a coercive force HcM in the machine direction to a coercive force HcT in the transverse direction, i.e., [HcM / HcT], is at least 2.2. This magnetic tape has a capacity capable of corresponding to mass storage of 1 TB or more, and achieves a high ratio of reproducing output to noises (C / N), particularly for signals within a short wavelength range, thus showing excellent high-density recording performance.

Owner:HITACHT MAXELL LTD

Magnetic recording medium

ActiveUS9311946B2Superior recording/reproducing characteristic and transport characteristicFlat surfaceMaterials with ironRecord information storageNon magneticHexane

A magnetic recording medium of the present invention is a magnetic recording medium including a non-magnetic substrate; a non-magnetic layer that is formed on one of principal surfaces of the non-magnetic substrate and contains a non-magnetic powder, a binder, and a lubricant; and a magnetic layer that is formed on a principal surface of the non-magnetic layer opposite to the non-magnetic substrate and contains a magnetic powder and a binder. The magnetic powder has an average particle size between 10 nm and 35 nm inclusive. The lubricant is migratable to the magnetic layer and forms a lubricant layer on a surface of the magnetic layer when a pressure is applied to the magnetic layer. When spacing of the surface of the magnetic layer before and after washing the lubricant with n-hexane is measured with a TSA (Tape Spacing Analyzer), the value of the spacing after washing is 3 to 10 nm, and the value of the spacing before washing is 1 to 5 nm smaller than the value of the spacing after washing.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

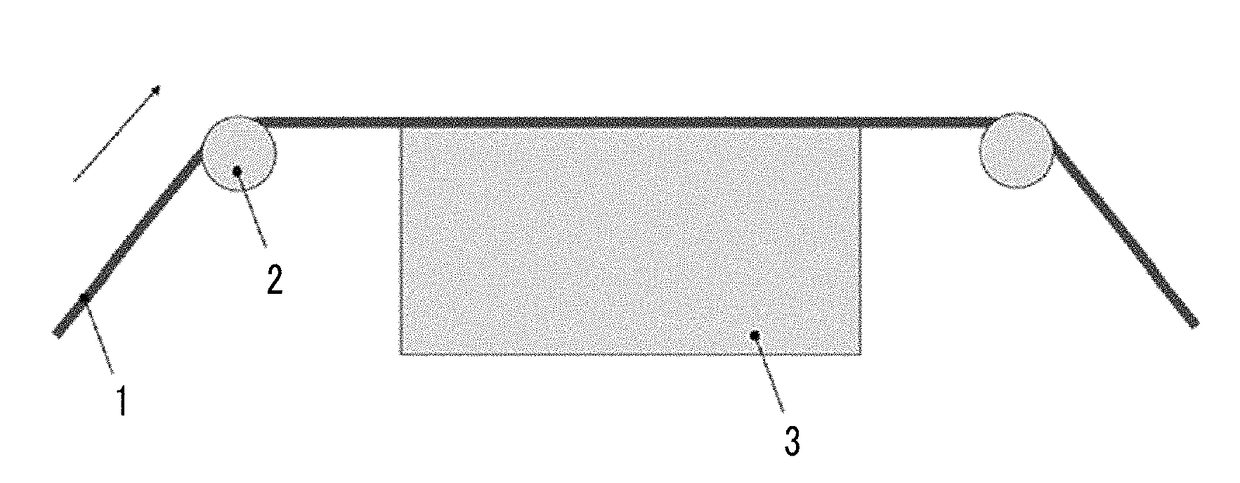

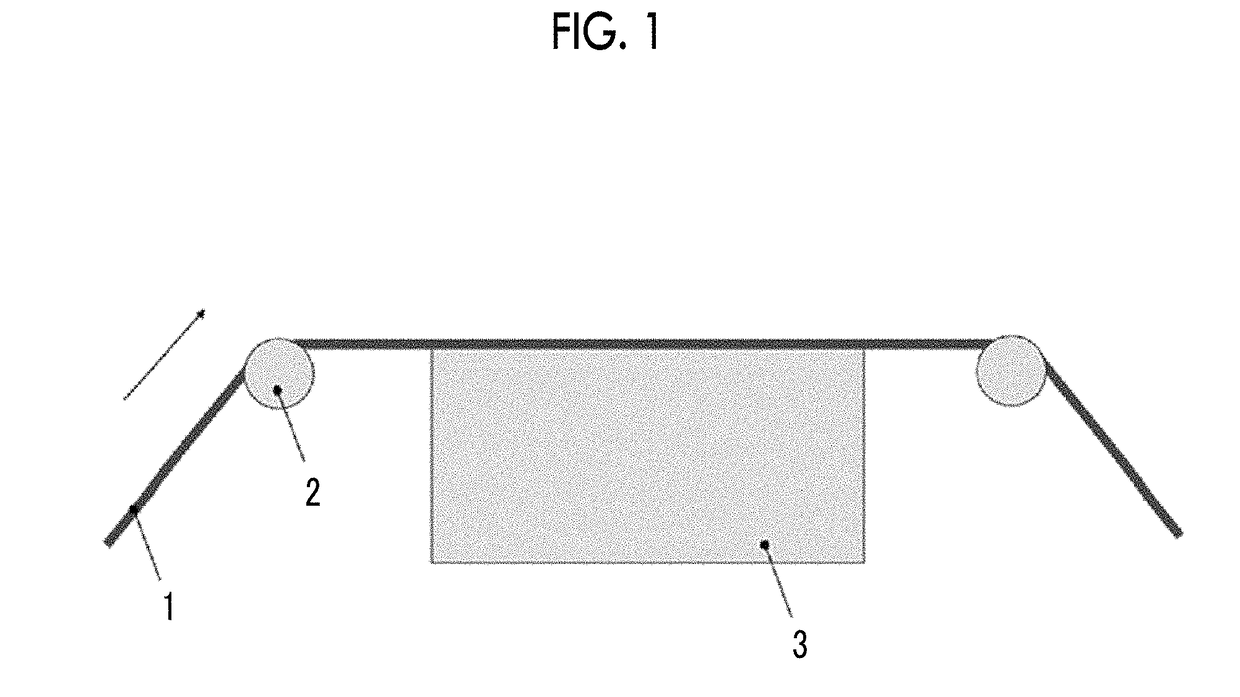

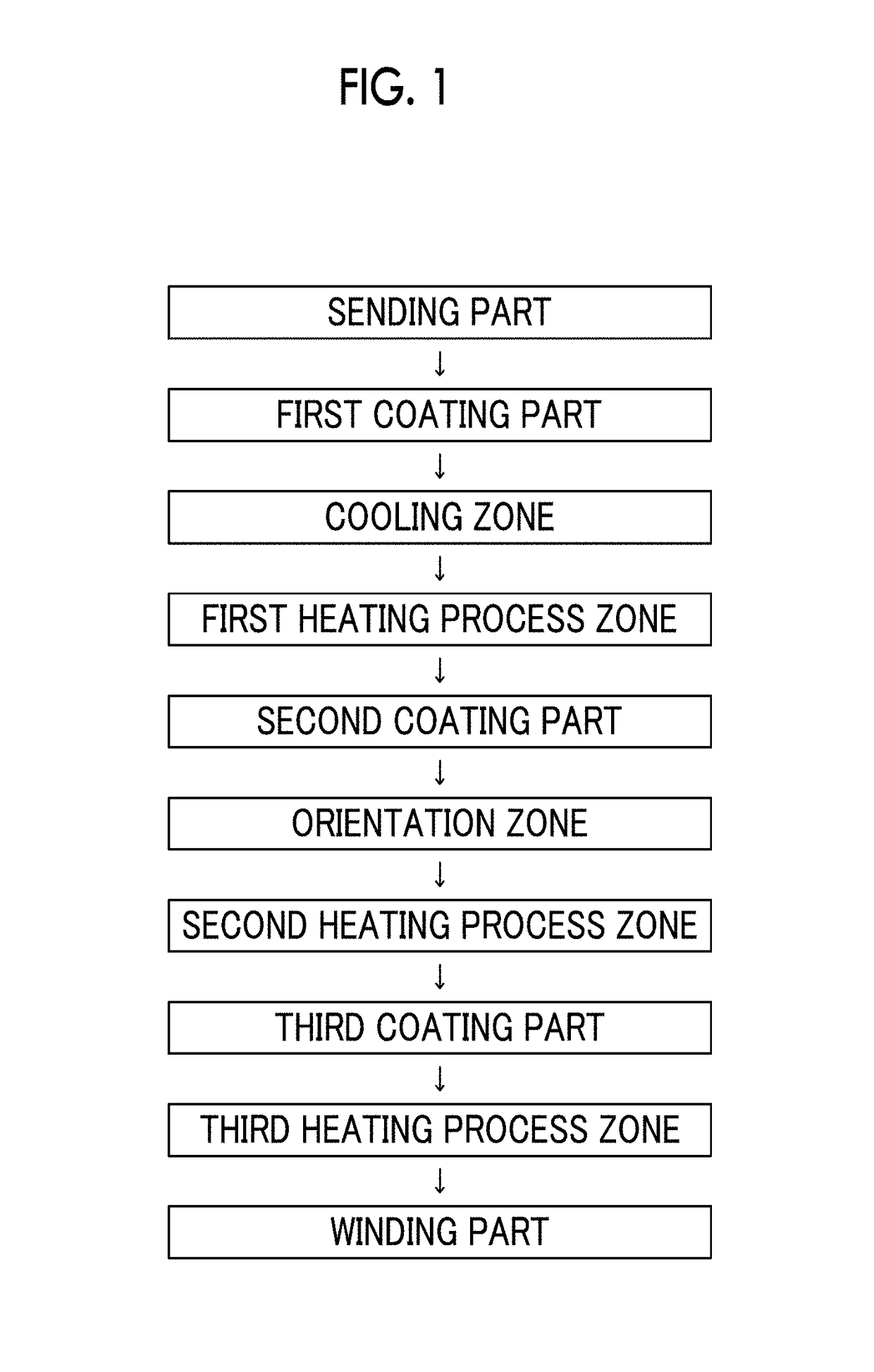

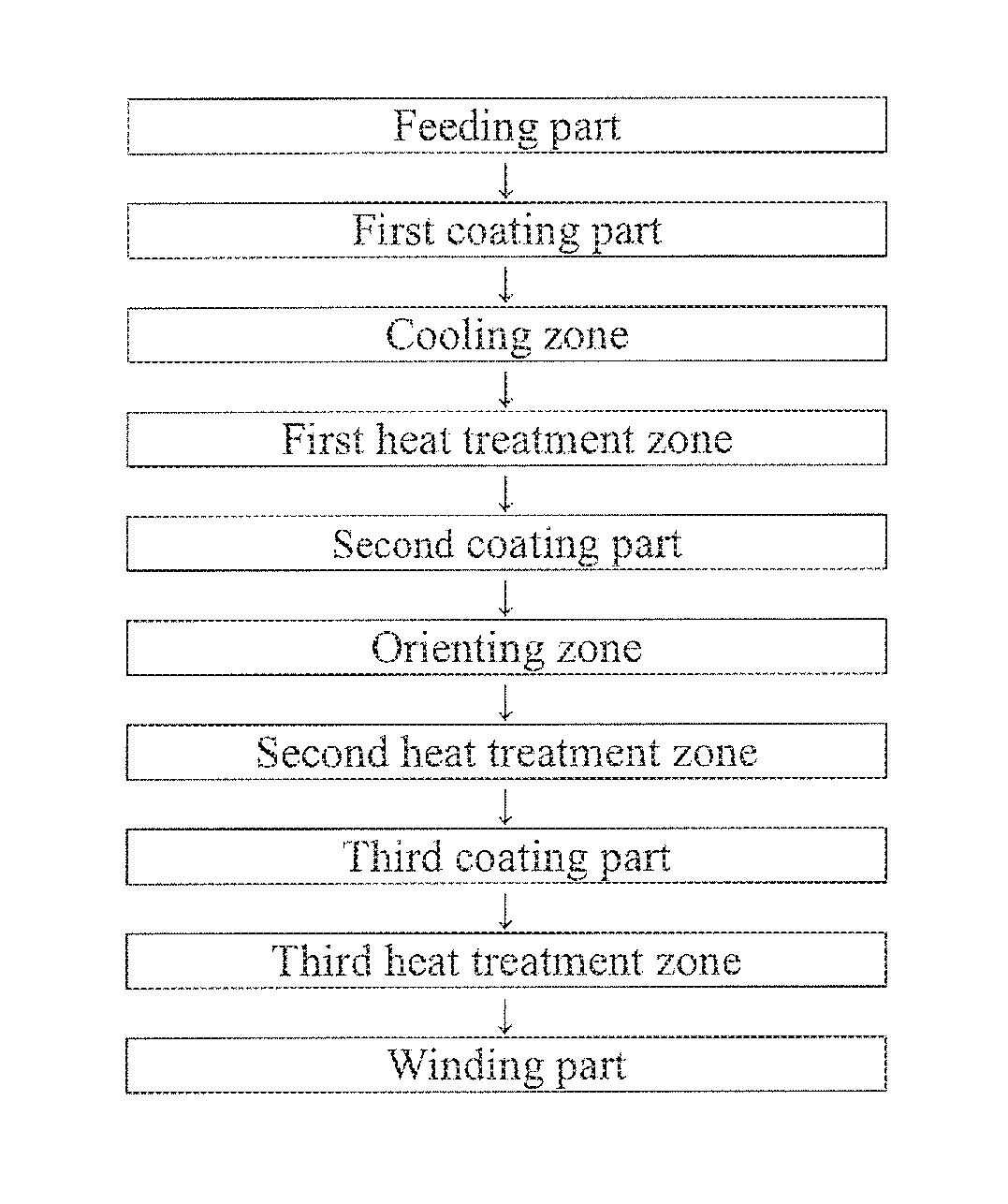

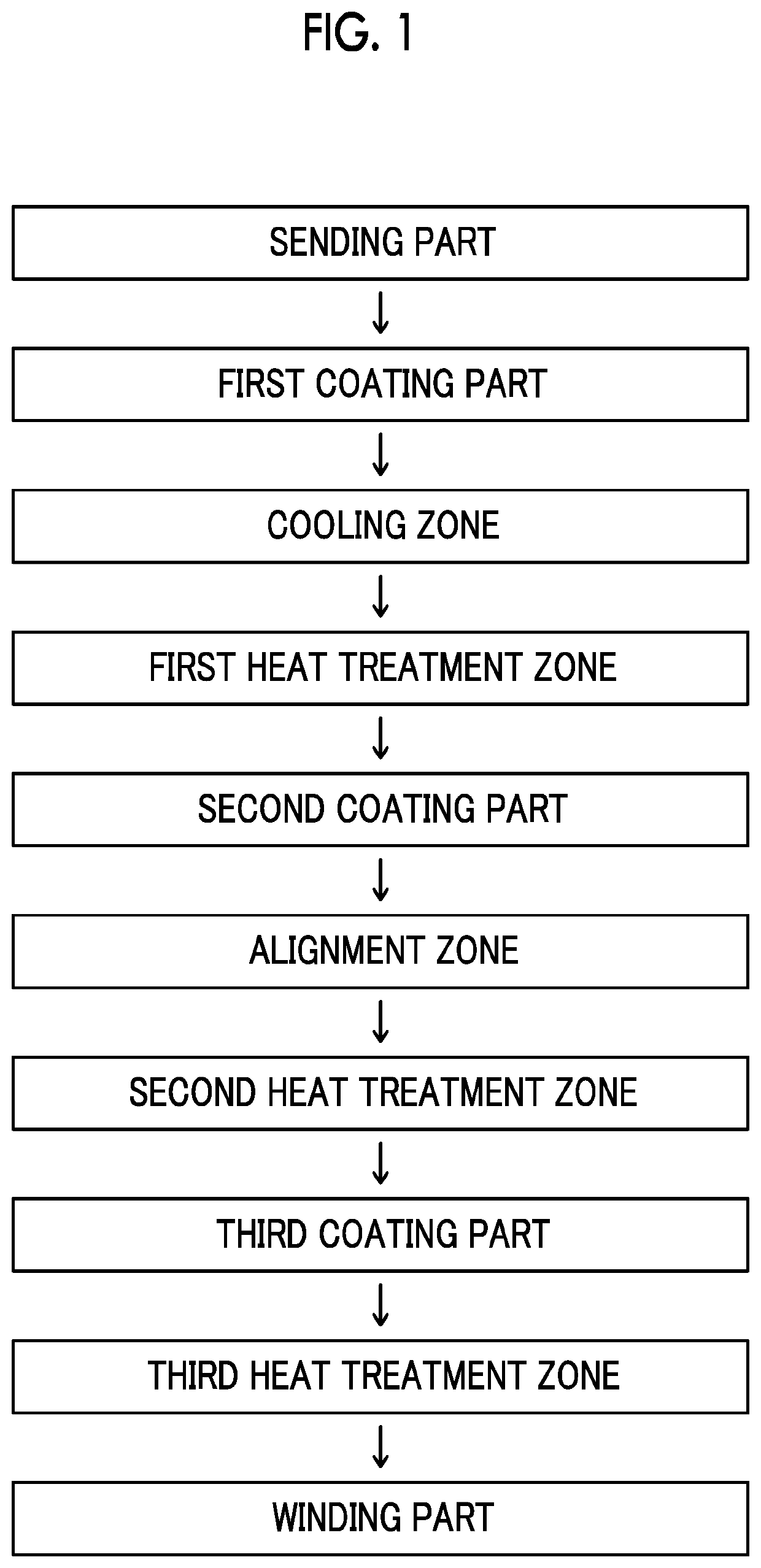

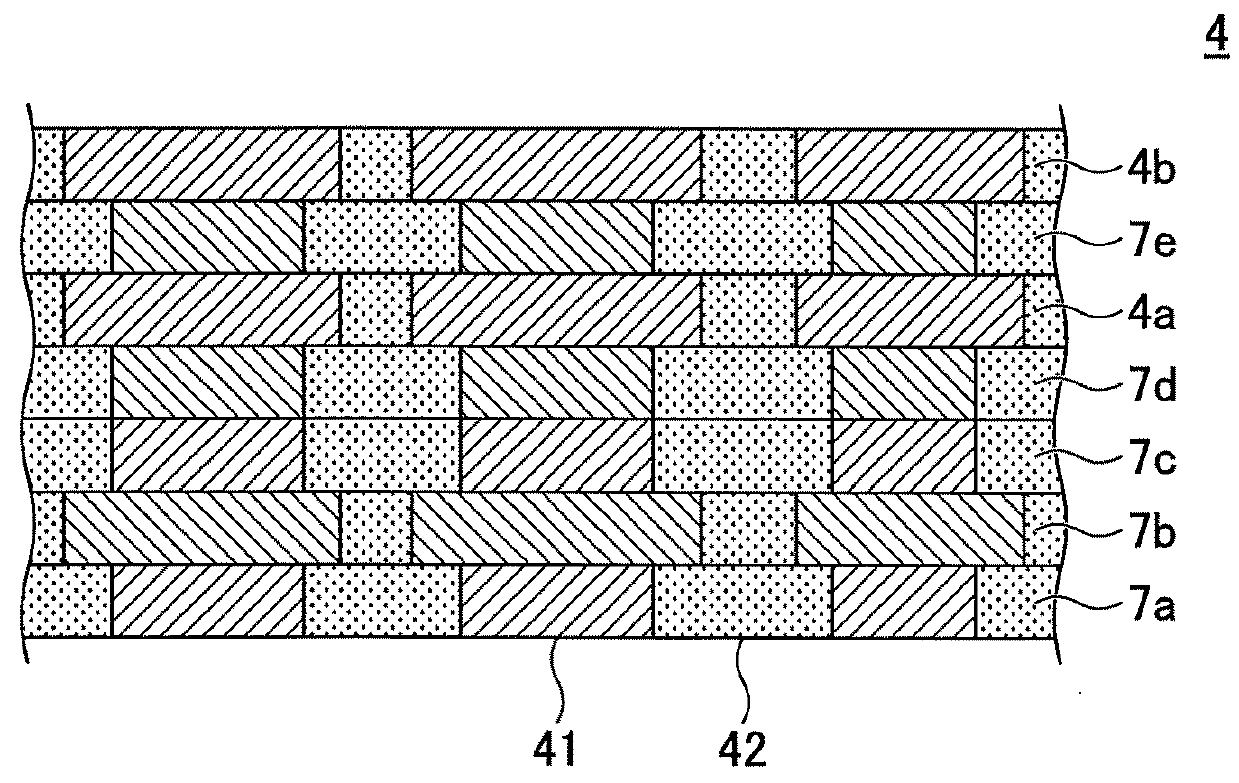

ActiveUS20170032812A1Increase the lengthReduce thicknessRecord information storageMaterials with non-metallic substancesMagnetic tapeNon magnetic

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on one surface of a nonmagnetic support, and has a backcoat layer containing nonmagnetic powder and binder on the other surface thereof, wherein the magnetic layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide; the backcoat layer has a thickness of less than or equal to 0.30 μm and contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a magnetic layer side C—H derived C concentration is greater than or equal to 45 atom %; and a backcoat layer side C—H derived C concentration is greater than or equal to 35 atom %.

Owner:FUJIFILM CORP

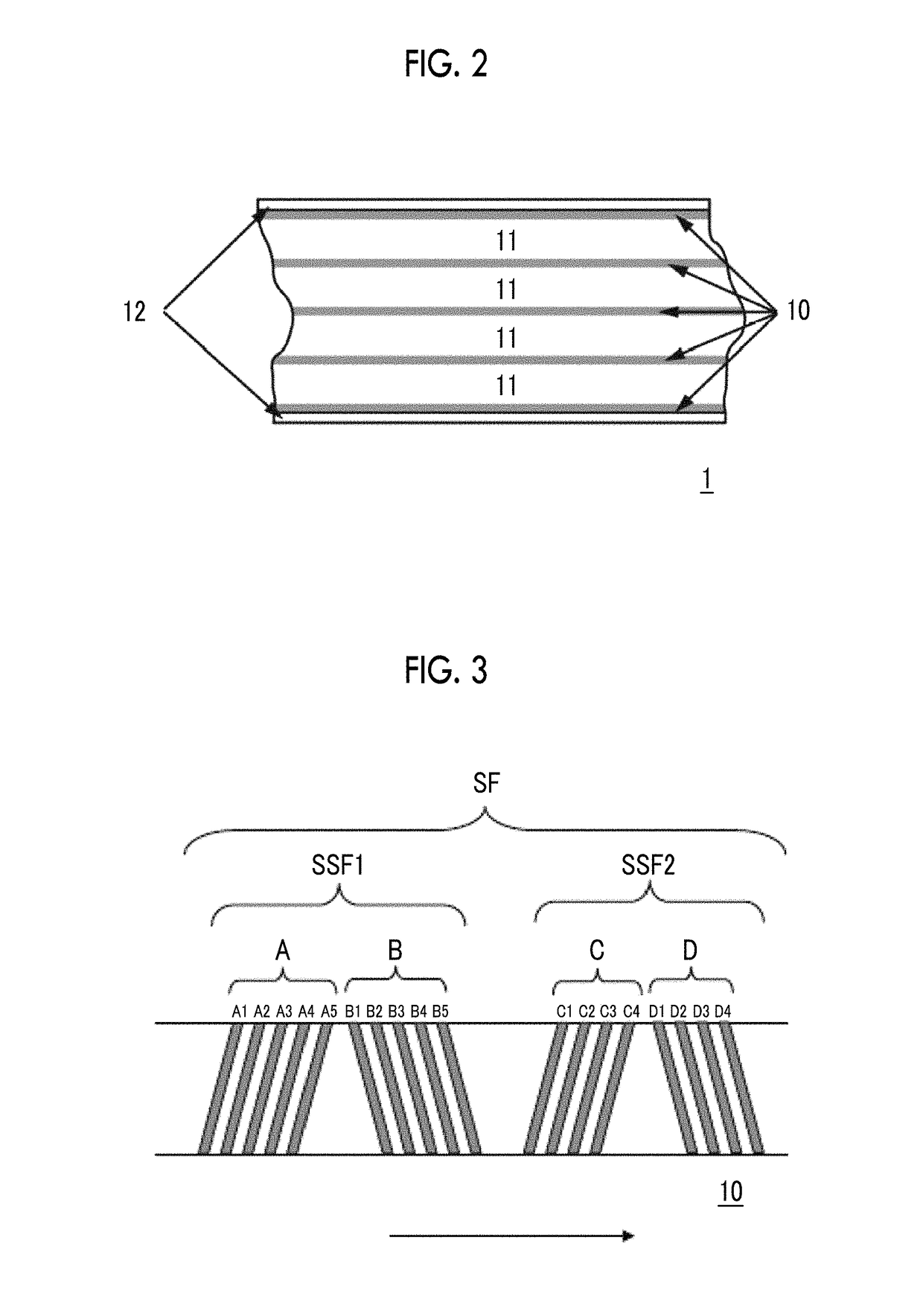

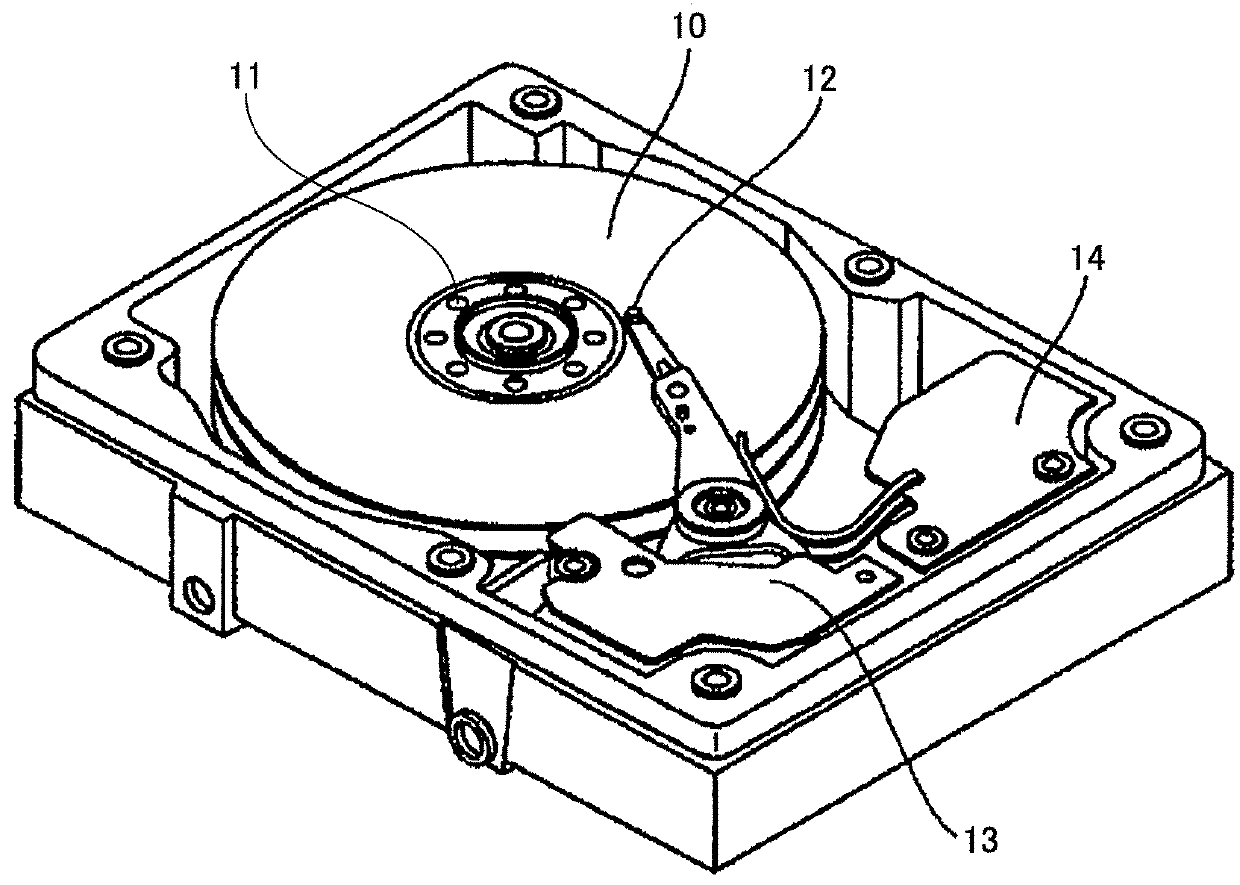

Magnetic tape device, magnetic reproducing method, and head tracking servo method

ActiveUS10134433B2Improve accuracyExact reproductionMaterials with ironAlignment for track following on tapesMagnetic tapeX-ray

Provided is a magnetic tape device in which a magnetic tape transportation speed is equal to or lower than 18 m / sec, Ra measured regarding a surface of a magnetic layer of a magnetic tape is equal to or smaller than 2.0 nm, a C-H derived C concentration calculated from a C-H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %, and ΔSFD (=SFD25° C.−SFD−190° C.) in a longitudinal direction of the magnetic tape is equal to or smaller than 0.50, with the SFD25° C. being SFD measured in a longitudinal direction of the magnetic tape at a temperature of 25° C., and the SFD−190° C. being SFD measured at a temperature of −190° C.

Owner:FUJIFILM CORP

Magnetic recording media

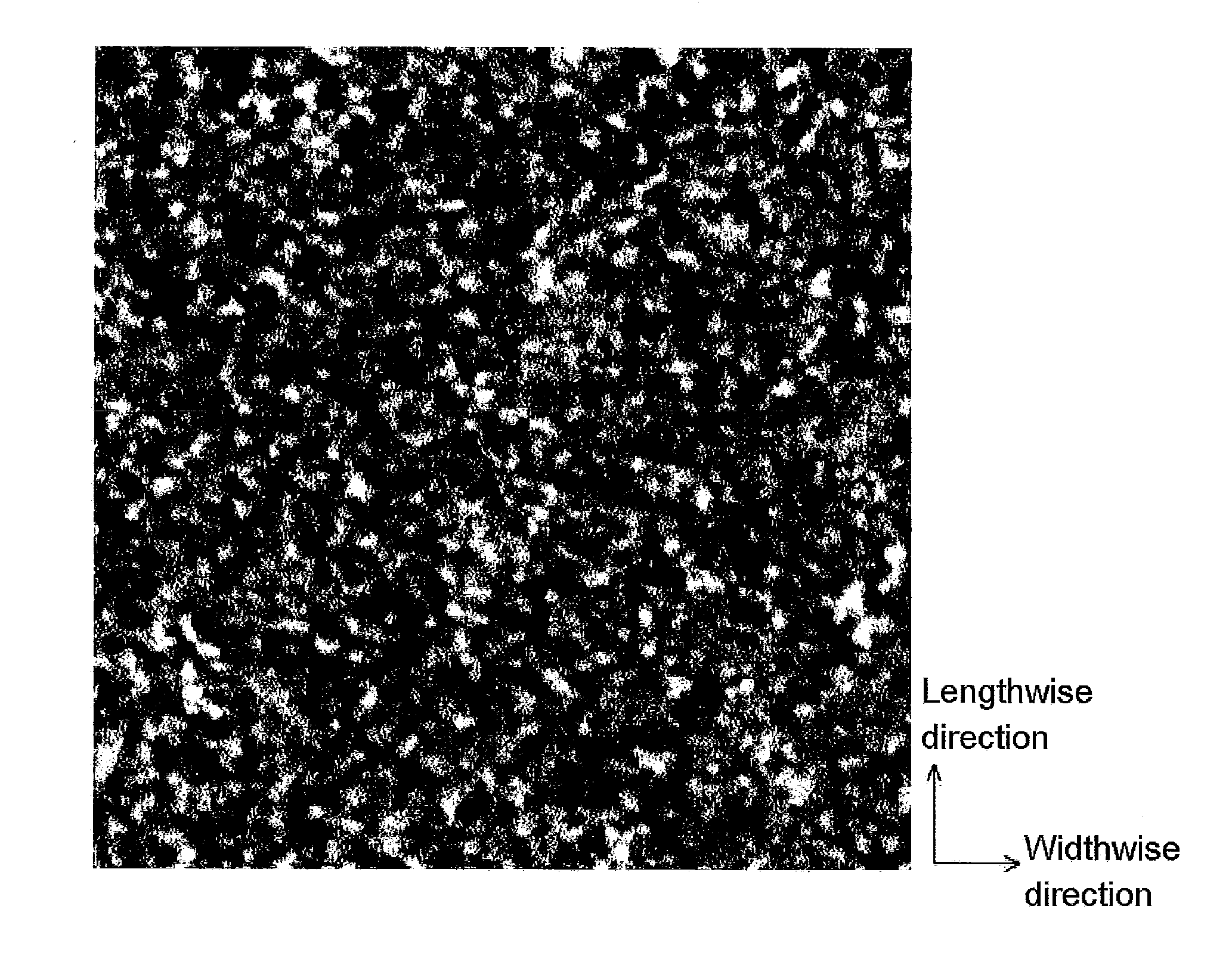

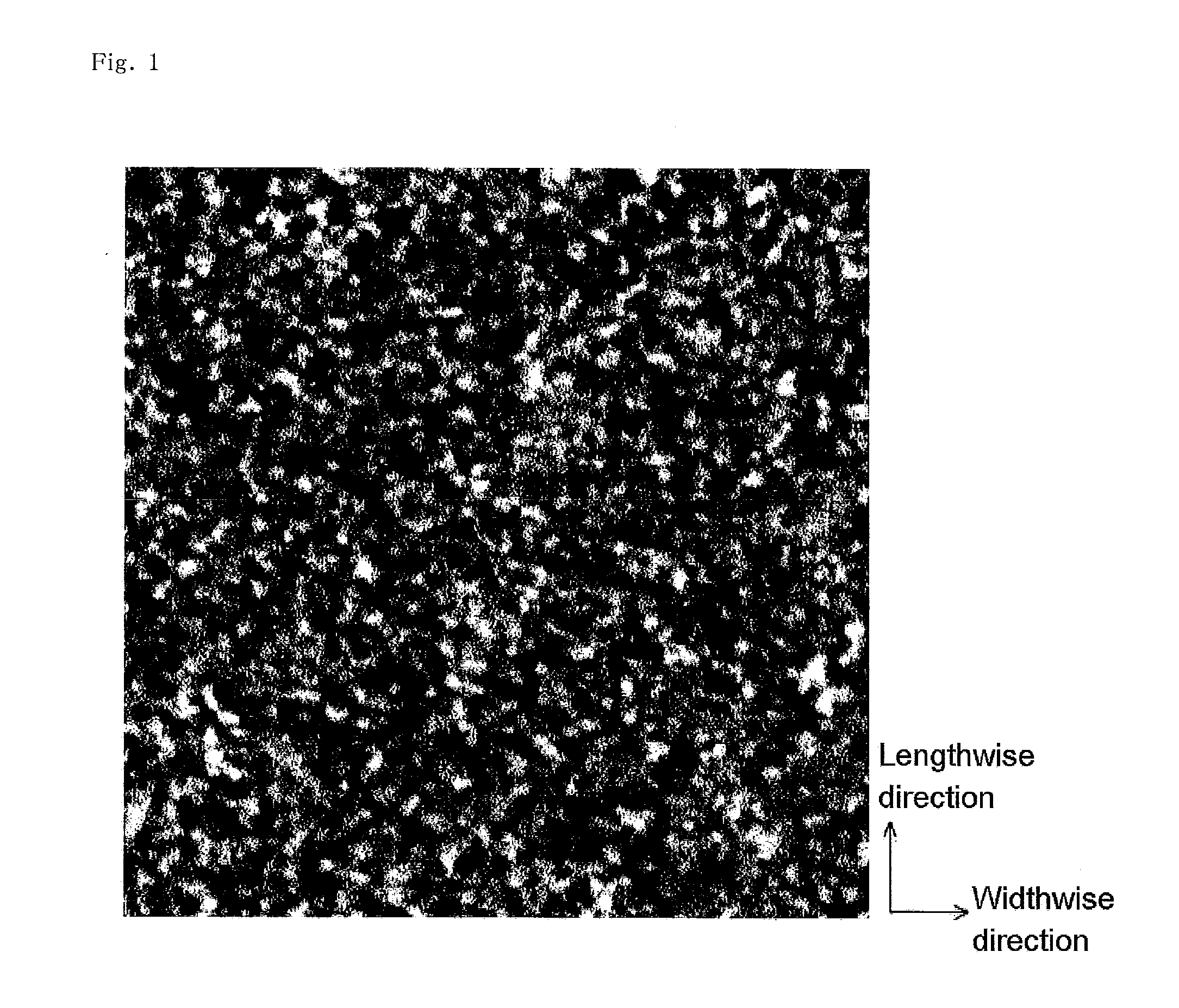

InactiveUS20110151281A1Medium noise is reducedSuitable for useRecord information storageMaterials with non-metallic substancesNon magneticMagnetic layer

A magnetic recording medium which has a non-magnetic substrate and a magnetic layer formed on the non-magnetic substrate, in which the magnetic layer contains magnetic powder with a particle size of 40 nm or less and a binder, an autocovariance length Ma of the magnetic layer in its lengthwise direction is 70 nm or less, an autocovariance length Mb of the magnetic layer in its widthwise direction is 80 nm or less, and a ratio Ma / Mb is from 0.80 to 1.20.

Owner:HITACHT MAXELL LTD

Magnetic tape

ActiveUS20180286443A1Deterioration of characteristicMaterials with ironRecord information storageMagnetic tapeFull width at half maximum

The magnetic tape has the total thickness of a non-magnetic layer and a magnetic layer of 0.60 μm or smaller, the magnetic layer including an abrasive and fatty acid ester, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer with respect to the total area of the region, obtained by plane observation performed by using an SEM of 0.02% or greater and less than 0.06%, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape of greater than 0 nm and 7.0 nm or smaller, and a difference between spacings before and after the vacuum heating of greater than 0 nm and 8.0 nm or smaller.

Owner:FUJIFILM CORP

Magnetic tape device, magnetic reproducing method, and head tracking servo method

ActiveUS20190051325A1Improve accuracyExact reproductionMaterials with ironAlignment for track following on tapesMagnetic tapeX-ray

Provided is a magnetic tape device in which a magnetic tape transportation speed is equal to or lower than 18 m / sec, Ra measured regarding a surface of a magnetic layer of a magnetic tape is equal to or smaller than 2.0 nm, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %, and ΔSFD (=SFD25°C.−SFD−190° C.) in a longitudinal direction of the magnetic tape is equal to or smaller than 0.50, with the SFD25° C. being SFD measured in a longitudinal direction of the magnetic tape at a temperature of 25° C., and the SFD−190° C. being SFD measured at a temperature of −190° C.

Owner:FUJIFILM CORP

Magnetic tape device, magnetic reproducing method, and head tracking servo method

ActiveUS20180286444A1Lower the resistance valueImprove accuracyMaterials with ironAlignment for track following on tapesMagnetic tapeX-ray

Provided is a magnetic tape device in which a magnetic tape transportation speed is equal to or lower than 18 m / sec, Ra measured regarding a surface of a magnetic layer of a magnetic tape is equal to or smaller than 2.0 nm, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %, and ΔSFD (=SFD25° C.−SFD−190° C.) in a longitudinal direction of the magnetic tape is equal to or smaller than 0.50, with the SFD25° C. being SFD measured in a longitudinal direction of the magnetic tape at a temperature of 25° C., and the SFD−19° C. being SFD measured at a temperature of −190° C.

Owner:FUJIFILM CORP

Magnetic Recording Medium, Linear Magnetic Recording and Reproduction System and Magnetic Recording and Reproduction Method

InactiveUS20090046396A1Raise the ratioIncreased durabilityDifferent record carrier formsRecord information storagePerpendicular directionUltimate tensile strength

The present invention relates to a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nomnagnetic support. A product, Mrδ, of a residual magnetization Mr of the magnetic layer and a thickness δ of the magnetic layer is equal to or greater than 2 mT•μm and equal to or less than 12 mT•μm, a squareness in a perpendicular direction is equal to or greater than 0.4 and equal to or less than 0.7, and a squareness in a longitudinal direction is equal to or greater than 0.3 but less than 0.6.

Owner:FUJIFILM CORP

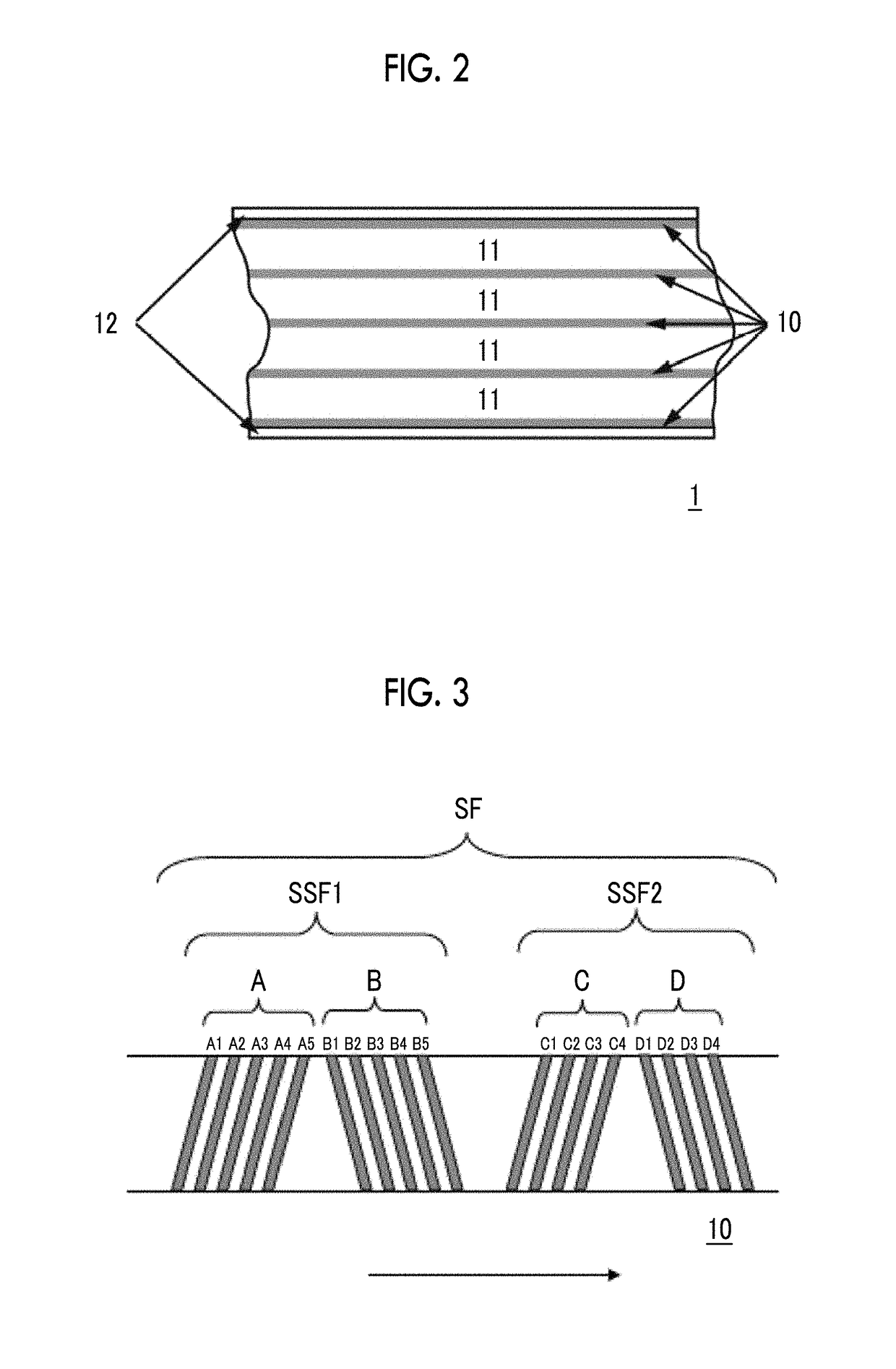

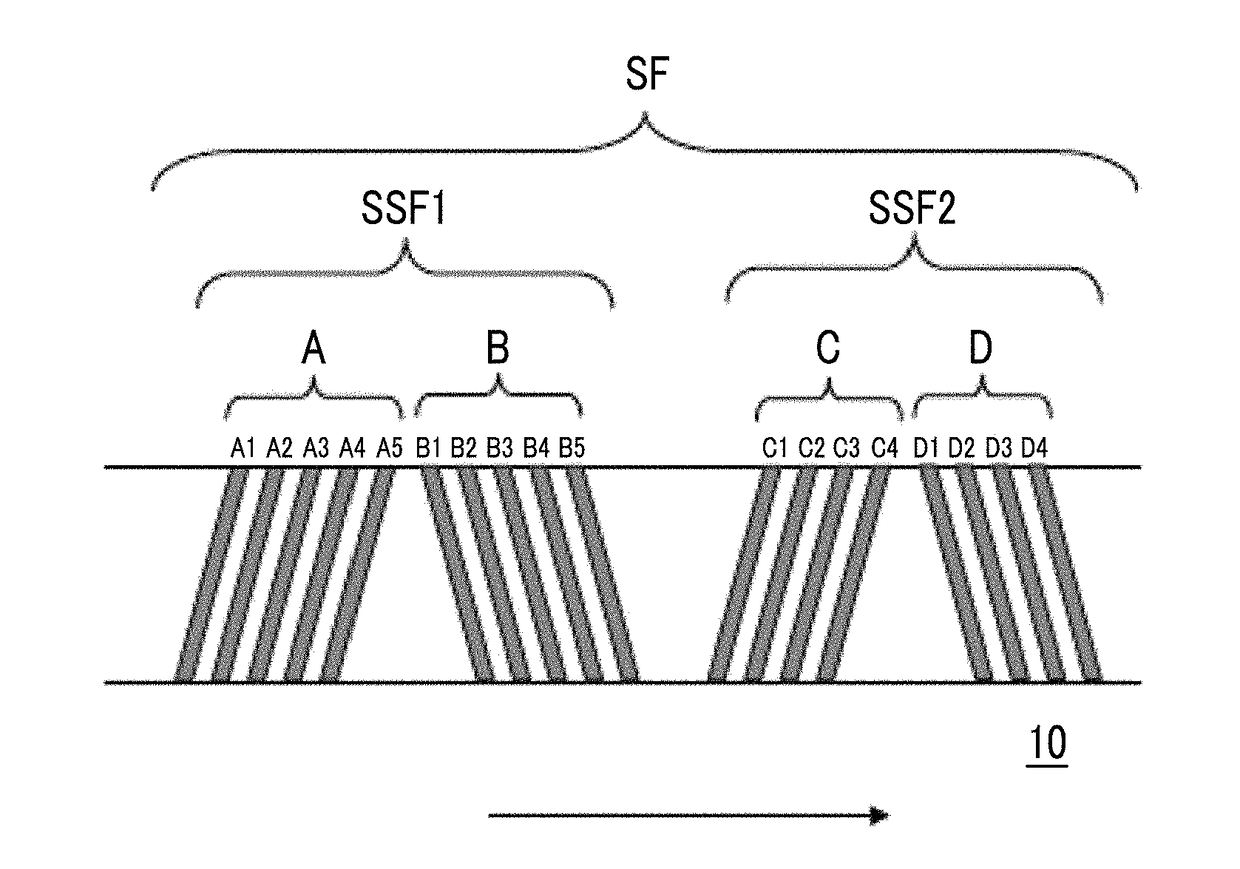

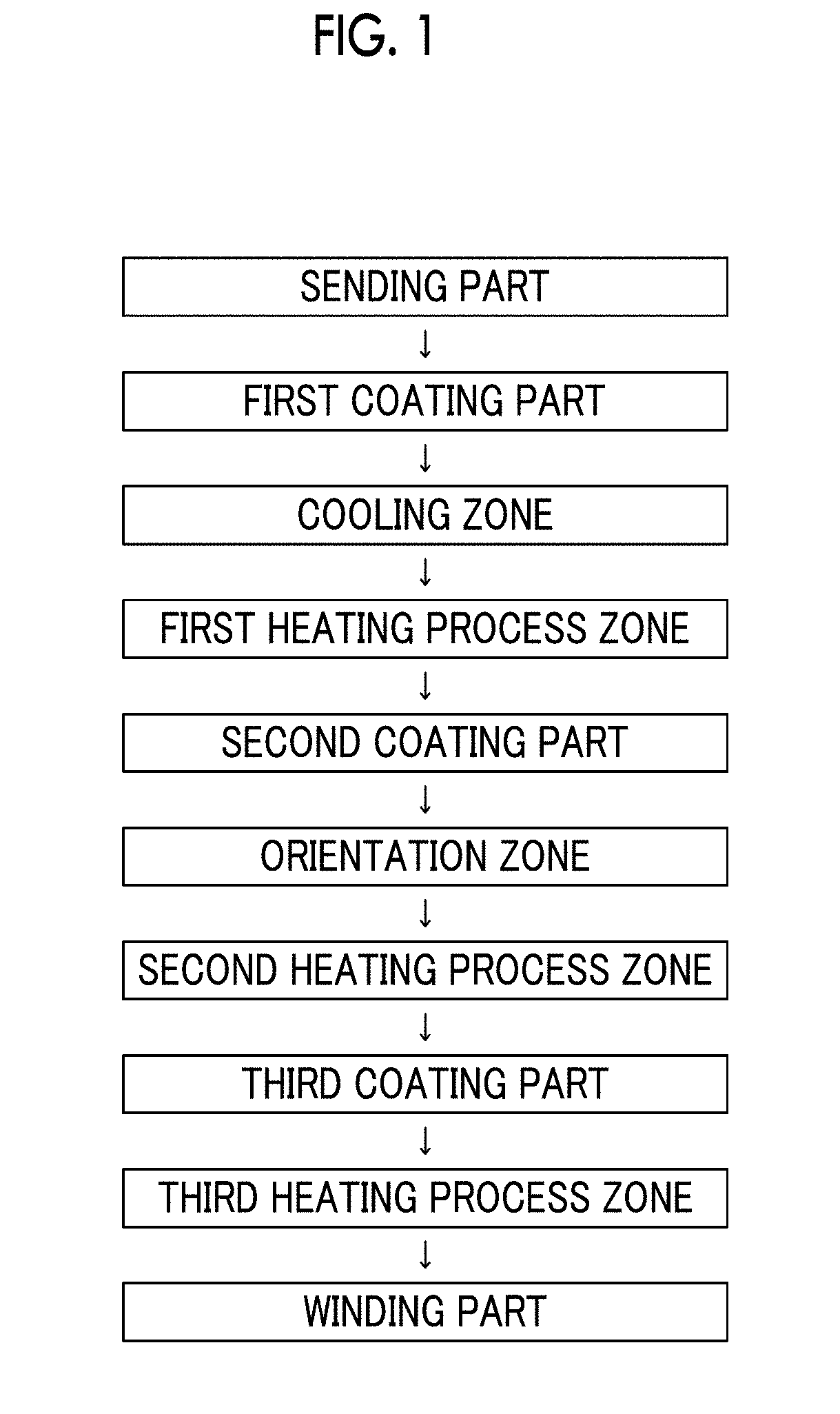

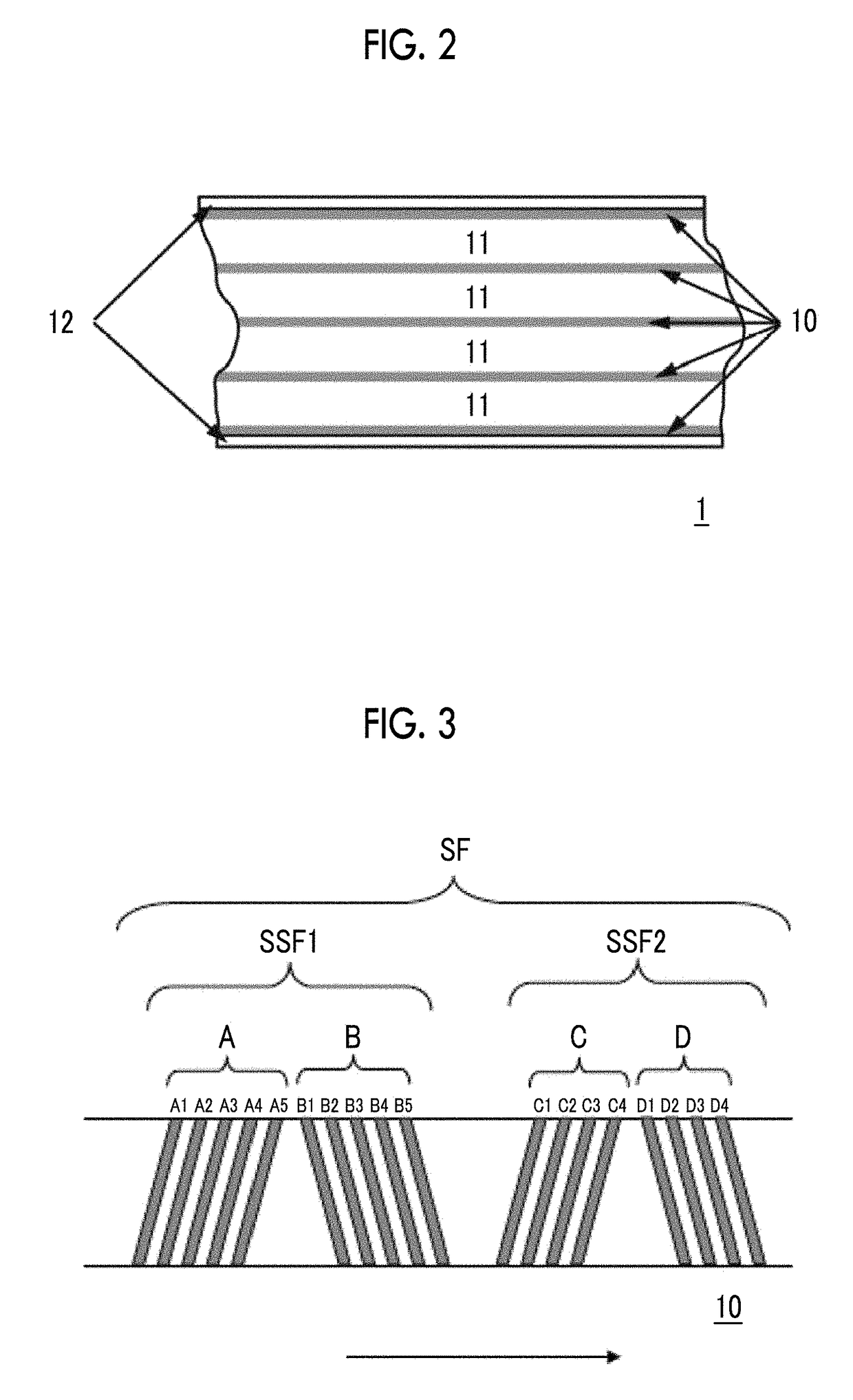

Magnetic tape including characterized magnetic layer, tape cartridge, recording and reproducing device, and method of manufacturing

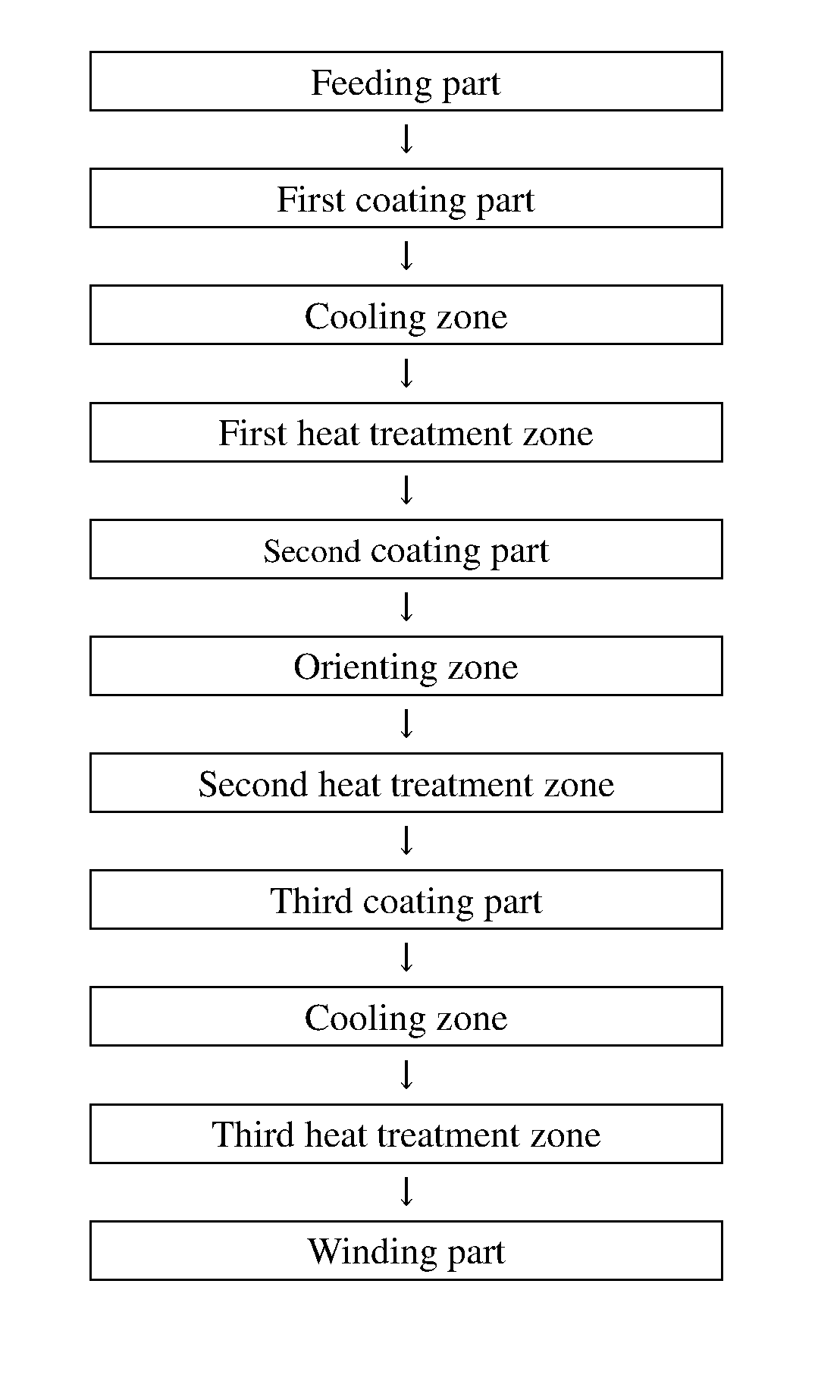

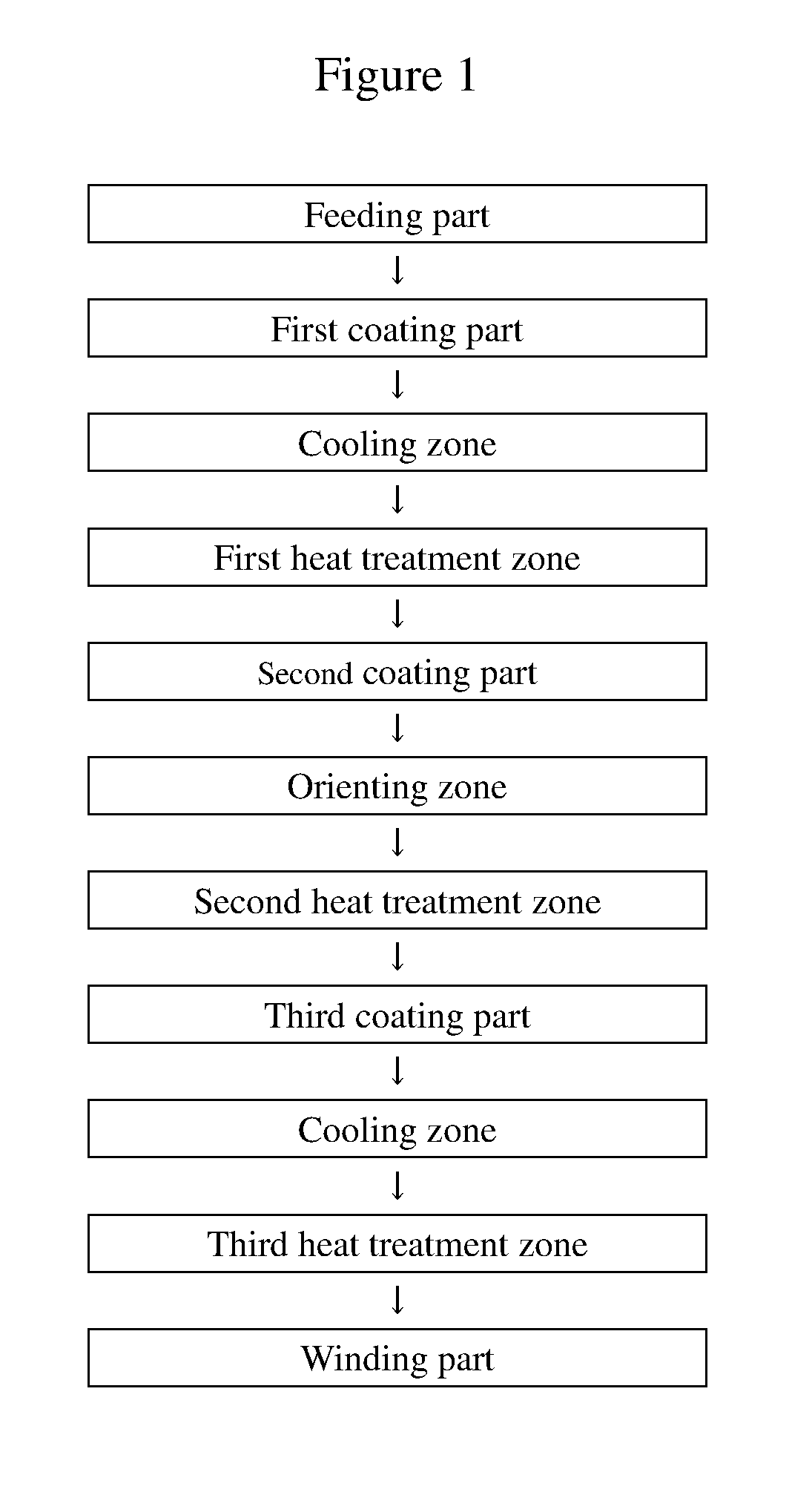

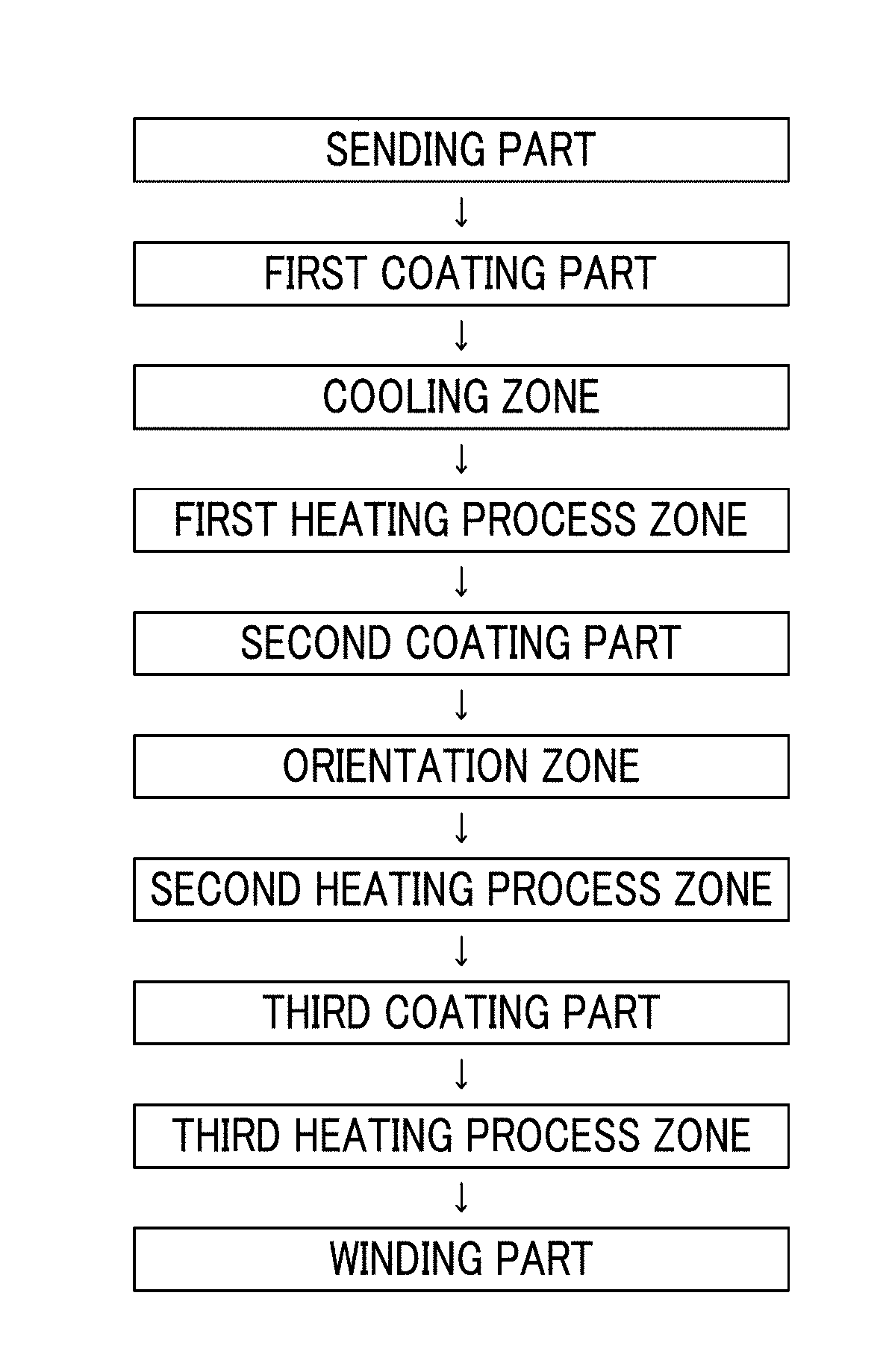

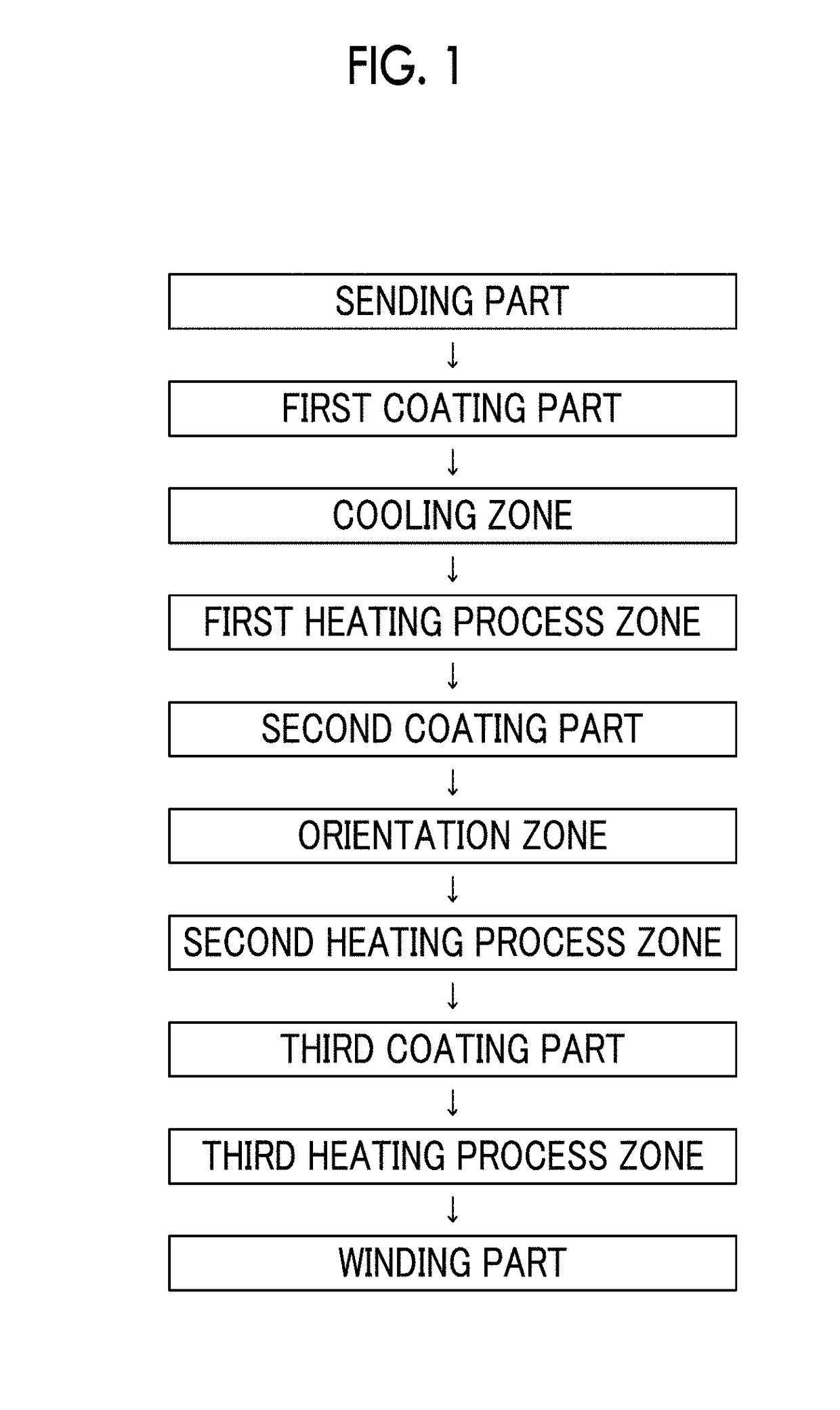

ActiveUS10522180B2Shorten the timeIncrease delivery speedBase layers for recording layersTape carriersMagnetic tapeMaterials science

Owner:FUJIFILM CORP

Iron nitride powder, method of manufacturing the same, and magnetic recording medium

InactiveUS20090087688A1Excellent magnetic propertiesSuited to high-density recordingPretreated surfacesRecord information storageMischmetalIron nitride

An aspect of the present invention relates to an iron nitride powder. The iron nitride powder is comprised chiefly of Fe16N2 and comprises, on at least a portion of the powder surface, a coating layer comprising at least one element selected from the group consisting of rare earth metal elements, aluminum, and silicon, and cobalt-containing ferrite having a composition denoted by (CoxFe1−x)Fe2O4, wherein 0<x≦1. The present invention further relates to a method of manufacturing iron nitride powders and a magnetic recording medium comprising the iron nitride powder.

Owner:FUJIFILM CORP

Method of manufacturing magnetic particles, magnetic particles, and magnetic recording medium

InactiveUS20060283290A1Inorganic material magnetismRecord information storageSpherical formMaterials science

A method of manufacturing magnetic particles, the method comprising synthesizing iron particles in a liquid phase, nitriding the iron particles, adjusting the average particle diameter to 5 to 25 nm, and making the iron particles substantially spherical. Also provided are magnetic particles and magnetic recording media.

Owner:FUJIFILM HLDG CORP +1

Magnetic recording medium and magnetic recording and reproducing device

ActiveUS20210090599A1Improve running stabilityBase layers for recording layersRecord information storageNon magneticFerromagnetism

The magnetic recording medium includes a non-magnetic support; and a magnetic layer including a ferromagnetic powder, in which one or more kinds of component selected from the group consisting of a fatty acid and a fatty acid amide are included in a portion of the magnetic layer side on the non-magnetic support, and a C—H derived C concentration calculated from a C—H peak surface area ratio in C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on a surface of the magnetic layer at a photoelectron take-off angle of 10 degrees, after pressing the magnetic layer at a pressure of 70 atm is 45 atom % or more.

Owner:FUJIFILM CORP

Magnetic recording medium and magnetic recording and reproducing device

ActiveUS20210082463A1Improve running stabilityBase layers for recording layersRecord information storageZeta potentialNon magnetic

The magnetic recording medium includes a non-magnetic support; and a magnetic layer including a ferromagnetic powder, in which an isoelectric point of a surface zeta potential of the magnetic layer after pressing the magnetic layer at a pressure of 70 atm is equal to or greater than 5.5.

Owner:FUJIFILM CORP

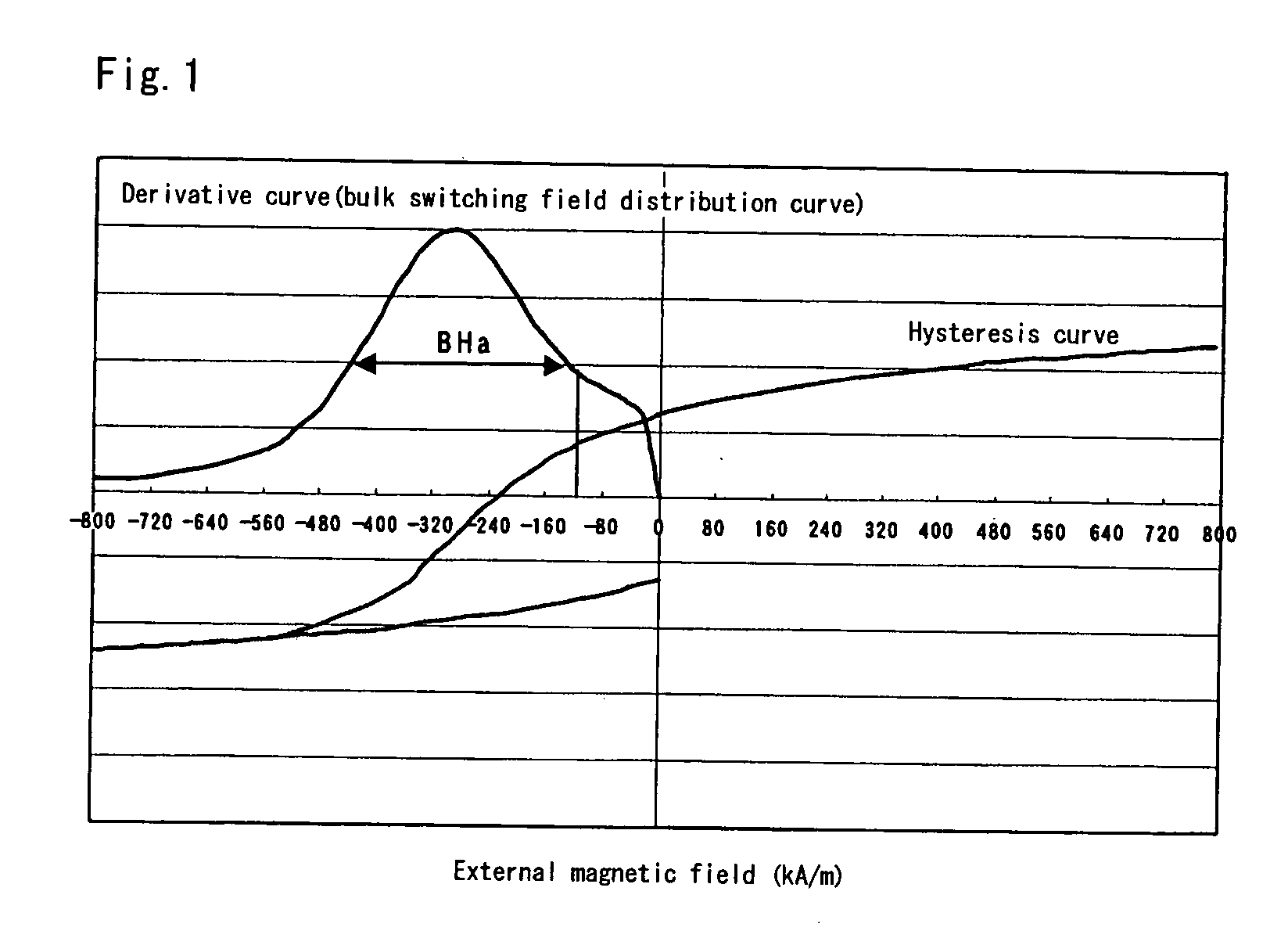

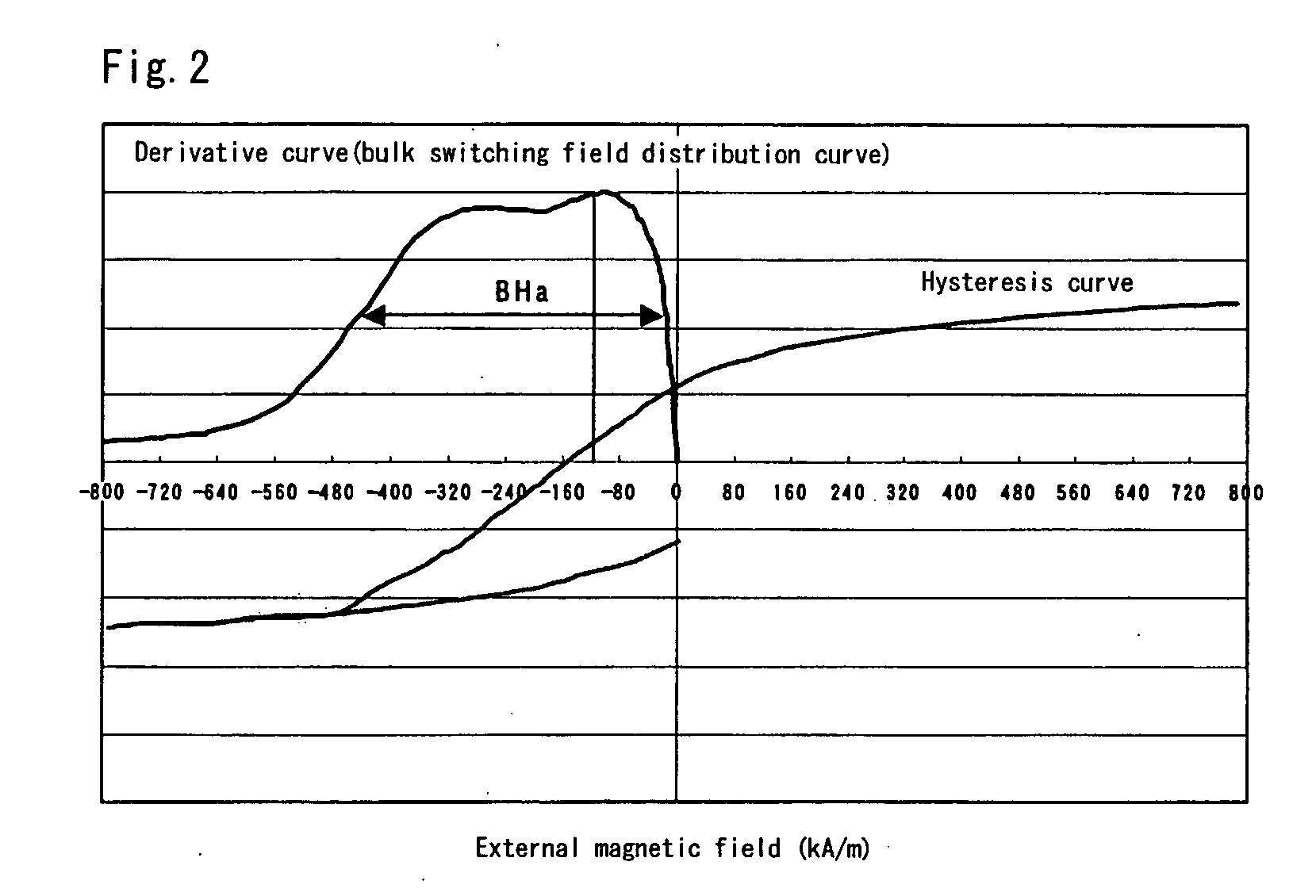

Iron nitride magnetic powder and method of producing the powder

InactiveUS20050123754A1Improve magnetic propertiesImprove the immunityMaterial nanotechnologyCyanogen compoundsHigh densityMetallurgy

An iron nitride magnetic powder comprised primarily of Fe16N2 phase is characterized in that its coercive force Hc is 200 KA / m or greater and bulk switching field distribution BSDF is 2 or less. The magnetic powder can be produced by allowing a nitriding reaction of Fe particles with a nitrogen-containing gas for producing nitrided particles of primarily Fe16N2 phase to proceed under an increased pressure of 0.1 MPa or greater. The enhanced properties of the iron nitride magnetic powder make it suitable as a magnetic material for high-density magnetic recording media.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

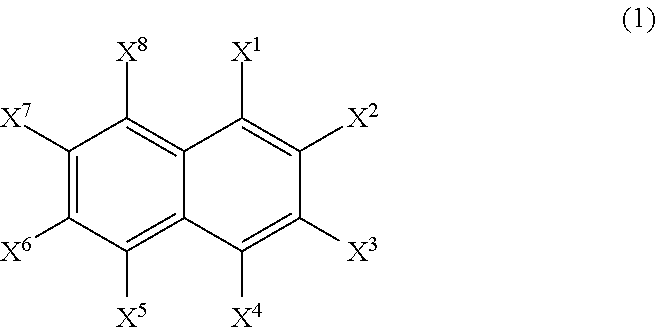

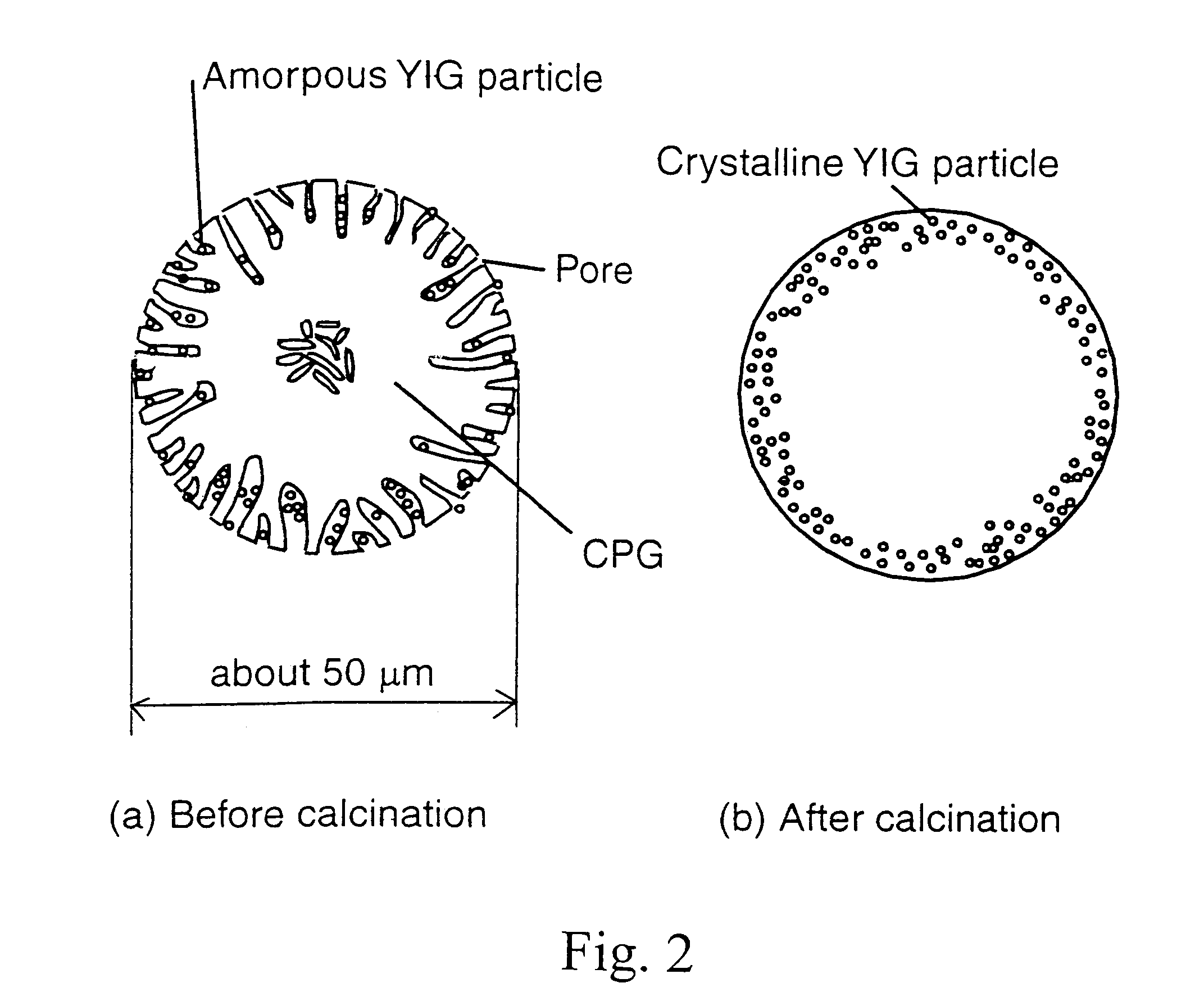

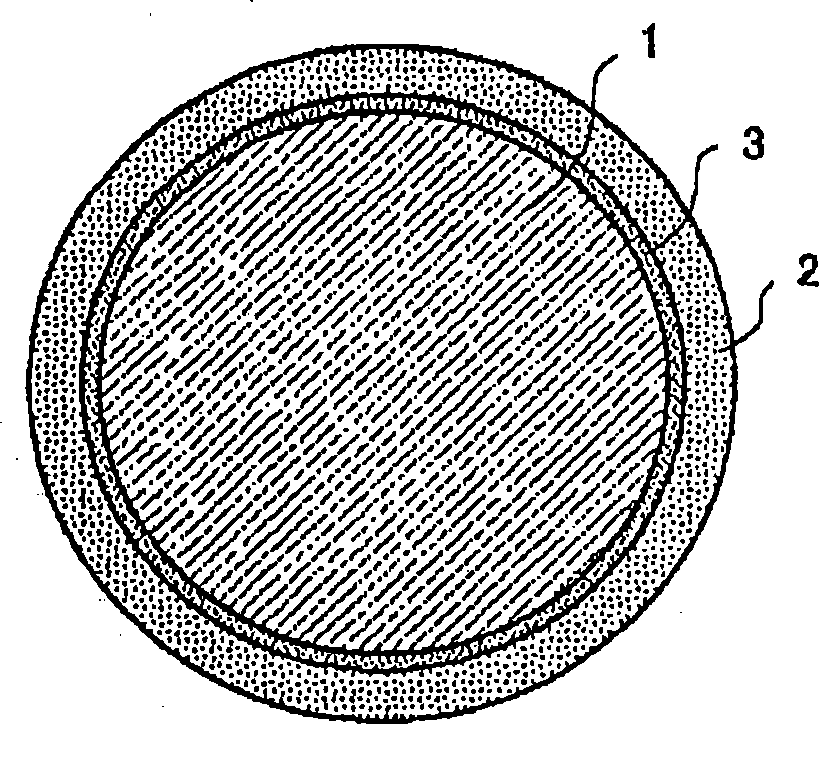

Glass composite including dispersed rare earth iron garnet nanoparticles

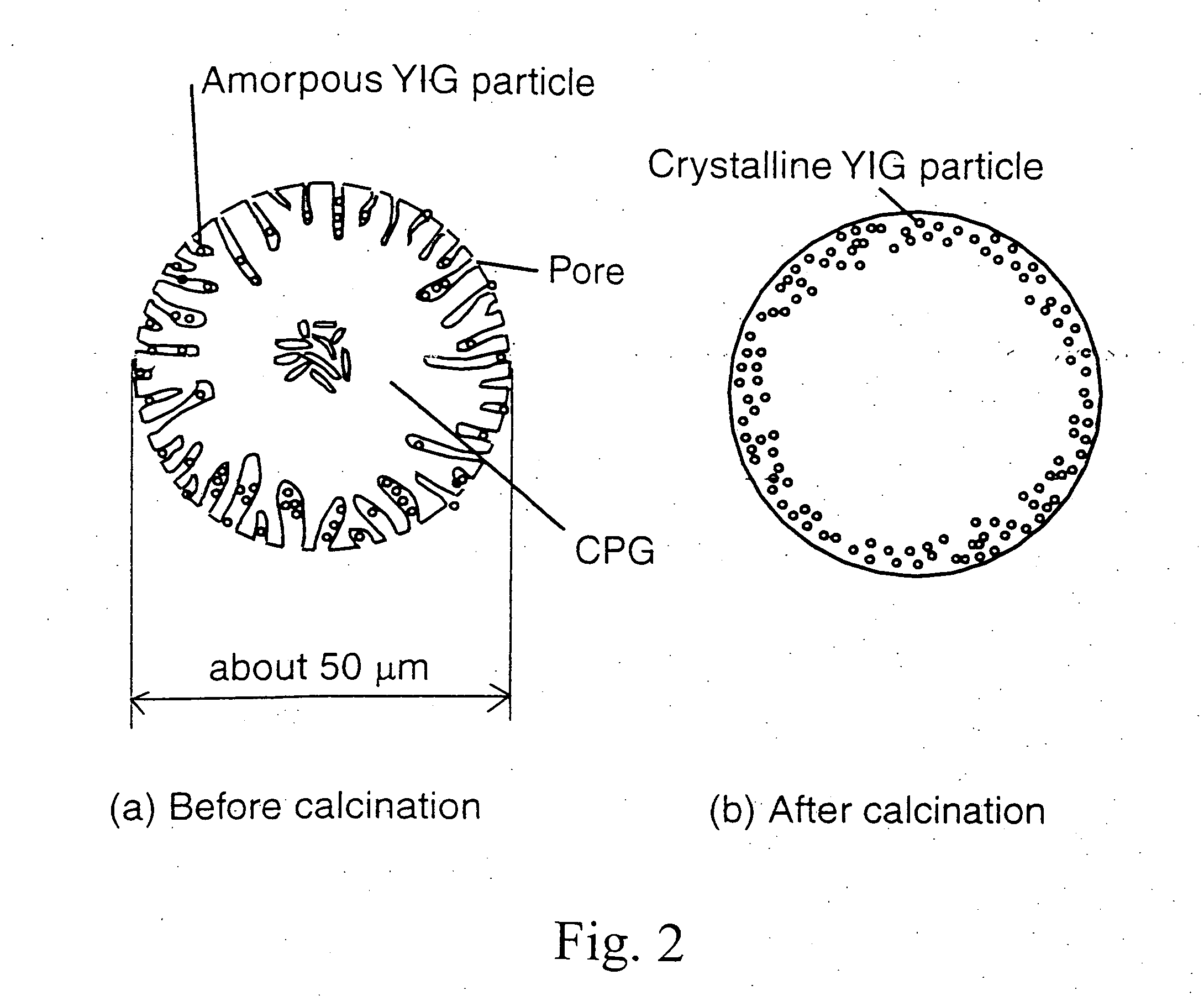

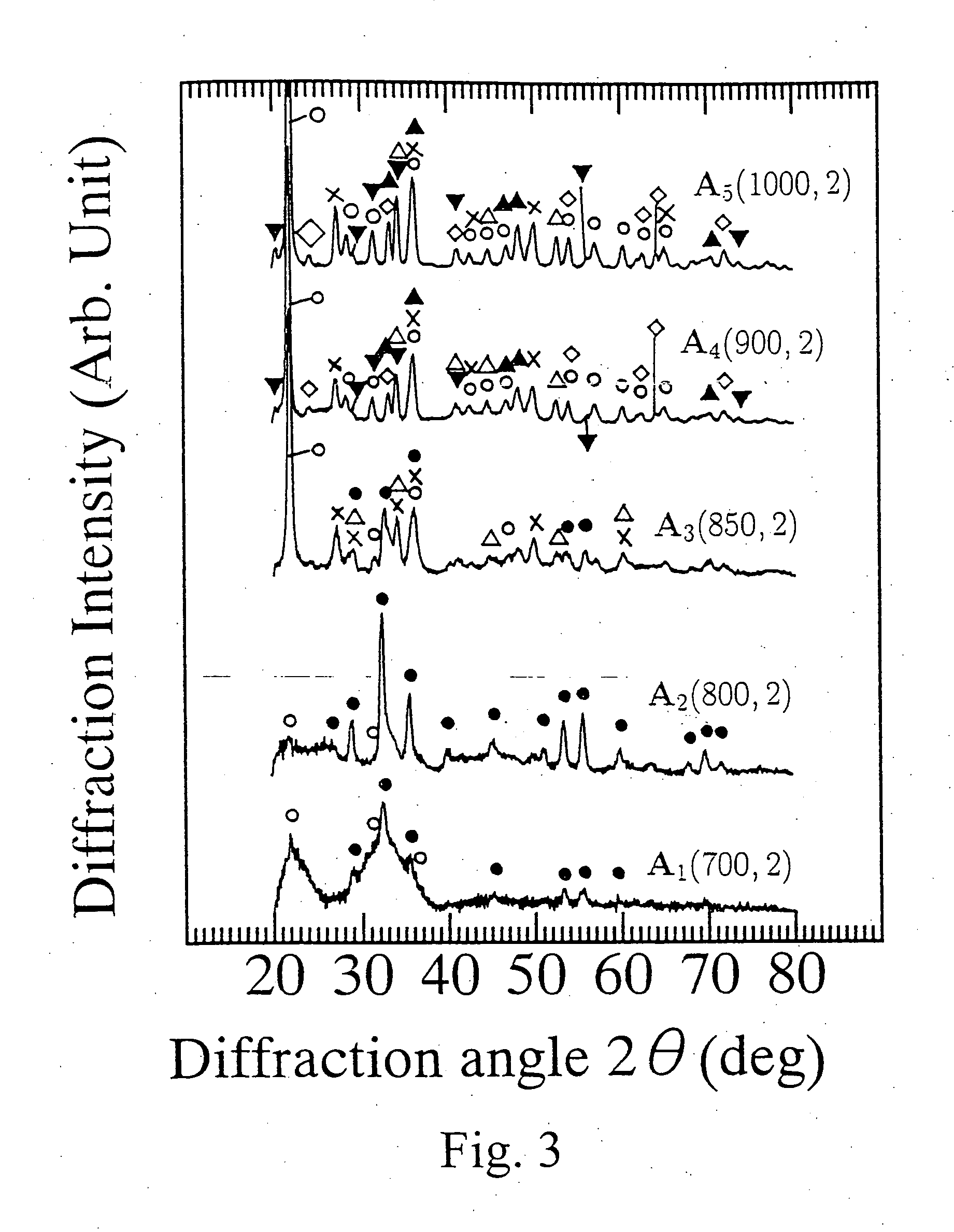

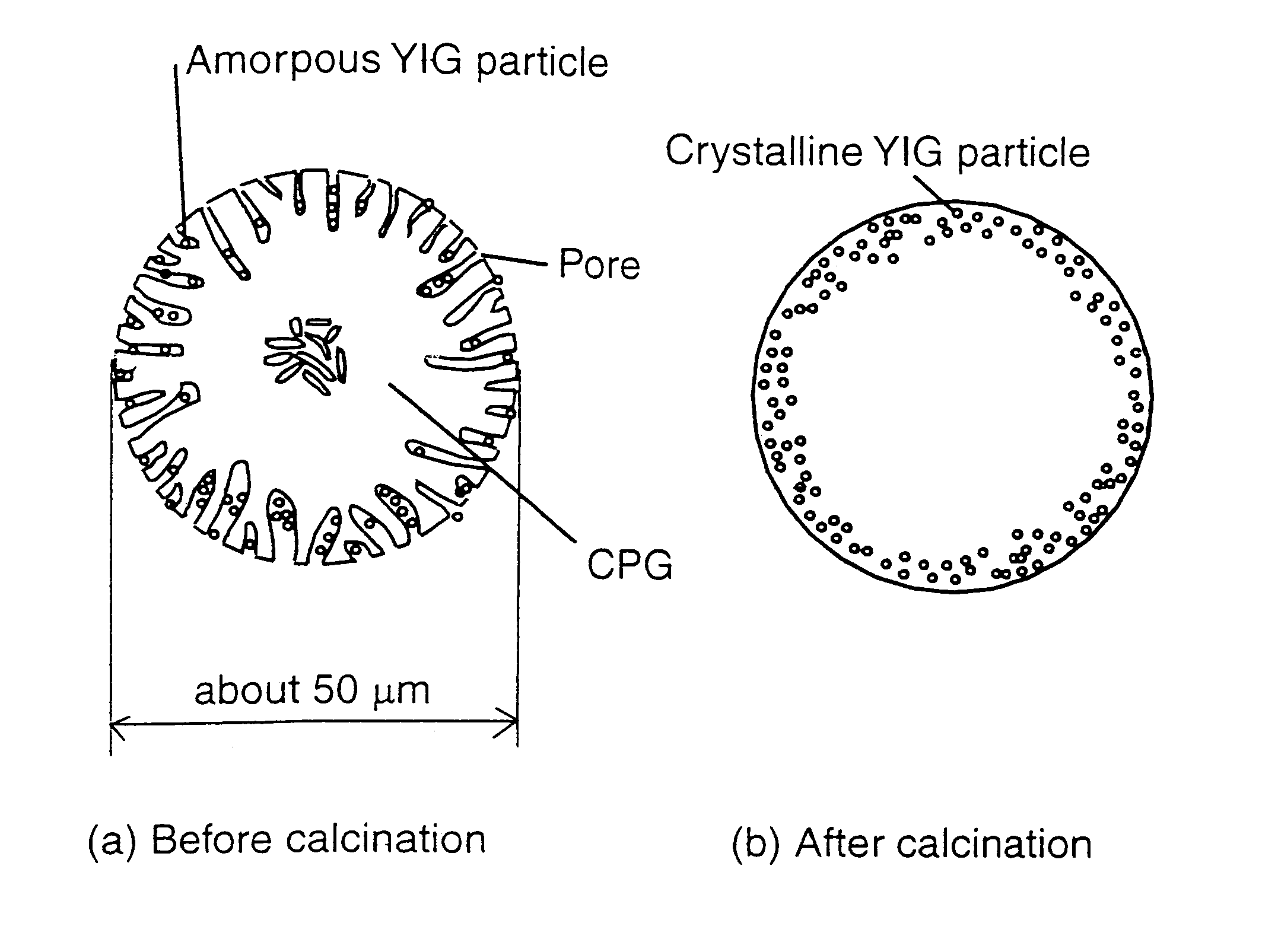

InactiveUS20050008875A1Record information storageMaterials with non-metallic substancesRare earthElectromagnetic radiation

Glass / nanoparticle composites are provided which include a glass matrix with a high density of heterologous nanoparticles embedded therein adjacent the outer surfaces of the composite. Preferably, the glass matrix is formed of porous glass and the nanoparticles are yttrium-iron nanocrystals which exhibit the property of altering the polarization of incident electromagnetic radiation; the composites are thus suitable for use in electrooptical recording media. In practice, a glass matrix having suitable porosity is contacted with a colloidal dispersion containing amorphous yttrium-iron nanoparticles in order to embed the nanoparticles within the surface pores of the matrix. The treated glass matrix is then heated under time-temperature conditions to convert the amorphous nanoparticles into a crystalline state while also fusing the glass matrix pores. Nanoparticle loadings on the order of 109 nanoparticles / mm2 of glass surface area are possible, allowing construction of recording media having a recordable data density many times greater than conventional media.

Owner:MATSUMOTO YUSHI SEIYAKU

Magnetic recording medium, magnetic signal reproduction device and method of manufacturing magnetic recording medium

ActiveUS20170092314A1Improve noiseReduce adhesionRecord information storageMaterials with non-metallic substancesNon magneticMinor axis

The magnetic recording medium has a magnetic layer containing multiple nonmagnetic particles having a ratio, major axis length / minor axis length, of less than or equal to 1.5, the multiple nonmagnetic particles are present in the magnetic layer in a state where, when the depth to which each of the multiple nonmagnetic particles is embedded in the magnetic layer in observation of a sectional image picked up by SEM is denoted as b and the thickness of the magnetic layer as t, the average value of the ratio of b / t is less than or equal to 0.9, and the number of protrusions 5 nm or greater in height is 800 or greater and the number of protrusions 20 nm or greater in height is 20 or less as measured by AFM per an area 40 μm×40 μm on the magnetic layer side surface of the magnetic recording medium.

Owner:FUJIFILM CORP

Glass composite including dispersed rare earth iron garnet nanoparticles

InactiveUS7078071B2Record information storageMaterials with non-metallic substancesRare earthElectromagnetic radiation

Glass / nanoparticle composites are provided which include a glass matrix with a high density of heterologous nanoparticles embedded therein adjacent the outer surfaces of the composite. Preferably, the glass matrix is formed of porous glass and the nanoparticles are yttrium-iron nanocrystals which exhibit the property of altering the polarization of incident electromagnetic radiation; the composites are thus suitable for use in electrooptical recording media. In practice, a glass matrix having suitable porosity is contacted with a colloidal dispersion containing amorphous yttrium-iron nanoparticles in order to embed the nanoparticles within the surface pores of the matrix. The treated glass matrix is then heated under time-temperature conditions to convert the amorphous nanoparticles into a crystalline state while also fusing the glass matrix pores. Nanoparticle loadings on the order of 109 nanoparticles / mm2 of glass surface area are possible, allowing construction of recording media having a recordable data density many times greater than conventional media.

Owner:MATSUMOTO YUSHI SEIYAKU

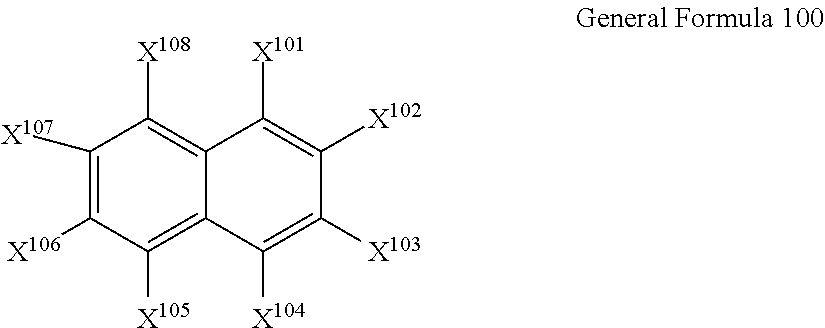

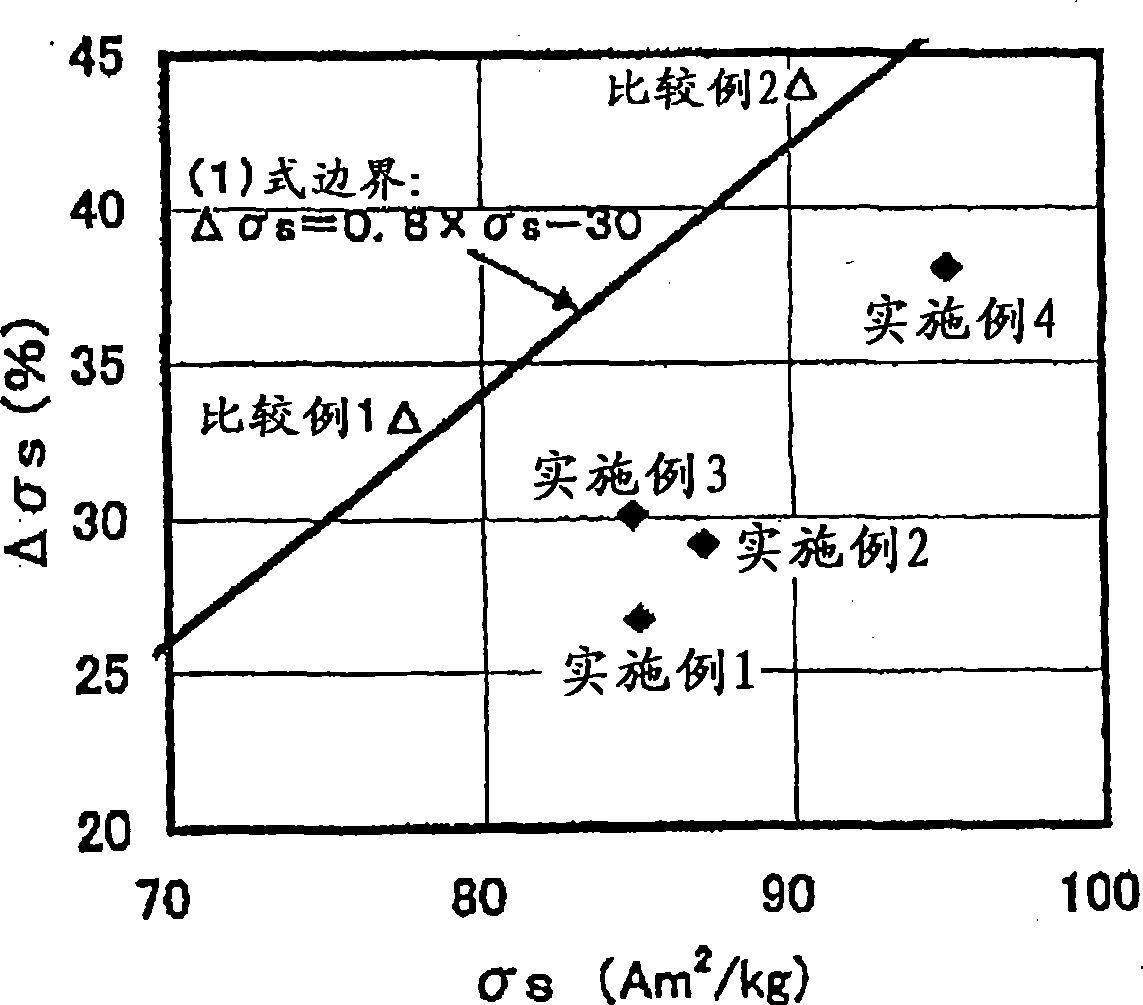

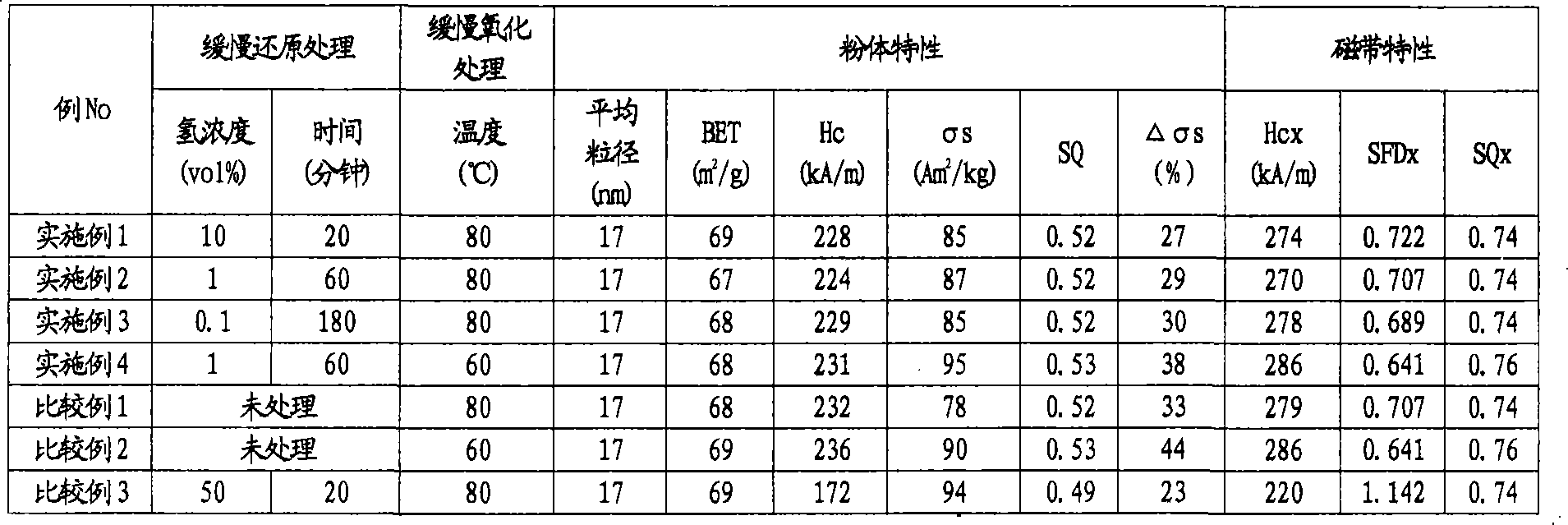

Iron nitride-based magnetic powder, process for producing the same, and magnetic recording medium

InactiveCN101467220AAging deterioration improvementIncreased durabilityMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsIron nitrideMagnetization

Provided is an iron nitride-based magnetic powder that comprises magnetic particles having a mean particle size of at most 20 nm. The magnetic particle has a core of a main phase of Fe 16 N 2 and has, on the outer side of the core, an oxide phase derived from a metal Fe phase formed by reduction of iron nitride. In relation to the weatherability index s and the saturation magnetization s thereof, the magnetic powder satisfies s 0.8 x s - 30. In this, s = (s - s 1 ) / s x 100. s 1 means the saturation magnetization of the magnetic powder kept in an atmosphere of 60 DEG C and 90 % RH for 1 week. The powder can be obtained by exposing powder particles having a main phase of Fe 16 N 2 to a reducing gas to partly reduce the region of the surface of the particles into a metal Fe phase (gradual reduction) followed by exposing them to an oxidizing gas to oxidize a part of the surface of the metal Fe phase into an oxide phase (gradual oxidation).

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Iron nitride system magnetic powder having good storage stability

InactiveUS20060131537A1Increase surface areaImprove surface activityMagnetic paintsSynthetic resin layered productsMetallurgyIron nitride

An iron nitride system magnetic powder comprising of particles comprised primarily of Fe16N2 (having an average particle diameter of up to 25 nm, for example) is provided, to which one or more elements selected from Si, P and Ti is adhered. The powder has a C / Fe atomic ratio of 0.5 to 30%, preferably a (Si+P+Ti) / Fe atomic ratio of 0.1 to 10%. With ΔHc defined (Hc0−Hc1) / Hc0×100, the powder has a ΔHc of up to 5%, and with Δσs defined as (σs0−σs1) / σs0×100, a Δσs of up to 20%. The powder can provide an ignition temperature of 140° C. or above, and a tap density of 1.0 g / cm3 or above. Hc0 and σs0 are the coercive force (kA / m) and saturation magnetization (Am2 / kg), respectively, of the iron nitride system magnetic powder after adhesion, and Hc1 and σs1 are the coercive force (kA / m) and saturation magnetization (Am2 / kg), respectively, of the powder after it has been stored in a thermo-hygrostat for one week at a temperature of 60° C. and a relative humidity of 90%.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

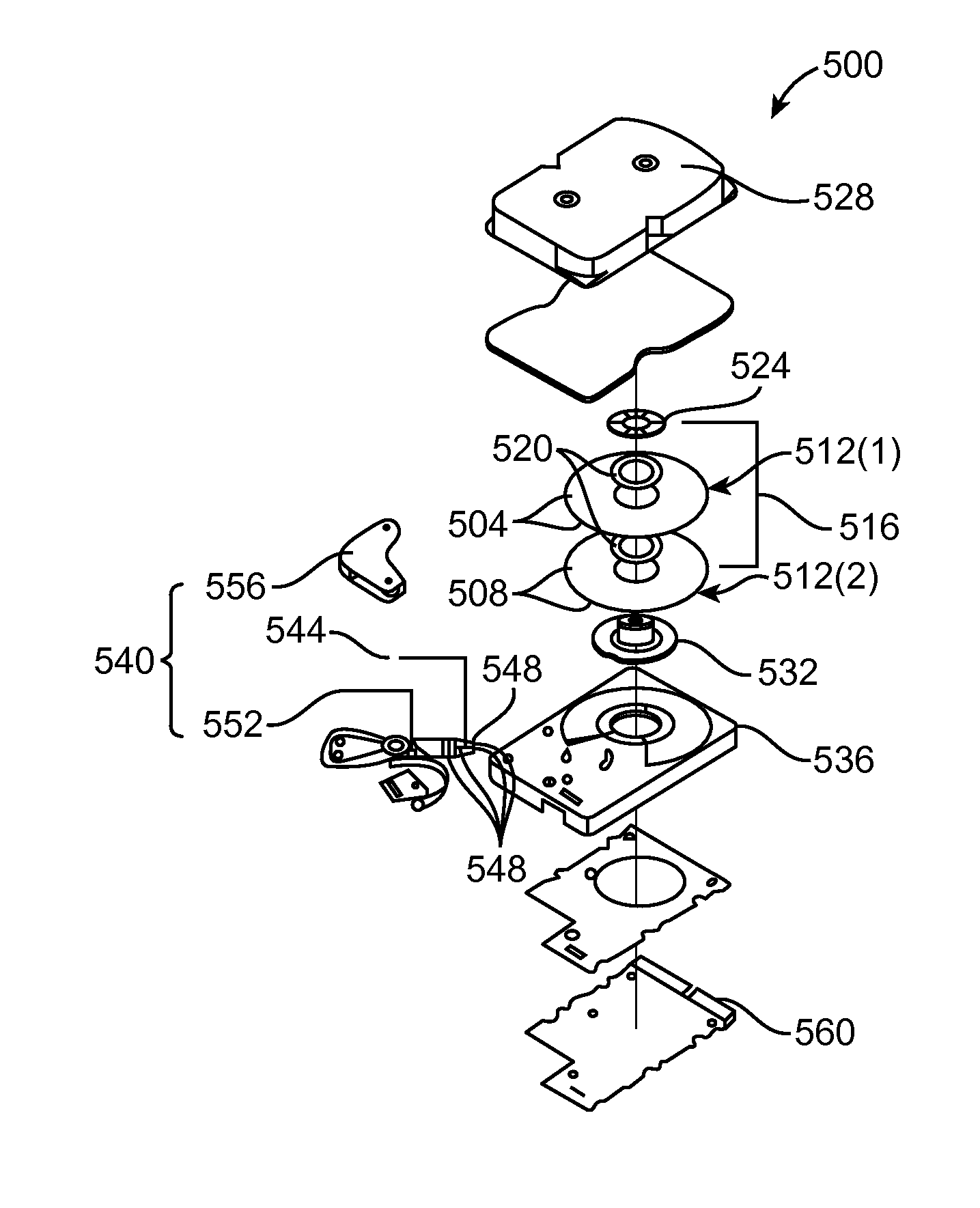

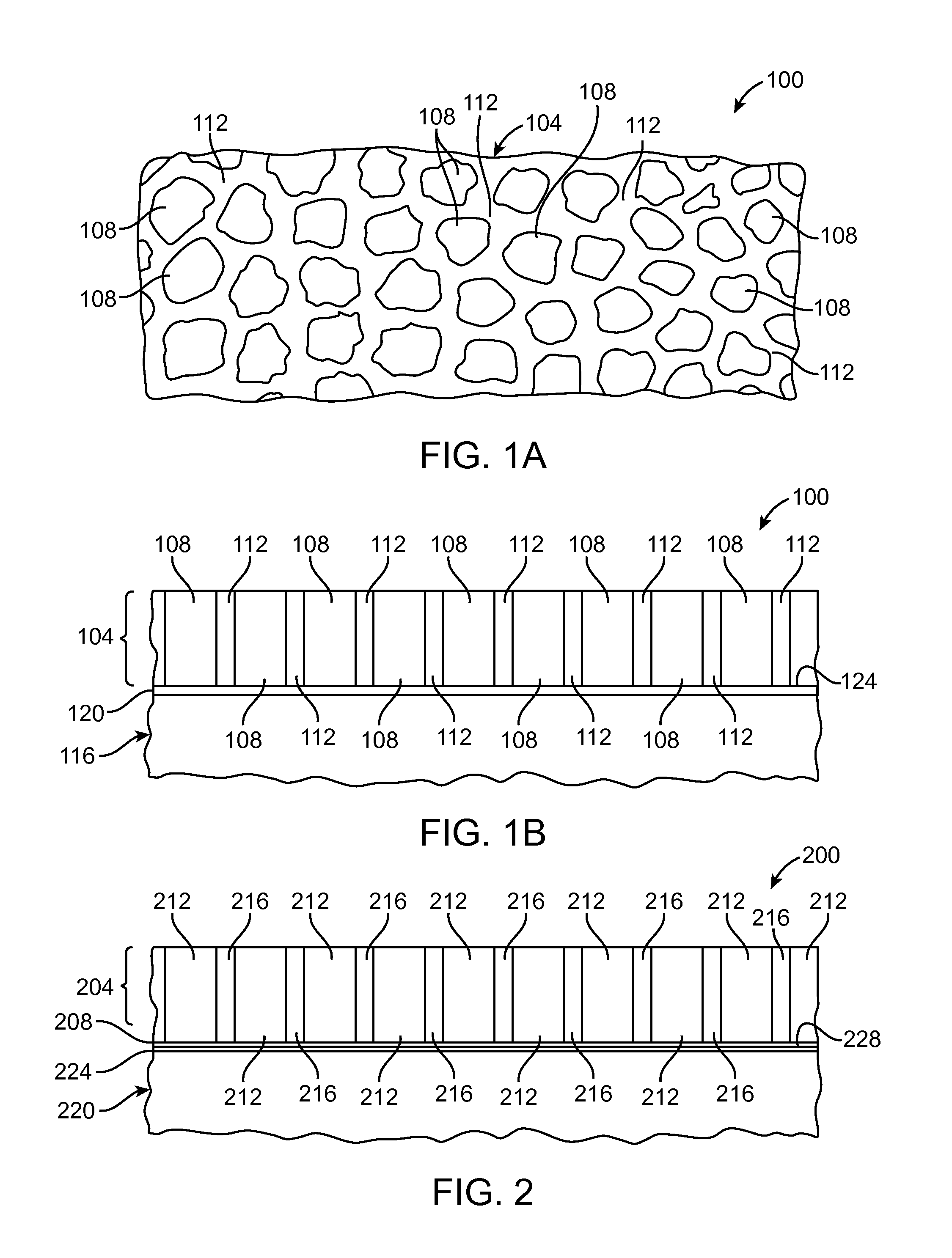

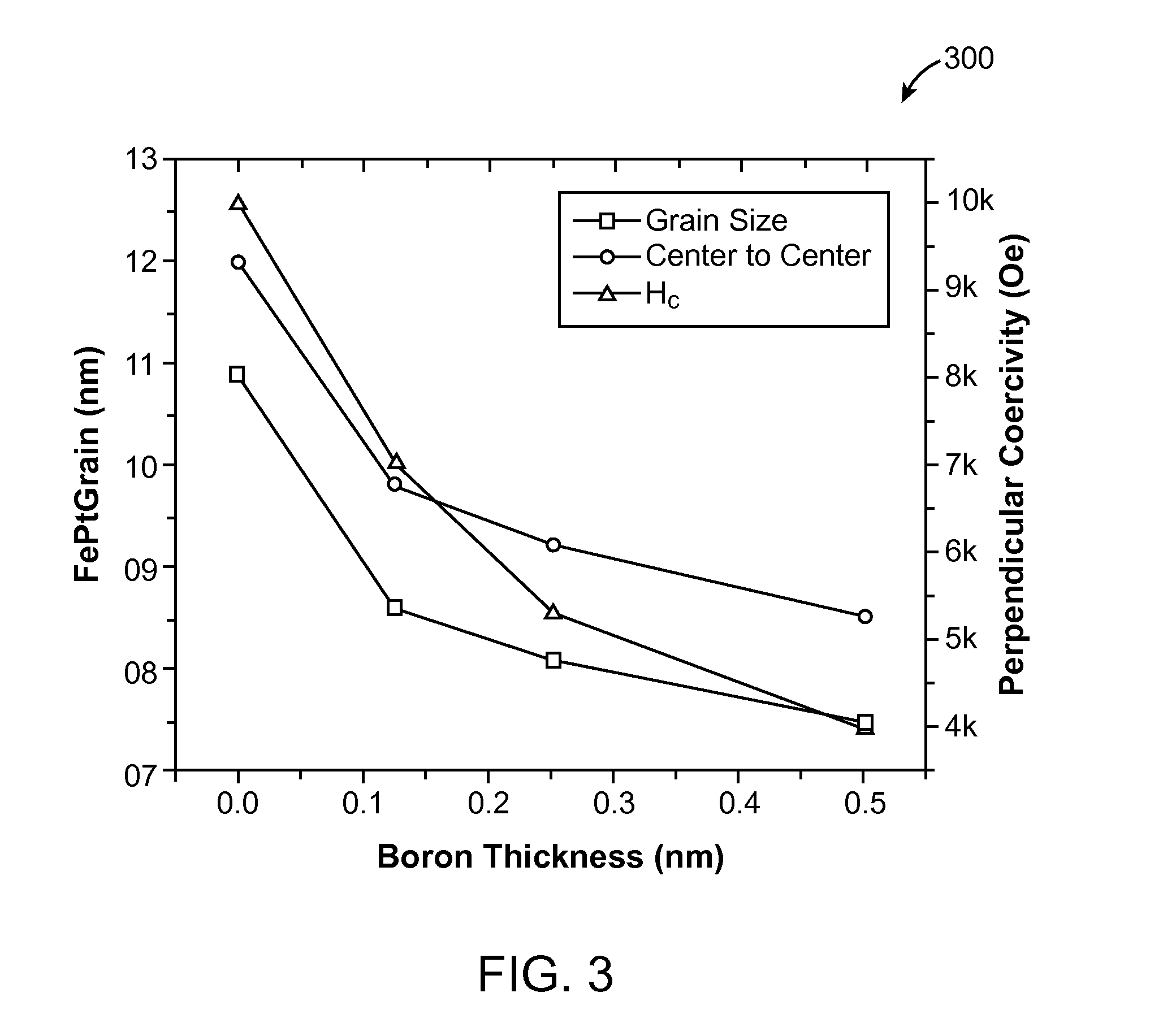

Thin Film Media Structure For Perpendicular Magnetic Recording and Storage Devices Made Therewith

Iron-platinum (FePt) based magnetic recording media structures that provide small grain size and isolated-grain configurations suitable for high-density magnetic recording. In one of the structures, the recording media structure includes a thin film containing grains of L10 FePt and boron as a segregant contained in intergranular regions located among the FePt grains. In another structure, the recording media structure includes a thin film containing grains of L10 FePt, wherein the film is formed on an underlayer containing at least one material selected to control the size of the FePt grains in the film. Proper choices of materials, relative amounts of the materials, processing parameters, and other variables permit these structures to be formed with grain sizes, magnetization orientations, and perpendicular coercivities that allow designers to create magnetic storage devices having storage densities of 1 Tbit / in2 and greater.

Owner:CARNEGIE MELLON UNIV

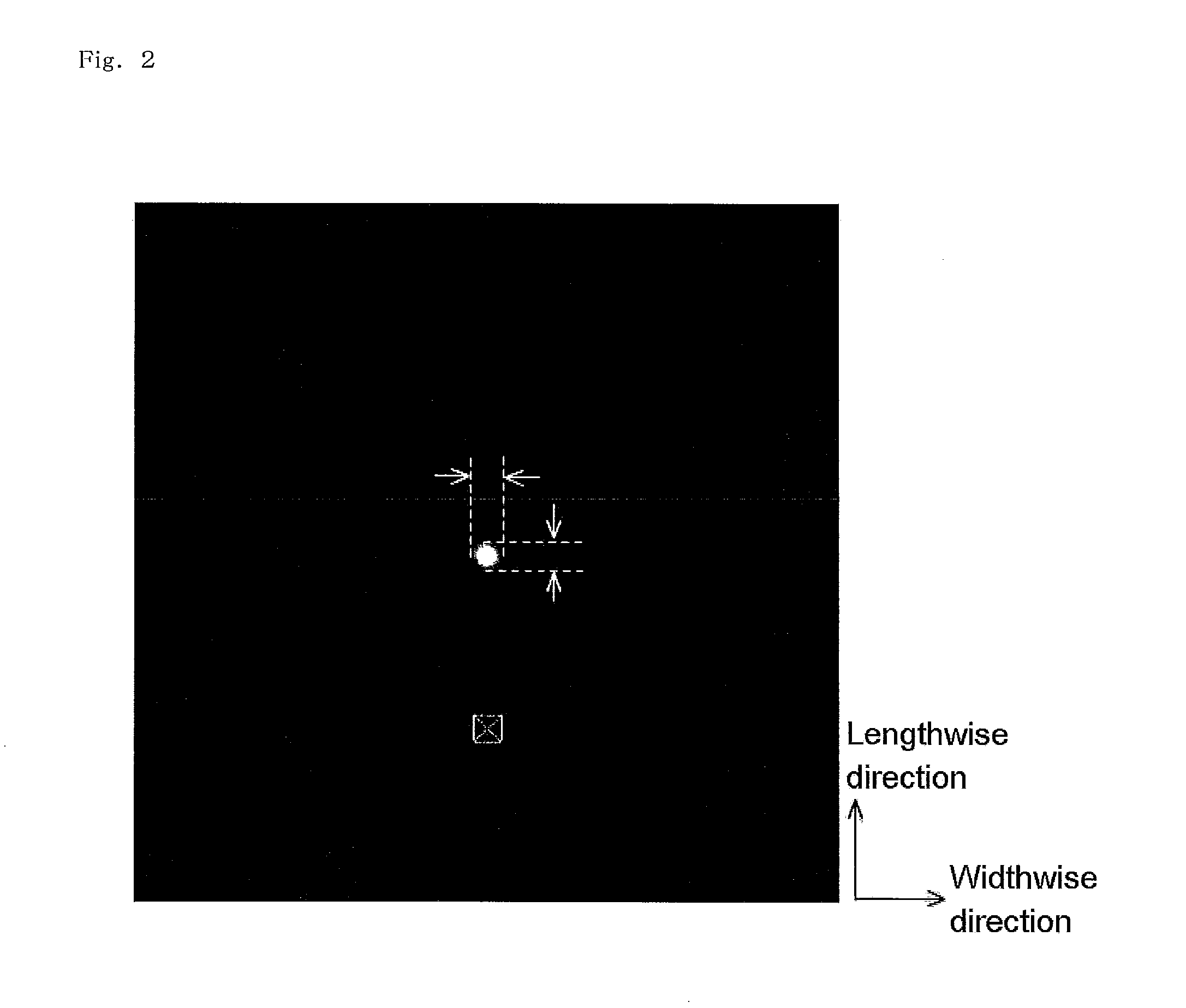

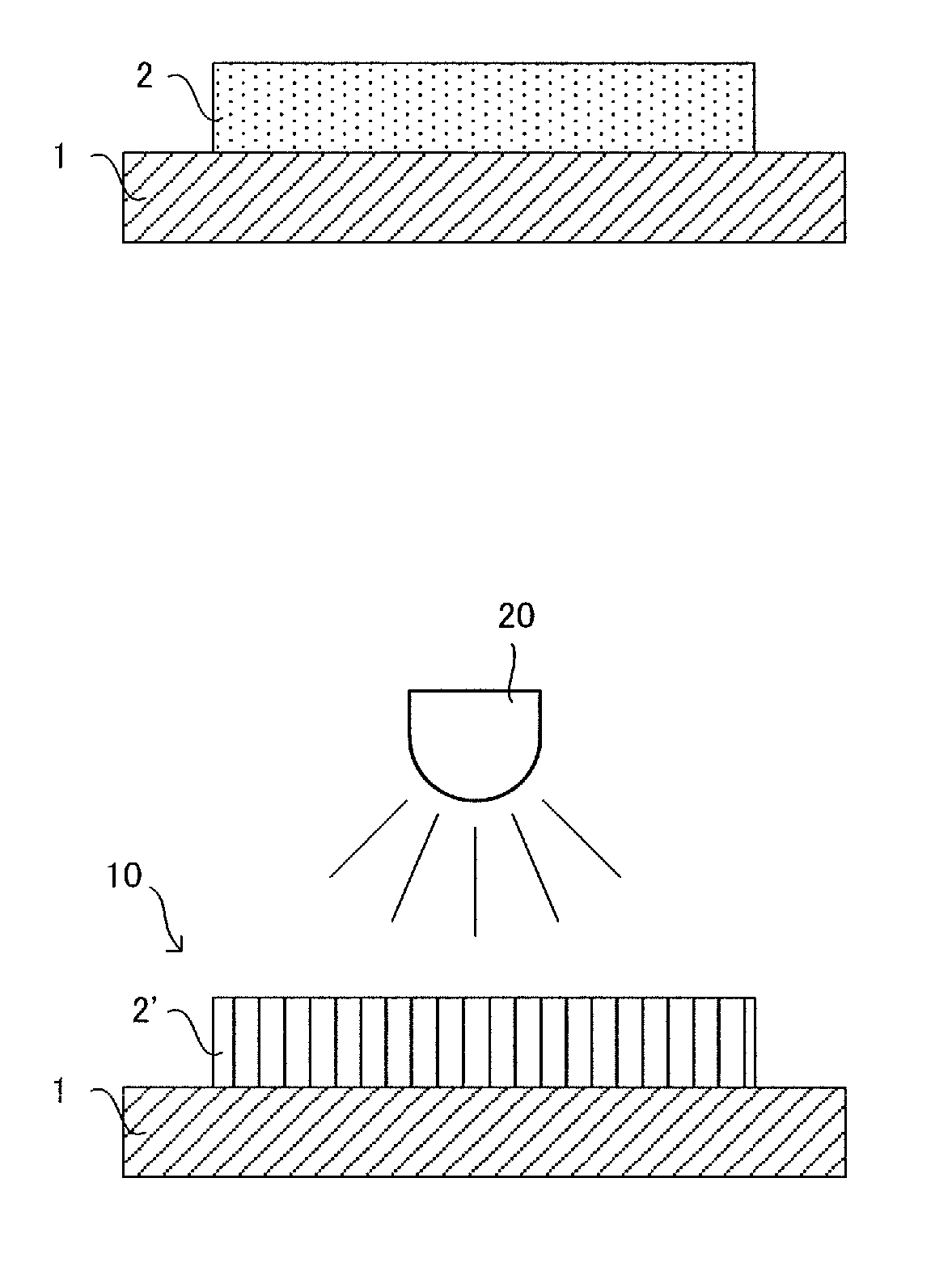

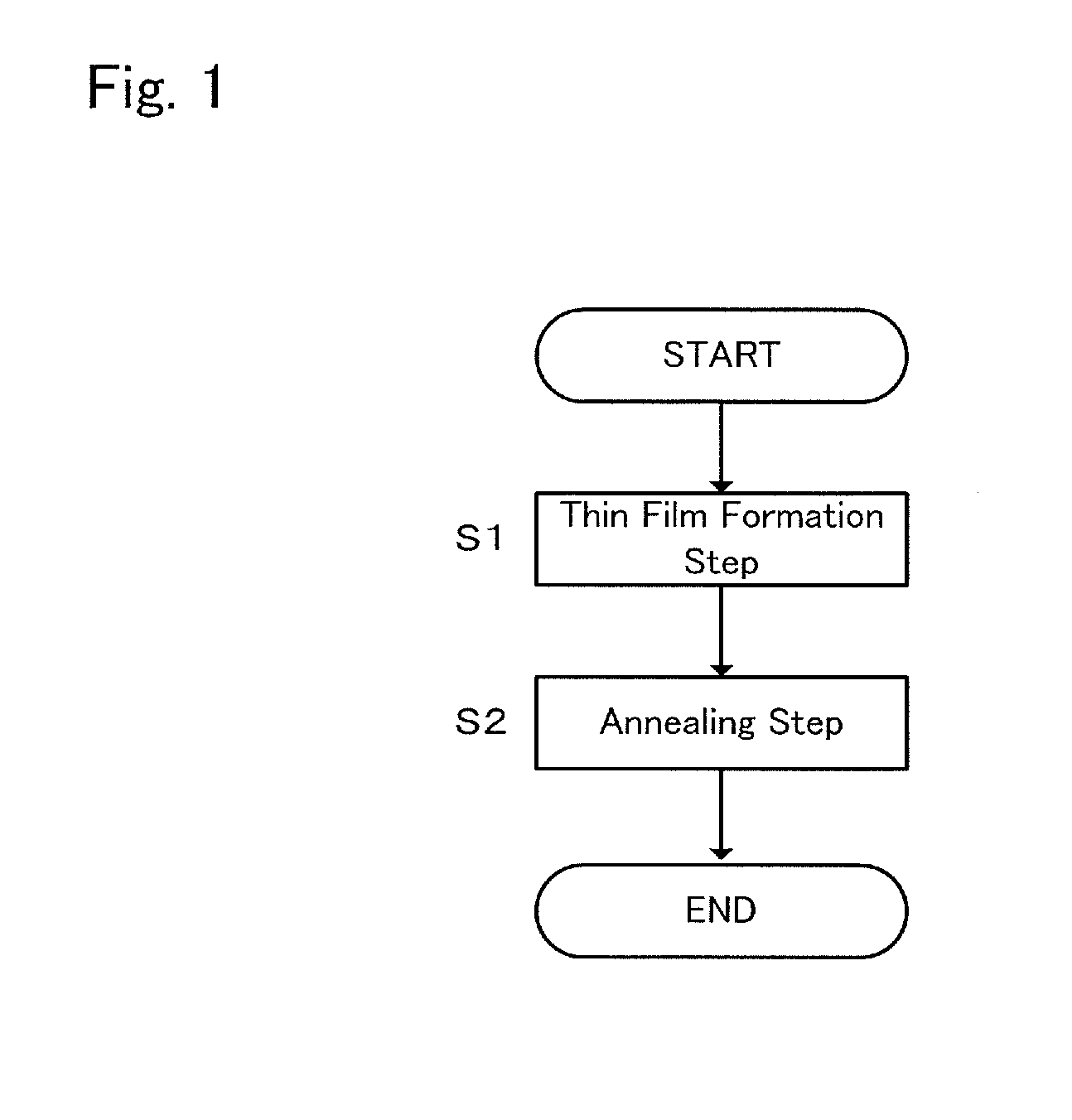

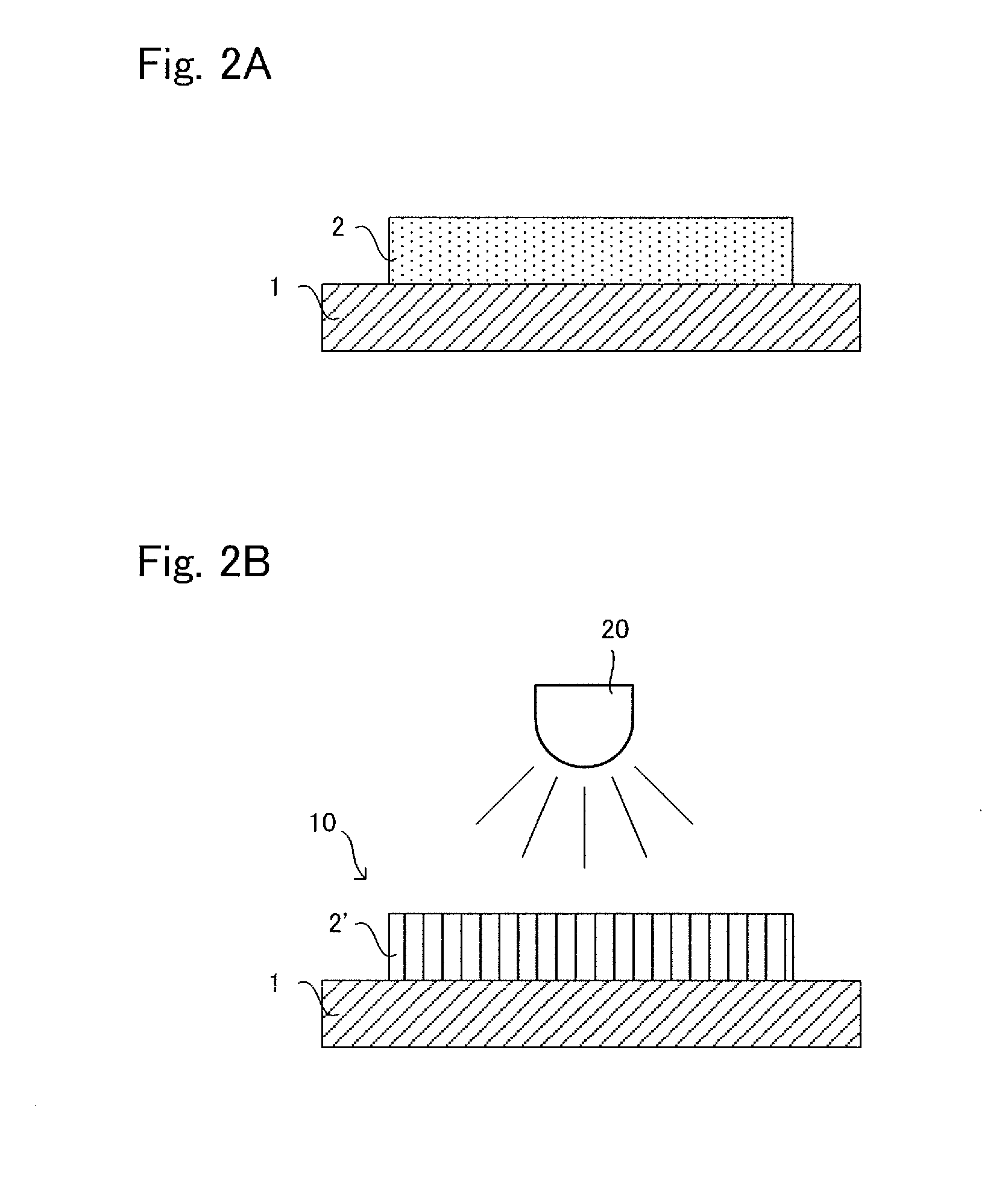

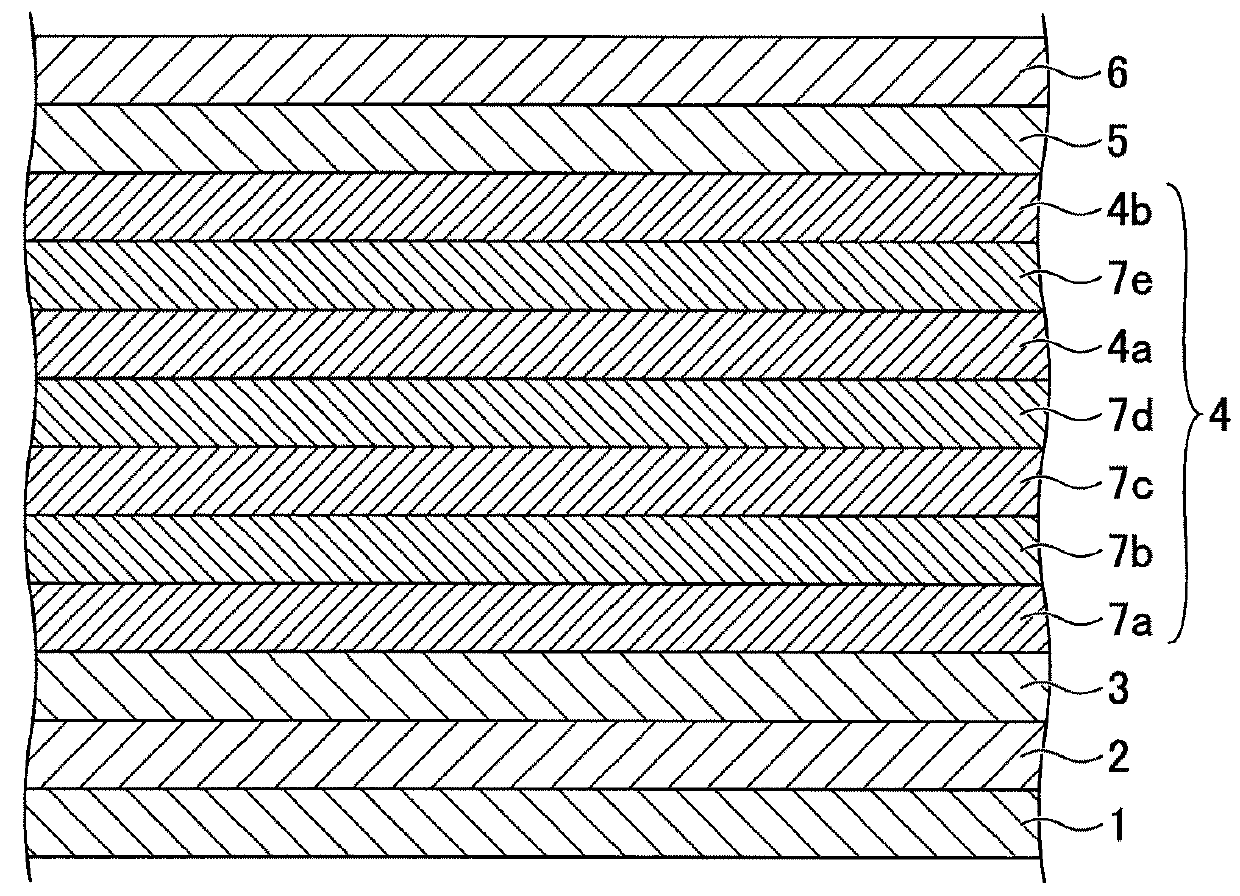

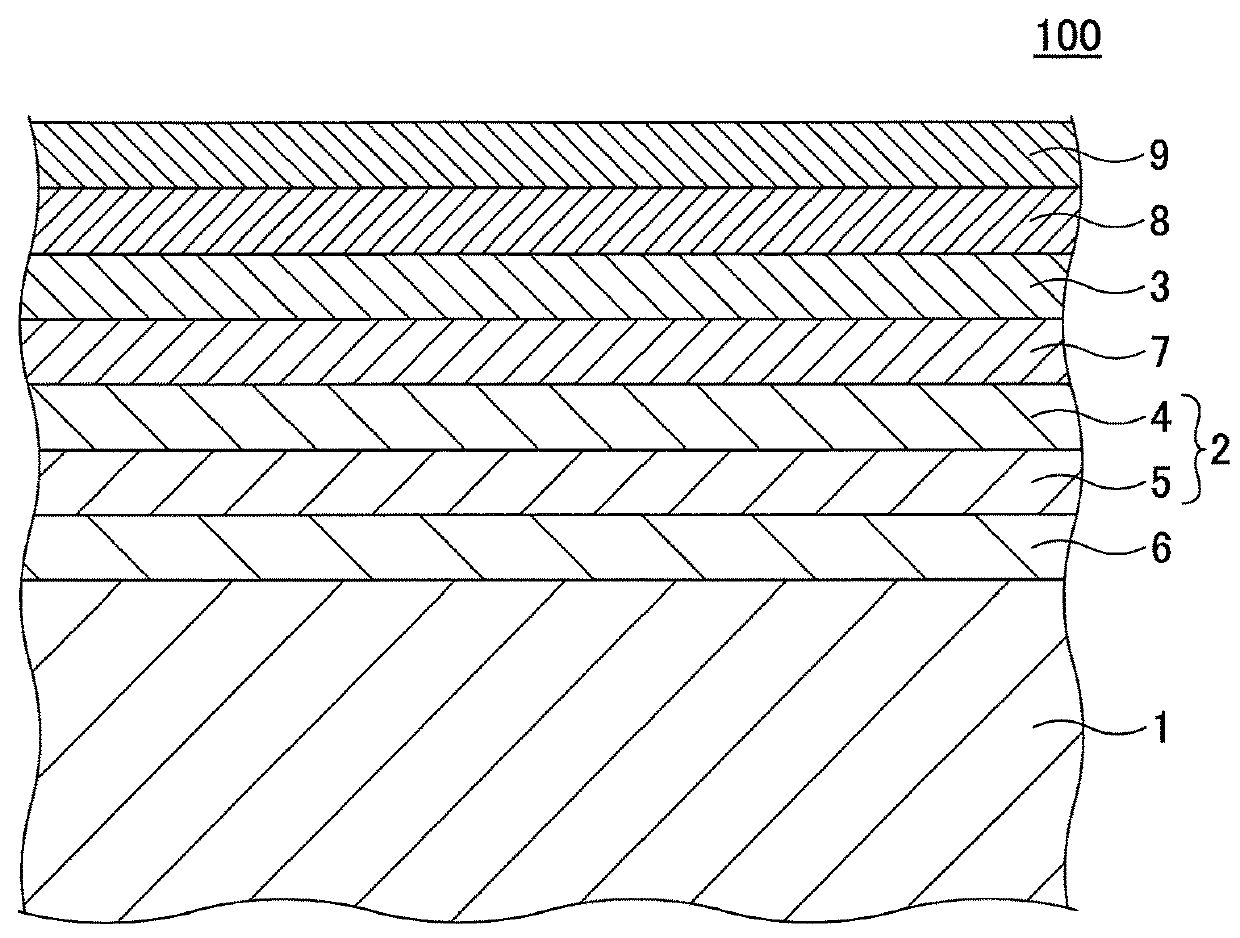

Magnetic recording medium and production method of magnetic recording medium

InactiveUS20130034748A1Easy to produceEasy to useMaterials with ironRecord information storageAlloyRecording layer

The present invention provides: a method of producing, at low temperature, a magnetic recording medium comprising an L10FePt thin film which is highly (001)-oriented and highly L10-ordered; and a magnetic recording medium comprising an L10FePt thin film that can be obtained by this method. In the production method of a magnetic recording medium (10), a thin film formation step S1 of forming a thin film 2 containing an FePt alloy and an oxide of metal having a melting point of 100° C. or more and 500° C. or less is carried out; an annealing step S2 of annealing the thin film 2 to a predetermined temperature is carried out; thereby a magnetic recording layer 2′ containing the FePt alloy having a L10-ordered structure and the oxide of metal is formed. The magnetic recording medium can be obtained by this production method.

Owner:AKITA UNIV

Magnetic recording medium

InactiveUS20070231613A1Increased durabilityReduce noiseRecord information storageMetals or alloysNon magneticIntrinsic viscosity

A magnetic recording medium including a nonmagnetic support and a magnetic layer containing ferromagnetic powder and a binder, wherein the magnetic layer contains diamond particles having an average particle size of from 20 to 100 nm, a volume per a particle of the ferromagnetic powder is from 100 to 8,000 nm3, and the support has an intrinsic viscosity of from 0.40 to 0.60 dl / g and is substantially free from particles.

Owner:FUJIFILM CORP

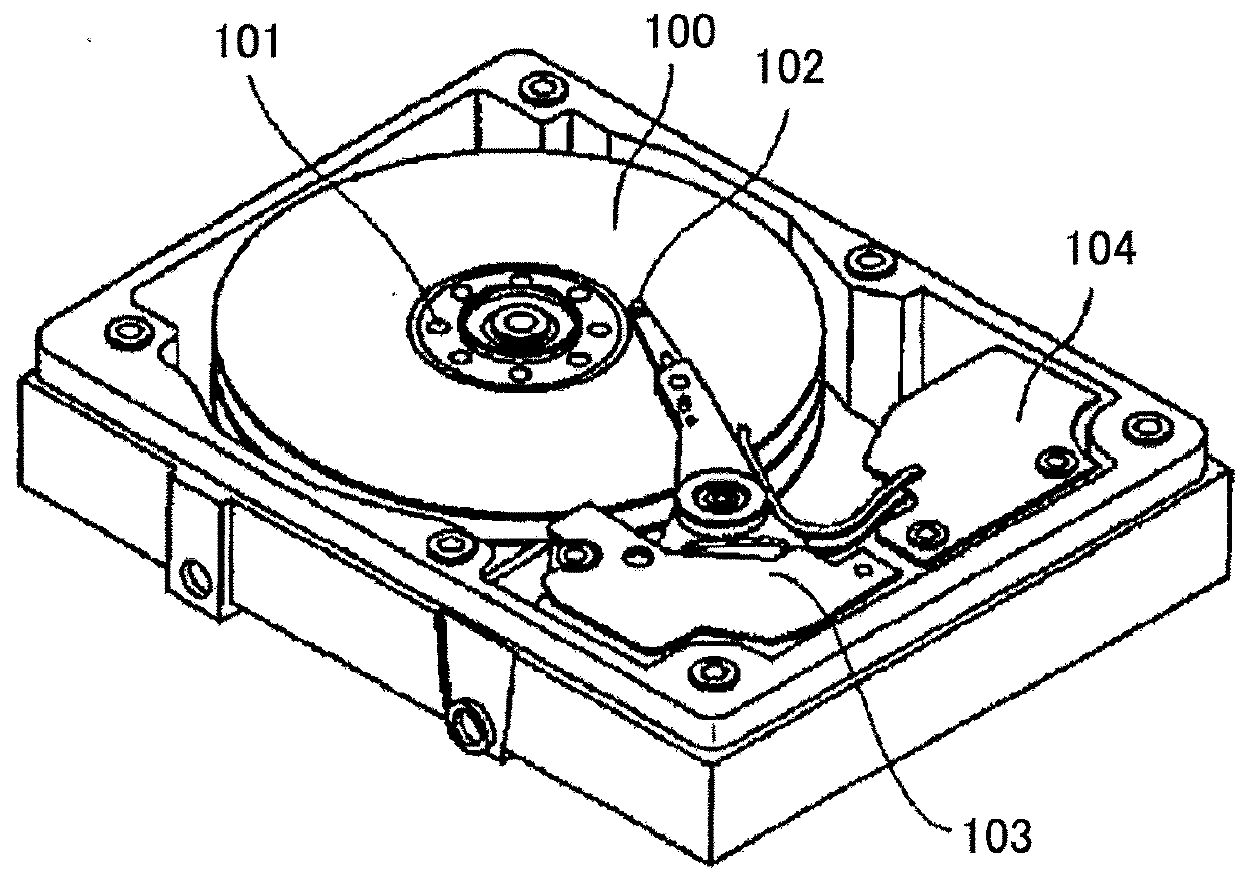

Magnetic recording medium, method for manufacturing magnetic recording medium and magnetic recording and reproducing apparatus

ActiveUS20180166100A1Preferable noise propertyImprove recording densityProtective coatings for layersBase layers for recording layersNon magneticNitride

A magnetic recording medium includes a non-magnetic substrate, a soft magnetic underlayer, an orientation control layer, a perpendicular magnetic layer, and a protective layer arranged in this order. The perpendicular magnetic layer includes a first magnetic layer and a second magnetic layer from the non-magnetic substrate side in this order. The second magnetic layer contains a magnetic grain and provided farthest from the non-magnetic substrate. The first magnetic layer has a granular structure that contains an oxide in a grain boundary. The second magnetic layer has a granular structure that contains a nitride of an element contained in the magnetic grain in a grain boundary.

Owner:RESONAC CORP

Magnetic recording medium and magnetic storage apparatus

InactiveUS20180182421A1Improve signal-to-noise ratioBase layers for recording layersRecord information storageMagnetic storageCrystal structure

A magnetic recording medium includes a substrate, an underlayer, and a magnetic layer including an alloy having a L10 type crystal structure with a (001) orientation, wherein the substrate, the underlayer, and the magnetic layer are stacked in this order, the underlayer includes a first underlayer, the first underlayer is a crystalline layer that includes a material containing W as a main component and a nitride whose content ranges from 1 mol % to 80 mol %, and the nitride includes one or more elements selected from a group consisting of Al, B, Si, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, and W.

Owner:SHOWA DENKO KK

Magnetic iron based powder having high coercive force, and their use for a magnetic recording medium

InactiveCN1975941AImprove performanceImprove magnetic propertiesMaterial nanotechnologyMaterials with ironRare-earth elementHigh density

A magnetic powder is provided composed of particles that, even when the particle size is refined, exhibits excellent magnetic properties, in particular, a high coercive force, for use in a high-density recording medium. The invention also provides a magnetic recording medium using the powder. The powder is an iron system magnetic powder containing, as an atomic ratio of Fe, a total of 0.01 to 10 atom% of one or more selected from W and Mo, particularly a magnetic powder comprised mainly of Fe16N2. The magnetic powder is able to exhibit a high coercive force of 238 kA / m (3000 Oe) or more. In addition to the W and Mo, the magnetic powder may contain, as an atomic ratio of Fe, a total of up to 25 atom% of one or more selected from Al and a rare earth element (defined as including Y).

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Iron system magnetic powder having high coercive force, and magnetic recording medium using same

InactiveUS20070111039A1Improve magnetic propertiesImprove coercive forceMaterial nanotechnologyMaterials with ironRare-earth elementHigh density

A magnetic powder is provided composed of particles that, even when the particle size is refined, exhibits excellent magnetic properties, in particular, a high coercive force, for use in a high-density recording medium. The invention also provides a magnetic recording medium using the powder. The powder is an iron system magnetic powder containing, as an atomic ratio of Fe, a total of 0.01 to 10 at. % of one or more selected from W and Mo, particularly a magnetic powder comprised mainly of Fe16N2. The magnetic powder is able to exhibit a high coercive force of 238 kA / m (3000 Oe) or more. In addition to the W and Mo, the magnetic powder may contain, as an atomic ratio of Fe, a total of up to 25 at. % of one or more selected from Al and a rare earth element (defined as including Y).

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com