Patents

Literature

938results about "Recording on magnetic tapes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

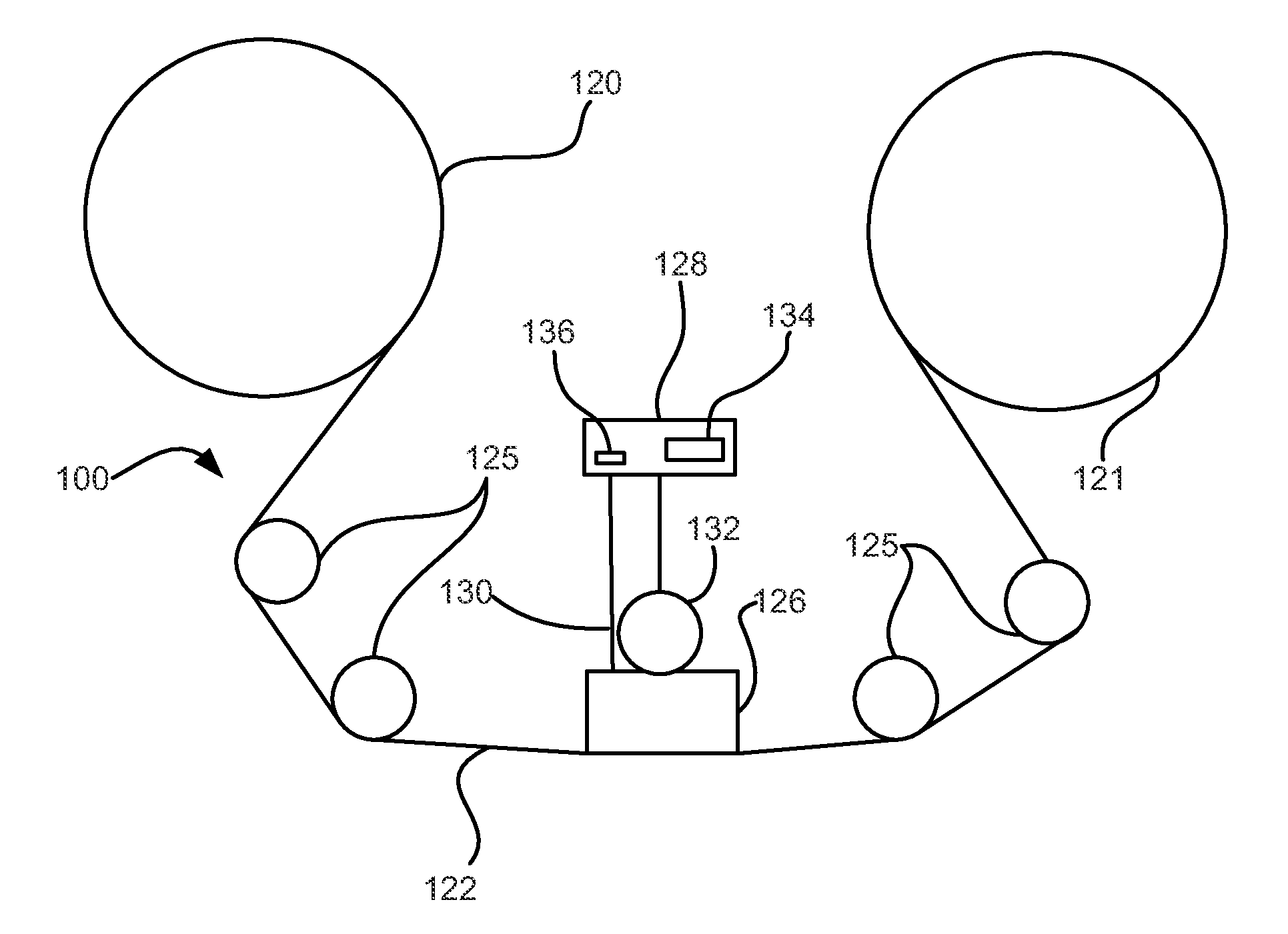

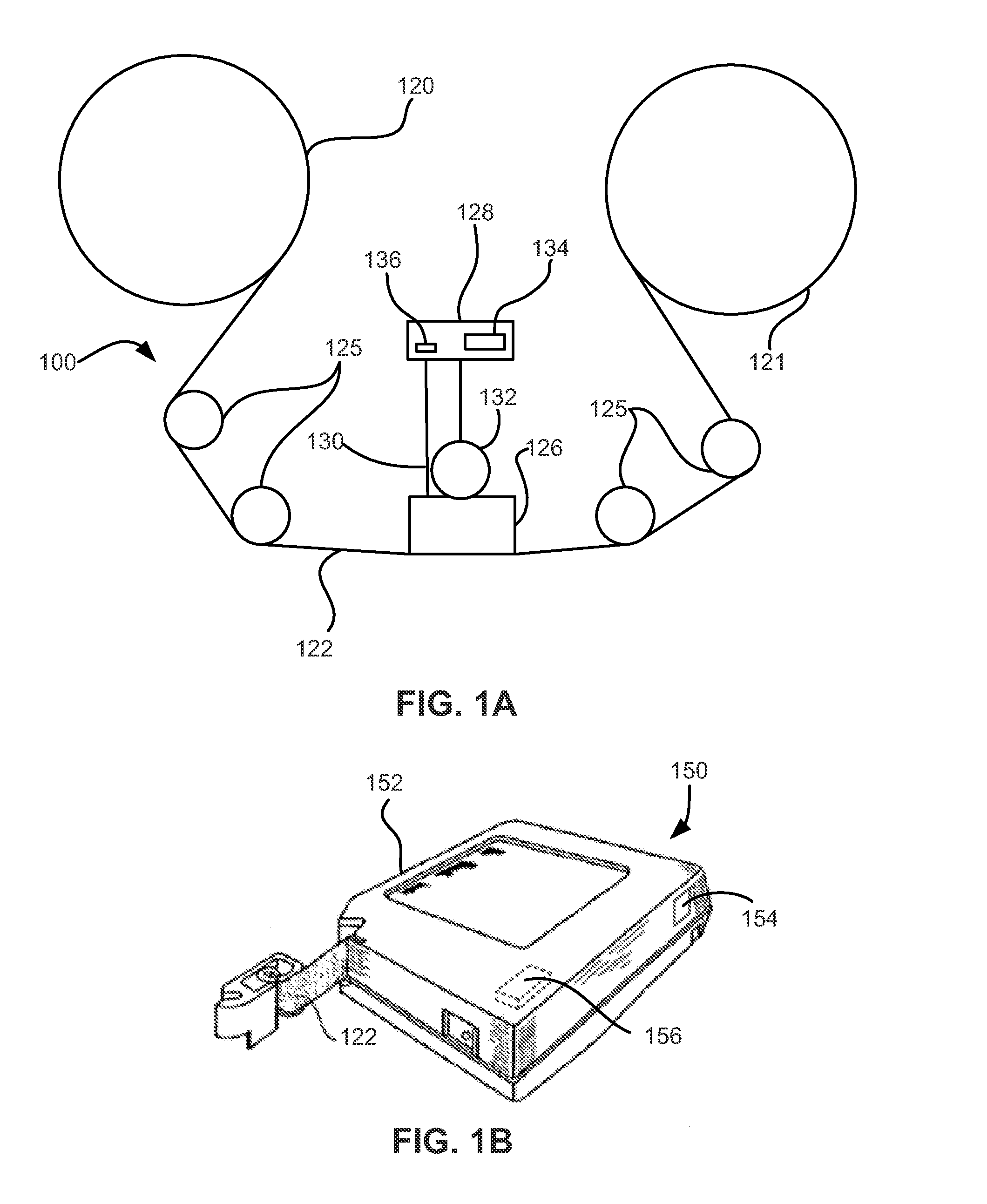

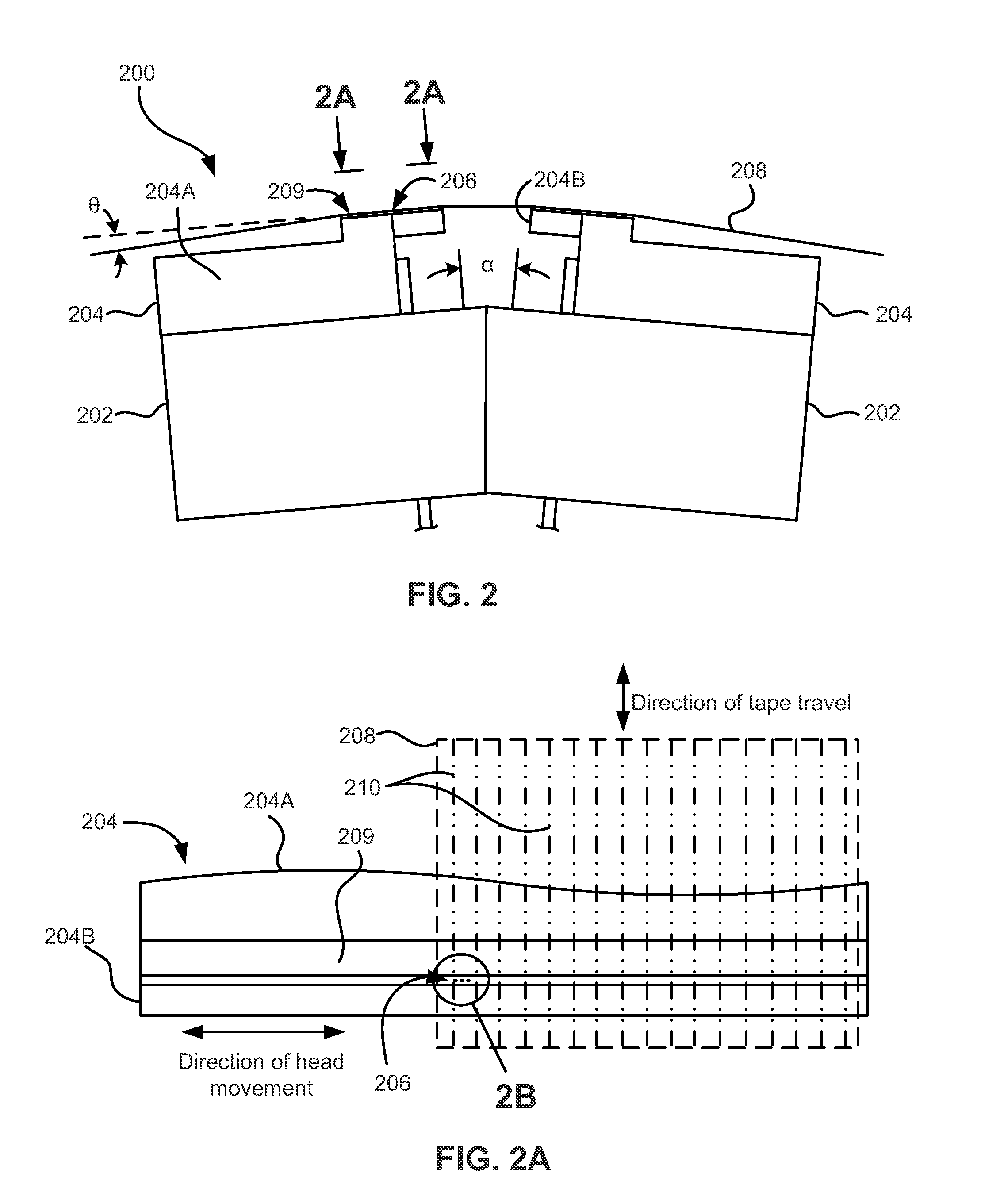

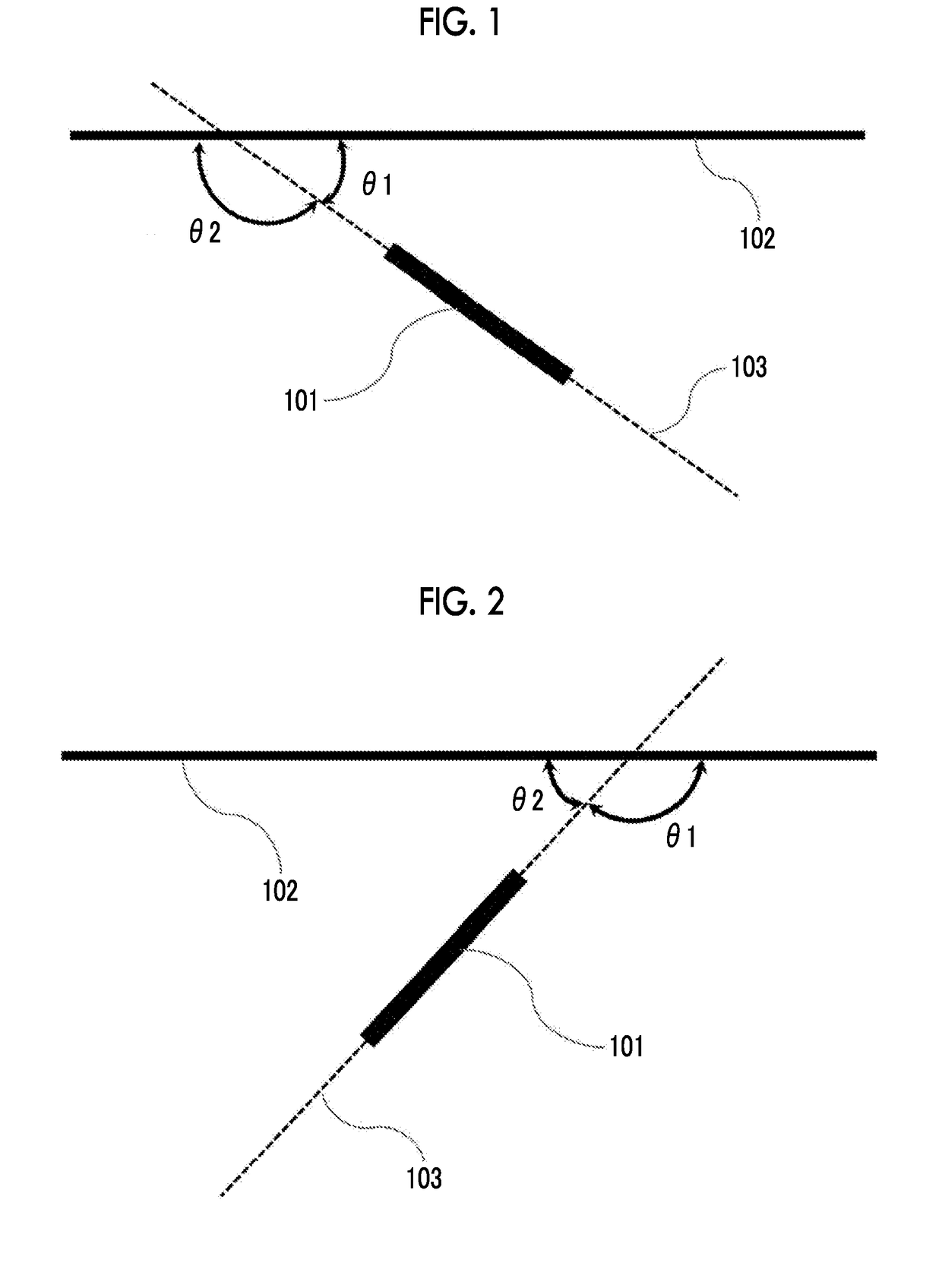

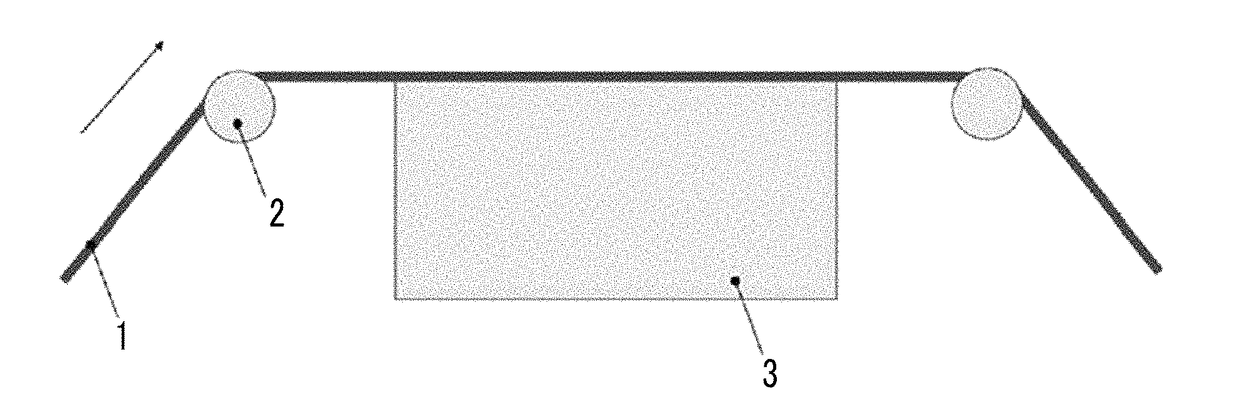

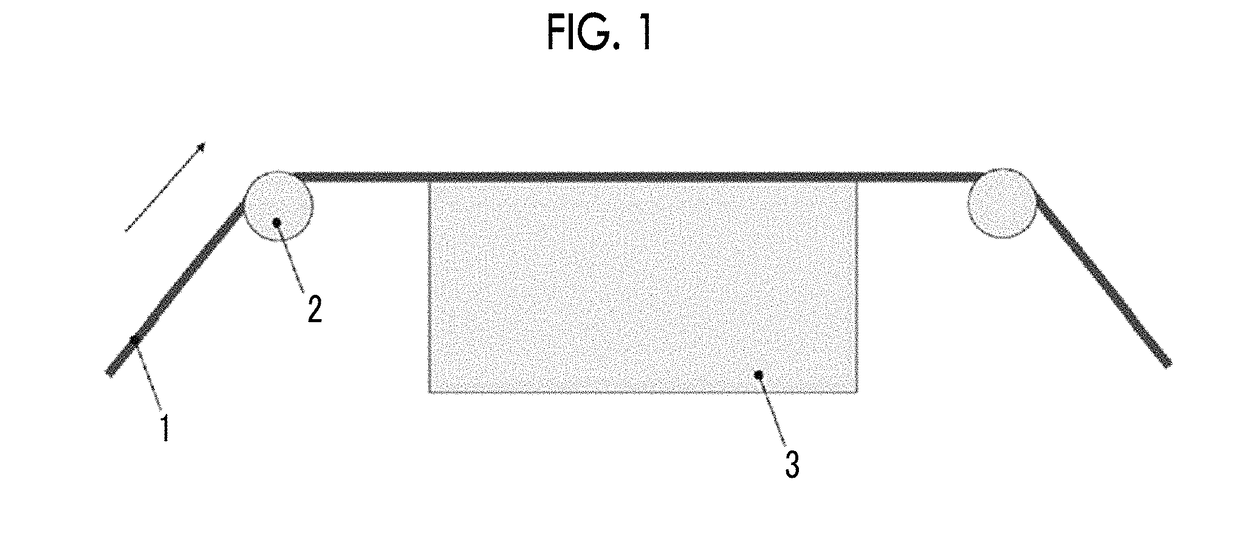

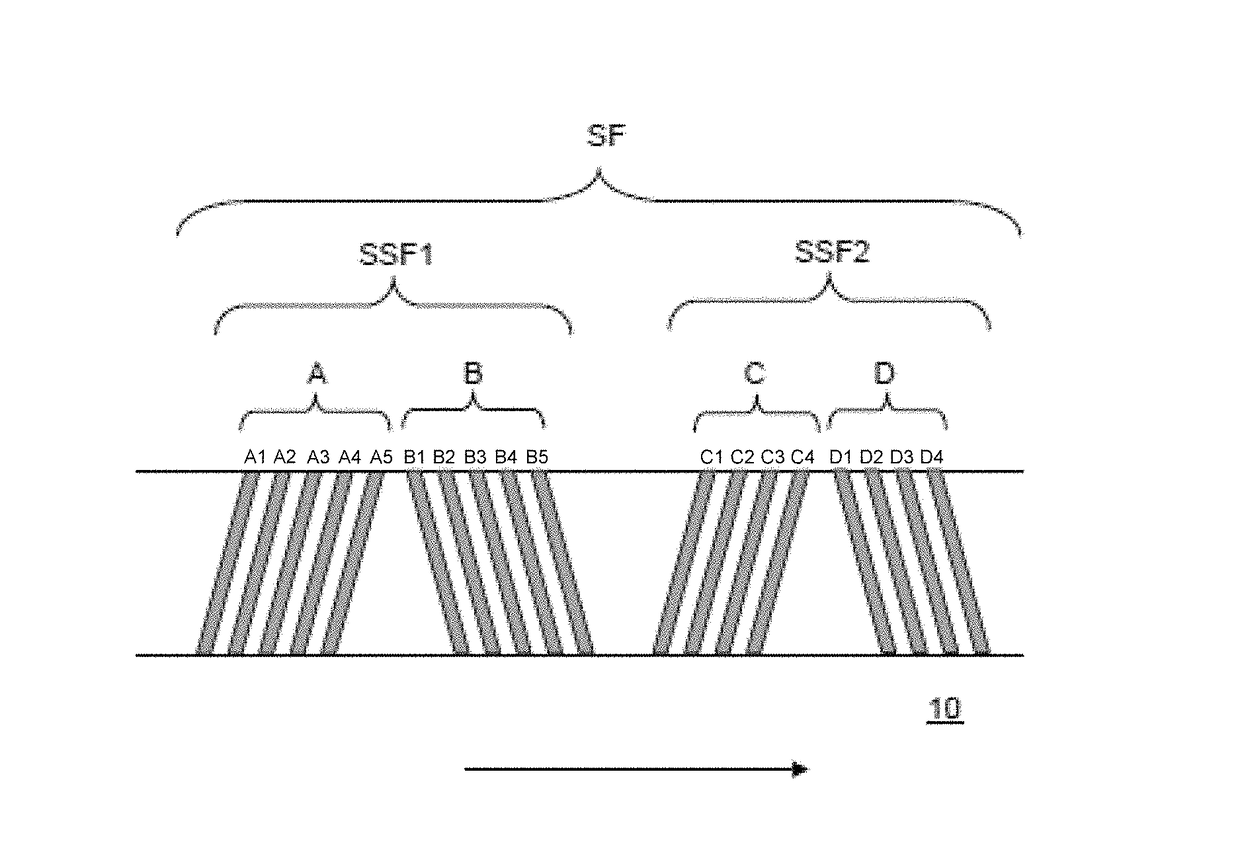

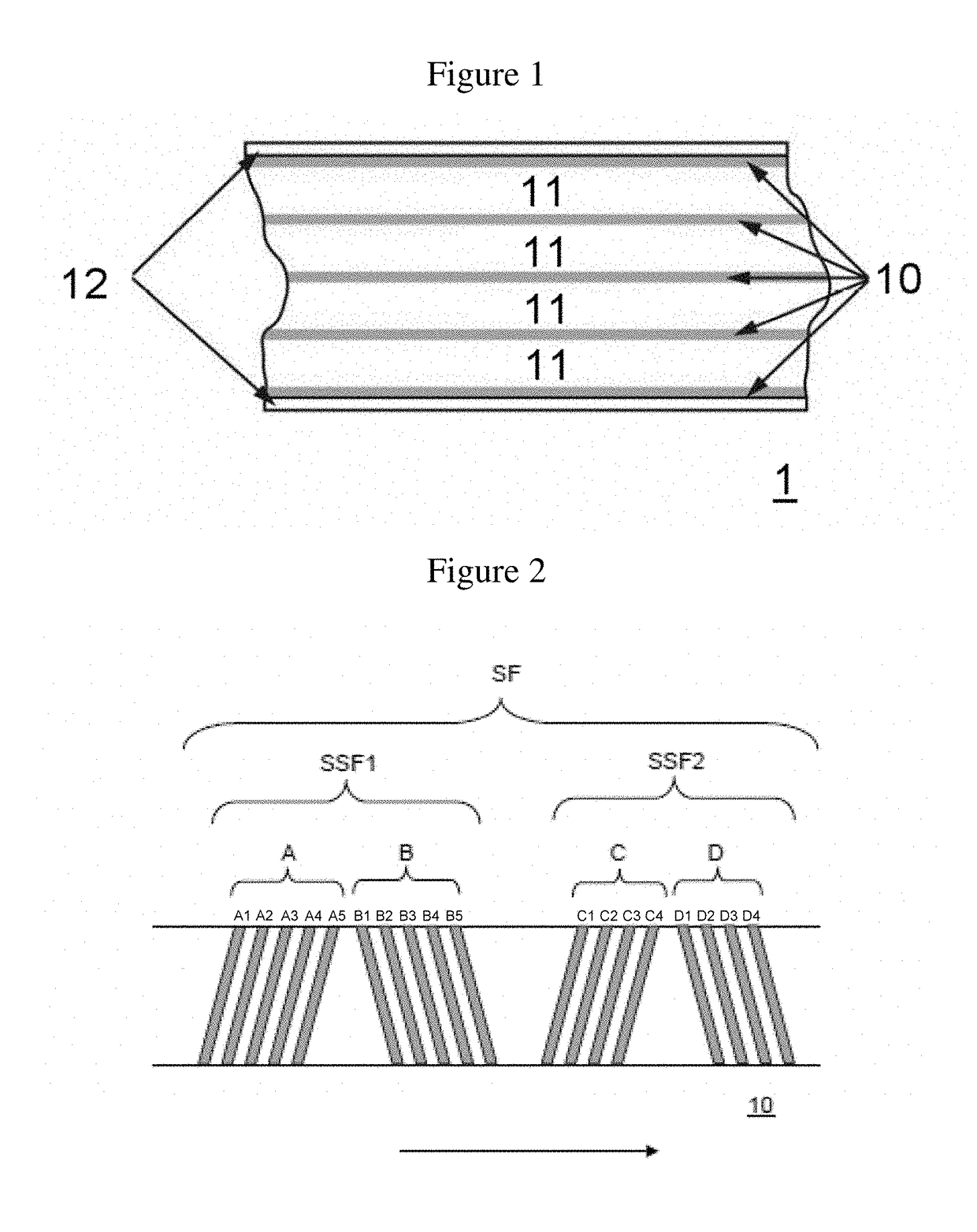

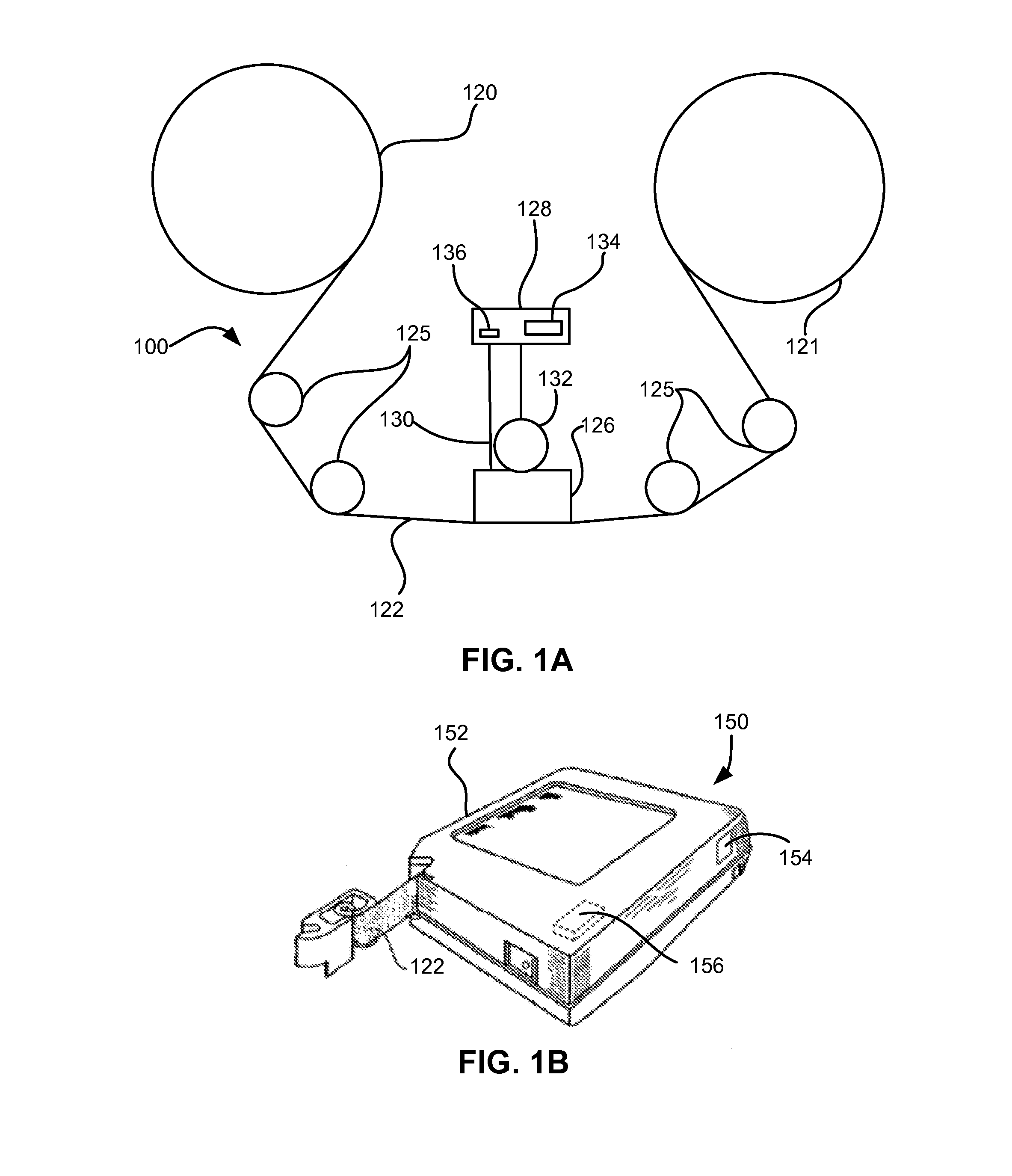

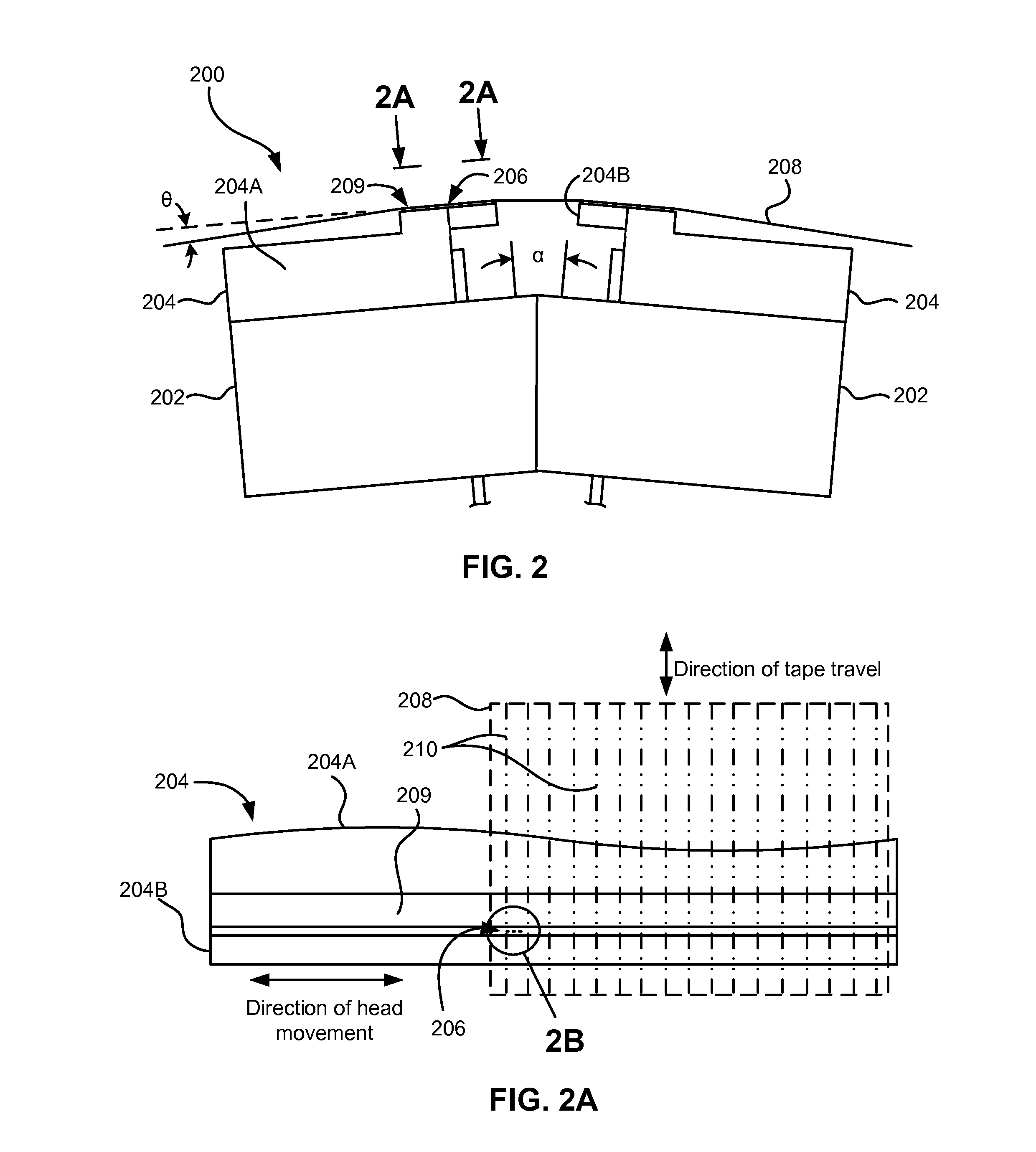

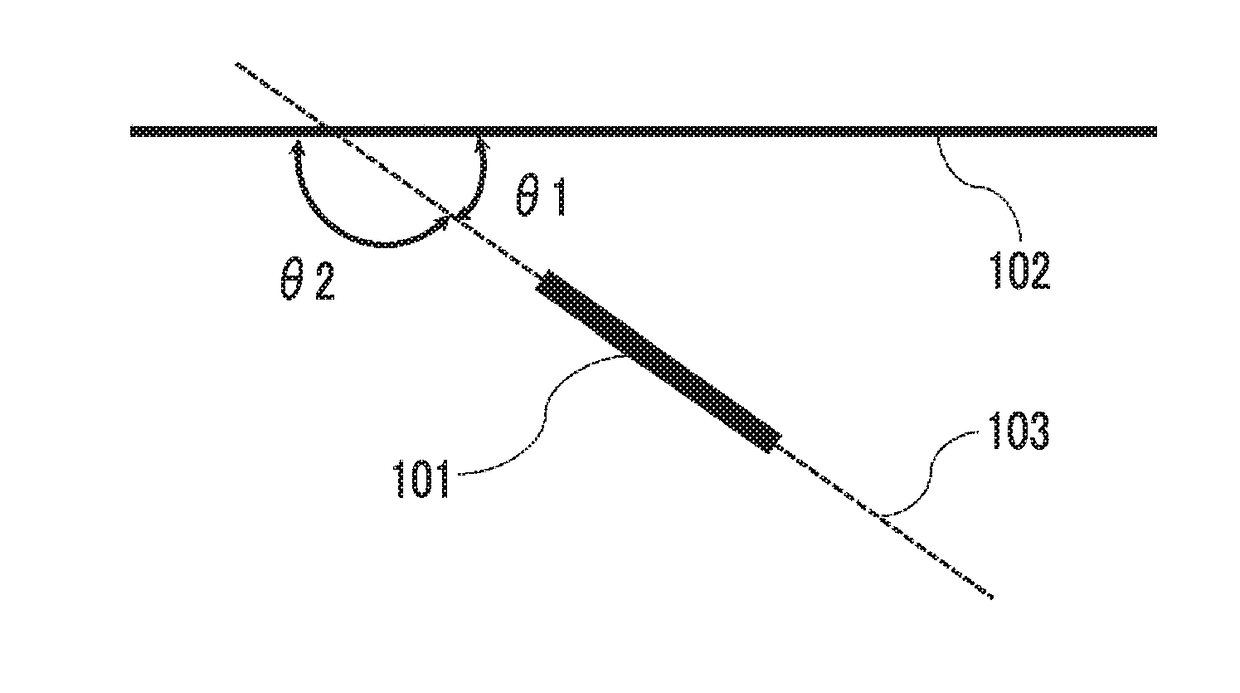

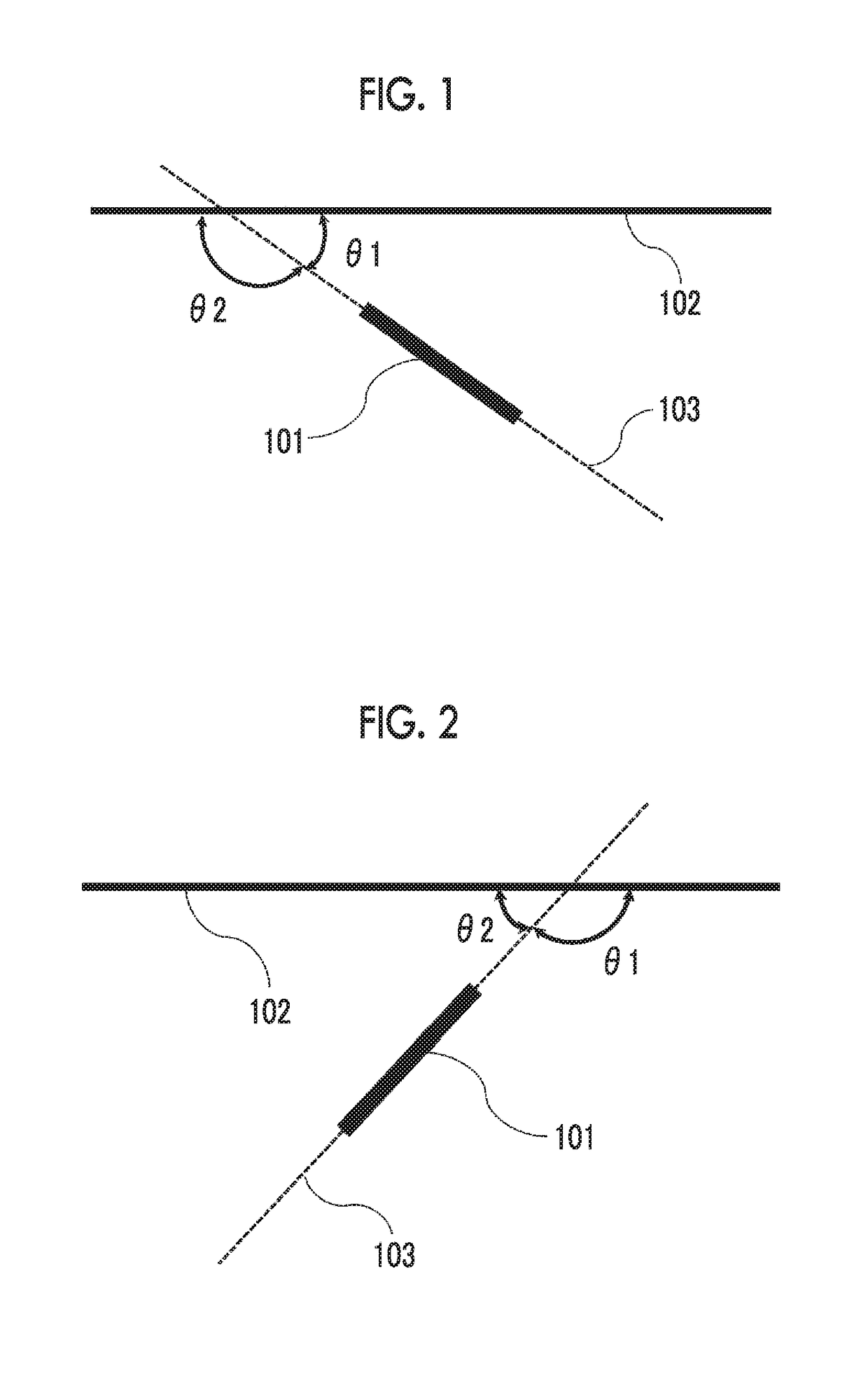

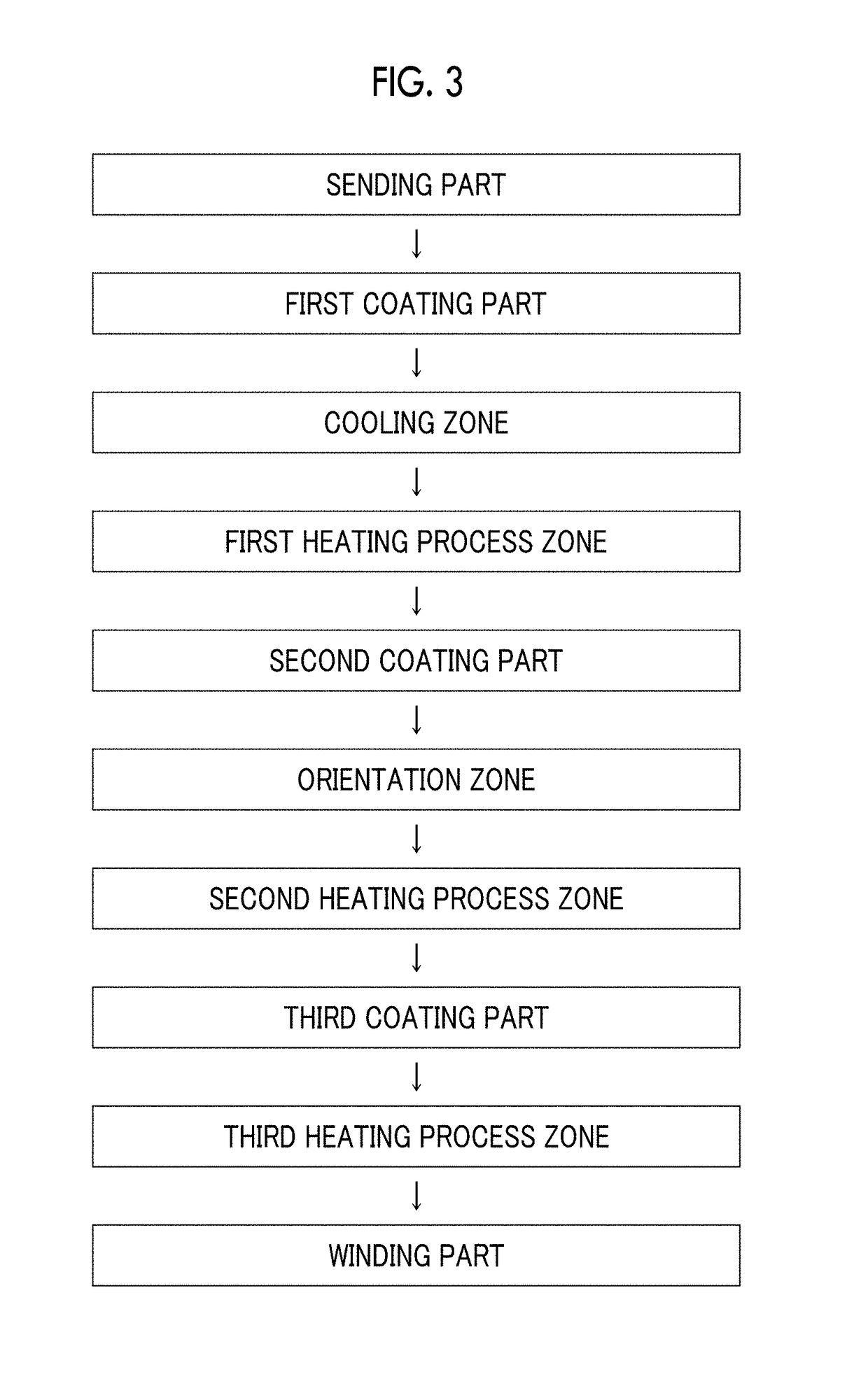

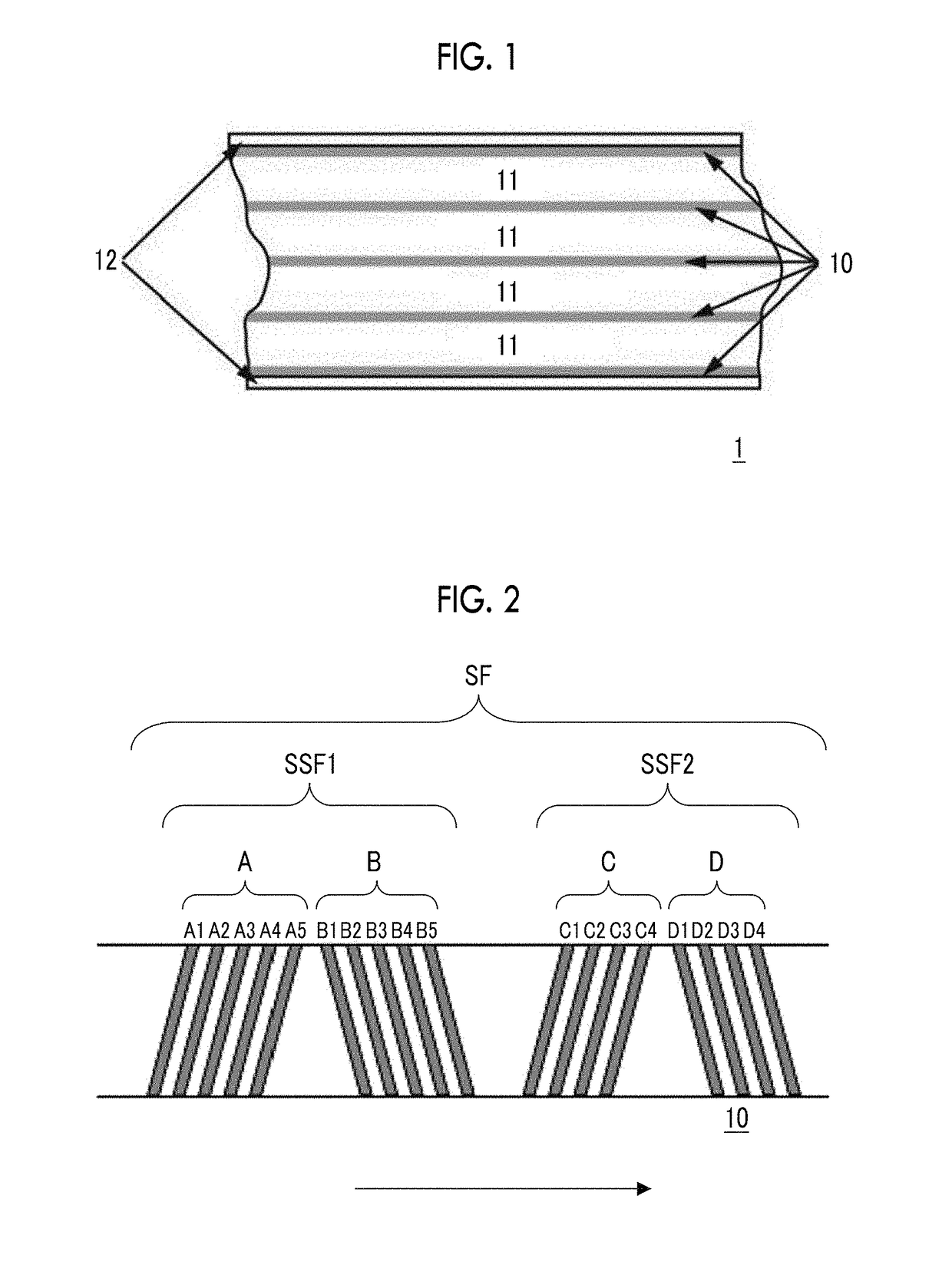

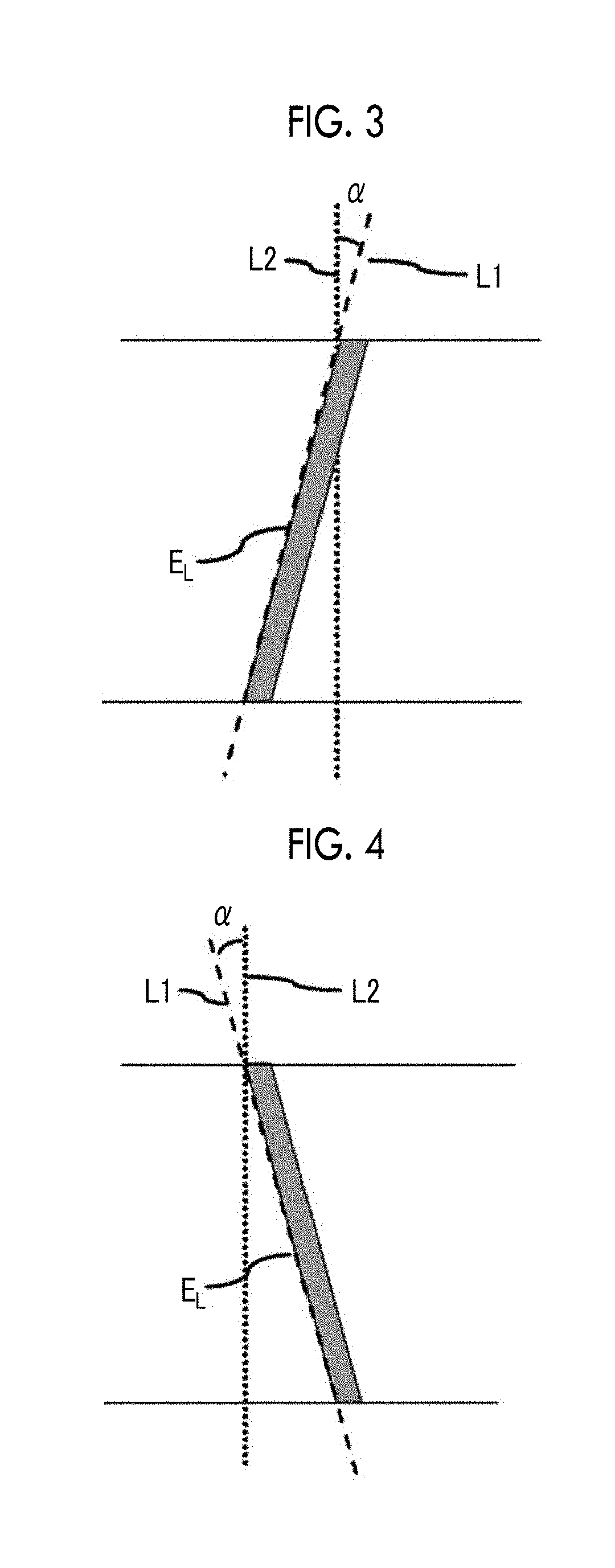

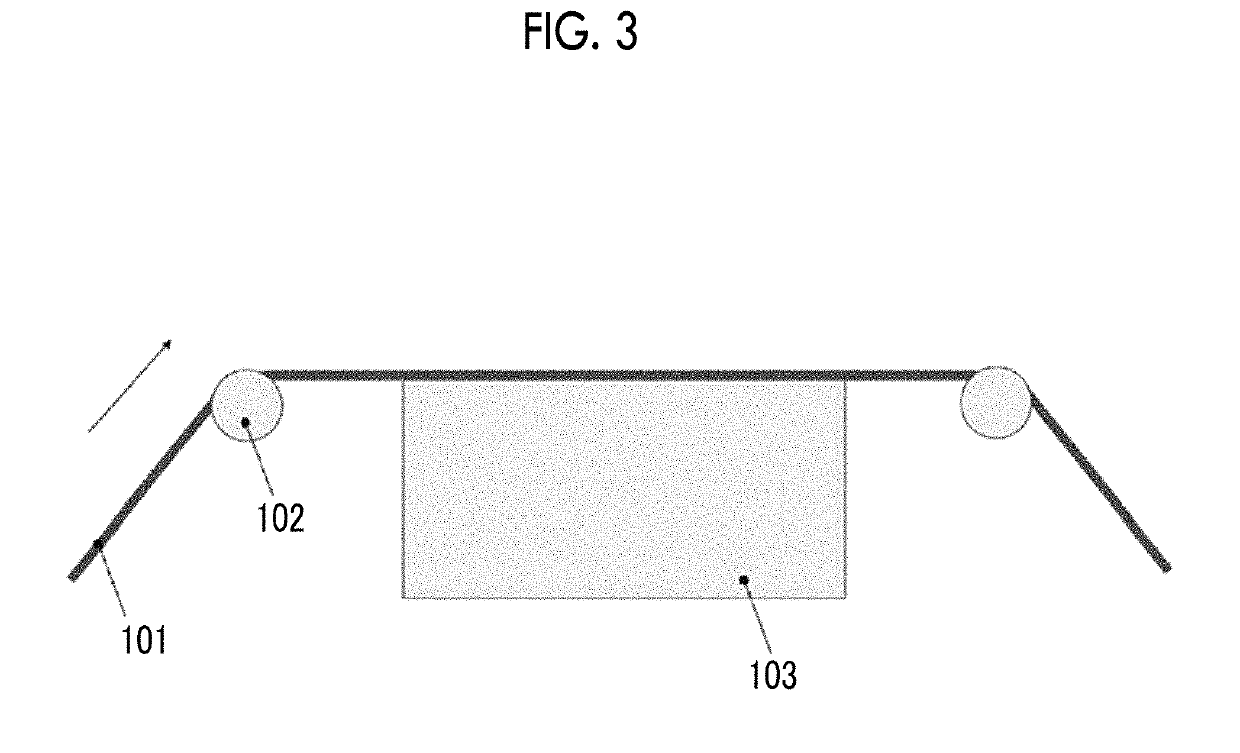

High density timing based servo format for use with tilted transducer arrays

A product, according to one embodiment, includes a magnetic recording tape having opposite ends, a longitudinal axis of the magnetic recording tape being defined between the ends. The magnetic recording tape has at least one servo track, the at least one servo track having a plurality of first magnetic bars and a plurality of third magnetic bars oriented to form chevron-like patterns with the first magnetic bars. The first magnetic bars each have a longitudinal axis oriented at a first angle between 2 and 88 degrees from the longitudinal axis of the magnetic recording tape. The third magnetic bars each have a longitudinal axis oriented at a second angle between 2 and 88 degrees from the longitudinal axis of the magnetic recording tape, the second angle having a different numerical absolute value than the first angle.

Owner:GLOBALFOUNDRIES US INC

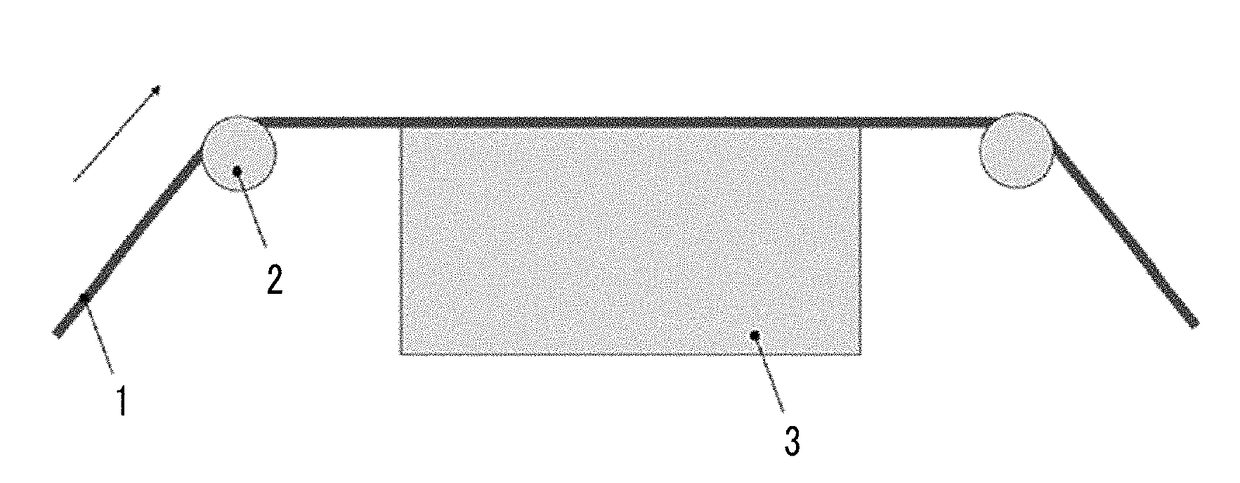

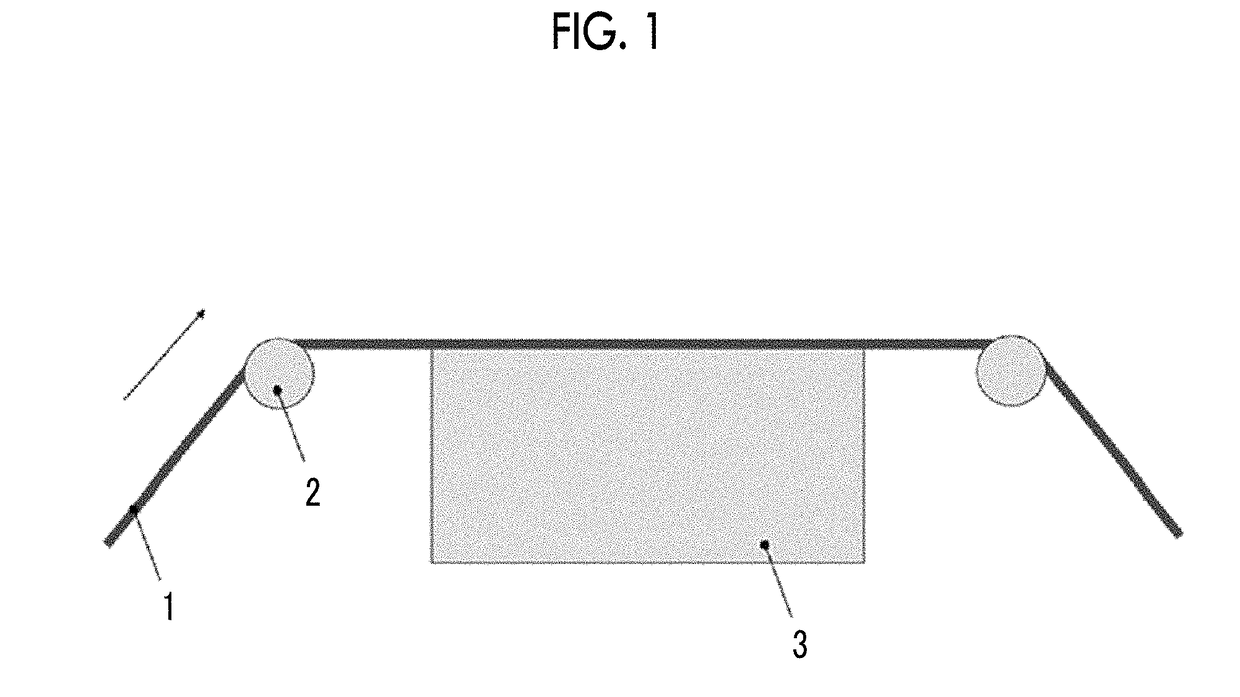

Magnetic tape device and magnetic reproducing method

ActiveUS20180286448A1Improve smoothnessImprove surface smoothnessMaterials with ironTape carriersMagnetic tapeFull width at half maximum

The magnetic tape device includes a TMR head (reproducing head); and a magnetic tape including a magnetic layer including ferromagnetic powder, a binding agent, and fatty acid ester, in which Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, a difference between spacings before and after the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm, and ΔSFD (=SFD25° C.−SFD−190° C.) in a longitudinal direction of the magnetic tape is equal to or smaller than 0.50.

Owner:FUJIFILM CORP

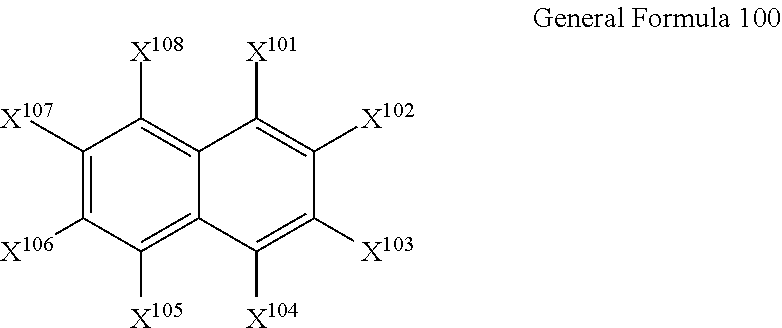

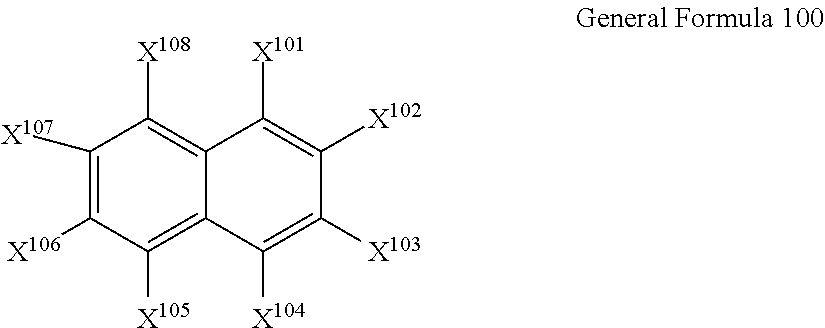

Magnetic tape

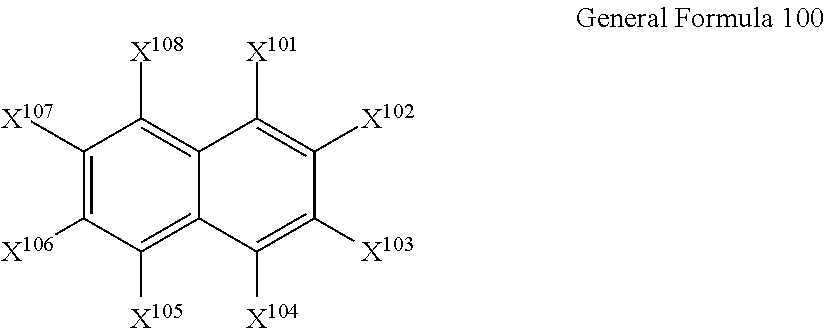

Provided is a magnetic tape in which ferromagnetic powder included in a magnetic layer is ferromagnetic hexagonal ferrite powder having an activation volume equal to or smaller than 1,600 nm3, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and an abrasive, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %, and a tilt cos θ of the ferromagnetic hexagonal ferrite powder with respect to the surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180286442A1Improve smoothnessImprove surface smoothnessMaterials with ironRecord information storageIn planeX-ray

The magnetic tape device includes a TMR head (reproducing head); and a magnetic tape including a magnetic layer including ferromagnetic hexagonal ferrite powder, a binding agent, and fatty acid ester, in which an XRD intensity ratio obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio is 0.65 to 1.00, Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between spacings before and after the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

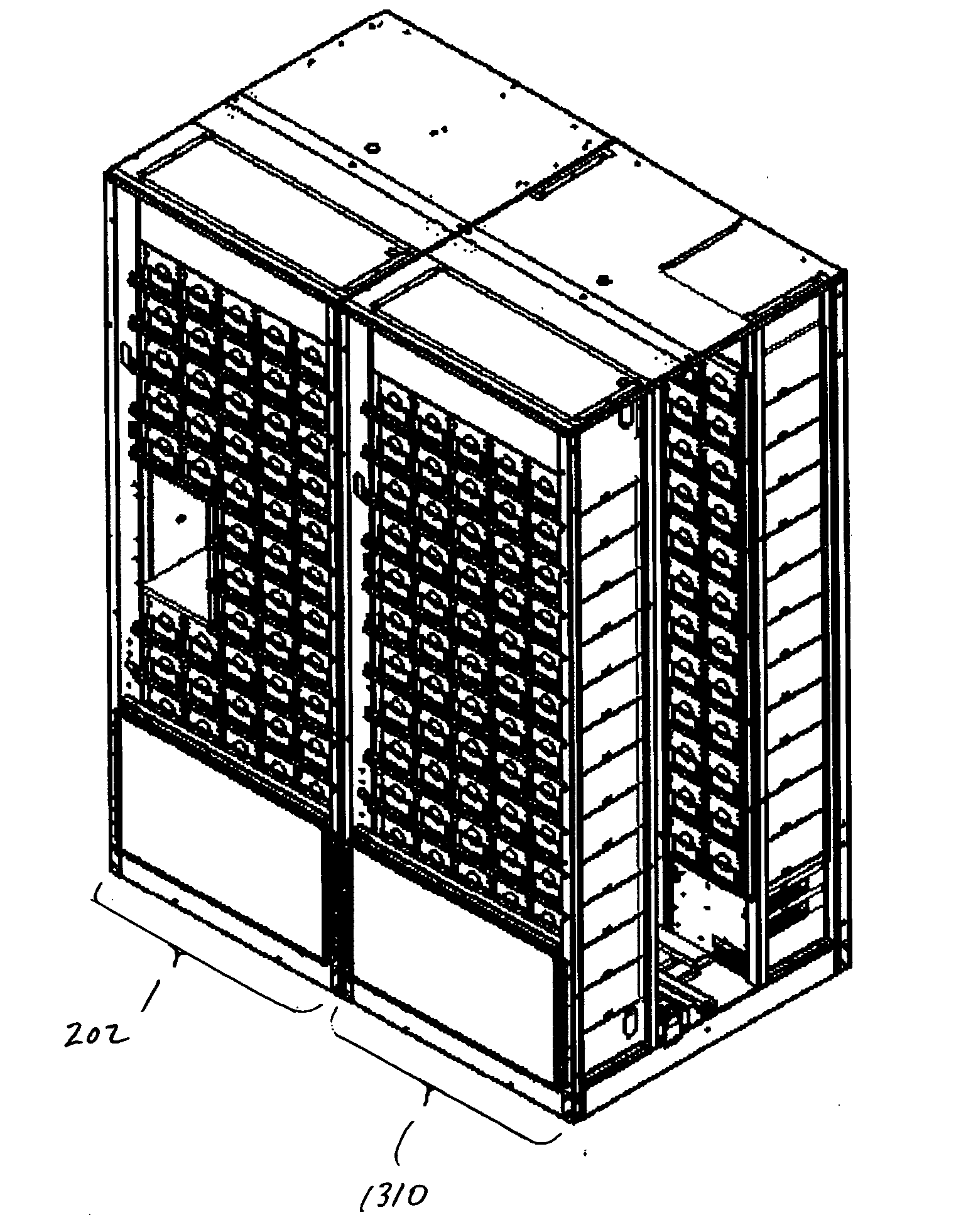

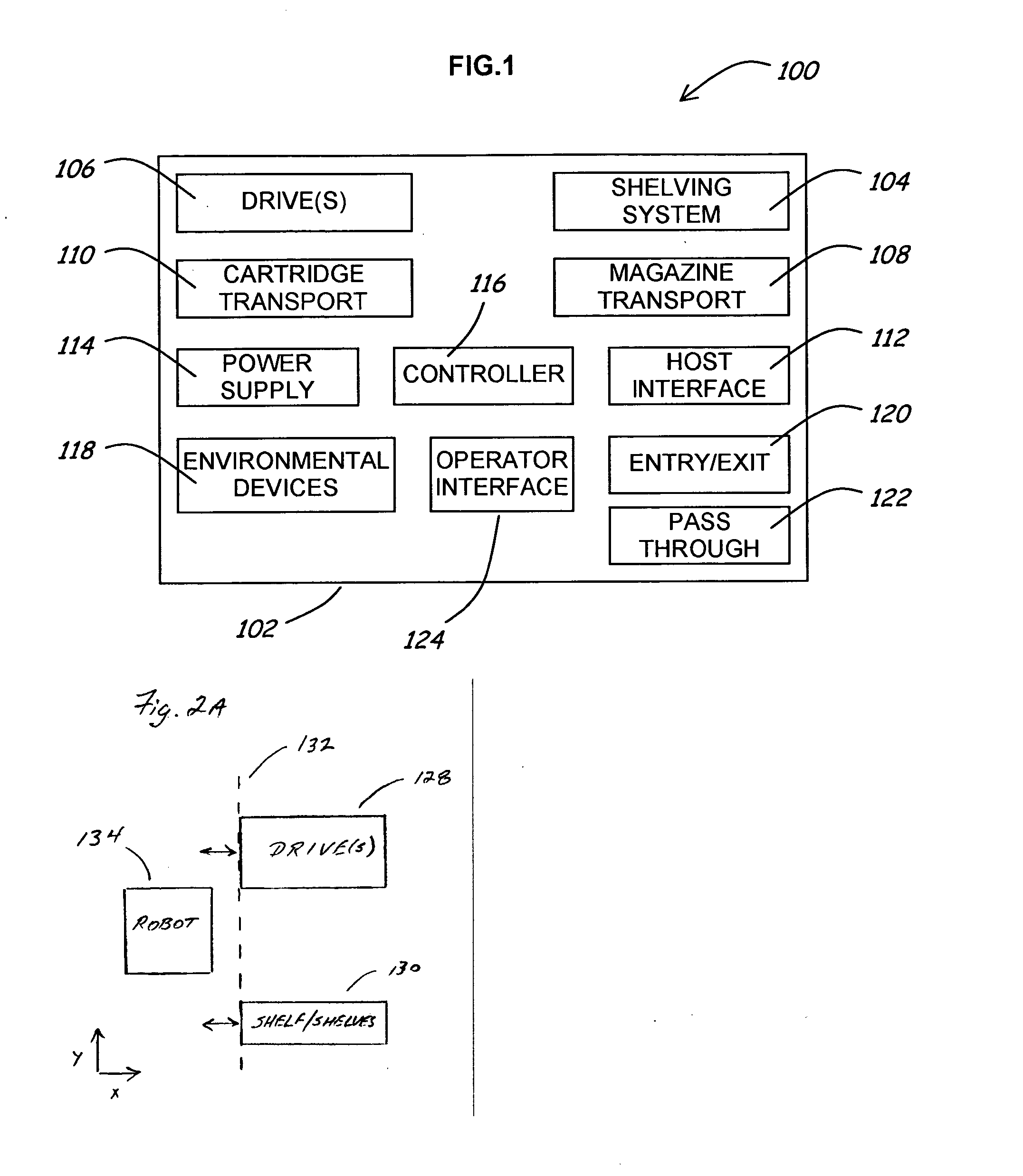

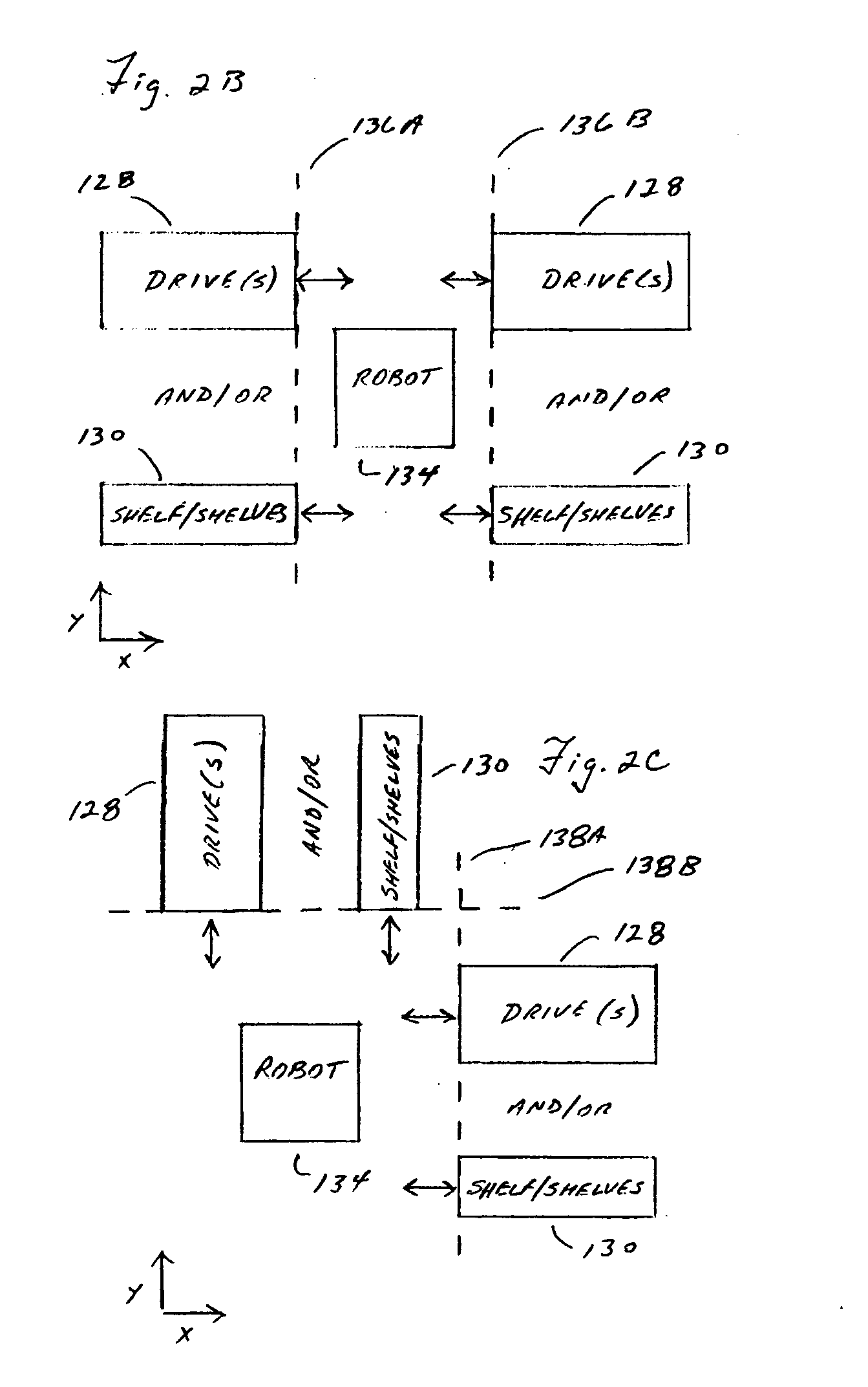

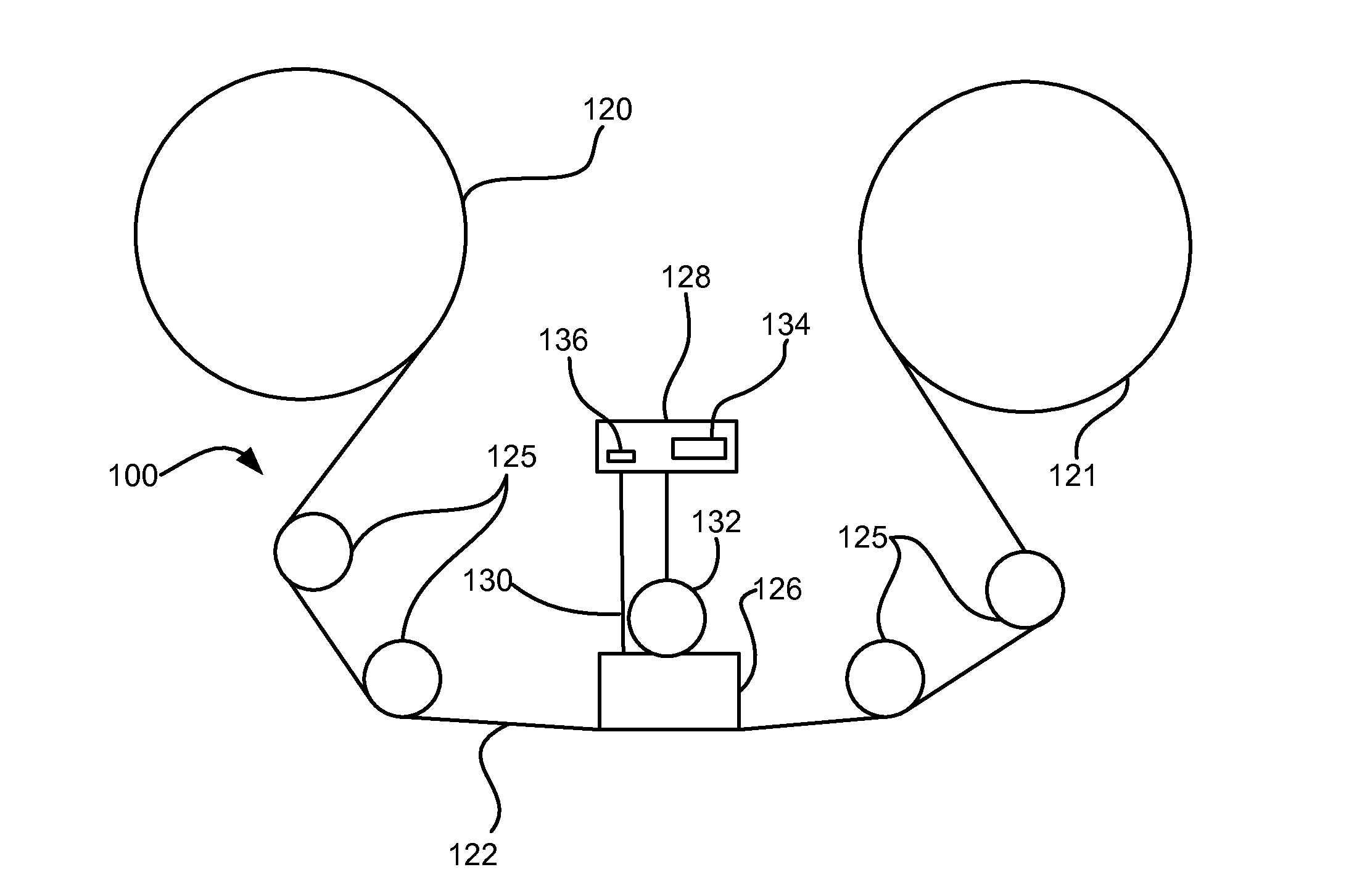

Magazine-Based Data Cartridge Library

InactiveUS20050007692A1Fast loadingLimited rangeRecord information storageAutomatic cassette changing arrangementsMagnetic tapeEngineering

The present invention provides a magazine-based data cartridge library that, in one embodiment, comprises a plurality of shelves that are capable of holding a plurality of data cartridge magazines, one or more drives, a magazine transport for moving magazines within the cabinet, and a cartridge transport for moving data cartridges between a magazine and a drive.

Owner:SPECTRA LOGIC

Magnetic tape and magnetic tape device

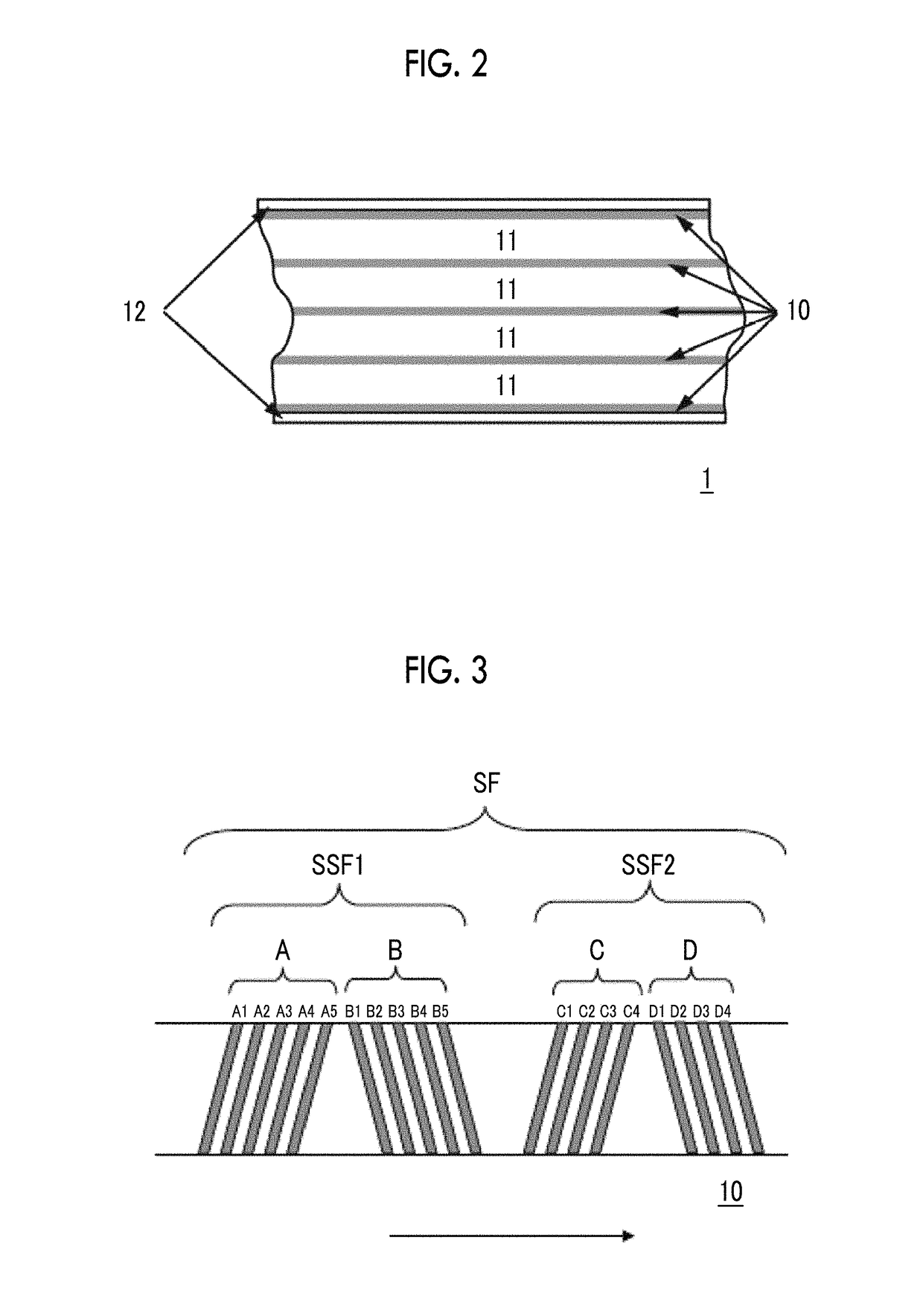

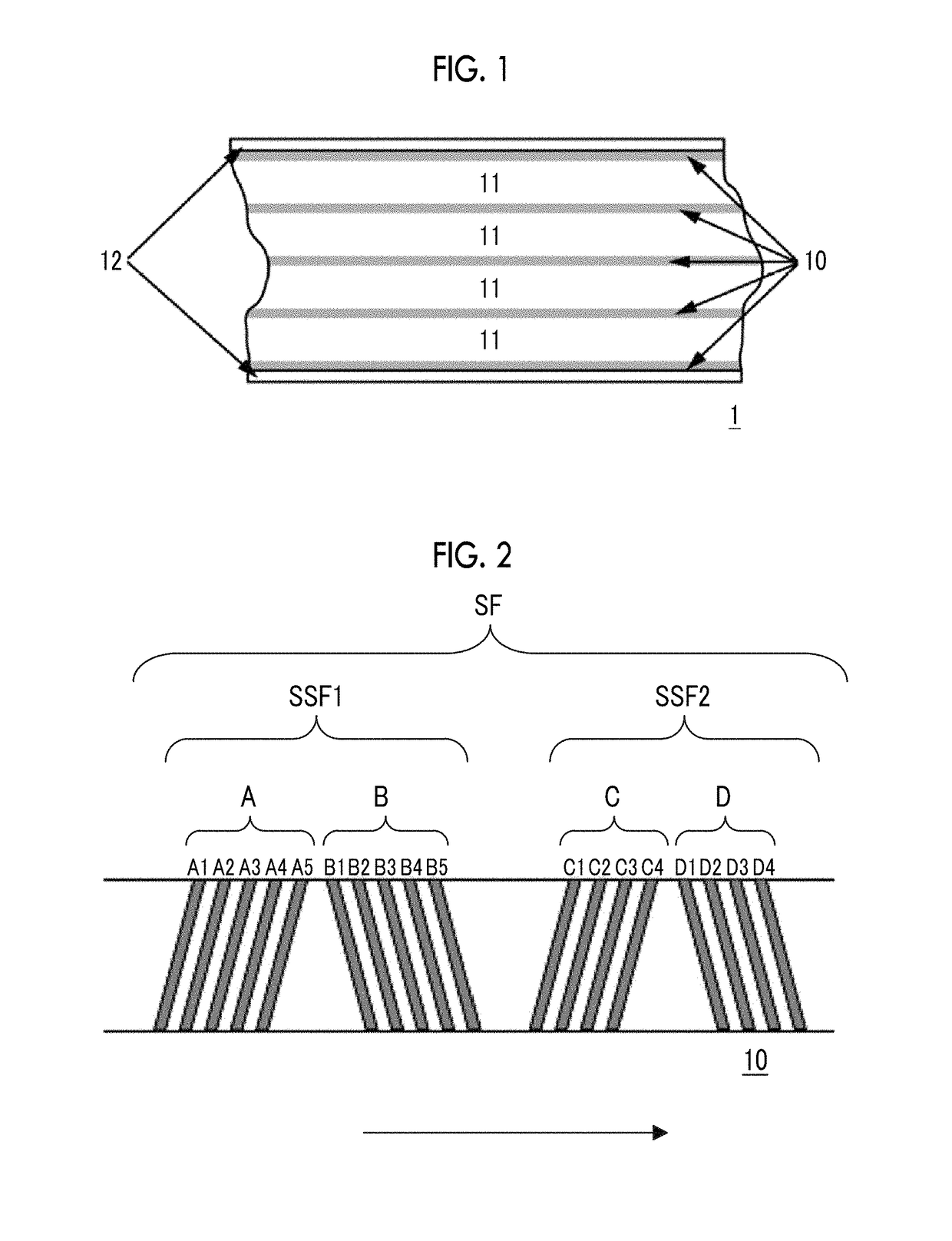

ActiveUS9837116B2Increase the number ofIncrease recording capacityAlignment for track following on tapesRecord information storageMagnetic tapeSurface roughness

Owner:FUJIFILM CORP

Magnetic recording medium and magnetic recording and reproducing device

ActiveUS20190103131A1Excellent electromagnetic conversion characteristicAvoid it happening againDisposition/mounting of recording headsMagnetic materials for record carriersIn planeX-ray

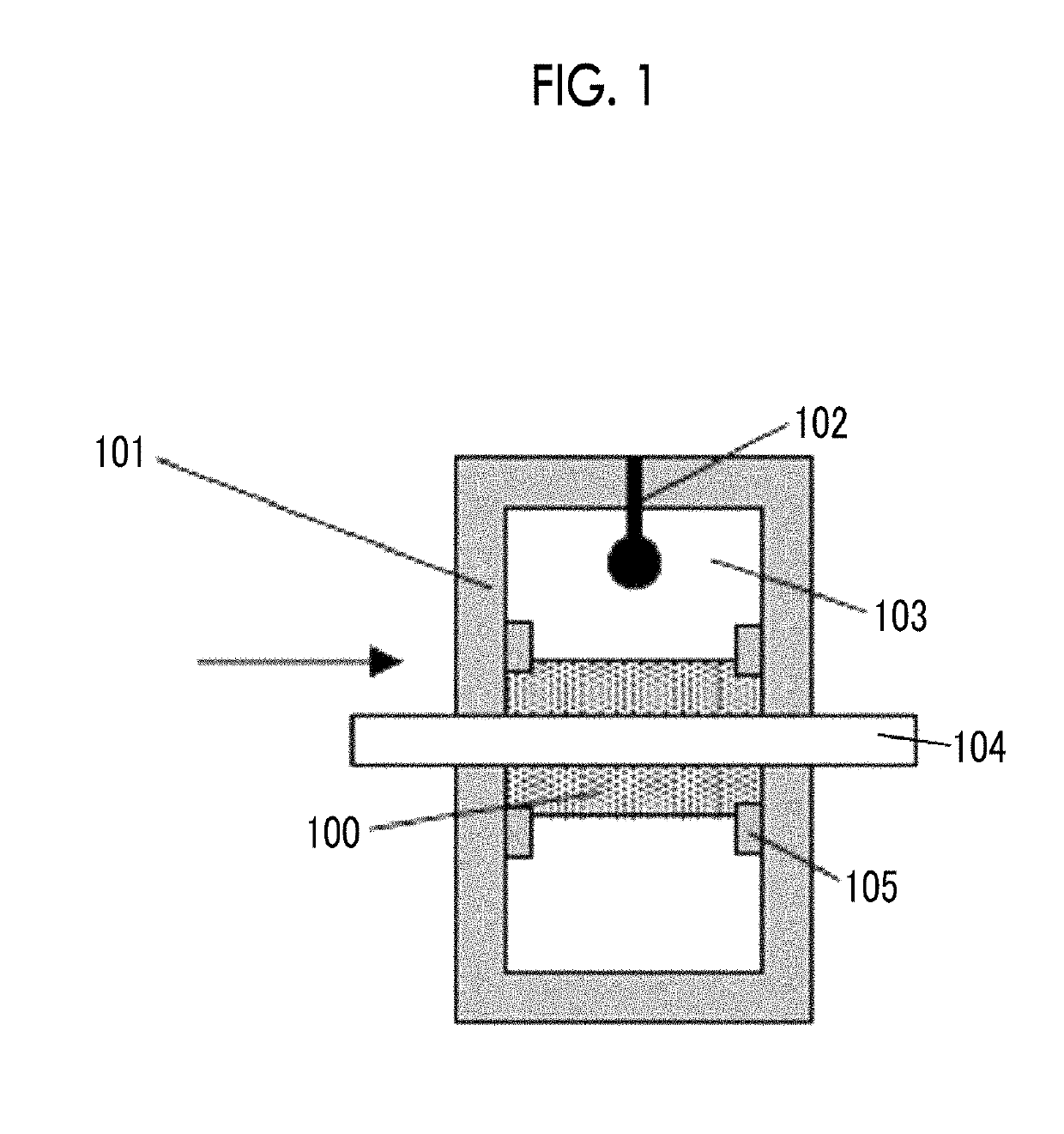

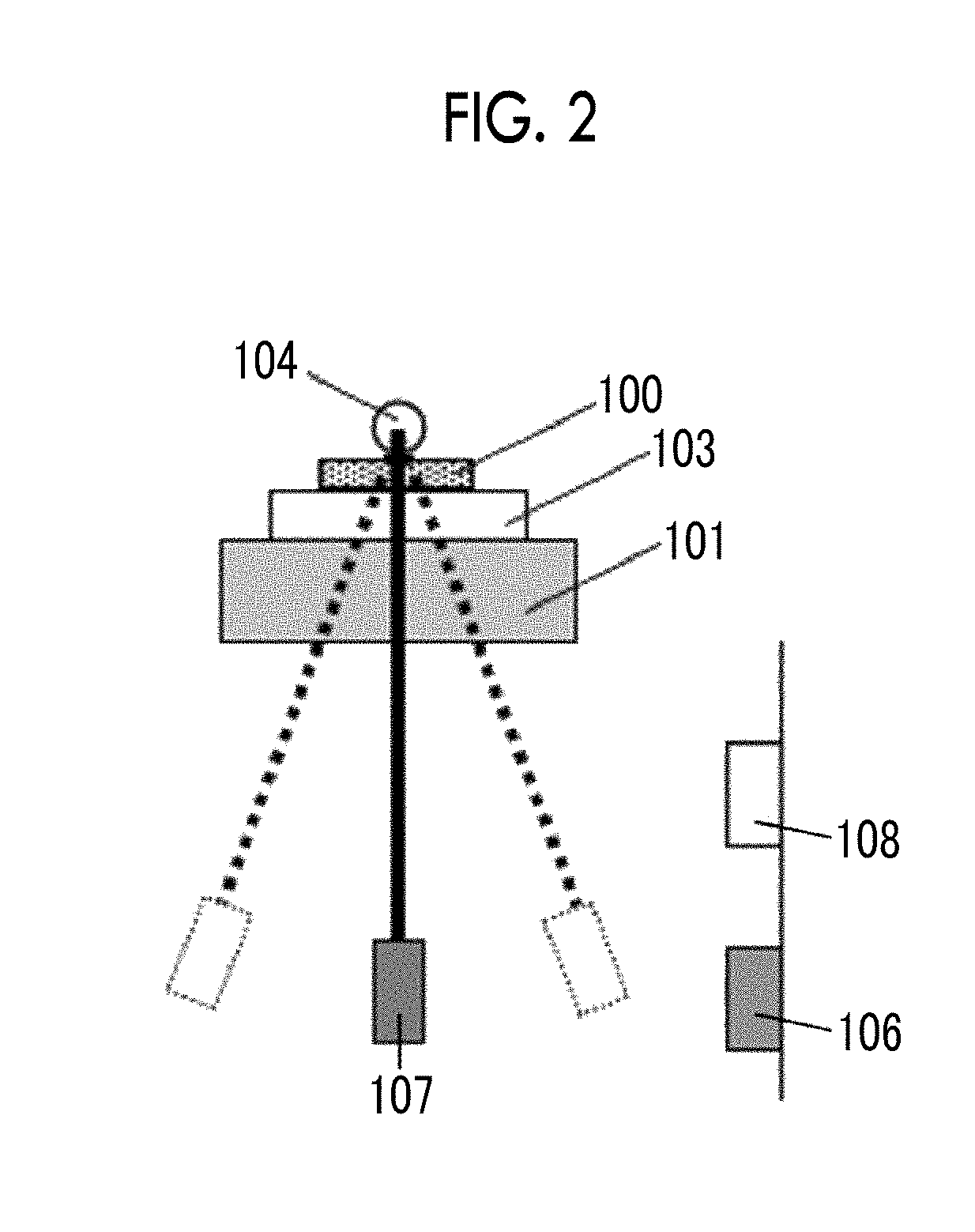

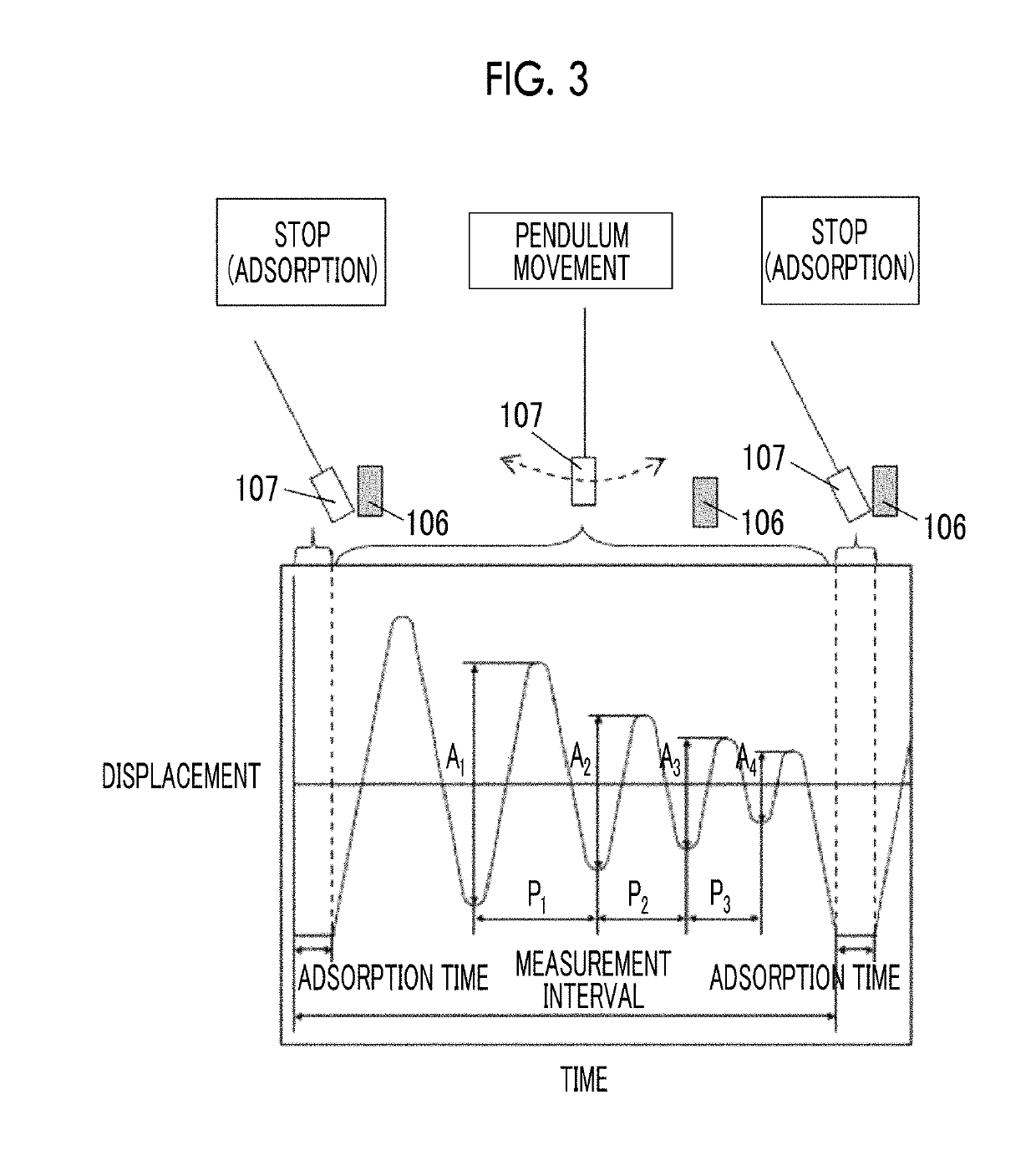

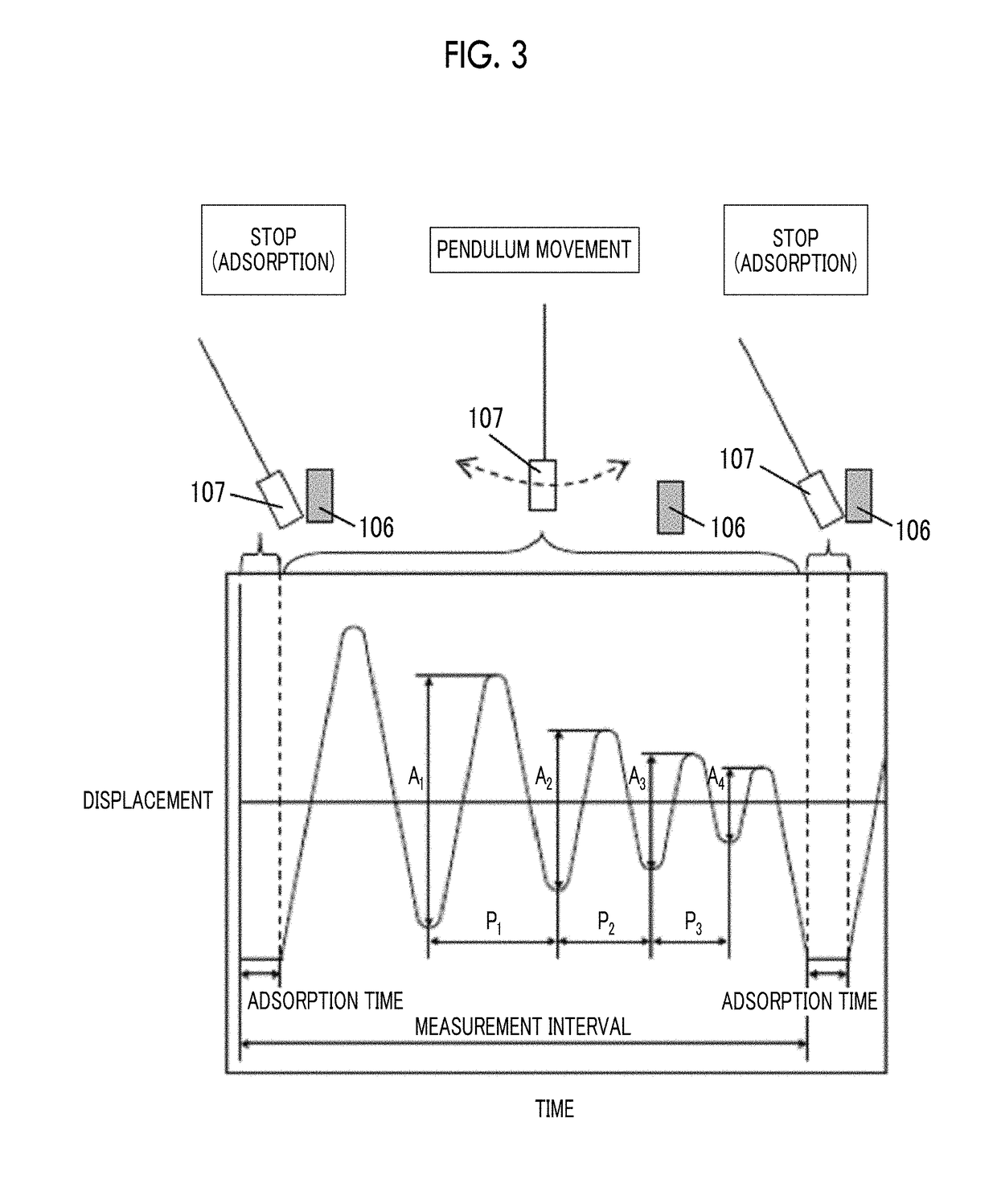

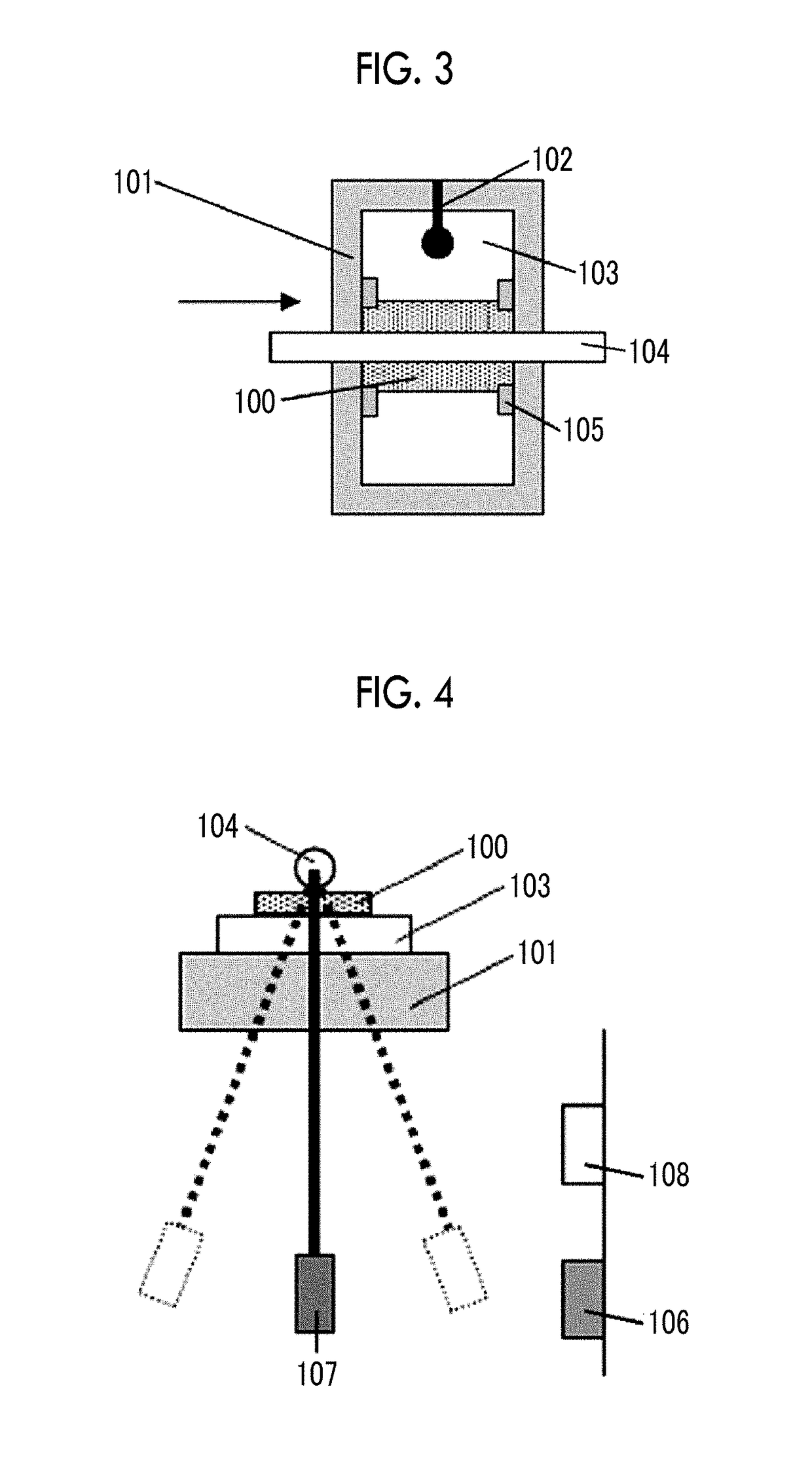

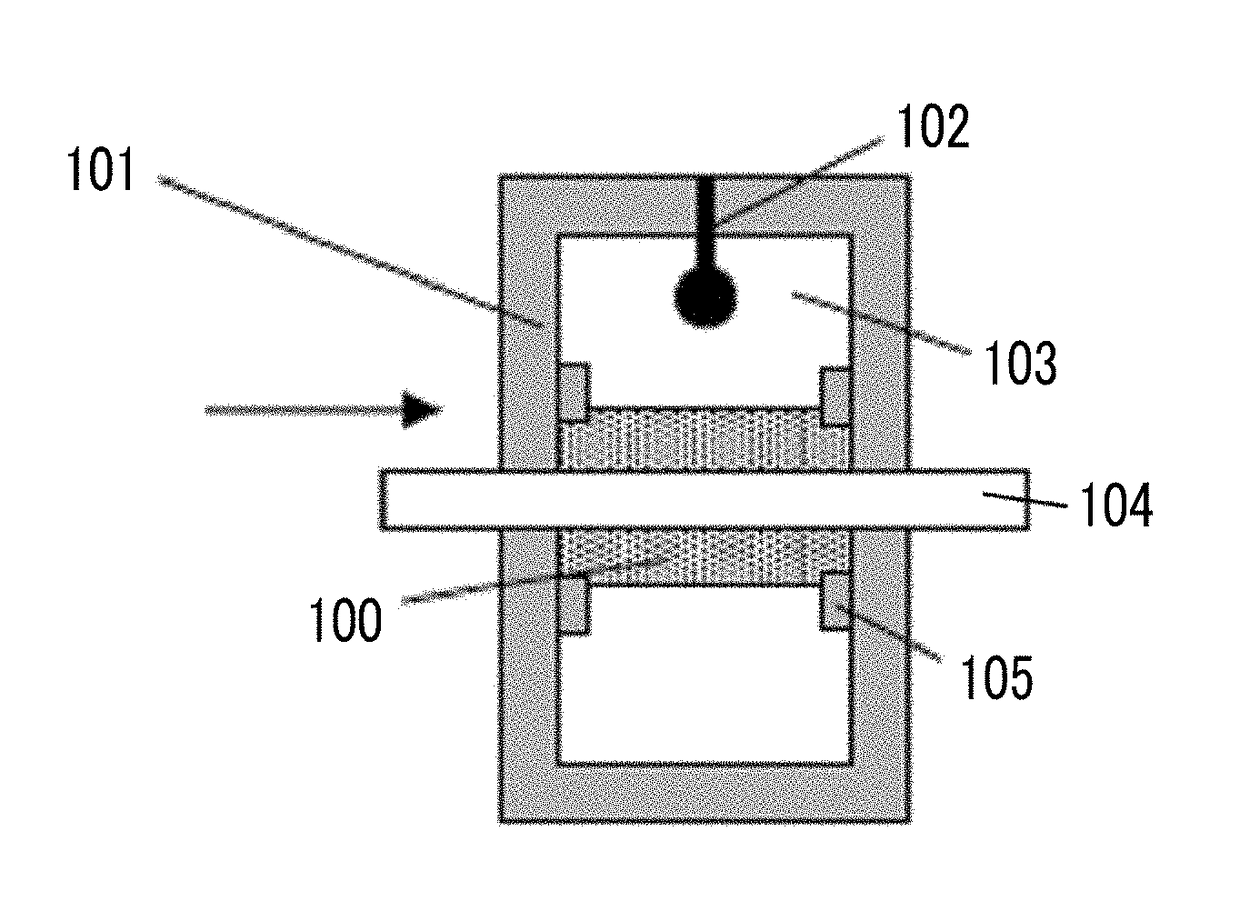

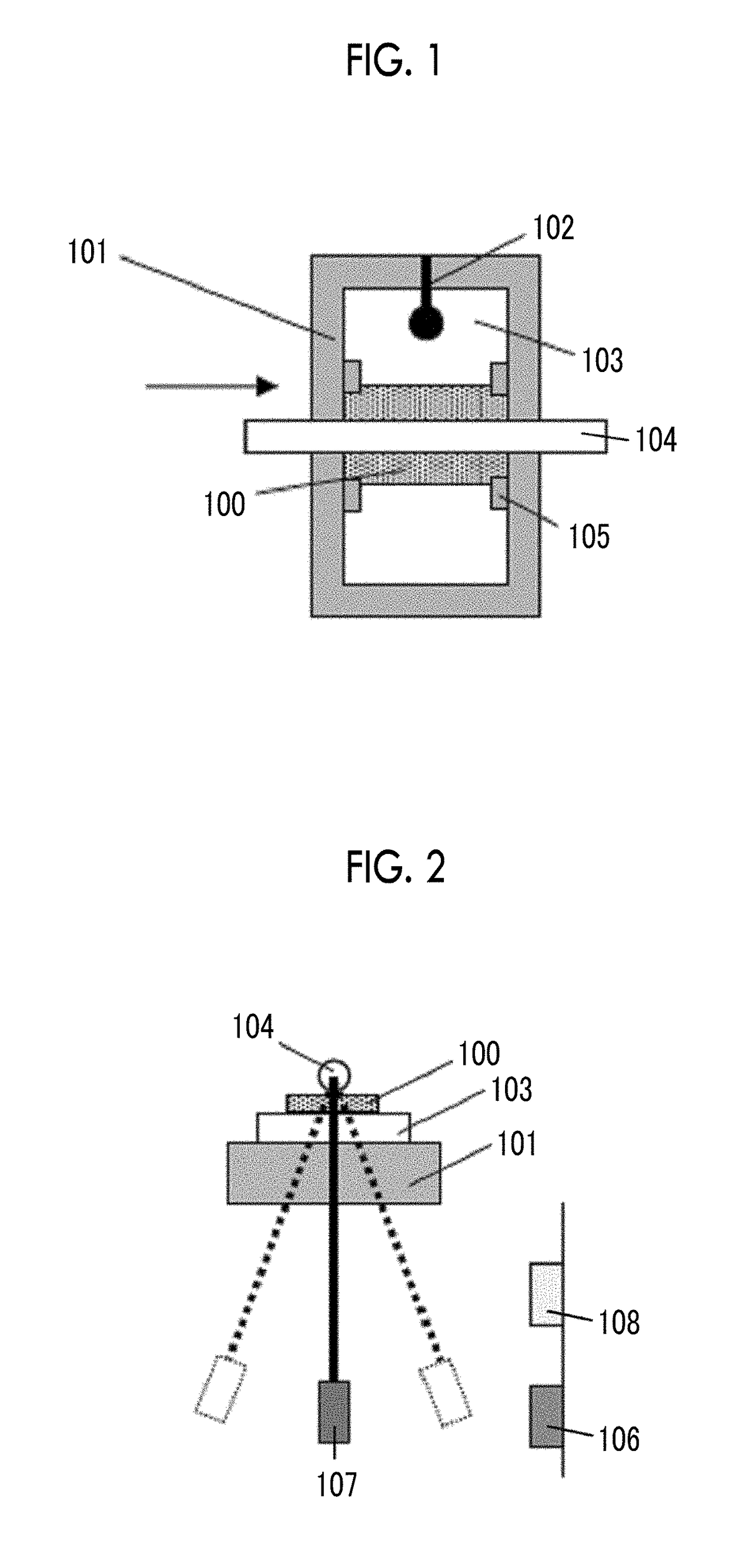

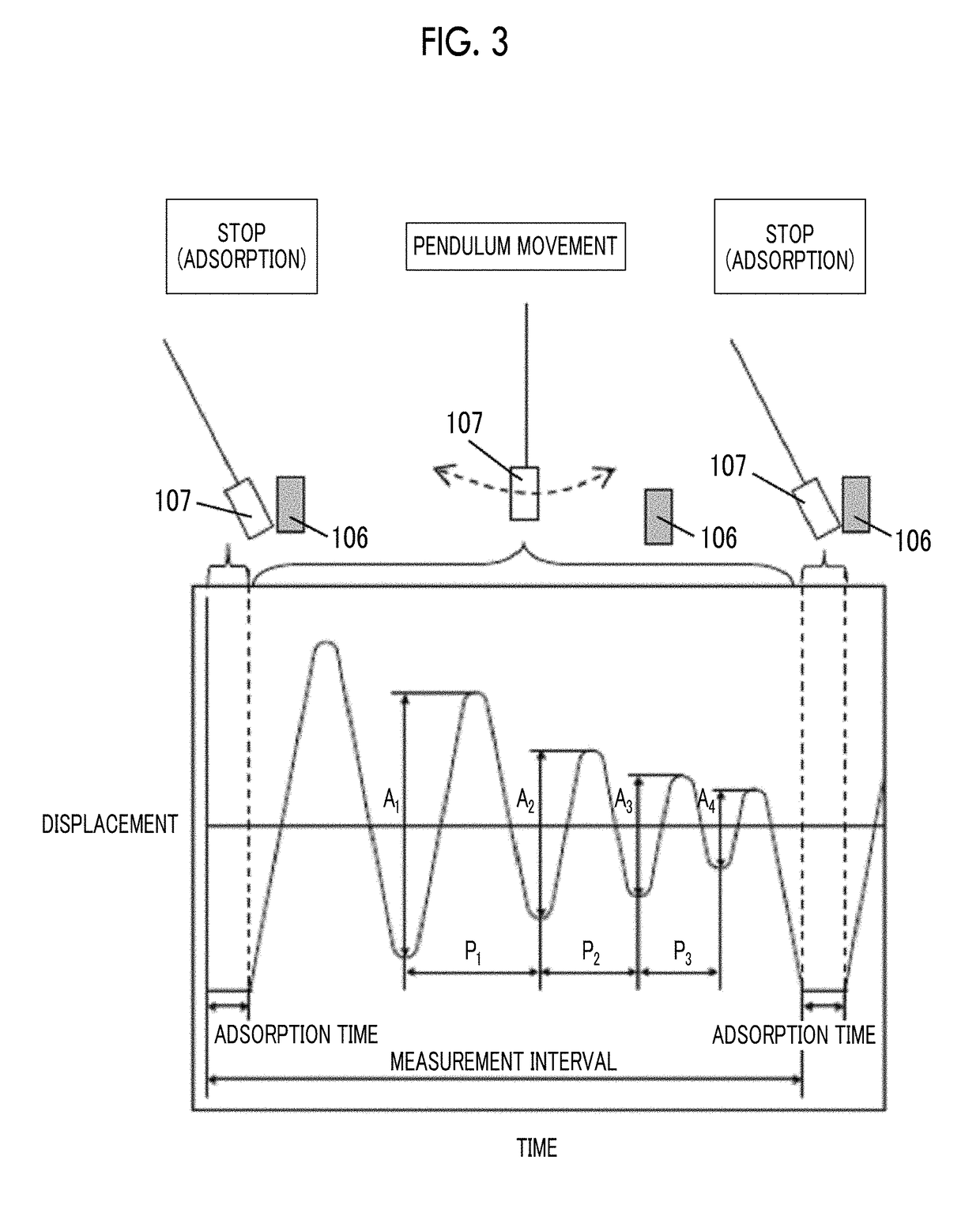

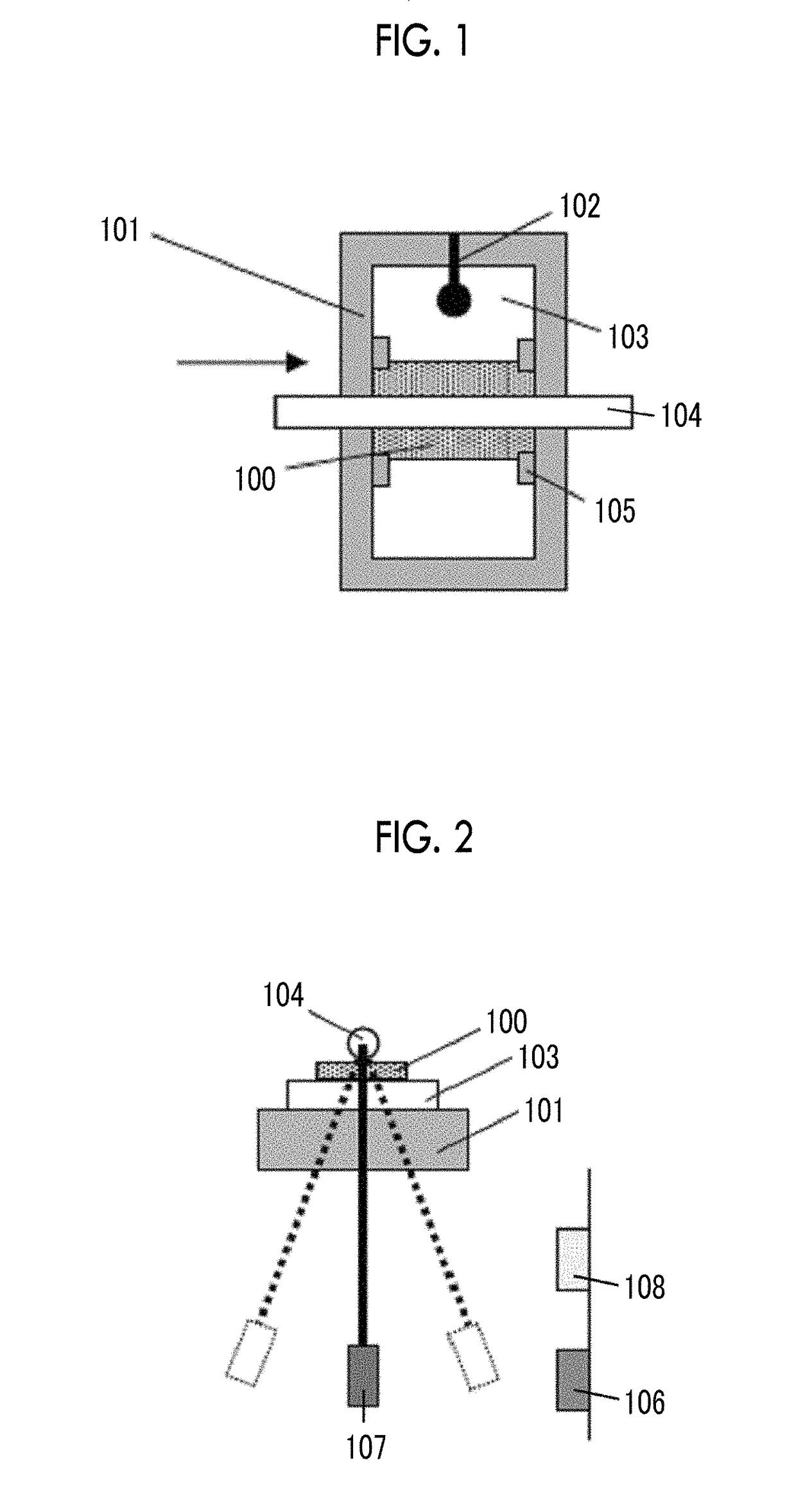

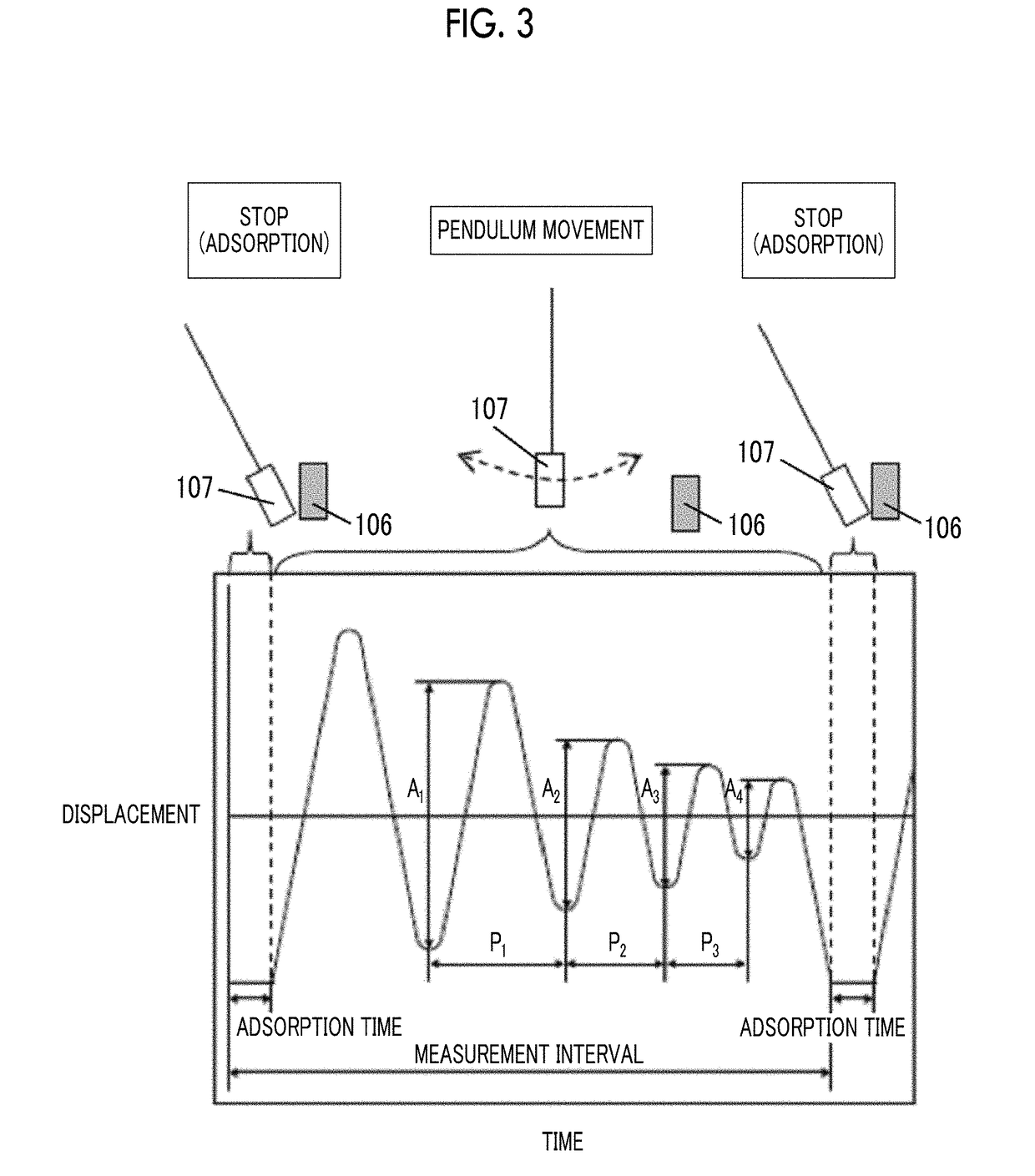

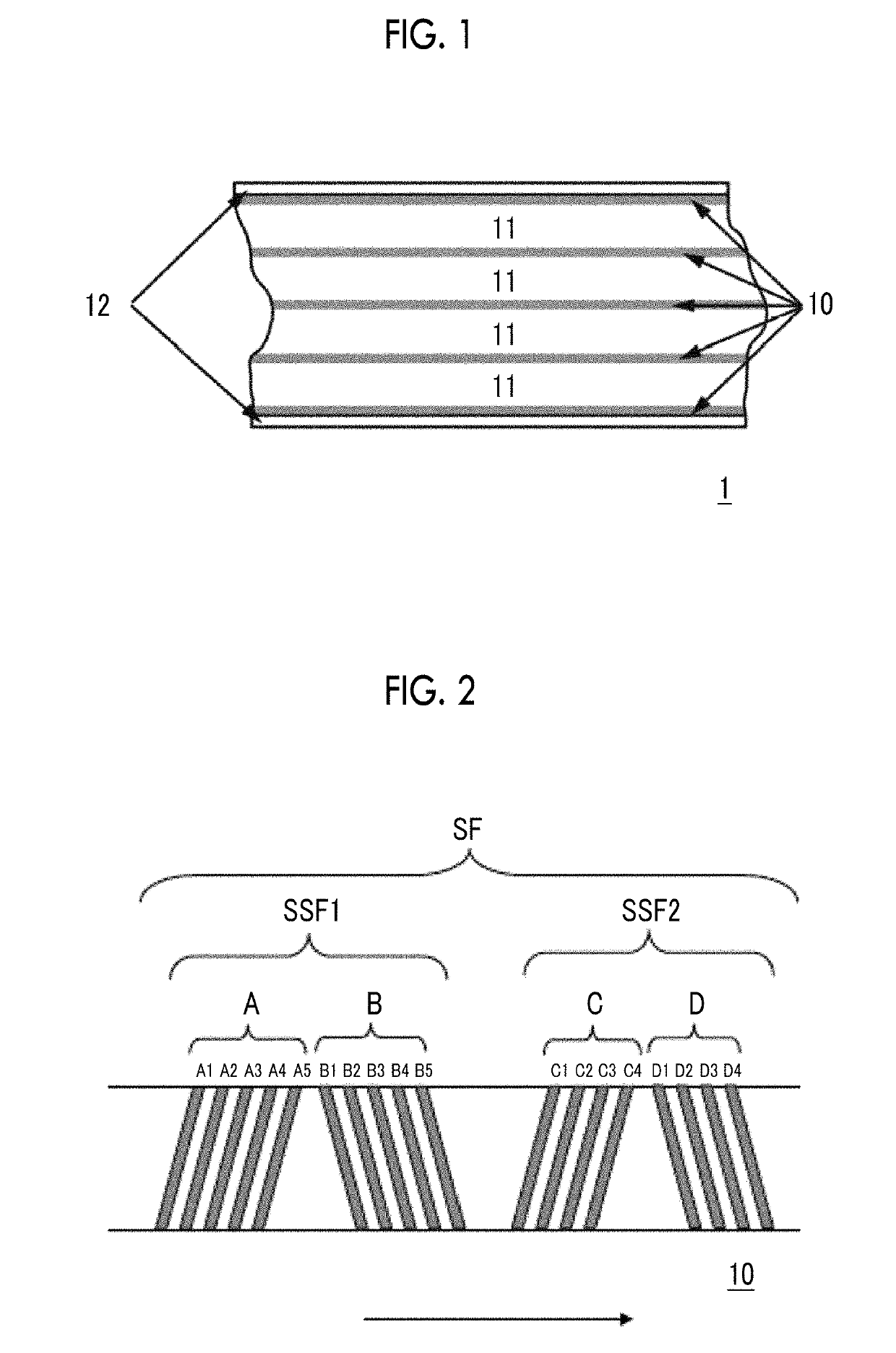

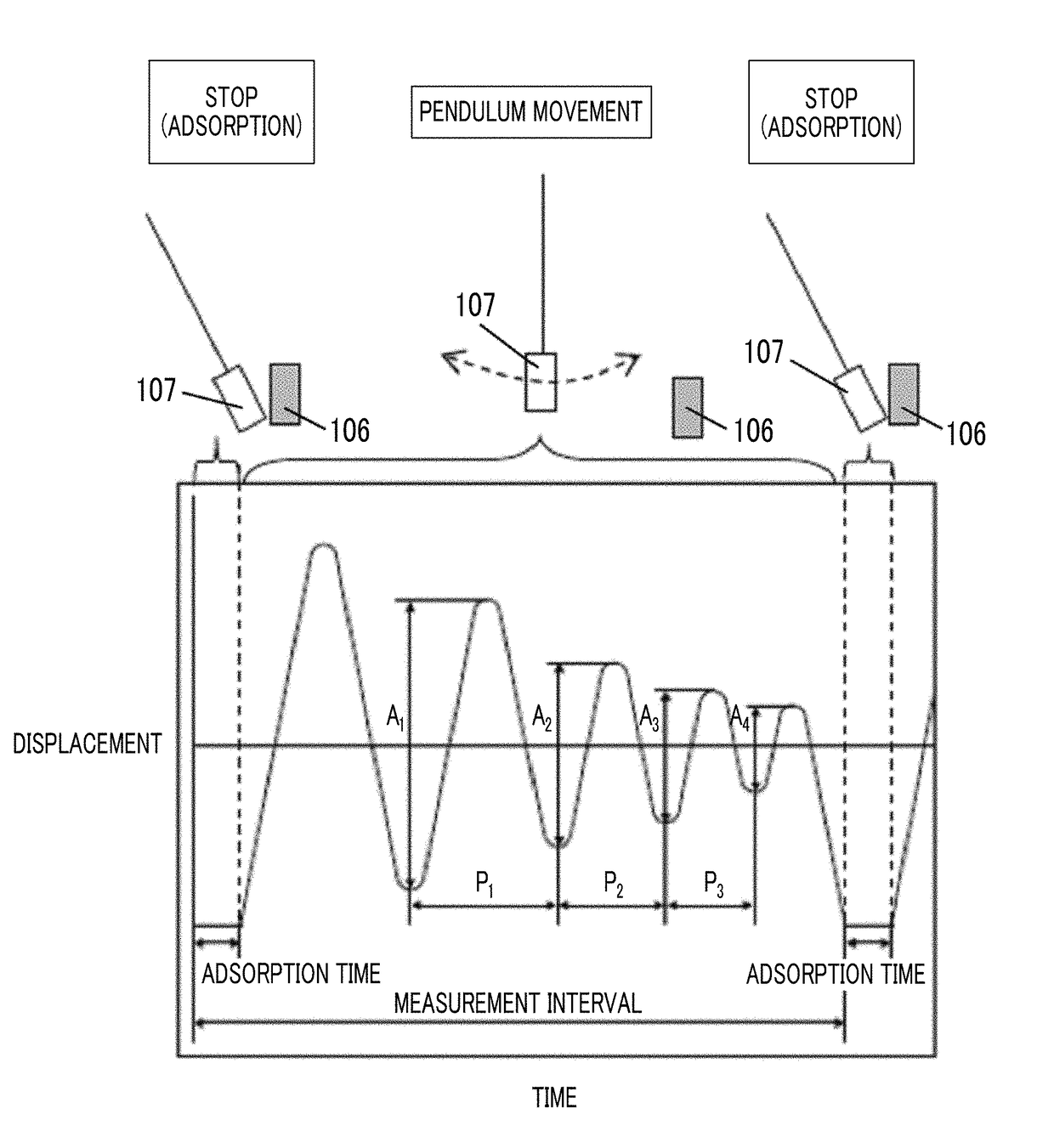

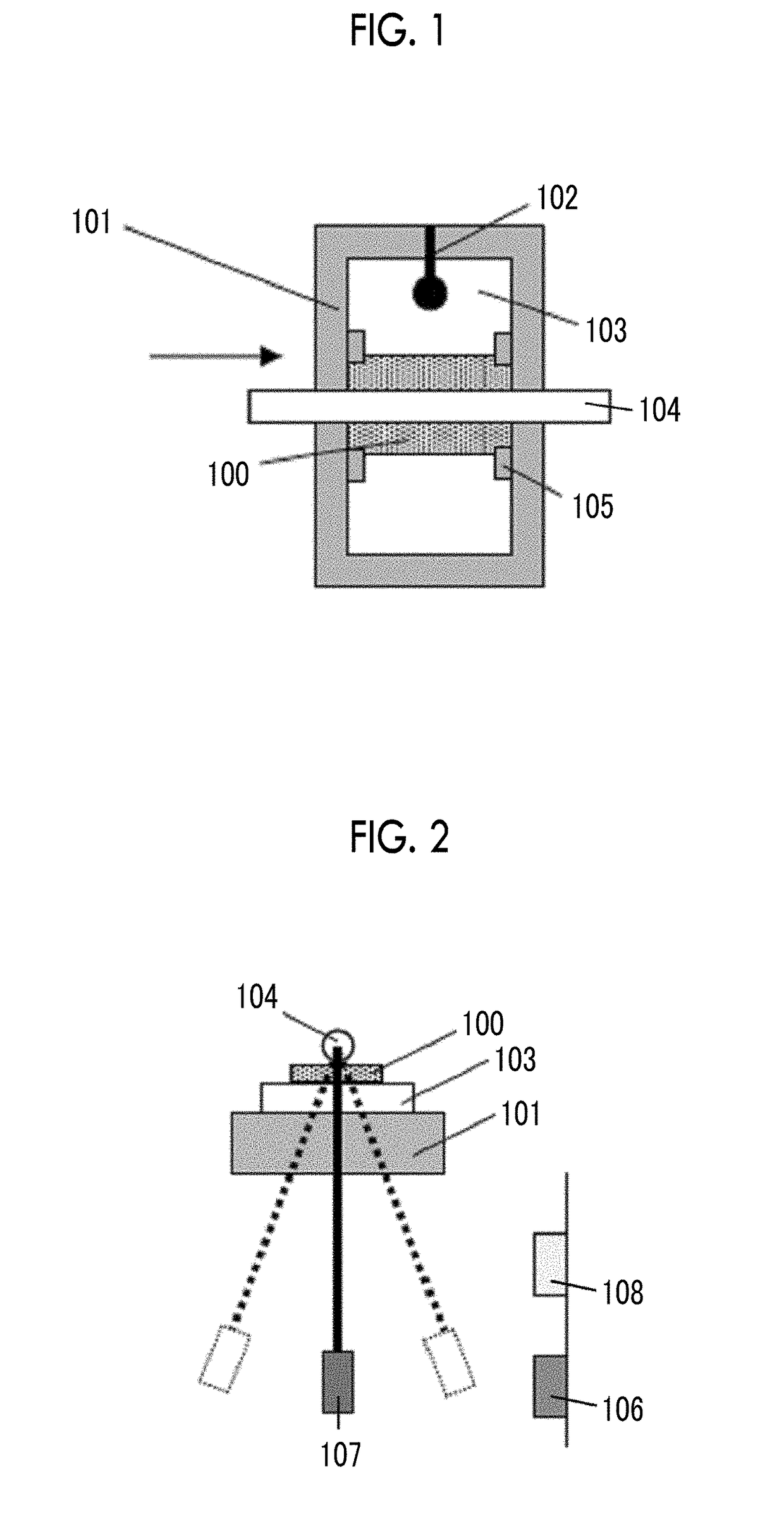

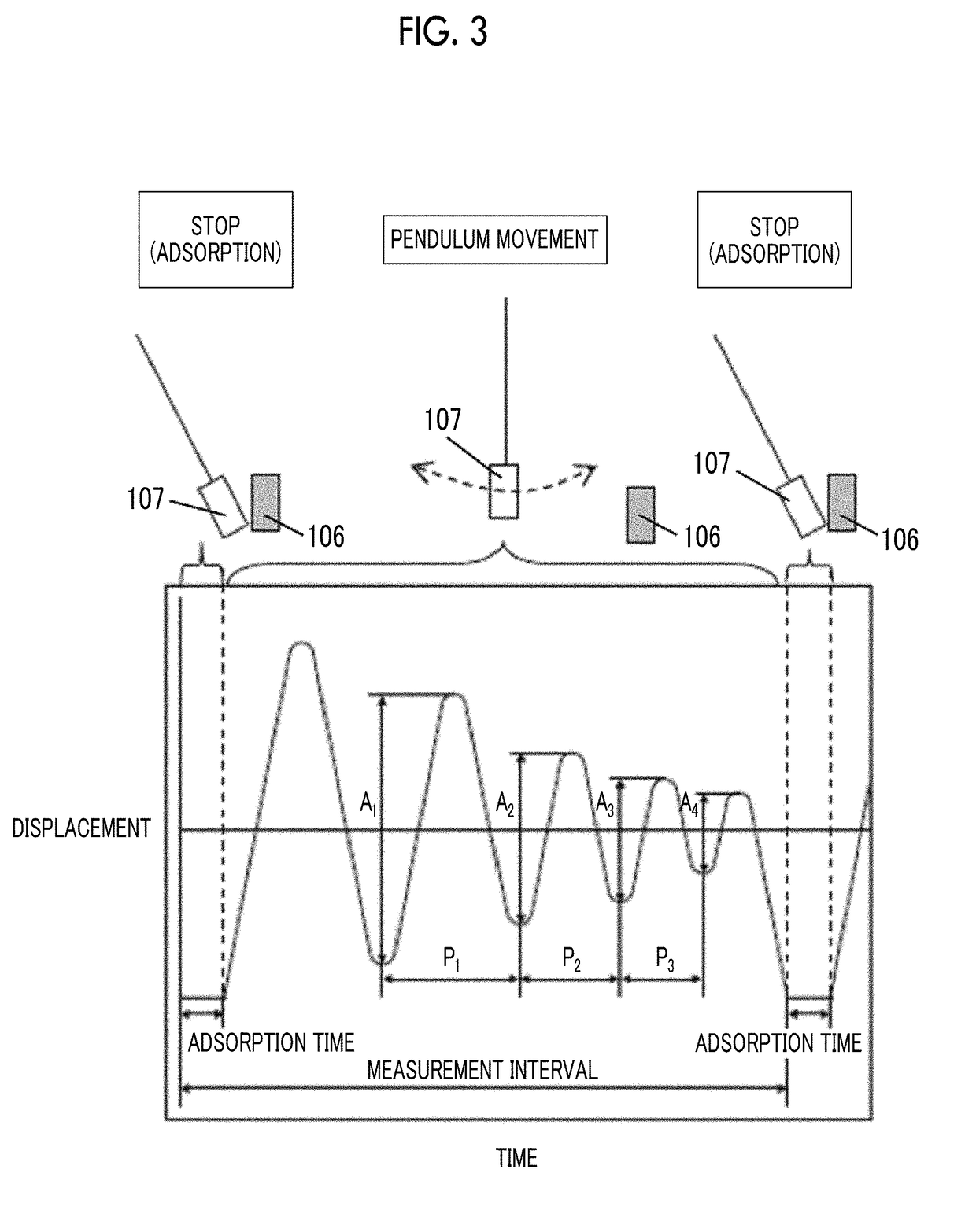

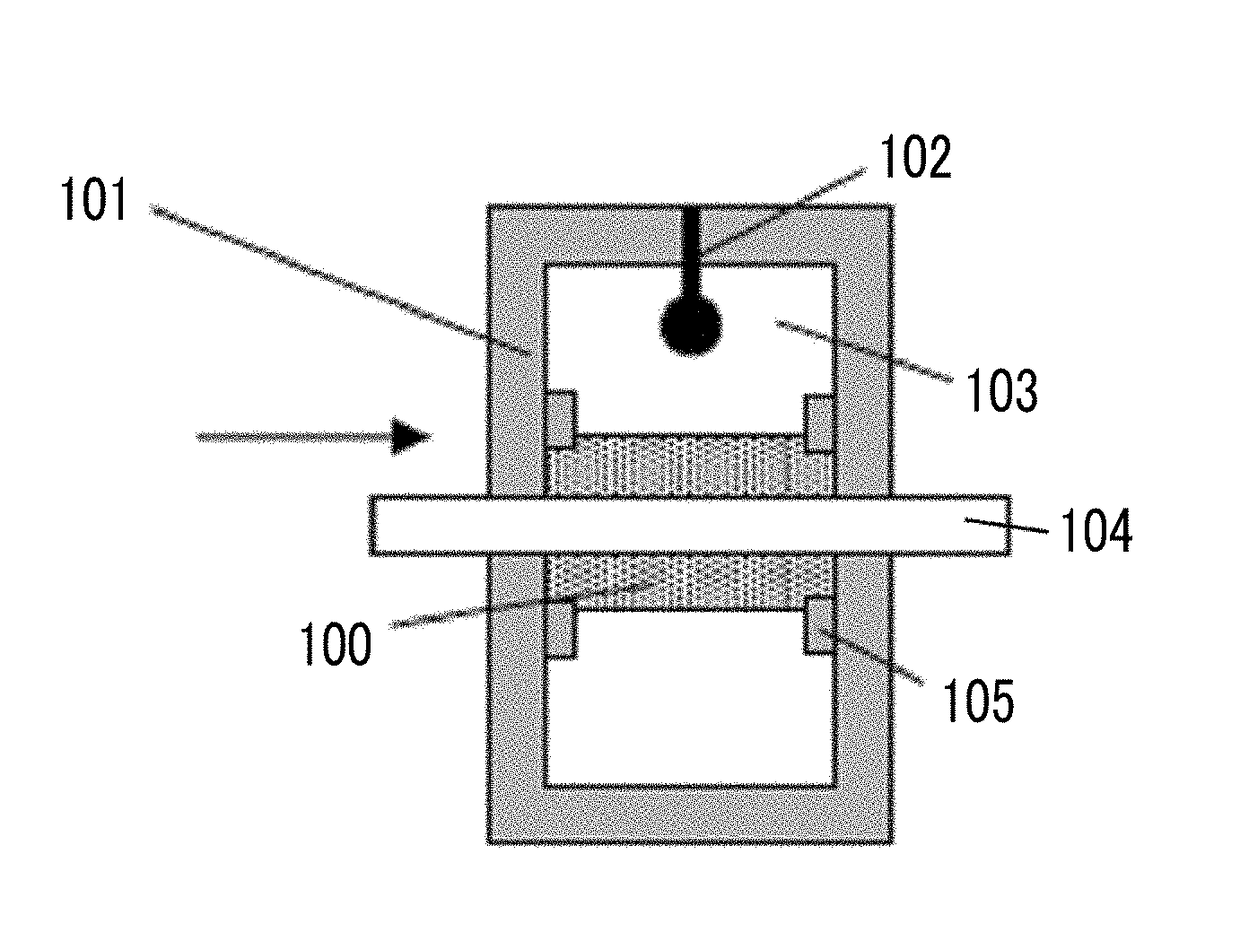

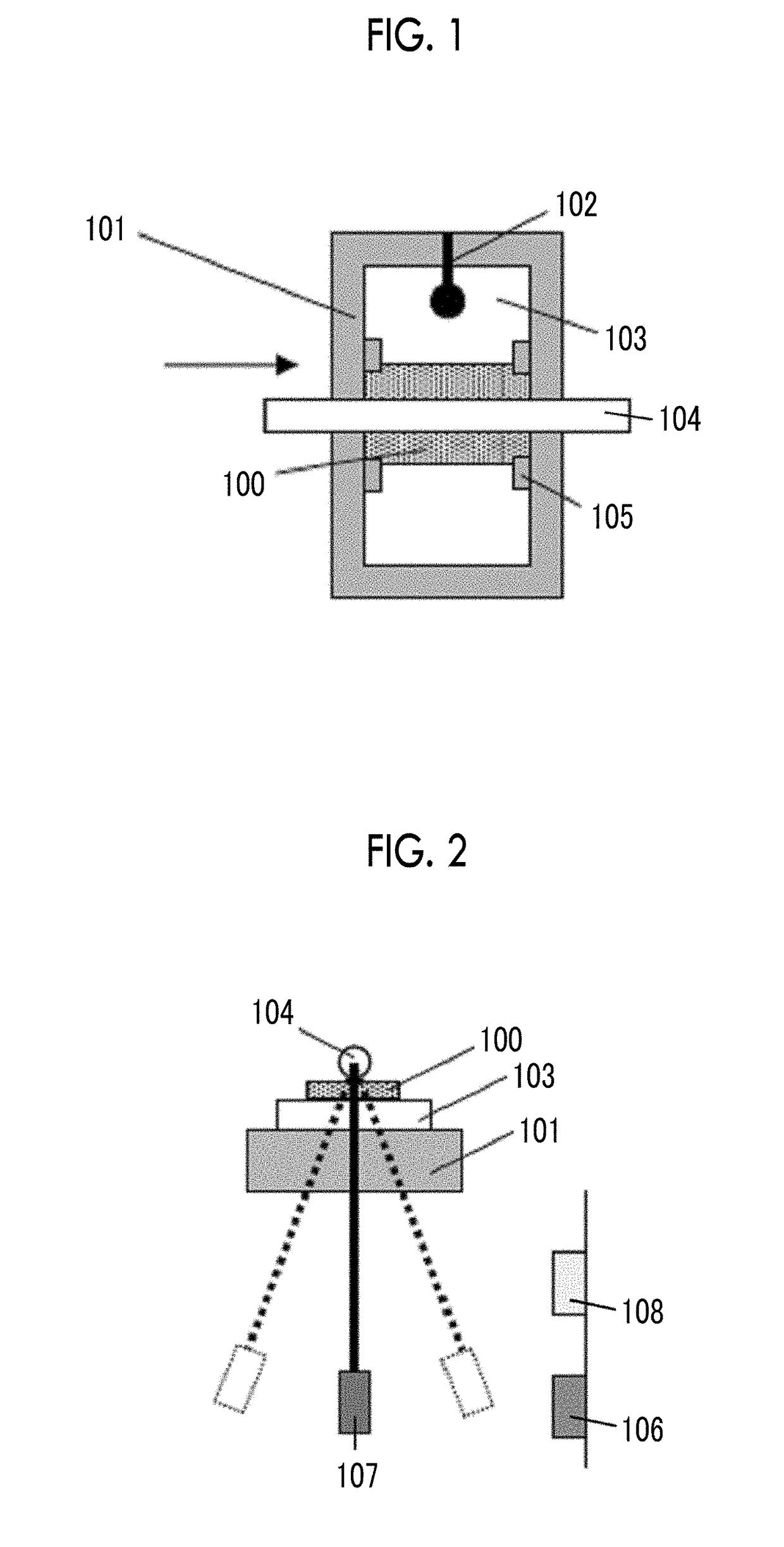

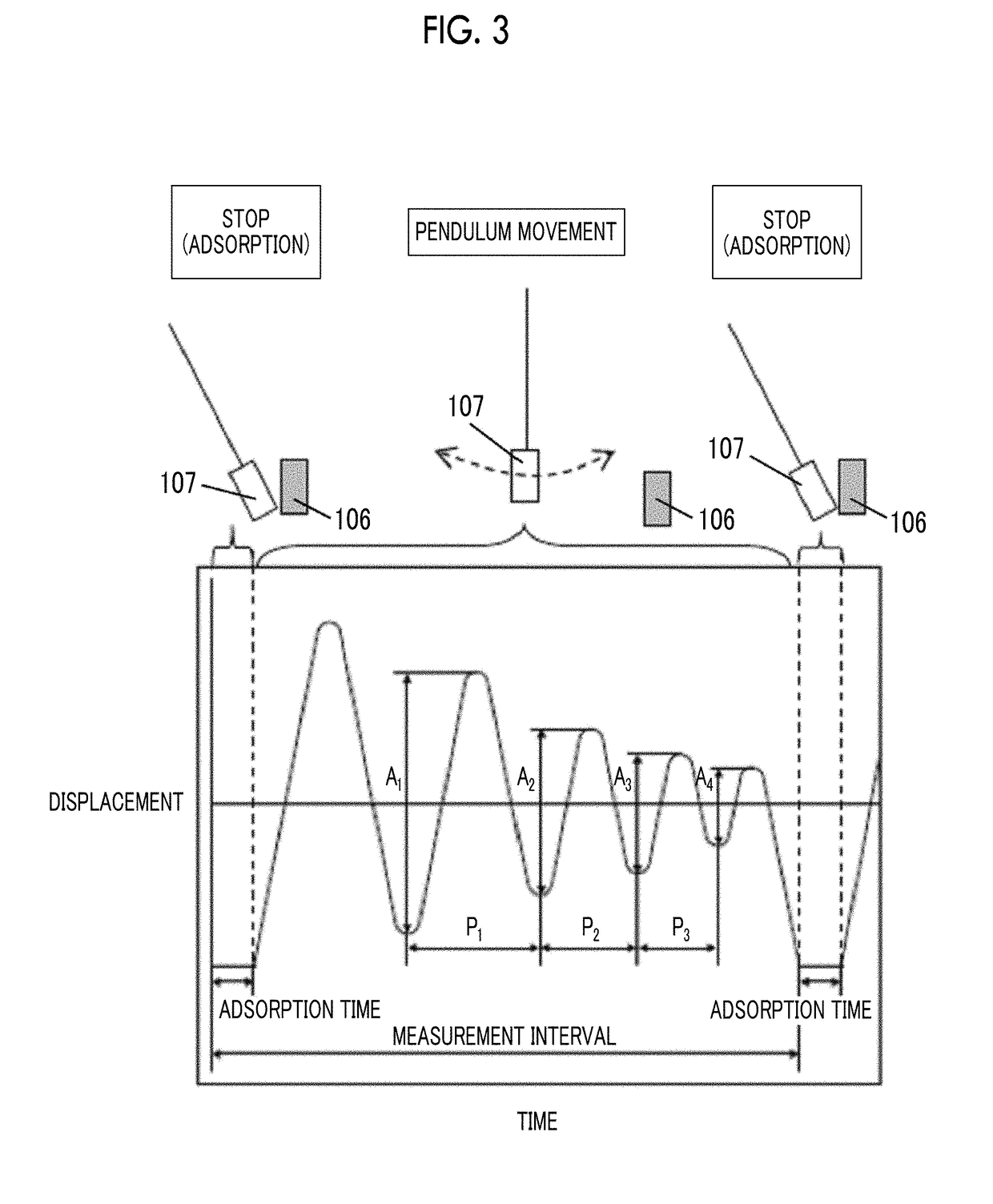

Provided are a magnetic recording medium, in which a magnetic layer includes ferromagnetic hexagonal ferrite powder, a binding agent, and an oxide abrasive, an intensity ratio Int(110) / Int(114) obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic recording medium is 0.65 to 1.00, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding a surface of the magnetic layer is equal to or smaller than 0.050, and an average particle diameter of the oxide abrasive obtained from a secondary ion image obtained by irradiating the surface of the magnetic layer with a focused ion beam is 0.04 μm to 0.08 μm, and a magnetic recording and reproducing device including this magnetic recording medium.

Owner:FUJIFILM CORP

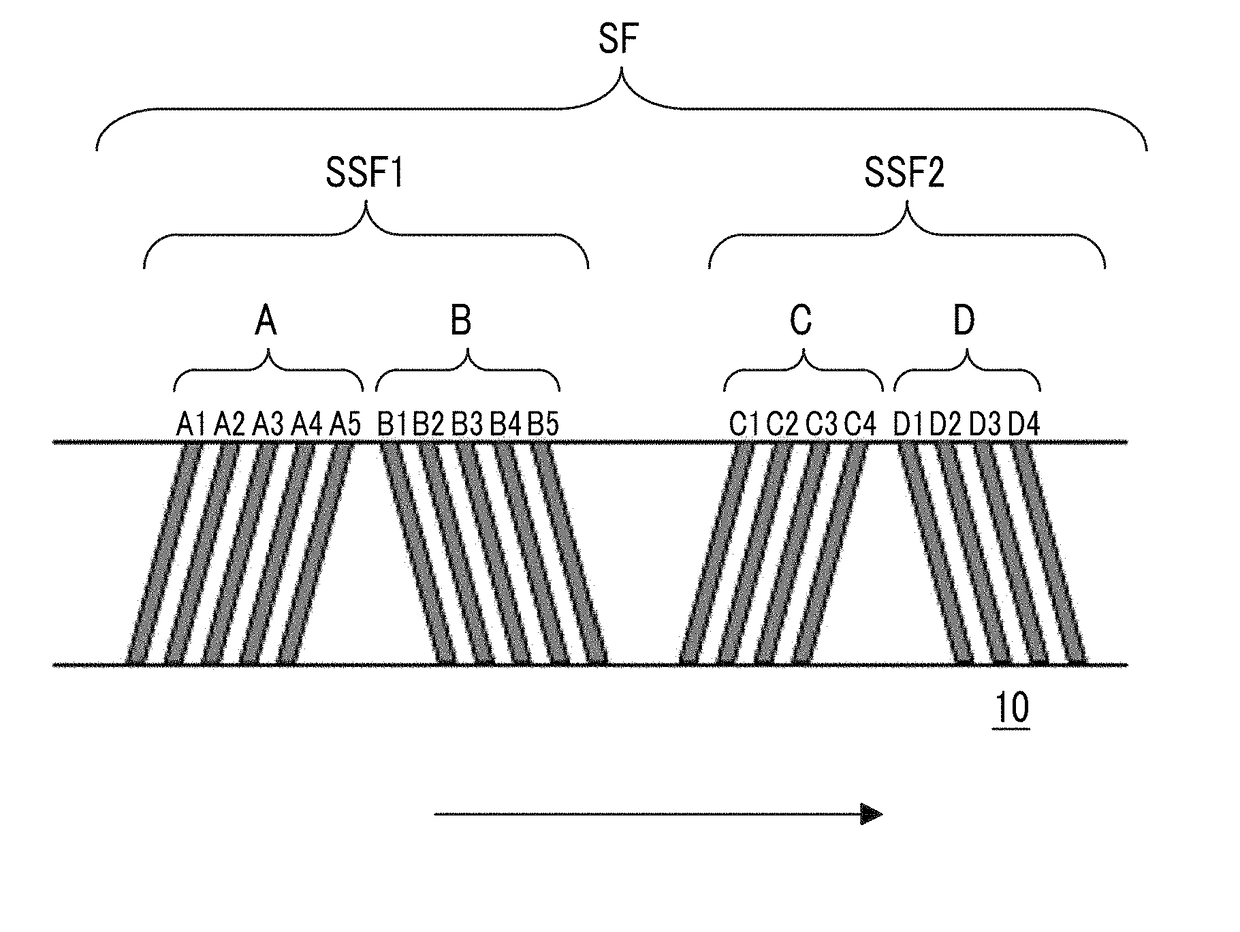

Measurement and correction of magnetic writer offset error

ActiveUS20160260449A1Reduced readback error rateImprove read performanceAlignment for track following on tapesRecord information storageComputer scienceComputer program

A method, according to one embodiment, includes writing a plurality of shingled tracks using an array of writers, determining first and second positions of an array of readers relative to the shingled tracks, the first and second positions being above and / or beyond track edges of the shingled tracks, repositioning the array of readers to various locations between the first and second positions and reading data from the shingled tracks, determining a read offset point where read performance is about the highest during the reading performed when repositioning the array of readers between the first and second positions, and computing, using the read offset point, data describing a lateral writing position to use during writing such that shingled tracks are written in a location specified by a format. Other systems, methods, and computer program products are described in additional embodiments.

Owner:IBM CORP

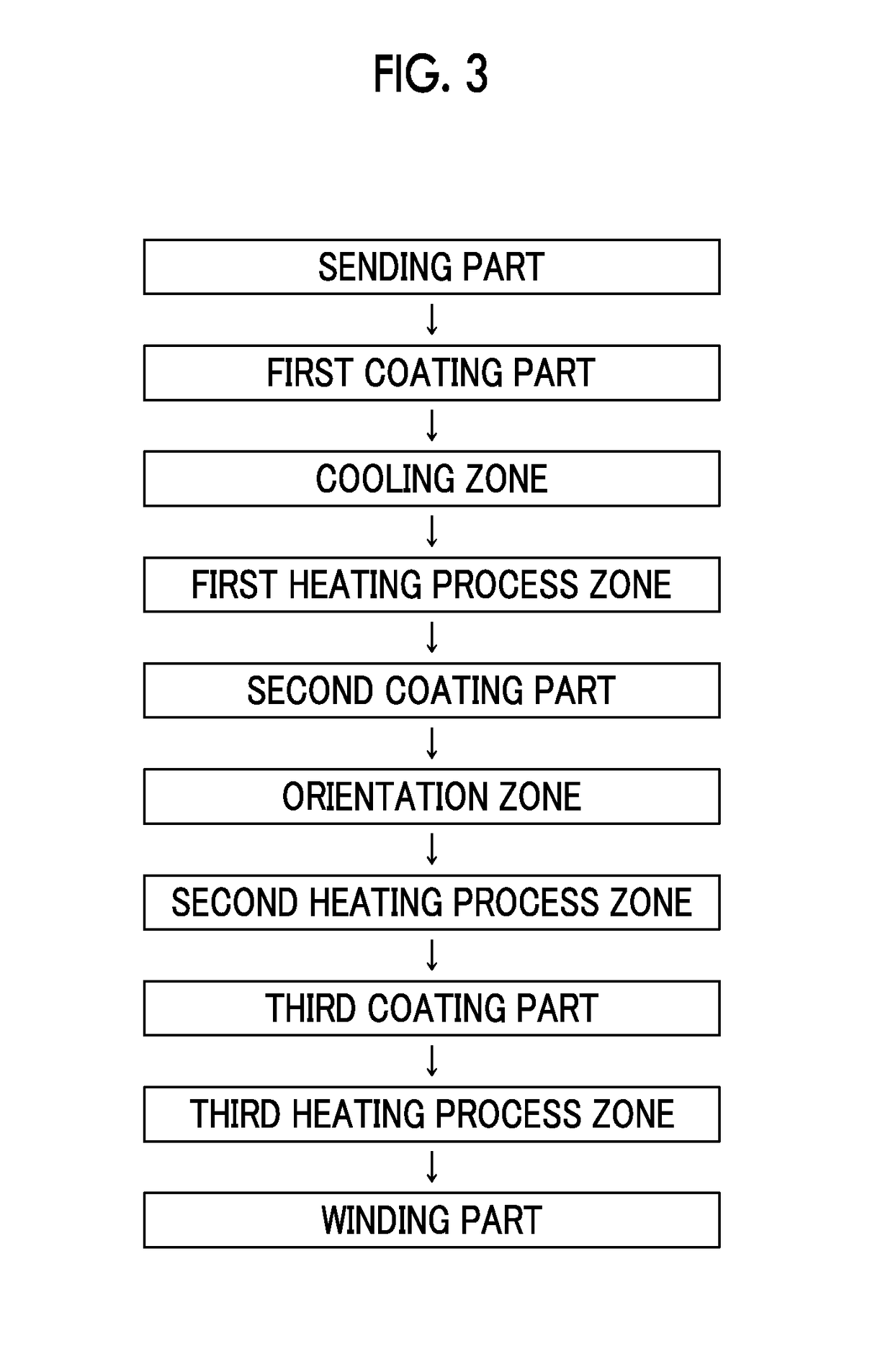

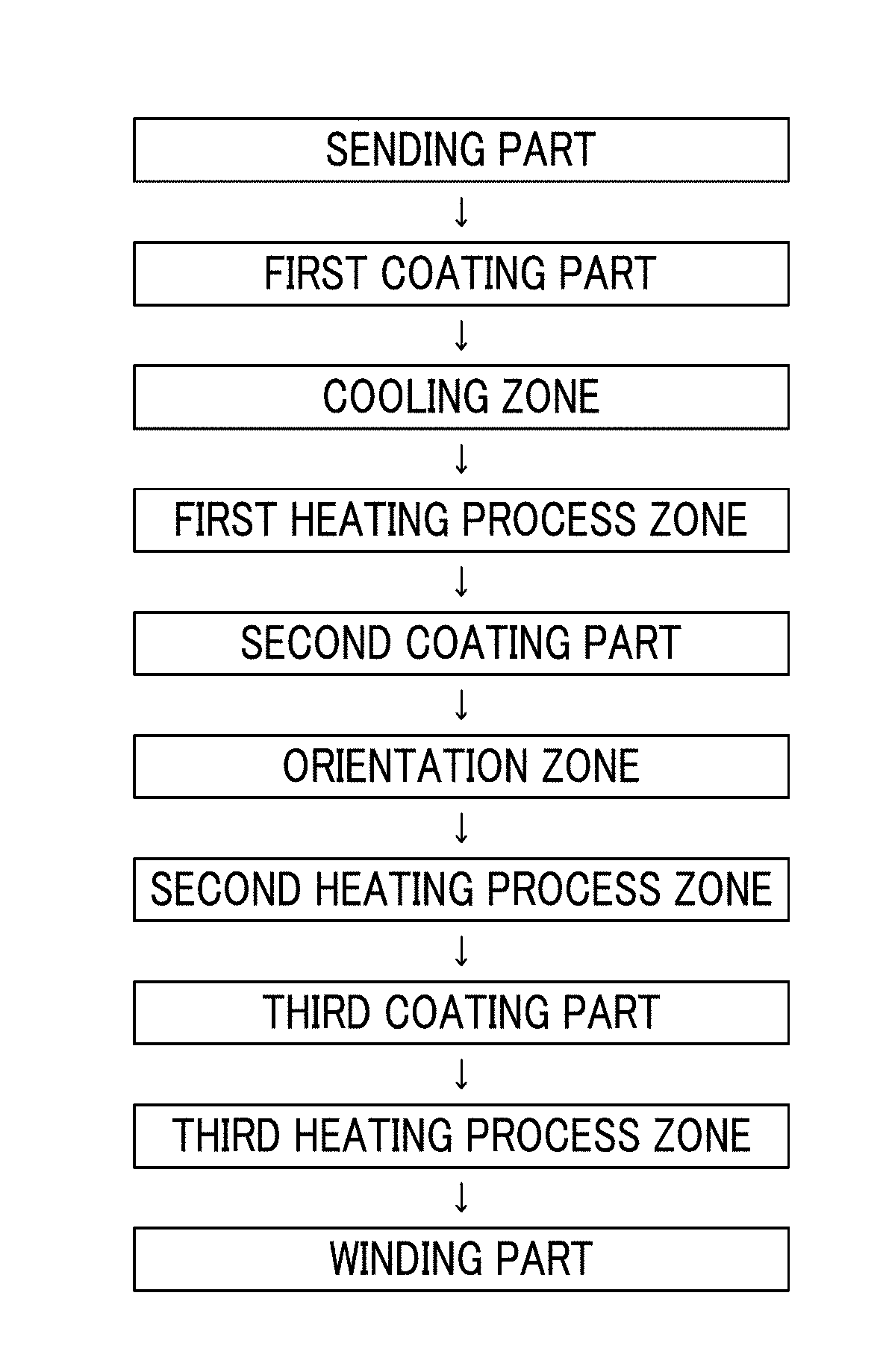

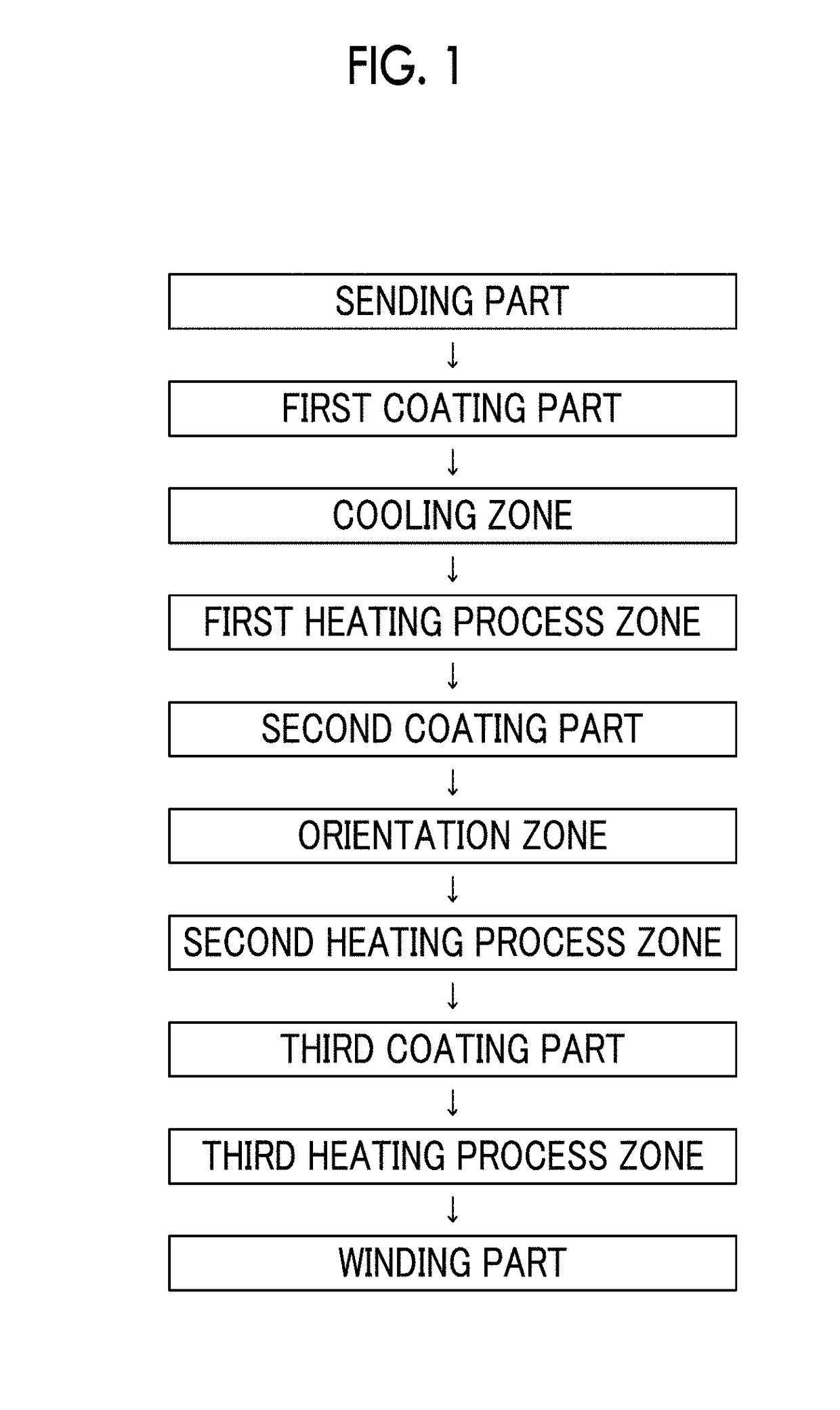

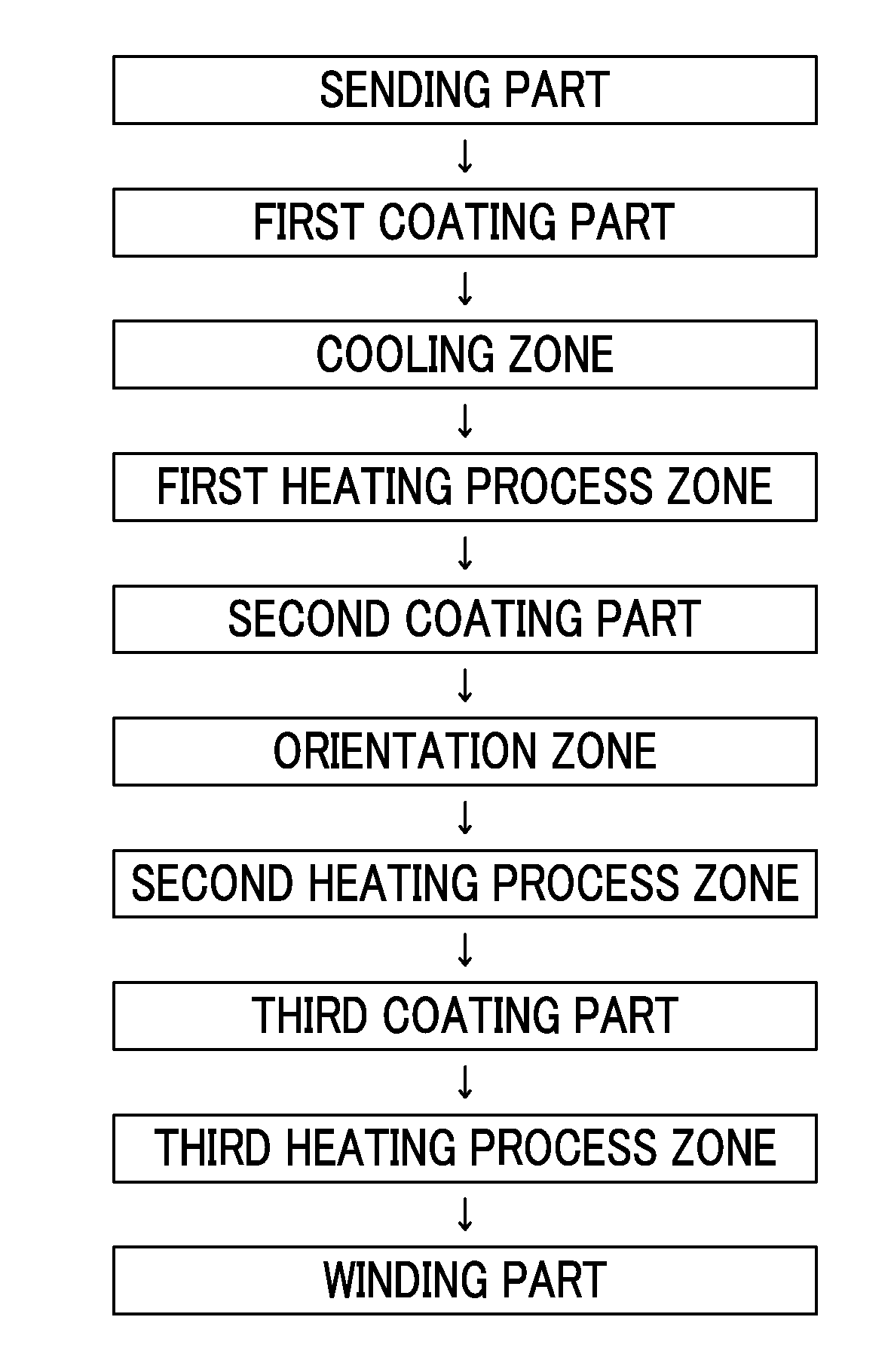

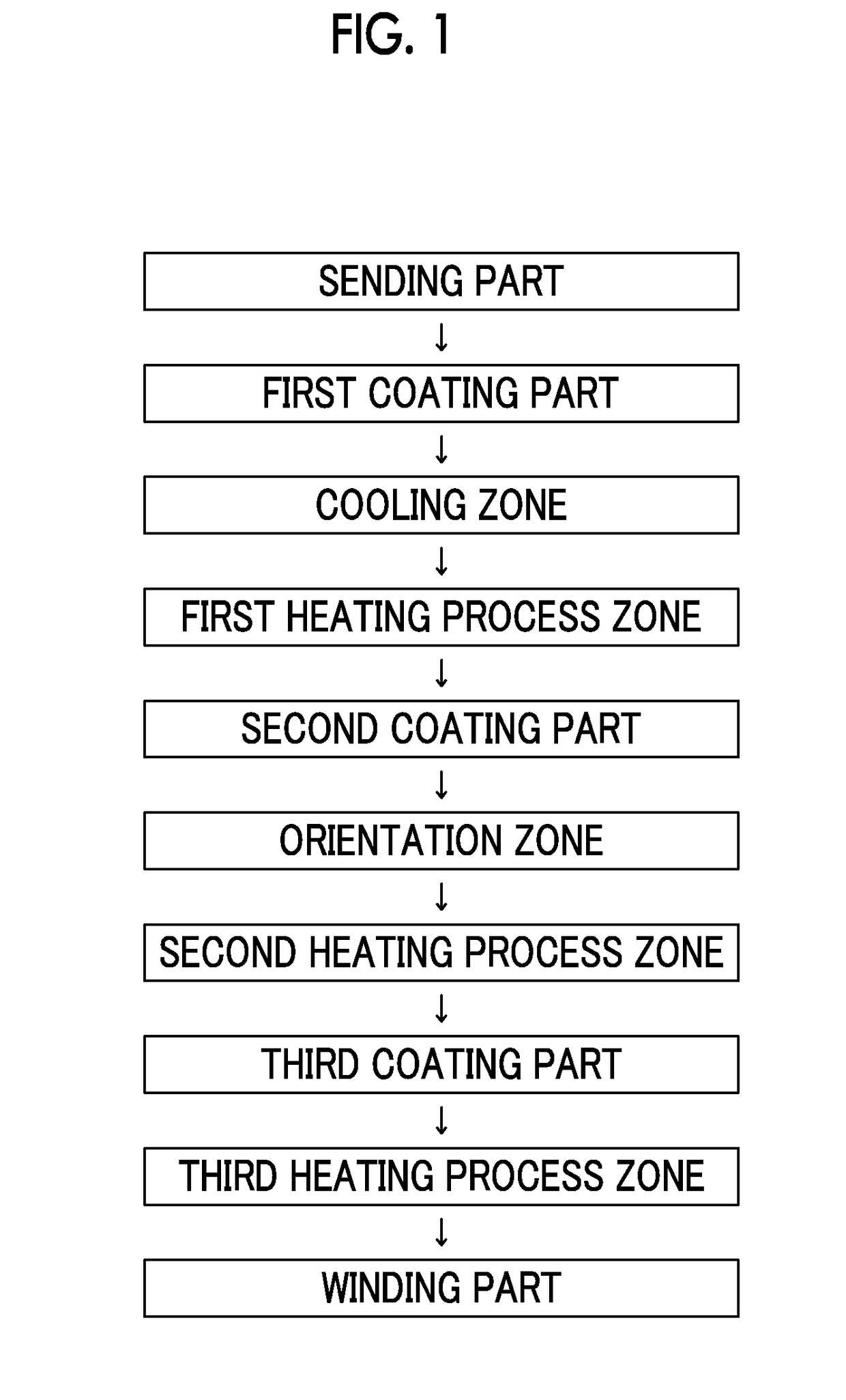

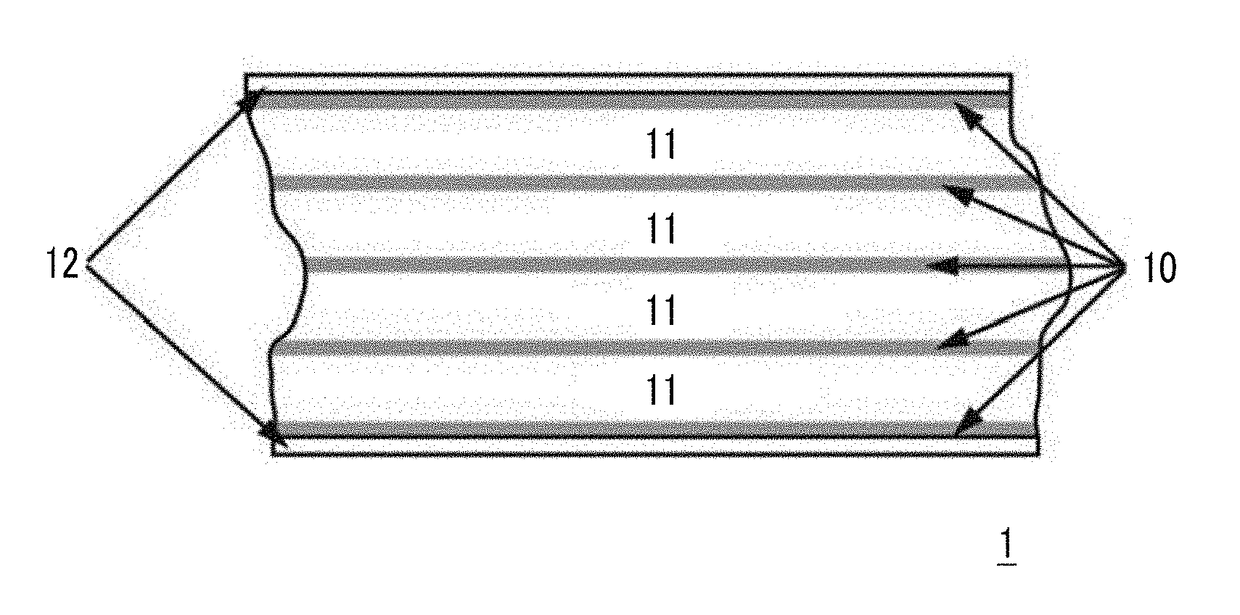

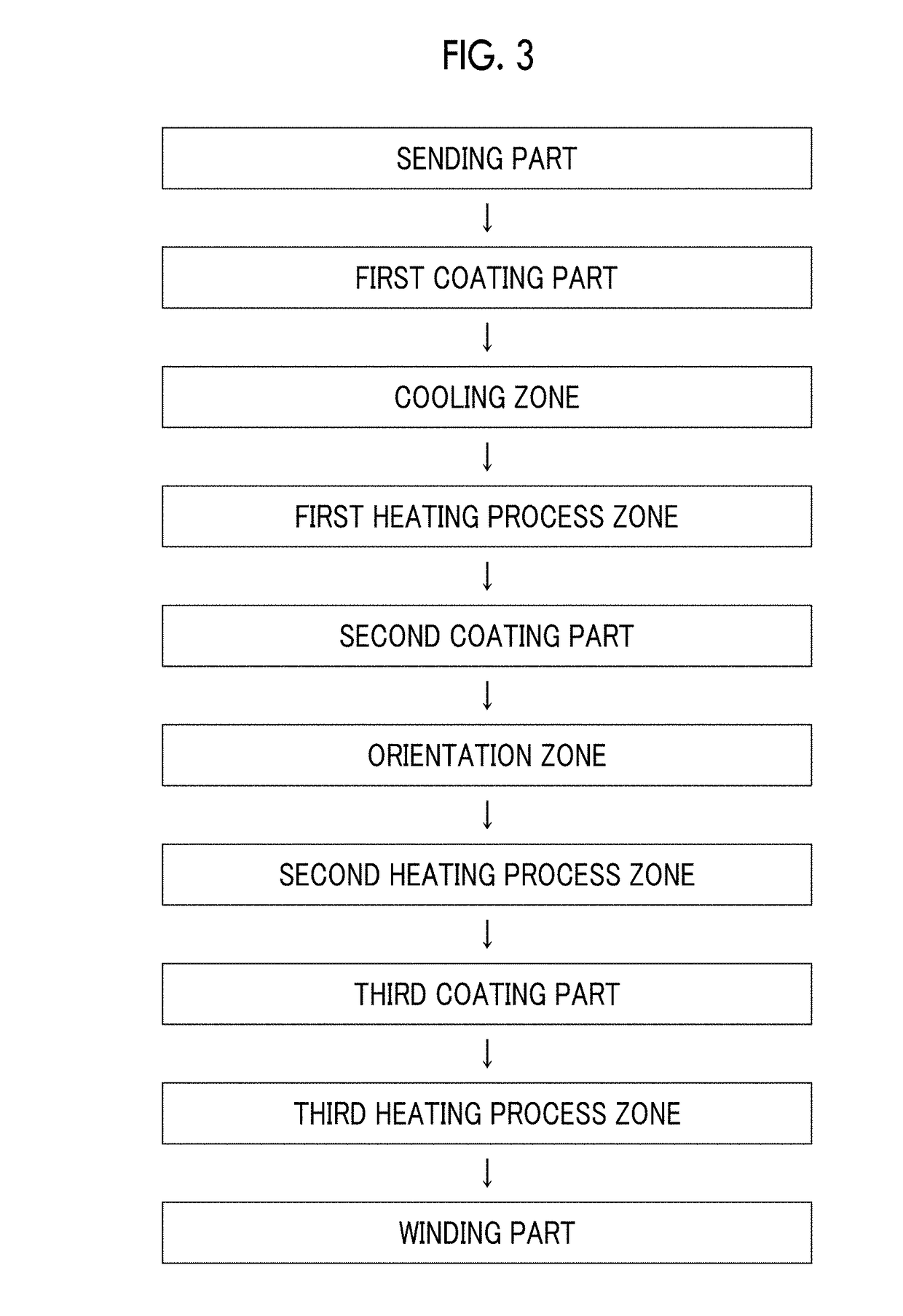

Magnetic tape and method of manufacturing the same, and magnetic recording device

ActiveUS20120243120A1Improve thermal stabilityImprove signal-to-noise ratioMagnetic materials for record carriersFilamentary/web record carriersDemagnetizing fieldMagnetic tape

Owner:FUJIFILM CORP

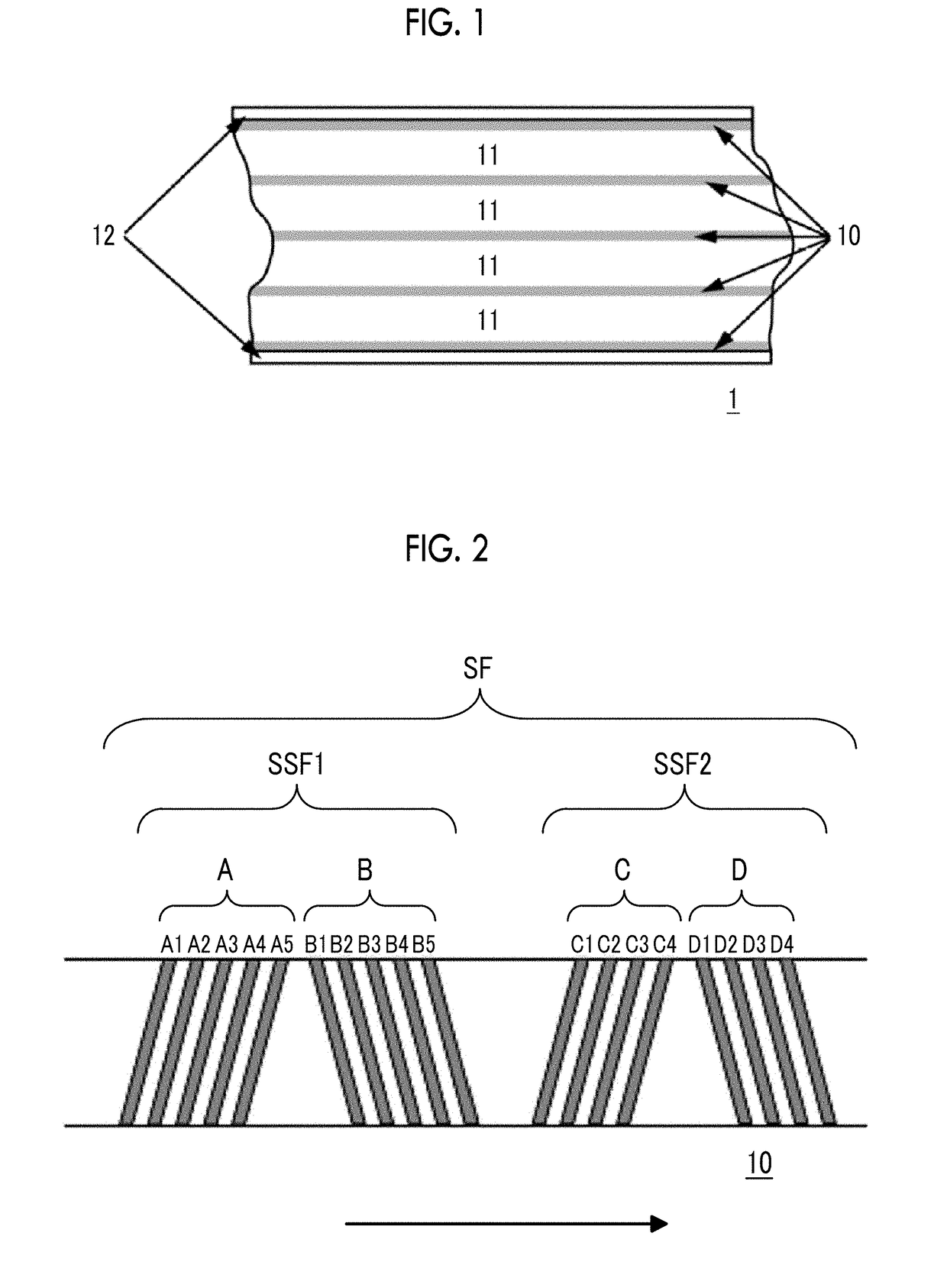

Magnetic tape device, magnetic reproducing method, and head tracking servo method

ActiveUS10134433B2Improve accuracyExact reproductionMaterials with ironAlignment for track following on tapesMagnetic tapeX-ray

Provided is a magnetic tape device in which a magnetic tape transportation speed is equal to or lower than 18 m / sec, Ra measured regarding a surface of a magnetic layer of a magnetic tape is equal to or smaller than 2.0 nm, a C-H derived C concentration calculated from a C-H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %, and ΔSFD (=SFD25° C.−SFD−190° C.) in a longitudinal direction of the magnetic tape is equal to or smaller than 0.50, with the SFD25° C. being SFD measured in a longitudinal direction of the magnetic tape at a temperature of 25° C., and the SFD−190° C. being SFD measured at a temperature of −190° C.

Owner:FUJIFILM CORP

Magnetic recording medium and magnetic recording and reproducing device

ActiveUS20190103134A1Excellent electromagnetic conversion characteristicAvoid it happening againMaterials with ironProtective coatings for layersIn planeX-ray

Provided are a magnetic recording medium, in which a magnetic layer includes ferromagnetic hexagonal ferrite powder, a binding agent, and an oxide abrasive, an intensity ratio Int(110) / Int(114) obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic recording medium is 0.65 to 1.00, a coefficient of friction measured regarding a base portion of a surface of the magnetic layer is equal to or smaller than 0.30, and an average particle diameter of the oxide abrasive obtained from a secondary ion image obtained by irradiating the surface of the magnetic layer with a focused ion beam is 0.04 μm to 0.08 μm, and a magnetic recording and reproducing device including this magnetic recording medium.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180286449A1Improve signal-to-noise ratioIncrease recording capacityRecord information storageManufacture of flux-sensitive headsMagnetic tapeX-ray

The magnetic tape device includes a magnetic tape and a TMR head, in which the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, an intensity ratio of a peak intensity Int(110) of a diffraction peak of a (110) plane with respect to a peak intensity Int(114) of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, and a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00.

Owner:FUJIFILM CORP

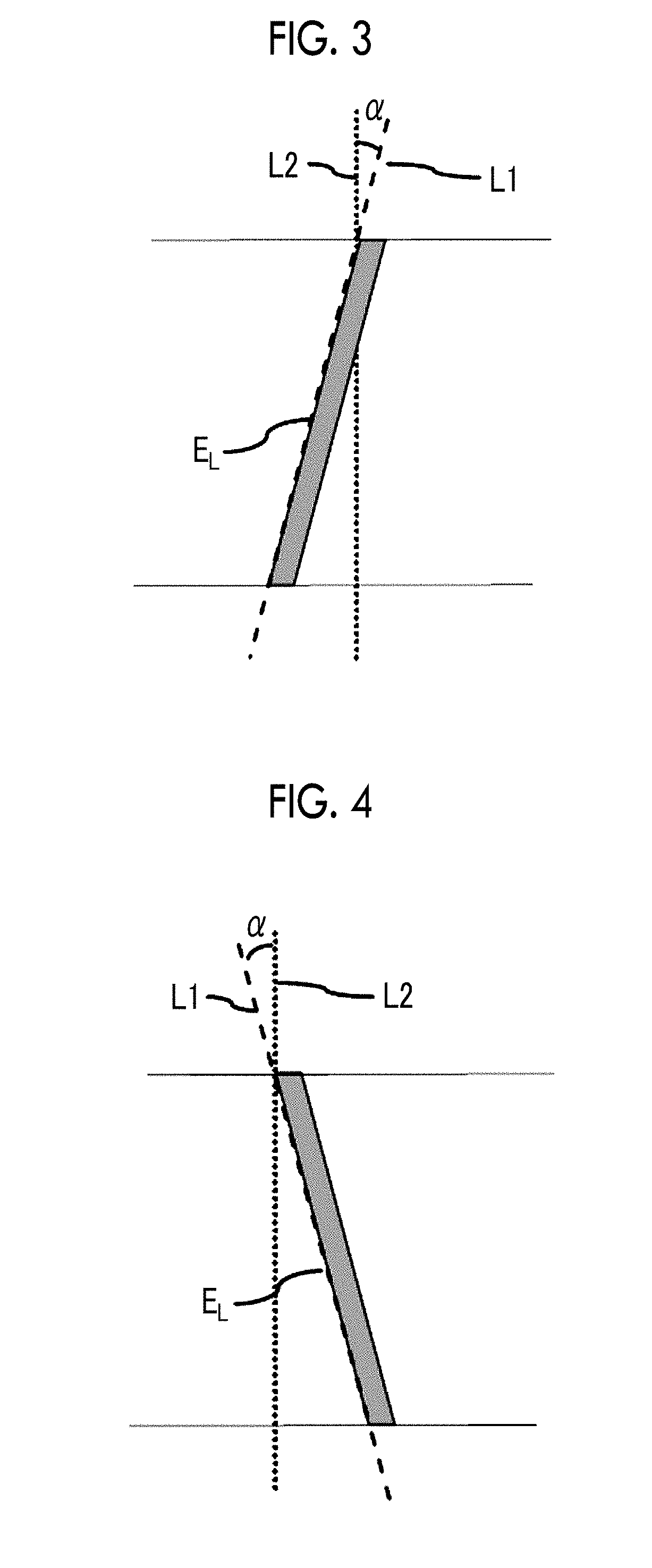

Magnetic tape and magnetic tape device

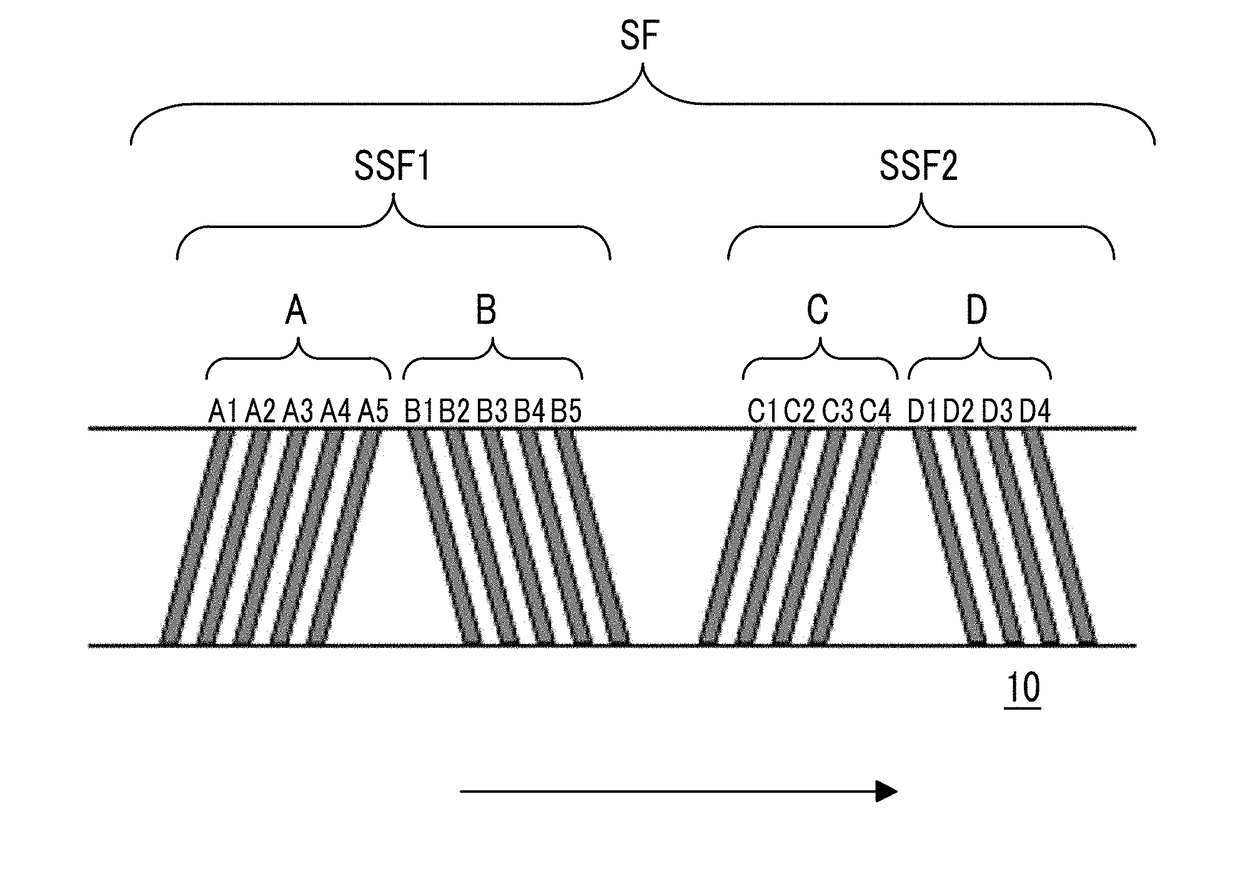

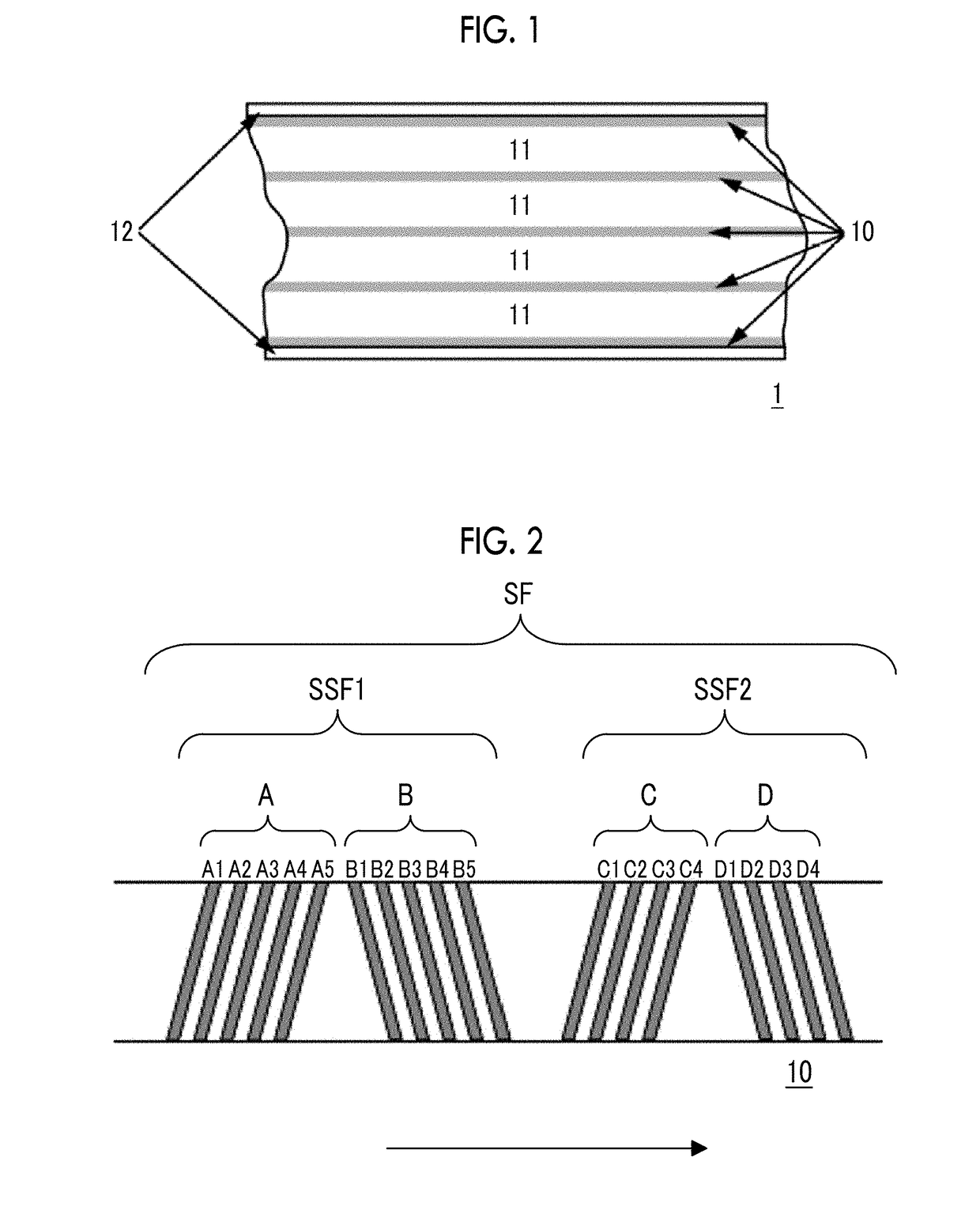

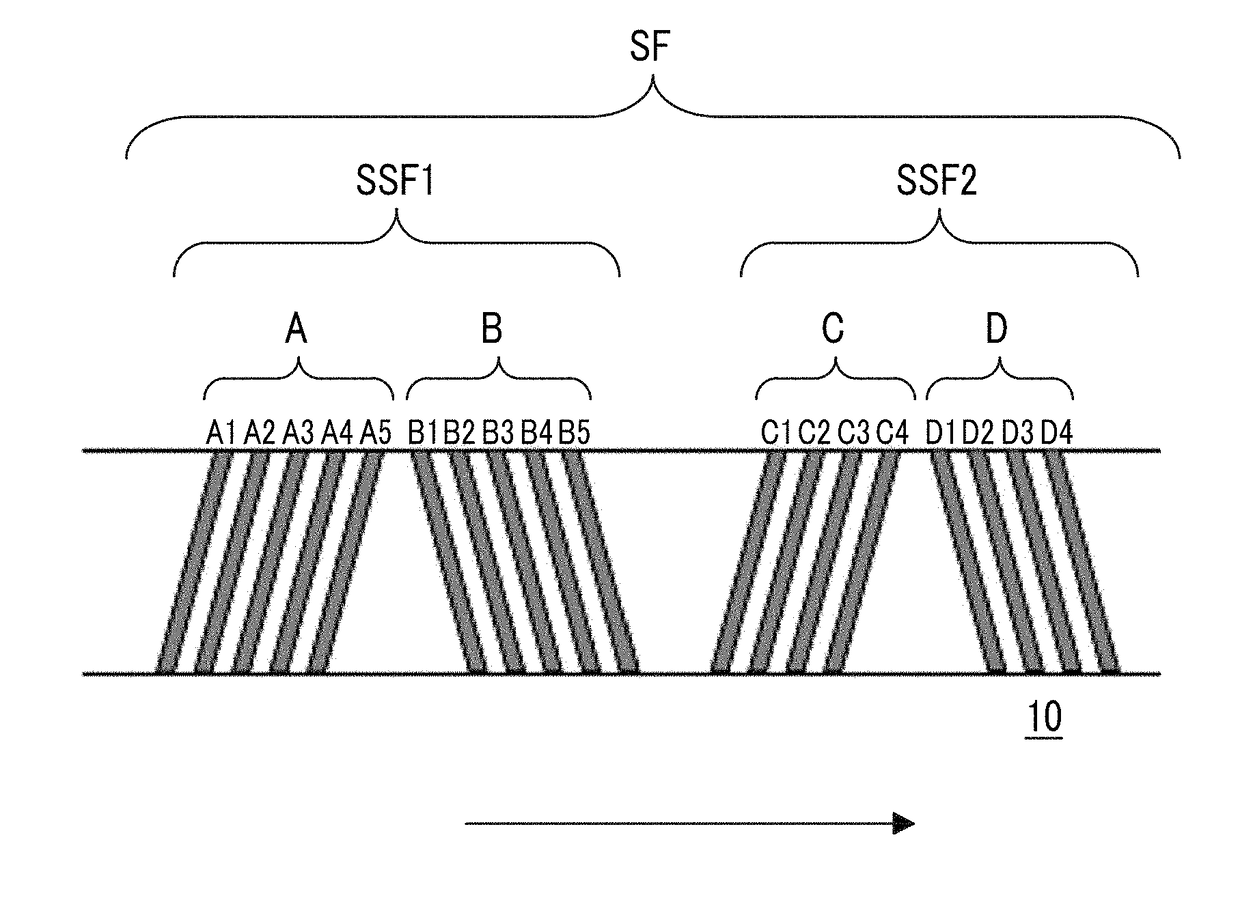

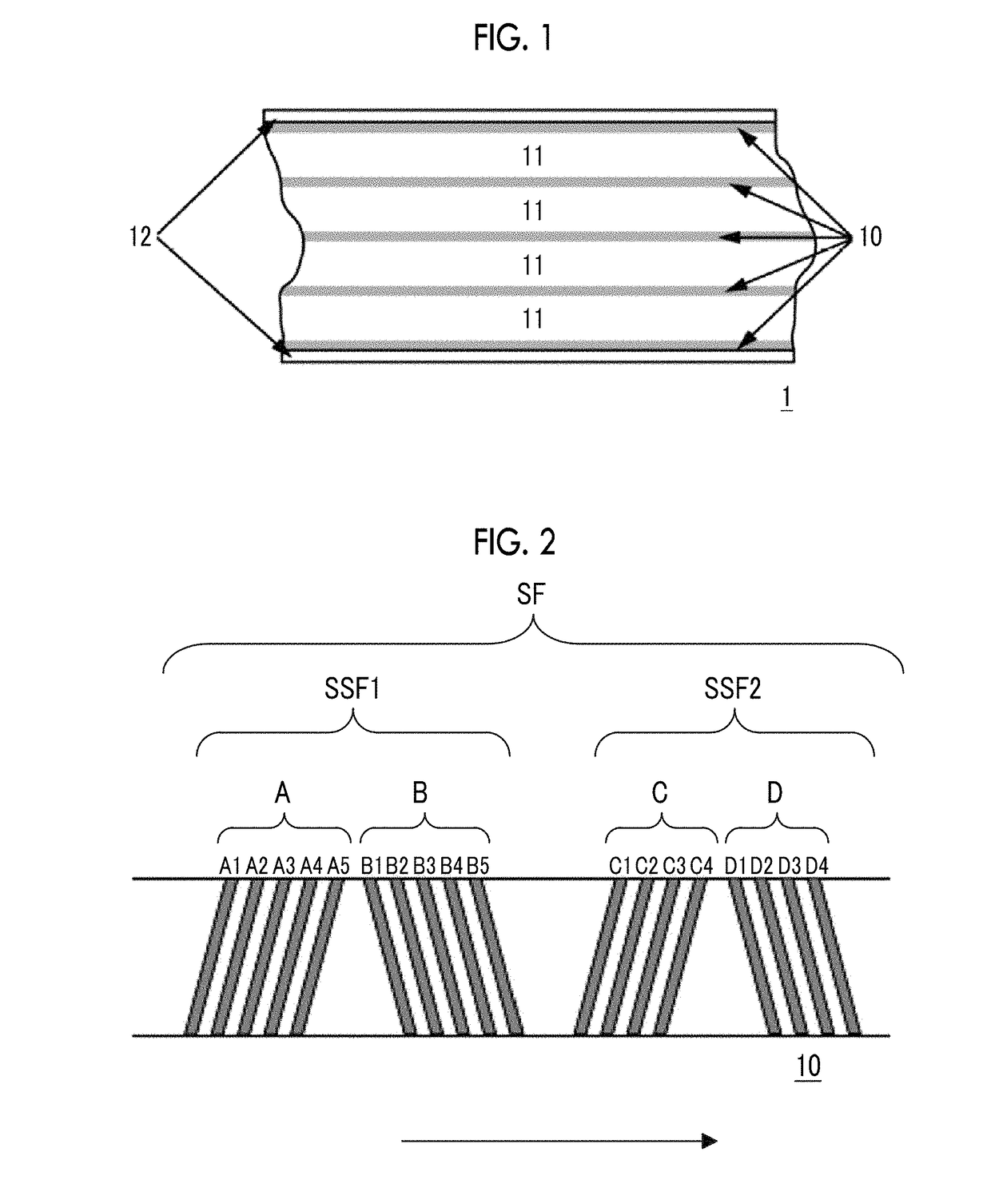

ActiveUS20180374507A1Improve accuracyExact reproductionMaterials with ironAlignment for track following on tapesIn planeMagnetic force microscope

The magnetic tape includes a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, in which the magnetic layer includes a timing-based servo pattern, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder having an activation volume equal to or smaller than 1,600 nm3, an XRD intensity ratio Int(110) / Int(114) obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, and an edge shape of the timing-based servo pattern specified by magnetic force microscope observation is a shape in which a difference (L99.9−L0.1) is equal to or smaller than 180 nm, and a magnetic tape device including the magnetic tape.

Owner:FUJIFILM CORP

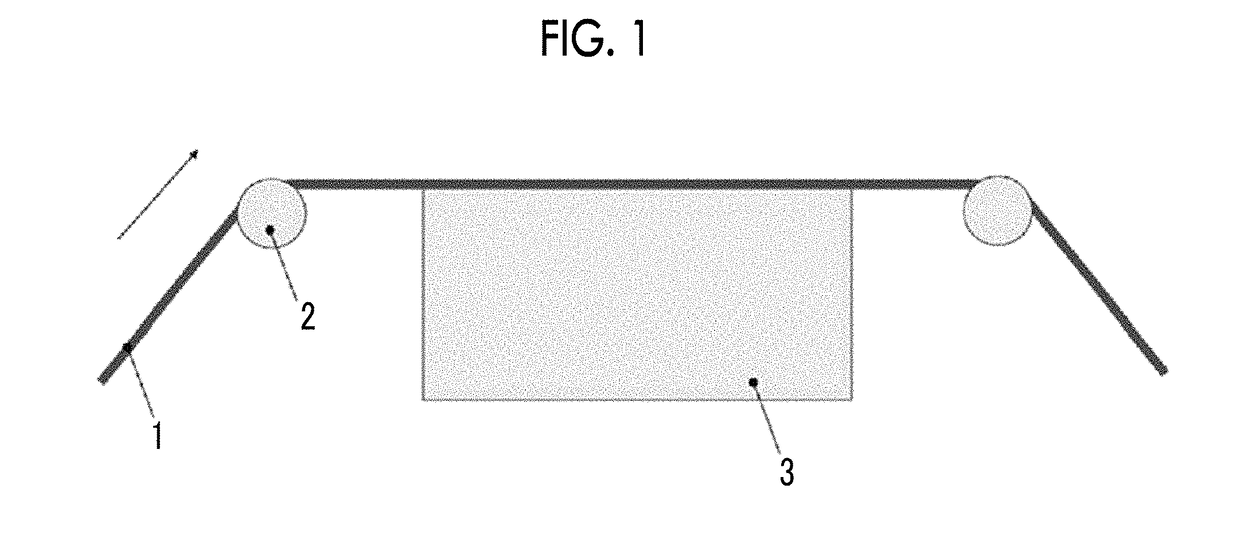

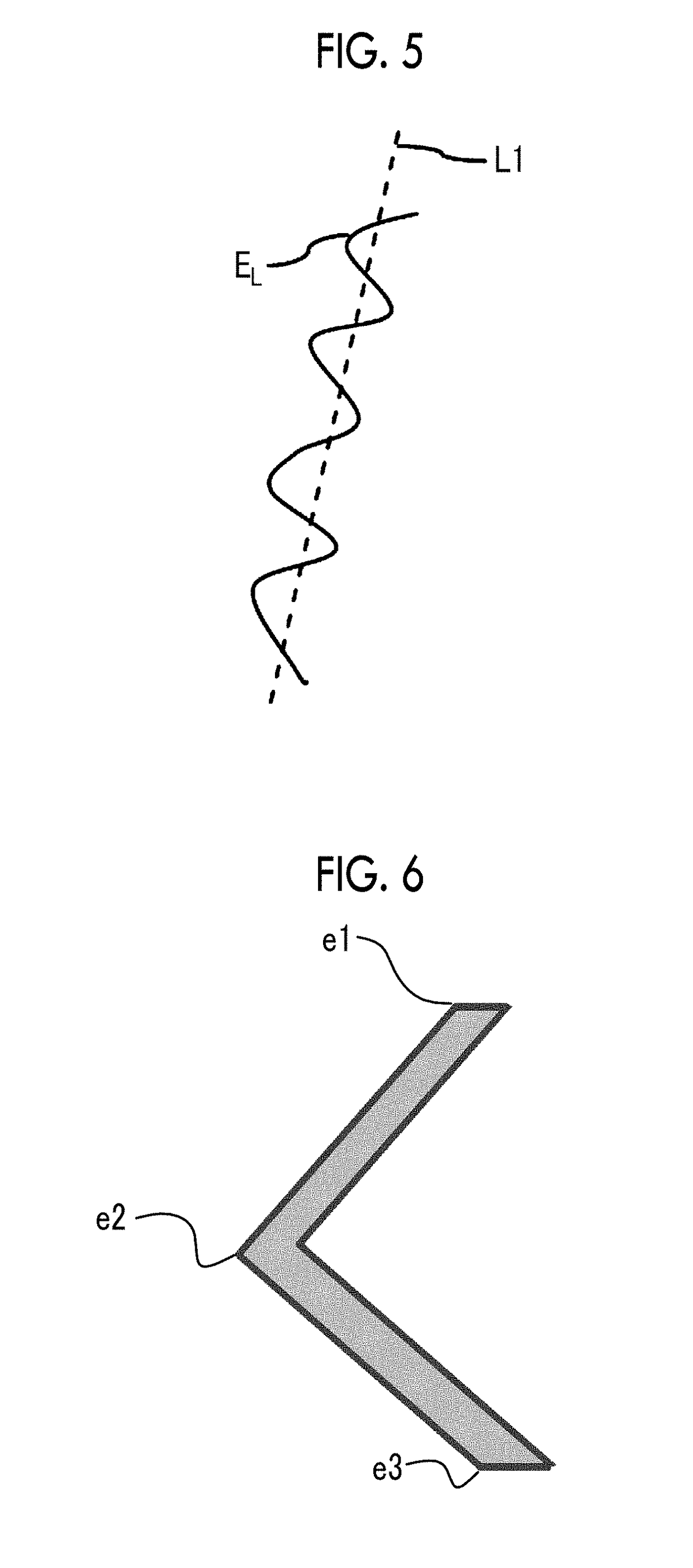

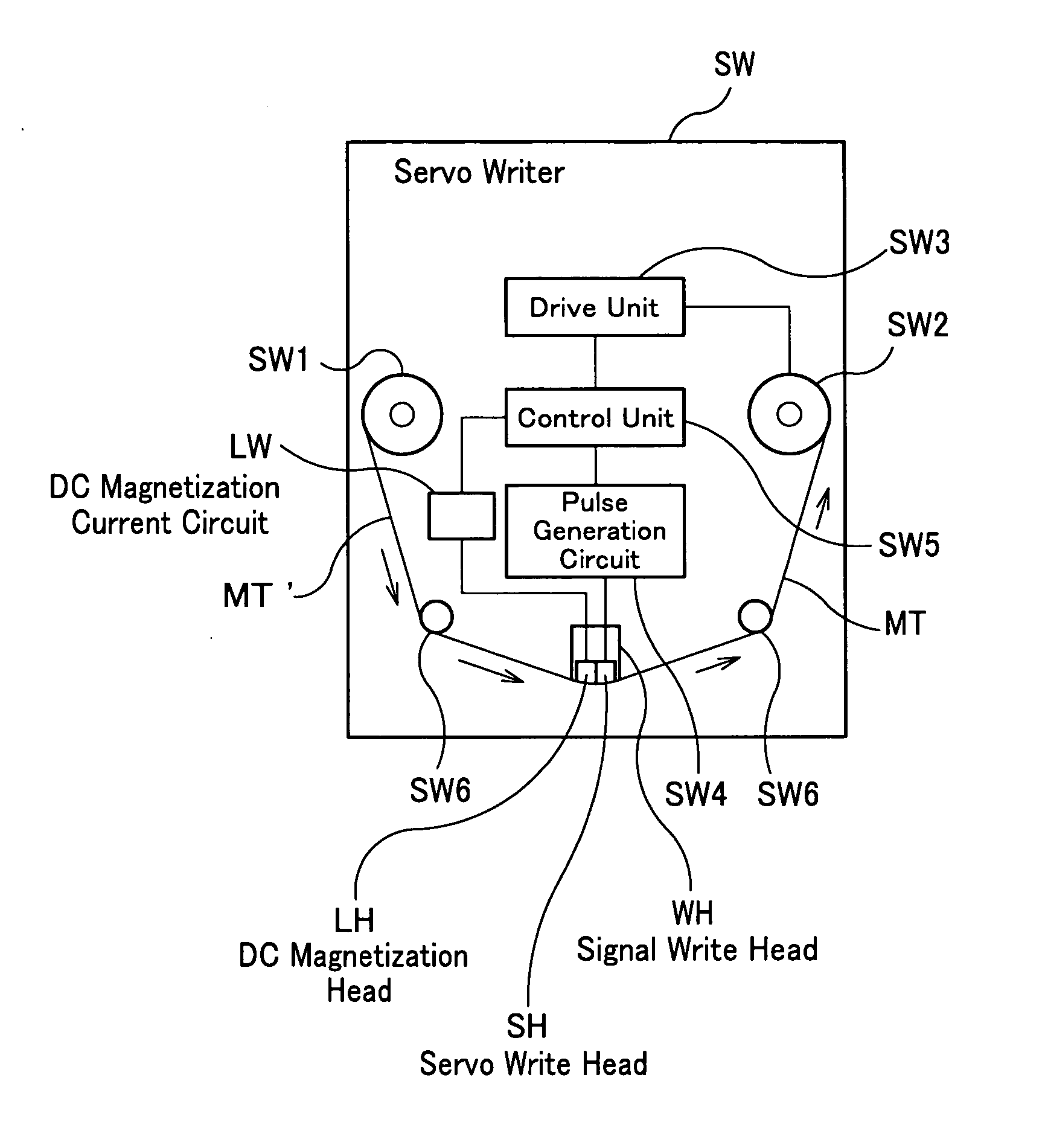

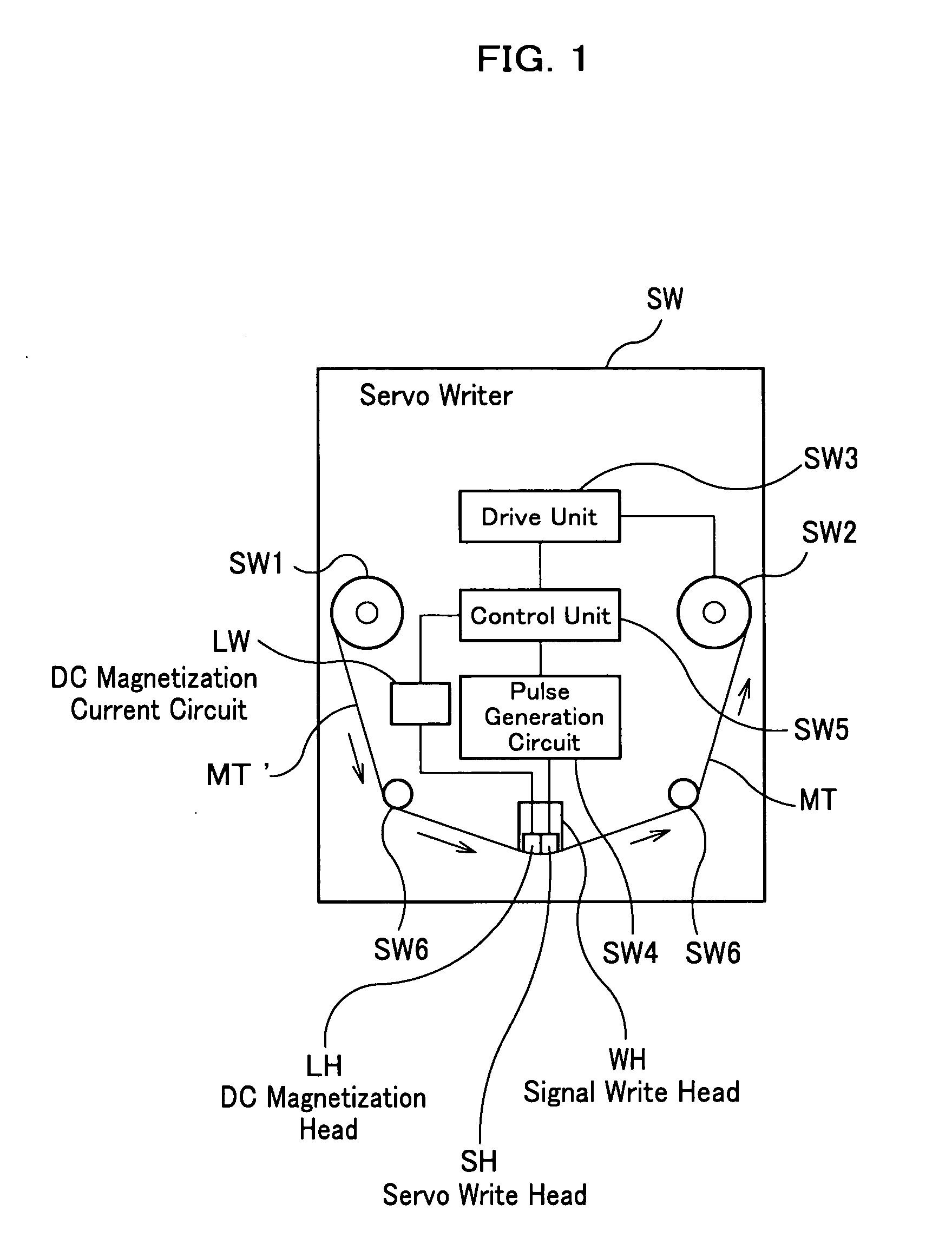

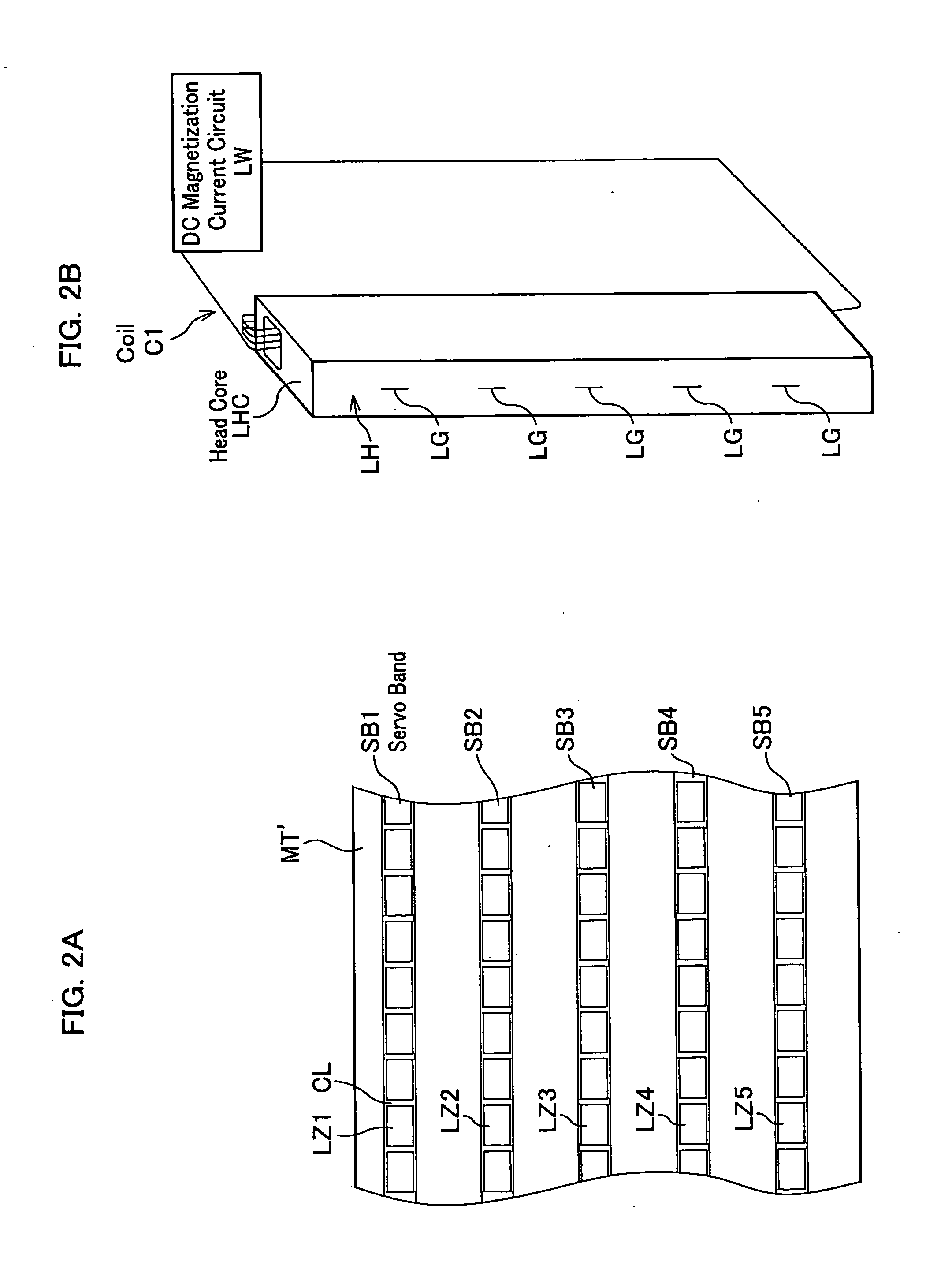

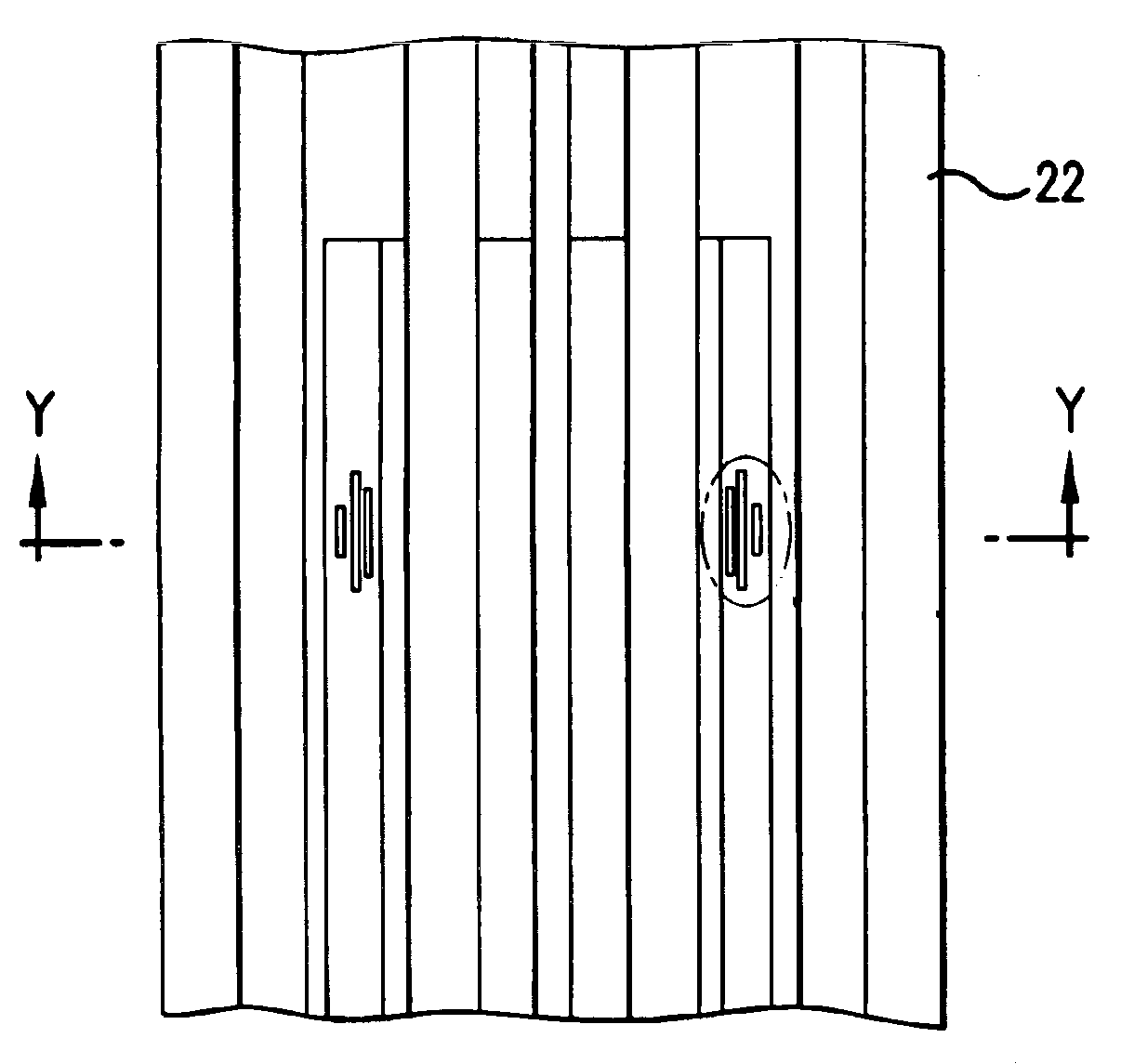

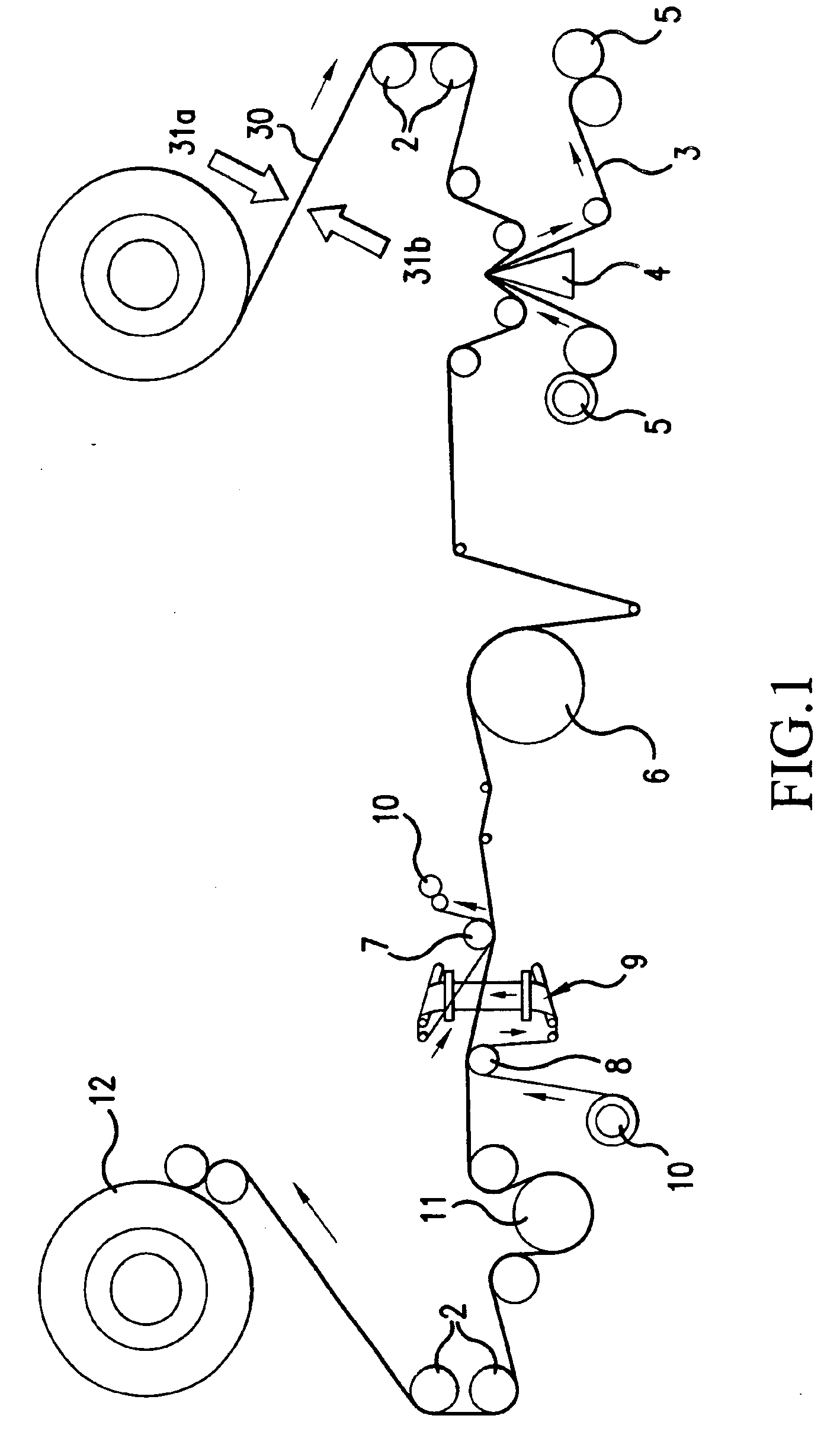

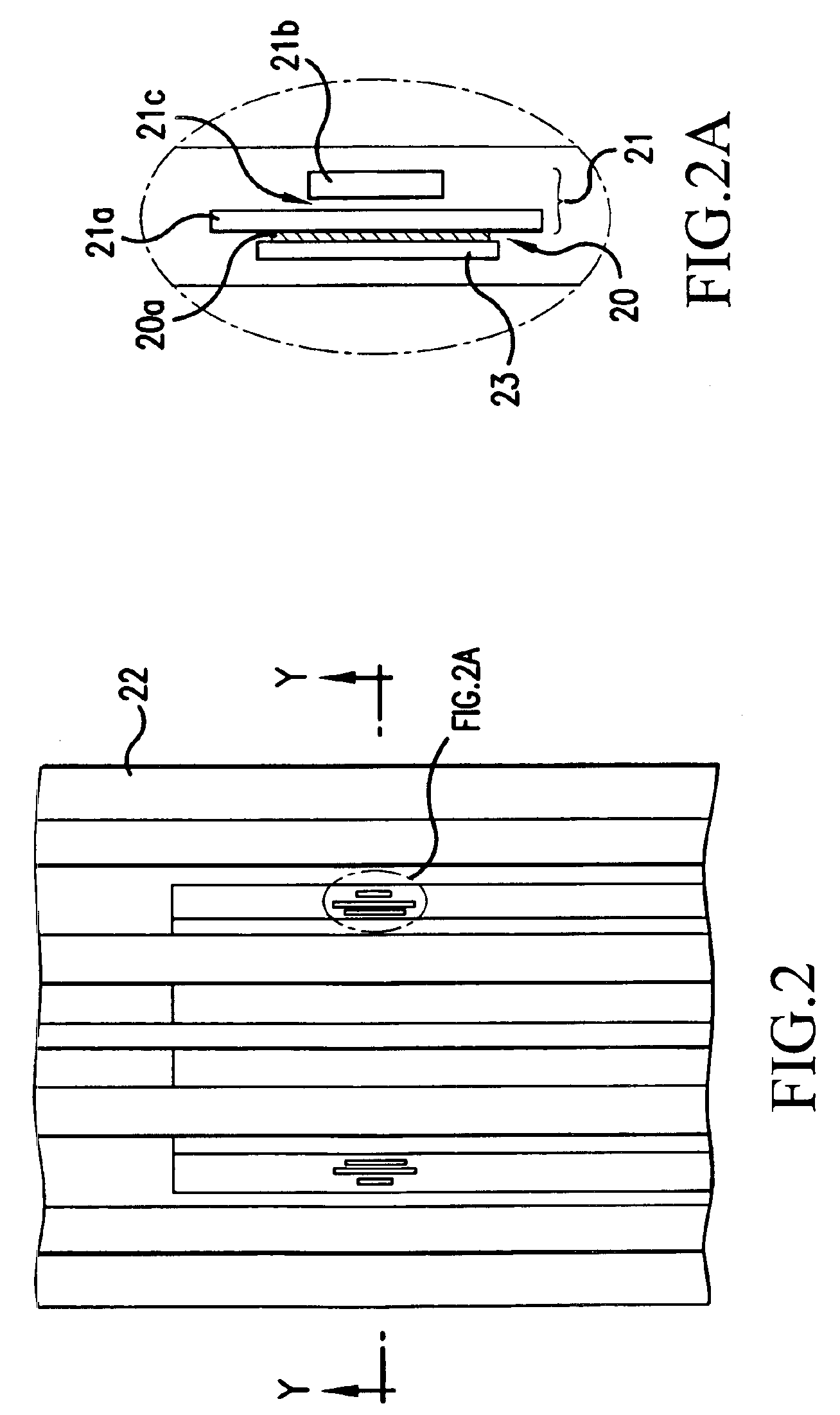

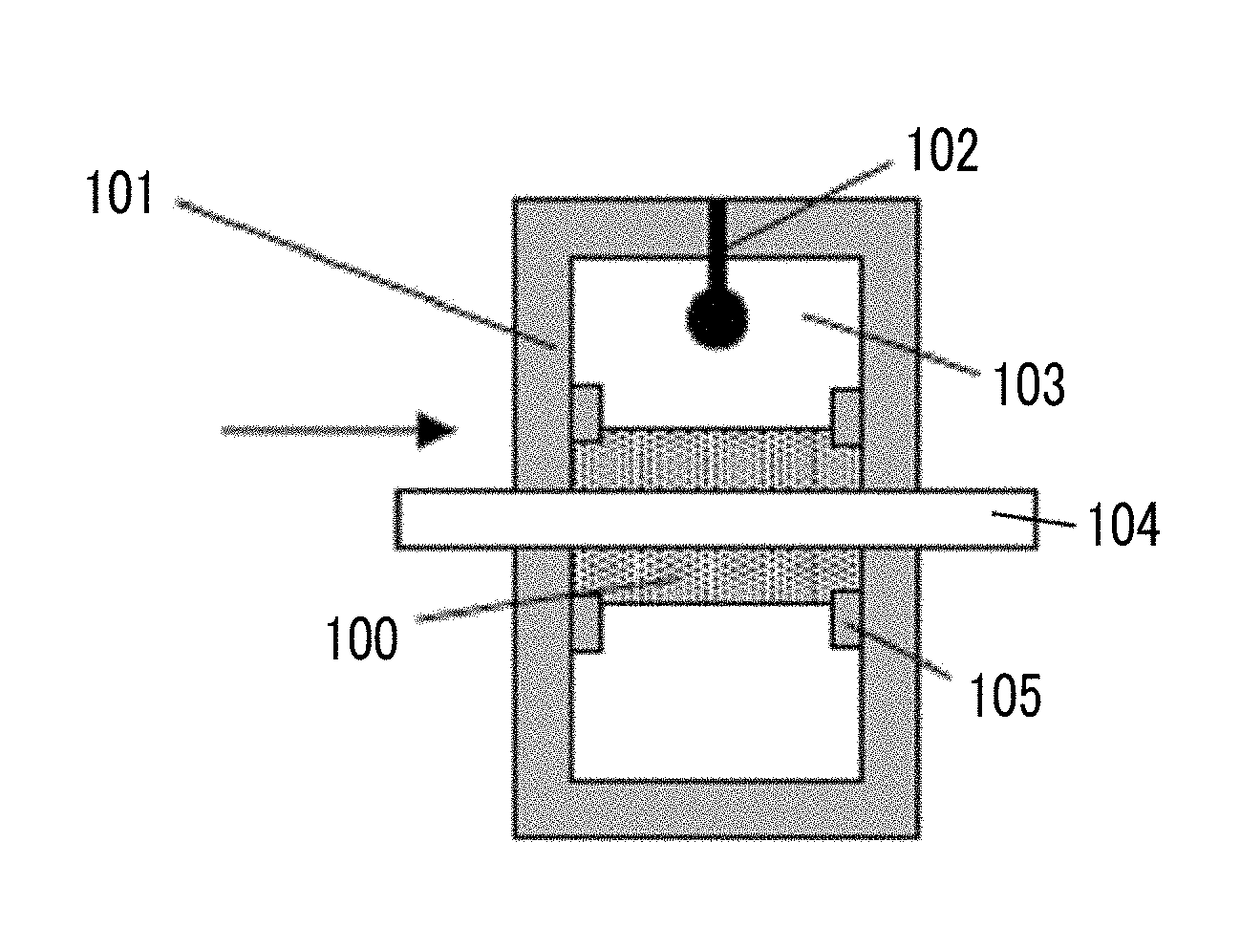

Magnetic tape and maufacturing method thereof, and servo writer and servo write method

ActiveUS20050057838A1Driving/moving recording headsAlignment for track following on tapesMagnetic tapeMagnetization

A magnetic tape of the present invention comprises a plurality of servo bands and servo signals for performing tracking-control of a magnetic head, wherein the servo signals are recorded on the servo bands, wherein a DC magnetization region magnetized in one direction by direct current is arranged along longitudinal directions of the magnetic tape on the servo bands, wherein each of the servo signals is magnetized in a reverse direction for the one direction of a DC magnetization and is recorded within the DC magnetization region, and wherein any of a relative ratio and relative difference of DC magnetization intensity in the DC magnetization region and recording magnetization intensity of each of the servo signals differs for each of the servo bands.

Owner:FUJIFILM HLDG CORP +1

Magnetic tape device and magnetic reproducing method

ActiveUS20180286450A1Improve smoothnessImprove surface smoothnessMaterials with ironRecord information storageIn planeX-ray

The magnetic tape device includes a magnetic tape including a magnetic layer; and a TMR head (reproducing head), in which an intensity ratio of a peak intensity of a diffraction peak of a (110) plane with respect to a peak intensity of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same, and magnetic recording device

ActiveUS8681451B2Improve thermal stabilityImprove signal-to-noise ratioMagnetic materials for record carriersFilamentary/web record carriersDemagnetizing fieldMagnetic tape

An aspect of the present invention relates to a magnetic tape comprising a magnetic layer containing a ferromagnetic powder and a binder on a nonmagnetic support, whereinthe ferromagnetic powder is a hexagonal ferrite powder,squareness in a vertical direction without demagnetizing field correction of the magnetic layer ranges from 0.6 to 1.0, andthe magnetic layer further comprises a compound in which a substituent selected from the group consisting of a carboxyl group and a hydroxyl group is directly substituted into a ring structure comprising a double bond and having a ClogP falling within a range of 2.3 to 5.5.

Owner:FUJIFILM CORP

Magnetic tape device and head tracking servo method

ActiveUS20180240481A1Lower the resistance valueAvoid it happening againAlignment for track following on tapesTape carriersX-rayEngineering

The magnetic tape device includes a TMR head as a servo head; and a magnetic tape which includes a magnetic layer including ferromagnetic hexagonal ferrite powder and a binding agent, and including a servo pattern, an XRD intensity ratio (Int(110) / Int(114)) of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, and a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180061446A1Deterioration of characteristicMagnetic materials for record carriersTape carriersConventional transmission electron microscopeScanning tunneling microscope

Provided is a magnetic tape in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes ferromagnetic hexagonal ferrite powder and an abrasive, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer by plane observation using a scanning electron microscope, with respect to the total area of the region is equal to or greater than 0.02% and less than 0.06%, and a tilt cos 0 of the ferromagnetic hexagonal ferrite powder with respect to a surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

Magnetic recording medium comprising a magnetic layer having specific thickness, surface roughness and friction coefficient

InactiveUS6921592B2Reduce space lossReduce error rateMagnetic materials for record carriersBase layers for recording layersSurface roughnessNon magnetic

A magnetic recording medium comprising a non-magnetic support, at least one primer layer formed on one surface of the non-magnetic support, a magnetic layer formed on the primer layer, and a backcoat layer formed on the other surface of the non-magnetic support, wherein the magnetic layer has a thickness of 0.30 μm or less and a centerline average surface roughness Ra of 3.2 nm or less, and (P1−P0) is 30 nm or less and (P1-P20) is 5 nm or less in which P0 is an averaged height of projections of the magnetic layer, and P1, P2, - - - and P20 are heights of the highest, the second highest, - - - and the 20th highest projections of the magnetic layer, respectively.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170358318A1Improve surface smoothnessImproved head positioning accuracyAlignment for track following on tapesRecord information storageMagnetic tapeX-ray

The magnetic tape includes a non-magnetic layer including non-magnetic powder and a binder on a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binder on the non-magnetic layer, in which the magnetic layer includes a timing-based servo pattern, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, one or more components selected from the group consisting of fatty acid and fatty acid amide are at least included in the magnetic layer, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170355022A1Improve accuracyExact reproductionMaterials with ironAlignment for track following on tapesMagnetic force microscopeMagnetic tape

The magnetic tape includes a magnetic layer having ferromagnetic powder and a binder on a non-magnetic support, in which the magnetic layer includes a timing-based servo pattern, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder having an activation volume equal to or smaller than 1,600 nm3, and an edge shape of the timing-based servo pattern specified by a magnetic force microscope observation is a shape in which a difference (l99.9−l0.1) between a value l99.9 of a cumulative frequency function of 99.9% of a position deviation width from an ideal shape in a longitudinal direction of the magnetic tape and a value l0.1 of the cumulative frequency function of 0.1% thereof is equal to or smaller than 180 nm.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180286443A1Deterioration of characteristicMaterials with ironRecord information storageMagnetic tapeFull width at half maximum

The magnetic tape has the total thickness of a non-magnetic layer and a magnetic layer of 0.60 μm or smaller, the magnetic layer including an abrasive and fatty acid ester, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer with respect to the total area of the region, obtained by plane observation performed by using an SEM of 0.02% or greater and less than 0.06%, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape of greater than 0 nm and 7.0 nm or smaller, and a difference between spacings before and after the vacuum heating of greater than 0 nm and 8.0 nm or smaller.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180286439A1Improve smoothnessImprove surface smoothnessTape carriersRecord information storageMagnetic force microscopeMagnetic tape

The magnetic tape device includes a TMR head and a magnetic tape, in which the magnetic tape includes fatty acid ester in a magnetic layer, Ra measured regarding a surface of the magnetic layer is 2.0 nm or smaller, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and 7.0 nm or smaller, a difference between spacings before and after the vacuum heating is greater than 0 nm and 8.0 nm or smaller, and a ratio of an average area Sdc of a magnetic cluster of the magnetic tape in a DC demagnetization state and an average area Sac of a magnetic cluster thereof in an AC demagnetization state measured with a magnetic force microscope is 0.80 to 1.30.

Owner:FUJIFILM CORP

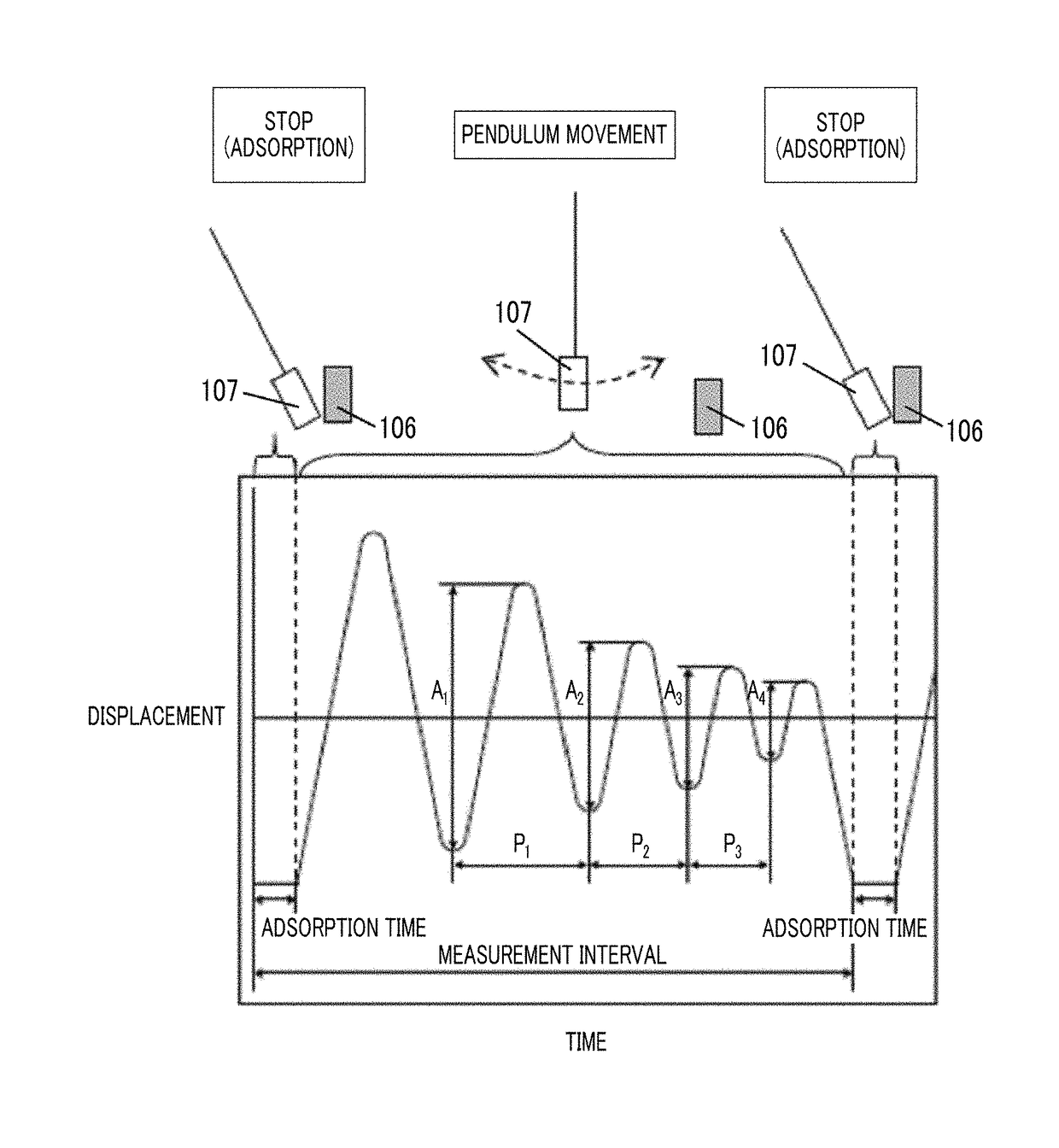

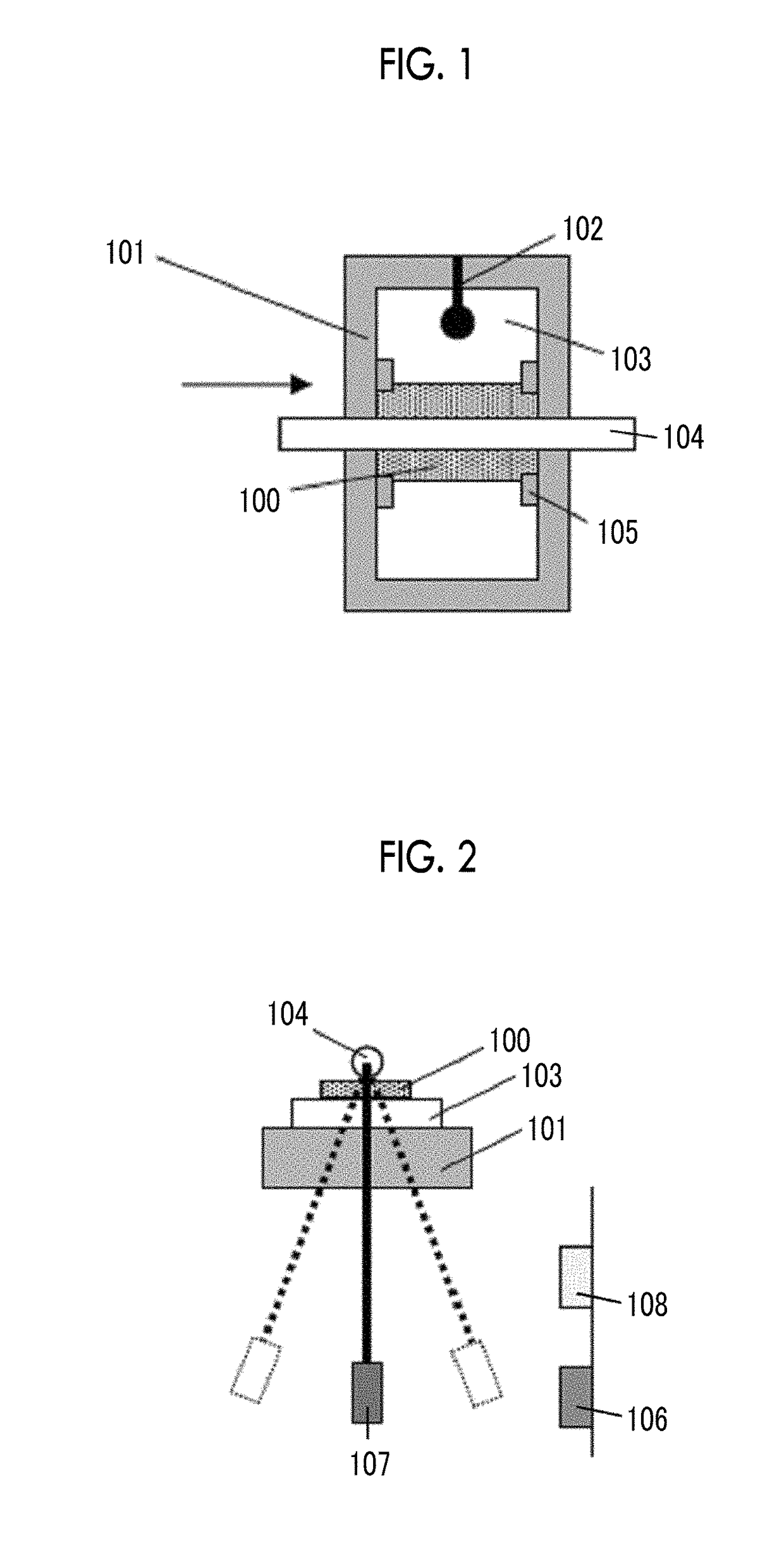

Magnetic tape and magnetic tape device

ActiveUS20170372727A1Restrain output decreaseImprove accuracyAlignment for track following on tapesRecord information storageMagnetic tapeNon magnetic

The magnetic tape includes a non-magnetic support; a non-magnetic layer including non-magnetic powder and a binder on the non-magnetic support; and a magnetic layer including ferromagnetic powder and a binder on the non-magnetic layer, in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes a timing-based servo pattern, and logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

Magnetic tape device and head tracking servo method

ActiveUS20180240489A1Lower the resistance valueAvoid it happening againMagnetic materials for record carriersRecord information storageMagnetic tapeSurface roughness

The magnetic tape device including: a magnetic tape including a servo pattern on a magnetic layer; and a TMR head as a servo head, in which a center line average surface roughness Ra measured regarding a surface of the magnetic layer of the magnetic tape is equal to or smaller than 2.0 nm, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050, and ΔSFD in a longitudinal direction of the magnetic tape calculated by Expression 1: ΔSFD=SFD25° C.−SFD−190° C. is equal to or smaller than 0.50, wherein the SFD25° C. is SFD measured in a longitudinal direction of the magnetic tape at a temperature of 25° C., and the SFD−190° C. is SFD measured in a longitudinal direction of the magnetic tape at a temperature of −190° C.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372726A1Improve surface smoothnessReduce frequencyAlignment for track following on tapesRecord information storageMagnetic tapeX-ray

The magnetic tape includes a magnetic layer having ferromagnetic powder and a binder on a non-magnetic support, in which a total thickness of the magnetic tape is equal to or smaller than 5.30 μm, the magnetic layer includes a timing-based servo pattern, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, one or more components selected from the group consisting of fatty acid and fatty acid amide are included in the magnetic layer, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180240479A1Lower the resistance valueImprove smoothnessManufacture head surfaceTape carriersMagnetic tapeSurface roughness

The magnetic tape device includes a magnetic tape; and a TMR head as a reproducing head, in which a center line average surface roughness Ra measured regarding a surface of the magnetic layer of the magnetic tape is equal to or smaller than 2.0 nm, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050, and ΔSFD in a longitudinal direction of the magnetic tape calculated by Expression 1: ΔSFD=SFD25° C.−SFD−190° C. is equal to or smaller than 0.50, wherein, in Expression 1, the SFD25° C. is a switching field distribution SFD measured in a longitudinal direction of the magnetic tape at a temperature of 25° C., and the SFD−190° C. is a switching field distribution SFD measured in a longitudinal direction of the magnetic tape at a temperature of −190° C.

Owner:FUJIFILM CORP

Magnetic tape device and head tracking servo method

ActiveUS20190096437A1Improve accuracyExact reproductionMaterials with ironAlignment for track following on tapesMagnetic tapeFull width at half maximum

The magnetic tape device includes a TMR head (servo head); and a magnetic tape, in which a magnetic layer of the magnetic tape includes fatty acid ester, Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, a difference between spacings before and after the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm, and ΔSFD (=SFD25° C.−SFD−#° C.) in a longitudinal direction of the magnetic tape is equal to or smaller than 0.50.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180240493A1Improve surface smoothnessPrevent decrease in reproduction outputMaterials with ironRecord information storageMagnetic tapeSurface roughness

The magnetic tape includes a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, in which a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050, and ΔSFD in a longitudinal direction of the magnetic tape calculated by Expression 1: ΔSFD=SFD25° C.−SFD−190° C. is equal to or greater than 0.35. In Expression 1, the SFD25° C. is a switching field distribution SFD measured in a longitudinal direction of the magnetic tape at a temperature of 25° C., and the SFD−190° C. is a switching field distribution SFD measured in a longitudinal direction of the magnetic tape at a temperature of −190° C.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducting method

ActiveUS20180240476A1Lower the resistance valueImprove smoothnessMagnetic materials for record carriersBase layers for recording layersMagnetic force microscopeMagnetic tape

The magnetic tape device includes a magnetic tape; and a reproducing head, in which the reproducing head is a TMR head, a center line average surface roughness Ra measured regarding a surface of the magnetic layer of the magnetic tape is equal to or smaller than 2.0 nm, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050, and a ratio (Sdc / Sac) of an average area Sdc of a magnetic cluster of the magnetic tape in a DC demagnetization state and an average area Sac of a magnetic cluster of the magnetic tape in an AC demagnetization state measured with a magnetic force microscope is 0.80 to 1.30.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com