Patents

Literature

563 results about "Porous glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous glass is glass that includes pores, usually in the nanometre- or micrometre-range, commonly prepared by one of the following processes: through metastable phase separation in borosilicate glasses (such as in their system SiO₂-B₂O₃-Na₂O), followed by liquid extraction of one of the formed phases; through the sol-gel process; or simply by sintering glass powder.

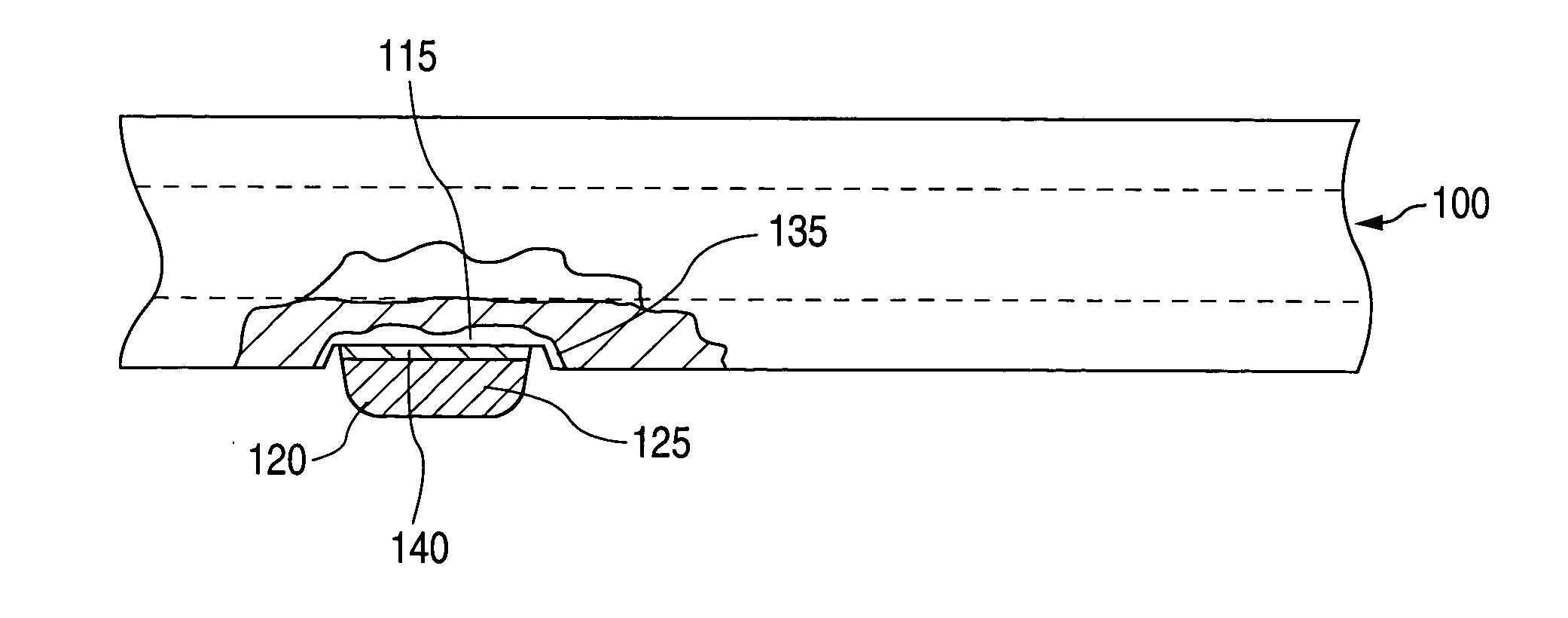

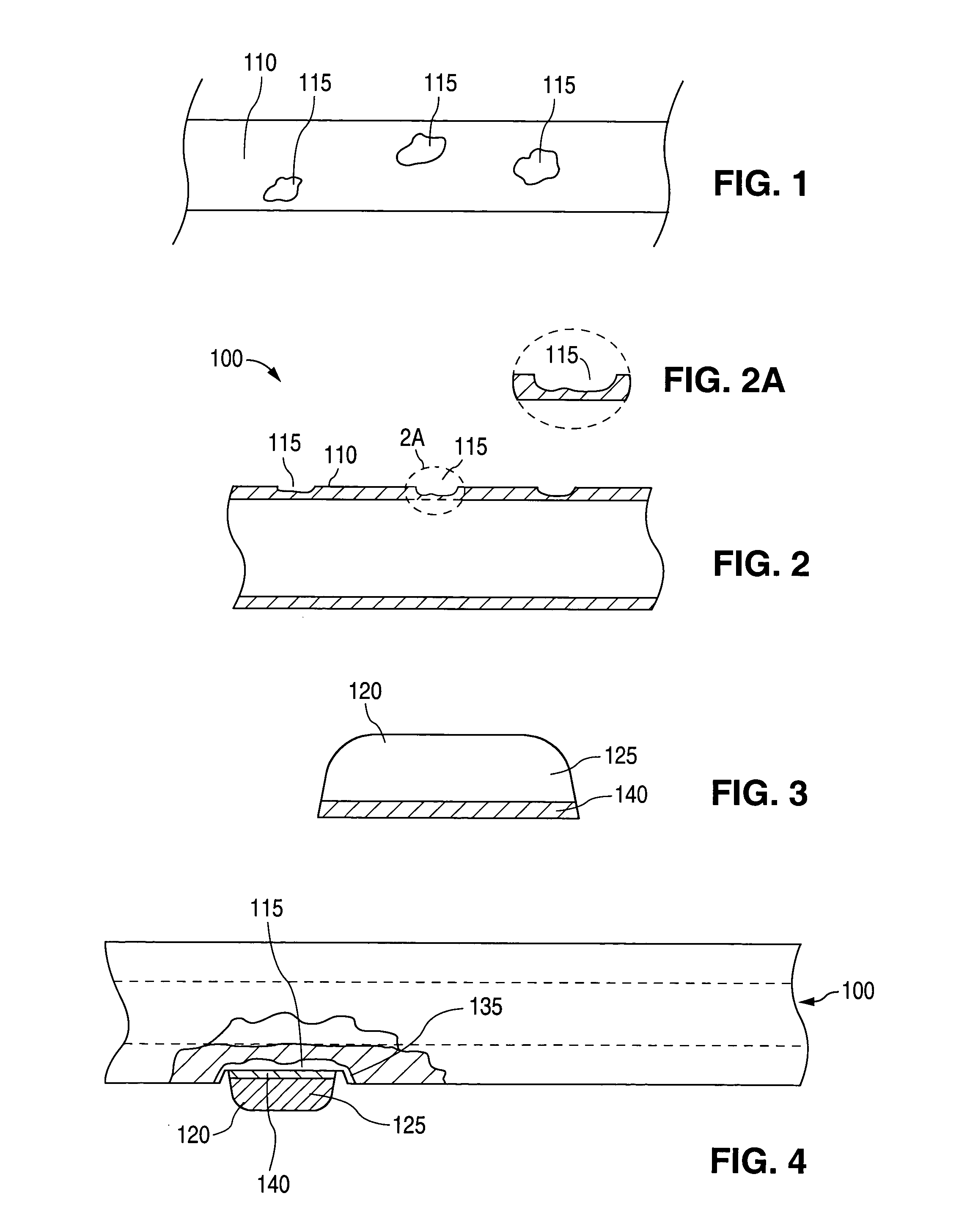

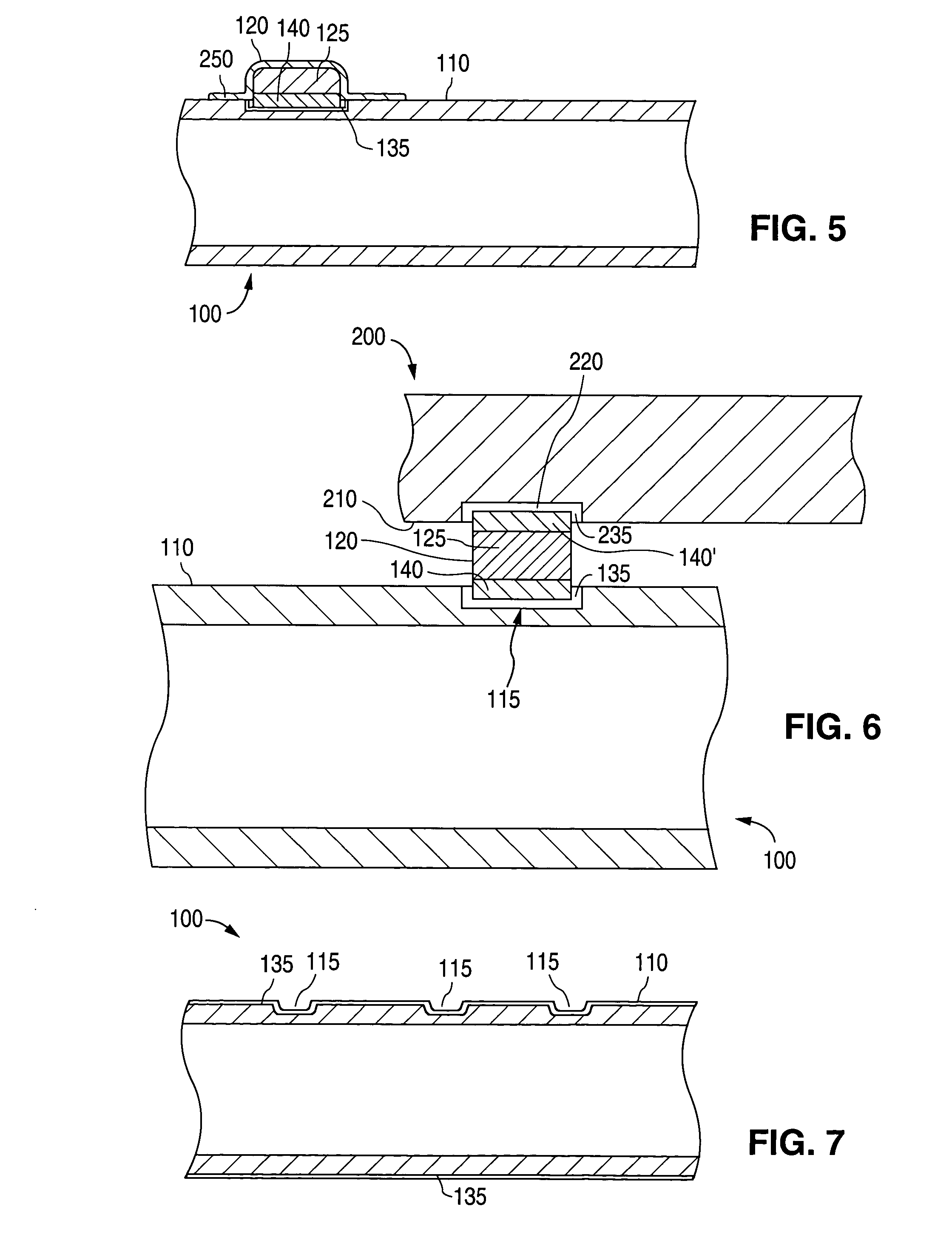

Porous glass fused onto stent for drug retention

Owner:ABBOTT CARDIOVASCULAR

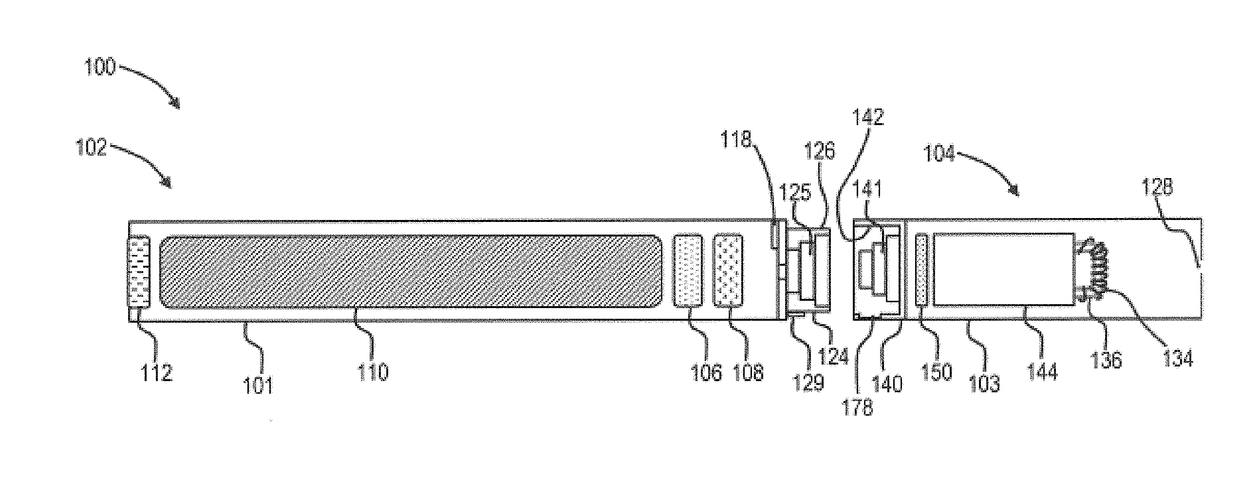

Aerosol delivery device with improved fluid transport

ActiveUS20170188626A1Suitable for useTobacco treatmentTobacco devicesFluid transportAerosol delivery

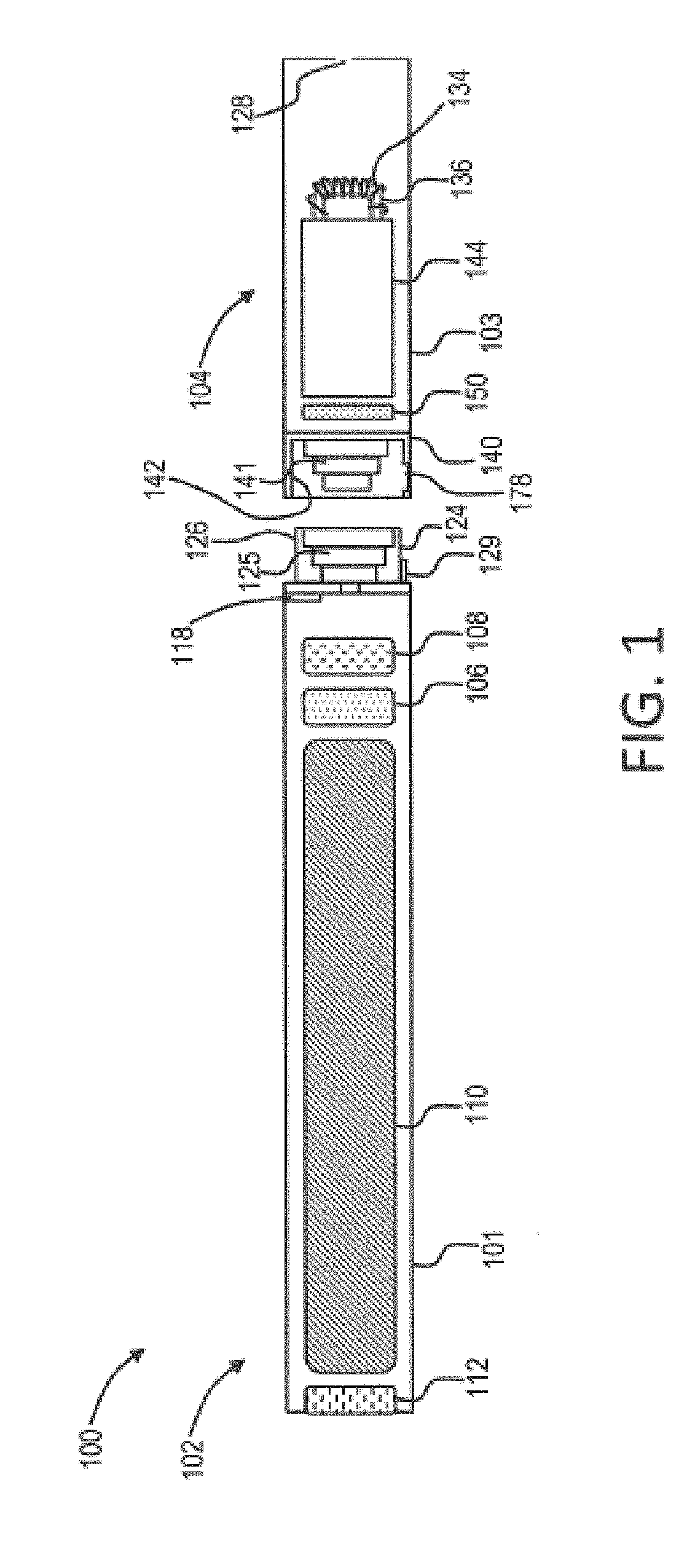

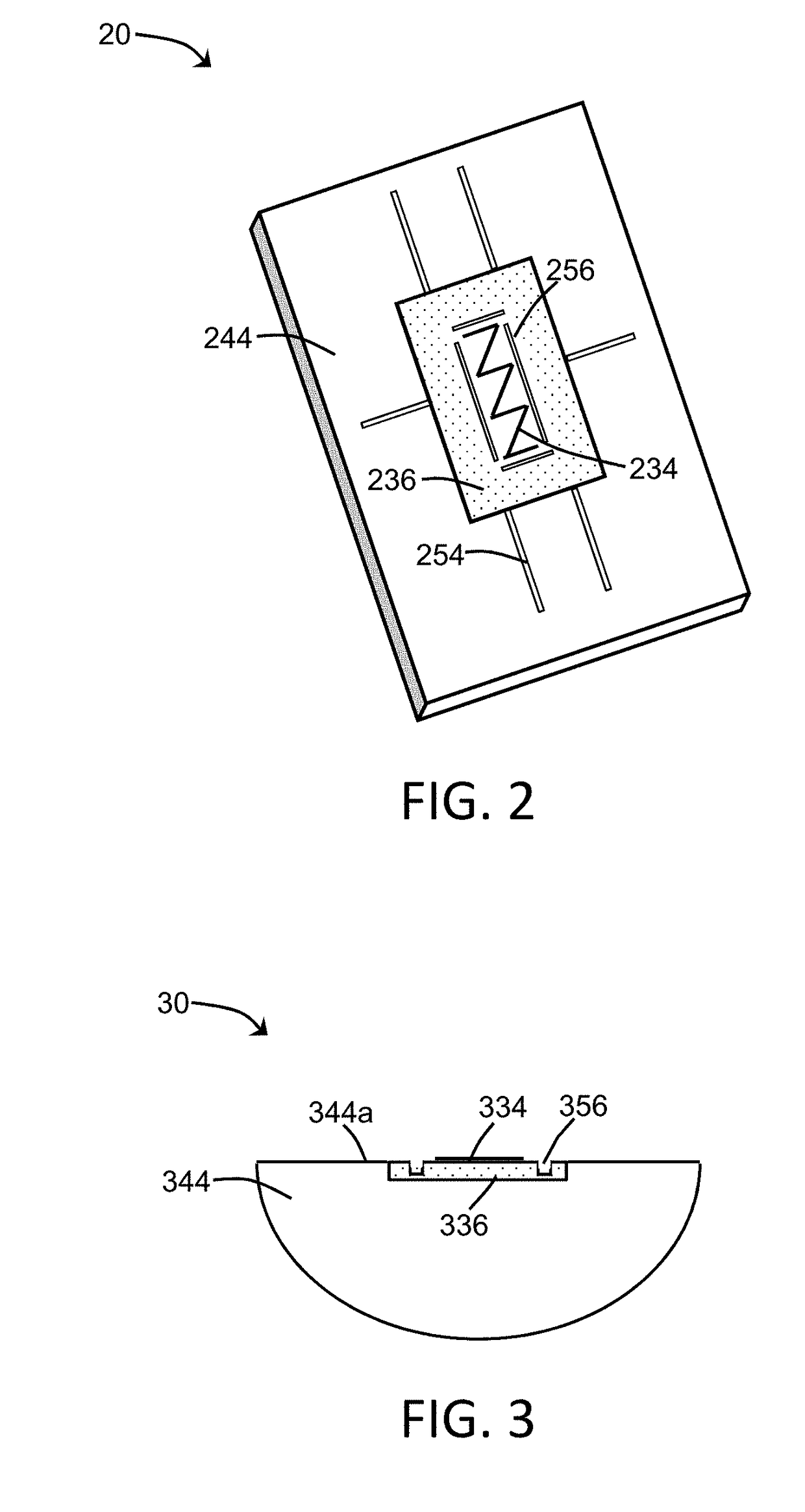

The present disclosure relates to aerosol delivery devices, methods of forming such devices, and elements of such devices. In some embodiments, the present disclosure provides devices configured for vaporization of an aerosol precursor composition that is stored in and / or transported to a heater by a porous monolith, which can be, for example, a porous glass or a porous ceramic. A heater can be in a heating arrangement with an external portion of the porous monolith or can be substantially internal to the porous monolith.

Owner:RAI STRATEGIC HLDG INC

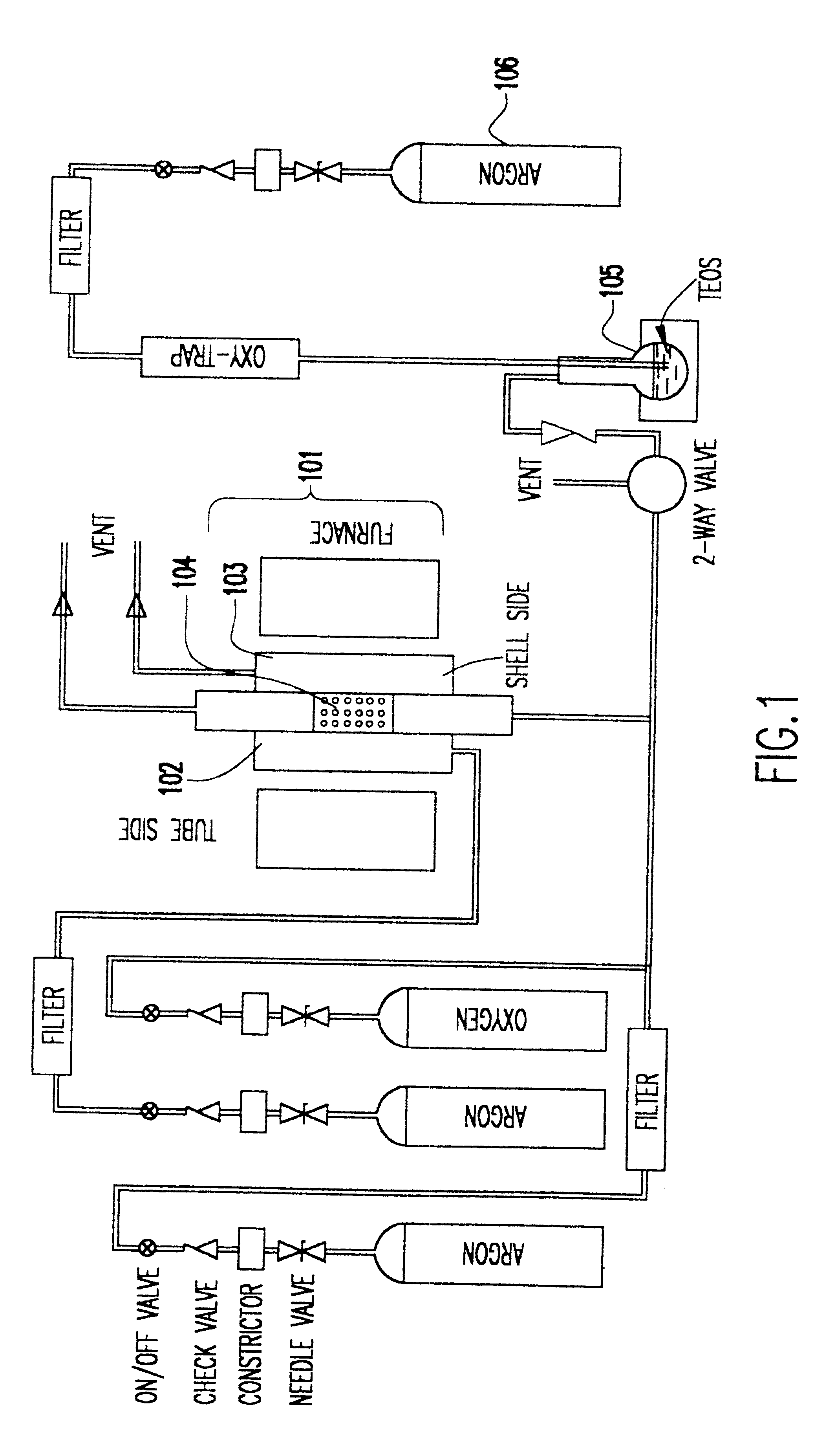

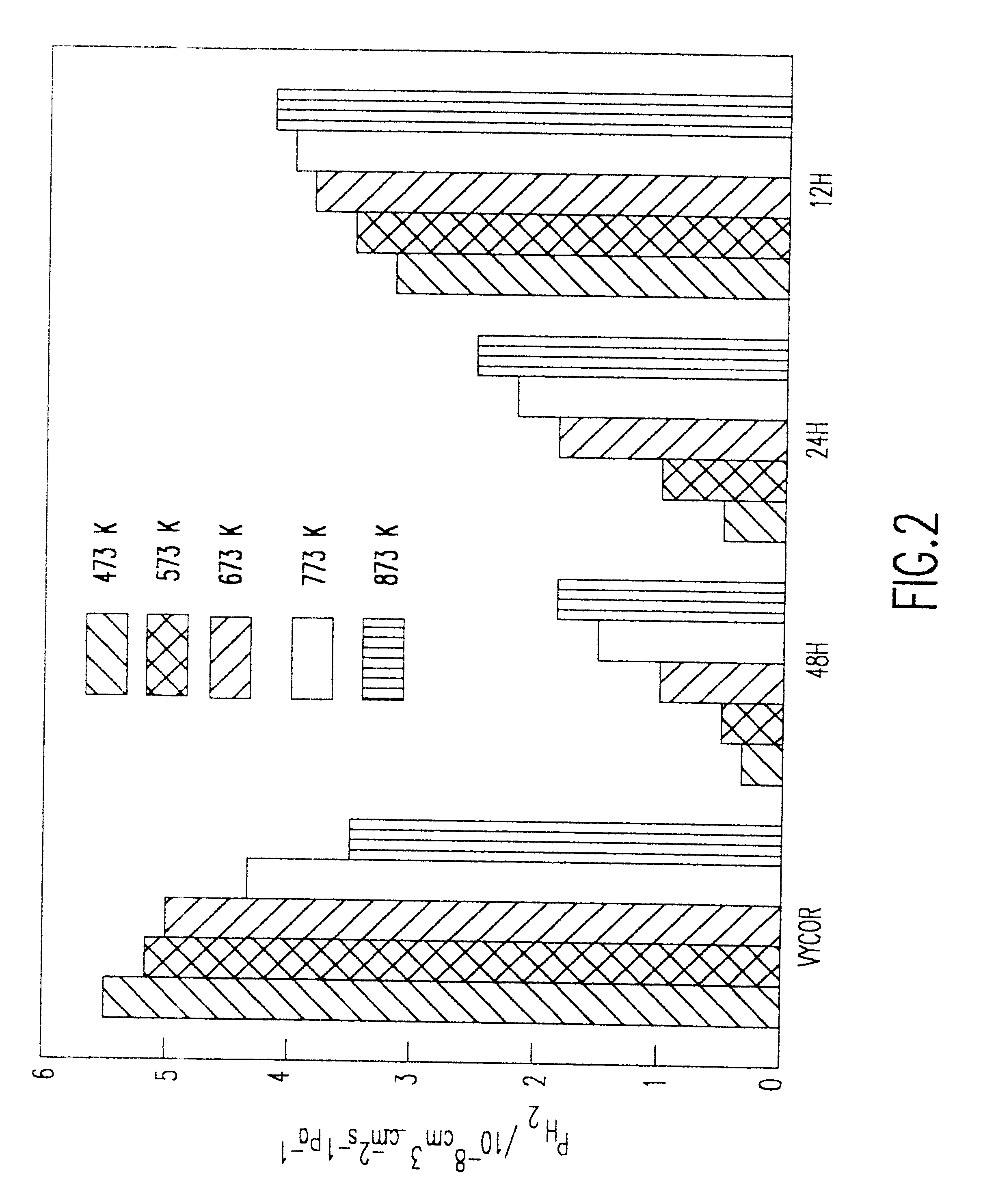

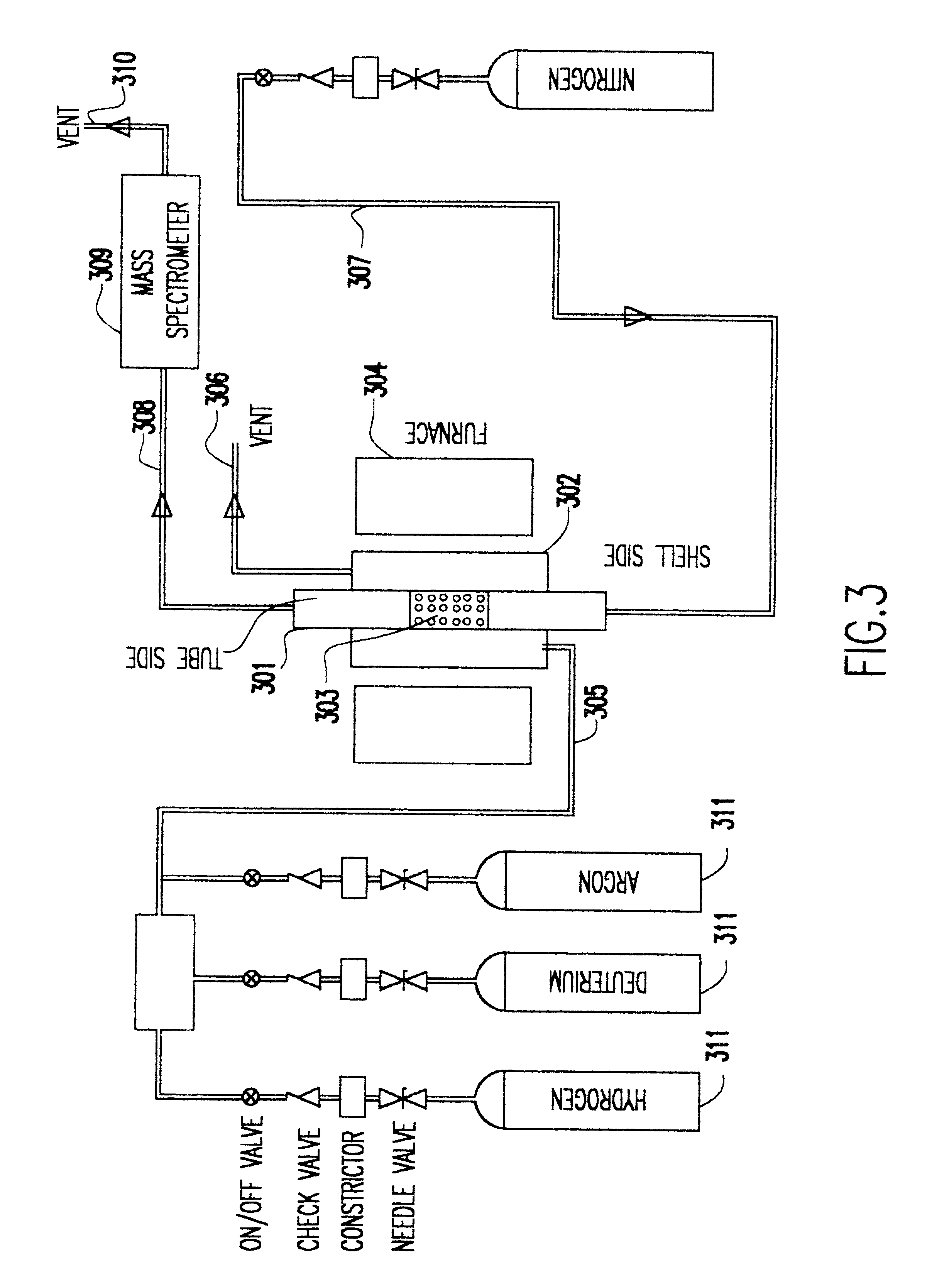

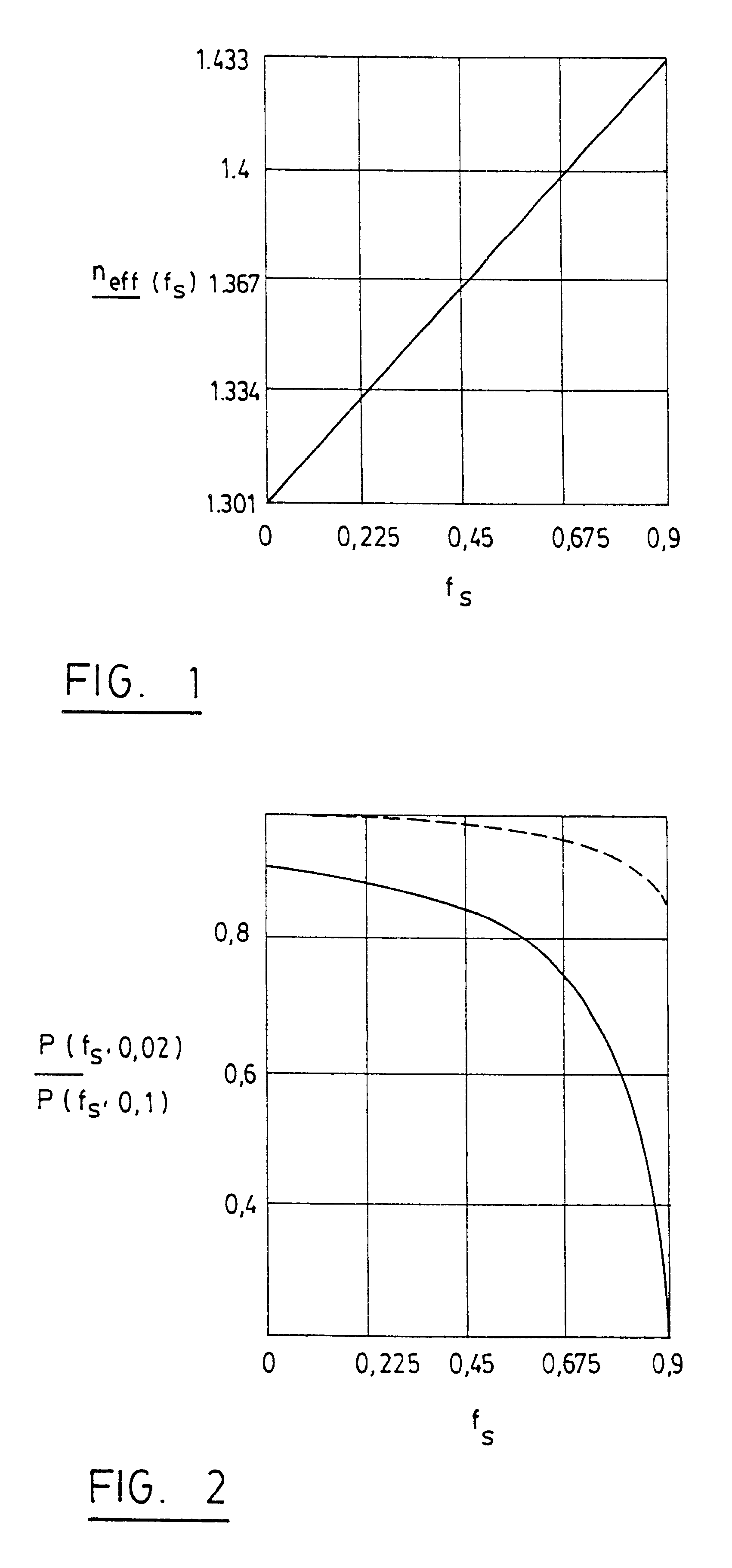

Hydrogen-selective silica based membrane

A new type of silica-modified membrane has been developed by the high-temperature, atmospheric-pressure CVD of Vycor glass. The new membrane, Nanosil, showed unprecedented selectivity to hydrogen (100%), without loss of permeability compared to the porous Vycor precursor. The membrane also showed high stability under hydrothermal conditions over prolonged time. The suitability of a Rh / Al2O3 catalyst for the methane reforming with carbon dioxide was also demonstrated. The limitations imposed by thermodynamics on methane conversion have been circumvented by the use of membranes to preferentially remove hydrogen during reaction. The shortcoming of the Knudsen mode of diffusion was overcome by the development of the modified porous glass membrane.

Owner:VIRGINIA TECH INTPROP INC

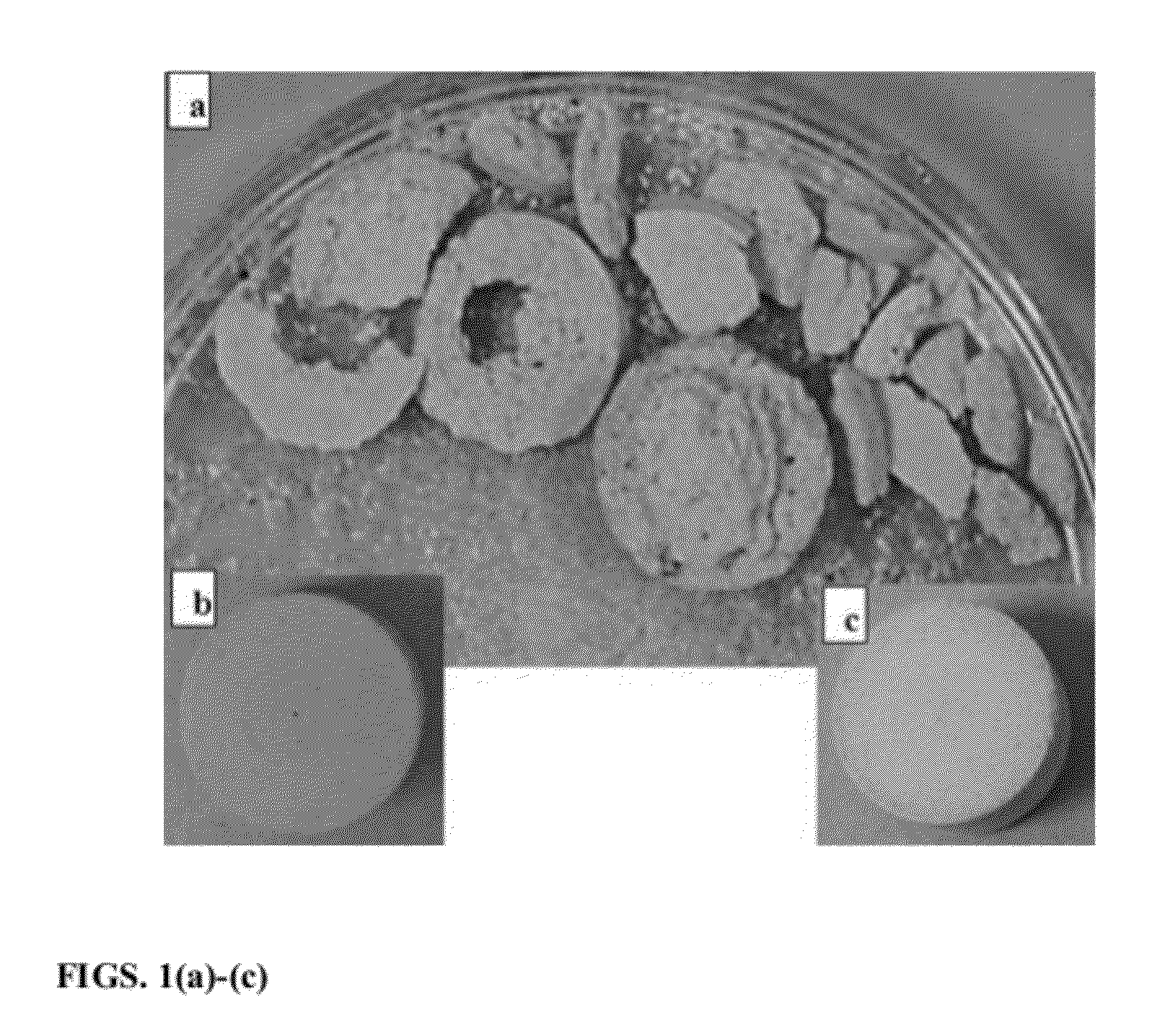

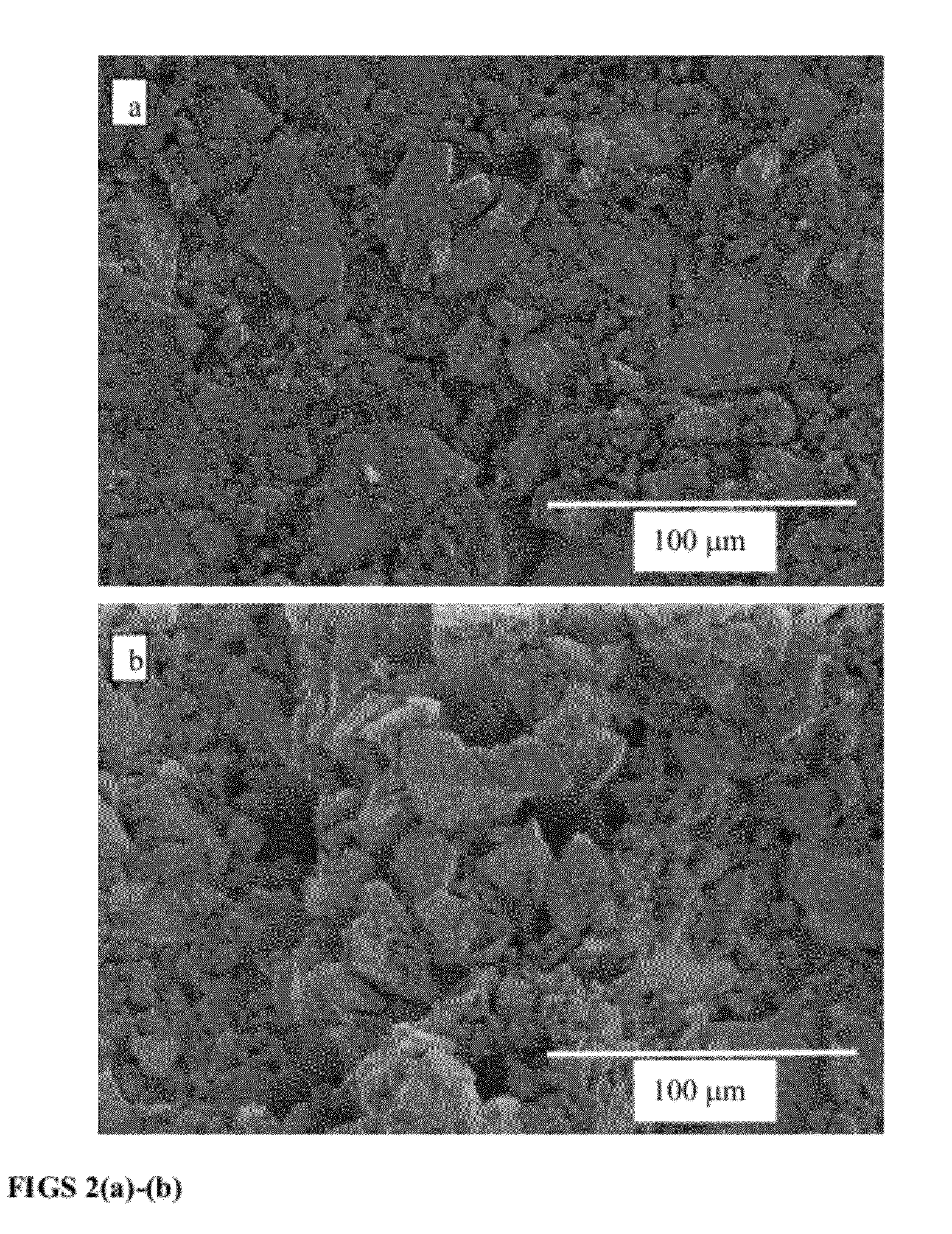

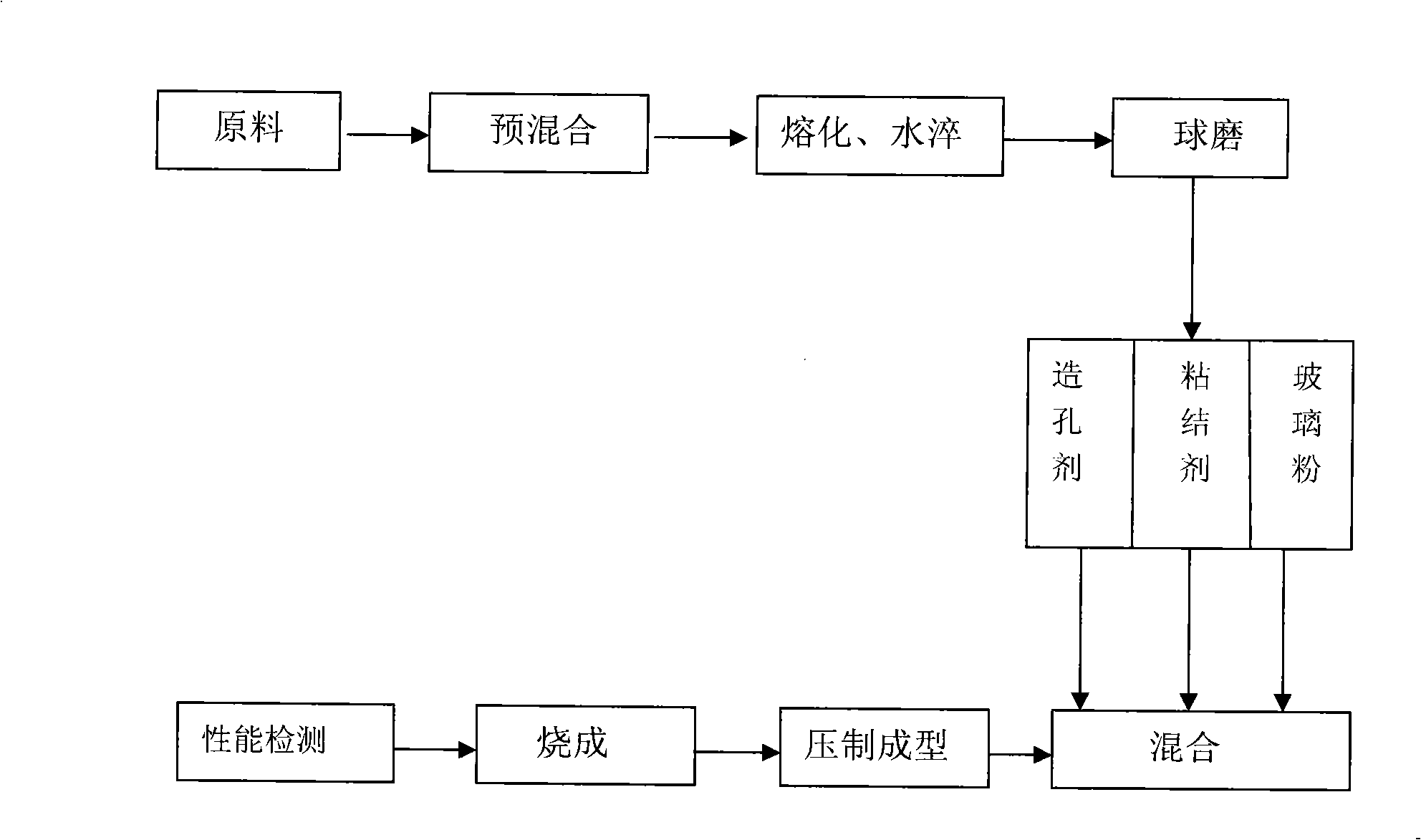

Methods to fabricate nano-macro porous glass using a water soluble pore former

Provided herein are methods for preparing nano-macroporous glass articles, such as bioscaffolds, from starting materials such as phosphosilicate glasses made by melt-quench methods, mixed with a soluble pore former such as a sugar, followed by steps of dissolving, heating, and leaching to yield a glass composition having a highly interconnected system of both macropores and large scale nanoporosity.

Owner:LEHIGH UNIVERSITY

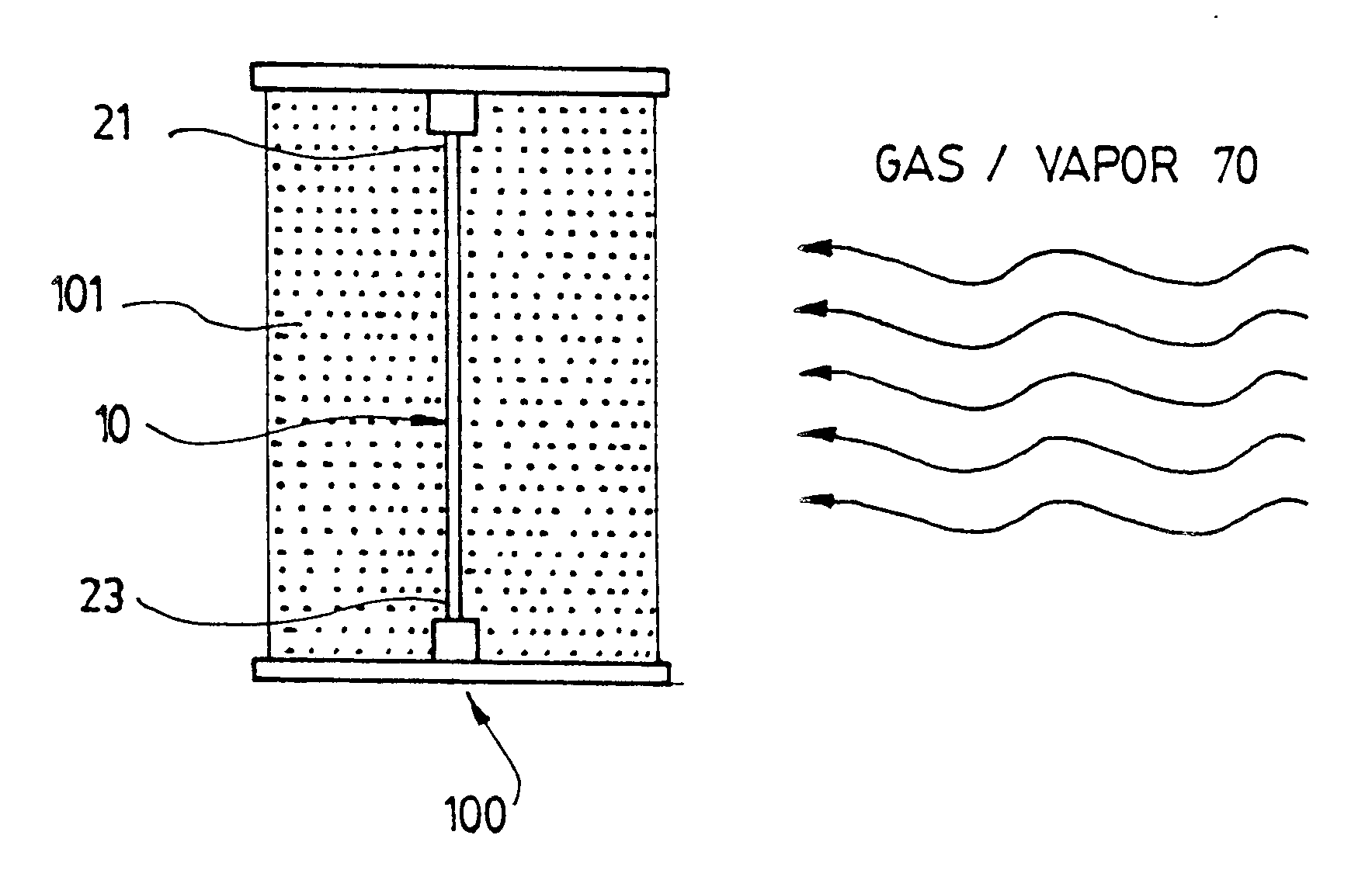

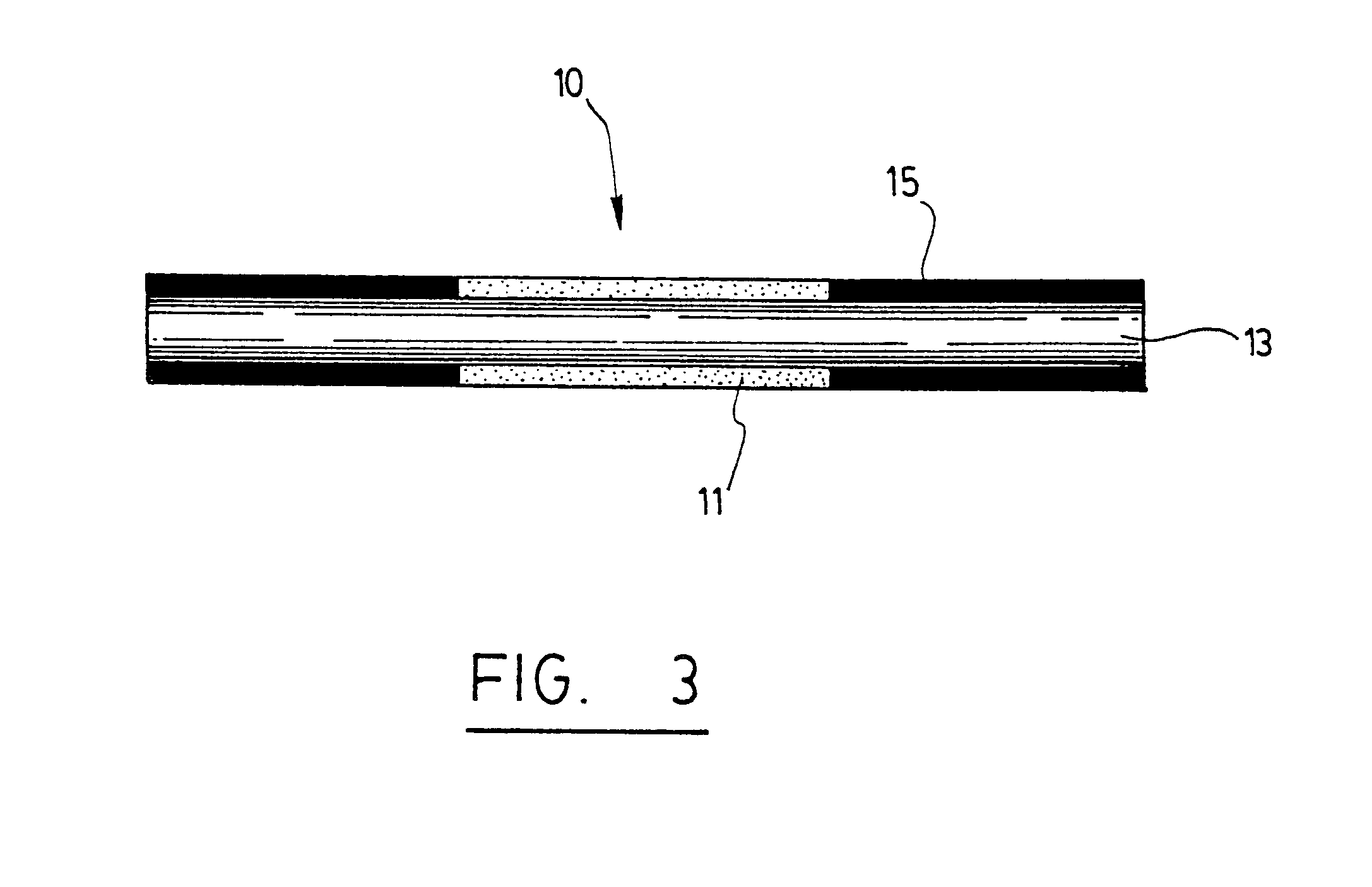

End-of-service indicator including a porous waveguide for respirator cartridge

An end-of-service indicator for use with a respirator cartridge, the end-of-service indicator having an optical waveguide having two extremities, one of the extremities being connected to a light source, the other of the extremities being connected to a detector which measures the intensity of light guided and transmitted by the fiber. An alarm is connected to the detector and is triggered when the intensity of light measured by the detector is below a predetermined level. An important aspect of the end-of-service indicator is that at least a portion of the optical fiber is porous. In use, the end-of-service indicator is placed inside a respirator cartridge having a gas / vapor sorbent, so that when the respirator cartridge is used in a toxic environment, the gas / vapor sorbent and the porous glass gradually become saturated. This porous glass will absorb the gas / vapor in the same fashion as the sorbent used in the respirator cartridge, thereby lowering the guiding and transmission properties of the optical fiber which loses the necessary conditions to guide light.

Owner:INSTITUT NATIONAL D'OPTIQUE +1

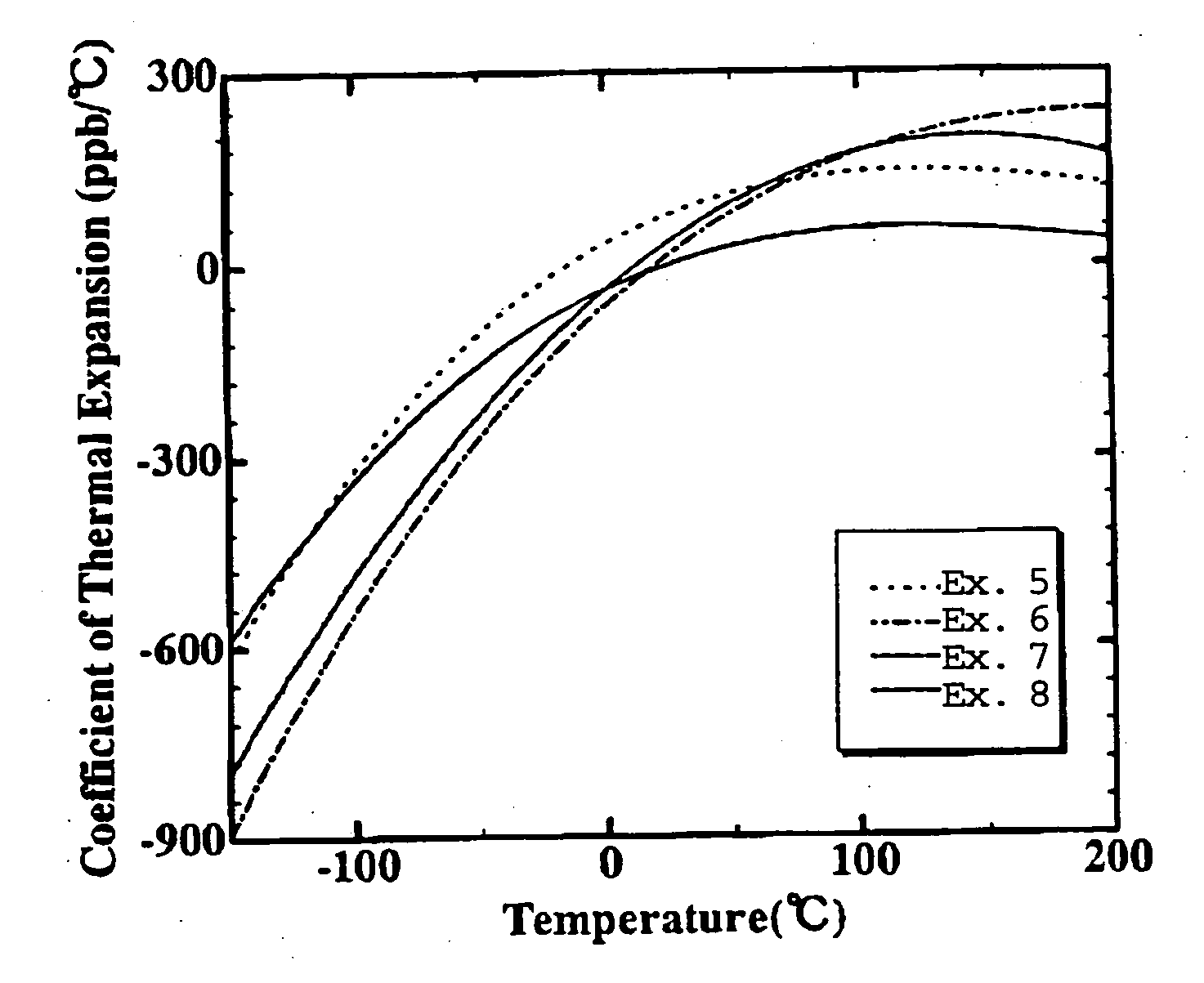

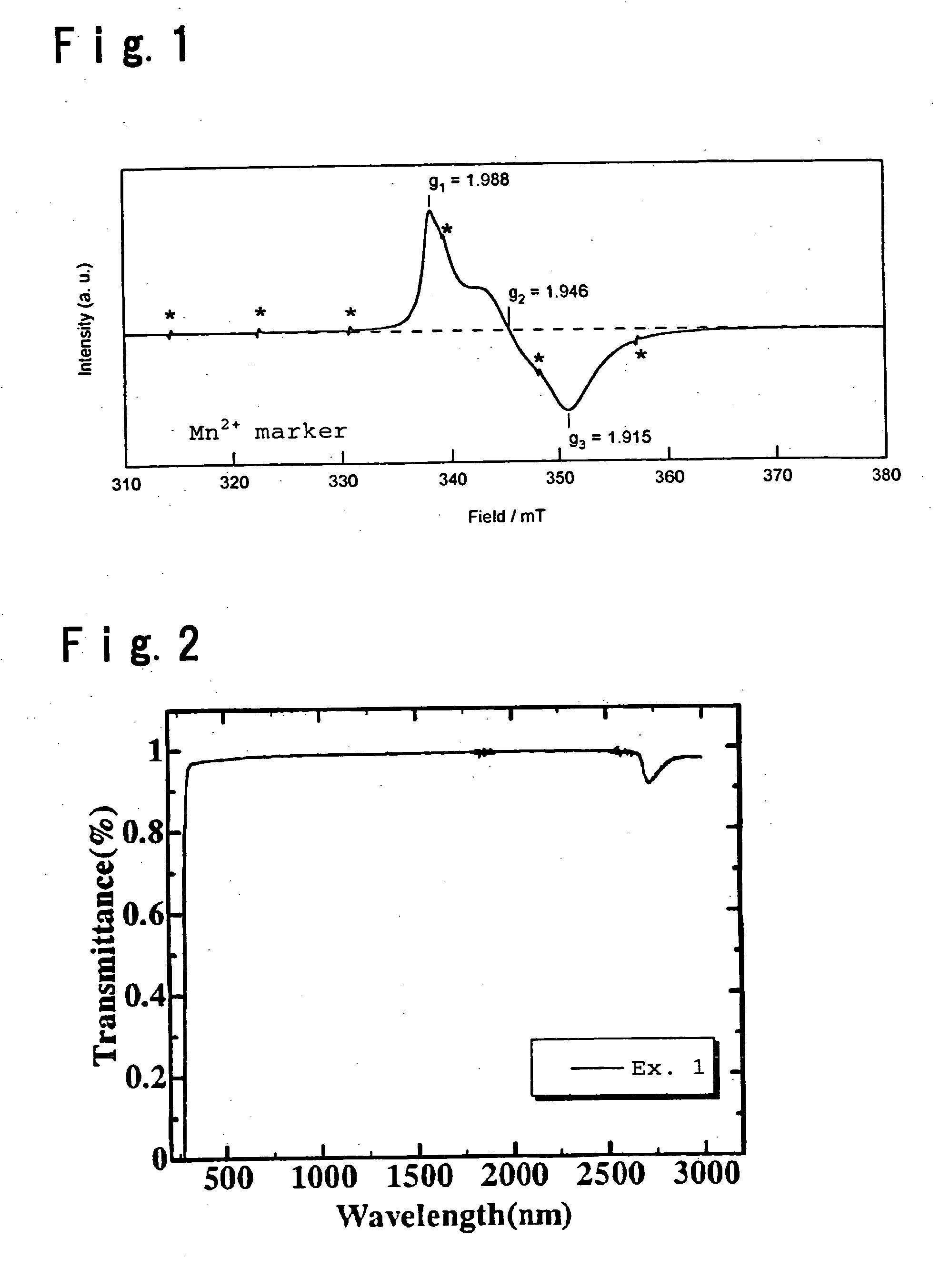

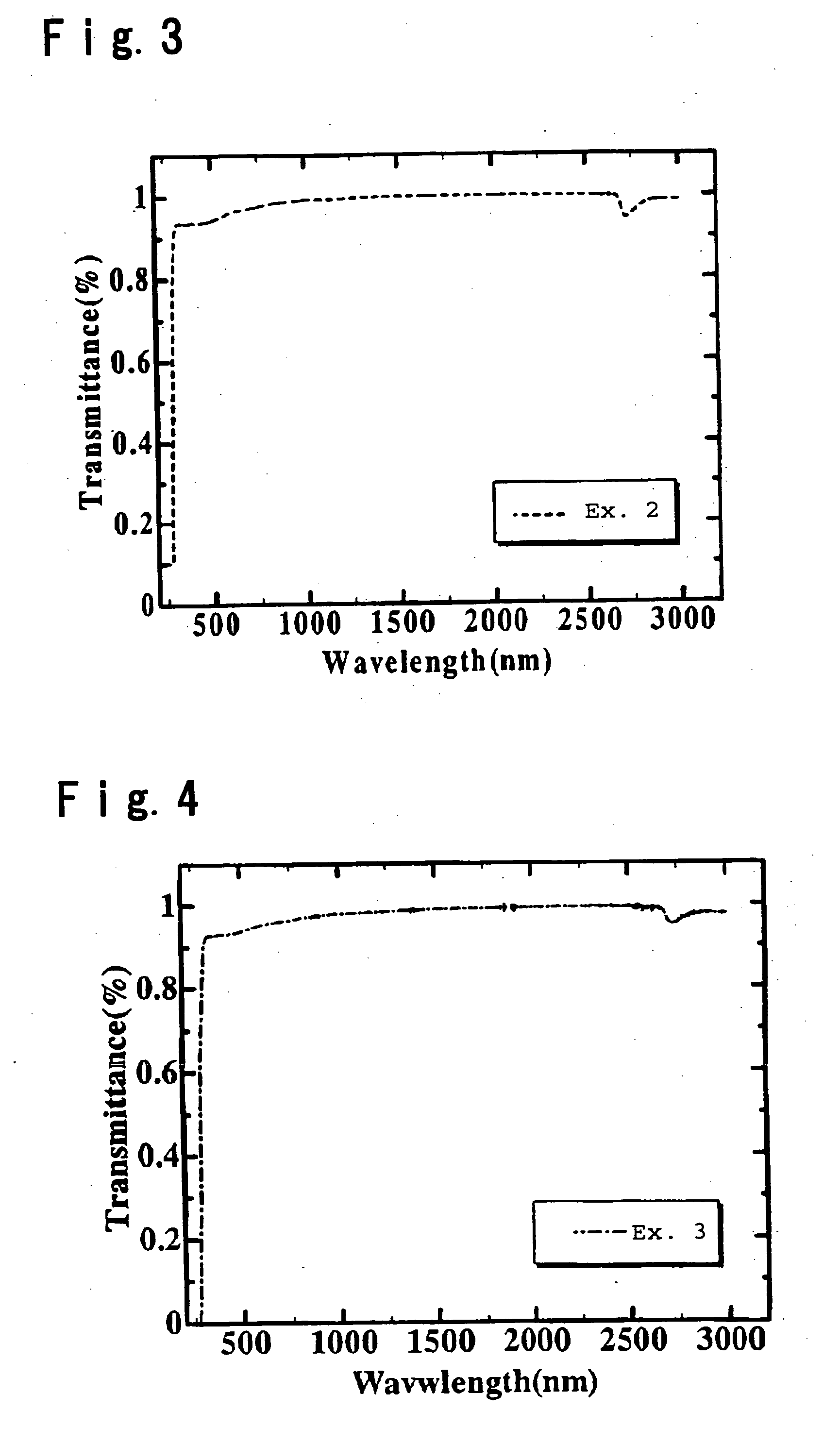

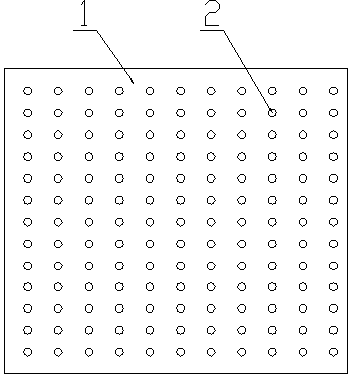

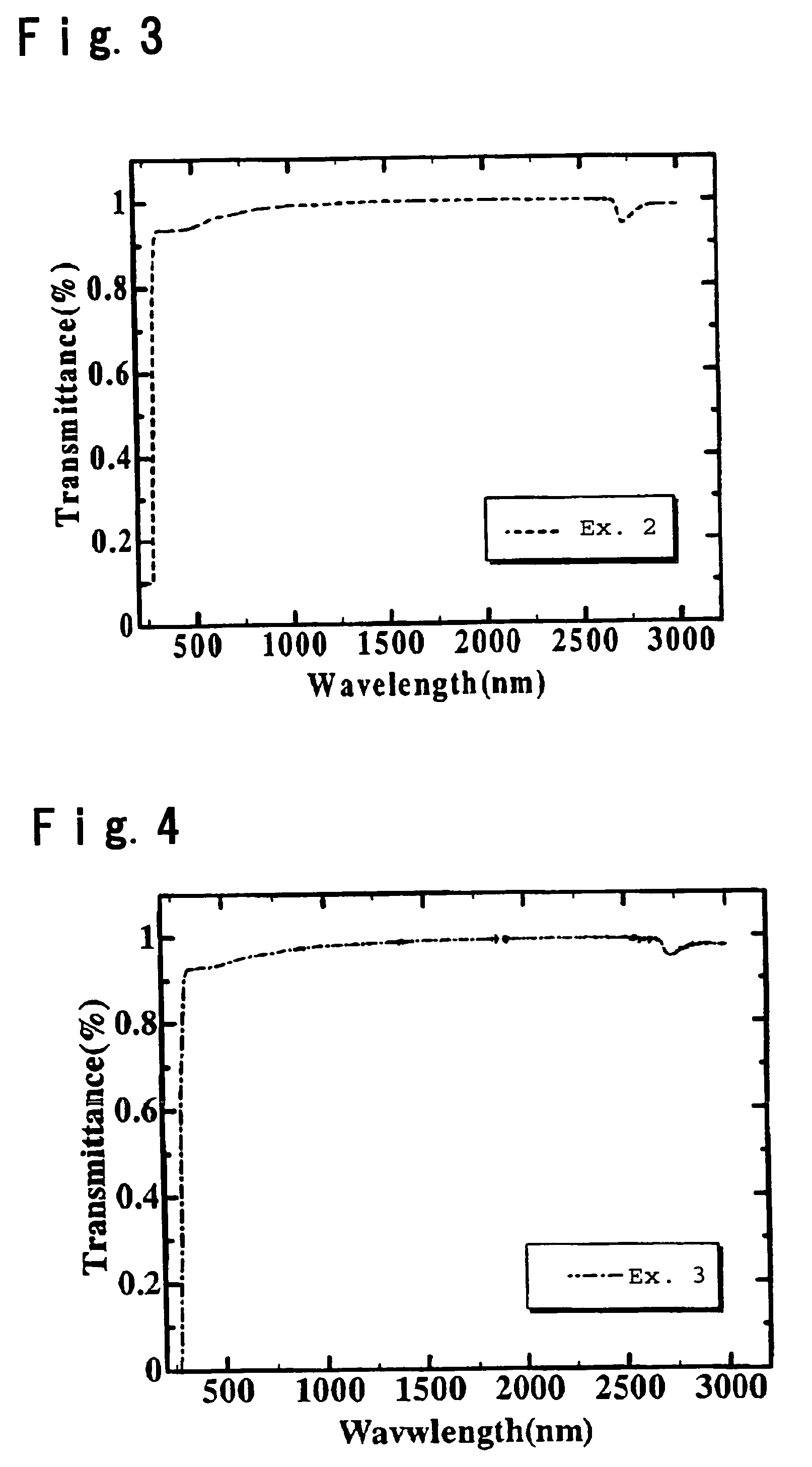

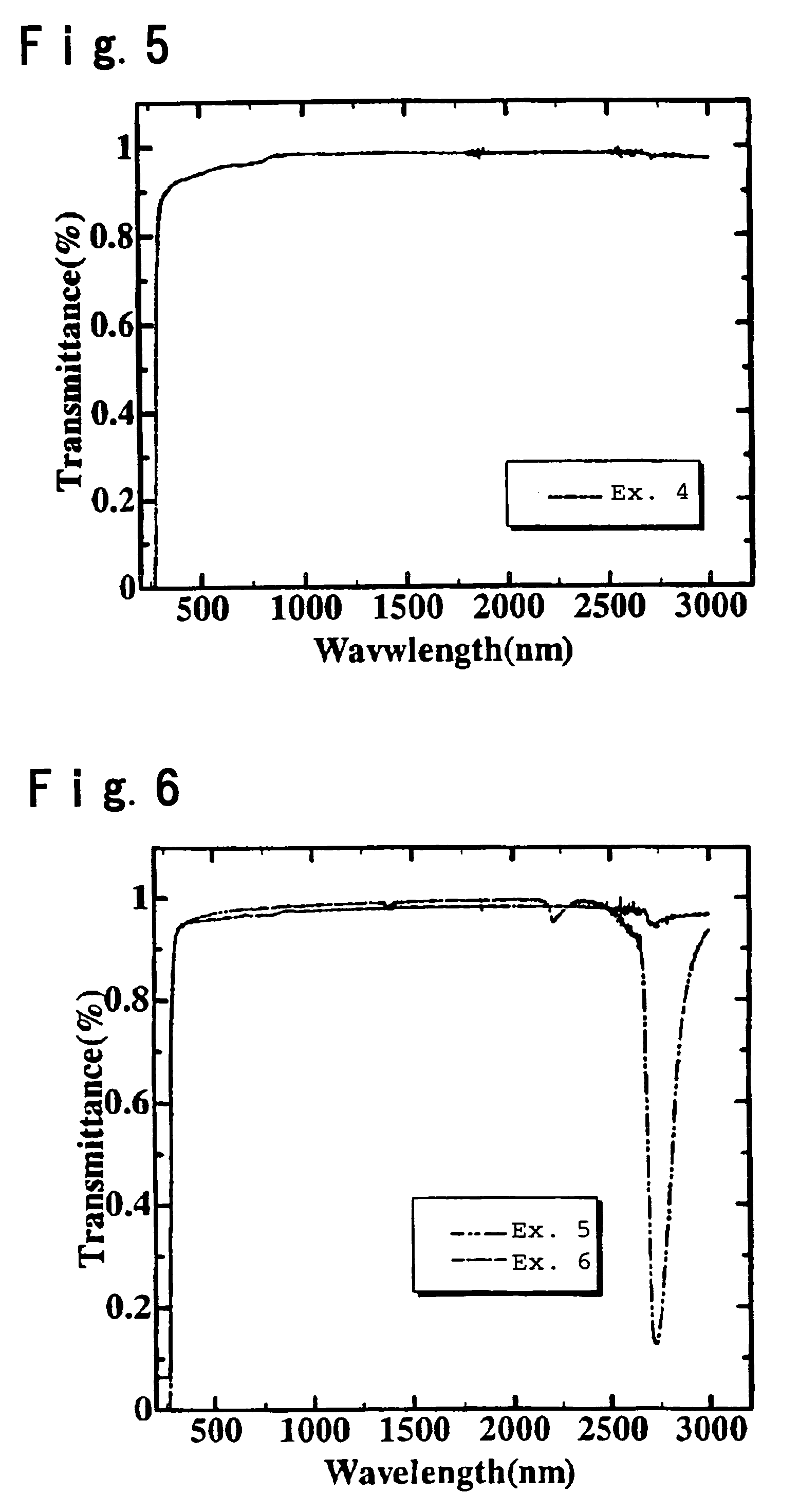

Silica glass containing TiO2 and process for its production

ActiveUS20070042893A1High light transmittanceHigh transparencyCharging furnaceGlass reforming apparatusVitrificationTransmittance

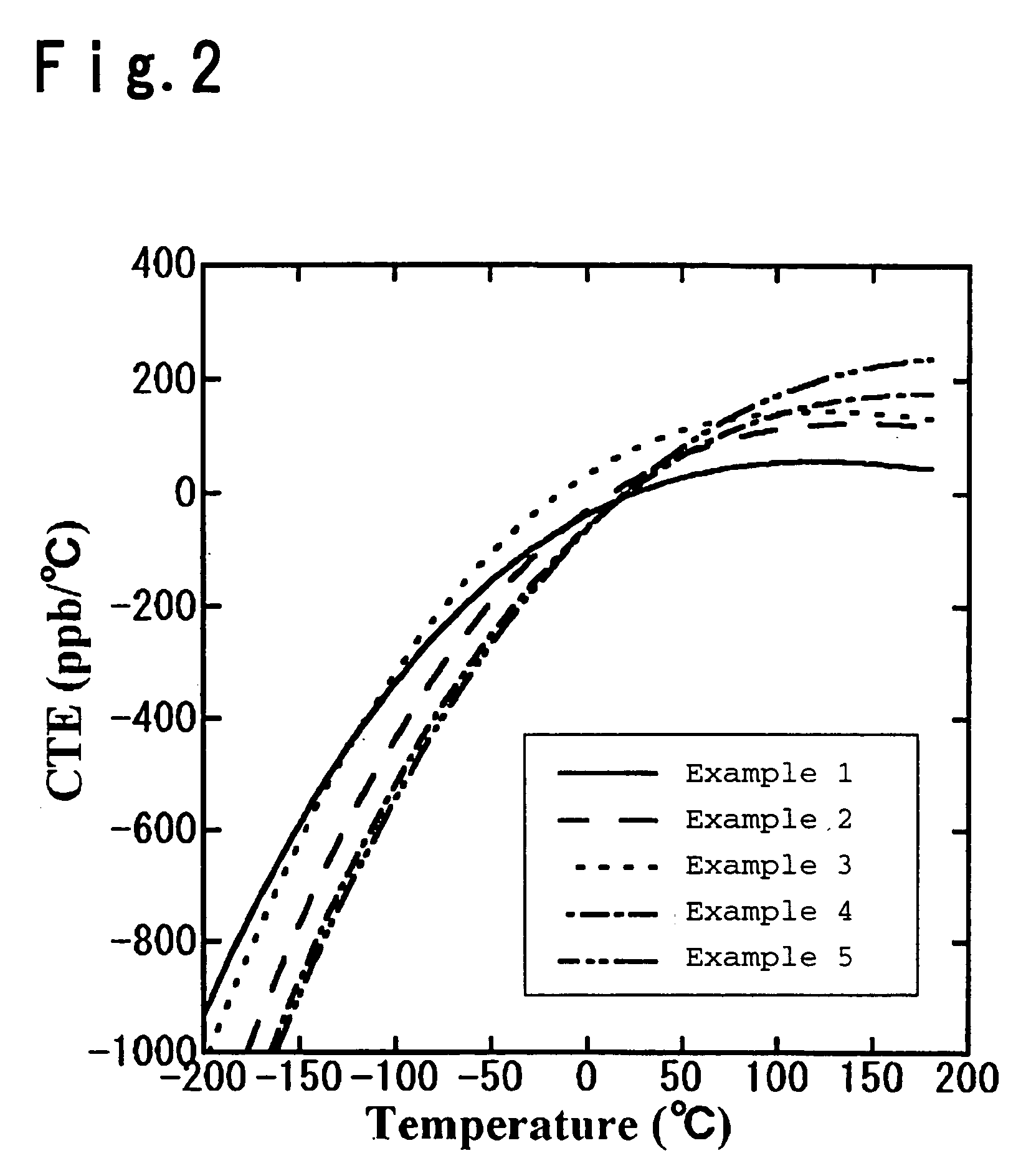

It is to provide a silica glass containing TiO2, having a wide temperature range wherein the coefficient of thermal expansion is substantially zero. A silica glass containing TiO2, which has a TiO2 concentration of from 3 to 10 mass %, a OH group concentration of at most 600 mass ppm and a Ti3+ concentration of at most 70 mass ppm, characterized by having a fictive temperature of at most 1,200° C., a coefficient of thermal expansion from 0 to 100° C. of 0±150 ppb / ° C., and an internal transmittance T400-700 per 1 mm thickness in a wavelength range of from 400 to 700 nm of at least 80%. A process for producing a silica glass containing TiO2, which comprises porous glass body formation step, F-doping step, oxygen treatment step, densification step and vitrification step.

Owner:ASAHI GLASS CO LTD

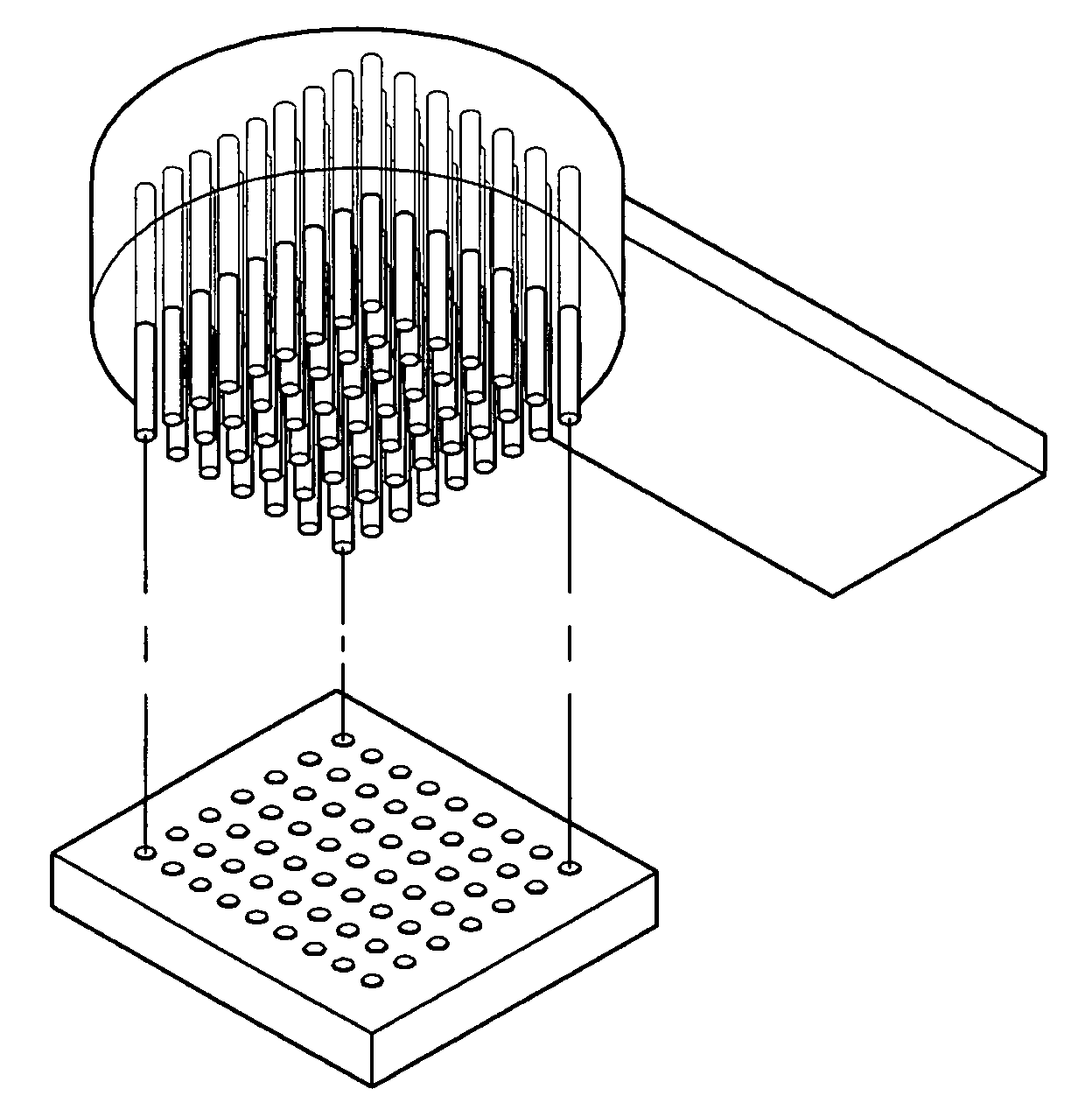

Porous glass

InactiveCN104344202AImprove breathabilityImprove sound absorptionSheets/panelsFlat glassOptoelectronics

The invention relates to porous glass which comprises a glass body (1), wherein a plurality of air holes (2) are formed in the glass body (1), are distributed in a rectangular array manner, penetrate through the whole glass body (1) in the thickness direction and are round, square or hexagonal. According to the porous glass, the plurality of air holes are formed in the plate glass of the porous glass in the rectangular array manner, so that the porous glass has good air permeability and sound absorption performance.

Owner:张玉芬

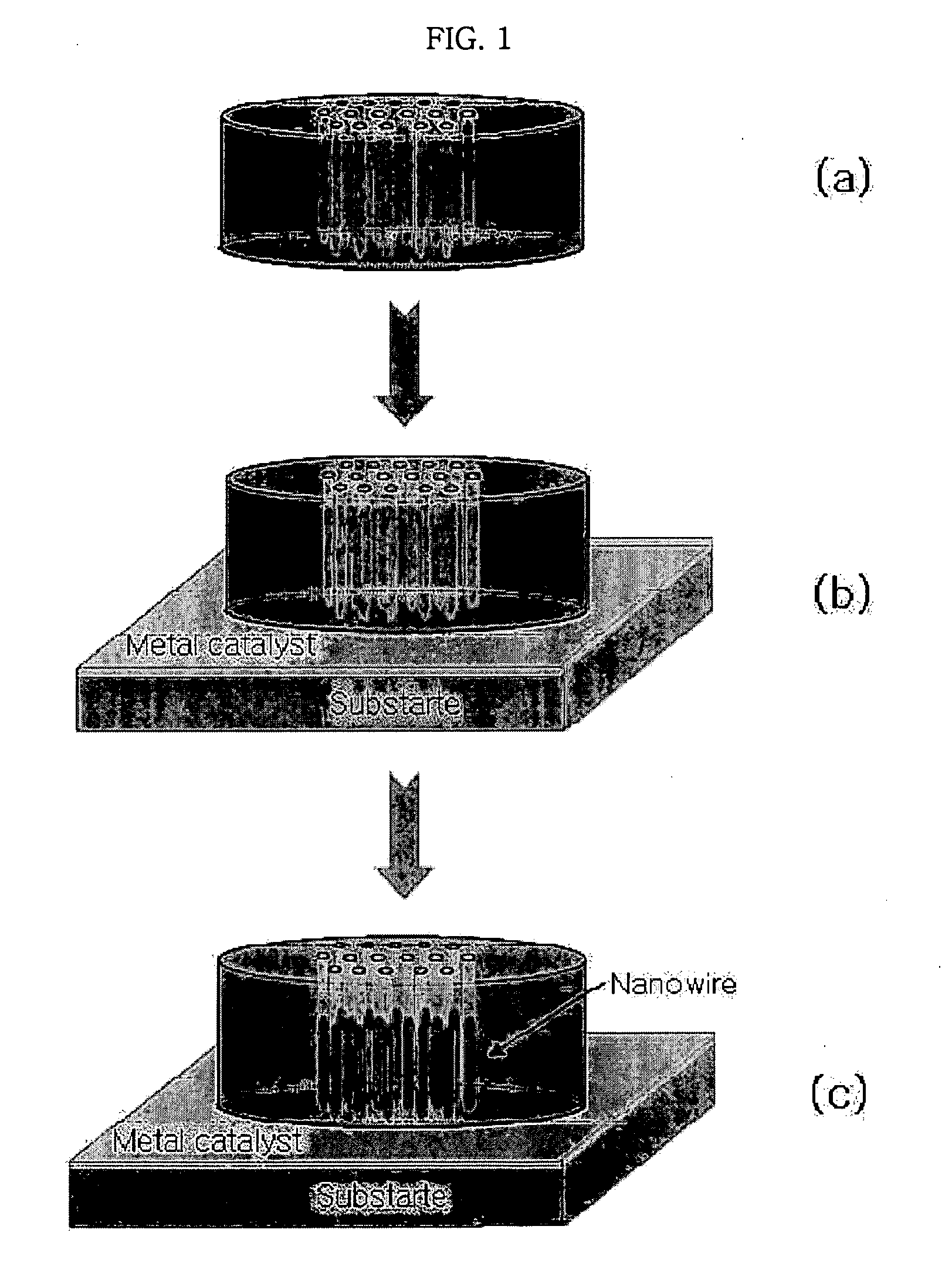

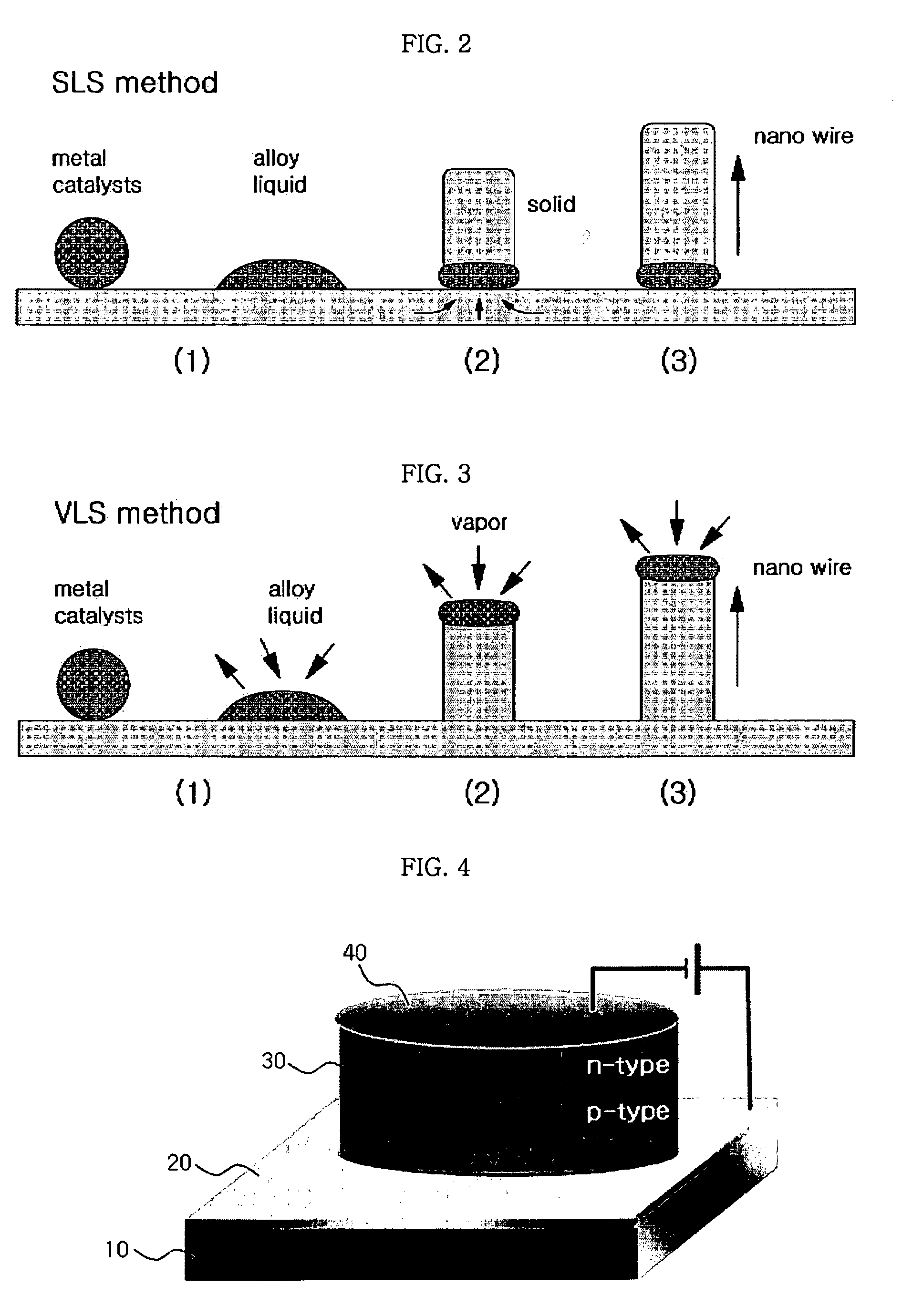

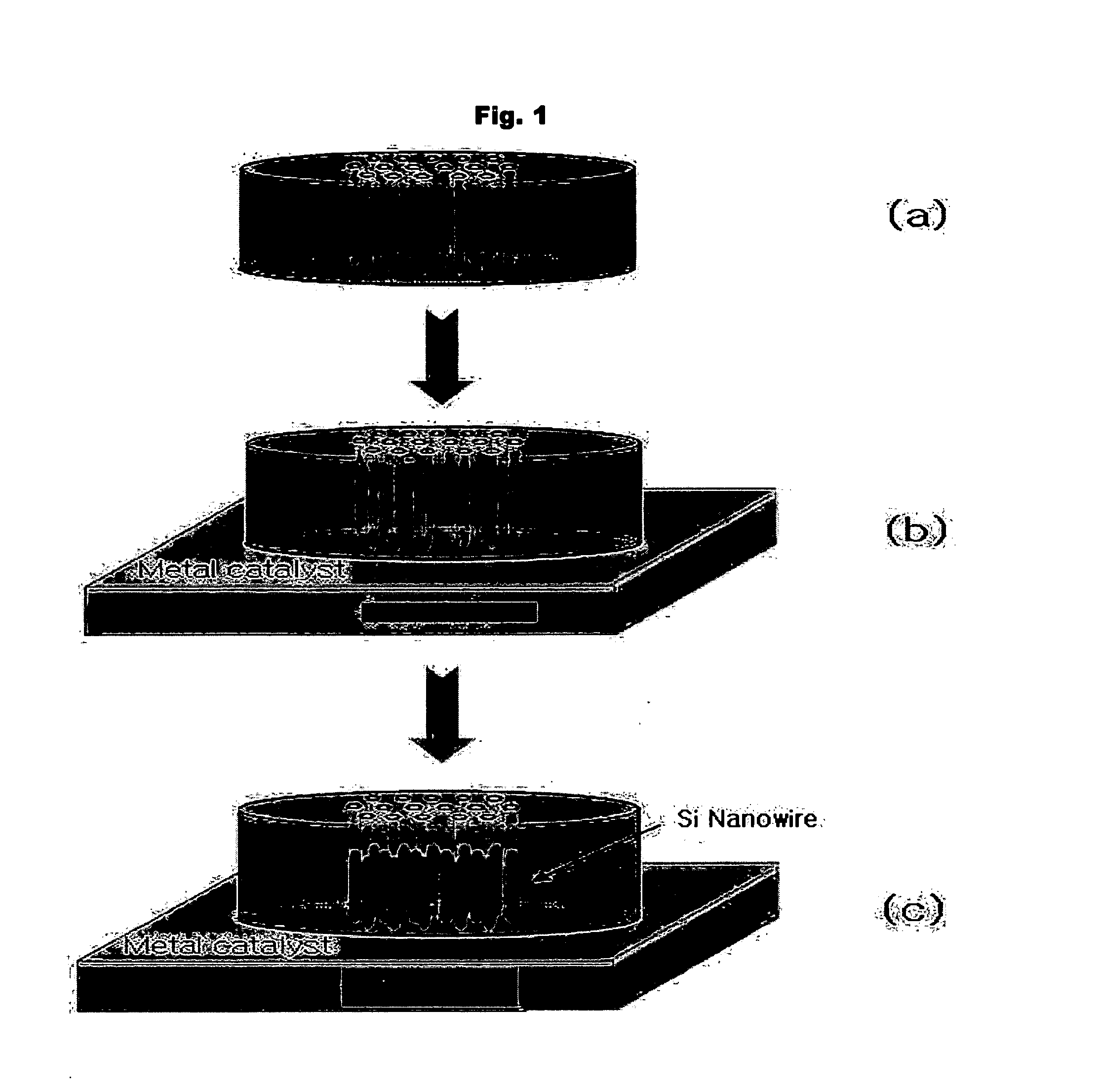

Method for producing nanowires using porous glass template, and multi-probe, field emission tip and devices employing the nanowires

InactiveUS20090045720A1Easy to controlMaterial nanotechnologyDischarge tube luminescnet screensVapor liquidNanowire

Disclosed herein is a method for producing nanowires, which features the use of a porous glass template in combination with a solid-liquid-solid or vapor-liquid-solid process for growing nanowires which are highly straight and have nanoparticles precisely arranged therein. The nanowires can be grown into composite structures of superlattices and hybrids by modulating the composition of the materials provided thereto. Also disclosed is the use of the nanowires in multi-probes, field emission tips, and devices.

Owner:SAMSUNG ELECTRONICS CO LTD

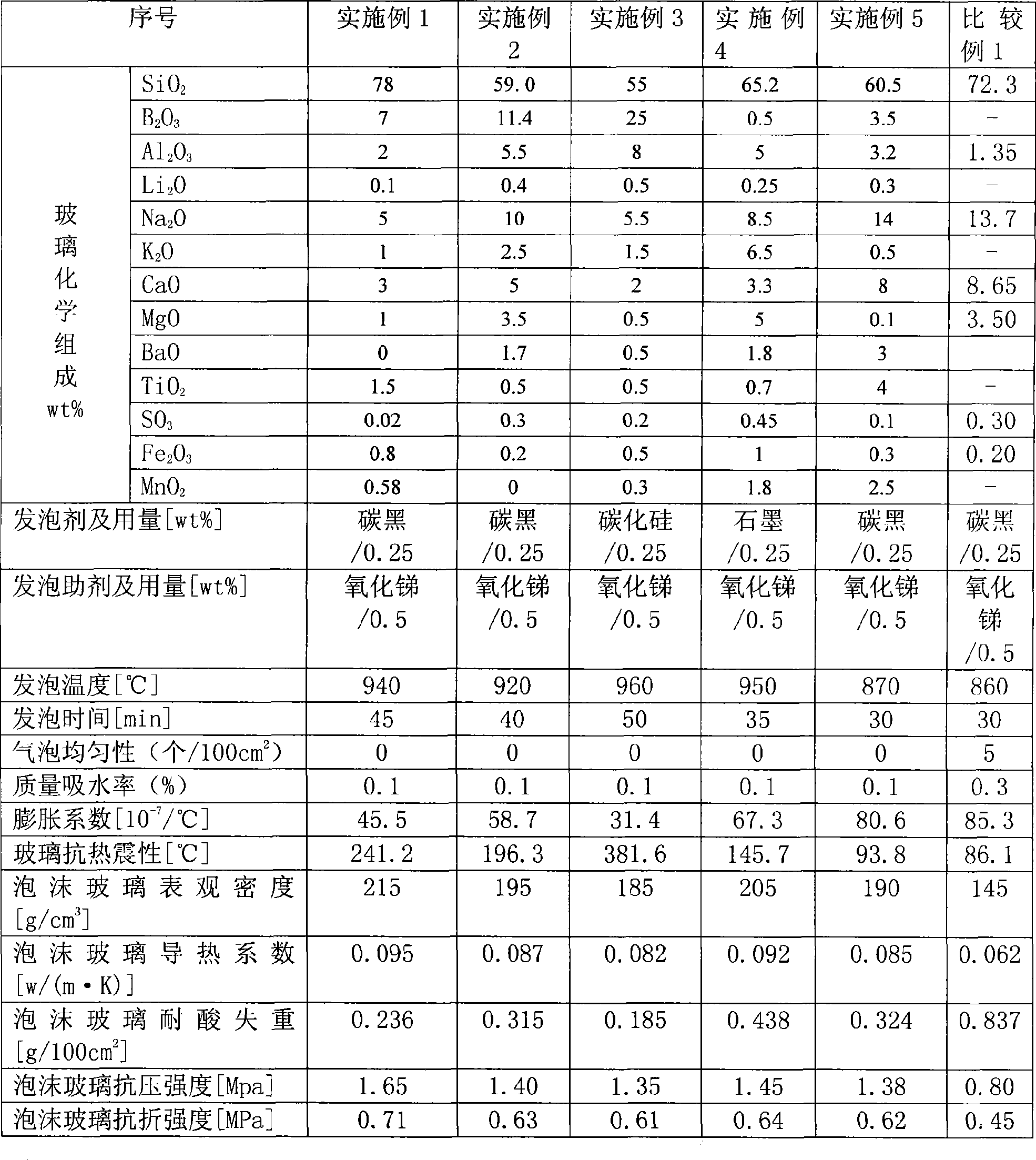

Method for preparing borosilicate foam glass

The invention relates to a method for preparing borosilicate foam glass, comprising the following steps: glass raw materials, foaming agent and blowing promoter are finely ground and evenly mixed to form batch mixture; the batch mixture is placed in a heat resistant mould; the batch mixture is prepared into multiaperture glass materials after the processes of preheating, sintering, frothing, annealing and the like; the method is characterized in that the chemical composition(wt%) of the glass materials is: SiO2: 55-78, B2O3: 0.5-25, Al2O3: 2-8, Li2O: 0.1-0.5, Na2O: 5-14, K2O: 0.5-6.5, MgO: 1-5, CaO: 3-8, BaO: 0-3, TiO2: 0.5-4, SO3: 0.02-0.45, Fe2O3: 0.2-1.0, MnO2: 0-2.5. the glass material belongs to the system of borosilicate glass and can be prepared into foam glass product featuring good acid fastness, good thermal shock stability, high mechanical strength, good scour resistance, low heat conducting coefficient and even aerated structure by adopting carbon blowing agents(carbon black, graphite, carborundum) and blowing promoter material.

Owner:BEIJING UNIV OF TECH

Powder comprising polymer-coated glass particles

Composite particles comprising core particles completely or partially coated with a precipitated polymer, where the d50 median diameter of the core particles is from 3 to 100 μm and wherein the glass core particle material is at least one selected from the group consisting of a solid glass bead, a hollow glass bead, a porous glass bead, and a foamed glass particle. A method to prepare the particles includes dissolution of a polymer in a solvent and precipitation of the polymer in the presence of a suspension of the core glass particles. Further provided is a layer by layer moulding process employing the composite particles and mouldings obtained therefrom.

Owner:EVONIK OPERATIONS GMBH

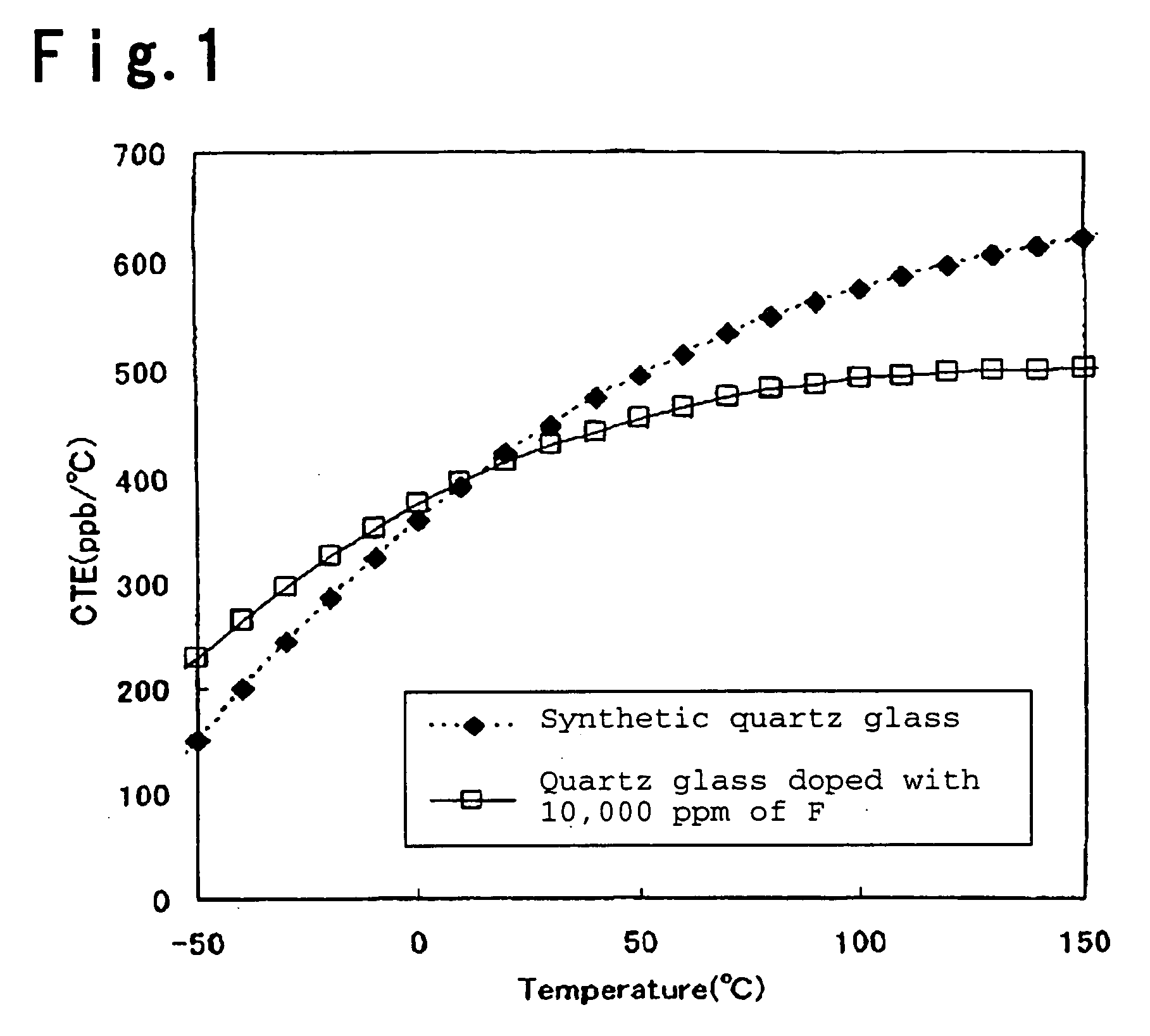

Silica glass containing TiO2 and process for its production

ActiveUS20050272590A1Excellent in of coefficientImprove uniformitySemiconductor/solid-state device manufacturingGlass shaping apparatusVitreous BodiesThermal expansion

A silica glass containing TiO2, which has a fictive temperature of at most 1,200° C., a F concentration of at least 100 ppm and a coefficient of thermal expansion of 0±200 ppb / ° C. from 0 to 100° C. A process for producing a silica glass containing TiO2, which comprises a step of forming a porous glass body on a target quartz glass particles obtained by flame hydrolysis of glass-forming materials, a step of obtaining a fluorine-containing porous glass body, a step of obtaining a fluorine-containing vitrified glass body, a step of obtaining a fluorine-containing formed glass body and a step of carrying out annealing treatment.

Owner:ASAHI GLASS CO LTD

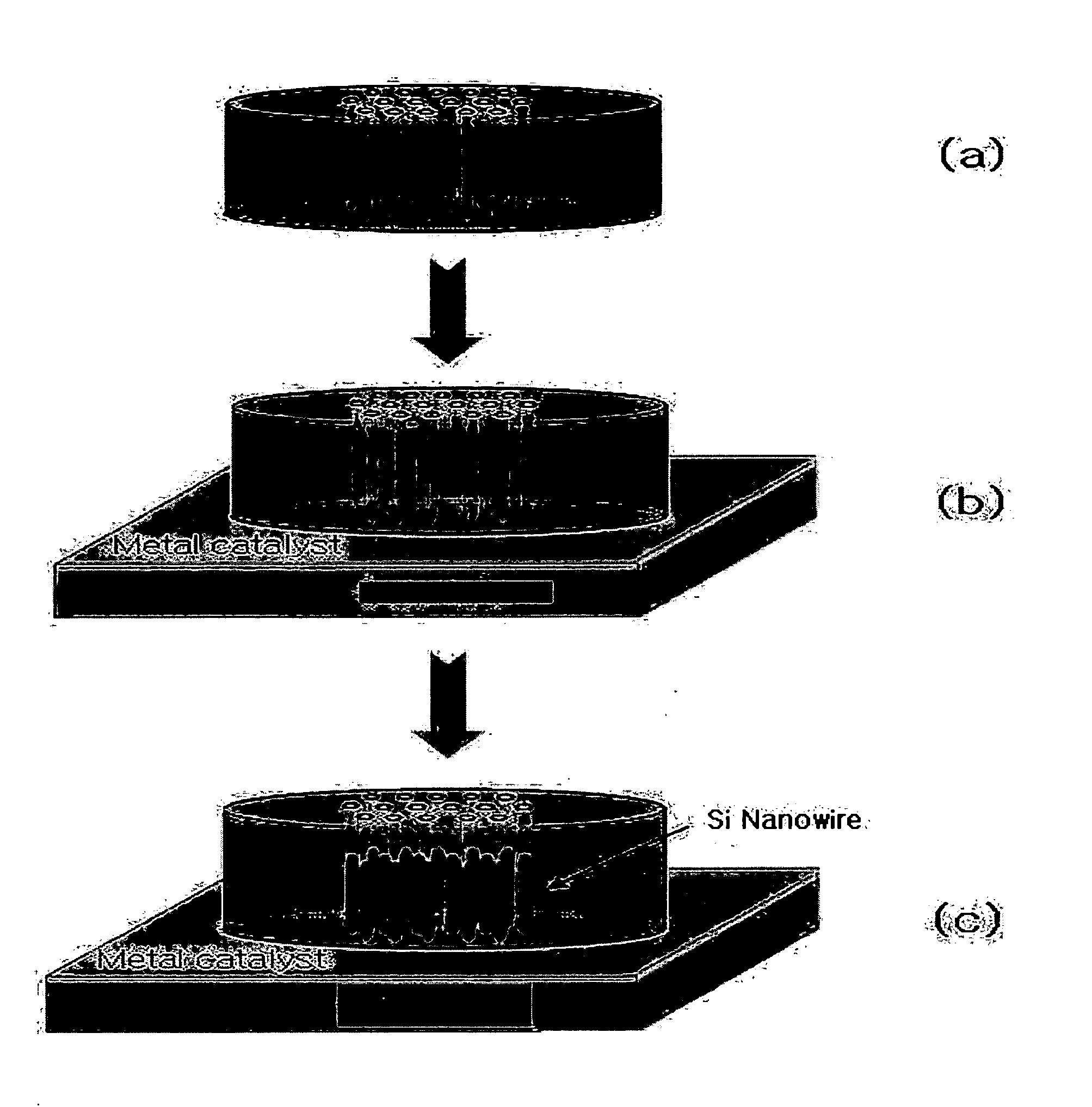

Method of manufacturing silicon nanowires using porous glass template and device comprising silicon nanowires formed by the same

InactiveUS20070232028A1Increasing structural efficiency of structureMaterial nanotechnologyPolycrystalline material growthVapor liquidPhotovoltaic detectors

A method of manufacturing silicon nanowires is characterized in that silicon nanowires are formed and grown through a solid-liquid-solid process or a vapor-liquid-solid process using a porous glass template having nanopores doped with erbium or an erbium precursor. In addition, a device including silicon nanowires formed using the above exemplary method according to the present invention can be effectively applied to various devices, for example, electronic devices such as field effect transistors, sensors, photodetectors, light emitting diodes, laser diodes, etc.

Owner:SAMSUNG ELECTRONICS CO LTD

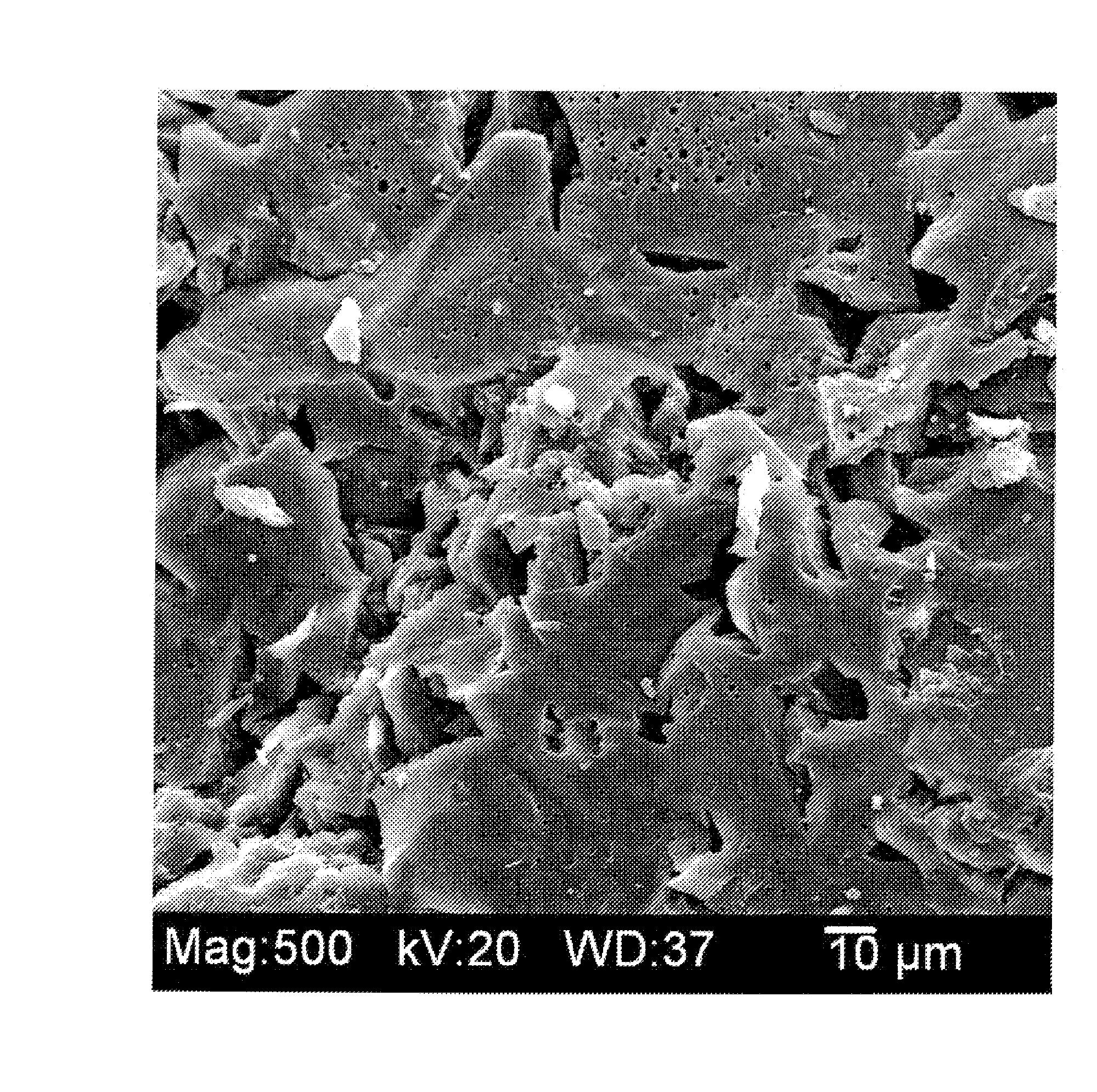

Biphasic nanoporous vitreous carbon material and method of making the same

A biphasic nanoporous vitreous carbon material with a cementitious morphology characterized by presence of non-round porosity, having superior hardness and tribological properties, as useful for high wear-force applications. The biphasic nanoporous vitreous carbon material is produced by firing, under inert atmosphere, of particulate vitrified carbon in a composition containing (i) a precursor resin that is curable and pyrolyzable to form vitreous carbon and, optionally, (ii) addition of one or more of the following: solid lubricant, such as graphite, boron nitride, or molybdenum disulfide; a heat-resistant fiber reinforcement, such as copper, bronze, iron alloy, graphite, alumina, silica, or silicon carbide; or one or more substances to improve electrical conductivity, such as dendritic copper powder, copper “felt” or graphite flake, to produce a superior vitreous carbon that is useful alone or as a continuous phase in reinforced composites, in relation to conventional glassy carbon materials.

Owner:CARBON CERAMICS CO LLC

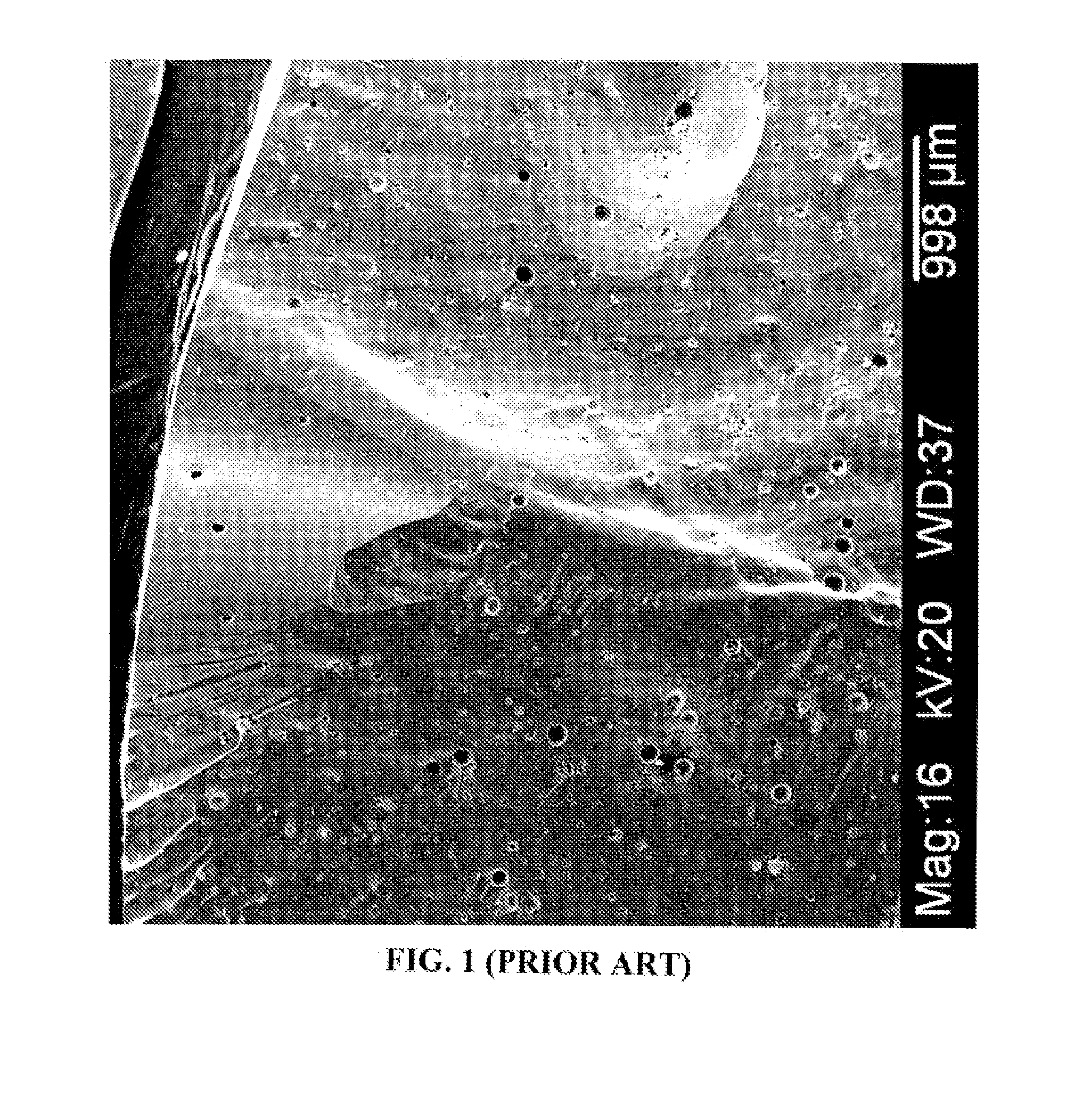

Geen light emitting vycor glass production method

The preparation method for vycor glass that emits green light comprises, using porous glass with SiO2 content over 95wt%, wherein, the aperture is 1.0-10nm and pore takes up volume of 23-28%; dipping the said glass into solution that contains rare-earth ion, such as Tb ion, or Tb ion and Ce ion, or gadolinium ion and Yt ion; sintering at temperature more than 1050Deg. The product has green light of 545nm when activating by ultraviolet light of 254nm.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

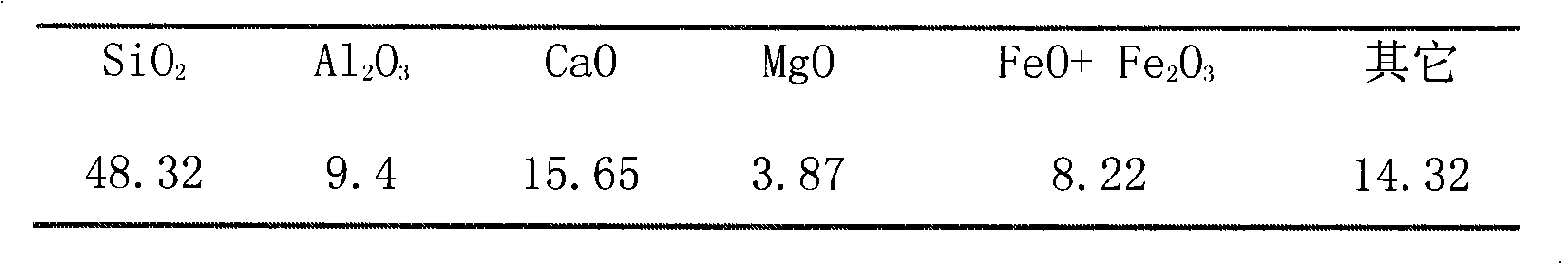

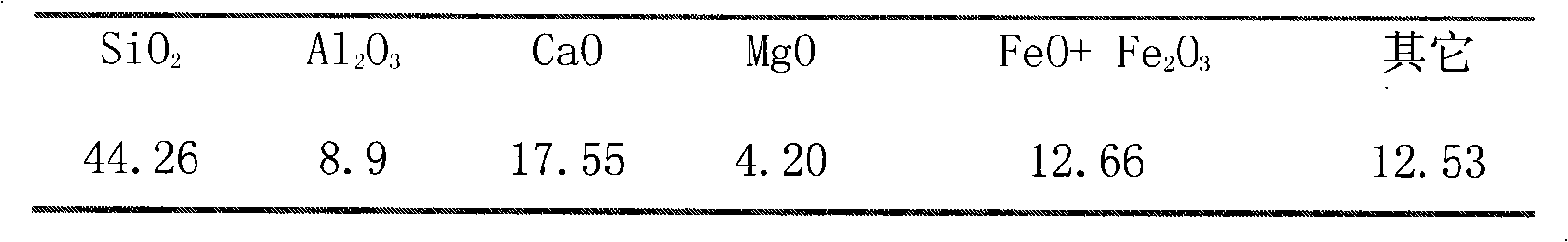

Porous devitrified glass and manufacturing method thereof

The invention relates to a porous glass-ceramics and a method for preparing the same belonging to the glass-ceramics filter material field, which is characterized by preparing a glass powder of CaO-MgO-Al2O3-SiO2 system by means of water quenching using fly ash and rare earth tailings as raw materials; preparing the porous glass-ceramics mainly open pores by adding pore formers. The rare earth tailings of the invention not only contains the main chemical compositions for preparing the glass-ceramics, but also contains rare earth, niobium and fluorite as composite nucleating agents which can reduce the nucleation activation energy, improve the nucleation and crystallization of the glass to make the microcrystalline finer, thereby improving the mechanical property of the glass-ceramics. Meanwhile the cost for preparing the porous glass-ceramics is greatly reduced and the high intensity communicating pore porous glass-ceramics which satisfies different filtration objects with an adjustable porosity and pore size distribution are obtained by adjusting the species, granularity, dosage and forming pressure of the pore formers.

Owner:内蒙古科韵环保材料股份公司

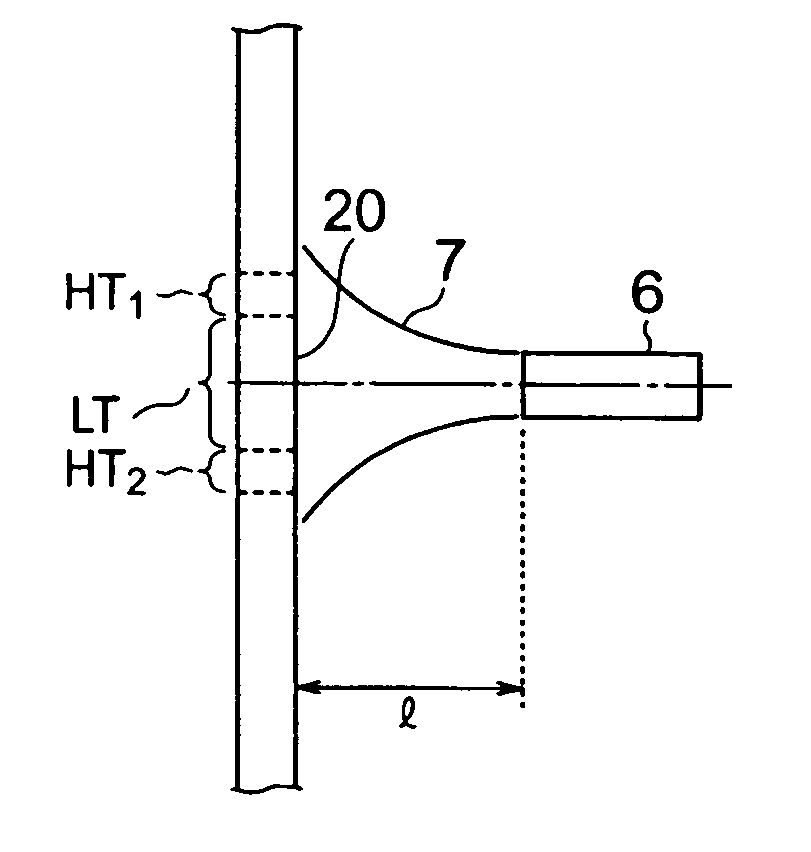

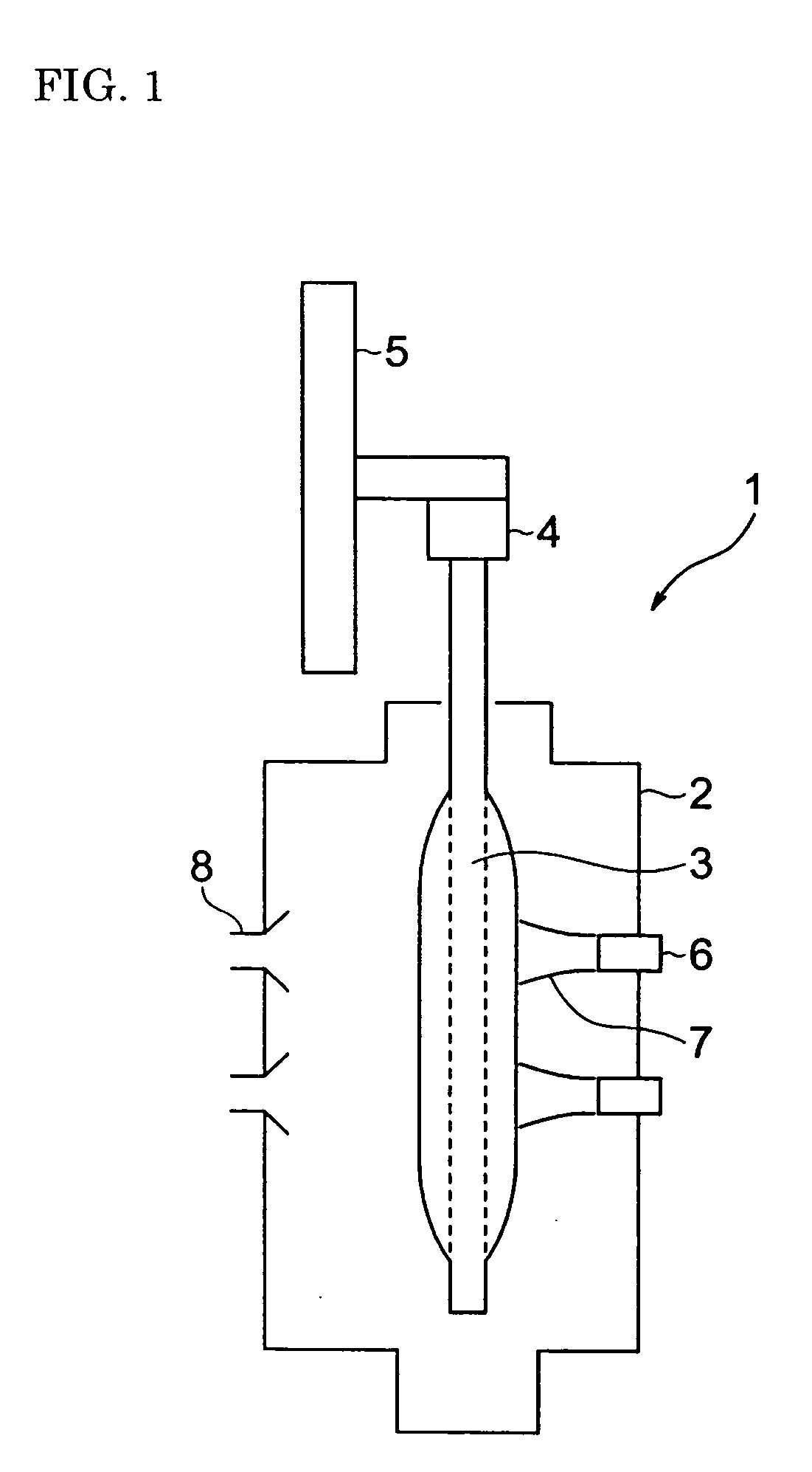

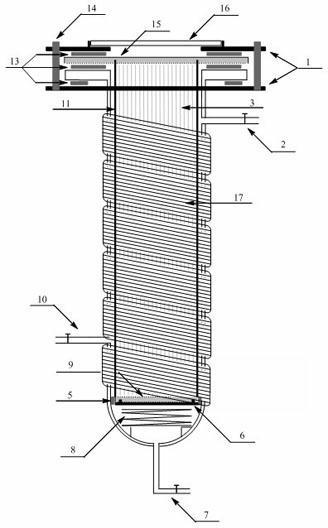

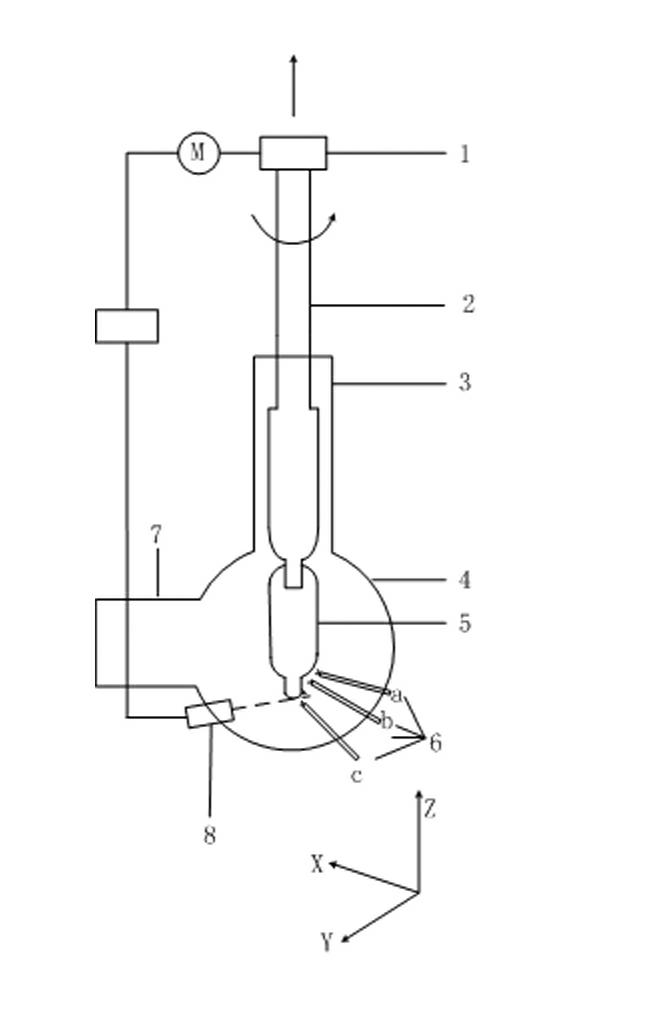

Method of producing porous glass-particle-deposited body and burner for synthesizing glass particles

InactiveUS20040182114A1Efficiency of the deposition of the glass particles on the surface of the starting member isImprove efficiencyGlass shaping apparatusGlass deposition burnersCombustorGlass particle

A method of producing a porous glass-particle-deposited body by effectively depositing the glass particles synthesized by a burner for synthesizing glass particles on a starting member with increased bonding strength between the deposited glass particles and decreased possibility of developing cracks and other problems, and a burner to be used for the production method. In the method of producing the deposited body by depositing the glass particles synthesized by a burner on the surface of the starting member, the glass particle deposition surface has (a) a region that is hit by the center portion of the flame issuing from the burner and (b) another region that has a temperature higher than that of the region hit by the center portion of the flame and that is located at the outside of the region hit by the center portion of the flame.

Owner:SUMITOMO ELECTRIC IND LTD

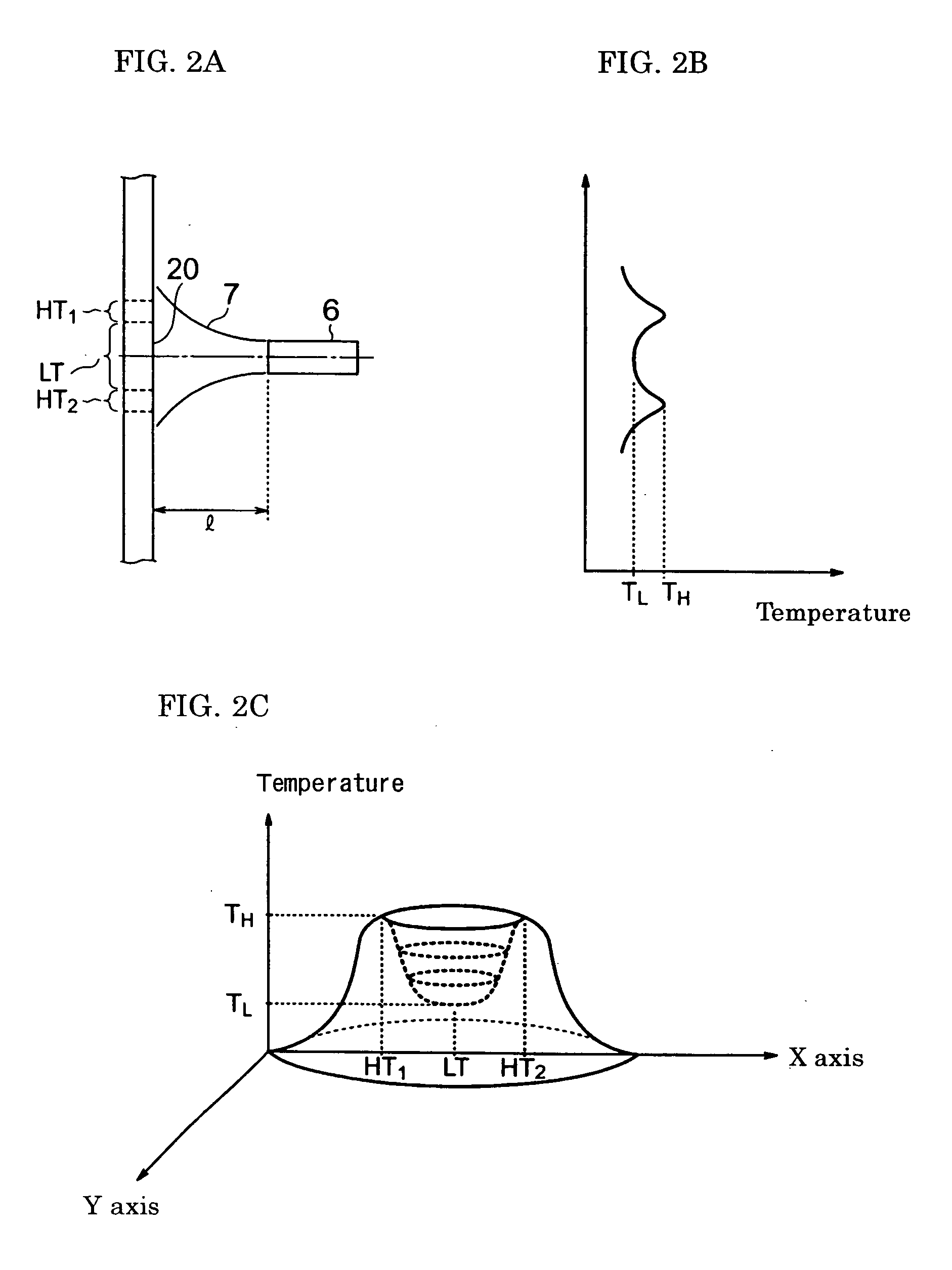

Titanium dioxide photo-catalytic micro-reactor

InactiveCN102580651ARaise the ratioSmall attenuationEnergy based chemical/physical/physico-chemical processesReaction layerFiber

The invention discloses a titanium dioxide photo-catalytic micro-reactor, characterized in that in the reactor, the lower ends of fibers are supported on a porous glass sand separator through a porous glass sheet, the upper end is fixed with a translucent sheet, the bottom of the reactor is provided with an air inlet pipe, and the side of the reactor is provided with a testing port and an injection port. According to the invention, the ratio of effective catalytic surface area to reactive volume is raised, the incident mode of a light source is changed into an internal reflection mode from a traditional external reflection mode, thus the attenuation after the light passes through the solution is reduced, and the utilization rate of the light is raised; compared with TiO2 nano-particles, the TiO2 nanotubes used as the photoreaction catalyst have higher catalysis catalysis effect; and compared with traditional coating modes, the reaction layer obtained by the catalyst layer of the photoreaction unit is more uniform, compact and firm.

Owner:NORTHWEST UNIV

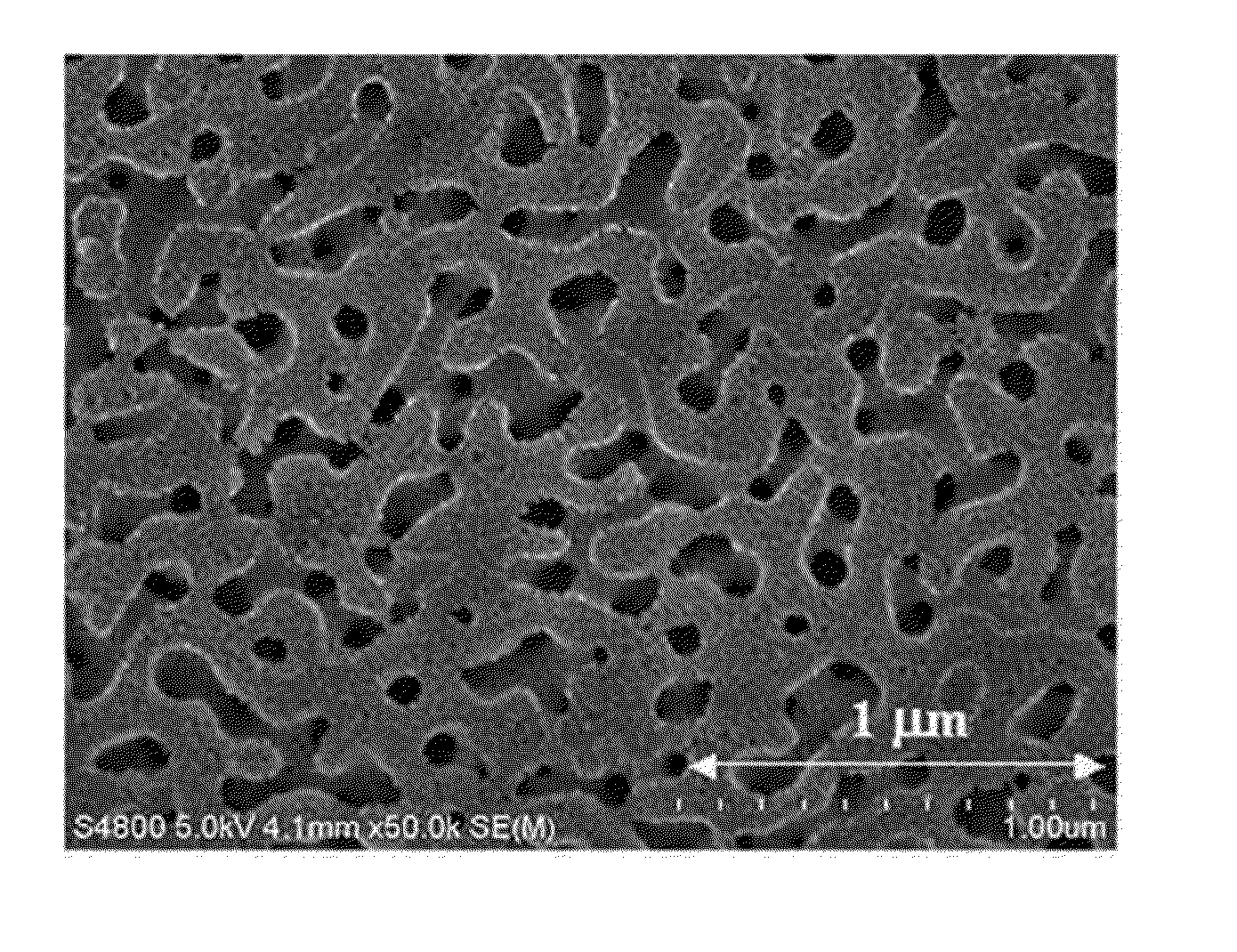

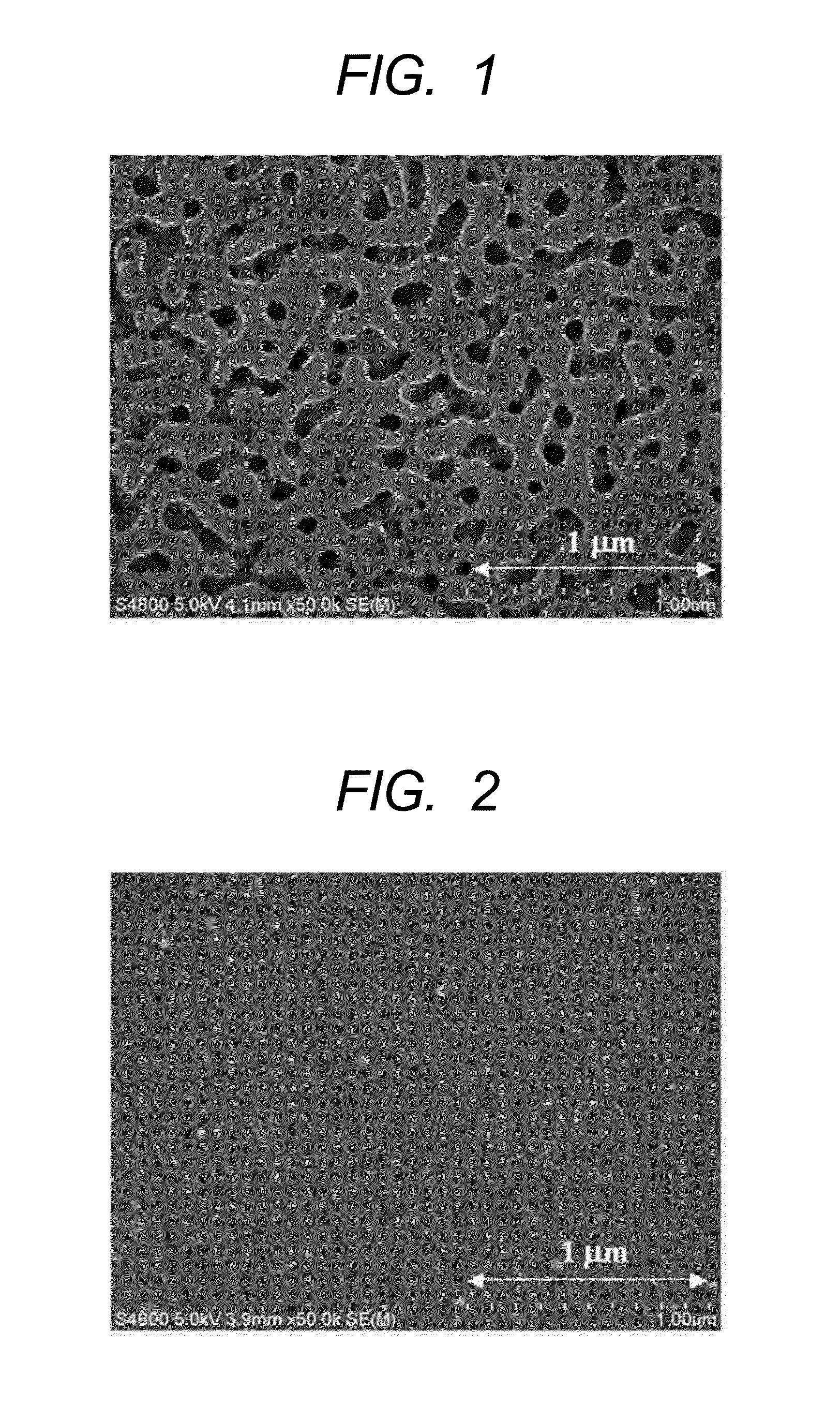

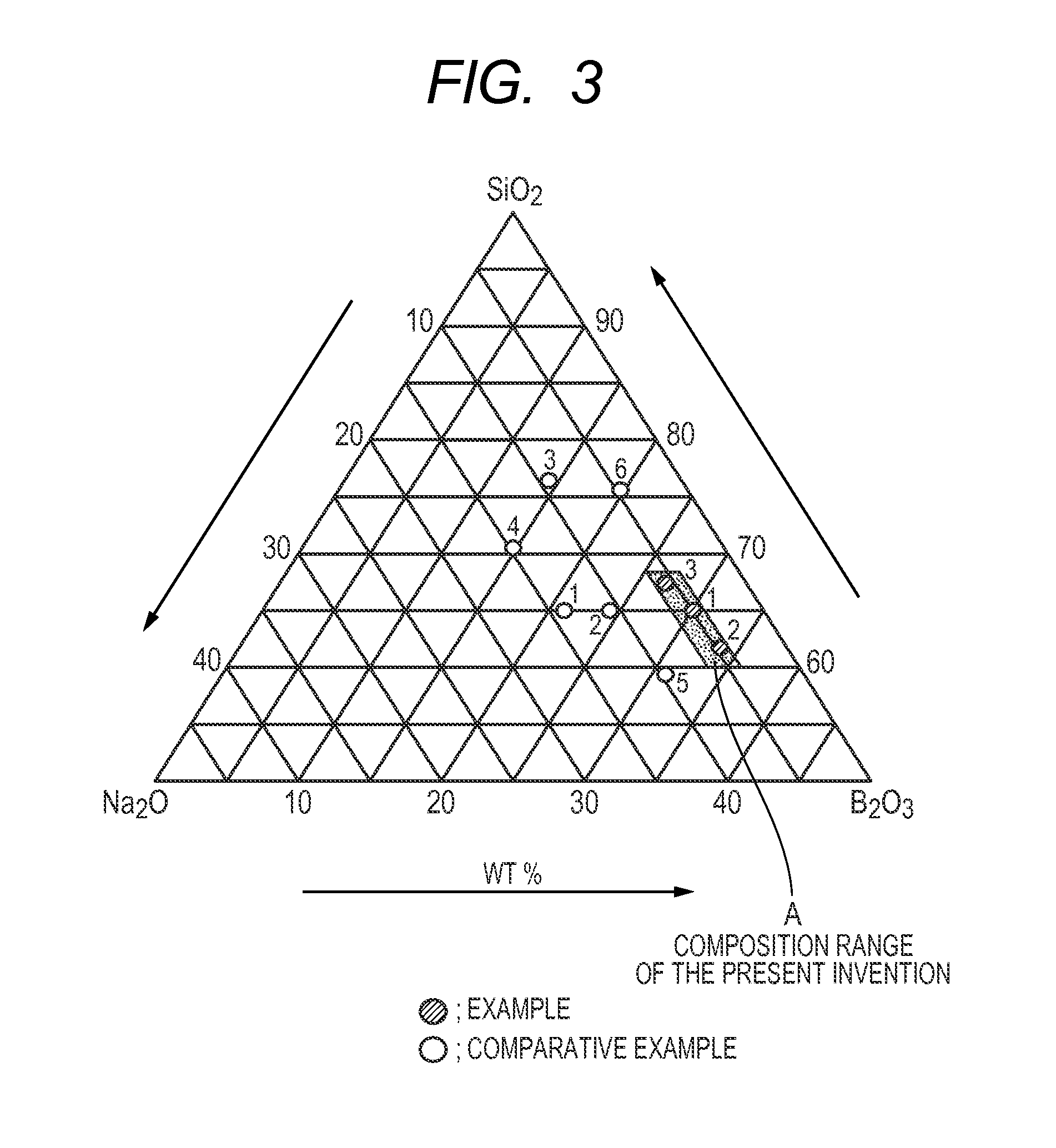

Method of producing porous glass

Provided is a method of producing a porous glass having a high strength by a safe, simple process that does not involve the use of any high-temperature heat treatment or acid treatment step. The method includes: mixing 4 wt % or more to 6.5 wt % or less of sodium oxide, 26 wt % or more to 36 wt % or less of boron oxide, and 60 wt % or more to 68 wt % or less of silicon oxide; heating the mixed materials to melt the materials and cooling the molten materials to obtain a glass body; and a step involving bringing the glass body into contact with water without reheating the glass body to obtain the porous glass.

Owner:CANON KK

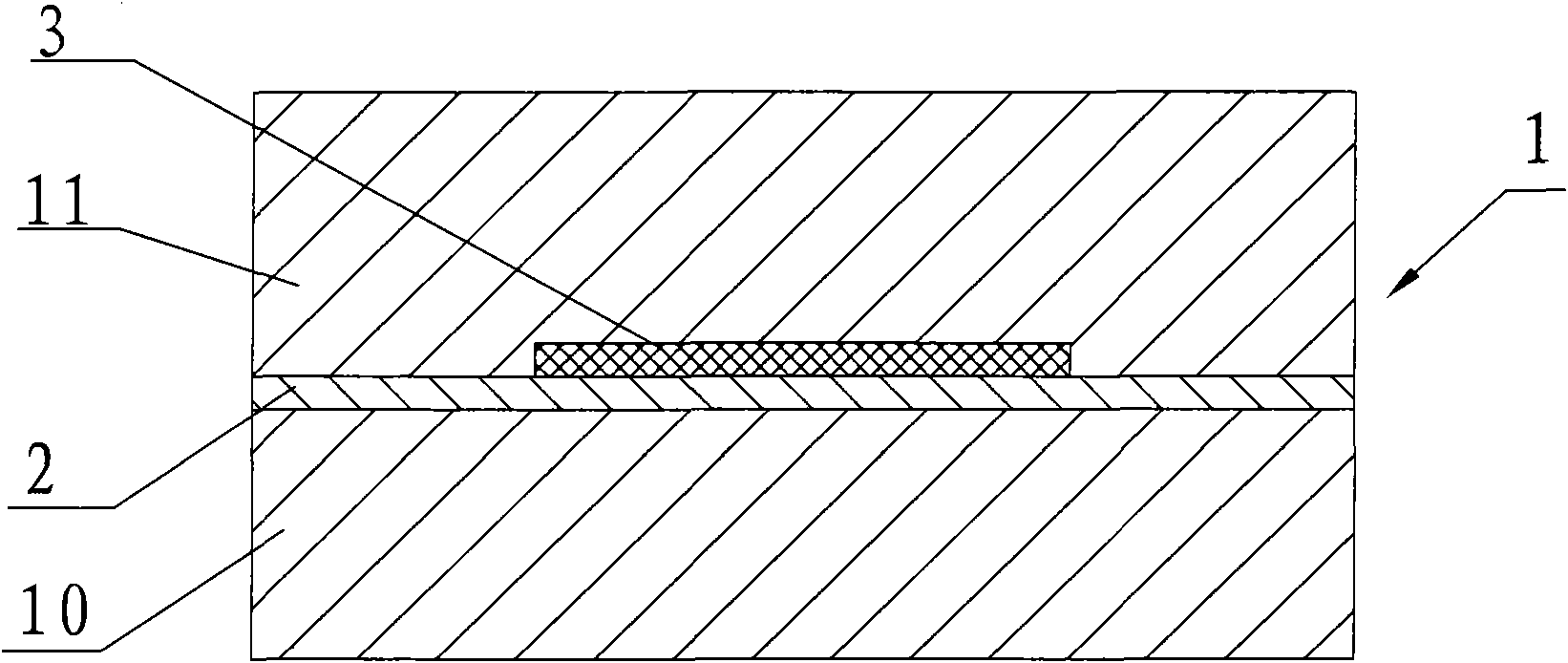

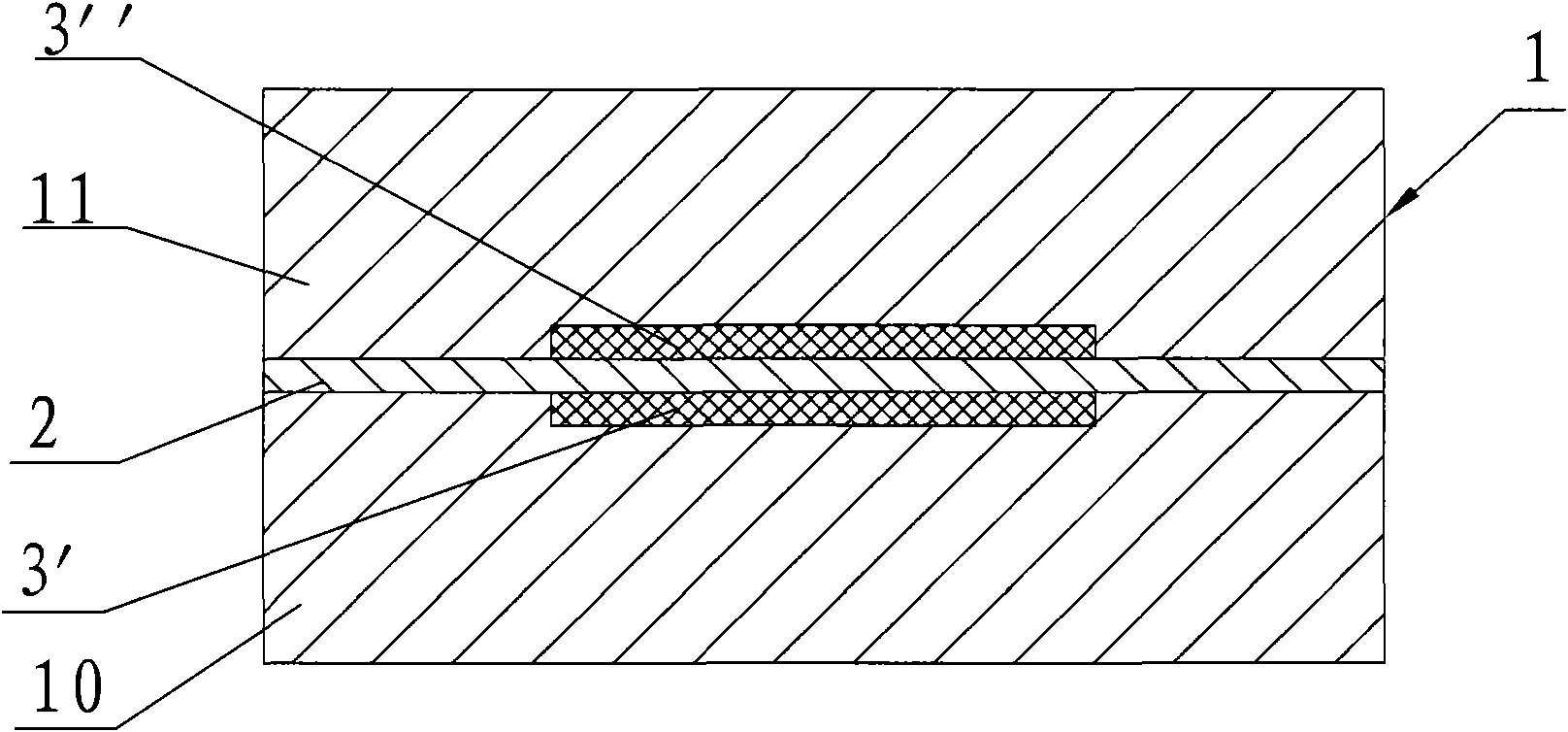

Fuse with built-in thermal-protective coating and manufacture process thereof

ActiveCN102013368AReduce heat transferLower resistanceFuse device manufactureCeramic compositeElectrical conductor

The invention relates to a fuse and a production process thereof, wherein the fuse comprises a glass-ceramic substrate, a fusible metallic conductor built in the glass-ceramic substrate, a thermal-protective coating arranged on at least one face of the fusible metallic conductor, and a terminal electrode arranged on the glass-ceramic substrate, and the thermal-protective coating is made of a porous glass-ceramic composite material. In the manufacture process, an ultraviolet curing technology is utilized, and the fuse is produced through low temperature cofiring after UV (ultraviolet) curing. The thermal-protective coating has low heat conductivity, so that the radiating of the metallic conductor is effectively reduced, and the required resistance is much smaller at the fuse demand of certain current intensity. The manufacture process provided by the invention is simple, each coating of the fuse is combined compactly, and the fuse has outstanding arc extinction performance and higher stability. The surface- mounted fuse in the structure not only has high reliable fusing property, but also has the characteristics of low resistance and low power consumption, therefore the energy consumption in the circuit can be reduced, energy sources are saved, and the fuse can be widely used in the circuit protection of mini portable electronic products.

Owner:AEM COMPONENTS (SUZHOU) CO LTD

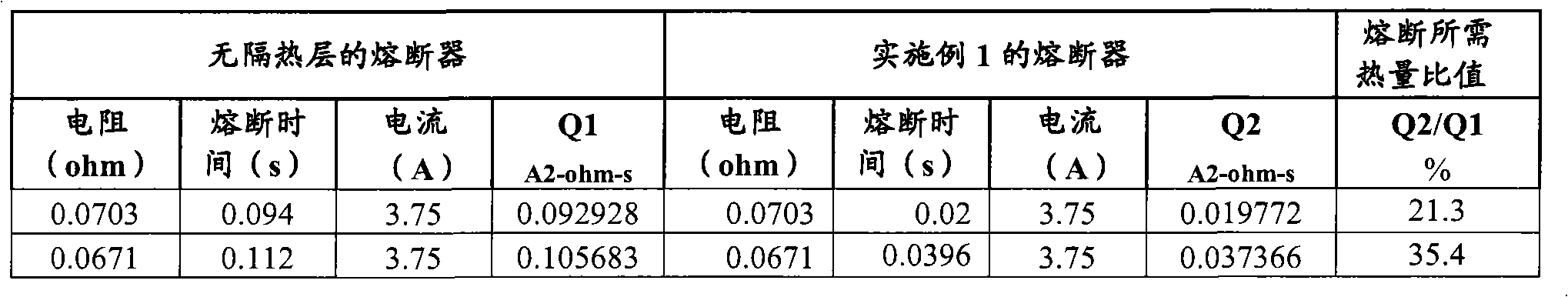

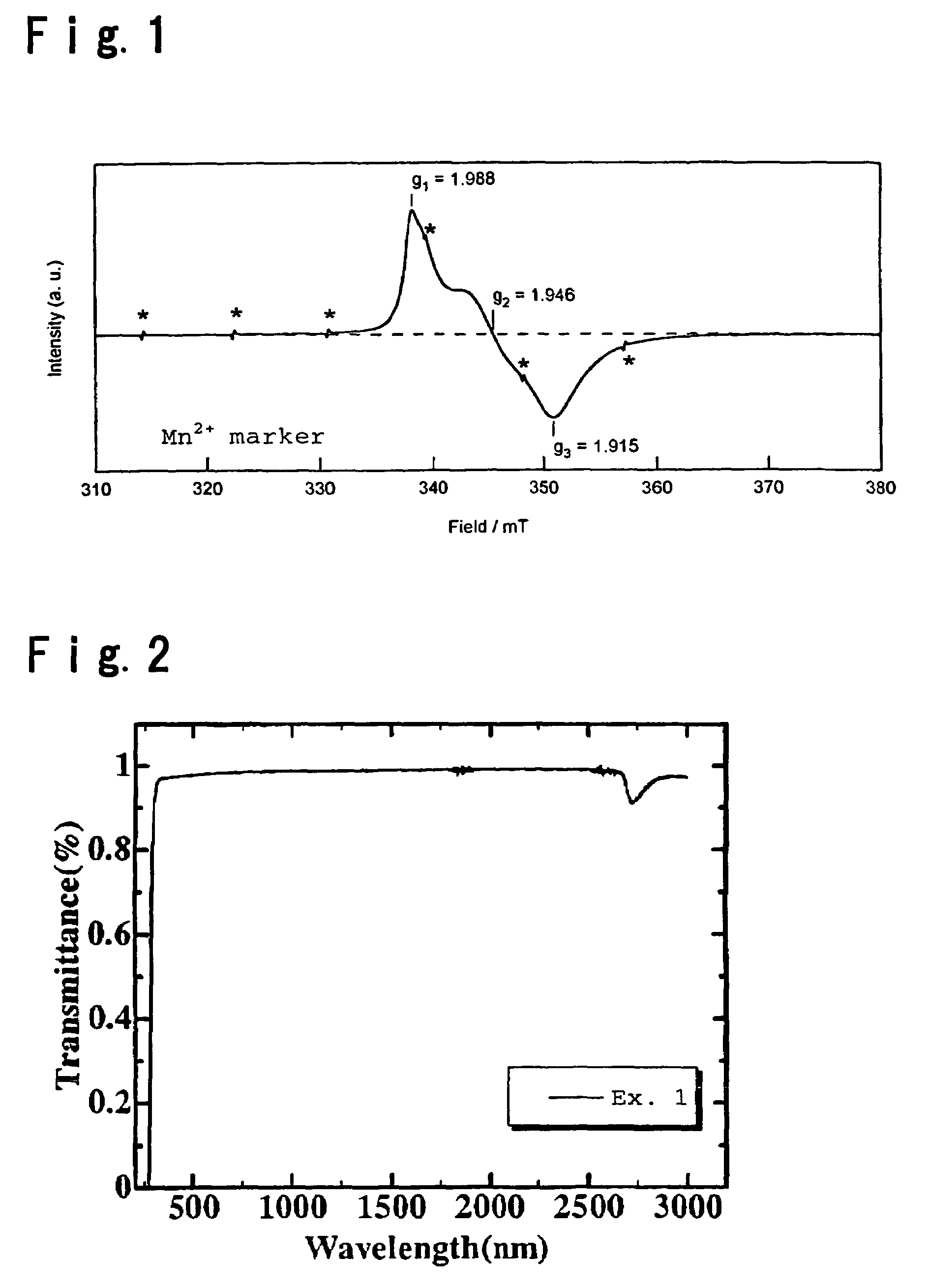

Silica glass containing TiO2 and process for its production

It is to provide a silica glass containing TiO2, having a wide temperature range wherein the coefficient of thermal expansion is substantially zero.A silica glass containing TiO2, which has a TiO2 concentration of from 3 to 10 mass %, a OH group concentration of at most 600 mass ppm and a Ti3+ concentration of at most 70 mass ppm, characterized by having a fictive temperature of at most 1,200° C., a coefficient of thermal expansion from 0 to 100° C. of 0±150 ppb / ° C., and an internal transmittance T400-700 per 1 mm thickness in a wavelength range of from 400 to 700 nm of at least 80%. A process for producing a silica glass containing TiO2, which comprises porous glass body formation step, F-doping step, oxygen treatment step, densification step and vitrification step.

Owner:ASAHI GLASS CO LTD

Steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents

ActiveCN102363286AImprove the speed of useExtended service lifeAbrasion apparatusCeramic compositeTissue density

The invention relates to a steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents, which is in a structure made of polycrystalline solid materials with the coexistence of glass and crystals and adopts the bonding agents of clay, feldspar, boron-containing microcrystal glass, pyrophyllite and soapstone to be made into high-intensity and low-shrinkage engineering ceramic bonding agents, good performance of the glass and the ceramics such as high mechnical intensity, wear resistance, corrosion resistance and the like are integrated, then, the glass and the ceramics are combined with mixed grinding materials, a molding pressing method is adopted for the high-pressure double-side pressing process forming, the low-temperature firing is adopted, the positive pressure reducing atmosphere heat simulation crystallization is adopted at the 800 DEG C heat insulation section, and the mixed grinding material and micro porous glass phase high-intensity microcrystal engineering ceramic composite structure is formed, so the intensity and the bonding degree of the steel blank grinding abrasion wheel are greatly improved, the use linear speed of the abrasion wheel is accelerated, and the safety factor is high. The steel blank grinding abrasion wheel belongs to the novel efficient special steel blank grinding abrasion wheel with the characteristics that the intensity andthe hardness are high, the tissue density is uniform, the grinding ratio is great under the condition of high-speed grinding, workpieces can not be damaged through firing, and the automation of iron and steel industries is easy to realize.

Owner:江苏华东砂轮有限公司

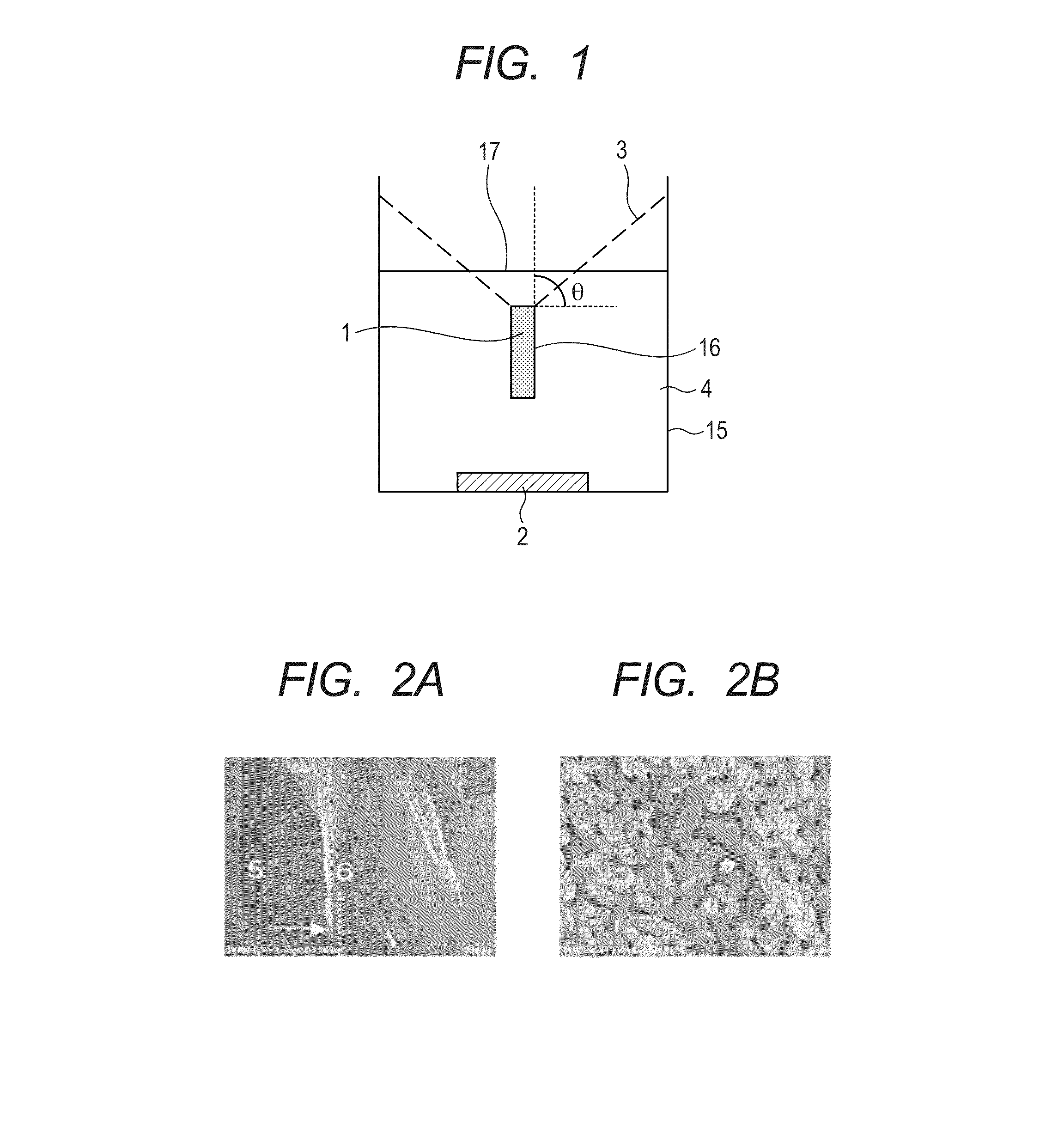

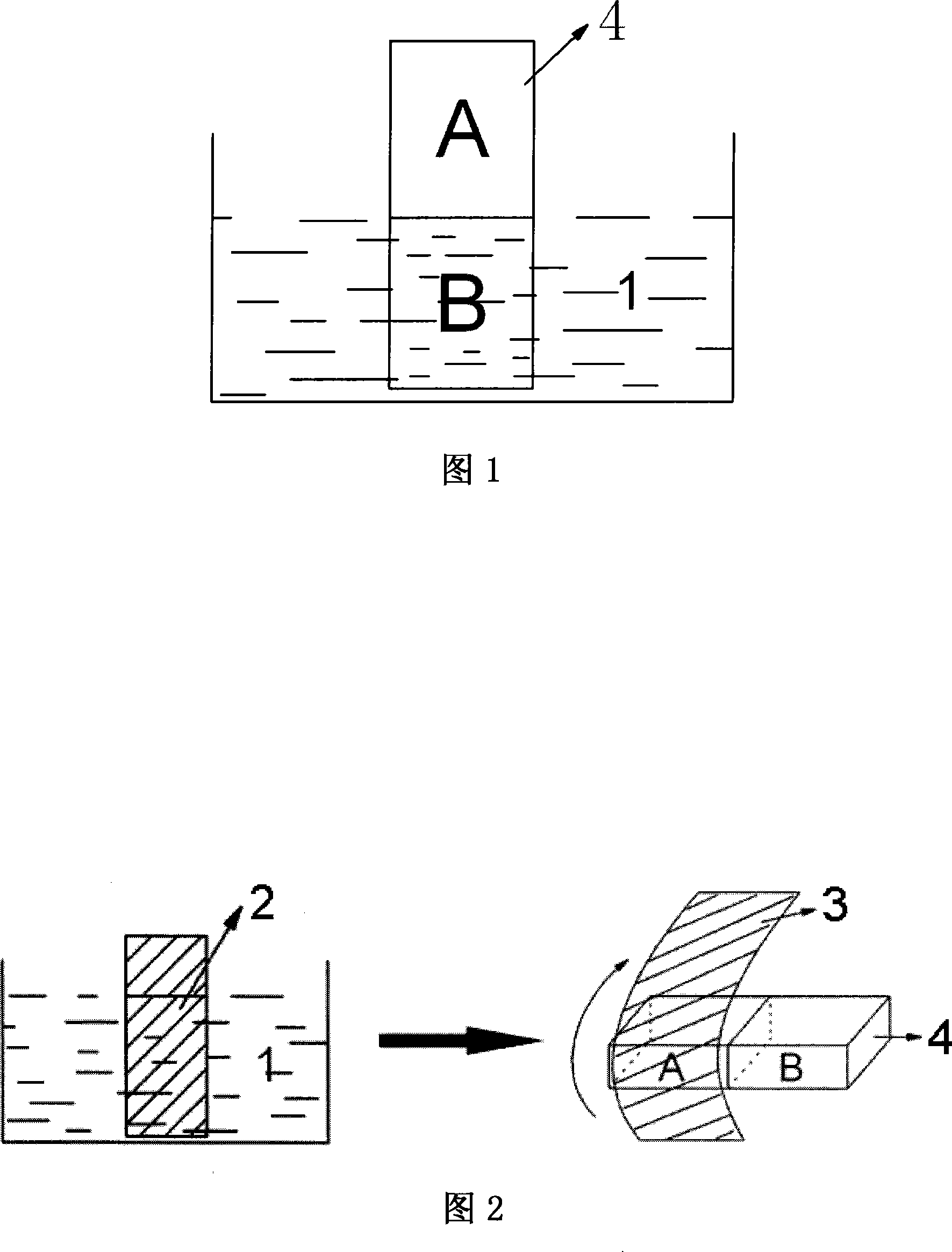

Method of producing porous glass

InactiveUS20130068725A1Shorten treatment timeSuppression problemPaper/cardboard articlesSilicon dioxideLiquid surfaces

Provided is a method of producing a porous glass, including selectively etching a phase-separated glass with an acid solution, in which the method allows a processing time to be shortened and suppresses gel-like silica from remaining and being deposited in pores of a porous portion. The method of producing a porous glass includes: immersing the phase-separated glass in a bath containing an acid solution; setting an angle θ, which is formed by a surface to be porosified of the phase-separated glass and a bath liquid surface, to 10° or more to 90° or less; and irradiating the bath with an ultrasonic wave to etch the phase-separated glass, thereby obtaining the porous glass.

Owner:CANON KK

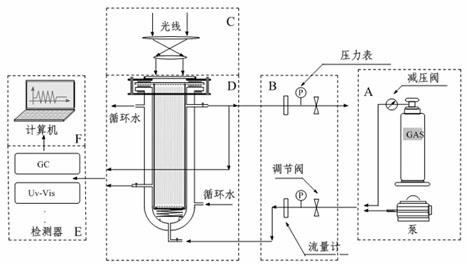

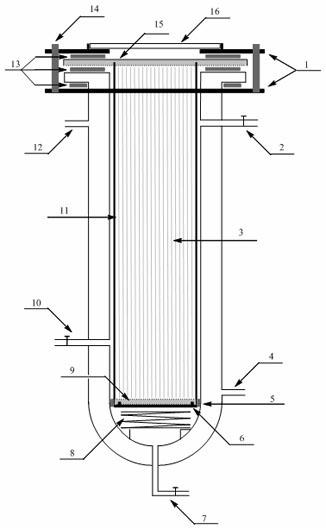

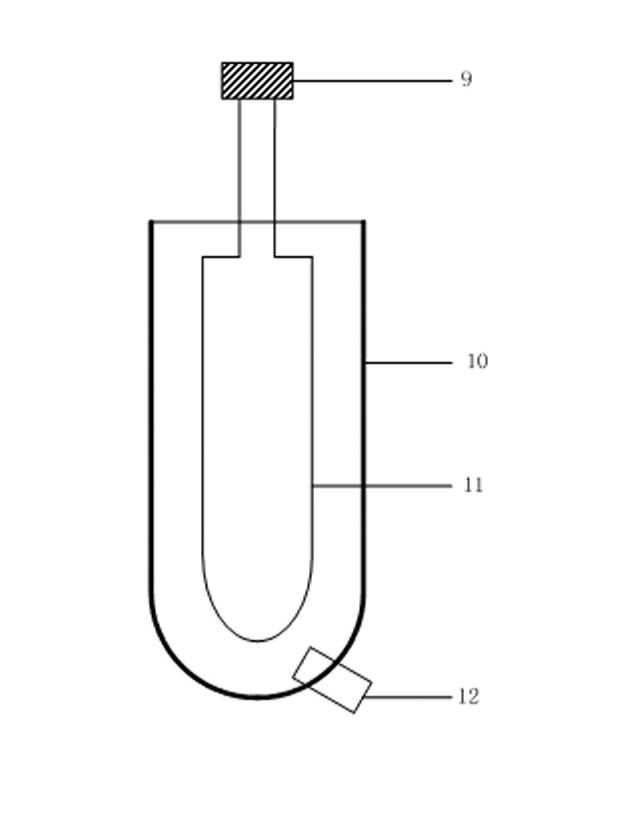

Method and equipment for manufacturing fully-synthesized oversize ultralow water peak optical fiber preform

ActiveCN102173572ASmall sizeLow water peakGlass deposition burnersGlass productionVitrificationFiber

The invention relates to a method and equipment for manufacturing a fully-synthesized oversize ultralow water peak fiber preform, in particular to a method for manufacturing an oversize ultralow water peak fiber preform. The method comprises the following steps of: firstly, adjusting the flow and the position of a blow lamp group so as to increase the core diameter under the condition that the diameter of a core raw material is unchanged; and then, respectively carrying out deuterium gas treatment before the vitrification process of a core powder rod and a porous glass preform. The equipment comprises a deposition device for the core raw material of the fiber preform and a sintering device for the core raw material of the fiber preform and the porous glass preform, wherein the deposition device for the core raw material of the fiber preform comprises a gas supply part, a rotary lifting part and a control part, and the rotary lifting part comprises a servo motor, a drive screw rod, a screw rod nut and a deposition boom; and the sintering device for the core raw material of the fiber preform and the porous glass preform comprises a sintering gas supply part, a preform rotary liftingpart and a sintering furnace.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD

Bayer process red mud porous glass ceramic and preparation method thereof

The invention relates to a Bayer process red mud porous glass ceramic and a preparation method thereof. The Bayer process red mud porous glass ceramic is processed and produced by taking Bayer process red mud as a main raw material, wherein the raw material comprises the following components in percentage by weight: 2-7% of a pore-forming agent, 3-15% of a polyvinyl alcohol aqueous solution of which the mass fraction is 3%, and the balance of basic glass which is processed and produced by taking the Bayer process red mud as the main raw material; and the basic glass comprises the following chemical components in percentage by mass: 40-55% of SiO2, 5-13% of Al2O3, 20-33% of CaO, 5-10% of Fe2O3, 3-12% of Na2O, 3-8% of B2O3, 2-6% of MgO and 1-4% of F<->. Compared with the conventional brick, the Bayer process red mud porous glass ceramic material prepared by the method has the characteristics of light weight, high strength, heat insulation, heat preservation, sound absorption, noise prevention and the like, so that the Bayer process red mud porous glass ceramic material is an ideal building material.

Owner:HENAN POLYTECHNIC UNIV

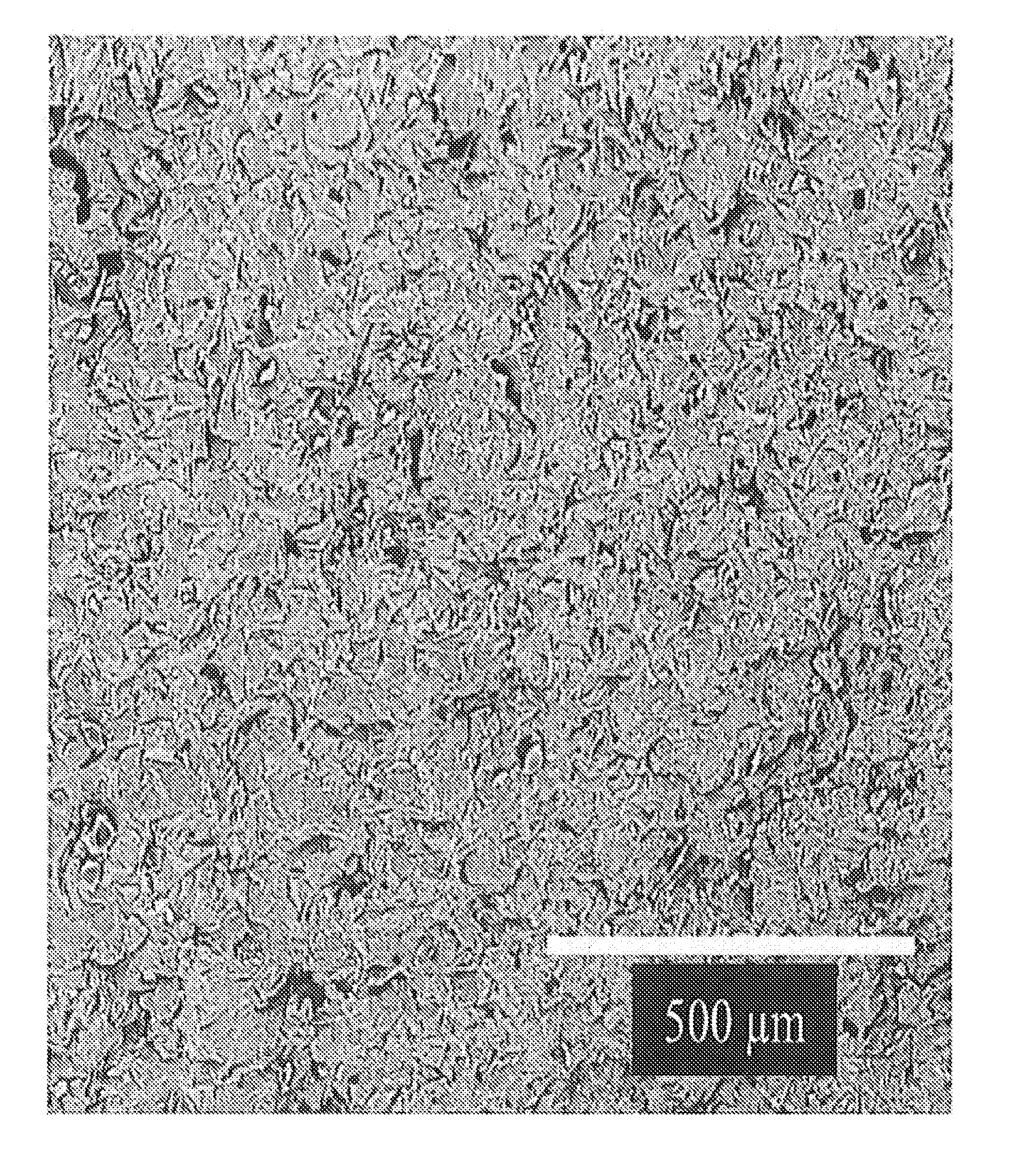

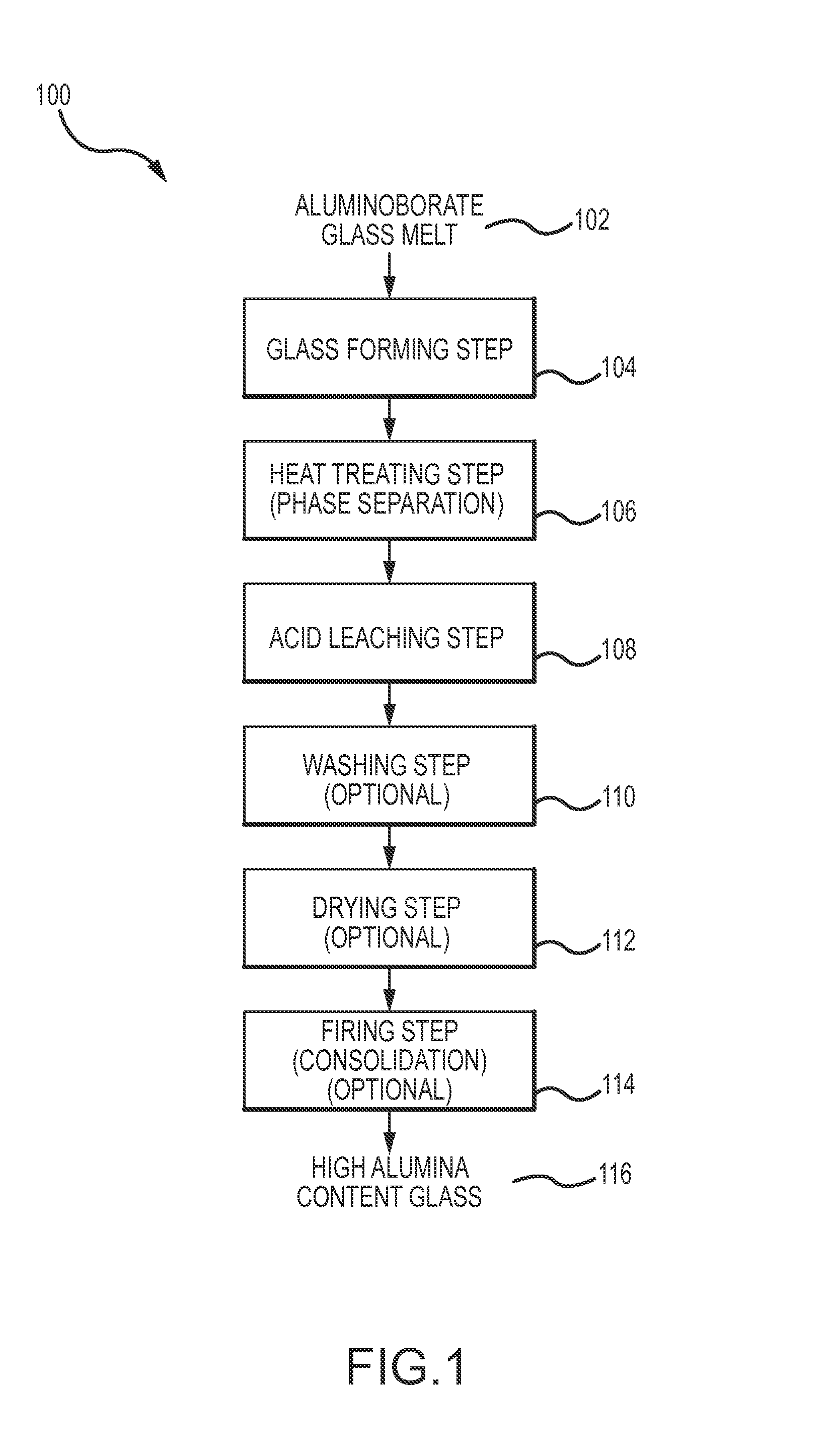

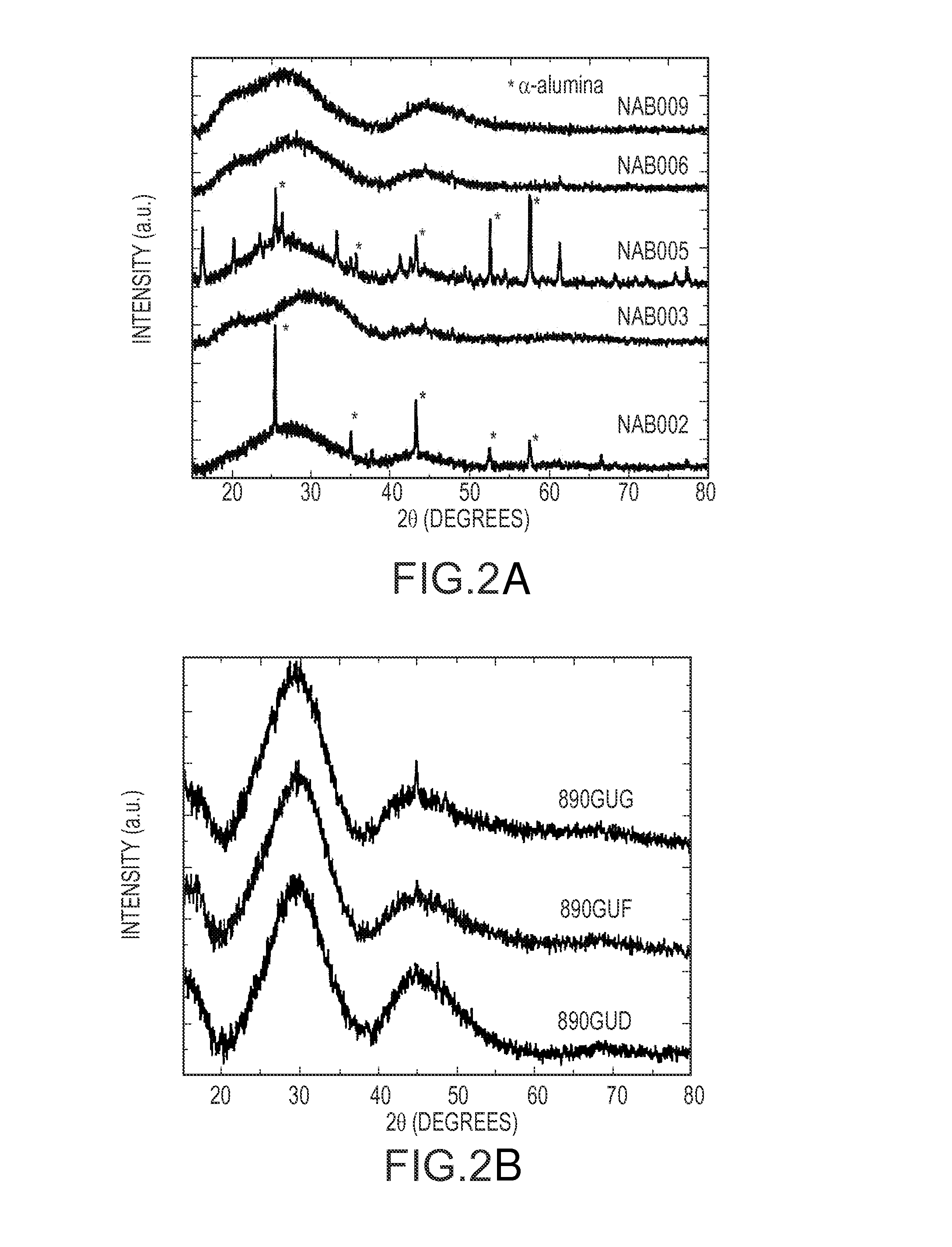

Alumina-rich glasses and methods for making the same

The invention relates to new glass formulations with alumina contents greater than 35 mol % and methods for making these glasses. The glass may be a porous glass or a dense glass.

Owner:COLORADO SCHOOL OF MINES

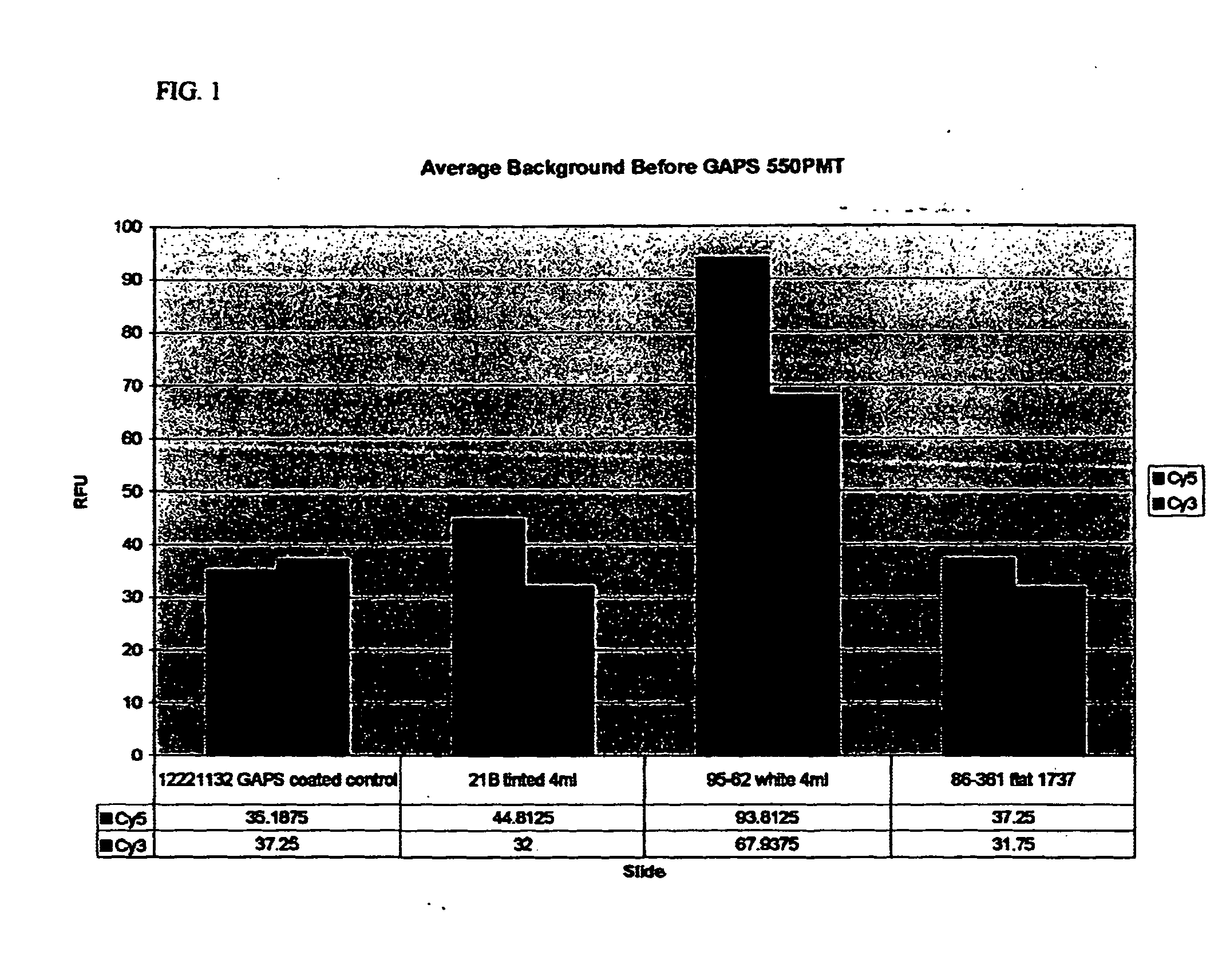

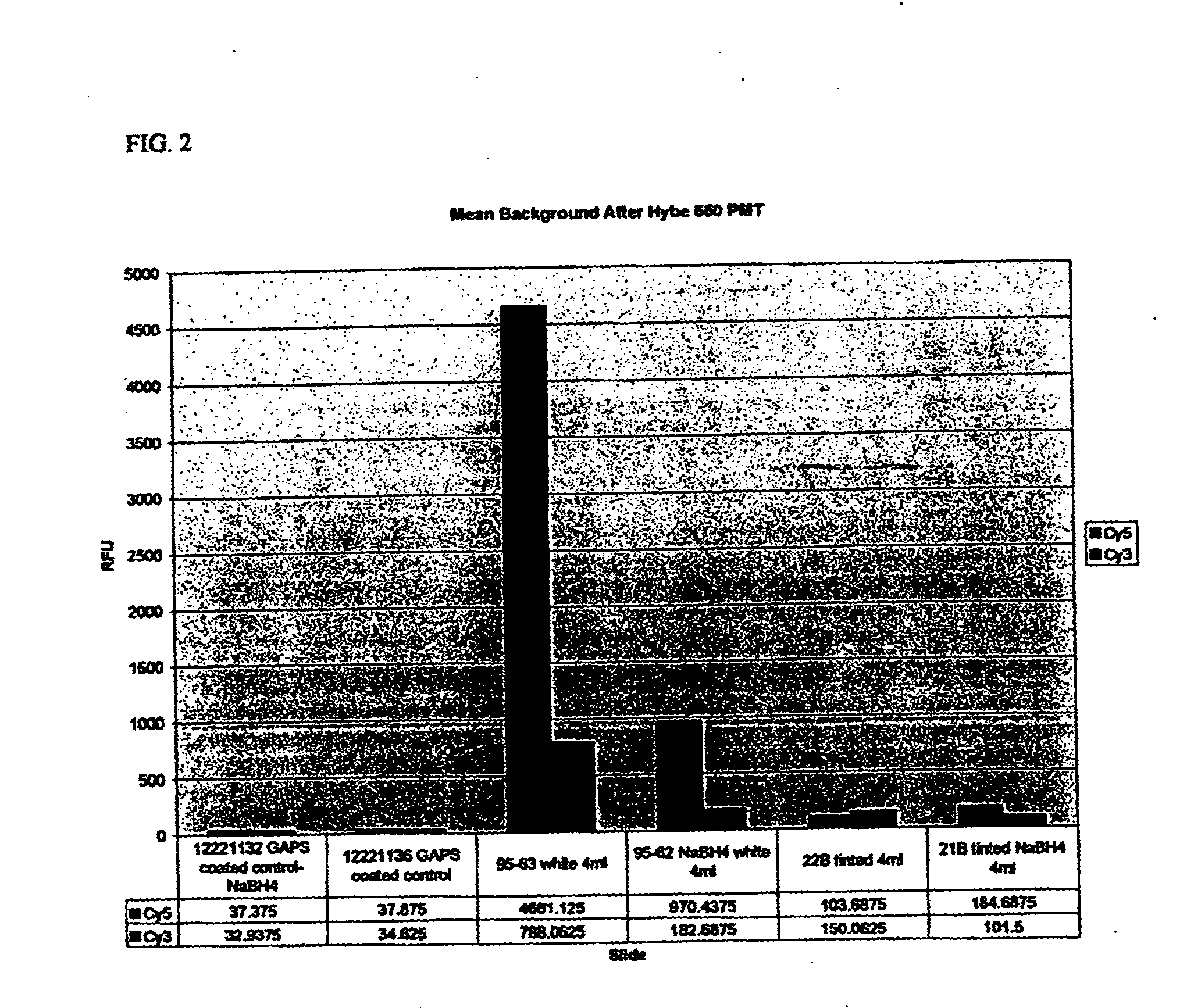

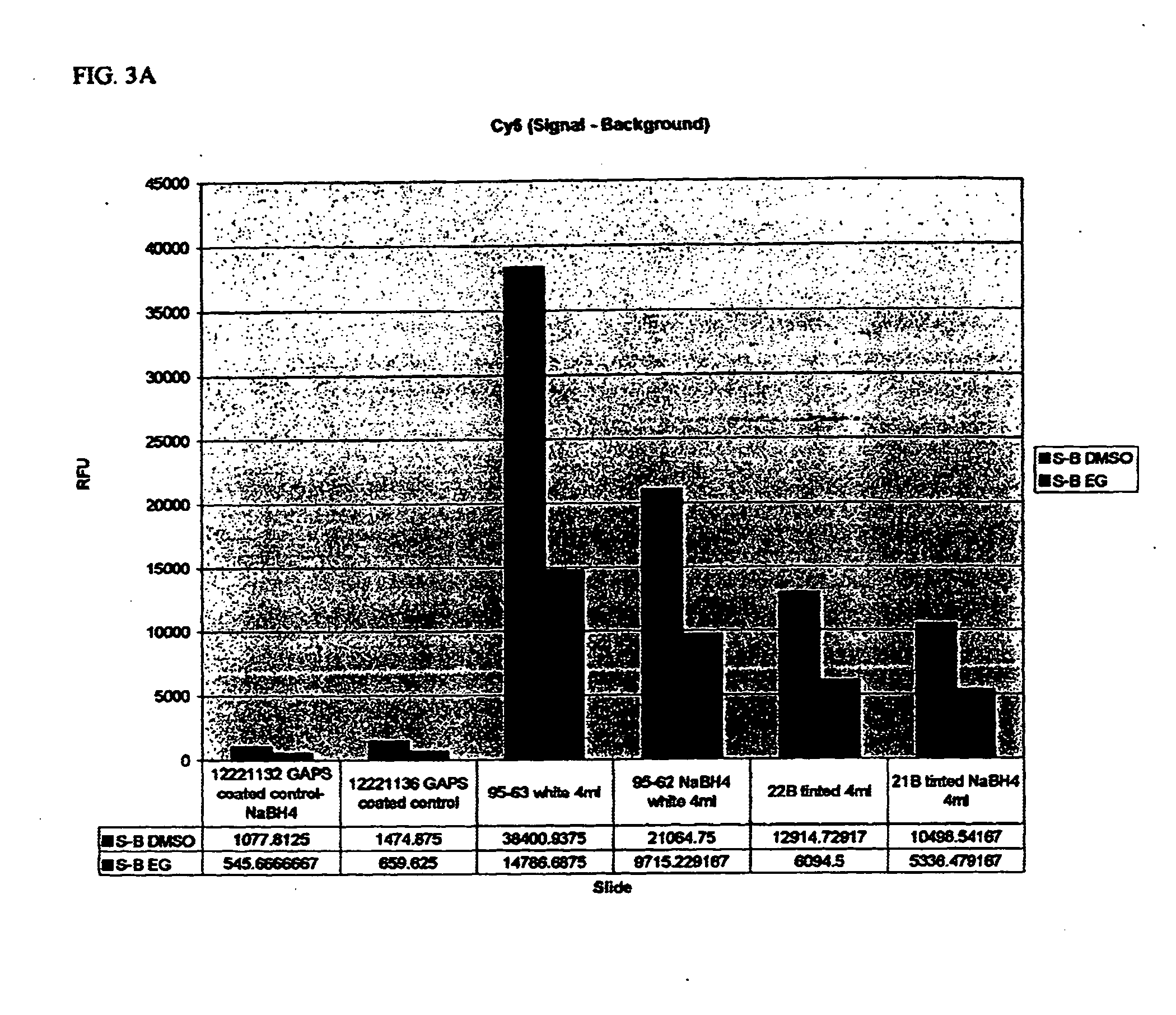

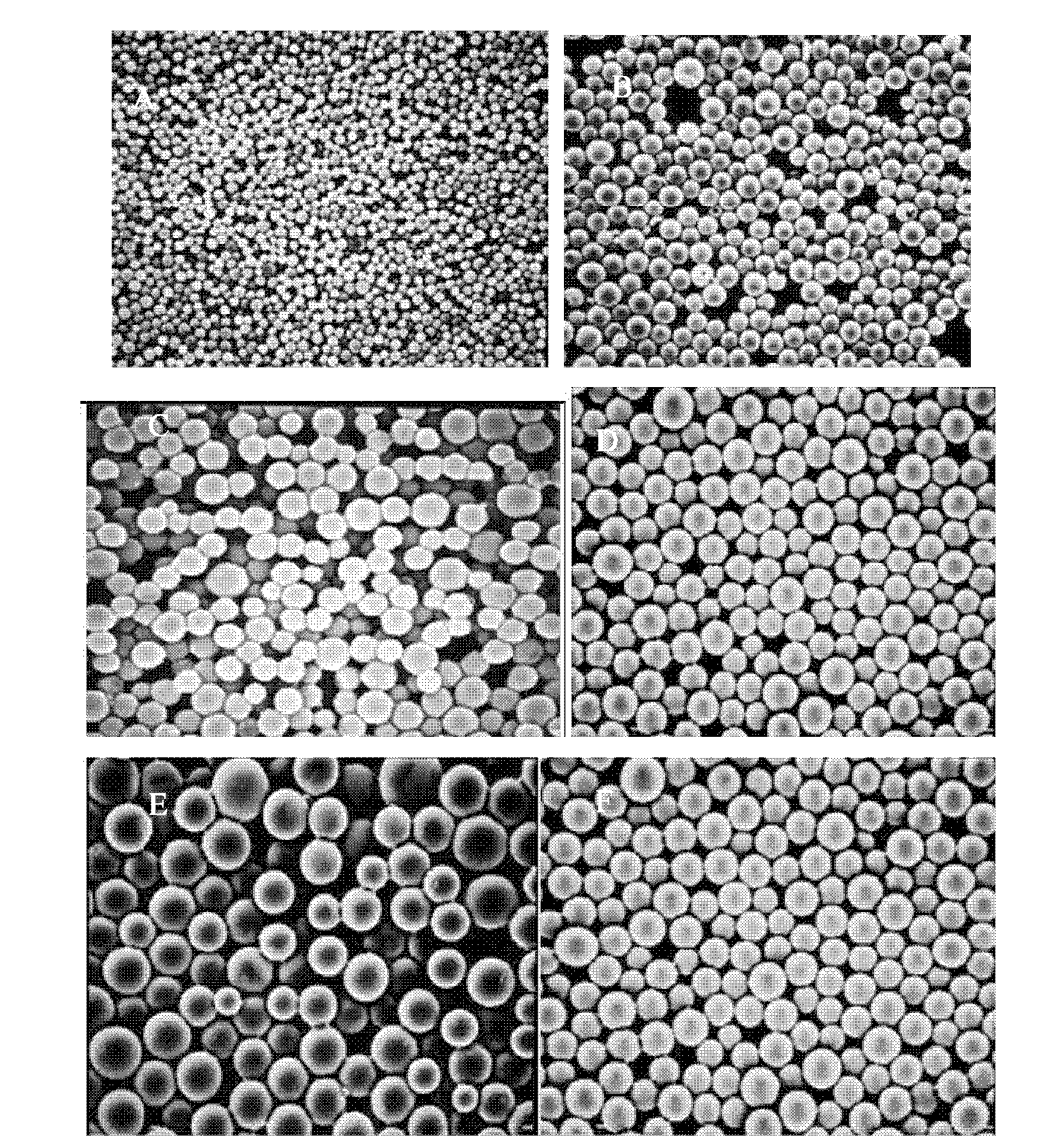

Porous glass substrates with reduced auto-fluorescence

InactiveUS20050048571A1High auto-fluorescenceImprove reflectivityBioreactor/fermenter combinationsPeptide librariesPorous glassCompound (substance)

A porous inorganic substrate that may be used as a support, upon which biological, biochemical, or chemical reactions may be executed, is provided. A porous layer of the substrate is tinted with a colorant agent, and the porous substrate has at least about 15-20% less auto-fluorescence background relative to a conventional “white” porous substrate. The tinted porous layer provides improved signal to noise ratios that are important in detection metrics when performing biological or chemical binding assays. Once the porous layer is functionalized, one may immobilize probe molecules on or within the porous layer to create a microarray having a greater probe concentration and retention capability than conventional non-porous inorganic substrates, without suffering relatively high levels of auto-fluorescence and other detriments common to un-tinted porous substrates.

Owner:CORNING INC

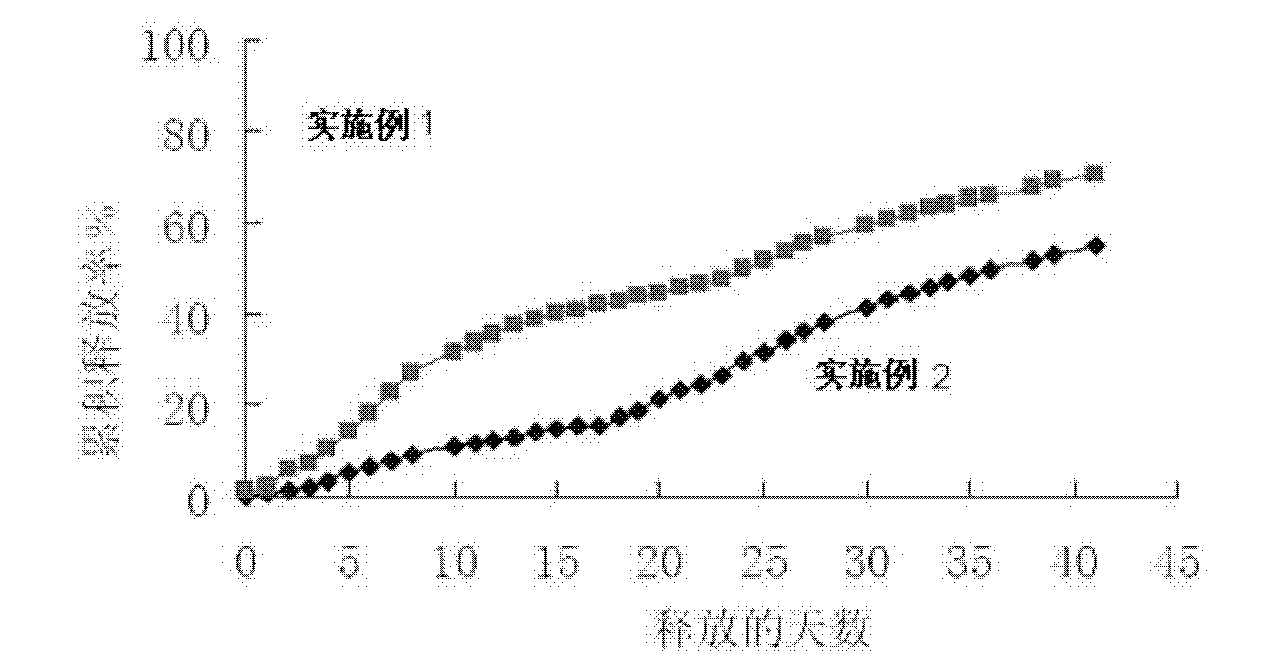

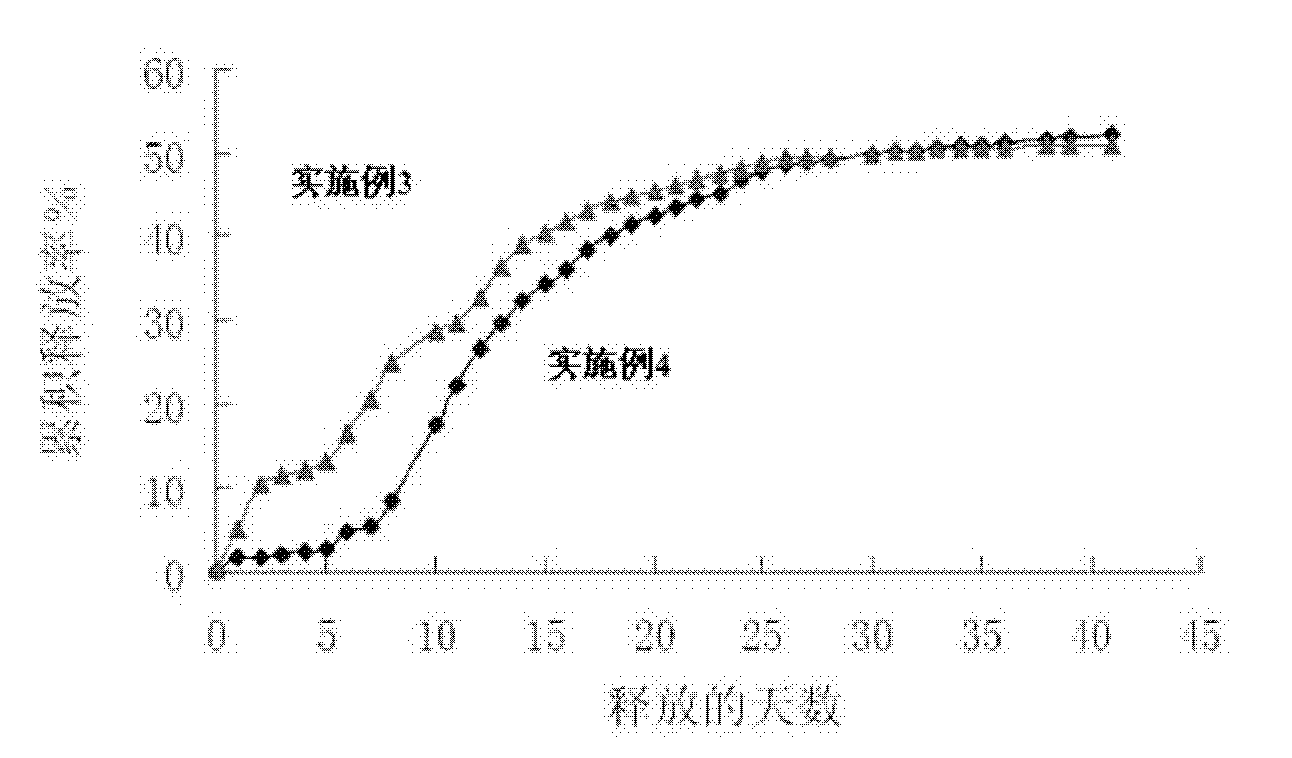

Microsphere preparation method for adjusting and controlling release behavior of risperidone microspheres and for controlling size thereof

InactiveCN102188384ASmooth and rounded surfaceParticles are regular and non-adhesiveOrganic active ingredientsPowder deliveryMicrosphereOil phase

The invention relates to a microsphere preparation method for adjusting and controlling the release behavior of risperidone microspheres and for controlling the size thereof, belonging to the technical field of nano-medicaments. The preparation method comprises the steps of: firstly, adding a sustained-release or controlled-release functional material to one or the mixture of dichloromethane, ethyl acetate and acetonitrile, swirling and dissolving to obtain an organic solution of the sustained-release or controlled-release functional material; then adding particles containing risperidone and an alkaline matter to the organic solution of the sustained-release or controlled-release functional material, i.e. stirring or swirling in the oil phase to evenly disperse to form even suspension; and adding the suspension to SPG (Shirasu Porous Glass) membrane emulsion with different bore diameters, enabling the suspension to enter brine containing a surfactant through the membrane emulsion by adjusting the pressure, stirring to form microspheres, and transferring into the brine for solidifying to finish preparation. The biodegradable risperidone microsphere sustained-release preparation prepared by the invention has quick effect taking speed and long drug release time, the particle size of the microspheres is controllable, the envelop rate is high, and the quality of the risperidone microspheres is controllable.

Owner:SHANGHAI JIAO TONG UNIV

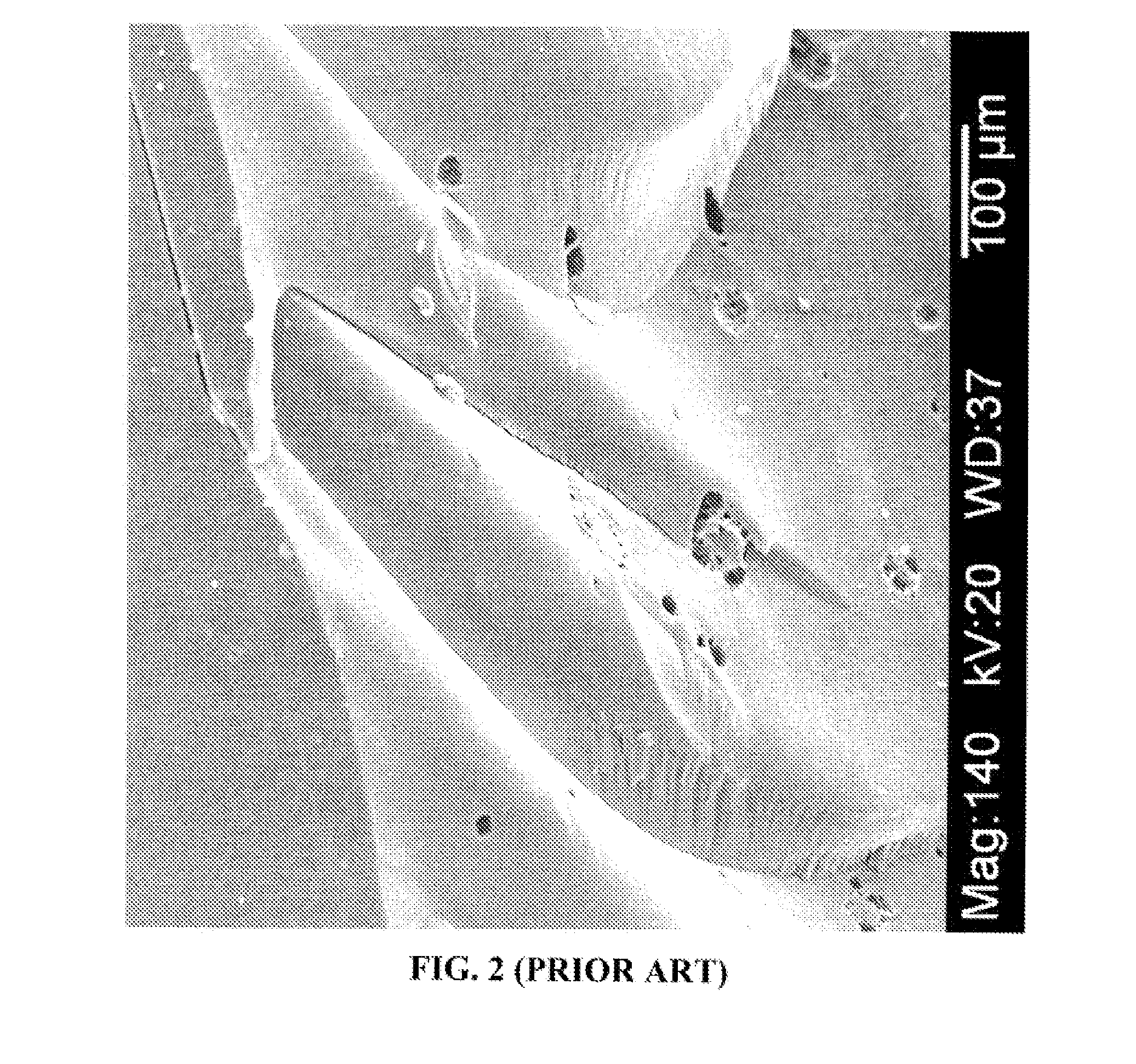

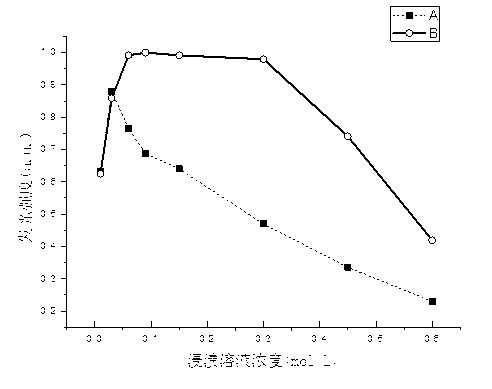

Method for manufacturing integrated color luminous vycor glass

A method for manufacturing integral chromatic luminous vycor glass, which is characterized in that the method comprises: (1) preparing cellular glass, (2) preparing rare earth with certain concentration or transition metal luminous solion, (3) introducing the rare earth or transition metal luminous solion in the cellular glass by employing the segmental doping method, (4) drying the cellular glass doped with the rare earth or transition metal luminous solion in the air at a temperature of 200-800DEG C and (5)placing the dried cellular glass doped with the luminous solion in a high temperature furnace and eliminating micropores to form dense, transparent and integral chromatic luminous vycor glass via solid-phase sintering of air at a temperature of 1100-1250DEG C or reducing atmosphere. The glass of the invention is colorless in appearance, dense and transparent, and can emit light with a plurality of colors when being shined by ultraviolet lamp. The method is simple in manufacturing process, needless in binding agent and low in cost, and has perfect optical property, chemical stability and mechanical strength, which are similar to that of quartz glass.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

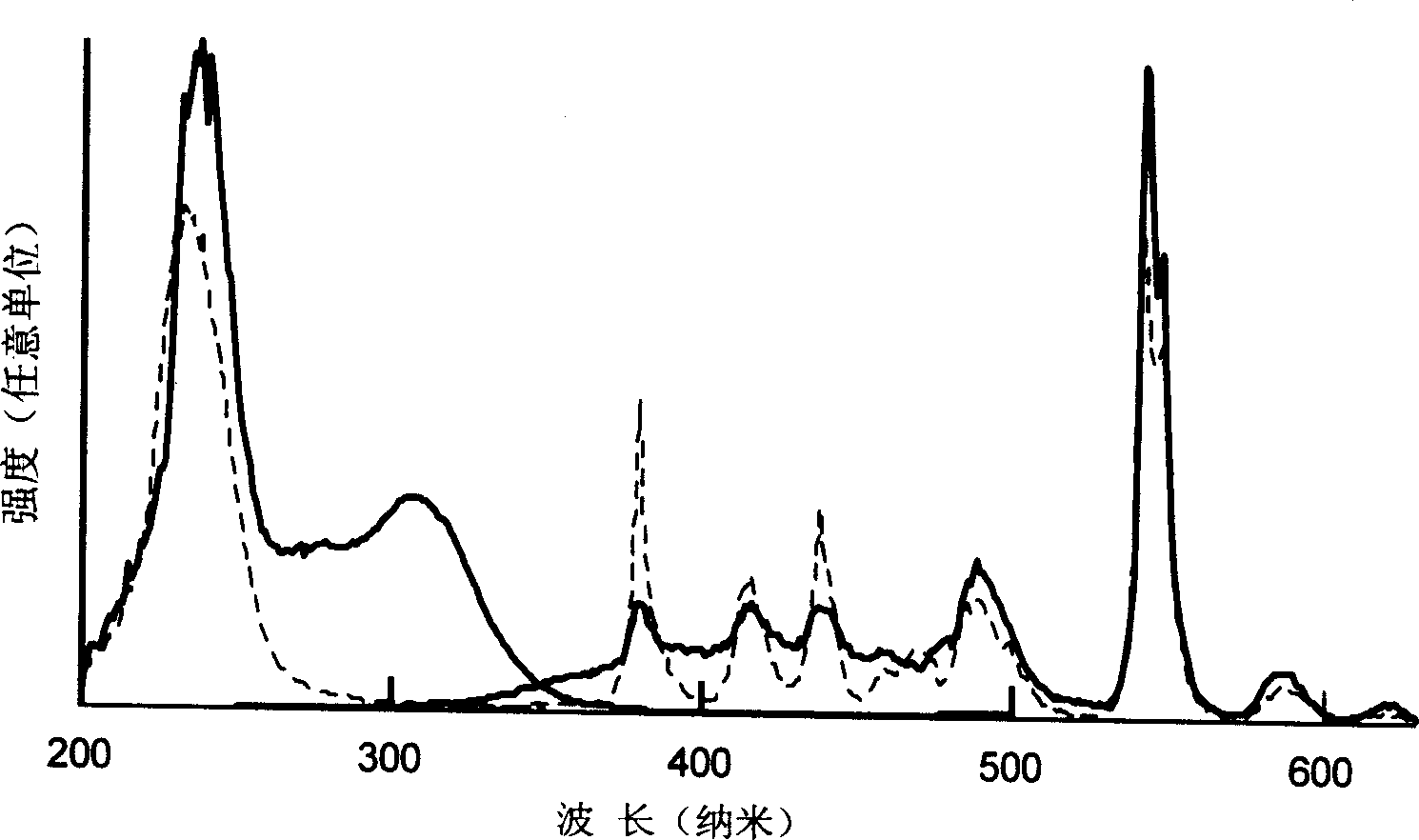

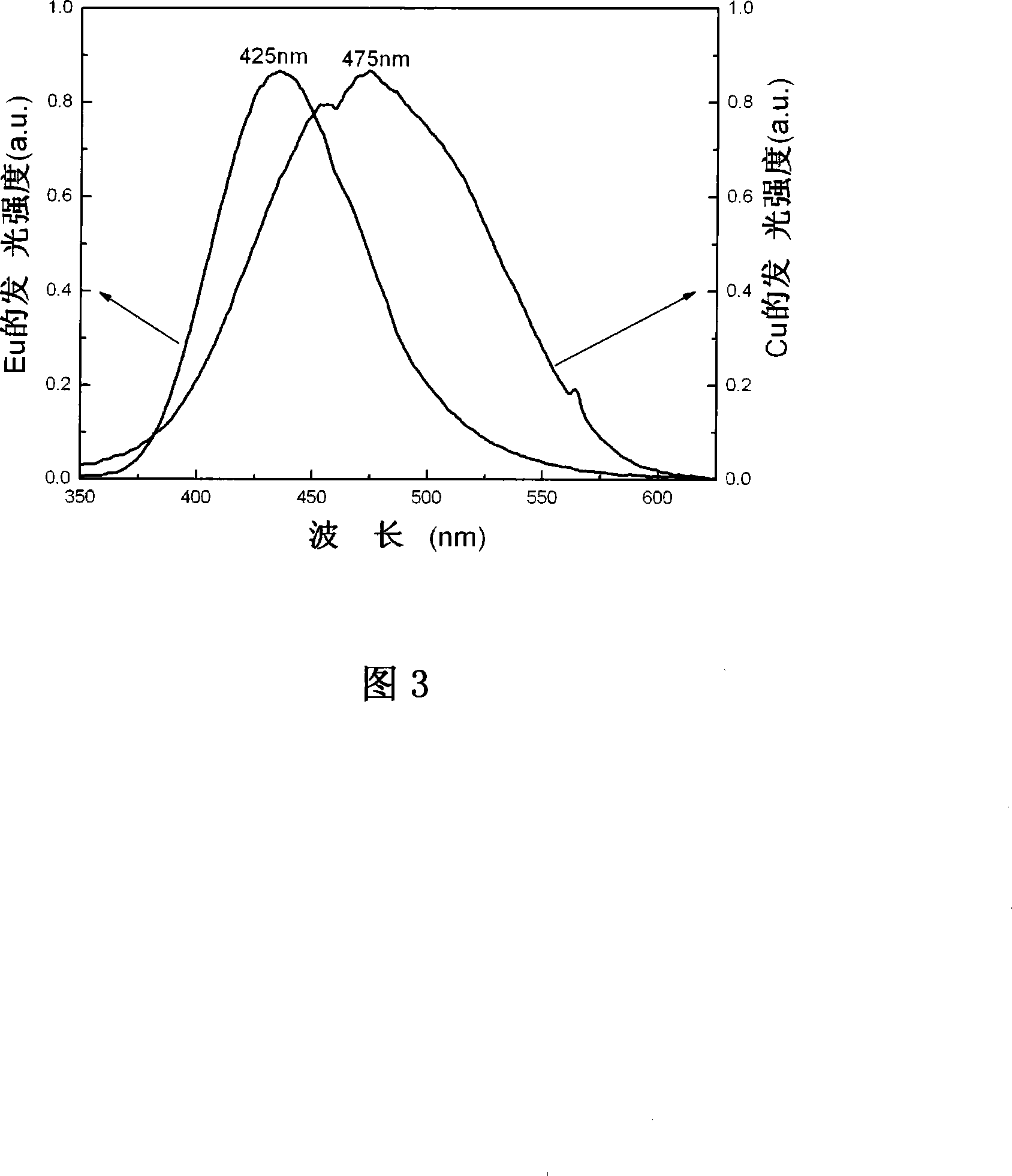

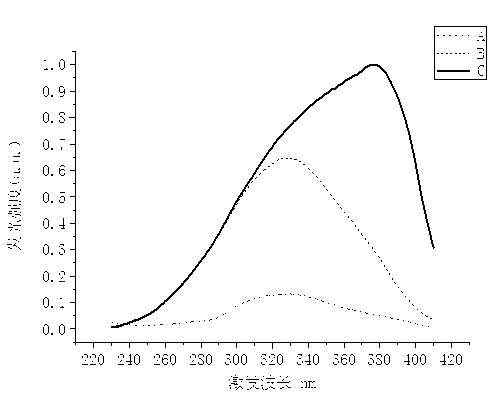

Preparation method of near ultraviolet-excited high silica blue-light-emitting glass

ActiveCN102701590AEnhance the degree of phase separationIncrease heat treatment temperatureLuminous intensityMaterials science

The invention discloses a preparation method of near ultraviolet-excited high silica blue-light-emitting glass. The preparation method comprises the steps of: firstly melting borosilicate glass, carrying out acid leaching to obtain large-aperture and intact porous glass after carrying out thermal treatment on split-phase at a higher temperature; dipping the porous glass into solution containing europium ion to soak and dope, and sintering at the high temperature in a reducing atmosphere to obtain the compact high silica blue-light-emitting glass. The glass disclosed by the invention greatly improves the doping concentration of the europium ion under the precondition of keeping the luminous intensity of the near ultraviolet-excited high silica blue light emitting, and facilitates laser excitation. The optimal excitation wavelength of the glass disclosed by the invention is expanded to a range of 350-390nm, so a high-pressure mercury lamp which is relatively safe to a human body and mature in the development and an LED (light-emitting diode) can be utilized as excitation light sources by the improvement, and the safety and convenience in application are improved. Therefore, the preparation method can be applied to the industries such as illumination and decoration and life purposes, and is expected to be a new laser material.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

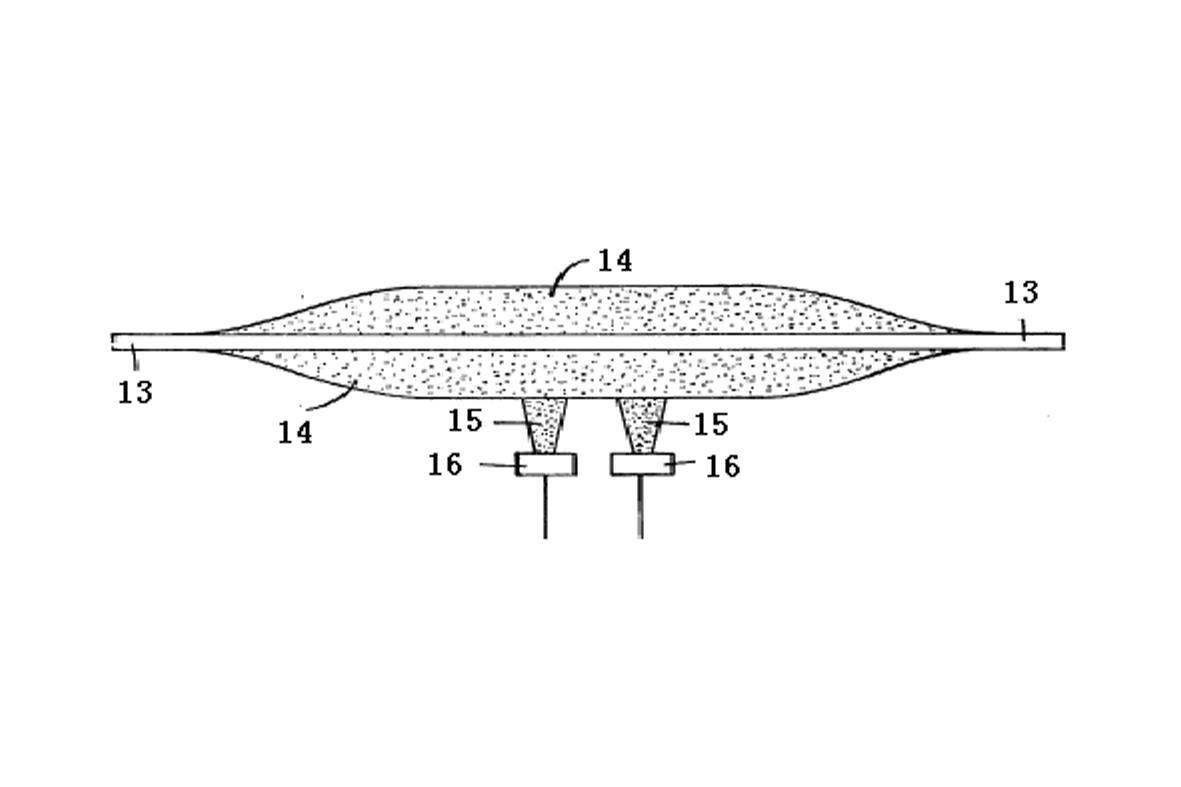

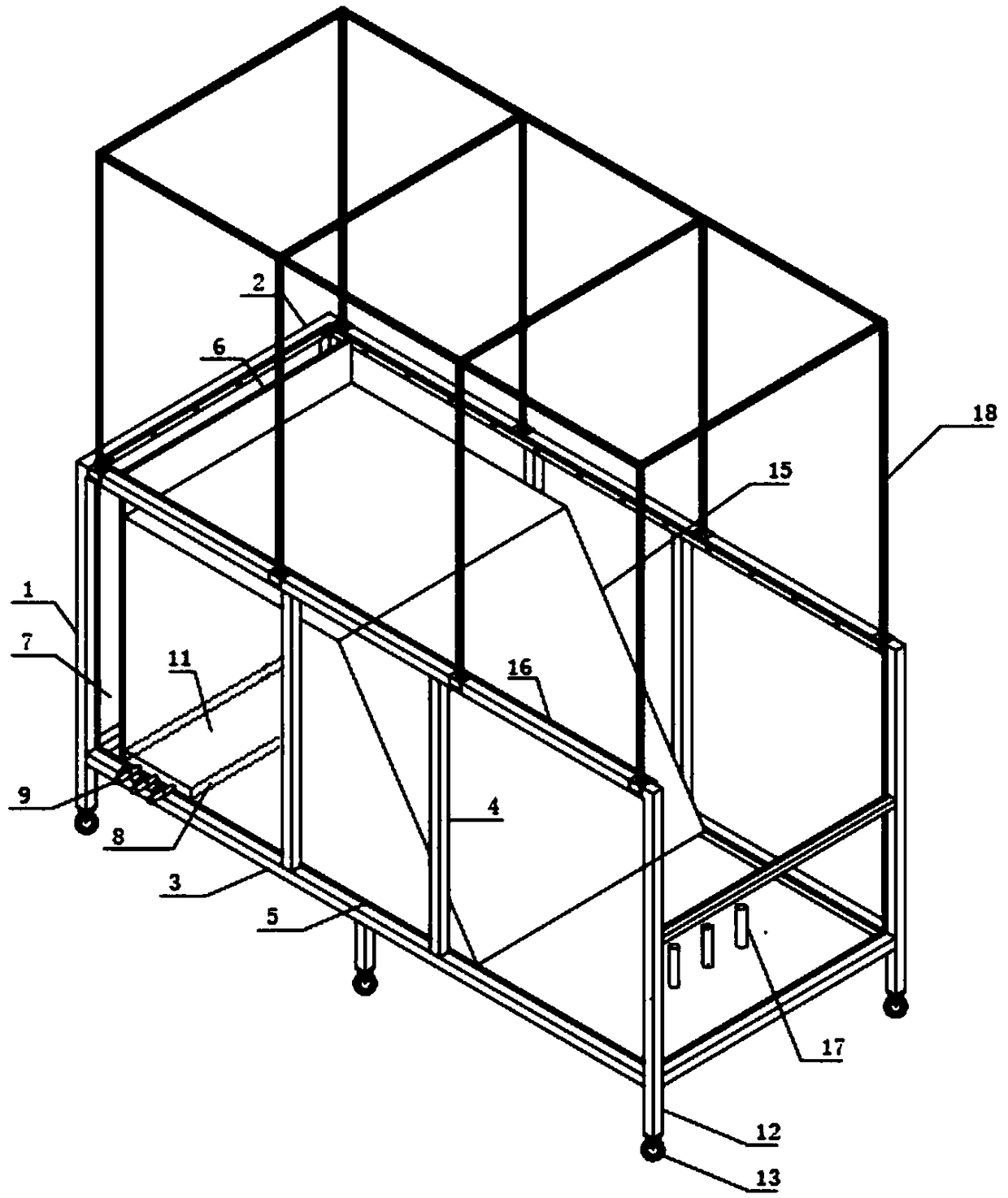

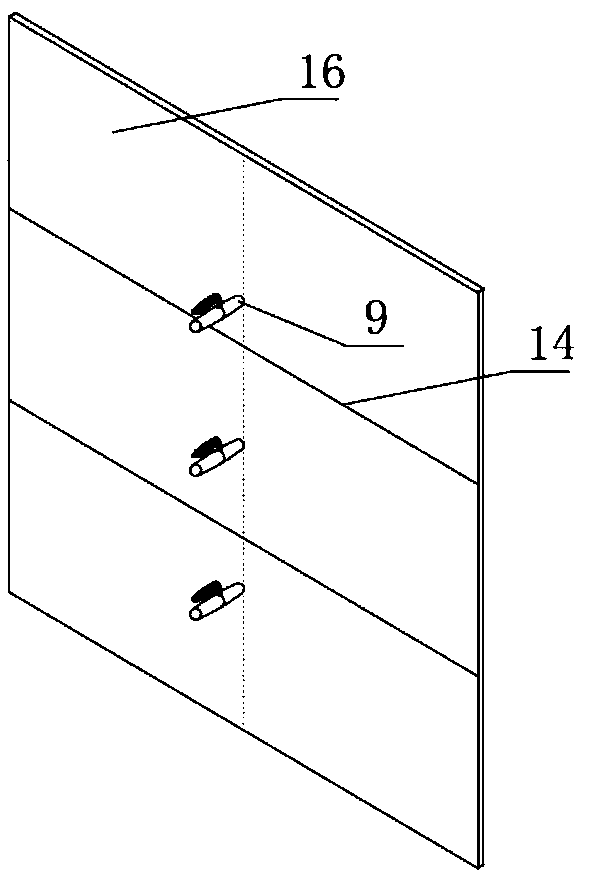

General model test system for slope stability mechanism research under multi-seepage conditions

InactiveCN108982814AEasy to manufactureImprove work efficiencyEarth material testingInstabilityEngineering

The invention discloses a general model test system for slope stability mechanism research under multi-seepage conditions which realizes different seepage conditions by designing three different boundaries in a model device for various types of induced slope seepage under complicated water environment changes. Boundary 1 (a rainfall device) can be used to simulate slope instability under rainfalleffect, boundary 2 (a water supply tank and a porous glass plate) can be used to simulate the lateral-seepage instability caused by the water filling of slope trailing edge cracks or the stable waterlevel change at the trailing edge, and boundary 3 (water injection space) can be used to simulate the seepage instability from the bottom to the top caused by slope bottom water level rise or the local pressure water effect. The three boundaries can be used alone or in combination with each other to achieve better simulation of the water environment change around the slope. According to differentactual engineering conditions, simulations are carried out through different working conditions in order to provide reference for slope stability disaster prevention and mitigation.

Owner:SHENZHEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com