Patents

Literature

44results about How to "Increase heat treatment temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for mu75 magnetic powder core of ferrosilicon aluminum

ActiveCN102360671AIncrease heat treatment temperaturePromote environmental protectionInorganic material magnetismInductances/transformers/magnets manufactureCompression moldingFerrosilicon

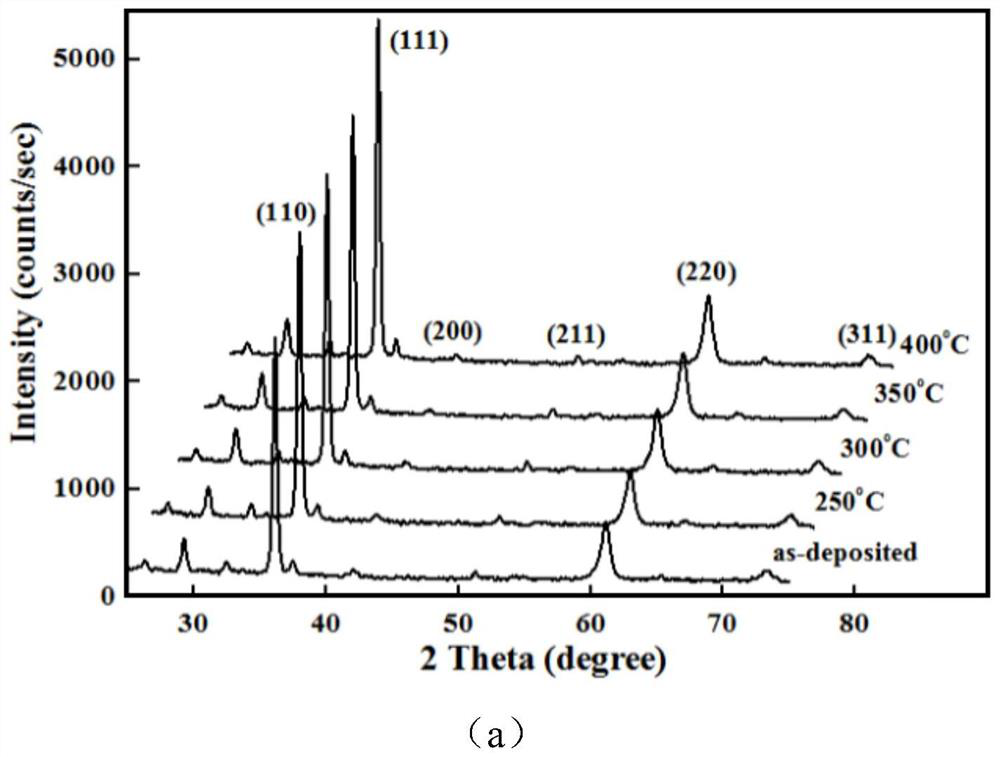

The invention belongs to the field of preparation of metallic soft magnetic materials, and particularly relates to a preparation method for a mu75 magnetic powder core of soft magnetic ferrosilicon aluminum, which includes steps of smelting, rough smashing, heat treatment, fine smashing, annealing treatment, powder grading, powder insulating, compression molding, secondary heat treatment and coating treatment and requires components, by weight, 9.10% of silicon, 5.95% of aluminum and the rest iron. The preparation is performed with the smelting temperature of 1600 DGE C, the compression molding pressure ranging from 1700MPa to 2000Mpa, magnetic powder core pressing temperature ranging from 600 DEG C to 800 DEG C, and one hour for warm keeping in a nitrogen-oxygen mixed atmosphere. The magnetic powder core mu=75+-6 at 100kHz, the magnetic conductivity mu is smaller than 1% in variation under 1000kHz, the magnetic powder core loss is accordant to Pcv (powder loss) 50kHZ / 50mT<=100Mw / cm3, and the direct-current bias magnetic field is not lower than 70Oe when the magnetic conductivity is reduced to 50%. The preparation method for the mu75 magnetic powder core of soft magnetic ferrosilicon aluminum has the advantages that added binder is solid organic binder, the heat treatment after molding includes keeping warm for one hour in the nitrogen-oxygen mixed atmosphere, and the prepared magnetic powder core is free of pulverization, high in strength and stable in performance and has fine direct current bias characteristics, frequency stability and low loss.

Owner:TDG HLDG CO LTD

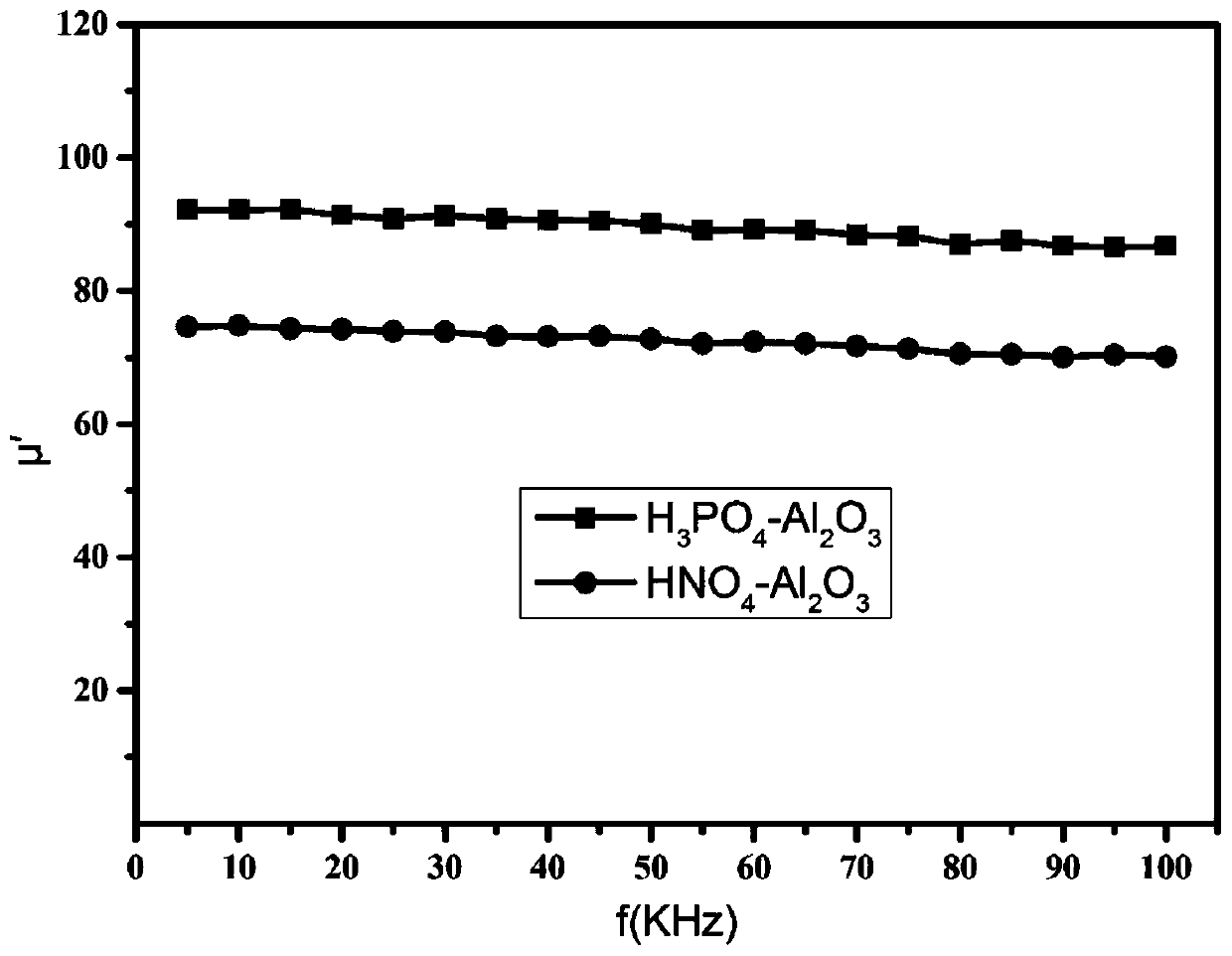

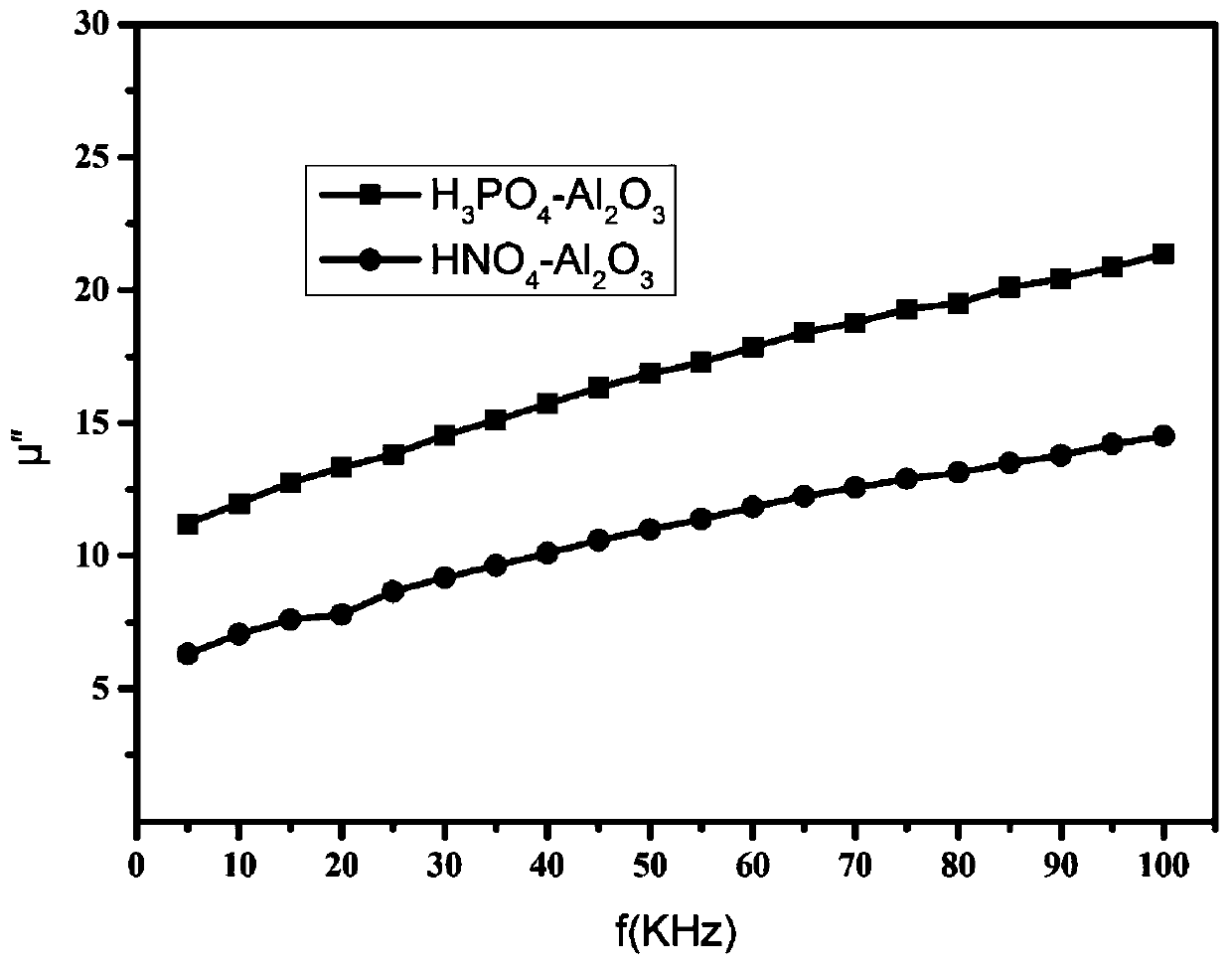

Fe-Si-Al magnetic core preparation method and inorganic composite insulation coating material for magnetic core

ActiveCN105304308AEasy to processGood temperature characteristicsInductances/transformers/magnets manufactureMagnetic materialsHeat treatingSurface coating

The invention discloses a Fe-Si-Al magnetic core preparation method and an inorganic composite insulation coating material for a magnetic core, belonging to the field of Fe-Si-Al magnetic material and used for solving the high eddy-current loss problem of existing magnetic cores and such problems caused by the fact that the existing magnetic cores usually use organic coating materials as stress is difficult to eliminate in a forming process, the insulation property of the material is poor, and the volatilization quantity of organics is large in heating processes such as heat treatment. The Fe-Si-Al magnetic core preparation method disclosed by the invention comprises the following steps: cast ingot smelting, powder making, surface phosphorization, insulation coating, compression moulding, annealing treatment and surface coating; the prepared Fe-Si-Al magnetic core has the advantages of low eddy-current loss, small magnetic conductivity temperature coefficient, good temperature stability, high direct current superposition characteristic, high saturation flux density and good high-frequency characteristic and meets the requirements for high frequency, small size, high power and electromagnetic interference resistance of electronic devices.

Owner:临沂银凤新材料技术服务有限公司

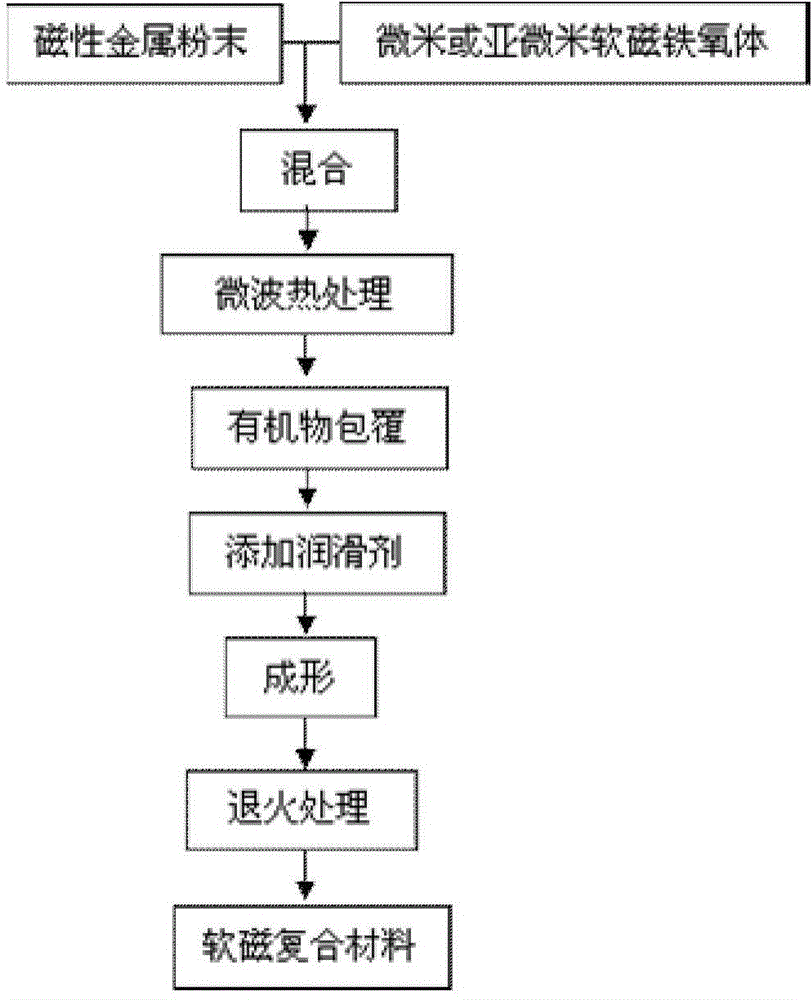

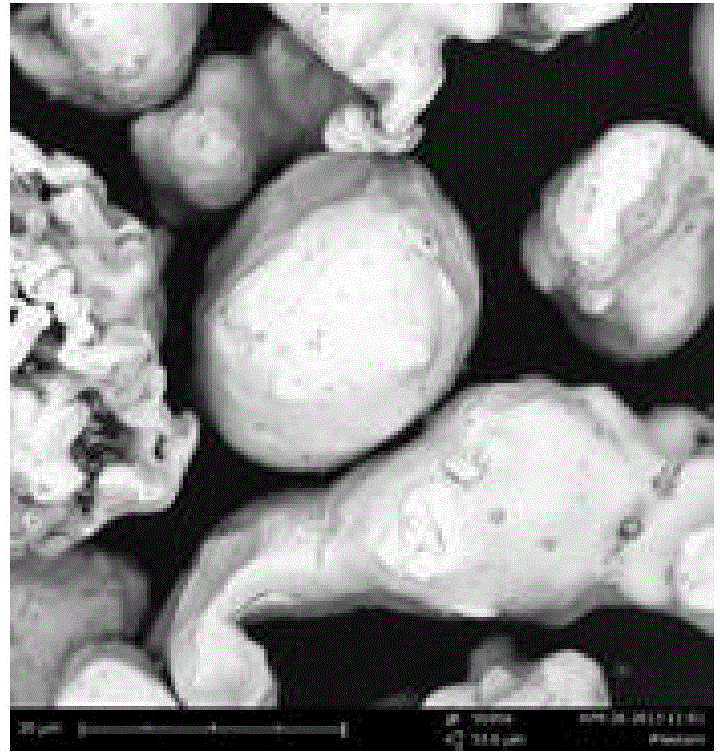

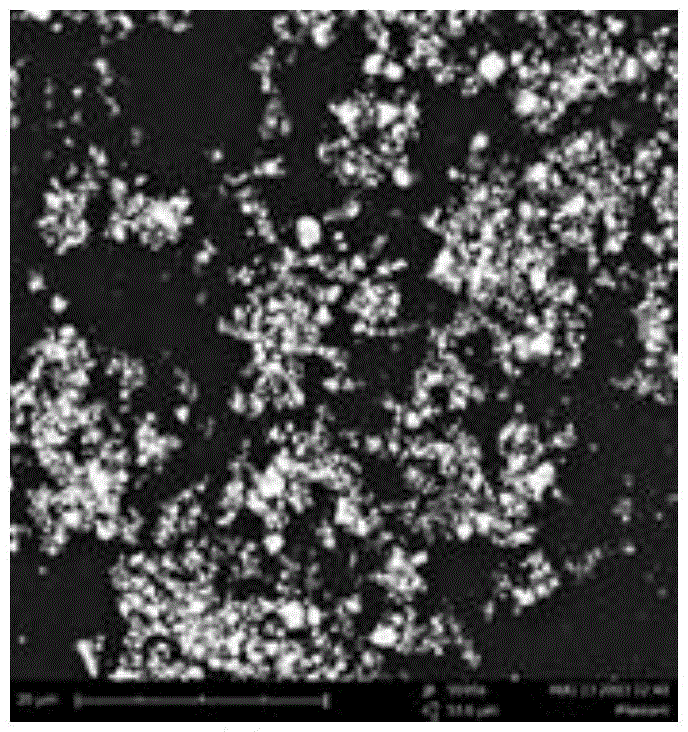

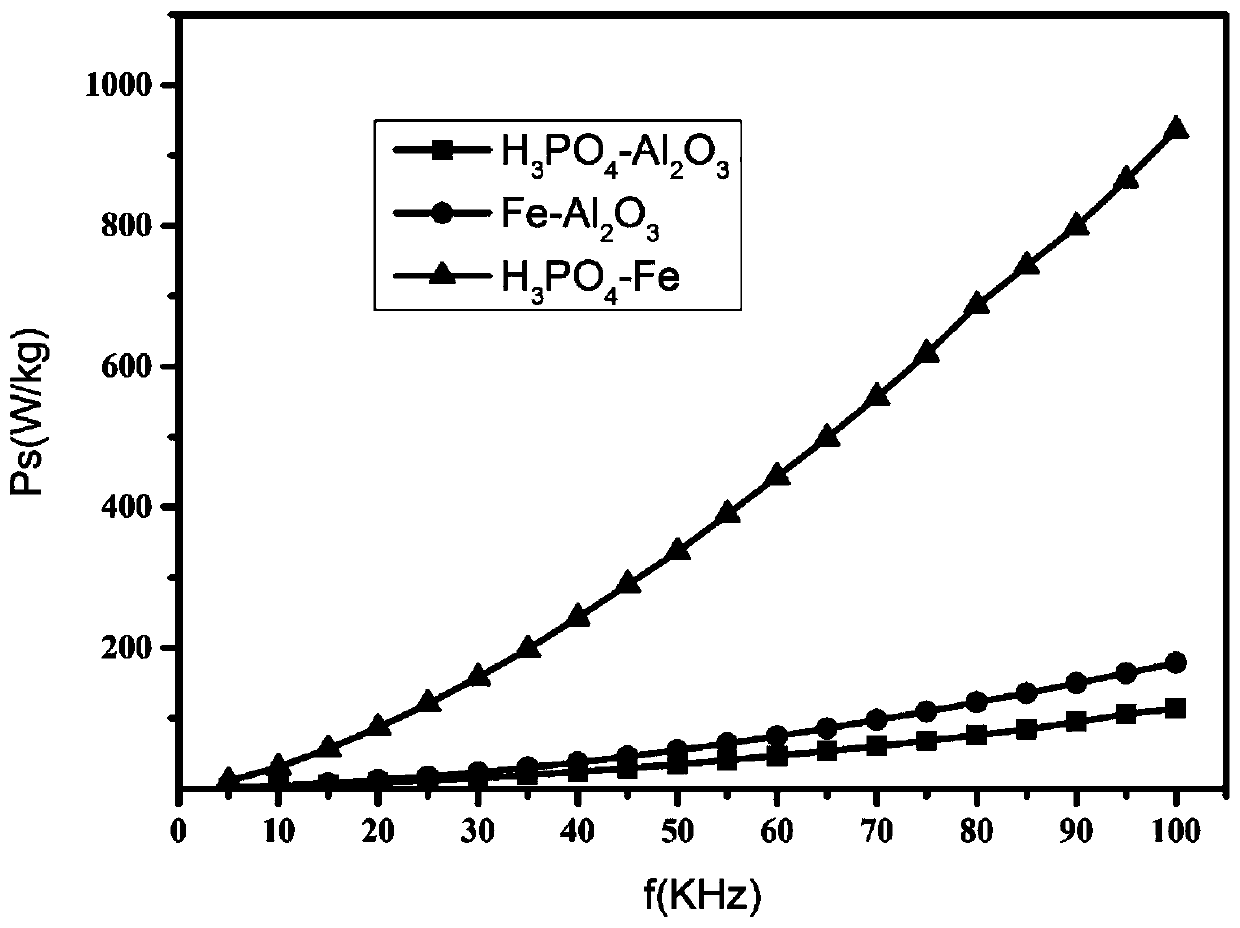

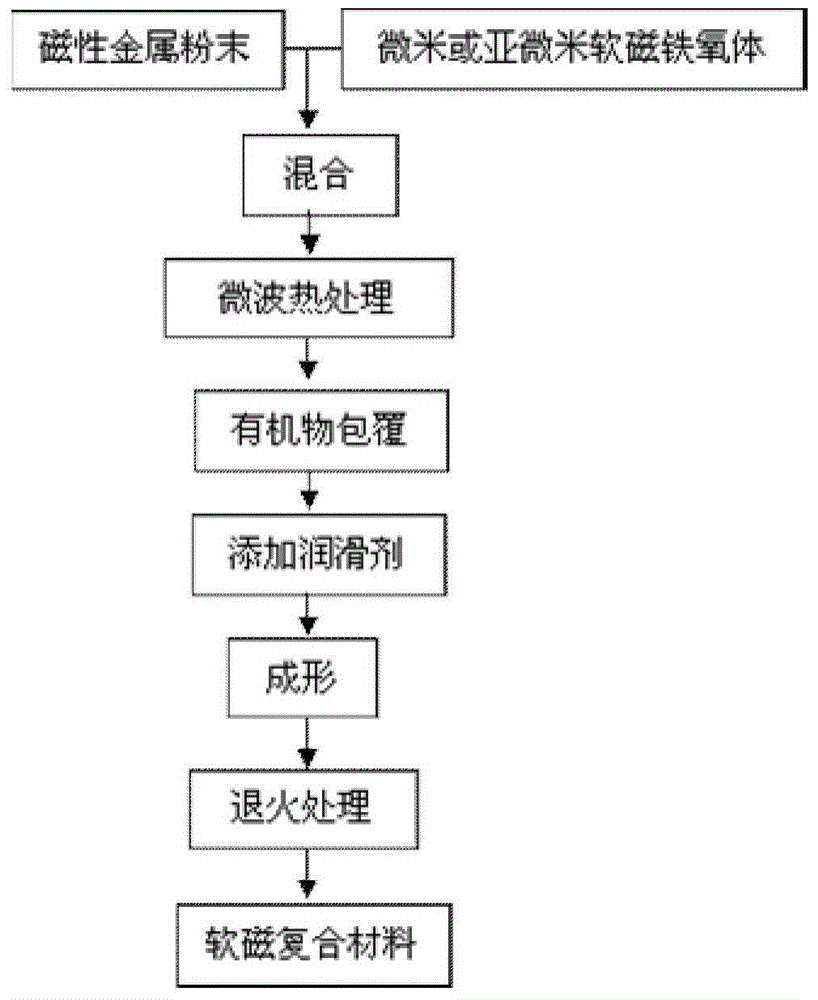

Method for coating metal magnetic powder on soft magnetic ferrites and method for preparing soft magnetic composite materials

ActiveCN104550940AConvenient sourceGood coating effectInorganic material magnetismTemperature resistanceNon magnetic

The invention provides a method for coating metal magnetic powder on soft magnetic ferrites. According to the method, the metal magnetic powder is mixed with trace micron or submicron soft magnetic ferrites, and then, a coating layer is formed through microwave high-temperature heat treatment. The invention also discloses a method for preparing the metal soft magnetic composite materials by adopting the coating powder. According to the method, the coating powder is subjected to organic matter coating, lubricating agents are added, pressing and forming are carried out, finally, annealing treatment is carried out, and the soft magnetic composite materials are obtained. The method has the advantages that the characteristics of magnetism, high electrical resistivity and high-temperature resistance of ferrite soft magnetic materials are sufficiently used, the two kinds of soft magnetic materials are compounded, non-magnetic substances are less than other kinds of soft magnetic composite materials, and in addition, a higher heat treatment temperature is realized, so that better magnetic performance is realized. The soft magnetic composite materials prepared by adopting the method provided by the invention have higher magnetic conductivity and low loss, the frequency stability is good, the magnetic loss at high frequency is low, in addition, the preparing process is simple, the environment is protected, the operation is easy, the cost is low, and the method is suitable for industrial mass and large-scale production.

Owner:NBTM NEW MATERIALS GRP

Multilayer-coated soft magnetic composite material and preparation method thereof

ActiveCN109754979AImprove uniformityPrecise thickness controlInorganic material magnetismInductances/transformers/magnets manufactureState of artHeat stability

The invention relates to a multilayer-coated soft magnetic composite material and a preparation method thereof. The composite material is of a core-shell structure, iron-based alloy powder is taken asa core, and a passivation layer and an Al2O3 coating layer are sequentially coated on the surface of the iron-based alloy powder. The preparation method comprises the following steps: performing reaction on the iron-based alloy powder in passivation solution, so that powder A is obtained; preparing Al2O3 colloid; performing ball-milling reaction on the powder A and the Al2O3 colloid; and performing high temperature calcining on the powder subjected to ball milling, so that a multilayer-coated soft magnetic composite material with high magnetic permeability and low loss is obtained. Compared with the prior art, the multilayer-coated soft magnetic composite material provided by the invention has the advantages that high-resistivity insulating substances are coated for multiple layers, so that magnetic loss of the composite material is relatively low under high frequency application condition, and an insulated coating layer which is better in uniformity and has the thickness capable of being accurately controlled can be obtained; and Al2O3 sol-gel has strong heat stability, density of magnetic powder can be improved to the utmost extent, and magnetic permeability of the magnetic powder is improved.

Owner:TONGJI UNIV

Glass for information recording media substrate, glass substrate for magnetic disk and magnetic disk

InactiveCN101417861ANot easy to peel offInhibited DiffusionWeather resistanceCondensed matter physics

To provide a glass for an information recording media substrate, which is excellent in weather resistance. A glass for an information recording media substrate, which comprises, as represented by mol % based on oxide, from 61 to 66% of SiO2, from 11.5 to 17% of Al2O3, from 8 to 16% of Li2O, from 2 to 8% of Na2O, from 2.5 to 8% of K2O, from 0 to 6% of MgO, from 0 to 4% of TiO2 and from 0 to 3% of ZrO2, provided that Al2O3+MgO+TiO2 is at least 12%, and Li2O+Na2O+K2O is from 16 to 23%, wherein in a case of where B2O3 is contained, its content is less than 1%. The above glass for an information recording media substrate, wherein when the glass is left under steam atmosphere at 120 DEG C. at 0.2 MPa for 20 hours, and the amount of Li, the amount of Na and the amount of K, which precipitate on a surface of the glass are represented as CLi, CNa and CK respectively, CNa is at most 0.7 nmol / cm2, and CLi+CNa+CK is at most 3.5 nmol / cm2.

Owner:ASAHI GLASS CO LTD

Method for processing high-performance modified polyethylene monofilaments for manufacturing fishing net

InactiveCN101851795AIncrease heat treatment temperatureHigh breaking strengthSpinning head liquid feederFilament manufactureWinding machineElastomer

The invention discloses a method for processing high-performance modified polyethylene monofilaments for manufacturing a fishing net, relates to a method for processing polyethylene monofilaments for manufacturing a fishing net and aims to provide a method for processing the high-performance modified polyethylene monofilaments for manufacturing the fishing net. In the technical scheme of the invention, a stirring machine, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry HDPE resin, a dry VERSIFYTM 6002 elastomer, white oil or a turpentine aid; uniformly mixing the materials to obtain an HDPE / VERSIFYTM 6002 elastomer blend and fusing and extruding the blend by using the single-screw extruder; cooling and pre-drafting fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments from which oil is removed with high-pressure air current and winding modified PE monofilaments by using the winding machine; and separating the modified PE monofilaments into the high-performance modified polyethylene monofilaments for manufacturing the fishing net by using the filament separating machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

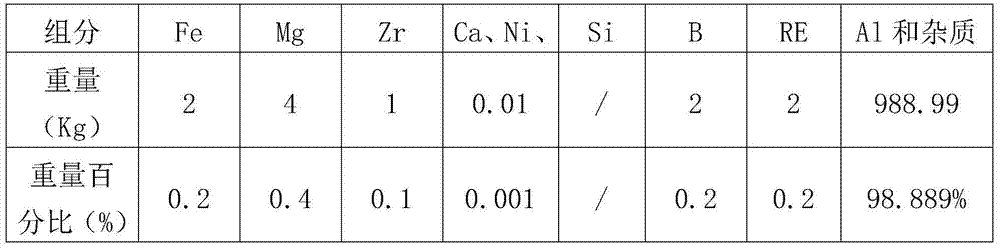

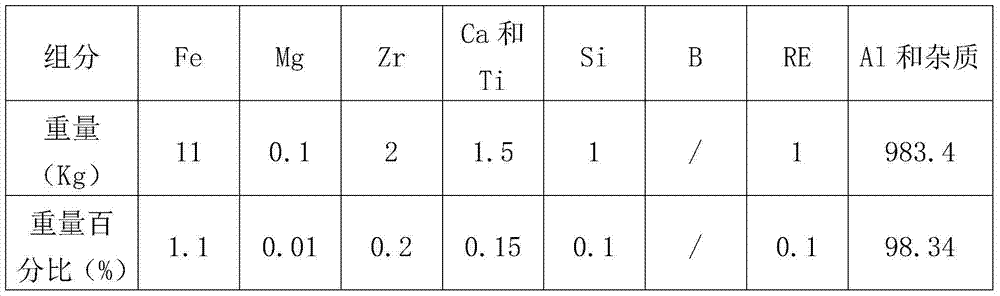

Al-Fe-Mg-Zr aluminum alloy used for coal mine cables, aluminum alloy cable and manufacturing method

PendingCN104299673AImprove performanceHigh mechanical strengthNon-insulated conductorsMetal/alloy conductorsCoalAluminium alloy

The invention discloses Al-Fe-Mg-Zr aluminum alloy used for coal mine cables. The Al-Fe-Mg-Zr aluminum alloy comprises 0.2 percent-1.1 percent of Fe, 0.01 percent-0.4 percent of Mg, 0.001 percent-0.2 percent of Zr, 0 percent-0.1 percent of Si, 0 percent-0.2 percent of B and the balance being Al and impurities, wherein the resistivity of the aluminum alloy is not larger than 0.028164 omega*mm<2> / m, the elongation at break is not lower than 10 percent, and ninety-degree fatigue bending frequency is larger than or equal to thirty. The aluminum alloy material is smelted, cast and rolled, so that an aluminum alloy rod is obtained; afterwards, the aluminum alloy rod is subjected to pulling, bunch stranding and softening, so that an aluminum alloy cable core is formed; next, the cable core is subjected to extruded insulation, cabling, sheath extrusion or armoring, so that an aluminum alloy cable is manufactured. The manufactured aluminum alloy cable has the advantages of being high in strength, high in electric conductivity, good in bending performance and the like, and therefore the requirements for cable performance in the field of coal mines can be satisfied.

Owner:ANHUI JOY SENSE CABLE

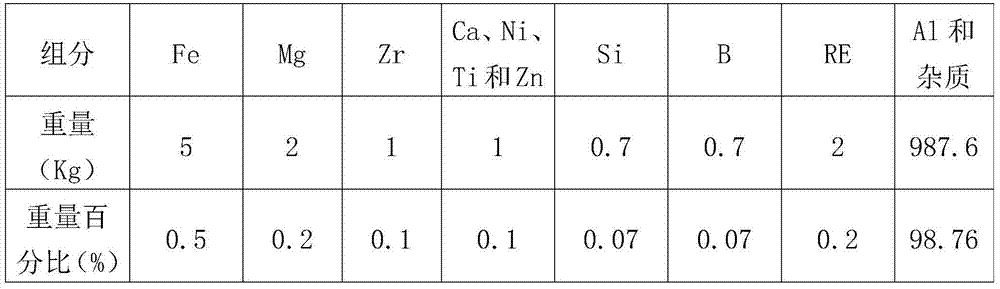

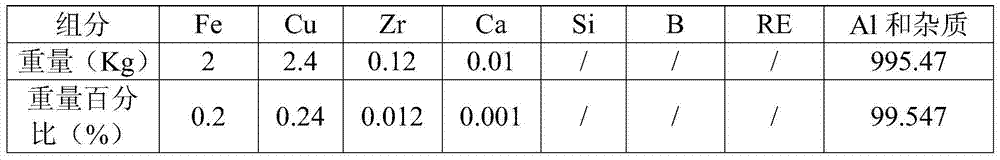

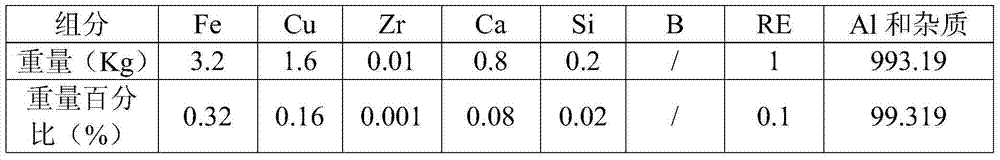

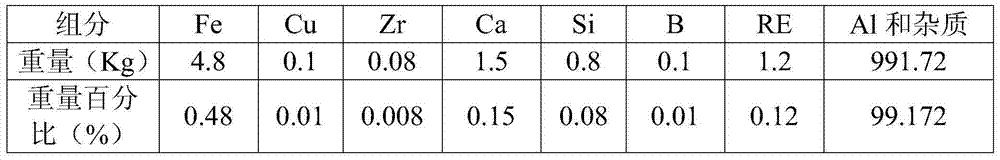

Al-Fe-Cu-Zr series aluminum alloy for cables for coal mines and aluminum alloy cable

PendingCN104294091AImprove performanceHigh mechanical strengthMetal/alloy conductorsCable/conductor manufactureAdditive ingredientHigh conductivity

The invention discloses an Al-Fe-Cu-Zr series aluminum alloy for cables for coal mines and an aluminum alloy cable. The aluminum alloy contains the ingredients in percentage by weight: 0.2-1.1% of Fe, 0.01-0.4% of Cu, 0.001-0.2% of Zr, 0-0.1% of Si, 0-0.2% of B, 0.001-0.15% of one element selected from Ca, Ni, Ti and Zn and the balance of Al and impurities. The aluminum alloy cable is produced through enabling the aluminum alloy to be subjected to the processes of melting, casting and rolling, so as to obtain aluminum alloy rods, then, carrying out drawing, stranding and softening, so as to form aluminum alloy wire cores, and then, carrying out extruded insulation, cabling and extruded sheathing or armoring on the conductor wire cores. The Al-Fe-Cu-Zr series aluminum alloy for the cables for the coal mines, disclosed by the invention, has the characteristics of high strength, high conductivity, good bending property and the like; the aluminum alloy cable produced from the aluminum alloy can meet the requirements on the properties of the cable in the field of the coal mines.

Owner:ANHUI JOY SENSE CABLE

Anisotropic magnetic powder and manufacturing method thereof

ActiveCN101393791ALow costAchieve mass productionInorganic material magnetismOxidation resistantMagnetic powder

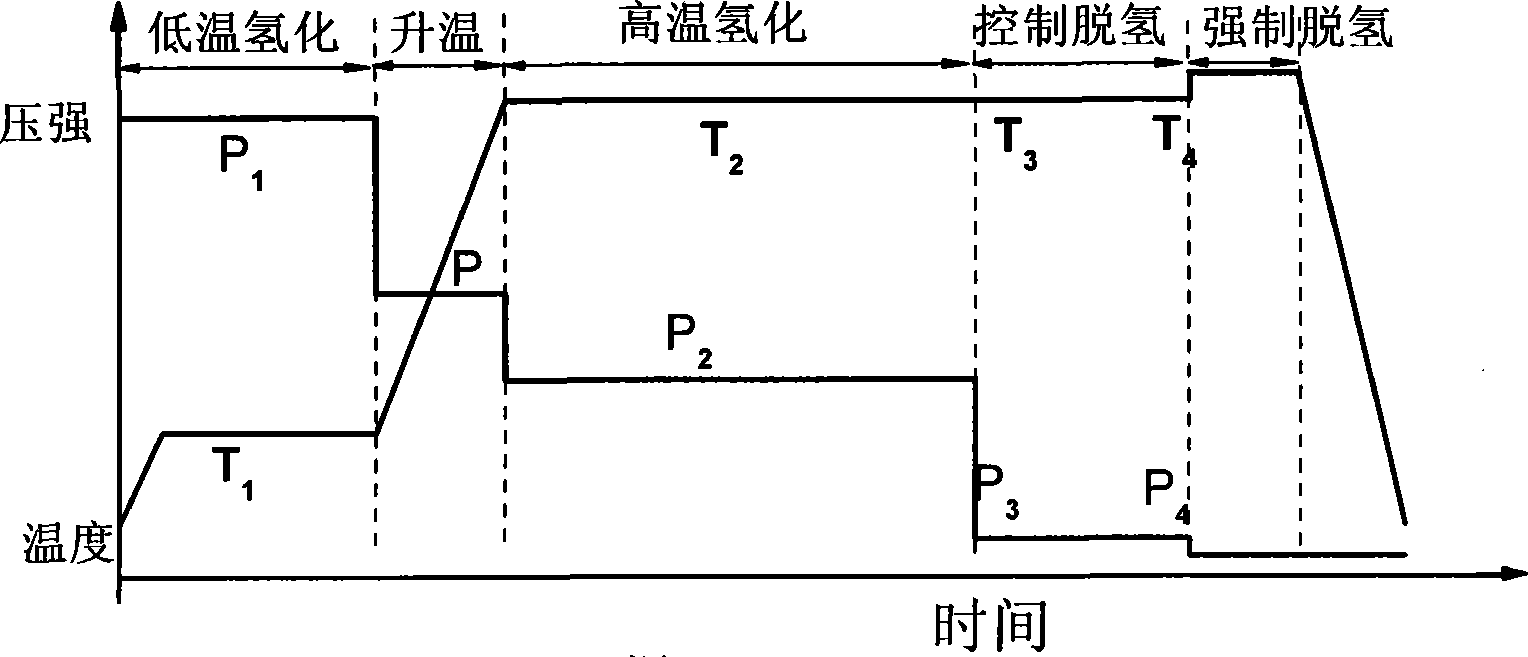

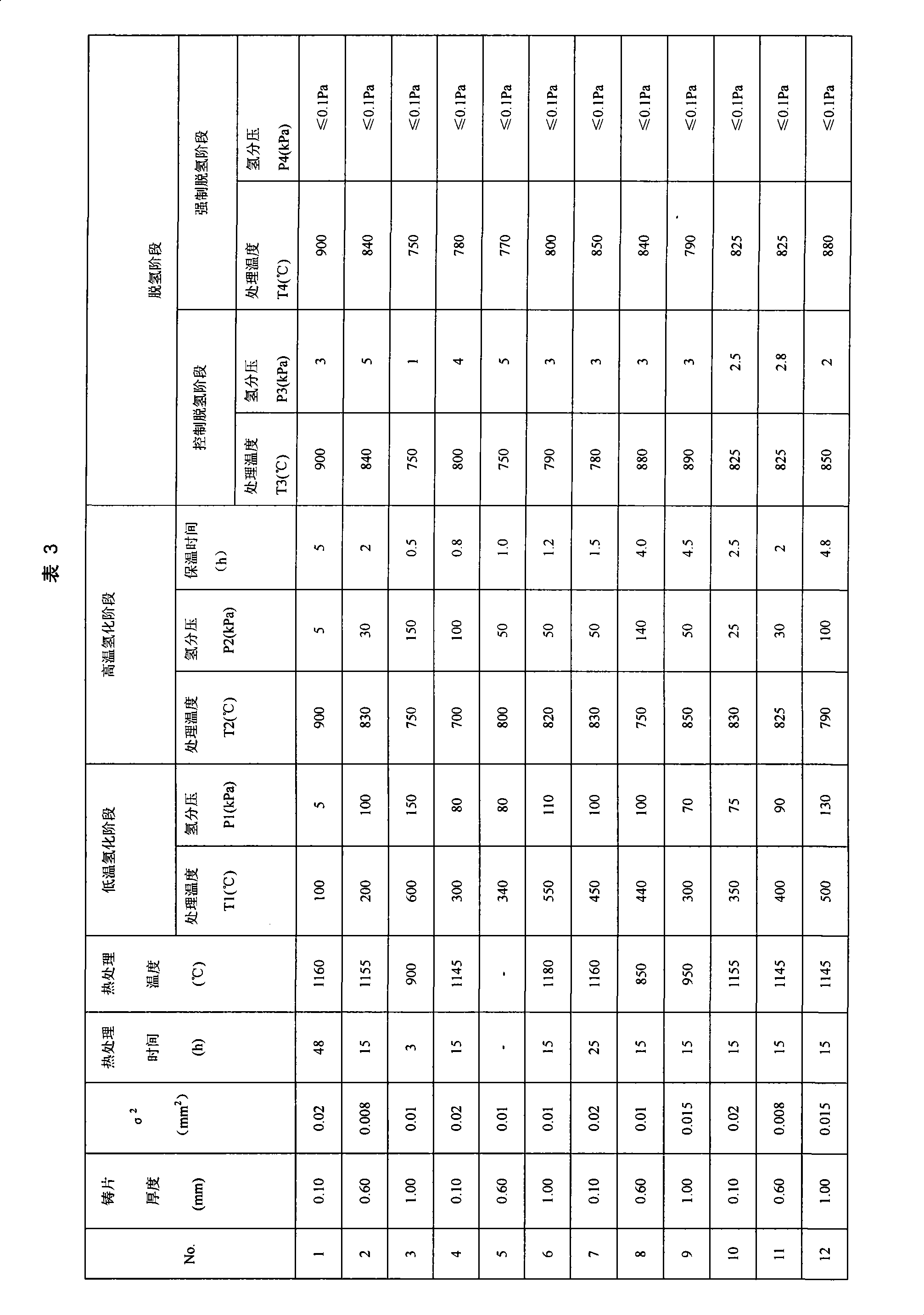

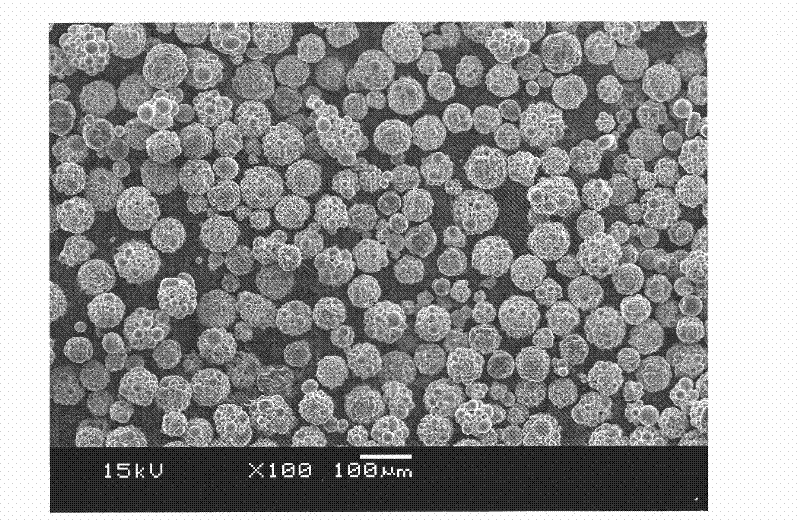

The invention provides a high-performance bonded rare earth permanent magnet powder and a preparation method thereof. Raw material compositions and the preparation method of the rare earth permanent magnet powder are as follows: an alloyed casting strip, the composition ratio of which is R1-xNdx8 to 20MyFebalB4 to 12(atm%), is prepared to be high-performance bonded anisotropic magnet powder through a heat treatment (or untreated process), a hydrogenation and dehydrogenation process and fragmentation. The preparation method comprises the following steps: a rare-iron-boron alloyed casting strip is prepared through a strip casting process, the thickness of the rare-iron-boron alloyed casting strip is 0.1 mm to 1.0 mm; and finally the bonding rare earth permanent magnet powder with high coercive force and high oxidation resistance are prepared through the processes of hydrogenation and dehydrogenation. Compared with the magnet powder taking the traditional cast ingot as the raw material, the bonded magnet powder has higher magnetism property and higher oxidation resistance property.

Owner:GRIREM ADVANCED MATERIALS CO LTD

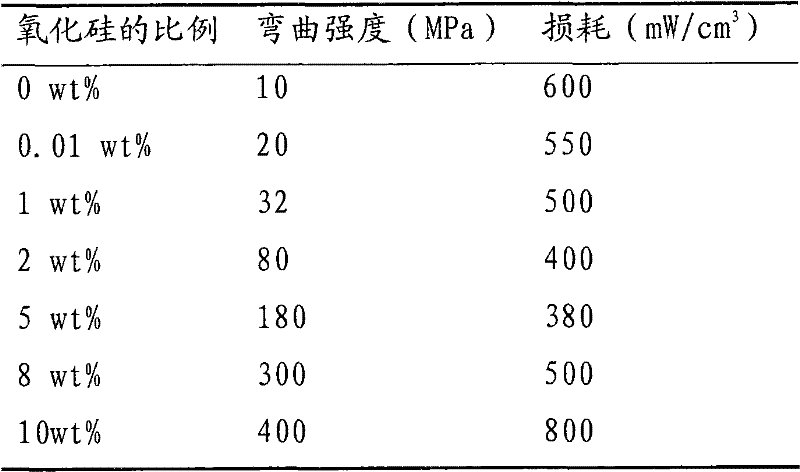

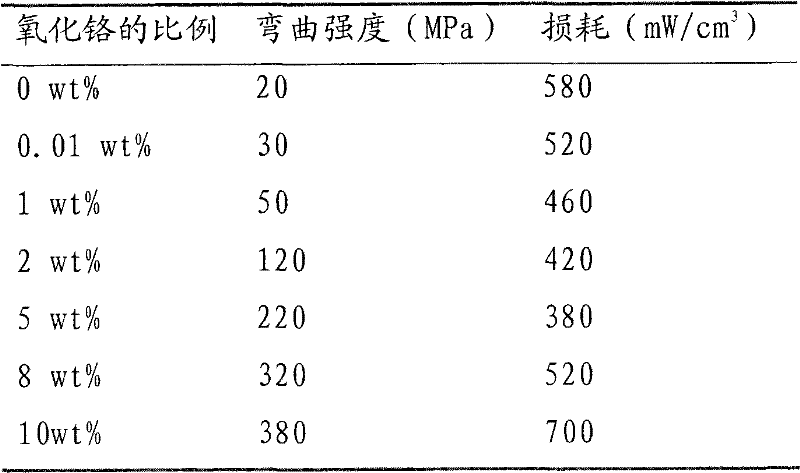

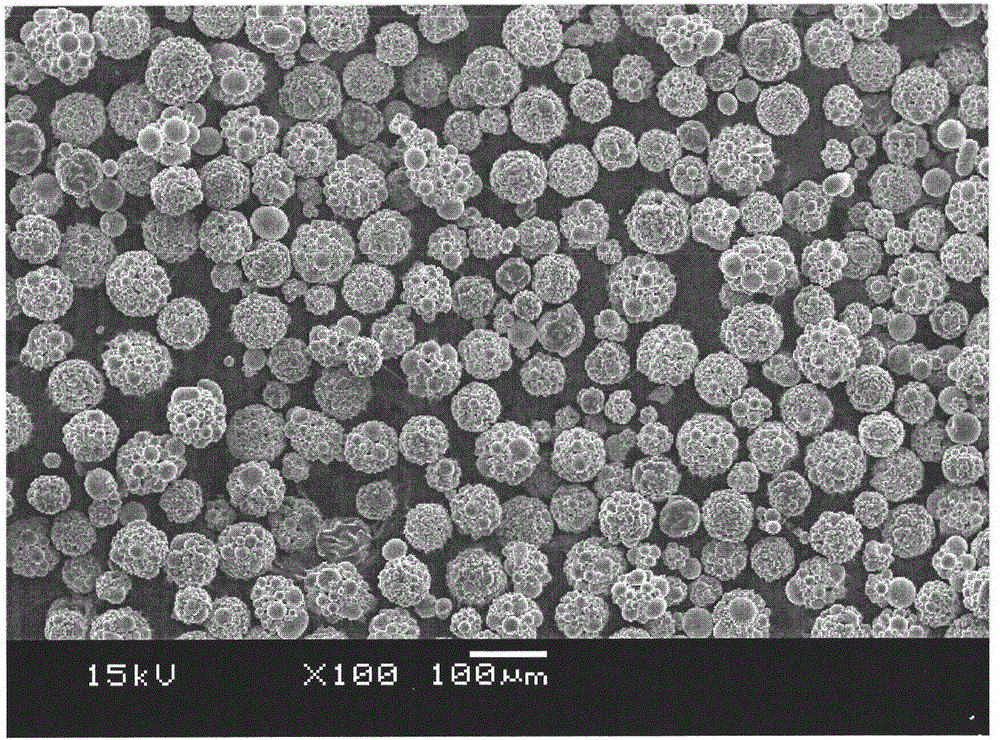

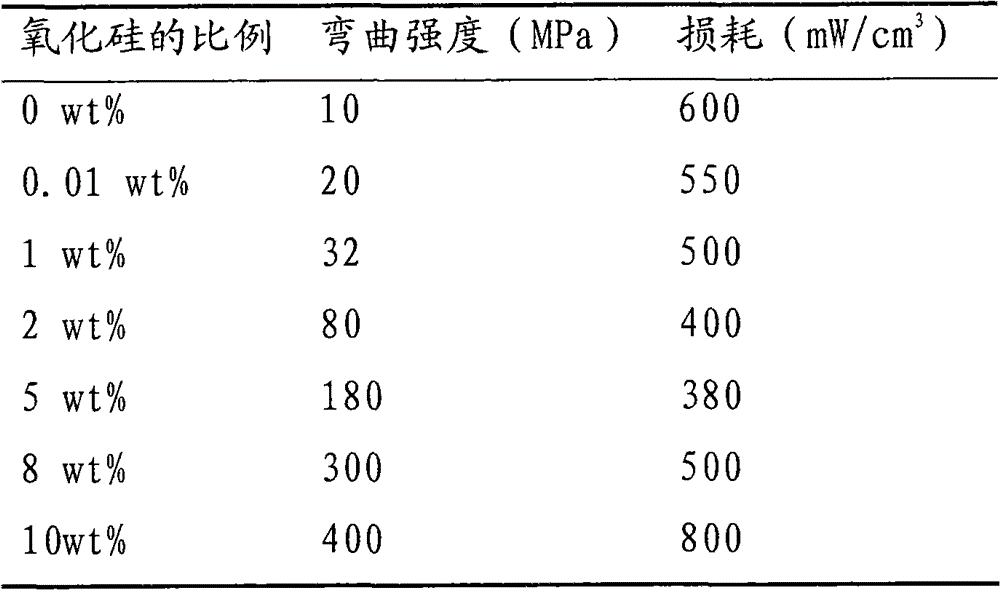

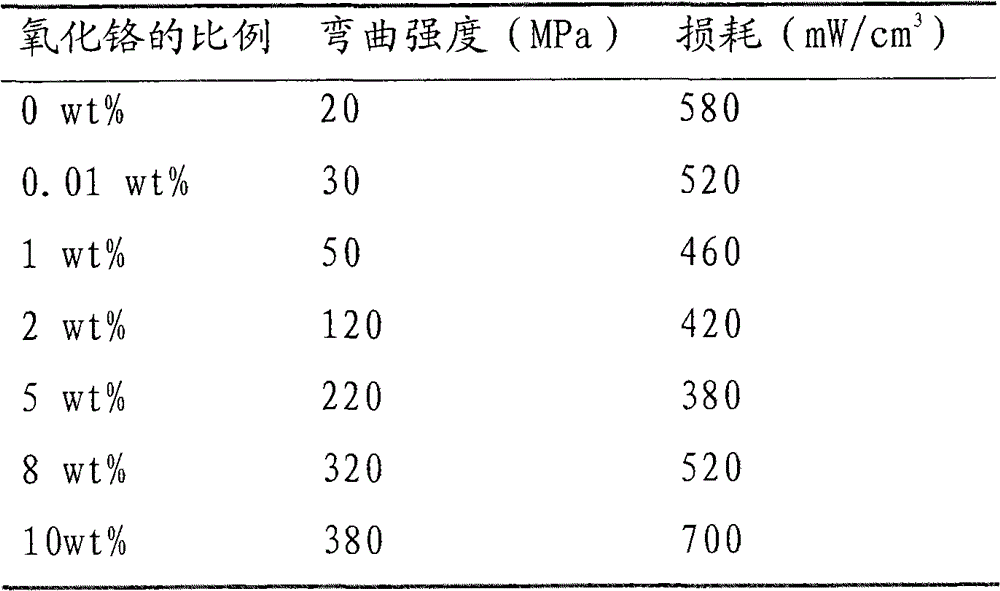

Insulating coating method and metal powder core prepared with same

ActiveCN101745637AHigh strengthIncrease heat treatment temperatureInductances/transformers/magnets manufactureFlexural strengthUltimate tensile strength

The invention provides an insulating coating method and a metal powder core prepared with the same. The insulating coating method is characterized by mixing high-temperature organic insulating coating agent with nano oxide at the proportion of 0.01-8 percent by weight. The insulating coating method can improve the heat treatment temperature of the metal powder core by over 50 DEG C, reduce the loss by over 50mW / cm3 and ensure that the three-point bending strength is over 5Mpa.

Owner:KUNSHAN CITONG NEW MATERIAL TECH CO LTD

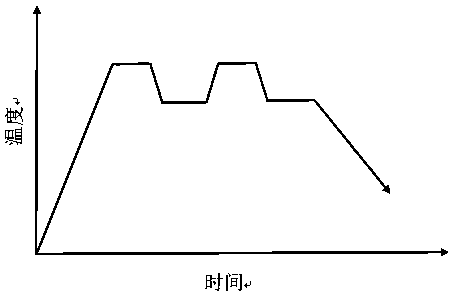

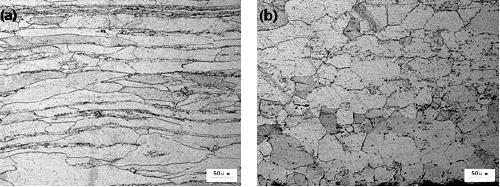

Two-phase region heat treatment process for ferritic stainless steel hot rolled strip

ActiveCN109536690AImprove plasticityInhibits the formation of cluster-like aggregatesHot rolledAustenite

The invention discloses a two-phase region heat treatment process for a ferritic stainless steel hot rolled strip. According to two-phase region heat treatment process for the ferritic stainless steelhot rolled strip, the ferritic stainless steel hot rolled strip is subjected to multiplex heat treatment in a temperature interval of a ferrite and austenite two-phase region, then a cold-rolling annealing process same as a conventional process for annealing a hot rolled strip by a bell-type furnace is adopted, cold rolling is performed to achieve a same thickness, and annealing and heat preservation are performed to obtain a sufficient recrystallized structure. Through the reversible phase change and recrystallization in the two-phase region heat treatment process, a strip-shaped structure in the original hot rolled strip can be effectively segmented and crushed, the plasticity of the hot rolled strip is improved, good raw material conditions are created for subsequent cold rolling and continuous annealing, and the formability and crease resistance of a final cold rolled strip are improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

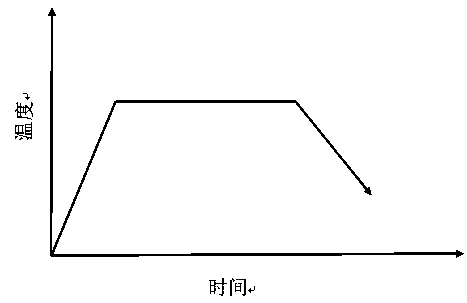

Aging strengthening heat treatment method for nickel-based alloy GH4169

InactiveCN110747417AReduce heating defectsImprove plasticitySolution treatmentUltimate tensile strength

The invention discloses an aging strengthening heat treatment method for nickel-based alloy GH4169. The method comprises full solution treatment and a two-stage aging treatment process. A nickel-basedalloy GH4169 material is subjected to the full solution treatment by preserving the heat for 1 to 3 hours at 980 to 1,070 DEG C; the two-stage aging treatment process comprises first-stage aging treatment, namely, rising the temperature of the nickel-based alloy GH4169 material to 730 to 780 DEG C at the speed of 150 to 200 DEG C / h and preserving the heat for 12 to 18 hours; and second-stage aging treatment, namely, cooling the nickel-based alloy GH4169 material to 630 to 680 DEG C at the speed of 55 DEG C / h and preserving the heat for 18 to 25 hours, discharging the nickel-based alloy GH4169material out of a furnace, and performing air-cooling to room temperature. According to the aging strengthening heat treatment method for the nickel-based alloy GH4169, the tensile strength and yieldstrength of the nickel-based alloy GH4169 at room temperature can be remarkably improved; the hardness at the room temperature is obviously improved; the comprehensive performance of the material isobviously improved; and the service life of the material is obviously prolonged.

Owner:HEBEI IRON AND STEEL

Manufacturing method of fibers of breeding nets of sea fish

ActiveCN104562284AImprove performanceReduce consumptionFilament forming substance formingConjugated synthetic polymer artificial filamentsLinear low-density polyethyleneFiber bundle

The invention provides a manufacturing method of fibers of breeding nets of sea fish. The manufacturing method adopts HDPE (high-density polyethylene) resin, an auxiliary agent, metallocene LLDPE (linear low density polyethylene) resin, a stirring machine, a single-screw extrusion machine, a twice-drawing electrical heating drawing machine, a silk collecting machine and a silk dividing machine. The manufacturing method is characterized in that the HDPE resin is sieved; the adding amount of the auxiliary agent is 0.6% of the weight of the HDPE resin; the adding amount of the metallocene LLDPE resin is 10.3% of the weight of the HDPE resin; the materials are stirred by the stirring machine for 19-31 minutes, so that the materials are uniformly stirred, and a mixture of the HDPE resin and the metallocene LLDPE resin is obtained; melt extrusion is performed on the mixture of the HDPE resin and the metallocene LLDPE resin by the single-screw extrusion machine, and primary silk obtained from melt extrusion is cooled and pre-drawn by a cooling water box and a first drawing roller; twice hot drawing is performed on the pre-drawn silk, the drawn silk is degreased by a high-pressure airflow, the degreased silk is rapidly cooled, and fiber bundles are collected and rolled by the silk collecting machine; the fiber bundles are divided into the fibers of the breeding nets of the sea fish by the silk dividing machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A method for coating soft magnetic ferrite with metal magnetic powder and a method for preparing soft magnetic composite materials

ActiveCN104550940BConvenient sourceGood coating effectInorganic material magnetismTemperature resistanceNon magnetic

The invention provides a method for coating metal magnetic powder on soft magnetic ferrites. According to the method, the metal magnetic powder is mixed with trace micron or submicron soft magnetic ferrites, and then, a coating layer is formed through microwave high-temperature heat treatment. The invention also discloses a method for preparing the metal soft magnetic composite materials by adopting the coating powder. According to the method, the coating powder is subjected to organic matter coating, lubricating agents are added, pressing and forming are carried out, finally, annealing treatment is carried out, and the soft magnetic composite materials are obtained. The method has the advantages that the characteristics of magnetism, high electrical resistivity and high-temperature resistance of ferrite soft magnetic materials are sufficiently used, the two kinds of soft magnetic materials are compounded, non-magnetic substances are less than other kinds of soft magnetic composite materials, and in addition, a higher heat treatment temperature is realized, so that better magnetic performance is realized. The soft magnetic composite materials prepared by adopting the method provided by the invention have higher magnetic conductivity and low loss, the frequency stability is good, the magnetic loss at high frequency is low, in addition, the preparing process is simple, the environment is protected, the operation is easy, the cost is low, and the method is suitable for industrial mass and large-scale production.

Owner:NBTM NEW MATERIALS GRP

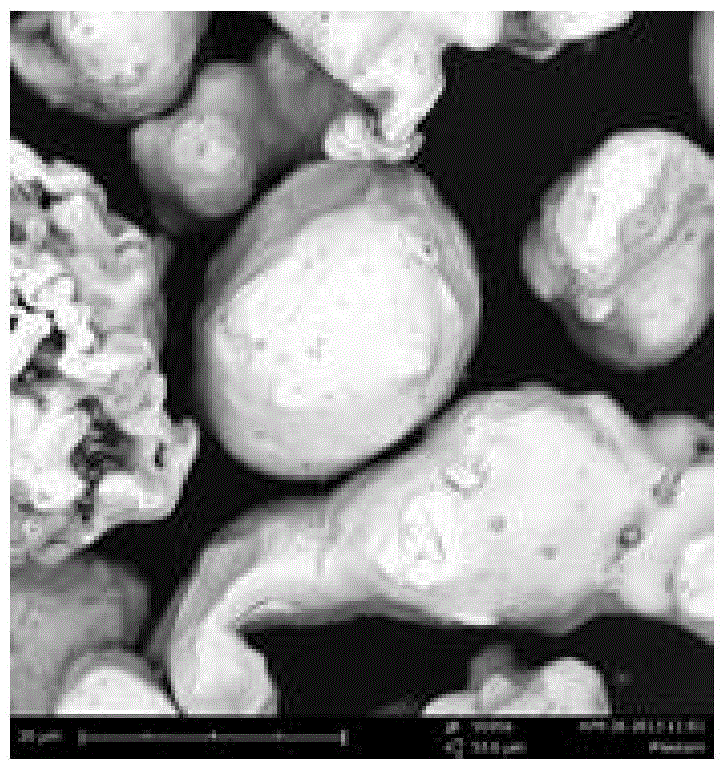

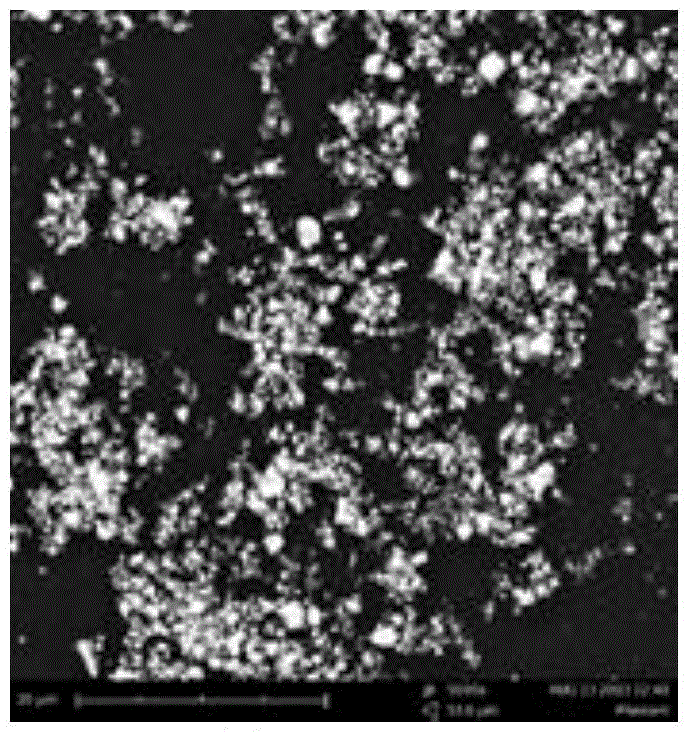

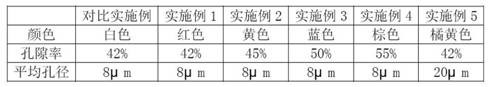

Colored porous ceramic atomizing core and preparation method thereof

The invention belongs to the technical field of ceramics, and particularly relates to a colored porous ceramic atomizing core and a preparation method thereof.The ceramic atomizing core is prepared from, by weight, 40%-90% of ceramic powder, 5%-40% of a colored sintering aid and 0-40% of a pore forming agents, and the colored ceramic sintering aid is prepared from a ceramic sintering agent and ceramic pigment powder as raw materials through high-temperature melting heat treatment. According to the colored ceramic sintering aid, the colored porous ceramic atomizing core is prepared from the colored ceramic sintering aid, so that ceramic atomizing cores with different porosities and pore sizes have different colors, the preparation process is simple, the identification degree is high, and the colored porous ceramic atomizing core can uniquely correspond to tobacco tar with different tastes and properties.

Owner:阿特麦哲(东莞)新材料科技有限公司

Sm-Co-based permanent-magnet thin film high in film-base binding force and preparation method thereof

ActiveCN104112562AIncrease heat treatment temperatureImprove bindingCathode sputtering applicationMagnetic layersFilm baseOptoelectronics

The invention provides an Sm-Co-based permanent-magnet thin film high in film-base binding force. A buffer layer is arranged between the Sm-Co-based permanent-magnet thin film and a base body and is of a two-layer structure, one layer is a copper thin film layer positioned on the surface of the base body while the other layer is a tungsten thin film layer positioned on the surface of the copper thin film layer, and binding force between the Sm-Co-based permanent-magnet thin film and the base body can be improved effectively. Experiments verify that heat treatment temperature of the Sm-Co-based permanent-magnet thin film of the structure during heat treatment can be increased substantially from 600-800 DEG C currently to above 900 DEG C, and the Sm-Co-based permanent-magnet thin film can still be well bound with the base body and cannot shed when the heat treatment temperature is as high as 1000 DEG C.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for manufacturing low-resistance protective layer of chip type thin film fixed resistor

InactiveCN106148895AImprove TCR pass rateImprove pass rateVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceHigh humidity

The invention relates to a method for manufacturing a low-resistance protective layer of a chip-type thin-film fixed resistor. A uniform SiO2 protective film layer is deposited on a nickel-chromium resistor body film layer by using a SiO2 target material radio frequency sputtering method. The invention greatly improves the stability and reliability of the product; it significantly improves the use of the product in the harsh environment of high temperature and high humidity; the welding resistance of the product sputtered with Taiwan's low-resistance target material is significantly improved; Improve the consistency of low-resistance heat treatment, increase the heat treatment temperature, and have no effect on the positive and negative TCR of the product, which can be within ±5ppm / °C, so this method can be applied to products with a temperature characteristic of thin film resistance of ±5ppm / °C , so that the TCR qualification rate of the low-resistance segment of the chip film fixed resistor has been greatly improved, and the delivery efficiency of the product has been improved.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

Preparation method for mu75 magnetic powder core of ferrosilicon aluminum

ActiveCN102360671BIncrease heat treatment temperaturePromote environmental protectionInorganic material magnetismInductances/transformers/magnets manufactureFerrosiliconOxygen

Owner:TDG HLDG CO LTD

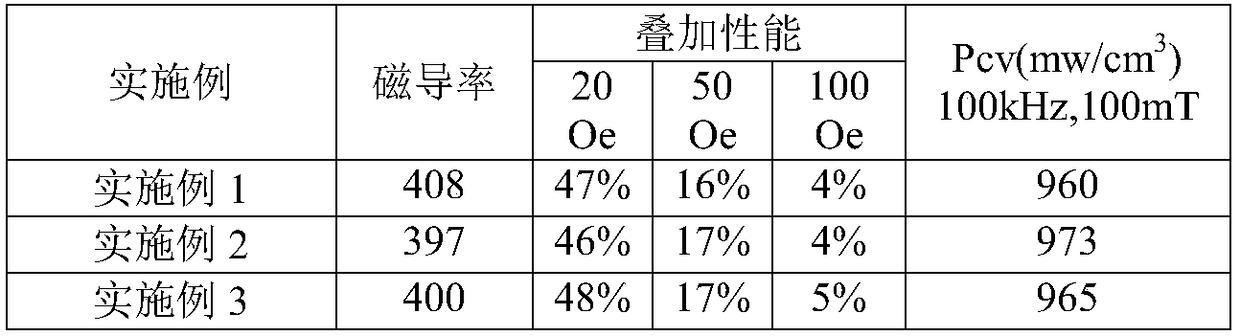

A kind of preparation method of iron-nickel-molybdenum metal magnetic powder core with magnetic permeability μ=400

ActiveCN107578873BUnbreakableImprove the wrapping effectInorganic material magnetismManufacturing technologyBiological activation

The invention relates to the technical field of metal soft magnetic material manufacture, in particular to a preparation method of an iron-nickel-molybdenum metal magnetic powder core with the magnetic permeability mu = 400. The preparation method comprises the steps of 1, weighing material; 2, gas atomization pulverizing; 3, granularity combination; 4, heat treatment; 5, activation treatment; 6,once insulating coating; 7, twice insulating coating; 8, compression molding; 9, core annealing; 10, immersion spraying. According to the preparation method of the iron-nickel-molybdenum metal magnetic powder core, before the insulating coating, the surface of the magnetic powder is activated by using an activator, the coating effect is increased, the formed coating layer is more uniform, and theprepared core is not easy to break; organic reagent is not used, and the preparation process is greener and more environmentally friendly; a high temperature release agent is adopted, the heat treatment temperature is high, the forming pressure is low, the magnetic permeability of the magnetic core is improved; the whole method is simple in process, easy to implement and strong in operability.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

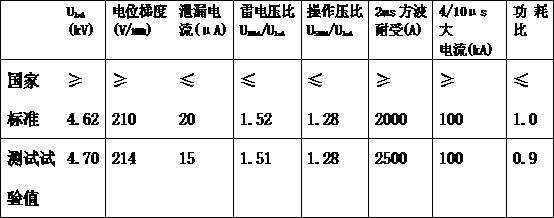

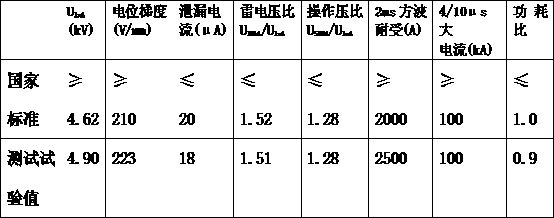

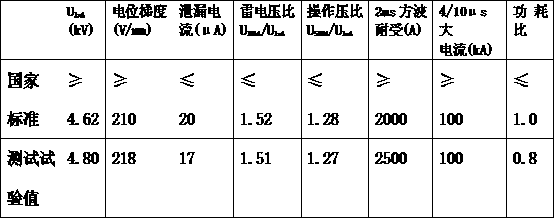

Resistance card for direct-current lightning arrester and production process thereof

ActiveCN102390992BMeet electrical requirementsImproved energy toleranceVaristor coresElectrical resistance and conductanceProcess engineering

The invention discloses a resistance card for a direct-current lightning arrester, which is made of twelve raw materials, namely Bi2O3, Sb2O3, Co2O3, MnCO3, NiO, ZrO2, Al(NO3)3, B2O3, a binding agent, a dispersing agent, a defoaming agent and ZnO. The resistance card adopts a novel formula system and a novel production process; elemental compositions which are added are less; the process is simple; the cost is low; the internal structure of the resistance card is more stable and uniform, thereby greatly improving various performances of age resistance, the stability of current surge, thermal conductivity, square wave through-flow capacity and the like; the requirements of various direct-current lightning arresters can be met completely; the various direct-current lightning arresters can be achieved to be universal; an alternating-current lightning arrester and the direct-current lightning arrester are achieved to be universal; the capacity is large; the pressure ratio is small; the allowable chargeability is high; and the resistance card for the direct-current lightning arrester has an enough safety margin.

Owner:NANYANG JINGUAN ELECTRIC

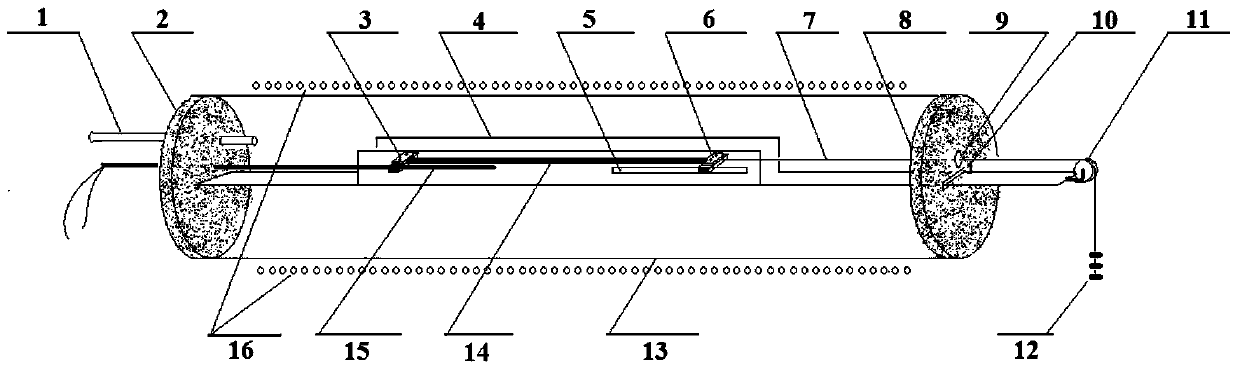

Method for manufacturing mu 125 sendust cores

ActiveCN102623123BIncrease heat treatment temperaturePromote environmental protectionInorganic material magnetismInductances/transformers/magnets manufactureSendustInsulation layer

The invention relates to a method for manufacturing mu 125 sendust cores. The method comprises the steps of alloy smelting, coarse crushing, heat treatment, fine crushing, annealing treatment, powder classification, powder insulation, compression moulding, secondary heat treatment and coating treatment. The mu 125 sendust cores comprise the following compositions: 9.10 percent of silicon, 5.95 percent of aluminum and the balance of iron; the sendust cores are smelted at 1,600DEG C, molded under the pressure of between 1,950 and 2,150MPa, subjected to heat treatment at the temperature of between 600 and 800DEG C, kept at the temperature for 30min, and subjected to heat treatment under the protection of nitrogen. The magnetic permeability mu of the sendust cores is equal to 125+ / -10 (10kHz / 1mT); the mu change rate in 1 MHz is less than 5%; Pcv is less than or equal to 190 mW / cm<3> (100kHz / 50mT); and the applied direct current bias field H is not less than 390e when the mu is 50%. A passivating solution does not contain chromium ions, which is environment-friendly; and an insulation layer between powder of the sendust cores has a glass phase structure containing P, which has high temperature for heat treatment and contributes to eliminating internal stress and reducing iron loss. A solid inorganic binder is adopted, so the adhesive strength is high, the performance is stable, and the process is simplified.

Owner:TDG HLDG CO LTD

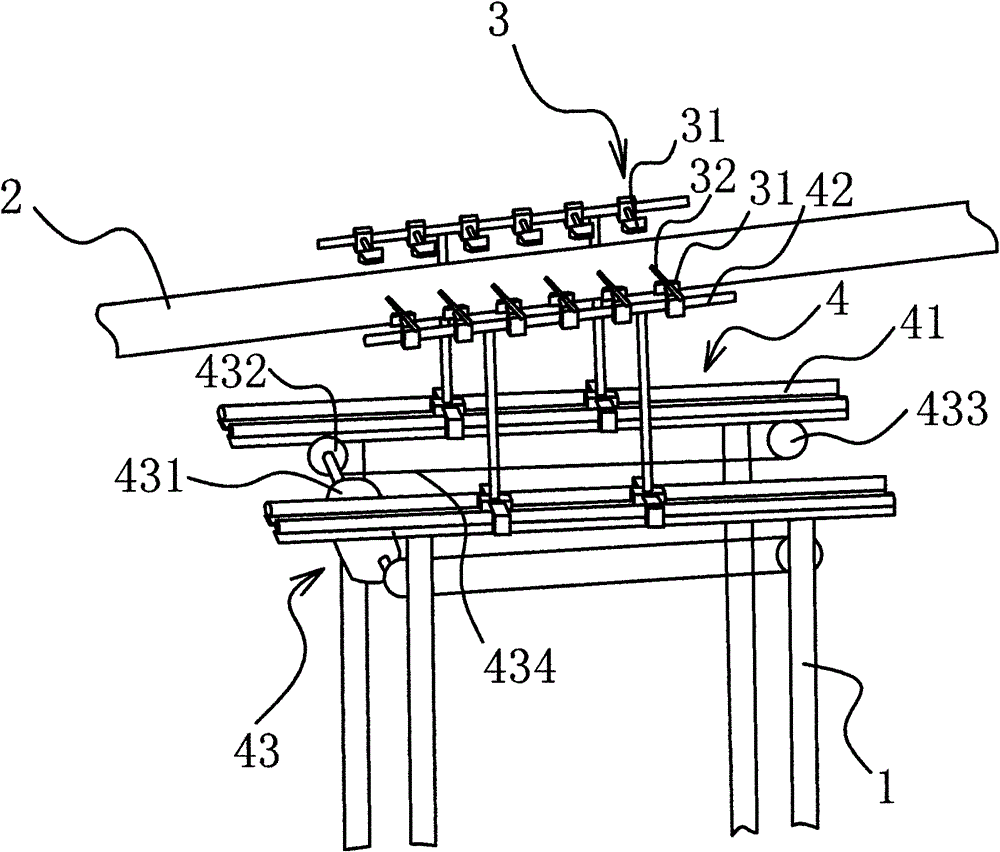

Glass container flame polishing machine

The invention relates to the technical field of glass processing, and especially relates to a glass container fire polishing machine, which solves technical problems in prior arts such as unreasonable design. The fire polishing machine comprises a frame, and a glass container conveyer belt arranged above the frame. The fire polishing machine is characterized in that: plural sets of fire polishing mechanism are arranged on the frame, wherein the fire polishing mechanisms are orderly arranged along the conveyer belt; each fire polishing mechanism is connected to the frame through an adjustable movable mechanism; the fire polishing mechanisms can move along the conveyer belt with the driving of the adjustable movable mechanism; while moving along the conveyer belt, the fire polishing mechanisms can be elevated in a vertical direction with the adjustable movable mechanism. Compared to prior arts, the glass container fire polishing machine has advantages of reasonable design, simple structure, high heat treatment temperature, and high speed. Meanwhile, flaws appeared during glass bottle production processes can also be solved by the machine. The processed glass containers have good surface fineness, no dust, and basically no pollution.

Owner:HANGZHOU ZHENHUA COSMETIC GLASS

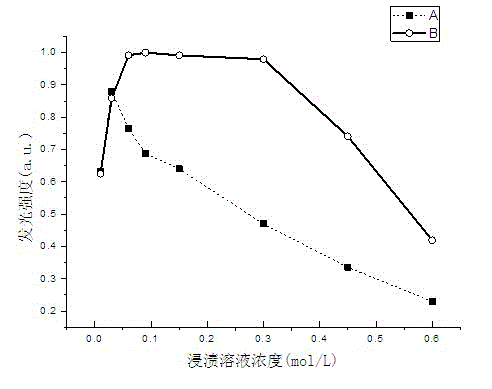

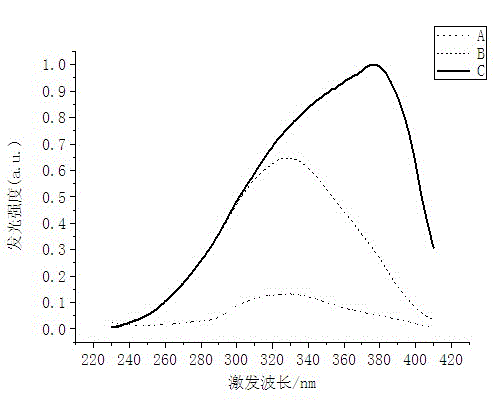

Preparation method of near-ultraviolet-excited high-silicon-oxygen blue-emitting glass

ActiveCN102701590BEnhance the degree of phase separationIncrease heat treatment temperatureLuminous intensityHigh pressure

Owner:HANGZHOU INSTITUTE OF OPTICS AND FINE MECHANICS

A kind of insulating coating method and metal powder core prepared according to the method

ActiveCN101745637BHigh strengthIncrease heat treatment temperatureInductances/transformers/magnets manufactureFlexural strengthUltimate tensile strength

The invention provides an insulating coating method and a metal powder core prepared with the same. The insulating coating method is characterized by mixing high-temperature organic insulating coating agent with nano oxide at the proportion of 0.01-8 percent by weight. The insulating coating method can improve the heat treatment temperature of the metal powder core by over 50 DEG C, reduce the loss by over 50mW / cm3 and ensure that the three-point bending strength is over 5Mpa.

Owner:KUNSHAN CITONG NEW MATERIAL TECH CO LTD

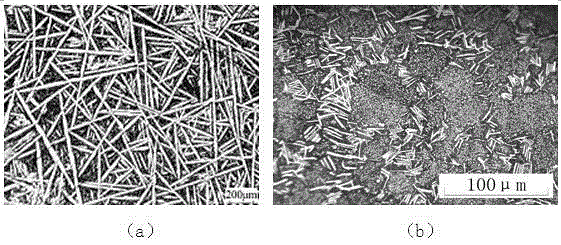

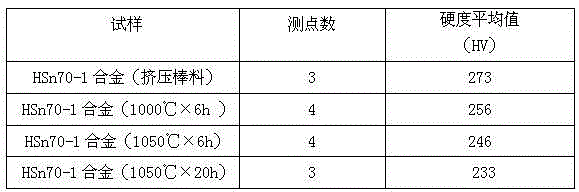

Hot working technology of improving performance of HSn70-1 alloy

The invention discloses a hot working technology of improving performance of HSn70-1 alloy. The hot working technology includes the steps of melting HSn70-1 alloy at 1400 DEG C, maintaining the temperature for 2 h, performing casting to obtain a sample, performing thermal treatment to the sample, and extruding the sample in a hot extrusion die, wherein the process parameter of the thermal treatment is 1000-1100 DEG C and 6-20 h.

Owner:周雪

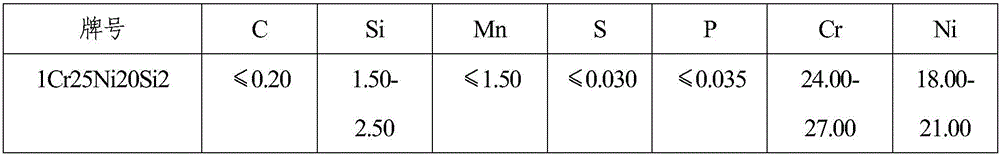

A kind of manufacturing method of silicon-containing stainless steel seamless pipe

The invention discloses a manufacturing method for a silicon-containing stainless steel seamless tube. The method comprises the following procedures: heating of a tube blank; perforating; cold rolling; heat treatment; straightening; and pickling. In the procedure of heat treatment, a short-time high-temperature heat treatment process is employed, heat treatment temperature is 1090 to 1110 DEG C, a heat preservation coefficient is 0.8 to 1.5 min / mm, and heat preservation time is determined according to steel tube thickness and is calculated by multiplying the heat preservation coefficient with the steel tube thickness; and in the procedure of straightening, a forward-backward bidirectional straightening method is employed, backward straightening is carried out after original unidirectional straightening, so the effect of integral fragmentation of a surface oxide skin is realized. According to the invention, the short-time high-temperature heat treatment process is employed, so the surface oxide skin becomes thinner and loose after heat treatment, which facilitates easy removal of the oxide skin during pickling; the forward-backward bidirectional straightening method is employed for integral fragmentation of the surface oxide skin, so the oxide skin left in pickling is eliminated, a better fragmentation effect is exerted on the loose oxide skin, and product surface quality after pickling is further guaranteed.

Owner:宝武特种冶金有限公司

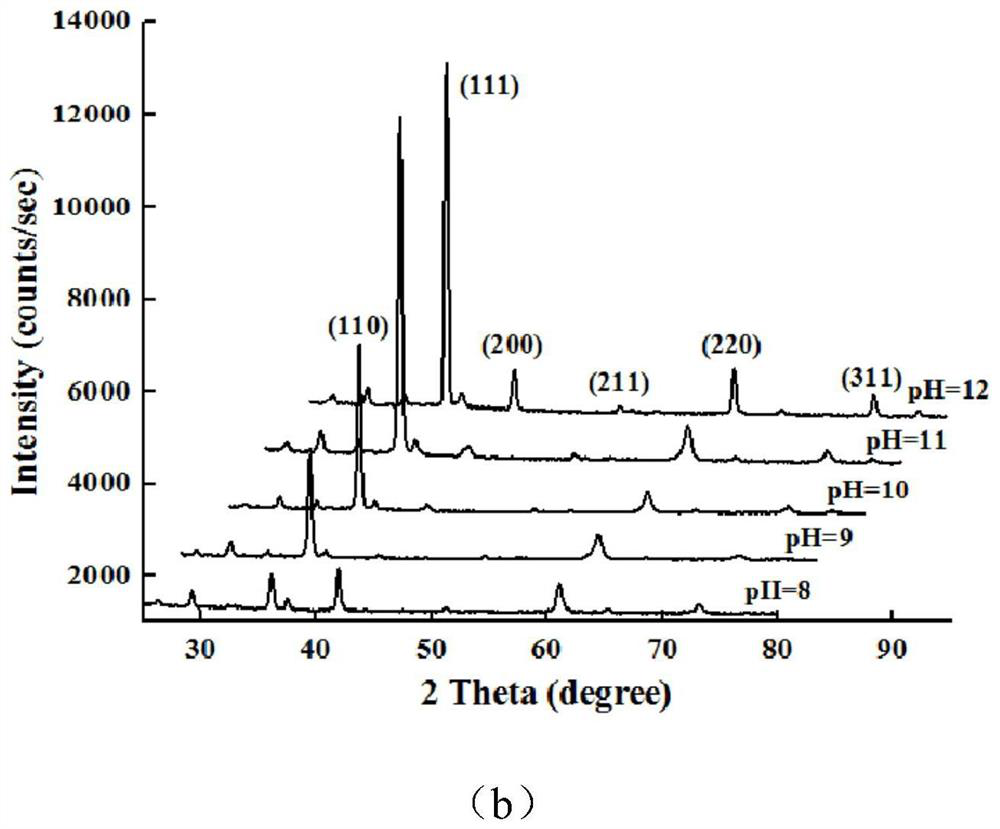

Cuprous oxide film with high photoelectrochemical performance and preparation method thereof

InactiveCN112853423AHigh purityReduce reaction materialsElectrolytic inorganic material coatingThin membraneElectrically conductive

The invention discloses a cuprous oxide film with high photoelectrochemical performance and a preparation method thereof. The preparation method comprises the following steps: preparing a deposition solution by taking a soluble copper salt, a lactate solution and a sodium hydroxide solution as raw materials; utilizing a tri-electrode electrochemical tank to perform film deposition on conductive glass; inserting a tri-electrode into the deposition solution to keep the temperature for 30 minutes at 50-70 DEG C; adjusting the pH value to be 9.0-12.0 and controlling deposition time for 20-60 minutes; cleaning and drying the obtained film; and performing carbon removal treatment on the film for one hour under a ventilating condition at 120-150 DEG C, and annealing and sintering the film for 2 hours at 250-400 DEG C. The prepared cuprous oxide film is uniform, compact and free of cracks, and has higher photoelectrochemical performance.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of sendust magnetic core and inorganic composite insulating coating material for magnetic core

ActiveCN105304308BEasy to processGood temperature characteristicsInductances/transformers/magnets manufactureMagnetic materialsSendustPhosphate

The invention discloses a preparation method of a sendust magnetic core and an inorganic composite insulating coating material for the magnetic core, which belongs to the field of sendust magnetic materials and is used to solve the problem of the high eddy current loss of the existing magnetic core and the use of organic coatings in the magnetic core. The problems caused by the cladding material are that the stress is difficult to eliminate during the molding process, the insulation performance of the material is poor, and the organic matter volatilizes a lot during the heating process such as heat treatment. The preparation method of the sendust magnetic core described in the present invention includes the steps of ingot smelting, powder making, surface phosphating treatment, insulation coating, press molding, annealing treatment and surface coating, and the prepared sendust magnetic core Low eddy current loss, small temperature coefficient of magnetic permeability, good temperature stability, high DC superposition characteristics, high saturation magnetic induction, good high frequency characteristics, suitable for high frequency, miniaturization, high power and anti-electromagnetic interference requirements of electronic devices .

Owner:临沂银凤新材料技术服务有限公司

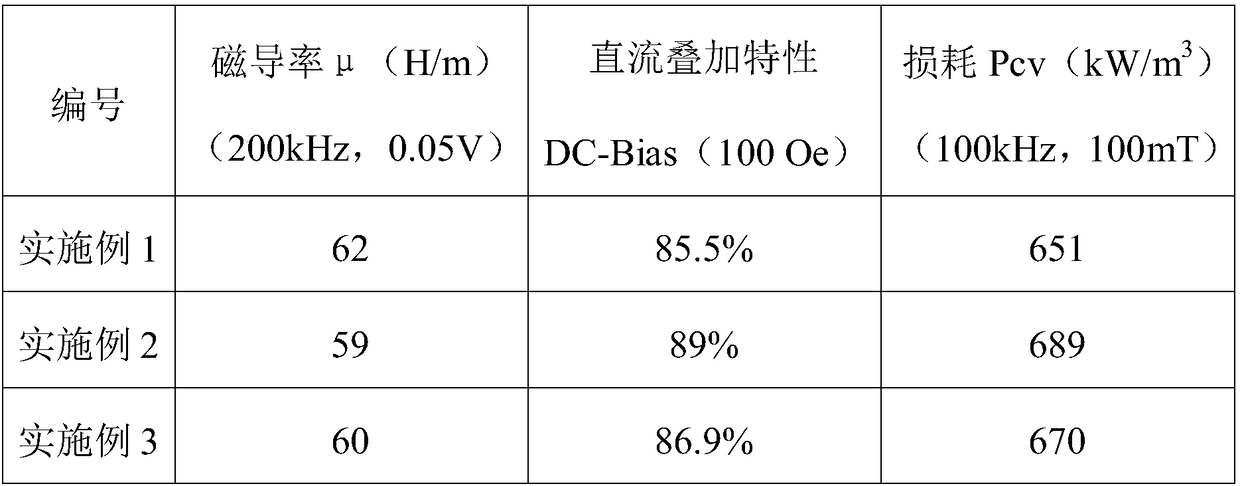

A preparation method of μ=60 iron-nickel soft magnetic powder core

ActiveCN106252013BReduce usageIncrease heat treatment temperatureTransportation and packagingMetal-working apparatusOrganic matterHeat treated

The invention discloses a preparation method of a μ=60 iron-nickel soft magnetic powder core. It uses gas-atomized FeNi powder, through the particle size ratio of iron-nickel powder, powder annealing treatment, insulation coating, compression molding, core heat treatment and surface coating process, to realize the preparation of μ = 60 iron-nickel soft magnetic powder core . The beneficial effects of the present invention are: the required equipment and process are simple, and the cost is low; the product performance is excellent, with high DC superposition performance, very low power loss and high quality factor, reaching the industry-leading level; avoiding organic The use of the binder increases the heat treatment temperature of the magnetic powder core, and at the same time reduces the exhaust gas pollution generated by the organic matter during the heat treatment process.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

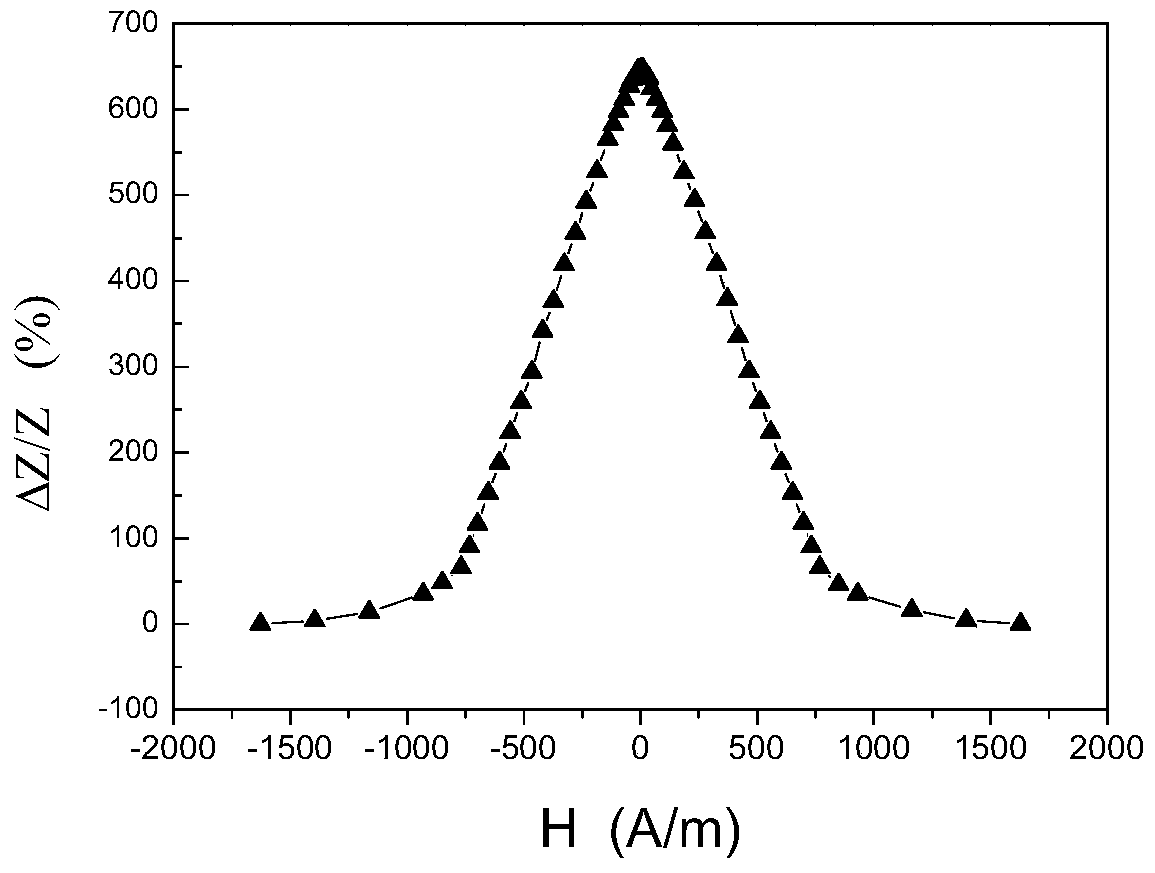

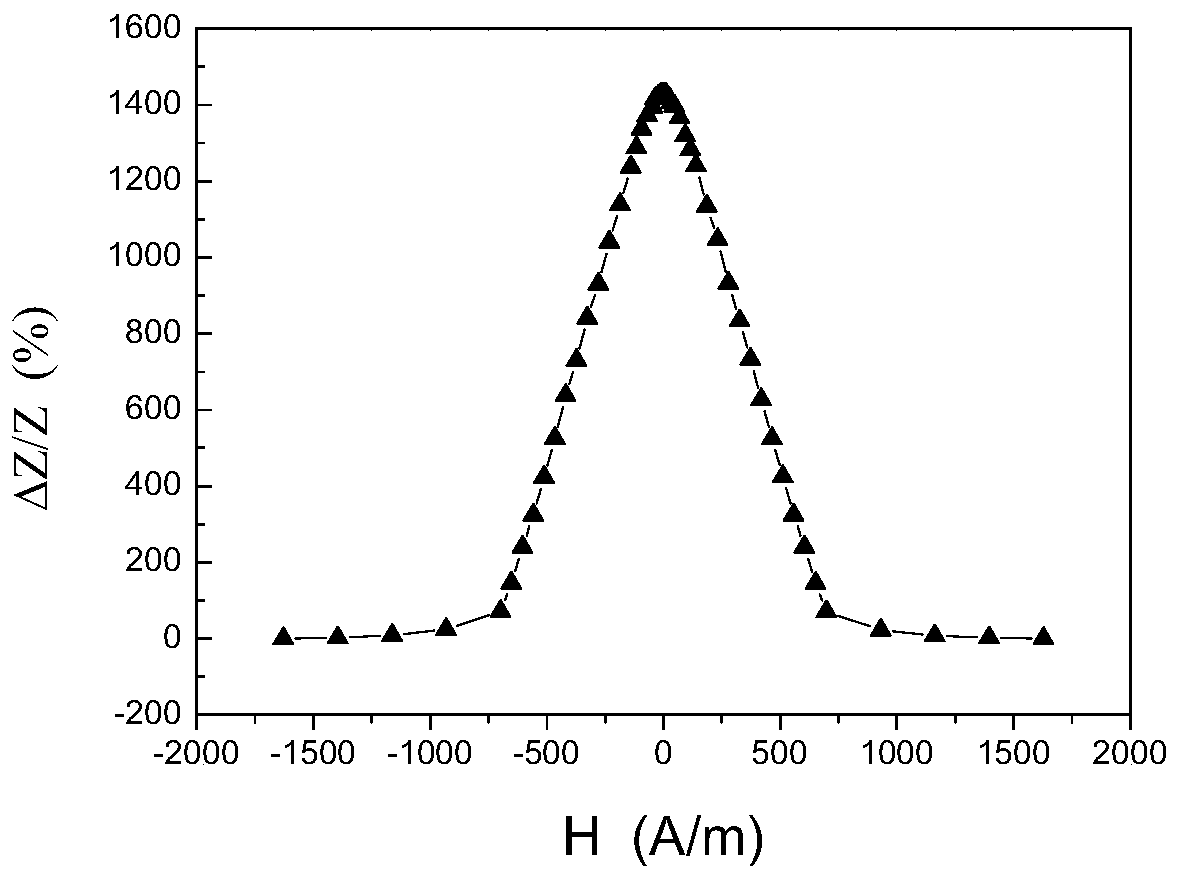

A method for preparing magnetically sensitive material with high sensitivity and wide linear region

ActiveCN105679486BSimple processEasy to controlMagnetic materialsProcess engineeringThermal treatment

The invention discloses a new method for preparing magnetically sensitive materials with high sensitivity and wide linear area. Compared with the existing technology, the technology of the present invention can be used to prepare magnetically sensitive materials with the advantages of wide linear area and high sensitivity at the same time. It has the advantages of simple process and easy control. There are few process parameters that need to be controlled, and it has the advantages of easy control of material properties and energy saving. There is no need to increase the processing temperature or increase the heat treatment time. Therefore, the present invention has significant energy saving advantages. Since the process is simple and easy to control, it requires The production equipment is simple, the cost is low, and it is easy to ensure the consistency of batch products. Therefore, it has the advantages of easy promotion and industrial transformation.

Owner:杭州仁才汇科技成果转化服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com