Hot working technology of improving performance of HSn70-1 alloy

A thermal processing and alloying technology, which is applied in the field of thermal processing of HSn70-1 alloy properties, can solve the problems of short service life and high cost, and achieve the effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

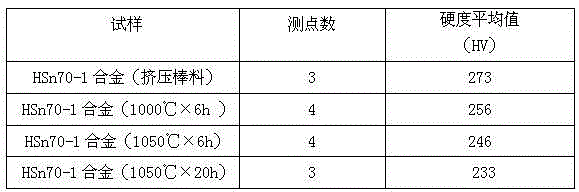

[0012] The material used in the experiment is copper (purity: 99.95%) as the matrix, mainly alloying element nickel (purity: 99.95%); melting at 1400 ° C, heat preservation for 2 hours, and then casting, the cast sample is heat treated, and then heated It can be extruded in an extrusion die. The heat treatment process parameters are: 1000°C-1100°C×6-20h.

[0013] Metallographic examination (material) HSn70-1 alloy, extruded bar, cast HSn70-1 alloy; (instrument) metallographic microscope; (reagent) hydrochloric acid, ferric chloride and water to prepare corrosion solution; X-ray diffraction test (Instrument) High temperature X-ray diffractometer; (Condition) Copper target; Vickers hardness test (Instrument) HVS-1000 microhardness tester; (Condition) F=9.8N, t=10s; Compression test (Material) Extrusion rod Material, 1050℃x20h; (instrument) Sansi XYA105C material testing machine.

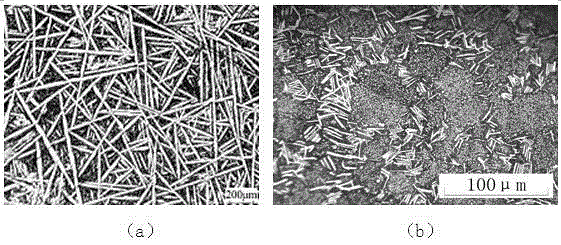

[0014] The as-cast structure of HSn70-1 alloy is as follows: figure 1 (a). It can be seen that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com