Patents

Literature

741results about How to "Long holding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

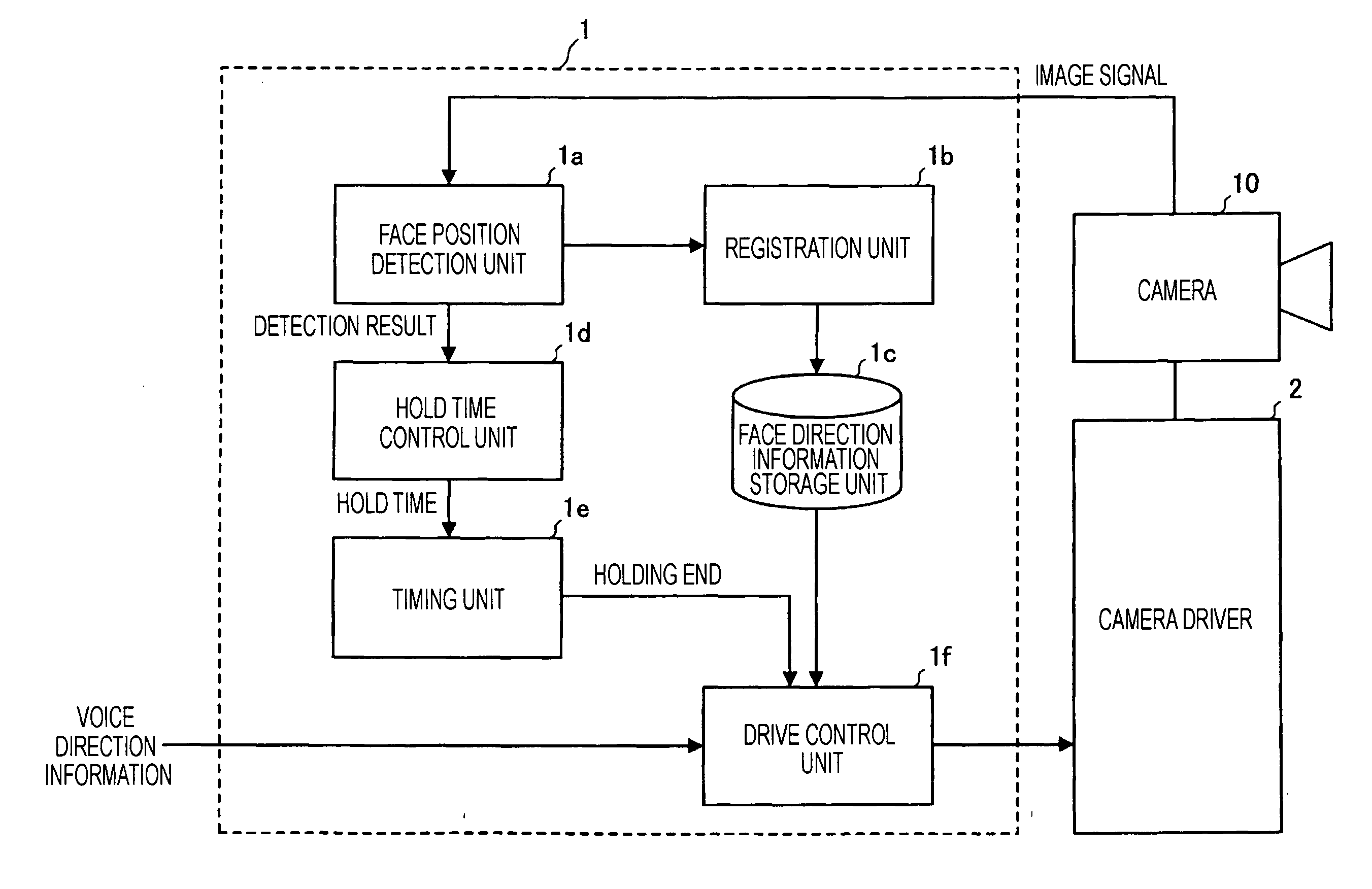

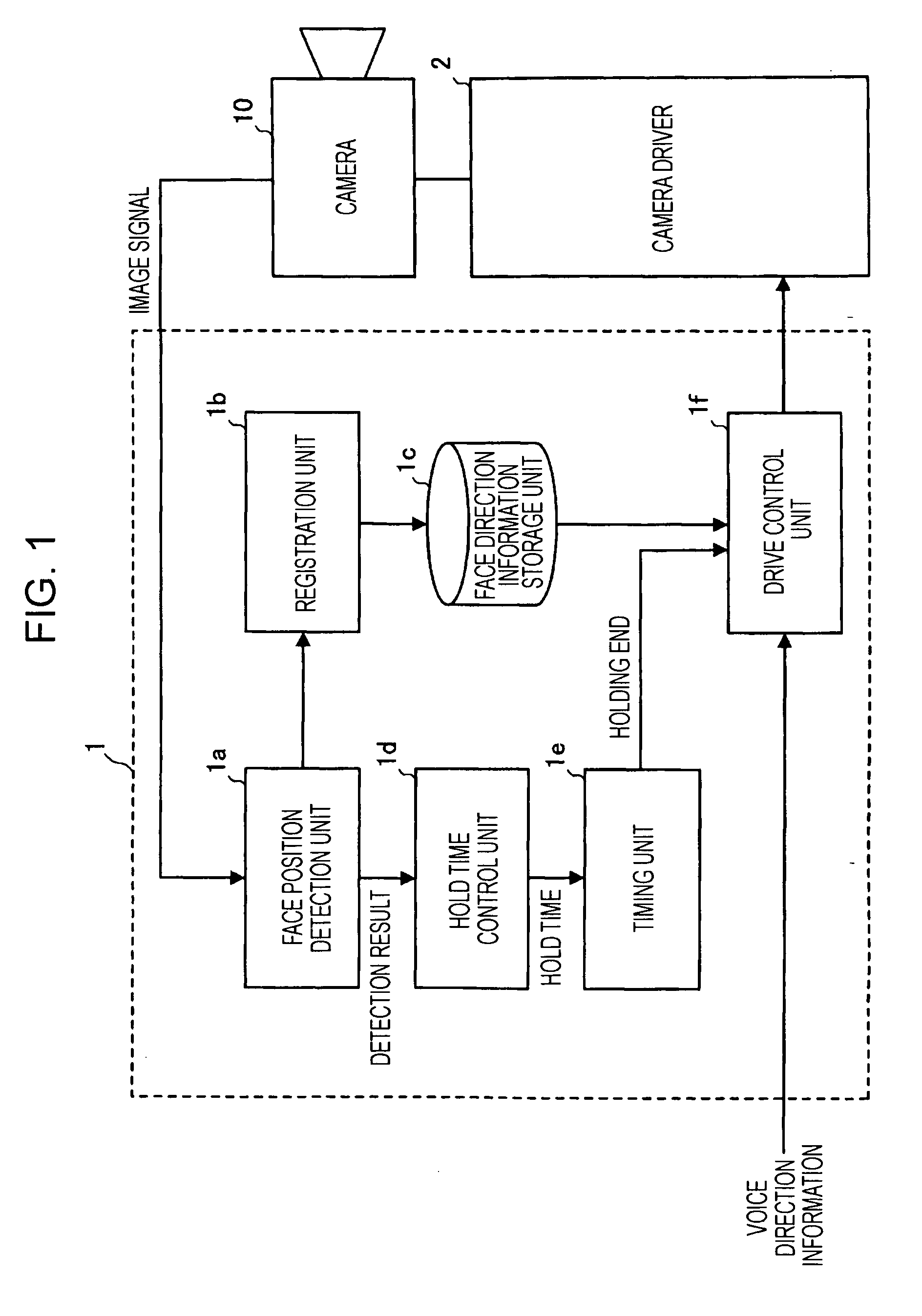

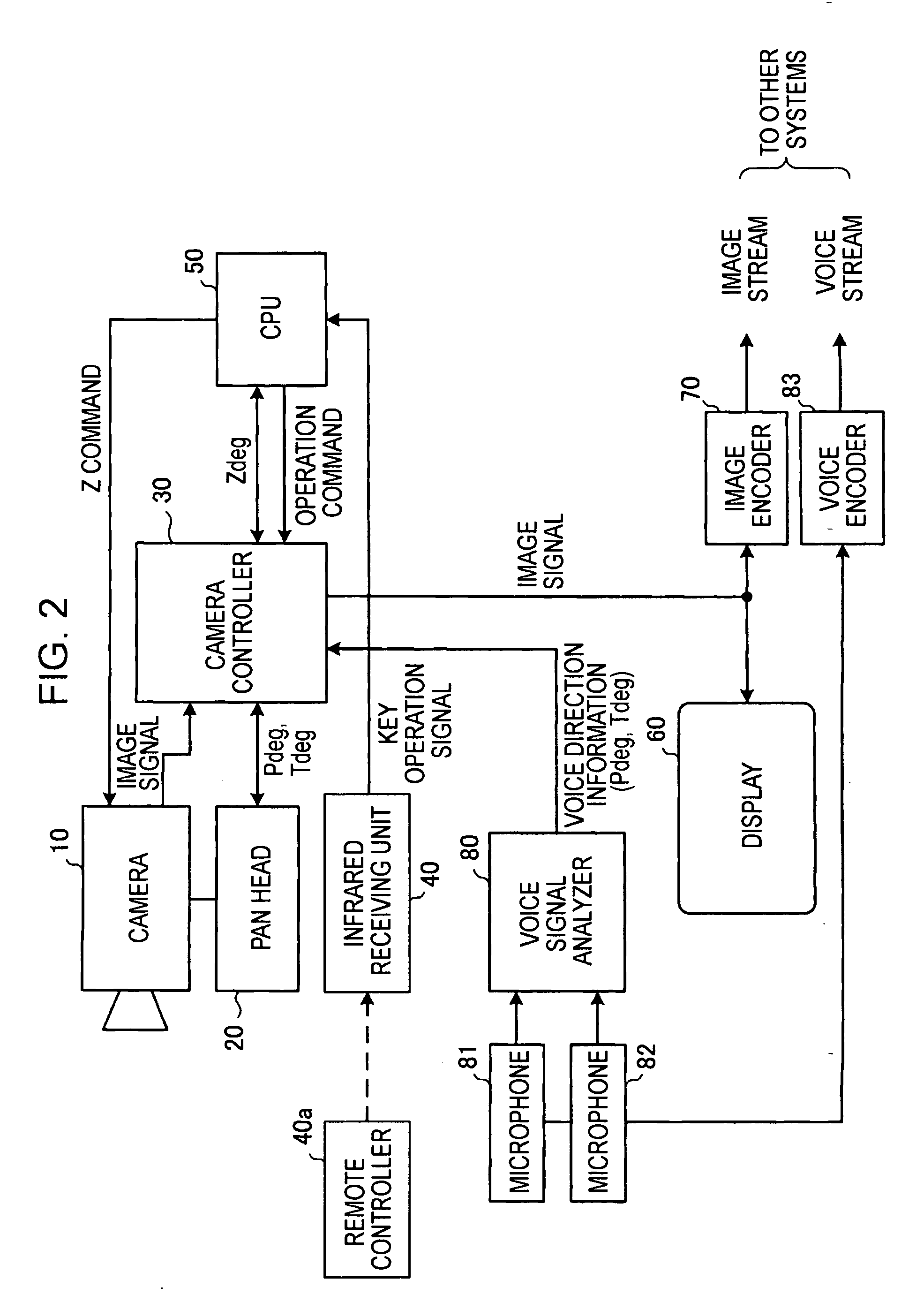

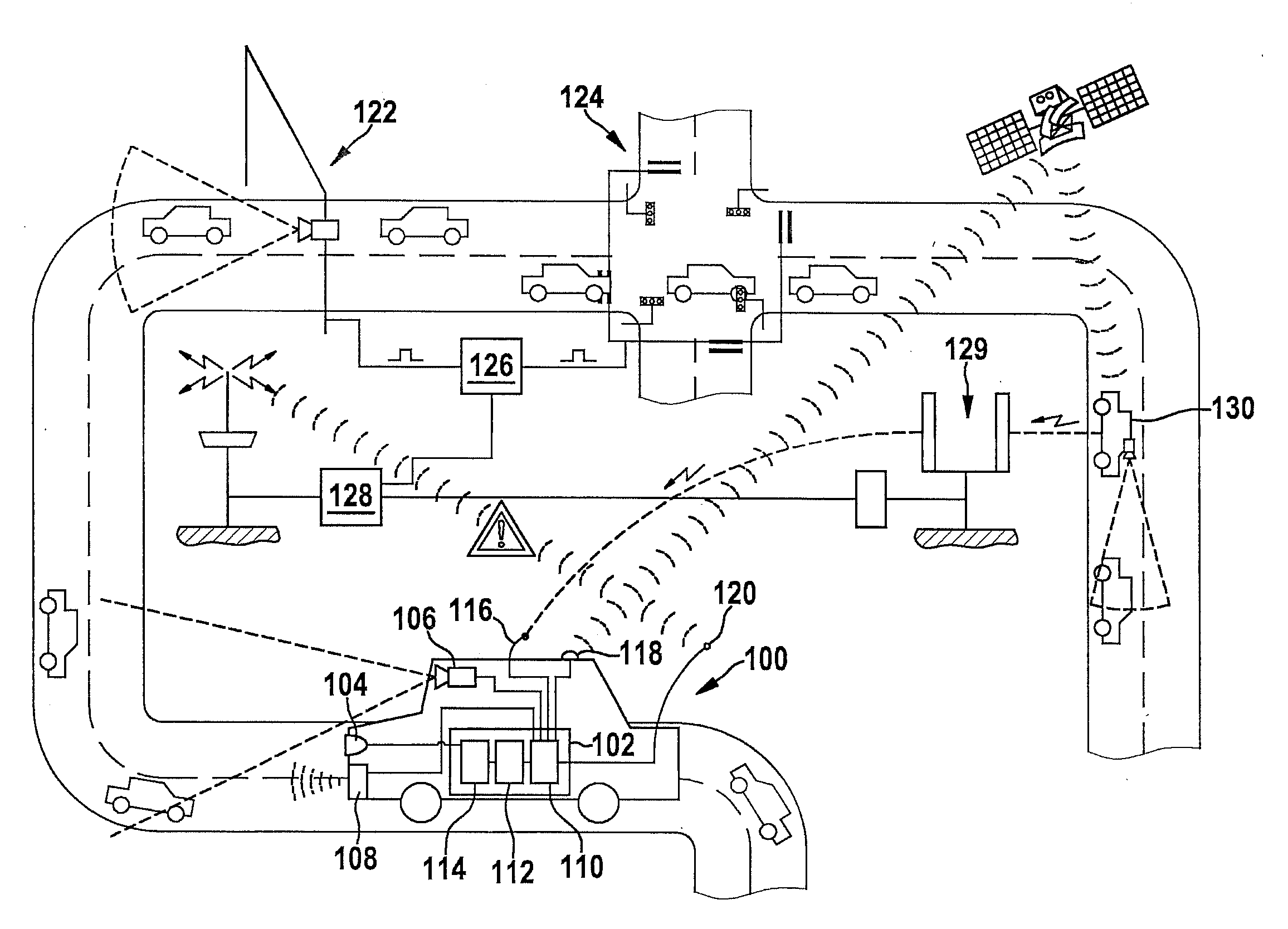

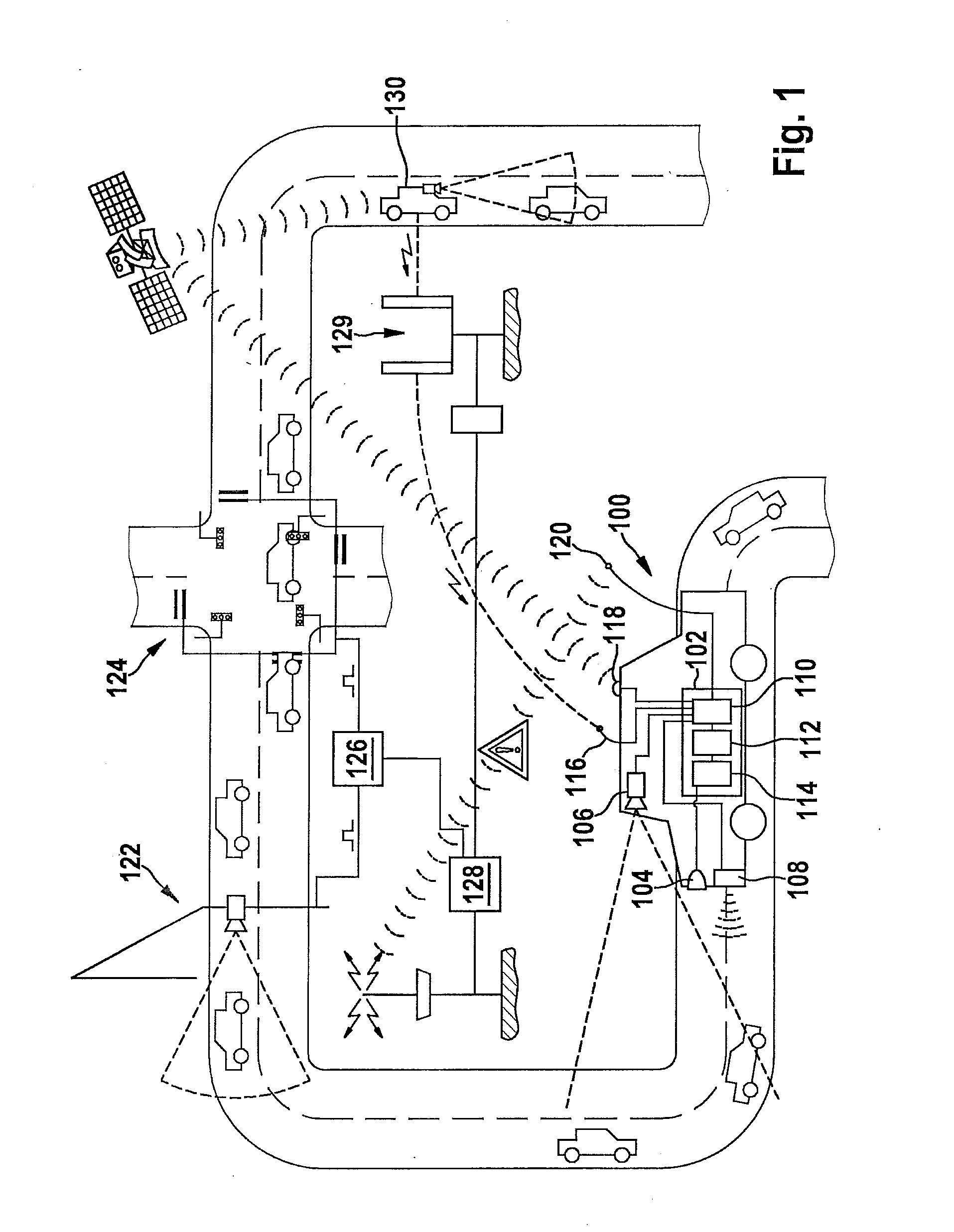

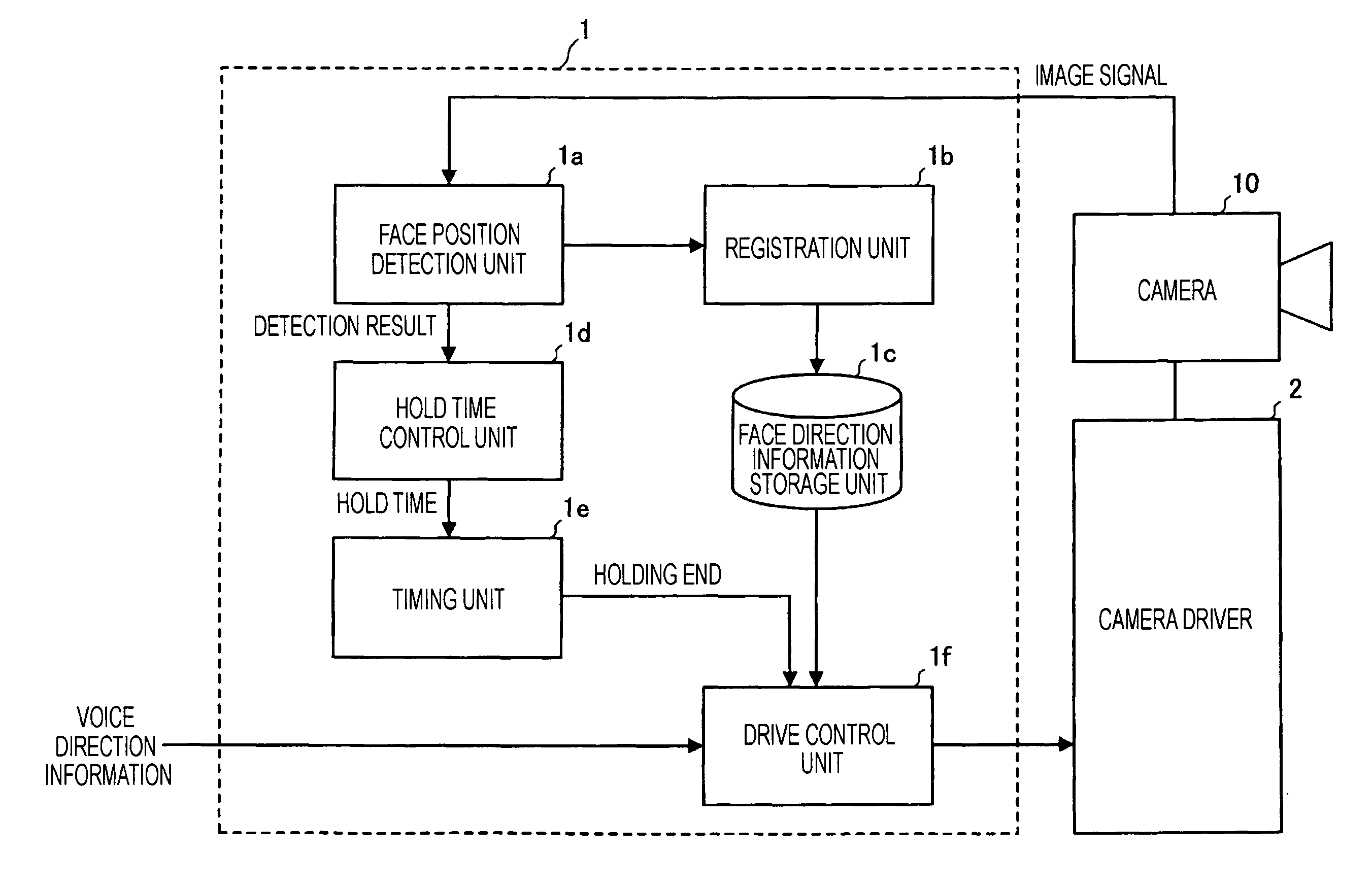

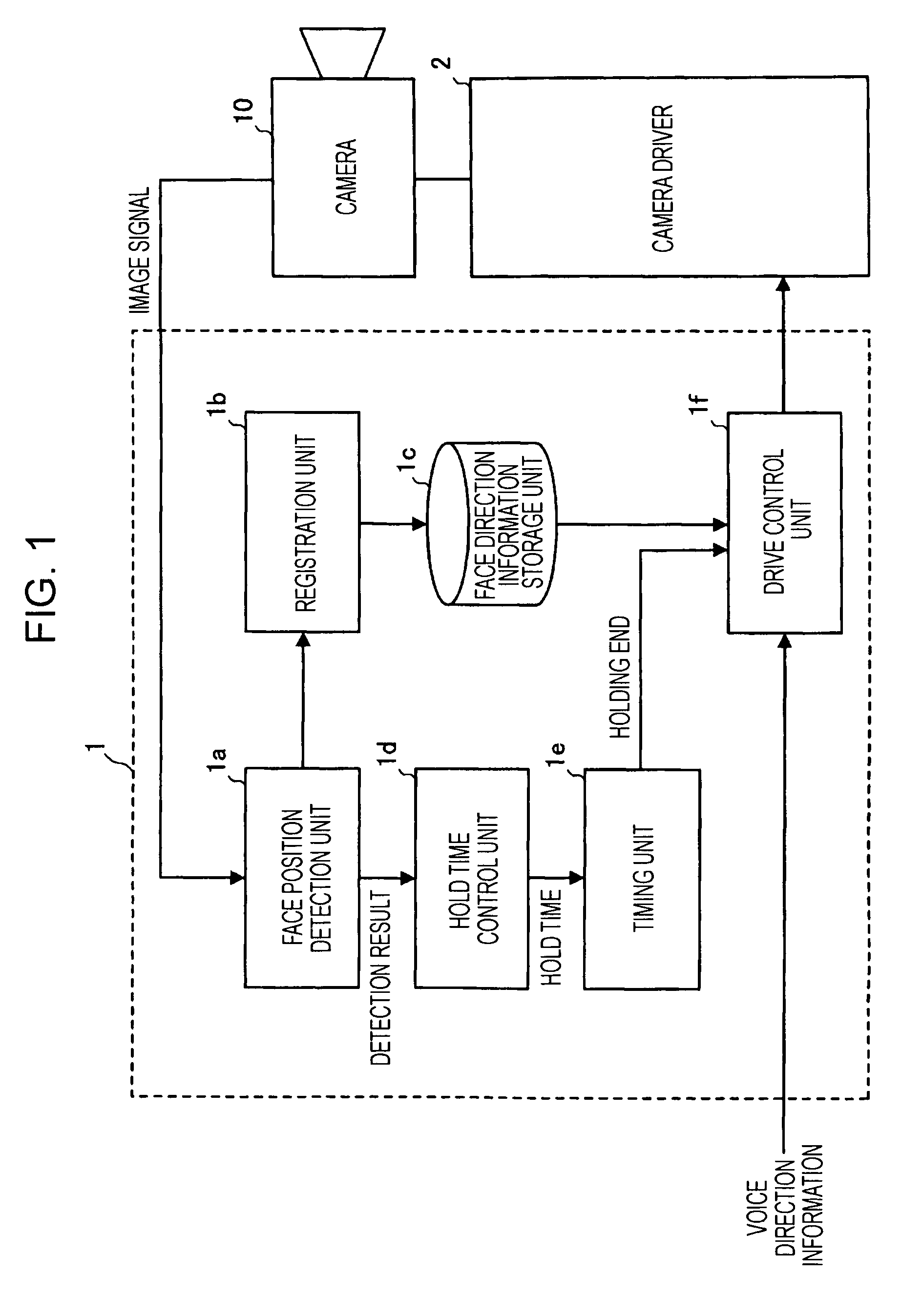

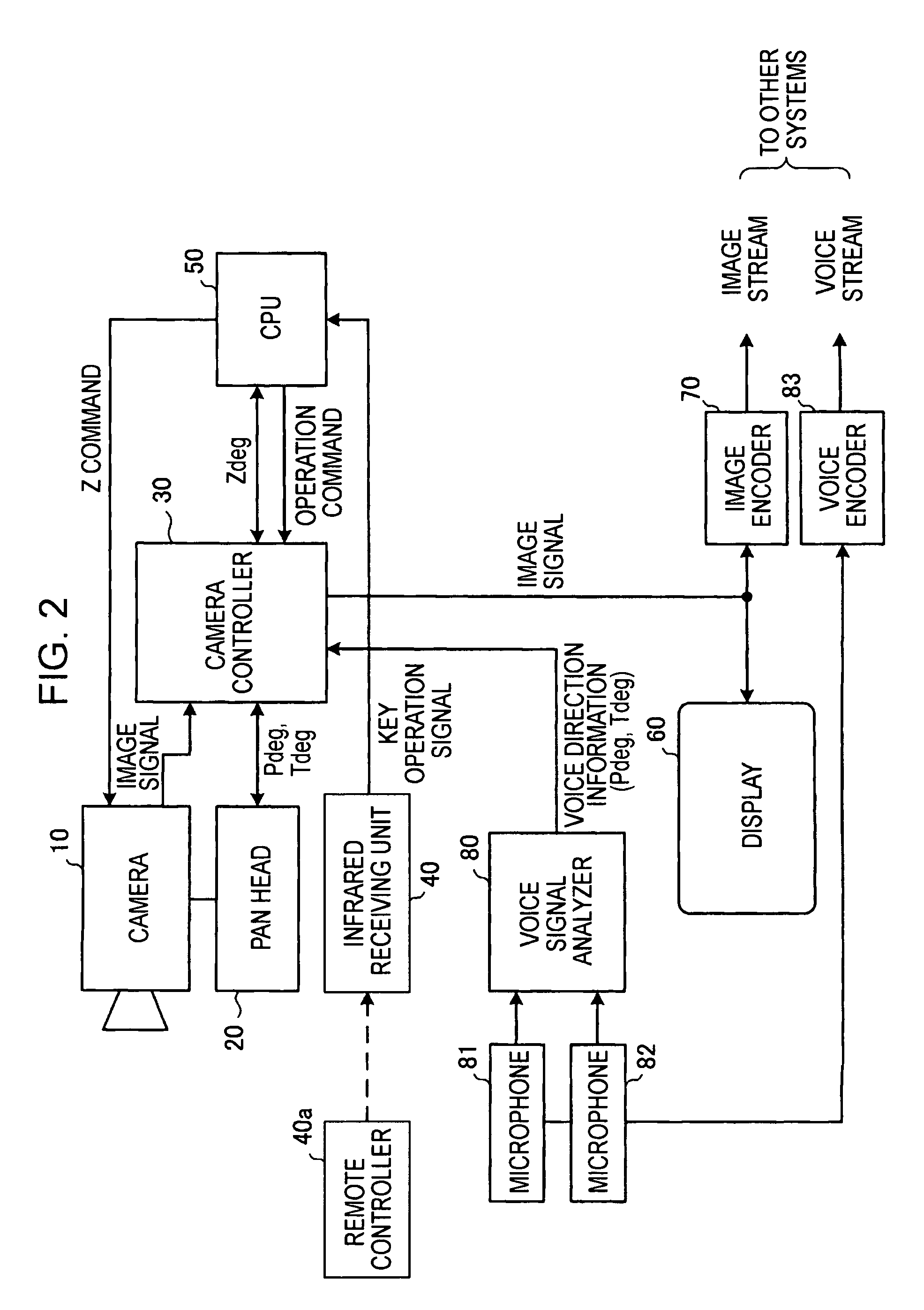

Camera controller and teleconferencing system

InactiveUS20070040903A1Move quicklyAccurately and stably imageTelevision conference systemsTwo-way working systemsCamera controlDriver/operator

Owner:SONY CORP

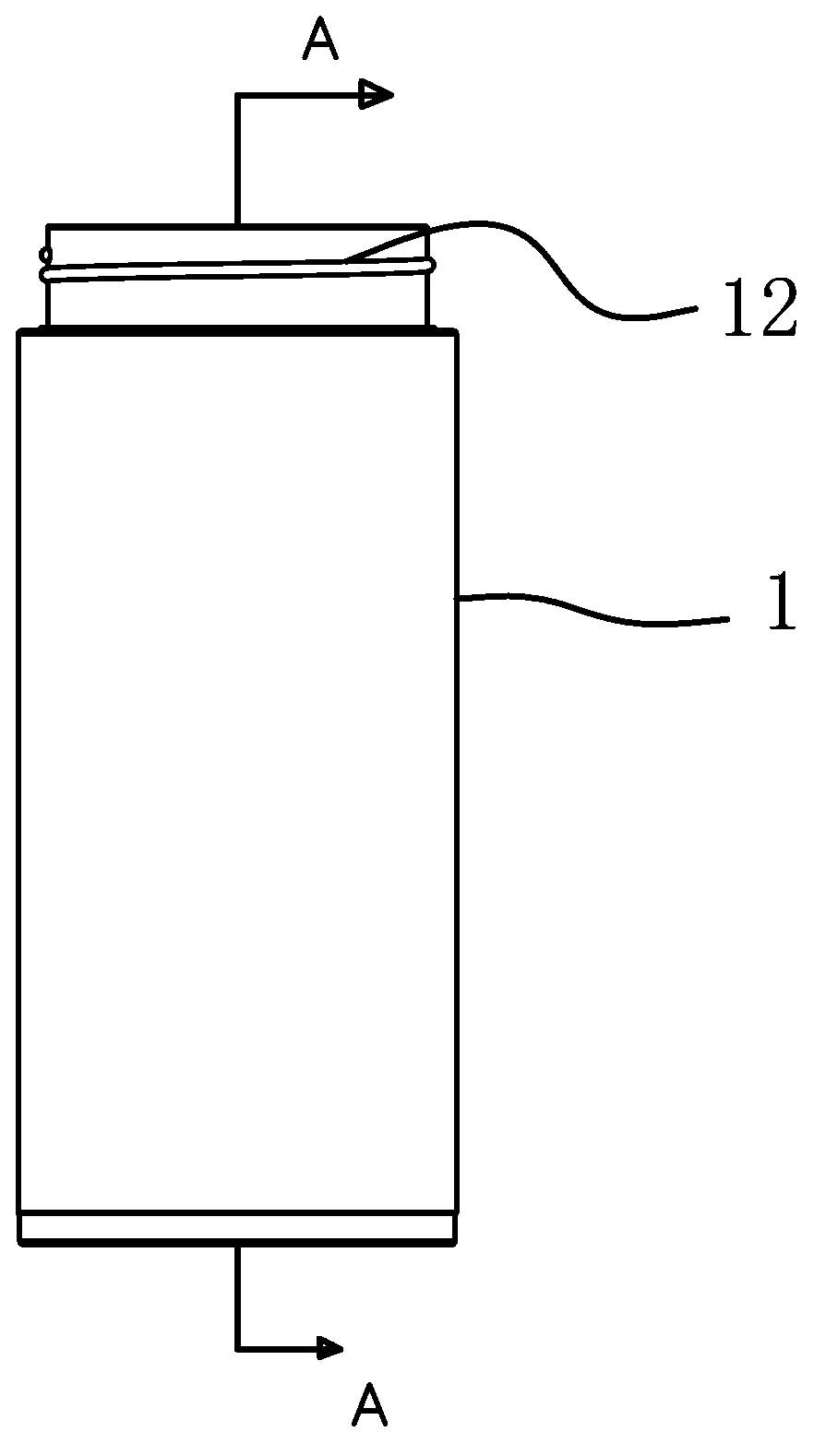

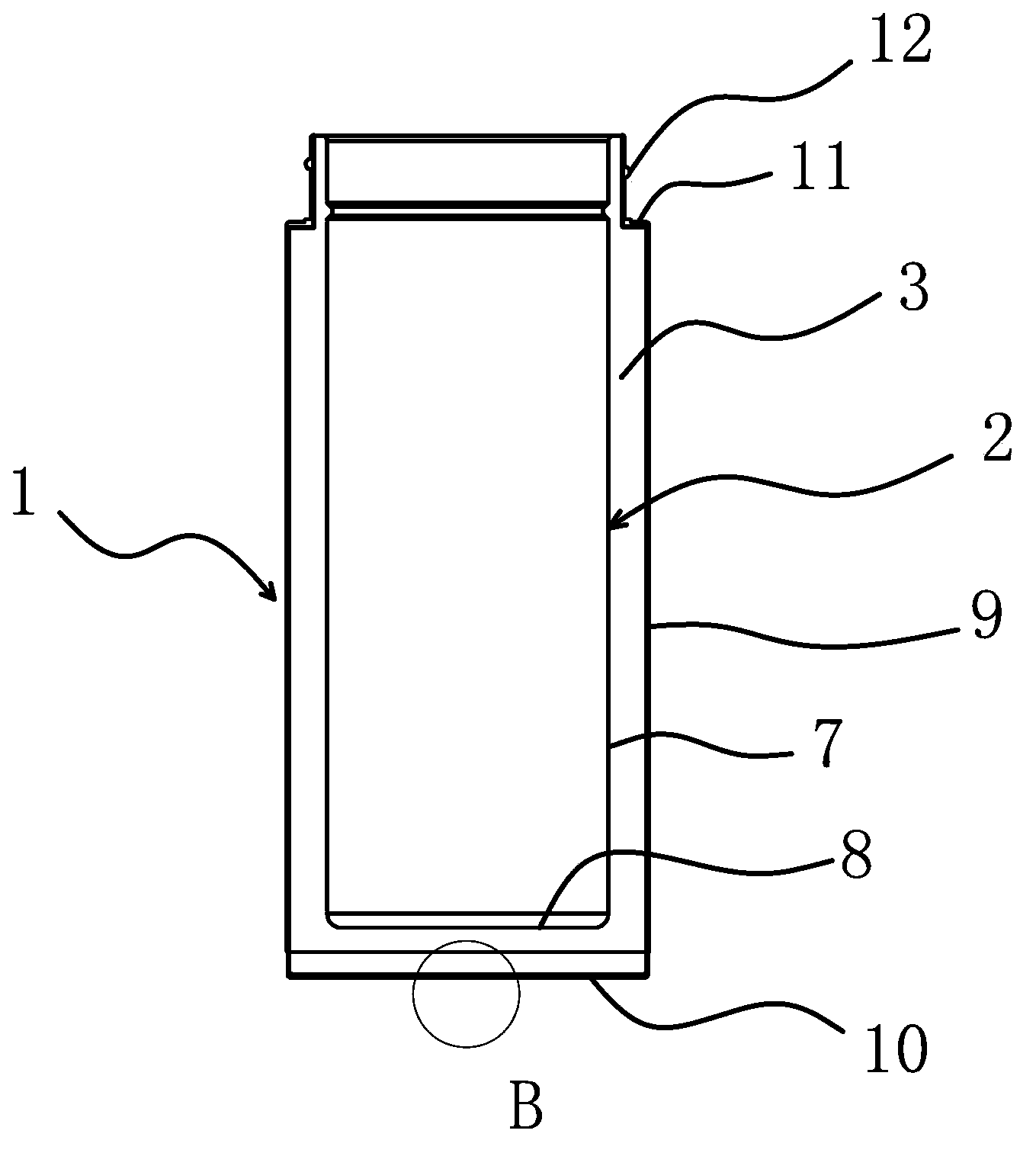

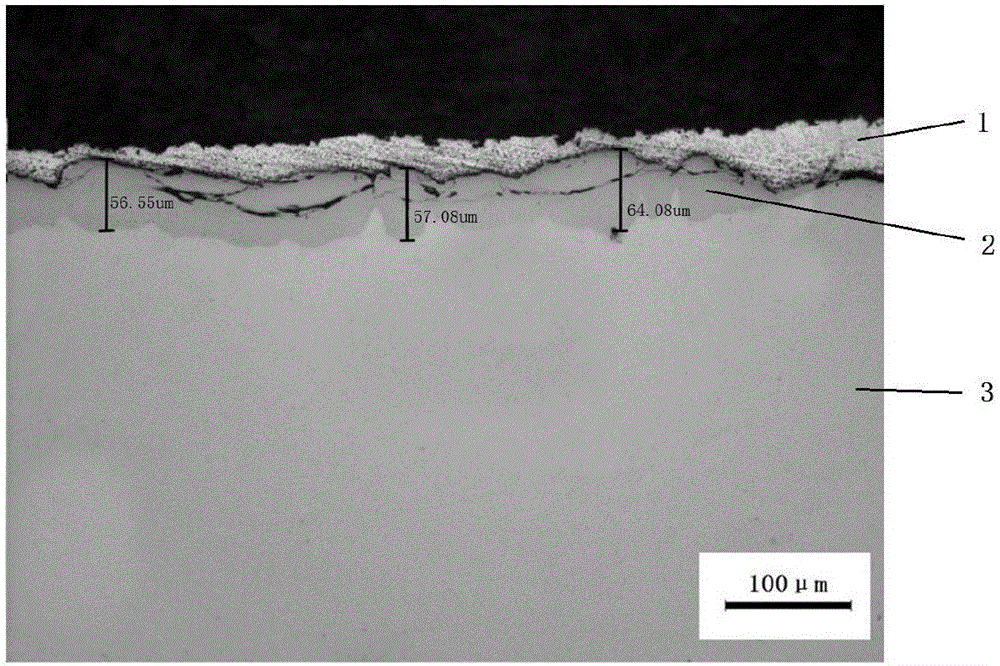

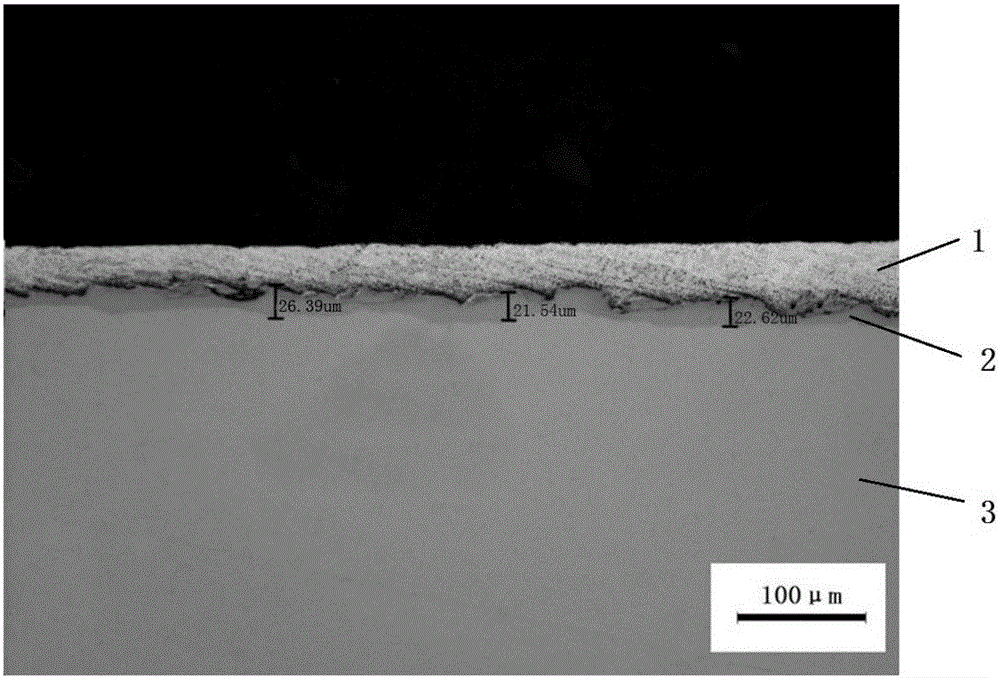

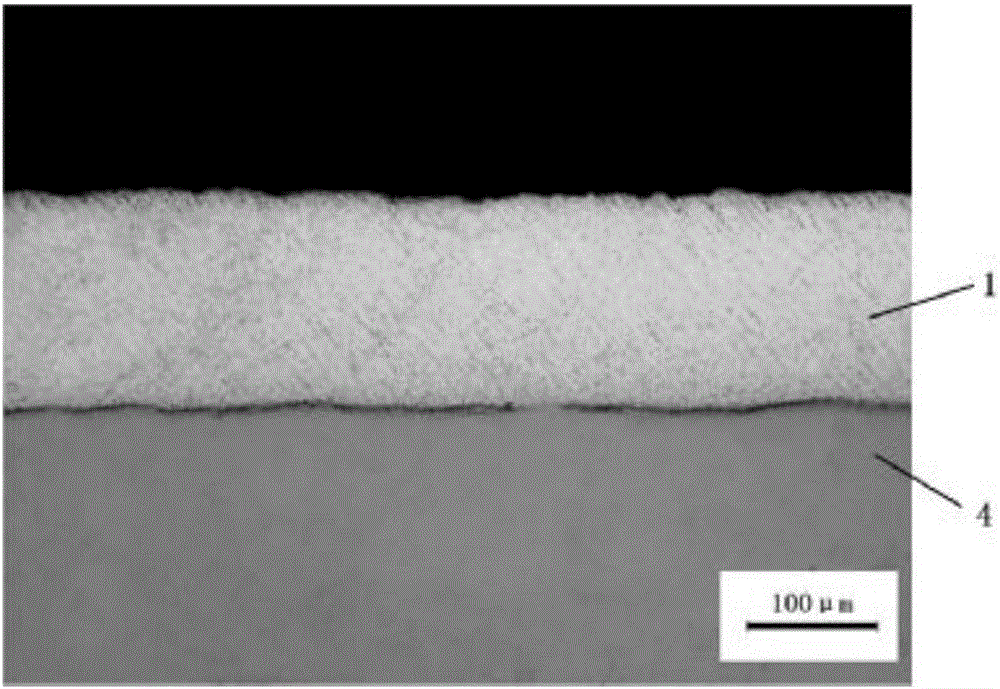

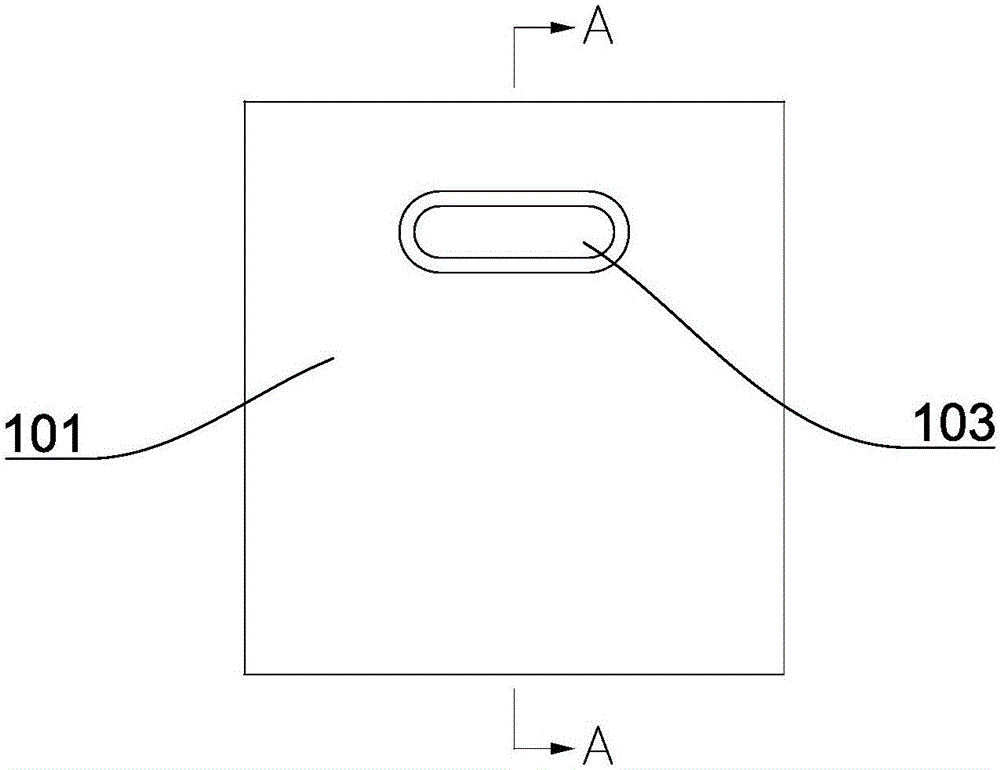

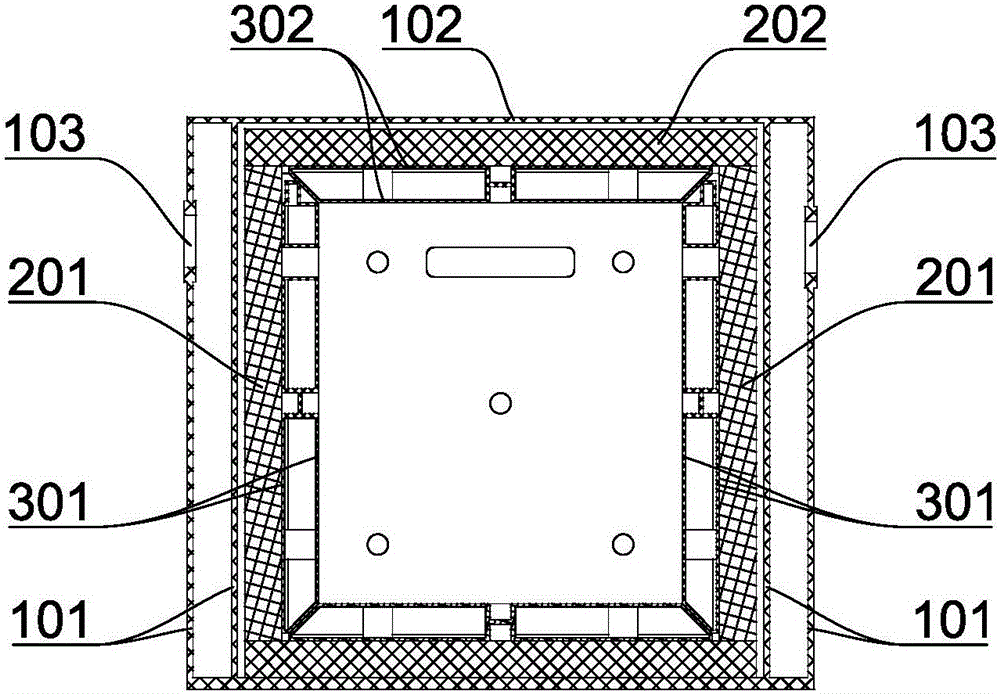

Titanium metal vacuum cup and manufacturing method thereof

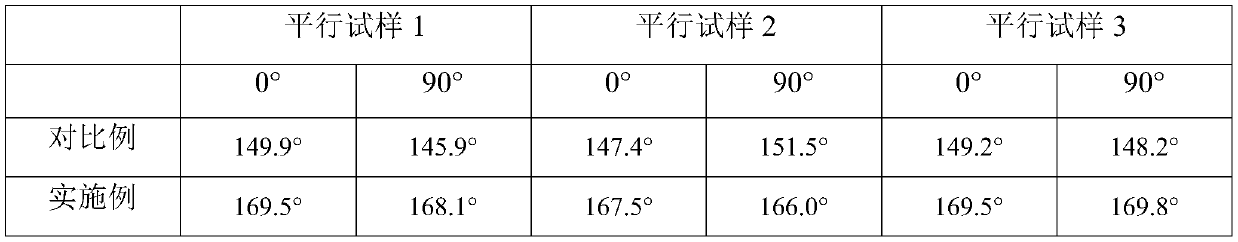

ActiveCN103405104AThermal insulationImprove corrosion resistanceDrinking vesselsVacuum pumpingTitanium metal

The invention provides a titanium metal vacuum cup and a manufacturing method thereof, belongs to the technical field of daily necessities, and solves the technical problems that a conventional vacuum cup is lower in corrosion resistance and attractiveness and the like. The vacuum cup comprises an outer cup body and an inner cup body, wherein the inner cup body is sleeved with the outer cup body; the orientation of cup rims of the inner cup body and the outer cup body is identical; the inner cup body and the outer cup body are sealed and fixed annularly at the cup rims; a vacuum interlayer is arranged between the inner cup body and the outer cup body; and both the outer cup body and the inner cup body are made of titanium metal pieces. The manufacturing method of the vacuum cup comprises the procedures as follows: a, blank preparation; b, expansion molding; c, cup bottom sheet installation; d, tailless vacuum pumping; and e, finished product blanking. The titanium metal vacuum cup has the advantages of good corrosion resistance, high attractiveness and the like.

Owner:亚钛军创(金华)控股有限公司

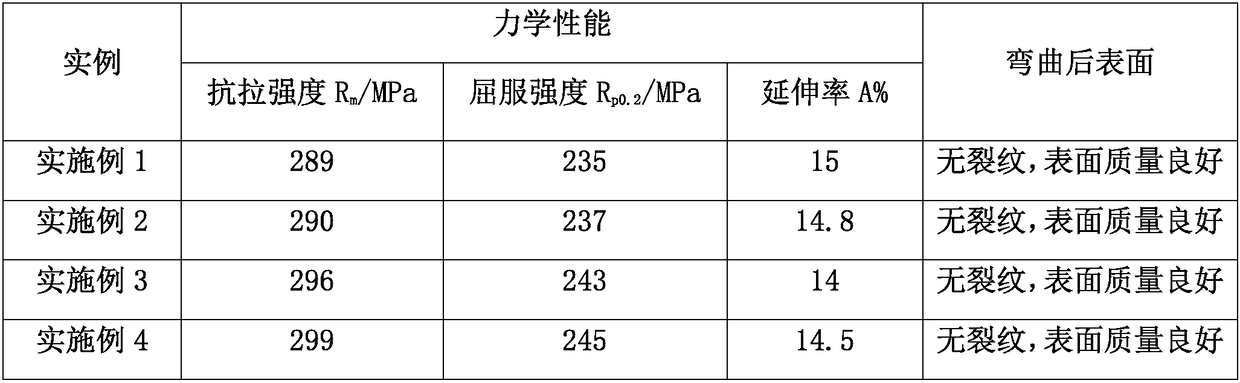

Grain-refined extruded aluminum alloy tubular product with large wall thickness and preparation method thereof

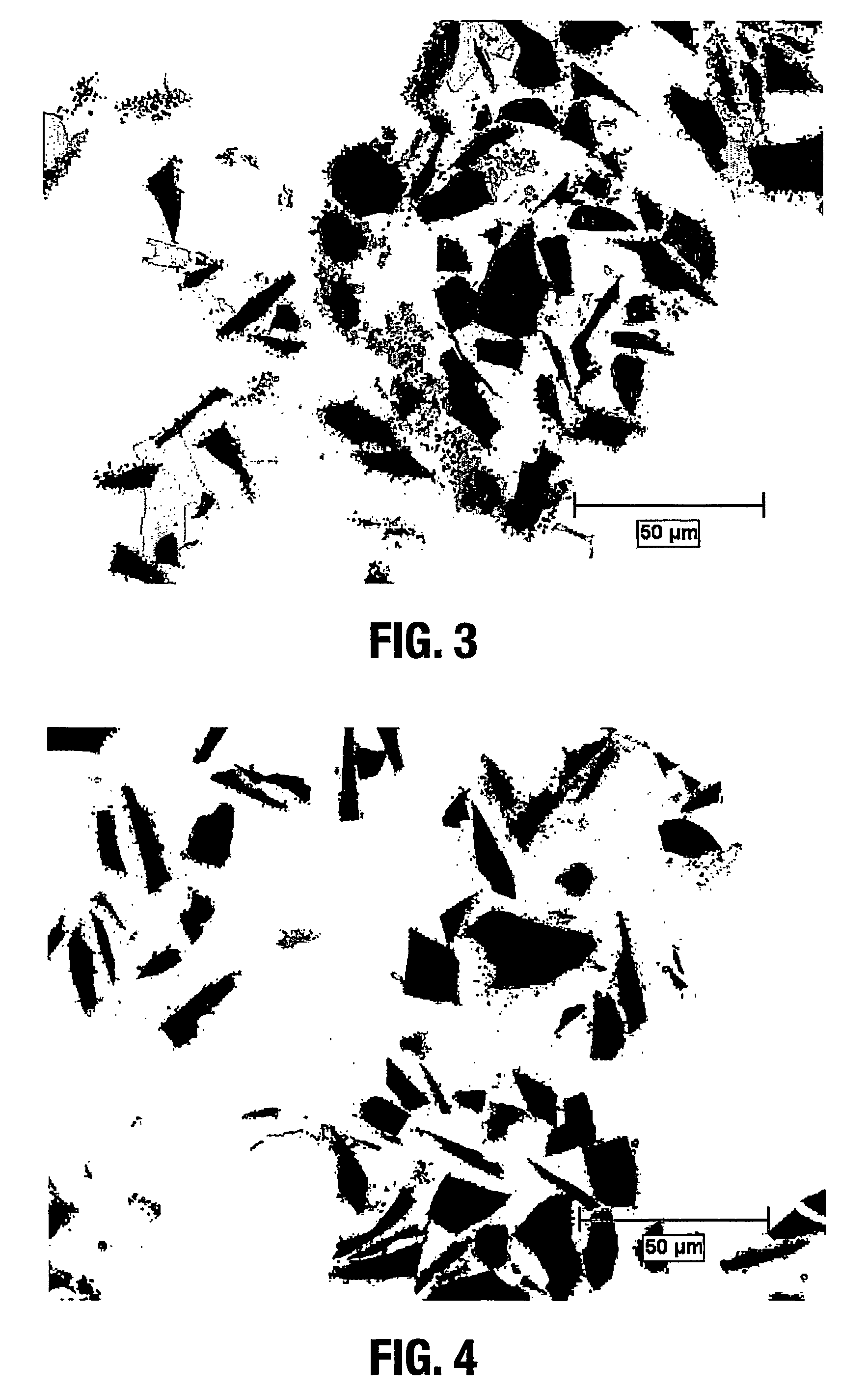

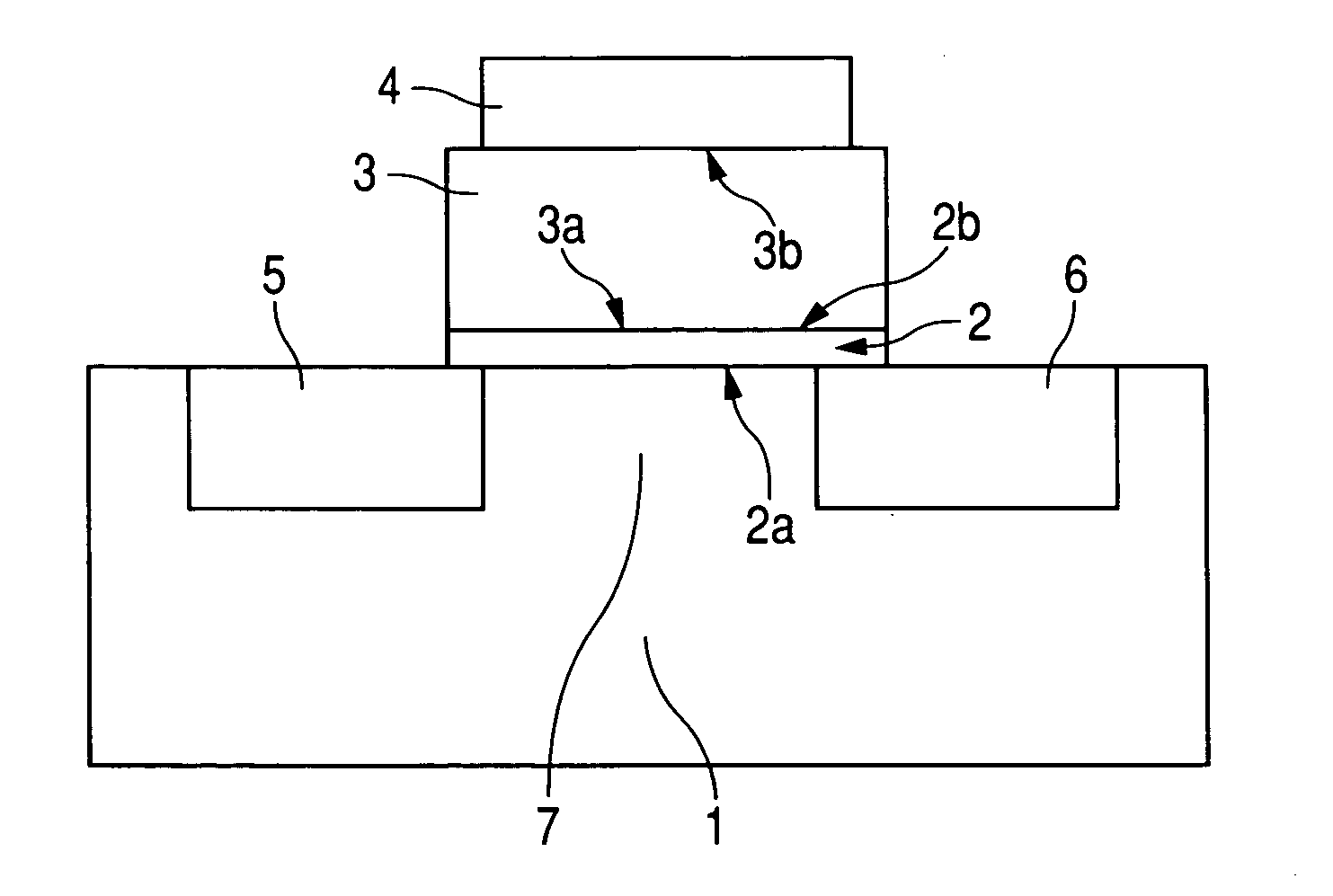

The invention discloses a grain-refined extruded aluminum alloy tubular product with large wall thickness and a preparation method thereof. The tubular product comprises the following metallic substances in percentage by weight: 1.0-1.15% of Mg, 0.60-0.75% of Si, 0.20-0.35% of Cu, 0.35% of Fe, 0.10% of Mn, 0.05-0.08% of Cr, 0.15% of Zn, 0.10% of Ti and the balance of aluminum. The invention further discloses a preparation method of the grain-refined extruded aluminum alloy tubular product with large wall thickness. The grain-refined extruded aluminum alloy tubular product with large wall thickness provided by the invention solves the problem that the grains of the base and surface of a 6061 alloy extruded aluminum alloy tubular product with great wall thickness are thick and big, the deficiency of bulky crystal spots generated after anodic oxidation can be eliminated and indexes of the final product, such as inner welding quality and mechanical performance, can satisfy the GB / T6892-2006 standard requirement.

Owner:龙口市丛林铝材有限公司

Tungsten titanium target material with high purity and high tungsten-rich phase, and preparation method thereof

ActiveCN101748365AUniform densityHigh strengthVacuum evaporation coatingSputtering coatingHigh densityRefractory

The invention relates to a refractory alloy tungsten titanium target material and a preparation method thereof, in particular to a tungsten titanium target material with high purity and high content of tungsten-rich phase, and a hot-pressing preparation method thereof, which belongs to the technical field of refractory alloy target materials. The method prepares high-density tungsten alloy targetmaterial by taking high-purity W powder and Ti powder, as well as high-purity Mo, Cr, Ta, Nb and other additive metal powder as raw materials and adopting a high-temperature high-pressure hot-pressing molding process, wherein the relative density of the target material reaches 95 to 99 percent, and the content of tungsten-rich phase reaches 80 to 93 percent. Relative to the prior art, the method adds part of high-purity Nb, Mo, Cr, Ta and other metal powder while mixing materials so as to stabilize the tungsten-rich phase in alloy, increase the content of the tungsten-rich phase in the alloy and improve the using quality of the target material.

Owner:有研资源环境技术研究院(北京)有限公司

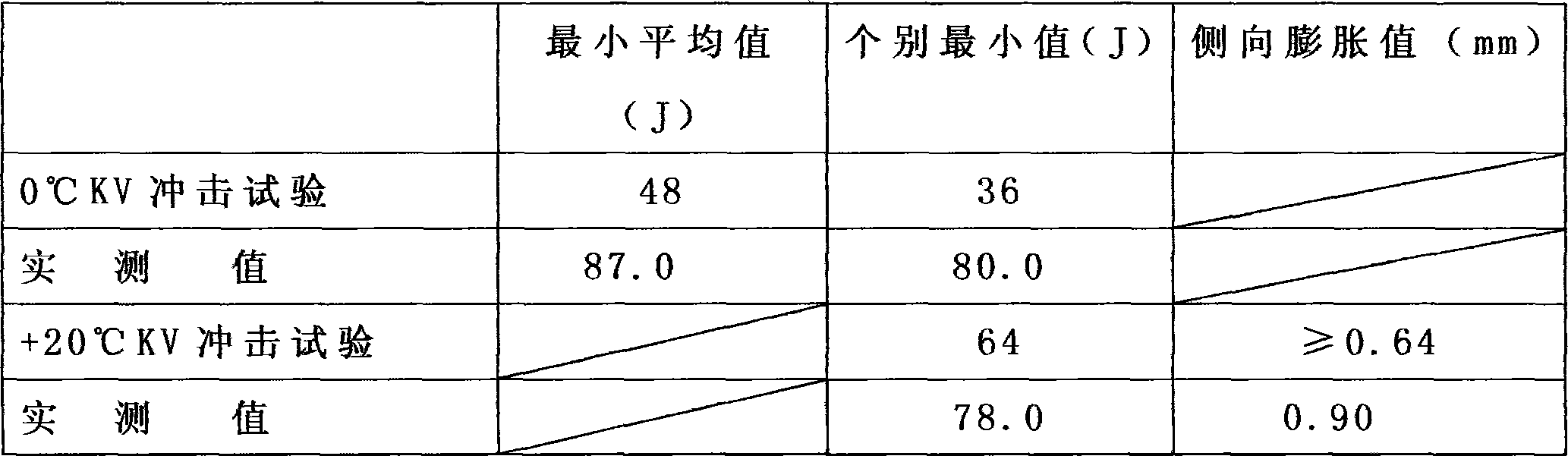

Million - kilowatts class nuclear power station reactor main bolt production process

ActiveCN101169150AUniform tissueFully heatedNuclear energy generationScrewsNuclear engineeringNuclear power

The invention discloses a pile main bolt manufacturing technique of a million kilowatt grade nuclear power station. The manufacturing technique includes material-selecting, melting, heating, forging, cooling, after-forging heat treatment, defect-detecting, and forging capability heat treating. When selecting the material, the microelement content of the materials is controlled, the heat preserving duration in the intermediate temperature stage is prolonged, the heat raising and the heat preserving duration in the high temperature stage are reduced, the distortion volume in the course of the forging is controlled between 30 percent and 70 percent, the forging rate reaches 5 above; after-forging heat treatment, ultrasonic defect detecting, and forging capacity heat treating are conducted when the forging is finished. The main bolt produced according to the manufacturing technique of the invention can improve the impact value under the circumstance that the intensity keeps unchanged, theproduct can meet the RCC-M standard requirements completely, and the reliability and the safety of the pile pressure container using the main bolt of the million kilowatt grade nuclear power station can be ensured.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

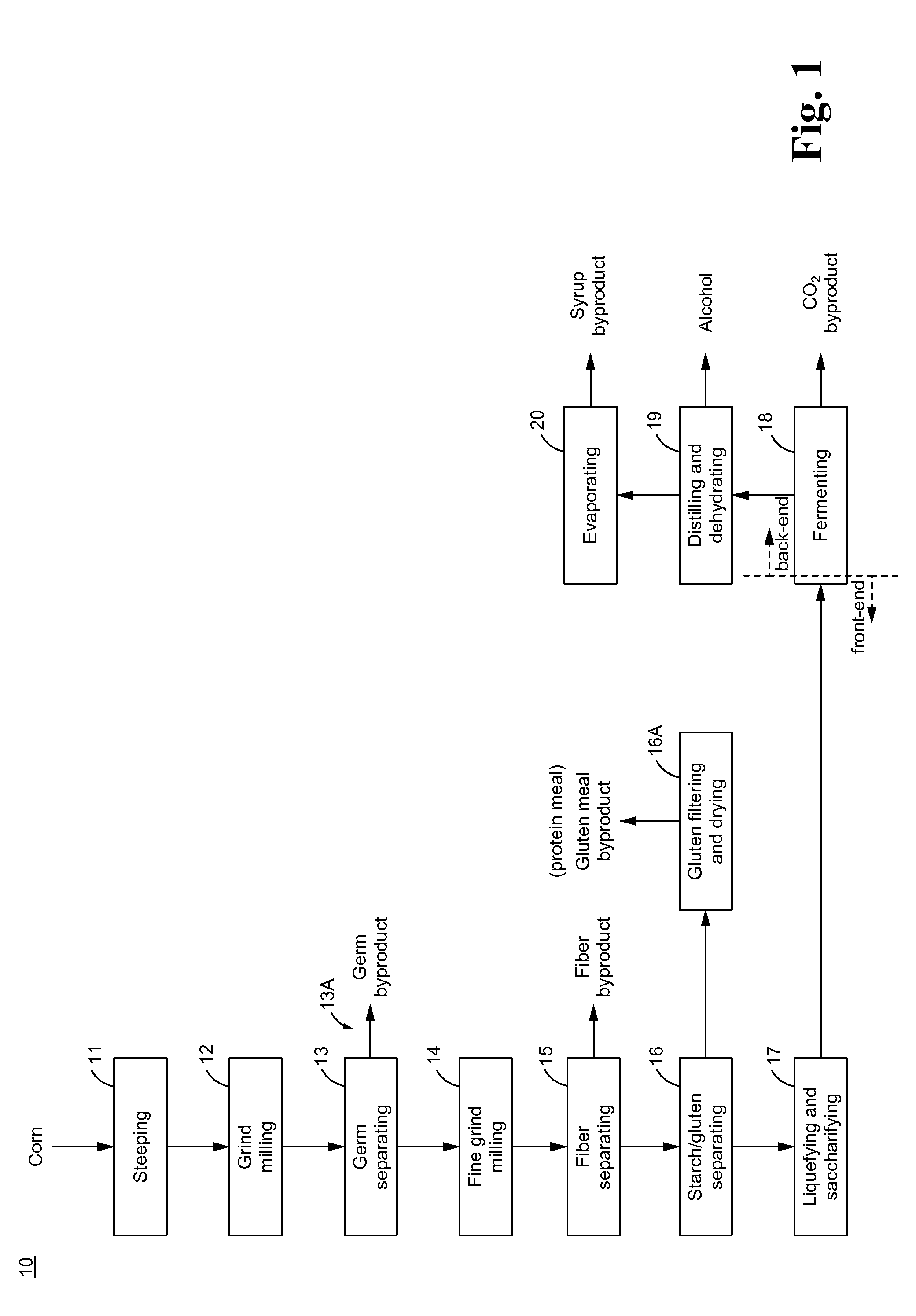

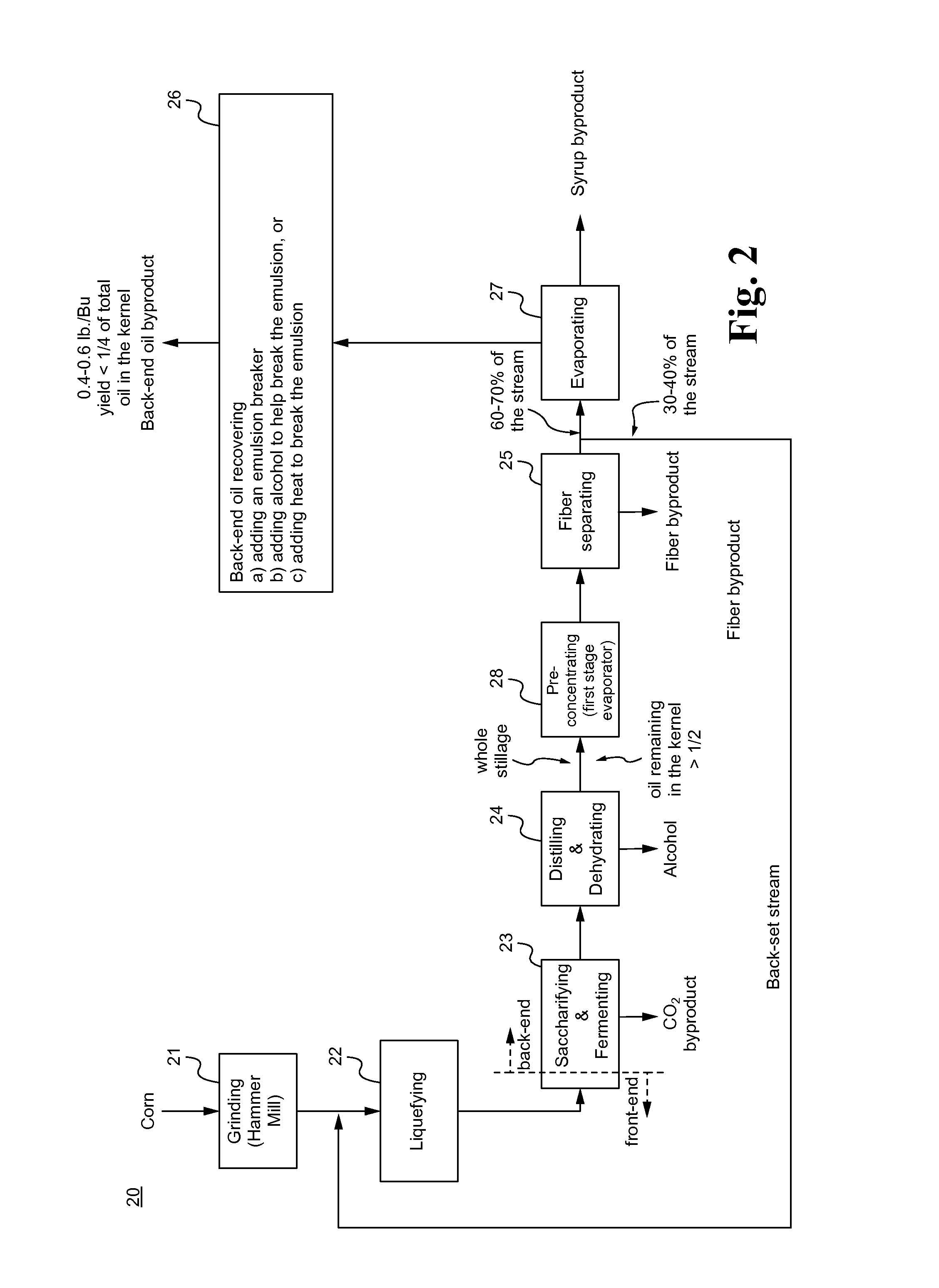

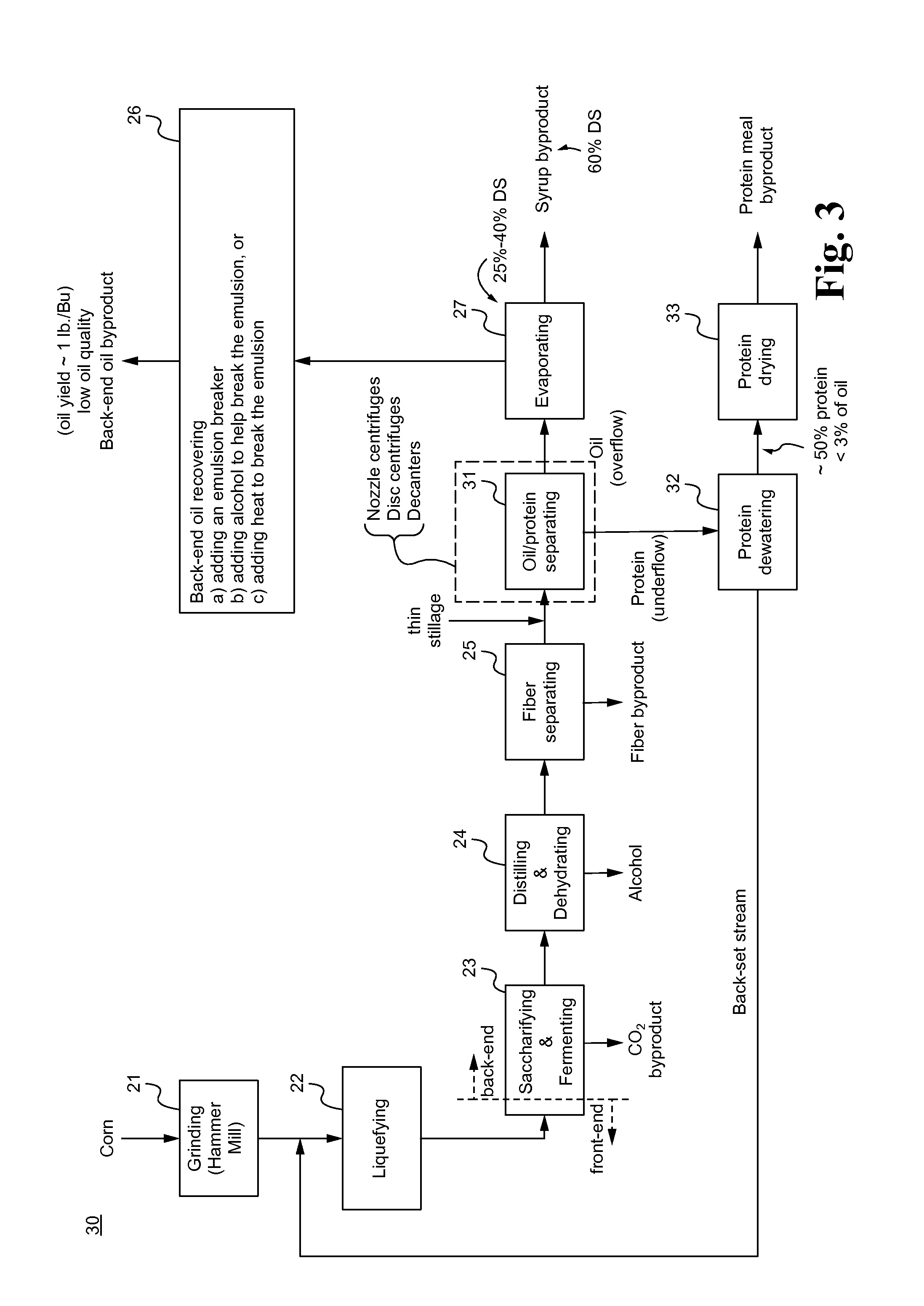

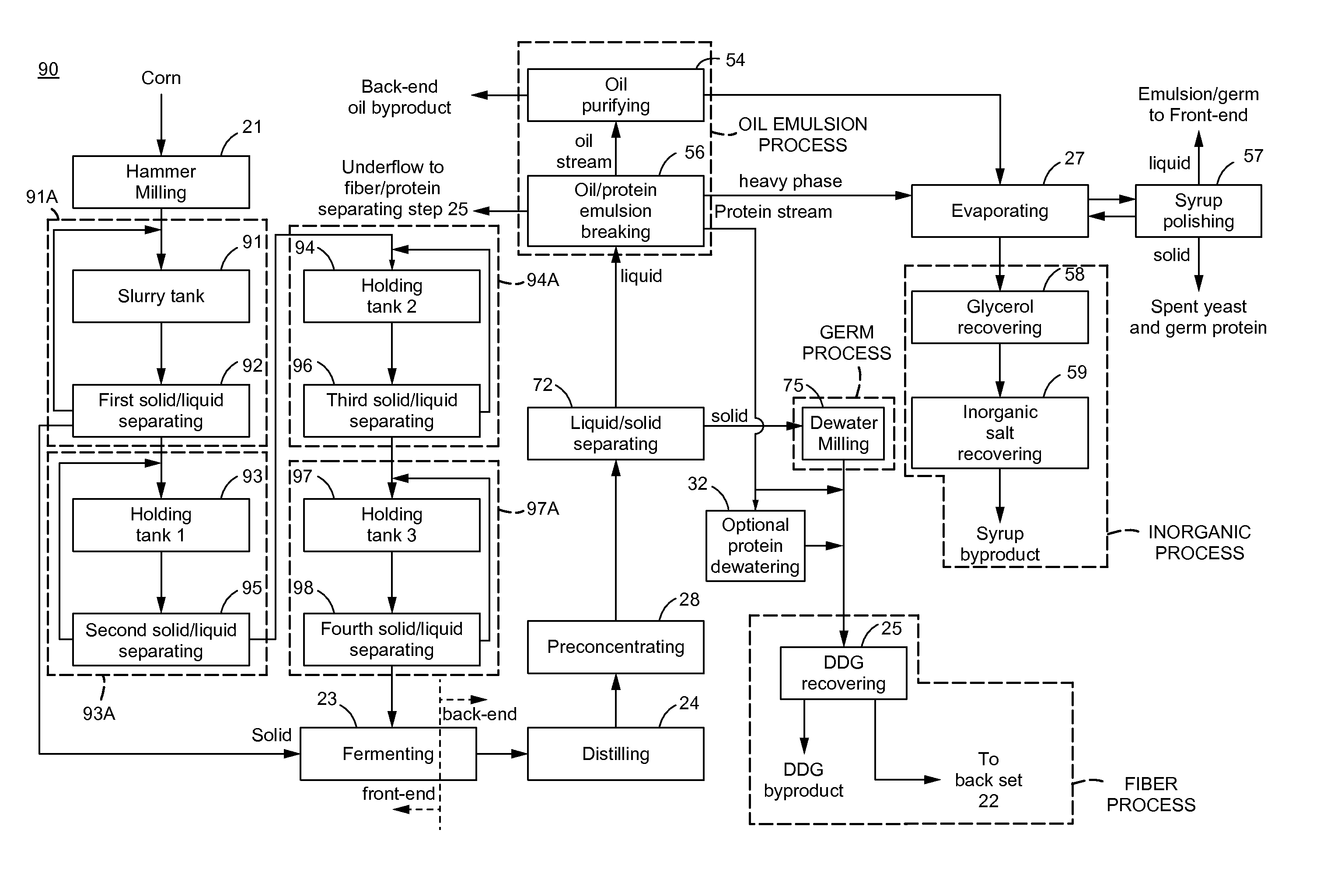

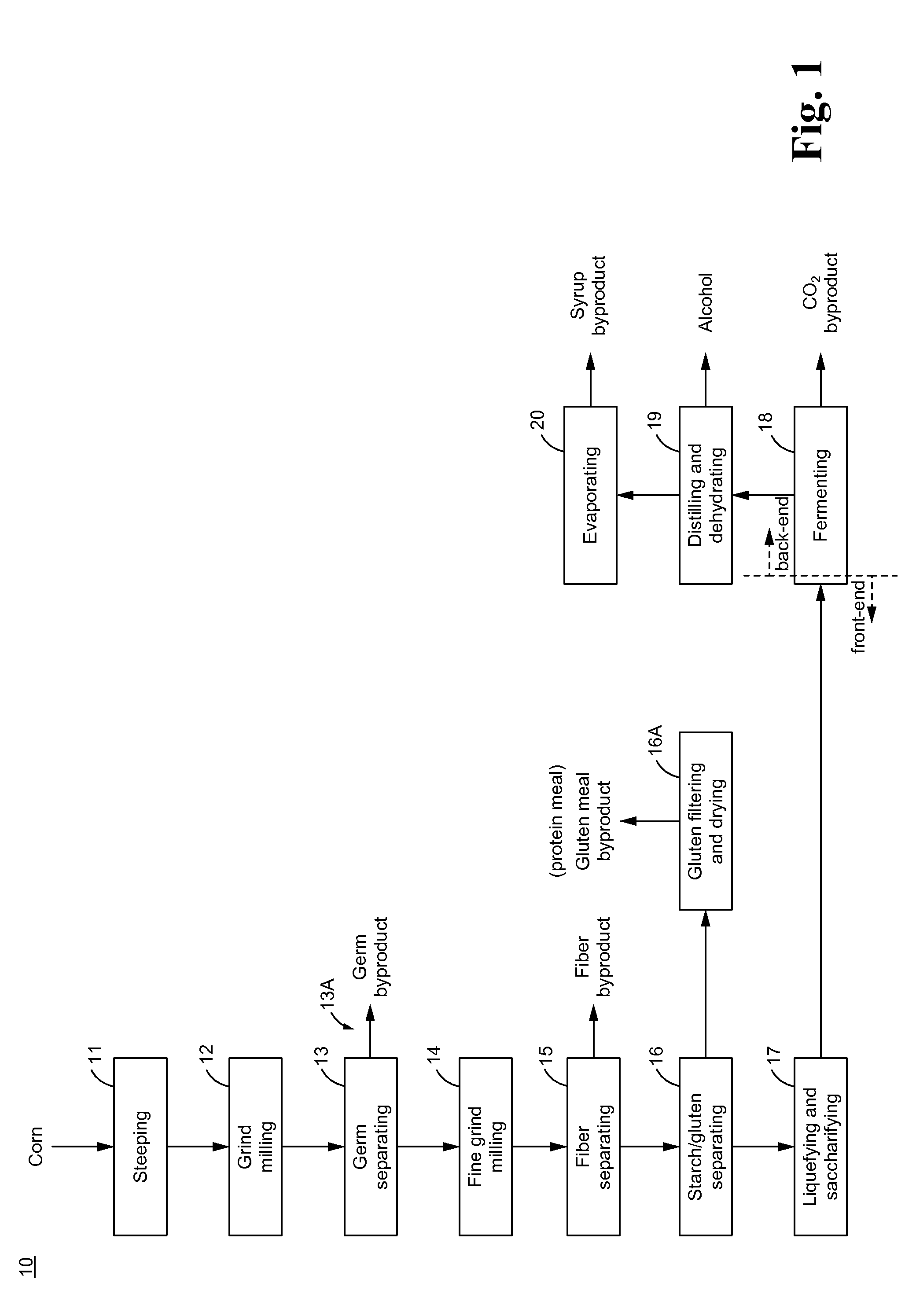

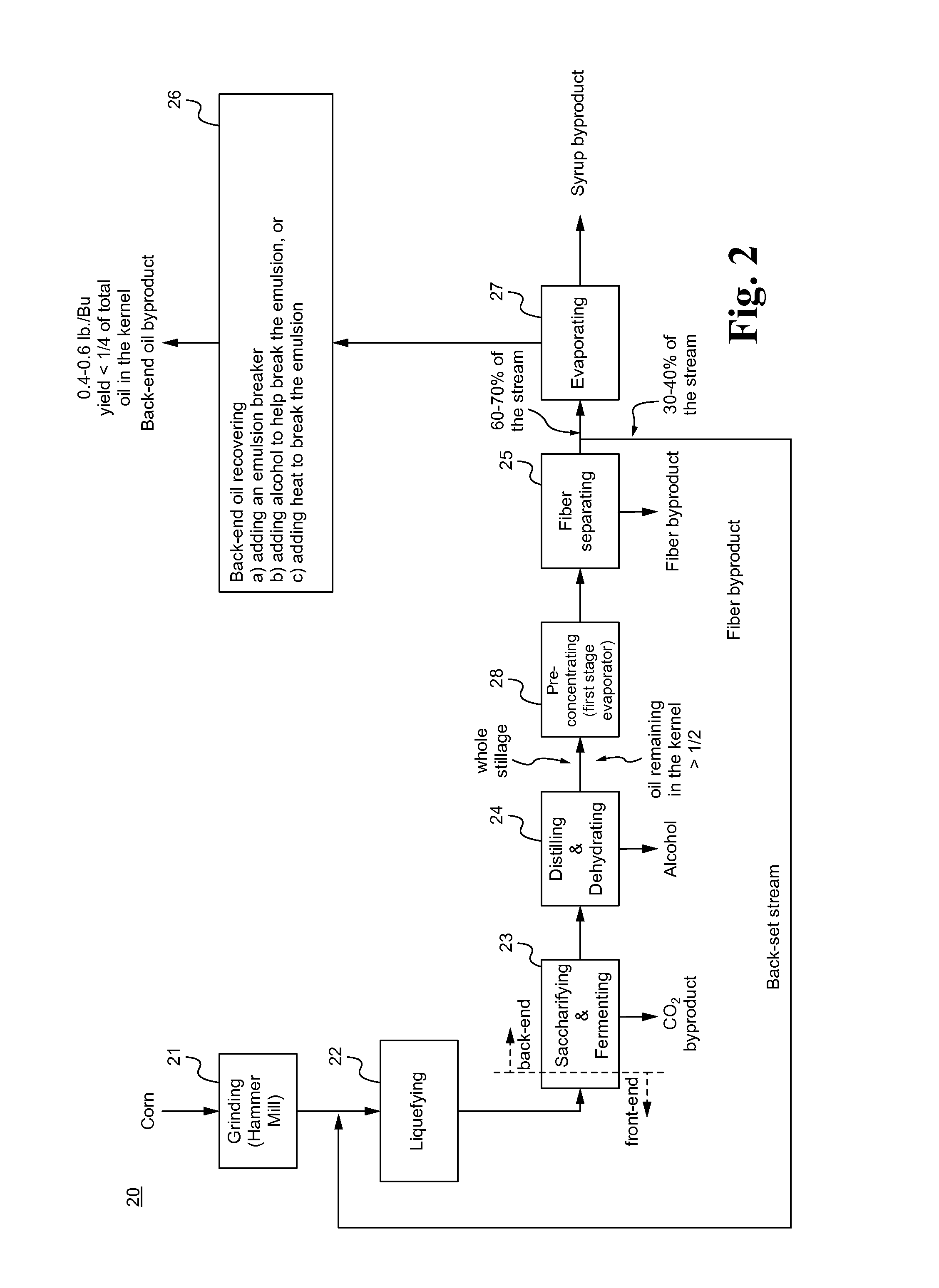

Method of and system for producing oil and valuable byproducts from grains in dry milling systems with a back-end dewater milling unit

ActiveUS20140053829A1High quality of oilHigh capital investmentFatty oils/acids recovery from wasteBioreactor/fermenter combinationsEmulsionChemistry

A method of and system for producing oil and valuable byproducts from grains, such as corn, in dry mills are disclosed. The method and system include dewater milling process after fermenting. Further, the method and system are able to produce oil without evaporating. Moreover, the method and system include one or more of the germ processing units, emulsion processing units, fiber processing units, high value protein producing units, and glycerol and inorganic salt producing units, such that high value byproducts are able to be generated.

Owner:LEE TECH LLC

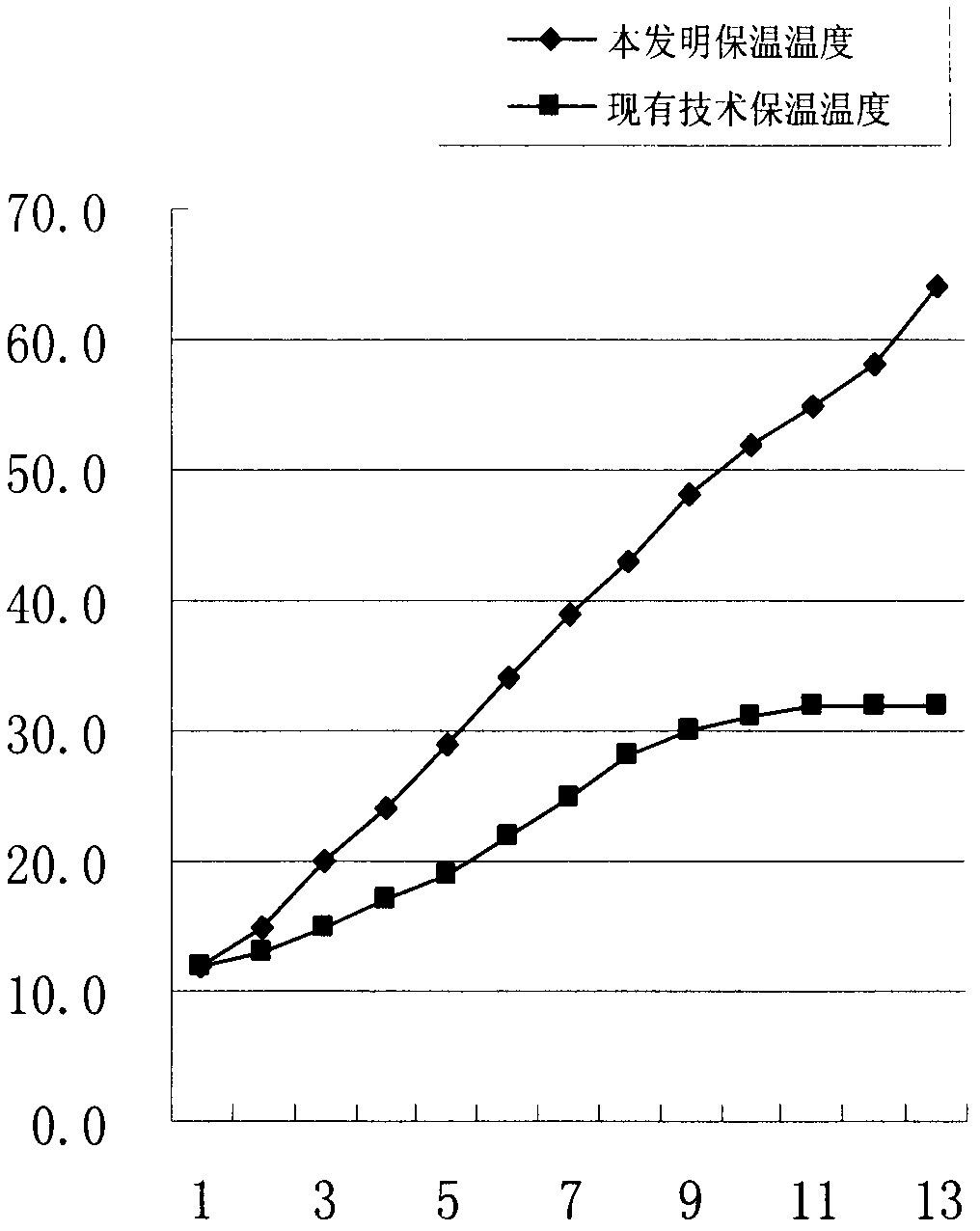

Exothermic insulating riser sleeve and preparation method thereof

InactiveCN103551512ALong holding timeFast feverFoundry mouldsFoundry coresSesquioxideThermal insulation

The invention discloses an exothermic insulating riser sleeve and a preparation method thereof and aims to solve the problems of bad heat insulation, insufficient heating and single effect in a conventional exothermic insulating riser sleeve. According to the formula, the exothermic insulating riser sleeve is prepared from quartz sand, vermiculite, potassium nitrate, calcium chloride, iron sesquioxide powder, graphite powder, aluminum powder, magnesium powder and modified sodium silicate. The method comprises the following steps: (1) weighing raw materials; (2) preparing a mixed wet material; and (3) filling the mixed wet material into a mold, pre-tightening while filling the wet material, performing compression molding, and demolding, thus finishing the operations. According to the formula of the exothermic insulating riser sleeve, the content of an exothermic agent is increased, the exothermic agent has the advantages of rapid heating, and a heating effect is improved. Moreover, the vermiculite serves as a thermal insulation material, is long in thermal insulation time and has a good thermal insulation effect, so that the molten iron feeding ratio in a riser is improved under the combined action of rapid heating and long thermal insulation.

Owner:HARBIN UNIV OF SCI & TECH

High purity zirconium boride / hafnium boride and preparation of superhigh temperature ceramic target material

The invention discloses a method for preparing a high-purity ultrahigh-temperature ceramic target material which belongs to the technical field of ceramic target materials, and in particular provides a method for preparing high-purity zirconium / hafnium boride powder and a ceramic target material thereof. The method comprises the steps of taking high-purity Zr powder, Hf powder and high-purity B powder as raw materials, adopting a self-propagating method to prepare high-purity ZrB2 and HfB2 powder respectively and then adopting a high-temperature high-pressure hot-pressing molding process to prepare a high-purity dense zirconium / hafnium boride ultrahigh-temperature ceramic target material, wherein the relative density of the target material reaches 95 to 99 percent. Relative to the prior art, metal powder in the method is slightly excessive when the materials are mixed, so as to make up for the metal loss during self-propagating reaction and further guarantee the component unicity of products. Relative to pressureless sintering, the sintering temperature needed in the method is greatly lowered; in addition, as the hot-pressing process adopts two-stage temperature, blank is uniform in temperature field, so as to ensure that the target material with uniform density can be obtained in the late hot-pressing process.

Owner:有研资源环境技术研究院(北京)有限公司

Method and control unit for activating at least one headlight of a vehicle using a traffic density

InactiveUS20140334168A1Increase probabilityLong holding timeNon-electric lightingVehicle headlampsRoad userControl parameters

Owner:ROBERT BOSCH GMBH

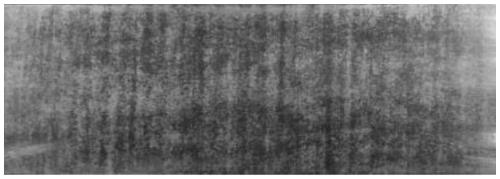

Preparation method of non-magnetic high-strength texture Ni-W alloy baseband

The invention discloses a preparation method of a non-magnetic high-strength texture Ni-W alloy baseband. The preparation method comprises the following steps: acquiring an Ni-9.6 at.% W alloy cast ingot by adopting vacuum induction smelting, carrying out hot forging and hot rolling on the cast ingot, and removing oxide skin positioned on the surface of a hot rolling blank by combining one-pass cold rolling with shot blast treatment; and successfully acquiring the non-magnetic high-strength strong-cube texture hectometre-level Ni-9.6 at.% W alloy baseband by carrying out warm rolling and the cold rolling with a certain deformation amount, introducing stress relief annealing twice in a cold rolling process, longitudinally shearing the cracked edge of a band in the cold rolling process and finally carrying out continuous recrystallizing heat treatment. The preparation method disclosed by the invention lays a good foundation for realizing the industrialized production of second-generation high-temperature superconductors.

Owner:HENAN NORMAL UNIV

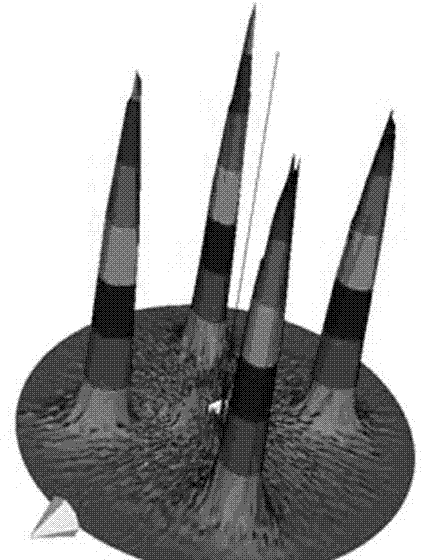

High temperature rare earth permanent magnetic material and its preparation method

InactiveCN1494092AImprove intrinsic coercive forceLow temperature coefficient of coercivityInorganic material magnetismMetallurgyRare earth

The invention relates to powder metallurgic method for manufacturing rare earth permanent magnet material Sm2 (Co, Pe, Cu, Zr)17, especially for designing component of 2:17 type SmCo permanent magnet as well as optimizing preparation technique. Thus, application temperature of the material is raised to 400 deg.C so as to meet requirement on the permanent magnet of electric equipment utilized in national defense and arms industry under high temperature environment.

Owner:CENT SOUTH UNIV

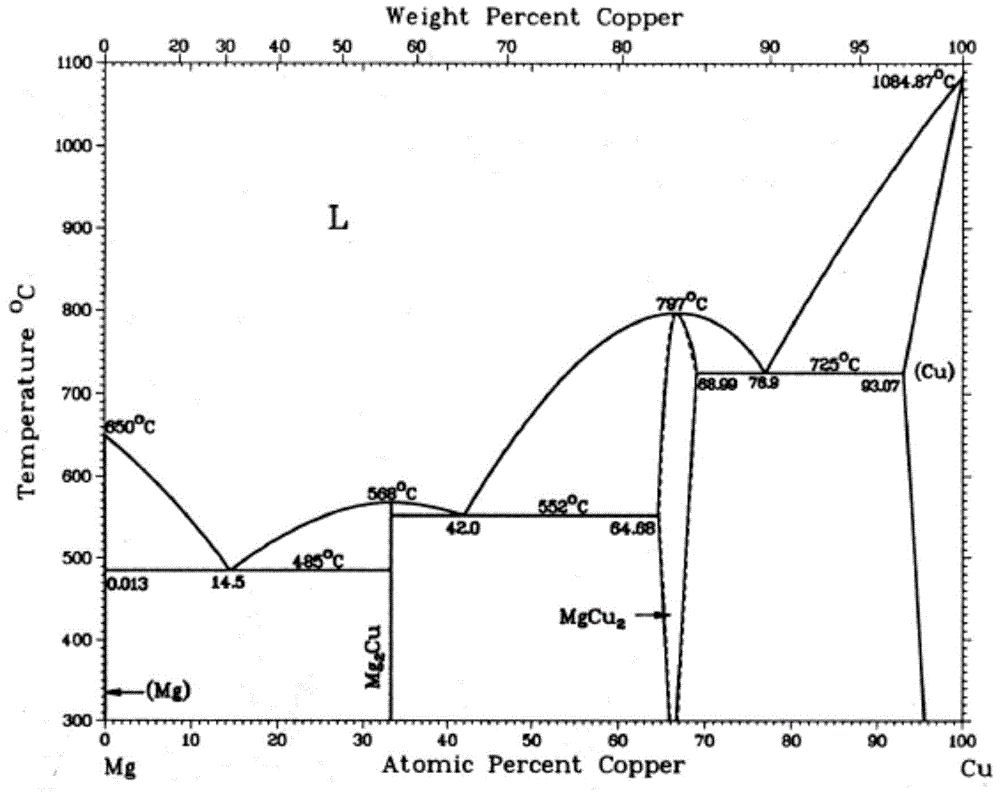

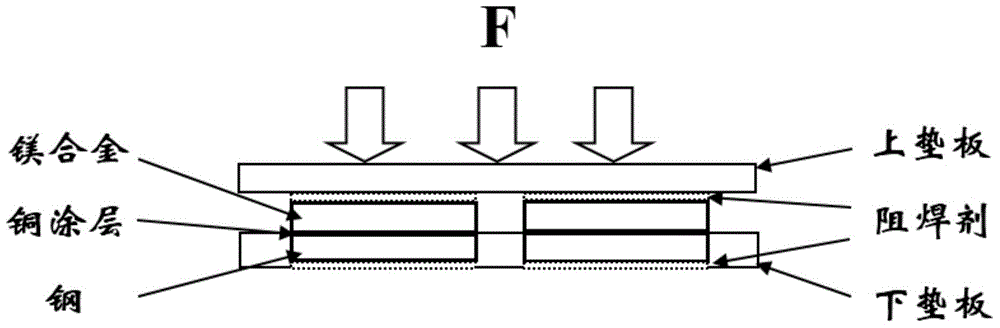

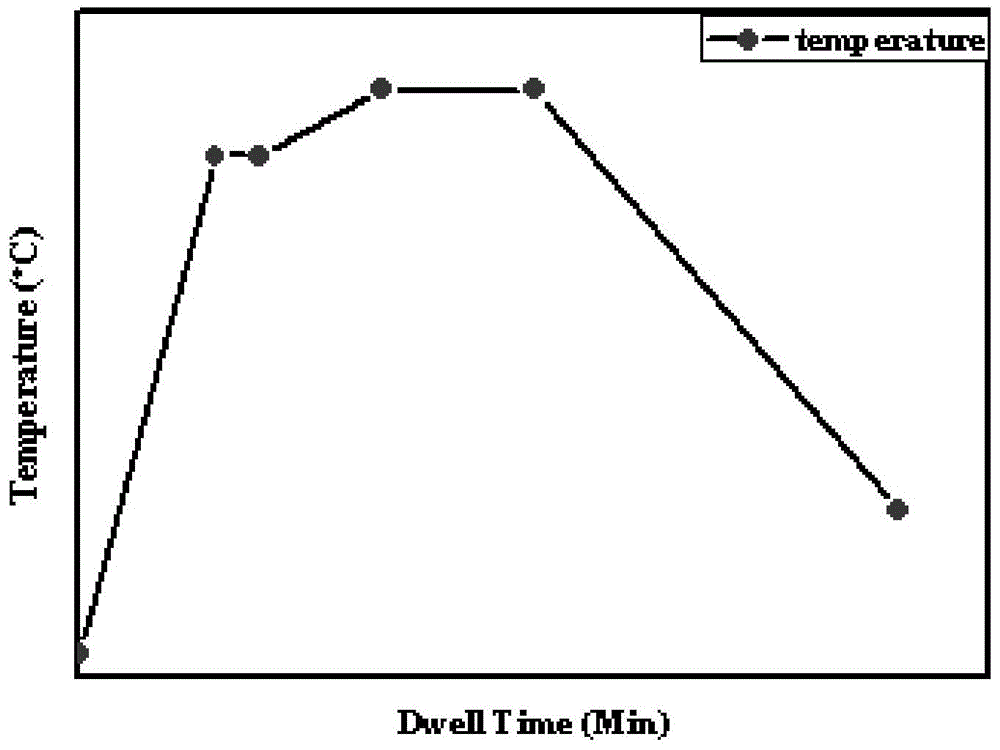

Diffusion brazing connecting method for contact reaction of magnesium alloy and steel

InactiveCN104084658AHigh strengthPrevent oxidationSoldering apparatusWelding/soldering/cutting articlesContact reactionsCopper

The invention discloses a diffusion brazing connecting method for a contact reaction of magnesium alloy and steel, and belongs to the field of dissimilar material connection. The melting point of the magnesium alloy is 650 DEG C only, and the magnesium alloy is sensitive to the welding temperature. Magnesium and steel are dissimilar materials. Particularly, the melting points and the linear expansion coefficients of the two dissimilar materials remarkably differ from each other, so that the welding difficulty of the magnesium and the steel is increased. The diffusion brazing connecting method comprises the steps that an intermediate pure copper layer is manufactured on the surface of the magnesium alloy, so that the magnesium alloy / Cu / steel brazing structure is formed in a combined mode; the magnesium alloy / Cu / steel brazing structure is fixedly arranged inside a vacuum diffusion furnace, the pressure of junction surfaces ranges from 0.0375 MPa to 0.2 MPa, the magnesium alloy / Cu / steel brazing structure is heated, the temperature of the magnesium alloy / Cu / steel brazing structure is kept constant, then, the magnesium alloy / Cu / steel brazing structure is reheated, the temperature of the magnesium alloy / Cu / steel brazing structure is kept constant, heating is stopped, the magnesium alloy / Cu / steel brazing structure is cooled with the furnace until the temperature of the magnesium alloy / Cu / steel brazing structure is smaller than 150 DEG C, and diffusion brazing connection of the contact reaction of the magnesium alloy and the steel is achieved. According to the diffusion brazing connecting method, the welding temperature is lower, the influence on the parent metal is small, no brazing filter metal is needed, the large surrounding and small surrounding phenomena are avoided, the aim that no defects (relative fusion welding) exist in brazing joints of welding of the magnesium alloy and the dissimilar metal is achieved to a certain degree, and the shearing strength of the brazing joints at indoor temperature can reach 39.6 MPa.

Owner:山东高熵金属科技有限公司

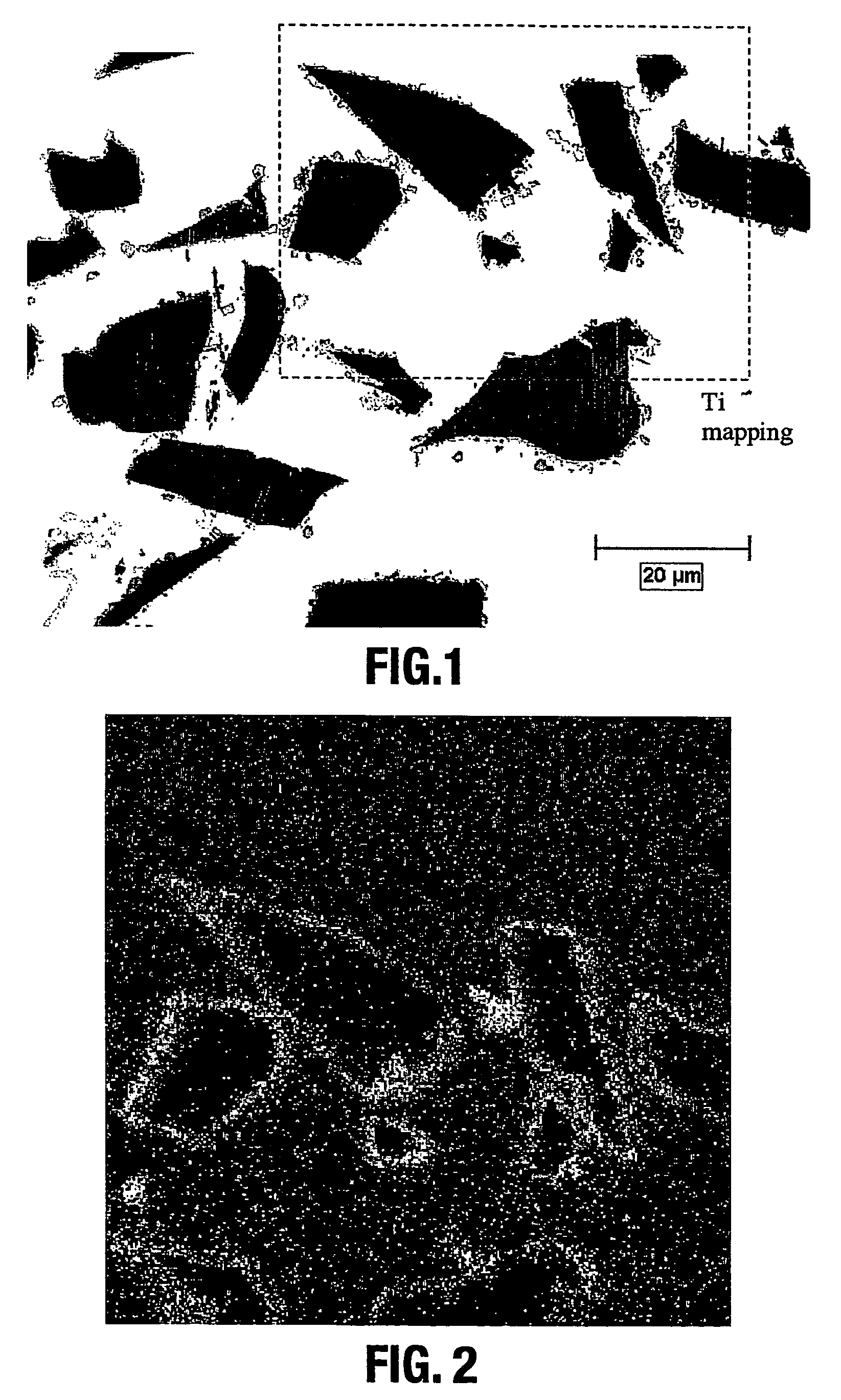

Aluminum alloy-boron carbide composite material

ActiveUS7562692B2Reduce liquidityAvoid attackNuclear energy generationFoundry mouldsBoron carbideTitanium

A cast composite material is prepared by furnishing an aluminum-based matrix alloy and forming a mixture of free-flowing boron carbide particles and the aluminum-based matrix alloy in molten form which is stirred to wet the matrix alloy to the boron carbide particles and to distribute the particles throughout the volume of the melt. The molten mixture is then cast. The fluidity of the molten mixture is maintained by (a) maintaining the magnesium content of the matrix metal below about 0.2% by weight, or (b) starting with a matrix metal containing less than 0.2% by weight magnesium and adding further magnesium to the mixture a short time before casting, or (c) having at least 0.2% by weight titanium present in the mixture.

Owner:ALCAN INT LTD

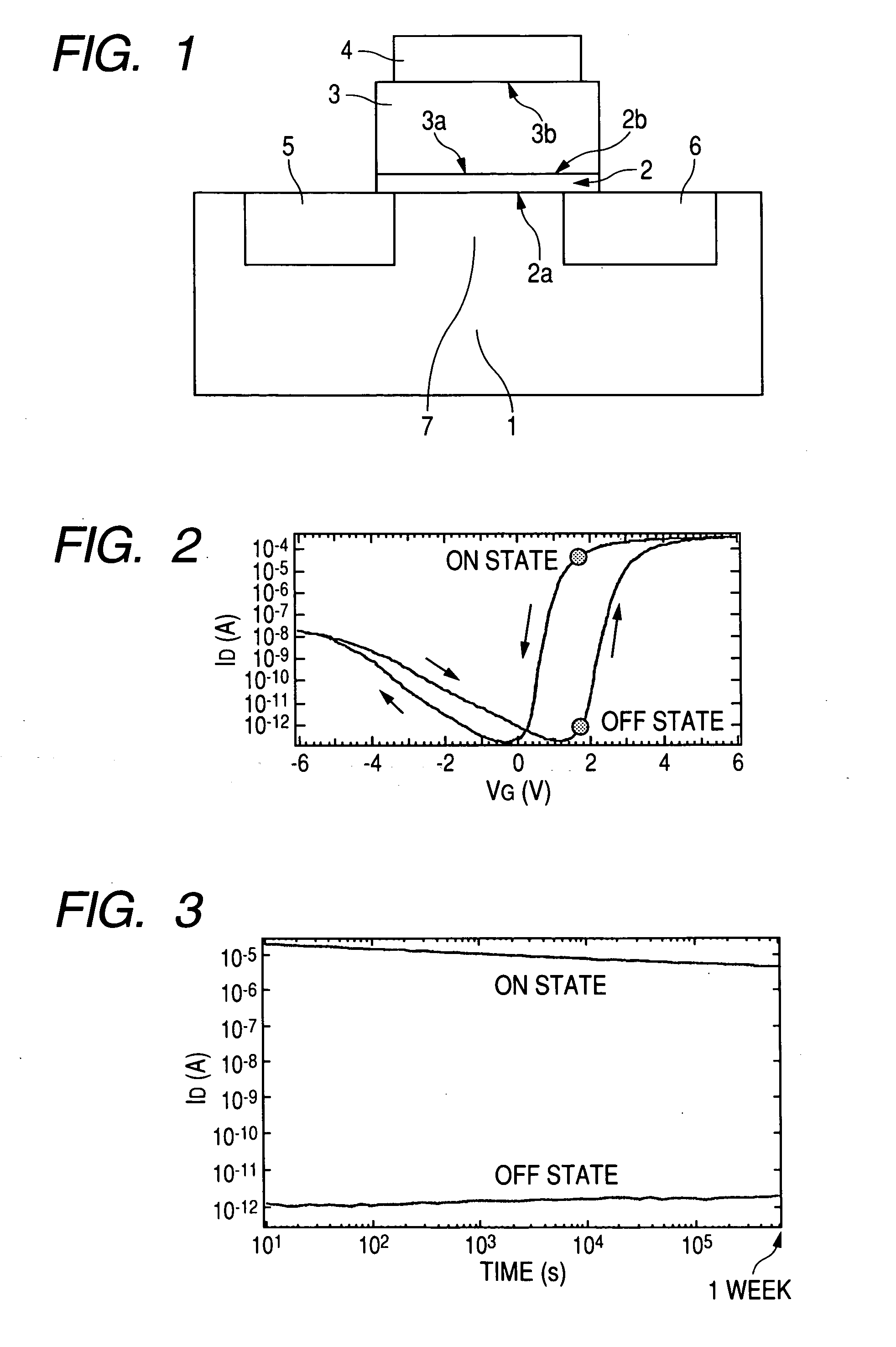

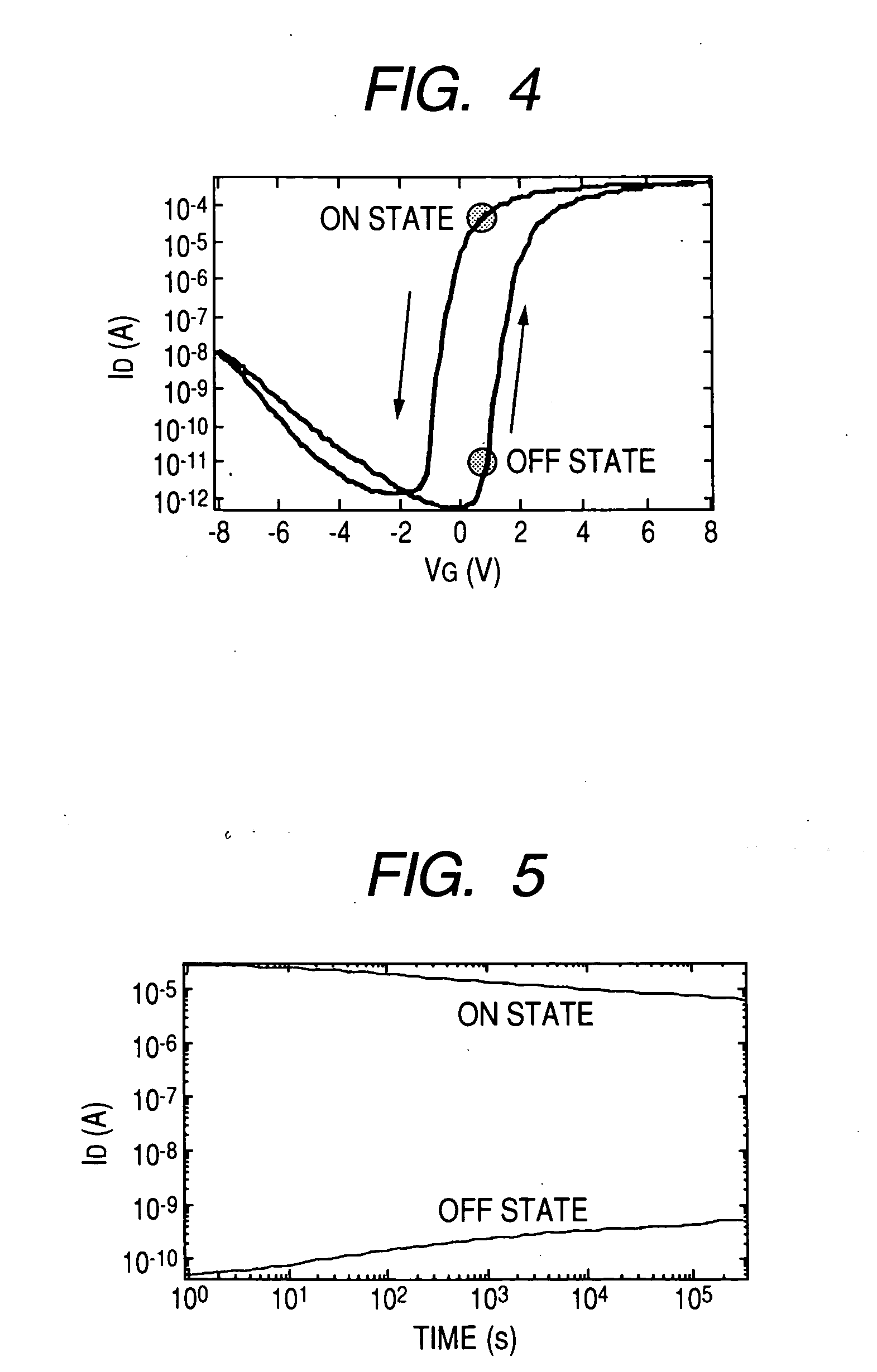

Semiconductor-ferroelectric storage device and its manufacturing method

ActiveUS20060017120A1Reduce leakage currentEnhanced surface irregularitySolid-state devicesVacuum evaporation coatingEngineeringElectrical conduction

The MFIS transistors heretofore have a problem that after data writing, the data disappear in terms of memory transistor operation in about one day at most. This is mainly because the buffer layer and the ferroelectric have a high leakage current and, hence, charge is accumulated around the interface between the ferroelectric and the buffer layer so as to shield the electric polarization memorized by the ferroelectric, making it impossible for the electric polarization of the ferroelectric to control electrical conduction between the source and the drain in the transistor. In the present invention, by constituting an insulator buffer layer 2 of HfO2+u or Hf1−xAl2xO2+x+y, the leakage current flowing through each of the insulator buffer layer 2 and a ferroelectric 3 can be reduced and a memory transistor having a truly sufficient long data holding time is realized.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Nano microcrystal wood floor and production method thereof

The invention discloses a nano microcrystal wood floor and a production method thereof. The technical point is that the nano microcrystal wood floor comprises the following components: PVC-S-4 or PVC-S-5 type PVC resin, heavy calcium carbonate with 250-800 meshes, nanoscale heavy calcium carbonate, flexibilizer, PVC dedicated coupling agent and heat stabilizer. The method comprises the following steps: evenly mixing the above components according to a certain proportion, drying, extruding a plate-type structure through an extruder according to a mould; vacuum sizing, cutting, sanding the bottom surface and the surface; and mortising grooves at the periphery and deeply processing the surfaces to obtain the wood floor. Because of adding a small amount of nanoscale heave calcium carbonate, the invention leads the nanoscale heavy calcium carbonate to be filled between big particles of the heavy calcium carbonate, thus forming complete packing to PVC resin particles and increasing specific surface area; reactivity is improved due to the increasing of specific surface area and improvement of reaction contact surface; the PVC resin particle has high hardness and strong plasticity; and the nano particles in a nano composite can block the formation of crystals, thus greatly improving thermal conductivity.

Owner:吉林吉瑞莱板材科技有限公司

Steel layer material of brazing composite strip and brazing aluminium-steel composite strip

The invention discloses a steel layer material of a brazing composite strip and a brazing aluminium-steel composite strip. The steel layer material comprises the following components in percentage by mass: 0.001-0.05% of C, 0.01-0.8% of Si, 0.26-1.6% of Mn and the balance of Fe and unavoidable impurity elements; the brazing aluminium-steel composite strip comprises an aluminium layer and a steel layer; the aluminium layer comprises the following components in percentage by mass: 0.8% of Si, equal to or less than 0.8% of Fe, equal to or less than 0.1% of Cu, equal to or less than 0.05% of Mn, equal to or less than 0.05% of Zn and the balance of Al and unavoidable impurity elements; and the steel layer is the steel layer material. According to the invention, through changing components of the steel layer material, generation temperature of intermetallic bristle compounds of the brazing composite strip is raised, the soaking time for generation of intermetallic bristle compounds of the brazing composite strip is prolonged, and the cost price of the steel layer is lowered.

Owner:YINBANG CLAD MATERIAL

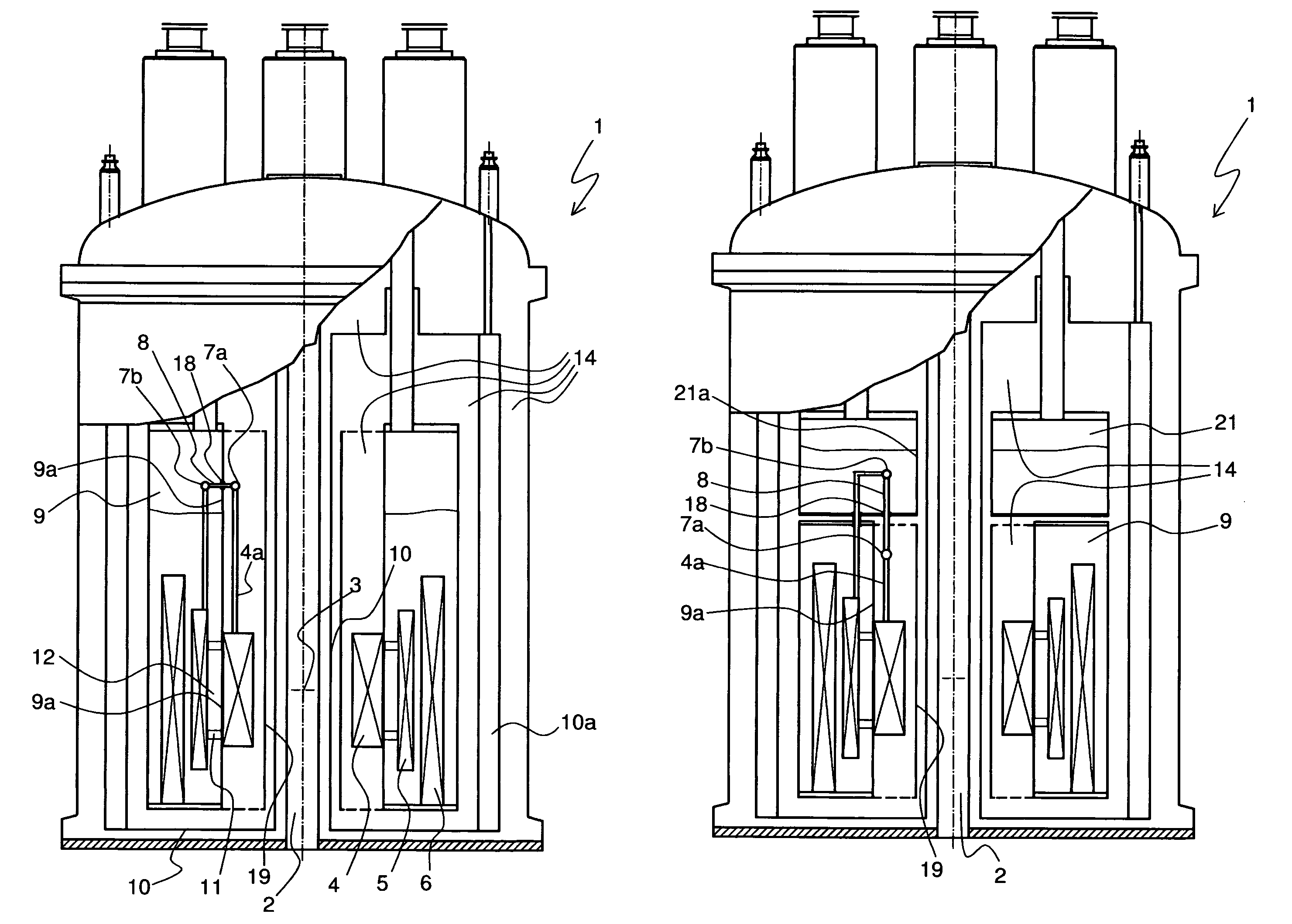

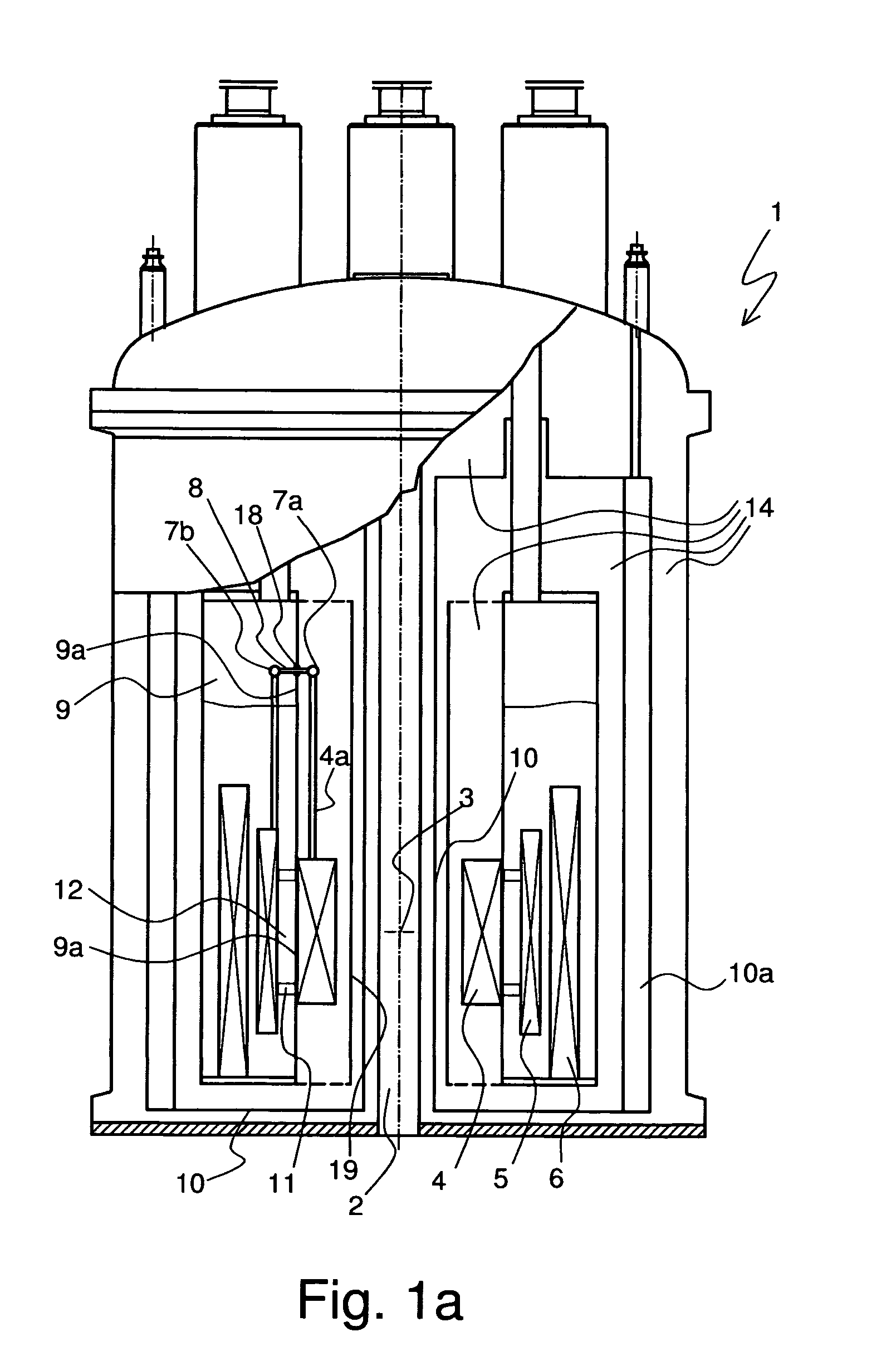

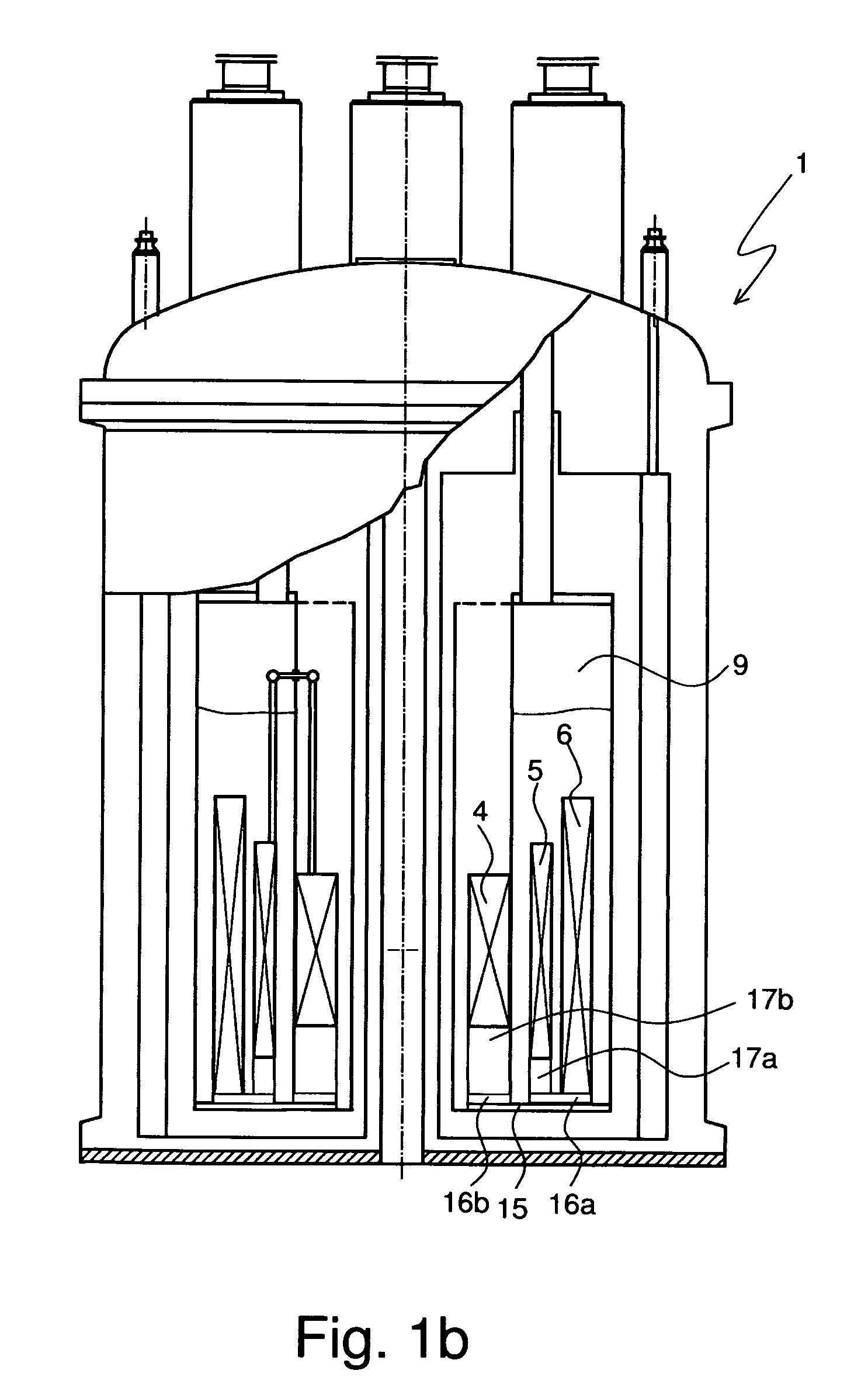

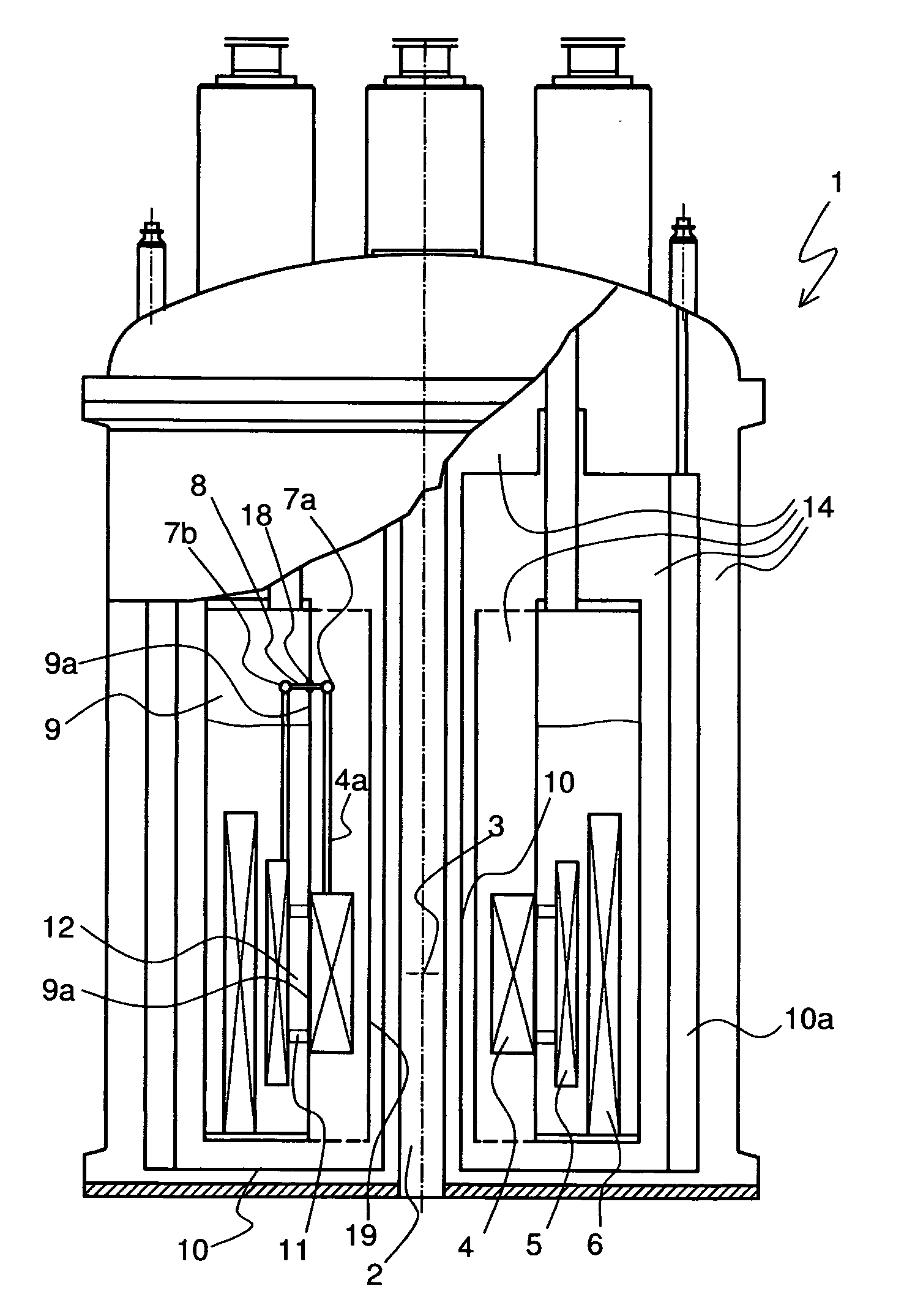

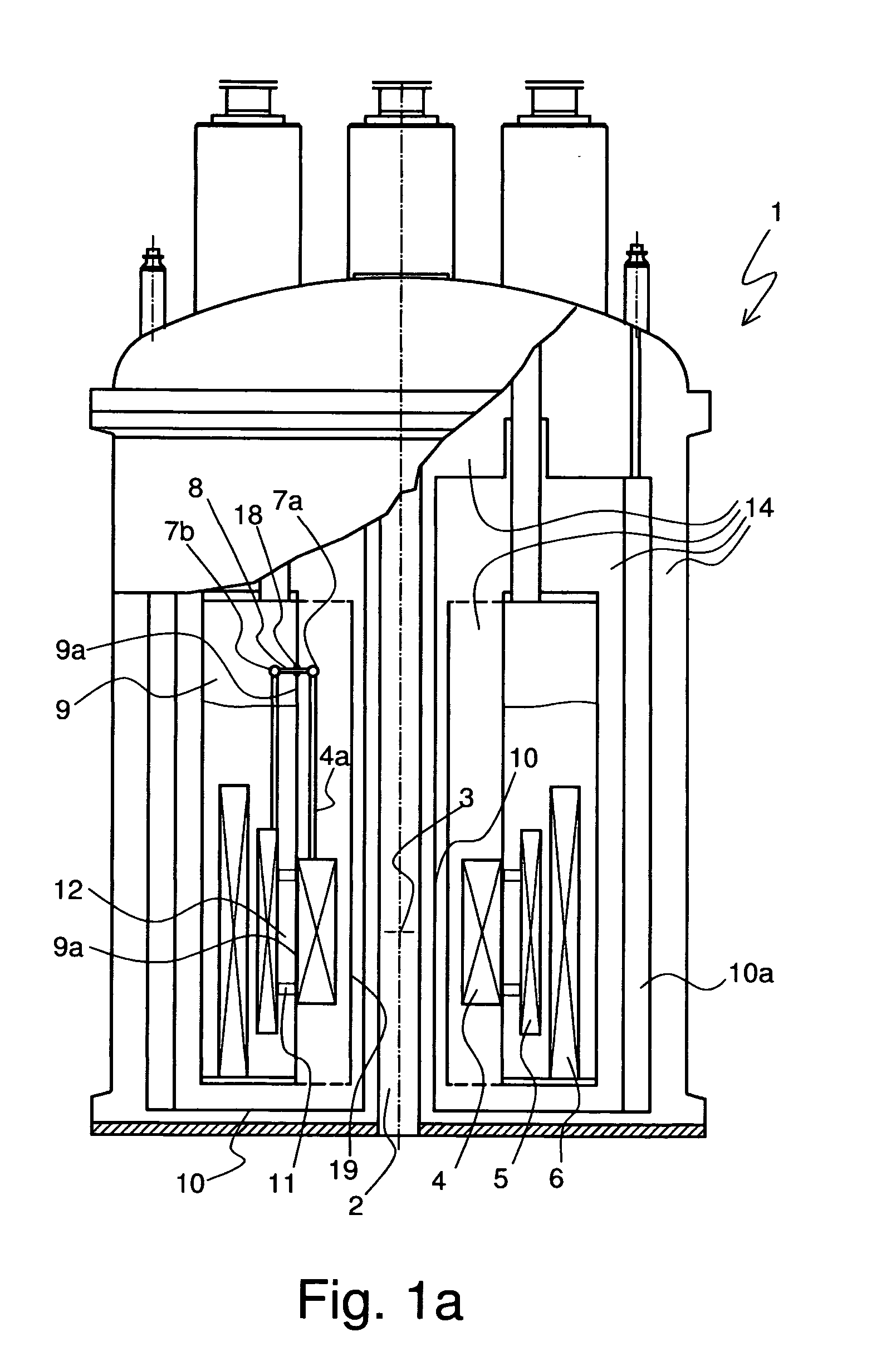

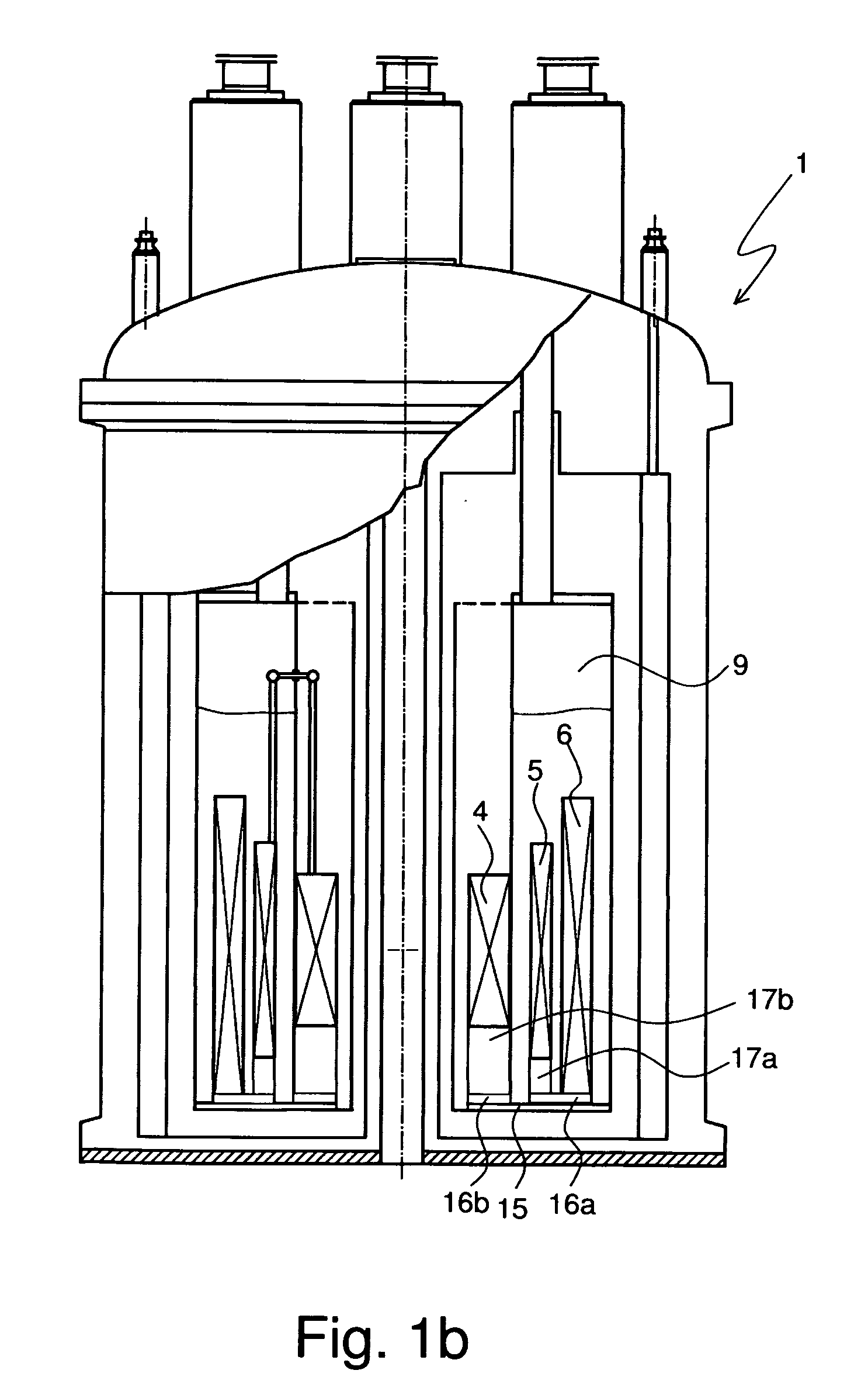

Cryostat having a magnet coil system, which comprises an LTS section and an HTS section, which is arranged in the vacuum part

InactiveUS7982566B2InhibitionPrevent evaporationMagnetic measurementsMagnetsHigh-temperature superconductivityRoom temperature

A cryostat (1) with a magnet coil system including superconductors for the production of a magnet field B0 in a measuring volume (3) within a room temperature bore (2) of the cryostat has a plurality of radially nested solenoid-shaped coil sections (4, 5, 6) which surround the room temperature bore and which are electrically connected in series, at least one of which being an LTS section (5, 6) with a conventional low temperature superconductor (LTS) and at least one of which being an HTS section (4) including a high temperature superconductor (HTS), wherein the LTS section (5, 6) is located in a helium tank (9) of the cryostat (1) along with liquid helium at a helium temperature TL. The apparatus is characterized in that the HTS section (4) is disposed radially within the LTS section (5, 6) in a vacuum portion of the cryostat and is separated from the LTS section (5, 6) by the helium tank (9) wall (9a) facing the room temperature bore. The HTS coil section can be reliably used in the cryostat over a long period of time (FIG. 1a).

Owner:BRUKER BIOSPIN

Cryostat Having A Magnet Coil System, Which Comprises An Lts Section And An Hts Section, Which Is Arranged In The Vacuum Part

ActiveUS20090045895A1High current capabilityIncrease efficiency of and operational safetyMagnetic measurementsMagnetsMagnet coilHigh-temperature superconductivity

Owner:BRUKER BIOSPIN

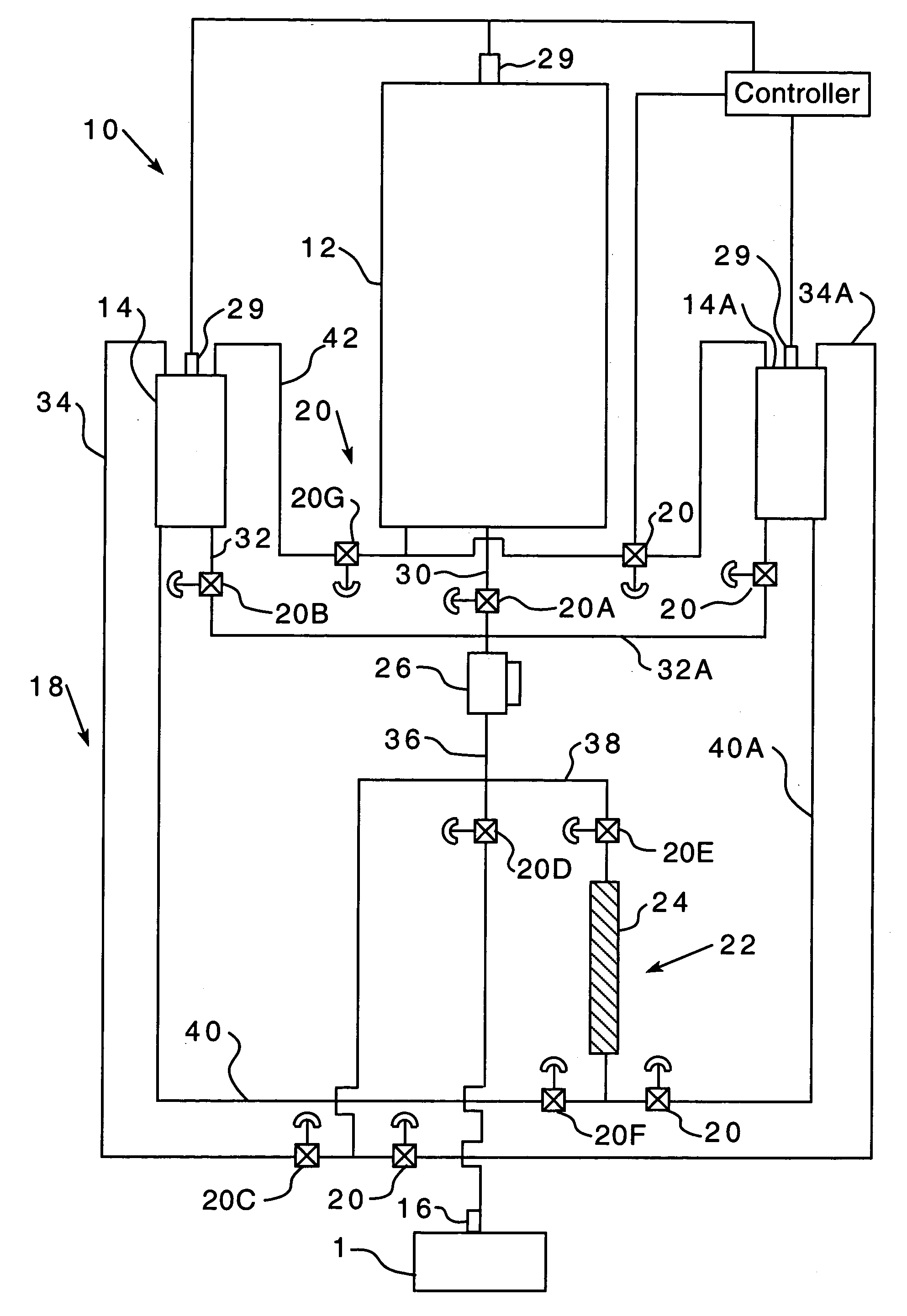

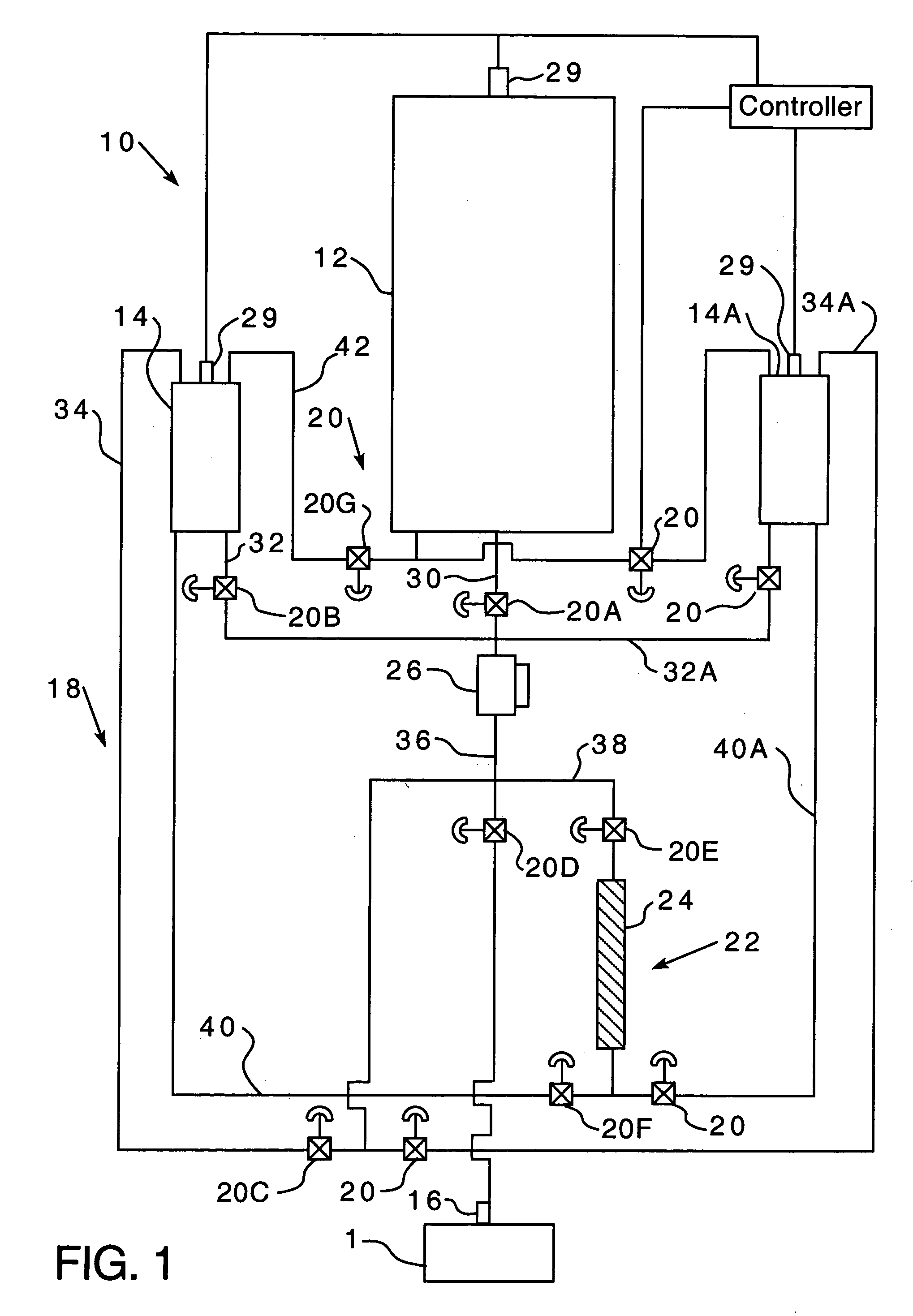

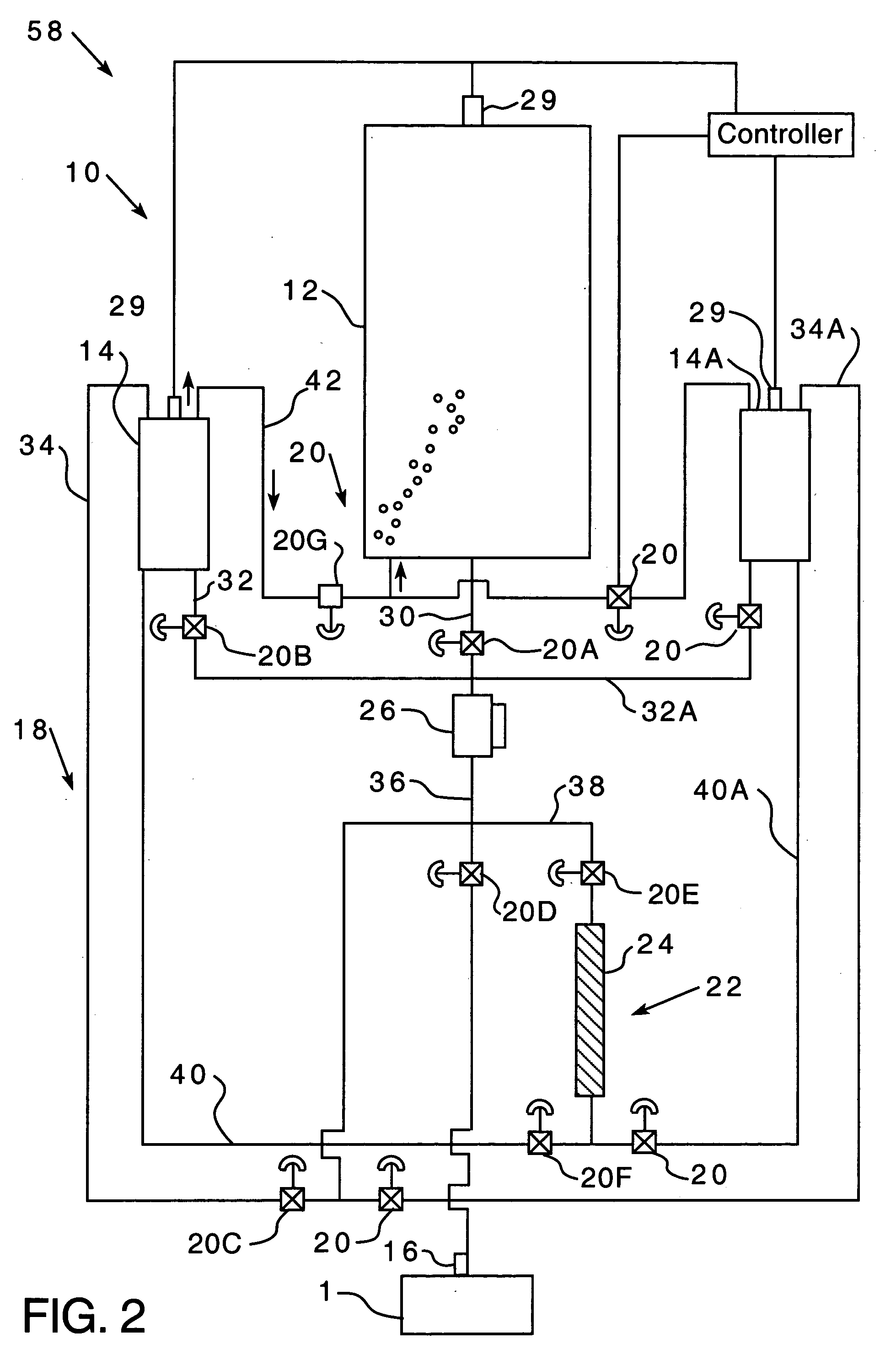

Pressurized liquid natural gas filling system and associated method

ActiveUS6901973B1Long hold timeFacilitate fillingVessel mounting detailsGas handling applicationsSystem structureEngineering

A liquid natural gas filling system structured to store a cryogenic fluid at a low pressure and fill a use vessel at a high pressure. The filling system includes a first, low pressure vessel, at least one second, high pressure vessel, a plurality of conduits, each conduit in the plurality having a valve, extending between, and in fluid communication within the first, low pressure vessel and the at least one second, high pressure vessel, a pressure building means coupled to the at least one second, high pressure vessel and structured to raise the pressure of a cryogenic liquid within the at least one second, high pressure vessel, and an outlet nozzle structured to be coupled to a use vessel, the outlet nozzle coupled via the plurality of conduits to, and in fluid communication with, the first, low pressure vessel and the second, high pressure vessel. The filling system is structured so that a cryogenic liquid may be stored in the first, low pressure vessel at a low pressure. The cryogenic liquid at a low pressure may further be transferred to the at least one second, high pressure vessel via the plurality of conduits. The pressure of the cryogenic liquid at a low pressure in the at least one second, high pressure vessel may be increased to a high pressure by actuating the pressure building means. Thus, the cryogenic liquid at a high pressure in the at least one second, high pressure vessel may be transferred from the at least one second, high pressure vessel to a use vessel via the plurality of conduits and the nozzle.

Owner:TW CRYOGENICS

Method of and system for producing oil and valuable byproducts from grains in dry milling systems with a back-end dewater milling unit

ActiveUS9388475B2Improve oil yieldGerm particle softening processFatty oils/acids recovery from wasteFood processingFiberInorganic salts

A method of and system for producing oil and valuable byproducts from grains, such as corn, in dry mills are disclosed. The method and system include dewater milling process after fermenting. Further, the method and system are able to produce oil without evaporating. Moreover, the method and system include one or more of the germ processing units, emulsion processing units, fiber processing units, high value protein producing units, and glycerol and inorganic salt producing units, such that high value byproducts are able to be generated.

Owner:LEE TECH LLC

Low temperature mullite ceramic sintering process

The low temperature mullite ceramic sintering process features that the alcohol solution of aluminum nitrate and the alcohol solution of ethyl silicate are mixed to prepare monophase mullite gel, and the gel is dried and sintere3d at 980-1000 deg.c to convert into mullite. The gel is added into the material for baking mullite ceramic homogeneously and converted into mullite distributed homogeneously in the mullite ceramic material like crystal seeds, so as to promote sintering, lower the sintering temperature to 1400 deg.c, 200 deg.c lower than traditional sintering temperature, and lower the power consumption greatly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cold-chain logistics heat preservation box and preparation method thereof

InactiveCN105819107AHigh strengthReduce wall thicknessDomestic cooling apparatusLighting and heating apparatusCold chainLogistics management

The invention discloses a cold chain logistics incubator and a preparation method thereof. The incubator includes an outer box, a middle box and an inner box nested sequentially from outside to inside, the outer box includes an outer box body and an outer box cover, and the outer box body Both the inner box and the outer box cover are made of corrugated board structure; the middle box includes the middle box body and the middle box cover, and the middle box body and the middle box cover are both made of vacuum insulation board structure; the inner box includes the inner box body and the inner box cover, the inner box body and the inner box cover. The inner box cover adopts the cold storage plate structure, and the cold storage liquid is arranged in the cold storage plate. The heat preservation box has the advantages of simple structure, convenient use, low cost, high effective volume ratio and long heat preservation time. The preparation method of the cold chain logistics incubator has the advantages of simple process and high degree of standardization.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Method for preparing high-density ultrafine-grained rare earth oxide doped tungsten alloy

ActiveCN110560700ASmall particlesHigh sintering activityIncreasing energy efficiencyPowder metallurgyHigh density

The invention provides a method for preparing high-density ultrafine-grained rare earth oxide doped tungsten alloy, and belongs to the field of powder metallurgy. The preparation method comprises thefollowing steps: preparing an oxide composite powder precursor by using ammonium metatungstate, rare earth nitrate, fuel and ammonium nitrate as raw materials and adopting a low-temperature solution combustion synthesis method, and then reducing by using H2 to prepare nano rare earth oxide doped tungsten alloy powder; and preparing the high-density ultrafine-grained rare earth oxide doped tungstenalloy by adopting multi-step discharge plasma sintering. According to the method, a low-temperature solution combustion synthesis method adopted can achieve the mixing at a molecular level, thus thetungsten oxide and the rare earth oxide in the obtained precursor are uniformly mixed, and the reduction product is alloy powder without subsequent special treatment; the SPS is suitable for rapid sintering of refractory metals and materials difficult to sinter, and the high-density ultrafine-grained rare earth oxide doped tungsten alloy can be obtained by adopting multi-step SPS; the relative density can reach 96-99%, and the average grain size is less than or equal to 300nm. The method has the advantages of simple and easily obtained raw materials, simple equipment and quick process, and issuitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

6060 aluminum alloy board for curtain wall and preparation method thereof

The invention belongs to the technical field of aluminum alloys, and relates to a 6060 aluminum alloy board for a curtain wall and a preparation method thereof. The alloy elements such as magnesium, iron and chromium are optimally adjusted, the product is enabled to have the relatively high elongation while having the high strength, the compound is enabled to be uniformly distributed in the thickness direction of the board through the optimized technologies of casting, hot rolling, cold rolling and solid solution and ageing, the size of the compound is thin and small, the aluminum alloy boardwith the high surface and bending performance and flat board shape can be obtained, meanwhile, by combining the specific rolling technology rule and solid solution ageing rule, the technological procedure is simple, and the aluminum alloy board is suitable for factory large-scale production, and has the high yield.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Six-series aluminum alloy sheet for outer plate of automotive body and preparation method thereof

The invention belongs to the field of aluminum alloy sheets for automotive bodies, and relates to a six-series aluminum alloy sheet for an outer plate of an automotive body and a preparation method thereof. The six-series aluminum alloy sheet is prepared from the following elemental constituents according to weight percentages: 0.55 to 0.65 % of Si, 0.10 to 0.20% of Fe, 0.10 to 0.20% of Cu, 0.05 to 0.15% of Mn, 0.65 to 0.75% of Mg, 0. 01 to 0.03% of Ti, less than or equal to 0.03% of single impurity, less than or equal to 0.10% of impurities in total, and the balance being Al. According to thepreparation method of the six-series aluminum alloy sheet, the rolling pass and working procedure time of hot rough rolling are strictly limited, and annealing is performed two times in the cold rolling process. Compared with a traditional 6016 alloy, the finished product has the advantages that the edge covering performance is significantly improved, the finished product has a smooth and fine surface without macroscopic Roping line defects after stamping, and the surface quality is significantly improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

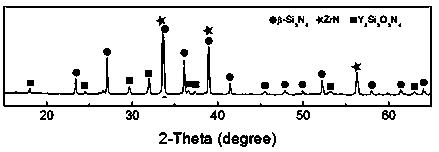

Method for rapidly preparing high heat conduction Si3N4 ceramic with low cost

The invention discloses a method for rapidly preparing high heat conduction Si3N4 ceramic with low cost. The method is characterized in that Si powder is taken as a raw material, ZrO2 powder is taken as a nitridation catalyst, ZrO2-MgO-Re2O3 is taken as a sintering aid, wherein Re2O3 is taken as a rare earth oxide, Si, ZrO2 and MgO-Re2O3 are mixed according to mass fraction and then dried to obtain a Si-ZrO2-MgO-Re2O3 mixing powder; the mixing powder is subjected to a two-step insulation method and a pressureless sintering process to obtain the high heat conduction Si3N4 ceramic; According to the ceramic material, the relative density is higher than 95%, hardness is 8-20 GPa, fracture toughness is 3-8MPa.m<1 / 2>, bending strength is 200-1000Mpa, and the thermal conductivity is 20-100W.m<-1>,K<-1>. By introducing a ZrO2 catalyst, Si powder nitridation IS accelerated, the introduction of ZrO2-MgO-Re2O3 can improve the densification of Si3N4, and the high heat conduction Si3N4 ceramic can be rapidly prepared with low cost.

Owner:GUANGDONG UNIV OF TECH

Method for synthesizing ethylene stearamide with octadecanoic acid

InactiveCN101665447AAvoid unresponsivePerfect conversionOrganic compound preparationCarboxylic acid amide separation/purificationEthylenediamineAntioxidant

The invention discloses a method for synthesizing ethylene stearamide with octadecanoic acid, comprising the following steps: octadecanoic acid, antioxidants and catalyst phosphoric acid are added ina boiling flask, nitrogen flows in at large flow rate, and then the octadecanoic acid is heated and melted down, when the temperature is 80-100 DEG C, ethene diamine is dropwise added for reaction for0.5-1 hour, and then high-temperature reaction is carried out for obtaining finished products. The method has the advantages that: 1. the process flow is simple and the reaction condition is not strict: the ethene diamine is added to lead the octadecanoic acid to be reacted completely at the temperature of 80-100 DEG C, and the conversion of the octadecanoic acid can be improved by heat insulation. 2. The reaction time is shortened: the method adopts dehydration at low temperature and then high-temperature reaction is carried out, so as to protect color well. 3. The product has good color andluster: as BHT antioxidants and the process conditions are adopted, the color and luster of the product are kept to be well.

Owner:RUGAO SHUANGMA CHEM

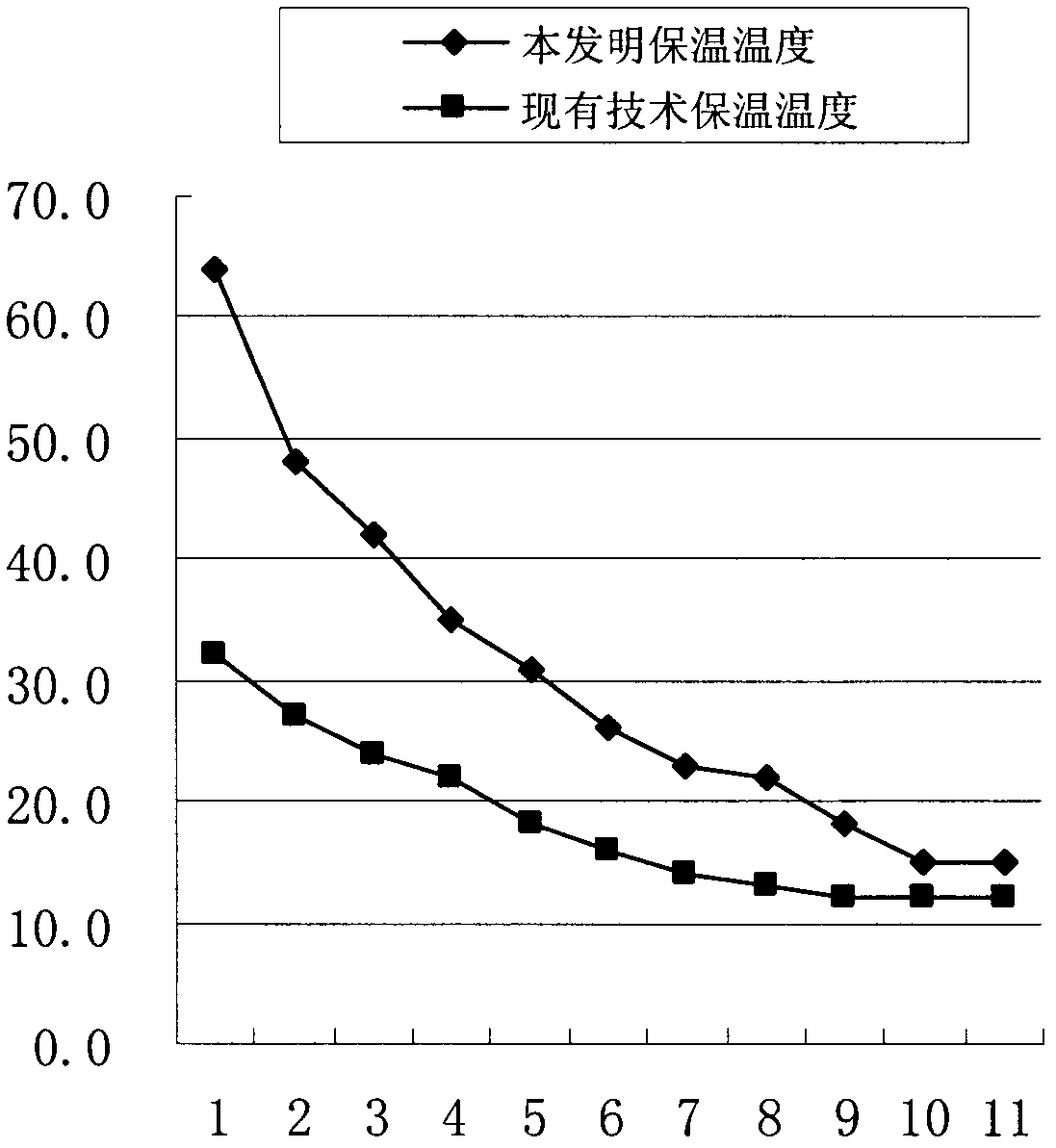

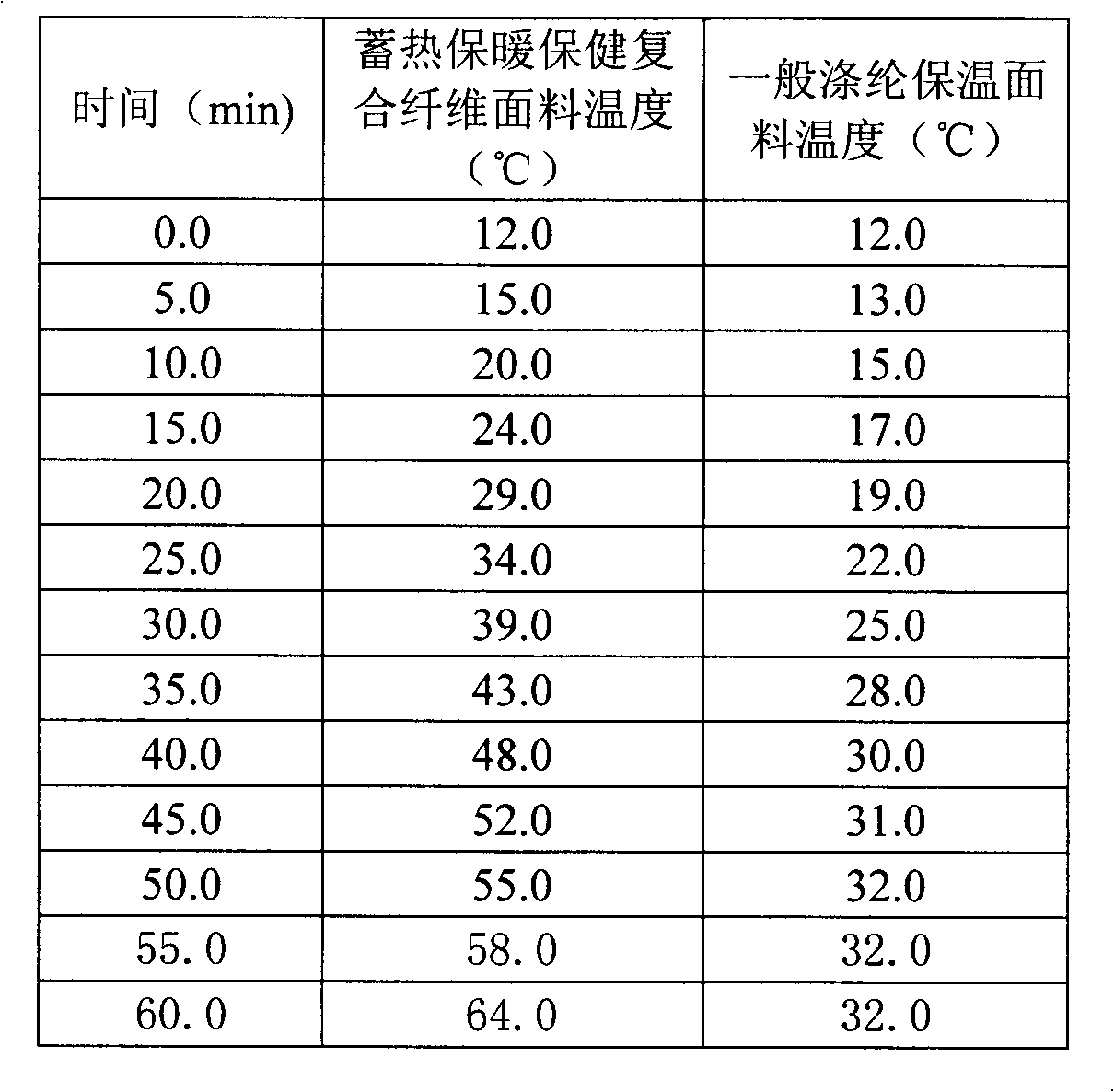

Composite fiber with effects of heat accumulation, heat preservation and health protection

InactiveCN103320888AHas heat storage, warmth and health care effectsAntibacterialMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterWax

The invention discloses a composite fiber with effects of heat accumulation, heat preservation and health protection. The composite fiber is obtained with the following technique: heating coffee grounds to a certain extent to generate nanometer-level coffee carbon; nanocrystallizing far-infrared material which contains a plurality of metal ions; uniformly mixing polyester slices, silane coupling agents, zine stearate as a surfactant and liquid wax as a dispersant to form a melted polyester material; uniformly mixing the nanometer-level coffee carbon, the far-infrared material and the melted polyester material in a weight ratio of 1:1:3.2 to 3.8 into a mixture; forming masterbatches from the mixture with a granulator; uniformly mixing the masterbatches and polyester slices in a weight ratio of 1:8.2 to 9.2 and melting filature to form composite filaments with effects of heat accumulation, heat preservation and health protection; and forming long fiber with effects of heat accumulation, heat preservation and health protection by drafting the composite filaments. The composite fiber provided by the invention has such functions as good moisture-absorbing capability and air permeability, strong capability in health protection and heat storage, and long heat preservation time and so on.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Drive gear and preparation method thereof

ActiveCN104195452ALow costImprove corrosion resistanceFurnace typesHeat treatment furnacesTemperingGear wheel

The invention discloses a drive gear and a preparation method thereof. The drive gear consists of the following chemical components in percentage by weight: C, Si, Mn, Cr, Ni, Nb, V, Cu, P, S, lanthanide-series rear earths and the balance of Fe. The preparation method for the drive gear comprises the following steps: preparing a blank by adopting a casting mode; then, carrying out thermal treatment on the blank, a cutting process on rough-turning gear ring gear blank, a rough-milling gear-hobbing process, carburizing and nitriding treatment, tempering, hardening and tempering thermal treatment; and finally, carrying out a finish turning process and finish-milling gear-hobbing process and then inspecting, packaging and storing. The drive gear is high in strength, hardness and abrasive resistance, good in corrosion resistance and oxidization resistance, high in yield strength and tensile strength; and the gear processing method is simple, low in cost and good in molding performance.

Owner:南京航迅机电有限公司

Camera controller and teleconferencing system

InactiveUS8044990B2Move quicklyAccurately and stably imageTelevision conference systemsTwo-way working systemsCamera controlMultiplexing

A teleconferencing system includes: a camera system for imaging a plurality of persons; a voice collector for capturing voices generated by a plurality of persons; and a transmitter for multiplexing an image signal acquired from the camera system and a voice signal acquired from the voice collector and transmitting a multiplexed signal via a communication line. The camera system includes: a camera; a driver for changing the viewing direction of the camera; and a camera controller for controlling the driver. The camera controller includes: a face position detection unit; a registration unit; a timing unit; a drive control unit; and a hold time control unit.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com