Steel layer material of brazing composite strip and brazing aluminium-steel composite strip

A composite strip and steel layer technology, which is applied in the field of steel layer materials and brazed aluminum-steel composite strips, can solve problems such as material failure, great impact on use, and delamination of aluminum-steel interfaces, so as to improve product yield, The effect of lowering the cost price and raising the generation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

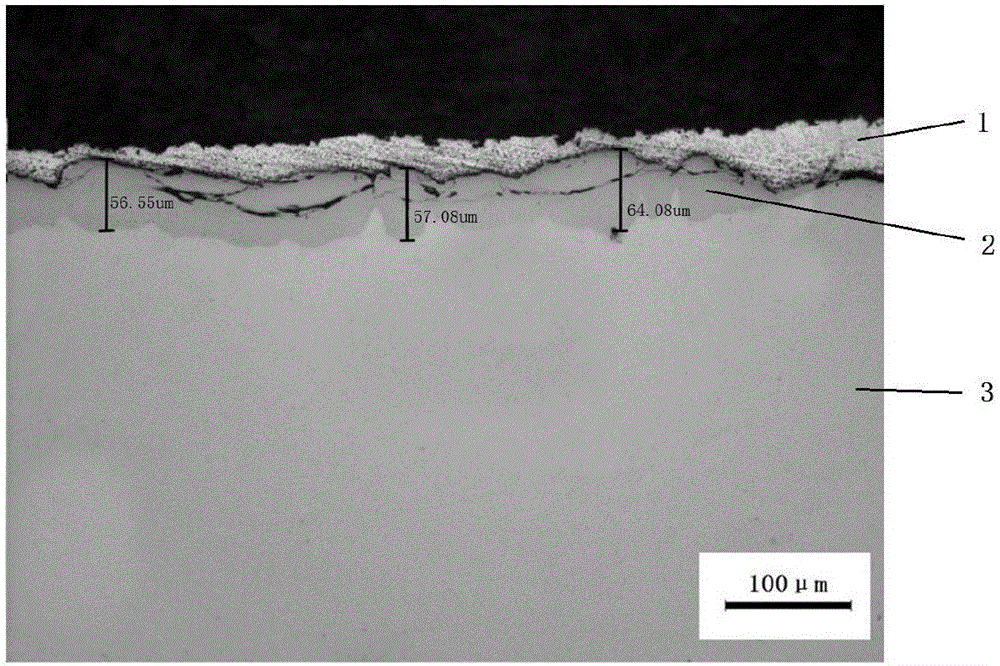

[0027] The mass percentage of the components of the aluminum layer used: 0.8% of silicon Si, 0.8% of iron Fe, 0.07% of copper Cu, 0.05% of manganese Mn, 0.04% of zinc Zn, and the rest are aluminum Al and unavoidable impurity elements The mass percentage of each component of the steel layer: carbon C is 0.05%, silicon Si is 0.017%, manganese Mn is 0.286%, phosphorus P is 0.02%, sulfur S is 0.004%, aluminum Al is 0.003%, and the rest is iron Fe and others Unavoidable impurity elements.

[0028] Such as image 3 As shown, the aluminum-steel composite strip with this composition was heated to 608°C and kept for 720 minutes for heat treatment, and no intermetallic brittle phase compound was produced.

Embodiment 2

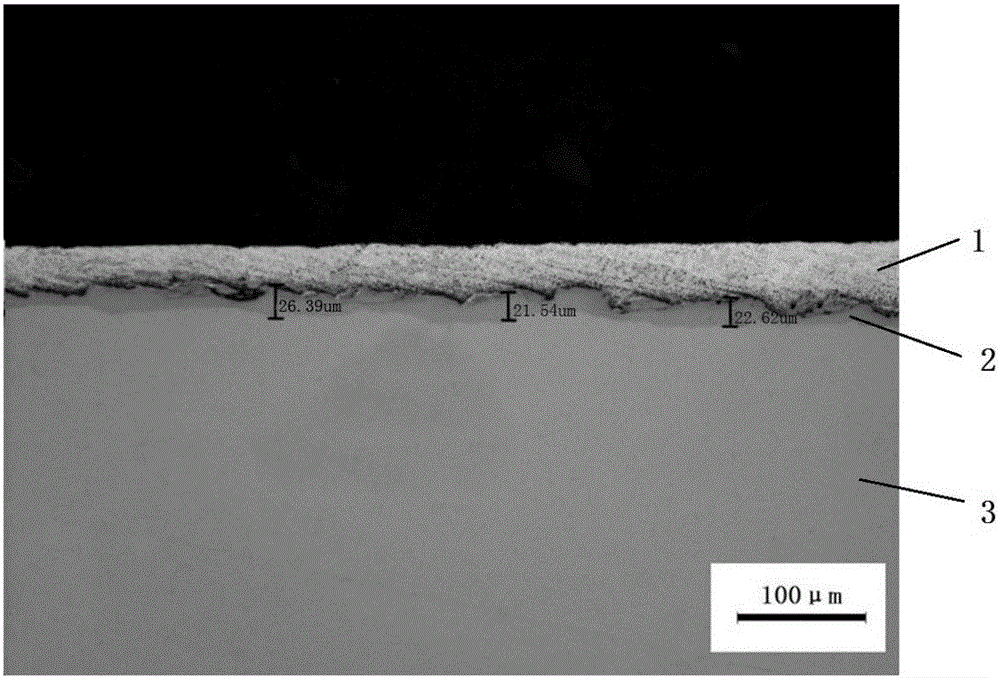

[0030] The mass percentage of the components of the aluminum layer used: 0.8% of silicon Si, 0.6% of iron Fe, 0.1% of copper Cu, 0.03% of manganese Mn, 0.04% of zinc Zn, and the rest are aluminum Al and unavoidable impurity elements The mass percentage of each component of the steel layer: carbon C is 0.0015%, silicon Si is 0.2%, manganese Mn is 0.284%, phosphorus P is 0.01%, sulfur S is 0.005%, aluminum Al is 0.004%, and the rest is iron Fe and others Unavoidable impurity elements.

[0031] Such as Figure 4 As shown, the aluminum-steel composite strip with this composition was heat-treated at 616°C for 60 minutes, and no intermetallic brittle phase compound was produced.

Embodiment 3

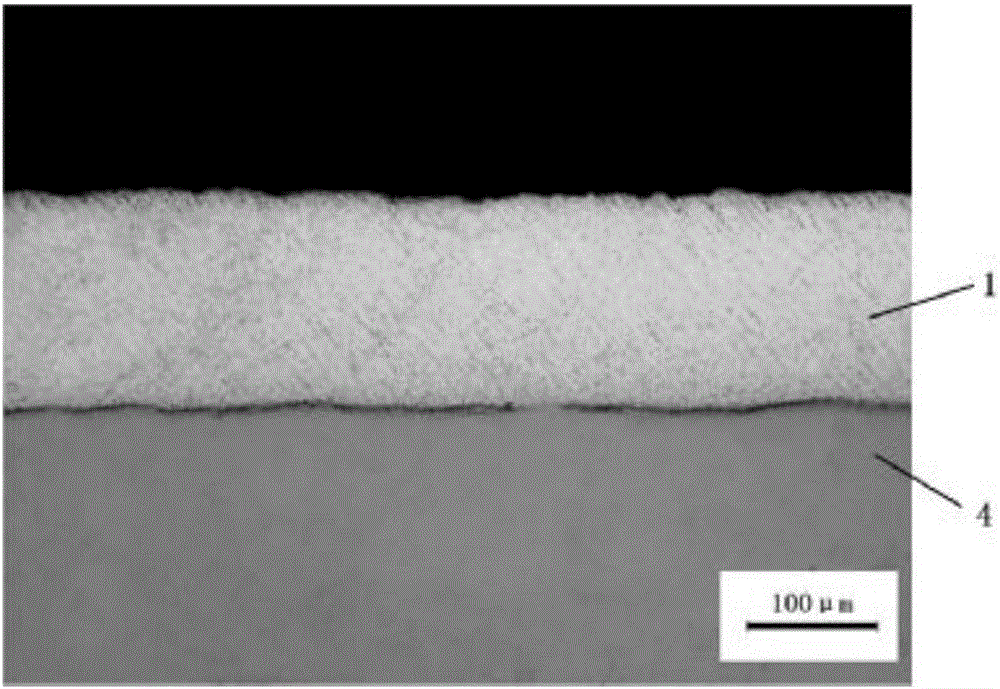

[0033] The mass percentage of the components of the aluminum layer used: 0.8% of silicon Si, 0.7% of iron Fe, 0.08% of copper Cu, 0.04% of manganese Mn, 0.05% of zinc Zn, and the rest are aluminum Al and unavoidable impurity elements The mass percentage of each component of the steel layer: carbon C is 0.0015%, silicon Si is 0.01%, manganese Mn is 1.6%, phosphorus P is 0.01%, sulfur S is 0.004%, aluminum Al is 0.005%, and the rest is iron Fe and others Unavoidable impurity elements.

[0034] Such as Figure 5 As shown, the aluminum-steel composite strip with this composition was heated to 608 ° C for 180 min heat treatment, and no intermetallic brittle phase compound was produced.

[0035] Such as Figure 6 As shown, the aluminum-steel composite strip with this composition was heated to 616°C and held for 60 minutes for heat treatment, and no intermetallic brittle phase compound was produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com