A clean treatment process for recycling waste fly ash and metallurgical dust

A technology for garbage fly ash and cleaning treatment, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc. Reduce environmental hazards and achieve effective degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

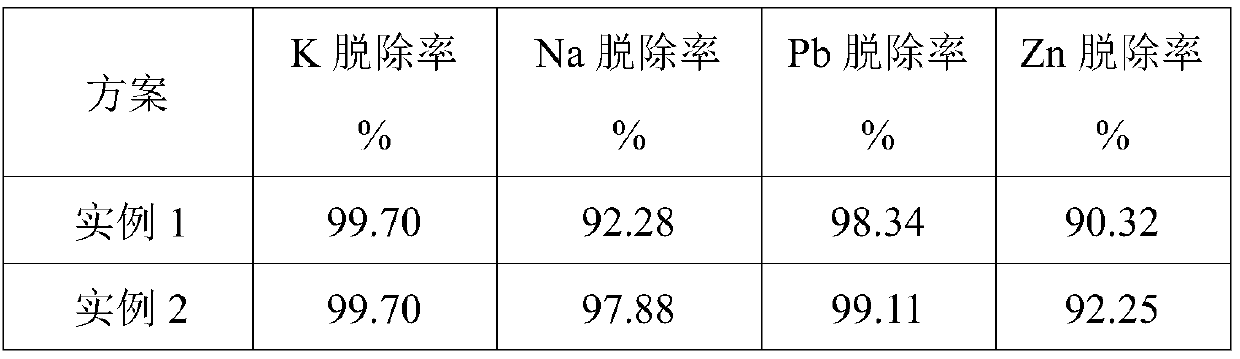

Embodiment 1

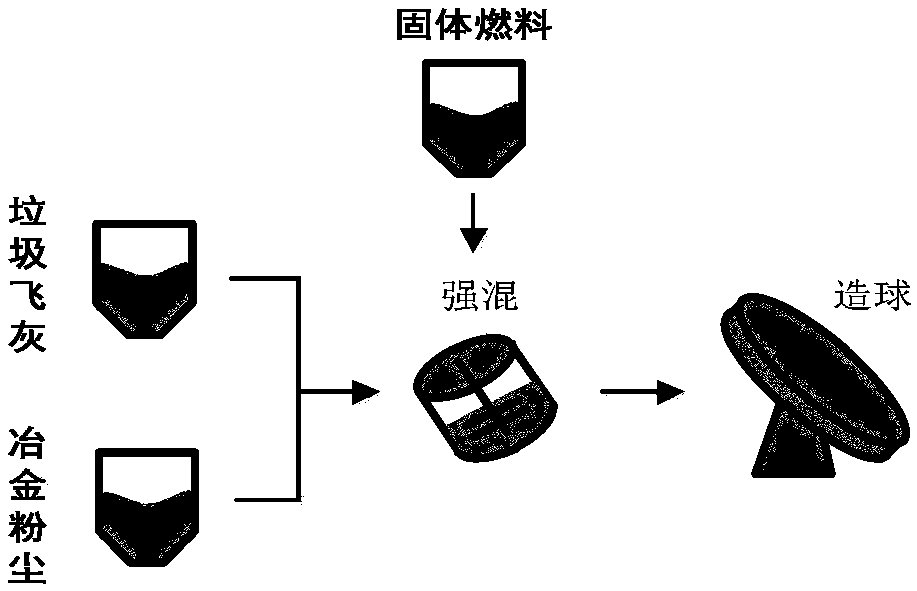

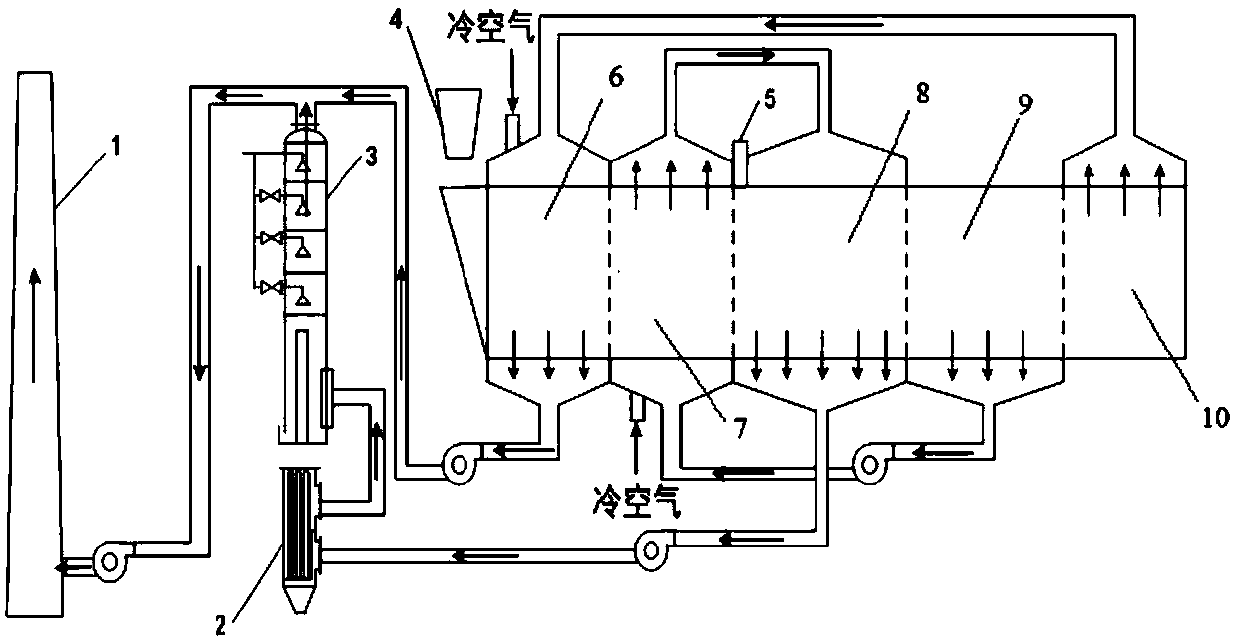

[0037] figure 1 , figure 2 As shown, a waste fly ash and metallurgical dust resource clean disposal process adopts the following steps in sequence:

[0038] Taking the treatment of garbage fly ash and metallurgical dust produced in a large city in my country as an example, the urban garbage fly ash, metallurgical dust, and coal powder are mixed according to the dosage ratio of 1:2:0.2, and then mixed by a powerful mixer ;

[0039] The mixed material is made into pellets with a particle size of 8mm by a disc pelletizer;

[0040] Distribute the balls evenly on the trolley through the distributor, and dry them through drying stage I. The temperature of the drying hot air is 80°C, the drying time is 30 minutes, and the gas flow rate is 1.8m / s. Most of the water in the balls is removed, and the flue gas can be directly emission;

[0041] The pellets enter the drying stage II and are blown to dry. The drying temperature is 500°C, the drying time is 6 minutes, and the gas flow ra...

Embodiment 2

[0047] figure 1 , figure 2 As shown, a waste fly ash and metallurgical dust resource clean disposal process adopts the following steps in sequence:

[0048] Taking the treatment of garbage fly ash and metallurgical dust produced in a large city in my country as an example, the urban garbage fly ash, metallurgical dust, and coal powder are mixed according to the dosage ratio of 1:5:0.3, and then mixed by a powerful mixer ;

[0049] Utilize the disc pelletizer to make the pellets with a granularity of 16mm from the mixed material;

[0050] Distribute the balls evenly on the trolley through the distributor, and dry them through drying stage I. The temperature of the drying hot air is 150°C, the drying time is 15 minutes, and the gas flow rate is 2.4m / s. Most of the water in the balls is removed, and the flue gas can be directly emission;

[0051] The pellets enter the drying stage II and are blown to dry. The drying temperature is 600°C, the drying time is 3 minutes, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com