Patents

Literature

82results about How to "Promote solid solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrochlore type high-entropy oxide solidified body and preparation method thereof

ActiveCN111533557AHigh selectivityPromote solid solutionRare-earth elementDeep geological repository

The invention relates to a pyrochlore type high-entropy oxide solidified body and a preparation method thereof. The high-entropy oxide solidified body has a pyrochlore structure, and the chemical formula is RE2M2O7, wherein RE is a rare earth element, and M is a transition metal element. The pyrochlore-type high-entropy oxide solidified body of the invention has excellent chemical stability. Radioactive nuclides of different valence states and types can be solidified in crystal lattices of a high-entropy oxide base material, deep geological disposal is facilitated, , and the system of solidification treatment of base materials for radioactive nuclear waste is enriched. The method is low-cost, is simple and feasible and has a wide application range. The process is high in efficiency and good in safety, and is expected to be applied to the technical field of radioactive nuclear waste treatment.

Owner:DONGHUA UNIV

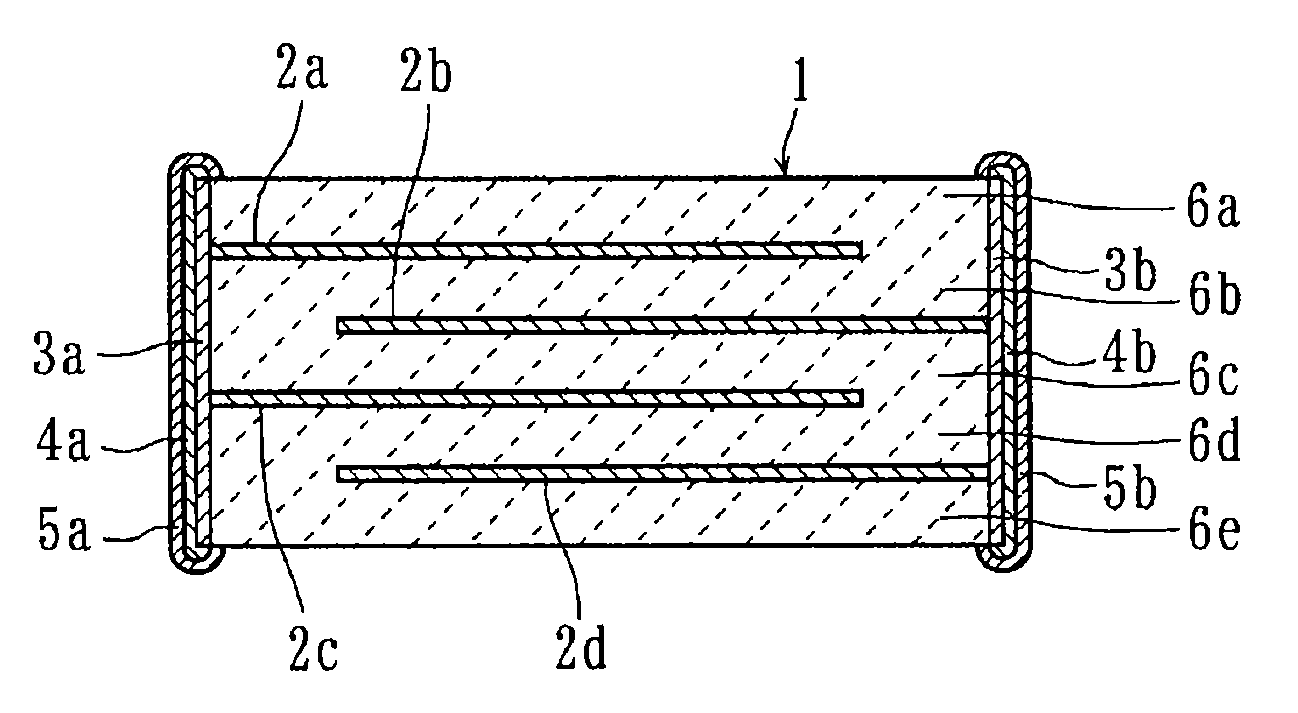

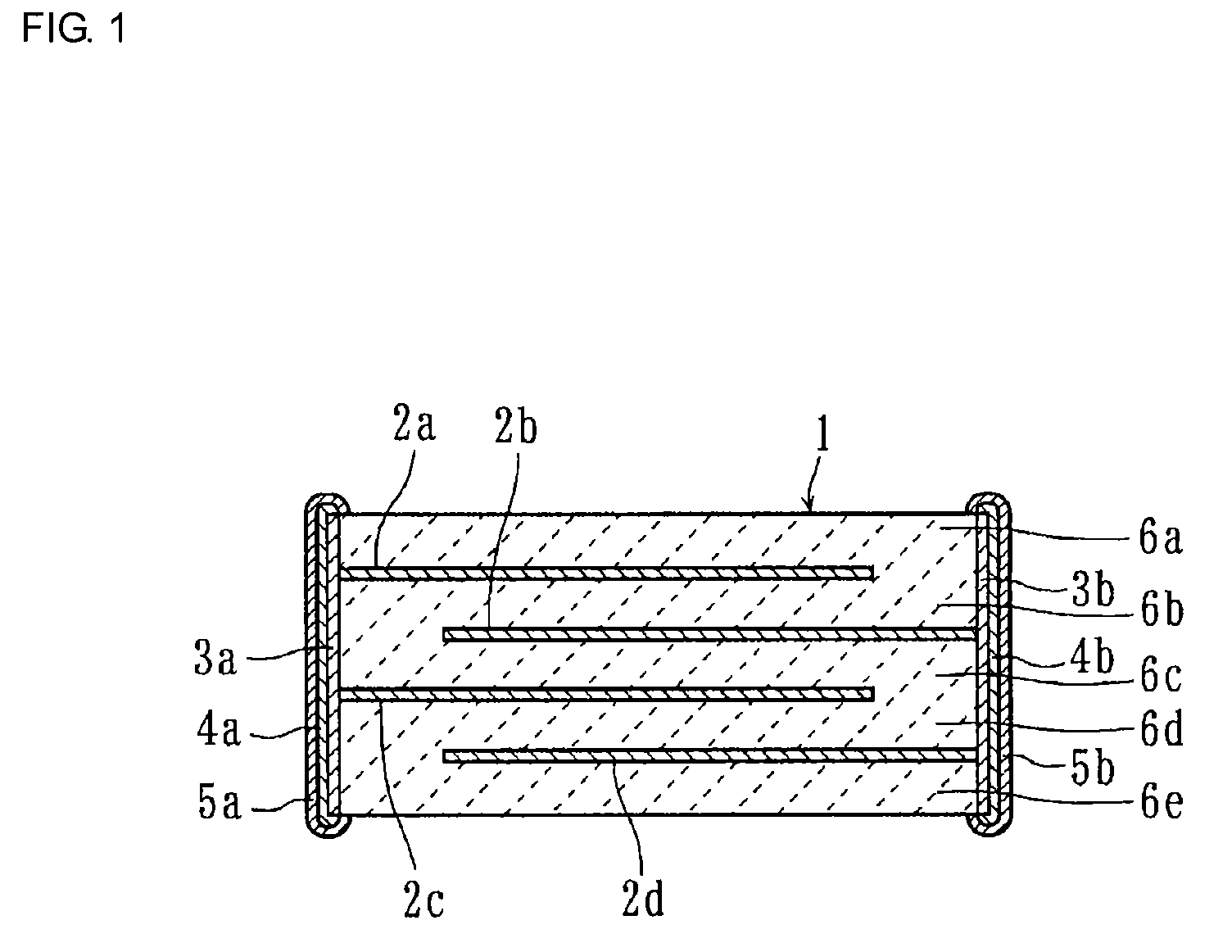

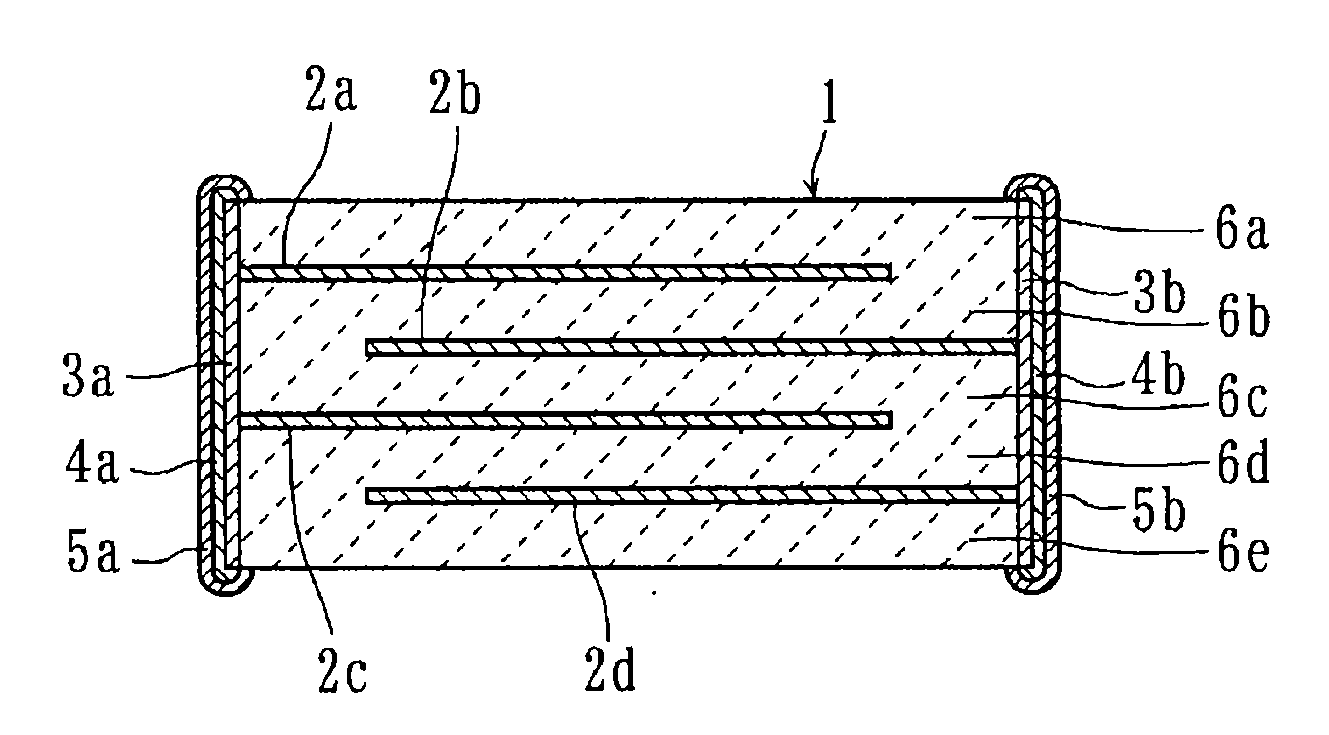

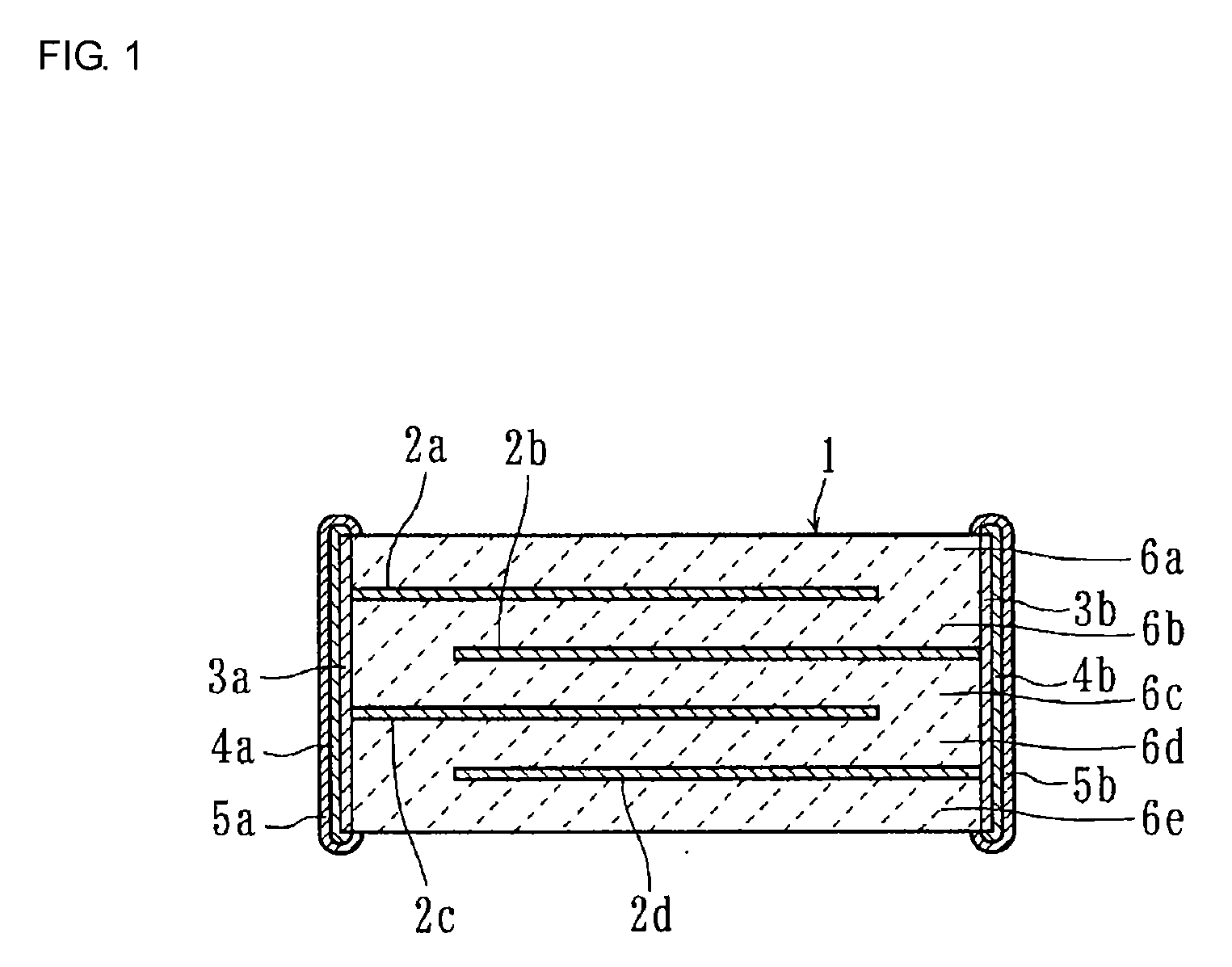

Dielectric ceramic, ceramic electronic element, and multilayer ceramic capacitor

ActiveUS7595975B2Easy to adjustEasy to useFixed capacitor dielectricZirconium compoundsDielectricCeramic capacitor

A dielectric ceramic including a perovskite compound represented by the general formula {(Ba1-x-yCaxSny)m(Ti1-zZrz)O3} as a primary component in which the x, y, z, and m satisfy 0.02≦x≦0.20, 0.02≦y≦0.20, 0≦z≦0.05, and 0.99≦m≦1.1 and is processed by a thermal treatment at a low oxygen partial pressure of 1.0×10−10 to 1.0×10−12 MPa. Accordingly, there are provided a dielectric ceramic which can be stably used in a high-temperature atmosphere without degrading dielectric properties, properties of which can be easily adjusted, and which generates no electrode breakage even when ceramic layers and conductive films are co-fired, and a ceramic electronic element, such as a multilayer ceramic capacitor, which uses the above dielectric ceramic.

Owner:MURATA MFG CO LTD

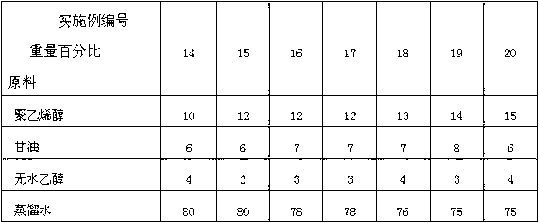

Method for preparing radioactive waste solidified body

InactiveCN102930915AImprove performanceEasy to excludeRadioactive decontaminationHigh densityPolyvinyl alcohol

The invention discloses a method for preparing a radioactive waste solidified body. The method is characterized by comprising the following steps of: finely grinding a raw material which comprises 9.53 to 29.41 weight percent of ZrSiO4, 23.36 to 32.12 weight percent of CaCO3, 31.07 to 38.46 weight percent of TiO2, 0 to 15.66 weight percent of Nd2O3, 0 to 29.09 weight percent of CeO2 and 0 to 3.97 weight percent of Al2O3; drying the raw material; and adding polyvinyl alcohol sol, granulating, screening, molding, discharging the sol, performing vacuum hot-pressing sintering, and thus obtaining the radioactive waste solidified body. By adoption of the method, the raw material is low in cost, a high-purity and high-density perovskite acorite and titanite combined mineral solidified body is prepared at low temperature by using a simple and practical hot-pressing sintering technology, and foundation is laid for engineering application to artificial rock solidification treatment of high-level waste.

Owner:SOUTHWEAT UNIV OF SCI & TECH

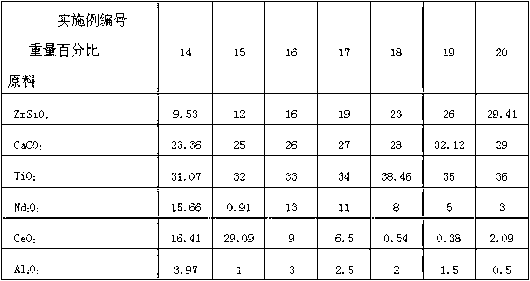

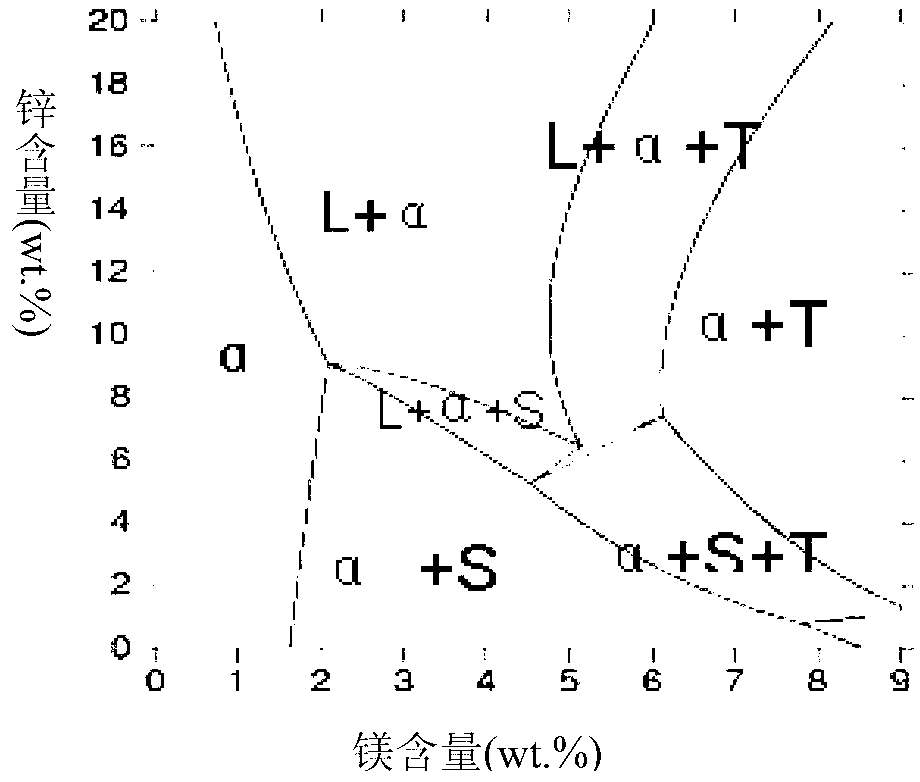

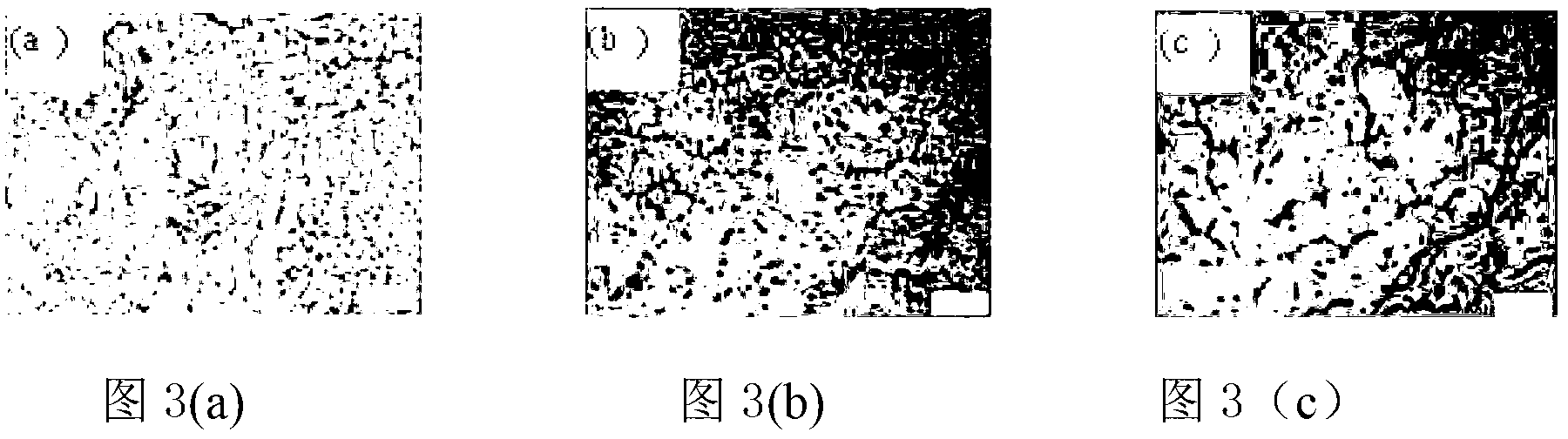

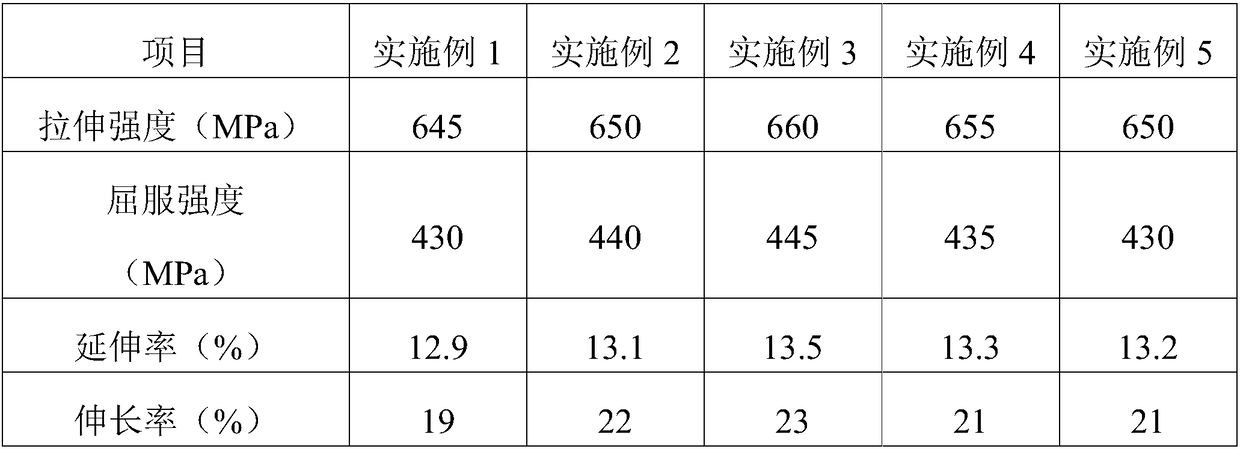

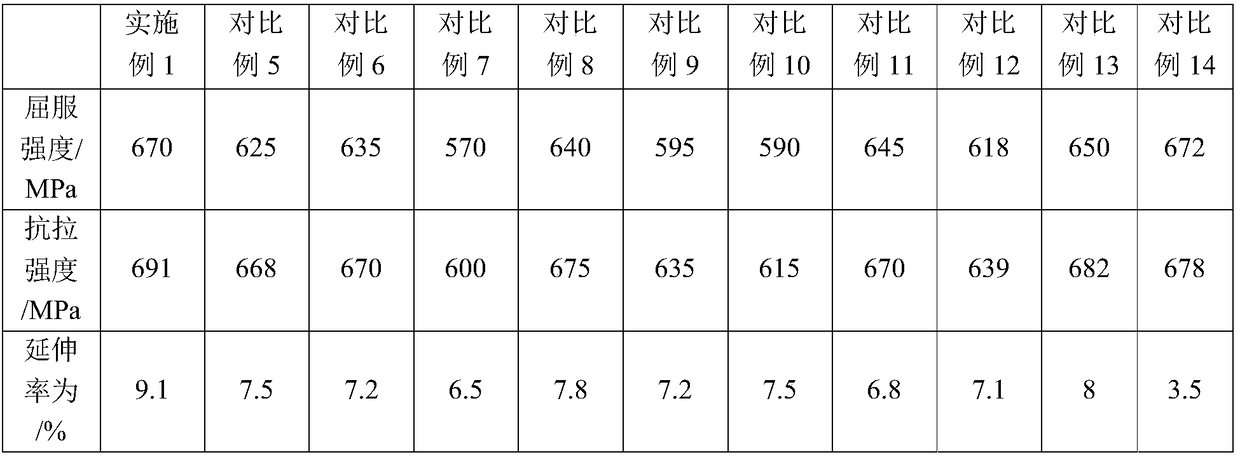

High-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and heat treatment method

The invention discloses a high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and a heat treatment method. The alloy comprises the following components by mass percentage: 6.5-8.3% of Zn, 2.3-3.0% of Mg, 0.8-1.2% of Cu, 0.1-0.2% of Zr, less than 0.15% of Fe, less than 0.1% of Si, and the balance of Al. A preparation method of the alloy comprises the steps of blending, smelting, semi-continuous casting, homogenizing, thermoplastic deformation, short time solid solution, and ageing heat treatment. For the high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy prepared with the method, the hardness (HV) is 185-209, the tensile strength sigma b is greater than or equal to 650Mpa, the percentage elongation delta is greater than or equal to 7%, the pitting resistance is high, the cast ingot yield is high, and the stress corrosion resistance is further improved while the mechanical property is kept after multiple regression reageing treatment. The alloy and the heat treatment method solve the problems that the cast ingot yield in the existing high-copper Al-Zn-Mg-Cu ultrahigh-strength aluminium alloy is low, and the strength, toughness and corrosion resistance cannot be compromised. The heat treatment method is simple to operate, and the industrial production is facilitated.

Owner:CENT SOUTH UNIV

Dielectric ceramic, ceramic electronic element, and multilayer ceramic capacitor

ActiveUS20090128989A1Improve sintering performanceEasy to useFixed capacitor dielectricZirconium compoundsDielectricCeramic capacitor

A dielectric ceramic including a perovskite compound represented by the general formula {(Ba1-x-yCaxSny)m(Ti1-zZrz)O3} as a primary component in which the x, y, z, and m satisfy 0.02≦x≦0.20, 0.02≦y≦0.20, 0≦z≦0.05, and 0.99≦m≦1.1 and is processed by a thermal treatment at a low oxygen partial pressure of 1.0×10−10 to 1.0×10−12 MPa. Accordingly, there are provided a dielectric ceramic which can be stably used in a high-temperature atmosphere without degrading dielectric properties, properties of which can be easily adjusted, and which generates no electrode breakage even when ceramic layers and conductive films are co-fired, and a ceramic electronic element, such as a multilayer ceramic capacitor, which uses the above dielectric ceramic.

Owner:MURATA MFG CO LTD

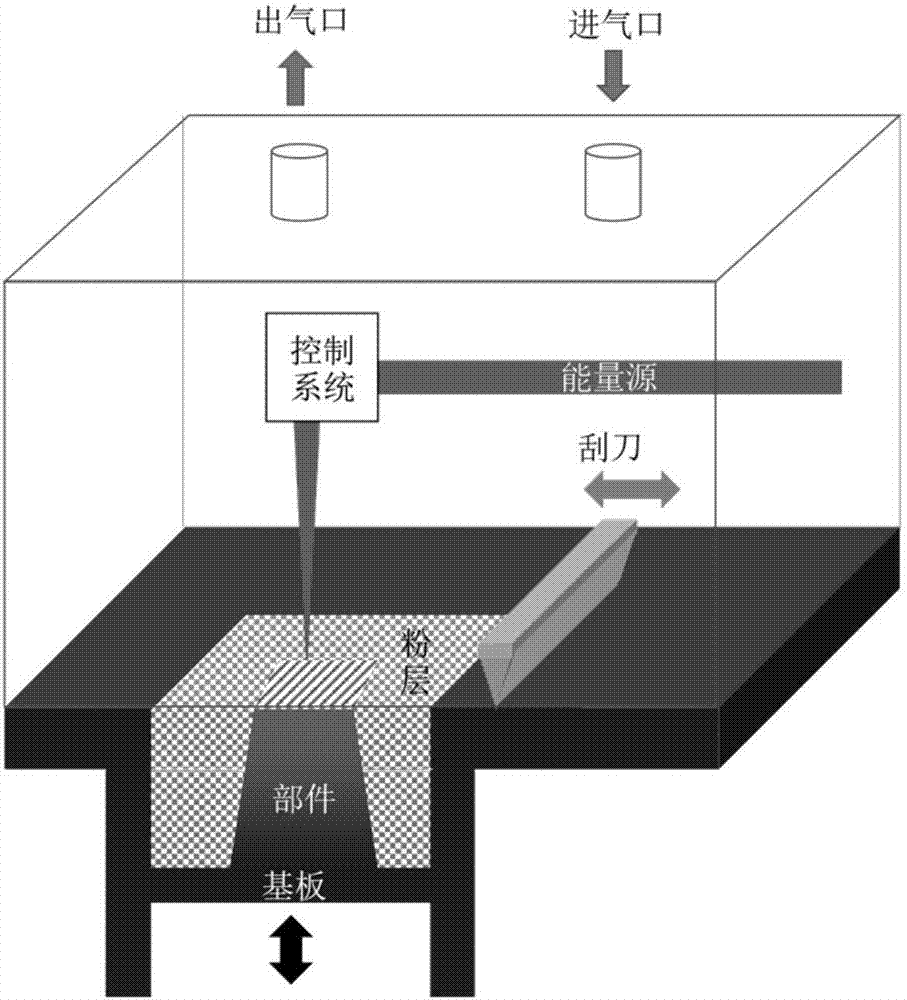

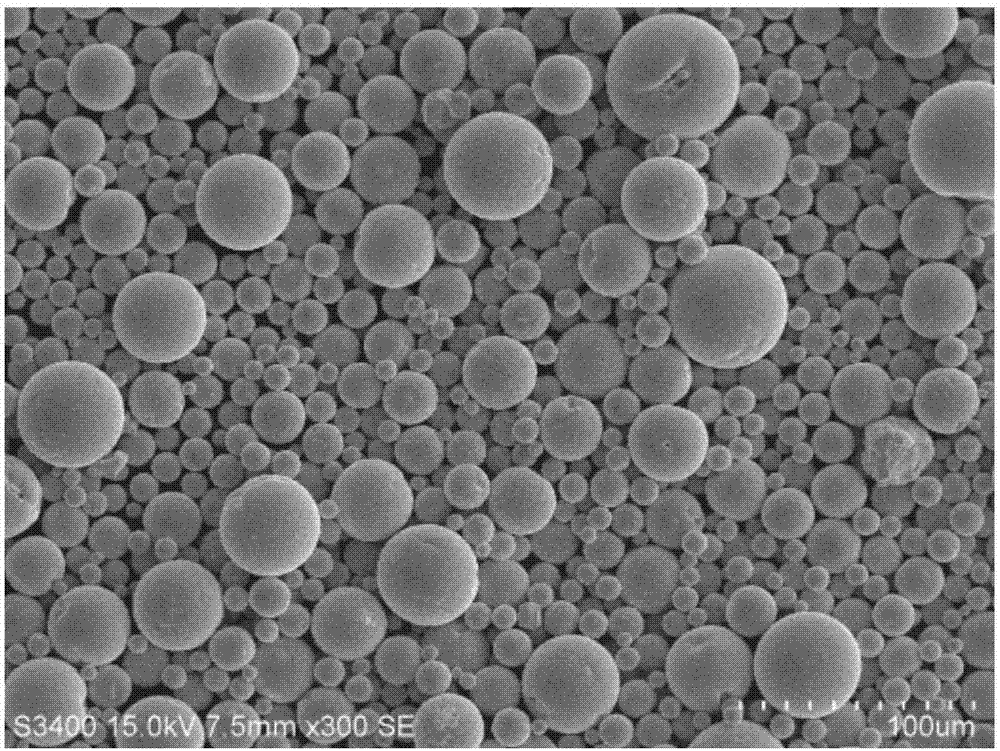

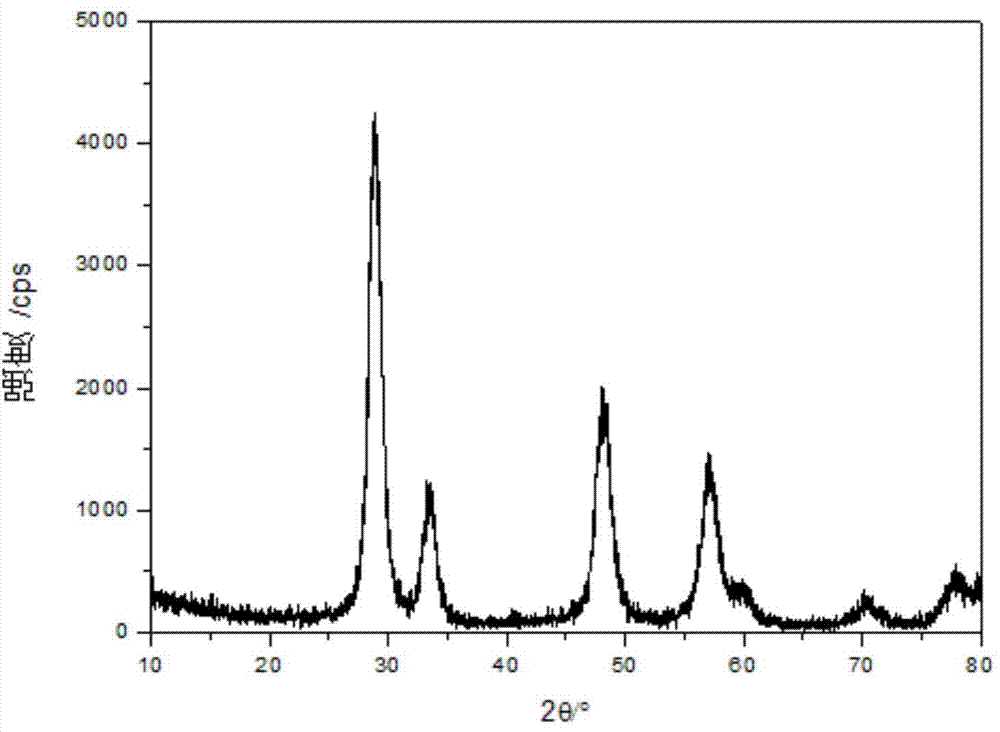

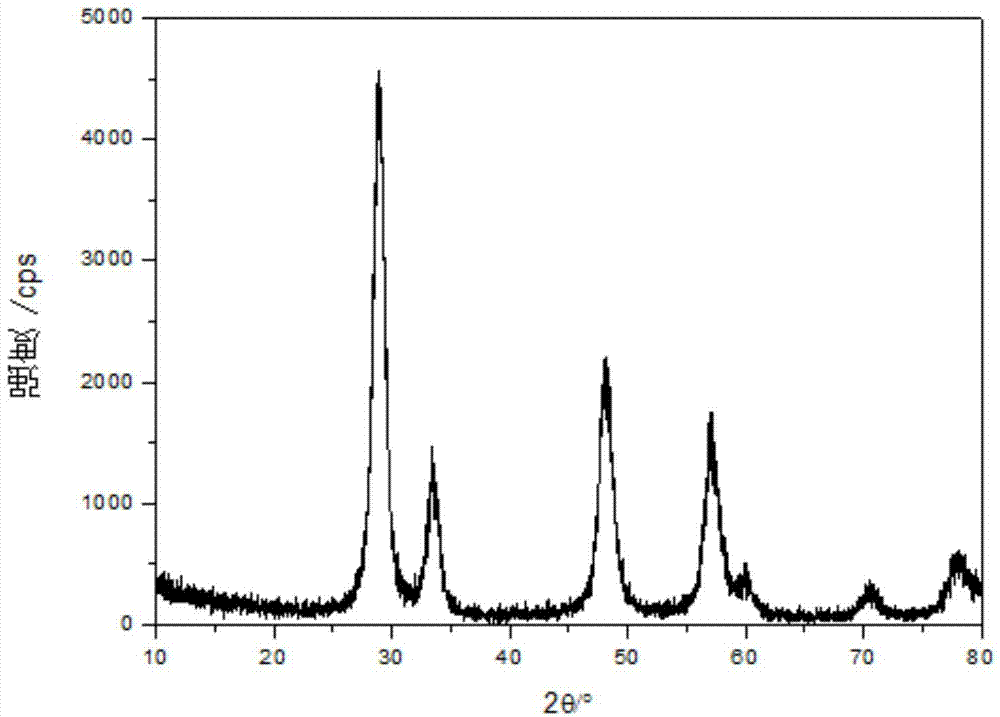

Tungsten alloy and preparation method thereof

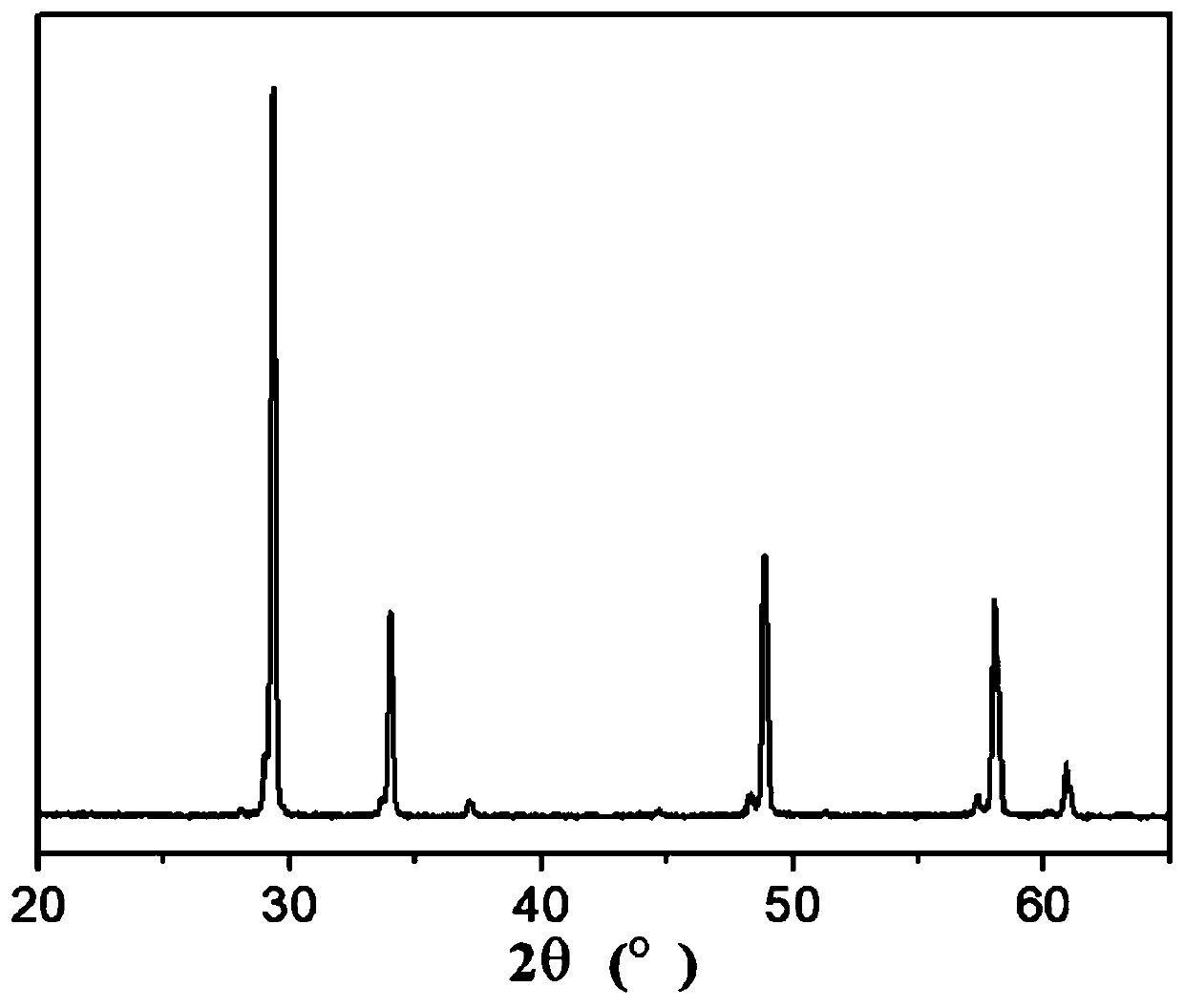

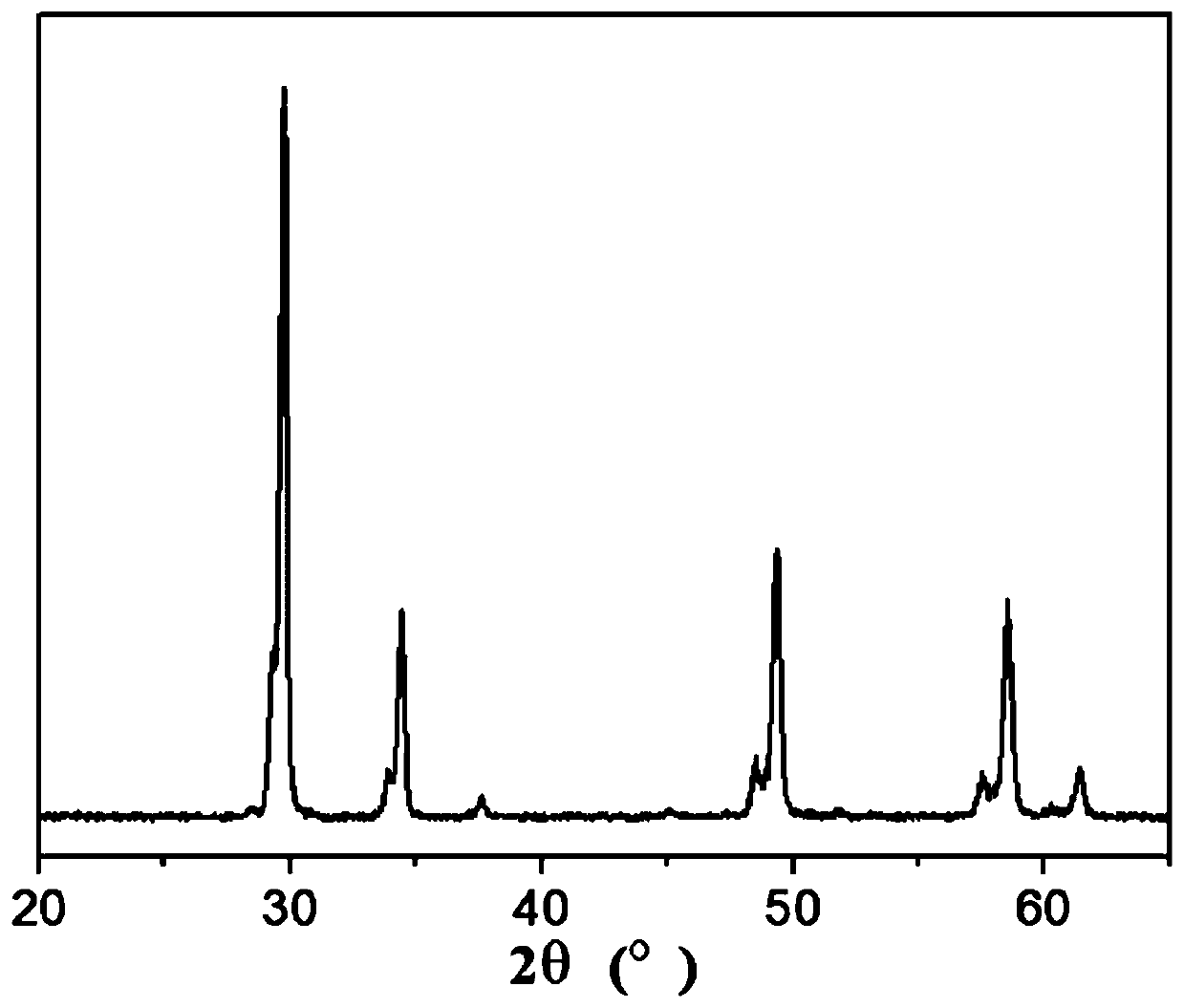

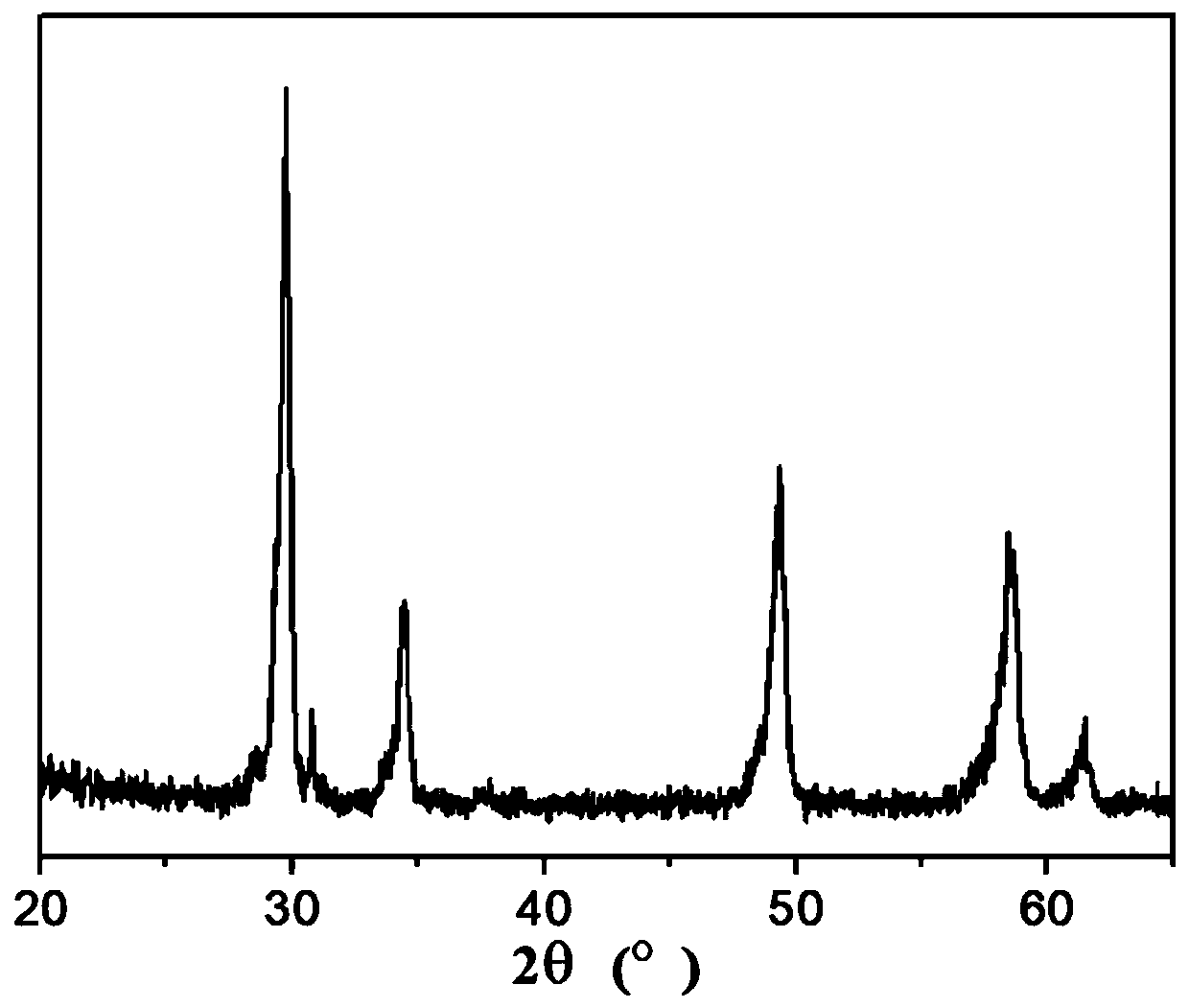

ActiveCN107541633AImprove plasticity and toughnessImprove grain deformation resistanceShieldingAlloy elementDuctility

The invention relates to a tungsten alloy and a preparation method thereof. The alloy is composed of a tungsten matrix and alloy elements. The solid solution of alloying elements into the tungsten matrix, based on the XRD test, can give full play to the solid solution strengthening effect, improve the strength and hardness of the alloy, and improve the plasticity and toughness of the alloy at the same time. The invention also provides a 3D pure shape preparation method of this novel tungsten alloy part.

Owner:TSINGHUA UNIV

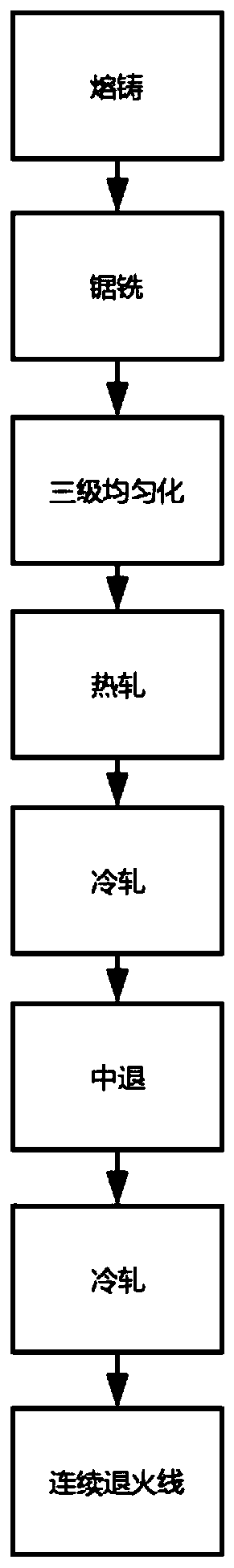

5182-0 aluminum alloy sheet preparation method for automobiles

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a 5182-0 aluminum alloy sheet preparation method for automobiles. Aluminum alloy raw materials are preparedfrom the components in percentage by mass: namely 0.01-0.08% of Si, 0.15-0.30% of Fe, 0.01-0.1% of Cu, 0.10-0.30% of Mn, 4.5-5.0% of Mg, less than or equal to 0.1% of Cr, less than or equal to 0.05%of Zn, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Ni, less than or equal to 0.05% of a single impurity, less than or equal to 0.15% of total, and the balance of Al. Aluminum alloycoils cold rolled to intermediate pass in cold rolling process are annealed and insulated at 320 DEG C for 2 h, wherein the annealing process of finished aluminum alloy coils is passed in a single layer mode in a continuous air cushion annealing furnace, the coils are blown to suspend in the furnace through hot air, and the problems that most parts of the local deformation of aluminum alloy sheets are cracked during the stamping deformation due to the uneven inner grain structure of aluminum alloy sheets prepared by existing aluminum alloy sheet preparation process are solved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

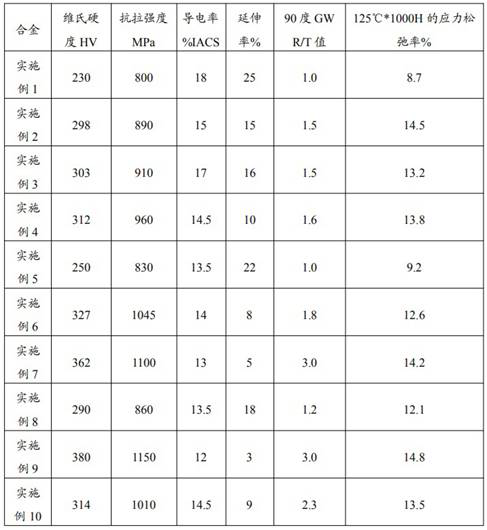

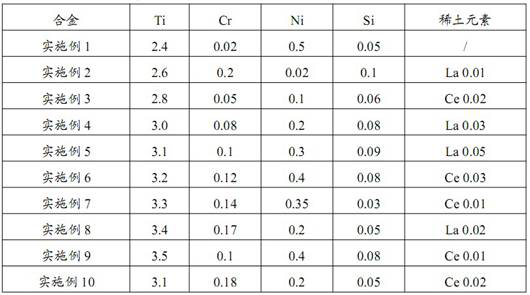

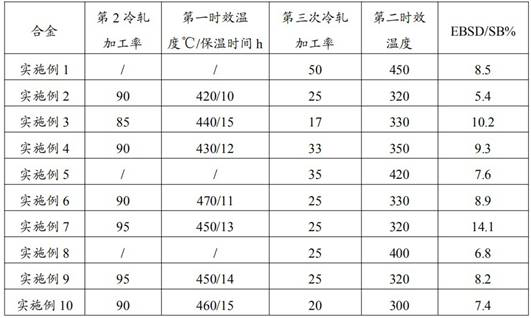

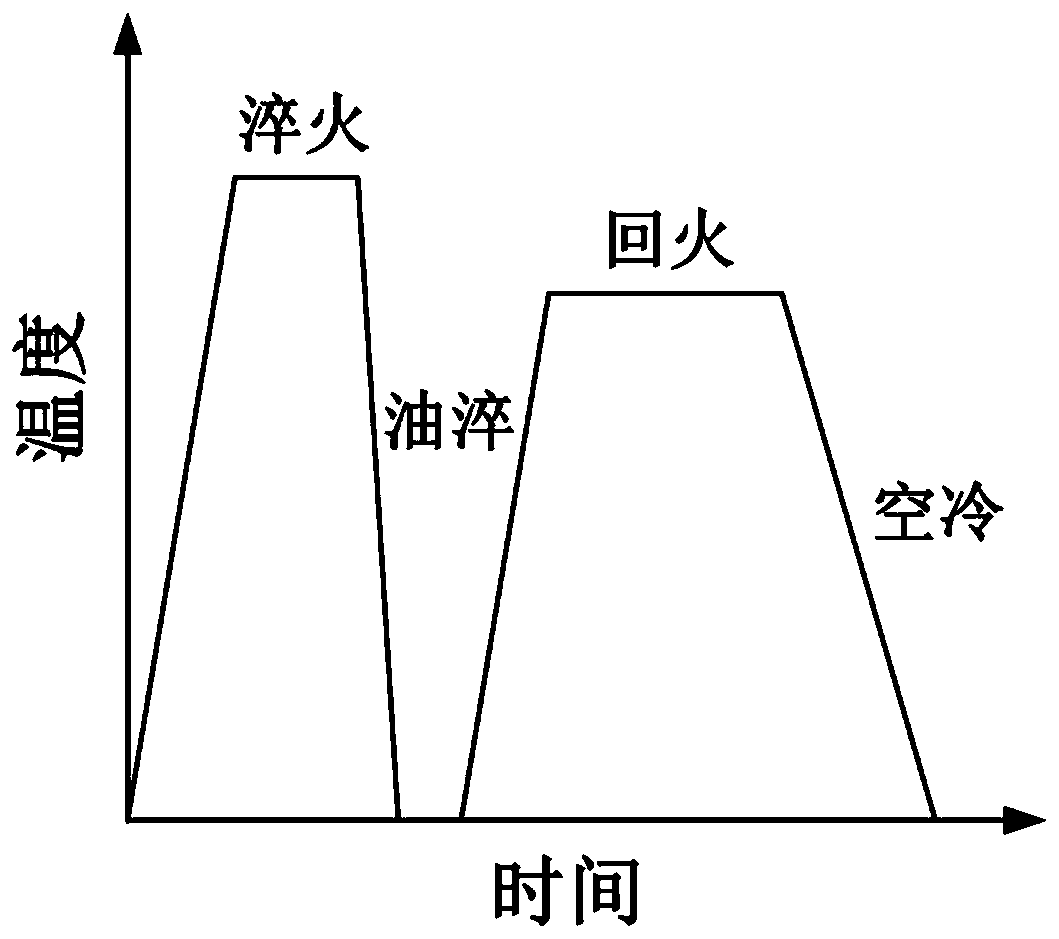

Elastic copper-titanium alloy and preparation method thereof

The invention relates to the technical field of copper alloys, and in particular to an elastic copper-titanium alloy and a preparation method thereof. The preparation method of the elastic copper-titanium alloy comprises the steps of melting and casting metal raw materials to obtain an ingot according to the composition of the elastic copper-titanium alloy; and sequentially performing hot rolling,first cold rolling, solution treatment, third cold rolling, second aging treatment and annealing treatment on the ingot to obtain the elastic copper-titanium alloy. The elastic copper-titanium alloyis prepared from the components in percentage by mass: Ti: 2.4% to 3.5%; Cr: 0.02% to 0.2%; Ni: 0.02% to 0.5%; Si: 0.05% to 0.1%, rare earth elements: 0% to 0.05%, and the balance of Cu. By changing the particle structure of the precipitated phase to match the composition of the copper-titanium alloy, the prepared elastic copper-titanium alloy has high strength, high elongation, high electrical conductivity, low stress relaxation rate, and good bending resistance.

Owner:NINGBO XINGYE SHENGTAI GROUP

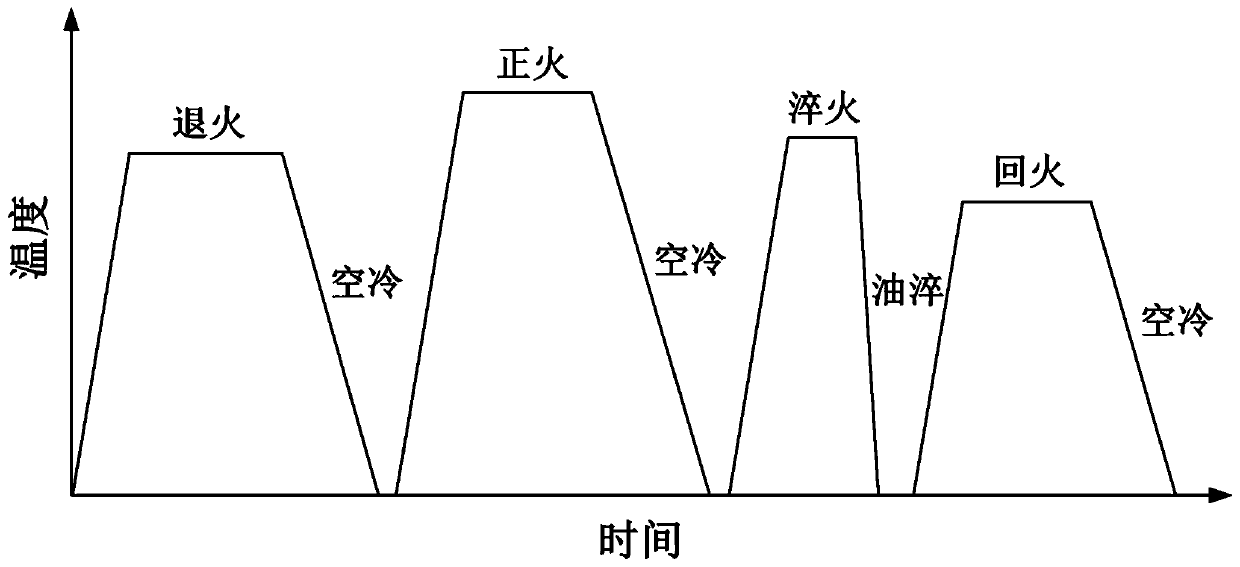

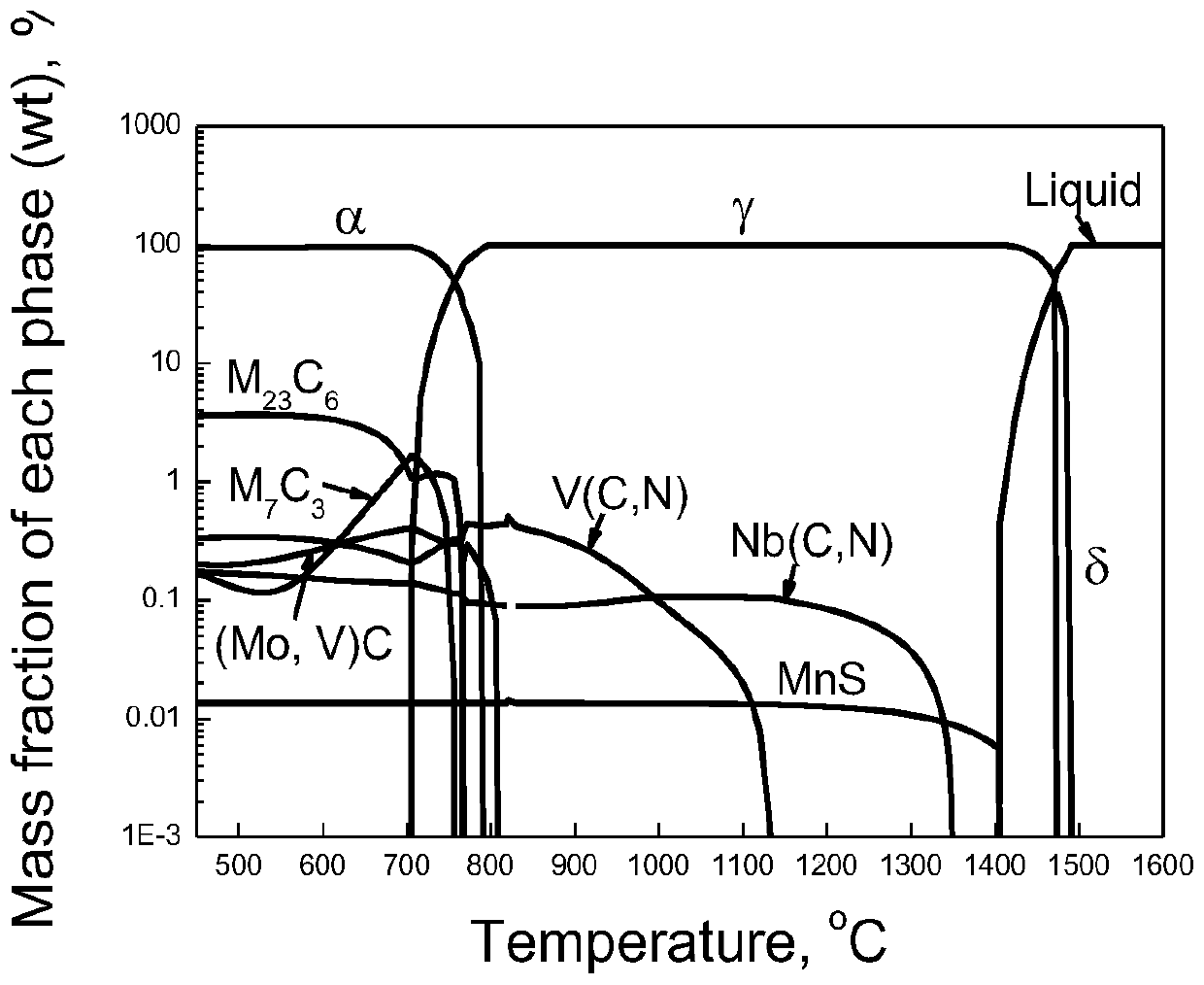

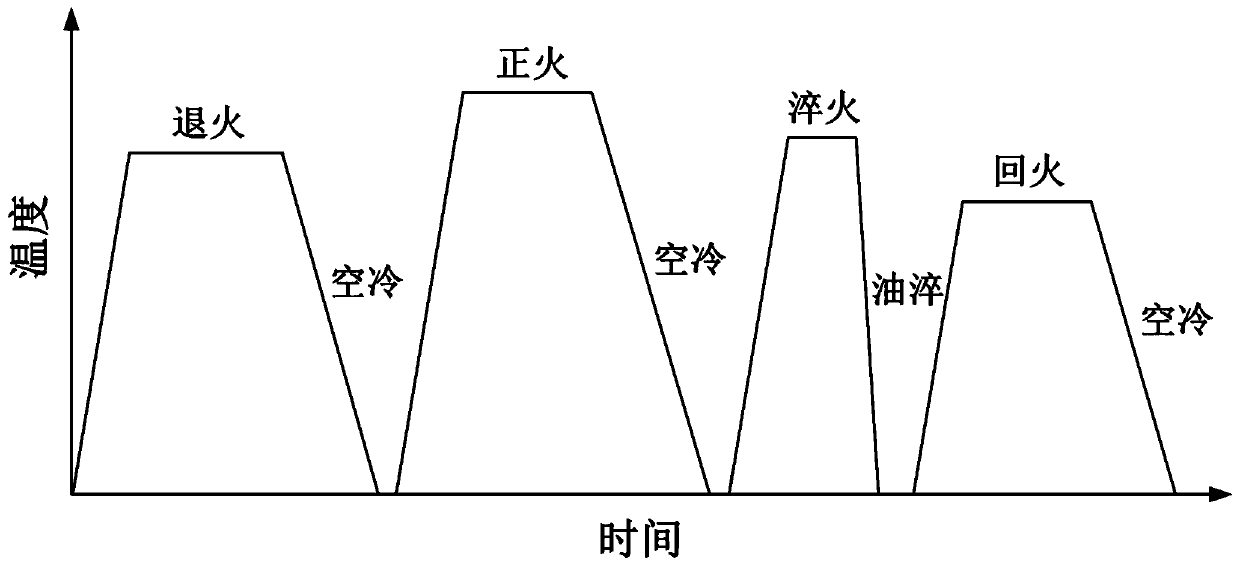

High-toughness cold-hot-fatigue-resistant cast steel for high-speed train brake disc and preparation method thereof

ActiveCN111360198AMatch mechanicsMatching cold and heat fatigue resistanceFoundry mouldsFurnace typesBrakeMetallic materials

The invention relates to high-toughness cold-hot-fatigue-resistant cast steel for a high-speed train brake disc and a preparation method thereof, belongs to the field of metal materials and preparation thereof, and solves the problem of matching of room-temperature toughness, high-temperature mechanical properties and cold and hot fatigue failure resistance of the cast steel for the high-speed train brake disc in the prior art. The high-toughness cold-hot-fatigue-resistant cast steel for the high-speed train brake disc comprises the following chemical components, in percentage by mass, of 0.20%-0.40% of C, 0.30%-0.70% of Si, 0.50%-2.00% of Mn, 0.50%-2.00% of Cr, 0.50%-2.00% of Ni, 0.40%-1.80% of Mo, 0.01%-0.30% of V, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% ofS, smaller than or equal to 0.010% of O, smaller than or equal to 0.015% of N, and the balance Fe and inevitable impurities, wherein the total content of the Mn, the Cr and the Ni is 2.00%-6.00%, andthe total content of the Mo and the V is 0.41%-2.00%. Through reasonable composition, organization structure and preparation process regulation and control, excellent room-temperature toughness, high-temperature mechanical property and cold and hot fatigue failure resistance of the cast steel are matched, the requirements for comprehensive mechanical property and long service life of the cast steel brake disc of a high-speed train are met, and the cast steel is suitable for being used as a material for the cast steel brake disc of the high-speed train.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

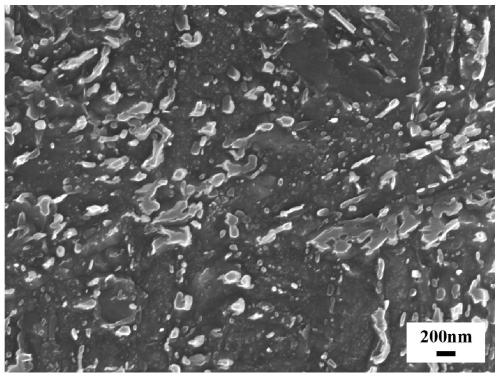

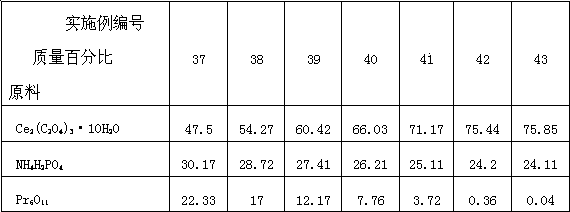

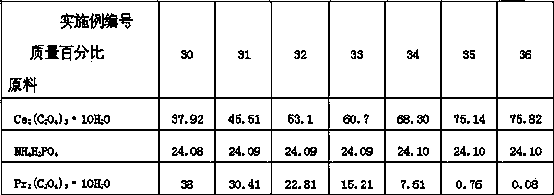

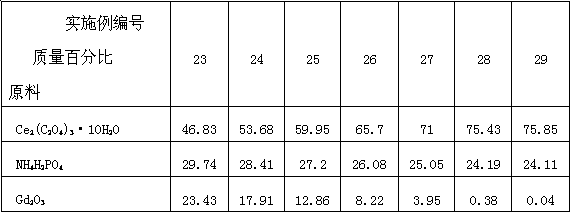

Preparation method of kularite ceramic solidifying body

InactiveCN103408304AThe process is simple and practicalGood for engineering applicationsHalf-lifeHigh-level waste

The invention discloses a preparation method of a kularite ceramic solidifying body. The preparation method is characterized in that Ce2(C2O4)3.10H2O, An2 (C2O4)3.10H2O / oxide of An (An=Gd, Pr and Eu) and NH4H2PO4 are taken as raw materials; the high-quality kularite ceramic solidifying body is prepared according to formulation designing and the steps such as fine grinding, drying, granulating, forming, adhesive removing and vacuum hot-pressing sintering at a lower temperature. The kularite ceramic solidifying body prepared according to the preparation method is high in heat stability, mechanical stability, chemical stability and anti-radiation stability, is applicable to the safe solidification treatment of high-level waste, particularly applicable to the safe solidification treatment of high-level minor actinides waste which is high in radioactivity and toxicity, and long in half life period, and also applicable to the engineering application of high-level waste ceramic solidification treatment needing remote operation.

Owner:SOUTHWEAT UNIV OF SCI & TECH

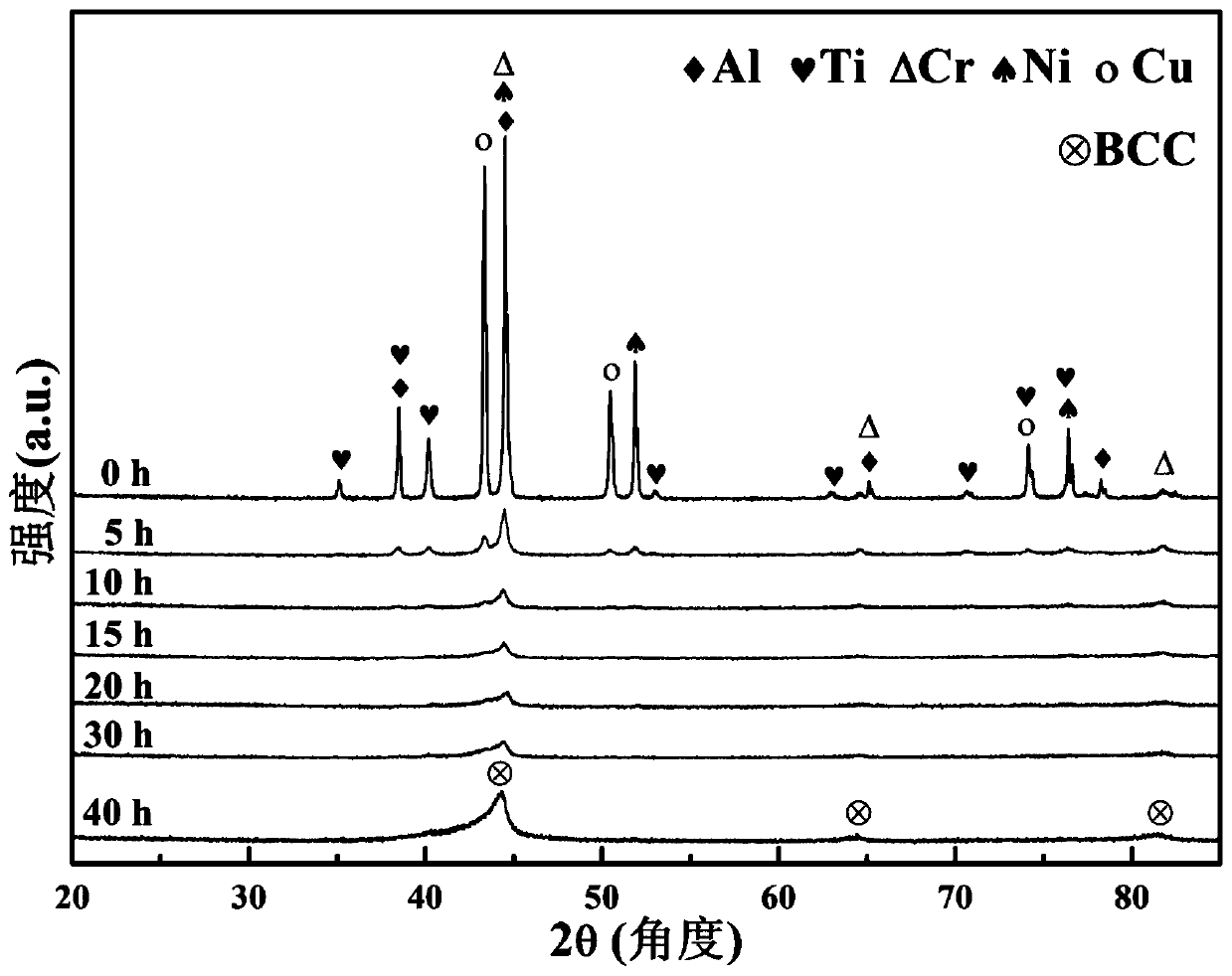

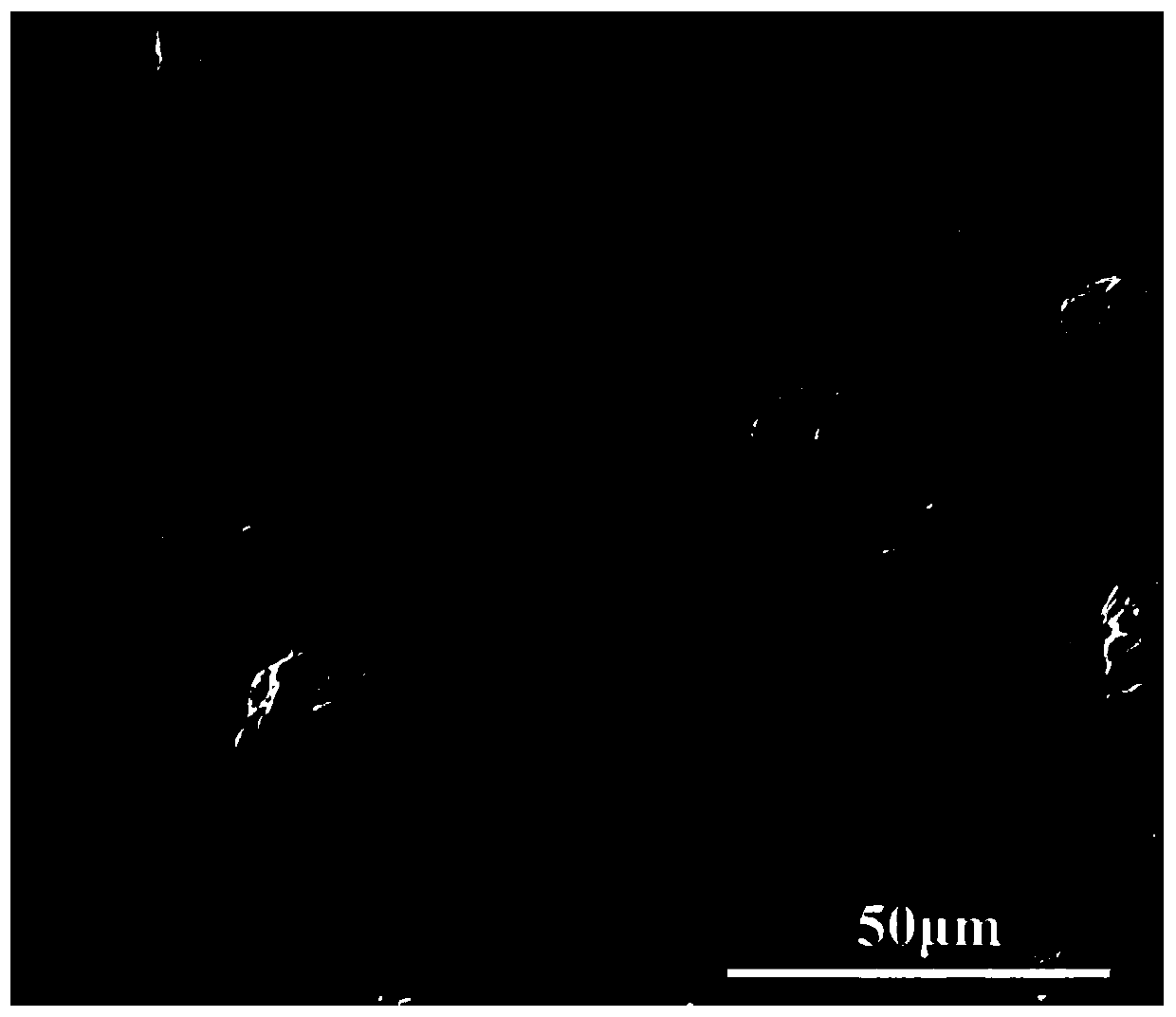

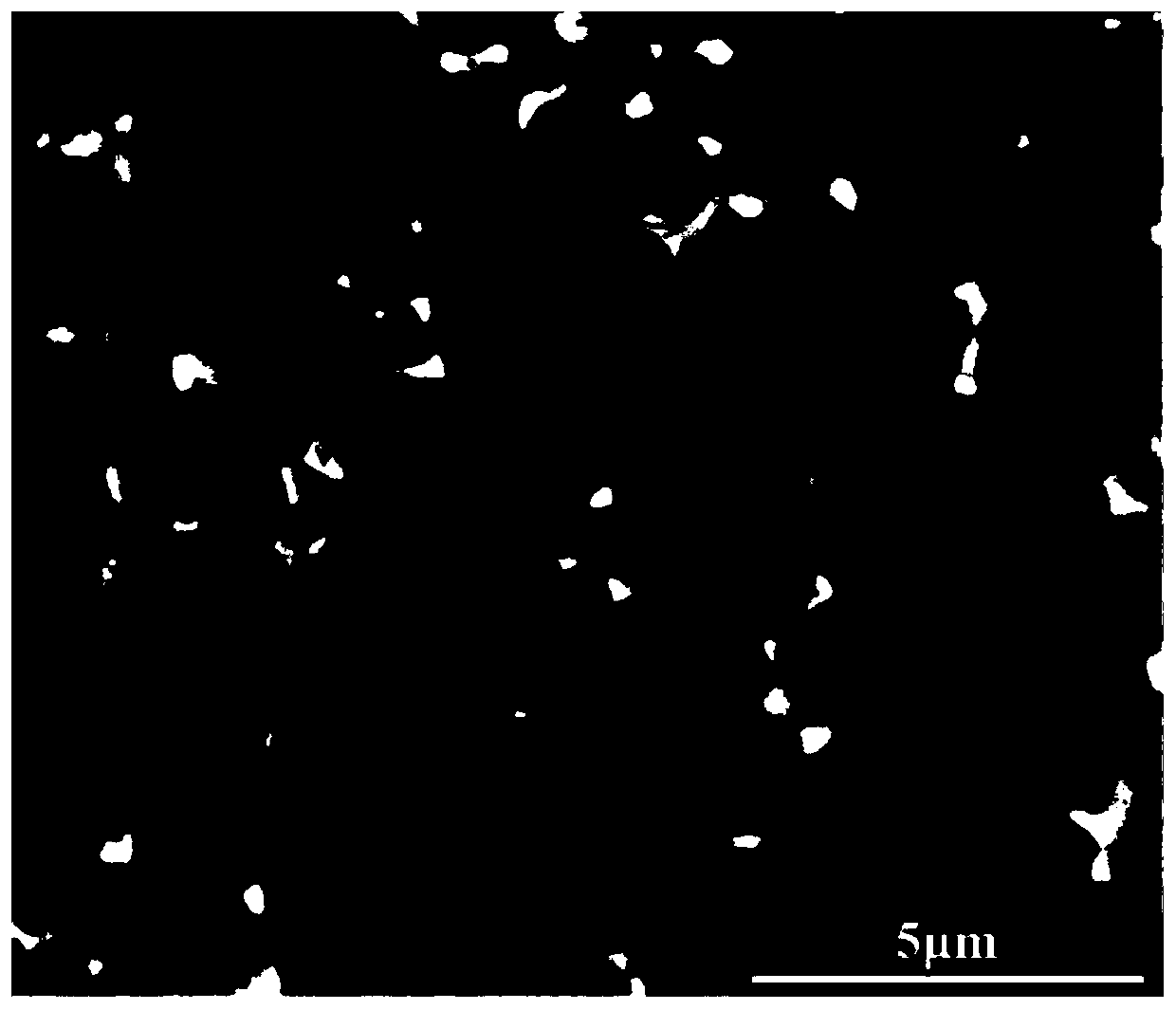

Low-density dual-phase high-entropy alloy material and preparing method thereof

The invention discloses a low-density dual-phase high-entropy alloy material and a preparing method thereof. The elemental composition of the low-density dual-phase high-entropy alloy material is AlxTiyCrNiCu, wherein x is 0.5-3, y is 0.5-3, the crystal structure of the alloy material is FCC+BCC dual-phase structure, and the density is 5.18-7.14 g / cm<3>. The method is a solid-state forming methodfor combining a mechanical alloying technology and a spark plasma sintering technology, the required temperature of the solid-state forming method is low, the sintering time is short, a bulk materialwhich is uniform in compositions and has near full density can be obtained through once sintering, and a near net forming can be realized; and the prepared low-density dual-phase high-entropy alloy material is fine in grain, uniform in structure, and high in strength, hardness, wear resistance, and has excellent comprehensive mechanical properties such as plasticity.

Owner:SOUTH CHINA UNIV OF TECH

High-nitrogen composite alloy and preparation method thereof

ActiveCN109365806AImproves tensile and flexural strengthGood impact resistanceTransportation and packagingMetal-working apparatusLanthanumFlexural strength

The invention belongs to the technical field of metallurgy, and provides a high-nitrogen composite alloy which is prepared from the following components in percentage by weight: 5 to 20 percent of nitrogen, 15 to 40 percent of titanium, 15 to 40 percent of niobium, 10 to 20 percent of chromium, 10 to 20 percent of silicon, 2 to 10 percent of manganese, 1 to 5 percent of rare earth lanthanum, lessthan or equal to 1.0 percent of carbon, less than or equal to 0.06 percent of sulfur, and less than or equal to 0.1 percent of phosphorus. A preparation method comprises the steps of premixing raw material, then mixing, rising temperature, pretreating, then rising temperature for three times under the vacuum condition, preserving heat, pressing and firing. According to the prepared high-nitrogen composite alloy, the nitrogen content is remarkably improved, and a reinforcing steel bar using the high-nitrogen composite alloy has high tensile strength and bending strength, good shock resistance,good toughness and excellent mechanical property. The high-nitrogen composite alloy provided by the invention solves the problems of instable quality and low nitrogen content of the high-nitrogen reinforcing steel bar in the prior art.

Owner:河北诺凡新材料科技有限公司

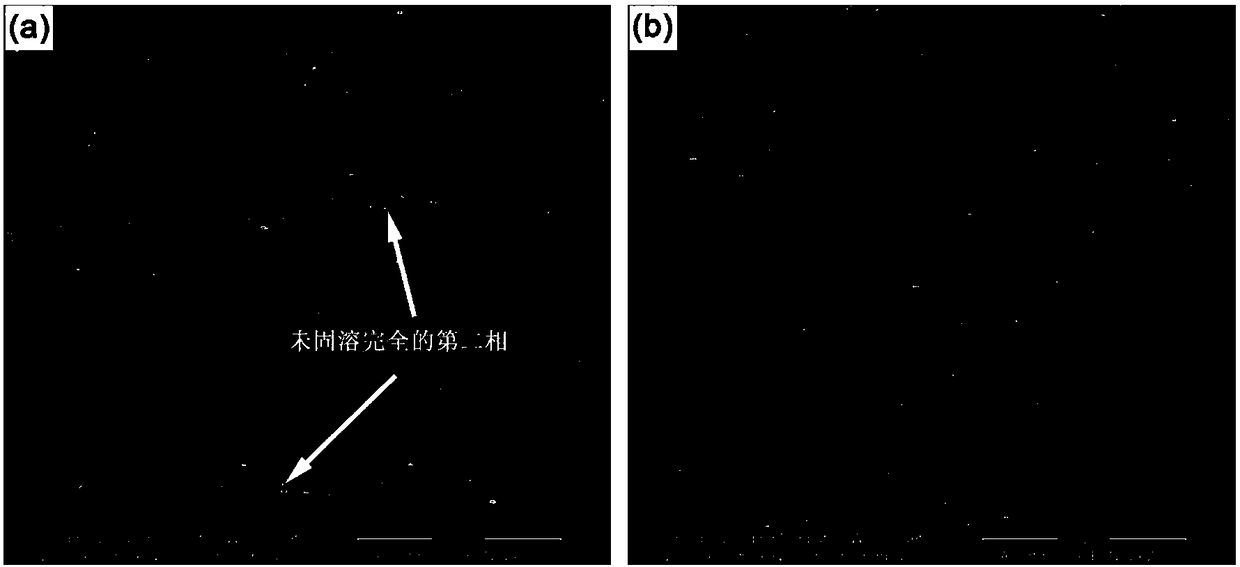

Strengthening and toughening heat treatment method of in-situ titanium boride particle reinforced aluminum matrix composite

The invention provides a strengthening and toughening heat treatment method of an in-situ titanium boride particle reinforced aluminum matrix composite. The method comprises following steps that the aluminum matrix composite is subjected to homogenization treatment and then is subjected to high-temperature pretreatment, heat extrusion treatment, annealing treatment, short-time high-temperature solid-solution treatment, pre-deforming treatment and aging treatment in sequence; according to the heat treatment method, the process is simple and reasonable, through high-temperature homogenization and solid solution treatment, segregation can be effectively removed, and solid solution of the second phase can be promoted; through extrusion deforming and low-temperature annealing, a stable substructure and a small grain boundary can be generated in the microstructure, and strengthening and toughening of the composite are facilitated; finally, through short-time high-temperature solid-solution quenching, pre-stretching deforming and short-time manual aging, the precipitated phase can be more evenly dispersed in the matrix alloy; and through the process, the strength and plasticity of the in-situ TiB2 nano particle reinforced aluminum matrix composite can be effectively improved.

Owner:SHANGHAI JIAO TONG UNIV

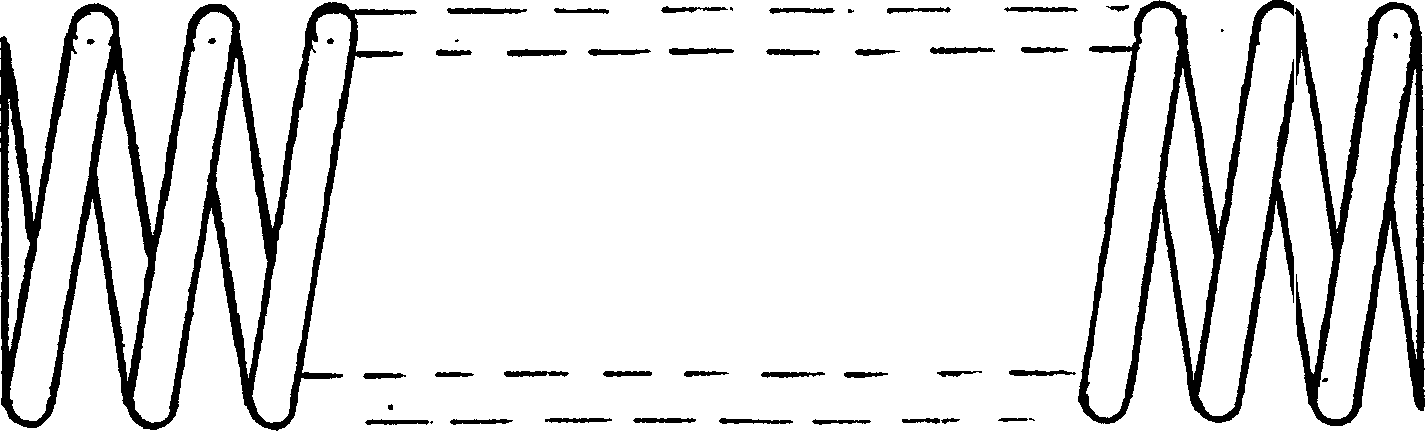

High temperature alloy spring for steam turbine steam locking and its processing method and detecting installation

InactiveCN1410688AImprove quality levelHigh thermal efficiencyLeakage preventionMachines/enginesQuality levelWorking temperature

The column type helical spring is made from Inconal X-750 (GH4145) alloy wire. The procedures for manufacturing the spring are as following: wrapping the semi-finished product of long coil of spring:cutting the long coil to single springs; washing the springs; carrying out the solid solution heat treatment; cutting end and adjusting the pitch, and carrying out the aging heat treatment. With the tests of rigidity and permangnet deformation in high temperature being completed, the finished springs are obtained. The device for testing rigidity of the spring includes the worktable, the electric stove and dial gauge etc. Testing indicates the performances of the spring: when the working temperature at 550 degree.C, the service life > or =25000 hr. The spring is easy to be assembled in the vapor lock.

Owner:DONGFANG TURBINE CO LTD

Method for preparing titanium and titanium obtained by the method

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

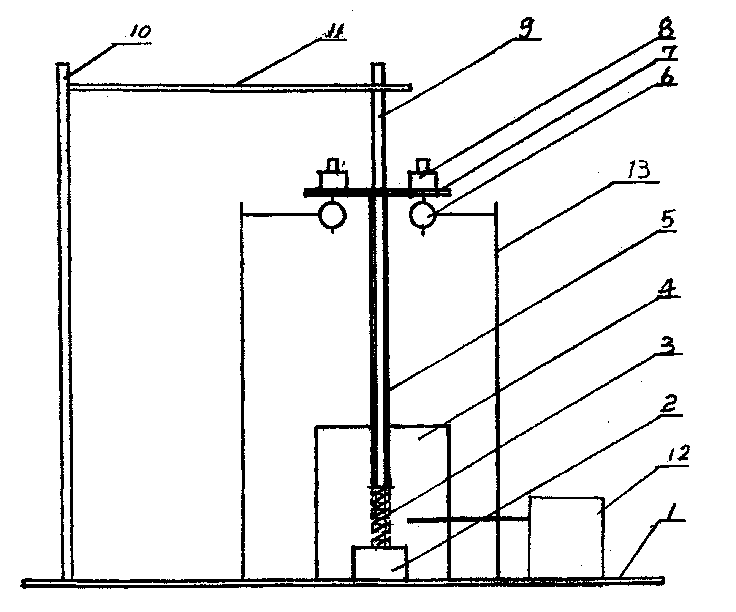

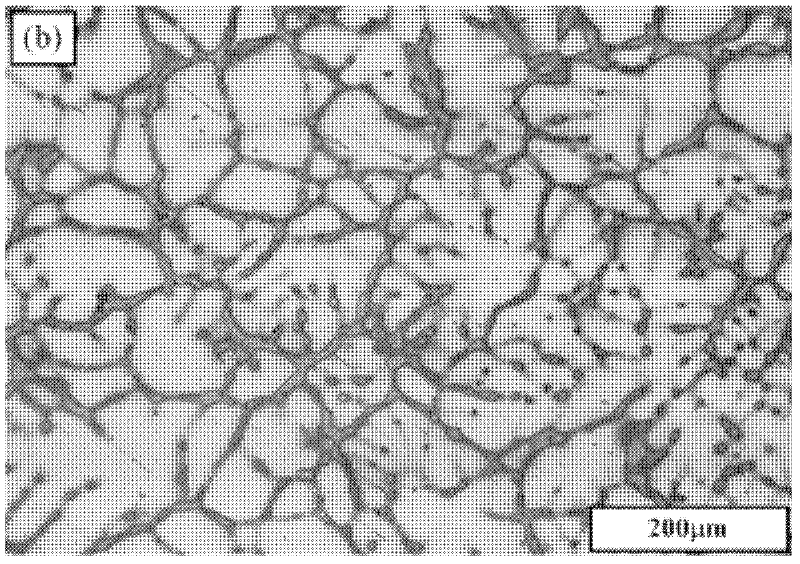

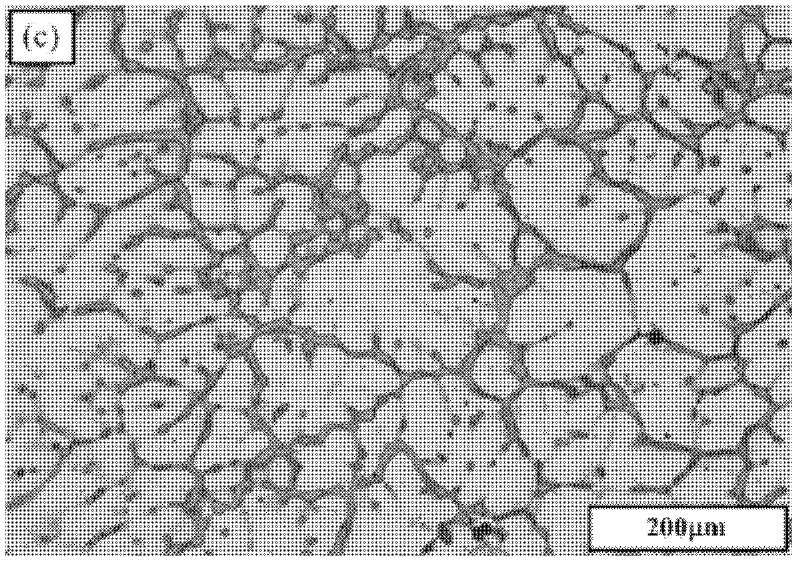

MC-MX containing precipitated phase high-speed train brake disc cast steel and preparation method

ActiveCN111304556ARaise room temperatureImprove mechanical propertiesMetallic materialsThermal stability

The invention discloses MC-MX containing precipitated phase high-speed train brake disc cast steel and a preparation method, and belongs to the fields of metal materials and preparation thereof. The problem of matching between room temperature toughness and high temperature mechanical properties of cast steel for high-speed train brake discs in the prior art is solved. The high-speed train brake disc cast steel comprises the chemical components of, by mass percent, 0.20-0.40% of C, 0.30-0.80% of Si, 0.50-2.00% of Mn, 0.50-2.00% of Cr, 0.50-2.00% of Ni, 0.40-1.60% of Mo, 0.01-0.30% of V, 0.01-0.20% of Nb, 0-0.015% of P, 0-0.010% of S, 0-0.010% of O, 0-0.015% of N and the balance Fe and inevitable impurities, wherein the total amount of Mn, Cr and Ni is 2.00-6.00%, and the total amount of Vand Nb is 0.02-0.40%. Through reasonable component design, organization structures and technology control, MC and MX precipitated phases which are fine, in dispersed distribution and excellent in heatstability are obtained, room temperature and high temperature mechanical properties of the high-speed train brake disc cast steel are comprehensively improved, the comprehensive requirements for theroom temperature and high temperature mechanical properties of the cast steel under the condition of high speed pure air emergency braking of a high-speed train are met, and the cast steel is suitablefor being used as cast steel brake discs of a high-speed train high in speed grade per hour.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

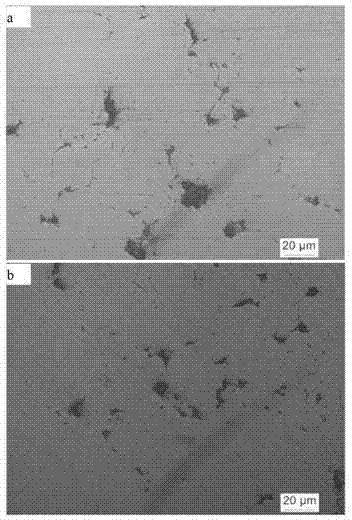

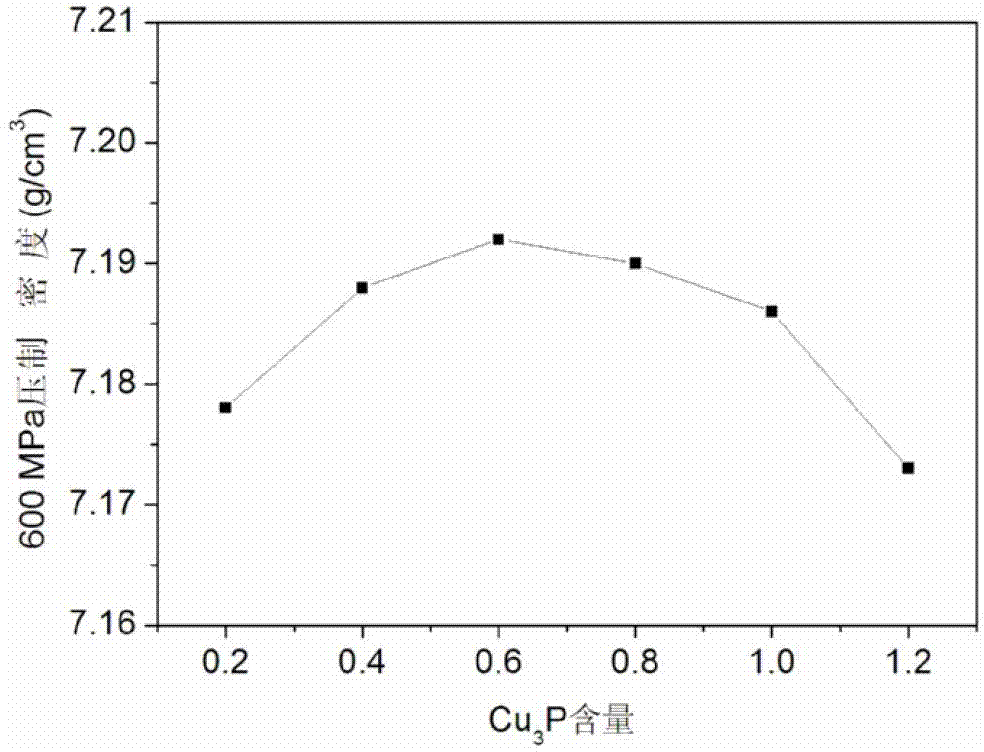

Additive activated low-alloy-content iron-based powder and preparation method of sintered materials

The invention discloses an additive activated low-alloy-content iron-based powder and preparation method of sintered materials. A small amount of superfine powders of copper and phosphorization cuprous are added into atomized iron powder or alloyed powder such as nickel. The preparation method of the iron-base alloy sintered materials is that the uniform mixed power is conducted single press and single sintering for one time, or the power is conducted pre-sintering in low temperature and then is carried out re-pressing and after-combustion. The superfine phosphorization cuprous power in the iron-based mixed powder can effectively improve pressing lubricity of iron powder, facilitate balling of hole gaps in matrix in a relative low temperature, and improve density of a sintering body. The density of products which are made by single press and single sintering can achieve 7.22g per cubic centimeter on the condition of 600MPa to 700MPa, density of products which are made by re-pressing and after-combustion can achieve 7.52g per cubic centimeter under the condition of 700MPa to 800MPa, and higher mechanical property is realized.

Owner:CENT SOUTH UNIV

Preparation method of high-toughness non-magnetic Ti(C,N)-based metal ceramic

The invention discloses a preparation method of high-toughness non-magnetic Ti(C,N)-based metal ceramic. The preparation method includes the following steps that firstly, TiO2 powder, W powder and active carbon powder serve as raw materials for burdening, high-energy ball milling is adopted, and an intermediate reaction product is obtained; then the obtained intermediate reaction product, TiN powder, Ni powder, Mo powder, Ti2AlN powder and AlN powder serve as raw materials for preparation of a mixture, wherein the mixture is prepared from components by mass parts: 24.0-30.3 parts of Ti, 11.5-16.1 parts of O, 14.0-19.3 parts of C, 1.9-2.3 parts of N, 18-32 parts of Ni, 10.0-11.1 parts of Mo, 4.0-4.5 parts of W and 0.4-0.6 part of Al; and adding of a forming agent, press-forming, removing ofthe forming agent and sintering are carried out, and the high-toughness non-magnetic Ti(C,N)-based metal ceramic is obtained. The sintered metal ceramic is not magnetic at room temperature and has high toughness and excellent comprehensive performance, there is no special requirement on production equipment, the energy consumption is reduced, and industrial application and popularization are facilitated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-work-hardening magnesium alloy and preparation method thereof

The invention relates to a high-work-hardening magnesium alloy and a preparation method thereof, which belong to the field of metal materials. The alloy comprises the following chemical components in percentage by mass: 2.3-4.5 percent of tin, 0.1-3.85 percent of zinc and the balance of magnesium and unavoidable impurities; the magnesium alloy can further comprise one or more of 0.01-2.0 percent by mass of silicon, 0.01-3.0 percent of antimony, 0.01-3.0 percent by mass of tellurium, 0.01-1.5 percent by mass of strontium, 0.01-2.0 percent by mass of manganese and 0.01-3.0 percent by mass of rare earth elements; and the rare-earth elements include neodymium, lanthanum, yttrium and cerium. The preparation method comprises the following steps of: melting magnesium, adding tin and zinc, and adding additive elements and rare earth elements; and blowing, stirring, refining, removing slag, standing, directly pouring a melt into an ingot, and thermally extruding into a tubular product, a section or a plate. The alloy has the advantages of high-work-hardening capability, high plastic molding, simple and reliable preparation process, easiness for popularizing and application, and the like.

Owner:JILIN UNIV

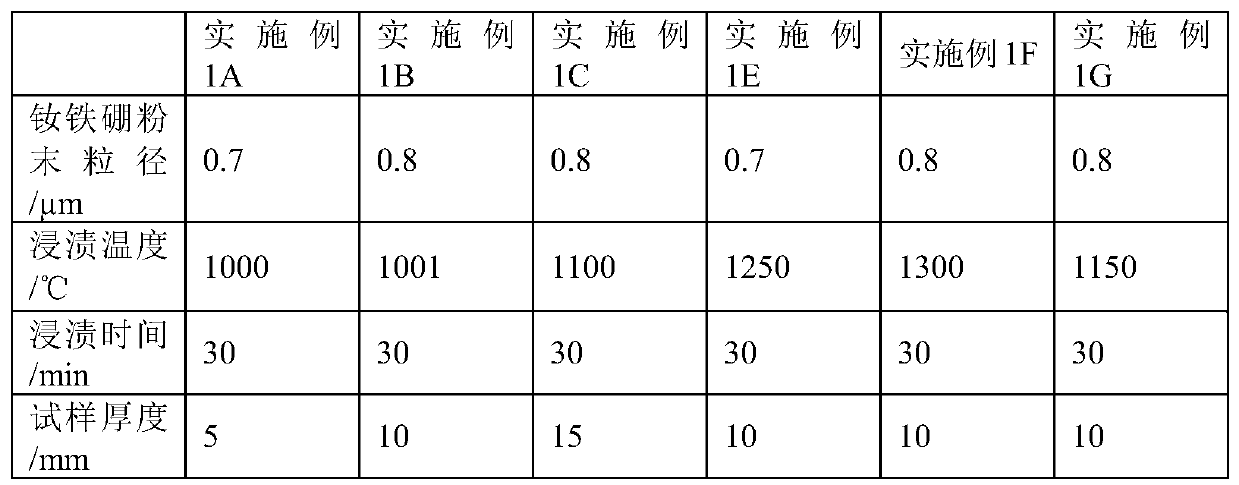

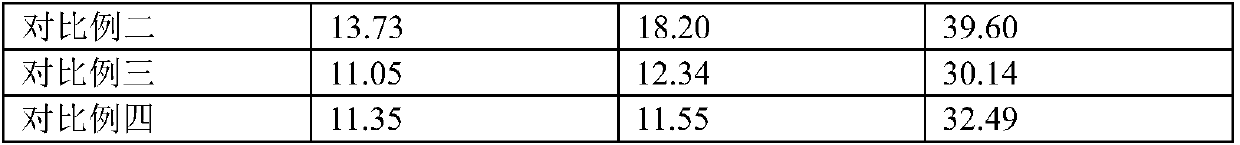

High-coercivity neodymium-iron-boron magnet preparation method and neodymium-iron-boron magnet thereof

PendingCN110111961AEnhance internal bondingReduce collapseInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMolten state

The invention relates to a neodymium-iron-boron magnet, and discloses a high-coercivity neodymium-iron-boron magnet preparation method and neodymium-iron-boron magnet thereof. The preparation method comprises the following steps: mixing neodymium-iron-boron powder and a low-melting-point metal adhesive for static pressure molding so as to obtain a compacted rough neodymium-iron-boron blank; mixingthe material containing heavy rare earth elements with the neodymium-iron-boron powder to heat to the molten state so as to obtain a heavy rare earth source melt; heating the rough neodymium-iron-boron blank in a protective atmosphere until the heating temperature is 200-250 DEG C higher than the melting point of the adhesive and keeping the temperature for 2-3h; then heating the S4-treated roughneodymium-iron-boron blank processed in S4 to 950 DEG C and immersing the rough neodymium-iron-boron blank in the heavy rare earth source melt, vacuumizing the rough neodymium-iron-boron blank and pressurizing the rough neodymium-iron-boron blank by piping in protective gas to the environment and taking out the rough neodymium-iron-boron blank after the immersing time so as to obtain the rough neodymium-iron-boron blank product; and performing surface treatment on the rough neodymium-iron-boron blank so as to obtain the finished product of the neodymium-iron-boron magnet. The obtained neodymium-iron-boron magnet has good grain boundary diffusion effect and higher coercivity than that of the neodymium-iron-boron magnet obtained by the existing grain boundary diffusion heavy rare earth element process.

Owner:宁波雄海稀土速凝技术有限公司

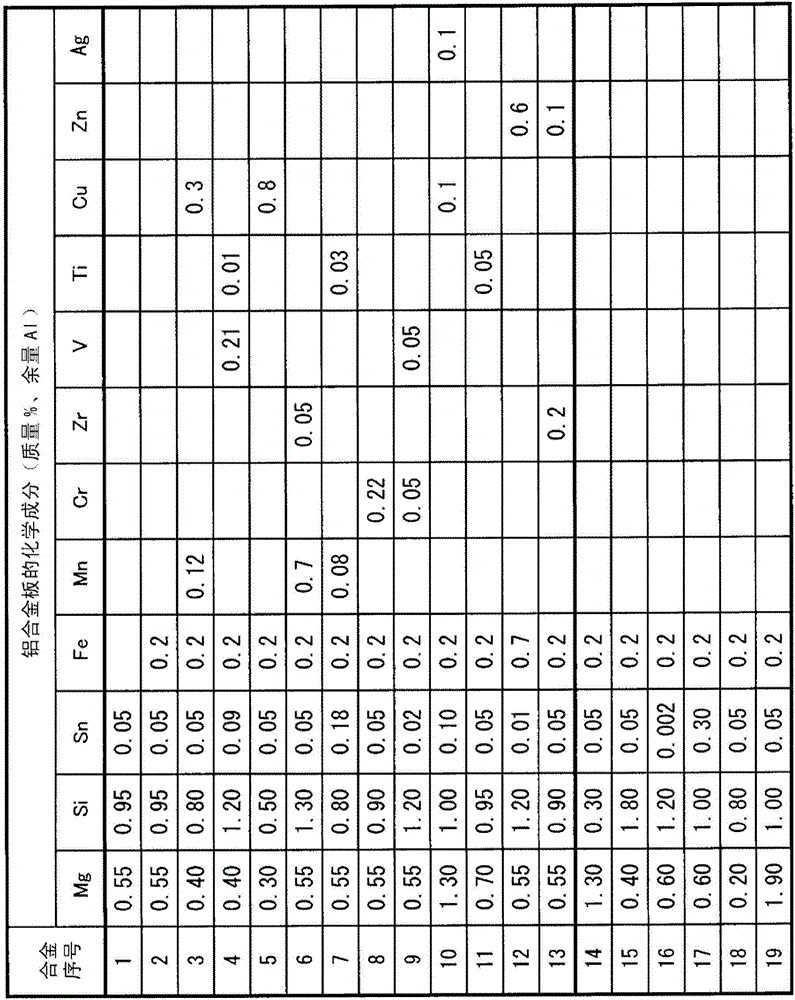

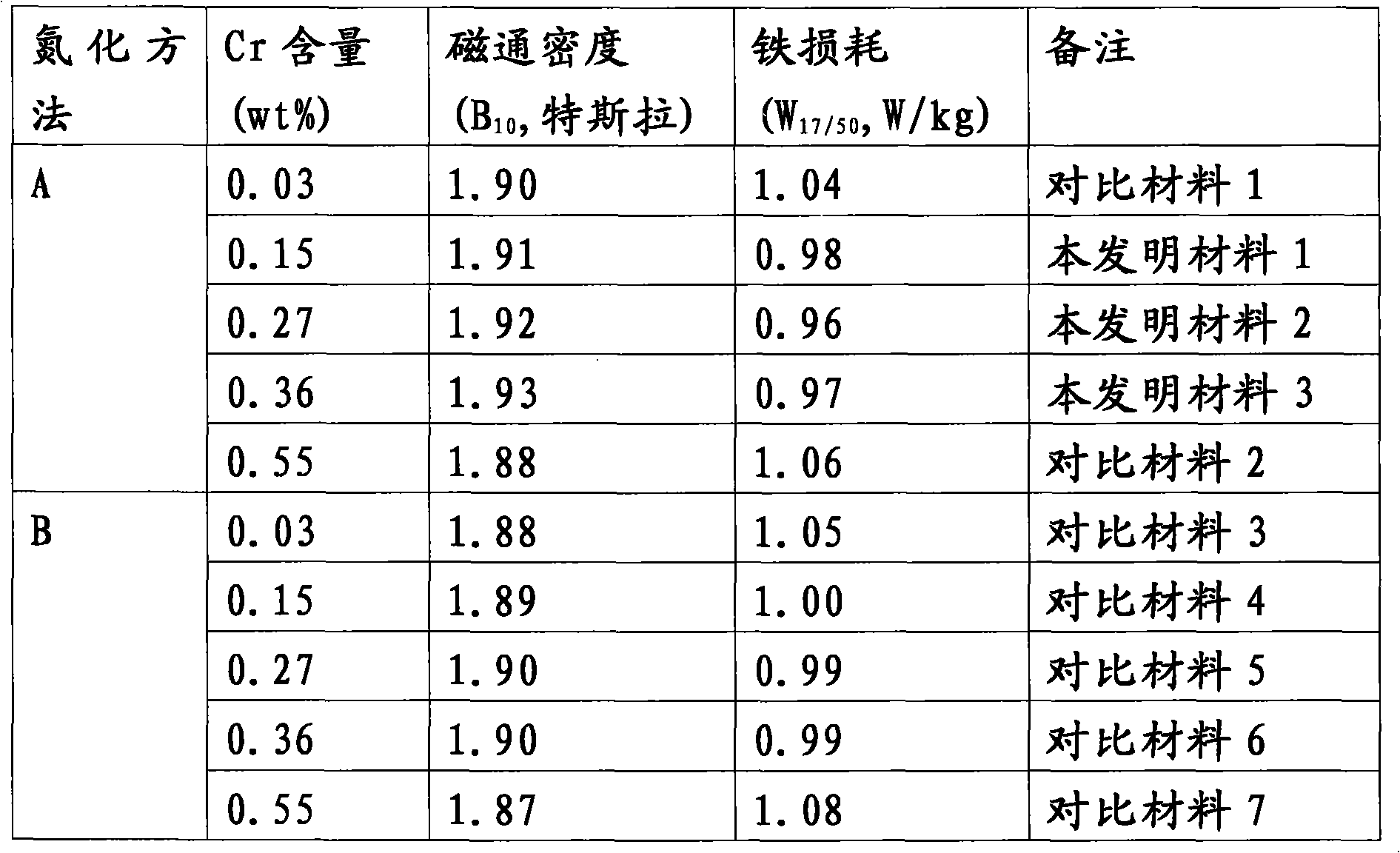

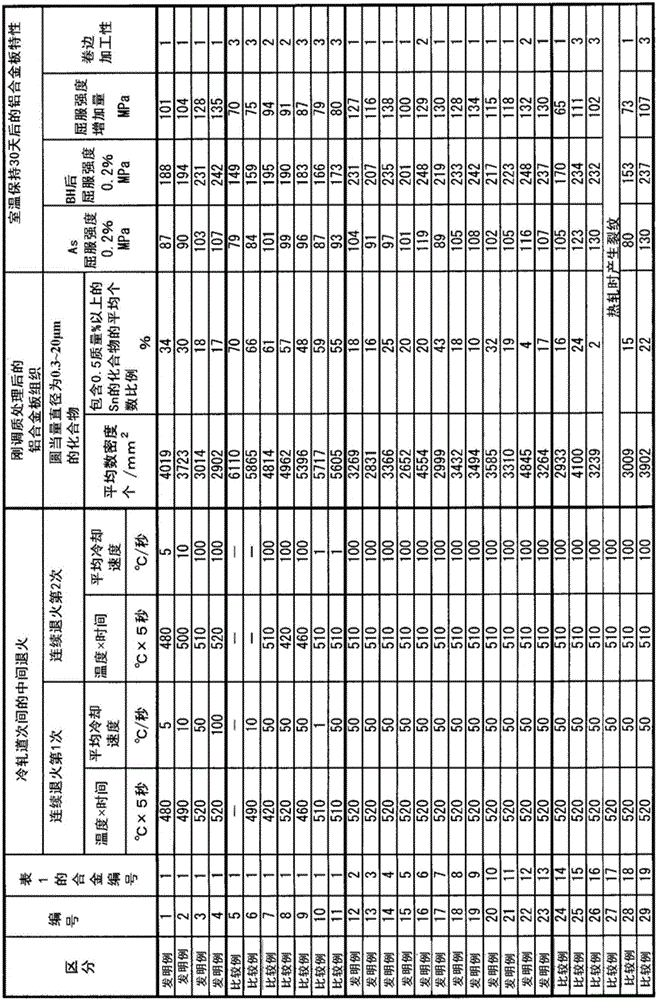

Aluminum alloy plate for molding

The present invention relates to an Al-Mg-Si-based aluminum alloy plate for molding which contains, in mass%, Mg 0.3-1.3%, Si 0.5-1.5% and Sn 0.005-0.2%, the remainder being Al and unavoidable impurities, wherein when the Sn content in the residue compound separated by a hot phenol residue extraction method and having a particle size exceeding 0.1 mu m is subtracted from the Sn content in the aluminum alloy plate, the resulting difference is a 0.005 mass% or greater quantity of Sn. The aluminum alloy plate for molding combines moldability and BH properties after long-term aging at room temperature.

Owner:KOBE STEEL LTD

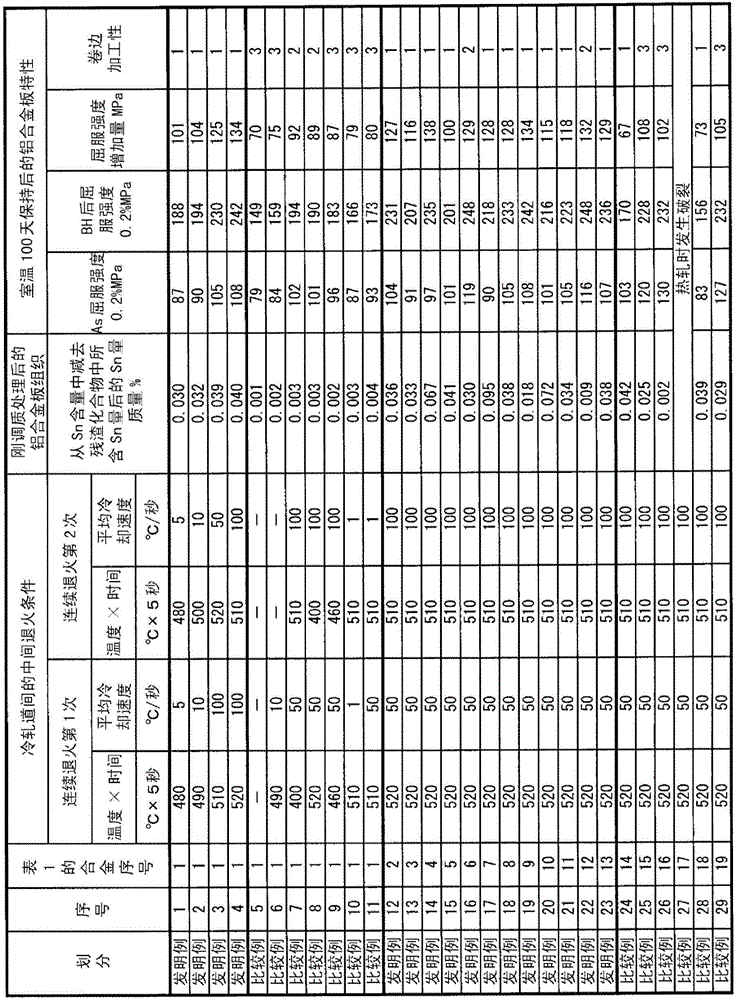

Aluminum titanate powder and its preparation method

The invention belongs to the field of ceramic raw material preparation, and particularly relates to an aluminum titanate powder and a preparation method thereof. The aluminum titanate powder is prepared from the following raw materials in percentage by weight: 40-50% of aluminum oxide, 40-60% of rutile titanium white, 1-10% of magnesium oxide, 0.5-5% of cerium oxide, 0.3-1.2% of ferric oxide, 1-5% of strontium carbonate and 0.2-2% of other additives. The aluminum titanate powder is a pre-synthesized titanic acid substance, and is beneficial to solid solution of multiple titanic acid substances. The spray drying is adopted and is beneficial to uniformity of the material. The element with approximate ionic radius to titanium is adopted, thereby being beneficial to replacement of the titanium ions. The commercially pure material is adopted, thereby lowering the manufacturing cost and being beneficial to industrial production.

Owner:泰晟新材料科技有限公司

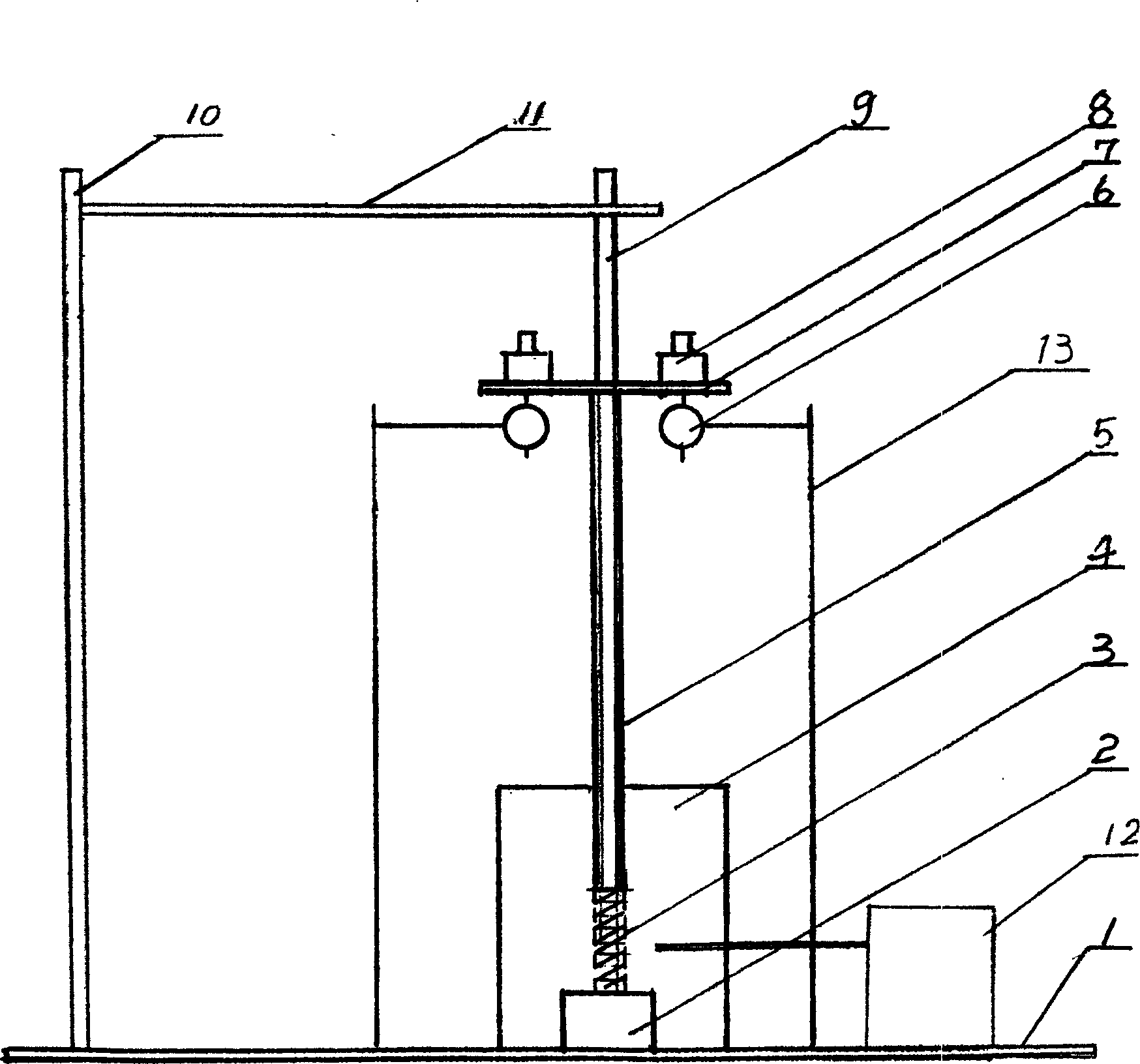

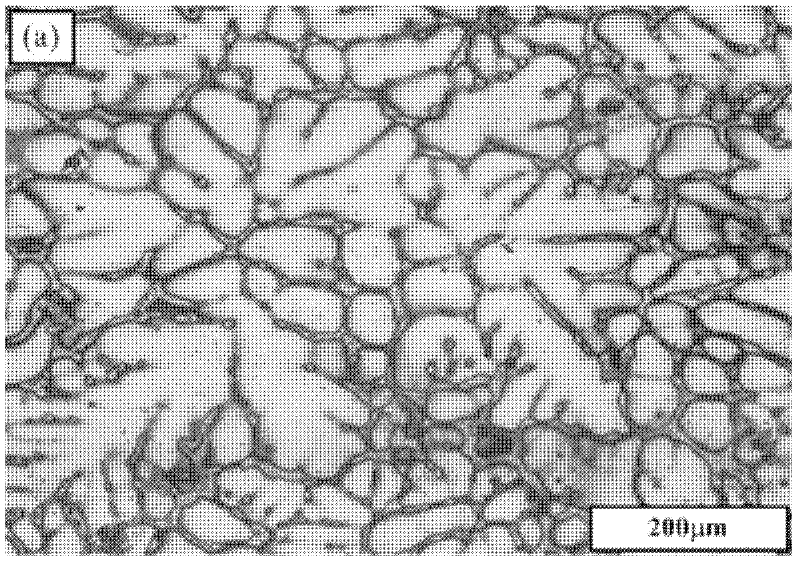

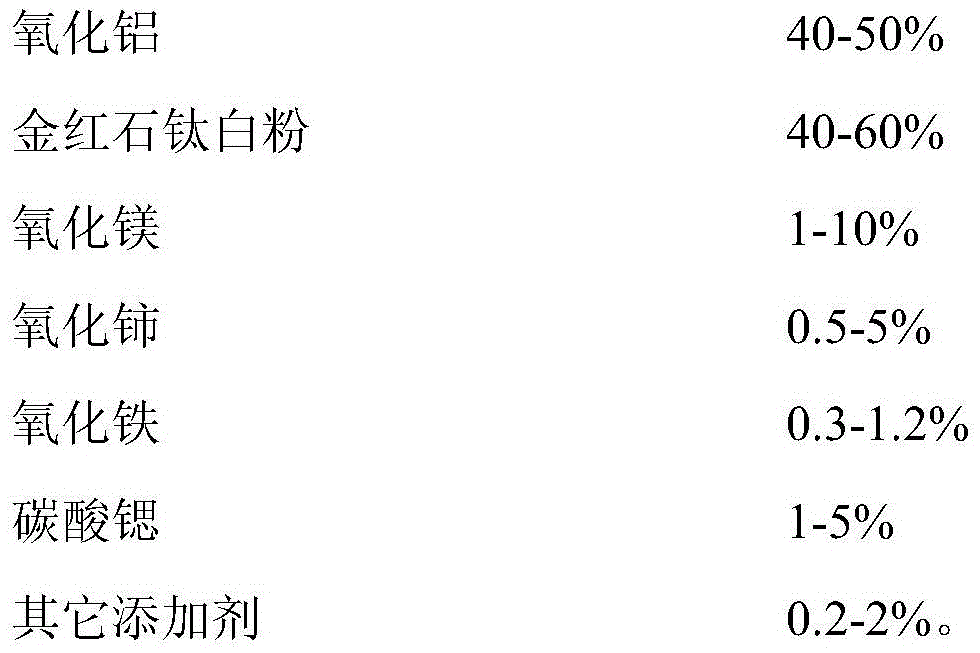

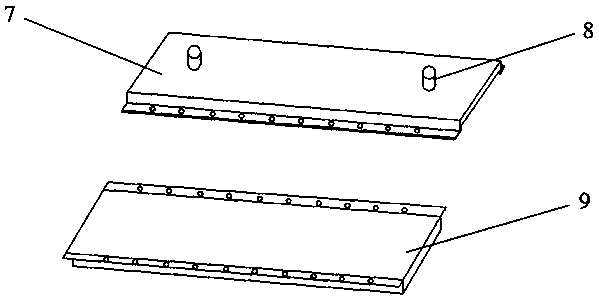

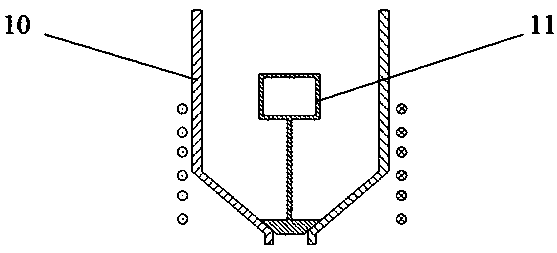

Continuous semi-solid slurry preparing device and method capable of inhibiting segregation of Sn element in ZCuSn10P1 alloy

The invention relates to a continuous semi-solid slurry preparing device and method capable of inhibiting the segregation of an Sn element in ZCuSn10P1 alloy and belongs to the technical field of material science. The continuous semi-solid slurry preparing device capable of inhibiting the segregation of the Sn element in the ZCuSn10P1 alloy comprises a cooling control device, an isothermal-like device and a pouring rotating disc device. In a solidification process, segregation inhibiting treatment is carried out on the alloy slurry, staged cooling control is carried out on melt through an inclined board melt cooling channel, and then, isothermal-like treatment is carried out on the slurry so as to promote the solid dissolving of the Sn element in a primary solid phase and reduce the concentration of the Sn element in a liquid phase. Finally, an even semi-solid melt structure with little inter-crystalline segregation is obtained.

Owner:KUNMING UNIV OF SCI & TECH

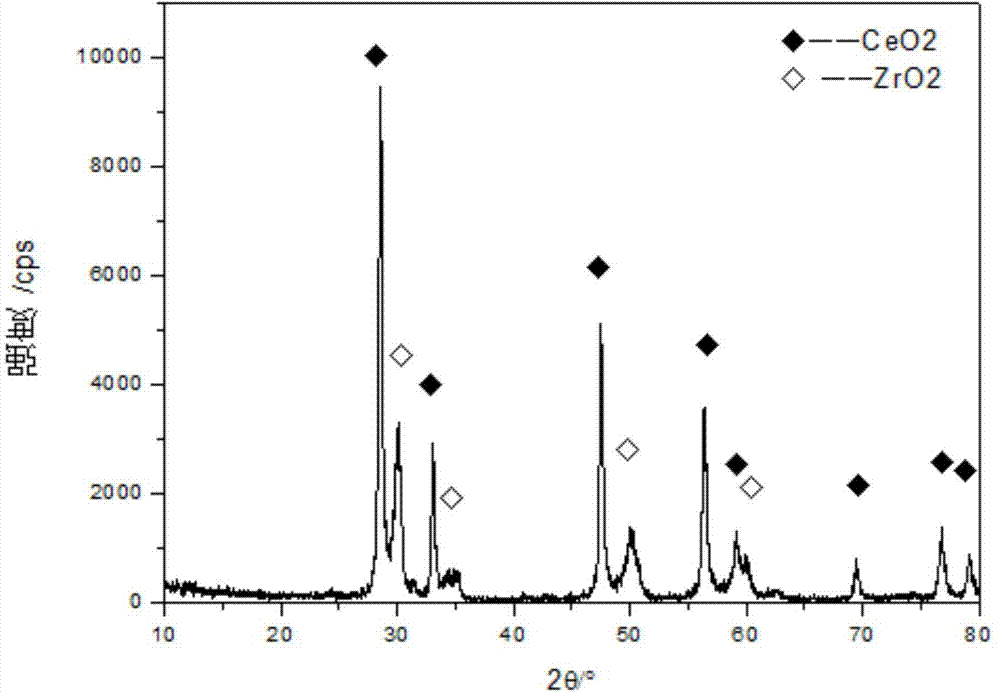

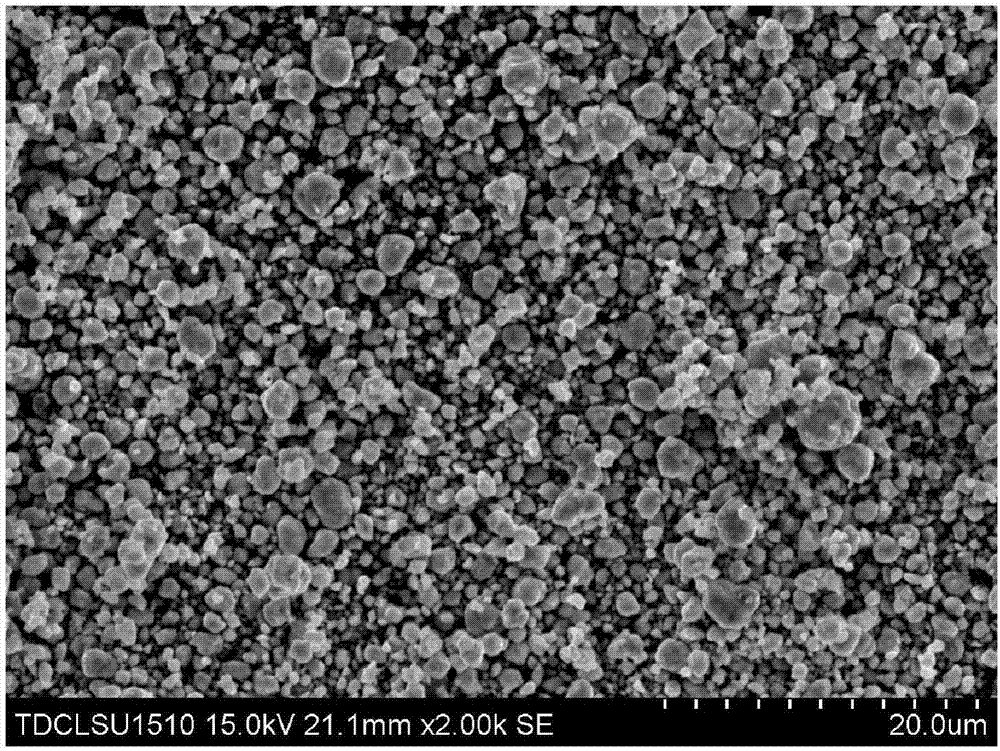

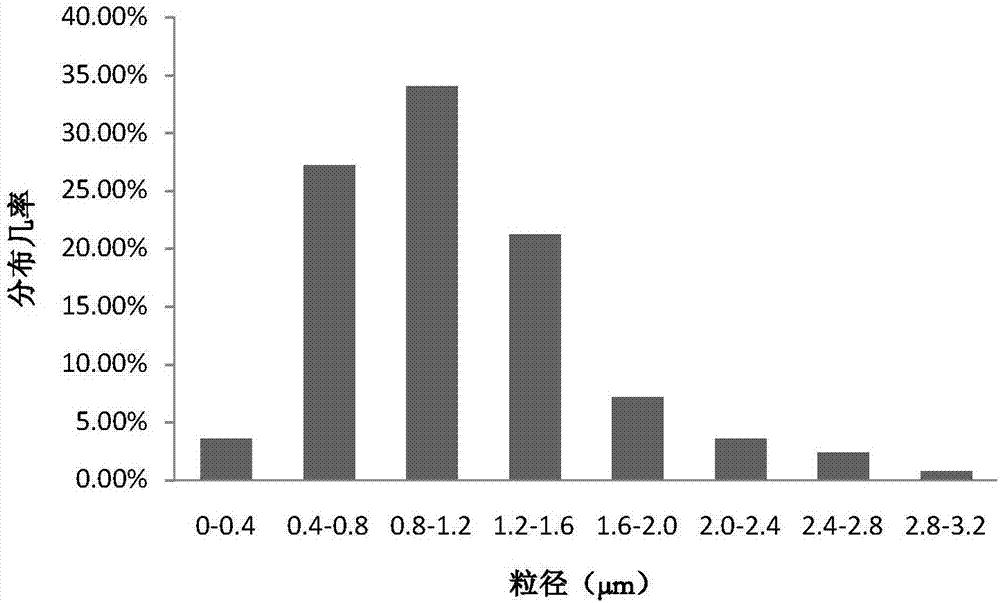

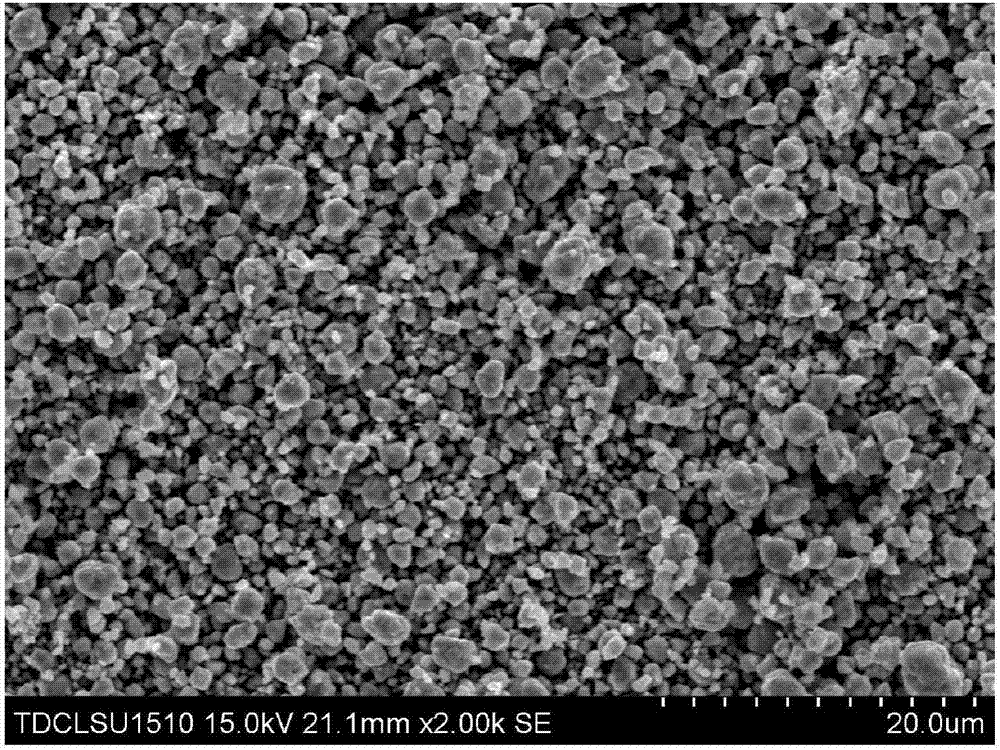

Preparation method of cerium-zirconium based solid solution

ActiveCN104492414AUniform particle sizeLarge particle sizeMetal/metal-oxides/metal-hydroxide catalystsCeriumBULK ACTIVE INGREDIENT

The invention discloses a preparation method of a cerium-zirconium based solid solution. The preparation method comprises the following sequential steps: (1) preparation of Ce<4+>; (2) preparation of active ingredient solution; (3) precipitation reaction; (4) surface modification; (5) roasting. The Ce<4+> is prepared firstly and then mixed with other rare earth ions and positively quadrivalent zirconium ions to obtain a mixed metal nitrate solution; as the mixed metal nitrate solution contains an organic complexing agent, the precipitation speed in the precipitation reaction process is controlled by virtue of complexing coordination of the organic complexing agent and the rare earth and zirconium ions, so that a precursor uniform and stable in particle size is obtained; the surface treatment is performed on the precipitate precursor by use of polyacrylic acid, and therefore, the agglomeration problem of particles in the roasting process is solved, and the pore diameter and the pore volume of the roasted product are increased, and consequently, the cerium-zirconium based solid solution catalytic material excellent in heat stability is obtained. The preparation method is suitable for the preparation of the solid solutions.

Owner:方复(上海)新材料科技有限公司

Ni-Mn-Mo-Si intermetallic compound porous material and preparation method thereof

The invention relates to a Ni-Mn-Mo-Si intermetallic compound porous material. The Ni-Mn-Mo-Si intermetallic compound porous material comprises the following components in parts by weight: 50-75 partsof Ni, 10-20 parts of Mn, 10-15 parts of Mo, and 5-15 parts of Si. The invention also relates to a preparation method of the abovementioned Ni-Mn-Mo-Si intermetallic compound porous material. The method comprises the steps of weighing Ni, Mn, Mo and Si powder; mixing; performing ball milling on the mixture to obtain mixed powder; overturning the materials and synchronously adding a stearic alcohol solution; drying the mixture in a vacuum drying box; screening the mixture through a 60-mesh screen after drying; taking the screen underflow; performing cold pressing; degreasing a cold-pressed blank; transferring the cold-pressed blank into a vacuum furnace for three-stage reaction sintering; and cooling the product to reach the room temperature after sintering. The prepared Ni-Mn-Mo-Si intermetallic compound porous material is stable in quality, high in repeatability, and applicable to the fields such as the field of filtering and the field of electrode materials.

Owner:CENT SOUTH UNIV

Alloy powder and preparation method thereof

The invention provides alloy powder and a preparation method thereof. The preparation method of the alloy powder comprises the following steps that complexing is carried out, wherein alloy components and citric acid are subjected to complexing in a solution, and a complexing solution is formed; gel forming is carried out, wherein polyethylene glycol is added into the complexing solution to form gel; drying is carried out, wherein the gel is subjected to drying treatment to obtain dried gel; and the dried gel is subjected to calcining treatment, reducing treatment and crushing treatment to obtain the alloy powder. The alloy powder and the preparation method thereof have the beneficial effects of being simple in process and capable of achieving precise matching and have large advantages on uniformity and economical efficiency; then, the obtained powder is subjected to short-time ball grinding on the basis of a sol-gel method, alloy elements can be subjected to solid solution better, and powder particles are smaller; compared with a traditional MA method, the alloy powder is closer to a spherical shape; and compared with a method of preparing prealloy powder through the general sol-gel method and then carrying out ball grinding, the particle size has a certain advantage.

Owner:TIANJIN UNIV

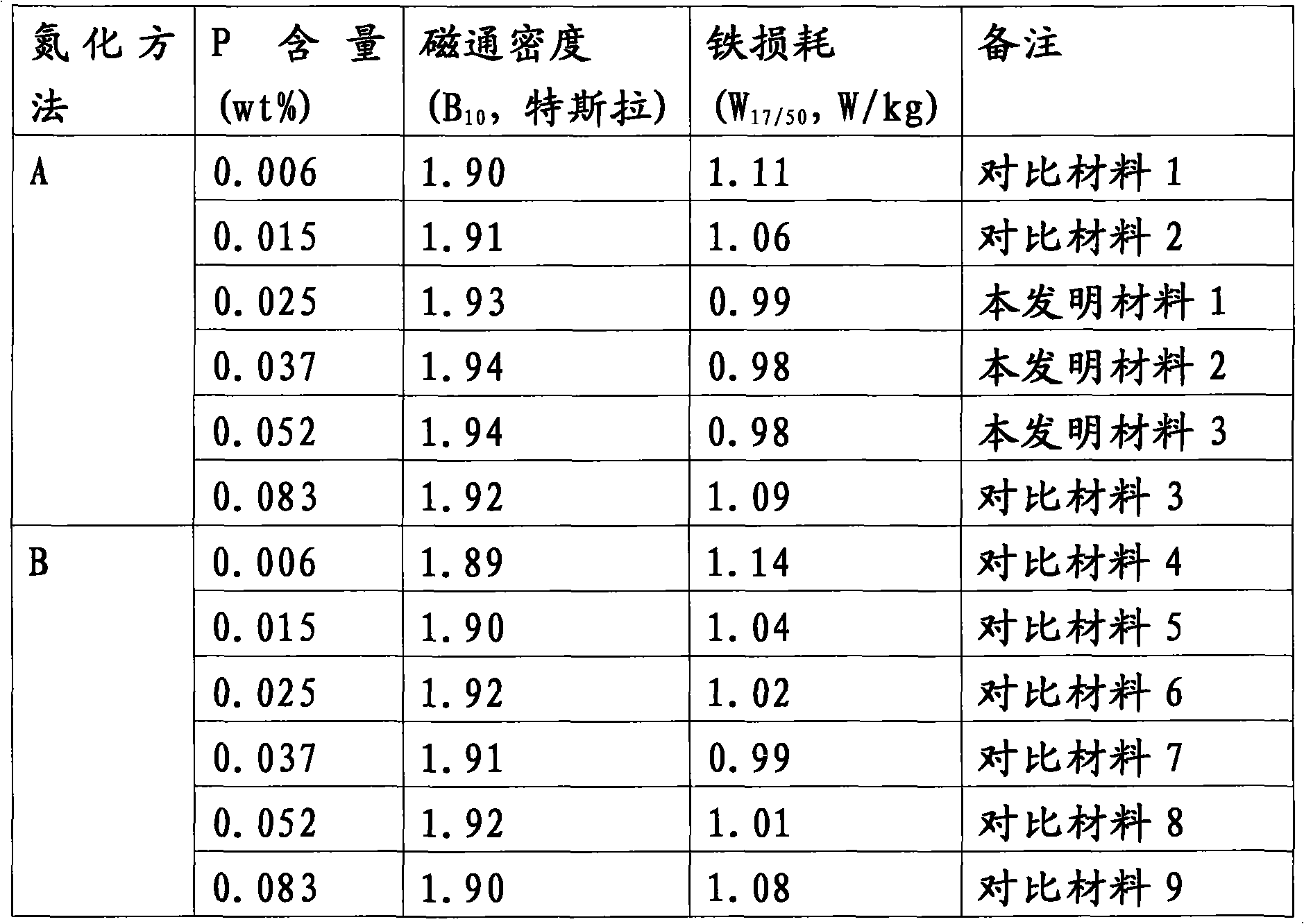

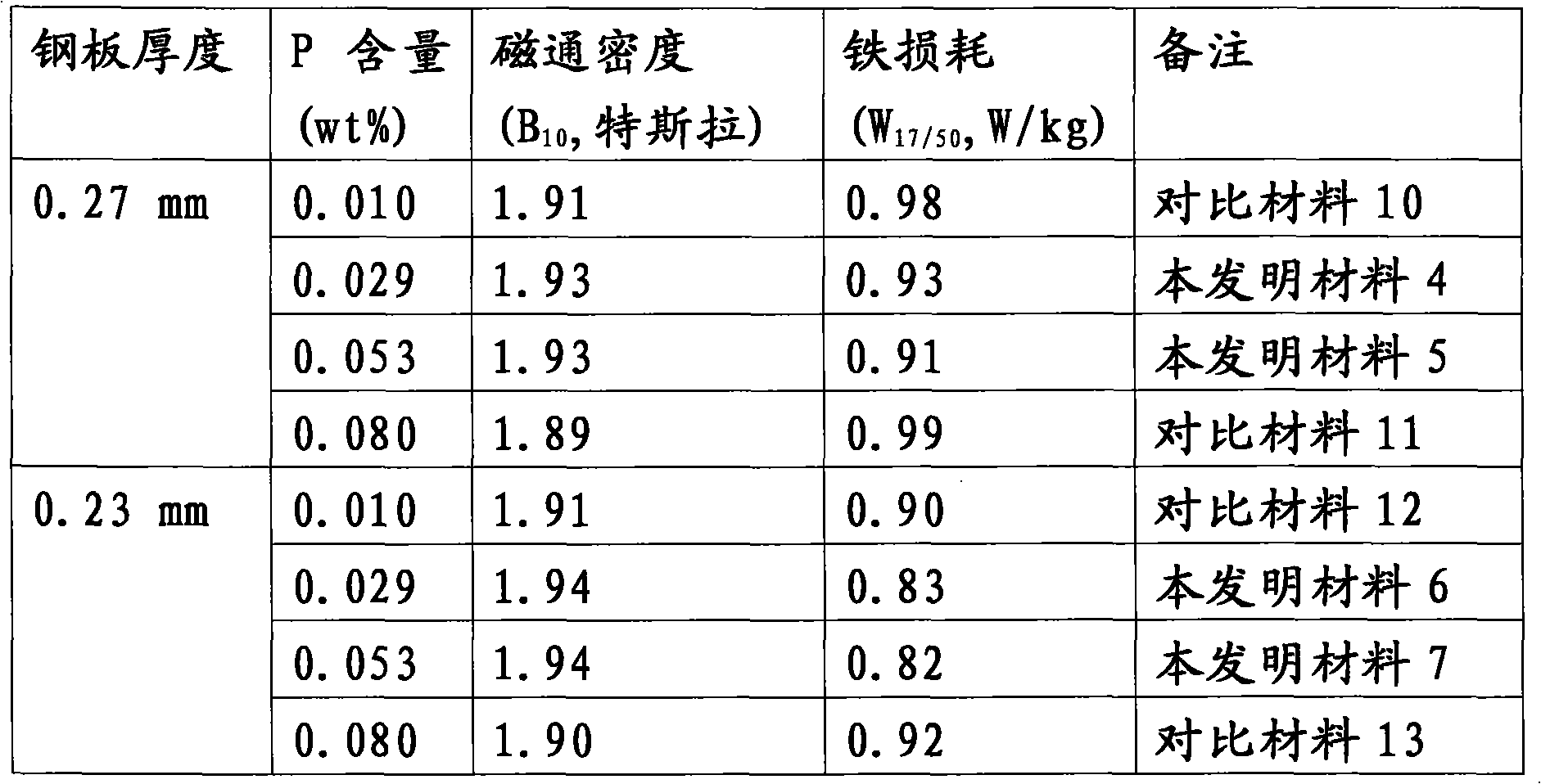

Method of manufacturing grain-oriented electrical steel sheets

Disclosed is a method of producing grain-oriented electrical steel sheets, which are used as iron core materials for electrical devices, including large-sized rotating machines such as various transformers and electric generators. More specifically, disclosed is a method for producing a grain-oriented electrical steel sheet having excellent magnetic properties, low iron loss, and high magnetic flux density, or at least one of these properties, the method comprising reheating a slab for the grain-oriented electrical steel sheet, hot-rolling the reheated slab to produce a hot-rolled sheet, optionally annealing the hot-rolled sheet, cold-rolling the resulting sheet, subjecting the cold-rolled sheet to simultaneous decarburization and nitriding annealing, and then subjecting the annealed sheet to secondary recrystallization annealing, wherein a vary small amount of N and S are added to the slab, such that AlN and MnS can be produced and completely dissolved in solution in the slab reheating.

Owner:浦项股份有限公司

High-chromium anti-crack wearable steel balls and preparation method thereof

InactiveCN106868421AIncreased thermal deformation activation energyImprove stabilityHardnessUltimate tensile strength

The invention discloses high-chromium anti-crack wearable steel balls which comprise the following components in percentage by weight: 0.15-0.25% of C, 1.5-2% of Si, 1-1.4% of Mn, 0.05-0.1% of Ni, 13-15% of Cr, 0.15-0.2% of Mo, 0.1-0.2% of Al, 0.1-0.3% of Cu, 0.01-0.02% of B, 0.05-0.07% of Ti, 0.3-0 .5% of Nb and the balance of Fe, wherein the expression that Mn plus 9.7Ni plus 13.4Ti is greater than 2% and smaller than 3.2% is met. The invention further discloses a preparation method of the high-chromium anti-crack wearable steel balls. Through the element interaction in conjunction with the limitation on a proper annealing temperature and time, the steel balls can maintain a high hardness, high strength and corrosion resistance while having a good toughness and impact resistance, and can also be prevented from fracture.

Owner:芜湖市永帆精密模具科技有限公司

Aluminum alloy sheet for forming

The present invention pertains to an Al-Mg-Si based aluminum alloy sheet for forming, that contains 0.2-2.0% of Mg, 0.3-2.0% of Si, and 0.005-0.3% of Si (all amounts given with respect to mass), the balance comprising Al and unavoidable impurities, wherein the aluminum alloy sheet for forming is characterized in that the structure of the aluminum alloy sheet is such that the average number density of compounds having a circle-equivalent diameter within a range of 0.3-20 [mu]m as measured by SEM at 500 times magnification is more than 0 / mm2 but not more than 5,000 / mm2, and of the compounds measured by SEM, the average count ratio of compounds that contain 0.5% by mass or more of Sn as identified using an X-ray spectrograph, is 0% or more but less than 50%. This aluminum alloy sheet for forming exhibits high BH properties and good workability.

Owner:KOBE STEEL LTD

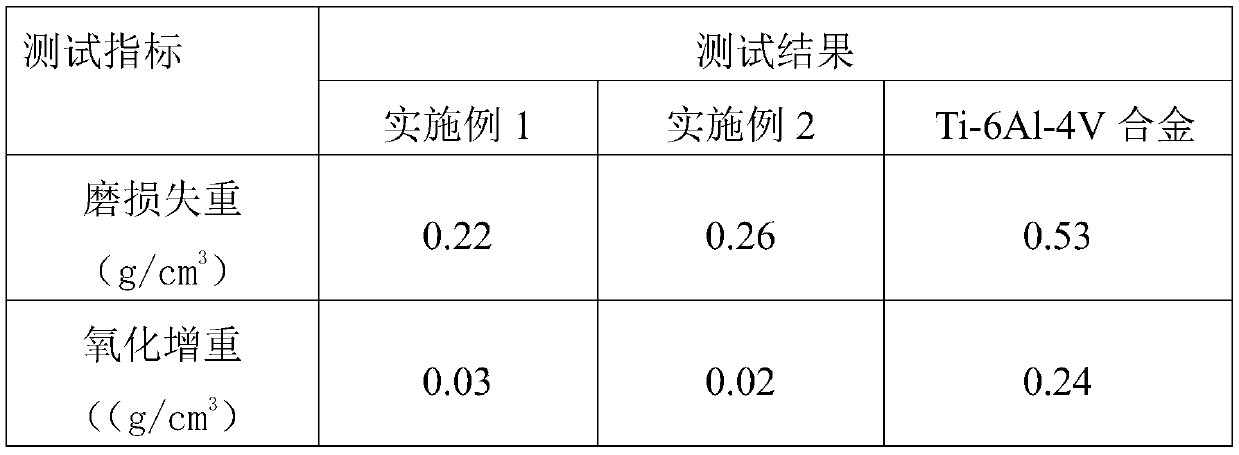

Method of forming TiB2 particle-reinforced high-entropy alloy coating on titanium alloy

ActiveCN111020579AImprove wear resistanceImprove antioxidant capacityVacuum evaporation coatingSputtering coatingHigh entropy alloysOxidation resistant

The invention discloses a method of forming a TiB2 particle-reinforced high-entropy alloy coating on titanium alloy. The method comprises the steps that a Co film, an Ni film and a Cr film are formedon the surface of a titanium alloy substrate in advance in sequence, then Co, Cr, Cu, Fe, Ni, Mo, Mn and TiB2 mixed powder covers the titanium alloy substrate with the pre-formed film in a fusion mode, and therefore the TiB2 particle-reinforced CoCrCuFeNiMoMn high-entropy alloy coating can be obtained. The coating which is obtained according to the method has the advantages of being high in wear resistance and high in oxidation resistance.

Owner:GUIZHOU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com