Elastic copper-titanium alloy and preparation method thereof

A copper-titanium alloy, elastic technology, applied in the field of elastic copper-titanium alloy and its preparation, can solve the problems of high price, poor working stability, shortened service life, etc., achieve high dislocation density and activation energy, and improve resistance to stress relaxation properties, promotion of formation and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing an elastic copper-titanium alloy, comprising the following steps:

[0025] Corresponding to the elemental composition of the elastic copper-titanium alloy, the metal raw materials are melted and cast to obtain ingots;

[0026] performing hot rolling, first cold rolling, solution treatment, third cold rolling, second aging treatment and annealing treatment on the ingot in sequence to obtain an elastic copper-titanium alloy;

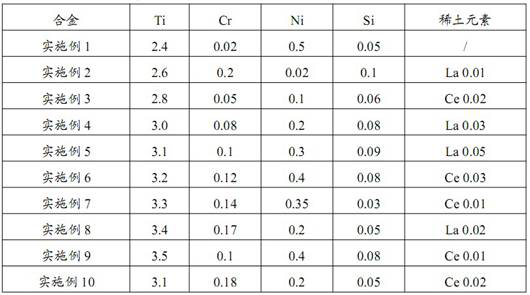

[0027] In terms of mass percentage, the element composition of the elastic copper-titanium alloy includes Ti: 2.4-3.5%, Cr: 0.02-0.2%, Ni: 0.02-0.5%, Si: 0.05-0.1%, rare earth elements 0-0.05% %, the rest is Cu.

[0028] The invention corresponds to the composition of the elastic copper-titanium alloy, and melts and casts various metal raw materials to obtain ingots. In the present invention, in terms of mass percentage, the element composition of the elastic copper-titanium alloy includes Ti: 2.4-3.5%...

Embodiment 1

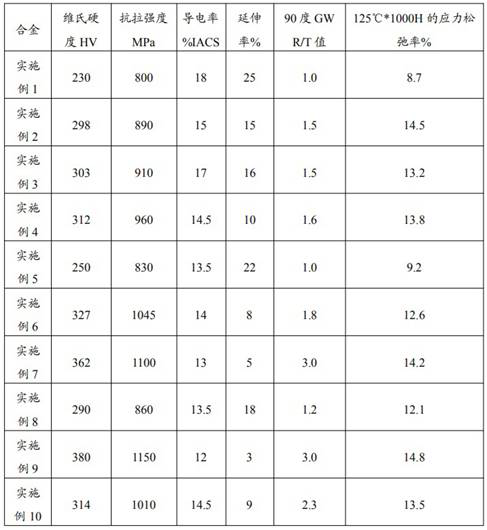

[0052] The composition of the alloy is shown in Example 1 of Table 1.

[0053] 1. Melting: Add electrolytic copper, pure titanium, copper-chromium alloy, copper-silicon alloy and metal nickel into the vacuum melting furnace, raise the temperature to 1250°C, and after the melt is completely melted, add covering agent and keep it warm for 10 minutes. After airing and removing impurities, keep it warm for 8 minutes, then fully stir it, let it stand for 5 minutes, and then cast it out of the furnace. The casting temperature is 1230°C.

[0054] 2. Hot rolling: heat the above-mentioned alloy ingots in a stepping box furnace at a temperature of 900°C and a holding time of 3 hours, then carry out hot rolling with a rolling rate of 90% and control the final rolling temperature at 760°C , followed by water cooling.

[0055] 3. The first cold rolling: the alloy plate after face milling is first rolled, and the cold rolling rate is 70%.

[0056] 4. On-line high-temperature rapid solutio...

Embodiment 2~10

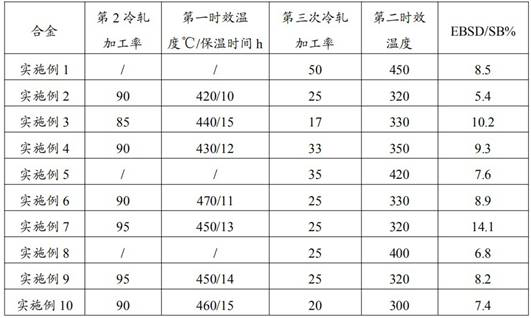

[0061] The difference from Example 1 lies in the elemental composition (see Table 1 for details) and the preparation process, wherein the preparation process is shown in Table 2, and the conditions of the unlisted parts are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com