Patents

Literature

525results about How to "Promote homogenization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

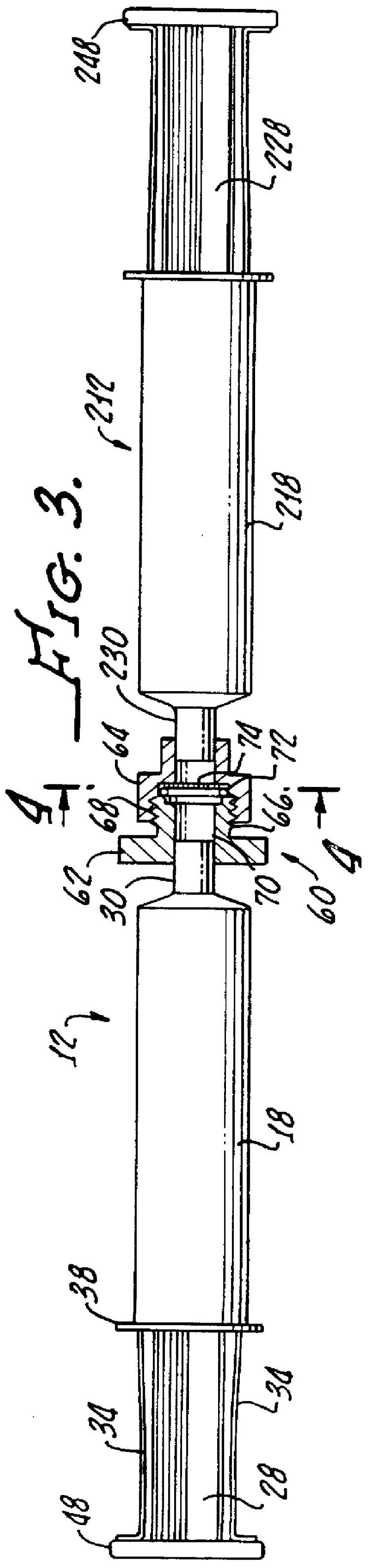

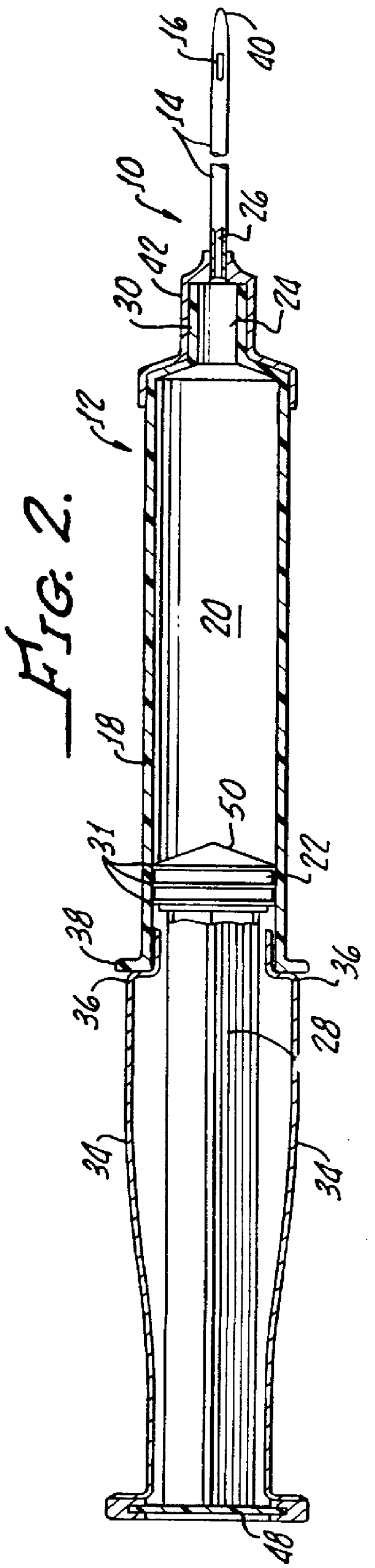

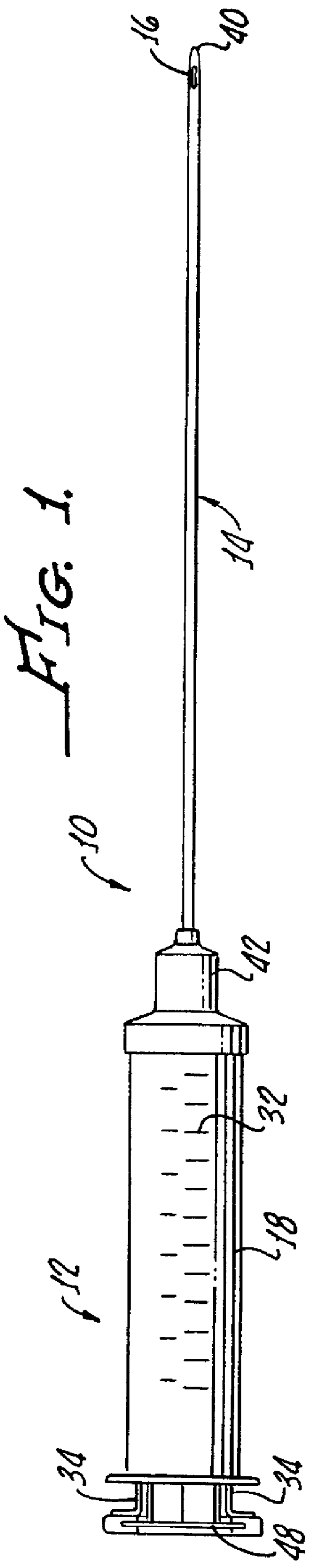

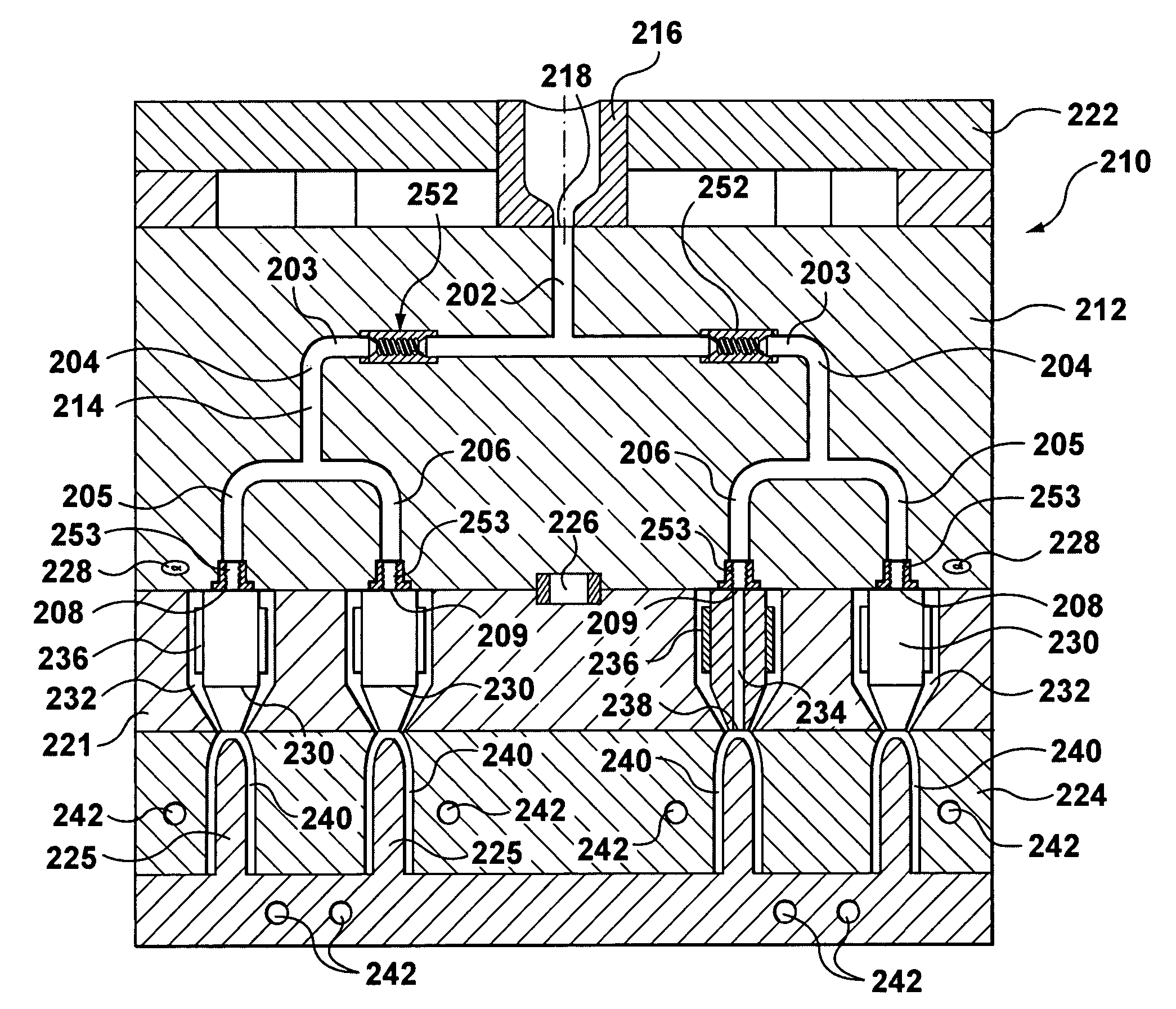

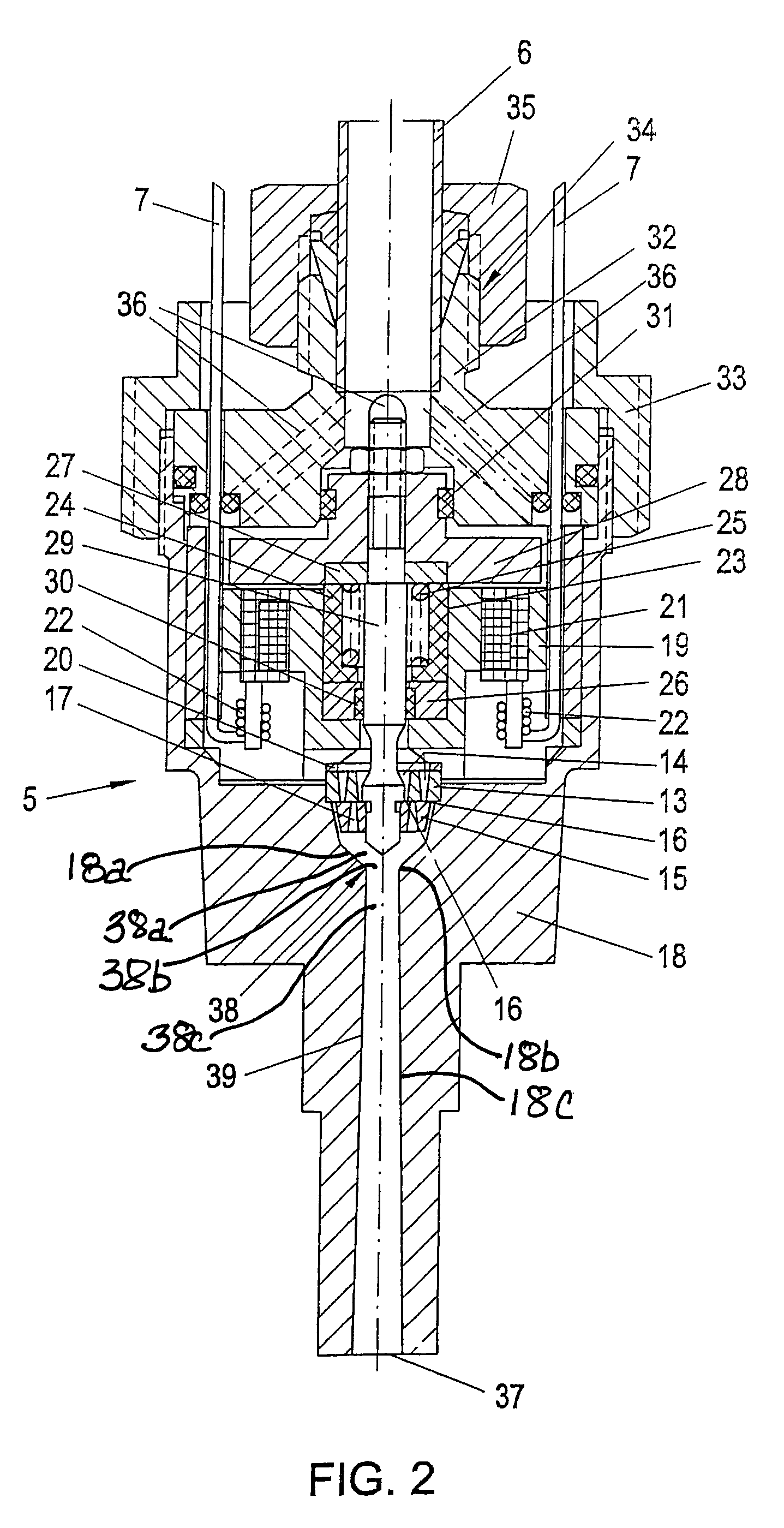

Devices for harvesting and homogenizing adipose tissue containing autologous endothelial cells

InactiveUS6020196AExpand the populationEasy to operateBioreactor/fermenter combinationsElectrotherapyAmbient pressureWhite adipose tissue

Disclosed herein are methods for harvesting adipose tissue so as to preserve an increased population of viable microvascular endothelial cells. Adipose tissue containing microvascular endothelial cells is harvested using a collection apparatus incorporating an elongate cannula having apertures with tissue cutting edges. A sub-ambient pressure is applied to a lumen in the cannula to draw the adipose tissue through the aperture where it is then severed using the cutting edge to disrupt the connective adipose matrix. This harvesting provides a cleaner, more homogeneous sample of adipose tissue, thereby increasing the population of viable microvascular endothelial cells obtained through further processing. Rapid and easy methods for the further homogenization of the harvested adipose tissue are also disclosed.

Owner:EDWARDS LIFESCIENCES CORP

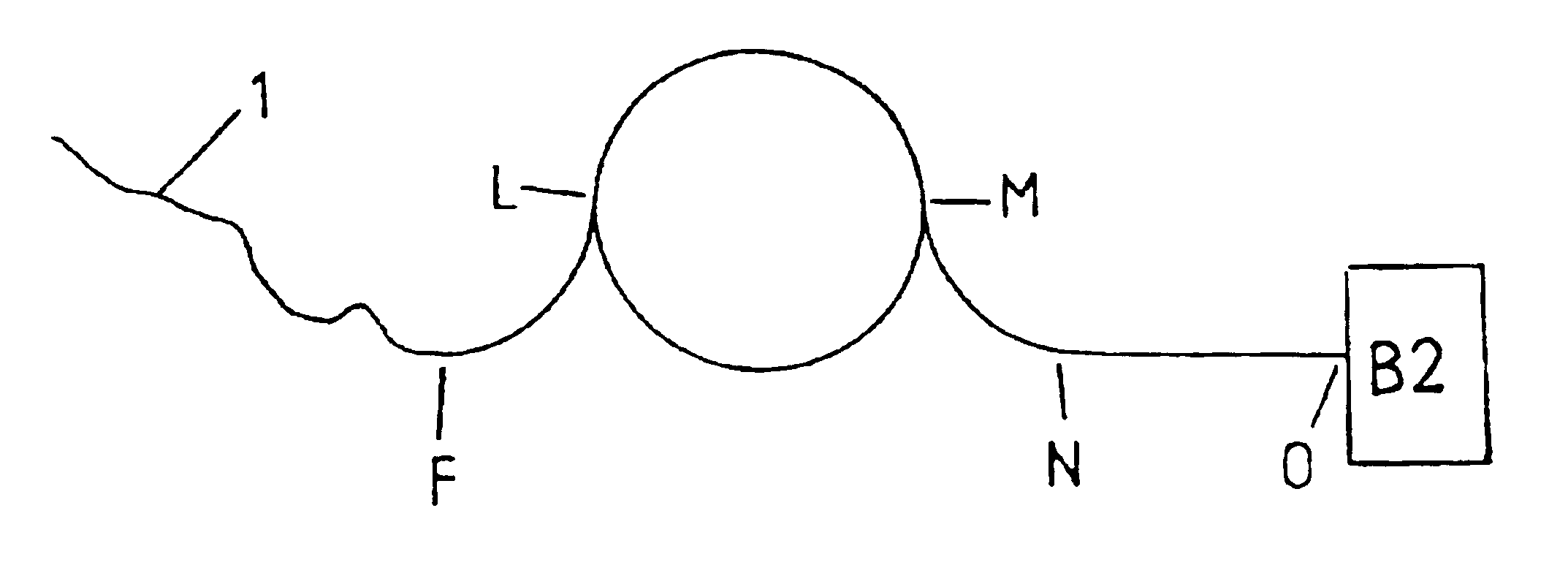

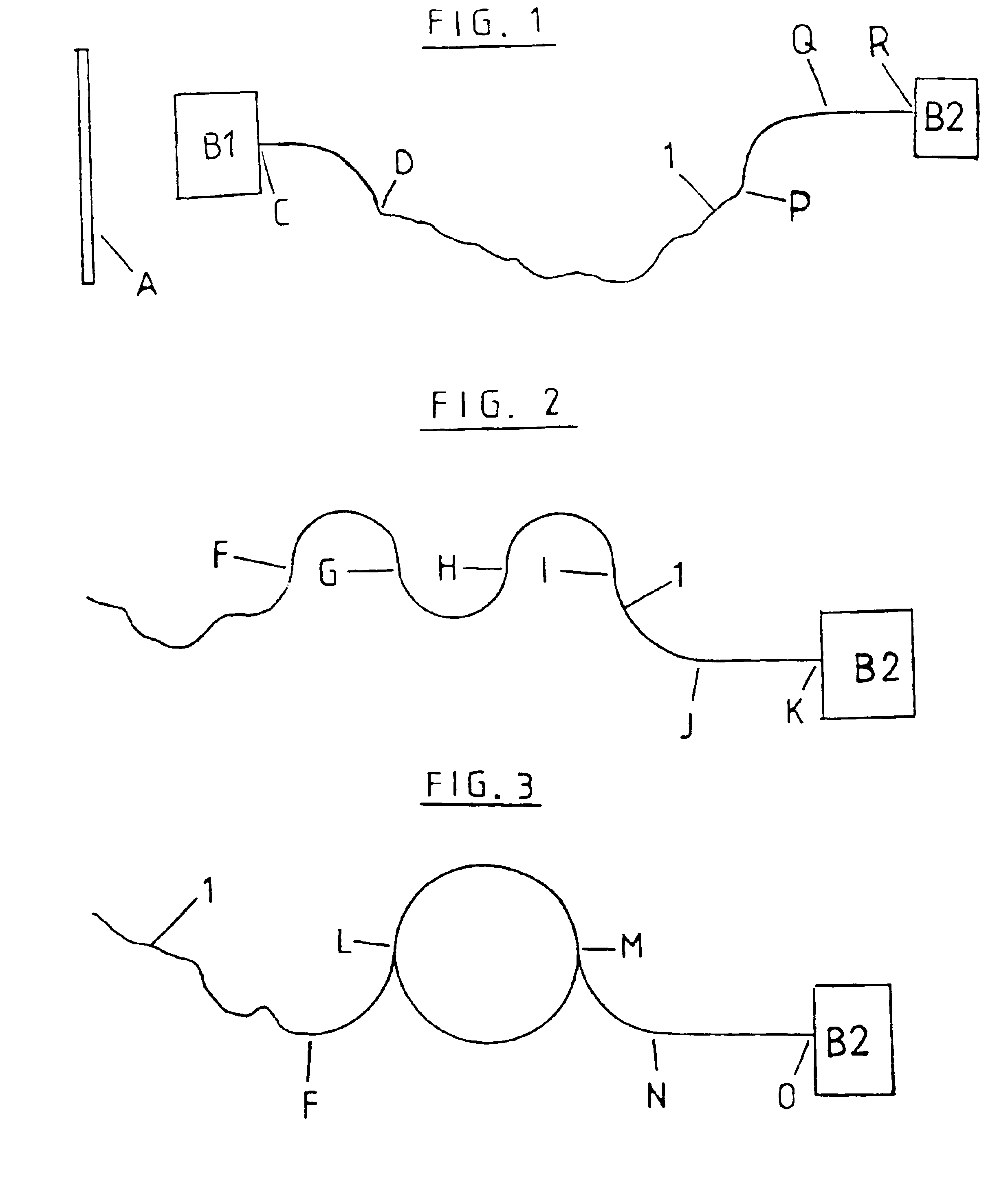

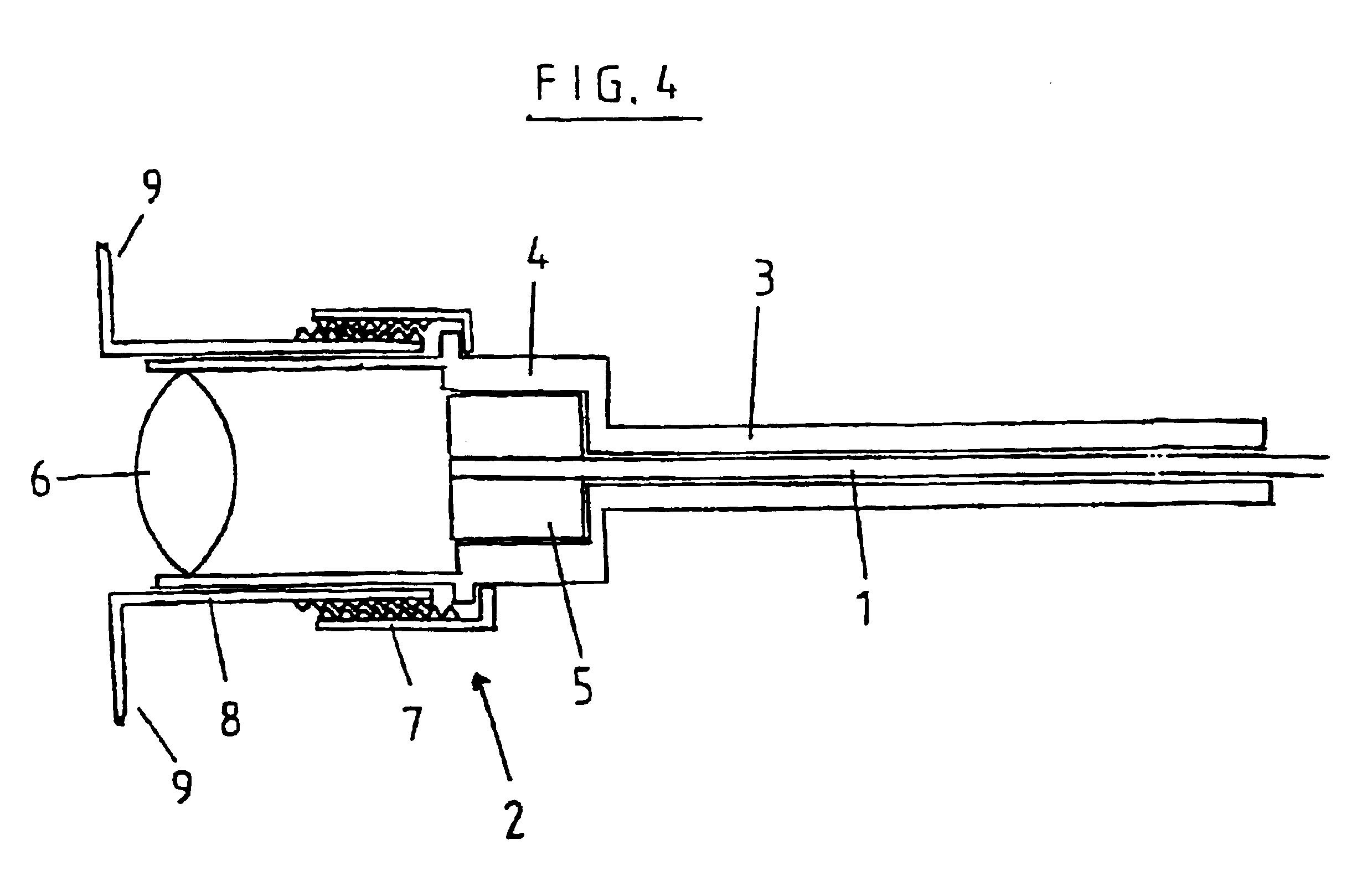

Device and method for transmitting light over an optical fiber

InactiveUS6947635B2Suppress changeEasily measureCoupling light guidesOptical waveguide light guideOptical measurementsMode mixing

The invention relates to a method and device for transmitting light over a fat fiber (1) between optical components (B1; B2) of an optical measuring device, which are provided at a launching end (C) and at an extraction end (R; K; O) of the fat fiber (1). Said measuring device comprises a guiding means for the curved rigid guidance of a first partial section (PQ; FGHI; IJ; FL; LM; MN) of the fat fiber (1). If the radius of curvature of the curved guidance falls below a first limit, the light beam profile of the fat fiber (1) is homogenized by a mode mixing. In order to diminish the effect on the transmitted light caused by a permitted change in position of the fat fiber (1), a stiffening means, which is rigidly connected to the guiding means, is provided for rigidly guiding a second partial section (QR; JK; NO) of the fat fiber (1). Said second partial section connects to the first partial section (PQ; FGH; IJ; FL; LM; MN) and extends essentially up to the optical component (B2) located at the extraction end (R; K; O), whereby the entire length of the first and second partial section is at least provided with a length that renders the extraction end (R; K; O) of the fat fiber (1) mechanically stable.

Owner:INSTR SYST

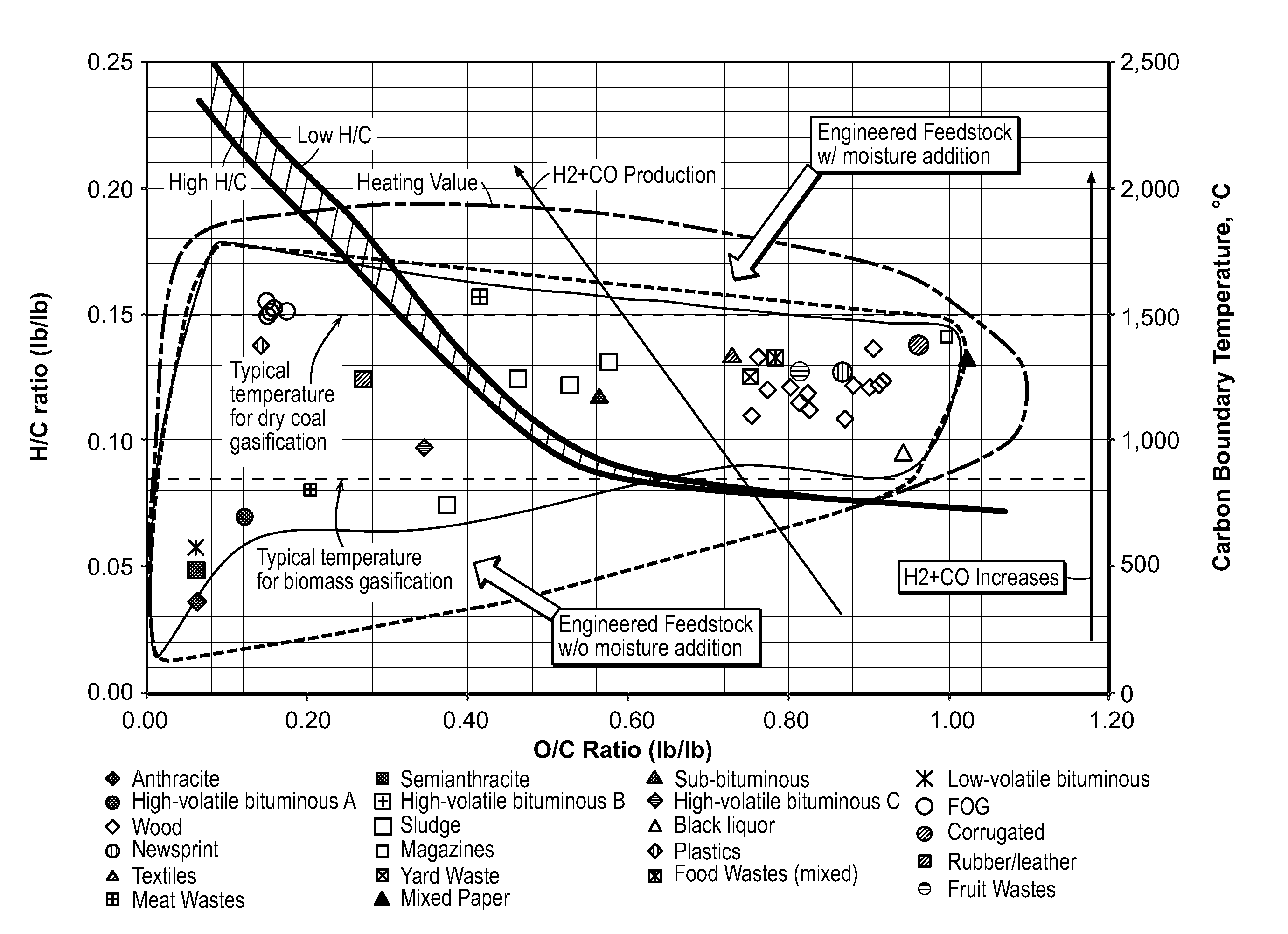

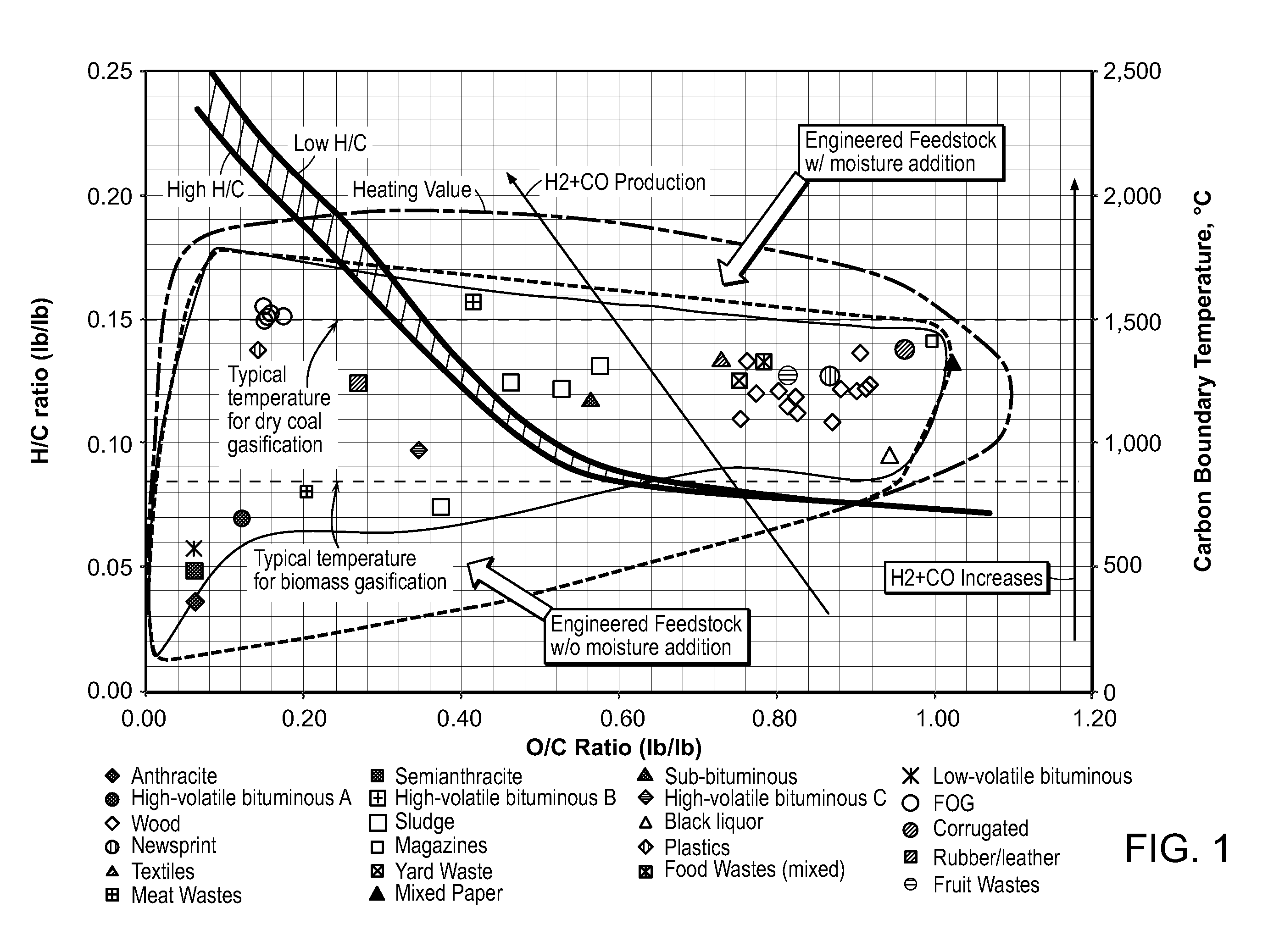

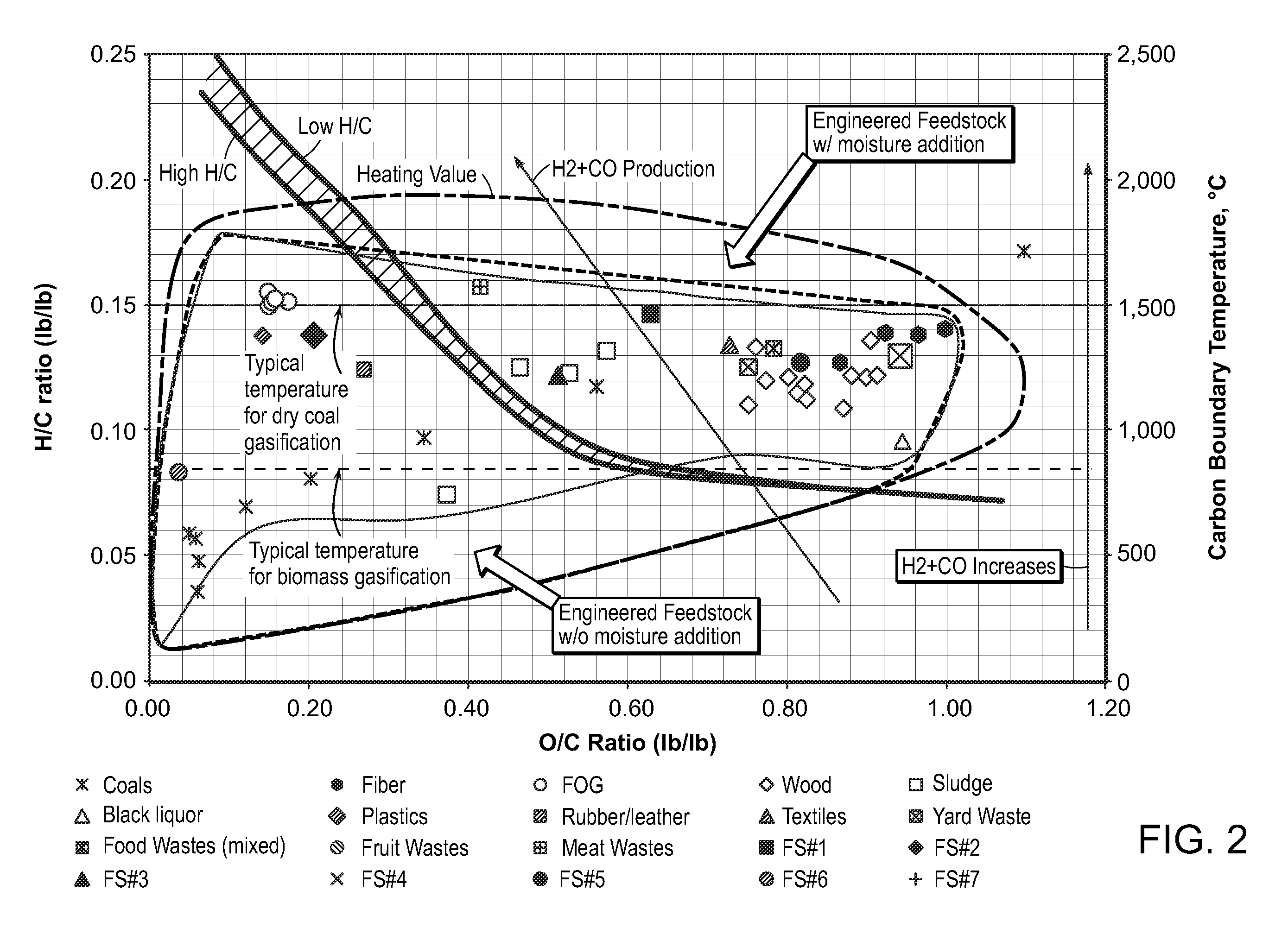

Engineered fuel feed stock

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels.

Owner:REPOWER IP LLC

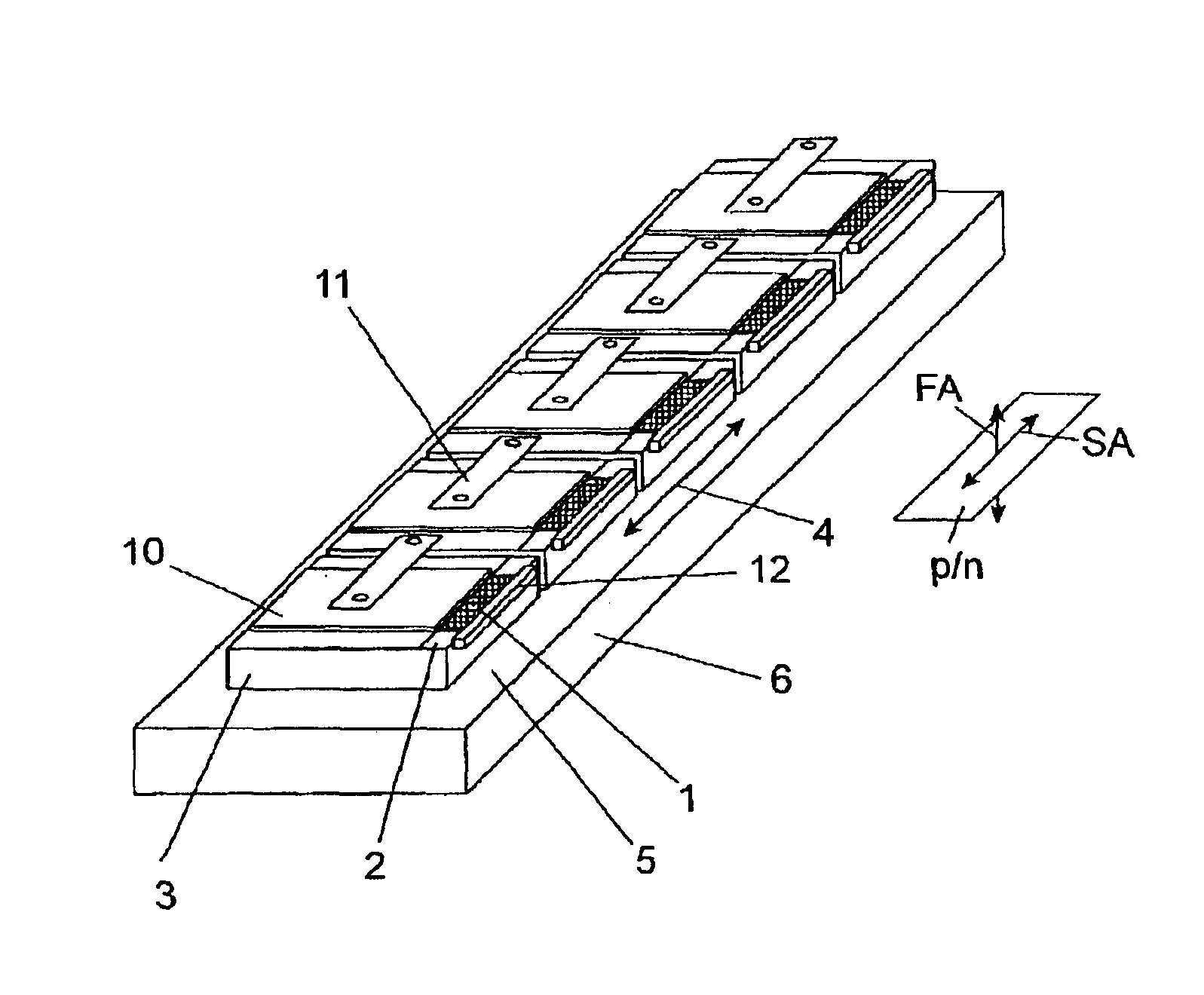

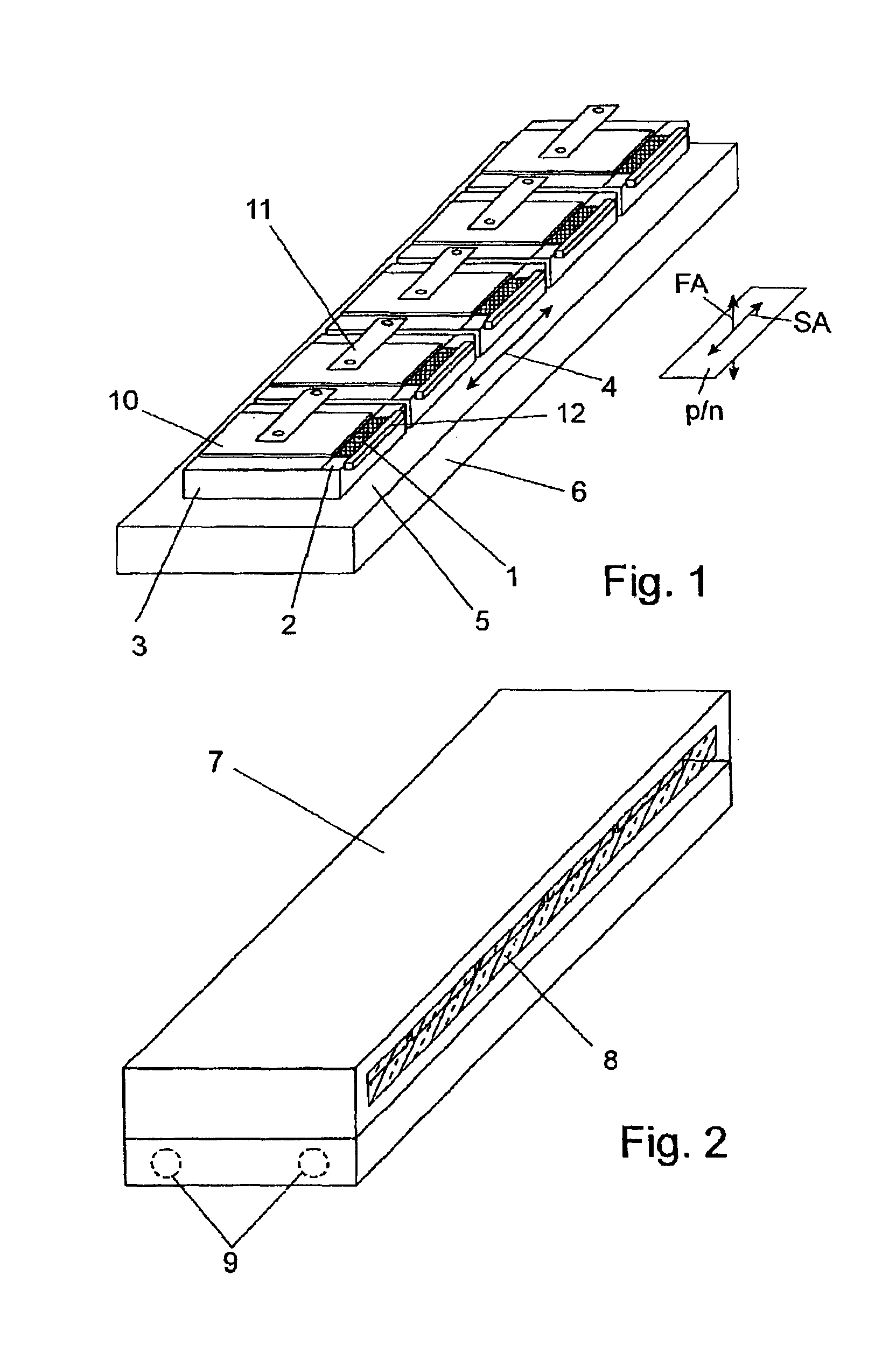

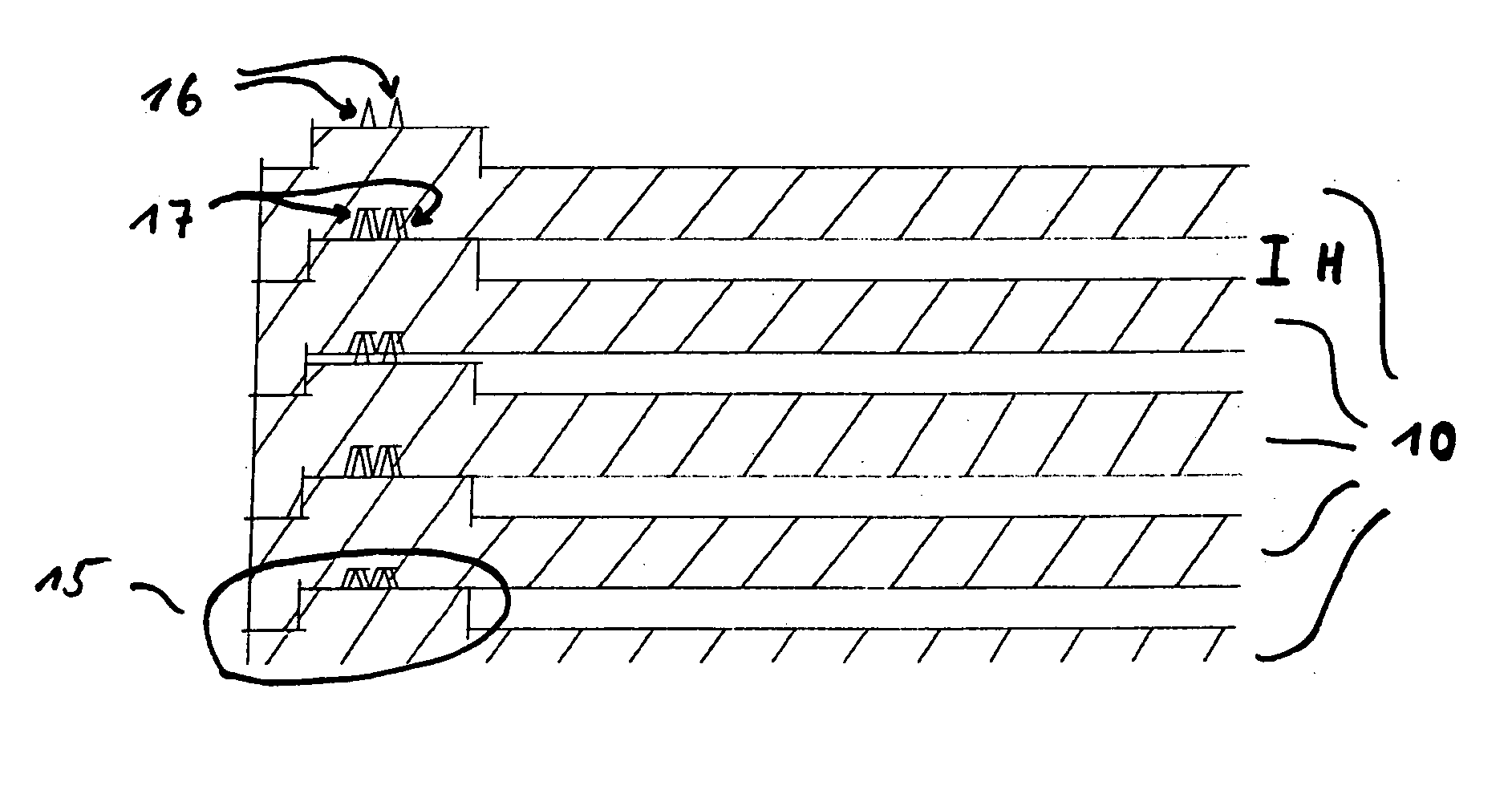

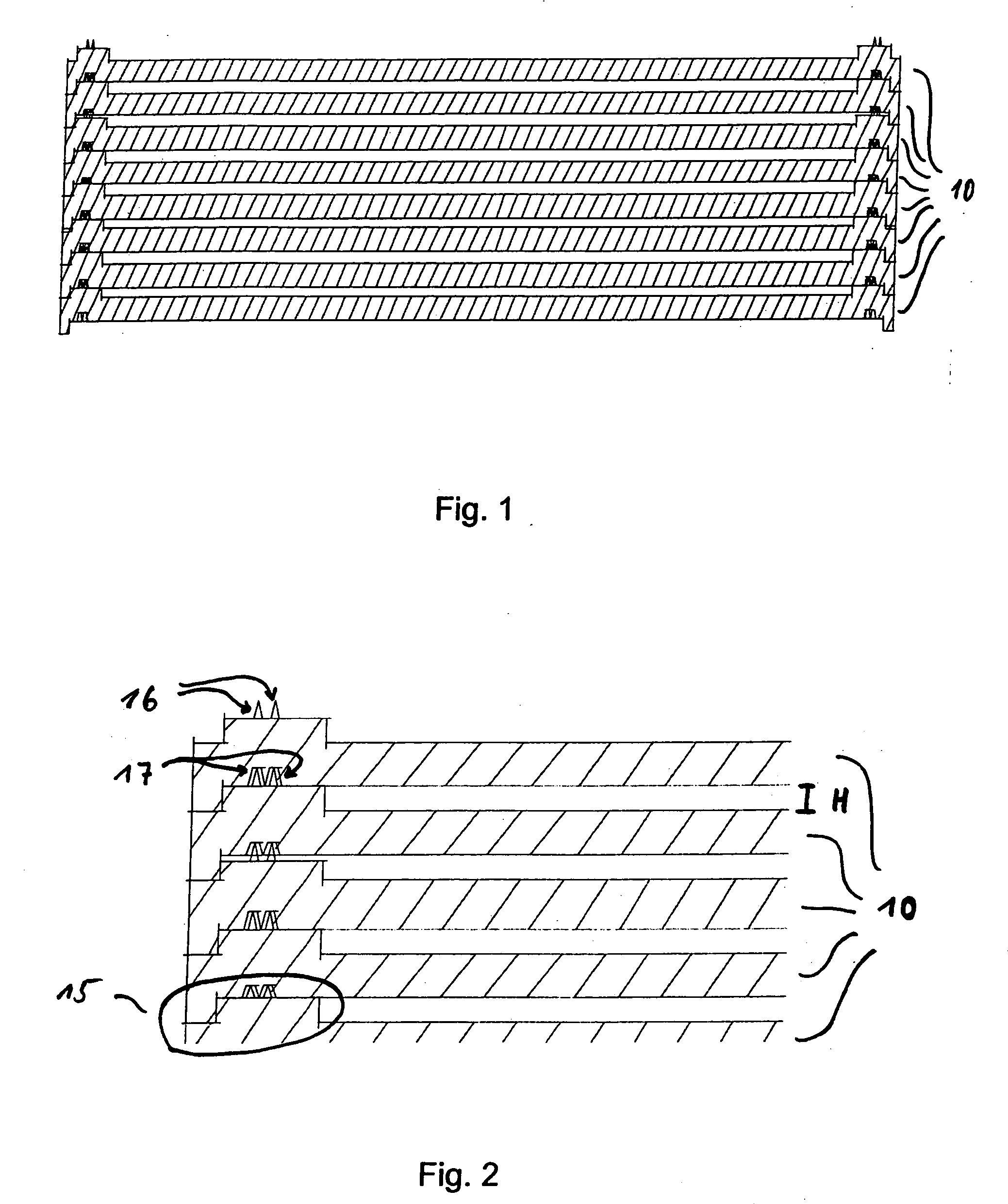

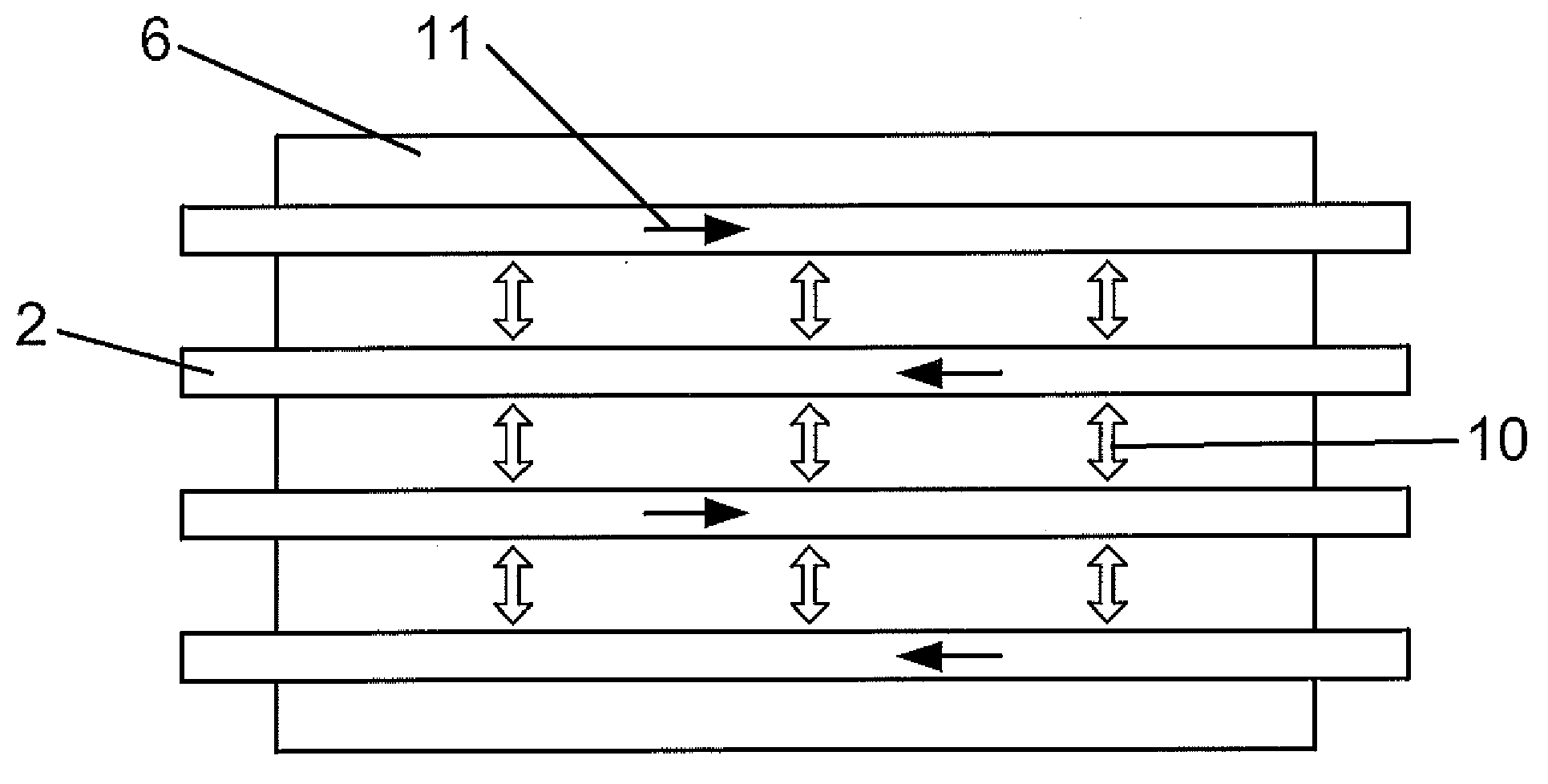

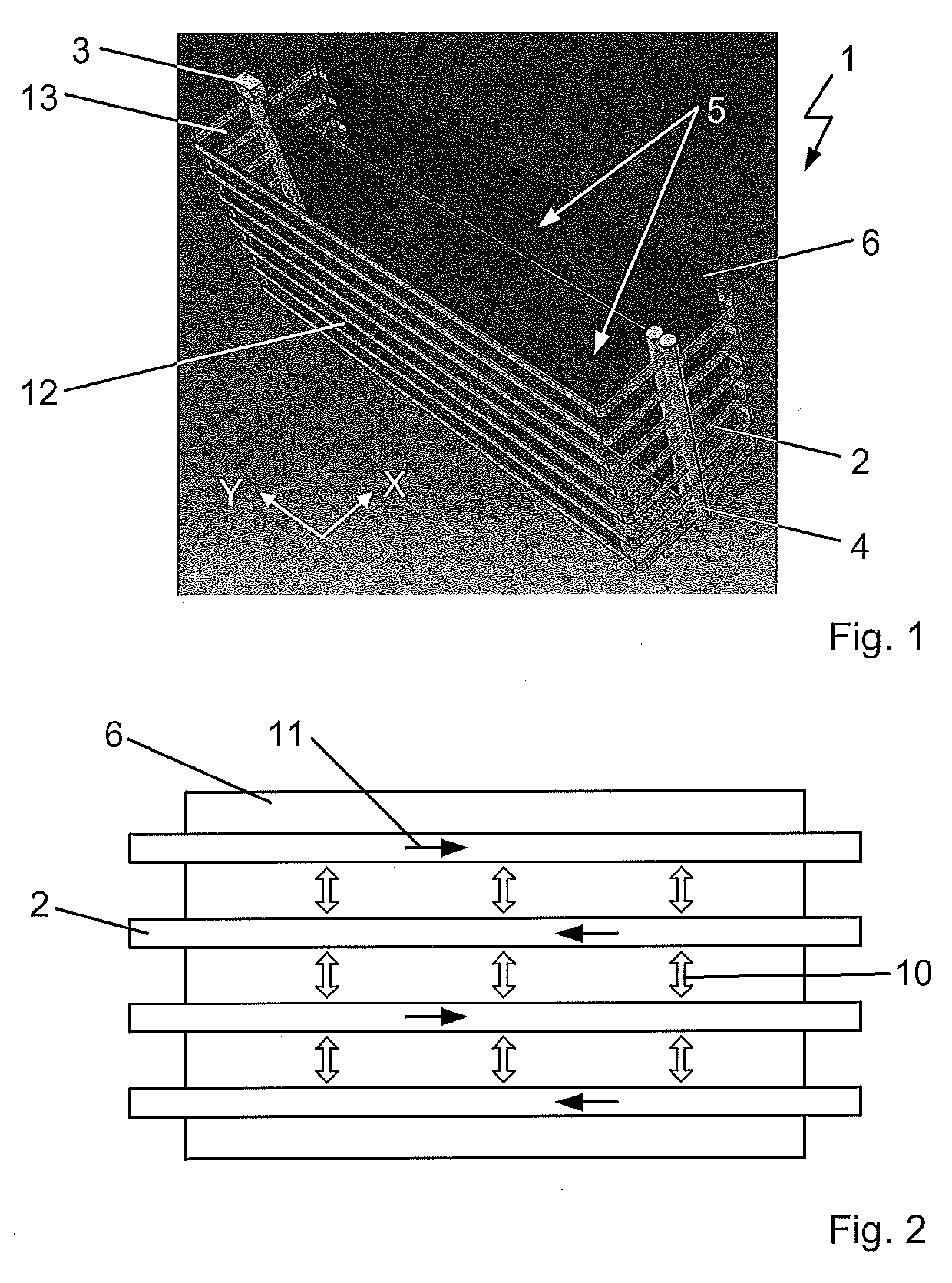

Diode laser arrangement with a plurality of diode laser arrays

InactiveUS6898222B2Promote homogenizationSemiconductor laser arrangementsExcitation process/apparatusLaser arrayRadiation field

A diode laser arrangement is disclosed wherein a radiation source is designed which can be scaled with respect to power such that different types of cooling can be applied and the configuration of the radiation field is suitable for adapting to different tasks in a simple manner. For this purpose, every diode laser is connected to a thermal contact surface of a separate, heat-spreading carrier which is fastened to a cooling surface of a common cooling element so as to be electrically insulated. The carriers are arranged adjacently in such a way that the line-shaped emission regions of the diode lasers are adjacent in series and the p-n junction planes extend parallel to the thermal contact surfaces. The diode laser arrangement is particularly suitable as a pump light source.

Owner:JENOPTIK LASERDIODE

E. coli transformant, method for producing flavin-bound glucose dehydrogenase using the same, and mutant flavin-bound glucose dehydrogenases

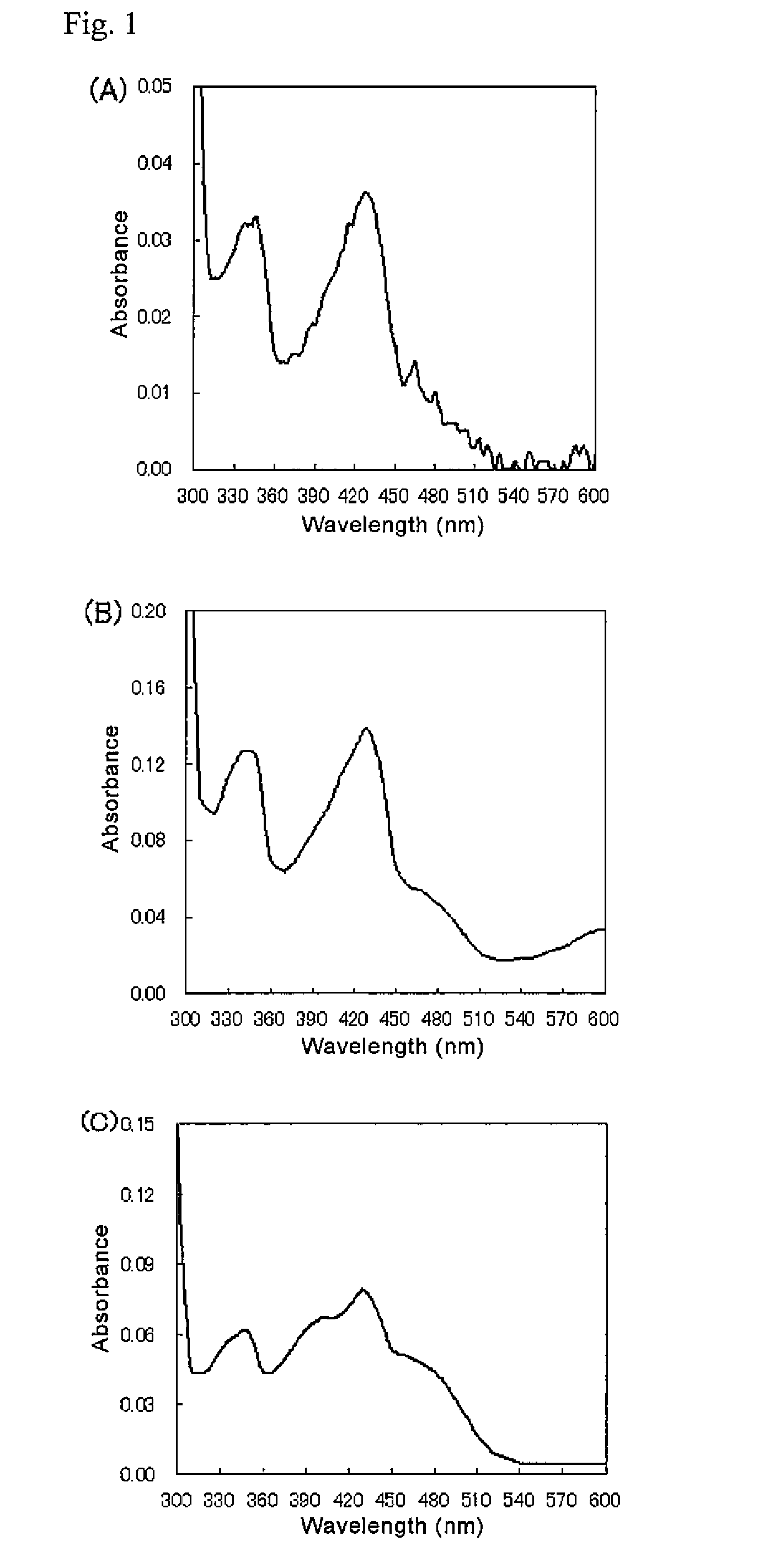

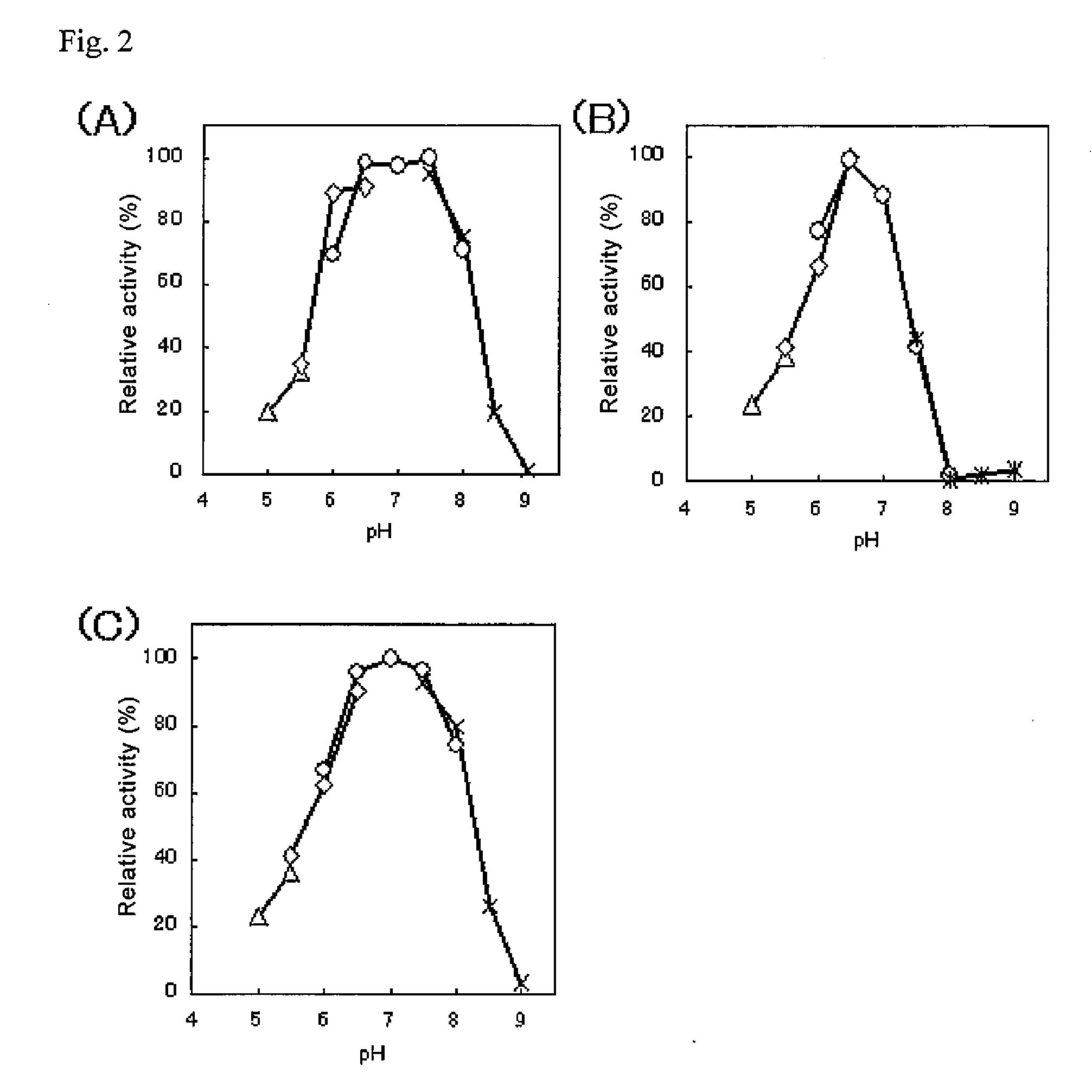

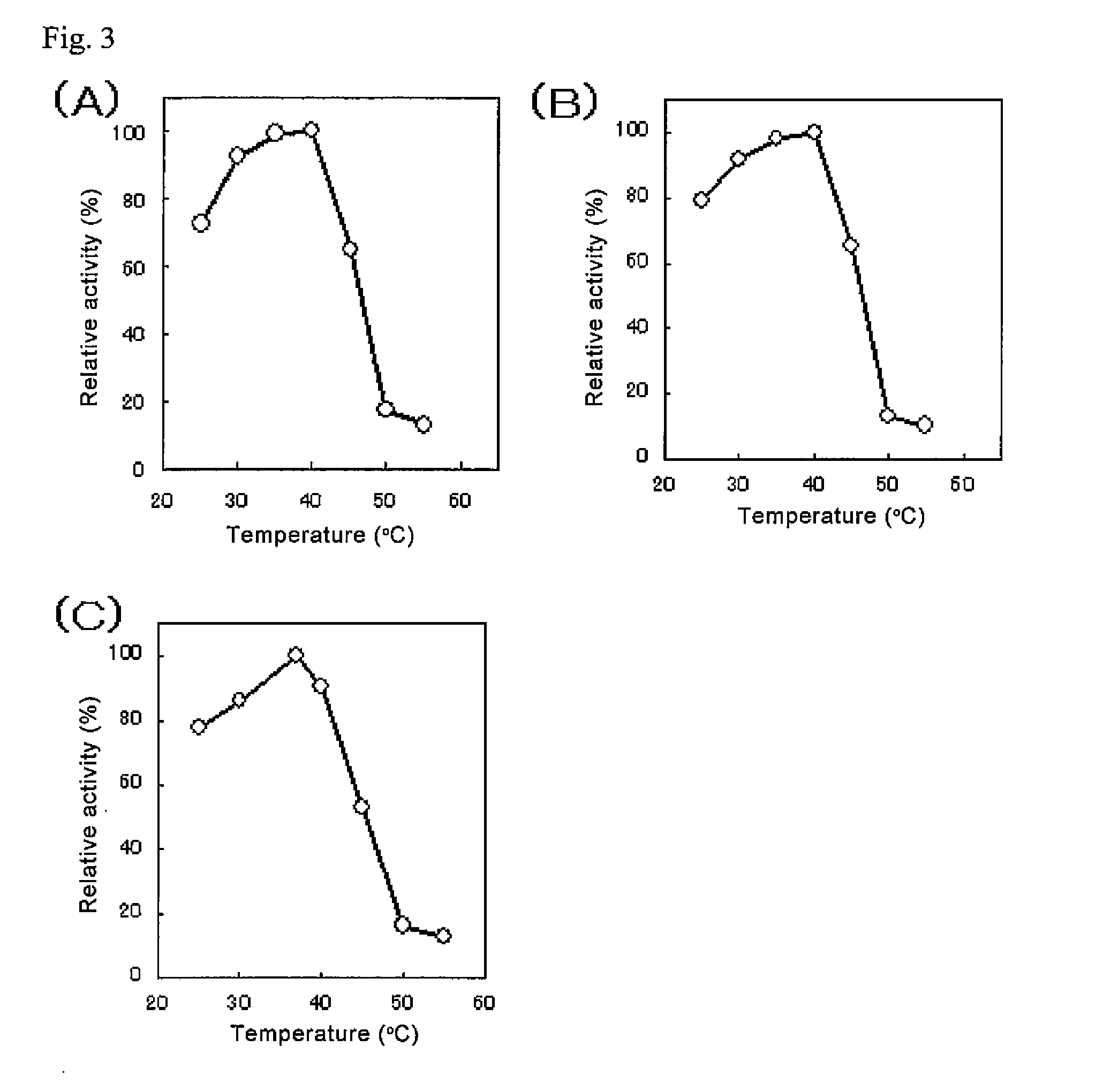

ActiveUS20130309750A1Accurate measurementEfficiently obtainedBacteriaOxidoreductasesEscherichia coliMicroorganism

A flavin-bound glucose dehydrogenase (FAD-GDH) with high substrate specificity for D-glucose. A gene encoding a mutant FAD-GDH with its N-terminal region, containing an amino acid sequence corresponding to MKITAAIITVATAFASFASA that exists in the N-terminal region, deleted from the amino acid sequence of a wild-type FAD-GDH derived from Mucor is introduced into E. coli to obtain an E. coli transformant. Subsequently, this E. coli transformant is cultured to obtain an FAD-GDH with a specific N-terminal region deleted. The transformant allows the production of a large amount of GDH in a short time as compared with the original microorganism. An FAD-GDH that is less susceptible to the effects of dissolved oxygen and allows accurate measurement of glucose even in the presence of sugar compounds other than glucose in a sample.

Owner:KIKKOMAN CORP

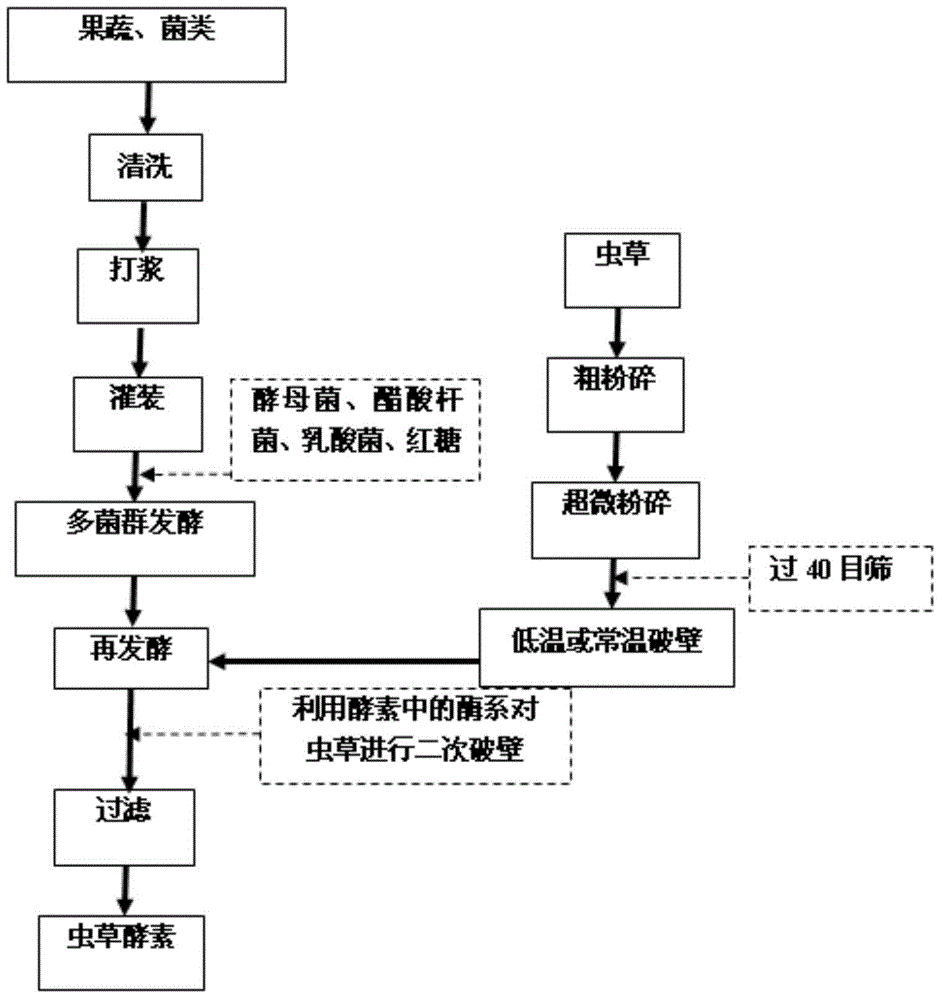

A cordyceps sinensis enzyme and a preparation method thereof

InactiveCN104856015ANo loss of nutritionImprove absorption rateFood preparationEnzyme systemBULK ACTIVE INGREDIENT

The present invention provides a cordyceps sinensis enzyme and a preparation method thereof. The enzyme is prepared by fermenting the following ingredients in parts by weight: fruits and vegetables 55-70 parts, fungi 8-12 parts, cordyceps sinensis 1-2 parts and sugar 15-20 parts with the addition of probiotic 0.2-0.8 part. The preparation method comprises the following steps: preparing cordyceps sinensis sporoderm-broken powder, preparing primary enzyme solution, fermenting the powder and the solution for preparing the cordyceps sinensis enzyme, etc. The enzyme uses ultramicro crushing technology to crush the cordyceps sinensis, and low temperature or room temperature sporoderm-breaking technology to conduct sporoderm-breaking on the cordyceps sinensis so that the nutrition loss of the cordyceps sinensis is prevented and the absorption rate of the cordyceps sinensis is improved; the enzyme utilizes rich enzyme systems of enzymes to conduct additional sporoderm-breaking on the sporoderm-broken powder, which facilitates the release and homogenization of active ingredients in the cordyceps sinensis, and improves the effect of drugs. The prepared enzyme contains proteins, amino acids, vitamins, enzyme substances, etc. essential for human bodies, effectively accumulates functional components of the cordyceps sinensis, and effectively improves various health-care effects of the enzymes.

Owner:西藏月王药诊生态藏药科技有限公司

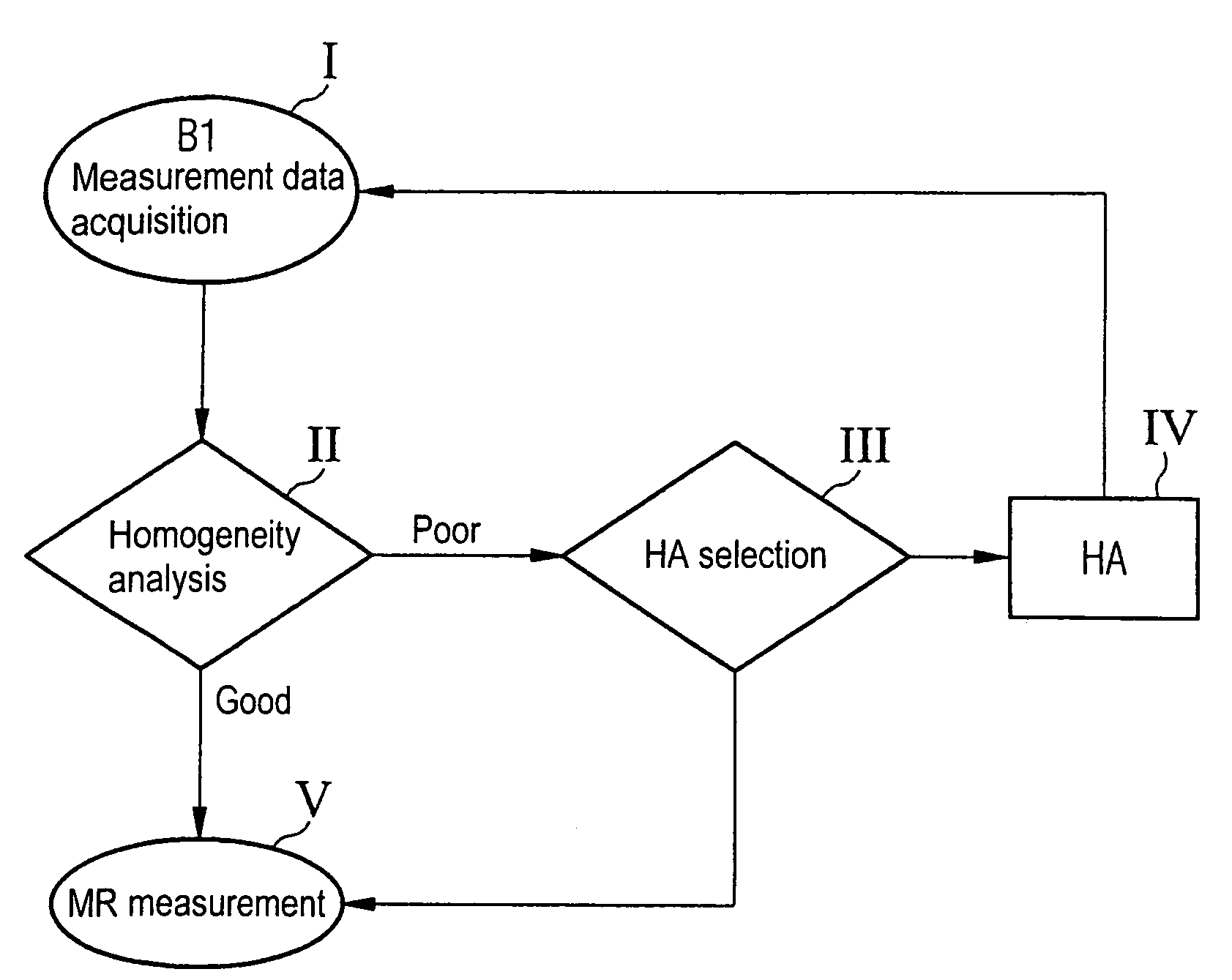

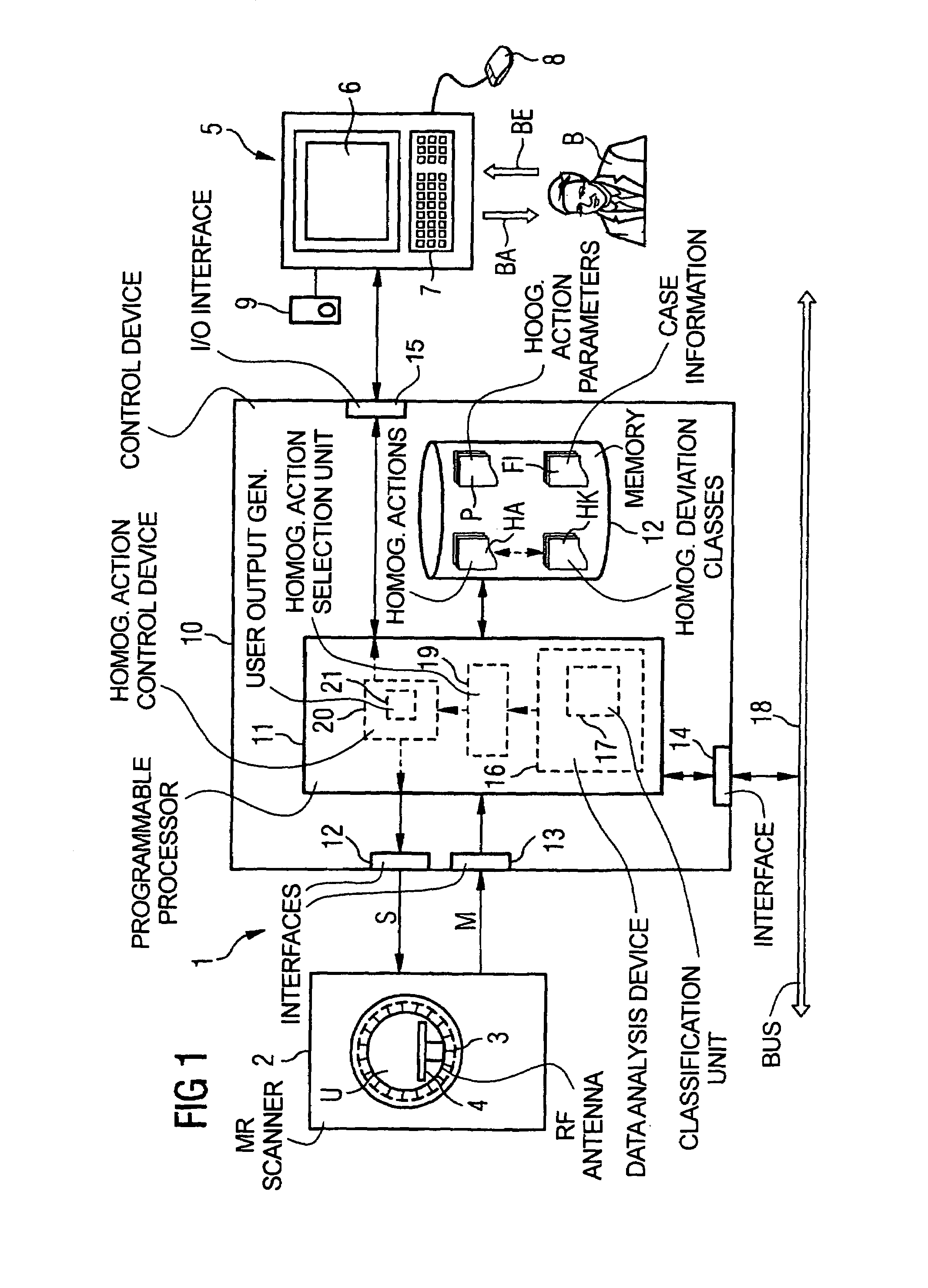

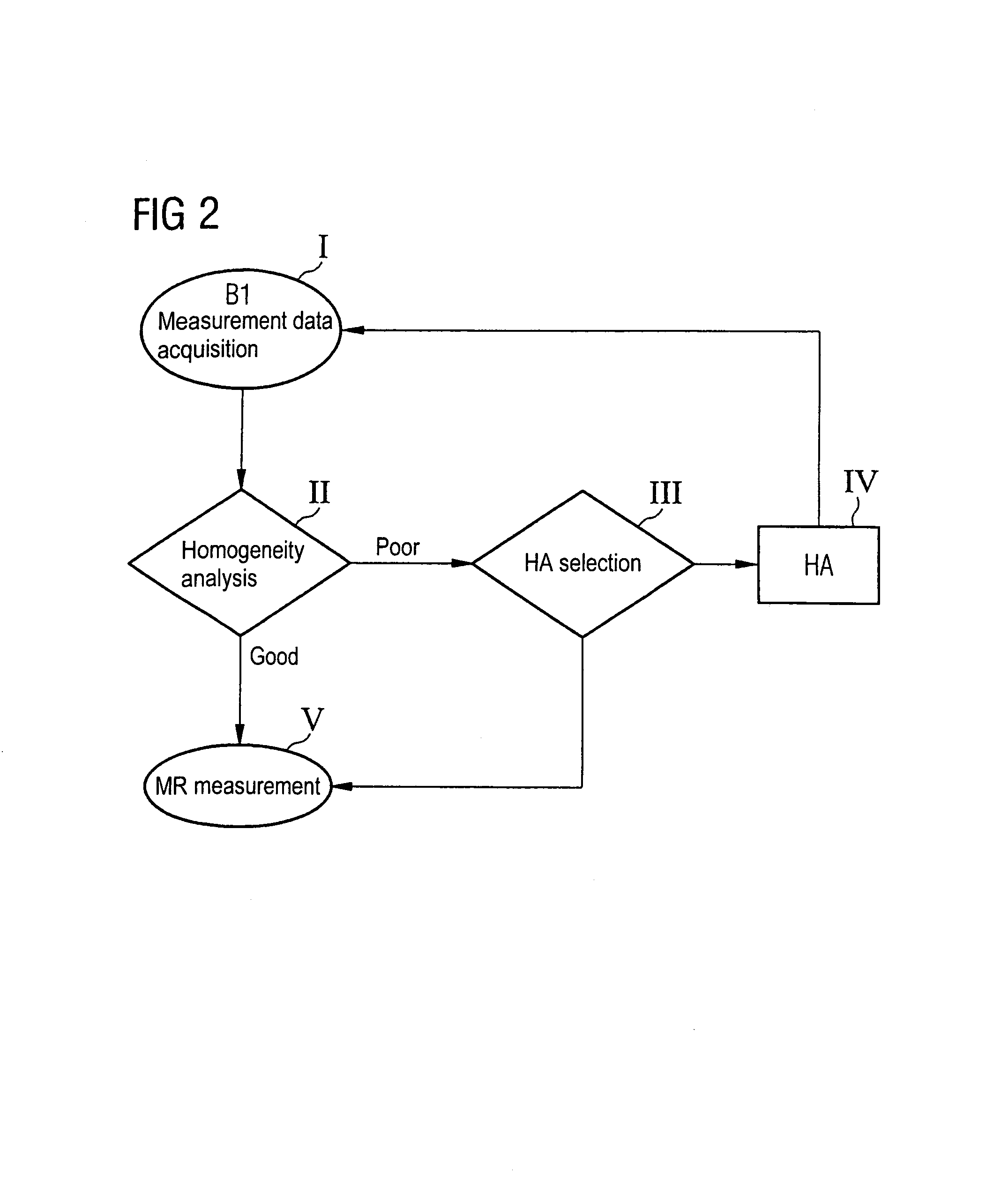

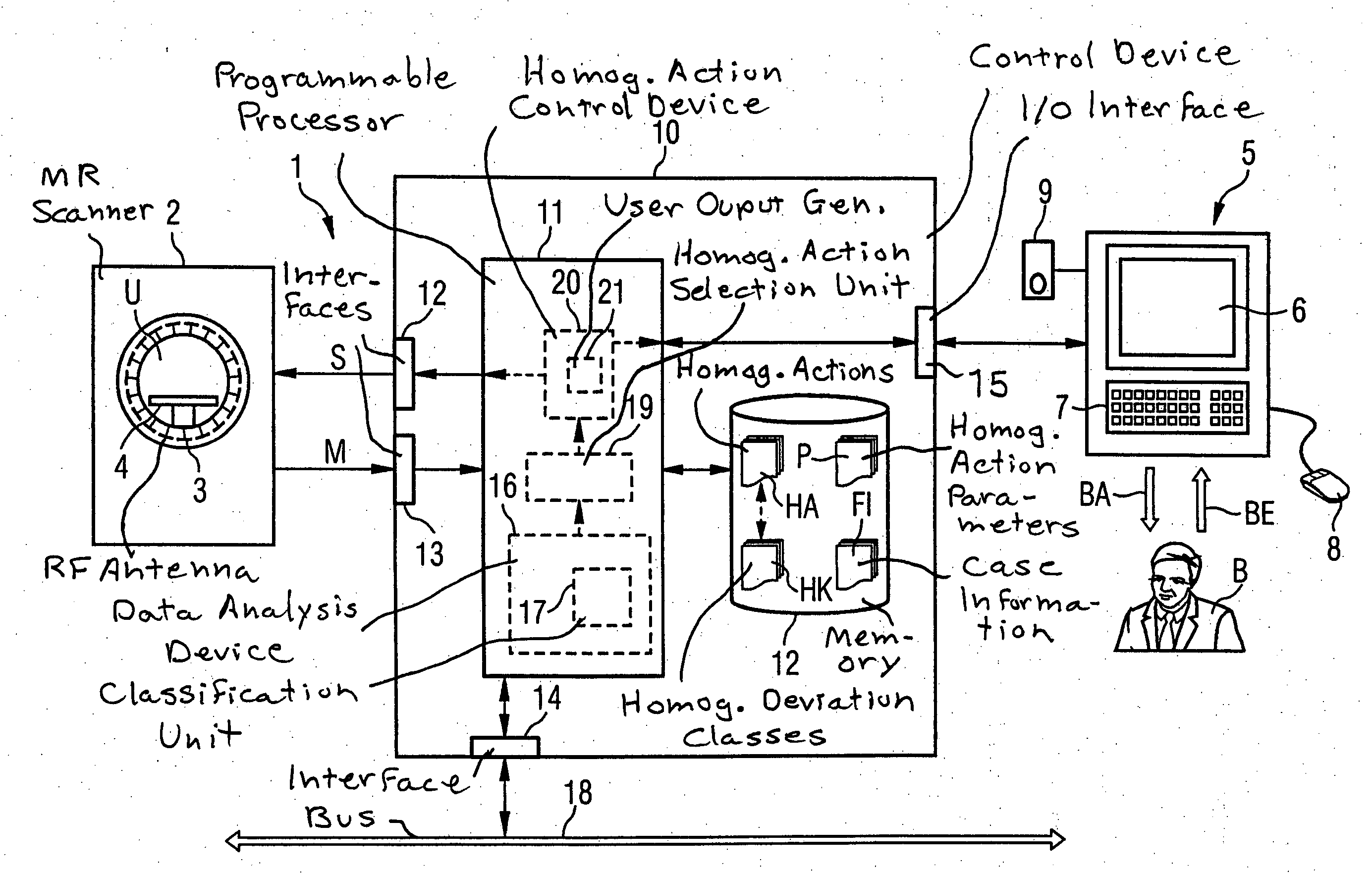

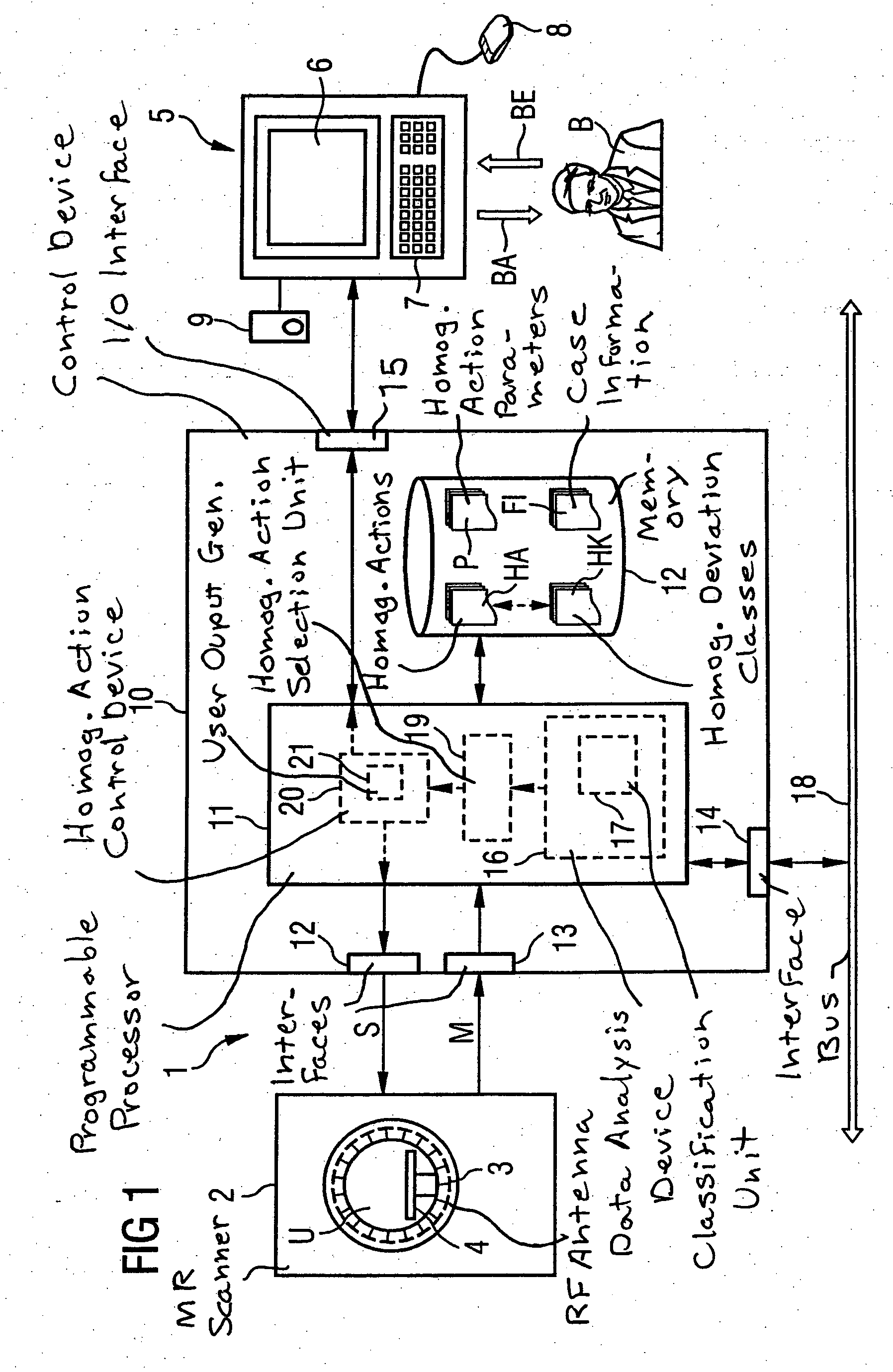

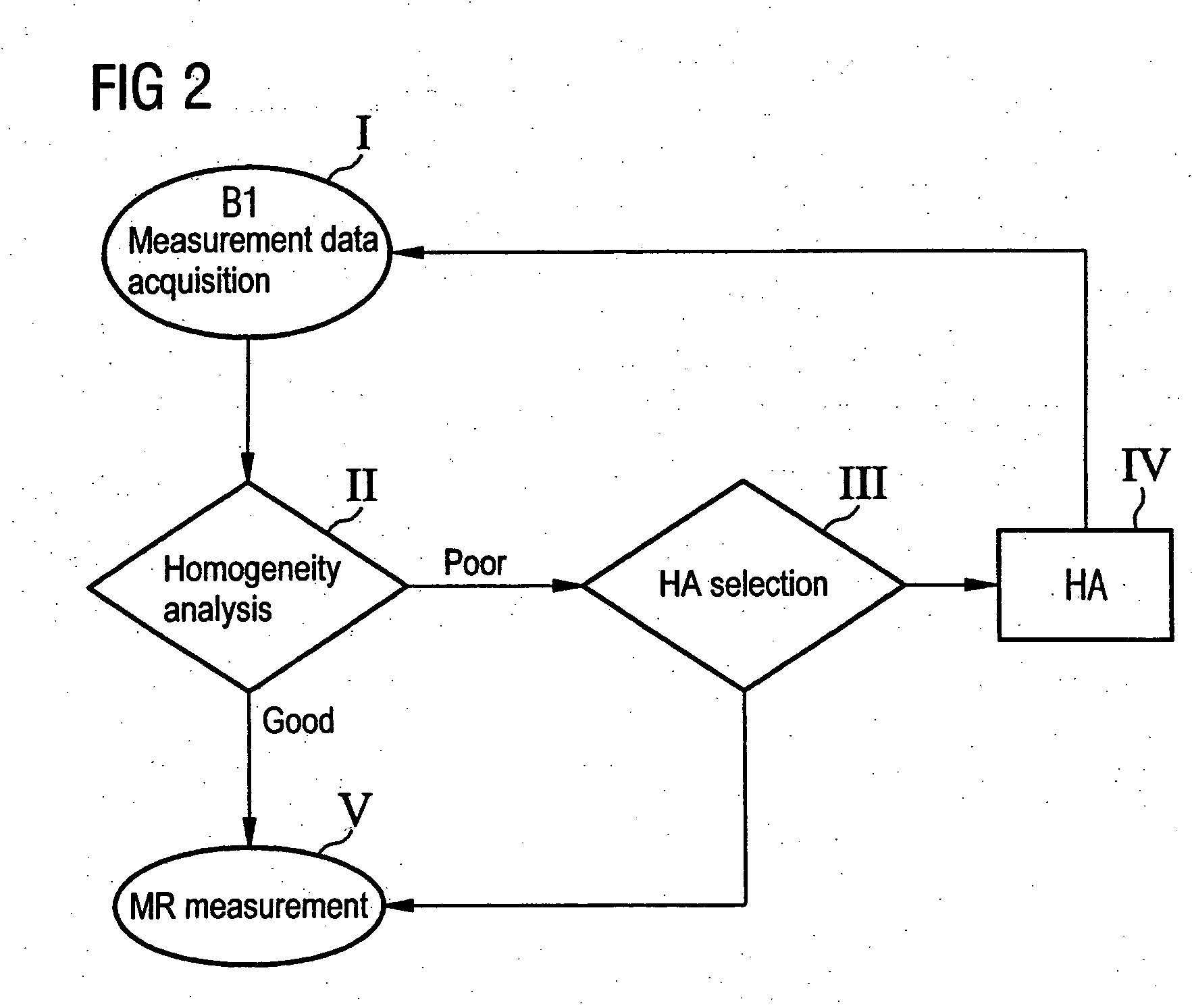

Method and magnetic resonance system for homogenizing the B1 field

ActiveUS7078901B2Promote homogenizationQuick searchElectric/magnetic detectionMeasurements using magnetic resonanceResonance measurementData acquisition

Owner:SIEMENS HEALTHCARE GMBH

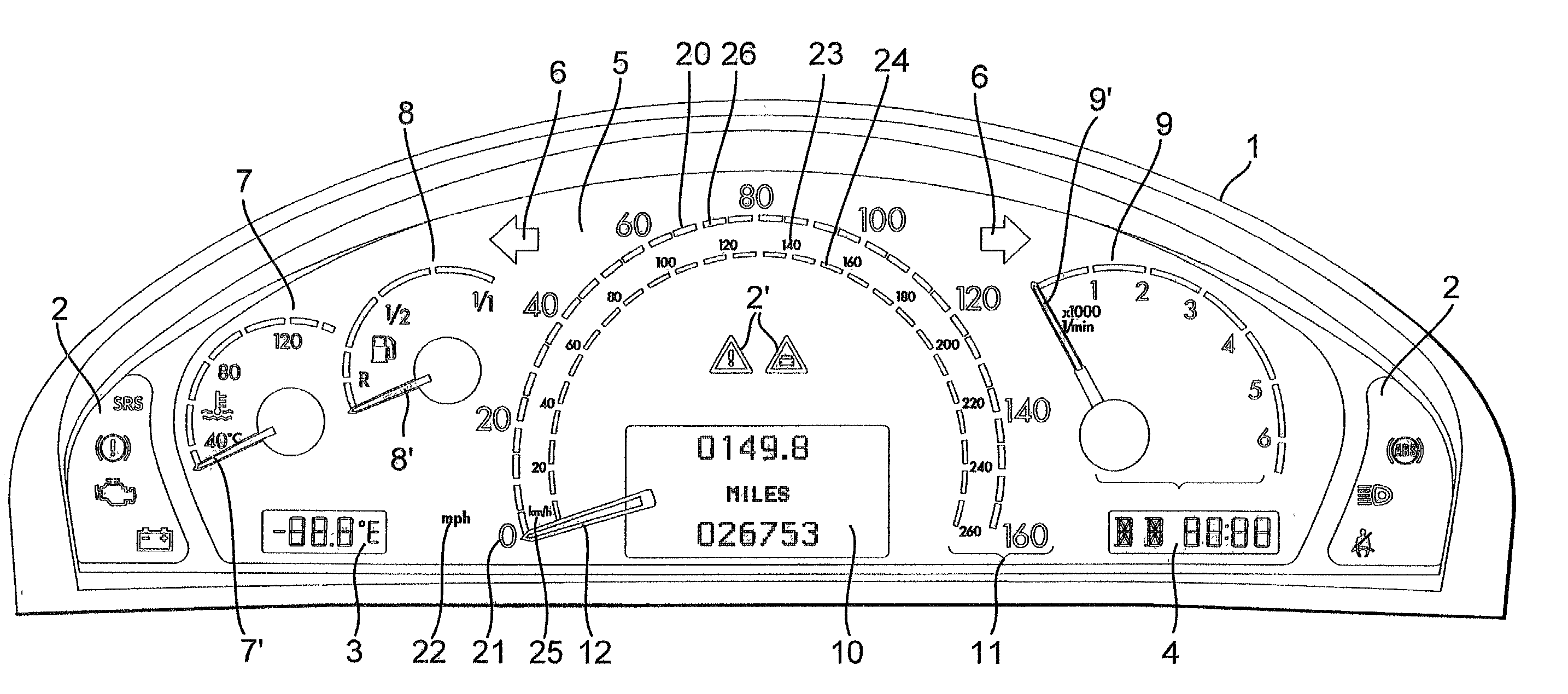

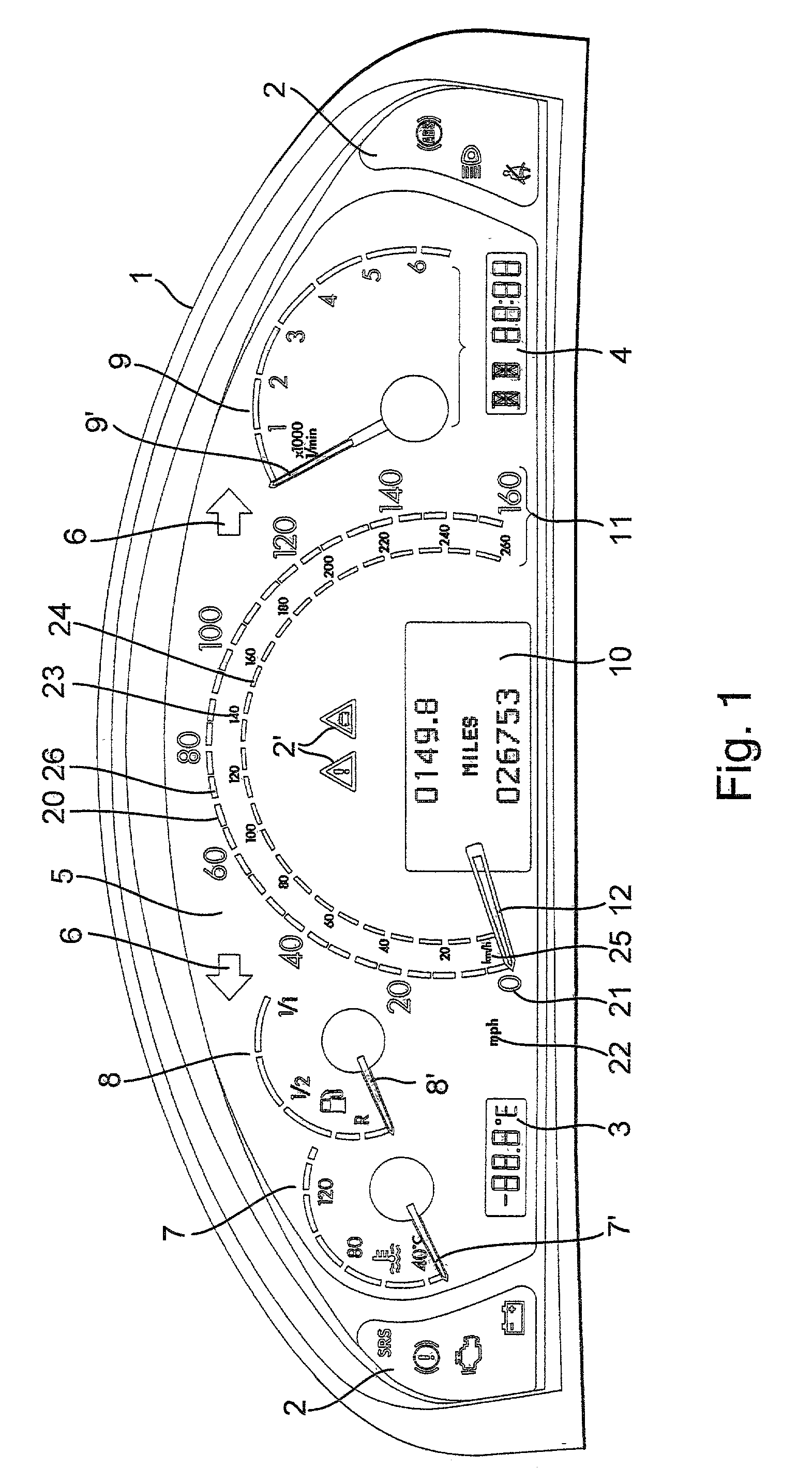

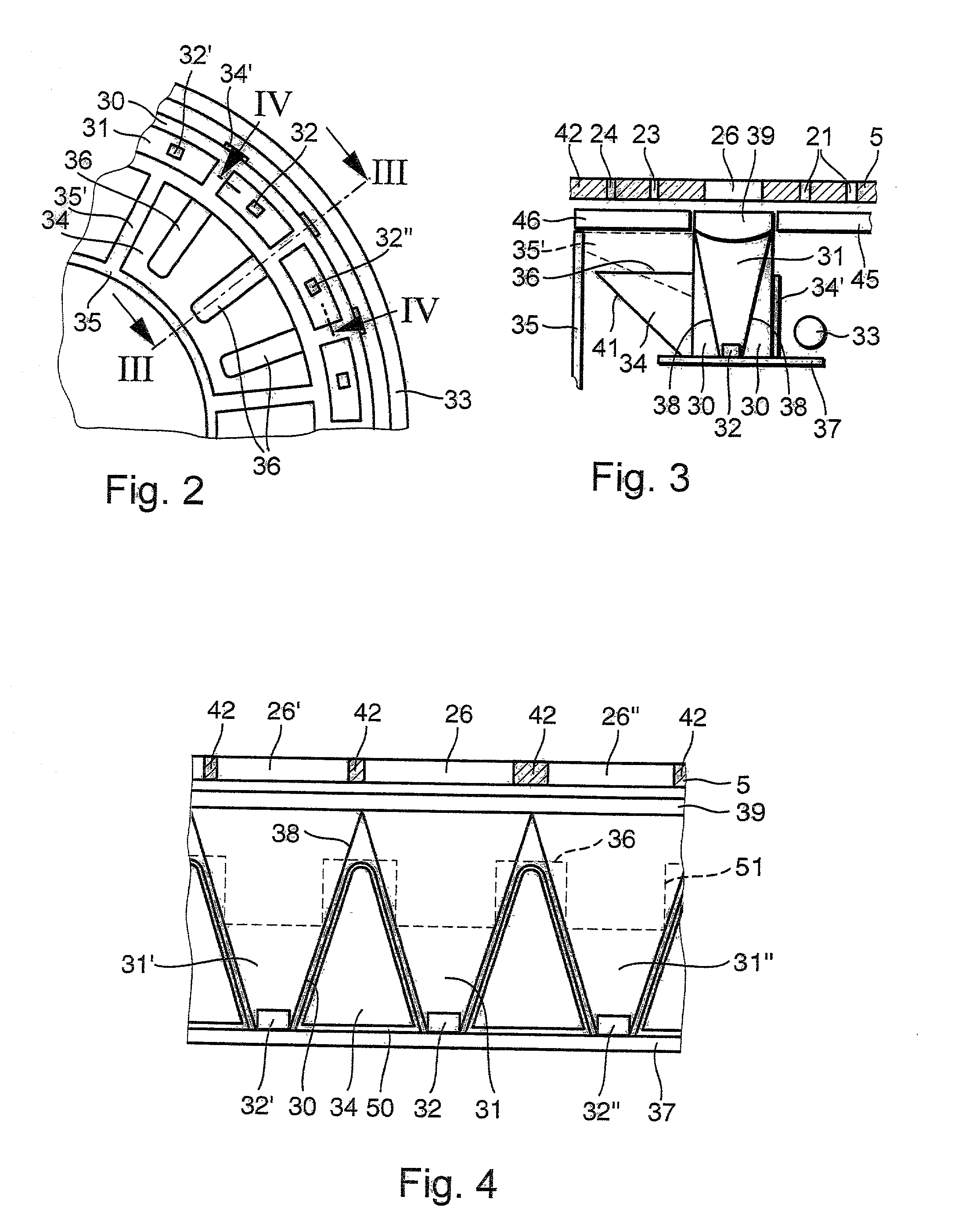

Illumination and display device

InactiveUS20020149495A1Easy to installSimple wayIndicator componentsMeasurement apparatus componentsComputer graphics (images)Display device

An illumination device for a display instrument is described which is used to illuminate two sets of scale markings and to separately illuminate a pointer scale of the display instrument. The light from a light source is guided past light funnels that are used to illuminate the pointer scale by an optical waveguide. This provides an efficient and economical means of illuminating a display instrument of this type.

Owner:ROBERT BOSCH GMBH

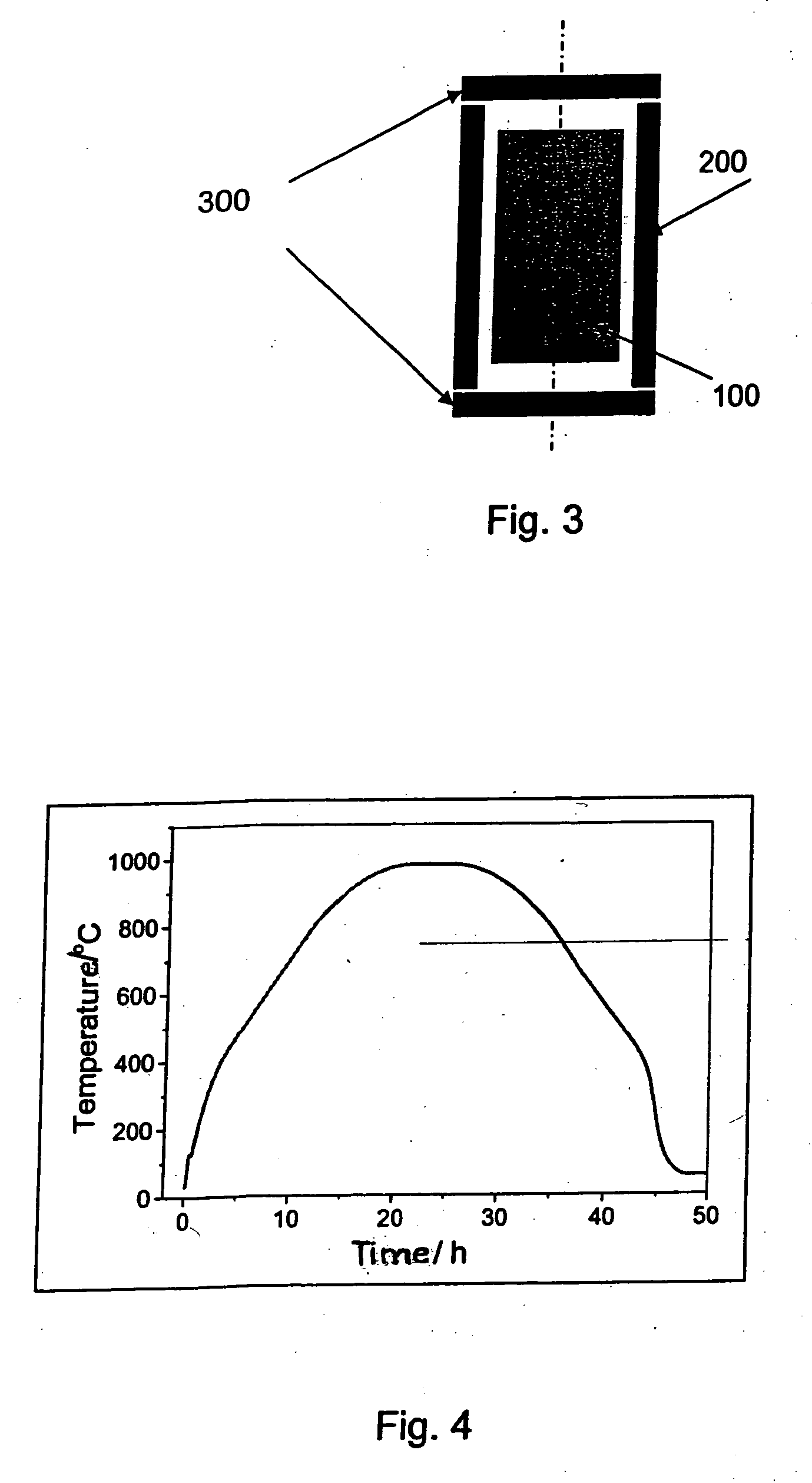

Device and process for heating III-V wafers, and annealed III-V semiconductor single crystal wafer

ActiveUS20070012242A1Good effectHigh heat conductivityFrom gel stateFrom solid stateDislocationEngineering

A device for heat treating (annealing) a III-V semiconductor wafer comprises at least one wafer support unit which is dimensioned such that a cover provided above the wafer surface is either spaced without any distance or with a distance of maximally about 2 mm to the wafer surface. A process for heat treating III-V semiconductor wafers having diameters larger than 100 mm and a dislocation density below 1×104 cm−2 is carried out in the device of the invention. SI GaAs wafers produced have an at least 25% increased characteristic fracture strength (Weibull distribution), an improved radial macroscopic and mesoscopic homogeneity and an improved quality of the mechano-chemically polished surface. The characteristic fracture strength is higher than 1900 MPa.

Owner:FREIBERGER COMPOUND MATERIALS

Aluminium alloy for vehicle hub and preparation method thereof

The invention provides an aluminium alloy for a vehicle hub and a preparation method thereof. The alloy comprises the following components by weight percent: 4.5-6.3% of Zn, 1.4-2.5% of Mg, 0.5-0.9% of Cu, 0.12-0.3% of Zr, 0.05-0.15% of Ti, 0.05-0.2% of Cr, 0.1-0.3% of Sc and the balance of Al. The preparation method of the aluminium alloy comprises the following steps: weighting raw materials, melting the raw materials except for magnesium blocks, adding a covering agent, then adding the preheated magnesium blocks, stirring, injecting nitrogen or argon to degas, filtering with a ported ceramic plate, reducing the temperature, standing for 20 minutes, and adopting a liquid forging mould and a liquid forging forming method to prepare the hub. The prepared vehicle hub has high strength, impact toughness and corrosion resistance; and the mechanical properties of the aluminium alloy hub can be ensured, the production cost can be reduced and the large-scale production of the hub is easy to perform.

Owner:ZHEJIANG GKO ALUMINUM

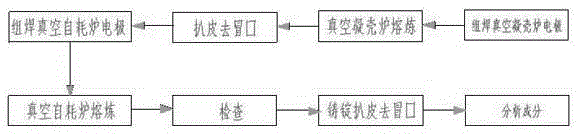

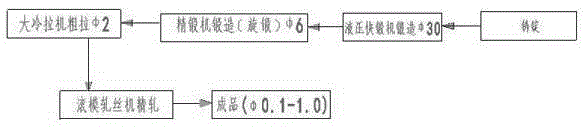

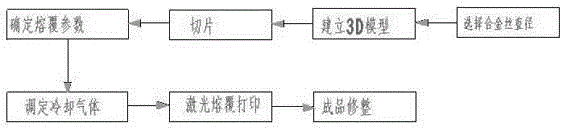

Additive manufacturing method for functional material part based on TiNi memory alloy wire

InactiveCN105268973ALarge molten poolGood for homogenizationAdditive manufacturing apparatusIncreasing energy efficiencyAlloy elementNickel base

The invention belongs to the technical field of forming and manufacturing of metal materials, and particularly relates to an additive manufacturing method for a functional material part based on a TiNi memory alloy wire. The additive manufacturing method comprises the following steps: smelting a titanium-nickel based memory alloy; preparing a titanium-nickel based memory alloy wire; taking the titanium-nickel based memory alloy wire as a raw material; carrying out a laser-cladding additive manufacturing process; and carrying out tissue control and deformation amount control on manufactured parts. A welding pool of a vacuum self-consumption skull furnace is great, and is beneficial for sufficiently homogenizing alloy elements and preventing alloy segregation; and smelting of the vacuum self-consumption skull furnace refers to controlling a cast titanium tissue of a cast ingot, thereby facilitating follow-up cold-hot processing.

Owner:SHENYANG HAINAXIN TECH CO LTD

Static mixing element having deflectors and a mixing device

InactiveUSRE36969E1Lower overall pressure dropReduce lossesFlow mixersTransportation and packagingEngineering

Owner:OTIS ELEVATOR CO

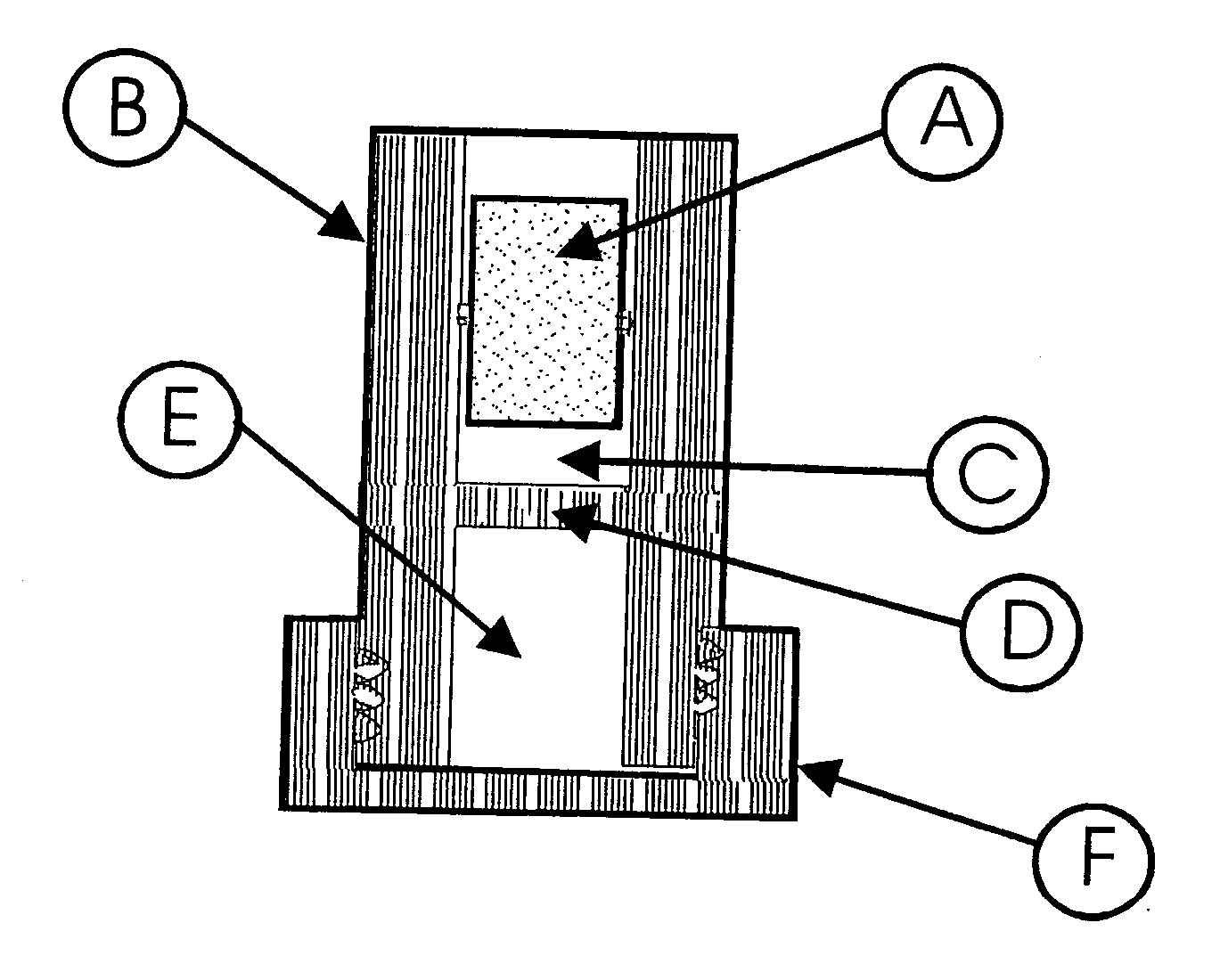

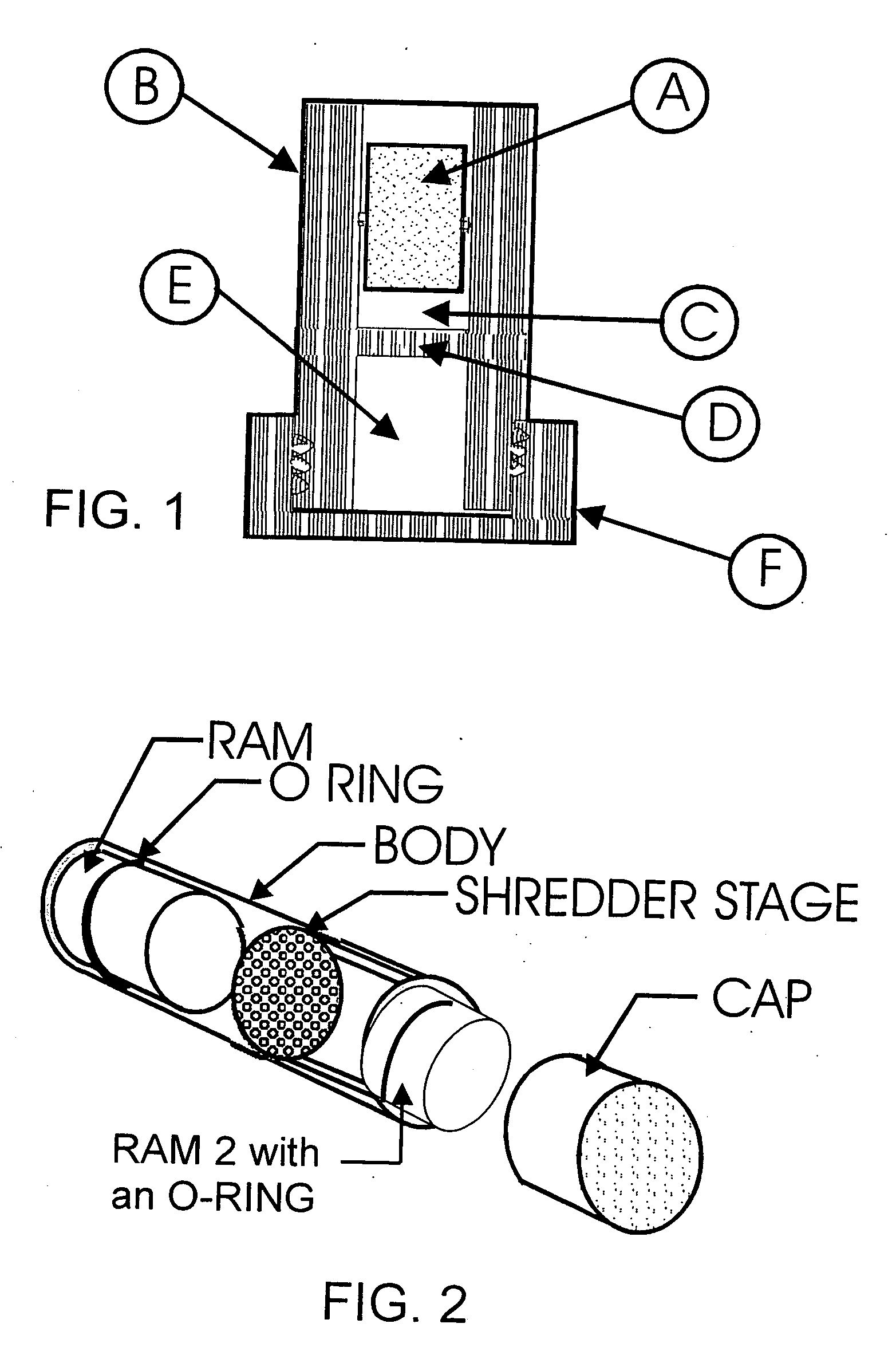

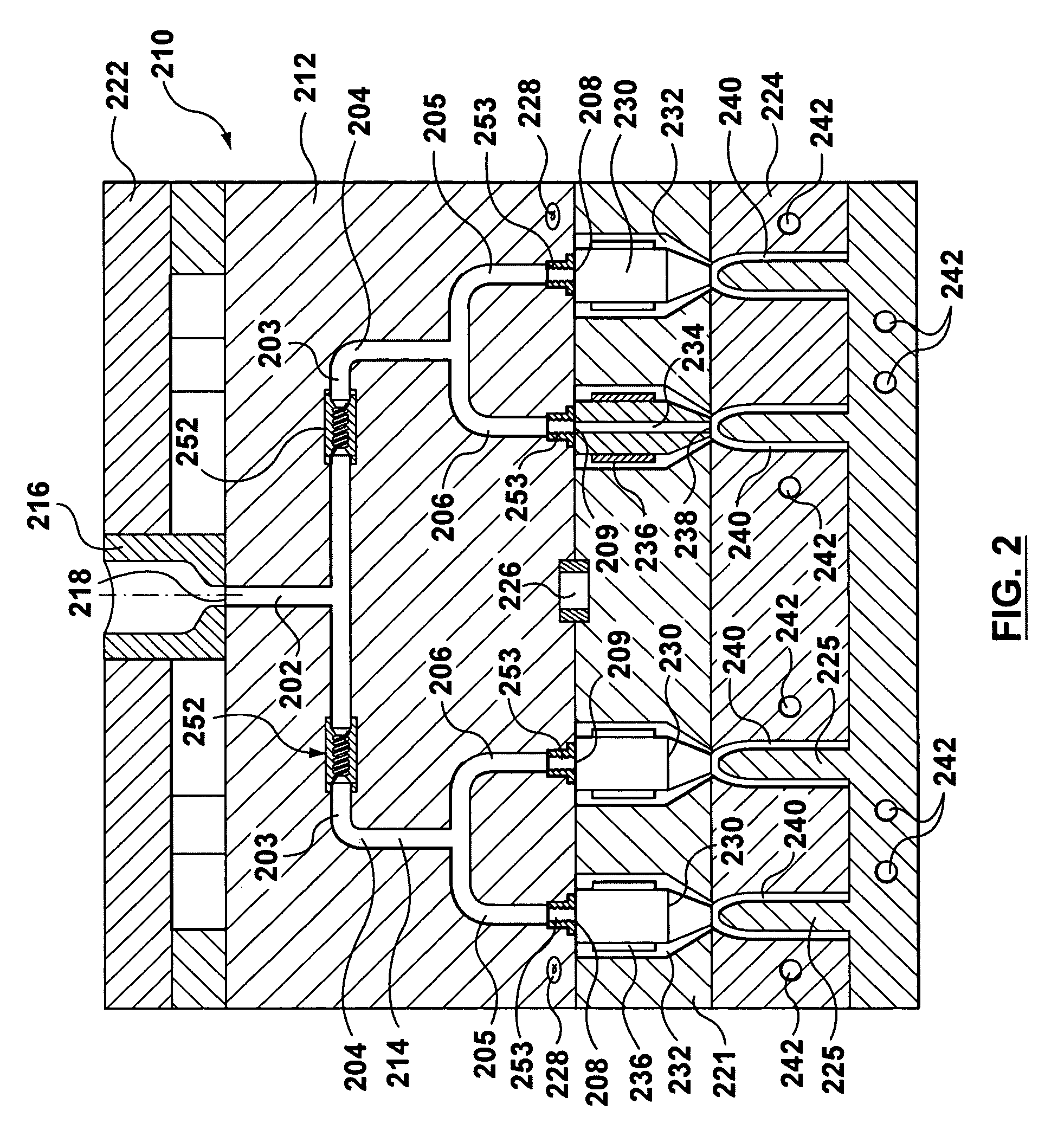

Multichamber device for processing of biological samples using high pressure

InactiveUS20070014690A1Suitable for automationSimple formatBioreactor/fermenter combinationsBiological substance pretreatmentsMetaboliteFungal microorganisms

Devices and methods are described for homogenization, processing, detection, and analysis of biological samples such as insects, fungi, bacteria, and plant and animal tissues. Multiple chambers in these devices permit different processing functions to be carried out at each stage, such that the resulting homogenized product can be further processed, purified, analyzed, and / or biomolecules such as metabolites, proteins and nucleic acids, or pharmaceutical products can be detected. The device can be used in a hydrostatic pressure apparatus, in which different activities, i.e. incubations, addition or renewal of reagent, and generation and detection of signal can be carried out in the appropriate chamber. The method improves the preservation of biomolecules from chemical and enzymatic degradation relative to conventional means. Additionally, this method enables automated sample preparation and analytical processes.

Owner:BBI BIOSEQ A MASSACHUSETTS CORP

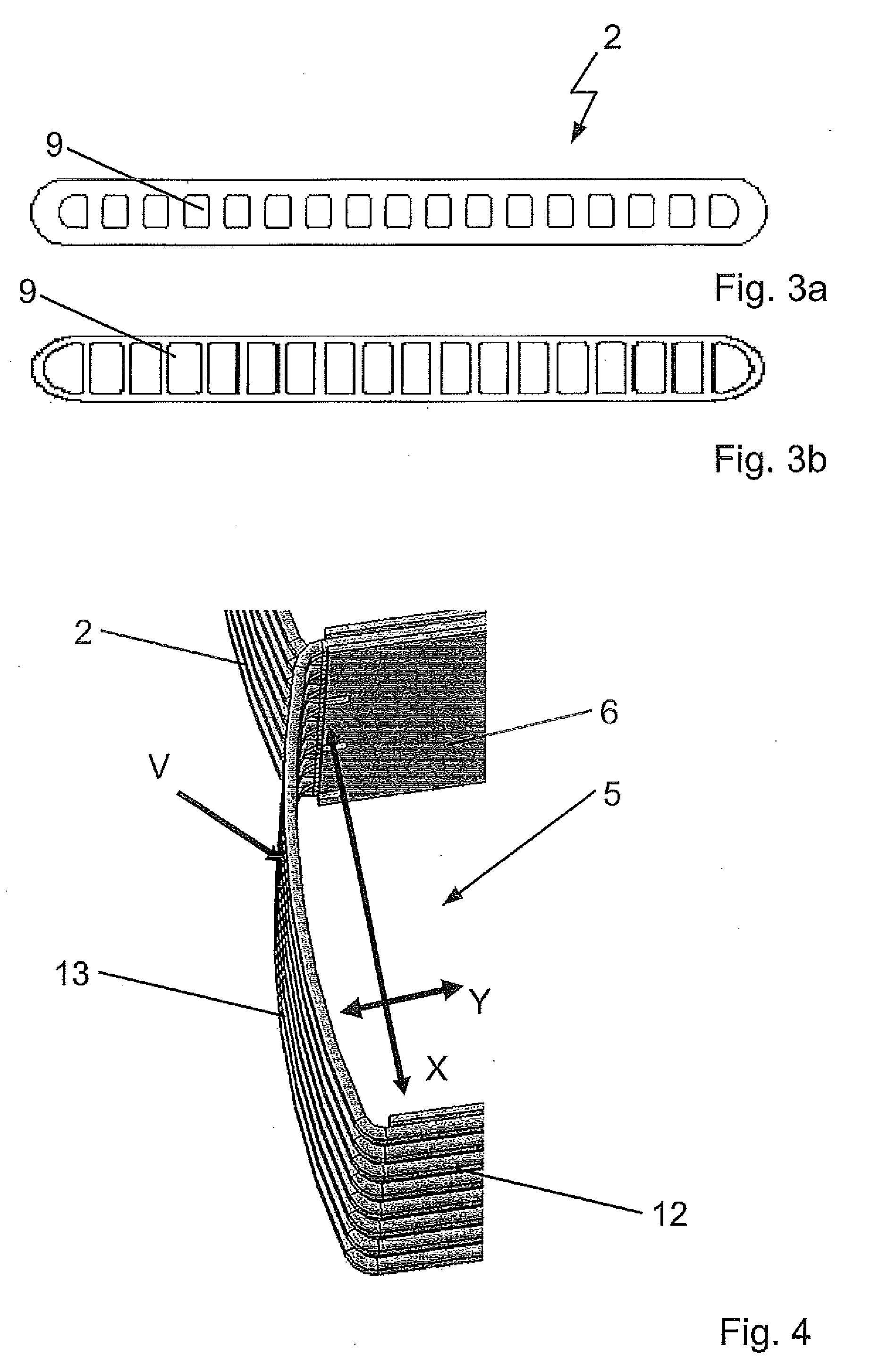

Heat exchanger for temperature control of vehicle batteries

ActiveUS20100147488A1Promote homogenizationSecondary cellsAir heatersTemperature controlPlate heat exchanger

The invention relates to a heat exchanger for temperature controlling and fastening of battery units of the battery of a vehicle. The heat exchanger includes flat tubes that are passable by a heat carrier and a collecting tube and distributing tube for conducting the heat carrier. The flat tubes are established as multi-channel flat tubes. The collecting tube and the distributing tube are connected to each other over the flat tubes so that a holding frame is established that provides a structure forming spaces. The spaces are provided as chambers for accommodating the battery units.

Owner:HANON SYST

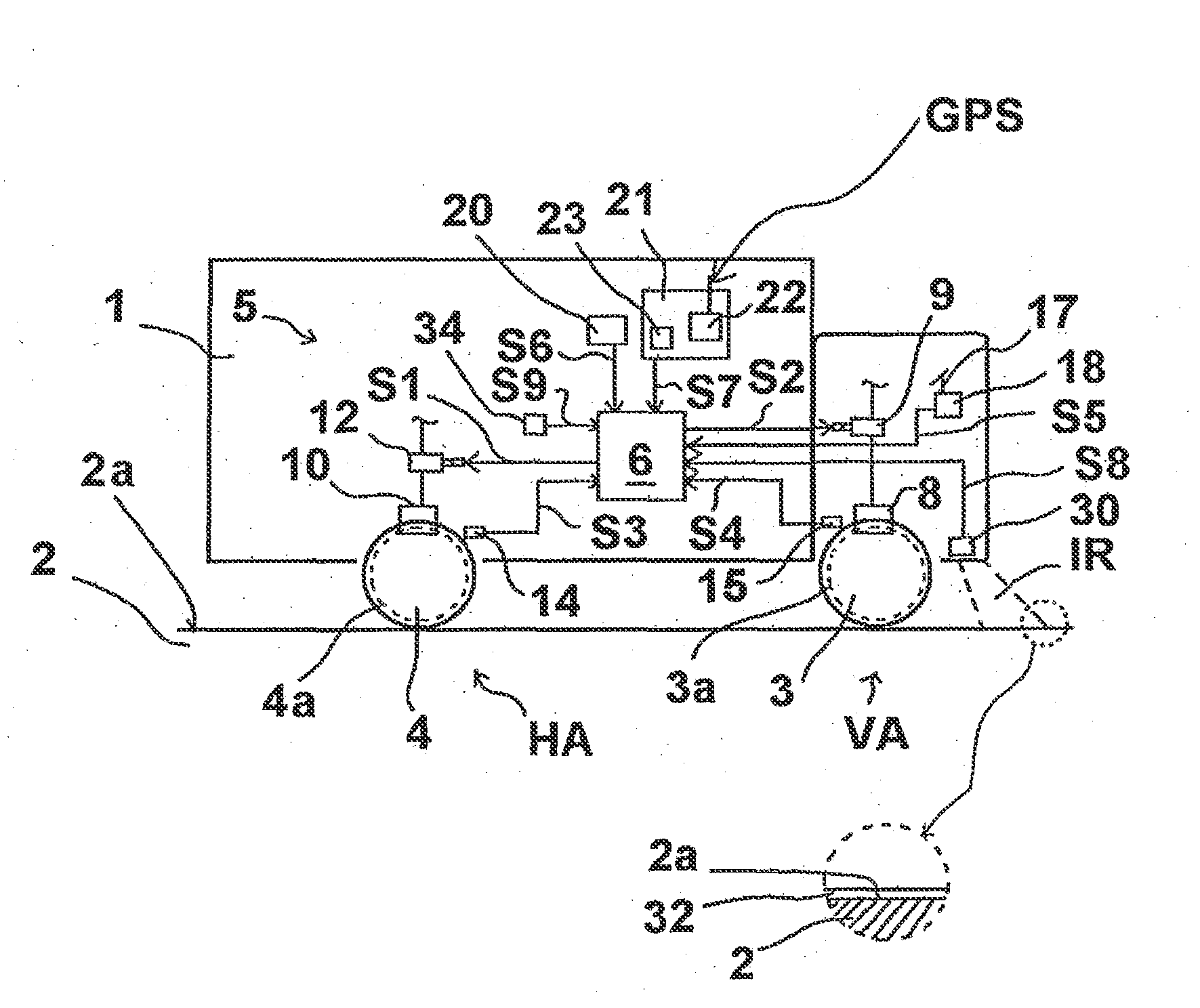

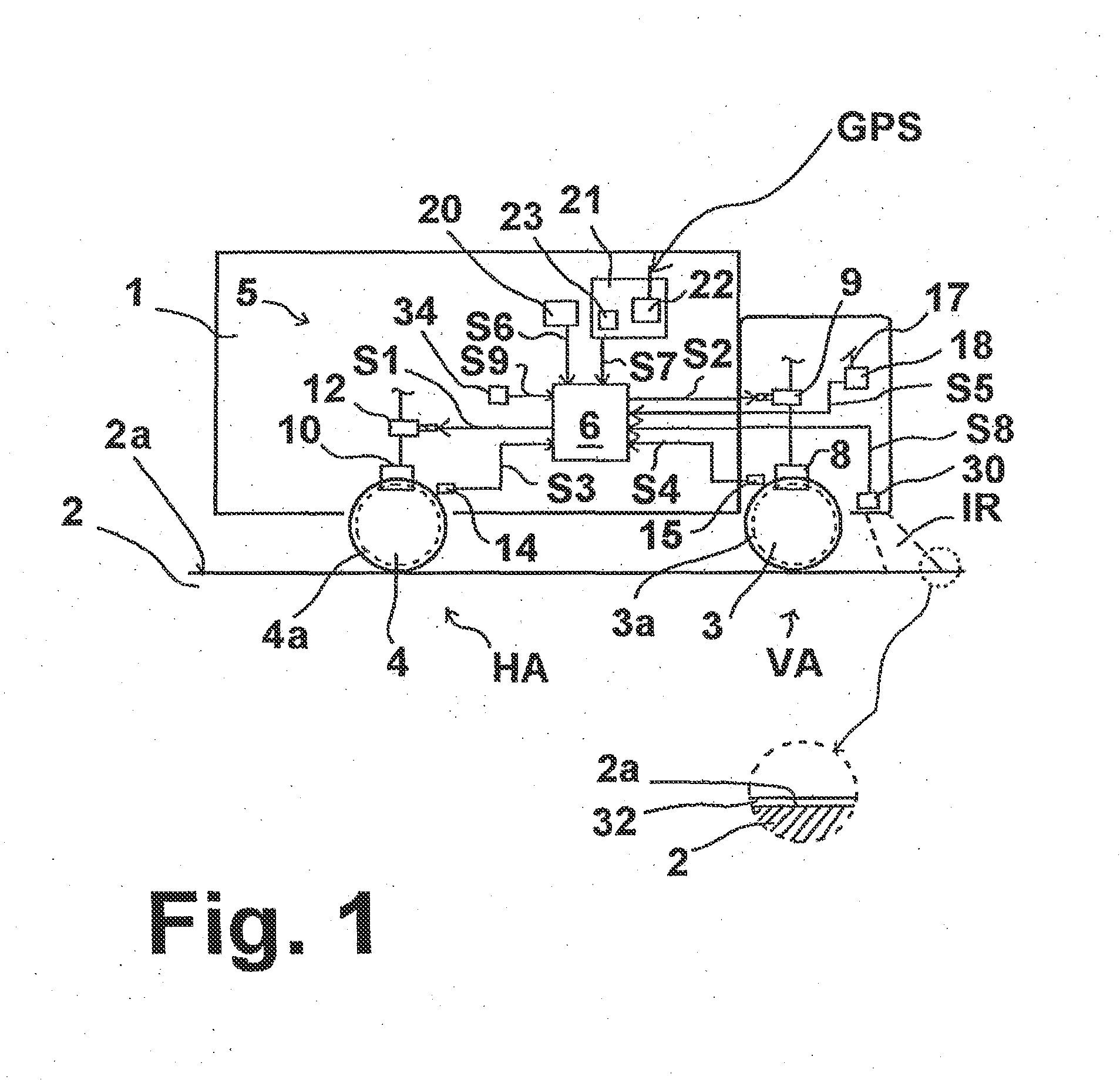

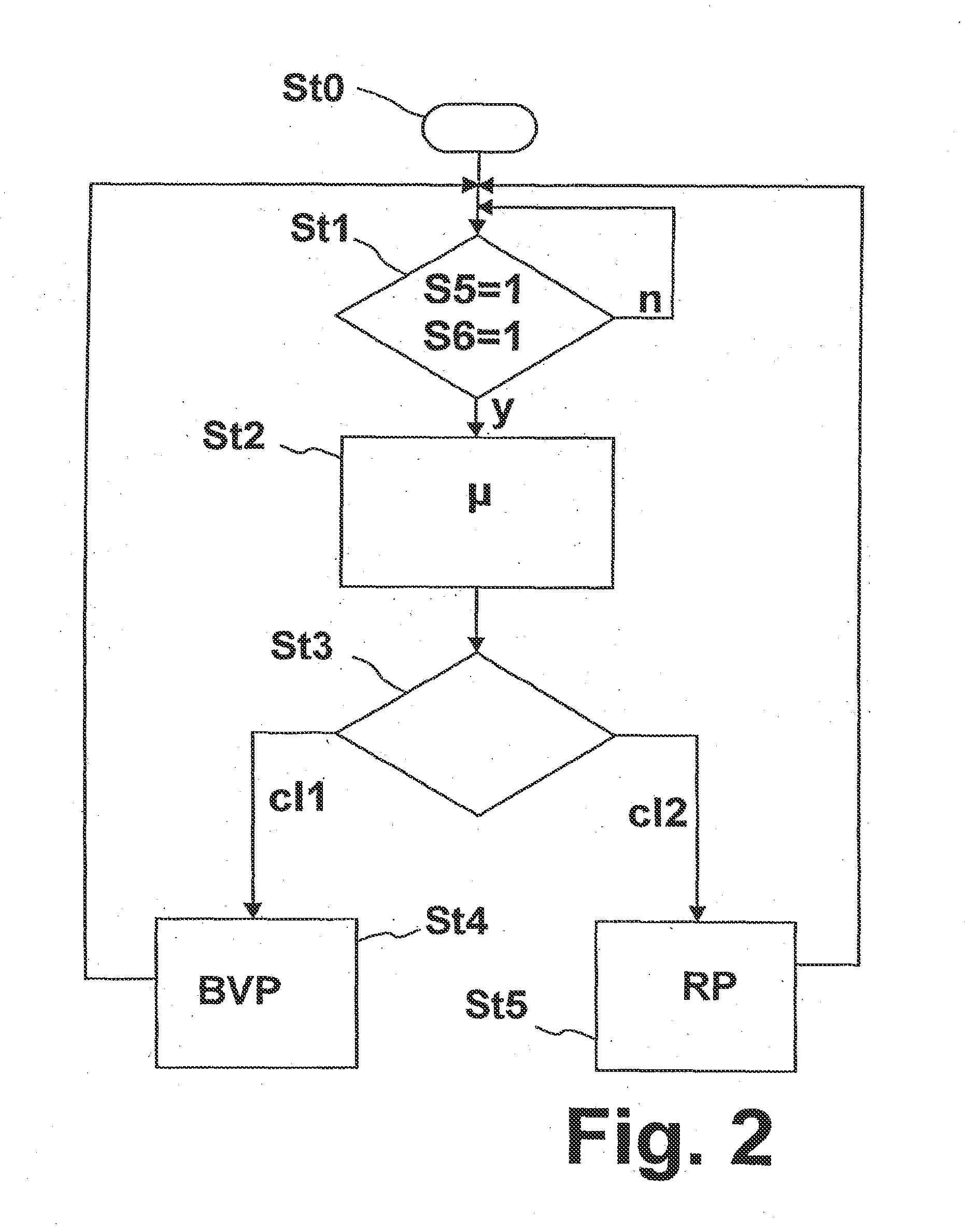

Method and Control Device fort Open-Loop or Closed-Loop Control of a Vehicle Brake System

ActiveUS20140188363A1Guaranteed uptimeImprove distributionAnalogue computers for trafficComputations using stochastic pulse trainsLoop controlClosed loop

A method for carrying out closed-loop or open-loop control of a vehicle brake system includes, when a braking request signal is present, setting brake pressures at brakes on axles and / or wheels of the vehicle by distributing brake pressure. Before braking is initiated on the basis of current, received or detected data relating to friction conditions or grip conditions between the roadway surface and tire surfaces of the vehicle, a determination is made as to whether, or to what extent, the distribution of brake pressure occurs in a brake wear pressure distribution or in a frictional engagement pressure distribution for the subsequent initiation of the braking process.

Owner:ZF CV SYST EURO BV

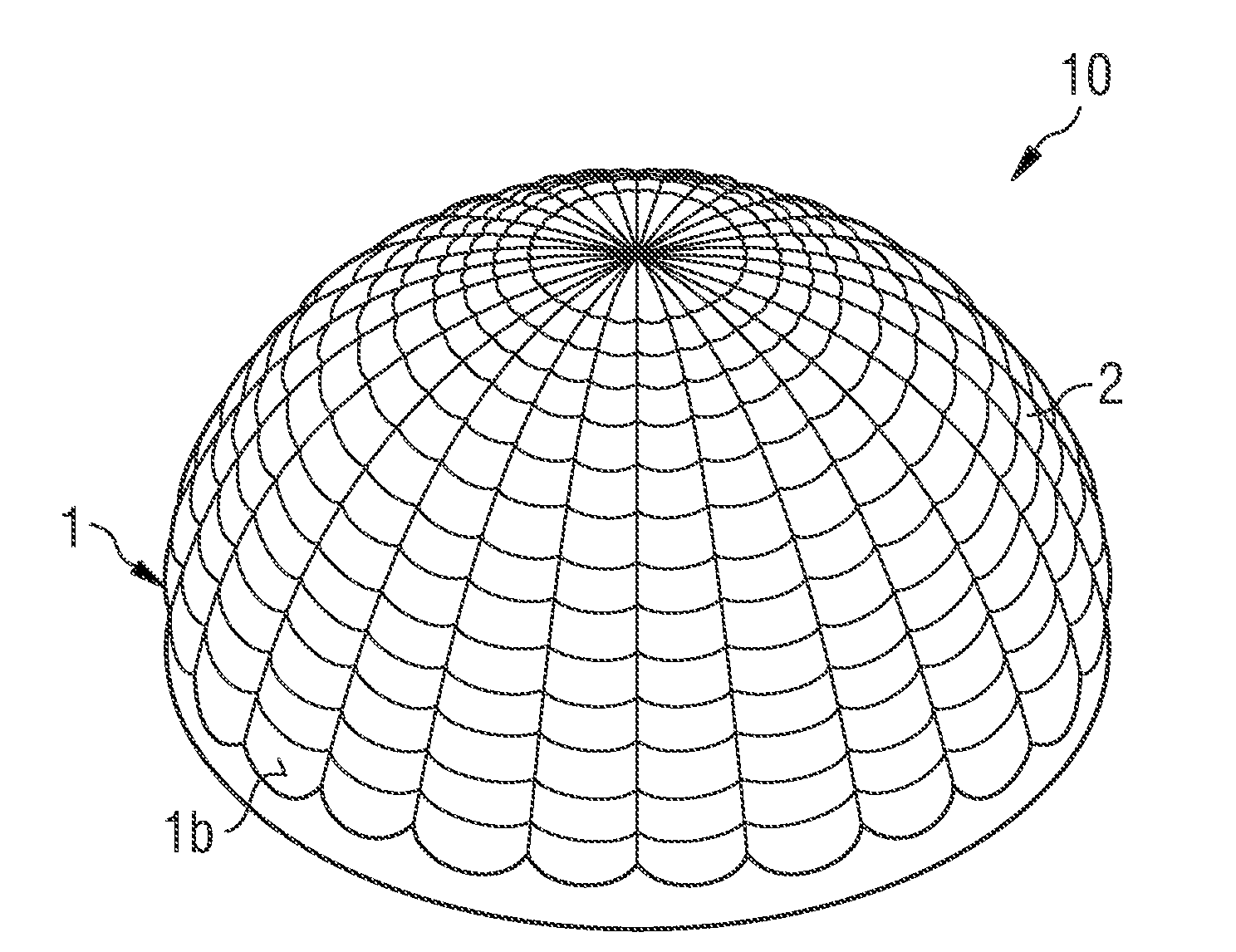

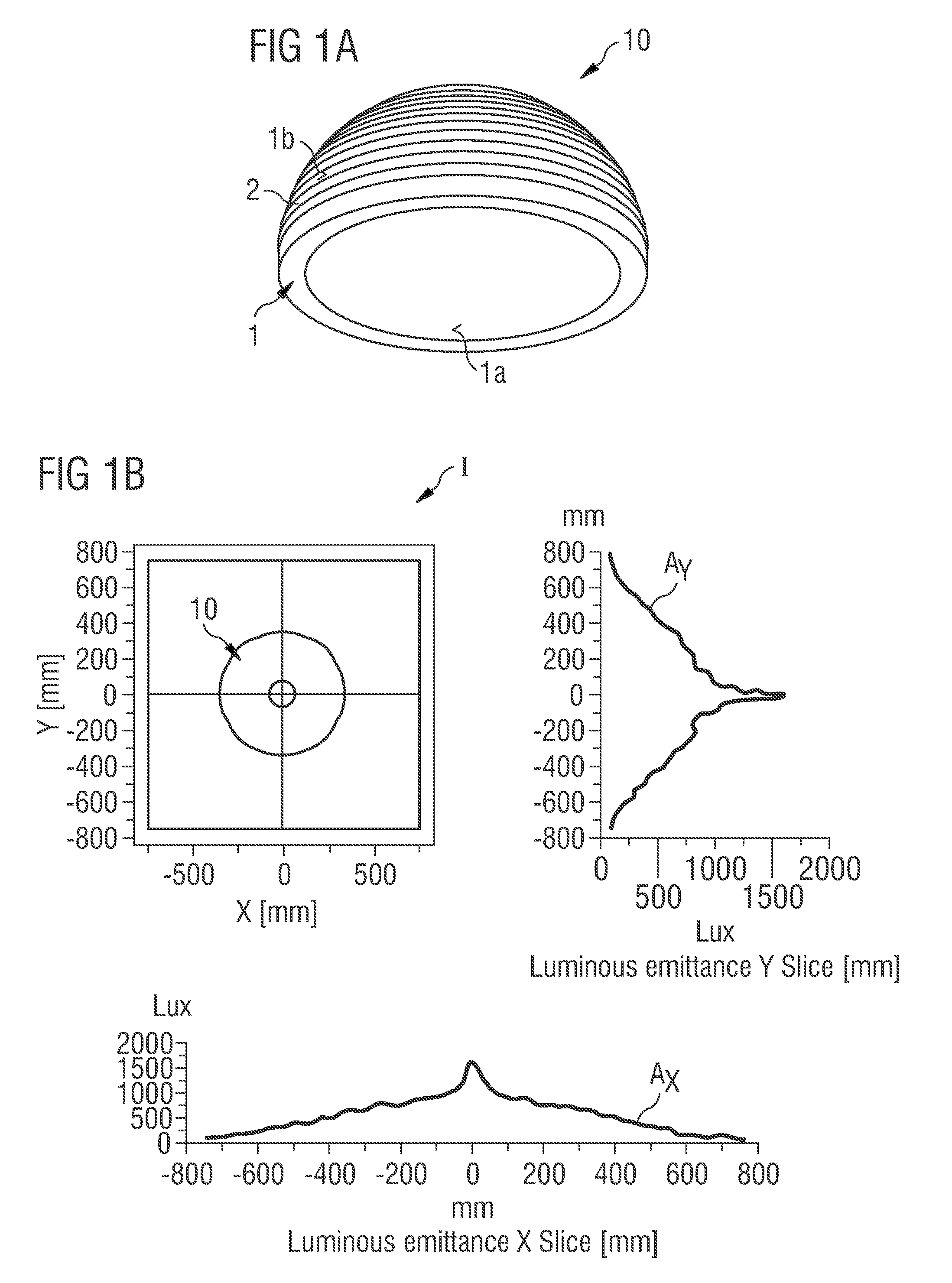

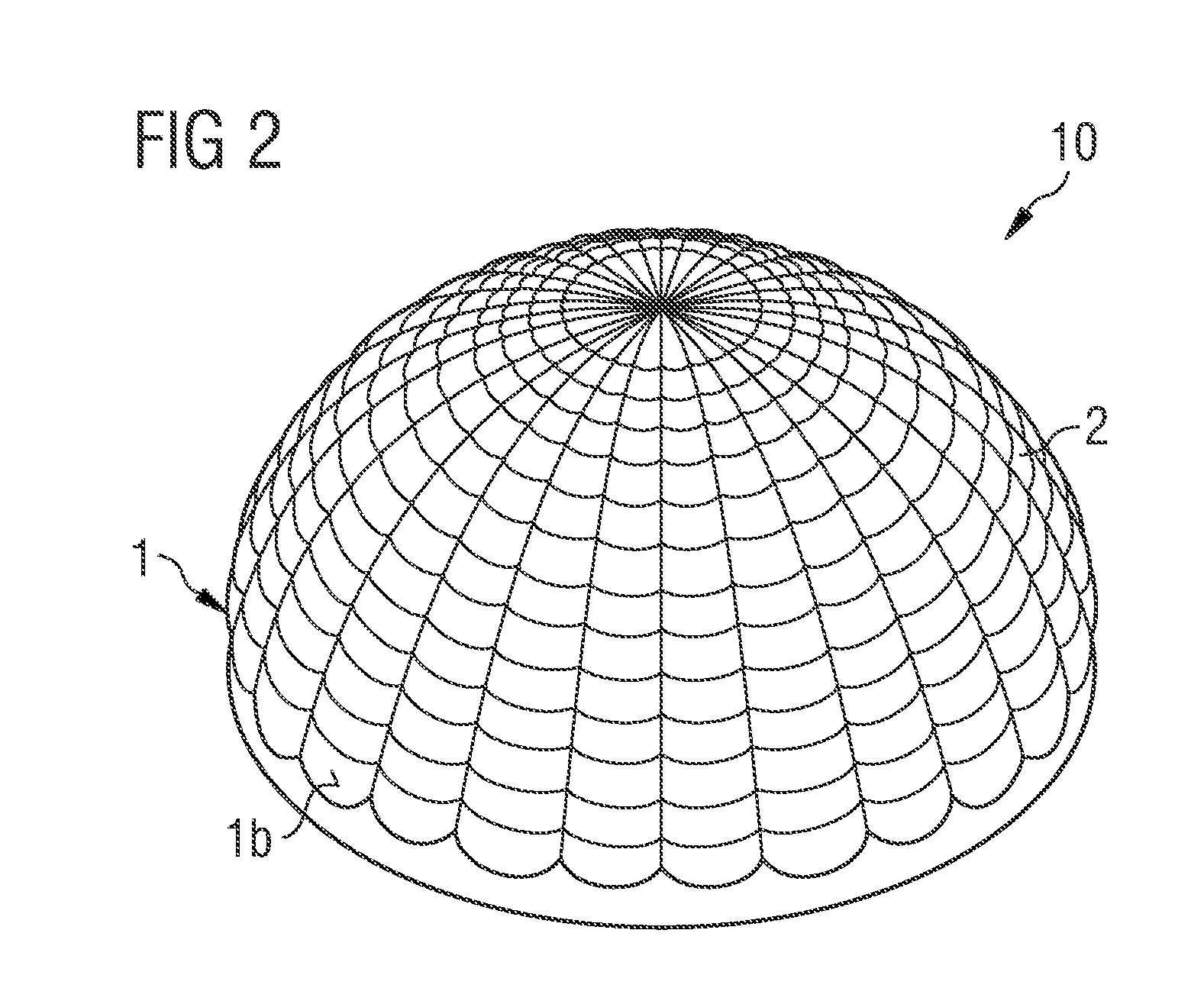

Optical Element and Radiation-Emitting Device Comprising Such an Optical Element

ActiveUS20140001507A1Obtain goodSimple designPlanar light sourcesSemiconductor devices for light sourcesLight scatteringMicrostructure

An optical element has an optical body and a number of microstructures. The optical body takes the form of a half-shell and has an inner face and an outer face. The microstructures form the inner and / or outer face of the optical body at least in places and are light-scattering refractive structures. The invention further relates to a radiation-emitting device having at least one semiconductor component and one such optical element.

Owner:OSRAM OLED

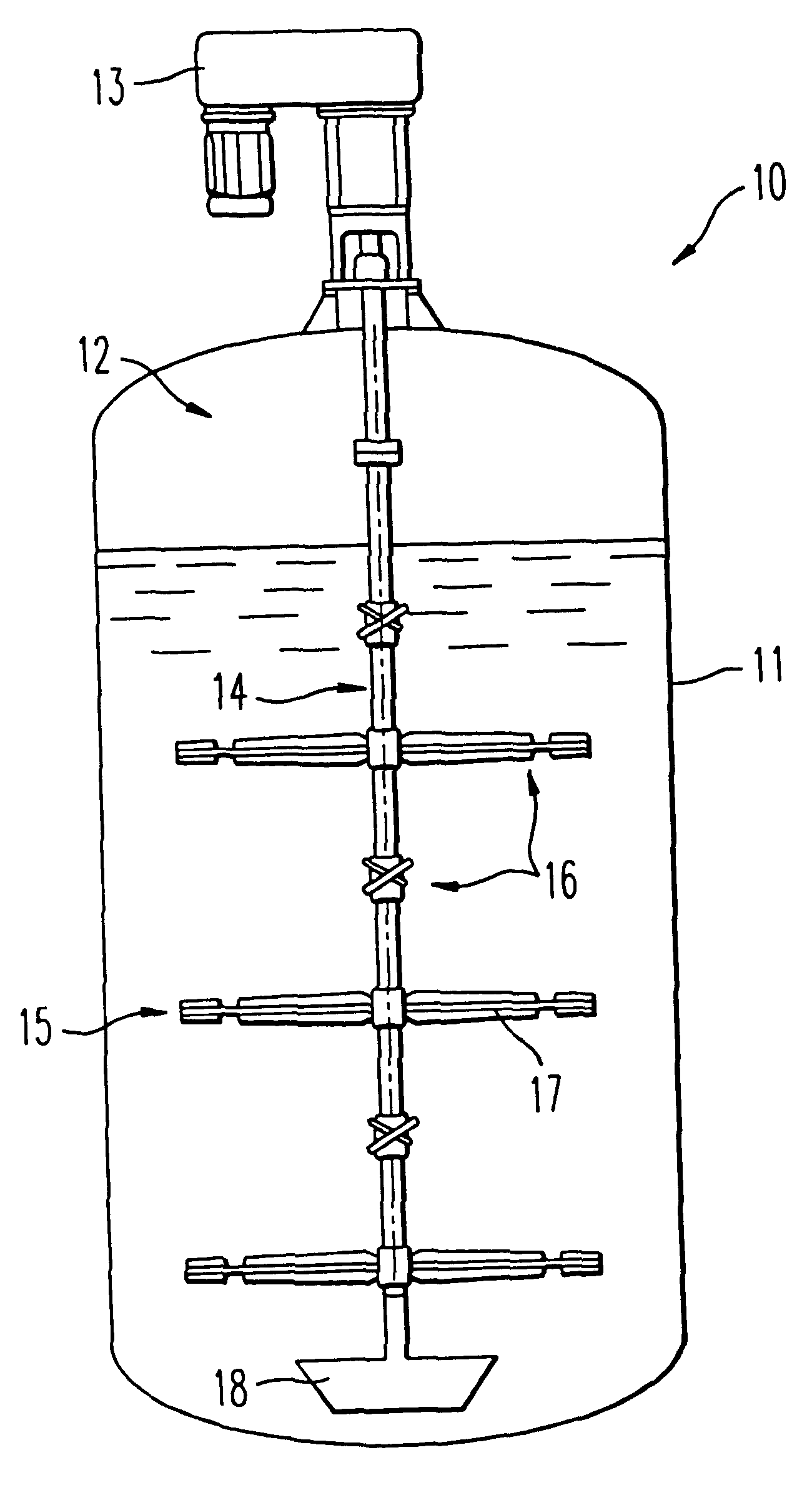

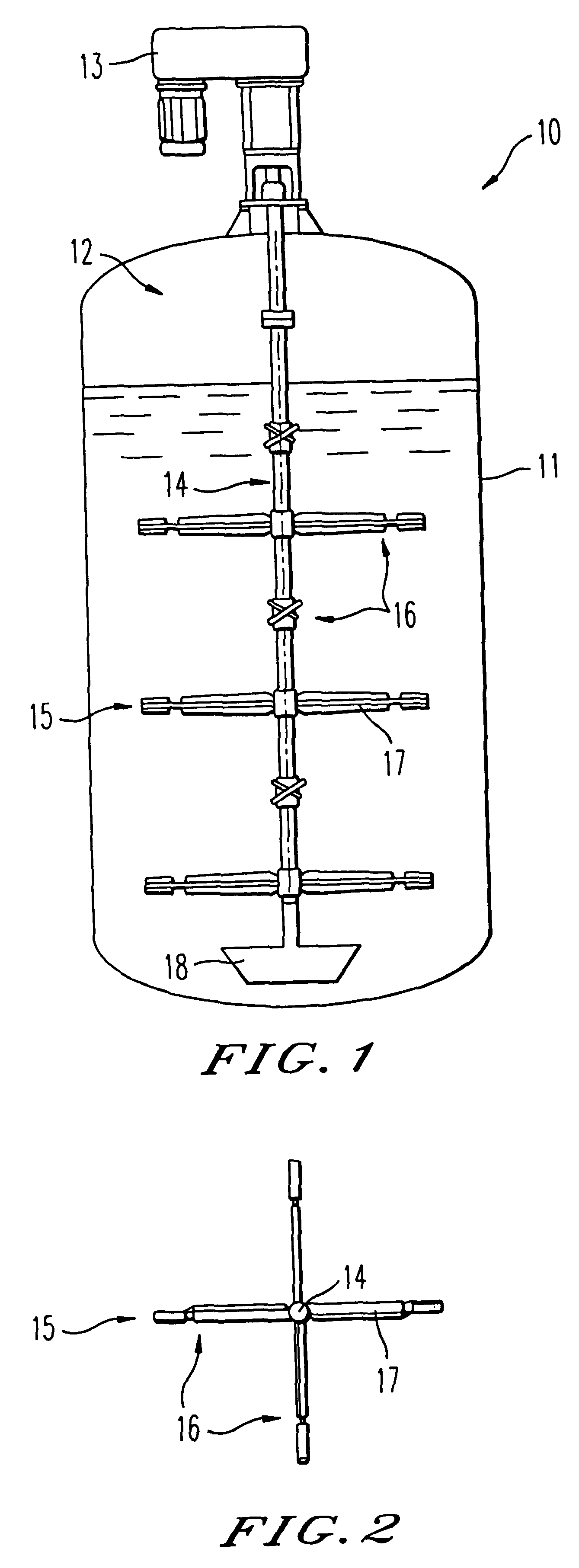

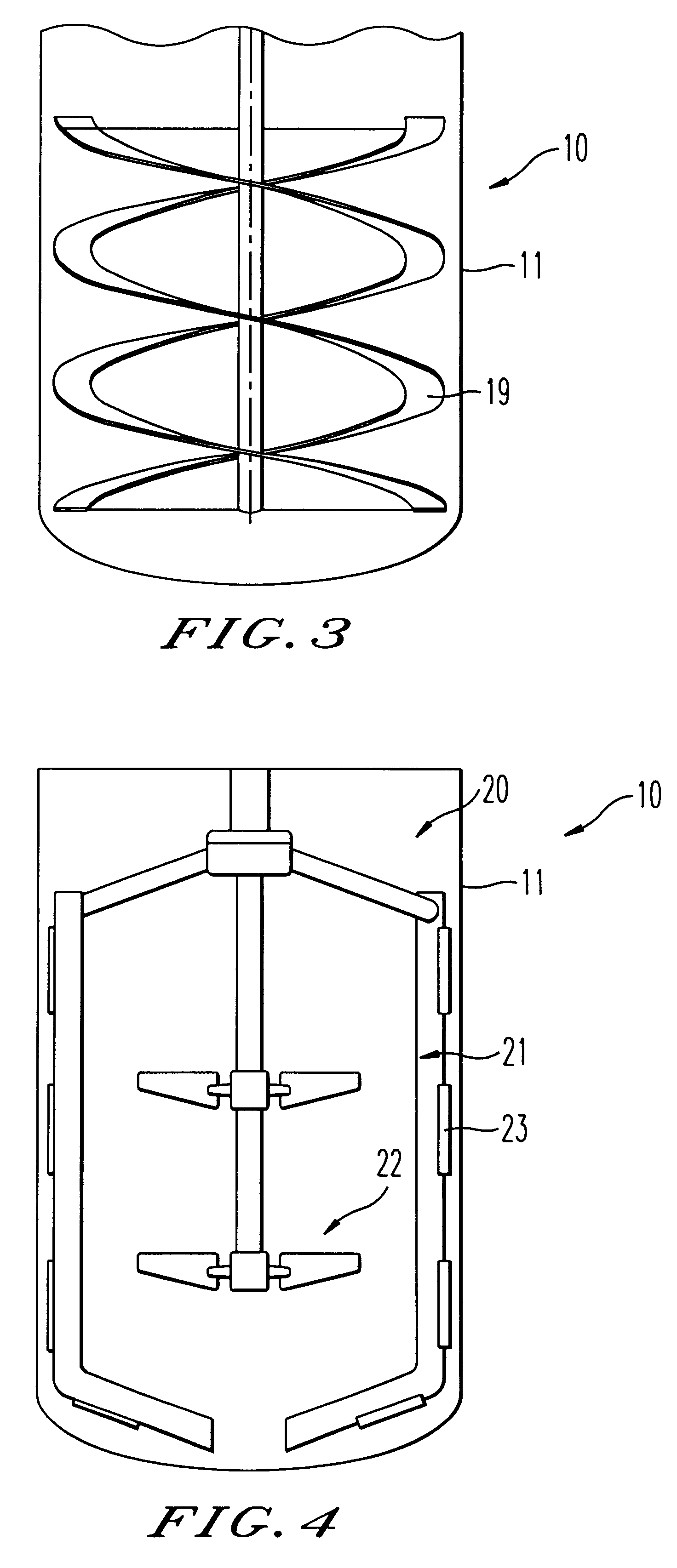

Use of a single-stage or multistage stirrer to prepare polymers

InactiveUS6252018B1Promote homogenizationImprove the overall coefficientRotary stirring mixersTransportation and packagingPolymer scienceSingle stage

At least one single-stage or multistage stirrer which produces not only a tangential flow component but also an axial flow field is used in a stirred-vessel reactor in connection with the preparation of polymers by liquid phase polymerization.

Owner:BASF AG

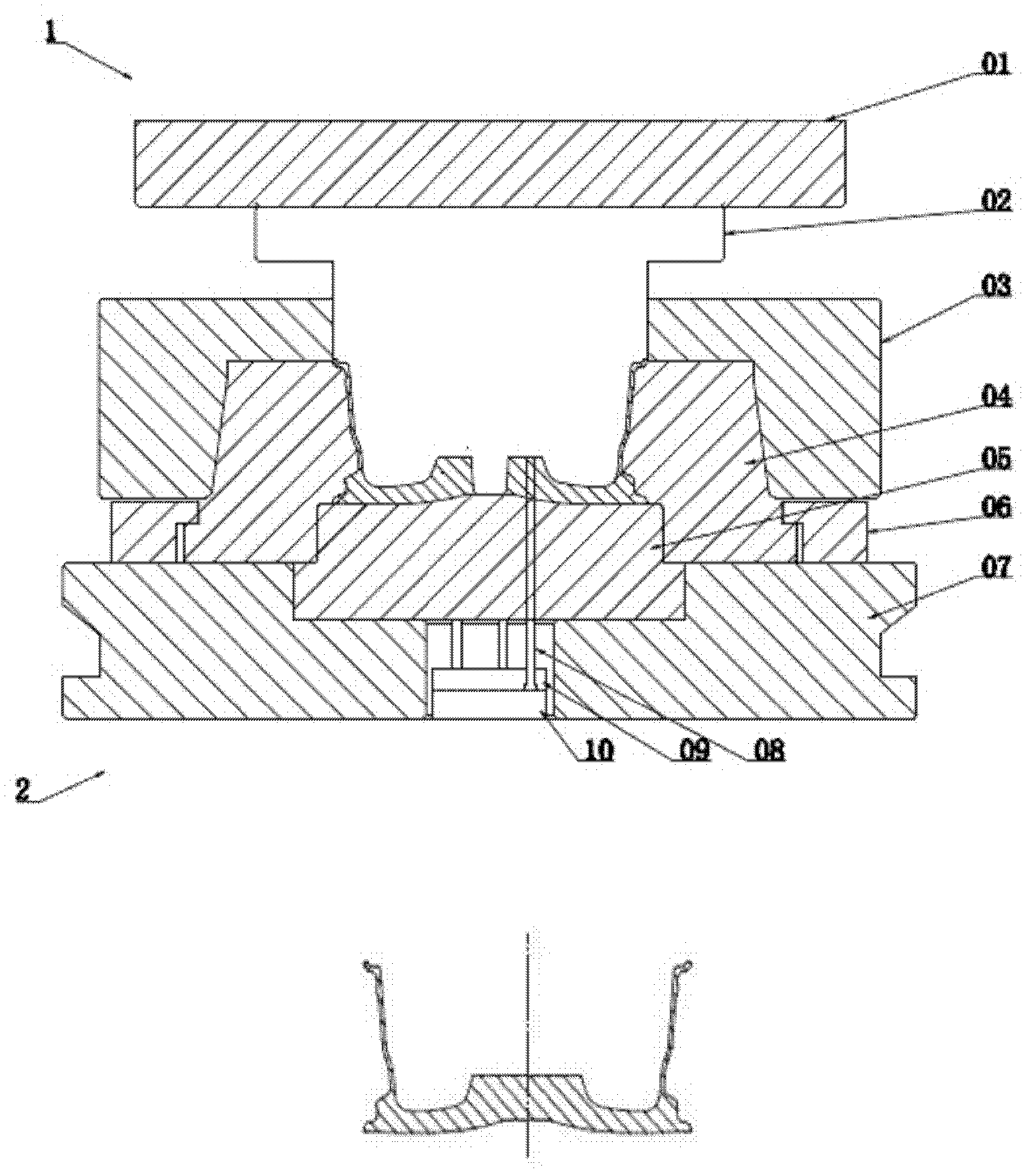

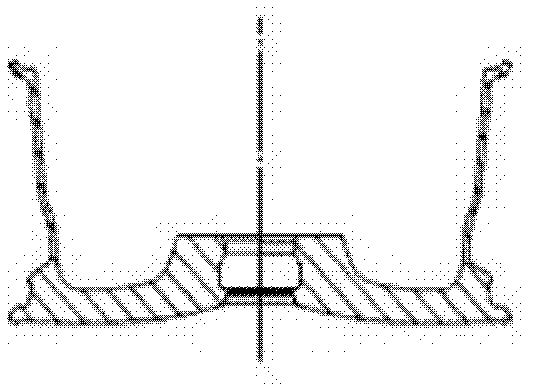

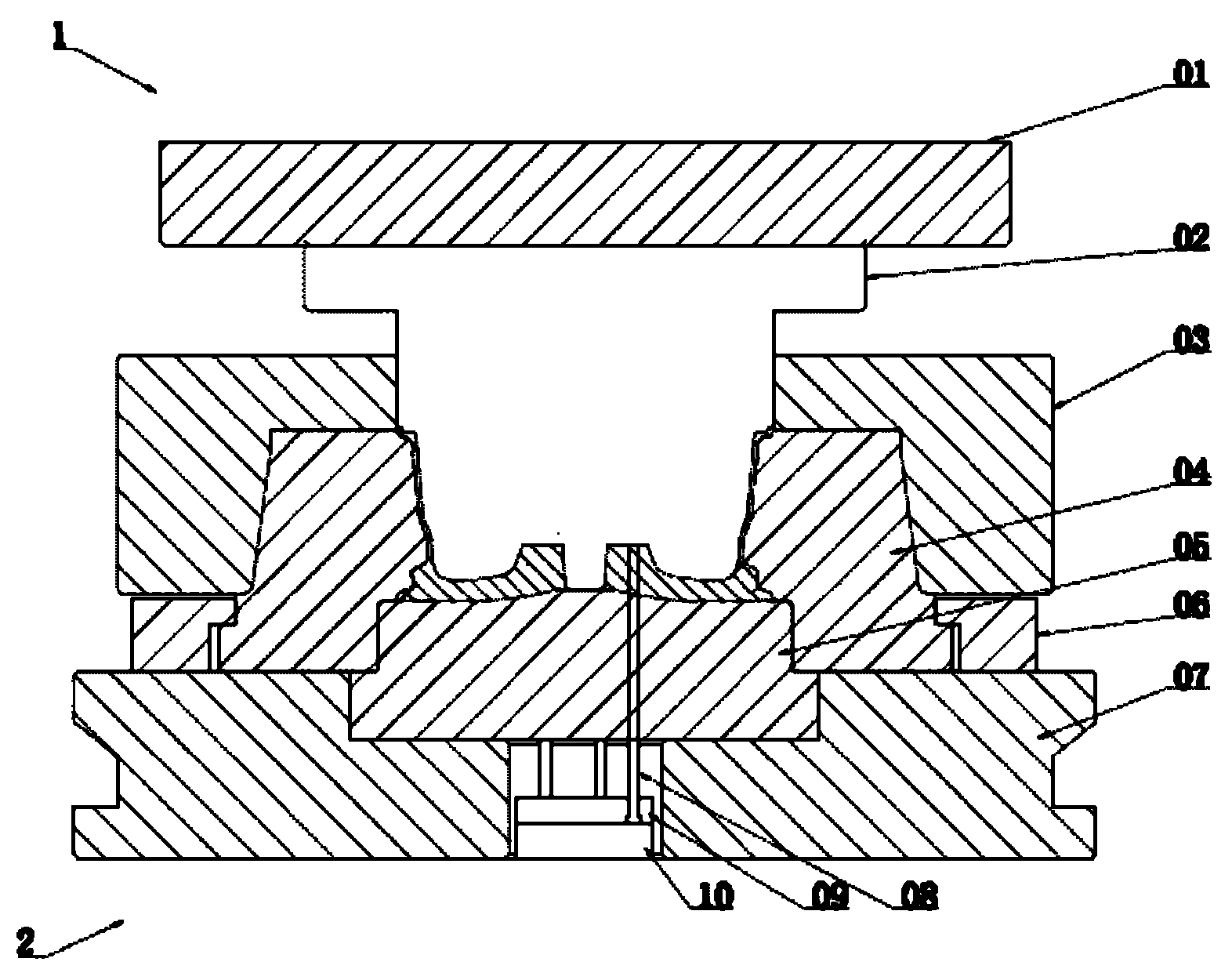

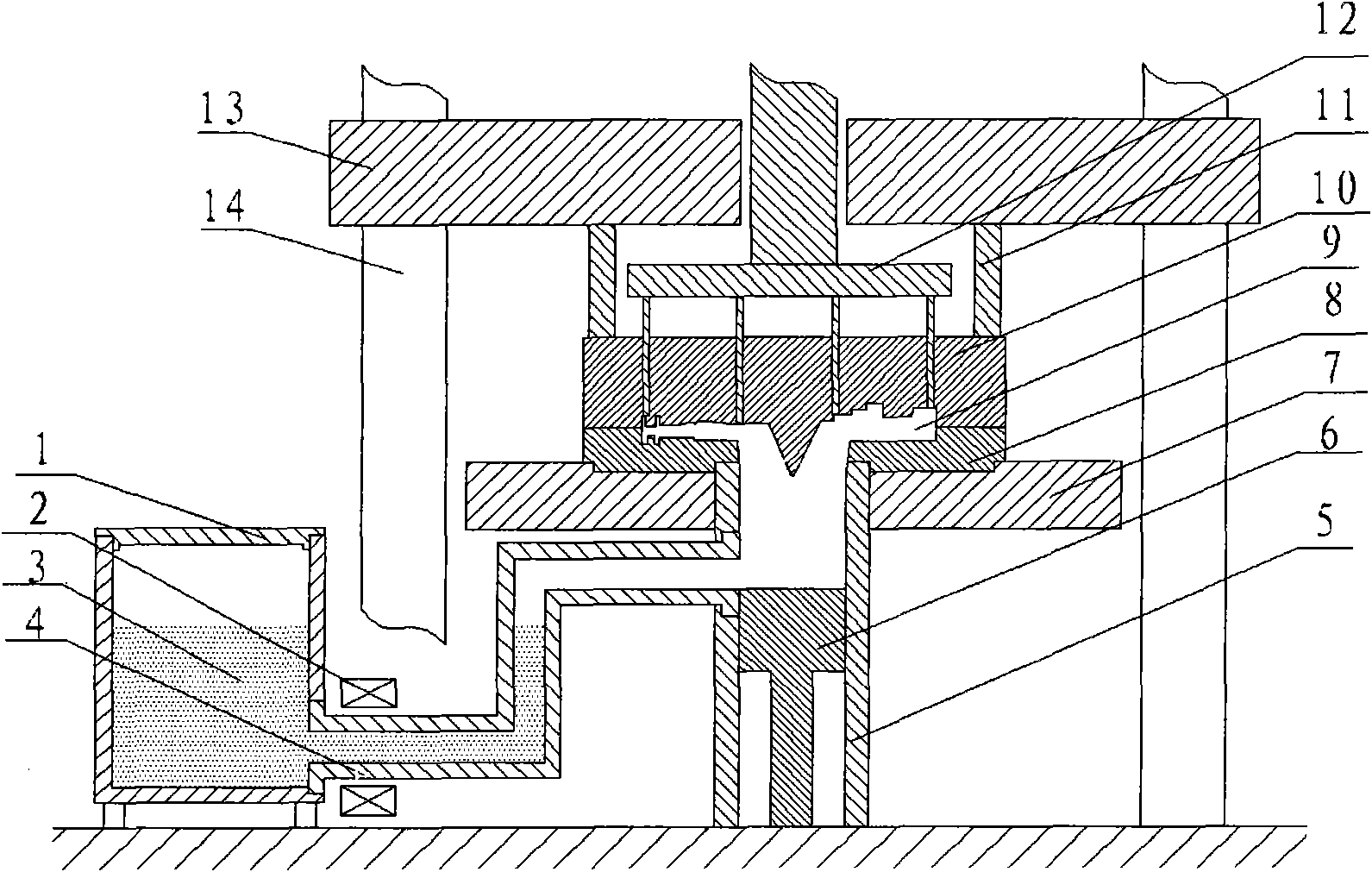

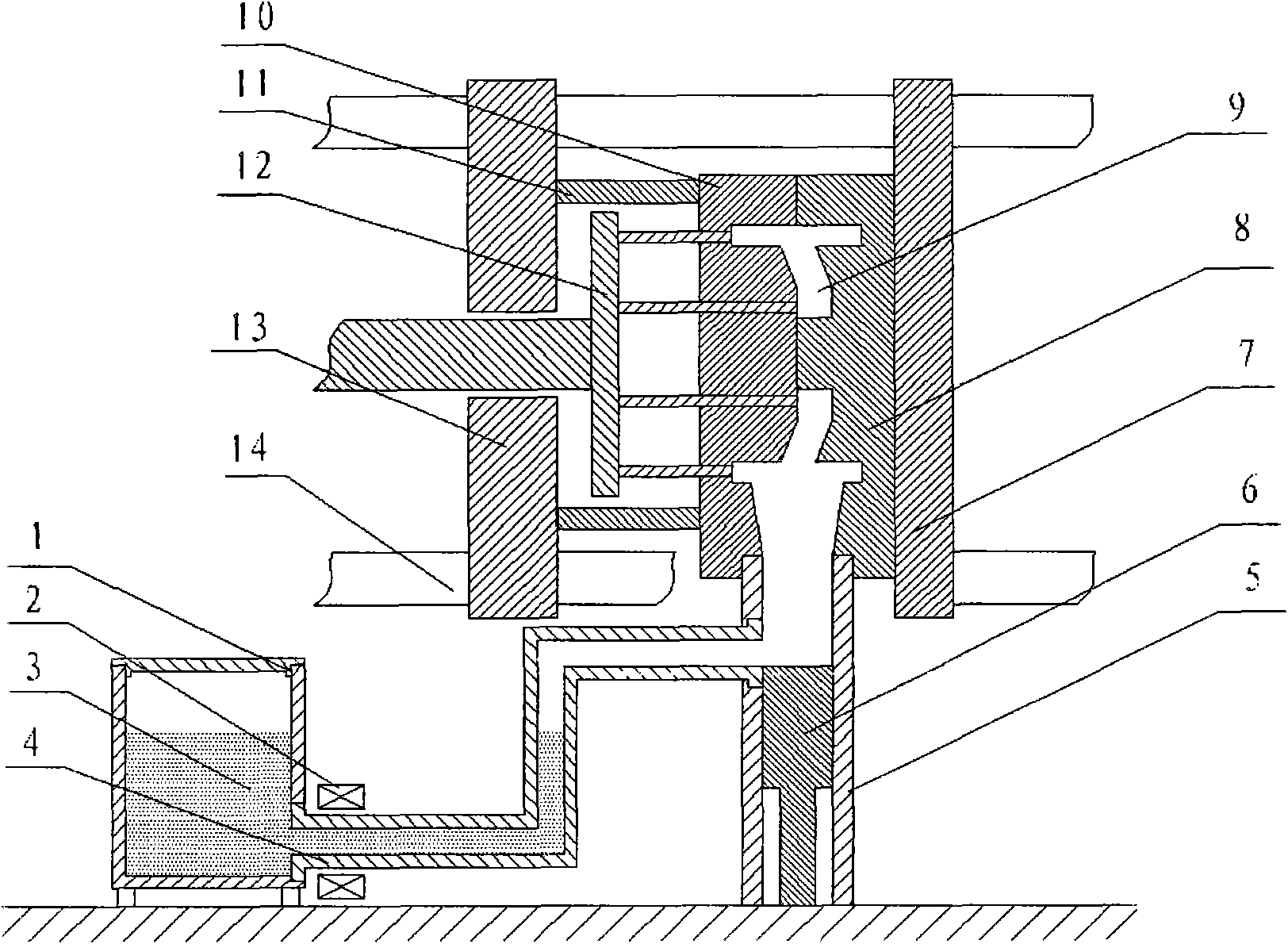

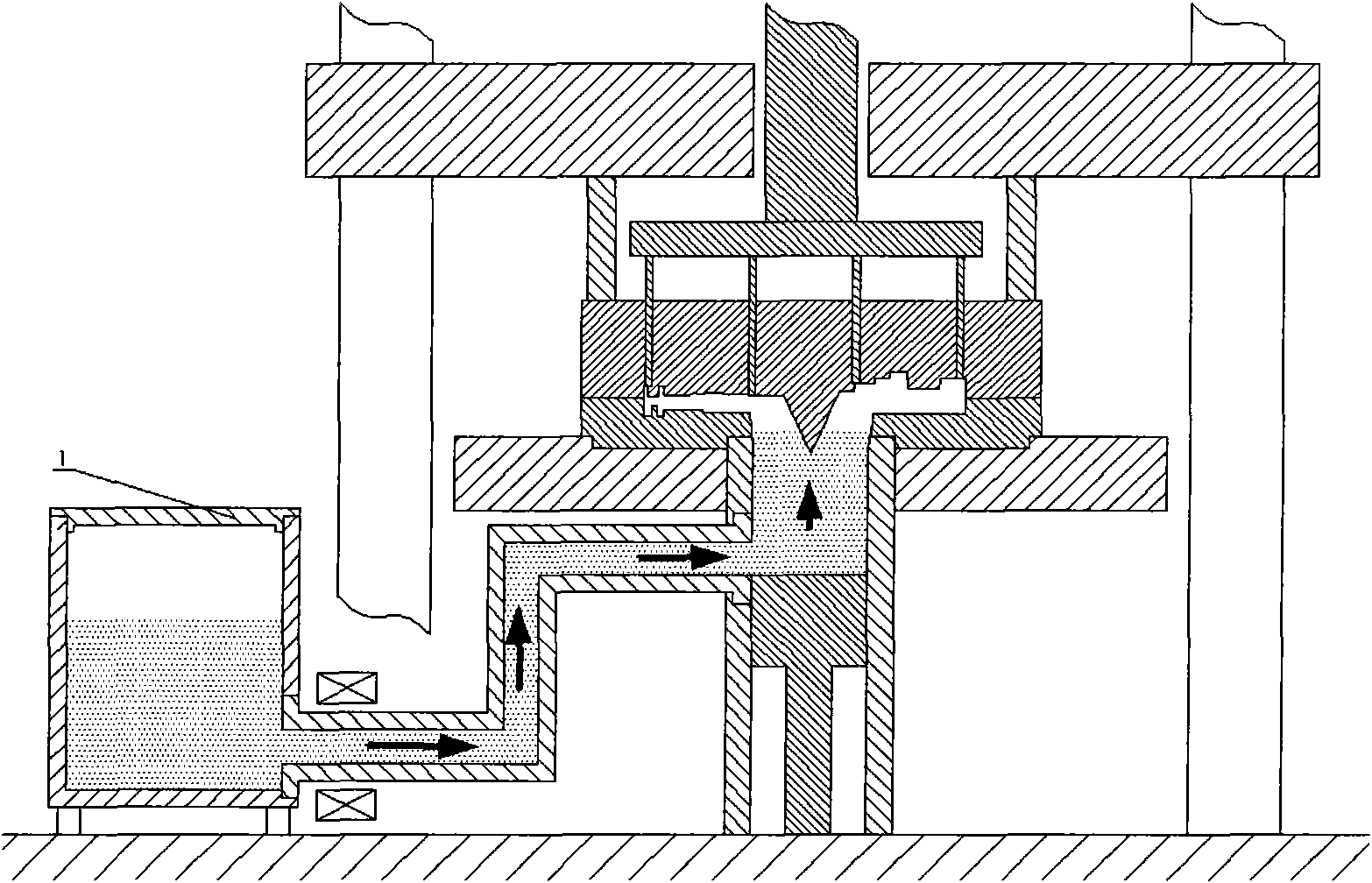

Method for indirect extrusion casting by utilizing filling of electromagnetic force and device thereof

The invention relates to a method for indirect extrusion casting by utilizing the filling of electromagnetic force and a device thereof. In the method, electromagnetic force is utilized to introduce liquid metal into an extrusion chamber to fill part of a mould cavity by a transmission pipeline; when the liquid metal in the mould cavity reaches a preset quantity, the transmission of the liquid metal is stopped; and an extrusion punching head ascends to push the liquid metal to fill the part which is not full in the mould cavity and continuously ascends to extrude and shape the liquid metal, and the liquid metal in the transmission pipeline flows back to a thermal insulation furnace under the function of reverse electromagnetic force. The invention has simple and convenient method, high automatization degree, good stability and skillful structural design of a special device. The liquid metal is transmitted and filled by a sealed transmission pipeline, and oxidation and air suction are reduced; the flow speed and the flow rate are controllable, and the quantification of extrusion casting is realized; at the time of extrusion shaping, the liquid metal in the transmission pipeline flows back, and the production efficiency is enhanced; and the friction and the abrasion of the extrusion punching head and the extrusion chamber are reduced, and the service lives of the extrusion punching head and the extrusion chamber are enhanced.

Owner:SOUTH CHINA UNIV OF TECH

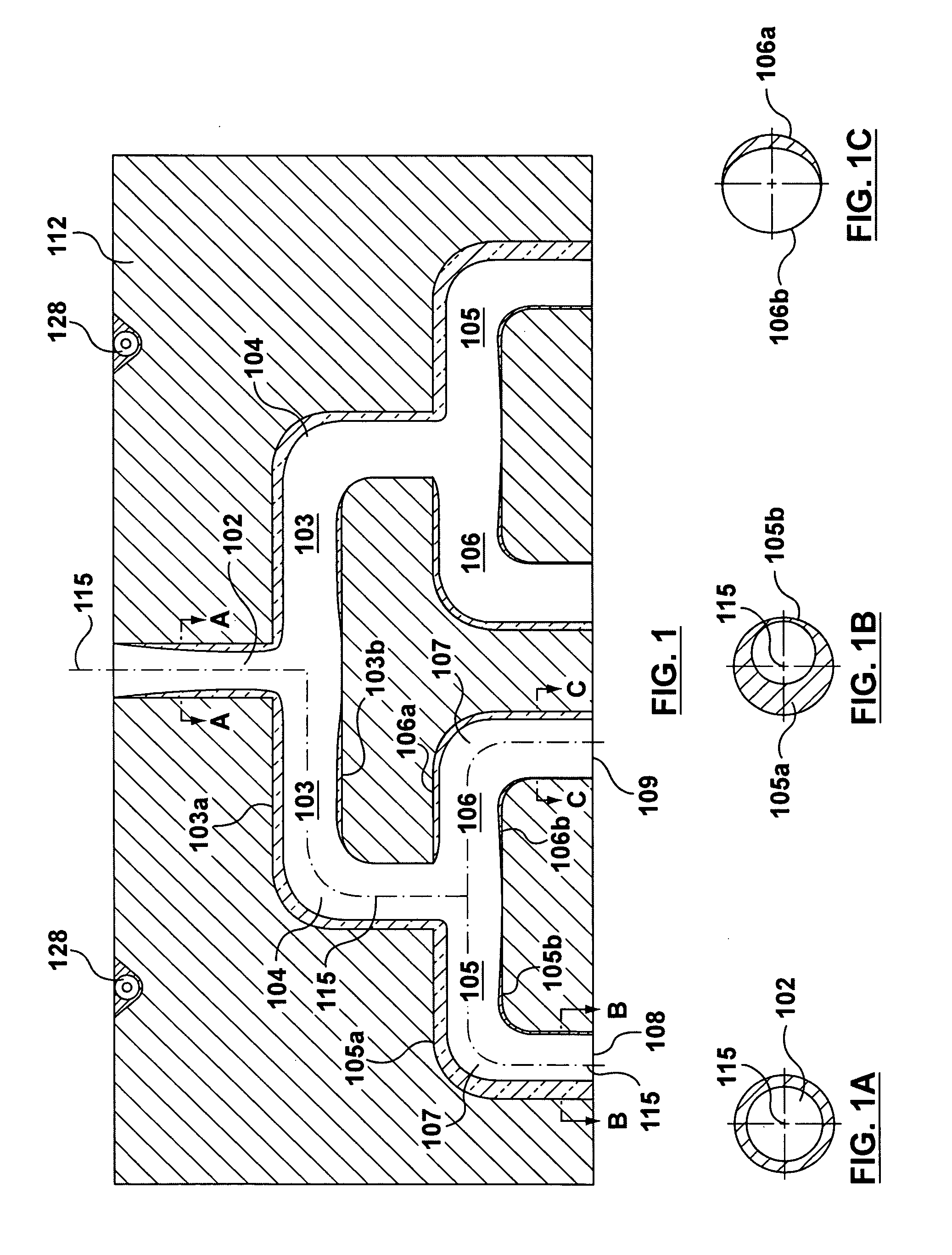

Melt redistribution element for an injection molding apparatus

ActiveUS20070077328A1Promote homogenizationReduce the overall diameterFlow mixersTransportation and packagingHot runnerShear stress

An injection molding apparatus having a manifold and several manifold melt channels communicating with several hot runner nozzles includes a melt redistribution element. The melt redistribution element is placed at specific locations along the melt channels to balance the uneven shear stress profile accumulated during the flow of a melt along the manifold channels. The melt redistribution element has an unobstructed central melt bore having at its inlet a narrowing tapered channel portion. The melt redistribution element also includes a helical melt pathway portion that surrounds the central melt bore. The incoming melt is first subjected to a pressure increase by the tapered portion that causes the melt to flow at a higher velocity through the central melt bore. The outer portion of the melt is forced to flow along the helical path and thus it changes direction multiple times and partially mixes with the melt flowing through the central melt bore. Accordingly, at the outlet of the melt redistribution element the shear stress profile is more evenly distributed than at the inlet of the redistribution element.

Owner:MOLD MASTERS 2007

Polyving alcohol composite hydrogel and preparation method thereof

The invention relates to polyving alcohol composite hydrogel and a preparation method thereof. The polyving alcohol composite hydrogel is prepared from the following raw materials in parts by weight through cross-linking solidifying compounding of boric acid solution containing solidifier: 30 to 90 parts of polyving alcohol, 0.1 to 50 parts of sodium alginate, 0.1 to 20 parts of inorganic nanoparticles, 1 to 20 parts of elastomer material, 0.5 to 5 parts of coupling agent and 200 to 2000 parts of water, wherein the degree of polymerization of polyving alcohol is 400 to 3000, and the alcoholysis degree is 75 to 99 percent. The polarity elastomer material and the inorganic nanoparitcles which are processed through the coupling agent are compounded with the polyving alcohol, the mechanical strength and flexibility of the polyving alcohol hydrogel can be improved through the toughening effect of the elastomer material and the synergistic effect of the inorganic nanoparticles, so that the service life is prolonged, and the requirement of the real application on the mechanical performance can be met; the preparation method of the polyving alcohol composite hydrogel is simple in process, easy to operate and applicable to the mass production.

Owner:CHINA PETROCHEMICAL CORP +2

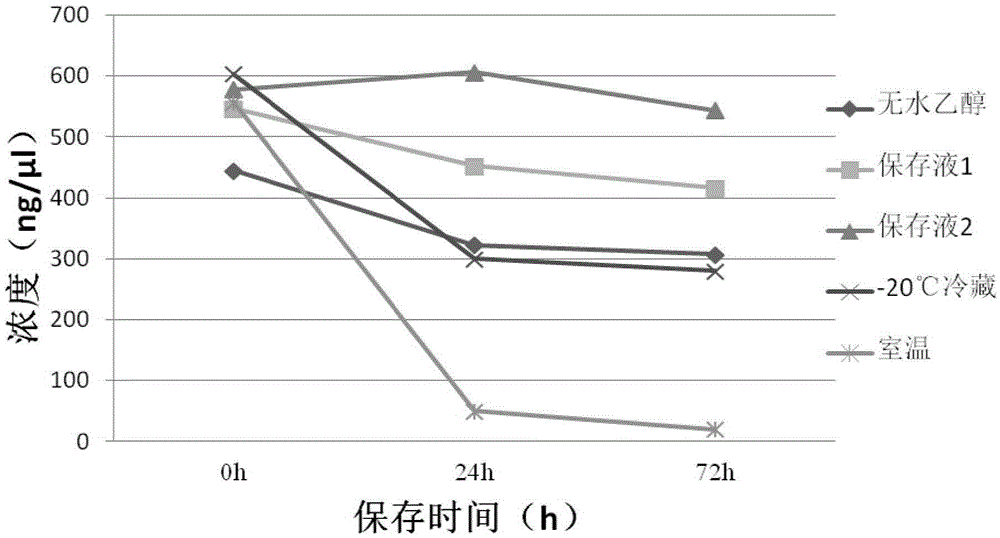

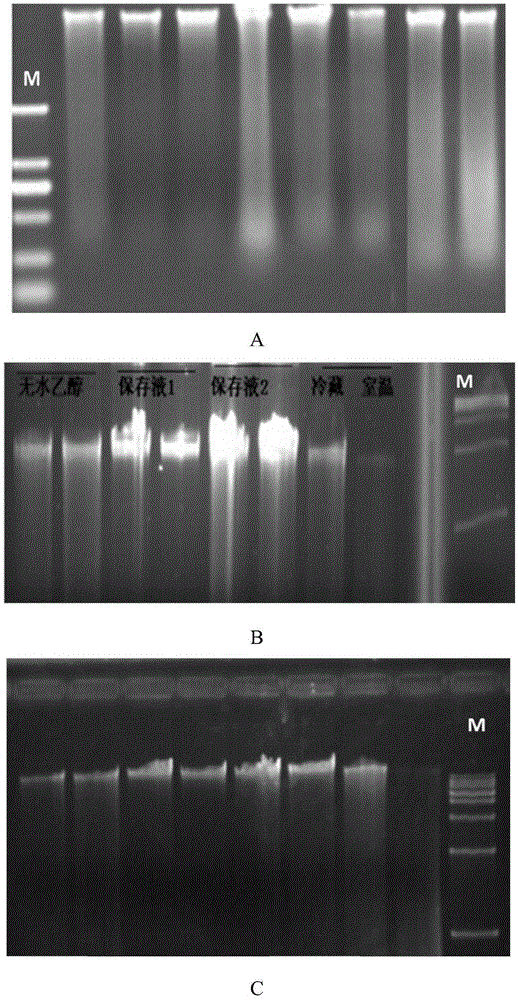

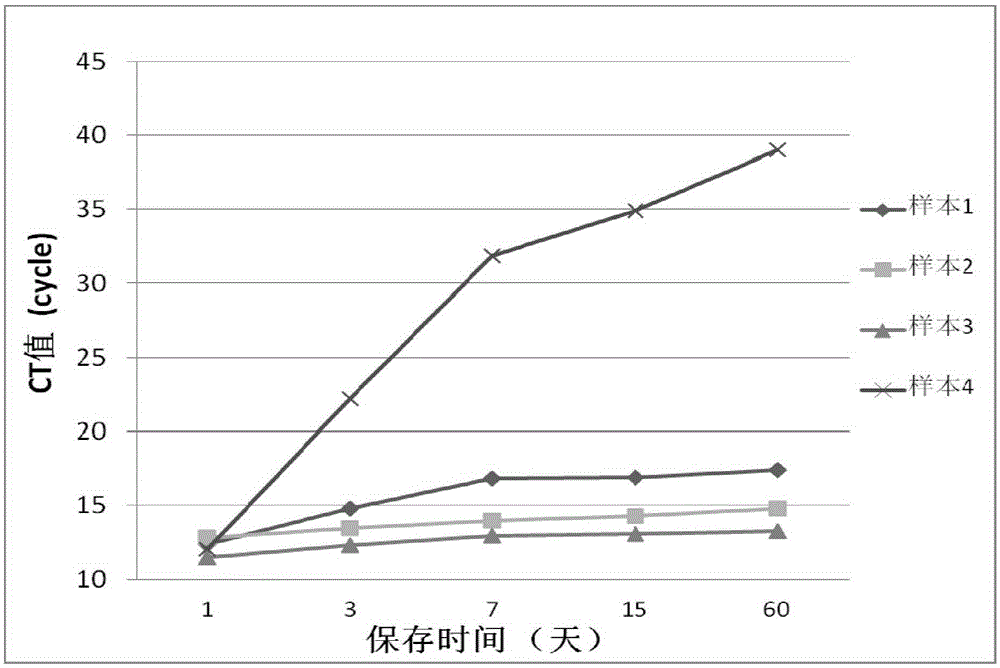

Stool sample preservation liquid, preparation method and application thereof

InactiveCN106596211AEasy to manufactureLow costPreparing sample for investigationIonic strengthAdjuvant

The invention discloses a stool sample preservation liquid, a preparation method and application thereof. Specifically, the stool sample preservation liquid contains: 45 vol%-60 vol% of a fixing agent; 0.1 mass%-15 mass% of a fixing agent adjuvant; 0.01 mass%-1.5 mass% of an anticoagulant; 10 vol%-15 vol% of a buffer solution; 0.01 mass%-1 mass% of an ionic strength maintenance agent; 0.01 vol%-0.5 vol% of a nonionic detergent; and the balance water. The stool sample preservation liquid provided by the invention has the characteristics of easy preparation and low cost, can preserve stool samples at room temperature, also can effectively inhibit DNA degradation and cell damage of stool samples, maintain cell shape, and can preserve samples for a long time, and the preserved samples have high qualification rate during reutilization.

Owner:SHENZHEN HUADA GENE INST

LCD sheet glass

The invention discloses a base plate glass with rare-earth element to dope liquid crystal display device (TFT-LCD), which is characterized by the following: comprising glass basic oxide, lanthanum oxide, cerium oxide, neodymium oxide and or yttrium oxide; setting the mass ratio at (60. 5-195):(0. 003-28) of the glass basic oxide and all rare-earth oxide; adding at least three rare-earth oxide; improving the fusion of the glass; accelerating clarification and equalization in the course of formation; preventing glass crystallizer; decreasing the liquid phase temperature; delaying devitrification speed of the glass; fitting for productive technology of float glass; improving chemical stability of the glass; decreasing the expansion coefficient; fitting for large scale float glass procession.

Owner:CHINA BUILDING MATERIALS ACAD

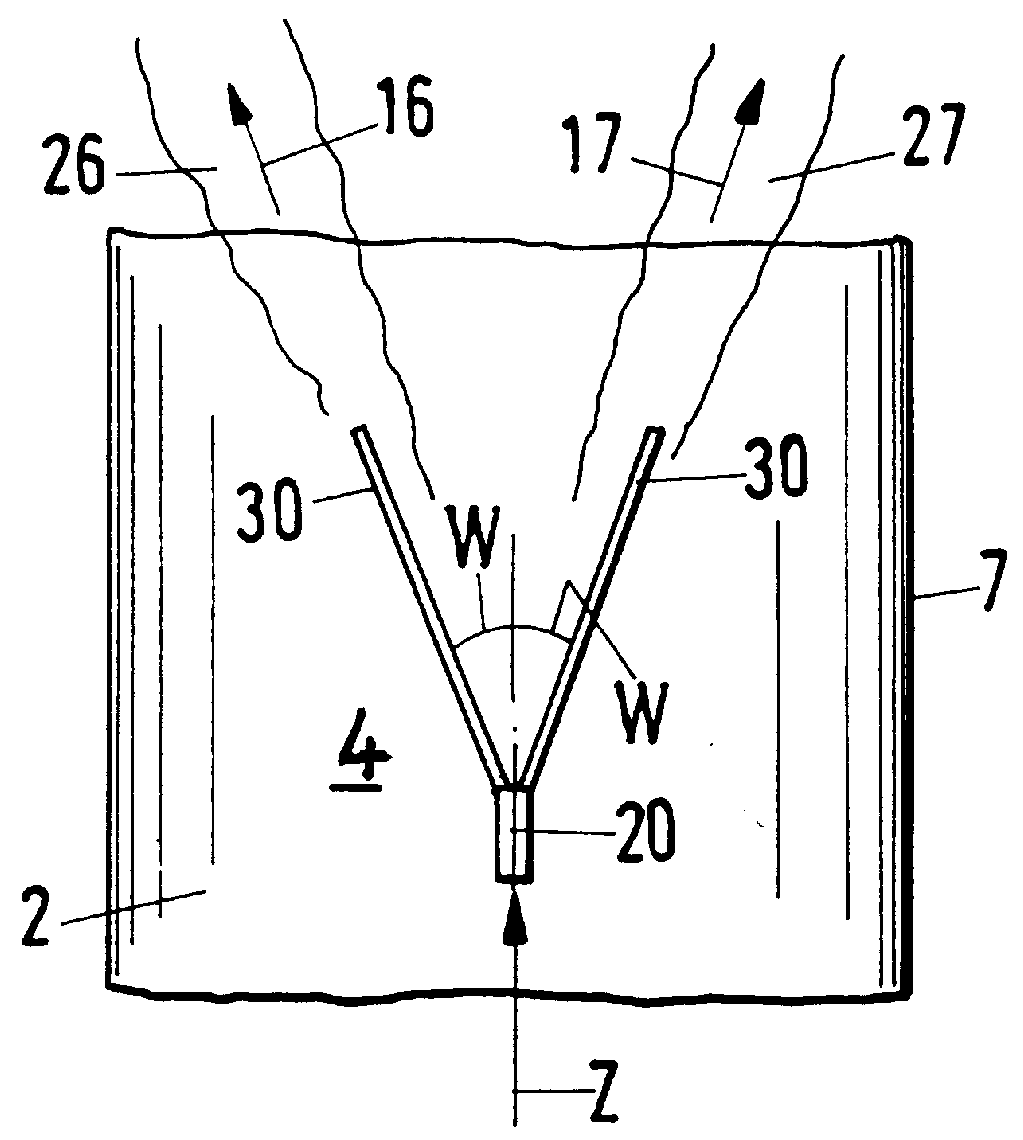

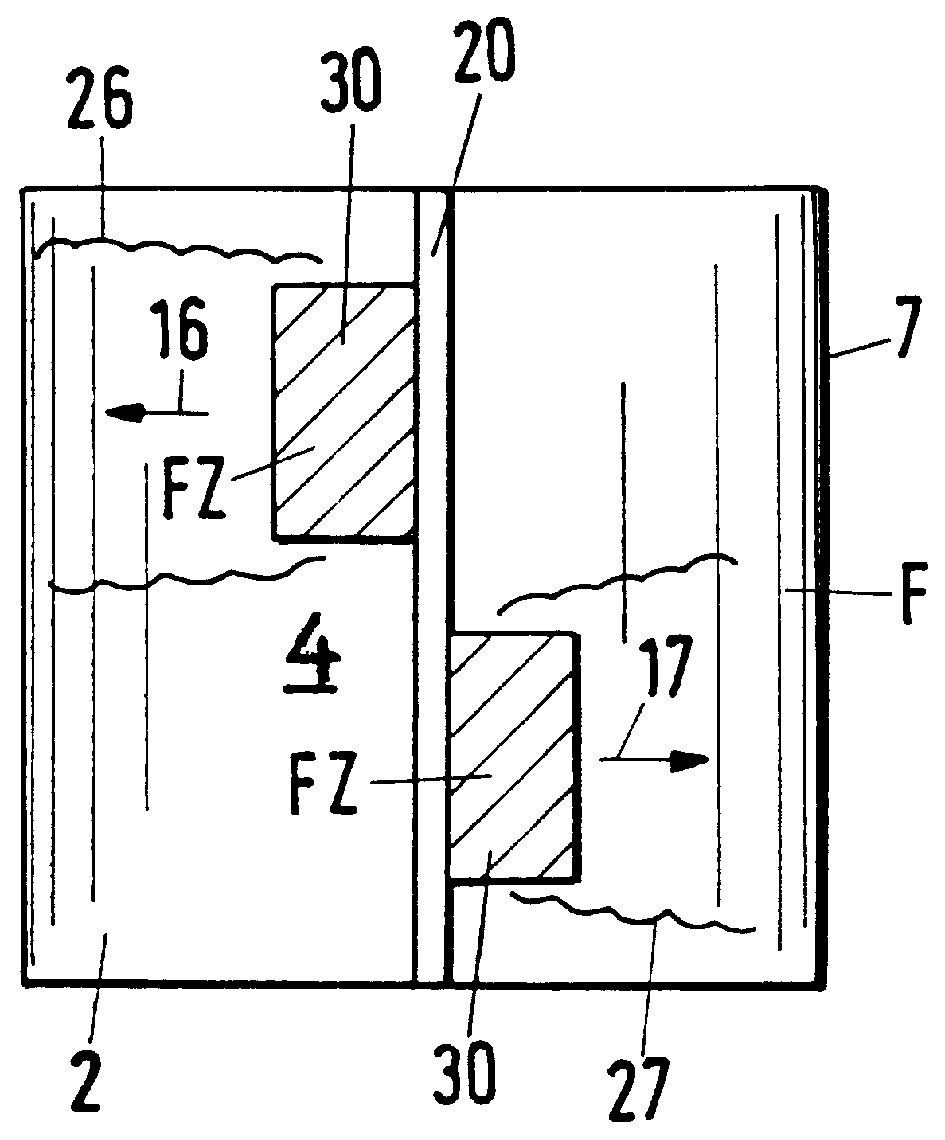

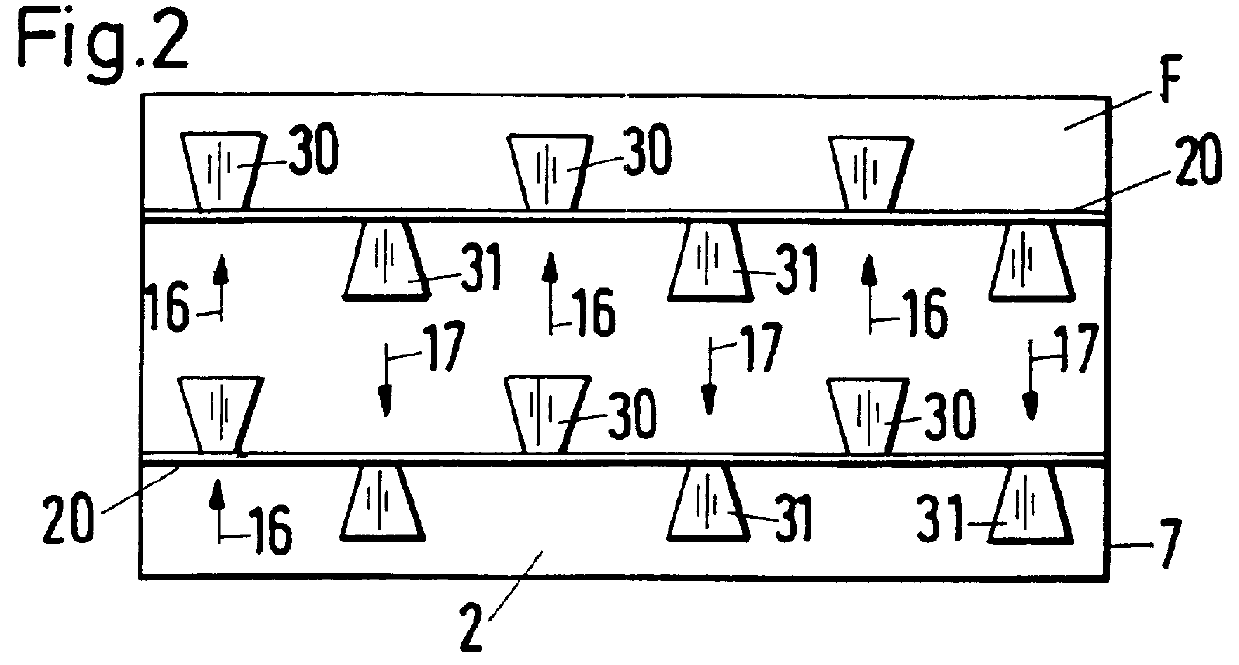

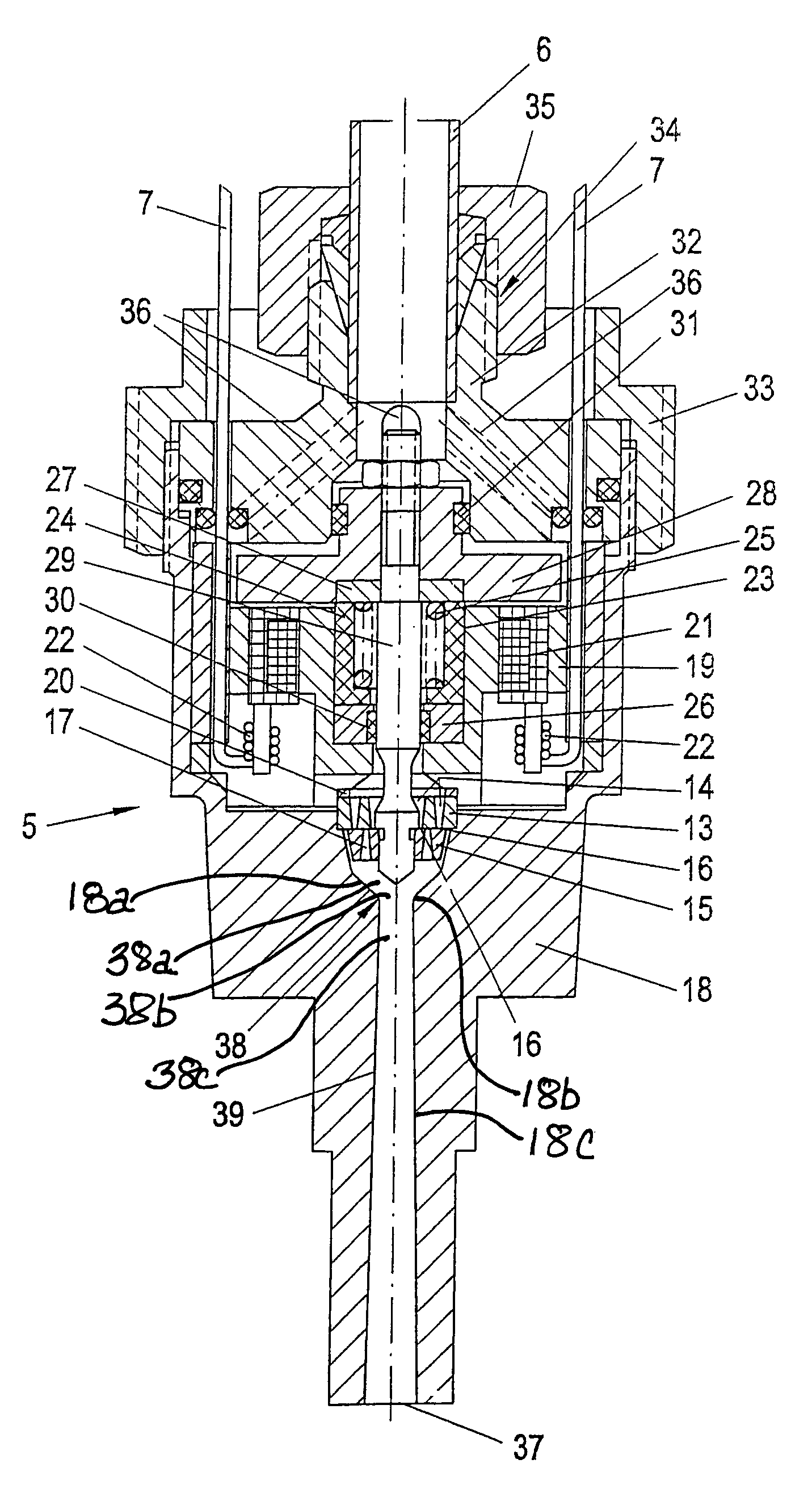

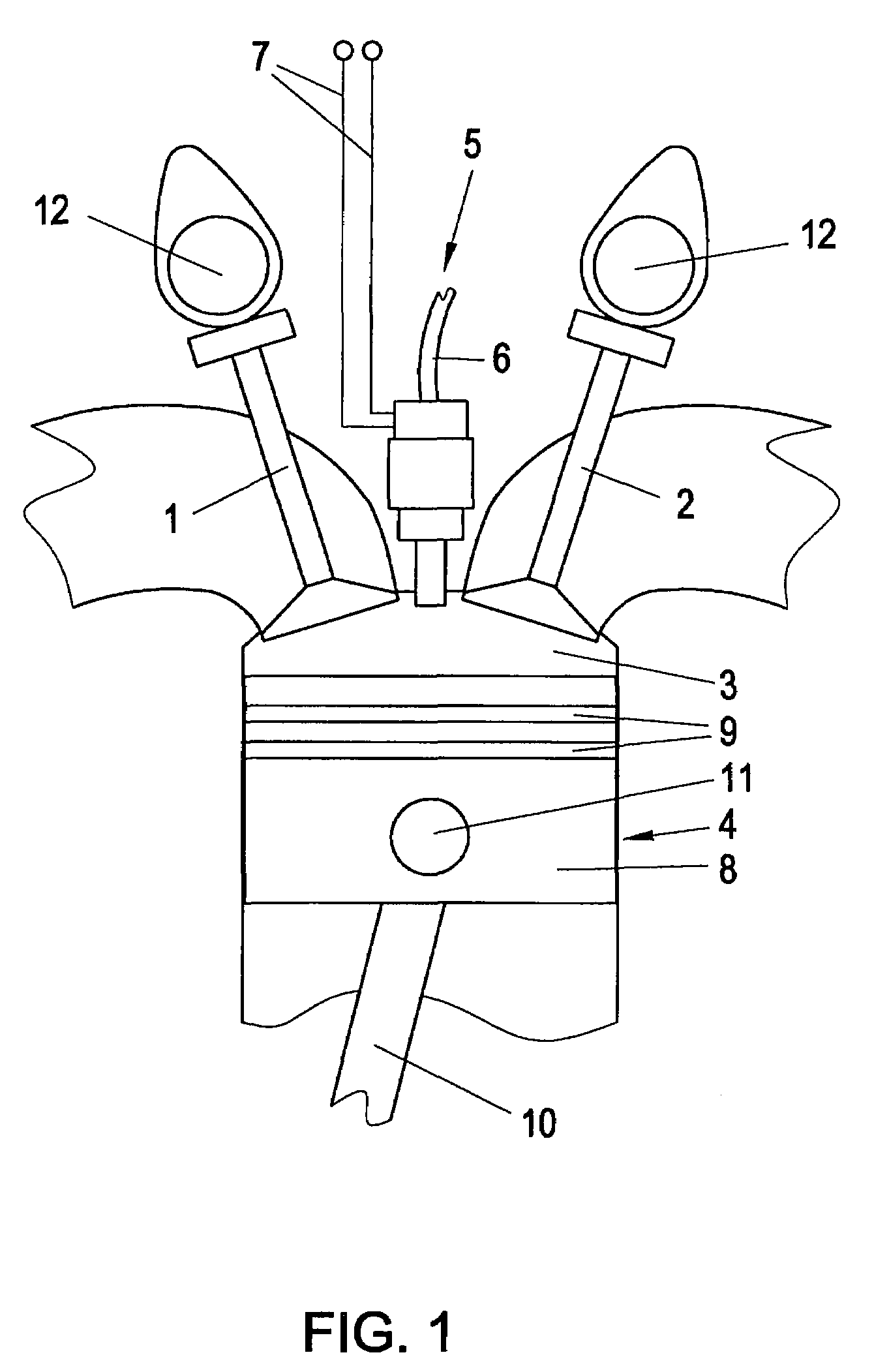

Electromagnetically actuated gas valve

ActiveUS7124998B2Improve sealingEasily and advantageously adjustedOperating means/releasing devices for valvesLift valveCombustion chamberEngineering

An electromagnetically actuated gas valve (5) for gas engines (4) includes a valve seat (13) that has at least one flow-through opening (14) and a corresponding sealing plate (15), with the sealing plate being movably arranged and guided essentially perpendicularly relative to the valve seat (13), with barrier surfaces (16) and discharge openings (17). The sealing plate (15) is loaded against the valve seat (13) by means of a return spring (25) and can be lifted for the purpose of opening it via a solenoid (21). In order to allow for the secure sealing and easy switchability even in the presence of the effect of the combustion chamber pressure, the sealing plate (15) is arranged on the discharge side of the valve seat (13) and connected by means of a stamp (29), which extends through the valve seat (13), with the anchor plate (28) of the solenoid (21). A Venturi tube meter (38) is arranged on the discharge side after the sealing plate (15) for the purpose of calibrating the flow-through correction value and for suppressing any dispersions due to manufacturing variations with regard to the effective flow cross-section, and the cross-section of the Venturi tube meter (38) is smaller than the sum of the effective flow-through cross-sections between valve seat (13) and opened sealing plate (15).

Owner:HOERBIGER KOMPRESSORTECHNIK HLDG GMBH

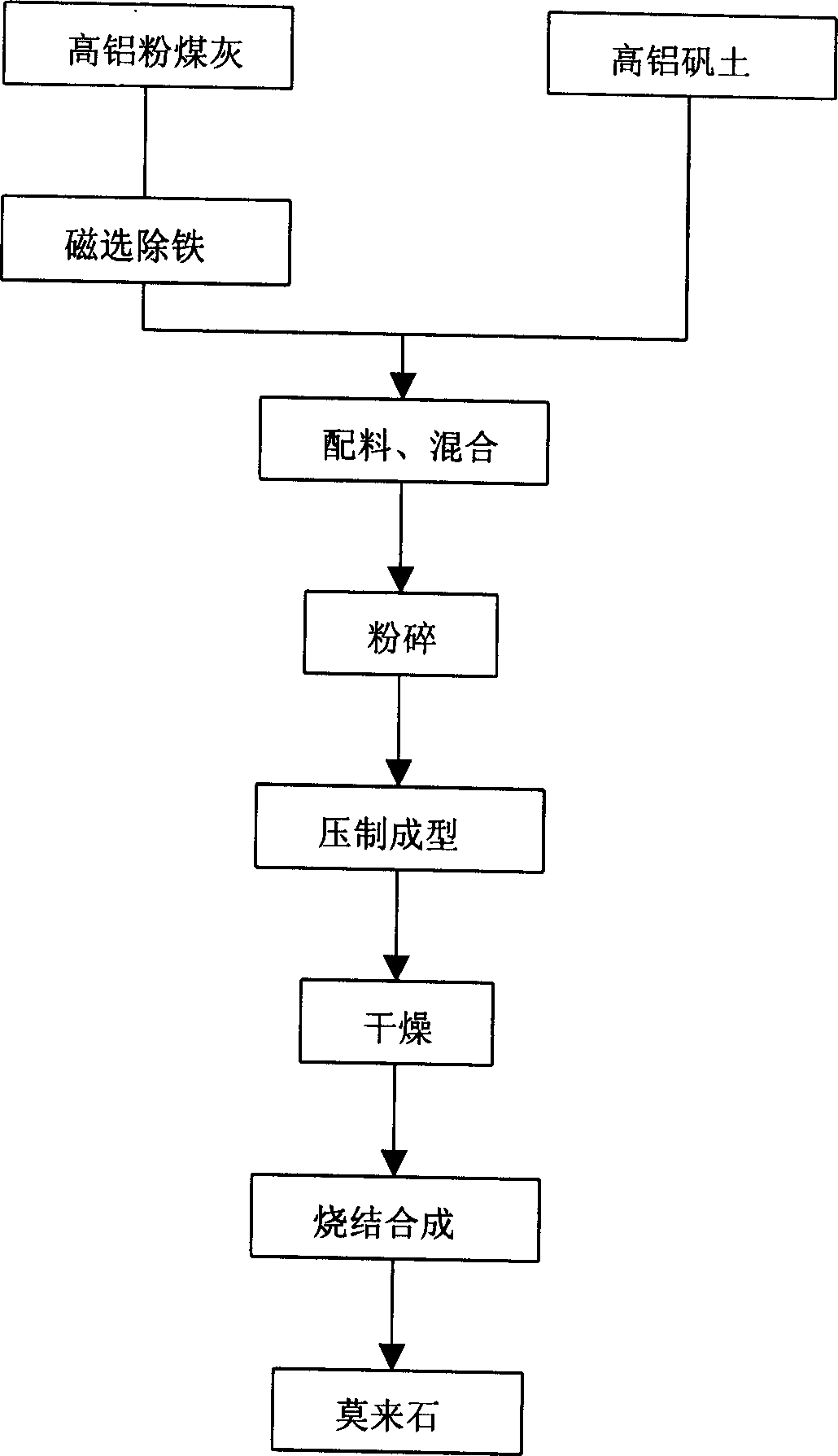

Agglomeration method for synthesizing mullite by using high aluminous fly ash

ActiveCN1696075ARealize comprehensive utilizationReduce manufacturing costTunnel kilnPolymer science

Owner:TSINGHUA UNIV +1

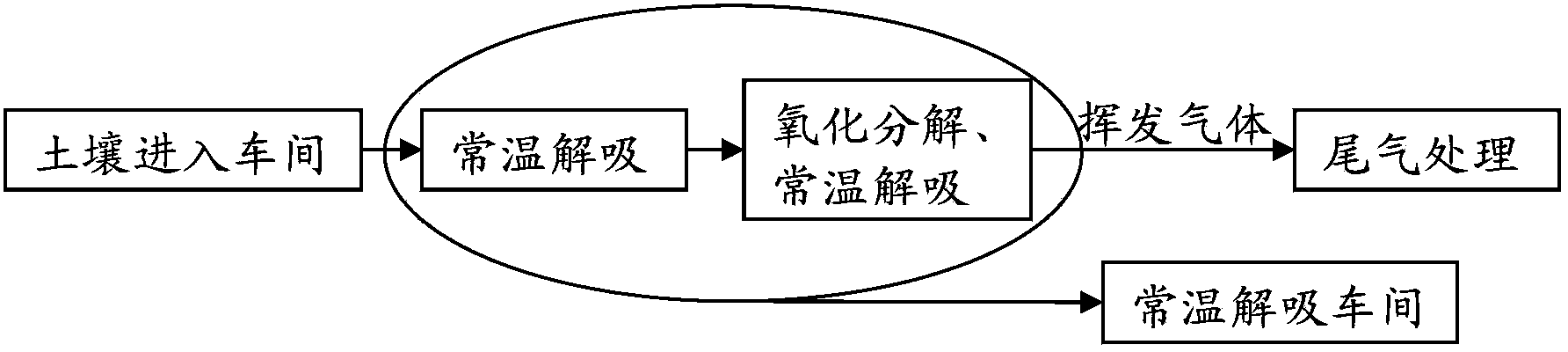

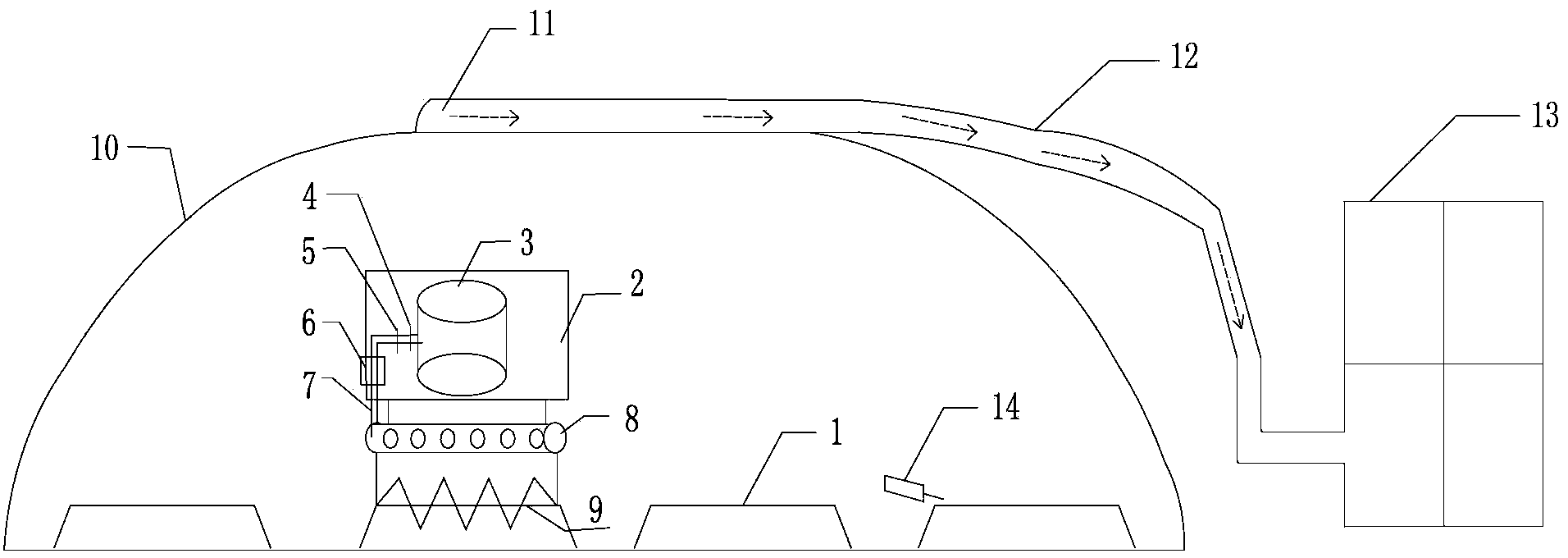

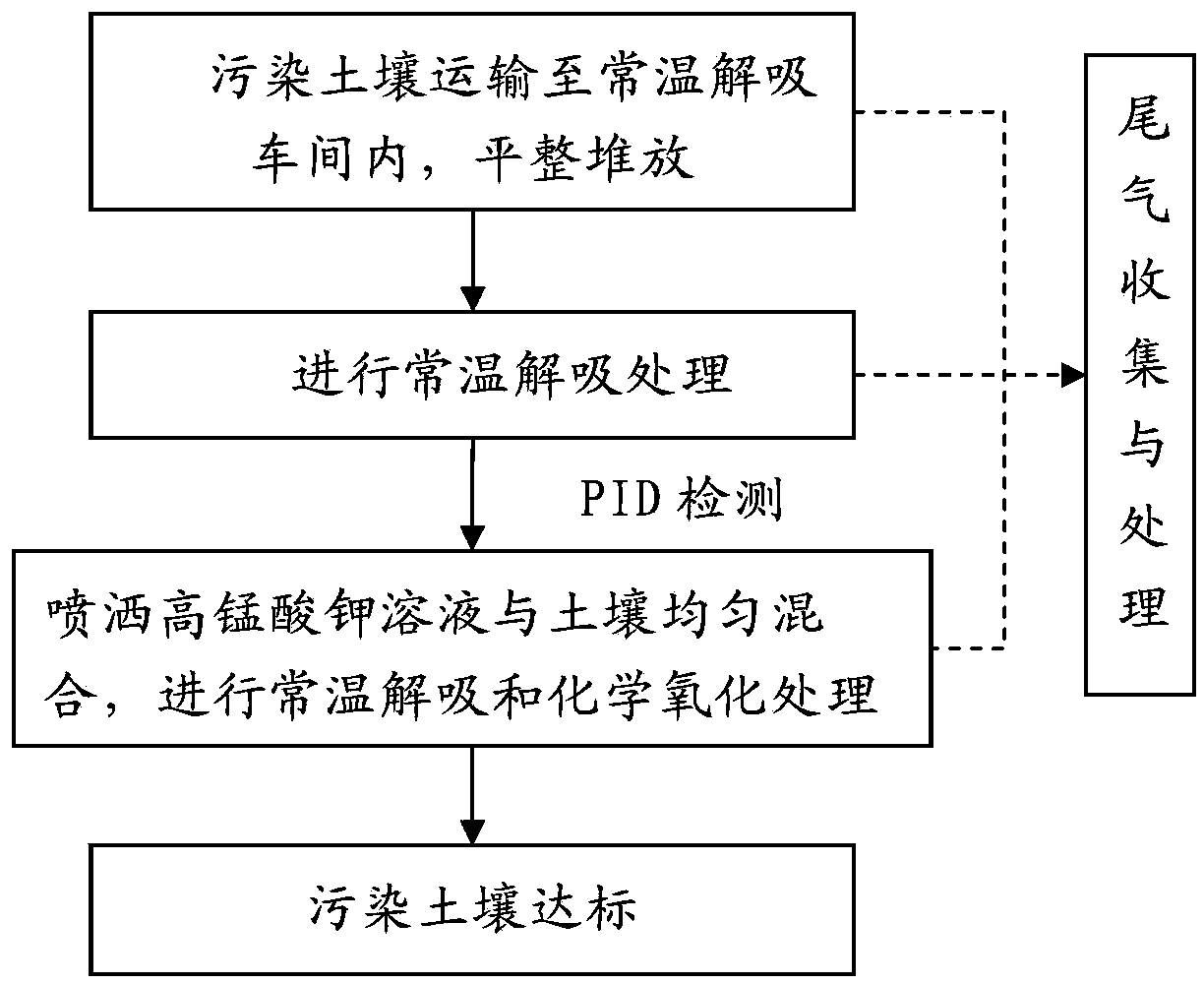

Method and treatment system for restoring organic pollution soil through combination of room temperature desorption and chemical oxidation

ActiveCN103406346AAvoid "smearing"Shorten repair timeContaminated soil reclamationDesorptionPotassium permanganate

The present invention discloses a method and a treatment system for restoring organic pollution soil through combination of room temperature desorption and chemical oxidation. The method comprises: placing organic matter polluted soil in a room temperature desorption workshop; adopting a moveable soil turner to turn the polluted soil, wherein one turning is performed every 2 h, a portable photoionization detector is adopted to rapidly detect the concentration of volatile or semi-volatile organic matters at a position above 15-25 cm of the polluted soil during a turning process, and turning is stopped until the detection data is stabilized; and adding a 6% potassium permanganate solution to a liquid tank, opening a water pump and a manual control valve, spraying the potassium permanganate solution to the polluted soil, concurrently adopting the soil turner to uniformly turn the potassium permanganate solution and the polluted soil, and stopping spraying and turning until the potassium permanganate content in the soil achieves the preset addition amount. The present invention further provides a treatment system for the method. With the method, organic pollutant soil restoring efficiency is high, the cost is low, and the method is a combination restoring method with strong practicability in the project.

Owner:中科华南(厦门)环保有限公司 +1

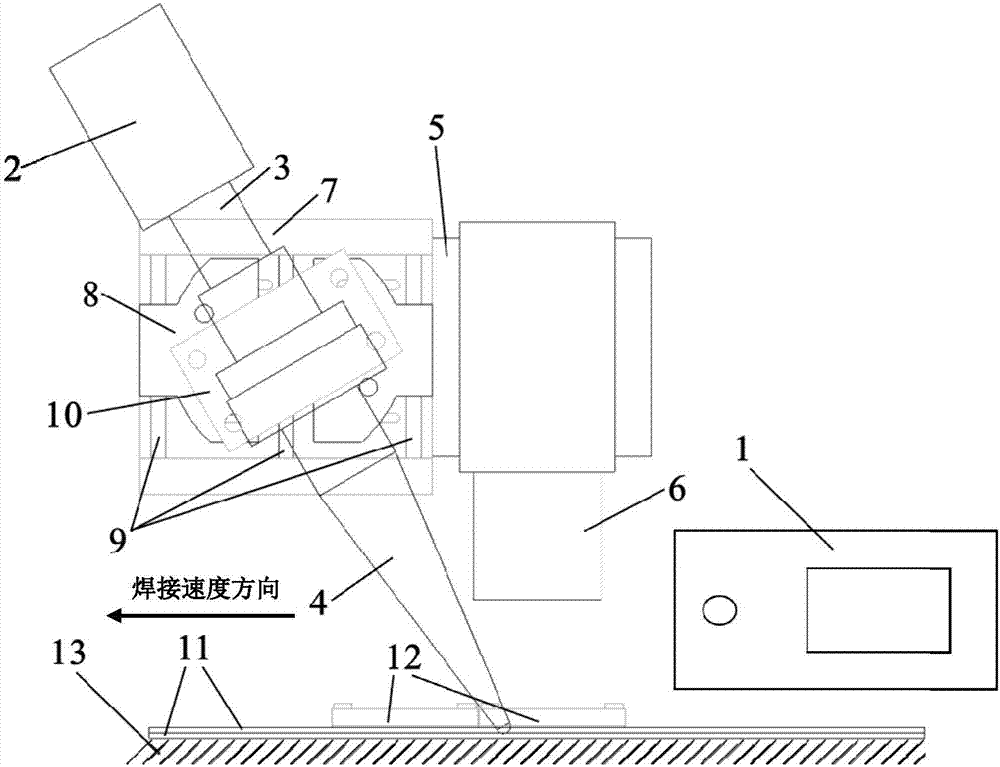

Ultrasonic vibration assisted laser welding method for heterogeneous material

ActiveCN107570872ASpeed up the flowFully dilutedLaser beam welding apparatusWeld seamAlternating current

The invention belongs to the technical field of laser welding and relates to an ultrasonic vibration assisted laser welding method for a heterogeneous material. Ultrasonic vibration is introduced intolaser welding of the heterogeneous material, specially, ultrasonic-frequency alternating current is produced by an ultrasonic generator, vibration production and amplitude magnification are implemented by an ultrasonic vibrator, and finally, the ultrasonic vibration is guided into a welding pool by the welding material. Follow-up regulation is performed on the laser welding process of the heterogeneous material by means of special effect produced through ultrasonic vibration in the welding pool. Compared with a traditional laser welding method for the heterogeneous material, designed ultrasonic vibration assisted laser welding equipment for the heterogeneous material can effectively inhibit formation of an incomplete fusion area and a brittle phase in a welding seam and homogenizes element distribution in the welding seam, so that mechanical performance and corrosion resistance of a welding joint are improved, meanwhile, a laser machining system is not required to be changed, and theapplication of the method is not limited by size of the welding material.

Owner:DALIAN UNIV OF TECH

Method and magnetic resonance system for homogenizing the B1 field

ActiveUS20050231203A1Promote homogenizationQuick searchElectric/magnetic detectionMeasurements using magnetic resonanceResonance measurementData acquisition

In a method and magnetic resonance system for homogenization of the B1 field for a magnetic resonance data acquisition with a number of iteration steps. An iteration step includes the following sub-steps: Measurement data are acquired that represent a B1 field distribution in at least one part of the examination volume of the magnetic resonance system. A B1 homogeneity analysis based on the acquired measurement data is automatically implemented. A specific homogenization action is automatically selected from among a number of possible homogenization actions based on the B1 homogeneity analysis, or the iterative homogenization method is ended if the diagnosed homogeneity is sufficient for an intended magnetic resonance measurement. The selected homogenization action is implemented.

Owner:SIEMENS HEALTHCARE GMBH

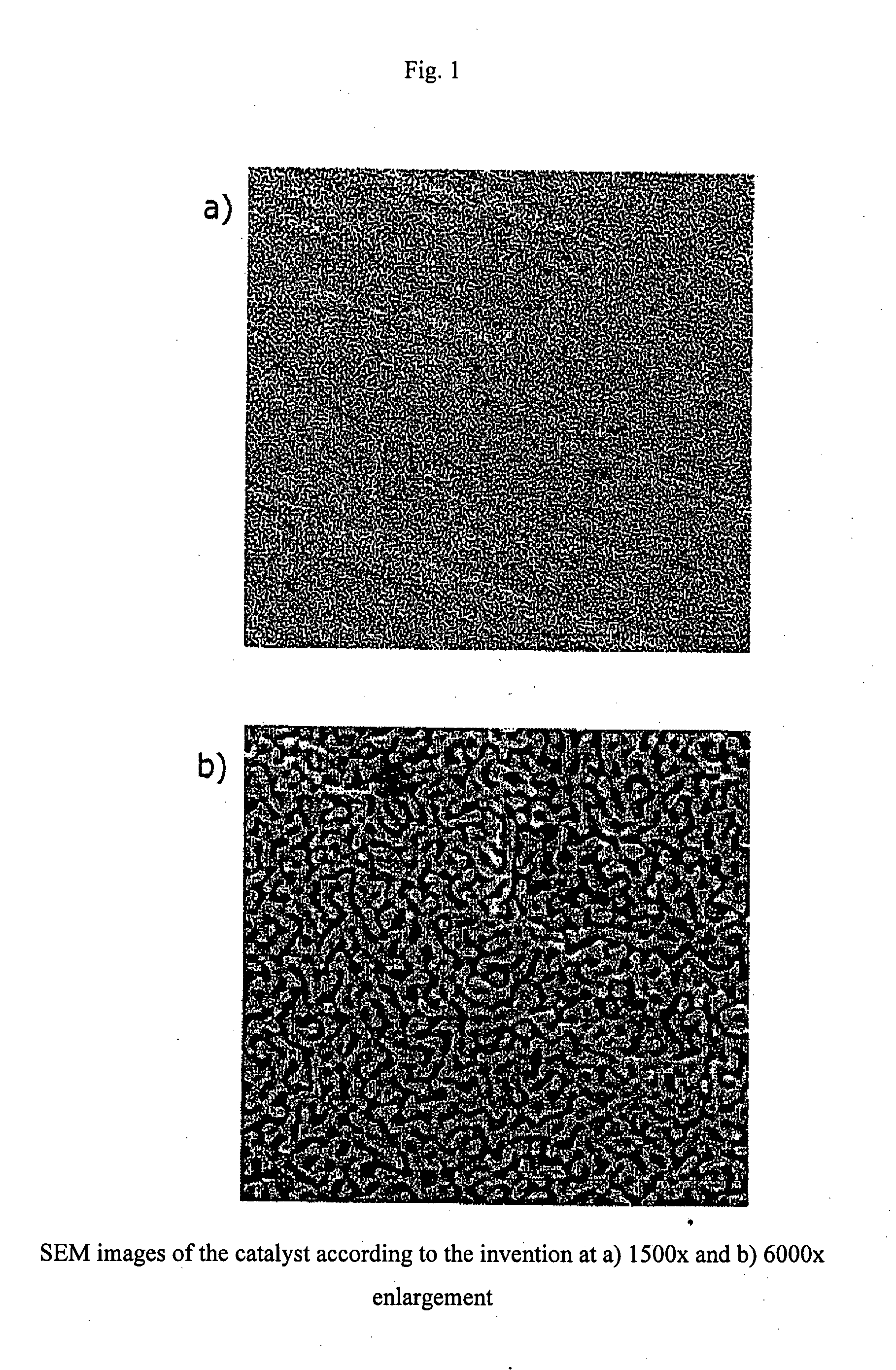

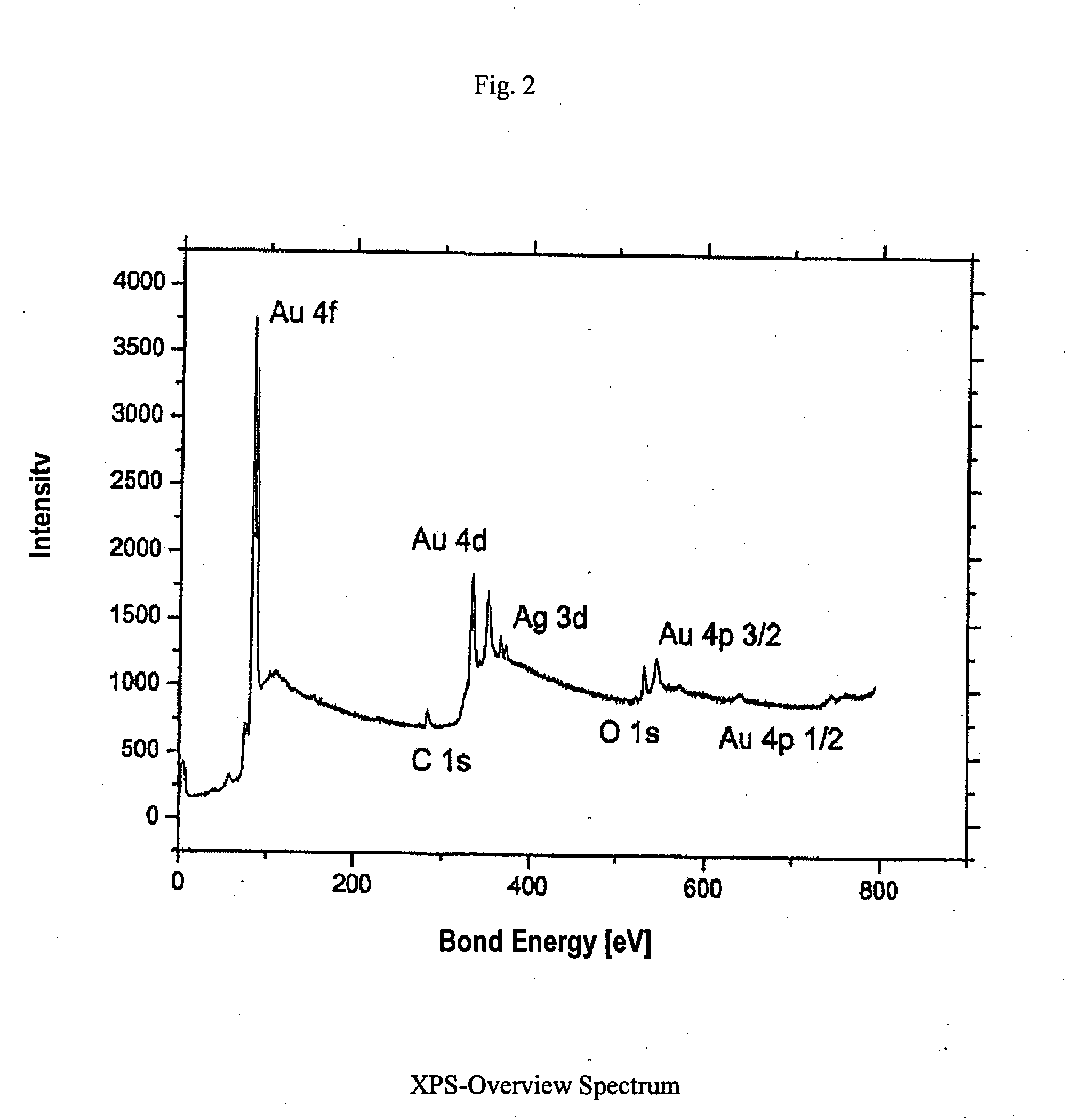

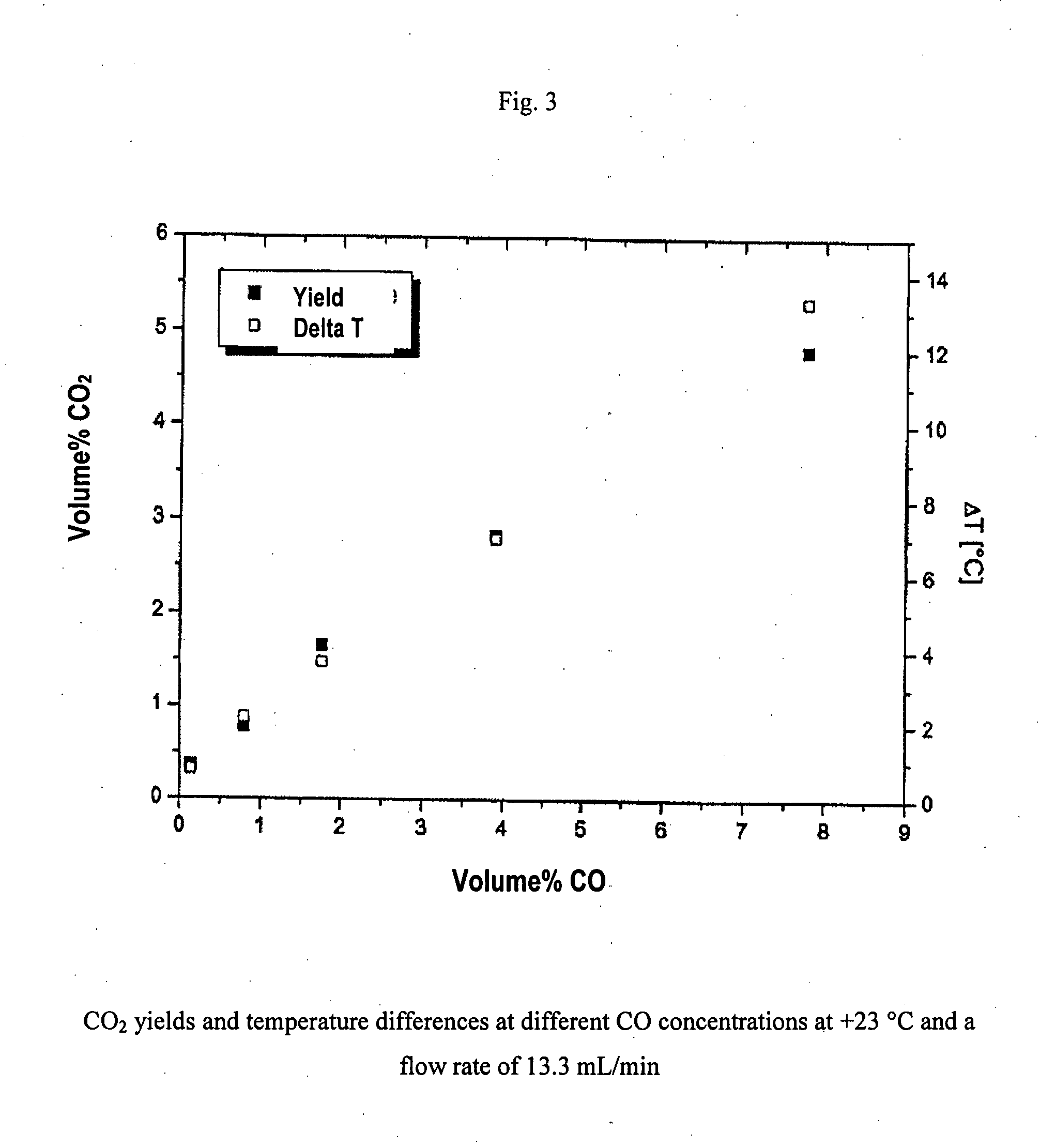

Gold-containing catalyst with porous structure

InactiveUS20070224099A1High possible activityLong possible service lifeCell electrodesDispersed particle separationAlloyHigh activity

The invention relates to a gold-containing catalyst with porous structure that is obtainable through a process that comprises the following steps: melting together of gold and at least one less noble metal that is selected from the group consisting of silver, copper, rhodium, palladium, and platinum, and at least partial removal by dissolving the at least one less noble metal out of the starting alloy thus obtained. The catalyst has high activity and great long-term stability, despite the fact that it does not contain a support material or a compound that serves as a support material. The catalyst can be used to accelerate and / or to influence the product selectivity of oxidation and reduction reactions. The catalyst is suitable, for example, for the oxidization of carbon monoxide to carbon dioxide, which makes it usable, among other things, in a fuel cell, in particular a polymer electrolyte membrane fuel cell (PEM), for protection of the anode catalyst against blocking by carbon monoxide.

Owner:UNIV OF BREMEN +1

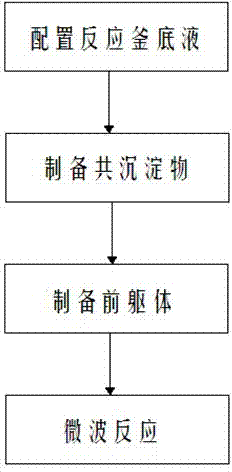

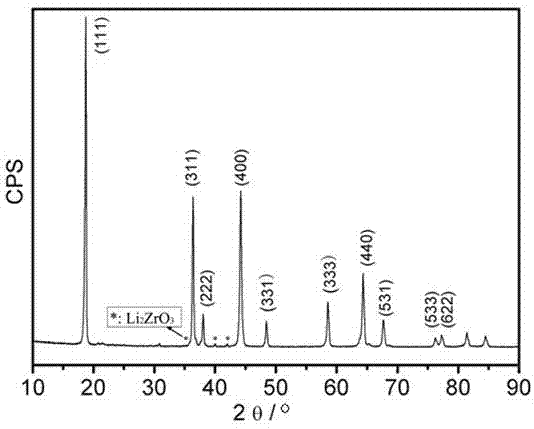

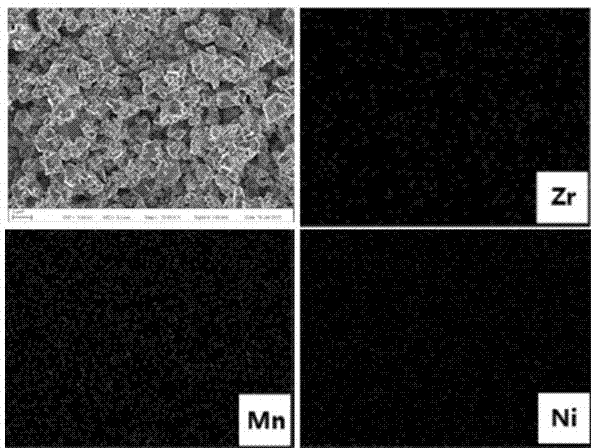

Preparation method of surface covered nickel lithium manganate positive electrode material

ActiveCN103794777AShorten microwave firing timeImprove cycle performanceCell electrodesSecondary cellsMicrowaveReaction temperature

The invention discloses a preparation method of a surface covered nickel lithium manganate positive electrode material. The preparation method comprises the following steps: a, preparing a reaction kettle bottom solution; b, preparing a coprecipitate; c, preparing a precursor; and d, performing a microwave reaction. The preparation method of the surface covered nickel lithium manganate positive electrode material provided by the invention has the advantages that as a microwave sensitized material, zirconia, is added in a precursor preparation process, a reaction material is urged to effectively absorb microwave to rapidly warm to the reaction temperature 700-950 DEG C, and the microwave firing time of the product is remarkably shortened to 1-10 minutes; when the nickel lithium manganate material is burnt at high temperature, the zirconia and a Li source can react at a nickel lithium manganate surface to generate a lithium ion conductor Li2ZrO3 coating layer, and thus the cycle property and the rate property of the product are remarkably improved.

Owner:威海区域创新中心有限责任公司

Method for preparing magnetic solid acid catalyst for production of biodiesel

The invention discloses a method for preparing a magnetic solid acid catalyst for the production of biodiesel. The solid acid catalyst is prepared by performing sulfonic acid group modification on zirconia-based Fe3O4 / ZrO2 compound. The preparation method comprises the following steps: after mixing ferrous chloride and ferric chloride, adding ammonia water or solution of sodium hydroxide to adjust the pH value of the mixture to between 10 and 12; ageing the mixture for 2 hours; washing the mixture by distilled water to be neutral to obtain a magnetic substrate; mixing the magnetic substrate and zirconium oxychloride in proportion, adding a certain amount of water to fully dissolve the zirconium oxychloride, uniformly oscillating the mixed solution, adjusting the pH value of the mixed solution to between 10 and 12 by ammonia water or the solution of sodium hydroxide; filtering and precipitating after ageing for 2 hours; fully washing the precipitate by deionized water until no Cl- exists; fully soaking the precipitate for 4 hours by ammonium sulfate or solution of concentrated sulfuric acid or solution of ammonium persulphate; and leaching and roasting a filter cake in a muffle furnace at the temperature of 500 DEG for 3 hours to obtain the magnetic catalyst.

Owner:GUANGXI ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com