Agglomeration method for synthesizing mullite by using high aluminous fly ash

A technology for synthesizing high-alumina fly ash and mullite is applied in the field of synthesis of refractory and ceramic materials, which can solve the problems of waste of resources, low conversion rate of mullite, high price of organic raw materials, etc., so as to save mineral resources and Energy, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

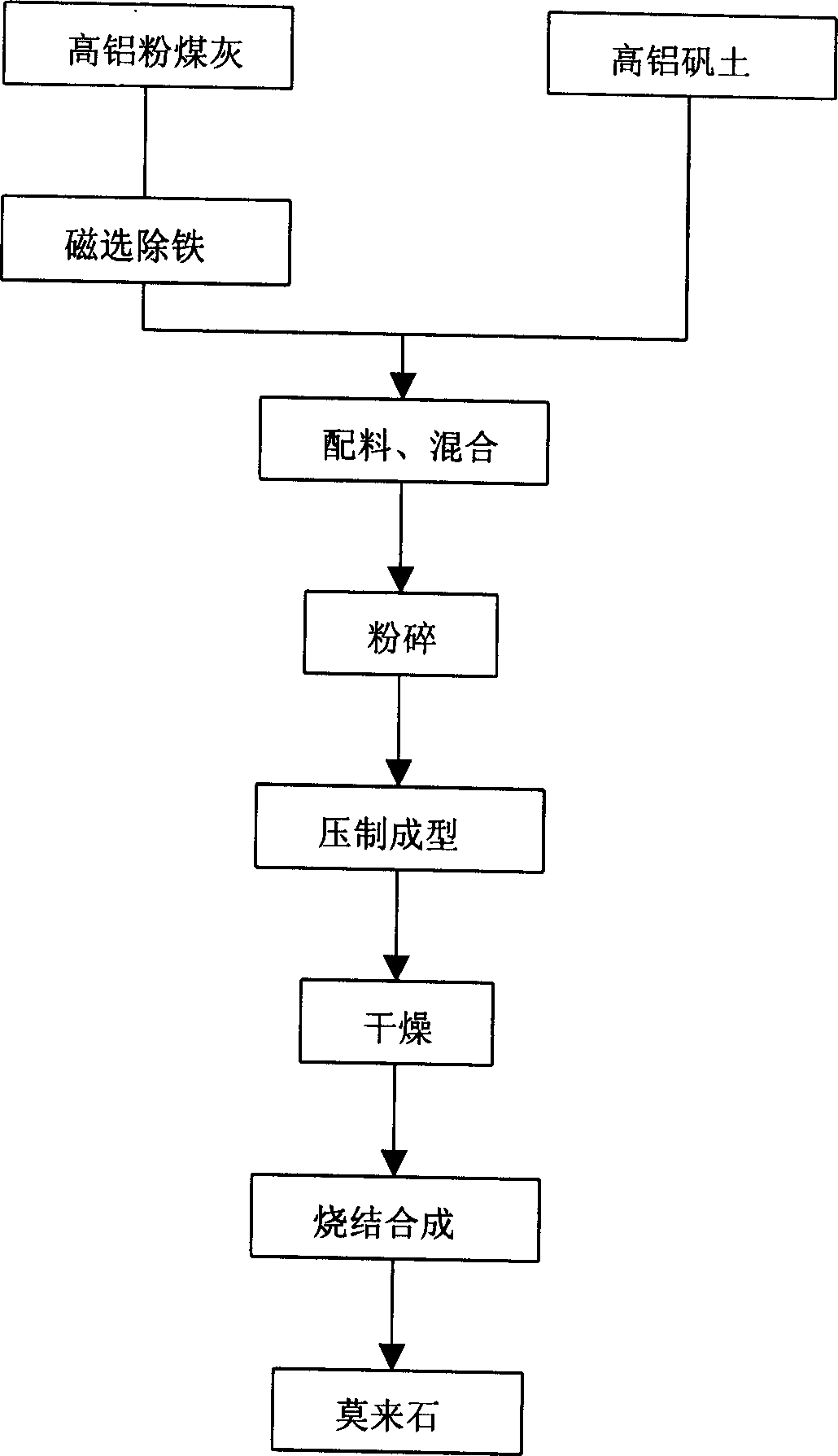

[0030] Embodiment 1: the production steps of synthetic mullite M70 are:

[0031] (1) Select Al 2 o 3 The content is 52%, SiO 2 The content is 38%, Fe 2 o 3 The high-aluminum fly ash with a content of 2.5% is the main raw material, and the Fe 2 o 3 The content is less than 1.5%.

[0032] (2) The high-alumina fly ash and high-alumina bauxite after iron removal are mixed, so that Al in the mixture 2 o 3 The content is 67.7%.

[0033] (3) Send the mixture into a ball mill and pulverize it into a material with an average particle size of less than 15 μm.

[0034] (4) Add water to the material and mix it, and press it into a blank with a size of 120mm×60mm×70mm by a 350t friction press.

[0035] (5) Send the shaped billet into a kiln at 100°C to dry until the residual moisture is lower than 1%.

[0036] (6) Put the dried blank into a high-temperature tunnel kiln for sintering and synthesis, the sintering temperature is 1650°C, keep warm for 6 hours, and after the kiln bod...

Embodiment 2

[0037] Embodiment 2: In the production step of synthesizing mullite M60, remove Al in the mixture when batching 2 o 3 The content is 59.7%, and the sintering temperature in the high-temperature tunnel kiln is 1600 ℃, other is the same as embodiment 1.

Embodiment 3

[0038] Embodiment 3: In the production step of synthesizing mullite M50, remove Al in the mixture when batching 2 o 3 The content is 50.4%, and the sintering temperature in the high-temperature tunnel kiln is 1550° C., the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com