Static mixing element having deflectors and a mixing device

a technology of deflectors and mixing elements, which is applied in the direction of mixing, transportation and packaging, chemical instruments and processes, etc., can solve the problems of relatively high pressure drop, limited mixing and homegenising abilities of these elements, and relatively high production costs, so as to reduce pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

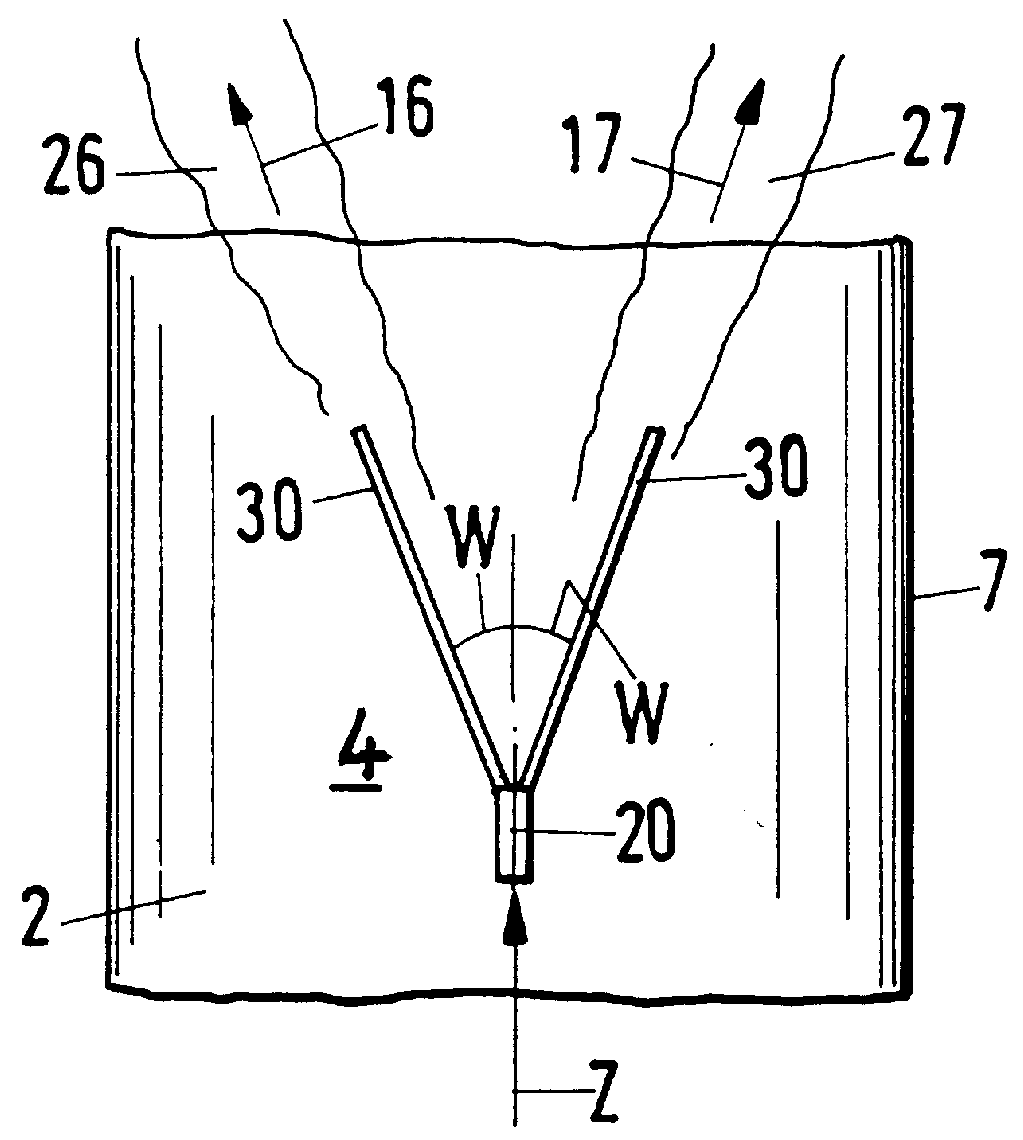

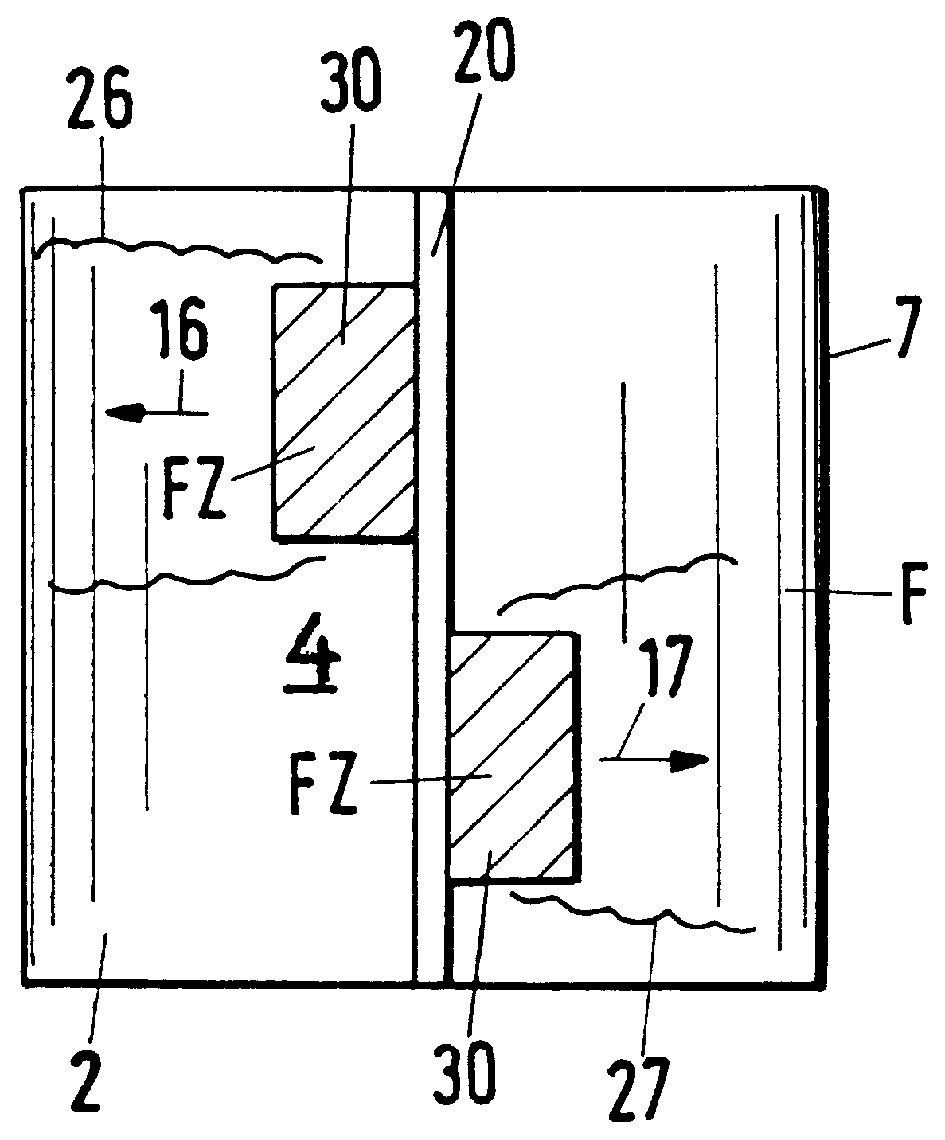

FIG. 1 shows two views of a mixing element 4 according to the invention comprising two deflectors 30 which are secured by way of a mounting 20 in a flow channel 7. The rectangular deflectors 30 are staggered relatively to one another and are each inclined, in opposite orientations to one another, to the main flow direction 8 of the fluid 2 at an angle W of e.g. 30.degree.. The deflectors 30 produce corresponding turbulent flow cones 26, 27 which are deflected in the directions 16, 17 and which cross one another in staggered relationship. The projection FZ of the two deflectors in the flow direction Z amounts to less than 50% of the flow channel cross-sectional area F (see FIG. 1b). A proportion FZ of as little as e.g. from 10% to 20% of F can according to the invention produce turbulent and intensively mixing cross-flows.

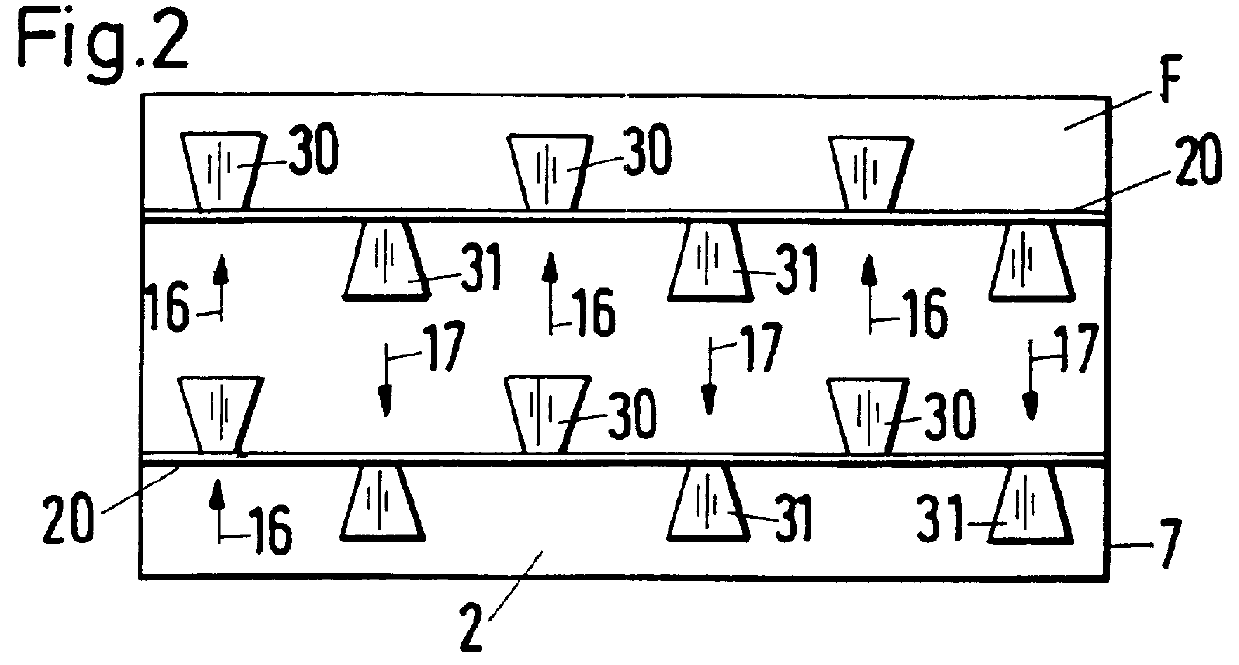

FIG. 2 shows a similar example having a number of deflectors 30 on two mountings 20 to provide regular covering of a complete channel cross-section F with the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com