Patents

Literature

527 results about "Effective surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

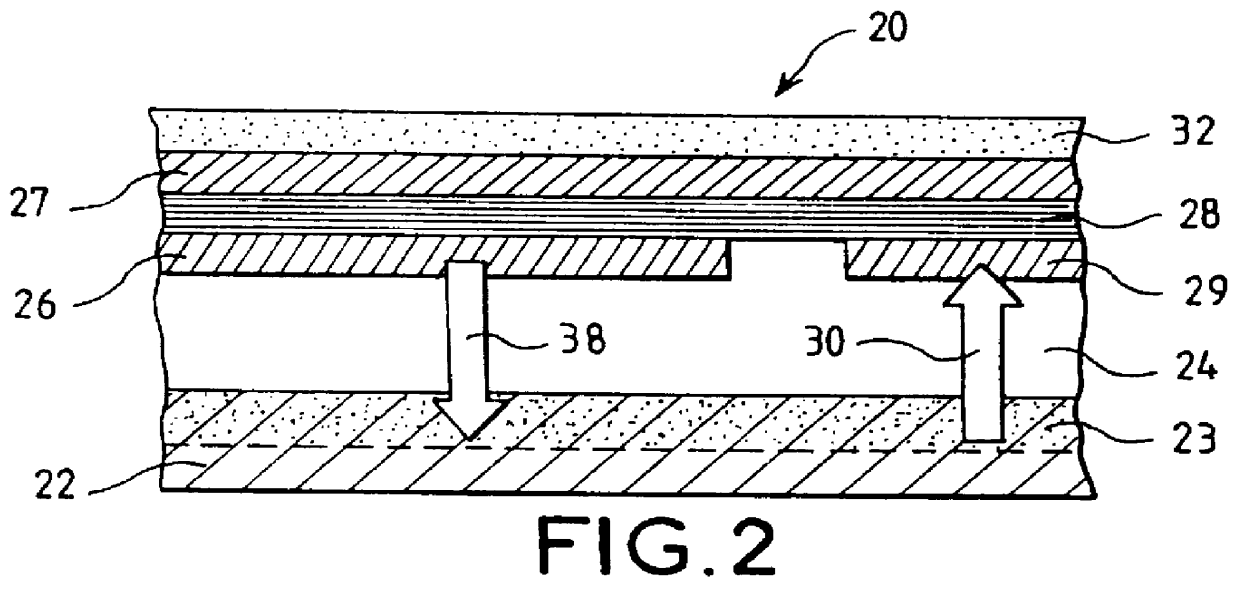

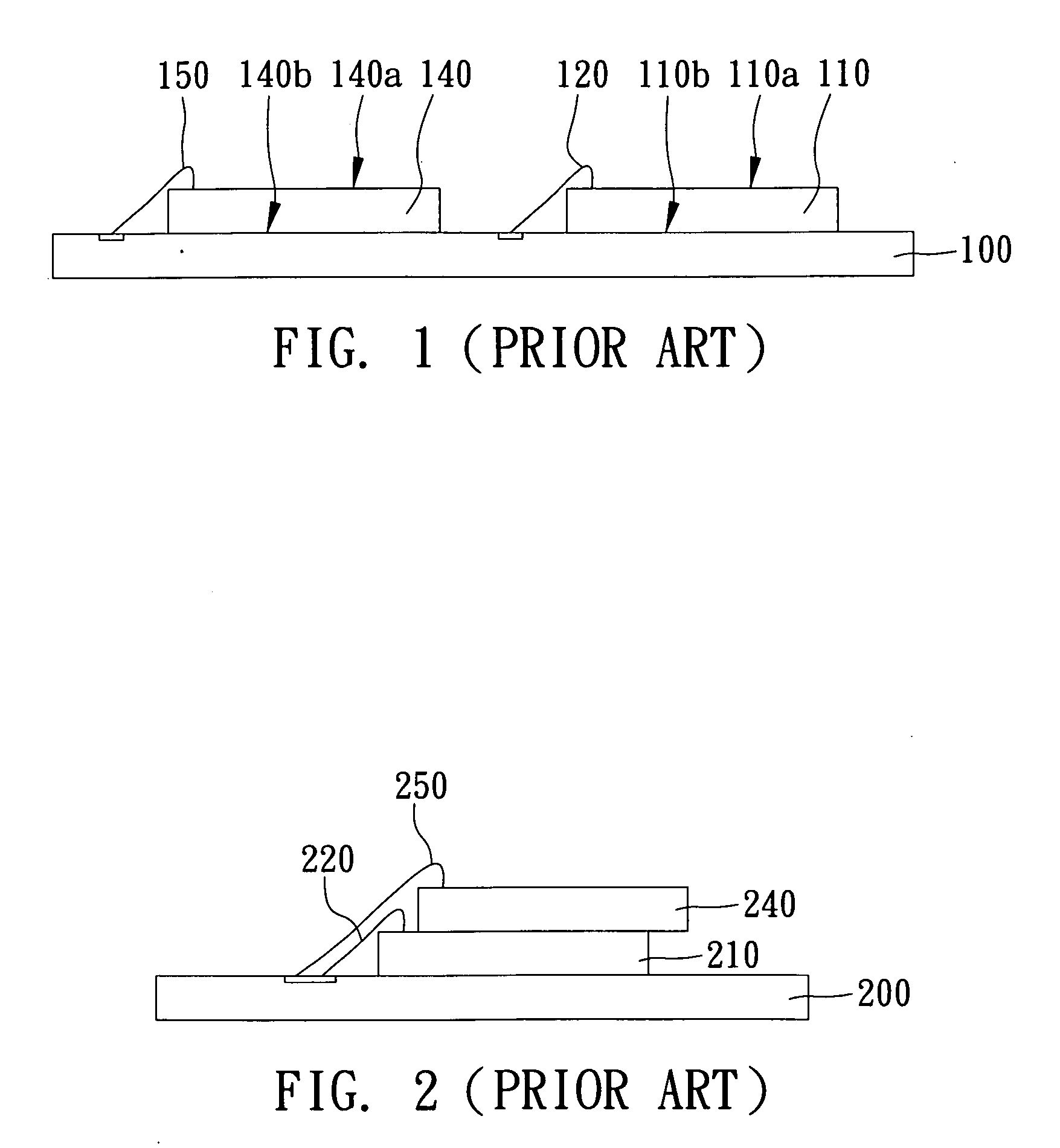

Fingerprint-reading system

InactiveUS6289114B1Image analysisElectric/magnetic contours/curvatures measurementsEffective surfaceRelative motion

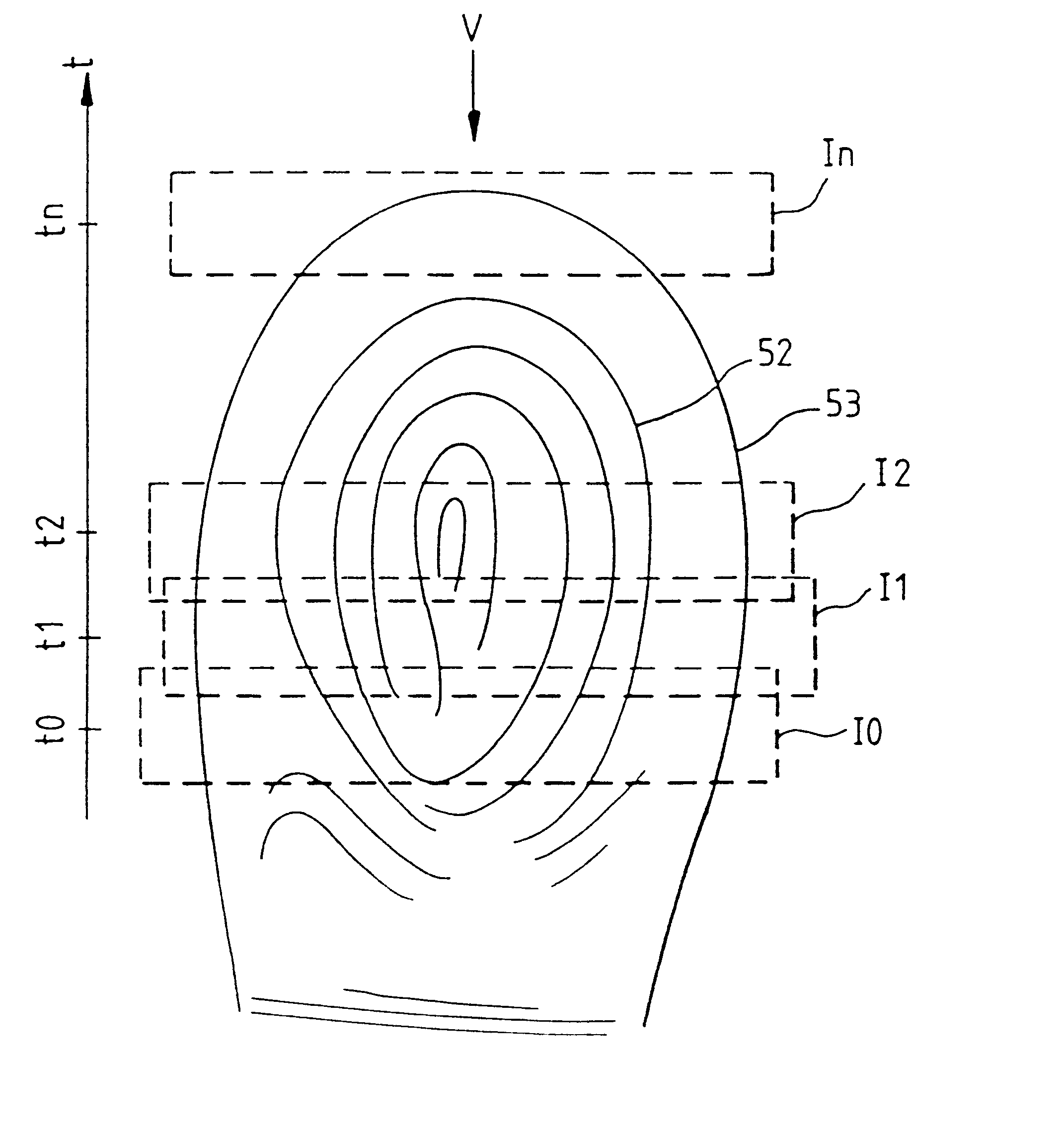

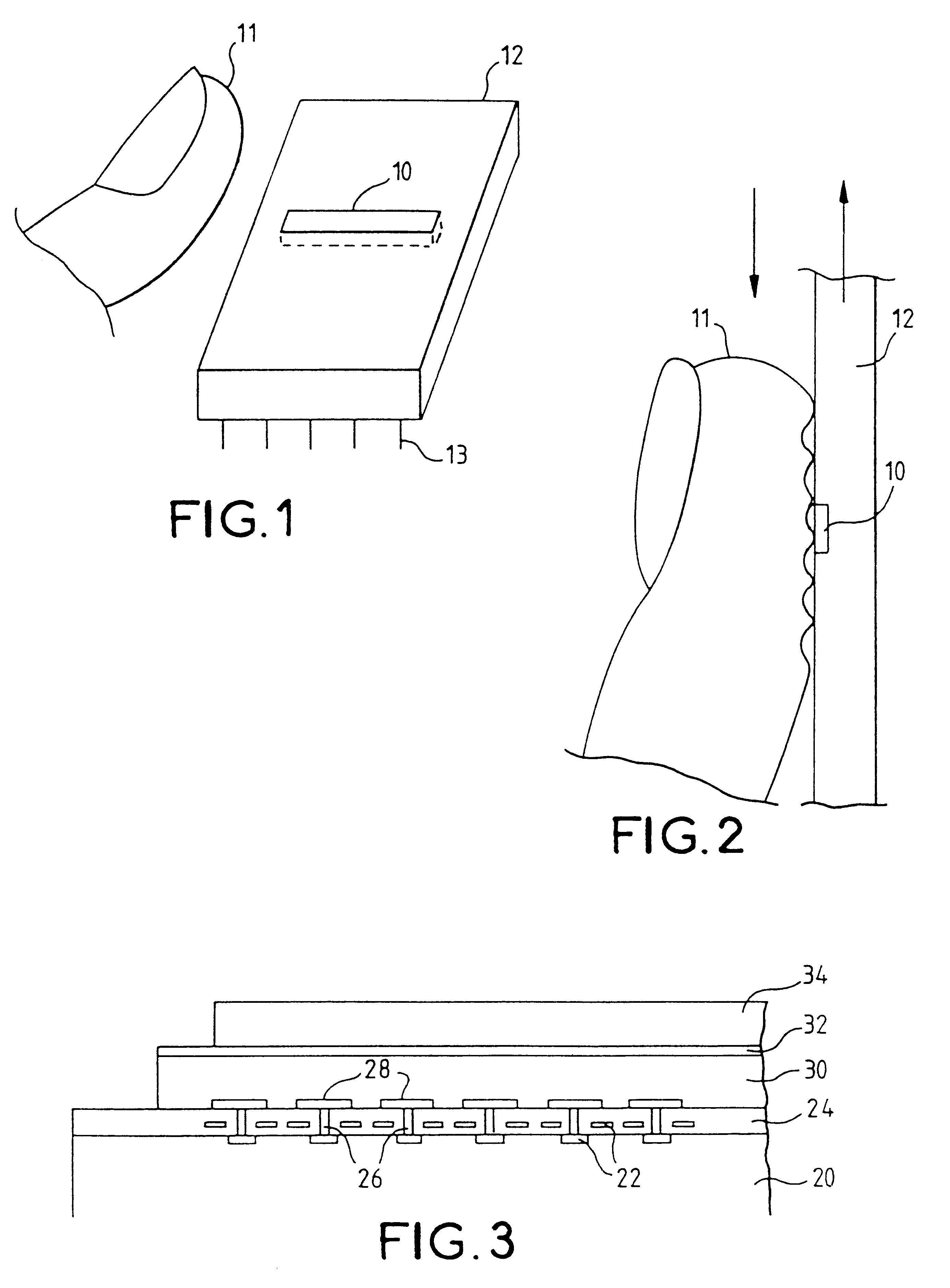

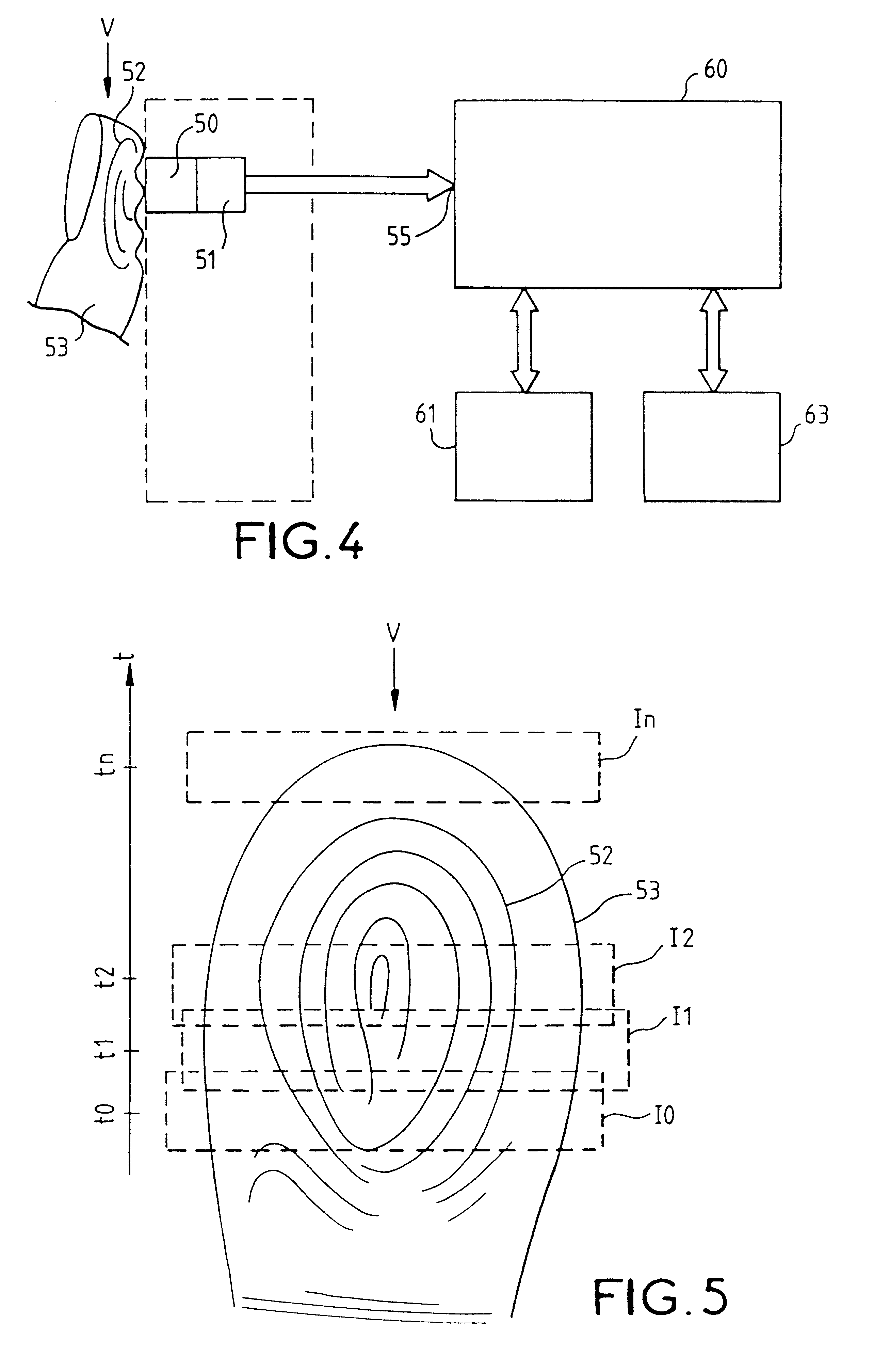

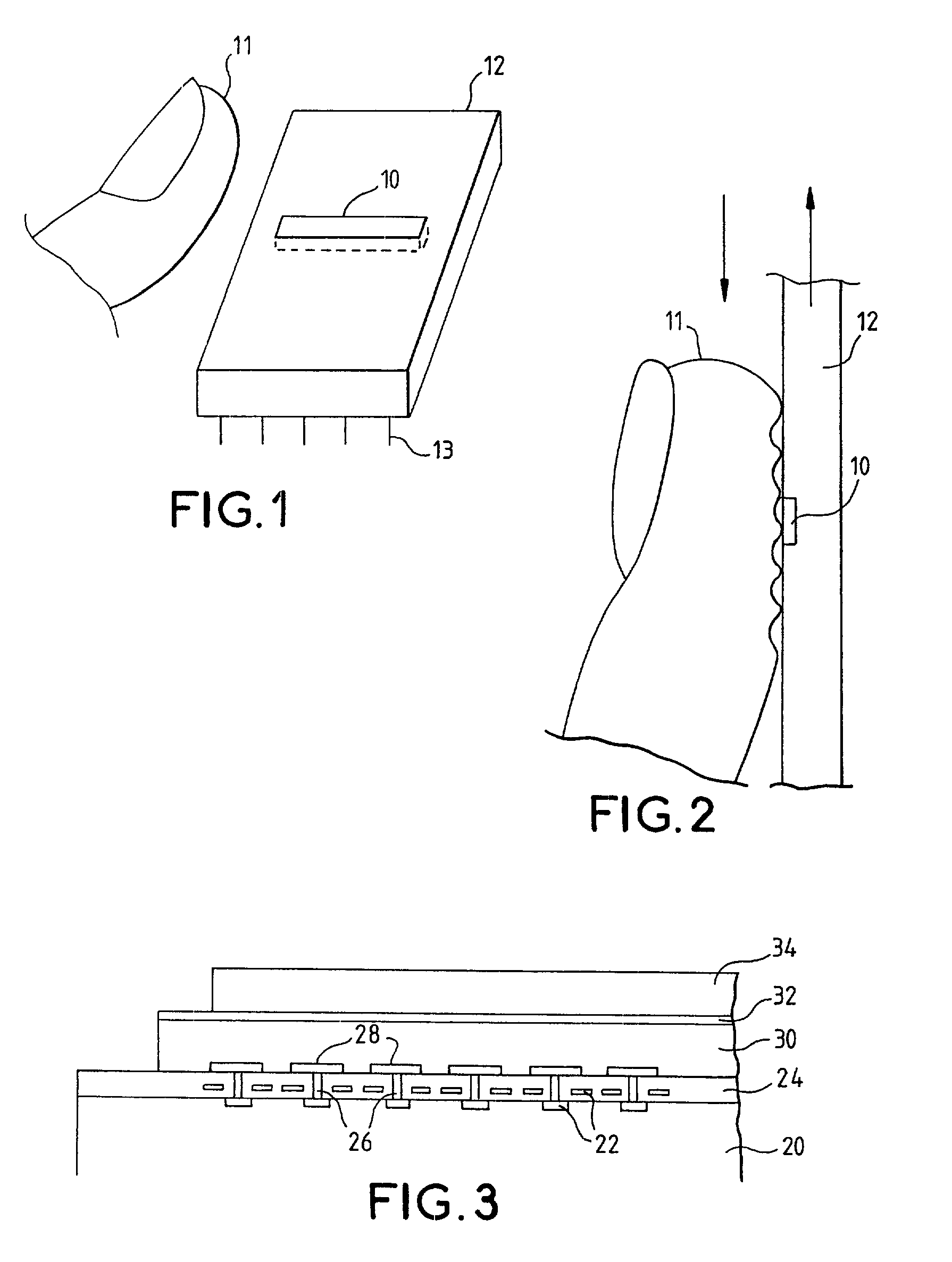

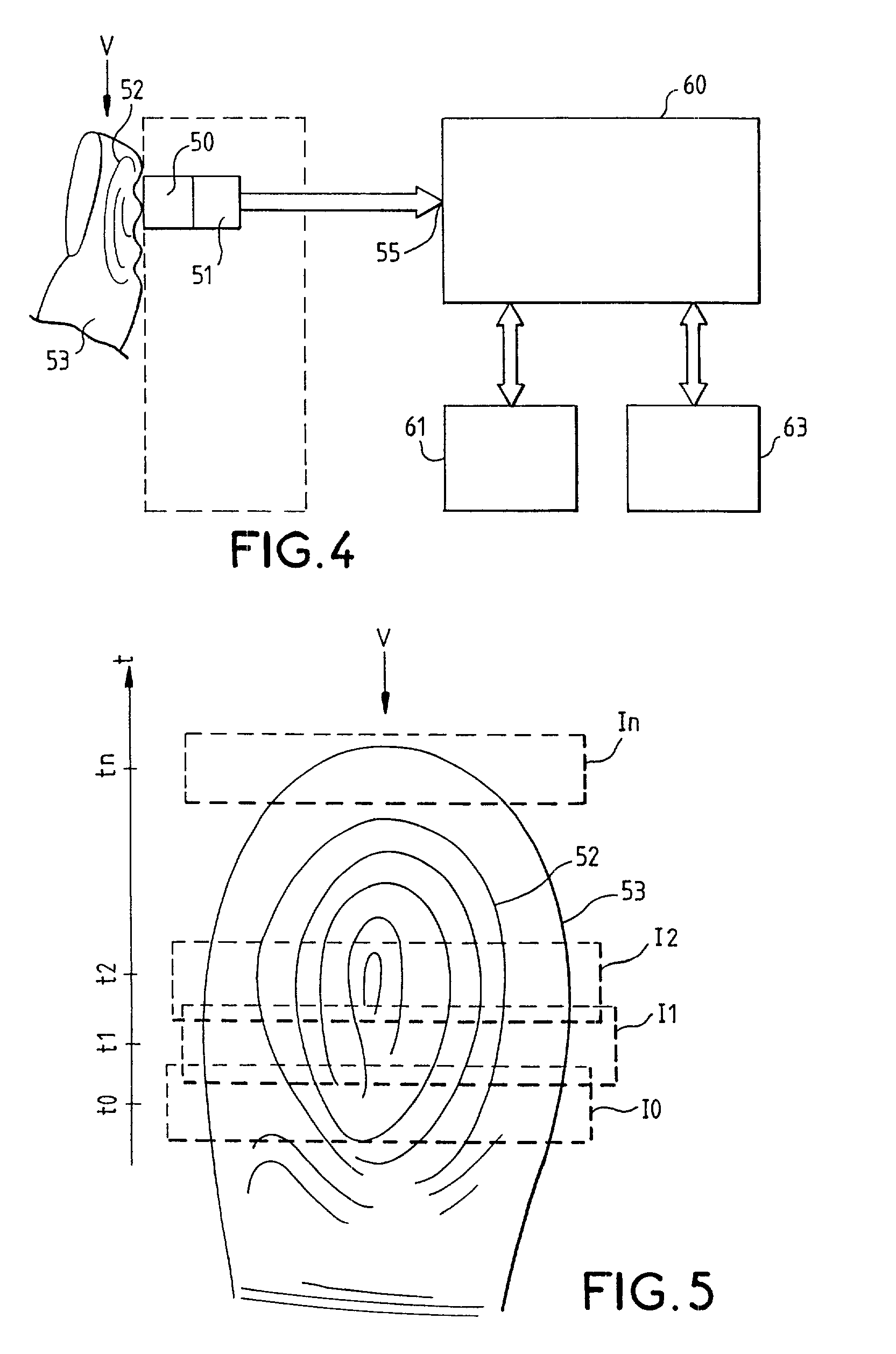

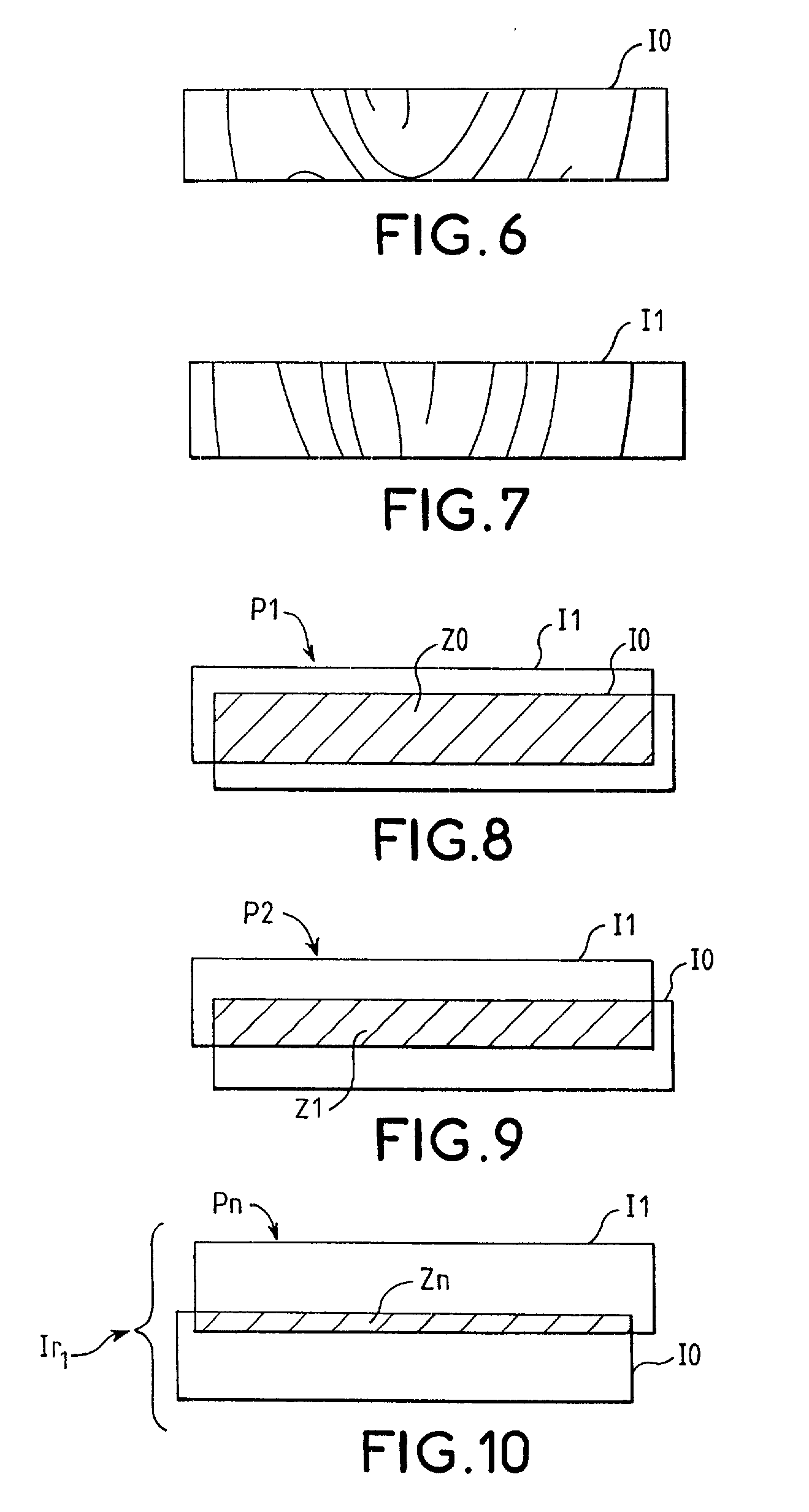

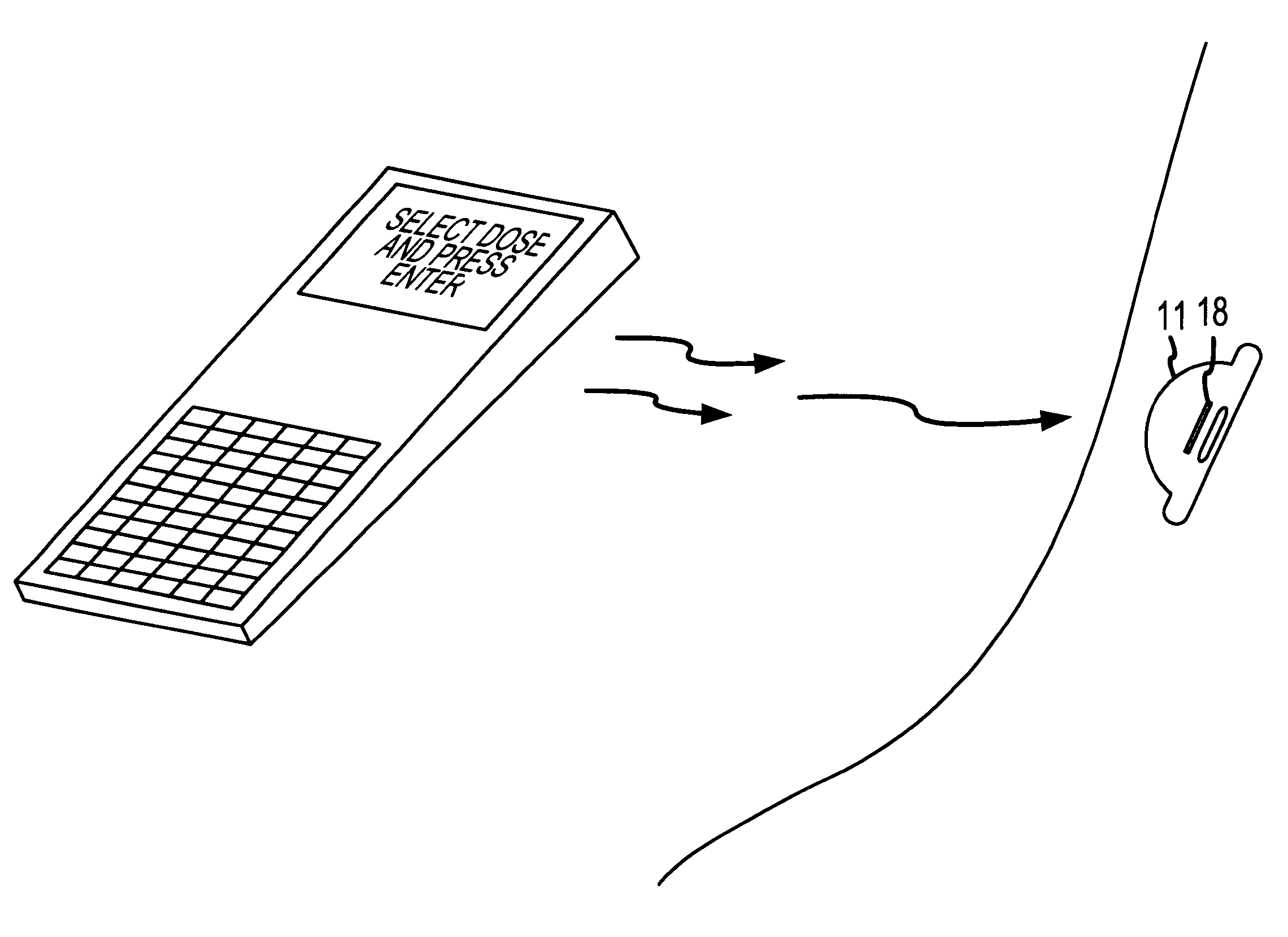

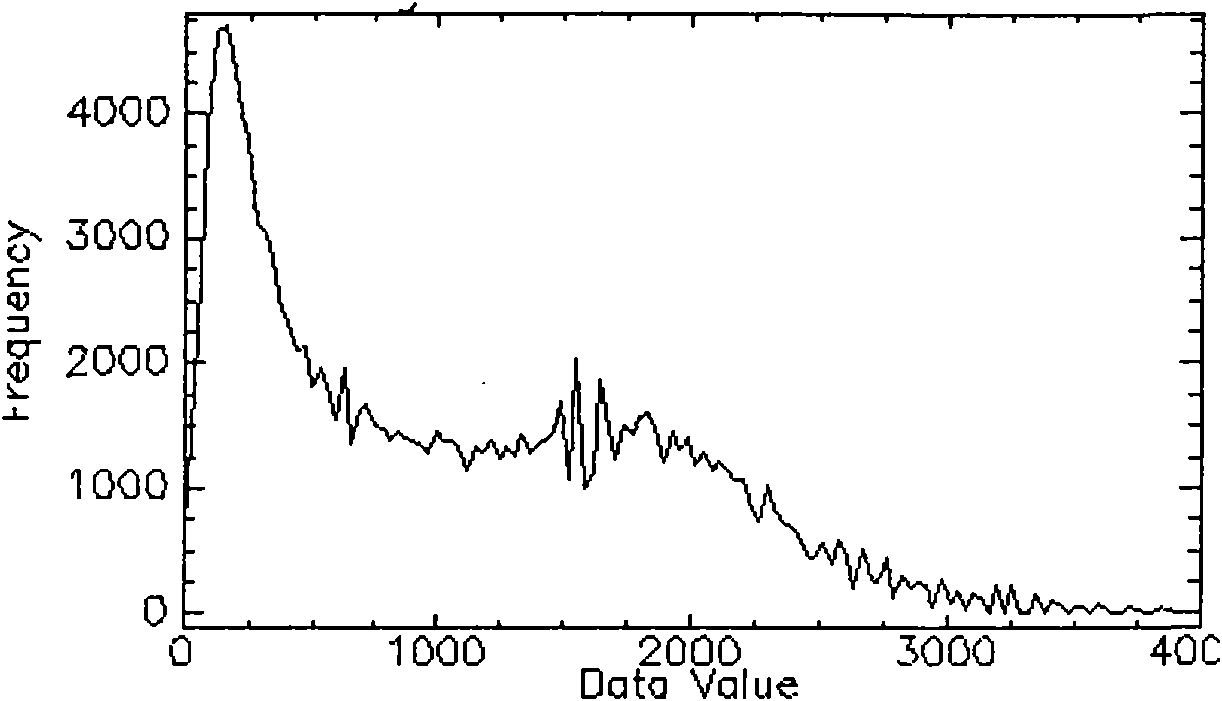

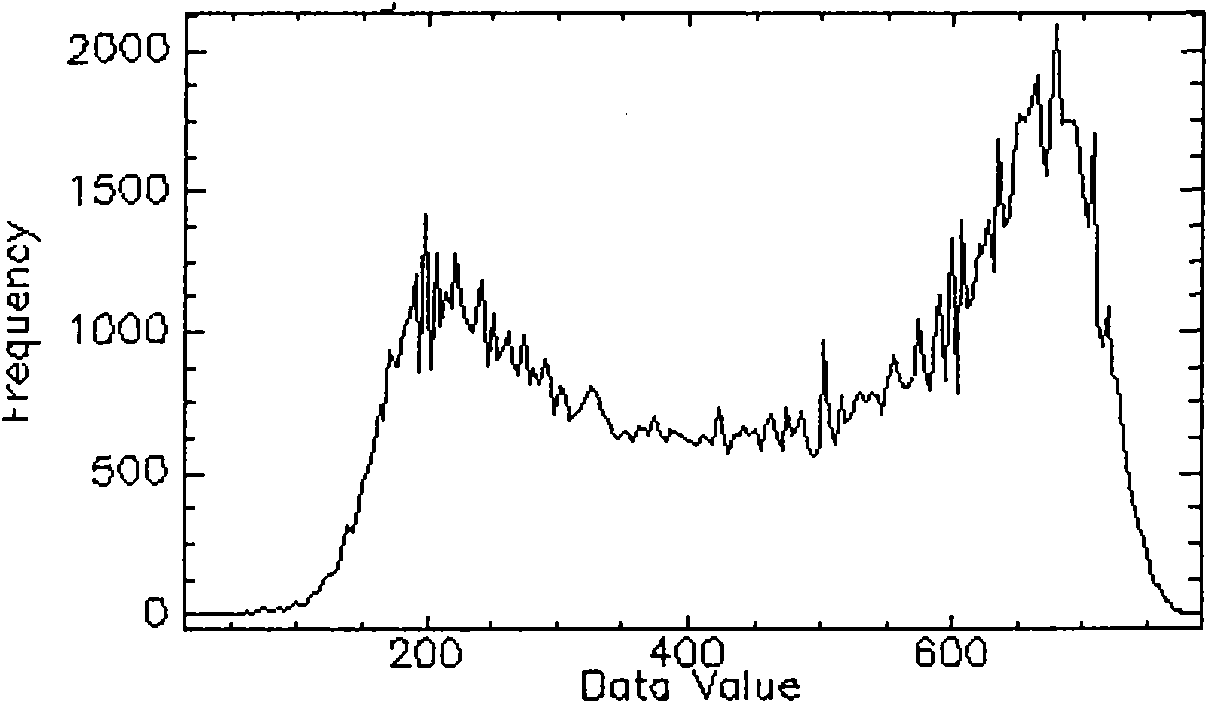

A fingerprint-reading system includes a fingerprint sensor having an active surface sensitive to the pressure and temperature of a finger. The surface area of this sensor is far smaller than the surface area of the fingerprint to be read. The reading is done when the sensor and the finger are in contact and in a relative motion of sliding of the sensor and the finger with respect to each other. The system reconstitutes a complete image of the fingerprint from the partial images given by the sensor during this motion.

Owner:APPLE INC

Fingerprint-reading system

InactiveUS20010026636A1Image analysisElectric/magnetic contours/curvatures measurementsEffective surfaceRelative motion

Owner:APPLE INC

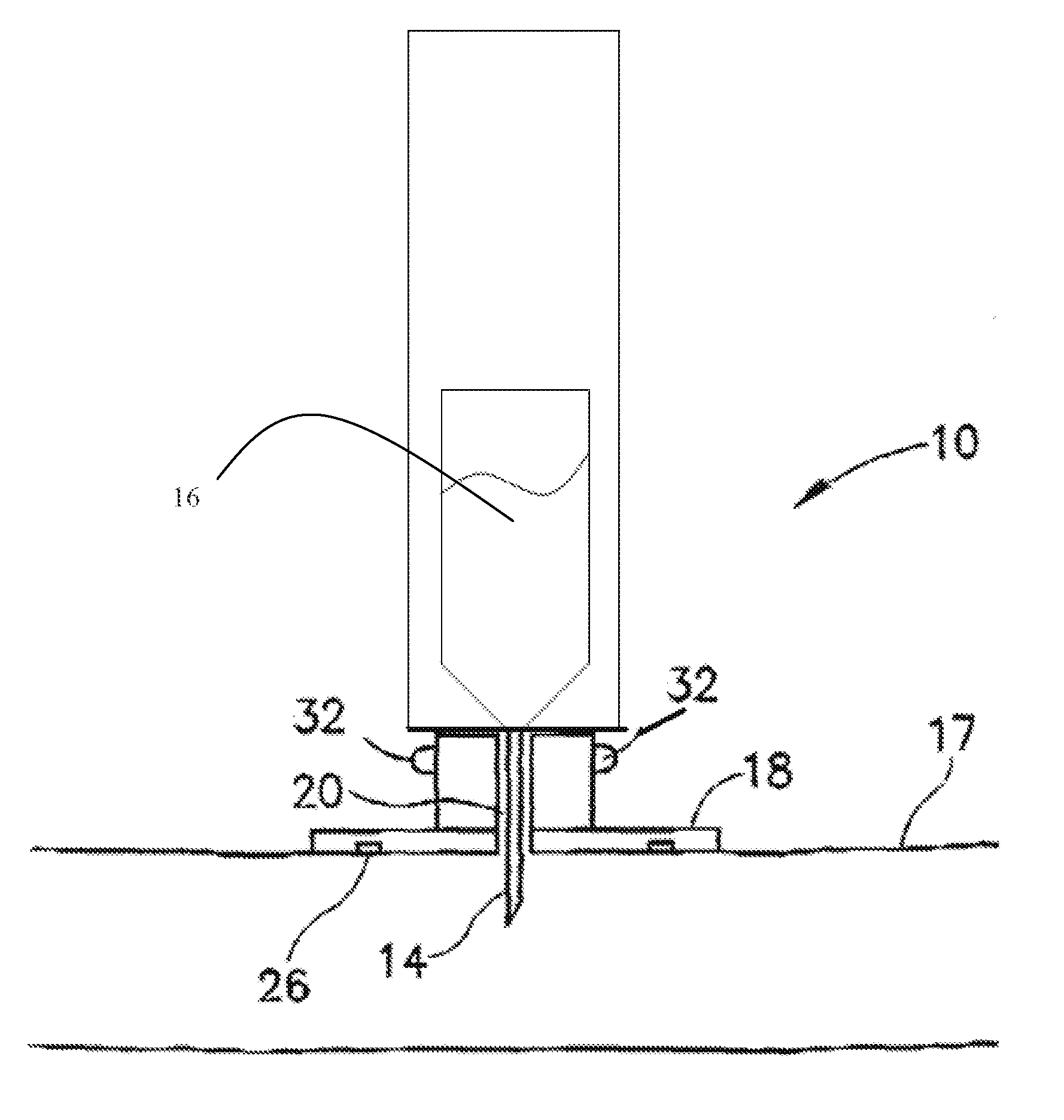

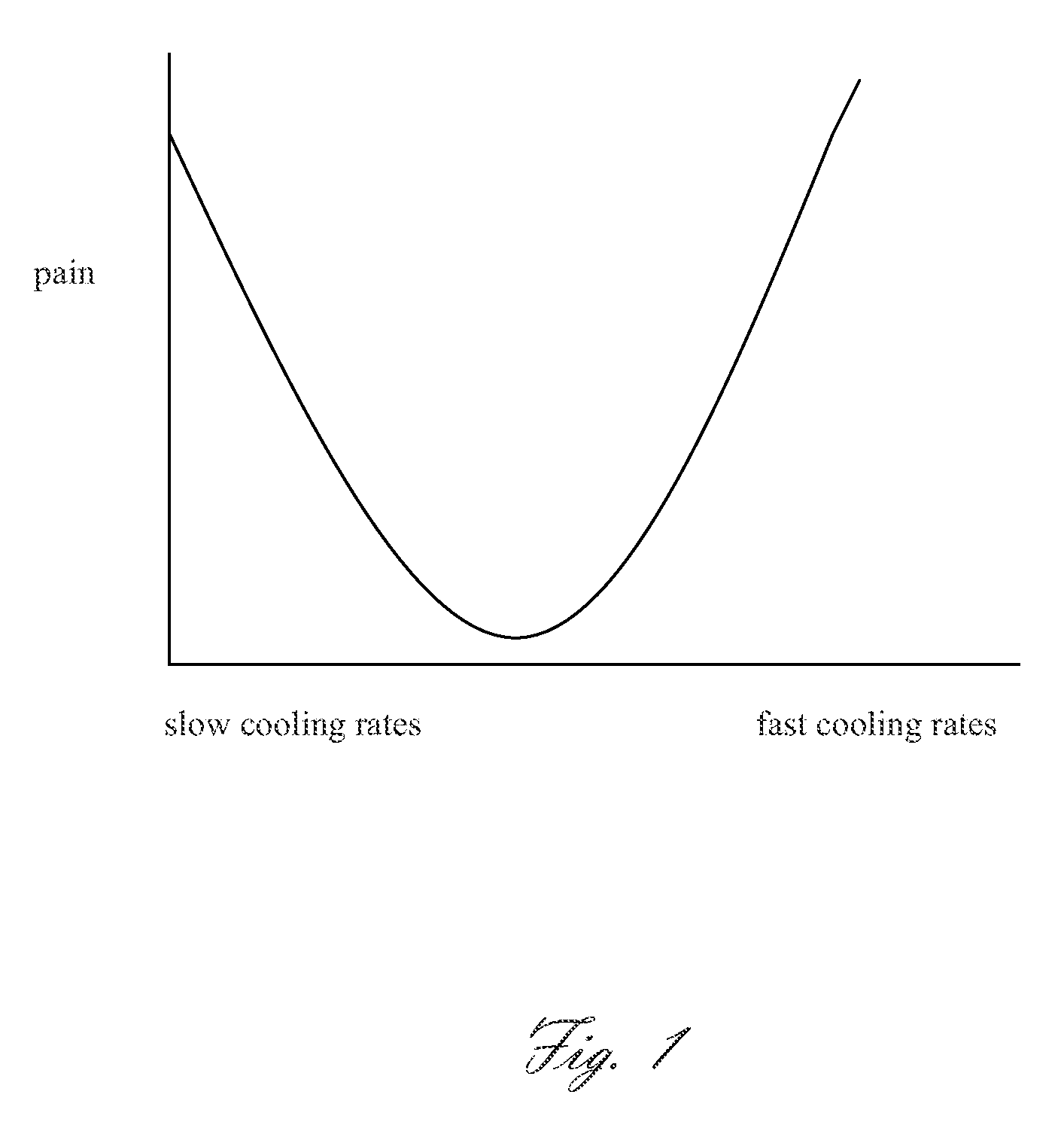

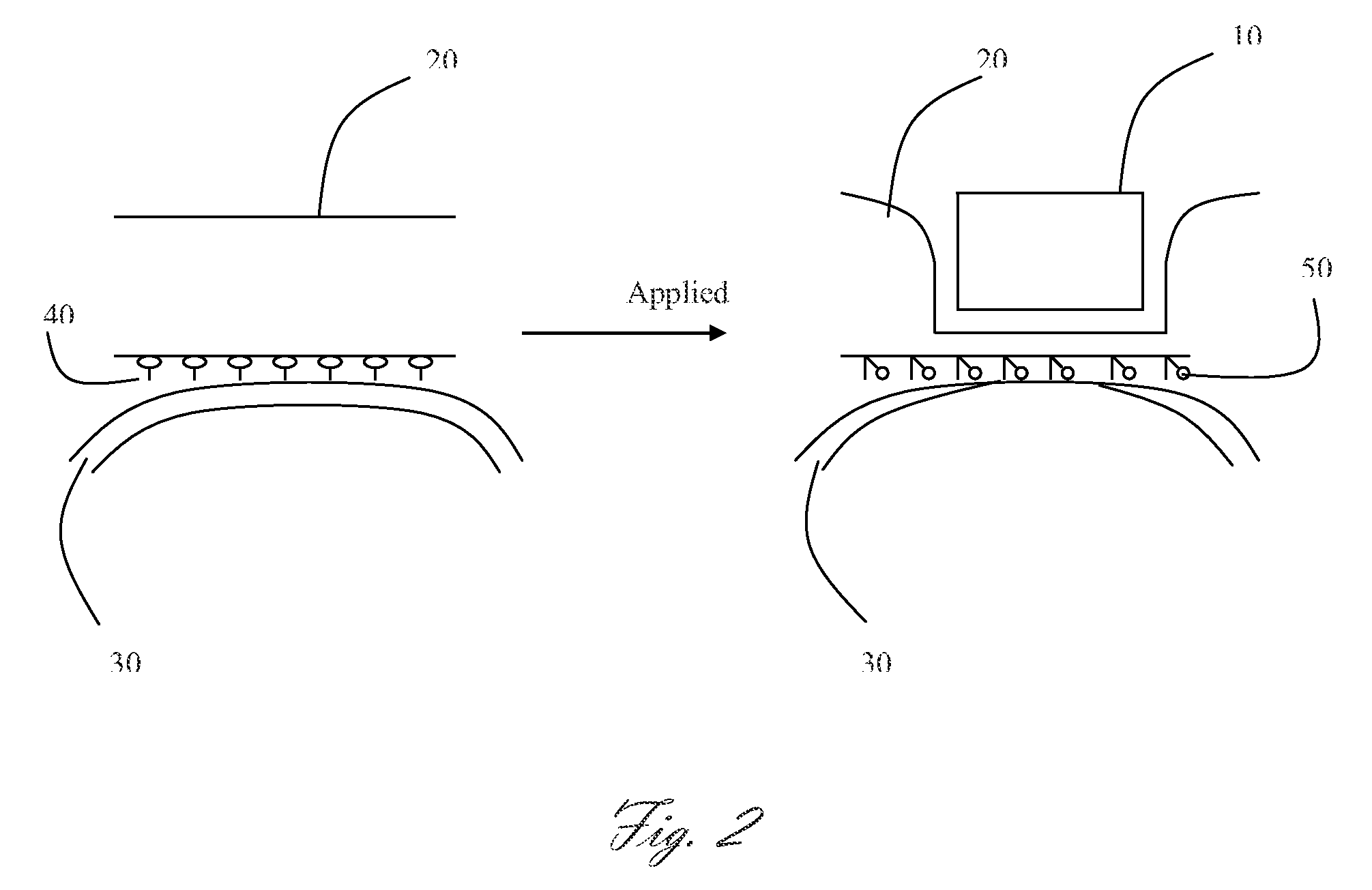

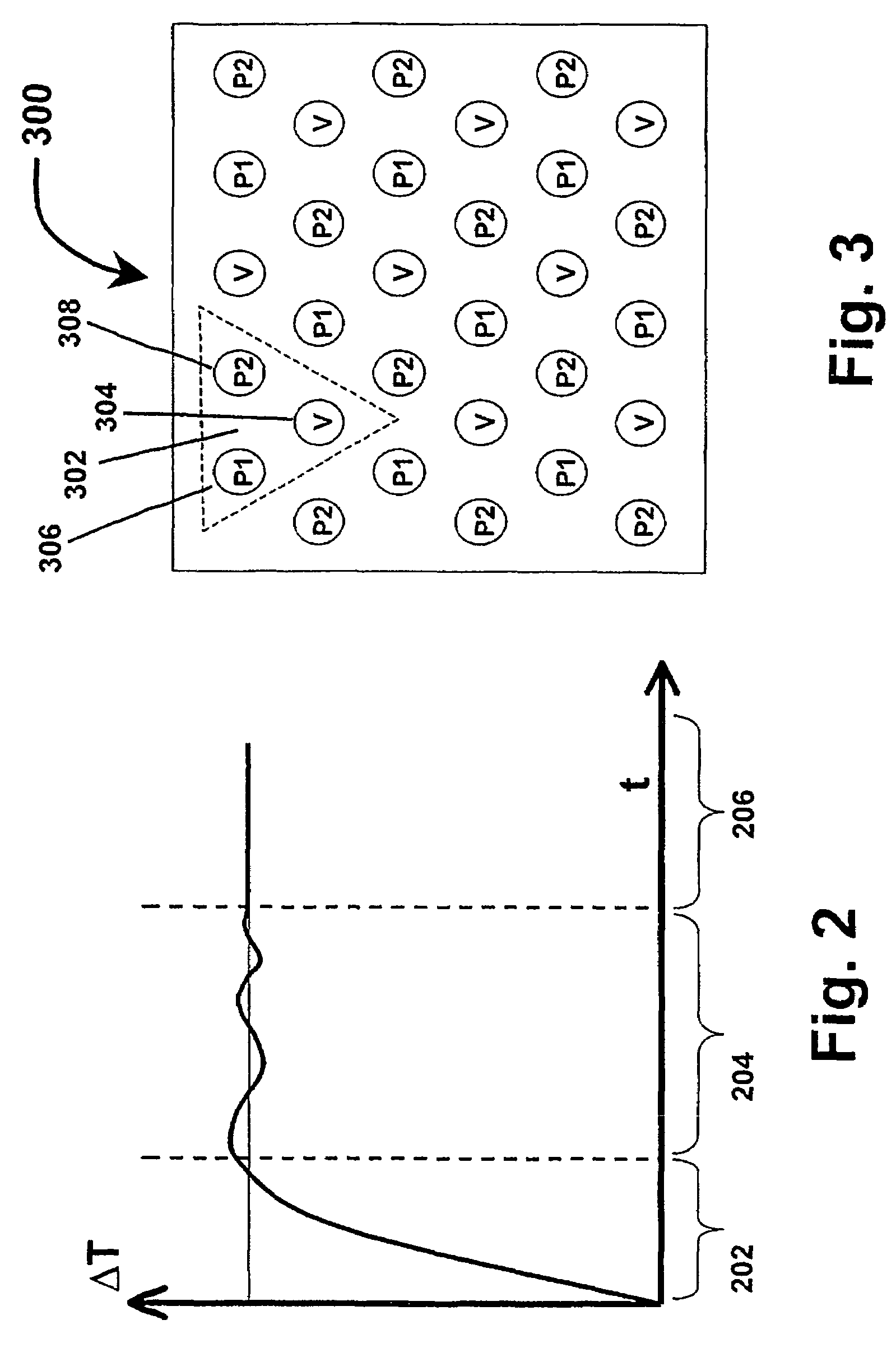

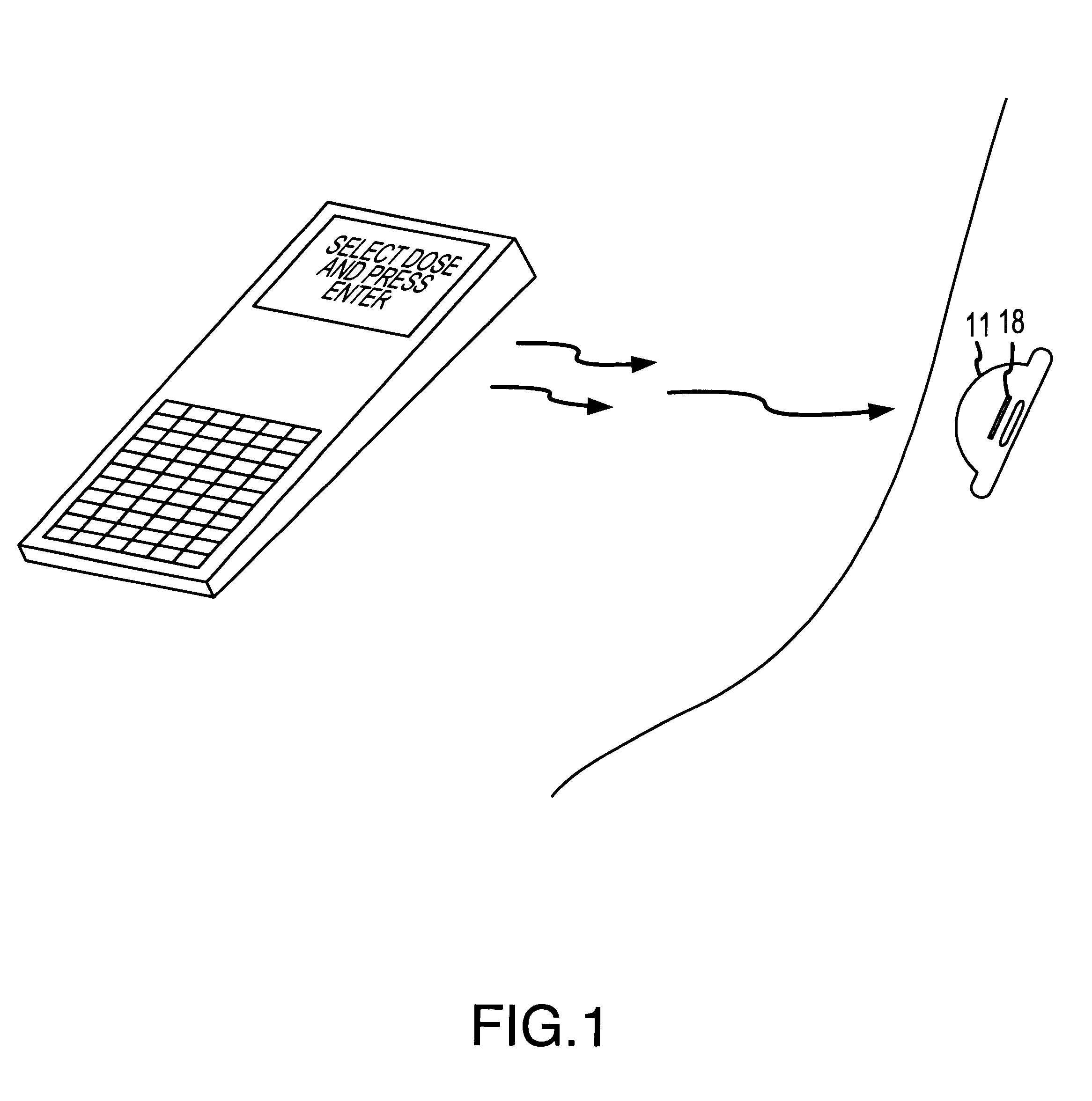

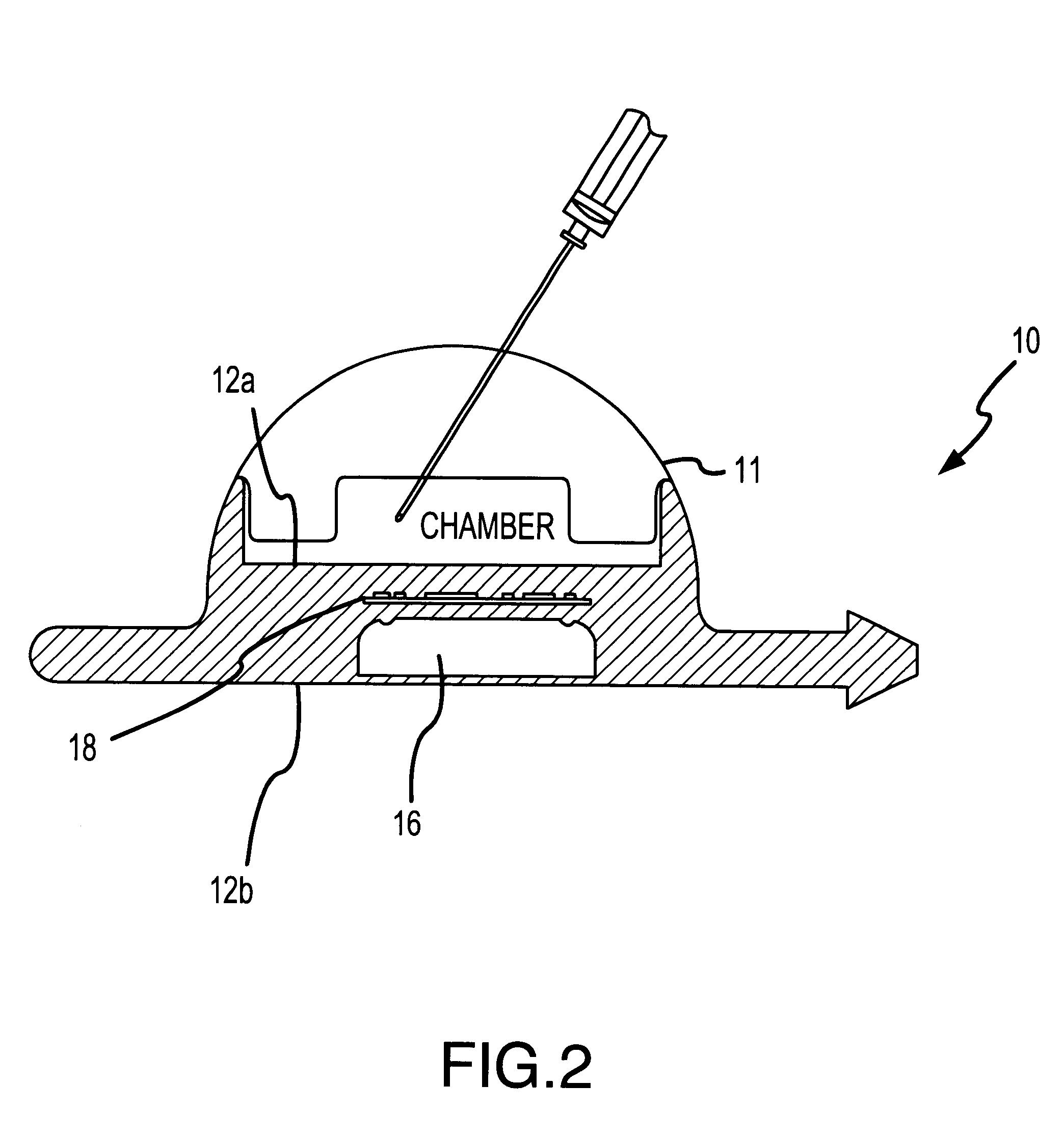

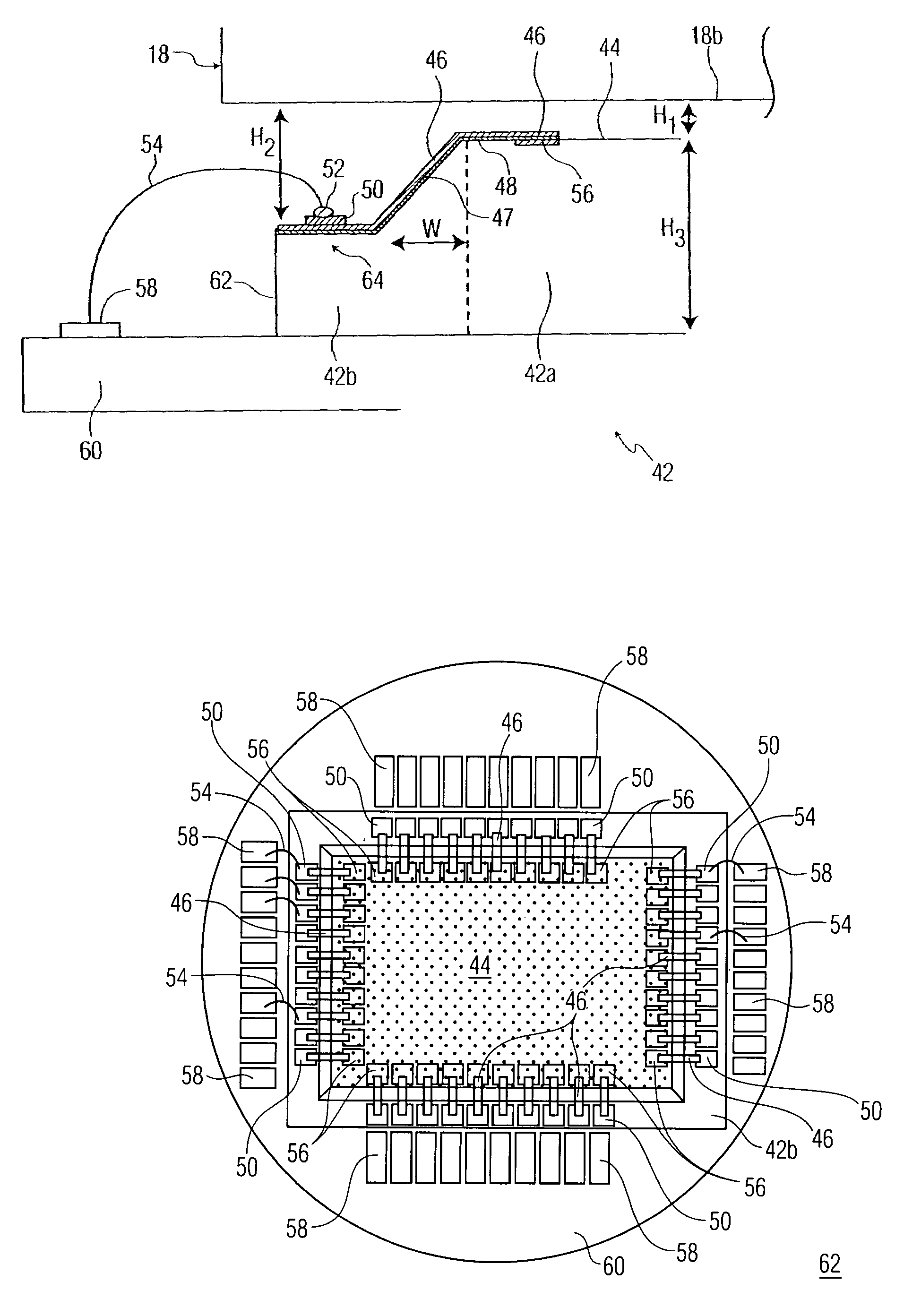

Device and method for piercing a patient's skin with an injector whilst reducing pain caused by the piercing

This invention generally relates to an injector for painlessly piercing a region of a patient's skin. The injector comprises (a) piercing mechanism, comprises: (i) at least one reciprocating needle; said at least one needle is characterized by diameter K; said needle penetrates to depth D in said skin; said depth D is characterized by an initial temperature T; (ii) at least one container having a medicament to be delivered to said patient. The injector further comprises (b) cooling mechanism, comprises at least one attachable cooling means, especially a Peltier Cooled Cold Plate (PCCP), in connection with a radiator and sufficient DC power supply; said PCCP is characterized by an effective surface area S; said effective surface S is optimized such that said pain caused by said piercing is eliminated; said PCCP is characterized by temperature TiPCCP; said PCCP adapted for cooling a portion of said skin prior to and / or during and / or after piercing thereof by said piercing mechanism such that the cooling is obtained at said depth D; said depth D is cooled from said initial temperature T to a final temperature TD(ΔT) in a period of time t (dt) by said PCCP; said final temperature TD Of said depth D is higher than about 0 and lower than about 13 degrees C.; said ΔT / dt is optimized such that said pain caused to said patient is eliminated. The injector further comprises (c) at least one aperture through which said needle is reversibly piercing said skin.

Owner:SINDOLOR MEDICAL

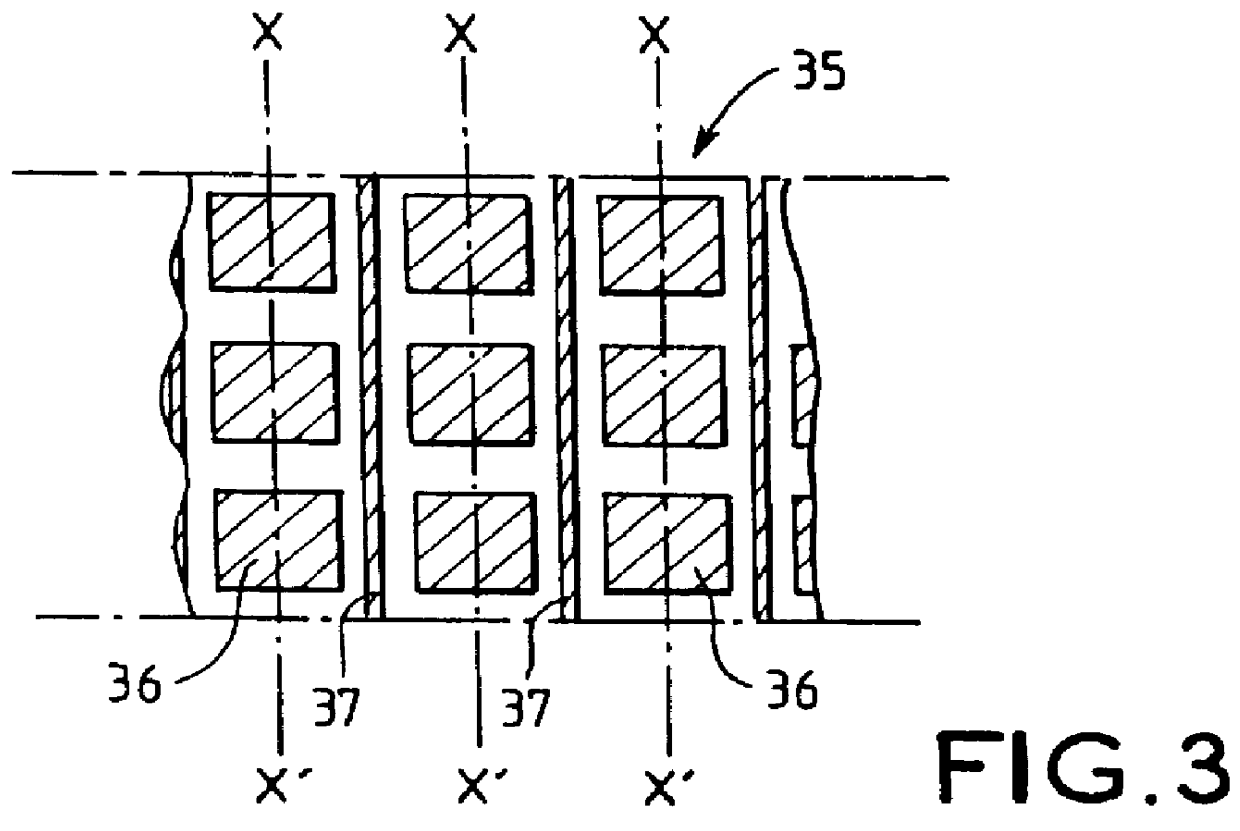

Fingerprint-reading system with integrated heating resistors

InactiveUS6061464AImage analysisPerson identificationElectrical resistance and conductanceEffective surface

A fingerprint-reading system including a sensor on which a finger, whose imprint is to be read, is pressed. The sensor has an active surface of elements sensitive to variations in temperature and integrated heating resistors that create a transient variation in the temperature of the sensitive elements thereby to generate temporary charges in each element when pressed by a finger. The charges are output in synchronism with creation of the transient variations in the temperature of the sensitive elements to provide stable images of the fingerprint which may be motionless. The output of the sensor enables real-time display of the fingerprint images and processing of authentication data. The heating resistor enables the sensor to produce stable images of a fingerprint by producing an internal excitation to offset the tendency of electrical charges, induced by variations of the physical temperature of the finger, from disappearing because the temperature of the finger has reached equilibrium.

Owner:THOMSON CSF SA

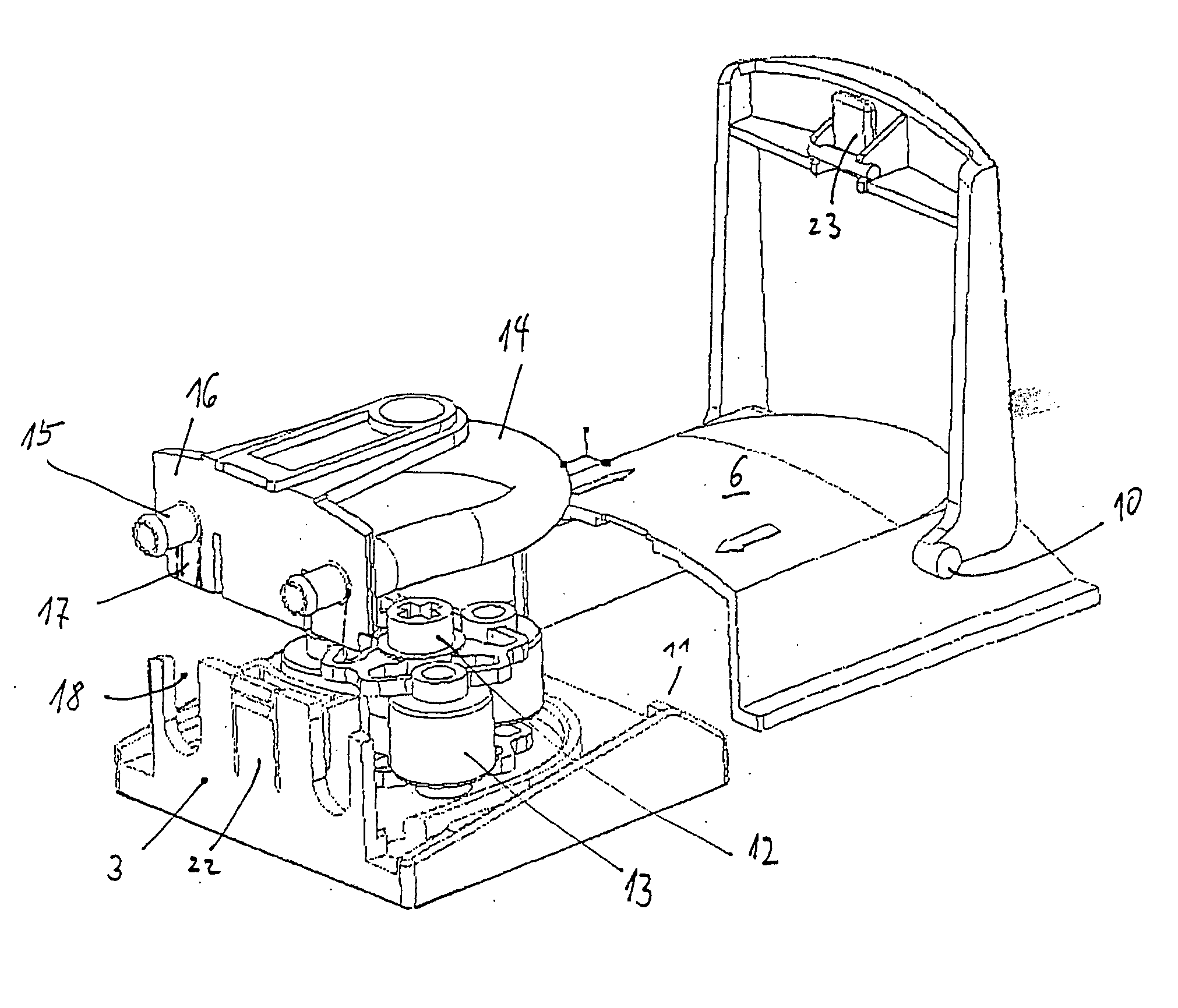

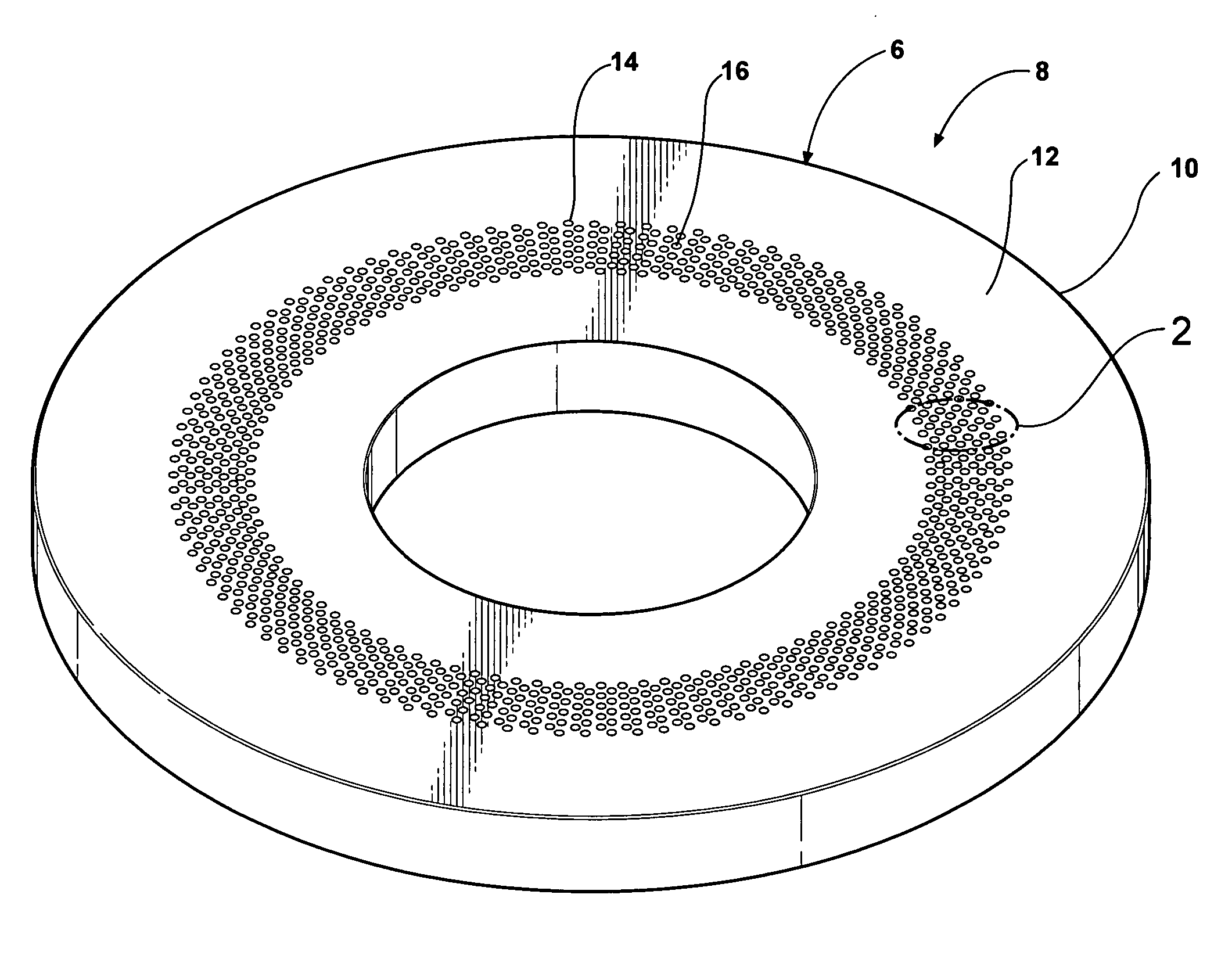

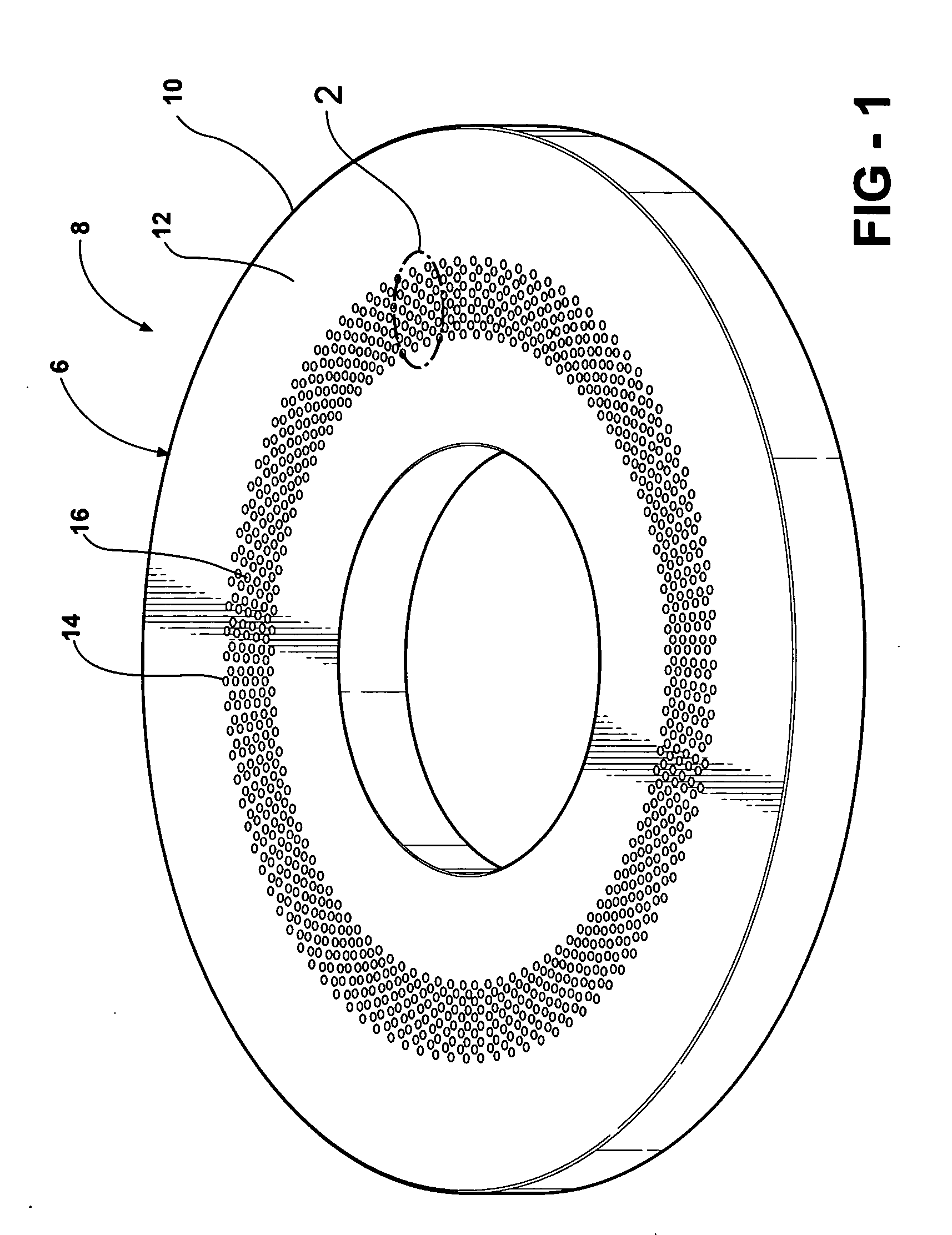

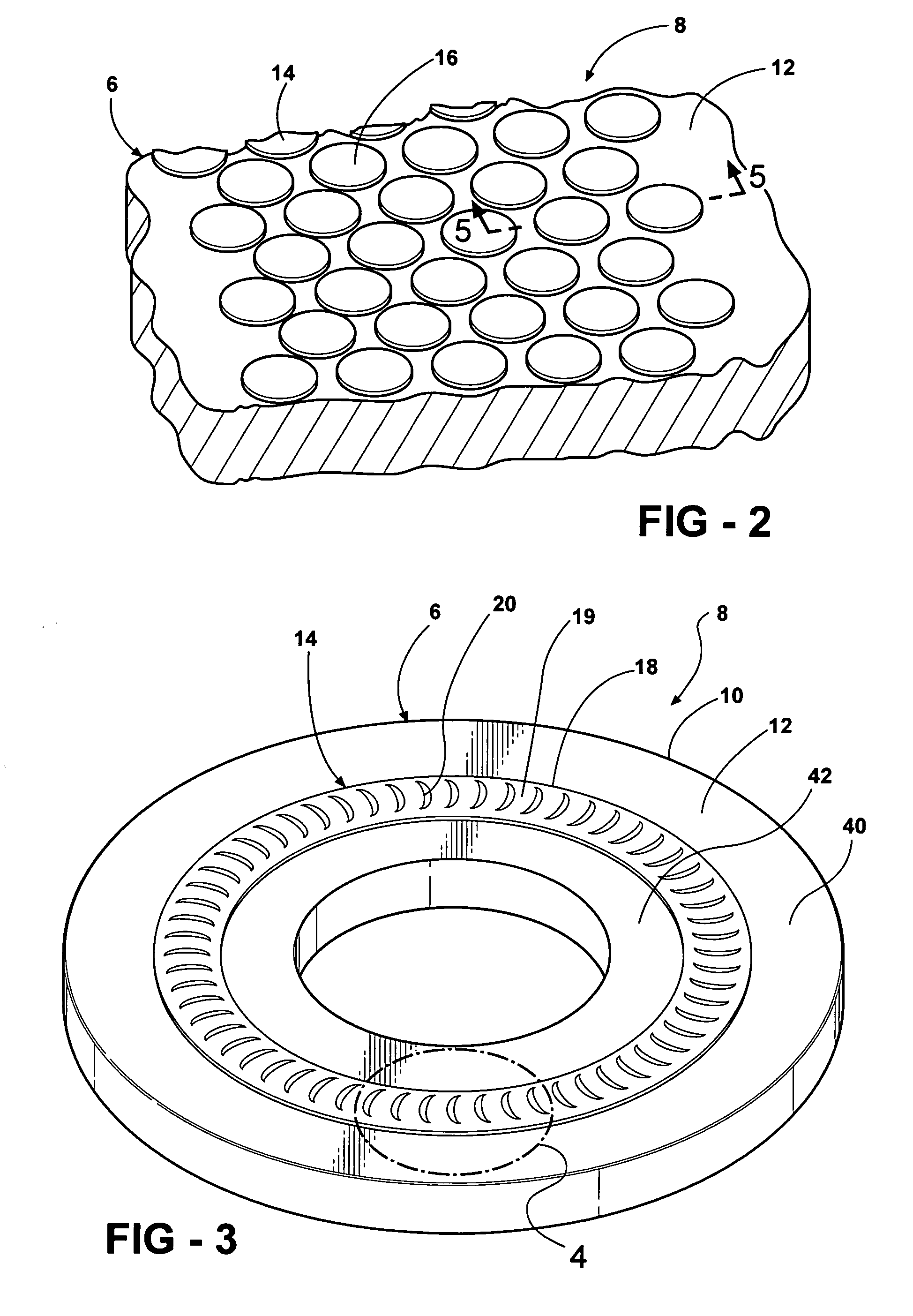

Gas separation devices

ActiveUS7517387B2Minimized volumeEasy to operateLiquid degasificationReversed direction vortexPhysiological fluidEffective surface

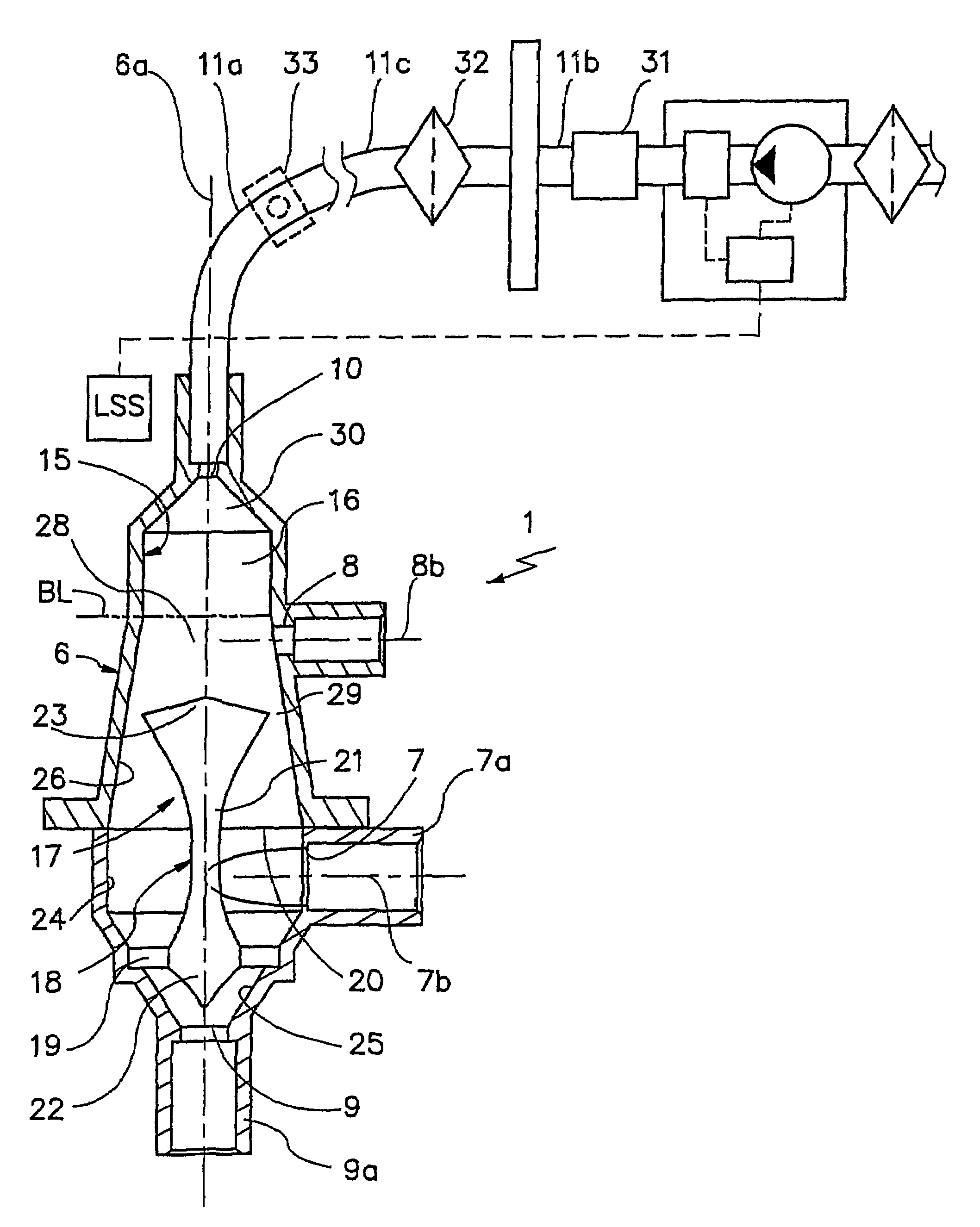

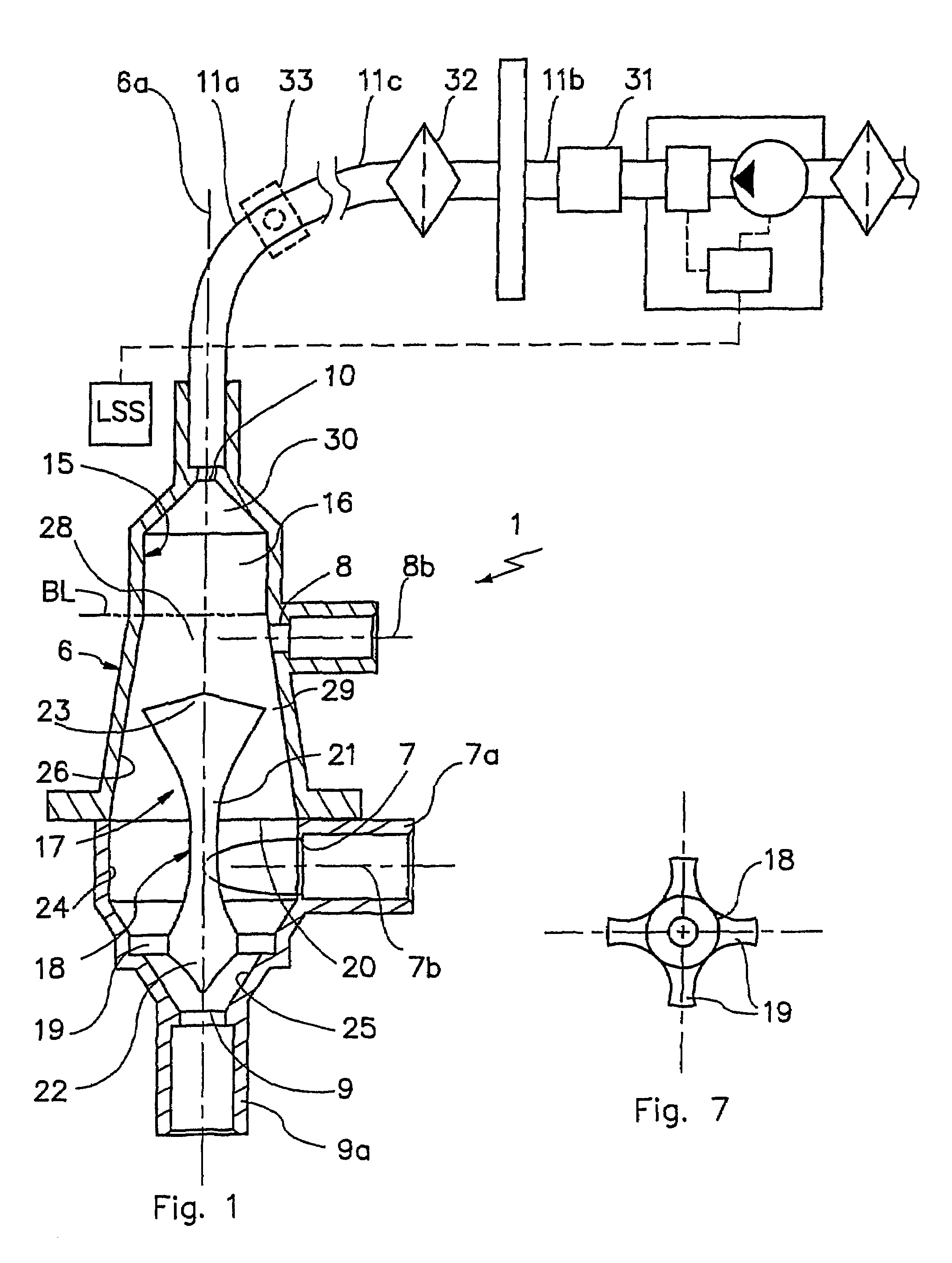

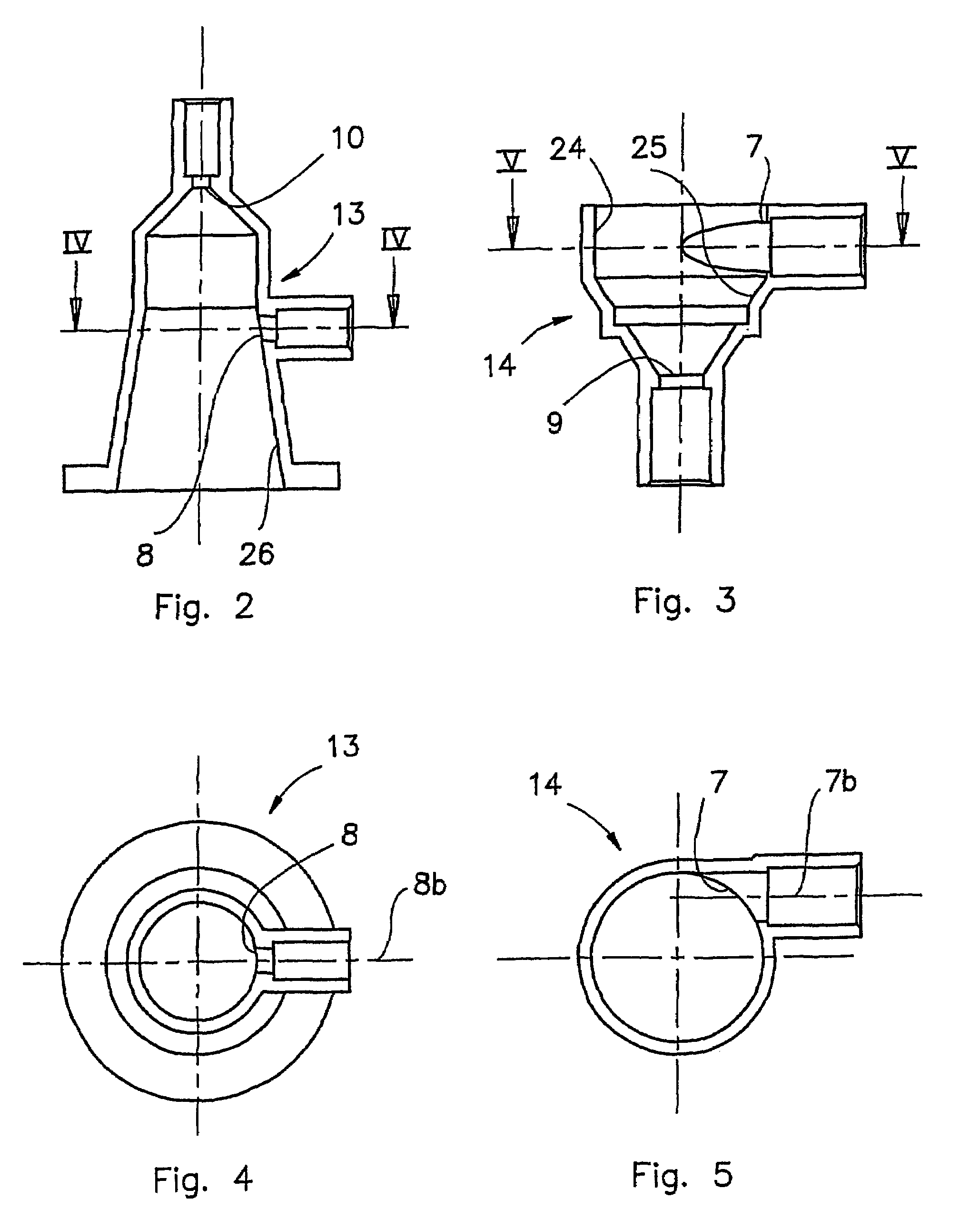

A description is given of a gas separation device for a physiological fluid, comprising a containing body (6) having at least a first inlet aperture (7) for a physiological fluid, positioned with a tangential direction of access, at least one outlet aperture (9) for the said fluid, spaced apart from the said inlet aperture, and a guide element (17) housed within the said body. The guide element (17) has a continuous active surface (15) designed to contact and guide the said fluid and delimits, together with the containing body (6), a first annular chamber (20) into which the first inlet aperture (7) opens directly.

Owner:GAMBRO LUNDIA AB

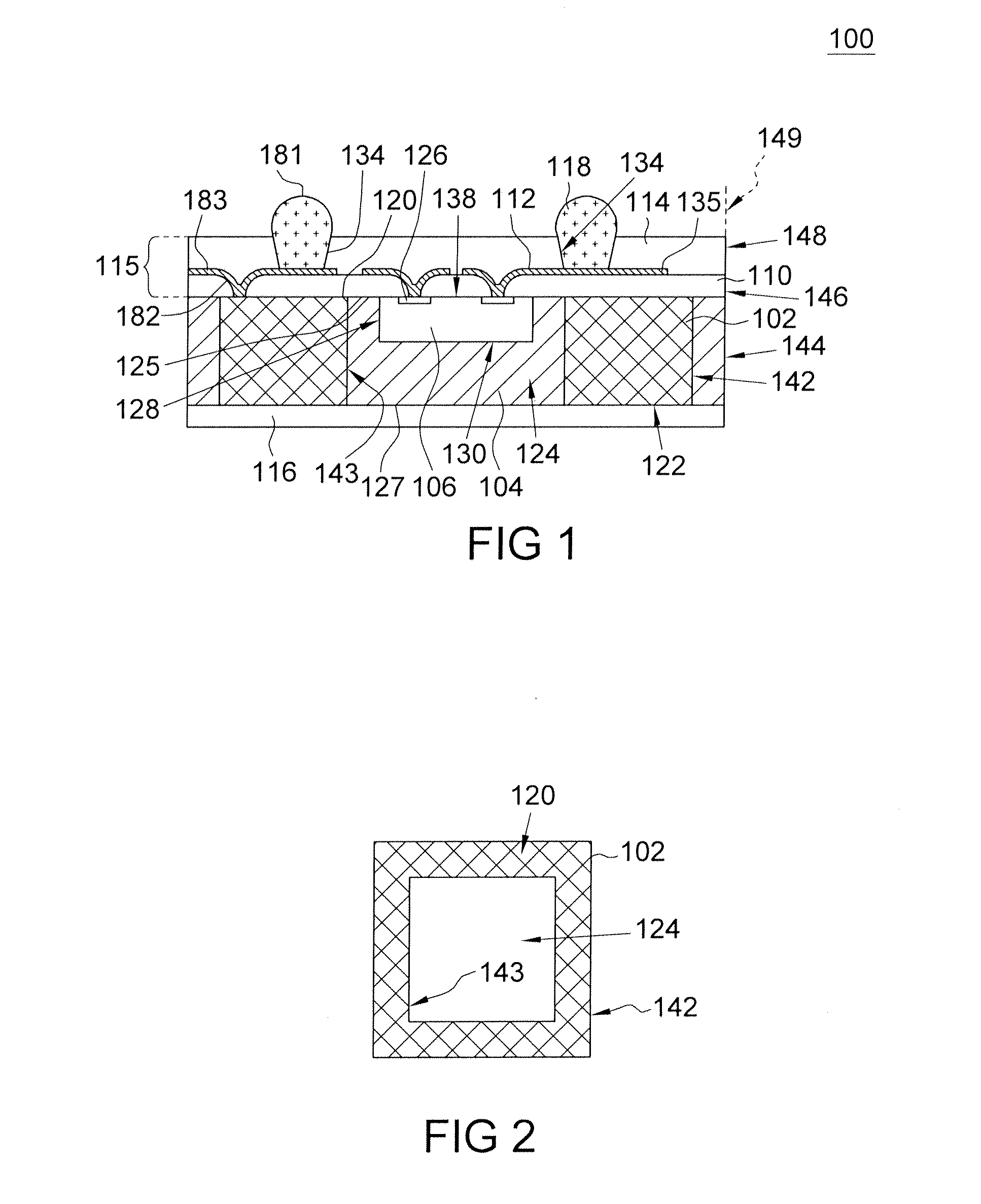

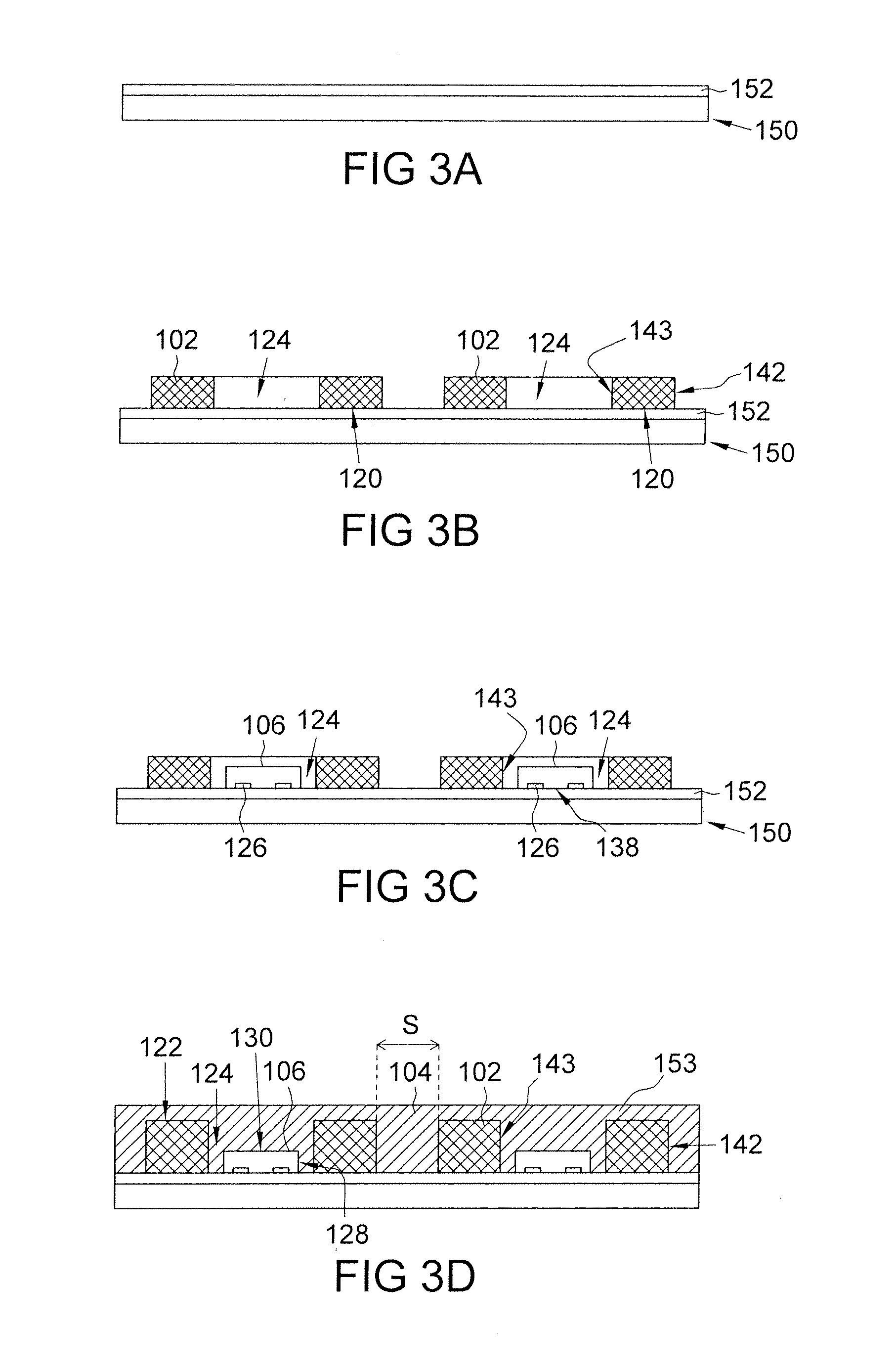

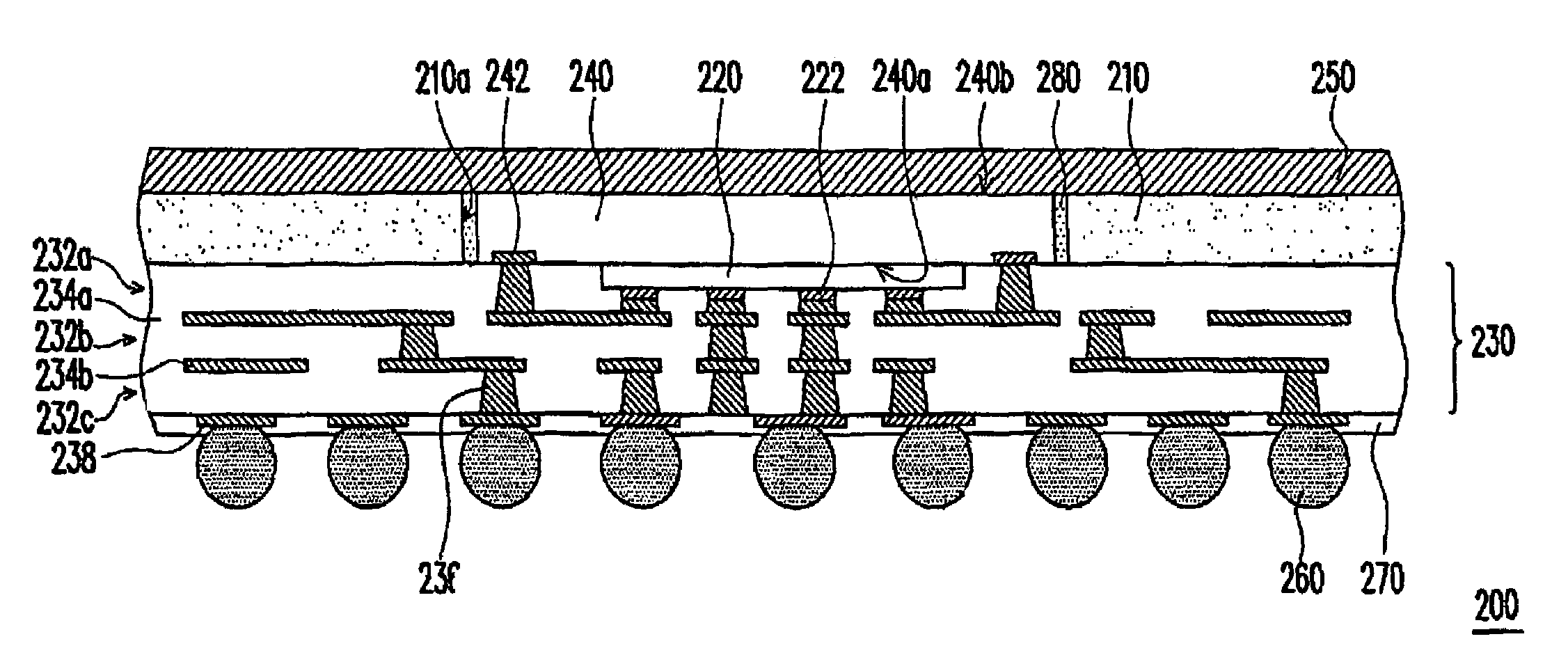

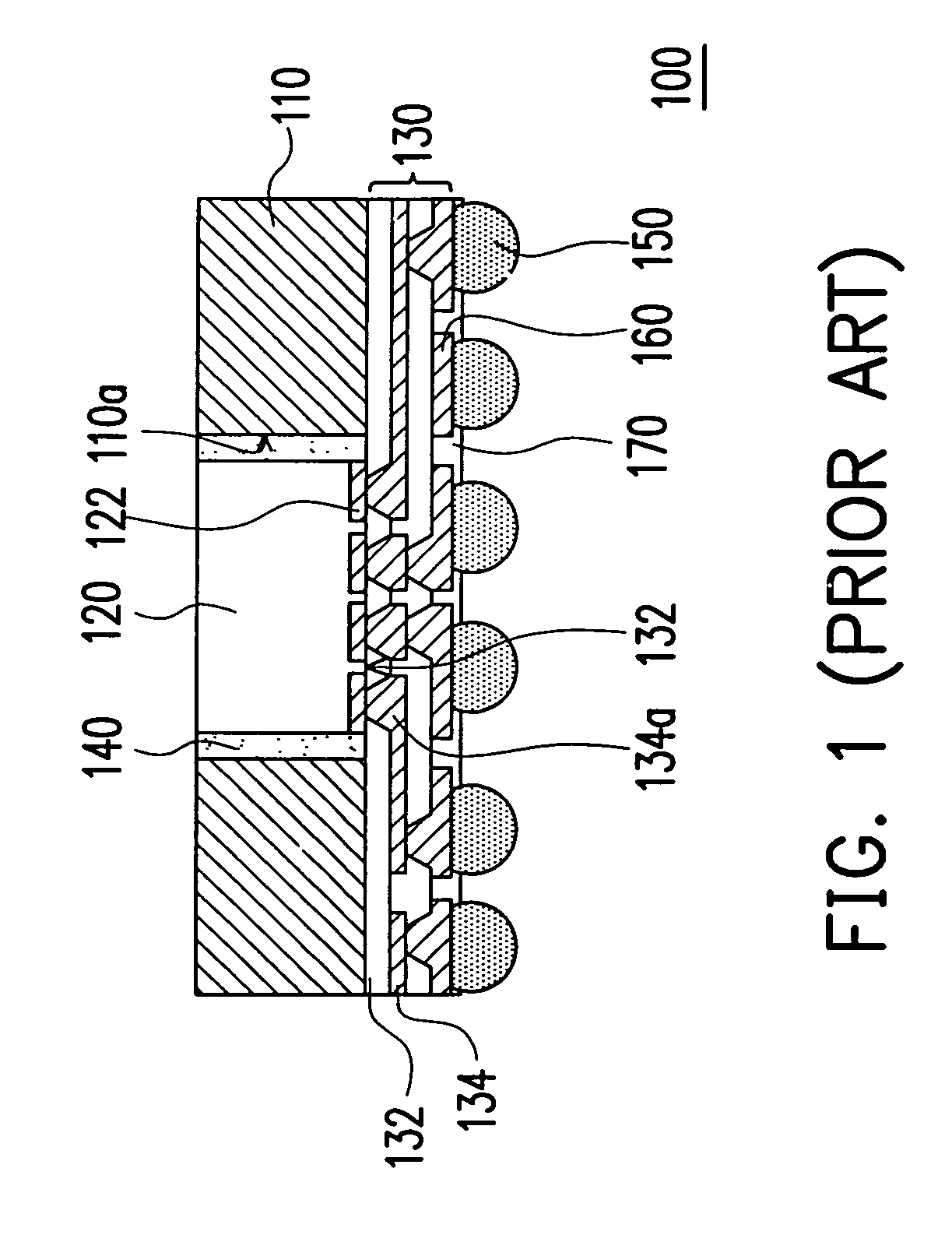

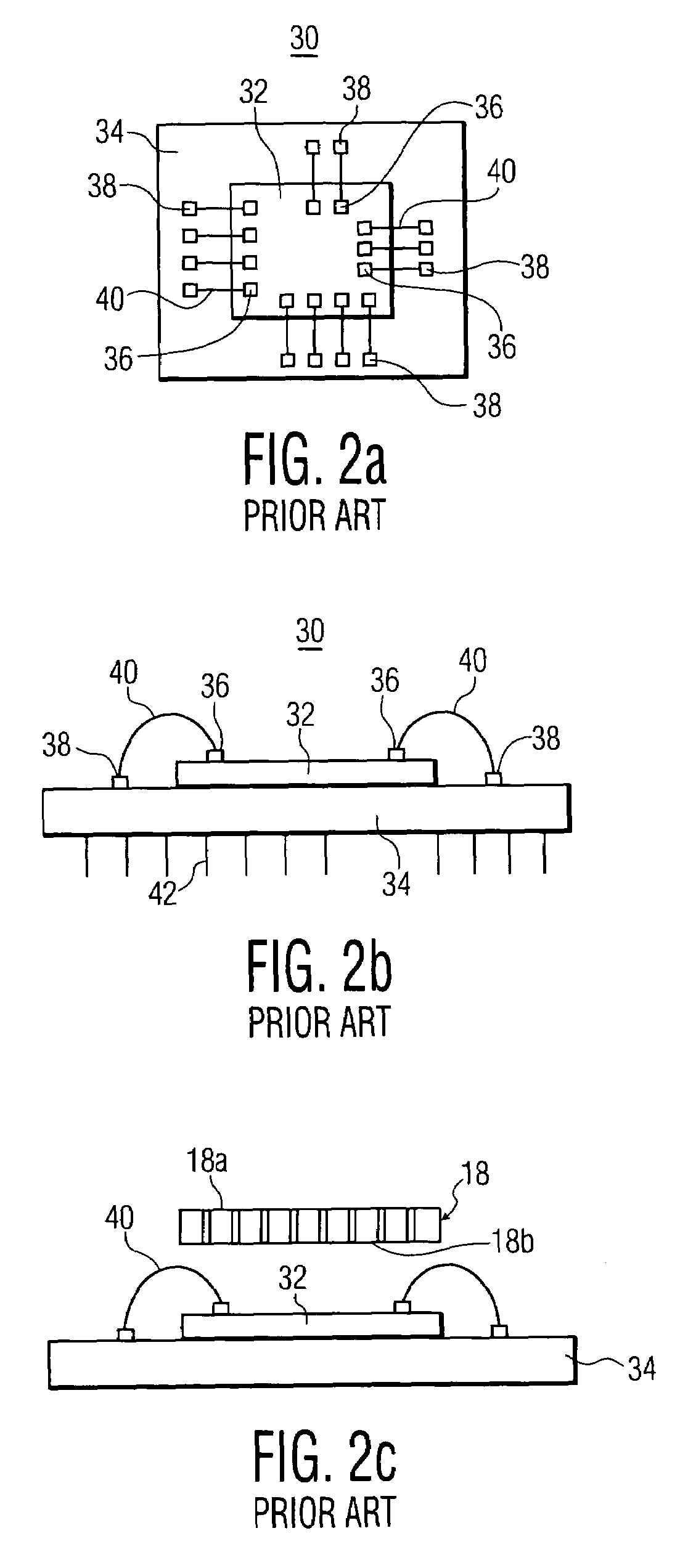

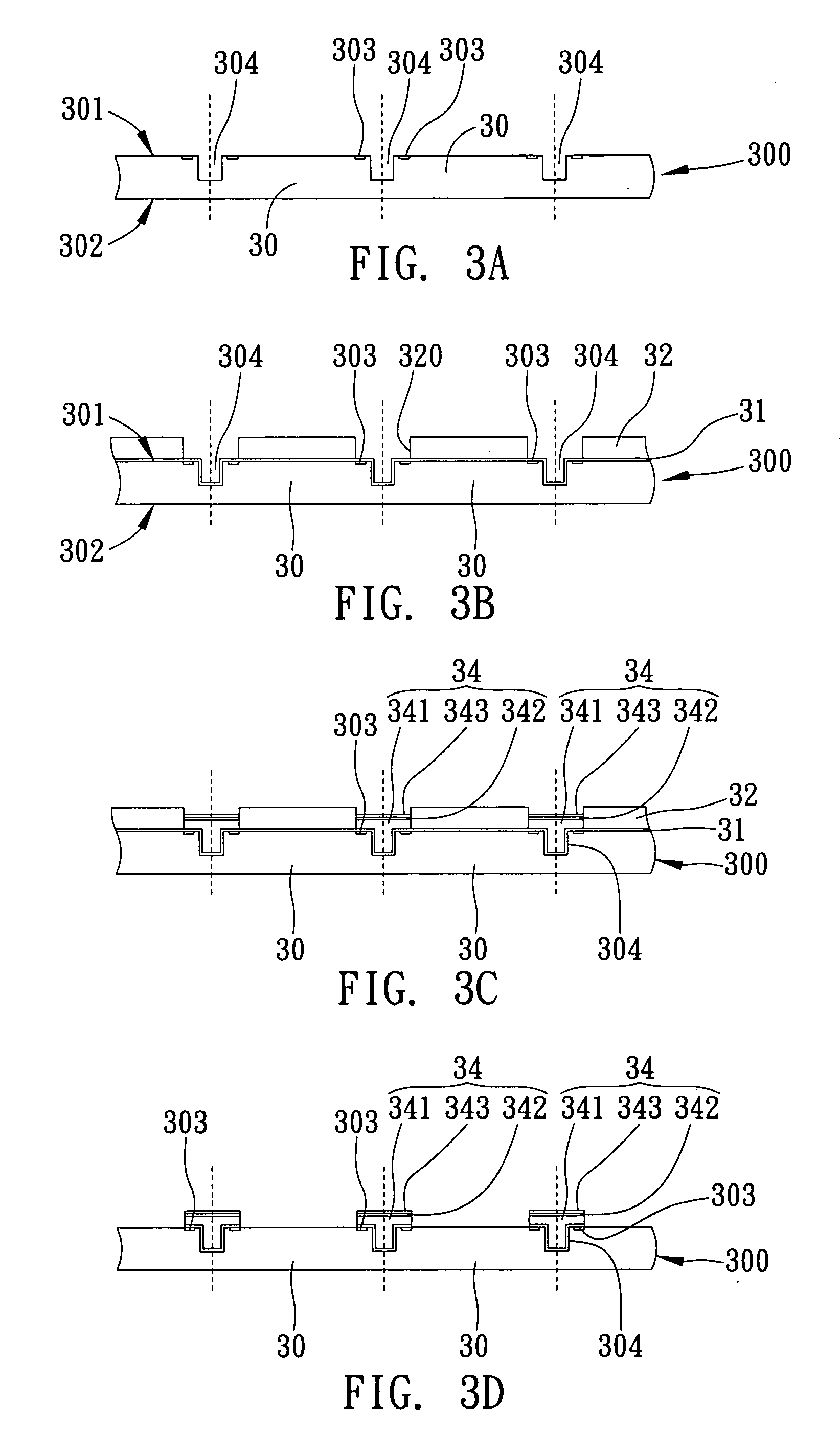

Semiconductor Package and Manufacturing Methods Thereof

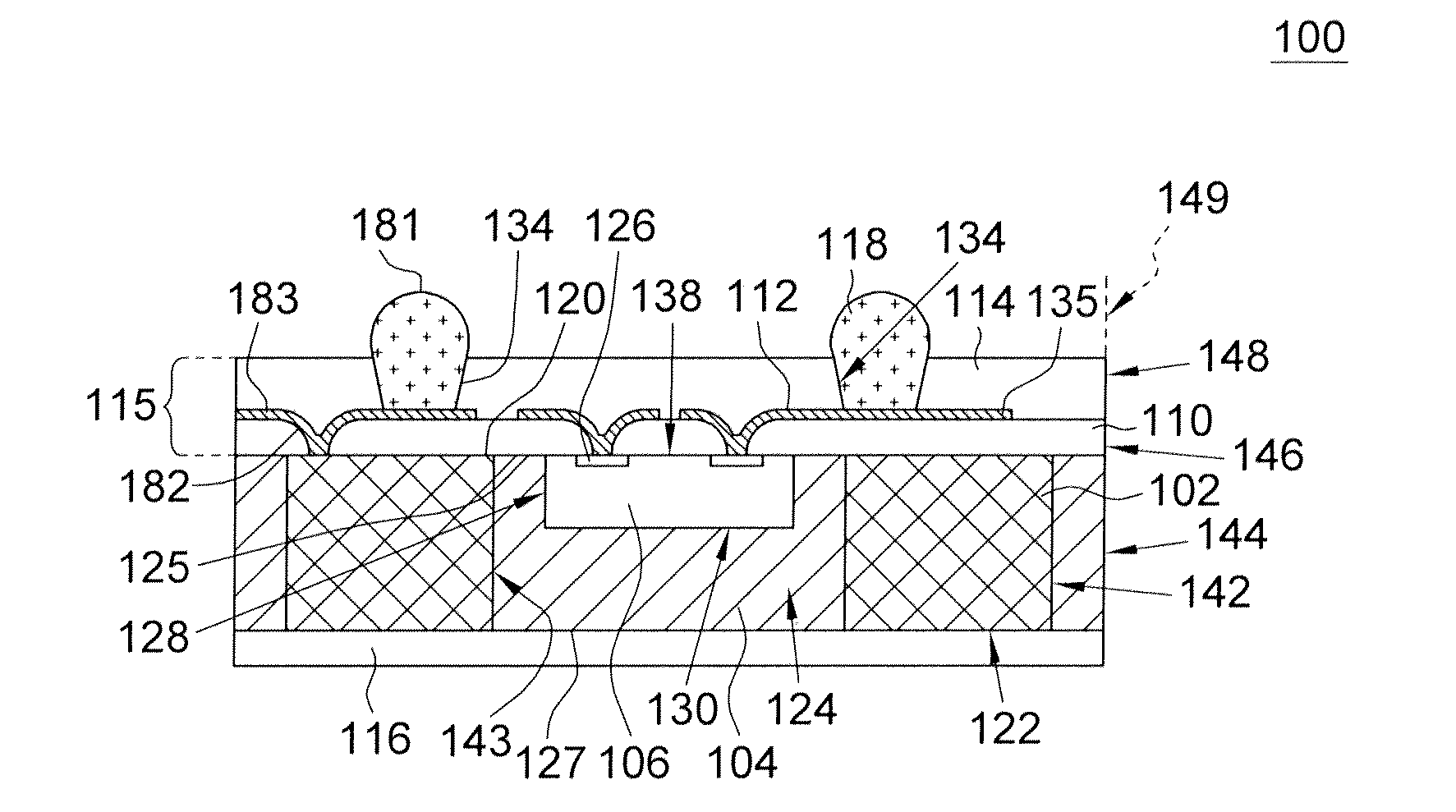

InactiveUS20110127654A1Semiconductor/solid-state device detailsSolid-state devicesEffective surfaceRedistribution layer

A semiconductor package and manufacturing methods thereof are provided. In one embodiment, the semiconductor package includes a die, a shield, a package body, and a redistribution layer. The die has an active surface and an inactive surface. The shield is disposed over the inactive surface of the die. The package body encapsulates the die and a first portion of the shield, where a first surface of the package body is substantially coplanar with the active surface of the die. The redistribution layer is disposed on the active surface of the die and on portions of the first surface of the package body.

Owner:ADVANCED SEMICON ENG INC

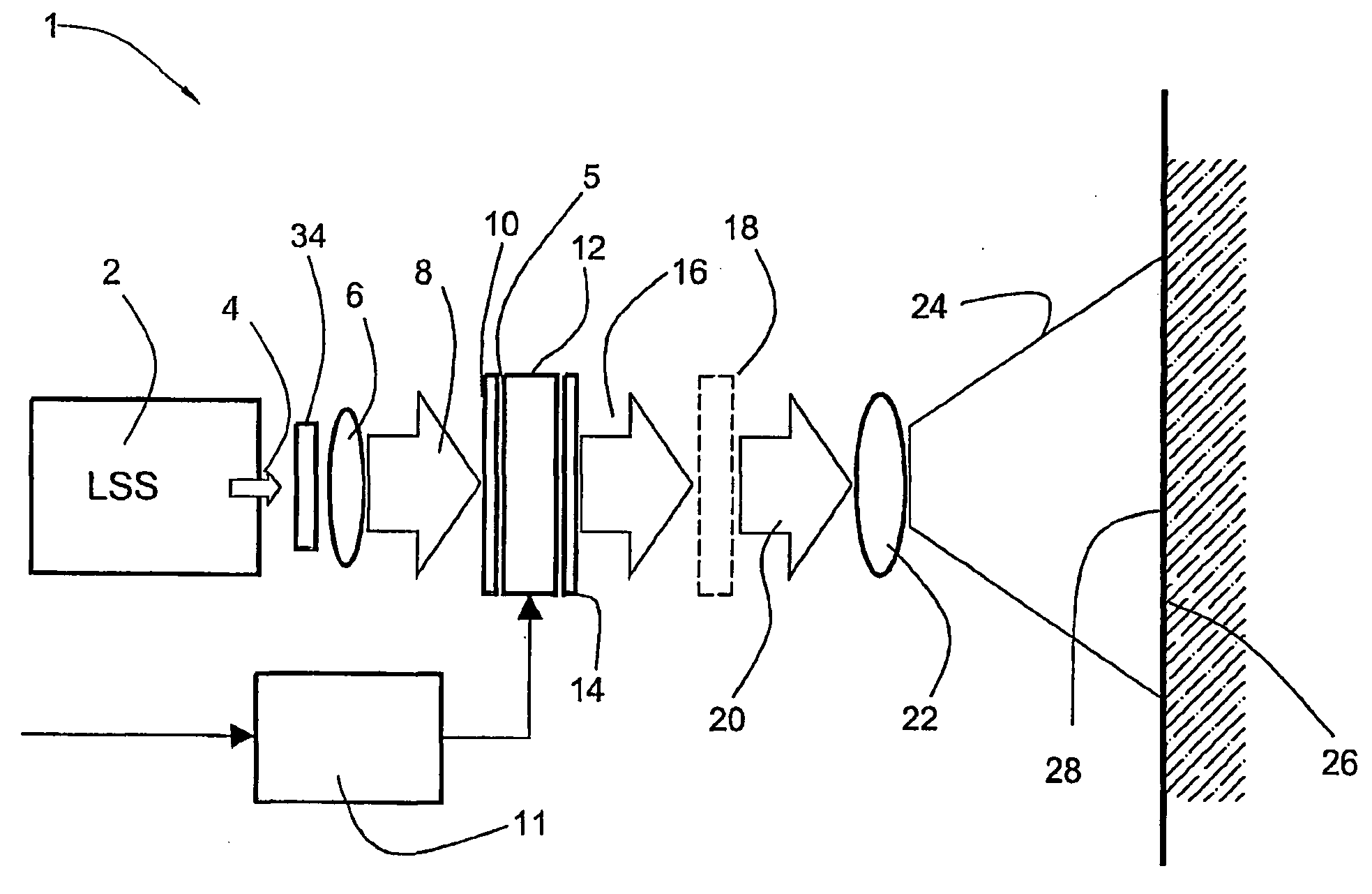

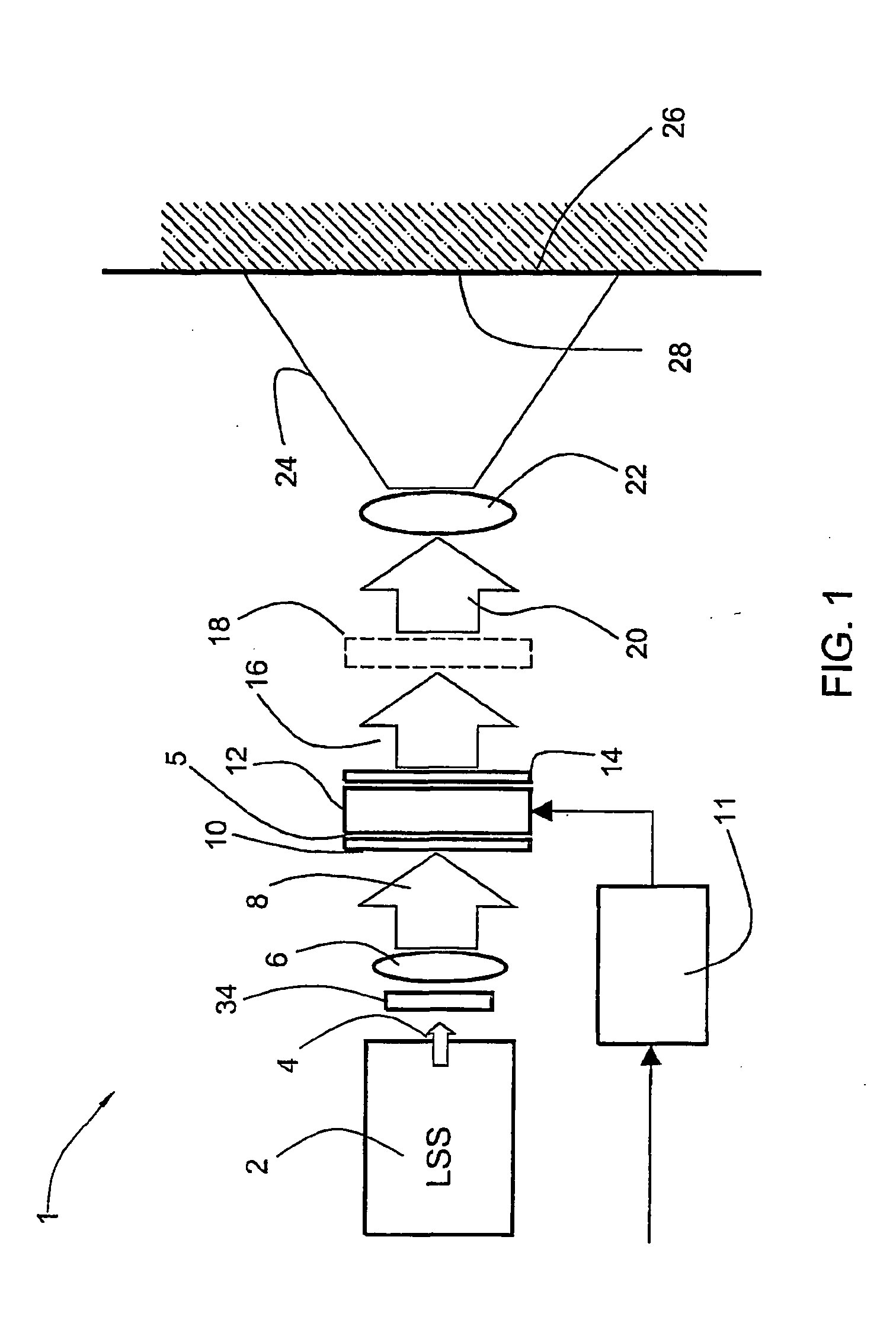

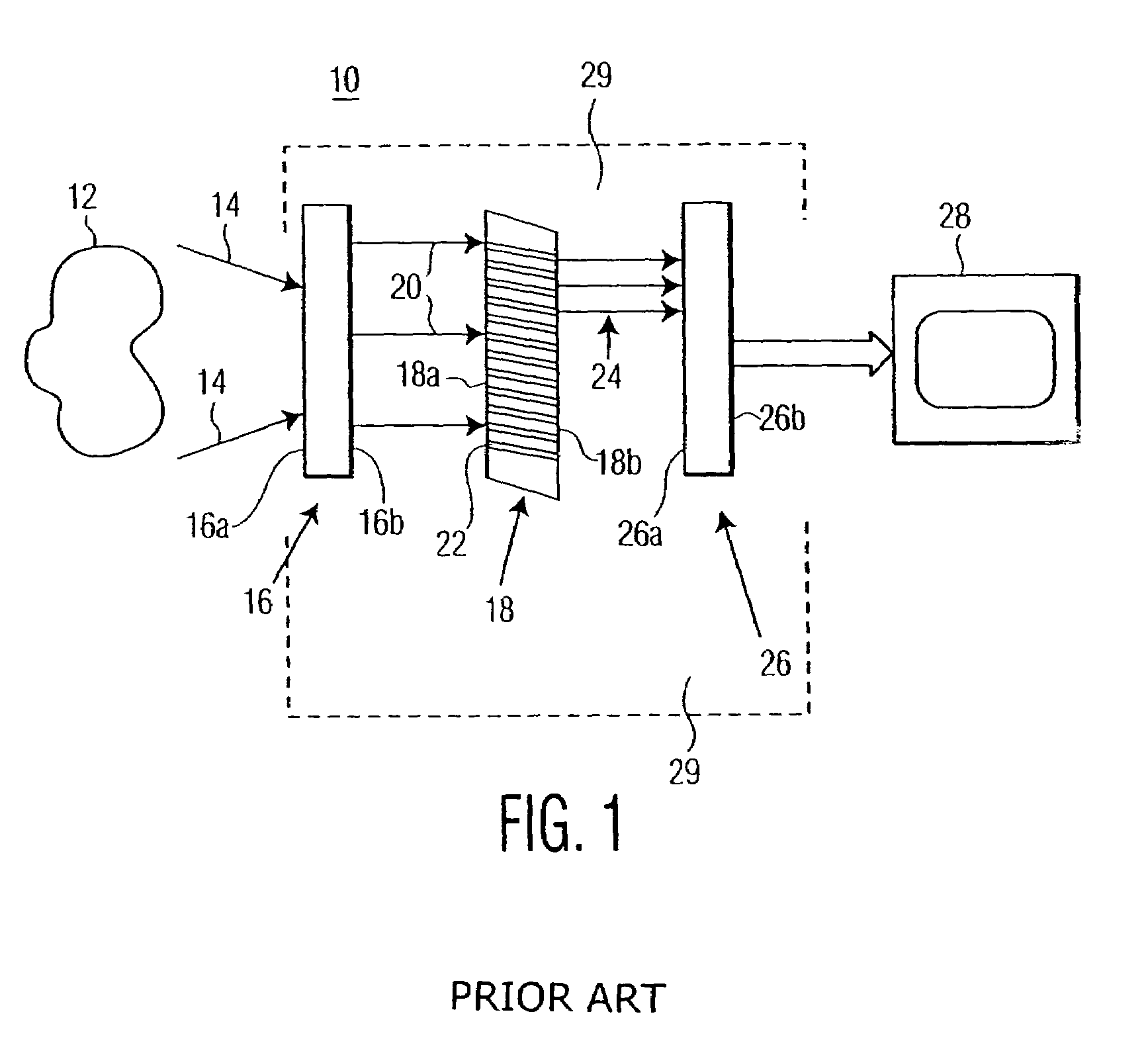

Image projecting device and method

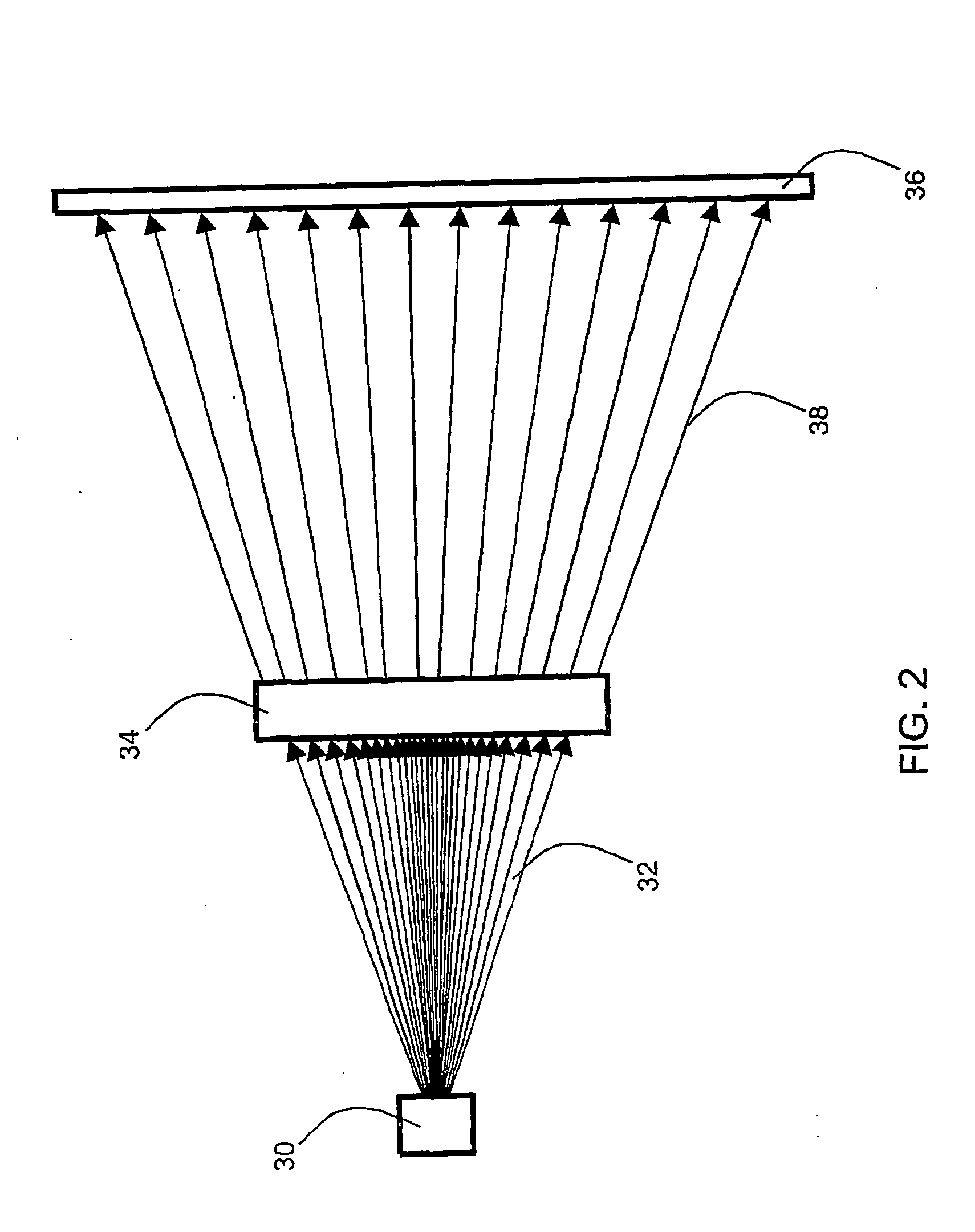

InactiveUS20040239880A1Improve efficiencyReduce impactTelevision system detailsProjectorsSpatial light modulatorEffective surface

An image projecting device and method are presented. The device comprises a light source system operable to produce a light beam to impinge onto an active surface of a spatial light modulator (SLM) unit formed by an SLM pixel arrangement; and a magnification optics accommodated at the output side of the SLM unit. The light beam impinging onto the SLM pixel arrangement has a predetermined cross section corresponding to the size of said active surface. The SLM unit comprises first and second lens' arrays at opposite sides of the pixel arrangement, such that each lens in the first array and a respective opposite lens in the second array are associated with a corresponding one of the SLM pixels

Owner:EXPLAY

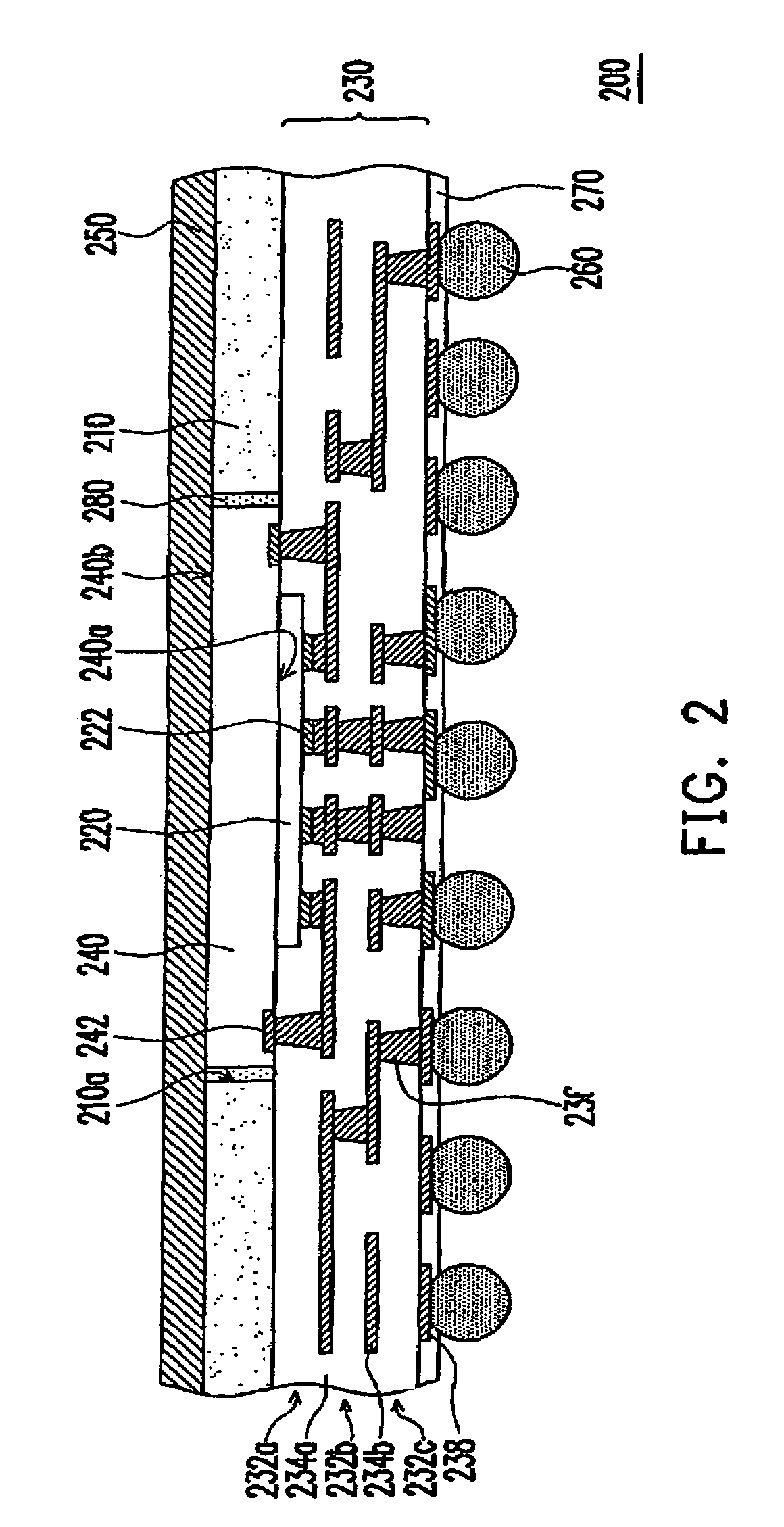

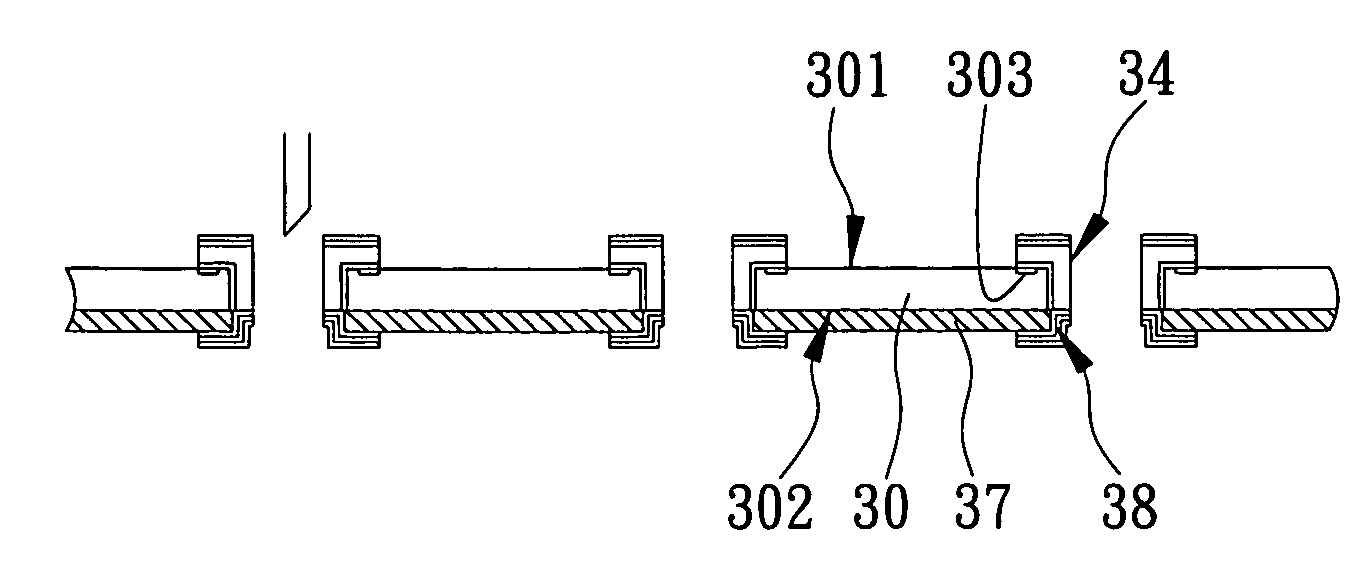

Chip package with embedded panel-shaped component

ActiveUS7224062B2Improve electrical performanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEffective surfaceEngineering

A bump-less chip package is provided. The bump-less chip package includes a chip, an interconnection structure and a panel-shaped component. The panel-shaped component has a plurality of electrical terminals on a first surface thereof. The back surface of the chip is disposed on the first surface of the panel-shaped component, and the chip has a plurality of first pads on the active surface thereof away from the panel-shaped component. The interconnection structure is disposed on the first surface of the panel-shaped component and the active surface of the chip. The first pads of the chip may electrically connect with the electrical terminals of the panel-shaped component through the interconnection structure. Furthermore, the interconnection structure has a plurality of second pads on the surface away from the chip.

Owner:VIA TECH INC

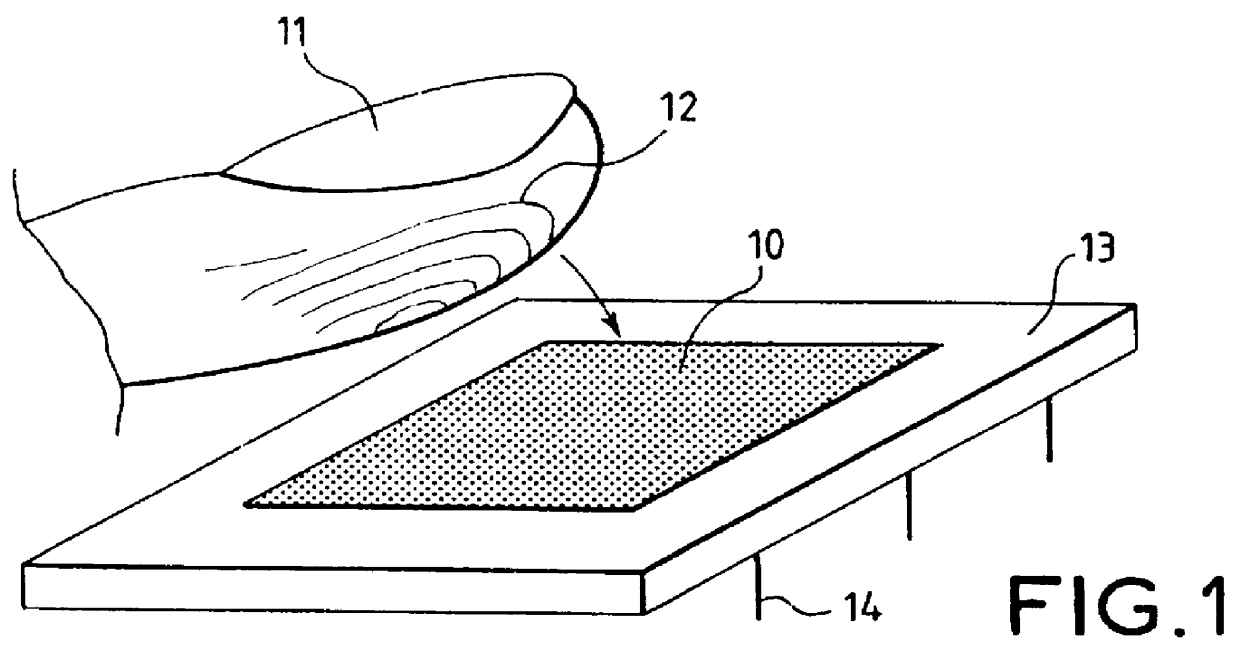

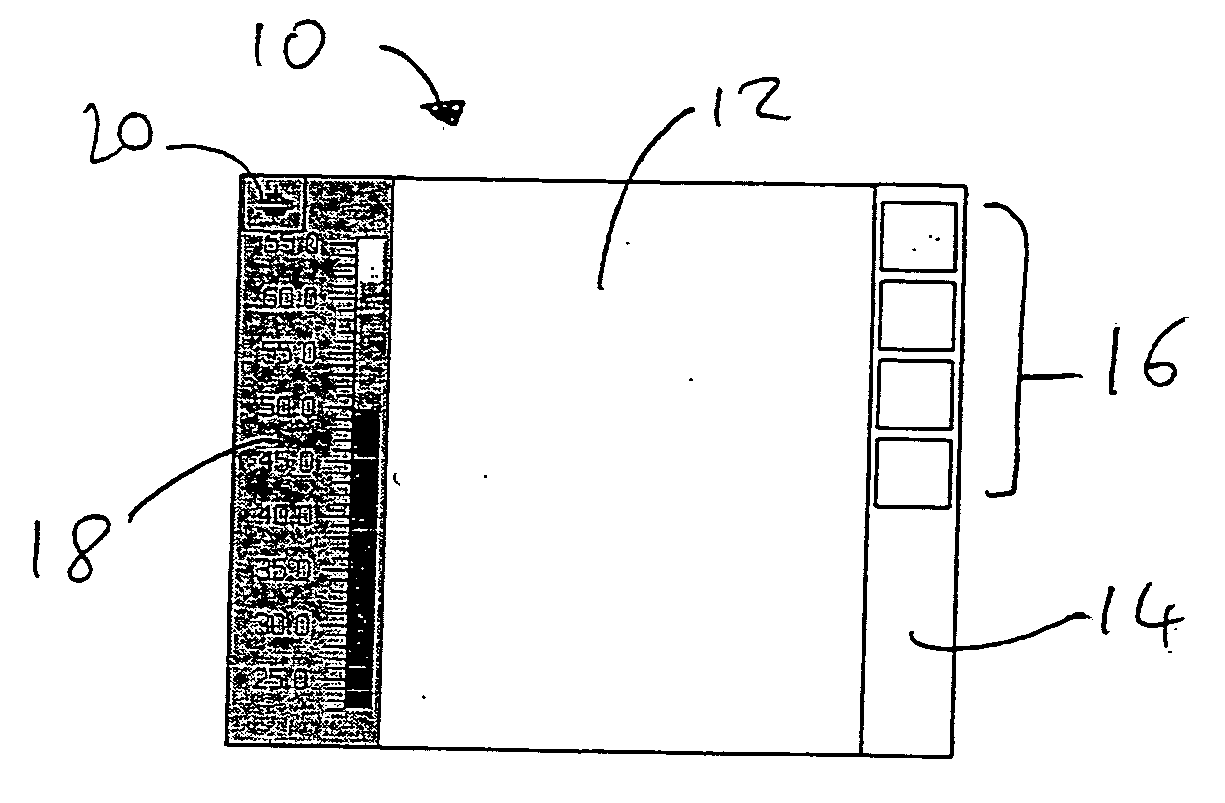

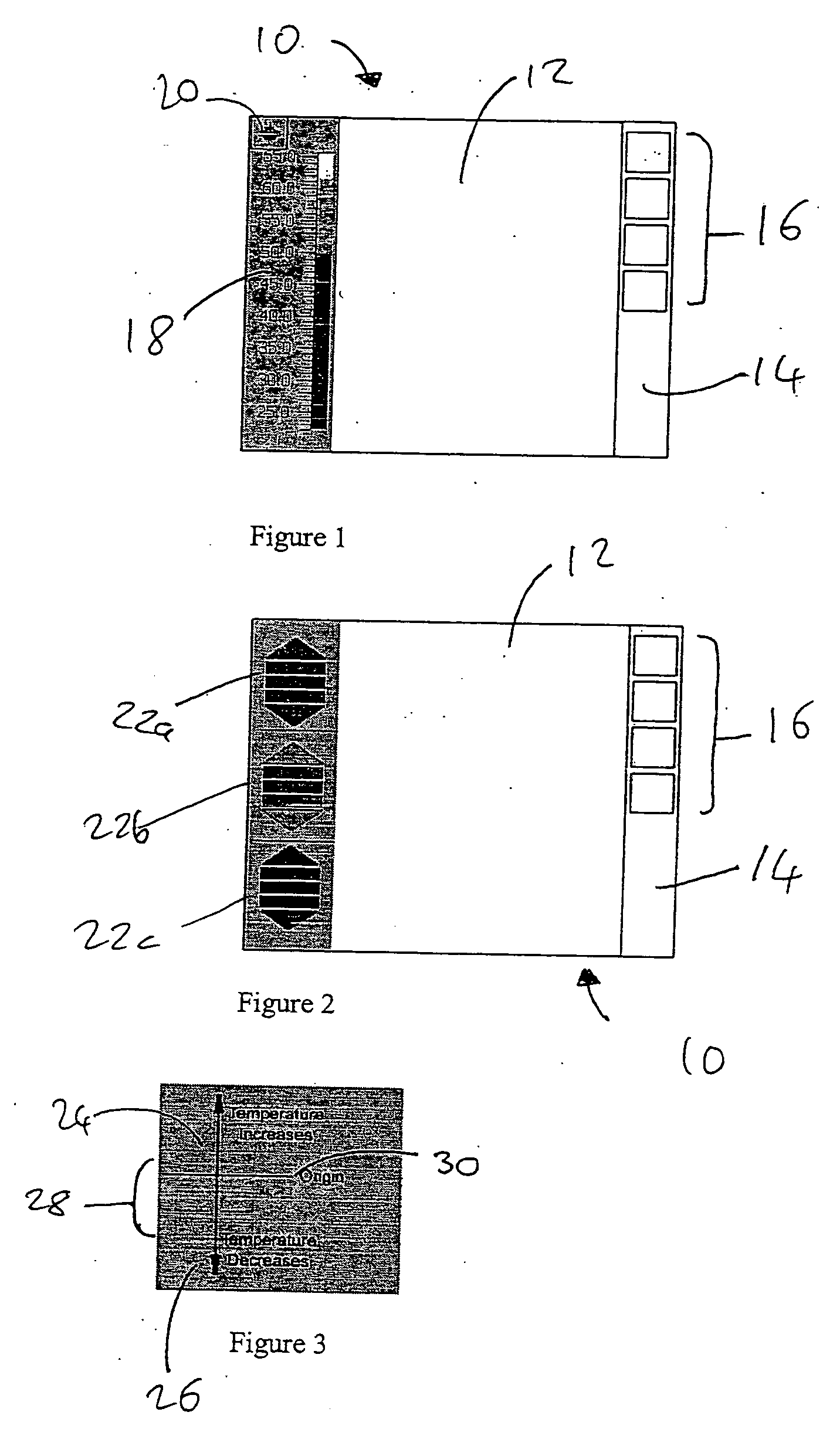

Touch screen control

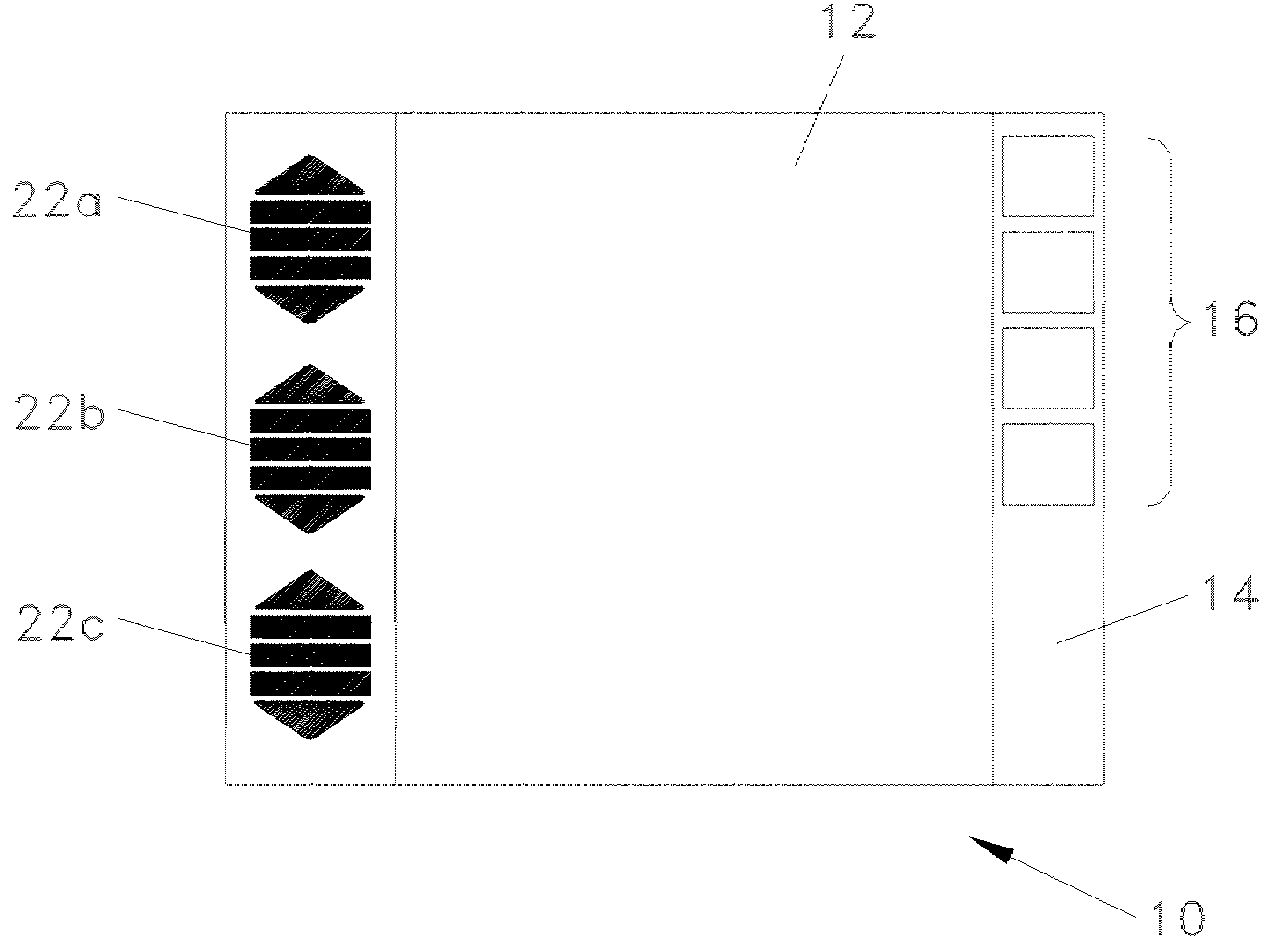

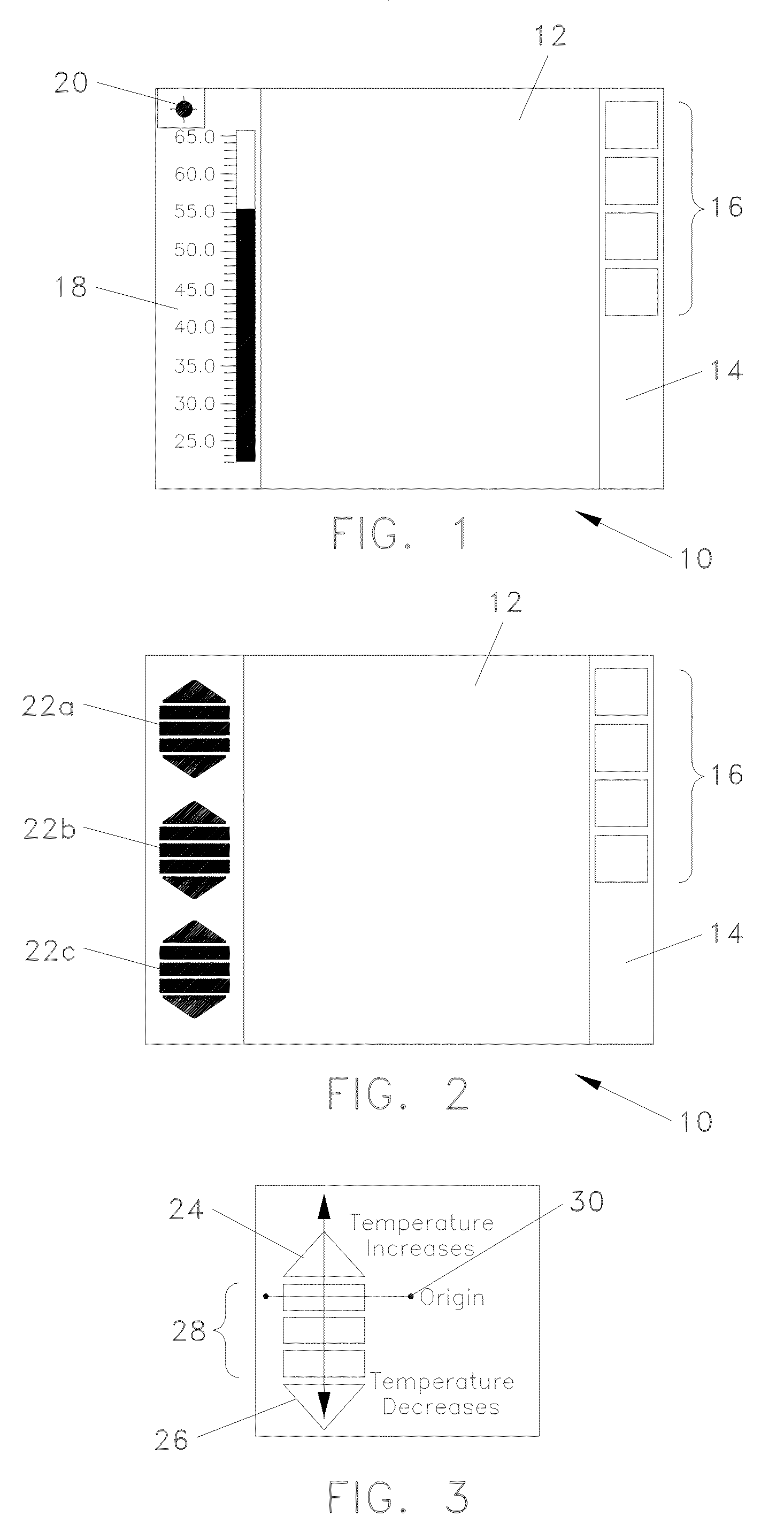

ActiveUS20060117108A1The process is simple and accurateIncrease/decrease the value of the image propertyTelevision system detailsCathode-ray tube indicatorsEffective surfaceDigital imaging

A digital imaging device is provided with a touch sensitive display screen 10. The screen 10 displays an image 12 captured by the imaging device. Along one side of the screen is a toolbar 14 upon which is provided a plurality of individual icons 16. The icons 16 represent particular control functions that may be selected by a user. Examples of such control functions represented by the icons 16 include but are not limited to save, send, retrieve or discard image; rotate, reflect, crop, resize or edit image; compare images; process image (e.g. sharpen, blur, emboss, edge detect, pixelise, apply filter or similar); or vary image properties (e.g. brightness, colour balance, colour depth, contrast, convert to greyscale / black and white, effective surface temperature displayed (for infrared images) or similar). The user can select icons by touching the screen either directly or more preferably by tapping the screen with a suitable implement such as. a pen, a stylus or similar. Once a user has selected an icon, further icons may be displayed on the screen to allow the user to operate the selected function as desired.

Owner:THERMOTEKNIX SYSTEMS LTD

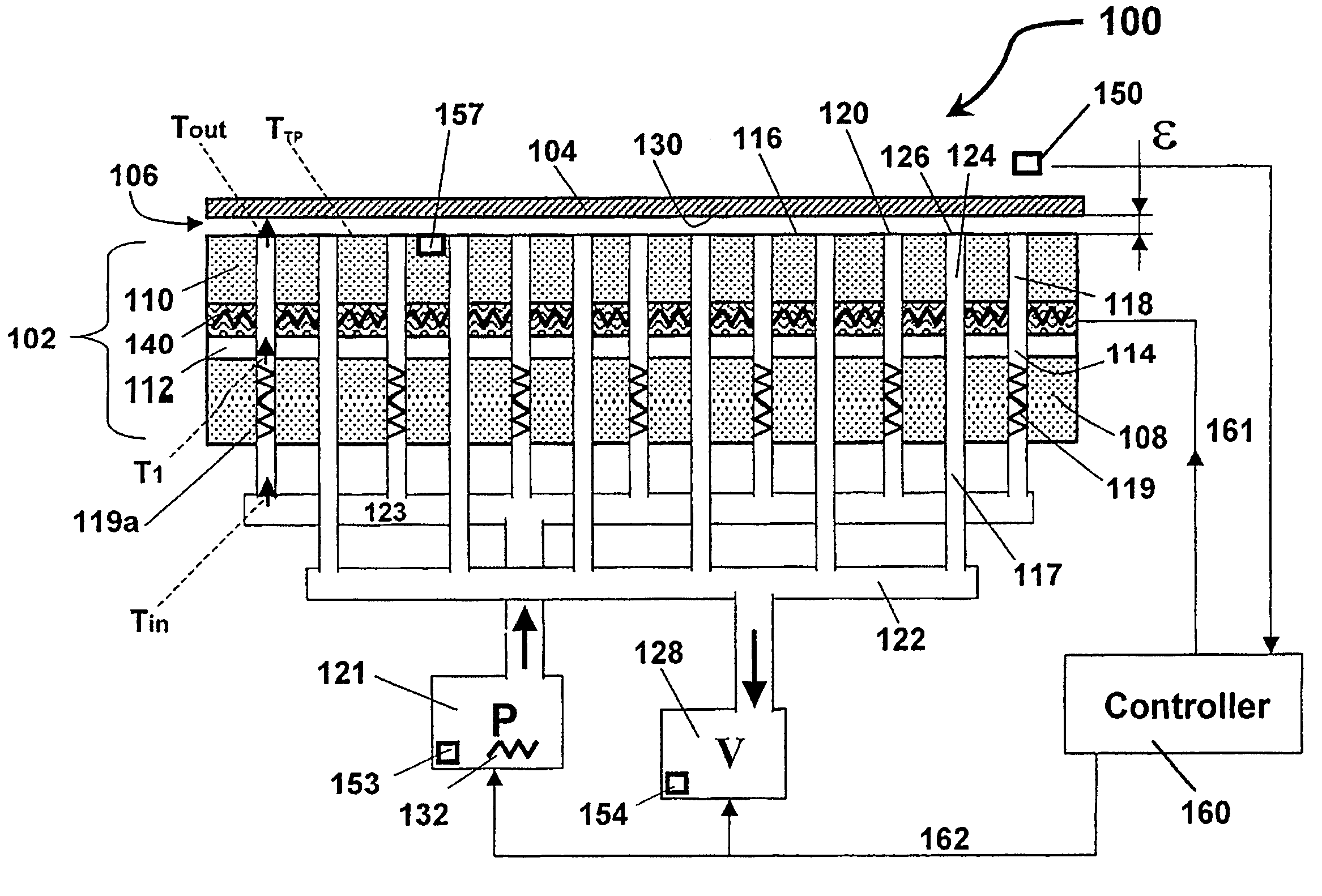

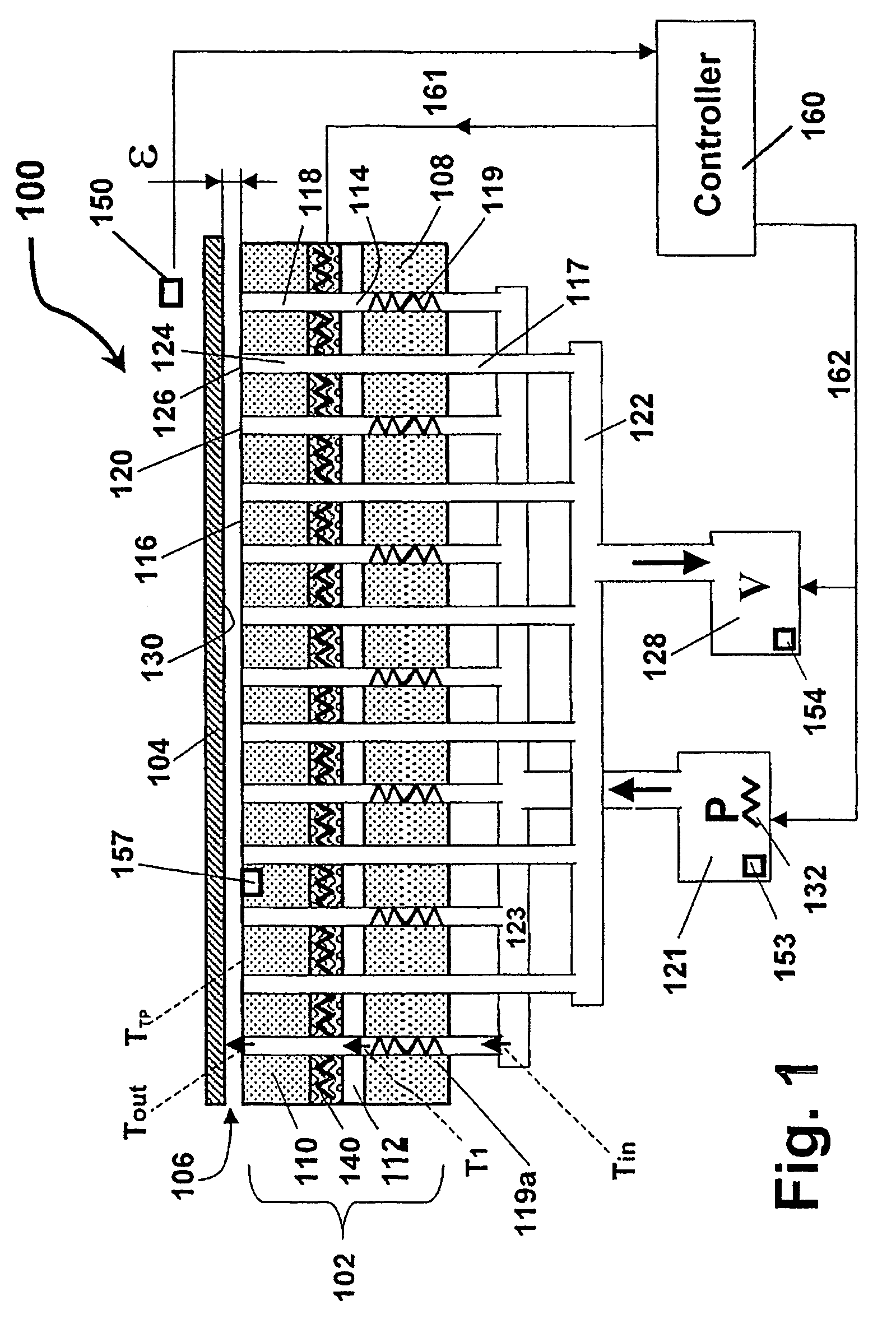

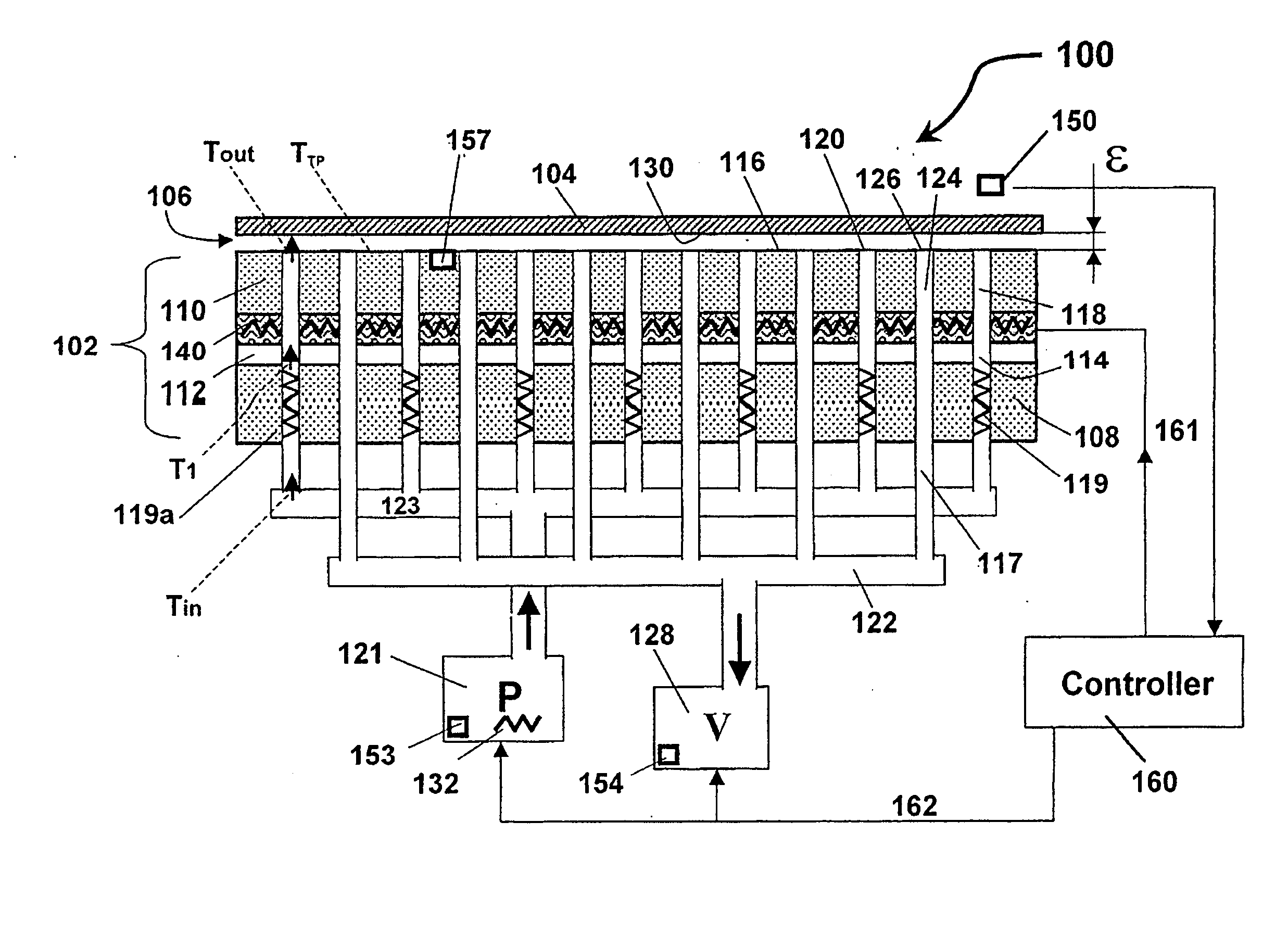

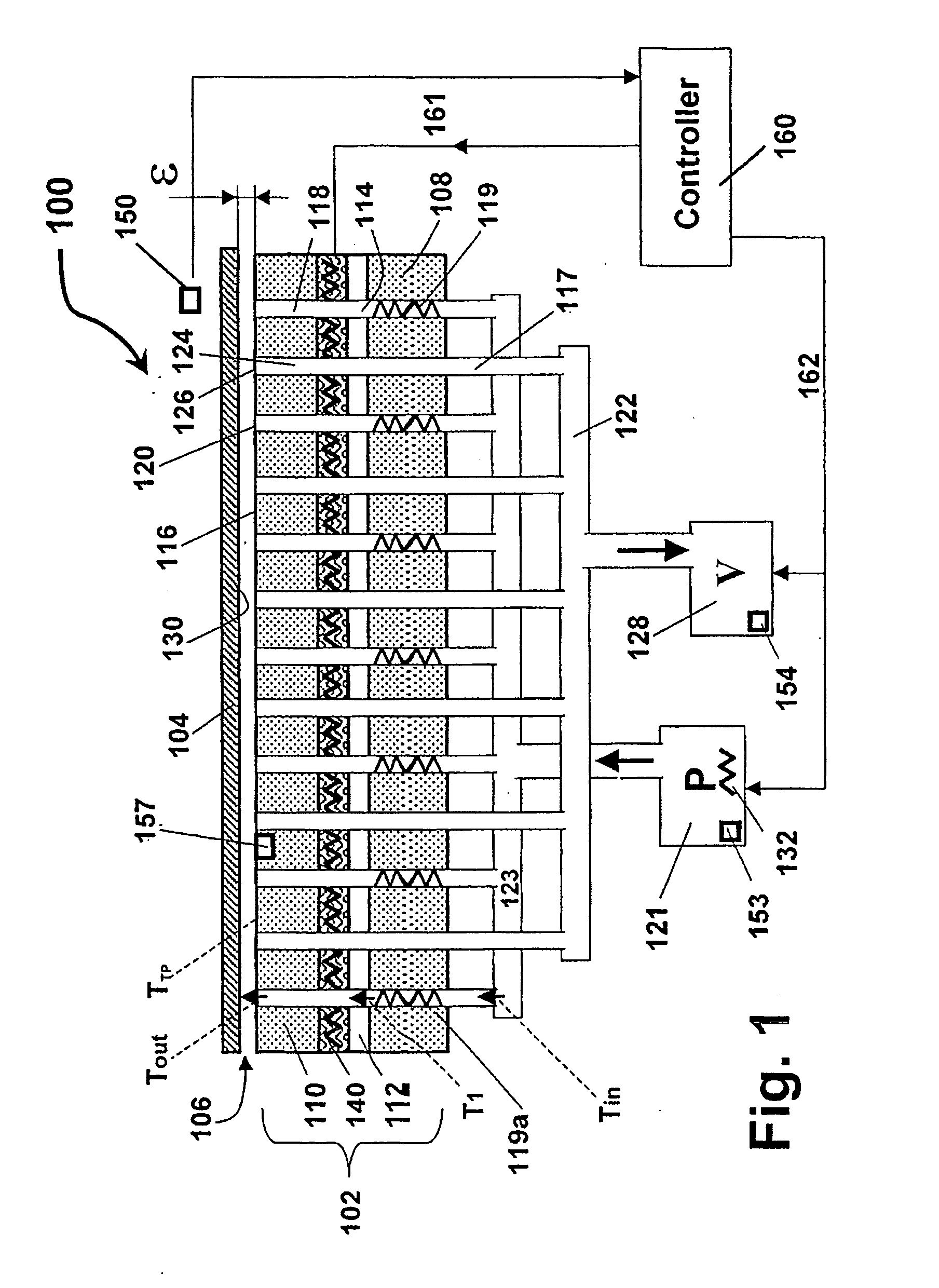

Non-contact thermal platforms

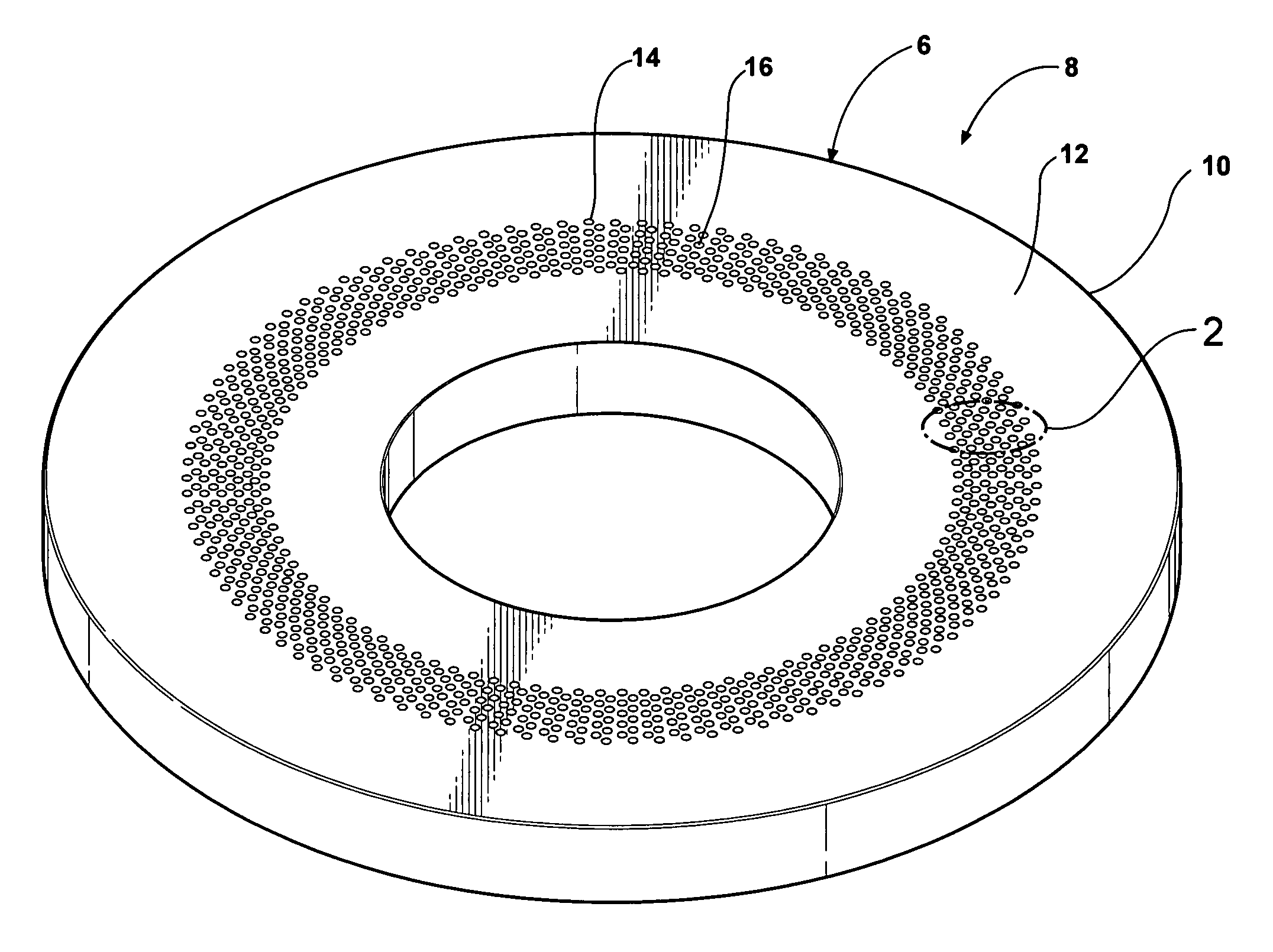

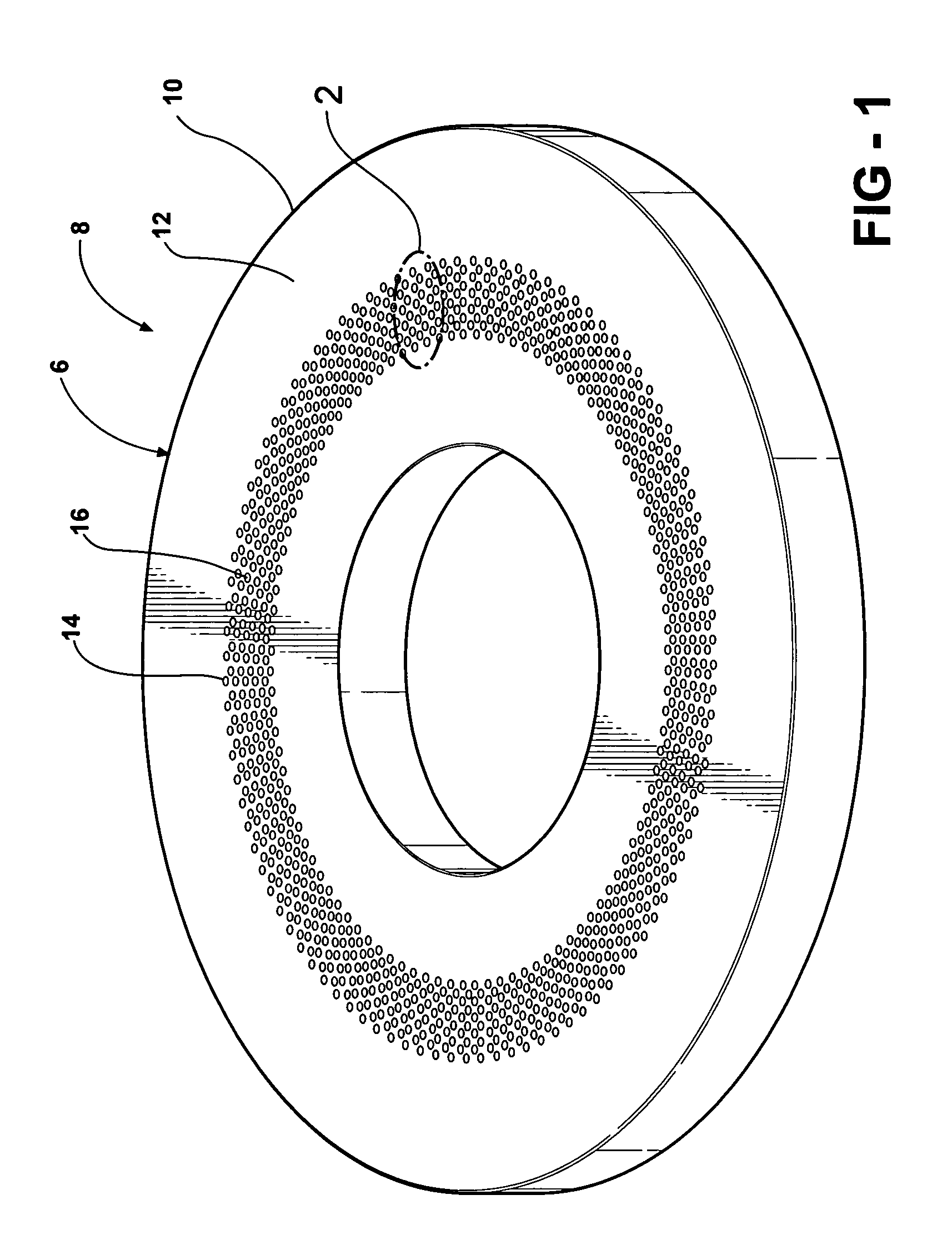

A thermal treatment system comprising at least one apparatus for thermally treating an object, the apparatus comprising: one platform or two substantially opposite platforms, where at least one of the platforms has at least one thermal means for heating or cooling of the object; and at least one of the platforms has fluid-mechanical means for supporting the object without contact. The platform has an active surface comprising at least one of a plurality of basic cells, each basic cell having at least one of a plurality of pressure outlets and at least one of a plurality of fluid-evacuation channels. At least one of the pressure outlets of each basic cell is fluidically connected through a flow restrictor to a high-pressure fluid supply, the pressure outlets providing pressurized fluid for maintaining a fluid-cushion between the object and the active-surface of the platform. The flow restrictor characteristically exhibits fluidic return spring behavior. Each of the evacuation channels has an inlet and outlet, for locally balancing mass flow for the basic cells.

Owner:COREFLOW SCI SOLUTIONS

Touch screen control

ActiveUS7489305B2The process is simple and accurateIncrease/decrease the value of the image propertyTelevision system detailsCathode-ray tube indicatorsEffective surfaceDigital imaging

A digital imaging device is provided with a touch sensitive display screen 10. The screen 10 displays an image 12 captured by the imaging device. Along one side of the screen is a toolbar 14 upon which is provided a plurality of individual icons 16. The icons 16 represent particular control functions that may be selected by a user. Examples of such control functions represented by the icons 16 include but are not limited to save, send, retrieve or discard image; rotate, reflect, crop, resize or edit image; compare images; process image (e.g. sharpen, blur, emboss, edge detect, pixelise, apply filter or similar); or vary image properties (e.g. brightness, colour balance, colour depth, contrast, convert to greyscale / black and white, effective surface temperature displayed (for infrared images) or similar). The user can select icons by touching the screen either directly or more preferably by tapping the screen with a suitable implement such as a pen, a stylus or similar. Once a user has selected an icon, further icons may be displayed on the screen to allow the user to operate the selected function as desired.

Owner:THERMOTEKNIX SYSTEMS LTD

Active antisepsis device

Owner:ROSE BIOMEDICAL DEV CORP +1

Low profile wire bond for an electron sensing device in an image intensifier tube

An electron sensing device for receiving electrons from an output surface of an electron gain device has a silicon die including an active surface area for positioning below the output surface of an electron gain device. The silicon die also includes a silicon step formed below and surrounding the active surface area, and a first array of bond pads formed on the silicon step for providing output signals from the silicon die. When the electron sensing device is positioned below the electron gain device, a tight vertical clearance is formed between the output surface of the electron gain device and the active surface area of the electron sensing device.

Owner:EXCELIS INC

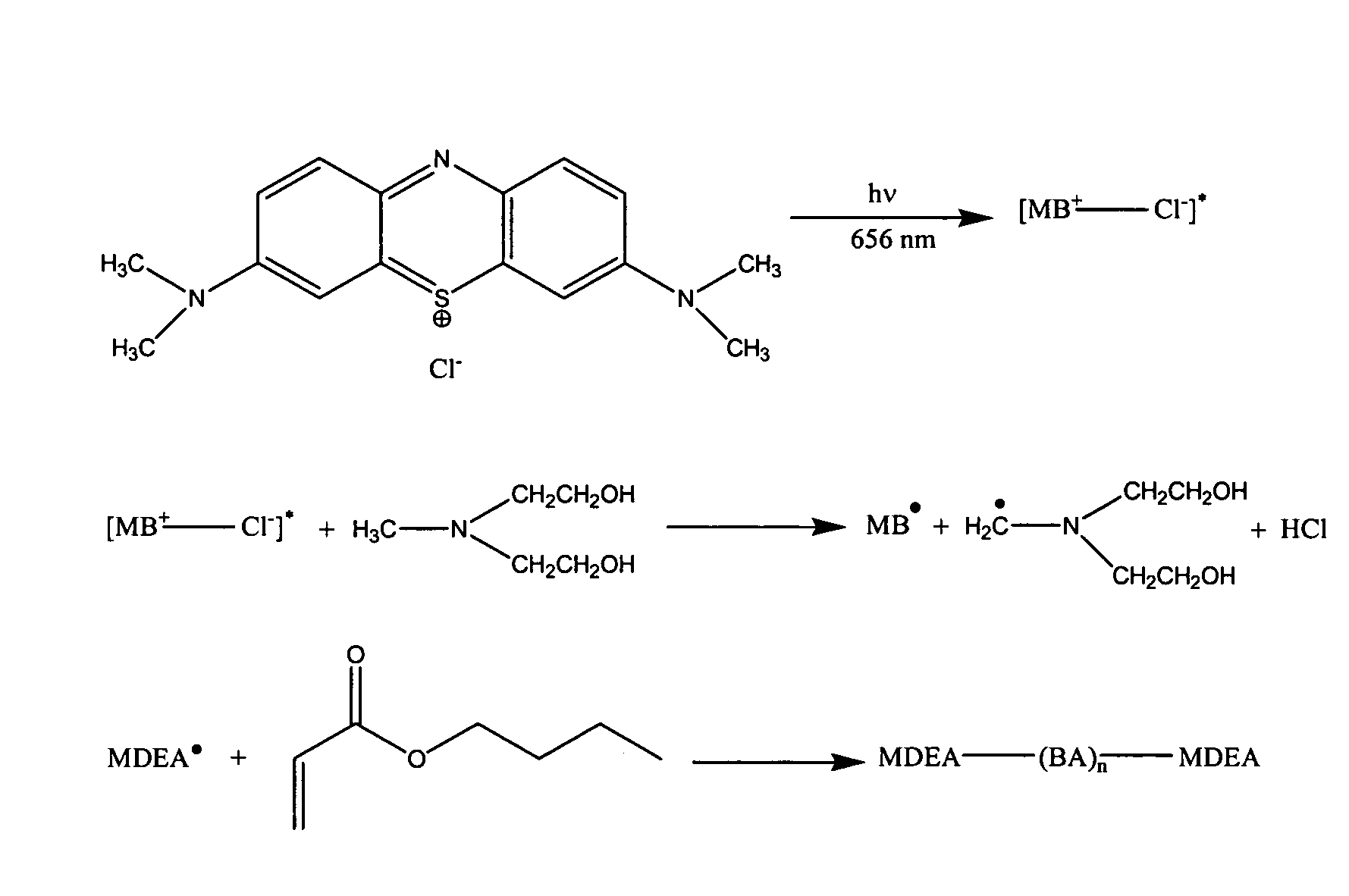

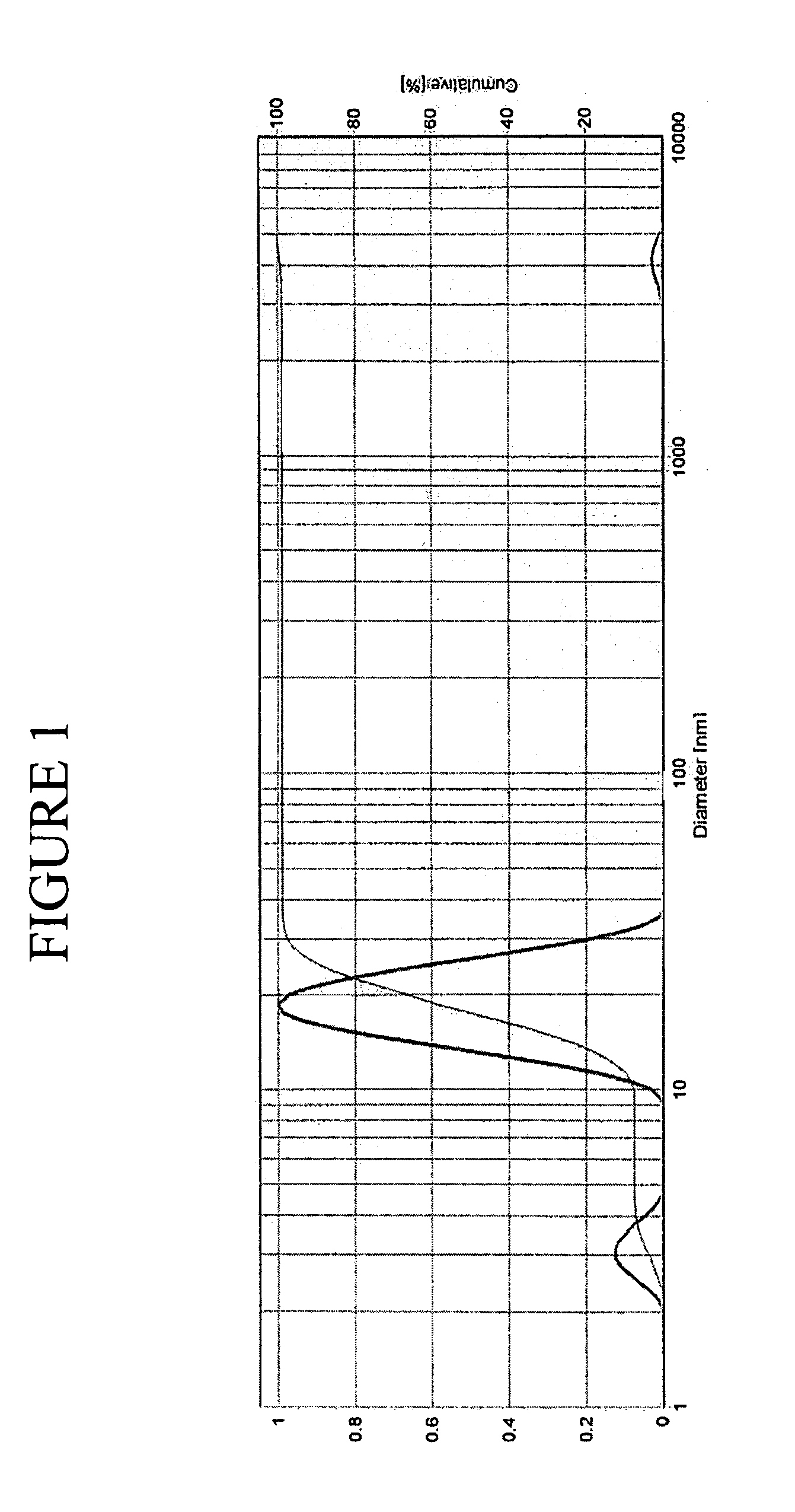

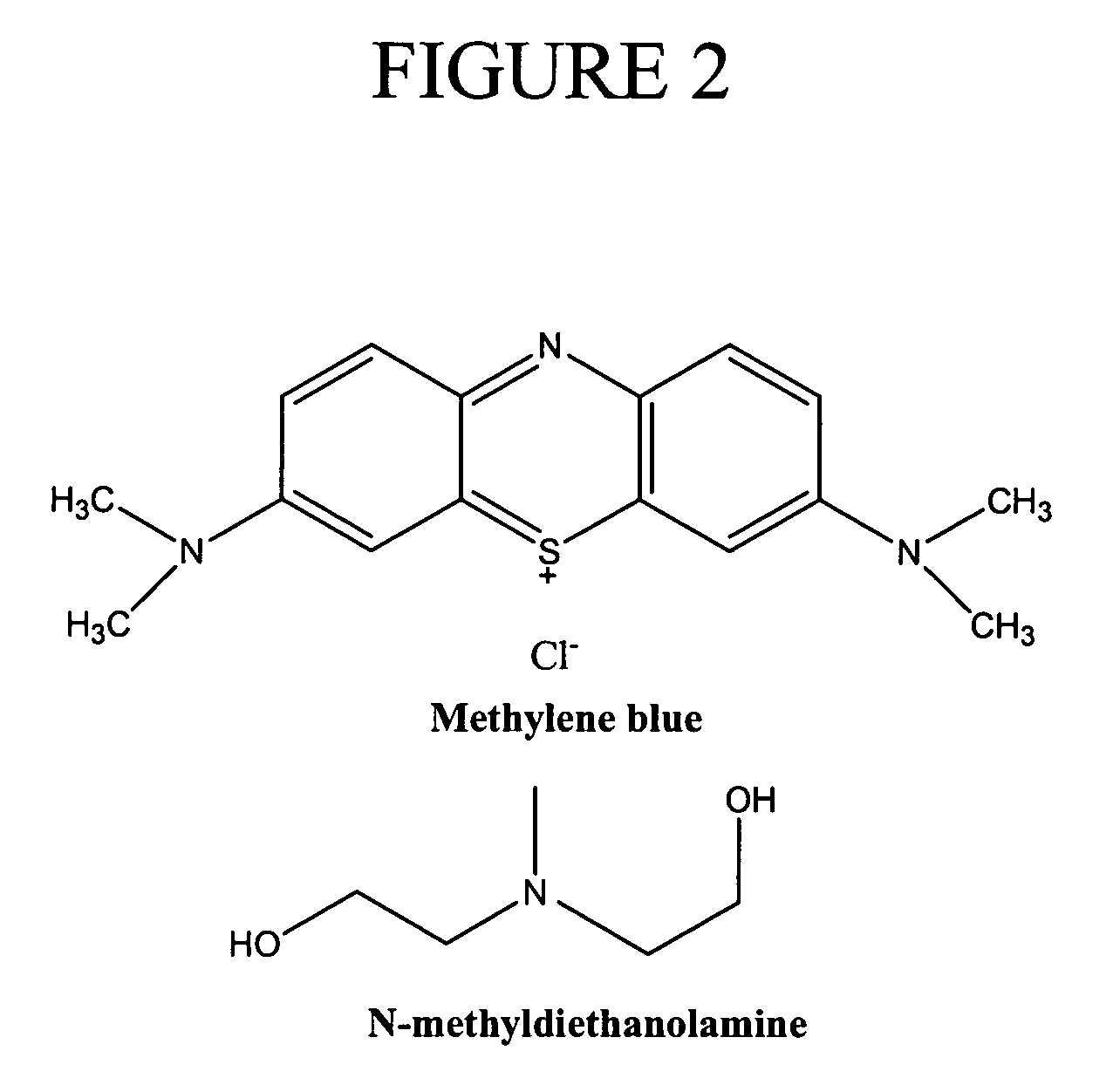

Method for producing polymers with controlled molecular weight and end group functionality using photopolymerization in microemulsions

InactiveUS7226957B1Improve shineExcellent abrasion resistanceOrganic chemistryLavatory sanitoryEffective surfaceOligomer

A method for producing polymers with controlled molecular weight and desired end functionalities and the resulting polymers. The method comprises a) forming a microemulsion comprising monomer, water, and an effective amount of an effective surfactant, b) adding to the microemulsion an amount of a water-soluble photo-initiator system wherein the initiator system produces one type of monomer-soluble radical active centers and wherein the radical active centers contain desired end group functionalities for a polymer or oligomer, and c) illuminating the microemulsion to photoinitiate polymerization of the monomer wherein the illuminating is according to a temporal and spatial illumination scheme, and wherein the amount of the initiator system and the temporal illumination scheme are chosen to produce a desired molecular weight of the polymer or oligomer. The microemulsion can further comprise an effective amount of an effective co-surfactant. The method can be used to produce polymers and copolymers.

Owner:UNIV OF IOWA RES FOUND

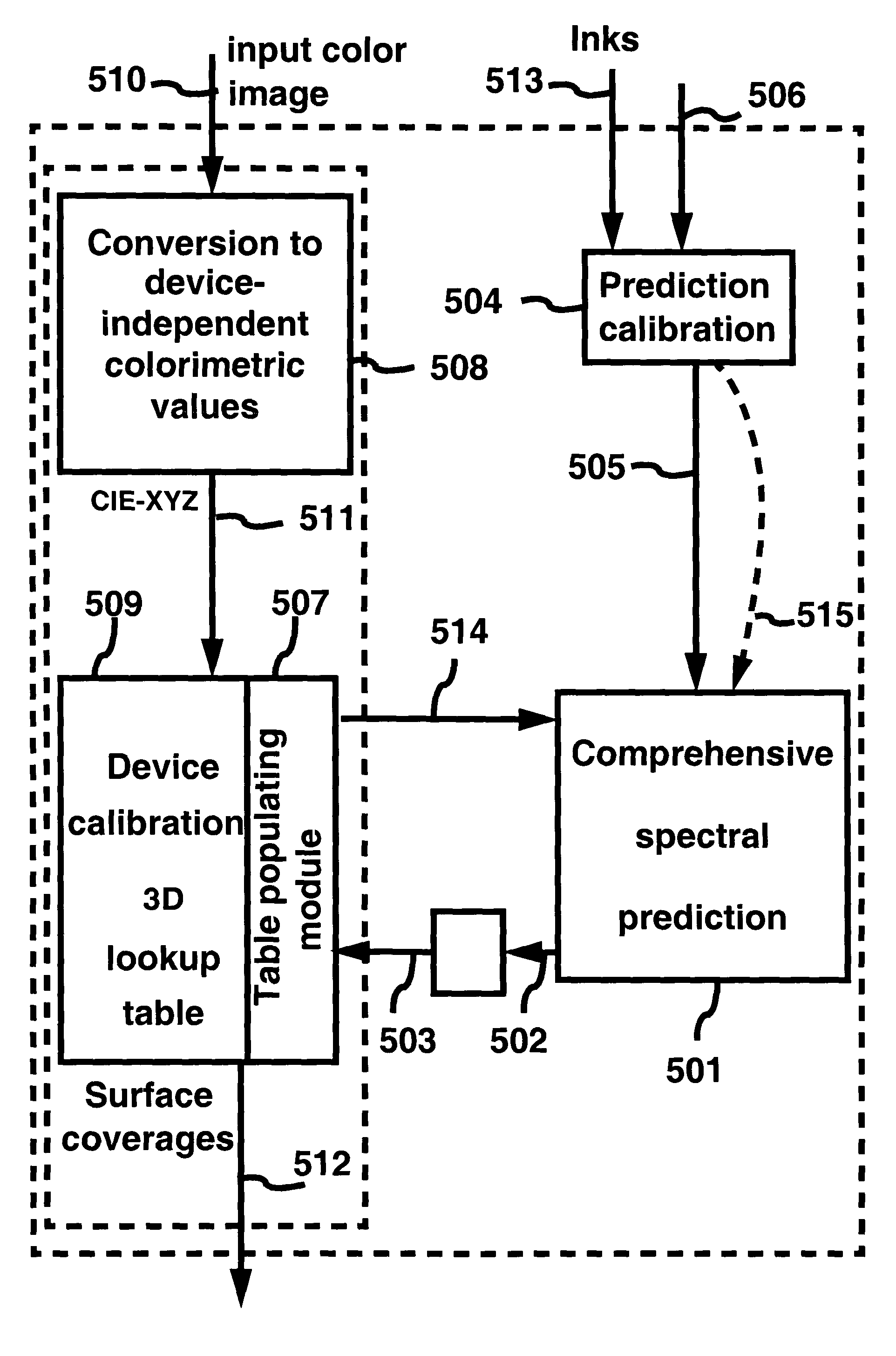

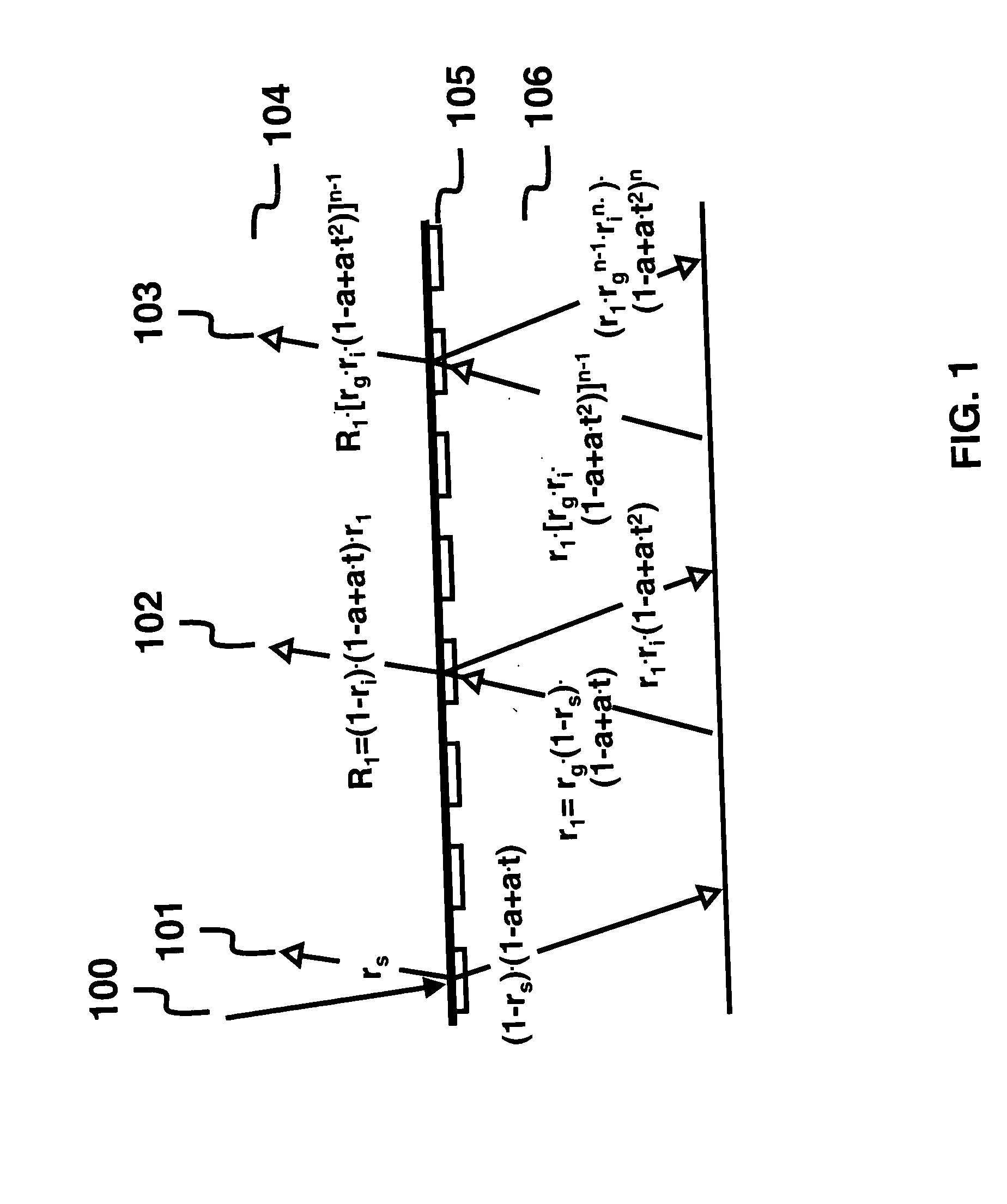

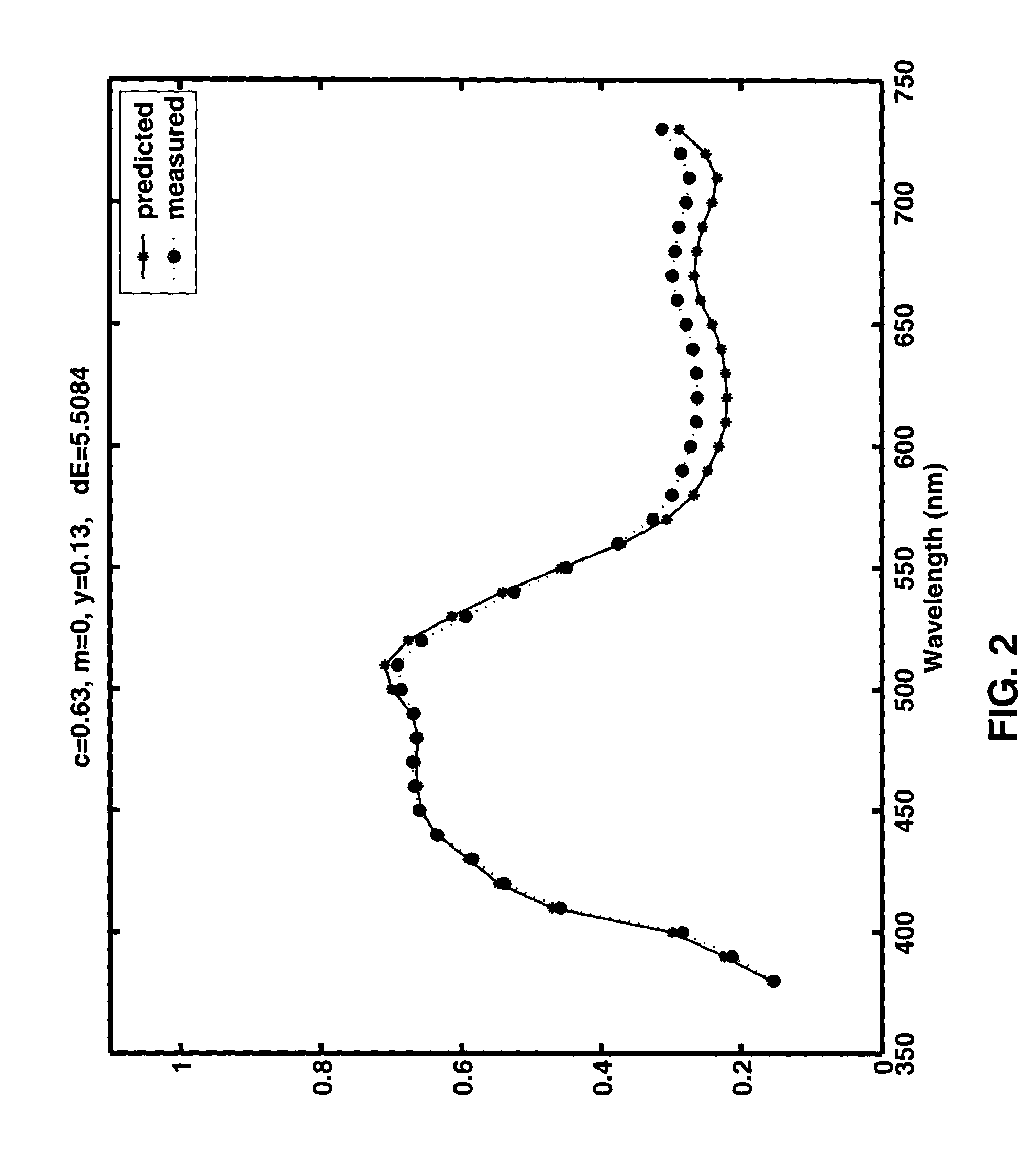

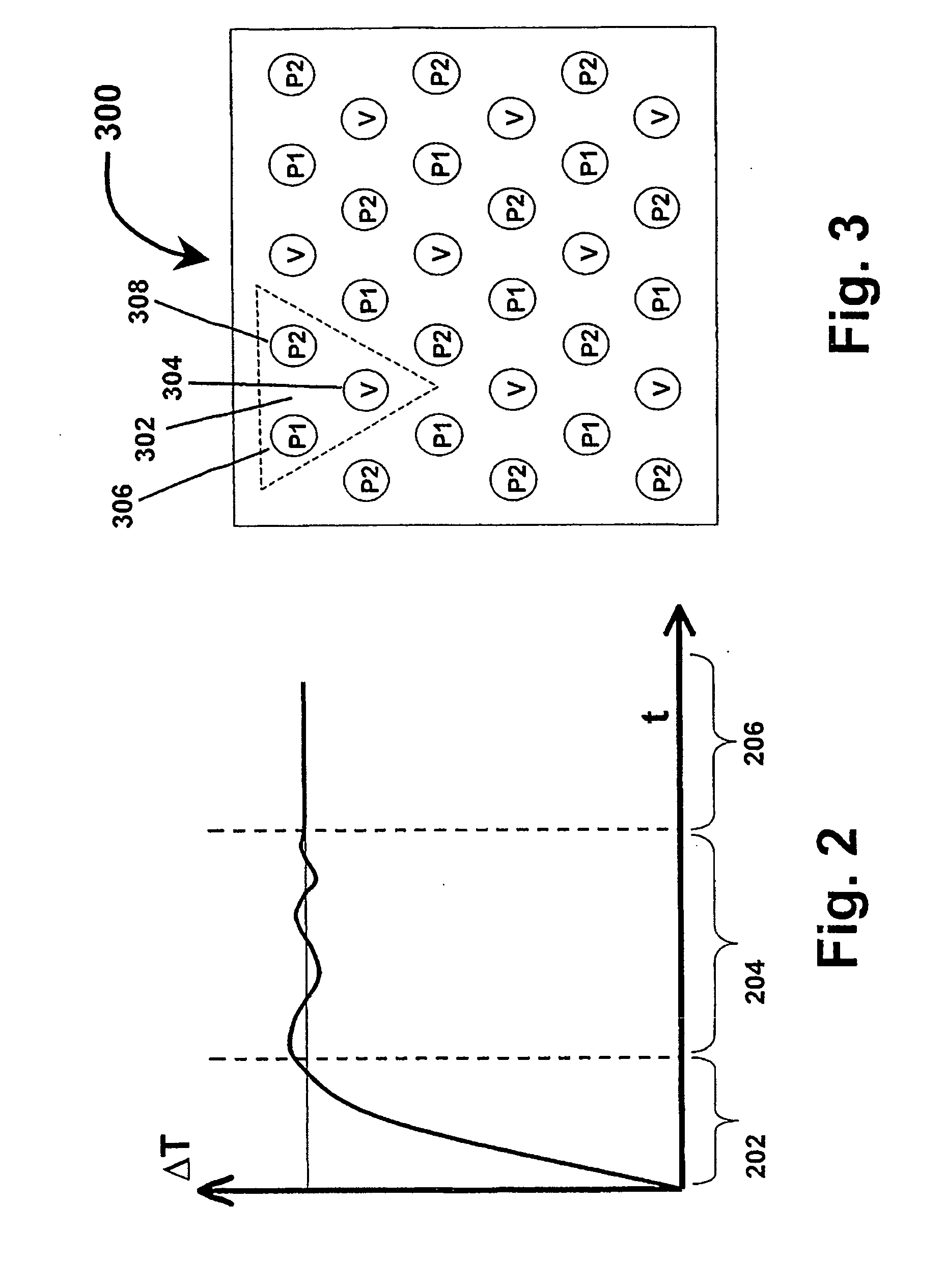

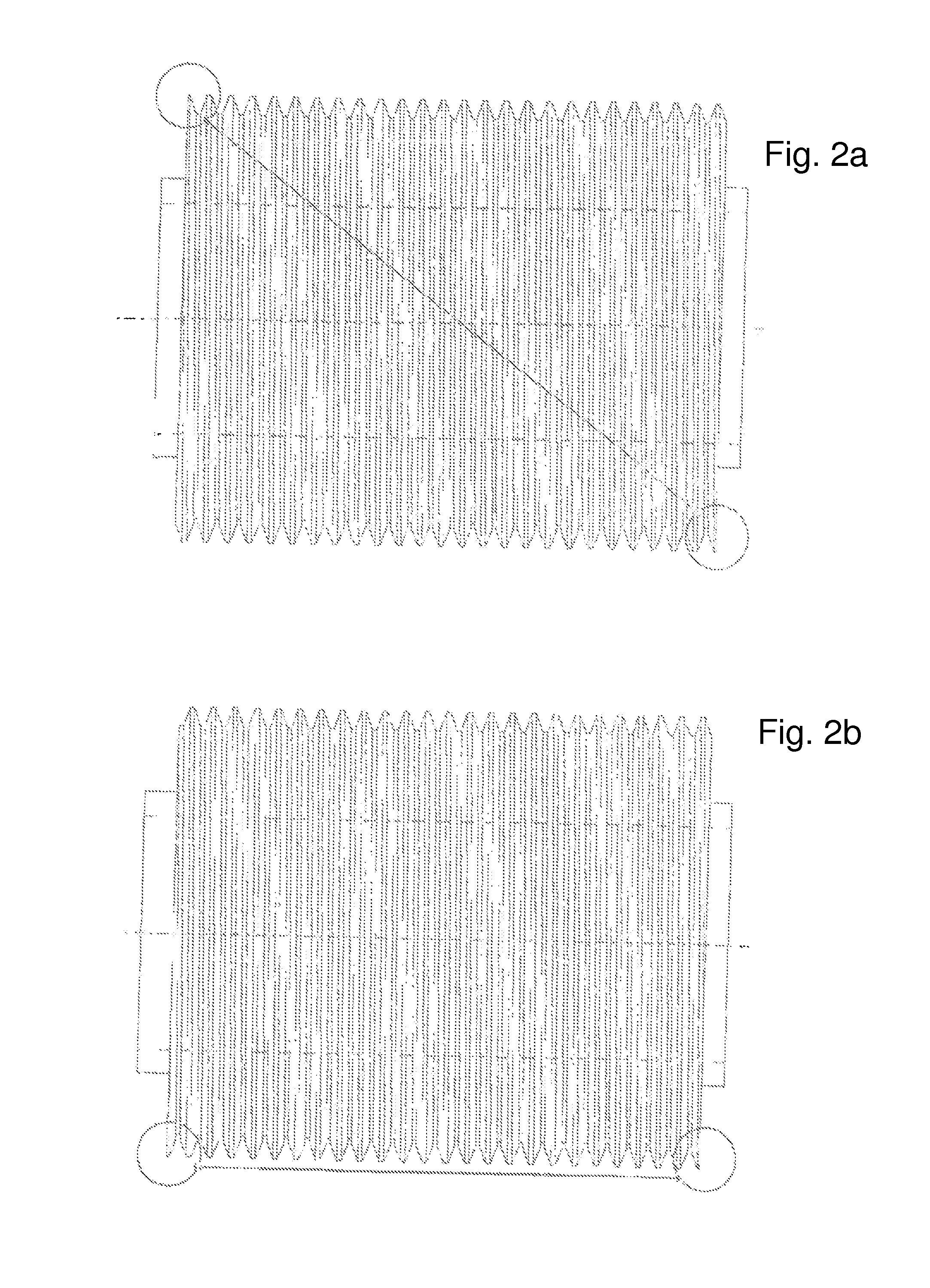

Prediction model for color separation, calibration and control of printers

InactiveUS20050083540A1Easy CalibrationImprove accuracyDigitally marking record carriersDigital computer detailsEffective surfaceHue

The present invention facilitates the calibration of printers and the color separation of input images into a set of inks by disclosing methods and systems for populating device-calibration lookup tables. The disclosed methods and systems rely on a comprehensive spectral prediction model which is capable of predicting at a high accuracy the reflectance spectra of halftone ink patches. The comprehensive spectral prediction model is composed of a first part predicting the reflection spectra as a function of physical (mechanical) surface coverages and of a second part comprising functions mapping nominal surface coverages to effective surface coverages. These mapping functions are calibrated by halftone patch wedges printed alone and by half-tone patch wedges printed in superposition with one or several solid inks. The part of the comprehensive spectral prediction model predicting the reflection spectra relies on a weighted average between one component behaving according to the Clapper-Yule model and another component behaving as the spectral Neugebauer model, extended to include multiple internal reflections at the paper-air boundary. The disclosed methods and systems can perform the color separation as well as the calibration of printers printing with standard cyan, magenta, and yellow inks as well as with inks comprising standard and non-standard inks such as Pantone inks (custom inks). They are also used for performing precise undercolour removal in order to carry out the color separation of images into cyan, magenta, yellow and black inks. They can further be used to carry out the color separation of images into cyan, magenta, yellow, black, light cyan and light magenta inks. In addition, the disclosed methods and systems can be used for printer control, i.e. to control printer actuation parameters in different types of printers e.g. liquid ink professional printers (offset, gravure, letterpress), electrophotographic printers, ink-jet printers, thermal transfer printers and in dye-sublimation printers.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

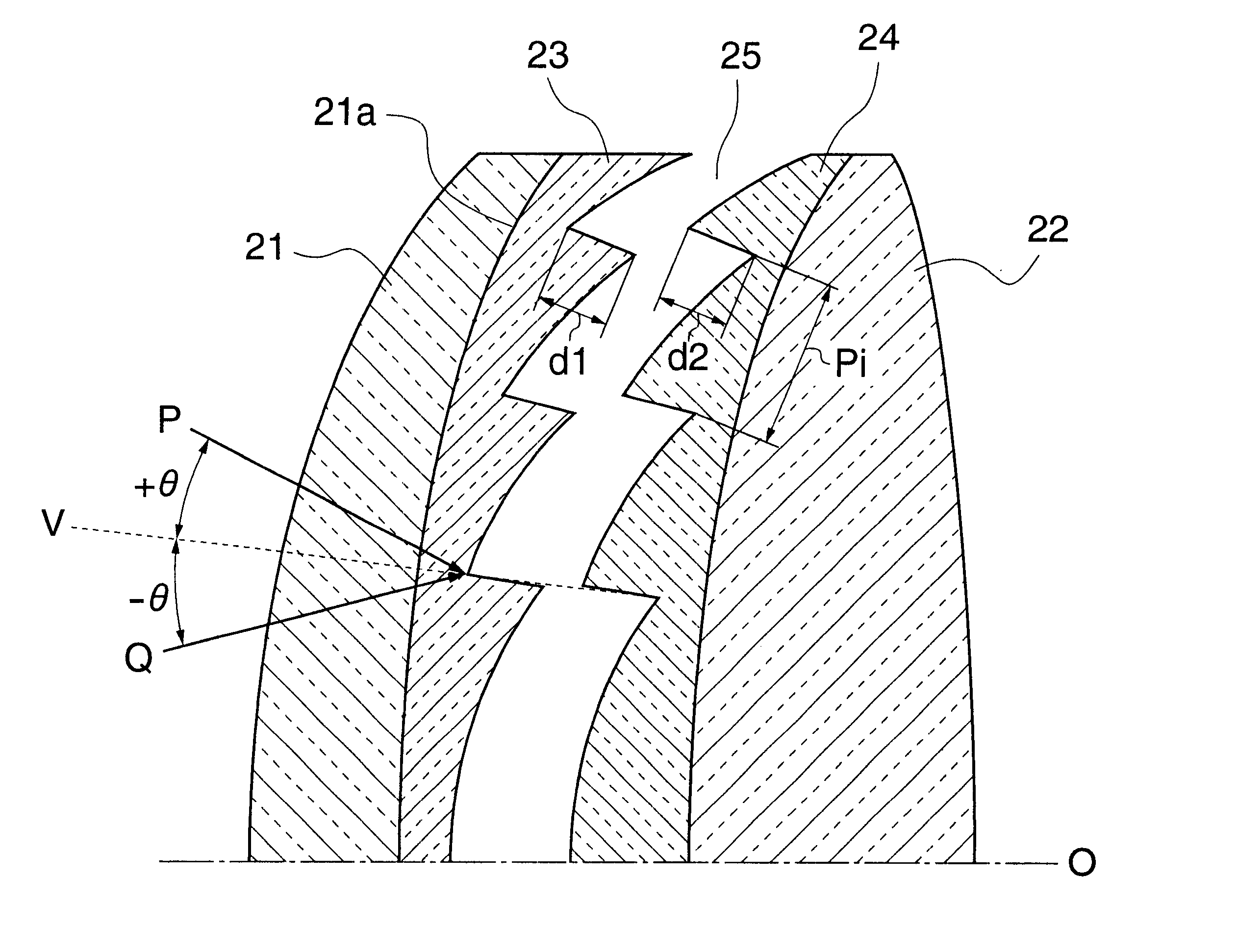

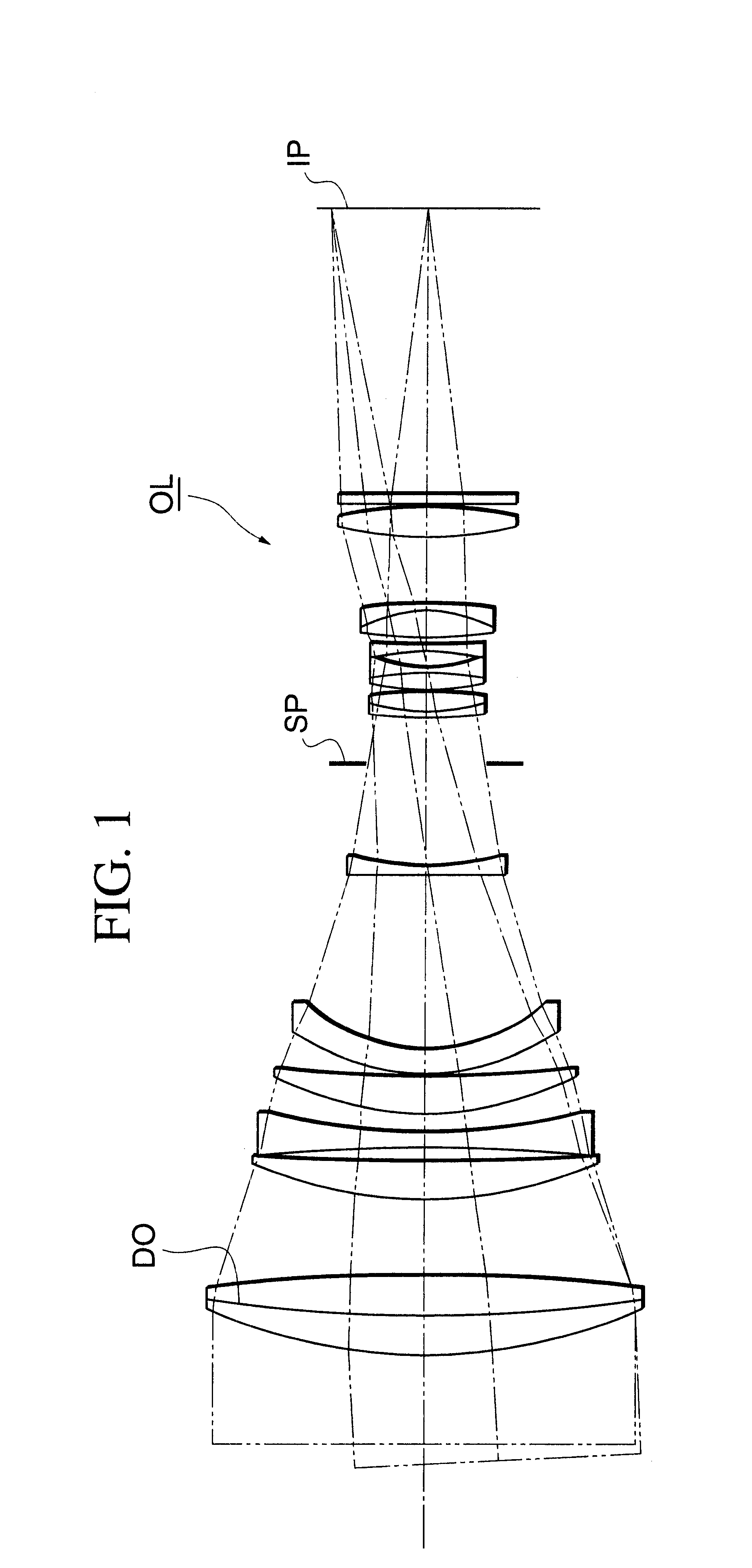

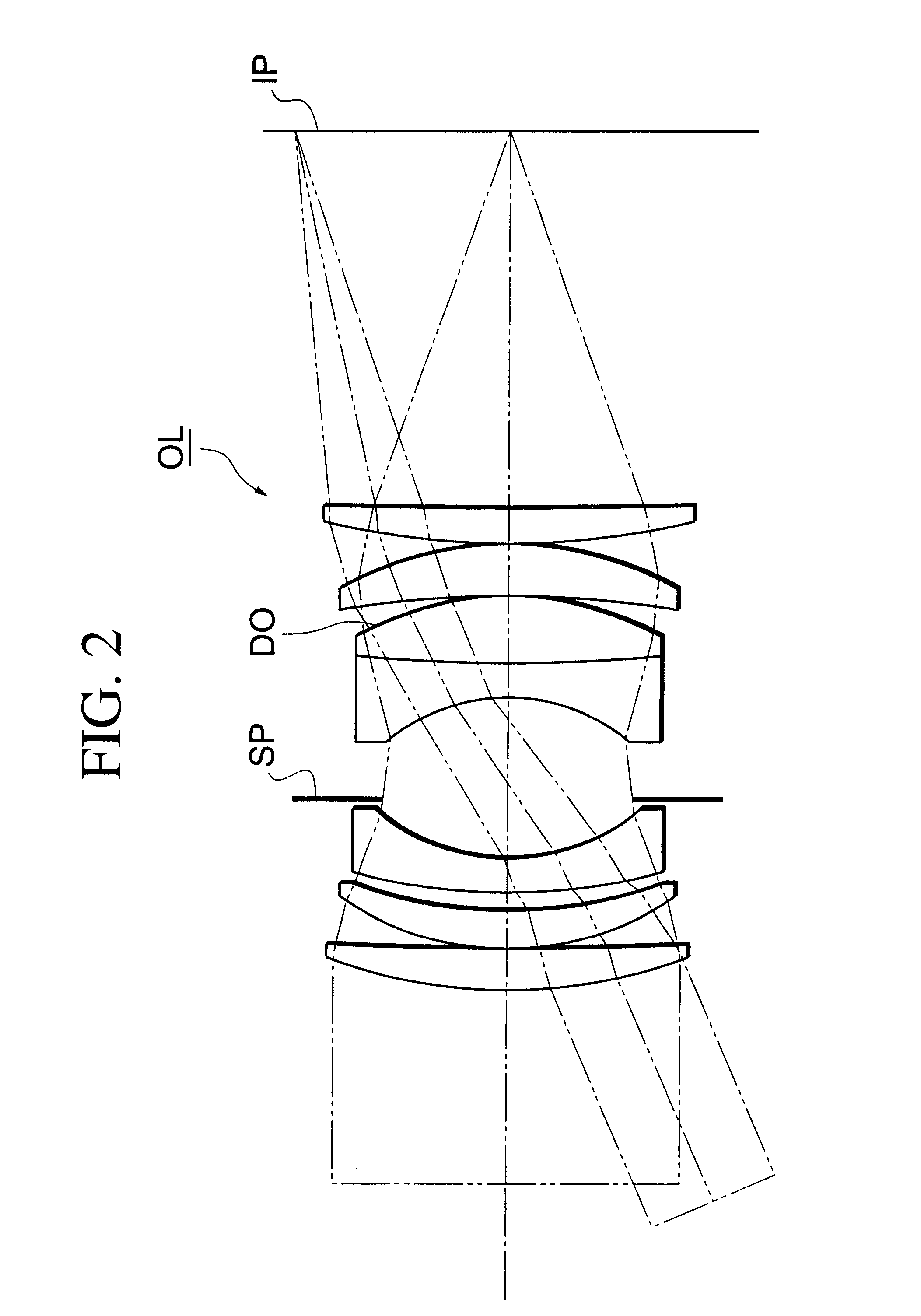

Optical system having a diffractive optical element, and optical apparatus

An optical system includes a diffractive optical element having a diffraction grating provided, on a lens surface having a curvature, in a concentric-circles shape rotationally-symmetrical with respect to an optical axis. The sign of the curvature of the lens surface having the diffraction grating provided thereon is the same as the sign of a focal length, at a design wavelength, of a system composed of, in the optical system, a surface disposed nearest to an object side to a surface disposed immediately before the lens surface having the diffraction grating provided thereon, and is different from the sign of the distance from the optical axis to a position where the center ray of an off-axial light flux enters the lens surface having the diffraction grating provided thereon. Further, the apex of an imaginary cone formed by extending a non-effective surface of the diffraction grating is located adjacent to the center of curvature of the lens surface having the diffraction grating provided thereon.

Owner:CANON KK

Non-Contact Thermal Platforms

A thermal treatment system comprising at least one apparatus for thermally treating an object, the apparatus comprising: one platform or two substantially opposite platforms, where at least one of the platforms has at least one thermal means for heating or cooling of the object; and at least one of the platforms has fluid-mechanical means for supporting the object without contact. The platform has an active surface comprising at least one of a plurality of basic cells, each basic cell having at least one of a plurality of pressure outlets and at least one of a plurality of fluid-evacuation channels. At least one of the pressure outlets of each basic cell is fluidically connected through a flow restrictor to a high-pressure fluid supply, the pressure outlets providing pressurized fluid for maintaining a fluid-cushion between the object and the active-surface of the platform. The f low restrictor characteristically exhibits fluidic return spring behavior. Each of the evacuation channels has an inlet and outlet, for locally balancing mass flow for the basic cells.

Owner:COREFLOW SCI SOLUTIONS

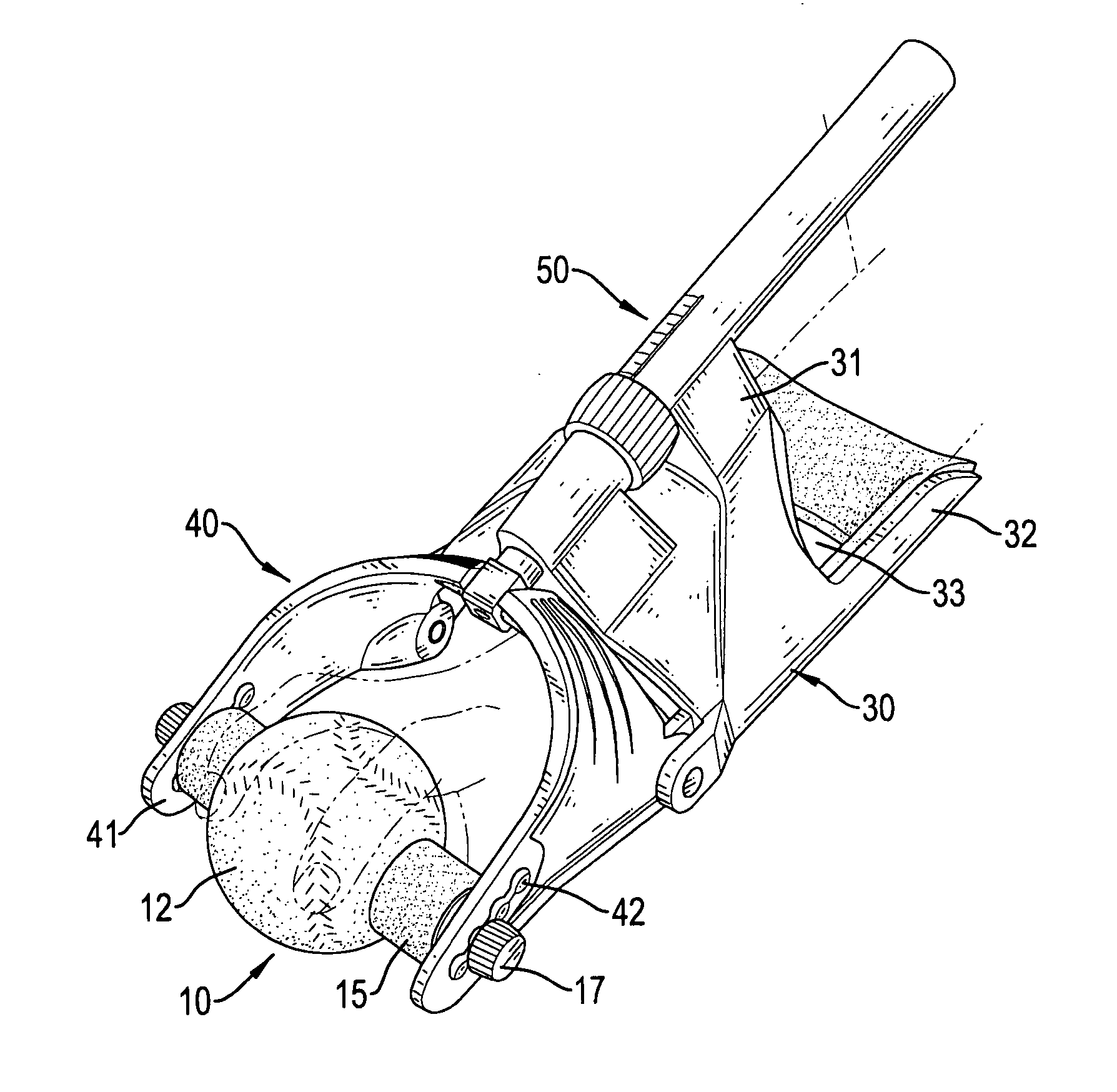

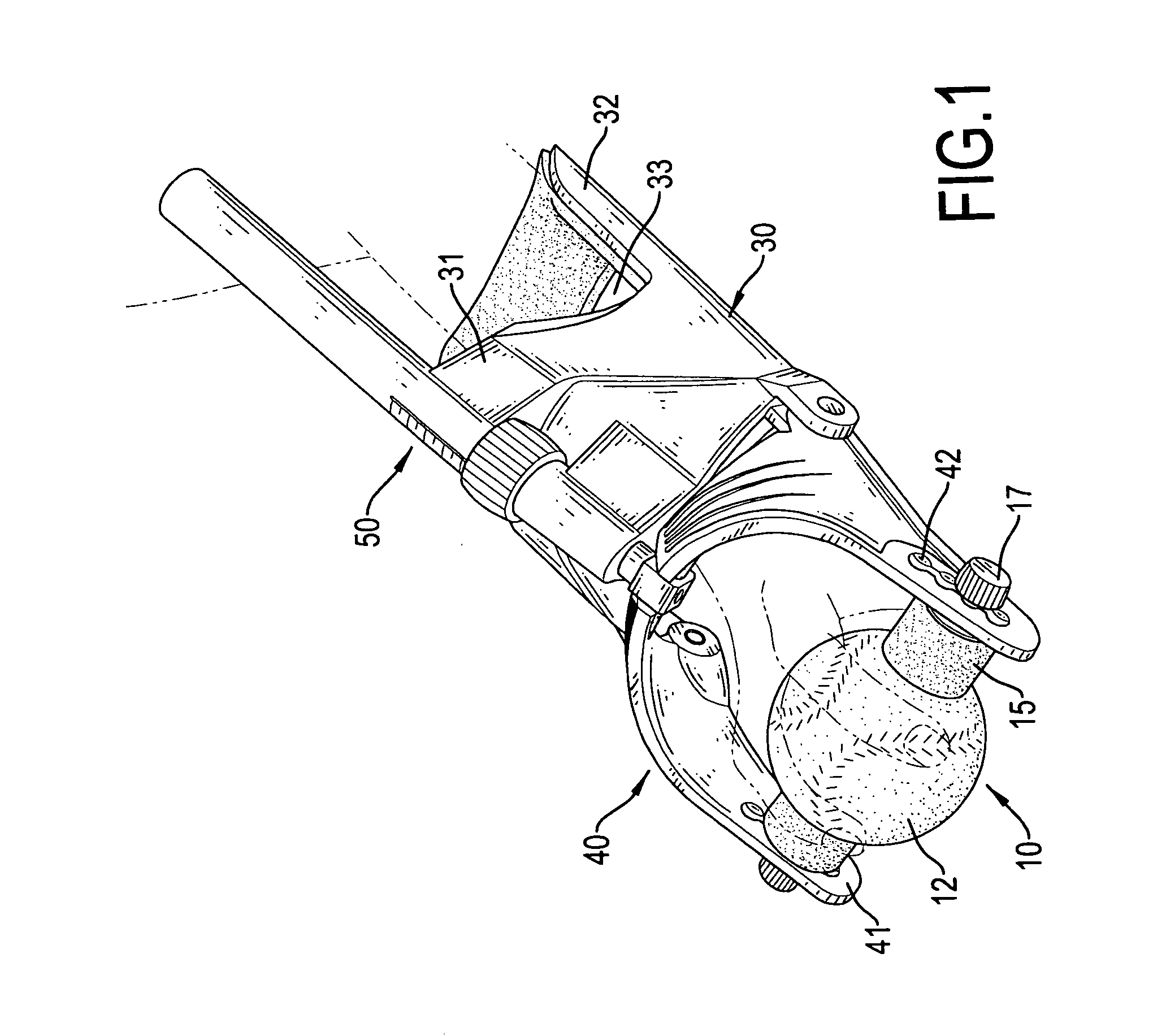

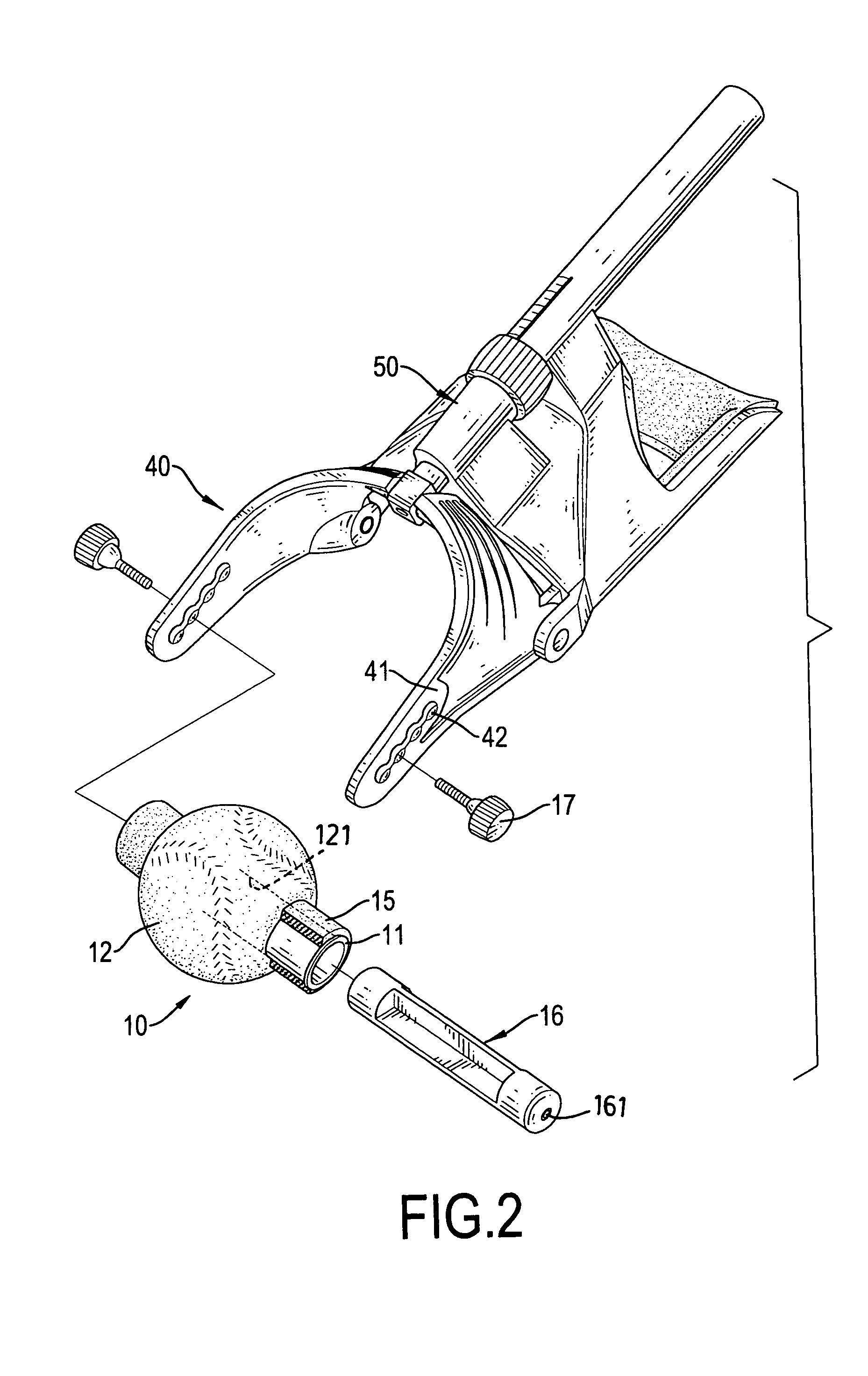

Apparatus with a raised grip for exercising wrist and forearm muscles

An apparatus for exercising wrist and forearm muscles includes a hollow body, a resistance assembly, a pivot bracket and a grip assembly. The resistance assembly is mounted on the body to provide a resistance. The pivot bracket is pivotally mounted in the body and connects to the resistance assembly. The grip assembly is mounted in the pivot bracket between the arms and has a shaft mounted on the pivot bracket and a raised grip rotatably mounted on the shaft. The raised grip could be of a baseball configuration, a football configuration and so on to provide a large effective surface for gripping. Therefore, the raised grip is convenient and comfortable to grip while exercising wrist and forearm muscles.

Owner:CHEN PING

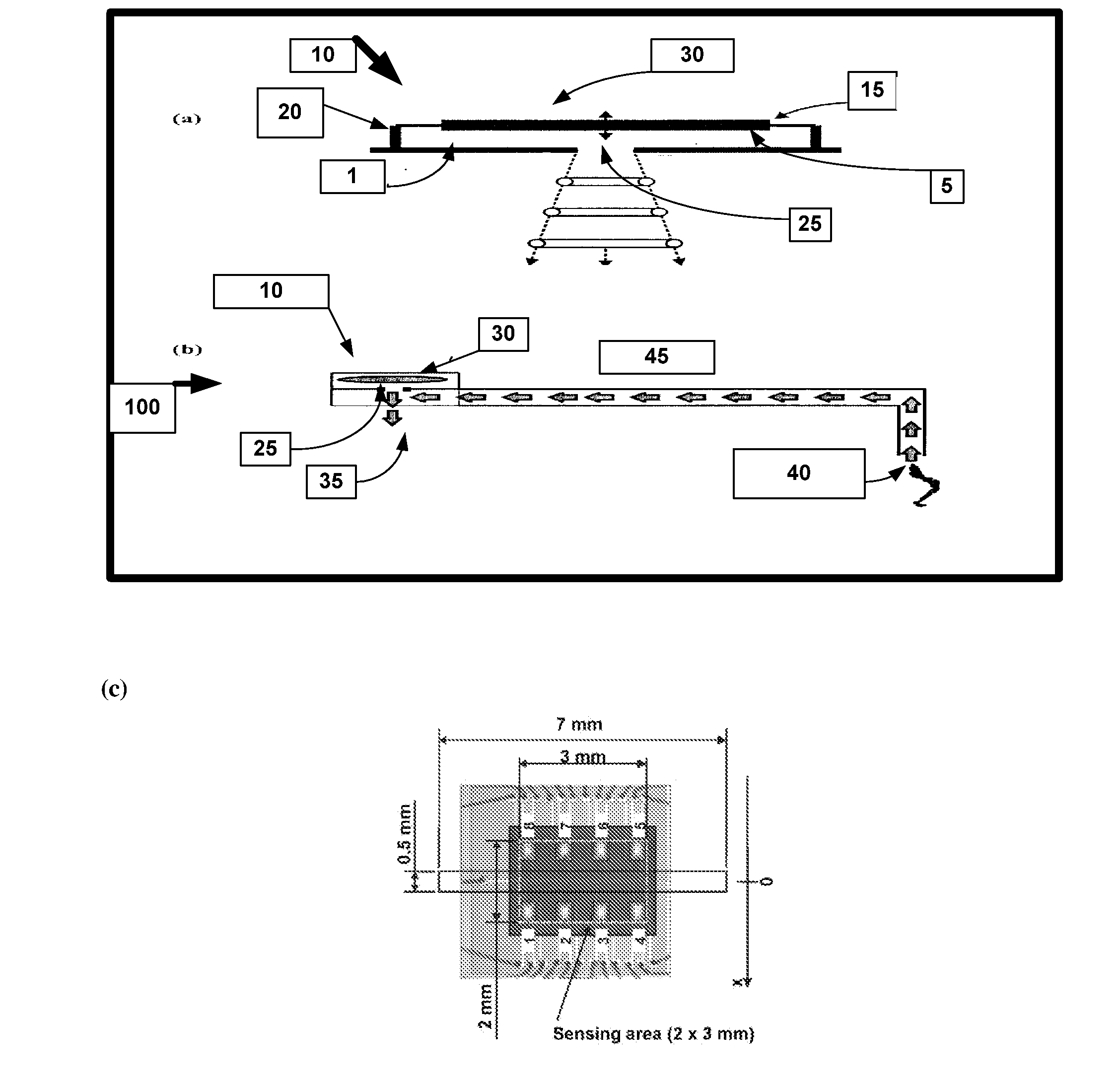

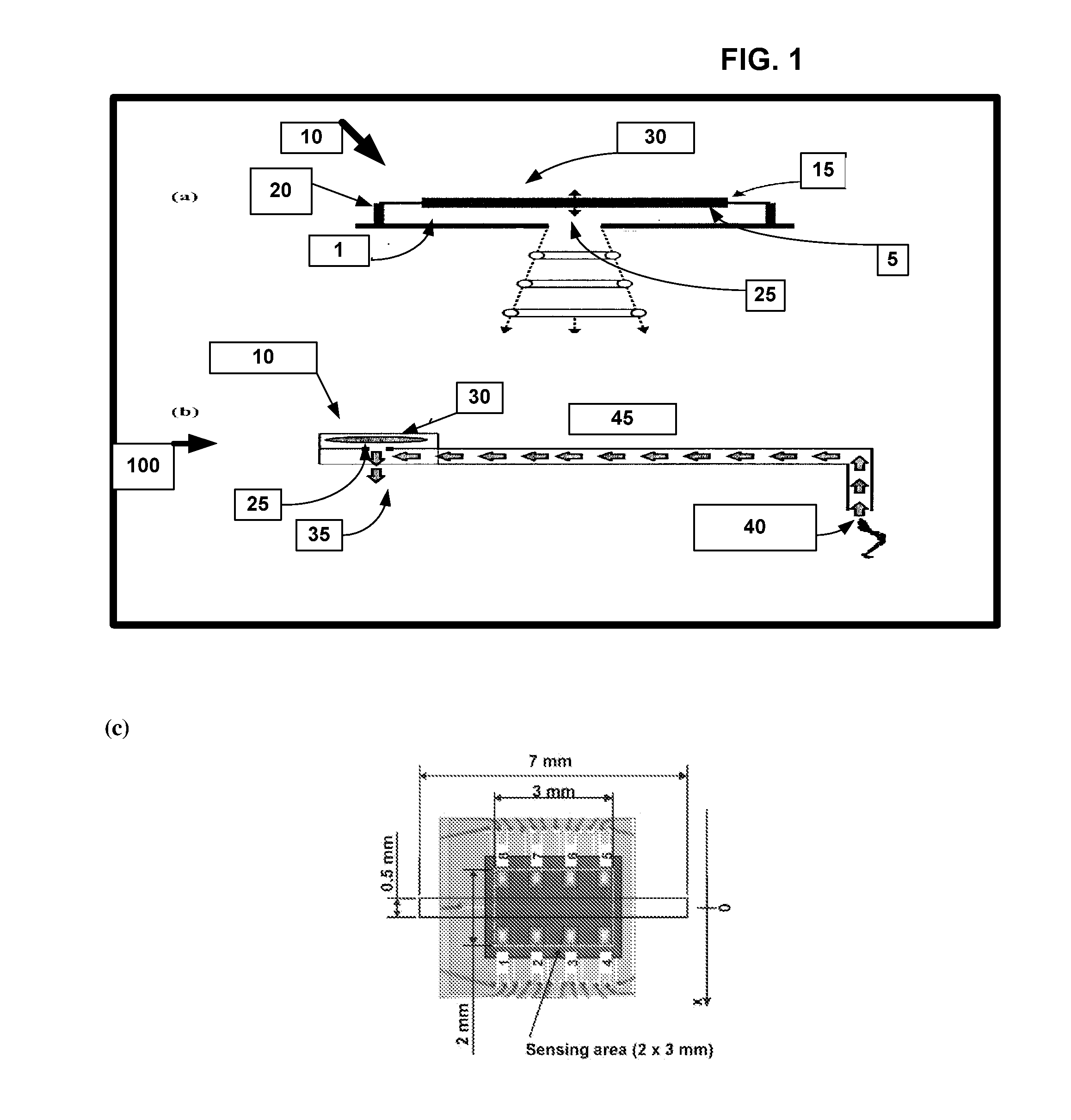

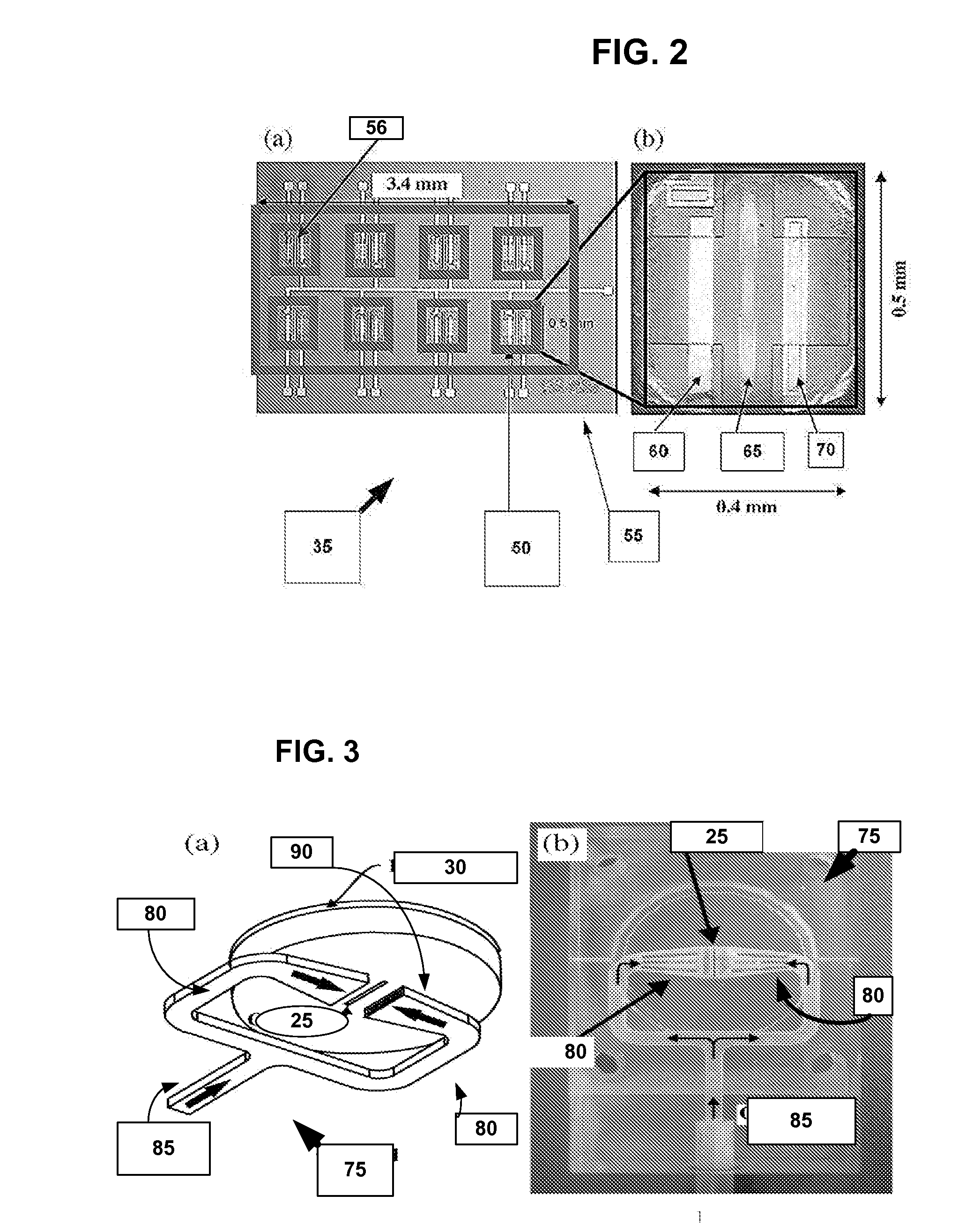

Fluidically-assisted sensor systems for fast sensing of chemical and biological substances

InactiveUS20100229658A1Easy to superviseKeep for a long timeAdditive manufacturing apparatusWithdrawing sample devicesEffective surfaceInhalation

The present invention is directed to devices and methods in which one or more miniature synthetic jet actuators are integrated with a chemical fluidic sensor (ChemFET) to effect inhalation and exhalation of ambient gas samples and induce small scale mixing at the surface of the sensor. The fluidically integrated jet transports ambient gas or liquid into the jet / sensor assembly through integrated gas or liquid channels, impinges the sample gas or liquid on the sensing element, and finally ejects the sample gas or liquid back into the ambient gas or liquid. The response of the sensor in the presence of the active jet is compared to its response when the jet is inactive. The jet actuator directs entrained ambient gas or liquid toward the active surface of the sensor, and the impingement of sample gas or liquid onto the surface of the sensor results in faster response time. Other embodiments are also claimed and described.

Owner:GEORGIA TECH RES CORP

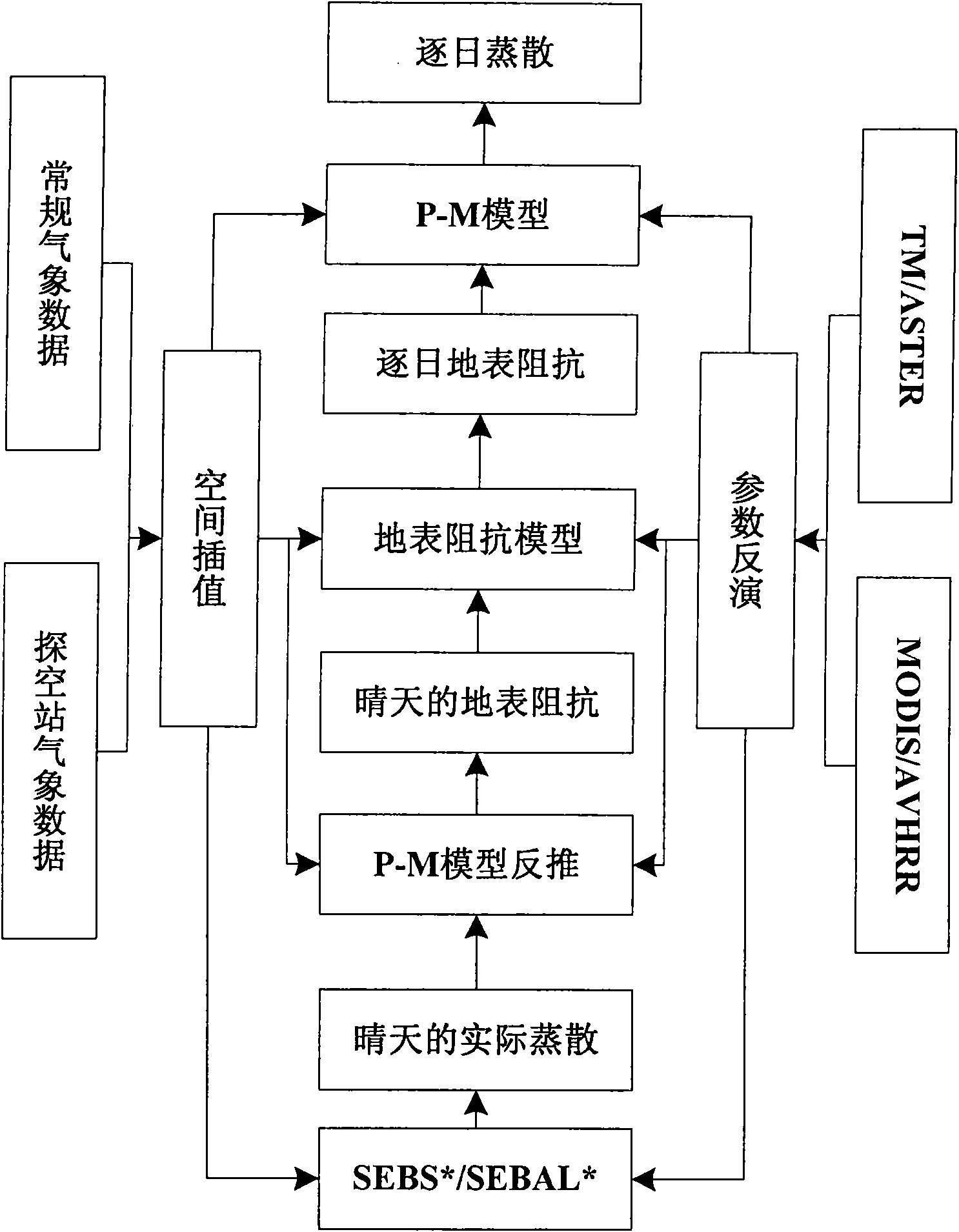

Method for monitoring regional evapotranspiration on the basis of remote sensing

InactiveCN101551459AHigh precisionImprove accuracyElectromagnetic wave reradiationICT adaptationEffective surfaceDown scaling

The invention provides a method for monitoring the regional evapotranspiration on the basis of remote sensing, comprising the following steps of: (1) obtaining the multi-temporal and multi-resolution satellite remote-sensing image data at a specific region; (2) carrying out remote sensing inversion to the key parameters on the ground surface; (3) calculating the impedance of each pixel during the exchanging process of the geogas energy by a remote-sensing geogas exchanging model, calculating the sensible heat flux used for heating the air above each pixel, calculating the latent heat energy by an energy remainder formula and inquiring into effective surface impedance; (4) establishing a surface impedance model in a daily dimension so as to obtain a daily ground surface impedance; and (5) working out the daily evapotranspiration by applying a P-M model repeatedly and carrying out time accumulation and dimension down-scaling, thus finally determining the regional ground surface evapotranspiration. According to the validation of the practical measurement at multi-regions, the method for monitoring the regional evapotranspiration is proved to be effective.

Owner:BEIJING WISEWATCH INFORMATION TECH

Smooth sleeves for drag and VIV reduction of cylindrical structures

A method for controlling drag and vortex induced vibration in a substantially cylindrical element by providing an ultra-smooth surface about the cylindrical element. The system for controlling drag and vortex induced vibration utilizes a substantially cylindrical marine element having an ultra-smooth effective surface.

Owner:SHELL OIL CO

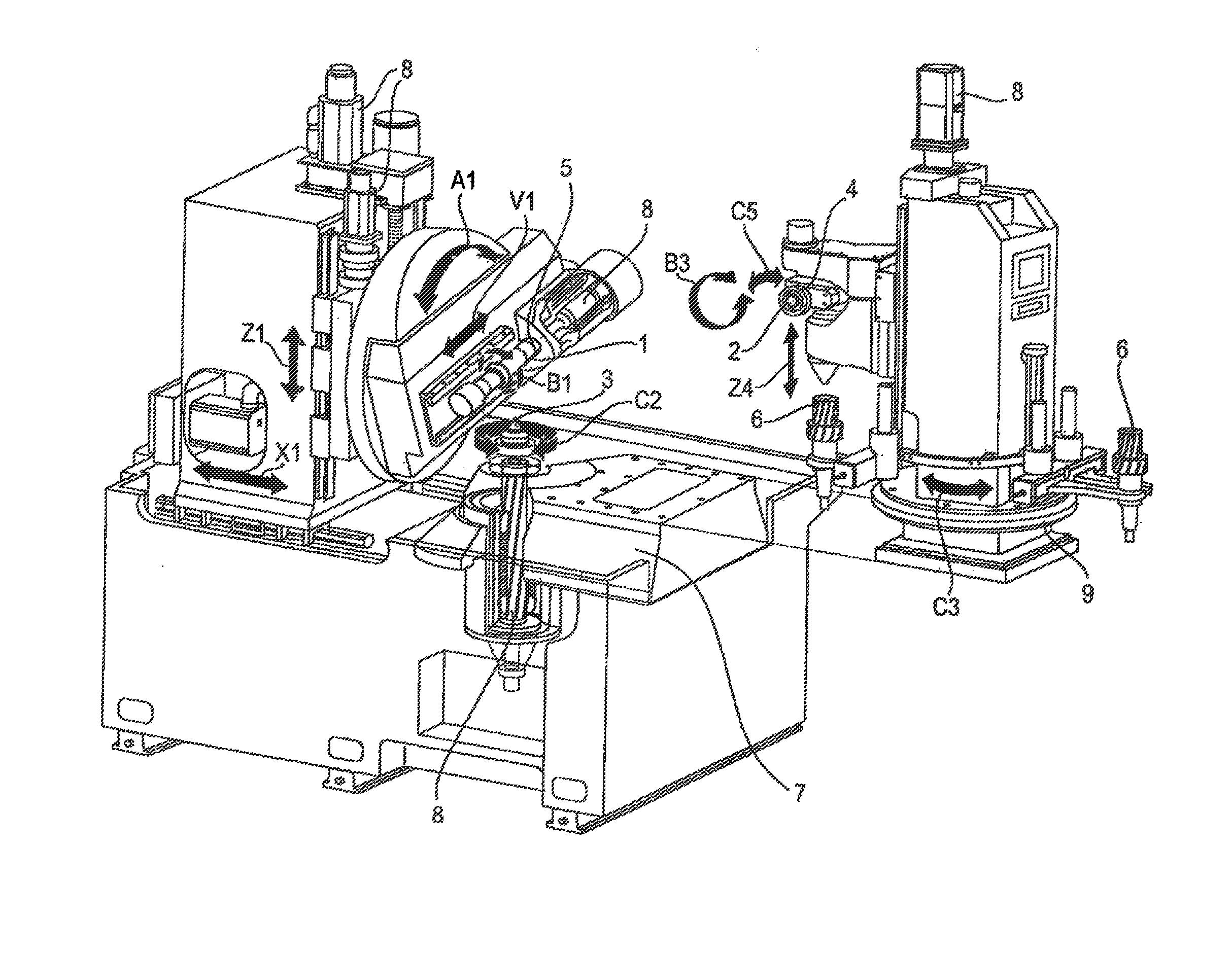

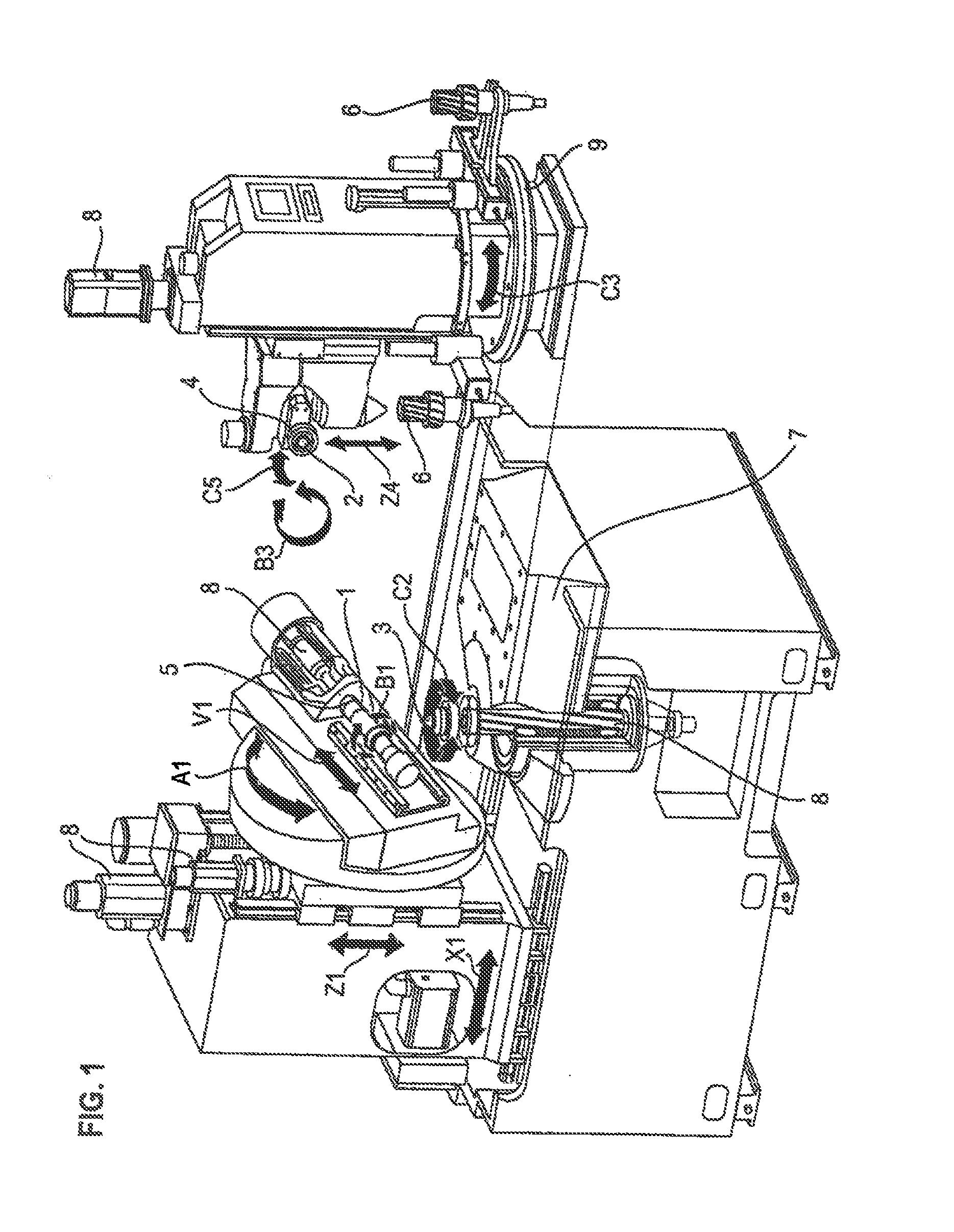

Method and apparatus for hard finishing modified gears

The present disclosure relates to a method for the manufacture of a workpiece having a corrected gear geometry and / or a modified surface structure, in particular by a hard finishing process, in particular generation grinding or honing. Provision is made in this respect that it is achieved by a direct generation of a wobble movement and / or of an eccentricity of the tool that a modification, in particular a profile modification or profile waviness, and / or a defined periodic flank waviness is generated on the active surface of the workpiece machined therewith.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

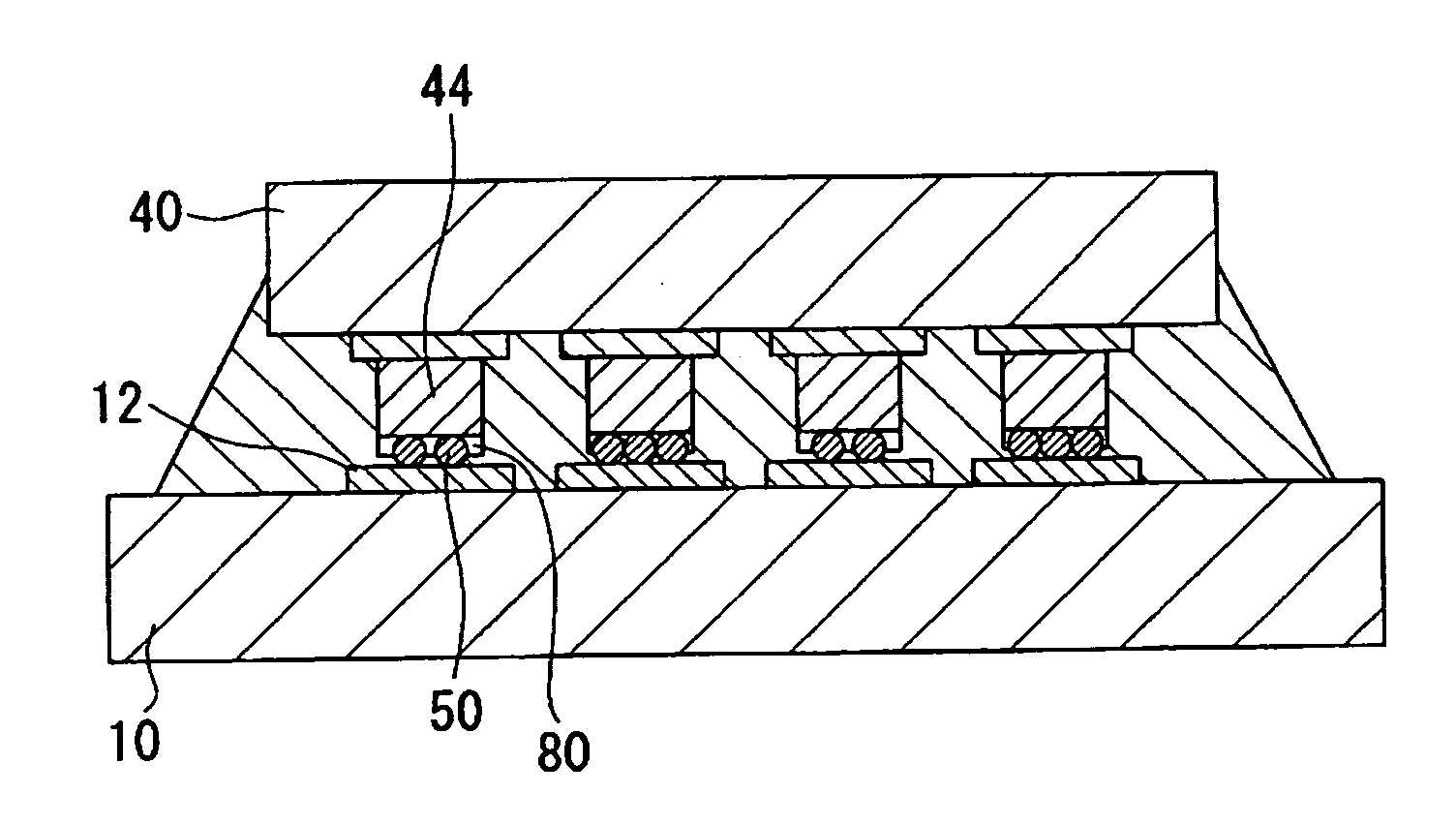

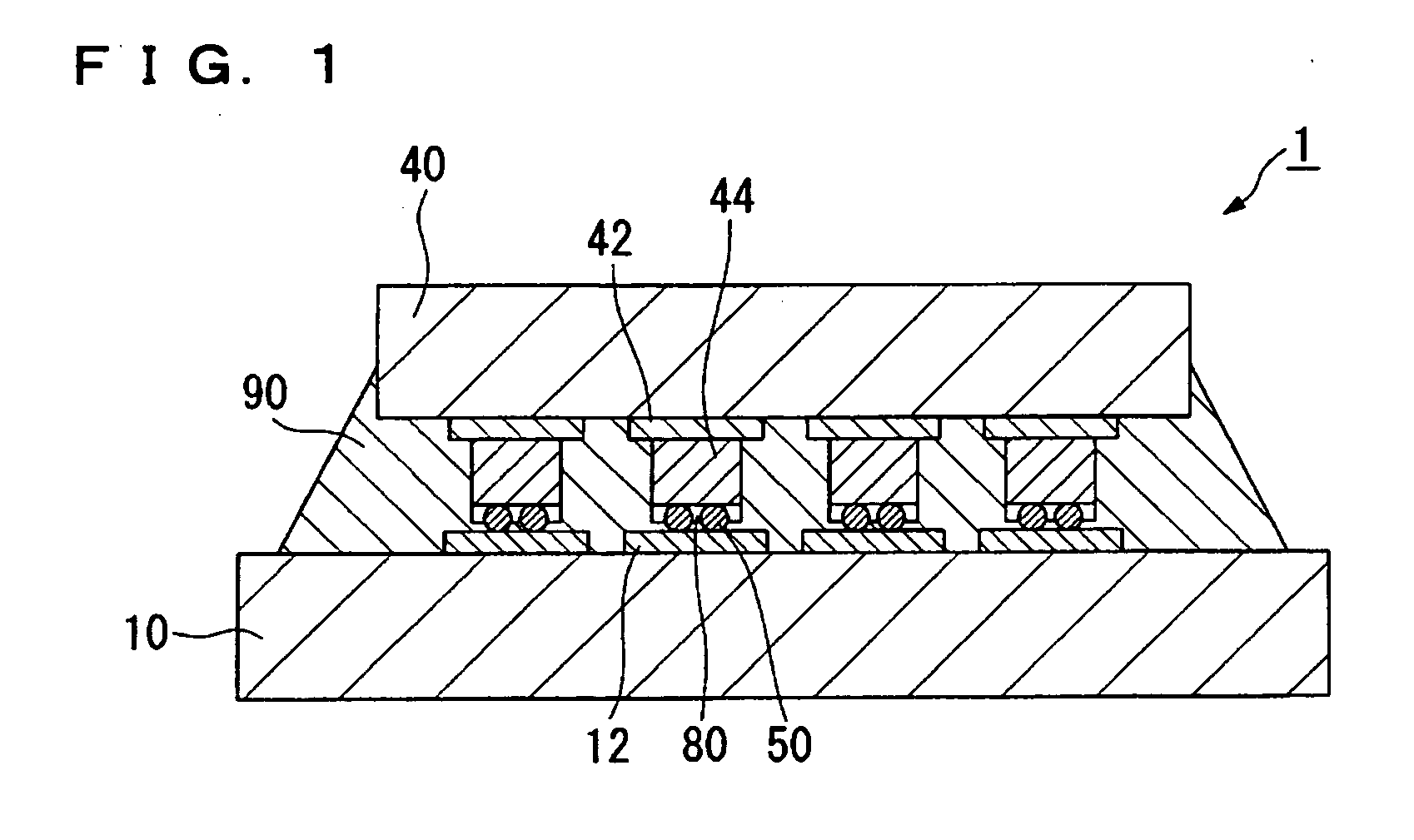

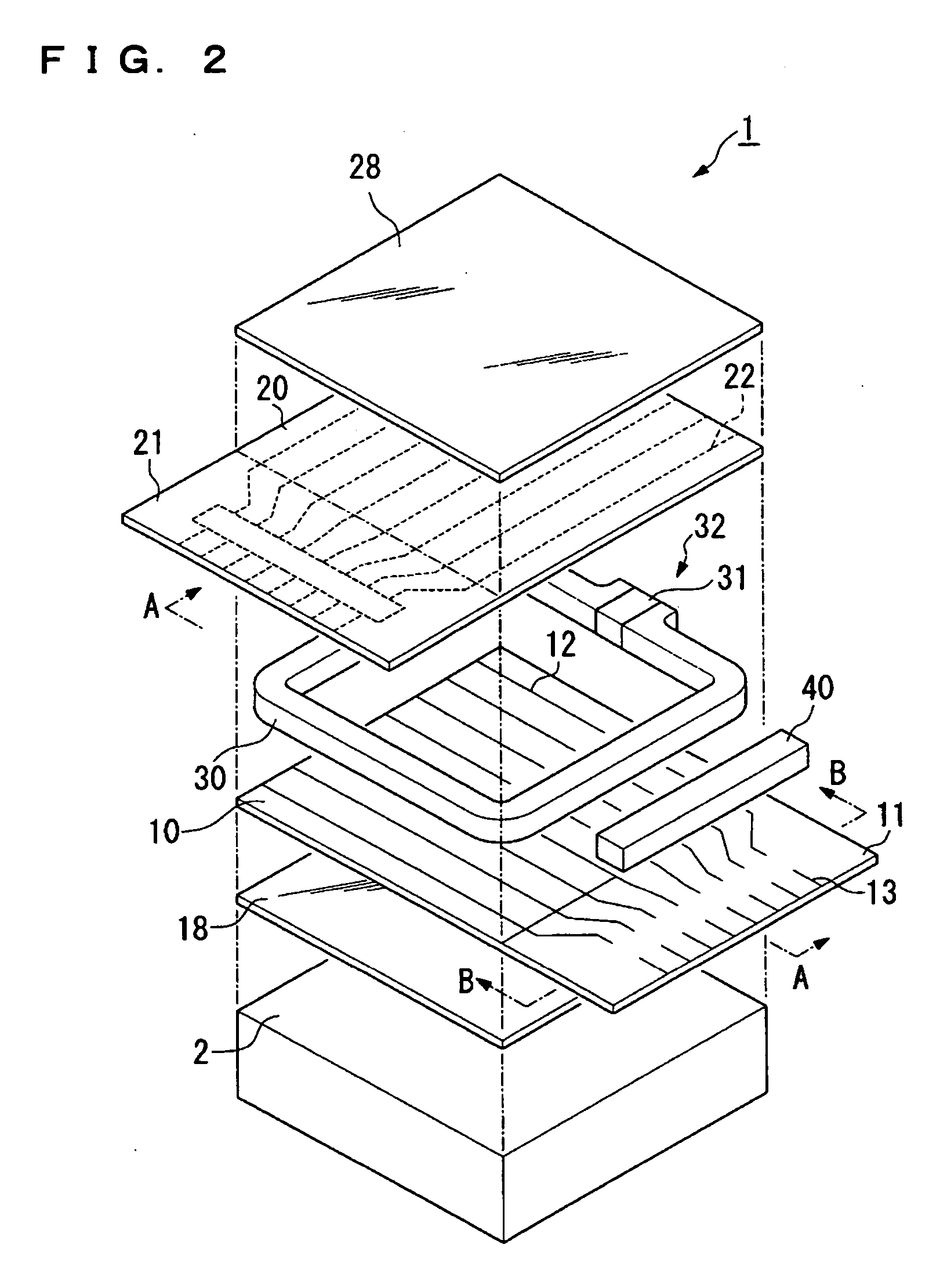

Method of manufacturing electronic part, electronic part, method of mounting electronic part, and electronic apparatus

ActiveUS20040224441A1Semiconductor/solid-state device detailsNon-mechanical controlsEffective surfaceEngineering

To provide a method of manufacturing an electronic part capable of reusing the remaining conductive particles and electrically connecting the electronic part to the counterpart substrate, a method of manufacturing an electronic part includes: forming a mask on an active surface of the wafer on which electrode pads of the electronic part are formed, the mask of a predetermined height having openings provided above the electrode pads, forming bumps inside of the openings of the mask provided above the electrode pads, the bumps having a height lower than that of the mask, scattering conductive particles above the active surface of the wafer, removing the conductive particles remaining on the surface of the mask, fixing the conductive particles on the surfaces of the bumps, removing the mask, and separating the electronic part from the wafer.

Owner:BOE TECH GRP CO LTD

Catalyst for selective catalytic reduction of nitric oxide and preparation method of catalyst

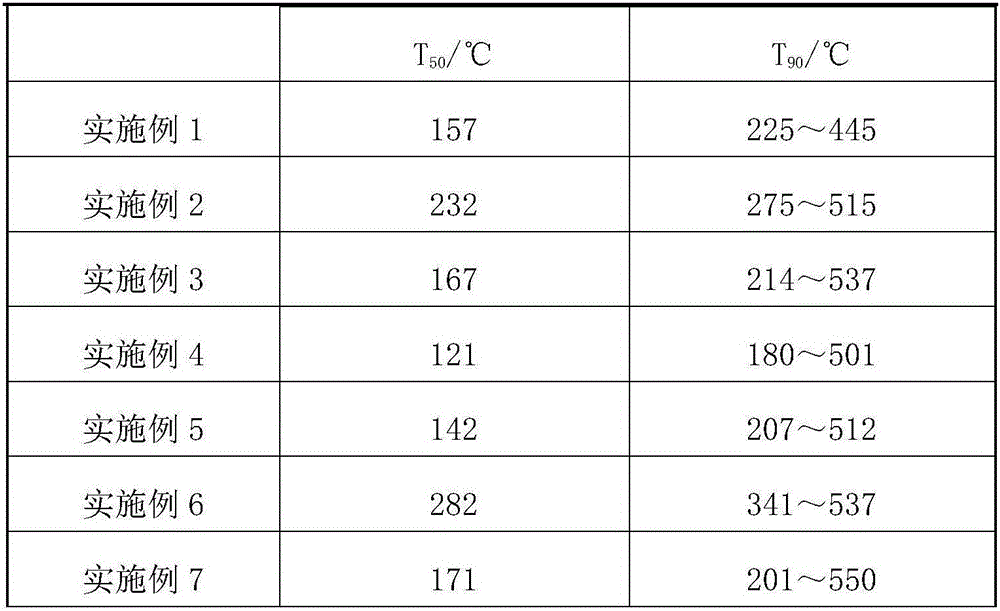

InactiveCN106111183AReduce dosageHigh low temperature activityMolecular sieve catalystsDispersed particle separationMolecular sieveEffective surface

The invention belongs to the technical field of environmental protection and catalysts, and particularly relates to a catalyst for selective catalytic reduction of nitric oxide and a preparation method of the catalyst. The catalyst comprises a molecular sieve and transition metal supported on the molecular sieve and is prepared from the molecular sieve and a transition metal precursor, and the molecular sieve is dried to remove adsorbed water; then the metal precursor is mixed with water, stirring is carried out for dissolving, and a solution is prepared; the prepared solution and the prepared molecular sieve are stirred and mixed, standing, drying and calcining are carried out, the product is cooled to normal temperature, and the catalyst for selective catalytic reduction of nitric oxide is obtained. The molecular sieve is used as a carrier, an effective surface is provided for adsorption and reacting of nitric oxide, high dispersion of active components can be kept, and the use amount of the active components can be reduced. By means of the characteristics of the carrier and the synergetic effect among different kinds of metals, the low temperature activity of the catalyst is improved, and the active window temperature range of the catalyst is widened. The preparation method of the catalyst is simple, easy to carry out and free of pollution.

Owner:碗海鹰

Method of making a sliding bearing

InactiveUS7458158B2Improve performanceCompromising performanceCrankshaftsBearing assemblyEffective surfaceFriction loss

This invention introduces a new category of engineered surfaces and corresponding production processes for better wear resistance and lower friction loss. The structured surfaces can be applied on many automobile components with frictional surfaces. The composite structure settles the usual conflicts between surface functions and stresses. Two sets of multiple-step processes are introduced to achieve high production efficiency and low cost. Unlike traditional surface technologies that generate single and uniform layers on the whole part surface, the new technology processes the part surface selectively for more effective surfaces with versatile functions.

Owner:FEDERAL MOGUL WORLD WIDE LLC

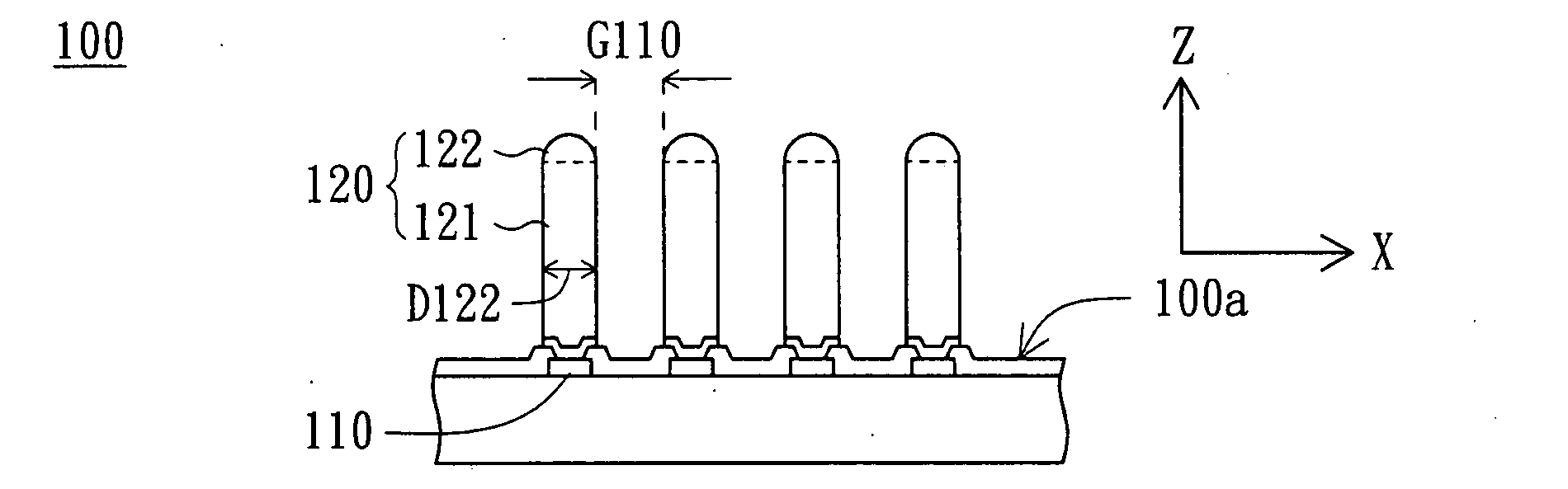

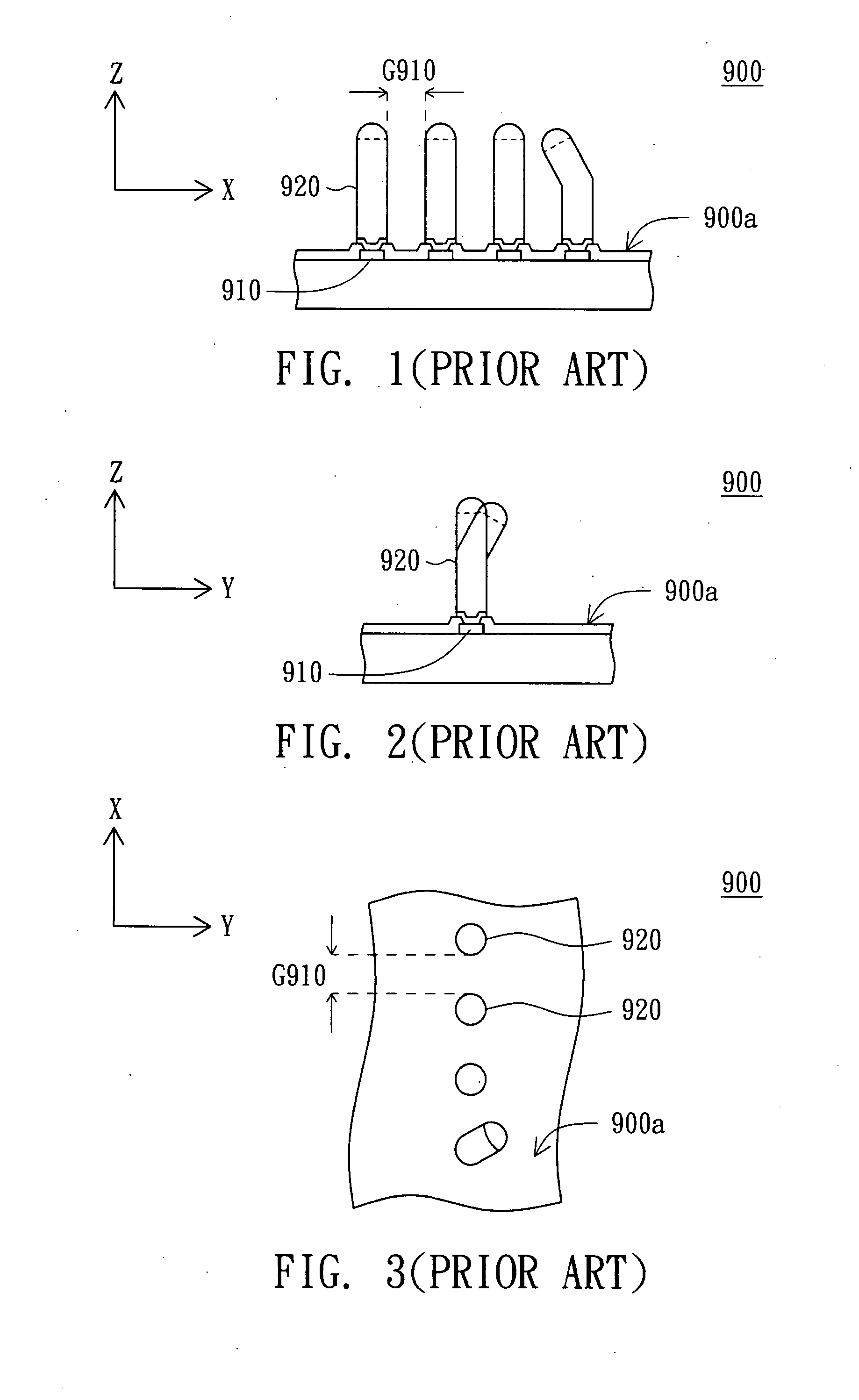

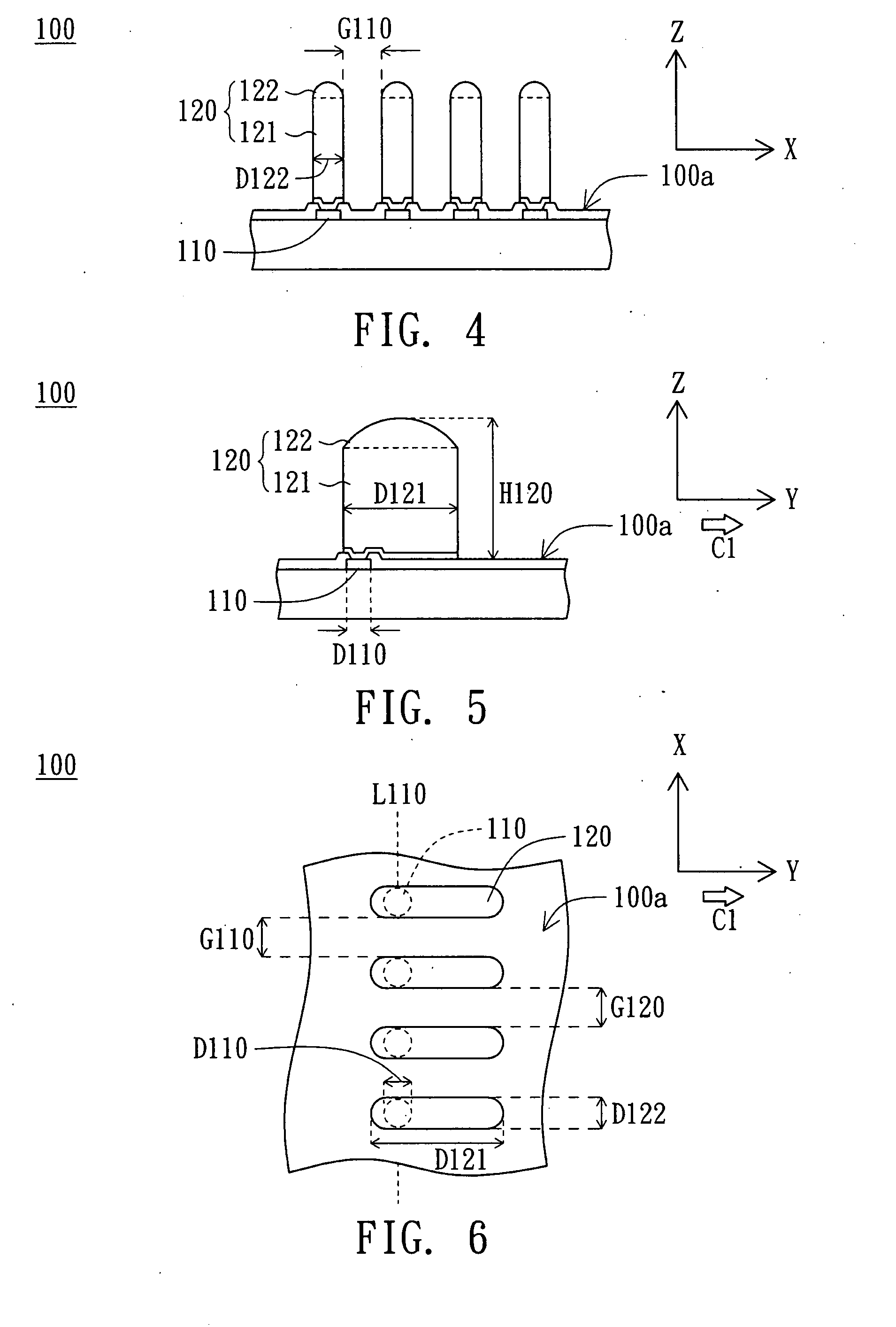

Stackable semiconductor device and fabrication method thereof

InactiveUS20080230913A1Reduce areaSimpler and cheap to implementSemiconductor/solid-state device detailsSolid-state devicesState of artEffective surface

The invention provides a stackable semiconductor device and a fabrication method thereof, including providing a wafer having a plurality of dies mounted thereon, both the die and the wafer having an active surface and a non-active surface opposing one another respectively, wherein each die has a plurality of solder pads formed on the active surface thereof and a groove formed between adjacent solder pads to form a first metal layer therein that is electrically connected to the solder pads; subsequently thinning the non-active surface of the wafer to where the grooves are located to expose the first metal layer therefrom, and forming a second metal layer on the non-active surface of the wafer for electrically connecting with the first metal layer; and separating the dies to form a plurality of stackable semiconductor devices. Thereby, the first and second metal layers formed on the active surface and the non-active surface of the semiconductor device can be stacked and connected to constitute a multi-die stack structure, thereby increasing integration without increasing the area of the stacked dies. Further, the problems known in the prior art of poor electrical connection, complicated manufacturing process and increased cost as a result of using wire bonding and TSV can be avoided.

Owner:SILICONWARE PRECISION IND CO LTD

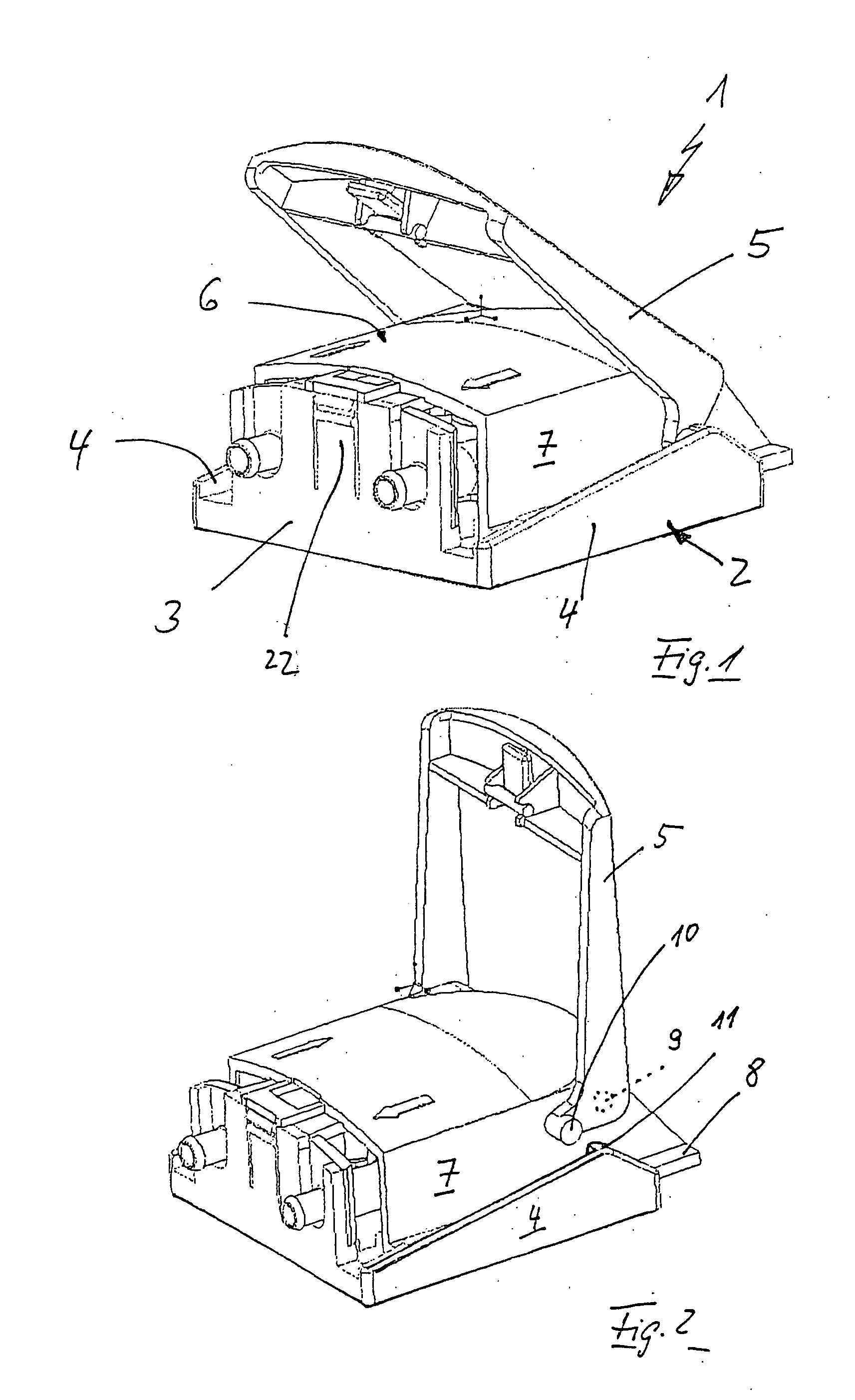

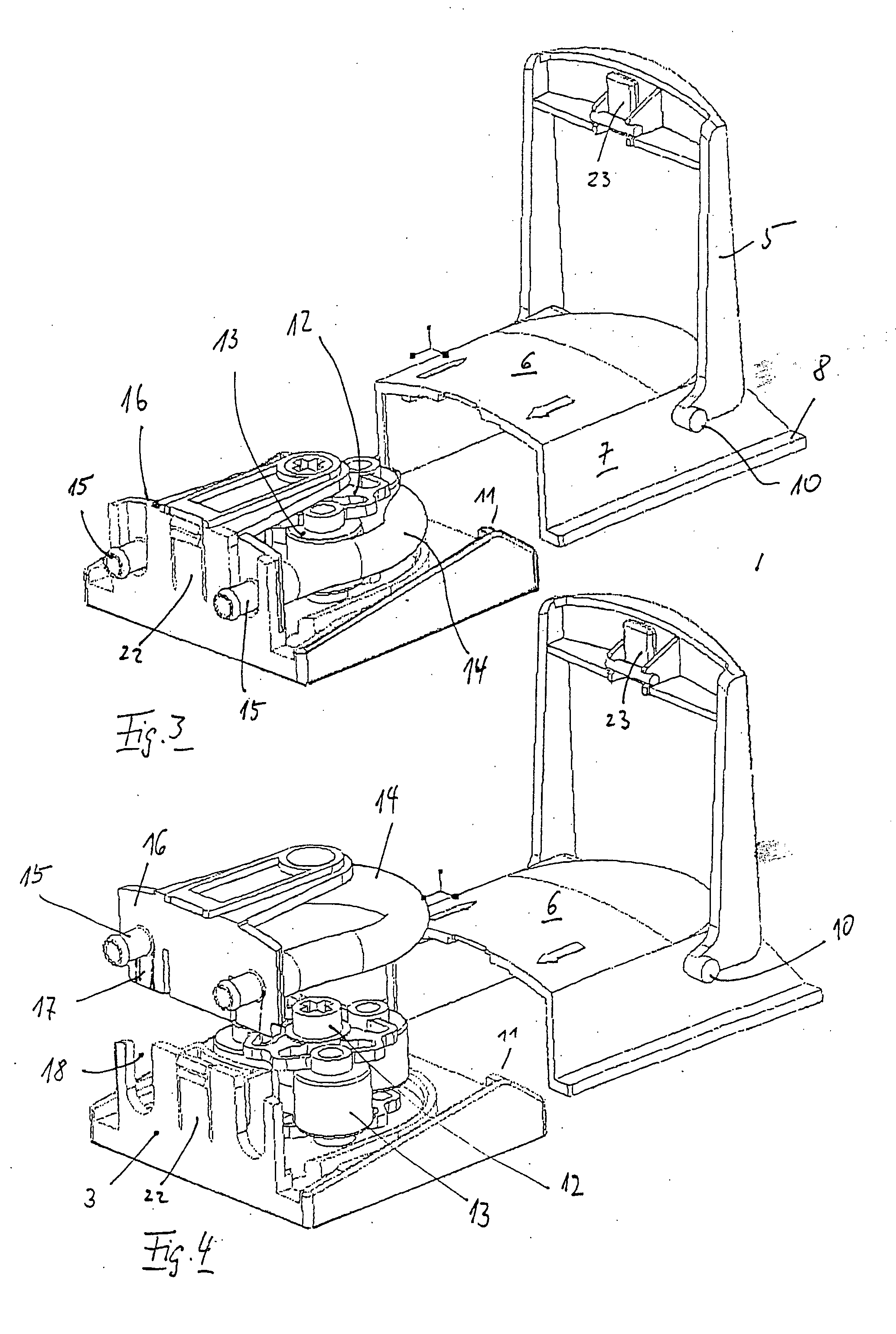

Peristaltic pump

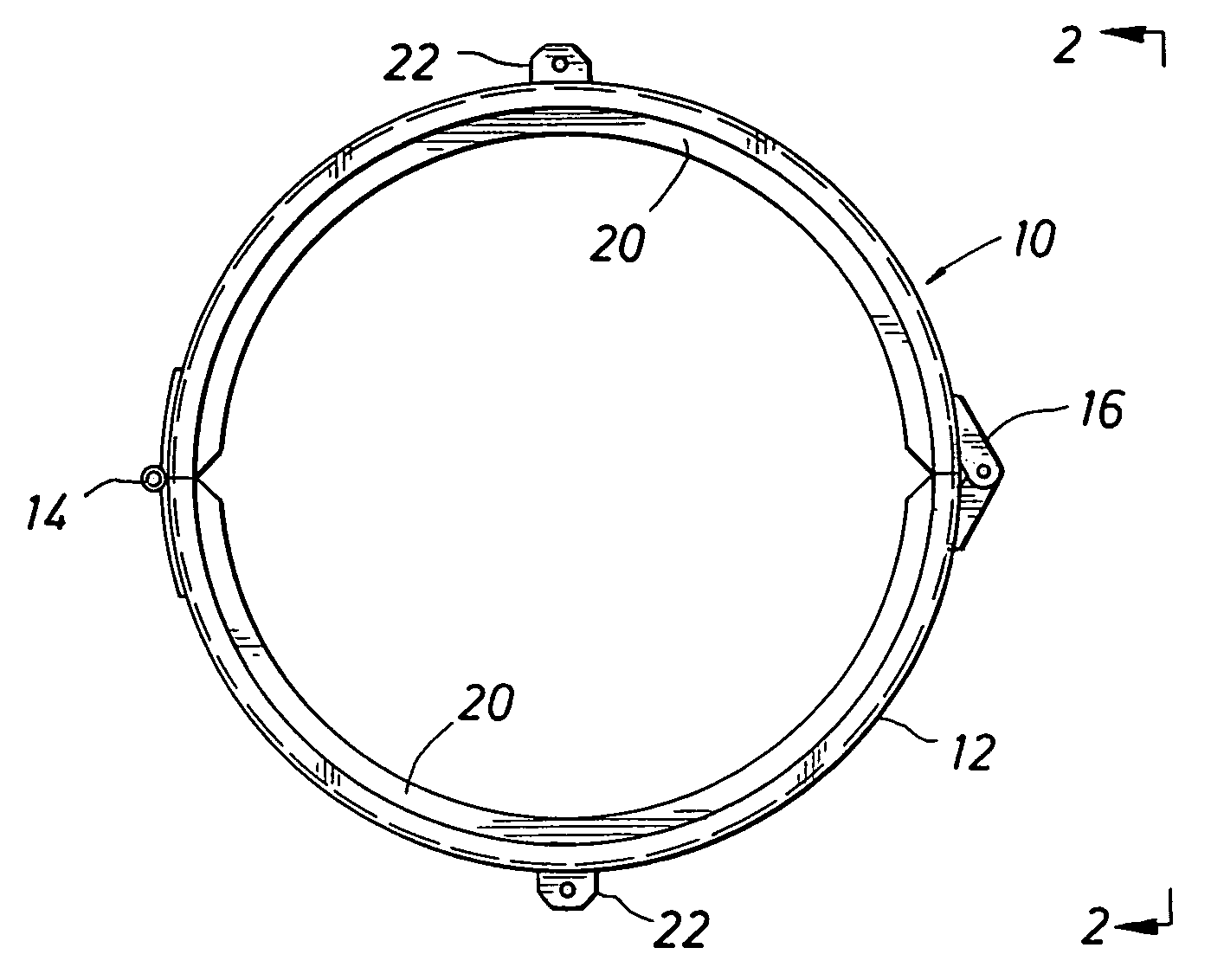

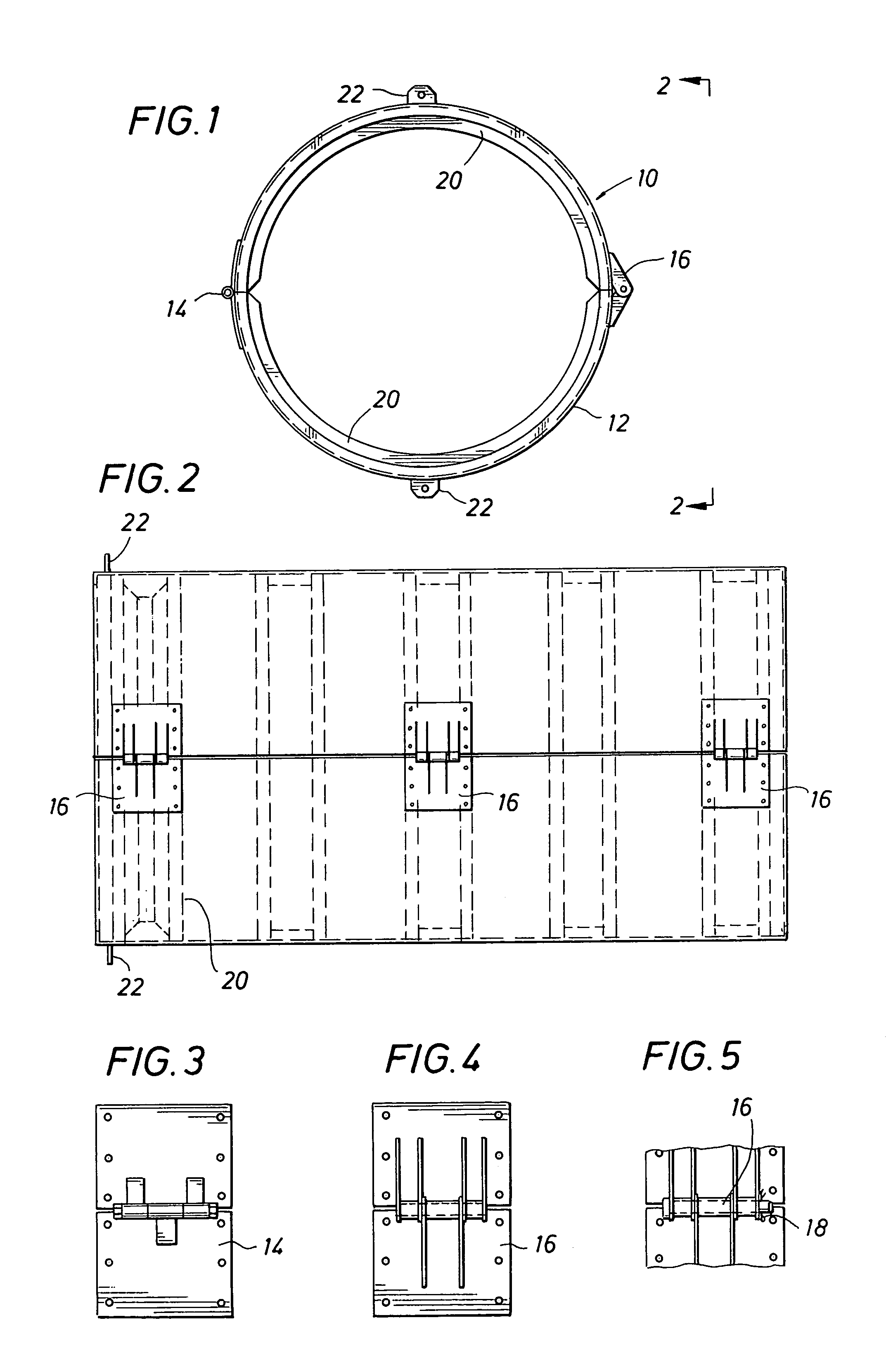

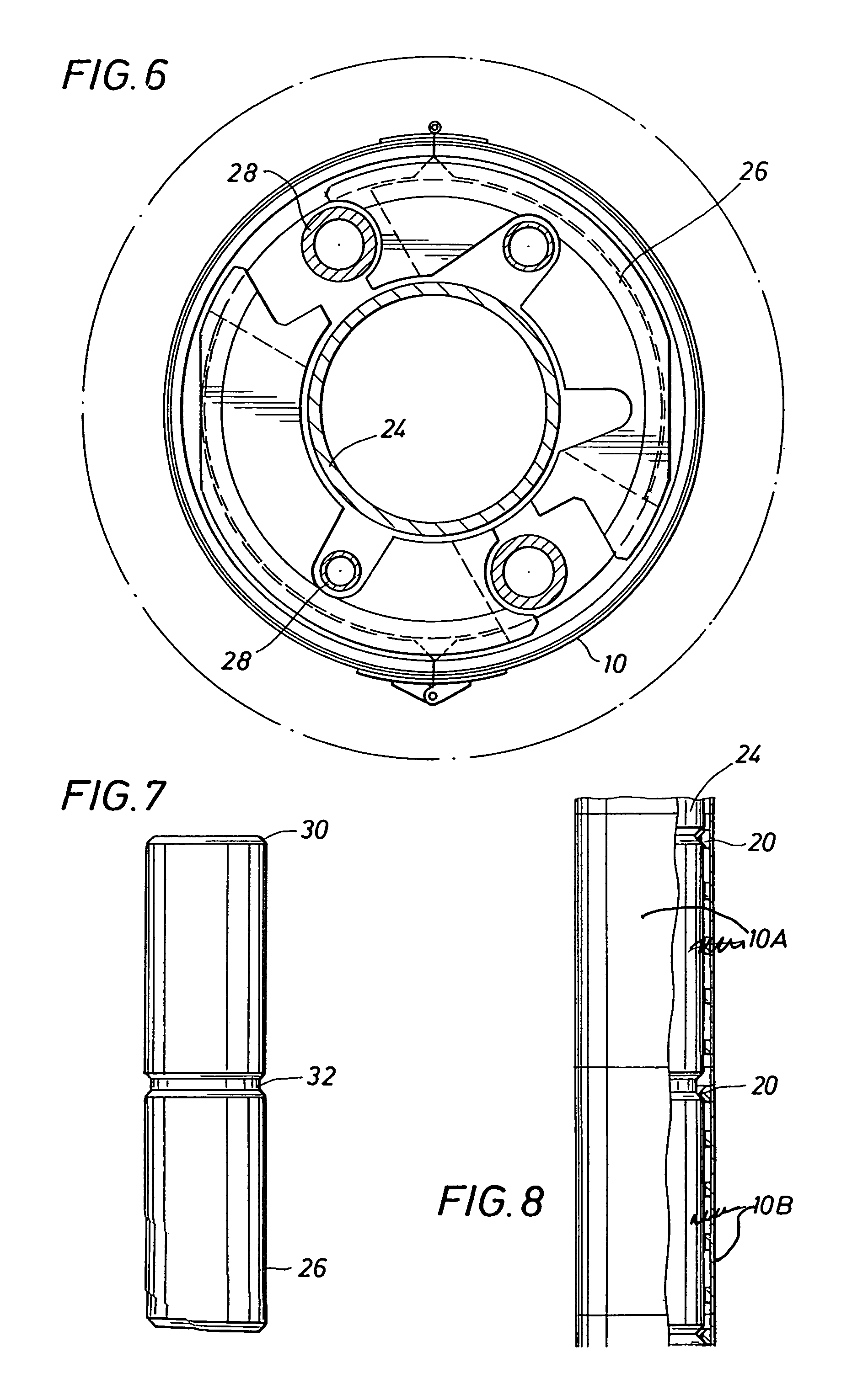

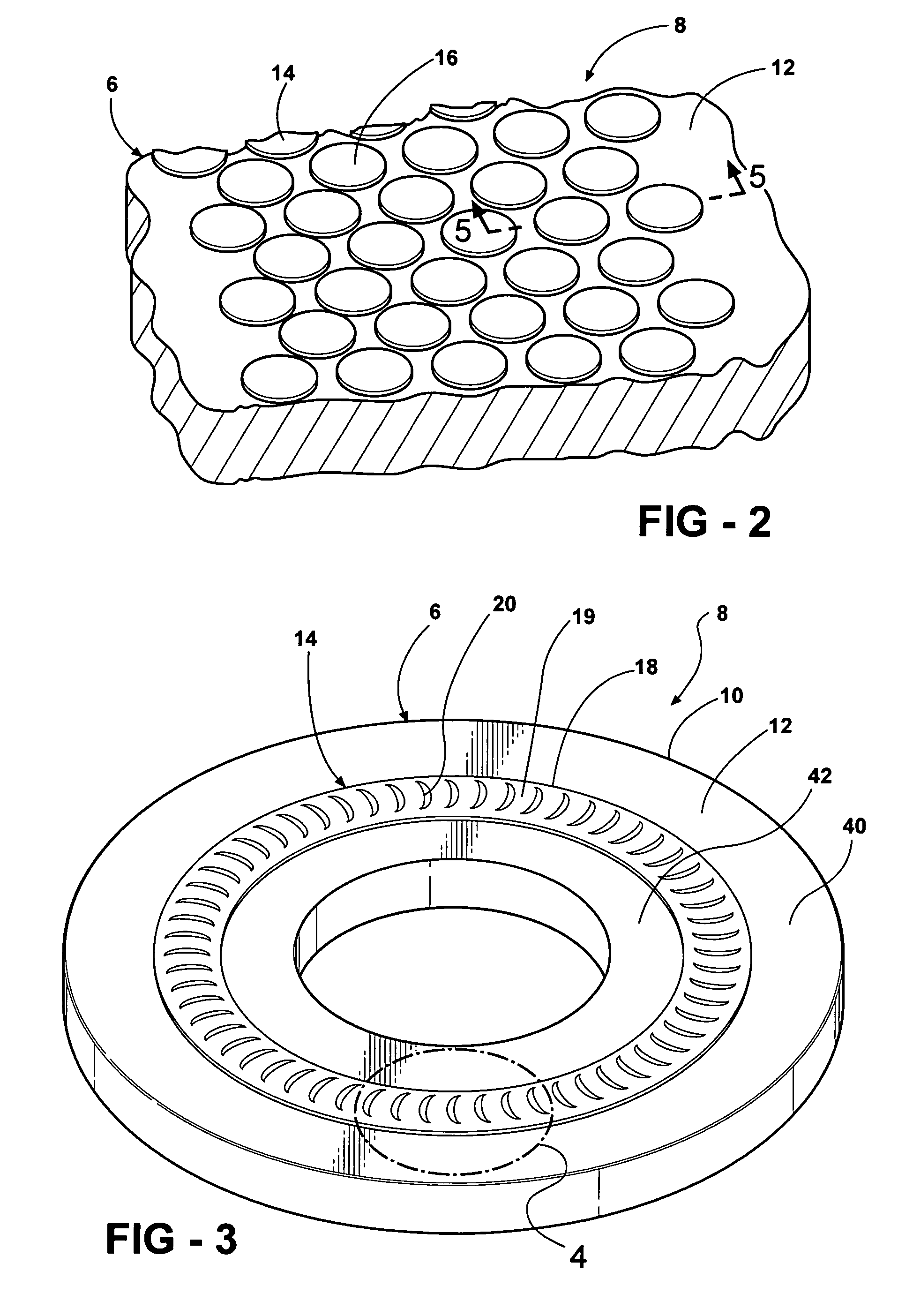

InactiveUS20050254978A1Precise positioningTableware washing/rinsing machine detailsFlexible member pumpsPeristaltic pumpEffective surface

A peristaltic pump (1) with a rotating squeeze roller carrier (12), a squeeze hose (14) partly looping around the squeeze rollers (13) and a curved contact wall (19) for the squeeze hose (14), the contact wall (19) being opposite to the effective surface of the squeeze rollers, whereby the contact wall (19) is movable by way of a setting lever (5) from a setting (FIG. 5), which enables fitting with the squeeze hose (14), to a work setting (FIG. 6), pressing the squeeze hose (14) against the squeeze rollers (13) and whereby the contact wall (19) forms a part of a pump housing cover (6) at which the setting lever (5) is positioned to be outwardly pivotable for displacement of the cover (6).

Owner:ECOLAB USA INC

Method of making a sliding bearing

InactiveUS20060288579A1Improve performanceImprove structural strengthCrankshaftsBearing assemblyEffective surfaceFriction loss

This invention introduces a new category of engineered surfaces and corresponding production processes for better wear resistance and lower friction loss. The structured surfaces can be applied on many automobile components with frictional surfaces. The composite structure settles the usual conflicts between surface functions and stresses. Two sets of multiple-step processes are introduced to achieve high production efficiency and low cost. Unlike traditional surface technologies that generate single and uniform layers on the whole part surface, the new technology processes the part surface selectively for more effective surfaces with versatile functions.

Owner:FEDERAL MOGUL WORLD WIDE LLC

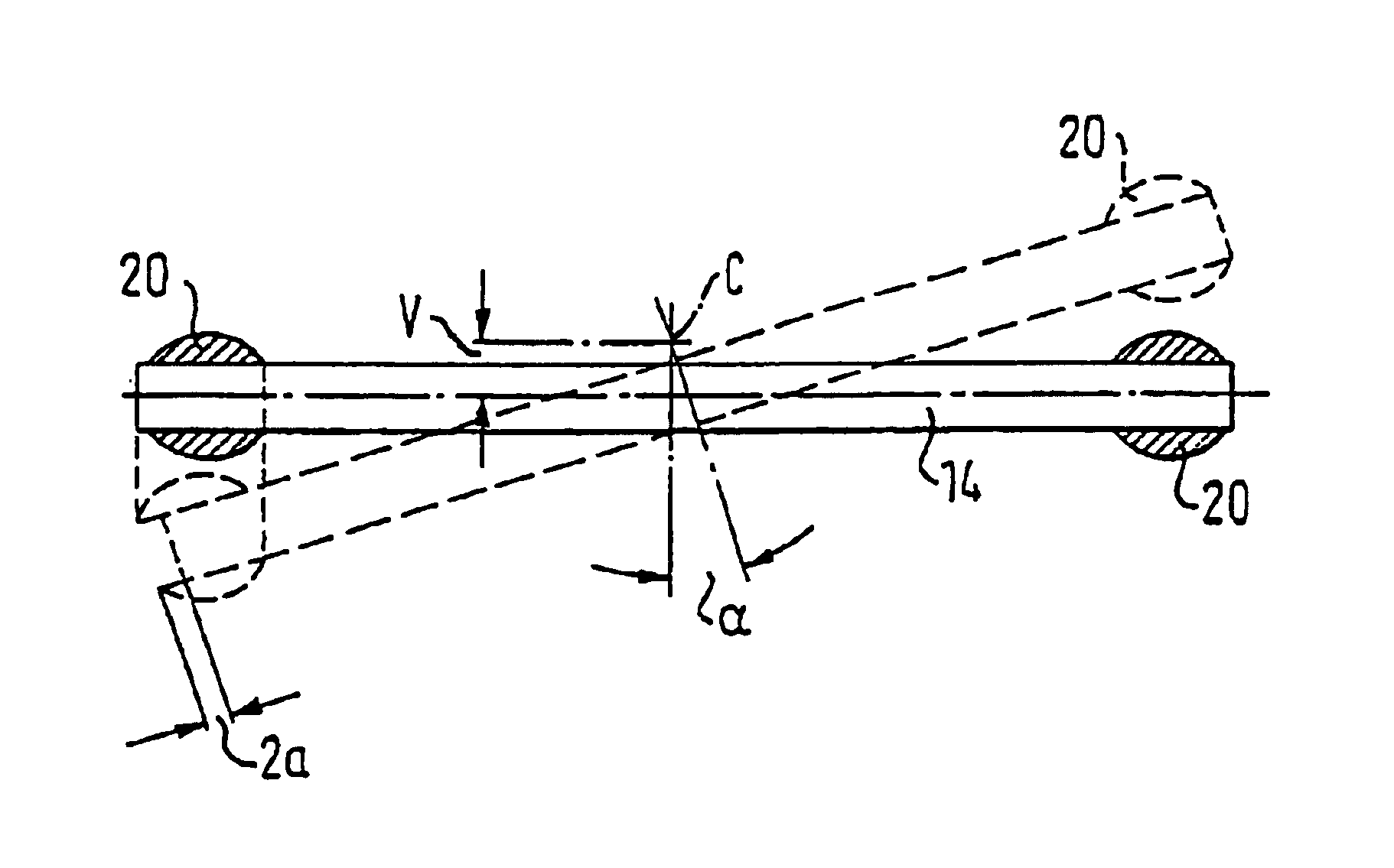

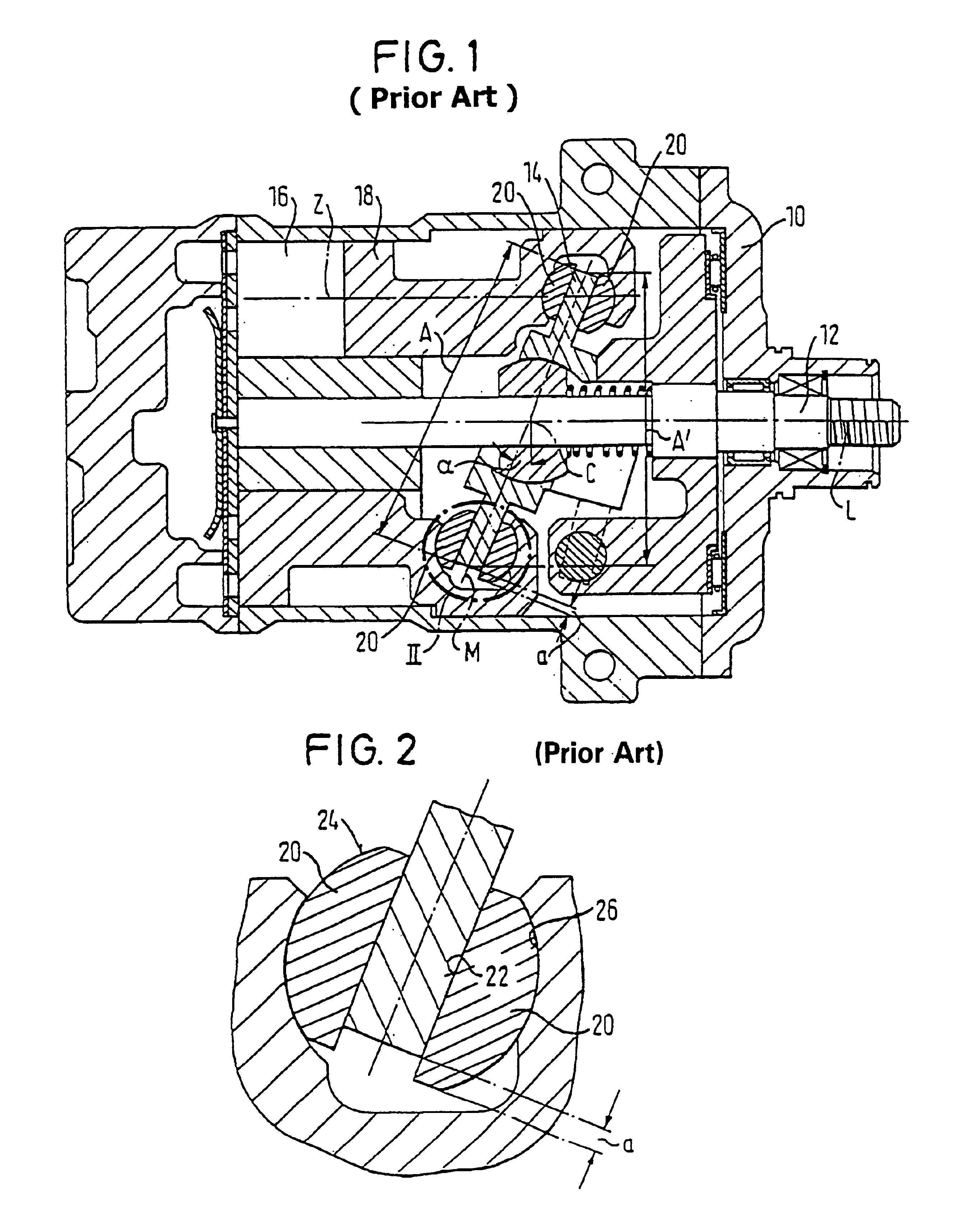

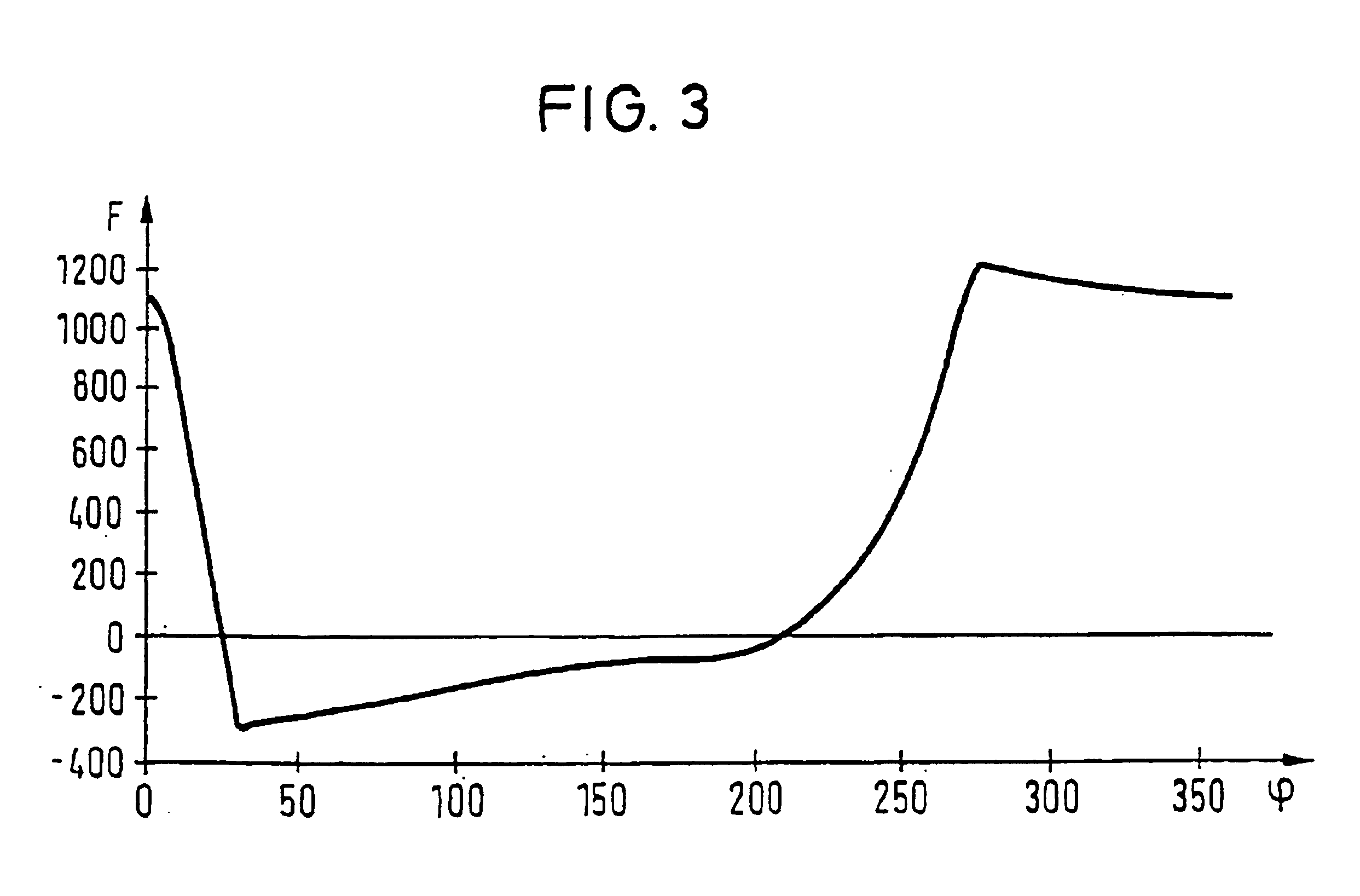

Axial piston displacement compressor

InactiveUS6766726B1Multi-stage pumpsPositive-displacement liquid enginesEffective surfaceDrive shaft

The invention relates to an axial piston displacement compressor, comprising a drive shaft (12), a disc (14) which is mounted on the drive shaft in such a way, that it can be pivoted about a pivotal axis (C) and at least one piston (18) which is provided with sliding blocks (20) that slide on a runway on the disc (14). The invention aims to reduce the maximum effective surface pressure between the disc (14) and the sliding blocks (20). To this end, the pivotal axis (C) of the disc (14) is located eccentrically in relation to the central plane of the disc.

Owner:ZEXEL VALEO COMPRESSOR EUROPE GMBH

Chip and manufacturing method thereof

ActiveUS20080088013A1Improve structural strengthImprove yieldSemiconductor/solid-state device detailsSolid-state devicesEffective surfaceSemiconductor

A semiconductor device and a manufacturing method thereof are provided. The semiconductor device has an active surface. The semiconductor device includes at least a connecting element and at least a bump. The connecting element is disposed on the activate surface and has a minimum dimension smaller than 100 microns. The bump is disposed on the connecting element and is electrically connected to the active surface by the connecting element. The bump includes a pillar part disposed on the connecting element and a top part disposed at the top of the pillar part. The pillar part has a first dimension and a second dimension both parallel to the active surface. The first dimension is longer than 1.2 times the second dimension. The top part is composed of solder and will melt under the determined temperature. The pillar part will not melt under a determined temperature.

Owner:ADVANPAK SOLUTIONS PTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com