Peristaltic pump

a peristaltic pump and pump body technology, applied in the direction of machines/engines, positive displacement liquid engines, tableware washing/rinsing machine details, etc., can solve the problems of loss of pump functional capability, peristaltic pump known design still comparatively expensive, and cover breakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

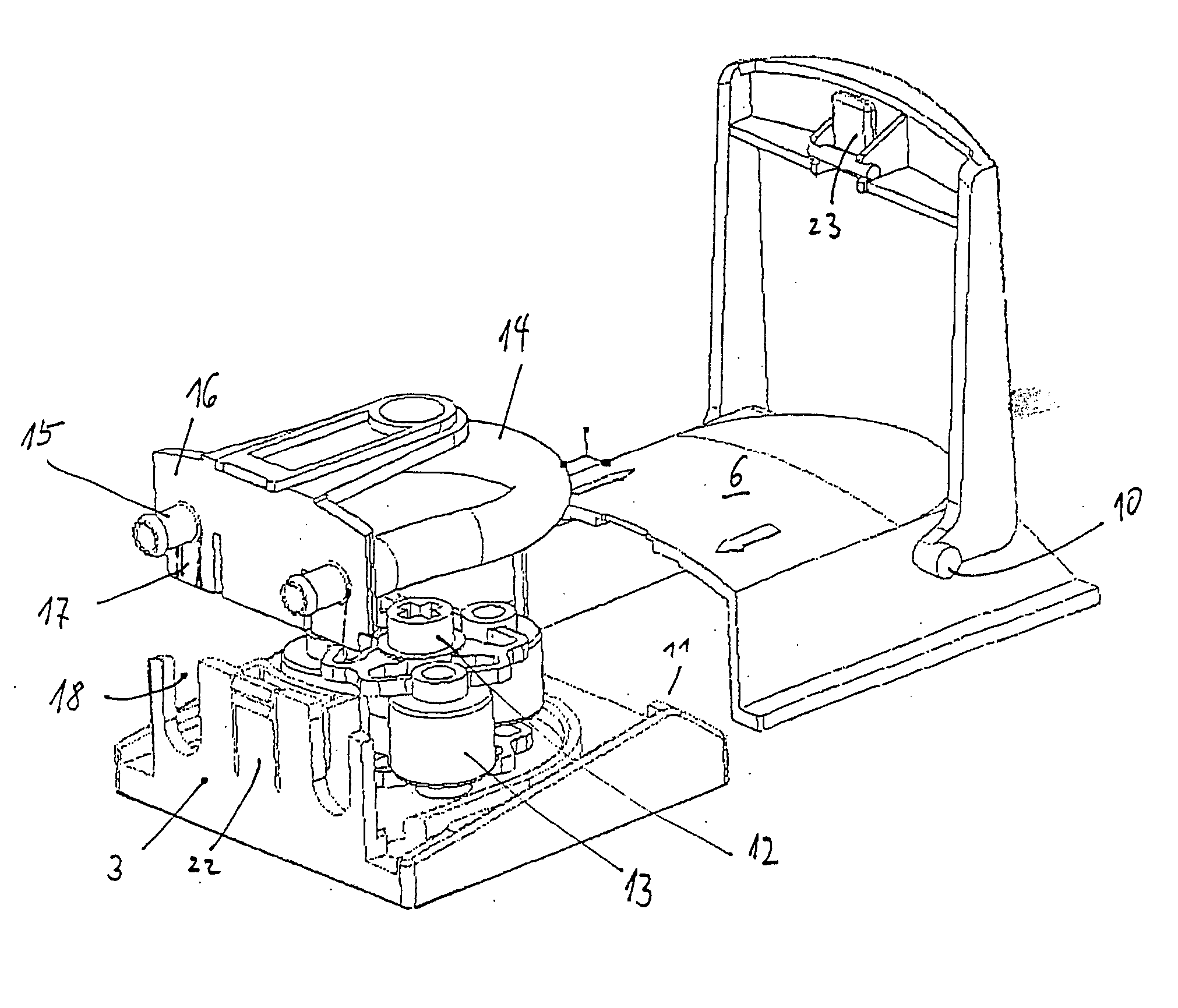

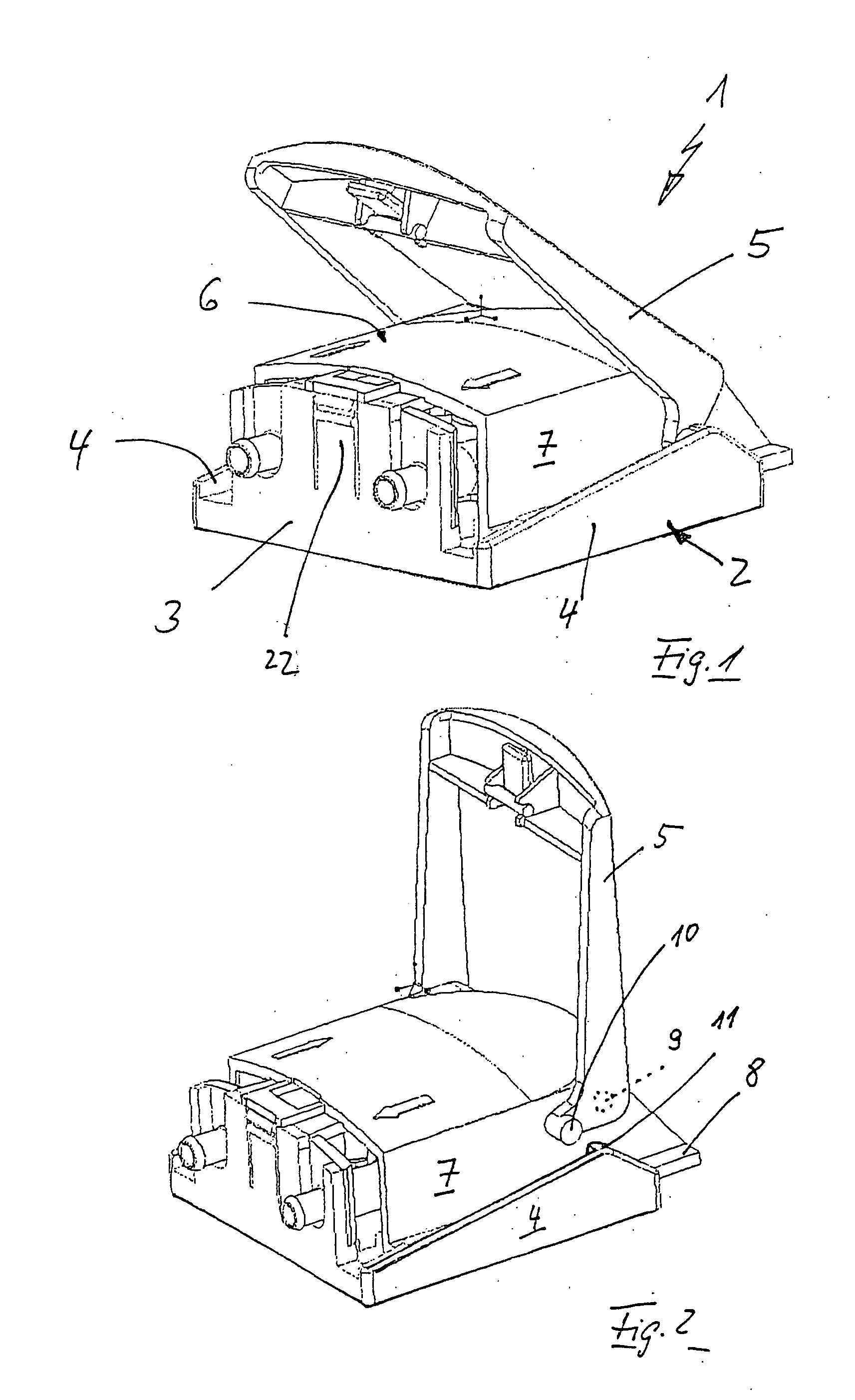

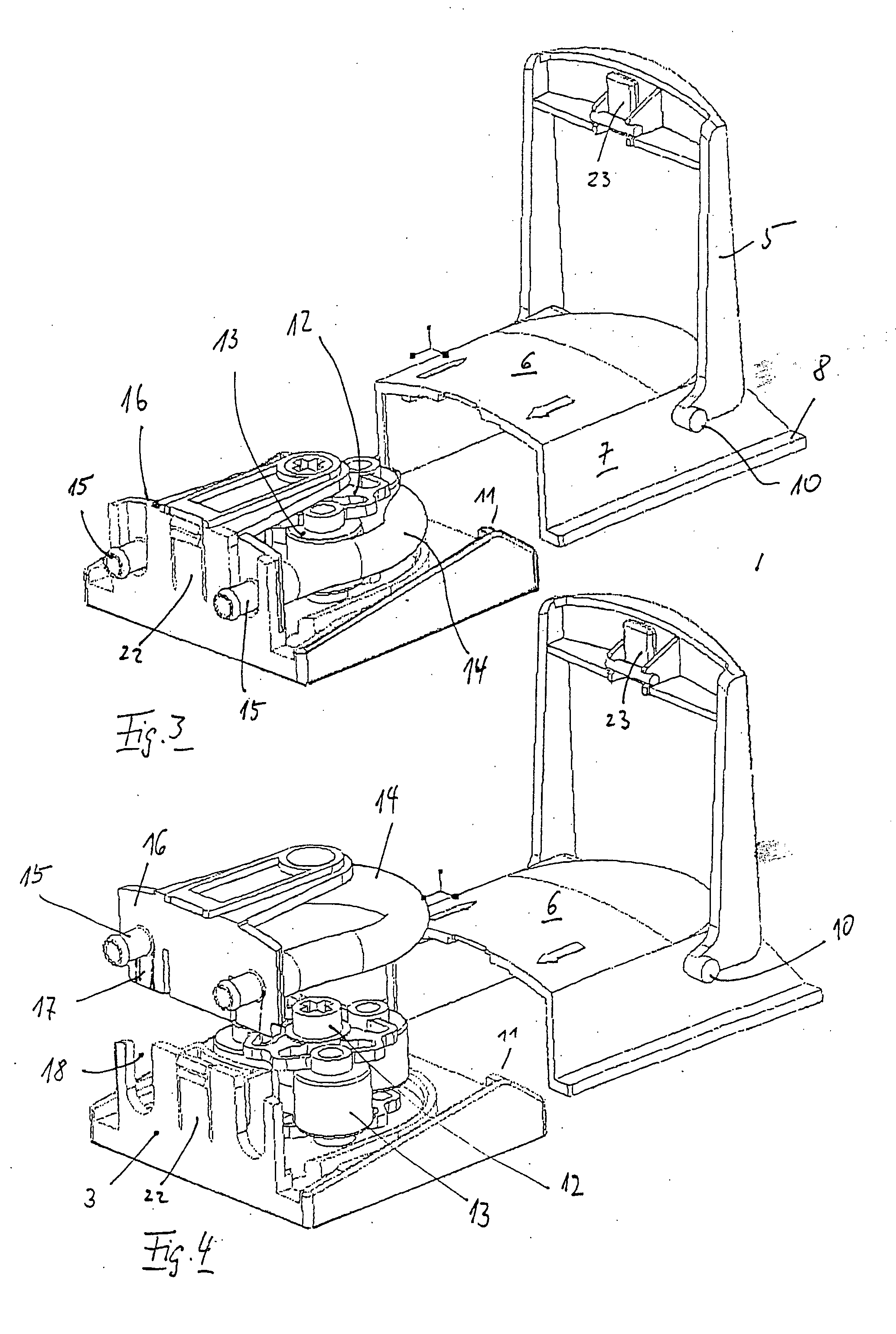

[0017] The pump head denoted generally by 1 comprises a base element 2 whith an integrally formed end wall 3 and two side walls 4 which are in turn integrally formed therewith, as well as a housing cover 6 which is displaceable by way of a pivot lever 5, and which in turn has integrally formed side wall surfaces 7 parallel to the side wall surfaces 4 of the base part. The side wall surfaces 7 of the housing cover have, at the lower outer edge thereof, integrally formed slide rails 8 which are displaceable guided in corresponding counter rails or grooves in the region of transition from the base of the side wall surfaces 4.

[0018] As evident particularly from FIG. 2, the pivot yoke 5 is pivotably mounted at the cover 6 by way of inwardly pointing hinge pins 9, wherein outwardly pointing pins 10 can bear against pivot projections 11 which are integrally formed at the side walls 4 of the base part to pint inwardly.

[0019] A rotor 12 (FIG. 4) with three squeeze rollers 13, which 6 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com